Page 1

DA98D Digital AC Servo Drive Unit

User Manual

(V5.00)

Page 2

In this User manual, we will exert ourselves to describe each item related

to operation of this drive unit. But due to reasons like limit in space and

specific product uses, detailed description of unnecessary or impossible

operation of this drive unit will be not included. Therefore, items that are

not specially indicated in this manual will all be regarded as “impossible”

or “disallowed” operations.

Copyright of this manual belongs to GSK Equipment Co., Ltd, and any

publication or copying of this manual by any unit or individual will be

deemed as illegal behaviors. GSK Equipment Co., Ltd shall reserve the

rights to ascertain legal liabilities of such behaviors.

1

Page 3

Company Profile

Currently, GSK Equipment Co., Ltd (hereafter GSK for short) is a China's

company with the domestically largest sale volumes of digital control systems.

As the digital control industry base in Southern China and one of the 20

manufacturers of key equipment in Guangzhou, GSK is an undertaker of key

projects listed in State 863 Supporting Technology for Middle-Grade Digital

Control Industrialization. For more than a decade, the company has been

dedicated to professional research & development, designing and

manufacturing of such products as digital control systems for machine tools,

digital control devices, drive units and servo motors. By launching campaign on

popularization of digital control machine tools and developing trade in digital

control machine tool, the company has developed into a large hi-tech company

that integrates science, education, industry and trade into itself. Currently the

company has more than 1,400 employees, among whom there are 4 doctors,

more than 50 masters and over 500 engineering technicians (more than 50

technicians with senior professional titles). With a superior cost performance,

GSK series of products have a very good sale in China and far in Southeastern

Asia. Between 2000 and 2006, its market share has ranked No.1 in China for 7

consecutive years and its yield and sale volumes have led the peers for 7

consecutive years, which have consolidated its position as the biggest

domestic production base of digital control system for machine tools.

Our main products include digital control equipment and devices like GSK

series of machine tools, milling machine and digital control system for

processing centers as well as Da98, DA98A, DA98B and DA98D series of full

digital AC servo drive units, DY3 series of hybrid stepper motor driver, DF3

series of reaction stepper motor driver, GSK·SJT series of AC servo motors

and CT-L digital control slipway. All the products follow state standards

(international standards), industry standards and supplementary company

standards (or internal control standards) in an all-round way. With powerful

strength in technology development and improved production and quality

assurance system, GSK has satisfied requirements of vast number of its

customers with stable and reliable product quality. Its improved and sound

II

Page 4

service mechanisms as well as the more than ten service offices set up in

domestic and foreign provinces and cities can guarantee swift and convenient

technical support and services within 24 to 48 hours. “Excellent products and

outstanding services” have built a brilliant GSK. Abiding by the operation

concept of “creating century-old company and molding gold brand”, GSK

people will make unrelenting efforts to build a digital control industry base in

Southern China and push forward national digital control industry.

Field Technical Support Services

If you have problems that cannot be resolved through phone calls, you can

receive our technical support on the spot. GSK will authorize technical support

engineer to the field to resolve your technical problems.

III

Page 5

Foreword

Foreword

Distinguished Customers,

It is a great honor for us to have you buy DA98D full digital AC servo drive units

of GSK Equipment Co., Ltd.

This manual will introduce requirements and notes about operation of DA98D

full digital AC servo drive unit.

! Improper operation will cause accidents, and the drive unit must be

operated by personnel with related qualifications

Please see to it that you have carefully read the manual prior to operation!

If there are changes to specifications and designs, we will not provide further

notices.

Sincere thanks to your friendly support for using products of GSK Equipment Co., Ltd.!

Chinese version of all technical documents in Chinese and English languages is

regarded as final.

IV

Page 6

Foreword

● Due to improvement in products, contents of this manual will have some changes, for

which we will not provide further notices.

● We will not be held accountable for any change made by the customer on the product

and the warranty form will hereby go invalid.

Please give special attention to the following warning sings when reading the manual!

Warning

Attention

Attention

Wrong operation may lead to disastrous consequences---death

or serious injury

Wrong operation may hurt the operator and the equipment may

also be damaged!

Improper operation may damage the product and equipment!

V

Page 7

Safety Warning

Safety Warning

● The product is not designed and manufactured to be used in machines or systems

threatening personal safety.

● When selecting the product, the customers shall consider safety protection measures when

designing and manufacturing their machines and systems, so as to avoid improper

operation or irregular accidents of the product.

Acceptance

● Damaged or broken-down products shall not be put into use.

Transportation

Warning

Attention

Attention

● Products must be stored and transported under conditions for storage and transportation.

● Over-height piling shall not be allowed to prevent products from falling.

● When being transferred, the products concerned shall be properly packed.

● The servo motor shall not be moved by drawing its wire, motor shaft or encoder.

● Outside force and impact shall not be imposed on servo drive units and servo motors.

Installment

Servo drive units and servo motors:

● Shall not be installed above or around combustible articles to prevent fire disaster.

● Shall avoid vibration. Impact shall be strictly forbidden.

● Shall not be installed when they are damaged or the parts are incomplete

Servo Drive unit:

● Must be installed in the control panel with sufficient degree of protection.

● Must keep sufficient intervals away from other equipment.

● Must have good conditions for heat emitting.

● Must prevent invasion of dust, corrosive air, conductive matters, liquid, combustible and

explosive substances.

Servo motors:

● Must be firmly installed to prevent loosening under vibration

● Must prevent motor and encoder from being damaged by the invaded liquids

● Shock on motor and motor shaft shall be strictly forbidden to prevent the encoder from

being damaged.

● Load surpassing its limit shall not be imposed on the motor shaft.

Attention

VI

Page 8

Safety Warning

Wiring

● Personnel involved in wiring or examination must possess sufficient competence in this

task.

● Wiring and examination must be conducted 5 minutes after the power is switched off.

● Servo drive units and servo motors must have good ground contact.

● Wrong voltage or electrode may cause explosion or operation accidents.

● Only after the servo drive unit and servo motor are properly installed can the wiring be

conducted.

● Ensure insulation of the wire and avoid pressing the wire to prevent electric shock.

● Wires must be connected in a correct and firm manner, otherwise, the servo motor may run

by error or the equipment may be damaged due to bad contact.

● Terminals of U, V and W in servo motor shall not be connected reversely, nor be connected

to AC power.

● Servo motor and servo drive unit must be directly connected and they shall not be

connected with capacitor, inductor or wave filter.

● Prevent conductive fastening elements and wire heads from entering in the servo drive unit.

● The wire and substances not resistant to heat shall not close up to the servo drive unit’s

radiator and servo motor.

● Continuous current diode connected in parallel to the DC relay for output signals shall not

be connected reversely.

Attention

Attention

Commissioning and Runing

Attention

● Confirm that the servo drive unit and servo motor have been properly and firmly installed

and that the power voltage and wiring are correct before switching on power.

● When commissioning, first run the servo motor without load; and after confirming that the

parameters are correctly set, run the servo motor with load. In this process, improper

operation shall be avoided to prevent the machine and equipment from being damaged.

Operation

● An emergency stop circuit shall be coupled in to ensure that the equipment can

immediately stop by timely switching off power in case of accidents.

● Confirm that the operation signal has been cut off before resetting an alarming signal;

otherwise, the signal will be restarted suddenly.

● Servo drive unit must be operated together with its matched set of servo motor.

● Do not frequently switch off or on power of the servo drive unit to prevent the system from

being damaged.

● The servo drive unit and servo motor may be very hot after long hours of operation, so do

Attention

Ⅶ

Page 9

Safety Warning

not touch the servo drive unit’s radiator or the servo motor with your hand within a short

time after the power is off.

● Do not refit the servo drive unit.

Failure Handling

● Even after the power of servo drive unit has been cut off, the voltage will remain for some

time. So do not dismantle the wire or touch the plate of terminals.

● Personnel involved in dismantlement and repair must possess corresponding professional

knowledge and working capacity.

● In case of alarming, the trouble must be shot. Before restarting the machine, the alarming

signal shall be reset.

● Keep away from the machine when re-switching on the power after instantaneous power

failure, for the machine may be restarted suddenly (when designing the machine, make

sure that there will be no danger when restarting the machine).

System Selecting and Matching

Attention

Attention

Attention

● Rated torque of the servo motor shall be greater than the valid continuous load torque.

● The ratio of load inertia to servo motor inertia shall be less than the recommended value.

● When selecting servo drive unit and servo motor, they shall be matched with each other.

Ⅷ

Page 10

DA98D User manual

Table of Contents

Chapter One Overview........................................................................................................1

1.1 Product Introduction.............................................................................................................. 1

1.2 Arrival Examination ................................................................................................................ 2

1.3 Product Appearance .............................................................................................................. 3

Chapter Two Installment.....................................................................................................6

2.1 Environmental Conditions.................................................................................................... 6

2.2 Installment of Servo Drive unit............................................................................................ 6

2.3 Installment of Servo Motor................................................................................................... 9

Chapter Three Wiring.........................................................................................................10

3.1 Standard Wiring..................................................................................................................... 10

3.2 Functions of Terminals........................................................................................................ 14

3.3 I/O Interface Principle .......................................................................................................... 19

Chapter Four Parameters.................................................................................................25

4.1 Checklist of Parameters...................................................................................................... 25

4.2 Functions of Parameters..................................................................................................... 27

4.3 List for comparison of Modle Codes & Parameters and Motor ................................ 34

Chapter Five Alarming and Handling............................................................................35

5.1 List of Alarms......................................................................................................................... 35

5.2 Methods for Handling Alarms............................................................................................ 36

Chapter Six Display and Operation ...............................................................................40

6.1 Keyboard Operation............................................................................................................. 40

6.2 Ways of Monitoring .............................................................................................................. 41

6.3 Parameter Setting ................................................................................................................. 43

6.4 Parameter Management ...................................................................................................... 44

6.5 Speed Trial Operation.......................................................................................................... 45

6.6 JOG Operation....................................................................................................................... 46

6.7 Others ......................................................................................................................................46

Chapter Seven Operation by Switching on Power....................................................47

7.1 Power Supply Connecting.................................................................................................. 47

7.2 Trial Operation....................................................................................................................... 49

7.3 Adjustment ............................................................................................................................. 51

Chapter Eight Product Specifications ..........................................................................53

8.1 Driver Specifications............................................................................................................ 53

8.2 Servo Motor Specifications................................................................................................ 54

8.3 Isolating Transformer .......................................................................................................... 59

1

Page 11

DA98D User manual

Chapter Nine Order Instructions....................................................................................65

9.1 Capacity Selecting................................................................................................................ 65

9.2 Electronic Gear Ratio........................................................................................................... 65

9.3 Stop Features......................................................................................................................... 66

9.4 Calculation Method for Selecting Models of Servo System and Position

Controller....................................................................................................................................... 66

2

Page 12

DA98D User Manual

Chapter One Overview

1.1 Product Introduction

The AC servo technology has undergone a rapid development since the beginning of 1990s,

during which period this technology has been increasingly mature and its performance has been

constantly improved. Now this technology has been widely applied to such automatic fields as

CNC machine tools, printing and packing machines, textile machinery and automatic production

lines.

