Page 1

TNC 310

NC Software

286 140-xx

286 160-xx

User's Manual

HEIDENHAIN Conversational

Programming

English (en)

4/2003

Page 2

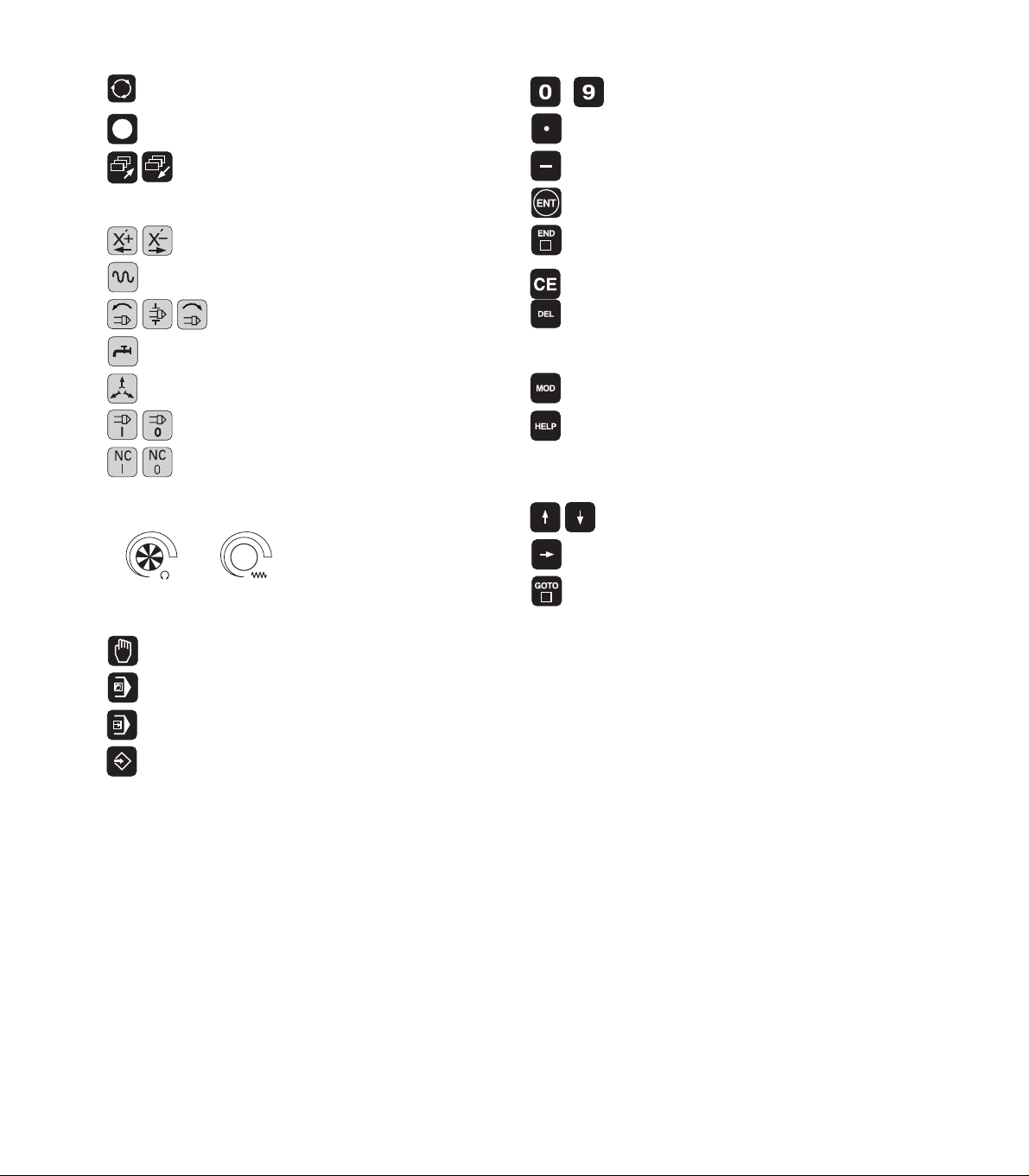

Controls on the visual display unit

Split screen layout

Numerical input, editing

... Numbers

Soft keys

Shift the soft-key rows

Machine control keys

Axis direction

Controls on the TNC

Rapid traverse

Direction of spindle rotation

Coolant

Tool release

Spindle ON/OFF

NC start/NC stop

Override control knobs for feed rate/spindle speed

100

1

50

50

S %

0

100

1

50

50

F %

0

Mode of operation

Manual Operation

Decimal point

Change arithmetic sign

Confirm entry and resume dialog

End block

Clear numerical entry or TNC error message

Abort dialog, delete program section

Programming aids

MOD functions

HELP function

Moving the cursor, going directly to blocks, cycles and

parameter functions

Move highlight

Move highlight, skip dialog question

Select blocks and cycles directly

Positioning with Manual Data Input (MDI)

Program Run/Test Run

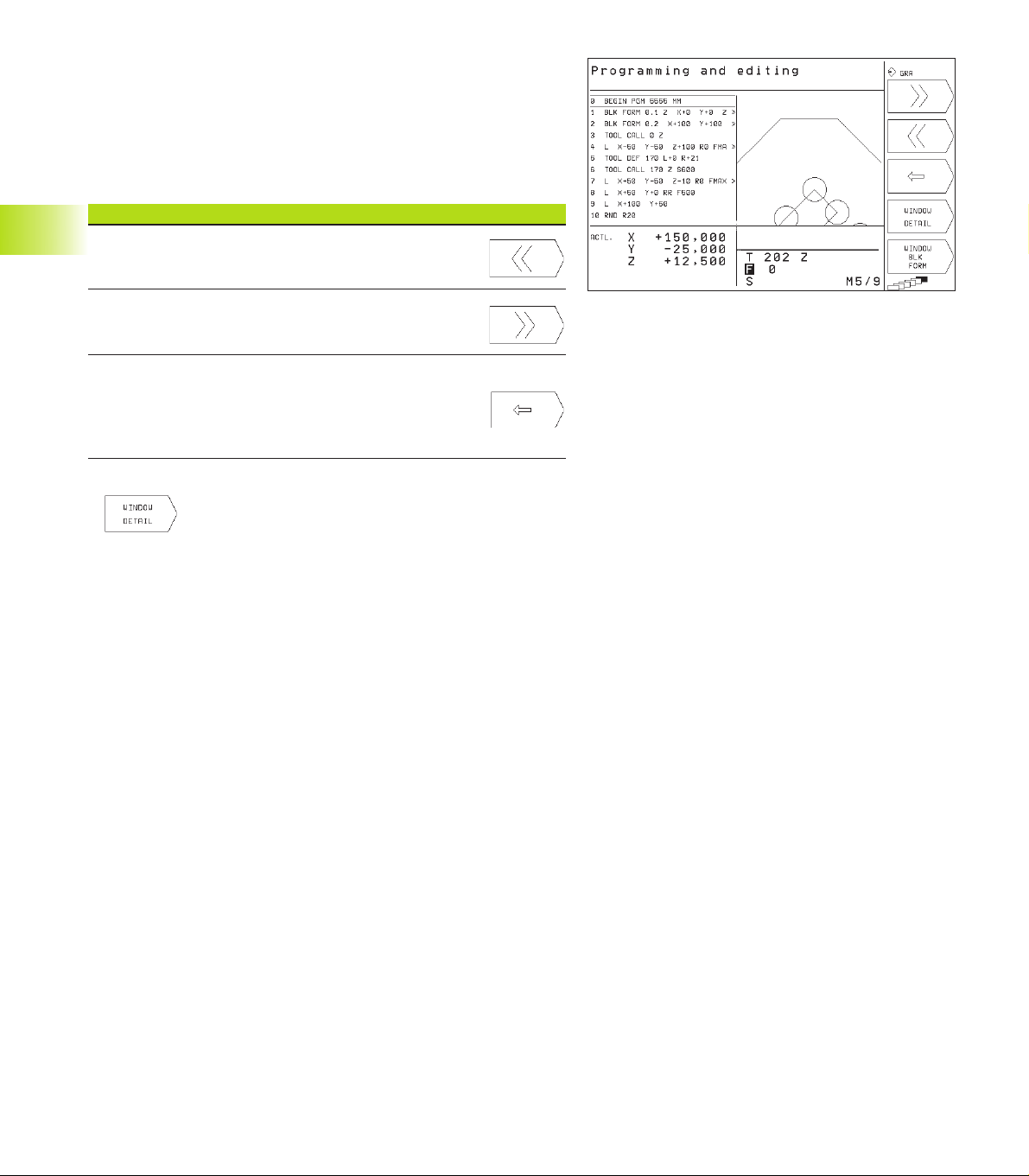

Programming and Editing

Page 3

Page 4

TNC Models, Software and

Features

This manual describes functions and features provided by

the TNCs with the following NC software numbers.

TNC Model NC Software No.

TNC 310 286 140-xx

TNC 310 M 286 160-xx

The machine tool builder adapts the useable features of the

TNC to his machine by setting machine parameters. Some

of the functions described in this manual may not be

among the features provided by the TNC on your machine

tool.

TNC functions that may not be available on your machine

include:

■ Probing function for the 3-D touch probe

■ Rigid tapping cycle

■ Boring cycle

■ Back boring cycle

Please contact your machine tool builder to become familiar

with the individual implementation of the control on your

machine.

Many machine manufacturers, as well as HEIDENHAIN,

offer programming courses for the TNCs. We recommend

these courses as an effective way of improving your

programming skill and sharing information and ideas with

other TNC users.

Contents

Location of use

The TNC complies with the limits for a Class A device in

accordance with the specifications in EN 55022, and is

intended for use primarily in industrially-zoned areas.

IHEIDENHAIN TNC 310

Page 5

Page 6

Contents

Introduction

1

Manual Operation and Setup

Positioning with Manual Data Input (MDI)

Programming: Fundamentals, File

Management, Programming Aids

Programming: Tools

Programming: Programming Contours

Programming: Miscellaneous Functions

Programming: Cycles

Programming: Subprograms and

Program Section Repeats

Programming: Q Parameters

Test Run and Program Run

3-D Touch Probes

2

Contents

3

4

5

6

7

8

9

10

11

12

MOD Functions

Tables and Overviews

13

14

IIIHEIDENHAIN TNC 310

Page 7

1 INTRODUCTION.....1

1.1 The TNC 310.....2

1.2 Visual Display Unit and Keyboard.....3

Contents

1.3 Modes of Operation.....4

1.4 Status Displays.....7

1.5 Accessories: HEIDENHAIN 3-D Touch Probes and Electronic Handwheels.....11

2 MANUAL OPERATION AND SETUP.....13

2.1 Switch-On.....14

2.2 Moving the Machine Axes.....15

2.3 Spindle Speed S, Feed Rate F and Miscellaneous Functions M.....18

2.4 Datum Setting (Without a 3-D Touch Probe).....19

3 POSITIONING WITH MANUAL DATA INPUT (MDI).....21

3.1 Programming and Executing Simple Positioning Blocks .....22

4 PROGRAMMING: FUNDAMENTALS OF NC, FILE MANAGEMENT, PROGRAMMING AIDS.....25

4.1 Fundamentals of NC.....26

4.2 File management.....31

4.3 Creating and Writing Programs.....34

4.4 Interactive Programming Graphics.....39

4.5 HELP function.....41

5 PROGRAMMING: TOOLS.....43

5.1 Entering Tool-Related Data.....44

5.2 Tool Data.....45

5.3 Tool Compensation.....51

IV

Contents

Page 8

6 PROGRAMMING: PROGRAMMING CONTOURS.....55

6.1 Overview of Tool Movements.....56

6.2 Fundamentals of Path Functions.....57

6.3 Contour Approach and Departure.....60

Overview: Types of paths for contour approach and departure.....60

Important positions for approach and departure.....60

Approaching on a straight line with tangential connection: APPR LT.....62

Approaching on a straight line perpendicular to the first contour point: APPR LN.....62

Approaching on a circular arc with tangential connection: APPR CT.....63

Approaching on a circular arc with tangential connection from a straight line to the contour: APPR LCT.....64

Departing tangentially on a straight line: DEP LT.....65

Departing on a straight line perpendicular to the last contour point: DEP LN.....65

Departing tangentially on a circular arc: DEP CT.....66

Departing on a circular arc tangentially connecting the contour and a straight line: DEP LCT.....67

