Page 1

Pilot

TNC 426

TN C 42 6B

TNC 4 30

TNC 43 0

NC-Software

280 476-xx

280 477-xx

8/2000

Page 2

The Pilot

Contents

... is your concise programming guide for the HEIDENHAIN

TNC 426 and TNC 430 contouring controls. For more

comprehensive information on programming and operating,

refer to the TNC User's Manual. There you will find complete information on:

Q-parameter programming

The central tool file

3-D tool compensation

Tool measurement

Certain symbols are used in the Pilot to denote specific

types of information:

Important note

WARNING: danger for the user or the machine!

The TNC and the machine tool must be prepared by

the machine tool builder to perform these functions!

Chapter in User's Manual where you will find more

detailed information on the current topic.

The information in this Pilot applies to TNCs with the following

software numbers:

Control NC Software Number

TNC 426, TNC 430 280 476-xx

TNC 426*, TNC 430* 280 477-xx

Fundamentals ................................................................... 4

Contour Approach and Departure .................................... 13

Path Functions .................................................................. 18

FK Free Contour Programming ........................................ 25

Subprograms and Program Section Repeats ................... 33

Working with Cycles ........................................................ 36

Cycles for Machining Holes and Threads ........................ 39

Pockets, Studs, and Slots ................................................. 56

Point Patterns ................................................................... 65

SL Cycles .......................................................................... 67

Multipass Milling .............................................................. 75

Coordinate Transformation Cycles................................... 78

Special Cycles ................................................................... 85

Digitizing 3-D Surfaces ..................................................... 88

Graphics and Status Displays ........................................... 94

ISO Programming ............................................................. 97

Miscellaneous Functions M ............................................. 103

Contents

*) Export version

3

Page 3

Fundamentals

Files in the TNC

File type

Programs/Files

See Programming, File Management

The TNC keeps its programs, tables and texts in files.

A file designation consists of two components:

THREAD2.H

File name File type

Maximum length: see table at right

16 characters

Fundamentals

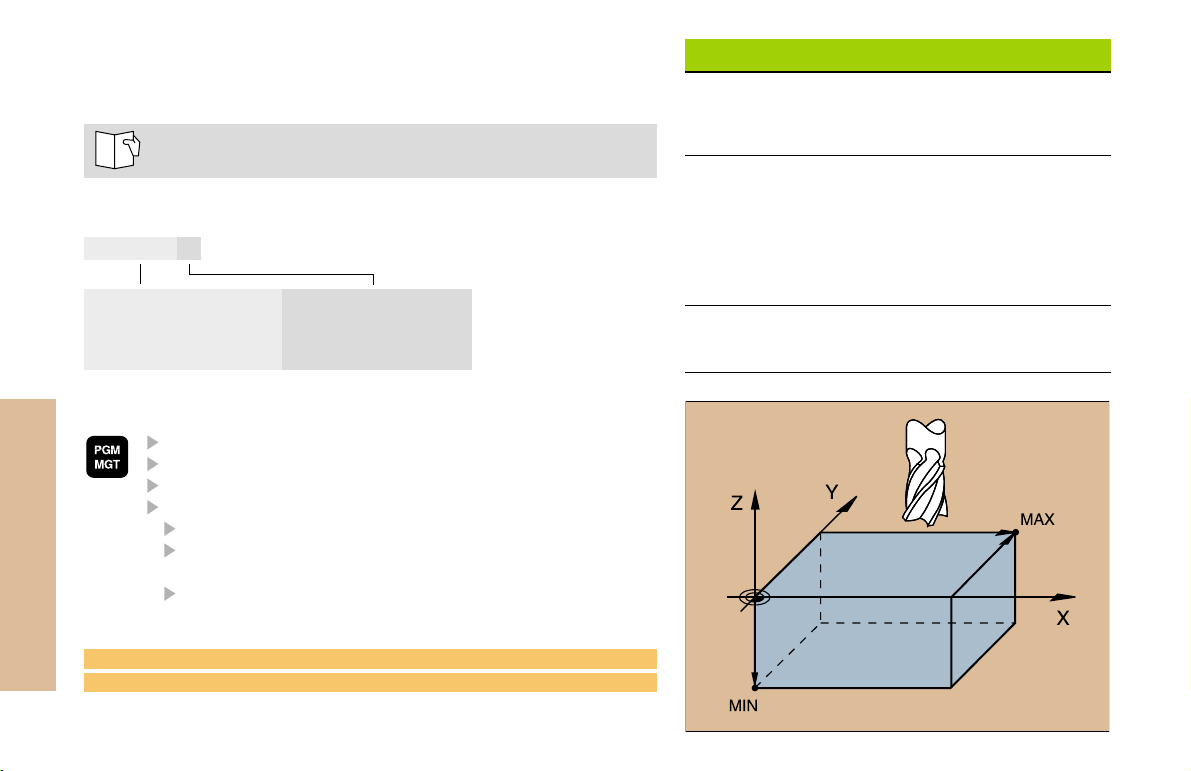

Creating a New Part Program

Select the directory in which the program is stored

Enter a new file name with file type

Select unit of measure for dimensions (mm or inches)

Define the blank form (BLK) for graphics:

Enter the spindle axis

Enter coordinates of the MIN point:

the smallest X, Y and Z coordinates

Enter coordinates of the MAX point:

the greatest X, Y and Z coordinates

1 BLK FORM 0.1 Z X+0 Y+0 Z-50

2 BLK FORM 0.2 X+100 Y+100 Z+0

Programs

in HEIDENHAIN format

in ISO format

Tables for

Tools

Datums

Pallets

Cutting data

Positions

Texts as

ASCII files

.H

.I

.T

.D

.P

.CDT

.PNT

.A

4

Page 4

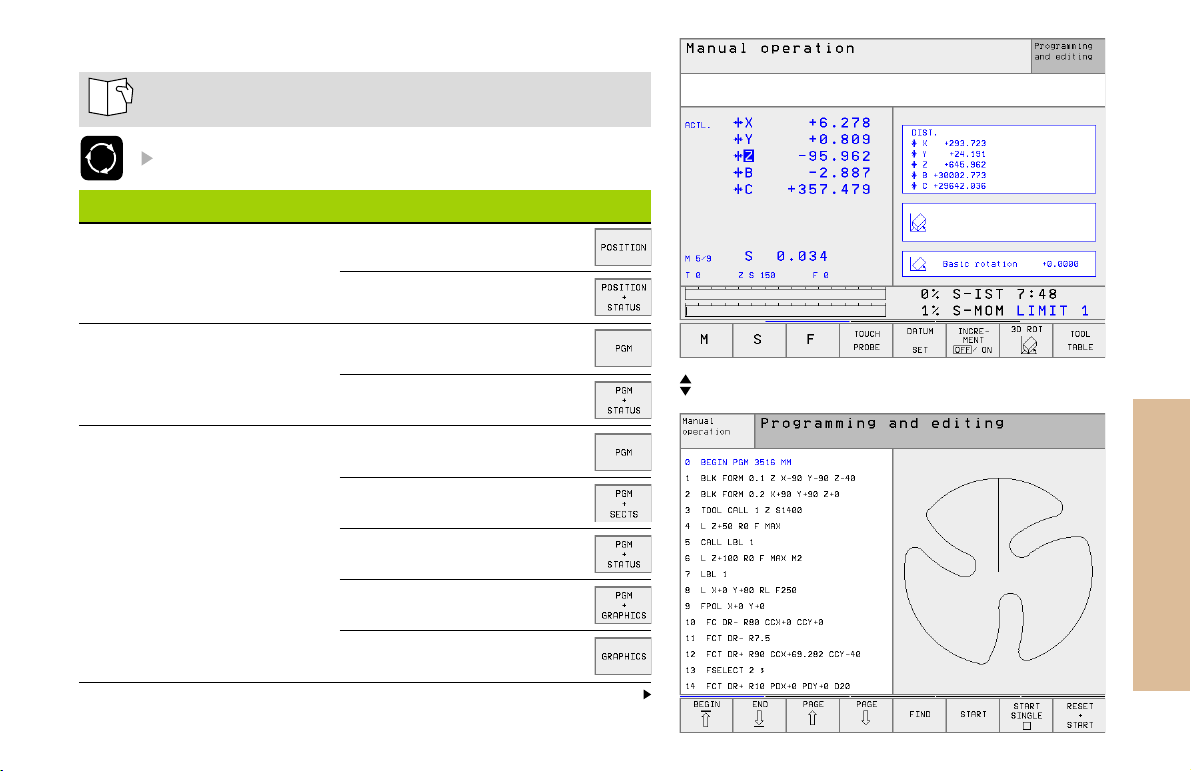

Choosing the Screen Layout

See Introduction, the TNC 426, TNC 430

Show soft keys for setting the screen layout

Mode of operation Screen contents

Manual operation

Electronic handwheel

Positioning with

manual data input

Program run,

full sequence

Program run,

single block test run

Positions

Positions at left

Status at right

Program

Program at left

Status at right

Program

Program at left

Program structure at right

Program at left

Status at right

Program at left

Graphics at right

Graphics

Positions at left, status at right

Program at left, graphics at right

Fundamentals

Continued

5

Page 5

Mode of operation Screen contents

Programming and editing

Program

Program at left

Program structure at right

Program at left

Programming graphics at right

Fundamentals

6

Program at left, program structure at right

Page 6

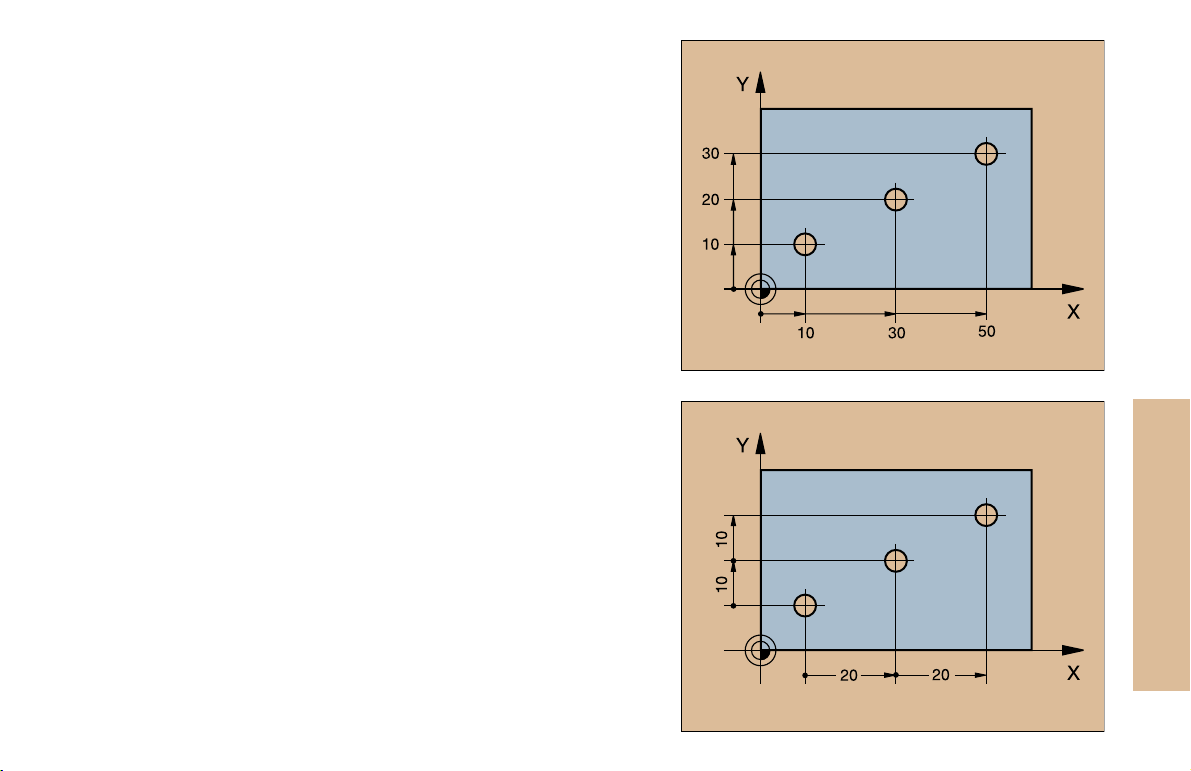

Absolute Cartesian Coordinates

The dimensions are measured from the current datum.

The tool moves to the absolute coordinates.

Programmable axes in an NC block

Linear motion: 5 axes

Circular motion: 2 linear axes in a plane or

3 linear axes with cycle 19 WORKING PLANE

Incremental Cartesian Coordinates

The dimensions are measured from the last programmed position of

the tool.

The tool moves by the incremental coordinates.

Fundamentals

7

Page 7

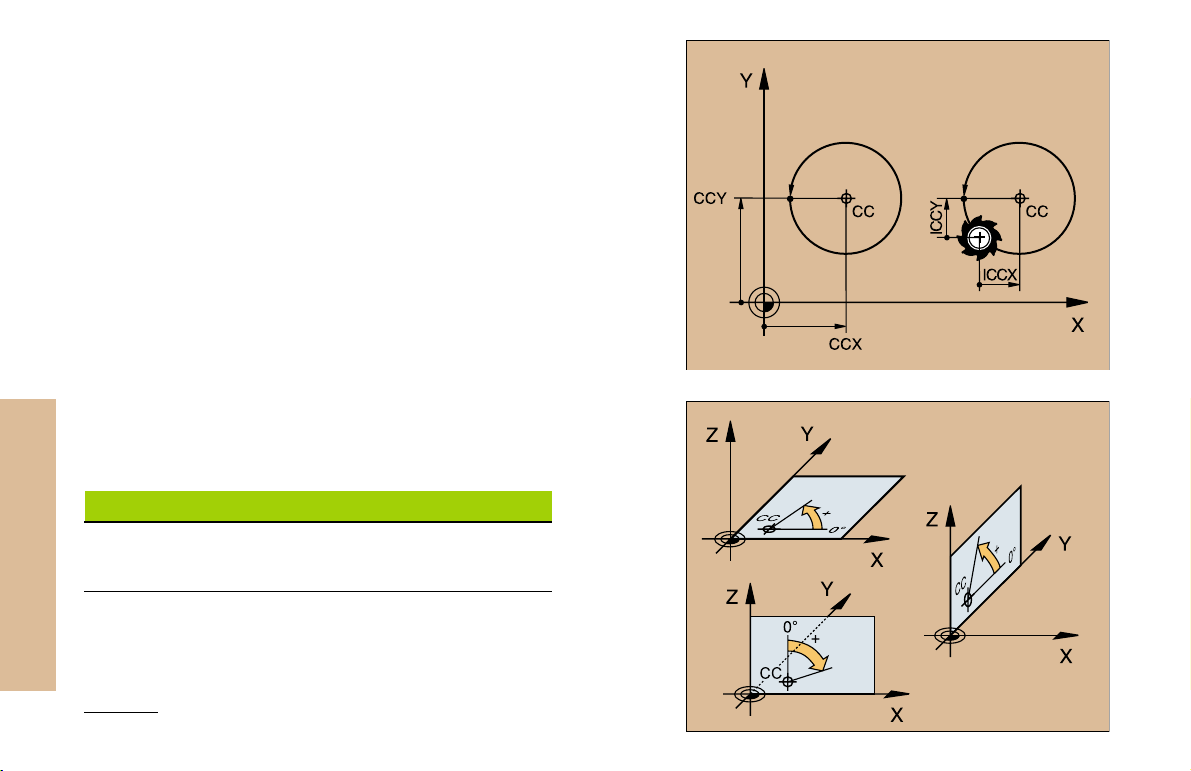

Circle Center and Pole: CC

The circle center (CC) must be entered to program circular tool

movements with the path function C (see page 21). CC is also needed

to define the pole for polar coordinates.

CC is entered in Cartesian coordinates*.

An absolutely defined circle center or pole is always measured from

the workpiece datum.

An incrementally defined circle center or pole is always measured

from the last programmed position of the workpiece.

Fundamentals

Angle Reference Axis

Angles such as a polar coordinate angle PA or an angle of rotation

ROT are measured from the angle reference axis.

Working plane Ref. axis and 0° direction

X/Y X

Y/Z Y

Z/X Z

8

*Circle center in polar coordinates: See FK programming

Page 8

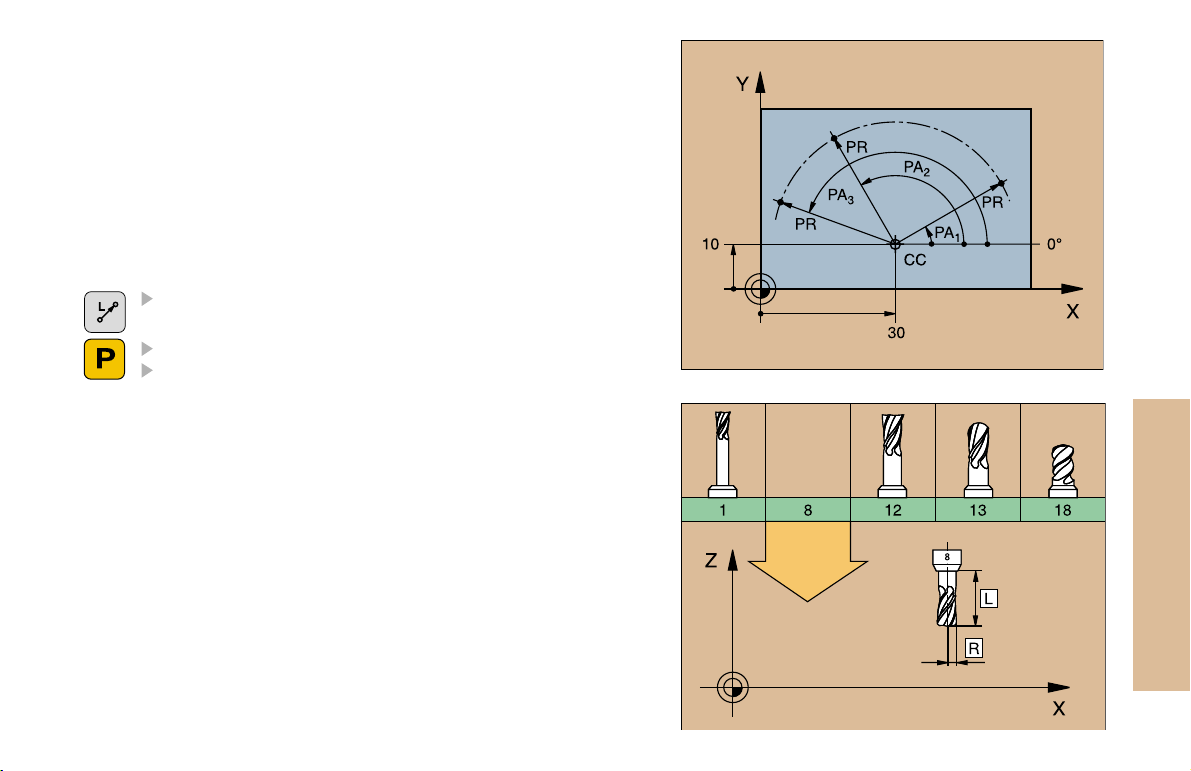

Polar Coordinates

Dimensions in polar coordinates are referenced to the pole (CC).

