gsk GSK GHBus AC User Manual

This user manual describes all proceedings concerning the

operations of this Drive Unit in detail as much as possible. However, it is

impractical to give particular descriptions for all unnecessary or unallowable

system operations due to the manual text limit, product specific applications

and other causes. Therefore, the proceedings not indicated herein should

be considered impractical or unallowable.

This user manual is the property of GSK CNC Equipment Co., Ltd.

All rights are reserved. It is against the law for any organization or individual

to publish or reprint this manual without the express written permission of

GSK and the latter reserves the right to ascertain their legal liability.

GH Series Bus AC Servo Drive Unit User Manual

PREFACE

Your Excellency,

It’s our pleasure for your patronage and purchase of this

GH2000/GH3000 Series Bus High-speed & High-accuracy Full Digit AC

Servo Drive Unit made by GSK CNC Equipment Co., Ltd.

This manual is entirely described the installation, wiring, operation and

debugging etc. of the GH2000/GH3000 Series Servo Drive Unit, which provides the

desired knowledge and precautions for using this drive unit; it is better to

operated machine after comprehending the safety precautions.

Adequately play the function of the GH2000/GH3000 Series Servo Drive Unit,

and ensure the safety. It is necessary to carefully read this manual before

operating this machine, and correctly use this drive unit based upon the

precautions and operation methods.

All improvements, specifications and the version update herein are subject

to change without further notice.

We do not assume any responsibilities for the change of the product by

user; therefore the warranty sheet will be void for this change.

Chinese version of all technical documents in Chinese and English languages

is regarded as final.

II

Safety Warning and Responsibility

SAFTY WARNING

To avoid the personal injury of the operators and others, as well the damage of

the mechanical equipments, pay more attention to the following warning flags when

reading this User Manual:

That the flags shown in the following items are the

danger levels during the operation, which is related with

the description of the operation safety flag. And

therefore, the contents are extremely important, and the

user should abide by it.

Danger

!

Caution

!

Notice

The severe injury or death may occur if the approved instruction

does not perform.

The secondary or light wound, as well the loss of the material

may occur if the approved instruction does not perform.

Unexpected results and states may occur if this Notice is

ignored.

It reminds user that the vital requirements and important

instructions are shown

III

GH Series Bus AC Servo Drive Unit User Manual

The following marks are indicated that the operations

should be performed or can not be performed:

means forbidden (it cannot be performed)

!

means enforced (it must be performed)

IV

Safety Warning and Responsibility

Danger

!

Confirm whether the

input power is power off

before wiring.

The electric shock may

occur if the approved

! !

instruction is not observed

Install the breaker,

interference filter and AC

reactor

The thundernstrike,

malfunction or damage

may occur if the approved

instruction is not observed.

It is better to wire or

detect by the

professional electrical

engineer

The electric shock or fire

may occur if the approved

! !

instruction is not obser ved

The movement, wiring,

detection or maintenance can

be performed after the power

is turned off for 10 minutes.

The electric shock may

occur if the approved

instruction is not obser ved.

The grounding terminal

PE of the servo unit

should be earthed.

The electric shock may

occur if the approved

! !

instruction is not observ ed

Install the ESP switch

The personal injury,

malfunction and machine

damage may occur if the

approved instruction is not

observed.

Do not operate the

switch with wet hands!

The electric shock may

occur if the approved

instruction is not observ ed.

Do not stretch your hands

into the servo unit!

The electric shock may

occur if the approved

instruction is not obse rved.

Do not open the cover of

the terminal block when

the power is turned on or

operated!

The electric shock may

occur if the approved

instruction is not observed.

Do not touch the main

circuit wiring terminal

directly!

The electric shock may

occur if the approved

instruction is not observed.

V

GH Series Bus AC Servo Drive Unit User Manual

Caution

!

It is necessary to connect

the wiring between the

drive unit and motor based

upon the wiring scheme

The equipment may be

! !

damaged if the approved

instruction is not observed.

The voltage level loaded

on each terminal only can

be used the one described

in this manual.

The equipment may be

damaged if the approved

instruction is not observed.

The load can be performed

only when the dry run of

the motor is executed.

The equipment may be

! !

damaged if the approved

instruction is not observed.

Firstly remove the alarm,

and then perform the

machine when the alarm

occurs.

The equipment may be

damaged if the approved

instruction is not observed.

It is essential to connect the

brake resistance based upon

the wiring scheme.

The motor should be

adapted with the appropriate

servo motor.

The equipment may be

! !

damaged if the approved

instruction is not observed.

The equipment may be

damaged if the approved

instruction is not observed.

Never attempt to modify,

disassemble or repair the

drive unit privately.

The equipment may be

damaged if the approved

instruction is not observed.

Do not hold the cable and

motor shaft during the

transportation of the motor.

The equipment may be

damaged if the approved

instruction is not observed.

Do not touch the motor and

brake resistance, as well the

radiating equipment, due to the

high temperature may occur.

The scald may be caused

if the approved instruction

is not observed.

Do not adjust and modify

the parameter extremely.

The equipment may be

damaged if the approved

instruction is not observed.

VI

Safety Warning and Responsibility

Caution

!

Do not connect the power

input cables R, S and T on

the U, V and W terminals of

the motor output cable!

The equipment may be

damaged if the approved

instruction is not observed.

If the components of the

spindle unit is absent or being

damaged, it is important to

touch the seller immediately

before operating.

The equipment may be

damaged if the approved

instruction is not observed.

Do not repeatedly used the

wasted internal electric

components of the drive unit,

and it only can be treated as

the industry trash!

The unexpected behave

may occur if the approved

instruction is not observed.

Do not frequently switch

on/off the input power!

The equipment may be

damaged if the approved

instruction is not observed.

VII

GH Series Bus AC Servo Drive Unit User Manual

Safety Precaution

■ Transportation and storage

The pile of the packing cantons should be less than 6 layers.

Do not climb, stand, as well as put the heavy materials on the product.

Do not use the conjoined cable with this product to drag or move the

machine.

Do not crash or scratch the panel and the screen.

Avoid damp, sunshine and rain for the product packing

■ Unpacking detection

Confirm whether the product is your purchased one after opening the

packing.

Check whether the product is being damaged during the transportation.

Check whether each accessory is prepared or being damaged comparing

the packing list.

Touch our company immediately if the product type is not matched with

the packing list or the components are absent or being damaged during

transportation.

■ Wiring

The wiring and detection should be performed by the corresponding

professional.

The product should be grounded stably, and its grounding resistance

should be less than 0.1Ω. Do not replace the grounding wire by the neutral

cable (zero).

The wiring should be correct and firm, so that the product malfunction or

unexpected result may occur

The surge absorb diode of the product should be connected based upon

the specified direction; otherwise, the product may be damaged.

The power should be turned off before plug-in/out or opening the case of

the product.

■ Maintenance

It is necessary to cut off the power before maintaining or changing the

components.

VIII

Safety Warning and Responsibility

Check the malfunction when the short-circuit or overload occurs; the

machine can be restart again after the malfunction removes.

Do not frequently power on/off. The power should be turned on again after

1min. at least.

Security Responsibility

Security responsibility of the manufacturer

——Manufacturer should take responsibility for the design and structure danger of the

motor and the accessories which have been eliminated and/or controlled.

——Manufacturer should take responsibility for the security of the motor and

accessories.

——Manufacturer should take responsibility for the offered information and

suggestions for the user.

Security responsibility of the users

——User should know and understand about the contents of security operations by

learning and training the security operations of the motor.

——User should take responsibility for the security and danger because of increasing,

changing or modifying the original motor or accessory by themselves.

——User should take responsibility for the danger without following the operations,

maintenances, installations and storages described in the manual.

This manual is reserved by final user.

We are full of heartfelt gratitude to you for supporting us in the use of GSK’s

products.

