Page 1

Page 2

This user manual describes all items concerning the operation of this CNC

system in detail. However, it is impossible to give particular descriptions for all

unnecessary or unallowable operations due to length limitation and product application

conditions;Therefore, the items not presented herein should be considered impractical

or unallowable.

Copyright is reserved to GSK CNC Equipment Co., Ltd. It is illegal for any

organization or individual to publish or reprint this manual. GSK CNC Equipment Co., Ltd.

reserves the right to ascertain their legal liability.

Page 3

User Manual for DAH01 and DAH2075E AC Servo Drive Unit

Dear users,

We are honored by your purchase of all-digital AC servo drive units with high speed

and high precision of DAH series of GSK CNC Equipment Co., Ltd.

This manual comprehensively introduces the installation, connection, debugging,

operation and maintenance of the all-digital AC servo drive unit of DAH Series (including

DAH01 and DAH2075E) for your easy understanding as well as flexible and efficient

application. It provides related knowledge and safety items for the application of the drive

unit. Please read the safety notes carefully before using the product.

In order to give full play to the function of the all-digital AC servo drive unit with high

precision and high speed of DAH series and ensure your safety, please read the manual

carefully before using the product and operate the drive unit correctly in strict accordance

with the safety notes and operation methods in the manual.

z Improvement, specification and version for the product are subject to change without

Preface

notice.

If the user modifies the product, our company doest not assume any responsibility,

z

meanwhile, the warranty certificate is no longer available.

This user manual shall be kept by end user.

Sincere appreciation—— Thank you for your kind support when you are using the

products of Guangzhou CNC Equipment Co., Ltd.

II

Page 4

Preface

To avoid operator and other personal injury and machine damage, please pay

special attention to the following warning labels while reading the manual.

The signs below indicate the danger levels during operation. The content of

them is extremely important and must be observed.

Warning

Danger

Incorrect operation will cause damage or death.

Incorrect operation will cause medium or slight injury, even

property loss.

Caution

Note

The following signs indicate what must be done and what must not be done.

If this label is not noticed, unexpected results and situation will occur.

Remind user of important requirements and instructions during the operation.

It indicates prohibition (must not be done)

!

It indicates enforcement (must be done)

III

Page 5

DAH01, DAH2075E AC Servo Drive Unit User Manual

Danger

!

Please tighten each terminal of the main

circuit with appropriate force.

If the user does not obey the

! !

instruction, it will cause

connection loosing, wire spark

and even a fire.

Please make sure the power is off before

wiring.

If the user does not obey the

! !

instruction, it will cause

electric shock.

Wiring and overhaul must be done by

electric engineering professionals.

If the user does not obey the

! !

instruction, it will cause

electric shock or a fire.

Please mount the drive unit on

nonflammable subject, and keep it far

away from inflammable materials.

If the user does not obey the

instruction, it will cause a fire.

Install a breaker, interference filter and

AC reactor.

If the user does not obey the

instruction, it will cause

lightning, fault or damage.

Operations of moving, wiring, checking

and maintenance can be done 5 minutes

after power off.

If the user does not obey the

instruction, it will cause

electric shock.

The ground terminal PE of the servo

unit must be earthed.

If the user does not obey the

! !

instruction, it will cause

electric shock.

IV

Install an emergency switch.

If the user does Not obey the

instruction, it will cause Injury,

fault and equipment damage. .

Page 6

Preface

!

Danger

Ensure the wiring is correct.

If the user does not obey the

! !

instruction, it will cause

equipment damage and electric

shock.

Please do not open the cover of the

terminal board in the state of Power On or

running.

If the user does not obey the

instruction, it will cause

electric shock.

Please do not touch the switch with

wet hand.

Please tight the power terminal and motor

output terminal.

If the user does not obey the

instruction, it will cause a fire.

Please do not directly touch the

connection terminal of the main

circuit of the drive unit.

the user does not obey

If

the instruction, it will cause

electric shock.

Please do n ot put hands into the servo

unit.

If the user does not obey the

instruction, it w ill cause

electric shock.

If the user does not obey the

instruction, it w ill cause

electric shock.

V

Page 7

DAH01, DAH2075E AC Servo Drive Unit User Manual

!

Caution

The wiring between the drive unit and

motor should be performed strictly in term

of the wiring diagram.

If the user does not obey the

! !

Load operation can be done after

successful no-load trial operation.

! !

instruction, it will cause

equipment damage.

If the user does not obey the

instruction, it will cause

equipment damage.

Please connect the brake resistance

according to the wiring diagram.

The voltage level loaded on each terminal

must use the one specified in the user

manual.

If the user does not obey the

instruction, it will cause

equipment damage.

Eliminate the fault before operation when

an alarm occurs.

If the user does not obey the

instruction, it will cause

equipment damage.

Match the motor with a proper servo

unit.

If the user does not obey the

! !

Please do not change, dismantle or repair

the drive unit.

instruction, it will cause

equipment damage.

If the user does not obey the

instruction, it will cause

equipment damage.

VI

If the user does not obey the

instruction, it will cause

equipment damage.

Do not hold the cable and motor shaft

during motor transportation.

If the user does not obey the

instruction, it will cause

equipment damage.

Page 8

Preface

Please do not touch the motor and radiator

of the servo unit which may be in high

temperature during operation.

If the user does not obey the

instruction, you will be burnt.

Do not connect power input wires R, S, T to

motor output terminals U, V, W.

If the user does not obey the

instruction, it will cause

equipment damage.

!

Caution

The parameters cannot be altered and

changed extremely.

If the user does not obey the

instruction, it will cause

equipment damage.

If the elements of the spindle drive unit are

incomplete or damaged, do not operate the

drive unit. Please contact the seller

immediately.

If the user does not obey the

instruction, it will cause

equipment damage.

The internal electronic devices of an

abandoned drive unit are not reusable and

taken as industrial waste.

If the user does not obey the

instruction, it will cause accident.

Please do not turn on/off the power

frequently.

If the user does not obey the

instruction, it will cause

equipment damage.

VII

Page 9

DAH01, DAH2075E AC Servo Drive Unit User Manual

Safety Responsibility

Manufacturer Responsibility

——Be responsible for the danger which has been eliminated and/or controlled on

design and configuration of the provided servo unit and accessories.

——Be responsible for the safety of the provided servo unit and accessories.

——Be responsible for the provided information and advice for the users.

User Responsibility

——Be trained with the safety operation of the servo unit and familiar with the safety

operation procedures.

——Be responsible for the dangers caused by adding, changing or altering the original

servo unit and the accessories.

——Be responsible for the danger without following the operations, maintenances,

installations and storages described in the manual.

VIII

Page 10

Contents

Contents

CHAPTER 1 OVERVIEW ··························································································1

1.1 Product Introduction ·························································································1

1.2 Confirmation of the Arrived Goods ···································································4

1.3 Product Appearance·························································································8

CHAPTER 2 INSTALLATION···················································································10

2.1 Ambient Conditions ························································································10

2.2 Installation for Servo Drive Unit······································································10

2.3 Installation for Servo Motor ············································································15

CHAPTER 3 CONNECTION····················································································16

3.1 Standard Wiring······························································································16

3.2 Terminal Function···························································································21

3.3 GSK-LINK Bus Communication Principle·······················································30

3.4 I/O Interface Principle·····················································································30

CHAPTER 4 PARAMETER······················································································35

4.1 Parameter List································································································35

4.2 Specification for Parameter Meaning ·····························································38

4.3 Comparison Table of Type Code Parameters and Spindle Motors ·················48

CHAPTER 5 ALARM AND TROUBLSHOOTING·····················································50

5.1 Alarm List ·······································································································50

5.2 Alarm Troubleshooting····················································································51

CHAPTER 6 DISPLAY AND OPERATION·······························································58

6.1 Keyboard Operation ·······················································································58

6.2 Monitoring Mode·····························································································59

6.3 Parameter Setting ··························································································61

6.4 Parameter Management·················································································61

6.5 Speed Trial Run······························································································63

6.6 JOG Operation ·······························································································64

6.7 Motor Test·······································································································64

6.8 User Shortcut Password·················································································64

6.9 Servo Parameter Auto Setting ········································································65

6.10 Others ··········································································································65

CHAPTER 7 RUN····································································································66

7.1 Power Supply Connection ··············································································66

7.2 Trial Run·········································································································68

7.3 Adjustment ·····································································································70

CHAPTER 8 PRODUCT SPECIFICATION······························································72

8.1 Specifications of Drive Unit·············································································72

IX

Page 11

DAH01, DAH2075E AC Servo Drive Unit User Manual

8.2 Servo Motor Specification·············································································· 74

8.3 Isolation Transformer····················································································· 78

Chapter 9 ORDER INSTRUCTION ········································································· 82

9.1 Capacity Selection························································································· 82

9.2 Electronic gear ratio······················································································· 84

9.3 Stop characteristcs ························································································ 85

9.4 Calculation methods of servo drive unit and position controller selection······ 85

X

Page 12

Chapter 1 Overview

CHAPTER 1 OVERVIEW

1.1 Product Introduction

The AC servo drive unit (all digital AC drive unit with high precision and high speed) of DAH

series (including DAH01 and DAH2075E) is a new generation of high-precision and high-speed AC

servo product produced by our company. It can be used together with various open-loop and

closed-loop control systems. The servo unit uses an international advanced special chip for motor

control (TMS320F2812PGFA DSP), a large scale programmable gate array(CPLD/FPGA)and an

IPM intelligent power module. It is of high integrated level, small dimension, safe protection and

high reliability. Its performance has reached the advanced level of similar foreign products, for an

optimal PID algorithm is used to complete PWM control; besides, it can intelligently identify various

servo motor models and has parameter auto setting function. Its servo motor uses a 17 bits

high-precision absolute encoder. The servo drive unit of the series can be applied to mechanical

manufacture, CNC machines, printing and packing machines, textile machines, robots, automatic

manufacturing lines and other automation fields.

DAH series AC servo unit has the following advantages:

z Using the most advanced 32-bit DSP processor (F2812) of TI Company to shorten signal

processing time and improve current sampling precision. System processing capability has been

greatly improved due to the 150MIPS of frequency of F2812.

z The system uses a 17-bit absolute encoder with 131072 lines. Compared with incremental

encoders, absolute encoders are characterized by high positioning precision, strong

anti-interference ability, motor rotor position memory and convenient installation.

z Bus communication uses GSK-LINK communication mode, which can fully meet the control

requirement of more than five axes. Up to 254 servo drive units can be connected theoretically,

and data transmission rate is 100Mbit/s;

z Fully closed loop control between CNC and servo unit, on-line upload and download of servo

parameters, diagnostic message feedback of the servo and servo alarm monitoring can be

realized in bus communication mode; memorizing workpiece coordinate system after power-off

and returning to zero point without a stroke limit switch are realized too;

z Analog instruction interface uses a high–precision A/D (16 bits) convertor. It has strong

anti-interference ability and small zero drift.

z High speed and high precision: a servo unit can drive a servo motor of 6000r/min; speed ratio: 1:

60000; it has stable torque characteristics from low speed to high speed; rotary positioning

precision: 0.0762μm;

z Intelligent identification for motor models and auto-setting control for parameters: DAH series AC

servo unit intelligently reads various models and parameters into the servo unit when power is

turned on. When a motor is replaced with the one of different model, its corresponding default

parameter can be resumed automatically; in different load inertia ratios, it can accurately identify

system control models and has parameter auto-setting function.

Simple and flexible control: set the operation mode and operation characteristics of the servo

z

drive unit by modifying parameters to meet different requirements.

1

Page 13

DAH01, DAH2075E AC Servo Drive Unit User Manual

1.1.1 Technical Specification of DAH Series Servo Drive Unit

Adaptive motor capacity

Input

Main circuit

power

supply

Control circuit

Control mode

Feedback mode 17-bit absolute encoder

conditions

Ambient

Temperature

Relative humidity

Vibration/impact

resistance

Speed control range

(based on no locked rotor

occurs at rated load)

Speed control mode

Speed variation rate

Speed frequency

response

Time of acceleration/

deceleration

External speed command

input

0.1kW~6kW

Single-phase or three-phrase AC (0.85~1.1)×220V

50Hz/60Hz

Single phase AC (0.85~1.1)×220V 50Hz/60Hz

Three-phase full wave rectification, IGBT PWM sine wave

drive

Working temperature: 0℃~+40℃

Storage temperature: -40℃~+70℃

< 90% (no dewing free from condensation)

<0.5G(4.9m/s

2

)/10Hz~60Hz(non-continuous operation)

1: 60000

0~100% load: ±0.01﹪

Rated voltage±10%:±0.01﹪

≥200Hz

0~10s

±10V input voltage

Internal speed setting Internal setting for four kinds of speed

Input impedance 20kΩ

Max. pulse input

frequency

Position control mode

0~6.5536M(Hz)

1 direction + pulse; 2 CCW+CW pulse train; 3 90° phase

Input pulse type

difference two-phase pulse; one of the three categories may

be selected. Any one of the three types may be selected.

