GSK990MA CNC SYSTEM Programming and Operation Manual

This manual describes the various matters concerning the

operations of this CNC system as much as possible. However, it is

impossible to give detailed descriptions to all the unnecessary or

unallowable operations due to space limitation and product specific

applications. Therefore, the matters not specially described herein

should be considered as “impossible” or “unallowable”.

This user manual is the property of GSK CNC Equipment Co.,

Ltd. All rights are reserved. It is illegal for any organization or

individual to publish or reprint this manual. GSK CNC Equipment Co.,

Ltd. reserves the right to ascertain their legal liability.

I

Preface and Precaution

Preface

Dear users,

It is our pleasure for your patronage and purchase of this machining

center CNC system of GSK990MA produced by GSK CNC Equipment Co.,

Ltd.

This book is “Programming and Operation Manual”, which introduces

the programming and operation of the machining center CNC system of

GSK990MA in detail.

To ensure the product works in a safe and efficient state, please read this manual

carefully before installation and operation.

Warnings

Improper operations may cause unexpected accidents. Only

those qualified staff are allowed to operate this system.

Special notes: The power supply fixed on/in the cabinet is exclusively

used for the CNC system made by GSK.

It cannot be applied for other purposes, or else it may

cause serious danger.

II

GSK990MA CNC SYSTEM Programming and Operation Manual

Declaration!

z We try to describe all the various matters as much as possible in this

manual. However, it is impossible to give detailed descriptions to all

the unnecessary or unallowable operations because there are too

many possibilities. Therefore, the matters not specially described

herein should be considered as “impossible” or “unallowable”.

z Before installing, connecting, programming and operating the product,

please read this manual and the manual provided by the machine tool

builder carefully, and operate the product according to these manuals.

Otherwise, the operation may cause damage to the product and

machine tool, or even cause personal injury.

Warning!

Caution!

z The functions and specifications (e.g., precision and speed) described

in this manual are only for this product itself. For those CNC machine

tools installing this product, the actual function configuration and

specifications depend on the designs of the machine tool builders.

Moreover, the function configuration and specifications of the CNC

machine tool are subject to the manual provided by the machine tool

All specifications and designs in this manual are subject to change without notice.

III

Preface and Precaution

Safety notes

■ Transportation and storage

z Do not pile up the packing boxes over 6 layers.

z Never climb the packing box, neither stand on it, nor place heavy objects on it.

z Do not move or drag the product by the cables connected to it.

z Avoid impact or scratch to the panel and screen.

z Packing box should be protected from dampness, insolation and drench.

■ Open-package inspection

z Confirm the product is the one you purchased after opening the package.

z Check whether the product is damaged during transportation.

z Confirm all the elements are complete without damage by referring to the list.

z If there is incorrect product type, incomplete accessories or damage, please

contact us in time.

■ Connection

z Only qualified personnel can connect and inspect the system.

z The system must be earthed. The earth resistance should not be greater than

0.1Ω, and a neutral wire (zero wire) cannot be used as an earth wire.

z The connection must be correct and secured. Otherwise, the product may be

damaged or unexpected results may occur.

z Connect the surge absorbing diode to the product in the specified direction;

otherwise the product may be damaged.

z Turn off the power before inserting or unplugging a plug, or opening the electric

cabinet.

■ Troubleshooting

z Turn off the power supply before troubleshooting or replacing components.

z Overhaul the system when there is a short circuit or overload, and do not restart

it until the trouble is removed.

z Do not turn ON/OFF the product frequently, and the ON/OFF interval should be

1 minute at least.

IV

GSK990MA CNC SYSTEM Programming and Operation Manual

BOOK PROGRAMMINGⅠ

This part gives an introduction to the specification, product

portfolio, parameter configuration, instruction codes as well as

program form

at.

This part gives an introduction to the operation of the machining

center CNC system of GSK 990MA .

This part gives an introduction to the use of the machining center

CNC system and its accessories of GSK990MA.

BOOK OPERATIONⅡ

APPENDIX

V

Preface and Precaution

Safety responsibility

Manufacturer Responsibility

——Be responsible for the danger which should be eliminated on the design

and configuration of the provided CNC systems

——Be responsible for the safety of the provided CNC and its accessories

——Be responsible for the provided information and advice

User Responsibility

——Be trained with the safety operation of CNC system operation

procedures and familiar with the safety operation.

——Be responsible for the dangers caused by adding, changing or

modifying the original CNC systems and accessories.

——Be responsible for the danger caused by failing to observe the

operation, maintenance, installation and storage in the manual.

This user manual shall be kept by the end user.

Thank you for your kind support when you are using the

products of Guangzhou CNC Equipment Co., Ltd.

VI

GSK990MA CNC System Programming and Operation Manual

CONTENT

Ⅰ OVERVIEW..........................................................................................................................1

1 Overview.............................................................................................................................2

Ⅱ PROGRAMMING.................................................................................................................3

1 General................................................................................................................................4

1.1 Tool movement along workpiece contour —interpolation................................................4

1.2 Feed——Feed function ...................................................................................................5

1.3 Cutting feedrate, spindle speed function .........................................................................6

1.4 Operation instruction——miscellaneous function............................................................6

1.5 Tool selection for various machining——Tool function ....................................................6

1.6 Tool figure and tool motion by program...........................................................................7

1.6.1 Tool length compensation ....................................................................................7

1.6.2 Tool radius compensation ....................................................................................7

1.7 Tool movement range——stroke.....................................................................................8

2 Part Program Composition...............................................................................................9