A position in the working plane is defined by

Polar coordinate radius PR = Distance of the position from the pole

Polar coordinate angle PA = Angle from the angle reference axis to

the straight line CC PR

Incremental dimensions

Incremental dimensions in polar coordinates are measured from the

last programmed position.

Programming polar coordinates

Select the path function

Press the P key

Answer the dialog prompts

Defining Tools

Tool data

Every tool is designated by a tool number between 1 and 254 or, if

you are using tool tables, by a tool name.

Entering tool data

You can enter the tool data (length L and radius R)

in a tool table (centrally, Program TOOL.T)

or

within the part program in TOOL DEF blocks (locally)

Fundamentals

9

Page 9

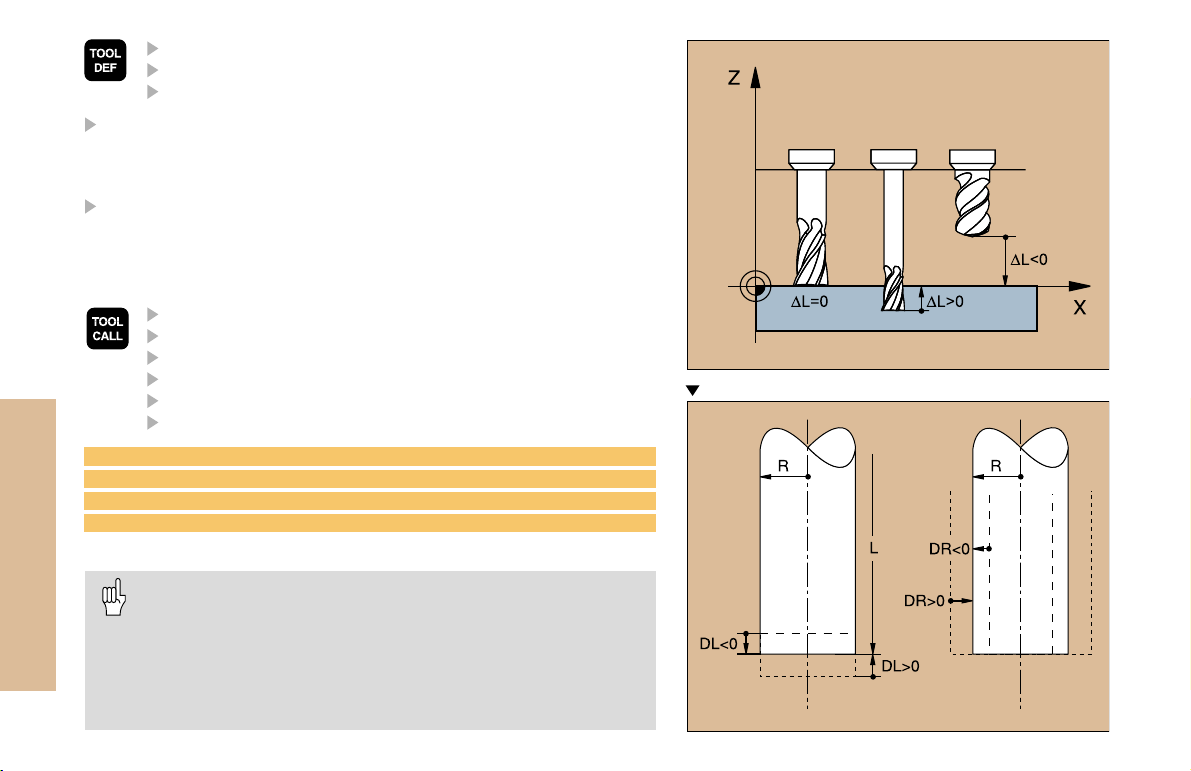

Program the tool length as its difference DL to the zero tool:

DL>0: The tool is longer than the zero tool

DL<0: The tool is shorter than the zero tool

With a tool presetter you can measure the actual tool length, then

program that length.

Calling the tool data

Fundamentals

3 TOOL DEF 6 L+7.5 R+3

4 TOOL CALL 6 Z S2000 F650 DL+1 DR+0.5

5 L Z+100 R0 FMAX

6 L X-10 Y-10 R0 FMAX M6

Tool change

10

Tool number

Tool length L

Tool radius R

Tool number or name

Working spindle axis: tool axis

Spindle speed S

Feed rate

Tool length oversize DL (e.g. to compensate wear)

Tool radius oversize DR (e.g. to compensate wear)

Beware of tool collision when moving to the tool change

position!

The direction of spindle rotation is defined by M function:

M3: Clockwise

M4: Counterclockwise

The maximum permissible oversize for tool radius or length

is ±99.999mm!

Oversizes on an end mill

Page 10

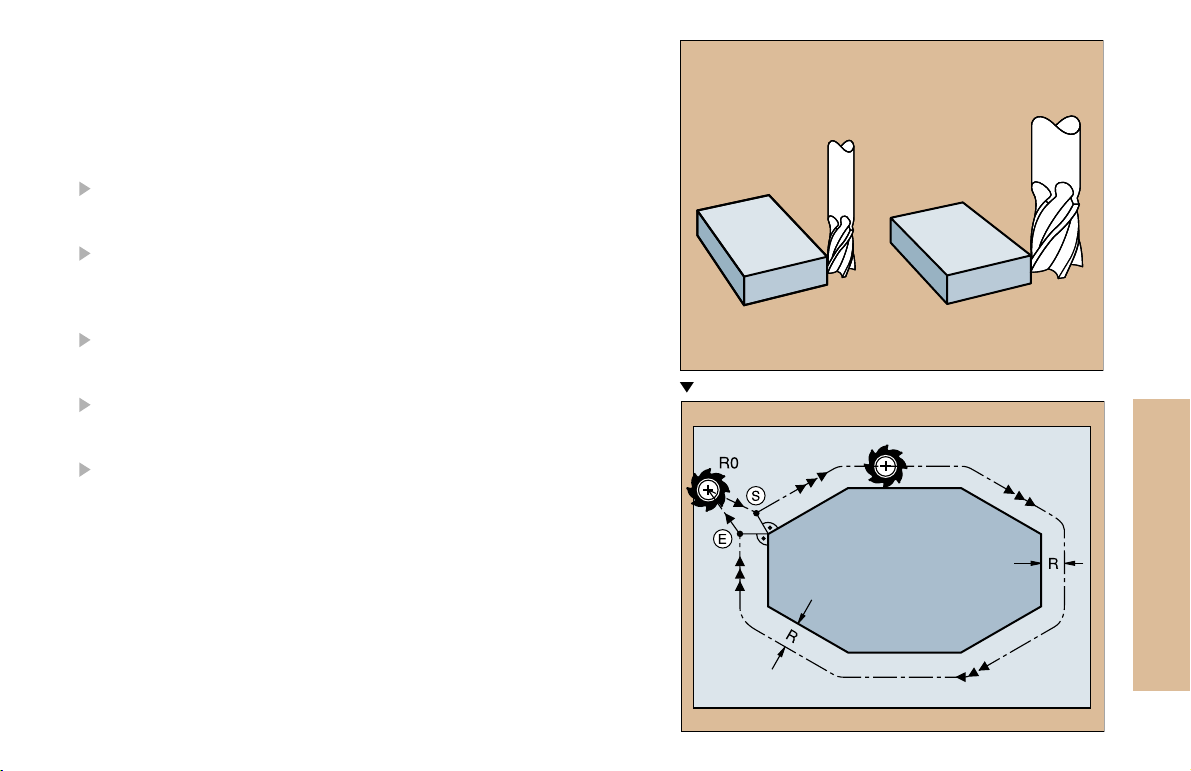

Tool Compensation

The TNC compensates the length L and radius R of the tool during

machining.

Length compensation

Beginning of effect:

Tool movement in the spindle axis

End of effect:

Tool exchange or tool with the length L=0

Radius compensation

Beginning of effect:

Tool movement in the working plane with RR or RL

End of effect:

Execution of a positioning block with R0

Working without radius compensation (e.g. drilling):

Tool movement with R0

S = Start; E = End

Fundamentals

11

Page 11

Datum Setting without a 3-D Touch Probe

During datum setting you set the TNC display to the coordinates of a

known position on the workpiece:

Insert a zero tool with known radius

Select the manual operation or electronic handwheel mode

Touch the reference surface in the tool axis with the tool and enter

its length

Touch the reference surface in the working plane with the tool and

enter the position of the tool center

Fundamentals

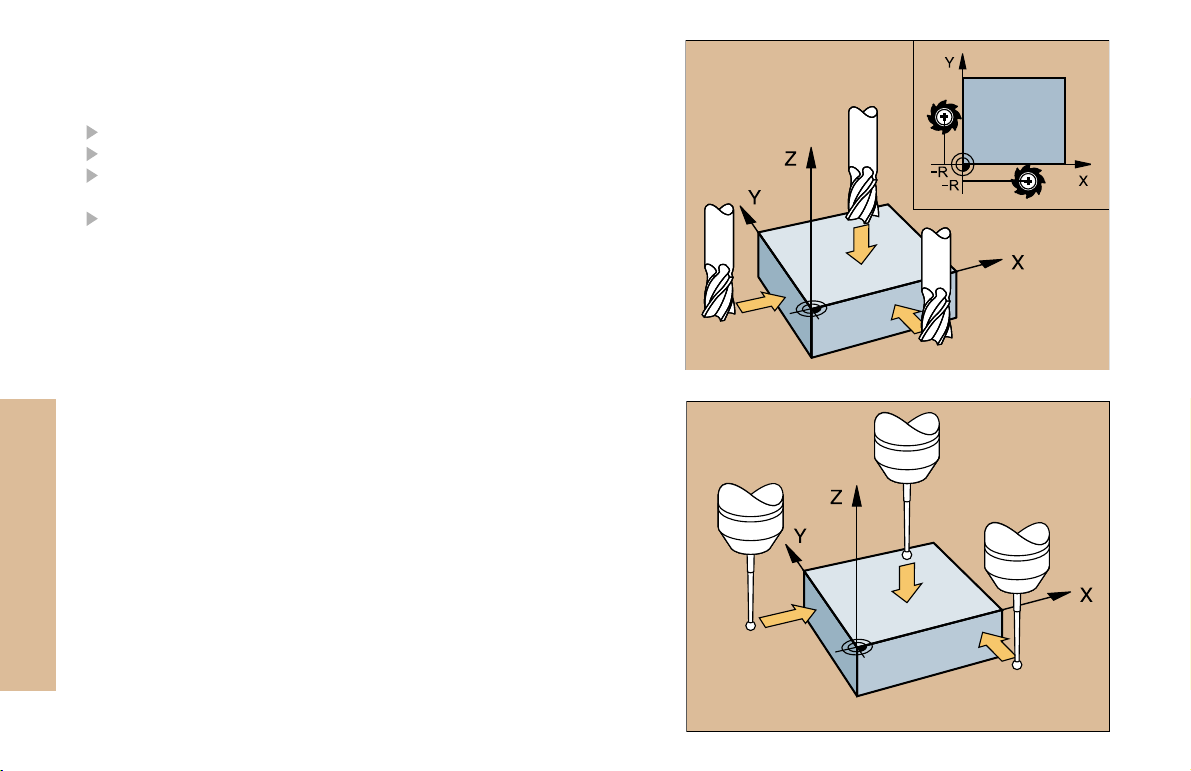

Setup and Measurement with 3-D Touch Probes

A HEIDENHAIN 3-D touch probe enables you to setup the machine very

quickly, simply and precisely.

Besides the probing functions for workpiece setup on the Manual and

Electronic Handwheel modes, the Program Run modes provide a

series of measuring cycles (see also the User's Manual for Touch

Probe Cycles):

Measuring cycles for measuring and compensating workpiece

misalignment

Measuring cycles for automatic datum setting

Measuring cycles for automatic workpiece measurement with

tolerance checking and automatic tool compensation

12

Page 12

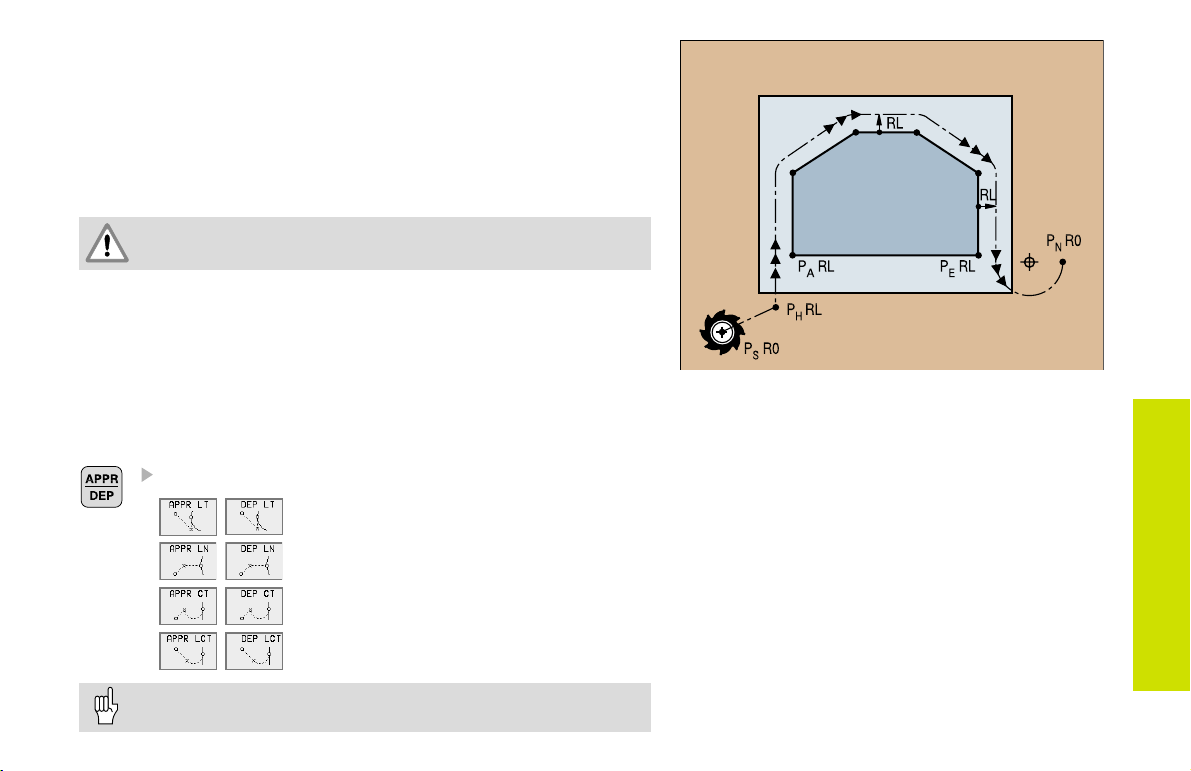

Contour Approach and Departure

Starting point P

PS lies outside of the contour and must be approached without radius

S

compensation.

Auxiliary point P

PH lies outside of the contour and is calculated by the TNC.

The tool moves from the starting point P

P

at the feed rate last programmed feed rate!

H

First contour point P

The first contour point PA is programmed in the APPR (approach) block.

H

and last contour point P

A

to the auxiliary point

S

E

The last contour point is programmed as usual.

End point P

PN lies outside of the contour and results from the DEP (departure)

block. P

N

is automatically approached with R0.

N

Path Functions for Approach and Departure

Press the soft key with the desired path function:

Straight line with tangential connection

Straight line perpendicular to the

contour point

Circular arc with tangential connection

Straight line segment tangentially connected to the contour through an arc

Contour Approach

and Departure

Program a radius compensation in the APPR block!

DEP blocks set the radius compensation to 0!