Input pulse form 1 differential input 2 open collector input

Electronic gear ratio 1< α/β <32767

Position signal output

1 phases A, B, Z differential output; 2 phase Z open collector

output

1. Servo enable; 2. Alarm clearing; 3. CCW drive prohibition;

I/O signal

Control input signal

4. CW drive disabling; 5. Deviation counter zeroing//speed

selection1; 6. Command pulse prohibition/speed selection 2;

7. Zero-speed clamping.

Control output signal

1. Servo Ready Output; 2. Servo alarm output 3. Positioning

completion output/speed arrival output; 4. Brake output

2

Page 14

Chapter 1 Overview

Internal

Communication function

High performance

function

Function

GSK-LINK communication mode; max. number of

connections: 254 axes; data transmission rate: 100Mbit/s

1. A high-definition encoder is used to realize stable machine

operation;

2. A 16-bit high precision A/D conversion chip is adopted to

realize high-precision closed loop control, feedback pulse

number can be adjusted freely(≤32768);

3. Motor model automatic identification;

4. On-line upload and download of servo parameters,

diagnostic information feedback of the servo and servo alarm

monitoring are realized in bus communication mode;

5. Power failure memory for workpiece coordinate system

and zero return without stroke limit switch are realized in bus

communication mode;

6. Control model identification and parameter auto setting

functions.

Regenerative braking Built-in

Frequency dividing output

of encoder signals

Overspeed, main power overvoltage,power module fault,

undervoltage, overcurrent, overload, overheat, brake

Protection function

Monitoring function

Display and operation 6-bit LED digital tube, 4 buttons

abnormality, encoder abnormality, encoder communication

failure, invalid motor model setting, control power

abnormality, position deviation, etc.

Motor speed, current position pulse number, position

command pulse number, position deviation, motor torque,

motor current, straight-line speed, rotor absolute position,

command pulse frequency, running state, input/output

terminal signal, currently given voltage, etc.

Pulse output: 16~32768 (pulse/revolution)

adjustable dividing frequency

3

Page 15

DAH01, DAH2075E AC Servo Drive Unit User Manual

1.2 Confirmation of the Arrived Goods

1) Please check the received goods in accordance with the following items:

(1) Check whether the packing box is in good condition and the products are damaged in delivery.

(2) Confirm whether the products are the ordered ones according to the nameplates of the servo

drive units and servo motors.

(3) Confirm whether the accessories in the packing box are complete in terms of the packing list.

Note

2) Instruction for Motor Model

DAH series AC servo drive units can be matched with a variety of servo motors with TAMAGAWA

absolute encoders at home and abroad. Users can choose one of these motors in their orders.

Information about GSK SJT series servo motors with absolute encoders is provided in chapter eight

in the manual, while relative information about servo motors of other models is provided together with

the servo motors.

A damaged or incomplete AC servo unit can not be installed.

An AC servo unit should be used together with its adaptive servo motor.

Any questions, please feel free to contact suppliers or our company.

4

Page 16

Chapter 1 Overview

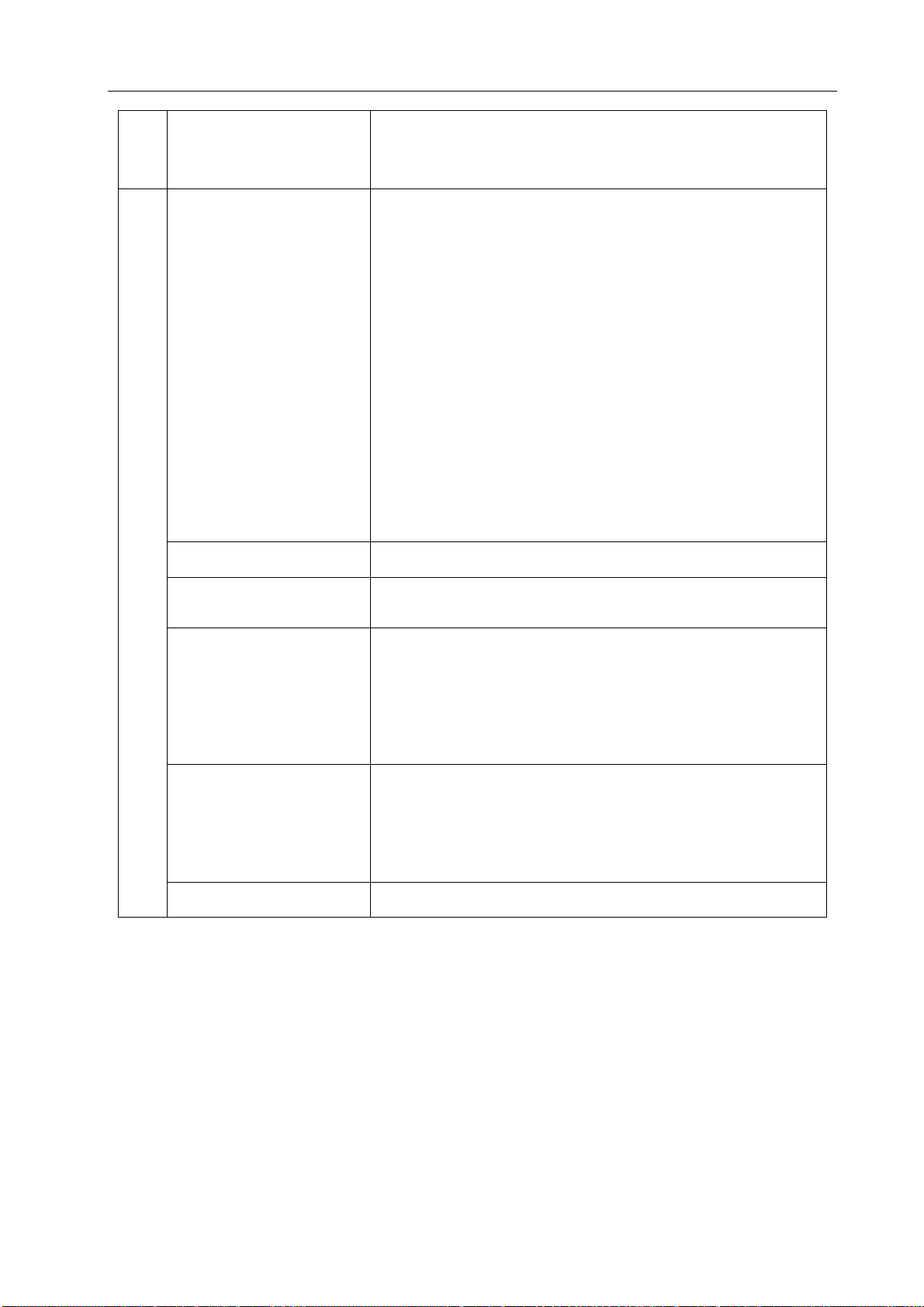

3) Mechanical Characteristics of Servo Motor

Speed (r/min)

nMAX

nN

Continuous

working area

0

T

———— rated torque ; T

N

———— rated speed ; n

n

N

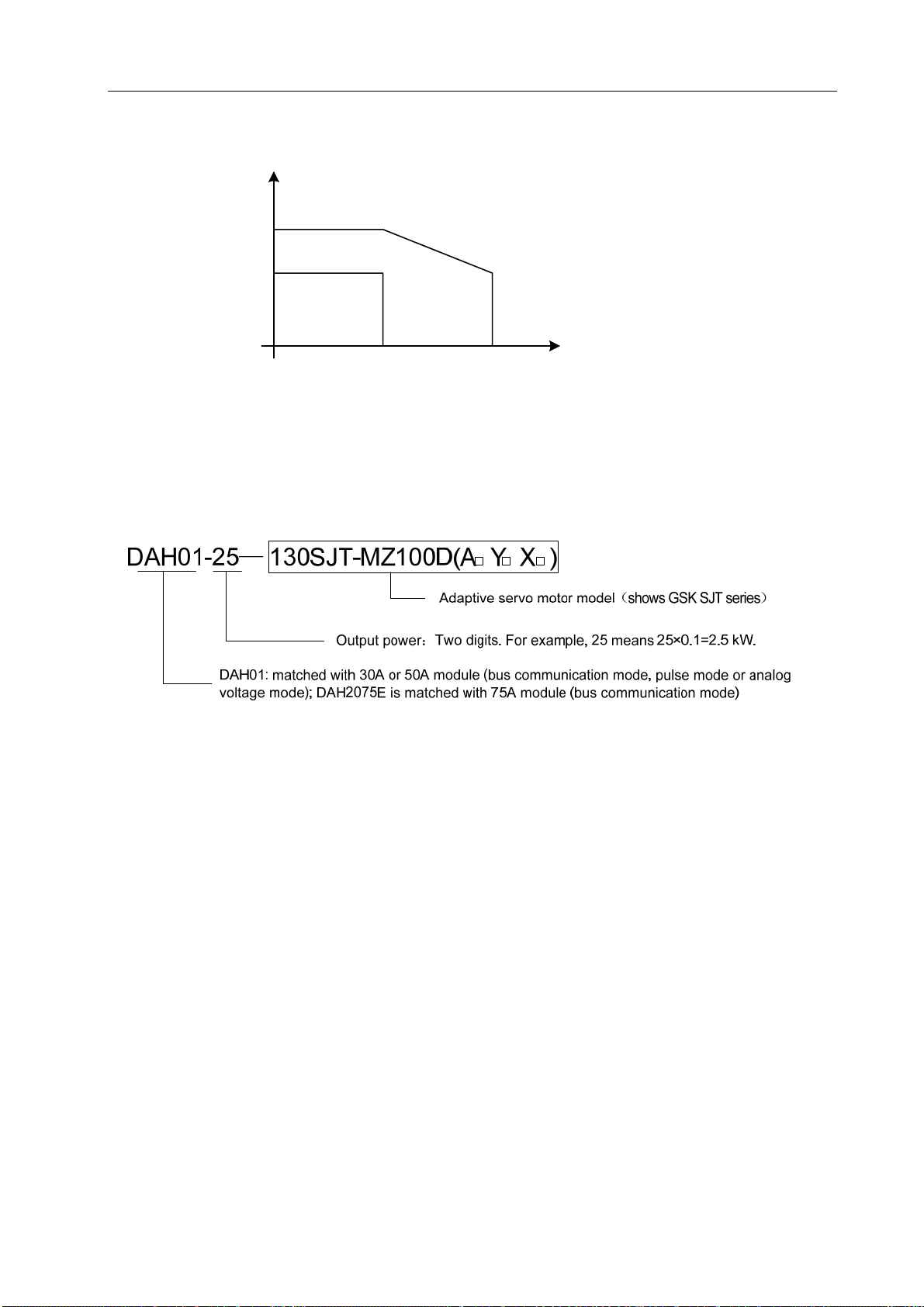

4) Order Model Instruction

1※ :Gsk servo motors with absolute encoders can be matched optionally by placing an order. The default

parameters of AC servo drive units only match the servo motors of SJT series. When other servo

motors are used, the ex-factory parameter has been backuped in EEPROM area and can be

recovered. When restoring the factory parameters, execute Backup Restoration instead of Default

Parameter Restoration.

2※ :Medium and small power (≤1.5KW) is standard configuration, medium power (>1.5W, ≤ 6KW)

uses thickened radiator.

Acceleration/

deceleration

area

TN TMAX

MAX

MAX

Torque(N.m)

———— maximum torque ;

———— maximum speed.

