Page 1

Technical Manual

TNC 426 CB/PB

TNC 430

NC-Software 280 470-12

280 471-12

280 472-12

280 473-12

280 474-12

280 475-12

280 476-01

280 477-01

April 1999

208 896 21 · 7 · 4/99 · S · Printed in Germany · Subject to change without notice

(208 896 EC)

Page 2

Foreword

This Technical Manual is intended for manufacturers and distributors of machine tools. It contains all

the necessary information for the assembly, electrical installation, start-up, and PLC programming

for the HEIDENHAIN contouring controls.

When hardware or software is improved in these HEIDENHAIN contouring controls you will

receive a free delivery of updated information. Please arrange and insert this updated information in

your manual without delay. This will ensure that your manual always remains at the current revision

level.

You can use extracts from this manual for your machine documentation. An enlargement of

the manual’s format (17 cm x 24 cm) by a factor of 1.225 will produce pages in A4 format.

No documentation can be perfect. Like all living things it must grow and change. Among

other things, it lives from your impulses and suggestions for improvement. Please help us by letting

us know your ideas.

DR. JOHANNES HEIDENHAIN GmbH

Department E/P

Dr.-Johannes-Heidenhain-Str. 5

D-83301 Traunreut

Germany

November 97 Foreword TNC 426B, TNC 430

Page 3

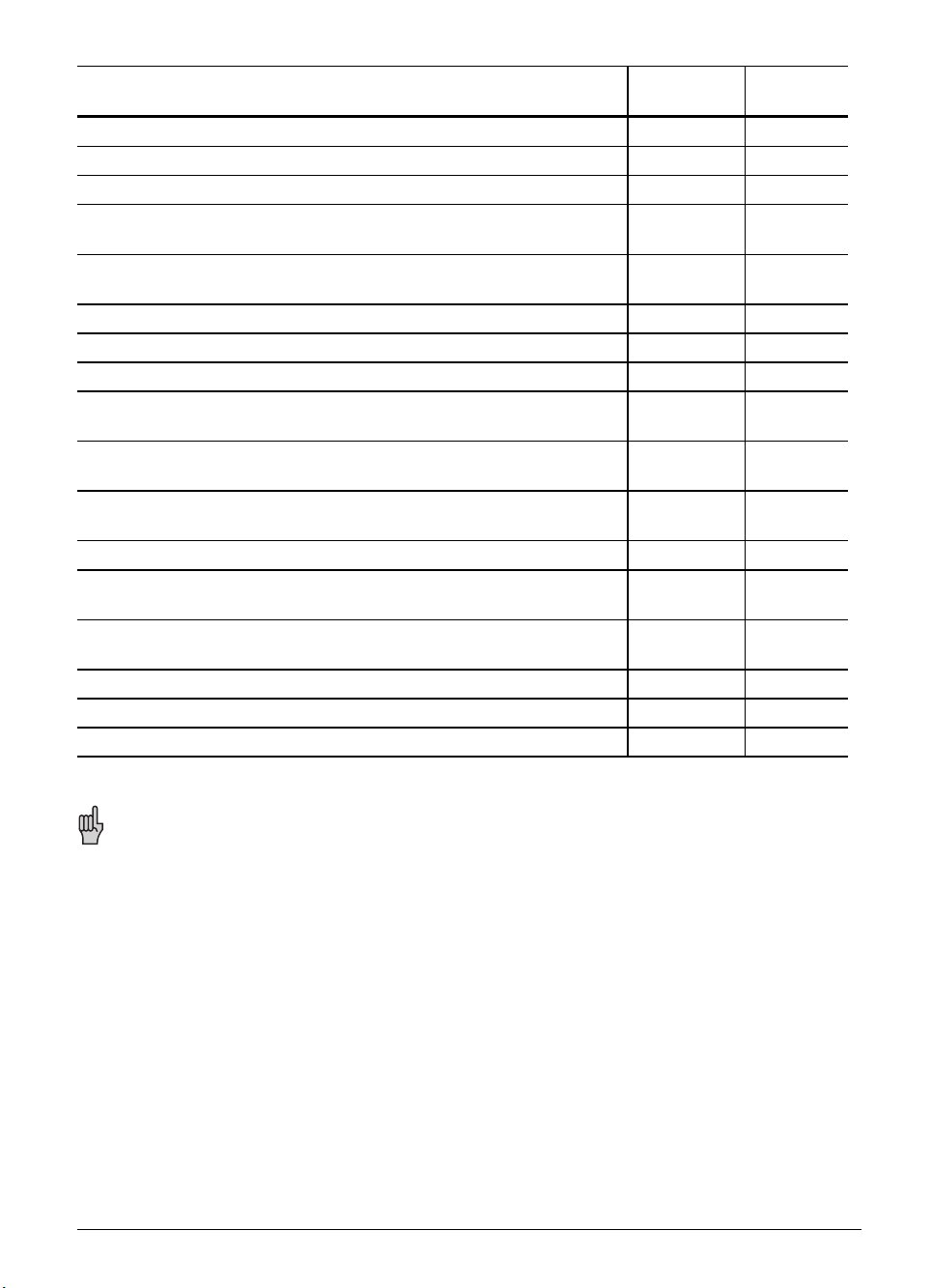

Contents Technical Manual TNC 426 B, TNC 430

Update Informations No. 12 - 7, older Informations

Update information for your TNC.

Introduction

Technical data and general information on software and ID numbers.

Mounting and Electrical Installation

Mounting restrictions, power supply, pin layouts of the units and cables.

Machine Integration

Detailed description of machine functions with the respective machine parameters, markers, words and

PLC modules.

PLC Programming

General information on the PLC, TRACE functions, complete set of PLC commands.

1

2

3

4

5

Data interfaces

Detailed description of the data interfaces.

Original Equipment Manufacturer’s (OEM) Cycles

Important on the OEM cycles.

Appendix

List of the PLC error messages, tables, dimensions, block diagrams, cable overviews.

Machine Parameters

Machine parameter input and output, complete list of the machine parameters.

List of Markers and Words

Complete list of the markers and words.

List of Modules

Complete list of the PLC modules.

