Page 1

GSK DA98B AC Servo Drive Unit

User Manual

Page 2

Page 3

The operating manual describes all matters concerning the operation of the system

in detail as much as possible. However, it is impractical to give particular

descriptions of all unnecessary and/or unavailable works on the system due to the

length limit of the manual, specific operations of the product and other causes.

Therefore, the matters not specified herein may be considered impractical or

unavailable.

This operating manual is the property of GSK CNC Equipment Co., Ltd. All rights

reserved. It is against the law for any organization or single to publish or reprint this

manual without the express written permission of GSK and the latter reserves the

right to ascertain their legal liability.

Page 4

Company Profile

GSK CNC EQUIPMENT CO., LTD.(GSK) , CNC Industry Base of South China, is

responsible for the National High Technology Research and Development Program of

China (863 Program): Moderate CNC Industrialization Key Technology. For ten years, we

are exclusively engaged in research, Development, manufacture, sale, training and

popularization of Machine Tool CNC system, Servo Motor and driver, and other

mechanical products. Today, GSK has already expressed into a large-scale new high-tech

enterprise that deals with research, teaching, working and trading. Our products support

more than 60 domestic manufacturers of machine tools with after-sales service network

through the country. With a yield in the lead in China for four years in succession, GSK

series products are in great demand in the domestic demand and have a ready sale in

Southeast Asia at high performance-to-price ratio.

Chinese version of all technical documents in Chinese and English languages is

regarded as final.

Page 5

Forward

Foreword

The manual describes functions and operation methods of DA98B AC servo Drive Unit to

ensure that you can comprehensively understand the servo unit to flexibly and

conveniently use it. Else, it also provides the knowledge and notes how to operate the

unit.

z All specifications and designs are subject to change without notice.

z We do not assume any responsibilities for the change of the product by users,

therefore the warranty sheet will be void for the change.

z Chinese version of all technical documents in Chinese and English languages is

regarded as final.

Thank you for using DA98B AC Servo Drive Unit and User Manual. Welcome you to

feedback your suggestions about our product and User Manual by the telephone or fax,

Email which has been addressed on the back cover of this manual, or feedback to our

headquarter by local outlet.

Ⅰ

Page 6

GSK CNC Enquipment Co., Ltd.

g

Warnin

Please read carefully the following warning marks, if not avoided, could result in injury or in

heavy damage to property.

■ The following warnings with varying degrees of severity appear in the User

Manual.

!

Danger: Indicate an immenently hazardous situation which, if not

avoided, will result in death or serious injury.

!

Caution: Indicate a potentially hazardous situation which, if not

avoided, may result in minor or moderate injury or in

damage to property.

Indicate a potential situation which, if not avoided, may

result in an undesirable result or state.

This symbol appears in the user Manaul whenever it is

necessary to draw your attention to an important item of

information.

■ The following symbols indicate some operations must not or must

be performed.

Forbid performing some operation (absolutely must not perform some

operation).

Perform some operation (must perform some operation).

Ⅱ

Page 7

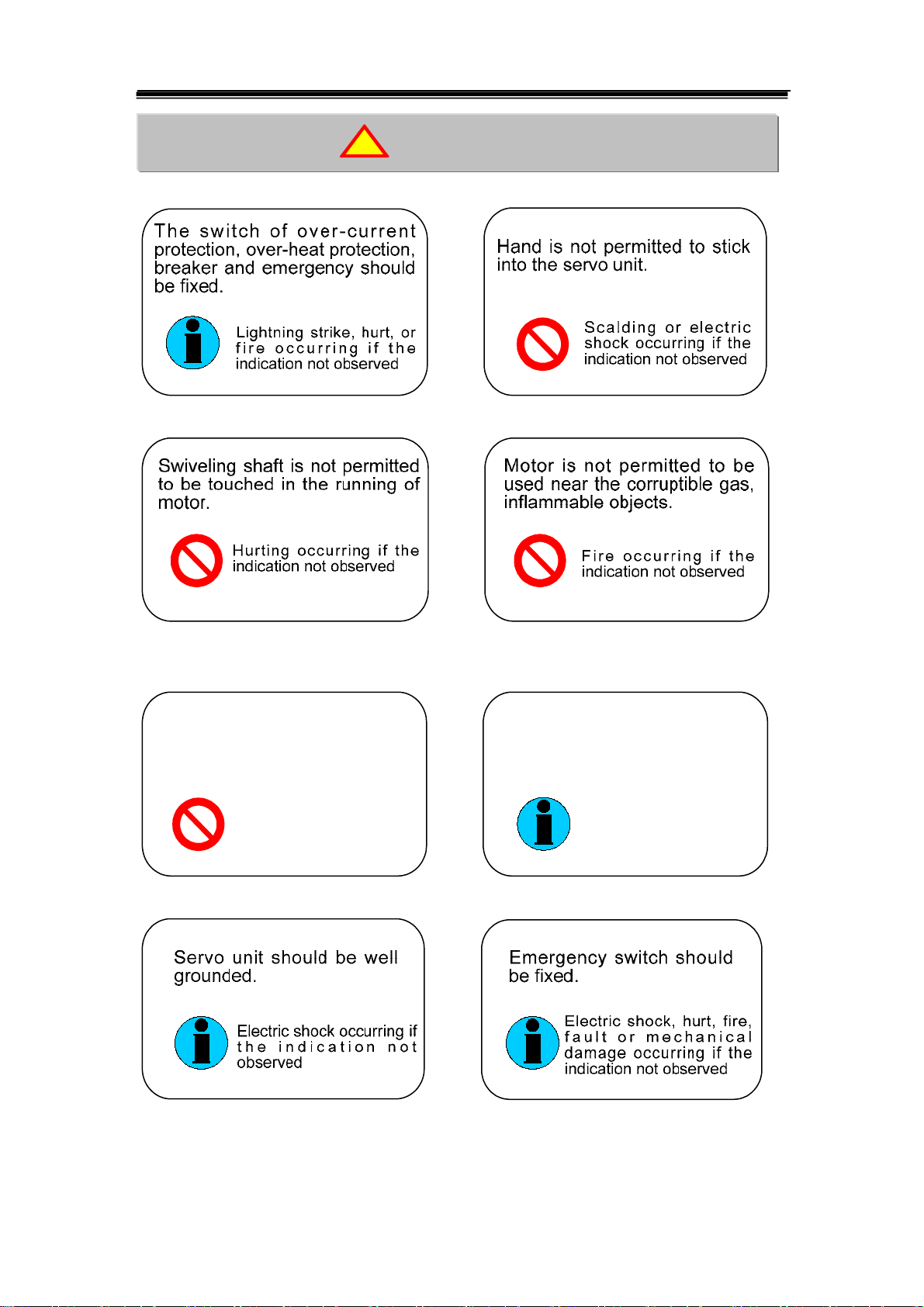

Warning

!

Danger

The cable is not permitted to be

put on the trenchant edge and

excessive pressure, load,

tension is not permitted to exert

on it

Electric shock, fault,

damage occurring if the

indication not observed

Moving, wiring and checking

can only be performed after

the power is switched off for

10 minutes.

Electric shock occurring

if the indication not

observed

Ⅲ

Page 8

GSK CNC Enquipment Co., Ltd.

When there is an alarm in the

running, it must be eliminated

before going on running.

Destructive result occurring

if the indication not

observed

Caution

!

Don't touch the motor, control

device or the brake resistance

for the heating in the running.

Scalding occurring if the

indication not observed

Ⅳ

Page 9

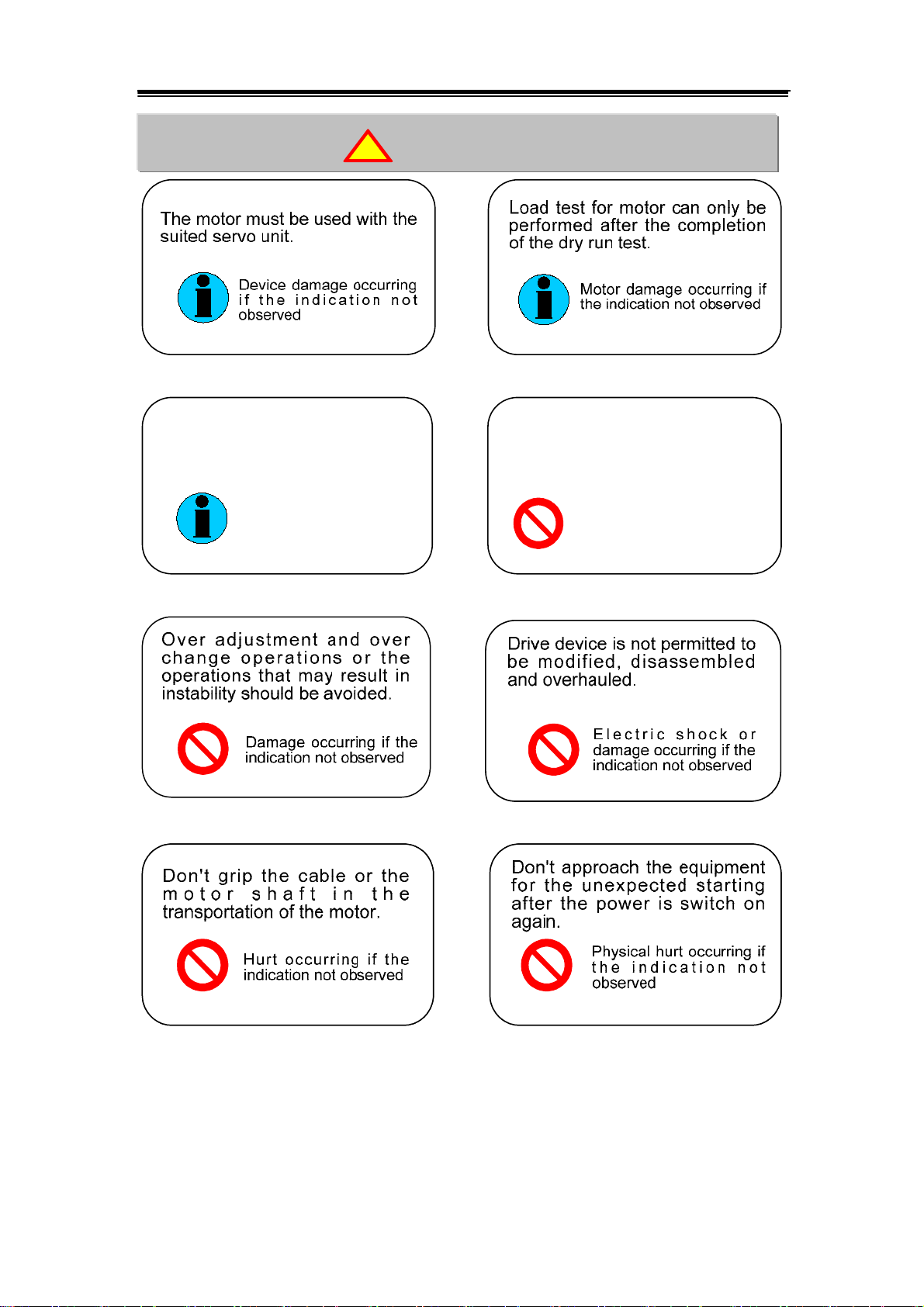

Warning

!

Notes

Ⅴ

Page 10

GSK CNC Enquipment Co., Ltd.

Ⅵ

Page 11

Content

Content

Chapter 1 Overview ...............................................................................................1

1.1 Introduction ................................................................................................................... 1

1.2 Check after delivery ...................................................................................................... 2

1.3 Outline............................................................................................................................ 4

Chapter 2 Installation............................................................................................5

2.1 Installing servo unit.......................................................................................................5

2.2 Installing motor.............................................................................................................. 7

Chapter 3 System configuration and assembly.............................................9

3.1 Servo unit specification................................................................................................. 9

3.2 Interior diagram block of servo unit...........................................................................11

3.3 Wiring............................................................................................................................11

3.4 I/O Interface fundamentals......................................................................................... 18

3.5 Standard conection...................................................................................................... 23

3.5.1 Orientation control .............................................................................................................23

3.5.2 Speed control .....................................................................................................................25

Chapter 4 Parameter ...........................................................................................27

4.3 Model code parameters for motors............................................................................ 33

Chapter 5 Display and operation.....................................................................35

5.1 Keys operation ............................................................................................................. 35

5.3 Parameter setting......................................................................................................... 39

Chapter 6 Trial run...............................................................................................43

6.1 Check before trial run................................................................................................. 43

6.2.1 Sequence of power on for servo unit....................................................................... 44

6.2.2 JOG running.......................................................................................................................45

6.2.3 (Sr-) trial run .......................................................................................................................46

6.2.4 Speed control run ..............................................................................................................46

6.2.5 Orientation control run ......................................................................................................49

6.3 Application of hold release signal............................................................................... 52

6.4 Parameter adjustment for machining characteristics improvement...................... 54

Chapter 7 Funciton for protection...................................................................57

Chapter 8 Isolated transformer ........................................................................64

Chapter 9 Order guide ........................................................................................69

9.1 Capacity selection........................................................................................................ 69

9.2 Electronic gear ratio.................................................................................................... 72

9.3 Stop characteristic....................................................................................................... 72

9.4 Servo and orientation controllor computation.......................................................... 73

1

Page 12

GSK CNC Enquipment Co., Ltd.

2

Page 13

Chapter 1 Overview

p

Chapter 1 Overview

1.1 Introduction

DA98B AC Servo Drive Uit is the second generation of fully digital AC Servo system

of our company which is employed with the new type exclusive chip DSP for motor

control, large-scale complex programmable logic device (CPLD) and IPM with big

power, which has a good integration, compact, perfect protection and highly reliability.

It is characterized with the f orientation control, interior speed control, analog speed

control etc. and is widely applied in the automation production line, packing

machinery and printing machinery and other automatic field.

Compared to stepper system,

DA98B AC Servo Driver Unit has advantages as follows:

z Avoiding out-of-step

Servomotor is equipped with encoder, its

orientation signal feedbacks to servo

driver with open loop orientation controller

to compose a semi-closed loop control

system.

Open loop control

Controller

z S

eed ratio, constant torque

The timing ratio is 1:5000,with stable

torque from low speed to high speed.

z High speed, high precision

Max. speed can be 3000rpm, and the

Positioning instruction

Feedback control

Stepper motor

Servo motor

speed fluctuation rate is less than 2%.

【Note】There is different rated speed

for different motors.

z Simple and flexible control

Controller

Feedback

Positioning instruction

Parameters can be modified to set properly operating mode, running performance of

servo system to meet different requirements.

1

Page 14

GSK CNC Equipment Co., Ltd.

1.2 Check after delivery

Item

1) Whether the packing is good and the goods is damaged.