6.4 Path Contours — Cartesian Coordinates.....68

Overview of path functions.....68

Straight line L.....69

Inserting a chamfer CHF between two straight lines.....69

Circle center CC.....70

Circular path C around circle center CC.....71

Circular path CR with defined radius.....72

Circular path CT with tangential connection.....73

Corner Rounding RND.....74

Example: Linear movements and chamfers with Cartesian coordinates.....75

Example: Circular movements with Cartesian coordinates.....76

Example: Full circle with Cartesian coordinates.....77

6.5 Path Contours—Polar Coordinates.....78

Polar coordinate origin: Pole CC.....78

Straight line LP.....79

Circular path CP around pole CC.....79

Circular path CTP with tangential connection.....80

Helical interpolation.....81

Example: Linear movement with polar coordinates .....83

Example: Helix .....84

Contents

VHEIDENHAIN TNC 310

Page 9

7 PROGRAMMING: MISCELLANEOUS FUNCTIONS.....85

7.1 Entering Miscellaneous Functions M and STOP.....86

7.2 Miscellaneous Functions for Program Run Control, Spindle and Coolant.....87

Contents

7.3 Miscellaneous Functions for Coordinate Data.....87

7.4 Miscellaneous Functions for Contouring Behavior.....89

7.5 Miscellaneous Function for Rotary Axes.....92

8 PROGRAMMING: CYCLES.....93

8.1 General Overview of Cycles.....94

8.2 Drilling Cycles.....96

PECKING (Cycle 1).....96

DRILLING (Cycle 200).....98

REAMING (Cycle 201).....99

BORING (Cycle 202).....100

UNIVERSAL DRILLING (Cycle 203).....101

BACK BORING (Cycle 204).....103

TAPPING with a floating tap holder (Cycle 2).....105

RIGID TAPPING (Cycle 17).....106

Example: Drilling cycles.....107

Example: Drilling cycles .....108

8.3 Cycles for Milling Pockets, Studs and Slots.....109

POCKET MILLING (Cycle 4).....110

POCKET FINISHING (Cycle 212).....111

STUD FINISHING (Cycle 213).....113

CIRCULAR POCKET MILLING (Cycle 5).....114

CIRCULAR POCKET FINISHING (Cycle 214).....116

CIRCULAR STUD FINISHING (Cycle 215) .....117

SLOT MILLING (Cycle 3).....119

SLOT with reciprocating plunge-cut (Cycle 210).....120

CIRCULAR SLOT with reciprocating plunge-cut (Cycle 211) .....122

Example: Milling pockets, studs and slots.....124

VI

Contents

Page 10

8.4 Cycles for Machining Hole Patterns.....126

CIRCULAR PATTERN (Cycle 220).....127

LINEAR PATTERN (Cycle 221) .....128

Example: Circular hole patterns.....130

8.5 Cycles for multipass milling.....132

MULTIPASS MILLING (Cycle 230).....132

RULED SURFACE (Cycle 231).....134

Example: Multipass milling.....136

8.6 Coordinate Transformation Cycles .....137

DATUM SHIFT (Cycle 7).....138

DATUM SHIFT with datum tables (Cycle 7).....138

MIRROR IMAGE (Cycle 8).....140

ROTATION (Cycle 10).....141

SCALING FACTOR (Cycle 11) .....142

Example: Coordinate transformation cycles.....143

8.7 Special Cycles .....145

DWELL TIME (Cycle 9) .....145

PROGRAM CALL (Cycle 12).....145

ORIENTED SPINDLE STOP (Cycle 13) .....146

Contents

9 PROGRAMMING: SUBPROGRAMS AND PROGRAM SECTION REPEATS.....147

9.1 Labeling Subprograms and Program Section Repeats.....148

9.2 Subprograms.....148

9.3 Program Section Repeats.....149

9.4 Nesting.....151

Subprogram within a subprogram .....151

Repeating program section repeats.....152

Repeating a subprogram.....153

Example: Milling a contour in several infeeds .....154

Example: Groups of holes .....155

Example: Groups of holes with several tools .....156

VIIHEIDENHAIN TNC 310

Page 11

10 PROGRAMMING: Q PARAMETERS.....159

10.1 Principle and Overview.....160

10.2 Part Families — Q Parameters in Place of Numerical Values.....161

Contents

10.3 Describing Contours through Mathematical Operations.....162

10.4 Trigonometric Functions .....164

10.5 If-Then Decisions with Q Parameters .....165

10.6 Checking and Changing Q Parameters .....166

10.7 Additional Functions .....167

10.8 Entering Formulas Directly.....173

10.9 Preassigned Q Parameters.....176

10.10 Programming Examples.....178

Example: Ellipse.....178

Example: Concave cylinder machined with spherical cutter .....180

Example: Convex sphere machined with end mill .....182

11 TEST RUN AND PROGRAM RUN.....185

11.1 Graphics.....186

11.2 Test run.....190

11.3 Program Run.....192

11.4 Blockwise Transfer: Running Longer Programs.....199

11.5 Optional Program Run Interruption.....200

12 3-D TOUCH PROBES.....201

12.1 Touch Probe Cycles in the Manual Operation Mode.....202

Calibrating a touch trigger probe.....203

Compensating workpiece misalignment.....204

12.2 Setting the Datum with a 3-D Touch Probe.....205

12.3 Measuring Workpieces with a 3-D Touch Probe.....208

VIII

Contents

Page 12

13 MOD FUNCTIONS.....211

13.1 Selecting, Changing and Exiting the MOD Functions.....212

13.2 System Information.....212

13.3 Entering the Code Number.....213

13.4 Setting the Data Interface.....213

13.5 Machine-Specific User Parameters.....216

13.6 Position Display Types.....216

13.7 Unit of Measurement.....216

13.8 Axis Traverse Limits .....217

13.9 Running the HELP File.....218

14 TABLES AND OVERVIEWS.....219

14.1 General User Parameters.....220

Input possibilities for machine parameters.....220

Selecting general user parameters.....220

External data transfer.....221

3-D Touch Probes.....222

TNC displays, TNC editor.....222

Machining and program run.....224

Electronic handwheels.....225

14.2 Pin Layout and Connecting Cable for the Data Interface.....226

RS-232-C/V.24 Interface .....226

14.3 Technical Information.....227

TNC features.....227

Programmable functions.....228

TNC Specifications.....228

14.4 TNC Error Messages.....229

TNC error messages during programming.....229

TNC error messages during test run and program run.....229

14.5 Exchanging the Buffer Battery.....232

Contents

IXHEIDENHAIN TNC 310

Page 13

Introduction

1

Page 14

1.1 The TNC 310

HEIDENHAIN TNC controls are shop-floor programmable

contouring controls for milling, drilling and boring machines.

You can program conventional milling, drilling and boring operations

right at the machine with the easily understandable interactive

conversational guidance. The TNC 310 can control up to 4 axes.

Instead of the fourth axis, you can also change the angular position

of the spindle under program control.

1.1 The TNC 310

Keyboard and screen layout are clearly arranged in a such way that

the functions are fast and easy to use.

Programming: HEIDENHAIN conversational format

HEIDENHAIN conversational programming is an especially easy

method of writing programs. Interactive graphics illustrate the

individual machining steps for programming the contour. Workpiece

machining can be graphically simulated during test run.

You can enter a program while the control is running another.

Compatibility

The TNC can execute all part programs that were written on

HEIDENHAIN controls TNC 150 B and later.

In addition, the TNC can also run programs with functions that

cannot be programmed directly on the TNC 310 itself, such as:

■ FK free contour programming

■ Contour cycles

■ ISO programs

■ Program call with PGM CALL

2

1 Introduction

Page 15

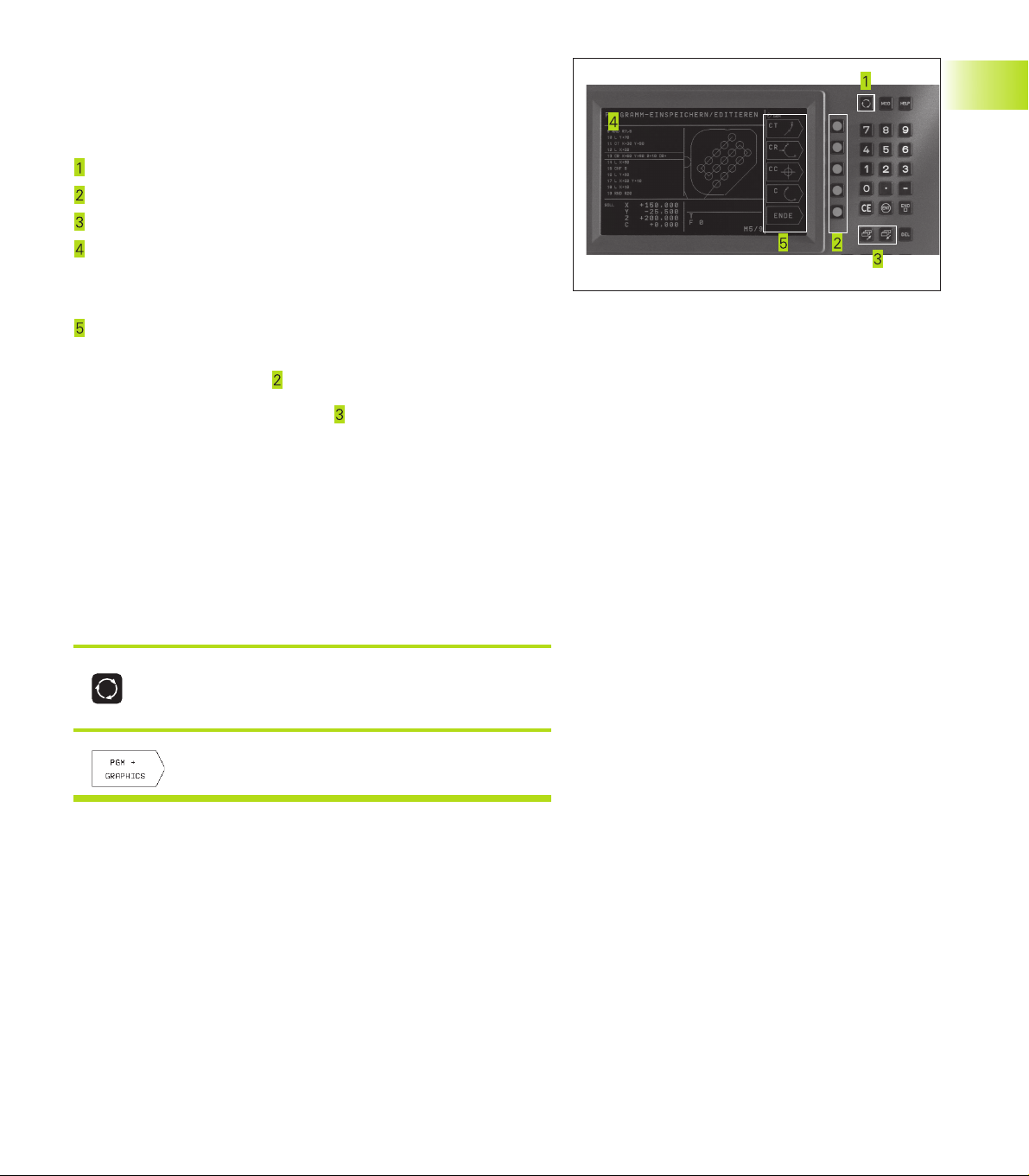

1.2 Visual Display Unit and Keyboard

Visual display unit

The figure at right shows the keys and controls on the VDU:

Setting the screen layout

Soft key selector keys

Switching the soft-key rows

Header

When the TNC is on, the selected operating mode is shown in

the screen header. Dialog prompts and TNC messages also

appear here (unless the TNC is showing only graphics).

Soft keys

In the right margin the TNC indicates additional functions in a softkey row. You can select these functions by pressing the keys

immediately beside them

are rectangular boxes indicating the number of soft-key rows.

These rows can be called with the

box representing the active soft-key row is filled in.

Screen layout

You select the screen layout yourself: In the PROGRAMMING AND

EDITING mode of operation, for example, you can have the TNC

show program blocks in the left window while the right window

displays programming graphics. You could also display help

graphics for cycle definition in the right window instead, or display

only program blocks in one large window. The available screen

windows depend on the selected operating mode.

. Directly beneath the soft-key row

outside right and left. The

1.2 Visual Display Unit and Keyboard

To change the screen layout:

Press the SPLIT SCREEN key: The soft-key row

shows the available layout options.

<

Select the desired screen layout.

3HEIDENHAIN TNC 310

Page 16

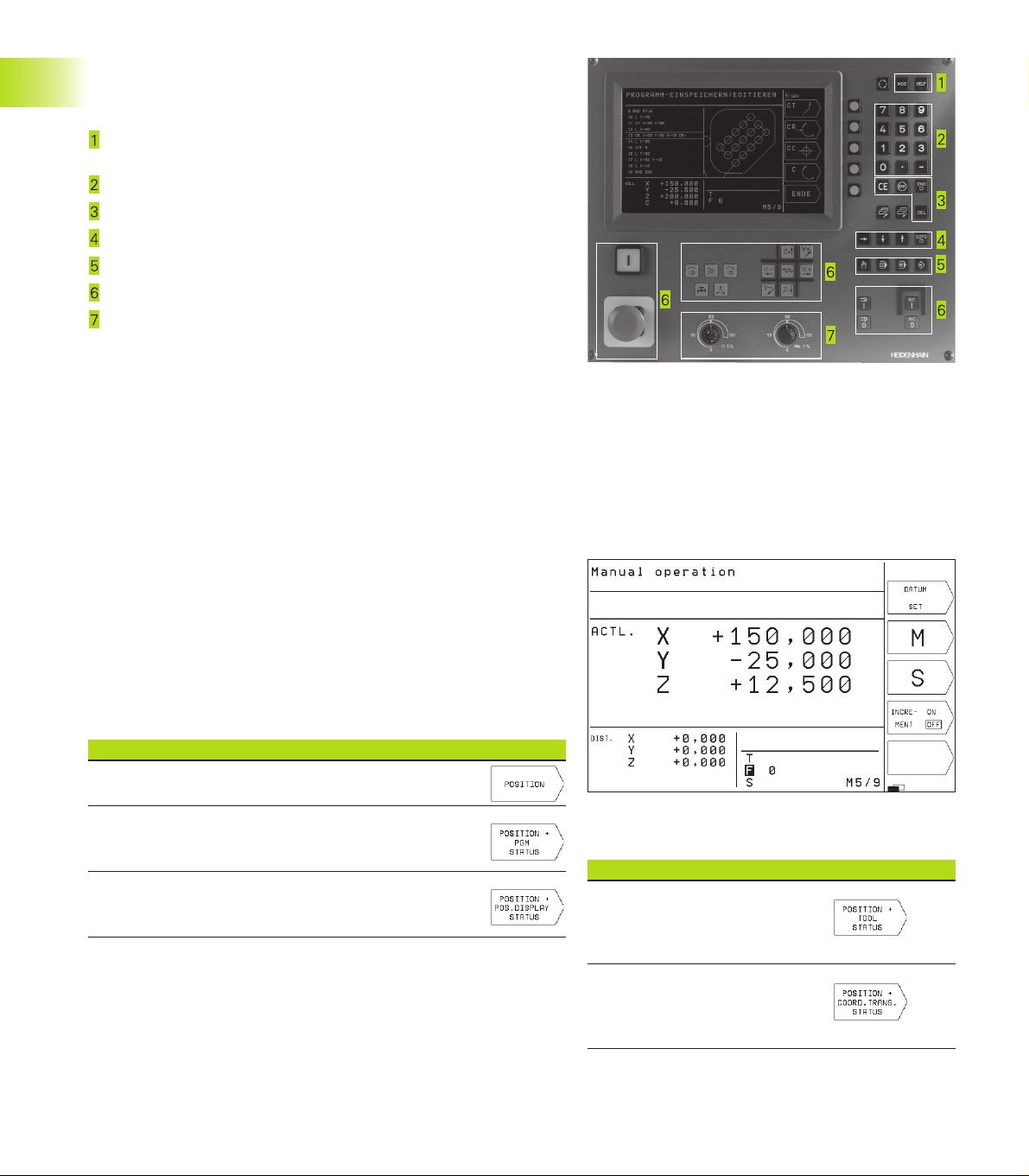

Keyboard

The figure at right shows the keys of the keyboard grouped

according to their functions:

MOD function,

HELP function

Numerical input

Dialog buttons

Arrow keys and GOTO jump command

Modes of Operation

Machine control buttons

Override control knobs for feed rate/spindle speed

1.3 Modes of Operation

The functions of the individual keys are described in the foldout of

the front cover. The exact functioning of the machine control

buttons, e.g. NC START, is described in more detail in your Machine

Manual.

1.3 Modes of Operation

The TNC offers the following modes of operation for the various

functions and working steps that you need to machine a workpiece:

Manual Operation and Electronic Handwheel

The Manual Operation mode is required for setting up the machine

tool. In this operating mode, you can position the machine axes

manually or by increments. Datums can be set by the usual

scratching method or by using the TS 220 triggering touch probe.

The TNC also supports the manual traverse of the machine axes

using a HR electronic handwheel.