6

7

8

9

10

11

Page 4

1 Update Informations No. 12 - 7, older informations 1–1

2 Introduction 2–1

2.1 Integrated Current Control 2–1

2.2 Brief Description 2–2

2.3 Software 2–7

2.3.1 NC Software 2–7

2.3.2 Software Option 2–7

2.3.3 PLC Software 2–8

2.3.4 Software Exchange 2–8

2.3.5 Data Backup 2–9

2.4 Hardware 2–9

2.4.1 ID Numbers 2–10

2.5 Release Dates 2–13

2.5.1 NC Software Versions 280 470 and 280 471 2–13

2.5.2 NC software versions 280 472 and 280 473 2–15

3 Mounting and Electrical Installation 3–1

3.1 Electrical Noise Immunity 3–1

3.2 Heat Generation and Cooling 3–2

3.3 Humidity 3–3

3.4 Mechanical Vibration 3–3

3.5 Mounting Position 3–3

3.6 Degree of Protection 3–6

3.7 Connection Overview 3–8

3.7.1 LE 426 CB 3–8

3.7.2 LE 426 PB (Spindle with up to 9000 rpm) 3–9

3.7.3 LE 426 PB (Spindle with up to 15 000 rpm) 3–10

3.7.4 LE 430 CA 3–11

3.7.5 LE 430 PA 3–12

3.8 Power Supply 3–15

3.8.1 NC Power Supply 3–15

3.8.2 Buffer Battery Backup 3–16

3.8.3 PLC Power Supply 3–17

3.8.4 Power Supply for the Visual Display Units 3–19

3.9 Measuring Systems 3–20

3.9.1 Encoders for Position 3–20

3.9.2 Encoders for Speed (TNC 426 PB and TNC 430 PA Only) 3–23

3.9.3 Adapter for Encoder Signals 3–24

3.10 Motor Power Stage Connection 3–25

3.11 Analog Inputs 3–29

3.12 Analog Outputs 3–32

November 97 Contents TNC 426 B, TNC 430 2

Page 5

3.13 Touch Probes 3–35

3.13.1 Triggering Touch Probe for Workpiece Measurement 3–35

3.13.2 Touch Trigger Probe for Tool Measurement 3–37

3.13.3 Measuring Touch Probe (Option) 3–38

3.14 Data Interface 3–41

3.14.1 RS-232-C/V.24 Data Interface 3–41

3.14.2 RS-422/V.11 Data Interface 3–42

3.14.3 Ethernet Interface (Option) 3–43

3.15 Handwheel Input 3–45

3.15.1 Connector Assignment on the LE 3–45

3.15.2 HR 410 Portable Handwheel 3–46

3.15.3 Panel-Mounted Handwheel HR 130 3–48

3.15.4 Handwheel Adapter HRA 110 3–49

3.16 Input: Spindle Reference Signal 3–53

3.17 Input: Drive Motor Enabling (Only TNC 426 PB, TNC 430 PA) 3–53

3.18 Switching Inputs 24 Vdc (PLC) 3–54

3.19 Switching Outputs 24 Vdc (PLC) 3–57

3.20 Connection of the PLC Expansion 3–60

3.21 Machine Operating Panel 3–65

3.22 TNC Keyboard 3–67

3.23 Visual Display Unit 3–69

3.24 Mounting the Optional PCBs 3–75

4 Machine Integration 4–1

4.1 Machine Axes 4–1

4.1.1 Encoders 4–2

4.1.2 Axis Designation 4–4

4.1.3 Assignment of Axes 4–5

4.1.4 Reading axis information 4–7

4.1.5 Traverse Ranges 4–8

4.1.6 Lubrication Pulse 4–10

4.2 PLC Axes 4–11

4.3 Axis Error Compensation 4–14

4.3.1 Backlash Compensation 4–14

4.3.2 Linear Axis-Error Compensation 4–15

4.3.3 Nonlinear Axis Error Compensation 4–16

4.3.4 Temperature Compensation 4–20

4.3.5 Compensation for Reversal Errors in Circular Motion 4–21

4.3.6 Compensation of Static Friction 4–24

4.3.7 Compensation of Sliding Friction 4–25

4.4 PLC Positioning Commands 4–26

November 97 Contents TNC 426 B, TNC 430 3

Page 6

4.5 Tilting Axes 4–29

4.5.1 “Tilt Working Plane” Feature 4–29

4.5.2 Automatic Compensation of Offset for Tilting Axes 4–37

4.5.3 Cylinder Surface 4–38

4.6 Synchronized Axes 4–39

4.6.1 Synchronization Control 4–39

4.6.2 Conventions 4–40

4.7 Reference Marks 4–41

4.7.1 Traversing the Reference Marks 4–42

4.8 The Control Loop 4–51

4.8.1 Interpolator 4–53

4.8.2 Position Controllers 4–56

4.8.3 Motor Speed Controller (Only TNC 426 PB, TNC 430 PA) 4–67

4.8.4 Current Controller (Only TNC 426 PB, 430 PA) 4–73

4.9 Offset Adjustment 4–75

4.9.1 Offset Adjustment by Code Number 4–75

4.9.2 Automatic Cyclic Offset Adjustment 4–75

4.9.3 Offset Adjustment with Integral Factor 4–76

4.10 Contour Behavior 4–76

4.10.1 Radial Acceleration 4–76

4.10.2 Contour Speed in Corners 4–77

4.11 Monitoring Functions 4–79

4.11.1 Position Monitoring 4–80

4.11.2 Nominal Speed Monitoring 4–81

4.11.3 Movement Monitoring 4–81

4.11.4 Standstill Monitoring 4–82

4.11.5 Positioning Window 4–82

4.11.6 NC Supply Voltage Monitoring 4–84

4.11.7 Temperature Monitoring 4–84

4.11.8 I²t Monitoring (Digital Axes Only) 4–85

4.11.9 Monitoring: Power Stage, DC-Link Voltage (Digital Axes Only) 4–87

4.11.10 Instantaneous Utilization of the Servo Drives (Digital Axes Only) 4–87

4.11.11 EMERGENCY STOP Monitoring 4–89

4.12 Spindle 4–94

4.12.1 Position Encoder of the Spindle 4–94

4.12.2 Analog and Digital Spindle Control 4–96

4.12.3 Coded Output of Spindle Speed 4–102

4.12.4 Oriented Spindle Stop 4–104

4.12.5 Tapping with Floating Tap Holder and Nominal Speed Output 4–108

4.12.6 Tapping with Floating Tap Holder and Coded Spindle-Speed Output 4–111

4.12.7 Rigid Tapping 4–112

4.12.8 Speed Controller (Only TNC 426 PB, TNC 430 PA) 4–114

4.12.9 Current Controller (Only TNC 426 PB, TNC 430 PA) 4–114

4.12.10 Wye Connection / Delta Connection (Only with Spindle DSP) 4–115

November 97 Contents TNC 426 B, TNC 430 4

Page 7

4.13 Display and Operation 4–117

4.13.1 Machine Datum 4–117

4.13.2 Color Adjustment 4–119

4.13.3 Graphic Display 4–122

4.13.4 Status Display 4–124

4.13.5 PLC Display 4–133

4.13.6 Small PLC Window 4–133

4.13.7 Large PLC Window 4–137

4.13.8 PLC Soft Keys 4–150

4.13.9 Help 4–152

4.13.10 Superimpose PLC Window 4–154

4.13.11 M Functions 4–156

4.13.12 Error Messages 4–159

4.13.13 Cycles 4–163

4.13.14 Returning to the Contour 4–167

4.13.15 Files 4–171

4.13.16 Datum Tables (.D) 4–172

4.13.17 Pallet Management 4–173

4.13.18 Freely Defined Tables 4–177

4.13.19 PLC Files 4–184

4.13.20 User Parameters 4–187

4.13.21 Code Numbers 4–188

4.13.22 Programming Station 4–188

4.13.23 Conversational Language 4–189

4.13.24 Memory Test 4–190

4.13.25 Arc End-Point Tolerance 4–190

4.13.26 Radius Compensation R+, R- 4–190

4.13.27 Power Interrupted Message 4–191

4.13.28 Operating Times 4–191

4.14 Keystroke Simulation 4–196

4.14.1 TNC Keyboard 4–196

4.14.2 Machine Operating Panel 4–201

4.15 Touch Probe 4–204

4.15.1 Standard Probing Cycles 4–204

4.15.2 Logging Probe Measurements 4–208

4.15.3 Digitizing with the Triggering Touch Probe 4–212

4.15.4 Digitizing with the Measuring Touch Probe 4–219

4.15.5 Tool Measurement 4–224

4.16 Electronic Handwheel 4–232

4.16.1 HR 130 Panel-Mounted Handwheel 4–234

4.16.2 HR 410 Portable Handwheel 4–235

4.16.3 HR 150 Panel-Mounted Handwheels with HRA 110 Adapter 4–236

November 97 Contents TNC 426 B, TNC 430 5

Page 8

4.17 PLC Inputs/Outputs 4–238

4.17.1 24-Vdc Switching Inputs/Outputs 4–238

4.17.2 Analog Inputs 4–240

4.17.3 Analog Outputs 4–241

4.18 Incremental Jog Positioning 4–242

4.19 Hirth Coupling 4–243

4.20 Datum Shift 4–244

4.21 Tool Changer 4–246

4.21.1 Tool Table, Pocket Table 4–246

4.21.2 Automatic Calculation of Cutting Data 4–254

4.21.3 Automatic Tool Recognition 4–257

4.21.4 Controlling the Tool Changer 4–267

4.21.5 PLC Programming Example 4–284

4.22 Special Functions for Laser Cutting Machines 4–297

4.22.1 Analog Voltage Output 4–297

4.22.2 Graphic Simulation Without TOOL CALL 4–299

4.22.3 Program Stop with M Functions and TOOL CALL S 4–300

4.23 Integrated Oscilloscope 4–302

4.24 Commissioning 4–307

4.24.1 Preparation 4–307

4.24.2 Digital Axis 4–307

4.24.3 Analog Axes 4–328

4.24.4 Digital Spindle for TNC 426 without Spindle DSP 4–333

4.24.5 Digital Spindle for TNC 430 / TNC 426 with Spindle DSP 4–337

4.24.6 Analog Spindle 4–339

5 PLC Programming 5–1

5.1 PLC Functions 5–1

5.1.1 Select PLC Operation 5–1

5.1.2 PLC Main Menu 5–2

5.1.3 File Management 5–4

5.1.4 TRACE Functions 5–5

5.1.5 Logic Diagram 5–6

5.1.6 TABLE Function 5–7

5.1.7 COMPILE Function 5–8

5.2 Operands 5–9

5.2.1 Operand Directory 5–9

5.2.2 Operand Addressing 5–10

5.2.3 Data Transfer 5–11

5.2.4 Data Transfer NC → PLC 5–11

5.2.5 Data Transfer PLC → NC 5–17

5.2.6 Timer 5–25

5.2.7 Counters 5–27

5.2.8 Fast PLC Inputs 5–29

November 97 Contents TNC 426 B, TNC 430 6

Page 9

5.3 Hard-Disk Organization 5–30

5.4 Program Creation 5–33

5.4.1 ASCII Editor 5–33

5.4.2 Program Format 5–33

5.4.3 Program structure 5–34

5.4.4 Logical Names for Files 5–34

5.4.5 PLC compatibility with TNC 415 / TNC 425 5–36

5.5 PLC Program Example 5–37

5.6 Commands 5–75

5.6.1 Execution Times 5–75

5.6.2 LOAD (L) L 5–77

5.6.3 LOAD NOT (LN) LN 5–79

5.6.4 LOAD TWO'S-COMPLEMENT (L–) 5–81

5.6.5 LOAD BYTE (LB) LB 5–82

5.6.6 LOAD WORD (LW) LW 5–82

5.6.7 LOAD DOUBLEWORD (LD) LD 5–82

5.6.8 ASSIGN (=) 5–84

5.6.9 ASSIGN BYTE (B=) 5–86

5.6.10 ASSIGN WORD (W=) W= 5–86

5.6.11 ASSIGN DOUBLEWORD (D=) 5–87

5.6.12 ASSIGN NOT (=N) 5–88

5.6.13 ASSIGN TWO'S COMPLEMENT (=-) 5–88

5.6.14 SET (S) 5–89

5.6.15 RESET (R) 5–90

5.6.16 SET NOT (SN) 5–91

5.6.17 RESET NOT (RN) RN 5–92

5.6.18 AND (A) 5–93

5.6.19 AND NOT (AN) AN 5–95

5.6.20 OR (O) O 5–97

5.6.21 OR NOT (ON) 5–99

5.6.22 EXCLUSIVE OR (XO) 5–101

5.6.23 EXCLUSIVE OR NOT (XON) XON 5–103

5.6.24 ADDITION (+) 5–105

5.6.25 SUBTRACTION (–) 5–106

5.6.26 MULTIPLICATION (x) 5–107

5.6.27 DIVISION (/) 5–108

5.6.28 REMAINDER (MOD) 5–109

5.6.29 INCREMENT (INC) 5–110

5.6.30 DECREMENT (DEC) 5–110

5.6.31 EQUAL TO (==) 5–111

5.6.32 LESS THAN (<) 5–112

5.6.33 GREATER THAN (>) 5–113

5.6.34 LESS THAN OR EQUAL TO (<=) 5–114

5.6.35 GREATER THAN OR EQUAL TO (>=) 5–115

November 97 Contents TNC 426 B, TNC 430 7

Page 10

5.6.36 UNEQUAL (<>) 5–116

5.6.37 AND [ ] (A[ ]) 5–117

5.6.38 AND NOT [ ] (AN[ ] 5–117

5.6.39 OR [ ] (O[ ]) 5–117

5.6.40 OR NOT [ ] (ON[ ]) 5–117

5.6.41 EXCLUSIVE OR [ ] (XO[ ]) 5–118

5.6.42 EXCLUSIVE OR NOT [ ] (XON[ ]) 5–118

5.6.43 ADD [ ] (+[ ]) 5–120

5.6.44 SUBTRACT [ ] (–[ ]) 5–120

5.6.45 MULTIPLICATION [ ] (x[ ]) 5–120

5.6.46 DIVISION [ ] (/[ ]) 5–120

5.6.47 REMAINDER [ ] (MOD[ ]) 5–121

5.6.48 EQUAL TO [ ] (==[ ]) 5–123

5.6.49 LESS THAN [ ] (<[ ]) 5–123

5.6.50 GREATER THAN [ ] (>[ ]) 5–123

5.6.51 LESS THAN OR EQUAL TO [ ] (<=[ ]) 5–123

5.6.52 GREATER THAN OR EQUAL TO [ ] (>=[ ]) 5–124

5.6.53 NOT EQUAL TO [ ] (<>[ ]) 5–124

5.6.54 SHIFT LEFT (<<) 5–126

5.6.55 SHIFT RIGHT (>>) 5–127

5.6.56 BIT SET (BS) 5–128

5.6.57 BIT RESET (BC) 5–129

5.6.58 BIT TEST (BT) 5–130

5.6.59 Load Data onto the Data Stack (PS) 5–131

5.6.60 Acquire Data from the Data Stack (PL) 5–132

5.6.61 Load Logic Accumulator onto the Data Stack (PSL) 5–132

5.6.62 Load Word Accumulator onto the Data Stack (PSW) 5–133

5.6.63 Acquire Logic Accumulator from the Data Stack (PLL) 5–133

5.6.64 Acquire Word Accumulator from the Data Stack (PLW) 5–133

5.6.65 Unconditional Jump (JP) 5–135

5.6.66 Jump if Logic Accumulator = 1 (JPT) 5–135

5.6.67 Jump if Logic Accumulator = 0 (JPF) 5–136

5.6.68 Call Module (CM) 5–137

5.6.69 Call Module if Logic Accumulator = 1 (CMT) 5–137

5.6.70 Call Module if Logic Accumulator = 0 (CMF) 5–138

5.6.71 End of Module, Program End (EM) 5–139

5.6.72 End of Module if Logic Accumulator = 1 (EMT) 5–139

5.6.73 End of Module if Logic Accumulator = 0 (EMF) 5–139

5.6.74 Jump Label (LBL) 5–139

5.7 INDEX Register 5–144

November 97 Contents TNC 426 B, TNC 430 8

Page 11

5.8 Commands for STRING Execution 5–146

5.8.1 LOAD (L) 5–147

5.8.2 ADD (+) 5–147

5.8.3 Storing a STRING (=) 5–147

5.8.4 Overwriting of a STRING (OVWR) 5–148

5.8.5 Logical Comparisons in STRING Execution 5–149

5.8.6 EQUAL TO (==) 5–149

5.8.7 LESS THAN (<) 5–149

5.8.8 GREATER THAN (>) 5–149

5.8.9 LESS THAN OR EQUAL TO (<=) 5–150

5.8.10 GREATER THAN OR EQUAL TO (>=) 5–150

5.8.11 UNEQUAL (<>) 5–150

5.8.12 Modules for String Execution 5–152

5.9 Submit Programs 5–153

5.9.1 Call up of the Submit Program (SUBM) 5–153

5.9.2 Status Interrogation of a Submit Program (RPLY) 5–154

5.9.3 Cancellation of a Submit Program (CAN) 5–154

5.10 Cooperative Multitasking

1)

5–156

5.10.1 Starting a Parallel Process 5–156

5.10.2 Control of Events 5–157

5.11 Constants Field (KF) 5–164

5.12 Program Structures 5–164

5.12.1 IF ... ELSE ... ENDI Structure 5–165

5.12.2 REPEAT ... UNTIL Structure 5–165

5.12.3 WHILE ... ENDW Structure 5–166

5.12.4 CASE Branch 5–166

5.13 Linking Files 5–168

5.13.1 USES Instruction 5–168

5.13.2 GLOBAL Instruction 5–169

5.13.3 EXTERN Instruction 5–170

5.14 PLC Modules 5–176

5.14.1 Markers, Bytes, Words, Doublewords 5–176

5.14.2 Number Conversion 5–179

6 Data Interfaces 6–1

6.1 Introduction 6–1

6.1.1 Principles of Data Transfer 6–2

6.1.2 Handshaking 6–7

6.2 TNC Data Interfaces 6–8

6.2.1 General 6–8

6.2.2 RS-232-C/V.24 Interface 6–8

6.2.3 RS-422/V.11 Interface 6–10

6.2.4 Saving/Reading Files 6–12

November 97 Contents TNC 426 B, TNC 430 9

Page 12

6.3 Configuration of Interfaces 6–14

6.3.1 Selection of Interfaces 6–14

6.3.2 Freely Configurable Interfaces 6–15

6.4 Data Transmission Protocols 6–19

6.4.1 Standard Transmission Protocol 6–19

6.4.2 Data Transfer with Block Check Character 6–23

6.4.3 LSV2 Protocol 6–30

6.5 Data Transfer by PLC 6–31

6.5.1 Settings 6–31

6.5.2 PLC Modules 6–31

6.6 External Programming 6–38

6.7 Error Messages 6–39

6.7.1 TNC Error Messages 6–39

6.7.2 Error Codes for HEIDENHAIN Peripherals 6–40

6.8 Ethernet Interface (Option) 6–42

6.8.1 Hardware 6–42

6.8.2 Software 6–42

7 Original Equipment Manufacturer's (OEM) Cycles 7–1

7.1 HEIDENHAIN Standard Cycles 7–1

7.2 CycleDesign 7–1

7.3 Application of OEM Cycles 7–1

7.4 Compatibility with “Old” OEM Cycles 7–4

8 Appendix 8–1

8.1 Error Messages 8–1

8.2 Tables 8–7

8.2.1 Seven-Bit ASCII Code 8–7

8.2.2 Powers of Two 8–11

8.3 Dimensions 8–12

8.3.1 LE 426 PB, LE 430 PA 8–12

8.3.2 LE 426 CB, LE 430 PA 8–13

8.3.3 TE 420 8–14

8.3.4 MB 420 8–15

8.3.5 BC 120 8–16

8.3.6 BF 120 8–17

8.3.7 PL 410 B 8–18

8.3.8 Adapter Block for Data Interface 8–19

8.3.9 Electronic Handwheels 8–20

8.3.10 Touch Probe Systems 8–26

8.4 Grounding Diagram 8–31

8.5 Basic Circuit Diagram: Motor Control with TNC 426 PB, TNC 430 PA 8–33

8.6 Block Diagram TNC 426 PB, TNC 430 PA 8–35

November 97 Contents TNC 426 B, TNC 430 10

Page 13

8.7 Cable Overview 8–37

8.7.1 TNC 426 8–37

8.7.2 TNC 430 8–39

9 Machine Parameters 9–1

9.1 What is a Machine Parameter? 9–1

9.2 Input and Output of Machine Parameters 9–2

9.2.1 Input Format 9–2

9.2.2 Activating the Machine Parameter Settings 9–3

9.2.3 Changing the Input Values 9–3

9.3 List of Machine Parameters 9–7

9.3.1 Encoders and Machine 9–7

9.3.2 Positioning 9–14

9.3.3 Operation with Velocity Feedforward 9–17

9.3.4 Operation with Servo Lag 9–18

9.3.5 Integral Speed and Current Control (Digital Axes Only) 9–19

9.3.6 Spindle 9–24

9.3.7 Integral PLC 9–27

9.3.8 Configuration of Data Interfaces 9–29

9.3.9 3-D Touch Probe 9–30

9.3.10 Digitizing with TS (Available Only with Digitizing Option) 9–32

9.3.11 Digitizing with Measuring Touch Probe (Available Only with Digitizing Option) 9–33

9.3.12 Tool Measurement with TT 9–34

9.3.13 Tapping 9–38

9.3.14 Display and Operation 9–39

9.3.15 Colors 9–45

9.3.16 Machining and Program Run 9–48

9.3.17 Hardware 9–54

9.3.18 Second Spindle 9–58

10 List of Markers and Words 10–1

10.1 List of Markers 10–1

10.2 List of Words 10–7

11 List of Modules 11–1

12 Subject Index 12–1

October 98 Contents TNC 426 B, TNC 430 11

Page 14

1 Update Information No. 6

The following NC software has been released:

NC Software Date of release

280 472 05 11/97 Export-Version: 280 473 05

Improvements:

• On the TNC 426 PB without spindle DSP (from hardware version xxx xxx 4x) the maximum

spindle speed was increased from 9000 rpm to 12 000 rpm.