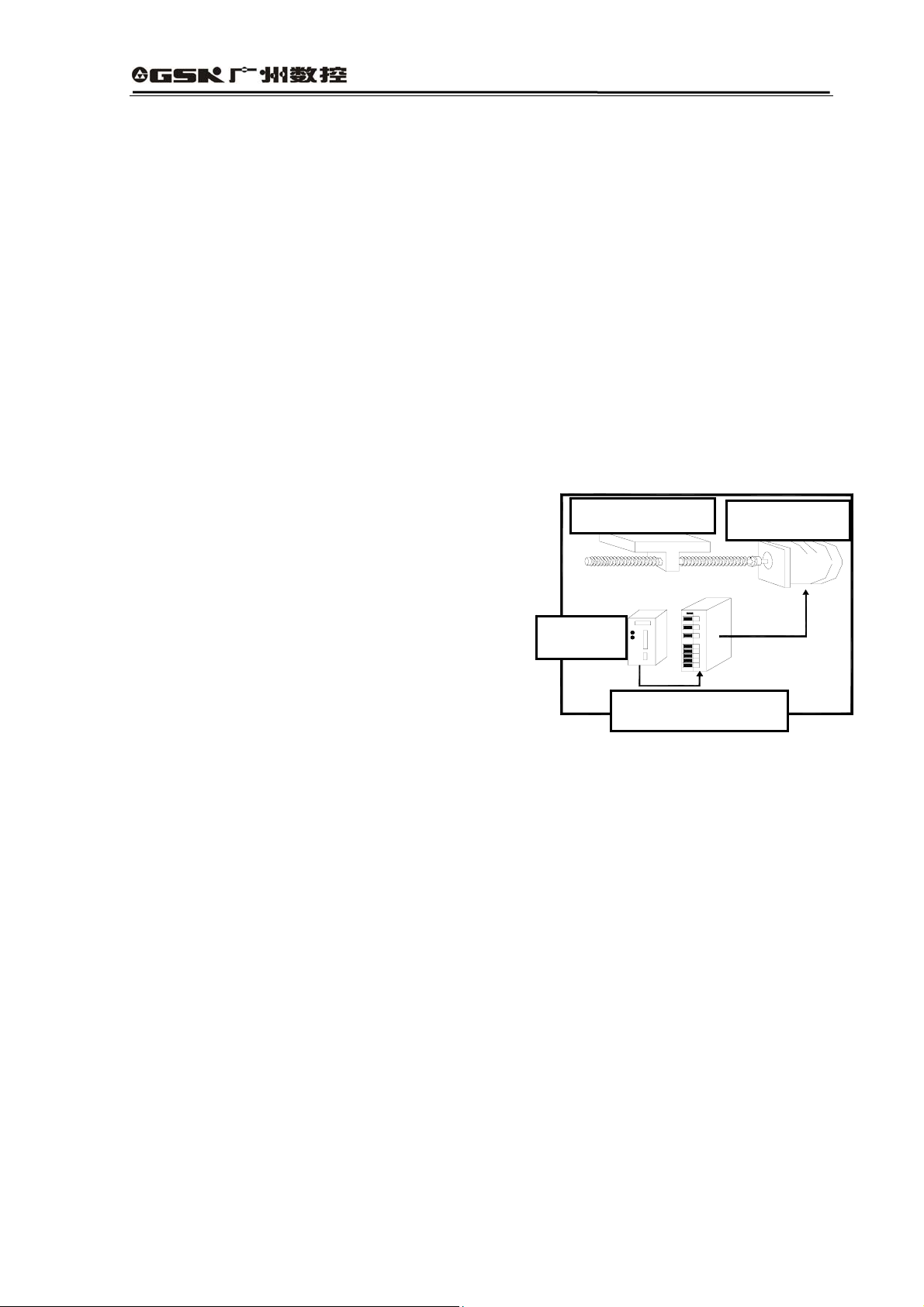

DA98D AC servo drive unit (all called full digital AC servo drive device) is a new generation of

full digital AC servo drive unit produced by our company. This product includes two control modes

of speed and position. It can be matched with various open-loop and closed-loop control systems

and has been widely applied to CNC machine tools and

automatization industry. Internationally advanced

special-purpose chip for motor control

(TMS320LF2407A DSP), complex programmable logic

display (CPLD) and MITSUBISHI intelligent power

module (IPM) are adopted inside the servo, so it has

such advantages as high degree of integration,

compact, perfect protection and good reliability. The

optimal PID is employed to achieve PWM control.

Performance of this product has reached

internationally advanced level among its peers at home

and aboard.

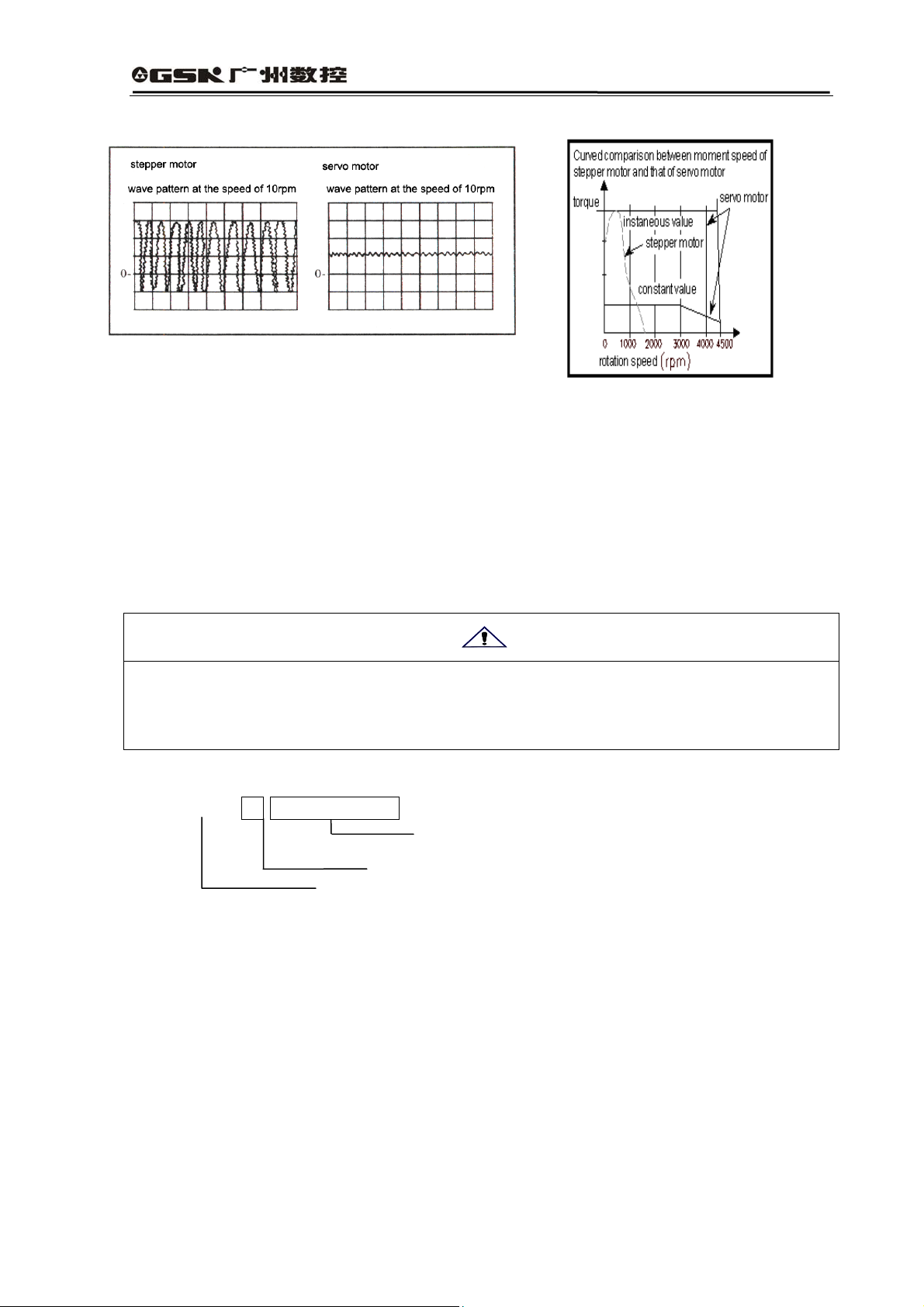

Compared with stepper drive, DA98D AC servo unit has the following strong points:

z Avoid out-of-Synchronization Phenomena

Servo motor has encoder on itself and the position signal will be fed back to the servo drive

unit, forming a semi-closed loop system together with the open-loop position controller.

z Wide speed ratio and constant torque

Speed ration is 1:5000, with stable torque characteristics from low speed to high speed.

z High speed and precision

The maximal rotation rate of servo motor can reach 3000r/min, with a rotary positioning

precision 1/10000r.

Notes: maximal rotatation rate is not the same with different models of servo motor.

z Easy and flexible control

Through parameter changing, working methods and characteristics of the servo drive unit

can be properly set to comply with different requirements.

open-loop control

controller

positioning command

stepper motor

1

Page 13

DA98D User Manual

1.2 Arrival Examination

1) After the product arrives, please see to examine the following aspects:

(1) Whether the packing case is in good conditions, and whether the product is damaged

during transportation?

(2) Check nameplates of the servo drive unit and servo motor to confirm whether the

products received comply with the order.

(3) Check packing list to confirm whether the accessories are complete.

Attention

z Servo system shall not be installed when it is damaged or does not have complete parts.

z Servo drive unit must be used together with the servo motor whose performance matches

that of the former.

z If there is any doubt about the products received, please contact supplier or us.

2) Model meaning:

a) Models of servo drive unit

DA98D-06-110SJT-M020E

Model matching servo motor (indicate GSK SJT series) 1※

Output power: two-digit (04, 06……23) correspond to 0.4~2.3KW 2※

Series Code

※1: It can be matched with other domestic or imported servo motor. If there is no parameter in

the drive unit, it can only be matched with SJT and ST series of servo motors.

※2: Small power (1.5KW or less) means standard configuration; medium power (more than

1.5KW but less than 1.6KW) means thicker radiator.

Notes: when the product is delivered from the factory, the product model has been

completed in the above column. Please check them with the product

nameplate.

b) Models of servo motor

DA98D AC servo drive unit can be matched with many domestic or exported servo motors,

which is at your option. Chapter Eight of this manual will provide information about SJT

2

Page 14

DA98D User Manual

series of servo motor from GSK and ST series of servo motor from New Motor Company of

Huazhong University. Information about other models will be provided with the servo motor

delivered.

2) Accessories

a) Standard Accessories of DA98D servo drive unit

① User Manual (this manual) 1

M4×8 countersunk head screws 4

②

③ CN1 Plug (DB44 female) 1 (note 1)

④ CN2 Plug (DB25 male) 1 (note 2)

Note 1: For matching our position controller, it will be provided together with the

signal cable, whose standard length is 3 meters.

Note 2: when we provide servo motor, you can ask us to provide its matching

feedback cable, whose standard length is 3 meters.

b) Standard accessories of servo motor will be provided according to user

instructions.