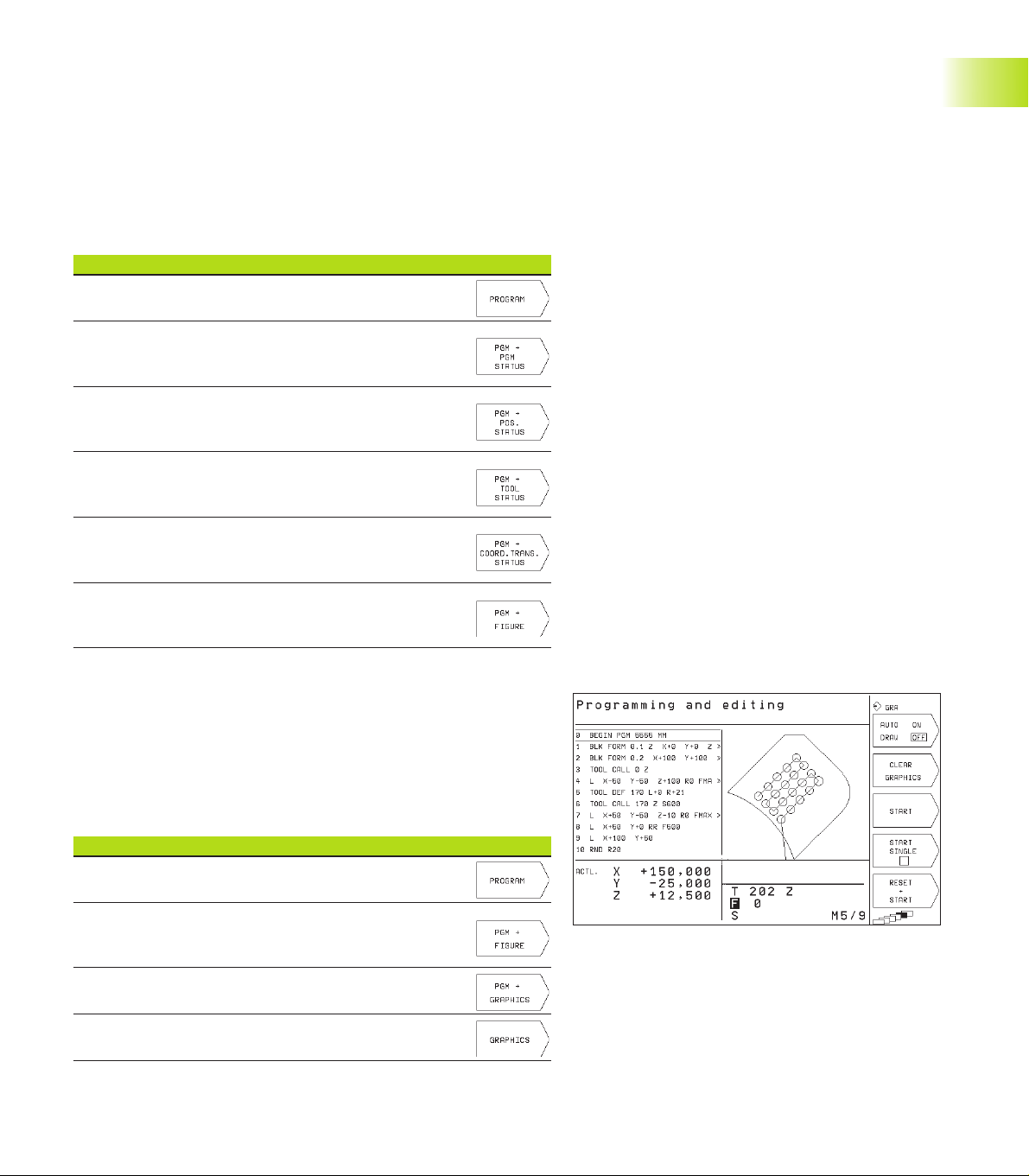

Soft keys for selecting the screen layout

Screen windows Soft key

Positions

Left: positions, right: general

program information

Left: positions, right: positions and

Coordinates

Screen windows Soft key

Left: positions, right:

information on

tools

Left: positions, right:

coordinate

transformations

4

1 Introduction

Page 17

Positioning with Manual Data Input (MDI)

The operating mode Positioning with Manual Data Input is

particularly convenient for simple machining operations or prepositioning of the tool. You can write the a short program in

HEIDENHAIN conversational programming and execute it

immediately. You can also call TNC cycles. The program is stored in

the file $MDI. In the operating mode Positioning with MDI, the

additional status displays can also be activated.

Soft keys for selecting the screen layout

Screen windows Soft key

Program

Left: program blocks, right: general

program information

Left: program blocks, right: positions and

Coordinates

Left: program blocks, right: tool

tools

Left: program blocks, right: coordinate

transformations

Left: program blocks, right: help graphics for

cycle programming (2nd soft-key level)

Programming and Editing

In this mode of operation you can write your part programs. The

various cycles help you with programming and add necessary

information. If desired, you can have the programming graphics

show the individual steps.

Soft keys for selecting the screen layout

1.3 Modes of Operation

Screen windows Soft key

Program

Left: program blocks, right: help graphics for

cycle programming

Left: program blocks, right: programming graphics

Interactive Programming Graphics

5HEIDENHAIN TNC 310

Page 18

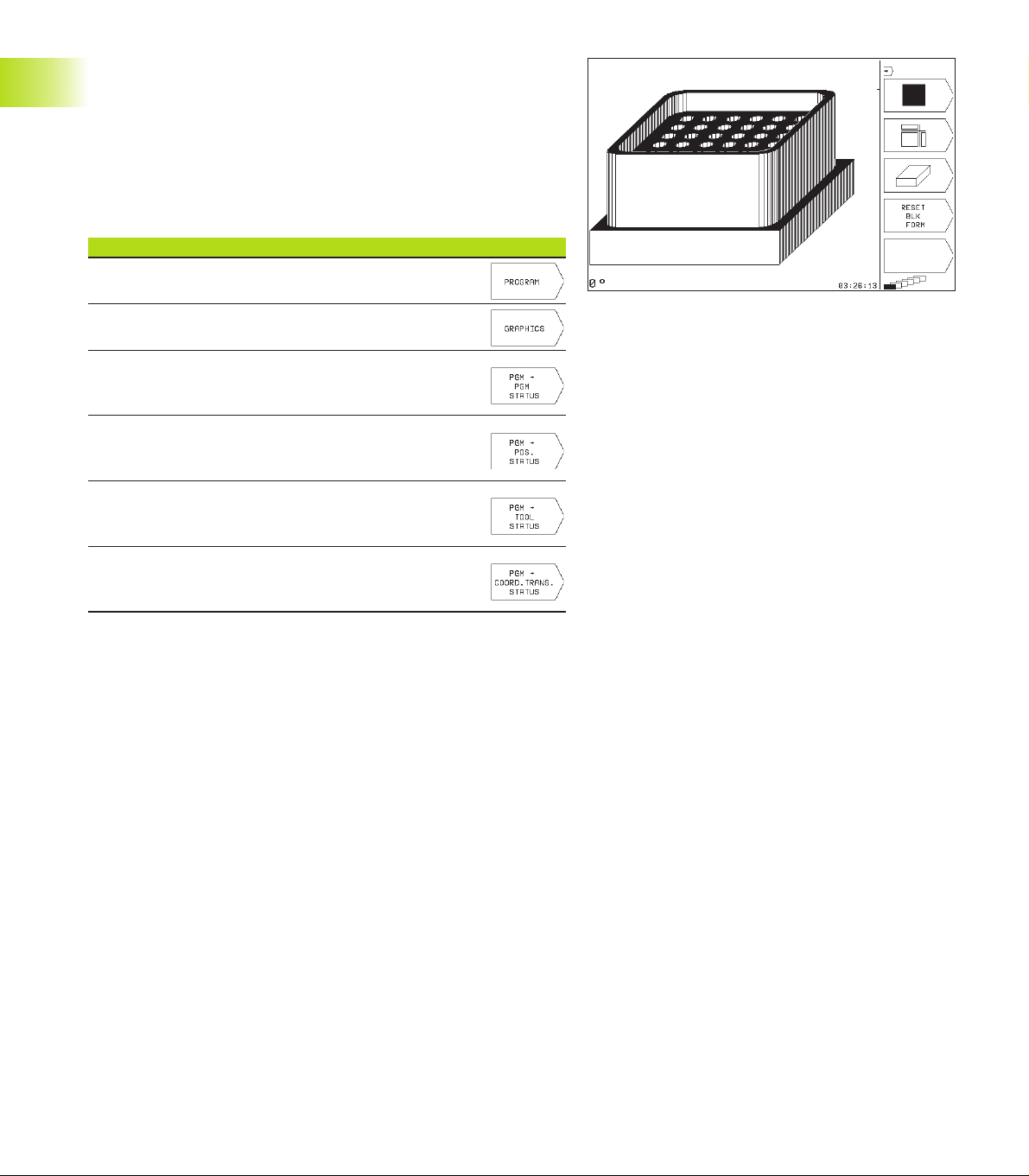

Test run

In the Test Run mode of operation, the TNC checks programs and

program sections for errors, such as geometrical incompatibilities,

missing or incorrect data within the program or violations of the

work space. This simulation is supported graphically in different

display modes. Use a soft key to activate the test run in the Program Run operating mode.

Soft keys for selecting the screen layout

Screen windows Soft key

Program

n Test run graphics

1.3 Modes of Operation

Left: program blocks, right: general

program information

Left: program blocks, right: positions and

Coordinates

Left: program blocks, right: tool

tools

Left: program blocks, right: coordinate

transformations

6

1 Introduction

Page 19

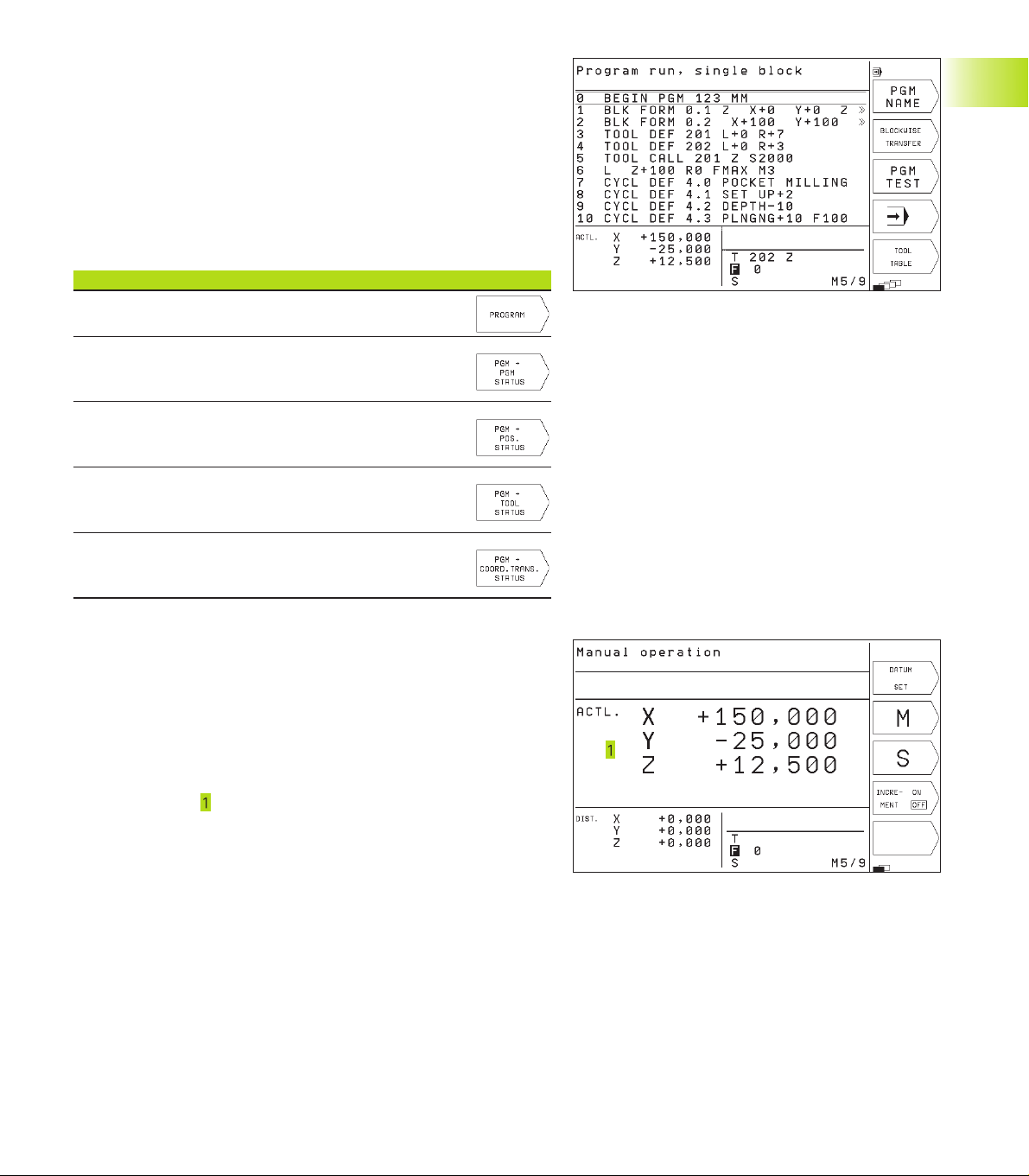

Program Run/Single Block and

Program Run/Full Sequence

In the Program Run, Full Sequence mode of operation the TNC

executes a part program continuously to its end or to a manual or

programmed stop. You can resume program run after an

interruption.

In the Program Run, Single Block mode of operation you execute

each block separately by pressing the NC START button.

Soft keys for selecting the screen layout

Screen windows Soft key

Program

Left: program blocks, right: general

program information

Left: program blocks, right: positions and

Coordinates

Left: program blocks, right: tool

tools

Left: program blocks, right: coordinate

transformations

1.4 Status Displays

1.4 Status Displays

“General” status display

The status display informs you of the current state of the machine

tool. It is displayed automatically in all modes of operation:

In the operating modes Manual Operation and Electronic

Handwheel and Positioning with MDI the status display appears in

the large window

.

7HEIDENHAIN TNC 310

Page 20

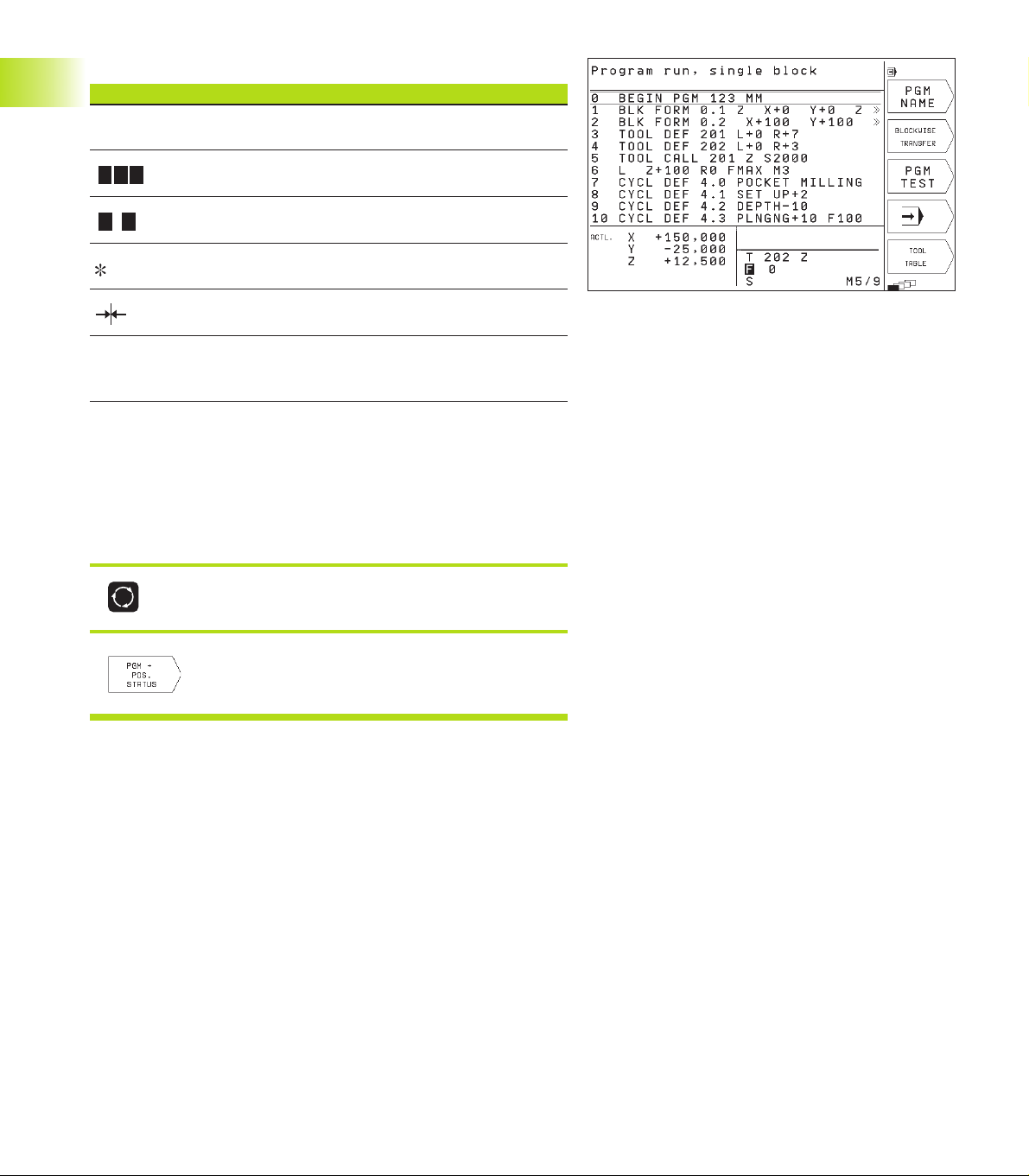

Information in the status display

The Meaning

ACTL. Actual or nominal coordinates of the current position

X Y Z Machine axes

S F M Spindle speed S, feed rate F and active M functions

1.4 Status Displays

ROT Axes are moving

Program run started

Axis locked

plain

Additional status displays

The additional status displays contain detailed information on the

program run. They can be called in all operating modes, except in

the Manual Operation mode.