5

Page 17

DAH01, DAH2075E AC Servo Drive Unit User Manual

Order models of servo drive units matching SJT series servo motors with absolute

encoders are as follows:

Order model

(Only match the servo motors of GSK

Servo motor model and specification Remark

SJT series)

DAH01-05-80SJT-M024C(A4) 0.5kW, 2.4N.m, 2000 r/min, 3A, (30A module)

DAH01-07-80SJT-M024E(A4) 0.75kW, 2.4N.m, 3000 r/min, 4.8A, (30A module)

DAH01-06-80SJT-M032C(A4) 0.66kW, 3.2N.m ,2000 r/min, 5A, (30A module)

DAH01-10-80SJT-M032E(A4) 1.0kW,3.2N.m, 3000 r/min, 6.2A, (30A module)

DAH01-10-110SJT-M040D(A4) 1.0kW, 4N.m, 2500 r/min, 4.5A, (30A module)

DAH01-15-110SJT-M060D(A4) 1.5 kW 6N.m, 2500 r/min, 7A, (30A module) ※

DAH01-10-130SJT-M040D(A4) 1.0 kW 4N.m, 2500 r/min, 4A, (30A module)

DAH01-13-130SJT-M050D(A4) 1.3 kW 5N.m, 2500 r/min, 5A, (30A module)

DAH01-15-130SJT-M060D(A4) 1.5 kW, 6N.m, 2500 r/min , 6A, (30A module)

DAH01-20-130SJT-M075D(A4) 1.88 kW, 7.5N.m, 2500 r/min, 7.5A, (30A module) ※

DAH01-15-130SJT-M100B(A4) 1.5 kW, 10N.m 1500 r/min, 6A, (30A module)

DAH01-25-130SJT-M100D(A4) 2.5 kW, 10N.m, 2500 r/min, 10A, (50A module) ※

DAH01-23-130SJT-M150B(A4) 2.3 kW, 15N.m, 1500 r/min, 8.5A, (30A module) ※

DAH01-39-130SJT-M150D(A4) 3.9 kW, 15N.m, 2500 r/min, 14.5A, (50A module) ※

DAH01-28-175SJT-M180B(A4) 2.8 kW, 18N.m, 1500 r/min, 15A, (50A module) ※

DAH01-38-175SJT-M180D(A4)

3.8 kW, 18N.m, 2500 r/min, 16.5A, (75A module) ※※

DAH2075E-38-175SJT-M180D(A4)

DAH01-35-175SJT-M220B(A4)

3.5 kW, 22N.m,1500 r/min, 17.5 A, (50A module) ※※

DAH2075E-35-175SJT-M220B(A4)

DAH01-45-175SJT-M220D(A4)

4.5 kW, 22N.m,2500 r/min, 19 A, (75A module) ※※

DAH2075E -45-175SJT-M220D(A4)

DAH01-38-175SJT-M300B(A4)

3.8 kW, 30N.m,1500 r/min, 19 A, (75A module) ※※

DAH2075E -38-175SJT-M300B(A4)

DAH01-60-175SJT-M300D(A4)

6 kW, 30N.m,2500 r/min, 27.5 A, (75A module) ※※

DAH2075E -60-175SJT-M300D(A4)

6

Page 18

Chapter 1 Overview

5) Accessories

Standard accessories

Order model

Driving device

(drive units and

motors)

Driving devices

matching CNC

(drive unit,

motor and

CNC)

DAH2075E,DAH01

(bus communication interface

mode)

(1) An instruction manual (this

one) for DAH series AC servo

drive unit.

(2) RJ45S crystal head and

network cable

(3) 3m motor wire, 3m encoder

feedback wire

(1) An instruction manual (this

one) for DAH series AC servo

drive unit.

(2) RJ45S crystal head and

network cable.

(3) 3m motor wire, 3m encoder

feedback wire

(Pulse/analog command

(1) An instruction manua (this

one) for DAH series AC

servo drive unit.

(2) One set of DB44 female

plugs.

(3) 3m motor wire, 3m encoder

feedback wire.

(1) An instruction manual (this

one) for DAH series AC

servo drive unit.

(2) 3m motor wire, 3m encoder

feedback wire.

(3) 3m signal wire from CNC to

drive unit.

DAH01

interface mode)

Note 1: Signal cable (standard 3m) can be provided when it is matched with our position controller.

Note 2: Users can select feedback cables (standard 3m) when our servo motors are provided.

Note 3: Standard accessories of servo motors are provided according to servo motor manual.

Remark

The

provided

cables

are

welded.

7

Page 19

DAH01, DAH2075E AC Servo Drive Unit User Manual

交流伺服驱动单

全数字式

系列

ncoder feetback signal

uttons

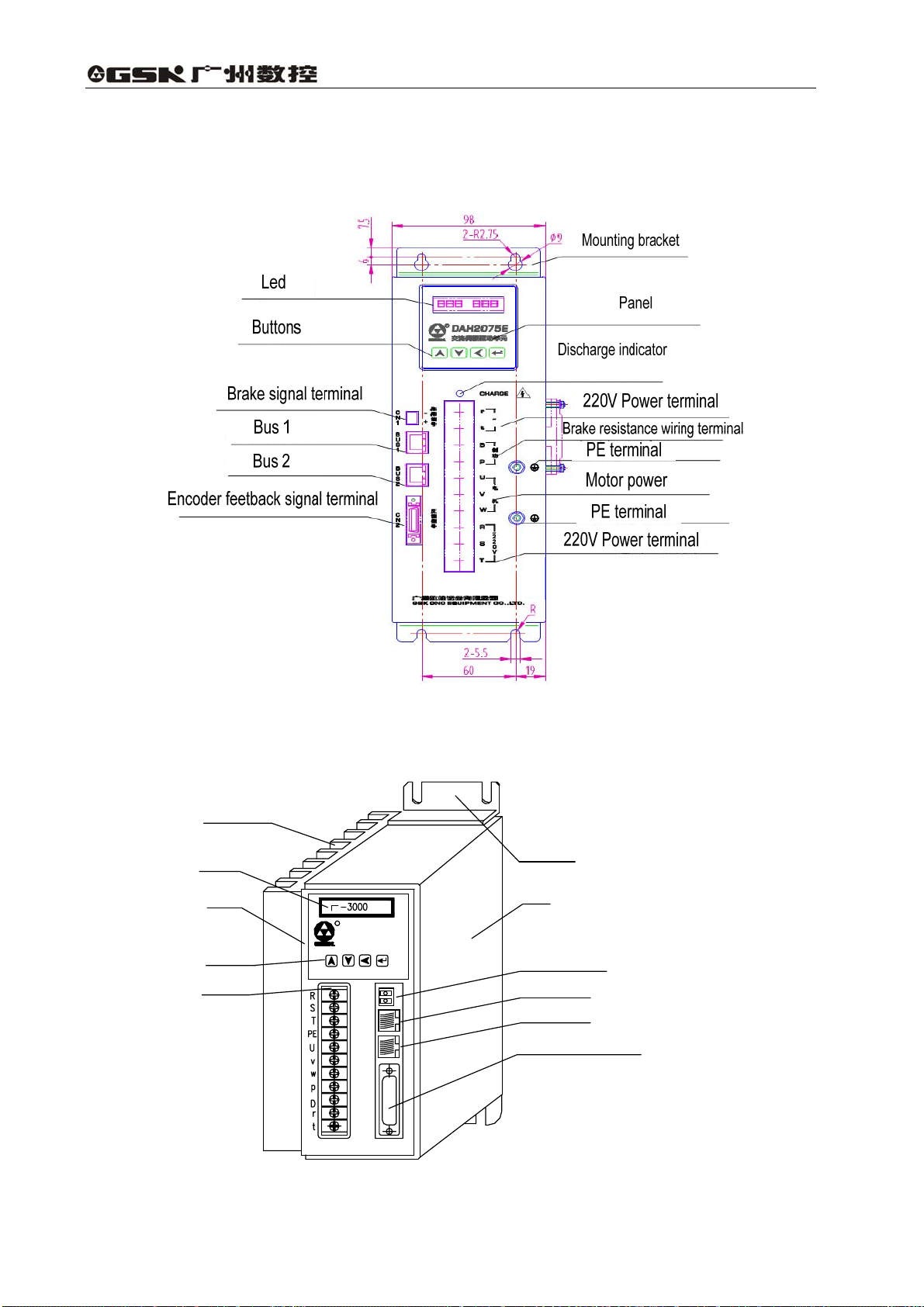

1.3 Product Appearance

1) DAH 2075E Servo Drive Unit

Fig. 1-2-1 DAH2075E (bus communication mode) Servo Drive Unit Appearance

2) Appearance of DAH01 Servo Drive Unit

Radiator

LED

Panel

B

PowerTB

R

D A H 0 1

元

+

CN1 控制信号

bracket

cabinet

Brake terminal

Bus 1

Bus 2

E

CN2 反馈信号

CN2

Fig. 1-3-2 Appearance of DAH01 (bus communication mode) Servo Drive Unit

8

Page 20

Chapter 1 Overview

ottons

ontrol signal

anel

adiator

交流伺服驱动单

全数字式R系列

R

LED

bracket

P

D A H 0 1

B

Power TB

元

cabinet

C

Encoder feetback

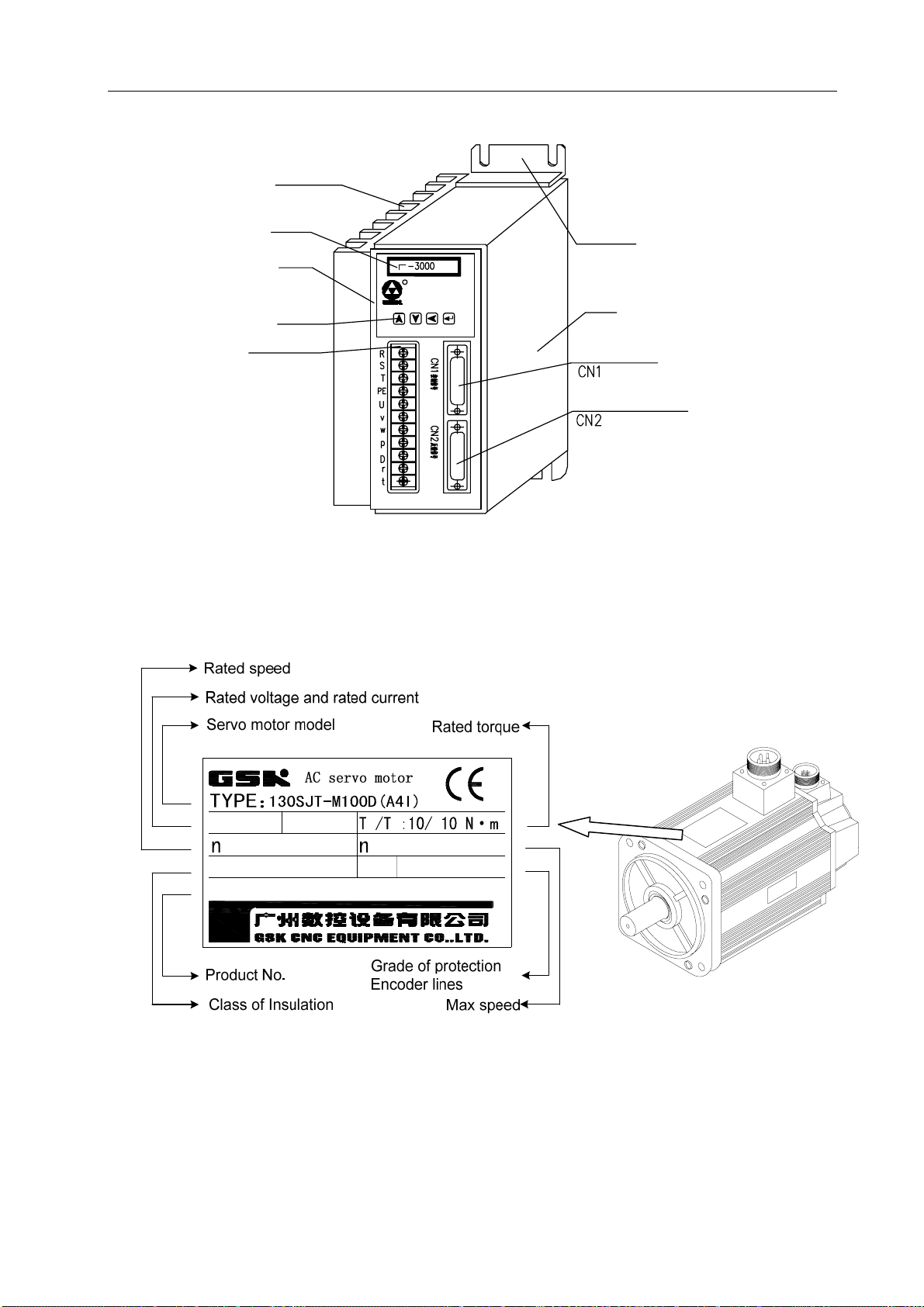

Fig. 1-3-3 Appearance of DAH01 (matched with DB44 female connector) Servo Drive Unit

2) Appearance of Servo Motor

交流伺服电动机

N

U :220V

N

: 2500r/min

S/N:

N

I :10A

081016100D0000107H

NS

max

: 3000 r/min

M: 17 bit

IP65INS.CLASS: B

Fig. 1-3-4 Appearance of Servo Motor

9

Page 21

DAH01, DAH2075E AC Servo Drive Unit User Manual

CHAPTER 2 INSTALLATION

Note

2.1 Ambient Conditions

Item

Operation

temperature/humidity

Storage

temperature/humidity

Atmospheric

environment

Elevation

Vibration

Protection grade IP43 IP65

Servo drive unit of DAH

series

0℃~+40℃ (no frost)

<90%RH (no dewing)

-40℃~+70℃

90%RH(no dewing)

No corrosive air, flammable

air, oil mist and dust in the

control cabinet.

