Page 1

Page 2

This user manual describes all items concerning the operation of

the system in detail as much as possible. However, it is impractical to give

particular descriptions of all unnecessary and/or unavailable operations of

the system due to the manual content limit, product specific operations and

other causes. Therefore, the operations not specified herein shall be

considered impossible or unallowable.

This user manual is the property of GSK CNC Equipment Co., Ltd.

All rights are reserved. It is against the law for any organization or individual

to publish or reprint this manual without the express written permission from

GSK and the latter reserves the right to ascertain their legal liability.

Page 3

DA98E Series AC Servo Drive Unit User Manual

FOREWORD

Dear user,

We are really grateful for your patronage and purchase of this product of GSK

CNC Equipment Co., Ltd.

The manual describes the performance as well as the instructions for

installation, wiring, commissioning, operation and maintenance of the DA98E

series bus-oriented AC servo Drive Unit.

The operations involve the contents of two software versions: 1) The Version V2.05

focuses on the configuration of servomotors with an incremental encoder; 2) The Version

V3.01 applies to the configuration of servomotor with a Tamagawa 17-bit absolute

encoder and specifies the inconsistencies with V2.05.

● The contents herein are subject to change as a result of product modification

without further notice.

● We assume no reliability for any consequence of user’s modification of the product.

In this case, the product warranty will become void.

To ensure the safety as well as the normal and efficient operation of the product, it is

important to thoroughly read this manual prior to the installation and operation of it.

Special attention shall be given to the following warnings and precautions while

reading this manual in order to prevent injury of operator and other persons as well as

damage of the mechanical equipment.

Warning

Incorrect operation may lead to severe injury or even

death.

Incorrect operation may cause moderate or slight injury

Caution

and property losses.

Attention

2

Negligence of the suggestion may result in an undesired

consequence and condition.

Page 4

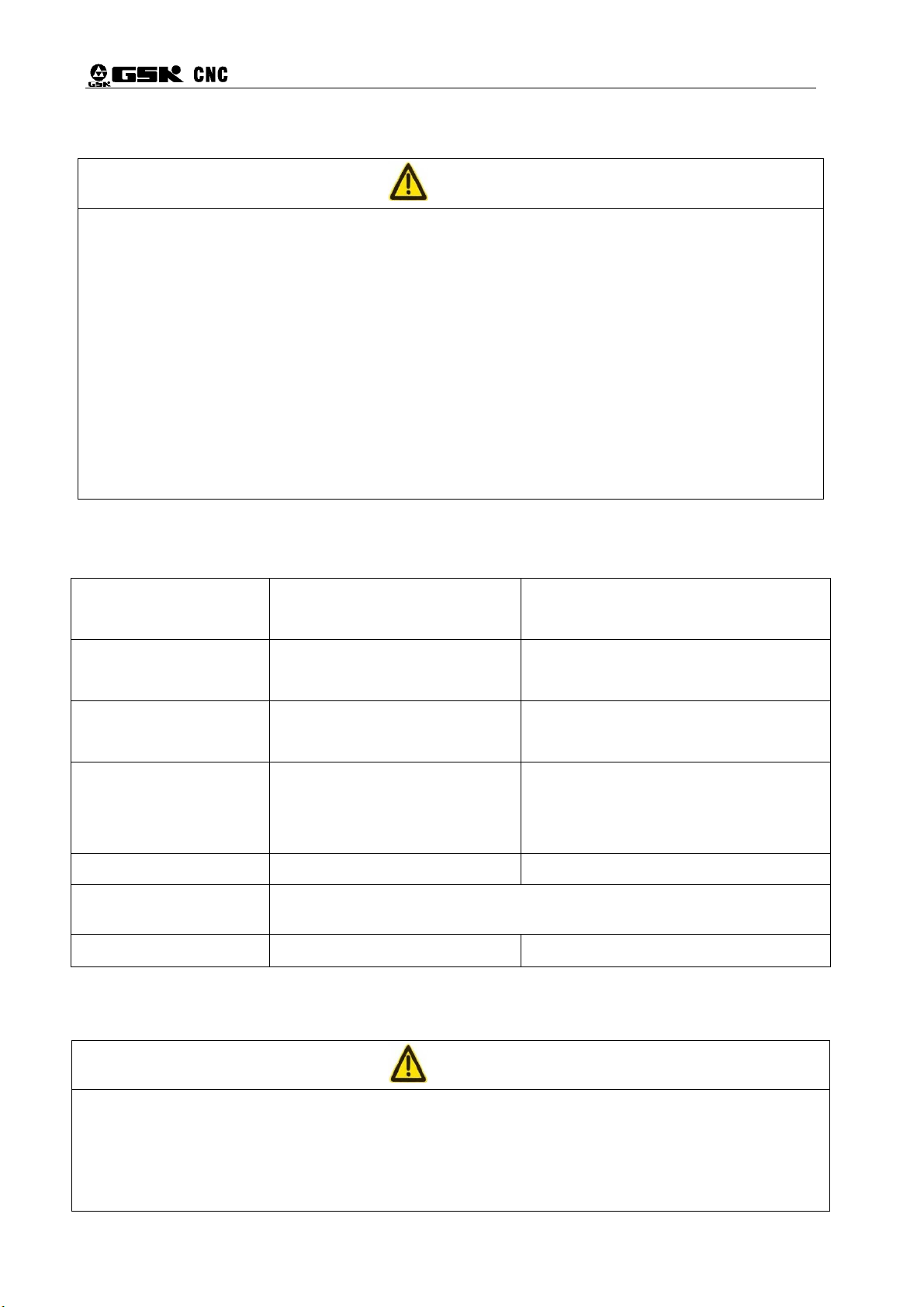

Safety Warnings

ger

Dan

Tighten all connecting terminals of the main

circuit with an appropriate torque.

Negligence of the instruction may

lead to loose conductor

connection, electric spark and

even fire.

Make sure the input power supply is

disconnected prior to wiring.

Negligence of the instruction may

lead to electric shock.

Have the wiring performed and inspected by a

qualified electrician.

Negligence of the instruction may

lead to electric shock or fire.

Make sure to install the drive unit on an

incombustible carrier and keep it away from

inflammable substances.

Negligence of the instruction may

lead to fire.

Always ground the protective earthing terminal

PE on the servo unit.

Negligence of the instruction may

lead to electric shock.

Make sure to disconnect the unit from power

supply and wait for at least five minutes before

moving, wiring, examining or maintaining it.

Negligence of the instruction may

lead to electric shock.

Strictly abide by the procedures herein in

wiring.

Negligence of the instruction may

lead to equipment damage and

electric shock.

Do not operate the switches with a wet hand. Do not reach your hands into the servo unit.

Negligence of the instruction may

lead to electric shock.

Do not open the cover of the terminal block

while the unit is energized or is operating.

Negligence of the instruction may

lead to electric shock.

Make sure to tighten the power supply terminals

and motor output terminals.

Negligence of the instruction may

lead to fire.

Negligence of the instruction may

lead to electric shock.

Do not directly touch the connecting terminals

on the main circuit of the drive unit.

Negligence of the instruction may

lead to electric shock.

3

Page 5

DA98E Series AC Servo Drive Unit User Manual

Attention

After the power supply is restored, do not

immediately perform any work on the coupling

of the servomotor as the drive unit may start

suddenly.

Negligence of the instruction may

cause personal injury.

Do not place the power cord on a sharp edge

or under load or stress.

Negligence of the instruction may

lead to electric shock, fault or

damage.

Do not stop heat elimination or place any foreign

matter into the fan or radiator.

Negligence of the instruction may

lead to equipment damages or a

fire.

Do not operate the energized servo drive unit

when the cover of the terminal block is removed.

Negligence of the instruction may

lead to electric shock.

Caution

The electric motor must be equipped with a

suitable servo unit.

Negligence of the instruction may

lead to equipment damage.

Loaded operation is only permitted after

successful no-load operation.

Negligence of the instruction may

lead to equipment damage.

Do not grasp the power cord or motor shaft

during the transport of the motor.

Negligence of the instruction may

lead to equipment damage.

The voltage applied on all terminals must be

consistent with the ratings specified on the

manual.

Negligence of the instruction may

lead to equipment damage.

In case of alarm, make sure to eliminate the

trouble before operation.

Negligence of the instruction may

lead to equipment damage.

In case of a missing or defective component of

the spindle drive unit, do not operate the motor

but immediately contact your dealer.

Negligence of the instruction may

lead to equipment damage.

4

Page 6

Safety Warnings

Do not connect the power input wires R, S and

T to the output terminals U, V and W of the

motor.

Negligence of the instruction may

lead to equipment damage.

Do not touch the heat sink for the motor and

servo unit during operation as they may

become very hot.

Negligence of the instruction may

lead to burn.

Caution

Do not turn on/off the input power supply.

Negligence of the instruction may

lead to equipment damage.

Do not perform any limit adjustment or change

of parameters.

Negligence of the instruction may

lead to equipment damage.

Do not attempt to modify, remove or repair the

drive unit without permission from your dealer.

Negligence of the instruction may

lead to equipment damage.

The electronic components inside a discarded

drive unit shall be disposed as industrial waste

without reuse.

Negligence of the instruction may

cause accidents.

5

Page 7

DA98E Series AC Servo Drive Unit User Manual

Safety Responsibilities

Safety Responsibilities of Manufacturer

—— The manufacturer shall be responsible for the risks eliminated and/or controlled in

the design and structure of the supplied servo unit and accompanying accessories.

——The manufacturer shall ensure the safety of the supplied servo unit and

accompanying accessories.

——The manufacturer shall be held responsible for the information and advices on

usage given to the user.

Safety Responsibilities of User

——A user shall study and be trained for the safe operation of the servo unit and

understand and master the knowledge regarding safe operation.

——The user shall take responsibility for the risks arising from his/her addition, change

or modification of the original servo unit and accessories.

——The user shall be held responsible for the risks caused by the operations,

adjustments, installation and transport of the product without following the

requirements of the manual.

This manual is retained by the end user.

Thank you for your friendly support in using the products of GSK

CNC Equipment Co., Ltd.

6

Page 8

Contents

Contents

Chapter 1 Summary ........................................................................................................................................ 1

1.1 Product Overview................................................................................................................................1

1.2 Fundamentals...................................................................................................................................... 2

1.3 Receiving Inspection ..........................................................................................................................8

1.4 Product Appearance......................................................................................................................... 10

Chapter 2 Installation ...................................................................................................................................12

2.1 Ambient Conditions ........................................................................................................................... 12

2.2 Installation of Servo Drive Unit........................................................................................................ 12

2.3 Installation of Servomotor ................................................................................................................ 15

Chapter 3 Wiring............................................................................................................................................ 17

3.1 Standard Connection........................................................................................................................18

3.2 Functions of Terminals .....................................................................................................................21

3.3 Circuitous Philosophy of I/O Interface ...........................................................................................28

Chapter 4 Parameters................................................................................................................................... 29

4.1 Summary of Parameters.................................................................................................................. 29

4.2 Functions of Parameters.................................................................................................................. 32

4.3 Checklist of Model Numbers and Specification of Motor ............................................................42

Chapter 5 Alarms and Remedies............................................................................................................... 44

5.1 Abnormalities Arising from Improper Usage ................................................................................. 44

5.2 Summary of Alarms .......................................................................................................................... 45

5.3 Solutions for Alarms.......................................................................................................................... 47

Chapter 6 Display and Operations............................................................................................................58

6.1 Keyboard Operations ....................................................................................................................... 58

6.2 Monitoring Mode ...............................................................................................................................59

6.3 Parameter Setting ............................................................................................................................. 61

6.4 Parameter Management ..................................................................................................................63

6.5 Speed Trial operation ....................................................................................................................... 65

6.6 JOG operation ...................................................................................................................................66

6.7 Other ................................................................................................................................................... 66

VII

Page 9

DA98E Series AC Servo Drive Unit User Manual

Chapter 7 Power-on and Operation .......................................................................................................... 67

7.1 Connection to Power Supply ...........................................................................................................67

7.2 Trial Operation ...................................................................................................................................69

7.3 Adjustments........................................................................................................................................71

Chapter 8 Product Specification................................................................................................................75

8.1 Specification of Drive Unit................................................................................................................75

8.2 Specification of Servomotor.............................................................................................................76

8.3 Isolation Transformer........................................................................................................................85

Chapter 9 Ordering Guide ...........................................................................................................................91

9.1 Capacity Selection.............................................................................................................................91

9.2 Electronic Gear Ratio........................................................................................................................91

9.3 Stop Characteristics..........................................................................................................................92

9.4 Calculation for Type Selection of Servo and Position Controller................................................92

9.5 Examples of Model Numbers Available for Ordering ...................................................................93

VIII

Page 10

Chapter 1 Summary

Chapter 1 Summary

1.1 Product Overview

The AC servo technology has been proved since the early 1990s. With ever-improving

performance, it is widely applied to NC machine tools, printing and packaging machines, textile

machines, automated production lines and other areas of automation.

DA98E series AC servo Drive Unit (also known as bus-oriented AC servo Drive Unit) is a

new generation of products with an up-to-date industrial Ethernet bus communication

interface developed by us.

The external control device for the series of Unit can communicate with several GSK-LINK

bus-oriented AC servo Drive Unit through only one network cable. They feature simple interfaces,

easy installation and high compatibility. Through a high-speed and reliable GSK-LINK field bus and

protocol, a NC system may receive/send diversified data including position, speed command, motor

encoder data, controlling parameters for current loop, speed loop and position loop, state parameters

of drive unit and other messages from/to a servo Drive Unit. By supporting diversified data, the

system may exert control over the operation of a motor and better realize the real-time monitoring of

the control and drive Unit through configuration of position, speed command and adaptive

parameters of the system, thereby further improving the processing efficiency and accuracy of the NC

system. With a built-in advanced and dedicated chip for control over the motor, a FPGA

(Field-Programmable Gate Array) and a new IPM intelligent power module, the servo drive unit is

characterized by high integrity, compactness, complete protection and high reliability.

DA98E AC servo unit has the following advantages over step drive Unit:

z No out-of-step

The servomotor is provided with an encoder that

feeds back position signal to the servo drive unit

and exerts semi-closed loop control with an

open-loop control device.

z Wide speed ratio and constant torque

Open-loop control Stepper motor

Speed regulation ratio of 1: 5000 and constant

torque characteristics at low to high speed;

z Incremental encoders or Tamagawa 17-bit

absolute encoders are available upon customer’s request.

z High speed and accuracy

Maximum rotating speed of servomotor: 3,000 rpm; rotary positioning accuracy: 1/10,000r

Note: The maximum rotating speed of servomotor varies with its model.