2) Whether the servo unit, servo motor is the ordered one by checking the nameplates

of the goods.

3)Whether the accessories are complete by checking the packing list.

z

z

z Please contact with our suppliers or our company if there are any questions

Do not install servo unit which is damaged or lacks of components.

Servo driver must be matched with servomotor which performance

matches the former.

after receiving goods.

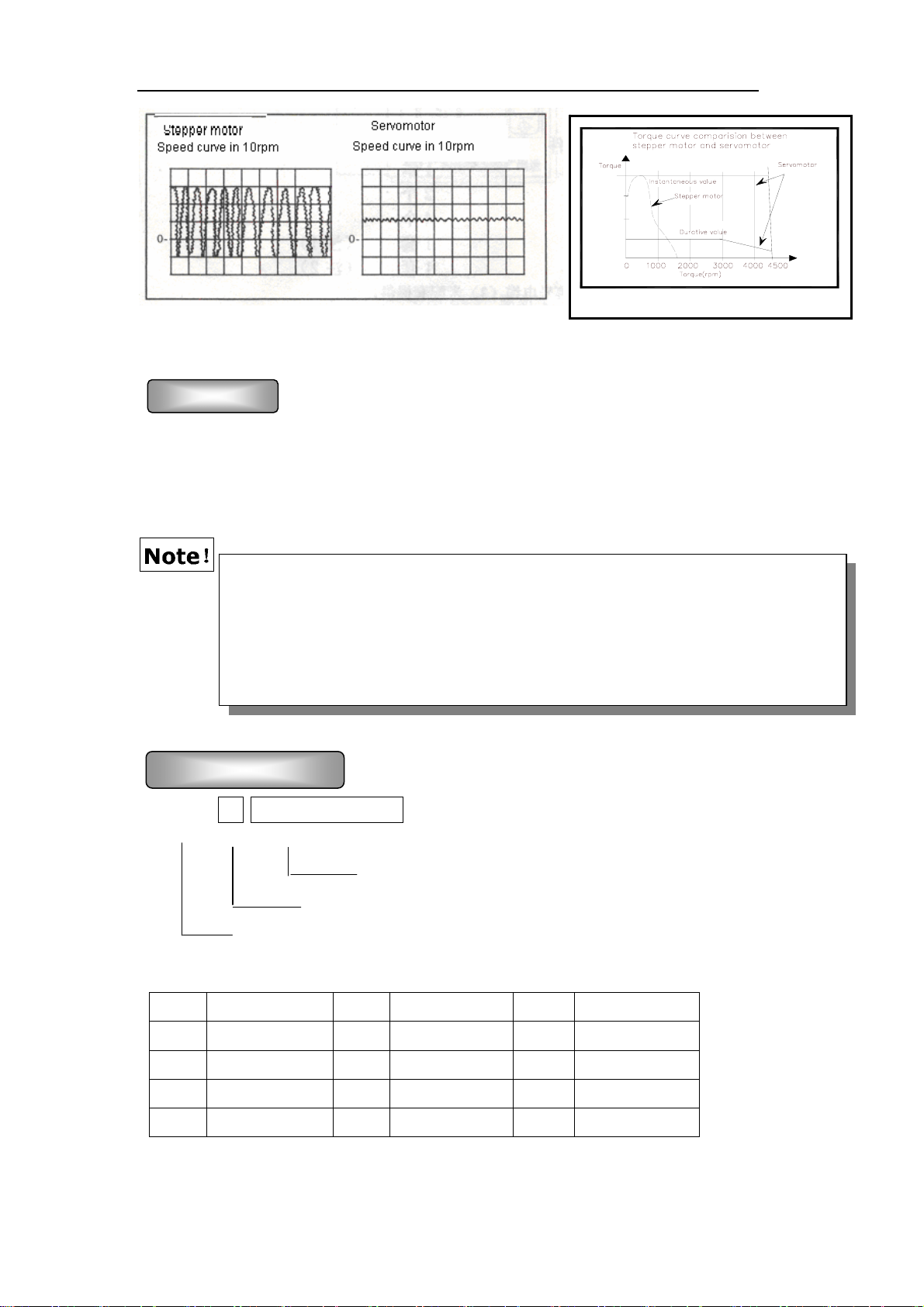

Model significance

DA98B-04-110SJT-M060D

Matched servo motor type

Output power (see table1-a)

Series code

Mark Rated output Mark Rated output Mark Rated output

04 0.4 kW 12 1.2 kW 18 1.8 kW

06 0.6 kW 14 1.4 kW 20 2.0 kW

08 0.8 kW 15 1.5 kW 23 2.3 kW

10 1.0 kW 17 1.7 kW 26 2.6 kW

Table 1-a

2

Page 15

(1) Standard accessories for DA98B servo unit:

① User Manual 1

② Installation bracket 2

③ M4×8 contersink bolt 4

④ CN1 socket(DB44 female) 1 set (note 1)

Chapter 1 Overview

CN2 plug⑤ (DB25 male) 1 set (note 2)

Accessory list

1:Signal cable (3m) can be provided when it is matched with our servo unit.

2:Feedback cable (3m) available should be used when our servo motor is provided.

(2) Standard accessories of servo motor are provided according to user manual of

servo motor.

3

Page 16

GSK CNC Equipment Co., Ltd.

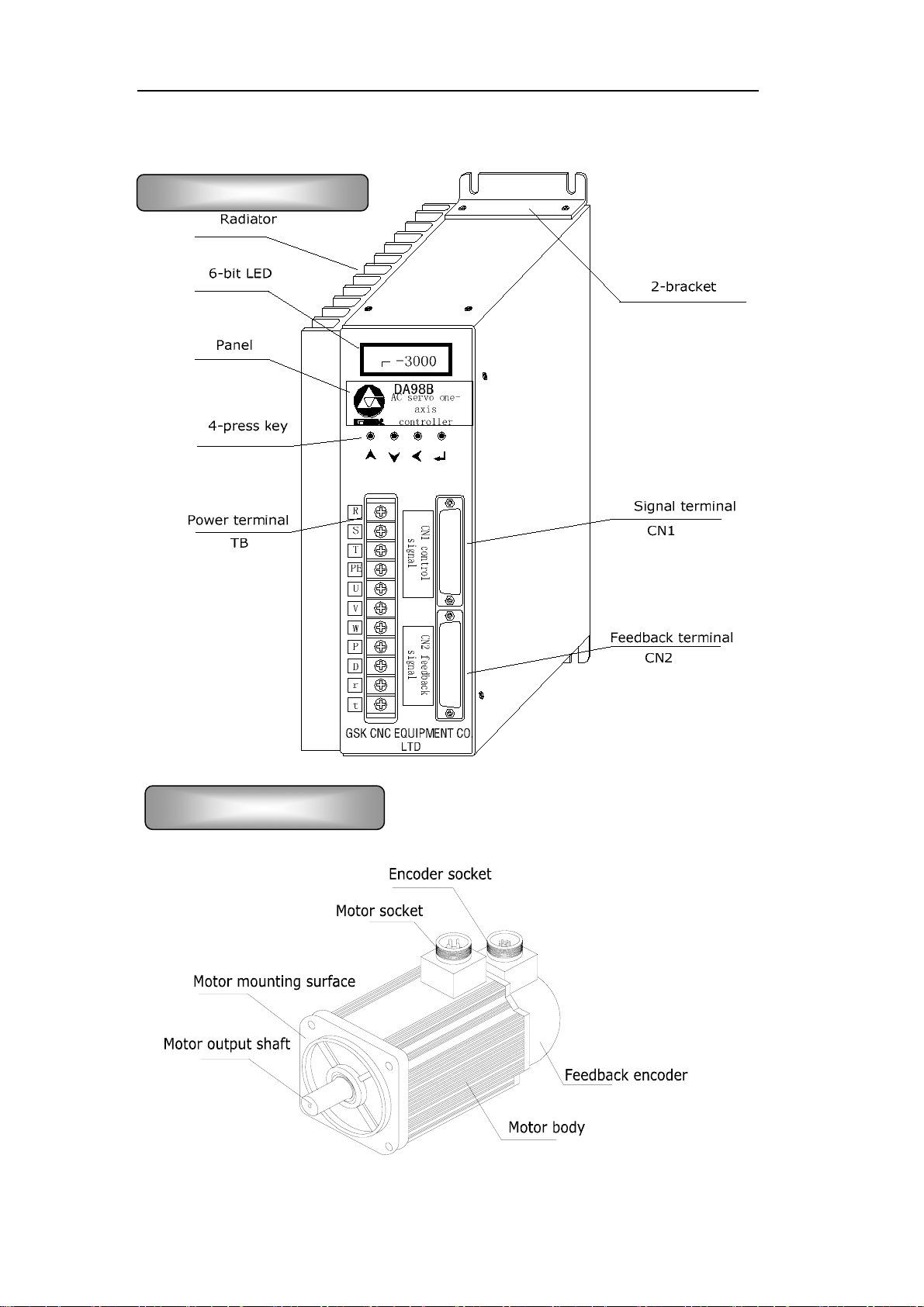

1.3 Outline

Outline of servo unit

Outline of servo motor

Fig. 1.1 Outline of servo unit

Fig. 1.2 Outline of servo motor

4

Page 17

Chapter 2 Installation

Chapter 2 Installation

Servo unit and servo motor should be correctly installed to avoid the mistaken operation,

to protect the machine from being broken or damaged.

2.1 Installing servo unit

Installation environment

Be careful for the protection against rain and sunlight while the servo unit is being

installed.

Servo unit must be installed in the electric cabinet to prevent dust, corrosive gas,

liquid, conductors and inflammable substances from entering it.

Servo unit should be fixed in the well ventilative, dampproof and dustproof

environment.

Fireproof material should be used in the installation with no permission to fix it on or

near the inflammable object.

Run the servo unit below the temperature of 45℃ for reliable long term usage.

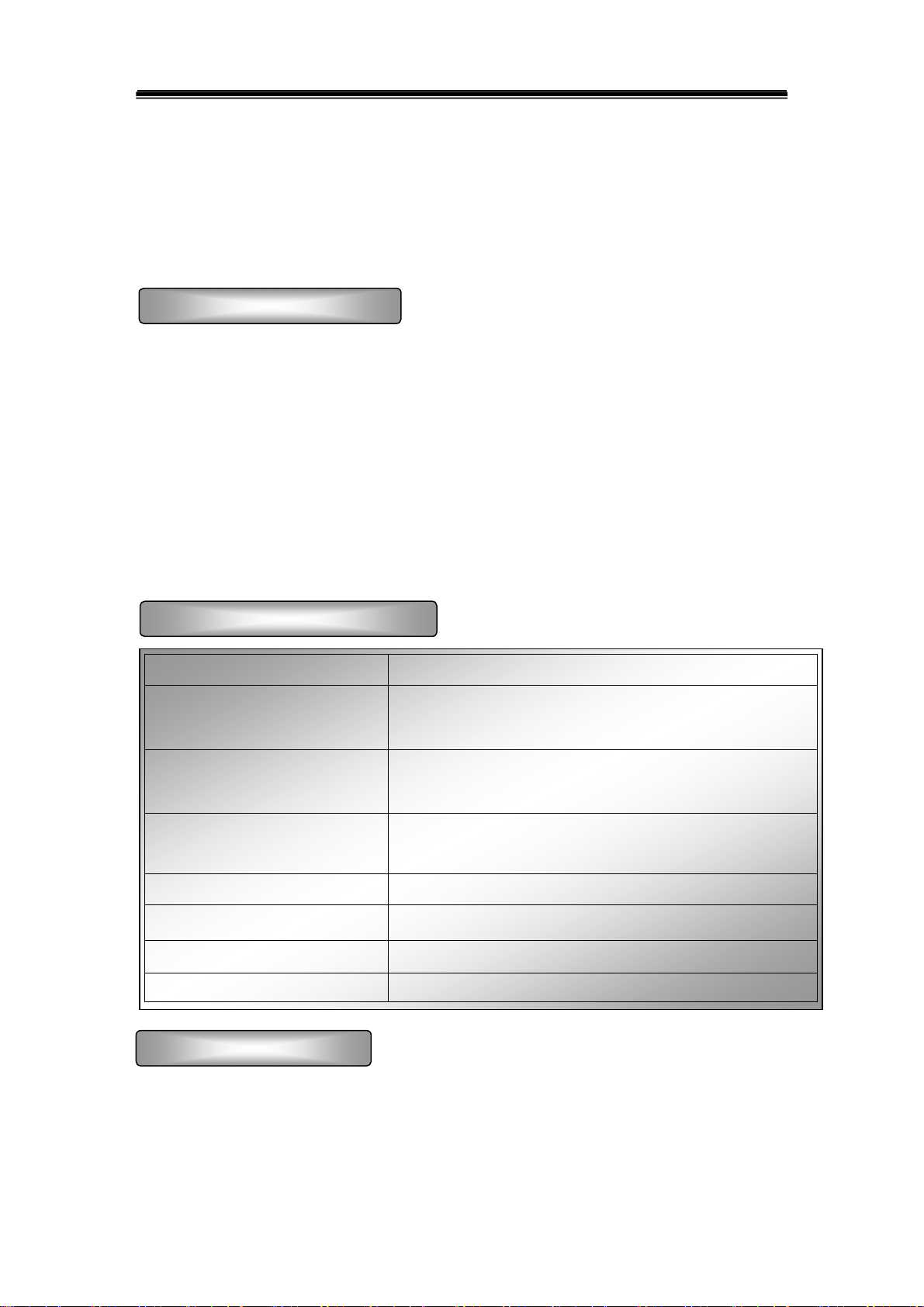

Environmental requirements

Item DA98B servo unit

0~55℃(no frost)

Operating temperature

Storage/delivery temperature

and humidity

Atmosphere environment

Altitude Altitude: below 1,000m

Vibration

Atmospheric pressure

Guard level IP43

Installation method

≤90%RH(no dewing)

-40~80℃

≤90%RH(no dewing)

There should be no corrosive gas,flammable gas, oil fog

or dust etc. in the control cabinet.

≤ 0.5G(4.9m/s2)10-60Hz

86kPa~106kPa

The driver is employed with bottom board or panel installation mode in the upright

direction of installation plane.

Fig. 2.1 is sketch map for bottom board installation and Fig. 2.2 for panel installation. (Unit

below: mm)

5

Page 18

GSK CNC Equipment Co., Ltd.

