Page 1

Operating Instructions

IK 5000

QUADRA-CHEK

(QC 5000)

Multisensor Systems

English (en)

2/2010

Page 2

Page 3

Quadra-Chek® 5000

User’s Guide

Page 4

Proprietary notice

Disclaimer

All information set forth in this document, all rights to such information,

any and all inventions disclosed herein and any patents that might be

granted by employing the materials, methods, techniques or apparatus

described herein are the exclusive property of Metronics Incorporated,

Bedford, New Hampshire.

No part of this document may be reproduced, stored in a retrieval system, or transmitted in any form or by any means, electronic, mechanical,

photocopying, recording, or otherwise, without the prior permission of

Metronics Incorporated. The information contained herein is designed

only for use with the Quadra-Chek 5000 Metrology Software. Metronics Incorporated is not responsible for any use of this information as applied to any other apparatus.

The information contained in this document is subject to change without notice. Metronics Incorporated assumes no responsibility or liability

for any errors or inaccuracies contained herein, or for incidental or consequential damage in connection with the furnishing, performance, or use

of this guide.

Metronics Inc. shall not be liable to the purchaser of this product or third

parties for damages, losses, costs, or expenses incurred by the purchaser

or third parties as a result of: accident, misuse, or abuse of this product or

unauthorized modifications, repairs, or alterations to this product, or failure

to strictly comply with Metronics Incorporated’s operating and maintenance instructions.

Trademarks

Revision

Metronics, Quadra-Chek, Quadra-Chek 5000, and QC5000 are registered trademarks of Metronics Incorporated.

Other product names used herein are for identification purposes only

and may be trademarks of their respective owners. Metronics Incorporated disclaims any and all rights to those marks.

September 2004 Fourth Printing

Revision 3.0

Part Number: 11A10521

Software Version 2.2

Printed in the USA.

Page 5

Contents

OvOv

erer

vievie

ww

Ov

er

OvOv

erer

Welcome to the QC-5000 .............................................................................1-1

About This Guide .........................................................................................1-3

Icons and Type Faces .....................................................................................1-4

Starting the QC-5000 ...................................................................................1-5

Windows and Toolbars ..................................................................................1-6

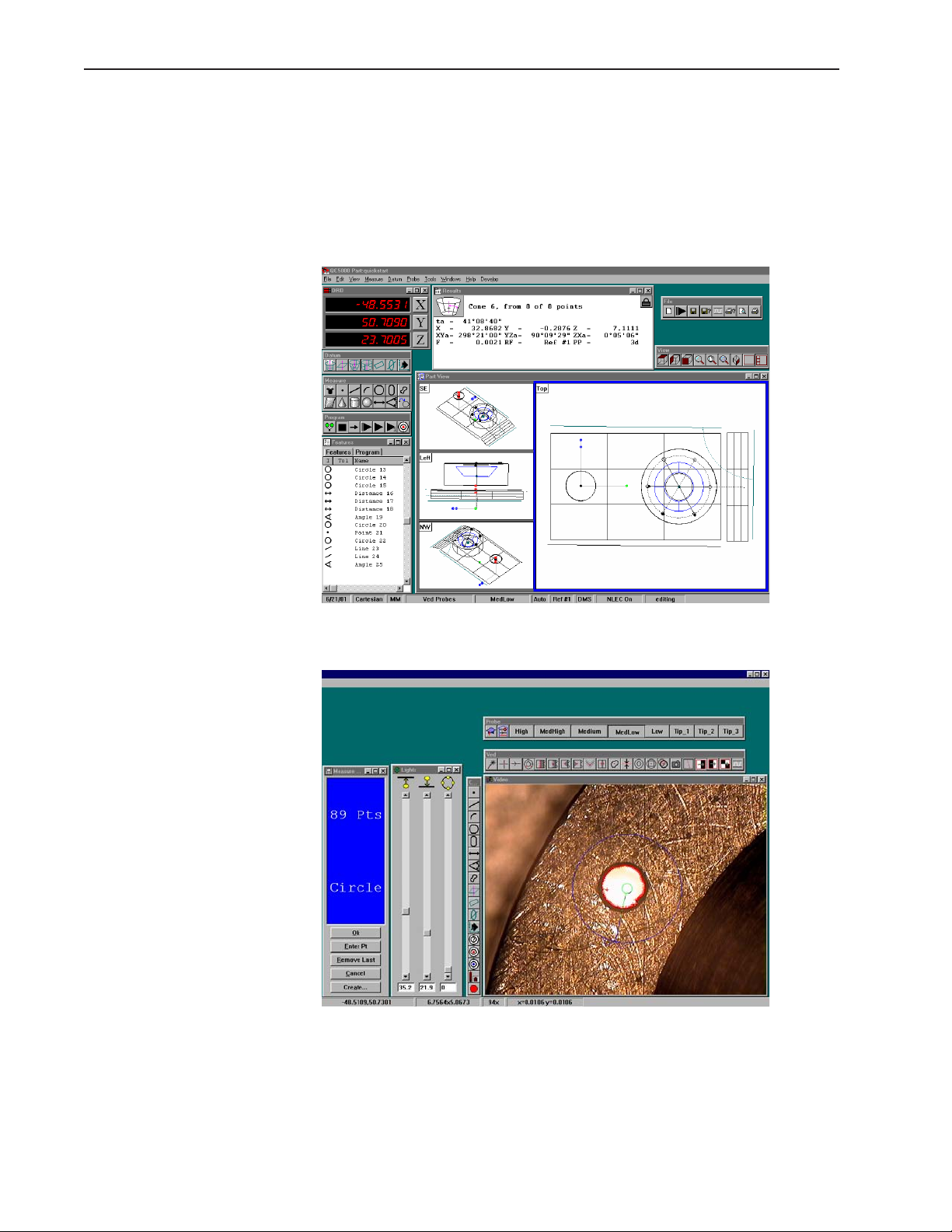

QC-5000 Windows....................................................................................... 1-8

The Results Window ..................................................................................... 1-8

The Part View Window ............................................................................... 1-12

View Rotator ...............................................................................................1-14

Template Windows...................................................................................... 1-15

Status Bar .................................................................................................... 1-18

Main Menu Bar...........................................................................................1-22

Toolbars.......................................................................................................1-22

....................................................................................................................................................

vie

w

..........................................................................

vievie

ww

....................................................................................................................................................

Warning ..................................................................................................1-4

Caution .................................................................................................. 1-4

Note ....................................................................................................... 1-4

Italics ......................................................................................................1-4

To open the QC-5000 ............................................................................1-5

DRO ...................................................................................................... 1-8

Feature Specifications .............................................................................. 1-8

To move information from the results window to the features list ...........1-9

Locked/unlocked features ......................................................................1-10

To unlock a feature ...............................................................................1-10

To lock a feature ................................................................................... 1-10

Feature type diagram /feature stamp .....................................................1-11

To open the feature stamp window .......................................................1-11

Single pane part view ............................................................................1-12

Four pane part view ..............................................................................1-13

To use the view rotator..........................................................................1-14

To separate template windows ...............................................................1-15

To nest template windows .....................................................................1-17

To add items to the status bar ...............................................................1-18

To delete items from the status bar........................................................1-20

Datum toolbar ...................................................................................... 1-22

Measure toolbar ....................................................................................1-22

Probe toolbar ........................................................................................ 1-22

View toolbar ......................................................................................... 1-22

Tolerance toolbar ..................................................................................1-22

Program toolbar .................................................................................... 1-23

File toolbar............................................................................................1-23

VED toolbar ......................................................................................... 1-23

Custom toolbar .....................................................................................1-23

To place a toolbar on the QC-5000 desktop .........................................1-24

To remove a toolbar from the QC-5000 desktop ..................................1-25

To add buttons to a toolbar................................................................... 1-26

To remove buttons to a toolbar ............................................................. 1-28

1-11-1

1-1

1-11-1

Contents-1

Page 6

Contents

QQ

uick Suick S

Q

uick S

QQ

uick Suick S

tartar

tt

..............................................................................................................................................

tar

t

.......................................................................

tartar

tt

..............................................................................................................................................