Controller

1

Page 11

DA98E Series AC Servo Drive Unit User Manual

z Simple and flexible control

It is possible to properly set the operating mode and characteristics of the servo system through

the system interface in order to meet different requirements.

DA98E compared to the traditional DA98 servo series

z The data transfer speed is up to 100MBit/s by using an industrial Ethernet bus for

communication transmission.

z High anti-jamming capacity, bit error rate: 10

-12

z The closed and open loops share one hardware structure with a communication data

length of 0~256 (bits) and minimum communication cycle of 50µs.

z It is easy to operate and adjust servo parameters and possible to adjust servo parameters

and monitor servo through the system interface.

1.2 Fundamentals

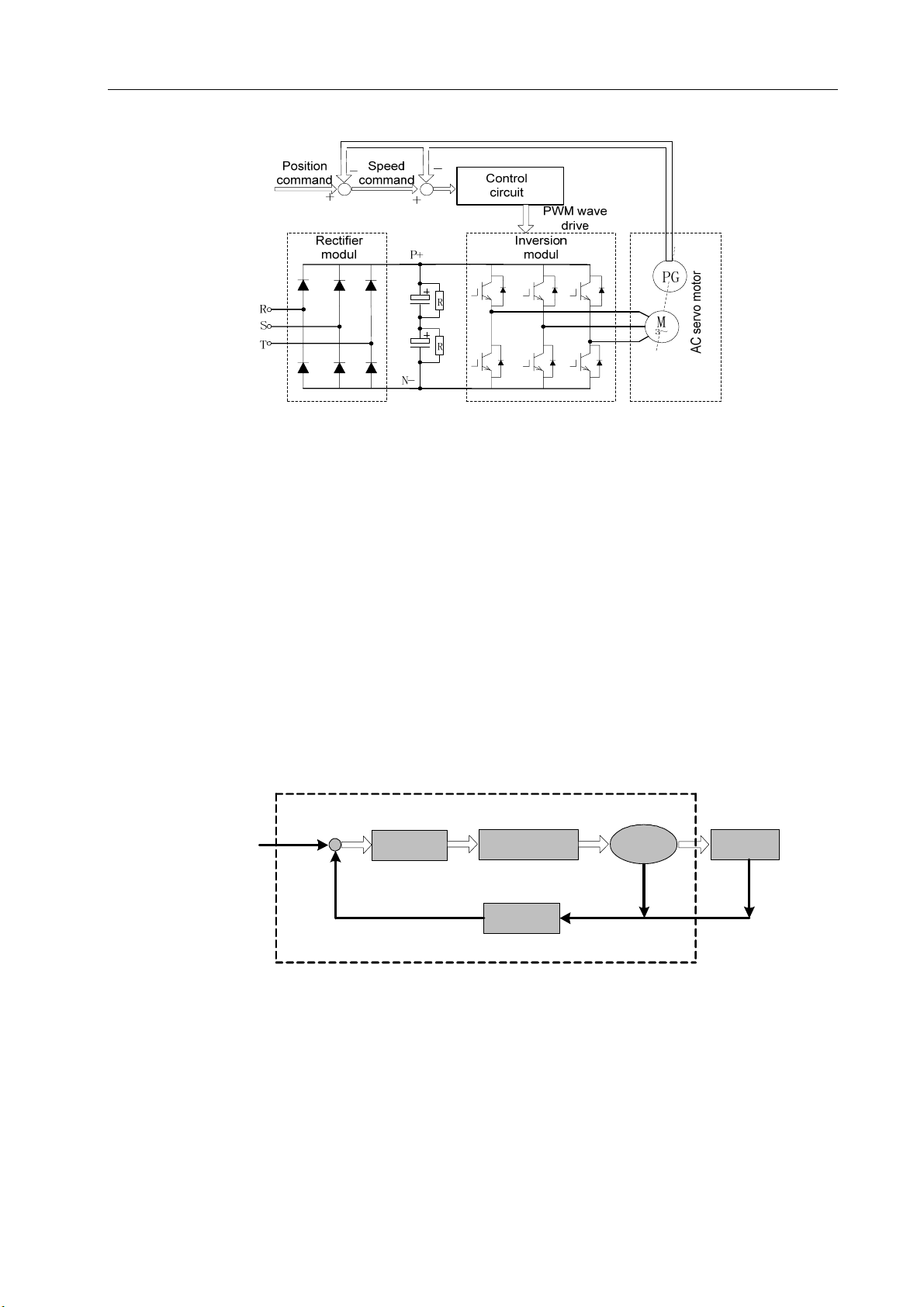

1) Operating Principle of AC Servo Drive Unit

The AC servo drive unit consists of an AC servo unit and an AC servomotor (3-phase

permanent-magnet synchronous motor, hereinafter called “servomotor”). The servo unit rectifies

3-phase alternating current into direct current (namely AC to DC) and produces approximately simple

harmonic alternating current with 120° phase difference in the 3-phase stator winding of the

servomotor by controlling the switching of the power switching tube. The current creates a rotating

field in the servomotor. The rotor of the servomotor is made of high anti-demagnetizing rare-earth

permanent magnetic material. The rotor of the servomotor is driven by the electromagnet torque as a

result of the interaction of the magnetic field of the rotor for the servomotor and its rotating magnetic

field. The higher the frequency of the current through the servomotor winding is, the faster the

servomotor rotates. The output torque (torque = force x length of moment arm) of the servomotor

increases with the amplitude of the current through the servomotor winding.

Figure 1-1 is the block diagram of the main circuit in which PG indicates an encoder.

2

Page 12

Chapter 1 Summary

Figure 1-1 Block diagram of the main circuit of AC servo drive unit

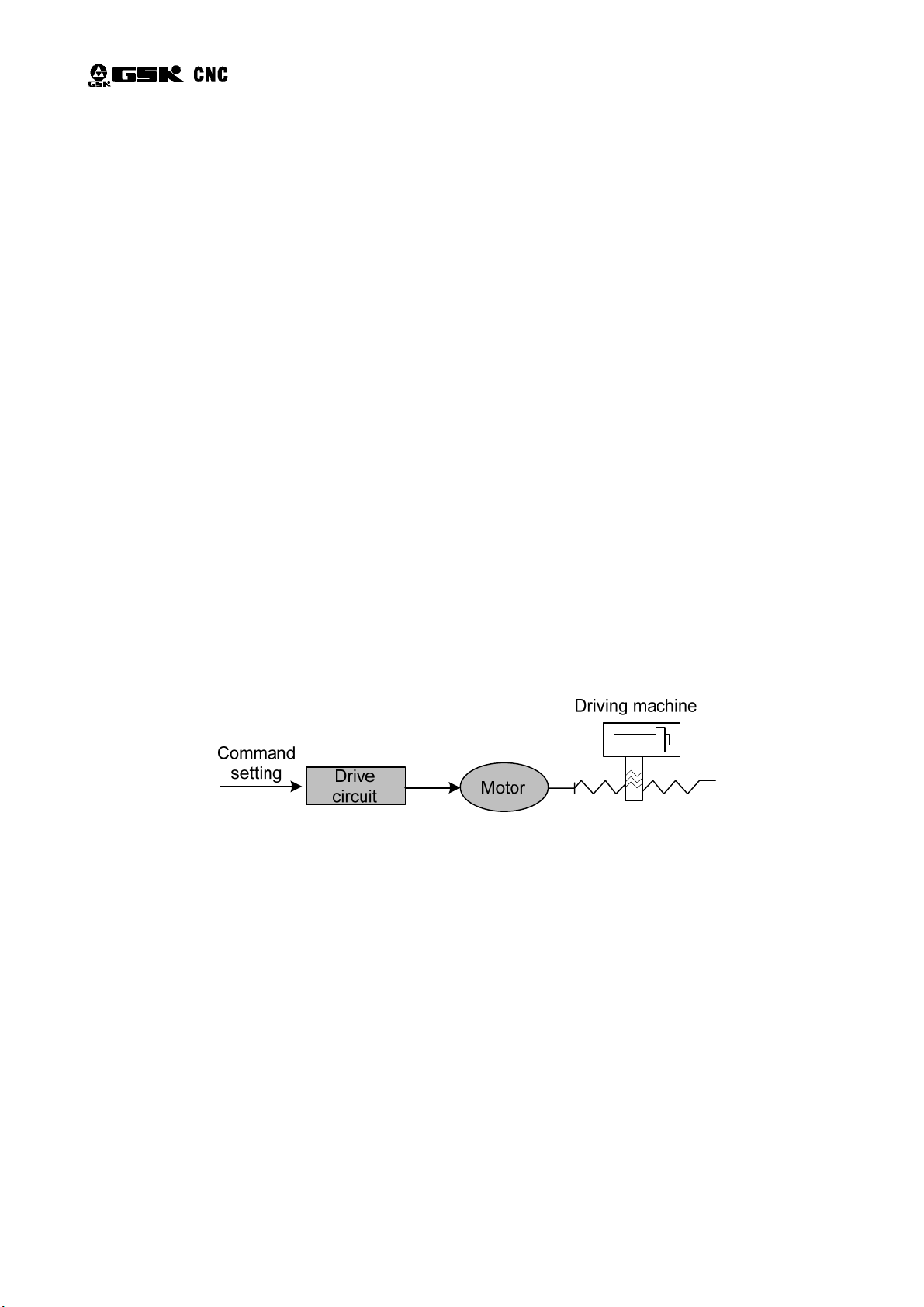

2) Basic Structure of AC Servo Drive Unit

The servo unit receives speed commands from a control unit (also known as host computer)

such as CNC system to control the amplitude and frequency of the current through the winding of the

servomotor so that the rotating speed (or angle of rotation) of the rotor for the servomotor is close to

the value of the speed (or position) commands, and knows the deviation of the real rotating speed (or

angle of rotation) of the servomotor rotor from the command value through the feedback signal of the

encoder. The servo unit keeps the deviation of the real rotating speed (or angle of rotation) of the

servomotor rotor from the command value within the required range by continuous regulating the

amplitude and frequency of the current through the winding of the servomotor. The basic structure of

the servo system is shown in Figure 1-2.

setting

CNC

equipment

+

-

AC servo drive equipment

Control

unit

Power drive unit

Feedback

check

Motor

Driving

machine

Figure 1-2 Basic structure of AC servo drive unit

3) General Glossaries regarding Control

z Control: Control refers to the procedure allowing the characteristics (e.g. rotating speed) of the

object (e.g. servomotor) to reach or become close to the expected value. The foregoing object is

called “controlled object”, its characteristics “controlled variable”, the device that realizes the control

“control unit (controller)”, the expected value (command value) of the controlled variable received by

3

Page 13

DA98E Series AC Servo Drive Unit User Manual

the control unit “setting”, the process that the controlled variable is affected as the input of the

controller “feedback” and the unit that is used to detect the controlled variable “feedback unit”.

Feedback is divided into positive feedback (in the same direction) and negative feedback (in opposite

direction). The controller that realizes the controlled variable, the controlled object and feedback unit

compose a “control system”. A drive is under closed-loop control or open-loop control depending on

the presence of a feedback unit and the position where the feedback unit is located in the drive. The

closed-loop control described in the manual is of negative feedback.

Among the AC servo Drive Unit described herein, the servo unit serves as a controller, the

servomotor controlled object, rotating speed (or angle of rotation of rotor) of motor controlled variable

and the encoder of the servomotor feedback unit. The encoder detects the actual rotating speed of

the motor for speed control so as to achieve speed feedback. Therefore the AC servo drive unit is a

closed-loop control system.

z Closed-loop control: The actual value of the controlled variable does not affect the output of the

controller if the control system is not provided with a feedback device. For a stepper motor drive, for

example, the rotor of a stepper motor shall rotate with the change in the phase sequence of its output

current. Since normally a stepper motor is not fitted with a speed or position feedback device,

excessive load or acceleration/deceleration may prevent the motor rotor from accurately rotation with

the change in the phase sequence of current, thereby causing the so-called “out-of-step”.

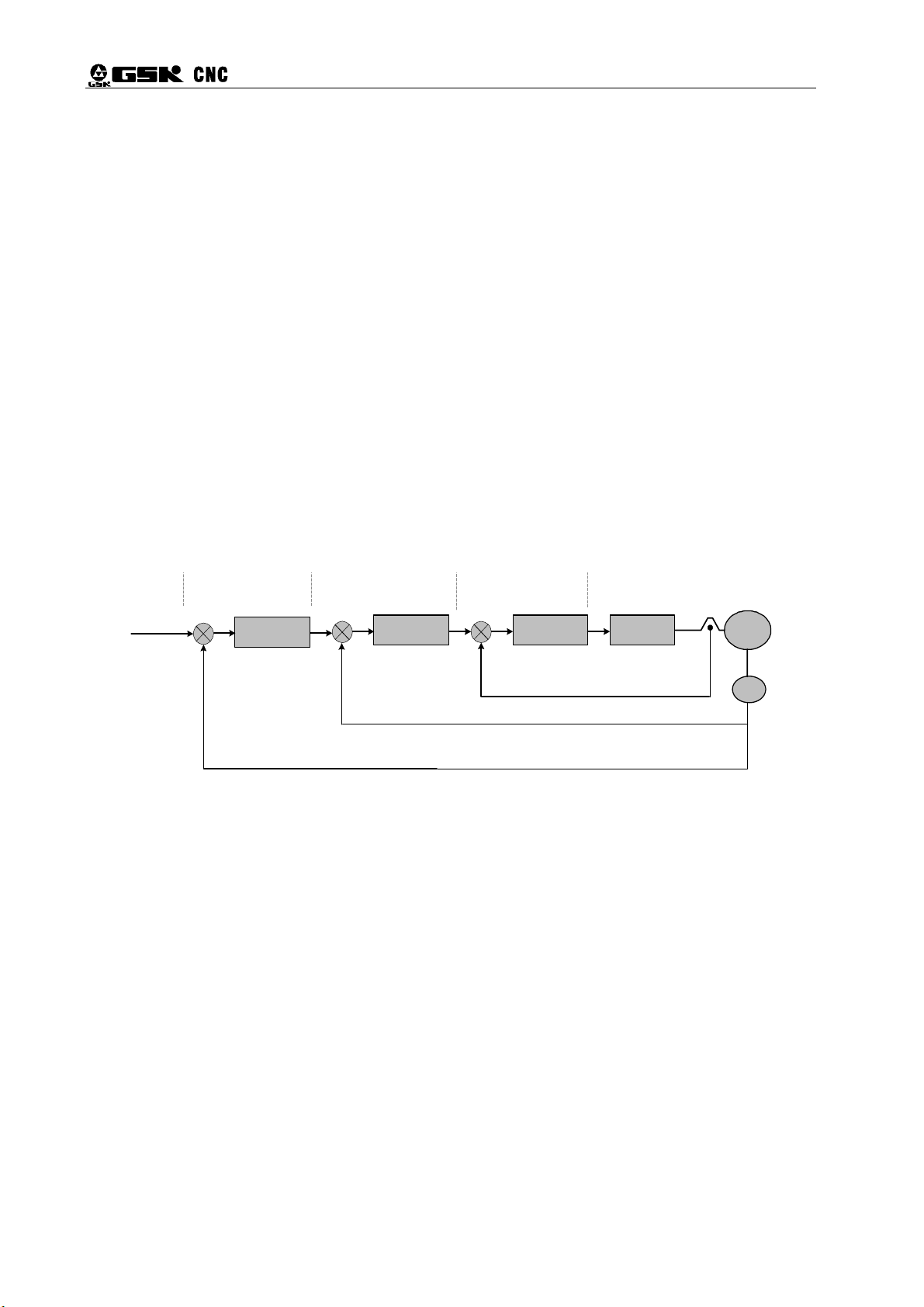

Open-loop control is as shown in Figure 1-3.