• On the TNC 426 PB with spindle DSP and the TNC 430 PA (from hardware version xxx xxx 4x)

the maximum spindle speed was increased from 15 000 rpm to 24 000 rpm.

• Module 9135 has been introduced:

The infrared touch probe TS 630 can be switched on by the PLC. If the touch probe does not

report readiness while M4056 is set, the feed rate enable is reset (previously: NC stop).

Call:

CM 9135

M4203= 0: no error during module execution

1: error during module execution

• MP3210.x extended:

Input range (S analog voltage or motor revolutions) increased to 100.000

• D364 (nominal speed) and D368 (actual speed) have been added, since speeds greater than

32767 rpm cannot be represented in the words W320 (nominal speed) and W322 (actual speed).

• In the print masks of the touch probe cycles, it is now possible to distinguish between languages

by means of code words. The text block defined in MP7230.0 is output.

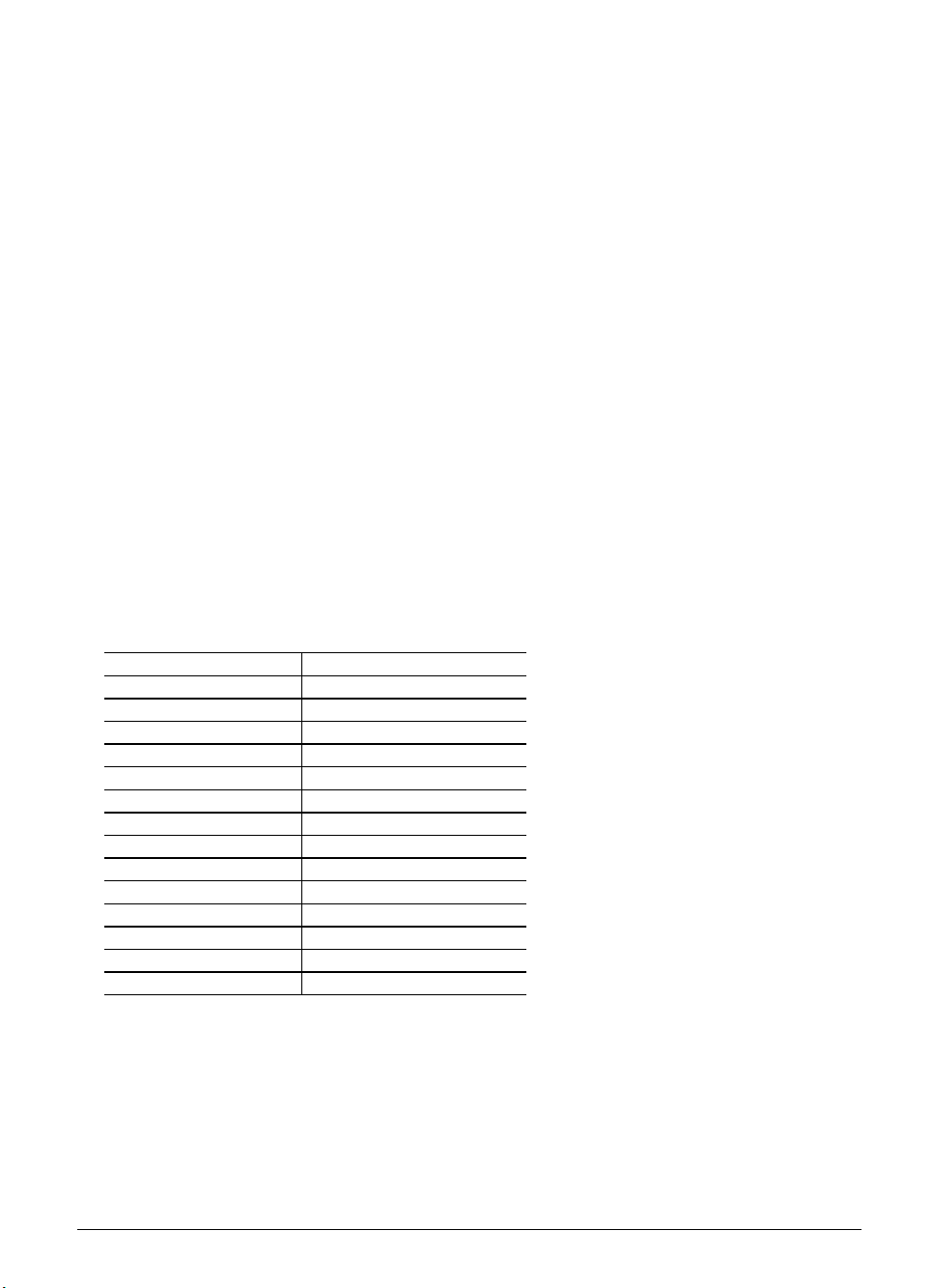

Language code word Dialog language

L_ENGLISH 0 = English

L_GERMAN 1 = German

L_CZECH 2 = Czech

L_FRENCH 3 = French

L_ITALIAN 4 = Italian

L_SPANISH 5 = Spanish

L_PORTUGUE 6 = Portuguese

L_SWEDISH 7 = Swedish

L_DANISH 8 = Danish

L_FINNISH 9 = Finnish

L_DUTCH 10 = Dutch

L_POLISH 11 = Polish

L_HUNGARIA 12 = Hungarian

L_ALL Language-neutral texts

• Code number for LOGBOOK has been added:

The data from the log can be transferred to an ASCII file. The user must specify a file name and

the time at which the data transfer is to begin. The log contains the most recent keystrokes,

control resets, error messages and the register status in case of blinking error messages.

December 97 Update Information No. 6 TNC 426 B, TNC 430 1–1

Page 15

• MP7471 has been added:

Maximum speed of linear axes for compensating movements caused by the positioning of

angular axes with M128.

• New machine parameters for new touch probe cycle (CALIBRATE TS):

MP6180.0-2, MP6181.0-2 and MP6182.0-2: Approximate position of the ring gauge center (X, Y

and Z in REF coordinates for three traverse ranges)

Input: –99 999.9999 to +99 999.9999 [mm]

MP6185: Distance below the upper edge of the ring gauge to be probed during calibration.

Input: 0.001 to 99 999.9999 [mm]

• FN18:SYSREAD has been expanded:

It is now possible to determine whether a datum table is selected in the current operating mode.

ID505

NR1

0 = no datum table selected

1 = datum table selected

• FN18: SYSREAD has been expanded:

It is now possible to determine whether the addressed MP exists.

ID1010

NRxxxx MP number

IDXxxxx MP index

0 = MP does not exist

1 = MP exists

NC software Date of release

280 472 06 12/97 Export version: 280 473 06

Improvements:

• New touch probe cycles. These cycles are defined like the fixed cycles via the TOUCH PROBE

key and soft keys. All touch probe system functions are now described in a separate manual:

User's Manual touch probe cycles – German 329203 10

– English 329203 20

• Three new markers for workpiece measurement:

Set Reset

M4065: All dimensions of the workpiece are OK NC PLC

M4066: Workpiece needs rework NC PLC

M4067: Workpiece must be scrapped NC PLC

• Timers T96 to T143 have been added:

The new timers can be started only through Module 9006. The timer is set immediately after

module call and reset after expiration of the run time.

• FN17:SYSWRITE has been expanded:

The touch probe monitoring can be switched on and off.

ID990

NR2 = numerical value

Numerical value = 0 touch probe monitoring off

Numerical value ≠ 1 touch probe monitoring on

• FN17:SYSWRITE has been expanded:

The touch probe data of the manual probing cycles are transferred to the tool table.

ID990

NR3 = Qxxx or any numerical value

1–2 TNC 426 B, TNC 430 Update Information No. 6 December 97

Page 16

• FN17:SYSWRITE has been expanded:

A point in the working plane (i.e., the plane perpendicular to the tool axis) of the workpiece

coordinate system can be transformed into the corresponding plane of the machine coordinate

system and vice versa, whereby the corresponding plane of the machine coordinate system is

the plane whose normal vector has the designation of the tool axis.

ID990

NR4

IDX 1 = Qxxx (Transformation of workpiece coordinate system to machine coordinate system)

2 = Qxxx (Transformation of machine coordinate system to workpiece coordinate system)

Qxxx Number of the first of four consecutive Q parameters

1. Q parameter: Coordinate of the 1st axis of the point to be transformed

2. Q parameter: Coordinate of the 2nd axis of the point to be transformed

3. Q parameter: Coordinate of the 1st axis of the transformed point

4. Q parameter: Coordinate of the 2nd axis of the transformed point

December 97 Update Information No. 6 TNC 426 B, TNC 430 1–3

Page 17

1 Update Information No. 5

1.1 NC Software

HEIDENHAIN has released a new NC software:

NC software Release

280 472 04 10/97 Export version: 280 473 04

Improvements:

• Code words LSV2TIME0 to LSV2TIME2 are new

• Module 9038 was expanded by transfer value –1

• DR2 can now be defined in the TOOL CALL block

• Spindle DSP limits max. torque to 2.5 • rated torque

1.2 Hardware

The maximum input frequency of the position encoder inputs X1 to X5 was reduced to 50 kHz for 1

V

signals. You will find the new ID numbers on page 3-10. Changeover date will be end of

PP

December 1997. We will still provide the old logic units with unchanged input frequency under the

old ID numbers upon special request.

1.3 Documentation

Various changes were made to the Technical Manual. The list on the next 3 pages gives an insight

into what changes were made, and where the information can be found.

November 97 Update Information No. 5 TNC 426 B, TNC 430 1–1

Page 18

1 Update Information No. 4

With Update Information No. 3 you received completely new pages for your TNC 426 B / TNC 430

Technical Manual. Since then the following changes have been made to the software.

1.1 NC Software 280 472

NC Software Release

280 472 01 6/97 Export version: 280 473 01

NC Software Release

280 472 02 7/97 Export version: 280 473 02

• MP6500 expanded:

Bit 9

reserved

Bit 10 probing routine (Bit 8 = 1)

0 = The starting point is pre-positioned in all three principle axes.

1 = The starting point is pre-positioned only in the tool axis and in the axis of the probing

direction (MP6505).

Bit 11 Checking the tool and adjusting the tool table

0 = After "tool checking" the tool table is adjusted.

1 = After "tool checking" the tool table is not adjusted.

• MP7500 expanded:

Bit 3 Setting the datum in a tilted coordinate system

0 = Datum setting is possible in tilted coordinate system.

1 = During datum setting the current positions of the tilting axes are not offset.

NC Software Release

280 472 03 8/97 Export version: 280 473 03

• MP7680 expanded:

Bit 10 see item 1.1.2 "Optimization of Tool-Radius-Compensated Outside Corners."

• The software also runs on the old hardware of the LE 426 CB/PB and LE 430 CA/PA, however

with less feature content.

1.1.1 Nominal Position Value Filter

For optimum adjustment of the velocity and acceleration the nominal position values are filtered.

This results in smoother (jerk-limited) traverse. The TNC calculates the filter parameters weighting

and width (order) using the permissible axis-specific jerk and the tolerance. The filter is effective in

all operating modes. For rigid tapping (Cycle 17) the nominal position value filter is automatically

switched off.

With MP1095 you can select whether the TNC uses a single or double filter. The single filter causes

a linear change in acceleration and therefore a step in the jerk.

With Cycle 32 the user can overwrite the tolerance defined in MP1096 for contour transitions. Cycle

32 was renamed to "fast contour milling" because the nominal position value filter is effective not

only for 3-D contours.

November 97 Update Information No. 4 TNC 426 B, TNC 430 1–1

Page 19

MP1095 Nominal position value filter

Input: 0 = single filter

1 = double filter

Suggested input value = 0

MP1096 Tolerance

Input: 0 = no nominal position value filter

0.001 to 3.000 [mm] = permissible tolerance at contour transitions

MP1097 Axis specific jerk for single filters (MP1096 = 0)

Input: 1 to 1 000 [m/s³]

MP1097.0-8 Axis 1 to axis 9

MP1098 Axis specific jerk for double filters (MP1096 = 1)

Input: 1 to 1 000 [m/s³]

Suggested input value = 2 • MP1097.x

MP1098.0-8 Axis 1 to axis 9

MP1099 Minimum filtering order

Input: 0 to 20

MP1099.0 Minimum filtering order for single filters (MP1096 = 0)

Suggested input value = 5

MP1099.1 Minimum filtering order for double filters (MP1096 = 1)

Suggested input value = 3

Commissioning

➤ Determine minimum filtering order. Suggested input values: MP1099.0 = 5, MP1099.1 = 3

➤ Switch off the nominal position value filter (MP1096 = 0).

➤ Determine MP1090.x, MP1092, MP1510.x as described on page 4-318/4-319. Enter the

optimum jerk values for each axis MP1097.x.

➤ In MP1098.x enter twice the value from MP1097.x.

➤ Define the tolerance in MP1096 (e.g. 0.02 mm)

1.1.2 Optimization of Tool-Radius-Compensated Outside Corners

With MP7680, bit 10 you set whether a circular arc or a spline should be inserted for the tool center

path at tool-radius-compensated outside corners. Inserting a spline has the advantage of limiting the

jerk at the corners and, when the nominal position value filter (MP1096 > 0) is active, of milling the

corners more precisely.