Getting Started ..............................................................................................2-1

General Preparation .......................................................................................2-1

To open the QC-5000 software .............................................................. 2-1

To set machine zero ................................................................................ 2-2

To display the feature list ........................................................................2-2

To display the program template .............................................................2-3

To nest the template windows ................................................................. 2-4

Select the Active Probe ............................................................................2-5

To select the active probe ........................................................................2-5

Probing Technique ........................................................................................2-5

Good probing techniques........................................................................ 2-5

Bad probing techniques ..........................................................................2-5

Recording the Quick Start Program .............................................................. 2-6

Clearance moves ..................................................................................... 2-6

To insert a clearance move ...................................................................... 2-7

Creating the Start Point .................................................................................2-8

To record the quick start program ...........................................................2-8

To move the probe to the start point .......................................................2-9

Recording the Part View Window ............................................................... 2-10

To record the part view window display ................................................2-10

Creating the Datum ....................................................................................2-11

To create the primary plane................................................................... 2-11

Creating the Secondary Alignment .............................................................. 2-14

To create a secondary alignment............................................................ 2-14

Creating the Zero Point ............................................................................... 2-17

To activate the VED probe group .........................................................2-17

To select a magnification....................................................................... 2-18

To create an arc tool.............................................................................. 2-18

To re-size a VED probe tool.................................................................. 2-21

To create a zero point ............................................................................2-22

Save the Reference Frame ............................................................................ 2-30

To save the reference frame ...................................................................2-30

To activate the contact probe group ......................................................2-31

Touch Probe Measurement ..........................................................................2-32

To measure a circle ................................................................................2-33

Measuring 3-D Features ..............................................................................2-36

To change the part view perspective ......................................................2-36

To measure a cone................................................................................. 2-38

To measure a cylinder ........................................................................... 2-41

To measure a plane ............................................................................... 2-50

2-D Measurement with VED ...................................................................... 2-53

To change the part view perspective ......................................................2-53

To activate the VED probe group .........................................................2-55

To create a circle probe tool................................................................... 2-56

To measure circle 3 ............................................................................... 2-59

To measure circle 4 ............................................................................... 2-61

To construct a bolt hole circle ............................................................... 2-64

To construct a nearest distance ..............................................................2-66

2-12-1

2-1

2-12-1

Contents-2

Page 7

Quadra-Chek® 5000

To construct a farthest distance .............................................................2-68

To construct a center-to-center distance ................................................2-70

Creating the Second Reference Frame..........................................................2-72

To change the part view ........................................................................2-72

To measure a circle ................................................................................2-74

To create the second reference frame ..................................................... 2-81

To save a reference frame.......................................................................2-83

To create a duplicate feature ..................................................................2-84

To construct an angle ............................................................................2-86

To select the active probe ......................................................................2-87

To measure a line ..................................................................................2-88

To measure a line ..................................................................................2-90

To construct an angle ............................................................................2-92

To perform a bi-directional tolerance ....................................................2-93

To perform a true position tolerance .....................................................2-97

To perform a width tolerance ..............................................................2-100

To open the all tolerance template....................................................... 2-102

To modify template properties ............................................................ 2-104

To enter a formula .............................................................................. 2-107

Dynamic data exchange ......................................................................2-109

To DDE output to Excel .................................................................... 2-109

To export a tab delimited file to a spreadsheet .....................................2-113

To export to a .csv file (comma separated value) ................................. 2-116

To export Access 2000 ........................................................................ 2-119

To complete the quick start program...................................................2-122

To run the quick start program ........................................................... 2-123

PP

rr

obesobes

P

r

PP

rr

............................................................................................................................................................

obes

..............................................................................

obesobes

............................................................................................................................................................

Video Edge Detection (VED) ....................................................................... 3-1

To create a new magnification................................................................. 3-1

To delete a magnification ........................................................................ 3-3

To assign a zoom position for a magnification ........................................3-5

VED Calibrations ......................................................................................... 3-7

To perform an auto focus teach ...............................................................3-7

To perform an edge teach ......................................................................3-12

Pixel calibration ....................................................................................3-15

To perform a pixel calibration ...............................................................3-15

To perform a camera calibration ........................................................... 3-20

Parcentricity calibration ........................................................................3-27

To perform a parcentricity calibration ...................................................3-27

VED Probes ................................................................................................3-34

New probe tool .....................................................................................3-34

To access the new probe tool ................................................................. 3-34

Hand cursors ........................................................................................ 3-36

To move a probe tool ............................................................................ 3-36

To re-size a probe tool ...........................................................................3-38

To rotate a probe tool............................................................................3-40

Simple probe .........................................................................................3-42

To create a simple probe........................................................................3-42

Circle probe ..........................................................................................3-44

To create a circle probe.......................................................................... 3-44

3-13-1

3-1

3-13-1

Contents-3

Page 8

Contents

Buffer probe ..........................................................................................3-46

To create a buffer probe ........................................................................ 3-46

Average probe .......................................................................................3-48

Nearest probe........................................................................................ 3-48

Farthest probe ....................................................................................... 3-49

Height probe ........................................................................................ 3-49

Width probe .........................................................................................3-50

Blob probe ............................................................................................3-50

Pattern probe ........................................................................................ 3-51

Worm probe ......................................................................................... 3-52

Video Probes ............................................................................................... 3-57

Crosshair probe..................................................................................... 3-57

Video charts probe ................................................................................3-57

Edge Teaching .............................................................................................3-58

To perform a simple edge teach .............................................................3-59

To perform an advanced edge teach ...................................................... 3-61

Probe Library............................................................................................... 3-64

Probe Families & Groups ............................................................................3-64

TouchProbe group ................................................................................ 3-65

StarProbe group ....................................................................................3-65

To create a new probe group .................................................................3-66

Probe Calibration ........................................................................................3-68

Master probe tips ..................................................................................3-69

To teach (qualify) a master probe tip.....................................................3-69

To teach (qualify) a non-master probe tip .............................................3-72

Cross Calibration of Touch Probe and Camera............................................ 3-75

To cross calibrate a touch probe to a VED camera ................................ 3-75

Using a Probe Rack ............................................................................... 3-82

Probe Rack Setup ........................................................................................3-82

Probe rack orientation........................................................................... 3-83

+X Orientation .....................................................................................3-83

+Y Orientation ..................................................................................... 3-84

-X Orientation ...................................................................................... 3-85

-Y Orientation .....................................................................................3-86

Probe Rack Calibration ...............................................................................3-87

Initial clearance: ....................................................................................3-87

Docking distance: .................................................................................3-87

Retract distance:.................................................................................... 3-87

Dropping in Z: .....................................................................................3-87

Pickup in Z:.......................................................................................... 3-87

Release in Z: .........................................................................................3-87

Approach in Z: ..................................................................................... 3-87

Port position offset:............................................................................... 3-88

DATRACK part program .....................................................................3-89

To check probe rack orientation ............................................................3-89

To run the DATRACK program ...........................................................3-90

To edit the initial settings of the DATRACK program.......................... 3-91

To enter the datum in the DATRACK program ...................................3-93

To load a probe .....................................................................................3-97

To unload a probe .................................................................................3-99

Contents-4

Page 9

Quadra-Chek® 5000

PP

rr

ogrammingogramming

P

r

ogramming

PP

rr

ogrammingogramming

Programming Overview ................................................................................4-1

The Program Toolbar .................................................................................... 4-2

Record/Edit Program .............................................................................. 4-2

Pause Program ........................................................................................ 4-2

New Run ................................................................................................4-2

Run Program From Current Step............................................................ 4-2

Run Just Current Step............................................................................. 4-2

Recording a Program .....................................................................................4-3

To create a program ................................................................................ 4-3

To open a saved program ........................................................................ 4-5

Running A Program ...................................................................................... 4-6

To run a program ....................................................................................4-6

Sample Program ............................................................................................4-7

To create a new part file ..........................................................................4-7

To record a program ................................................................................4-8

To display the feature list ........................................................................ 4-9

To display the program template ...........................................................4-10

To record the part view window display ................................................ 4-11

To insert a clearance move.................................................................... 4-12

To measure the primary plane ...............................................................4-13

To measure the secondary line ............................................................... 4-16

To switch the active probe to VED ....................................................... 4-19

To create an arc tool ..............................................................................4-20

To measure the zero feature ................................................................... 4-23

To create a zero point ............................................................................4-30

To save the reference frame ................................................................... 4-31

To measure a circle ................................................................................4-32

To construct a distance.......................................................................... 4-35

To save a program .................................................................................4-37

To run a program ..................................................................................4-38

Program Properties ...................................................................................... 4-39

Fixturing tab .........................................................................................4-40

General tab ...........................................................................................4-41

Initial Settings .............................................................................................4-42

Display part view map ..........................................................................4-42

Hide position indicator .........................................................................4-42

Light control .........................................................................................4-42

Probe path data .....................................................................................4-42

Editing Programs.........................................................................................4-44

To edit a wait for point(s) step .............................................................. 4-44

To edit a light control statement ........................................................... 4-46

To change coordinate of a clearance move or goto position step ............ 4-48

Creating User Messages ...............................................................................4-50

To Insert A User Message ......................................................................4-50

Programming Wizards .................................................................................4-51

Grids..................................................................................................... 4-51

To create a grid ..................................................................................... 4-51

Polar grids .............................................................................................4-55

To create a polar grid ............................................................................ 4-55

Palletize................................................................................................. 4-60

........................................................................................................................................

