Page 1

Preface

In this user manual we try to describe the matters concerning the

operation of this GS Series Spindle Servo Drive Unit to the greatest extent.

However, it is impossible to give particular descriptions for all unnecessary

or unallowable operations due to length limitation and products application

conditions; Therefore, the items not presented herein should be regarded as

“impossible” or “unallowable”.

Copyright is reserved to GSK CNC Equipment Co., Ltd. It is

illegal for any organization or individual to publish or reprint this manual.

GSK CNC Equipment Co., Ltd. reserves the right to ascertain their legal

liability.

I

Page 2

GS Series Spindle Servo Drive Unit User Manual

Preface

Dear customers,

We are honored and thankful for your purchase of this GSK product!

This manual describes items concerning GS Series Spindle Servo

Drive Unit in detail, such as performance, installation, connection,

commissioning, usage and maintenance etc.

To ensure safe and effective running, please read this manual carefully

before installation and operation.

To avoid injury to operators and other personnels, and damage to the

mechanical equipments, please pay special attention to the following

warning signs when reading this manual.

Danger Mal-operation may lead to serious injury or death.

Caution Mal-operation may lead to minor injury or physical

damage.

Notice It indicates a potential situation which, if not avoided, may result

in an undesirable result or state.

It reminds users of the important instructions and requirements.

II

Forbidden (definitely cannot be done)

Compulsive (must be done)

Page 3

Caution

Tighten all terminals of main circuits

properly.

Failure to observe it may

result in loose connection

!

Make sure that the input power is OFF

before wiring.

!

Wire layout or overhaul should be

done by electrical engineering

technician.

which can easily lead to spark

hazard or even fire disaster.

Failure to observe it may

result in electric shock.

Danger

Mount the drive unit on

noncombustible, and keep it far away

from inflammables.

Moving, checking, and maintaining

equipments or wiring should be

performed 5 minutes after power-off.

Failure to observe it may

!

Make sure the grounding terminal

PE of servo unit is well grounded.

!

result in fire disaster.

Failure to observe it may

result in electric shock.

Failure to observe it may

!

Wiring should be performed according

to the method described in User

Manual.

!

DO NOT operate the switch with

wet hand.

result in electric shock or fire

disaster.

Failure to observe it may

result in equipment damage

and electric shock.

Failure to observe it may

result in electric shock.

Failure to observe it may

!

DO tighten the power terminals and

motor output terminals.

!

DO NOT put hand into servo unit.

result in electric shock.

。

Failure to observe it may

result in fire disaster.

Failure to observe it may

result in electric shock.

DO NOT open the terminal strip cover

after power-on or in running state.

Failure to observe it may

result in electric shock.

DO NOT touch the wiring terminals of

servo unit main circuits.

Failure to observe it may

result in electric shock.

III

Page 4

GS Series Spindle Servo Drive Unit User Manual

The servo unit may be activated suddenly

after power resumption, so DO NOT

operate the servo motor axes connection

device immediately.

Failure to observe it may

result in personal injury.

DO NOT place cables beside sharp

edges, and AVOID heavy load or tension

imposing on cables.

Failure to observe it may

result in electric shock,

equipment fault or damage.

Danger

DO NOT prevent radiation or put

objects in cooling fan or radiator.

Failure to observe it may

result in equipment damage or

fire disaster.

DO NOT perform live-wire operation on

the servo drive device when the cover

of terminal strip is taken apart.

Failure to observe it may

result in electric shock.

Caution

IV

Page 5

Caution

DO NOT connect power input wires R, S,

T to motor output wire terminals U, V, W.

Failure to observe it may

result in device damage.

DO NOT touch the radiation device of

motor and servo unit when they are

running, because high temperature may

be caused.

Failure to observe it may

result in scald.

DO NOT alter, dismantle or repair the

drive unit without authorization.

Caution

DO NOT turn ON/OFF the input power

frequently.

Failure to observe it may

result in device damage.

DO NOT make excessive changes to

parameters.

Failure to observe it may

result in device damage.

The scrapped components of servo unit

should be handled as industrial waste

and cannot be reused.

Failure to observe it may

result in device damage.

Failure to observe it may

result in accident.

V

Page 6

GS Series Spindle Servo Drive Unit User Manual

Safety Responsibility

Manufacturer’s Responsibility

——Be responsible for the danger which should be eliminated and/or controlled on

design and configuration of the provided Servo Drive Unit and accessories.

——Be responsible for the safety of the provided Servo Drive Unit and accessories.

——Be responsible for the provided information and advice for the users.

User’s Responsibility

——Be trained with the safety operation of Servo Drive Unit and familiar with the safety

operation procedures.

——Be responsible for the dangers caused by adding, changing or altering to the

original Servo Drive Unit and the accessories.

——Be responsible for the failure to observe the provisions for operation, adjustment,

maintenance, installation and storage in the manual.

This manual is reserved by end user.

We are full of heartfelt gratitude to you for supporting us in the

use of GSK’s products.

VI

Page 7

Contents

Contents

CHAPTER I INSTRUCTION ...................................................................................................................... 1

1.1 Basics .............................................................................................................................................. 1

1.2 Product Confirmation ....................................................................................................................... 6

1.2.1 Instruction of AC Spindle Servo Motor Model ........................................................................... 6

1.2.2 Instruction of Spindle Servo Unit .............................................................................................. 7

1.2.3 Overall Appearance of Spindle Servo Unit ............................................................................... 8

1.3 Technical Specification .................................................................................................................. 11

1.3.1 Technical Specification of Spindle Motor ................................................................................ 11

1.3.2 Technical Specification of AC Spindle Servo Unit .................................................................. 13

1.4 Ordering Guidelines ....................................................................................................................... 15

1.4.1 Model Selection Process ........................................................................................................ 15

1.4.2 Examples ................................................................................................................................ 15

1.4.3 Standard Ex-factory Accessories ............................................................................................ 17

CHAPTER II INSTALLATION/MOUNTING ............................................................................................. 21

2.1 Spindle Servo Motor ...................................................................................................................... 21

2.1.1 Dimensions for Spindle Motor Installation .............................................................................. 21

2.1.2 Installation of Spindle Motor ................................................................................................... 23

2.2 Spindle Servo Unit ......................................................................................................................... 25

2.2.1 Installation Dimension ............................................................................................................. 26

2.2.2 Installation Intervals ................................................................................................................ 28

CHAPTER III CONNECTION .................................................................................................................. 31

3.1 Connection of Peripheral Equipments ........................................................................................... 32

3.2 Connection of Main Circuit ............................................................................................................ 37

3.2.1 Connection .............................................................................................................................. 37

3.2.2 Wiring of Main Circuit .............................................................................................................. 38

3.2.3 Servo Motor Connection Instruction ....................................................................................... 38

3.3 Connection of Control Signal ......................................................................................................... 40

3.3.1 CN1 Control Signal ................................................................................................................. 40

3.3.2 Speed Command Input ........................................................................................................... 43

3.3.3 Position Command Input ........................................................................................................ 44

3.3.4 Digital Input ............................................................................................................................. 47

3.3.5 Digital Output .......................................................................................................................... 49

3.3.6 Position Signal Output ............................................................................................................ 52

3.4 Connection of Position Feedback Signal ....................................................................................... 53

3.4.1 Motor Encoder Position Feedback Signal Interface CN2 ....................................................... 53

VII

Page 8

GS Series Spindle Servo Drive Unit User Manual

3.4.2 2nd Position Feedback Signal Interface CN3 ........................................................................ 57

3.4.3 Interface CN3 of GS Series MDR Products ........................................................................... 58

3.5 GSK-CAN Communication ............................................................................................................ 59

3.6 Connection in Different Working Mode ......................................................................................... 60

3.6.1 Connection in Speed Mode .................................................................................................... 60

3.6.2 Connection in Position Mode ................................................................................................. 63

3.6.3 Connection in Speed/Position Mode ...................................................................................... 65

CHAPTER IV DISPLAY AND OPERATION ........................................................................................... 69

4.1 Operation Panel ............................................................................................................................ 69

4.2 Display Menu ................................................................................................................................ 70

4.3 Status Monitoring .......................................................................................................................... 71

4.4 Parameter Setting ......................................................................................................................... 74

4.5 Parameter Management ............................................................................................................... 75

CHAPTER V GENERAL COMMISSIONING .......................................................................................... 77

5.1 Running in Manual/JOG Mode...................................................................................................... 78

5.1.1 Manual Running ..................................................................................................................... 79

5.1.2 JOG Running.......................................................................................................................... 80

5.2 Running in Speed Mode ............................................................................................................... 81

5.2.1 Analog Speed Command ....................................................................................................... 81

5.2.2 Internal Speed Command ...................................................................................................... 84

5.3 Running in Position Mode ............................................................................................................. 85

5.4 Running in Speed/Position Mode ................................................................................................. 87

CHAPTER VI FUNCTIONALITY TESTING ............................................................................................ 91

6.1 Instruction for Basic Performance Parameters Setting ................................................................. 91

6.1.1 Setting Methods ..................................................................................................................... 91

6.1.2 Three Gains of Closed-Loop Control ..................................................................................... 93

6.2 Switching of Motor Rotation Directions ......................................................................................... 94

6.3 Braking Stop.................................................................................................................................. 96

6.4 Testing in Position Mode ............................................................................................................... 97

6.4.1 Electronic Gear Ratio of Position Command ......................................................................... 97

6.4.2 Position Arrival Signal ............................................................................................................ 98

6.4.3 Position Deviation Clear ......................................................................................................... 99

6.4.4 Pulse Command Inhibition ..................................................................................................... 99

6.5 Testing in Speed Mode ............................................................................................................... 100

6.5.1 Orientation Function ............................................................................................................. 100

6.5.2 Adjustment of Analog Commands ....................................................................................... 105

6.5.3 Speed Arrival Signal ............................................................................................................. 106

VIII

Page 9

Contents

6.5.4 Zero Speed Clamp ................................................................................................................ 107

6.5.5 Speed Command Electronic Gear Ratio .............................................................................. 108

6.6 Spindle Clamp Interlock Signal (BREF)....................................................................................... 109

CHAPTER VII PARAMETERS .............................................................................................................. 111

7.1 Parameter List ............................................................................................................................. 111

CHAPTER VIII ABNORMALITIES AND REMEDIES ............................................................................ 123

8.1 Remedies for Normal Faults ........................................................................................................ 123

8.1.1 Speed Mode ............................................................................................................................. 123

8.1.2 Position Mode ....................................................................................................................... 125

8.1.3 Others ................................................................................................................................... 126

8.2 Alarms and Remedies ................................................................................................................. 128

8.3 Inspection and Maintenance ........................................................................................................ 133

APPENDIX A Model Code Parameters and Feed Servo Motors Table ................................................ 135

APPENDIX B Peripheral Equipments ................................................................................................... 136

B.1 Circuit Breaker and Contactor (essential) ................................................................................... 136

B.2 Three-phase AC filter (recommended)........................................................................................ 136

B.3 AC Reactor (recommended) ....................................................................................................... 137

APPENDIX C BRAKING RESISTOR SELECTION............................................................................... 138

APPENDIX D CONNECTION DIAGRAMS BETWEEN SPINDLE SERVO UNIT AND CNC SYSTEM

............................................................................................................................................................... 141

IX

Page 10

Page 11

Chapter I Instruction

CHAPTER I INSTRUCTION

1.1 Basics

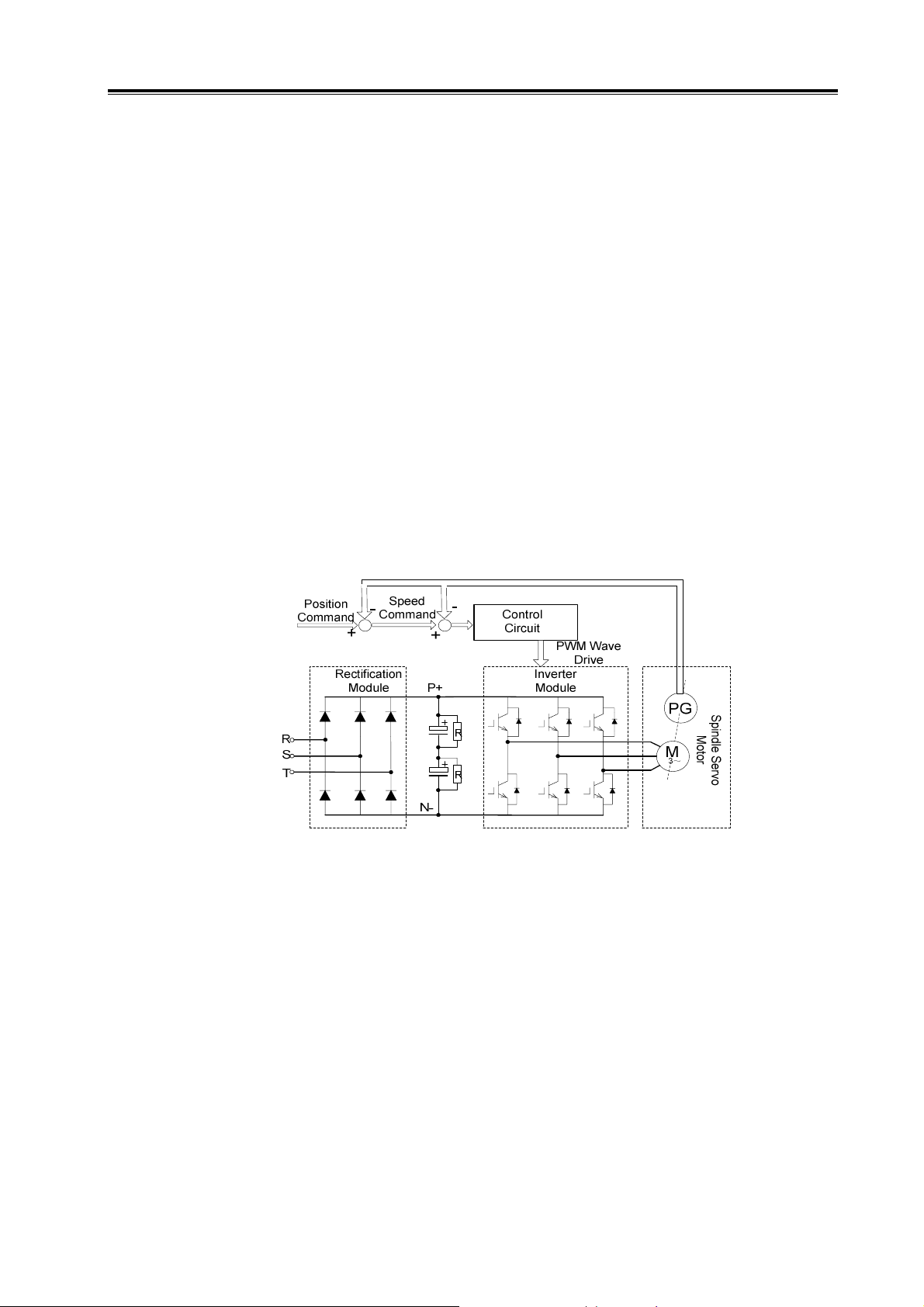

¾ Fundamental principles and circuits of spindle servo drive

The spindle servo drive is composed of spindle servo unit and spindle servo motor (three-phase

AC asynchronous servo motor, hereinafter called servo motor). The servo unit rectifies AC to DC, and

by controlling the ON/OFF of power transistor, it generates current approximated to sinewave whose

phase difference is 120° in the three-phase stator winding of servo motor (i.e., DC-AC). Thus, a

magnetic field is created in the servo motor, and the rotator generates current as a result of magnetic

field induction. The interaction between the inductive current and magnetic field leads to the

generation of a torque which causes the rotator to work. Higher frequency of current which goes

through the servo motor winding corresponds to quicker servo motor speed; the larger current

amplitude corresponds to larger output torque of the servo motor (torque= force × arm length). Figure

1-1 shows the main circuit of servo unit; PG represents the encoder.