To switch on the additional status display:

Call the soft-key row for screen layout.

<

Select the layout option for the additional status

display, e.g. positions and coordinates.

You can also choose between the following additional status

displays:

8 1 Introduction

Page 21

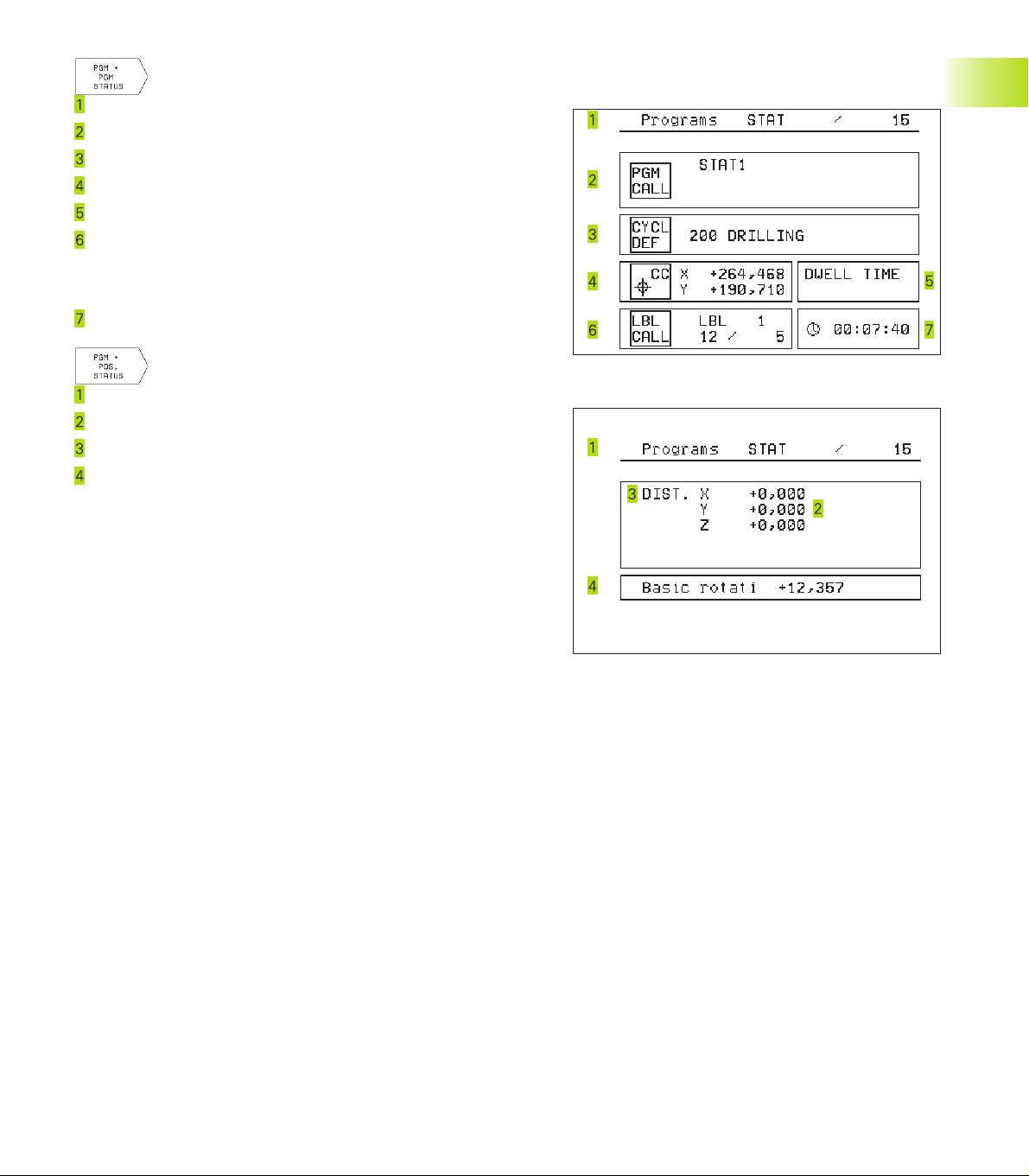

General program information

Name of main program / Active block number

Program called via Cycle 12

Active machining cycle

Circle center CC (pole)

Dwell time counter

Number of the active subprogram or active program section

repeats/

Counter for current program section repeat

(5/3: 5 repetitions programmed, 3 remaining to be run)

Operating time

Positions and coordinates

Name of main program / Active block number

Position display

Type of position display, e.g. distance-to-go

Angle of a basic rotation

1.4 Status Displays

9HEIDENHAIN TNC 310

Page 22

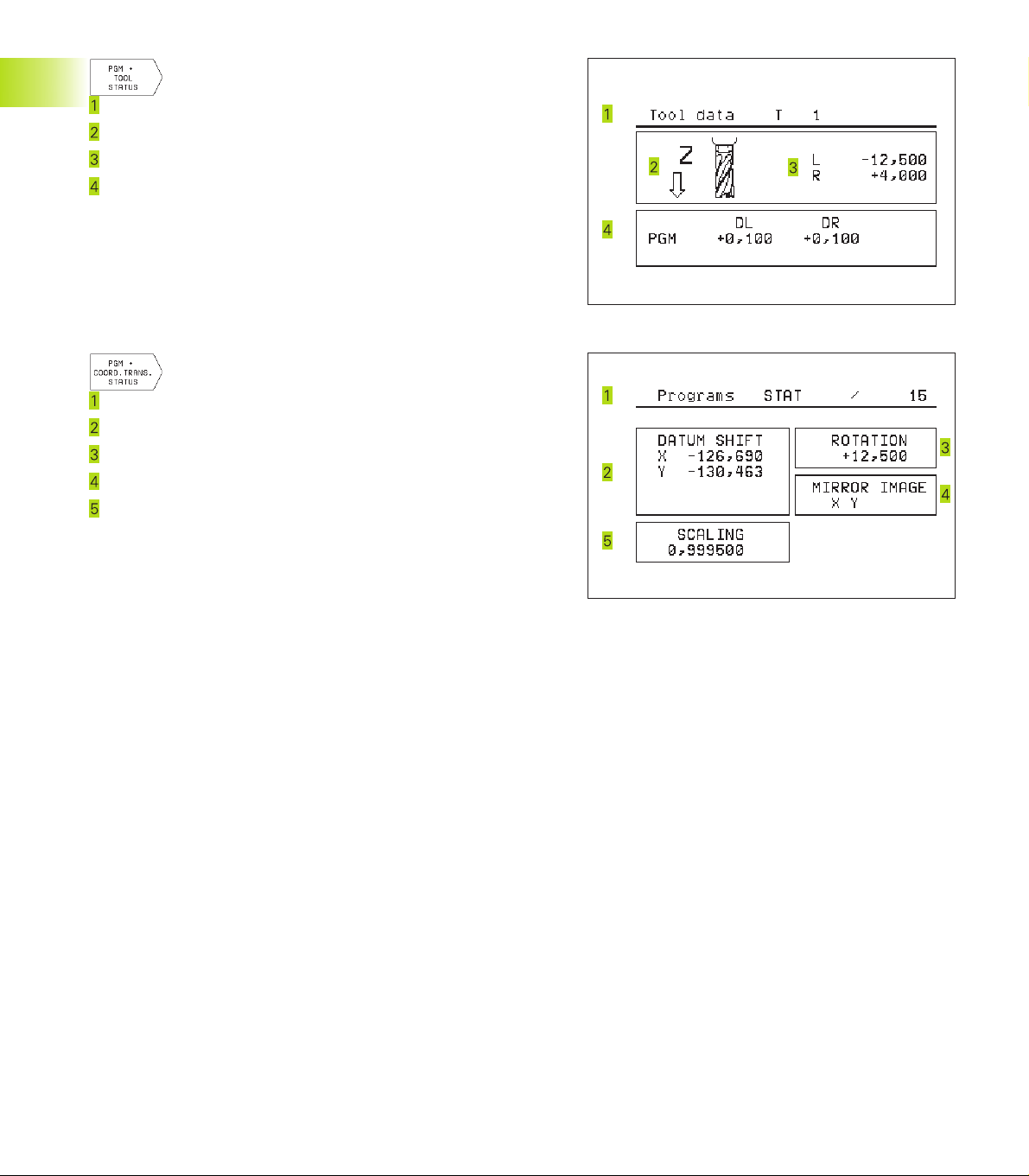

Information on tools

T: Tool number

Tool axis

Tool length and radius

Oversizes (delta values) from TOOL CALL block

1.4 Status Displays

Coordinate transformations

Name of main program / Active block number

Active datum shift (Cycle 7)

Active rotation angle (Cycle 10)

Mirrored axes (Cycle 8)

Active scaling factor (Cycle 11)

For further information, refer to section 8.6 “Coordinate Transformation Cycles.”

10

1 Introduction

Page 23

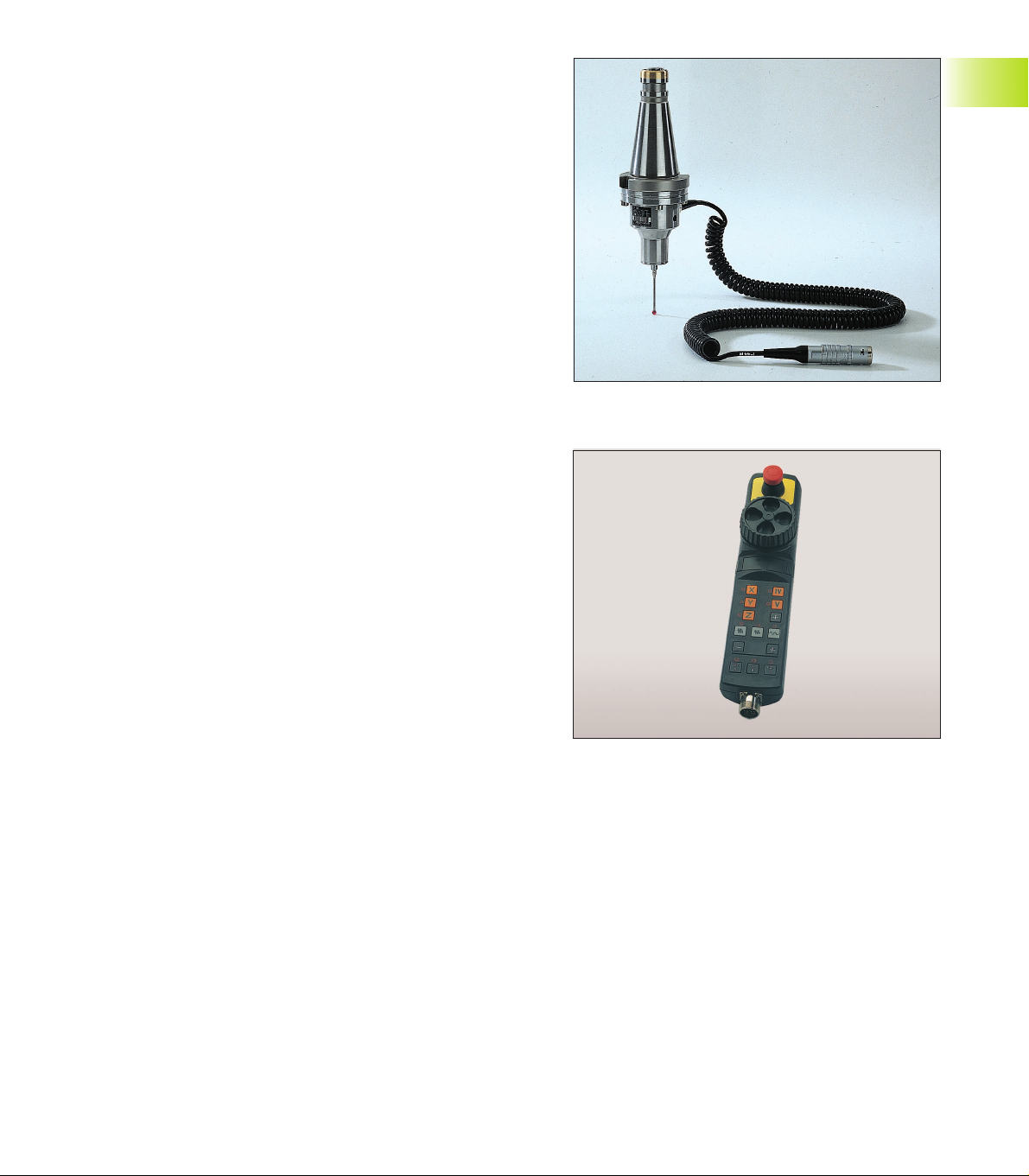

1.5 Accessories: HEIDENHAIN 3-D Touch Probes and Electronic Handwheels

3-D Touch Probes

With the various HEIDENHAIN 3-D touch probe systems you can:

■ Automatically align workpieces

■ Quickly and precisely set datums

TS 220 touch trigger probe

This touch probe is particularly effective for automatic workpiece

alignment, datum setting and workpiece measurement. The TS 220

transmits the triggering signals to the TNC via cable.

Principle of operation: HEIDENHAIN triggering touch probes feature

a wear resisting optical switch that generates an electrical signal as

soon as the stylus is deflected. This signal is transmitted to the

TNC, which stores the current position of the stylus as an actual

value.