....................................................................

........................................................................................................................................

4-14-1

4-1

4-14-1

Contents-5

Page 10

Contents

To palletize multiple parts ..................................................................... 4-60

Random Placement ............................................................................... 4-63

To insert reference steps in a part program ............................................4-63

To create a random placement ...............................................................4-65

To run a parts program with a random placement ................................ 4-66

To copy and paste special ...................................................................... 4-67

Expanding the Program Toolbar .................................................................. 4-72

Program Toolbar ..........................................................................................4-74

Toggle Break Point ................................................................................4-74

Program Comment ...............................................................................4-74

Edit Steps.............................................................................................. 4-74

If-Goto ................................................................................................. 4-74

If-Then .................................................................................................4-74

Else .......................................................................................................4-75

Else-If ................................................................................................... 4-75

Super Step............................................................................................. 4-75

Goto Label ............................................................................................ 4-75

Offset Positions..................................................................................... 4-75

To add buttons to a toolbar .................................................................. 4-76

To delete buttons from a toolbar ...........................................................4-78

Conditional Statements ...............................................................................4-80

Test Conditions .................................................................................... 4-80

Actions.................................................................................................. 4-80

Arithmetic Operators ............................................................................ 4-81

If-Goto Statement .................................................................................4-82

If-Then Statement ................................................................................ 4-83

Else Statement....................................................................................... 4-84

Else-If Statement................................................................................... 4-85

TT

olerancing & olerancing &

T

olerancing &

TT

olerancing & olerancing &

Tolerancing .................................................................................................... 5-1

Tolerance Toolbar ....................................................................................5-1

To view the tolerance toolbar .................................................................. 5-1

Bi-directional tolerance (circles, points, arcs, spheres) .............................5-3

To perform a bi-directional tolerance ...................................................... 5-3

Pass/ Fail Displays ...................................................................................5-5

True position tolerance (circles, points arcs, spheres) ............................... 5-5

To perform a true position tolerance .......................................................5-5

To perform a MMC tolerance .................................................................5-8

To perform a LMC ............................................................................... 5-11

Concentricity tolerance (circles, arcs) ....................................................5-14

To perform a concentricity tolerance ..................................................... 5-14

Straightness tolerance (lines) .................................................................5-16

To perform a straightness tolerance (lines) ............................................ 5-16

Circularity/sphericity tolerance (circles, spheres) ...................................5-18

To perform a circularity tolerance ......................................................... 5-18

To perform a sphericity tolerance ..........................................................5-20

Cylindricity tolerance (cylinders)........................................................... 5-22

To perform a cylindricity tolerance ........................................................5-22

Flatness tolerance (planes) ..................................................................... 5-24

To perform a flatness tolerance .............................................................. 5-24

TT

emplatesemplates

T

emplates

TT

emplatesemplates

......................................................................................................

...................................................

......................................................................................................

5-15-1

5-1

5-15-1

Contents-6

Page 11

Quadra-Chek® 5000

Perpendicularity tolerance (lines, cylinders, cones) ................................5-26

To perform a perpendicularity tolerance ................................................5-26

Parallelism/Co-planarity tolerance (linear features)................................ 5-28

To perform a parallelism tolerance ........................................................ 5-28

To perform a co-planarity tolerance....................................................... 5-30

Circular runout tolerance ...................................................................... 5-32

To perform a circular runout tolerance ..................................................5-32

Angle tolerance ..................................................................................... 5-34

To perform an angle tolerance ...............................................................5-34

Width tolerance ....................................................................................5-36

To perform a width tolerance ................................................................5-36

Templates ....................................................................................................5-38

Features Template ........................................................................................5-39

To open the features template ............................................................... 5-39

Adding Data to Templates ........................................................................... 5-41

To drag & drop a results window field to the features list...................... 5-41

To drag & drop multiple results window fields to the features list .........5-42

Sorting the Features List .......................................................................5-43

To sort data in the features list .............................................................. 5-43

Reports Template ......................................................................................... 5-44

To open the reports template .................................................................5-44

Adding Data to the Reports Template ................................................... 5-46

To drag & drop a results window field to the reports template ..............5-46

To drag and drop multiple results window fields to the

reports template ..........................................................................5-47

Sorting Data in the Reports Template ...................................................5-48

To sort data in the reports template....................................................... 5-48

Report Headers............................................................................................5-49

To show a report header ........................................................................5-49

Customizing Report Headers ................................................................5-51

To place a graphic in a report header ................................................... 5-51

To arrange text and graphics in a report header ..................................... 5-52

Automated Text Input & Prompting ...........................................................5-53

Overlays ...................................................................................................... 5-54

To save a report header as an overlay ..................................................... 5-54

To place an overlay in a report header ...................................................5-55

Program Template .................................................................................5-56

To open the program template ..............................................................5-56

Template Properties ...............................................................................5-58

To access the template features dialog box .............................................5-58

Template Features Dialog Box .............................................................. 5-59

Display tab ........................................................................................... 5-59

Filters tab ....................................................................................................5-64

To create a filter ....................................................................................5-64

To modify a filter .................................................................................. 5-70

To remove a filter ..................................................................................5-72

Misc tab (miscellaneous) ....................................................................... 5-73

Column Properties ...................................................................................... 5-74

Standard column properties .................................................................. 5-74

Appearance tab ..................................................................................... 5-74

Formulas tab .........................................................................................5-74

Contents-7

Page 12

Contents

Sample Formula .......................................................................................... 5-77

To create the sample formula ................................................................ 5-77

To modify a formula ............................................................................. 5-82

To remove a formula .............................................................................5-84

Runs Template ............................................................................................. 5-85

To open the runs template ....................................................................5-85

To add data to the runs template .......................................................... 5-86

Nesting Template Windows .........................................................................5-87

To nest template windows .....................................................................5-87

To separate template windows ...............................................................5-88

Creating New Templates .............................................................................. 5-89

To create a new template .......................................................................5-89

UU

ser Sser S

U

UU

etup Scretup Scr

ser S

etup Scr

ser Sser S

etup Scretup Scr

Encoder setup program.................................................................................. 6-2

Configuring analog and TTL encoders ...................................................6-2

Calibrating analog encoders ....................................................................6-3

Setup Tools/Customize screens .....................................................................6-6

Colors screen........................................................................................... 6-6

Changing item colors .......................................................................6-6

Color list items ................................................................................. 6-7

Dark edge and light edge tools .........................................................6-8

DRO axis, digits and window ..........................................................6-8

Feature stamp background, filtered and selected point......................6-9

QC5000 window ............................................................................. 6-9

Results text and window ...................................................................6-9

Part view parents, probe indicator, selection border, window ..........6-10

Pattern finder failure and success .................................................... 6-10

Point stake marks ...........................................................................6-11

Temporary stake marks ................................................................... 6-11

Profile background .........................................................................6-11

Probe selector background, current probe,

new qualification, old qualification and text ............................ 6-12

Whiskers (used to display profile form errors) ................................ 6-12

Help screen ...........................................................................................6-12

Misc screen ...........................................................................................6-14

Errors screen ......................................................................................... 6-15

System error messages..................................................................... 6-15

Statusbar screen.....................................................................................6-17

Toolbars screen ...................................................................................... 6-18

Displaying toolbar buttons ............................................................. 6-18

Adding buttons to a toolbar ........................................................... 6-19

Removing buttons from a toolbar................................................... 6-19

Enable/Disable raised edges for toolbar buttons ............................. 6-20

Allows/Prohibit toolbar docking .....................................................6-20

Mapping parts to a toolbar ............................................................. 6-20

Mapping workspaces to toolbar ...................................................... 6-21

Creating custom toolbars................................................................ 6-22

eenseens

....................................................................................................................

eens

..........................................................

eenseens

....................................................................................................................

