HEIDENHAIN

DRJOHANNES HEIDENHAIN Gmbti

D-8225Traunreut~ ?B(O8669) 31-O

*

SERVICE MANUAL *

TNC 35X/355

Subject to Change/Further Dovelopmontn

DR. JOHANNES HEIDENHAIN is constantly working on technically improving

its units. It is therefore possible that details of your Control may

differ slightly from those described herein.

order a suitably revised issue of the Service Manual.

If that is the case please

Copying/Duplication

This

manual

shall be reproduced in any form or

in writing.

Issue: 06/92

is provided

subject

to the condition that no part of it

by

any means without our prior consent

HEIDENHAIN

DRJOHANNES HEIDENHAJN GmbH

D-8225Traunreut.Tel. (08669)31-O

Kundendienst

Contents

SERVICE NAMUAL TNC 3511355

Page 1

Page

1. Bow to use the Service Manual

2.

Error Messages

2.1 Possible Causes for Error Messages

3. Fault Hessages and their Causes

4.

LOGIC Unit LE 351/355

4.1 Designation of the LOGIC Unit

4.2 Hardware Components of the LOGIC Unit

4.3 Connector Layout LE 351/355

4.4 PROCESSOR Board

4.5 CLP PROCESSOR Board

4.6 Grounding Diagram

5. Kxternal Supply

5.1 Requirements

5.2 Supply for the NC-Part

5.3 Testing the POWER SUPPLY Board Assembly

5.4 24V-DC Supply for the PLC-Part

5.5 Buffer Battery

of

the External Supply

6. KEYBOARD Unit TE 351/355

6.1 Overview

6.2 Circuit Diagram of the KEYBOARD Unit

6.3 Testing the KEYBOARD Unit

6.4 Key Matrix

I.

DISPLAY Unit BE 2121412

7.1 Display for TNC 351

7.2 Display for TNC 355

7.3 Testing the Display

8. Measuring Systems

8.1 Error Messages

8.2 Possible Error Cause

8.3 Testing the Measuring

Systems

9. Bandwheel

9.1 Overview

9.2 Testing the Handwheel

10.

3D-Touch Probe

10.1 Overview

10.2 Error Messages

3

4

1

8

13

13

14

15

22

23

24

25

25

26

29

32

34

35

35

36

37

38

41

41

41

42

44

44

44

44

46

46

46

47

41

48

HEIDENHAIN

DR. JOHANNES HEIDENHAIN GmbH

D-8225

Kundendienst

Contents

SERVICE HANUAL TNC 3511355

Page 2

Traunreut ‘Tel. (08669) 31-O

Page

11. M-232-C Interface

11.1 Operating Modes ME-FE-EXT

11.2 Selecting Baud-Rate

11.3 Connecting Cable and Adapter for the

RS-232~C/V.24

11.4 Machine Parameters for the RS-232-C/V.24-Interface

11.5 Connecting Cable for Printer

11.6 Error Messages

12. External Data I/O

12.1 External Data Output

12.2 External Data Input

13. Analog Outputs

13.1 Technical Data

13.2 Measuring the Analog Output Voltages

13.3 Changing Positional Display Mode

13.4 Speed Adjustment

13.5 Offset Adjustment

14. PLC- I/O

14.1 Technical Data

14.2 Control of PLC- I/O

49

49

49

50

51

52

52

56

56

59

63

63

63

65

65

66

67

67

68

14.3 Test for PLC-Output “Control Ready” and its Acknowledgement

15. Test Units

15.1 Test Unit for the POWER SUPPLY Board Assembly

15.2 Test Unit for the Analog Outputs

15.3 Test Units for the PLC-I/O

15.4 Test Unit for the KEYBOARD Unit

15.5 Test Adapters and Extension Cables

16. Exchange Information

16.1 General

16.2 Exchange Procedure for the LOGIC Unit

16.3 Exchange Procedure for the PROCESSOR Board

16.4 Exchange Procedure for the CLP PROCESSOR Board

16.5 Exchange Procedure for the POWER SUPPLY Board Assembly

16.6 Exchange Procedure for the PLC POWER I/O Board PL 300

16.7 Exchange Procedure for the EPROMs

17. Machine Parameter Listing

70

72

72

72

73

74

75

76

76

80

82

84

86

88

90

91

HEIDENHAIN

DR. JOHANNES HElDENHAlN Gmb,,

D-8225

Kundendienst

SERVICE NANDAL TNC 351/355

Page 3

Traunreut ‘Tel. (08669) 31-O

IL-

How to use the TNC 351/355

Service Manual

The TNC 351/355 Service Manual can be used for fault diagnosis, fault loca-

lisation and elimination of a TNC-controlled machine tool.

In order to determine the fault condition on an NC-machine, a fundamental

knowledge of the machine and the servo amplifiers is necessary, as well

as a knowledge of their interaction with the Control and measuring system.

In addition, improper

use

of the Control, such as incorrect NC-programming

or incorrect selection of machine parameters can lead to the occurrence of

fault conditions. Further information in this respect can be found in the:

.Wachine Documentation of the Wanufacturer

-Service Manual

-Handbook for the Machine

Hanufacturer

The handbook for the machine manufacturer is not enclosed with every control

as the service manual.

It is generally only supplied to the machine manufacturer and is submitted

to a “change service” by HEIDENHAIN, Traunreut.

It is therefore absolutely

necessary to consult the machine manufacturer in the case of errors concerning the machine parameters or the interface of the control. Support can

also be obtained by the HEDIENHAIN service,

Traunreut or by HEIDENHAIN

agencies.

Telephone numbers or addresses and telex/telefax connections can be found

on the inner side of the cover page and on the rear side of the service

manual.

HEIDENHAIN

ORJOHANNES HElOENHPlN GmbH

D-8225

Kundendienst

Traunreut Tel. (08669) 31-O

SERVICE MANUAL TNC 351/355

Page 4

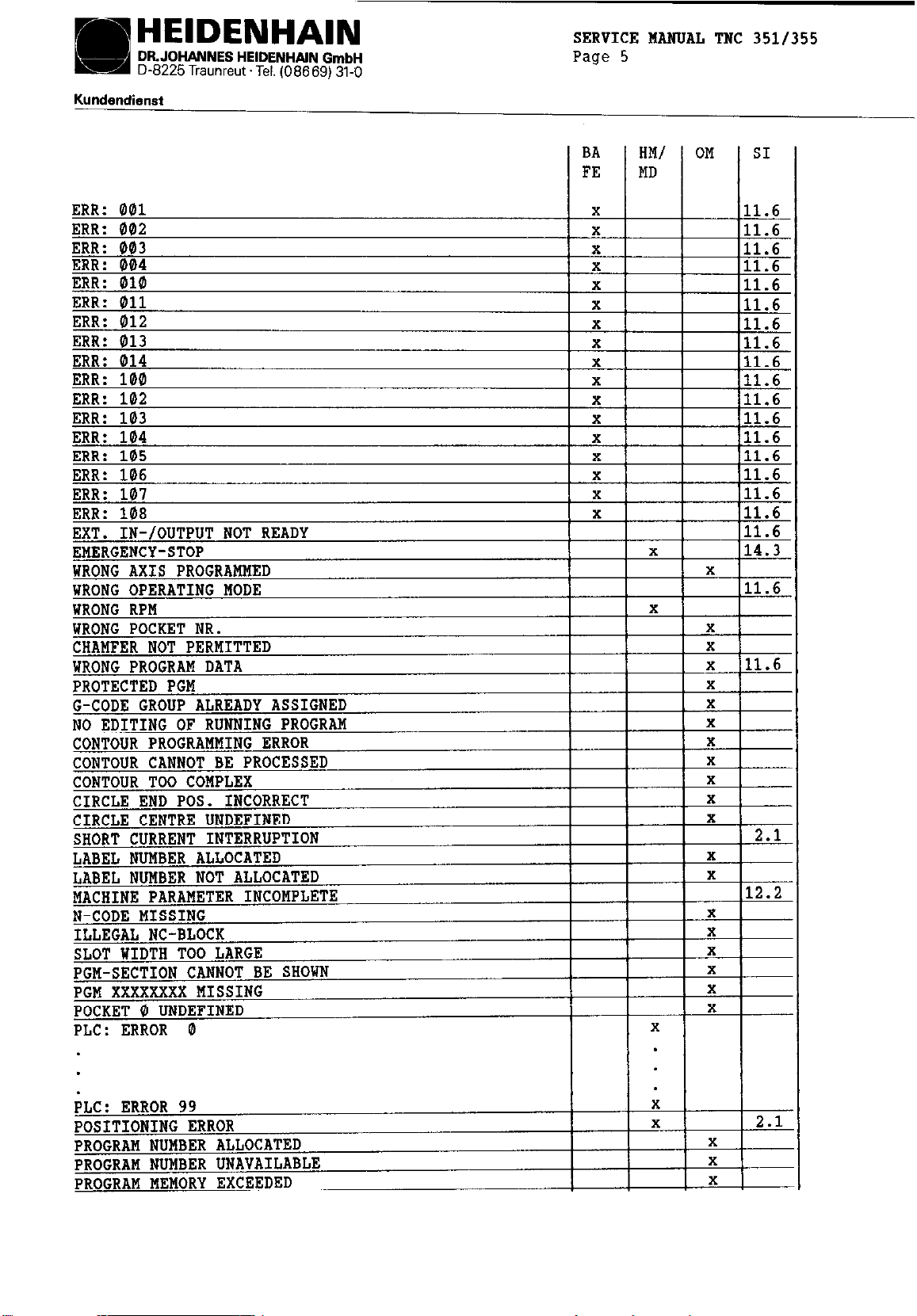

The TNC 351/355 contains a comprehensive, integrated supervision system to

avoid input or operating errors, to localize and diagnose faults of tech-

nical defects of the whole plant (TNC, measuring system, machine, cabling

etc.).

The supervision system is a fix component of the TNC-hardware and software

and is always operative when the control is switched on. The recognition

of a technical defect or an operating error is displayed in plain language

on the screen.

Insignificant error messages can be erased with the m-key.

The error messages listed are described more precisely in the following in-

structions:

- Service Manual, section:

- TNC 355 Operating Manual

- Handbook for the machine manufacturer, resp.

machine documentation of the manufacturer

OM

x

x

x

x

x

x

x

x

x

A...x

x

SI

8.2

2.1

HEIDENHAIN

DRJOHANNES HEIDENHAJN GmbH

D-8225 Traunreut .Tel. (08669) 31-O

Kundendienst

SERVICE BANUAL TNC 351/355

Page 5

HEIDENHAIN

DRJOHANNES HEIDENHAIN GmbH

D-8225

Kundendienst

SERVICE MANUAL TNC 351/355

Page 6

Traunreut.Tel. (08669) 31-O

1 BA 1 HM/ 1 OM

KEY NON FUNCTIONAL

EXCHANGE TOUCH PROBE BATTERY

STYLUS ALREADY IN CONTACT

PROBE SYSTEM NOT READY

TOOL CALL MISSING

TOOL DEF MISSING

TOOL DEF n R.,Yrn nna"rmmPn

ILLEGA:

PROGRAM-START UNDEFINE

WRONG SIGN PROGRAMME:

MIRROR IMAGE ON 'I

I

I I

! !

I I

I I

, x I

1 x 110.2

I x 110.2

I x 110.2

1 x I

_.

