Page 1

Addendum

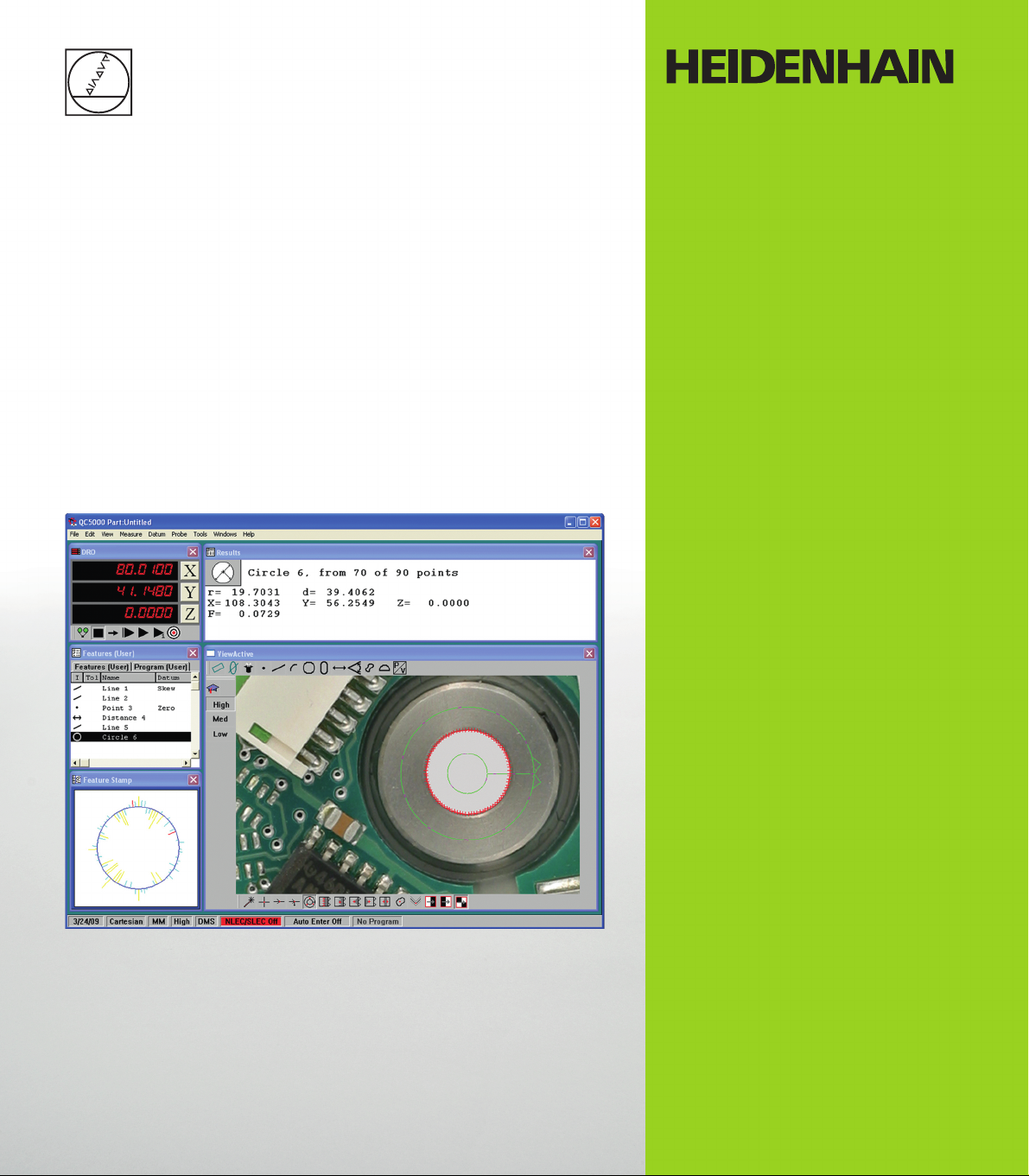

IK 5000

QUADRA-CHEK

Software Version

3.0.x

English (en)

12/2013

Page 2

Page 3

Information contained in this manual

This addendum covers the operating and setup feature additions and improvements implemented in IK 5000 Software v3.0.x.

For OEM setup feature additions refer to the IK 5000 QUADRA-CHEK OEM Addendum (ID 1041353-2x), available by request

from HEIDENHAIN.

Minimum system requirements

Component w/o 3D Profiling w/ 3D Profiling

PC 2.66 GHz dual-core Pentium 2.8 GHz quad-core Pentium

Operating System (OS) Windows XP

Windows Vista 32-bit

Windows 7 32-bit, Windows 7 64-bit

Windows 8 32-bit, Windows 8 64-bit

RAM 1GB 2GB

Available Hard Disk 500MB 1GB

PCI 1 PCI slot and 1 to 3 additional empty slots (depending on the version)

Note: PCI Express slot required for PC2-COMP Express frame grabber board, refer to "PC2-

COMP Express frame grabber board on page 80”. The PC2-COMP Express frame grabber

board is compatible with 32-bit operating systems only.

Video Display Unit 1024 x 768 resolution

Windows users rights Administrator

Backward compatibility

The IK 5000 QUADRA-CHEK v3.0.x software version is compatible with several previous versions down to version 2.93.0. It

can be used to update any prior version starting at version 2.93.0 and up. To update a previous version refer to “Software

Updates” below.

Software updates

End users should only update the IK 5000 software after consultation with the machine manufacturer. Observe the system

requirements as described in “Minimum System Requirements” above. For software updating procedures, refer to " Updating

the IK 5000 software on page 78”.

Fonts used in these instructions

Items of special interest or concepts that are emphasized to the user are shown in bold type.

Software controls and Windows are shown in letter gothic bold type.

IK 5000 QUADRA-CHEK 3

Page 4

4 Preface

Page 5

1 Operation ..... 9

1.1 Operation ..... 10

Adjusting for change of part size ..... 10

Part scaling example ..... 11

Auto probe a plane ..... 12

Grid pattern auto probe ..... 12

Disc pattern auto probe ..... 13

Programming changes ..... 14

Programming wizards ..... 15

Grids ..... 15

Polar grids ..... 19

Palletize ..... 21

Random placement ..... 24

Additional tolerance check Axial Runout for Plane feature ..... 34

Palletizing multiple parts ..... 35

Profile import points ..... 36

Measuring rectangles ..... 38

Profile3D measurements ..... 39

Profile3D measurement screen functions ..... 40

Profile3D window menu ..... 41

The Profile3D measurement process ..... 42

Start Profile3D measurement ..... 43

Import part profile ..... 43

Enable or prohibit data shifts for Profile3D fit ..... 45

Assign tolerances ..... 46

Probe part surfaces ..... 48

Perform Profile3D fit analysis ..... 49

Profile3D automatic fit analysis ..... 50

Profile3D Pass Only option ..... 51

Six point alignment ..... 52

Resetting the fit analysis ..... 53

Adjust the display magnification of error whiskers ..... 54

Add Profile3D feature to the Feature template ..... 55

IK 5000 QUADRA-CHEK 5

Page 6

Auto Focus (option) ..... 57

Autofocus final check ..... 60

Exploding the Data Cloud ..... 61

Rotating and positioning of VED tools using part reference frame ..... 62

ISO Tolerance ..... 62

Continuous probe firing ..... 66

Programming continuous probe firing ..... 67

Initial settings step ..... 67

Program step ..... 68

Measure shortcuts ..... 69

Ellipse shortcut ..... 69

Torus shortcut ..... 69

Profile shortcut ..... 69

Profile3D shortcut ..... 69

Symmetry tolerance ..... 70

Symmetry tolerance applied to a line ..... 70

Symmetry tolerance applied to a plane ..... 72

Plane probing technique ..... 74

6

Page 7

2 Setup ..... 77

2.1 Setup ..... 78

Updating the IK 5000 software ..... 78

Files and folders ..... 79

PC2-COMP Express frame grabber board ..... 80

Use current reference frame ..... 81

Camera parameters ..... 83

Specify video probe parameters ..... 84

Spotter camera options ..... 85

Scale factor for Open Loop joystick control (Optional) ..... 87

Shutdown ..... 89

Debounce parameters ..... 90

Touch probe requalification and starting point ..... 91

Reset template text colors ..... 92

Default fixtures files location ..... 93

External amplifier Open Loop control (Optional) ..... 94

Backup system settings ..... 78

Uninstall old software version ..... 78

Install new software version ..... 78

Restore system settings ..... 78

Joystick button assignment ..... 95

IK 5000 QUADRA-CHEK 7

Page 8

8

Page 9

Operation

Page 10

1.1 Operation

Adjusting for change of part size

The location of features in a part under measure can change due to

change in size of the part. A program can adjust to measure the

features at the new locations by using the Prompt user for part scaling

function. This function prompts the user for a scaling factor that

repositions all features in a program. The new feature position is

1.1 Operation

calculated using the recorded feature position multiplied by the scaling

factor. The scaling factor is prompted for each time the program is run.

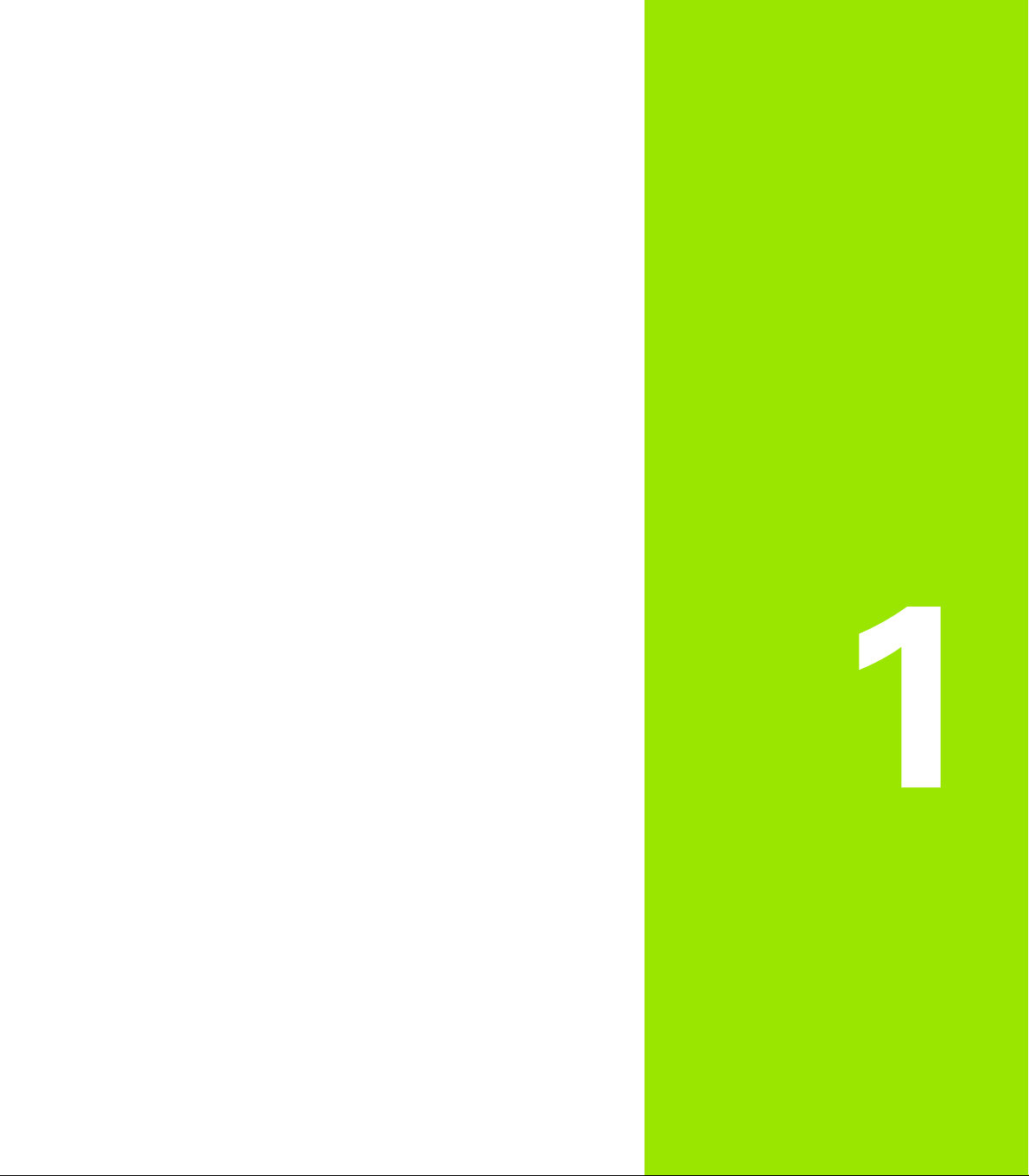

The Prompt user for part scaling function is located in the General tab

of the Program Properties dialog.

The size of the features under measure in the program are

not altered by the part scaling function, hence the system

will probe the features at the recorded size but new scaled

position.

To prompt a user for part scaling:

Start recording a program

Double click Program Properties in the Program template window

Click the General tab

Check the check box next to Prompt user for part scaling and

then click OK

The operator will now be prompted to enter a scaling factor when the

program is run.

Selecting Prompt User for Part Scaling

10 1 Operation

Page 11

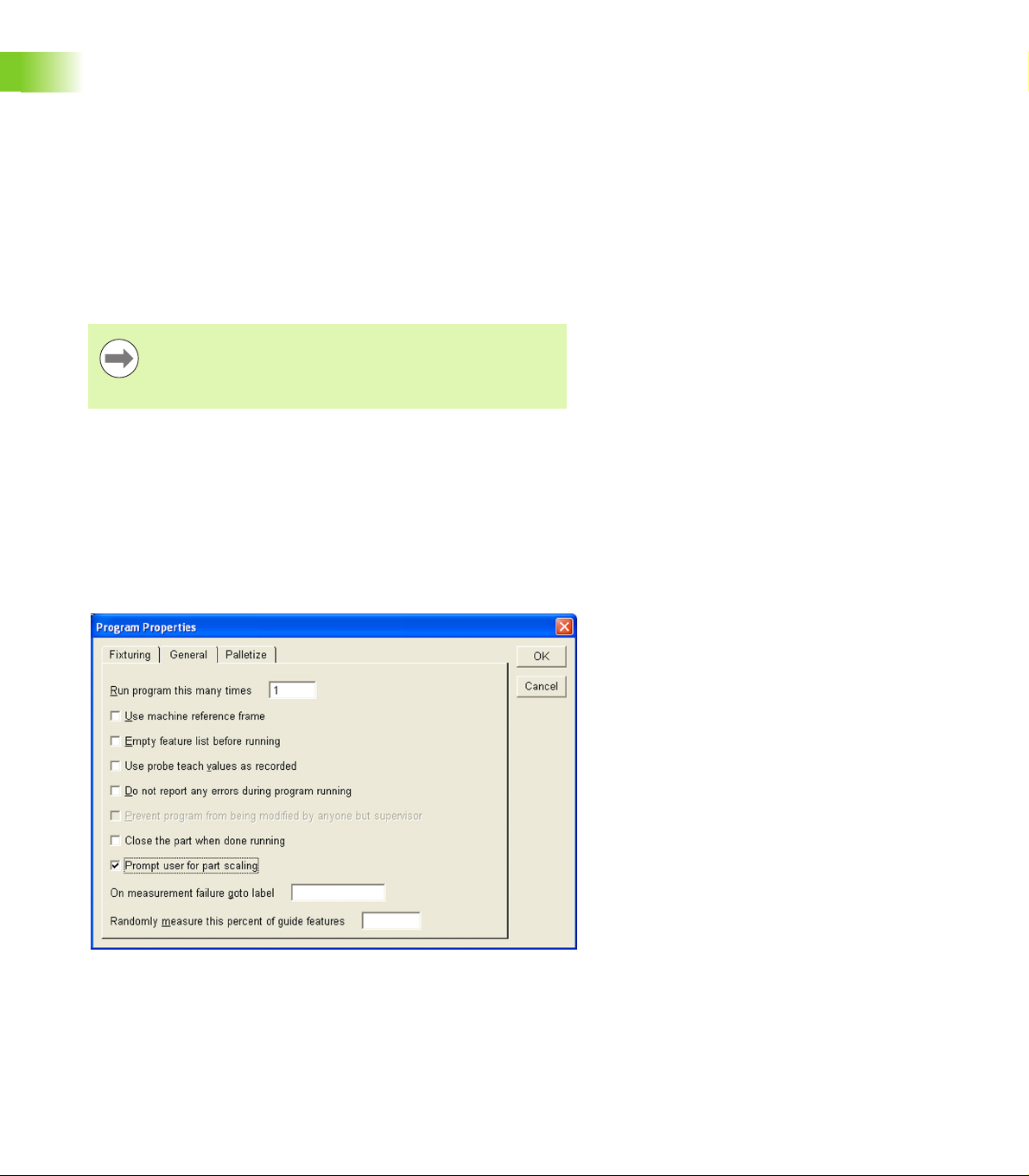

Part scaling example

This example shows measurement results before and after part

scaling has been applied.

