Page 1

Technical Manual

Functional Safety (FS)

NC software iTNC 530 HSCI

606 420-02

606 421-02

NC software TNC 640

340 590-01

340 591-01

April 2012

Page 2

Page 3

Contents

1 Update Information

1.1 General information............................................................................7

1 Update Information No. 02 – Functional Safety

1.1 Overview..............................................................................................9

1.1.1 Released service packs ............................................................9

1.2 NC Software 606 42x-01 SP 06 ........................................................10

1.2.1 Important notes......................................................................10

1 Update Information No. 03 – Functional Safety

1.1 Overview............................................................................................13

1.1.1 Released service packs ..........................................................13

1.2 NC Software 606 42x-02...................................................................14

1.2.1 Important notes......................................................................14

1.2.2 New splcapimarker.def definition file.....................................15

1.3 New Safety Functions ......................................................................17

1.4 (S)PLC.................................................................................................21

1 Update Information No. 04 – functional safety

1.1 Overview............................................................................................25

1.1.1 Service packs released for the iTNC 530 HSCI.......................25

1.1.2 NC software versions released for the TNC 640....................25

1.2 Notes..................................................................................................26

1.2.1 NC software 340 59x-01, 606 42x-02 SP 02...........................26

1.2.2 General information................................................................26

1.3 NC software 340 59x-01 (TNC 640)..................................................27

1.3.1 Notes......................................................................................27

2Introduction

2.1 Meaning of the symbols used in this manual ................................29

2.2 Warnings............................................................................................30

2.3 Proper and intended operation........................................................33

2.4 Trained personnel .............................................................................33

2.5 General information..........................................................................34

2.6 Overview of FS components............................................................40

2.6.1 List of approved control components.....................................41

2.6.2 List of approved inverter components....................................44

2.6.3 Differences between systems with and without

functional safety (FS) ..............................................................46

April 2012 3

Page 4

3 Directives and standards

3.1 Applicable directives.........................................................................49

3.2 Basis for testing ................................................................................50

3.3 Requirements on safety integrity....................................................53

3.4 SIL and target failure measures.......................................................53

3.5 Storage and operating temperatures .............................................53

3.6 Limit values for EM noise immunity...............................................53

3.7 Mission time......................................................................................53

4 Realization and safety functions

4.1 Glossary .............................................................................................55

4.2 Realization of the HEIDENHAIN safety system..............................59

4.3 Activation of functional safety (FS).................................................59

4.4 (S)PLC programs ...............................................................................60

4.5 SPLC ...................................................................................................61

4.6 SKERN................................................................................................63

4.7 Cross comparison .............................................................................66

4.8 Description of the safety/monitoring functions ............................67

4.8.1 Overview of the safety functions ...........................................67

4.8.2 Overview of monitoring functions ..........................................69

4.8.3 Safe stop 0 (SS0)....................................................................70

4.8.4 Safe stop 1 (SS1) – Fastest possible stopping .......................71

4.8.5 Safe stop 1D (SS1D) – Delayed SS1.......................................74

4.8.6 Safe stop 1F (SS1F) – Fastest possible stopping ...................74

4.8.7 Safe stop 2 (SS2) – Controlled stopping.................................75

4.8.8 Summary of the stop reactions ..............................................79

4.8.9 Safe torque off (STO)..............................................................81

4.8.10 Safe operating stop (SOS) ......................................................83

4.8.11 Safely limited speed (SLS)......................................................84

4.8.12 Safely limited position (SLP)...................................................85

4.8.13 Safe brake control (SBC).........................................................88

4.8.14 Safely limited increment (SLI).................................................89

4.8.15 Nominal-actual value comparison...........................................89

4.8.16 Nominal-actual value comparison with position values ..........90

4.8.17 Nominal-actual value comparison with speed values .............90

4.8.18 Protection against unexpected start-up..................................91

4.8.19 dv/dt monitoring of the braking processes.............................92

4.8.20 Response times, definitions, demand rates...........................93

4.8.21 Safe status bits.......................................................................98

4.8.22 Fault reaction to safe status bits ..........................................101

4.8.23 Behavior when a fault is detected........................................103

4.8.24 Stop reactions depending on the fault situations .................105

4.9 Special features of various software versions.............................112

4.10 Requirements the application must meet....................................116

4.11 Remaining risks...............................................................................118

4 HEIDENHAIN Technical Manual Functional Safety (FS)

Page 5

5 Safety-related MPs and signals

5.1 Safety-related machine parameters (SMPs).................................119

5.2 SMP commissioning.......................................................................142

5.3 Acceptance test...............................................................................149

5.4 Safety-related hardware signals....................................................150

5.5 Further settings...............................................................................154

6 Safety-related operating modes and

interfaces

6.1 Operating modes (SOM Safe Operating Modes).........................157

6.1.1 Operating mode 1 (SOM_1)..................................................158

6.1.2 Operating mode 2 (SOM_2)..................................................159

6.1.3 Operating mode 3 (SOM_3)..................................................161

6.1.4 Operating mode 4 (SOM_4)..................................................163

6.1.5 Operating mode – restricted spindle operation (SOM_S).....165

6.1.6 Operating mode selection – inputs.......................................166

6.1.7 Configuration of axis groups.................................................168

6.1.8 Magazine axes......................................................................170

6.1.9 Non-safe axes and spindles..................................................171

6.1.10 Electronic handwheel ...........................................................172

6.1.11 Use of several operating units..............................................175

6.2 Safety-related hardware interfaces...............................................176

6.2.1 Interfaces of the SPL............................................................176

6.2.2 Interfaces of the SMOP........................................................186

6.2.2.1 Interfaces of the handwheel (HR).........................................189

7 Safety-Related Tests and Forced

Dynamic Sampling

7.1 Safety Self-Test...............................................................................191

7.2 Self-Test Sequence .........................................................................194

7.3 Test of the cut-out channels ..........................................................197

7.4 Test of machine control voltage....................................................198

7.5 Test of the chain of normally closed contacts .............................198

7.6 Test of the guard doors..................................................................198

7.7 Test of the motor brake control ....................................................199

7.8 Motor Brake Test ............................................................................202

7.8.1 Brake test of the iTNC 530 for synchronized axes ...............204

7.8.2 Brake test of the TNC 6xx for synchronized axes.................211

7.8.3 Brake test with PLC module 9143........................................215

7.9 Test of the machine configuration ................................................217

7.10 Test of the machine keys and permissive buttons/keys.............217

7.11 Test of the emergency-stop circuit ...............................................217

April 2012 5

Page 6

8 SPLC – safety-related PLC

8.1 General information........................................................................219

8.2 Safe software structure..................................................................220

8.3 Software structure of PLC / SPLC .................................................220

8.4 Glossary ...........................................................................................221

8.5 SPLC development tool..................................................................223

8.6 PLC and SPLC programs.................................................................224

8.7 Safety of the SPLC program ..........................................................226

8.8 Requirements to be met by the SPLC program...........................227

8.8.1 Axis groups / working spaces for an example

milling machine.....................................................................227

8.8.2 Moving the axes with open guard doors..............................228

8.9 Interfaces of the SPLC ....................................................................229

8.9.1 The splcapimarker.def definition file.....................................229

8.9.2 Safety-related inputs, FS inputs............................................231

8.9.3 Safety-related outputs, FS outputs.......................................232

8.9.4 SKERN --> SPLC programming interface..............................234

8.9.5 SPLC --> SKERN programming interface..............................237

8.9.6 PLC --> SPLC programming interface...................................238

8.9.7 SPLC --> PLC programming interface...................................240

8.9.8 Diagnosis of the SPLC operands..........................................241

8.10 Tasks of the SPLC program............................................................242

8.10.1 Operation with open guard door...........................................242

8.10.2 Selecting a safety-related operating mode (SOM)................243

8.10.3 Requirements to be met by SPLC outputs...........................243

8.10.4 Requirements on the data of the ApiToSafety structure......246

8.10.5 Filtering of inputs..................................................................265

8.11 Sample cases...................................................................................267

8.11.1 Movement of NC axes and spindle ......................................267

8.11.2 Movement of the axes of the tool magazine........................274

6 HEIDENHAIN Technical Manual Functional Safety (FS)

Page 7

1 Update Information

1.1 General information

Update Information for the Functional Safety Technical Manual appears at

irregular intervals, often as part of a new software version. This is preliminary

information in PDF format, containing brief descriptions of new software

functions as well as new hardware components. After the Update Information

has been published, the new items are included in the Functional Safety

Technical Manual.

The Technical Manual and each Update Information are saved in the

HEIDENHAIN HESIS-Web including Filebase on the Internet, where

registered users can access them at http://portal.heidenhain.de.

Registered users of the HEIDENHAIN HESIS-Web including Filebase on the

Internet receive an e-mail notification when a new Update Information

appears.

This version of the Technical Manual includes all Update Information

documents up to and including number 04, meaning that the contents of this

Technical Manual correspond to the scope of functions of software version

606 42x-02 for the iTNC 530 HSCI or 340 59x-01 for TNC 640.

April 2012 1.1 General information 7

Page 8

8 HEIDENHAIN Technical Manual Functional Safety

Page 9

1 Update Information No. 02 – Functional Safety

1.1 Overview

1.1.1 Released service packs

The following service packs were released for 606 42x-01:

Service pack 01: August 2010

Service pack 02: December 2010

Service pack 03: February 2011

Service pack 04: March 2011 (not for functional safety)

Service pack 05: May 2011 (approved for functional safety)

Service pack 06: October 2011

(approved for functional safety)

October 2011 1.1 Overview 9

Page 10

1.2 NC Software 606 42x-01 SP 06

1.2.1 Important notes

SS1D when MP549 = 2 leads to SS2 with subsequent SOS of the axis

group

In case of an SS1D for an axis group (e.g., for the spindle when releasing the

permissive key while the door is open) the system until now waited until all

interlinked axis groups (SMP610.x) had terminated an active SS2 or SS1D.