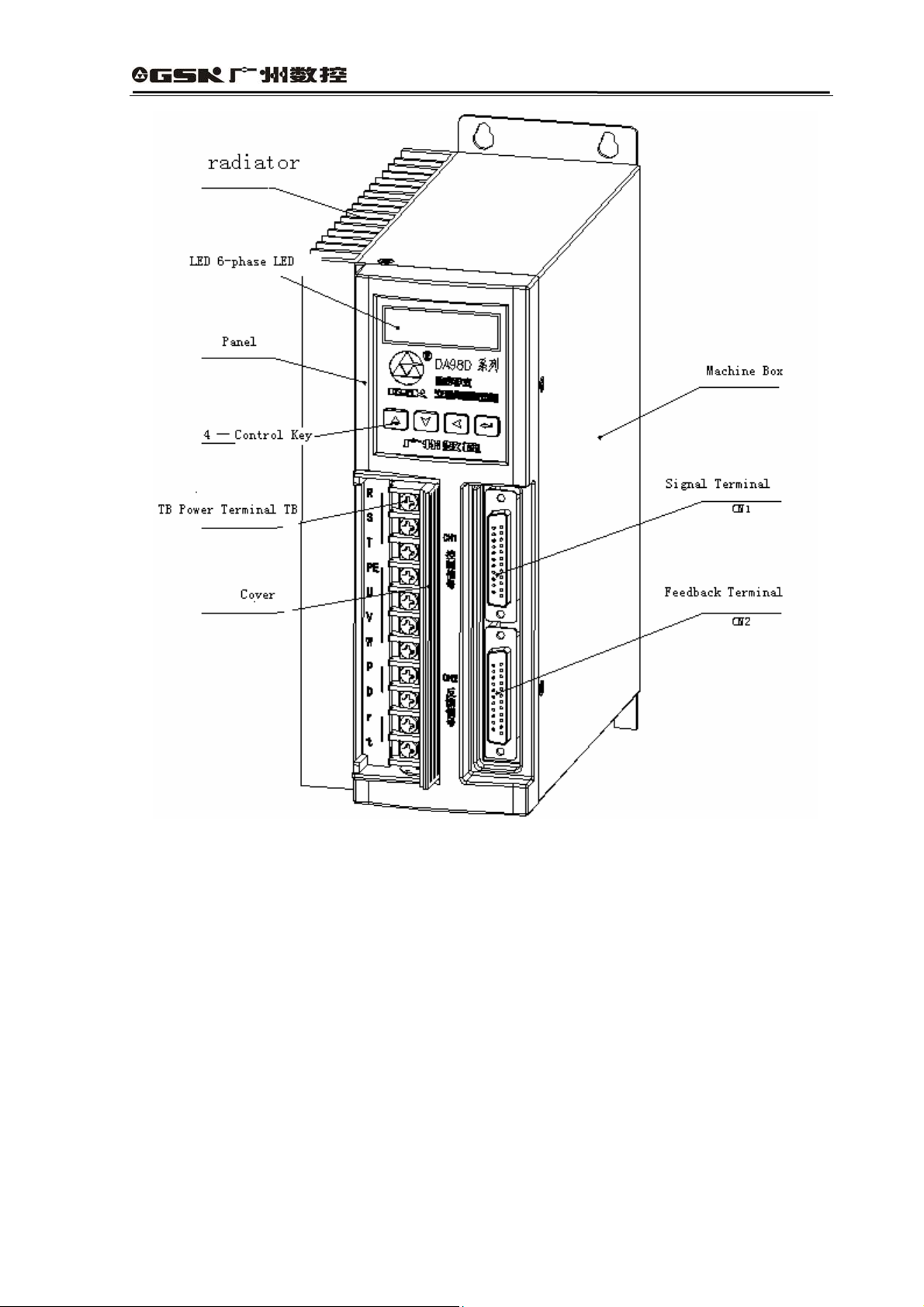

1.3 Product Appearance

1) Appearance of servo drive unit

3

Page 15

DA98D User Manual

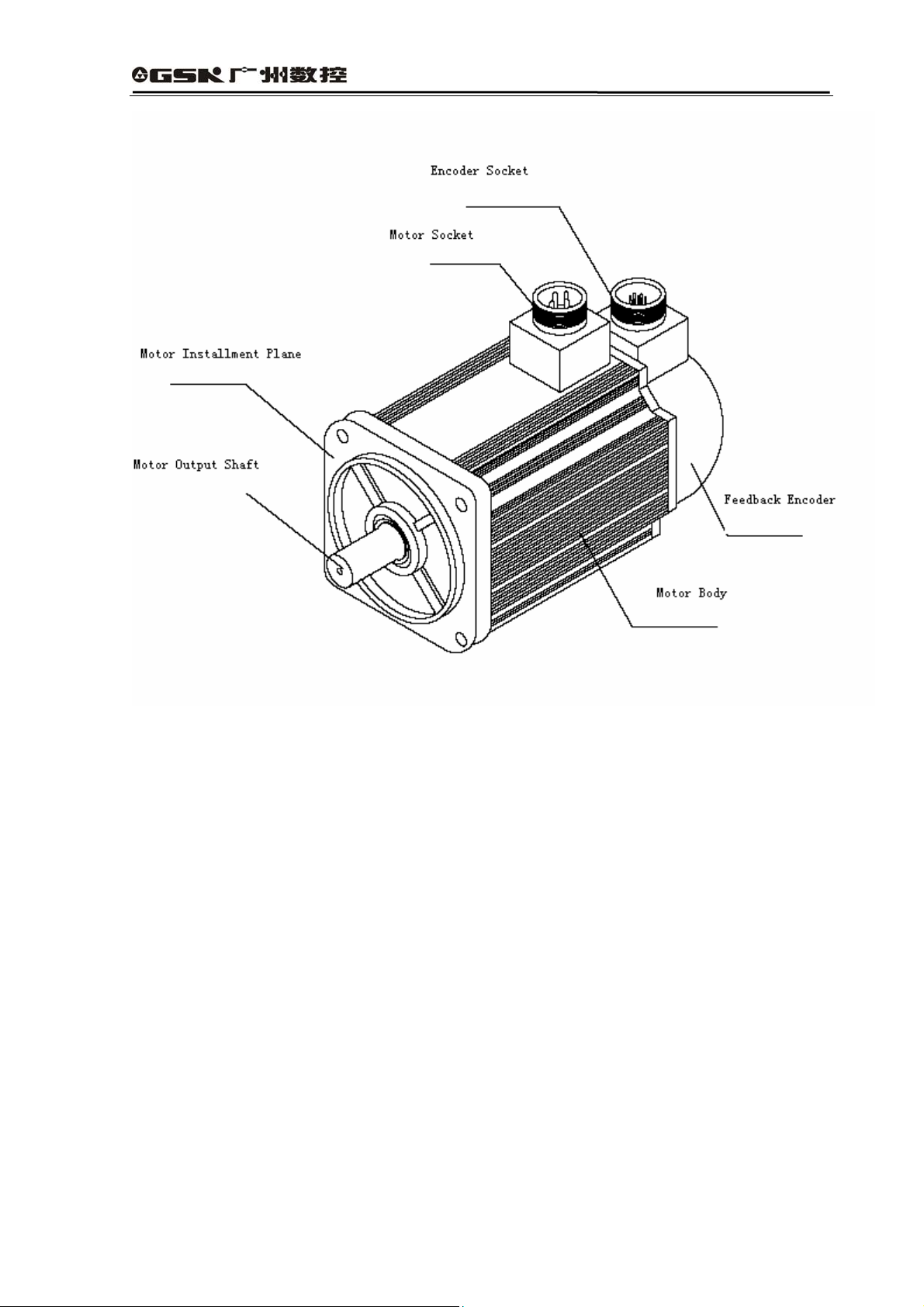

2) Servo motor appearance

Fig. 1-1 Appearance of Servo Drive unit

4

Page 16

DA98D User Manual

Fig. 1-2 Servo Motor Appearance

5

Page 17

DA98D User Manual

Chapter Two Installment

z The products must be stored and installed according to the requirements for environmental

conditions.

z The products can be piled up with a limited number; over-piling shall not be allowed to

prevent the products from being damaged or falling.

z The products must be stored and transported with original package.

z Product shall not be installed when it is damaged or does not have complete parts.

z Fireproof material is needed for the product installment; the product shall not be installed

above or around combustible article to prevent fire.

z Servo drive unit must be installed within electric cabinet to prevent invasion of dust, corrosive

air, conductive matters, liquid, combustible and explosive substances.

z Servo drive unit and servo motor shall avoid vibration. Impact shall be strictly forbidden.

z It is forbidden to draw wire, motor shaft and encoder of the servo motor.

Attention

2.1 Environmental Conditions

Items DA98DServo Drive unit GSK SJT Series of AC Servo Motor

Operation

Temperature/

Humidity

Storage

Temperature/

Humidity

Atmospheric

Environment

Height

0℃~55℃ (no frozen frost)

Less than 90%RH (no dew

condensation)

-20℃~80℃

90%RH(no dew)

Within the control panel, there

shall be not corrosive air,

combustible air, oil fog or dust.

Less than 1000m above sea

level

-10℃~40 (℃ no frozen frost))

90%RH (no dew condensation)

-40℃~55℃

85%RH ( no dew)

Within the room (no insolation), there shall be

not corrosive air, combustible air, oil fog and

dust.

Less than 1000m above sea level

Vibration Less than 0.5G(4.9m/s2)10 Hz -60Hz (non-continuous operation)

Degree of

Protection

IP00 IP54

2.2 Installment of Servo Drive unit

z Servo drive unit must be installed in the electric cabinet with good protection.

z Servo drive unit must be installed according to direction and interval as stipulated. Good

conditions for heat radiating should be guaranteed.

z It shall not be installed above or around combustible articles to prevent fire.

1) Installment Environment

(1) Protection

Attention

6

Page 18

DA98D User Manual

The servo driver does not have any protection within its own structure, so it must be

installed within the electric cabinet with good protection and prevented from contact of

corrosive and combustible air. Conductive matters, metal dust, oil fog or liquid shall be

prevented from entering inside.

(2) Temperature and Humidity

The environmental temperature shall be kept between 0 and 50 , while temperature for ℃℃

long-term safety operation shall be kept below 45 . Good conditions for heat radiating ℃

shall be guaranteed.

(3) Vibration and Impact

When installing the drive unit, vibration shall be avoided. Vibration reduction measures shall

be taken to control the vibration below 0.5G (4.9m/S2).

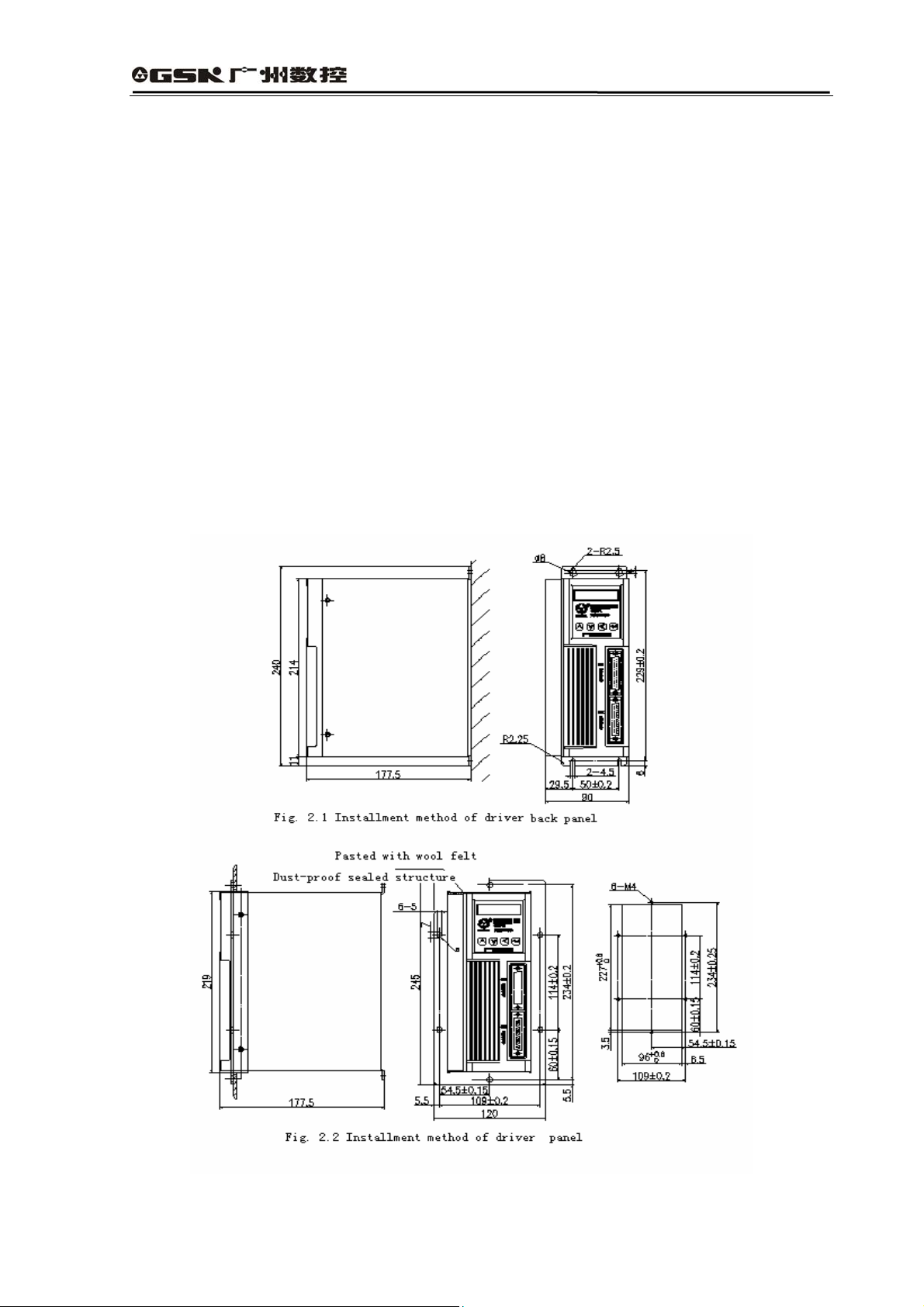

2) Installment Methods

(1) Ways of Installment

The user can adopt the ways of installment by back panel or panel. The installment shall form

an upward right angle with the installment plane. Fig. 2.1 is a schematic diagram for

installment by back panel and Fig. 2.2 is a schematic diagram for installment by panel.