Fig. 1-1 Main circuit of spindle servo unit

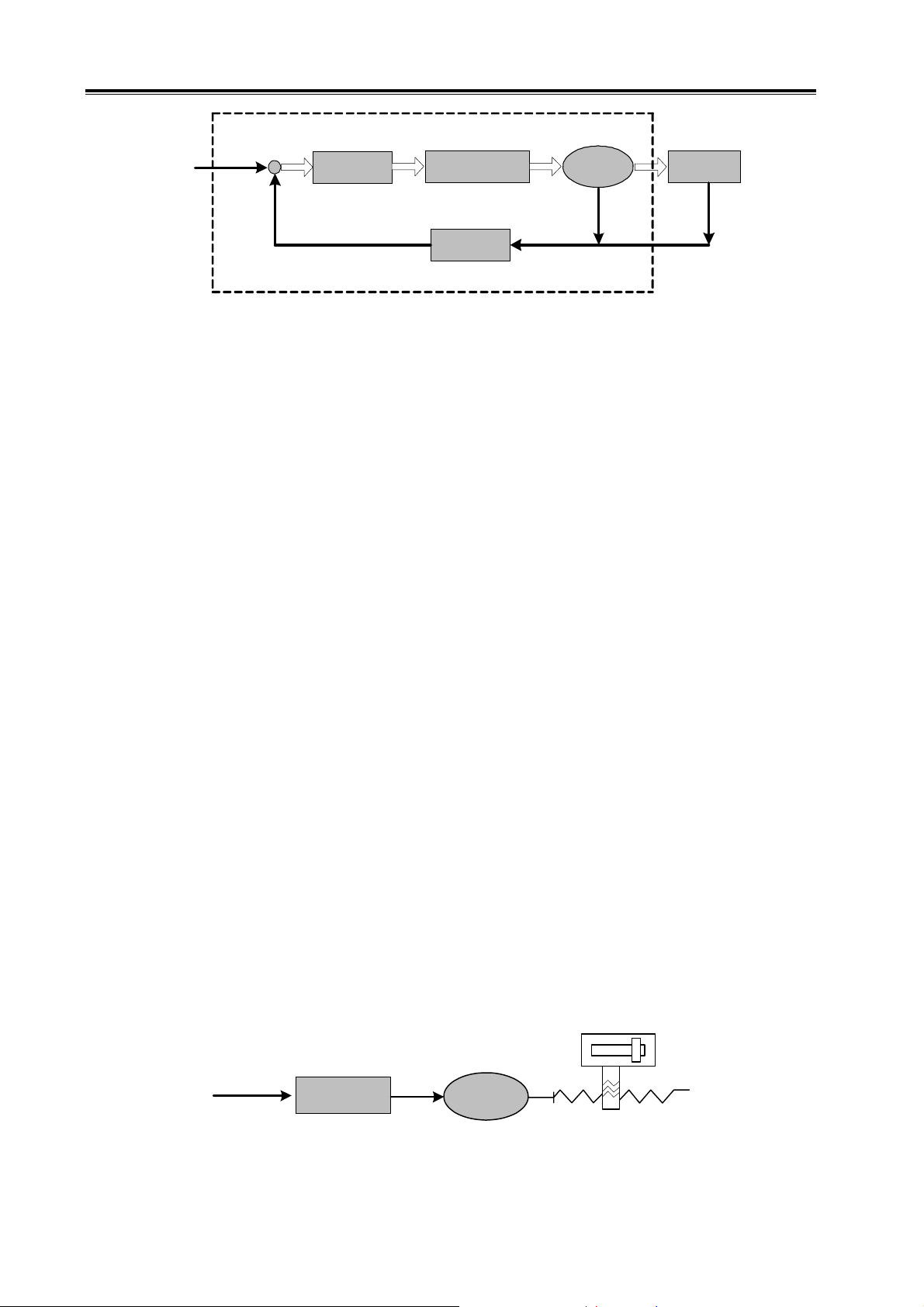

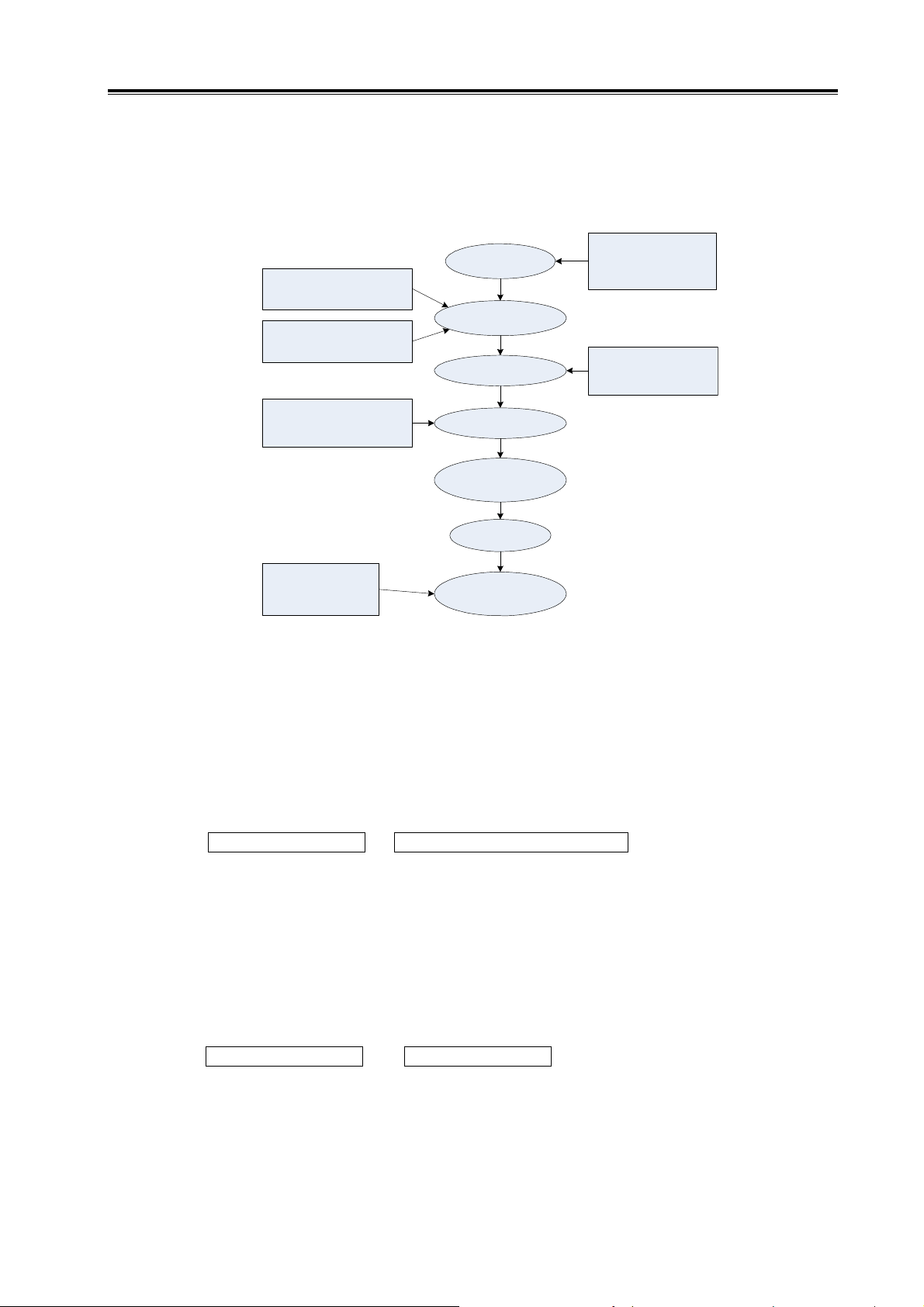

¾ Basic structure of spindle servo drive

The servo unit receives speed (or position) commands from control device (also called upper

computer) such as CNC system. It controls the frequency and magnitude of current which goes

through the servo motor winding, so that the rotation speed (or angle) of servo motor rotator can be

approximated to the speed (or position) command value, and the difference between actual rotation

speed (or angle) and commanded value can be detected. By constantly adjusting the frequency and

magnitude of current, the servo unit can limit the differences within the required range. Figure 1-2

shows the basic structure of spindle servo drive.

1

Page 12

GS Series Spindle Servo Drive Unit User Manual

Specify

CNC

System

¾ General concept of control

z

Control: A process of the characteristics (such as speed) of an object (such as servo motor)

reaching or approximating to the desired value is called CONTROL. The object herein is called

PLANT; and its characteristic is called CONTROLLED VARIABLES; the unit which realizes the

control is called CONTROL UNIT; the process of receiving the desired value by the control unit is

+

-

Spindle Servo Drive

Control

Unit

Fig. 1-2 Basic structure of spindle servo drive

Power Drive

Unit

Feedback

Detection

Motor Machine

called SPECIFY; the process of inputting and reacting to controlled variable is called FEEDBACK; the

unit that detects the controlled variables is called FEEDBACK UNIT; the feedback can be divided into

positive feedback (same direction) and negative feedback( reversed direction) according to the

controlled variables and output direction. The drive is composed of plant, feedback unit and control

unit. There are two kinds of drives: open-loop control device and closed-loop control device. They are

distinguished by the absence/presence of feedback unit and its position in drive. The closed-loop

control device described in this manual is negative feedback closed-loop control device.

In this manual, the spindle servo unit is the control unit; the plant is the servo motor; the motor

rotation speed (or angle) is the controlled variable; the encoder is the feedback unit; the speed

feedback is realized when actual speed is detected by encoder for speed control. Spindle servo unit

belongs to closed-loop control device.

z Open-loop control device: Feedback unit is absent in the control device, so the actual

controlled variables do not affect the output of control unit. Take stepper motor drive for example:

after the servo unit outputs the phase sequence changes of current, the rotator of stepper motor

should follow the change; however, since there is no feedback unit, the rotator may not catch up with

the changes due to overload or fast acceleration/deceleration, this is the so-called

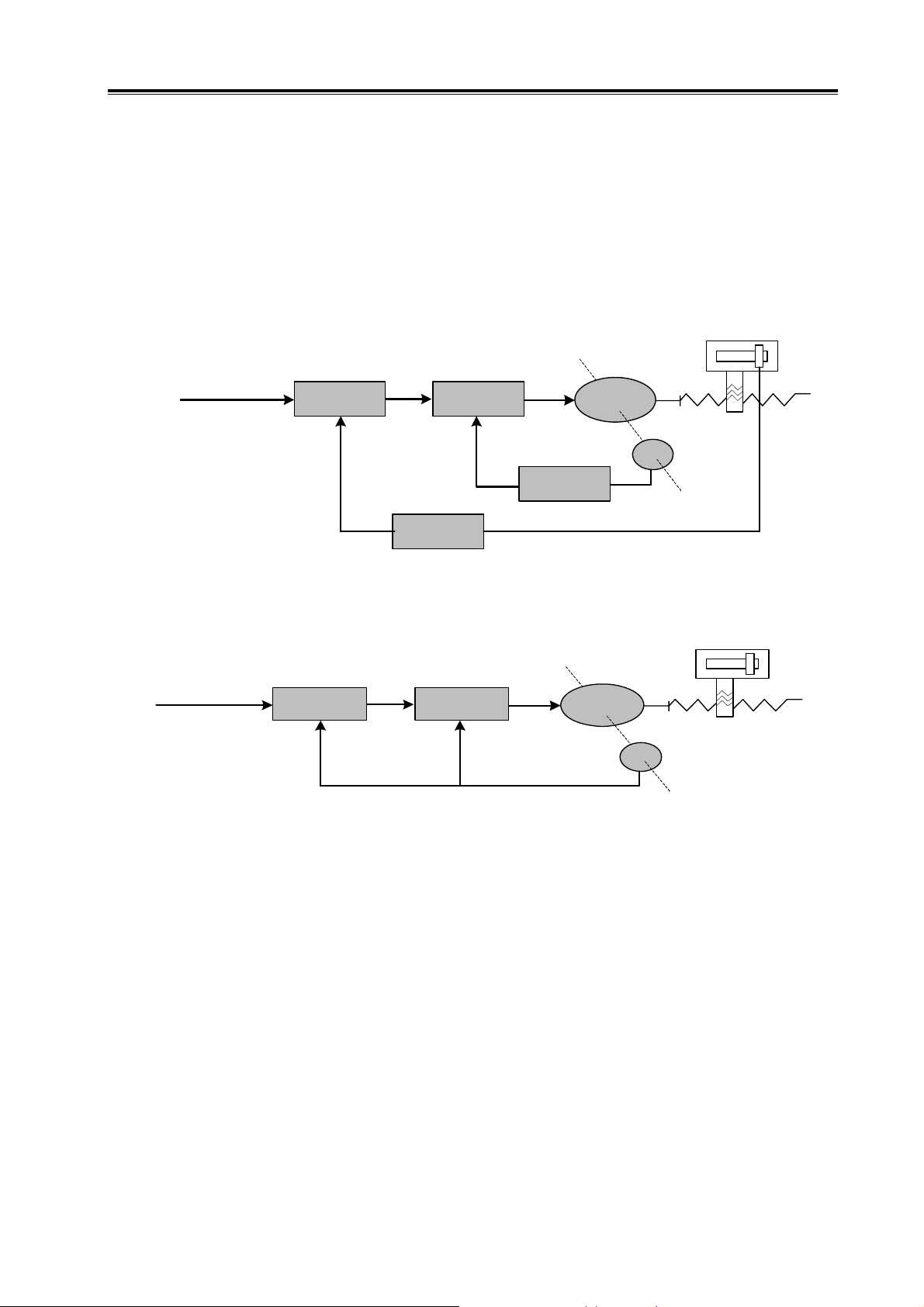

“out-of-synchronism”. Shown in Figure 1-3.

Machine

Specify

Command

z Closed-loop control: The controlled variable is detected by feedback unit and sent to

2

Drive

Circuit

Fig. 1-3 Open-loop control device

Motor

Page 13

Chapter I Instruction

control unit. According to the detection points, the closed-loop control device can be divided into

full-closed-loop control and semi-closed-loop control. The former one is to detect the controlled

variables directly for feedback (see Fig. 1-4); the mechanical position is controlled variables; the

grating ruler mounted on the machine is taken as feedback unit; the encoder on the servo motor

serves as speed feedback unit. Thus the full-closed-loop control can be realized. If there is no grating

ruler, the encoder serves as both position and speed feedback unit (see Fig. 1-5). Thus, the

semi-closed-loop control can be realized.

Machine

Specify

Command

Specify

Command

+

+

Position

Comparision

Position

Comparision

+

Speed

Comparision

--

Speed

Feedback

Position

Feedback

Fig. 1-4 Full-closed-loop control device

+

Speed

Comparision

--

Fig. 1-5 Semi-closed-loop control device

Motor

PG

Machine

Motor

PG

z PID control: It is the most commonly used algorithm. “P” is Proportional, representing the

linear proportional relationship between input and output of control unit. The larger the value is, the

more sensitive the system is, and the smaller the steady-state error will be (impossible to eliminate);

however, too large proportional coefficient will lead to system instability. “I” is Integral, representing

the accumulation of past errors. Larger integral time constant means the system is more stable till the

stead-state error is eliminated; however, it also may lead to lower response of the system. “D” is

Differential, representing the prediction of future errors, based on current rate of change. It can

decrease the following error and improve the dynamic property. When the integral is too large, the

system will be unstable. P, I, D are interacted for the balance among system response, control

precision and stability. Since the integral control will easily cause impact and oscillation, PI control

(i.e., proportion and integral control) is mainly described in this manual.