Then all drives of the affected axis group (e.g., the spindle) were stopped

with an SS1. Until now this always led to removal of power from the axis

group (STO) for which the SS1D had been initiated.

As of service pack 06, if SMP549.x = 2 is set, the axis group (e.g., the

spindle) for which an SS1D was initiated is braked with an SS2 after the

interlinked axis groups have been braked. At standstill SOS becomes active

for this axis group instead of STO. This means that in case of an SS1D or

SS2 at standstill, SMP549.x = 2 leads to the SOS state.

Please note that upon SS1D this function now initiates an SS2 stop reaction

for the affected axis group, and not an SS1 as previously.

SMP (iTNC 530): SMP549.x

Description: Axis-group-specific configuration defining whether

Input: 0: Default (spindle in STO, axes in SOS)

the axis group is to be switched to SOS instead of

STO upon an initiated SS1D or SS2 (e.g., spindle)

(used for lathes).

1: Axis group in STO upon SS1D or SS2

2: Axis group in SOS upon SS1D or SS2

Default value: 0

10 HEIDENHAIN Technical Manual Functional Safety

Page 11

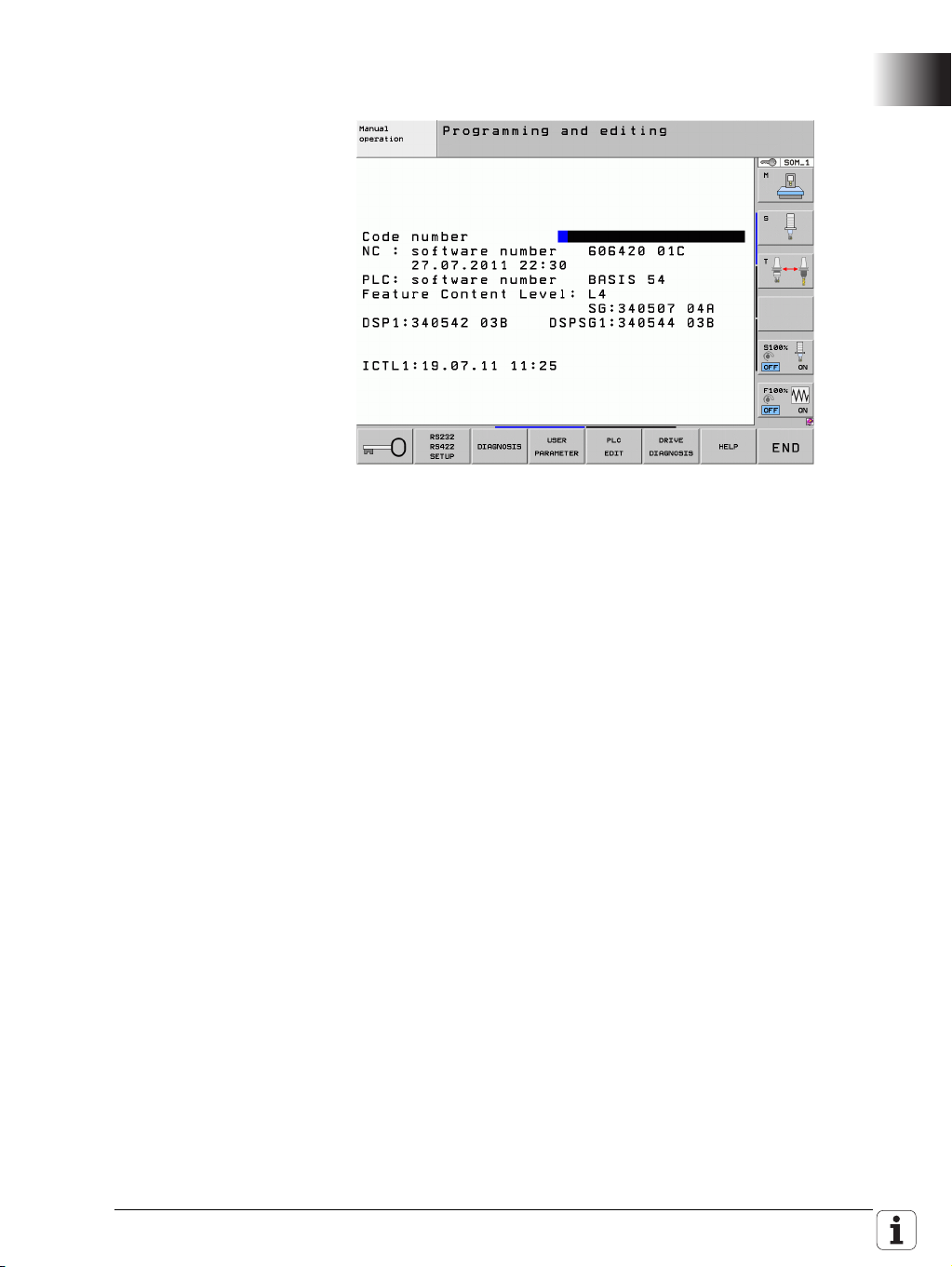

Display of the installed NC software and SKERN software

If you press the MOD key in any operating mode, the ID numbers and

versions of the installed software packages are displayed:

NC : software number: NC software with date

PLC : software number: PLC program

SG: SKERN software of the MC

DSPx: DSP software of CC number x

DSPSGx: SKERN software of CC number x

ICTLx: Current controller of CC number x

October 2011 1.2 NC Software 606 42x-01 SP 06 11

Page 12

12 HEIDENHAIN Technical Manual Functional Safety

Page 13

1 Update Information No. 03 – Functional Safety

1.1 Overview

1.1.1 Released service packs

The following service packs were released for 606 42x-01:

Service pack 01: August 2010

Service pack 02: December 2010

Service pack 03: February 2011

Service pack 04: March 2011 (not for functional safety)

Service pack 05: May 2011 (approved for functional safety)

Service pack 06: September 2011

(approved for functional safety)

The following software versions were released for applications with integrated

functional safety (FS):

606 42x-02: December 2011

March 2012 1.1 Overview 13

Page 14

1.2 NC Software 606 42x-02

Note

1.2.1 Important notes

Release of software

for FS applications

Until now you received a HEIDENHAIN Filebase Info when a new NC software

version or service pack was released for applications with integrated

functional safety (FS). The software could then be downloaded from the usual

directories for your control via HESIS-Web including Filebase (e.g. Controls/

iTNC 530/Software EXLREQ).

In order to improve the overview of which software versions have been

released for applications with integrated functional safety (FS), new directories

were created in HESIS-Web including Filebase. These directories have the

additional code "FS" in their name (e.g. Controls/iTNC 530/

Software FS EXLREQ). Once HEIDENHAIN has released the respective NC

software for applications with integrated functional safety, the NC software

will be stored in these new directories. Every software version that you find in

these FS directories has been released for applications with integrated

functional safety (FS). You will continue to be informed about released

software via HEIDENHAIN Filebase Infos. When downloading NC software

from one of the existing standard directories, you will be informed that these

software versions are not approved for use with integrated functional safety

(FS).

Controls using integrated functional safety (FS) from HEIDENHAIN are to

be operated only with software versions found in the HESIS-Web including

Filebase directories with FS in their names.

The same applies to Technical Manuals and Update Information documents

for functional safety. Starting immediately, these will also be in directories

identified with "FS" (e.g. Controls/iTNC 530/Documentation FS OEM).

PLC outputs Single-channel outputs (standard PLC outputs) configured as output type 3

(switch-off upon EMERGENCY STOP) with IOconfig until now were not

switched off automatically upon an emergency stop. The PLC program had to

switch the outputs off. With software version 02 these single-channel PLC

outputs will be switched off automatically when an external or internal

emergency stop is initiated. The outputs remain switched off until the

emergency-stop is rescinded and the control voltage has been switched back

on. Just rescinding the emergency-stop situation does not suffice to switch

these outputs back on.

14 HEIDENHAIN Technical Manual Functional Safety

Page 15

1.2.2 New splcapimarker.def definition file

Software version 606 42x-02 contains a slightly modified splcapimarker.def

definition file (version 56). However, the modifications are only preparatory

measures for future enhancements. In software version 02 they do not result

in any direct improvements of any functions. The number of possible axes was

raised from 18 to 22, which shifts the spindle index to 22. This change results

in a new memory layout of the SPLC run-time system, which necessitates a

new acceptance test. Version 55 of splcapimarker.def must be replaced by

version 56 after the software update.

Proceed as follows:

Replace the splcapimarker.def file:

During the update of the NC software, a new version of splcapimarker.def

was automatically copied to the PLC partition of the control.

Switch to the Programming and Editing operating mode.

Enter the MOD code number 807667 to switch to the PLC Programming

mode of operation.

Press the PGM MGT key to open the file manager.

Switch to the PLC:\proto\plc directory.

Copy splcapimarker.def to the program directory of your SPLC program.

Overwrite the existing splcapimarker.def file.

Change the entry in SMP693 for the new SPLC-API version to 56.

Put the change in SMP693 into effect after rebooting the control by using

the OEM password

Check and compile the SPLC program with the new splcapimarker.def file.