Start recording a program

Measure a feature and note the position of the feature

Feature measurement results

Stop recording the program

Activate Prompt user for part scaling as described on page 10.

Run the recorded program. A prompt will appear requiring the user

to enter a part scaling factor.

1.1 Operation

Enter Part Scaling prompt

Re-measure the feature and complete program execution

Note that the program feature CIRCLE 2 will now be probed at a

position scaled by a factor of 0.500 (X=4.00000, Y=2.50000,

Z=0.00000)

IK 5000 QUADRA-CHEK 11

Page 12

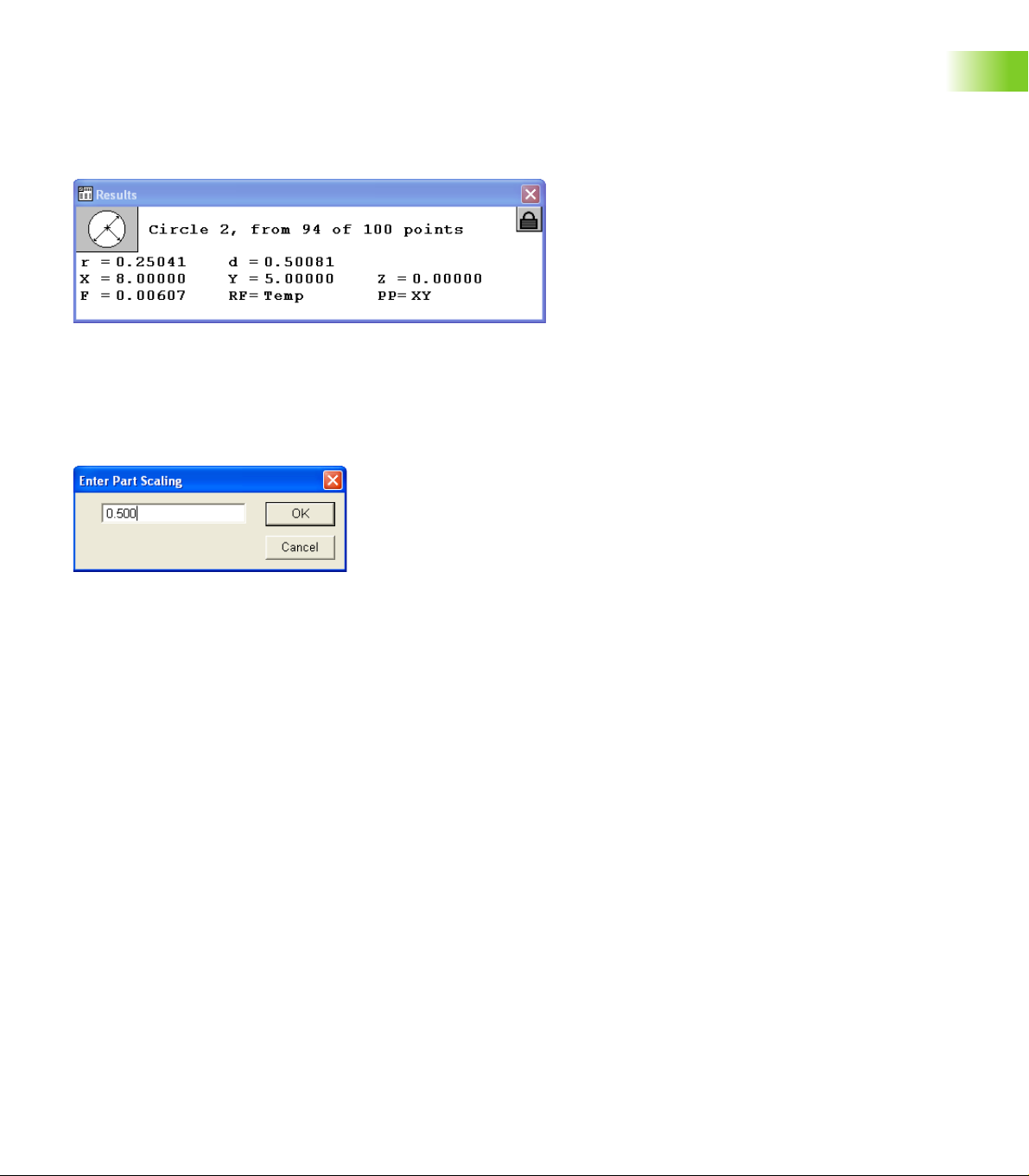

Auto probe a plane

1

345

2

Plane measurement accuracy is increased by probing more than the

three required points. IK 5000 systems with CNC and touch probe

options can automatically probe multiple points by using the

Auto Probe Plane feature in the Measure Plane Dialog.

To auto probe a plane:

Click the Auto Probe... button in the Measure Plane dialog.The

Auto Probe Plane dialog appears.

1.1 Operation

Select the Grid or DISC tab

Probe the required positions and enter the required parameters

Click OK

Grid pattern auto probe

Grid dialog

Parame ter Description

1 Corner position 1 The first corner position in the grid

2 Corner position 2 The second corner position in the

grid

3 Corner position 3 The third corner position in the grid

4 # Points on longer side The number of points on the longest

side of the grid

5 # Points on shorter

side

Normal position A position above the plane for the

12 1 Operation

The number of points on the

shortest side of the grid

probe to retract to after probing a

point

Grid pattern

Page 13

Disc pattern auto probe

1

3

4

5

2

1.1 Operation

Disc dialog

Parameter Description

1 Center position The center position of the disc pattern

2 Number of rings The number of rings in the pattern

3 # Points per ring The number of points probed per ring

4 Inner radius The radius of the inner ring of the pattern

5 Outer radius The radius of the outer ring of the pattern

Normal position A position above the plane for the probe

to retract to after probing a point

Disc pattern

IK 5000 QUADRA-CHEK 13

Page 14

Programming changes

While recording a program that is intended to include a looping

function (such as a loop, grid, polar grid, palletize or random

placement), it is important to record the entire program with the

looping function before completing the program and running or editing

it. This ensures proper handling of any datum steps in the loop, if any,

and proper insertion of offset recall tags.

1.1 Operation

When a feature is under measure during program playback, that

feature is now removed from the feature list. Previously, the recorded

feature was maintained in the feature list during measurement and

replaced by the newly measured feature once the measurement was

completed.

Grids, polar grids, palletizations and random placements are described

in Programming wizards on page 15.

Tags are not displayed in the program.

14 1 Operation

Page 15

Programming wizards

Use programming wizards to create the following program steps:

Grids

Polar grids

Palletizations

Random placements

Grids

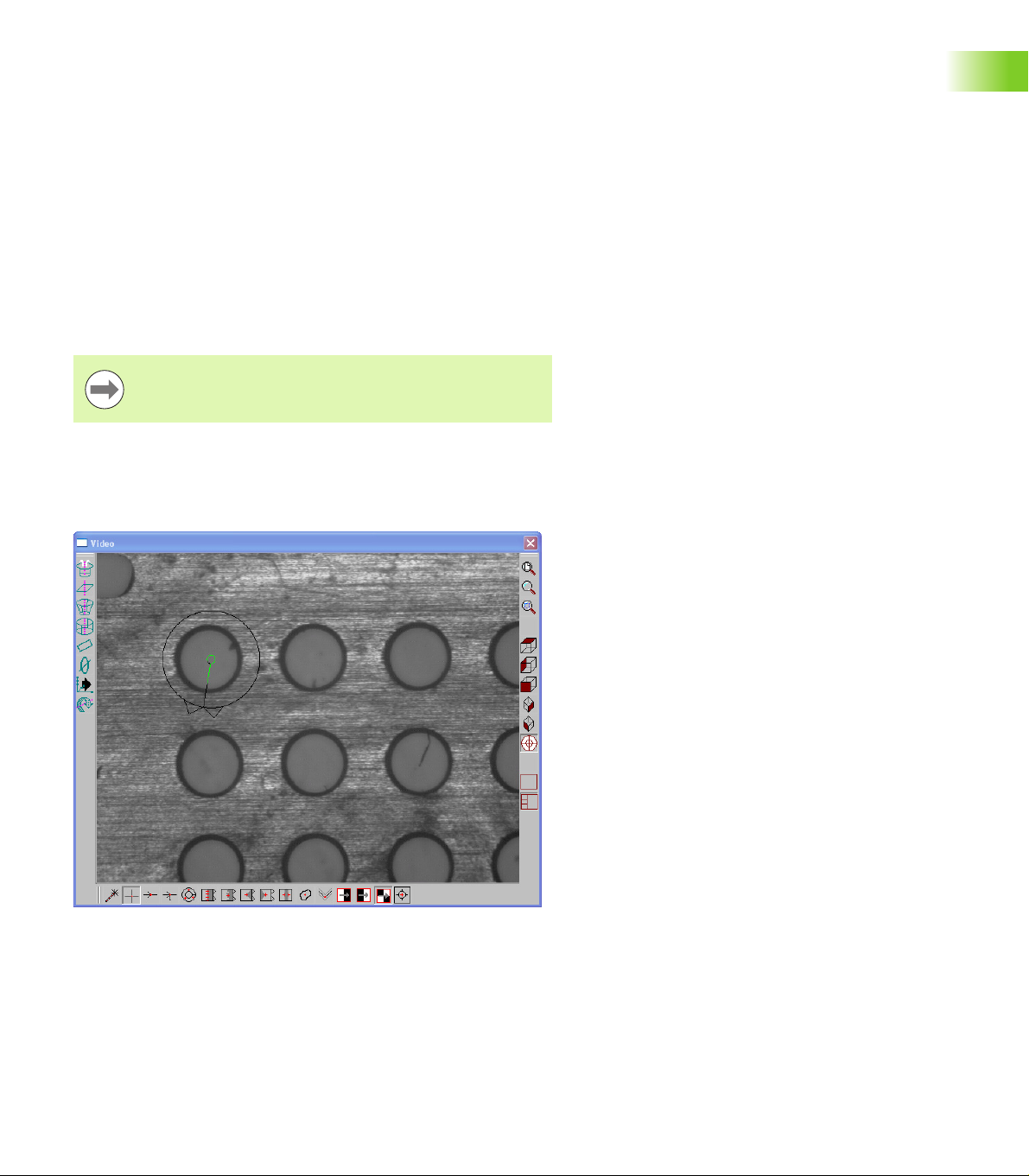

Use the Create a Grid wizard to measure arrays or a series of like

features within a single part. For example, create a grid to measure an

array of evenly spaced holes on a pc board. The IK 5000 requires the

user to input the X and Y offset distance, the X and Y distance from

one feature to the next.

All features in a grid must be evenly spaced.

Before creating a grid begin a new part program with a datum.

To create a grid:

Position the first array feature as shown

1.1 Operation

IK 5000 QUADRA-CHEK 15

Page 16

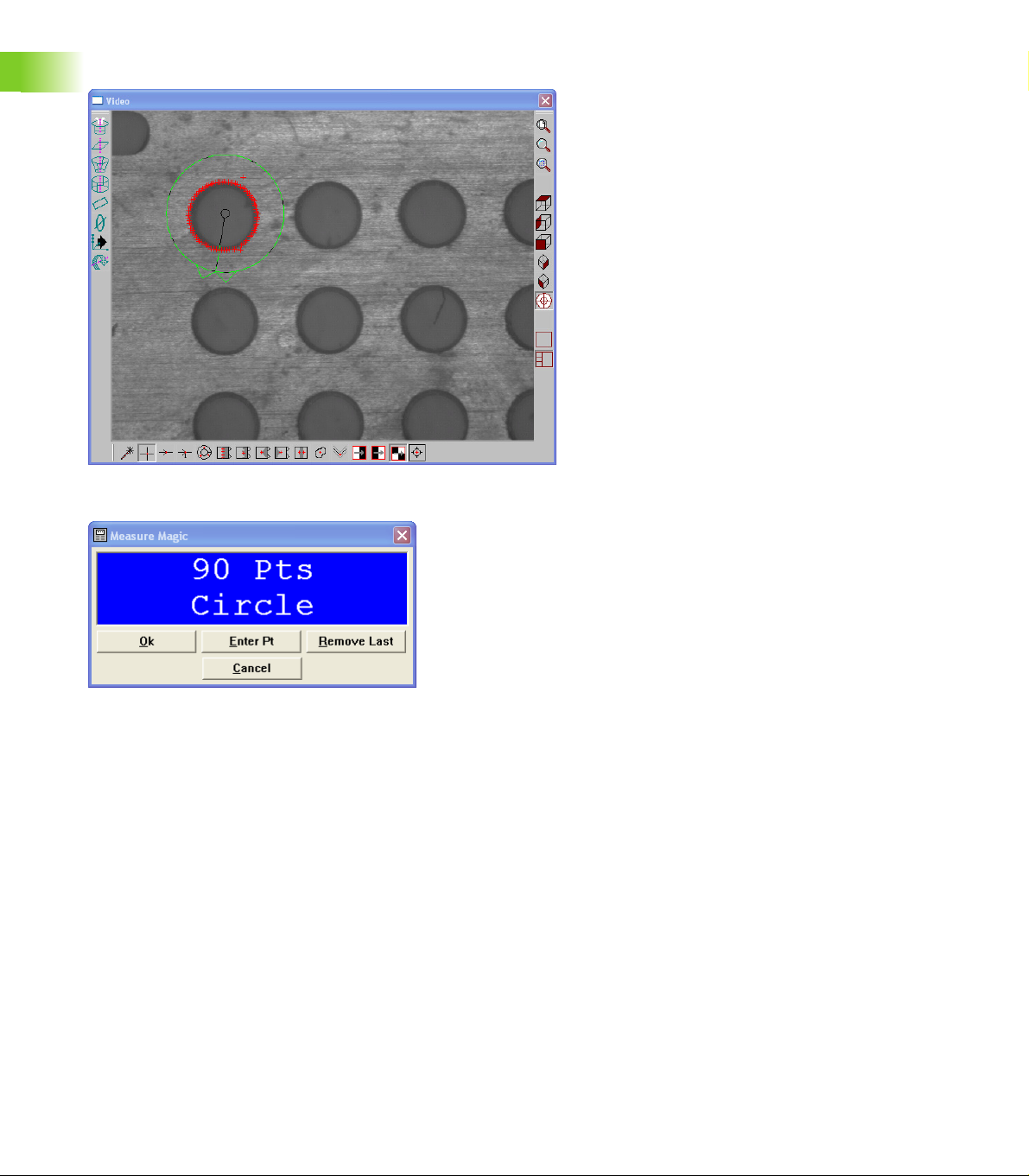

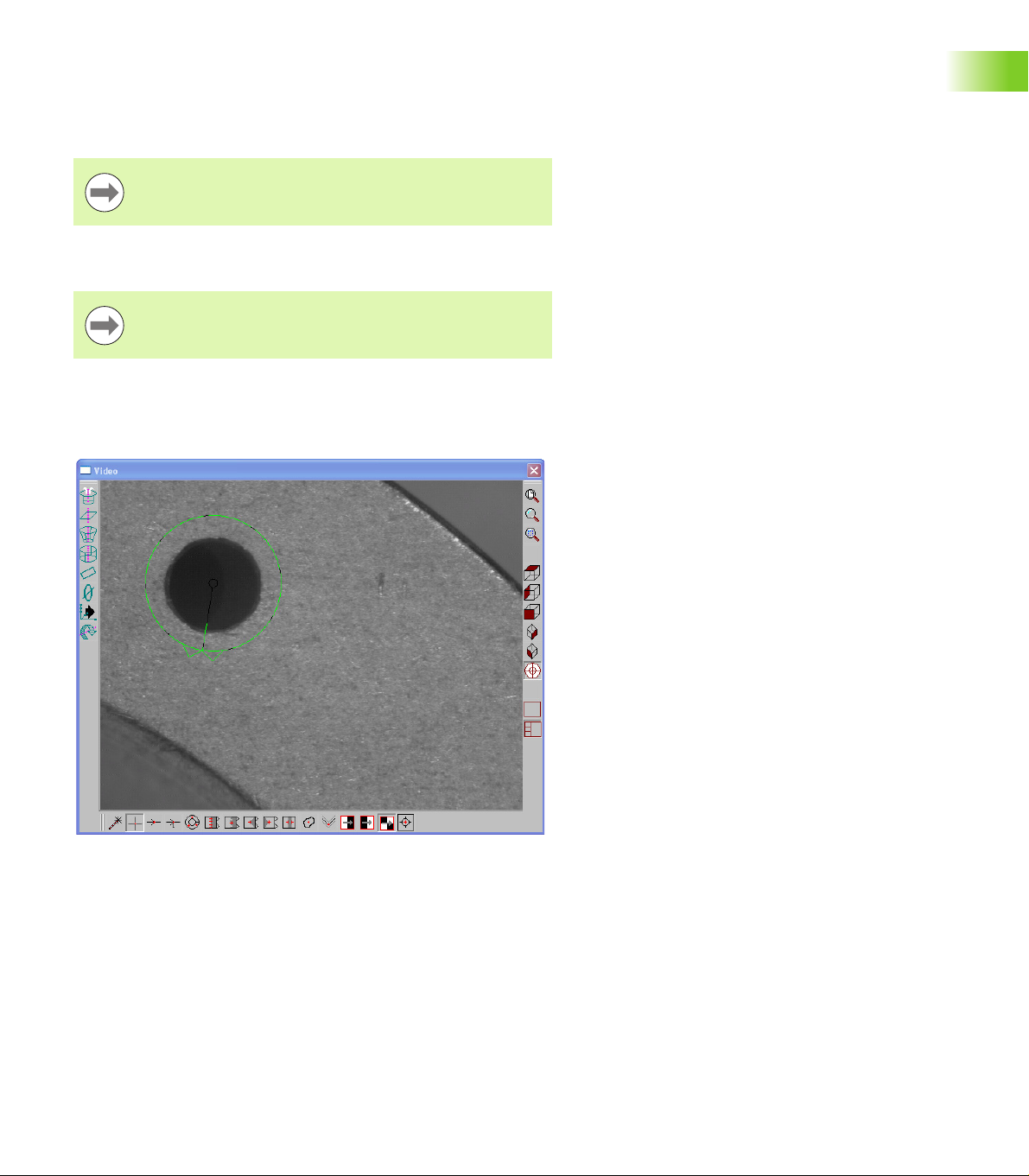

Click the center mouse button to fire the probe tool

1.1 Operation

Click OK in the dialog box

16 1 Operation

Page 17

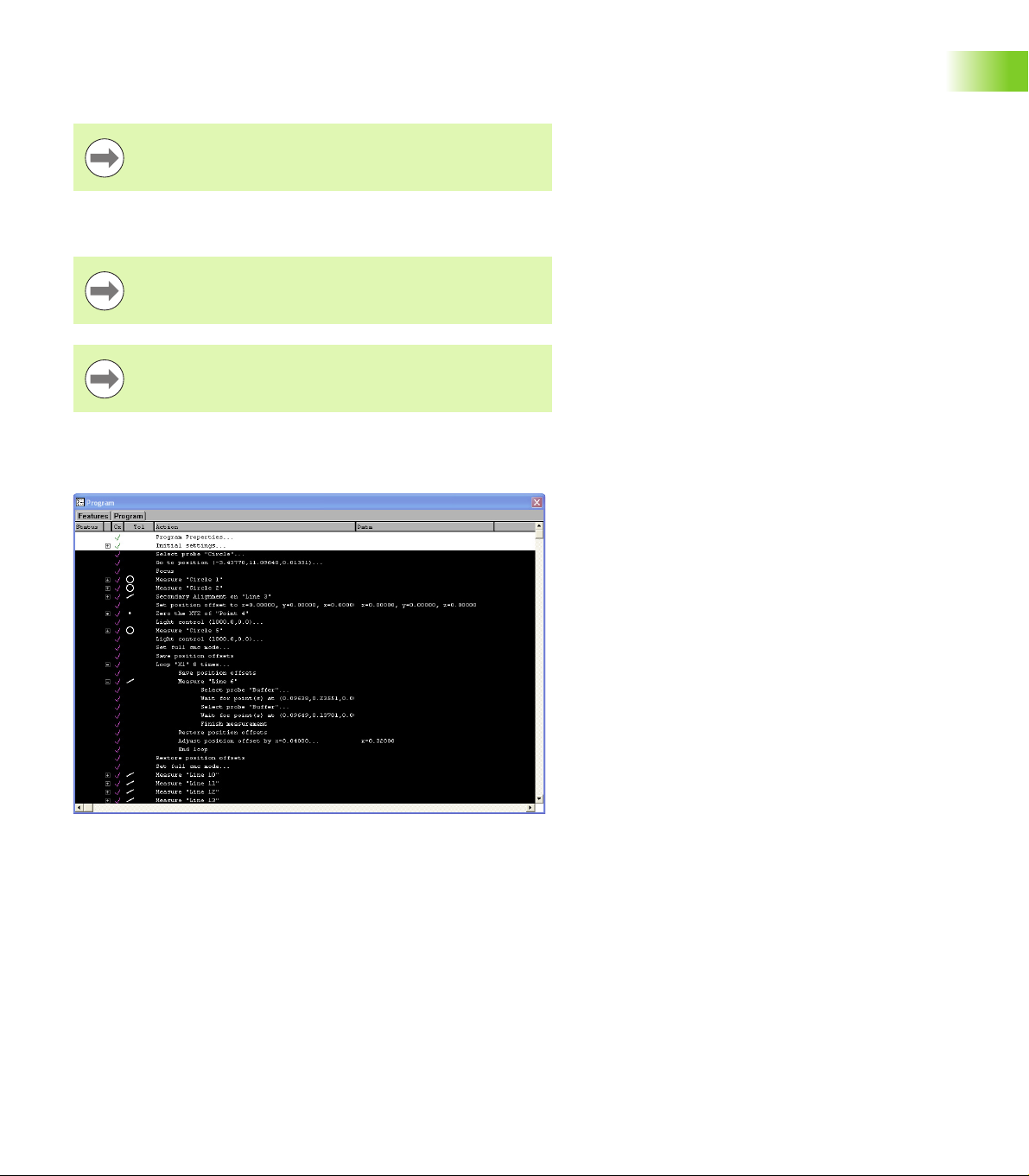

Highlight the first array feature in the Program template as shown

Right-click in the Program template and select Programming Wizards,

then select Create a Grid

1.1 Operation

IK 5000 QUADRA-CHEK 17

Page 18

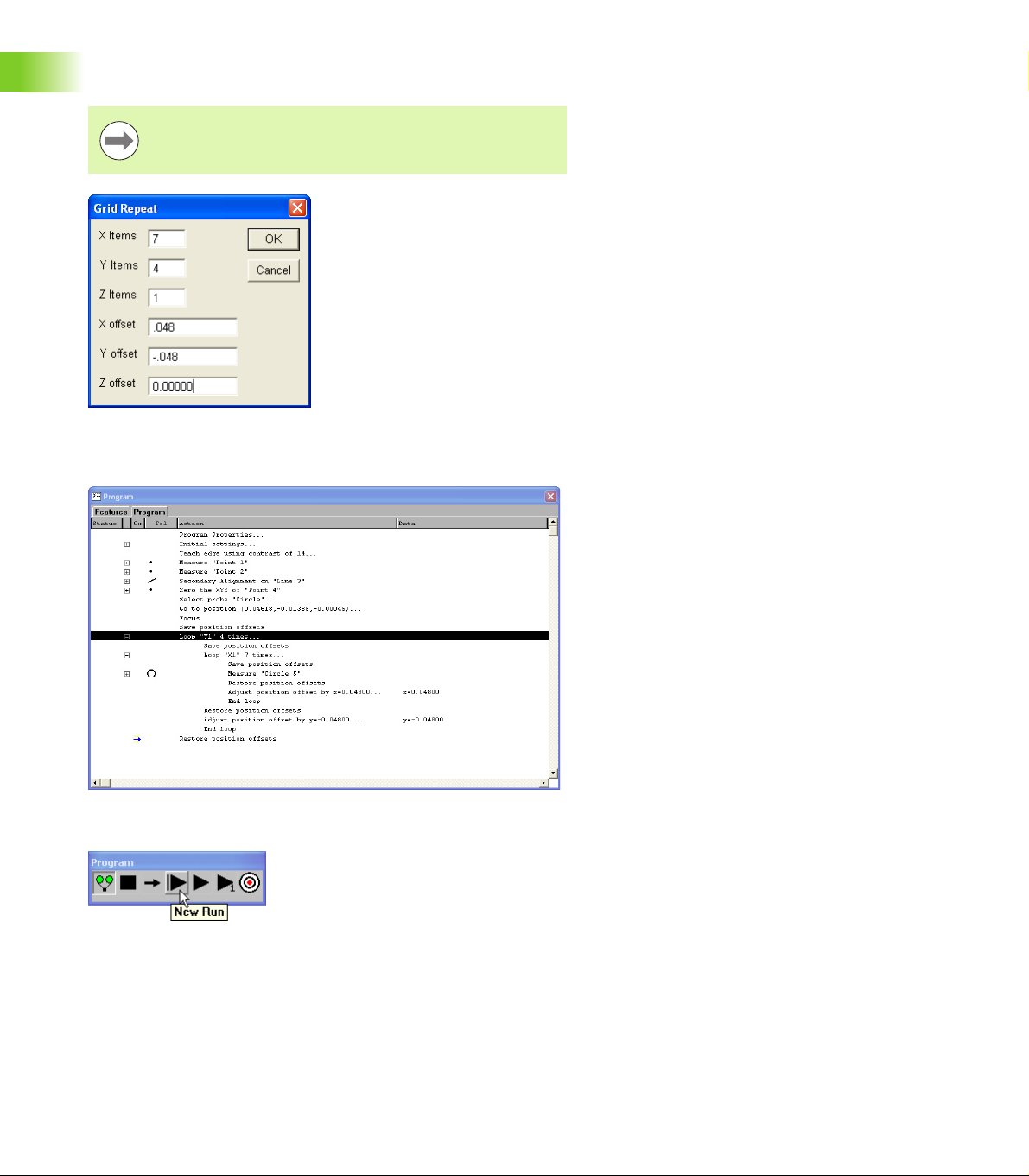

Enter the number of features and type in the desired X and Y offsets

as shown

Items are the number of features in each axis direction.

Offsets are the distance to the next feature relative from

previous feature.

1.1 Operation

Click OK in the dialog box

The grid is created and the program is ready to run

Click New Run to run the program

18 1 Operation

Page 19

Polar grids

A polar grid measures a part with like features that are in a rotational

array. For example, create a polar grid to measure a bolt hole pattern.

The programming wizard that creates a polar grid requires the user to

input the number of features and the angle between the features.

All features in a polar grid must be evenly spaced.

Before creating a polar grid, create a new part program. Use the center

of the polar grid features as the zero point of the part.

Make certain the program is recording before completing

the following steps.

To create a polar grid:

Position the first feature in the polar array in the center of the field

of view as shown

1.1 Operation

IK 5000 QUADRA-CHEK 19

Page 20

Select Measure>Circle

1.1 Operation

Click Enter Point in the Measure Circle dialog

Click OK

Select the measured Circle in the Program template

Select Tools>Programming>Programming Wizards>Create a Polar

Grid

Enter the number of times to loop in the Times to Repeat field

Enter the loop increment angle in the Angle Increment field

Click OK

The polar grid is created and the program is ready to run.

20 1 Operation

Page 21

Palletize

Use the Palletize wizard for measuring multiple parts placed on a

precision fixture.

All palletized parts must be in a fixture that evenly spaces

the individual parts.

Before palletizing parts, create a new part program measuring all the

features of the part.

Save the reference frame in the part program immediately

after creating the datum.

Make certain the program is recording before completing

the following steps.

