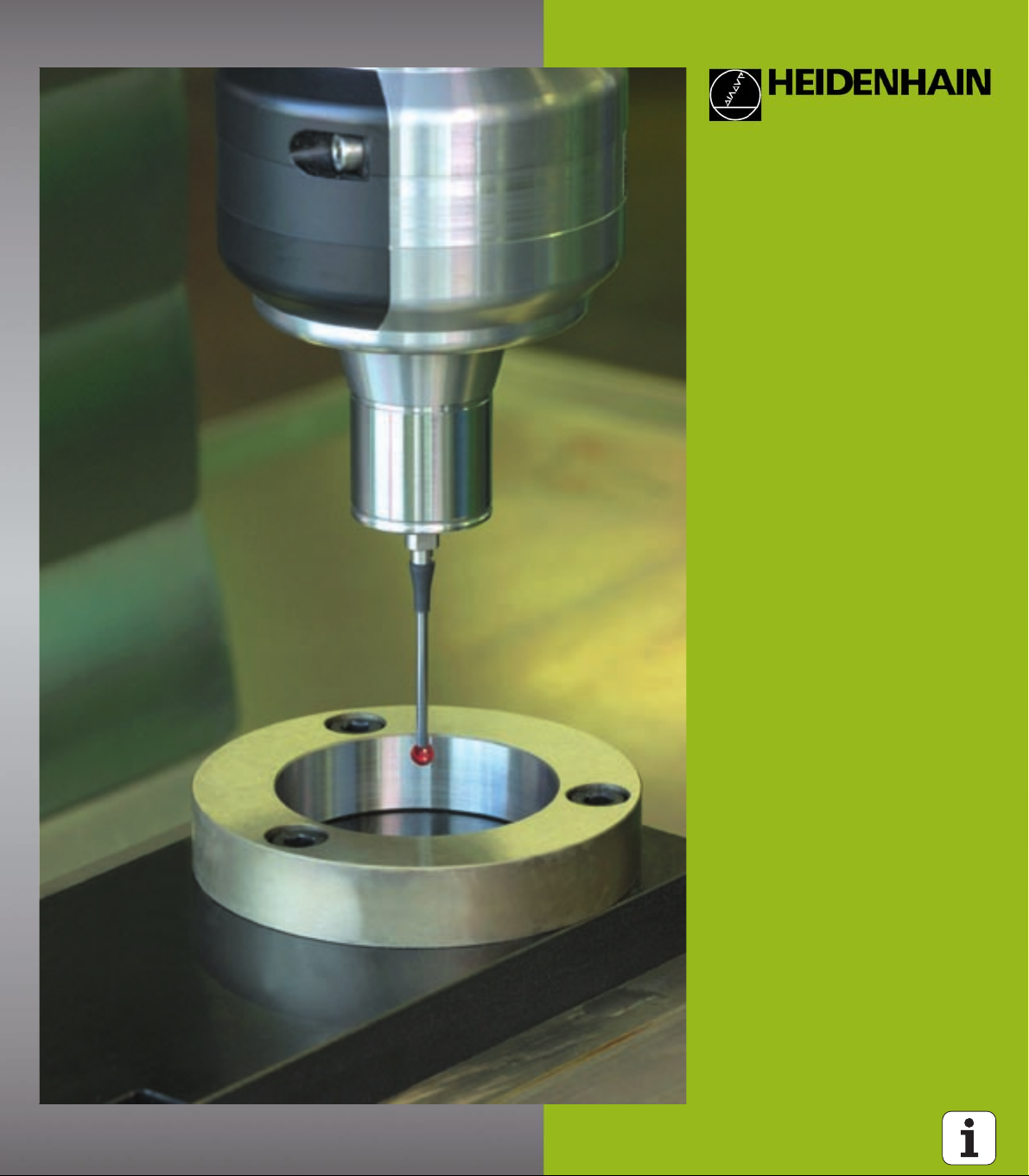

Page 1

Touch Probe Cycles

TNC 426

TNC 430

NC Software

280 472-xx

280 473-xx

280 474-xx

280 475-xx

280 476-xx

280 477-xx

User’s Manual

English (en)

6/2003

Page 2

Page 3

TNC Model, Software and Features

This manual describes functions and features provided by TNCs as of

the following NC software numbers.

TNC model NC software number

TNC 426, TNC 430 280 472-10

TNC 426, TNC 430 280 474-13

TNC 426, TNC 430 280 476-04

The suffixes E and F indicate the export versions of the TNC The

export versions of the TNC have the following limitations:

n Linear movement is possible in no more than 4 axes simultaneously.

The machine tool builder adapts the useable features of the TNC to his

machine by setting machine parameters. Some of the functions

described in this manual may not be among the features provided by

your machine tool.

TNC functions that may not be available on your machine include:

n Digitizing option

n Tool Measurement with the TT

Please contact your machine tool builder to become familiar with the

features of your machine.

Many machine manufacturers, as well as HEIDENHAIN, offer

programming courses for the TNCs. We recommend these courses as

an effective way of improving your programming skill and sharing

information and ideas with other TNC users.

User’s Manual:

All TNC functions that have no connection with touch

probes are described in the User's Manual of the

respective control. Please contact HEIDENHAIN if you

need a copy of this User’s Manual.

Location of use

The TNC complies with the limits for a Class A device in accordance

with the specifications in EN 55022, and is intended for use primarily

in industrially-zoned areas.

HEIDENHAIN TNC 426, TNC 430 I

Page 4

New features of the NC software 280 476-xx

n Management of an arbitrary number of calibration data with the TS

triggering touch probe (see “Managing more than one block of

calibrating data (as of NC software 280 476-xx)” on page 15)

n Cycles for automatic tool measurement with the TT 130 according

to ISO (see “Overview” on page 112)

n Cycle for measuring the thermal behavior of a machine (see

“MEASURE AXIS SHIFT (touch probe cycle 440, ISO: G440,

available as of NC software 280 476-xx)” on page 106)

Changed features of the NC software 280 476-xx

n All cycles for the automatic datum setting can now also be run

during an active basic rotation (see “Characteristics common to all

touch probe cycles for datum setting” on page 43).

n Cycle 431 find the angular values needed for tilting the working

plane with a spatial angle (see “MEASURE PLANE (touch probe

cycle 431, ISO: G431)” on page 97).

II

Page 5

Contents

Introduction

Touch Probe Cycles in the Manual and

Electronic Handwheel Modes

Touch Probe Cycles for Automatic

Workpiece Inspection

Touch Probe Cycles for Automatic Tool

Measurement

1

2

3

4

Digitizing

5

HEIDENHAIN TNC 426, TNC 430 III

Page 6

Page 7

1 Introduction ..... 1

1.1 General Information on Touch Probe Cycles ..... 2

Function ..... 2

Touch Probe Cycles in the Manual and Electronic Handwheel Modes ..... 3

Touch probe cycles for automatic operation ..... 3

1.2 Before You Start Working with Touch Probe Cycles! ..... 5

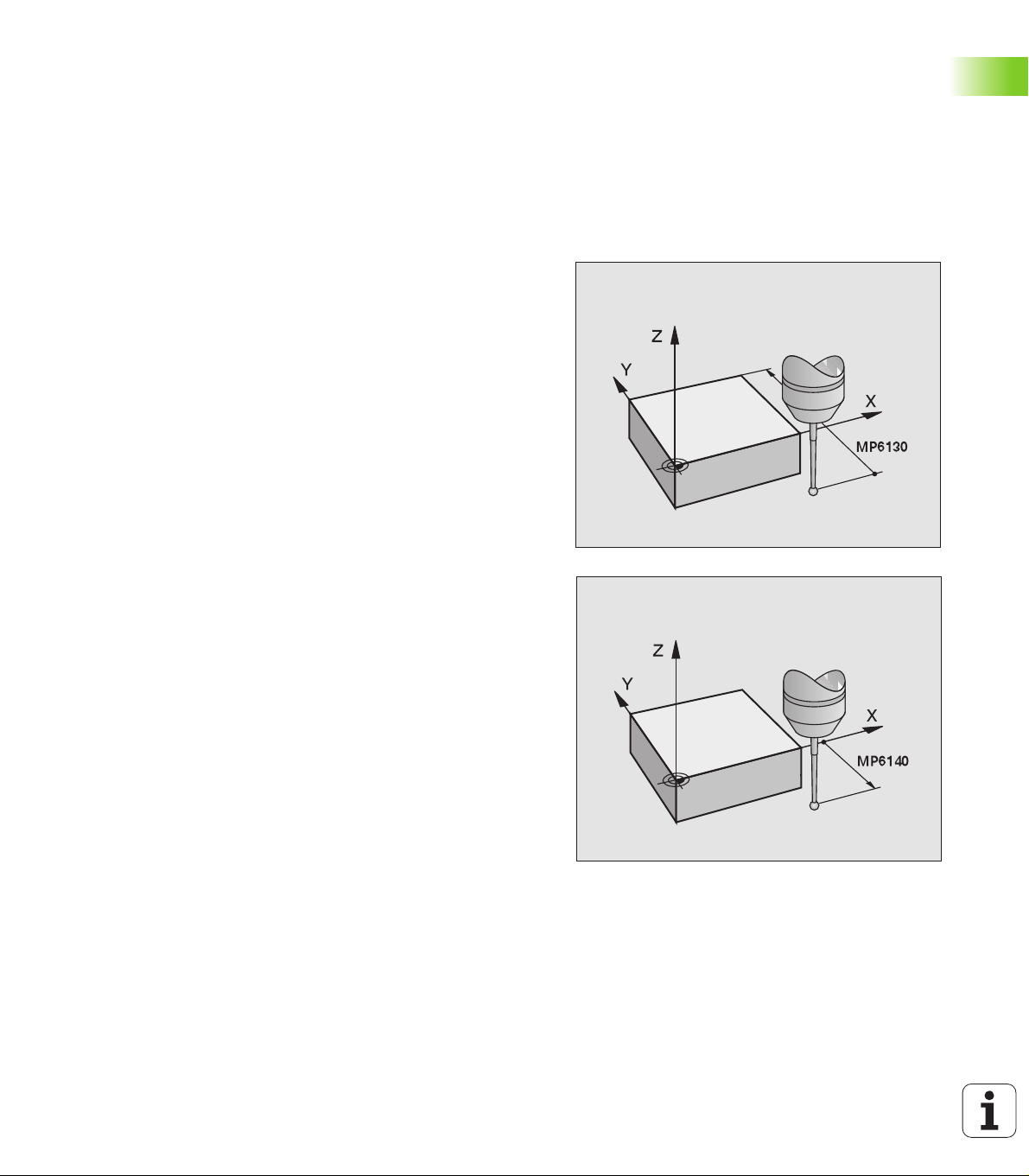

Maximum traverse to touch point: MP6130 ..... 5

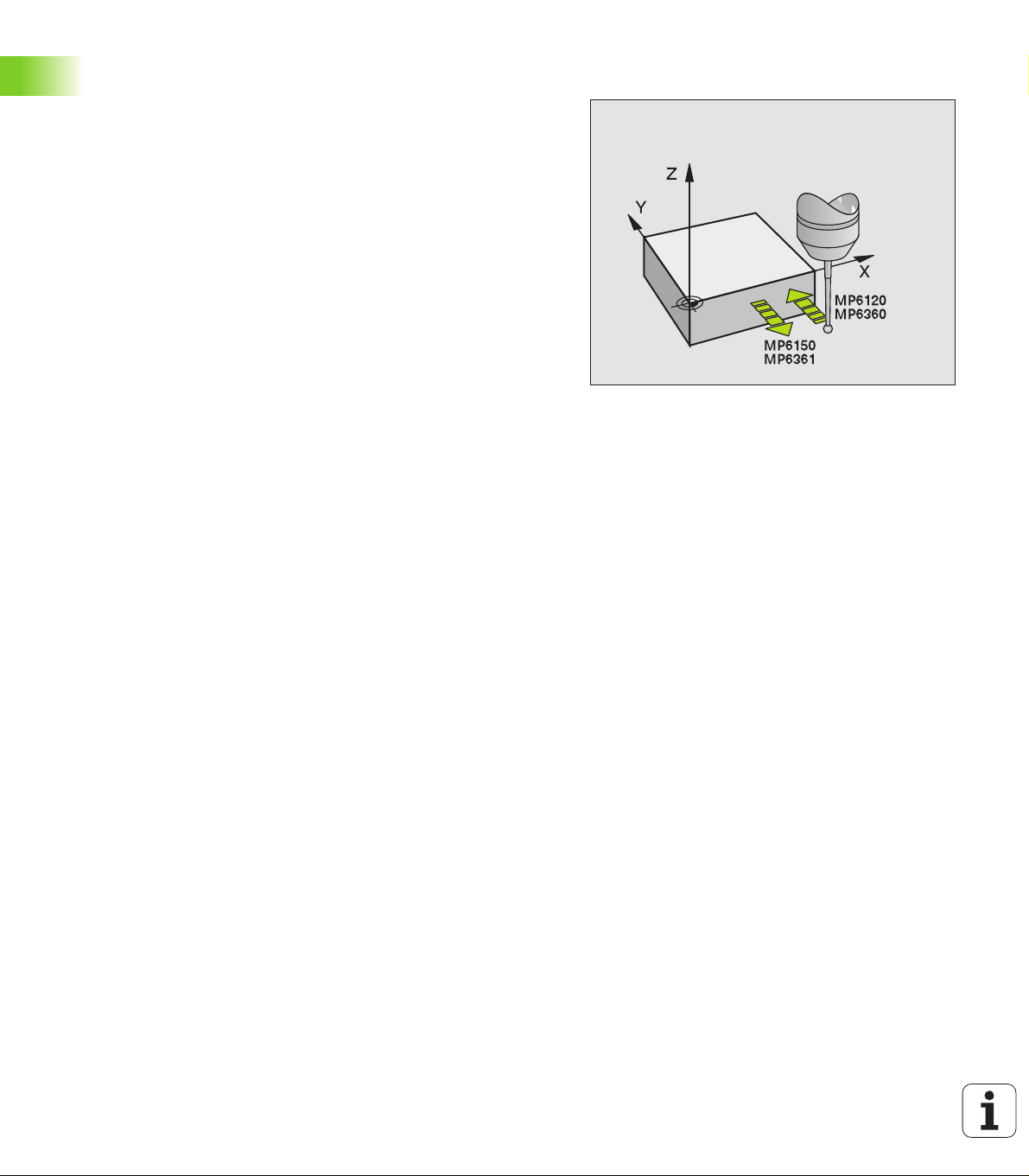

Safety clearance to touch point: MP6140 ..... 5

Orient the infrared touch probe to the programmed probe direction: MP6165 (as of 280 476-10) ..... 5