, 2% ,

I Y I

HEIDENHAIM

DR.JOtWNNES HEIDENHAN GmbH

D-8225 Traunreut ‘Tel. (08669) 31-O

Kundendienst

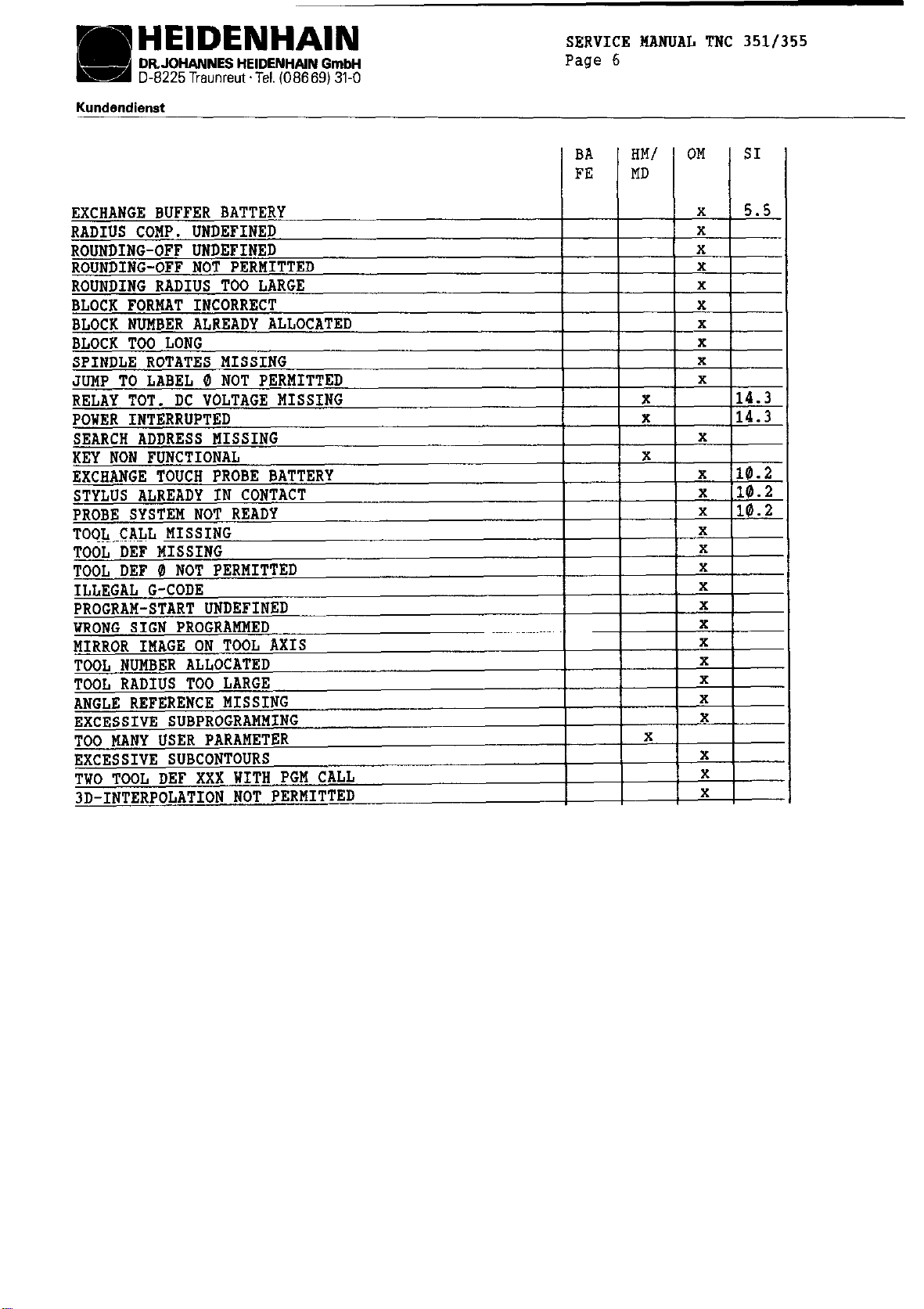

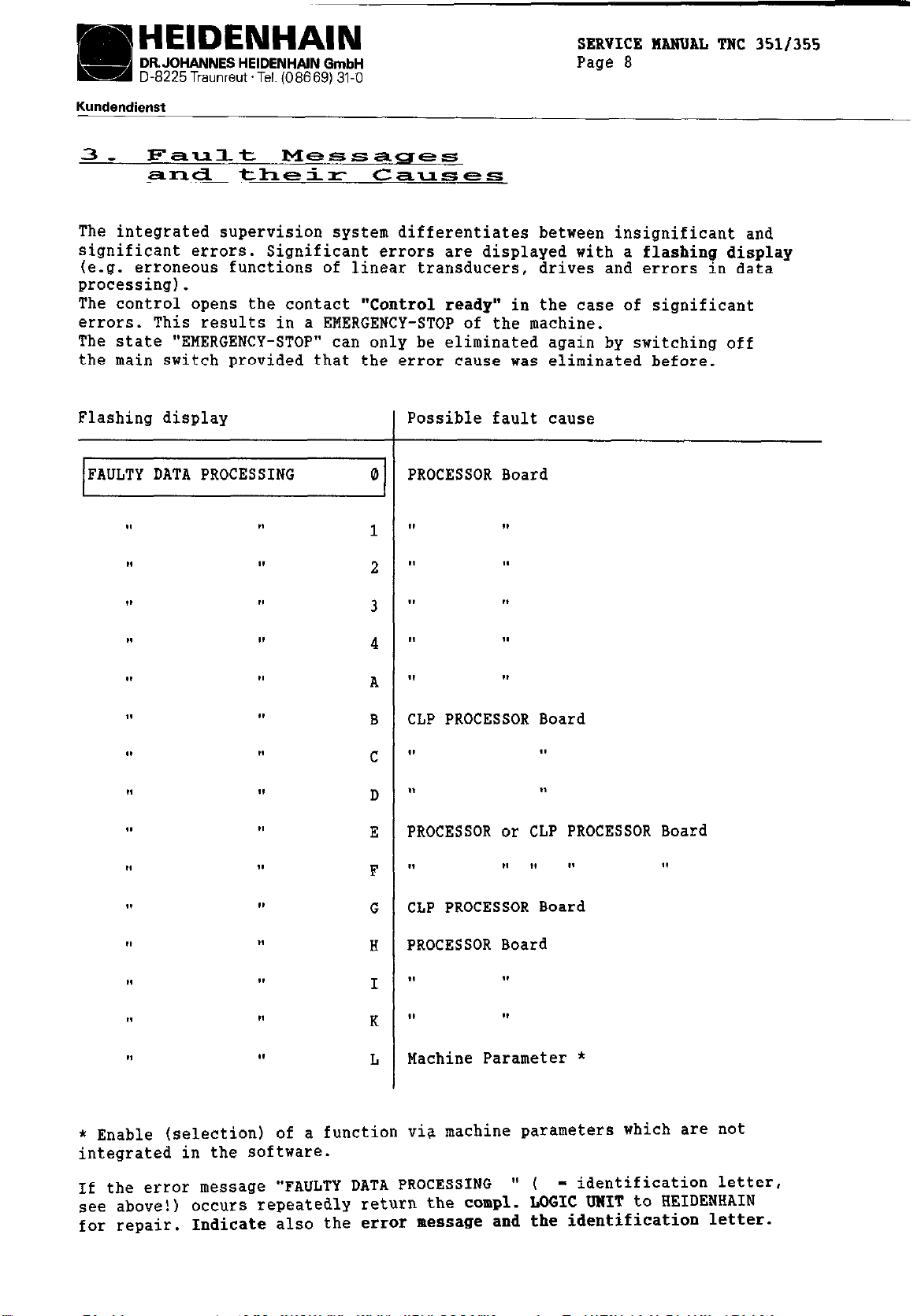

2.2 Possible Causes for Error Messaqes

1 OPERATING PARAMETERS ERASED 1

- The machine parameters are principally erased with new units and exchange

units.

- Software exchange with different software updates

- Buffer batteries and rechargeable NiCd batteries defective

- RAM-error on PROCESSOR Board

SERVICE NANUAL TNC 3511355

Page 7

LIMIT SWITCH Xt

- “Manual” operating mode

When traversing with directional keys the adjusted software limit switch or

the additional limitation in the auxiliary operating modes was reached.

- “Automatic” operating mode

The positioning path calculated with the current block lies out of the software limit switch or out of the additional limitation. The positioning is

not carried out.

Machine parameters for software limit switches

M;F’4 1 M;-45 1 MZ=+46 1 M;-47 1 M;+48 1 M;-49 1 MT,:” I “iv”’ I MPV;25 I MPV;26

SHORT CURRENT INTERRUPTION

- Short collapse of supply to TNC (approx. 120 - 150 ms)

- Important machine parameters were changed; e.g. HP 12, MP 20, MP 60, MP 12,

MP 90, MP 170, MP 184, MP 217, MP 236 etc.

(e.g.)

POSITIONING ERROR

- The position supervision entered in machine parameter 56 or 175 is effec-

tive (control approach behaviour of axis, optimize again, if required).

HEIDENHAIN

DRJOHANNES HElDENHAlN GmbH

D-8225

Kundendienst

SERVICE MANUAL TNC 351/355

Page 8

Traunreut.Tel.(08669)31-0

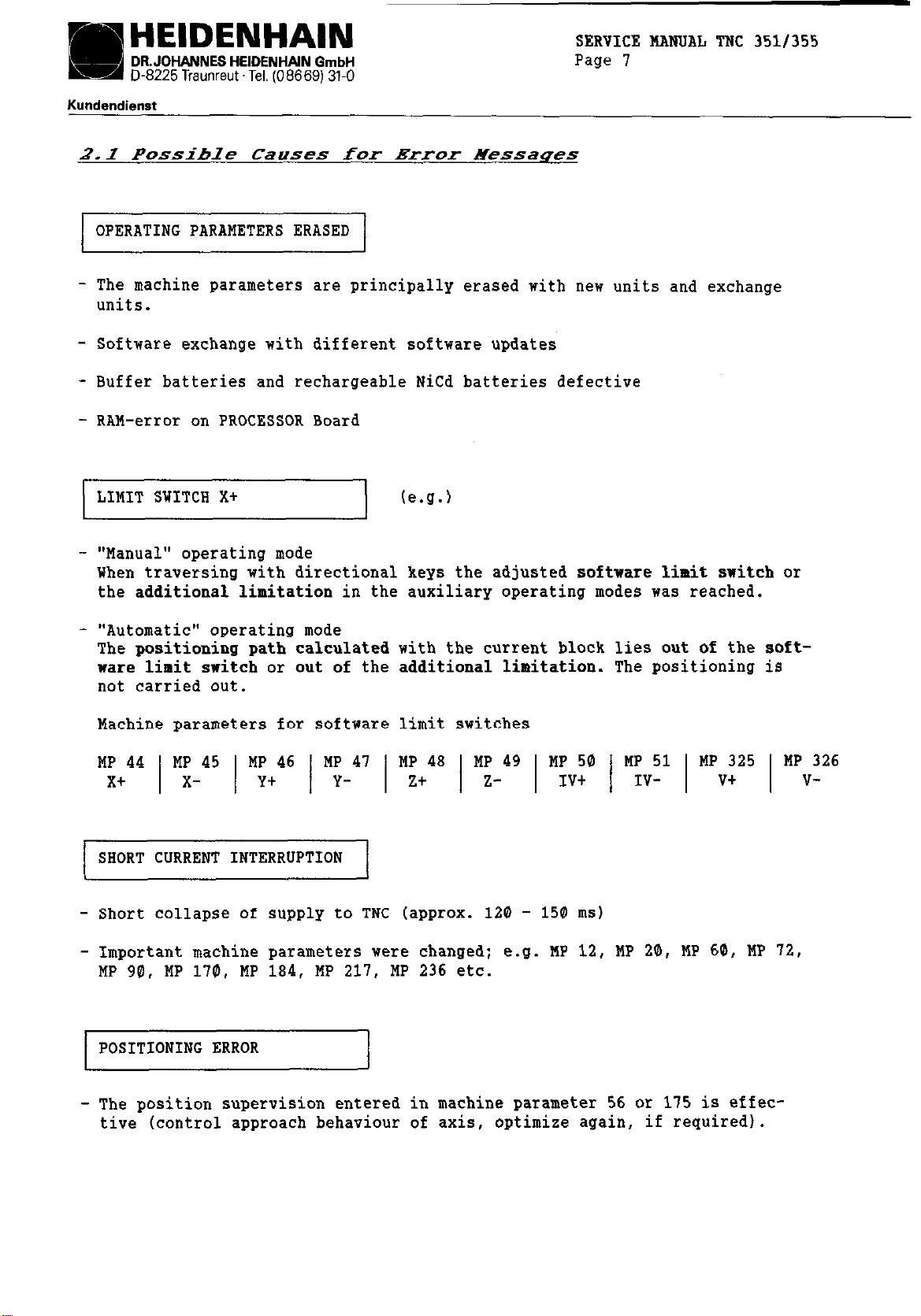

3- Fault

Messages

and their Causes

The integrated supervision system differentiates between insignificant and

significant errors. Significant errors are displayed with a flashing display

(e.g. erroneous functions of linear transducers,

drives and errors in data

processing).

The control opens the contact "Control ready" in the case of significant

errors. This results in a EMERGENCY-STOP of the machine.

The state “EMERGENCY-STOP” can only be eliminated again by switching off

the main switch provided that the error cause was eliminated before.

Flashing display

FAULTY DATA PROCESSING

Possible fault cause

PROCESSOR Board

0

II II

1

II II

2

II II

3

II II

4

II II

A

CLP PROCESSOR Board

B

II II

C

II II

D

PROCESSOR or CLP PROCESSOR Board

E

II II II II

F

CLP PROCESSOR Board

G

PROCESSOR Board

H

II II

I

II II

K

Machine Parameter *

L

* Enable (selection) of a function via machine parameters which are not

integrated in the software.

If the error message “FAULTY DATA PROCESSING

W ( = identification letter,

see above!) occurs repeatedly return the compl. LOGIC UNIT to HEIDENHAIN

for repair. Indicate also the error message and the identification letter.

HEIDENHAIN

DR. JOHANNES HEIDENHAIN GmbH

D-8225 Traunreut ‘Tel. (08669) 31-O

Kundendienst

SERVICE MANUAL TNC 351/355

Page 9

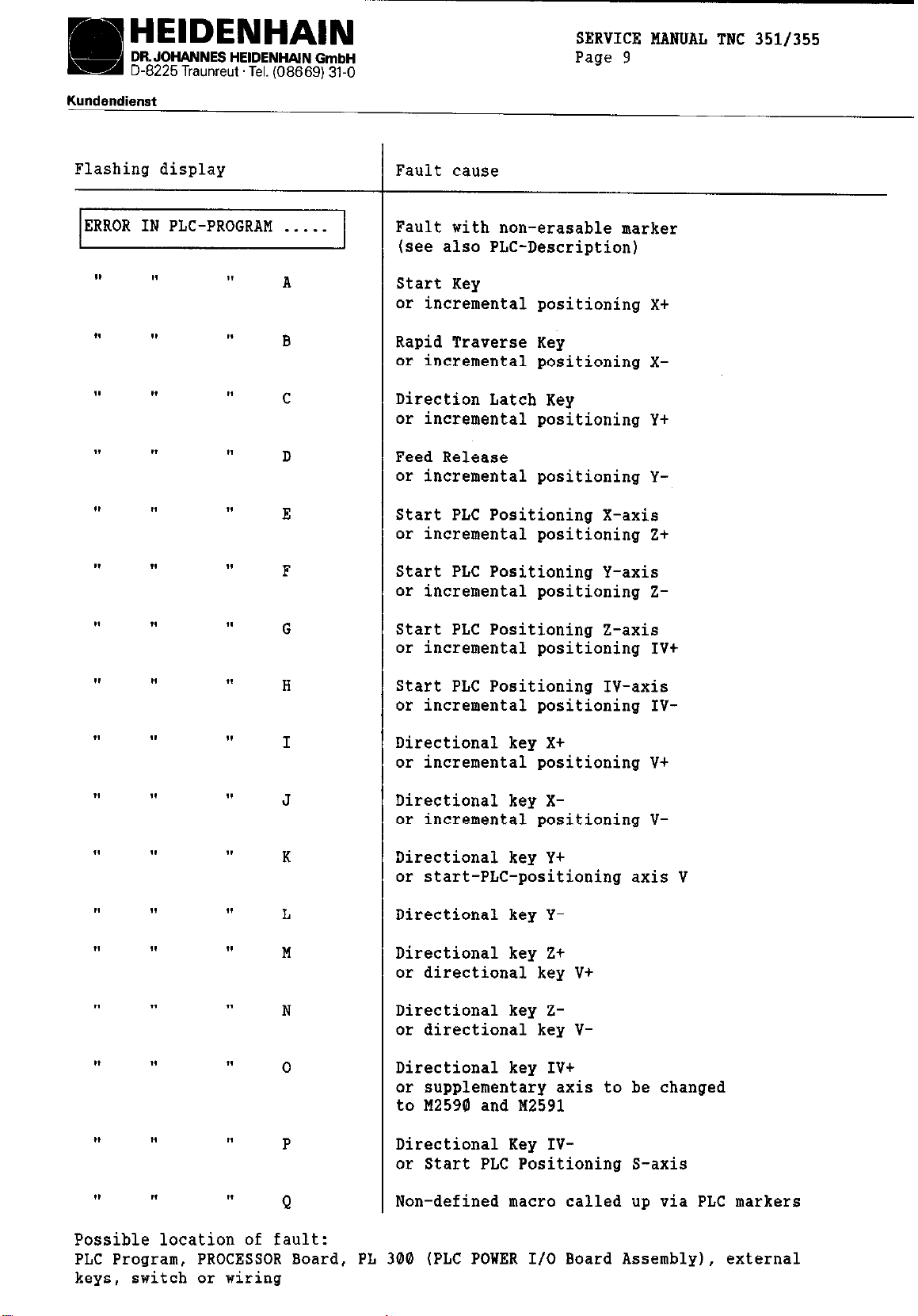

Flashing display

ERROR IN PLC-PROGRAM . . .._

A

B

C

D

E

F

G

Fault cause

Fault with non-erasable marker

(see also PLC-Description)