To palletize multiple parts:

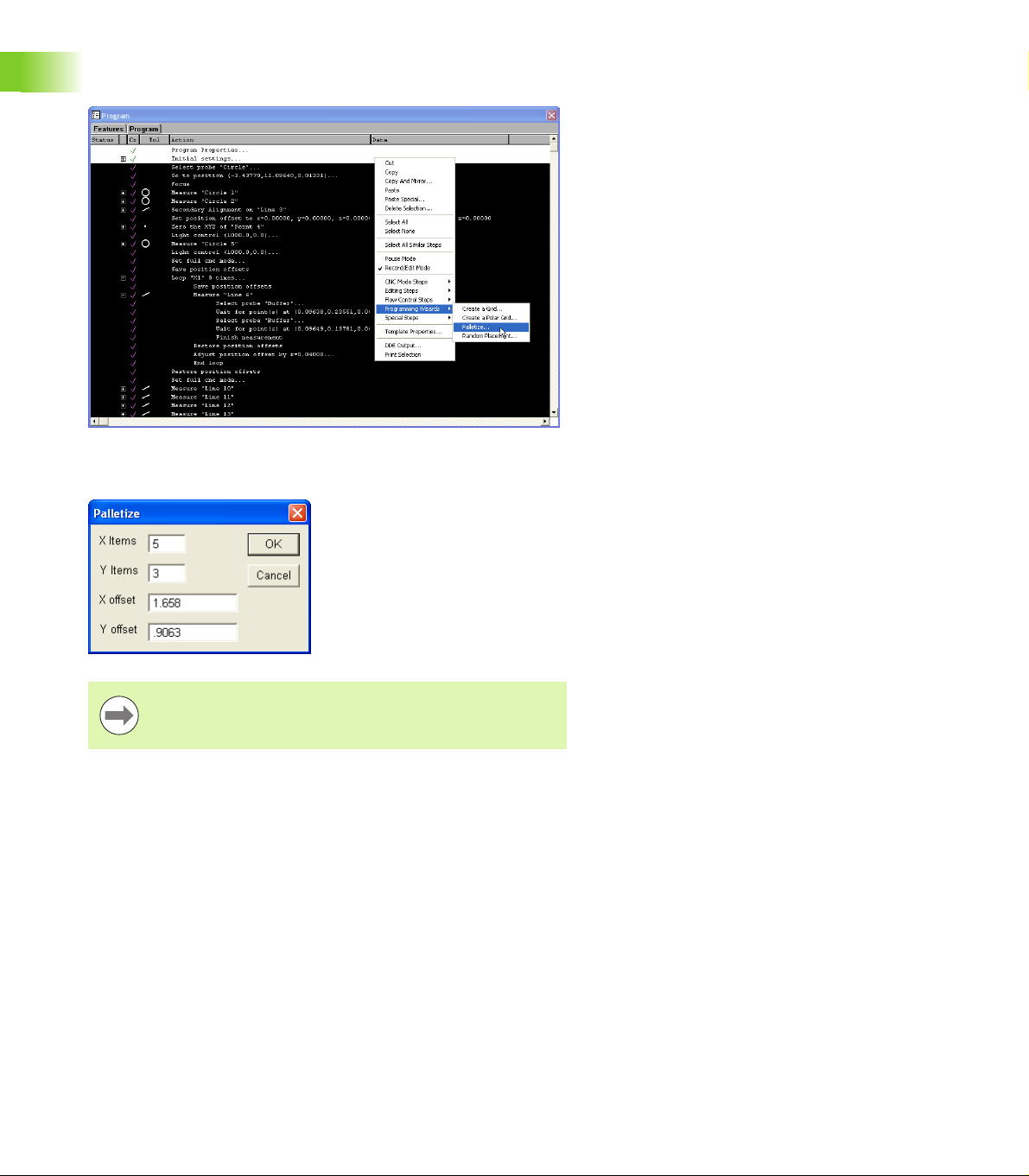

Highlight the desired features as shown

1.1 Operation

IK 5000 QUADRA-CHEK 21

Page 22

Right-click in the Program template and select Programming Wizards,

then select Palletize

1.1 Operation

Enter the number of features and type in the desired X and Y offsets

as shown

Items are the number of parts in each axis direction.

Offsets are the distance to the next part relative from

previous part.

22 1 Operation

Page 23

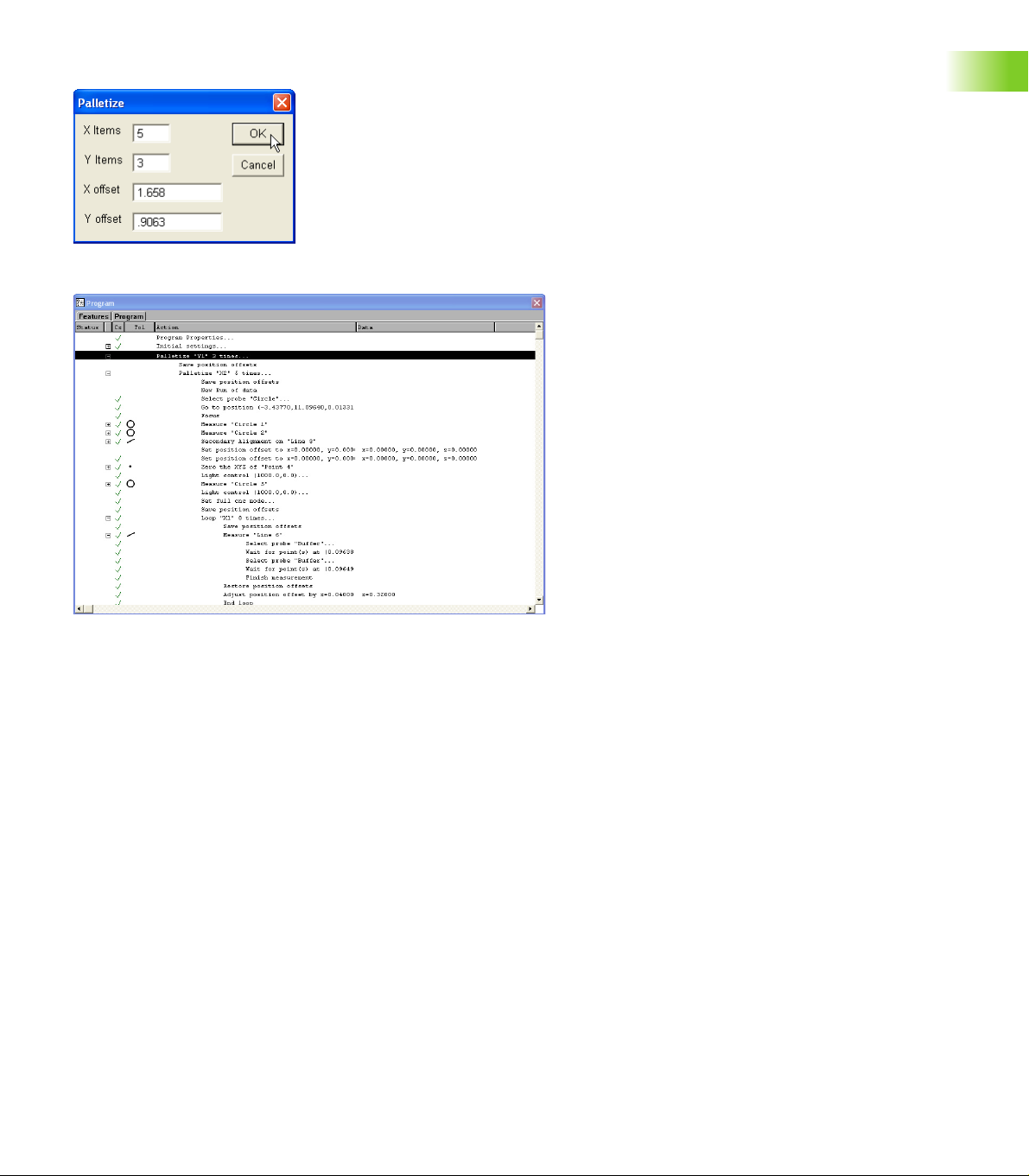

Click OK in the dialog box

The palletization is completed and the program is ready to run.

1.1 Operation

Click New Run to run the program

IK 5000 QUADRA-CHEK 23

Page 24

Random placement

Use the Random Placement wizard for multiple parts on a stage

without a fixture.

All parts must have the same orientation on the stage and

be square to the axes of the machine.

Before creating a random placement, create a new part program with

1.1 Operation

reference steps.

Reference steps

To insert reference steps in a part program:

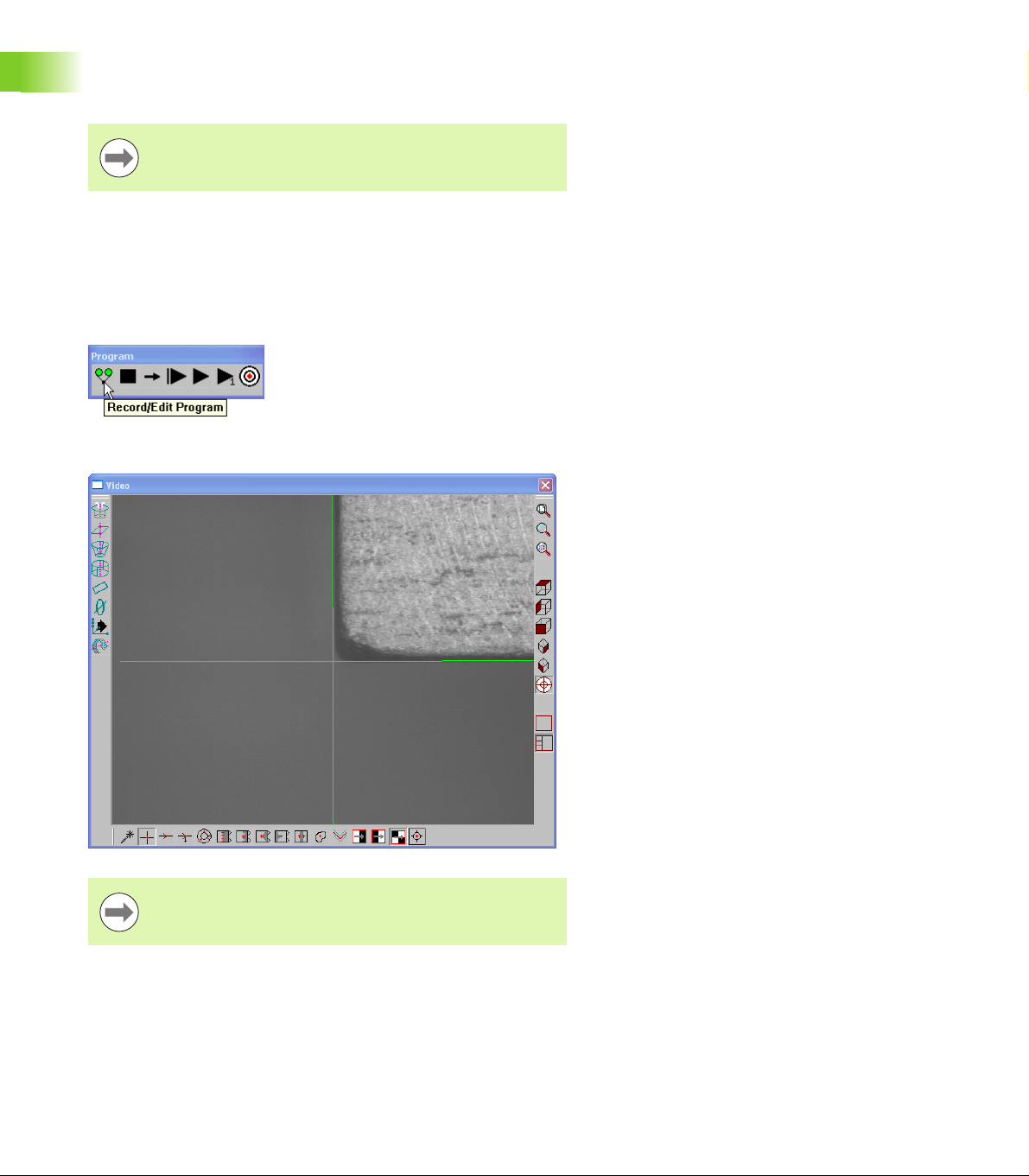

Click the Record/Edit button on the Program toolbar

Position the desired reference feature as shown

The reference feature is a repeatable point to help the

IK 5000 locate the randomly placed parts.