Figure 1-3 Open-loop control

z Closed-loop control: The controlled variable of the control system is detected and transferred to

the controller by the feedback device to affect the output of the controller and thereby to change the

controlled variable. Closed-loop control is classified as full-closed loop control and semi-closed

loop control by the detection points. The feedback device’s direct detection of the controlled variable

and use of it for feedback is called full-closed loop control (e.g. Figure 1-4) and the position of the

gear is the controlled variable. The full-closed loop control over the position of the gearing is achieved

by using the grating mounted on the gearing as a position feedback device and the encoder for the

Gearing

servomotor as a speed feedback. In the absence of the grating, the encoder for the servomotor is

used as a position and speed feedback (see Figure 1-5). In this case, this is the semi-closed control

over a mechanical position.

4

Page 14

Figure 1-4 Full-closed loop control

Chapter 1 Summary

Figure 1-5 Semi-closed loop control

z PID Control: Also called PID regulation, it is the common algorithm used by the controller

for mathematical treatment of the input data (setting and feedback). “P” is the abbreviation of

“proportional” and refers to the linear proportional relationship between the input and output of a

controller. The bigger a proportional control factor is, the more sensitively the system will respond and

the smaller (cannot be completely eliminated) the steady state error will become. Excessive

proportional control factor leads to the disturbance and instability of the system. “I” stands for

“integral” and means the influence of controller input time integral upon output (input gradually affects

output). The bigger an integral time constant is, the more smoothly the system runs without steady

state error and the slower the system responds. “D” is the initial of “Differential”, indicating the

influence of input differential (the slope of input change). Differential control can forecast, produces

advanced correction, reduces following error and improves dynamic performance. Excessive

differential coefficient may cause system disturbance and instability. Proportional, integral and

differential controls influence each other. In a specific control system it is required achieve the

balance of the response speed, control accuracy and stability by adjusting the PID control parameters.

As differential control tends to produce impact and unsteadiness, the servo system described herein

employs PI control, i.e. only proportional and integral control.

5

Page 15

DA98E Series AC Servo Drive Unit User Manual

4) Glossaries with regard to Servo Control

The servo system is provided with three basic control modes: position control, speed control and

torque control. The block diagram of the system is as shown in Figure 1-6.

z Position control: The direction and angle of rotation of the motor are set by means of digital

pulse or data communication. The servo unit controls the motor rotor so that it rotates by a proper

angle in the given direction. Both the angle (position) and speed of rotation are controllable.

z Speed control: The direction and angle of rotation of the motor are set by means of analog

voltage or data communication. The servo unit controls the motor rotor so that it rotates in the given

direction at the given speed.

z Torque control: The amplitude and direction of the output torque of the motor are set by

means of analog voltage or data communication. The servo unit controls the direction of rotation and

output torque of the motor rotor.

The servo unit described herein currently does not receive any torque setting signal or provide

torque controlling mode.

+

Command

position

Position

controller

Position

adjustment

-

Position

feedback signal

Speed

controller

+ Speed

adjustment

-

Speed feedback

signal

+

Current

controller

Current

adjustment

-

Current feedback

signal

Power

amplification

Motor

PG

Figure 1-6 Block diagram of three-loop control

5) Indexes of Servo Performance

Characteristics of servo dynamic response: the response speed, dynamic control error and

steady-state control error. Figure 1-7 is the response characteristic diagram of the given step signal

from the servo signal (The solid line indicates given signal and dotted line the output signal from the

servo system in the following text.):

6

Page 16

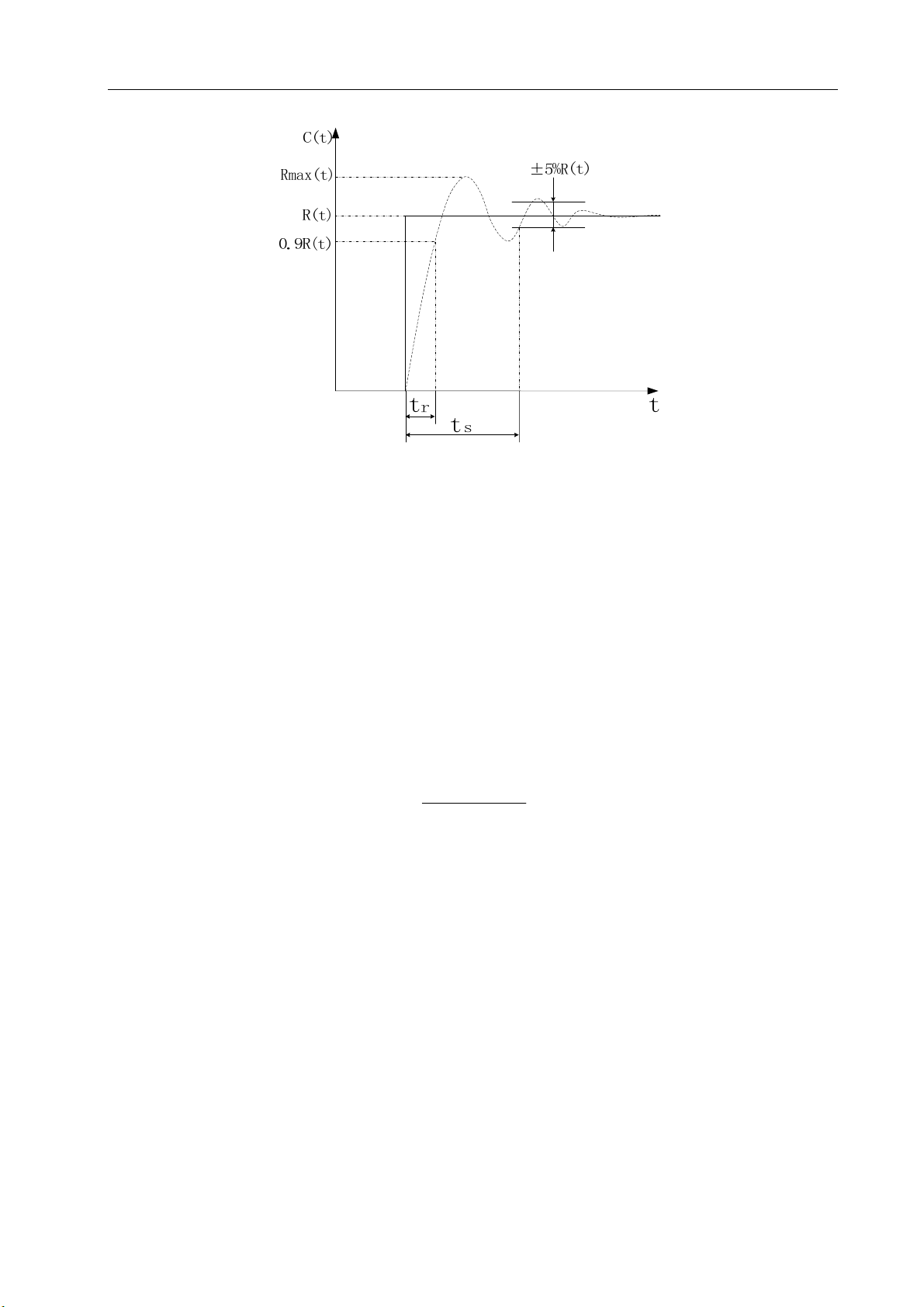

Figure 1-7 Servo dynamic response curve

Chapter 1 Summary

Rise time t

of steady state value R (t). It indicates the rapidity of dynamic response.

Adjustment time t

value of the step response curve is considered a permissible error band. The minimum time required

for the response curve to reach but not go beyond the error band is the adjustment time which is used

to measure the rapidity of the complete adjustment process of the unit.

Overshoot σ: It refers to the ratio of the maximum rotating speed difference (Rmax(t)-R (t)) between

rotating speed output and steady-state value to steady-state value R (t). It reflects the relative stability

of a servo unit and is as follows when indicated by percentage:

Steady-state error: The difference between the expected steady-state value and actual output of the

system after rotating speed becomes steady during system response.

Servo static performance: The most important for a servo control system is its stability. The key

: It refers to the time elapsed when the rotating speed output rises from zero to 90 percent

r

: The range within ±5% of the steady-state value taken near the steady-state

s

)()(

−

σ

(%)

max

=

tRtR

)(

tR

%100

×

static performance index of servo is positioning accuracy, which refers to the degree of deviation of

the actual state from expectation at the end of the system transition. The steady-state accuracy of

servo is subject to the error of position measuring appliance and system error and is related to the

structure and parameters of the system. Figure 1-8 is a position servo static curve graph.

7

Page 17

DA98E Series AC Servo Drive Unit User Manual

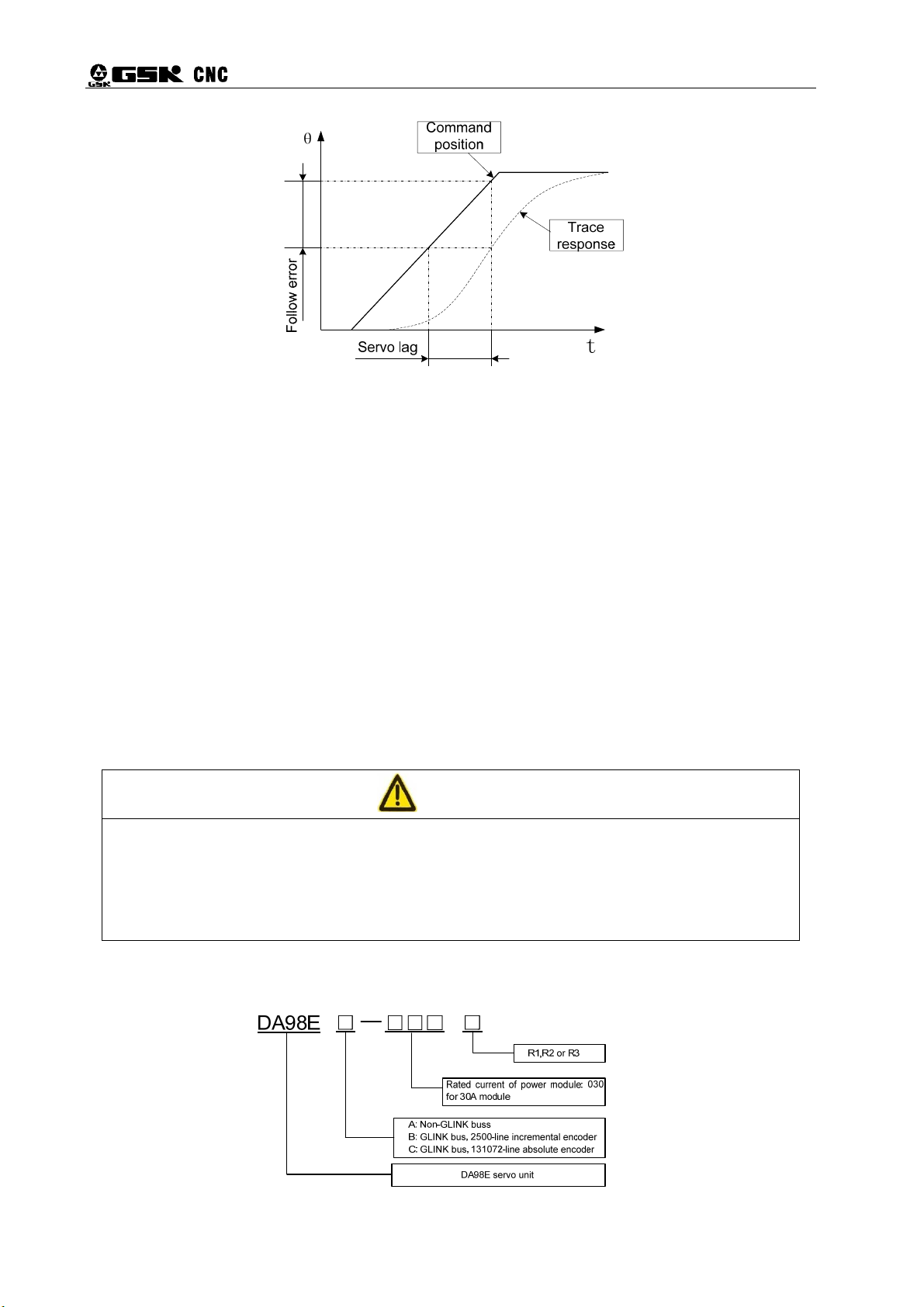

Figure 1-8 Position servo static curve

Following error: It refers to the difference between the displacement of workbench required by

command signal (command position) and its actual displacement. That is to say, Following error =

(Command position value) – (Actual position value)

Servo gain: It refers to the capability of a servo system’s resistance against the position deviation

resulting from load interference.

1.3 Receiving Inspection

1) When the goods is received, make sure to inspect the following items:

(1) Check that the packing case is integrate and no cargo is damaged in transport;

(2) Check that the received goods are those ordered against the nameplates on the

servo drive unit and servomotor;

(3) Check that the accessories are complete against the packing list.

Attentions

z Do not install a defective or incomplete servo unit;

z The servo drive unit shall be used in combination with a servomotor with matching

performance;

z Please contact your dealer or us for any question when the goods are received.