Elevation< 1000m Elevation< 1000m

<0.5G(4.9m/s

2

)10Hz~60Hz (non-continuous running)

2.2 Installation for Servo Drive Unit

Note

AC servo motor of GSK SJT

series

0℃~+40℃ (no frost)

90%RH 以下 (no dewing)

-40℃~+70℃

<90%RH(no dewing)

Indoor environment (no insolation): no

corrosive air, flammable air, oil mist and

dust.

1) Installation environment

(1) Protection

The structure of the servo drive unit has no protection, so it must be installed into an electricity

cabinet with good protection and kept away from corrosive and flammable air, conductive objects,

metal dust, oil mist and liquid.

(2) Temperature and humidity

Environment temperature 0℃~+40 , ℃ ensure good radiating conditions.

10

Page 22

Chapter 2 Installation

A

(3) Vibration and impact

Avoid vibration when installing the drive unit, vibration reducing measures should be taken to

2

keep vibration under 0.5G(4.9m/s

installation.

2) Installation Method

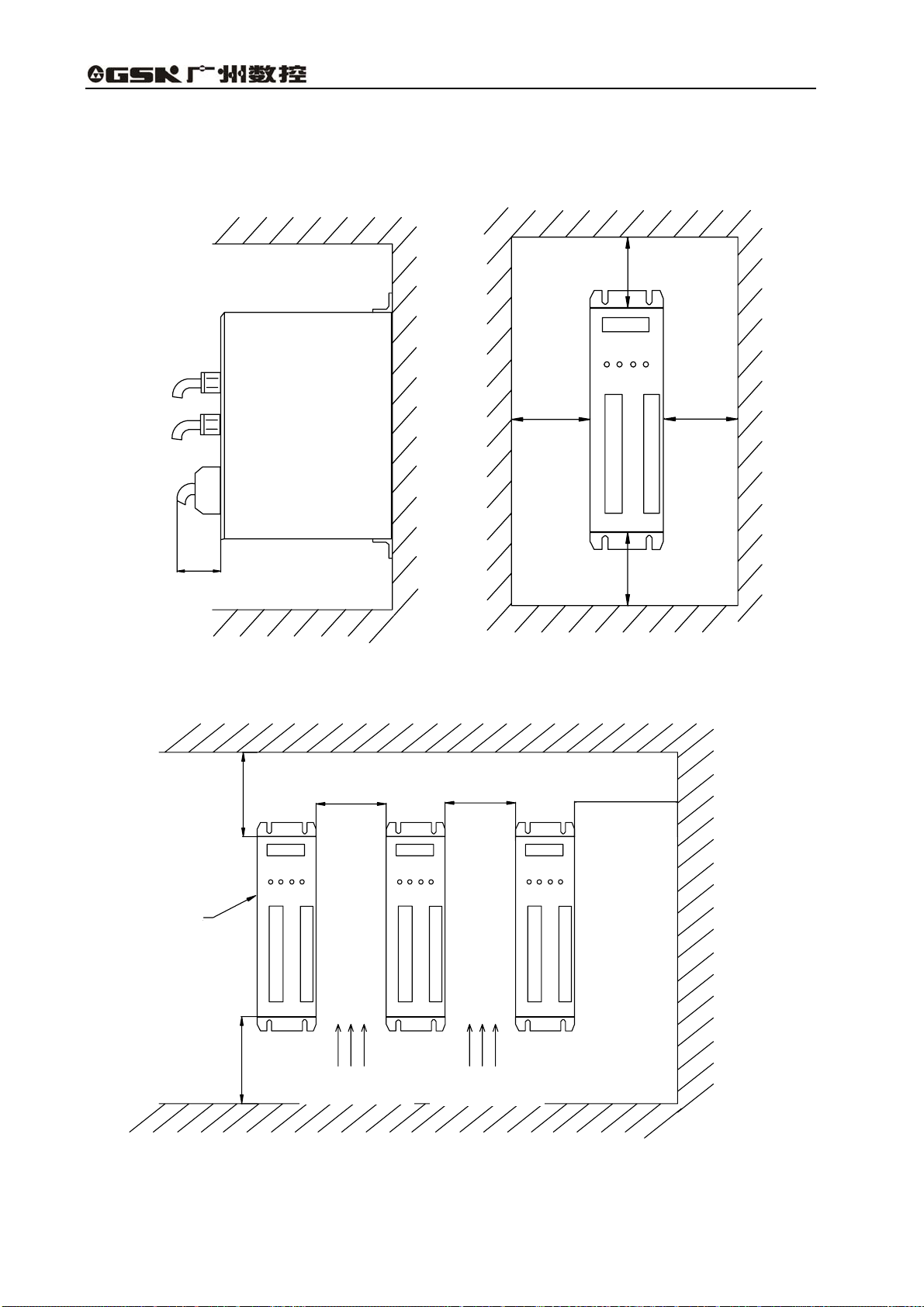

(1) Installation Dimension and Installation Method for DAH01

DAH01 can be installed with base-plate installation or panel installation, with its installation

direction perpendicular to mounting surface. Figure 2-1 is the sketch map for base-plate installation;

Figure 2-2 is the sketch map for panel installation.

) , and drive unit should not bear weight and impact during its

R

DAH01

全数字式

交流伺服驱动单元

抱

闸

总

线

1

总

线

2

Fig. 2-1 Base-plate Installation Mode for Drive Unit

图2-1 驱动单元底板安装方式

pplication of wool felt

Sealing against dust

贴羊毛毡

密封防尘

R

DAH01

全数字式

交流伺服驱动单元

抱

闸

总

线

1

总

线

CN2

反

馈

信

号

2

CN2

反

馈

信

号

User installation

用户安装加工图

processing drawing

Fig. 2-2 Panel Installation Mode for Drive Unit

图2-2 驱动单元面板安装方式

11

Page 23

DAH01, DAH2075E AC Servo Drive Unit User Manual

(2) DAH01 Installation Interval

Figure 2-3 shows installation intervals for a single drive unit, figure 2-4 shows installation

intervals for multiple drive units, large space should be left for keeping good radiating conditions

in the actual installation.