7

Page 19

DA98D User Manual

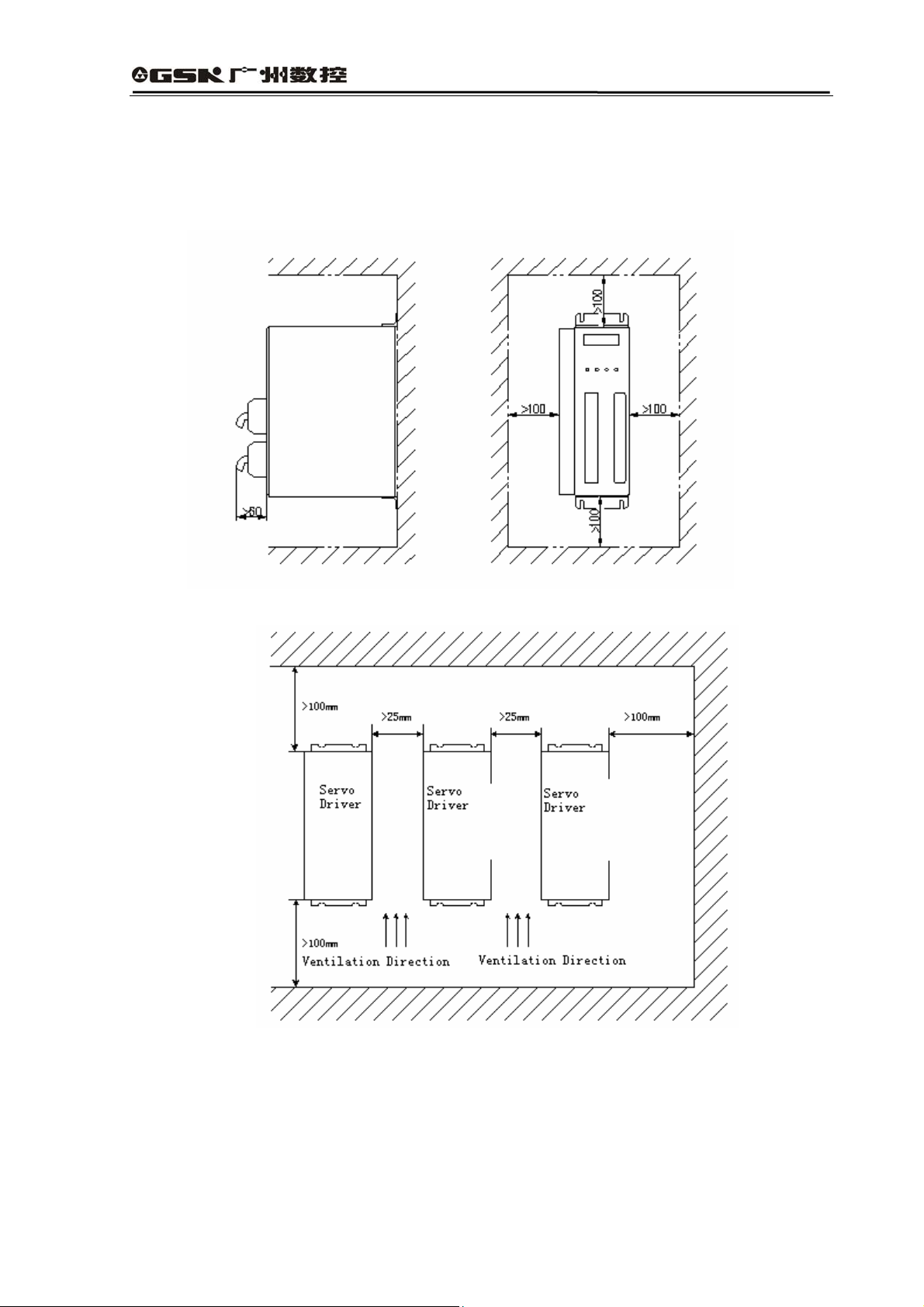

(2) Installment Interval

Fig. 2.3 shows the installment interval for single drive unit and Fig. 2.4 shows the installment

interval for multiple drive units. In actual installment, the interval shall be as great as possible

to ensure good conditions for heat radiating.

Fig. 2.3 Installment for Single Drive unit

Fig. 2.4 Installment Interval for Multiple Drive units

(3) Heat Radiating

To ensure that surrounding temperature of the drive unit will not be constantly increased,

there shall be convective-current wind blowing towards radiator of the drive unit within the

electric cabinet.

8

Page 20

DA98D User Manual

2.3 Installment of Servo Motor

z Shock on the motor shaft or encoder shall be forbidden to prevent the motor from vibration or

impact.

z The motor shall not be moved by drawing motor shaft, leading-out wire or encoder.

z Load on the motor shaft shall not surpass its limit; otherwise, the motor may be damaged.

z The motor must be firmly installed with anti-loosening measures.

1) Installment Environment

(1) Protection

Currently, GSK SJT series and Huazhong Series of servo motor are not water

resistant, so liquid must not be spattered on the motor during installment. Oil or

water must be prevented from entering inside the motor through leading-out wire or

the motor shaft.

Attention

Notes: if the user needs water-resistant servo motor, please make a clear

indication in the order.

(2) Temperature and Humidity

The environmental temperature shall be kept between -10 and 40 . After long ℃℃

hours of operation, the motor will have an increasingly hot temperature, so

compulsory heat radiating shall be considered when the surrounding space is

relatively small or there are heating equipment.

The humidity shall not be more than 90%RH, without dew condensation.

(3) Vibration

Servo motor shall not be installed at places with vibration. The vibration inflicted on

the motor shall not be more than 0.5G (4.9m/s

2) Installment Methods

Ways of Installment

(1)

Currently, SJT and ST series of motors adopt the way of installment by the flange with

arbitrary installment direction.

(2) Notes:

2

).

z When dismantling or installing the belts and wheels, shock on the motor or motor

shaft shall be forbidden to prevent the encoder from being damaged. Screw

pressing tools shall be employed in the dismantlement or installment.

z Currently, most of the SJT and ST series of motors cannot bear shaft-direction or

radial-direction loads. Coupling is recommended for connecting the loads.

z When fastening the motor, the anti-loosening washer shall be used to prevent the

motor from loosening.

9

Page 21

DA98D User Manual

c

e

Chapter Three Wiring

Warning

●Personnel involved in wiring or examination must possess sufficient abilities in this task.

●Wiring and examination must be conducted 5 minutes after the power is off for preventing electri

shock.

●The wires must be connected according to terminal voltage and electrode to prevent th

equipment from being damaged or personnel from being hurt.

● The drive unit and servo motor must have good ground contact.