¾ Concept about servo control

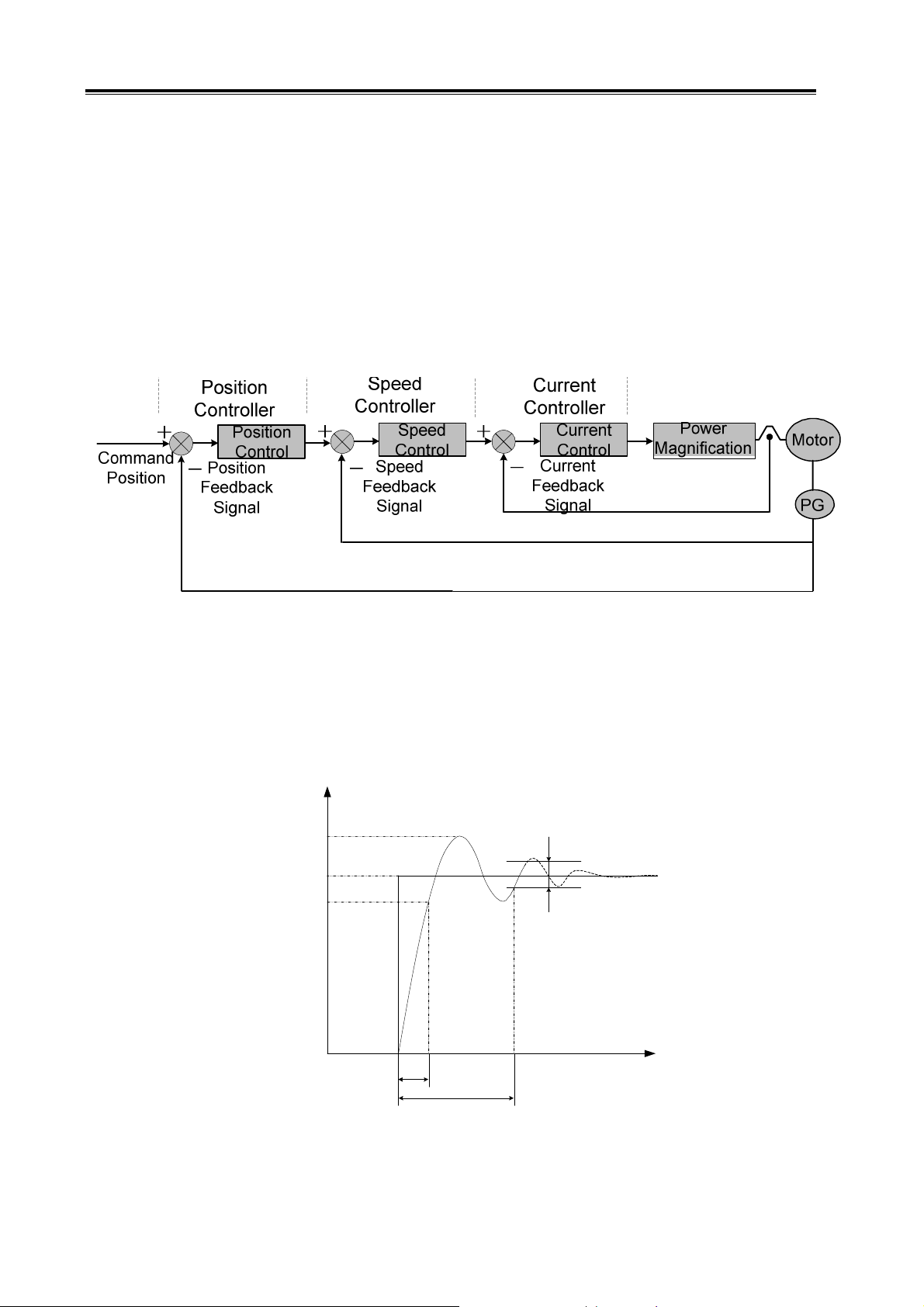

There are three kinds of control mode: position control, speed control and torque control. Shown

3

Page 14

GS Series Spindle Servo Drive Unit User Manual

in Fig. 1-6:

z

Position control: Specify the rotation direction and angle (position) of the motor in forms of

digital pulse or data communication.

z Speed control: Specify the rotation direction and speed of the motor in forms of analog

voltage or data communication.

z Torque control: Specify the magnitude and direction of output torque of the motor in forms of

analog voltage or data communication.

The servo drive described in this manual repels the torque control signal, therefore the torque

control mode is not provided here.

Fig. 1-6 Three-loop control system

¾ Performance norm of spindle servo drive

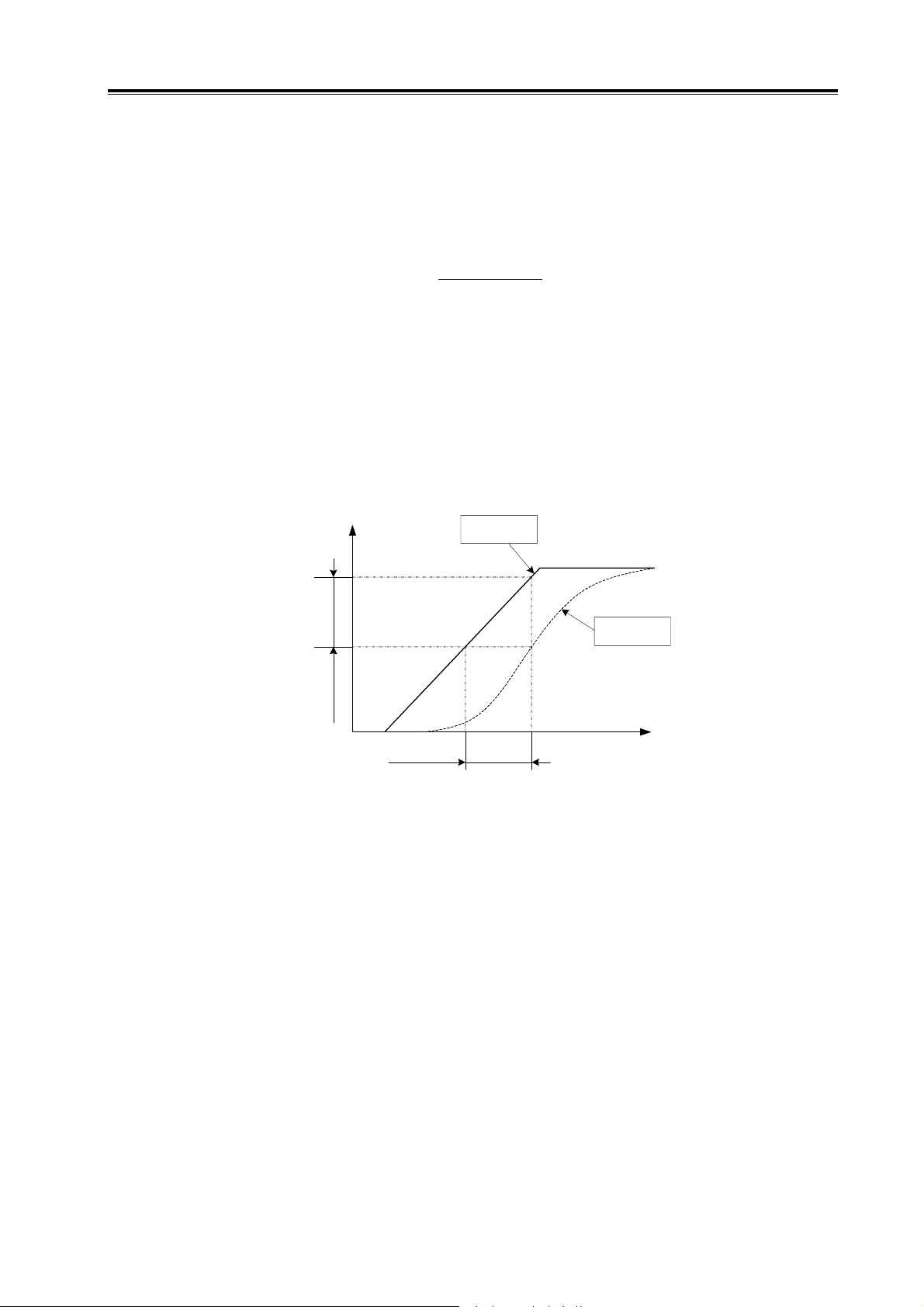

Dynamic performance:

spindle servo drive when the load is specified or changed. The following figure shows the dynamic

response of step signal specified by spindle servo drive (the full line represents the specified signal

and dashed line represents the output signal; similarly hereinafter).

means the response speed, dynamic error and steady-state error of

C(t)

Rmax(t)

R(t)

0.9R(t)

±5%R(t)

t r

s

t

Fig. 1-7 Dynamic response curve

Rise time tr: The duration that the rotation output value rises from 0 to 90% of the steady-state

value for the first time. It represents the speed of dynamic response.

4

t

Page 15

Chapter I Instruction

Settling time ts: The range -5%~+5% of the steady-state value is taken as permitted error zone.

The settling time is the minimum duration of the response curve to reach the zone (no excess any

more). It is used to measure the speed of the whole control process.

Percent overshoot σ: It is the maximum fraction by which the response overshoots the

steady-state value and expressed as a percentage, i.e.

)()(

−

σ

(%)

max

=

tRtR

×

)(

tR

%100

Steady-state error

: The difference between the steady-state output value to the reference input

value at steady state is called the steady state error of the system.

Static performance: Stability is the crucial factor of a spindle servo drive. The static

performance mainly refers to positioning accuracy which means the difference between the reference

state and actual state after the transient process. The static precision can be affected by

measurement device error as well as the system error which is related to the system structure and

parameters. Fig. 1-8 shows the static curve of position servo drive.

θ

Error

Following

Lag

Commanded

Position

Following

Response

t

Fig. 1-8 Static curve

Following error: The difference between the required position and actual position is called

following error. It equals to commanded position value minus actual position value.

Servo rigidity: The capacity of resisting deviation which is caused by load.

¾ Comparison between spindle servo drive and inverter drive

Although both two kinds of devices can realize the conversion of AC-DC-AC, and drive the

three-phase asynchronous motor, the spindle servo drive bears larger current frequency range and

wider valid regulating range. Since an encoder is mounted on servo motor, the spindle servo drive

belongs to closed-loop control device. Whereas, no encoder is mounted on an inverter-fed motor, the

inverter drive belongs to open-loop control device. Motor’s rotation speed will change as the load

changes; however, since feedback control function is not available, the inverter cannot recover the

speed like the servo unit does. To reduce cost, the overload capacity of inverter is 10%~20%, and

that of servo unit is greater than 50%. Higher overload capacity means faster acceleration and

response.

Compared with inverter drives, the spindle servo drives have the following advantages:

5

Page 16

GS Series Spindle Servo Drive Unit User Manual

z Both speed and position control are available; the control precision is high;

z Wider regulating range; capable of outputting valid torque in zero-speed state;

z Small speed fluctuation when load changes; quick to recover;

z Strong overload capacity; fast response; high efficiency; adaptable to sudden start/stop

conditions;

1.2 Product Confirmation

Check the following items after receiving the products. Please contact us or the supplier if you

come across any question.

Item Remark

Check the consistency of servo

unit and servo motor

Check the completeness of

accessories

Check whether the product is

damaged during delivery

Check whether the screw is

loose

Check the contents on packing list and contact

the supplier if an inconsistency is found.

Check for loose connection with a screwdriver.

Check the nameplate.

Check the overall appearance.

Caution

1. Spindle servo unit with loss or damage of parts should not be installed.

2. Servo unit should be matched with a servo motor with suitable power.

3. There are two types of GS series products: D-SUB and MDR. Make sure that the

used product meets the requirements.

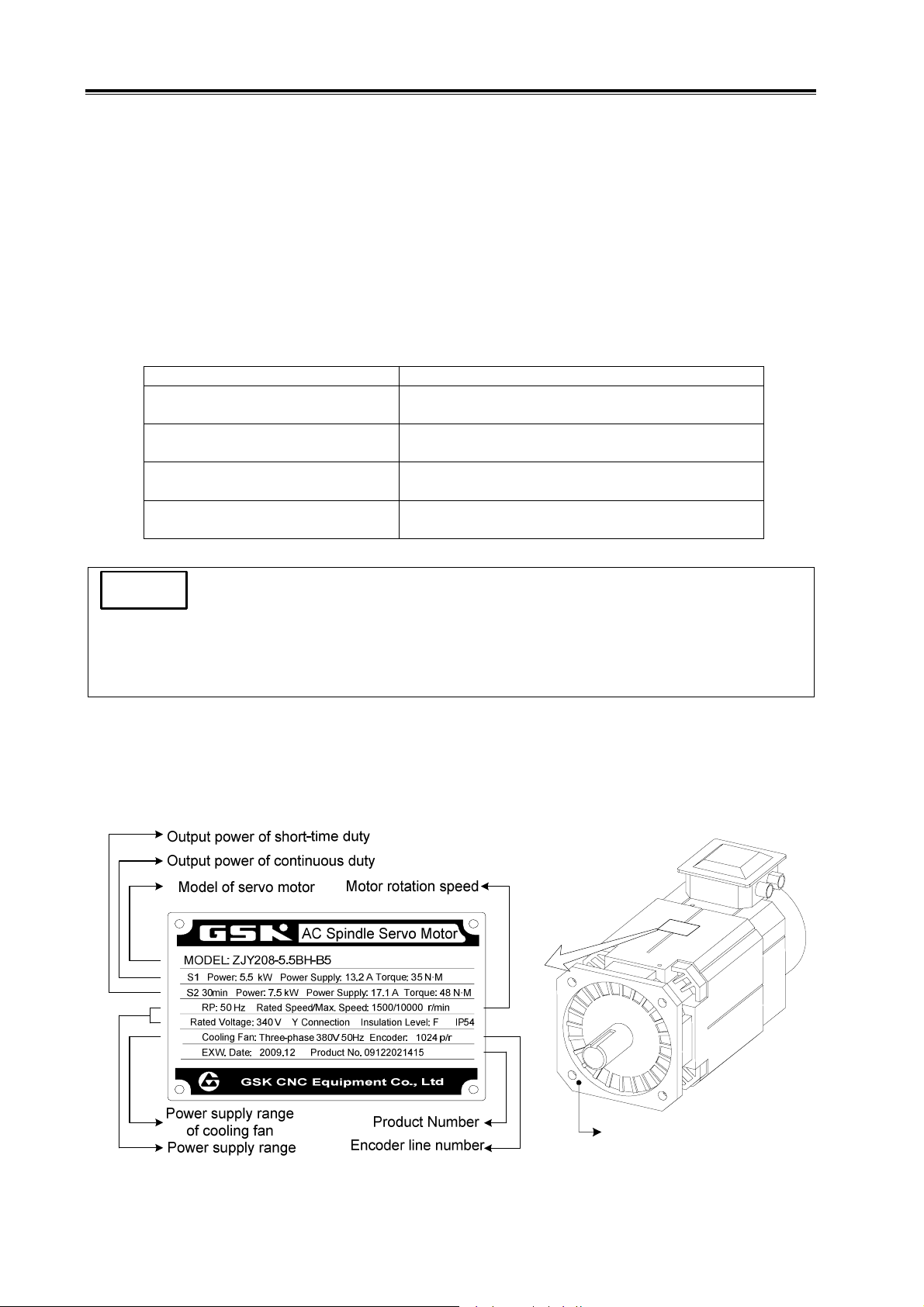

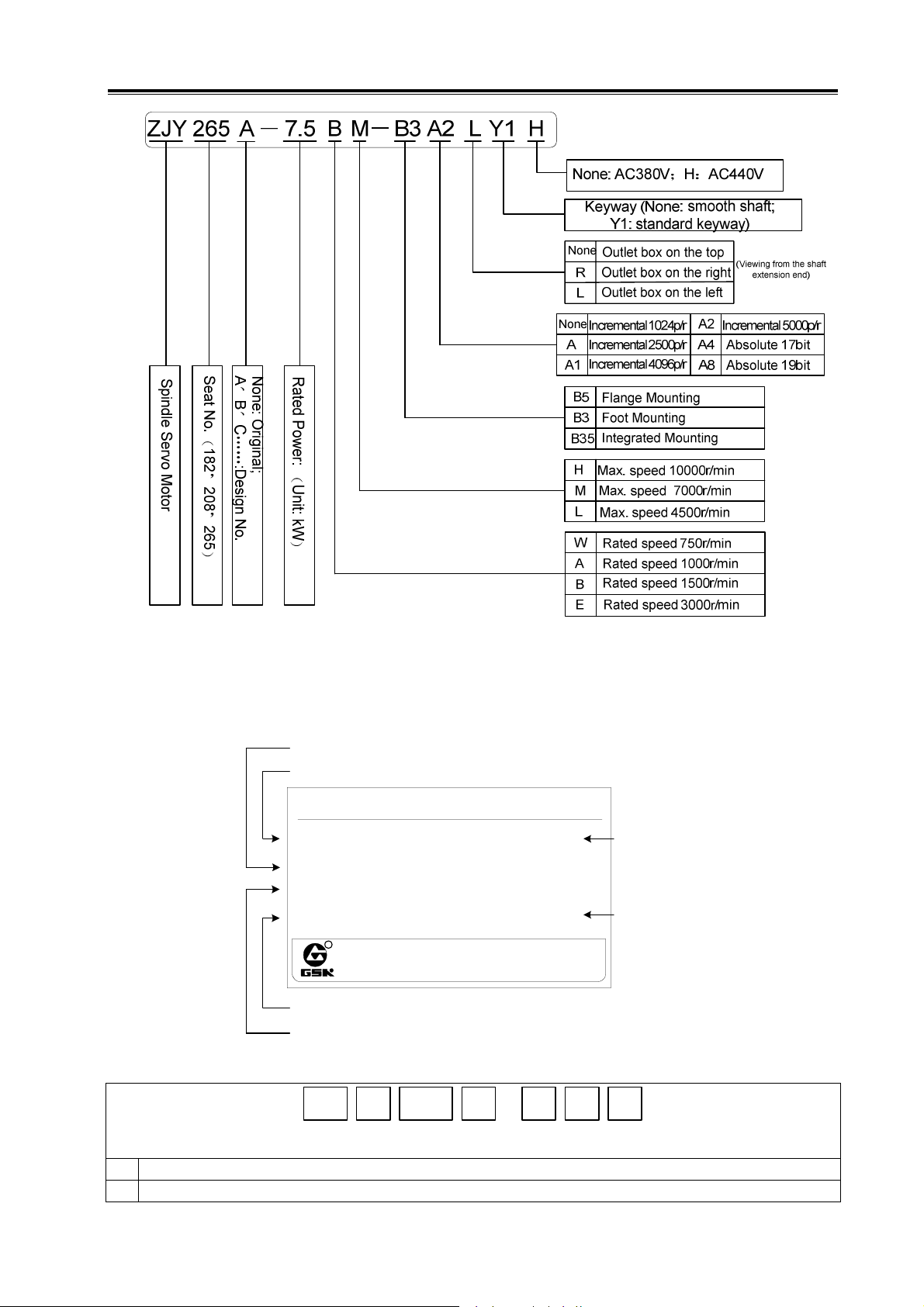

1.2.1 Instruction of AC Spindle Servo Motor Model

¾ Nameplate of spindle servo motor:

Flange mounting plane B5

¾ Instruction of spindle servo motor model:

6

Page 17

Chapter I Instruction

1.2.2 Instruction of Spindle Servo Unit

Example: (nameplate)

Corresponding servo motor model

Product model

AC Asynchronous Spindle Servo Unit

Model: SVD:

GS3075Y-CP2-7.5

Servo Motor

Input Power

No.