Multiple measurement: MP6170 ..... 5

Confidence interval for multiple measurement: MP6171 ..... 5

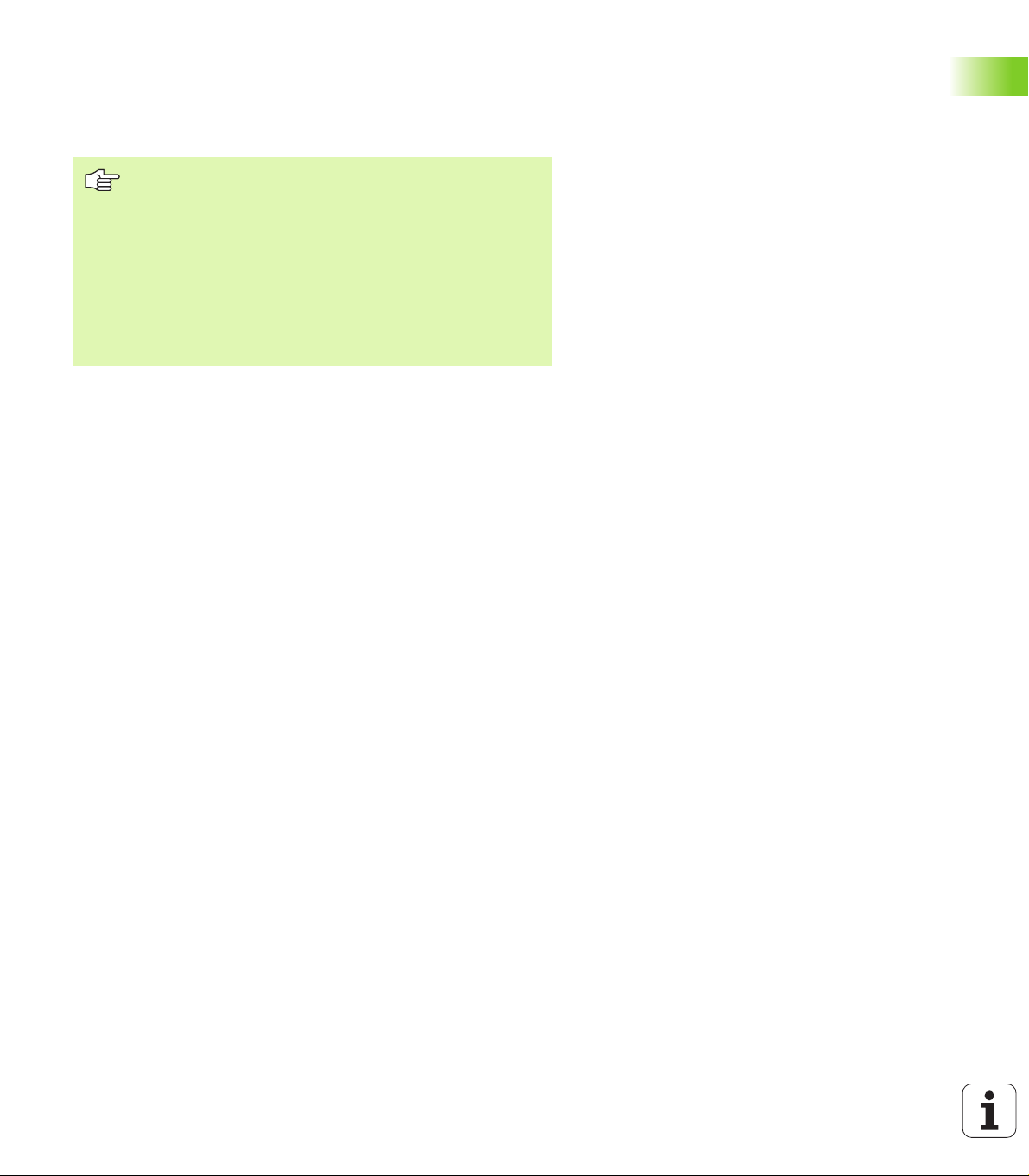

Touch trigger probe, probing feed rate: MP6120 ..... 6

Touch trigger probe, rapid traverse for pre-positioning: MP6150 ..... 6

Measuring touch probe, probing feed rate: MP6360 ..... 6

Measuring touch probe, rapid traverse for pre-positioning: MP6361 ..... 6

Running touch probe cycles ..... 7

HEIDENHAIN TNC 426, TNC 430 V

Page 8

2 Touch Probe Cycles in the Manual and Electronic Handwheel Modes ..... 9

2.1 Introduction ..... 10

Overview ..... 10

Selecting probe cycles ..... 10

Recording Measured Values from the Probe Cycles ..... 11

Writing the measured values from probe cycles in datum tables ..... 12

2.2 Calibrating a Touch Trigger Probe ..... 13

Introduction ..... 13

Calibrating the effective length ..... 13

Calibrating the effective radius and compensating center misalignment ..... 14

Displaying calibration values ..... 15

Managing more than one block of calibrating data (as of NC software 280 476-xx) ..... 15

2.3 Calibrating a Measuring Touch Probe ..... 16

Introduction ..... 16

Course of actions ..... 16

Displaying calibration values ..... 17

2.4 Compensating Workpiece Misalignment ..... 18

Introduction ..... 18

Measuring the basic rotation ..... 18

Displaying a basic rotation ..... 19

Cancel a basic rotation ..... 19

2.5 Setting the Datum with a 3-D Touch Probe ..... 20

Introduction ..... 20

To set the datum in any axis (see figure at right) ..... 20

Corner as datum—using points that were already probed for a basic rotation (see figure at right) ..... 21

Corner as datum—without using points that were already probed for a basic rotation ..... 21

Circle center as datum ..... 22

Setting datum points using holes/cylindrical studs ..... 23

2.6 Measuring Workpieces with a 3-D Touch Probe ..... 24

Introduction ..... 24

To find the coordinate of a position on an aligned workpiece: ..... 24

Finding the coordinates of a corner in the working plane ..... 24

Measuring workpiece dimensions ..... 25

To find the angle between the angle reference axis and a side of the workpiece ..... 26

VI

Page 9

3 Touch Probe Cycles for Automatic Workpiece Inspection ..... 27

3.1 Measuring Workpiece Misalignment ..... 28

Overview ..... 28

Characteristics common to all touch probe cycles for measuring workpiece misalignment ..... 28

BASIC ROTATION (touch probe cycle 400, ISO: G400) ..... 29

BASIC ROTATION from two holes (touch probe cycle 401, ISO: G401) ..... 31

BASIC ROTATION over two studs (touch probe cycle 402, ISO: G402) ..... 33

BASIC ROTATION compensation via rotary axis (touch probe cycle 403, ISO: G403) ..... 35

SET BASIC ROTATION (touch probe cycle 404, ISO: G404, available as of NC software 280 474-xx) ..... 37

Compensating workpiece misalignment by rotating the C axis (touch probe cycle 405, ISO: G405, available as of

NC software 280 474-xx) ..... 38

3.2 Automatic Datum Setting ..... 42

Overview ..... 42

Characteristics common to all touch probe cycles for datum setting ..... 43

DATUM FROM INSIDE OF RECTANGLE (touch probe cycle 410, ISO: G410) ..... 44

DATUM FROM OUTSIDE OF RECTANGLE (touch probe cycle 411, ISO: G411) ..... 46

DATUM FROM INSIDE OF CIRCLE (touch probe cycle 412, ISO: G412) ..... 48

DATUM FROM OUTSIDE OF CIRCLE (touch probe cycle 413, ISO: G413) ..... 50

DATUM FROM OUTSIDE OF CORNER (touch probe cycle 414, ISO: G414) ..... 52

DATUM FROM INSIDE OF CORNER (touch probe cycle 415, ISO: G415) ..... 55

DATUM CIRCLE CENTER (touch probe cycle 416, ISO: G416) ..... 58

DATUM IN TOUCH PROBE AXIS (touch probe cycle 417, ISO: G417) ..... 60

DATUM AT CENTER BETWEEN 4 HOLES (touch probe cycle 418, ISO: G418) ..... 61

HEIDENHAIN TNC 426, TNC 430 VII

Page 10

3.3 Automatic Workpiece Measurement ..... 68

Overview ..... 68

Recording the results of measurement ..... 69

Measurement results in Q parameters ..... 70

Classification of results ..... 70

Tolerance monitoring ..... 70

Tool monitoring ..... 71

Reference system for measurement results ..... 71

REFERENCE PLANE (touch probe cycle 0, ISO: G55) ..... 72

DATUM PLANE (touch probe cycle 1) ..... 73

MEASURE ANGLE (touch probe cycle 420, ISO: G420) ..... 74

MEASURE HOLE (touch probe cycle 421, ISO: G421) ..... 76

MEASURE CIRCLE OUTSIDE (touch probe cycle 422, ISO: G422) ..... 79

MEASURE RECTANGLE FROM INSIDE (touch probe cycle 423, ISO: G423) ..... 82

MEASURE RECTANGLE FROM OUTSIDE (touch probe cycle 424, ISO: G424) ..... 85

MEASURE INSIDE WIDTH (touch probe cycle 425, ISO: G425) ..... 88

MEASURE RIDGE WIDTH (touch probe cycle 426, ISO: G426) ..... 90

MEASURE COORDINATE (touch probe cycle 427, ISO: G427) ..... 92

MEASURE BOLT HOLE CIRCLE (touch probe cycle 430, ISO: G430) ..... 94

MEASURE PLANE (touch probe cycle 431, ISO: G431) ..... 97

3.4 Special Cycles ..... 103

Overview ..... 103

CALIBRATE TS (touch probe cycle 2) ..... 104

MEASURING (touch probe cycle 3, available as of NC software 280 474-xx) ..... 105

MEASURE AXIS SHIFT (touch probe cycle 440, ISO: G440, available as of NC software 280 476-xx) ..... 106

VIII

Page 11

4 Touch Probe Cycles for Automatic Tool Measurement ..... 109

4.1 Tool Measurement with the TT Tool Touch Probe ..... 110

Overview ..... 110

Setting the machine parameters ..... 110

Display the results of measurement ..... 111

4.2 Available Cycles ..... 112

Overview ..... 112

Differences between Cycles 31 to 33 and Cycles 481 to 483 ..... 112

Calibrating the TT ..... 113

Measuring the tool length ..... 114

Measuring the tool radius ..... 116

Measuring tool length and radius ..... 118

5 Digitizing ..... 121

5.1 Digitizing with Triggering or Measuring Touch Probe (Option) ..... 122

Overview ..... 122

Function ..... 123

5.2 Programming Digitizing Cycles ..... 124

Selecting digitizing cycles ..... 124

Defining the digitizing range ..... 124

Point Tables ..... 126

5.3 Types of Digitizing ..... 129

Meander digitizing ..... 129

Contour line digitizing ..... 131

Unidirectional line digitizing ..... 133

Digitizing with rotary axes ..... 136

5.4 Using Digitized Data in a Part Program ..... 140

Resulting NC blocks of a file containing data that were digitized with the CONTOUR LINES cycle. ..... 140

HEIDENHAIN TNC 426, TNC 430 IX

Page 12

X

Page 13

Introduction

1

Page 14

1.1 General Information on Touch

Probe Cycles

The TNC must be specially prepared by the machine tool

builder for the use of a 3-D touch probe.

If you are carrying out measurements during program run,

be sure that the tool data (length, radius) can be used from

the calibrated data or from the last TOOL CALL block

(selected with MP7411).

If you are working alternately with a triggering and a

measuring touch probe, be sure that

n You have selected the correct touch probe in MP 6200.

n The measuring and triggering touch probes are never

connected to the control at the same time.

The TNC cannot detect which probe is actually in the

spindle.