13

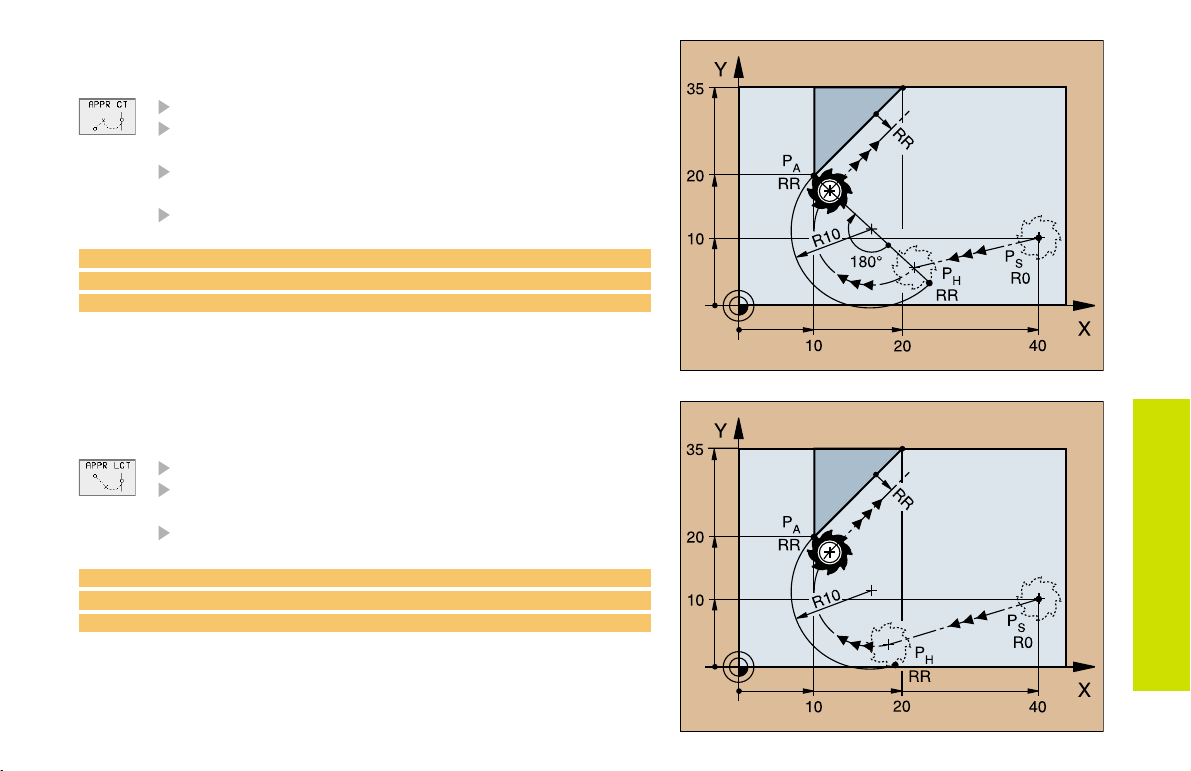

Page 13

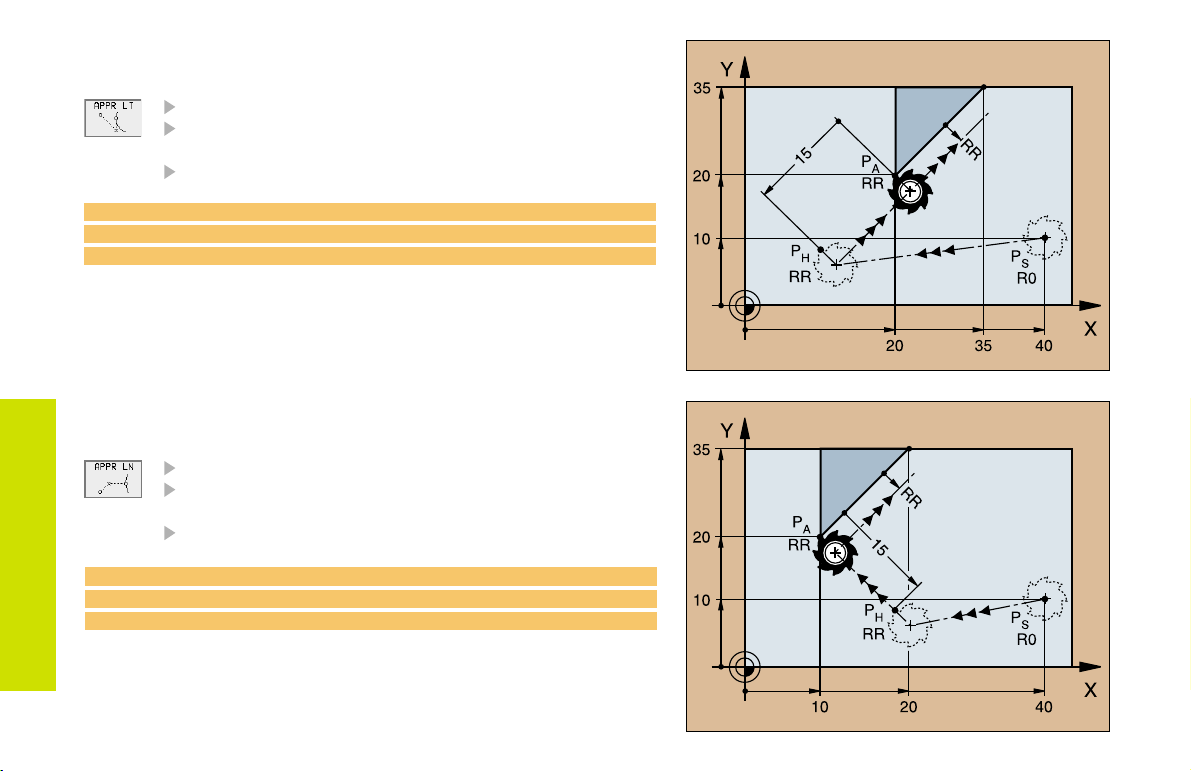

Approaching on a Straight Line with

Tangential Connection

Coordinates for the first contour point P

Distance Len (length) from PH to P

Enter a length Len > 0

Tool radius compensation RR/RL

A

7 L X+40 Y+10 R0 FMAX M3

8 APPR LT X+20 Y+20 LEN 15 RR F100

9 L X+35 Y+35

Contour Approach

and Departure

Approaching on a Straight Line Perpendicular

to the First Contour Element

Coordinates for the first contour point P

Distance Len (length) from PH to P

Enter a length Len > 0

Tool radius compensation RR/RL

7 L X+40 Y+10 R0 FMAX M3

8 APPR LN X+10 Y+20 LEN 15 RR F100

9 L X+20 Y+35

A

A

A

14

Page 14

Approaching Tangentially on an Arc

Coordinates for the first contour point P

Radius R

Enter a radius R > 0

Circle center angle (CCA)

Enter a CCA > 0

Tool radius compensation RR/RL

A

7 L X+40 Y+10 R0 FMAX M3

8 APPR CT X+10 Y+20 CCA 180 R10 RR F100

9 L X+20 Y+35

Approaching Tangentially on an Arc

and a Straight Line

Coordinates for the first contour point P

Radius R

Enter a radius R > 0

Tool radius compensation RR/RL

7 L X+40 Y+10 R0 FMAX M3

8 APPR LCT X+10 Y+20 R10 RR F100

9 L X+20 Y+35

A

Contour Approach

and Departure

15

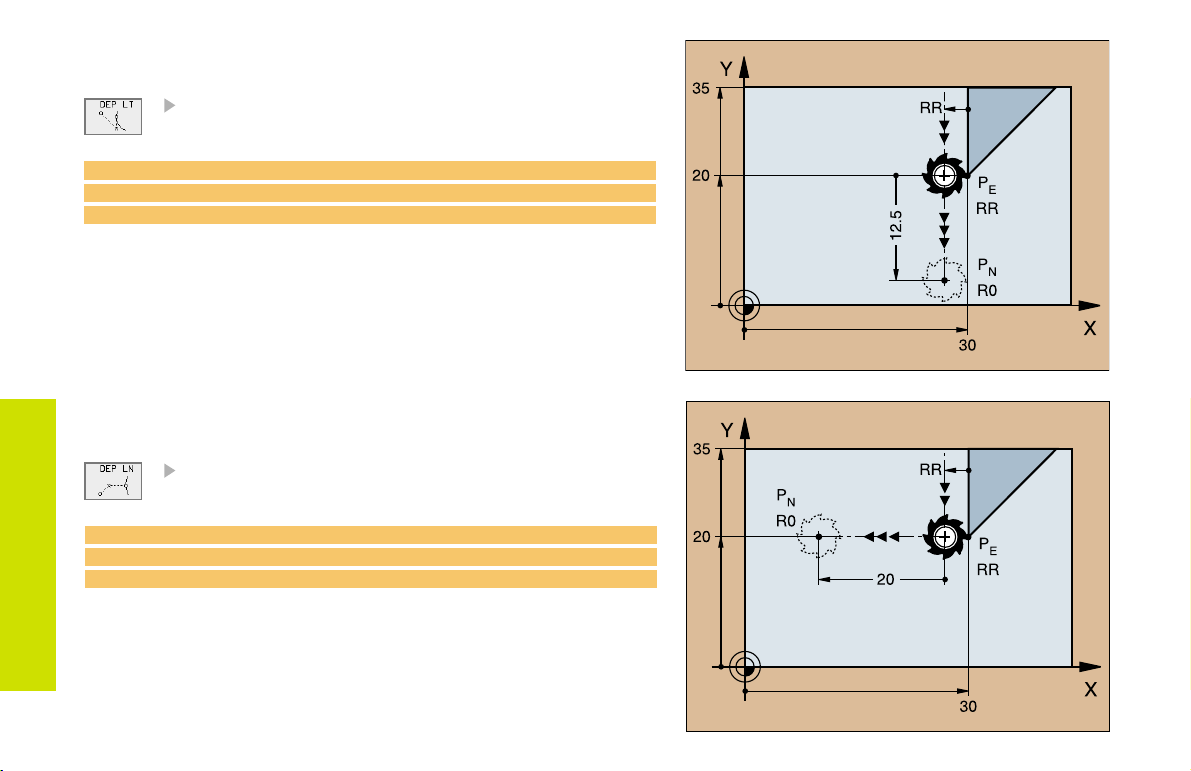

Page 15

Departing Tangentially on a Straight Line

Distance Len (length) from PE to P

Enter a length Len > 0

N

23 L X+30 Y+35 RR F100

24 L Y+20 RR F100

25 DEP LT LEN 12.5 F100 M2

Contour Approach

and Departure

Departing on a Straight Line

Perpendicular to the Last Contour Element

Distance Len (length) from PE to P

Enter a length Len > 0

23 L X+30 Y+35 RR F100

24 L Y+20 RR F100

25 DEP LN LEN+20 F100 M2

N

16

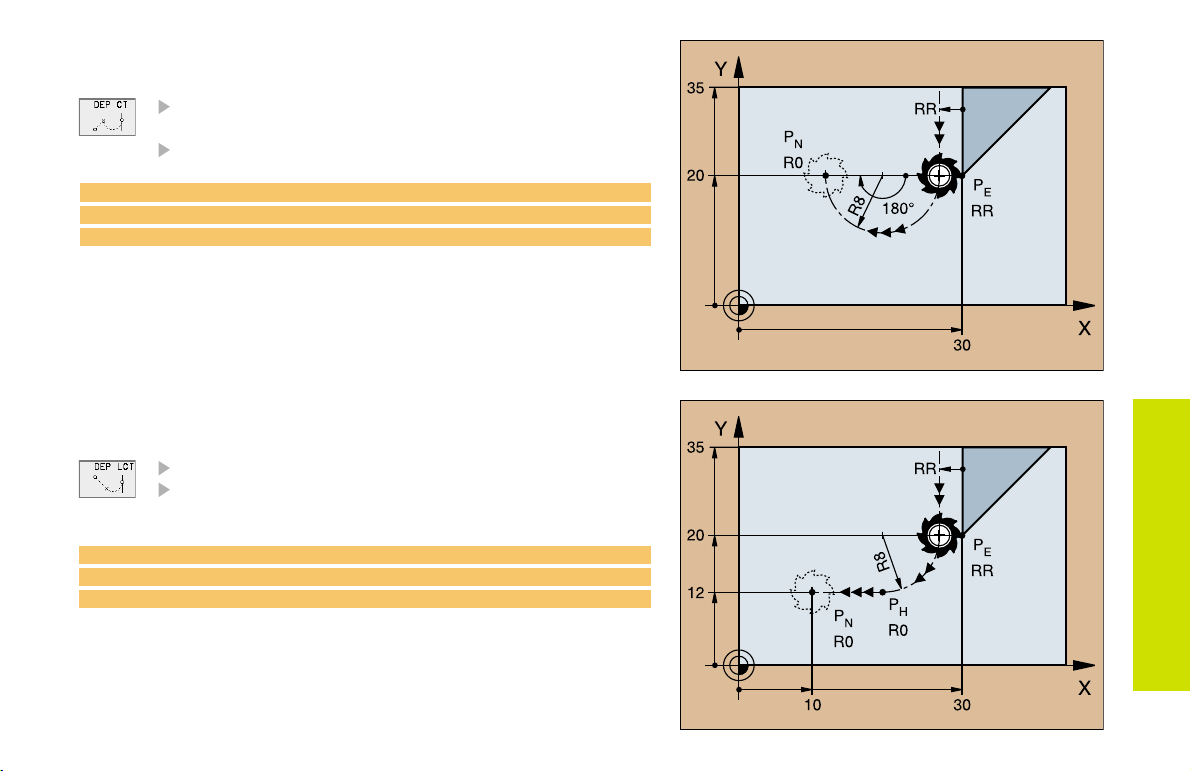

Page 16

Departing Tangentially on an Arc

Radius R

Enter a radius R > 0

Circle center angle (CCA)

23 L X+30 Y+35 RR F100

24 L Y+20 RR F10

25 DEP CT CCA 180 R+8 F100 M2

Departing on an Arc Tangentially Connecting

the Contour and a Straight Line

Coordinates of the end point P

Radius R

Enter a radius R > 0

23 L X+30 Y+35 RR F100

24 L Y+20 RR F100

25 DEP LCT X+10 Y+12 R8 F100 M2

N

Contour Approach

and Departure

17

Page 17

Path Functions for Positioning Blocks

Path functions

See Programming: Programming contours.

Programming the Direction of Traverse

Regardless of whether the tool or the workpiece is actually moving,

you always program as if the tool is moving and the workpiece is

stationary.

Entering the Target Positions

Target positions can be entered in Cartesian or polar coordinates

either as absolute or incremental values, or with both absolute and

incremental values in the same block.

Entries in the Positioning Block

Path Functions

A complete positioning block contains the following data:

Path function

Coordinates of the contour element end points (target position)

Radius compensation RR/RL/R0

Feed rate F

Miscellaneous function M

Before you execute a part program, always pre-position the tool to

prevent the possibility of damaging the tool or workpiece!

Straight line

Chamfer between two

straight lines

Corner rounding

Circle center or pole for

polar coordinates

Circular path aroundthe

circle center CC

Circular path with

known radius

Circular path with

tangential connection to

previous contour

Page 19

Page 20

Page 20

Page 21

Page 21

Page 22

Page 23

18

FK Free Contour

Programming

Page 25

Page 18

Straight Line

Coordinates of the straight line end point

Tool radius compensation RR/RL/R0

Feed rate F

Miscellaneous function M

With Cartesian coordinates:

7 L X+10 Y+40 RL F200 M3

8 L IX+20 IY-15

9 L X+60 IY-10

With polar coordinates:

12 CC X+45 Y+25

13 LP PR+30 PA+0 RR F300 M3

14 LP PA+60

15 LP IPA+60

16 LP PA+180

You must first define the pole CC before you can program

polar coordinates!

Program the pole CC only in Cartesian coordinates!

The pole CC remains effective until you define a new one!

Path Functions

19

Page 19

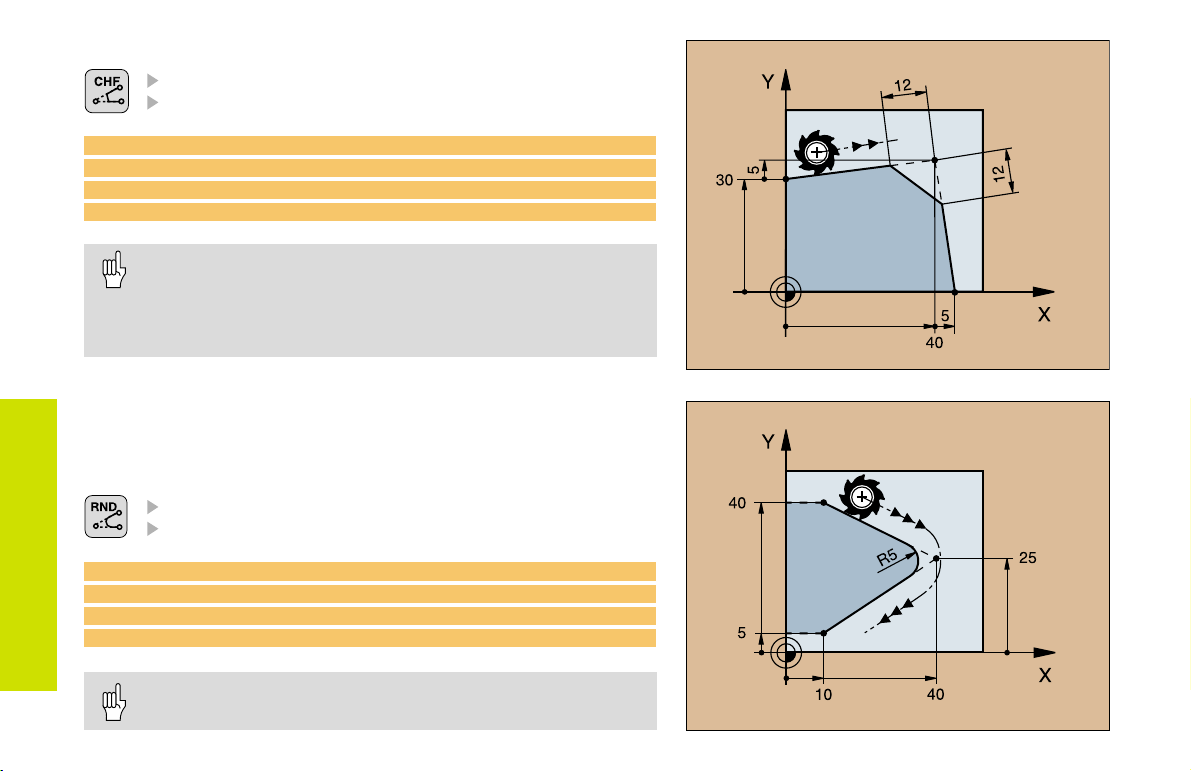

Inserting a Chamfer Between Two Straight Lines

Chamfer side length

Feed rate F for the chamfer

7 L X+0 Y+30 RL F300 M3

8 L X+40 IY+5

9 CHF 12 F250

10 L IX+5 Y+0

You cannot start a contour with a CHF block!

The radius compensation before and after the CHF block must

be the same!

An inside chamfer must be large enough to accommodate

the current tool!

Path Functions

Corner Rounding

The beginning and end of the arc extend tangentially from the previous

and subsequent contour elements.

Radius R of the circular arc

Feed rate F for corner rounding

5 L X+10 Y+40 RL F300 M3

6 L X+40 Y+25

7 RND R5 F100

8 L X+10 Y+5

20

An inside arc must be large enough to accommodate the

current tool!