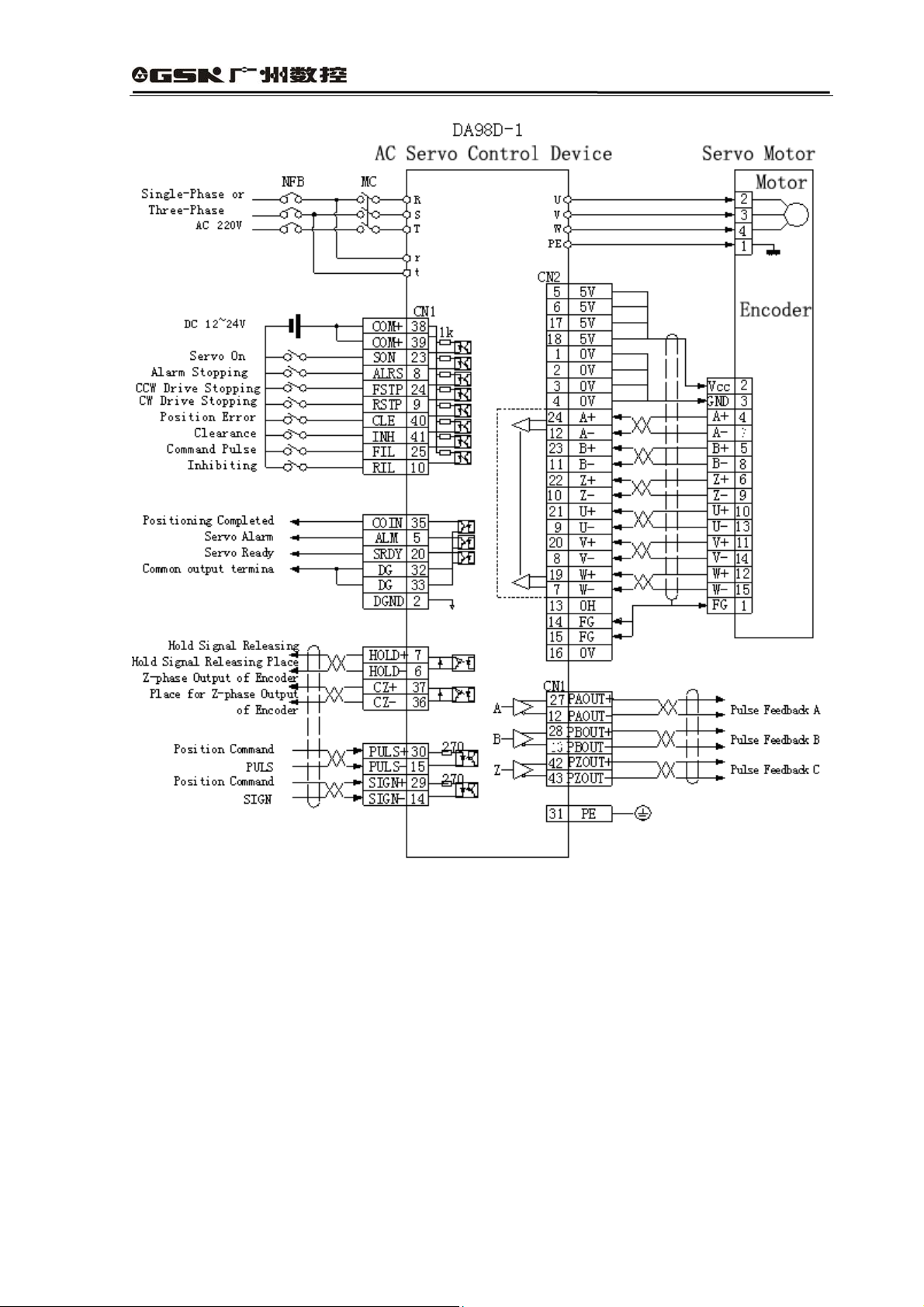

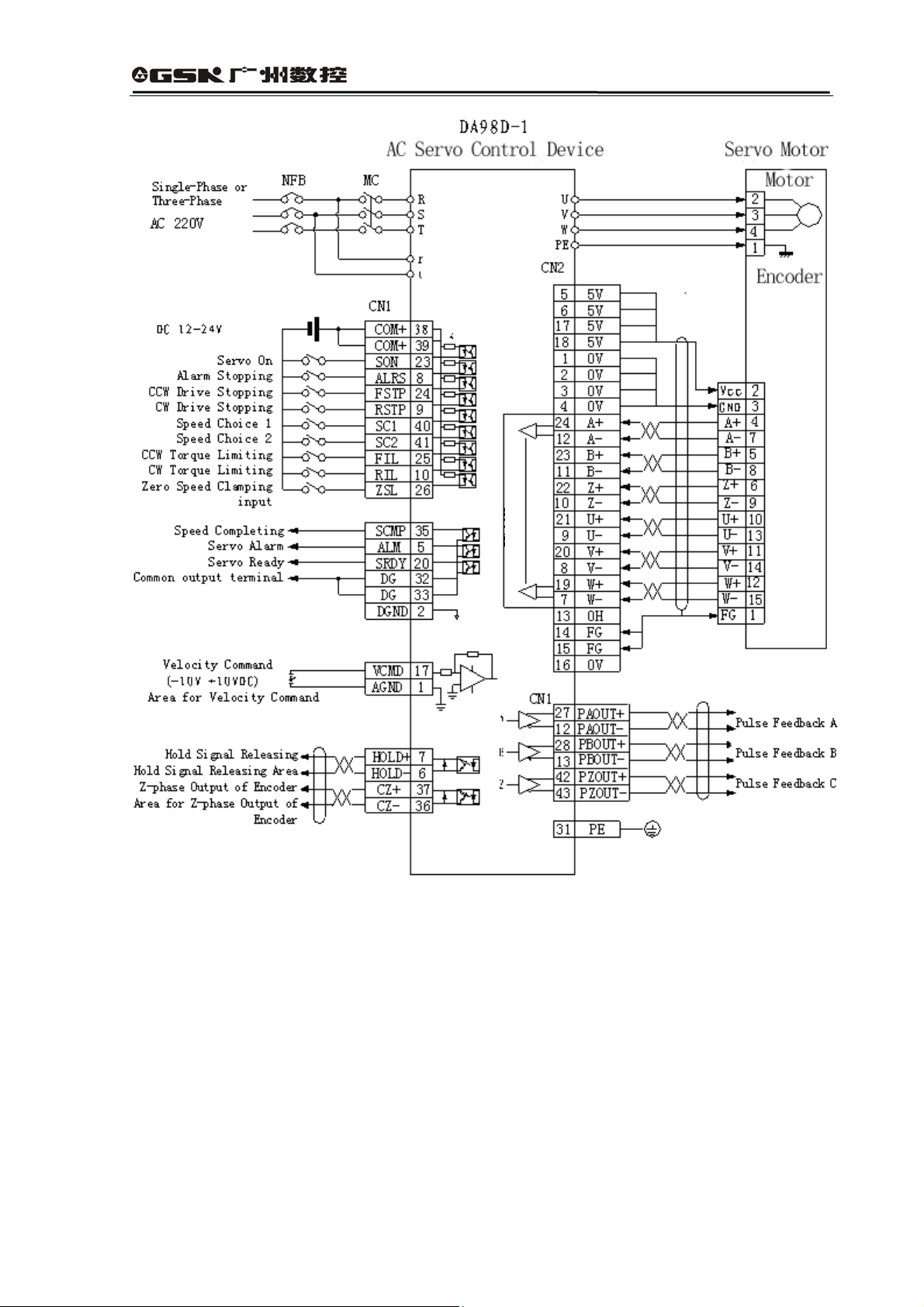

3.1 Standard Wiring

External connection of the drive unit is related to the control modes.

1) Position Control Mode

Fig. 3.1 shows standard wiring for the position control mode.

2) Speed Control Mode:

Fig. 3.2 shows the standard wiring for the speed control mode.

3) Wire Distributing

(1) Power Terminal TB

z Wire cross-sectional area: Terminals of R, S, T, PE, U, V and W have an area

2

1.5mm

(AWG16-18) and more.

z Grounding: the grounding wire shall be as thick as possible. The servo driver and

motor has ground contact at the point of PE terminal with a grounding resistance

less than 100Ω.

z Terminal connection adopts SVM2-4 pre-insulation cold pressing terminal. The

connection must be fastened.

z It is recommended to supply power with three-phase isolating transformer, which

will reduce the possibility of electric shock.

z It is recommended that the power supply gives power through noise filter for

enhancing anti-jamming ability.

z Please install non-fuse breaker (NFB) in order to cut off external power supply

when the driver breaks down.

(2) CN2Contrl Signal CN1 and Feedback Signal CN2

z Wire material selecting: employ shielding cable (best with inter-twisted shielding

cable), the cross-section area of the core shall be 0.12mm

The shielding layer shall be connected with FG terminal.

z Wire and cable length: wire and cable shall be as short as possible; control signal

CN1 shall not be longer than 3 meters while the feedback signal CN2 cable shall not

be longer than 20 meters.

z Wire laying: Wire shall be laid far away from the power circuit to prevent jamming.

(AWG14-16) and more while terminals of r and t have an area 1.0 mm2

Attention

2

(AWG24-26) and more.

10

Page 22

DA98D User Manual

e

e

a

5

z Please install surge absorbing elements in sensible elements (loop) in related

circuits: DC loop is reversely connected in parallel with continuous current diode

while AC loop is connected in parallel with capacitance-resistance absorbing return

circuit.

Attention

U, V and W shall be connected with motor winding in the way of one-to-one correspondence. Revers

connecting shall be forbidden.

The wires and leads shall be fastened firmly and avoid approaching radiator of the drive unit and th

motor for the fear that the insulation performance will be reduced due to heat.

There will remain large quantities of electrolyzed capacitance in the servo drive unit, so there will

high remaining voltage even after the power is cut off. Do not touch drive unit or motor within

minutes after the power is off!

11

Page 23

DA98D User Manual

AM26LS32 Receiver

Fig. 3.1 Standard Wiring for Position Control Mode

12

Page 24

DA98D User Manual

AM26LS32 Receiver

Fig. 3.2 Standard Wiring for Speed Control Mode

13

Page 25

DA98D User Manual

3.2 Functions of Terminals

1) Configuration of Terminal

Fig. 3.3 is a configuration chart for interface terminals of the servo drive unit. TB is the plate

of terminals; CN1 is for connector of DB44 with male socket and female plug; CN2 is also

for connector of DB28 with female socket and male plug.

14

Page 26

T

R

S

T

PE

U

W

t

DA98D User Manual

B

V

P

D

r

CN2

13

12

11

25

24

23

10

22

19

6

18

17

15

14

1

9

21

8

20

7

5

4

16

3

2

MHP

NC

AA+

B-

B+

Z-

Z+

U-

U+

VV+

WW+

+5V

+5V

+5V

+5V

0V

0V

0V

FG

0V

FG

0V

DB25

Fig. 3.3 Configuration Chart for Interface Terminals of Servo Drive unit

2) Power Terminal TB

Table 3.1 Power Terminal TB

Terminal

No.

TB-1 R

TB-2 S

TB-3 T

TB-4 PE

TB-5 U

TB-6 V

TB-7 W

TB-8 P Back up

TB-9 D Back up

TB-10 r

TB-11 T

Terminal

Mark

Terminal Name Functions

Major Loop

Power

Single-phase or

Three-phase

Input terminal of major return circuit power

~220V 50Hz

Notes: Do not connect with motor output terminals

of U, V and W.

Grounding terminals

Product

Earthling

Grounding resistance is less than 100Ω;

Servo motor output and power input have ground

contact at the common point.

Servo Motor

Output

Control Power

Single-Phase

Servo motor output terminal; shall be connected

with motor terminals of U, V and W in the way of

one-to-one correspondence

Input terminal for control circuit power

~220V 50Hz

3) Control Terminal CN1

Simplified form of Control Modes:

P stands for position control mode

S stands for speed control mode

15

Page 27

DA98D User Manual

e

e

r

Table 3.2 Control Signal Input/Output Terminal CN1

Terminal

No.

Terminal

Name

Mark I/O Mode Functions

Power

CN1-38

CN1-39

Anode of

Input

COM+ Type l

Terminal

CN1-23 Servo On SON Type1

CN1-8

CN1-24

CN1-9

Alarm

Stopping

CCW Driv

Stopping

CW Driv

Stopping

Error Mete

Clearance

ALRS Type1

FSTP Type1

RSTP Type1

CLE Type1 P

CN1-40

Speed

Choice 1

SC1 Type1 S

Power anode of input terminal

Used to drive photoelectrical coupler in the input

terminal

DC12~24V, current ≥100mA

Servo on input terminal

SON ON: allow driving operation

SON OFF: the driver is closed and stops work; the

motor is under free state

Note 1 before switching SON OFF to SON ON, the

motor must be in stillness;

Note 2: after SON ON is switched on, wait at least

50ms before inputting commands.

Input terminal for alarm stopping

ALRS ON: stop system alarm

ALRS OFF: maintain system alarm

Note1: Alarm for failure code larger than 8 can not

be stopped with this method; it needs to cut off the

power for examination and repair, and then switch

on power.

Input terminal for CCW(counter clockwise) drive

stopping

FSTP ON: allow CCW driving operation

FSTP OFF: stop CCW driving operation

Note 1: If limit of the machine is surpassed, the

CCW torque will remain zero when switching on

OFF.

Note 2: The function of FSTP OFF can be

screened off or the function of “ON” can

permanently surface by setting No.20 parameter.

Input terminal for CW(clockwise direction) drive

stopping

RSTP ON: allow CW driving operation

RSTP OFF: stop CW driving operation

Note 1: If limit of the machine is surpassed, the

CW torque will remain zero when switching on

OFF.

Note 2: The function of FSTP OFF can be

screened off or the function of “ON” can

permanently surface by setting No.20 parameter.

Input terminal for clearing position error meter

CLE ON: Position control ; the position error meter

will be cleared

Input terminal for speed choice 1

Under the speed control mode, the combination of

SC1 and SC2 can be used to select different

internal speeds

SC1 OFF,SC2 OFF: internal speed 1

SC1 ON,SC2 OFF: internal speed 2

SC1 OFF,SC2 ON: internal speed 3

SC1 ON,SC2 ON: internal speed 4

Note: the values of internal speed 1 to 4 can be

changed with parameters.

16

Page 28

DA98D User Manual

e

r

r

r

CN1-41

CN1-41

CN1-25

CN1-10

CN1-20

CN1-5

CN1-35

Command

Pulse

Inhibiting

Command

Pulse

Inhibiting

Speed

Choice 2

CCW

Torque

Limiting

CW Torqu

Limiting

Servo

Ready fo

Output

Servo Alarm

Output

Output fo

Positioning

Completing

Output fo

Speed

Completing

INH Type1 P

INH Type1 P

SC2 Type1 S

FIL Type1

RIL Type1

SRDY Type2

ALM Type2

COIN Type2 P

SCMP Type2 S

Input terminal for command pulse inhibiting

INH ON: command pulse input is inhibited

INH OFF: command pulse input is valid

Input terminal for position command pulse

inhibiting

INH ON: command pulse input is inhibited

INH OFF: command pulse input is valid

Input terminal for speed choice 2

Under the speed control mode, the combination of

SCA and SC2 can be used to select different

internal speeds.

SC1 OFF,SC2 OFF: internal speed 1

SC1 ON:SC2 OFF: internal speed 2

SC1 OFF,SC2 ON: internal speed 3

SC1 ON,SC2 ON: internal speed 4

Input terminal for CCW(counter-clockwise

direction) torque limiting

FIL ON:CCW torque is limited within the scope of

parameter No.36

FIL OFF: CW torque is not limited by parameter

No.36

Note 1: No matter FIL is on or off, CCW torque will

still be limited by parameter No.34. Generally,

parameter No.34 > parameter No.36

Input terminal for CW(clockwise direction) torque

limiting

RIL ON: CW torque is limited within the scope of

parameter No.37.

RIL OFF: CW torque is not limited by parameter

No.37

Note 1: No matter FIL is on or off, CCW torque will

still be limited by parameter No.35. Generally,

parameter No.351 > parameter No.371

Terminal of Servo Ready for Output

SRDY ON: Control power supply and main power

supply are normal, the driver alarm does not

occur, and the servo gets Ready for Output ON.

SRDY OFF: the main power supply is not cut off or

the driver alarm occurs, and the servo gets Ready

for outputting OFF.

Output terminal for servo alarm

ALM ON: servo driver alarm dose not occur, and

the servo is Ready for outputting ON.

ALM OFF: servo driver alarm occurs and the servo

is Ready for outputting OFF.

Output terminal for positioning completing

COIN ON: when the value of position error meter

is within the set scope of positioning, ON will be

output for positioning completing.

Output terminal for speed completing

SCMP ON: when the speed reaches or surpasses

the set speed, On will be output for speed

completing.