>100mm

>50mm

Fig. 2-3 Installation Intervals for a Single Drive Unit

>100mm

>25mm

>25mm

>100mm

>100mm

>100mm

>100mm

Servo drive unit

伺服驱动单元

Figure 2-4 Installation Intervals for Multiple Drive Units

12

>100mm

Wind direction

通风方向通风方向

Wind direction

Page 24

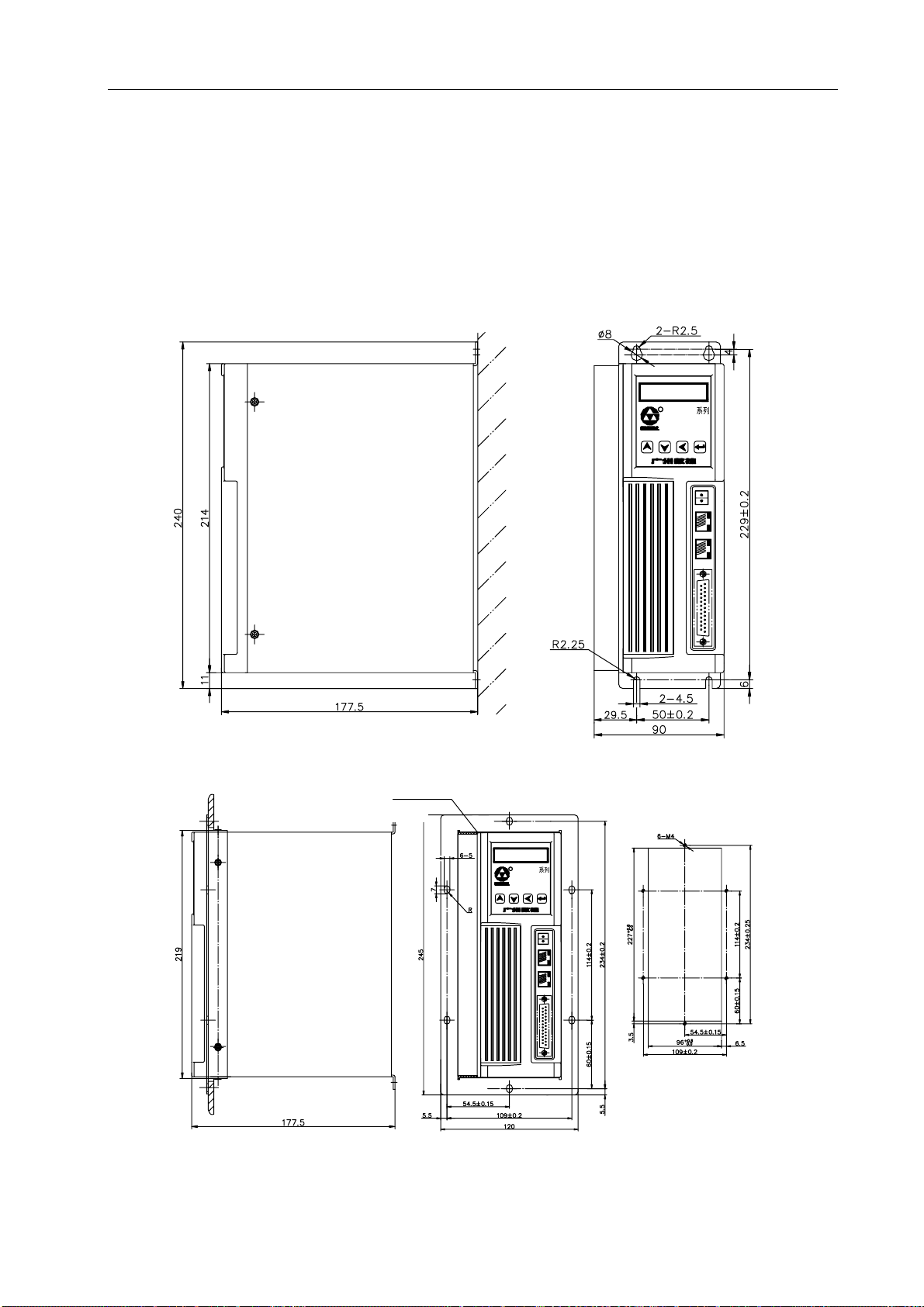

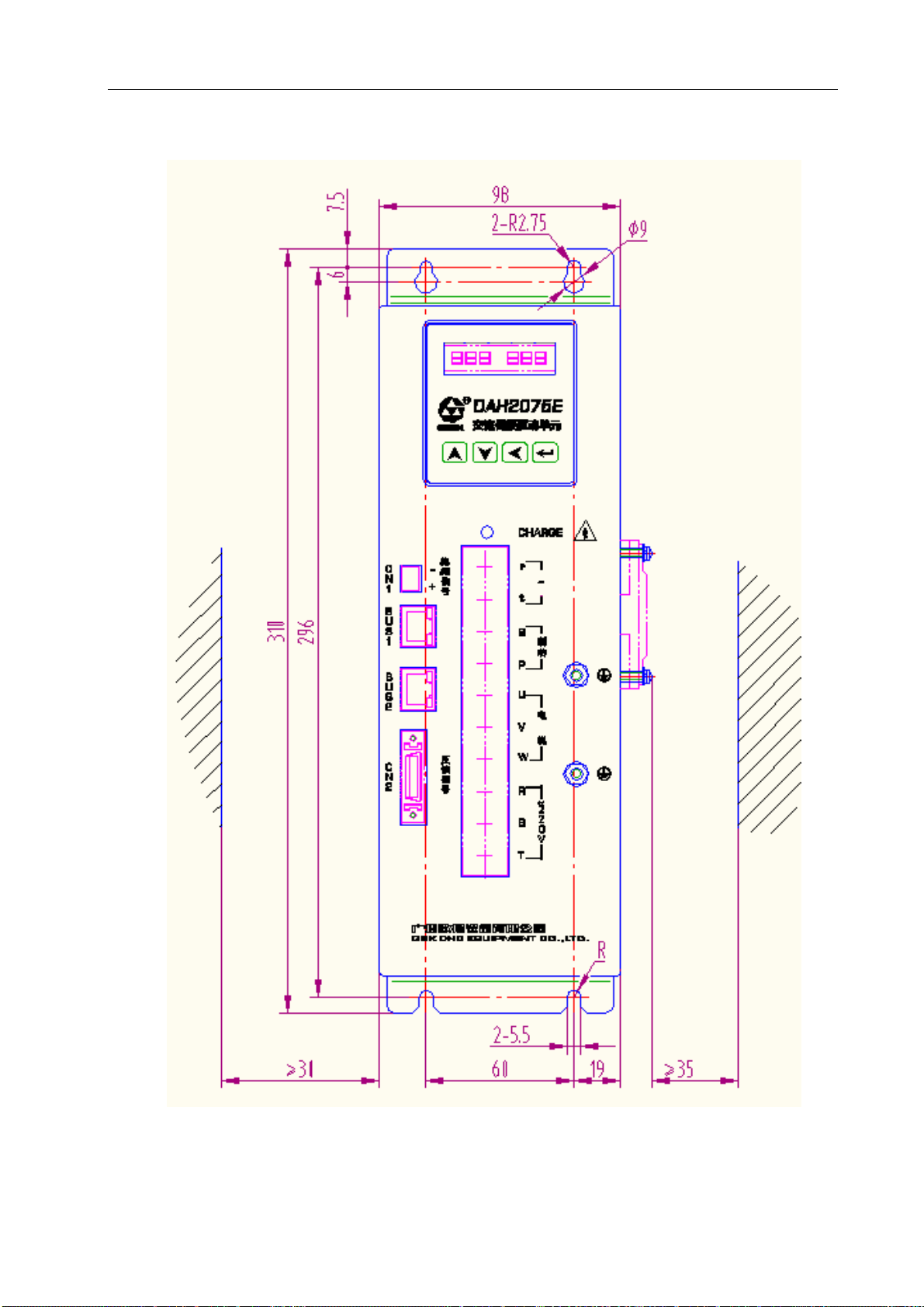

(3) Installation Dimension and Installation Method for DAH2075E

Fig. 2-5 Base-plate Installation Dimension and Intervals (Front) for DAH 2075 Drive Unit

Fig. 2-5 Installation Dimension for DAH 2075 Drive Unit

Chapter 2 Installation

13

Page 25

DAH01, DAH2075E AC Servo Drive Unit User Manual

Fig. 2-6 Base-plate Installation Dimension and Intervals (Side) for DAH 2075 Drive Unit

3) Heat Dissipation

To prevent the ambient temperature of the servo unit from rising continuously, radiators blowing

convection wind towards the unit should be installed in the electric cabinet.

14

Page 26

Chapter 2 Installation

2.3 Installation for Servo Motor

Note

1) Installation Environment

(1) Protection

Prevent liquid from spraying to the motor and prevent oil and water from entering the motor

through its lead-in wire and motor shaft, for the servo motors of GSK SJT series and Huazhong

ST series are not water-proof.

Note: Please declare in your order if you need a water-proof motor.

(2) Temperature and Humidity

Keep the environment temperature between 0~+40 . Motor temperature rise℃ s after

long-term running, so forced air cooling should be taken when there are heating elements or

small space around the motor.

Relative humidity should be less than 90%RH,with no dewing.

(3) Vibration

The servo motor should not be installed in the situation with vibration, and the vibration

should be no more than 0.5G (4.9m/s2)。

2)Installation Method

(1) Installation Method

SJT series motor adopts flange installation mode currently and its installation direction is

arbitrary.

(2) Cautions:

z It is forbidden to strike the motor or motor shaft to prevent the encoder from being

damaged when disassembling or assembling belt wheels.

z Most SJT series motors can not bear big axial and radial loads currently. It is suggested

that elastic couplings be used to connect loads.

z Fix the motor with anti-loosened gaskets to prevent it from coming loose.

15

Page 27

DAH01, DAH2075E AC Servo Drive Unit User Manual

CHAPTER 3 CONNECTION

Caution

!

Only qualified persons can connect the system or check the

connection

Wiring and checking cannot be done in 5 minutes after the power

supply is switched off to avoid electric shock.

Wiring must be performed in terms of the terminal voltage and

polarity to avoid equipment damage and personnel injury.

The drive unit and servo motor must be grounded well.

3.1 Standard Wiring

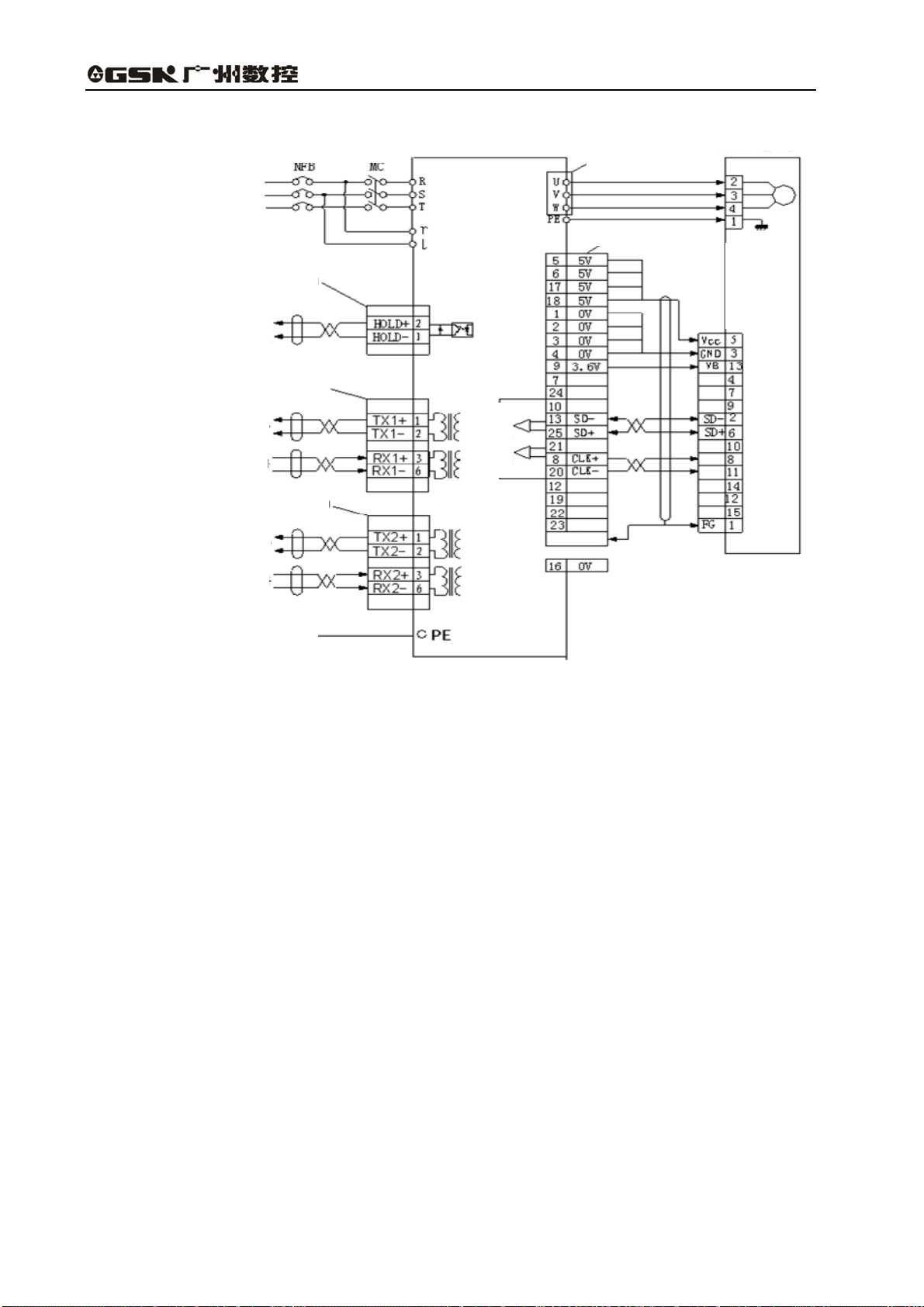

1) Ethernet Bus Mode

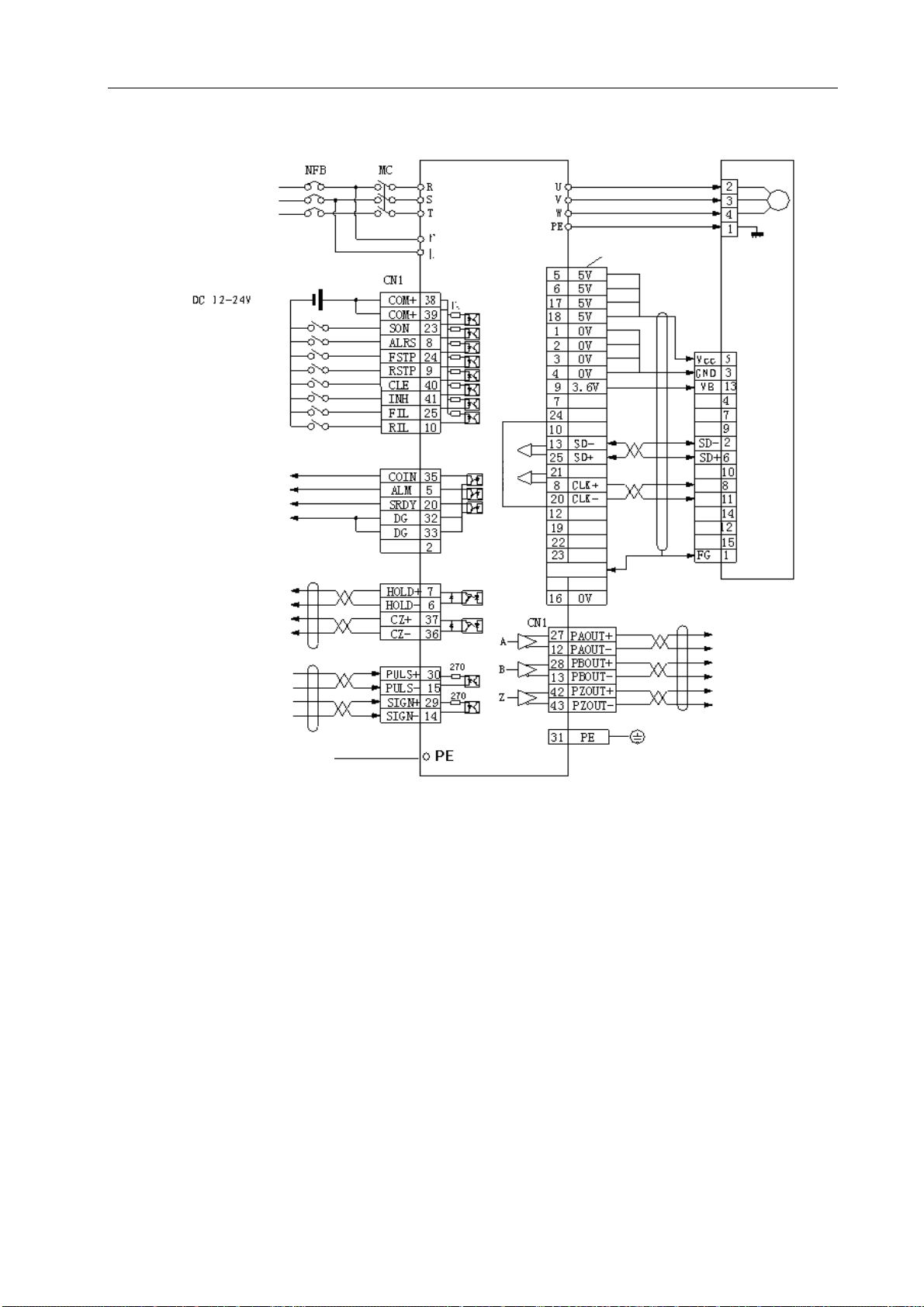

Figure 3-1-1 and figure 3-1-2 show the Ethernet bus standard wiring for DAH01 and

DAH2075E respectively.

2) Position Control Mode (Pulse Mode)

Figure 3-1-3 shows the standard wiring for position control (pulse mode).

3) Speed Control Mode (Analog Voltage Mode)

Figure 3-1-4 shows the standard wiring for speed control (analog voltage mode).