6-16-1

6-1

6-16-1

Contents-8

Page 13

Quadra-Chek® 5000

Setup Tools/Options screens .......................................................................6-23

VEDscreen ............................................................................................6-23

Automatic probe alignment and the high accuracy mode ...............6-23

Specifying the advanced teach mode............................................... 6-24

Scaling video charts to magnification ............................................. 6-25

Specifying pattern search rings........................................................6-26

Specifying search ring overlap......................................................... 6-27

Calibrating the display of magnification value................................ 6-28

Allow crosshair probes to rotate ......................................................6-30

Allowing video charts to rotate .......................................................6-30

Moving video charts with a mouse .................................................6-31

Moving video charts with the part.................................................. 6-31

Specifying video camera image type................................................ 6-31

Specifying video probe animation rate ............................................6-32

Specifying maximum field of view for worm tool (probe) ...............6-32

Specifying pattern file names ..........................................................6-33

FOV spherical and NLEC corrections ............................................6-34

Specifying a larger video window.................................................... 6-34

Probes screen......................................................................................... 6-36

Specifying probe qualification sphere diameter ...............................6-36

Debouncing the touch probe.......................................................... 6-36

Preventing multiple probe hits........................................................6-37

Specifying probe re-qualification across sessions .............................6-37

Adding requalification to the features list .......................................6-37

Specifying maximum form error for qualification ...........................6-37

Specifying indexable probe type...................................................... 6-37

Specifying interchangeable probes .................................................. 6-38

Specifying the probe requalification interval ................................... 6-38

Specifying user prompts for probe position change .........................6-38

Programming screen .............................................................................6-39

Starting program recording automatically....................................... 6-39

Including light adjustments in programs ........................................ 6-40

Including probe qualifications in programs ....................................6-40

Specifying vector probing ...............................................................6-40

Enabling sounds during program execution ...................................6-43

Specifying the minimum percentage of VED points....................... 6-43

Specifying CNC movement warnings.............................................6-43

Delaying VED tool firing after CNC moves ..................................6-43

Showing program complete messages .............................................6-44

Showing VED tools in the video window in max speed mode ........6-44

Enabling collision avoidance for touch probes ................................ 6-44

Halting execution for failure to select features ................................6-44

Runs screen ...........................................................................................6-45

Sounds screen........................................................................................6-46

Locks screen ..........................................................................................6-47

Locking Windows .......................................................................... 6-47

Locking programs........................................................................... 6-47

Locking templates ..........................................................................6-47

Locking results ............................................................................... 6-48

Locking the status bar ....................................................................6-48

Locking the DRO ..........................................................................6-48

Contents-9

Page 14

Contents

Locking the run mode ....................................................................6-48

Locking part ................................................................................... 6-48

Locking supervisor settings ............................................................. 6-48

Locking user settings ......................................................................6-48

Locking the video window.............................................................. 6-48

Measure screen ......................................................................................6-49

Specifying feature display defaults .................................................. 6-49

Specifying distance type.................................................................. 6-50

Starting Measure Magic automatically............................................ 6-50

Pre-selecting features for construction............................................. 6-51

Displaying distances as absolute values ........................................... 6-51

Enabling magnetic planes ............................................................... 6-51

Automatically complete point measurements.................................. 6-51

Specifying the maximum number of measurement points ..............6-52

Part view screen.....................................................................................6-53

Specifying part view tiles ................................................................ 6-54

Specifying probe position indicator type .........................................6-54

Specifying point size .......................................................................6-54

Specifying feature selection zones size .............................................6-55

Specifying automatic redraw of part view ....................................... 6-55

Zooming to view whole part on measurements .............................. 6-55

Zooming to view whole part on constructions ................................6-56

Displaying feature numbers and names on part views .................... 6-56

Displaying only features .................................................................6-56

Displaying features with numbers .................................................. 6-57

Displaying features with numbers and names .................................6-58

Highlighting parents of constructed features ..................................6-60

Saving layers with settings files .......................................................6-61

Displaying grid lines in planes ........................................................6-61

Displaying 3-D features as wireframes ............................................6-62

Buttons screen....................................................................................... 6-63

Level-based button functions ..........................................................6-64

Button functions that are invoked only once ..................................6-64

Feature measure functions .............................................................. 6-65

View from probe ............................................................................ 6-65

Axis lock......................................................................................... 6-65

Speed toggle ................................................................................... 6-66

Motors off ......................................................................................6-66

Swap Z joystick ..............................................................................6-66

Swap Z digital positioner................................................................ 6-66

Swap Q joystick.............................................................................. 6-66

Go to here ......................................................................................6-66

Pause program ................................................................................6-66

Run program ..................................................................................6-66

Display screen ....................................................................................... 6-67

Specifying display resolution...........................................................6-67

Formatting the display of time, date and angles.............................. 6-67

Displaying the distance to target surfaces for CNC moves ............. 6-68

Encoder screen ......................................................................................6-69

Specifying encoder resolution ......................................................... 6-69

Specifying encoder unit of measure ................................................ 6-69

Specifying encoder count direction .................................................6-69

Contents-10

Page 15

Quadra-Chek® 5000

Specifying encoder reference marks................................................. 6-70

Reference offsets .............................................................................6-70

Files screen ............................................................................................6-71

Specifying file locations .................................................................. 6-71

File types ........................................................................................6-72

Backups ..........................................................................................6-72

Exports ........................................................................................... 6-72

Imports .......................................................................................... 6-72

Overlays .........................................................................................6-72

Parts ...............................................................................................6-72

Templates ....................................................................................... 6-72

Patterns ..........................................................................................6-72

Saving part files automatically ........................................................6-73

Showing full file names .................................................................. 6-73

Performing automatic backups ....................................................... 6-73

General screen .......................................................................................6-74

User access to settings .....................................................................6-74

Sending coefficient data to the serial port .......................................6-75

Setting machine zero ......................................................................6-75

Moving the datum on alignments ..................................................6-76

Starting Datum Magic automatically .............................................6-77

Displaying results in wide format ...................................................6-77

Opening the last part automatically................................................ 6-77

Tracking user activity ......................................................................6-77

Setup Tools/CNC screens ...........................................................................6-79

Joystick screen .......................................................................................6-79

Enabling/Disabling joystick motion control ................................... 6-79

Viewing current position values...................................................... 6-79

Sharing axes ...................................................................................6-80

Specifying a deadband ....................................................................6-81

Calibrating the joystick ..................................................................6-81

Viewing calibration values .............................................................. 6-81

Specifying axis motion direction .....................................................6-81

Specifying normal and fine velocities .............................................. 6-82

Specifying the axis motion profile................................................... 6-82

Axis velocity ...................................................................................6-83

Joystick displacement......................................................................6-83

Motion mouse screen ............................................................................ 6-83

Specifying X and Y axis movement sensitivity ................................6-83

Specifying X and Y axis movement direction ..................................6-84

Specifying Z-axis movement sensitivity ..........................................6-84

Specifying Z-axis movement direction ............................................ 6-85

Enabling/disabling the motion mouse ............................................ 6-85

Probe Rack Settings screen ....................................................................6-86

Probe rack installation ....................................................................6-87

Probe Rack Calibration ..................................................................6-88

Defining the probe rack type .......................................................... 6-88

Probe rack parameters.....................................................................6-88

Initial clearance ..............................................................................6-88

Docking distance ............................................................................6-88

Retract distance ..............................................................................6-88

Contents-11

Page 16

Contents

Dropping in Z................................................................................ 6-89

Pickup in Z ....................................................................................6-89

Release in Z ....................................................................................6-89

Approach in Z ................................................................................ 6-89

Entering port position offset ...........................................................6-89

Checking the probe rack orientation .............................................. 6-89