R

Product number

Input power supply

Model instruction:

ZJY-208-7.5BH

Three-phase 380V(-15%~+10%)50/60Hz

100620

EXW. Date

GSK CNC Equipment Co., Ltd

Tel .020 -83969288 Fax.81997083

V3.04

2010/9

Software version

Ex-factory date

GS 3 075 Y C P

①② ③

GS Series MDR Servo Unit, G: GSK; S: SERVO

①

Voltage grade code, 2: 220V; 3: 380V; 4: 440V.

②

④

-

⑤⑥2⑦

7

Page 18

GS Series Spindle Servo Drive Unit User Manual

Nominal current of power component (in three digits): 048, 050, 075, 100, 148, 150 (unit: A)

③

Motor type: T: synchronous servo motor; Y: asynchronous servo motor.

④

Communication bus code; N: none; C: GSK-CAN; L: GSK-Link

⑤

Feedback (encoder) interface type code; P: incremental encoder; A: Absolute encoder, no backup battery; B:

⑥

absolute encoder (with backup battery which is used when power-off).

Feedback (encoder) interface configuration code (in 1 digit); 1: The input interface CN2 for motor feedback

(i.e., the 1

⑦

feedback.

Position feedback signal interface type and configuration:

st

position feedback); 2: Input interfaces CN2 and CN3 for motor feedback and the 2nd position

⑥ ⑦

1

CN2; incremental encoder;

Instruction for feedback (encoder) interface type and configuration

P

2 CN2 and CN3; incremental encoder;

CN2; incremental encoder or absolute encoder (compatible with Biss and TAMAGAWA

1

A

(B)

communication protocols; automatic identification);

CN2 and CN3; incremental encoder or absolute encoder (compatible with Biss and

2

TAMAGAWA communication protocols; automatic identification);

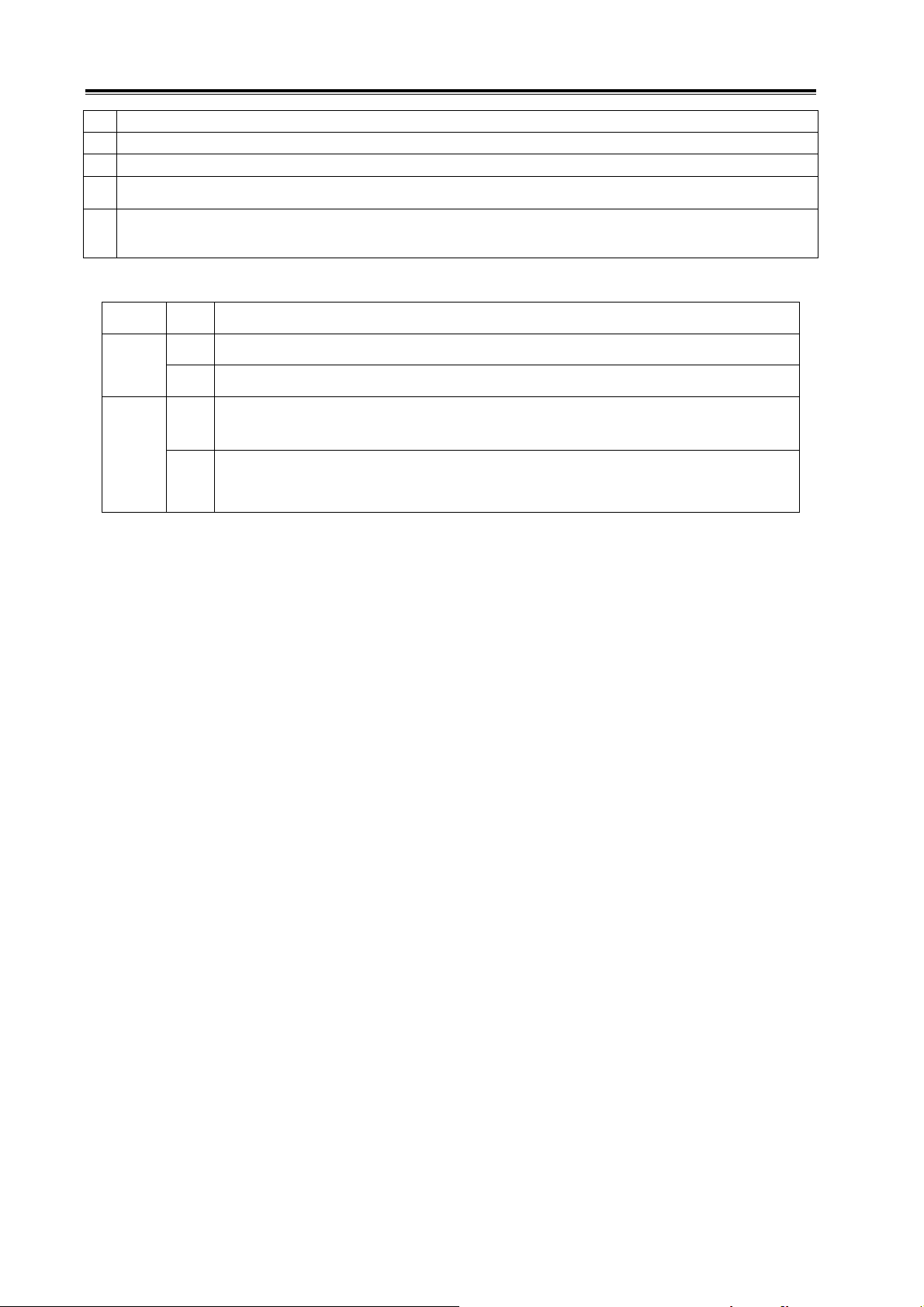

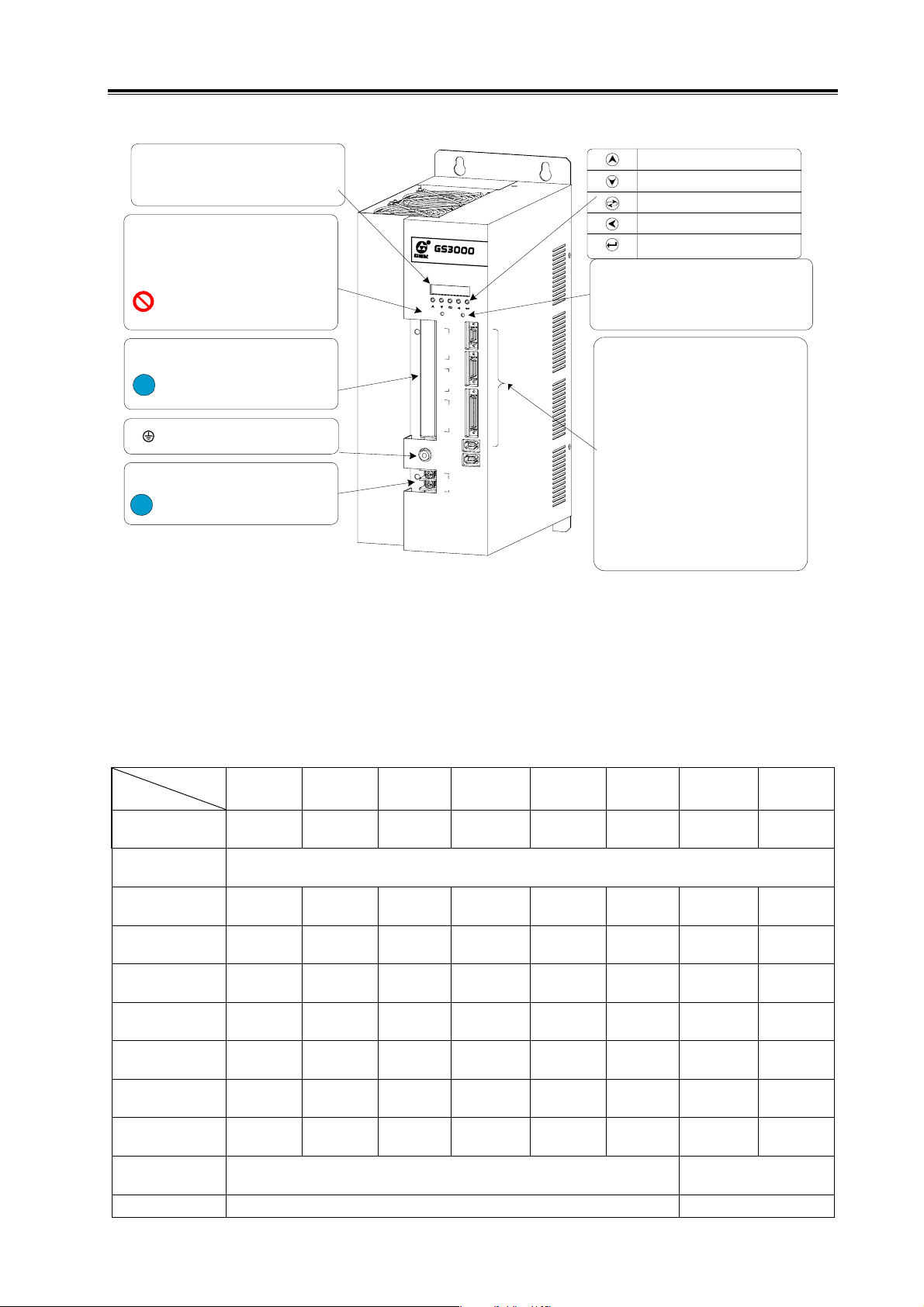

1.2.3 Overall Appearance of Spindle Servo Unit

According to different signal interfaces, the GS Series Spindle Servo Unit can be divided into

D-SUB type and MDR type. The products that adopt D-SUB interfaces provided by WIESON

Company belong to D-SUB type. They are matched with incremental encoder and not equipped with

GSK-CAN. The products that adopt MDR interfaces provided by 3M Company belong to MDR type.

They are compatible with absolute encoder and equipped with GSK-CAN bus.

8

Page 19

Chapter I Instruction

z Overall Appearance of GS Series AC Spindle Servo Unit (D-SUB Type)

The figure below shows the structure of following products: GS3048Y-N Series, GS3050Y-N

Series, GS3075Y-N Series GS3100Y-N Series, GS3148Y-N Series, GS4048Y-N Series, GS4050Y-N

Series, GS4075Y-N Series, GS4100Y-N Series, GS4148Y-N Series.

Increase parameter number

and value.

Decrease parameter

number and value.

Move to the digit to be edited.

Return to the previous menu or

cancel the last operation.

Enter to a sub-menu or

confirm the operation

Indicator

‘CHARGE” is the indicator of DC

bus voltage in the main circuit.

ON: normal

OFF: the bus is discharged

When ‘CHARGE' indicator comes

ON, connecting or disconnecting the

servo unit line, power supply line, motor

line or braking resistor line is forbidden.

Terminal block of main circuit

Connection should be done

according to contents in Section

!

3.2.2 with suitable terminals, and

tighten the screw afterwards.

:input power ground; GND

of motor protective ground

R

S

r

e

i

e

s

C

A

e

S

o

v

r

M

t

o

r

o

D

i

r

e

v

U

n

t

i

C

H

A

G

R

E

P

O

W

E

R

C

N

3

C

N

2

C

N

1

LED monitoring window

Monitor the running status or

parameter modification and

management.

Indicator

‘POWER’ is the indicator of

power supply of control circuit.

ON: normal

OFF: power failure

CN1: Control signal interface

(44-pole DB female)

For external speed command signal,

position command signal and output

signal

CN2: encoder feedback input interface

For incremental encoder differential

signal, motor position feedback input

(25-pole DB female)

CN3: 2nd position encoder feedback

input interface

For incremental encoder differential signal,

spindle encoder position feedback input

(9-pole DB female)

Open

R

~380V

S

T

BRAKE

P

B

U

MOTOR

V

W

r

380V

t

Terminal block of main circuit

Check the nameplate before

!

connection; make sure that the input

power voltages R, S, T, r, t are

correct. Connect to U, V, W as

market at the terminal end; if Err-27

occurs, exchange any of the two

phases.

Fig. 1-9 (a) Overall appearance of GS Series AC spindle servo unit (D-SUB type)

9

Page 20

GS Series Spindle Servo Drive Unit User Manual

The figure below shows the structure of following D-SUB products: GS3150Y-N Series,

GS4150Y-N Series.