Function

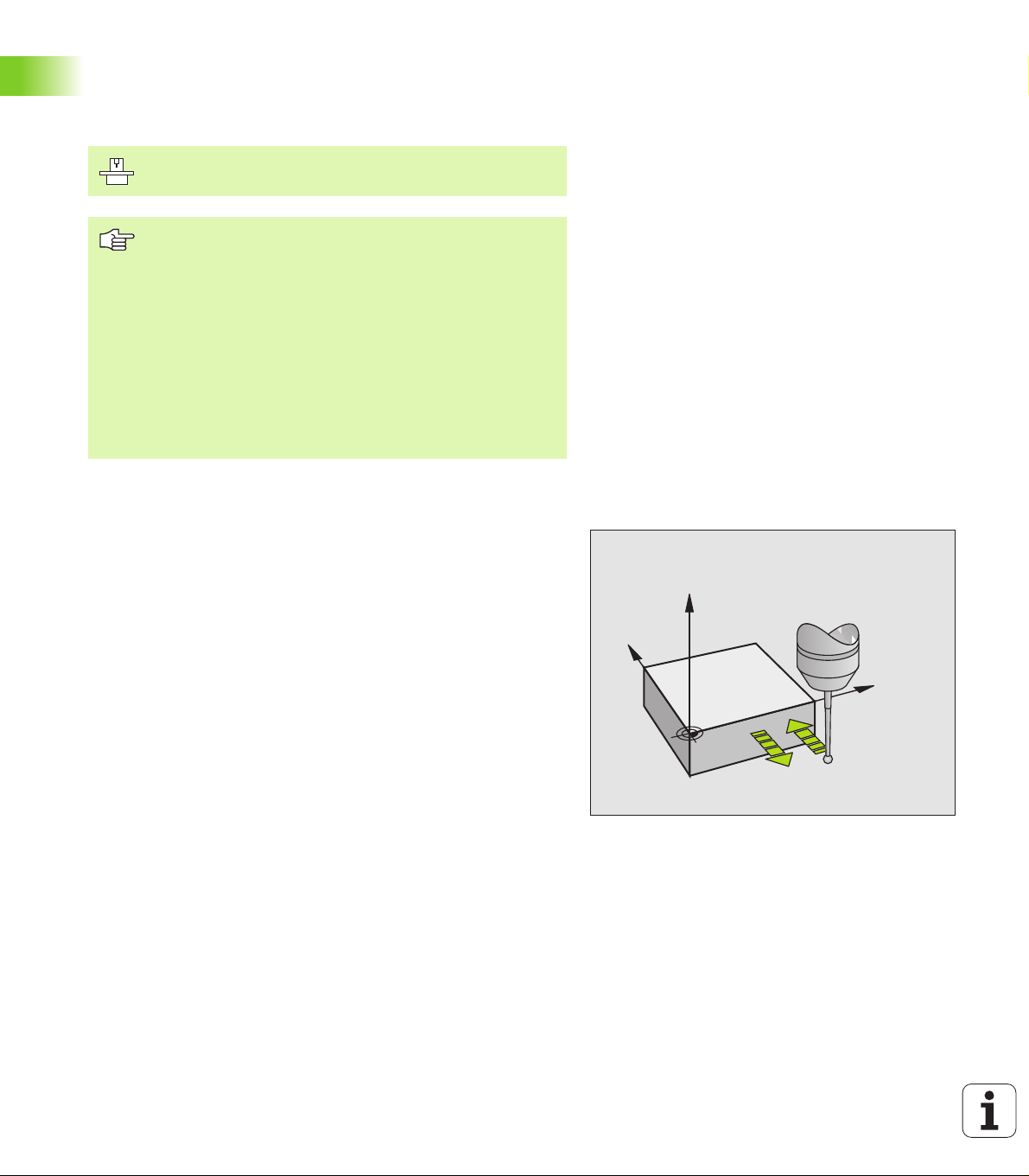

Whenever the TNC runs a touch probe cycle, the 3-D touch probe

approaches the workpiece in one linear axis. This is also true during an

active basic rotation or with a tilted working plane. The machine tool

builder determines the probing feed rate in a machine parameter (see

“Before You Start Working with Touch Probe Cycles” later in this

chapter).

When the probe stylus contacts the workpiece,

1.1 General Information on Touch Probe Cycles

n the 3-D touch probe transmits a signal to the TNC: the coordinates

of the probed position are stored,

n the touch probe stops moving, and

n returns to its starting position in rapid traverse.

If the stylus is not deflected within a distance defined in MP 6130), the

TNC displays an error message.

Z

Y

F

F MAX

X

2 1 Introduction

Page 15

Touch Probe Cycles in the Manual and Electronic Handwheel Modes

In the Manual and Electronic Handwheel operating modes, the TNC

provides touch probe cycles that allow you to:

n Calibrate the touch probe

n Compensate workpiece misalignment

n Datum setting

Touch probe cycles for automatic operation

Besides the touch probe cycles, which you can use in the Manual and

Electronic handwheel operating modes, the TNC provides numerous

cycles for a wide variety of applications in automatic operation:

n Calibrating the touch probe (Chapter 3)

n Compensating workpiece misalignment (Chapter 3)

n Setting datums (Chapter 3)

n Automatic workpiece inspection (Chapter 3)

n Automatic workpiece measurement (Chapter 4)

Digitizing with triggering or measuring touch probe (Option, Chapter 5)

n

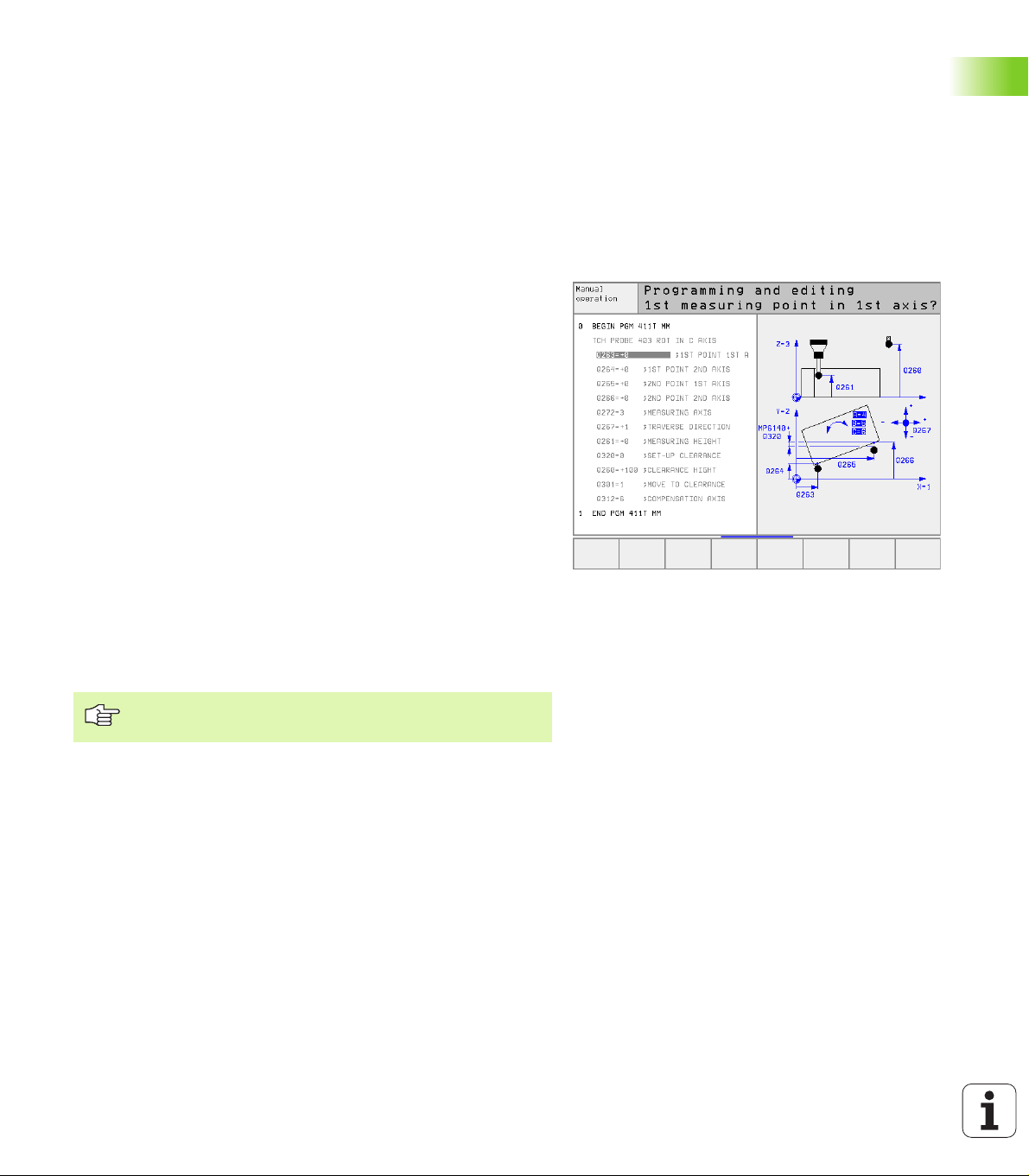

You can program the touch probe cycles in the Programming and

Editing operating mode via the TOUCH PROBE key. Like the most

recent fixed cycles, touch probe cycles use Q parameters with

numbers of 400 and above as transfer parameters. Parameters with

the same function that the TNC requires in several cycles always have

the same number: For example, Q260 is always assigned the

clearance height, Q261 the measuring height, etc.

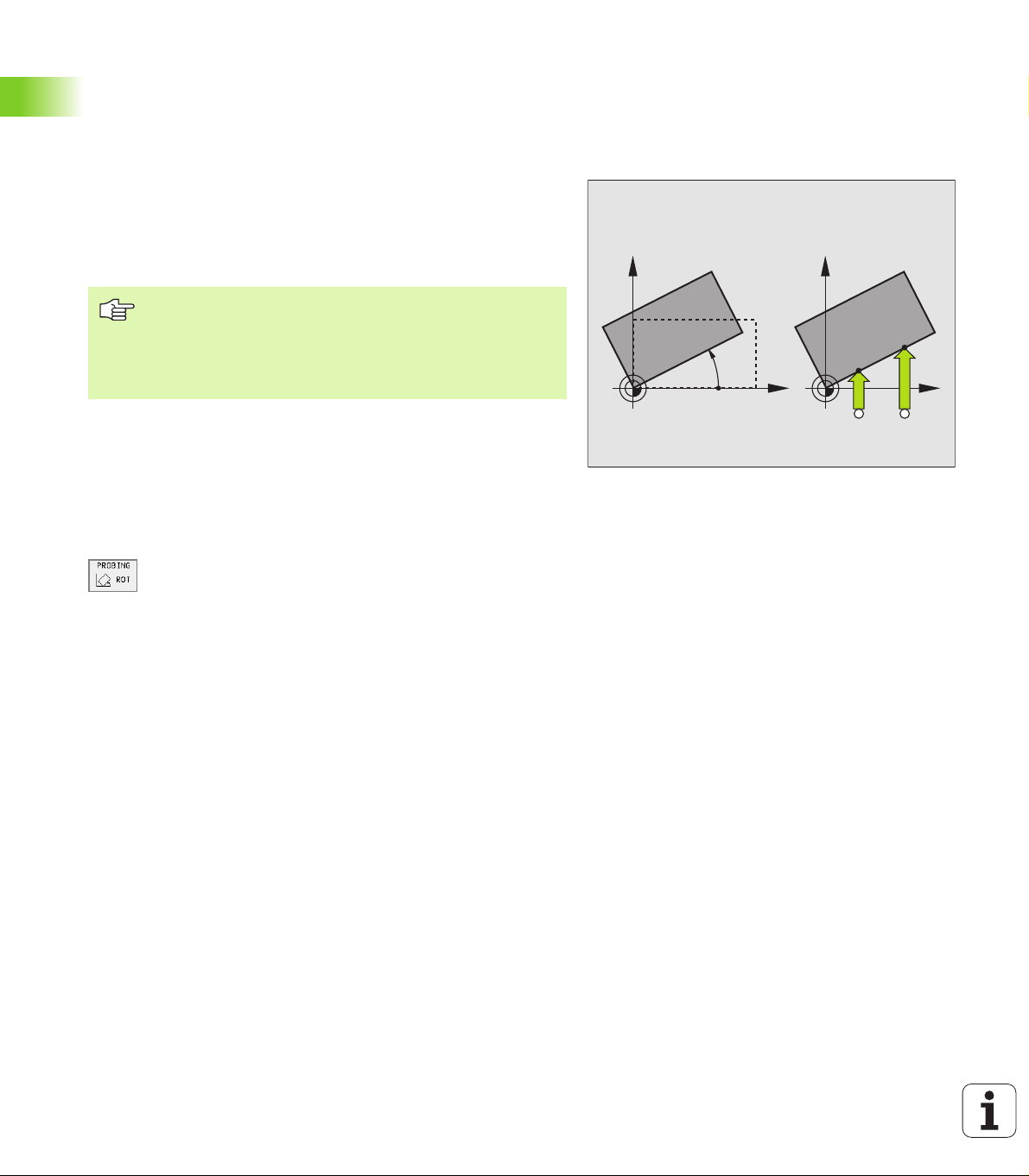

To simplify programming, the TNC shows an illustration during cycle

definition. In the illustration, the parameter that needs to be entered is

highlighted (see figure at right).

1.1 General Information on Touch Probe Cycles

To improve clarity, the help illustrations sometimes omit

certain parameters.

HEIDENHAIN TNC 426, TNC 430 3

Page 16

Defining the touch probe cycle in the Programming and Editing

operation mode

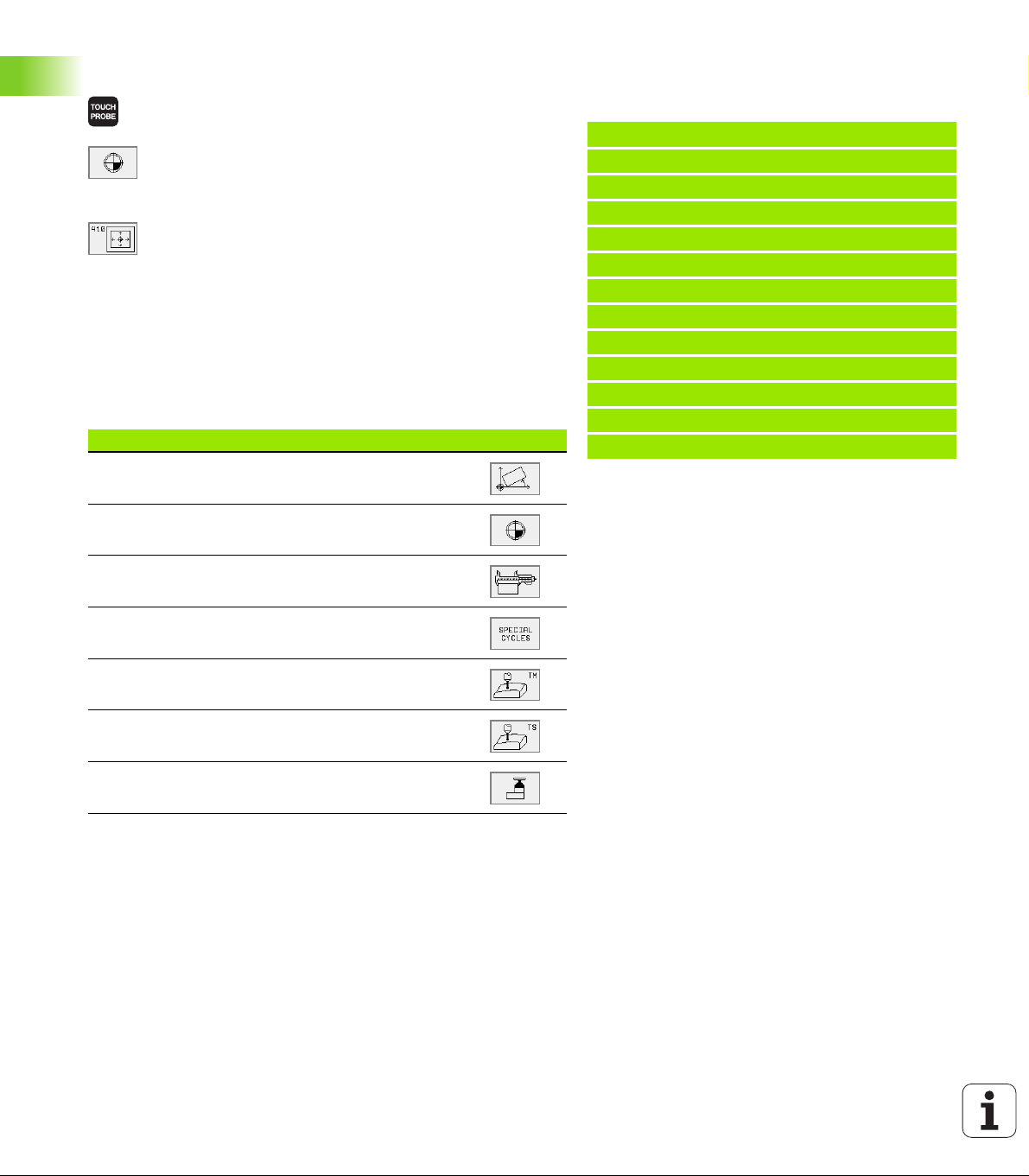

UUUU The soft-key row shows all available touch probe

functions divided into groups.