Running the DATRACK part program .......................................... 6-90

Entering the datum in the DATRACK program ............................6-92

AA

ppendix A Pppendix A P

A

ppendix A P

AA

ppendix A Pppendix A P

Operator screens and menus ......................................................................... A-2

The Measure Profile window ........................................................................ A-2

Measure profile menu and toolbar ................................................................ A-3

Conducting manual profile measurements ................................................... A-4

Displaying the Measure toolbar ............................................................. A-5

Initiating a profile measurement ............................................................ A-5

Importing a nominal part profile ........................................................... A-5

Importing for drawing file ............................................................... A-6

Importing from the Features template ............................................. A-7

Measure Profile window functions ................................................................ A-8

Allowing (or prohibiting) data shifts during profile fit analyses .............. A-8

Assigning measurement tolerances ......................................................... A-8

Equal bilateral tolerances ................................................................. A-9

Unequal tolerances .......................................................................... A-9

Entering part data from the Measure Profile window ........................... A-10

Importing part data from the Features template................................... A-10

Removing the last data point entered ................................................... A-10

Initiating a fit analysis.......................................................................... A-11

Canceling a profile measurement ......................................................... A-11

Resetting the fit results and restoring data points ................................. A-11

Selecting data in the Measure Profile window ...................................... A-11

Displaying the form error of a single data point or whisker.................. A-12

Accessing the Measure Profile menu .................................................... A-12

Completing the profile measurement ................................................... A-13

Measure profile menuand toolbar functions ............................................... A-14

Printing the contents of the Measure Profile window ........................... A-15

Zooming to display all images in the Measure Profile window ............. A-15

Zooming in and out to display more or less detail................................ A-15

Panning to reposition the image in the Measure Profile window .......... A-16

Showing or hiding profile fit information ............................................ A-17

Results........................................................................................... A-17

Filtered .......................................................................................... A-18

Tolerance ....................................................................................... A-18

Material......................................................................................... A-19

Points ............................................................................................ A-20

Passed ............................................................................................ A-21

Failed ............................................................................................ A-21

Magnifying the display of form error whiskers ..................................... A-22

Fixed magnification ....................................................................... A-22

Automatic magnification ............................................................... A-22

User-defined magnification ........................................................... A-23

rr

ofile measurofile measur

r

ofile measur

rr

ofile measurofile measur

ementement

ement

ementement

....................................................................

..................................

....................................................................

A-1A-1

A-1

A-1A-1

Contents-12

Page 17

Quadra-Chek® 5000

Driving the CNC stage to a selected point location ............................. A-23

Sending (exploding) the profile fit data as points and distances to the

Features template ................................................................................. A-24

Filtering selected points from the part data .......................................... A-25

Filtering the worst (form error) point from the part data ..................... A-25

Unfiltering (restoring) filtered data points............................................ A-25

Manually fitting part data to the nominal profile ................................. A-26

Clicking and dragging (translating) data points............................. A-26

Clicking and rotating data points .................................................. A-26

Contents-13

Page 18

Contents

Contents-14

Page 19

Welcome to the QC-5000

Chapter 1

Overview

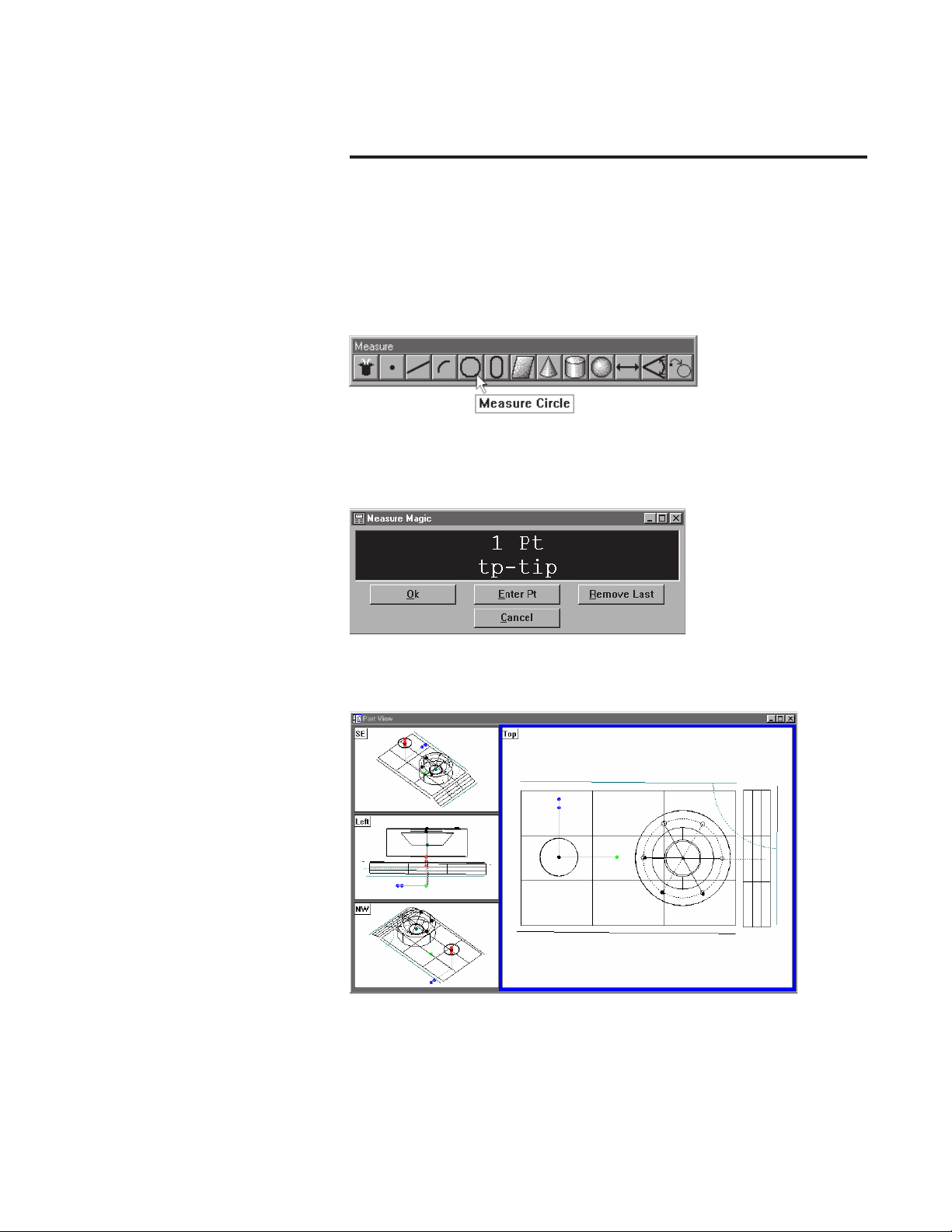

The Quadra-Chek 5000 is an advanced software application for multisensor measurement systems. It features a graphical user interface for

simple point and click operation. Point the cursor to a feature on the

measure toolbar and click.

The QC-5000 measures part features using the simplest geometric components: points. Lines can be created from two points, circles from three

points, and cones from six points. Simply probe the points and the QC5000 measures the feature.

Once the required number of points are entered the QC-5000 displays

the feature in the part view window.

The QC-5000 continues building the part in the part view window as

features are added.

1-1

Page 20

Chapter 1 Overview

It is easy to use the QC-5000 because each measurement requires only a

few points. All geometry and mathematics are handled by the software.

Once the basic measuring principles are understood the QC-5000 can be

programmed to handle repetitive measuring tasks. Finally, inspection

and quality reports can be produced to document your results.

1-2

Page 21

About This Guide

Quadra-Chek® 5000

This guide is intended for end users of the QC-5000 metrology software,

supervisory, and installation personnel. A basic familiarity with the Windows computing environment and operation of attached measuring systems is assumed. Material in this guide is divided into five chapters covering everything from basic operation to system configuration. Keep this

guide in a convenient location for future reference.

Chapter 1: Overview

It all begins here, just point and click. There are only two things in the

QC-5000 interface: windows and toolbars. This chapter tells you which

is which and what to do with them. Understanding each window and

toolbar helps you get the most from the QC-5000.

Chapter 2: Quick Start

This chapter gets you up and running quickly. Use this chapter to learn

the most basic QC-5000 tasks. Each task in this chapter is described in

greater detail elsewhere in this guide.