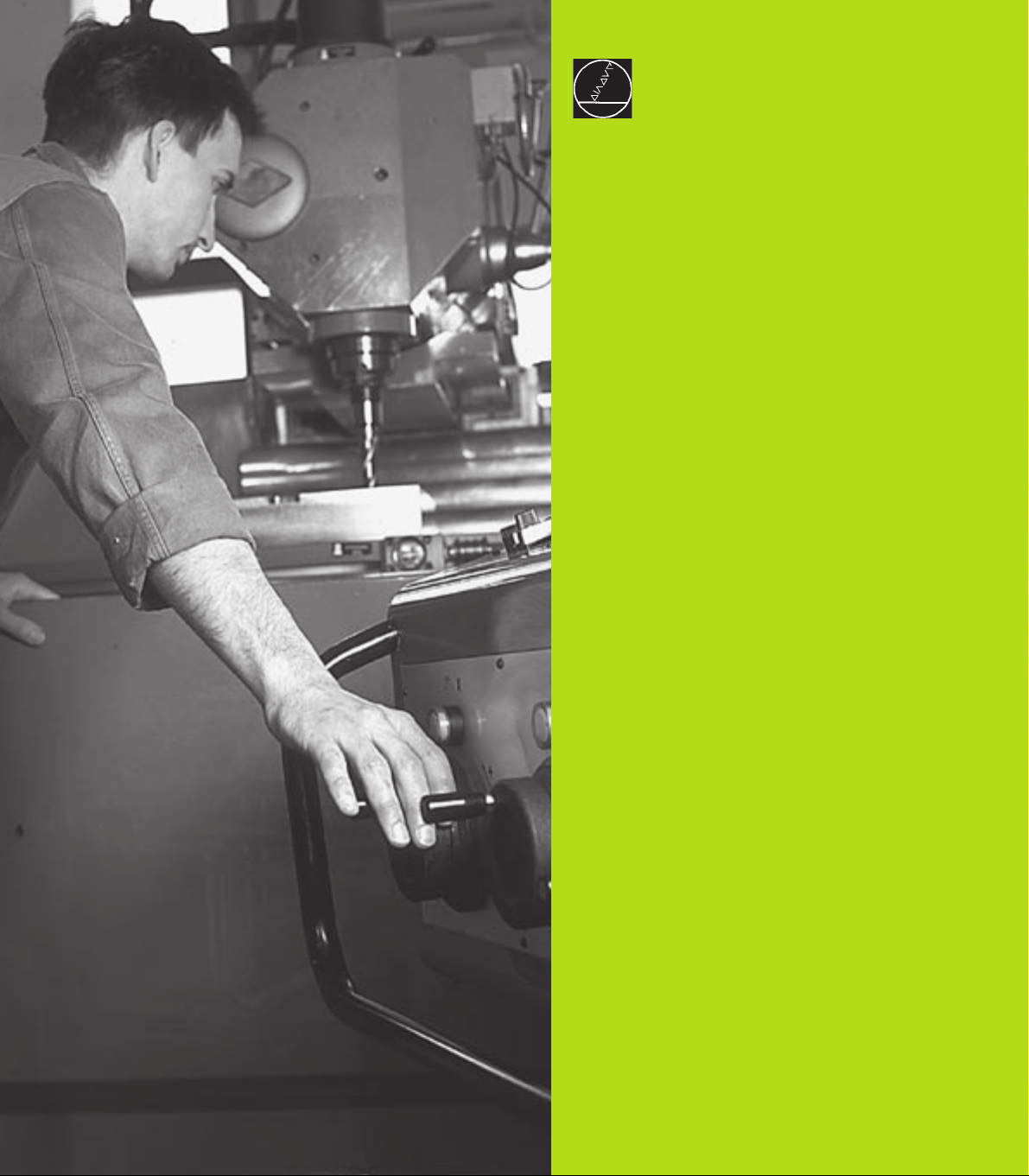

HR electronic handwheels

Electronic handwheels facilitate moving the axis slides precisely by

hand. A wide range of traverses per handwheel revolution is

available. Apart from the HR 130 and HR 150 integral handwheels,

HEIDENHAIN also offers the HR 410 portable handwheel.

1.5 Accessories: HEIDENHAIN 3-D Touch Probe and Electronic Handwheels

11HEIDENHAIN TNC 310

Page 24

Page 25

2

Manual Operation and Setup

Page 26

2.1 Switch-On

Switch-on and traversing the reference points can vary

depending on the individual machine tool. Your machine

manual provides more detailed information.

ú Switch on the power supply for control and machine.

2.1 Switch-On

The TNC automatically initiates the following dialog

Memory test

<

The TNC memory is automatically checked.

Power interrupted

<

TNC message that the power was interrupted

— clear the message.

TRANSLATE PLC program

<

The PLC program of the TNC is automatically compiled.

Relay Ext. DC Voltage Missing

<

Switch on the control voltage.

The TNC checks the functioning of the

EMERGENCY STOP circuit.

Traverse Reference Points

<

Cross the reference points in any sequence:

Press and hold the machine axis direction

button for each axis until the reference point has

been traversed, or

Cross the reference points with several axes at

the same time: Use soft keys to select the axes

(axes are then shown highlighted on the

screen), and then press the NC START button.

The TNC is now ready for operation in the

Manual Operation mode.

14

2 Manual Operation and Setup

Page 27

2.2 Moving the Machine Axes

Traversing the machine axes with the axis direction keys

is a machine-dependent function. Refer to your machine

tool manual.

Traverse the axis with the axis direction keys

Select the Manual Operation mode.

<

Press the axis direction button and hold it as

long as you wish the axis to move.

...or move the axis continuously:

and Press and hold the axis direction button, then

press the NC START button: The axis continues

to move after you release the keys.

2.2 Moving the Machine Axes

Press the NC STOP key to stop the axis.

You can move several axes at a time with these two methods.

15HEIDENHAIN TNC 310

Page 28

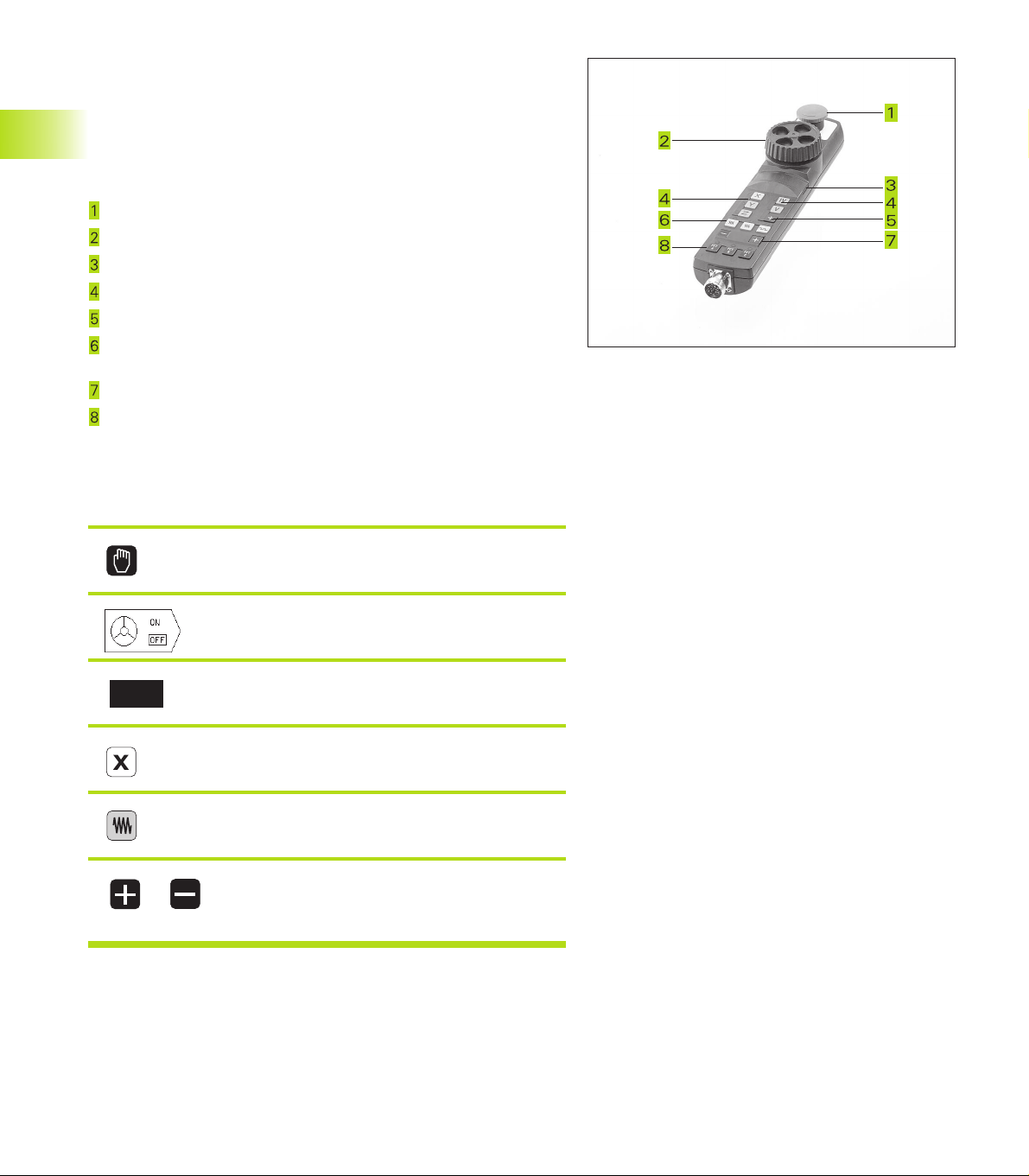

Traversing with the HR 410 electronic handwheel

The portable HR 410 handwheel is equipped with two permissive

buttons. The permissive buttons are located below the star grip.

You can only move the machine axes when an permissive button is

depressed (machine-dependent function).

The HR 410 handwheel features the following operating elements:

EMERGENCY STOP

Handwheel

Permissive buttons

Axis address keys

Actual-position-capture key

Keys for defining the feed rate (slow, medium, fast; the feed rates

are set by the machine tool builder)

Direction in which the TNC moves the selected axis

2.2 Moving the Machine Axes

Machine function

(set by the machine tool builder)

The red indicators show the axis and feed rate you have selected.

To move an axis:

Select the Manual Operation mode.

<

Activate handwheel, set soft key to ON

<

Press the permissive button.

<

Select the axis on the handwheel

<

Select the feed rate.

<

or Move the active axis in the positive or negative

direction.

16

2 Manual Operation and Setup

Page 29

16

X

Z

8

8

8

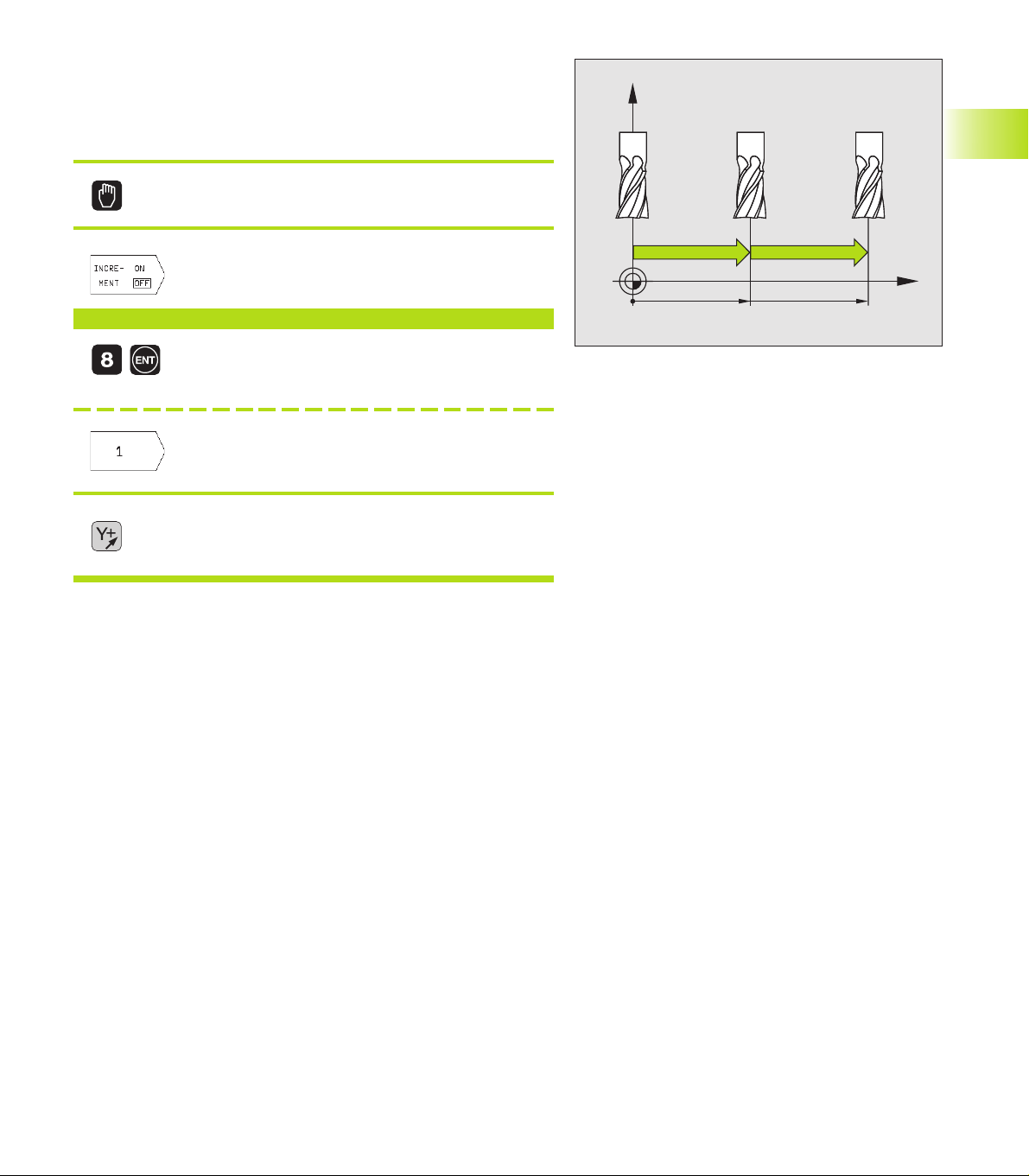

Incremental jog positioning

With incremental jog positioning you can move a machine axis by a

preset distance each time you press the corresponding axis

direction button.

Select the Manual Operation mode.

<

Select incremental jog positioning, set the soft

key to ON

JOG INCREMENT?

<

Enter the jog increment in millimeters

(here, 8 mm).

Select the jog increment via soft key (select 2nd

or 3rd soft-key row)

<

Press the axis direction button to position as

often as desired

2.2 Moving the Machine Axes

17HEIDENHAIN TNC 310

Page 30

2.3 Spindle Speed S, Feed Rate F and

Miscellaneous Functions M

In the Manual Operation mode, enter the spindle speed S and the

miscellaneous function M using soft keys. The miscellaneous

functions are described in Chapter 7 ”Programming: Miscellaneous

Functions.” The feed rate is defined in a machine parameter and can

be changed only with the override knobs (see next page).

Entering values

Example: Entering the spindle speed S

To enter the spindle speed, press the S soft key.

SPINDLE SPEED S=

<

1000 Enter the desired spindle speed,

and confirm with the NC START button

The spindle speed S with the entered rpm is started with a

miscellaneous function.

Proceed in the same way to enter the miscellaneous functions M.

Changing the spindle speed and feed rate

With the override knobs you can vary the spindle speed S and feed

rate F from 0% to 150% of the set value.

The knob for spindle speed override is effective only on

machines with an infinitely variable spindle drive.