Start Key

or incremental positioning xt

Rapid Traverse

Key

or incremental positioning XDirection Latch Key

or incremental positioning Yt

Feed Release

or incremental positioning YStart PLC Positioning X-axis

or incremental positioning Zt

Start PLC Positioning Y-axis

or incremental positioning ZStart PLC Positioning Z-axis

or incremental positioning

IV+

H

I

J

K

L

M

N

0

P

Start PLC Positioning IV-axis

or incremental positioning IV-

Directional key Xt

or incremental positioning Vt

Directional key Xor incremental positioning V-

Directional key Yt

or start-PLC-positioning axis V

Directional key YDirectional key Zt

or directional key V+

Directional key Z-

or directional key VDirectional key IV+

or supplementary axis to be changed

to

M2590

and M2591

Directional Key IVor Start PLC Positioning S-axis

Q

Non-defined macro called up via PLC markers

Possible location of fault:

PLC Program, PROCESSOR Board, PL 300 (PLC POWER I/O Board Assembly), external

keys,

switch or wiring

HEIDENHAIN

DR. JOHANNES HEIDENHAJN GmbH

D-8225 Traunreut ‘Tel. (08669) 31-O

Kundendienst

SERVICE NANUAL TNC 351/355

Page 10

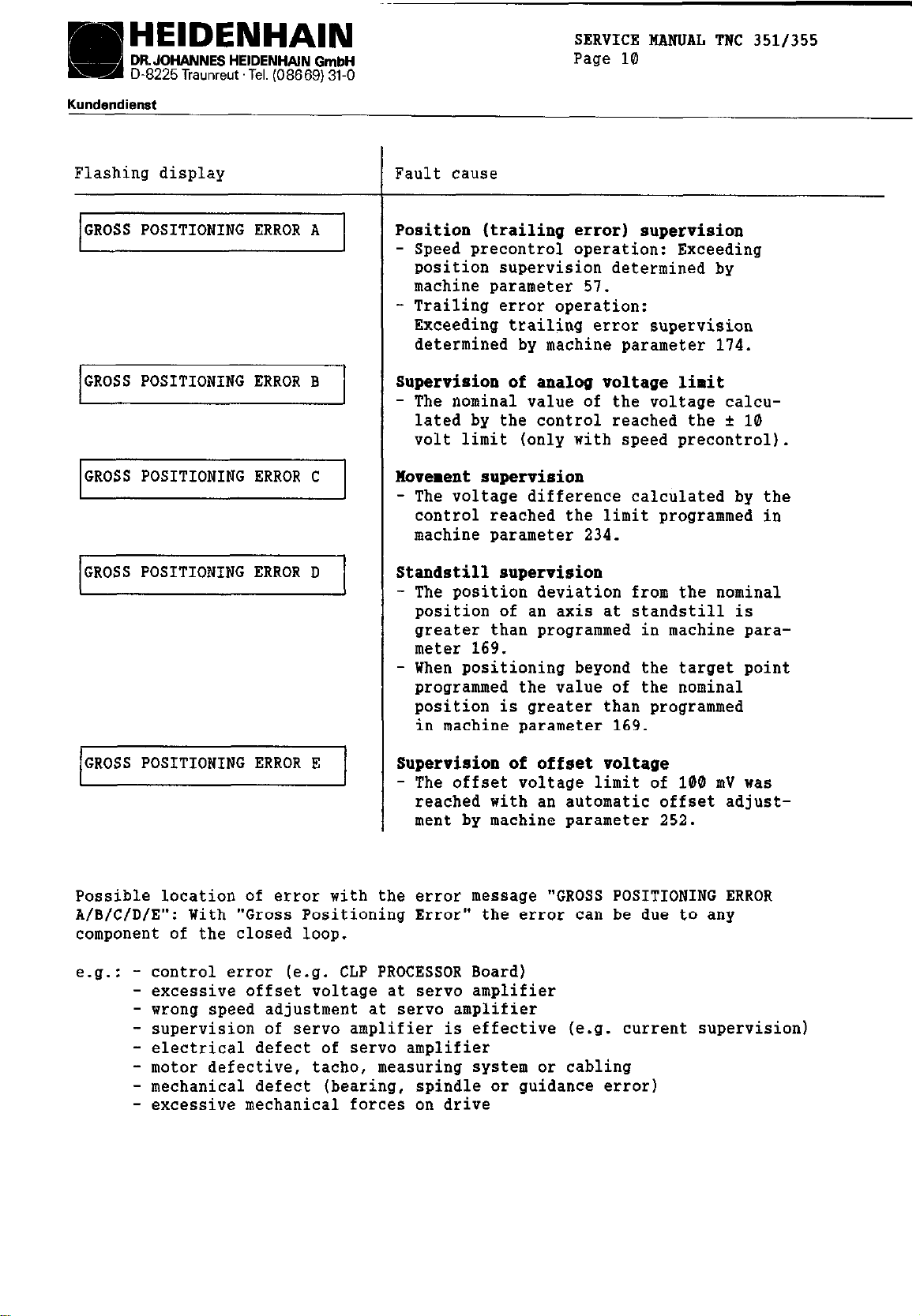

Flashing display

/GROSS POSITIONING ERROR A 1

/GROSS POSITIONING ERROR B 1

GROSS POSITIONING ERROR C

GROSS POSITIONING ERROR D

Fault cause

Position (trailing error) supervision

- Speed precontrol operation: Exceeding

position supervision determined by

machine parameter 57.

- Trailing error operation:

Exceeding trailing error supervision

determined by machine parameter 174.

Supervision of analog voltage limit

- The nominal value of the voltage calcu-

lated by the control reached the f 10

volt limit (only with speed precontrol).

Move8ent supervision

- The voltage difference calculated by the

control reached the limit programmed in

machine parameter 234.

Standstill supervision

- The position deviation from the nominal

position of an axis at standstill is

greater than programmed in machine parameter 169.

- When positioning beyond the target point

programmed the value of the nominal

position is greater than programmed

in machine parameter 169.

GROSS POSITIONING ERROR E

Possible location of error with the error message “GROSS POSITIONING ERROR

A/B/C/D/E":

component of the closed loop.

e.g. :

- control error (e.g. CLP PROCESSOR Board)

- excessive offset voltage at servo amplifier

- wrong speed adjustment at servo amplifier

- supervision of servo amplifier is effective (e.g. current supervision)

- electrical defect of servo amplifier

- motor defective, tacho, measuring system or cabling

- mechanical defect (bearing, spindle or guidance error)

- excessive mechanical forces on drive

With “Gross Positioning Error” the error can be due to any

Supervision of offset voltage

- The offset voltage limit of 100 mV was

reached with an automatic offset adjustment by machine parameter 252.

HEIDENHAIN

DRJOHANNES HEIDENHAIN GmbH

D-8225 Traunreut ‘Tel. (08669) 31-O

Kundendienst

SERVICE KANUAL TNC 351/355

Page 11

Flashing display

TRANSDUCER X DEFECTIVE A

TRANSDUCER X DEFECTIVE B

WRONG REFERENCE POINT

I

1

Fault cause

Fault code: A = signal amplitude fault

B = signal frequency fault

- Measuring system not connected

- Cable damaged

- Glass scale dirty or damaged

- Scanning head damaged

- Measuring system supervision defective

(CLP PROCESSOR Board)

Supervision of measuring systems, see section a.3

Wrong distance of reference mark with transducers having distance-coded reference marks

(counting error caused by measuring system

or LOGIC Unit).

TNC OPERATING TEMP. EXCEEDED

EMERGENCY STOP DEFECTIVE

IEMERGENCY STOP PLC

PLC: ERROR 00

to

PLC: ERROR 99

1) Instead of PLC: ERROR 00 . . . 99, also another dialog may appear with a

customized PLC-program. Detailled information can be obtained from the

machine manufacturer.

Temperature in the inner side of the LOGIC

Unit greater than t65OC.

- Fault with the supervision routine for the

I

I,

1,

output "Control Ready" when switching on

machine (see section 14.3).

The error message only appears if marker

2815 is set without additional markers

CM2924 - M3023).

Marker 2924

to and marker 2815 was set

Marker 3023

HEIDENHAIN

DRJOHMJNES HEIDENHAIN GmbH

D-8225 Traunreut ‘Tel. (08669) 31-O

Kundendienst

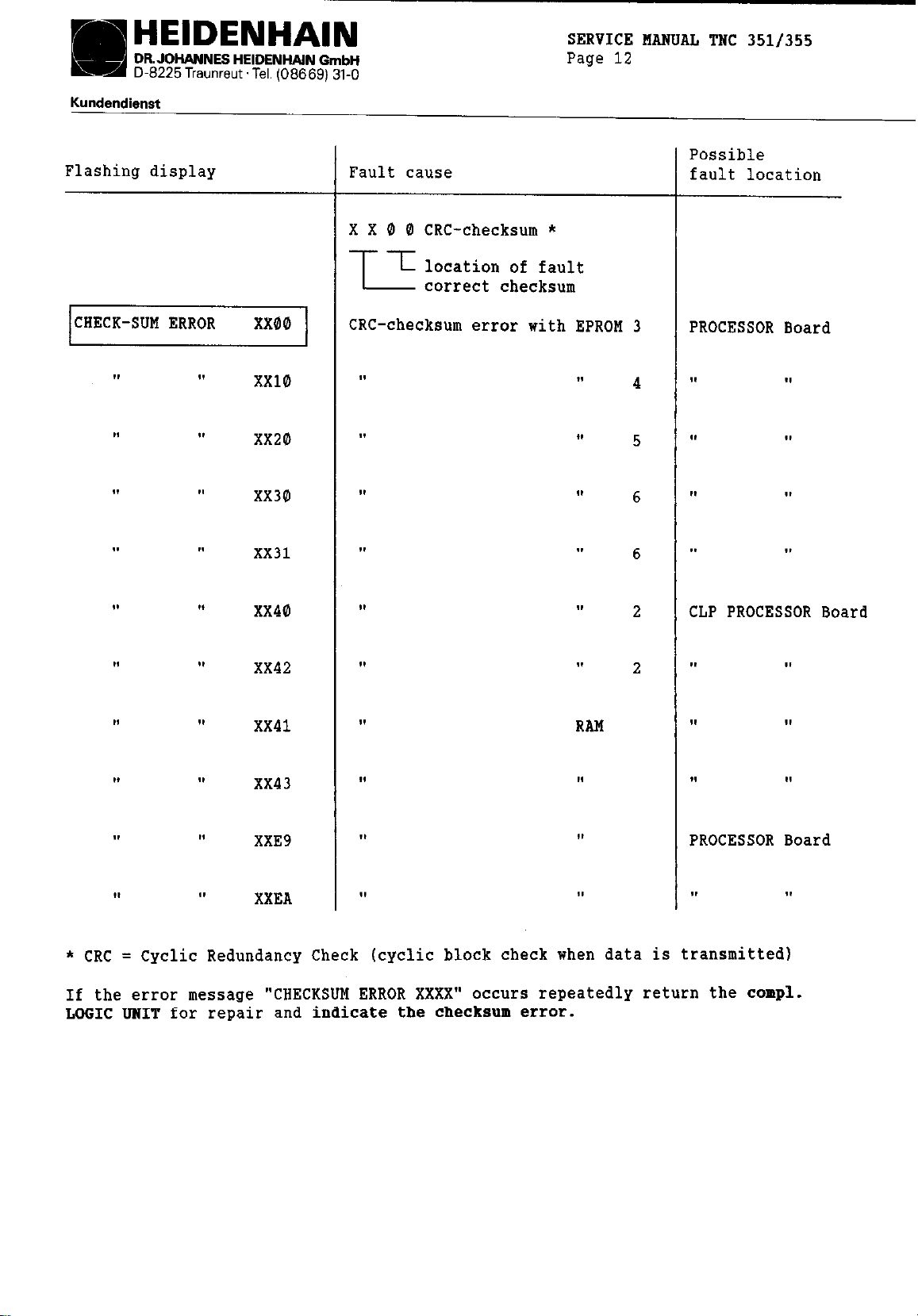

Flashing display

Fault cause

X X 0 0 CRC-checksum *

71 location of fault

correct checksum

SERVICE MANUAL TNC 351/355

Page 12

Possible

fault location

CHECK-SUM ERROR

xx00 1

xx10

xx20

XX30

xx31

XX40

XX42

xx41

xx43

CRC-checksum error with EPROM 3

RAM

PROCESSOR Board

CLP PROCESSOR Board

II II

XXE9

PROCESSOR Board

XXEA

* CRC = Cyclic Redundancy Check (cyclic block check when data is transmitted)

If the error message "CHECKSUM ERROR XXXX" occurs repeatedly return the compl.

LOGIC UNIT for repair and indicate the checksum error.