4) Wiring

(1) Power Terminal TB

z Wire cross-sectional area: For terminals R、S、T、PE 、 U 、 V and W, cross-sectional

area≥1.5mm2(AWG14~16); for terminals r and t, cross-sectional area ≥1.0 mm2(AWG16~

18).

z Grounding: grounding wires should be as thick as possible. Drive unit shell, servo motor and

system shell are earthed at one point of PE terminal. Earthing resistance <0.1Ω.

z Terminal connection adopts SVM2-4 pre-insulated cold-press terminals which must be

connected securely.

z It is suggested that the power be supplied through a three-phase isolation transformer to

reduce the possibility of electric shock.

z It is suggested that the power supply through connecting a noise filter to improve

anti-interference capability.

z Please install a non-fuse breaker (NFB) to cut off the power in time when a fault occurs in the

drive unit.

Control Signal CN1 and Feedback Signal CN2

z Wire selection: use screen cables (twisted ones are recommended ), Cross-sectional area

≥0.12mm2(AWG24~26),shield layer must be connected to FG terminal.

z Wire length: wires should be as short as possible, the wire for controlling CN1 should not be

longer than 3m, and feedback signal for controlling CN2 should not be longer than 20m.

16

Page 28

Chapter 3 Connection

z Wiring: wiring should be far from power circuit to prevent interference.

z Please install surge absorbing components for inductive components (coil): DC coil

connects to the freewheel diode in parallel back to back while AC coil connects to the RC

absorbing circuit in parallel.

z Bus interface connecting wire uses UTP- five categories (network cable) with both ends

suppressed with crystal heads. Direct network cable and cross network cable can be

suppressed.

Note

Absoulute

encoder

RS485 transceiver

Fig. 3-1-1 Standard Connection for Ethernet Bus Mode of DAH2075E

Note: there must be good electrical connection between drive shell grounding and system shell grounding, or

else unexpected results will occur.

17

Page 29

DAH01, DAH2075E AC Servo Drive Unit User Manual

3-phase or single

phase AC220v

Brake signal terminal(CN1)

Brake release signal

Brake release signal ground

Bus interface(Bus 1)

Bus 1 (sending signal)

Bus 1 (Receiving signal)

Bus interface(Bus 2)

Bus 2 (sending signal)

DAH01 AC servo drive unit

RS485 transceiver

Shell

Motor cable

terminal

Encoder interface 2

Servo motor

Absoulute

encoder

Bus 2 (Receiving signal)

To connect to system shell GND

Fig. 3-1-2 Standard Connection for Ethernet Bus Mode of DAH01

Note: there must be good electrical connection between drive shell grounding and system shell grounding, or

else unexpected results will occur.

18

Page 30

Chapter 3 Connection

3-phase or single

phase AC220v

Servo enable

Alarm chearing

CCW drive prohibition

CW drive prohibition

Position deviation zeroing

Command pulse prohibition

CCW torque limitation

CW torque limitation

Positioning completion

Servo alarm

Servo ready

Output common terminal

Brake release signal

Brake release signal Ground

Encoder Z phase output

Encoder Z phase output GND

DAH01 AC servo drive unit

RS485 transceiver

Shell

Motor cable

terminal

Encoder interface 2

Servo motor

Absoulute

encoder

Pulse feedback A

Position command

Rotation direction command

To connect to system shell GND

Pulse feedback B

Pulse feedback C

Fig. 3-1-3 Standard Connection for Position Control (pulse mode)

Note: there must be good electrical connection between drive shell grounding and system shell grounding, or

else unexpected results will occur.

19

Page 31

DAH01, DAH2075E AC Servo Drive Unit User Manual

3-phase or single

phase AC220v

Servo enable

Alarm chearing

CCW drive prohibition

CW drive prohibition

Speed selection 1

Speed selection 2

CCW torque limitation

CW torque limitation

Zero-speed clamping input

Speed arrival

Servo alarm

Servo ready

Output common terminal

DAH01 AC servo drive unit

RS485 transceiver

Shell

Motor cable

terminal

Encoder interface 2

Servo motor

Absoulute

encoder

Speed command (-10V~+10V DC)

Brake release signal Ground

Encoder Z phase output GND

Speed command ground

Brake release signal

Encoder Z phase output

Pulse feedback A

Pulse feedback B

Pulse feedback C

To connect to system shell GND

Figure 3-1-4 Standard Connection for DAH01 Speed Control (Analog Voltage Mode)

Note: there must be good electrical connection between drive shell grounding and system shell grounding, or

else unexpected results will occur.

20

Page 32

Chapter 3 Connection

3.2 Terminal Function

3.2.1 Terminal Configuration for DAH01 (Ethernet Interface), DAH2075E Servo Drive Unit Interface

1) Terminal Configuration

In figure 3-2-1-1, BUS1 indicates bus interface 1, BUS2 indicates bus interface 2; in figure

3-2-1-2, CN2 indicates the connector of a 26-pin encoder.

总线接口1(BUS1)

Bus interface 1 (BUS 1)

Bus interface 1 (BUS 1) pin explanation

总线接口1(BUS1)引脚 说 明

引脚说明

TX1+ ,白绿色线

TX1- ,绿色线

RX1+ ,橙白色线

NC ,兰色线

NC ,兰白色线

RX1- ,橙色线

NC ,棕白色线

NC ,棕色线

引脚说明

TX2+ ,白绿色线

TX2- ,绿色线

RX2+ ,橙白色线

NC ,兰色线

NC ,兰白色线

RX2- ,橙色线

NC ,棕白色线

NC ,棕色线

12

PEA+ (for test)

10

PEZ+ (for test)

CLK+ 8

+5V 6

0V 4

2

0V

Pin number Explanation

引脚号

1

8

7

6

5

4

3

2

1

1 TX1+, white-green wire

2

2 TX1+, green wire

3

3 RR1+, orange-white wire

4

4 NC, blue wire

5

5 NC, blue wire

6

6 RX2-, orange wire

7

7 NC, brown-white wire

8

8 NC, brown wire

总线接口2(BUS2)

Bus interface 2 (BUS 2)

8

7

6

5

4

3

2

1

Bus interface 2 (BUS) pin explanation

总线接口2(BUS2)引脚 说 明

1 TX2+ white-green wire

引脚号

2 TX2- green wire

1

3 RX2+, orange-white wire

2

3

4 NC, blue wire

4

5 NC, blue-white wire

5

6 RX2-, orange wire

6

7 NC, brown-white wire

7

8 NC, brown wire

8

Fig. 3-2-1-1 Wiring for Bus Interface 1 and 2 of Servo Unit of DAH01

(Ethernet Interface) and DAH2075E

26

24

22

18

PEA-(for test)

PEZ-(for test)

CLK- 20

+5V

0V 16

FG 14

23

21

19

SD+25

PEB-(for test)

+5V 17

FG 15

SD- 13

11

PEB+(for test)

+3.6V 9

7

+5V 5

0V 3

1

0V

Type of CN2 Plug Connector: 10126-3000PE

Type of CN2 Shell Kit: 10326-52F0-008

Fig. 3-2-1-2 Wiring for Servo Unit Encoder Interface CN2 (26 Pins) of DAH01

(Ethernet Interface) and DAH2075E

21

Page 33

DAH01, DAH2075E AC Servo Drive Unit User Manual

Fig. 3-2-1-3 Wiring for Encoder Interface CN2 (26 Pins) of Servo Unit of DAH01

(Ethernet Interface) and DAH2075E

Note: +5V and 0V power lines are respectively connected to the aviation plug with 4 and 5 wires combined

together, 3.6 V power line is connected to the aviation plug with 2 wires combined together, pin 7 and

pin 9 need to be shorted in high-density 26-pin plug in order to reduce the power voltage attenuation

during long-distance cable transmission.

3.2.2 Terminal Configuration for Servo Drive Unit Interface of DAH01 (Pulse and Analog

Command Mode)

1) Terminal Configuration

In figure 3-2-2-1, CN1 is a DB44 connector, with male socket and female plug; in figure

3-2-2-4, CN2 is a DB25 connector, with female socket and male plug.

22

Page 34

Chapter 3 Connection

T

g

16

1 SG Analog command ground

31 PE 保护接地

31 PE protective earthin

17 VCMD analog speed command

17 VCMD 模拟速度指令

2

20 SRDY servo ready output

20 SRDY 伺服准备好输出

5 ALM alarm output

5 ALM 报警输出

35 COIN positioning completion /speed arrival

35 COIN 定位完成/速度到达

6 HOLD- 抱闸输出

6 HOLD- brake output

36 Z- Z signal output-

36 Z- Z 信号输出-

7 HOLD+ 抱闸输出+

7 HOLD+ brake output +

37 Z+ Z 信号输出+

37 Z+ Z signal output +

23 SON 伺服使能

23 SON servo enable

8 ALRS 报警清除

8 ALM alarm clearing

38 COM+ 控制信号电源输入(24VDC)

38 COM+ control signal power input (24V DC)

24 FSTP CCW 驱动禁止

24 FSTP CCW drive prohibition

9 RSTP CW 驱动禁止

9 RSTP CW drive prohibition

39 COM+ control signal power input (24VDC)

25 FIL CCW torque limit

10 RIL CCW torque limit

40 CLE/SC1 deviation zeroing/speed selection 1

26 ZSL zero-speed clamping

41 INH/SC2 command pulse prohibition/speed selection2

27 PAOUT+ pulse feedback A+

12 PAOUT- pulse feedback A42 PZOUT+ pulse feedback Z+

28 PBOUT+ pulse feedback B+

13 PBOU

43 PZOUT- pulse feedback Z-

29 SIGN+ direction signal input+

14 SIGN- direction signal input-

44 GND internal digital ground

30 PULS+ pulse command signal input +

15 PULS- pulse command signal input -

-pulse feedback B-

Fig. 3-2-2-1 Connection for Control Port CN1 (Pulse and Analog Command Mode) of DAH01

23

Page 35

DAH01, DAH2075E AC Servo Drive Unit User Manual

R

S

T

PE

U

V

W

P

D

r

t

TB

Fig. 3-2-2-2 Connection for DAH2075E Fig. 3-2-2-3 Connection for DAH01

Power Terminals Power Terminals

Servo unit

Servo motor

13

CN2

DB25

25

12

24

11

23

10

22

9

21

8

20

7

19

6

18

5

17

4

16

3

15

2

14

1

Fig. 3-2-2-4 Connection for Encoder Interface CN2 (25 pins) of Drive Unit of DAH01

Brown wire

SD-

棕线

Green wire

绿线

SD+

Red wire

红线

15-pin motor socket

Blue-white wire

蓝白线

+3.6V

Purple-white wire

紫白线

CLK+

Black-white wire

黑白线

CLK-

Black wire

黑线

Green-white wire

绿白线

+5V

Blue wire

蓝线

+5V

Yellow wire

+5V

黄线

Orange wire

橙线

+5V

Yellow-white wire

黄白线

0V

Purple wire

紫线

0V

Orange-white wire

橙白线

0V

Ground wire

FG

地线

Brown-white wire

0V

棕白线

Ground wire

FG

地线

Red-white wire

红白线

0V

电机的 15 针插座

FG

SD0V

+5V

SD+

+3.6V

CLK+

CLK-

Ground wire (grey wire and

wire fence)

1

Blue-black wire

2

Black, brown-black

3

Red wire

5

Blue wire

6

13

8

11

Absolute

encoder

interface

24

Page 36

2) DAH01 Drive Unit Power Terminal TB

Table 3-1 Power Terminal TB

Chapter 3 Connection

Terminal

number

TB-1 R

TB-2 S

TB-3 T

Terminal

mark

Signal name Function

Single-phase or

three-phase

major loop

power

Major loop power input terminal

AC220V 50Hz

Note: do not connect it to motor output

terminals U,V and W.

grounding terminal

TB-4 PE

System

grounding

grounding resistance<0.1Ω;

The servo motor output and power input are

grounded at a common point.

TB-5 U

TB-6 V

TB-7 W

Servo motor

output

The servo motor output terminal must be

connected to motor terminals U, V and W

correspondingly.

TB-8 P reserved

TB-9 D reserved

TB-10 r

TB-11 t

single-phase

control power

Control loop power input terminal

supply

AC 220V 50Hz

3) DAH01 Drive Unit Control Terminal CN1

Control mode abbreviation: P for position control mode

S for speed control mode

Table 3-2 control signal input/output terminal CN1

Term inal

number

CN1-38

CN1-39

Term inal

name

Mark I/O Mode Function

Power

supply

positive pole

COM+ Type1

of input

terminal

The positive pole of the input terminal is used

to drive the photoelectric coupler of the input

terminal.

DC12 V~24V,current≥100mA

Servo enable input terminal

SON ON:to enable the operation of the drive

unit

SON OFF:The drive unit is turned off and

CN1-23

Servo

enable

SON Type1

Note 1: before SON OFF is switched to SON ON,

the motor must be in the state of rest.