24 1 Operation

Page 25

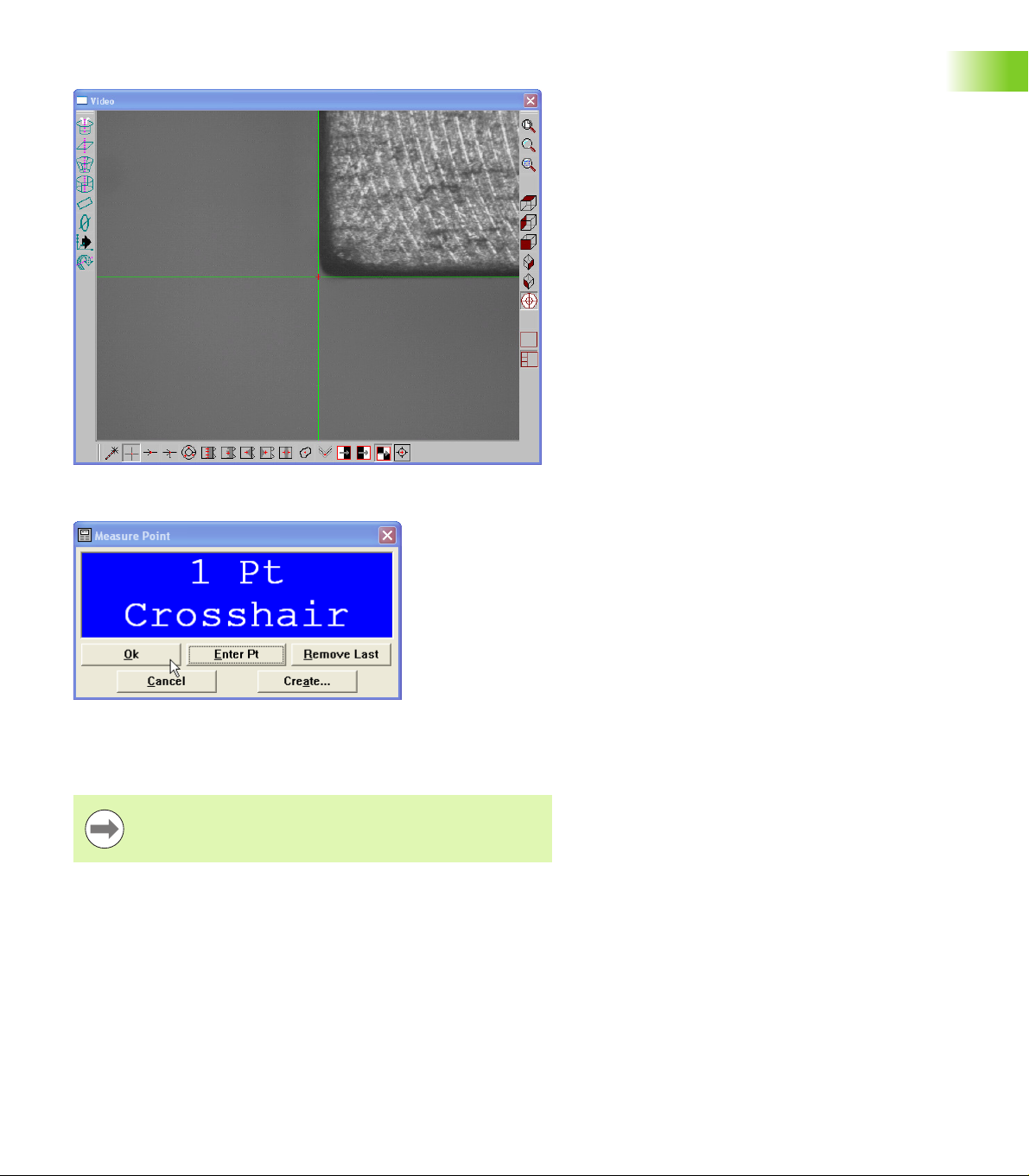

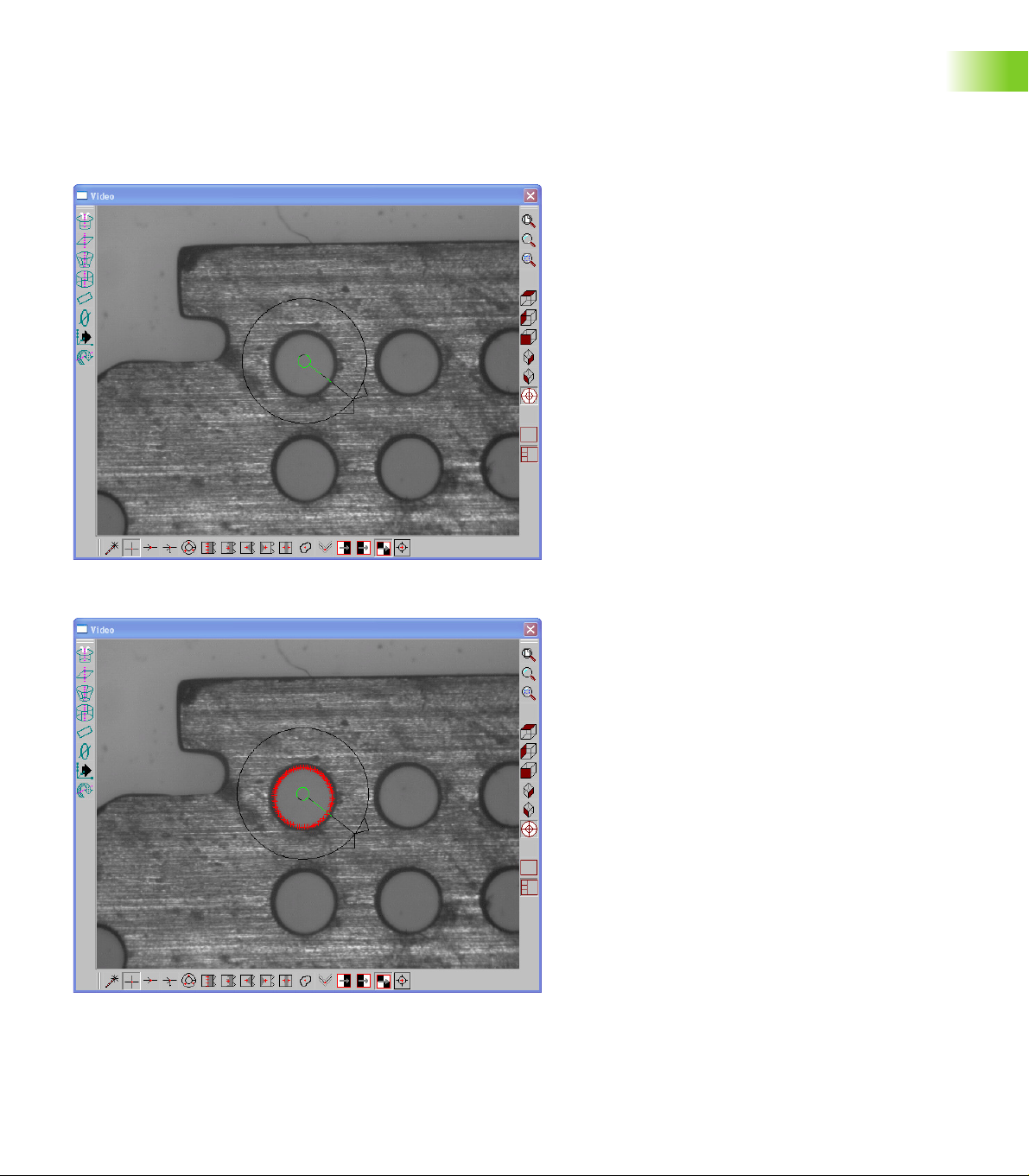

Click the center mouse button to fire the probe tool

Click OK in the dialog

1.1 Operation

The IK 5000 will use this feature to locate the randomly place parts.

Create a the rest of the part program measuring all the features of the

part.

Save the reference frame in the part program immediately

after creating the datum.

IK 5000 QUADRA-CHEK 25

Page 26

Random Placement

To create a random placement:

Make certain the program is recording before completing

the following steps.

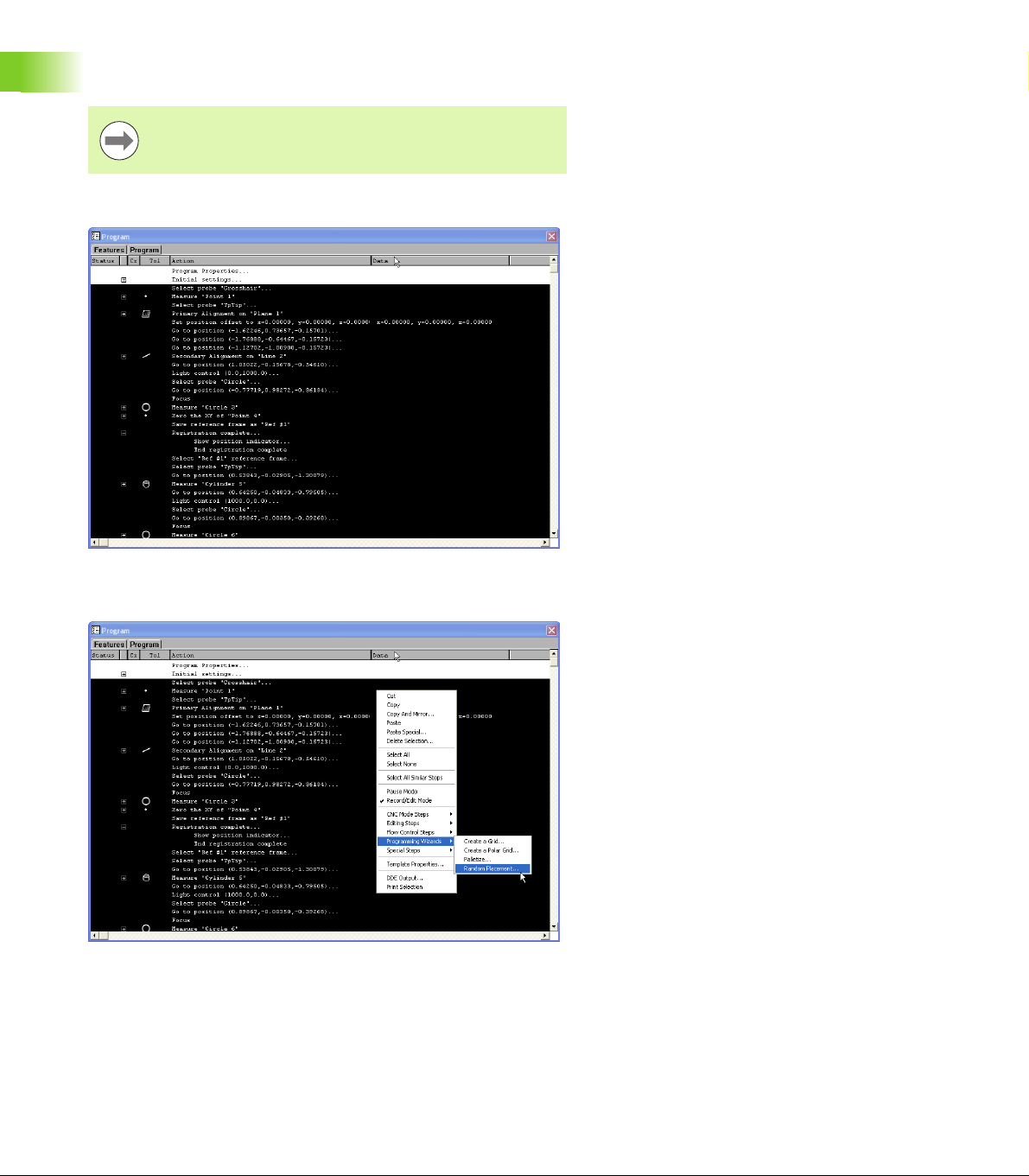

Highlight the desired features, and the reference point as shown

1.1 Operation

Right-click in the Program template and select Programming Wizards,

then select Random Placement

26 1 Operation

Page 27

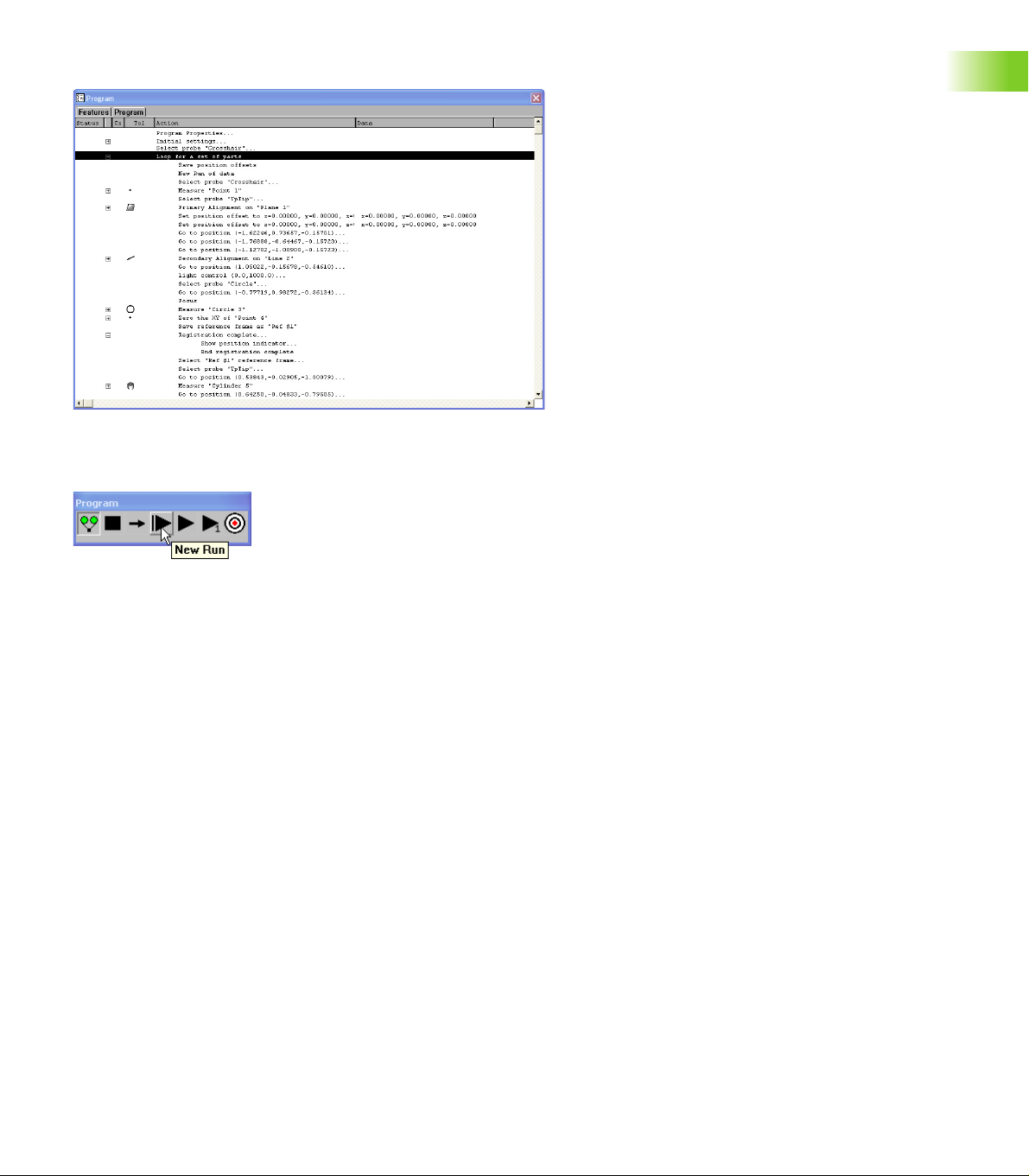

The IK 5000 inserts the required steps for the random placement.

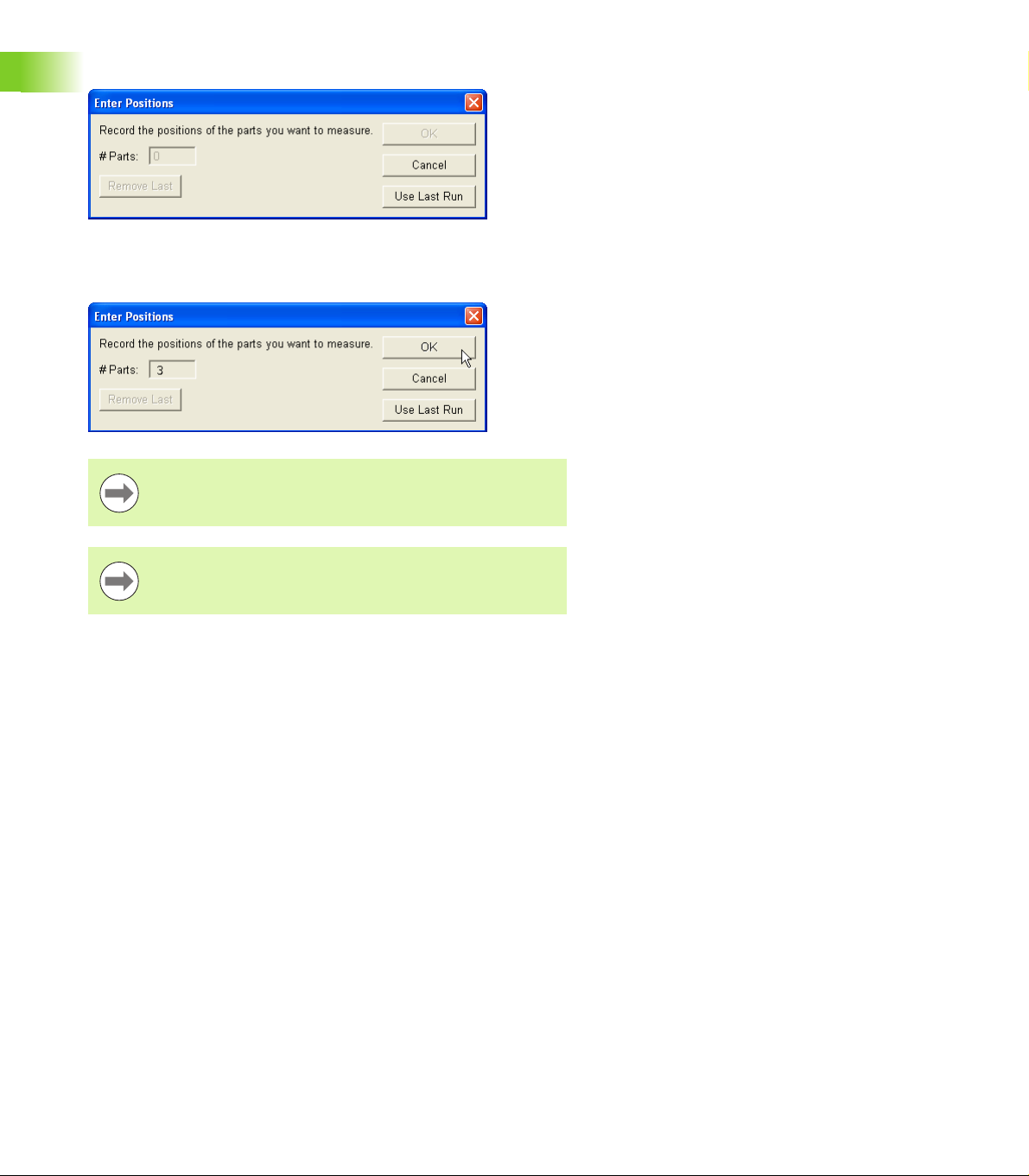

To run a parts program with a random placement:

Click the New Run button on the Program toolbar

1.1 Operation

IK 5000 QUADRA-CHEK 27

Page 28

Measure the reference point for the first part

1.1 Operation

Repeat these steps until all parts are entered.