HEIDENHAIN

DR. JOHANNES HEIDENHAIN GmbH

D-8225Traunreut.Tel.(08669) 31-O

Kundendienst

SERVICE MANUAL TNC 351/355

Page 13

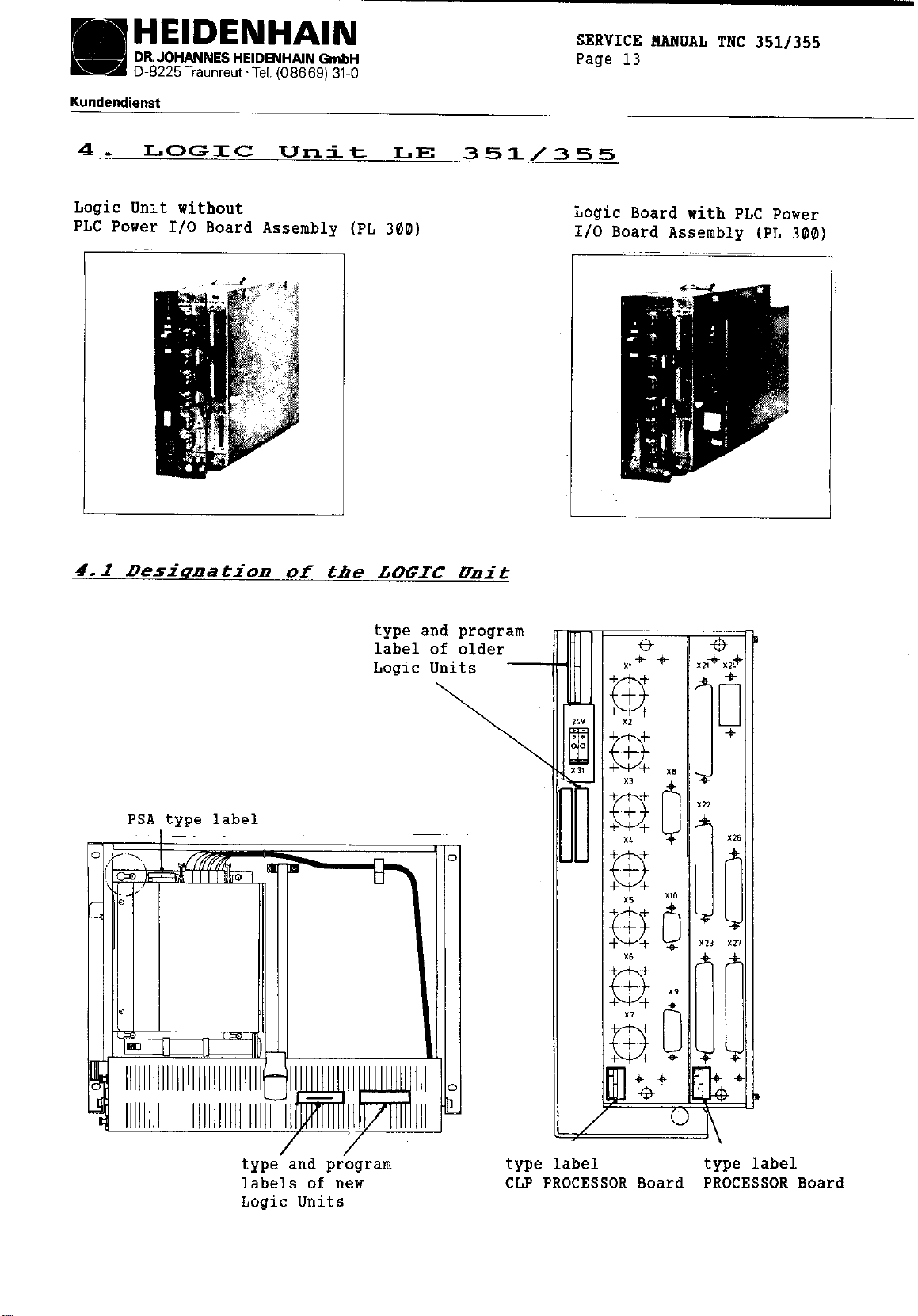

4,

LOGIC Unit LE

35x/355

Logic Unit without

PLC Power I/O Board Assembly (PL 300)

4.1 Desiunation of the LOGIC Unit

Logic Board with PLC Power

I/O Board Assembly (PL 300)

type and program

label of older

Logic Units

type and program

labels of new

Logic Units

type label

type label

CLP PROCESSOR Board PROCESSOR Board

HEIDENHAIN

DR. JOHANNES HElDENHAlN GmbH

D-8225

Kundendienst

Traunreut.Tel.(08669)31-0

SERVICE NANUAL TNC 3511355

Page 14

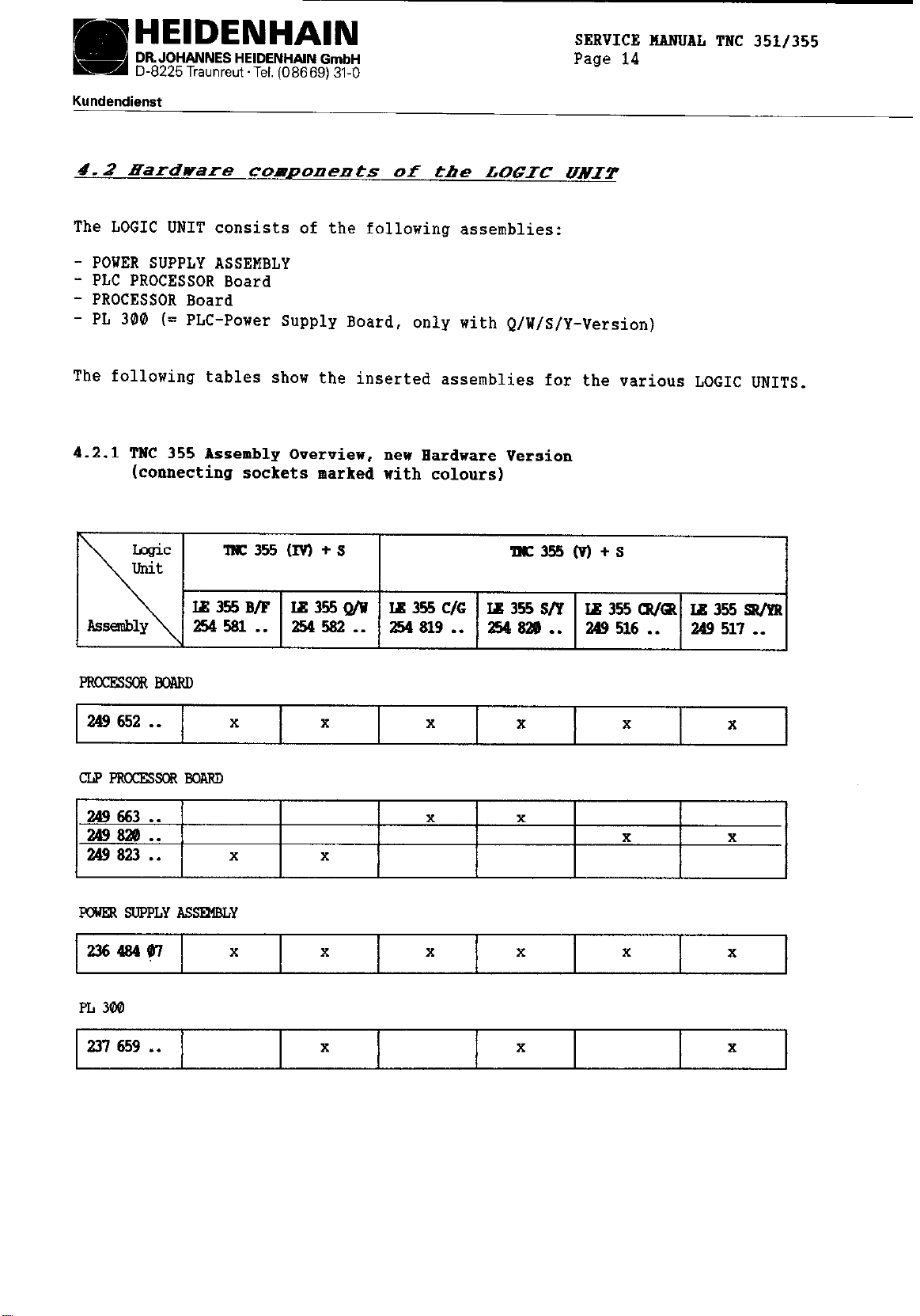

The LOGIC UNIT consists of the following assemblies:

- POWER SUPPLY ASSEMBLY

- PLC PROCESSOR Board

- PROCESSOR Board

- PL 300 (= PLC-Power Supply Board, only with

Q/W/S/Y-Version)

The following tables show the inserted assemblies for the various LOGIC UNITS.

4.2.1 TNC 355 Assembly Overview, new Bardware Version

(connecting sockets marked with colours)

Ig355C/G Is355SpI IE355Wa1 IE355 WYR

254819.. 254a-a..

249 516 . .

24!3 517 . .

249652.. x x x x x x

a49663..

x x

249828 . . x x

249 a23 . .

RmER SUPPLY Asmy

2364a-407

231 659 . .

x x

x x

x

x x x x

x x

HEIDENHAIN

DR. JOHANNES HElDENHAlN GmbH

D-8225

Kundendienst

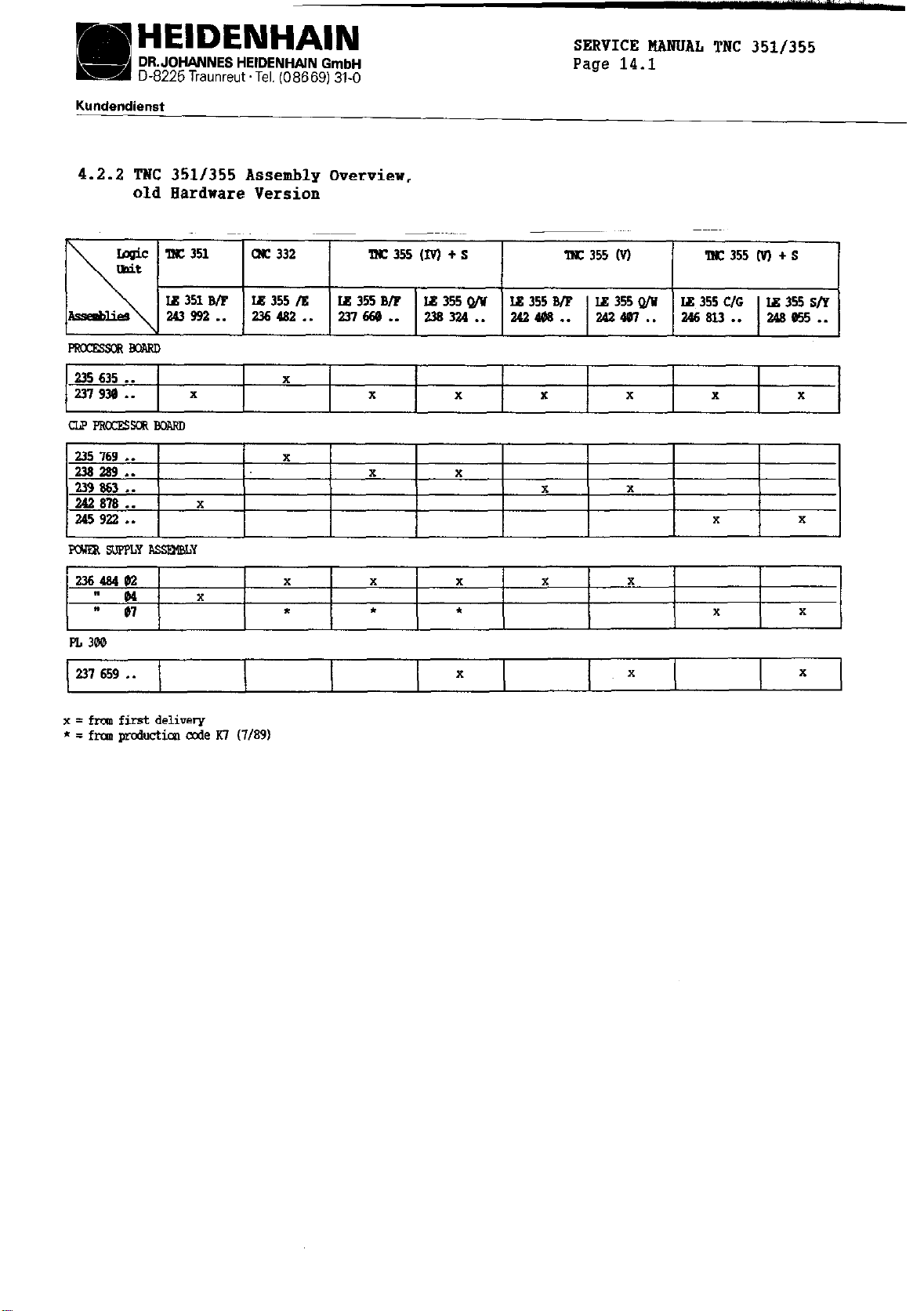

4.2.2 TNC 351/355 Assembly Overview,

old Hardware Version

Traunreut ‘Tel. (08669) 31-O

oa! 332 ltCE.5 (M +S nC 355 M M: 355 M + S

SERVICE MANUAL TNC 351/355

Page 14.1

xz 355 m la 355 n/p IB 355 p/w la 355 a/F la 355 Q/n

2.36482 . . x3766( . .

F7+oIsmBoARD

235635.. I x

23793a.. x

cLPpRocEsscRBoARD

235 769 I. x

238289 . .

239 863 ,.

242 878 . . x

245922 . . x x

2.3608492

I

n

r7 x

PL 300

237 659 . .

x = fmn first delivery

* = fw prcdwticm ade K7 (7/89)

x x x x

*

x

x x

* *

2.38324.. 242aea.. 242407.. 246m.. 24se55..

x x x

I

x x

x

x x

IE 355 C/G lx 355 s/Y

x x

x

x

x

HEIDENHAIN

DRJOHMINES HEIDENI-WN GmbH

D-8225 Traunreut ‘Tel. (08669) 31-O

Kundendienst

SERVICE MANUAL TWC 351/355

Page 15

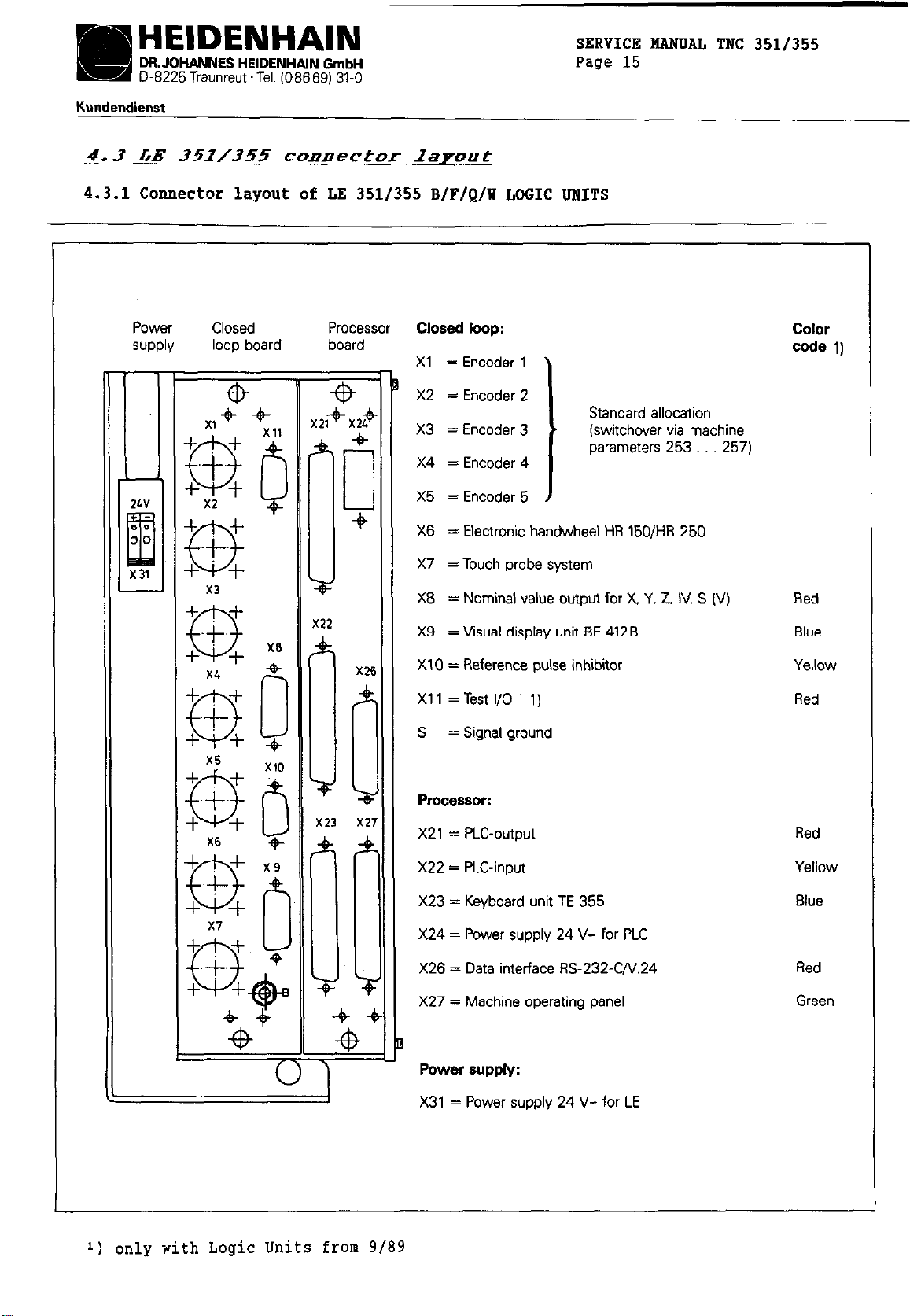

4.3.1 Connector layout of LE 351/355 B/P/Q/Y LOGIC WITS

Power

SUPPlY

Closed

loop board

PRXeSSCN

board

Closed loop:

