HEIDENHAIN TNC 370 User Manual

HEIDENHAIN

User’s Manual

HEIDENHAIN Conversational

Programming

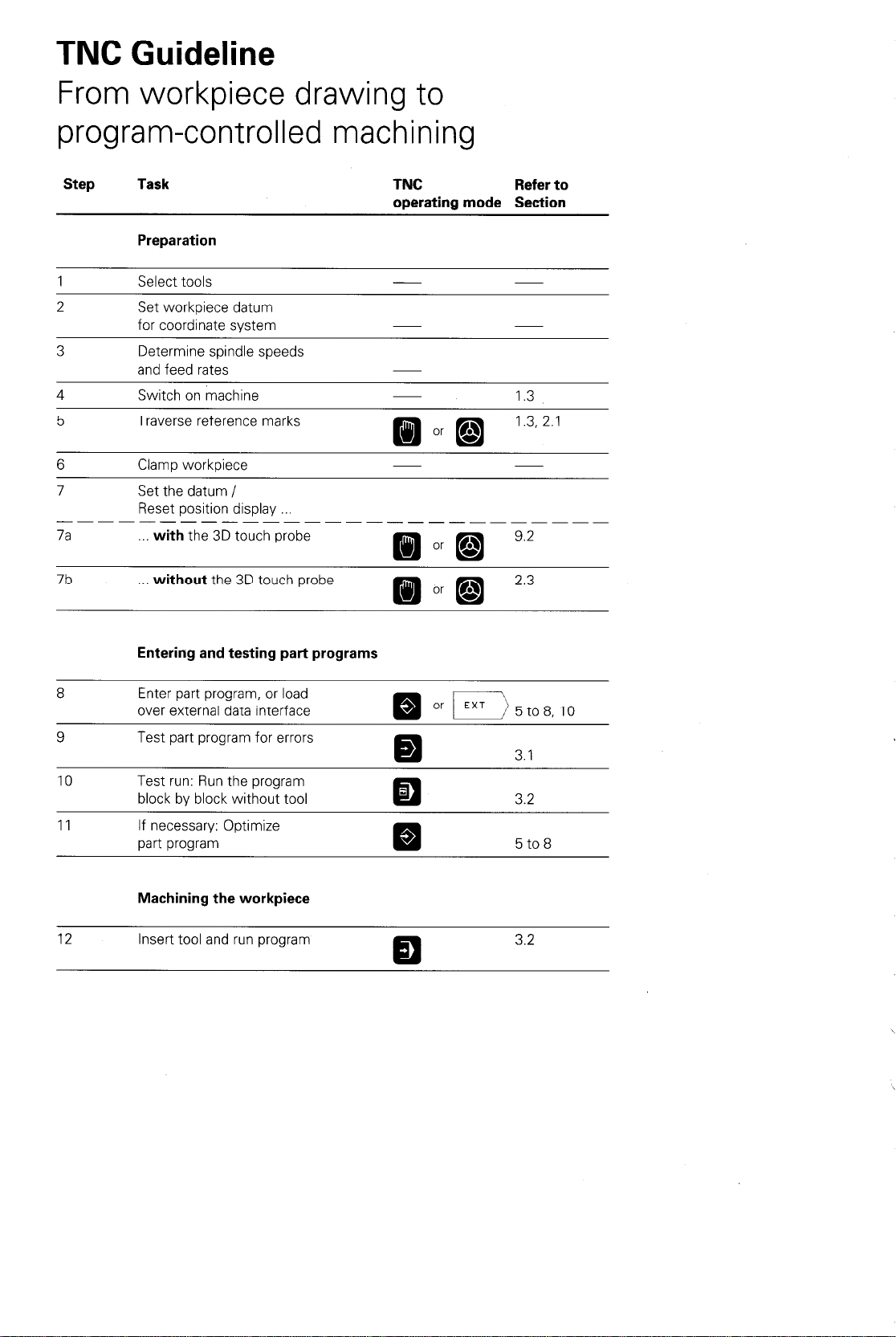

TNC Guideline

3

From workpiece drawing to

program-controlled machining

Step Task

Preparation

1

2

3

4 Switch on machine 1.3

5 Traverse reference marks

6 Clamp workpiece

7 Set the datum /

--- --- --- -----7a

Select tools

Set workpiece datum

for coordinate system

Determine spindle speeds

and feed rates

Reset position display

with the 3D touch probe

TNC Refer to

operating mode Section

J

d

d

7b

8 Enter part program, or load

9 Test part program for errors

10

11 If necessary: Optimize

12 Insert tool and run program 3.2

without the 3D touch probe

Entering and testing pat-t programs

over external data interface m Or /EXT)5to8,10

Test run: Run the program

block by block without tool

part program

Machining the workpiece

z

BJ

3.2

5 to 8

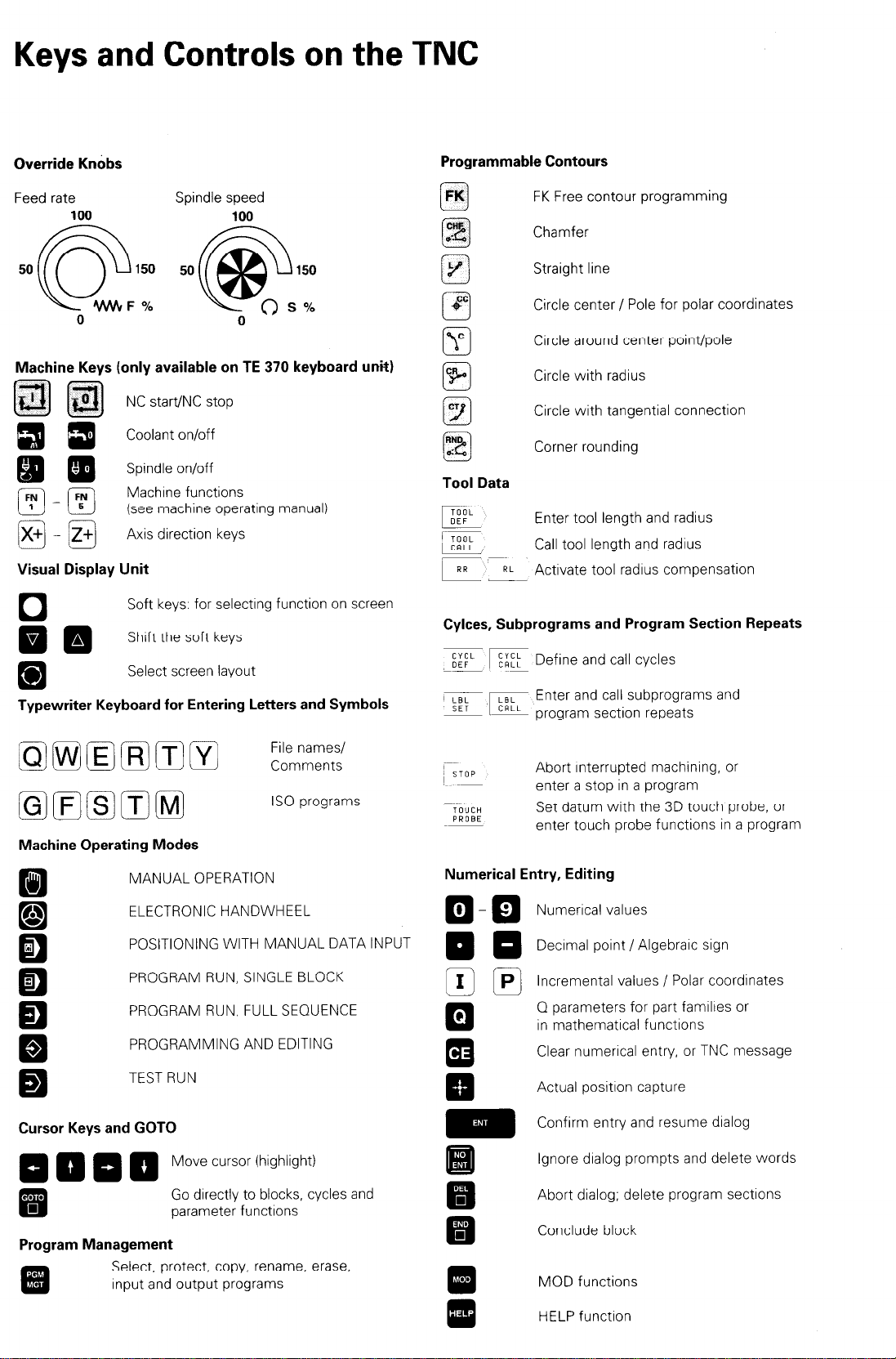

Keys and Controls on the TNC

Override Knobs

Feed rate Spindle speed

100

5oQ: 50@:

0

Machine Keys (only available on TE 370 keyboard unit)

EJl@j

Elm

mm Spindle on/off

W-B

@g-m

Visual Display Unit

0

mm

m

Typewriter Keyboard for Entering Letters and Symbols

NC start/NC stop

Coolant on/off

Machrne functions

(see machine operating manual)

Axis direction keys

Soft keys: for selectrng function on screen

Shaft the soft keys

Select screen layout

100

0

Programmable Contours

FK

0

CHF

.A

0

RWD

od

0

Tool Data

EE&

I- TOOL

w

- ~~

k RL- Activate tool radius compensation

Cylces, Subprograms and Program Section Repeats

E:F’ Eb:: Define and call cycles

%-m

FK Free contour programming

Chamfer

Straight line

Circle center / Pole for polar coordinates

Circle around center point/pole

Circle with radius

Circle with tangential connection

Corner rounding

Enter tool length and radius

Call tool length and radius

Enter and call subprograms and

program section repeats

0 iw] (El (R1 (Tl m p:;;;::

(GjIFj/S)ITj(Mj

Machine Operating Modes

m

f;s1

0

r.1

El

z

a

Q

Q

Q

Cursor Keys and GOT0

0000

. .

m

Program Management

MANUAL OPERATION

ELECTRONIC HANDWHEEL

POSITIONING WITH MANUAL DATA INPUT

PROGRAM RUN, SINGLE BLOCK

PROGRAM RUN, FULL SEQUENCE

PROGRAMMING AND EDITING

TEST RUN

Move cursor (highlight)