17

Page 29

DA98D User Manual

Common

CN1-32

CN1-33

edge of

Output

DG

Common

edge

terminal

Z-Phase

CN1-37

output of

CZ Type2

Encoder

CN1-26

Zero Speed

Clamping

ZSL Type1

CN1-36 CZCOM

CN1-30 PULS+

CN1-15

Command

Pulse Input

PULS-

Type3 P

CN1-29 SIGN+

CN1-14

Command

Pulse Input

SIGN-

Type3 P

Earthling common edge of control signal output

terminal (excluding CZ)

Output terminal for Z-phase of encoder

Output Z-phase pulse of servo motor’s

photoelectric code

CZ ON: Z-phase signal appears

ZSL ON: Servo driver is not under the control of

analog voltage, and zero speed is output.

ZSL OFF: servo driver is under the control of

analog voltage

Common edge of encoder’s Z-phase output

terminal

Input terminal for external command pulse

Note 1: the pulse input modes are set by PA14.

Mode of command pulse+ symbol;

Mode of CCW/CW command pulse

CN1-31

CN1-2

CN1-16

CN1-17

CN1-1

CN1-7

CN1-6

CN1-27

CN1-12

CN1-28

Shielding

Ground

Wire

Analog

Ground

Input

Simulation

Command

Input Analog

command

Ground

Positive

Terminal of

Hold Output

Negative

Terminal of

Hold

Output

Code disc

Pulse A+

Code disc

Pulse A-

Code disc

Pulse B+

FG Earthling shielding terminal

AGND S Analog ground

VCMD S

Type4

SG

S

HOLD+ S/P

Type2

HOLD-

S/P

Input analog command+-10V

Input resistance of 20K

Open-loop output of drain electrode, the

photoelectric coupler is open under normal

operation. ON is output

The power is off and the drive stops. When alarm

stops, the photoelectric coupler is closed. OFF is

output

Feedback output signal of encoder. The standard

PAOUT

+

Type5

S

is 2500/line

Output linear speed can be adjusted through

electronic gears of output PA 41 and PA42, e.g. if

PAOUT- S

the encoder has 2500 pulses per round, setting

PA41/42=4/5, then the A and B-phase signals

output from drive unit will be 2500 X

PBOUT

+

PA41/PA42=2000 pluses/round.

18

Page 30

DA98D User Manual

CN1-13

CN1-42

CN1-43

Code disc

Pulse B-

Code disc

Pulse Z+

Code disc

Pulse Z-

PBOUT-

PZOUT

+

PZOUT-

Feedback Signal Terminal CN2

Table 3.3 Encoder Signal Input/Output Terminal CN2

Terminal

No.

Terminal Name

Terminal Mark

Mark I/O Mode

CN2-5

CN2-6

CN2-17

Power Output+ +5V

CN2-18

CN2-1

CN2-2

CN2-3

Power Output- OV

CN2-4

CN2-16

CN2-24

CN2-12

CN2-23

CN2-11

CN2-22

CN2-10

CN2-21

CN2-9

CN2-20

CN2-8

Encoder A+Input

Encoder A-Input

Encoder B+Input

Encoder B-Input

Encoder Z+Input

Encoder Z-Input

Encoder U+Input

Encoder U-Input

Encoder V+Input

Encoder V-Input

A+

A-

B+

B-

Z+

Z-

U+

U-

V+

V-

3.3 I/O Interface Principle

Type4

Type4

Type4

Type4

Type4

One pulse will be output from one round of the

motor.

Color Functions

Photoelectric encoder of the servo

motor employs + 5V power supply;

When the cable is relatively long, it

should use multiple component wires

that are connected in parallel.

Connected with A+ phase of the servo

motor’s photoelectric encoder

Connected with A- phase of the servo

motor’s photoelectric encoder

Connected with B+ phase of the servo

motor’s photoelectric encoder

Connected with B- phase of the servo

motor’s photoelectric encoder

Connected with Z+ phase of the servo

motor’s photoelectric encoder

Connected with Z- phase of the servo

motor’s photoelectric encoder

Connected with U+ phase of the servo

motor’s photoelectric encoder

Connected with U- phase of the servo

motor’s photoelectric encoder

Connected with V+ phase of the servo

motor’s photoelectric encoder

Connected with V+ phase of the servo

motor’s photoelectric encoder

19

Page 31

DA98D User Manual

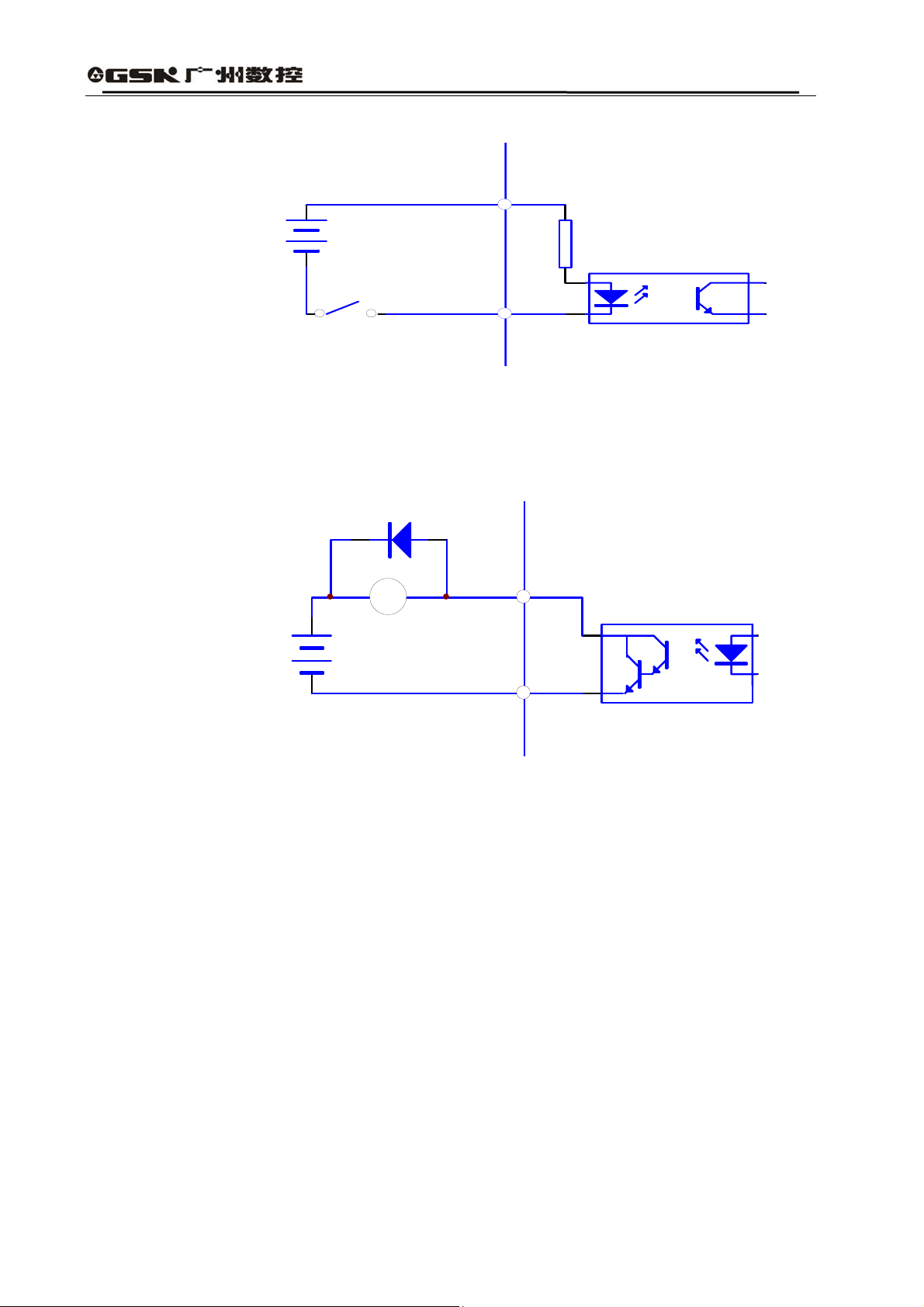

1) Switch Value Input Interface

COM+

SW

Fig. 3.4 Type1 Switch Value Input Interface

(1) Power supply is provided by the user, DC12~24V, current≥100mA;

(2) Note: if the electrodes are reversely connected, the servo driver will not work.

servo amplifier

Driver Sideface

4.7K12~24V

2) Switch Value Output Interface

Driver Side

servo amplifier

max 50mA

max 25V

Fig. 3.5 Type2 Switch Value Ouput Interface

(1) The external power supply is provided by the user, but attention must be given to the case

that if electrodes of the power supply are reversely connected, the servo drive unit may be

damaged.

(2) The output is an open-circuit form of collector, with a maximal current of 50mA and a maximal

external power voltage of 25V. Therefore, the load of switch value output signal must satisfy

this limited requirement. If the limited requirement is surpassed or the output terminal is

directly connected with the power supply, the servo drive unit will be damaged;

(3) If the loads are inductive ones like relay, two sides of the load must be reversely connected in

parallel with the continuous current diode. If the continuous current diode is reversely

connected, the servo drive unit will be damaged.

3) Analog Input Interface

20

Page 32

DA98D User Manual

1. Input signal is connected with twisted-pair cable lines.

2. The circuit adopts the enlarged different-mode form, with an input resistance of 20K.

4) Pulse Output Interface

B

5

6

Fig. 3.6 Type4 Analog Command Input Interface

Driver Sideface

servo am pl i fier

PULS+

220

PULS-

SIGN+

220

7

SIGN-

Fig. 3.7 Type3 Differential Drive Mode of Pulse Input Interface

servo am plifier

VCC

PULS+

R

R

PULS-

SIGN+

SIGN-

Driver Side

220

220

Fig. 3.8 Type4 Uni-polar Drive Mode of Pulse Input Interface

(1) For correctly transmitting pulse data, it is recommended to adopt the differential drive mode;

(2) Under differential drive mode, AM26LS31 and MC3487 or similar cable driver of RS422;

(3) The uni-polar drive mode will reduce the motion frequency. According to the requirements on

the pulse amount input circuit: driving current 10~15mA and limited maximal external power

voltage of 25V, empirical data are as follows: VCC=24V,R=1.3 ~ 2k;VCC=12V,R=510 ~

21

Page 33

DA98D User Manual

820Ω;VCC=5V,R=82~120Ω.

(4) When adopting uni-polar drive mode, the external power supply will be provided by the user, but

attention must be given to the case that if the power electrodes are reversely connected, the

servo drive unit may be damaged.

(5) Refer to Table 3.4 for details about the pulse input forms, in which the arrow means counting

trend. Table 3.5 shows the time sequence and parameters for pulse input.

Table 3.4 Pulse Input Forms

Forms of Pulse

CCW CW Set Parameter Values

Command

Symbol for Pulse

Train

PULS

0

Command Pulse+

Symbol

SIGN

CCW Pulse Train

CW Pulse Train

PULS

1

CCW Pulse/CCW

Pulse

SIGN

Table 3.5 Time sequence Parameters for Pulse Input

Parameter Differential Drive Input Uni-polar Drive Input

t

ck

>2μS >5μS

th >1μS >2.5μS

tl >1μS >2.5μS

trh <0.2μS <0.3μS

trl <0.2μS <0.3μS

ts >1μS >2.5μS

t

>8μS >10μS

qck

tqh >4μS >5μS

tql >4μS >5μS

t

<0.2μS <0.3μS

qrh

t

<0.2μS <0.3μS

qrl

tqs >1μS >2.5μS

22

Page 34

DA98D User Manual

t

PULS

SIGN

90%

10%

90%

10%

h

t

t

rh

t

rl

CW

s

t

rh

t

ck

t

s

t

rl

CCW

t

l

Fig. 3.9 Time sequence Diagram for Pulse+Symbol Input Interface (Maximal Pulse

Frequency:500kHz)

t

ck

t

h

90%

PULS

10%

t

l

CW

t

rh

t

SIGN

90%

rl

10%

CCW

t

s

t

rh

t

rl

CW

Fig. 3.10 Time sequence for CCW Pulse/CW Pulse Input Interface(Maximal Pulse

Frequency:500kHz)

4) Driver Speed Signal Output Interface

Driver Side

servo ampli fi erservo motor

X+

X-

X=A,B,Z,U,V,W

Fig. 3.11 Type5 Driver Speed Signal Output Interface

5) Input Interface for Servo Driver’s Photoelectric Encoder

AM 26LS32

23

Page 35

DA98D User Manual

Motor Side

Driver Side

X+

X-

servo ampli fi erservo motor

AM 26LS32

X=A,B,Z,U,V,W

Fig. 3.12 Input Interface for Servo Driver’s Photoelectric Encoder

24

Page 36

DA98D User Manual

Chapter Four Parameters

Attention

z Personnel involved in parameter adjusting must know parameter meanings for wrong

setting may damage the equipment or hurt the personnel.

z It is recommended that the parameters should be adjusted when the motor has no load.

z The default motor parameters are adaptable to GSK SJT and Huazhong ST series of

servo motors. If other servo motors are used, the parameters shall be adjusted

accordingly; otherwise, the motor may not work normally.