IX

GH Series Bus AC Servo Drive Unit User Manual

CONTENT

1 BRIEF························································································································ 1

1.1 Product Brief································································································································· 1

1.1.1 Product Character ················································································································· 1

1.1.2 Use Area ································································································································ 1

1.1.3 Product Appearance ·············································································································· 2

1.2 Product Technical Specification···································································································· 2

1.2.1 Technical Specification of the Drive Unit ··············································································· 2

1.2.2 The Technical Specification of the Servo Motor ···································································· 4

2 INSTALLATION ········································································································11

2.1 Ambinet Condition ·······················································································································11

2.2 The Installation of the Drive Unit ································································································ 12

2.2.1 Installation Ambient·············································································································· 12

2.2.2 Installation Dimension ········································································································· 12

2.3 Servo Motor Installation ················································································································ 15

2.3.1 Installation Ambient·············································································································· 15

2.3.2 Installation Dimension ········································································································· 16

3 WIRING··················································································································· 21

3.1 Peripheral Equipment Connection······························································································ 22

3.1.1 The Explanation of the Wiring port ······················································································ 22

3.1.2 Peripheral Equipment Connection Diagram ········································································ 22

3.2 Bus Connection ·························································································································· 24

3.3 Motor Interface Connection ········································································································ 27

3.3.1 Motor Power and Brake Wiring···························································································· 27

3.3.2 Encoder Wiring ···················································································································· 28

3.4 Battery Connection····················································································································· 29

4 DEBUGGEING ········································································································ 31

4.1 Parameter Explanation··············································································································· 31

4.1.1 Parameter List ····················································································································· 31

4.1.2 Parameter Significant Details ······························································································ 34

4.1.3 The Code Explanation of the Servo Motor Type ································································· 38

4.2 Display Operation······················································································································· 39

4.2.1 Key Explanation··················································································································· 39

4.2.2 Main Menu Explanation ······································································································· 40

4.2.3 Monitoring Menu Explanation······························································································40

4.2.4 User Shortcut Password······································································································ 42

X

Content

4.2.5 Parameter Management······································································································ 43

4.3 Function Debugging ··················································································································· 45

4.3.1 Sr Dry Run··························································································································· 45

4.3.2 JOG Operation ···················································································································· 46

4.3.3 Motor Type Write-in ············································································································· 46

4.3.4 Motor Zeroing ······················································································································ 47

5 ALARM AND TROUBLESHOOTING ·······································································49

5.1 Alarm List ··································································································································· 49

5.2 Alarm Troubleshooting ··············································································································· 50

6 ORDERING INSTRUCTION ····················································································55

6.1 The Selection of the Drive Unit ·································································································· 55

6.1.1 The Type Explanation of the Drive Unit··············································································· 55

6.1.2 The Comparison Table of the Drive Unit Adapted Motor····················································· 55

6.2 The Selected Servo Motor ········································································································· 56

6.2.1 The Type Explanation of the Servo Motor ··········································································· 56

6.3 The Selection of the Cable and Connector ················································································ 57

6.3.1 The Specification and Type of the Cable and Connector···················································· 57

6.4 The Selection of the Peripheral Equipment ··············································································· 57

6.4.1 Brake Resistance (Necessary equipment)·········································································· 57

6.4.2 Breaker and Contactor (Necessary equipment)·································································· 58

6.4.3 Three-phase AC Filter (Recommended equipment) ··························································· 59

6.4.4 Insulation Transformer (Necessary equipment) ·································································· 60

6.4.5 AC Reactor (Recommended Equipment)············································································ 63

XI

Chapter One Brief

1 BRIEF

1.1 Product Brief

The GH2000/GH3000 Series Bus AC Servo Drive Unit (It is the one

high-accuracy and high-speed full digit AC servo drive unit) is the updated

developed one based upon the GSK-Link Ethernet Bus Agreement of our company,

which provides a reliable drive control of the AC servo motor with the absolute

encoder.

1.1.1 Product Character

It uses the GSK-Link Ethernet bus communication method; and its data transmission

rate can be performed up to about 100Mbits/s; the on-line data real-time

uploading/downloading can be carried out.

It uses the servo motor installed with the absolute encoder, and its encoder number

can be set from17 to 28.

One interface supports variable encoder agreed communications, for example,

TAMAGAWA, HEIDEHAIN, DANAHER, and NIKON.

Intelligently identify the motor’s type; the SJT (A4) series servo motor type or the

default parameter call can be identified after the power is turned on.

There are two kinds power mode selection, one is that the GH3000 series uses

AC380V; the other is that the GH2000 uses AC220V.

Multiple power selection, the power module 30A/50A/75A/100A/150A can be

selected.

1.1.2 Use Area

It can be used in these areas, such as the mechanical manufacture, CNC machine,

printing & packing machine, spinning machine, robot and the automatic assembly line.

1

GH Series Bus AC Servo Drive Unit User Manual

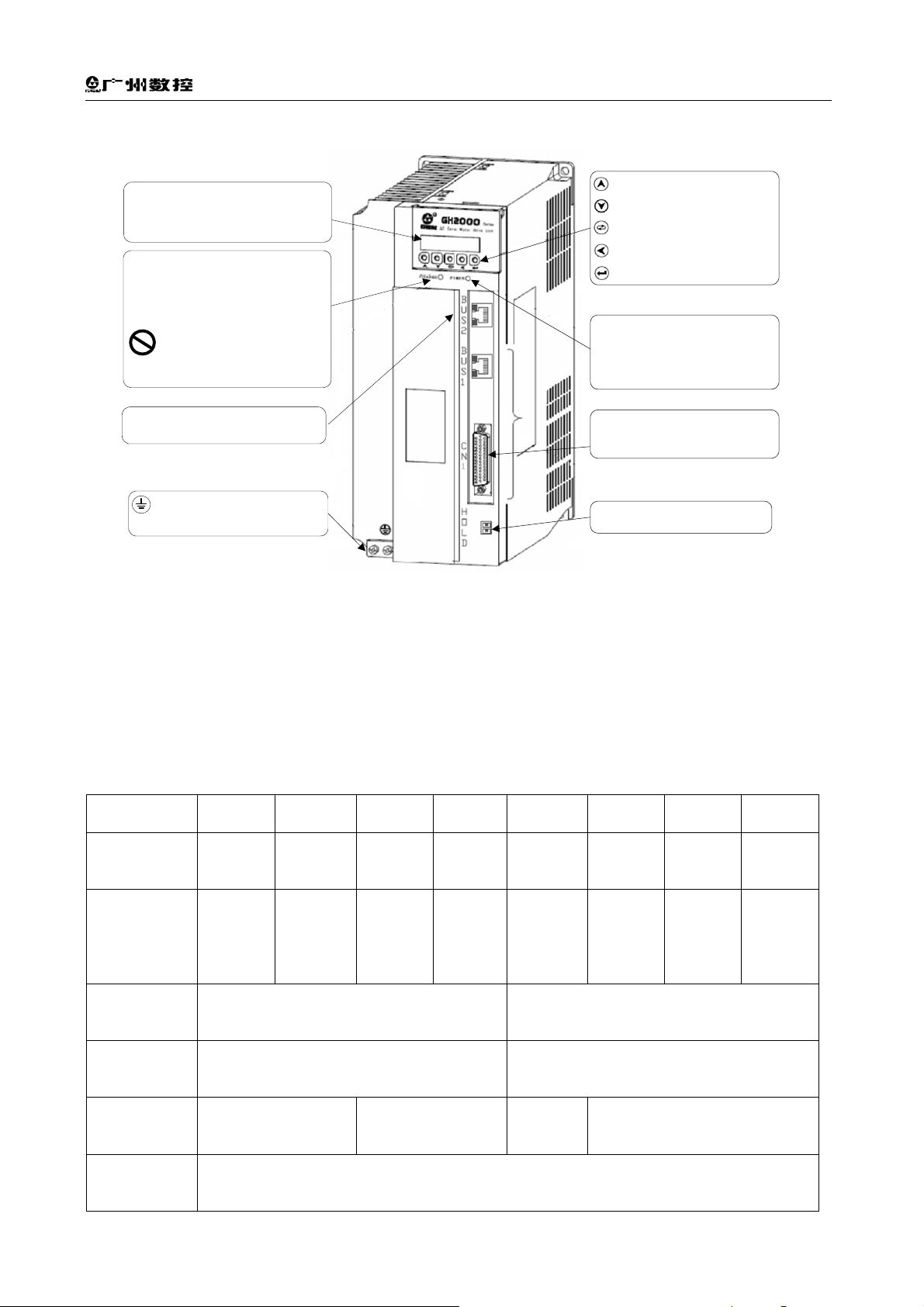

1.1.3 Product Appearance

LED monitoring window

The state monitoring and the

modification and administration of

the parameter can be performed.