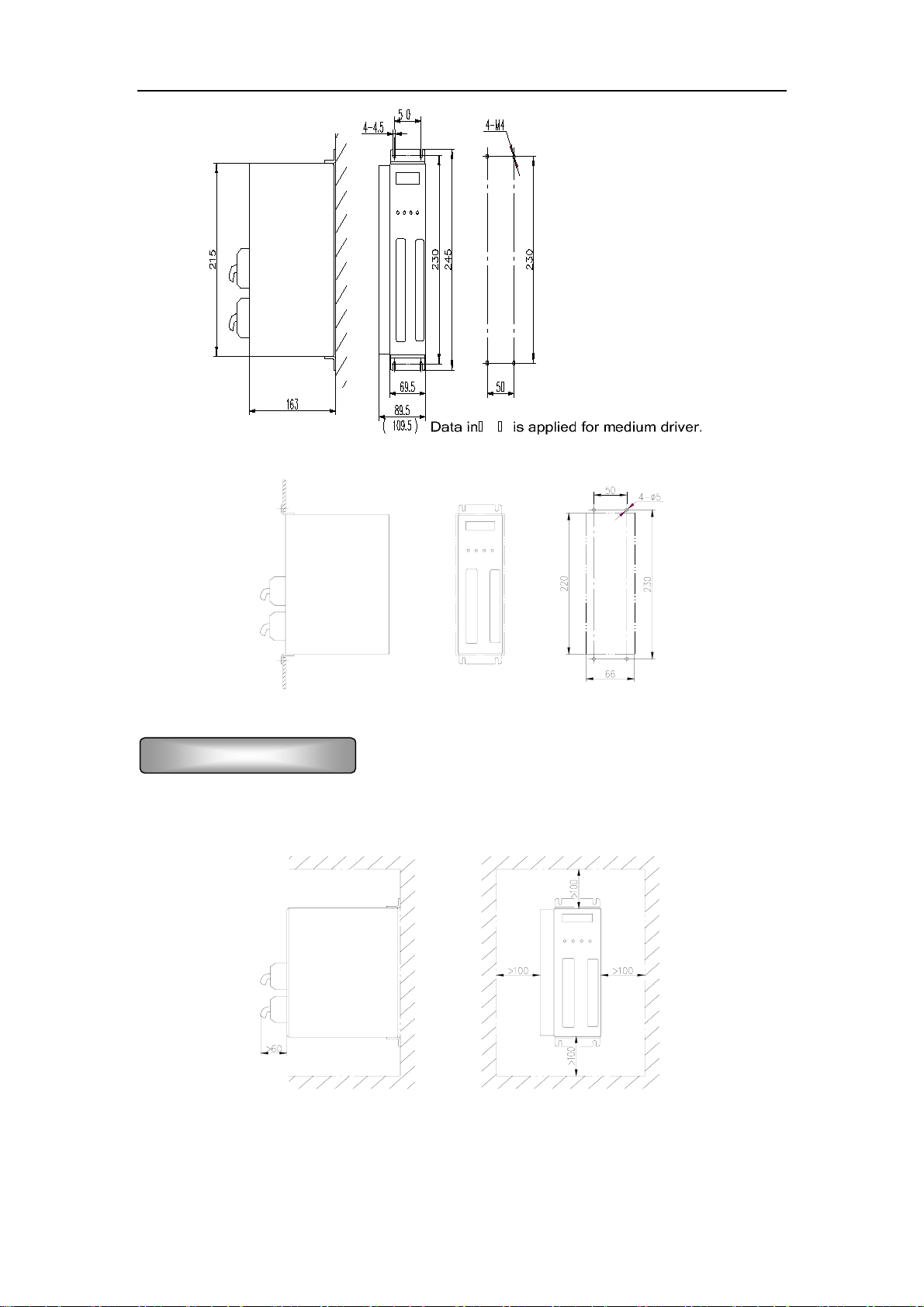

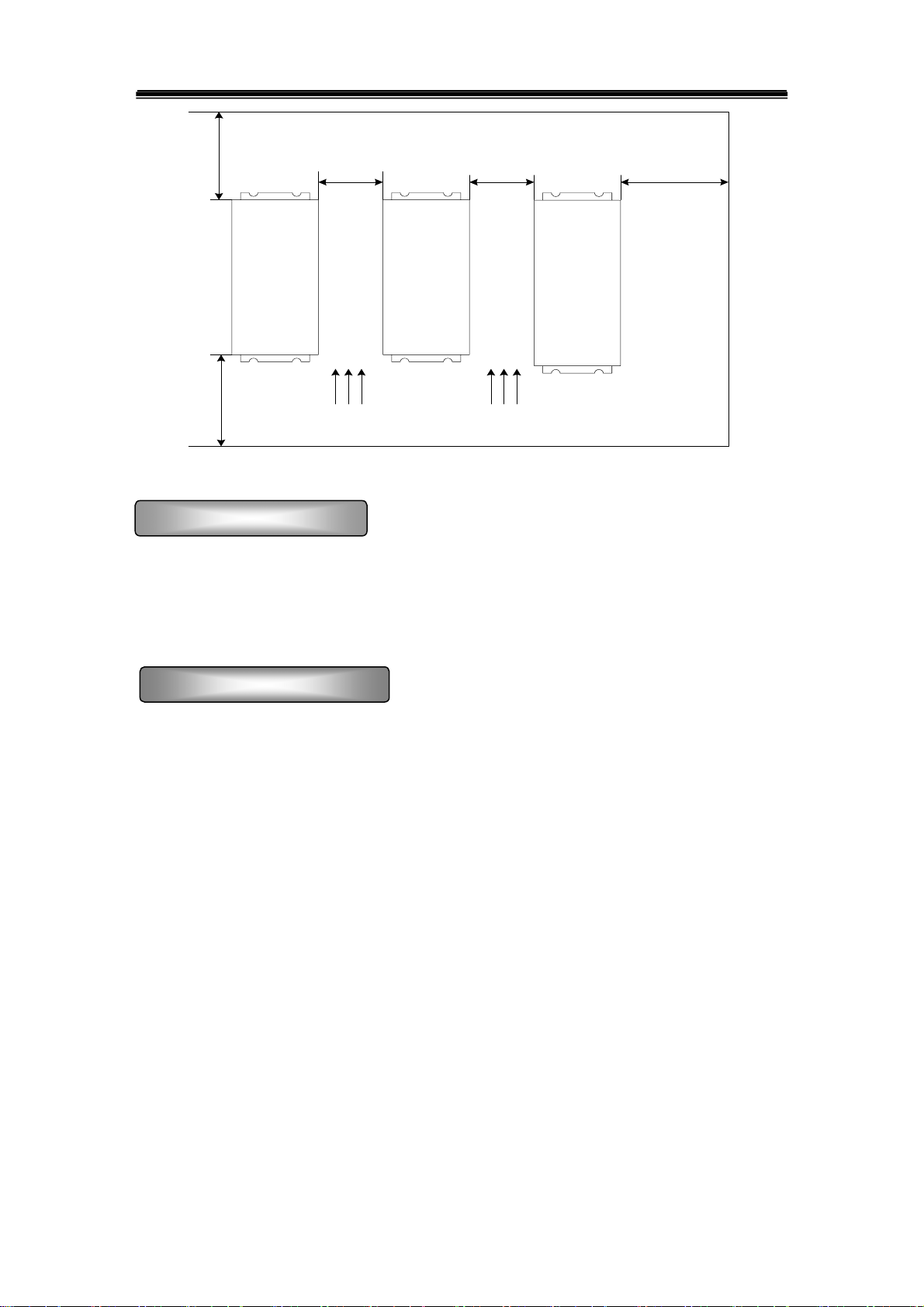

Fig 2.1 Bottom board installation pattern

Fig 2.2 Panel installation pattern

Installation interval

Fig. 2.3 is installation interval for one servo unit and Fig. 2.4 is for servo units. The actual

interval for installation should be larger as possible as to get a good heat radiation.

Fig. 2.3 Installation interval for a single servo unit

6

Page 19

Chapter 2 Installation

>100mm

Servo driver

>100mm

Ventilation direction Ventilation direction

Fig. 2.4 Installation interval for servo units

Servo driver

Servo driver

>100mm>25mm >25mm

Heat radiation

There should be convective air to the radiator of the servo unit in electric cabinet to inhibit

its environmental temperature from continuously rising.

2.2 Installing motor

Installation environment

Be careful for the protection against rain and sunlight.

The motor must be installed in the electric cabinet to prevent dust, corrosive gas,

liquid, conductors and inflammable substances from entering it.

The motor should be fixed in the well ventilative, dampproof and dustproof

environment.

■ The motor should be fixed in a place that is convenient for the maintenance, check

and cleaning of the motor.

7

Page 20

GSK CNC Equipment Co., Ltd.

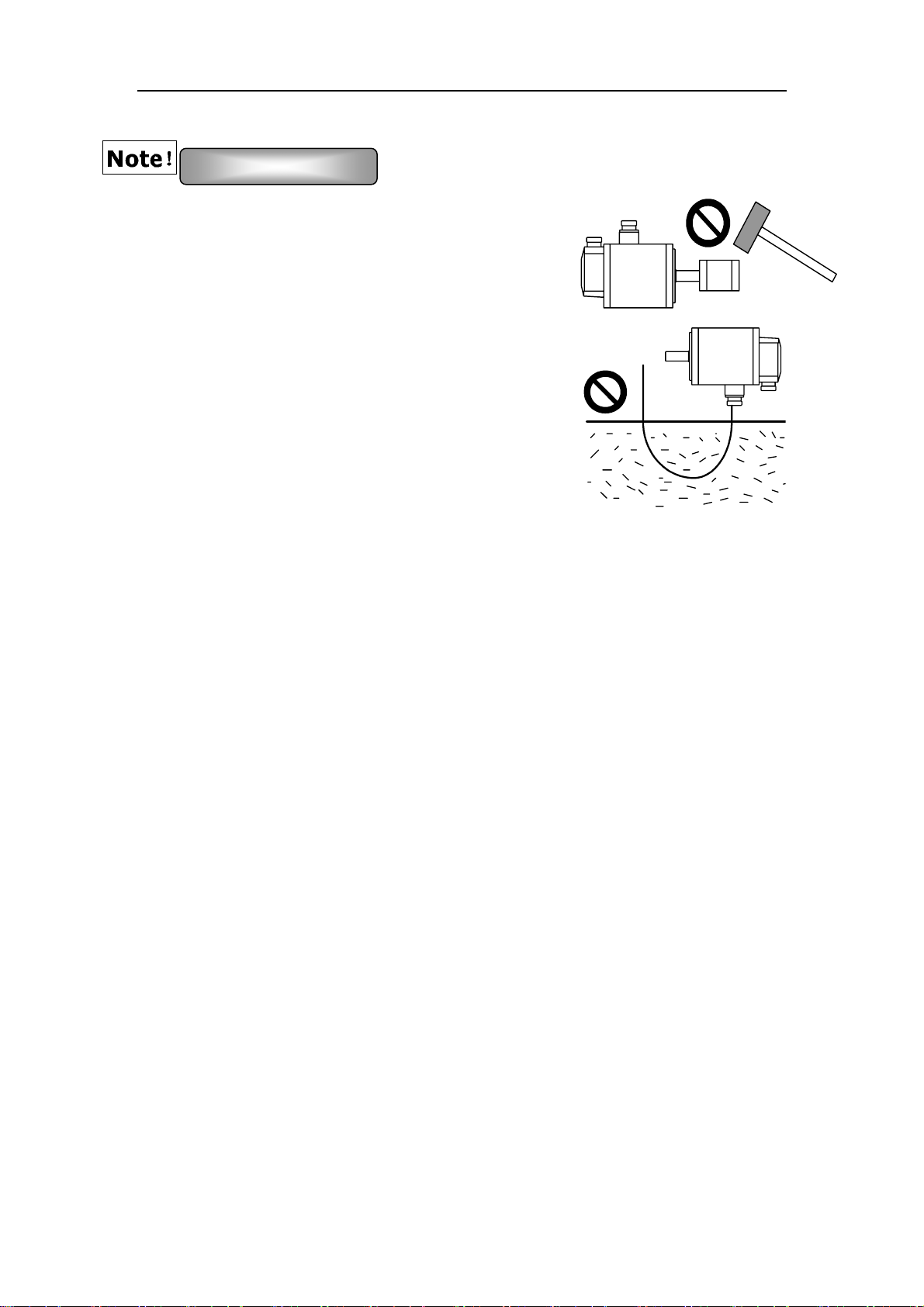

Installation notes

■ Do not hammer the motor or its shaft to

protect the encoder from being damaged

when removing or assembling belt wheel.

Helically pressing or drawing tools should be

used for removing and assembling.

■ Servo motor cannot support heavy axial,

radial load. It should be employed with

flexible shaft coupling for load.

■ Anti-loose washer should be used to fix the motor

against loosing.

■ Oil and water should be protected from the motor for

that the oil or water from the cable which has been dipped in the oil or water can be

sticked to the motor, so such possibility should be avoided.