UUUU Select the desired probe cycle, for example datum

setting. Digitizing cycles and cycles for automatic tool

measurement are available only if your machine has

been prepared for them.

UUUU Select a cycle, e.g. datum setting at pocket. The TNC

initiates the programming dialog and asks all required

input values. At the same time a graphic of the input

parameters is displayed in the right screen window.

The parameter that is asked for in the dialog prompt

is highlighted.

UUUU Enter all parameters requested by the TNC and

conclude each entry with the ENT key.

UUUU The TNC ends the dialog when all required data has

been entered.

Group of measuring cycles Soft key

Cycles for automatic measurement and compensation

of workpiece misalignment

Cycles for automatic datum setting

Example: NC blocks

5 TCH PROBE 410 DATUM INSIDE RECTAN.

Q321=+50 ;CENTER IN 1ST AXIS

Q322=+50 ;CENTER IN 2ND AXIS

Q323=60 ;1ST SIDE LENGTH

Q323=60 ;1ST SIDE LENGTH

Q324=20 ;2ND SIDE LENGTH

Q261=-5 ;MEASURING HEIGHT

Q320=0 ;SET-UP CLEARANCE

Q260=+20 ;CLEARANCE HEIGHT

Q301=0 ;TRAVERSE TO CLEAR HEIGHT

Q305=10 ;NO. IN TABLE

Q331=+0 ;DATUM

Q332=+0 ;DATUM

Cycles for automatic workpiece inspection

Automatic calibration cycle

1.1 General Information on Touch Probe Cycles

Cycles for digitizing with measuring touch probe

(option, not available for ISO)

Cycles for digitizing with measuring touch probe

(option, not available for ISO)

Cycles for automatic tool measurement (enabled by

the machine tool builder, not ISO)

4 1 Introduction

Page 17

1.2 Before You Start Working with

Touch Probe Cycles!

To make it possible to cover the widest possible range of applications,

machine parameters enable you to determine the behavior common

to all touch probe cycles:

Maximum traverse to touch point: MP6130

If the stylus is not deflected within the path defined in MP6130, the

TNC outputs an error message.

Safety clearance to touch point: MP6140

In MP6140 you define how far from the defined (or calculated) touch

point the TNC is to pre-position the touch probe. The smaller the value

you enter, the more exactly must you define the touch point position.

In many touch probe cycles you can also define a setup clearance in

addition that is added to machine parameter 6140.

Orient the infrared touch probe to the

programmed probe direction: MP6165 (as

of 280 476-10)

To increase measuring accuracy, you can use MP 6165 = 1 to have an

infrared touch probe oriented in the programmed probe direction

before every probe process. In this way the stylus is always deflected

in the same direction.

Multiple measurement: MP6170

To increase measuring certainty, the TNC can run each probing

process up to three times in sequence. If the measured position

values differ too greatly, the TNC outputs an error message (the limit

value is defined in MP6171). With multiple measurement it is possible

to detect random errors, e.g., from contamination.

If the measured values lie within the confidence interval, the TNC

saves the mean value of the measured positions.

Confidence interval for multiple measurement: MP6171

In MP6171 you store the value by which the results may differ when

you make multiple measurements. If the difference in the measured

values exceeds the value in MP6171, the TNC outputs an error

message.

HEIDENHAIN TNC 426, TNC 430 5

1.2 Before You Start Working with Touch Probe Cycles!

Page 18

Touch trigger probe, probing feed rate: MP6120

In MP6120 you define the feed rate at which the TNC is to probe the

workpiece.

Touch trigger probe, rapid traverse for prepositioning: MP6150

In MP6150 you define the feed rate at which the TNC pre-positions the

touch probe, or positions it between measuring points.

Measuring touch probe, probing feed rate: MP6360

In MP6360 you define the feed rate at which the TNC is to probe the

workpiece.

Measuring touch probe, rapid traverse for prepositioning: MP6361

In MP6361 you define the feed rate at which the TNC pre-positions the

touch probe, or positions it between measuring points.

1.2 Before You Start Working with Touch Probe Cycles!

6 1 Introduction

Page 19

Running touch probe cycles

All touch probe cycles are DEF active. This means that the TNC runs

the cycle automatically as soon as the TNC executes the cycle

definition in the program run.

Make sure that at the beginning of the cycle the

compensation data (length, radius) from the calibrated

data or from the last TOOL CALL block are active

(selection via MP7411, see the User's Manual of the

respective control, “General User Parameters”).

NC software 280.476-xx

You can also run the touch probe cycles 410 to 418 during

an active basic rotation. Make sure, however, that the

basic rotation angle does not change when you use cycle

7 “zero shift from datum table” after the measuring cycle.

Touch probe cycles with a number greater than 400 position the touch

probe according to a positioning logic:

n If the current coordinate of the south pole of the stylus is less than

the coordinate of the clearance height (defined in the cycle), the TNC

retracts the touch probe in the probe axis to the clearance height

and then positions it in the working plane to the first starting

position.

n If the current coordinate of the south pole of the stylus is greater

than the coordinate of the clearance height, the TNC first positions

the probe in the working plane to the first starting position and then

moves it immediately to the measuring height in the touch probe

axis.

HEIDENHAIN TNC 426, TNC 430 7

1.2 Before You Start Working with Touch Probe Cycles!

Page 20

Page 21

2

Touch Probe Cycles in the Manual and Electronic Handwheel Modes

Page 22

2.1 Introduction

Overview

The following touch probe cycles are available in the manual mode:

Function Soft key

Calibrate the effective length

2.1 Introduction

Calibrate the effective radius

Measure a basic rotation using a line

Datum setting in any axis

Set the datum at a corner

Set the datum at a circle center

Measure a basic rotation using two holes/cylindrical

studs

Set the datum using four holes/cylindrical studs

Set the circle center using three holes/cylindrical studs

Selecting probe cycles

UUUU Select the Manual Operation or Electronic Handwheel mode of

operation.

UUUU To choose the touch probe functions, press the

TOUCH PROBE soft key. The TNC displays additional

soft keys—see table at right.

UUUU To select the probe cycle: press the appropriate soft

key, for example PROBING ROT, and the TNC

displays the associated menu.

10 2 Touch Probe Cycles in the Manual and Electronic Handwheel Modes

Page 23

Recording Measured Values from the Probe Cycles

The TNC must be specially prepared by the machine tool

builder for use of this function. The machine tool manual

provides further information.

After executing any selected probe cycle, the TNC displays the soft

key PRINT. If you press this soft key, the TNC will record the current

values determined in the active probe cycle. You can then use the

PRINT function in the menu for setting the data interface (see the

User's Manual Chapter 12, “MOD Functions, Setting the Data

Interfaces”) to define whether the TNC is to

n print the measuring result,

n store the measuring results on the TNC’s hard disk, or

n store the measuring results on a PC.

If you store the measuring results, the TNC creates the ASCII file

%TCHPRNT.A. Unless you define a specific path and interface in the

interface configuration menu, the TNC will store the %TCHPRNT file

in the main directory TNC:\.

When you press the PRINT soft key, the %TCHPRNT.A

file must not be

active in the Programming and Editing mode of operation.

The TNC will otherwise display an error message.

The TNC stores the measured data in the %TCHPRNT.A

file only. If you execute several probe cycles in succession

and want to store the resulting measured data, you must

make a backup of the contents stored in %TCHPRNT.A

between the individual cycles by copying or renaming the

file.

Format and contents of the %TCHPRNT file are preset by

the machine tool builder.

2.1 Introduction

HEIDENHAIN TNC 426, TNC 430 11

Page 24

Writing the measured values from probe cycles in datum tables

This function is active only if you have datum tables active

on your TNC (bit 3 in machine parameter 7224.0 =0).

With the ENTER IN DATUM TABLE soft key, the TNC can write the

values measured during a probe cycle in a datum table:

UUUU Select any probe function.

2.1 Introduction

UUUU Enter the desired coordinates of the datum in the appropriate input

fields (depends on the touch probe cycle being run).

UUUU Enter the datum number in the datum number = input box.

UUUU Enter the name of the datum table (complete path) in the datum

table input box.

UUUU Press the soft key ENTER IN DATUM TABLE. The TNC displays

whether the data are to be transferred to the indicated datum table

as actual values or reference values.

If, in addition to the desired coordinate of the datum, you wish to enter

an incremental distance in the table, switch the soft key DISTANCE to

ON. The TNC then displays an additional input box for each axis, in

which you can enter the desired distance. The TNC then writes the

sum of the desired datum and its assigned distance into the table.

If immediately after probing you have used the probing

menu to reset the datum, do not write the probe values to

a datum table. The probe values saved by the TNC are

always based on the datum that was active at the time of

probing. Writing the probe values to a datum table would

result in incorrect entries.

12 2 Touch Probe Cycles in the Manual and Electronic Handwheel Modes

Page 25

2.2 Calibrating a Touch Trigger

Probe

Introduction

The touch probe must be calibrated in the following cases:

n Commissioning

n Stylus breakage

n Stylus exchange

n Change in the probe feed rate

n Irregularities caused, for example, when the machine heats up

During calibration, the TNC finds the “effective” length of the stylus

and the “effective” radius of the ball tip. To calibrate the touch probe,

clamp a ring gauge of known height and known internal radius to the

machine table.

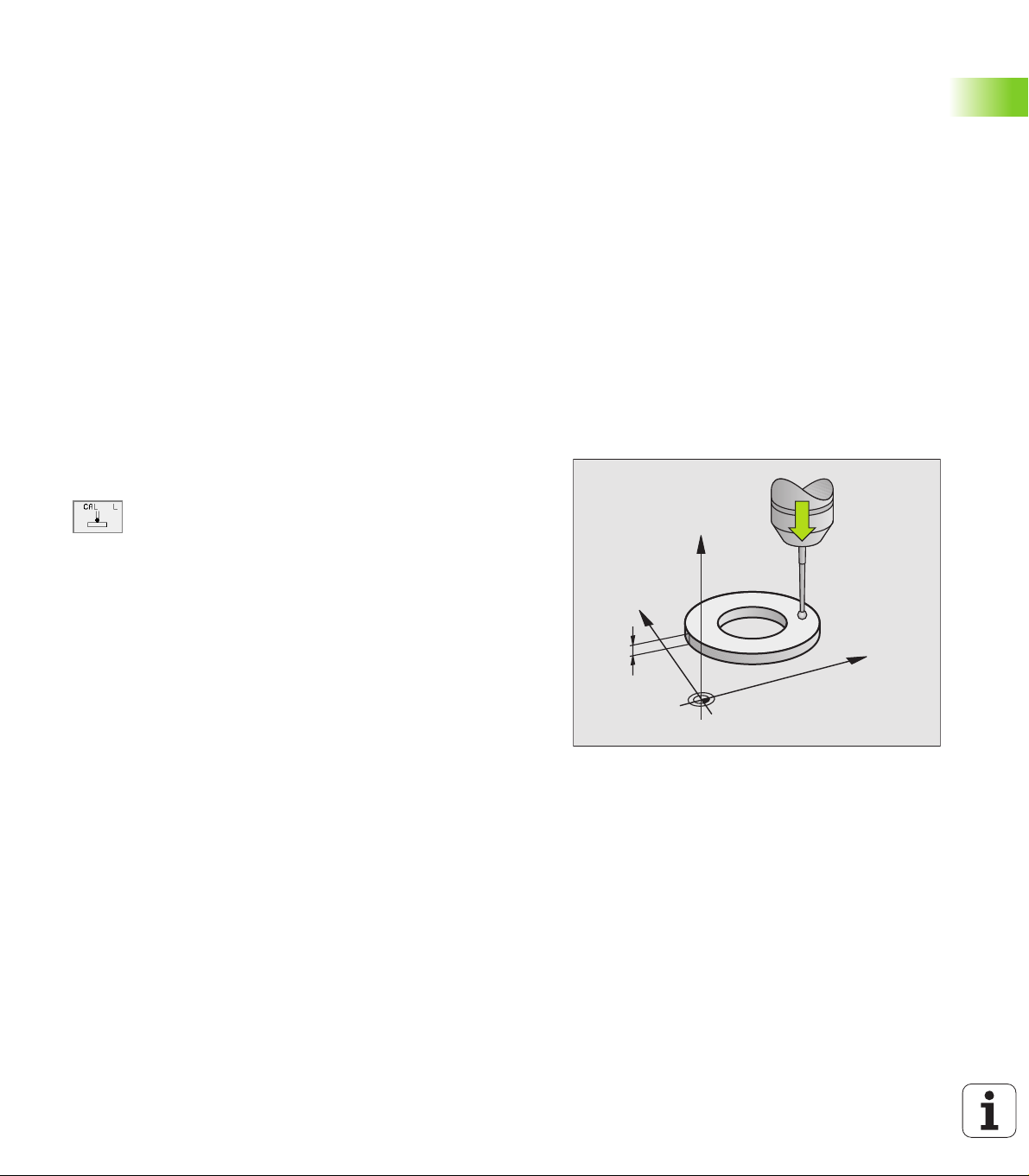

Calibrating the effective length

UUUU Set the datum in the spindle axis such that for the machine tool table

Z=0.