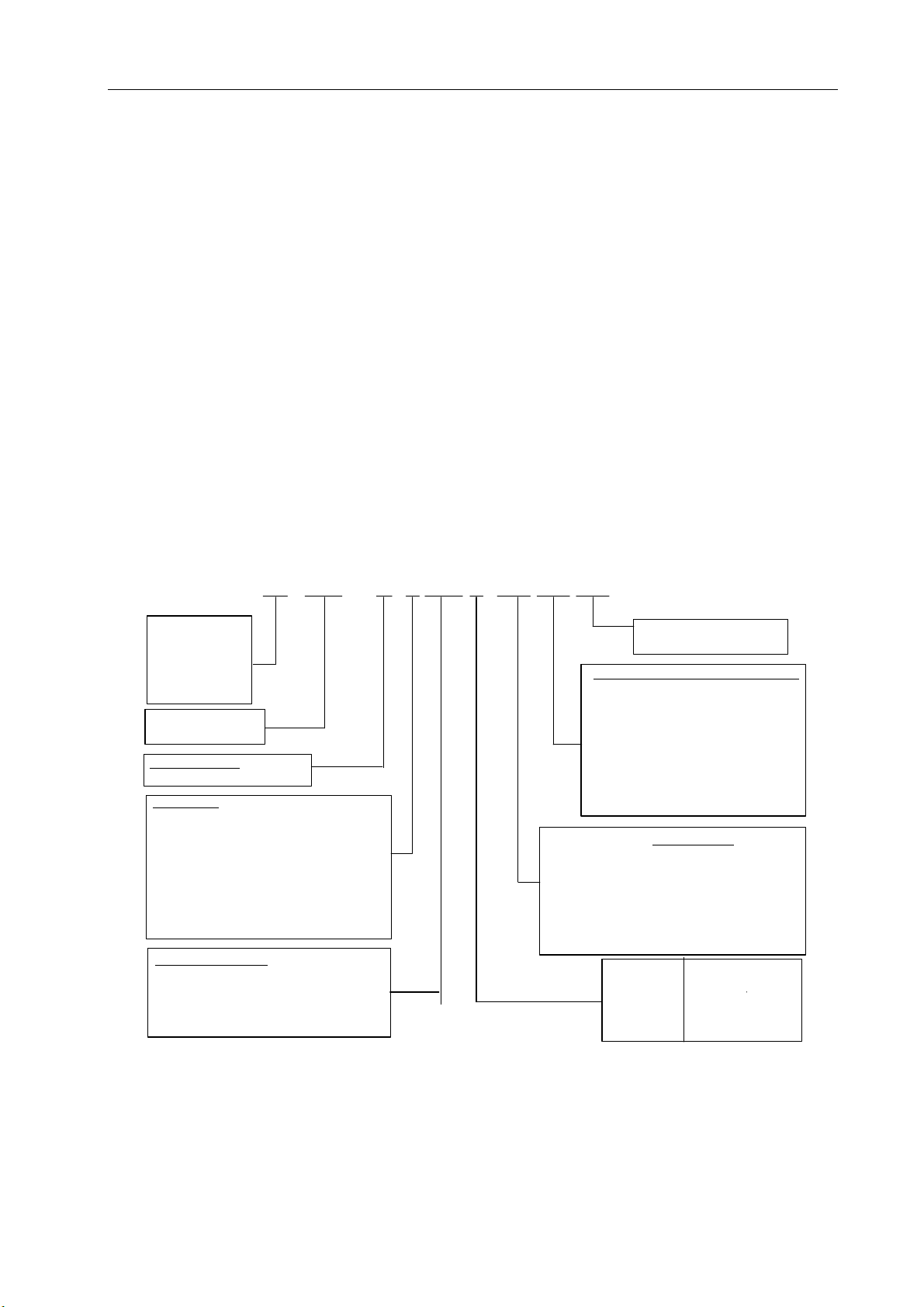

2) Description of Model Number

(1) Model Number of Servo Drive Unit

8

Page 18

Chapter 1 Summary

Note: Type R1 is a thin radiator, R2 thick radiator and R3 a thick radiator with a fan.

Note 1: Optional imported or home-made servomotor is available upon request. The default parameters of the

drive unit are only adaptive to SJT and ST series of servomotors. For other servomotors, the delivery

parameters are backed up in EEPROM. To recover the delivery parameters, make sure to perform recovery

backup but not to restore default parameters.

Note 2: Use standard configuration for middle or low power (≤1.5kW) and thick radiator for the power above middle

level (> 1.5kW).

Note 3: The above boxes have been completed before product delivery. Please check them against the nameplate of

the product.

(2) Model Number of Servomotor

The DA98E series of bus-oriented AC servo drive Unit may be used in conjunction with many foreign

and domestic servomotors that can be selected by user in ordering. The Chapter 8 of this manual

offers the information on the SJT series of GSK and the new ST series of servomotors made by New

Type Motor Factory affiliated with Huazhong University of Science and Technology. The information

on other types of servomotors is supplied with them.

130 SJT

Machine model:

80

110

130

175

AC synchronous

servo motor

Feedback unit:

M:Photoelectric encoder

Safe brake

None : None ; Z: Available

Remark: The working power supply of safe brake

is DC(0.9~ 1.1)×24V, the interface is 3-cord

socket, pin 1 and pin 2 are power supply terminal

(not differ polarity), pin 3 is earth terminal. When

pin 1 and pin 2 i s connecte d the power supply,

the sa fe brake doesn’t work; when the power is

OFF, it works. The brake operation time is ≤0.1s.

Zero-speed torque

Remark: It is represented by three

digits, and the value is in three digits

-1

,the unit is N ·m.

×10

For example, 150×10

Note 1: The working power supply for the dead electromagnet brake is DC (0.9~1.1) ×24V and its connector a

-1

=15N·m.

MZ150 D(A□Y□X

-

□

)

None:Aviation socket type

X:Cable direct type

Shaft extenstion or installation config.

None:Standard shaft extension

Y□:Special cylinder shaft extension

Z□:Special cone shaft extension

S□:Stepping motor installation config.

Remark: In the blank“□”, it is digit code;

about the number representing the detailed

special axis extension, refer to the

installation overall drawing of the motor.

Encoder type

A or None:

A2:Increment type 5000 p/r

A3:Increment split-type 2500 p/r

A4:Absolute type 17bit

A41:Danaher multi-circle 17bit absolute type

A4S1:Danaher single-circle 17bit absolute type

Rated speed

Increment type 2500 p/r

1000 r/min

A

:

1500 r/min

B

:

2000 r/min

C

:

2500 r/min

D

:

E

:

3000 r/min

3-pin socket whose Pin 1 and 2 are power inputs (not polarity specific) and Pin 3 is a ground terminal. When

Pin 1 and 2 are connected to power supply, the dead electromagnet brake does not function. When they are

disconnected from power supply, it operates for a duration less than or equal to 0.1s.

-1

Note 2: “150” indicates that its value consists of three digits 150×10

=15 in N·m.

9

Page 19

DA98E Series AC Servo Drive Unit User Manual

Note 3: ‘□’ is a numeral code. See the installation diagram of the motor for the specific special shaft extension

indicated by a figure.

3) Accessories

(1) Standard accessories for DA98E servo drive unit

① User Manual (this manual) 1

② Mounting bracket 2

③ M4×8 countersunk head screws 4

④ BUS1 plug (DB9 jack), BUS2 plug (DB9 pin) 1 set (Note 1)

⑤ CN1 plug (DB26 jack) 1 set (Note 2)

⑥

The standard accessories of a servo motor will be supplied to its operation manual.

Note 1: Our Ethernet bus communication position control device is supplied with a CAT-5e UTP signal cable (standard

length: 3m).

Note 2: A feedback cable (standard length: 3m) is available with our servomotor upon user’s request.

Note 3: The encoder feedback connector CN1 with an absolute encoder is a MDR26 plug.

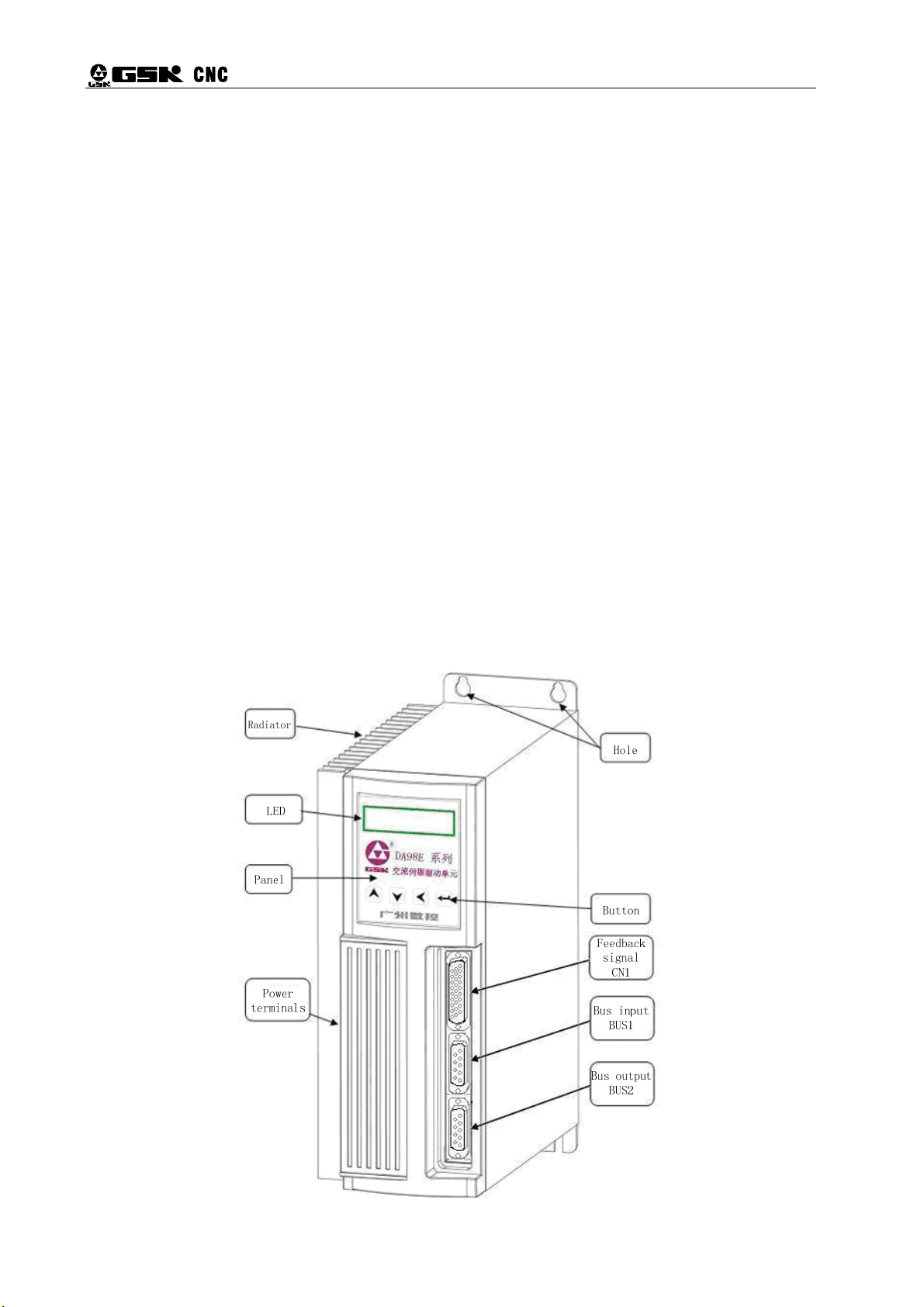

1.4 Product Appearance

1) Appearance of Servo Drive Unit

10

Page 20

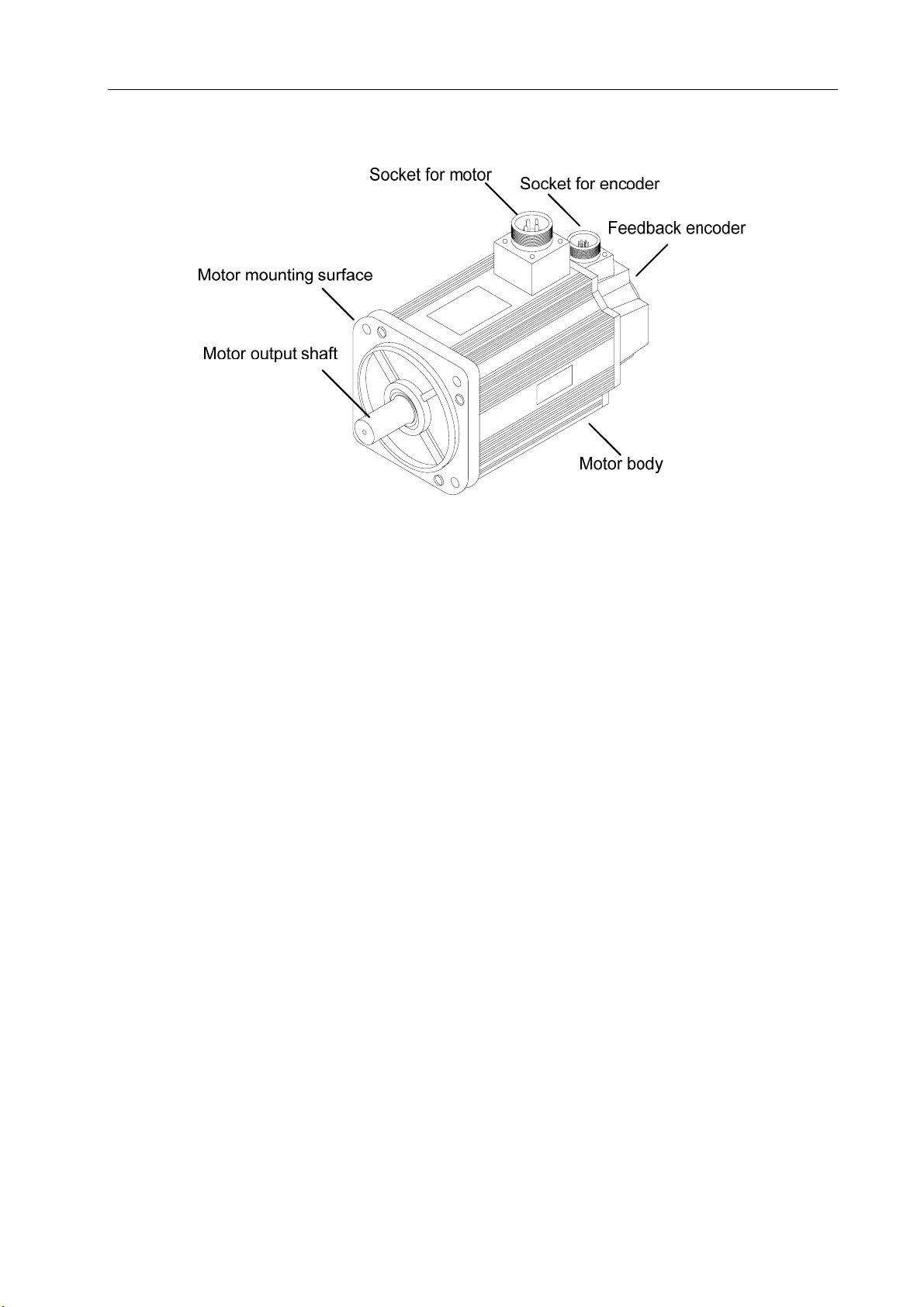

2) Appearance of Servomotor

Chapter 1 Summary

11

Page 21

DA98E Series AC Servo Drive Unit User Manual

Chapter 2 Installation

Attention

z The product shall be stored and installed in an environment meeting the requirements of the

specification.

z Do not stack up too many products as they are subject to damage under pressure and falling

down.

z The original package must be used for the storage and transport of the product.

z A damaged or incomplete product must not be installed and used.

z Always use fire-proof material for the installation of the product. Do not install it on or near

combustible materials to prevent fire.

z The servo drive unit must be installed in an electric cabinet in order to prevent dust, corrosive gas,

conductive substances and combustible matters from entering.

z The servo drive unit and servomotor shall be protected from vibration and impact.

z Never pull the motor cable, shaft and encoder.