Go drrectly to blocks, cycles and

parameter functions

Select, protect, copy, rename, erase,

Input and output programs

IS0 programs

Abort interrupted machrnrng, or

enter a stop in a program

Set datum with the 3D touch probe, or

enter touch probe functions in a program

Numerical Entry, Editing

Numerical values

Decrmal point / Algebrarc sign

Incremental values / Polar coordinates

0 parameters for part familres or

in mathematrcal functions

Clear numerical entry, or TNC message

Actual positron capture

Confirm entry and resume dialog

Ignore dialog prompts and delete words

Abort dialog; delete program sections

Conclude block

MOD functions

HELP function

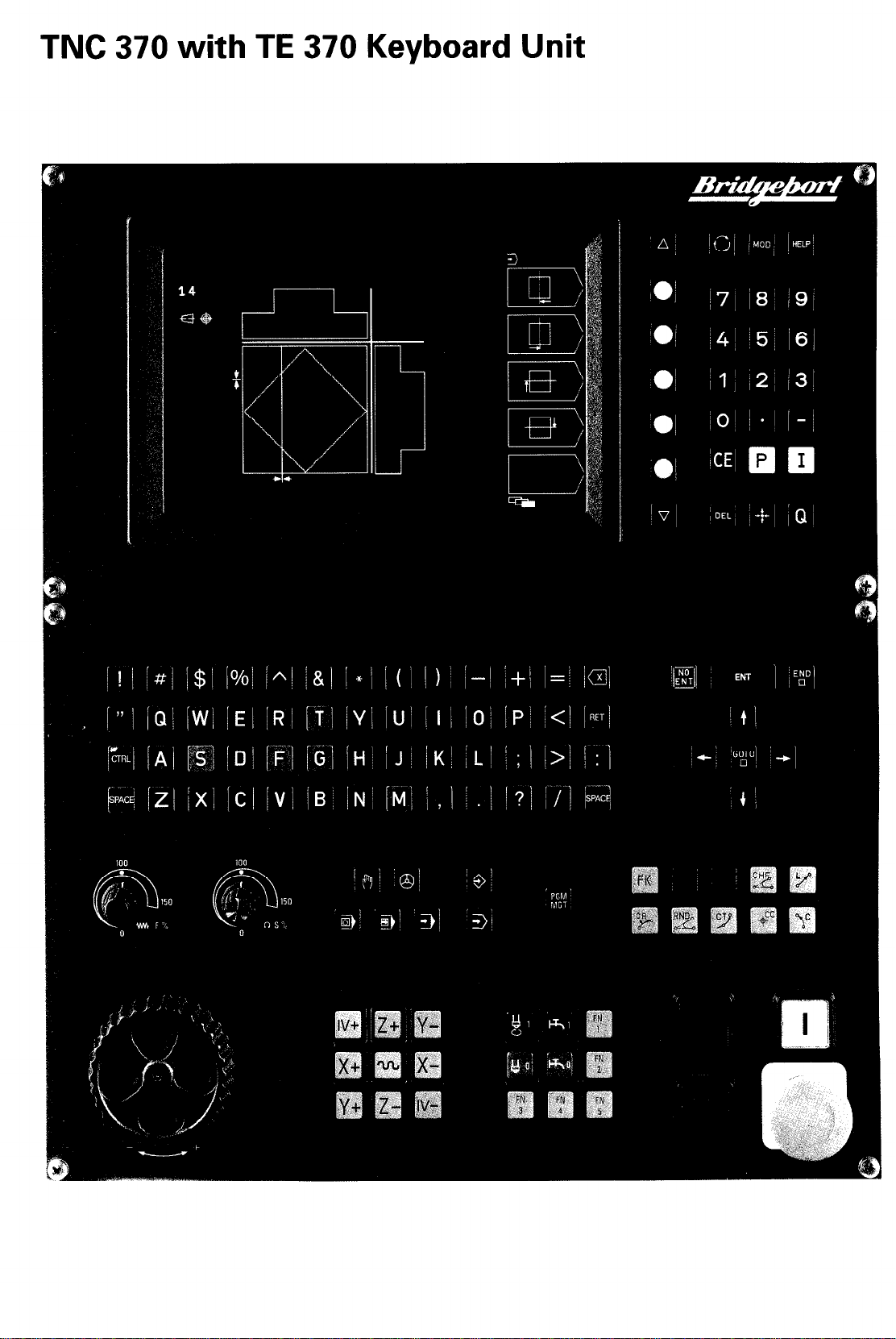

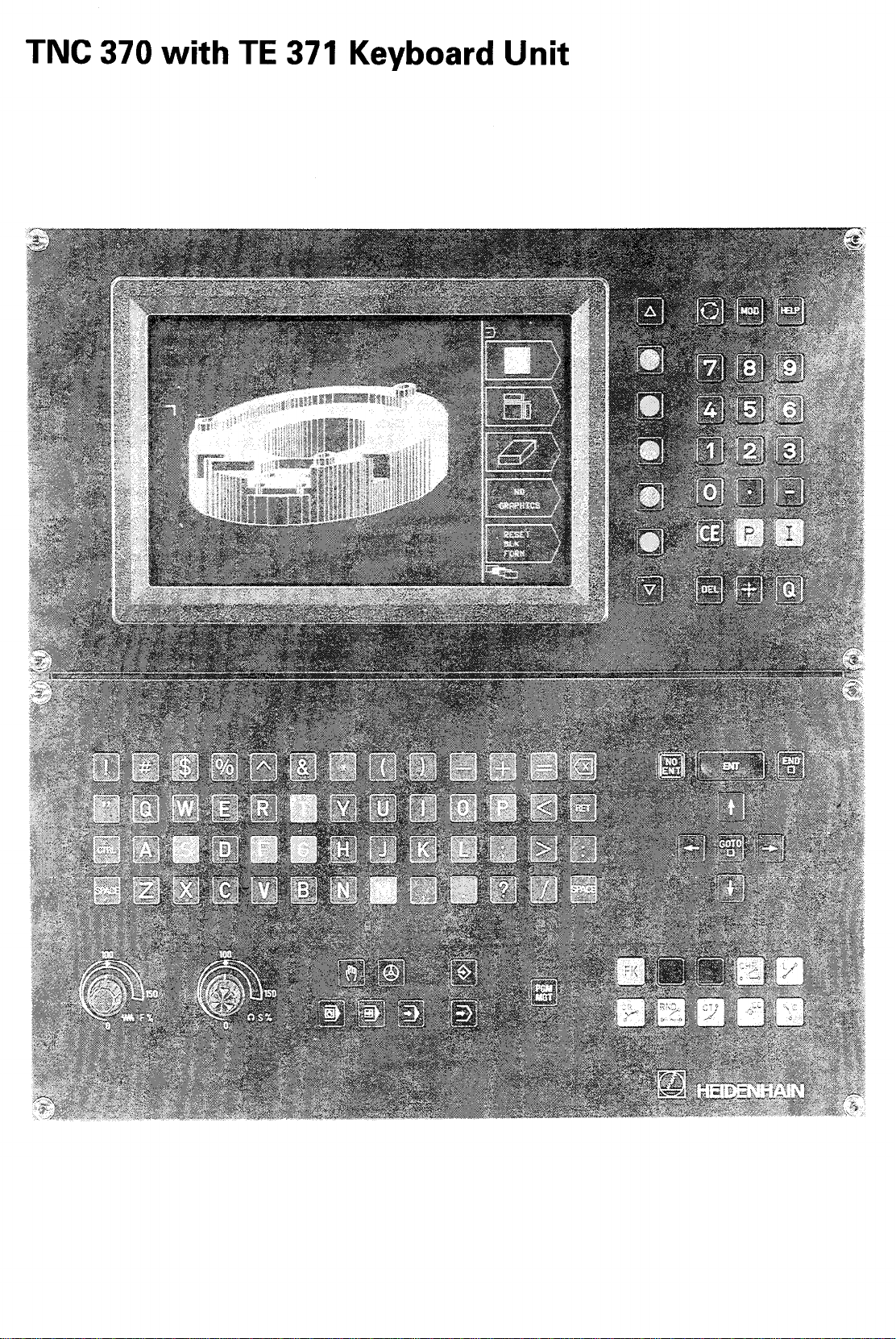

TNC 370 with TE 370 Keyboard Unit

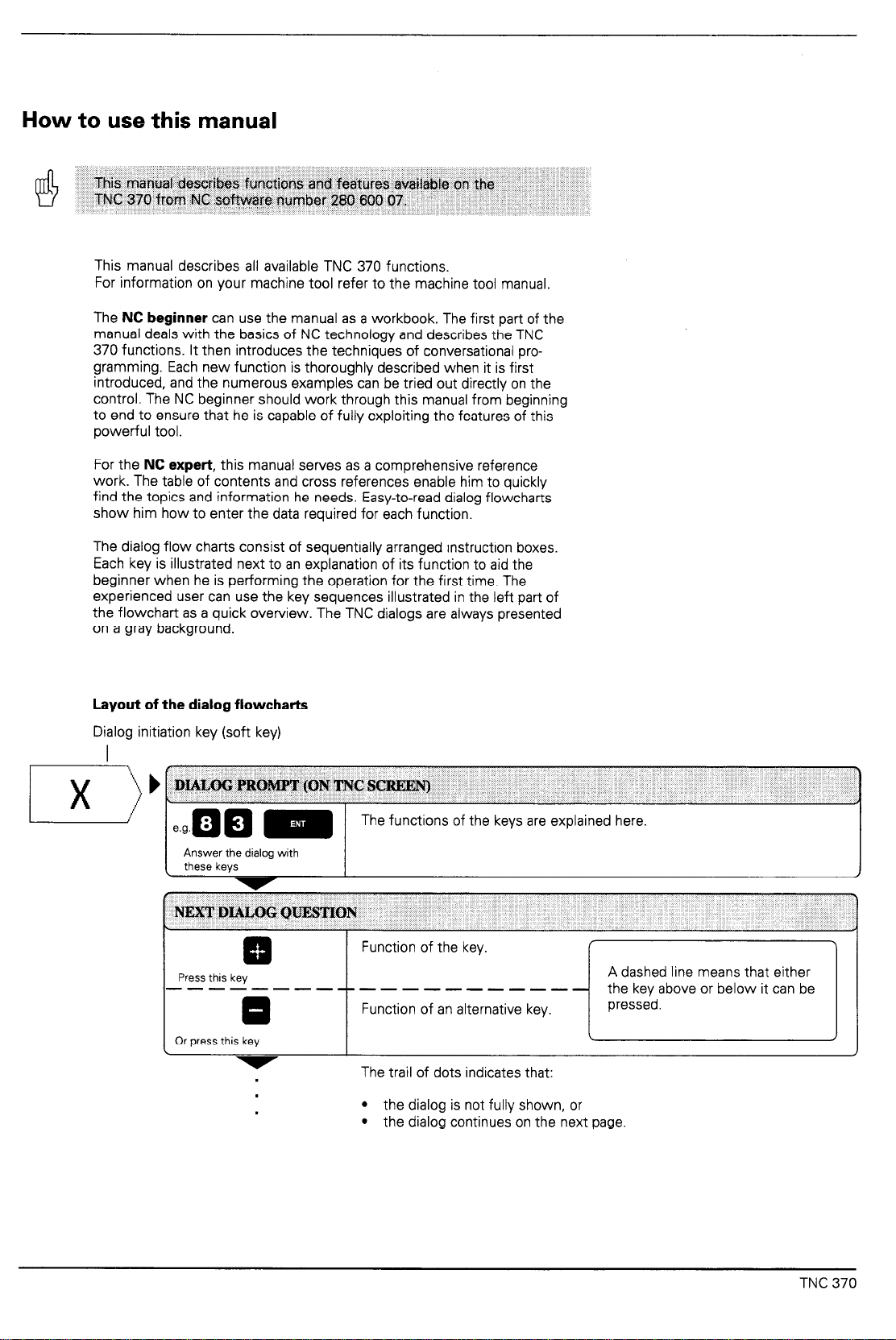

How to use this manual

This manual describes functions and fezitures

TNC 370 from MC so%re

This manual describes all available TNC 370 functions.