MP7680 Machines parameters with multiple function

Input: %xxxxxxxxxxx

Bit10 Tool-radius-compensated outside corners

0 = Insert a circular arc

1 = Insert a spline curve

Suggested input value = %1xxxxxxxxxx

1–2

TNC 426 B, TNC 430 Update Information No. 4 November 97

Page 20

1.1.3 New Backlash Compensation

A new type of backlash compensation is effective beginning with NC software 280 470 08 and

280 472 01. Unlike the backlash compensation possible with MP710, you can compensate the

backlash in the entire controlled system with MP750 and MP752. This means that you can now also

compensate play between the motion of the motor and the table with position measurement via

linear encoders. This feature also compensates the reversal spikes resulting from circular traverse,

and the machine parameters MP711 to MP716 are therefore no longer needed.

In MP750 you enter the backlash in mm. In MP752 you enter the time within which the

compensated distance should be traversed.

Example:

MP750 = 0.03 mm, MP752 = 15 ms

For every reversal in axis direction, for 15 ms a nominal speed command signal is output

corresponding to a feed rate of 120 mm/min (0.03 mm / 15 ms = 0.002 m/s = 120 mm/min).

MP750 Backlash

Input: –1.0000 to +1.0000 [mm]

MP750.0-8 Axis 1 to axis 9

MP752 Compensation time for value from MP750.x

Input: 0 to 1000 [ms]

MP750.0-8 Axis 1 to axis 9

Commissioning

➤ Enter the following test program:

LBL 1

L X100 R0 F10

L X0

CALL LBL 1 REP 100/100

➤ With the internal oscilloscope, record ACTL.SPEED and V (ACT RPM)

t

➤ At the reversal point the actual feed rate lags behind the actual RPM with the time delay

➤ Input values: MP750 = t • ∆ACTL.SPEED

MP752 = approx. 20 ms (optimum value determined empirically with this test)

.

1.1.4 Other Changes in the Technical Manual

• MP7460 (constant contouring speed at corners) has been replaced by MP1096 (tolerance), pages

4-77, 9-45.

• MP1091 (Jerk limiting for 3-D milling with Cycle 32) will not be introduced, pages 4-62, 4-78,

9-13.

• Module 9037 (read general axis information) was renamed to Module 9038, pages 4-7,

11-1.

November 97 Update Information No. 4 TNC 426 B, TNC 430

1–3

Page 21

1.2 NC Software 280 470

NC Software Release

280 470 08 5/97 Export version: 280 471 08

• Hungarian dialog added

• D760 (Offset for tilting axes, probe center offset) added

• MP750 and MP752 (backlash compensation) added

• MP3143 expanded:

3 = same as input value 1, except that the second reference mark is evaluated first.

NC Software Release

280 470 09 6/97 Export version: 280 471 09

• MP6500 expanded:

Bit 9

reserved

Bit 10 probing routine (bit 8 = 1)

0 = The starting point is pre-positioned in all three principle axes.

1 = The starting point is pre-positioned only in the tool axis and the axis for the probing direction

(MP6505).

Bit 11 Checking the tool and adjusting the tool table

0 = After "tool checking" the tool table is adjusted.

1 = After "tool checking" the tool table is not adjusted.

NC Software Release

280 470 10 7/97 Export version: 280 471 10

1–4

TNC 426 B, TNC 430 Update Information No. 4 November 97

Page 22

1 Update Information No. 3

HEIDENHAIN released the new NC software 280 472 01 in June 1997. This software will only run

on logic units with Id. Nr. xxx xxx 4x.

The new functions (listed below) and the changes in hardware are described in detail in the

new Technical Manual (English version not yet available).

Conditions of delivery

As of June 1997 HEIDENHAIN will only supply the new hardware (Id. Nr. xxx xxx 4x). The NC

software 280 480 runs on this new hardware as of version 06. For the present the new software (Id.

Nr. 280 472 xx) will be supplied only where expressly ordered. As of September 1997 the old NC

software will no longer be delivered.

NC software Release

280 472 01 6/97 Export version: 280 473 01

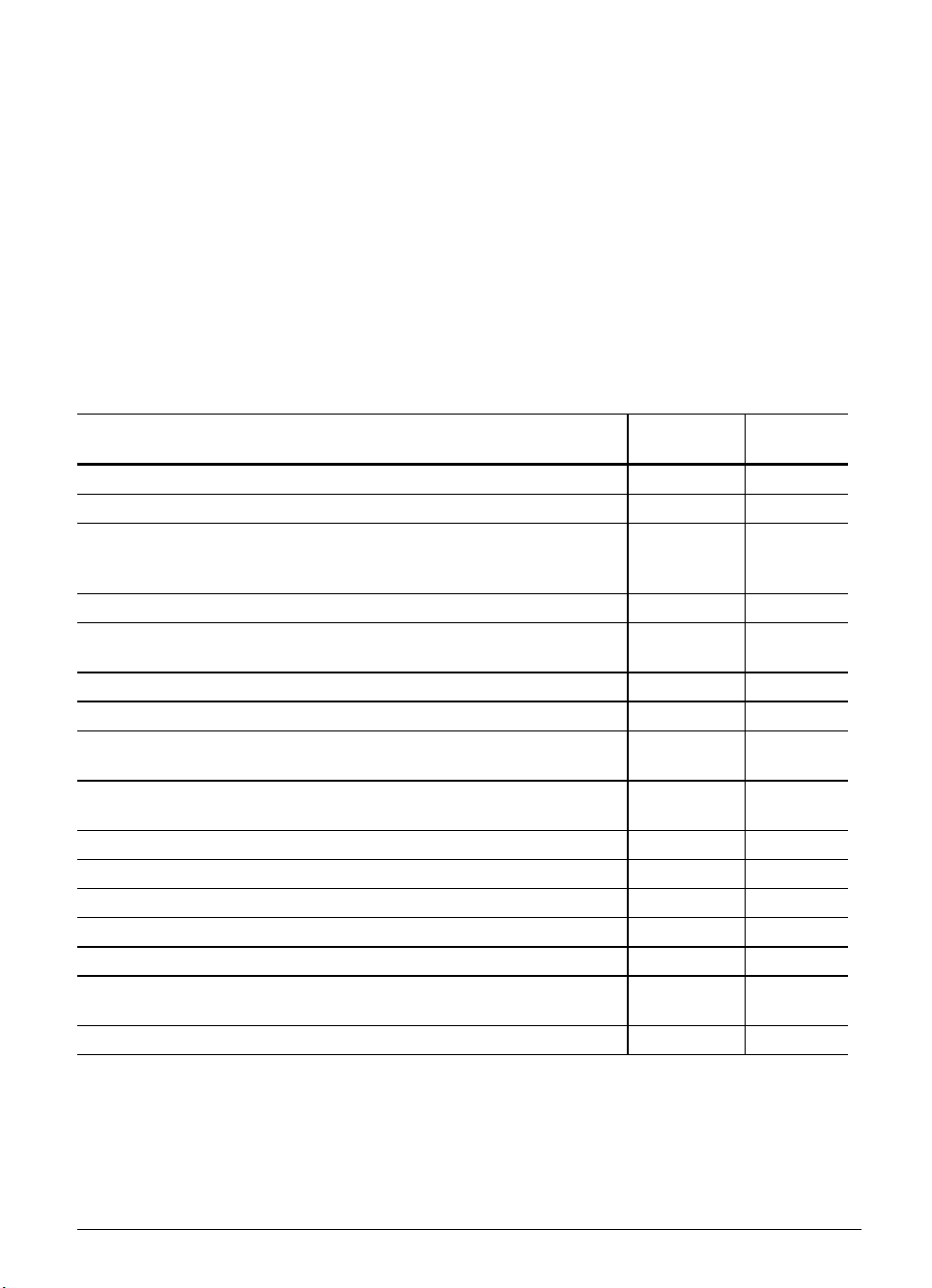

Improvements Technical

Manual

New function "3-D milling": Cycle 32 or G62 and MP1091.x 4–78 213

Automatic calculation of cutting data 4–255 92

TCPM (Tool Center Point Management): With M128 you can

superimpose manual axis traverse during program run. Misalignments

in the tilting axes are then automatically compensated.

Additional information with HELP key 4–154 64

Input menu for fixed input values can be selected with the GOTO key

(e.g. baud rate)

New pallet management 4–174 65

Freely-definable tables 4–178 95

You can select between standard and enhanced file management with

the MOD function PGM MGT

The positions of all nine axes are shown in the status display. The

spindle position overwrites the ninth axis

Copying progress is shown in a superimposed window – 35

The number of Q parameters was increased from 299 to 399 – 250

Q parameters also permissible in FK blocks – 125

M110 also effective in contour pocket cycle – 146

Cycle 204: Counterbore back – 163

With MP7682 Bit 2 you can set whether rotary axes should always be

positioned by the shorter path

A chamfer feed rate can be entered in the NC block "Chamfer" (CHF) – 109

– 151

– 326

– 330

–5

4–124 148

User's

Manual

November 97 Update Information No. 3 TNC 426 B, TNC 430 1–1

Page 23

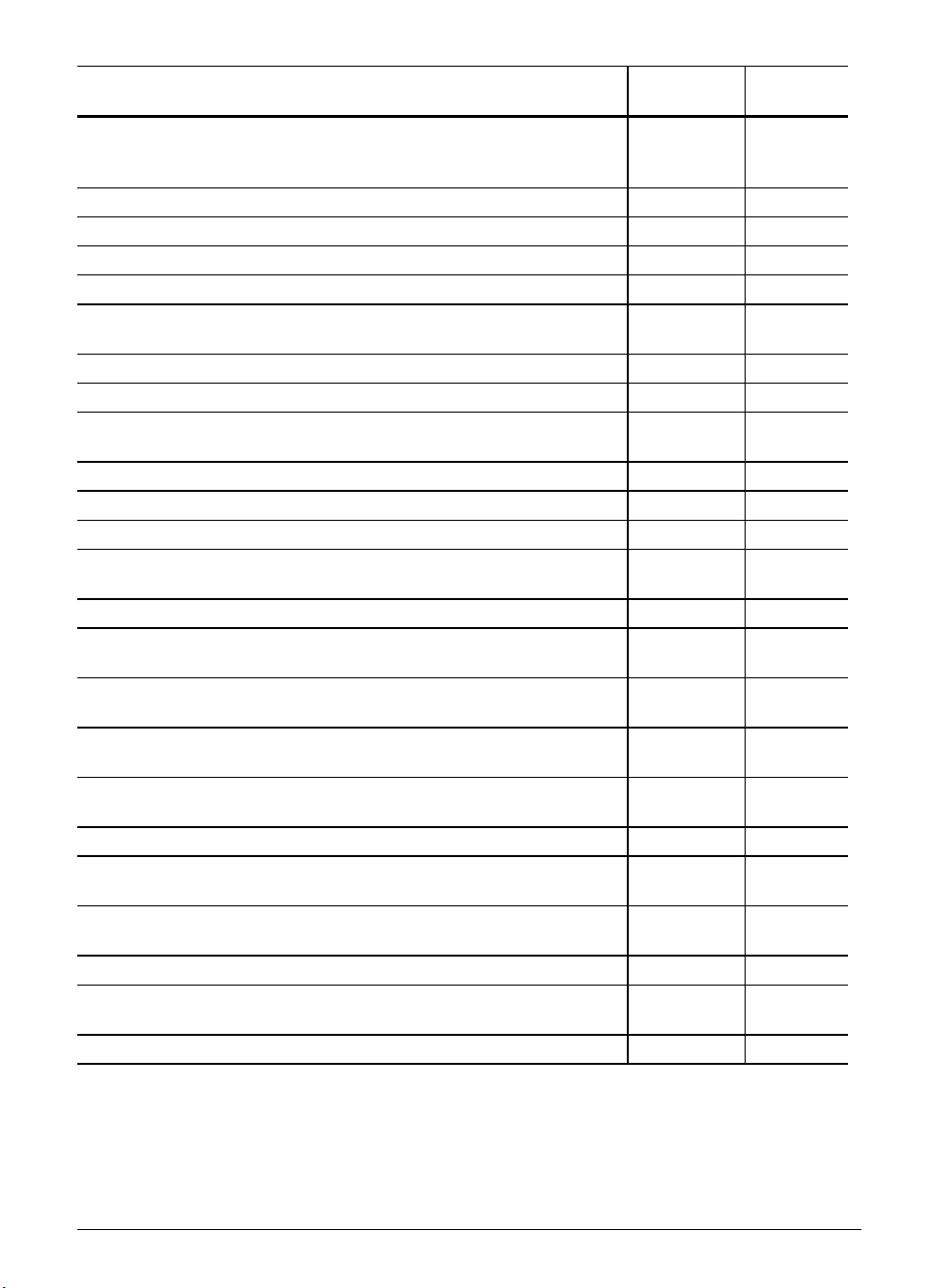

Improvements Technical

Manual

Cycle 19 "Machining plane" was expanded by the parameters feed rate

and setup clearance (only when the tilting axes are positioned with

Cycle 19. This is set in MP7500)

M114 can also be used with non-controlled or PLC axes 4–34 150

Hungarian as additional conversational language 4–189 344

All soft keys appear in the set conversational language – –

Language-dependent soft keys for OEM cycles – –

The soft keys for FK programming only appear once you press the FK

key

Soft key F for feed rate in the manual operating modes 4–127 17

New soft key: INCREMENT OFF/ON 4–242 17

New soft key: HIDE TOOLS OFF/ON: the only tools shown in the tool

table are those in the tool magazine

New soft keys for copying fields in the tool table – 74

PLC soft keys can be added to NC soft-key rows 4–151 –

Ethernet: the name of a network printer can be given 6–40 –

The probe results of the manual probing function can be taken over

immediately in the datum tables

MP6170, MP6171: Multiple measurement with measuring tolerance 4–207 305

A separate block of calibration data for TS and TT for every traverse

range

With MP6500 Bit 4 you can set whether or not speed should be

limited to 1000 rpm during tool measurement with TT

MP6500 Bit 9: Automatic determination of the basic rotation for

cubical probe contacts

W760: Angular offset of the tilting axes for automatic adjustment of

the touch probe center offset

The TS calibration data can be stored in the tool table using soft key – 297

Cycles 31 to 33 (Tool measurement) were expanded by the input field

"Q parameters for result"