Page 20

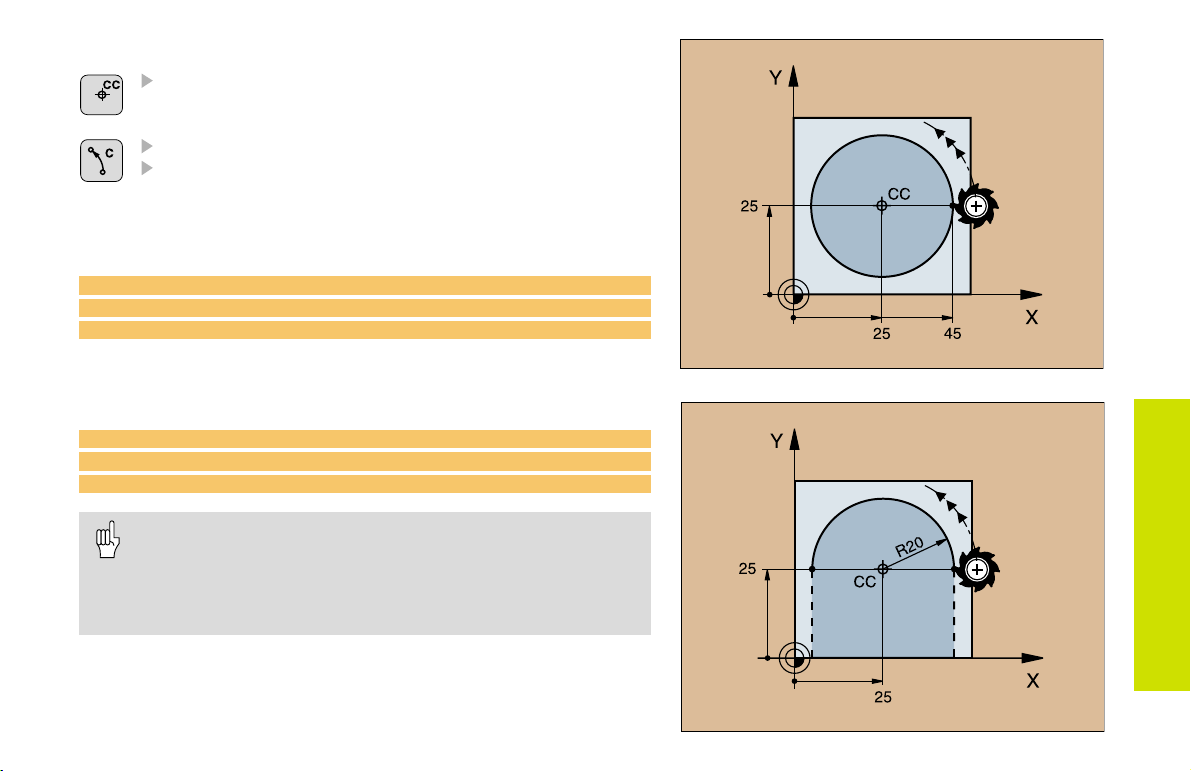

Circular Path Around the Circle Center CC

Coordinates of the circle center CC

Coordinates of the arc end point

Direction of rotation DR

C and CP enable you to program a complete circle in one block.

With cartesian coordinates:

5 CC X+25 Y+25

6 L X+45 Y+25 RR F200 M3

7 C X+45 Y+25 DR+

With polar coordinates:

18 CC X+25 Y+25

19 LP PR+20 PA+0 RR F250 M3

20 CP PA+180 DR+

Define the pole CC before programming polar coordinates!

Program the pole CC only in Cartesian coordinates!

The pole CC remains effective until you define a new one!

The arc end point can be defined only with the polar

coordinate angle (PA)!

Path Functions

21

Page 21

Circular Path with Known Radius (CR)

Coordinates of the arc end point

Radius R

If the central angle ZW > 180, R is negative.

If the central angle ZW < 180, R is positive.

Direction of rotation DR

10 L X+40 Y+40 RL F200 M3 Arc starting point

11 CR X+70 Y+40 R+20 DR- Arc

11 CR X+70 Y+40 R+20 DR+ Arc

1

2

or

Path Functions

10 L X+40 Y+40 RL F200 M3 Arc starting point

11 CR X+70 Y+40 R-20 DR- Arc

11 CR X+70 Y+40 R-20 DR+ Arc

22

3

4

or

Arcs

and

1

2

Arcs 3 and

4

Page 22

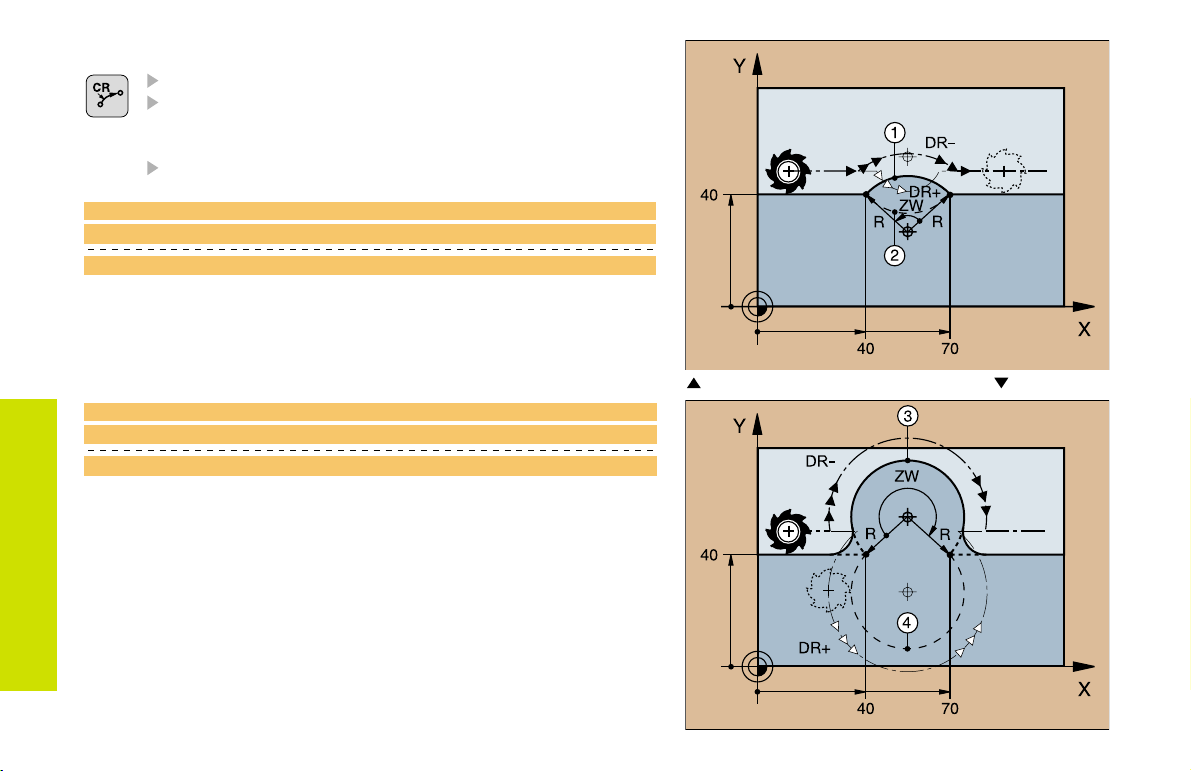

Circular Path CT with Tangential Connection

Coordinates of the arc end point

Radius compensation RR/RL/R0

Feed rate F

Miscellaneous function M

With cartesian coordinates:

5 L X+0 Y+25 RL F250 M3

6 L X+25 Y+30

7 CT X+45 Y+20

8 L Y+0

With polar coordinates:

12 CC X+40 Y+35

13 L X+0 Y+35 RL F250 M3

14 LP PR+25 PA+120

15 CTP PR+30 PA+30

16 L Y+0

Define the pole CC before programming polar coordinates!

Program the pole CC only in Cartesian coordinates!

The pole CC remains effective until you define a new one!

Path Functions

23

Page 23

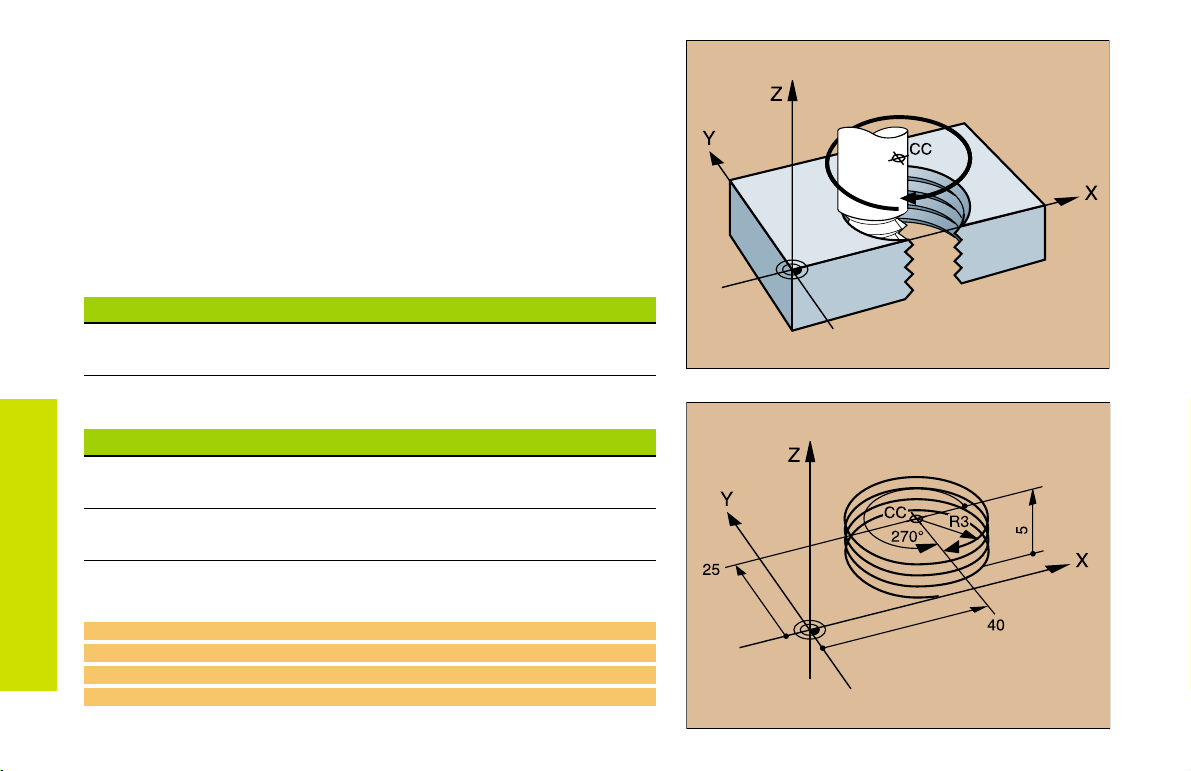

Helix (Only in Polar Coordinates)

Calculations (upward milling direction)

Path revolutions: n = Thread revolutions + overrun at start and

end of thread

Total height: h = Pitch P x path revolutions n

Incr. coord. angle: IPA = Path revolutions n x 360°

Start angle: PA = Angle at start of thread + angle for

overrun

Start coordinate: Z = Pitch P x (thread revolutions + thread

overrun at start of thread)

Shape of helix

Internal thread Work direction Direction Radius comp.

Right-hand Z+ DR+ RL

Left-hand Z+ DR RR

Path Functions

Right-hand Z DR RR

Left-hand Z DR+ RL

External thread

Right-hand Z+ DR+ RR

Left-hand Z+ DR RL

Right-hand Z DR RL

Left-hand Z DR+ RR

24

M6 x 1 mm thread with 5 revolutions

12 CC X+40 Y+25

13 L Z+0 F100 M3

14 LP PR+3 PA+270 RL

15 CP IPA-1800 IZ+5 DR- RL F50

:

Page 24

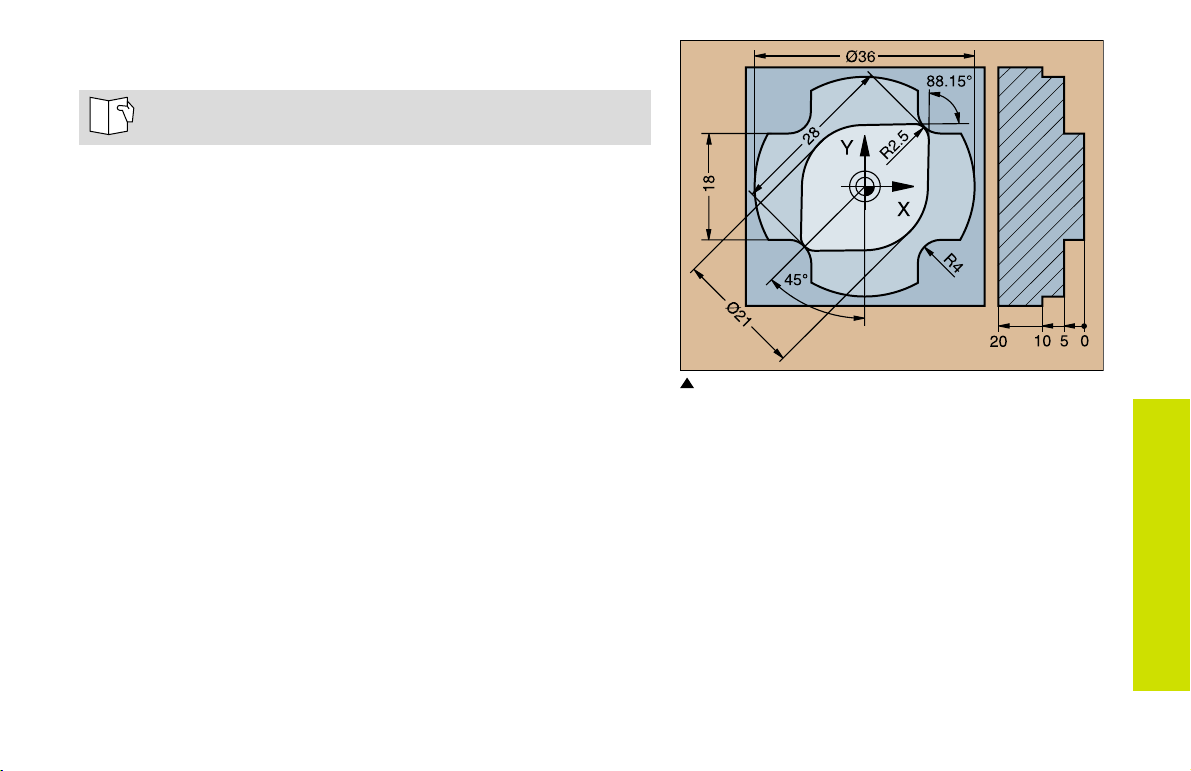

FK Free Contour Programming

See Programming Tool Movements FK Free Contour

Programming

If the end point coordinates are not given in the workpiece drawing

or if the drawing gives dimensions that cannot be entered with the

gray path function keys, you can still program the part by using the

FK Free Contour Programming.

Possible data on a contour element:

Known coordinates of the end point

Auxiliary points on the contour element

Auxiliary points near the contour element

A reference to another contour element

Directional data (angle) / position data

Data regarding the course of the contour

To use FK programming properly:

All contour elements must lie in the working plane.

Enter all available data on each contour element.

If a program contains both FK and conventional blocks, the FK

contour must be fully defined before you can return to conventional

programming.

These dimensions can be programmed with FK

FK Free Contour

Programming

25

Page 25

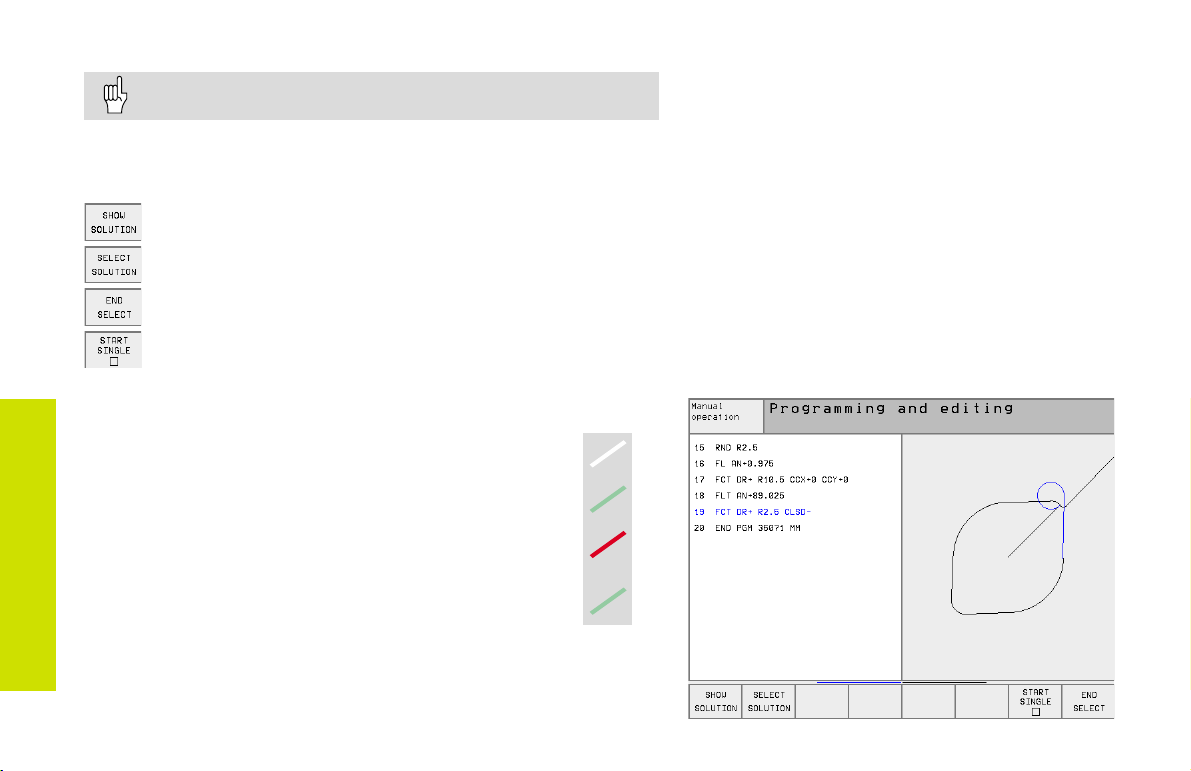

Working with the Interactive Graphics

Select the PGM+GRAPHICS screen layout!

The interactive graphics show the contour as you are programming it.