4.1 Checklist of Parameters

z The following factory parameters listed are used to match the drive unit of GSK 10SJT-M020E

digital control machine tool (2N.m,3000r/min) as an example. Related parameters of different

motors are not the same.

z Software version is V804

Table 4.1 Checklist of Parameters

No. Name Mode Parameter

range

0 Password P,S 0~9999 315

1 Model Code P,S 0~569 30*

2 Software Version (Read only) P,S * *

3 Initial Display State P,S 0~20 0

4 Choice of Control Mode P,S 0~5 0

5 Speed Proportion Gain P,S 5~2000 100* Hz

6 Speed Integral Time Constant P,S 1~1000 20* ms

7 Torque Command Filter P,S 1~500 100 %

8 Low pass Filter for Speed Inspection P,S 1~500 100 %

9 Position Proportion Gain P 1~1000 40 1/S

10 Position Feed Forward Gain P 0~100 0 %

11 Low Pass Filter Cut-off Frequency for

Position Feed-forward

12 Position Command Pulse Frequency

Division Numerator

13 Position Command Pulse Frequency

Division Denominator

14 Position Command Pulse Input Mode P 0~1 0

15 Position Command Pulse Direction

Reversing

16 Range for Positioning Completing P 0~30000 20 Pulse

17 Inspection Range for Position Excess P 0~30000 400 ×100

18 Invalid Position Excess Error P 0~1 0

19 Position Command Smoothing Filter P 0~30000 0 0.1ms

20 Invalid Drive Stopping Input P,S 0~1 0

21 JOG Operation Speed S -3000~3000 120 r/min

22 Reservation

23 Maximal Speed Limit P,S 0~4000 3600 r/min

24 Internal Speed 1 S -3000~3000 0 r/min

25 Internal Speed 2 S -3000~3000 100 r/min

P 1~1200 300 Hz

P 1~32767 1

P 1~32767 1

P 0~1 0

Factory

Values

Unit

Pulse

25

Page 37

DA98D User Manual

26 Internal Speed 3 S -3000~3000 300 r/min

27 Internal Speed 4 S -3000~3000 -100 r/min

28 Speed Completing S 0~3000 500 r/min

29 Reservation

30 Linear Velocity Conversion Numerator P,S 1~32767 10

31 Linear Velocity Conversion

P,S 1~32767 1

Denominator

32 Decimal Position of Linear Velocity P,S 0~5 3

33 Zero Speed Scope for Analog

S 0~1000 3

Command

34 Internal CCW Torque Limiting P,S 0~300 300* %

35 Internal CW Torque Limiting P,S -300~0 -300* %

36 External CCW Torque Limiting P,S 0~300 100 %

37 Internal CW Torque Limiting P,S -300~0 -100 %

38 Torque Limiting for Speed Trial

S 0~300 100 %

Operation and JOG Operation

39 Acceleration Time Constant S 1~10000 0 ms

40 Deceleration Time Constant S 1~10000 0 ms

41 Numerator of Output Electronic Gear

S 1~255 1

Ratio

42 Denominator of Output Electronic Gear

S 1~255 1

Ratio

43 Choice of Speed Command S 0~1 1

44 High Speed AD Zero Point S 412~1600 1024

45 Low Speed AD Zero Point S 412~1600 1024

46 Motor Rotation Direction Control S 0~3 0

47 Analog Command Gain S 20~3000 100

48 Anti-jamming Scope for Analog

S 0~1000

Command

49 Choice of Zero Adjustment Channels

S 0~1 0

for Analog Speed

52 Analog Command Transition Mode S 0~1 0

53 Zero-point Slope S 0~1023 0

26

Page 38

DA98D User Manual

4.2 Functions of Parameters

Table 4.2 Functions of Parameters

No Name Functions

Prevent the parameters from being wrongly changed. Generally,

when needing to set parameters, first set the parameter as the

correct password, then set the parameters. After commissioning,

reset the parameter back to 0 to ensure that the parameter will not be

wrongly changed in the future.

0 Password

1 Model Code

Software

2

Version

Passwords have different classes respectively for user parameters,

system parameters and whole parameters.

When changing model code parameter (PA1), the model code

password must be used. Other passwords can not be used for

changing this parameter.

User password is 315.

Model code password is 385.

Correspond to the same series of drive units and motors with

different frequency classes.

Different model codes correspond to different default parameter

values. And when restoring the function of default parameter values,

the parameter concerned must be correct.

When EEPROM alarm (No.20) occurs, the parameter must be reset

after the repair, then restore the default parameter value. Otherwise,

the driver many not work normally or be damaged.

When changing the parameter, first set the password PAO as 385,

then the parameter concerned can be changed.

Please refer to this chapter for detained meanings about parameters.

The software version No. can be checked, but cannot be changed.

Parameter

range

0~9999

0~69

*

3

Initial

Display

State

Select display states of the driver screen after being electrified.

0: Display motor rotation rate;

1: Display that current position is lower by 5 (pulses);

2: Display that current position is higher by 5;

3: Display that current position command (means accumulated pulse

value)is lower by 5;

4: Display that current position command (means accumulated pulse

value)is higher by 5;

5:Display that position error is lower by 5;

6: Display that position error is higher by 5;

7:Display motor torque;

8:Display motor current;

9:Display linear velocity;

10:Display control mode;

11:Display position command pulse frequency;

12:Display speed command;

13:Display torque command;

14:Display absolute position of rotor during one round;

15:Display input terminal state;

16: Display output terminal state;

17:Display encoder input signal;

18:Display operation state;

19:Display alarm code;

20: Reservation.

0~20

27

Page 39

~

e

~

Choice of

Control

4

Mode

DA98D User Manual

①Control mode of the driver can be selected by setting this

parameter:

0:Position control mode;

1:Speed control mode;

2:Tiral operation control mode;

3:JOG control mode;

4: Encoder’s zero adjusting mode.

5: Opern-loop operation mode (used for testing motor and

encoder).

② Position control mode: position command is input through the

pulse input port

Speed control mode: speed command is input through the pulse

input port or analog input, which can be determined by the

parameter (internal and external speed command choice) PA42.

When internal speed is employed, the combination of SC1 and

SC2 can be used to select different internal speeds.

SC1 OFF,SC2 OFF : Internal speed 1

SC1 ON,SC2 OFF : Internal speed 2

SC1 OFF,SC2 ON : Internal speed 3

SC1 ON,SC2 ON : Internal speed 4

Trial operation control mode: the speed command is input through

the keyboard, used to test driver and motor.

JOG control mode, i.e. itching mode: after the JOG operation is

entered, press down ↑ and hold on, the motor will run at JOG

speed; leave the key, the motor will stop and keep zero speed;

press down ↓ and hold on, the motor will reversely run at JOG

speed; leave the key, the motor will stop and keep zero speed.

Encoder’s zero adjusting mode: used to adjust zero point of the

encoder disc when leaving factory

0~5

Speed

Proportion

5

Gain

Speed

Integral Tim

6

Constant

Torque

7

Command

Filter

Set proportion gain of the speed regulator.

The higher the value is set, the gain will be larger and rigidity

greater. Parameter value shall be determined by specific models

and loads of the servo drive unit. Generally, the greater the load

inertia is, the higher the value will be set.

Under the condition that the system will not produce vibration, the

value can be set as high as possible.

Set integral time constant of the speed regulator

The lower the value is set, the faster the integral speed will be and

the greater the rigidity. Parameter value shall be determined by

specific models and loads of the servo drive unit. Generally, the

greater the load inertia is, the higher will the value be set.

Under the condition that the system will not produce vibration, the

value can be set as low as possible.

Set features of the torque command filter to inhibit resonance

(sharp vibration noise produced by motor) produced by the torque;

If the motor produces sharp vibration noise, please reduce the

parameter value;

The lower the value is, the smaller the cut-off frequency will be and

the less the motor noise. If the load inertia is very great, the set

value can be properly reduced. If the value is too low, the response

will become slow and may cause instability.

The higher the value is, the greater the cut-off frequency will be

and the faster the response. If relatively high machinery rigidity is

needed, the value can be increased properly.

5 Hz

2000Hz

1 ms

1000ms

1%~500%

28

Page 40

Low Pass

~

×

×

P

Filter for

8

Speed

Inspection

Position

Proportion

9

Gain

Position

Feed-forward

10

Gain

Low Pass

Filter Cut-off

11

Frequency

for Position

Feed-forward

Position

Command

Pulse

12

Frequency

Division

Numerator

Position

Command

Pulse

13

Frequency

Division

Denominator

DA98D User Manual

Set features of low pass filter for speed inspection.

The lower the value is, the smaller will be the cut-off frequency will

be and the less the motor noise. If the load inertia is very great, the

set value can be properly reduced. If the value is too low, the

response will become slow and may cause vibration.

1%~500%

The higher the value, the greater the cut-off frequency will be and

the faster the response. If relatively fast response is needed, the

set value can be properly increased.

Set proportion gain of the position regulator.

The higher the value is, the greater the gain will be and the less the

position lagging amount will be under the condition of command

pulse with the same frequency. But if the value is too high, it may

1~1000 /S

cause vibration or over-adjustment.

The parameter is determined by specific models of the servo drive

unit and concrete loads.

Set feed-forward gain of the position loop.

When the value is set at 100%, it means that the position lagging

value will be always 0 under command pulse with any frequency.

If the position feed-forward gain is increased, the high-speed

response feature of the control system will be enhanced, but the

0%~100%

position loop of the system will be instable and easy to cause

vibration.

If not specially requiring very fast response, the feed-forward gain

of the position loop is generally set as 0.

Set low pass filter cut-off frequency of the position feed-forward.

The function of this filter is to enhance stability of the composite

position control.

1 Hz

1200Hz

Set frequency division of the command pulse (electronic gear).

Under position control mode, it can be conveniently matched with

various pulse sources by setting PA12 and PA13 parameters, thus

reaching the ideal control resolving power (i.e. angle/pulse)

required by the user.

4××=× CNGP

P: Pulse number of the input command;

G: Electronic gear ratio;

N: Motor rotation rounds;

1~32767

C: Coil round number of the photoelectric encoder. In this system C

=2500.

〖Example〗 if the input command pulse is 6000, the servo motor

rotates one round:

CN

G

=

××

=

6000

5

4250014

=

3

then the parameter PA12 is set as 5 and PA13 as 3.

⑤ Recommended range of electronic gear ratio:

1

50

50

≤≤ G

①Refer to parameter PA12. 1~32767

29

Page 41

Position

t

r

0

r

0

~

e

Command

14

Pulse Inpu

Mode

Position

Command

15

Pulse

Direction

Reversing

Range fo

16

Positioning

Completing

Inspection

Range fo

17

Position

Excess

Invalid

Position

18

Excess Error

Position

Command

19

Smoothing

Filter

Invalid Driv

20

Stopping

Input

DA98D User Manual

Set input mode of the position command pulse.

Three input modes can be set through parameters:

0: Pulse+symbol;

1:CCW pulse/CW pulse;

CCW is counter-clockwise rotation observed from the servo motor

shaft direction, defined as positive direction.