2.1 Ambient Conditions

Item

Operating temp/humidity

Storage and transport

temp/humidity

Atmospheric

environment

Elevation Altitude below 2000m Altitude below 2000m

Vibration

Level of protection IP20 IP54

DA98E series of servo drive

Unit

0℃~40℃ (nonfreezing)

RH<90% (noncondensing)

-20℃~70℃

90%RH (noncondensing)

In a control cabinet without

corrosive or combustible gas, oil

mist, dust, etc.

< 0.5G(4.9m/s2)10 H

GSK SJT series of servomotors

-10℃~40℃ (nonfreezing)

RH<90% (noncondensing)

-40℃~70℃

RH<85% (noncondensing)

Indoors (without direct sunlight) without

corrosive or combustible gas, oil mist,

~60HZ (discontinuous operation)

Z

dust, etc.

2.2 Installation of Servo Drive Unit

Attention

z The servo drive unit must be installed in an electric cabinet properly protected (≥IP43).

z The servo drive unit must be installed in the direction with spacing as specified and provided with

good heat eliminating condition.

z It must not be installed on or near combustible materials to prevent fire.

12

Page 22

Chapter 2 Installation

1) Installation Environment

(1) Protection

Since the structure of the servo drive unit is of IP 20, it must be installed in an electric cabinet

(≥IP43) properly protected and protected from exposure to corrosive and combustible gas and entry

of conductive matters, metallic dust, oil dust and liquid.

2) Temperature/humidity

Ambient temperature: 0℃~50℃. For extended safe operation, the unit shall be installed in an

environment at altitude less than 2000m and temperature below 40℃ and protected with good

ventilation conditions.

(1) Vibration and Impact

The drive unit shall be protected from vibration. Measures shall be taken to control vibration

under 0.5(4.9m/s

2

) as the drive unit cannot bear any high pressure or impact.

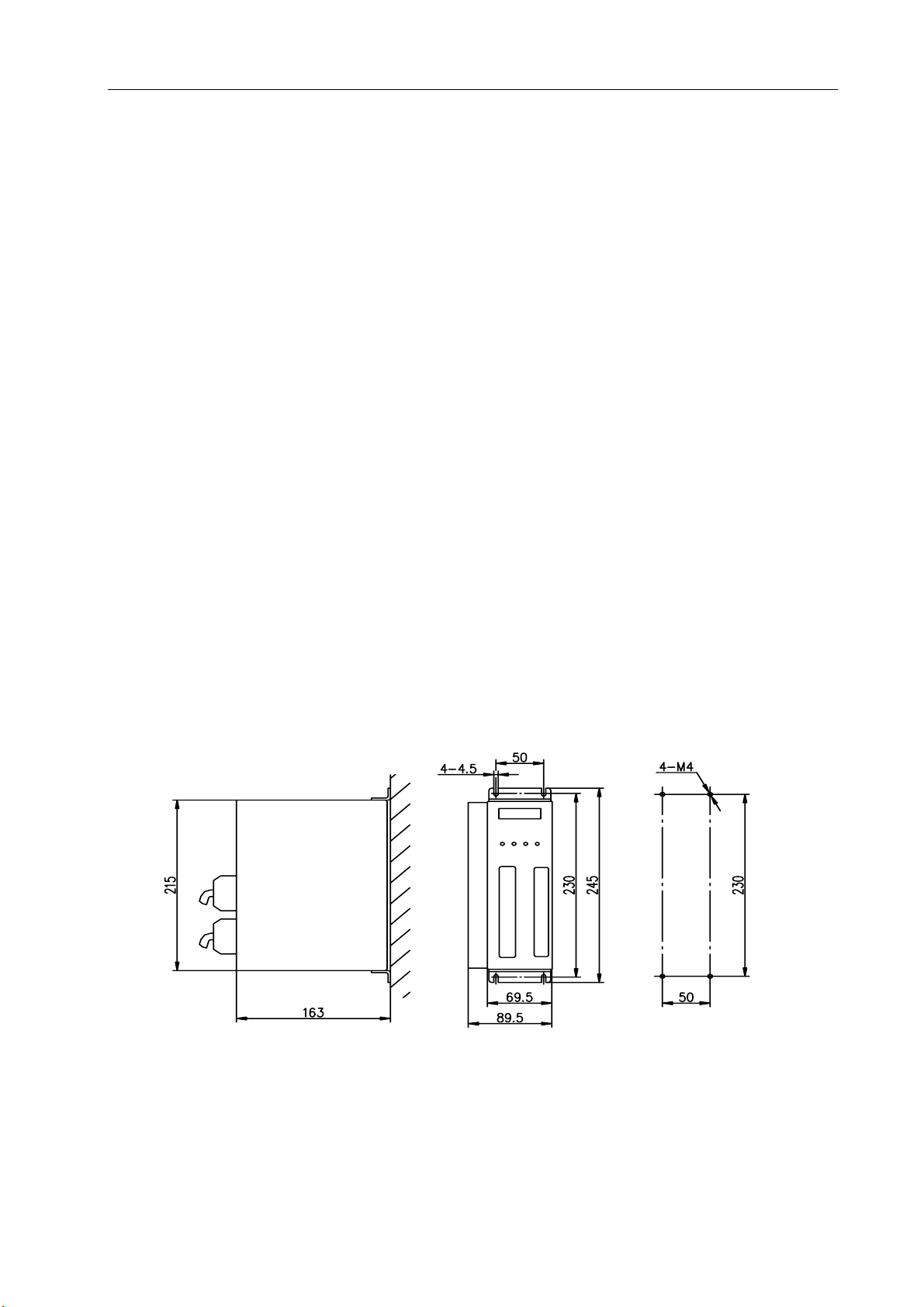

3) Installation Procedure

(1) Installation Means

The user may install the unit by means of base or face plate in a direction perpendicular to the

mounting surface. See Figure 2-1 for the diagram of base-plate mounting and Figure 2-2 face-plate

mounting.

Figure 2-1 Base-plate mounting of drive unit

13

Page 23

DA98E Series AC Servo Drive Unit User Manual

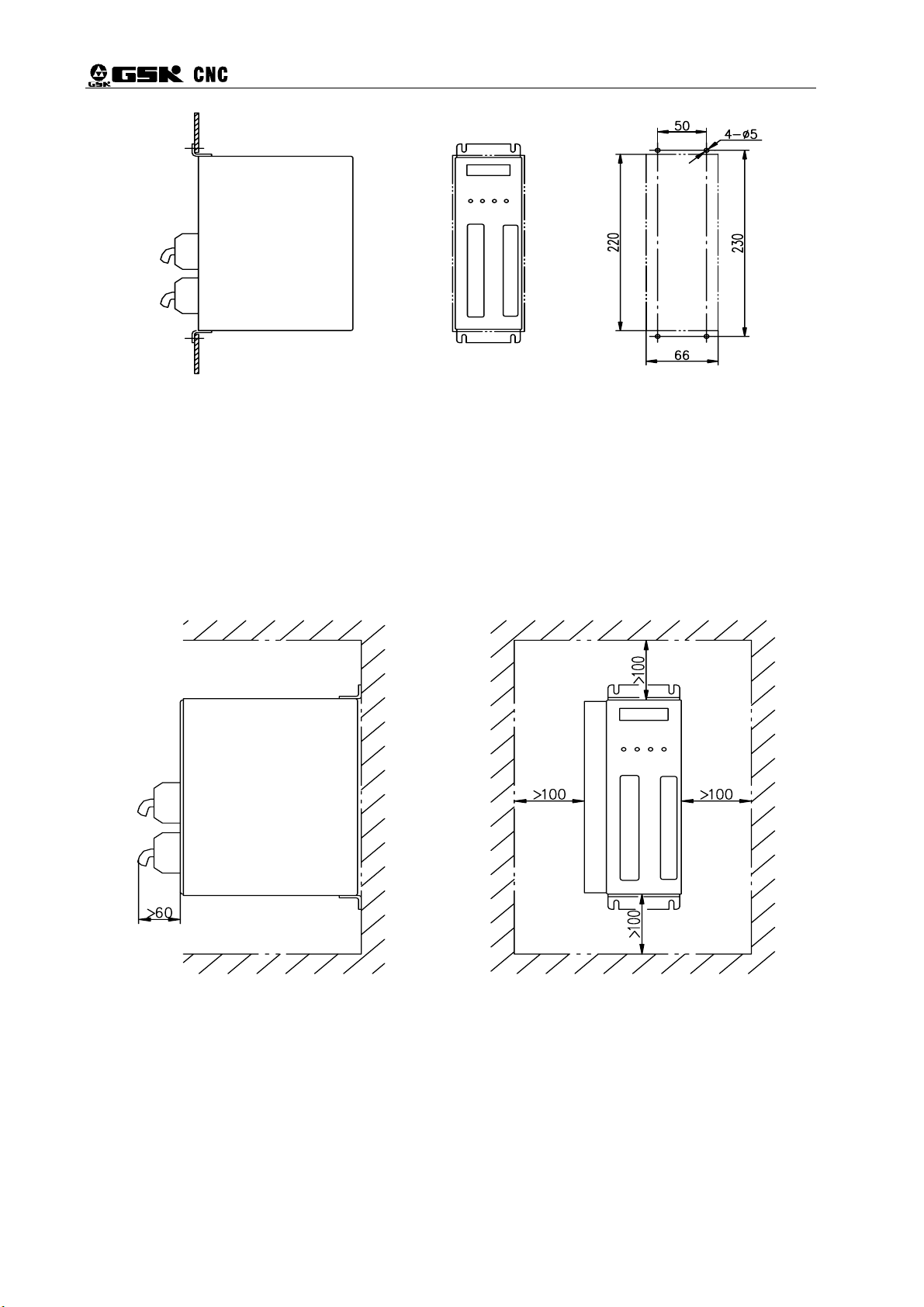

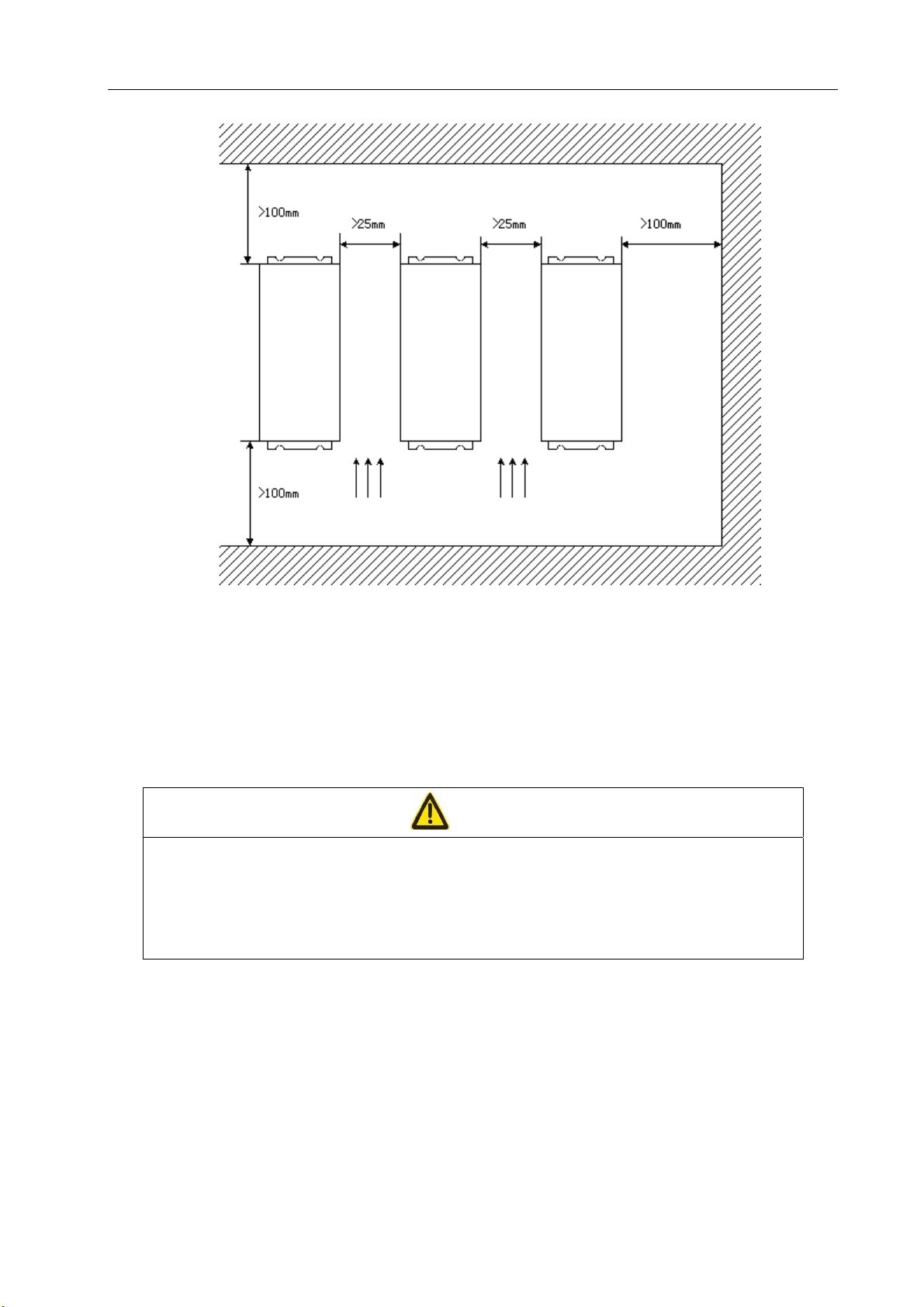

(2) Installation Space

Figure 2-3 shows the installation space for a single drive unit and Figure 2-4 the spacing

Figure 2-2 Face-plate mounting of drive unit

between several drive Unit. In actual installation, a space as big as possible shall be kept to

ensure good heat ventilation.