With MP6500 Bit 5 and Bit 6 you can define how to proceed if tool

breaks

FN17, FN18 ID990 NR1 Programmed probing 5–13 –

FN17: ID210 NR6 Tilting the working plane during program run

active/inactive

FN18 ID350 Enhanced touch probe data 5–20 263

4–29 227

– 126

–74

– 293

4–206 –

4–227 –

4–227 –

4–207 –

–87

4–227 –

5–13 –

User's

Manual

1–2 TNC 426 B, TNC 430 Update Information No. 3 November 97

Page 24

Improvements Technical

Manual

User's

Manual

FN23: CDATA Calculating the circle center from 3 touch points – 255

FN24: CDATA Calculating the circle center from 4 touch points – 255

FN25: Setting the datum 4–117 –

ISO: Cycles with a number ≥ 200 can be programmed with graphic

––

support (also OEM cycles)

ISO: Cycles G75 and G76 (Rectangular pocket) were expanded by the

––

input field "corner radius"

ISO: Parameter H (max. permissible angle) can be entered after M112 – –

ISO: G60 Running digitized data is new – –

MP2000 was removed. Digital axes can be defined in MP120 4–6 –

In the compensation value tables COM and CMA you can use soft

4–17 –

keys to select the columns for the desired axes

Non-linear axis error compensation: Max. number of compensation

4–16 –

points increased from 640 to 1280

A formula can be input in MP2020 (Distance covered in one motor

4–81 –

revolution)

MP2541, MP2551: Frequency filter for spindle 4–114 –

The number of tools in the tool table was increased from 254 to

4–248 71

65 535

M4014: Reversing the count direction of the linear encoder for the

4–97 –

spindle

Cooperative multi-tasking in the PLC (SPAWN command) 5–156 –

Module 9019: Check program storage 5–34 –

Oscilloscope recordings can be stored in a file. 4–305 –

If you are using OEM cycles, you need to create a new cycle structure with CycleDesign to

be able to program the new HEIDENHAIN cycles 32 and 204. You will need the

CycleDesign software version 1.21

November 97 Update Information No. 3 TNC 426 B, TNC 430 1–3

Page 25

New hardware

Since February 1997 HEIDENHAIN has been delivering a new hardware for the LE 426 B and

LE 430.

The advantages of the new hardware:

• 3-row VGA connector for BC 120. With the new connecting cable Id. Nr. 312 878 .. there is no

longer need for an adapter connector

• Internal working memory doubled (4 MB)

• More memory space available on larger hard disk (1.5 GB)

• LE 426 PB and LE 430 PA: Three current controllers. Maximum speed = value from Siemens

data sheet

The NC software 280 470 runs on this new hardware as of version 06.

The full benefit of its new range of features can only be seen however if the new hardware is used

together with the new NC software 280 472 as of version 01.

LE 426 PB with digital spindle to 15 000 rpm

As an option the LE 426 PB is supplied for digital spindles with up to 15 000 rpm. See pages 2–10

and 3–10 in the new Technical Manual.

1–4 TNC 426 B, TNC 430 Update Information No. 3 November 97

Page 26

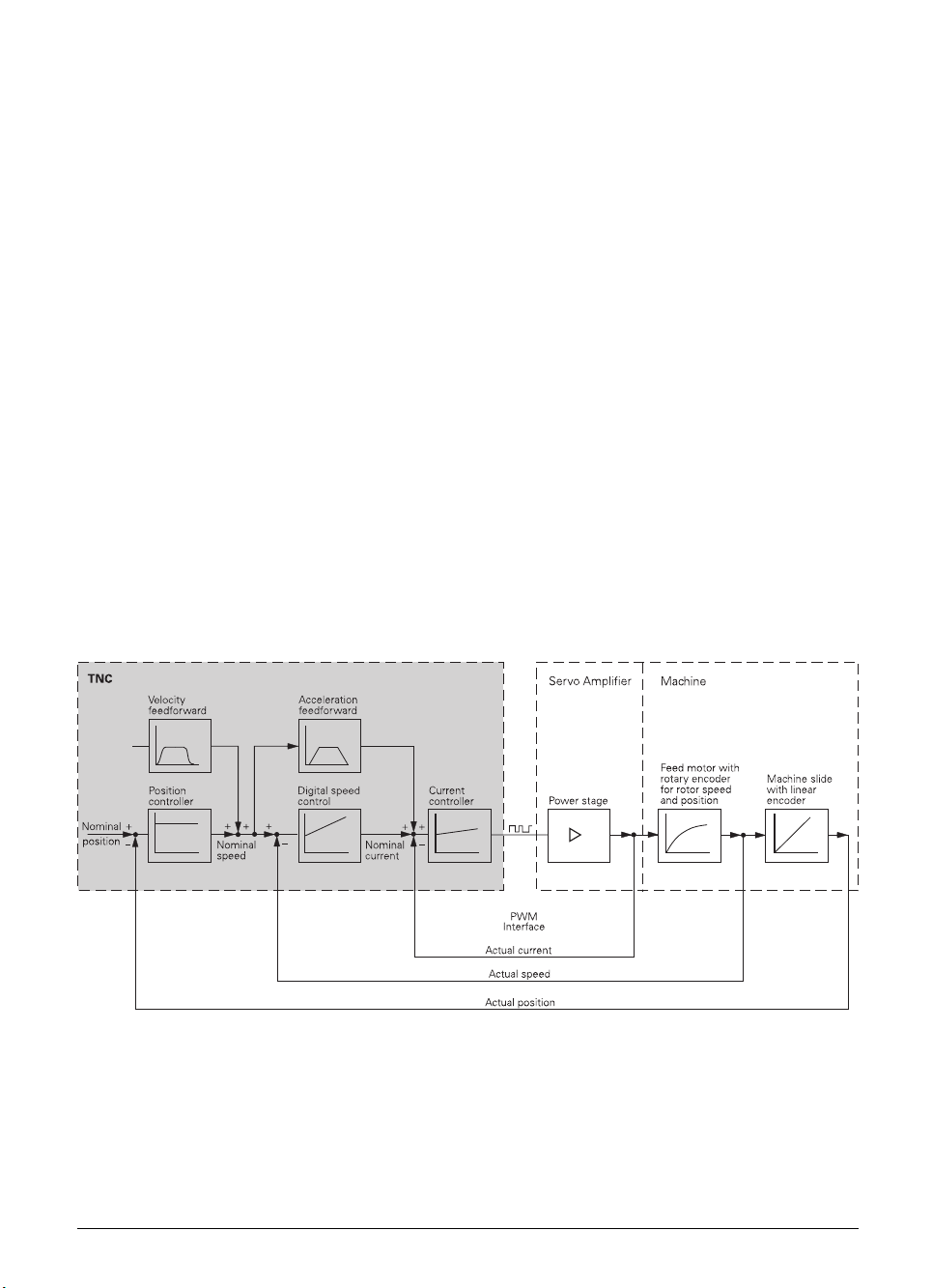

2 Introduction

2.1 Integrated Current Control

HEIDENHAIN contouring controls are designed for integration in milling, drilling and boring machines

as well as machining centers.

The TNC 426 PB / TNC 430 PA has integral drive controllers; these control the drive amplifier by

means of Pulse Width Modulated (PWM) signals.

Integration of the drive controllers in the TNC 426 PB / 430 PA offers the following advantages:

• All the software is contained centrally in the NC; this means that the individual components of

the NC such as feed axes, spindle, NC or PLC are optimally matched.

• High control quality, because the position control, speed control and current control are

combined into one unit.

• For commissioning, optimization and diagnosis, the same functions are available both for the

feed drive and the main spindle.

The TNC 426 PB can control machines with up to five axes and spindle speeds up to 9000 rpm,

option: 15 000 rpm (spindle speeds are valid for motors with two pole pairs). Powerful

microprocessor hardware and an integrated hard disk with 900 MB guarantee almost unlimited NC

memory and a short processing time — even for long programs. These are ideal preconditions for

tool and mold construction.

The TNC 430 PA supports six digitally controlled NC axes and three analog controlled secondary

axes, as well as digitally controlled spindle speeds up to 15 000 rpm (for motors with two pole pairs).

Control concept of the TNC 4xx PA

The TNC 426 CB is the version of the TNC 426 that is equipped with analog speed command

interface and can control machines with up to five axes plus spindle.

The TNC 430 CA also has analog speed command interface for machines with up to eight axes plus

spindle. A ninth axis can be controlled with an additional PCB.

November 97 Integrated Current Control TNC 426 B, TNC 430 2–1

Page 27

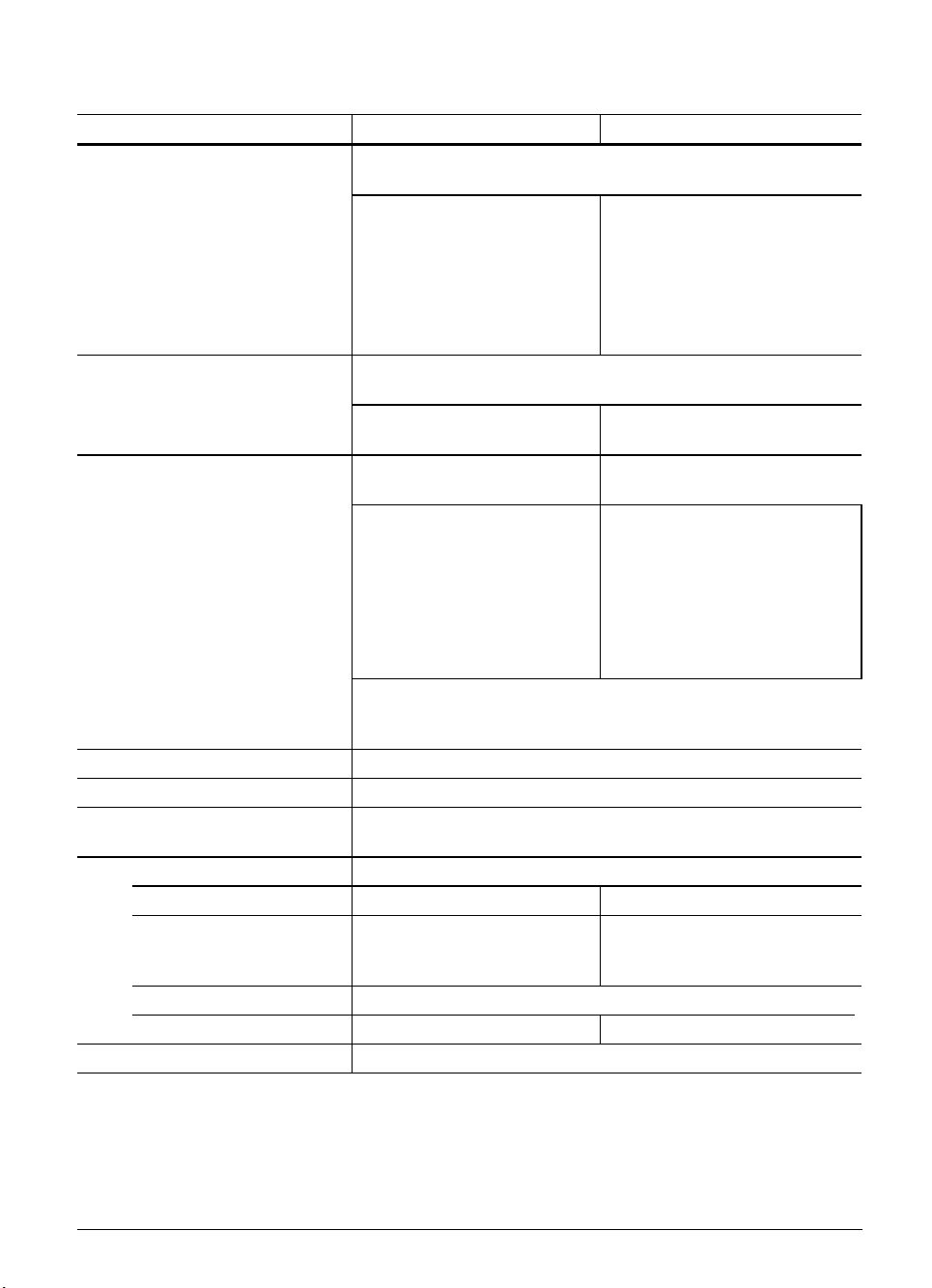

2.2 Brief Description

Technical Data TNC 426 TNC 430

Basic model with integral drive

control

All position encoder and motor encoder inputs 1 V

TNC 426PB:

5 axes plus spindle

(max. 9000 rpm, option:

15 000 rpm) with position

encoder and motor encoder

inputs.