Chapter 3: Probes

If it’s about probes, it’s in this chapter. Learn to manage and calibrate

VED and touch probes using probe library. All data comes into the QC5000 through probes. Use the information in this chapter and you won’t

go wrong.

Chapter 4: Programming

Programming puts it all together. This chapter shows you how to create

a streamlined, computer-prompted procedure to handle repetitive inspections with speed and accuracy. Use the programming feature to maximize your productivity with the QC-5000.

Chapter 5: Templates & Tolerancing

Picking up where chapter 4 leaves off this chapter covers datum magic,

measure magic, layers, offset alignments, and tolerancing. The QC-5000

organizes and present data in a number of formats. For your convenience

there are several data templates you can use to organize and present your

results. Use this chapter to learn how to use templates more efficiently.

This chapter also describes how to export QC-5000 data to other software.

Appendix A

Appendix A describes profile measurement. The appendix includes discussions of nominal profiles, profile tolerances, measurement results and

the on-screen tools and windows provided to facilitate profile measurement.

Index

There’s nothing worse than skimming through a user guide looking for

something when you’re in a hurry. To save you the hassle we indexed this

guide. Simply flip to the back, find your topic, and off you go.

1-3

Page 22

Chapter 1 Overview

Icons and Type Faces

This guide uses the following icons and type faces to highlight information:

WARNING

The raised hand icon warns of situations or conditions that can lead to

personal injury or death. Do not proceed until you read and thoroughly

understand a warning message. Warning messages are shown in bold

type.

CAUTION

The exclamation point icon indicates situations or conditions that can

lead to measurement error, equipment malfunction or damage. Do not

proceed until you read and fully understand a caution message. Caution

messages are shown in bold type.

NOTE

The note icon indicates additional or supplementary information about

an activity or concept. Notes are shown in bold type.

Warnings, cautions, and notes are shown in this typeface.

Italics

Italics indicate menu items or button icons. For example,

Step 1

Select customize from the tools menu.

The italics instruct the user that customize is an item on the tools pulldown menu.

1-4

Page 23

Starting the QC-5000

Quadra-Chek® 5000

To open the QC-5000

Step 1

Double-click the QC-5000 icon on the Windows desktop.

The following screen indicates that the program is loading. It takes a

couple seconds for the program to load completely.

1-5

Page 24

Chapter 1 Overview

Windows and Toolbars

The QC-5000 uses a graphical user interface which means that instead of

typing in a bunch of complicated commands you can do things by pointing and clicking the mouse.

In this manual we’ll refer to the graphical user interface as the QC-5000

desktop. Although setups may vary, a typical QC-5000 desktop looks

like this.

1-6

There are only two things to point and click at on the QC-5000 desktop:

windows and toolbars. Here’s how to tell them apart.

Page 25

Quadra-Chek® 5000

Windows display information. Some windows contain buttons or require input but their basic function is to display information. For example, the part view window displays a graphic of the part.

Toolbar buttons execute common tasks. For example, the measure toolbar contains buttons for various measurement functions. To perform a

measurement, click on the desired feature button (line, circle, plane, etc.).

1-7

Page 26

Chapter 1 Overview

QC-5000 Windows

The Results Window

The QC-5000 desktop has four windows: DRO (digital readout), results,

part view, and features list.

DRO

The DRO window displays the location of the X, Y, and Z axes (in mm or

inches) from the datum. Click the button beside the respective axis to

zero it.

The results window displays the results of a feature measurement. This

window contains the following:

• Feature specifications

• Lock/unlock feature

• Feature type diagram / feature stamp

Feature Specifications

Feature information is displayed in the results window. Use the results

window to add information to the features list.

1-8

Page 27

Quadra-Chek® 5000

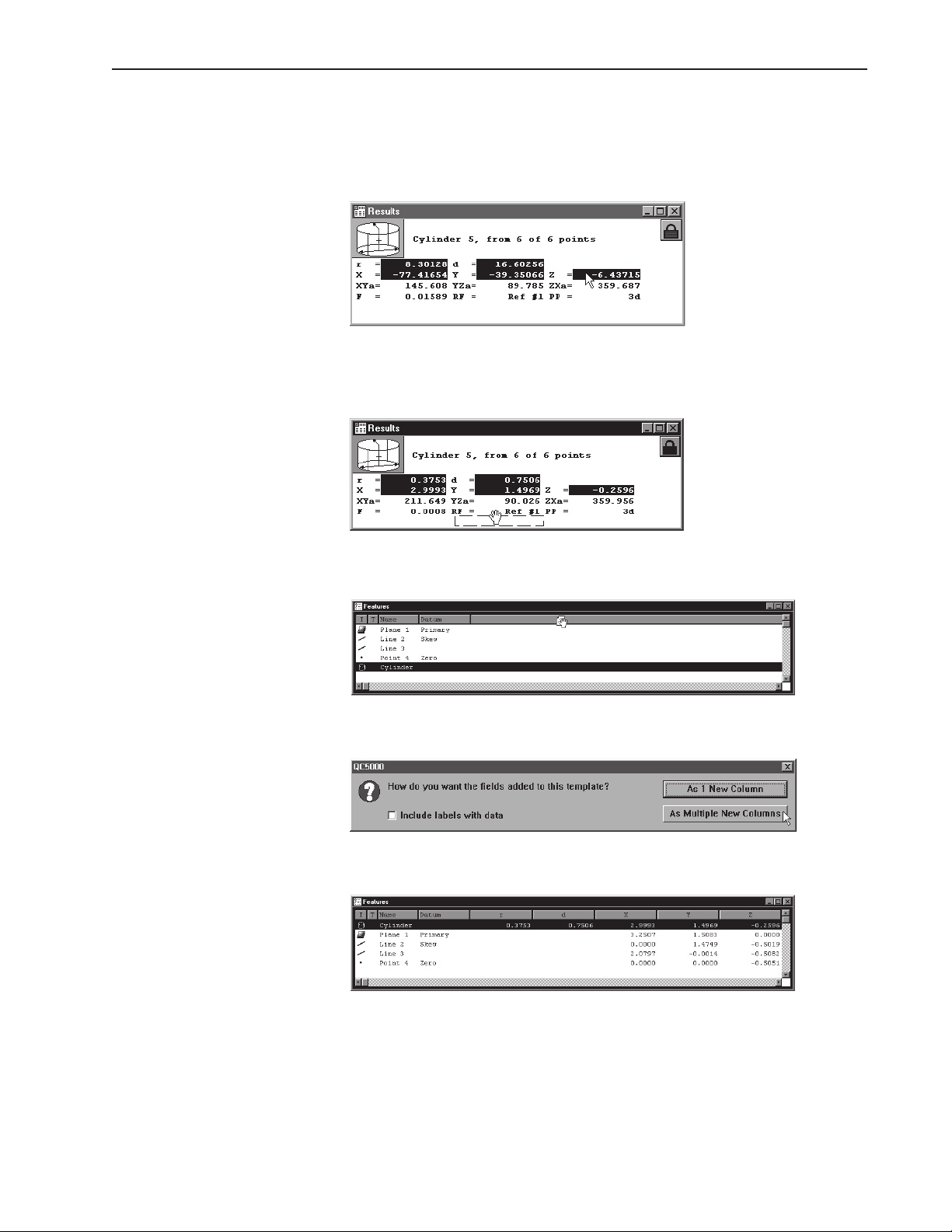

To move information from the results window to the features

list

Step 1

Highlight the desired information in the results window.

Step 2

Hold down the left mouse button and drag the information to the features list.

Step 3

Release the mouse button.

Step 4

Click the as multiple new columns button in the dialog box.

The feature window now displays the new parameters.

Information in this window is dependent on the type of feature. For

example, the window shows radius/diameter values for spherical features

but not for linear ones.

1-9

Page 28

Chapter 1 Overview

Locked/unlocked features

Some parts use more than one reference frame to measure all its features.

Locked features always display results from the reference frame they are

measured in the results window. Unlocked features are display results for

the current reference frame.

To unlock a feature

Step 1

Click the lock icon in the results window.

To lock a feature

Step 1

Click the lock icon in the results window.