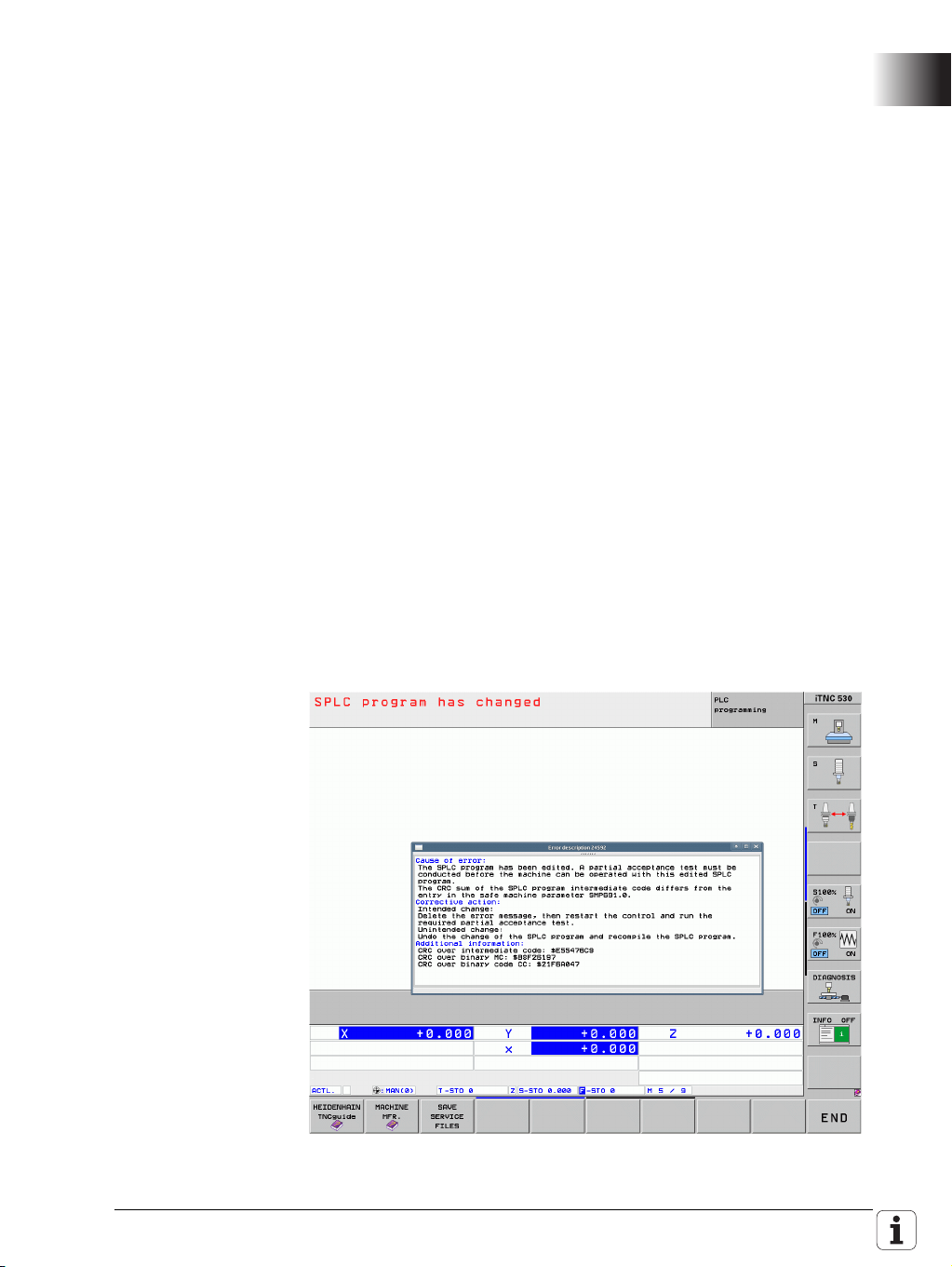

The following message than appears, since the intermediate and binary

code of the SPLC program has changed:

March 2012 1.2 NC Software 606 42x-02 15

Page 16

Included in the message, under the heading "Additional information," are the

Note

Danger

new CRC checksums for the intermediate code, binary code MC and binary

code CC. Enter these values in SMPs 691.0, 691.1 and 691.2.

Put the changes in SMP691.x into effect after rebooting the control by using

the OEM password.

Please also copy the splcapimarker.def file to your PC as well, and add it to

the PLCdesignNT project. Otherwise, during the next transfer of SPLC

project files to the control, the file might be overwritten by the old version.

The SPLC-API programming interface can also be included in the standard PLC

program (INCLUDE). If this is the case, the data from ApiFromSafety and

ApiToSafety are copied to the double-word range of the PLC. This data can

then be used for additional interrogations or diagnostic purposes in the PLC

program.

Since the number of possible axes was raised from 18 to 22 (indexes 0 to 21),

the index of the first spindle is shifted to 22. Please take this into account in

your SPLC program, and make any necessary adjustments. So that you don't

always have to modify the SPLC program when there are such changes in the

future, HEIDENHAIN recommends using the constant FIRST_SPINDLE for the

spindle in the SPLC program.

You must subject the machine to a new acceptance test, as a consequence

of the changed SPLC-API version.

16 HEIDENHAIN Technical Manual Functional Safety

Page 17

1.3 New Safety Functions

Extended SPLC diagnostics

• A predefined watch list is available for the static diagnosis of the SPLC

markers defined in splcapimarker.def. It can be called from the PLC

diagnostics via the WATCH LIST soft key and the program manager

(PGM MGT key). The file can be found at: PLC:\DEBUG\SPLCAPI.WLT

• Under the DIAGNOSIS soft key in the PLC operating mode there is

another soft key: GENERATE TRACE FILES. Pressing it triggers the

generation of HSCI and SPLC trace files. These files (xxx.trace and

xxx.sco) are stored in the folder PLC:\DEBUG\.

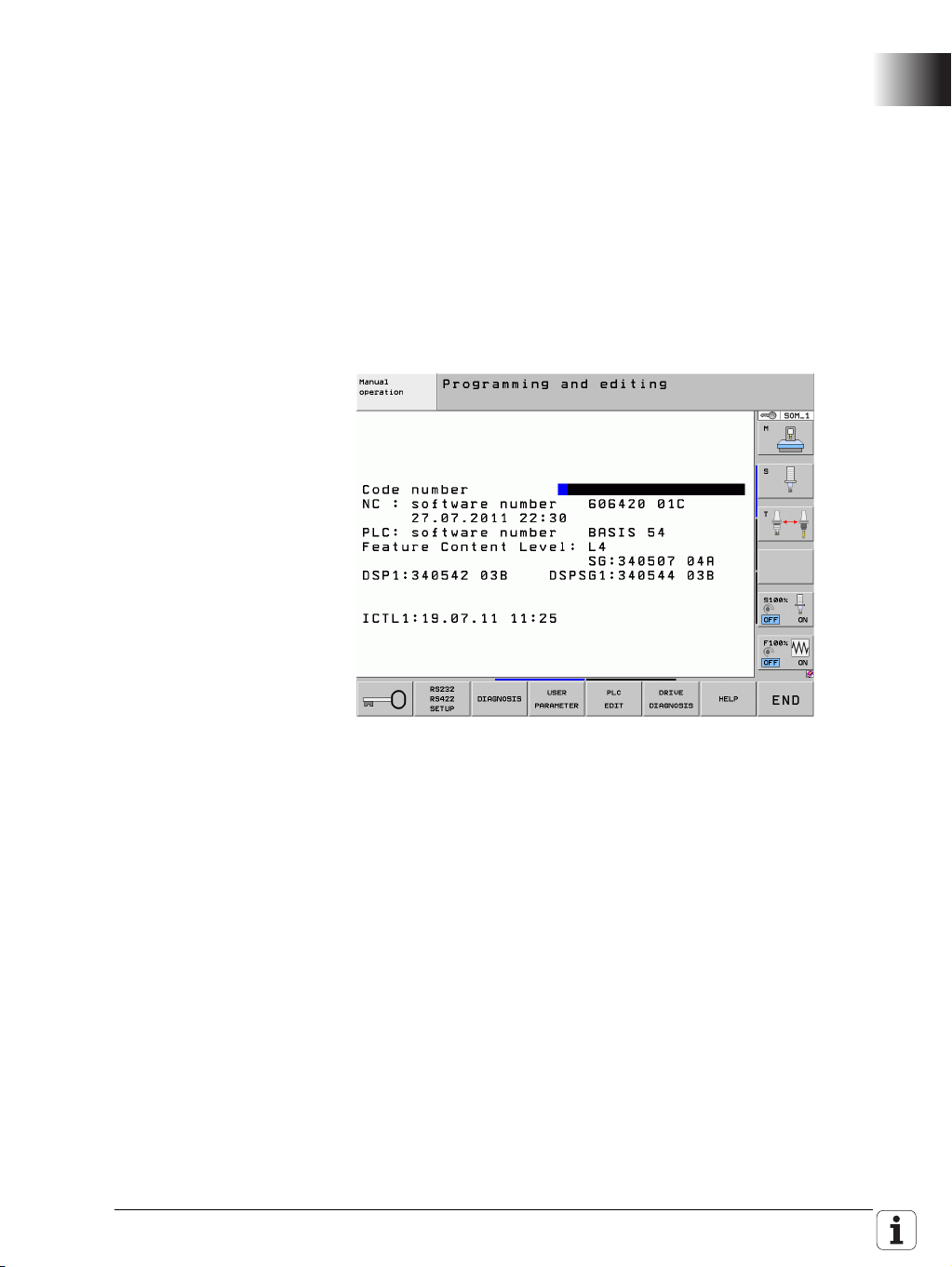

Display of the installed NC software and SKERN software

If you press the MOD key in any operating mode, the ID numbers and

versions of the installed software packages are displayed:

NC : software number: NC software with date

PLC : software number: PLC program

SG: SKERN software of the MC

DSPx: DSP software of CC number x

DSPSGx: SKERN software of CC number x

ICTLx: Current controller of CC number x

Standstill monitoring in SOS state

If, however, the maximum permissible path defined in SMP545.x (limit

value for standstill monitoring in [mm] or [°]) was exceeded while adhering

to the limit values for the spindle speed and axis feed rate in SOS, the SS0

safety function was initiated globally for all axes, and SS1 for the spindles.