For information on your machine tool refer to the machine tool manual.

The NC beginner can use the manual as a workbook. The first part of the

manual deals with the basics of NC technology and describes the TNC

370 functions. It then introduces the techniques of conversational programming. Each new function is thoroughly described when it is first

introduced, and the numerous examples can be tried out directly on the

control. The NC beginner should work through this manual from beginning

to end to ensure that he is capable of fully exploiting the features of this

powerful tool.

For the NC expert, this manual serves as a comprehensive reference

work. The table of contents and cross references enable him to quickly

find the topics and information he needs. Easy-to-read dialog flowcharts

show him how to enter the data required for each function.

The dialog flow charts consist of sequentially arranged instruction boxes.

Each key is illustrated next to an explanation of its function to aid the

beginner when he is performing the operation for the first time. The

experienced user can use the key sequences illustrated in the left part of

the flowchart as a quick overview. The TNC dialogs are always presented

on a gray background.

number 280 K?O Of.

aYailr;tble on the

Layout of the dialog flowcharts

Dialog initiation key (soft key)

I

Answer the dialog with

these keys

I

NEXTDIALOGQUESfJQN

c

Press this key

----------------

0

Or press this key

L

.

.

.

The functions of the keys are explained here.

Function of the key.

A dashed line means that either

Function of an alternative key.

The trail of dots indicates that:

l

the dialog is not fully shown, or

l

the dialog continues on the next page

I

/

TNC 370

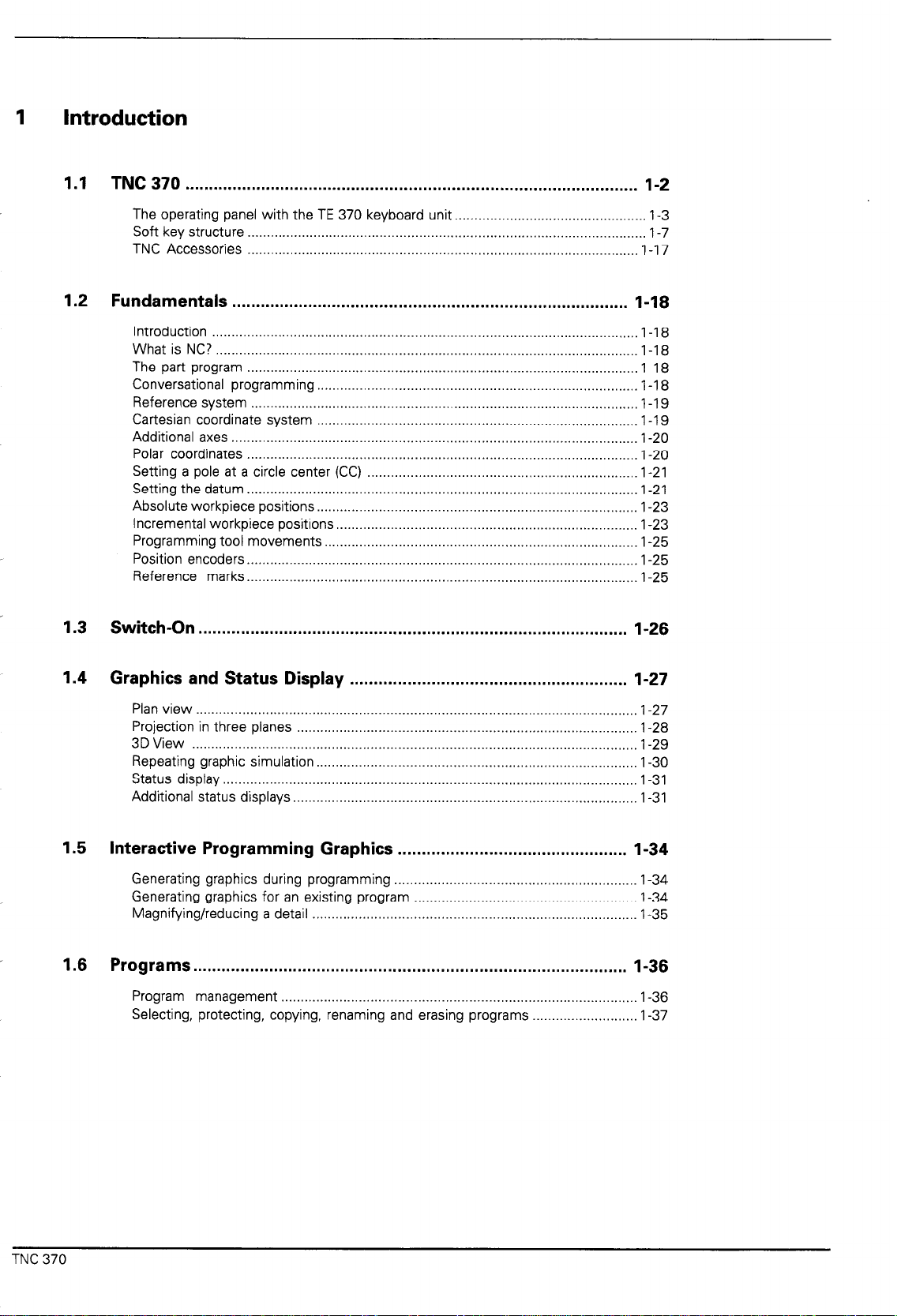

Contents User's Manual TNC 370

Introduction

Manual Operation and Setup

Test Run and Program Run

Programming

Programming Tool Movements

Subprograms and Program Section Repeats

Programming with Q Parameters

Cycles

3D Touch Probes

External Data Transfer

MOD-Functions, HELP Functions

1

2

3

4

5

6

7

8

9

10

11

Tabels, Overviews and Dialogs

12

Introduction

1.1 TNC370

The operating panel with the TE 370 keyboard

Soft key structure ......................................................................................................

TNC Accessories

1.2 Fundamentals

Introduction .............................................................................................................

What is NC7 ............................................................................................................

The part program ....................................................................................................

Conversational

Reference system ...................................................................................................

Cartesian coordinate

Additional axes ........................................................................................................

Polar coordinates

Setting a pole at a circle center (CC) .....................................................................

Setting the datum

Absolute workpiece positions..

Incremental workpiece positions..

Programming tool

Position encoders.. ..................................................................................................

Reference marks ....................................................................................................

...............................................................................................

unit.. ...............................................

....................................................................................................

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-18

programming ..................................................................................

system ..................................................................................

.................................................................................................... I-20

....................................................................................................

................................................................................

........................................................................... 1-23

movements.. ..............................................................................

1.3 Switch-On . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ..*..............................

1-2

1-3

1-7

1-l 7

l-l 8

1-18

l-l 8

l-l 8

l-l 9

1-l 9

I-20

l-21

I-21

1-23

1-25

1-25

1-25

1-26

1.4 Graphics and Status Display

Plan view .................................................................................................................

Projection in three planes

3D View ..................................................................................................................

Repeating graphic simulation..

Status display ..........................................................................................................

Additional status displays.. ......................................................................................

.......................................................................................

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-27

................................................................................

1.5 Interactive Programming Graphics ................................................

Generating graphics during programming

Generating graphics for an

Magnifying/reducing a detail ...................................................................................

existing program .........................................................

..............................................................

1.6 Programs ...........................................................................................

Program management

Selecting, protecting,

...........................................................................................

copying, renaming and erasing programs ...........................

1-27

1-28

1-29

I-30

1-31

1-31

1-34

1-34

l-34

1-35

1-36

1-36

1-37

TNC 370

2 Manual Operation and Setup

2.1 Moving the Machine Axes

Traversing with the axis direction keys .....................................................................

Traversing with the electronic handwheel

Working with the HR 330 electronic handwheel .......................................................

Positioning with manual data input ...........................................................................

Incremental jog positioning .......................................................................................

.................................................................

................................................................ 2-3

2.2 Spindle Speed S, Feed Rate F and Miscellaneous Functions

To enter the spindle speed S ....................................................................................

To change the spindle speed S

To change the feed rate F

To enter the miscellaneous function M

2.3 Setting the Datum without a 3D Touch Probe

Setting the datum in the tool axis ............................................................................

Setting the datum in the working plane

................................................................................

........................................................................................ 2-6

.....................................................................

.................................

.................................................................... 2-8

M

...

2-2

2-2

2-3

2-4

2-4

2-5

2-5

2-5

2-6

2-7

.2-7

TNC 370

3 Test Run and Program Run

3.1

3.2

3.3

3.4

3.5

Test Run

To do a test run

Program Run

To run a part program ................................................................................................ 3-3

Interrupting machining .............................................................................................. 3-4

Resuming program run after an interruption

Blockwise Transfer: Executing Long Programs

Skipping Blocks During Program Run/Test Run

..............................................................................................

......................................................................................................... 3-2

........................................................................................

............................................................. 3-5

................................ 3-6

............................ 3-7

Optional Interruption of a Program Run ..........................................

3-2

3-3

3-7

4 Programming

4.1

Editing

Part Programs

Layout of a program.. ...............................................................................................

Plain language dialog

Editing functions .......................................................................................................

.......................................................................

...............................................................................................

4.2 Tools ....................................................................................................

Determining tool data ...............................................................................................

Oversizes for lengths and radii - delta values..

Entering tool data into the program .........................................................................

Entering tool data in program

Entering tool

Pocket table

Calling tool data ......................................................................................................

Tool change ...........................................................................................................

data in tables ......................................................................................

for tool changer ................................................................................. .4-l 2

TO0L.T

....................................................................

........................................................

4-2

.4-2

.4-2

,4-3

4-5

,4-5

4-6

.4-7

.4-8

.4-9

4-l 3

.4-l 4

4.3 Tool Compensation Values ............................................................. 4-15

Effect of tool compensation values..

Tool radius compensation ......................................................................................

Machining corners

..................................................................................................

......................................................................

4.4 Program Creation .............................................................................

.4-l 5

.4-l 6

.4-l 8

4-19

Creating a new

Defining the blank form

part program

.................................................................................