TNC 430PA:

• 5 axes plus spindle

(max. 15000 rpm) with

position encoder and motor

encoder inputs

th

axis with motor encoder

•6

input

PP

Basic model with analog speed

All position inputs 1 V

PP

command interface

TNC 426CB:

5 axes plus spindle

Options Position inputs for the axes:

11 µA

PP

–

• Digitizing with 3-D triggering touch probe

• Digitizing with 3-D measuring touch probe

• Ethernet interface

Display 15-inch CRT color monitor

Program memory Hard disk with 900 MB

Input precision and

display step

Interpolation

Straight lines 5 of 5 axes 5 of 9 axes

Circular arcs 2 of 5 axes;

Helices Combination of circular and linear motion

Spline

Block processing time From the hard disk: 4 ms

Up to 0.1 µm for linear axes

Up to 0.0001° for angular axes

3 of 5 axes with tilted

working plane

–

TNC 430CA:

8 axes plus spindle

–

TNC 430CA:

Position input for 9

th

axis

TNC 430PA:

• Position inputs for 3

additional axes with analog

speed command interface

• Position input for 6

th

axis

2 of 9 axes;

3 of 9 axes with tilted

working plane

Cubical splines can be input

2–2 TNC 426 B, TNC 430 Brief Description November 97

Page 28

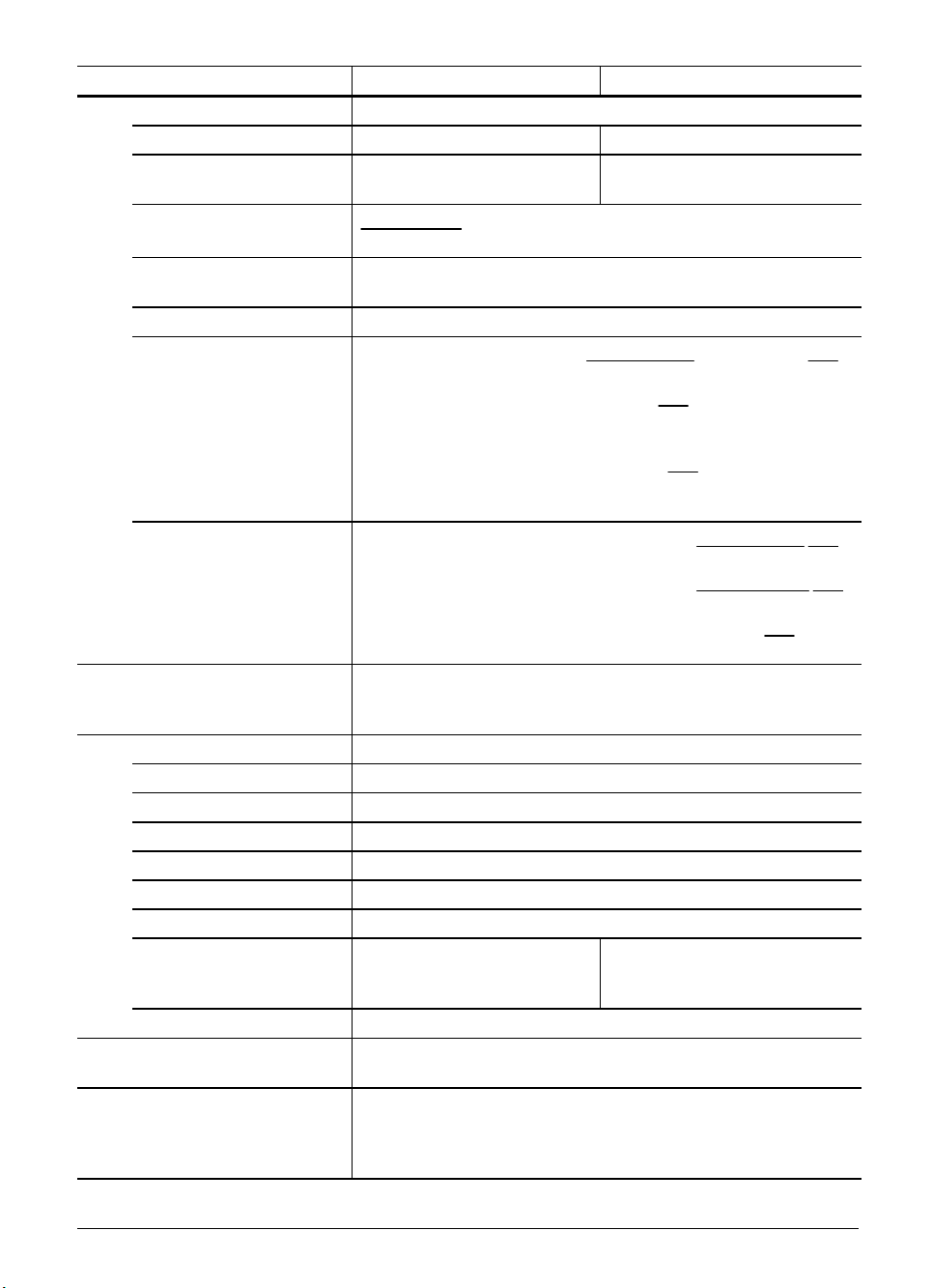

Machine Integration TNC 426 TNC 430

Control

Integral drive control TNC 426 PB TNC 430PA

Analog speed command

interface

Position loop resolution

Cycle time: path

interpolation

Cycle time: speed TNC 426 PB, TNC 430PA: 0.6 ms

Feed rate

Speed

Error compensation Linear / non-linear axis error, backlash, reversal spikes during

Integrated PLC

PLC memory Hard disk

Main memory (RAM) 128 KB (approx. 16000 commands)

PLC cycle time 21 ms

PLC inputs 24 Vdc 56 (additional inputs as option: see PL 410B)

PLC outputs 24 Vdc 31 (additional outputs as option: see PL 410 B)

Analog inputs ±10 V 3 (additional analog inputs as option: see PL 410 B)

Analog outputs ±10 V TNC 426 PB: 13

Inputs for thermistors 3 (additional inputs as option: see PL 410B)

Commissioning aids • Oscilloscope

Data interfaces • One each RS-232-C/ V.24 and RS-422/ V.11 up to 115 kbaud

TNC 426CB TNC 430CA

Signal period

1024

3 ms

TNC 426PB, TNC 430 PA:

TNC 426 CB, TNC 430 CA: Up to 60

TNC 426PB (standard):

TNC 426PB (option), TNC 430 PA:

TNC 426 CB, TNC 430 CA: 100 000

circular movements, offset, thermal expansion, stiction,

sliding friction

TNC 430CB: 7 (with 5 NC

axes + spindle)

• Trace function

• Expanded data interface with LSV2 protocol for external

operation of the TNC

• Option: Ethernet interface, approx. 200 to 1000 kilobaud

18 000

No. pole pairs

20 µm grating period

Up to 300

100 µm grating period

TNC 430 PA: 13

TNC 430 CA: 3 (with 9 NC

axes + spindle)

• Screw pitch

m

for encoders with

min

m

for encoders with

min

18 000

No. pole pairs

30 000

No. pole pairs

1

min

min

min

1

1

1

min

November 97 Brief Description TNC 426 B, TNC 430 2–3

Page 29

User Functions TNC 426 TNC 430

Programming HEIDENHAIN plain language and ISO

Position data Nominal positions for straight lines and circular arcs in Cartesian

or polar coordinates, absolute or incremental dimensional data,

display and entry in mm and inches

Contour approach and departure • Via straight line: tangential or perpendicular (APPR/DEP),

• Via circular arc (APPR-/DEP)

• Via rounding radius (RND)

Tool compensation • Tool radius in the working plane and tool length

• Radius-compensated contour look ahead for up to 99 blocks

(M120)

Cutting data tables For the automatic calculation of speed and feed rate from

various definable cutting/workpiece material combinations

Constant contouring speed • Relative to the tool's center point path

• Relative to the tool's cutting edge (M109, M110, M111)

3-D machining • Insertion of rounding radius between two straight line

segments (M112, M113, M124)

• Feed rate reduction during plunging (M103)

• 3-D tool compensation through surface normal vectors

• Automatic compensation of machine geometry when

working with tilted axes (M114, M115, M128, M130)

• Changing the position of the swivel head with the electronic

handwheel during program run. The position of the tool tip

does not change.

• Jolt reduction

• Spline

Machining with rotary tables • Programming of cylindrical contours

• Feed rate in mm/min (M116)

FK free contour programming FK free contour programming in HEIDENHAIN plain language

with graphic support for workpiece drawings not dimensioned

for NC

Subprogramming Program section repeats, subprograms, program calls

Background

programming

Fixed cycles • Peck drilling, tapping with or without a floating tap holder,

Coordinate transformation • Datum shift, rotation, mirror image

Creating programs while another program is being run, also with

graphic support

reaming, boring, hole patterns, slot milling, rectangular and

circular pocket milling, multipass milling of plane surfaces

• OEM cycles (special cycles developed by the machine tool

builder) can also be integrated.

• Contour pockets – also contour-parallel

• Contour train

• Scaling factor (axis specific)

• Tilting the working plane

2–4 TNC 426 B, TNC 430 Brief Description November 97

Page 30

User Functions TNC 426 TNC 430

Q parameters; programming

with variables

Programming aids • Pocket calculator

Teach in Actual positions can be transferred directly into the NC program

Test graphics Graphic simulation before a program run:

Programming graphics In the Programming and Editing operating mode, the contours of

Program run graphics; display

modes

Machining time • Calculation of machining time in the Test Run operating

Returning to the contour • Mid-program startup in any block in the program, returning

Datum tables Several datum tables, each with 254 datums

Pallet tables Several pallet tables with various different entries for selection

• Mathematical functions =, +,–, *, ÷, sin α, cos α,

angle α from sin α and cos α, a, a² + b²

• Logical comparisons (=, ≠, <, >)

• Parentheses

• tan α, arc sin, arc cos, arc tan, an, en, ln, log, absolute value

of a number, constant π, negation

decimal point

• Structuring of part programs

• Graphic support for the programming of cycles

• Plan view

• Projection in three planes

• 3-D representation

• Magnification of details

the NC blocks are drawn while they are being entered

(2-D pencil-trace graphics)

Graphic simulation during real time machining:

• Plan view

• Projection in three planes

• 3-D representation

mode

• Display of the current machining time in the program run

modes

the tool to the calculated nominal position to continue

machining

• Program interruption, contour departure and reapproach

of pallets, NC programs and datums

truncation before or after

,

Export versions TNC 426 CF, TNC 426 PF TNC 430 CE, TNC 430 PE

Linear interpolation 4 of 5 axes 4 of 9 axes

November 97 Brief Description TNC 426 B, TNC 430 2–5

Page 31

Accessories TNC 426 TNC 430

Electronic handwheels One HR 410 portable handwheel, or

one HR 130 panel-mounted handwheel, or

up to 3 HR 150 panel-mounted handwheels via HRA 110

handwheel adapter

Superimpose handwheel positioning during program run (M118)

Touch probe systems TS 220 3-D triggering touch probe with cable

connection, or

TS 630 3-D triggering touch probe with infrared

transmission

TT 120 3-D triggering touch probe for tool

measurement and inspection

Digitizing of 3-D surfaces • Option: with the TS 220 3-D triggering touch probe and a

software module for the TNC

• Option: adapter kit for a 3-D measuring touch probe.

• PC evaluation software for digitized data: SUSA

PC evaluation software for

SUSA for PCs

digitized data

Interface card TNC 426 PB, TNC 430 PA: For connection of

power modules for the SIMODRIVE 611 inverter system

Protective PCB for dc-link

power supply

Protective PCB for integration in the SIEMENS input module to

secure the dc-link power supply of the logic unit.

PLC input/output unit Up to four PL 410 B

Version 1:

Additional 64 PLC inputs and 31 PLC outputs per input/output

unit

Version 2:

Additional 64 PLC inputs and 31 PLC outputs, plus four

± 10 V analog inputs and 4 inputs for thermistors per

input/output unit

2–6 TNC 426 B, TNC 430 Brief Description November 97

Page 32

2.3 Software

The logic unit contains separate software for the NC section and the PLC section. The software is

identified by an eight-figure number.

After switching on the control, the NC software, PLC software and software-options

numbers are displayed on the screen. The software number can also be directly requested with the aid

of the MOD function.

2.3.1 NC Software

NC software number

The first 6 figures of the NC software number identify the type of control, the last two identify the

version of the software.

Software type

Due to restrictions on the export of the TNC, HEIDENHAIN can also deliver a special export version.

This export version differs from the standard control through the installed software type.

HEIDENHAIN assigns a new software type whenever comprehensive new functions are introduced.

Software type Linear interpolation

TNC 426 PB, TNC 426 CB

TNC 430 PA, TNC 426 CA

TNC 426 PF, TNC 426 CF

TNC 430 PE, TNC 426 CE

280 470 280 472 Up to 5 axes

280 471 280 473 Up to 4 axes

2.3.2 Software Option

HEIDENHAIN offers “Digitizing with a Triggering Touch Probe” and “Digitizing with Triggering and

Measuring Touch Probes” as software options (see chapter “Machine Integration”). Whenever a

contouring control is ordered with one of these options, HEIDENHAIN installs an additional software

module or PCB in the logic unit and assigns another variant to the part identification number (Id. Nr.)

of the logic unit. The option number is displayed on the screen in addition to the NC and PLC

software numbers.

Logic units already in the field can be retrofitted by the end user with the digitizing software

module. Please contact HEIDENHAIN

Option Option No. Id. Nr. of the

Digitizing with triggering touch probe 1 286 405 01 246 051 01

Digitizing with measuring and triggering

touch probes

SP 2/1 11 311 647 51 –

November 97 Software TNC 426 B, TNC 430 2–7

for more information.

component set

Id. Nr. of the

software module

Page 33

2.3.3 PLC Software

The PLC software is stored on the hard disk of the TNC. HEIDENHAIN has developed a PLC

commissioning program for the TNC. The source code is available from HEIDENHAIN. This program

can be easily adapted to suit your machine with the PLC programming software PLCdesign.

2.3.4 Software Exchange

The NC software is located on EPROMs (the sockets are illustrated below). The dialog languages are

stored on the hard disk. If there are no up-to-date dialog languages on the hard disk, load the English

dialog language from the EPROMs (selectable with MP7230.x). If a software exchange becomes

necessary, HEIDENHAIN

dialog languages.

Procedure for software exchange:

The software must be exchanged only by trained personnel.

⇒ Enter the code number 95148

⇒ Press the MOD key

⇒ Press the UPDATE DATA and CONVERT BIN=>ASC soft key:

All files on the hard disk will be converted from binary to ASCII format. The free space on the

hard disk must be at least 50% larger than the largest file. If this is not the case you must save

this file through the data interface. The extensions of the binary files and of the corresponding

converted ASCII files are:

.H ⇔ .H% .I ⇔ .I% .T ⇔ .T%

.TCH ⇔ .TC% .D ⇔ .D% .P ⇔ .P%

.PNT ⇔ .PN% .COM ⇔ .CO% .CMA ⇔ .CM%

⇒ Exchange the EPROMs

will provide the EPROMs with the NC software and a floppy disk with all

Sockets on processor board

IC 3

NC 4 MB

IC S

SW module

Danger of electrical shock!