8

Page 21

Chapter 3 System configuration and assembly

Chapter 3 System configuration and assembly

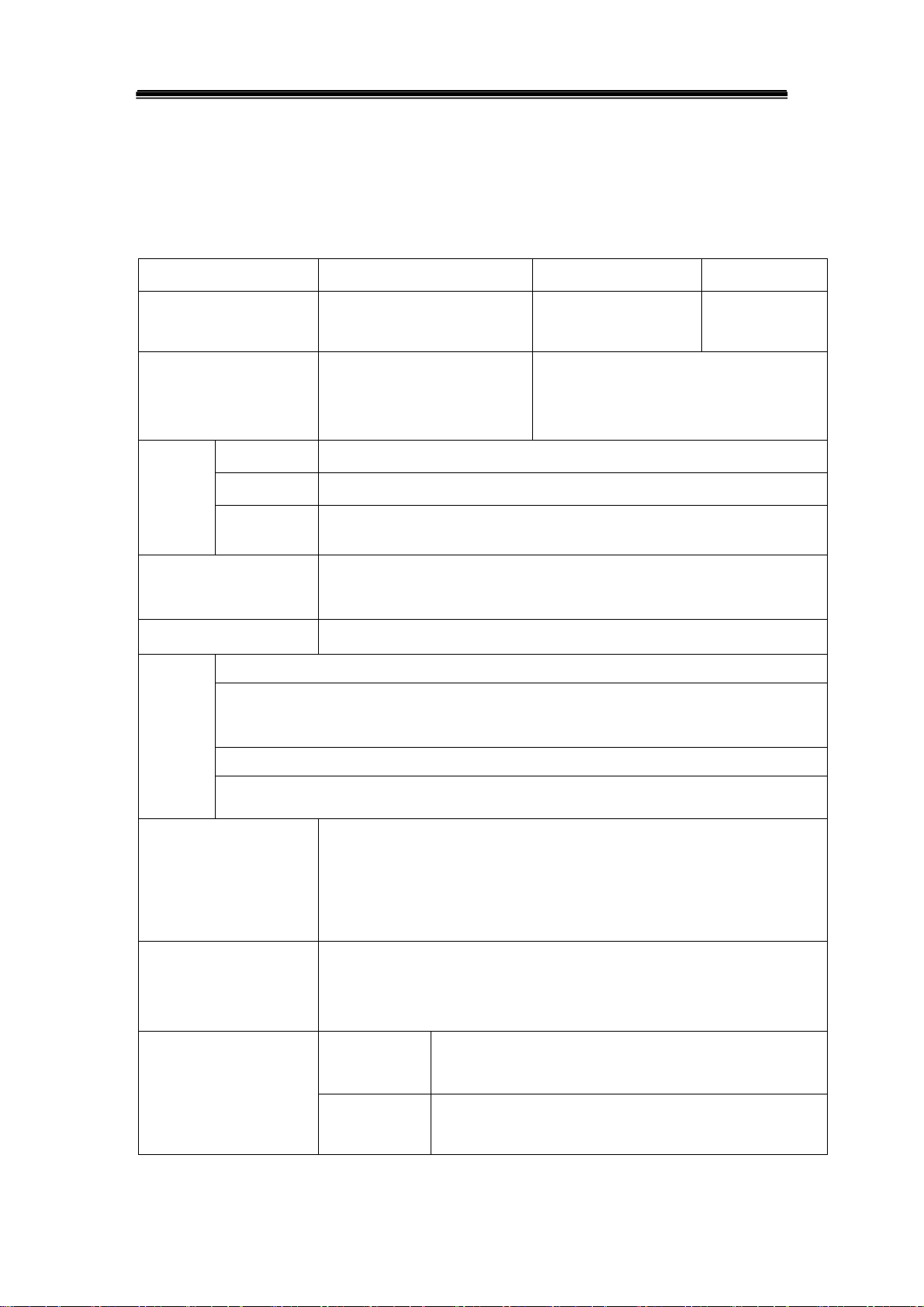

3.1 Servo unit specification

Table 3-1 Servo unit specification

Output power (kW)

Motor rated torque

(N·m)

Single phase or

Input power supply

Environment

Temperature

Humidity

Vibration

Control method

Energy brake Built-in

characteristics

Speed frequency response: 200Hz or more

Speed fluctuation rate: <±0.03(load 0~100%);<±0.02(power supply -15~

Control

+10%)(numerical value corresponding to rated speed)

three-phase AC220V

-15~+10% 50/60Hz

Working:0~55 Storage℃ :-20℃~80℃

Less than 90%(no dewing)

Less than 0.5G(4.9m/s2),10~60 Hz(non-continuous running)

① Orientation control ②External speed control Internal speed ③

control Trial speed run JOG speed ④⑤⑥Encoder zero-adjusting

0.4~0.8 1.0~1.5 1.7~2.6

2~4 4~10 6~15

three-phase AC220V

-15~+10% 50/60Hz

Timing ratio: 1:5000

Pulse frequency: ≤500kHz

Control input

Control output

Orientation control

Servo on① Alarm cancellation② Disable in positive direction③

Disable in negative direction④ ⑤Zero-speed clamping ⑥Error

counter reset/speed choice11 ⑦Disable instruction pulse/speed

choice 2 ⑧CCW torque limit ⑨CW torque limit ⑩Universal I/O port

① Servo ready output ② Servo alarm output ③ Orienting completing

output/speed in-orientation output ④Hold release ⑤Zero speed

output ⑥Universal output ⑦Pulse feedback output

Input mode

Electronic

gear ratio

① Pulse+ direction ②CCU pulse /CW pulse ③A/B

orthogonal phases pulse

Ratio numerator:1~32767 Ratio denominator: 1~

32767

9

Page 22

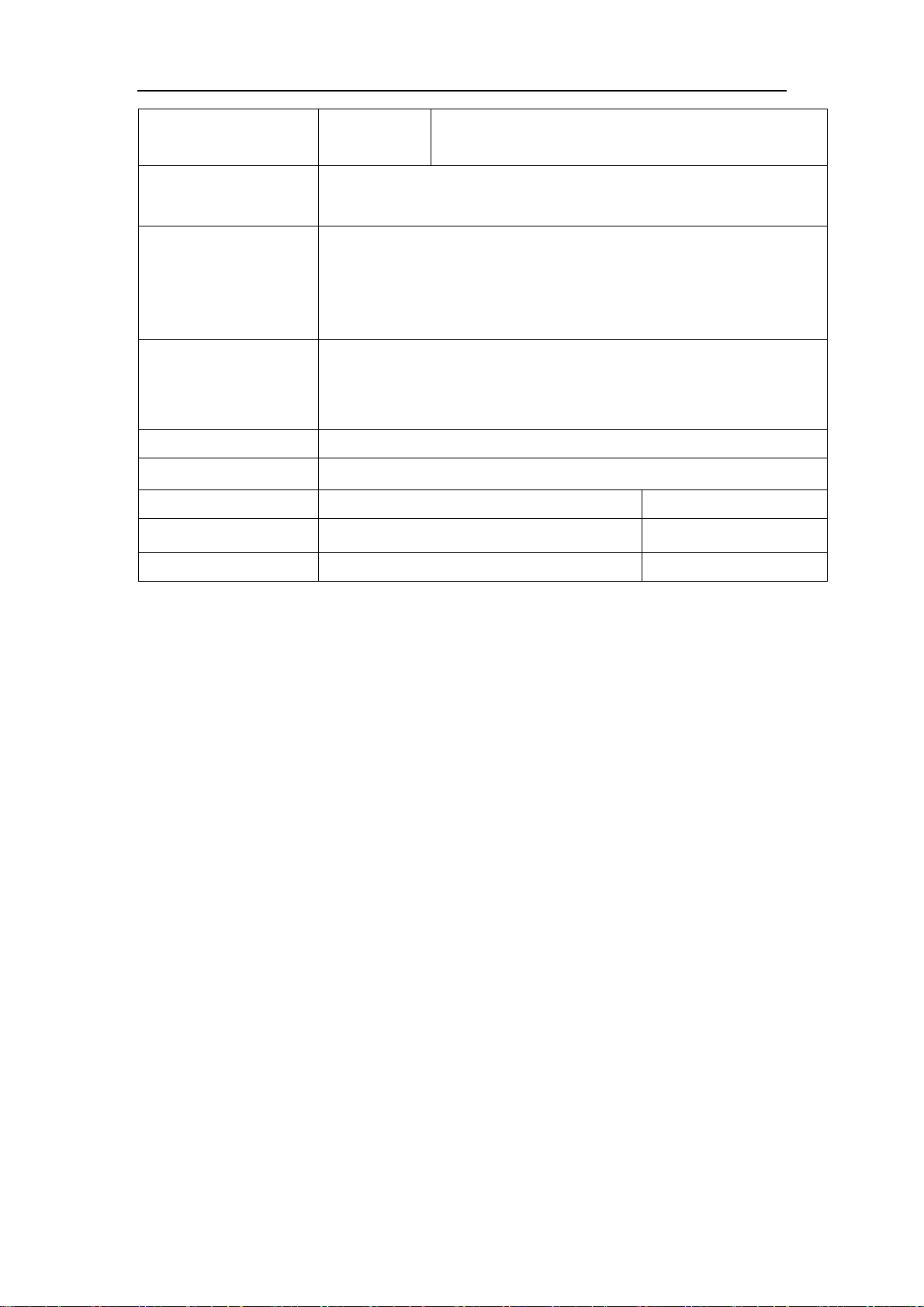

GSK CNC Equipment Co., Ltd.

Encoder

Feedback

Speed control

Monitor function

Protection function

Display, operation 6-bit LED digital tube, 4 buttons

Load inertia Less than quintuple of motor inertia

Thin radiating fin Thick radiating fin

Weight 2.67Kg 3.48Kg

Dimension 244×163×92mm 244×163×112mm

4 kinds of internal speed instructions and (+10~-10) external analog

voltage instructions

Speed, current orientation, instruction pulse accumulation,

Orientation deviation, motor torque, motor current, linear

speed, rotor absolute orientation, instruction pulse frequency,

running state, input/output terminal signal and so on

Overspeed, overvoltage/under-voltage of main power supply,

overcurrent, overload, brake abnormity, encoder abnormity, control

power supply abnormity, orientation oversize

2500 pulse/rev (resolution:10000) incremental

encoder

10

Page 23

Chapter 3 System configuration and assembly

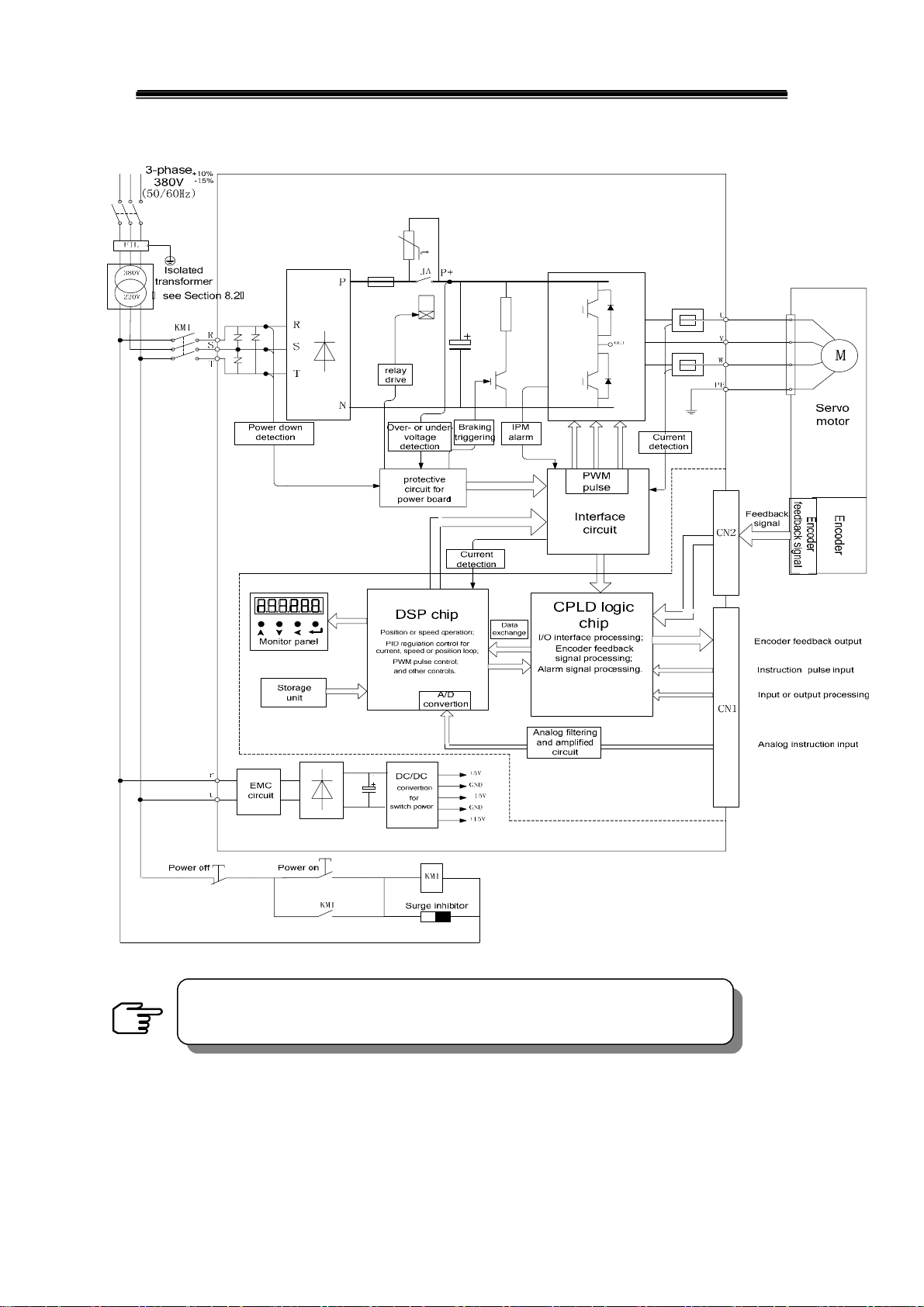

3.2 Interior diagram block of servo unit

3.3 Wiring

Fig. 3.1 Interior diagram block for DA98B servo unit

Control board diagram block inside the broken line and power supply board

diagram block outside the broken line above.

There are several control modes for DA98B: orientation control mode, speed control

mode etc. Personnel who take up the wiring and checking should be qualified for

11

Page 24

GSK CNC Equipment Co., Ltd.

the work, they must do wiring as the terminal voltage and poles by the manual for

prevention of the device damage or the injury to personnel.