UUUU To select the calibration function for the touch probe

length, press the TOUCH PROBE and CAL L soft

keys. The TNC then displays a menu window with

four input fields.

UUUU Enter the tool axis (with the axis key).

UUUU Datum: Enter the height of the ring gauge.

UUUU The menu items Effective ball radius and Effective

length do not require input.

UUUU Move the touch probe to a position just above the ring

gauge.

UUUU To change the traverse direction (if necessary) press a

soft key or an arrow key.

UUUU To probe the upper surface of the ring gauge, press

the machine START button.

Z

2.2 Calibrating a Touch Trigger Probe

Y

5

X

HEIDENHAIN TNC 426, TNC 430 13

Page 26

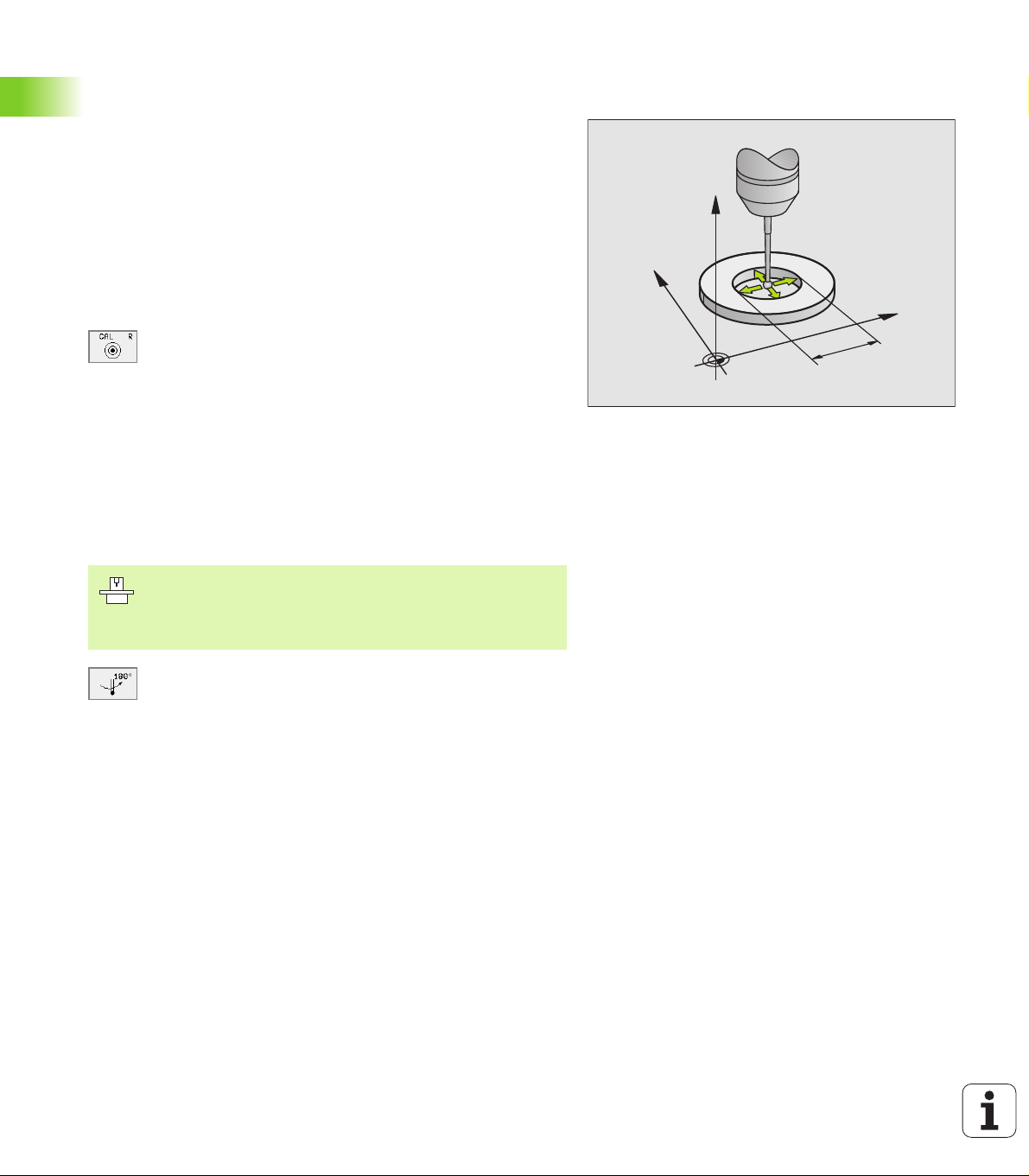

Calibrating the effective radius and compensating center misalignment

After the touch probe is inserted it normally needs to be aligned

exactly with the spindle axis. The misalignment is measured with this

calibration function and compensated electronically.

For this operation the TNC rotates the 3-D touch probe by 180°. The

rotation is initiated by a miscellaneous function that is set by the

machine tool builder in machine parameter 6160.

The center misalignment is measured after the effective ball tip radius

is calibrated.

UUUU In the Manual Operation mode, position the ball tip in the bore of the

ring gauge.

UUUU To select the calibration function for the ball-tip radius

and the touch probe center misalignment, press the

CAL R soft key.

UUUU Select the tool axis and enter the radius of the ring

gauge.

UUUU To probe the workpiece, press the machine START

button four times. The touch probe contacts a

position on the bore in each axis direction and

calculates the effective ball-tip radius.

2.2 Calibrating a Touch Trigger Probe

UUUU If you want to terminate the calibration function at this

point, press the ENDE soft key.

Z

Y

X

10

In order to be able to determine ball-tip center

misalignment, the TNC needs to be specially prepared by

the machine manufacturer. The machine tool manual

provides further information.

UUUU If you want to determine the ball-tip center

misalignment, press the180° soft key. The TNC

rotates the touch probe by 180°.

UUUU To probe the workpiece, press the machine START

button four times. The touch probe contacts a

position on the bore in each axis direction and

calculates the ball-tip center misalignment.

14 2 Touch Probe Cycles in the Manual and Electronic Handwheel Modes

Page 27

Displaying calibration values

The TNC stores the effective length and radius, as well as the center

misalignment, for use when the touch probe is needed again. You can

display the values on the screen with the soft keys CAL L and CAL R.

Storing calibration values in the TOOL.T tool table

This function is only available if bit 0 in machine parameter

7411 = 1 is set (activate touch probe data with TOOL CALL),

and tool table TOOL.T is active (machine parameter 7260

not equal to 0).

If you conduct measurements during program run, the compensation

data for the touch probe can be activated from the tool table via a TOOL

CALL. To store the calibration data in the TOOL.T tool table, enter the

tool number in the calibration menu (confirm with ENT) and then press

the ENTER R IN TOOL TABLE or the ENTER L IN TOOL TABLE soft

key.

Managing more than one block of calibrating data (as of NC software 280 476-xx)

To be able to use more than one block of calibration data, you must set

bit one in machine parameter 7411. The calibration data (length,

radius, center misalignment, and spindle angle) are then always saved

by the TNC in the tool table TOOL.T under a tool number that can be

selected in the calibration menu (see also User's Manual, section 5.2,

“Tool Data”).

2.2 Calibrating a Touch Trigger Probe

If you use this function, you must first activate the

corresponding tool number with a tool call before

executing a touch probe cycle, regardless of whether you

wish to run the touch probe cycle in automatic mode or

manual mode.

You can view and edit the calibration data in the calibration menu, but

you must make sure to write the changes back into the tool table by

pressing the ENTER R IN TOOL TABLE or ENTER L IN TOOL TABLE

soft key. The TNC does not write the calibration values into the table

automatically!

HEIDENHAIN TNC 426, TNC 430 15

Page 28

2.3 Calibrating a Measuring Touch

Probe

Introduction

If the TNC displays the error message "Stylus already in

contact," select the 3-D calibration menu and press the

RESET 3D soft key.

The measuring touch probe must be calibrated whenever

the machine parameters for 3-D touch probes are changed.

The effective length is calibrated in the same way as with

triggering touch probes. You must also enter tool radius R2

(corner radius).

With MP6321 you can define whether the TNC should

probe to find the stylus center.

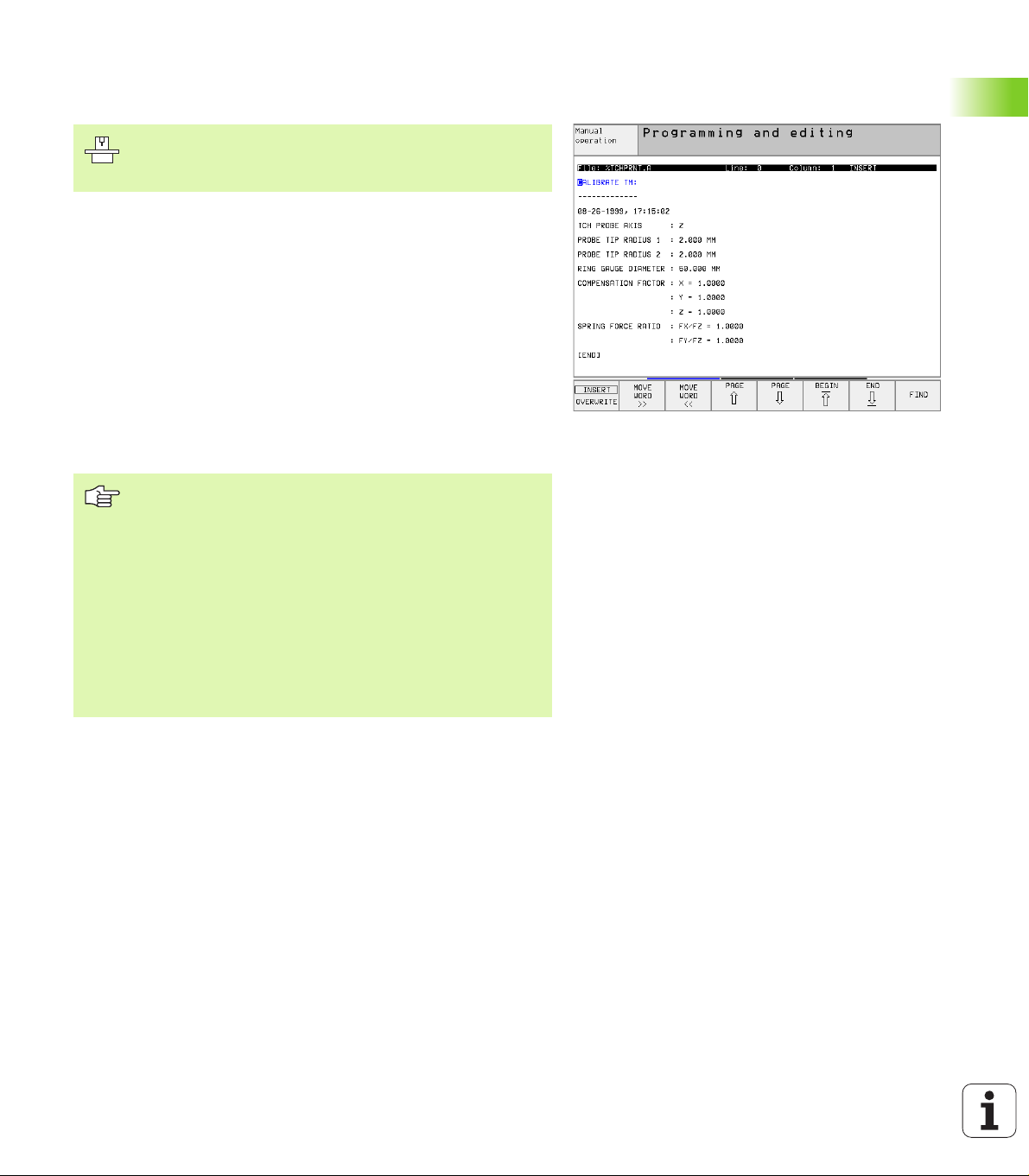

The 3-D calibration cycle for measuring touch probes enables you to

measure a standard ring gauge fully automatically. (The standard ring

gauge is available from HEIDENHAIN). Fix the standard ring gauge to

the machine table with fixing clamps.

From the data measured during calibration, the TNC calculates the

spring rate of the touch probe, the stylus deflection and the stylus

center misalignment. At the end of the calibration cycle, the TNC

automatically stores these values in the input menu.

2.3 Calibrating a Measuring Touch Probe

Course of actions

UUUU In the Manual Operation mode, position the touch probe to a

position approximately in the center of the standard ring gauge and

set it to 180°.

UUUU To select the 3-D calibration cycle, press the 3D CAL

soft key

UUUU Enter the values for stylus radius 1 and stylus radius 2.

Enter the same value for stylus radius 1 and 2 if you

are using a stylus with ball tip. Enter different values

for stylus radius 1 and 2 if you are using a stylus with

a corner radius.

UUUU Diameter ring gauge: The diameter is engraved on the

standard ring gauge.

UUUU

To start the calibration cycle, press the machine START

button: The touch probe measures the standard ring

gauge in a programmed sequence of steps.

UUUU Rotate the touch probe to 0° as soon as the TNC asks

you to.

UUUU To start the calibration cycle once again to determine

center misalignment, press the machine START

button. The touch probe again measures the standard

ring gauge in a programmed sequence of steps.

