Page 1

NC Software

280 620-xx

280 621-xx

286 180-xx

User’s Manual

Conversational

Programming

English (en)

4/2001

Page 2

1

50

0

50

100

F %

Controls on the visual display unit

Split screen layout

Switch between machining or

programming modes

Soft keys for selecting functions in screen

Switching the soft-key rows

Changing the screen settings

(only BC 120)

Typewriter keyboard for entering letters and symbols

File names

Comments

ISO

programs

Machine operating modes

MANUAL OPERATION

INCREMENTAL JOG

POSITIONING WITH MDI

PROGRAM RUN, SINGLE BLOCK

PROGRAM RUN, FULL SEQUENCE

Programming modes

PROGRAMMING AND EDITING

TEST RUN

Program/file management, TNC functions

Delete programs and files (only TNC 406)

Activate external data transfer (only TNC 406)

Pocket calculator

Select programs and files

Moving the highlight, going directly to blocks, cycles

and parameter functions

Go directly to blocks, cycles and parameter

Move highlight

functions

Override control knobs for feed rate/C axis

100

0

1

S %

50

50

Programming path movements

Straight line

Circle center/pole for polar coordinates

Circle with center

Circle with radius

Circular arc with tangential connection

Corner rounding

Electrode data

Enter and call electrode length and radius

Activate electrode radius compensation

Cycles, subprograms and program section

repeats

Program stop in a program

Enter touch probe functions in a program

Define and call cycles

Enter and call labels for subprogramming and

program section repeats

Coordinate axes and numbers:Entering and editing

. . .

. . .

Decimal point

Change arithmetic sign

Polar coordinates

Incremental dimensions

Q parameters

Capture actual position

Skip dialog questions, delete words

Confirm entry and resume dialog

End block

Clear numerical entry or TNC error

message

Abort dialog, delete program section

Select coordinate axes or

enter them into the program

Numbers

Page 3

Page 4

Page 5

Page 6

TNC Models, Software and Features

This manual describes functions and features provided by the TNCs as

of the following NC software numbers.

TNC Model NC Software No.

TNC 406 280 620-12

TNC 416 286 180-06

Location of use

The TNC complies with the limits for a Class A device in accordance

with the specifications in EN 55022, and is intended for use primarily

in industrially-zoned areas.

280 621-12

280 622-12

New features of the NC software 280 62x-xx and 280 180-xx

Cycle 14 CONTOUR GEOMETRY (see also ”Cycle 14 CONTOUR

GEOMETRY” on page 137)

Q parameters for the roughness (see also ”Data from the erosion

table” on page 203)

Q parameters for the gap size (see also ”Gap size LS max when

machining which Cycle 1 GENERATOR: Q164” on page 206)

After manual traverse, the incremental coordinates always refer to

the actual position (see also ”Resuming program run with the

GOTO key” on page 226)

Expansion of the tool table with tool pocket number, tool undersize

and radius (see also ”Entering electrode data in tables” on page 74)

Probed values can be written to a datum table as well as to a tool

table (see also ”Writing probed values to tables” on page 28)

Enhancement of functions FN14 and FN15 (see also ”Output of Q

Parameters and Messages” on page 197)

M108/M109 (see Overview of Miscellaneous Functions on the

inside rear cover of this manual)

HEIDENHAIN TNC 406, TNC 416 I

Page 7

Page 8

Contents

Introduction

Manual Operation, Setup and Probing

Functions

Positioning with manual data input

(MDI)

Programming: Fundamentals, Files,

Program Entry, Spark Erosion, Erosion

Ta b l e s

1

2

3

4

Programming: Tools

Programming: Programming Contours

Programming: Miscellaneous Functions

Programming: Cycles

Programming: Subprograms and

Program Section Repeats

Programming: Q Parameters

Test Run and Program Run

MOD Functions

Tables and Overviews

5

6

7

8

9

10

11

12

13

HEIDENHAIN TNC 406, TNC 416 III

Page 9

Page 10

1 Introduction ..... 1

1.1 The TNC 406, the TNC 416 ..... 2

Controls ..... 2

Visual display unit and keyboard ..... 2

Programming ..... 2

Graphics ..... 2

Compatibility ..... 2

1.2 Visual Display Unit and Keyboard ..... 3

Visual display unit ..... 3

Screen layout ..... 4

Keyboard ..... 5

1.3 Modes of Operation ..... 6

Manual Operation, Incremental Jog, and Positioning with Manual Data Input ..... 6