..........................................................................................

,4-l 9

.4-l 9

4.5 Entering Tool-Related Data ............................................................. 4-21

Feed rate

Spindle speed S ......................................................................................................

F

.............................................................................................................

.4-21

4-22

4.6 Entering Miscellaneous Functions and STOP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-23

4.7 Actual Position Capture . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-24

4.8 Marking

Blocks to be Skipped . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-25

4.9 Entering Comments in the Part Program ..*.......................*............ 4-26

TNC 370

Programming Tool Movements

5.1

General Information on Programming Tool Movements..

5.2 Contour Approach and Departure

Starting and end positions

Smooth approach and departure ..............................................................................

.......................................................................................

.................................................... 5-4

..............

5.3 Path Functions ....................................................................................

General information ................................................................................................. .5-7

Machine axis movement under program control ..................................................... .5-7

Overview of path functions ....................................................................................... 5-8

5.4 Path Contours - Cartesian Coordinates

Straight line

Chamfer ..................................................................................................................

Circles and circular arcs - General information

Circle center CC ...................................................................................................... 5-1 5

Circular path C around the circle center CC..

Circular path CR with defined radius ...................................................................... 5-20

Circular path CT with tangential connection .......................................................... .5-23

Corner rounding RND

.............................................................................................................. .5-9

.............................................................................................

........................................ 5-9

.....................................................

.........................................................

5-2

.5-4

5-6

5-7

5-l 2

5-14

5-l 7

5-25

5.5 Path Contours -

Polar coordinate origin: Pole CC.. .......................................................................... .5-27

Straight line

Circular path CP around pole CC ........................................................................... 5-30

Circular path CTP with tangential connection..

Helical interpolation ................................................................................................. 5-33

5.6 Contours - FK Free Contour Programming

Programming contour elements with FK ................................................................

Interactive graphics during FK programming

FK Functions .......................................................................................................... .5-39

Free programming of straight lines

Free programming of circular arcs.. ........................................................................ 5-44

Identifying closed contours .....................................................................................

Polar Coordinates .............................................. 5-27

LP

........................................................................................................

.......................................................

...................................

.........................................................

.........................................................................

5-27

5-32

5-36

5-36

5-38

5-40

5-47

5.7 M Functions for Contouring Behavior and Coordinate Data ....... 5-51

Smoothing corners: M90..

Machining small contour steps: M97

Complete machining of open contours: M98 ......................................................... .5-53

Setting the coordinates for the datum: M91/M92 .................................................. .5-54

Reducing rotary axis display values to under 360”: M94 ...................................... .5-55

Optimized traverse of rotary axes: Ml 26 ............................................................... 5-55

Feed rate at circular arcs: Ml 09/Ml IO/Ml 11 ........................................................ 5-56

.......................................................................................

......................................................................

5-51

5-52

5.8 Positioning with Manual Data Input (MDI)

......................................

5-57

6 Subprograms and Program Section Repeats

6.1 Subprograms

Principle .................................................................................................................... 6-2

Operating limits ......................................................................................................... 6-2

Programming and calling subprograms

................................................................. . ....................

6.2 Program Section Repeats

Principle

Programming notes..

Programming and calling a program section repeat ................................................

.................................................................................................................... 6-5

................................................................................................. 6-5

6.3 Program as Subprogram

Principle .................................................................................................................... 6-8

Operating limits ......................................................................................................... 6-8

Calling a program as a subprogram ......................................................................... 6-8

6.4 Nesting

Nesting depth

Subprogram in a subprogram ................................................................................... 6-9

Repeating program section repeats

Repeating subprograms .......................................................................................... 6-l 2

................................................................................................ 6-9

...........................................................................................................

6-2

.................................................................... 6-3

................................................................. 6-5

6-5

................................................................... 6-8

.6-9

.......................................................................

6-l 1

TNC 370 -

7 Programming with Q Parameters

7.1

7.2

7.3

7.4

7.5

7.6

Part Families - Q Parameters Instead of Numerical Values..

Describing Contours Through

Overview

...................................................................................................................

Mathematical

Functions ................ 7-6

...... 7-4

7-6

Trigonometric Functions ................................................................... 7-8

Overview ..................................................................................................................

If-Then Operations with Q Parameters

Jumps ...................................................................................................................

Overview ..................................................................................................................

Checking and Changing Q

Parameters ......................................... 7-11

Output of Q Parameters and Messages

Displaying error messages ....................................................................................

Output through an external data interface..

Assigning values for the

PLC

..................................................................................

............................................ 7-9

......................................... 7-12

............................................................

.7-8

,7-9

.7-9

.7-l 2

7-l 3

7-l 3

7.7

7.8

Reading from System Data ..................

Examples for Exercise.. ...................................................................

Rectangular pocket with corner rounding and tangential approach

Bolt hole circle ........................................................................................................

Ellipse

Machining a hemisphere with an end mill

..................................................................................................................

..* ......................................... 7-14

7-15

....................... 7-l 5

.7-l 6

..............................................................

.7-20

7-l 8

8 Cycles

8.1

8.2

8.3

General Overview of Cycles .............................................................. 8-2

Programming a cycle ...............................................................................................

Drilling Cycles

PECKING (Cycle 1) .................................................................................................

DRILLING (Cycle 200) ............................................................................................. .8-7

REAMING (Cycle 201) .............................................................................................

BORING (Cycle 202) ............................................................................................... .8-9

UNIVERSAL DRILLING CYCLE (Cycle 203) ........................................................ .8-l 0

TAPPING with a floating tap holder (Cycle 2) ....................................................... .8-l 2

RIGID TAPPING (Cycle 17). ...................................................................................

Examples for exercise.. ..........................................................................................

....................................................................................

.8-3

8-5

.8-6

.8-8

8-13

.8-l 4

Cycles for Milling Pockets, Studs and Slots ................................. 8-16

POCKET MILLING (Cycle 4) ................................................................................. .8-17

POCKET FINISHING (Cycle

STUD FINISHING (Cycle 213) ...............................................................................

CIRCULAR POCKET MILLING (Cycle 5). ............................................................. .8-22

CIRCULAR POCKET FINISHING

CIRCULAR STUD FINISHING (Cycle 215) ........................................................... ,8-25

SLOT MILLING (Cycle 3). ......................................................................................

SLOT with reciprocating plunge-cut

CIRCULAR SLOT with reciprocating plunge-cut (Cycle 210) ................................ 8-30

Examples for exercise.. .......................................................................................... .8-32

212) ......................................................................... .8-18

8-20

(Cycle 214) ...................................................... .8-23

.8-27

(Cycle

210) ...................................................

.8-28

8.4

8.5

8.6

8.7

8.8

Cycles for Machining Hole Patterns ............................................... 8-34

CIRCULAR PATTERN (Cycle 220) ....................................................................... .8-35

LINEAR PATTERN (Cycle 221) ..............................................................................

Examples for exercise.. .......................................................................................... .8-38

8-36

SL Cycles .......................................................................................... 8-40

CONTOUR GEOMETRY (Cycle 14). ...................................................................... 8-41

ROUGH-OUT (Cycle 6) .........................................................................................

SL Cycles: Overlapping contours .......................................................................... .8-44

PILOT DRILLING (Cycle 15)

CONTOUR MILLING (Cycle 16). ........................................................................... .8-51

................................................................................. .8-50

.8-42

Cycles for Multipass Milling ............................................................ 8-54

MULTIPASS MILLING (Cycle 230) ........................................................................ 8-55

RULED SURFACE (Cycle 231) .............................................................................. 8-57

Examples for exercise.. ..........................................................................................

.8-59

Cycles for Coordinate Transformations ........................................ 8-60

DATUM SHIFT (Cycle 7) ........................................................................................ 8-61

MIRROR IMAGE (Cycle 8) ....................................................................................

ROTATION (Cycle IO) ........................................................................................... .8-65

SCALING FACTOR (Cycle 1 1) ..............................................................................

.8-63

.8-66

Special Cycles .................................................................................. 8-68

DWELL TIME (Cycle 9).

PROGRAM CALL (Cycle 12)

ORIENTED SPINDLE STOP

.........................................................................................

.8-68

.................................................................................. 8-68

(Cycle 13). ............................................................... .8-69

TNC 370

9 3D Touch Probes

9.1

9.2

9.3

9.4

General Information on Touch Probes

TS 120 Triggering touch probe ................................................................................ .9-2

TS 630 Triggering touch probe ................................................................................. 9-2

lT 120 Touch probe for tool measurement.. ...........................................................

............................................. 9-2

Touch Probe Cycles in the MANUAL and

ELECTRONIC HANDWHEEL Operating Modes

To select the touch probe functions ......................................................................... 9-4

Calibrating a triggering 3D touch probe .................................................................... 9-5

Compensating workpiece misalignment ................................................................... 9-7

Setting the datum with the 3D touch probe system .................................................

............................... 9-4

Measuring Workpieces with a 3D Touch Probe ............................

Finding the coordinate of a position on an aligned workpiece ............................... 9-l 4

Finding the coordinates of a corner in the working plane ....................................... 9-14

Measuring workpiece dimensions. .......................................................................... 9-l 5

Measuring angles ...................................................................................................

Measuring with the 3D touch probe during program run ....................................... .9-18

Digitizing with a Triggering 3D Touch Probe (Optional)

Defining the digitizing range.. .................................................................................

Input data ............................................................................................................... .9-22

Setting the scanning range ....................................................................................

Line-by-line digitizing with Cycle 6 MEANDER ....................................................... 9-24

Contour line digitizing with Cycle 7 CONTOUR LINES ......................................... .9-26

Input data ................................................................................................................ 9-27

.............. 9-21

.9-3

9-9

9-14

.9-l 6

.9-22

.9-22

9.5

9.7

Using Digitized Data in a Part Program

Executing a part program from digitized data .......................................................

......................................... 9-29

Measuring Tools with the TT 120 Touch Probe ............................

Calibrating the TT 120 ............................................................................................ 9-33

Measuring the tool length ....................................................................................... 9-34

Measuring the tool radius .......................................................................................

.9-30

9-31

9-36

External Data Transfer

10.1 Functions for External Data Transfer

Blockwise transfer ................................................................................................... 1 O-2

.............................................

10.2 Pin Layout and Connecting Cable for Data Interface

RS-232-C/V.24 Interface ..........................................................................................

10.3 Preparing the Devices for Data Transfer

HEIDENHAIN devices

Non-HEIDENHAIN devices ...................................................................................... IO-4

............................................................................................. IO-4

.........................................

....................

IO-2

.lO-3

1 O-3

10-4

TNC 370

11 MOD Functions, HELP Functions

11.1 Calling and Exiting the MOD Functions

11.2 Machine-Specific User Parameters

. . . . . . . . . . . . . . . . . . . . . . . ..m..................*...