Switch off the main switch before opening the housing.

2–8 TNC 426 B, TNC 430 Software November 97

IC 1

NC 4 MB

IC 4

NC 4 MB

IC 2

NC 4 MB

Page 34

⇒ Edit or erase the machine parameters. You will find information on the machine parameters in

the MPDOC.A file on the supplied floppy disk.

⇒ Press the END key to exit the machine parameter editor. The error message LANGUAGE LOAD

ERROR appears.

⇒ On the PC, enter the SETUP command to load the NC dialogs, HEIDENHAIN cycles etc. from the

provided floppy disk. The floppy disk also contains a detailed description in the README.TXT file.

⇒ Press the UPDATE DATA and CONVERT ASC=>BIN soft key:

All files on the hard disk are converted from ASCII into binary format.

⇒ Reload the files that you have backed up through the data interface.

⇒ Switch the TNC off and on to activate the new NC dialogs.

2.3.5 Data Backup

HEIDENHAIN provides a free program, TNCBACK.EXE, for backing up files in the TNC 426. We

recommend to the manufacturer whenever he supplies a machine tool to also provide a floppy disk

containing a copy of all machine-specific data, backed up with TNCBACK.EXE. The floppy disk

must also contain a copy of TNCBACK.EXE.

Before exchanging his control unit, the customer can save the data from the TNC,

especially the TNC:\ partition with its directories containing the part programs (see the user's

instructions on the floppy disk).

2.4 Hardware

The eight-digit ID number of the logic unit consists of the 6-digit basic ID number followed by the 2digit version number. The basic ID number designates significant hardware differences (e.g. type of

logic unit encoder inputs). The version number identifies the following differences:

version xy:

x = Identifier for a hardware change

y = 3 = Export version with “Digitizing with Triggering Touch Probe” option

4 = Standard version with “Digitizing with Triggering Touch Probe” option

7 = Standard version with “Digitizing with Measuring and Triggering Touch Probes” option

8 = Export version without option

9 = Standard version without option

November 97 Hardware TNC 426 B, TNC 430 2–9

Page 35

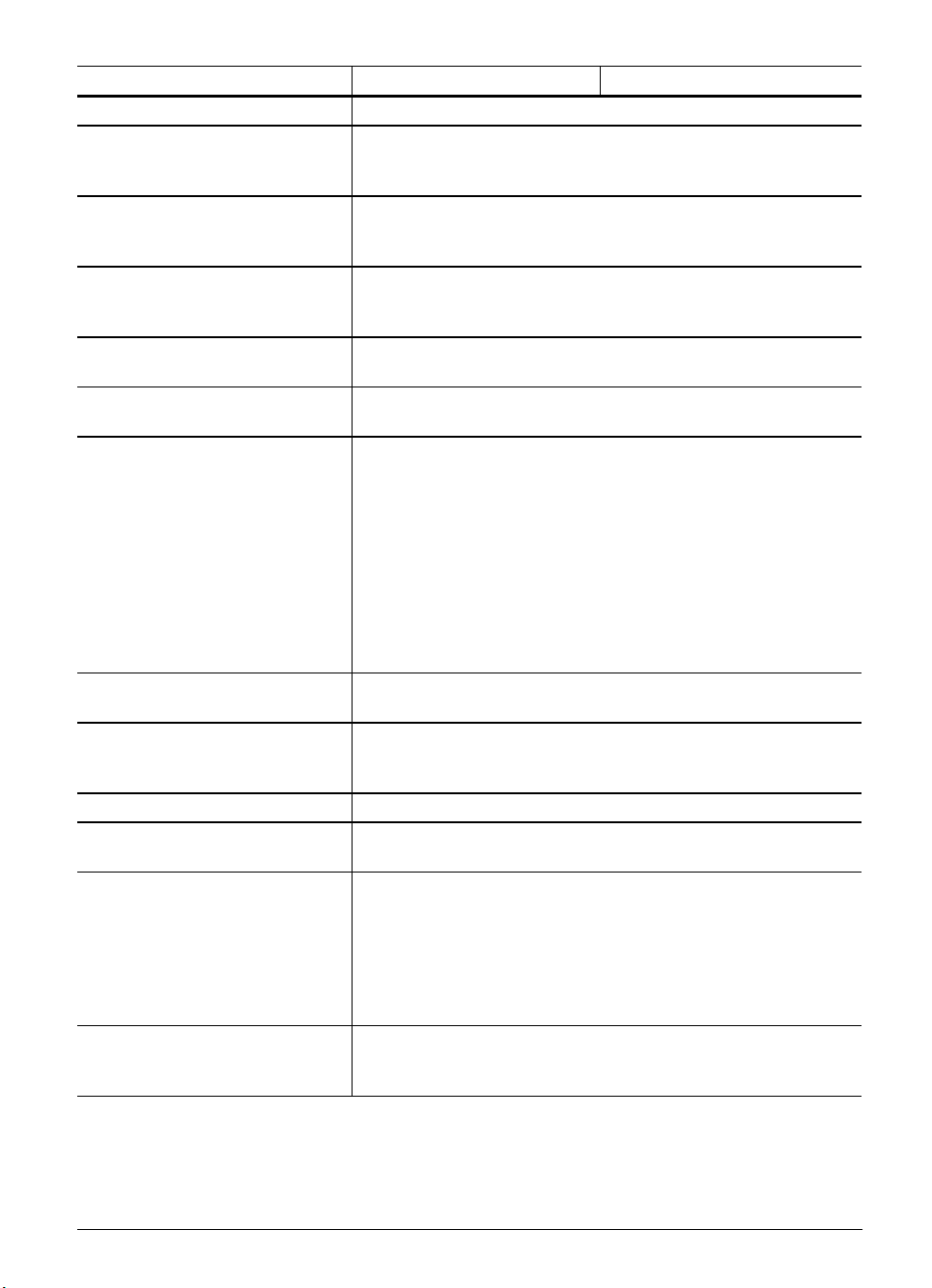

2.4.1 ID Numbers

BC 120 BF 120

LE 426 CB

5 position inputs 1 V

1 spindle position 1 V

5 position inputs 1 V

1 spindle position 1 V

5 position inputs 11 µA

1 spindle position 1 V

(350 kHz)

PP

(350 kHz)

PP

(50 kHz)

PP

(350 kHz)

PP

(50 kHz)

PP

(350 kHz)

PP

LE 426 PB

5 position inputs 1 V

1 spindle position 1 V

6 motor encoder inputs 1 V

(350 kHz)

PP

(350 kHz)

PP

PP

Spindle with up to 9000 rpm Id. Nr. 312 000 .. Id. Nr. 313 527 ..

Spindle with up to 15 000 rpm Id. Nr. 315 475 .. Id. Nr. 318 178 ..

5 position inputs 1 V

1 spindle position 1 V

6 motor encoder inputs 1 V

(50 kHz)

PP

(350 kHz)

PP

PP

Spindle with up to 9000 rpm Id. Nr. 326 414 .. Id. Nr. 326 421 ..

Spindle with up to 15 000 rpm Id. Nr. 326 416 .. Id. Nr. 326 420 ..

5 position inputs 11 µA

1 spindle position 1 V

6 motor encoder inputs 1 V

PP

(350 kHz)

PP

PP

(50 kHz)

Spindle with up to 9000 rpm Id. Nr. 311 999 .. Id. Nr. 313 526 ..

Spindle with up to 15 000 rpm Id. Nr. 317 349 .. Id. Nr. 318 177 ..

LE 430 CA

8 position inputs 1 V

1 spindle position 1 V

5 position inputs 1 V

3 position inputs 1 V

1 spindle position 1 V

(350 kHz)

PP

(350 kHz)

PP

(50 kHz)

PP

(350 kHz)

PP

(350 kHz)

PP

LE 430 PA

5 position inputs 1 V

1 spindle position 1 V

7 motor encoder inputs 1 V

5 position inputs 1 V

1 spindle position 1 V

7 motor encoder inputs 1 V

(350 kHz)

PP

(350 kHz)

PP

PP

(50 kHz)

PP

(350 kHz)

PP

PP

Id. Nr. 312 001 .. Id. Nr. 313 524 ..

Id. Nr. 326 415 .. Id. Nr. 326 419 ..

Id. Nr. 312 002 .. Id. Nr. 313 525 ..

Id. Nr. 311 050 .. Id. Nr. 313 523 ..

Id. Nr. 326 418 .. Id. Nr. 326 424 ..

Id. Nr. 311 049 .. Id. Nr. 313 521 ..

Id. Nr. 326 417 .. Id. Nr. 325 716 ..

Version Change

xxx xxx 2x First issue

xxx xxx 3x More powerful inverter

xxx xxx 4x 4 MB RAM; 3-row VGA connection; 3-phase current controller

2–10 TNC 426 B, TNC 430 Hardware November 97

Page 36

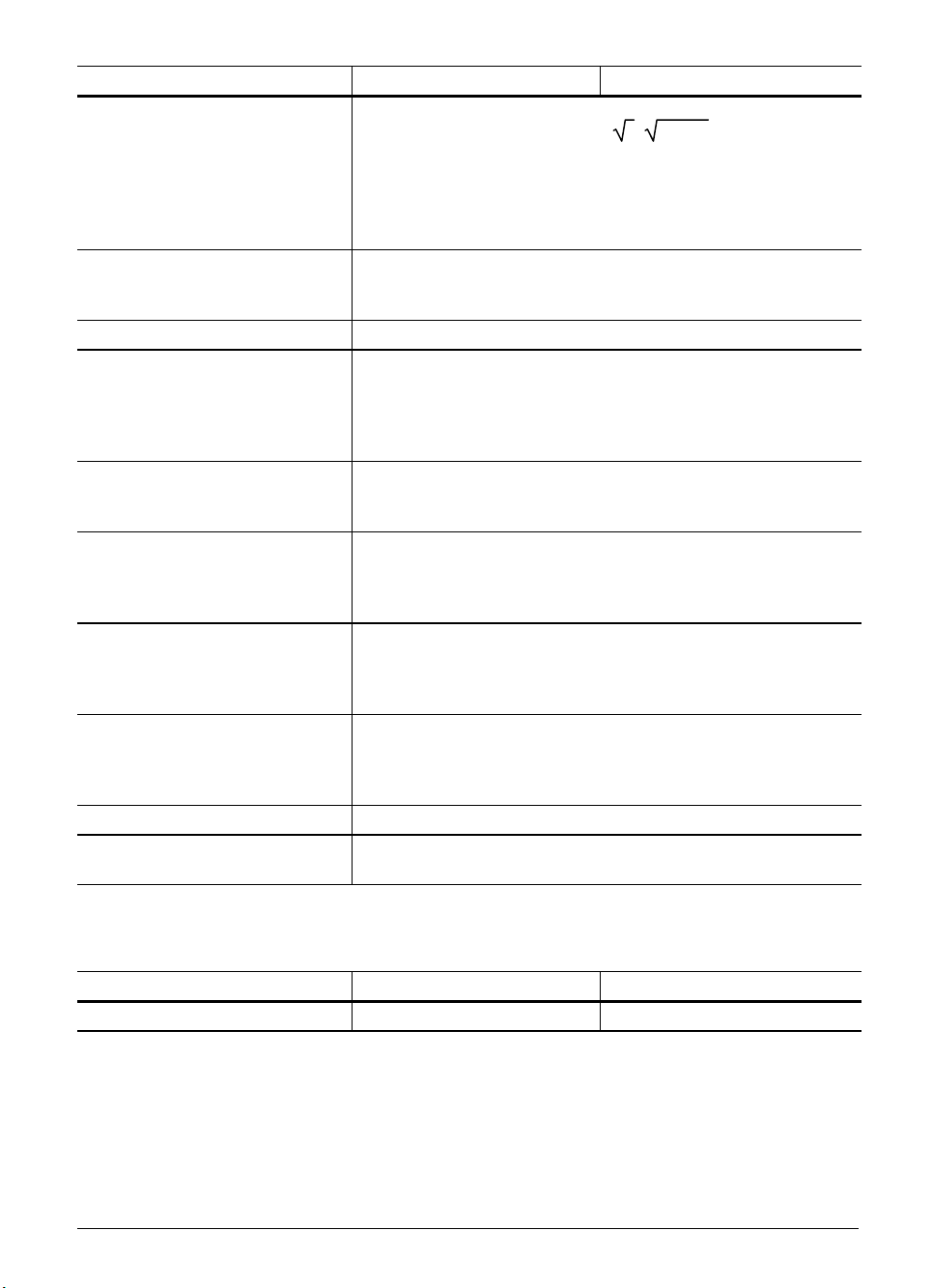

TE 401 B

Suitable for BC 110 B (black) Id. Nr. 250 517 05

TE 420

Suitable for BC 120 / BF 120 (gray) Id. Nr. 313 038 10

MB 420

Suitable for BC 120 / BF 120 (gray) Id. Nr. 293 757 12

BC 110 B (black)

14-inch screen with color graphics

Id. Nr. 260 520 01

(640 x 490 pixels)

2-row/3-row adapter for connection to LE

Id. Nr. 313 434 01

with Id. Nr. xxx xxx 4x via connecting

cable Id. Nr. 312 878 ..

2-row/3-row adapter for connection to

Id. Nr. 324 862 01

LE with Id. Nr. xxx xxx 4x via connecting

cable Id. Nr. 250 477 ..