Programming and Editing ..... 7

Test Run ..... 7

Program Run, Full Sequence and Program Run, Single Block ..... 8

1.4 Status Display ..... 9

General status display ..... 9

Additional status displays ..... 9

1.5 Accessory: Electronic Handwheels from HEIDENHAIN ..... 13

HR electronic handwheels ..... 13

HEIDENHAIN TNC 406, TNC 416 I

Page 11

2 Manual Operation, Setup and Probing Functions ..... 15

2.1 Switch-on ..... 16

Switch-on ..... 16

2.2 Moving the Machine Axes ..... 18

Note ..... 18

To traverse with the machine axis direction buttons: ..... 18

Traversing with the HR 410 electronic handwheel ..... 19

Incremental jog positioning ..... 20

Positioning with manual data input (MDI) ..... 20

Eroding a workpiece manually ..... 21

2.3 Datum Setting ..... 22

Example ..... 22

2.4 Calibration and Setup ..... 23

Using an electrode ..... 23

Select the touch probe function ..... 24

Calibrating the probing electrode ..... 25

Compensating workpiece misalignment ..... 27

2.5 Datum Setting with a Probing Electrode ..... 28

Functions for setting the datum ..... 28

Writing probed values to tables ..... 28

Datum setting in any axis ..... 29

Manual probing ..... 29

Workpiece center as datum ..... 30

Corner as datum ..... 31

Circle center as datum ..... 32

2.6 Measuring with a Probing Electrode ..... 33

Introduction ..... 33

To find the coordinate of a position on an aligned workpiece ..... 33

Finding the coordinates of a corner in the working plane ..... 33

Measuring workpiece dimensions ..... 34

Measuring angles ..... 35

2.7 Entering and Starting Miscellaneous Functions M ..... 36

Entering values ..... 36

3 Positioning with Manual Data Input (MDI) ..... 37

3.1 Positioning with Manual Data Input (MDI) ..... 38

Positioning with manual data input (MDI) ..... 38

Protecting and erasing programs in $MDI ..... 39

II

Page 12

4 Programming: Fundamentals, Files,

Program Entry, Spark Erosion, Erosion Tables ..... 41

4.1 Fundamentals of Positioning ..... 42

Introduction ..... 42

What is NC? ..... 42

The part program ..... 42

Programming ..... 42

Position encoders and reference marks ..... 43

Reference system ..... 43

Reference system with EDMs ..... 44

Programming electrode movement ..... 44

Polar coordinates ..... 45

Absolute and incremental workpiece positions ..... 46

Setting the datum ..... 47

4.2 Files ..... 48

File directory ..... 48

Selecting, copying, deleting and protecting files ..... 50

4.3 Creating and Writing Programs ..... 51

Organization of an NC program in HEIDENHAIN conversational format. ..... 51

Defining the blank form–BLK FORM ..... 51

Creating a new part program ..... 52

Programming tool movements in conversational format ..... 54

Editing a program ..... 55

4.4 Automatic Workpiece Change with WP-Call ..... 57

Programming a workpiece change ..... 57

4.5 Fundamentals of Spark Erosion ..... 58

4.6 Erosion Tables ..... 61

Using erosion tables in a program ..... 61

Working without an erosion table ..... 61

Ready-to-use erosion tables ..... 61

HEIDENHAIN TNC 406, TNC 416 III

Page 13

4.7 Parameters in the Erosion Table ..... 62

To enter erosion parameters in the erosion table ..... 63

Power stage (NR) ..... 64

Low voltage current (LV) ..... 64

High voltage current (HV) ..... 64

Gap voltage (GV) ..... 64

Pulse-on duration and pulse-off duration ..... 65

Servo sensitivity SV ..... 65

Erosion time ET, Auto jump distance AJD ..... 65

Arc sensitivity (AR) ..... 66

Electrode polarity (P) ..... 66

High voltage selector HS ..... 66

Wear rate WR ..... 67

Surface finish RA ..... 67

Stock removal SR ..... 68

Two-times gap (2G) ..... 68

Minimum undersize (UNS) ..... 69

Auxiliary parameters AUX 1, AUX 2, ... AUX 6 ..... 69

5 Programming: Tools ..... 71

5.1 Electrodes ..... 72

Electrode axis C ..... 72

Determining the electrode data ..... 72

Entering electrode data into a program ..... 73

Entering electrode data in tables ..... 74

Calling electrode data ..... 76

Following electrode ..... 77

Changing the electrode ..... 77

Electrode compensation ..... 78

5.2 Electrode Compensation Values ..... 79

Electrode length compensation ..... 79

Electrode radius compensation ..... 80

Radius compensation: Machining corners ..... 82

5.3 Entering Electrode-Related Data ..... 83

Introduction ..... 83

Feed rate F ..... 83

5.4 Actual Position Capture ..... 84

Function ..... 84

IV

Page 14

6 Programming: Programming Contours ..... 85

6.1 General Information on Programming Electrode Movements ..... 86

Path functions ..... 86

Machines with 5 axes ..... 86

Subprograms and program section repeats ..... 86

Cycles ..... 87

Parametric programming ..... 87

6.2 Contour Approach and Departure ..... 88

Starting point and end point of machining ..... 88

Tangential contour approach and departure ..... 91

6.3 Path functions ..... 92

General ..... 92

Programmed machine axis movement ..... 92

6.4 Path Contours — Cartesian Coordinates ..... 93

Overview of path functions ..... 93

Straight line L ..... 94

Inserting a chamfer CHF between two straight lines ..... 96

Corner rounding RND ..... 97

Circles and circular arcs ..... 97

Circle center CC ..... 98

Circular path C around circle center CC ..... 100

Circular path CR with defined radius ..... 101

Circular path CT with tangential connection ..... 103

6.5 Path Contours — Polar Coordinates ..... 109

Overview ..... 109

Polar coordinate origin: Pole CC ..... 109

Straight line LP ..... 110

Circular path CP around pole CC ..... 111

Circular path CTP with tangential connection ..... 112

Helical interpolation ..... 113

HEIDENHAIN TNC 406, TNC 416 V

Page 15

7 Programming: Miscellaneous functions ..... 119

7.1 Entering Miscellaneous Functions M and STOP ..... 120

Fundamentals ..... 120

7.2 Miscellaneous Functions for Program Run Control, Electrode and Flushing ..... 122

Overview ..... 122

7.3 Miscellaneous Functions for Contouring Behavior and Coordinate Data ..... 123

Introduction ..... 123

Machining small contour steps: M97 ..... 123

Machining open contours: M98 ..... 124

Programming machine-referenced coordinates: M91/M92 ..... 124

Retracting electrode to block starting point at end of block: M93 ..... 125

7.4 Vacant miscellaneous functions ..... 126

VI

Page 16

8 Programming: Cycles ..... 129

8.1 General Overview of Cycles ..... 130

Prerequisites ..... 130

Start of effect ..... 130

Dimensions in the electrode axis ..... 130

OEM cycles ..... 130

Programming a cycle ..... 131

8.2 Cycle 1 GENERATOR ..... 133

Working with an erosion table ..... 133

Working without an erosion table ..... 133

To enter Cycle 1.0 GENERATOR ..... 133

Changing the power stage ..... 134

8.3 Electrode Definition ..... 135

Cycle 3 TOOL DEF ..... 135

Example NC blocks ..... 136

8.4 Erosion Cycles ..... 137

Overview ..... 137

Cycle 14 CONTOUR GEOMETRY ..... 137

Cycle 16 ORBIT ..... 139

Cycle 17 DISK ..... 142

Cycle 2 ERO.TIME LIM. ..... 145

Cycle 4 SPARK-OUT TIME ..... 146

8.5 Coordinate Transformation Cycles ..... 155

Cycles for electrode definition ..... 155

Coordinate transformation cycles ..... 155

DATUM SHIFT (Cycle 7) ..... 156

Working with datum tables ..... 157

MIRROR IMAGE (Cycle 8) ..... 158

ROTATION (Cycle 10) ..... 159

SCALING FACTOR (Cycle 11) ..... 160

WORKING PLANE (Cycle 19) ..... 161

8.6 Other Cycles ..... 171

DWELL TIME (Cycle 9) ..... 171

PGM-CALL (Cycle 12) ..... 171

HEIDENHAIN TNC 406, TNC 416 VII

Page 17

9 Programming: Subprograms and Program Section Repeats ..... 173

9.1 Labeling Subprograms and Program Section Repeats ..... 174

Labels ..... 174

9.2 Subprograms ..... 175

Operating sequence ..... 175

Programming notes ..... 175

Programming a subprogram ..... 175

Calling a subprogram ..... 175

9.3 Program Section Repeats ..... 176

Label LBL ..... 176

Operating sequence ..... 176

Programming notes ..... 176

Resetting the program repeat counters after an interruption ..... 176

Programming a program section repeat ..... 176

Calling a program section repeat ..... 177

9.4 Separate Program as Subprogram ..... 178

Operating sequence ..... 178

Programming notes ..... 178

Calling any program as a subprogram ..... 178

9.5 Nesting ..... 179

Types of nesting ..... 179

Nesting depth ..... 179

Subprogram within a subprogram ..... 179

Repeating program section repeats ..... 180

Repeating a subprogram ..... 181

VIII

Page 18

10 Programming: Q Parameters ..... 185

10.1 Principle and Overview ..... 186

Automatic deletion of Q parameters ..... 186

10.2 Part Families – Q Parameters in Place of Numerical Values ..... 187

Example NC blocks ..... 187

Example ..... 187

To assign numerical values to Q parameters ..... 188

10.3 Describing Contours through Mathematical Operations ..... 189

Function ..... 189

Overview ..... 189

Programming example for basic mathematical operations ..... 190

10.4 Trigonometric Functions ..... 192

Definitions ..... 192

Overview of functions ..... 193

10.5 If-Then Decisions with Q Parameters ..... 194

Function ..... 194

Unconditional jumps ..... 194

Programming If-Then decisions ..... 194

Abbreviations used: ..... 195

10.6 Checking and Changing Q Parameters ..... 196

Procedure ..... 196

10.7 Output of Q Parameters and Messages ..... 197

Output of error messages ..... 197

Output through an external data interface ..... 197

Indexed assignment ..... 198

Transferring values to/from the PLC ..... 198

10.8 Measuring with a probing electrode during program run ..... 199

Introduction ..... 199

To program the use of a probing electrode ..... 200

10.9 Q Parameters with Special Functions ..... 202

Vacant Q parameters ..... 202

Preassigned Q parameters ..... 202

Q parameters with special functions ..... 202

Preassigned Q parameters ..... 202

Q parameters with special functions ..... 206

HEIDENHAIN TNC 406, TNC 416 IX

Page 19

11 Test run and Program Run ..... 215

11.1 Graphics ..... 216

Function ..... 216

Overview of display modes ..... 216

Plan view ..... 217

Projection in 3 planes ..... 217

3-D view ..... 217

Magnifying details ..... 218

Repeating graphic simulation ..... 219

11.2 Test run ..... 220

Function ..... 220

Running a program test ..... 220

Running a program test up to a certain block ..... 221

Operating time ..... 221

11.3 Program run ..... 222

Application ..... 222

Background programming ..... 222

Operating time ..... 222

Changing the erosion parameters during program run ..... 222

Running a part program ..... 223

Interrupting machining ..... 223

Mid-program startup (block scan) ..... 224

Resuming program run after an interruption ..... 225

Returning to the interruption spot ..... 226

Resuming program run with the GOTO key ..... 226

Resetting the counters ..... 227

Time capture table TIME.W ..... 227

X

Page 20

12 MOD Functions ..... 229

12.1 MOD functions ..... 230

Selecting, Changing and Exiting the MOD Functions ..... 230

Overview of MOD functions ..... 230

Position Display Types ..... 231

Unit of measurement ..... 231

System Information ..... 232

Setting the external data interfaces ..... 232

BAUD RATE ..... 232

RS-232-C interface ..... 232

12.2 External Data Transfer ..... 233

Application examples ..... 233

LSV-2 protocol ..... 233

Protecting files ..... 233

12.3 Menu for External Data Transfer ..... 233

To select external data transfer ..... 233

Windows for external data transfer ..... 234

12.4 Selecting and Transferring Files ..... 235

Selecting the transfer function ..... 235

Selecting a file ..... 235

Transferring files ..... 235

Formatting disks ..... 236

Deleting files ..... 236

12.5 Software for Data Transfer ..... 237

Software for data transfer ..... 237

12.6 Enter Axis Traverse Limits ..... 240

Introduction ..... 240

12.7 Machine-Specific User Parameters ..... 242

Function ..... 242

12.8 Code Number ..... 243

Function ..... 243

12.9 Q Parameter Status Display ..... 244

Function ..... 244

HEIDENHAIN TNC 406, TNC 416 XI

Page 21

13 Tables and Overviews ..... 245

13.1 General User Parameters ..... 246

Entering machine parameters ..... 246

Selecting the General User Parameters ..... 246

13.2 Pin Layout and Connecting Cable for the Data Interfaces ..... 254

RS-232-C/V.24 Interface HEIDENHAIN devices ..... 254

RS-422/V.11 Interface ..... 255

13.3 Preparing the Devices for Data Transfer ..... 256

HEIDENHAIN devices ..... 256

Non-HEIDENHAIN devices ..... 256

13.4 Technical Information ..... 257

13.5 TNC Error Messages ..... 259

TNC error messages during programming ..... 259

TNC error messages during test run and program run ..... 259

XII

Page 22

Introduction

1

Page 23

1.1 The TNC 406, the TNC 416

Controls

The TNC 406 and the TNC 416 are shop-floor programmable

contouring controls for EDM machines with up to five axes.

Visual display unit and keyboard

The 14-inch color monitor (TNC 406) and 15-inch color monitor

(TNC 416) display all information necessary for effective use of the

TNC’s capabilities.

Program entry is supported by soft keys on the monitor.

The keys on the operating panel are grouped according to function.

This makes it easier to create programs and use the TNC’s functions.

Programming

1.1 The TNC 406, the TNC 416

The user programs the TNC 406/TNC 416 right at the machine with

interactive conversational-type guidance.

Graphics

Workpiece machining can be graphically simulated. Various display

modes are available.

Compatibility

The TNC 406/TNC 416 can execute all programs whose commands

belong to the command set of the TNC 406/TNC 416.

2 1 Introduction

Page 24

1.2 Visual Display Unit and

Keyboard

Visual display unit

The TNC 406 is delivered with the BC 110 color monitor (CRT); the

TNC 416 can be delivered with the BC 120 color monitor (CRT) or the

BF 120 flat-screen color monitor (TFT). The figure at top right shows

the keys and controls on the BC 120, and the figure at bottom right

shows those of the BF 120.