‘CHARGE’is the high-pressure

Indicator

indicator of the servo unit main

circuit DC bus.

ON: The DC bus is with the high

pressure voltage.

OFF: The DC bus is already

discharged.

When the‘CHARGE’ Indicator

is ON, the assemble or disassemble

of the servo unit or the power cable,

motor and the brake resistance

cable can not be performed.

‘BUS1/BUS2’is the communication

bus interface of the Ethernet.

The grounding terminals of the

input power and the motor

protection one

Fig. 1-1 Product appearance

Parameter series No. or value adds, or

the menu pages up

Parameter series No. or value reduces,

or the menu pages down.

Circularly move the modified data bit

Return to the previous operation menu

or cancel it

Enter the next operation menu or

confirm it.

‘POWER’is the power

Indicator

indicator of the servo unit

control circuit.

ON: Normal.

OFF: Power-down

‘CN1’ is the servo unit

encoder feedback input (high

density DB26 socket)

‘Hold’ is the brake output

terminal

1.2 Product Technical Specification

1.2.1 Technical Specification of the Drive Unit

Table 1-1 The main technical specification parameter of the drive unit

Drive unit type

IPM module

power (A)

Adapted

servo motor

rated current

(A)

Main circuit

power

Control circuit

power

GH2030 GH2050 GH2075 GH2100 GH3048 GH3050 GH3075 GH3100

30 50 75 100 50 50 75 100

4<I≤6 7<I≤10 10<I≤15

15<

I≤29

4<I≤6 7<I≤10

Three-phase, AC 220V Three-phase, AC 380V

Single-phase, AC 220V Single-phase, AC 380V

10<

I≤15

15<

I≤29

Brake

resistance

Control

method

2

Three-phase full-wave rectification IGBT PWN sine wave drive

Built-in

External needed

(without built-in)

Built-in

External needed (without

built-in)

Chapter One Brief

Feedback

method

Communicat

ion method

Speed

frequency

response

Speed-regul

ation ratio

The least

speed control

PID

response

frequency

17-bit absolute encoder (It is compatible with TAMAGAWA, HEIDEHAIN,

DANAHER, and NIKON)

GSK-LINK bus communication method: the Max. connection number: 254 axes; the

data transmission ratio: 100Mbits/s

≥200Hz

1: 60000

±0.1r/min

Velocity loop: 10KHz Current loop: 10KHz

Working

method

Working

ambient

temperature

Working

ambient

humidity

Vibration-res

istance/impa

ct-resistance

Protective

function

Manual, JOG, external velocity (Bus agreement)

Working temperature: 0℃~+40℃ Storage temperature: -40℃~+70℃

Less than 90% (No condensation)

Less than 0.5G (4.9m/s

2

)(Discontinuous operation in the 10Hz~60Hz)

Overspeed, overpressure, main circuit open-phase, power module failure,

underpressure, overload, overheat, brake abnormal, encoder abnormal, encoder

communication failure, motor type setting enabled, control power abnormal etc.

Monitoring

Motor speed, encoder feedback single-circle value/multiple-circle value, motor

current, operation state, CUP use rate, Ethernet state, speed command value, alarm

function

prompt.

Display

6-digit LED Nixie tube, 5 keys.

operation

3

GH Series Bus AC Servo Drive Unit User Manual

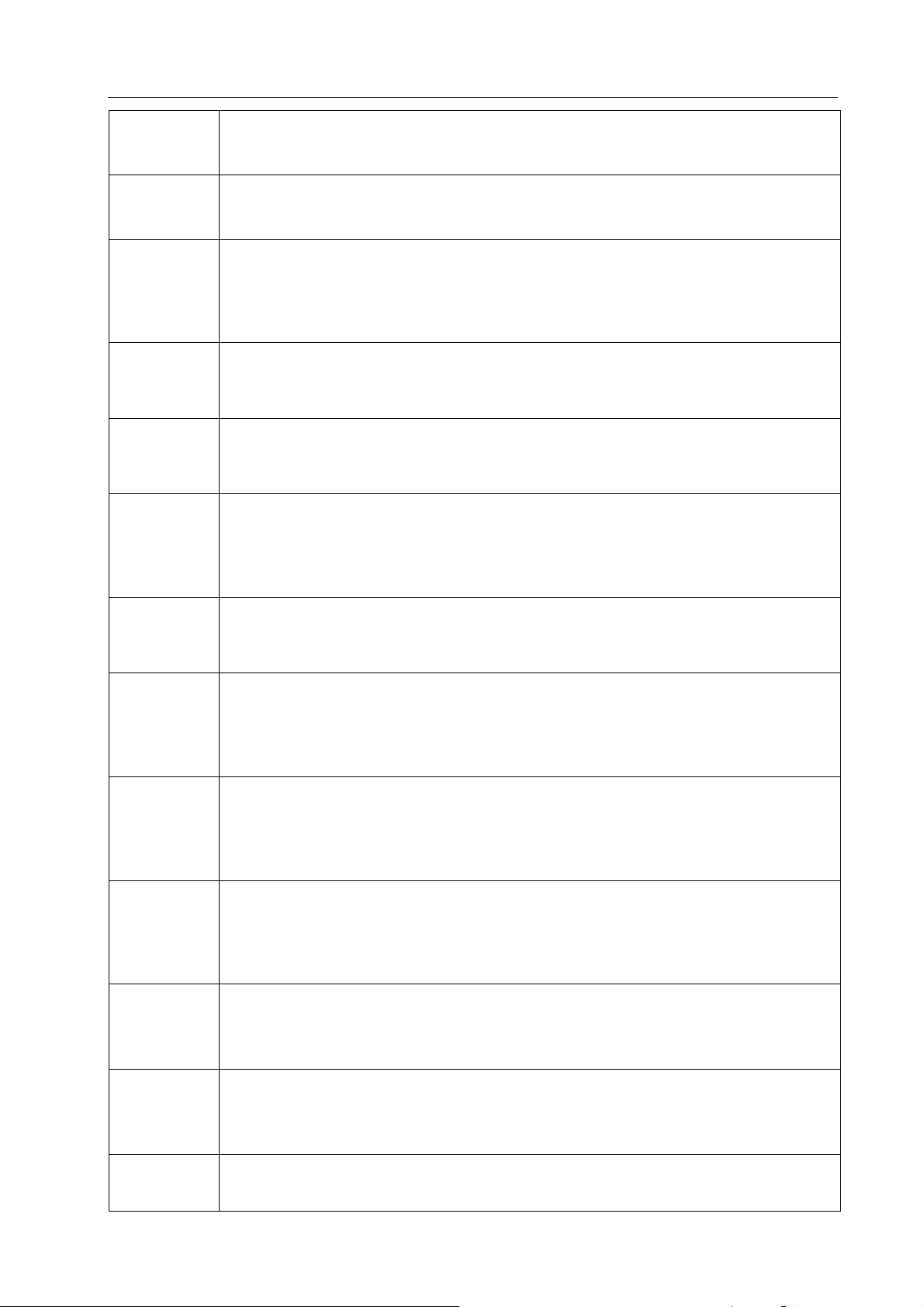

1.2.2 The Technical Specification of the Servo Motor

Table 1-2 The technical parameter of 80 series motor

Type

Item

Rated power (kW) 0.5 0.75 0.66 1.0

Polar logarithm 4

Rated current (A) 3 4.8 5 6.2

80SJT-M024C 80SJT-M024E 80SJT-M032C 80SJT-M032E

Zero speed torque

2.4 2.4 3.2 3.2

(N.m)