Xl = Encoder 1

X2 = Encoder 2

Standard allocation

X3 = Encoder 3

X4 = Encoder 4

X5 = Encoder 5 I

X6 = Electronic handwheel HR 150/HR 250

X7 = Touch probe system

X8 = Nominal value output for X, Y. Z. IV. S (V)

X9 = Visual display unit BE 4128

X10 = Reference pulse inhibitor

X11 =Test I/O 1)

S = Signal ground

(switchover via machine

parameters 253 257)

Color

cde 1)

Red

Blue

Yellow

Red

1) only with Logic Units from 9/89

Processor:

x21 = PLC-output

X22 = PLC-input

X23 = Keyboard unit TE 355

X24 = Power supply 24 V- for PLC

X26 = Data interface RS-232.C/V.24

X27 = Machine operating panel

Power supply:

X31 = Power supply 24 V- for LE

Red

Yellow

Blue

Red

Green

HEIDENHAIN

DRJOHANNES HElDENHAlN GmbH

D-8225

Kundendienst

SERVICE KANUAL TNC 351/355

Page 15.1

Traunreut ‘Tel. (08669) 31-O

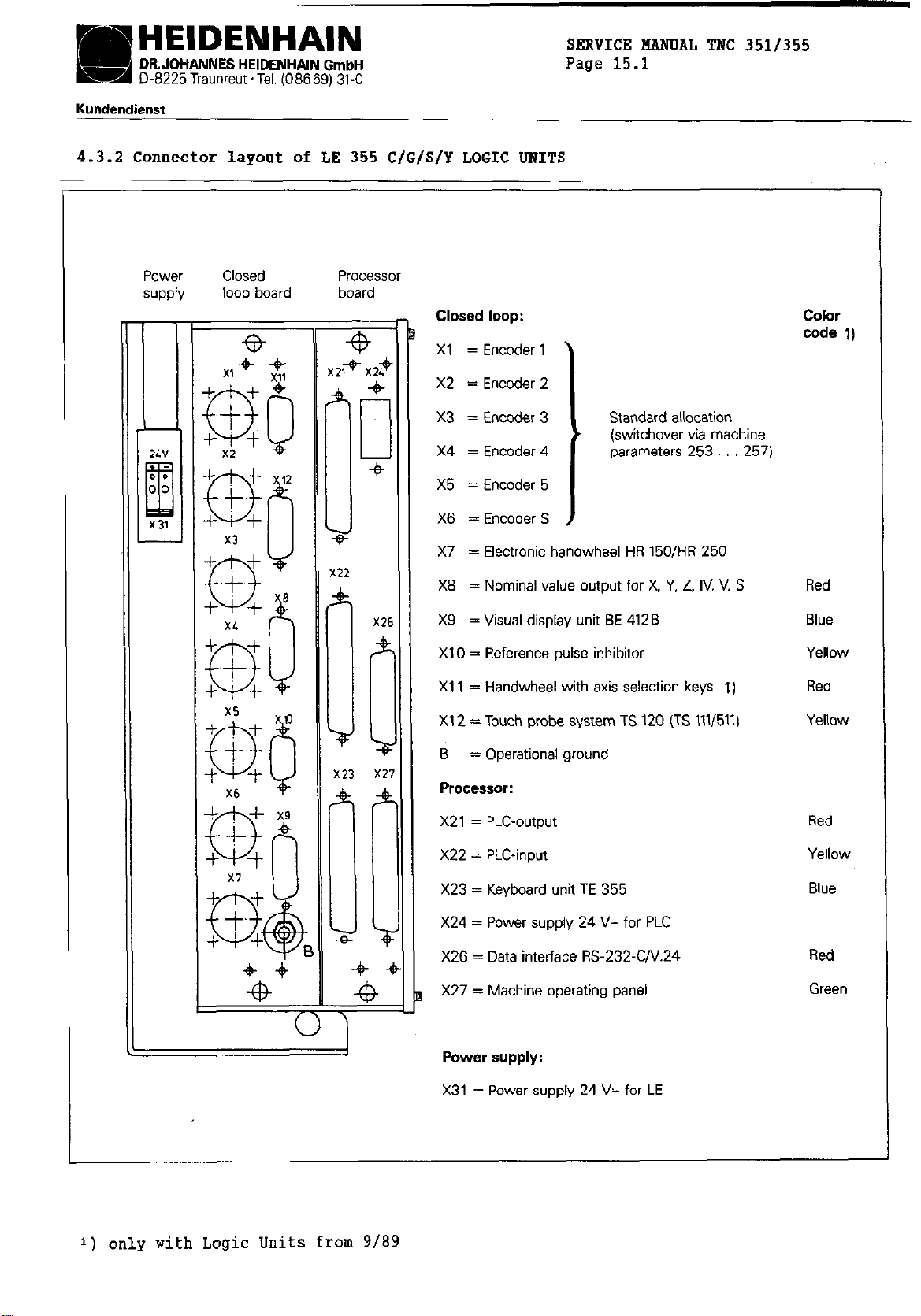

4.3.2

Connector

Power

SuPPlY

layout of LE 355 C/G/S/Y LOGIC UNITS

Closed

loop board

Processor

board

Closed loop:

Xl = Encoder 1

X2

= Encoder 2

X3

= Encoder 3

X4 = Encoder 4

X5 = Encoder 5

X6

= Encoder S

X7 = Electronic handwheel HR 150/HR 250

X8 = Nominal value output for X. Y. Z. IV. V. S

Standard allocation

,

(switchover via machine

parameters 253 257)

C&Jr

code 1)

Red

X9 = Visual display unit BE 4128

X10 = Reference pulse inhibitor

Xl 1 = Handwheel with axis selection keys 1)

Xl 2 = Touch probe system TS 120 (TS lW511)

B = Operational ground

Processor:

x21 = PLC-output

X22 = PLC-input

X23 = Keyboard unit TE 355

X24

= Power supply 24 V- for PLC

X26

= Data interface RS-232.W.24

X27 = Machine operating panel

Power supply:

Blue

Yellow

Red

Yellow

Red

Yellow

Blue

Red

Green

1) only with Logic Units from 9/89

X31 = Power supply 24 V- for LE

HEIDENHAIN

DRJOHANNES HEIDENHAJN GmbH

D-8225 Traunreut ‘Tel. (08669) 31-O

Kundendienst

SERVICE HANUAL TNC 3511355

Page 15.2

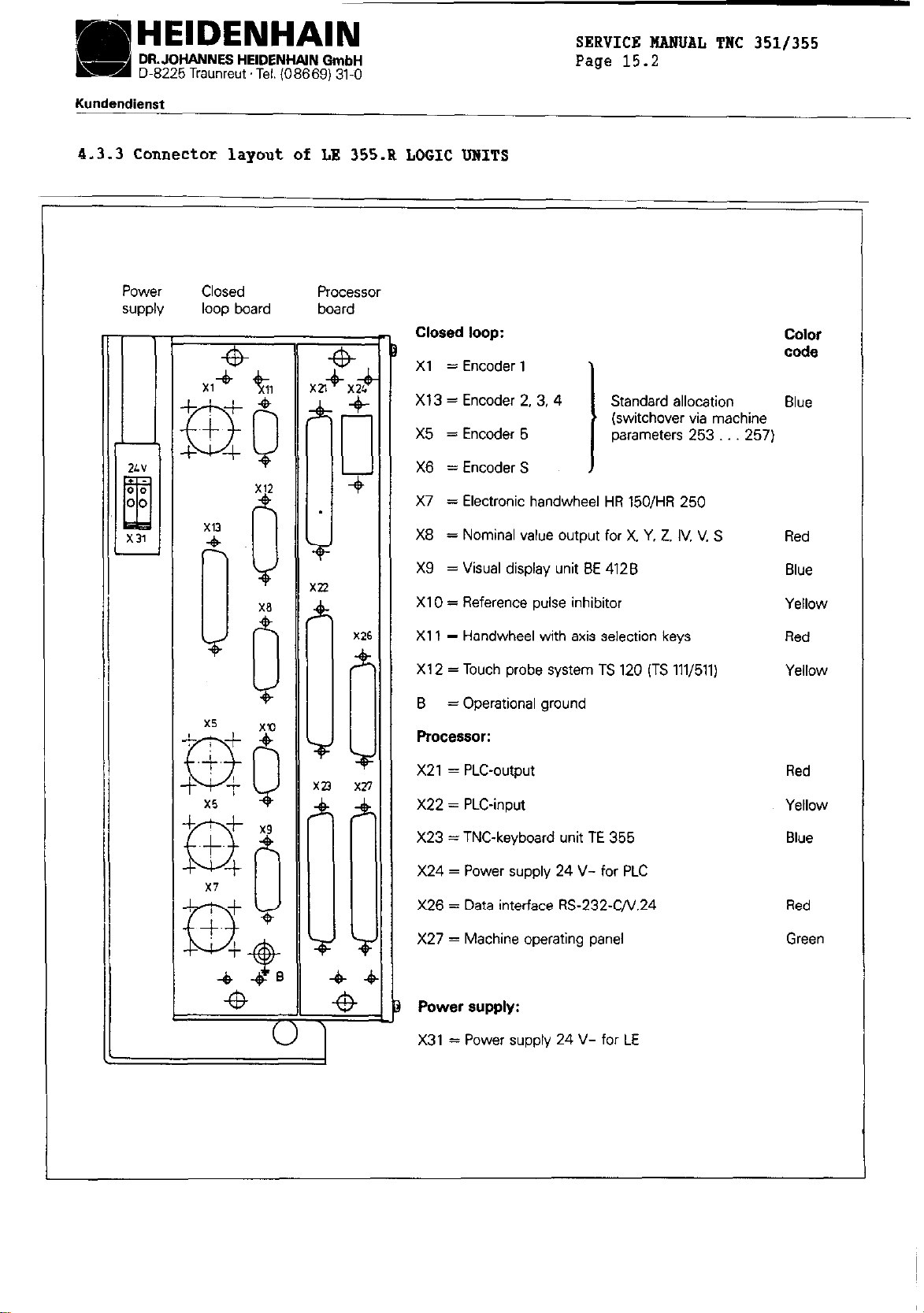

4.3.3

Connector layout

Power Closed

SUPPlY

loop board

of

LE 355-R LOGIC UNITS

PRXeSSOr

board

Closed loop:

Xl = Encoder 1

Xl 3 = Encoder 2, 3. 4

X5 = Encoder 5

X6 = Encoder S

X7 = Electronic handwheel HR 150/HR 250

X8 = Nominal value output for X, Y. Z. IV. V. S

X9 = Visual display unit BE 4126

Xl 0 = Reference pulse inhibitor

Color

code

Standard allocation Blue

(switchover via machine

parameters 253 257)

Red

Blue

Yellow

Xl 1 = Handwheel with axis selection keys

Xl 2 = Touch probe system TS 120 ITS W/511)

8 = Operational ground

Processor:

x21 = PLC-output

X22 = PLC-input

X23 = TNC-keyboard unit TE 355

X24 = Power supply 24 V- for PLC

X26 = Data interface RS-232~C/V.24

X27 = Machine operating panel

Power supply:

X31 = Power supply 24 V- for LE

Red

Yellow

Red

Yellow

Blue

Red

Green

HEIDENHAIN

DRJOHANNES HEIDENHAIN GmbH

D-8225 Traunreut .Tel. (08669) 31-O

Kundendienst

SERVICE MANUAL TNC 351/355

Page 16

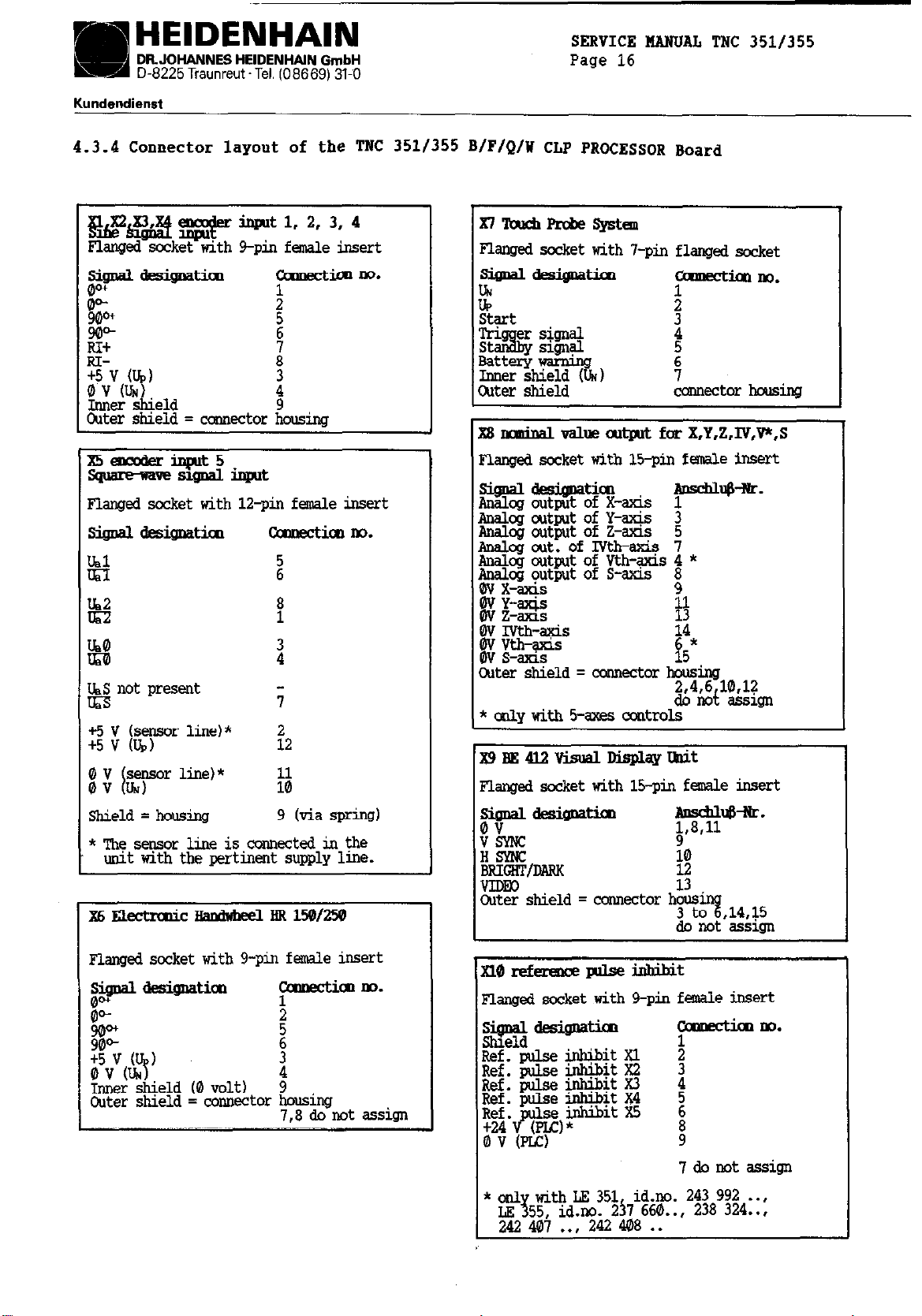

4.3.4

Connector

&$2&&f~inpltl.2.3,4

Flanged socket rnth P-pin female insert

x5Qaderinplt5

scluarerave~*~

Flanged socket with la-pin feaaJ.e insert

sigoal designatim

89

layout of the TNC 351/355 B/F/Q/W CLP PROCESSOR Roard

w.

z

1

x7lbudtPrcaesystem

IQnwd socket with 7-pin flanged socket

siQnaldesignatim

ui 1

x8 IlLmiml value altplt fcu x,Y,z,IV,w,s

Flaged socket with U-pin female insert

no.

iis

%

8% n0t presmt

t5 v bnsor line)*

+5 v (UP,)

8; gymline)*

I

Shield = housing

*Thesensorliaeiscunnect&inthe

wit with the pertinent supply line.

X6ElectrmiCBanhheel HR l50l250

FJ.anged socket with P-pin female insert

!

i

;

i2

2

9 (via spring)

xPBE4l2visual~tit

Flanged socket with S-pin female insert

ks,gwldesignatjm

FEY*-

, ,

Kh?c

Hsnc

BRIGHT/m

E shield = connector hous’

xl0referempulseinait

Flanged socket with P-pin female insert

9

g

“g 3 to ,14,&5

do not assign

110.

1

do not assign

I

* ~%i$%fo~5h%~: , 2%%: : :

..,

242 408

. .

HEIDENHAIN

DRJOHANNES HEIDENWN GmbH

D-8225 Traunreut ‘Tel. (08669) 31-O

Kundendienst

SERVICE MANUAL TNC 351/355

Page 16.1

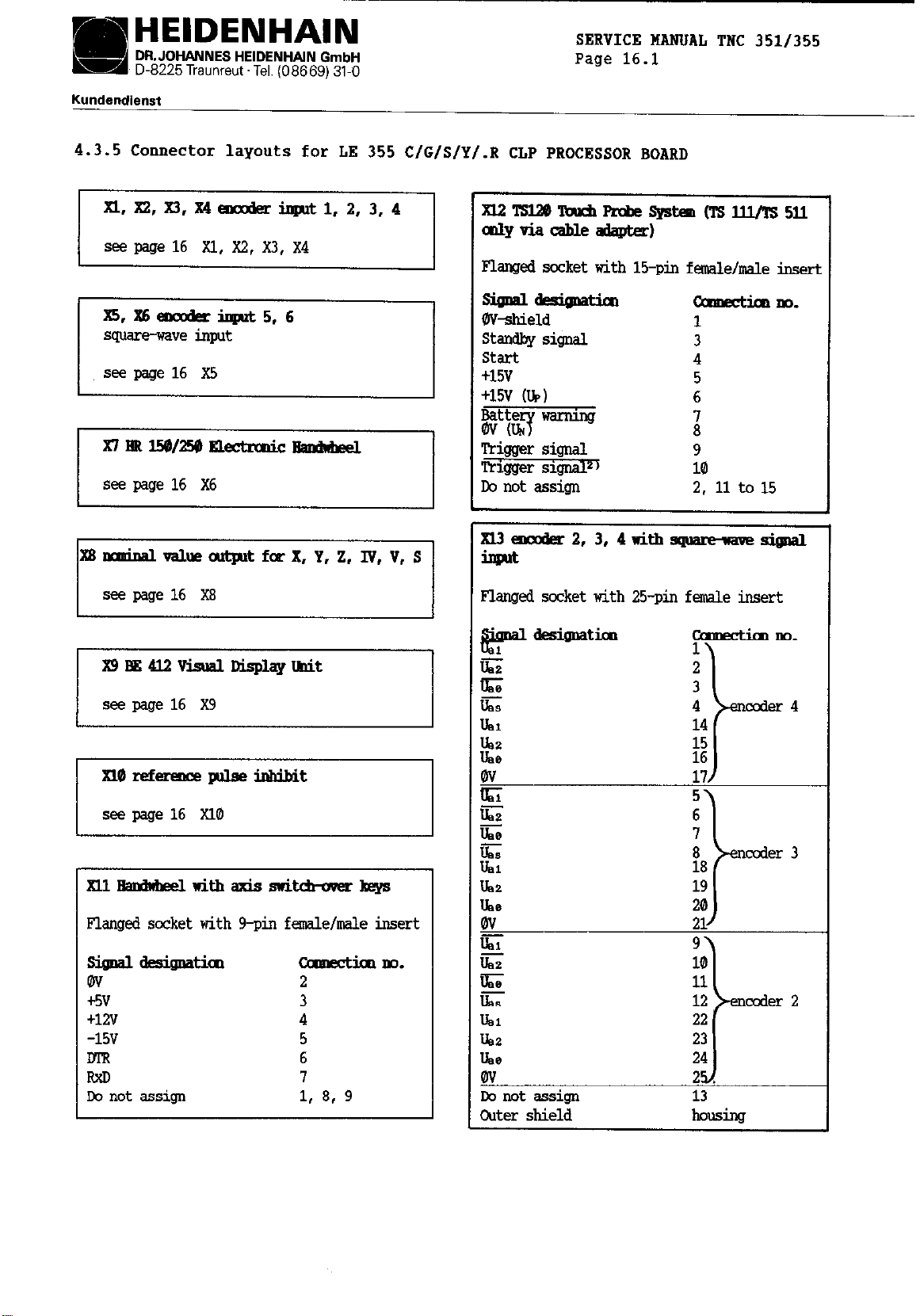

4.3.5 Connector layouts for LE 355 ClGfS1Yf.R CLP PROCESSOR BOARD

xl2lSl2@TarhPrcbsSystmmSlJlrrS5ll

calyticabledapter)

Flanged socket with 15-pin female/m& insert

sigrmldesigna~ ID.

X%X6mccderinplt 5, 6

square-wave input

0V-shield 1

Standby signal

start 4

seepage16 X5

I

t15v

+15v (rp) 6

Ft3 - ;I

~BRl50/250ElebmicBimdrdreel

Trigger signal 9

Trigger signals

see page 16 X6

Donotassign 2, 11 to 15

3

5

10

XRlmxiJml valueanplt fcrX,Y, 2, IV, v, s

seepage16 X8

x9BE422vhalDisplaylbit

see page 16 X9

xl0 ref-

pulseildlibit

seepage16 Xl0

xll-uithaxisswi-keys

Flangadsccketwith g-pin female/male insert

signal~ticm

M.

0v 2

t5v

3

t12v 4

-15v

ml7

RXD

Don&assign

5

6

1

1,

8, 9

Flauged socket with 25-pin female insert

deeguatico

$?

uas

Uat

2:

lLj

Yi" Iy)-

4 coder4

14

:2

2 3 "

& 17 5

G

iiz

6

7

coder3

zi

Da2

Uee

Ov

iiz

us

iiz

Dal

Da2

use

i&T

0-J

Do mt assign

Outer shield

L

!8

19

20

I-

21

10

11

12 coder2

22

23

24

9 i-

2.

13

-ins

HEIDENHAIN

DR. JOHANNES HEIDENHAIN GmbH

D-8225

Kundendienst

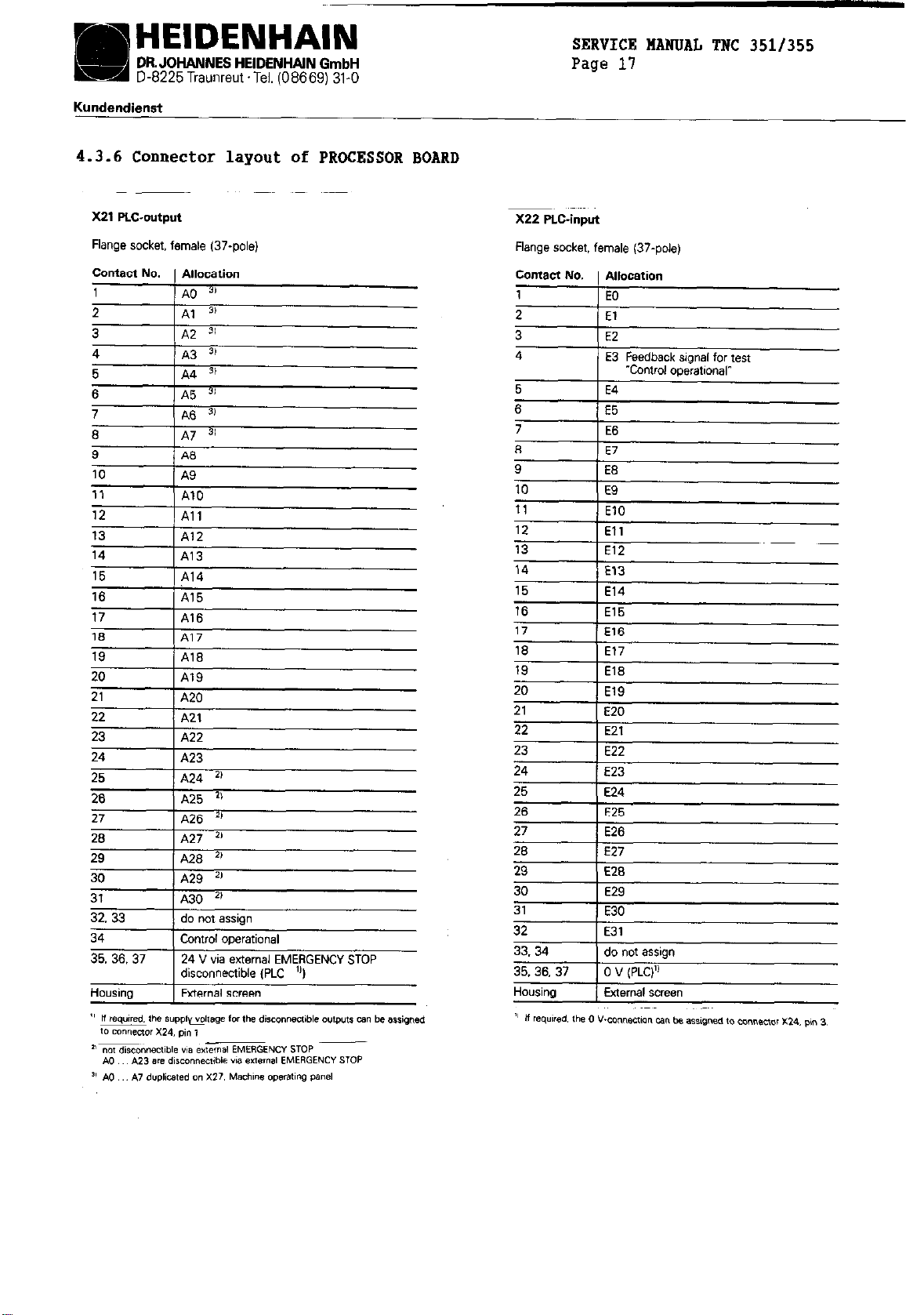

4.3.6 Connector layout of PROCESSOR BOARD

x21

PLC.output

Traunreut .Tel. (08669) 31-O

SERVICE HANUAL TNC 351/355

Page 17

X22 WC-input

Flange socket. female (37-p&)

Contact No.