14

Figure 2-3 Installation space for single drive unit

Page 24

Chapter 2 Installation

Servo

driver

Figure 2-4 Installation spacing between several drive Unit

(3) Heat Elimination

To prevent ambient temperature of the drive Unit from rising, radiators shall be fitted in the

electric cabinet to blow convection air to the Drive Unit.

Servo

driver

Servo

driver

Direction of ventilation Direction of ventilation

2.3 Installation of Servomotor

Attention

z Never knock the motor shaft or encoder. Protect the motor from vibration or impact.

z For handling of the motor, do not pull its shaft, outgoing wires or encoder.

z The motor shaft shall be protected from overloading as this may cause damage to it.

z The motor must be installed securely and protected from becoming loose.

1) Installation Environment

(1) Protection

In consideration of that currently GSK SJT series and Huazhong ST series of servomotors are

not waterproof, the motors must be kept away from liquid and oil or water prevented from entering the

motors along the outgoing wires and motor shaft.

Note: Please specify in ordering of a waterproof servomotor.

15

Page 25

DA98E Series AC Servo Drive Unit User Manual

(2) Temperature/humidity

The ambient temperature of the motor shall be kept between -10℃ and 40℃. A forced heat

eliminating means shall be considered when its surrounding space is limited or when there is a

heating device nearby.

The ambient humidity shall be above 90% RH (noncondensing).

(3) Vibration

The servomotor shall not in a location with vibration over 0.5G (4.9m/s

2

).

2) Installation Procedure

(1) Installation Means

At present the SJT and ST series of motors are installed in any direction by means of flange.

(2) Precautions for Installation:

z While removing the pulley, do not know the motor or its shaft as this may cause damage to

the encoder. Remove or fit it with a spiral pressing and pulling tool.

z Currently most of the SJT and ST series of motors cannot bear high axial and radial loads. It

is recommended to connect a load with flexible coupling.

z Use lock washers to prevent the motor from becoming loose while fixing the motor.

Note: Refer to Chapter 8 for the specification and installation dimensions of the servomotor.

16

Page 26

Chapter 3 Wiring

Chapter 3 Wiring

Carefully read and strictly abide by the following precautions which ensure your operating safety

and reliability.

The wiring shall be properly carried out by a well-trained and qualified technician by

Attention

following the associated instruction.

Any wiring or repair work on the servo unit can be performed only when you make

sure the voltage-to-ground on all the terminals of the main circuit are safe five

minutes after it is disconnected from the servo unit. Otherwise it may cause an

electric shock.

Make sure the servo unit and servomotor are correctly grounded.

For wiring, do not damage the cable with a sharp object or forcibly pull it as it may

lead to electric shock or poor line contact.

Never extend connecting cables for the main circuit and signal cables through the

same conduct or bind them together. In wiring, the connecting cables for the main

circuit and signal cables shall be routed separately or crosswise with spacing over

30cm in order to prevent heavy-current lines from interfering the signal cables and

causing the malfunction of the servo unit.

Do not frequently turn on/off the power supply as the built-in high-capacity

capacitors in the servo unit generates high charging current during powering on and

frequent switching of the power supply may deteriorate the performance the

components in the servo unit. A switching interval of 3min or longer is advised.

Do not fit any additional power capacitor, surge arrester, wireless noise filter and

other devices between the servo unit output side and servomotor.

The wiring of the main circuit and signal cables shall be kept away from heat sink

and electric motor in order to prevent their insulating property from deterioration by

heating.

After the wiring of the main circuit, attach the terminal cover to avoid electric shock.

17

Page 27

DA98E Series AC Servo Drive Unit User Manual

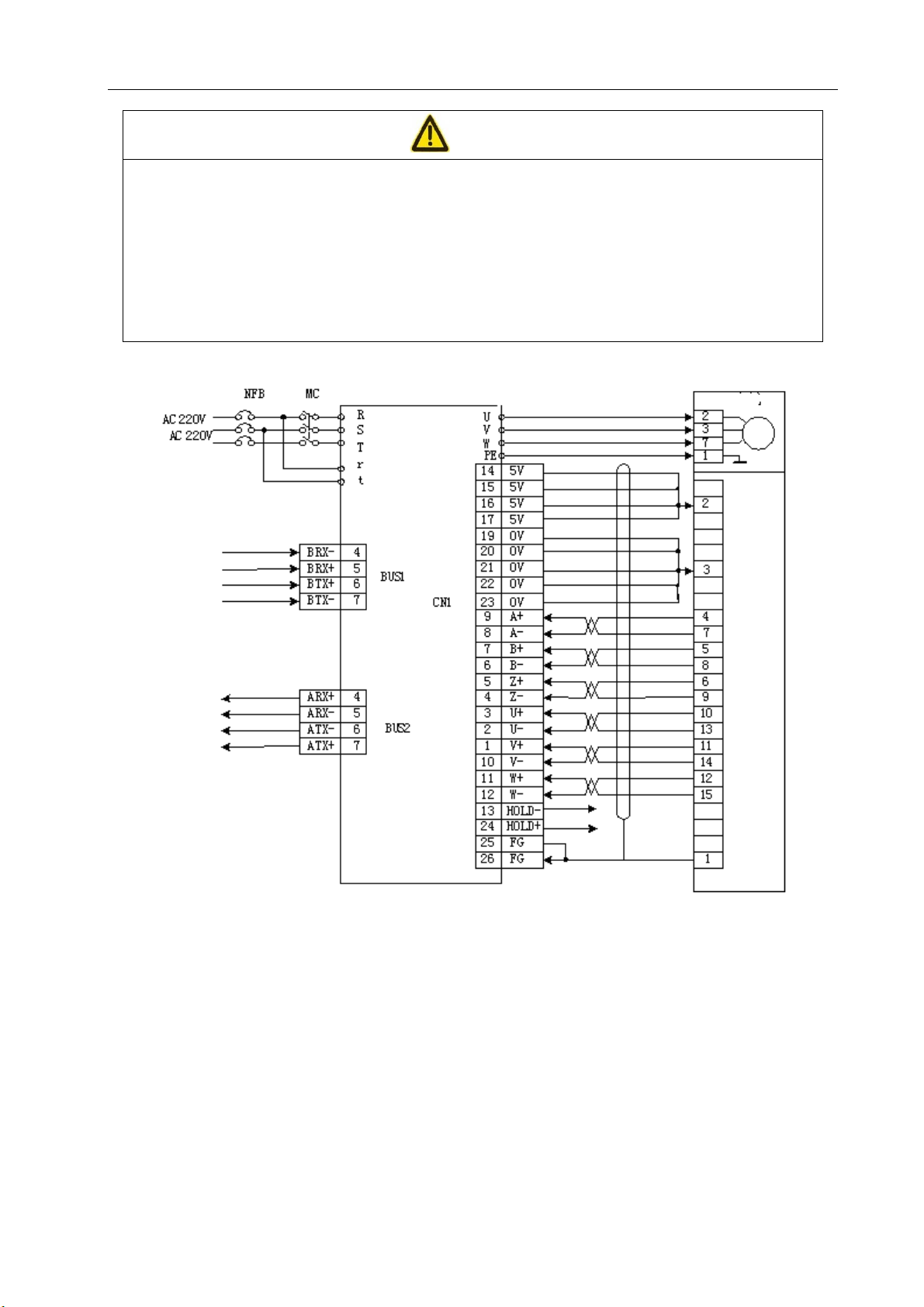

3.1 Standard Connection

The external connection of the drive unit depends on its control mode.

1) Position control mode:

Figure 3-1 shows the standard connection for the position control mode.

2) Speed control mode:

Figure 3-1 shows the standard connection for the speed control mode.

3) Wiring

(1) TB Power Terminals

2

z Wire sizes: Diameters of the wires to terminals R, S, T, PE, U, V and W ≥1.5mm

and those of terminals r and t ≥1.0 mm

2

(AWG16-18)

z Grounding: The ground wire shall be big and short as much as possible and the drive unit and

(AWG14-16),

servomotor share the PE terminal.

z JUT-1.5-4 pre-insulated cold-pressed terminals are used for terminal connection. Always

connect them securely.

z It is recommended to supply power to the unit using a three-phase insulating transformer to

minimize the potential of electric shock.

z It is recommended to supply power through a noise filter in order to improve the anti-jamming

capacity of the unit.

z Install non-fusible (NFB) breaker so that the external power supply can be duly disconnected

in the event of drive unit fault.

(2) Control Signals BUS1 and BUS2 and Feedback Signal CN1

z CAT-5e UTP engineering cables are used control signal cables;

z Sizes of the feedback signal wires: A shielded cable (it is advisable to use a twisted shielded

cable) whose wire diameter shall not be less than 0.12mm2(AWG24-26) and shielding layer shall be

connected to the Terminal FG.

z Cable length: The power cord shall be as short as possible and the length of the feedback

signal CN1 cable must not be longer than 30m.

z Wiring: The wires shall be routed away from power lines to prevent cross-interference.

z Fit a surge arresting element for the inductive components (coils). Connect DC coils and a

freewheel diode in parallel reversely. Connect AC coils and resistance-capacitance absorbing circuit

in parallel.

18

Page 28

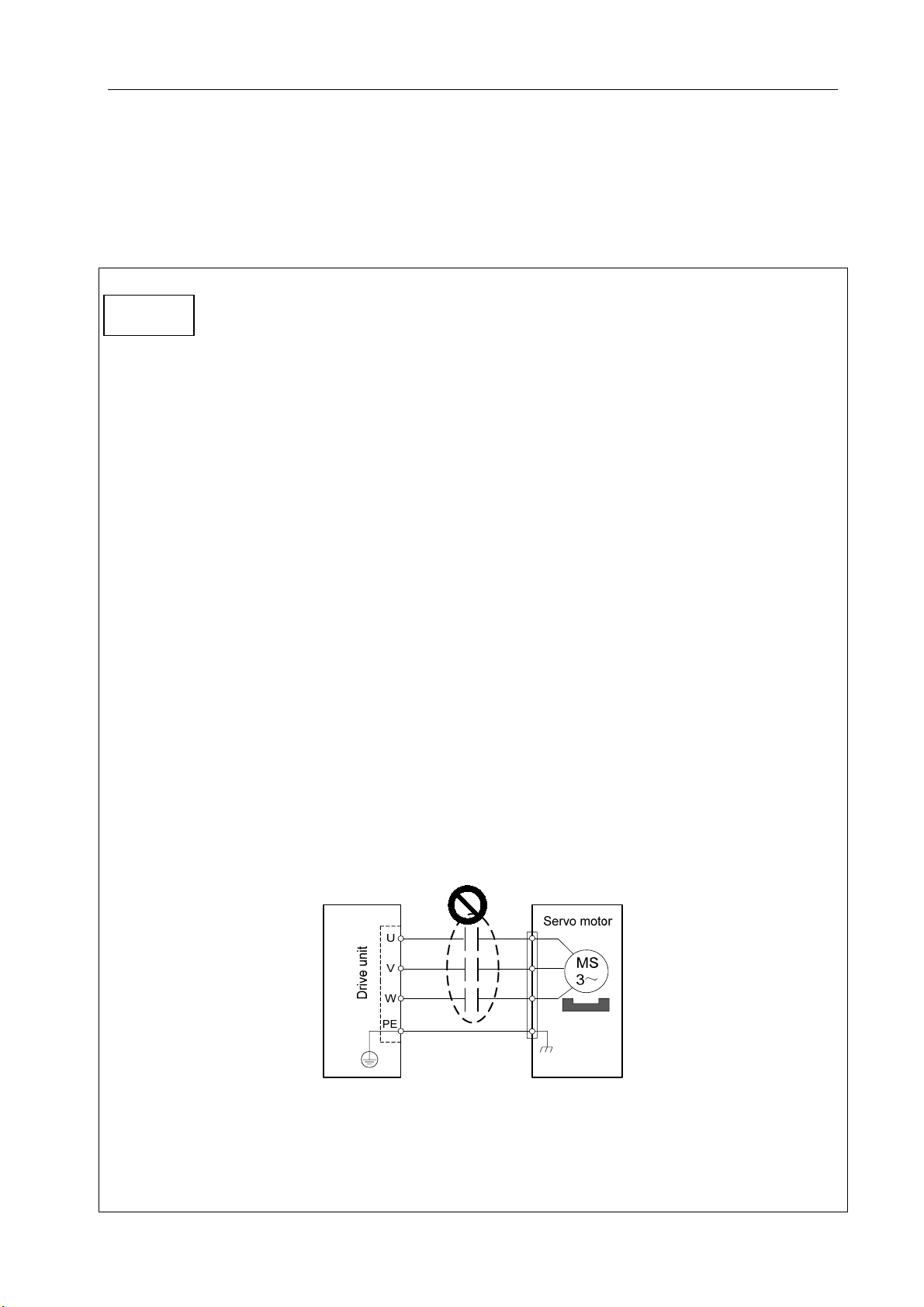

z Connect U, V and W to motor windings correspondingly. Never connect them reversely.

z Tighten the cables and conductors and keep them away from the drive unit radiator and

motor in order to prevent their insulating property from deterioration by heating.

z The high-capacity electrolytic capacitors in the servo drive unit maintain high voltage

(residual voltage) immediately after power-off. Do not touch the drive unit and the motor

within five minutes after power-off.