16 2 Touch Probe Cycles in the Manual and Electronic Handwheel Modes

Page 29

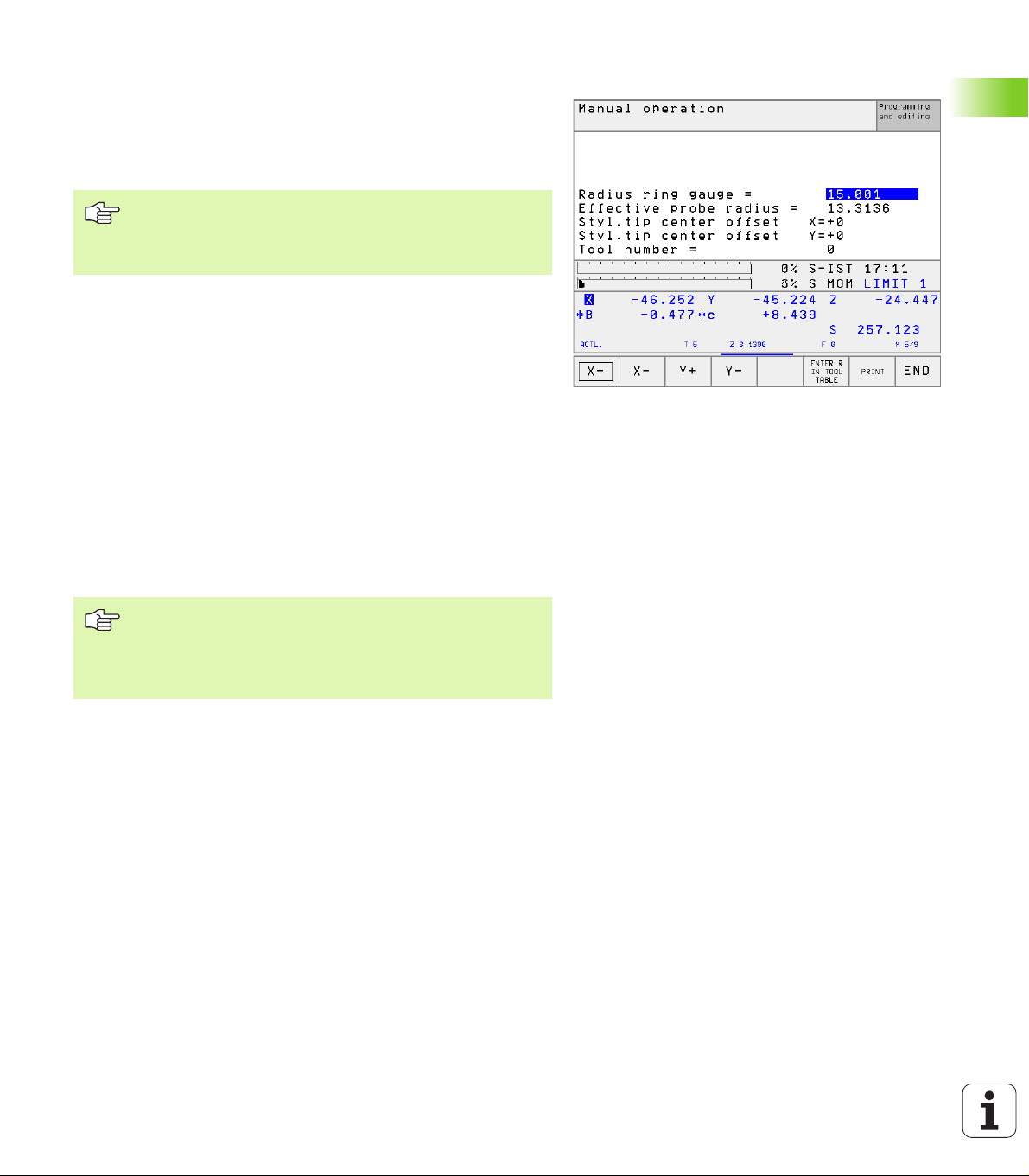

Displaying calibration values

The compensation factors and force ratios are stored in the TNC for

later use whenever the measuring touch probe is needed.

You can display the stored values on the screen by pressing the 3D

CAL soft key.

Storing calibration values in the TOOL.T tool table

This function is only available if machine parameter 7411

= 1 is set (activate touch probe data with TOOL CALL), and

tool table TOOL.T is active (machine parameter 7260 not

equal to 0).

If you conduct measurements during program run, the compensation

data for the touch probe can be activated from the tool table via a TOOL

CALL. To store the calibration data in the TOOL.T tool table, enter the

tool number in the calibration menu (confirm with ENT) and then press

the ENTER R IN TOOL TABLE soft key.

The TNC stores the stylus radius 1 in the R column, and the stylus

radius 2 in the R2 column.

2.3 Calibrating a Measuring Touch Probe

HEIDENHAIN TNC 426, TNC 430 17

Page 30

2.4 Compensating Workpiece

Misalignment

Introduction

The TNC electronically compensates workpiece misalignment by

computing a “basic rotation.”

For this purpose, the TNC sets the rotation angle to the desired angle

with respect to the reference axis in the working plane. See figure at

right.

Select the probe direction perpendicular to the angle

reference axis when measuring workpiece misalignment.

To ensure that the basic rotation is calculated correctly

during program run, program both coordinates of the

working plane in the first positioning block.

Measuring the basic rotation

UUUU Select the probing function by pressing the PROBING

ROT soft key.

2.4 Compensating Workpiece Misalignment

The TNC saves the basic rotation in non-volatile memory. The basic

rotation is effective for all subsequent program runs and graphic

simulation.

UUUU Position the ball tip at a starting position near the first

touch point.

UUUU Select the probe direction perpendicular to the angle

reference axis: Select the axis by soft key.

UUUU To probe the workpiece, press the machine START

button.

UUUU Position the ball tip at a starting position near the

second touch point.

UUUU To probe the workpiece, press the machine START

button.

Y

PA

Y

X

A B

X

18 2 Touch Probe Cycles in the Manual and Electronic Handwheel Modes

Page 31

Displaying a basic rotation

The angle of the basic rotation appears after ROTATION ANGLE

whenever PROBING ROT is selected. The TNC also displays the

rotation angle in the additional status display (STATUS POS.).

In the status display a symbol is shown for a basic rotation whenever

the TNC is moving the axes according to a basic rotation.

Cancel a basic rotation

UUUU Select the probing function by pressing the PROBING ROT soft key.

UUUU Enter a rotation angle of zero and confirm with the ENT key.

UUUU To terminate the probe function, press the END key.

HEIDENHAIN TNC 426, TNC 430 19

2.4 Compensating Workpiece Misalignment

Page 32

2.5 Setting the Datum with a 3-D

Touch Probe

Introduction

The following functions are available for setting the datum on an

aligned workpiece:

n Datum setting in any axis with PROBING POS

n Defining a corner as datum with PROBING P

n Setting the datum at a circle center with PROBING CC

To set the datum in any axis (see figure at right)

UUUU Select the probing function by pressing the PROBING

POS soft key.

UUUU Move the touch probe to a starting position near the

touch point.

UUUU Select the probe axis and direction in which you wish

to set the datum, such as Z in direction Z–. Selection

is made via soft keys.

UUUU To probe the workpiece, press the machine START

button.

UUUU Datum: Enter the nominal coordinate and confirm your

entry with ENT.

Z

Y

X

2.5 Setting the Datum with a 3-D Touch Probe

20 2 Touch Probe Cycles in the Manual and Electronic Handwheel Modes

Page 33

Corner as datum—using points that were

already probed for a basic rotation (see figure at

right)

UUUU To select the probe function, press ANTASTEN P.

UUUU Touch points of basic rotation ?: Press ENT to transfer

the touch point coordinates to memory.

UUUU Position the touch probe at a starting position near the

first touch point of the side that was not probed for

basic rotation.

UUUU Select the probe direction with a soft key.

UUUU To probe the workpiece, press the machine START

button.

UUUU Position the touch probe near the second touch point

on the same side.

UUUU To probe the workpiece, press the machine START

button.

UUUU Datum: Enter both datum coordinates into the menu

window, and confirm your entry with the ENT key.

UUUU To terminate the probe function, press the END key.

Corner as datum—without using points that

were already probed for a basic rotation

Y=?

Y

P

X=?

Y

P

X

X

UUUU To select the probe function, press PROBING P.

UUUU Touch points of basic rotation?: Press NO ENT to ignore the

previous touch points. (The dialog question only appears if a basic

rotation was made previously.)

UUUU Probe both workpiece sides twice.

UUUU Enter the coordinates of the datum and confirm your entry with ENT.

UUUU To terminate the probe function, press the END key.

HEIDENHAIN TNC 426, TNC 430 21

2.5 Setting the Datum with a 3-D Touch Probe

Page 34

Circle center as datum

With this function, you can set the datum at the center of bore holes,

circular pockets, cylinders, studs, circular islands, etc.

Inside circle

The TNC automatically probes the inside wall in all four coordinate axis

directions.

For incomplete circles (circular arcs) you can choose the appropriate

probing direction.

UUUU Position the touch probe approximately in the center of the circle.

UUUU To select the probe function, press ANTASTEN CC.

UUUU To probe the workpiece, press the machine START

button four times. The touch probe touches four

points on the inside of the circle.

UUUU If you are probing to find the stylus center (only

available on machines with spindle orientation,

depending on MP6160), press the 180° soft key and

probe another four points on the inside of the circle.

UUUU If you are not probing to find the stylus center, press

the END key.

UUUU Datum: Enter both circle center coordinates into the

menu window, and confirm your entry with ENT.

UUUU To terminate the probe function, press the END key.

Y

Y+

X+X–

Y–

X

Y

Y–

X+

Outside circle

UUUU Position the touch probe at the starting position for the first touch

point outside of the circle.

UUUU Select the probe direction with a soft key.

2.5 Setting the Datum with a 3-D Touch Probe

UUUU To probe the workpiece, press the machine START button.

UUUU Repeat the probing process for the remaining three points. See

figure at lower right.

UUUU Enter the coordinates of the datum and confirm your entry with ENT.

After the probing procedure is completed, the TNC displays the

coordinates of the circle center and the circle radius PR.

Y+

X–

X

22 2 Touch Probe Cycles in the Manual and Electronic Handwheel Modes

Page 35

Setting datum points using holes/cylindrical studs

A second soft-key row provides soft keys for using holes or cylindrical

studs to set datums.

Define whether a hole or stud is to be probed

UUUU Select the probing functions with the TOUCH PROBE,

shift the soft-key row.

UUUU Select the probing function: For example, press the

PROBING ROT soft key.

UUUU Select holes or cylindrical studs: the selected element

appears in a box

Probing holes

Pre-position the touch probe approximately in the center of the hole.

After you have pressed the external START key, the TNC automatically

probes four points on the wall of the hole.

Move the touch probe to the next hole and have the TNC repeat the

probing procedure until all the holes have been probed to set datums.

Probing cylindrical studs

Position the ball tip at a starting position near the first touch point of

the stud. Select the probing direction by soft key and press the

machine START button to start probing. Perform the above procedure

four times.

Overview

Cycle Soft key

Basic rotation using 2 holes:

The TNC measures the angle between the line

connecting the centers of two holes and a nominal

position (angle reference axis).

Datum using 4 holes:

The TNC calculates the intersection of the line

connecting the first two probed holes with the line

connecting the last two probed holes. You need to

probe diagonally opposite holes one after another (as

shown on the soft key), as otherwise the datum

calculated by the TNC will be incorrect.

Circle center using 3 holes:

The TNC calculates a circle that intersects the centers

of all three holes, and finds the center.

2.5 Setting the Datum with a 3-D Touch Probe

HEIDENHAIN TNC 426, TNC 430 23

Page 36

2.6 Measuring Workpieces with a

3-D Touch Probe

Introduction

You can also use the touch probe in the Manual and Electronic

Handwheel operating modes to make simple measurements on the

workpiece. With a 3-D touch probe you can determine:

n position coordinates, and from them,

n dimensions and angles on the workpiece.

To find the coordinate of a position on an aligned workpiece:

UUUU Select the probing function by pressing the PROBING

POS soft key.

UUUU Move the touch probe to a starting position near the

touch point.

UUUU Select the probe direction and axis of the coordinate.

Use the corresponding soft keys for selection.

UUUU To probe the workpiece, press the machine START

button.

The TNC shows the coordinates of the touch point as datum.

Finding the coordinates of a corner in the working plane

Find the coordinates of the corner point: See “Corner as datum—

without using points that were already probed for a basic rotation,”

page 21. The TNC displays the coordinates of the probed corner as

2.6 Measuring Workpieces with a 3-D Touch Probe

datum.

24 2 Touch Probe Cycles in the Manual and Electronic Handwheel Modes

Page 37

Measuring workpiece dimensions

UUUU Select the probing function by pressing the PROBING

POS soft key.

UUUU Position the touch probe at a starting position near the

first touch point A.

UUUU Select the probing direction with a soft key.

UUUU To probe the workpiece, press the machine START

button.

UUUU If you will need the current datum later, write down

the value that appears in the datum display.

UUUU Datum: Enter “0”.

UUUU To terminate the dialog, press the END key.

UUUU Select the probing function by pressing the PROBING

POS soft key.

UUUU Position the touch probe at a starting position near the

second touch point B

UUUU Select the probe direction with the soft keys: Same

axis but from the opposite direction.

UUUU To probe the workpiece, press the machine START

button.

The value displayed as datum is the distance between the two points

on the coordinate axis.

Z

Y

B

A

X

l

To return to the datum that was active before the length

measurement:

UUUU Select the probing function by pressing the PROBING POS soft key.

UUUU Probe the first touch point again.

UUUU Set the datum to the value that you wrote down previously.

UUUU To terminate the dialog, press the END key.

Measuring angles

You can use the 3-D touch probe to measure angles in the working

plane. You can measure

n the angle between the angle reference axis and a workpiece side, or

n the angle between two sides.

The measured angle is displayed as a value of maximum 90°.

HEIDENHAIN TNC 426, TNC 430 25

2.6 Measuring Workpieces with a 3-D Touch Probe

Page 38

To find the angle between the angle reference axis and a side of the workpiece

UUUU Select the probing function by pressing the PROBING

ROT soft key.

UUUU Rotation angle: If you will need the current basic

rotation later, write down the value that appears

under Rotation angle.