Rated torque

2.4 2.4 3.2 3.2

(N.m)

The Max. torque

7.2 7.2 9.6 9.6

(N.m)

Rated speed

2000 3000 2000 3000

(r/min)

The Max. speed

2500 4000 2500 4000

(r/min)

Inertia of moment

0.83×10-4

0.83×10-4 1.23×10-4 1.23×10-4

(kg·m2)

Weight (kg) 2.8 2.9 3.4 3.5

Insulation level

F(GB 755—2008)

Vibration level

Defense level

Installation type

Working system

R(GB 10068—2008)

IP65(GB 4208—2008/IEC 60529:2001,GB/T 4942.1—2006)

IMB5(Flange installation)(GB/T 997—2008 / IEC 60034-7:2001)

S1(Consecutive working system)(GB 755—2008)

Power-down brake Not available

Increment 2500p/r, 5000p/r etc., absolute encoder 17 bit single circle

Adapted encoder

or multiple circles

4

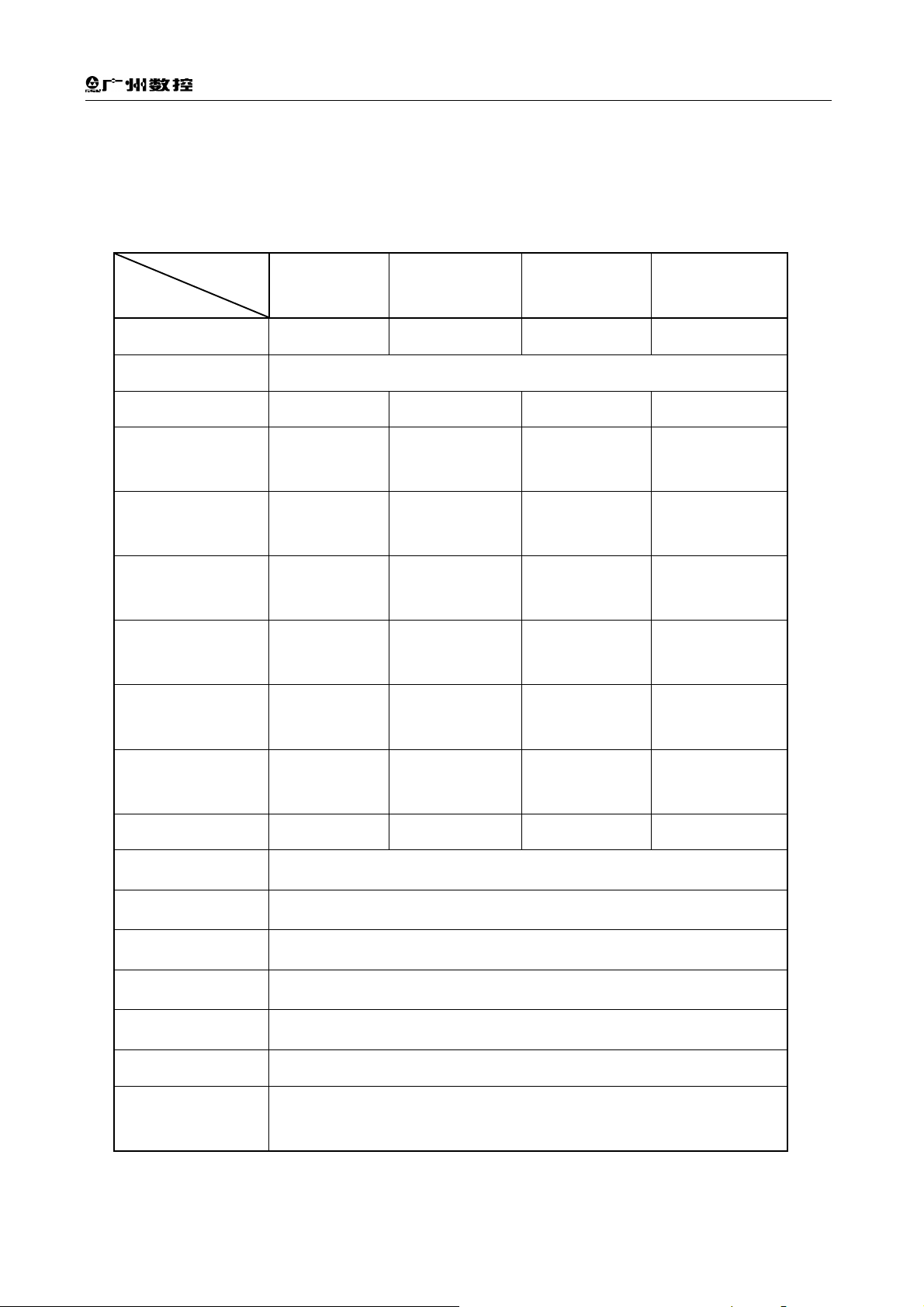

Chapter One Brief

)

The torque-speed character figure (T – M) of the servo motor is shown below:

A: Continuous working area B: Short time working area

Speed (r/min)

Torque (N.m)

Speed (r/min)

Torque (N.m) Torque (N.m)

Speed (r/min

Torque (N.m)

Speed (r/min)

Table 1-3 The technical parameter of 110 series motor

Type

Item

Rated power

(kW)

Polar

logarithm

Rated

current (A)

Zero speed

torque (N.m)

Rated torque

(N.m)

The Max.

torque (N.m)

110SJT-M 040D 110SJT-M 040E 110SJT-M 060D 110SJT-M 060E 130SJT-M 040D 130SJT-M 050D

1.0 1.2 1.5 1.8 1.0

1.3

4

4.5 5 7 8 4

4 4 6 6

4 4 6 6 4

12 10 12 12 10

5

5

5

12.5

Rated speed 2500 3000 2500 3000 2500 2500

The Max.

speed

Inertia of

moment

3000 3300 3000 3300 3000 3000

0.68×10-3 0.68×10-3 0.95×10-3 0.95×10-3 1.1×10-3 1.1×10-3

Weight (kg) 6.1 6.1 7.9 7.9 6.5 6.5

The motor

weight with

the

7.7 7.7 9.5 9.5 8.1 8.1

power-down

brake (kg)

Insulation

level

Vibration

level

Defense

B(GB 755-2008)

R(GB 10068-2008)

IP65(GB/T4942.1-2006)