Main circuit wiring

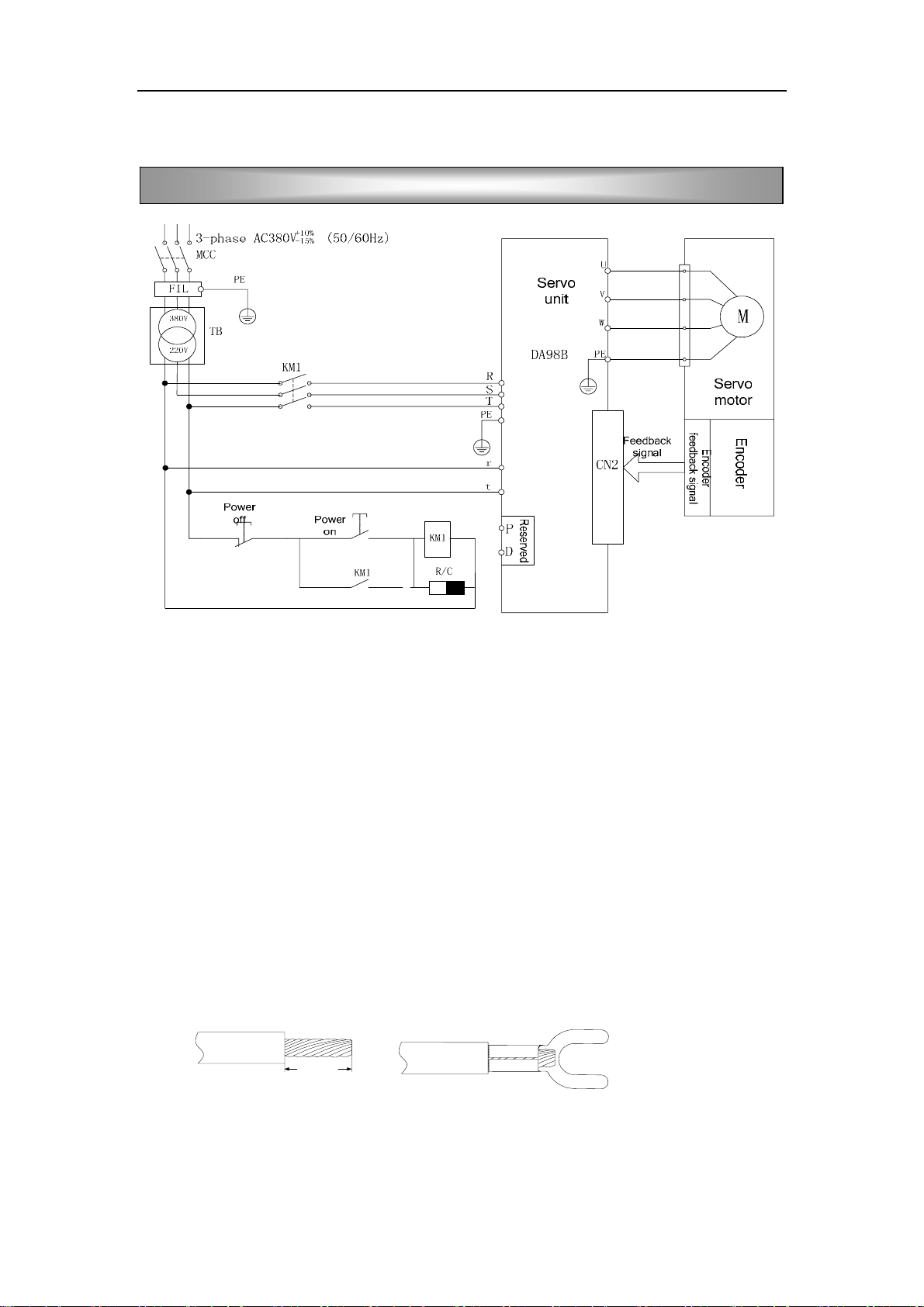

Fig.3.2 Typical wiring for the main circuit

MCC : Breaker FIL :Disturbance filter

TB : Isolated transformer KM1 :AC contactor

R/C : Surge inhibitor P, D :Reserve

■ The breaker should be selected B type short circuit device, the drop-away current is

more1.3 times than servo rated input one, otherwise is less than 1.05 times than the

servo rated input current.

■ Single phase power supply AC220V(+10%~-15%) can be employed when the

precision is comparative low and the power is less than 0.8KW for servo unit, and its

the wiring is as fig.3.2

■ While connecting the terminals, peel the insulative surface of the wire and twist the

naked copper wires, compress the wiring by the pre-insulation cold pressing terminals

to fasten the connection.

Table 3-2 Wire sections for main circuit (Unit: mm

6~8mm

2

)

12

Page 25

r

Output

power

Typ e

0.4~0.8(kW)

Chapter 3 System configuration and assembly

R S T PE U V W r t

Input terminals

of the main

power supply

1.5 1.5 1.5 ≥2.0 1.5 1.5 1.5 1.0 1.0

Protection

earthing

Output

terminals of

power

Input

terminals of

the control

power

1.0~1.5(kW)

1.7~2.6(kW)

!

Caution to main circuit wiring:

2.0 2.0 2.0 ≥2.0 2.0 2.0 2.0 1.0 1.0

2.5 2.5 2.5 ≥2.5 2.5 2.5 2.5 1.0 1.0

①Wires from power supply must not be directly connected with the U, V, W

terminals.

②U, V, W wires should connect with motor terminals correspondingly.

Operation of reverse rotation for motor by exchanging the wires of

three-phase terminals is not allowed.

③Due to the high frequency switch current in the motor, the leaking current is

relatively larger, the motor grounding terminal must be connected with the

servo unit grounding terminal PE and the grounding resistance should be less

than 100Ω.

④Do not touch the servo unit and motor in 5 minutes after the power supply

is switched off because there is large electrolytic capacitance keeping high

voltage inside the servo unit even if it is switched off.

⑤Operator should keep a certain distance to the servo unit and motor afte

the power is switched on.

⑥Servo motor must not be drived by the industrial power directly connecting

to the U, V, W terminals of motor in the absence of servo unit, or the servo

motor will be damaged.

13

Page 26

GSK CNC Equipment Co., Ltd.

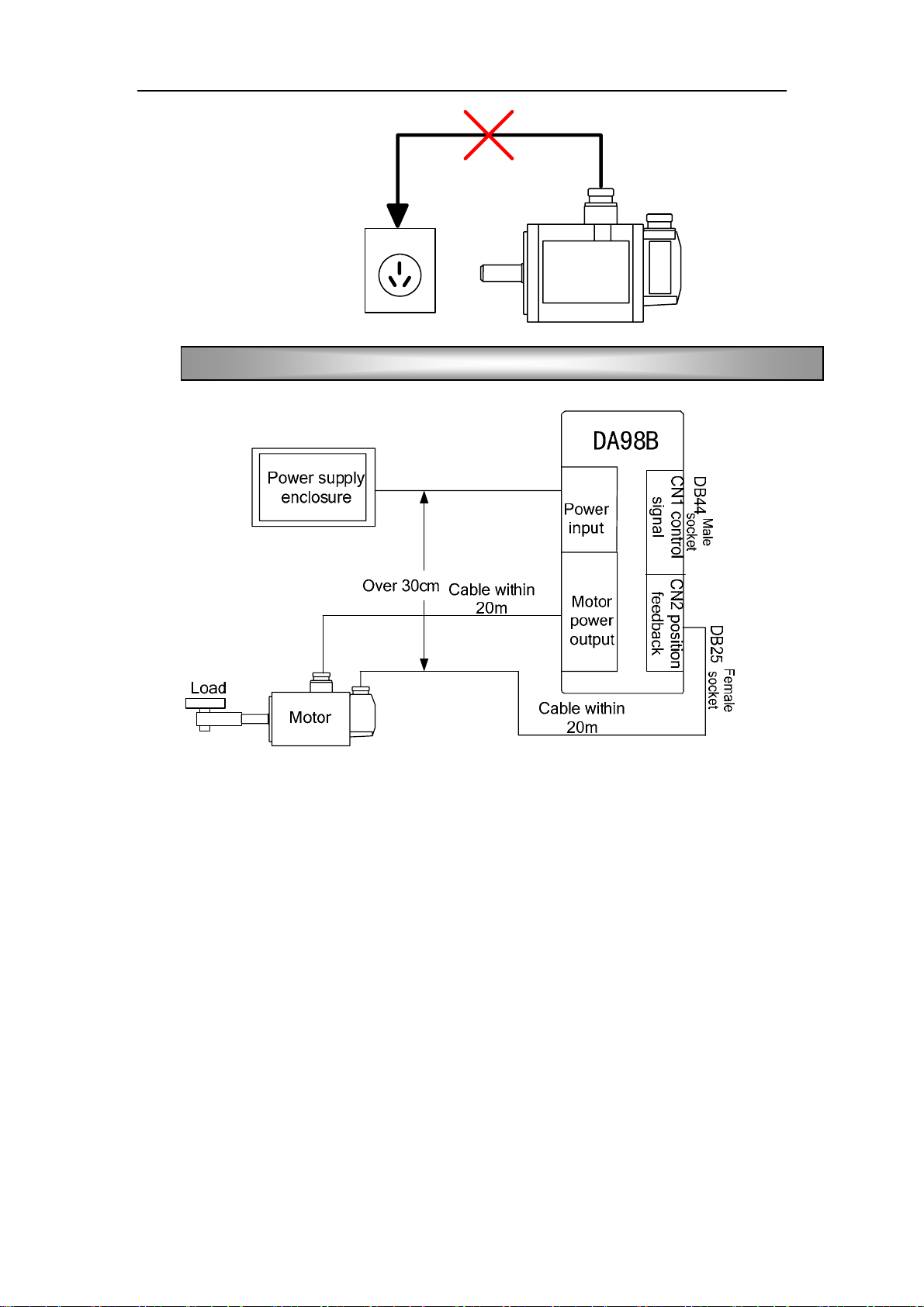

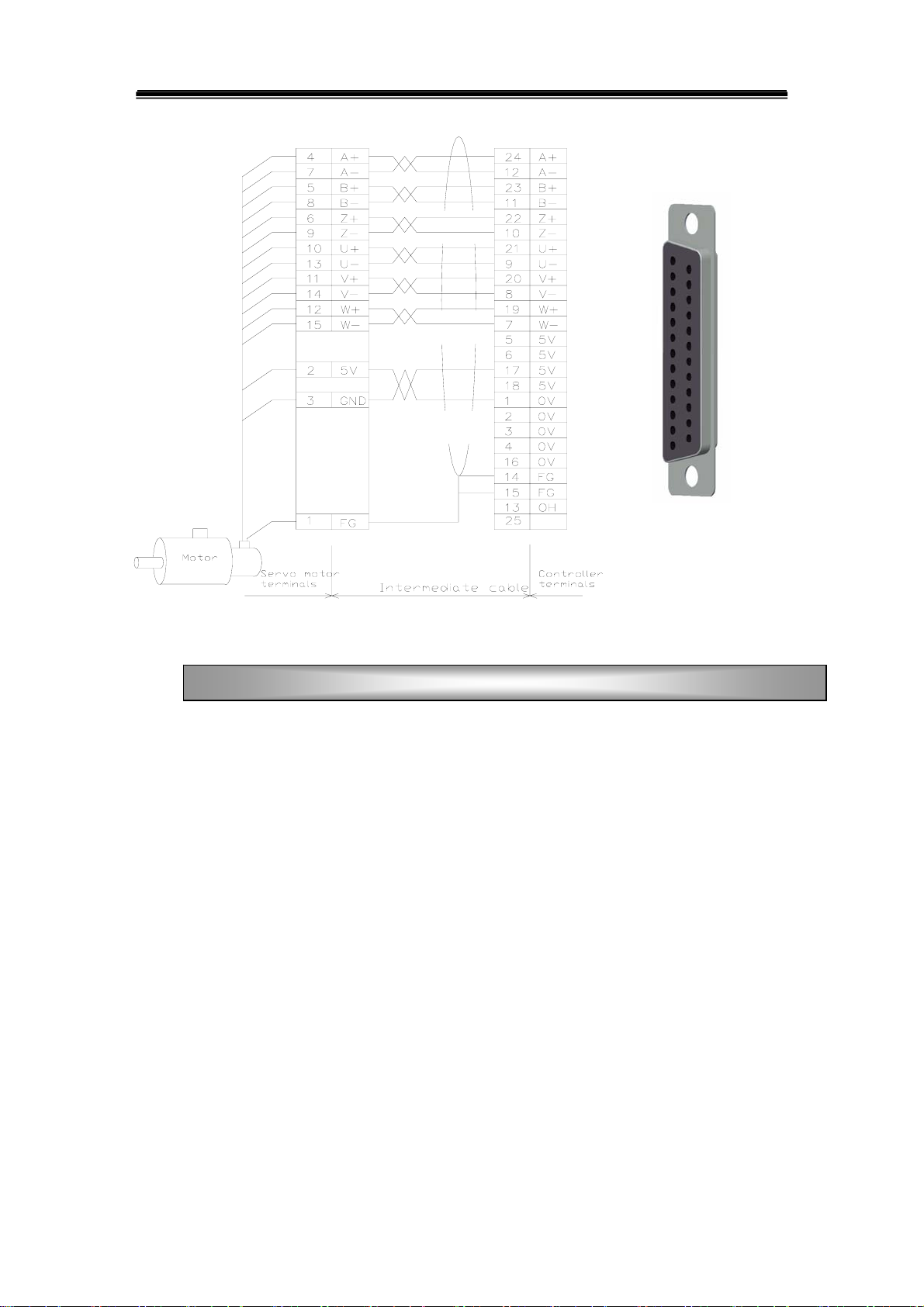

CN2 terminal wiring

①The cable length between the servo unit and motor should be within 20 meters.

②The distance between the feedback cable of encoder and main circuit cable

should be over 30cm as well as the both cables should not use the same tube or be

bound together.

③Shielded cable with the size 0.15mm²~0.20mm²(AWG24-26) should be used for

feedback signal cable, and the shielded tier should connect with FG terminal.

④The cables and wares should be well fixed as well as not be adjacent to servo unit

radiator or motor for their protection of insulation against heating.

⑤The wiring of CN2 in the following sketch map is done by accordance of GSK SJT

series motor. If user uses motor from other manufacturers or self-made wires, the

wiring below should be followed by.

connect to OH, OV terminals for motor with temperature controller.)

(Leading wires of temperature controller

14

Page 27

Chapter 3 System configuration and assembly

Vacancy

CN2 (DB25F)

Fig.3.3 Encoder wiring

① The cable length of the control signal should be within 3m.

② The distance to the main circuit cable should be above 30cm as well as the both

cables should not use the same tube or be bound together for protection against

disturbance.

③ The external power supply should be provided by user.

④ There are different wirings for CN1 terminal in different control modes, see

section 3.5 for details.

CN1 terminal wiring

15

Page 28

GSK CNC Equipment Co., Ltd.

Fig.3.4 Terminals and definition of CN1

16

Page 29

Chapter 3 System configuration and assembly

Input and output interface pattern for CN1

Ta b l e 3―3 Terminal signal type

Input terminals Output terminals Other terminals

Pin No. Sign Signal type Pin No. Sign Signal type No. Sign

23 SON 19 ZSP 2 DGND

8 ALRS 35 COIN/SCMP 4 AGND

9 RSTP 34 GOU1

24 FSTP 5 ALM 31 PE

40 CLE/SC1 20

41 INH/SC2 7 33 DG

10 RIL 6

25 FIL 36 39 COM+

SRDY

HOLD+

HOLD_

CZ+

16 AGND

32 DG

38 COM+

26 ZSL 37

11 GIN1

1 AGND 21

17 VCMD

30 12

15

29 13

14

PULS+

PULS-

SIGN+

SIGN-

43

CZ-

22

27

RLYOU+

RLYOU-

PAOUT+

44 PE

PAOUT-

28

42

PBOUT+

PBOUT-

PZOUT+

PZOUT-

17

Page 30

GSK CNC Equipment Co., Ltd.

3.4 I/O Interface fundamentals

CN1 interface signal

There are 7 types of CN1 interface signal as following:

Switching volume input,

resistance in series for one internal photoelectric coupling; K lateral pole is connected

to input terminal for one photoelectric coupling.

Switching volume output,

to output terminal for two internal photoelectric couplings. The max. current ≤15mA

Switching volume output,

pole to output terminal for two internal Darlington output photoelectric couplings. The

max. current ≤50mA

Pulse input interface,

terminal via a resistance in series and K pole to negative input terminal for one

internal high speed photoelectric coupling.