1 Header

When the TNC is on, the selected operating modes are shown in

the screen header.

2 Soft keys

In the footer the TNC indicates additional functions in a soft-key

row. You can select these functions by pressing the keys

immediately below them. The lines immediately above the softkey row indicate the number of soft-key rows that can be called

with the black arrow keys to the right and left. The line

representing the active soft-key row is highlighted.

3 Soft key selector keys

4 Switching the soft-key rows

5 Setting the screen layout

6 Shift key for switchover between machining and programming

modes

1

1

2

4

3

1

5

7

9

8

10

4

6

1

1.2 Visual Display Unit and Keyboard

Keys on BC 120 only

7 Screen demagnetization; Exit main menu for screen settings

8 Select main menu for screen settings:

In the main menu: Move highlight downward

In the submenu: Reduce value or move picture to the left or

downward

9 In the main menu: Move highlight upward

In the submenu: Increase value or move picture to the right or

upward

10 In the main menu: Select submenu

In the submenu: Exit submenu

5

1

Main menu dialog Function

BRIGHTNESS Adjust brightness

CONTRAST Adjust contrast

H-POSITION Adjust horizontal position

V-POSITION Adjust vertical position

V-SIZE Adjust picture height

HEIDENHAIN TNC 406, TNC 416 3

1

2

4

6

4

11

3

1

Page 25

Main menu dialog Function

SIDE-PIN Correct barrel-shaped distortion

TRAPEZOID Correct trapezoidal distortion

ROTATION Correct tilting

COLOR TEMP Adjust color temperature

R-GAIN Adjust strength of red color

B-GAIN Adjust strength of blue color

RECALL No function

The BC 110 and BC 120 are sensitive to magnetic and electromagnetic

noise, which can distort the position and geometry of the picture.

Alternating fields can cause the picture to shift periodically or to

become distorted.

Screen layout

You select the screen layout yourself: In the TEST RUN mode of

operation, for example, you can have the TNC show program blocks in

the left window while the right window displays programming

graphics. You could also display the tool status in the right window

1.2 Visual Display Unit and Keyboard

instead, or display only program blocks in one large window. The

available screen windows depend on the selected operating mode.

To change the screen layout:

Press the SPLIT SCREEN key: The soft-key row

shows the available layout options (see ”Modes of

Operation” on page 6).

Select the desired screen layout.

4 1 Introduction

Page 26

Keyboard

The figure at right shows the keys of the keyboard grouped according

to their functions:

1 Alphabetic keyboard for entering text and file names

2 File management

MOD functions

3 Programming modes

4 Machine operating modes

5 Initiation of programming dialog

6 Arrow keys and GOTO jump command

7 Numerical input and axis selection

The functions of the individual keys are described on the inside front

cover. Machine panel buttons, e.g. NC START, are described in the

manual for your machine tool.

1

5

2

1

4

1

5

3

7

6

1.2 Visual Display Unit and Keyboard

HEIDENHAIN TNC 406, TNC 416 5

Page 27

1.3 Modes of Operation

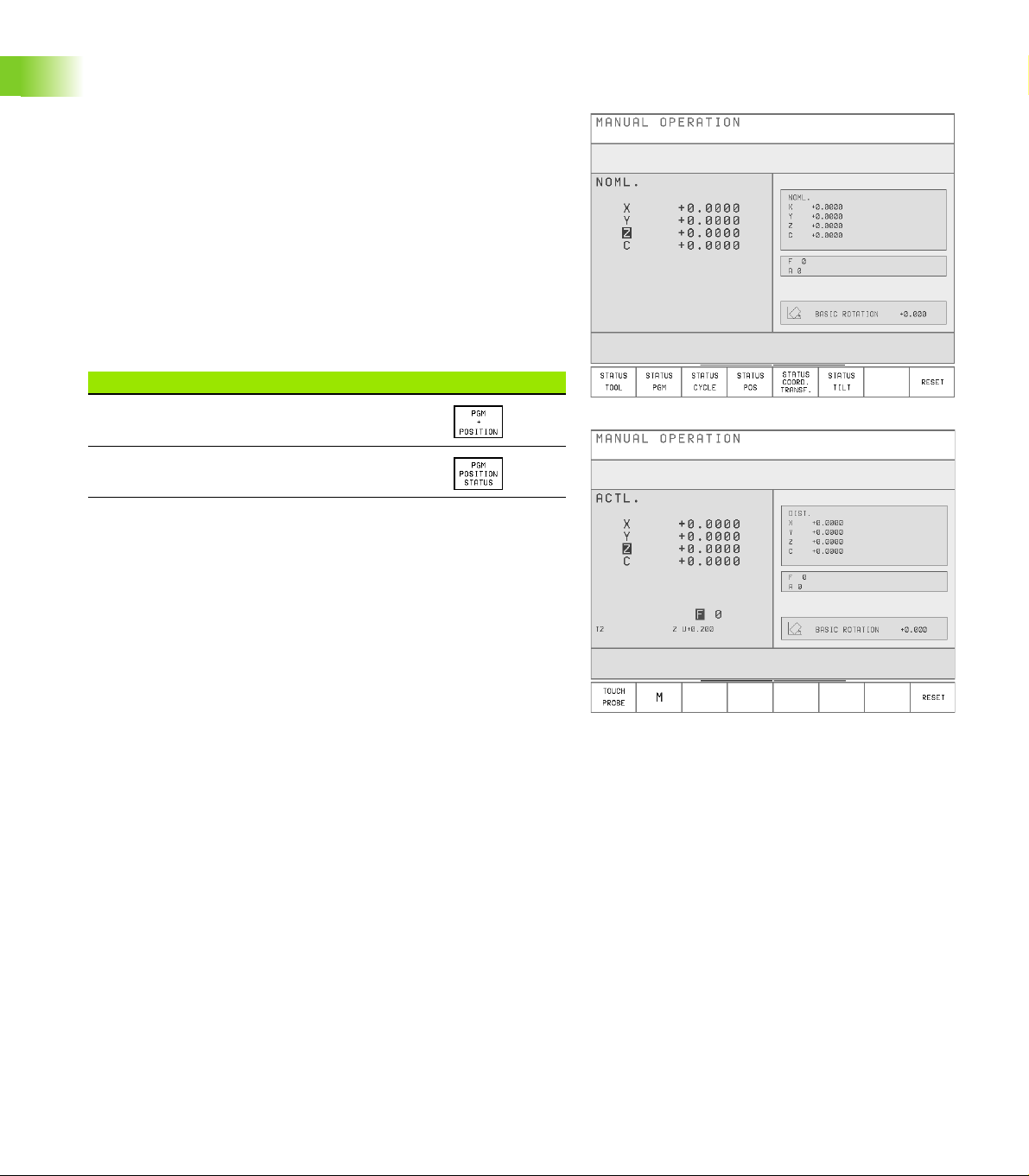

Manual Operation, Incremental Jog, and Positioning with Manual Data Input

The Manual Operation mode is required for setting up the machine

tool. In this mode of operation, you can position the machine axes

manually or by increments, set the datums, and tilt the working plane.

The Incremental Jog mode of operation allows you to move the

machine axes manually with the HR electronic handwheel.

Simple traverse movements can be programmed in the Positioning

with Manual Data Input (MDI) mode of operation.

Soft keys for selecting the screen layout (see ”Screen layout” on

page 4)

1.3 Modes of Operation

Screen windows Soft key

Positions

Left: positions. Right: status display.