Fig. 1-9 (b) Overall appearance of GS Series AC spindle servo unit (D-SUB type)

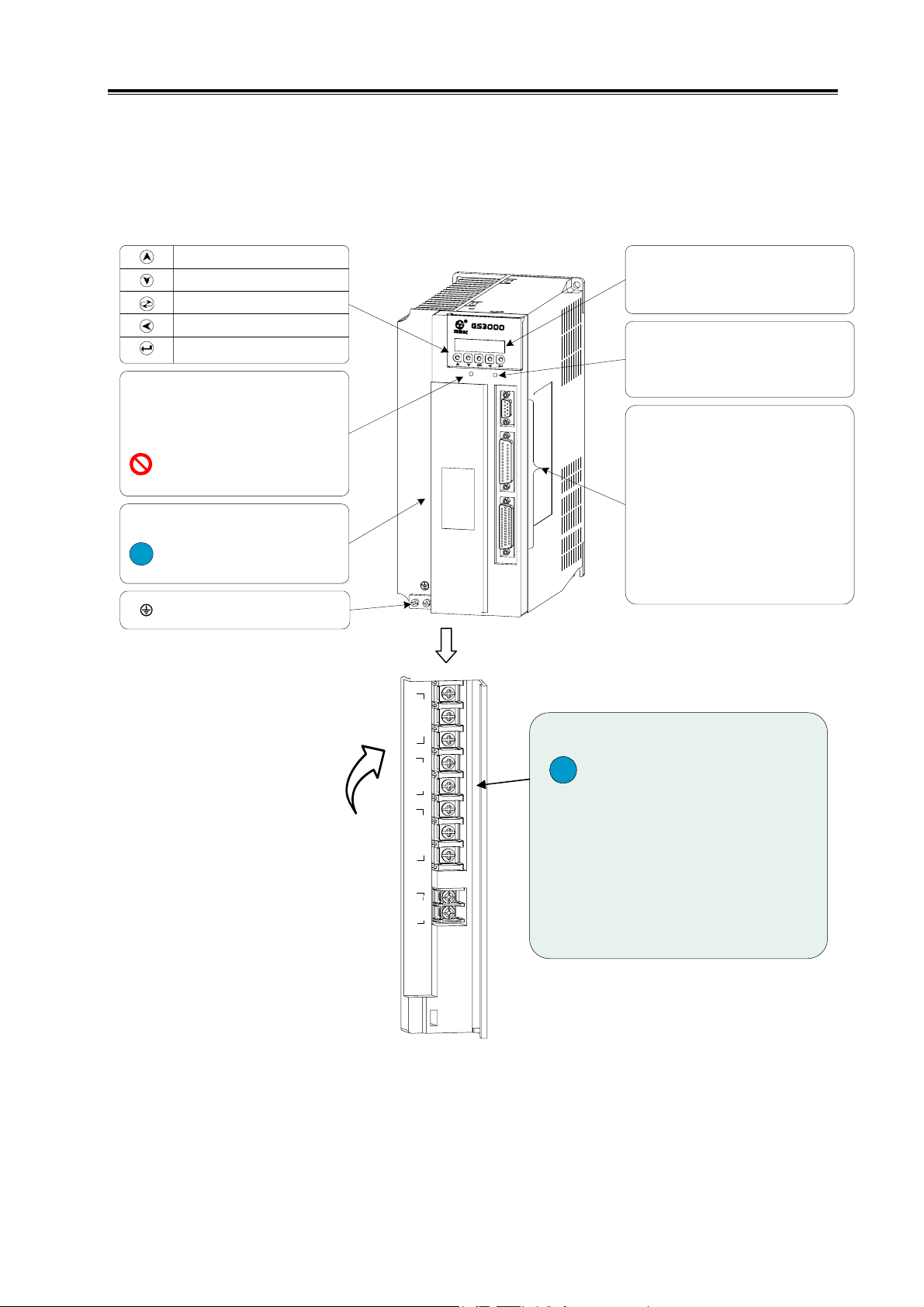

z Overall Appearance of GS Series AC Spindle Servo Unit (MDR Type)

The figure below shows the structure of following products: GS3048Y-C Series, GS3050Y-C

Series, GS3075Y-C Series, GS3100Y-C Series, GS3148Y-C Series, GS4048Y-C Series,

GS4050Y-C Series, GS4075Y-C Series, GS4100Y-C Series, GS4148Y-C Series.

Backup battery

(See the instruction of servo unit model)

Increase parameter number

and value.

Decrease parameter

number and value.

Move to the digit to be edited.

Return to the previous menu or

cancel the last operation.

Enter to a sub-menu or

confirm the operation

Indicator

‘CHARGE” is the indicator of DC

bus voltage in the main circuit.

ON: normal

OFF: the bus is discharged

When ‘CHARGE' indicator comes

ON, connecting or disconnec ting the

servo unit line, power supply line, motor

line or braking resistor line is forbidden.

Terminal block of main circuit

Connection should be done

according to contents in Section 3.2. 2

with suitable terminals, and tighten

!

the screw afterwards.

:input power ground; GND

of motor protective gr ound

R

S

r

e

s

i

e

A

C

S

e

o

r

v

M

o

o

r

t

D

v

r

i

e

U

n

i

t

C

R

A

H

E

G

P

O

R

E

W

C

N

3

C

N

2

C

N

1

C

N

4

C

N

5

LED monitoring window

Monitor the running sta tus or

parameter modification and

management.

Indicator

‘POWER’ is the indicator of power

supply of control circuit.

ON: normal

OFF: power failure

CN1: control signal interface

(50-pin high-density )

For external speed command signal, posit ion

command signal, input/output signal.

CN2: encoder feedback input

interface (26-pin high-density)

For incremental or absolute encoder

feedback input signal

CN3: 2nd position encoder feedback

input interface (20-pin high-density)

For spindle encoder position feedback

input, incremental or absolute input signal.

CN4, CN5: GSK-CAN

communication interface

Realize servo unit commissioning and

real-time monitoring.

10

Fig. 1-10 (a) Overall appearance of GS Series AC spindle servo unit (MDR type)

Page 21

Chapter I Instruction

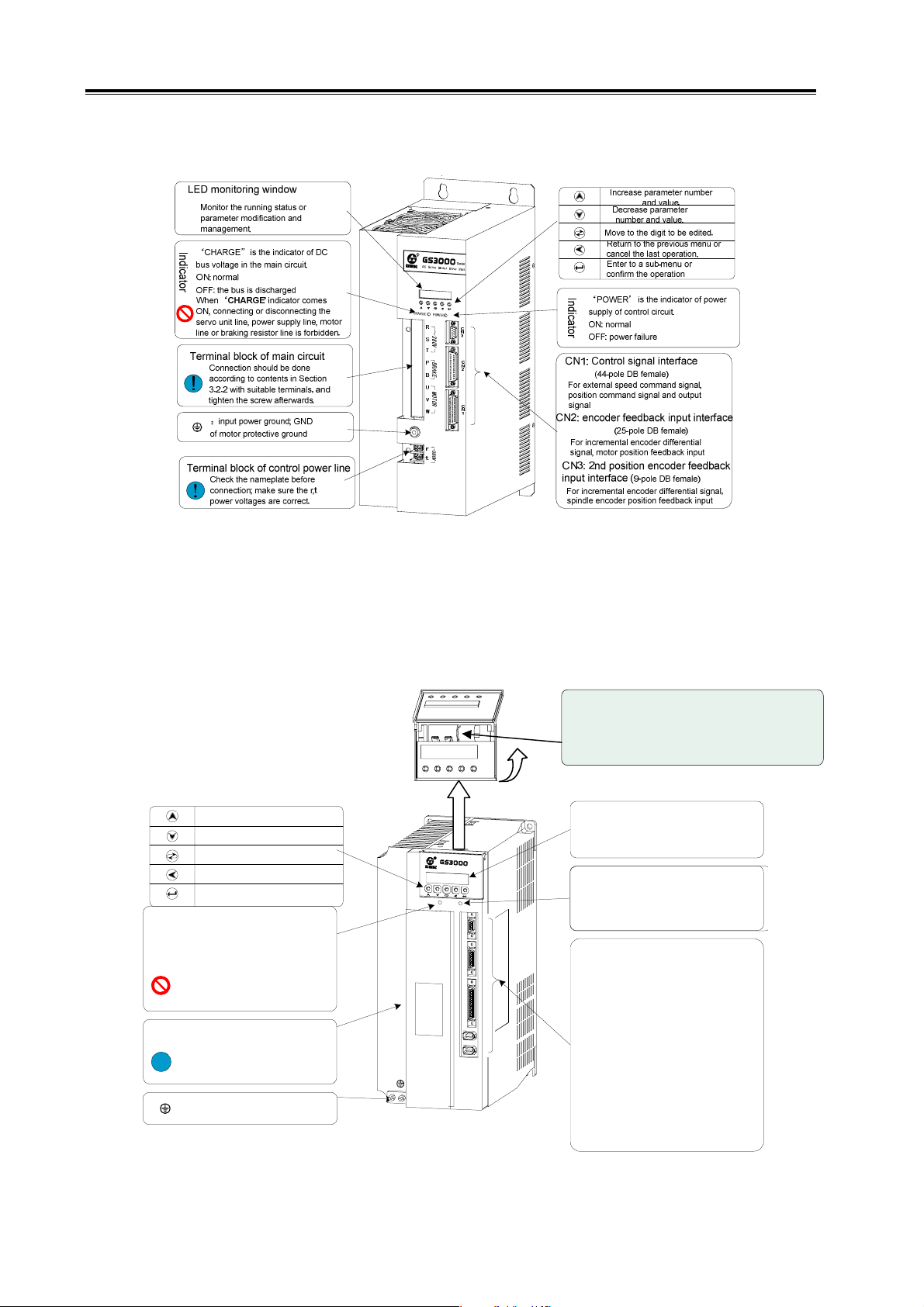

The figure below shows the structure of following products: GS3150Y-C Series, GS4150Y-C Series.

LED monitoring window

Monitor the running status or

parameter modification and

management.

Indicator

‘CHARGE” is the indicator of DC

bus voltage in the main circuit.

ON: normal

OFF: the bus is discharged

When ‘CHARGE' indicator comes

ON, connecting or disconnecting the

servo unit line, power supply line, motor

line or braking resistor line is forbidden.

Terminal block of main circuit

Connection should be done

according to contents in Section 3.2.2

with suitable terminals, and tighten

!

the screw afterwards.

:input power ground; GND

of motor protective ground

Terminal block of control power line

Check the nameplate before

connection; make sure the r,t

!

power voltages are correct.

Fig. 1-10 (b) Overall appearance of GS Series AC spindle servo unit (MDR type)

R

C

A

H

S

e

r

i

e

S

e

r

v

o

P

O

W

~380V

BRAKE

MOTOR

380V

s

M

t

o

o

r

D

r

v

i

e

U

i

n

t

E

R

C

N

3

C

N

2

C

N

1

C

N

4

C

N

5

A

C

R

G

E

R

S

T

P

B

U

V

W

r

t

Increase parameter number

and value.

Decrease parameter

number and value.

Move to the digit to be edited.

Return to the previous menu or

cancel the last operation.

Enter to a sub-menu or

confirm the operation

Indicator

‘POWER’ is the indicator of power

supply of control circuit.

ON: normal

OFF: power failure

CN1: control signal interface (50-

pin high-density )

For external speed command signal, position

command signal, input/output signal.

CN2: encoder feedback input

interface (26-pin high-density)

For incremental or absolute encoder

feedback input signal

CN3: 2nd position encoder feedback

input interface (20-pin high-density)

For spindle encoder position feedback

input, incremental or absolute input signal.

CN4, CN5: GSK-CAN

communication interface

Realize servo unit commissioning and

real-time monitoring.

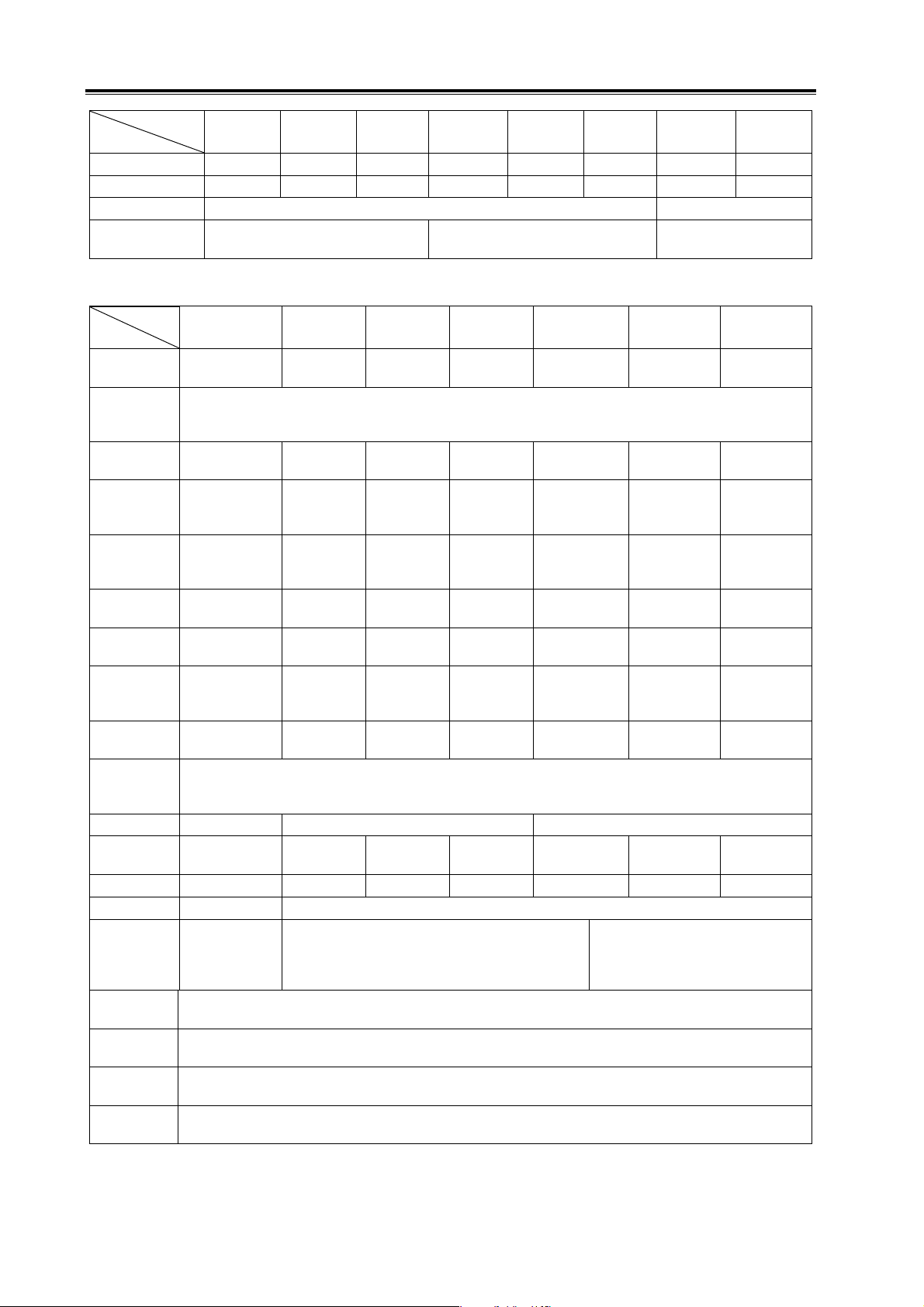

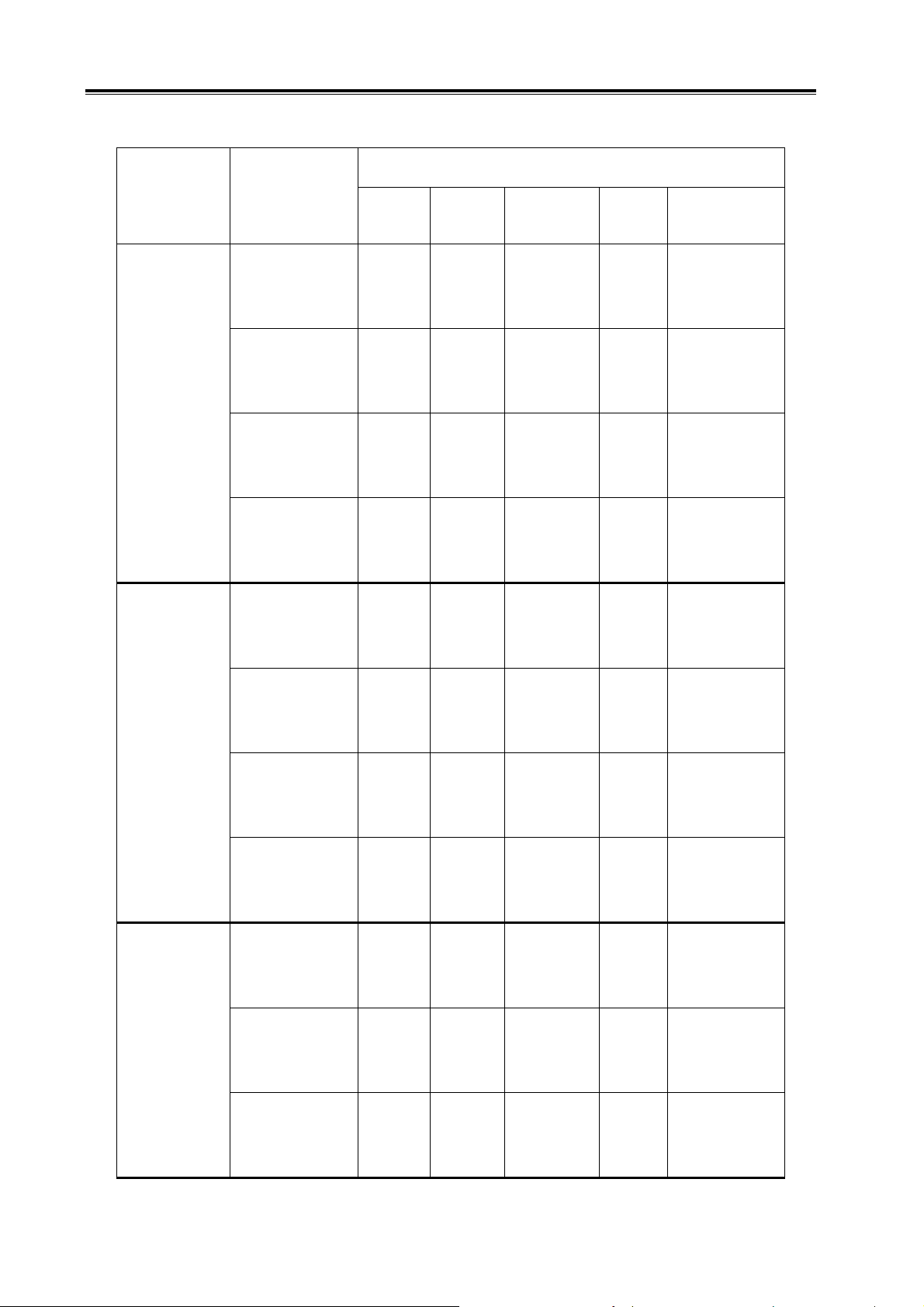

1.3 Technical Specification

1.3.1 Technical Specification of Spindle Motor

SPEC

Item

Rated power

(kW)