Differential output,

differential output chip 26LS31

A lateral pole is connected to COM+ via 3kΩ

,

E lateral pole is connected to DG terminal, C pole

,

E lateral pole is connected to DG terminal, C

,

A lateral pole is connected to positive input

,

internally connecting the output terminal of

,

Analog signal input,

Analog signal output,

amplified circuit.

Input interface of switching

interior is the difference-analog amplified circuit input.

,

internally connecting the output of operational

,

Controller side

Fig. 3.5 Input interface of switching volume

(1) Power supply is provided by user,DC12~24V,current≥100mA;

(2) Note: if power polarities are wrongly connected, the servo unit does not work.

18

Page 31

Chapter 3 System configuration and assembly

Output interface of switching

控制装置侧

Controller side

max 50mA

max 24V

Fig. 3.6 Output interface of switching volume

(1) External power supply is provided by user, and if its polarities are connected

reversely, the servo unit will be damaged;

(2) Output is electron collector open circuit, max. current is 50mA, and the max.

external DC power voltage is 25V. Load of switching volume output signal must

meet the requirement. If the load exceeds them or output is connected directly

with power supply, the servo unit may be damaged;

(3) If the load is an inductive one such as relay, terminals of load must be connected

with freewheeling diode in parallel. If they are connected reversely, the servo unit

will be damaged.

Pulse volume input interface

Controller side

控制装置侧

PULS+

PULS-

SIGN+

SIGN-

Fig. 3.7 Differential drive mode of pulse volmue input interface

270

270

19

Page 32

GSK CNC Equipment Co., Ltd.

控制装置侧

VCC

PULS+

R

PULS-

Controller side

270

SIGN+

R

SIGN-

270

Fig. 3.8 Single terminal drive mode of pulse volume input interface

(1) It is suggested to apply differential drive mode to correctly transmit pulse volume

data;

(2) AM26LS31, MC3487 or RS422 linear driver are employed in the differential drive

mode;

(3) Action frequency will be reduced in single terminal drive mode. According to pulse

volume input circuit, Resistance R is determined by the max. 25V voltage of external

power and 10 ~ 15mA drive current of the pulse input circuit. Practical data:

VCC=24V,R=1.3~2K;VCC=12V,R=510~820Ω;VCC=5V,R=82~120Ω.

(4) Refer to Table

Table

3-5 shows pulse input time sequence and parameter. If two-phase input

3-4 about pulse input form, arrowhead indicates counting curb, and

form is employed, 4-fold pulse frequency is less than 500kHz.

Table

3-4 Pulse input pattern

Pulse instruction form CCW CW Parameter setting value

Pulse string sign

PULS

0

Instruction pulse +sign

SIGN

CCW pulse string

CW pulse string PULS

1

CCW pulse /CCW pulse

SIGN

A phase pulse string

B phase pulse string PULS

2

2-phase instruction

pulse

SIGN

20

Page 33

Chapter 3 System configuration and assembly

Table 3-5 Pulse input sequence parameter

Parameter Differential drive input Single terminal drive input

t

ck

>2µS >5µS

th >1µS >2.5µS

tl >1µS >2.5µS

trh <0.2µS <0.3µS

trl <0.2µS <0.3µS

ts >1µS >2.5µS

t

>8µS >10µS

qck

tqh >4µS >5µS

tql >4µS >5µS

t

<0.2µS <0.3µS

qrh

t

<0.2µS <0.3µS

qrl

tqs >1µS >2.5µS

t

PULS

SIGN

90%

10%

90%

10%

h

t

t

rh

t

rl

s

t

ck

t

t

l

s

t

CW

rh

CCW

t

rl

CW

Fig. 3.9 Sketch map of pulse +sign input interface time sequence

(max. pulse frequency 500kHz)

t

ck

t

h

90%

PULS

SIGN

10%

90%

10%

t

rh

CCW

t

l

t

rl

t

s

t

rh

t

rl

CW

Fig. 3.10 CCW pulse /CW pulse input interface time sequence (max.

pulse frequency 500kHz)

21

Page 34

GSK CNC Equipment Co., Ltd.

t

t

90%

PULS

10%

t

qrh

qs

t

qrl

t

90%

SIGN

10%

Fig. 3.11 2-phase instruction pulse input interface time sequence

(max. pulse frequency 125kHz)

Input interface of photoelectric encoder

qck

qh

t

ql

t

qs

t

qrl

t

qrh

CCW

Controller side Motor side

控制装置侧电机侧

CW

X+

X-

AM26LS32

X=A,B,Z,U,V,W

Fig. 3.12 Input interface of servo motor photoelectric encoder

22

Page 35

Chapter 3 System configuration and assembly

g

3.5 Standard conection

3.5.1 Orientation control

Standard Wirin

Fig.3.13 Standard wiring of orientation control mode

Terminal functions of position control mode

Table 3-6 Terminal functions of orientation control mode

Sign Function Sign Function

Encoder A phase differential positive

SON

ALRS

Servo on input terminal

Alarming cancellation input

PAOUT+

PAOUT-

PBOUT+

23

output

Encoder A phase differential negative

output

Encoder B phase differential positive

Page 36

GSK CNC Equipment Co., Ltd.

o

FSTP

RSTP

PULS+

PULS-

SIGN+

SIGN-

GIN

terminal

CCW drive stop

CW drive stop

PLUS instruction pulse input

SIGN instruction pulse input

Universal input terminal

PBOUT-

PZOUT+

PZOUT-

SRDY

ALM

CZ+

CZ-

COIN

output

Encoder B phase differential negative

output

Encoder Z phase differential positive

output

Encoder Z phase differential negative

utput

Output terminal ready, identical to the

time sequence of HOLD signal, and

also used for hold release output

(see section 6.3)

Alarm output terminal

Z phase pulse output of photoelectric

encoder

Common terminal of z phase pulse output

terminal

Orienting completion output

CLE

INH

FIL

RIL

COM+

DG

DGND

PE

Orientation deviation reset

input

Instruction pulse disabled input

CCW torque limit input

CW torque limit input

Power supply positive of input

terminal, used for driving

photoelectric coupling of

input terminal

DC12~24V,Current≥100mA

External input(12 ~ 24VDC)

reference earthing

Internal digital earthing

Protection earthing

GOU1

General output 1

RLYOU+

RLYOU-

Reserved

HOLD+

HOLD-

Hold release output of motor

Hold release grounding output of motor

(see section 6.3)

24

Page 37

3.5.2 Speed control

Chapter 3 System configuration and assembly

Single- or

three- phase

AC 220V

DC 12~24V

Servo on

Alarm cancellation

CCW drive stop

CW drive stop

Speed choice 1

Speed choice 2

CCW torque limit

CW torque limit

Universal input 1

Zero-speed clamping input

Universal output 1

Speed in position

Zero speed output of motor

Output common terminal

Servo alarm

Servo ready

FIL

Standard Wiring

KM1

R

DA98B

S

AC servo

T

one-axis controller

r

t

CN1

COM+

38

COM+ 39

SON 23

ALRS 8

FSTP 24

RSTP 9

SC1

SC2

FIL

RIL

GIN1

ZSL

GOU1

SCMP

ZSP

ALM 5

SRDY

DGND

1k

40

41

25

10

11

26

34

35

19

20

32

DG

33

DG

2

U

V

W

PE

CN2

55V

6

17

18

1

20V

3

4

24 A+

12

23

11 B22 Z+

10

21

9U20 V+

8

19

7W13 OH

14 FG

15 FG

16

Motor

2

3

4

1

5V

5V

5V

0V

0V

0V

AB+

ZU+

VW+

0V

Vcc

GND

A+

AB+

BZ+

ZU+

UV+

VW+

WFG

encoder

2

3

4

7

5

8

6

9

10

13

11

14

12

15

1

Speed instruction

(-10V +10VDC)

Speed instruction earthing

Hold release signal

Hold release signal earthing

Z-phase output of encoder

Z-phase output earthing of encoder

reserved

reserved

VCMD

AGND

HOLD+ 7

HOLDRLYOU+ 22

RLYOU- 21

CZ+

CZ- 36

17

1

CN1

6

37

CN1

27

A

B

Z

12

28

13

42

43

31

44

PAOUT+

PAOUTPBOUT+

PBOUTPZOUT+

PZOUT-

PE

PE

Fig3.14 Standard wiring for speed control mode

Terminal functions for speed control mode

Table 3-7 Terminal functions for speed control mode

Sign Function Sign Function

Encoder A phase differential positive

SON

ALRS

Servo on input terminal

Alarming cancellation input

terminal

PAOUT+

PAOUT-

PBOUT+

PBOUT-

output

Encoder A phase differential

negative output

Encoder B phase differential positive

output

Encoder B phase differential

negative output

Pulse feedback A

Pulse feedback B

Pulse feedback C

25

Page 38

GSK CNC Equipment Co., Ltd.

SC1

SC2

GIN

FSTP

RSTP

FIL

RIL

Forward rotation signal input for

analog instruction voltage 0~10 V

input

Backward rotation signal input for

analog instruction voltage 0~10 V

input

General input terminal

CCW drive stop

CW drive stop

CCW torque limit input

CW torque limit input

PZOUT+

PZOUT-

SRDY

ALM

CZ+

CZ-

SCMP

GOU1

RLYOU+

RLYOU-

Encoder Z phase differential positive

output

Encoder Z phase differential negative

output

Output terminal ready, identical to

the sequence of HOLD signal,

and also used for hold release

output (see section 6.3)

Alarm output terminal

Z phase pulse output of photoelectric

encoder

Common terminal of z phase pulse

output terminal

Speed in orientation output

General output 1

Reserved

VCMD

AGND

ZSL

COM+

DG

DGND

PE

Speed analog instruction input, the

instruction voltage range:-10~+10

VDC

Earthing of analog instruction input

terminal

Zero speed clipping input terminal

Power supply positive of input

terminal, used for driving

photoelectric coupling of input

terminal

DC12~24V,Current≥100mA

External input(12 ~ 24VDC)

reference earthing

Internal digital earthing

Protection earthing

HOLD+

HOLD-

ZSP

Hold release output of motor

Hold release grounding output of

motor (see section 6.3)

Zero speed output of motor

26

Page 39

Chapter 4 Parameter

Chapter 4 Parameter

There are various parameters in the servo unit to be adjusted and set to the performance,

characteristics and so on, which can meet the requirement for the different functions by

user. The user should make a complete study of the parameters before searching, setting

and adjusting the parameters by the control panel.

4.1 Parameter list

P: orientation S: speed

No. Name Applicable

mode

PA 00 Password 0~9999 315

PA 01 Motor type code 0~63 0

PA 02 Software version (read only) 2.04

PA 03 Initial display state 0~20 0

PA 04 Control mode selection 0~5 1

PA 05 Speed proportional gain P,S 5~2000 600

PA 06 Speed integration time constant P,S 1~1000 15

PA 07 Torque instruction filter

PA 08 Speed detecting low pass filter constant P,S 1~5000 200

PA 09 Orientation proportional gain P 1~1000 40 1/S

PA 10 Orientation feedforward gain P 0~100 0 %

PA 11 Orientation feedforward instruction filter

cut-off frequency

PA 12 Orientation instruction pulse dividing

numerator

PA 13 Orientation instruction pulse dividing

denominator

PA 14 Input and analog instruction selection of

orientation instruction pulse

PA 15 Orientation instruction pulse reverse

direction

PA 16 Orienting completing range P 0~30000 20 Pulse

PA 17

PA 18

Orientation out-of-tolerance detecting

range

Orientation out-of-tolerance invalid

P,S 1-1500 500 %

P 1~1200 300 Hz

P 1~32767 1

P 1~32767 1

P

P 0~1 0

P 0~30000 400 ×100 pulse

P 0~1 0

Setting range Factory setting Unit

0~3

0

PA 19 Reverse analog speed S 0~1 0

PA 20 Drive stop input invalid P,S 0~1

PA 21 JOG running speed instruction S -31000~31000 2000 0.1rpm

PA 22 Analog speed instruction aberrance S -500~500 0 0.1rpm

PA 23 Max. speed limit P,S 0~31000 30000 0.1rpm

PA 24 Internal speed 1 S -30000~30000 1000 0.1rpm

27

Page 40

GSK CNC Equipment Co., Ltd.

PA 25 Internal speed 2 S

PA 26 Internal speed 3 S -30000~30000 2000 0.1rpm

PA 27 Internal speed 4 S -30000~30000 -3000 0.1rpm

PA 28 Speed in orientation S

PA 29 Max. speed of analog instruction S

PA 30 Conversion numerator for linear speed P,S

PA 31 Conversion denominator for linear speed P,S

PA 32 Decimal point for linear speed P,S

PA 34 Internal CCW torque limit P,S

PA 35 Internal CW torque limit P,S

PA 36 External CCW torque limit P,S

PA 37 External CW torque limit P,S

PA 38 JOG torque limit of trial speed S

PA 52 Latency for hold stop P,S

-30000~30000 -500 0.1rpm

0~30000

0~31000

1~32767

1~32767

0~5

0~300

-300~0

0~300

-300~0

0~300

5000 0.1rpm

25000 0.1rpm

10

1

3

300 %

-300 %

300 %

-300 %

300 %

0-32767 0 ms

4.2 Parameter function

No. Name

PA 00 Password

PA 01 Motor type code The motor models Corresponding to PA01 are as following, refer to

PA 02 Software version

PA 03 Initial display state

(Display state

selection after servo

unit power is

switched on)

Function

It is used for parameter not to be modified by mistake. Set it for 315

when a parameter is needed to set. After debugging, set it for 0 to

ensure it not to be modified by mistake later.

Section 4.3 for details.

PA01 Motor model

12 110SJT-M060D

17 130SJT-M100D

19 130SJT-M150D

35 110ST-M04030H

① Software version can be seen but can not be modified.

0: Motor speed display;

1: Low 5-bit digit display of current orientation;

2:High 5-bit digit display of current orientation;

3: Low 5-bit digit display of orientation instruction(instruction pulse

accumulation );

4:High 5-bit digit display of orientation instruction(instruction pulse

accumulation );

5:Low 5-bit digit display of orientation deviation;

6: High 5-bit digit display of orientation deviation;

46 130ST-M06025H

Parameter

range

0~9999

0~63

Ver 2.04

0~20

28

Page 41

Chapter 4 Parameter

7: Motor torque display;

8: Motor current display;

9: Linear speed display;

10:Control mode display;

11: Orientation instruction pulse frequency display;

12: Speed instruction display;

15: Input terminal state display;

16: Output terminal state display;

17: Encoder input signal display;

18: Running state display;

19: Alarm code display;

20: Reserved.