CW is clockwise rotation of observed from the servo motor shaft

direction, defined as negative direction.

Set as

0:Normal;

1: opposite to position command pulse direction.

Set pulse range for positioning completing under position control

mode.

The parameter provides a basis for judging whether drive unit has

completed the positioning under position control mode. When the

remaining pulse number in the position error meter is less than or

the same with this parameter value, the driver is deemed to

complete the positioning with the positioning completing signal of

COIN ON. Otherwise it will be COIN OFF.

SCMP.Under position control mode, the positioning completing

signal of COIN is output; under other control modes, the speed

completing signal will be output.

Set inspection range for position excess alarm.

Under the position control mode, position excess alarm will occur in

the servo drive unit when the number on the position error meter

exceeds this parameter value.

①Set as

0: Valid inspection for position excess alarm;

1: Invalid inspection for position excess alarm, stop inspecting

position excess error.

Smoothing filter of the command pulse, acceleration and

deceleration with exponential form, and the value means time

constant.

The filter will not lose input pulse but it may cause delayed

command;

The filter is used in:

Upper controller without deceleration function;

Electronic gear with relatively high frequency division (>10);

Relatively low command frequency;

Motor with leaping-forward and instable steps during operation.

When the position points to 0, the filter will not work.

①Set as

0: Valid CCW and CW drive stopping. When CCW drive stopping

switch (FSTP) is ON, CCW drive is allowed; when CCW drive

stopping switch (FSTP) is OFF, CCW torque keeps 0. Likewise, if

CCW and CW drive stopping switches are both OFF, the alarm for

drive stopping input error will occur.

1: Cancel CCW and CW input stopping. No matter what state

CCW and CW drive stopping switches are in, CCW and CW drive

will be allowed. Meanwhile, if CCW and CW drive stopping

switches are both OFF, the alarm for drive stopping input error will

not occur.

0~1

0~1

0 ~3000

pulses

0 ~3000

×100

pulses

0~1

0ms

30000×0.1

ms

0~1

30

Page 42

DA98D User Manual

21

JOG

Operation

Speed

Set JOG operation speed.

-3000 r/min

~3000r/min

22 Reservation

Maximal

23

Speed Limit

Set maximal speed limit of the servo motor.

Unrelated with the rotation direction.

If the set value surpasses the rated rotation rate, the actual highest

speed limit will be the rated rotation rate.

0 r/min

~3000

r/min

Set internal speed 1

24

Internal

Speed1

Under the speed control mode, the combination of SC1 OFF and

SC2 OFF will be used to select internal speed 1 as the speed

-3000 r/min

~3000 r/min

command.

Set internal speed 1

25

Internal

Speed 2

Under the speed control mode, the combination of SC1 ON and

SC2 OFF will be used to select internal speed 2 as the speed

-3000 r/min

~3000 r/min

command.

Set internal speed 3

26

Internal

Speed 3

Under the speed control mode, the combination of SC1 Off and

SC2 ON will be used to select internal speed 3 as the speed

-3000 r/min

~3000 r/min

command.

Set internal speed 4

27

Internal

Speed 4

Under the speed control mode, the combination of SC1 On and

SC2 ON will be used to select internal speed 4 as the speed

-3000 r/min

~3000 r/min

command.

Speed

28

Completing

Linear

Velocity

30

Conversion

Numerator

Linear

Velocity

31

Conversion

Denominator

Set speed completing.

Under non-position control modes, if the motor speed surpasses

this set value, the signal of SCMP ON will be output. Otherwise, the

signal of SCMP OFF will be output.

Under the position control mode, this parameter will not be used.

0 r/min

~3000

r/min

Unrelated to rotation direction.

Compared with other apparatus, it has slow-moving feature.

Used to display linear operation speed of the system

Decimal position of the linear velocity is determined by parameter

PA32. 0 means no decimal, 1 means the decimal position is at the

1~32767

tens, 2 means the decimal point is are the hundreds… the process

goes on by analogy.

〖Example〗 If the servo motor drives a 10mm ball lead screw, the

linear velocity conversion numerator is set at10, the denominator at

1, and decimal point at 3, then the linear velocity can be displayed

on the screen (counted in m/min). When the motor velocity is

500r/min, the linear velocity will be displayed as 5000m/min.

①Refer to parameter PA30. 1~32767

31

Page 43

Decimal

e

Position of

32

Linear

Velocity

Zero Speed

Scope for

Analog

33

Command

Internal

CCW Torque

Limiting

34

Internal CW

Torque

Limiting

35

External

CCW Torqu

Limiting

36

DA98D User Manual

Refer to Parameter PA30.① 0~5

Since there is jamming in the process of transmitting analog

command, the command received is not necessarily 0 when the

upper machine gives the analog zero speed command, under

which circumstances the motor can not stop steadily and cause

0~1000

shake. The shake caused by jamming can be inhibited by

increasing this parameter, but the response speed will be reduced

and the processing error be increased at that same time.

Set internal CCW torque limiting for the servo motor.

The value set is the percentage of rated torque, e.g., if the value

needs to be set is two times as much as the rated torque, set the

value at 200.

At any time, this limit will be valid.

0%~300%

If the value set surpasses the maximal over-loading capacity of the

system, the actual torque limiting will be the maximal over-loading

capacity permitted by the system.

Set internal CW torque limiting for the servo motor.

The value set is the percentage of rated torque, e.g., if the value

needs to be set is two times as much as the rated torque, set the

value at -200.

At any time, this limit will be valid.

-300%~0%

If the value set surpasses the maximal over-loading capacity of the

system, the actual torque limiting will be the maximal over-loading

capacity permitted by the system.

Set external CCW torque limiting for the servo motor.

The value set is the percentage of rated torque, e.g., if the value

needs to be set is as much as the rated torque, set the value at

100.

This limiting will be valid only when the input terminal (FIL) for

CCW torque limiting is ON.

0%~300%

When the limiting is valid, the actual torque limiting will be the

minimal one among the three values of maximal over-loading

capacity, internal CCW torque limiting and external CCW torque

limiting permitted by the system.

Internal CW

Torque

Limiting

37

Torque

Limiting for

Speed Trial

38

Operation

and JOG

Operation

Set external CW torque limiting for the servo motor.

The value set is the percentage of rated torque, e.g., if the value

needs to be set is as much as the rated torque, set the value at

-100.

This limiting will be valid only when the input terminal (FIL) for CCW

torque limiting is ON.

When the limiting is valid, the actual torque limiting will be the

minimal one among the three values of maximal over-loading

capacity, internal CW torque limiting and external CW torque

limiting permitted by the system.

Set torque limiting under the modes of speed trial operation and

JOG operation.

Unrelated to rotation direction, valid for both directions.

The value set is the percentage of rated torque, e.g., if the value

needs to be set is as much as the rated torque, set the value at

-100.

Both internal and external torque limiting will still be valid.

32

-300%~0%

0%~300%

Page 44

DA98D User Manual

s

s

Acceleration

Time

Constant

39

Deceleration

Time

Constant

40

Numerator of

Output

Electronic

41

Gear Ratio

Denominator

of Output

42

Electronic

Gear Ratio

Choice of

Speed

43

Command

High Speed

44

AD Zero

Point

Low Speed

45

AD Zero

Point

Motor

Rotation

Direction

46

Control

The set value means the acceleration time of motor ranging from

0r/min to 1000r/min

The acceleration and deceleration have a linear feature.

Only valid for speed control mode, invalid for position control mode.

1ms

~10000ms

If the drive unit is used together with external position loop, thi

parameter shall be set as 0.

The set value means the deceleration time of motor ranging from

0r/min to 1000r/min

The acceleration and deceleration have a linear feature.

Only valid for speed control mode, invalid for position control mode.

1ms

~10000ms

If the drive unit is used together with external position loop, thi

parameter shall be set as 0.

Feedback pulse from each coil of the encoder will be output

through the gear within the drive unit. E.g., there are 2500 pulses in

each coil of the encoder, setting PA41/42=4/5, then the A and

0~255

B-phase signals output from the drive unit will be 2500 X

PA41/PA42=2000 pulses/coil.

This parameter must be more than or the same with parameter

No.41.

0~255

Whether the operation speed is from internal speed or analog

command:

0 Internal speed

0~1

1 Analog command

When restoring default value, this parameter will not be recovered. 412~1600

When restoring default value, this parameter will not be recovered. 412~1600

0 Normal

1 Opposite to the analog speed command

2 Opposite to the output pulse rotation direction

0~3

3 Opposite to both.

Analog

47

Command

Gain

Anti-jamming

Scope for

48

Analog

Command

Choice of

Zero

Adjustment

Channels for

49

Analog

Speed

Analog

Command

52

Transition

Mode

Analog command is transited to speed gain.

The function is the same with parameter No.33, but the function

range includes all speeds rather than zero speed only. It is

recommended that this parameter not be used simultaneously

together with parameter No.33.

0 Low speed AD for low speed and high speed AD for high speed.

1 High speed AD for both high and low speed

This parameter is used only for AD zero adjusting: to improve the

resolving power of analog command, AD switch with different

multiplying factors are employed for high and low speed. First set

this parameter as 1 to adjust zero point for high speed AD, then set

the parameter as 0 to adjust zero point for low speed AD.

0 Speed AD is transited to speed command with curve of second

order

1 Speed AD is transited to speed command with straight line.

33

20~3000

0~1000

0~1

0~1

Page 45

DA98D User Manual

53

Zero-point

Slope

When analog command AD is transited to speed command with

curve of second order, the zero-point slope for the curve is 1024

0~1023

times.

4.3 List for comparison of Modle Codes & Parameters and Motor

Table 4.3 List for Comparison of Parameter No.1 and ST Series of Servo Motors

№1

Parameter

30 110ST-M02030H,0.6kw, 300V, 3000r/min 4A, 0.33×10-3kg.m

35 110ST-M04030H,1.2kw, 300V, 3000 r/min, 5A, 0.65×10-3kg.m

36 110ST-M05030H,1.5kw, 300V, 3000 r/min, 6A, 0.82×10-3kg.m

37 110ST-M06020H,1.2kw, 300V, 2000 r/min, 6A, 1.00×10-3kg.m

38 110ST-M06030H,1.6kw, 300V, 3000 r/min, 8A, 1.00×10-3kg.m2 ※

39 130ST-M04025H,1.0kw, 300V, 2500 r/min, 4A, 0.85×10-3kg.m

45 130ST-M05025H,1.3kw, 300V, 2500 r/min, 5A, 1.06×10-3kg.m

46 130ST-M06025H,1.5kw, 300V, 2500 r/min, 6A, 1.26×10-3kg.m

47 130ST-M07720H,1.6kw, 300V, 2000 r/min, 6A, 1.58×10-3kg.m

49 130ST-M10015H,1.5kw, 300V, 1500 r/min, 6A, 2.14×10-3kg.m

50 130ST-M10025H,2.6kw, 300V, 2500 r/min, 10A, 2.14×10-3kg.m2 ※

51 130ST-M15015H,2.3kw, 300V, 1500 r/min, 9.5A, 3.24×10-3kg.m

Table 4.4 List for Comparison of Parameter No.1 and SJT Series of Servo Motors

№1

Parameter

60 110SJT-M020E,0.6kw, 300V, 3000 r/min, 3A, 0.34×10-3kg.m

61 110SJT-M040D,1.0kw, 300V, 2500 r/min, 4.5A, 0.68×10-3kg.m2

62 110SJT-M060D,1.5kw, 300V, 2500 r/min, 7A, 0.95×10-3kg.m2 ※

63 130SJT-M040D,1.0kw, 300V, 2500 r/min, 4A, 1.19×10-3kg.m2

64 130SJT-M050D,1.3kw, 300V, 2500 r/min, 5A, 1.19×10-3kg.m2

65 130SJT-M060D,1.5kw, 300V, 2500 r/min , 6A, 1.95×10-3kg.m2

66 130SJT-M075D,1.88kw, 300V, 2500 r/min, 7.5A, 1.95×10-3kg.m2 ※

67 130SJT-M100B,1.5kw, 300V, 1500 r/min, 6A, 2.42×10-3kg.m2