Three-phase or

single-phase

Chapter 3 Wiring

Attention

Electric motor

Servo

driver

Encoder

Figure 3-1 Standard wiring for position and speed control modes when an incremental encoder is

provided

19

Page 29

Three-phase or

g

p

sin

le-

hase

DA98E Series AC Servo Drive Unit User Manual

Electric motor

Servo driver

Absolute encoder

Figure 3-2 Standard wiring for position and speed control modes when a Tamagawa absolute

encoder is provided

20

Page 30

Chapter 3 Wiring

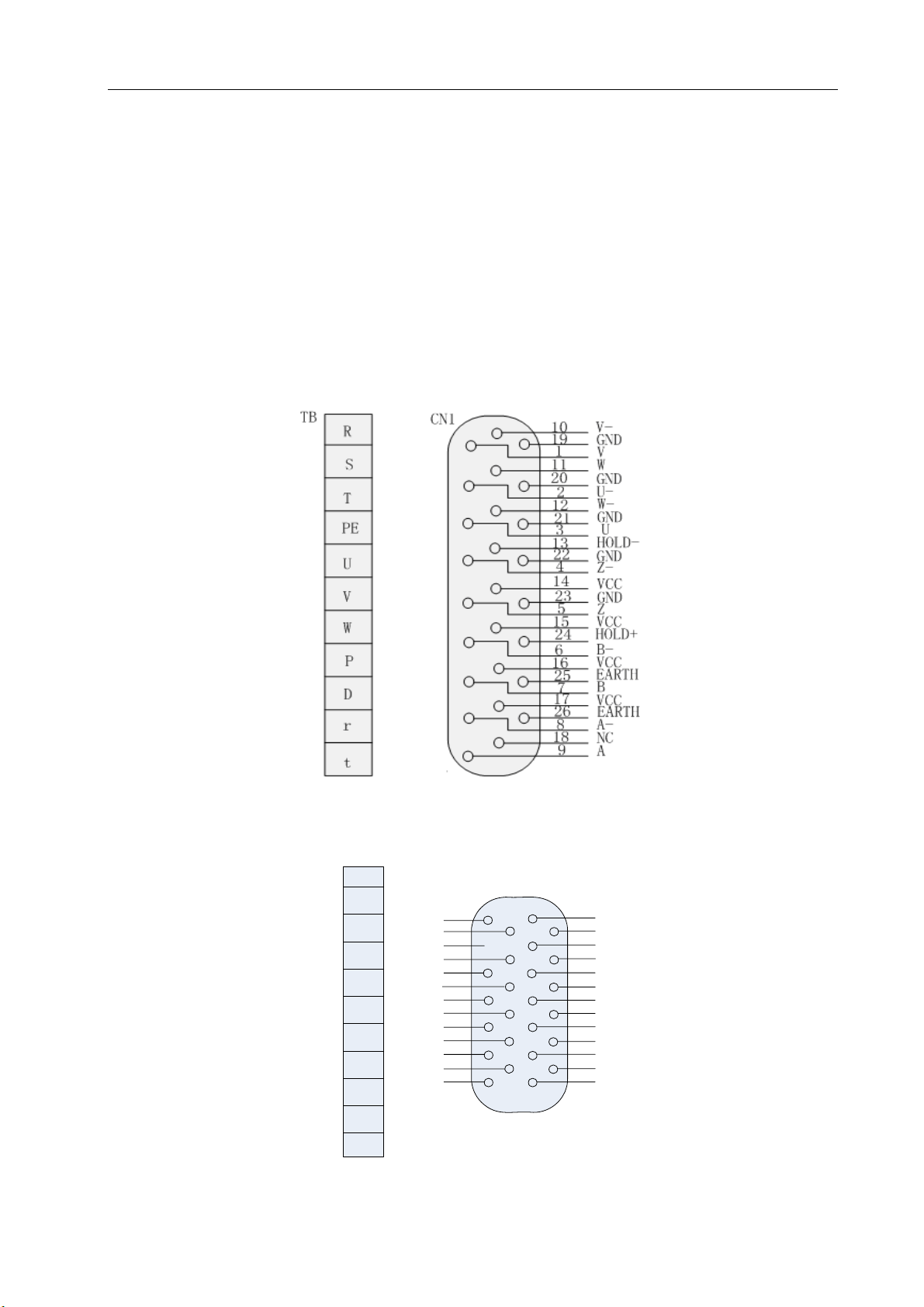

3.2 Functions of Terminals

(1)Terminal Configuration

Figure 3-3 is the diagram of configuring the terminals on the servo drive unit and incremental

encoder type motor. In the diagram TB is a terminal block and BUS1 and BUS2 are DB9 connectors.

The socket is of three-hole type and the plug has three blades.

Figure 3-4 is the diagram of configuring the terminals on the servo drive unit and absolute

encoder type motor. In the diagram TB is a terminal block and BUS1 and BUS2 are DB9 connectors.

CN1 is a MDR26 connector.

BD-26 female

Figure 3-3 Diagram of configuring the terminals on the drive unit and incremental encoder type motor

TB

R

S

T

PE

U

V

W

P

D

r

t

CN1

1

GND

2

GND

3

GND

4

GND

VCC VCC

5

6

VCC

7

HOLD-

8

9

HOLD+

10

11

12

13

SD-

14

15

16

17

18

19

20

21

22

23

24

25

26

MDR26

EARTH

EARTH

GND

VCC

3.6V

3.6V

SD+

Figure 3-4 Diagram of configuring the terminals on the drive unit and absolute encoder type motor

21

Page 31

DA98E Series AC Servo Drive Unit User Manual

(2)Functions of Terminals

1) TB Power Terminals

Table 3-1 TB Power Terminals

Terminal

Terminal

Signal designation Function

No.

TB-1 R

TB-2 S

marking

Power supply of main

circuit

Single-phase or

Power input terminals of main circuit AC

220V 50Hz

Caution: Do not connect power supply to the

TB-3 T

3-phase

output terminals U, V and W of the motor.

Ground terminal

Grounding of the

Earth resistance<100Ω;

TB-4 PE

system

The output and power input of the servo

motor share one grounding terminal.

TB-5 U

TB-6 V

Output of servo motor

TB-7 W

Output terminals of servo motor

They must be connected to the terminals

U, V and W of the motor correspondingly.

TB-8 P Reserved

TB-9 D Reserved

TB-10 r

TB-11 T

Control power supply

Single-phase

Power input terminals of the control circuit

AC 220V 50Hz

BD 9 holes BD 9 pins

Figure 3-5 Diagram of configuring control terminals

22

Page 32

2) Control terminal BUS1

Table 3-2 BUS1 Control Signal Input/output Terminals

Chapter 3 Wiring

Terminal

Signal

Marking I/O Mode Function

No.

designation

BUS1-4 BRX- Typel Bus differential data reception

BUS1-5 BRX+ Typel Bus differential data reception

BUS1-6 BTX+ Typel Bus differential data sending

BUS1-7 BTX- Typel Bus differential data sending

3) Control terminal BUS2

Table 3-3 BUS2 Control Signal Input/output Terminals

Terminal

Signal

Marking I/O Mode Function

No.

designation

BUS2-4 ARX+ Typel Bus differential data reception

BUS2-5 ARX- Typel Bus differential data reception

BUS2-6 ATX- Typel Bus differential data sending

BUS2-7 ATX+ Typel Bus differential data sending

Brief Description of Bus Communication:

Control terminals BUS1 and BUS2 are the connection network created by the control device and

servo in order to compose a closed loop of Ethernet transfer. The data transferred through Ethernet

includes periodic and non-periodic data. Periodic data is transferred once per Interpolation period and

non-periodic data in idle time.

a) Periodic data: It refers to Master Data Telegram (“MDT”). A CNC sends system control

commands and position/speed/torque data to a servo while the latter transfers the current position

information and the current key state of the servo to the CNC through a bus.

The format of the data sent by CNC --- 3 words:

Length of periodic data (10 bytes )

16bits 16bits 6 bytes

Control word Position/speed/torque data Reserved

23

Page 33

DA98E Series AC Servo Drive Unit User Manual

The format of the MDT control words send by CNC:

Format of control words sent by the system(16bits)

Control bit Meaning Remarks

Bit0 To enable a servo “1” is valid.

Bit1 To clear an alarm “1” is valid.

Bit2 To disable CCW “1” is valid.

Bit3 To disable CW “1” is valid.

Bit4 To zero position deviation “1” is valid.

Bit5 To disable command pulse “1” is valid.

Bit6 To limit CCW torque “1” is valid.

Bit7 To limit CW torque “1” is valid.

Bit8 To enable zeroing “1” is valid.

Bit9 Zeroing direction “1” is valid.

Bit10…Bit15 Reserved

The format of the MDT data send by the servo unit—5 words:

Length of periodic data (10 bytes )

16bits 32bits 32bits

Control word Current position information Reserved

The format of the MDT control words send by the servo unit:

The format of the control words send by the servo (16bits)

Control bit Meaning Remarks

Bit0 Servo is ready. “1” is valid.

Bit1 Contracting brake output “1” is valid. (Reserved for the time being)

Bit2 Positioning completed/speed

“1” is valid.

reached

Bit3 Zeroing completed “1” is valid.

Bit4-bit8 Servo alarm 5 bits: Max. alarm No. 32 indicates (000 0001

1111 0000 B)

Bit9..Bit15 Reserved

24

Page 34

Chapter 3 Wiring

b) Non-periodic data: It refers to a general data telegram (“GDT”) that comprises control

words and data. The functions of a non-periodic data in final version include: setting of

Ethernet communication parameters, setting and change of servo parameters, allowing a

servo to save the current change in parameters, reception of servo parameters, reception of

servo diagnostic messages, etc;

c) Determination of the axes X, Y and Z of a servo drive unit:

Servo unit

Slave station 1

Cat-5e UTP

Servo unit

Slave station 2

Master station

of CNC system

Servo unit

Slave station n

Servo unit

Slave station

Figure 3-6 Diagram of connecting a CNC to servo Unit

The servo connecting the bus interface of the CNC (i.e. BUS2 of CNC) to the servo BUS1 (DB 9

holes) is the first axis (Axis X). The servo connecting BUS2 (DB 9 pins) back to the bus interface 1 of

the system (i.e. BUS1 of CNC) is the last axis.

4) Feedback signal terminal CN1------Feedback signal from an incremental encoder

Table 3-4 Signal input/output terminal CN1 of encoder

No.

CN1-14

CN1-15

CN1-16

CN1-17

CN1-19

CN1-20

CN1-21

CN1-22

CN1-23

Signal designation

Power output + VCC

Power output - GND

Terminal marking Color Functions Terminal

Marking I/O Mode

The photoelectric encoder for the

servomotor uses +5V power supply.

For a long cable, connect several core

wires in parallel.

25

Page 35

DA98E Series AC Servo Drive Unit User Manual

CN1-9 Encoder A+input A+

Type4

CN1-8 Encoder A-input A-

CN1-7 Encoder B+input B+

Type4

CN1-6 Encoder B-input B-

CN1-5 Encoder Z+input Z+

Type4

CN1-4 Encoder Z-input Z-

CN1-3 Encoder U+input U+

Type4

CN1-2 Encoder U-input U-

Connecting the A+ of the photoelectric

encoder for the servomotor

Connecting the A- of the photoelectric

encoder for the servomotor

Connecting the B+ of the photoelectric

encoder for the servomotor

Connecting the B- of the photoelectric

encoder for the servomotor

Connecting the Z+ of the photoelectric

encoder for the servomotor

Connecting the Z- of the photoelectric

encoder for the servomotor

Connecting the U+ of the photoelectric

encoder for the servomotor

Connecting the U- of the photoelectric

encoder for the servomotor

CN1-1 Encoder V+input V+

Type4

CN1-10 Encoder V-input V-

CN1-11 Encoder W+input W+

Type4

CN1-12 Encoder W-input W-

CN1-13

CN1-24

Contracting brake

HOLD- Power supply, GND

output

TYP4

Contracting brake

HOLD+

output

Connecting the V+ of the photoelectric

encoder for the servomotor

Connecting the V- of the photoelectric

encoder for the servomotor

Connecting the W+ of the

photoelectric encoder for the

servomotor

Connecting the W- of the photoelectric

encoder for the servomotor

0V input of relay

26

Page 36

Chapter 3 Wiring

r

5) CN1 feedback signal terminal –Feedback signal from Tamagawa 17-bit absolute encoder

Table 3-5 CN1 Signal Input/output Terminals of Absolute Encoder

Terminal

Signal designation

No.

CN1-5

CN1-6

Power output + +5V

CN1-17

CN1-18

CN1-1

CN1-2

Power output - GND

CN1-3

CN1-4

CN1-13 Encoder SD- i1nput SD-

CN1-26 Encoder SD+ input SD+

Terminal marking

Color Functions

Marking I/O Mode

The absolute encoder for the

servomotor uses +5V power supply.

For a long cable, connect several core wi

in parallel.

Connecting the A+ of the photoelectric

encoder for the servomotor

Type 4

Connecting the A- of the photoelectric

encoder for the servomotor

The absolute encoder for the

CN1-24

CN1-25

CN1-14

CN1-15

CN1-7

CN1-9

Battery input + +3.6V

Type 4

Shielded earth wire EARTH

Contracting brake

HOLD- Power supply, GND

output

TYP4

Contracting brake

HOLD+

output

0V input of relay

servomotor uses +3.6V power supply to

maintain the data of several loops. For a

long cable, connect several core wires

in parallel. If the servo unit is not

powered on for an extended period of

time, the data of several loops is subject

to loss due to low battery voltage.

Connecting the B- of the photoelectric

encoder for the servomotor

27

Page 37

DA98E Series AC Servo Drive Unit User Manual

3.3 Circuitous Philosophy of I/O Interface

1) Input Interface of Incremental Photoelectric Encoder for Servomotor

Motor side

X+

X-

Drive unit side

AM26LS32

X=A,B,Z,U,V,W

Figure 3-7 Input Interface of Incremental Photoelectric Encoder for Servomotor

2) Input Interface of Tamagawa Absolute Photoelectric Encoder for Servomotor

Motor side Drive unit side

28

Figure 3-8 Input Interface of Absolute Encoder for Servomotor

Page 38

Chapter 4 Parameters

Chapter 4 Parameters

Attention

z Each personnel involved in parameter adjustment shall understand the meaning of

parameters as incorrect setting may cause equipment damage and personal injury.

z It is recommended to adjust the parameters when the servomotor is idling.

z The motor parameters are adaptive to GSK SJT and Huazhong ST series of servomotors. To

use other servomotors, it is required to adjust the relevant parameters. Otherwise the motor

will not operate normally.

4.1 Summary of Parameters

z The delivery settings in the following table are adaptive to the drive unit of GSK 110SJT-M040D

(4N.m, 2500rpm) motor as an example. The relevant parameters vary with motors.

z The current software version is V2.05 – for servomotors with incremental encoder.