1-10

Page 29

Quadra-Chek® 5000

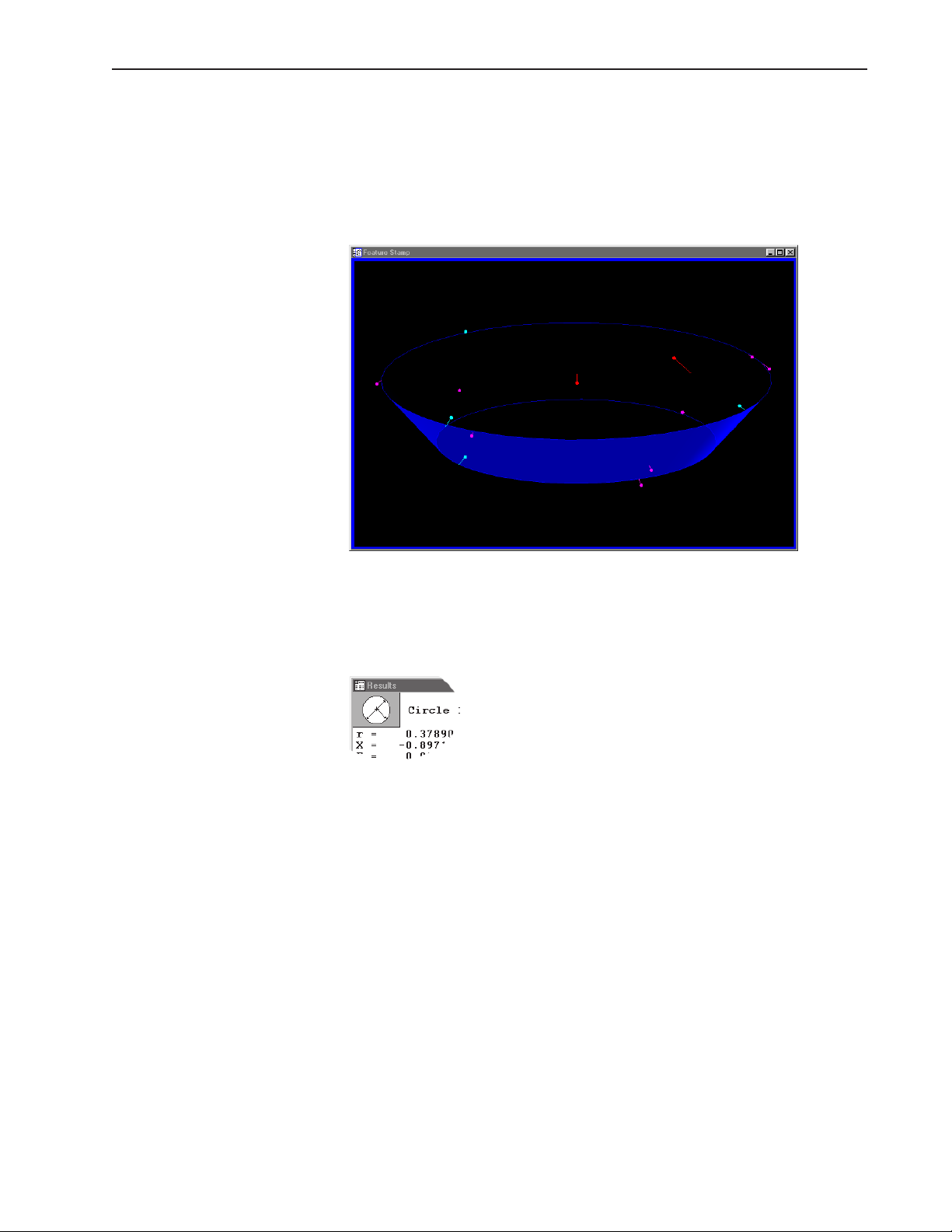

Feature type diagram /feature stamp

Clicking on the feature stamp icon opens the feature stamp window. The

feature stamp window shows a graphic display of the feature and the

distribution of the measurement points. Points discarded from the measurement are shown in red. Use the view toolbar to change the perspective in the feature stamp window.

To open the feature stamp window

Step 1

Click the feature stamp button in the results window.

1-11

Page 30

Chapter 1 Overview

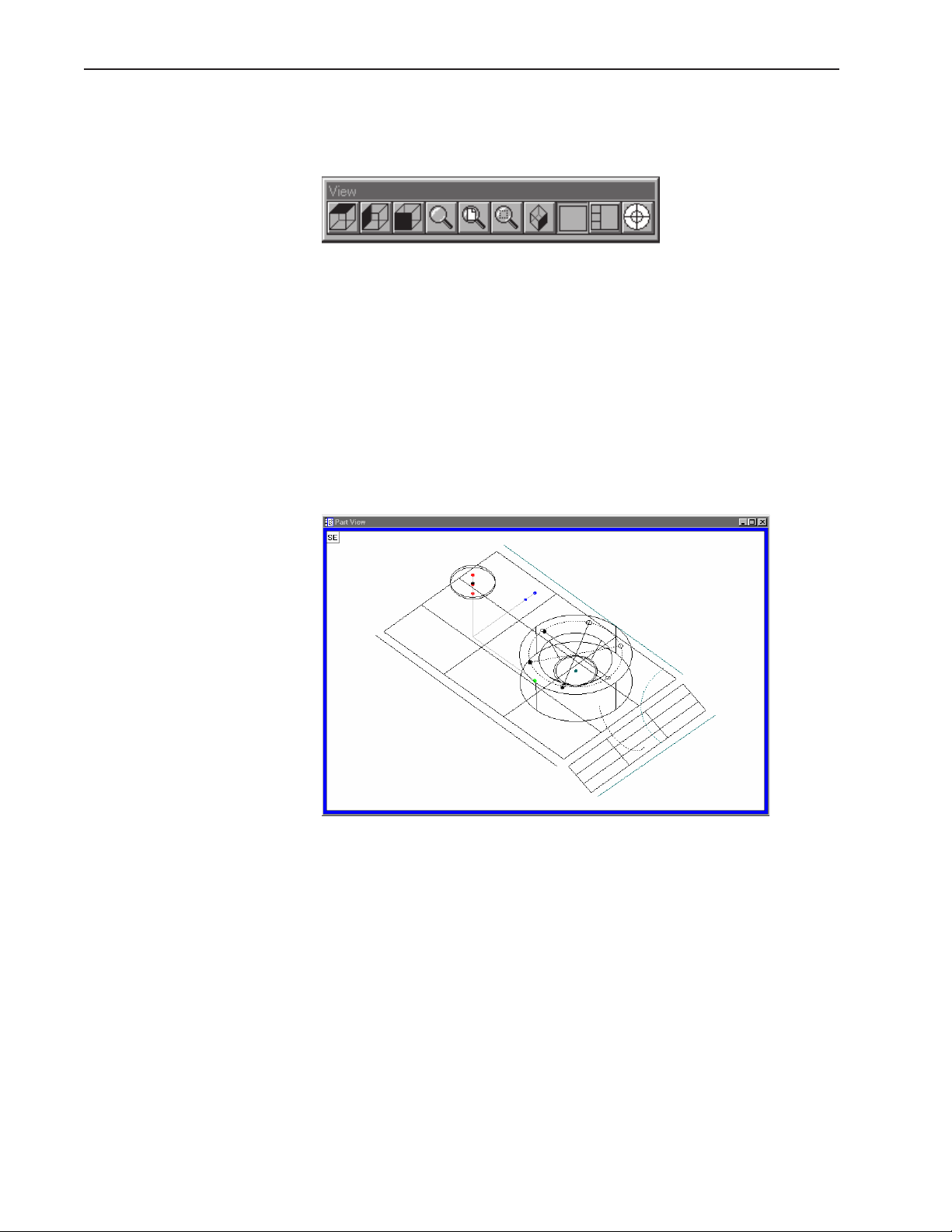

The Part View Window

The part view window displays a graphical representation of the part and

its features. Use the view toolbar to change the appearance of the part

view window.

This is a typical view toolbar. Remember that QC-5000 toolbars can be

customized. Toolbars pictured in this guide may vary from those on your

system.