Now an SS0 reaction is initiated for the affected drive (axis or spindle), and

an SS1F reaction for all other drives.

March 2012 1.3 New Safety Functions 17

Page 18

Standstill monitoring of the spindle with SS2

The new machine parameters SMP556, SMP557 and SMP558 can be used

to specify a maximum value for standstill monitoring of the spindle upon on

SS2 reaction. If the permitted number of spindle revolutions are exceeded

during the SS2 reaction, an SS1 reaction is initiated.

• SMP556 - Maximum value for standstill monitoring during SS2 of

spindle in SOM_2

Input: 1 to 100 [revolutions]

Default value = 2

• SMP557 - Maximum value for standstill monitoring during SS2 of

spindle in SOM_3

Input: 1 to 100 [revolutions]

Default value = 5

• SMP558 - Maximum value for standstill monitoring during SS2 of

spindle in SOM_4

Input: 1 to 100 [revolutions]

MP1310.x – Sequence for approaching the test positions

The axis sequence of the soft keys for approaching the test positions can

now be configured with MP1310. As previously, the operator can change

the sequence by selecting the soft keys. The parameter index determines

the position of the soft key in the soft-key row. The value of the parameter

defines the axis to be displayed in the soft-key image in reference to MP100.

All parameters after a programmed value 0 are not taken into consideration.

The remaining safe axes is shown in the same sequence as in MP100. If a

negative value is entered, the axis is shown in gray, and only becomes active

once the axes with positive entries have been moved to the reference point

or the operator selects the axis.

Example:

MP100: CBAaZYX

MP1310.0: 7

MP1310.1: 6

MP1310.2: -4

MP1310.3: 0

Soft-key row: C B a X Y Z A a=gray

Default value = 5

Input in MP1310.x:

1 to 18 [number indicating the axis' position in the test sequence]

0 = Not active

Displaying the distance-to-go during axis check

During the automatic movement of an axis in the "Check axis position" mode

to the test position, the distance-to-go display showed the distance

remaining to the software limit switch instead of the distance remaining to

the test position. Now, for approaching the test position and for incremental

jog, the distance remaining to the target is displayed.

Analog axes via CMA-H

As of software version 606 42x-02, analog axes can be configured and

operated via the CMA-H module. The integrated functional safety from

HEIDENHAIN does not monitor analog axes. Monitoring, switch-off, etc.

must occur through suitable external circuitry.

18 HEIDENHAIN Technical Manual Functional Safety

Page 19

SS1D when MP549 = 2 leads to SS2 with subsequent SOS of the axis

group

In case of an SS1D for an axis group (e.g., for the spindle when releasing the

permissive key while the door is open) the system until now waited until all

interlinked axis groups (SMP610.x) had terminated an active SS2 or SS1D.

Then all drives of the affected axis group (e.g., the spindle) were stopped

with an SS1. Until now this always led to removal of power from the axis

group (STO) for which the SS1D had been initiated.

As of NC software version 606 42x-01 SP 06, if SMP549.x = 2 is set, the axis

group (e.g., the spindle) for which an SS1D was initiated is braked with an

SS2 after the interlinked axis groups have been braked. At standstill SOS

becomes active for this axis group instead of STO. This means that in case

of an SS1D or SS2 at standstill, SMP549.x = 2 leads to the SOS state.

Please note that upon SS1D this function now initiates an SS2 stop reaction

for the affected axis group, and not an SS1 as previously.

SMP (iTNC 530): SMP549.x

Description: Axis-group-specific configuration defining whether

the axis group is to be switched to SOS instead of

STO upon an initiated SS1D or SS2 (e.g., spindle)

(used for lathes).

Input: 0: Default (spindle in STO, axes in SOS)

1: Axis group in STO upon SS1D or SS2

2: Axis group in SOS upon SS1D or SS2

Default value: 0

Protection against unexpected movement with SMP 549.x = 2

If SMP549.x = 2 for the axis group (including spindles), the axis group now

remains in the SOS state or under control in the following cases even while

at standstill. This means that there is no automatic transition to STO:

• if the permissive key or button is not pressed at standstill or while in the

SOS state.

• if the override potentiometers are at 0% when guard doors are opened.

• if M19 is active when guard doors are open (only for spindle axis group).

March 2012 1.3 New Safety Functions 19

Page 20

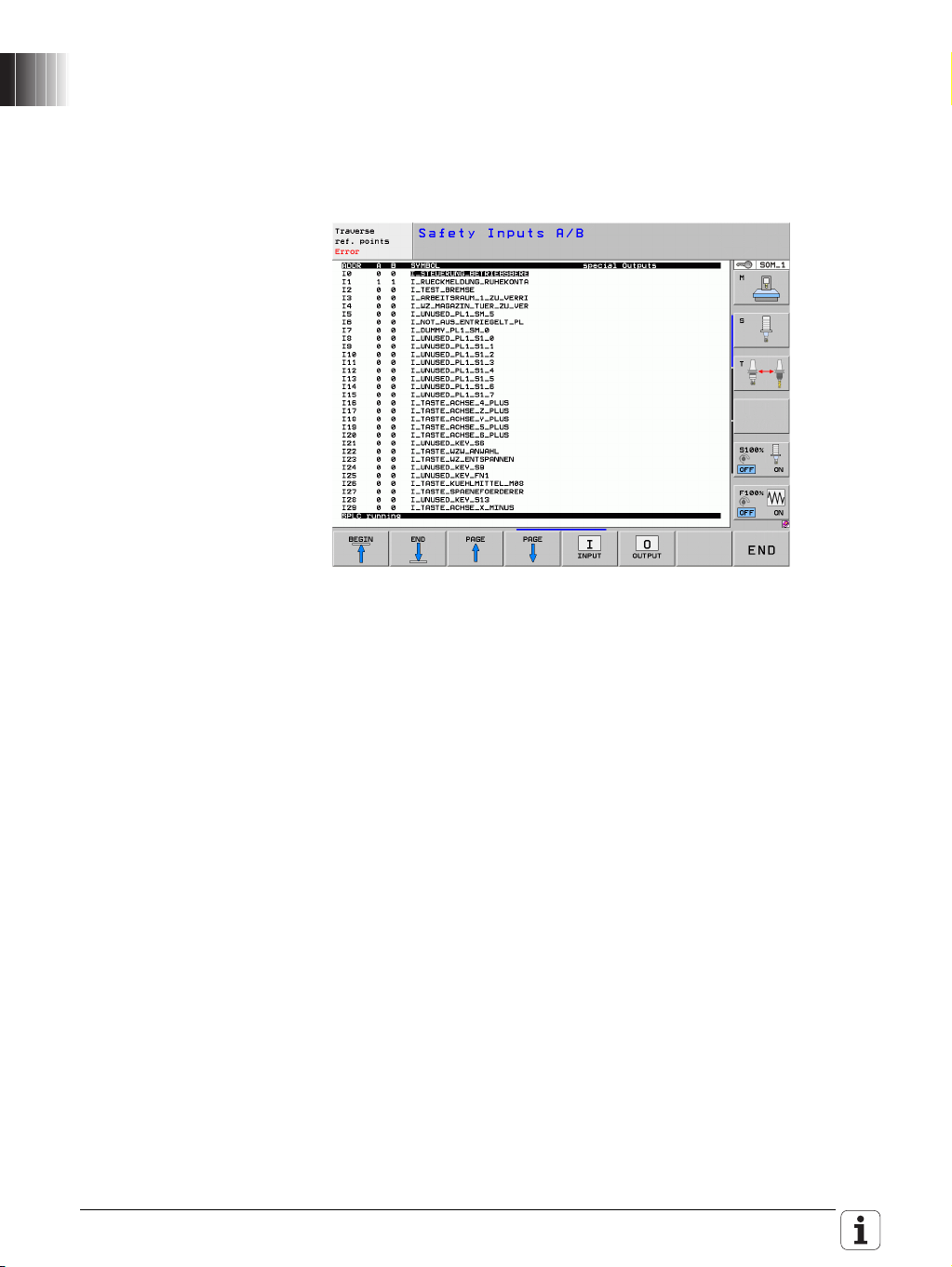

Diagnosis of the SPLC inputs and outputs

In the PLC programming mode (code number 807667) the last soft-key row

under the table function (TABLE soft key) has a soft-key called S-PLC

DIAGNOSIS. There you will find a list of all FS inputs and FS outputs, along

with their current state. The regular FS outputs as well as the "special"

outputs, such as TEST.A, TEST.B, STO.A.G and STOS.A.G, are also shown.

The table shows the operand address, the state of the A and B channel

inputs, and the symbolic name.

Fault reaction to safe status bits

Until now, if –PF.PS.DC was active, the watchdogs of the MC were not

retriggered. The other HSCI participants therefore detected the MC as being

defective, and it was not possible to switch off the DC-link voltage without

an error message. Until now the CC initiated an SS1 reaction. The SKERN

MC and CC now no longer evaluate the -PF.PS.DC status bit, and there is no

longer a reaction by the SKERN.