Note 2: after switching to SON ON, do nto input

commands until 50ms is waited.

stops working, the motor is in free

state.

25

Page 37

CN1-8

CN1-24

CN1-9

CN1-40

Alarm

clearance

CCW drive

prohibition

CW drive

prohibition

Deviation

counter

zeroing

Speed

selection 1

DAH01, DAH2075E AC Servo Drive Unit User Manual

Alarm clearance input terminal

ALRS ON:clear system alarm

ALRS OFF:keep system alarm

ALRS Type1

Note: this method is not available to clear

those alarms with fault codes above 8.

In this case, turn off the power and

overhaul the drive unit, then turn on

the power again.

CCW (counter clockwise) drive prohibition

input terminal

FSTP ON:CCW drive enable

FSTP OFF:CCW drive prohibition

FSTP Type1

Note 1: used for mechanical ultra limit.

When the switch is OFF, the CCW

torque remains unchanged at 0.

Note 2: setting parameter No. 20 can shield

this function or make the switch

always ON.

CW (clockwise) drive prohibition input

terminal

RSTP ON:CW drive enable

RSTP OFF:CW drive prohibition

RSTP Type1

Note 1: used for mechanical ultra limit.

When the switch is OFF, the CW

torque remains unchanged at 0.

Note 2: setting parameter No. 20 can shield

this function or make the switch

always ON.

The input terminal of the position deviation

CLE Type1 P

counter zeroing

CLE ON: position deviation counter zeroing

during position control

Speed selection 1 input terminal

In speed control mode, the combination of

SC1 and SC2 is used to choose different

kinds of internal speed.

SC1 OFF,SC2 OFF:internal speed 1

SC1 Type1 S

SC1 ON,SC2 OFF:internal speed 2

SC1 OFF,SC2 ON:internal speed 3

SC1 ON,SC2 ON:internal speed 4

26

Note: values 1~4 of internal speed can be

modified with parameters.

Page 38

Continued:

CN1-41

CN1-25

CN1-10

CN1-20

CN1-5

Command

pulse

prohibition

Speed

selection 2

CCW torque

limit

CW torque

limitation

Servo ready

output

Servo alarm

output

INH Type1 P

SC2 Type1 S

FIL Type1

RIL Type1

SRDY Type2

ALM Type2

Chapter 3 Connection

Position command pulse prohibition input

terminal

INH ON:command pulse input prohibition

INH OFF:command pulse input enabled

Speed selection 2 input terminal

In speed control mode, the combination of

SC1 and SC2 is used to choose different

kinds of internal speed.

SC1 OFF,SC2 OFF:internal speed 1

SC1 ON:SC2 OFF:internal speed 2

SC1 OFF,SC2 ON:internal speed 3

SC1 ON,SC2 ON:internal speed 4

CCW (counter clockwise) torque limitation

input terminal

FIL ON:CCW torque limitation is within the

range of parameter No.36.

FIL OFF : CCW torque limitation is not

restricted by parameter No. 36.

Note: whether FIL is valid or invalid, CCW torque

is restricted by parameter No. 34. In

general, parameter No.34>parameter No.36

CW (clockwise) torque limitation input

terminal

RIL ON:CW torque limitation is within the

range of parameter No. 37.

RIL OFF:CW torque limitation is not restricted

by parameter No. 37.

Note: whether RIL is valid or invalid, CW torque is

restricted by parameter No. 35.

Servo ready output terminal

SRDY ON:The control power and the main

power are normal, the drive unit

does not alarm, and the servo

ready output is ON.

SRDY OFF:The main power is not switched

on or an alarm occurs in the

drive unit, the servo ready

output is OFF.

Servo alarm output terminal

ALM ON:The servo drive unit does not alarm,

servo alarm output is ON.

ALM OFF:An alarm occurs in the servo drive

unit, the servo alarm output is

OFF.

27

Page 39

DAH01, DAH2075E AC Servo Drive Unit User Manual

Continued:

Positioning

completion

COIN Type2 P

output

CN1-35

Speed

arrival

SCMP Type2 S

output

Common

CN1-32

CN1-33

terminal of

output

DG

Common

terminal

terminal

Encoder

CN1-37

phase Z

CZ Type2

output

CN1-26

Zero-speed

clamping

ZSL Type1

CN1-36 CZCOM

Positioning completion output terminal

COIN ON:When the value of the position

deviation counter is within the range of

the specified positioning, positioning

completion output is ON.

Speed arrival output terminal

SCMP ON : When the speed reaches or

exceeds the setting speed, the speed arrival

output is ON.

Common terminal of grounding wire for

control signal output terminal (except CZ)

Encoder phase Z output terminal

Photoelectric encoder phase Z pulse output

of the servo motor

CZ ON: Phase Z signal appears

ZSL ON:The servo drive unit is beyond the

control of analog voltage and outputs zero

speed.

ZSL OFF:The servo drive unit is under the

control of the analog voltage.

The common terminal of Z-phase output

terminal of the encoder

CN1-30 PULS+

CN1-15

CN1-29 SIGN+

CN1-14

Command

pulse

PLUS input

Command

pulse SIGN

input

Type3 P

PULS-

Type3 P

SIGN-

shielding

CN1-31

ground

FG Shielding ground wire terminal

wire

CN1-2

CN1-16

analog

ground

AGND S analog ground

Input

CN1-17

analog

VCMD S

command

Type4

CN1-1

Input

analog

command

SG

ground

External command pulse input terminal

Note: the pulse input mode is set by

parameter PA14.

(1) Command pulse+ sign mode;

(2) CCW/CW command pulse

mode;

Input analog command ±10V

Input impedance 20kΩ

S

28

Page 40

Continued:

Brake

CN1-7

output

positive

HOLD+ S/P

terminal

Break

CN1-6

output

negative

HOLD-

terminal

CN1-27

CN1-12

CN1-28

CN1-13

CN1-42

CN1-43

Encoder

pulse A+

Encoder

pulse A-

Encoder

pulse B+

Encoder

pulse B-

Encoder

pulse Z+

Encoder

pulse Z-

PAOU T+ S

PAOU T- S

PBOUT+

PBOUT-

PZOUT+

PZOUT-

4) Feedback Signal Terminal CN2

Table 3-3 Encoder Signal Input/Output Terminal CN2

Terminal

number

Signal name

Terminal mark

Mark I/O Mode

CN2-5

CN2-6

CN2-17

Power output + +5V

CN2-18

CN2-1

CN2-2

CN2-3

Power output - OV

CN2-4

CN2-16

CN2-7

CN2-8

Battery output + +3.6V

CN2-9

CN2-13

Encoder

SD-input

SD-

Type2

Type5

Type6

When the drain electrode open circuit output

works normally, the photoelectric coupler

conducts and the output is ON.

When an alarm occurs, the photoelectric

coupler is cut off and the output is OFF.

S/P

Encoder feedback output signal, standard is

2500/line.

The desired pulse number may be output by

adjusting PA41 (output pulse number

parameter), e.g., if requiring the encoder to

output 15000 pulses per revolution, let

PA41=15000, then the signals of phase A and

phase B which are output from the drive unit

side are 15000 pulses/revolution.

Motor outputs one pulse per revolution

Color Function

Chapter 3 Connection

The servo motor absolute encoder uses

+5V power; When its cable is long,

multiple core wires should be used in

parallel connection mode.

The servo motor absolute encoder uses

+3.6V power to retain multiple-revolution

data; When its cable is long, it should use

multiple core wires connected in parallel.

When the servo unit is not powered for a

long time, the multiple-revolution data will

be lost because of low battery.

Be connected to the absolute encoder SDof the servo motor

29

Page 41

DAH01, DAH2075E AC Servo Drive Unit User Manual

r

CN2-25

CN2-14

CN2-15

CN2-20

CN2-8

Encoder SD +

input

Shielding

ground wire

for function

extension

For function

Extension

SD+

FG Shielding ground wire terminal

CLK- For function Extension

CLK+ For function Extension

Be connected to the absolute encode

SD+ of the servo motor

3.3 GSK-LINK Bus Communication Principle

GSK-LINK adopts an Ethernet physical layer chip and uses UTP-five categories as its

transmission medium. Cyclic data can only be transferred between master station and servo slave

station while non-cyclic data can be transferred within any stations. GSK-LINK adopts double-loop

topological structure, and the bus topology is shown as figure 3-3-1. The communication module

structure of a master station is the same as that of a slave station.

B

S e rvo un it

Slave station 1

A

U TP-five c atego rie s

Master station of

CNC system

A

B

Fig. 3-3-1 Topology Structure of GSK-Link

3.4 I/O Interface Principle

1) Switch Value Input Interface

B

A

B

A

B

IO m odu le

Slave station n+1

A

Servo unit

Slave station 2

Servo unit

Slave station n

30

Fig. 3-4-1 Type1 Switch Value Input Interface

Page 42

Note

2) Switch Value Output Interface

Note

Chapter 3 Connection

Fig.3-4-2 Type2 Switch Output Interface

3) Analog Value Input Interface

Fig.3-4-3 Type4 Analog Command Input Interface

Note

4) Pulse Value Input Interface

PULS+

PULS-

5

6

Drive unit side

servo amplifier

220

B

7

SIGN+

SIGN-

Fig. 3-4-4 Differential Drive Mode for Pulse Amount Input Interface

220

31

Page 43

DAH01, DAH2075E AC Servo Drive Unit User Manual

servo amplifier

VCC

PULS+

R

PULS-

Drive unit side

220

SIGN+

R

SIGN-

220

Fig. 3-4-5 Type4 Single-ended Drive Mode for Pulse Amount Input Interface

It is suggested to adopt differential drive mode in order to transfer t h e

data of pulse amount correctly.

Adopt AM26LS31, MC3487 or similar RS422 line drive units in the differential

drive mode.

Th e adopt i o n of the single-ended drive mode may reduce the d y n a mic

frequency. D et e r m i n e the value of resistance R under the condition s of

10mA~15mA of current and 25V of max. voltage of the external power in the

pulse input circuit. Empirical data:

Vcc=24V,R=1.3kΩ~2kΩ; Vcc=12V,R=510Ω~820Ω; Vcc=5V,R=82Ω~120Ω。

The external power supply is provided by user s in the single-ended drive

mode. It must be noted that the se r vo drive unit will be damaged if the

power polarity is reversed.

Refer to table 3-4 for the pulse inp u t form. The arrow in it indicates th e

counting edge. Table 3-5 shows the pulse input time sequence parameter.

Table 3-4-1 Pulse input form

32

Page 44

Chapter 3 Connection

Table 3-4-2 Pulse input time sequence parameter

Parameter Differential drive input Single-ended drive input

t

ck

th >0.0763μs >0.191μs

tl >0.0763μs >0.191μs

trh <0.0152μs <0.0228μs

trl <0.0152μs <0.0228μs

ts >0.0763μs >0.191μs

t

>0.608μs >0.76μs

qck

tqh >0.304μs >0.382μs

tql >0.304μs >0.382μs

t

<0.0152μs <0.0228μs

qrh

t

<0.0152μs <0.0228μs

qrl

tqs >0.0763μs >0.191μs

>0.152μs >0.381μs

PULS

SIGN

90%

10%

trh trl

90%

10%

th

CW

ts

trh

tck

CCW

tl

ts

trl

CW

Fig. 3-4-6 Time sequence for pulse+sign input interface (max. pulse frequency: 6.5536MHz)

tck

th

90%

PULS

SIGN

10%

trh trl

90%

10%

tl

ts

CCW

trh

trl

CW

Fig. 3-4-7 Time sequence for CCW/CW pulse input interface (max. pulse frequency: 6.5536MHz)

33

Page 45

DAH01, DAH2075E AC Servo Drive Unit User Manual

5) Output interface for drive unit speed signal

Drive unit side

X+

X-

se rvo a mplifierse rvo m otor

AM26LS32

X=A,B,Z,U,V,W

Fig. 3-4-8 Type5 speed signal output of drive unit

6) Input interface for servo motor absolute encoder

Motor side

Fig. 3-4-9 Type6 Input interface of servo motor absolute encoder

Drive unit side

34

Page 46

Chapter 4 Parameter

CHAPTER 4 PARAMETER

4.1 Parameter List

z The factory value in the following table is an example for the drive units matched with GSK

130SJT-M075D(A4) motors (7.5N.m、3000r/min). Corresponding parameters vary with various

motors.

z Software version: V3.48

z P: position control S: speed control : drive un

bus mode interface.