If the data you enter can apply to more than one solution, the following

soft keys will appear:

To show the possible solutions

To enter the displayed solution in the part program

To enter data for subsequent contour elements

FK Free Contour

Programming

Standard colors of the interactive graphics

Fully defined contour element

The displayed element is one of a limited number of

possible solutions

The element is one of an infinite number of solutions

Contour element from a subprogram

To graphically display the next programmed block

26

Page 26

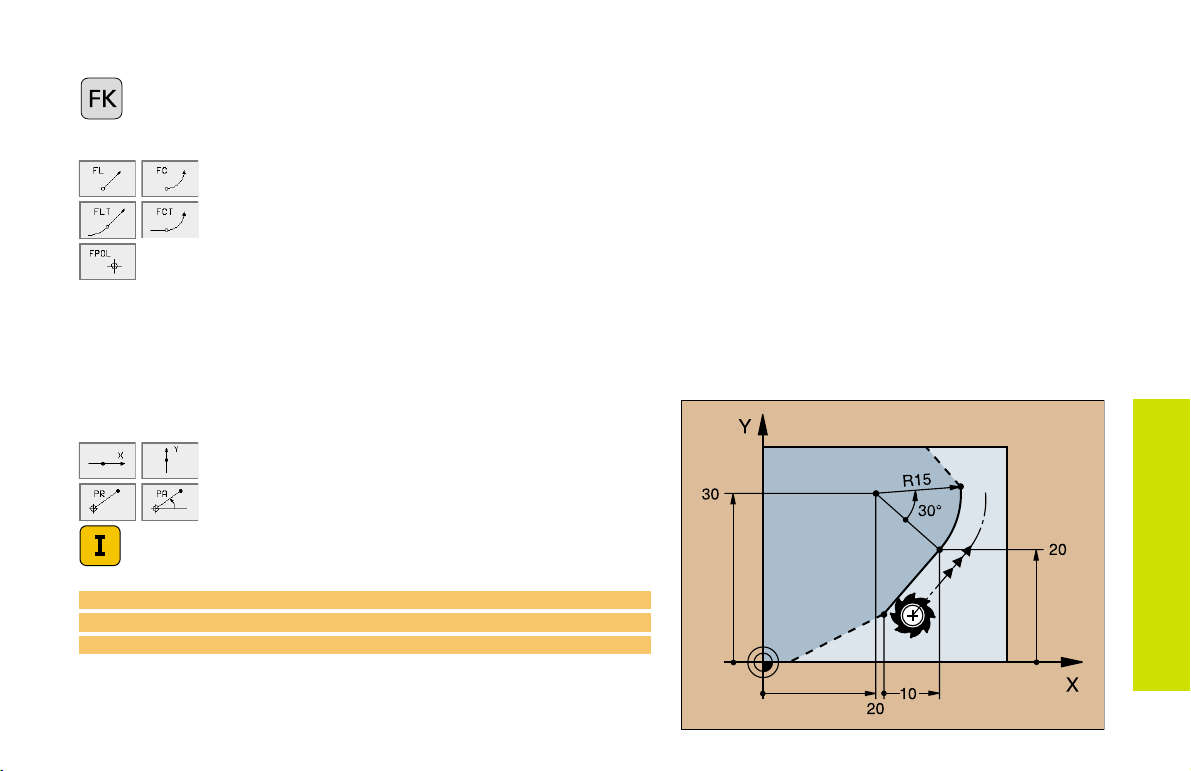

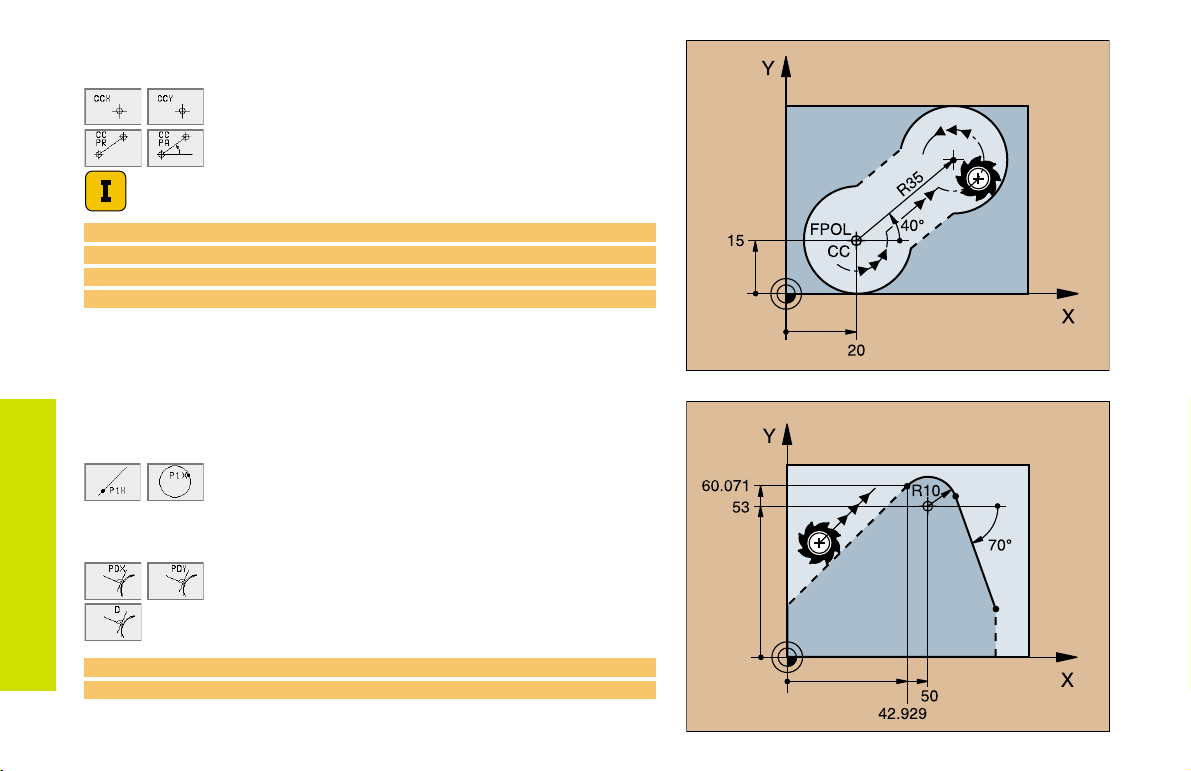

Initiating the FK Dialog

Initiate the FK dialog

Straight Circular

Contour element without tangential connection

Contour element with tangential connection

Pole for FK programming

End Point Coordinates X, Y or PA, PR

Cartesian coordinates X and Y

Polar coordinates referenced to FPOL

Incremental input

7 FPOL X+20 Y+30

8 FL IX+10 Y+20 RR F100

9 FCT PR+15 IPA+30 DR+ R15

FK Free Contour

Programming

27

Page 27

Circle Center (CC) in an FC/ FCT block

Cartesian coordinates of the circle center

Polar coordinates of the circle center

referenced to FPOL

Incremental input

10 FC CCX+20 CCY+15 DR+ R15

11 FPOL X+20 Y+15

...

13 FC DR+ R15 CCPR+35 CCPA+40

FK Free Contour

Programming

Auxiliary Points

... P1, P2, P3 on a contour

:

For straight lines

For circles: up to 3 auxiliary points

... next to a contour

Coordinates of the auxiliary points

Perpendicular distance

up to 2 auxiliary points

28

13 FC DR- R10 P1X+42.929 P1Y+60.071

14 FLT AN-70 PDX+50 PDY+53 D10

Page 28

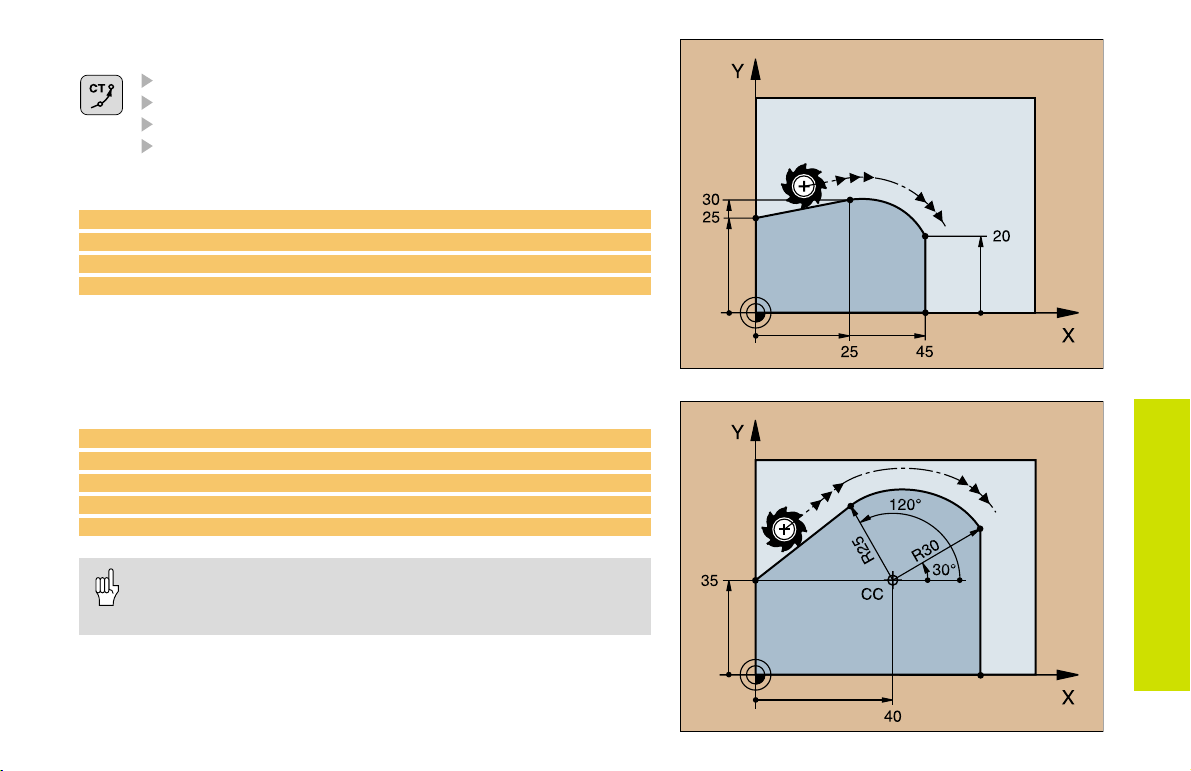

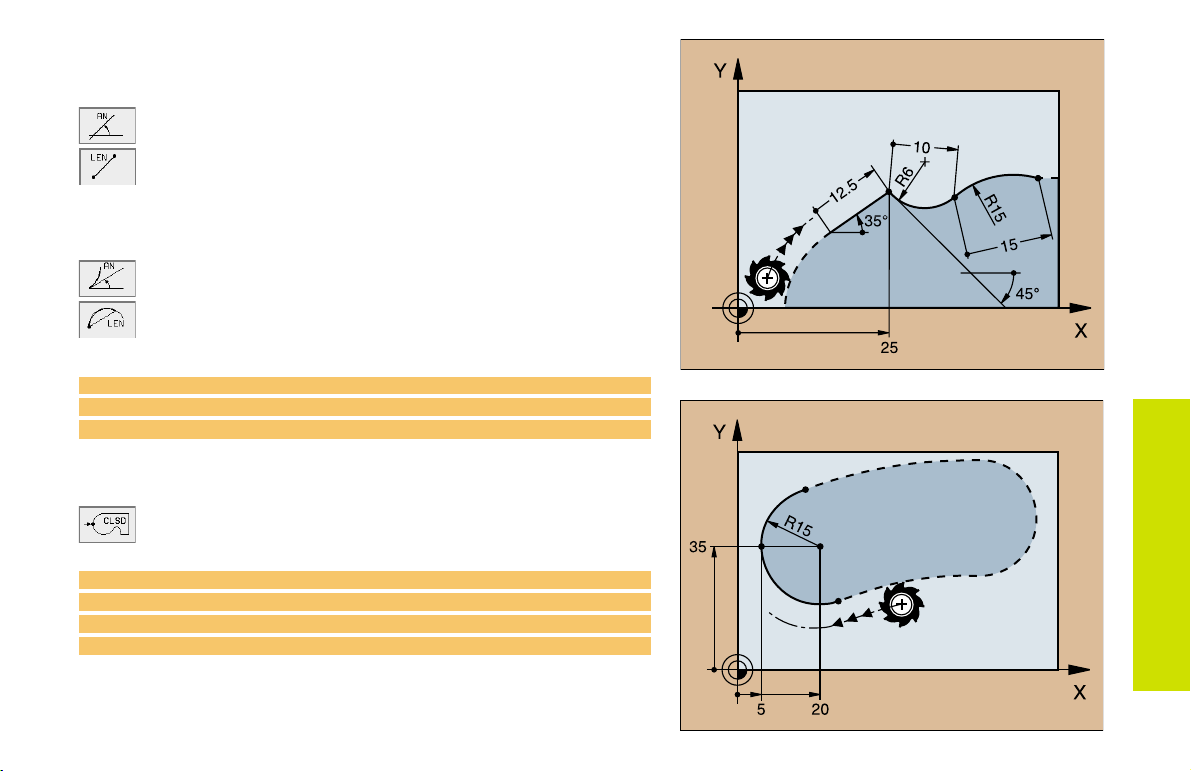

Direction and Length of the Contour Element

Data on a straight line

Gradient angle of a straight line

Length of a straight line

Data on a circular path

Gradient angle of the entry tangent

Length of an arc chord

27 FLT X+25 LEN 12.5 AN+35 RL F200

28 FC DR+ R6 LEN 10 AN-45

29 FCT DR- R15 LEN 15

Identifying a closed contour

Beginning: CLSD+

End: CLSD

12 L X+5 Y+35 RL F500 M3

13 FC DR- R15 CLSD+ CCX+20 CCY+35

...

17 FCT DR- R+15 CLSD-

FK Free Contour

Programming

29

Page 29

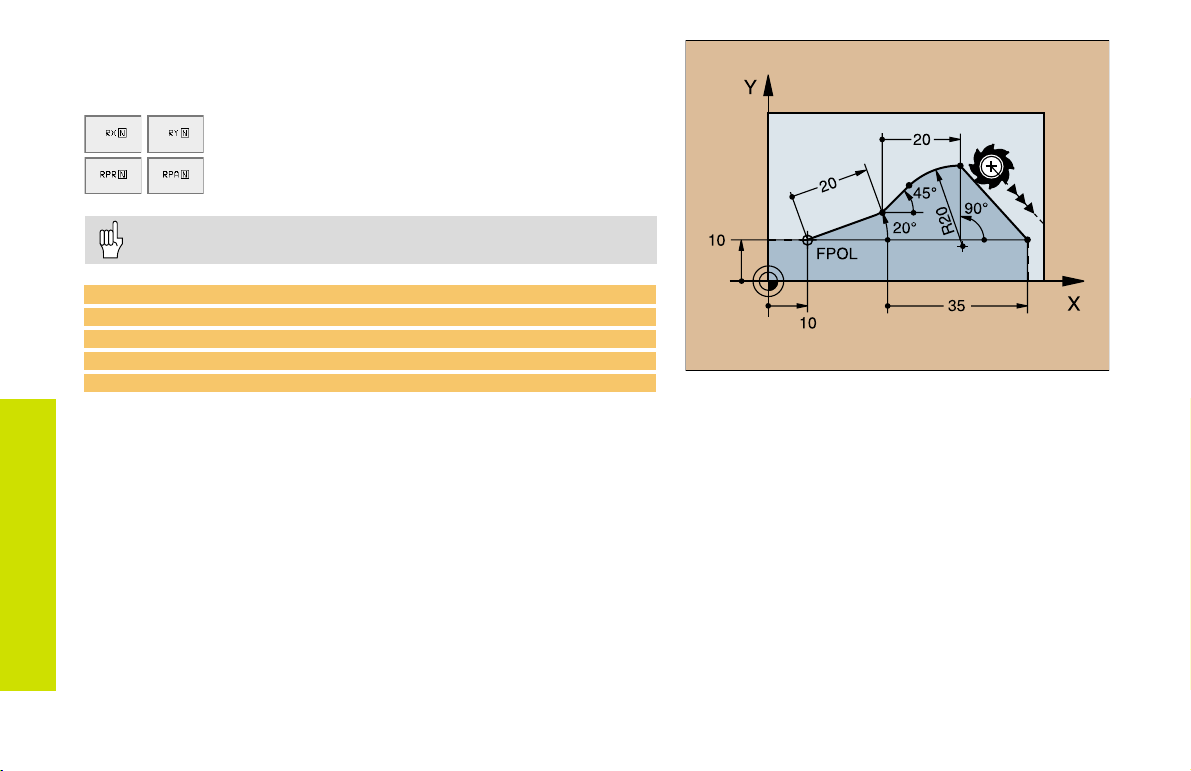

Values Relative to Block N:

Entering Coordinates

Cartesian coordinates relative to block N

Polar coordinates relative to block N

Relative data must be entered incrementally!

CC can also be programmed in relative values!

12 FPOL X+10 Y+10

13 FL PR+20 PA+20

14 FL AN+45

FK Free Contour

15 FCT IX+20 DR- R20 CCA+90 RX 13

Programming

16 FL IPR+35 PA+0 RPR 13

30

Page 30

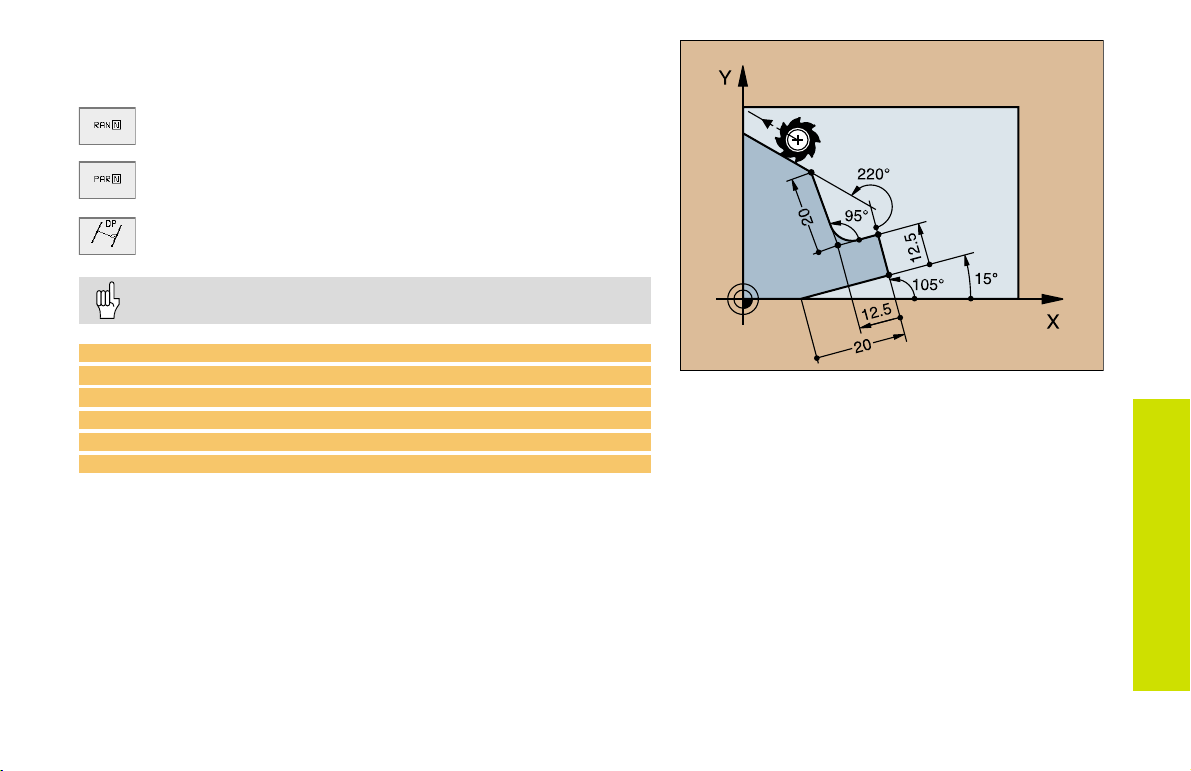

Values Relative to Block N:

Direction and Distance of the Contour Element

Gradient angle

Parallel to a straight contour element

Parallel to the entry tangent of an arc

Distance from a parallel element

Always enter relative values incrementally!