5

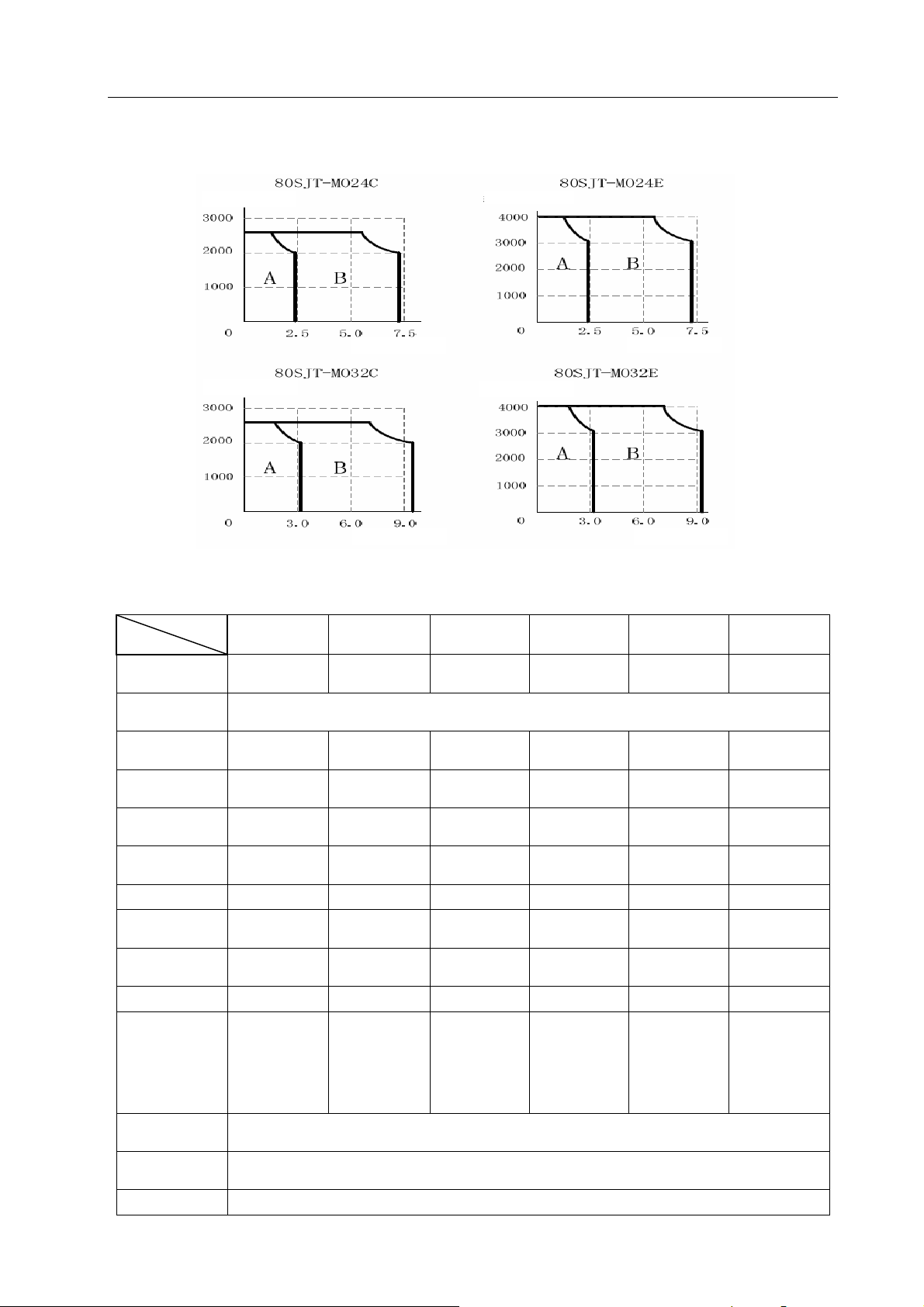

GH Series Bus AC Servo Drive Unit User Manual

)

level

Installation

type

Working

system

Adapted

encoder

IMB5(Flange installation)(GB/T 997-2008 / IEC 60034-7:2001)

S1(Consecutive working system)(GB 755-2008)

Increment 2500p/r, 5000p/r etc., absolute encoder 17 bit single circle or multiple

circles

The torque-speed character figure (T – M) of the servo motor is shown below:

A: Continuous working area B: Short time working area

Speed (r/min)

Speed (r/min)

Torque (N.m)

Torque (N.m)

Speed (r/min

Speed (r/min)

Torque (N.m)

Torque (N.m)

Speed (r/min)

Torque (N.m)

Speed (r/min)

Torque (N.m)

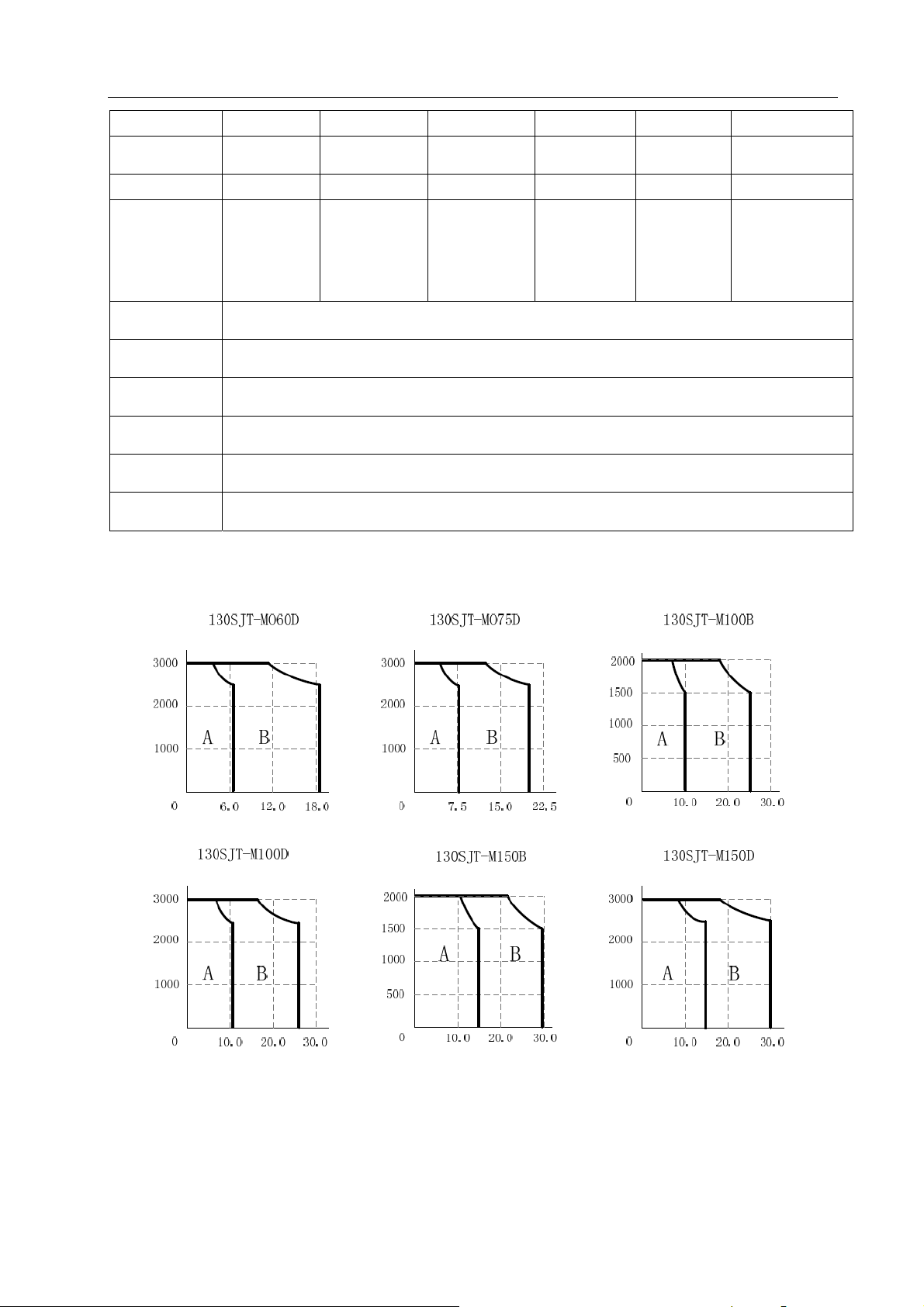

Table 1-4 The main technical parameter of the 130SJT series motor (to be continued table 1-3)

Type

Item

Rated power

(kW)

Polar

logarithm

Rated

current (A)

Zero speed

(N.m)

Rated torque

(N.m)

The Max.

torque (N.m)

130SJT-M 060D 130SJT-M 075D 130SJT-M 100B 130SJT-M 100D 130SJT-M 150B 130SJT-M 150D

1.5 1.88 1.5 2.5 2.3

3.9

4

6 7.5 6 10 8.5 14.5

6 7.5 10 10 15 15

6 7.5 10 10 15 15

18 20 25 25 30 30

Rated speed 2500 2500 1500 2500 1500 2500

The Max.