UUUU Make a basic rotation with the side of the workpiece

(see “Compensating Workpiece Misalignment” on

page 18).

UUUU Press the PROBING ROT soft key to display the angle

between the angle reference axis and the side of the

workpiece as the rotation angle.

UUUU Cancel the basic rotation, or restore the previous basic

rotation:

UUUU This is done by setting the rotation angle to the value

that you wrote down previously.

PA

To measure the angle between two workpiece sides:

UUUU Select the probing function by pressing the PROBING ROT soft key.

UUUU Rotation angle: If you will need the current basic rotation later, write

down the value that appears under Rotation angle.

UUUU Make a basic rotation with the side of the workpiece (see

“Compensating Workpiece Misalignment” on page 18).

UUUU Probe the second side as for a basic rotation, but do not set the

rotation angle to zero!

UUUU Press the PROBING ROT soft key to display the angle PA between

the two sides as the rotation angle.

UUUU Cancel the basic rotation, or restore the previous basic rotation by

setting the rotation angle to the value that you wrote down

previously.

2.6 Measuring Workpieces with a 3-D Touch Probe

100

Y

–10

Z

L?

α?

X

α?

100

26 2 Touch Probe Cycles in the Manual and Electronic Handwheel Modes

Page 39

3

Touch Probe Cycles for Automatic Workpiece Inspection

HEIDENHAIN TNC 426, TNC 430 27

Page 40

3.1 Measuring Workpiece

Misalignment

Overview

The TNC provides five cycles that enable you to measure and

compensate workpiece misalignment. In addition, you can reset a

basic rotation with Cycle 404.

Cycle Soft key

400 BASIC ROTATION Automatic measurement

using two points. Compensation via basic

rotation.

401 ROT OF 2 HOLES Automatic measurement

using two holes. Compensation via basic

rotation.

402 ROT OF 2 STUDS Automatic measurement

using two studs. Compensation via basic

rotation.

403 ROT IN ROTARY AXIS Automatic

measurement using two points. Compensation

via basic rotation.

405 ROT IN C AXIS Automatic alignment of an

angular offset between a hole center and the

3.1 Measuring Workpiece Misalignment

positive Y axis. Compensation via table rotation.

404 SET BASIC ROTATION Setting any basic

rotation

Characteristics common to all touch probe cycles for measuring workpiece misalignment

For the cycles 400, 401 and 402 you can define through parameter

Q307 Default setting for basic rotation whether the

measurement result is to be corrected by a known angle a (see figure

at right). This enables you to measure the basic rotation against any

straight line 1 of the workpiece and to establish the reference to the

actual 0° direction 2.

28 3 Touch Probe Cycles for Automatic Workpiece Inspection

1

2

Page 41

BASIC ROTATION (touch probe cycle 400, ISO: G400)

Touch probe cycle 400 determines a workpiece misalignment by

measuring two points, which must lie on a straight surface. With the

basic rotation function the TNC compensates the measured value

(See also “Compensating Workpiece Misalignment” on page 18).

1 The TNC positions the touch probe to the starting points at rapid

traverse (value from MP6150 or MP6361) following the positioning

logic (see “Running touch probe cycles” on page 7) to the

programmed starting point 1. The TNC offsets the touch probe by

the safety clearance in the direction opposite the defined traverse

direction.

2 Then the touch probe moves to the entered measuring height and

probes the first touch point at the probing feed rate (MP6120 or

MP6360).

3 Then the touch probe moves to the next starting position 2 and

probes the second position.

4 The TNC returns the touch probe to the clearance height and

performs the basic rotation.

Before programming, note the following:

Before a cycle definition you must have programmed a

tool call to define the touch probe axis.

The TNC will reset an active basic rotation at the beginning

of the cycle.

1

2

3.1 Measuring Workpiece Misalignment

HEIDENHAIN TNC 426, TNC 430 29

Page 42

UUUU First measuring point in the 1st axis Q263

(absolute): coordinate of the first touch point in the

reference axis of the working plane.

UUUU First measuring point in the 2nd axis Q264

(absolute): coordinate of the first touch point in the

minor axis of the working plane.

UUUU Second measuring point in the 1st axis Q265

(absolute): coordinate of the second touch point in the

reference axis of the working plane

UUUU Second measuring point in the 2nd axis Q266

(absolute): coordinate of the second touch point in the

minor axis of the working plane

UUUU Measuring axis Q272: axis in the working plane in

which the measurement is to be made:

1: Reference axis = measuring axis

2: Minor axis = measuring axis

UUUU Traverse direction 1 Q267: direction in which the

probe is to approach the workpiece:

-1: Negative traverse direction

+1: Positive traverse direction

UUUU Measuring height in the touch probe axis Q261

(absolute): coordinate of the ball tip center (= touch

point) in the touch probe axis in which the

measurement is to be made.

UUUU Setup clearance Q320 (incremental): additional

3.1 Measuring Workpiece Misalignment

distance between measuring point and ball tip. Q320

is added to MP6140.

UUUU Clearance height Q260 (absolute): coordinate in the

touch probe axis at which no collision between tool

and workpiece (fixtures) can occur.

UUUU Traversing to clearance height Q301: definition of

how the touch probe is to move between the

measuring points:

0: Move at measuring height between measuring

points

1:

Move at clearance height between measuring

points

UUUU Default setting for basic rotation Q307

(absolute): If the misalignment is to be measured

against a straight line other than the reference axis,

enter the angle of this reference line. The TNC will

then calculate the difference between the measured

value and the angle of the reference line for the basic

rotation.

Y

Q272=2

Q266

Q264

Q263

–

Q265

Example: NC blocks

5 TCH PROBE 400 BASIC ROTATION

Q263=+10 ;1ST POINT 1ST AXIS

Q264=+3.5 ;1ST POINT 2ND AXIS

Q265=+25 ;2ND POINT 1ST AXIS

Q266=+2 ;2ND POINT 2ND AXIS

Q272=2 ;MEASURING AXIS

Q267=+1 ;TRAVERSE DIRECTION

Q261=-5 ;MEASURING HEIGHT

Q320=0 ;SET-UP CLEARANCE

Q260=+20 ;CLEARANCE HEIGHT

Q301=0 ;TRAVERSE TO CLEAR HEIGHT

Q307=+0 ;PRESET BASIC ROTATION

+

Q267

–

MP6140

+

Q320

X

Q272=1

+

30 3 Touch Probe Cycles for Automatic Workpiece Inspection

Page 43

BASIC ROTATION from two holes (touch probe cycle 401, ISO: G401)

The touch probe cycle 401 measures the centers of two holes. Then

the TNC calculates the angle between the reference axis in the

working plane and the line connecting the two hole centers. With the

basic rotation function the TNC compensates the calculated value

(See also “Compensating Workpiece Misalignment” on page 18).

1 Following the positioning logic (see “Running touch probe cycles”

on page 7), the TNC positions the touch probe at rapid traverse

(value from MP6150 or MP6361) to the point entered as center of

the first hole 1.

2 Then the probe moves to the entered measuring height and

probes four points to find the first hole center.

3 The touch probe returns to the clearance height and then to the

position entered as center of the second hole 2.

4 The TNC moves the touch probe to the entered measuring height

and probes four points to find the second hole center.

5 Then the TNC returns the touch probe to the clearance height and

performs the basic rotation.

Before programming, note the following:

Before a cycle definition you must have programmed a

tool call to define the touch probe axis.

The TNC will reset an active basic rotation at the beginning

of the cycle.

2

1

3.1 Measuring Workpiece Misalignment

HEIDENHAIN TNC 426, TNC 430 31

Page 44

UUUU First hole: Center in 1st axis Q268 (absolute):

center of the first hole in the reference axis of the

working plane.

UUUU First hole: Center in 2nd axis Q269 (absolute):

center of the first hole in the minor axis of the working

plane.

UUUU Second hole: Center in 1st axis Q270 (absolute):

center of the second hole in the reference axis of the

working plane.

UUUU Second hole: Center in 2nd axis Q271 (absolute):

center of the second hole in the minor axis of the

working plane.

UUUU Measuring height in the touch probe axis Q261

(absolute): coordinate of the ball tip center (= touch

point) in the touch probe axis in which the

measurement is to be made.

UUUU Clearance height Q260 (absolute): coordinate in the

touch probe axis at which no collision between tool

and workpiece (fixtures) can occur.

UUUU Default setting for basic rotation Q307

(absolute): If the misalignment is to be measured

against a straight line other than the reference axis,

enter the angle of this reference line. The TNC will

then calculate the difference between the measured

value and the angle of the reference line for the basic

3.1 Measuring Workpiece Misalignment

rotation.

Example: NC blocks

5 TCH PROBE 401 ROT OF 2 HOLES

Q268=-37 ;1ST CENTER 1ST AXIS

Q269=+12 ;1ST CENTER 2ND AXIS

Q270=+75 ;2ND CENTER 1ST AXIS

Q271=+20 ;2ND CENTER 2ND AXIS

Q261=-5 ;MEASURING HEIGHT

Q260=+20 ;CLEARANCE HEIGHT

Q307=+0 ;PRESET BASIC ROT.

32 3 Touch Probe Cycles for Automatic Workpiece Inspection

Page 45

BASIC ROTATION over two studs (touch probe cycle 402, ISO: G402)

The touch probe cycle 402 measures the centers of two studs. Then

the TNC calculates the angle between the reference axis in the

working plane and the line connecting the two stud centers. With the

basic rotation function the TNC compensates the calculated value

(See also “Compensating Workpiece Misalignment” on page 18).

1 Following the positioning logic (see “Running touch probe cycles”

on page 7), the TNC positions the touch probe in rapid traverse

(value from MP6150 or MP6361) to the starting point for probing

the first stud 1.

2 Then the probe moves to the entered measuring height 1 and

probes four points to find the center of the first stud. The touch

probe moves on a circular arc between the touch points, each of

which is offset by 90°.

3 The touch probe returns to the clearance height and then to the

starting point for probing 5 the second stud.

4 The TNC moves the touch probe to the entered measuring height

2 and probes four points to find the center of the second stud.

5 Then the TNC returns the touch probe to the clearance height and

performs the basic rotation.

Before programming, note the following:

Before a cycle definition you must have programmed a

tool call to define the touch probe axis.

The TNC will reset an active basic rotation at the beginning

of the cycle.

Y

5

1

X

3.1 Measuring Workpiece Misalignment

HEIDENHAIN TNC 426, TNC 430 33

Page 46

UUUU First stud: Center in 1st axis Q268 (absolute):

center of the first stud in the reference axis of the

working plane.

UUUU First stud: Center in 2nd axis Q269 (absolute):

center of the first stud in the minor axis of the

working plane.

UUUU Diameter of stud 1 Q313: approximate diameter of

the 1st stud. Enter a value that is more likely to be too

large than too small.

UUUU Measuring height 1 in the probe axis Q261

(absolute): coordinate of the ball tip center (= touch

point in the touch probe axis) at which stud 1 is to be

measured.

UUUU Second stud: Center in 1st axis Q270 (absolute):

center of the second stud in the reference axis of the

working plane.

UUUU Second stud: Center in 2nd axis Q271 (absolute):

center of the second stud in the minor axis of the

working plane.

UUUU Diameter of stud 2 Q314: approximate diameter of

the 2nd stud. Enter a value that is more likely to be

too large than too small.

UUUU Measuring height 2 in the probe axis Q315

(absolute): coordinate of the ball tip center (= touch

point in the touch probe axis) at which stud 2 is to be

3.1 Measuring Workpiece Misalignment

measured.

UUUU Setup clearance Q320 (incremental): additional

distance between measuring point and ball tip. Q320

is added to MP6140.

UUUU Clearance height Q260 (absolute): coordinate in the

touch probe axis at which no collision between tool

and workpiece (fixtures) can occur.

UUUU Traversing to clearance height Q301: definition of

how the touch probe is to move between the

measuring points:

0: Move at measuring height between measuring

points

1: Move at clearance height between measuring

points

UUUU Default setting for basic rotation Q307

(absolute): If the misalignment is to be measured

against a straight line other than the reference axis,

enter the angle of this reference line. The TNC will

then calculate the difference between the measured

value and the angle of the reference line for the basic

rotation.

Y

Q271

Q269

Q313

Q268 Q270

Z

Q261

Q315

MP6140

+

Q320

Example: NC blocks

5 TCH PROBE 402 ROT OF 2 STUDS

Q268=-37 ;1ST CENTER 1ST AXIS

Q269=+12 ;1ST CENTER 2ND AXIS

Q313=60 ;DIAMETER OF STUD 1

Q261=-5 ;MEASURING HEIGHT 1

Q270=+75 ;2ND CENTER 1ST AXIS

Q271=+20 ;2ND CENTER 2ND AXIS

Q314=60 ;DIAMETER STUD 2

Q315=-5 ;MEASURING HEIGHT 2

Q320=0 ;SET-UP CLEARANCE

Q260=+20 ;CLEARANCE HEIGHT

Q301=0 ;TRAVERSE TO CLEAR HEIGHT

Q307=+0 ;PRESET BASIC ROT.

Q314

X

Q260

X

34 3 Touch Probe Cycles for Automatic Workpiece Inspection

Page 47

BASIC ROTATION compensation via rotary axis (touch probe cycle 403, ISO: G403)

Touch probe cycle 403 determines a workpiece misalignment by

measuring two points, which must lie on a straight surface. The TNC

compensates the misalignment by rotating the A, B or C axis. The

workpiece can be clamped in any position on the rotary table.

1 The TNC positions the touch probe to the starting points at rapid

traverse (value from MP6150 or MP6361) following the positioning

logic (see “Running touch probe cycles” on page 7) to the

programmed starting point 1. The TNC offsets the touch probe by

the safety clearance in the direction opposite the defined traverse

direction.

2 Then the touch probe moves to the entered measuring height and

probes the first touch point at the probing feed rate (MP6120 or

MP6360).

3 Then the touch probe moves to the next starting position 2 and

probes the second position.

4 The TNC returns the touch probe to the clearance height and

moves the rotary axis, which was defined in the cycle, by the

measured value.