17 FL LEN 20 AN+15

18 FL AN+105

19 FL LEN 12.5 PAR 17 DP 12.5

20 FSELECT 2

21 FL LEN 20 IAN+95

22 FL IAN+220 RAN 18

FK Free Contour

Programming

31

Page 31

Values Relative to Block N:

Circle Center CC

Cartesian coordinates of a circle center relative to

block N

Polar coordinates of the circle center relative to

block N

Always enter relative data as incremental values!

FK Free Contour

Programming

13 FL ...

14 FL X+18 Y+35

15 FL ...

16 FL ...

17 FC DR- R10 CCA+0 ICCX+20 ICCY-15

RCCX12 RCCY14

32

12 FL X+10 Y+10 RL

Page 32

Subprograms and Program Section

Repeats

Subprograms and program section repeats enable you to program a

machining sequence once and then run it as often as needed.

Working with Subprograms

The main program runs up to the subprogram call CALL LBL1.

1

The subprogram labeled with LBL1 runs through to its end LBL0.

2

The main program resumes.

3

It's good practice to place subprograms after the main program

end (M2).

Answer the dialog prompt REP with the NOENT key!

You cannot call LBL0!

Working with Program Section Repeats

The main program runs up to the call for a section repeat CALL LBL1

1

REP2/2.

The program section between LBL1 and CALL LBL1 REP2/2 is

2

repeated the number of times indicated with REP.

After the last repetition the main program resumes.

3

S = Jump; R = Return jump

Subprograms

Altogether, the program section is run once more than the

number of programmed repeats!

33

Page 33

Subprogram Nesting:

A Subprogram within a Subprogram

The main program runs up to the first subprogram call CALL LBL1.

1

Subprogram 1 runs up to the second subprogram call CALL LBL2.

2

Subprogram 2 runs to its end.

3

Subprogram 1 resumes and runs to its end.

4

The main program resumes.

5

A subprogram cannot call itself!

Subprograms can be nested up to a maximum depth

of 8 levels!

Subprograms

34

= Jump; R = Return jump

S

Page 34

Any Program as a Subprogram

The calling program A runs up to the program call CALL PGM B.

1

The called program B runs through to its end.

2

The calling program A resumes.

3

The called program must not end with M2 or M30!

S = Jump; R = Return jump

Subprograms

35

Page 35

Working with Cycles

Certain frequently needed machining sequences are stored in the TNC

as cycles. Coordinate transformations and some special functions are

also available as cycles.

In a cycle, positioning data entered in the tool axis are

always incremental, even without the I key!

The algebraic sign of the cycle parameter depth determines

the working direction!

Example

6 CYCL DEF 1.0 PECKING

7 CYCL DEF 1.1 SET UP 2

8 CYCL DEF 1.2 DEPTH -15

Working with Cycles

9 CYCL DEF 1.3 PECKG 10

...

Feed rates are entered in mm/min, the dwell time in seconds.

Defining cycles

Select the Cycle Overview:

Select the cycle group

Cycles for Machining Holes

and Threads

1 PECKING Page 39

200 DRILLING Page 40

201 REAMING Page 41

202 BORING Page 42

203 UNIVERSAL DRILLING Page 43

204 COUNTERBORE BACK Page 44

205 UNIVERSAL PECKING Page 45

208 BORE MILLING Page 46

2 TAPPING Page 47

206 TAPPING NEW Page 48

17 RIGID TAPPING Page 48

207 RIGID TAPPING NEW Page 49

18 THREAD CUTTING Page 49

209 TAPPING W/ CHIP BRKG Page 50

262 THREAD MILLING Page 51

263 THREAD MLLNG/CNTSNKG Page 52

264 THREAD DRILLNG/MLLNG Page 53

265 HEL. THREAD DRLG/MLG Page 54

267 OUTSIDE THREAD MLLNG Page 55

36

Select the cycle

Continued on next page

Page 36

Pockets, Studs, and Slots

4 POCKET MILLING Page 56

212 POCKET FINISHING Page 57

213 STUD FINISHING Page 58

5 CIRCULAR POCKET MILLING Page 59

214 CIRCULAR POCKET FINISHING Page 60

215 CIRCULAR STUD FINISHING Page 61

3 SLOT MILLING Page 62

210 SLOT WITH RECIP. PLUNGE Page 63

211 CIRCULAR SLOT Page 64

SL Cycles

14 CONTOUR GEOMETRY Page 67

20 CONTOUR DATA Page 68

21 PILOT DRILLING Page 69

22 ROUGH-OUT Page 69

23 FLOOR FINISHING Page 70

24 SIDE FINISHING Page 70

25 CONTOUR TRAIN Page 71

27 CYLINDER SURFACE Page 72

28 CYLINDER SURFACE SLOT Page 73

Point Patterns

220 CIRCULAR PATTERN Page 65

221 LINEAR PATTERN Page 66

Multipass Milling

30 RUN DIGITIZED DATA Page 74

230 MULTIPASS MILLING Page 75

231 RULED SURFACE Page 76

Working with Cycles

Cycles for Coordinate Transformations

7 DATUM SHIFT Page 78

247 DATUM SETTING Page 79

8 MIRROR IMAGE Page 80

10 ROTATION Page 81

19 WORKING PLANE Page 82

11 SCALING FACTOR Page 83

26 AXIS-SPECIFIC SCALING Page 84

Spezial Cycles

9 DWELL TIME Page 85

12 PGM CALL Page 85

13 ORIENTED SPINDLE STOP Page 86

32 TOLERANCE Page 87

37

Page 37

Graphic Support During Cycle Programming

As you create a program, the TNC provides you with graphic illustrations of the input parameters.

Calling a Cycle

The following cycles are effective as soon as they are defined:

Cycles for coordinate transformations

DWELL TIME cycle

The SL cycles CONTOUR GEOMETRY and CONTOUR DATA

Point patterns

TOLERANCE cycle

All other cycles go into effect when they are called through

CYCL CALL: effective for one block

CYCL CALL PAT: used non-modally in connection with point tables

Working with Cycles

M99: effective for one block

M89: effective until canceled (depends on machine parameter

settings)

38

Page 38

Cycles for Machining

Holes and Threads

PECKING (1)

CYCL DEF: Select Cycle 1 PECKING

Set-up clearance:

Total hole depth (distance from the workpiece surface to the bottom

of the hole):

Pecking depth:

Dwell time in seconds

Feed rate F

If the total hole depth is greater than or equal to the pecking depth,

the tool drills the entire hole in one plunge.

6 CYCL DEF 1.0 PECKING

7 CYCL DEF 1.1 SET UP +2

8 CYCL DEF 1.2 DEPTH -15

9 CYCL DEF 1.3 PECKG +7.5

10 CYCL DEF 1.4 DWELL 1

11 CYCL DEF 1.5 F80

12 L Z+100 R0 FMAX M6

13 L X+30 Y+20 FMAX M3

14 L Z+2 FMAX M99

15 L X+80 Y+50 FMAX M99

16 L Z+100 FMAX M2

A

B

C

Cycles for Machining

Holes and Threads

39

Page 39

DRILLING (200)

CYCL DEF: Select Cycle 200 DRILLING

The TNC automatically pre-positions the tool in the tool axis. If the

depth is greater than or equal to the pecking depth, the tool drills to

Cycles for Machining

the depth in one plunge.

Holes and Threads

11 CYCL DEF 200 DRILLING

Q200 = 2 ;SET-UP CLEARANCE

Q201 = -15 ;DEPTH

Q206 = 250 ;FEED RATE FOR PLUNGING

Q202 = 5 ;PLUNGING DEPTH

Q210 = 0 ;DWELL TIME AT TOP

Q203 = +0 ;SURFACE COORDINATE

Q204 = 100 ;2ND SET-UP CLEARANCE

Q211 = 0.1 ;DWELL TIME AT DEPTH

12 L Z+100 R0 FMAX M6

13 L X+30 Y+20 FMAX M3

14 CYCL CALL

15 L X+80 Y+50 FMAX M99

16 L Z+100 FMAX M2

40

Set-up clearance: Q200

Depth Distance between workpiece surface and bottom

of hole: Q201

Feed rate for plunging: Q206

Pecking depth: Q202

Dwell time at top: Q210

Surface coordinate: Q203

2nd set-up clearance: Q204

Dwell time at depth: Q211

Page 40

REAMING (201)

CYCL DEF: Select Cycle 201 REAMING

Set-up clearance: Q200

Depth Distance between workpiece surface and bottom

of hole: Q201

Feed rate for plunging: Q206

Dwell time at depth: Q211

Retraction feed rate: Q208

Surface coordinate: Q203

2nd set-up clearance: Q204

The TNC automatically pre-positions the tool in the tool axis.

11 CYCL DEF 201 REAMING

Q200 = 2 ;SET-UP CLEARANCE

Q201 = -15 ;DEPTH

Q206 = 100 ;FEED RATE FOR PLNGNG

Q211 = 0.5 ;DWELL TIME AT DEPTH

Q208 = 250 ;RETRACTION FEED RATE

Q203 = +0 ;SURFACE COORDINATE

Q204 = 100 ;2ND SET-UP CLEARANCE

12 L Z+100 R0 FMAX M6

13 L X+30 Y+20 FMAX M3

14 CYCL CALL

15 L X+80 Y+50 FMAX M99

16 L Z+100 FMAX M2

Cycles for Machining

Holes and Threads

41

Page 41

BORING (202)

CYCL DEF: Select Cycle 202 BORING

Set-up clearance: Q200

Depth Distance between workpiece surface and bottom of hole:

Q201

Feed rate for plunging: Q206

Cycles for Machining

Holes and Threads

Dwell time at depth: Q211

Retraction feed rate: Q208

Surface coordinate: Q203

2nd set-up clearance: Q204

Disengaging directn (0/1/2/3/4) at bottom of hole: Q214

Angle for oriented spindle stop: Q336

The TNC automatically pre-positions the tool in the tool axis.

The machine and TNC must be prepared for the BORING

cycle by the machine tool builder!

This cycle requires a position-controlled spindle!

Danger of collision! Choose a disengaging direction that

moves the tool away from the wall of the hole.

42

Page 42

UNIVERSAL DRILLING (203)

CYCL DEF: Select Cycle 203 UNIVERSAL DRILLING

Set-up clearance: Q200

Depth Distance between workpiece surface and bottom

of hole: Q201

Feed rate for plunging: Q206

Pecking depth: Q202

Dwell time at top: Q210

Surface coordinate: Q203

2nd set-up clearance: Q204

Decrement after each pecking depth: Q212

Nr of breaks Number of chip breaks before retraction: Q213

Min. pecking depth if a decrement has been entered: Q205

Dwell time at depth: Q211

Retraction feed rate: Q208

Retract dist. for chip breaking: Q256

The TNC automatically pre-positions the tool in the tool axis. If the

depth is greater than or equal to the pecking depth, the tool drills to

the depth in one plunge.

Cycles for Machining

Holes and Threads

43

Page 43

COUNTERBORE BACK (204)

CYCL DEF: Select Cycle 204 COUNTERBORE BACK

Set-up clearance: Q200

Depth of counterbore: Q249

Material thickness: Q250

Tool edge off-center distance: Q251

Cycles for Machining

Holes and Threads

Tool edge height: Q252

Feed rate for pre-positioning: Q253

Feed rate for counterboring: Q254

Dwell time at counterbore floor: Q255

Workpiece surface coordinate: Q203

2nd set-up clearance: Q204

Disengaging direction (0/1/2/3/4): Q214

Angle for oriented spindle stop: Q336

The machine and TNC must be prepared for the

COUNTERBORE BACK cycle by the machine tool builder!

This cycle requires a position-controlled spindle!

Danger of collision! Select the disengaging direction that

gets the tool clear of the counterbore floor!

Use this cycle only with a reverse boring bar!

44

Page 44

UNIVERSAL PECKING (205)

CYCL DEF: Select Cycle 205 UNIVERSAL PECKING

Set-up clearance: Q200

Depth: Distance between workpiece surface

and bottom of hole: Q201

Feed rate for plunging: Q206

Pecking depth: Q202

Workpiece surface coordinate: Q203

2nd set-up clearance: Q204

Decrement after each pecking depth: Q212

Minimum pecking depth if decrement value entered: Q205

Upper advanced stop distance: Q258

Lower advanced stop distance: Q259

Infeed depth for chip breaking: Q257

Retract dist. for chip breaking: Q256

Dwell time at bottom: Q211

Cycles for Machining

Holes and Threads

45

Page 45

BORE MILLING (208)

Pre-position to the center of the hole with R0

CYCL DEF: Select Cycle 208 BORE MILLING

Set-up clearance: Q200

Depth: Distance between workpiece surface

and bottom of hole: Q201

Feed rate for plunging: Q206

Infeed per helix: Q334

Workpiece surface coordinate: Q203

2nd set-up clearance: Q204

Nominal diameter of hole: Q335

Pilot-drilled diameter: Q342

Cycles for Machining

Holes and Threads

46

Page 46

TAPPING (2) with Floating Tap Holder

Insert the floating tap holder

CYCL DEF: Select cycle 2 TAPPING

Set-up clearance:

Total hole depth (thread length = distance between the

workpiece surface and the end of the thread):

Dwell time in seconds (a value between 0 and 0.5 seconds)

Feed rate F = Spindle speed S x thread pitch P

For tapping right-hand threads, actuate the spindle with M3,

for left-hand threads use M4!

25 CYCL DEF 2.0 TAPPING

26 CYCL DEF 2.1 SET UP 3

27 CYCL DEF 2.2 DEPTH -20

28 CYCL DEF 2.3 DWELL 0.4

29 CYCL DEF 2.4 F100

30 L Z+100 R0 FMAX M6

31 L X+50 Y+20 FMAX M3

32 L Z+3 FMAX M99

A

B

Cycles for Machining

Holes and Threads

47

Page 47

TAPPING NEW (206) with Floating Tap Holder

Insert the floating tap holder

CYCL DEF: Select Cycle 206 TAPPING NEW

Cycles for Machining

Holes and Threads

RIGID TAPPING (17) without Floating Tap Holder

CYCL DEF: Select cycle 17 RIGID TAPPING

48

Set-up clearance: Q200

Depth: thread length = distance between the

workpiece surface and the end of the thread: Q201

Feed rate F = spindle speed S x thread pitch P: Q206

Dwell time at bottom (enter a value between 0 and 0.5 seconds):

Q211

Workpiece surface coordinate: Q203

2nd set-up clearance: Q204

For tapping right-hand threads, actuate the spindle with M3, for

left-hand threads use M4!

Machine and TNC must be prepared by the machine tool

builder to perform rigid tapping!

In rigid tapping, the spindle speed is synchronized with the

tool axis feed rate!

Set-up clearance:

Tapping depth (distance between workpiece surface and end

of thread):

Pitch:

C

The algebraic sign determines the direction of the thread:

Right-hand thread: +

Left-hand thread:

A

B

Page 48

Z

X

Q203

Q204

Q200

Q201

Q239

RIGID TAPPING NEW (207) without Floating Tap Holder

Machine and TNC must be prepared by the machine tool

builder to perform rigid tapping!

Rigid tapping is carried out with a controlled spindle!

CYCL DEF: Select Cycle 207 RIGID TAPPING NEW

Set-up clearance: Q200

Depth: thread length = distance between workpiece

surface and end of thread: Q201

Pitch: Q239

The algebraic sign determines the direction of the thread:

Right-hand thread: +

Left-hand thread:

Workpiece surface coordinate: Q203

2nd set-up clearance: Q204

THREAD CUTTING (18)

The machine and TNC must be prepared by the machine

tool builder for THREAD CUTTING!

The spindle speed is synchronized with the tool axis feed

rate!

CYCL DEF: Select cycle 18 THREAD CUTTING

Depth (distance between workpiece surface and end of

thread):

Pitch:

The algebraic sign:

Right-hand thread: +

Left-hand thread:

B

C

Cycles for Machining

Holes and Threads

49

Page 49

TAPPING WITH CHIP BREAKING (209)

Z

X

Q203

Q204

Q200

Q201

Q239

CYCL DEF: Select Cycle 209 TAPPING W/ CHIP BRKG .

Set-up clearance: Q200

Thread depth: Thread length = Distance between workpiece

surface and thread termination: Q201

Thread pitch: Q239

The algebraic sign determines the direction of the thread:

Right-hand thread: +

Left-hand thread:

Coordinate of top of workpiece: Q203

Cycles for Machining

Holes and Threads

2nd set-up clearance: Q204

Infeed depth for chip breaking: Q257

Retraction distance for chip breaking: Q256

Angle for spindle orientation: Q336

The machine and TNC must be prepared for the TAPPING

WITH CHIP BREAKING cycle by the machine tool builder!

This cycle requires a position-controlled spindle!