The machine tool builder determines which

miscellaneous functions M are available on your TNC and

what effects they have.

2.3 Spindle Speed S, Feed Rate F and Miscellaneous Functions M

18 2 Manual Operation and Setup

Page 31

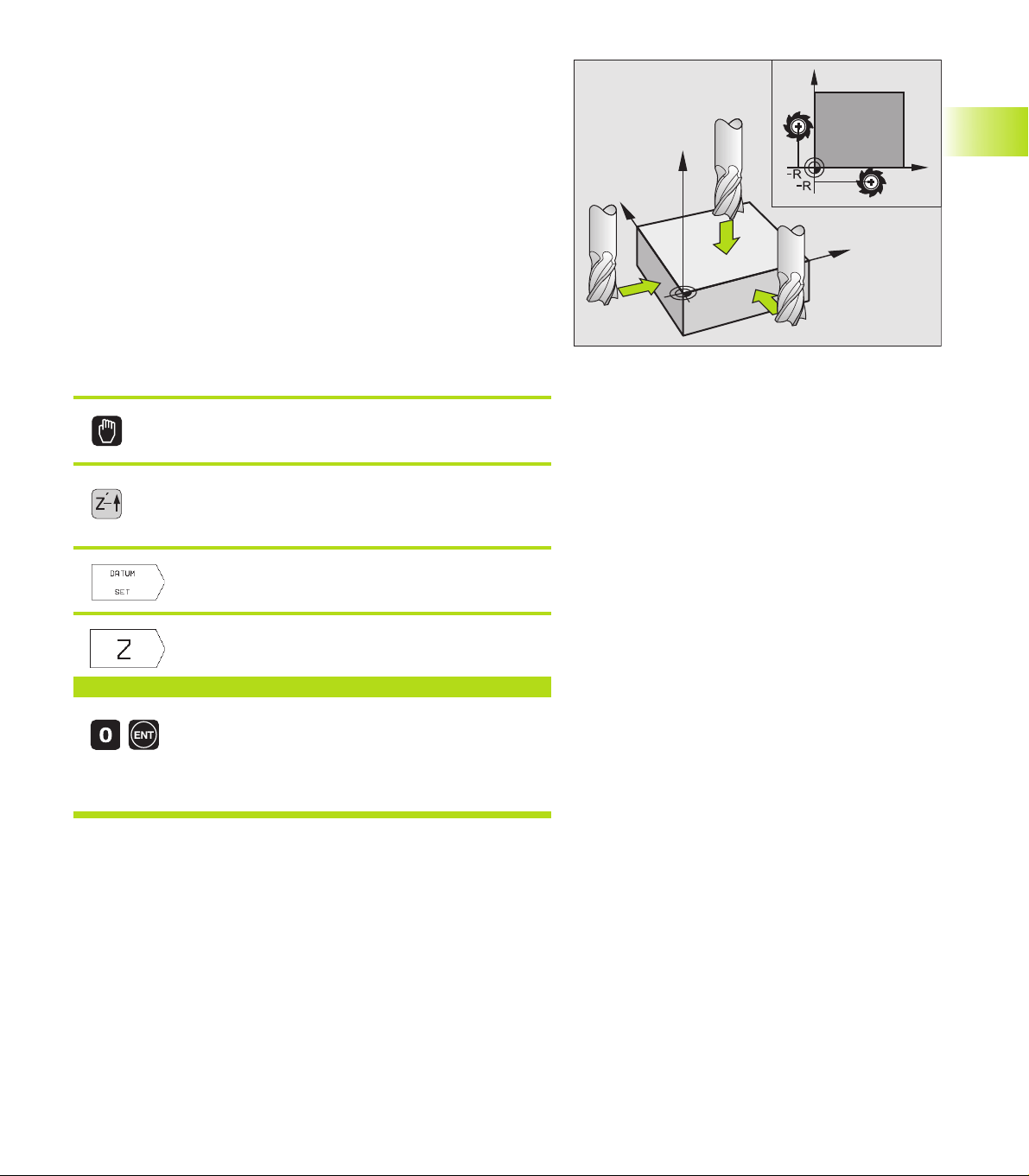

2.4 Datum Setting (Without a 3-D Touch Probe)

You fix a datum by setting the TNC position display to the

coordinates of a known position on the workpiece.

Preparation

ú Clamp and align the workpiece.

ú Insert the zero tool with known radius into the spindle.

ú Ensure that the TNC is showing the actual position values.

Y

Z

X

Y

X

Datum setting

Fragile workpiece? If the workpiece surface must not be scratched,

you can lay a metal shim of know thickness

tool axis datum value that is larger than the desired datum by the

d

.

value

Select the Manual Operation mode.

<

Move the tool slowly until it touches the

workpiece surface.

<

Select the function for setting the datum

<

Select the axis.

DATUM SET Z=

<

Zero tool in spindle axis: Set the display to a

known workpiece position (here, 0) or enter the

d

thickness

the tool radius.

of the shim. In the tool axis, offset

d

on it. Then enter a

2.4 Setting the Datum

Repeat the process for the remaining axes.

If you are using a preset tool, set the display of the tool axis to the

length L of the tool or enter the sum Z=L+d.

19HEIDENHAIN TNC 310

Page 32

Page 33

3

Positioning with Manual Data Input (MDI)

Page 34

3.1 Programming and Executing Simple Positioning Blocks

The operating mode Positioning with Manual Data Input is

particularly convenient for simple machining operations or prepositioning of the tool. You can write the a short program in

HEIDENHAIN conversational programming and execute it

immediately. You can also call TNC cycles. The program is stored in

the file $MDI. In the operating mode Positioning with MDI, the

additional status displays can also be activated.

Select the Positioning with MDI mode of

operation. Program the file $MDI as you wish.

To start program run, press the machine START

button.

Limitations:

The following functions are not available:

- Tool radius compensation

- Programming graphics

- Programmable probing functions

- Subprograms, program section repeats

- Path functions CT, CR, RND and CHF

- Cycle 12 PGM CALL

Z

Y

Example 1

A hole with a depth of 20 mm is to be drilled into a single

workpiece. After clamping and aligning the workpiece and setting

the datum, you can program and execute the drilling operation in a

few lines.

3.1 Programming and Executing Simple Positioning Blocks

First you pre-position the tool in L blocks (straight-line blocks) to the

hole center coordinates at a setup clearance of 5 mm above the

workpiece surface. Then drill the hole with Cycle 1 PECKING.

0 BEGIN PGM $MDI MM

1 TOOL DEF 1 L+0 R+5

2 TOOL CALL 1 Z S2000

3 L Z+200 R0 FMAX

4 L X+50 Y+50 R0 FMAX M3

22

50

50

Define tool: zero tool, radius 5

Call tool: tool axis Z

Spindle speed 2000 rpm

Retract tool (FMAX = rapid traverse)

Pos. tool aboveholeatFMAX , spindle On

3 Positioning with Manual Data Input (MDI)

X

Page 35

5 L Z+5 F2000

6 CYCL DEF 1.0 PECKING

7 CYCL DEF 1.1 SET UP 5

8 CYCL DEF 1.2 DEPTH -20

9 CYCL DEF 1.3 PECKG 10

10 CYCL DEF 1.4 DWELL 0.5

11 CYCL DEF 1.5 F250

12 CYCL CALL

13 L Z+200 R0 FMAX M2

14 END PGM $MDI MM

The straight-line function is described in section 6.4 “Path Contours

— Cartesian Coordinates,” the PECKING cycle in section 8.3 “Dril-

ling Cycles.”

Position tool to 5 mm above hole

Define PECKING cycle:

Setup clearance of the tool above the hole

Total hole depth (Algebraic sign=working direction)

Depth of each infeed before retraction

Dwell time in seconds at the hole bottom

Feed rate for pecking

Call PECKING cycle

Retract tool

End of program

3.1 Programming and Executing Simple Positioning Blocks

23HEIDENHAIN TNC 310

Page 36

Protecting and erasing programs in $MDI

The $MDI file is generally intended for short programs that are only

needed temporarily. Nevertheless, you can store a program, if

necessary, by proceeding as described below:

Select operating mode: Programming

and Editing

<

Call up the file manager: PGM NAME soft key

<

Move the highlight to the $MDI file.

<

Select „Copy file“: Press the COPY soft key

Target file =

<

1225 Enter the name under which you want to save

the current contents of the $MDI file.

<

Copy the file.

<

Exit the file manager: END key

Erasing the contents of the $MDI file is done in a similar way:

Instead of copying the contents, however, you erase them with the

DELETE soft key. The next time you select the operating mode

Positioning with MDI, the TNC will display an empty $MDI file.

3.1 Programming and Executing Simple Positioning Blocks

For further information, refer to section 4.2 “File Management.”

24 3 Positioning with Manual Data Input (MDI)

Page 37

4

Programming:

Fundamentals of NC,

File Management,

Programming Aids

Page 38

4.1 Fundamentals of NC

Position encoders and reference marks

The machine axes are equipped with position encoders that

register the positions of the machine table or tool. When a machine

axis moves, the corresponding position encoder generates an

electrical signal. The TNC evaluates this signal and calculates the

precise actual position of the machine axis.

If there is an interruption of power, the calculated position will no

longer correspond to the actual position of the machine slide. The

CNC can re-establish this relationship with the aid of reference

marks when power is returned. The scales of the position encoders

contain one or more reference marks that transmit a signal to the

TNC when they are crossed over. From the signal the TNC identifies

4.1 Fundamentals of NC

that position as the machine-axis reference point and can reestablish the assignment of displayed positions to machine axis

positions.

Linear encoders are generally used for linear axes. Rotary tables

and tilt axes have angle encoders. If the position encoders feature

distance-coded reference marks, you only need to move each axis a

maximum of 20 mm (0.8 in.) for linear encoders, and 20° for angle

encoders, to re-establish the assignment of the displayed positions

to machine axis positions.

Z

Y

X

X

MP

X (Z,Y)

26

4 Programming: Fundamentals of NC, File Management, Programming Aids

Page 39

Reference system

A reference system is required to define positions in a plane or in

space. The position data are always referenced to a predetermined

point and are described through coordinates.

The Cartesian coordinate system (a rectangular coordinate system)

is based on three coordinate axes X, Y and Z. The axes are mutually

perpendicular and intersect at one point called the datum. A

coordinate identifies the distance from the datum in one of these

directions. A position in a plane is thus described through two

coordinates, and a position in space through three coordinates.

Coordinates that are referenced to the datum are referred

to as absolute coordinates. Relative coordinates are referenced to

any other known position (datum) you define within the coordinate

system. Relative coordinate values are also referred to as

incremental coordinate values.

Reference systems on milling machines

When using a milling machine, you orient tool movements to the

Cartesian coordinate system. The illustration at right shows how

the Cartesian coordinate system describes the machine axes. The

figure at right illustrates the “right-hand rule” for remembering the

three axis directions: the middle finger is pointing in the positive

direction of the tool axis from the workpiece toward the tool (the Z

axis), the thumb is pointing in the positive X direction, and the index

finger in the positive Y direction.

The TNC 310 can control up to 4 axes. The axes U, V and W are

secondary linear axes parallel to the main axes X, Y and Z,

respectively. Rotary axes are designated as A, B and C. The

illustration shows the assignment of secondary axes and rotary

axes to the main axes.

+Y

Z

Y

X

4.1 Fundamentals of NC

+Z

+Y

+X

+Z

+X

V+

Z

Y

W+

C+

B+

A+

X

U+

27HEIDENHAIN TNC 310

Page 40

Polar coordinates

If the production drawing is dimensioned in Cartesian coordinates,

you also write the part program using Cartesian coordinates.

For parts containing circular arcs or angles it is often simpler to give

the dimensions in polar coordinates.

While the Cartesian coordinates X, Y and Z are three-dimensional

and can describe points in space, polar coordinates are twodimensional and describe points in a plane. Polar coordinates have

their datum at a circle center (CC), or pole. A position in a plane can

be clearly defined by the

■ Polar Radius, the distance from the circle center CC to the

position, and the

■ Polar Angle, the size of the angle between the reference axis and

the line that connects the circle center CC with the position.

4.1 Fundamentals of NC

See figure at lower right.

Definition of pole and angle reference axis

The pole is set by entering two Cartesian coordinates in one of the

three planes. These coordinates also set the reference axis for the

polar angle PA.

Coordinates of the pole (plane) Reference axis of the angle

XY +X

YZ +Y

ZX +Z

10

Z

Y

PR

PA

2

PA

3

PR

CC

PA

PR

1

0°

X

30

Y

Z

Y

X

Z

Y

28

X

X

4 Programming: Fundamentals of NC, File Management, Programming Aids

Page 41

Absolute and relative workpiece positions

Absolute workpiece positions

Absolute coordinates are position coordinates that are referenced

to the datum of the coordinate system (origin). Each position on the

workpiece is uniquely defined by its absolute coordinates.

Example 1: Holes dimensioned in absolute coordinates

Hole

X=10 mm X=30 mm X=50 mm

Y=10 mm Y=20 mm Y=30 mm

Hole Hole

30

20

10

Y

3

2

1

Relative workpiece positions

Relative coordinates are referenced to the last programmed

nominal position of the tool, which serves as the relative (imaginary)

datum. When you write a part program in incremental coordinates,

you thus program the tool to move by the distance between the

previous and the subsequent nominal positions. Incremental

coordinates are therefore also referred to as chain dimensions.

To program a position in incremental coordinates, enter the prefix

“I”(soft key) before the axis.

Example 2: Holes dimensioned with relative coordinates

Absolute coordinates of hole

:

X= 10 mm

Y= 10 mm

referenced to hole Hole referenced to hole

Hole

IX= 20 mm IX= 20 mm

IY= 10 mm IY= 10 mm

Absolute and incremental polar coordinates

Absolute polar coordinates always refer to the pole and the

reference axis.

Incremental polar coordinates always refer to the last programmed

nominal position of the tool.

10

10 10

3010

50

4.1 Fundamentals of NC

Y

6

5

4

X

20

10

20

Y

X

10

PR

+IPA

+IPR

PR

+IPA

30

CC

PA

PR

0°

X

29HEIDENHAIN TNC 310

Page 42

Selecting the datum

A production drawing identifies a certain form element of the

workpiece, usually a corner, as the absolute datum. Before setting

the datum, you align the workpiece with the machine axes and

move the tool in each axis to a known position relative to the

workpiece. You then set the TNC display to either zero or a

predetermined position value. This establishes the reference

system for the workpiece, which will be used for the TNC display

and your part program.

If the production drawing is dimensioned in relative coordinates,

simply use the coordinate transformation cycles. For further

information, refer to section 8.6 “Coordinate Transformation

Cycles.”

If the production drawing is not dimensioned for NC, set the datum

4.1 Fundamentals of NC

at a position or corner on the workpiece, which is the most suitable

for deducing the dimensions of the remaining workpiece positions.

The fastest, easiest and most accurate way of setting the datum is

by using a 3-D touch probe from HEIDENHAIN. For further

information, refer to section 12.2 “Setting the Datum with a 3-D

Touch Probe.”