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11-2

11-2

11.3 Selecting the Programming Format and Unit of Measure............ 11-3

11.4 Setting the Axis Traverse Limits

11.5 Setting the External Data Interface

RS-232-C Interface ................................................................................................. 1 1-5

BAUD RATE ............................................................................................................

11.6 Selecting Position Display Types

11.7 Code Numbers

..................................................................................

. . . . . . . . ..~.........................................

.................................................

...................................................

11-4

11-5

1 1-5

11-6

11-7

11.8 NC and PLC Software Numbers, Free Memory

.........................................

11.9 HELP Function ........................................

Selecting and exiting HELP .................................................................................... 1 l-8

.

.............................

11-7

11-8

12 Tables, Overviews and Dialogs

12.1 General User Parameters .......................................

Selecting the general user parameters. ..................................................................

External data transfer

3D Touch probes and digitizing ..............................................................................

TNC displays, TNC editor

Machining and program run

Override behavior, electronic handwheel ............................................................... 12-9

12.2 Miscellaneous Functions (M Functions)

Miscellaneous functions with predetermined effect.

Vacant miscellaneous functions

12.3 Preassigned Q Parameters

12.4 Features, Specifications and Accessories

Accessories ........................................................................................................... 12-l 6

12.5 TNC Error Messages

TNC error messages during programming

TNC error messages during test run and program run ........................................

TNC error messages during digitizing

............................................................................................. 12-3

....................................................................................... 12-6

.................................................................................... 12-8

....... . .............................. 12-10

............................................. 12-l 0

...........................................................................

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

.................................. 12-14

......................................................................

...........................................................

..................................................................

. ........................

12-2

12-2

12-4

12-l 1

12-12

12-17

12-l 7

12-18

12-21

TNC 370

1 Introduction

1.1 TNC 370

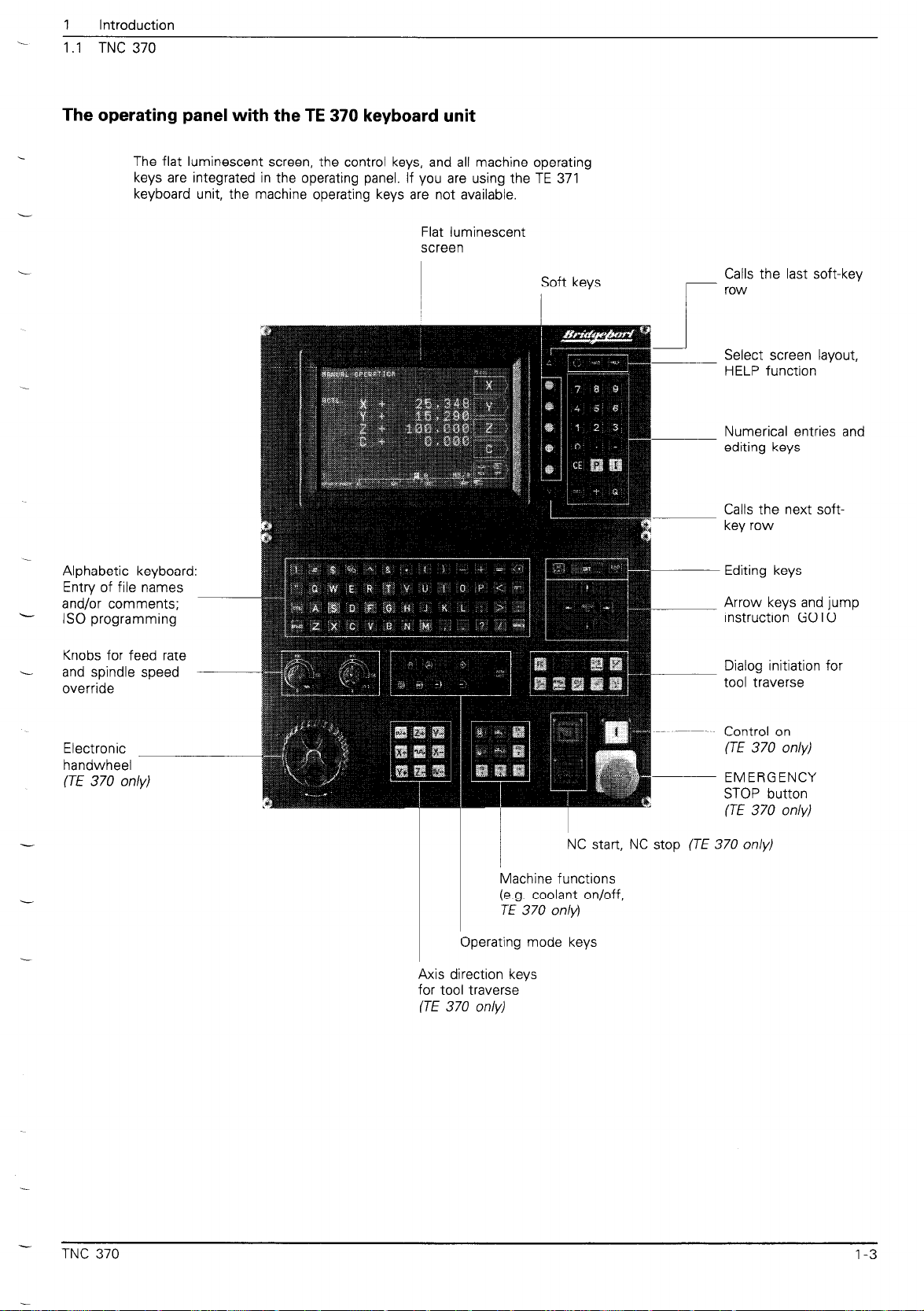

The operating panel with the TE 370 keyboard unit

Soft key structure

TNC Accessories ....................................................................................................

...............................................................................................

1.2 Fundamentals

introduction .............................................................................................................

What is NC? ............................................................................................................

The part program

Conversational programming

Reference system ...................................................................................................

Cartesian coordinate system

Additional axes .......................................................................................................

Polar coordinates .................................................................................................... I-20

Setting a pole at a circle center (CC)

Setting the datum ...................................................................................................

Absolute workpiece positions

Incremental workpiece positions ............................................................................

Programming tool movements

Position encoders ...................................................................................................

Reference marks ...................................................................................................

1.3 Switch-On

...............................................

..................................................................................................... 1-7

...................................................................................

.................................................................................................... l-l 8

................................................................................. l-l 8

................................................................................. l-l 9

.................................................................... 1-21

.................................................................................

............................................................................... 1-25

..........................................................................................

1-2

1-3

l-l 7

1-18

1-I 8

l-l 8

l-l 9

I-20

I-21

l-23

I-23

1-25

I-25

1-26

1.4 Graphics and Status Display

Plan view .................................................................................................................

..................................................................................... I-28

................................................................................. I-30

1.5

1.6

Projection in three planes..

3D View ..................................................................................................................

Repeating graphic simulation

Status display .........................................................................................................

Additional status displays .......................................................................................

Interactive Programming Graphics

Generating graphics during programming

Generating graphics for an existing program

Magnifying/reducing a detail ..................................................................................

Programs..

Program management ..........................................................................................

Selecting, protecting, copying, renaming and erasing programs

.........................................................................................

..........................................................

................................................

............................................................. I-34

........................................................ 1-34

.........................

I-27

1-27

1-29

1-31

1-31

l-34

I-35

1-36

1-36

I-37

1

Introduction

1.1 TNC 370

Control

The TNC 370 is a shop-floor programmable contouring control for milling

machines with up to four axes. The spindle can be rotated to a given

angular stop position (oriented spindle stop).

Visual Display Unit and Operating Panel

The flat luminescent monochrome screen clearly displays all information

necessary for operating the TNC 370. The keys on the operating panel

are grouped according to their functions. This simplifies operating and

programming the control. The following keyboard units are available:

l

TE 370 with machine operating keys

(such as NC start, NC stop, coolant on/off)

l

TE 371 without machine operating keys

Programming

The TNC 370 is programmed directly at the machine with the easy-to-

use HEIDENHAIN plain language dialog format. Programming in IS0

format is also possible, and is described in the TNC 370 User’s Manual

for IS0 Programming.

4

Graphics

The graphic simulation feature enables you to test programs before

actual machining. Several types of graphic representation can be

selected.

Compatibility

The TNC 370 can execute any part program that was created on a TNC

150B or subsequent HEIDENHAIN control.

1-2 TNC 370 .-

1 Introduction

1 .I TNC 370

The operating panel with the TE 370 keyboard unit

The flat luminescent screen, the control keys, and all machine operating

keys are integrated in the operating panel. If you are using the TE 371

keyboard unit, the machine operating keys are not available.

Flat luminescent

screen

Soft keys

!

Calls the last soft-key

row

r

Select screen layout,

HELP function

Numerical entries and

editing keys

Alphabetic keyboarl

Entry of file names

and/or comments;

IS0 programming

Knobs for feed rate

and spindle speed

override

Electronic

handwheel

(TE 370 only)

d:

Calls the next softkey row

Editing keys

Arrow keys and jump

instruction GOT0

Dialog initiation for

tool traverse

Control on

(TE 370 only)

EMERGENCY

STOP button

(TE 370 only)

NC start, NC stop (TE 370 only)

Machine functions

(e.g. coolant on/off,

TE 370 only)

Operating mode keys

TNC 370

Axis direction keys

for tool traverse

(TE 370 only)