50

Page 50

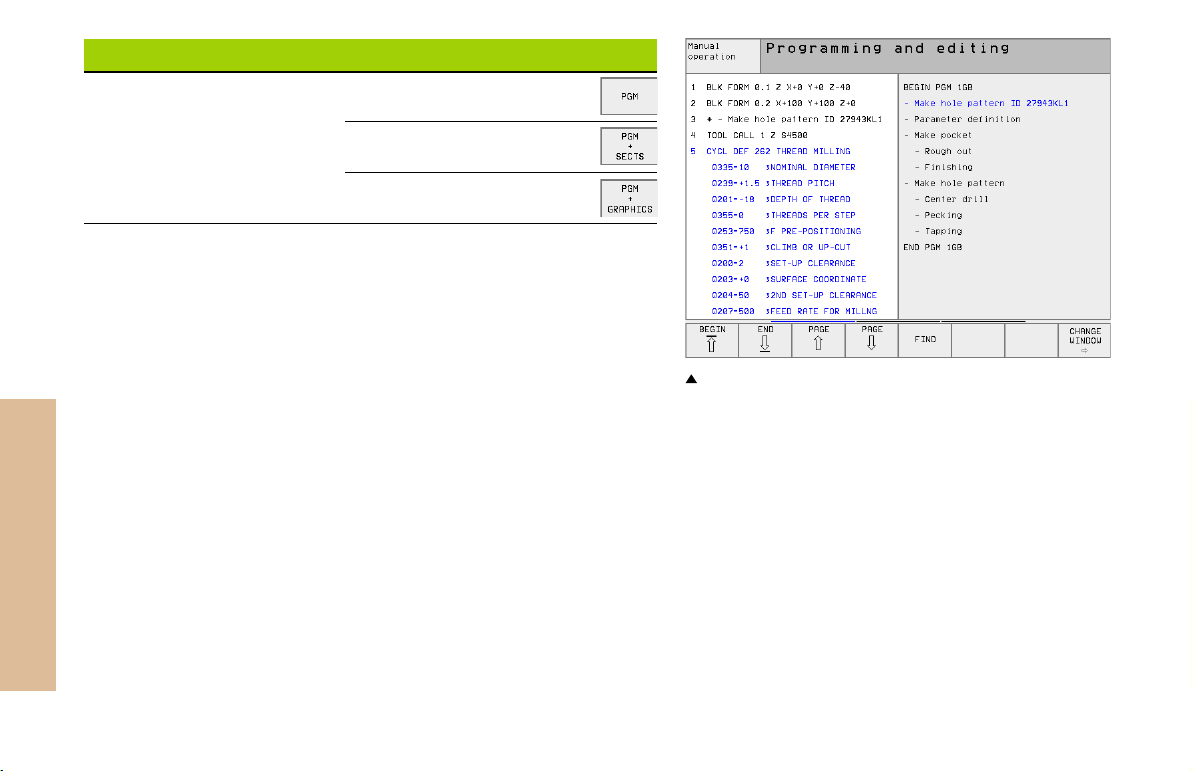

THREAD MILLING (262)

X

Z

Q203

Q253

Q239

Q201

Q204

Q200

X

Y

Q207

Q335

Pre-position above the hole center with R0

CYCL DEF: Select Cycle 262 THREAD MILLING

Nominal diameter of the thread: Q335

Thread pitch: Q239

The algebraic sign determines the thread direction:

Right-hand thread: +

Left-hand thread:

Thread depth: Distance from top of workpiece to thread

termination: Q201

Number of threads per step: Q355

Feed rate for pre-positioning: Q253

Type of milling: Q351

Climb: +1

Up-cut: 1

Set-up clearance: Q200

Workpiece surface coordinate: Q203

2nd set-up clearance: Q204

Feed rate for milling: Q207

Cycles for Machining

Holes and Threads

51

Page 51

THREAD MILLING AND COUNTERSINKING (263)

Pre-position above the hole center with R0

CYCL DEF: Select Cycle 263 THREAD MILLING AND

COUNTERSINKING

Nominal diameter of thread: Q335

Thread pitch: Q239

The algebraic sign determines the direction of the thread:

Right-hand thread: +

Left-hand thread:

Thread depth: Distance from top of workpiece to thread

termination: Q201

Countersinking depth: Distance from workpiece surface to bottom

of hole: Q356

Feed rate for pre-positioning: Q253

Cycles for Machining

Holes and Threads

Type of milling: Q351

Climb: +1

Up-cut: 1

Set-up clearance: Q200

Lateral set-up clearance: Q357

Sinking depth at front: Q358

Countersinking offset at front: Q359

Workpiece surface coordinate: Q203

2nd set-up clearance: Q204

Feed rate for counterboring: Q254

Feed rate for milling: Q207

Z

Q358

Q356

Z

Q359

Q253

Q239

Q200

Q204

Q201

Q203

X

52

X

Q357

Page 52

THREAD DRILLING AND MILLING (264)

X

Z

Q203

Q239

Q201

Q204

Q200

Q253

Q202

Q257

Q356

X

Z

Q359Q359

Q358

Pre-position over the hole center with R0

CYCL DEF: Select Cycle 264 THREAD DRLLNG/MLLNG

Nominal diameter of thread: Q335

Thread pitch: Q239

The algebraic sign determines the thread direction:

Right-hand thread: +

Left-hand thread:

Thread depth: Distance from top of workpiece to thread

termination: Q201

Hole depth: Distance from top of workpiece to bottom of hole: Q201

Feed rate for pre-positioning: Q253

Type of milling: Q351

Climb: +1

Up-cut: 1

Plunging depth: Q202

Upper advanced stop distance: Q258

Infeed depth for chip breaking: Q257

Retraction distance for chip breaking: Q256

Dwell time at bottom: Q211

Sinking depth at front: Q358

Countersinking offset at front: Q359

Set-up clearance: Q200

Workpiece surface coordinate: Q203

2nd set-up clearance: Q204

Feed rate for plunging: Q206

Feed rate for milling: Q207

Cycles for Machining

Holes and Threads

53

Page 53

HELICAL THREAD DRILLING AND MILLING (265)

Pre-position over the hole center with R0

CYCL DEF: Select Cycle 265 HEL. THREAD DRLG/MLG

Nominal diameter of the thread: Q335

Thread pitch: Q239

The algebraic sign determines the thread direction:

Right-hand thread: +

Left-hand thread:

Thread depth: Distance from top of workpiece to thread

termination: Q201

Feed rate for pre-positioning: Q253

Sinking depth at front: Q358

Countersinking offset at front: Q359

Countersink: Q360

Cycles for Machining

Holes and Threads

Set-up clearance: Q200

Workpiece surface coordinate: Q203

2nd set-up clearance: Q204

Feed rate for countersinking: Q254

Feed rate for milling: Q207

Z

Q358

Q253

Z

Q239

Q200

Q204

Q201

Q203

X

Q359

54

X

Page 54

OUTSIDE THREAD MILLING (267)

X

Z

Q203

Q253

Q201

Q204

Q200

Q239

Q335

X

Y

Q207

Q335

Pre-position over the hole center with R0

CYCL DEF: Select Cycle 267 OUTSIDE THREAD MLLNG

Nominal diameter of thread: Q335

Thread pitch: Q239

The algebraic sign determines the thread direction:

Right-hand thread: +

Left-hand thread:

Hole depth: Distance from top of workpiece to bottom of hole: Q201

Number of threads per step: Q355

Feed rate for pre-positioning: Q253

Type of milling: Q351

Climb: +1

Up-cut: 1

Set-up clearance: Q200

Sinking depth at front: Q358

Countersinking offset at front: Q359

Workpiece surface coordinate: Q203

2nd set-up clearance: Q204

Feed rate for countersinking: Q254

Feed rate for milling: Q207

Cycles for Machining

Holes and Threads

55

Page 55

Pockets, Studs, and Slots

POCKET MILLING (4)

This cycle requires either a center-cut end mill (ISO 1641) or

pilot drilling at the pocket center!

The tool begins milling in the positive axis direction of the longer side.

In square pockets it moves in the positive Y direction.

The tool must be pre-positioned over the center of the slot with tool

radius compensation R0

CYCL DEF: Select cycle 4 POCKET MILLING

Set-up clearance:

Milling depth (depth of the pocket):

Pecking depth:

Feed rate for pecking

First side length (length of the pocket, parallel to the first main axis

Pockets, Studs, and Slots

of the working plane):

Second side length (width of pocket, sign always positive):

Feed rate

Rotation clockwise: DR

Climb milling with M3: DR+

Up-cut milling with M3: DR

Rounding-off radius R (radius for the pocket corners)

12 CYCL DEF 4.0 POCKET MILLING

13 CYCL DEF 4.1 SET UP2

14 CYCL DEF 4.2 DEPTH-10

15 CYCL DEF 4.3 PECKG4 F80

16 CYCL DEF 4.4 X80

17 CYCL DEF 4.5 Y40

18 CYCL DEF 4.6 F100 DR+ RADIUS 10

19 L Z+100 R0 FMAX M6

20 L X+60 Y+35 FMAX M3

21 L Z+2 FMAX M99

56

A

C

B

D

E

Page 56

POCKET FINISHING (212)

CYCL DEF: Select Cycle 212 POCKET FINISHING

Set-up clearance: Q200

Depth Distance between workpiece surface and bottom of hole:

Q201

Feed rate for plunging: Q206

Pecking depth: Q202

Feed rate for milling: Q207

Surface coordinate: Q203

2nd set-up clearance: Q204

Center in 1st axis: Q216

Center in 2nd axis: Q217

First side length: Q218

Second side length: Q219

Corner radius: Q220

Allowance in 1st axs: Q221

The TNC automatically pre-positions the tool in the tool axis and in the

working plane. If the depth is greater than or equal to the pecking

depth, the tool drills to the depth in one plunge.

Pockets, Studs, and Slots

57

Page 57

STUD FINISHING (213)

CYCL DEF: Select Cycle 213 STUD FINISHING

Set-up clearance: Q200

Depth Distance between workpiece surface and bottom of hole:

Q201

Feed rate for plunging: Q206

Pecking depth: Q202

Feed rate for milling: Q207

Surface coordinate: Q203

2nd set-up clearance: Q204

Center in 1st axis: Q216

Center in 2nd axis: Q217

First side length: Q218

Second side length: Q219

Pockets, Studs, and Slots

Corner radius: Q220

Allowance in 1st axs: Q221

The TNC automatically pre-positions the tool in the tool axis and in the

working plane. If the depth is greater than or equal to the pecking

depth, the tool drills to the depth in one plunge.

58

Page 58

CIRCULAR POCKET MILLING (5)

This cycle requires either a center-cut end mill (ISO 1641) or

pilot drilling at pocket center!

The tool must be pre-positioned over the center of the slot with tool

radius compensation R0

CYCL DEF: Select cycle 5

Set-up clearance:

Milling depth (depth of the pocket):

Pecking depth:

Feed rate for pecking

Circle radius R (radius of the pocket)

Feed rate

Rotation clockwise: DR

Climb milling with M3: DR+

Up-cut milling with M3: DR

17 CYCL DEF 5.0 CIRCULAR POCKET

18 CYCL DEF 5.1 SET UP 2

19 CYCL DEF 5.2 DEPTH -12

20 CYCL DEF 5.3 PECKG 6 F80

21 CYCL DEF 5.4 RADIUS 35

22 CYCL DEF 5.5 F100 DR+

23 L Z+100 R0 FMAX M6

24 L X+60 Y+50 FMAX M3

25 L Z+2 FMAX M99

A

B

C

Pockets, Studs, and Slots

59

Page 59

CIRCULAR POCKET FINISHING (214)

CYCL DEF: Select Cycle 214 CIRCULAR POCKET FINISHING

Set-up clearance: Q200

Depth Distance between workpiece surface and bottom of hole:

Q201

Feed rate for plunging: Q206

Pecking depth: Q202

Feed rate for milling: Q207

Surface coordinate: Q203

2nd set-up clearance: Q204

Center in 1st axis: Q216

Center in 2nd axis: Q217

Workpiece blank dia.: Q222

Finished part dia.: Q223

Pockets, Studs, and Slots

The TNC automatically pre-positions the tool in the tool axis and in the

working plane. If the depth is greater than or equal to the pecking

depth, the tool drills to the depth in one plunge.

60

Page 60

CIRCULAR STUD FINISHING (215)

CYCL DEF: Select Cycle 215 CIRCULAR STUD FINISHING

Set-up clearance: Q200

Depth Distance between workpiece surface and bottom of hole:

Q201

Feed rate for plunging: Q206

Pecking depth: Q202

Feed rate for milling: Q207

Surface coordinate: Q203

2nd set-up clearance: Q204

Center in 1st axis: Q216

Center in 2nd axis: Q217

Workpiece blank dia.: Q222

Finished part dia.: Q223

The TNC automatically pre-positions the tool in the tool axis and in the

working plane. If the depth is greater than or equal to the pecking

depth, the tool drills to the depth in one plunge.

Pockets, Studs, and Slots

61

Page 61

SLOT MILLING (3)

This cycle requires either a center-cut end mill (ISO 1641)

or pilot drilling at the starting point!

The cutter diameter must be smaller than the slot width and

larger than half the slot width!

The tool must be pre-positioned over the midpoint of the slot and

offset by the tool radius with tool radius compensation at R0

CYCL DEF: Select cycle 3 SLOT MILLING

Set-up clearance:

Milling depth (depth of the slot):

Pecking depth:

Feed rate for pecking (traverse velocity for plunging)

First side length ? (length of the slot):

Pockets, Studs, and Slots

The algebraic sign determines the first cutting direction

Second side length ? (width of the slot):

Feed rate (for milling)

10 TOOL DEF 1 L+0 R+6

11 TOOL CALL 1 Z S1500

12 CYCL DEF 3.0 SLOT MILLING

13 CYCL DEF 3.1 SET UP 2

14 CYCL DEF 3.2 DEPTH -15

15 CYCL DEF 3.3 PECKG 5 F80

16 CYCL DEF 3.4 X50

17 CYCL DEF 3.5 Y15

18 CYCL DEF 3.6 F120

19 L Z+100 R0 FMAX M6

20 L X+16 Y+25 R0 FMAX M3

62

21 L Z+2 M99

A

C

B

D

E

Page 62

SLOT WITH RECIPROCATING PLUNGE-CUT (210)

The cutter diameter must be no larger than the width of the

slot, and no smaller than one third!

CYCL DEF: Select Cycle 210 SLOT RECIP. PLNG

Set-up clearance: Q200

Depth Distance between workpiece surface and bottom of hole:

Q201

Feed rate for milling: Q207

Pecking depth: Q202

Machining operation (0/1/2) 0 = roughing and finishing,

1 = roughing only, 2 = finishing only: Q215

Surface coordinate: Q203

2nd set-up clearance: Q204

Center in 1st axis: Q216

Center in 2nd axis: Q217

First side length: Q218

Second side length: Q219

Angle of rotation (angle by with the slot is rotated): Q224

Infeed for finishing: Q338

The TNC automatically pre-positions the tool in the tool axis and in the

working plane. During roughing the tool plunges obliquely into the

metal in a back-and-forth motion between the ends of the slot. Pilot

drilling is therefore unnecessary.

Pockets, Studs, and Slots

63

Page 63

CIRCULAR SLOT with reciprocating plunge (211)

The cutter diameter must be no larger than the width of the

slot, and no smaller than one third!

CYCL DEF: Select Cycle 211 CIRCULAR SLOT

Set-up clearance: Q200

Depth Distance between workpiece surface and bottom of hole:

Q201

Feed rate for milling: Q207

Pecking depth: Q202

Machining operation (0/1/2) 0 = roughing and finishing,

1 = roughing only, 2 = finishing only: Q215

Surface coordinate: Q203

2nd set-up clearance: Q204

Pockets, Studs, and Slots

Center in 1st axis: Q216

Center in 2nd axis: Q217

Pitch circular dia.: Q244

Second side length: Q219

Starting angle of the slot: Q245

Angular length of the slot: Q248

Infeed for finishing: Q338

The TNC automatically pre-positions the tool in the tool axis and in the

working plane. During roughing the tool plunges obliquely into the

metal in a back-and-forth helical motion between the ends of the slot.

Pilot drilling is therefore unnecessary.

64

Page 64

Point Patterns

CIRCULAR PATTERN (220)

CYCL DEF: Select Cycle 220 CIRCULAR PATTERN

Center in 1st axis: Q216

Center in 2nd axis: Q217

Angle of rotation: Q244

Starting angle: Q245

Stopping angle: Q246

Stepping angle: Q247

Nr of repetitions: Q241

Set-up clearance: Q200

Surface coordinate: Q203

2nd set-up clearance: Q204

Move to clearance height: Q301

Cycle 220 POLAR PATTERN is effective immediately upon

definition!

Cycle 220 automatically calls the last defined fixed cycle!

Cycle 220 can be combined with Cycles 1, 2, 3, 4, 5, 17, 200,

201, 202, 203, 204, 205, 206, 207, 208, 209, 212, 213, 214, 215,

262, 263, 264, 265, 267

In combined cycles, the set-up clearance, surface coordinate

and 2nd set-up-clearance are always taken from Cycle 220!

The TNC automatically pre-positions the tool in the tool axis and in the

working plane.

Point Patterns

65

Page 65

LINEAR PATTERN (221)

CYCL DEF: Select Cycle 221 LINEAR PATTERN

Startng pnt 1st axis: Q225

Startng pnt 2nd axis: Q226

Spacing in 1st axis: Q237

Spacing in 2nd axis: Q238

Number of columns: Q242

Number of lines: Q243

Angle of rotation: Q224

Set-up clearance: Q200

Surface coordinate: Q203

2nd set-up clearance: Q204

Move to clearance height: Q301

Point Patterns

The TNC automatically pre-positions the tool in the tool axis and in the

working plane.

66

Cycle 221 LINEAR PATTERN is effective immediately upon

definition!

Cycle 221 automatically calls the last defined fixed cycle!

Cycle 221 can be combined with Cycles 1, 2, 3, 4, 5, 17, 200,

201, 202, 203, 204, 205, 206, 207, 208, 209, 212, 213, 214, 215,

262, 263, 264, 265, 267

In combined cycles, the set-up clearance, surface coordinate

and 2nd set-up-clearance are always taken from Cycle 221!

Page 66

SL Cycles

General Information

SL cycles are useful when you wish to machine a contour consisting of

several subcontours (up to 12 islands or pockets).

The subcontours are defined in subprograms.

When working with subcontours, always remember:

For a pocket the tool machines an inside contour, for an

island it is an outside contour!

Tool approach and departure as well as infeed in the

tool axis cannot be programmed in SL cycles!

Each contour listed in Cycle 14 CONTOUR GEOMETRY

must be a closed contour!

There is a limit to the amount of memory an SL cycle can

occupy! A maximum of 128 straight line blocks, for example,

can be programmed in an SL cycle.

The contour for cycle 25 CONTOUR TRAIN must not be

closed!

Make a graphic test run before actually machining a part. That

way you can be sure that you defined the contour correctly!

SL Cycles

67

Page 67

CONTOUR GEOMETRY (14)

In Cycle 14 CONTOUR GEOMETRY you list the subprograms that you

wish to superimpose to make a complete closed contour.

CYCL DEF: Select Cycle 14 CONTOUR GEOMETRY

Label nubers for contour: List the LABEL numbers of the

subprograms that you wish to superimpose to make a complete

closed contour.

Cycle 14 CONTOUR GEOMETRY is effective immediately

upon definition!

4 CYCL DEF 14.0 CONTOUR GEOM

5 CYCL DEF 14.1 CONTOUR LABEL 1/2/3

...

SL Cycles

36 L Z+200 R0 FMAX M2

37 LBL1

38 L X+0 Y+10 RR

39 L X+20 Y+10

40 CC X+50 Y+50

...

45 LBL0

46 LBL2

...

58 LBL0

A and B are pockets, C and D islands

68

Page 68

CONTOUR DATA (20)

Cycle 20 CONTOUR DATA defines the machining information for

cycles 21 to 24.