Servo Unit

Power Supply

Rated Current

(A)

Rated

Frequency(Hz)

Rated

Torque(N·m)

30min Power

(kW)

30min Current

(A)

30min Torque

(N·m)

Rated Speed

(r/min)

Constant Power

Range

Max. Speed

ZJY208

-2.2AM

ZJY208

-3.7AM

ZJY208

-5.5AM

ZJY265

-7.5AM

2.2 3.7 5.5 7.5 11 15 1.5 2.2

Three-phase AC 380V 50 Hz /60Hz

6.7 10.2 15.5

21 31 48.3

33.3 33.3 33.3 33.3 33.3 33.3 50 50

21 35 53

72 105 143

3.7 5.5 7.5 11 15 18.5 2.2 3.7

9.8 13.8 19.6

35 53 72

1000

1000

1000

28 39 56

105 143 177

1000 1000 1000

1000~4000

M:7000 H:10000

ZJY265

-11AM

ZJY265

-15AM

ZJY182

-1.5BH

ZJY182

-2.2BH

7.3 7.5

9.5 14

9.3 11

14 24

1500

1500

11

Page 22

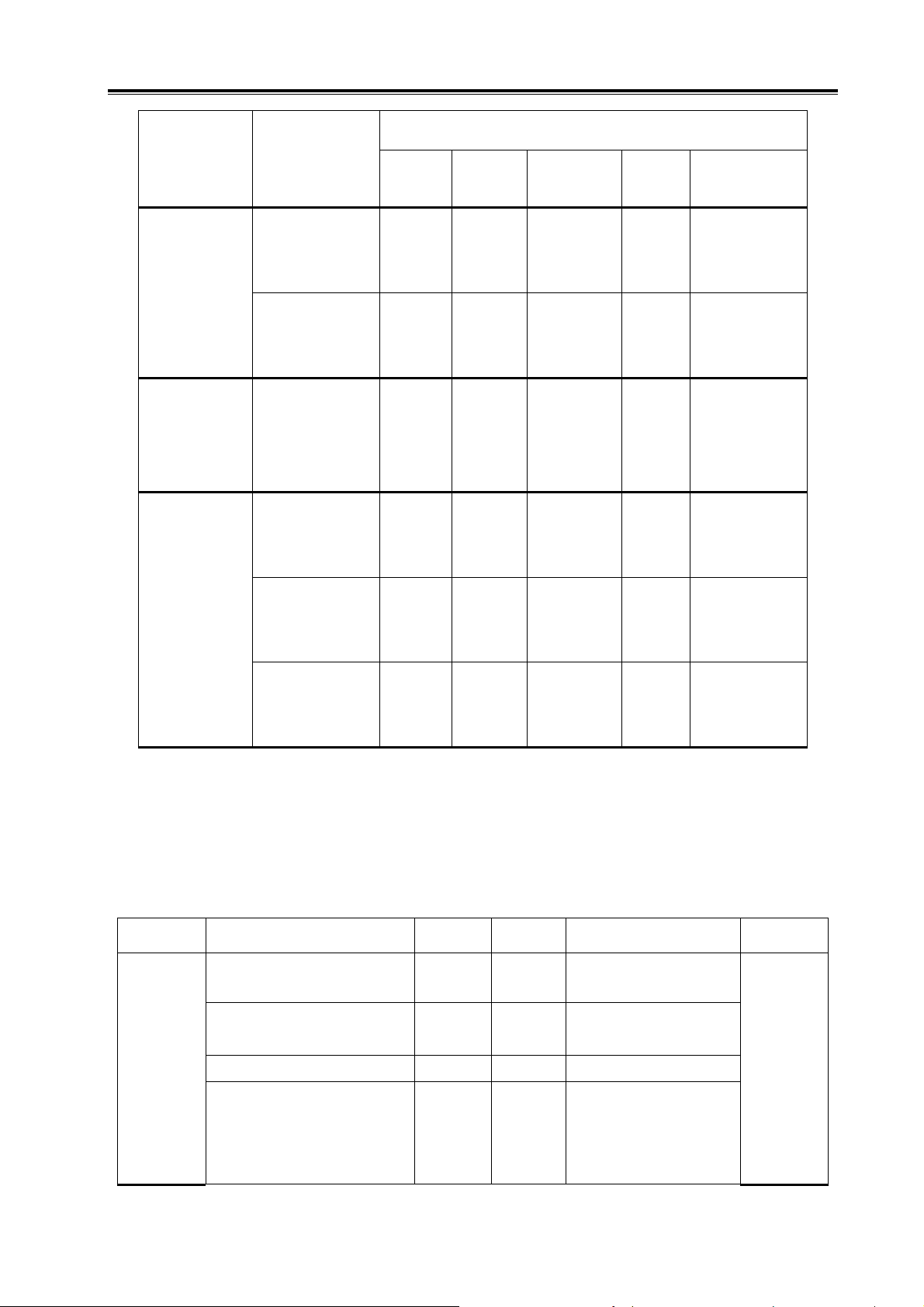

GS Series Spindle Servo Drive Unit User Manual

SPEC

Item

Rotary Inertia

Weight (kg)

Installation

Power Supply of

Cooling Fan

SPEC

Item

Rated Power

(kW)

Servo Unit

Power

Supply

Rated

Current (A)

Rated

Frequency

(Hz)

Rated

Torque

(N·m)

30min Power

(kW)

30min

Current (A)

30min

Torque

(N·m)

Rated Speed

(r/min)

Constant

Power

Range

Max. Speed

Rotary

Inertia

Weight (kg)

Installation

Power

Supply of

Cooling Fan

Protection

Level

Insulation

Level

Vibration

Level

Internal

Encoder

ZJY182-3.7BH

Three-phase

ZJY208

-2.2AM

0.0168 0.0238 0.0309 0.0413 0.0826 0.086 0.0056 0.0074

51 66 77 51 125 143 27 32

Three-phase AC 380V 50Hz 40W

3.7 3.7 5.5 7.5 7.5 11 15

15.5

50 50 50 50 50 50 50

24

5.5 5.5 7.5 11 11 15 18.5

19.6

35

1500

H:10000 M:7000, H:10000 M:7000

0.0115 0.0168 0.0238 0.0309 0.0413 0.0744 0.0826

43 51 66 77 89 107 125

IM B35 IM B5 or B3

AC 380V

50Hz 30W

0.08A

ZJY208

-3.7AM

0.14A

ZJY208-3.7B ZJY208-5.5B ZJY208-7.5B ZJY265-7.5BM ZJY265-11BM ZJY265-15B

8.9 13.7 18.4 18 26 35

24 35 48 49 72 98

13 18 25 26 34 42

35 48 70 74 100 123

1500 1500 1500 1500 1500 1500

Three-phase AC 380V 50Hz 40W 0.14A

ZJY208

-5.5AM

IM B5 or B3 IM B35

Three-phase AC 380V 50 Hz /60Hz

ZJY265

-7.5AM

Three-phase AC 380V 50Hz 70W

1500~5000

IP54(GB/T 4942.1—2006)

F (GB 755—2008)

R(GB 10068—2008)

Incremental encoder1024 p/r

ZJY265

-11AM

0.21A

ZJY265

-15AM

Three-phase AC 380V 50Hz

ZJY182

-1.5BH

Three-phase AC 380V

50Hz 30W 0.08A

70W 0.21A

ZJY182

-2.2BH

M

12

Page 23

Chapter I Instruction

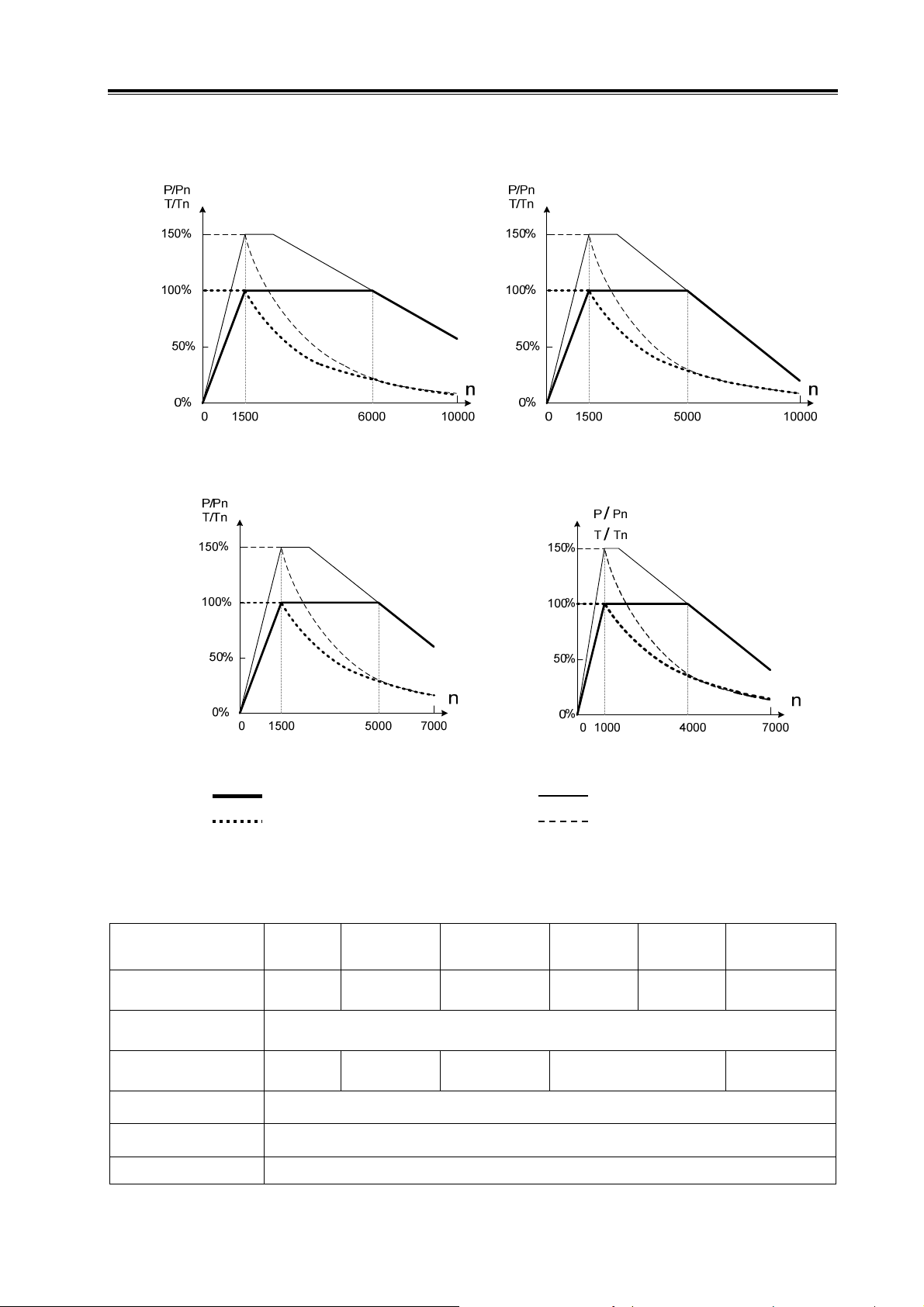

Mechanical Characteristics of Motor

P/P

: Power/Rated power; T/TN: Torque/Rated torque; n: Rotation speed of spindle servo motor;

N

ZJY182 rated rotation speed: 1500r/min ZJY208 rated rotation speed: 1500r/min

ZJY265 rated rotation speed: 1500r/min ZJY208, ZJY265 rated rotation speed: 1500r/min

Power in continuous working status; Power in 30min’s working status;

Torque in continuous working status; Torque in 30min’s working status

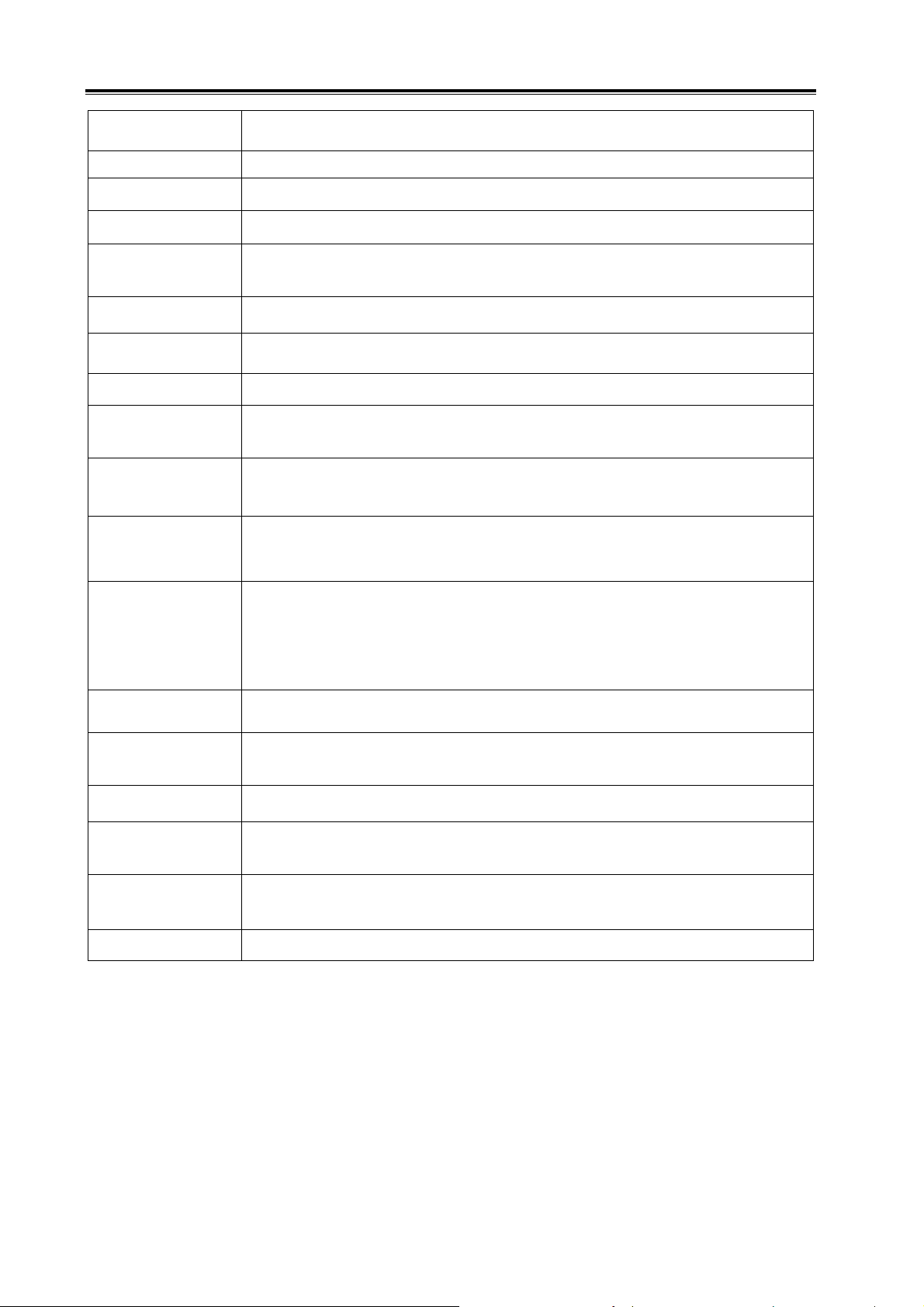

1.3.2 Technical Specification of AC Spindle Servo Unit

Model

Rated Power (kW)

Input Power

Dimension (mm)

(width×height×depth)

Regulating Range

(r/min)

Speed Fluctuation

Rate

Working Mode

GS3048Y

GS4048Y

1.5, 2.2 3.7, 5.5 5.5, 7.5 7.5, 11 11 15, 18.5

Input power of GS3□□□Y Series is: Three-phase AC380V(0.85~1.1), 50/60Hz±1Hz

Input power of GS4□□□Y Series is: Three-phase AC440V(0.85%~1.1), 50/60Hz±1Hz

112×230×1

82

GS3050Y

GS4050Y

120×270×218 130×305×248.5 160×305×273.5 160×370×273.5

MANUAL, JOG, SPEED, POSITION, SPEED/POSITION

GS3075Y

GS4075Y

< Rated Speed ×0.1%

GS3100Y

GS4100Y

1~10000

GS3148Y

GS4148Y

GS3150Y

GS4150Y

13

Page 24

GS Series Spindle Servo Drive Unit User Manual

Internal Speed Mode

External Speed Mode

External Speed

Command Mode

Speed Command

Electronic Gear

Position Mode

Position Command

Pulse Mode

Position Command

Electronic Gear

Positioning Accuracy

Orientation

Motor Feedback Input

nd

2

Position Feedback

Input

(optional)

Position Feedback

Output

Communication Bus

Input Signal

Output Signal

Function Protection

Operation and Display

Braking Resistor

Motor rotates at the speeds set by internal parameters (speed closed-loop control)\

Running speed is selected by input signal.