Example

The workpiece drawing at right illustrates the holes

are dimensioned to an absolute datum with the coordinates X=0

Y=0. The holes

absolute coordinates X=450 Y=750. By using the DATUM SHIFT

cycle you can shift the datum temporarily to the position X=450,

Y=750 and program the holes

calculations.

to are referenced to a relative datum with the

to without any further

to , which

750

320

Z

Y

X

Y

150

0

7

6

-150

0,1

5

±

300

1

3

0

2

4

30

325

450 900

950

4 Programming: Fundamentals of NC, File Management, Programming Aids

X

Page 43

4.2 File management

Files and file management

When you write a part program on the TNC, you must first enter a

file name. The TNC then stores the program as a file with the same

name. You can also store tables as files.

File names

The name of a file can have up to 8 characters. When you store

programs and tables as files, the TNC adds an extension to the file

name, separated by a point. This extension identifies the file type

(see table at right).

35720 .H

File name File type

Files in the TNC Type

Programs

in HEIDENHAIN conversational format .H

4.2 File Management

Table for

Tools .T

The TNC can manage up to 64 files. Their total size, however, must

not exceed 128 MB.

Working with the file manager

This section informs you about the meaning of the individual

screen information, and describes how to select files. If you are not

yet familiar with the TNC file manager, we recommend that you

read this section completely and test the individual functions on

your TNC.

Calling the file manager

Press the PGM NAME soft key:

the TNC displays the file management window

The window shows all of the files that are stored in the TNC. Each

file is shown with additional information that is illustrated in the

table on the next page.

Table for

Datums .D

display. Meaning

FILE NAME Name with up to 8 characters

and file type Number following

the name:

File size in bytes

Status Properties of the file:

M Program is in a

Program Run mode of

operation.

P File is protected against

editing and erasure

(Protected)

31HEIDENHAIN TNC 310

Page 44

Selecting a file

Calling the file manager

<

Use the arrow keys to move the highlight to the desired file:

Move the highlight up or down.

Deleting a file

ú Move the highlight to the file you want to delete.

ú To select the erasing function,

press the DELETE soft key.

The TNC inquires whether you

really intend to erase the file.

ú To confirm erasure: Press the YES

soft key. Abort with the NO soft key

if you do not wish to erase the

directory

Enter the first or more numbers of the file you wish to select and

4.2 File Management

then press the GOTO key: The highlight moves to the first file that

matches these numbers.

<

The selected file is opened in the operating

mode from which you have the called file

manager: Press ENT.

Copying a file

ú Move the highlight to the file you wish to copy.

ú Press the COPY soft key to select the copying

function.

ú Enter the name of the destination file and confirm your entry with

the ENT key: The TNC copies the file. The original file is retained.

Renaming a file

ú Move the highlight to the file you wish to rename.

ú Select the renaming function.

ú Enter the new file name; the file type cannot be

changed.

ú To execute renaming, press the ENT key.

Protecting a file/Canceling file

protection

ú Move the highlight to the file you want to protect.

ú To enable file protection, press the

PROTECT/UNPROTECT soft key.

The file now has status P.

You also need to enter the code number 86357.

To cancel file protection, enter the code number

86357.

32

4 Programming: Fundamentals of NC, File Management, Programming Aids

Page 45

Read in/read out files

ú To read in or read out files: Press the ENT soft key.

The TNC provides the following functions:

Functions for reading in/reading out files Soft key

Read in all files

Only read in selected files; To accept a file suggested

by the TNC, press the YES soft key;

Press the NO soft key if you do not want to accept it.

Read in the selected file: Enter the file name

Read out the selected file: Move the highlight

to the desired file and confirm with ENT

Read out all of the files in the TNC memory

Display the file directories of the external unit

on your TNC screen

4.2 File Management

33HEIDENHAIN TNC 310

Page 46

4.3 Creating and Writing Programs

Organization of an NC program in HEIDENHAIN

conversational format.

A part program consists of a series of program blocks. The figure at

right illustrates the elements of a block.

The TNC numbers the blocks in ascending sequence.

The first block of a program is identified by “BEGIN PGM,” the

program name and the active unit of measure.

The subsequent blocks contain information on:

■ The blank form:

■ tool definitions and tool calls,

■ Feed rates and spindle speeds as well as

■ Path contours, cycles and other functions

The last block of a program is identified by “END PGM,” the pro-

gram name and the active unit of measure.

4.3 Creating and Writing Programs

Defining the blank form — BLK FORM

Immediately after initiating a new program, you define a cuboid

workpiece blank. This definition is needed for the TNC’s graphic

simulation feature. The sides of the workpiece blank lie parallel to

the X, Y and Z axes and can be up to 30 000 mm long. The blank

form is defined by two of its corner points:

■ MIN point: the smallest X, Y and Z coordinates of the blank form,

entered as absolute values.

■ MAX point: the largest X, Y and Z coordinates of the blank form,

entered as absolute or incremental values.

Block:

10 L X+10 Y+5 R0 F100 M3

Path function Words

Block number

Z

Y

MAX

X

34

The TNC can display the graphic only if the short side of

the BLK FORM is longer than 1/64 of the long side.

4 Programming: Fundamentals of NC, File Management, Programming Aids

MIN

Page 47

Creating a new part program

You always enter a part program in the Programming and Editing

mode of operation.

Program initiation in an example:

Select the Programming and Editing mode of

operation.

<

Call up the file manager: Press the PGM NAME

soft key

File name =

<

3056 Enter the new program number and confirm

your entry with the ENT key.

File name = 3056.H

<

Select the default setting for unit of

measurement (mm): Press the ENT key, or

Switch to inches: Press the MM/INCH soft key

and confirm with ENT.

4.3 Creating and Writing Programs

35HEIDENHAIN TNC 310

Page 48

Define the blank

Open the dialog for blank definition: Press the

BLK FORM soft key

Working spindle axis X/Y/Z ?

<

Enter the spindle axis.

Def BLK FORM: Min corner?

<

0 Enter in sequence the X, Y and Z coordinates of

the MIN point.

0

-40

Def BLK FORM: Max-corner?

4.3 Creating and Writing Programs

<

100 Enter in sequence the X, Y and Z coordinates of

the MAX point.

100

0

The program blocks window shows the following BLK FORM

definition

0 BEGIN PGM 3056 MM

1 BLK FORM 0.1 Z X+0 Y+0 Z-40

2 BLK FORM 0.2 X+100 Y+100 Z+0

3 END PGM 3056 MM

The TNC automatically generates the block numbers as well as the

BEGIN and END blocks.

36

4 Programming: Fundamentals of NC, File Management, Programming Aids

Program begin, name, unit of measure

Tool axis, MIN point coordinates

MAX point coordinates

Program end, name, unit of measure

Page 49

Programming tool movements in conversational

format

To program a block, initiate the dialog by pressing a soft key. In the

screen headline, the TNC then asks you for all the information

necessary to program the desired function.

Example of a dialog

Initiate the dialog.

Coordinates ?

<

10 Enter the target coordinate for the X axis.

<

5 Enter the target coordinate for the Y axis,

and go to the next question with ENT.

Radius comp. RL/RR/no comp. ?

<

Enter “No radius compensation” and go to the

next question with ENT.

Feed rate ? F=

<

100 Enter a feed rate of 100 mm/min for this path

contour; go to the next question with ENT.

Miscellaneous function M ?

<

3 Enter the miscellaneous function M3 “spindle

ON”; pressing the ENT key will terminate this

dialog.

Functions during the dialog Key

Ignore the dialog question

End the dialog immediately

Abort the dialog and erase the block

4.3 Creating and Writing Programs

The program blocks window will display the following line:

3 L X+10 Y+5 R0 F100 M3

37HEIDENHAIN TNC 310

Page 50

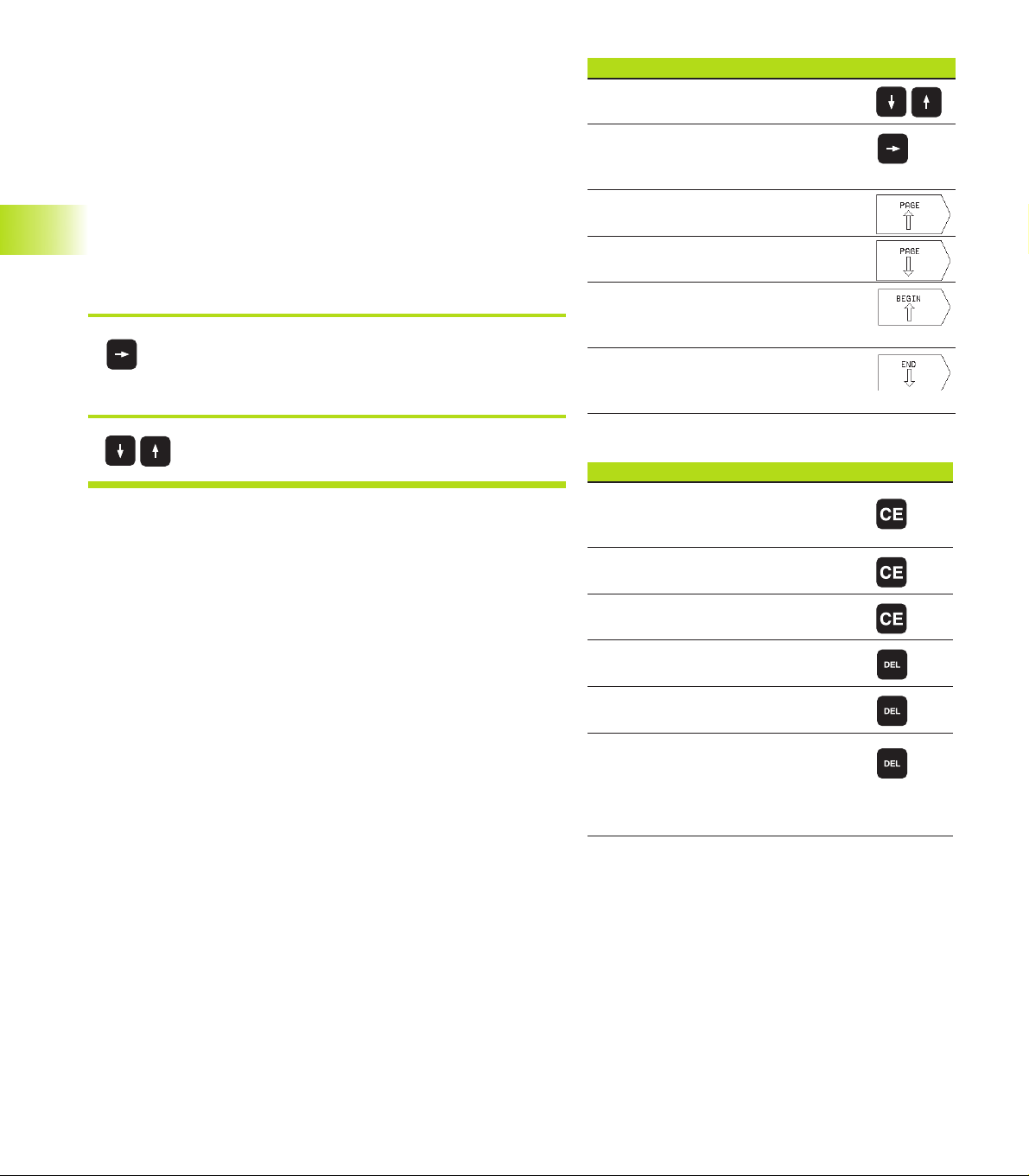

Editing program lines

While you are creating or editing a part program, you can select any

desired line in the program or individual words in a block with the

arrow keys (see table at top right).

Selecting blocks or words Soft keys/keys

Move from one block to the next

Scrolling through the program

ú Press the GOTO key

ú Enter the block number and confirm with ENT, and the TNC will

go to the indicated block, or

ú Press one of the superimposed soft keys to scroll to another page

(see table at top right.)

Looking for the same words in different blocks

To select a word in a block, press the arrow keys

repeatedly until the highlight is on the desired

word.

4.3 Creating and Writing Programs

Select a block with the arrow keys.

The word that is highlighted in the new block is the same as the

one you selected previously.

Inserting blocks at any desired location

ú Select the block after which you want to insert a new block and

initiate the dialog.

Inserting the previously edited (deleted) block at any location

ú Select the block after which you want to insert the block you have

just edited (deleted.)

ú If you wish to insert a block you have stored in the buffer memory,

press the soft key INSERT NC BLOCK

Select individual words in a

block

Go to the previous page

Go to the next page

Jump to beginning

of program

Jump to beginning

End

Erasing blocks and words Key

Set the value of the selected word to

zero

Erase an incorrect number

Clear a (non-blinking) error message

Delete the selected word

Delete the selected block (cycle)

Editing and inserting words

ú Select a word in a block and overwrite it with the new one. The

plain-language dialog is available while the word is highlighted.

ú To accept the change, press the END key.

If you want to insert a word, press the horizontal arrow keys

repeatedly until the desired dialog appears. You can then enter the

desired value.

38

4 Programming: Fundamentals of NC, File Management, Programming Aids

Delete the program sections:

First select the last block of the

program section to be erased, then

erase with the DEL key.

Page 51

4.4 Interactive Programming Graphics

While you are writing the part program, you can have the TNC

generate a graphic illustration of the programmed contour.

To generate/not generate graphics during programming:

ú To switch the screen layout to displaying program blocks to the

left and graphics to the right, press the SPLIT SCREEN key and

PGM + GRAPHICS soft key.

ú Set the AUTO DRAW soft key to ON. While you are

entering the program lines, the TNC generates

each path contour you program in the graphics

window in the right screen half.

If you do not wish to have graphics generated during programming,

set the AUTO DRAW soft key to OFF.

AUTO DRAW ON does not simulate program section repeats.

To generate a graphic for an existing program:

ú Use the arrow keys to select the block up to which you want the

graphic to be generated, or press GOTO and enter the desired

block number.

ú To generate graphics, press the RESET + START

soft key.

Additional functions are listed in the table at right.

To erase the graphic:

ú Shift the soft-key row (see figure at right)

ú Delete graphic: Press CLEAR GRAPHIC soft key

Functions Soft key

Generate interactive graphics

blockwise

Generate a complete graphic

or complete it after

RESET + START

Interrupt interactive graphics

This soft key only appears while the

TNC generates the interactive graphics

4.4 Interactive Programming Graphics

39HEIDENHAIN TNC 310

Page 52

Magnifying or reducing a detail

You can select the graphics display by selecting a detail with the

frame overlay. You can now magnify or reduce the selected detail.

ú Select the soft-key row for detail magnification/reduction

(last row, see figure at right)

The following functions are available:

Function Soft key

Reduce the frame overlay — press and

hold the soft key to reduce the detail

Enlarge the frame overlay — press and

hold the soft key to magnify the detail

Move the frame overlay to the left:

Press and hold the soft key. Move the

frame overlay to the right:

Press and hold the arrow to the right soft key

4.4 Interactive Programming Graphics

With the WINDOW BLK FORM soft key, you can restore the original

section.

ú Confirm the selected section with the WINDOW

DETAIL soft key

40

4 Programming: Fundamentals of NC, File Management, Programming Aids

Page 53

4.5 HELP function

Certain TNC programming functions are explained in more detail in

the HELP function. You can select a HELP topic using the soft keys

.

Select the HELP function

ú Press the HELP key

ú Select a topic: Press one of the available soft keys

Help topics / Functions Soft key

M functions

Cycle parameters

HELP that is entered by the machine manufacturers

(optional, not executable)

Go to previous page

Go to next page

Go to beginning of file

Go to end of file

Select search functions; Enter a number,

Begin search with ENT key

The HELP provided by the machine manufacturer can

only be displayed and not executed.