1

2

3 A2 31

4 A3 31

5 A4 ”

6

7 A6 3’

6

9

10 A9

11

12 All

13 A12

14

15 Al4

16 A15

17 Al6

18 Al7

19 A16

20 A19

21 A20

22 A21

23 A22

24 A23

25

28 A25 21

27 A26 ‘I

26 A27 21

29 A26 ”

30 A29 21

31 A30 ”

32.33

34 Control Operational

35. 36. 37 24 V via etiernal EMERGENCY STOP

Housing External screen

” n required. the suppiygme for me disconnmible oY,p”ts Cal be assigned

10 mnne”orX24. pin 1

“naldisconnenible via external EMERGENCY STOP

110. b.23 are dirconnenlble Yia enem* EMERGENCY STOP

” 00 A7 d”Plicafsd on x*7. Mashine oczer~ti”P Panel

Allocation

A0 3

Al 3’

A5 ‘I

A7 31

A6

A10

Al3

A24 *’

do not assign

disconnetiible (PLC ‘I)

Flange socket. female 137-p&)

6 j E5

7

8

9 1 E8

10 I E9

15 1 El4

16 I El5

17 / El6

16 1 El7

19 I El8

20 1 El9

21

22 1 E21

23 1 E22

29 E26

30 E29

31 E30

35,36. 37 1 0” (PLC)“HCUSi”g Exlernal Screen

I E6

) E7

I

I E20

HEIDENHAIN

DRJOHANNES HEIDENHAN GmbH

D-8225

Traunreut.Tel.(09669)31-0

SERVICE BABUAL TNC 351/355

Page 18

Kundendienat

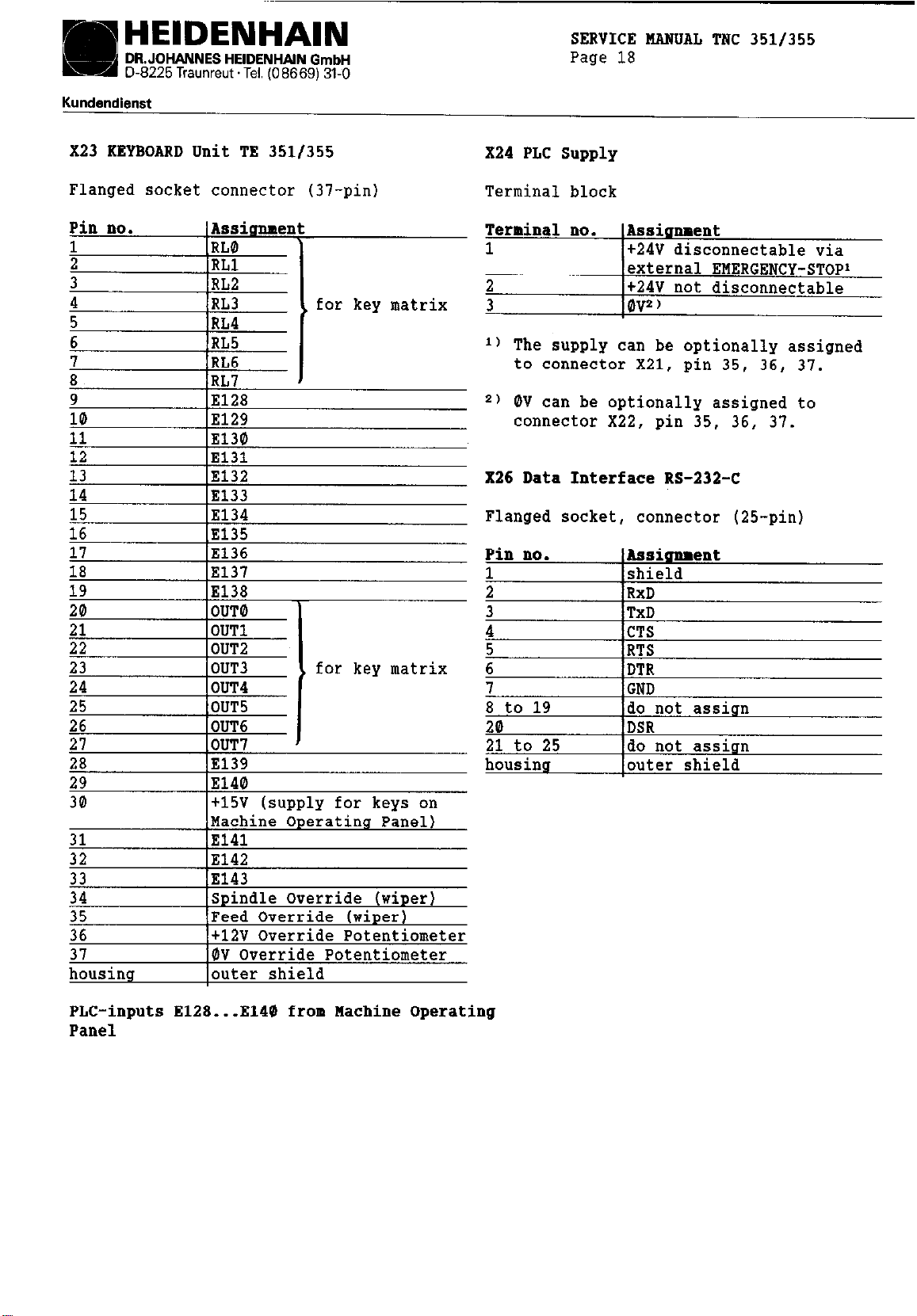

X23 KEYBOARD Unit TE 351/355

Flanged socket connector (37-pin)

Pin no.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

77

28

29

30

Assignment

RLO

RLl

RL2

RL3 , for key matrix

RL4

RL5

RL6

RL7

El28

El29

El30

El31

El32

El33

El34

El35

El36

El37

El38

OUT0

OUT1

OUT2

OUT3 , for key matrix

OUT4

OUT5

OUT6

r-mT7

El39

El40

t15V (supply for keys on

Machine Operating Panel)

31

32

33

34

35

36

37

housing

El41

El42

El43

Spindle Override (wiper)

Feed Override (wiper)

t12V Override Potentiometer

0V Override Potentiometer

outer shield

-

X24 PLC Supply

Terminal block

Terminal no. IAssianment

1

1t24V disconnectable via

Iexternal EMERGENCY-STOP'

2

-4

1t24V not disconnectable

lfiV2)

I) The supply can be optionally assigned

to connector X21, pin 35, 36, 37.

*) 0V can be optionally assigned to

connector X22, pin 35, 36, 37.

X26 Data Interface RS-232-C

Flanged socket, connector (25-pin)

Pin no.

1

A55ignment

shield

2 RxD

3 TxD

4 CTS

5 RTS

6 DTR

7 GND

8 to 19 do not assign

21 to 25

housing

Ido not assign

Iouter shield

PLC-inputs El28 . ..E140 from Hachine Operating

Panel

HEIDENHAIN

DR. JOHANNES HEIDENHAN GmbH

D-8225 Traunreut .Tel. (08669) 31-O

Kundendienst

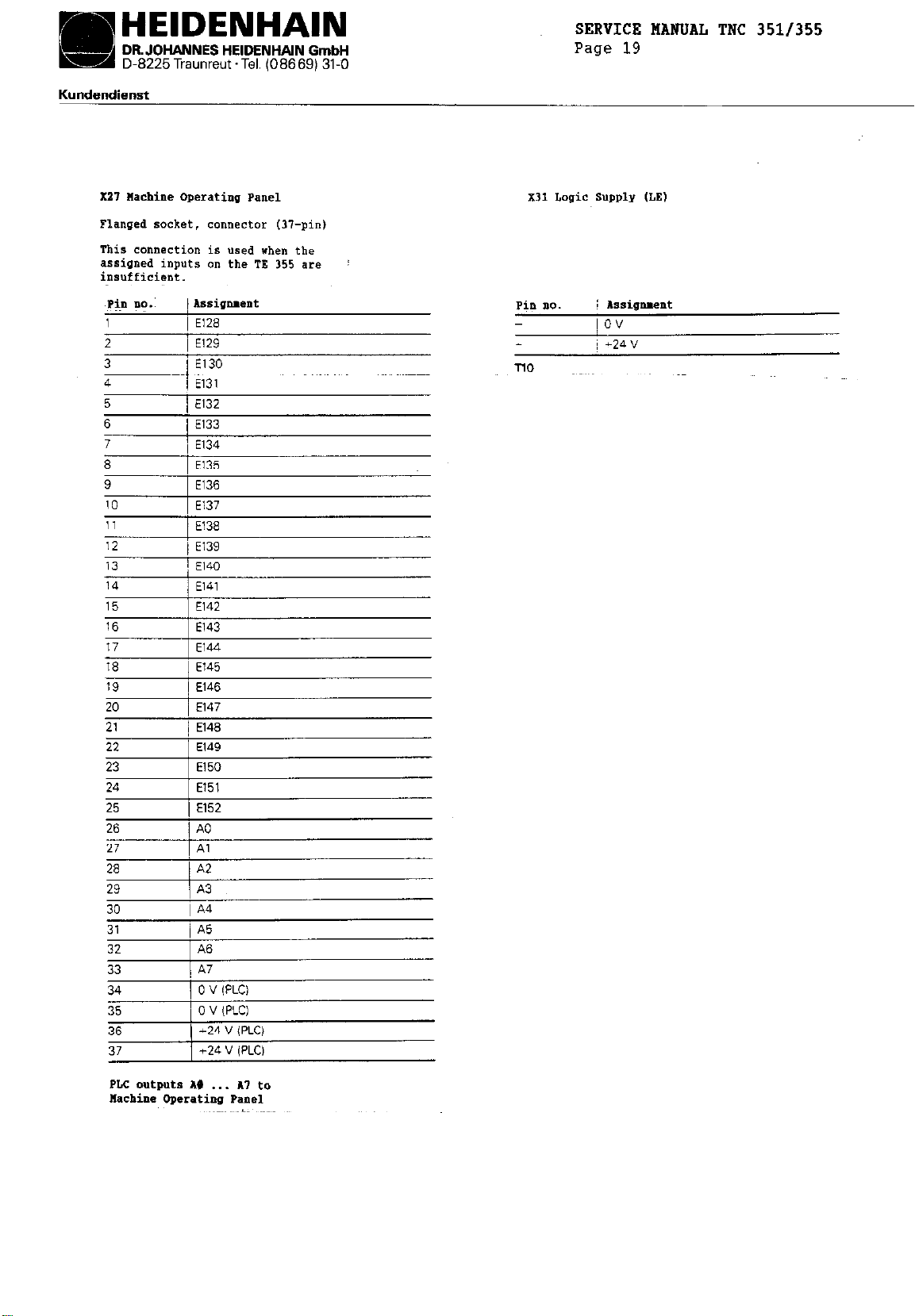

Flanged socket. cOnneCtor UT-pin,

This connection is used *hen the

assipned inputs on the TE 355 are :

insufficient.

SERVICE MANUAL TNC 351/355

Page 19

1

2

3 I

4

5

6

1

El28

i El29

El30

!

El31

/

El32

I

E133

7 i El34

8

12

13

14

15

16

1

El35

j

Et39

! El40

/ El41

E142

1

El43

28

29

30

31

32

33

34

35

36

37

A2

A3

I A4

/ A5

A.6

! 117

I 0 " IPLCI

i 0 V (PLCI

-24 " IPLC)