20 HEIDENHAIN Technical Manual Functional Safety

Page 21

1.4 (S)PLC

The PLC Module 9143 for triggering the brake test can now also be used in

systems with functional safety. The brake test during the safety self-test is not

affected by this, and continues to test the motor holding brake. It is now

possible, via this module and the (S)PLC program, regardless of the self-test,

to test the motor holding brakes at any time for specific axes, and even for

specific brakes of an axis. The module only tests the holding torque of the

brake, but not the dual-channel controllability of the brake. The dual-channel

controllability is still part of the self-test. The procedure for testing two brakes

of an axis via Module 9143 could be as follows:

The SPLC program controls the opening and closing of the brake

simultaneously for the motor holding brake and the supplementary brake

The SPLC program controls the opening and closing of the brake only for the

motor holding brake

The supplementary brake is opened

PLC Module 9143 performs the brake test for the motor holding brake

The SPLC program controls the opening and closing of the brake

simultaneously for the motor holding brake and the supplementary brake

The SPLC program controls the opening and closing of the brake only for the

supplementary brake

The motor holding brake is opened

PLC Module 9143 performs the brake test for the supplementary brake

The SPLC program controls the opening and closing of the brake

simultaneously for the motor holding brake and the supplementary brake

Module 9143 Activate the brake test

With this module an axis-specific brake test with the configuration from the

machine parameters or with other values for MPs 2230 and 2232 can be

started. Refer also to the information in the Technical Manual of your control.

Constraints:

Synchronized axes

For synchronized axes, only the brake test of the master can be configured

and requested via the PLC module. If a brake test for an associated slave

drive of the synchronized axis is configured via MP2230.x, then the slaves

are automatically tested together with the master. The settings in the

machine parameters are used for the brake test of the slave drives.

In order to start the brake test of synchronized axes via PLC Module 9143,

all drives of a synchronized axis must be switched on via the PLC program

before the brake test can be performed. If a servo drive involved is not

switched on, the brake test is canceled with the error message 8330 Brake

test was canceled.

Programming it in a submit job blocks other submit jobs until the test is

completed.

The PLC module automatically passes the processing time to other spawn

and submit processes.

March 2012 1.4 (S)PLC 21

Page 22

Call:

PS K/B/W/D <>Axis number>

0 = 1st axis, 1 = 2nd axis, etc.

PS K/B/W/D <>Multiplier for motor stall current>

Value in 1/1000 or

0: Default MP2230 (factor of nominal current)

PS K/B/W/D <>Permissible traverse path>

Value in 0.1 [um] or

0: Default MP2232

CM 9143

PL B/W/D <>Status/Error>

0: Brake OK

1: Brake defective

2: Invalid axis or negative values for rated current or traverse

path

3: Call during running NC program or during other PLC jobs

4: Call was made from a cyclic PLC program

5: Error during data exchange

6: Not allowed for safe control

7: Drive not ready

8: Brake test was canceled (e.g. by emergency stop)

Error recognition:

Marker Val ue Meaning

M4203 0 No error

1 Error code in W1022

W1022 2 Invalid axis programmed (invalid axis number, not a

closed-loop axis, axis currently open-loop axis or slave

axis) or negative values for the traverse path or current

are programmed

8 Module is not allowed for control with functional

safety

20 Module was not called in a spawn job or submit job

21 Call during program run or during other active PLC jobs

for the programmed axis

40 Drive not ready

45 Canceled due to error during data exchange or due to

external influences (e.g. emergency stop)

22 HEIDENHAIN Technical Manual Functional Safety

Page 23

Module 9037 Read FS status information

PLC Module 9037 determines safety-oriented information. The number of the

desired information, and possibly another number (for certain information)

must be programmed in the module.

Constraints:

Only for HSCI-based systems with SPLC can the time until the next self-test

be interrogated via number 4.

The causes for the stop reactions (number 7) are not stored statically. The

values are only set for the time in which the stop reaction occurs.

Call:

PS B/W/D/K/S<>Number of the status information>

0 to 3: Reserved

4: Time until the next self-test

5: Spindle speed at open guard door

6: Axis feed rate with open guard door

7: Stop reaction of axis group

PS B/W/D/K <>Number of the additional information>

For info 5: Spindle number starting with 0

For info 6: Axis number starting with 0

For info 7: Axis-group number starting with 0

CM 9037

PL B/W/D <>Type of operand>

0: Error

Response from the status information

For info 4: Time until the next self-test in seconds

For info 5: Spindle speed at open guard door in 0.001 [1/min]

For info 6: Feed rate with open guard door in 0.001 [mm/

min] or [°/min]

For info 7: Stop reaction of axis group

(0 = no stop reaction, 1 = SS2, 2 = SS1D, 3 = SS1,

4=SS1F, 5=SS0)

Error recognition:

Marker Valu e Meaning

M4203 0 No error

1 Error code in W1022 (also see return values of the

module)

W1022 1 Invalid number of the status information

2 Invalid number of the axis group, axis or spindle

43 The module was called in a control without integrated

functional safety

51 This status information is not supported by this

system

March 2012 1.4 (S)PLC 23

Page 24

24 HEIDENHAIN Technical Manual Functional Safety

Page 25

1 Update Information No. 04 – Functional Safety

Hinweis

1.1 Overview

1.1.1 Service packs released for the iTNC 530 HSCI

The following service packs for software version 606 42x-01 will be released

for applications with integrated functional safety (FS):

Service pack 02: April 2012

NC software 606 42x-02 service pack 01 was not approved for applications

with integrated functional safety (FS).

1.1.2 NC software versions released for the TNC 640

The following software versions were released for applications with integrated

functional safety (FS):

340 59x-01: April 2012

Controls using integrated functional safety (FS) from HEIDENHAIN are to

be operated only with software versions that are identified by FS in their

names in the HESIS-Web including Filebase directories of your control.

Software versions that are not identified by FS in their names in the HESISWeb including Filebase directories of your control are not approved for use

in applications with integrated functional safety (FS).

April 2012 1.1 Overview 25

Page 26

1.2 Notes

1.2.1 NC software 340 59x-01, 606 42x-02 SP 02

Protection against unexpected start-up

Up to now, the protection against unexpected start-up was disabled by

pressing a valid permissive button/key, which sets the interface signal

pp_AxGrpPB to 1. With software versions 340 59x-01 and 606 42x02 SP 02, the same behavior is enabled for the interface signal

pp_AxGrpActivate, which disables the activation of the protection against

unexpected startup if it is set to 1. As a result, the automatic transition to

SOS/STO state (transition from SLS --> SOS) is also prevented at feed rates

< 50 mm/min by merely pressing an axis key (pp_AxGrpActivate = 1).

SMP549.x is effective only for the axis group of the spindles

The setting in SMP549.x is effective only for the axis group of the spindles.

SMP549.x does not take effect for axis groups of NC or PLC axes.

SMP (iTNC 530): SMP549.x

Description: Axis-group-specific configuration defining whether

the axis group of the spindle is to be switched to SOS

instead of STO after SS1D or SS2 has been triggered

(used for lathes).

Input: 0: Default (spindle in STO, axes in SOS)

1: Axis group of the spindle in STO upon SS1D or SS2

2: Axis group of the spindle in SOS upon SS1D or SS2

Default value: 0

1.2.2 General information

Use of non-HEIDENHAIN encoders for safe axes/spindles for

Basic circuit diagram – leading main-switch contact

HEIDENHAIN control systems with functional safety (FS)

HEIDENHAIN cannot make any statement regarding the use of nonHEIDENHAIN encoders for the safe monitoring of axes/spindles in control

systems with functional safety (FS). Your contact person at HEIDENHAIN

will be glad to assist you in finding suitable HEIDENHAIN encoders for your

safe applications.

The leading main-switch contact that is proposed in the present

HEIDENHAIN basic circuit diagram is only intended for electrical protection

of the machine's main switch. The leading contact opens the main contactor

in the UV(R) before the main switch separates the connection to the power

line. This means that the main switch always separates the connection

while the system is not under power, even if the user accidentally switches

off the machine via the main switch while the drives are still in closed-loop

control. When using a leading contact, please keep in mind the associated

residual risks described in Chapter 4.11 of the Functional Safety (FS)

Technical Manual.

HEIDENHAIN merely wanted to point out that there is the possibility of

using a leading contact. However, you need not use a leading contact. It will

be omitted from the future versions of the basic circuit diagram. Without

this contact, the control behaves in the same way as during a power failure

when it is switched off via the main switch, i.e. the drives are decelerated

at the limit of current upon switch-off.

26 HEIDENHAIN Technical Manual Functional Safety (FS)

Page 27

1.3 NC software 340 59x-01 (TNC 640)

1.3.1 Notes

Missing functions The following functional safety (FS) functions are not contained in software

version 340 59x-01 of the TNC 640 in comparison with software version

606 42x-02 of the iTNC 530:

New "SPlcApiMarker.def version 56" definition file

The TNC 640 with software version 01 is still using SPlcApiMarker.def

version 55.

Standstill monitoring of the spindle upon SS2 (SMP556, SMP557,

SMP558)

Operating-mode-specific monitoring of the SS2 reaction of the spindle is not

yet possible with the TNC 640. In every SOM_x operating mode, the

TNC 640 uses the entry in SMP distLimitStop2 for SS2 monitoring of the

spindle.

Sequence for approaching the test positions

On the iTNC 530, the axis sequence of the soft keys for approaching the

test positions can be configured using MP1310. This is not yet possible on

the TNC 640 with software version 01.

Handwheels

The HR 5xx handwheels with display are not yet supported by software

version 01 of the TNC 6xx.

Software version 340 59x-01 of the TNC 640 is identical to software version

606 42x-02 of the iTNC 530 HSCI in all other functional safety (FS) functions.

SPLC program Please note that an SPLC program of the iTNC 530 needs to be modified for

use on the TNC 640. In particular, the spindle index in the SPLC program is

different. With the iTNC 530, the spindle is always assigned to the last index

(this is index 22 in SPlcApiMarker.def version 56). With the TNC 640, the

spindle is assigned to the index defined via axisList.