6 1 Introduction

Page 28

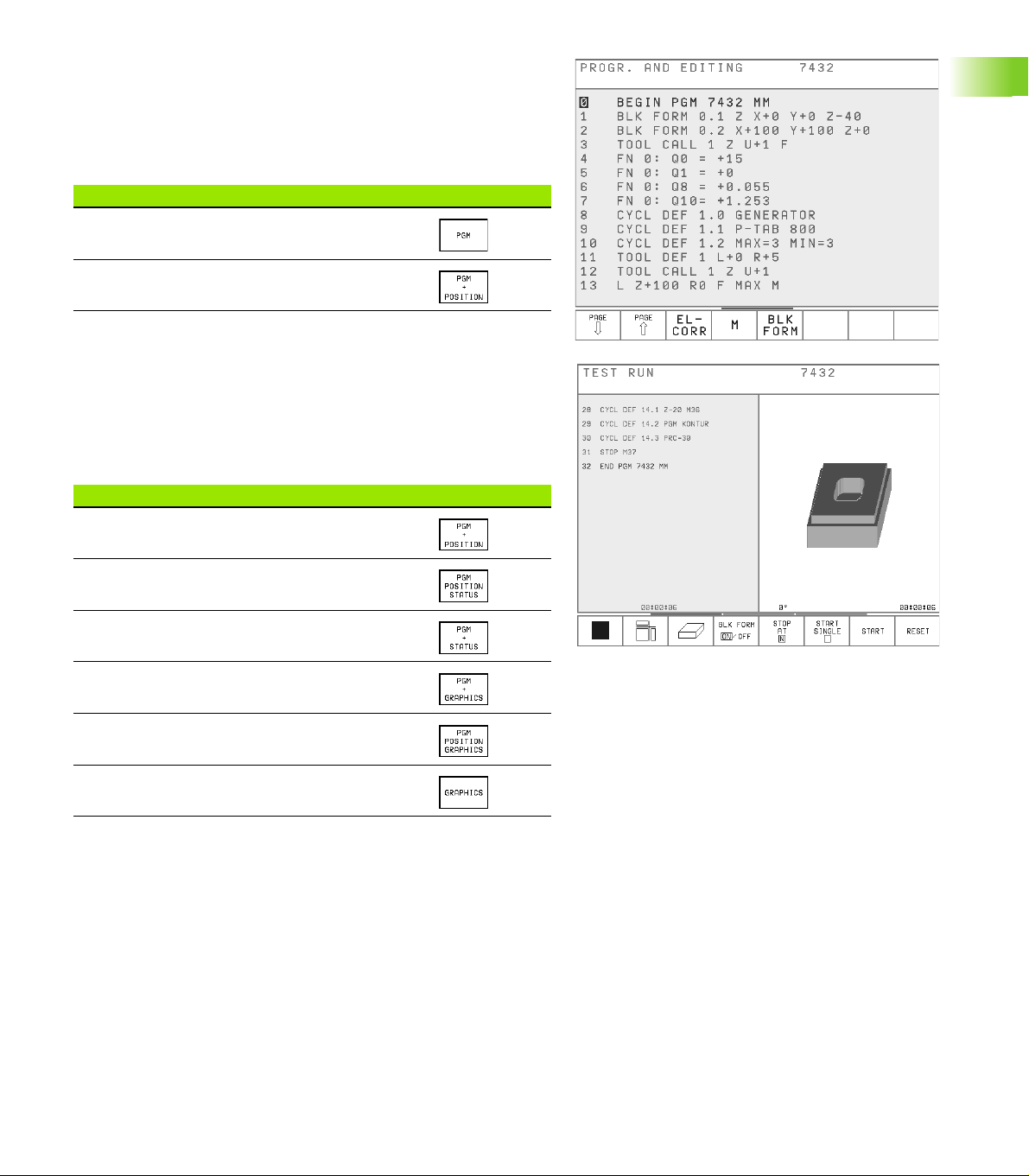

Programming and Editing

In this mode of operation you can write your part programs. The

various cycles and Q parameter functions help you with programming

and add necessary information.

Soft keys for selecting the screen layout

Screen windows Soft key

Top: program. Bottom: positions

Top left: program. Top right: status

Bottom: positions

Test Run

In the Test Run mode of operation, the TNC checks programs and

program sections for errors, such as geometrical incompatibilities, or

missing or incorrect data within the program. This simulation is

supported graphically in different display modes.

Soft keys for selecting the screen layout

Screen windows Soft key

Top: program. Bottom: positions

Top left: program. Top right: status

Bottom: positions

Left: program. Right: status

Left: program. Right: graphics

Top left: program. Top right: graphics

Bottom: positions

Graphics

1.3 Modes of Operation

HEIDENHAIN TNC 406, TNC 416 7

Page 29

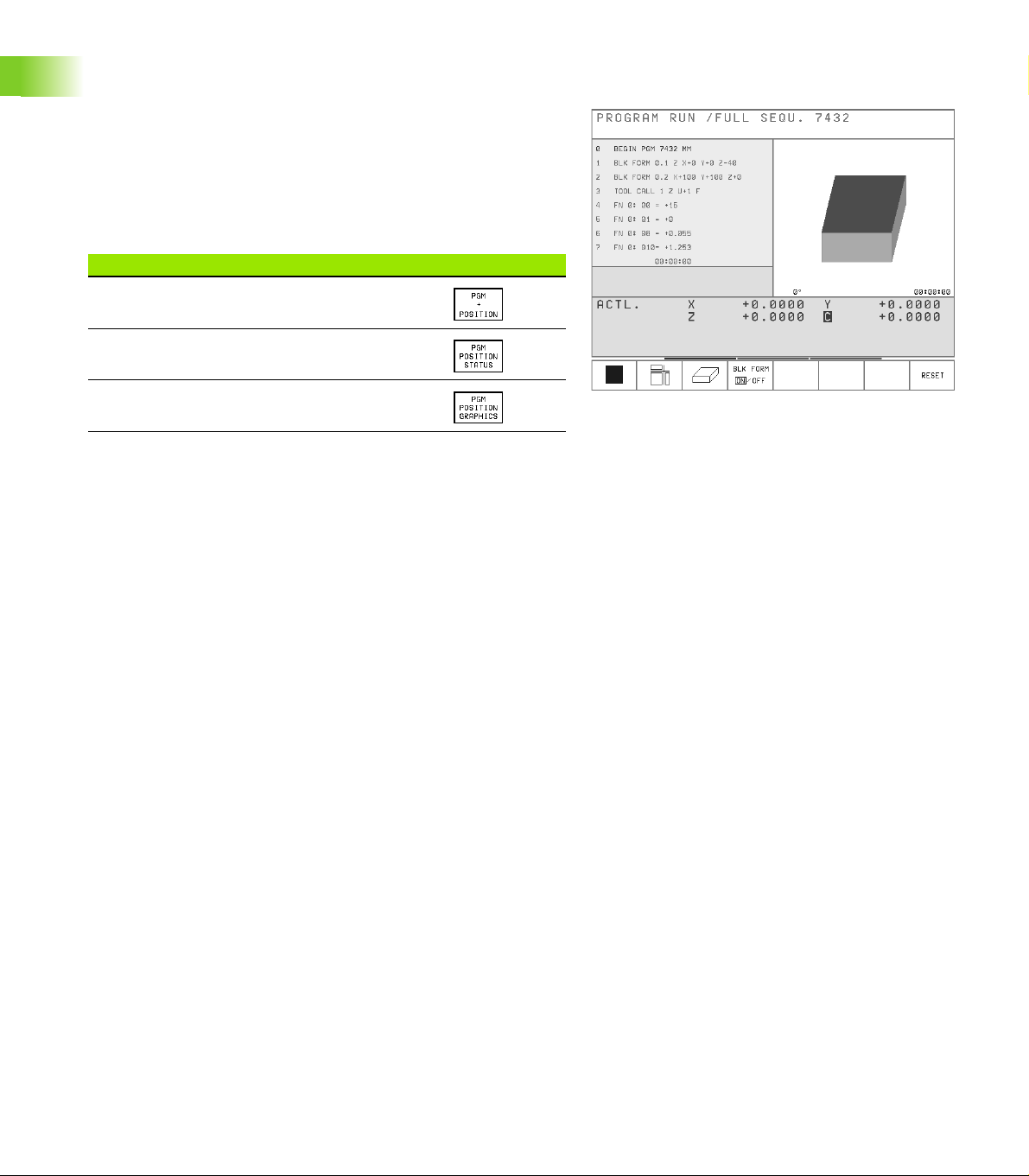

Program Run, Full Sequence and Program Run, Single Block

In the Program Run, Full Sequence mode of operation the TNC

executes a part program continuously to its end or to a manual or

programmed stop. You can resume program run after an interruption.

In the Program Run, Single Block mode of operation you execute each

block separately by pressing the machine START button.

Soft keys for selecting the screen layout

Screen windows Soft key

Top: program. Bottom: positions

Top left: program. Top right: status

1.3 Modes of Operation

Bottom: positions

Top left: program. Top right: graphics

Bottom: positions

8 1 Introduction

Page 30

1.4 Status Display

General status display

Besides the coordinates, the status display also contains the following

information:

Type of position display (ACTL, NOML, etc.)

Axis is locked ( on the axis)

Number of the current electrode T

Electrode axis

Feed rate F

Active miscellaneous functions M

TNC is in operation (indicated by )

Name of the selected erosion table

Permissible power stages (GENERATOR cycle)

Current power stage

Additional status displays

In all modes of operation (except PROGRAMMING AND EDITING),

you can split the screen layout to display additional status information

in the right screen window:

1.4 Status Display

Additional status display

Information on the current electrode

General program information

Information on the current OEM cycle

Positions and coordinates

Active coordinate transformations

Tilting the working plane

HEIDENHAIN TNC 406, TNC 416 9

Soft

keys

Page 31

Information on the current electrode

1 Electrode length

2 Electrode radius

3 Electrode undersize

4 Electrode axis

1.4 Status Display

General program information

1 Programs called with PGM CALL

2 Active cycle

3 Active circle center

4 Dwell time counter

5 Status for eroding with time limit

6 Operating time

1

2

3

4

1

2

3

4

5

10 1 Introduction

6

Page 32

Information on the current OEM cycle

1 Active OEM cycle (number and name)

2 Number of the transfer parameters

3 Content of each transfer parameter

Positions and coordinates

1 Second position display

2 Feed rate and angular position for Cycle 17 DISK

3 Active basic rotation

1

23

1.4 Status Display

1

2

3

HEIDENHAIN TNC 406, TNC 416 11

Page 33

Active coordinate transformations

1 Active datum table and active datum number

2 Datum shift

3 Rotation

4 Mirror image

5 Scaling factor

1

2

3

4

1.4 Status Display

Tilting the working plane

1 Active basic rotation

2 Active tilting angle

5

1

2

12 1 Introduction

Page 34

1.5 Accessory: Electronic

Handwheels from HEIDENHAIN

HR electronic handwheels

The electronic handwheels facilitate precise manual control of the axis

slides.

Similar to a conventional machine tool, you move the machine slide a

defined distance by turning the handwheel.

A wide range of traverses per revolution is available.

Portable handwheels, such as the HR 410, are connected via cable to

the TNC.

Integral handwheels, such as the HR 130, are built into the machine

control panel.

Your machine manufacturer can tell you more about the handwheel

configuration of your machine.