CYCL DEF: Select Cycle 20 CONTOUR DATA

Milling depth Q1:

Distance from workpiece surface to pocket floor; incremental

Path overlap factor Q2:

Q2 x tool radius = stepover factor k

Allowance for side Q3:

Finishing allowance for the walls of the pocket or island

Allowance for floor Q4:

Finishing allowance for the pocket floor

Workpiece surface coordinates Q5:

Coordinate of the workpiece surface referenced to the current

datum; absolute

Set-up clearance Q6:

Distance from the tool to the workpiece surface; incremental

Clearance height Q7:

Height at which the tool cannot collide with the workpiece;

absolute

Rounding radius Q8:

Rounding radius of the tool at inside corners

Direction of rotation Q9:

Clockwise Q9 = 1

Counter clockwise Q9 = +1

SL Cycles

Cycle 20 CONTOUR DATA is effective immediately upon

definition!

69

Page 69

PILOT DRILLING (21)

CYCL DEF: Select Cycle 21 PILOT DRILLING

Pecking depth Q10; incremental

Feed rate for pecking Q11

Rough mill Q13: Number of the roughing tool

SL Cycles

ROUGH-OUT (22)

The tool moves parallel to the contour at every pecking depth.

CYCL DEF: Select Cycle 22 ROUGH-OUT

Pecking depth Q10; incremental

Feed rate for pecking Q11

Feed rate for milling Q12

Coarse roughing tool number Q18

Feed rate for reciprocation Q19

70

Page 70

FLOOR FINISHING (23)

During finishing, the surface is machined parallel to the contour and to

the depth previously entered under ALLOWANCE FOR FLOOR.

CYCL DEF: Select Cycle 23 FLOOR FINISHING

Feed rate for pecking Q11

Feed rate for milling Q12

SIDE FINISHING (24)

Finishing the individual contour elements

CYCL DEF: Select Cycle 24 SIDE FINISHING

Direction of rotation? Clockwise = 1 Q9:

Clockwise Q9 = 1

Counterclockwise Q9 = +1

Pecking depth Q10; incremental

Feed rate for pecking Q11

Feed rate for milling Q12

Finishing allowance for side Q14: Allowance for finishing

in several passes

The sum of Q14 + finishing mill radius must be smaller than

the sums Q3 (Cycle 20) + roughing tool radius!

Call Cycle 22 ROUGH-OUT before calling Cycle 24!

SL Cycles

71

Page 71

CONTOUR TRAIN (25)

This cycle is for entering data for machining an open contour that has

been defined in a contour subprogam.

CYCL DEF: Select Cycle 25 CONTOUR TRAIN

Milling depth Q1; incremental

Allowance for side Q3:

Finishing allowance in the working plane

Workpiece surface coordinates Q5:

Coordinates referenced to the workpiece datum; absolute

Clearance height Q7:

Height at which the tool cannot collide with the workpiece; absolute

Pecking depth Q10; incremental

Feed rate for pecking Q11

SL Cycles

Feed rate for milling Q12

Climb or up-cut ? Up-cut = 1 Q15

Climb milling: Q15 = +1

Up-cut milling: Q15 = 1

Alternately in reciprocating cuts: Q15 = 0

Cycle 14 CONTOUR can have only one label number.

A subprogram can hold no more than 128 line segments.

72

Page 72

CYLINDER SURFACE (27)

This cycle requires a center-cut end mill (ISO 1641)!

Cycle 27 CYLINDER SURFACE enables you to program a cylindrical

contour in only two axes, as if in a plane. The TNC then rolls it onto a

cylindrical surface.

Define a contour in a subprogram and list it in Cycle 14 CONTOUR

GEOMETRY

CYCL DEF: Select Cycle 27 CYLINDER SURFACE

Milling depth Q1

Finishing allowance for side Q3: Enter the finishing allowance

(Either Q3>0 or Q3<0)

Set-up clearance ? Q6: Distance from the tool to the workpiece

Plunging depth Q10

Feed rate for plunging Q11

Feed rate for milling Q12

Cylinder radius Q16: Radius of the cylinder

Dimension type? Deg=0 mm/inch=1 Q17: You can enter

coordinates in the subprogram in degrees or millimeters

The machine and TNC must be prepared for the CYLINDER

SURFACE cycle by the machine tool builder!

The workpiece must be set up concentrically on the rotary

table!

The tool axis must be perpendicular to the axis of the rotary

table!

Cycle 14 CONTOUR GEOMETRY can have only one label

number!

A subprogram can hold no more than 128 line segments!

SL Cycles

The unrolled contour

73

Page 73

CYLINDER SURFACE (28)

This cycle requires a center-cut end mill (ISO 1641)!

Cycle 28 CYLINDER SURFACE enables you to program a slot in only

two axes and then machine it on a cylindrical surface without distorting the angle of the slot walls.

Define a contour in a subprogram and list it in Cycle 14 CONTOUR

GEOMETRY.

CYCL DEF: Select Cycle 28 CYLINDER SURFACE

Milling depth Q1

Finishing allowance for side Q3: Enter the finishing allowance

(Q3>0 or Q3<0)

Set-up clearance Q6: Distance from the tool to the workpiece

SL Cycles

surface

Plunging depth Q10

Feed rate for plunging Q11

Feed rate for milling Q12

Cylinder radius Q16: Radius of the cylinder

Dimension type? Deg=0 mm/inch=1 Q17: Coordinates in the

subprogram in degrees or millimeters

Slot width Q20

The machine and TNC must be prepared for the CYLINDER

SURFACE CYCLE by the machine tool builder!

The unrolled contour

74

The workpiece must be set up concentrically on the table!

The tool axis must be perpendicular to the rotary table axis!

Cycle 14 CONTOUR GEOMETRY can have only one label

number!

A subprogram can hold no more than 128 line segments!

Page 74

Multipass Milling

RUN DIGITIZED DATA (30)

This cycle requires a center-cut end mill as per ISO 1641!

CYCL DEF: Select Cycle 30 RUN DIGITIZED DATA

pgm name for digitized data

MIN. point range

MAX. point range

Set-up clearance:

Pecking depth:

Feed rate for pecking:

Feed rate:

Miscellaneous function M

7 CYCL DEF 30.0 RUN DIGITIZED DATA

8 CYCL DEF 30.1 PROGRAM1

9 CYCL DEF 30.2 X+0 Y+0 Z-35

10 CYCL DEF 30.3 X+250 Y+125 Z+15

11 CYCL DEF 30.4 SET UP 2

12 CYCL DEF 30.5 PECKG 5 F125

13 CYCL DEF 30.6 F350 M112 T0.01 A+10

A

C

D

B

Multipass Milling

75

Page 75

MULTIPASS MILLING (230)

From the current position, the TNC positions the tool

automatically at the starting point of the first machining

operation, first in the working plane and then in the tool axis.

Pre-position the tool in such a way that there is no danger

of collision with the workpiece or fixtures.

CYCL DEF: Select Cycle 230 MULTIPASS MILLING

Starting point in 1st axis: Q225

Starting point in 2nd axis: Q226

Starting point in 3rd axis: Q227

First side length: Q218

Second side length: Q219

Number of cuts: Q240

Multipass Milling

Feed rate for plunging: Q206

Feed rate for milling: Q207

Stepover feed rate: Q209

Set-up clearance: Q200

76

Page 76

RULED SURFACE (231)

Starting from the initial position, the TNC positions the tool at

the starting point (point 1), first in the working plane and then

in the tool axis.

CYCL DEF: Select Cycle 231 RULED SURFACE

Starting point in 1st axis: Q225

Starting point in 2nd axis: Q226

Starting point in 3rd axis: Q227

2nd point in 1st axis: Q228

2nd point in 2nd axis: Q229

2nd point in 3rd axis: Q230

3rd point in 1st axis: Q231

3rd point in 2nd axis: Q232

3rd point in 3rd axis: Q233

4th point in 1st axis: Q234

4th point in 2nd axis: Q235

4th point in 3rd axis: Q236

Number of cuts: Q240

Feed rate for milling: Q207

Multipass Milling

77

Page 77

Cycles for Coordinate Transformation

Cycles for coordinate transformation permit contours to be

Shifted Cycle 7 DATUM SHIFT

Mirrored Cycle 8 MIRROR IMAGE

Rotated (in the plane) Cycle 10 ROTATION

Tilted out of the plane Cycle 19 WORKING PLANE

Enlarged or reduced Cycle 11 SCALING

Cycle 26 AXIS-SPECIFIC SCALING

Cycles for coordinate transformation are effective upon definition

until they are reset or redefined. The original contour should be

defined in a subprogram. Input values can be both absolute and

incremental.

Cycles for Coordinate

Transformations

DATUM SHIFT (7)

CYCL DEF: Select Cycle 7 DATUM SHIFT

Enter the coordinates of the new datum or the number of the

datum from the datum table.

To cancel a datum shift: Re-enter the cycle definition with the input

value 0.

9 CALL LBL1 Call the part subprogram

10 CYCL DEF 7.0 DATUM SHIFT

11 CYCL DEF 7.1 X+60

12 CYCL DEF 7.2 Y+40

13 CALL LBL1 Call the part subprogram

78

When combining transformations, the datum shift must be

programmed before the other transformations!

Page 78

DATUM SETTING (247)

CYCL DEF: Select Cycle 247 DATUM SETTING

Datum number: Enter the number from the active datum table

containing the REF coordinates of the datum to be set.

Reset

You can reactivate the datum that was last set in the Manual operating

mode by entering the miscellaneous function M104.

If required, activate the desired datum table with the NC

block SEL TABLE.

The TNC sets the datum only in the axes that are active in

the datum table.

Cycle 247 always interprets the values saved in the datum

tables as coordinates relative to the machine datum.

Machine parameter 7475 has no influence.

Cycles for Coordinate

Transformations

79

Page 79

MIRROR IMAGE (8)

CYCL DEF: Select Cycle 8 MIRROR IMAGE

Enter the mirror image axis: Either X, Y, or both

To reset the mirror image, re-enter the cycle definition with NO ENT.

15 CALL LBL1

16 CYCL DEF 7.0 DATUM SHIFT

17 CYCL DEF 7.1 X+60

18 CYCL DEF 7.2 Y+40

19 CYCL DEF 8.0 MIRROR IMAGE

20 CYCL DEF 8.1 Y

21 CALL LBL1

Cycles for Coordinate

Transformations

The tool axis cannot be mirrored!

The cycle always mirrors the original contour (in this example

in subprogram LBL1)!

80

Page 80

Rotation (10)

CYCL DEF: Select Cycle 10 ROTATION

Enter the rotation angle:

Input range 360° to +360°

Reference axes for the rotation angle

Working plane Reference axis and 0° direction

X/Y X

Y/Z Y

Z/X Z

To reset a ROTATION, re-enter the cycle with the rotation angle 0.

12 CALL LBL1

13 CYCL DEF 7.0 DATUM SHIFT

14 CYCL DEF 7.1 X+60

15 CYCL DEF 7.2 Y+40

16 CYCL DEF 10.0 ROTATION

17 CYCL DEF 10.1 ROT+35

18 CALL LBL1

Cycles for Coordinate

Transformations

81

Page 81

WORKING PLANE (19)

Cycle 19 WORKING PLANE supports machining operations with a

swivel head and/or tilting table.

Call the tool

Retract the tool in the tool axis (to prevent collision)

If required, use an L block to position the rotary axes to the desired

angle

CYCL DEF: Select Cycle 19 WORKING PLANE

Enter the tilt angle of the corresponding axis or angle in space

If required, enter the feed rate of the rotary axes during automatic

positioning

If required, enter the setup-clearance

Activate compensation: move all the axes

Cycles for Coordinate

Program the contour as if the plane were not tilted

Transformations

To cancel the WORKING PLANE cycle, re-enter the cycle definition

with a 0° angle.

The machine and TNC must be prepared for the WORKING

PLANE cycle by the machine tool builder!

4 TOOL CALL 1 Z S2500

5 L Z+350 R0 FMAX

6 L B+10 C+90 R0 FMAX

7 CYCL DEF 19.0 WORKING PLANE

8 CYCL DEF 19.1 B+10 C+90

9 L Z+200 R0 F1000

10 L X-50 Y-50 R0

82

Page 82

SCALING (11)

CYCL DEF: Select Cycle 11 SCALING

Enter the scaling factor (SCL):

Input range 0.000001 to 99.999999:

To reduce the contour ... SCL < 1

To enlarge the contour ... SCL > 1

To cancel the SCALING, re-enter the cycle definition with SCL1.

11 CALL LBL1

12 CYCL DEF 7.0 DATUM SHIFT

13 CYCL DEF 7.1 X+60

14 CYCL DEF 7.2 Y+40

15 CYCL DEF 11.0 SCALING

16 CYCL DEF 11.1 SCL 0.75

17 CALL LBL1

SCALING can be effective in the working plane only or in all

three main axes (depending on machine parameter 7410)!

Cycles for Coordinate

Transformations

83

Page 83

AXIS-SPECIFIC SCALING (26)

CYCL DEF: Select Cycle 20 AXIS-SPEC. SCALING

Axis and factor: Coordinate axes and factors for extending or

compressing contour dimensions

Centerpoint coord. of extention: Center of the extension or

compression

To cancel the AXIS-SPEC. SCALING, re-enter the cycle definition

assigning the factor 1 to the affected axes.

Coordinate axes sharing coordinates for arcs must be

extended or compressed by the same scaling factor!

Cycles for Coordinate

Transformations

25 CALL LBL1

26 CYCL DEF 26.0 AXIS-SPEC. SCALING

27 CYCL DEF 26.1 X 1.4 Y 0.6 CCX+15 CCY+20

28 CALL LBL1

84

Page 84

Special Cycles

DWELL TIME (9)

The program run is interrupted for the duration of the DWELL TIME.

CYCL DEF: Select cycle 9 DWELL TIME

Enter the dwell time in seconds

48 CYCL DEF 9.0 DWELL TIME

49 CYCL DEF 9.1 DWELL 0.5

PGM CALL (12)

CYCL DEF: Select cycle 12 PGM CALL

Enter the name of the program that you wish to call

Cycle 12 PGM CALL must be called to become active!

7 CYCL DEF 12.0 PGM CALL

8 CYCL DEF 12.1 LOT31

9 L X+37.5 Y-12 R0 FMAX M99

Special-Cycles

85

Page 85

Spindle ORIENTATION

CYCL DEF: Select cycle 13 ORIENTATION

Enter the orientation angle referenced to the angle reference axis

of the working plane:

Input range 0 to 360°

Input resolution 0.1°

Call the cycle with M19 or M20

The machine and TNC must be prepared for spindle

ORIENTATION by the machine tool builder!

12 CYCL DEF 13.0 ORIENTATION

13 CYCL DEF 13.1 ANGLE 90

Special-Cycles

86

Page 86

TOLERANCE (32)

The machine and the TNC must be specially prepared for fast

contour milling by the machine tool builder!

Cycle 32 TOLERANCE is effective as soon as it is defined in

the part program!

The TNC automatically smooths the contour between any (compensated

or uncompensated) contour elements. The tool therefore moves continuously on the workpiece surface. If necessary, the TNC automatically

reduces the programmed feed rate so that the program can be run at

the fastest possible speed and without "jerk".

A contour deviation results from the smoothing out. The size of this

deviation (TOLERANCE VALUE) is set in a machine parameter by the

machine manufacturer. You can change the pre-set tolerance value

with Cycle 32 (see figure at top right).

CYCL DEF: Select Cycle 32 TOLERANCE

Tolerance T: permissible contour deviation in mm

T

Z

X

Special-Cycles

87

Page 87

Digitizing 3D Surfaces

The machine and TNC must be prepared for digitizing by the

machine tool builder!

The TNC features the following cycles for digitizing with a measuring

touch probe:

Fix the scanning range: TCH PROBE 5 RANGE

TCH PROBE 15 RANGE

Digitize in reciprocating lines: TCH PROBE 16 MEANDER

Digitize level by level: TCH PROBE 17 CONTOUR LINES

Digitize in unidirectional lines: TCH PROBE 18 LINE

The digitizing cycles can be programmed only in plain language dialog.

They can be programmed for the main axes X, Y and Z as well as for

the rotary axes A, B and C.

Digitizing

Digitizing is not possible while coordinate transformations

or a basic rotation is active!

Digitizing cycles need not be called. They are effective

immediately upon definition!

Selecting digitizing cycles

Call an overview of touch probe functions

Select digitizing cycles

88

e.g. select Cycle 15

Page 88

Digitizing Cycle RANGE (5)

Define the data transmission interface

TOUCH PROBE: Select Cycle 5 RANGE

PGM name for digitized data: Enter a name for the

NC program in which the digitized data should be stored.

Tch probe axis: Enter the axis of the touch probe

MIN. point range

MAX. point range

Clearance heigth: Height at which the stylus cannot collide

with the model surface: Z

5 TCH PROBE 5.0 RANGE

6 TCH PROBE 5.1 PGM NAME: DIGI1

7 TCH PROBE 5.2 Z X+0 Y+0 Z+0

8 TCH PROBE 5.3 X+100 Y+100 Z+20

9 TCH PROBE 5.4 HEIGHT: +100

S

Digitizing

89

Page 89

Digitizing Cycle RANGE (15)

Define the data transmission interface

TOUCH PROBE: Select Cycle 15 RANGE

PGM name for digitized data: Enter a name for the

NC program in which the digitized data should be stored.

Tch probe axis: Enter the axis of the touch probe

PGM name for range data: The name of the point table in

which the range is defined

MIN point TCH PROBE axis: The minimum point in the touch probe

axis

MAX point TCH PROBE axis: The maximum point in the

touch probe axis

Clearance height: Height at which the stylus cannot collide

Digitizing

with the model surface: Z

5 TCH PROBE 15.0 RANGE

6 TCH PROBE 15.1 PGM DIGIT.: DATA

7 TCH PROBE 15.2 Z PGM RANGE: TAB1

8 TCH PROBE 15.3 MIN:+0 MAX:+35 HEIGHT:+125

S

90

Page 90

Digitizing Cycle MEANDER (16)

Cycle 16 MEANDER is for digitizing a 3D contour in a series of

back-and-forth line movements.

Define Cycle 5 RANGE or 15 RANGE

TOUCH PROBE: Select Cycle 16 MEANDER

Line direction: Coordinate axis in whose positive direction the

probe moves after touching the first contour point

Scanning angle: Direction of touch probe traverse relative to

the axis entered in line direction

Feed rate F: Maximum digitizing feed rate

Min. feed rate: Feed rate for scanning the first line

Feed rate reduction at edges: Distance at which the TNC begins to

reduce the scanning feed rate before steep edges

Min. line spacing: Minimum distance moved forward to start the

next line at steep surfaces

Line spacing: Max. distance moved forward to start the next line

Max. probe point interval

Tolerance value: The TNC suppresses the storage of probe points

whose distance from a straight line defined by the last two stored

points is less than the tolerance value.

The line spacing and max. probe point interval cannot exceed

20 mm!