Documentation The previous Functional Safety (FS) Technical Manual for the iTNC 530 HSCI

was enhanced with regard to the TNC 640. This Technical Manual covers both

controls. Differences that need to be kept in mind are indicated in this Update

Information and in the Technical Manual (e.g. machine parameters of the

TNC 640 are identified by "NCK-SMP:".)

April 2012 1.3 NC software 340 59x-01 (TNC 640) 27

Page 28

28 HEIDENHAIN Technical Manual Functional Safety (FS)

Page 29

2 Introduction

Danger

Attention

Note

2.1 Meaning of the symbols used in this manual

Failure to comply with this information could result in most serious or fatal

injuries, and/or in substantial material damage.

Failure to comply with this information could result in injuries and

interruptions of operation, including material damage.

Tips and tricks for operation as well as important information, for example

about standards and regulations as well as for better understanding of the

document.

April 2012 2.1 Meaning of the symbols used in this manual 29

Page 30

2.2 Warnings

Danger

The functional safety as provided by HEIDENHAIN only handles the safety

functions stated and described in this manual. Functional safety can reduce

the inherent risks of machine tools. However, it is impossible to implement

safety measures that ensure that nothing will ever go wrong with a

machine tool.

In order for functional safety to take effect, the machine manufacturer must

do the following:

Verify the theoretical and actual setup of the machine tool, the necessary

(S)PLC programs and the machine-parameter settings with a thoroughly

documented acceptance test. This acceptance test must be performed

by qualified personnel.

Thoroughly understand the information contained in this manual and

other documentation for the control and other electronic components

being used (such as inverters and motors), as well as understand and

enforce the safety instructions, constraints and relevant standards.

Draw up a risk analysis, as required by the EC machinery directive.

implement all measures deemed necessary based on the risk analysis of

the machine. These measures may be implemented as a part of

functional safety, or with other suitable equipment or procedures. All

measures must be validated.

30 HEIDENHAIN Technical Manual Functional Safety (FS)

Page 31

Danger

Many safety-related machine parameters (SMP) and the safety-related PLC

Attention

program (SPLC program) are important for ensuring the safety of the

machine when it is controlled by an iTNC 530 or TNC 6xx with functional

safety.

Changing these safety-related machine parameters or the SPLC program

can result in loss of the machine safety as specified in the applicable

standards!

Safety-related machine parameters are therefore protected by a special

OEM password that is only known to the machine manufacturer.

Changes to the safety-related machine parameters and the SPLC program

may only be performed by trained personnel of the OEM. He is responsible

for the safety of the machine and compliance with the applicable standards,

in particular with EN 12417.

The HEIDENHAIN safety strategy cannot detect erroneous

parameterization or programming by the OEM. The necessary level of

safety can only be achieved with thorough acceptance testing of the

machine.

When exchanging a power module or motor, the same type must be used,

since otherwise the settings of the machine parameters could lead to

different reactions by the safety functions. If an encoder is exchanged, the

affected axis must be recalibrated.

Hardware components of the machine tool may only be exchanged by

trained personnel.

Prior to the initial operation or shipping of a machine tool, the

machine manufacturer must conduct a complete acceptance test.

All of the machine's safety functions must be tested. Furthermore, the

input values of the safety-related machine parameters and the entire SPLC

program must be checked for correctness.

If the SPLC program is changed subsequently, the entire acceptance

test must be repeated.

If individual machine parameters are changed subsequently, a partial

acceptance test is required.

Upon subsequent changes the safety functions affected by the respective

change must be tested. The changes and the necessary acceptance tests

may only be performed by trained personnel of the OEM.

April 2012 2.2 Warnings 31

Page 32

Attention

The machine tool is not in a safe state until after it has booted completely

and the safety self-test was passed successfully!

During start-up or the reset phase, the control is not in a safe state (e.g.

installation of a service pack). Axes and spindles are without torque

during this time!

When exchanging hardware components, also use the same model. If an

encoders is exchanged, then the motor affected must be referenced and

tested again.

Depending on the changes during an exchange or update of the

software, either a partial or complete acceptance test becomes

necessary. The following must be ensured before or during an exchange

or update of the software:

• All openings (e.g. doors) to the working space must be closed

• Emergency stop must be activated

• There must be no tools in the spindle

• Vertical axes must be protected against falling

• No persons are permitted in the danger zone

The control must be shut down correctly before the machine is switched

off via the main switch. Should this not be possible due to an error, an

emergency stop is to be triggered via the man switch before removing

power from the machine.

32 HEIDENHAIN Technical Manual Functional Safety (FS)

Page 33

2.3 Proper and intended operation

The described components may only be installed and operated as described

in this manual. Commissioning, maintenance, inspection and operation are

only to be performed by trained personnel.

HEIDENHAIN contouring controls and their accessories are designed for

integration in milling, drilling and boring machines, and machining centers.

2.4 Trained personnel

Trained personnel in the sense of this manual means persons who are familiar

with the installation, mounting, commissioning, and operation of the

HEIDENHAIN components. Furthermore, electrical engineering work on the

system may be carried out only by trained electrical engineering technicians or

persons trained specifically for the respective application.

Basically, persons who perform work on HEIDENHAIN components must

meet the following requirements:

They must have been trained or instructed in the standards of safety

engineering.

They must have appropriate safety equipment (clothing, measuring

systems).

They should be skilled in first-aid practice.

April 2012 2.4 Trained personnel 33

Page 34

2.5 General information

Danger

Only the following controls from HEIDENHAIN can currently be used for

Other controls (e.g. the TNC 6xx NCK-based controls) and NC software

Controls using integrated functional safety (FS) from HEIDENHAIN are to

Software versions that are not identified by FS in their names in the

Every machine tool operator is exposed to certain risks.

Although protective devices (safeguards) can prevent access to dangerous

points, the operator must also be able to work with the machine without this

protection (e.g. if the guard door is open).

Guidelines and regulations to minimize these risks have been developed

within the last few years.

applications with functional safety.

• iTNC 530 HSCI with the NC software 606 42x

• TNC 640 with the NC software 340 59x

versions do not support the use of functional safety!

be operated only with software versions that are identified by FS in their

names in the HESIS-Web including Filebase directories of your control.

Only these software versions are released by HEIDENHAIN for

application on control systems with functional safety.

HESIS-Web including Filebase directories of your control are not

approved for use in applications with integrated functional safety (FS).

34 HEIDENHAIN Technical Manual Functional Safety (FS)

Page 35

Machinery Directive 2006/42/EC obligates you as a machine-tool

manufacturer to perform detailed risk assessments in order to prove operator

safety during the various operating phases of the machine. The combination

of hazard analysis and risk evaluation leads to the determination of how much

risks must be reduced by design measures or control methods in order to

achieve an appropriate level of safety.

In accordance with EN 12417, the electronic controls of universal machines,

milling machines, lathes and machining centers must fulfill the requirements

of EN 13849-1 category 3 (previously EN 954-1) for their safety-related parts.

In particular this means that the control must be designed such that an

individual fault does not lead to loss of the safety function, and that any

individual fault is detectable if this is possible in an acceptable manner.

According to EN ISO 12100-1/2 (Safety of Machinery), it is important for safe

operation of the machine that the safety measures permit simple and

continuous use of the machine and that they do not impair its correct and

intended operation. If this is not the case, then this can lead to the safety

measures being circumvented in order to attain the simplest possible

operation of the machine.

The HEIDENHAIN safety strategy integrated in the iTNC 530 HSCI and

TNC 6xx complies with Category 3 as per EN 13849-1 and SIL 2 as per

IEC 61508, features safety-related operating modes in accordance with

EN 12417, and assures extensive operator protection.

The basis of the HEIDENHAIN safety concept is the dual-channel processor

structure, which consists of the main computer (MC) and one or more drive

controller modules (CC= control computing unit).

All monitoring mechanisms are designed redundantly in the control systems.

Safety-related system data is subject to a mutual cyclic data comparison, see

page 4–66.

Safety-related errors always lead to safe stopping of all drives through defined

stop reactions.

Defined safety functions are triggered and safe operating states are achieved

via safety-related inputs and outputs (in two channels) which have an influence

on the process in all operating modes.

April 2012 2.5 General information 35

Page 36

Additional

Note

Note

information

Documentation

This manual is a supplement to the Technical Manual of your control, and

describes the functions of the functional safety (FS) and the SPLC from

HEIDENHAIN. Therefore, please also refer to the following documentation:

• Technical Manual of your control

• "Inverter Systems and Motors" Technical Manual

• Online help of the PLCdesignNT development environment for (S)PLC

programming

Documentation of the hardware components

For the documentation of the iTNC 530 HSCI or TNC 6xx hardware

generation, please refer to your control's Technical Manual.

You can download manuals, other documentation and PC software tools for

machine manufacturers from the HESIS-Web including Filebase.

Specifics and constraints

The first software versions for functional safety do not include the full range

of features necessary to provide functional safety for all machine models.

Please see page 4–112. Your contact person at HEIDENHAIN will be glad to

answer any questions concerning the with functional safety on your control.

Before planning a machine with functional safety, please inform yourself of

whether the current scope of functional safety features suffices for your

machine design.