PA 04 Control mode

selection

PA 05 Speed proportional

gain

Set control mode of the servo unit by the parameter:

0:Orientation control mode, orientation instruction input by pulse input

port

1:Speed control mode, speed instruction input by VCMDIN, VCMDINC

analog input terminals

2:Internal speed control mode

3:Manual mode

4:JOG mode

5:Encoder zero-adjusting mode

① Proportional gain set of speed loop regulator

② The bigger the setting value is, the higher the gain is and the bigger

the rigidity is. Parameter value is

SC2 SC1

OFF OFF 1

OFF ON 2

ON OFF 3

ON ON 4

determined by specific servo unit

Internal speed

0~5

5~2000Hz

PA 06 Speed integral time

model and load. Generally, the bigger the load inertia, the bigger the

setting value is.

③ Set the bigger value if there is no vibration for system.

① Integral gain set of speed loop regulator

29

1~1000ms

Page 42

GSK CNC Equipment Co., Ltd.

constant ② The bigger the setting value is, the higher the integral speed is and

the bigger the rigidity is. Parameter value is

specific servo unit model and load. Generally, the bigger the load

inertia, the smaller the setting value is.

③ Set the bigger value if there is no vibration for system.

PA 07 Torque instruction

filter

PA 08 Speed detecting low

pass filter constant

PA 09 Orientation

proportional gain

PA 10 Orientation

feedforward gain

PA 11 Orientation

feedforward

instruction filter

coefficient

PA 12 Orientation

instruction pulse

dividing numerator

PA 13 Orientation instruction

pulse dividing

① Set cut-off frequency of low pass filter of torque instruction.

② It is used for limiting the frequency band of current instruction to get

the stable current response against the impact and vibration of the

current.

③ Set the bigger value if there is no vibration for system.

① Low pass filter cut-off frequency set for speed detection

② The smaller the setting value is and the lower the cut-off frequency

is, the lower the noise from motor is. If the load inertia is very large,

reduce the setting value properly. If the value is too small, vibration

may be caused by slow response.

③ The bigger the setting value is and the higher the cut-off frequency

is, the quicker the speed feedback response. If higher speed

response is

appropriately.

①Proportional gain set of orientation loop regulator

②he bigger the setting value is, the higher the gain is and the bigger the

rigidity is, the smaller the orientation lag is. But if the value is too big, the

vibration and overshoot may occur.

③The value is decided by special servo unit model and load.

① Feedforward gain set of orientation loop

② When it is set for 4096, it means that orientation lag is 0 in any

instruction pulse frequency.

③ If the feedforward gain of orientation loop increases and the high

response of the control system is raised, overshoot may occur for the

instability of the system orientation loop caused.

④Unless the high response is needed, the feedforward gain of

orientation loop is usually 0.

①Cut-off frequency determination of orientation

pass filter.

②The low pass filter is used for increasing the stability of complex

orientation control.

③The bigger the parameter value is and the higher the cut-off frequency

is, the more liable the noise and overshoot are to occur in running.

Refer to Section 6.2.5.

Refer to Section 6.2.5.

determined by

needed, the setting value can be increased

loop feedforward low

1-1500%

1~5000

1~1000/S

0~100%

1~1200

1~32767

1~32767

30

Page 43

denominator

PA 14 Input and analog

instruction selection

of orientation

instruction pulse

PA 15 Orientation

instruction pulse

reverse direction

Chapter 4 Parameter

① there are 4 modes to be selected:

0 pulse+sign; analog voltage(-10 ~ +10) valid in analog instruction

mode

1 CCW pulse/CW pulse

2 two-phase orthogonal pulse input

3 analog voltage(0~+10) instruction valid in analog instruction mode

(SC2, SC1 for forward and reverse rotation selection)

② CCW rotation is defined as the forward direction when viewed from

the axial direction.

③ CW rotation is defined as the reverse direction when viewed from

the axial direction.

① Reverse direction of orientation instruction pulse, set for

0:normal;

1:reverse direction of orientation instruction pulse.

0~3

0~1

PA 16 Orienting completing

range

PA 17

Orientation out-of-

tolerance detecting

range

PA 18

PA 19 Reverse analog

Orientation out-of-

tolerance

speed

invalid

① Pulse range set for orienting completion in orientation control mode.

② The parameter provides factors the servo unit judges whether the

orienting is completed in orientation control. When remainder pulses

in orientation

value of the parameter, the servo unit defaults that the orienting is

completed and the signal for it is COIN ON, otherwise it is COIN OFF.

③ Orienting completing output signal is COIN in orientation control

mode, and speed in-orientation output signal is SCMP in other control

mode.

① Alarm detection range set of orientation out-of-tolerance.

② In orientation control mode, servo unit makes alarm of orientation

out-of-tolerance when the counting of orientation deviation counter

exceeds the parameter setting.

① Orientation out-of-tolerance enabling parameter, set for

0:The alarm is valid.

1:The alarm is invalid.

Reverse of analog speed instruction, set for

0:Normal.

deviation counter are less than or equal to the setting

0~30000

pulse

0~30000×

100 pulse

0~1

0~1

PA 20 Drive stop invalid

input

PA 21 JOG running speed

instruction The running speed set in JOG mode.

PA 22 Analog speed

instruction

1:Reverse of analog speed instruction.

Drive stop invalid input setting, set for

0:Allowable input of drive stop signal

1:Not allowable input of drive stop signal.

Analog speed instruction aberrance set

31

0~1

-31000~31

000

0.1r/min

-500~500

0.1r/min

Page 44

GSK CNC Equipment Co., Ltd.

aberrance

PA 23 Max. speed limit

PA 24 Internal speed 1

PA 25 Internal speed 2

PA 26 Internal speed 3

PA 27 Internal speed 4

PA 28 Speed in orientation

PA 29 Max. speed of

analog instruction

PA 30 Conversion

numerator for linear

speed

① Max. speed limit set of servomotor.

② It is irrelevant to rotary direction.

③ If the setting exceeds the rated speed, the actual max. speed limit is

the rated speed.

① Internal speed 1 set.

See PA04.

① Internal speed 2 set.

②See PA04.

①Internal speed 3 set.

②See PA04.

①Internal speed 4 set.

②See PA04.

① Speed in orientation set

② Not available in orientation control mode

③ Irrelative to rotation direction

Instruction value of max. speed corresponding to max. analog voltage

output

① Used for linear speed

② Linear speed = motor speed (r/min)×

0~31000

0.1r/min

-30000 ~

30000

0.1r/min

-30000 ~

30000

0.1r/min

-30000 ~

30000

0.1r/min

-30000 ~

30000

0.1r/min

0~30000

0.1r/min

0~31000

0.1r/min

1~32767

speedlinear for numerator conversion

speedlinear for r denominato conversion

③ The orientation of linear speed decimal point is determined by

parameter PA32. And 0 stands for no point, 2 for 2-bit and so on.

④ 【Example】If servo motor drives 10mm ball screw, then set the

conversion numerator for linear speed for 10, conversion

denominator for linear speed for 1, the decimal point orientation of

linear speed is 3. linear speed can be displayed in monitor with the

unit m/min. When the speed of motor is 500r/min, linear speed

5.000m/min will be displayed.

PA 31 Conversion

denominator for

linear speed

PA 32 Decimal point for

linear speed

PA 34 Internal CCW torque

limit

32

See parameter No.30.

See parameter PA30.

① Internal torque limit set in CCW direction of servo motor.

② The setting is the percent of rated torque. e.g. if the setting is the

double of rated torque, the setting is 200.

1~32767

0~5

0~300%

Page 45

PA 35 Internal CW torque

limit

PA 36 External CCW

torque limit

PA 37 External CW torque

limit

PA 38 JOG torque limit of

trial speed

PA 52 Latency for hold

stop

Chapter 4 Parameter

③ The limit is valid under any conditions.

④ If the setting exceeds max. overload allowable, the actual torque

limit is the max. loading.

①Internal torque limit set in CW direction of servo motor.

②The setting is the percent of rated torque. e.g. if the setting is the

double of rated torque, the setting is 200.

③The limit is valid under any conditions.

④If the setting exceeds max. overload allowable, the actual torque limit

is the max. loading.

① External torque limit set in CCW direction of servo motor.

② The setting is the percent of rated torque. e.g. if the setting is the

rated torque, the setting is 100.

③ The limit is valid only when the CCW torque limit input terminal (FIL)

is ON.

④ If the limit is valid, the actual torque limit is the minimum of the

absolute values among the max. overload allowable, internal or

external torque limit.

① External torque limit set in CW direction of servo motor.

② The setting is the percent of rated torque. e.g. if the setting is the

rated torque, the setting is 100.

③ The limit is valid only when the CW torque limit input terminal (RIL)

is ON.

④ If the limit is valid, the actual torque limit is the minimum of the

absolute values among the max. overload allowable, internal or

external torque limit..

①The setting is the percent of rated torque. e.g. if the setting is the rated

torque, the setting is 100.

② Internal or external torque limit is valid in any conditions.

①As for the motor with brake, if the servo on signal is cancelled, the

motor will be activated for working for some time by servo unit.

② Latency=setting value×4ms

(Refer to Section 6.3.)

-300~0%

0~300%

-300~0%

0~300%

ms

4.3 Model code parameters for motors

PA01 parameters for STZ series servo motor

PA01 parameter Model and technological parameters of servo motor Remark

10

110SJT-M020E,0.6kW,220V, 3000rpm,3A,0.34×10

-3

kg.m2

11 110SJT-M040D, 1.0kW,220V, 2500rpm,4.5A,0.68×10-3kg.m2

12 110SJT-M060D, 1.5kW,220V, 2500rpm,7A,0.95×10-3kg.m2

13 130SJT-M040D, 1.0kW,220V, 2000rpm,4A,1.19×10-3kg.m2

33

Page 46

GSK CNC Equipment Co., Ltd.

14 130SJT-M050D, 1.3kW,220V, 2000rpm,5A,1.19×10-3kg.m2

15 130SJT-M060D, 1.5kW,220V, 2000rpm,6A,1.95×10-3kg.m2

16 130SJT-M075D, 1.88kW,220V, 2000rpm,7.5A,1.95×10-3kg.m2

17 130SJT-M100D, 2.5kW,220V, 2500rpm,10A,2.42×10-3kg.m2 ※

18 130SJT-M100B, 1.5kW,220V, 1500rpm,6A,2.42×10-3kg.m2

19 130SJT-M150B, 2.3kW,220V, 1500rpm,8.5A,3.1×10-3kg.m2 ※

20 130SJT-M150D, 3.9kW,220V, 2500rpm,14.5A,3.6×10-3kg.m2 ※

34

35

36

37

39

45

46

47

49

110ST-M02030H,0.6kW,220V, 3000rpm,4A,0.33×10

110ST-M04030H,1.2kW,220V, 3000rpm,5A,0.65×10

110ST-M05030H,1.5kW,220V, 3000rpm,6A,0.82×10

110ST-M06020H,1.2kW,220V, 2000rpm,6A,1.00×10

130ST-M04025H,1.0kW,220V,2500rpm,4A,0.85×10

130ST-M05025H,1.3kW,220V, 2500rpm,5A,1.06×10

130ST-M06025H,1.5kW,220V, 2500rpm,6A,1.26×10

130ST-M07720H,1.6kW,220V, 2000rpm,6A,1.58×10

130ST-M10015H,1.5kW,220V, 1500rpm,6A,2.14×10

-3

kg.m

-3

kg.m

-3

kg.m

-3

kg.m

-3

kg.m

-3

-3

-3

-3

kg.m

kg.m

kg.m

kg.m

2

2

2

2

2

2

2

2

2

50

51

60

130ST-M10025H,2.6kW,220V, 2500rpm,10A,2.14×10-3kg.m2

130ST-M15015H,2.3kW, 220V, 1500rpm,9.5A,3.24×10-3kg.m

150ST-M27020H,5.5kW,220V, 2000rpm,20.5A

※

2

※

For the motor above with the “※” mark, thickened radiator should

be applied for the suited servo unit.

34

Page 47

Chapter 5 Display and operation

Chapter 5 Display and operation

5.1 Keys operation

The DA98B servo unit is very easy to operate that the functions required can be set

by only 4 keys. The outline of its panel is as following:

For decrease of sequence number, value or backward selection

6-bit digital LED displayer

For increment of sequence number,

value or forward selection

Entering into the next layer of optional

menu or input confirmation

Back to the upper layer of optional

menu or operation cancellation

Operation procedure

1) In the speed monitoring mode, after switching on the power supply of the servo

unit, the default display is:

2) The operation is performed according to multi-layer menus. The first layer is the

r 0.0

;

main menu that consists of 9 kinds of operation modes, the second layer is the

function menus in various operation modes. The fig.5.1 shows the diagram block

of the main menu:

3) According to the diagram block above, pressing ‘

into the main menu, then press‘

After selecting a mode, press

Press ‘

Holding ‘ ’or ‘ ’key on, the operation will be repeated. The more the

holding time is, the faster the speed repeated is.

’ key to return if backing to upper menu is required.

’ or ‘ ’key to select any mode in the 9 modes.

key to enter the next menu of the mode.

’key or holding ‘ ’ can enter

35

Page 48

GSK CNC Equipment Co., Ltd.

Monitor mode

Parameter setting

Parameter

management

Speed trial run

JOG run

Encoder zero-

adjusting

Analog zero-

adjusting

Fig. 5.1 Diagram block of main menu

5.2 Monitoring mode

① Select “ ”in the main menu and press ‘ ‘ key to enter into

monitoring mode.

② There’re 21 display modes in monitoring mode. Select the desired display mode

by

‘ 、 ’keys, then press to enter into monitoring mode.

‘ ’

36

Page 49

Chapter 5 Display and operation

Fig. 5.2 Diagram block of monitoring mode

Explanation

1. or

r: Speed code for motor. It displays‘-’if the motor runs reversely in that

speed.

1000.0:Speed value for motor Unit: rev/min

2. The pulse number unit in this servo unit is 10000 pulse/rev, and orientation pulse

number is comprised by two parts of high 4-bit and low 5-bit. e.g.

=1245806 pulses

i.d. orientation instruction pulse number is also comprised by two parts, e.g.:

=1245810 pulses

10000

100000 +

+

37

Page 50

GSK CNC Equipment Co., Ltd.

Therefore, the formula for orientation deviation is:

3. Alarm display:

Alarm number

4. Running display

=

=

-

-

:No alarm, normal

:No.1 alarm

:No.36 alarm

5. Instruction pulse values in orientation mode are the magnified ones through

electronic gear.

6. Pulse frequency of orientation instruction is the actual one before inputting it

to the electronic gear with positive number for positive direction and negative

number for negative direction and its min. unit is 0.1kHz.