4.5 HELP Function

End the HELP function

Press the END key.

41HEIDENHAIN TNC 310

Page 54

Page 55

Programming:

Tools

5

Page 56

5.1 Entering Tool-Related Data

Feed rate F

The feed rate is the speed (in millimeters per minute or inches per

minute) at which the tool center moves. The maximum feed rates

can be different for the individual axes and are set in machine

parameters.

Input

You can enter the feed rate in every positioning block. For further

information refer to section 6.2 “Fundamentals of Path Contours.”

Rapid traverse

If you wish to program rapid traverse, enter FMAX. To enter FMAX,

press the ENT key or the FMAX soft key as soon as the dialog

question “Feed rate F = ?” appears on the TNC screen.

Duration of effect

A feed rate entered as a numerical value remains in effect until a

5.1 Entering Tool-Related Data

block with a different feed rate is reached. F MAX is only effective in

the block in which it is programmed. After the block with F MAX is

executed, the feed rate will return to the last feed rate entered as a

numerical value.

Changing during program run

You can adjust the feed rate during program run with the feed-rate

override knob.

Spindle speed S

The spindle speed S is entered in revolutions per minute (rpm) in a

TOOL CALL block.

Z

S

S

Y

F

X

Programmed change

In the part program, you can change the spindle speed in a TOOL

CALL block by entering the spindle speed only:

ú To program a tool call, press the

TOOL CALL soft key (3rd soft-key row)

ú Ignore the dialog question for „Tool number ?“ with

the right arrow key

ú Ignore the dialog question for „Working spindle axis

X/Y/Z ?“ with the right arrow key

ú Enter the new spindle speed for the dialog

question “Spindle speed S= ?”.

Changing during program run

You can adjust the spindle speed during program run with the

spindle-speed override knob.

44

5 Programming: Tools

Page 57

5.2 Tool Data

You usually program the coordinates of path contours as they are

dimensioned in the workpiece drawing. To allow the TNC to

calculate the tool center path — i.e. the tool compensation — you

must also enter the length and radius of each tool you are using.

Tool data can be entered either directly in the part program with

TOOL DEF or (and) separately in tool tables. The TNC will consider

all of the data entered when executing the part program.

Tool number

Each tool is identified by a number between 0 and 254.

The tool number 0 is automatically defined as the zero tool with the

length L=0 and the radius R=0. In tool tables, tool 0 should also be

defined with L=0 and R=0.

Tool length L

There are two ways to determine the tool length L:

1 The length L is the difference between the length of the tool and

that of a zero tool L

For the algebraic sign:

■ The tool is longer than the zero tool L>L

■ The tool is shorter than the zero tool: L<L

To determine the length:

ú Move the zero tool to the reference position in the tool axis

(e.g. workpiece surface with Z=0).

ú Set the datum in the tool axis to 0 (datum setting).

ú Insert the desired tool.

ú Move the tool to the same reference position as the zero tool.

ú The TNC displays the difference between the current tool and the

zero tool.

ú Enter the value in the TOOL DEF block or in the tool table by

pressing the „ACTUAL POSITION“ key

2 If you determine the length L with a tool presetter, this value can

be entered directly in the TOOL DEF block without further

calculations.

.

0

0

0

Z

L

0

5.2 Tool Data

X

45HEIDENHAIN TNC 310

Page 58

Tool radius R

You can enter the tool radius R directly.

Delta values for lengths and radii

Delta values are offsets in the length and radius of a tool.

A positive delta value describes a tool oversize (DR>0), a negative

5.2 Tool Data

delta value describes a tool undersize (DR<0). Enter the delta

values when you are programming with TOOL CALL.

Input range: You can enter a delta value with up to ± 99.999 mm.

R

L

DR<0

R

Entering tool data into the program

The number, length and radius of a specific tool is defined in the

TOOL DEF block of the part program.

ú To select tool definition, press the TOOL DEF key.

ú Enter the Tool number: Each tool is uniquely

identified by its number. When the tool table is

active, enter tool numbers greater than 99

(dependent on MP7260)

ú Enter the tool length: Enter the compensation

value for the tool length.

ú Enter the Tool radius.

During the dialog, you can take the values for length and

radius directly from the position display with the soft

keys „CUR.POS X, CUR.POS Y or CUR.POS Z“.

Resulting NC block:

4 TOOL DEF 5 L+10 R+5

DR>0

DL<0

DL>0

46

5 Programming: Tools

Page 59

Entering tool data in tables

You can define and store up to 254 tools and their tool data in the

tool table (the maximum number of tools in the table can be set in

machine parameter 7260).

Tool table: Available input data

Abbr. Input

T Number by which the tool is called in the program

L Value for tool length compensation L

R Compensation value for the tool radius R

Editing the tool table

The tool table has the name TOOL.T is automatically active in a

program run operating mode.

To open the tool table TOOL.T:

ú Select any machine operating mode.

ú To select the tool table, press the TOOL TABLE soft

key.

ú Set the EDIT soft key to ON.

ú Select the Programming and Editing mode of operation.

ú Calls the file manager.

ú Move the highlight to TOOL.T. Confirm with the

ENT key.

Dialog

–

Tool length?

Tool radius?

5.2 Tool Data

When you have opened the tool table, you can edit the tool data by

moving the cursor to the desired position in the table with the

arrow keys (see figure at center right). You can overwrite the stored

values, or enter new values at any position. The available editing

functions are illustrated in the table on the next page.

If you edit the tool table parallel to tool change the TNC

does not interrupt the program run. However, the

changed data does not become effective until the next

tool call.

To leave the tool table:

ú Finish editing the tool table: Press the END key.

ú Call the file manager and select a file of a different type, e.g. a

part program.

47HEIDENHAIN TNC 310

Page 60

Editing functions for tool tables Soft key

Take the value from the position

display

Select previous page in table

(2nd soft-key row)

5.2 Tool Data

Select next page in table

(2nd soft-key row)

Move the highlight one column to

the left

Move the highlight one column to

the right

Delete incorrect numerical value,

re-establish preset value

Re-establish the last value stored

Move the highlight back to beginning of line

48

5 Programming: Tools

Page 61

Calling tool data

A TOOL CALL block in the part program is defined with the

following data:

ú Select the tool call function with the TOOL CALL

key

ú Tool number: Enter the number of the tool. The

tool must already be defined in a TOOL DEF block

or in the tool table.

ú Working spindle axis X/Y/Z: Enter the tool axis.

ú Spindle speed S

ú Tool length oversize: Enter the delta value for the

tool length.

ú Tool radius oversize: Enter the delta value for the

tool radius.

Example:

Call tool number 5 in the tool axis Z with a spindle speed 2500 rpm.

The tool length is to be programmed with an oversize of 0.2 mm,

the tool radius with an undersize of 1 mm.

20 TOOL CALL 5 Z S2500 DL+0.2 DR-1

The character D preceding L and R designates delta values.

Tool change

The tool change function can vary depending on the

individual machine tool. Refer to your machine tool

manual.

5.2 Tool Data

Tool change position

A tool change position must be approachable without collision. With

the miscellaneous functions M91 and M92, you can enter machinereferenced (rather than workpiece-referenced) coordinates for the

tool change position. If TOOL CALL 0 is programmed before the

first tool call, the TNC moves the tool spindle in the tool axis to a

position that is independent of the tool length.

Manual tool change

To change the tool manually, stop the spindle and move the tool to

the tool change position:

ú Move to the tool change position under program control.

ú Interrupt program run (see section 11.3 “Program Run”).

ú Change the tool.

ú Resume the program run (see section 11.3 “Program Run”).

49HEIDENHAIN TNC 310

Page 62

Pocket table for tool changer

The TOOLP.TCH (TOOL Pocket)table must be programmed to enable

automatic tool change.

To select the pocket table:

ú In the Programming and Editing mode,

5.2 Tool Data

ú In a machine operating mode

ú Calls the file manager.

ú Move the highlight to TOOLP.TCH. Confirm with the

ENT key.

ú To select the tool table, press the TOOL TABLE soft

key.

ú To select the pocket table,

press the POCKET TABLE soft key

ú Set the EDIT soft key to ON

Editing functions for pocket table Soft key

Select previous page in table

(2nd soft-key row)

When you have opened the pocket table, you can edit the tool data

by moving the cursor to the desired position in the table with the

arrow keys (see figure at upper right). You can overwrite the stored

values, or enter new values at any position.

You may not use a tool number twice in the pocket table. If you do

so the TNC will output an error message when you exit the table.

You can enter the following information on a tool into a pocket table

Abbr. Input

P Pocket number of the tool in the tool magazine

T Tool number

ST Special tool with large radius requiring more than one

pocket (ST: If your special tool takes up pockets in front

of and behind its actual pocket, these additional

pockets need to be locked (status L).

F Fixed tool number.

The tool is always returned to the same pocket.

L Locked pocket

PLC Information on this tool pocket that is to be

sent to the PLC

Select next page in table

(2nd soft-key row)

Move the highlight one column to

the left

Move the highlight one column to

the right

Reset pocket table

Dialog

–

Tool number?

Special tool ?

Fixed pocket?

Locked pocket?

PLC status?

50

5 Programming: Tools

Page 63

5.3 Tool Compensation

The TNC adjusts the spindle path in the tool axis by the

compensation value for the tool length. In the working plane, it

compensates the tool radius.

If you are writing the part program directly on the TNC, the tool

radius compensation is effective only in the working plane.

Tool length compensation

Length compensation becomes effective automatically as soon as a

tool is called and the tool axis moves. To cancel length

compensation call a tool with the length L=0.

If you cancel a positive length compensation with TOOL

CALL 0, the distance between tool and workpiece will

be reduced.

After TOOL CALL, the path of the tool in the tool axis, as

entered in the part program, is adjusted by the difference

between the length of the previous tool and that of the

new one.

For tool length compensation, the TNC takes the delta values from

the TOOL CALL block into account:

Compensation value = L + DL

L is the tool length L from the TOOL DEF block or tool

table

DL

TOOL CALL

is the oversize for length DL in the TOOL CALL block

(not taken into account by the position display)

TOOL CALL

where

5.3 Tool Compensation

Tool radius compensation

The NC block for programming a tool movement contains:

■ RL or RR for compensation in the tool radius

■ R+ or R– for radius compensation in single-axis movements

■ R0 if no radius compensation is required

Radius compensation becomes effective as soon as a tool is called

and is moved in the working plane with RL or RR. To cancel radius

compensation, program a positioning block with R0.

51HEIDENHAIN TNC 310

Page 64

For tool radius compensation, the TNC takes the delta values from

the TOOL CALL block into account:

Compensation value = R + DR

TOOL CALL,

where

R is the tool radius R from the TOOL DEF block or tool

table

DR

TOOL CALL

is the oversize for radius DR in the TOOL CALL block

(not taken into account by the position display)

Tool movements without radius compensation: R0

The tool center moves in the working plane to the programmed

path or coordinates.

Applications: Drilling and boring, pre-positioning

(see figure at center right)

5.3 Tool Compensation

Tool movements with radius compensation: RR and RL

RR The tool moves to the right of the programmed contour

RL The tool moves to the left of the programmed contour

The tool center moves along the contour at a distance equal to the

radius. “Right” or “left” are to be understood as based on the

direction of tool movement along the workpiece contour (see

illustrations on the next page).

Between two program blocks with different radius

compensations (RR and RL) you must program at least

one block without radius compensation (that is, with R0).

Radius compensation does not come into effect until the

end of the block in which it is first programmed.

Whenever radius compensation is activated with RR/RL

or canceled with R0, the TNC positions the tool

perpendicular to the programmed starting or end

position. Position the tool at a sufficient distance from

the first or last contour point to prevent the possibility of

damaging the contour.

RL

R0

R

R

Z

Y

X

Y

X

52

5 Programming: Tools

Page 65

Entering radius compensation

When you program a path contour, the following dialog question is

displayed after entry of the coordinates:

Radius comp.: RL/RR/no comp. ?

<

To select tool movement to the left of the

contour, press the RL soft key, or

To select tool movement to the right of the

contour, press the RR soft key, or

Y

RL

To select tool movement without radius

compensation or to cancel radius

compensation, press the ENT key or the R0 soft

key.

To terminate the dialog, press the END key.

X

5.3 Tool Compensation

Y

RR

X

53HEIDENHAIN TNC 310

Page 66

Radius compensation: Machining corners

Outside corners

If you program radius compensation, the TNC moves the tool in a

transitional arc around corners. The tool “rolls around” the corner

point. If necessary, the TNC reduces the feed rate at outside

corners to reduce machine stress, for example at very great

changes of direction.

Inside corners

The TNC calculates the intersection of the tool center paths at

inside corners under radius compensation. From this point it then

starts the next contour element. This prevents damage to the

workpiece. The permissible tool radius, therefore, is limited by the

geometry of the programmed contour.

5.3 Tool Compensation

To prevent the tool from damaging the contour, be

careful not to program the starting or end position for

machining inside corners at a corner of the contour.

Machining corners without radius compensation

If you program the tool movement without radius compensation,

you can change the tool path and feed rate at workpiece corners

with the miscellaneous function M90. See ”7.4 Miscellaneous

Functions for Contouring Behavior.”

RL

RL RL

54

5 Programming: Tools

Page 67

6

Programming:

Programming Contours

Page 68

6.1 Overview of Tool Movements

Path functions

A workpiece contour is usually composed of several contour

elements such as straight lines and circular arcs. With the path

functions, you can program the tool movements for straight lines

and circular arcs.

Miscellaneous functions M

With the TNC’s miscellaneous functions you can affect

■ Program run, e.g., a program interruption

■ Machine functions, such as switching spindle rotation and coolant

supply on and off

■ Contouring behavior of the tool

Subprograms and program section repeats

6.1 Overview of Tool Movements

If a machining sequence occurs several times in a program, you can

save time and reduce the chance of programming errors by

entering the sequence once and then defining it as a subprogram

or program section repeat. If you wish to execute a specific program section only under certain conditions, you also define this

machining sequence as a subprogram. In addition, you can have a

part program call a separate program for execution.

How subprograms and program section repeats are used in

programming is described in Chapter 9.

L

L

CC

L

C

Y

80

60

40

CC

R40

56

11510

X

6 Programming: Programming Contours

Page 69

6.2 Fundamentals of Path Functions

Programming tool movements for workpiece

machining

You create a part program by programming the path functions for

the individual contour elements in sequence. You usually do this by

entering the coordinates of the end points of the contour

elements given in the production drawing. The TNC calculates the

actual path of the tool from these coordinates, and from the tool

data and radius compensation.

The TNC moves all axes programmed in a single block

simultaneously.

Movement parallel to the machine axes

The program block contains only one coordinate. The TNC thus

moves the tool parallel to the programmed axis.

Depending on the individual machine tool, the part program is

executed by movement of either the tool or the machine table on

which the workpiece is clamped. Nevertheless, you always program path contours as if the tool moves and the workpiece remains

stationary.

Example:

L X+100

L Path function for “straight line”

X+100 Coordinate of the end point

The tool retains the Y and Z coordinates and moves to the position

X=100. See figure at upper right.

Movement in the main planes

The program block contains two coordinates. The TNC thus moves

the tool in the programmed plane.

Example:

L X+70 Y+50

The tool retains the Z coordinate and moves in the XY plane to the

position X=70, Y=50. See figure at center right.

50

Z

Y

X

100

Z

6.2 Fundamentals of Path Functions

Y

X

70

Z