6

3000 3000 2000 3000 2000 3000

Chapter One Brief

speed

Inertia of

moment

Weight (kg) 7.2 8.1 9.6 9.7 11.9 12.7

The motor

weight with

the

power-down

brake (kg)

Insulation

level

Vibration

level

Defense

level

Installation

type

Working

system

Adapted

encoder

1.33×10-3 1.85×10-3 2.42×10-3 2.42×10-3 3.1×10-3 3.6×10-3

10.1 11 12.5 12.6 14.8 15.6

B(GB 755-2008)

R(GB 10068-2008)

IP65(GB/T4942.1-2006)

IMB5(Flange installation)(GB/T 997-2008 / IEC 60034-7:2001)

S1(Consecutive working system)(GB 755-2008)

Increment 2500p/r, 5000p/r etc., absolute encoder 17bit single circle or multiple

circles

The torque-speed character figure (T – M) of the servo motor is shown below:

A: Continuous working area B: Short time working area

Speed (r/min)

Speed (r/min)

Torque (N.m)

Speed (r/min)

Torque (N.m)

Speed (r/min)

Speed (r/min)

Speed (r/min)

Torque (N.m)

Torque (N.m)

Torque (N.m)

Torque (N.m)

7

GH Series Bus AC Servo Drive Unit User Manual

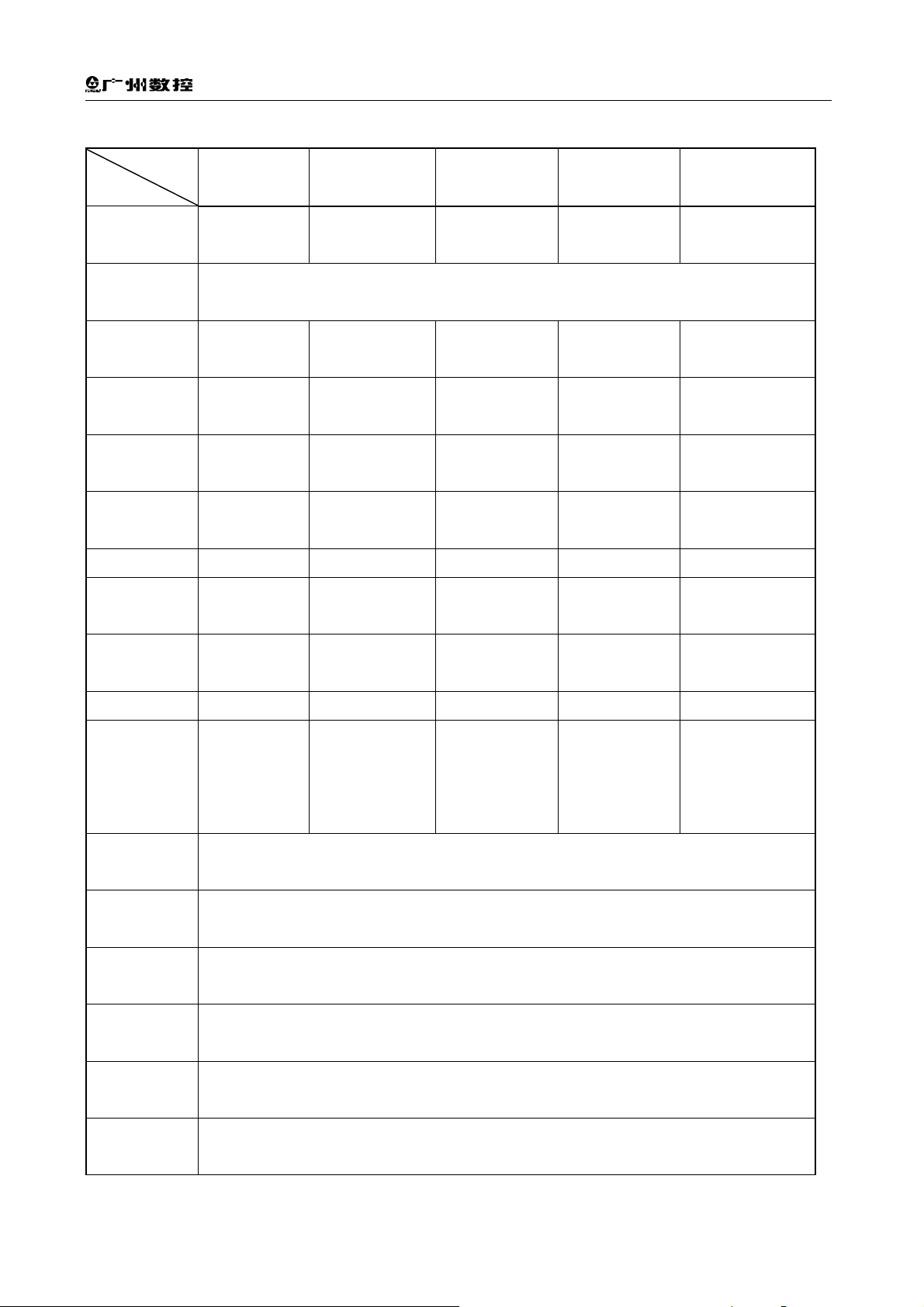

Table 1-5 The main technical parameter of the 175SJT series motor

Type

Item

175SJT-M120E 175SJT-M150B 175SJT-M150D 175SJT-M180B 175SJT-M180D

Rated power

3 2.4 3.1 2.8 3.8

(kW)

Polar

3

logarithm

Rated

13 11 14 15 16.5

current (A)

Zero torque

12 15 15 18 18

(N.m)

Rated torque

9.6 15 12 18 14.5

(N.m)

The Max.

19.2 30 24 36 29

torque (N.m)

Rated speed 3000 1500 2500 1500 2500

The Max.

2000 3000 2000 3000

speed

3300

Inertia of

5.1×10-3 5.1×10-3 5.1×10-3 6.5×10-3 6.5×10-3

moment

Weight (kg) 18.9 18.5 19 22.8 22.9

The motor

weight with

24.5 24.1 24.6 28.4 28.5

power-down

brake (kg)