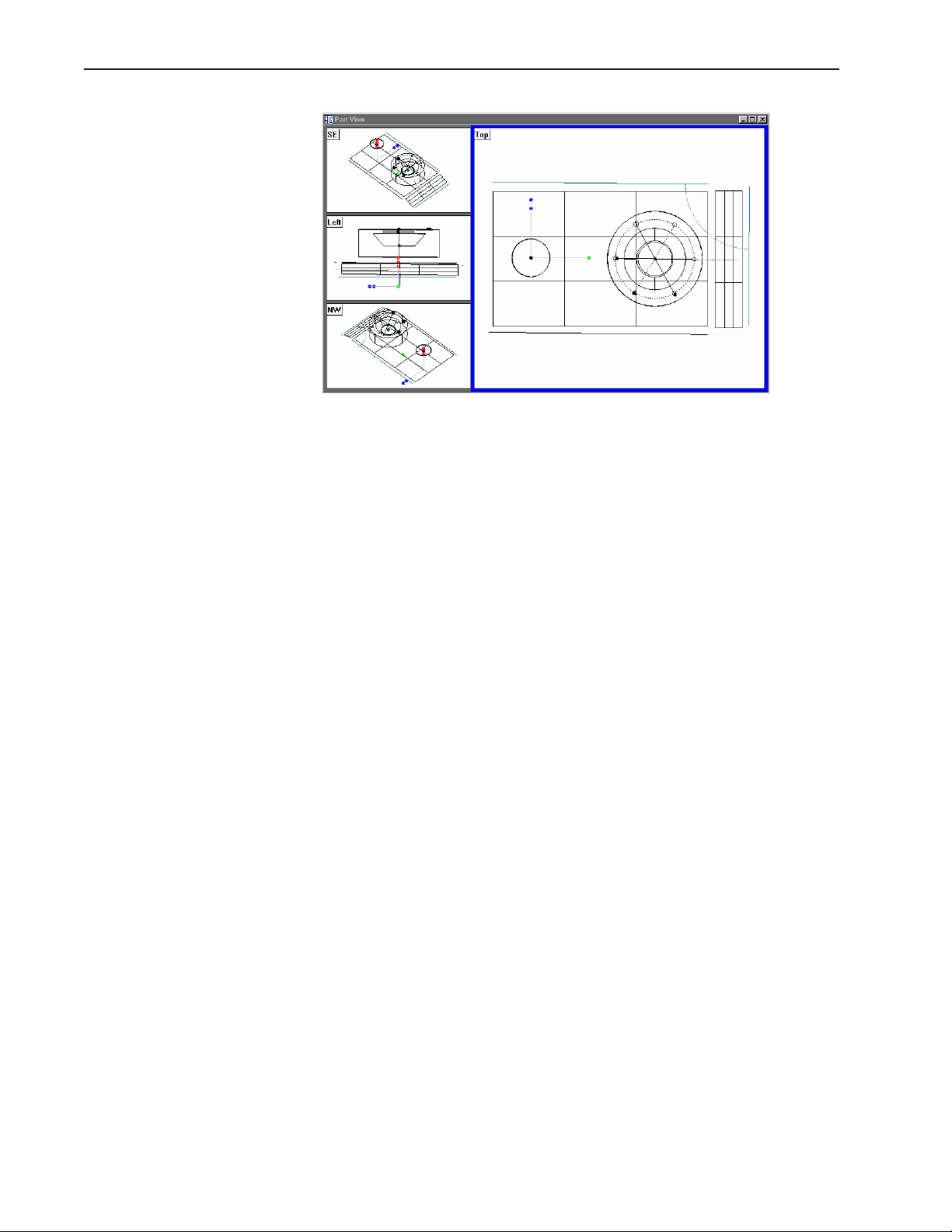

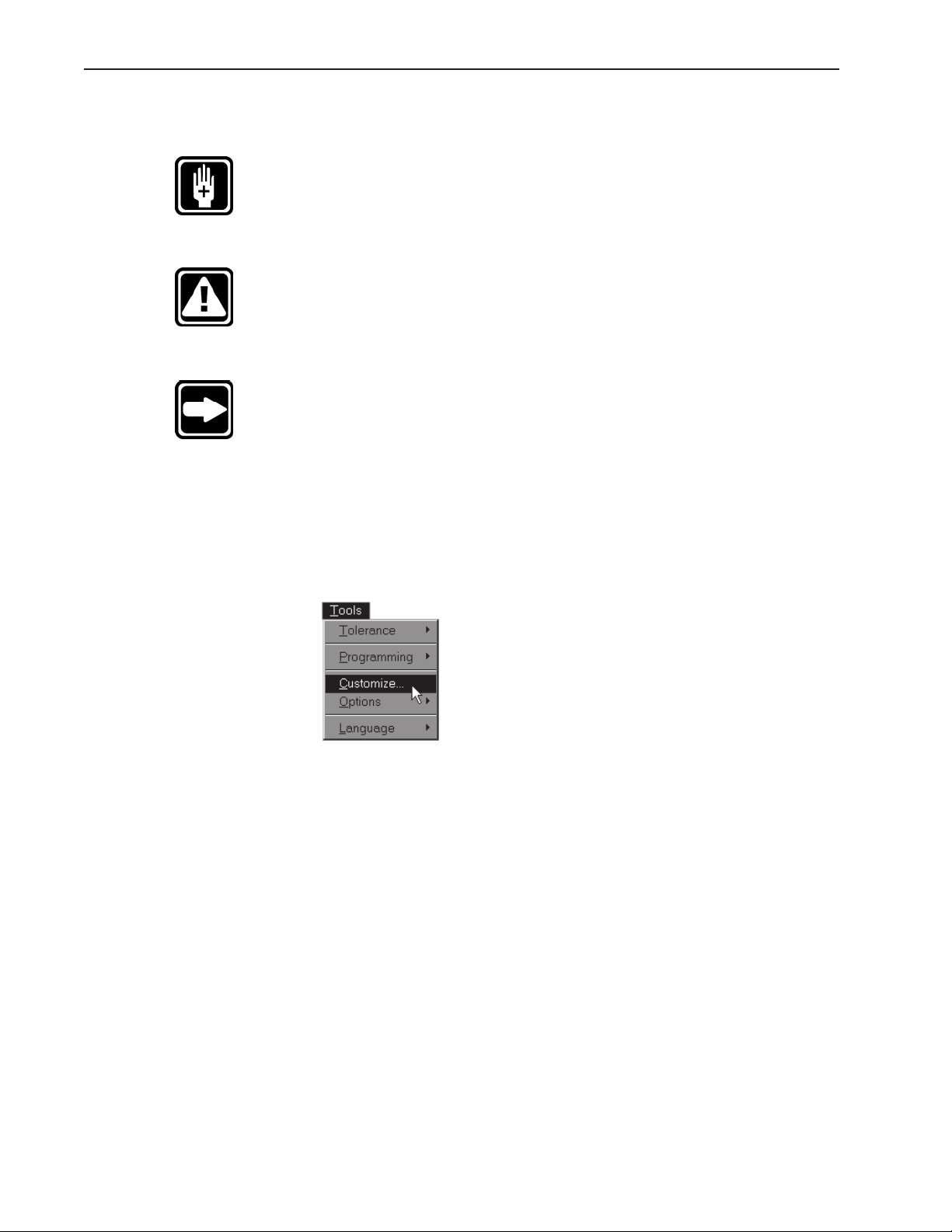

Four pane part view displays the part from four separate vantage points.

Highlighted panes are outlined in blue. Place the cursor on the pane and

click to highlight. Only one pane can highlighted at a time.

The most common part view window appearances are shown here.

Single pane part view

1-12

Page 31

Four pane part view

Quadra-Chek® 5000

1-13

Page 32

Chapter 1 Overview

View Rotator

Change the display angle of the part view window with the view rotator.

To use the view rotator

Step 1

Click the view rotator button on the view toolbar OR select view rotator

from the view menu..

Step 2

Place the cursor over the view rotator window as shown.

Step 3

Move the cursor over the view rotator window until the part is displayed

as desired.

1-14

Page 33

Template Windows

Quadra-Chek® 5000

Template windows display data output from QC-5000 measurements and

programs. See Chapter 5: Tolerancing & Templates for more information

on using template windows.

Nest templates windows as shown to conserve space on the QC-5000

screen. For example, the window below contains the features, program,

and report templates nested in a single window. View the desired template by selecting the proper tab. In the example below, the feature tab is

selected.