HEIDENHAIN TNC 406, TNC 416 13

1.5 Accessory: Electronic Handwheels from HEIDENHAIN

Page 35

Page 36

2

Manual Operation, Setup and Probing Functions

Page 37

2.1 Switch-on

Switch-on

Switch-on and traversing the reference points can vary

depending on the individual machine tool. Refer to your

machine manual.

2.1 Switch-on

Switch on the power supply for control and machine. The TNC

automatically initiates the following dialog

MEMORY TEST

The TNC memory is automatically checked.

POWER INTERRUPTED

TNC message that the power was interrupted —

clear the message.

TRANSLATE PLC PROGRAM

The PLC program of the TNC is automatically compiled.

RELAY EXT. DC VOLTAGE MISSING

Switch on external dc voltage. The TNC checks the

functioning of the EMERGENCY STOP circuit.

MANUAL OPERATION

TRAVERSE REFERENCE POINTS

Cross the reference points manually in the displayed

sequence: For each axis press the machine START

button, or

Cross the reference points in any sequence: Press

and hold the machine axis direction button for each

axis until the reference point has been traversed.

16 2 Manual Operation, Setup and Probing Functions

Page 38

The TNC is now ready for operation in the Manual Operation mode.

The reference points need only be traversed if the

machine axes are to be moved. If you intend only to write,

edit or test programs, you can select the Programming

and Editing or Test Run modes of operation immediately

after switching on the control voltage.

You can traverse the reference marks later by choosing

the Manual mode of operation.

2.1 Switch-on

HEIDENHAIN TNC 406, TNC 416 17

Page 39

2.2 Moving the Machine Axes

and

Note

The TNC shows the position of up to five machine axes.

The machine manufacturer can enable the position of the

fifth axis, for example with the machine axis-direction

buttons, with jog increments, with the electronic

handwheel or through ”PLC positioning”.

Contact your machine manufacturer if you need to

position a fifth axis.

To traverse with the machine axis direction buttons:

2.2 Moving the Machine Axes

Select the Manual Operation mode.

Press the machine axis-direction button and hold it as

long as you wish the axis to move, or

Move the axis continuously: Press and hold the

machine axis direction button, then press the

machine START button

To stop the axis, press the machine STOP button.

18 2 Manual Operation, Setup and Probing Functions

Page 40

Traversing with the HR 410 electronic

or

handwheel

The portable HR 410 handwheel is equipped with two permissive

buttons. The permissive buttons are located below the star grip.

You can only move the machine axes when an permissive button is

depressed (machine-dependent function).

The HR 410 handwheel features the following operating elements:

1 EMERGENCY STOP

2 Handwheel

3 Permissive buttons

4 Axis address keys

5 Actual-position-capture key

6 Keys for defining the feed rate (slow, medium, fast; the feed rates

are set by the machine tool builder)

7 Direction in which the TNC moves the selected axis

8 Machine function (set by the machine tool builder)

1

2

4

6

8

3

4

5

7

The red indicators show the axis and feed rate you have selected.

It is also possible to move the machine axes with the handwheel

during a program run.

To move an axis:

Select the Jog Increment mode.

Press and hold the permissive button.

Select the axis.

Select the feed rate.

Move the active axis in the positive or negative

direction.

2.2 Moving the Machine Axes

HEIDENHAIN TNC 406, TNC 416 19

Page 41

If short-circuit monitoring is active: When the electrode

makes sparking contact, the TNC stops positioning in the

direction of the workpiece, and only permits retracting in

the opposite direction. Also, the axes cannot be switched.

After they have been retracted at least 10 µm, the TNC

switches back to normal Handwheel operation mode.

This function is not active while the reference marks are

being traversed.

The axes can also be positioned with the electronic

handwheel in the PROGRAMMING AND EDITING mode.

You must set machine parameter MP7655=1.

Incremental jog positioning

With incremental jog positioning you can move a machine axis by a

preset distance.

Incremental Jog Positioning must be enabled by the

machine tool builder. Refer to your machine manual.

2.2 Moving the Machine Axes

Select the Jog Increment mode.

Z

INTERPOLATION FACTOR =

Enter interpolation factor, i.e. 4

Go to JOG INCREMENT.

JOG INCREMENT =

Enter the jog increment in millimeters, i.e. 8 mm.

The axis moves by the jog increment every time an

external axis-direction button is pressed.

Positioning with manual data input (MDI)

Positioning with manual input of the target coordinates is described in

Chapter 3 (see ”Positioning with Manual Data Input (MDI)” on page

38).

8 8

816

X

20 2 Manual Operation, Setup and Probing Functions

Page 42

Eroding a workpiece manually

The MANUAL and JOG INCREMENT modes of operation enable you

to erode a workpiece manually. This function is especially useful for

initial erosion and datum setting. The present gap must be taken into

account when setting the datum.

Prerequisite

Cycle 1 GENERATOR must be active.

Procedure

8 Select the MANUAL or JOG INCREMENT mode of operation.

8 Switch on the generator with M36

8 Use the axis direction buttons to preposition the electrode in the

working plane. During free run of the electrode, the manual feed

rate is effective.

8 Move the electrode with the axis direction button until it touches the

workpiece. Gap control becomes effective upon contact. The TNC

deduces the eroding direction from the axis direction button that

was last pressed.

In the MANUAL mode of operation, you can erode up to

the limit switch. In the JOG INCREMENT mode of

operation, the workpiece is eroded the preset distance.

During erosion you can only move the electrode in the

other axes by using the handwheel.

2.2 Moving the Machine Axes

8 To end the erosion process, press the machine axis-direction button

for the opposite direction.

HEIDENHAIN TNC 406, TNC 416 21

Page 43

2.3 Datum Setting

The production drawing identifies a certain form element of the

workpiece (usually a corner) as the absolute datum, and usually one or

more form elements as relative datums (see ”Setting the datum” on

page 47). Through the datum setting process, the origin of the

absolute or relative coordinate systems is set to these datums:

The workpiece – aligned to the machine axes – is brought into a certain

position relative to the electrode, and the display is set to zero or the

appropriate position value (i.e., to account for the electrode radius).

Example

2.3 Datum Setting

Coordinates of Point 1:

X = 10 mm

Y = 5 mm

Z = 0 mm

The datum of the rectangular coordinate system is located

negative 10 mm on the X axis and negative 5 mm on the Y axis from

Point 1.

The fastest, easiest and most accurate way of setting the datum is by

using the probing functions for datum determination.

Z

Y

X

Z

Y

X

1

5

10

22 2 Manual Operation, Setup and Probing Functions

Page 44

2.4 Calibration and Setup

Using an electrode

An electrode and the probing functions of the TNC 406 can

significantly reduce setup time. The TNC 406 offers the following

probing functions:

Compensation of workpiece misalignment

(Basic rotation)

Datum setting

Measuring

- lengths and positions on the workpiece

- angles

- circle radii

- circle centers

Measurements during program run

The TNC must be prepared by the machine tool builder

before the probing functions can be used.

In probing functions, the electrode starts moving after the external

START button is pressed. The machine tool builder determines the

feed rate F for movement towards the workpiece.

When the probing electrode touches the workpiece,

the TNC stores the coordinates of the probed position,

the probing electrode stops moving,

the probing electrode returns to its starting position in rapid

traverse.

2.4 Calibration and Setup

F

F

Machine parameter 6100 determines whether each

probing process is to be executed once or several times

(maximum number of probing processes: 5). If you wish to

probe several times, the TNC calculates the average of all

touch points. This average value is the probing result.

(See also ”Selecting the General User Parameters” on

page 246)

HEIDENHAIN TNC 406, TNC 416 23

F

max

Page 45

Select the touch probe function

Overview

The following probing functions are available in the Manual and Jog

Increment modes:

Function Soft key

Measuring a basic rotation using a line

Manual probing

Set the datum in any axis

Set the datum at a workpiece center

2.4 Calibration and Setup

Set the datum at a circle center

Set the datum at a corner

Select the calibration function for the electrode length

(second soft-key row)

Select the calibration function for the electrode radius

(second soft-key row)

Select the touch probe function

8 Select the Manual Operation or Jog Increment mode.

8 Select the probing function by pressing the TOUCH

PROBE soft key. The TNC displays additional soft

keys- see table above.

8 To select the probe cycle: press the appropriate soft

key, for example PROBING ROT, and the TNC

displays the associated menu.

24 2 Manual Operation, Setup and Probing Functions

Page 46

Calibrating the probing electrode

The probing electrode is to be calibrated in the following situations:

During commissioning

When the electrode is changed

When the probing feed rate is changed

In case of irregularities, such as those arising when the machine

heats up

During calibration, the TNC finds the effective length and the effective

radius of the electrode.

To calibrate the electrode, clamp a ring gauge of known height and

inside diameter to the machine table.

To calibrate the effective length:

8 Set the datum in the spindle axis such that for the machine tool table

Z=0.

8 Select the calibration function for the electrode length

(second soft-key row).

8 (QWHUWKHWRROD[LVZLWKWKHD[LVNH\

8 'DWXP(QWHUWKHKHLJKWRIWKHULQJJDXJH

8 Move the probing electrode to a position just above

the ring gauge.

8 ,IQHFHVVDU\FKDQJHWKHGLUHFWLRQZLWKWKHFXUVRU

NH\V

8 The electrode probes the surface of the ring gauge:

Press the START button.

2.4 Calibration and Setup

HEIDENHAIN TNC 406, TNC 416 25

Page 47

To calibrate the effective radius:

8 Position the probing electrode in the hole of the ring gauge.

8 Select the calibration function for the electrode radius

(second soft-key row).