Ⅰ it pulse/analog command interface : drive unit Ⅱ

Table 4-1 parameter list

No. Description Application Parameter

range

0 password

1 Type code

2 Software version (read

only)

3 Initial state display

4 Control mode selection

5 Speed proportional gain

6 Speed integral time

constant

7 Torque command filter

8 Speed detection low-pass

filter

9 Postion proportional gain P 1~2000 245 ● ●

10 Position feedforward gain P 0~1280 200 0.1 ● ●

11 Position feedforward

low-pass filter cut-off

frequency

12 Position command pulse

division frequency

numerator

P,S

P,S

P,S

P,S

P,S

P,S

P,S

P,S

P,S

P 1~2000 300 Hz ● ●

P 1~32767 8192 ● ●

0~9999 315 ● ●

0~100 66* ● ●

* * ● ●

0~21 0 ● ●

0~7 0 ● ●

5~1280 * 0.1 ● ●

1~32767 * 0.1ms ● ●

40~2000 100 % ● ●

10~2000 40 % ● ●

Factory

value

Unit

Drive unit

interface type

Ⅰ Ⅱ

35

Page 47

DAH01, DAH2075E AC Servo Drive Unit User Manual

Continued:

No. Description Application Parameter

range

Factory

value

Unit

Drive unit

interface type

Ⅰ Ⅱ

13 Position command division

P 1~32767 500 ● ●

pulse denominator

14 Position command pulse

P 0~2 0 ● ○

input mode

15 Position command pulse

P 0~1 0 ● ○

reverse direction

Position command pulse

direction inversion

16 Positioning completion

P 0~32767 20 pulse ● ○

range

17 Position deviation

P 0~32767 4000 ×100 ● ●

detection range

18 Invalid position deviation P 0~1 0 ● ●

19 Speed command low-pass

P 15~15000 100 Hz ● ●

filter cut-off frequency

20 Invalid drive prohibition

P,S

0~1 0 ● ○

input

21 JOG running speed S -6000~6000 120 r/min ● ●

22 Speed command filter

P 0~1 0 ● ●

switch

23 Maximum speed limit

P,S

0~3000 2500 r/min ● ●

24 Internal speed 1 S -6000~6000 0 r/min ● ○

25 Internal speed 2 S -6000~6000 100 r/min ● ○

26 Internal speed 3 S -6000~6000 300 r/min ● ○

27 Internal speed 4 S -6000~6000 -100 r/min ● ○

28 Arrival speed S 0~6000 500 r/min ● ○

29 Reserved

30 Straight-line speed

P,S

1~32767 10 ● ●

conversion numerator

31 Straight-line speed

P,S

1~32767 1 ● ●

conversion denominator

32 Linear speed decimal point

P,S

0~5 3 ● ●

position

33 Speed in motor test mode P 0~6000 100 r/min ● ●

34 Internal CCW torque limit

35 Internal CW torque limit

36 External CCW torque limit

37 External CW torque limit

38 Speed trial run, JOG

P,S

P,S

P,S

P,S

S 0~300 100 % ● ●

0~300 300* % ● ●

-300~0 -300* % ● ●

0~300 100 % ● ○

-300~0 -100 % ● ○

running torque limit

36

Page 48

Chapter 4 Parameter

Continued:

No. Description Application Parameter

range

39 Acceleration time constant S 0~10000 0 1ms ● ●

40 Deceleration time constant S 0~10000 0 1ms ● ●

41 Servo unit output pulse

S 16~32767 2500 p/r ● ○

number

42 Reserved

P,S

0~1 0

43 Speed command selection S 0~1 1 ● ○

44 reserved

45 reserved

46 Motor rotation direction

S 0~3 0 ● ●

control

47 AD conversion analog

S 20~3000 1000 ● ○

command gain

48 AD conversion analog

S 0~32767 2767 ● ○

command zero drift

adjustment

49 reserved

50 Analog command low-pass

S 0~32767 200 Hz ● ○

filter cut-off frequency

51 Analog command AD

S 0~32767 ● ○

result filter low-pass

frequency

52 Parameter auto setting

P,S

1~100 40 % ● ●

current limit value

53 Parameter auto setting

P,S

10~2000 200 ● ●

speed filter coefficient

54 analog gain in positive

S 20~3000 1000 0.001 ● ○

analog voltage

55 Analog gain in negative

S 20~3000 1000 0.001 ● ○

analog voltage

56

When Feedback pulse >

S 0~32767 0.1ms ● ○

10000, pulse output time in

advance

57 reserved

58 Acceleration feedback gain

P,S

0~-10000 0 0.001 ● ●

59 reserved P 1~4 2

60 Current proportional gain

61 Current integral time

P,S

P,S

0~12800 1500 ● ●

0~32767 110 0.1ms ● ●

constant

Note: ● for validity, ○ for invalidity

Factory

value

Unit

Drive unit

interface type

Ⅰ Ⅱ

37

Page 49

DAH01, DAH2075E AC Servo Drive Unit User Manual

4.2 Specification for Parameter Meaning

Table 4-2 Parameter Function

No.

Description Parameter

range

Default

value

Unit Application

Drive unit

interface type

Ⅰ Ⅱ

PA0

PA1

Parameter

password

0~9999 315

P,S

● ●

① Used for preventing parameters from being modified by mistake. In general, when a

parameter needs to be set, set the parameter to desired password firstly, and then

perform adjustment. After debugging, set the parameter to 0 to ensure the parameter will

not be modified by mistake.

② There are different password levels corresponding to user parameter, system parameter

and all parameter respectively.

③ Only type code passwords can be used to modify type code parameters (PA1), other

passwords are unavailable for modifying the parameters.

User password is 315, and type code password is 385.

Motor type code 0~100 66

P,S

● ●

① Corresponds to a series of servo units and motors with different power.

② Different type codes correspond to different parameter default values. When using the

function of default parameter restoration, ensure the correctness of the parameter.

③ When absolute encoder disconnection alarm or invalid motor type alarm occurs

immediately after power is turned on, default parameters should not be restored

automatically until the trouble is cleared. Otherwise, the drive unit will be abnormal or

damaged.

④ Before modifying the parameter, set password PA0 to 385.

⑤ See this chapter for detailed information about the parameter.

38

PA2

PA3

Software version \ 3.06

P,S

● ●

Software version can be checked but not be modified (read only)

Initial display state 0~20 0

Parameter

value

Explanation Parameter

value

P,S

● ●

Explanation

PA3=0 Display motor speed PA3=11 Display position command

pulse frequency

PA3=1 Display current position low

PA3=12 Display speed command

order 4 digits

PA3=2 Display current position high

PA3=13 Display torque command

order 4 digits

PA3=3 Display position command

(accumulation) low order 4

PA3=14 Display absolute encoder

single-revolution data

digits

Page 50

Continued:

Parameter

value

PA3=4 Display position command

(accumulation) high order 4

PA3=5 Display position deviation

PA3

PA3=6 Display position deviation high

PA3=7 Display motor torque PA3=18 Display encoder input signal

PA3=8 Display motor current PA3=19 Display running state

PA3=9 Display linear speed PA3=20 Display alarm code

PA3=10 Display control mode PA3=21 Display analog command

No. Description

Control mode

selection

①:Set the control modes of the drive unit by this parameter.

Explanation Parameter

value

PA3=15 Display absolute encoder

digits

PA3=16 Display input terminal state

lower order 4 digits

PA3=17 Display output terminal state

order 4 digits

Parameter

range

Default

value

Unit Application

0~7 0

P,S

Chapter 4 Parameter

Explanation

multiple-revolution data

voltage value

Drive unit

interface type

Ⅰ Ⅱ

● ●

PA4

0:Position control mode 1:Speed control mode

2:Trial run control mode 3:JOG control mode

4:Encoder zero-setting mode 5:Motor test mode

6:Open-loop running mode (used for motor test and encoders)

7:Drive unit type writing mode

② Explanation

a:Position control mode: position command is output from the pulse input port.

b:Speed control mode: whether the speed commands are input from input terminals or

analog value is decided by parameter [internal or external speed command selection]

(PA42). When using internal speed, use the combination of SC1 and SC2 to select

different kinds of internal speed.

c:Trial run control mode: the speed command is input from the keyboard. It is used for

testing drive units and motors.

d:JOG control mode: In JOG mode, the motor runs at JOG speed when ↑ is pressed and

held, while the motor stops and remains zero speed when the button is released; the

motor runs reversely at JOG speed when ↓ is pressed and held, while the motor stops

and remains zero speed when the button is released.

e:Encoder zero-setting mode: used for the adjustment of the code disc zero point before

delivery.

f:Motor test mode: used to test drive units and motors in position control mode.

g:Open-loop running mode: used for equipment maintenance by manufacturer technician.

h:Drive unit type writing mode: used for writing drive unit types before delivery.

39

Page 51

Continued:

No. Description

Speed proportional

gain

PA5

① Set the proportional gain for the speed loop regulator.

② The greater the setting value is, the higher the gain is and the bigger the rigid is. The

parameter value is decided by actual servo drive unit types and load conditions.

③ Set the value as big as possible when no vibration is produced in the system.

Speed integral time

constant

① It sets the integral time constant for the speed loop regulator.

PA6

② The smaller the setting value is, the faster the integral speed is and the bigger the rigid is.

The parameter value is decided by actual servo drive unit types and load conditions. In

general, the greater the load inertia is, the greater the setting value is.

③ Set the value as small as possible when no vibration is produced in the system.

Torque command

filter coefficient

① It sets torque command filter characteristics. Resonance (sharp vibration noise made by

PA7

the motor) produced by the torque can be curbed.

② If the motor makes sharp vibration noise, please reduce the parameter value.

③ The smaller the value is, the lower the cut-off frequency and the motor noise are. If the load

inertia is too large, reduce the setting value appropriately. An excessively small value will

cause slow response and instability.

④ The greater the value is, the higher the cut-off frequency is and the faster the response is.

If higher mechanical rigid is required, increase the setting value appropriately.

Speed detection

low-pass filter

coefficient

① It sets speed detection low-pass filter characteristics;

PA8

② The smaller the value is, the lower the cut-off frequency and the motor noise are. If the load

inertia is too large, reduce the setting value appropriately. An excessively small value will

cause slow response and vibration.

③ The greater the value is, the higher the cut-off frequency is and the faster the speed

feedback response is. If higher speed response is required, increase the setting value

appropriately.

Position proportional

gain

① It sets the proportional gain for the position loop regulator

PA9

② The greater the setting value is, the higher the gain is, the bigger the rigid is and the

smaller the position lag is. However, an excessively big value may cause vibration or

overshoot.

③ The parameter value is decided by actual servo drive unit types and load conditions.

DAH01, DAH2075E AC Servo Drive Unit User Manual

Drive unit

Parameter

range

5~1280 155 0.1

0~32767 85 0.1ms

40~2000 100 %

10~2000 40 %

Default

value

Unit Application

P,S

P,S

P,S

P,S

interface type

Ⅰ Ⅰ

● ●

● ●

● ●

● ●

0~2000 245 0.001 P ● ●

40

Page 52

Continued:

×

No. Description

Position feedforward

gain

① It sets the feedforward gain for the position loop.

② When it is set to100%, it means the position lag is always zero in any frequency of

PA10

PA11

A12

command pulses.

③ Increasing the position loop feedforward gain can improve the high-speed response

characteristics of the control system, but also cause system instability and vibration.

④ The position loop feedforward gain is usually 0 unless extremely high response

characteristic is needed.

Position feedforward

low-pass cut-off

frequency

① It sets the feedforward low-pass filter cut-off frequency for position loop

② This filter is used for increasing the stability of compound position control.

Position command

pulse frequency

division numerator

① It sets the frequency division and frequency doubling (electronic gear) for position

command pulse

② In the position control mode, various pulse sources can be matched conveniently by setting

parameter PA12 and PA13 to reach desired control resolution (i.e., angle/pulse).

③

P: pulse number of input command;

G: electronic gear ratio

=G

N: motor rotation number

C: photoelectric encoder line/revolution, C=131072 in this system.

④ Example: when the input pulse is 6000, the servo motor rotates 1 time,

=

G

P

Then parameter PA12 is set to 8192, PA13 is set to 375.

⑤ The recommended range for electronic gear ratio is:

Division frequency

PA13

denominator of position

command pulse

Refer to PA12.

Chapter 4 Parameter

Drive unit

interface type

Ⅰ Ⅰ

4××=× CNGP

Parameter

range

0~1280 0 0.1 P ● ●

1~2000 300 Hz P ● ●

0~32767 8192 P ● ●

Default

value

Unit Application

numeratorfrequency Division

rdenominatofrequency Division

1310721

×

CN

=

6000

8192

=

375

1

50

0~32767 500 P ● ●

50

≤≤ G

41