BC 120 (gray)

15-inch screen with color graphics

Id. Nr. 313 037 01

(640 x 490 pixels)

3-row/2-row adapter for connection to LE

Id. Nr. 313 434 02

with Id. Nr. xxx xxx 3x

BF 120

TFT color flat-panel display Id. Nr. 313 506 10

PL 410 B

64 switching inputs 24 Vdc

Id. Nr. 263 217 12

31 switching outputs 24 Vdc

64 switching inputs 24 Vdc

Id. Nr. 263 217 02

31 switching outputs 24 Vdc

4 analog inputs ±10 V

4 inputs for thermistors

November 97 Hardware TNC 426 B, TNC 430 2–11

Page 37

Options

Interface card for connection of

Id. Nr. 291 070 01

power modules for the SIMODRIVE 611

inverter system

Protective PCB for dc-link power supply Id. Nr. 296 965 01

Additional position input for a 6th/9

th

axis

Id. Nr. 311 537 51

(350 kHz)

Position inputs for 3 additional axes with

Id. Nr. 294 130 51

nominal speed command interface

(350 kHz)

Ethernet interface Id. Nr. 293 890 51

Digitizing with triggering 3-D touch probe Id. Nr. 286 405 01

Digitizing with measuring 3-D touch

Id. Nr. 311 647 51

probe (SP 2/1)

Adapter for encoder signals

TTL (HEIDENHAIN layout) / 1 V

TTL (SIEMENS layout) / 1 V

11 µAPP / 1 V

PP

PP

PP

Id. Nr. 317 505 01

Id. Nr. 317 505 02

Id. Nr. 313 119 01

2–12 TNC 426 B, TNC 430 Hardware November 97

Page 38

2.5 Release Dates

2.5.1 NC Software Versions 280 470 and 280 471

NC software Release date

280 470 01 05/96 Export version: 280 471 01

First release:

NC software Release date

280 470 02 06/96 Export version: 280 471 02

Improvements:

• M132 with TIME parameter

• Module 9035 Parameter 21: Control model

• M118, M120 also in ISO

• Cycle 27: Cylinder surface also in tilted working plane

• MP7680 Bit 9 was added

• MP2423, MP2425, MP2427, MP2433, MP2451, MP2451, MP7245, MP7250 were removed

• MP2402 was changed: Gain for axis current controller at maximum speed

NC software Release date

280 470 03 08/96 Export version: 280 471 03

Improvements:

• GROSS POSITIONING ERROR F is new

NC software Release date

280 470 04 09/96 Export version: 280 471 04

Improvements:

• MP6500 Bit 4 and Bit 5 were added

• FN18: Group numbers 350 and 500 are new

• FN17: Group number 500 is new

• A Q-parameter was added to the cycles for tool measurement (31 to 33), where the

measurement result will be stored

NC software Release date

280 470 05 12/96 Export version: 280 471 05

Improvements:

• Rotary axes can be synchronized axes

• MP7682 Bit 1 was added

• In the compensation value tables .CMA and .COM the numbers of the axes will be entered as

opposed to the names

• Threshold for PLC: Time Out was increased from 200% to 300%

• MP6500 Bit 5, Bit 6 and Bit 8 were added

• FN18: Group numbers 51 and 52 are new

• FN17: Group number 210 is new

• Input range for MP2500 and MP2501 increased to 1000

• The maximum number of points for all compensation value tables was increased to 1280

• Coded NC error messages are displayed in the conversational format

November 97 Release Dates TNC 426 B, TNC 430 2–13

Page 39

NC software Release date

280 470 06 2/97 Export version: 280 471 07

Improvements:

• Datums can be set using the keys A B, C, X, Y, Z, U, V, W, a, b, c, x, y, z, u, v, w

• The software also runs on the special hardware version of the LE 426 PB with spindle speeds up

to 15 000 rpm

• The NC software also runs on the new LE 426 B and LE 430 hardware with the

Id. Nr. xxx xxx 4x

NC software Release date

280 470 07 03/97 Export version: 280 471 07

Improvements:

• MP2541 and MP2551 (frequency filter for spindle) are new. Input as with MP2540 and MP2551

for the axes.

• The compensation of reversal peaks during circular traverse was improved (MP711.x to

MP716.x).

NC software Release date

280 470 08 5/97 Export version: 280 471 08

Improvements:

• Hungarian conversational language new

• D760 (offset for tilting axes, touch probe center offset) new

• MP750 and MP752 (compensation of reversal error) new

• MP3143 expanded:

3 = as for input value 1, however the second reference mark is evaluated first

NC software Release date

280 470 09 6/97 Export version: 280 471 09

Improvements:

• MP6500 expanded: bit 10 and bit 11

NC software Release date

280 470 10 7/97 Export version: 280 471 10

2–14 TNC 426 B, TNC 430 Release Dates November 97

Page 40

2.5.2 NC software versions 280 472 and 280 473

NC software Release date

280 472 01 4/97 Export version: 280 473 01

Improvements:

• New function "Fast contour milling": Cycle 32 or G62 and MP1091.x

• Automatic calculation of cutting data

• TCPM (Tool Center Point Management

during machine run. Any misalignments in tilted axes are then corrected automatically.

• Additional information with the HELP key

• Input menu for fixed input values can be selected with the GOTO key

(e.g. baud rate)

• New pallet management

• Freely-definable tables

• NC blocks can be transferred in spline format

• More hard-disk memory space (1.5 gigabytes)

• You can select between standard and enhanced file management with the MOD function PGM

MGT

• The positions of all nine axes are shown in the status display. The spindle position overwrites the

ninth axis

• Copying progress is shown in a superimposed window

• The number of Q parameters was increased from 299 to 399

• Q parameters also permissible in FK blocks

• M110 also effective in contour pocket cycle

• Cycle 204: Back boring

• With MP7682 Bit 2 you can set whether rotary axes should always be positioned by the shorter

path

• A chamfer feed rate can be entered in the NC block "Chamfer" (CHF)

• Cycle 19 "Machining plane" was expanded by the parameters feed rate and setup clearance

(only when the tilting axes are positioned with Cycle 19. This is set in MP7500)

• M114 can also be used with non-controlled or PLC axes

• Hungarian as additional conversational language

• All soft keys appear in the set conversational language

• Language-dependent soft keys for OEM cycles

• The soft keys for FK programming only appear once you press the FK key

• Soft key F for feed rate in the manual operating modes

• New soft key: INCREMENT OFF/ON

• New soft key: HIDE TOOLS OFF/ON: the only tools shown in the tool table are those in the tool

magazine

• New soft keys for copying fields in the tool table

• PLC soft keys can be added to NC soft-key rows

• Ethernet: the name of a network printer can be given

• The probe results of the manual probing function can be taken over immediately in the datum

tables

• MP6170, MP6171: Multiple measurement with measuring tolerance

• A separate block of calibration data for TS and TT for every traverse range

• With MP6500 Bit 4 you can set whether or not speed should be limited to 1000 rpm during tool

measurement with TT

• MP6500 Bit 9: Automatic determination of the basic rotation for the cubical probe contact

• W760: Angular misalignment of the tilting axes for automatic adjustment of the touch probe

center misalignment

• The TS calibration data can be stored in the tool table via soft key

November 97 Release Dates TNC 426 B, TNC 430 2–15

: With M128 you can superimpose manual axis traverse

)

Page 41

• Cycles 31 to 33 (Tool measurement) were expanded by the input field "Q parameters for result"

• With MP6500 Bit 5 and Bit 6 you can define how to proceed if tool breaks

• FN17, FN18 ID990 NR1 Programmed probing

• FN17: ID210 NR6 Tilting the working plane during program run active/inactive

• FN17: ID50 Overwrite tool table

• FN17: ID210 Overwrite basic rotation

• FN18 ID350 Enhanced touch probe data

• FN23: CDATA Calculating the circle center from 3 touch points

• FN24: CDATA Calculating the circle center from 4 touch points

• FN25: Setting the datum

• ISO: Cycles with a number ≥ 200 can be programmed with graphic support (also OEM cycles)

• ISO: Cycles G75 and G76 (Rectangular pocket) were expanded by the input field "corner radius"

• ISO: Parameter H (max. permissible angle) can be entered after M112

• ISO: G60 Running digitized data is new

• MP2000 was removed. Digital axes can be defined in MP120

• In the compensation value tables COM and CMA you can use soft keys to select the columns for

the desired axes

• Non-linear axis error compensation: Max. number of compensation points increased from 640 to

1280

• A formula can be input in MP2020 (Distance covered in one motor revolution)

• MP2541, MP2551: Frequency filter for spindle

• The number of tools in the tool table was increased from 254 to 37 767

• M4019: Reversing the count direction of the linear encoder on the spindle

• Cooperative multi-tasking in the PLC (SPAWN command)

• Automatic tool recognition (BIS)

• String operand S#Axx new

• Module 9019: Checking program storage

• Module 9035: Expansion of parameters 3, 1000, 1001

• Module 9038: Reading axis information

• Module 9096: Deleting a line in the tool table

• Module 9112: Sending ASCII characters via RS-232

• Module 9113: Receiving ASCII characters via RS-232

• Module 9151: Selecting traverse range and axis designation

• Module 9200/9201: Expanded (PLC soft keys can be added to NC soft-key rows)

• Module 9215: Superimposing PLC window

• Module 9270: Reading from OEM.SYS

• Module 9271: Writing to OEM.SYS

• Automatic offset compensation of the encoder signals

• The oscilloscope recordings can be stored in a file.

• MP7365.5: Selected oscilloscope channel (input $00000FF)

2–16 TNC 426 B, TNC 430 Release Dates November 97

Page 42

NC software Release date

280 472 02 7/97 Export version: 280 473 02

Improvements:

• Cycle 32 changed to "Tolerance"

• M134 new

• System file TNC.SYS new

• MP6500 expanded: Bit 10 Probing routine, Bit 11 Checking tool and changing the tool table

• MP7500 expanded: Bit 3 Setting the datum in a tilted coordinate system

• Editor for creating the format of freely-definable tables

• FN18: ID200 and ID270 new

• FN17: ID350 new

• M4161 new

• PLC commands BTX, BCX, and BSX new

NC software Release date

280 472 03 8/97 Export version: 280 473 03

Improvements:

• Spline blocks also in tilted working plane

• MP7680, bit 10 new (spline at compensated outside corners)

• This software also runs on the old LE 426 CB/PB and LE 430 CA/PA hardware, however with

reduced function range

• Cycle 19: Dialog box "Setup clearance" new

NC software Release date

280 472 04 10/97 Export version: 280 473 04

Improvements:

• Code words LSV2TIME0 to LSV2TIME2 new

• Module 9038 expanded by transfer parameter –1

• DR2 can now be defined in TOOL CALL block

• Spindle DSP limits maximum torque to 2.5 • rated torque

November 97 Release Dates TNC 426 B, TNC 430 2–17

Page 43

✎

2–18 TNC 426 B, TNC 430 Release Dates November 97

Page 44

3 Mounting and Electrical Installation

3.1 Electrical Noise Immunity

Location for use

This device corresponds to Class A according to EN 55022 and is intended primarily for operation in

industrially zoned areas.

Remember that the vulnerability of electronic equipment to noise increases with faster signal

processing and higher sensitivity. Protect your equipment by observing the following rules and

recommendations.

Noise voltages are mainly produced and transmitted by capacitive and inductive coupling. Electrical

noise can be picked up by the inputs and outputs to the equipment, and the cabling.

Likely sources of interference are:

• Strong magnetic fields from transformers and electric motors

• Relays, contactors and solenoid valves

• High-frequency equipment, pulse equipment and stray magnetic fields from switch-mode power

supplies

• Mains leads and leads to the above equipment

Electrical interference can be avoided by:

• A minimum distance between the logic unit (and its leads) and interfering equipment > 20 cm.

• A minimum distance between the logic unit (and its leads) and cables carrying interference

signals > 10 cm. (Where signal cables and cables that carry interference signals are laid together

in metallic ducting, adequate decoupling can be achieved by using a grounded separation shield.)

• Shielding according to IEC 742 EN 50 178.

• Potential compensating lines dia. ≥ 6 mm² (see Grounding Diagram).

• Use of original HEIDENHAIN cables, connectors and couplings.

November 97 Electrical Noise Immunity TNC 426 B, TNC 430 3–1

Page 45

3.2 Heat Generation and Cooling

Please note that the reliability of electronic equipment is greatly reduced by continuous operation at

high temperatures. Be sure to make the necessary arrangements to keep within the permissible

ambient temperature range.

Permissible ambient temperature in operation: 0° C to 45° C

The following means may be employed to ensure adequate heat removal:

• Provide sufficient space for air circulation.

• Build in a ventilator fan to circulate the air inside the control cabinet. The fan must reinforce the

natural convection. It must be mounted so that the warm air is extracted from the logic unit and

no pre-warmed air is blown into the unit. The warmed-up air should flow over surfaces that have

good thermal conductivity to the external surroundings (e.g. sheet metal).

• For a closed steel housing without assisted cooling, the figure for heat conduction is 3 watt/m² of

surface per °C air temperature difference between inside and outside.

• Use of a heat exchanger with separate internal and external circulation.

• Cooling by blowing external air through the control cabinet to replace the internal air. In this case

the ventilator fan must be mounted so that the warm air is extracted from the control cabinet

and only filtered air can be drawn in. HEIDENHAIN advises against this method of cooling, since

the function and reliability of electronic assemblies are adversely affected by contaminated air

(fine dust, vapors etc.). In addition to these disadvantages, a filter that is not adequately serviced

leads to a loss in cooling efficiency. Regular servicing is therefore absolutely vital.

LE

Incorrect

Obstructive

elements

Heat generating

elements

Correct

LE

3–2 TNC 426 B, TNC 430 Heat Generation and Cooling November 97

Page 46

3.3 Humidity

Permissible humidity: < 75% in continuous operation,

< 95% for not more than 30 days p.a. (randomly distributed).

In tropical areas it is recommended that the TNC not be switched off, so that condensation is

avoided on the circuit boards. The heat generation prevents condensation and has no further

disadvantages.

3.4 Mechanical Vibration

Permissible vibration: < 0.5 g

3.5 Mounting Position

Note the following fundamental points on mounting:

• mechanical accessibility,

• permissible environmental conditions,

• electrical noise immunity,

• the electrical regulations that are in force in your country.

November 97 Humidity TNC 426 B, TNC 430 3–3

Page 47

LE 426 CB Logic Unit, TNC 430 CA

>110

>4.33"

Minimum clearance

for servicing!

recommended: =

approx. 250 mm

40

1.57"

80