Motor rotates at the speed specified by external analog voltage (speed closed-loop control)

-10V~+10V or 0V~+10V, selected by parameters

Speed command frequency multiplication; frequency division coefficient:1~100

Motor rotates by position pulse command (position closed-loop control); the direction and

quantity of pulse command determine the rotation direction and angle; the pulse frequency

determines the rotation speed.

Pulse/direction; CCW pulse/CW pulse; A/B two-phase orthogonal pulse; max. pulse

frequency: 1MHz

Command pulse frequency multiplication coefficient: 1~32767; Command pulse frequency

division coefficient: 1~32767

±0.088° (matched with incremental encoder with 1024 lines)

4-point orientation; 4 orientation angle is set by parameters; orientation position is selected

through input signal; orientation error is ±180°/C (C is the line number of position feedback

encoder)

GS3□□□Y-NP2 and GS4□□□Y-NP2(D-SUB type: adopt incremental encoder;

GS3□□□Y-C□2 and GS4□□□Y-C□2(MDR type: adopt incremental encoder or absolute

encoder (compatible with two communication protocols: Biss and TAMAGAWA).

GS3□□□Y-NP2(D-SUB type: adopt incremental encoder;

GS3□□□Y-C□2(MDR type: adopt incremental encoder or absolute encoder (compatible with

two communication protocols: Biss and TAMAGAWA).

nd

GS3□□□Y-NP2(D-SUB type: motor feedback input signal or 2

signal output in 1:1;

GS3□□□Y-C□2(MDR type): motor feedback input signal or 2

position feedback input

nd

position feedback input

signal output in frequency division; the range of numerator and dominator in position

feedback output gear ratio is 1~32767, and the dominator should be larger than or equal to

numerator;

GS3□□□Y-NP2 and GS4□□□Y-NP2(D-SUB type): no communication bus;

GS3□□□Y-C□2 and GS4□□□Y-C□2(MDR type): GSK-CAN

Servo enable; CCW start; CW start; orientation/speed selection; orientation start; 2

nd

speed

gain selection; spindle clamping interlock signal; zero-speed clamping; alarm clear;

speed/position switching

Servo ready; zero speed output; position/speed arrival; orientation completed; alarm output

speed/position status; encoder zero point;

Undervoltage protection; overvoltage protection; servo unit overcurrent protection; servo

motor thermal overload protection; overspeed protection; overshoot protection; brake

abnormality protection; encoder abnormality protection; motor overheat protection.

5 keys for manual, JOG operation and parameter modification, setting, writing and backup;

6-digit LED displays rotation speed, current position, command pulse accumulation, position

deviation, motor torque, motor current, absolute position of rotator, I/O signal status etc.

Externally connected (no internal braking resistor)

Note: CCW means the motor rotates in counter clockwise direction (viewing from the shaft extension side).

CW means the motor rotates in clockwise direction (viewing from the shaft extension side).

14

Page 25

Chapter I Instruction

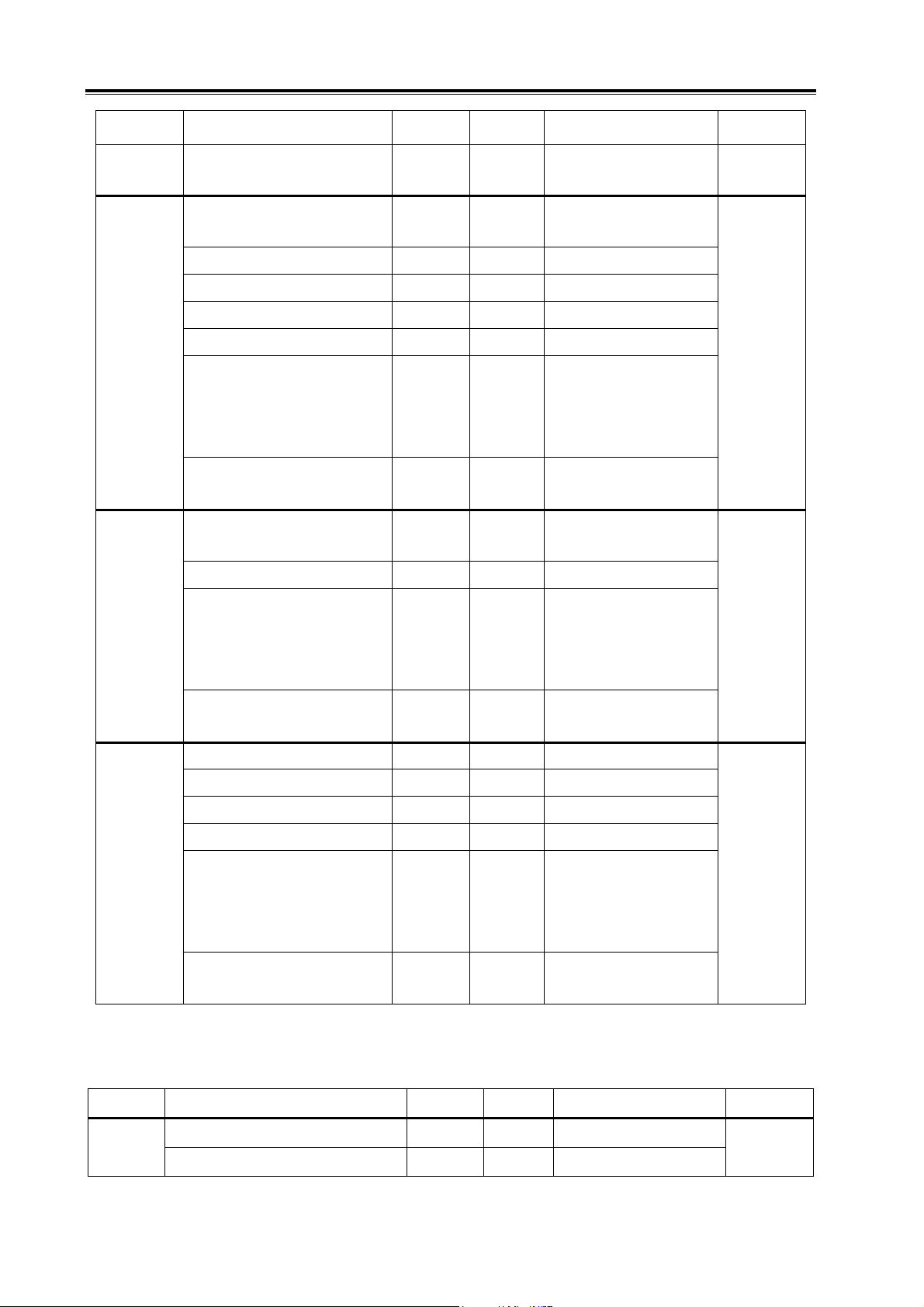

1.4 Ordering Guidelines

1.4.1 Model Selection Process

1.5,2.2,3.7,5.5,

7.5,11,15,18.5 are

optional (Unit: kW)

1. Low: 4500r/min;

2: Medium:7000r/min;

3. High: 10000r/min;

Rated rotation speed is

1000r/min (recommended in

turning machine)

Rated rotation speed is

1500r/min (recommended in

milling machine)

1. Flange mounting or foot

mounting;

2. With or without a keyway;

Pay attention to the

difference between

economical type and

universal type

Select motor

power

Select the rated

rotation speed

Select the max.

rotation speed

Select the

mounting method

Select the

encoder

Select the

motor model

Select the servo

unit model

After selecting the motor model, you can select the servo unit model according to the relationship

described in 1.4.2.

1.4.2 Examples

1. The model of GS Series servo device (including ZJY Series spindle servo motor) is shown as

follows:

GS servo unit model — ZJY spindle servo motor model

Example: GS3075Y-NP2—ZJY208-7.5BM -B5LY1

Instruction: the model of spindle servo unit is GS3075Y-NP2, and the corresponding model

of spindle servo motor is ZJY208-7.5BM -B5ALY1. The accessories are the

standard ones (see Section 1.4.3).

2. The model of GS Series servo device (not including ZJY Series spindle servo motor) is shown

as follows:

GS servo unit model —

Example: GS3075Y-NP2—(ZJY208-7.5BM -B5LY1)

Instruction: the model of spindle servo unit is GS3075Y-NP2, and the ex-factory parameters

should be set according to the model in the brackets. The accessories are the

standard ones (see Section 1.4.3).

(Servo motor model )

15

Page 26

GS Series Spindle Servo Drive Unit User Manual

Model list of GS Series servo unit and ZJY Series servo motor:

Servo Unit

Model

GS3048Y-NP2

GS3048Y-CP2

GS4048Y-NP2

GS4048Y-CP2

Major Parameters of Spindle Motor

Motor Model

ZJY182-1.5BH 1.5kW 1500 rpm 10000rpm 7.3 A

ZJY182-2.2BH 2.2kW 1500 rpm 10000rpm 7.5 A

ZJY208-2.2AM 2.2kW 1000rpm 7000rpm 6.7A

ZJY208-2.2BM 2.2kW 1500rpm 7000rpm 9.3A

ZJY182-3.7BH 3.7kW 1500 rpm

Rated

Power

Rated

Speed

Max. Speed

Rated

Current

7000rpm

15.5 A

(10000rpm)

Standard Encoder

1024-line

incremental

encoder

1024-line

incremental

encoder

1024-line

incremental

encoder

1024-line

incremental

encoder

1024-line

incremental

encoder

GS3050Y-NP2

GS3050Y-CP2

GS4050Y-NP2

GS4050Y-CP2

GS3075Y-NP2

GS3075Y-CP2

GS4075Y-NP2

GS4075Y-CP2

ZJY208-3.7AM 3.7kW 1000rpm 7000rpm 10.2A

ZJY208-3.7BM

3.7kW 1500rpm

(ZJY208-3.7BH)

ZJY208-5.5BM

5.5kW 1500rpm

(ZJY208-5.5BH)

ZJY208-5.5AM 5.5kW 1000rpm 7000rpm 15.5A

ZJY208-7.5BM

7.5kW 1500rpm

(ZJY208-7.5BH)

7000rpm

8.9A

(10000rpm)

7000rpm

13.7A

(10000rpm)

7000rpm

18.4A

(10000rpm)

1024-line

incremental

encoder

1024-line

incremental

encoder

1024-line

incremental

encoder

1024-line

incremental

encoder

1024-line

incremental

encoder

1024-line

16

ZJY265-7.5BM 7.5kW 1500rpm 7000rpm 18A

incremental

encoder

Page 27

Chapter I Instruction

Servo Unit

Model

GS3100Y-NP2

GS3100Y-CP2

GS4100Y-NP2

GS4100Y-CP2

GS3148Y-NP2

GS3148Y-CP2

GS4148Y-NP2

GS4148Y-CP2

GS3150Y-NP2

GS3150Y-CP2

GS4150Y-NP2

GS4150Y-CP2

Major Parameters of Spindle Motor

Motor Model

ZJY265-7.5AM 7.5kW 1000rpm 7000rpm 21A

ZJY265-11BM 11kW 1500rpm 7000rpm 26A

ZJY265-11AM 11kW 1000rpm 7000rpm 31A

ZJY265-15AM 15kW 1000rpm 7000rpm 48.3A

ZJY265-15BM 15kW 1500rpm 7000rpm 35A

Rated

Power

Rated

Speed

Max. Speed

Rated

Standard Encoder

Current

1024-line

incremental

encoder

1024-line

incremental

encoder

1024-line

incremental

encoder

1024-line

incremental

encoder

1024-line

incremental

encoder

1024-line

ZJY265-18.5BM 18.5kW 1500rpm 7000rpm 48.7A

incremental

encoder

1.4.3 Standard Ex-factory Accessories

The standard ex-factory accessories are listed in the table below. If additional accessories

are needed otherwise, please contact our sales office or technical personnels.

z GS Series MDR product accessories list

Type Name Model Number Explanation Remark

Servo unit

(separate

order

-no spindle

servo

motor)

DB-44 male plug and plastic

case

DB-25 male plug and plastic

case

DB-9 male plug and plastic case 1 CN3 connecting plug

Aluminum-shell braking resistor Including 1m connecting

1

1

CN1 connecting plug

CN2 connecting plug

line (refer to Appendix C

for the specification and

quantity)

17

Page 28

GS Series Spindle Servo Drive Unit User Manual

Type Name Model Number Explanation Remark

Servo unit

and spindle

servo

motor

Servo unit

(without

spindle

servo

motor) and

CNC

system

GS Series Spindle Servo Unit

Manual

DB-44 male plug and plastic

case

DB-9 male plug and plastic case 1 CN3 connecting plug

Motor encoder line -00-761A 1 Standard length: 3m

Motor encoder line -00-765* 1 Standard length: 3m

Motor fan line -00-768A 1 Standard length: 3m

Aluminum-shell braking resistor Including 1m connecting

GS Series Spindle Servo Unit

Manual

DB-25 male plug and plastic

case

DB-9 male plug and plastic case 1 CN3 connecting plug

Aluminum-shell braking resistor Including 1m connecting

GS Series Spindle Servo Unit

Manual

1 Technical materials

1

1 Technical materials

1

CN1 connecting plug

line (refer to Appendix C

for the specification and

quantity)

CN2 connecting plug

line (refer to Appendix C

for the specification and

quantity)

Technical materials

1

Matched

with ZJY

Series

spindle

servo motor

CN1-CNC

signal

connecting

cable is

provided

together

with CNC

system

DB-9 male plug and plastic case 1 CN3 connecting plug

CN1-CNC

signal

connecting

cable is

provided

together

with CNC

system

Servo unit,

spindle

servo

motor and

CNC

system

Motor encoder line -00-761A 1 Standard length: 3m

Motor power line -00-765* 1 Standard length: 3m

Motor fan line -00-768A 1 Standard length: 3m

Aluminum-shell braking resistor Including 1m connecting

line (refer to Appendix C

for the specification and

quantity)

GS Series Spindle Servo Unit

Manual

1 Technical materials

Note 1: A fan with 440V power should be selected to match with GS4000 Series spindle motor.

z GS Series MDR product accessories list

Type Name Model Number Explanation Remark

Servo unit,

servo

MDR20 (20pin) plug and plastic case 1 CN3 connecting plug

Motor encoder line -00-761A 1 Standard length: 3m

Servo signal

line,

18

Page 29

Chapter I Instruction

motor and

CNC

system

Motor power line -00-765* 1 Standard length: 3m; “*”

indicates the suffix letters

(see the Motor Power Line

Specification)

Aluminum-shell braking resistor Including 1m connecting

line; see Appendix C for

specification and quantity

GS Series Spindle Servo Unit Manual

1 Technical materials

GSK-CNC

communicati

on line and

terminal plug

are provided

together with

CNC system

Note 2: So far, GSK-CAN serial bus is supported in GSK988T. GS300Y-CP2 Series MDR spindle

servo unit is applicable.