1-3

1 Introduction

1.1 TNC 370

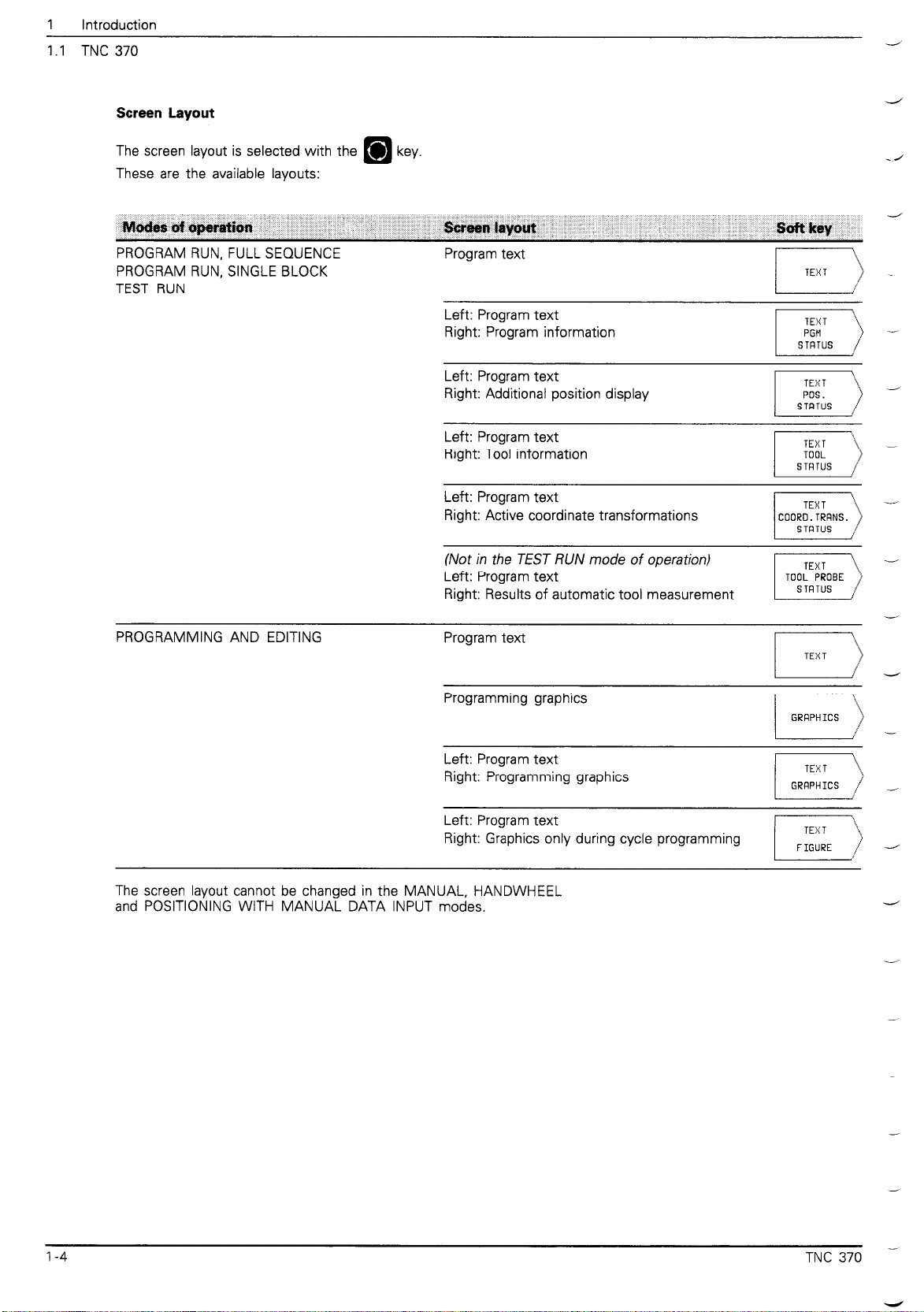

Screen Layout

-/

J

The screen layout is selected with the

These are the available layouts:

Modes of apcarcvtion

PROGRAM RUN, FULL SEQUENCE

PROGRAM RUN, SINGLE BLOCK

TEST RUN

key.

!breen layout

Program text

Left: Program text

Right: Program information

Left: Program text

Right: Additional position display

Left: Program text

Right: Tool information

Left: Program text

Right: Active coordinate transformations

(Not in the TEST RUN mode of operation)

Left: Program text

Right: Results of automatic tool measurement

.,

-/

-

-/

.-

PROGRAMMING AND EDITING

Program text

Programming graphics

Left: Program text

Right: Programming graphics

Left: Program text

Right: Graphics only during cycle programming

The screen layout cannot be changed in the MANUAL, HANDWHEEL

and POSITIONING WITH MANUAL DATA INPUT modes.

-

1

-/

d

1-4

TNC 370 -

i-

1 Introduction

1.1 TNC 370

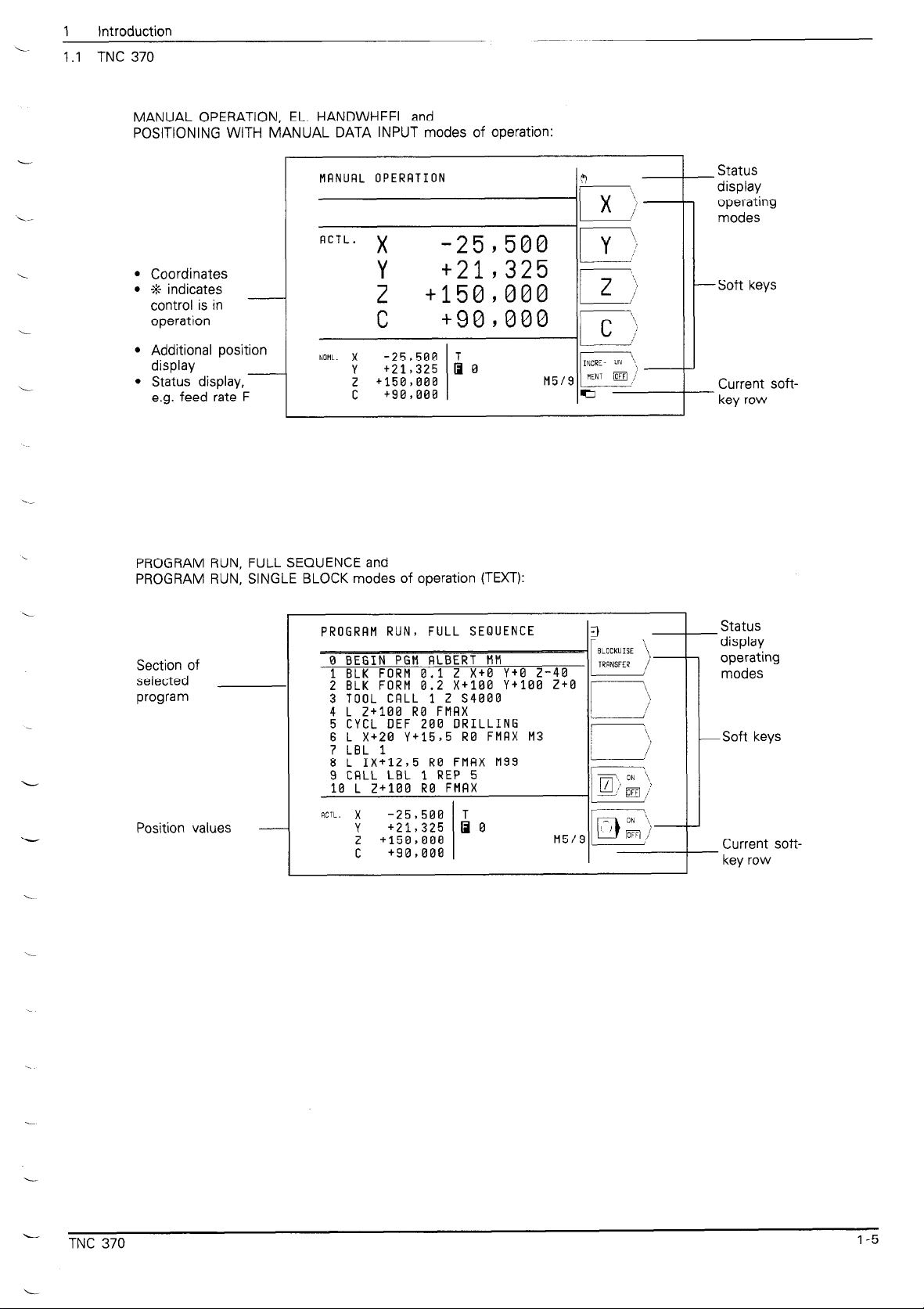

MANUAL OPERATION, EL. HANDWHEEL and

POSITIONING WITH MANUAL DATA INPUT modes of operation:

MRNURL OPERRTION

ACTL.

l

Coordinates

l

t indicates

control is in

operation

l

Additional position

display

l

Status display,

e.g. feed rate F

PROGRAM RUN, FULL SEQUENCE and

PROGRAM RUN, SINGLE BLOCK modes of operation (TEXT):

NOHL. x

X

Y

2

-25,580 1 y ;,

+21,325

+1509080 2 ';‘

c +909000 c ‘)

I

-25,588 T

Y

+21,325 I a

+150,008 H5/9

f

+90,068

R -

II

i.

if

__ Status

display

operating

modes

-Soft keys

Current soft-

- key row

Section of

selected

program

Position values

PROGRRM RUN, FULL SEQUENCE

5

CYCL DEF 268

I

Status

display

operating

modes

DRILLING

-Soft keys

Current softkey row

L

L

TNC 370

1-5

1

Introduction

1.1 TNC 370

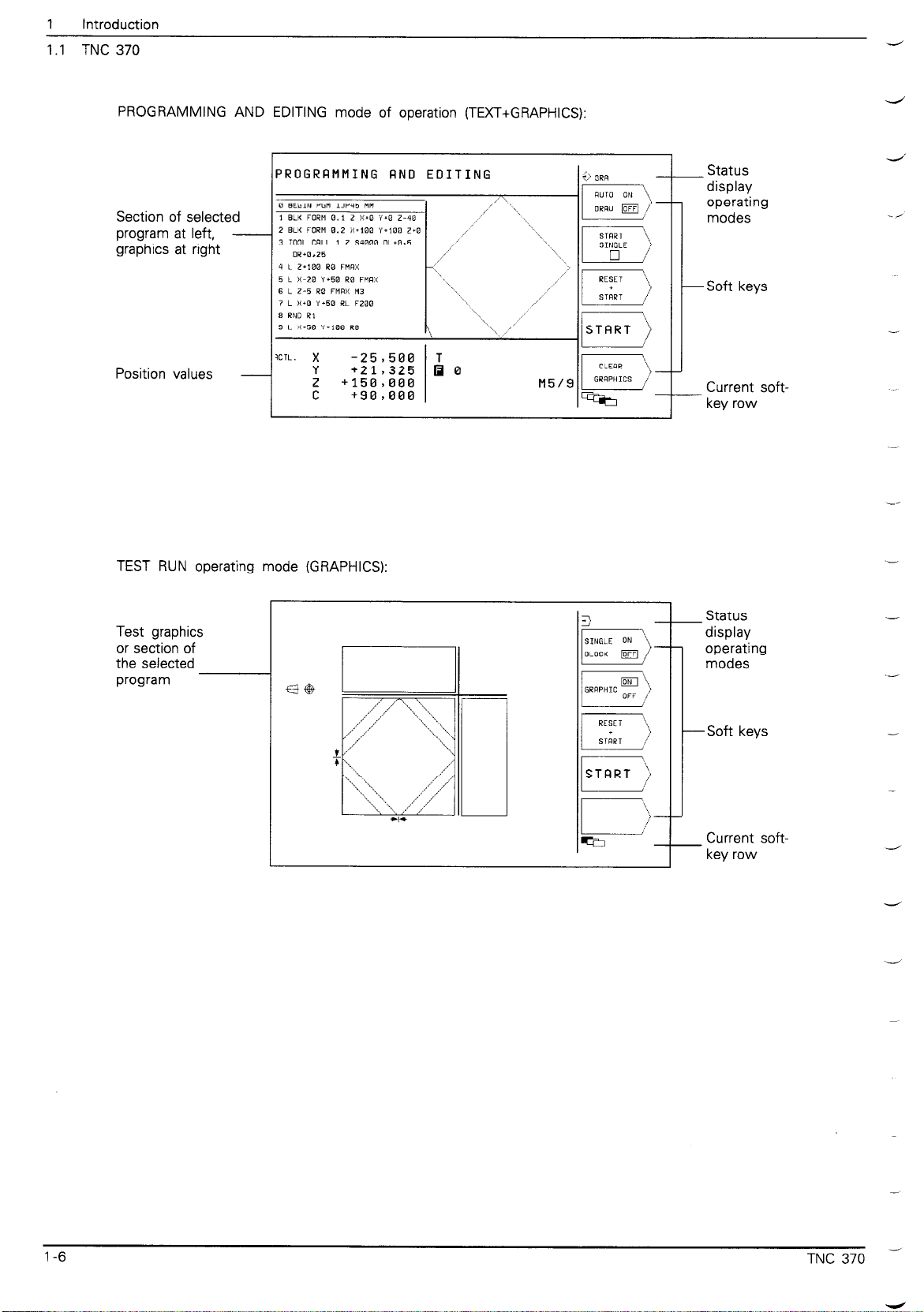

PROGRAMMING AND EDITING mode of operation (TEXT+GRAPHICS):