Table 4-1 Summary of Parameters

S/N Name Applicable

mode

0 Password P, S 0~9999 315

1 Model code P, S 0~78 60

2 Software version (read-only) P, S * *

3 Initial display status P, S 0~21 0

4 Selection of control mode P, S 0~5 0

5 Proportional gain of speed P, S 5~2000 240* Hz

6 Integral time constant of speed P, S 1~1000 25* ms

7 Torque command filter P, S 1~500 100 %

Range of

parameter

Delivery

setting

Unit

8 Low pass filter for speed

detection

9 Proportional gain of position P 1~1000 40 1/S

10 Feedforward gain of position P 0~100 0 %

11 Cut-off frequency of positional

feedforward low-pass filter

P, S 1~500 120 %

P 1~1200 300 Hz

Page 39

DA98E Series AC Servo Drive Unit User Manual

12 Numerator of position command

P 1~32767 1

countdown

13 Denominator of position

P 1~32767 1

command countdown

14 Reserved

15 Reversal of position command

P 0~1 0

countdown

16 Positioning range P 0~30000 20 Pulse

17 Range of position

out-of-tolerance detection

18 Erroneous and invalid position

P 0~30000 200 ×100

pulse

P 0~1 0

out-of-tolerance

19 Position command smoothing

P 0~30000 0 0.1ms

filter

20 Invalid drive disabling input P, S 0~1 0

21 Speed of JOG operation S -3000~3000 120 rpm

22 Selection of internal and external

S 0~4 0

commands

23 Limitation of maximum speed P, S 0~4000 3000 rpm

24 Internal speed 1 S -3000~3000 0 rpm

25 Internal speed 2 S -3000~3000 100 rpm

26 Internal speed 3 S -3000~3000 300 rpm

27 Internal speed 4 S -3000~3000 -100 rpm

28 Arriving speed S 0~3000 500 rpm

Contracting brake release signal

P, S 0~1000 4 4*10ms

29

delay

Numerator of linear speed

P, S 1~32767 10

30

conversion

Denominator of linear speed

P, S 1~32767 1

31

conversion

30

Position of decimal point in linear

P, S 0~5 3

32

speed

Stoppage delay time of

P, S 0~1000 10 10*10ms

33

contracting brake

Limitation of internal CCW

P, S 0~300 300* %

34

torque

Page 40

Chapter 4 Parameters

35 Limitation of internal CW torque P, S -300~0 -300* %

Limitation of external CCW

P, S 0~300 100 %

36

torque

37 Limitation of external CW torque P, S -300~0 -100 %

Torque limitation of speed trial

S 0~300 100 %

38

operation and JOG operation

V2.04--Reserved;

39

V3.00---Writing-in of drive unit

P, S 0~100 0

type

40 Acceleration time constant S 1~10000 0 ms

41 Deceleration time constant S 1~10000 0 ms

Note 1: The current version of the software for the servo with a Tamagawa absolute type encoder is V3.01. The

version only applies to the servomotor with a Tamagawa 17-bit absolute encoder.

Note 2: No. 39 parameter in V3.01 is “Writing-in of drive unit type”.

31

Page 41

DA98E Series AC Servo Drive Unit User Manual

4.2 Functions of Parameters

Table 4-2 Functions of Parameters

S/

N

0

Name Function

Password

① The parameter is used to prevent the parameters from

accidental alteration. To change a parameter, normally change

the password to the required password and then set the

parameter. After adjustment, finally set this parameter to 0 in

order to prevent the parameters from accidental alteration.

② Different password levels correspond to user, system and all

parameters.

③ The change of the Model code parameter (PA1) requires the

use of a Model code password. Other passwords cannot be

used change the parameter.

④ User password: 315。

⑤ Model code password: 385

Model code

① Different model codes correspond to the Drive Unit and motors

Range of

parameter

0~9999

1

2

Software

version

(read-only)

at different power levels in the same series.

② Different model codes correspond to different default

parameter settings. Always ensure the correctness of this

parameter while using the default parameter recovery function.

③ In the event of EEPROM alarm (No. Alarm 20), make sure to

set this parameter again and then recover the default

parameter. Otherwise the drive unit may operate abnormally or

become damaged.

④ To change the parameter, first set the password PA0 to 385

and then modify this parameter.

⑤ Refer to Section 4.3 of this chapter for the check list of motor

models and codes.

① The version number of the software may be reviewed but not

changed.

② Meaning of the parameter: Z205.30—incremental type,

0~78

*

32

V2.05, with a 30A module;

J301.30—absolute type, V3.01, with a 30A module;

Page 42

Chapter 4 Parameters

Initial display

3

status

① To select the display status of the display when the drive unit is

powered on

0: To display the rotating speed of the motor;

1: To display the lower 5 digits of current position;

2: To display the upper 5 digits of current position;

3: To display the lower 5 digits of position command (command

pulse accumulation);

4: To display the upper 5 digits of position command (command

pulse accumulation);

5: To display the lower 5 digits of position deviation;

6: To display the upper 5 digits of position deviation;

7: To display the torque of the motor;

8: To display the current of the motor;

0~21

9: To display a linear speed;

10: To display control modes;

Selection of

control mode

11: To display the frequency of position command pulse;

12: To display a speed command;

13: To display a torque command;

14: To display the absolute position of the rotor in a revolution;

15: To display the state of input terminal;

16: To display the state of the output terminal;

17: To display the input signal of the encoder;

18: To display the operating state;

19: To display alarm codes;

20: To display the last upgrading data of the software;

21; Reserved。

① It is possible to set the control mode of the drive unit through

this parameter:

0: Position control mode;

1: Speed control mode;

2: Trial operation control mode;

4

0~5

3: JOG control mode;

4: Encoder zeroing mode;

5: Open-loop operating mode (for test of motor and encoder);

② Position control mode: Position command data is input through

a bus;

33

Page 43

DA98E Series AC Servo Drive Unit User Manual

Speed control mode: Speed command is selected through

PA22 parameter (see PA22 for details);

③ Trial operation control mode; Speed commands are input

through a keyboard to test the drive unit and motor.

JOG control mode is known as inching mode. After entering

JOG operation, the motor runs at JOG speed when the ↑ key is

pressed and held, and stops and maintains at zero speed when

the key is released. The motor runs inversely at JOG speed when

the ↓ key is pressed and held, and stops and maintains at zero

speed when the key is released.

④ Encoder zeroing mode: It is used to set the encoder to zero

before shipping the motor.

Proportional

5

Integral time

constant of

6

gain of

speed

speed

① The parameter is used to set the proportional gain of the speed

ring adjuster.

② The bigger the setting is, the higher the gain and rigidity and

the smaller the speed overshooting during acceleration and

deceleration will be. The setting of the parameter depends on

the specific model number and load of the drive system. As a

general rule, the setting declines with the increase of load

inertia.

③ It shall be set as big as possible provided that the system

does not produce any disturbance.

① The parameter is used to set the integral time constant of the

speed ring adjuster.

② The smaller the setting is, the higher the integral speed and

rigidity will be. The setting of the parameter depends on the

specific model number and load of the servo drive system. As a

5 Hz

~2000Hz

ms~1000ms

34

general rule, the setting rises with the increase of load inertia.

③ It shall be set as small as possible provided that the system

does not produce any disturbance.

Page 44

Chapter 4 Parameters

7

Torque

command

filter

① It is used to limit the current command frequency band and

suppress the resonance caused by torque (the motor produces

sharp vibration noise) so that current response becomes

smooth.

② Reduce the parameter if the motor makes sharp vibration

noise;

③ The smaller the setting is, the lower the cut-off frequency, the

better the filtering effect and the lower the noise produced by

the motor will be. In case of high load inertia, it is possible to

appropriately reduce the setting. Excessively small setting may

slow down response and cause instability.

④ The bigger the setting is, the higher the cut-off frequency and

the faster the response will be. It is possible to appropriately to

increase the setting if relatively high mechanical rigidity is

required.

1%~500%

8

Proportional

Low pass

filter for

speed

detection

gain of

position

① The parameter is used to set the characteristics of the

low-pass filter for speed detection.

② The smaller the setting is, the lower the cut-off frequency, the

better the filtering effect and the lower the noise produced by

the motor will be. In case of high load inertia, it is possible to

appropriately reduce the setting. Excessively small setting may

1%~500%

slow down response, increase speed fluctuation and cause

disturbance.

③ The bigger the setting is, the higher the cut-off frequency and

the faster the response will be. It is possible to appropriately to

increase the setting if relatively high mechanical rigidity is

required.

① The parameter is used to set the proportional gain of the

position ring adjuster.

② The gain and rigidity increase with the setting. Under the same

frequency command pulse condition, the position lag becomes

9

1~1000 /s

less but excessive setting may cause disturbance or

overshooting.

③ The setting of the parameter depends on the version and load

of the servo drive system.

35

Page 45

DA98E Series AC Servo Drive Unit User Manual

Feedforward

10

frequency of

11

feedforward

gain of

position

Cut-off

positional

low-pass

① The parameter is used to set the feedforward gain of the

position ring.

② When it is set to 100%, it indicates that the position lag is

always 0 under the command pulse at any frequency.

③ When the feedforward gain of the position ring rises, the

high-speed response of the control system is improved but

this may lead to the instability of position ring of the system

and tend to cause disturbance.

④ The feedforward gain of the position ring is generally 0 unless

very high response characteristics are required.

① This parameter is used to set the cut-off frequency of the

low-pass filter for the position feedforward quantity.

② This filter is intended to improve the compound position

control.

0~100%

1 Hz

~1200Hz

Numerator of

countdown

12

filter

position

command

① This parameter is used to set the frequency division and

multiplication of command pulse (electronic gear).

② In position control mode, it is very easy to be adaptive to all

pulse sources by setting the PA12,PA13 parameter in order to

achieve the optimal control resolution (i.e. angle/pulse) of

user.

③

4××=×CNGP

P: Pulse number of input command;

G: Electronic gear ratio:

divisionfrequency of Numerator

=G

divisionfrequency of rDenominato

N: Number of rotations of motor;

C: Number of lines of photoelectric encoder/rotation, V2.03

incremental C=2500;

V3.01 with Tamagawa 17-bit absolute encoder C= 2

17

=

1~32767

36

131072

④ 〖Example〗 Calculation of the gear ratio for V2.03: When

the input command pulse is 6000, the servomotor rotates by

one turn

Page 46

Chapter 4 Parameters

×

×

×

5

××

CN

=

G

Then Parameter PA12 is set to 5 and PA13 to 3.

⑤ Calculation of the gear ratio for V3.01: When the input

command pulse is 6000, the servomotor rotates by one turn

=

P

6000

4250014

=

3

Denominator

13

15

16

of position

command

countdown

Reversal of

position

command

countdown

Positioning

range

××

CN

=

G

P

① See Parameter PA12. 1~32767

① It is set to

0: Normal; or

1: Reverse pulse direction of position command

① This parameter is used to set the range of positioning pulse

under position control.

② This parameter provides the basis for the drive unit to judge

whether positioning is completed in position control mode.

When the remaining pulse number in the position deviation

counter is less than or equal to the setting of the parameter,

the drive unit unit considers that the positioning has been

13107214

=

6000

=

8192

375

0~1

0~30,000

pulses

out-of-tolera

17

nce detection

and invalid

18

position out-

of-tolerance

Range of

position

Erroneous

completed. The positioning completion signal is COIN ON.

Otherwise it is COIN OFF.

③ The output positioning completion signal is COIN in the

position control mode and the output speed reaching signal

SCMP.

① This parameter is used to set the range of position

out-of-tolerance alarm detection

② In the position control mode, the servo drive unit gives a

position out-of-tolerance alarm when the count value of the

position deviation counter goes beyond the setting of this

parameter.

① 0: The position out-of-tolerance alarm detection is enabled.

1: The position out-of-tolerance alarm detection is disabled.

0~30000

×100 pulses

0~1

37

Page 47

DA98E Series AC Servo Drive Unit User Manual

19

Position

command

smoothing

filter

Invalid drive

① Command pulses are smoothed. The acceleration and

deceleration are in exponential form. The numerical value

indicates a time constant.

② The filter is not subject to loss of input pulse but command

delay.

③ The filter is used when

z A host controller has no acceleration and deceleration

functions;

z The frequency division and multiplication of the electronic

gear are high (>10);

z The command frequency is low;

z The motor is subject to step leaping and instability during

operation;

④ When it is set to 0, the filter does not work.

① 0: CCW and CW input disabling is active. When the CCW

0~30000×0.1

(ms)

20

21

disabling

input

Speed of

JOG

operation

Selection of

drive disabling switch (FSTP) is turned ON, CCW drive is

allowed. When the CCW drive disabling switch (FSTP) is

turned OFF, the torque in CCW direction is 0. The same

goes for CW.

If both CCW and CW drive disabling switches are turned off,

a drive disabling input error alarm will be given.

1: CCW and CW input disabling is deactivated. CCW and

CW drives are allowed irrespective of the state of CCW and

CW drive disabling switches. At the same time, a drive

disabling input error alarm will not be given if both CCW and

CW drive disabling switches are turned off.

① This parameter is used to set the running speed of JOB

operation.

① When it is set to 0, the speed command is bus entry;

0~1

-3000 rpm

~3000rpm

38

22

23

internal and

external

commands

Limitation of

maximum

② When it is set to 1, the speed command is Internal speed 1;

③ When it is set to 2, the speed command is Internal speed 2;

④ When it is set to 3, the speed command is Internal speed 3;

⑤ When it is set to 4, the speed command is Internal speed 4;

① It is used to set the upper speed limit of the servomotor.

② It is independent of direction of rotation.

0~4

0 rpm ~

3000 rpm

Page 48

Chapter 4 Parameters

24

25

26

27

28

speed

Internal

speed 1

Internal

speed 2

Internal

speed 3

Internal

speed 4

Arriving

speed

③ If the setting goes beyond the rated rotating speed, the actual

maximum speed limit the rated rotating speed.

① This parameter is used to set Internal speed 1

② See PA22.

① This parameter is used to set Internal speed 2

② See PA22.

① This parameter is used to set Internal speed 3

② See PA22.

① This parameter is used to set Internal speed 4

② See PA22.

① It is used to set the arriving speed.

② In a non-position control mode, it is set to SCMP ON if the

motor speed exceeds the setting. Otherwise it is set to SCMP

OFF.

③ This parameter is not used in position control mode.

-3000 rpm

~3000 rpm

-3000 rpm

~3000 rpm

-3000 rpm

~3000 rpm

-3000 rpm

~3000 rpm

0 ms ~

3000rpm

29

Contracting

brake

release

signal delay

④ It is independent of direction of rotation.

⑤ The comparator has lagging characteristics.

① When the drive unit is enabled (SON is ON), the contracting

brake release signal will delay the output by following the