7. The formula for effective value of phase current of motor is as follows:

1

3

222

)(

IIII ++=

WVU

:Servo unit is being running

:Main circuit having been charged

:Main circuit having not been charged

8. The absolute orientation of rotor in a revolution means the relative orientation

of rotor to stator, where a revolution for a period with the range 0~9999.

9. The orientations of input terminals, output terminals and encoder signal are

38

Page 51

Chapter 5 Display and operation

shown as follows, and their definitions are shown in Fig.5.3, Fig.5.4, Fig. 5.5.

Fig. 5.3 Input terminal display (bright light is ON and dark light is OFF)

Fig. 5.4 Output terminal display (bright light is ON and dark light is OFF)

Fig. 5.5 Encoder signal display (bright light is ON and dark light is OFF)

5.3 Parameter setting

Prior to parameter setting, modify the parameter by the user password according to the

PA00 parameter in the parameter list. After the setting, press the‘

the setting. Attention should be paid for the parameter setting range against accident.

Select “PA-”in the first layer and press‘

parameter number by

‘ 、 ’,then press‘ ’to display the value of the parameter,

’to enter into parameter setting mode. Select

’key for confirming

modify the value by

the parameter value, press and hold on

value for the parameter. When the parameter value is modified, the decimal point of

rightmost LED digital tube is lighted, press‘

the decimal point of rightmost LED digital tube is put out. And the modified value will

‘ 、 ’. Press ‘ ’ or‘ ’key for once to increase or decrease 1 for

‘ ’or‘ ’to continuously increase or decrease

’to confirm the modification, and then

39

Page 52

GSK CNC Equipment Co., Ltd.

immediately be reflected in the control process, press‘ ’or‘ ’to go on modify

parameters till the completion of modification, then press

selection mode. Do not press‘

‘ ’to cancel it to make the parameter recover to its original value and back to the

press

’to confirm if the parameters modified are not proper,

‘ ’to back to parameter

parameter selection mode.

The following is the parameter setting procedure for GSK 110SJT-M040D servo motor

Power on

Back a layer

Back a layer

Menu selection

Forward a layer

Parameter value

Modification

Confirmation

Back a layer

Parameter selection

Parameter value

Modification

Confirmation

Back a layer

Back a layer

Menu selection

Forward a layer

Default call

Hold for 2s

Model code parameter

of the respective motor

:

Fig. 5.5 Diagram block of parameter setting

5.4 Parameter management

The parameter management is mainly used for memory and EEPROM operation.

Select “EE-” in the first layer and press‘

mode. 5 operation modes can be selected by

“ parameter writing ” , select “EE-Set”,then press‘

second, the monitor displays “

into EEPROM. After 1~2 seconds, the monitor displays “

successful, otherwise“ ” is displayed. Press ‘ ’again to return to operation

selection mode.

z EE-Set: parameter writing. It means to write the parameters in the memory into

EEPROM parameter area. The parameters modified by user only change the

’to enter into parameter management

‘ 、 ’keys. For example, for

’and hold it on for over 1

” that means the parameter is being written

” if the writing is

parameter values in the memory that they will restore to their original values after

power is on again. If the parameter values are changed permanently, parameter

writing should be executed to write the parameters in the memory into the

EEPROM parameter area, so the modified parameter values will be valid after

40

Page 53

Chapter 5 Display and operation

power is on again.

z EE-rd: parameter reading. It means to read the data in EEPROM parameter

area into the memory. The process will be executed automatically when power is

on. At the beginning, the parameters in the memory are the same as that of

EEPROM parameter area. If the parameters are modified by user, the parameter

values in the memory will be changed. If the user is not satisfied with the modified

parameter values or the parameters are disordered, the parameter reading can be

executed to read data in EEPROM parameter area into the memory to recover the

original parameters in the state of power on.

z

EE-bA: Parameter backup. (Reserved)

z EE-rs: Restoring backup. (Reserved)

z EE-dEF: Restoring default value. It means to read all default values (factory

setting) of parameters into the memory and write them into EEPROM parameter

area that they will be used when power is on again. Perform the above operation

to restore all parameters to their factory setting if the parameters are disordered

by user that cause the system to run abnormally. Because the different servo

motor corresponds to different parameter default value of the servo unit, the model

code of the servo motor must be ensured (parameter PA01) when restoring

default parameters.

Fig. 5.6 Diagram block of parameter management

41

Page 54

GSK CNC Equipment Co., Ltd.

g

The parameter setting will not be saved after the power is down and the

modification is invalid if the writin

modified parameter.

has not been executed for the

5.5 Additional information

The function of automatic gain adjustment being developed at present is not available.

The encoder zero-adjusting function unallowable to be used by user is provided for motor

manufacturer.

42

Page 55

Chapter 6 Trial run

Chapter 6 Trial run

6.1 Check before trial run

① Check wiring:

z Ensure the wiring, especially the connections of the power supply wiring and motor

wiring of servo unit.

z Ensure the earthing connection.

② Check power supply to ensure the normal voltage.

③ Fix the servo motor securely against overturning or bumping.

④ Perform the dry run operation in trial run to make sure the normal running prior to loading

running.

43

Page 56

GSK CNC Equipment Co., Ltd.

6.2.1 Sequence of power on for servo unit

The connection of power supply is shown as Fig.6.1, switch on the power by

following steps:

1) Put the power supply to the power input terminals of main circuit ( 3-phase to R,

S, T respectively, single phase to R,S) by electromagnetic contactor

(NFB、

MC).

2) The r, t terminals of control circuit should be switched on prior to the main circuit

power (or with it simultaneously without MC), then switch on the main circuit

manually. The cut-off function of main power for alarm is attached to the circuit.

Fig.6.1 Power supply wiring

3) If servo on (SON) is ON after the connection of the control power with the main

circuit power, the motor is activated and the system is on running. If servo on

signal is switched off or alarming occurs, the base electrode circuit closes and

the motor is in a free state.

a) If servo on (SON) is switched on with power supply, the motor is activated

in about 100 ms.

b) Frequent switching on or off the power supply may damage the soft start

circuit and energy hold circuit. The frequency limit for switching on or off

should be 5 times per hour or 30 times per day. If the servo unit or motor is

overheated, only by cooling of 30 minutes after the fault is exterminated,

can the power supply be switched on again.

4) Sequence for power switch on

44

Page 57

Chapter 6 Trial run

Power

supply

power on

ALRS

SON

Motor

activated

SRDY

power off

<600ms

ALM

6.2.2 JOG running

reset

OFFOFF ON ON OFF

power on

t<600us

power off

t<1ms

power on

power off

OFF ON OFF ON OFF

t<300us

alarm on

power on detection

t= PA52× 4

power down

800ms

Do switch off load prior to JOG running. If the JOG running is well done, it means that the

connection between the motor and the servo unit is correct.

Steps:

Connect CN1 for the control signal : OFF for servo enabling, ON for CCW drive ⑴

stop(FSTP), ON for CW drive stop(RSTP).

Power on for servo unit and the initial display is:⑵

Press‘⑶

’key, it displays:

Repress‘⑷

’key to back to the first layer menu, it displays

Press ‘⑸

’or ‘ ’key to find the parameter setting menu

Press‘⑹

’key, it displays

Press ‘⑺

’or ‘ ’key to find the No.4 parameter (others)

Press ‘⑻ ’or ‘ ’key to set No.4 parameter to 4, it displays

45

Page 58

GSK CNC Equipment Co., Ltd.

Press‘⑼ ’key to confirm the setting of the No.4 parameter,

it displays

i.b., set the PA21 parameter ⑽ to the motor speed required,

i.e. the JOG speed

Press ‘⑾

find the JOG mode

’key to back to the first main menu layer to

Press‘⑿

’key, it displays

Set ON for the enabling, press‘⒀ ’key and hold it on, the motor runs by the setting speed,

release the key, the motor running stops; press‘

reversely by the setting speed, release the key, the motor running stops with zero speed.

’key and hold it on, the motor runs

6.2.3 (Sr-) trial run

Change the value in PA-4 by 3 according to the JOG running steps above; select “Sr-” in the

first layer, press

and its unit is 0.1r/min. The system is in a speed control mode and the instructions of speed

are provided by keys operation. C, the motor runs by the speed instructions changed

by

‘ 、 ’key. Pressing ‘ ’key increases the speed, and pressing‘ ’key decreases the

speed. While the speed displayed is positive number, the motor runs forward; and negative

number for backward.

‘ ’key to enter into trial run mode. The prompt for speed trial run is “r”,

6.2.4 Speed control run

There’re two kinds of running control for speed. One is the analog speed instruction input,

the other is internal speed instruction. Details are as follows:

Analog speed instruction input

1) Input the control signal by the Fig.6.2 wiring diagram block: OFF for servo on (SON),

ON for CCW drive stop (FSTP), ON for CW drive stop (RSTP).

2) Set the analog voltage instruction for 0 V, ON for servo on (SON), the motor is activated

46

Page 59

Chapter 6 Trial run

V

with zero speed. If the motor runs in low speed, adjust the parameter PA22 to make the

motor to be in zero speed state.

3) Slowly adjust the analog voltage, the motor speed will vary by the voltage variation. The

highest motor speed in ±10V input voltage can be adjusted by modifying parameter

PA29. Be attentive that the highest running speed is limited by PA23.

4) Modify parameter PA19 if the rotation direction is required to be changed.

When PA19=0, motor runs forward (CCW) for positive voltage, backward(CW) for

negative voltage;

When PA19=1, motor runs backward (CW) for positive voltage, forward(CCW) for

negative voltage;

5) If vibration occurs in the CNC closed loop running, adjust parameter PA08 for feedback

filtering.

Wiring diagram block: pameter list

DC

12-24V

DC

-10V-+10

38

23

24

17

9

1

COM+

SON

FSTP

RSTP

VCMD

AGND

Sequence

number

PA04 Control mode

PA08 Low pass filter for

PA19 Reverse of analog

PA22 Instruction deviation

PA23 Highest speed setting

PA29 Highest speed of

Name Setting range Factory

0~6

selection

1~5000

speed detecting

0~1

speed

-500~500

of analog speed

-30000~30000

for motor

-30000~30000

analog instruction

Fig.6.2 Wiring for analog instruction control

Wirings for two types of CNC system for milling machines made by us.

setting

1

200

0

0

25000

25000

47

Page 60

GSK CNC Equipment Co., Ltd.

AGN

VCM

D

D

A

#

A

B

#

B

Z

#

Z

1

1

4

3

1

5

4

1

6

5

1

7

VCMD-

1

VCMD+

1

7

1

2

PAOUT

PAOUT

2

7

1

3

PBOUT

2

8

PBOUT

4

3

PZOUT

4

2

PZOUT

-

+

-

+

-

+

1

1

7

9

2

2

1

0

2

3

1

8

0

22

1

0

0

5

+VC

*PC

1

2

PCA

7

1

3

*PC

8

PCB

1

1

*PC

6

4

SRDY+

9

SON

3

+24

SON

1

4

2

1

5

5

3

0

5

9

4

6

7

8

PAOUT

PAOUT

PBOUT

PBOUT

PZOUT

PZOUT

ALM

SON

COM

COM

D

RST

FST

ALM

SON

PULS+

PULS-

SIGN+

SIGN-

CZCOM

C

Z

COM

-

+

-

+

-

+

+

+

G

P

P

+

IN0

OUT

1

XCP

+

XCP

-

XDIR+

XDIR-

PC0

+24

V

GND

Fi.g 6.3(a)Valid for analog and pulse instructions

-VC

A

B

Z

PCZ

2

3

1

2

1

3

3

3

VCMD-

1

VCMD+

1

7

1

2

2

7

1

3

2

8

4

3

4

2

5

2

+

V

-

0

V

0

V

3

3

9

3

8

3

2

9

2

4

(b)Valid for analog instruction

Internal speed instruction

48

Page 61

Chapter 6 Trial run

1) Input the control signal by connecting CN1: OFF for servo on(SON), OFF for speed

choose1 (SC1), speed choose2 (SC2), ON for CCW drive stop (FSTP), ON for CW

drive stop (RSTP).

2) Switch on the power supply of the control circuit, the servo unit displayer will light.

Check connection if alarming occurs.

3) Set the control mode selection(parameter PA04) for speed running mode(set for 2), set

the speed parameters PA24~PA27 as required.

4) Set servo on(SON) for ON, the motor will be activated for internal speed running state.

5) Change the states of input signal SC1, SC2 for different combinations of internal speed,

which is shown as following table:

SC1

I n t e r n a l s p e e d Parameter Setting range Unit

SC2

0

1 PA24

-30000~+30000

0.1rpm

0

0

2 PA25

-30000~+30000

0.1rpm

1

1

3 PA26

-30000~+30000

0.1rpm

0

1

4 PA27

-30000~+30000

0.1rpm

1

6.2.5 Orientation control run

1) Input the control signal by the Fig.6.4 wiring diagram block: OFF for servo on(SON),

ON for CCW drive stop (FSTP), ON for CW drive stop (RSTP).

2) Switch on the power and adjust the parameters, set appropriate electronic gear ratio

(PA12, PA13).

The so-called ‘electronic gear function’ is a function that compared to the mechanical

gear, the motor moving that is equivalent to the input instruction pulse can be set for any

value by the adjustment of servo parameters without considering the mechanical

reduction ratio and encoder pulses in controlling. By the setting of PA12, PA13

parameters, it is easy for user to match with various pulse resources to get the desirable

control resolution (i.e. angle/pulse).

The formula for electronic gear ratio is as follows:

4××=× CNGP

P:pulse amount of input instruction;

49

Page 62

GSK CNC Equipment Co., Ltd.

P

G:electronic gear ratio;

G=dividing numerator / dividing denominator

Recommended range of G is:

N:motor rotating circles;

C:photoelectric encoder lines/rev, in this system C=2500

【Example 1】When input instruction pulse is 6000, and servo motor rotation is 1:

5

4250014

6000

××

=

3

××

CN

=

G

so parameter PA12 is set for 5 and PA 13 is set for 3.

=

1

50

50

≤≤ G

【Example 2】

If the workpiece is required to move 10mm

Electronic gear ratio not used

For a 6mm moving in a revolution, it

needs 10÷6=1.6666 revolution; as for

2500×4 pulses for a revolution, the

instruction pulse input is

1.6666×2500×4=16666 pulses. And

the operation must be executed in the

upper device.

Electronic gear ratio used

The mechanical condition and

instruction unit must be defined in

advance by electronic gear ratio. If

the instruction unit is set for 1 um,

10mm moving needs

10mm÷1um=10000 pulses.

3) Set servo on(SON) for ON on condition that no alarming and abnormity occurs. The

motor will be actuated for zero speed.

4) Input low frequency pulse to make the motor run in a low speed, and check whether

the motor speed is the setting one. Stop inputting low frequency pulse to see