In practice, and in the sense of this document, a HEIDENHAIN control system

for a machine tool consists of:

a HEIDENHAIN NC control with integrated safety and HSCI, an MC main

computer and CC controller units

peripheral units such as screen, keyboard, machine operating panel and

handwheel

the SPL or PL assemblies with their I/O modules for connecting safety and

standard inputs and outputs

synchronous and asynchronous feed and spindle motors

position and speed encoders

supply modules and inverters

36 HEIDENHAIN Technical Manual Functional Safety (FS)

Page 37

A prerequisite for the functional safety of HEIDENHAIN controls is the

USB

HR xxx FS

MB 620 FS

TE 6xx

PL 62xx FS

MC 6xxx

HDL

HSCI

BF 2xx

Cabinet

Panel

PSL

Inverter

CC 6110

X79

(X112)

UVW

POWER MODULE

READY

RESET

UVW

Permissive Buttons,

Key Switches

Emergency Stop,

Door Contacts,

Relais

connection of the actual control components via the common HSCI

connection (HSCI = HEIDENHAIN Serial Controller Interface).

Figure 3.1: Possible setup of an HSCI system

April 2012 2.5 General information 37

Page 38

HEIDENHAIN control components for setting up a system with functional

safety:

Series Component of the control system

MC 6xxx, MC 7xxx MC main computer with HSCI interface for the

HEIDENHAIN NC control

CC 6xxx CC controller units with HSCI interface and

support for a variable number of control loops

PLB 6xxx FS Functional safety (FS) version of a bus module,

serves as carrier for several PLD-H xx-xx-xx (FS)

I/O modules. Designated SPL in this document.

PLD-H xx-xx-xx FS Functional safety (FS) version of an I/O module.

Designated SPLD in this document.

MB 6xx FS, MB 7xx FS Functional safety (FS) version of a machine

operating panel. Designated SMOP in this

document.

TE 6xx, TE 7xx Keyboard unit (ASCII keyboard, keys for

supporting the operator) without safety-relevant

tasks.

TE 6xx FS, TE 7xx FS Functional safety (FS) version of a keyboard unit

with an integrated MB 6xx FS machine operating

panel. The MB is designated SMOP in this

document.

HR xxx FS Functional safety (FS) version of an HR

handwheel.

BF xxx Screen with HDL connection.

Position and speed

encoders

UM 1xxD(W),

UVR 1x0D(W),

UV 130D, UR 2xxD,

UE 2xxD and UE 1xx

SIEMENSSIMODRIVE 611

HEIDENHAIN encoders with analog, EnDat 2.1

and EnDat 2.2 interface.

HEIDENHAIN power modules (UM), supply

modules (UV), regenerative supply modules

(UVR), inverter units (UE) and regenerative

inverters (UR).

The use of modules from Siemens'

SIMODRIVE 611 power module product family or

other non-HEIDENHAIN inverters has not been

approved for the integrated functional safety!

38 HEIDENHAIN Technical Manual Functional Safety (FS)

Page 39

The HEIDENHAIN safety strategy enables you to implement the protection

objectives defined in Directive 2006/42/EC easily and enjoy economic benefits

at the same time.

The following items may no longer be required:

Safety contactor combinations for emergency stop and guard door control

Time delay relays and auxiliary relays

Limit switch

Wiring effort

April 2012 2.5 General information 39

Page 40

2.6 Overview of FS components

Note

HSCI combines the communication between axis system and automation into

one bus system between control components. Along with simplifying the

connection technology, HSCI is also the basis for safe, dual-channel, digital

communication, which is the technical prerequisite for integrated safety

functions, referred to as "functional safety."

The following tables give an overview of the HSCI, FS and inverter

components of the control systems with functional safety. The individual

HEIDENHAIN components are described in your control's Technical Manual

and the Technical Manual for Inverters and Motors.

In systems with functional safety, certain hardware components assume

safety-relevant tasks. Approval for these components must be granted for

each variant individually by HEIDENHAIN. In the following table you will find

the basic ID number and variant for those hardware components that have

safety-relevant tasks.

The following lists, consisting of hardware components and their variants,

contain all hardware components that may be used in systems with

functional safety.

In HSCI systems with integrated functional safety (FS) you may use only

devices or variants that have been certified for use in such systems.

Please take the following lists into account when configuring your machine

and in case servicing is required. The right-most table column contains the

approved ID numbers of these components.

40 HEIDENHAIN Technical Manual Functional Safety (FS)

Page 41

2.6.1 List of approved control components

Note

In systems with functional safety, certain hardware components assume

safety-relevant tasks. Approval for these components must be granted for

each variant individually by HEIDENHAIN. In the following table you will find

the basic ID number and variant for those hardware components that have

safety-relevant tasks.

Systems with FS may consist of only those safety-relevant components for

which the variant is listed in the table below (e.g. xxx xxx-03).

Components indicated in this list with -xx do not assume any safety-relevant

task in the sense of functional safety (FS). You can use any variant of these

components.

Components indicated in this list with "Not yet approved for FS" are not

approved for use in systems with functional safety.

The list will be expanded or revised correspondingly when new components

are approved for use in systems with functional safety (FS). Should a

component you wish to use not be listed, please ask your contact person at

HEIDENHAIN if the component may be used.

Hardware component ID

MC 6241 Main computer 1.8 GHz with HDR, electrical cabinet version,

without Profibus

MC 6241 Main computer 1.8 GHz with HDR, electrical cabinet version,

with Profibus

MC 6222 Main computer with 15-inch TFT display, 1.8 GHz with SSDR,

operating-panel version, without Profibus

MC 6222 Main computer with 15-inch TFT display, 1.8 GHz with SSDR,

operating-panel version, with Profibus

MC 6341 Main computer with 15-inch TFT display, 2.2 GHz dual core with

HDR, electrical-cabinet version

MC 6341 Main computer with 15-inch TFT display, 2.2 GHz dual core with

HDR, electrical-cabinet version, with Profibus

573398-03

653220-03

634109-02

634113-02

Not yet

approved for FS

Not yet

approved for FS

BF 250 15-inch TFT display with HDL connection 599916-xx

BF 260 19-inch TFT display with HDL connection 617978-xx

BF 750 15-inch TFT display with HDL connection 785080-xx

BF 760 19-inch TFT display with HDL connection 732589-xx

CC 6106 Controller unit for HSCI for max. 6 control loops 662636-01

CC 6108 Controller unit for HSCI for max. 8 control loops 662637-01

CC 6110 Controller unit for HSCI for max. 10 control loops 662638-01

April 2012 2.6 Overview of FS components 41

Page 42

Hardware component ID

UEC 111 Controller unit with inverter and PLC, 4 control loops 625777-xx

UEC 112 Controller unit with inverter and PLC, 5 control loops 625779-xx

UEC 111 FS Controller unit with inverter and PLC, 4 control loops, functional

safety

UEC 112 FS Controller unit with inverter and PLC, 5 control loops, functional

safety

UMC 111 FS Controller unit with inverter and PLC for power supply via

external DC link, 4 control loops, functional safety

CMA-H 04-04-00 SPI expansion module for analog nominal-value outputs 688721-xx

Not yet

approved for FS

Not yet

approved for FS

664231-02

PSL 130 Low-voltage power supply unit, 750 W, for +24 V NC and +24 V

PLC

PSL 135 Low-voltage power supply unit, 750 W, for +24 V NC, +24 V

PLC and +5 V NC

If other low-voltage power supply units are used for +24 V NC

and +24 V PLC, the output voltages must fulfill the

requirements for Protective Extra Low Voltage (PELV) with

double basic insulation according to EN 50 178, also see the

Technical Manual, Chapter 3.8.

MS 110 Mounting case for multi-row configuration 658132-xx

MS 111 Mounting case for multi-row assembly, additional connection

for 24 V supply to the fan

TE 620 Keyboard unit without touchpad 625806-xx

TE 720 Keyboard unit without touchpad 805488-xx

TE 630 Keyboard unit with touchpad 617976-xx

TE 730 Keyboard unit with touchpad 805489-xx

TE 740 Keyboard unit with touchpad 886546-xx

TE 635Q FS TE with touchpad and integrated MB for HSCI connection,

functional safety

TE 735 FS TE with touchpad and integrated MB for HSCI connection,

functional safety

TE 645Q FS TE with touchpad and integrated MB for HSCI connection,

functional safety (19-inch)

TE 745 FS TE with touchpad and integrated MB for HSCI connection,

functional safety (19-inch)

575047-xx

627032-xx

673685-xx

662255-01

805493-01

685394-01

805482-01

MB 620 FS Machine operating panel for HSCI connection, functional safety 660090-01

MB 720 FS Machine operating panel for HSCI connection, functional safety 805474-01

PLB 6001 FS HSCI adapter for OEM-specific machine operating panel,

functional safety

42 HEIDENHAIN Technical Manual Functional Safety (FS)

Not yet

approved for FS

Page 43

Hardware component ID

HR 410 FS Portable electronic handwheel with cable connection 337159-11,

578114-03

HR 520 FS Portable electronic handwheel with cable connection and

display

HR 550 FS Portable electronic handwheel with wireless transmission and

display

HRA 551 FS Handwheel adapter with integrated charger 731928-01

HRA 550 FS Handwheel adapter with integrated charger 633108-02

PLB 6104 PLB for HSCI, 4 slots 591828-xx

PLB 6106 PLB for HSCI, 6 slots 630058-xx

PLB 6108 PLB for HSCI, 8 slots 630059-xx

PLB 6204 PLB for HSCI, 4 slots, with system module 591832-xx

PLB 6206 PLB for HSCI, 6 slots, with system module 630054-xx

PLB 6208 PLB for HSCI, 8 slots, with system module 630055-xx

PLB 6104 FS PLB for HSCI, 4 slots, functional safety 590479-03

PLB 6106 FS PLB for HSCI, 6 slots, functional safety 804755-01

PLB 6108 FS PLB for HSCI, 8 slots, functional safety 804756-01

PLB 6204 FS PLB for HSCI, 4 slots, with system module, functional safety 586789-03

PLB 6206 FS PLB for HSCI, 6 slots, with system module, functional safety 622721-03

PLB 6208 FS PLB for HSCI, 8 slots, with system module, functional safety 620927-03

PLD-H 16-08-00 PL for PLB 6xxx: 16 digital inputs, 8 digital outputs 594243-xx

PLD-H 08-16-00 PL for PLB 6xxx: 8 digital inputs, 16 digital outputs 650891-xx

PLD-H 08-04-00 FS

PLD-H 04-08-00 FS

PLA-H 08-04-04 PL for PLB 6xxx, eight +/- 10 V inputs, four +/- 10 V analog

PL for PLB 6xxx FS: 8 digital inputs, 4 digital outputs, functional

safety

PL for PLB 6xxx FS: 4 digital inputs, 8 digital outputs, functional

safety

outputs, and four PT 100 inputs

670304-01,

670305-01

598515-02,

606622-02

598905-01,

598905-02

727219-02

675572-xx

If other low-voltage power supply units are used for +24V NC

and +24V PLC, the output voltages must fulfill the requirements for Protective

Extra Low Voltage (PELV) with double basic insulation according to EN50178,

also see the Technical Manual, Chapter 3.8.