Click OK in the dialog box

Click the Remove Last button to remove the last point

enter. Reenter the point for that part.

Click the Use Last Run button to use the same offsets as

the previous run.

28 1 Operation

Page 29

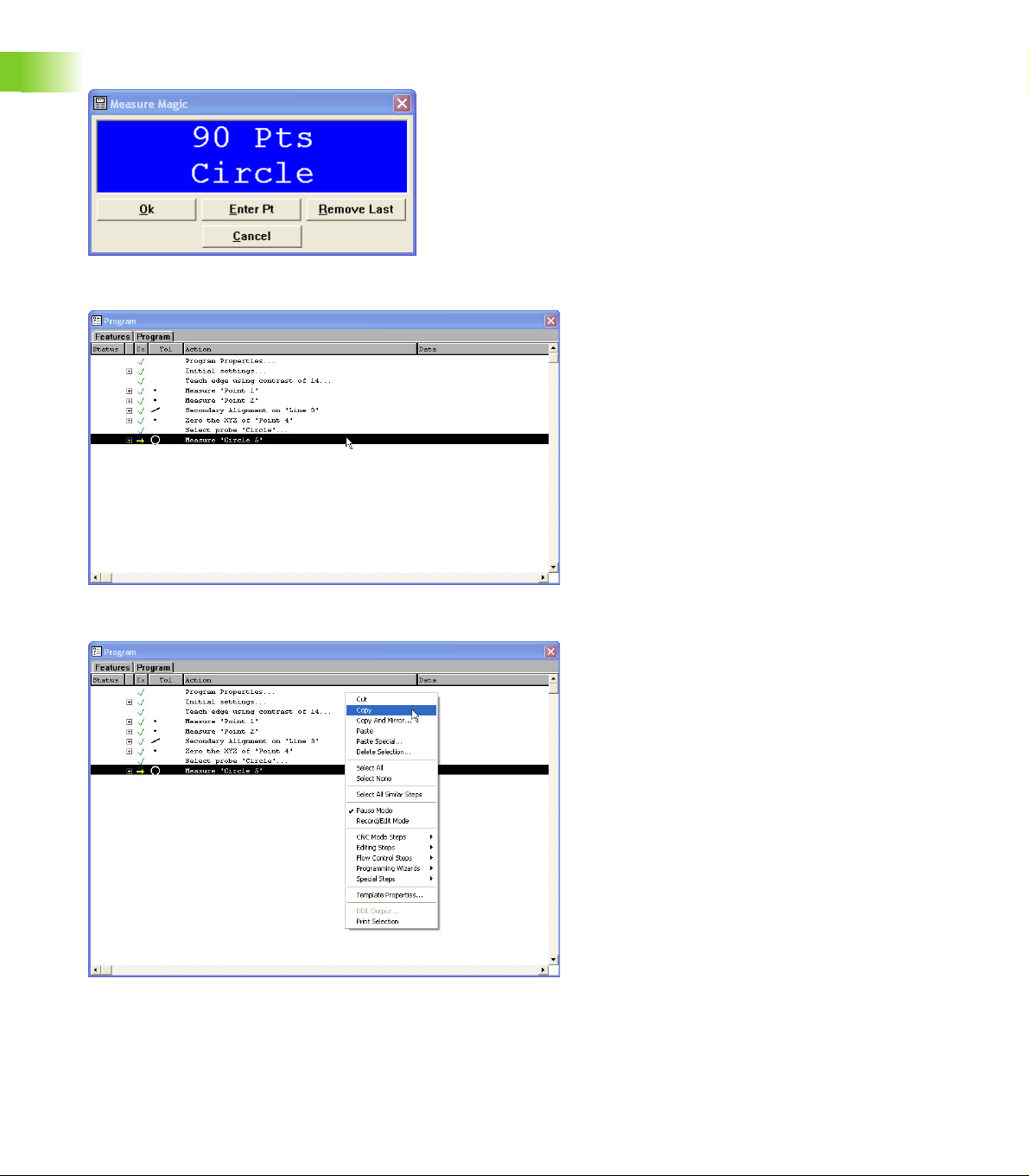

Copy and paste special

Before performing a copy and paste special, record a new part

program with a datum.

To copy and paste special:

Position the first array feature as shown

1.1 Operation

Click the center mouse button to fire the probe tool

IK 5000 QUADRA-CHEK 29

Page 30

Click OK in the dialog box

1.1 Operation

Highlight the first array feature in the Program template as shown

Right-click in the Program template and select Copy

30 1 Operation

Page 31

Right-click in the Program template and select Paste Special

Enter the number of Items and type the desired X and Y offsets as

shown

1.1 Operation

Items are the number of features in each axis direction.

Offsets are the distance to the next feature relative from

previous feature.

IK 5000 QUADRA-CHEK 31

Page 32

Click OK in the dialog box

1.1 Operation

The IK 5000 creates a grid on the part view and assigns a numbered

feature name to each feature in the grid.

32 1 Operation

Page 33

The copied and pasted parts appears in the Part View window as

shown.

The program is ready to run.

1.1 Operation

IK 5000 QUADRA-CHEK 33

Page 34

Additional tolerance check Axial Runout for Plane feature

Axial runout tolerance can be applied to a Plane feature that is

perpendicular to a reference axis, e.g. plane to cylinder.

To apply axial runout tolerance:

Measure a cylinder to be used as a reference in the tolerance

Measure the plane to apply the axial runout tolerance to

1.1 Operation

Select the Plane feature in the Features template

Select Tools>Tolerance>Axial Runout

Enter tolerance parameters

Click ok

Tolerance results are displayed.

Select

Tools>Tolerance>Axial Runout

34 1 Operation

Enter tolerance parameters and

click OK

Tolerance results are displayed

Page 35

Palletizing multiple parts

A pallet is a rectangular arrangement of identical parts organized into

a consistent matrix of columns and rows. The X and Y offsets between

parts in the matrix must be the same for all parts.

Once a part program is created and tested for a single part, it can be

run on each of the identical parts contained in a pallet. The IK 5000 will

begin measuring parts at the lower-left corner of the pallet, and will

proceed from left to right and from bottom to top.

To specify the fixturing mode:

Double click Program Properties in the Program template. The

Program Properties dialog is displayed.

Click the Palletize tab. The pallet setup parameters will be

displayed.

Enter the Number of Columns and Number of Rows into the fields

provided

Enter the X Offset and Y Offset between parts into the fields

provided

When it is known that some pallets will not be full, the program can

prompt the operator at the beginning of each run to specify the

location of parts contained by the current pallet. Check the Prompt

user for position of loaded pallet elements check box to

prompt the operator.

Click OK

1.1 Operation

Pallet of 12 identical parts

Enter pallet parameters

IK 5000 QUADRA-CHEK 35

Page 36

Profile import points

Probed points from features can be imported into a profile

measurement when recording a program. This eliminates the need to

re-probe points for contours that make up features already measured

in the same program.

All features whose points are used in the import process

need to exist during program playback or the import

1.1 Operation

To import points into a Profile measurement:

Start recording a program

Measure features into the program by probing them

function will fail.

Start a Profile measurement

Select the features whose data cloud will be imported into the

measurement as probed points

36 1 Operation

Page 37

Click Import Pts

Points are imported into the Profile measurement.

1.1 Operation

Click OK

IK 5000 QUADRA-CHEK 37

Page 38

Measuring rectangles

3

21

5

4

3

Precisely five probed points are required to measure a rectangle. The

five points must be located in an exact pattern, and can be probed in

either clockwise or counterclockwise order.

The correct pattern of points probed around the rectangle are:

Two points evenly distributed along one long side

One point on the closest end

1.1 Operation

One point on the approximate center of the second long side

The last point on the remaining end

Probing a different pattern of points, or probing out of

either clockwise or counterclockwise order will result in

erroneous rectangle measurements.

Measurement results are shown in the Features template, Part View

window and Results window. The Results window shows:

The feature identification number

The number of points used in the measurement

The length and width of the rectangle

The angular orientation of the rectangle

The coordinate location of the center of the rectangle

Only the rectangle shape and orientation are shown in the Feature

stamp of the Results window.

12

5

4

Clockwise probing order

Counterclockwise probing order

38 1 Operation

Page 39

Profile3D measurements

Profile3D measurements compare probed part surfaces to nominal

part profiles from drawing or part data files. Probed surfaces and

nominal profile surfaces are compared in the Measure Profile3D

window.

The nominal part profile can be imported into the Measure Profile3D

window from a drawing file in .IGS or .STP formats.

As surfaces are probed, their points are displayed in the Measure

Profile3D window. When the desired surface measurements are

complete, a fit operation is performed. During the fit operation, the

system positions the probed data over the nominal profile and adjusts

the X, Y, Z and rotational orientation of the probed points to achieve

the best fit. Data points are shown as dots and form errors are shown

as whiskers.

1.1 Operation

Probed points shown in Measure

Profile3D window

Tolerances can be applied to Profile3D measurements as bilateral

limits or as unilateral pass/fail boundaries. Bilateral tolerances can be

distributed equally or unequally on opposite sides of a surface.

The form errors, the number of data points and tolerance pass/fail

results can be displayed in the Measure Profile3D window at the

conclusion of the Fit operation. Upon completion of the Profile3D

measurement, the Profile3D feature is listed in the Features template.

The form error of each surface point is listed in the Points Detail

template and can be visually inspected using the Profile3D Feature

Stamp.

Points Detail template Profile3D feature stamp

Fit operation performed and form

error whiskers shown

IK 5000 QUADRA-CHEK 39

Page 40

Profile3D measurement screen functions

Functions for conducting Profile3D measurements are located across

the bottom of the Measure Profile3D window. These functions are

discussed in detail later in the Profile3D measurement instructions.

1.1 Operation

Measure Profile3D window

The Measure Profile3D window functions are shown below:

Functions Function descriptions

OK Complete the Profile3D measurement

Enter Pt Probe part surfaces

Remove Last Remove the last probed points

Cancel Cancel the Profile3D measurement

Fit Fit probed data to the nominal Profile3D

Reset Reset the fit operation

Export Export the adjusted Profile3D model

Tolerance Assign surface tolerances

Allow X, Y, Z Allow (or prohibit) data shifts during Profile3D fit analyses

Allow AX, AY, AZ Allow (or prohibit) data rotation during Profile3D fit analyses

Pass Only Enable (or disable) Pass Only option

40 1 Operation

Page 41

Profile3D window menu

Functions for evaluating and displaying Profile3D measurement

results are contained in the Measure Profile3D window menu.

Right-click anywhere in the Measure Profile3D window to display the

Measure Profile3D menu.

1.1 Operation

Measure Profile3D window menu

The Measure Profile3D window menu functions are shown below:

Functions Function descriptions

Zoom All Zoom to fit model in window

Zoom Window Click and drag to select an area to zoom in on

Zoom In Zoom in to show more detail

Zoom Out Zoom out to show less detail

Rotate Rotate the model around the datum

Pan Move the model in the measure window

Maximize Expand the measure window to the full size of the IK 5000 application window

Preset views Set the viewpoint of the model to a predefined view

Solidify Toggle between a wireframe and solid model

Transparency Adjust the percentage of transparency for surfaces of a solid model

Error Mag Magnify the display of form error whiskers

Alignment Adjust the model to match the orientation of the part to the shape

IK 5000 QUADRA-CHEK 41

Page 42

The Profile3D measurement process

1

2

3

8

4

5

6

7

A

B

C

Typical steps required to complete a Profile3D measurement are

shown below. Details regarding the use of measurement windows,

menus and toolbar tools are included in the instructions.

1.1 Operation

Profile3D measurement process

Profile3D measurement process steps are shown below:

Requirement Step System activity

A Measure 1 Start Profile3D measurement

A Measure 2 Import part profile

A Measure 3 Enable data shifts for fit

A Measure 4 Assign tolerances

A Measure 5 Probe part surfaces

A Measure 6 Perform Profile3D fit analysis. Go to step 5 and probe more points

B Review and adjust results 7 Adjust display magnification of error whiskers. Go to step 5 and

C Complete measurement 8 Add Profile3D feature to the Feature template

42 1 Operation

if needed.

probe more points if needed.

Page 43

Start Profile3D measurement

To begin a Profile3D measurement:

Click Measure>Profile3D

or

Click the Profile3D icon button on the Measure toolbar

Start a Profile3D measurement from the Measure toolbar

The Import Profile dialog will be displayed. A nominal part profile can

be imported from a drawing file. Drawing files can be in the .IGS or

.STP format.

Import part profile

Select the desired .IGS or .STP file and then Click Open

1.1 Operation

Start a Profile3D measurement from the Measure

menu

Select file

IK 5000 QUADRA-CHEK 43

Page 44

The nominal Profile3D will be shown in the Measure Profile3D

window.

1.1 Operation

Nominal Profile3D shown in Measure Profile3D window

44 1 Operation

Page 45

Enable or prohibit data shifts for Profile3D fit

The Profile3D fit algorithm shifts the probed data points in the

cartesian or polar coordinate system to achieve the best fit between

the probed points and the nominal part profile.

Maximum degrees of freedom are given to the fit algorithm by

checking the Allow X, Allow Y, Allow Z, Allow AX, Allow AY and

Allow AZ check boxes across the bottom of the window. Clearing a

check box prohibits data movement in the indicated orientation.

To give maximum degrees of freedom to the Profile3D fit algorithm:

Check the Allow X, Allow Y, Allow Z, Allow AX, Allow AY and

Allow AZ check boxes across the bottom of the Measure Profile3D

window

1.1 Operation

Check all check boxes for maximum degrees of freedom

Clear a check box to prohibit movement of data in the indicated

orientation

Allowing the maximum degrees of freedom for the

Profile3D fit algorithm is recommended for most

applications.

IK 5000 QUADRA-CHEK 45

Page 46

Assign tolerances

Bilateral or unilateral tolerances can be assigned to Profile3D

measurements. Bilateral tolerances can be equal or unequal.