8 Select the tool axis and enter the radius of the ring

gauge.

8 To probe the workpiece, press the machine START

button four times. The probing electrode touches the

hole in each axis direction.

8 If you want to terminate the calibration function at this

point, press the END soft key.

Z

Y

10

Displaying calibration values

The effective length and radius of the probing electrode are stored in

the TNC’s memory, and are taken into account when the electrode is

used later.

2.4 Calibration and Setup

The stored values are displayed on the screen whenever the

calibration functions are selected.

X

26 2 Manual Operation, Setup and Probing Functions

Page 48

Compensating workpiece misalignment

The TNC electronically compensates workpiece misalignment by

computing a ”basic rotation”.

For this purpose, the rotation angle is set to the desired angle with

respect to the reference axis in the working plane. If the tilt working

plane function is used, the TNC also takes the basic rotation into

account in the tilted system.

Measuring the basic rotation

8 Select probing function BASIC ROTATION.

8 Set ROTATION ANGLE to the nominal value.

8 Move the electrode to position A near the first probe

point 1.

8 Select the probe direction perpendicular to the angle

reference axis: Select the axis by soft key.

8 To probe the workpiece, press the machine START

button.

8 Move the electrode to position B near the second

probe point 2.

8 To probe the workpiece, press the machine START

button.

A basic rotation is stored in nonvolatile memory and is effective for all

subsequent program runs and graphic simulations.

Y

Y

2.4 Calibration and Setup

PA

X

A B

X

Displaying a basic rotation

The angle of the basic rotation is shown after ROTATION ANGLE. The

rotation angle is also shown in the additional status display window

whenever a basic rotation is active.

To cancel a basic rotation:

8 Select BASIC ROTATION again.

8 Enter a rotation angle of zero and confirm with the ENT key.

8 To terminate the probe function, press the END key.

HEIDENHAIN TNC 406, TNC 416 27

Page 49

2.5 Datum Setting with a

Probing Electrode

Functions for setting the datum

Function Soft key

Set the datum in any axis

Manual probing

Set the datum at a workpiece center

Set the datum at a circle center

Set the datum at a corner

After probing you can set a new datum or transfer the captured values

to a datum or tool table.

Writing probed values to tables

In order to write probed values to datum tables, the tables

2.5 Datum Setting with a Probing Electrode

The TNC writes the probed value to a table after the TRANSFER TO

TABLE soft key is pressed. You can choose a datum table (NAME.D)

as well as a tool table (NAME.T):

8 Select manual probing by pressing the TOUCH PROBE soft key.

8 Enter the name of the datum or tool table.

8 Enter the datum number or tool number.

8 Select the probing function and begin probing.

8 Press the TRANSFER TO TABLE soft key for the TNC to write the

probed value to the selected table.

Writing probed values to a table while a program is running

You can also write probed values to the TOOL table during program

run. Use miscellaneous function M109 to transfer the contents of the

Q parameters Q81 to Q84 into the table TOOL.T.

You can also use M108 to read the tool compensation values from the

TOOL table into parameters Q81 to Q84 (see also ”Q parameters for

the datum table: Q81 to Q84” on page 206).

28 2 Manual Operation, Setup and Probing Functions

must be active on your TNC (bit 2 in machine parameter

7224 = 0).

Page 50

Datum setting in any axis

8 Select the probing function by pressing the PROBING

POS soft key.

8 Move the touch probe to a starting position near the

touch point.

8 Select the probe axis and direction in which you wish

to set the datum, such as Z in direction Z–. Selection

is made via soft keys.

8 To probe the workpiece, press the machine START

button.

8 Datum: Enter the nominal coordinate and confirm your

entry with ENT.

Manual probing

The PROBING DEPTH function enables you to probe the workpiece as

often as desired in one axis. At the same time, you can move all

remaining axes with the electronic handwheel. This probing function

is particularly convenient for finding peaks and valleys.

In this process, the TNC always stores the last point of electrode

contact with the workpiece. You can end the probing process with the

CYCLE STOP button.

8 Select the probing function PROBING DEPTH.

8 Move the probing electrode to a starting position near the touch

point.

8 Set the axis traverse limit, i.e. the maximum permissible traverse of

the electrode in the probing axis, and confirm with ENT.

8 Select the probe axis and direction in which you wish to set the

datum, such as Z in direction Z–.

8 Start the probing process. The TNC moves the electrode in the

selected axis direction until it makes contact with the workpiece.

This coordinate is stored in the TNC memory.

The probing process is repeated until you end the probing function

with CYCLE STOP.

8 Use the electronic handwheel to move the electrode in any of the

remaining axes to be scanned for peaks or valleys.

8 Enter the nominal coordinate of the datum and confirm with ENT.

2.5 Datum Setting with a Probing Electrode

HEIDENHAIN TNC 406, TNC 416 29

Page 51

Workpiece center as datum

With the function PROBING CENTER, you can find the center of

square or rectangular workpieces and set the datum at that point. The

workpiece must be aligned paraxially to use this function.

8 Select the probing function by pressing the PROBING

CENTER soft key.

8 Move the probing electrode to a position near the first

touch point.

8 Select the probing direction via soft key, e.g. X+.

8 To probe the workpiece, press the machine START

button.

8 Move the probing electrode to a position near the

second touch point.

8 To probe the workpiece, press the machine START

button.

8 Enter the first coordinate of the datum, for example on

the X axis.

8 Repeat the process for the third and fourth touch

points on the second axis, for example on the Y axis.

8 Enter the second coordinate of the datum, for

example on the Y axis.

8 End the probing function.

Z

Y

l

X

1

2

2.5 Datum Setting with a Probing Electrode

30 2 Manual Operation, Setup and Probing Functions

Page 52

Corner as datum

8 To select the probe function, press PROBING P.

8 Move the probing electrode to a position near the first

touch point.

8 Select the probing direction via soft key, e.g. X+.

8 To probe the workpiece, press the machine START

button.

8 Position the probing electrode near the second touch

point on the same side.

8 To probe the workpiece, press the machine START

button.

8 Probe two points on the next edge in the same

manner.

8 Datum: Enter both datum coordinates into the menu

window, and confirm your entry with the ENT key.

8 To terminate the probe function, press the END key.

Y=?

Y

P

X=?

Y

P

X

X

HEIDENHAIN TNC 406, TNC 416 31

2.5 Datum Setting with a Probing Electrode

Page 53

Circle center as datum

With this function, you can set the datum at the center of bore holes,

circular pockets, cylinders, studs, circular islands, etc.

Inside circle

The TNC automatically probes the inside wall in all four coordinate axis

directions.

For incomplete circles (circular arcs) you can choose the appropriate

probing direction.

8 Move the electrode to a position approximately in the center of the

circle.

8 To select the probe function, press PROBING CC.

8 To probe the workpiece, press the machine START

button four times. The touch probe touches four

points on the inside of the circle.

8 Datum: Enter both circle center coordinates into the

menu window, and confirm your entry with ENT.

8 To terminate the probe function, press the END key.

Outside circle

8 To select the probe function, press PROBING CC.

8 Move the probing electrode to a position near the first

touch point outside of the circle.

8 Select the probe direction with a soft key.

8 To probe the workpiece, press the machine START

2.5 Datum Setting with a Probing Electrode

After the probing procedure is completed, the TNC displays the

coordinates of the circle center and the circle radius PR on the

monitor.

button.

8 Repeat the probing process for the remaining three

points. See figure at lower right.

8 Enter the coordinates of the circle center.

Y

Y+

X+X–

Y–

X

Y

Y–

X+

X–

Y+

X

32 2 Manual Operation, Setup and Probing Functions

Page 54

2.6 Measuring with a

Probing Electrode

Introduction

An electrode can be used to determine

position coordinates, and from them,

dimensions and angles on the workpiece.

To find the coordinate of a position on an aligned workpiece

8 Select the probing function by pressing PROBING

POS.

8 Move the probing electrode to a starting position near

the touch point.

8 Select the probe direction and axis of the coordinate.

Use the corresponding soft keys for selection.

8 To probe the workpiece, press the machine START

button.

The TNC shows the coordinates of the touch point as datum.

Finding the coordinates of a corner in the working plane

Find the coordinates of the corner point as described under ”Corner

as datum”.

The TNC displays the coordinates of the probed corner as datum.

2.6 Measuring with a Probing Electrode

HEIDENHAIN TNC 406, TNC 416 33

Page 55

Measuring workpiece dimensions

8 Select the probing function by pressing PROBING

POS.

8 Move the probing electrode to a position near the first

touch point 1.

8 Select the probing direction with a soft key.

8 To probe the workpiece, press the machine START

button.

8 If you will need the current datum later, write down

the value that appears in the Datum display.

8 Set the datum to 0.

8 To terminate the dialog, press the END key.

8 Select the touch probe function again:

Press PROBING POS.

8 Move the probing electrode to a position near the

second touch point 2.

8 Select the probe direction with the soft keys: Same

axis but from the opposite direction.

8 To probe the workpiece, press the machine START

button.

The value displayed as DATUM is the distance between the two

points on the coordinate axis.

2.6 Measuring with a Probing Electrode

To return to the datum that was active before the length

measurement:

8 Select the probing function by pressing PROBING POS.

8 Probe the first touch point again.

8 Set the DATUM to the value that you wrote down previously.

8 To terminate the dialog, press the END key.

Z

Y

l

X

1

2

34 2 Manual Operation, Setup and Probing Functions

Page 56

Measuring angles

You can also use the probing electrode to measure angles in the

working plane. You can measure

the angle between the angle reference axis and a workpiece side, or

the angle between two sides.