PROGRRMMING RN0 EDITING

Section of selected

program at left, -

graphics at right

ICTL. x

Position values _

TEST RUN operating mode (GRAPHICS):

Test graphics

or section of

the selected

program

-25,506 T

+21,325

r

+15o,oaB M5/9

C

+9a,aaa

3 GRA

I, ~-

0 0 )--

Q=e -

-Status

display

operating

modes

-Soft keys

Current soft-

- key row

_ Status

display

operating

modes

Soft keys

_ Current soft-

key row

l-6

TNC 370 -

L

1 Introduction

1.1 TNC 370

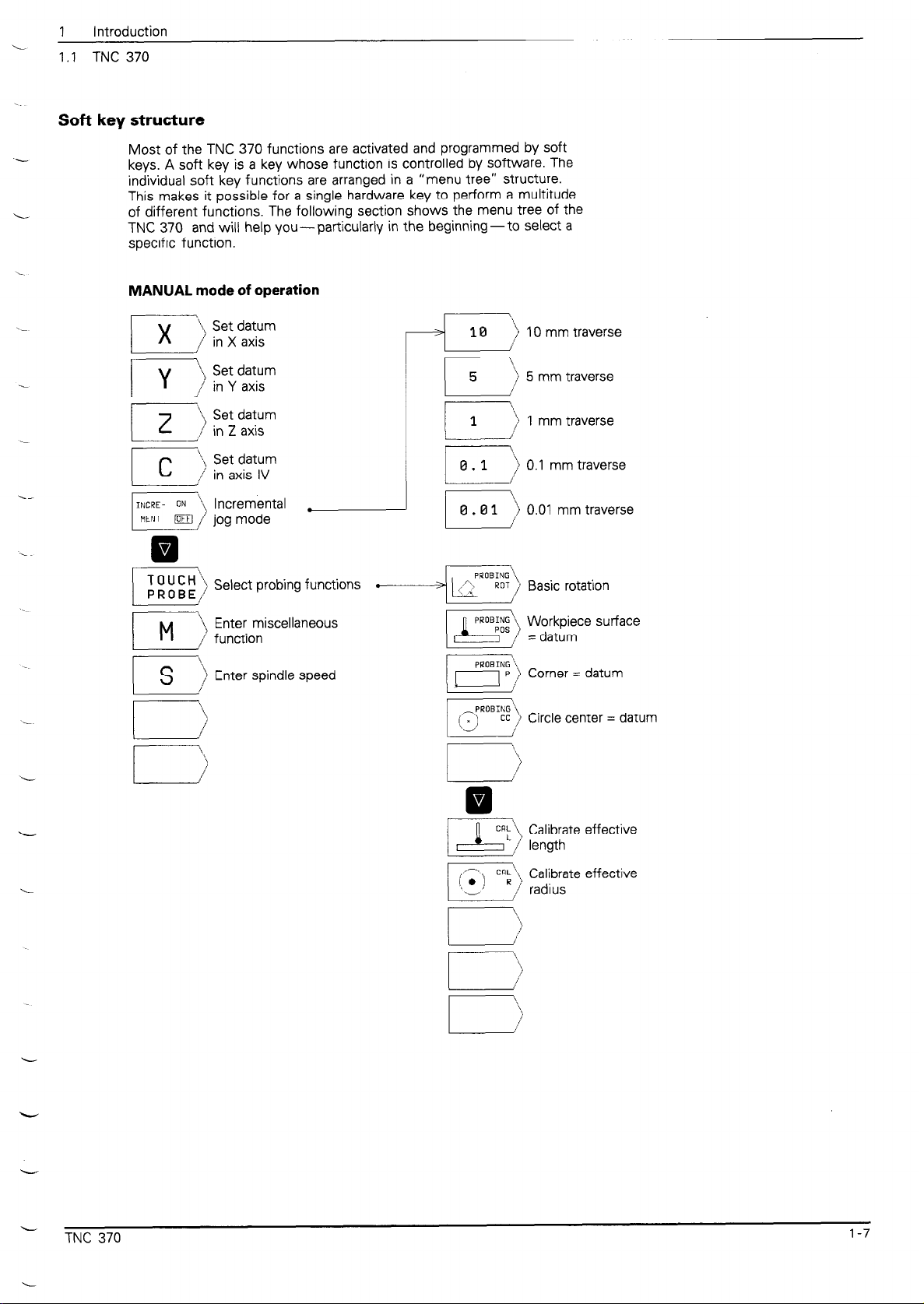

Soft key structure

Most of the TNC 370 functions are activated and programmed by soft

keys. A soft key is a key whose function is controlled by software. The

individual soft key functions are arranged in a “menu tree” structure.

This makes it possible for a single hardware key to perform a multitude

of different functions. The following section shows the menu tree of the

TNC 370 and will help you-particularly in the beginning-to select a

specific function.

MANUAL mode of operation

v

0

Set datum

in X axis

Select probing functions

‘\

10

4

I

L-

r

0.1

0.01

1 IOmm / traverse

\

5

: 5 mm traverse

:

1 \,

1 mm traverse

,.a’

‘\

,) 0.1 mm traverse

\

i 0.01 mm traverse

L-J

--

( , 1 PRO,,,,)

Workpiece surface

= datum

Corner = datum

Circle center = datum

L

TNC 370

Calibrate effective

length

Calibrate effective

radius

1-7

1 Introduction

1.1 TNC 370

ELECTRONIC HANDWHEEL mode of operation

Set datum in X axis

x 1

tz

y ‘)

I----

I 2

r

0

L-IQ

with handwheel

Set datum in Y axis

with handwheel

\

Set datum in 2 axis

with handwheel

/

Set datum in axis IV

with handwheel

incremental .

jog mode

Select probing functions

Enter miscellaneous

function

Enter spindle speed

10 mm traverse

5 mm traverse

mm traverse

0.1 mm traverse

0.01 mm traverse

pRoB;$ ,) y;;;or;ce surface

i

Corner = datum

Circle center = datum

CRL’\. Calibrate effective

l&Z1 C$\ Cal!brate effective

I

/’ radrus

1-8

TNC 370 -

---

1

Introduction

1.1 TNC 370

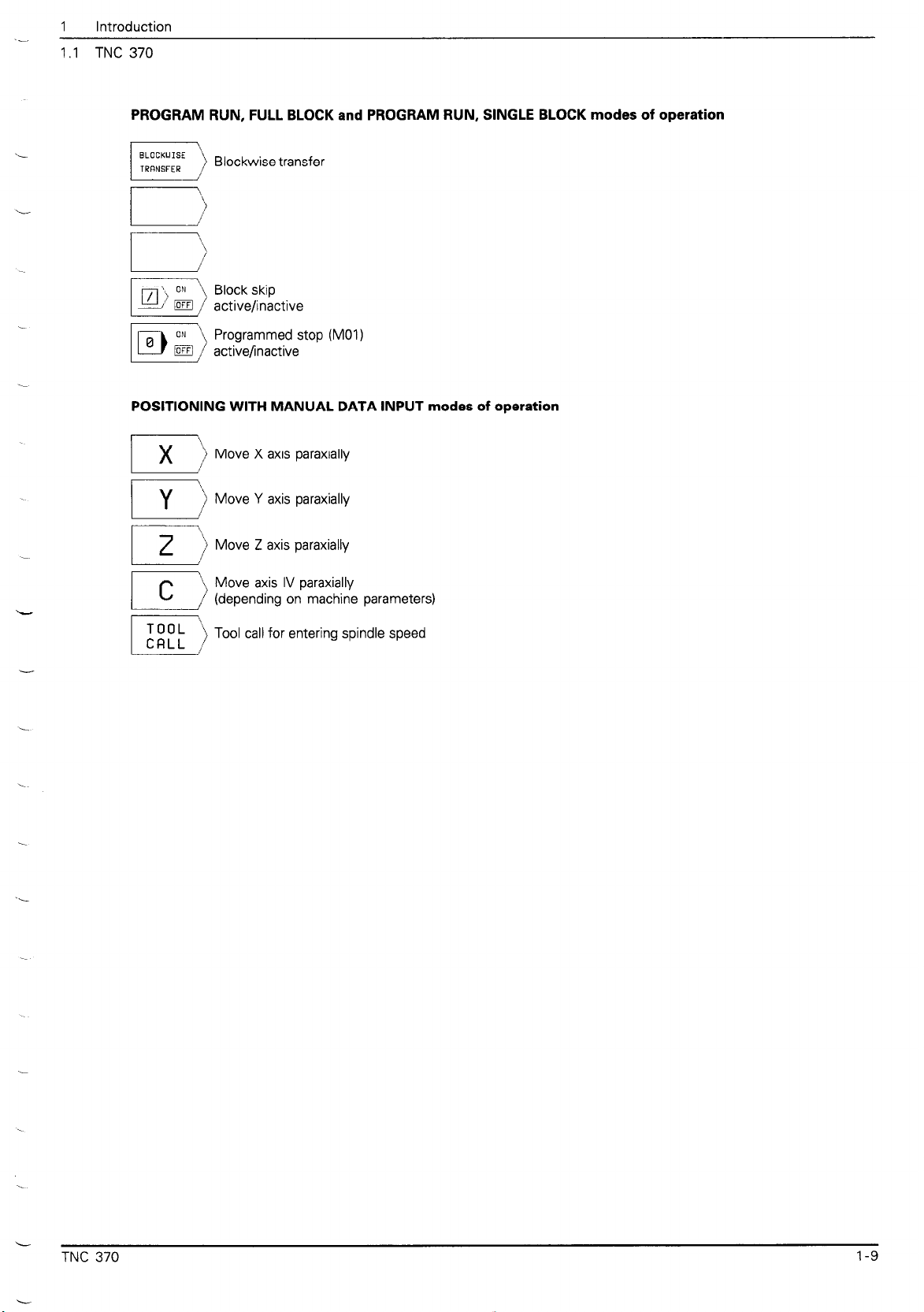

PROGRAM RUN, FULL BLOCK and PROGRAM RUN, SINGLE BLOCK modes of operation

i

\-

POSITIONING WITH MANUAL DATA INPUT modes of operation

I y

2

r-

Blockwise transfer

Move X axis paraxially

\

Move Y axis paraxially

i

:)