To begin applying tolerances:

Click the Tolerance button to display the Profile Tolerance Edit

dialog

1.1 Operation

Begin applying tolerances

46 1 Operation

Page 47

Equal bilateral tolerances

Bilateral tolerance values will be centered on the surface of the

nominal profile. For example, an equal bilateral tolerance of 0.005 will

be applied as ±0.0025.

To apply an equal bilateral tolerance:

Check the Bilateral check box, enter the desired tolerance value

into the Tolerance field for equal bilateral tolerances and then click

OK

Apply equal bilateral tolerances

Unequal tolerances

Unequal or unilateral tolerance values are specified by the user for Inmaterial and Out-material tolerances.

To apply an unequal tolerance:

Uncheck the Bilateral check box, enter the desired

In material Tol and Out material Tol tolerance values in the

fields provided and then click OK

1.1 Operation

Apply unequal tolerances

IK 5000 QUADRA-CHEK 47

Page 48

Probe part surfaces

As part surfaces are probed and points are collected, they appear in

green in the Measure Profile3D window.

When Auto Enter is enabled points will be entered

automatically as they are probed.

To enter a probed point manually:

1.1 Operation

Click Enter Pt in the Measure Profile3D window

Enter points from the Measure Profile3D window

To remove the last point(s) collected:

Click Remove Last

To cancel the Profile3D measurement:

Click Cancel

If a point was probed in a non-perpendicular direction to

the surface during program recording, the system will

probe that point orthogonal to the surface during program

playback as long as the fit analysis was done and

completed.

48 1 Operation

Page 49

Perform Profile3D fit analysis

When all the required points have been probed, the points can be fit

to the nominal part model.

When the fit operation is complete, the green probed points will be

shifted to match the part model as closely as possible and form error

whiskers will indicate differences between the probed locations and

the nominal part surfaces.

1.1 Operation

Points shown before fit calculation Form error whiskers shown after fit operation

To perform a fit analysis:

Click Fit

To decrease the fit analysis time, well distributed points all

around the part under measure are recommended. In

addition, part alignment and datum can be performed

before commencing the Profile3D measurement or using

the Six Point alignment function in the Profile3D

measurement.

IK 5000 QUADRA-CHEK 49

Page 50

Profile3D automatic fit analysis

The fit analysis can be set to be performed automatically once the

measurement is completed by clicking the OK button.

To select the Profile3D automatic fit analysis option:

Select Tools>Options...

Select the Measure tab

Select the Automatically fit Profile3D when measurement

complete checkbox

1.1 Operation

Select Tools>Options

Click OK

50 1 Operation

Page 51

Profile3D Pass Only option

The Pass Only option on the Profile3D Measure window specifies that

the fitting algorithm terminates the fitting process when it finds a fit

that is within all specified surface tolerances. If the Pass Only option

is checked, and a tolerance has been specified for every surface on

which points have been probed, then the fitting algorithm will

terminate as soon as it finds a fit in which all probed points pass their

tolerance. If no such fit can be found then the fitting algorithm will

continue the process of fitting until it either finds the best fit it can or

none is found.

The Pass Only option is used to improve performance in cases where

time is a more important factor than accuracy. This is to be used when

a tolerance pass/fail is all that is required and not the exact amount of

the error. The amount of performance improvement varies depending

on how loose the tolerance is, and how close the part is to its nominal

form. The fitting of a part that fails its tolerance will not have any

performance improvement by using the Pass Only option.

To select the Pass Only option:

Select Measure>Profile3D

Select the Pass Only checkbox

Click OK

1.1 Operation

Select the Pass Only checkbox

IK 5000 QUADRA-CHEK 51

Page 52

Six point alignment

A six point alignment allows the operator to align the model with the

orientation of the part on the stage.

To perform a six point alignment:

Right click in the Measure Profile3D window

Select Alignment>Six Point. A prompt appears with directions for

marking points on the model.

Select OK in the prompt

1.1 Operation

Mark three points on the model surface to define a primary plane

Mark two points on the model on a surface that is close to

perpendicular to the first surface to define a secondary line

Mark one point on the model on a surface that is close to

perpendicular to both the first and second surfaces to define a zero

point

When six points are selected the first point is highlighted on the model

Six points selected and first point highlighted

Probe the first point on the part. The next point is highlighted on the

model.

Repeat probing the remaining five points

Select Fit in the Measure Profile3D window. The six point

alignment is completed and the initial fit is done.

52 1 Operation

Page 53

Resetting the fit analysis

The results of a fit analysis can be reset and the point data refined in

preparation for revised fit operations. The user can review the

positions of data points, remove data points or change the degrees of

freedom for the fit analysis.

To reset the fit analysis back to the original probed point locations:

Click Reset

1.1 Operation

Points shown after resetting the fit analysis

IK 5000 QUADRA-CHEK 53

Page 54

Adjust the display magnification of error whiskers

During the fit analysis, probed points that do not fall precisely on the

nominal profile generate form errors. When tolerances are specified,

the errors are divided into two groups, those that pass (Passed) and

those that fail (Failed) tolerance criteria.

The passed and failed form errors can be displayed as whiskers that

extend from the nominal surface. The length of each whisker is

proportional to its magnitude of error.

Typically, the magnitude of most form errors is so small in proportion

1.1 Operation

to the part displayed that without magnification they would not be

visible. The Measure Profile3D window menu and toolbar include

fixed, automatic and user-definable levels of magnification for

displaying error whiskers.

Fixed magnifications: display magnifications are selected directly by

the user.

Automatic magnification (AX): the system optimizes the display of

error whiskers based on the maximum form error value.

User-defined magnification (UX): A data field will be displayed for

specifying the level of magnification.

To adjust the display magnification of form error whiskers:

Right-click the Measure Profile3D window to display the Measure

Profile3D window menu

Click Error Mag to display a menu of magnification alternatives

Click the desired magnification selection

Select error magnification from Measure Profile3D

window menu

54 1 Operation

Page 55

Add Profile3D feature to the Feature template

When the final fit analysis is finished, the Profile3D measurement can

be completed and the Profile3D feature can be added to the Feature

template.

To complete the Profile3D measurement:

Click OK in the Measure Profile3D window

1.1 Operation

Complete the Profile3D measurement

IK 5000 QUADRA-CHEK 55

Page 56

To view the Profile3D measurement results:

Click on the Feature Stamp Icon in the results window

1.1 Operation

Profile3D feature stamp

Measurements results are also available in the PointDetails

template.

PointDetails template

If the PointDetails template is not open it can be viewed

by clicking Windows>Open Template... and selecting

PointDetails.5ft.

56 1 Operation

Page 57

Auto Focus (option)

The Auto Focus teach function has been removed from the IK 5000

software. The focus search distance is now entered directly into the

search distance field. The previous Auto Focus algorithm used the

teach function to teach the optimum search distance and Z axis

velocity, depending on the connected camera's frame rate. This could

cause an intermittent Auto Focus failure when used on a significantly

different surface from the surface used during the teach process. The

algorithm now automatically adjusts the Z axis velocity depending on

the camera frame rate and the user specified search distance.

High resolution cameras may produce less than optimal results which

can be improved by decreasing the search distance. Decreasing

search distance also speeds up the focal point acquisition time but

requires initial position to be closer to the targeted focal point. On

some cameras turning on the despeckle filter prior to performing auto

focus will improve results, despeckle filter can then be turned off after

focus.

To turn on the despeckle filter:

Right click on the Video window and select Filter...

Check the Despeckle checkbox

Click OK

1.1 Operation

Right click the Video

window and select Filter...

IK 5000 QUADRA-CHEK 57

Check the Despeckle box and click OK

Page 58

To set Auto Focus options:

Click Tools>Options

Verify the Supervisor Password is entered and the Keep privileges

until program is exited option is checked

Click Probe>Probe Library

Click on the target camera

1.1 Operation

Verify the Password is entered and Keep

Click Probe>Probe Library Click on the target camera

privileges until program is exited is

checked

Click on the target magnification

Click the Auto Focus tab

Enter the desired search distance in the Search Distance field

Click OK to save the changes and exit the Probe Library

Click on the target magnification Click the Auto Focus tab Enter the desired search distance and

click OK

58 1 Operation

Page 59

Auto focus will search and make as many passes as necessary until a

optimum focus point is found. The Max two passes feature limits the

number of auto focus passes to two. Selecting this feature can speed

up the auto focus process but may result in less reliable repeatability

of the auto focus height.

To enable Max two passes:

Select the Max two passes check box

Select the Max two passes check box

1.1 Operation

IK 5000 QUADRA-CHEK 59

Page 60

Autofocus final check

An option to perform a final autofocus check is available from the

Auto Focus tab in the Probe Library.

Enabling a final check helps to avoid missing an optimum focus point

when autofocusing with a search distance smaller than 1 mm and a

magnification greater than 20 x. An optimum focus point can be

missed due to skipping of the focus frames during the focus search,

machine drive mechanics, changes in lighting, or the objective lens

1.1 Operation

being used.

A final check compares the difference in contrast values of frames in

the range of 5 µm above to 5 µm below the initial focus point. If there

is a point with a larger contrast value found the system will focus on

the point of greater contrast.

To enable the the autofocus final check:

Select Probe>Probe Library...

Select the target camera and target magnification

Select the Autofocus tab

Check the check box next to Enable final check

Click Probe>Probe Library... Check the check box next to Enable final check

60 1 Operation

Page 61

Exploding the Data Cloud

Explode Data Cloud is used to extract point features from the data

cloud used in a probed feature.

To extract point features from the data cloud:

Verify the system is in No Program or Editing state of programming

Probe a feature

Select the target feature

1.1 Operation

Verify the system is in

No Program or Editing

state

Click Tools>Explode Data Cloud.

The Features List is populated with point features created from the

data cloud of the selected feature.

Probe a feature Select the target feature

Click Tools>Explode Data Cloud Point features are created from the data cloud

IK 5000 QUADRA-CHEK 61

Page 62

Rotating and positioning of VED tools using part reference frame

If a part datum has been performed, the system will rotate and

position the VED tools, including the Video Charts, to the part

reference frame.

ISO Tolerance

1.1 Operation

The ISO tolerance enables the use of data stored in ISO 286-2

Standard tables.

The ISO tolerance can be added to the following features:

Point

Circle

Arc

Sphere

Line

Slot

Torus

Rectangle

The ISO tolerance is applied to a feature similar to other tolerances, for

instance by right-clicking on a feature in the Features list template.

Right-click on a feature in the Feature list

62 1 Operation

Page 63

Once the ISO tolerance is selected the ISO Tolerance Entry dialog

box appears. The ISO Tolerance Entry dialog box is used to select

which ISO tolerance table entry will be used to tolerance each

applicable feature parameter.

ISO tolerance entry table

Available parameter selections are:

ISO table

ISO Index

The ISO index entry can be used to select which column, 1 through

18, to use for the selected ISO tolerance table. For questions about

the ISO tolerance table selection please refer to the ISO 286-2

standard.

1.1 Operation

IK 5000 QUADRA-CHEK 63

Page 64

The nominal value for the feature parameter along with the selected

ISO tolerance table and index entries are used to determine the low

and high limits to be used when tolerancing the feature. These limits

are calculated through a look-up into the ISO tolerance table. If no ISO

tolerance table entry or ISO tolerance index entry is specified then the

tolerance is considered empty and the tolerance will pass. Also, if the

nominal value for the feature parameter is outside of the range of

nominal values found within the selected tolerance table, then the

tolerance will also pass.

1.1 Operation

ISO tolerance results

Similar to all tolerances, the ISO tolerance can be added to features

within a program.

ISO tolerance added to a feature in a program

The ISO tolerance results can also be viewed in reports when using

the AllTol template.

64 1 Operation

Page 65

AllTol template

1.1 Operation

IK 5000 QUADRA-CHEK 65

Page 66

Continuous probe firing

Probes can be dry-fired continuously to show data points that would

be acquired under the current light, focus, part alignment and other

current measurement conditions if the probe were actually fired. The

data points are shown in blue until the probe is fired to acquire points,

then the acquired points are shown momentarily in red.

1.1 Operation

Continuous Fire enabled

Continuous probe firing is useful for setup and

troubleshooting activities, but requires substantial system

resources and should be avoided during routine use to

maintain high throughput.

To enable Continuous Fire:

Right-click the Live Video window to display the Window menu

Select Other>Continuous Fire

or

Click the Continuous Fire button on the VED toolbar

Enable Continuous Fire from VED toolbar

Enable Continuous Fire from menu

66 1 Operation

Page 67

Programming continuous probe firing

Continuous probe firing is programmable. A Continuous Fire mode

step is recorded in the Initial settings program step when a new

program is recorded. Continuous probe firing is turned off in the Initial

settings step by default.

After a program is run the state of Continuous Fire returns

to the same state that was in place before the program

was executed.

Initial settings step

Enable Continuous Fire from Initial settings... step

1.1 Operation

To turn Continuous Fire on in the Initial settings:

Click the + sign next to Initial settings... to expand the Initial

settings step in the program window

Double-click Turn off continuous fire mode...

The text changes to Turn on continuous fire mode.... Continuous

Fire mode will now be turned on when the program is run.

IK 5000 QUADRA-CHEK 67

Page 68

Program step

When the state of Continuous Fire is changed from the Live Video

window or the VED toolbar, a separate Continuous Fire step is

recorded in the program. The state of this step can be changed.

1.1 Operation

Change the state of a Continuous Fire program step

To turn Continuous Fire off in an existing program step:

Double-click on Turn on continuous fire mode...

Turn off continuous fire mode... is displayed in the Program

window and the program will now turn Continuous Fire off at this step

in the program.

To turn Continuous Fire on in an existing program step:

Double-click on a Turn off continuous fire mode... step

Turn on continuous fire mode... is displayed in the Program window

and the program will now turn Continuous Fire on at this step in the

program.

68 1 Operation

Page 69

Measure shortcuts

Keyboard shortcuts for starting Ellipse, Torus, Profile, and Profile3D

measurements are now available. The shortcuts are listed in the

Measure menu.

In addition to the new measure shortcuts, the Rectangle menu item

has been moved to a more appropriate location in the Measure menu.

Ellipse shortcut

To start an Ellipse measurement:

Press Ctrl+E on the keyboard

Torus shortcut

To start a Torus measurement:

Press Ctrl+T on the keyboard

Profile shortcut

To start a Profile measurement:

Press Ctrl+F2 on the keyboard

Profile3D shortcut

To start a Profile3D measurement:

Press Ctrl+F12 on the keyboard

1.1 Operation

Measure menu

IK 5000 QUADRA-CHEK 69

Page 70

Symmetry tolerance

/LQH

5HIHUHQFHOLQH

/LQH

A symmetry tolerance can be applied to Line and Plane features that

are symmetrical to a reference feature.

Symmetry tolerance applied to a line

/LQH

1.1 Operation

To apply the symmetry tolerance to a line:

Measure four lines, two lines on opposite sides that are considered

to be master edges and two lines from edges that are to be

symmetrically toleranced. Lines 1 and 2 are measured from master

edges while lines 3 and 4 are measured from the edges to be

symmetrically toleranced.

Construct a reference line from lines 1 and 2

Construct the line to be tolerance for symmetry from lines 3 and 4

Select the resultant line from the construction using lines 3 and 4

7ROHUDQFHGOLQH

/LQH

70 1 Operation

Page 71

Apply symmetry tolerance with the constructed line from lines 1 and

2 as the reference feature

1.1 Operation

The actual tolerance is calculated by doubling the

maximum distance between the endpoints of the

constructed tolerance line from the endpoints of the

constructed reference line.