The measured angle is displayed as a value of maximum 90°.

To find the angle between the angle reference axis and a side of

the workpiece

8 Select the probing function by pressing the PROBING

ROT soft key.

8 Rotation angle: If you will need the current basic

rotation later, write down the value that appears

under Rotation angle.

8 Make a basic rotation with the side of the workpiece

(see ”Compensating workpiece misalignment” on

page 27).

8 Press the PROBING ROT soft key to display the angle

between the angle reference axis and the edge of the

workpiece as the rotation angle.

8 Cancel the basic rotation, or restore the previous basic

rotation by setting the Rotation angle to the value that

you wrote down previously.

To measure the angle between two workpiece sides:

8 Select the probing function by pressing the PROBING ROT soft key.

8 Rotation angle: If you will need the current basic rotation later, write

down the value that appears under Rotation angle.

8 Make a basic rotation with the side of the workpiece (see

”Compensating workpiece misalignment” on page 27).

8 Probe the second side as for a basic rotation, but do not set the

Rotation angle to zero!

8 Press the PROBING ROT soft key to display the angle PA between

the two sides as the Rotation angle.

8 Cancel the basic rotation, or restore the previous basic rotation by

setting the Rotation angle to the value that you wrote down

previously.

100

Y

–10

PA

2.6 Measuring with a Probing Electrode

Z

L?

α?

X

α?

100

HEIDENHAIN TNC 406, TNC 416 35

Page 57

2.7 Entering and Starting

Miscellaneous Functions M

Entering values

Miscellaneous function M

To enter the miscellaneous function, press the M soft

key.

MISCELLANEOUS FUNCTION M =

6

The machine tool builder determines which miscellaneous

functions M are available on your TNC and what

function they have. Refer to your machine manual.

2.7 Entering and Starting Miscellaneous Functions M

Enter a miscellaneous function, e.g. M6.

Start the miscellaneous function.

36 2 Manual Operation, Setup and Probing Functions

Page 58

3

Positioning with Manual Data Input (MDI)

Page 59

3.1 Positioning with Manual Data

Input (MDI)

The POSITIONING WITH MANUAL DATA INPUT mode of operation is

particularly convenient for simple machining operations or exact prepositioning of the electrode. You can write a program in conversational

programming and execute it immediately. You can also define and call

TNC cycles. The program is stored in the file $MDI.

PGM CALL can not be used to call a program.

LBL CALL can not be used for calling sub-routines or

repeating sections of programs.

For a TOOL CALL block to processed, the

corresponding TOOL DEF tool definition must be

programmed within the $MDI file.

Incremental positionings always refers to the present

electrode position.

Programming a radius compensation (RL/RR) is not

permitted.

Positioning with manual data input (MDI)

Select the Positioning with MDI mode of operation.

Program the file $MDI as you wish.

3.1 Positioning with Manual Data Input (MDI)

Example: Programming and processing a line

38 3 Positioning with Manual Data Input (MDI)

To start program run, press the machine START button.

Select operating mode: Positioning with MDI.

Select the axis, and enter the end-point coordinates

of the line and the feed rate,

i.e.: L X+125 R F100 M

Conclude entry.

Start positioning block.

Page 60

Protecting and erasing programs in $MDI

74523

The $MDI file is generally intended for short programs that are only

needed temporarily. Nevertheless, you can store a program, if

necessary, by proceeding as described below:

Select the Programming and Editing mode of

operation.

To call the file manager, press the PGM MGT key

(program management).

Move the highlight to the $MDI file.

To select the file copying function, press the COPY

soft key.

TARGET FILE =

Enter the name under which you want to save the

current contents of the $MDI file.

End the copying process with the ENT key.

Erasing the contents of the $MDI file is done in a similar way: Instead

of copying the contents, however, you erase them with the DELETE

soft key. The next time you select the operating mode Positioning with

MDI, the TNC will display an empty $MDI file.

If you wish to delete $MDI, then

you must not have selected the Positioning with MDI

mode.

you must not have selected the $MDI file in the

Programming and Editing mode.

HEIDENHAIN TNC 406, TNC 416 39

3.1 Positioning with Manual Data Input (MDI)

Page 61

Page 62

4

Programming: Fundamentals, Files, Program Entry, Spark Erosion, Erosion Tables

Page 63

4.1 Fundamentals of Positioning

Introduction

This chapter covers the following topics:

What is NC?

The part program

Programming

Position encoders and reference marks

Reference system

Reference system with electrical discharge machines (EDM)

Programming electrode movement

Polar coordinates

Absolute and incremental workpiece positions

Setting the datum

What is NC?

NC stands for Numerical Control, that is, the operation of a machine

4.1 Fundamentals of Positioning

tool by a series of coded instructions comprised of numbers.

Modern controls such as TNCs have a built-in computer for this

purpose and are therefore called CNC (Computerized Numerical

Control).

The part program

The part program is a complete list of instructions for machining a part.

It contains such information as the target position of an electrode

movement, the path function (how the electrode should move toward

the target position) and the feed rate.

Information on the radius and length of the electrode and the electrode

axis must also be included in the program.

Programming

Conversational programming is a particularly easy method of writing

and editing part programs.

HEIDENHAIN NCs were developed specifically for the machine

operator who keys in programs right at the machine. This is why they

are called TNC (Touch Numerical Control).

You begin each machining step by pressing a key. The TNC then asks

you for all the information it needs to execute the step.

42 4 Programming: Fundamentals, Files, Program Entry, Spark Erosion, Erosion Tables

Page 64

Position encoders and reference marks

The machine axes are equipped with position encoders that register

the positions of the machine table or tool. When a machine axis

moves, the corresponding position encoder generates an electrical

signal. The TNC evaluates this signal and calculates the precise actual

position of the machine axis.

If there is an interruption of power, the calculated position will no

longer correspond to the actual position of the machine slide. The TNC

can re-establish this relationship with the aid of reference marks when

power is returned. The scales of the position encoders contain one or

more reference marks that transmit a signal to the TNC when they are

crossed over. From the signal the TNC identifies that position as the

machine-axis reference point and can re-establish the assignment of

displayed positions to machine axis positions.

Linear encoders are generally used for linear axes. Rotary tables and

tilt axes have angle encoders. If the position encoders feature

distance-coded reference marks, you only need to move each axis a

maximum of 20 mm (0.8 in.) for linear encoders, and 20° for angle

encoders, to re-establish the assignment of the displayed positions to

machine axis positions.

X

MP

X (Z,Y)

Z

Y

Reference system

A reference system is required to define positions in a plane or in

space. The position data are always referenced to a predetermined

point and are described through coordinates.

The Cartesian coordinate system (a rectangular coordinate system) is

based on the three coordinate axes X, Y and Z. The axes are mutually

perpendicular and intersect at one point called the datum. A

coordinate identifies the distance from the datum in one of these

directions. A position in a plane is thus described through two

coordinates, and a position in space through three coordinates.

Coordinates that are referenced to the datum are referred to as

absolute coordinates. Relative coordinates are referenced to any other

known position (datum) you define within the coordinate system.

Relative coordinate values are also referred to as incremental

coordinate values.

X

4.1 Fundamentals of Positioning

Z

Y

X

HEIDENHAIN TNC 406, TNC 416 43

Page 65

Reference system with EDMs

When using an EDM, you orient tool movements to the Cartesian

coordinate system. The illustrations at right show how the Cartesian

coordinate system describes the machine axes. The figure at center

right illustrates the ”right-hand rule” for remembering the three axis

directions: the middle finger is pointing in the positive direction of the

tool axis from the workpiece toward the tool (the Z axis), the thumb is

pointing in the positive X direction, and the index finger in the positive

Y direction.

The TNC 406/TNC 416 can control up to 5 axes. The axes U, V and W

are secondary linear axes parallel to the main axes X, Y and Z,

respectively. Rotary axes are designated as A, B and C. The illustration

at lower right shows the assignment of secondary axes and rotary

axes to the main axes.

Programming electrode movement

Depending on the machine tool, either the machine table with the

workpiece moves or the electrode moves.

You always program as if the electrode moves and the

4.1 Fundamentals of Positioning

If the machine table moves, the corresponding axes are identified on

the machine operating panel with a prime mark (e.g., X’, Y’). The

programmed direction of such axis movement always corresponds to

the direction of electrode movement relative to the workpiece but in

the opposite direction.

workpiece remains stationary, no matter the type of

machine.

+Y

+Z

+X

+Z

+Y

+X

+X

Z

Y

W+

C+

B+

V+

A+

X

U+

44 4 Programming: Fundamentals, Files, Program Entry, Spark Erosion, Erosion Tables

Page 66

Polar coordinates

If the production drawing is dimensioned in Cartesian coordinates, you

also write the part program using Cartesian coordinates. For parts

containing circular arcs or angles it is often simpler to give the

dimensions in polar coordinates (see „Path Contours — Polar

Coordinates” on page 109).

While the Cartesian coordinates X, Y and Z are three-dimensional and

can describe points in space, polar coordinates are two-dimensional

and describe points in a plane. Polar coordinates have their datum at a

circle center (CC), or pole. A position in a plane can be clearly defined

by the:

Polar Radius, the distance from the circle center CC to the position,

and the

Polar Angle, the size of the angle between the reference axis and

the line that connects the circle center CC with the position.

See figure at upper right.

Definition of pole and angle reference axis

The pole is set by entering two Cartesian coordinates in one of the

three planes. These coordinates also set the reference axis for the

polar angle PA.