Insulation

B(GB 755-2008)

level

Vibration

R(GB 10068-2008)

level

Defense

IP65(GB/T4942.1-2006)

level

Installation

IMB5(Flange installation)(GB/T 997-2008 / IEC 60034-7:2001)

type

Working

S1(Consecutive working system)(GB 755-2008)

system

Adapted

encoder

Increment 2500 p/r, 5000 p/r etc., absolute encoder 17 bit single circle or multiple

circles

8

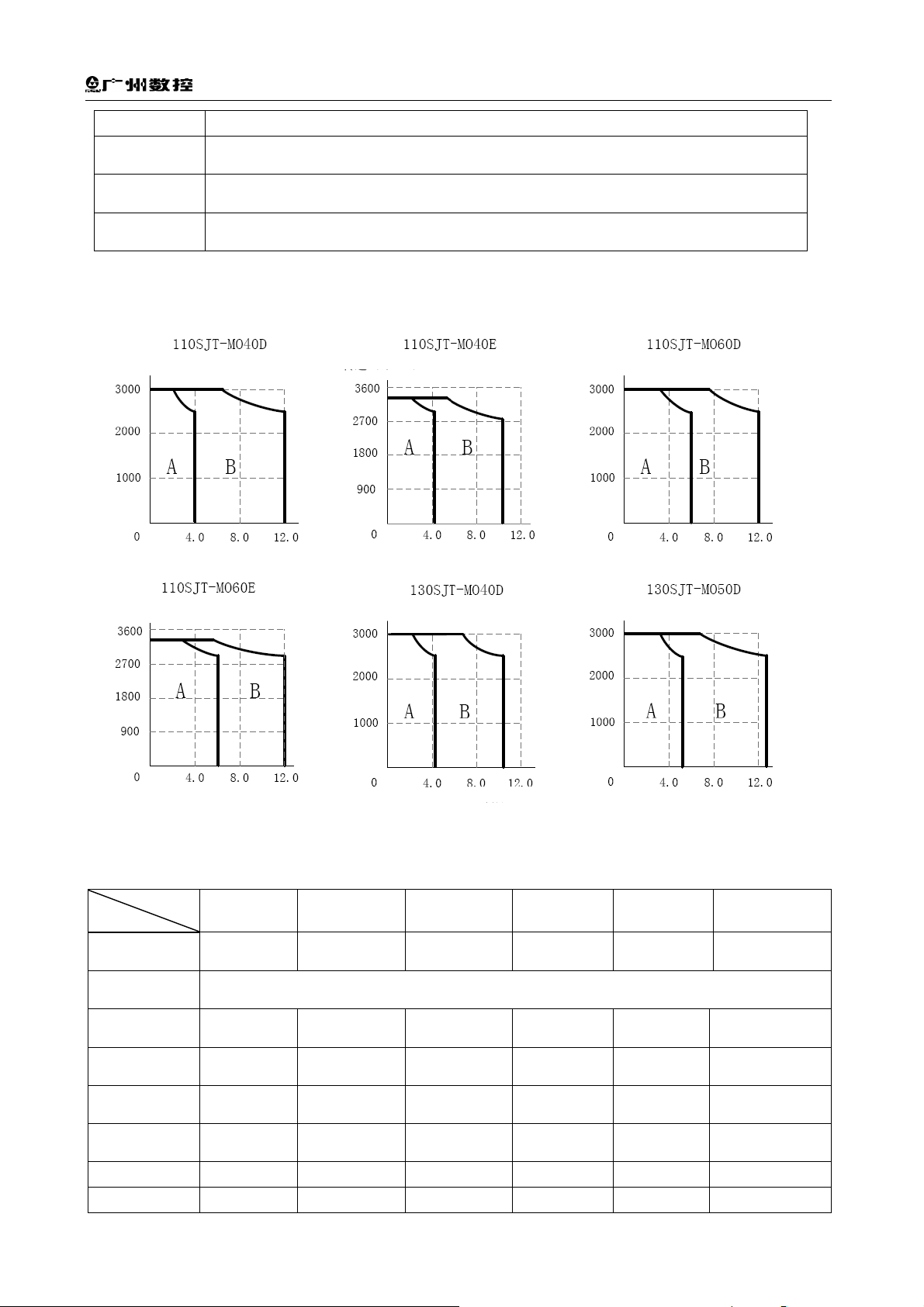

Chapter One Brief

)

The torque-speed character figure (T – M) of the servo motor is shown below:

A: Continuous working area B: Short time working area

Speed (r/min)

Torque (N.m)

Speed (r/min)

Speed (r/min

Torque (N.m)

Torque (N.m)

Speed (r/min)

Speed (r/min)

Torque (N.m)

Torque (N.m)

Table 1-6 The main technical parameter of the 175SJT series motor (to be continued the table 1-5)

Type

175SJT-M220B 175SJT-M220D 175SJT-M300B 175SJT-M300D 175SJT-M380B

Item

Rated power

(kW)

Polar logarithm

Rated current

(A)

Zero speed

torque (N.m)

Rated torque

(N.m)

The Max. torque

(N.m)

Rated speed

The Max.

speed

Inertia of

moment

3.5

17.5

22

22

44

1500

2000

9.0×10-3

4.5 3.8 6 6

3

19 19 27.5 29

22 30 30 38

17.6 24 24 38

35.2 48 48 76

2500 1500 2500 1500

3000 2000 3000 1800

9.0×10-3 11.2×10-3 11.2×10-3

14.8×10-3

Weight (kg) 28.9 29.2 34.3 34.4 42.4

The motor weight

with power-down

34.5 36.8 42 42.1 50.1

brake (kg)

Insulation level

B(GB 755-2008)

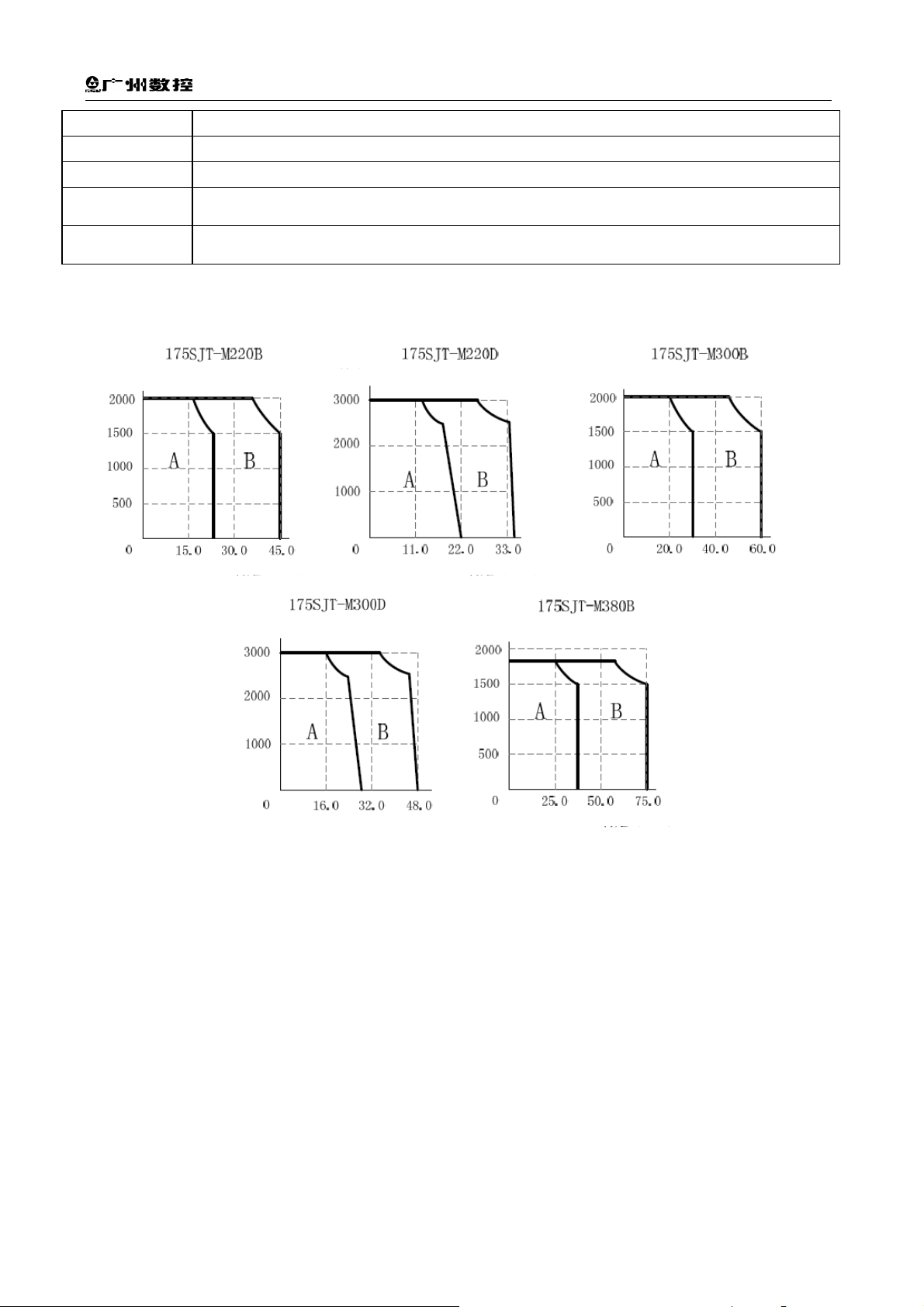

9

GH Series Bus AC Servo Drive Unit User Manual

)