IK 5000 QUADRA-CHEK 71

Page 72

Symmetry tolerance applied to a plane

3ODQH

5HIHUHQFHSODQH

3ODQH

3ODQH

7ROHUDQFHGSODQH

1.1 Operation

3ODQH

To apply the symmetry tolerance to a plane:

Measure four planes, two planes on opposite sides that are

considered to be master surfaces and two planes from surfaces that

are to be symmetrically toleranced (see drawing above). Planes 1

and 2 are measured from master surfaces while planes 3 and 4 are

measured from the surfaces to be symmetrically toleranced.

Construct a reference plane from planes 1 and 2

Construct the plane to be toleranced for symmetry from

planes 3 and 4

Select the resultant plane from the construction using

planes 3 and 4

72 1 Operation

Page 73

Apply symmetry tolerance with the constructed plane from planes

1 and 2 as the reference feature

1.1 Operation

The actual tolerance is calculated by doubling the

maximum distance between the endpoints of the

constructed tolerance plane from the endpoints of the

constructed reference plane.

IK 5000 QUADRA-CHEK 73

Page 74

Plane probing technique

6HHGSRLQW

6HHGSRLQW

6HHGSRLQW

3UREHGSODQH

$FWXDOSODQHVXUIDFH

6HHGSRLQW

3UREHGSODQH

A plane can be measured by probing three seed points for the data

cloud. The IK 5000 fitting algorithm uses these three points as the first

three corners of the plane.

1.1 Operation

It is important to probe the three seed points on the corner surfaces

of the actual plane if the Add Probe Points function is used to add

more points to the data cloud of the plane measurement.

6HHGSRLQW

6HHGSRLQW

$FWXDOSODQHVXUIDFH

$GGHGSUREHSRLQWV

Correct probing technique

74 1 Operation

Page 75

In some cases it may be necessary to probe the seed points in a

6HHGSRLQW

6HHGSRLQW

6HHGSRLQW

3UREHGSODQH

$FWXDOSODQHVXUIDFH

5HDFKDEOH

SUREHG

6HHGSRLQW

3UREHGSODQH

different order and location. For example, probing the seed points

where the first two are located at the immediate corners facing the

operator while the third point is probed on the middle point of the

opposite edge.

The resulting plane cannot be used with the Add Probe Points

function because it will fail due to some points being located outside

the actual surface. The system will miss target points as they will be

located outside the actual plane and cannot be reached.

6HHGSRLQW

6HHGSRLQW

1.1 Operation

8QUHDFKDEOH

SUREHG

SRLQWV

Incorrect probing technique

$FWXDOSODQHVXUIDFH

SRLQWV

IK 5000 QUADRA-CHEK 75

Page 76

1.1 Operation

76 1 Operation

Page 77

Setup

Page 78

2.1 Setup

Updating the IK 5000 software

The update should be performed according to the following

procedure:

2.1 Setup

Make a backup of the IK 5000 system settings

Uninstall the installed IK 5000 software

Install the new IK 5000 software version

Restore the IK 5000 system settings

Backup system settings

Make a backup of the IK 5000 system settings (via

menu: Help>Backup Settings...)

Uninstall old software version

Uninstall the installed IK 5000 software with the tools provided by

the operating system (control panel)

Install new software version

Install the new software version 3.0.x

Restore system settings

Restore the IK 5000 system settings (via

menu: Help>Restore Settings...)

If an option that requires a license key is enabled the current license

key remains valid. A new license key is not required.

78 2 Setup

Page 79

Files and folders

IK 5000 files and folders locations are distributed throughout Windows

operating system folder locations in accordance with the operating

system's files and folders location guidelines.

The files and folders are distributed as follows:

IK 5000 files are located in the HEIDENHAIN\IK 5000 folder which is

in the Program Files OS folder

IK 5000 application is located in HEIDENHAIN folder in the Start

menu

Configuration files are stored in IK 5000 folder in Program Data OS

folder

User settings files are saved to the IK 5000 folder in Local User OS

folder

User document files are saved to the IK 5000 folder in the Documents

OS folder

Some file types that were supported in previous versions

are no longer used. File type .met is no longer supported.

Files of this type have been removed from the system.

2.1 Setup

IK 5000 QUADRA-CHEK 79

Page 80

PC2-COMP Express frame grabber board

The IK 5000 supports the PC2-COMP Express, PCI Express frame

grabber board produced by TeledyneDalsa Inc. This frame grabber can

be used in place of the previous Bandit II frame grabber board. The

PC2-COMP Express can be installed in systems running Windows XP,

Vista and 7.

2.1 Setup

The PC2-COMP Express frame grabber board is

compatible with 32-bit operating systems only.

This board must be obtained from HEIDENHAIN

This board must be installed on a computer with PCI Express slot

Bandit II and PC2-Comp Express cannot be installed at the same

time

PC2-COMP Express board

80 2 Setup

Page 81

Use current reference frame

Program Properties window

The Use machine reference option in the Program Properties dialog

has been renamed to Use current reference frame. When an

existing program is loaded into IK 5000 SW v3.0.0 or higher, the

Use current reference frame option will take on the opposite state

of the Use machine reference option.

The reference frame that is in place when a program is first recorded

is now stored within the program. If Use current reference frame is

unchecked, the program will use this stored reference frame as its

initial reference frame when the program is executed.

If Use current reference frame is checked, the program will use the

current part reference frame when the program is executed.

To change the current part reference frame:

Select a different part reference frame from the status bar

2.1 Setup

IK 5000 QUADRA-CHEK 81

Page 82

The default state of Use current reference frame is unchecked. If a

part reference frame has been created before the program is first

recorded Use current reference frame will be automatically

checked.

Programs written prior to SW v2.96.0 do not include the reference

frame that was in place when the program was first recorded. If

2.1 Setup

Use current reference frame is unchecked the program will use the

machine reference frame as the initial reference frame when the

program is executed.

If Use machine reference was previously used the same behavior can

be obtained with Use current reference frame.

To obtain the same behavior:

Select the machine reference frame prior to recording the program

Uncheck Use current reference frame in the Program Properties

dialog prior to executing the program

or

Check Use current reference frame

Select the machine reference frame prior to executing the program

82 2 Setup

Page 83

Camera parameters

The IK 5000 supports the configuration of camera and image quality

parameters through DirectShow interfaces. The configurable

parameters are limited to those provided by the camera driver support

for DirectShow. The IK 5000 cannot modify a parameter that the

camera driver does not allow to be modified.

Example configurable parameters are gamma, brightness, contrast

and color saturation. Brightness and contrast settings are saved when

the IK 5000 is shut down and restored on the next start up.

To access digital camera parameters:

Right-click in the Video window

Select Video Properties

A video properties window will open displaying the available camera

parameters that can be edited.

2.1 Setup

Right click in the Video window and select Video

Properties

Example video properties window

IK 5000 QUADRA-CHEK 83

Page 84

Specify video probe parameters

Use the VED screen in video edge detection systems to specify video

probe measurements parameters.

To display the VED screen:

Click Tools>Options...>VED

2.1 Setup

Digital video probe and measurement parameters will be displayed for

your system.

New options:

Camera: Select the camera to use for VED (previously unnamed)

Image format: Select the image color format

VED screen example

84 2 Setup

Page 85

Spotter camera options

The digital camera selected as the spotter camera and the format for

the spotter camera can be set from the VED setup tab.

2.1 Setup

Spotter camera options

IK 5000 QUADRA-CHEK 85

Page 86

Supported image formats:

UYVY

RGB24

RGB32

To access Spotter camera options:

2.1 Setup

Select Tools>Options...

Select the VED tab

Select a digital camera from the Spotter drop down menu

Select an image format from the Image Format drop down menu

Click OK

86 2 Setup

Page 87

Scale factor for Open Loop joystick control (Optional)

A CNC system can be operated in either Closed Loop or Open Loop

joystick control mode. This can cause a system to move with different

velocities when a user switches from one mode to the other. To make

the velocity comparable, a user can apply a scaling factor to the

joystick parameters when in open loop control mode. The Scale factor

ranges from 0.01 to 1.00. This is a unit-less value. The default value is

0.5.

Verify the system is set to Open Loop joystick control mode:

Click Tools>CNC...

Enter the Password

Click the General tab

Select the Set joystick control to Open Loop mode checkbox if

not already selected

2.1 Setup

Set joystick control to Open Loop mode

Click OK

IK 5000 QUADRA-CHEK 87

Page 88

Set Scale factor:

Click TOOLS>CNC...

Enter the Password

Click the Joystick tab

Enter the desired scaling factor into the Scale factor field

2.1 Setup

Enter the desired scaling factor

Click Apply

Click OK

88 2 Setup

Page 89

Shutdown

The Shutdown function applies to CNC enabled systems only. During

system shutdown the probe returns to a position defined in machine

coordinates regardless of probe type. The position may be specified

using X, Y and Z coordinates or by choosing the current probe location.

Shutdown settings window

To specify the probe position at shutdown:

Select Tools>CNC...

Enter the Supervisor password into the Password field

Select the Shutdown tab

Select the Enabled checkbox

Enter the X, Y and Z coordinates or click Use Current Location

Click OK

2.1 Setup

IK 5000 QUADRA-CHEK 89

Page 90

Debounce parameters

Y and Z axis debounce count values for the digital positioner use their

own axis value. Previously they used the X axis value.

2.1 Setup

Digital Positioner settings window

To specify debounce count values:

Select Tools>CNC...

Enter the Supervisor password into the Password field

Select the Digital Positioner tab

Enter values into the Debounce (cnts) fields

Click OK

90 2 Setup

Page 91

Touch probe requalification and starting point

Touch probe auto requalification can be set to Use circular moves and

to begin the requalification measurements at the top of the sphere and

not along the diameter.

Deselecting this option allows the automatic

requalification to be executed by linear movements,

minimizing stage vibrations for systems with large

measuring stages.

Auto Requal settings window

2.1 Setup

To select 'Auto Requal' parameters:

Select Tools>CNC...

Enter the Supervisor password into the Password field

Select the Auto Requal tab

Select the Begin measurement at top of sphere and Use circular

moves checkboxes

Click OK

IK 5000 QUADRA-CHEK 91

Page 92

Reset template text colors

It is possible to set the text color of a template to the same color as

the background. When this happens the text is not readable.

The Reset Template Text Colors option makes it simple to revert the

text colors for all open templates back to the default color. The default

2.1 Setup

text color for all templates is black.

To reset template text colors:

Select Help>Diagnostics>Reset Template Text Colors. A prompt

appears requesting verification to reset the text colors.

Select Help>Diagnostics>Reset Template Text Colors

Click Yes

Click Yes

92 2 Setup

Page 93

Default fixtures files location

A default location for Fixtures files can be selected. The IK 5000 uses

this location to save and load reference frames.

The default location is the Fixtures subfolder of the IK 5000 folder

located in the user's system documents folder.

To change the Fixtures file location:

Select Tools>Options...

Select the Files tab

Browse or enter a new Fixtures file location

2.1 Setup

Browse or enter a new Fixtures file location

IK 5000 QUADRA-CHEK 93

Page 94

External amplifier Open Loop control (Optional)

IK 5000 Open Loop joystick control provides the ability to toggle

between two joystick speeds when Speed Toggle is assigned to a

joystick button. External amplifier Open Loop joystick control provides

the ability to toggle between three speeds. The ability to toggle

between three speeds provides increased control over the velocity of

2.1 Setup

movements.

When Set joystick to Open Loop mode and Use external amplifier

for Open Loop control are enabled, Open Loop functionality is

controlled by the HEIDENHAIN amplifier connected to the IK 5000

system. Use external amplifier for Open Loop control is disabled

by default.

CNC window General settings tab

To enable external amplifier Open Loop control:

Select Tools>CNC...

Select the General tab

Select the Set joystick to Open Loop mode and Use external

amplifier for Open Loop control checkboxes

Click OK

94 2 Setup

Page 95

Joystick button assignment

Speed Toggle must be assigned to a joystick button in order use

joystick speed control. The HEIDENHAIN QUADRA-STEP setup

software is used to assign joystick button functions in the

HEIDENHAIN amplifier. QUADRA-STEP setup software and the

QUADRA-STEP setup guide can be downloaded from

www.heidenhain.de.

The IK 5000 and external amplifier both sense joystick button presses.

When Speed Toggle is assigned to a joystick button in the external

amplifier, the same button must be set to No Assignment in the

IK 5000 Options settings.

Options window Buttons tab

To set a IK 5000 joystick button assignment:

Click Tools>Options

Select the Buttons tab

Click the drop-down arrow for the joystick button Speed Toggle was

assigned to in the external amplifier

Select No Assignment

Click OK

2.1 Setup

IK 5000 QUADRA-CHEK 95

Page 96

2.1 Setup

96 2 Setup

Page 97

A

Auto focus ....................................... 57

Auto probe

Disc ............................................ 13

Grid ............................................ 12

Plane .......................................... 12

Autofocus final check ...................... 60

Axial runout ..................................... 34

C

Camera parameters ......................... 83

Continuous probe firing ................... 66

Copy and paste special .................... 29

D

Debounce parameters ..................... 90

Disc pattern auto probe ................... 13

E

Error whiskers display magnification ....

54

Explode data cloud .......................... 61

P

Palletize ........................................... 21

Palletizing multiple parts .................. 35

Part scaling ...................................... 10

PC2-COMP express frame grabber

board ............................................. 80

Plane auto probe .............................. 12

Plane probing ................................... 74

Polar grids ........................................ 19

Profile import points ........................ 36

Profile3D

Automatic fit analysis ................. 50

Data shifts .................................. 45

Fit analysis ................................. 49

Fit analysis reset ........................ 53

Measurement process ............... 42

Measurement screen functions 40,

41

Measurements ........................... 39

Pass only setting ........................ 51

Programming changes ..................... 14

Programming wizards ...................... 15

Index

F

Files and folders locations ............... 79

Fixtures files location ....................... 93

G

Grid pattern auto probe ................... 12

Grids ................................................ 15

I

ISO tolerance ................................... 62

K

Keyboard shortcuts

Ellipse ........................................ 69

Measure ..................................... 69

Profile ......................................... 69

Profile3D .................................... 69

Torus .......................................... 69

M

Measure

Rectangle ................................... 38

O

Open Loop control

External amplifier ....................... 94

Joystick button assignment ....... 95

Joystick control .......................... 87

R

Random placement ................... 24, 26

Reference steps .............................. 24

Reset template text colors .............. 92

S

Scale factor ...................................... 87

Shutdown ........................................ 89

Six point alignment .......................... 52

Spotter camera options ................... 85

Symmetry tolerance ........................ 70

System requirements ........................ 3

T

Touch probe

Requalification and starting point ....

91

U

Updating software ........................... 78

Use current reference frame ........... 81

V

VED tools

Rotating and positioning using part

reference frame ...................... 62

Video probe parameters .................. 84

IK 5000 QUADRA-CHECK 97

Page 98

Index

98 Index

Page 99

Page 100

809541-24 · Ver04 · pdf · 12/2013

Loading...

Loading...