Move Z axis paraxially

Move axis IV paraxially

(depending on machine parameters)

Tool call for entering spindle speed

TNC 370

1-9

1 Introduction

1.1 TNC 370

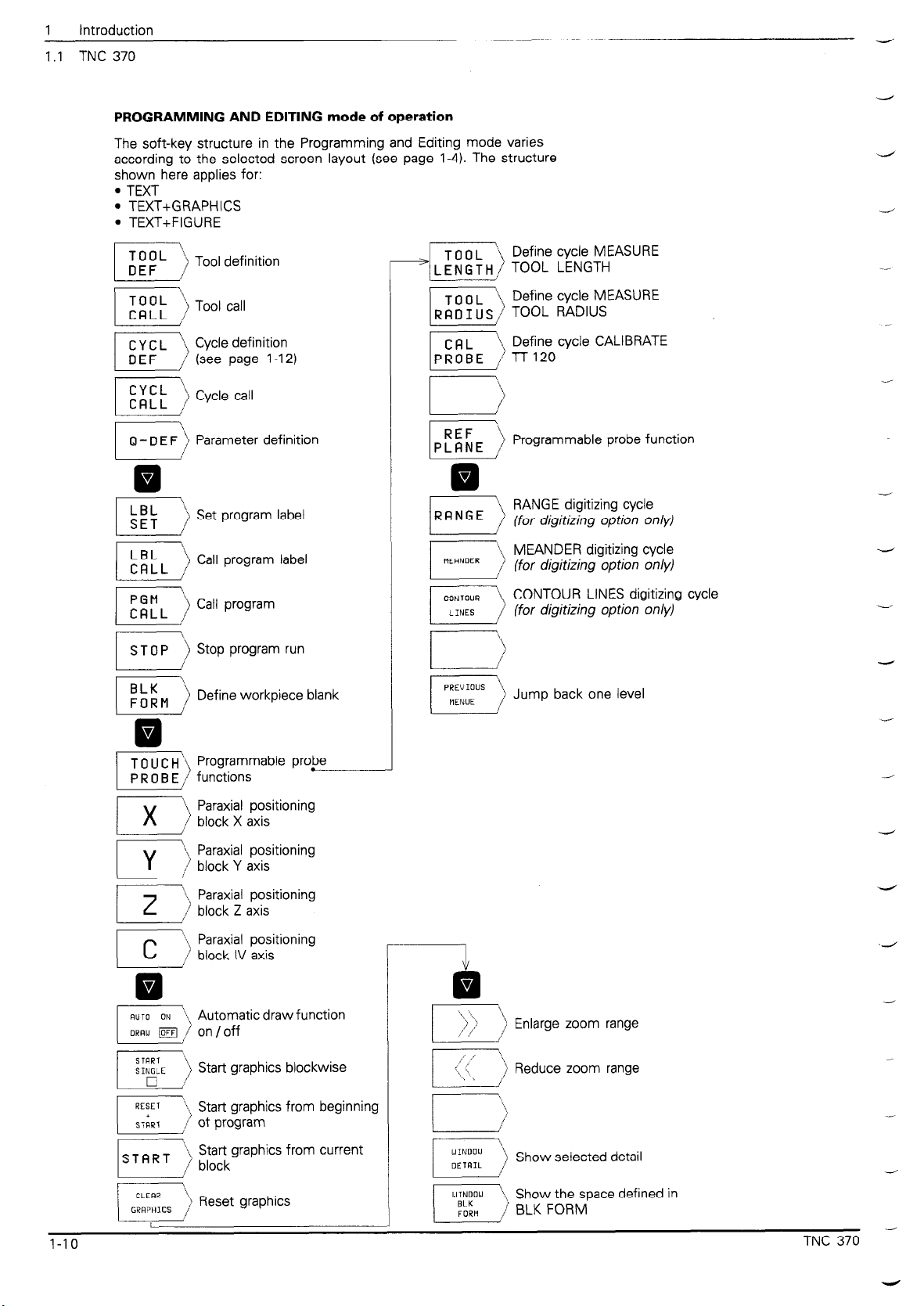

PROGRAMMING AND EDITING mode of operation

The soft-key structure in the Programming and Editing mode varies

according to the selected screen layout (see page l-4). The structure

shown here applies for:

l

TEXT

l

TEXT+GRAPHICS

l

TEXT+FIGURE

4

d

4

I

I\ Define cycle MEASURE

RBIUS/ TOOL RADIUS

IR,

\$ Define cycle CALIBRATE

i l-r120

Programmable probe function

v

0

Set program label

Call program label

Stop program run

Define workpiece blank

r---y

i)

RANGE digitizing cycle

(for digitizing option only)

MEANDER digitizing cycle

(for digitizing option only)

\ CONTOUR LINES digitizing cycle

/ (for digitizing option only)

Jump back one level

_-

_

-

-

-i

v

0

I-IO

Paraxial positioning

Paraxial positioning

v

0

Automatic draw function

on /off

Start graphics blockwise

Start graphics from beginning

Start graphics from current

! Enlarge zoom range

Reduce zoom range

-

Show selected detail

Show the space defined in

TNC 370 -

.-

1

Introduction

1 .I TNC 370

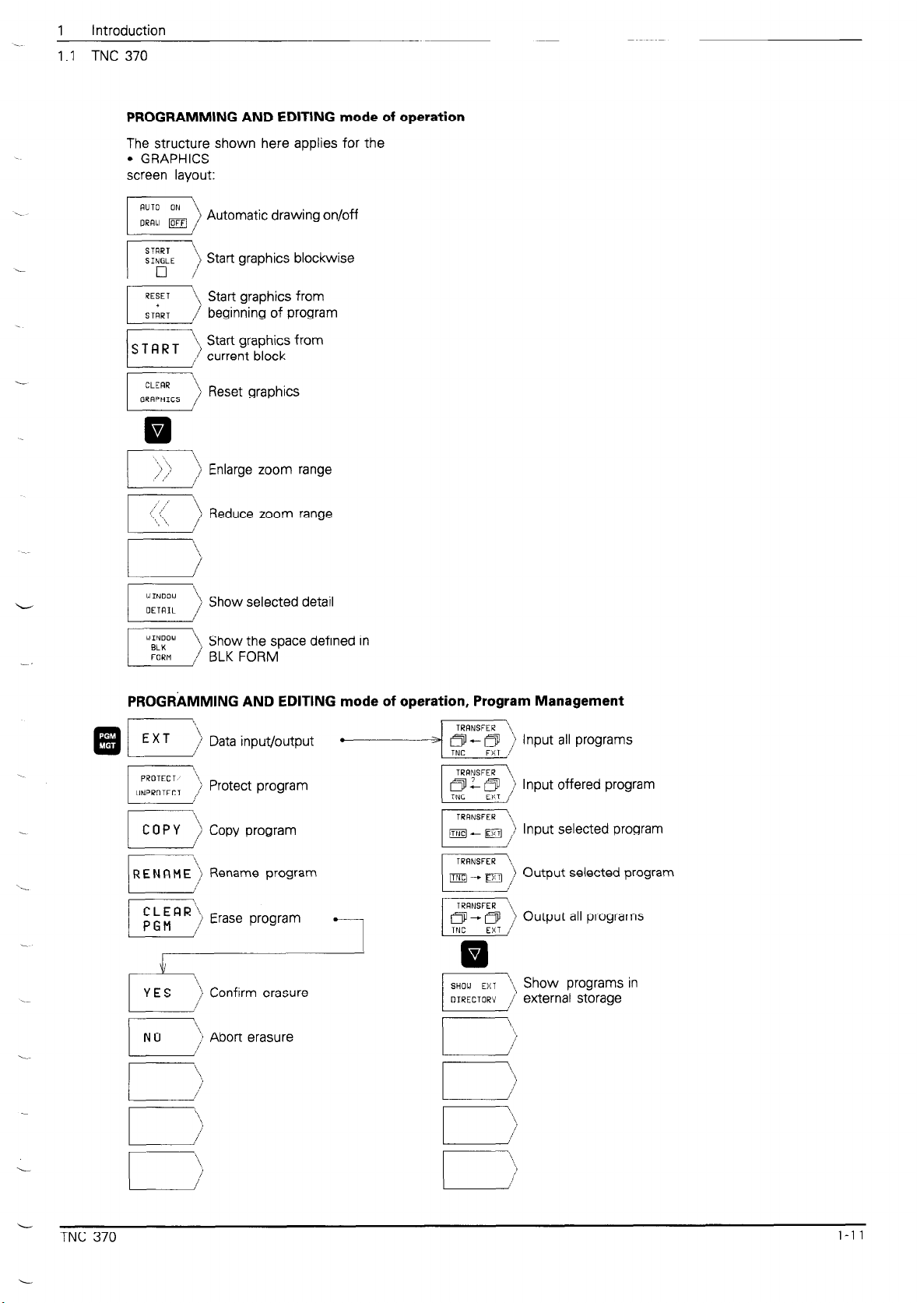

PROGRAMMING AND EDITING mode of operation

The structure shown here applies for the

l

screen layout:

GRAPHICS

Automatic drawing on/off

Start graphics blockwise

Start graphics from

beginning of program

s T FI R T

‘1, Start graphics from

/ current block

Reset graphics

Enlarge zoom range

I ,’

,. ’ /’

‘, \

‘*, ‘,

WINOO,.

OETRIL /

WINDOW \

BLK

FORM

Reduce zoom range

)

‘\

Show selected detail

1

Show the space defined in

/

BLK FORM

PROGRnMMlNG AND EDITING mode of operation, Program Management

@ E> Data input/output

) Protect program

l

Input offered program

L

TNC 370

Input selected program

Rename program

y) Erase program FJ) Output all programs

-

Output selected program

i,, Show programs in

N 0

‘i Abort erasure

/

I

\\,

/

l-l 1

Loading...

Loading...