April 2012 2.6 Overview of FS components 43

Page 44

2.6.2 List of approved inverter components

Danger

In HSCI systems with integrated functional safety (FS) you may use only

inverters or power supply modules that have been approved for use in such

systems.

Please take this into account when configuring your machine and in case

servicing is required. Suitable devices are listed below in the right column of

the table.

Components indicated in this list with "Not yet approved for FS" are not yet

approved for use in systems with functional safety.

The list will be expanded or revised correspondingly when new components

are approved for use in systems with functional safety (FS). Should a

component you wish to use not be listed, please ask your contact person at

HEIDENHAIN if the component may be used.

Below you will find an overview of the devices that—according to

ISO 13849-1—are permitted for use in systems with FS:

Hardware component Device ID for systems

Inverter modules

UM 117DW Not yet approved for FS

UM 116D Not yet approved for FS

UM 116DW Not yet approved for FS

UM 115D 671566-01

UM 114D 671288-01

UM 113D 730435-01

UM 112D 731984-01

UM 122D 667633-01

UM 121BD 667942-01

UM 111BD 671968-01

UM 121D 667838-01

UM 111D 667945-01

Power supply modules

UVR 120D 728252-01

UV 130D Not yet approved for FS

UVR 130D 728248-01

UVR 140D 728253-01

UVR 150D 728255-01

UVR 160D 728257-01

UVR 160DW 728258-01

UVR 170DW Not yet approved for FS

UVR 170D Not yet approved for FS

with integrated FS

44 HEIDENHAIN Technical Manual Functional Safety (FS)

Page 45

Hardware component Device ID for systems

with integrated FS

Non-regenerative compact inverters

UE 210D Not yet approved for FS

UE 211D Not yet approved for FS

UE 212D Not yet approved for FS

UE 230D Not yet approved for FS

UE 240D Not yet approved for FS

UE 241D Not yet approved for FS

UE 242D Not yet approved for FS

UE 110 Not yet approved for FS

UE 111 Not yet approved for FS

UE 112 Not yet approved for FS

Regenerative compact inverters

UR 242D Not yet approved for FS

UR 230D Not yet approved for FS

UR 240D Not yet approved for FS

April 2012 2.6 Overview of FS components 45

Page 46

2.6.3

Note

Differences between systems with and without functional safety (FS)

With the following HSCI control components, you must make a distinction

between those that are required in a system with functional safety and those

that can be used in a system without functional safety. Devices with FS are

listed below in the middle column:

Please refer to the lists of components approved for FS.

Device designation Device ID for systems

with integrated FS

Machine operating panels and keyboard units

In systems with FS you must use a machine operating panel for functional-

safety applications. In these operating panels, all keys have twin channels. A

movement can therefore be executed without additional permissive button/

key.

MB 620 (FS) 660090-xx 617973-xx

TE 635Q (FS) 662255-xx 617975-xx

TE 645Q(FS) 685394-xx 682104-xx

MB 720(FS) 805474-xx 784803-xx

TE 735(FS) 805493-xx 771898-xx

TE 745(FS) 805482-xx 679817-xx

PLB basic modules

In FS systems, mixed use of PLB basic modules with and without FS is possible.

However, at least one PLB 62xx FS must be used in systems with FS.

PLB 6104 (FS) 590479-xx 591828-xx

PLB 6106 (FS) 804755-xx 630058-xx

PLB 6108 (FS) 804756-xx 630059-xx

PLB 6204 (FS) 586789-xx 591832-xx

PLB 6206 (FS) 622721-xx 630054-xx

PLB 6208 (FS) 620927-xx 630055-xx

PLB 6001 (FS) Not yet available 668792-xx

PLD-H I/O modules

In systems with FS, the mixed use of PLD-H modules with and without FS is

possible in PLB basic modules with FS. However, do not insert PLD-H

modules with FS in PLB basic modules without FS. Furthermore, the

modules with FS must always be inserted into the PLB with FS starting from

the left.

PLD-H 16-08-00,

PLD-H 08-04-00FS

PLD-H 08-16-00,

PLD-H 04-08-00FS

598905-xx 594243-xx

727219-xx 650891-xx

Device ID for systems

without integrated FS

46 HEIDENHAIN Technical Manual Functional Safety (FS)

Page 47

Device designation Device ID for systems

with integrated FS

Handwheels

In FS systems, handwheels with cross-circuit proof permissive buttons must

be used. Handwheels for which this has been implemented are identified

with FS.

HR 410(FS) 337159-xx,

578114-xx (with detent)

HR 520 (FS) 670304-xx,

670305-xx (with detent)

Device ID for systems

without integrated FS

296469-xx,

535220-xx (with detent)

670302-xx,

670303-xx (with detent)

April 2012 2.6 Overview of FS components 47

Page 48

48 HEIDENHAIN Technical Manual Functional Safety (FS)

Page 49

3 Directives and standards

3.1 Applicable directives

Compliance with the following directives is mandatory for the design of

machine tools:

Directives Applicable since

Machinery Directive 2006/42/EC 29.12.2009

EMC Directive 2004/108/EC 20.07.2007

Low Voltage Directive 2006/95/EC 16.01.2007

HEIDENHAIN controls with integrated safety strategy fulfill their share of the

requirements as specified in the above directives, thus enabling you as the

manufacturer to produce your machines in accordance with the machinery

directives.

HEIDENHAIN controls with integrated functional safety (FS), for which safetyrelevant specifications (suitability for certain PL or SIL levels) will be indicated

in the future, are not considered safety components in the sense of Machinery

Directive 2006/42/EC (article 2, letter c). Since these controls are also not

"partly completed machinery" (article 2, letter g), they do not fall under the

provisions of the Machinery Directive. For this reason we do not issue any EC

Declaration of Conformity nor a Declaration of Incorporation in the sense of

the Machinery Directive.

April 2012 3.1 Applicable directives 49

Page 50

3.2 Basis for testing

The safety functions described as well as the devices for controls with

functional safety (FS) are tested by TÜV Süd. The directives and standards

serving as the basis for testing are listed below:

European directives

Directives Applicable since

Machinery Directive 2006/42/EC 29.12.2009

EMC Directive 2004/108/EC 20.07.2007

Low Voltage Directive 2006/95/EC 16.01.2007

Functional safety

Safety standards Requirement Meaning / Designation

DIN EN 61508-1 to 4

(2001)

EN 954-1 (1996) Cat 3 Safety of Machinery – Safety-

DIN EN ISO 13849-1

(2008)

Due to the applications of the device or system, the following directives and

standards are also valid:

Safety standards Meaning / Designation

IEC 61800-5-2 (FDIS) (2006) Adjustable Speed Electrical Power

DIN EN 60204-1 (2007) Safety of Machinery – Electrical

SIL 2 Functional Safety of Electrical/

Electronic/Programmable

Electronic Safety-Related

Systems

Related Parts of Control

Systems

Cat 3 / PL d Safety of Machinery – Safety-

Related Parts of Control

Systems

Drive Systems – Part 5-2: Safety

Requirements – Functional

Equipment of Machines – Part 1:

General Requirements

50 HEIDENHAIN Technical Manual Functional Safety (FS)

Page 51

Primary safety

Safety standards Meaning / Designation

DIN EN 50178 Electronic Equipment for Use in Power

Installations

Electromagnetic compatibility

Safety standards Meaning / Designation

DIN EN 61800-3 EMC product standard including

specific test methods for electrical

power drive systems

"EMC and functional safety for power drive systems with integrated safety

functions" principle for testing dated February 2007

April 2012 3.2 Basis for testing 51

Page 52

Requirements of

IEC 61508 SIL 2

The goal is to control or avoid errors in the control, and to limit the probability

of dangerous failures to defined values. Safety integrated levels (SIL) have

been defined to measure the achieved level of safety-related performance.

The entire system, including all associated components, must achieve the

required safety integrated level. For systems with programmable electronics,

the SIL capability and the limited failure rate PFH (probability of dangerous

failure per hour) result from applying IEC 61508 during the development and

manufacture of these systems.

A safety integrated level corresponds to a defined range of probability for the

dangerous failure of safety functions. By achieving SIL 2, which the

HEIDENHAIN controls with functional safety do, the probability of failure of

the safety functions is between 10

-6

and 10-7 failures per hour.

Requirements

of EN 13849-1

Category 3,

Performance

Level d

Fulfillment of the

requirements

The EN 13849 standard (previously EN 954) is of special importance.

This standard groups the requirements for safety-related control components

into categories (B, 1, 2, 3, 4) and performance levels (a, b, c, d, e) in ascending

degrees of safety-related effectiveness.