Before programming, note the following:

Before a cycle definition you must have programmed a

tool call to define the touch probe axis.

2

11

3.1 Measuring Workpiece Misalignment

HEIDENHAIN TNC 426, TNC 430 35

Page 48

UUUU First measuring point in the 1st axis Q263

(absolute): coordinate of the first touch point in the

reference axis of the working plane.

UUUU First measuring point in the 2nd axis Q264

(absolute): coordinate of the first touch point in the

minor axis of the working plane.

UUUU Second measuring point in the 1st axis Q265

(absolute): coordinate of the second touch point in the

reference axis of the working plane

UUUU Second measuring point in the 2nd axis Q266

(absolute): coordinate of the second touch point in the

minor axis of the working plane

UUUU Measuring axis Q272: axis in which the measurement

is to be made:

1: Reference axis = measuring axis

2: Minor axis = measuring axis

3: Touch probe axis = measuring axis

UUUU Traverse direction 1 Q267: direction in which the

probe is to approach the workpiece:

-1: Negative traverse direction

+1: Positive traverse direction

UUUU Measuring height in the touch probe axis Q261

(absolute): coordinate of the ball tip center (= touch

point) in the touch probe axis in which the

measurement is to be made.

3.1 Measuring Workpiece Misalignment

UUUU Setup clearance Q320 (incremental): additional

distance between measuring point and ball tip. Q320

is added to MP6140.

UUUU Clearance height Q260 (absolute): coordinate in the

touch probe axis at which no collision between tool

and workpiece (fixtures) can occur.

UUUU Traversing to clearance height Q301: definition of

how the touch probe is to move between the

measuring points:

0: Move at measuring height between measuring

points

1: Move at clearance height between measuring

points

UUUU Axis for compensation motion Q312: assignment of

the rotary axis in which the TNC is to compensate the

measured misalignment:

4: Compensate misalignment with rotary axis A

5: Compensate misalignment with rotary axis B

6: Compensate misalignment with rotary axis C

Y

Q272=2

–

A

B

C

Q266

Q264

Q263

Example: NC blocks

5 TCH PROBE 403 ROT IN C-AXIS

Q263=+0 ;1ST POINT 1ST AXIS

Q264=+0 ;1ST POINT 2ND AXIS

Q265=+20 ;2ND POINT 1ST AXIS

Q266=+30 ;2ND POINT 2ND AXIS

Q272=1 ;MEASURING AXIS

Q267=+1 ;TRAVERSE DIRECTION

Q261=-5 ;MEASURING HEIGHT

Q320=0 ;SET-UP CLEARANCE

Q260=+20 ;CLEARANCE HEIGHT

Q301=0 ;TRAVERSE TO CLEAR HEIGHT

Q312=6 ;COMPENSATION AXIS

Q265

+

Q267

–

MP6140

+

Q320

X

Q272=1

+

36 3 Touch Probe Cycles for Automatic Workpiece Inspection

Page 49

SET BASIC ROTATION (touch probe cycle 404,

ISO: G404, available as of NC software

280 474-xx)

With touch probe cycle 404 you can set any basic rotation

automatically during program run. This cycle is intended primarily for

resetting a previous basic rotation.

UUUU Preset value for basic rotation: Angular value at

which the basic rotation is to be set.

Example: NC blocks

5 TCH PROBE 404 BASIC ROTATION

307=+0 ;PRESET BASIC ROTATION

3.1 Measuring Workpiece Misalignment

HEIDENHAIN TNC 426, TNC 430 37

Page 50

Compensating workpiece misalignment by rotating the C axis (touch probe cycle 405, ISO: G405, available as of NC software 280 474-xx)

With touch probe cycle 405 you can measure

n the angular offset between the positive Y axis of the active

coordinate system and the center of a hole, or

n the angular offset between the nominal position and the actual

position of a hole center.

The TNC compensates the misalignment by rotating the C axis. The

workpiece can be clamped in any position on the rotary table, but the

Y coordinate of the hole must be positive. If you measure the angular

misalignment of the hole with touch probe axis Y (horizontal position

of the hole), it may be necessary to conduct the cycle more than once

because the measuring strategy causes an inaccuracy of approx. 1%

of the misalignment.

1 The TNC positions the touch probe to the starting points at rapid

traverse (value from MP6150 or MP6361) following the positioning

logic (see “Running touch probe cycles” on page 7) to the starting

point 1. The TNC calculates the probe starting points from the data

in the cycle and the safety clearance from MP6140.

2 Then the touch probe moves to the entered measuring height and

probes the first touch point at the probing feed rate (MP6120 or

MP6360). The TNC derives the probing direction automatically

from the programmed starting angle.

3 Then the touch probe moves in a circular arc either at measuring

3.1 Measuring Workpiece Misalignment

height or at clearance height to the next starting point 2 and probes

the second touch point.

4 The TNC positions the probe to starting point 3 and then to starting

point 4 to probe the third and fourth touch points and positions the

touch probe on the hole centers measured.

5 Finally the TNC returns the touch probe to the clearance height and

aligns the workpiece by rotating the table. The TNC rotates the

rotary table so that the hole center after compensation lies in the

direction of the positive Y axis, or on the nominal position of the

hole center—both with a vertical and horizontal touch probe axis.

The measured angular misalignment is also available in parameter

Q150.

2

111

3

4

Before programming, note the following:

To prevent a collision between the touch probe and the

workpiece, enter a low estimate for the nominal diameter

of the pocket (or hole).

If the dimensions of the pocket and the safety clearance

do not permit pre-positioning in the proximity of the touch

points, the TNC always starts probing from the center of

the pocket. In this case the touch probe does not return to

the clearance height between the four measuring points.

Before a cycle definition you must have programmed a

tool call to define the touch probe axis.

38 3 Touch Probe Cycles for Automatic Workpiece Inspection

Page 51

UUUU Center in 1st axis Q321 (absolute value): Center of

the pocket in the reference axis of the working plane.

UUUU Center in 2nd axis Q322 (absolute value): Center of

the pocket in the minor axis of the working plane If

you program Q322 = 0, the TNC aligns the hole center

to the positive Y axis. If you program Q322 not equal

to 0, then the TNC aligns the hole center to the

nominal position.

UUUU Nominal diameter Q262: approximate diameter of the

circular pocket (or hole). Enter a value that is more

likely to be too small than too large.

UUUU Starting angle Q325 (absolute): angle between the

reference axis of the working plane and the first touch

point.

UUUU Stepping angle Q247 (incremental): Angle between

two measuring points. The algebraic sign of the

stepping angle determines the direction of rotation

(negative = clockwise) in which the touch probe

moves to the next measuring point. If you wish to

probe a circular arc instead of a complete circle, then

program the stepping angle to be less than 90°.

The smaller the angle, the less accurately the TNC can

calculate the circle center. Minimum input value: 5°.

Q322

Y

Q247

Q325

Q262

X

Q321

3.1 Measuring Workpiece Misalignment

HEIDENHAIN TNC 426, TNC 430 39

Page 52

UUUU Measuring height in the touch probe axis Q261

(absolute): coordinate of the ball tip center (= touch

point) in the touch probe axis in which the

measurement is to be made.

UUUU Setup clearance Q320 (incremental): additional

distance between measuring point and ball tip. Q320

is added to MP6140.

UUUU Clearance height Q260 (absolute): coordinate in the

touch probe axis at which no collision between tool

and workpiece (fixtures) can occur.

UUUU Traversing to clearance height Q301: definition of

how the touch probe is to move between the

measuring points:

0: Move at measuring height between measuring

points

1: Move at clearance height between measuring

points

UUUU Set to zero after alignment Q337: definition of

whether the TNC should set the display of the C-axis

to zero, or write the angular misalignment in column

C of the datum table:

0: Set display of C to 0

>0: Write the angular misalignment, including

algebraic sign, in the datum table. Line number =

value of Q337. If a C-axis shift is registered in the

datum table, the TNC adds the measured angular

misalignment.

3.1 Measuring Workpiece Misalignment

Z

Q261

MP6140

+

Q320

Example: NC blocks

5 TCH PROBE 405 ROT IN C-AXIS

Q321=+50 ;CENTER IN 1ST AXIS

Q322=+50 ;CENTER IN 2ND AXIS

Q262=10 ;NOMINAL DIAMETER

Q325=+0 ;STARTING ANGLE

Q247=90 ;STEPPING ANGLE

Q261=-5 ;MEASURING HEIGHT

Q320=0 ;SET-UP CLEARANCE

Q260=+20 ;CLEARANCE HEIGHT

Q301=0 ;TRAVERSE TO CLEAR HEIGHT

Q337=0 ;SET TO ZERO

Q260

X

40 3 Touch Probe Cycles for Automatic Workpiece Inspection

Page 53

Example: Determining a basic rotation from two holes

0 BEGIN PGM CYC401 MM

1 TOOL CALL 0 Z

2 TCH PROBE 401 ROT OF 2 HOLES

Q268=+25 ;1ST CENTER 1ST AXIS

Q269=+15 ;1ST CENTER 2ND AXIS

Q270=+80 ;2ND CENTER 1ST AXIS

Q271=+35 ;2ND CENTER 2ND AXIS

Q261=-5 ;MEASURING HEIGHT

Q260=+20 ;CLEARANCE HEIGHT

Q307=+0 ;PRESET BASIC ROTATION

3 CALL PGM 35K47

4 END PGM CYC401 MM

Y

35

15

25

Center of the 1st hole: X coordinate

Center of the 1st hole: Y coordinate

Center of the 2nd hole: X coordinate

Center of the 2nd hole: Y coordinate

Coordinate in the touch probe axis in which the measurement is

made

Height in the touch probe axis at which the probe can traverse

without collision

Angle of the reference line

Part program call

80

X

Y

Z

3.1 Measuring Workpiece Misalignment

HEIDENHAIN TNC 426, TNC 430 41

Page 54

3.2 Automatic Datum Setting

Overview

The TNC provides nine cycles for automatic datum setting or

automatic entry of the measured values into the active datum table:

Cycle Soft key

410 DATUM INSIDE RECTAN. Measuring the

inside length and width of a rectangle, and

defining the center as datum

411 DATUM OUTSIDE RECTAN. Measuring the

outside length and width of a rectangle, and

defining the center as datum

412 DATUM INSIDE CIRCLE Measuring any four

points on the inside of a circle, and defining the

center as datum

3.2 Automatic Datum Setting

413 DATUM OUTSIDE CIRCLE Measuring any

four points on the outside of a circle, and defining

the center as datum

414 DATUM OUTSIDE CORNER Measuring two

lines from the outside of the angle, and defining

the intersection as datum

415 DATUM INSIDE CORNER Measuring two

lines from within the angle, and defining the

intersection as datum

416 DATUM CIRCLE CENTER (2nd soft-key

level) Measuring any three holes on a bolt hole

circle, and defining the bolt-hole center as datum

417 DATUM IN TS AXIS (2nd soft-key level)

Measuring any position in the touch probe axis

and defining it as datum

418 DATUM FROM 4 HOLES (2nd soft-key level)

Measuring 4 holes crosswise and defining the

intersection of the lines between them as datum

42 3 Touch Probe Cycles for Automatic Workpiece Inspection

Page 55

Characteristics common to all touch probe cycles for datum setting

In TNCs with NC software 280 476-xx you may also run

the touch probe cycles 410 to 418 during an active basic

rotation (basic rotation or Cycle 10). In previous versions

the TNC displays an error message if the basic rotation is

active.

Datum point and touch probe axis

From the touch probe axis that you have defined in the measuring

program the TNC determines the working plane for the datum:

Active touch probe axis Datum setting in

Z or W X and Y

Y or V Z and X

X or U Y and Z

Writing the calculated datum to a datum table

In all cycles for datum setting you can use the input parameter Q305

to define whether you wish the TNC to set the calculated datum

shown in the display or enter it in a datum table.

If you want the calculated datum to be entered in a datum

table, you must first activate a datum table (status M) in a

program run mode before starting the measuring program.

When writing to a datum table, the TNC observes machine

parameter 7475:

MP7475 = 0: Values are referenced to workpiece datum,

MP7475 = 1: Values are referenced to the machine datum.

If you change the setting in MP7475, the TNC does not

convert the values already saved in datum tables.

3.2 Automatic Datum Setting

HEIDENHAIN TNC 426, TNC 430 43

Page 56

DATUM FROM INSIDE OF RECTANGLE (touch probe cycle 410, ISO: G410)

Touch probe cycle 410 finds the center of a rectangular pocket and

defines its center as datum. If desired, the TNC can also enter the

coordinates into a datum table.

1 The TNC positions the touch probe to the starting points at rapid

traverse (value from MP6150 or MP6361) following the positioning

logic (see “Running touch probe cycles” on page 7) to the starting

point 1. The TNC calculates the probe starting points from the data

in the cycle and the safety clearance from MP6140.

2 Then the touch probe moves to the entered measuring height and

probes the first touch point at the probing feed rate (MP6120 or

MP6360).

3 Then the touch probe moves either paraxially at the measuring

height or linearly at the clearance height to the next starting point

2 and probes the second touch point.

4 The TNC positions the probe to starting point 3 and then to starting

point 4 to probe the third and fourth touch points.

3.2 Automatic Datum Setting

5 Finally the TNC returns the touch probe to the clearance height and

sets the datum in the pocket center, or enters the coordinates of

the pocket center in the active datum table.

Before programming, note the following:

To prevent a collision between touch probe and

workpiece, enter low estimates for the lengths of the 1st

and 2nd sides.

If the dimensions of the pocket and the safety clearance

do not permit pre-positioning in the proximity of the touch

points, the TNC always starts probing from the center of

the pocket. In this case the touch probe does not return to

the clearance height between the four measuring points.

Before a cycle definition you must have programmed a

tool call to define the touch probe axis.

4

1

3

2

44 3 Touch Probe Cycles for Automatic Workpiece Inspection

Page 57

UUUU Center in 1st axis Q321 (absolute value): Center of

the pocket in the reference axis of the working plane.

UUUU Center in 2nd axis Q322 (absolute value): Center of

the pocket in the minor axis of the working plane.

UUUU First side length Q323 (incremental value): Pocket