Coordinates of the pole (plane) Reference axis of the angle

X/Y +X

10

Z

Y

R

H

2

H

3

R

CC

R

H

1

0°

X

30

Y

4.1 Fundamentals of Positioning

Y/Z +Y

Z/X +Z

Z

Y

X

Z

Y

X

X

HEIDENHAIN TNC 406, TNC 416 45

Page 67

Absolute and incremental workpiece positions

Absolute workpiece positions

Absolute coordinates are position coordinates that are referenced to

the datum of the coordinate system (origin). Each position on the

workpiece is uniquely defined by its absolute coordinates.

Example 1: Holes dimensioned in absolute coordinates

Hole 1 Hole 2 Hole 3

X = 10 mm X = 30 mm X = 50 mm

Y = 10 mm Y = 20 mm Y = 30 mm

Incremental workpiece positions

Incremental coordinates are referenced to the last programmed

nominal position of the tool, which serves as the relative (imaginary)

datum. When you write a part program in incremental coordinates,

you thus program the tool to move by the distance between the

previous and the subsequent nominal positions. Incremental

coordinates are therefore also referred to as chain dimensions.

To program a position in incremental coordinates, enter the prefix "I"

before the axis.

4.1 Fundamentals of Positioning

Example 2: Holes dimensioned in incremental coordinates

Absolute coordinates of hole 4

X = 10 mm

Y = 10 mm

Hole 5, referenced to 4 Hole 6, referenced to 5

X = 20 mm X = 20 mm

Y = 10 mm Y = 10 mm

Absolute and incremental polar coordinates

Absolute polar coordinates always refer to the pole and the reference

axis.

Incremental polar coordinates always refer to the last programmed

nominal position of the tool.

30

20

10

10

10 10

Y

3

1

2

1

1

1

X

3010

50

Y

6

1

5

1

4

1

X

10

20

20

Y

+IPR

PR

10

PR

+IPA

+IPA

CC

PA

PR

0°

X

30

46 4 Programming: Fundamentals, Files, Program Entry, Spark Erosion, Erosion Tables

Page 68

Setting the datum

The production drawing identifies a certain form element of the

workpiece (usually a corner) as the absolute datum, and usually one or

more form elements as relative datums. Through the datum setting

process, the origin of the absolute or relative coordinate systems is set

to these datums: The workpiece – aligned to the machine axes – is

brought into a certain position relative to the electrode, and the display

is set to zero or the appropriate position value (i.e., to account for the

electrode radius) (see „Datum Setting” on page 22).

Example

The workpiece drawing at right shows holes (1 to 4) whose

dimensions are shown with respect to an absolute datum with the

coordinates X=0, Y=0. The holes (5 to 7) are dimensioned with respect

to a relative datum with the absolute coordinates X=450, Y=750. With

the DATUM SHIFT cycle you can temporarily set the datum to the

position X=450, Y=750, to be able to program the holes (5 to 7)

without further calculations.

Z

Y

MAX

X

MIN

750

320

Y

4.1 Fundamentals of Positioning

150

7

1

0

6

1

-150

5

1

0,1

±

300

1

1

325

3

1

0

2

1

450 900

950

4

1

X

HEIDENHAIN TNC 406, TNC 416 47

Page 69

4.2 Files

The TNC 416 saves programs and tables as files. The TNC can store

up to 100 files. A file is identified by its file name and file extension.

4.2 Files

The file name is entered when a new file is created.

The file extension is separated from the file name by a period, and

indicates what type of file it is.

Files in the TNC Ty p e

Programs

In HEIDENHAIN format .H

Tables for

Erosion

Datum

Tools

Time capture

The tool table TOOL.T is only active if bit 2 of MP7224 is

set to 0.

File directory

You call the file directory with the PGM NAME key (TNC 406) or the

PGM MGT key (TNC 416).

To delete files from the TNC, use CL PGM on the TNC 406 to call up

the directory.

Overview of the file management functions:

.E

.D

.T

Time.W

File

... Create or

... Edit or

... Delete or

... Test or

... Run or

48 4 Programming: Fundamentals, Files, Program Entry, Spark Erosion, Erosion Tables

Operating

mode

Call file directory with

Page 70

The file directory contains the following information:

Display Meaning

FILE NAME Name (up to 8 characters plus file extension)

BYTE File size in bytes

STATUS

R

E

P

I

STORAGE AREA

AND NUMBER

INTERNAL

FILES

EXTERNAL FILES

Files in ROM

Pressing the ROM soft key displays files that the machine tool builder

wrote and stored in ROM, such as erosion tables. These files can be

edited.

Identification of protected files

The TNC inserts a ”P” in the first and last lines of write- and eraseprotected files.

The file directory also shows a ”P” next to the file name.

Properties of the file:

File is active for Program Run/Program Test.

File is active for Programming and Editing.

File is protected against editing and erasure.

Dimensions are given in inches.

Files in the TNC memory

Files, e.g., on a PC 401

4.2 Files

HEIDENHAIN TNC 406, TNC 416 49

Page 71

Selecting, copying, deleting and protecting files

Activate the file directory

8 Use the PGM MGT key with the TNC 416, and the PGN NAME key

with the TNC 406. If you want to delete files with the TNC 406, you

4.2 Files

must call the file directory with the CL PGM key.

Select the file

8 Enter the file name (not for CL PGM) or move the highlight with the

cursor keys to the desired file.

Function Soft key

Go to the next page

Go to the previous page

Display files in ROM

Select file (such as for a test run)

Copy file: Enter the name of the target file

File protection

Cancel file protection

Deleting a file

Close the file directory

50 4 Programming: Fundamentals, Files, Program Entry, Spark Erosion, Erosion Tables

Page 72

4.3 Creating and Writing Programs

Organization of an NC program in HEIDENHAIN conversational format.

A part program consists of a series of program blocks. The figure at

right illustrates the elements of a block.

The TNC numbers the blocks in ascending sequence.

The first block of a program is identified by BEGIN PGM, the program

name and the active unit of measure.

The subsequent blocks contain information on:

The workpiece blank

Tool definitions, tool calls

Feed rates and spindle speeds, as well as

Path contours, cycles and other functions

The last block of a program is identified by END PGM, the program

name and the active unit of measure.

Defining the blank form–BLK FORM

Immediately after initiating a new program, you define a cuboid

workpiece blank. If you wish to define the blank at a later stage, press

the BLK FORM soft key. This definition is needed for the TNC’s

graphic simulation feature. The sides of the workpiece blank lie parallel

to the X, Y and Z axes and can be up to 30 000 mm long. The blank

form is defined by two of its corner points:

MIN point: the smallest X, Y and Z coordinates of the blank form,

entered as absolute values.

MAX point: the largest X, Y and Z coordinates of the blank form,

entered as absolute or incremental values.

Blocks

10 L X+10 Y+5 R0 F100 M3

Path function

Block number

Z

Y

MAX

Words

4.3 Creating and Writing Programs

X

You only need to define the blank form if you wish to run

a graphic test for the program!

MIN

HEIDENHAIN TNC 406, TNC 416 51

Page 73

Creating a new part program

0

You always enter a part program in the Programming and Editing

mode of operation. Program initiation in an example:

Select the Programming and Editing mode of

operation.

Press the key to call the file directory.

FILE NAME = 7432

Enter the new program name and confirm your entry

with the ENT key.

Choose the type of file: Press the .H, .E or .D soft key.

The TNC changes to the program window.

4.3 Creating and Writing Programs

WORKING SPINDLE AXIS X/Y/Z ?

DEF BLK FORM: MIN-CORNER ?

0

-40

DEF BLK FORM: MAX-CORNER ?

100

100

0

To define the BLK-FORM, press the BLK-FORM soft

key. The TNC opens a dialog for defining the

BLK FORM.

Enter the spindle axis.

Enter in sequence the X, Y and Z coordinates of the

MIN point.

Enter in sequence the X, Y and Z coordinates of the

MAX point.

52 4 Programming: Fundamentals, Files, Program Entry, Spark Erosion, Erosion Tables

Page 74

Example: Display the BLK form in the NC program.

0 BEGIN PGM NEW MM

1 BLK FORM 0.1 Z X+0 Y+0 Z-40

2 BLK FORM 0.2 X+100 Y+100 Z+0

3 END PGM NEW MM

The TNC automatically generates the block numbers as well as the

BEGIN and END blocks.

If you do not wish to define a blank form, cancel the dialog

at Working spindle axis X/Y/Z by pressing the DEL key!

The TNC can display the graphic only if the ratio of the

short side to the long sides of the BLK FORM is greater than

1:64!

Program begin, name, unit of measure

Spindle axis, MIN point coordinates

MAX point coordinates

Program end, name, unit of measure

4.3 Creating and Writing Programs

HEIDENHAIN TNC 406, TNC 416 53

Page 75

Programming tool movements in conversational

20

3

format

To program a block, initiate the dialog by pressing a function key. In the

screen headline, the TNC then asks you for all the information

necessary to program the desired function.

Example of a dialog

Dialog initiation

COORDINATES ?

10

RADIUS COMP. RL/RR/NO COMP. ?

4.3 Creating and Writing Programs

FEED RATE ? F= / F MAX = ENT

100

MISCELLANEOUS FUNCTION M ?

6

The program blocks window will display the following line:

3 L X+10 Y+20 R0 F100 M36

Enter the target coordinate for the X axis.

Enter the target coordinate for the Y axis, and go to

the next question with ENT.

Enter ”No radius compensation” and go to the next

question with ENT.