I +24" IPLCi

HEIDENHAIN

DFLJOHANNES HElDENHAlN GmbH

D-8225 Traunreut ‘Tel. (08669) 31-O

Kundendienst

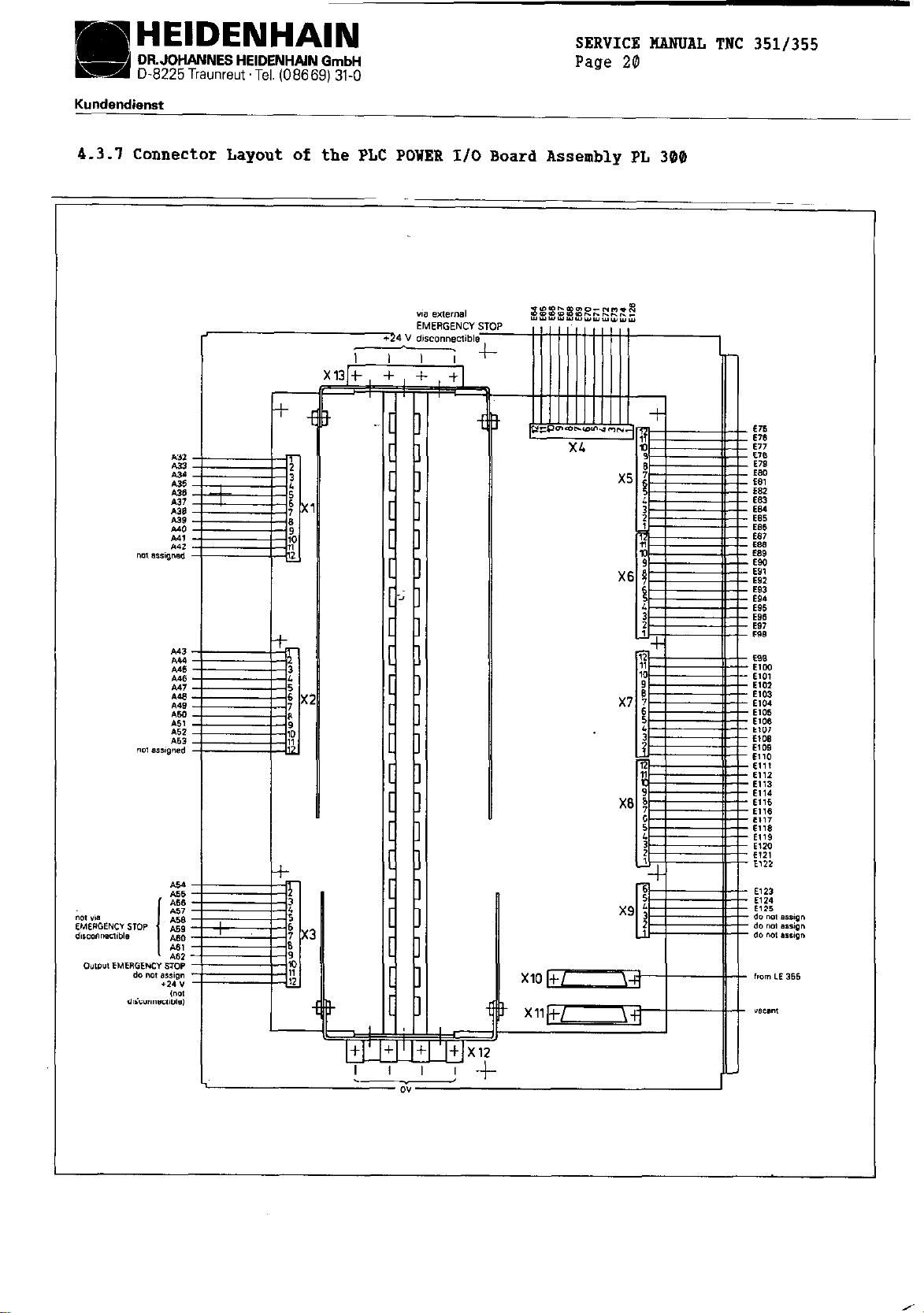

4.3.1 Connector Layout of the PLC POUER I/O Board Assembly PL 300

SERVICE HANUAL TNC 351/355

Page 20

[’ 1

c 1

r 1

[ 1

[I

c I

HEIDENHAIN

DR.JOHANNES HElDENHAlN GmbH

D-8225 Traunreut ‘Tel. (08669) 31-O

Kundendienst

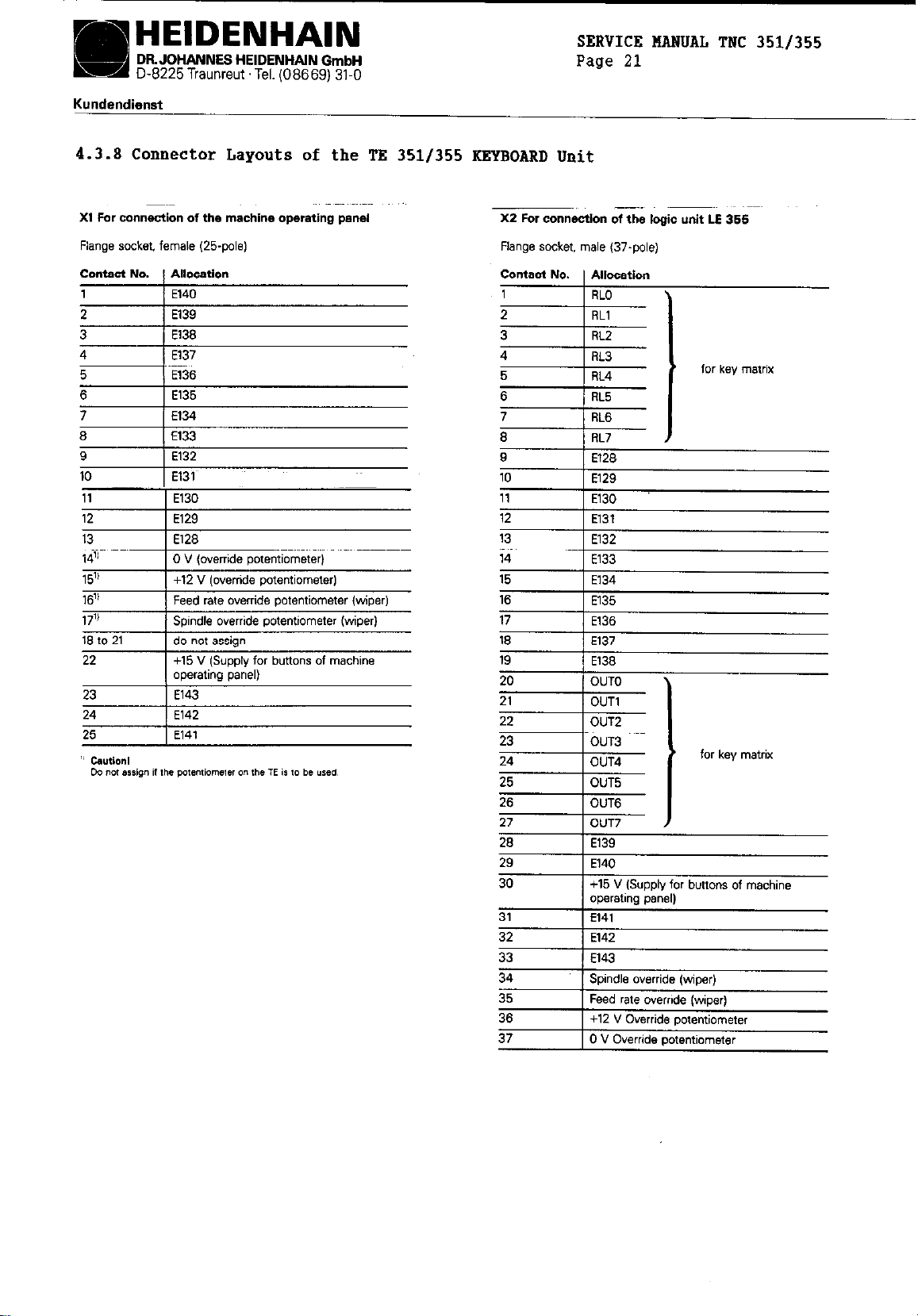

4.3.8 Connector Layouts of the TE 351/355 KEYBOARD Unit

Page 21

SERVICE IMNIJAL TNC 351/355

Xl For conneotion of the machine operating panel

Flange socket female (25.pole)

contact NO. , Allocation

1

2 1 El39

3 / El39

4 1 El37

5 1 El36

7 El34

8 El33

15”

16”

17”

16 to 21

22

23

24

26

1 El40

I

+12 V (override potentiometer)

Feed rate override potentiometer (wiper)

Spindle override potentiometer (wiper)

do not assign

+15 V (Supply for bunons of machine

operating panel)

El43

El42

F141

X2 Far connection of the logic unit LE 365

Flange socket, male (37.pole)

Contact No. I Allocation

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

22

23

24

25

26

21

27

28

29

30

RL5

RL6

RL7 I

El29

El29

El30

El31

El32

El33

El34

El35

El36

El37

El38

OUT0

OUT2

OUT3

OUT4

OUT5

OUT6

OUT1

OUT7 1

El39

El40

+15 V ISupply for buttons of machine

operating mnell

for key matrix

HEIDENHAIN

DRJOHPNNES HEIDENHAJN GmbH

D-8225 Traunreut .Tel. (08669) 31-O

Kundendienst

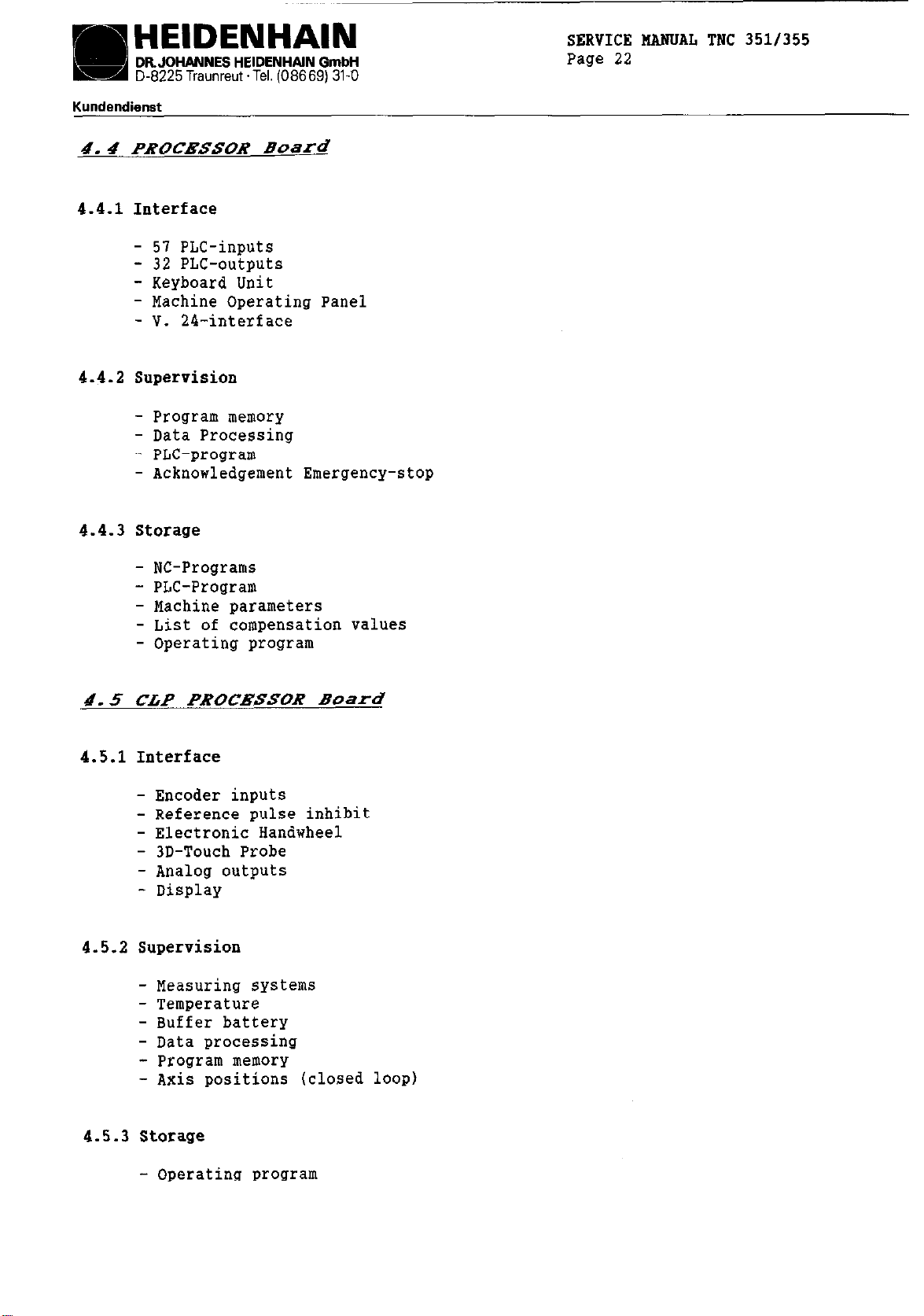

4.4 PROCRSSOR Board

4.4.1 Interface

- 57 PLC-inputs

- 32 PLC-outputs

- Keyboard Unit

- Machine Operating Panel

- V. 24-interface

4.4.2 Supervision

- Program memory

- Data Processing

- PLC-program

- Acknowledgement Emergency-stop

SERVICE HANUAL TNC 351/355

Page 22

4.4.3 Storage

- NC-Programs

- PLC-Program

- Machine parameters

- List of compensation values

- Operating program

4.5 CAP PROCXSSOR Board

4.5.1 Interface

- Encoder inputs

- Reference pulse inhibit

- Electronic Handwheel

- 3D-Touch Probe

- Analog outputs

- Display

4.5.2 Supervision

- Measuring systems

- Temperature

- Buffer battery

- Data processing

- Program memory

- Axis positions (closed loop)

4.5.3

Storage

- Operating program

HEIDENHAIN

DRJOHANNES HElDENHAlN GmbH

D-8225 Traunreut ‘Tel. (08669) 31-O

Kunda ?ndienst

SERVICE HANUAL TNC 351/355

Page 23

Notes

HEIDENHAIN

DR. JOHANNES HEIDENHAJN GmbH

D-8225

Kundendienst

SERVICE MANUAL TNC 351/355

Page 24

Traunreut.Tel.(08669)31-0

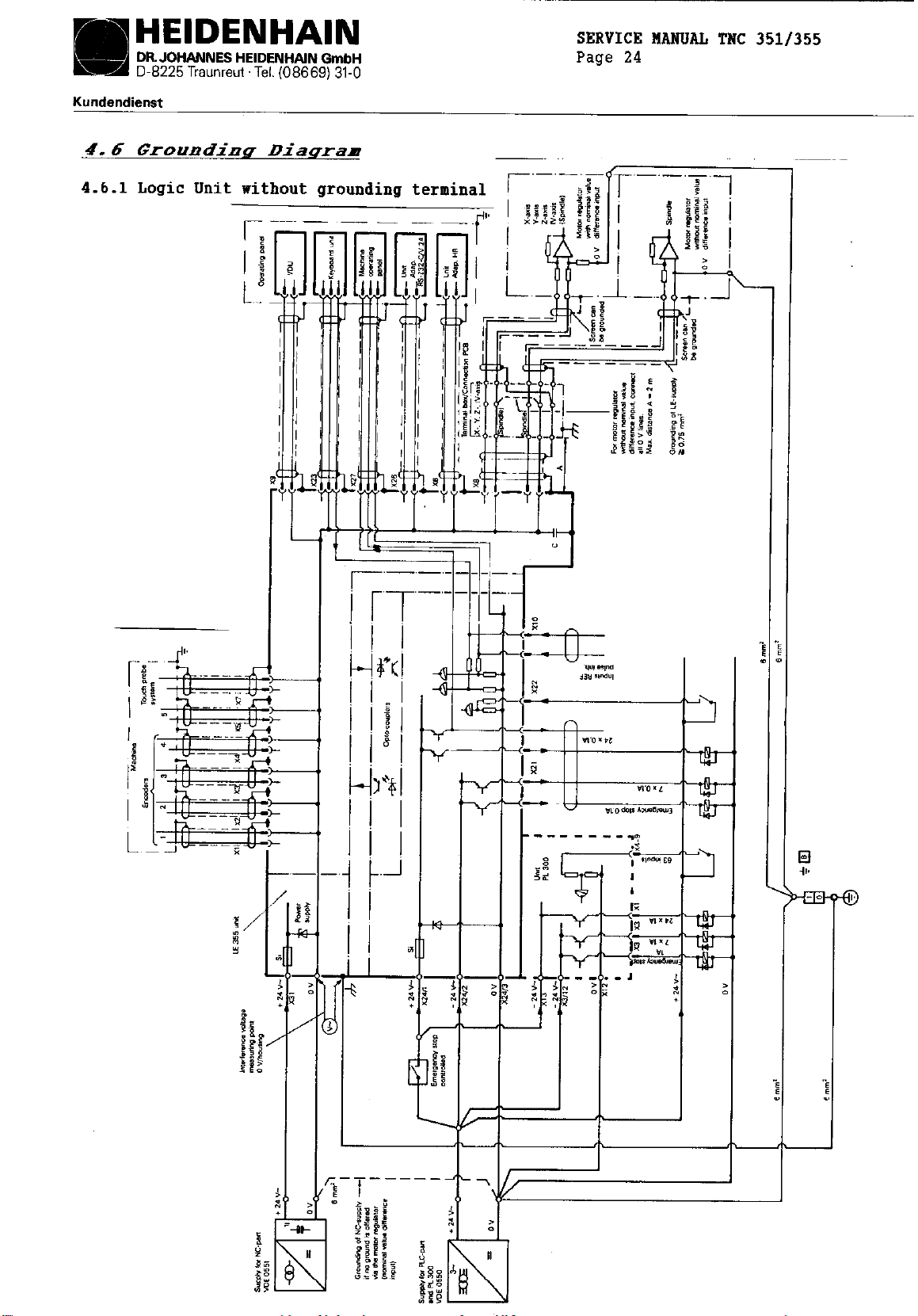

4.6.1 Logic Unit

without grounding terminal

.

-

-

-

-

-

\r’

Y

r

-

-

-

-

<

-

HEIDENHAIN

DR. JOHANNES HElDENHAlN GmbH

D-8225Traunreut~Tel. (08669)31-O

Kundendlanst

SERVICE NANUAL TNC 351/355

Page 24.1

4.6.2

Logic

Unit

with grounding terminal

I

k

I

I I I 1 -

-.-.-.----.

”

T

.

V'

Loading...

Loading...