Vibration level

Defense level

Installation type

Working

R(GB 10068-2008)

IP65(GB/T4942.1-2006)

IMB5(Flange installation)(GB/T 997-2008 / IEC 60034-7:2001)

S1(Consecutive working system)(GB 755-2008)

system

Adapted

Increment 2500p/r, 5000p/r etc., absolute encoder 17 bit single circle or multiple circles

encoder

The torque-speed character figure (T – M) of the servo motor is shown below:

A: Continuous working area B: Short time working area

Speed (r/min)

Torque (N.m)

Speed (r/min

Torque (N.m)

Speed (r/min)

Torque (N.m)

Speed (r/min)

Torque (N.m)

Speed (r/min)

Torque (N.m)

10

Chapter Two Installation

p

2 INSTALLATION

Notice

The storage and installation of the product should be suitable for the ambient

conditions.

The pile number of the product should be controlled, which can not be piled

them together too many, so that the product may be crushed or dropped.

The storage and transportation of the product should be used the original

packing.

Do not use the product with damaged or absent components.

Do not install it on the flammable surface or near, to avoid the fire hazard.

The servo drive unit should be installed inside the electric cabinet; prevent

the dust, corrosive gas, conductive material, liquid and the inflammable

matter from entering the machine.

The servo drive unit and servo motor can not be shocked and im

acted.

2.1 Ambinet Condition

Item GH2000/GH3000 series servo drive unit SJT series AC servo motor

Using

temperature/

humidity

Storage

temperature/

humidity

Atmosphere

ambient

Altitude Blow 1000m Below 1000m

Vibration

Defense level IP43 IP65

Below 90%RH (No condensation)

-40℃ ~ +70℃, 90%RH (No

condensation)

There is no corrosive gas, inflammable

gas, oil mist or dust inside the control

cabinet.

Less than 0.5G (4.9m/s

0℃~+40℃(No freeze)

2

) 10Hz~60Hz (Nonconsecutive)

0℃~+40℃ (No freeze)

Below 90%RH(No condensation)

Below -40℃ ~ +70℃, 90%RH (No

condensation)

There is no corrosive gas,

inflammable gas, oil mist or dust in the

house (without sunshine).

11

GH Series Bus AC Servo Drive Unit User Manual

2.2 The Installation of the Drive Unit

2.2.1 Installation Ambient

Defense

The servo drive unit should be installed well-mounted electric cabinet, because its structure is

without defense. Prevent the corrosive gas, inflammable gas, as well as the conductive material, metal

dust, oil mist and liquid from entering the machine.

Temperature, humidity

The ambient temperature is 0℃~+40℃, and ensure the radiating condition.

Vibration and impact

The installation of the drive unit can not be shocked, and the vibration control should be less than

0.5G (4.9m/s

from the heavy load and impact.

2

) based upon the buffering measure. The installation of the drive unit must be far away

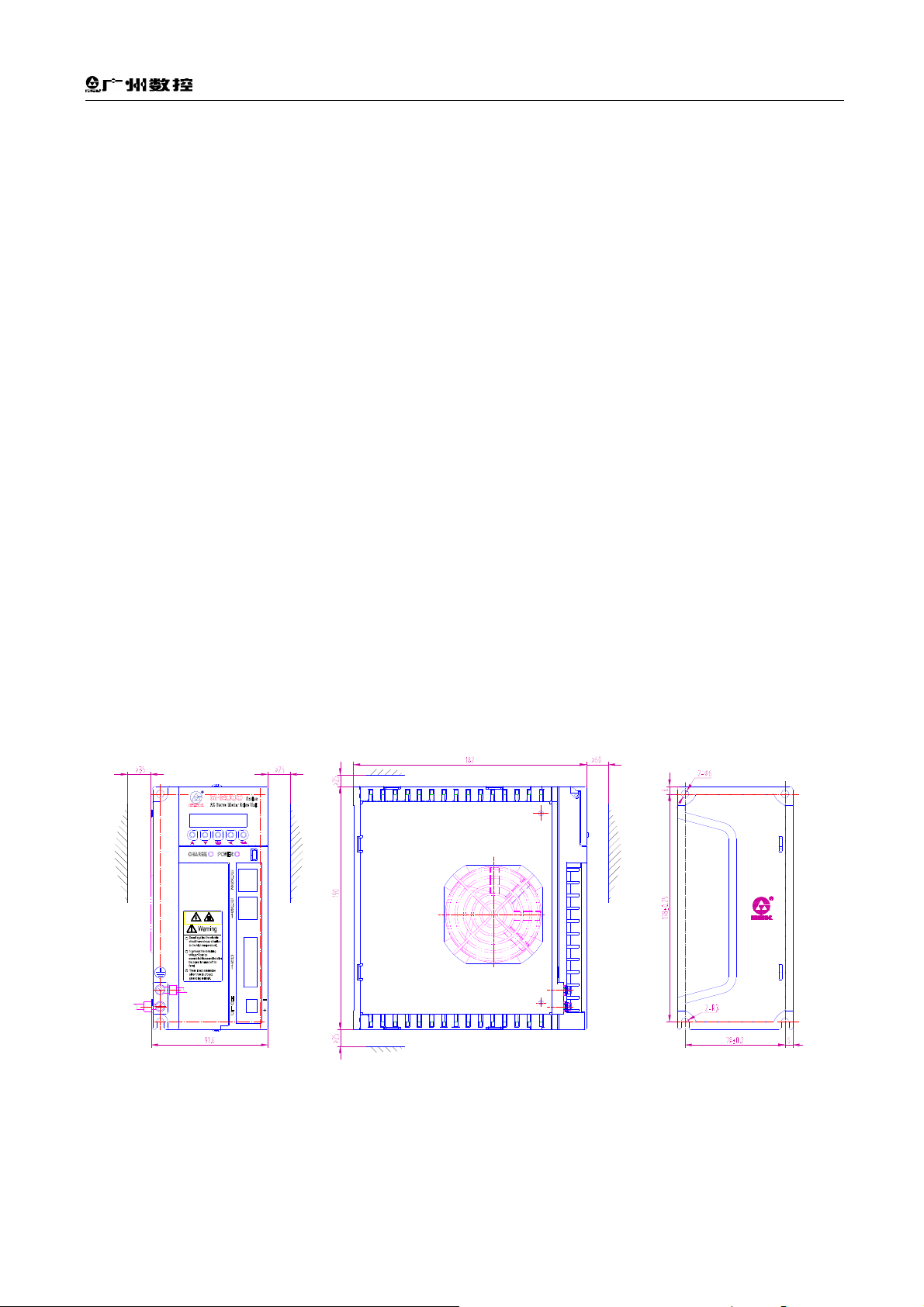

2.2.2 Installation Dimension

The GH2000/GH3000 series drive unit adopts base plate installation method, of which its

installation direction is vertical to the installation surface and upward. The front is forward and the top

surface is upward for cooling when the drive unit is installed. Note that the necessary space around the

machine should be reserved.

In order to guarantee the ambient temperature of the drive unit does not rise consecutively, the

convection air should blow to the radiator of the drive unit inside the electric cabinet.

Fig. 2-1 GH2030T installation dimension (Unit: mm)

12

Loading...

Loading...