1. Make clear the model, quantity of products to be ordered (servo unit, servo motor,

isolation transformer and CNC). When you need an exclusive software/hardware

version or optional accessories, write it on the order sheet.

2. Make clear the type, specification, quantity of non-standard accessories (such as special

cable or cable length, or special cable processing).

3. Make clear the code of shaft-extension, structure or leading-out pattern of servo motor.

Write special items on the order sheet.

4. When only servo unit (without servo motor) is ordered, write the model of servo model

behind the servo unit mode (for example: GS3050T-NP2

(ZJY182-3.7BH)). So that

relevant parameters can be set before delivery.

5. The spindle servo unit and servo motor with 3-phase AC440V input power are out of

stock. They are produced according to the order.

19

Page 30

GS Series Spindle Servo Drive Unit User Manual

20

Page 31

Chapter II Installation/Mounting

EFG

P

Q

L

KNA

CHAPTER II INSTALLATION/MOUNTING

2.1 Spindle Servo Motor

2.1.1 Dimensions for Spindle Motor Installation

φH

φJ

E F

T

S

φJ

G

Fig. 2-1 Flange mounting (B5)

4-φI

K

C

45°

B

φD

A

C

4-φ

Fig. 2-2 Foot mounting (B3)

E F

G

S

φJ

φH

P G

C L

4-φZ

K

45°

φD

4-φI

N

A

Fig. 2-3 Integrated Mounting (B35)

21

Page 32

GS Series Spindle Servo Drive Unit User Manual

Table 2-1 Motor Dimensions

SPEC

DIM

Eternal Dimension

ZJY208-2.

2AM

A 208 208 208 265 265 265 182 182

B 104 104 104 132 132 132

C 188 188 188 216 216 216 126 126

D 215 215 215 265 265 265 185 185

E 60 80 80 110 110 110 60 60

F 413 468 523 443 533 578 324 351

G 237 292 347 260 350 395 198 225

H 180h7 180h7 180h7 230h7 230h7 230h7 150h7 150h7

I 15 15 15 15 15 15 12 12

J 28h6 38h6 38h6 48h6 48h6 48h6 28h6 28h6

K 272 272 272 300 300 300 184 184

L 106 106 106 135 135 135 93 93

N 180 180 180 230 230 230 156 156

P 40 40 40 40 40 40 32 32

Q 210 265 320 225 315 355 132 159

S 60 80 80 110 110 110 60 60

T 5 5 5 5 5 5 4 4

Z 12 12 12 15 15 15 12 12

ZJY208-3.

7AM

ZJY208-5.

5AM

ZJY265-7.

5AM

ZJY265-1

1AM

ZJY265-1

5AM

ZJY182

-1.5BH

ZJY182

-2.2BH

DIM

Eternal Dimension

SPEC

ZJY182

-3.7BH

A 182 208 208 208 265 265 265 265 265

B 104 104 104 132 132 132 132 132

C 126 188 188 188 216 216 216 216 216

D 185 215 215 215 265 265 265 265 265

E 60 60 80 80 110 110 110 110 110

F 406 413 468 523 443 488 533 578 633

G 280 237 292 347 260 305 350 395 450

H 150h7 180h7 180h7 180h7 230h7 230h7 230h7 230h7 230h7

I 12 15 15 15 15 15 15 15 15

J 28h6 28h6 38h6 38h6 48h6 48h6 48h6 55h6 55h6

K 184 272 272 272 300 300 300 300 300

L 93 106 106 106 135 135 135 135 135

N 156 180 180 180 230 230 230 230 230

P 32 40 40 40 40 40 40 40 40

Q 214 210 265 320 225 270 315 355 410

S 60 60 80 80 110 110 110 110 110

T 4 5 5 5 5 5 5 5 5

Z 12 12 12 12 15 15 15 15 15

ZJY208

-3.7B

ZJY208

-5.5B

ZJY208

-7.5B

ZJY265

-7.5BM

ZJY265

-11BM

ZJY265

-15BM

ZJY265-

18.5BM

ZJY26522BM

22

Page 33

Chapter II Installation/Mounting

Standard Keyway Dimension

A: GB/T 1096—2003; dimension: 8×7×50; adaptable to motors ZJY182-1.5B, ZJY182-2.2B,

ZJY182-3.7B, ZJY208-3.7B. The shaft keyway dimension is shown in following figure:

2-R

5 50

60

24

0

-0.2

φ

-0.036

0

28h6

0

-0.013

8N9

B: GB/T 1096—2003; dimension: 10×8×70; adaptable to motors ZJY208-5.5B,

ZJY208-7.5B. The shaft keyway dimension is shown in following figure:

2-R

5 70

80

33

0

-0.2

0

φ

-0.036

38h6

10N9

0

-0.016

C: GB/T 1096—2003; dimension: 14×9×90; adaptable to motors ZJY265-7.5B, ZJY265-11B,

ZJY265-15B. The shaft keyway dimension is shown in following figure:

110

42.5

0

-0.2

φ 48h6

0

-0.016

2-R

7 90

2.1.2 Installation of Spindle Motor

Ambient for installation, storage and transportation:

Item Norm

Working Temperature

Storage and Transportation Temperature

Working Humidity

Storage and Transportation Humidity ≤95% (40 )℃

Atmospheric Environment No corrosive and flammable gas, oil fog or dust

Altitude Below 1000m

0

-0.043

14N9

℃~40℃

0

℃~70℃

-40

~95% (Non-condensing)

30%

23

Page 34

GS Series Spindle Servo Drive Unit User Manual

plug

¾ B5 flange mounting (or B35 flange mounting)

Motor ZJY182 adopts M10×35 Bolt or hex socket head bolt. A homemade socket head wrench

whose length is greater than that of the motor can be used to detach the robber plug on the cooling

fan. The robber plug should be pushed back after the bolt at the rear end is fastened. Shown as

follows:

Homemade

Bolt

Robber plug

Motor ZJY208 and ZJY265 adopt M12×45 Bolt or hex socket head bolt.

¾ B3 foot mounting (or B35 foot mounting)

Detach the covers of two sides at the rear end. For B35, it is needed to detach the robber plug on

the foot hole (see the following figure). Motor ZJY182 and ZJY208 adopt M10 Bolt or hex socket head

bolt; ZJY265 adopts M12 Bolt or hex socket head bolt.

24

Robber

The covers at two sides of the rear end should be mounted after the motor is firmly

fixed; otherwise, the cooling effect will be reduced as a result of air leak, thus causing

motor overheat.

1. If the motor running speed needs to be more than 2000r/min, a motor with smooth shaft

is recommended. Fasten the belt pulley with keyless locking device. Both of them have

undergone the dynamic balancing and meet the requirement of G1; otherwise, great

vibration will occur during high-speed running.

2. Reserve a certain space near outlet box cover for the convenience of screw detaching

and wiring. Please contact us if you cannot do it by yourself. Do not change the structure of

the motor.

Page 35

Chapter II Installation/Mounting

g

Prevent the motor from direct sun light and rain splash. The mounting parts need

to be ventilated, dampproof and dust-proof.

Avoid flammable atmosphere in case of fire disaster.

Do not strike the spindle motor with hard objects during installation and

dismantling.

There are fragile components in the

encoder. Do not subject the

encoder to any force or shock

during installation!

Do not subject the

wheel belly to any

force or shock

durin

installation!

2.2 Spindle Servo Unit

The installation ambient greatly affects the servo unit function and life cycle; please pay

attention to the following cautions:

Caution

Storage and Transportation Temperature

Storage and Transportation Humidity

z Avoid rain splash and direct sunlight.

z

Install the servo unit in electrical cabinet to avoid the invasion of dust,

corrosive gas, conductive contents and combustibles.

z

The mounting parts need to be ventilated, dampproof and dust-proof.

z

Avoid flammable atmosphere in case of fire disaster.

z

Select a proper installation position for easy maintaining and inspection.

Item Norm

Working Temperature

Working Humidity

Atmospheric Environment No corrosive and flammable gas, oil fog or dust

Altitude Below 1000m

Vibration ≤0.6G(5.9m/s2)

Atmospheric Pressure

℃~40℃

0

-40

℃~70℃

30%

~95% (Non-condensing)

≤95%

(40℃)

86kPa

~106kPa

25

Page 36

GS Series Spindle Servo Drive Unit User Manual

2.2.1 Installation Dimension

The dimensions of GS Series spindle servo unit are shown as follows:

Fig. 2-4 GS3048, GS4048 Series installation dimension (Unit: mm)

2- 6

6

Series

AC Servo Motor Drive Unit

CHARGE

POWER

C

N

3

C

N

2

258±0.25

C

N

1

C

N

4

C

N

5

2-R3

6

108±0.2

218

120

Fig. 2-5 GS3050, GS4050 Series installation dimension (Unit: mm)

270

26

Page 37

6

2- 6

Chapter II Installation/Mounting

Series

AC Servo Mo to r Dr iv e Un it

CHARGE POWER

C

N

3

C

N

2

C

N

1

305

293±0.25

C

N

4

C

N

5

2-R6

6

118±0.2

130

248.5

Fig. 2-6 GS3075, GS4075 Series installation dimension (Unit: mm)

2-φ6

6

Series

AC Servo Motor Drive Unit

C

N

3

C

N

2

305

273.5

2-R3

C

N

1

C

N

293±0.25

4

C

N

5

148

160

Fig. 2-7 GS3100, GS3148, GS4100, GS4148 Series installation dimension (Unit: mm)

27

Page 38

GS Series Spindle Servo Drive Unit User Manual

Fig. 2-8 GS3150, GS4150 Series installation dimension (Unit: mm)

2.2.2 Installation Intervals

GS Series spindle servo unit is installed vertically on the motherboard with the front side

facing forward and top side facing upward. Enough intervals should be reserved.

28

Fig. 2-9 Minimum intervals of GS3048, GS4048 Series spindle servo unit installation

Page 39

Chapter II Installation/Mounting

Cabinet

mm

100

Wiring

space

Up

Front

100 mm

Heat

Cabinet

CHARGE

POWER

100 mm

C

N

3

C

N

2

Installation Surface

50mm

Cooling

air

Heat

C

N

1

C

N

4

C

N

5

100 mm

Down

Fig. 2-10 Minimum interval of GS3050, GS4050 Series spindle servo unit installation

Front

Radiator from which cool air blows to the servo unit should be installed in the electric

cabinet in case of the increase in temperature.

Cabinet

Heat

100mm

Cooling

air

Heat

CHARGE POWER

100mm

100mm

C

N

3

C

N

2

C

N

1

C

N

4

C

N

5

60mm

Cabinet

Installation Surface

mm

100

Wiring

space

Down

Up

Fig. 2-11 Minimum interval of GS3075, GS4075 Series spindle servo unit installation

29

Page 40

GS Series Spindle Servo Drive Unit User Manual

Cabinet

Cabinet

Heat

100mm

Front

100mm

C

N

3

60mm

C

N

2

Installation Surface

Cooling

air

Heat

100mm

C

N

1

C

N

4

C

N

5

Fig. 2-12 Minimum interval of GS3100, GS3148, GS4100, GS4148 Series spindle servo unit

mm

100

Wiring

space

Down

Up

Front

80mm

Cabinet

120mm

CHARG

E

installation

Cabinet

Heat

Installation Surface

Up

mm

80mm

POWE

R

R

S

T

P

B

U

V

W

C

~380V

N

3

C

N

BRAKE

2

MOTOR

C

N

1

C

N

4

C

N

5

~380V

r

t

100

Wiring

space

Down

120mm

Cooling air

Fig. 2-13 Minimum interval of GS3150, GS4150 Series spindle servo unit installation

When more than one servo units are installed, enough intervals should be reserved for well

radiating.

30

Page 41

Chapter III Connection

CHAPTER III CONNECTION

The following cautions should be read carefully and observed strictly so as to ensure safe

and success operation.

The connection should be done by professional personnel according to relevant instructions.

Connection or inspection should be done 5min later after the servo unit is power-off and the

grounding voltage of main circuit terminal is confirmed to be safe; otherwise, it is easy to get

electric shock.

Ensure that the servo unit and servo motor are properly grounding.

Wire layout should be carefully done to avoid pointed objects. Cables should not be dragged

by force; otherwise, it is easy to lead to electric shock or poor connection.

Do not lay the main circuit and the signal line in one pipe nor bound them together. They

should be laid independently or crossly, and the distance should be over 30cm, thus to prevent

high voltage circuit’s interference to signals and ensure normal working of the servo unit.

Do not turn ON or OFF the power frequently. Since in the spindle servo unit, there is large bulk

capacitance which will generate large charging current at power-on, frequent ON/OFF

switching will cause performance degradation on inner components. It is advised that the

interval between power ON and OFF should be more than 3min.

Devices such as power capacitor, surge absorber and radio noise filter should not be installed

between spindle servo unit output side and serve motor side.

The main circuit and signal lines should be kept away from radiator and motor in case of

insulation performance degradation because of heating.

After the main circuit is connected, the terminals should be protected by a cover to avoid

electric shock.

31

Page 42

GS Series Spindle Servo Drive Unit User Manual

3.1 Connection of Peripheral Equipments

Some peripheral equipments are needed for the running of spindle servo unit. Proper

peripheral equipments ensure the stable running of servo unit and servo motor and prolong the

life cycle.

In the connection diagram, the following points should be noted:

z The equipments in the dashed box are free to choose; the equipments in the solid line

box are available from GSK.

z The selections for circuit breaker, AC filter, isolation transformer, AC reactor and AC

contactor are described in Appendix B.

z Refer to Appendix C for the selection of braking resistor.

z The equipments marked with “essential” can ensure safe and reliable operation of the

servo unit and minimize the loss to the greatest extent when fault occurs.

z The equipments marked with “optional” can ensure stable running in poor power supply

environment.

32

Page 43

Chapter III Connection

z Peripheral equipments connection of Series (D-SUB type) GS3048Y-N, GS3050Y-N,

GS3075Y-N, GS3100Y-N, GS3148Y-N and Series GS4048Y-N, GS4050Y-N,

GS4075Y-N, GS4100Y-N, GS4148Y-N should be done according to the following figure;

as for the later group of Series products, L1, L2, L3 should be connected to 3N

50/60Hz 440V.

L3L2L1

3N~50/60Hz 380V

Circuit breaker

(essential)

2nd position

feedback (CN3)

Filter (optional)

AC Reactor (optional)

AC Contactor

(essential)

CNC System

R

S

T

P

B1

B

U

V

W

r

t

~

380V

BRAKE

MOTOR

~

380V

R

i

e

r

e

S

s

v

e

i

r

D

r

o

o

t

M

o

v

r

e

S

C

A

t

i

n

U

Optional

E

G

R

A

H

C

R

E

W

O

P

C

N

3

C

N

2

C

N

1

~

PE

Control circuit (see

Section 3.2.1)

Cooling fan

line

Motor

power line

Braking resistor (essential)

External braking resistor to P, B;

B1 to none;

High temperature! Do

not touch!

Fig. 3-1 (a) Connection diagram of GS Series spindle servo unit (D-SUB type) peripheral equipments

33

Page 44

GS Series Spindle Servo Drive Unit User Manual

z Peripheral equipment connection of Series (D-SUB type) GS3150Y-N and Series

GS4150Y-N should be done according to the following figure; as for the later Series, L1,

L2, L3 should be connected to 3N

~50/60Hz 440V.

Fig. 3-1 (b) Connection diagram of GS Series spindle servo unit (D-SUB type) peripheral equipments

34

Page 45

Chapter III Connection

z Peripheral equipments connection of Series (MDR type) GS3048Y-C, GS3050Y-C,

GS3075Y-C, GS3100Y-C, GS3148Y-C and Series GS4048Y-C, GS4050Y-C,

GS4075Y-C, GS4100Y-C, GS4148Y-C should be done according to the following figure;