2.1 Program composition ......................................................................................................9

2.1.1 Program name .....................................................................................................9

2.1.2 Sequence number and block .............................................................................10

2.1.3 Instruction word..................................................................................................10

2.2 General structure of a program ..................................................................................... 11

2.2.1 Subprogram edit...............................................................................................12

2.2.2 Subprogram call.................................................................................................12

2.2.3 Program end ......................................................................................................13

3 Programming Fundamentals..........................................................................................14

3.1 Controlled axis ..............................................................................................................14

3.2 Axis name .....................................................................................................................14

3.3 Coordinate system ........................................................................................................14

3.3.1 Machine coordinate system ...............................................................................14

3.3.2 Reference point..................................................................................................14

3.3.3 Workpiece coordinate system ............................................................................15

3.3.4 Absolute programming and relative programming .............................................16

3.4 Mode and non-mode.....................................................................................................17

3.5 Decimal point programming ..........................................................................................18

4 Preparatory Function: G code........................................................................................19

4.1 Classification of G code ................................................................................................19

4.2 Simple G code ..............................................................................................................21

4.2.1 Rapid positioning G00........................................................................................21

VII

Contents

4.2.2 Linear interpolation G01 ....................................................................................23

4.2.3 Circular (helical) interpolation G02/G03............................................................. 24

4.2.4 Absolute/ incremental programming G90/G91................................................... 28

4.2.5 Dwell (G04)........................................................................................................ 29

4.2.6 Unidirectional positioning (G60)......................................................................... 30

4.2.7 System parameter online modification (G10).....................................................31

4.2.8 Workpiece coordinate system G54~G59.......................................................... 32

4.2.9 Additional workpiece coordinate system............................................................ 34

4.2.10 Machine coordinate system selection G53 ......................................................35

4.2.11 Floating coordinate system G92 ......................................................................35

4.2.12 Plane selection G17/G18/G19 ......................................................................... 37

4.2.13 Polar coordinate system setup/cancel G16/G15.............................................. 38

4.2.14 Scaling in plane G51/G50................................................................................ 40

4.2.15 Coordinate system rotation G68/G69 ..............................................................43

4.2.16 Skip function G31 ............................................................................................47

4.2.17 Inch/metric conversion G20/G21 .....................................................................48

4.2.18 Arbitrary angle chamfering/corner rounding..................................................... 49

4.3 Reference point G code................................................................................................ 50

4.3.1 Reference point return G28 ............................................................................... 50

4.3.2 2

nd

, 3rd , 4th reference point return G30 ..........................................................52

4.3.3 Automatic return from reference point G29........................................................ 52

4.3.4 Reference point return check G27..................................................................... 53

4.4 Canned cycle G code ...................................................................................................53

4.4.1 Rough milling of inner circular groove G22/G23................................................ 58

4.4.2 Fine milling cycle within a circle G24/G25 .........................................................61

4.4.3 Outer circle finish milling cycle G26/G32 ........................................................... 62

4.4.4 Rectangular groove rough milling G33/G34....................................................... 64

4.4.5 Inner rectangular groove finish milling cycle G35/G36 ......................................66

4.4.6 Rectangle outside finish milling cycle G35/G36 ................................................. 67

4.4.7 High-speed peck drilling cycle G73 ...................................................................69

4.4.8 Drilling cycle, spot drilling cycle G81 .................................................................71

4.4.9 Drilling cycle, counterboring cycle G82.............................................................. 72

4.4.10 Drilling cycle with chip removal G83 ................................................................74

4.4.11 Right-handed tapping cycle G84 ..................................................................... 76

4.4.12 Left-handed tapping cycle G74........................................................................ 78

4.4.13 Fine boring cycle G76...................................................................................... 79

4.4.14 Boring cycle G85 .............................................................................................81

4.4.15 Boring cycle G86 .............................................................................................83

4.4.16 Boring cycle, back boring cycle G87................................................................ 85

4.4.17 Boring cycle G88 .............................................................................................87

4.4.18 Boring cycle G89 .............................................................................................88

4.4.19 Left-handed rigid tapping G74....................................................................... 90

4.4.20 Right-handed rigid tapping G84 .......................................................................92

VIII

GSK990MA CNC System Programming and Operation Manual

4.4.21 Peck drilling rigid tapping (chip removal) cycle ................................................94

4.4.22 Canned cycle cancel G80 ................................................................................96

4.5 Tool compensation G code............................................................................................98

4.5.1 Tool length compensation G43, G44, G49.........................................................98

4.5.2 Tool radius compensation G40/G41/G42.........................................................102

4.5.3 Explanation of tool radius compensation .........................................................109

4.5.4 Corner offset circular interpolation(G39) .....................................................125

4.5.5 Tool offset value and number input by program(G10) .................................126

4.6 Feed G code ...............................................................................................................127

4.6.1 Feed mode G64/G61/G63 ...............................................................................127

4.6.2 Automatic override for inner corners(G62) ..................................................127

4.7 Macro G code .............................................................................................................130

4.7.1 Custom macro..................................................................................................130

4.7.2 Macro variables................................................................................................130

4.7.3 Custom macro call ...........................................................................................135

4.7.4 Custom macro function A.................................................................................136

4.7.5 Custom macro function B.................................................................................141

5 Miscellaneous Function M code....................................................................................148

5.1 M codes controlled by PLC .........................................................................................149

5.1.1 Forward and reverse rotation instructions(M03, M04) ..............................149

5.1.2 Spindle stop (M05)...........................................................................................149

5.1.3 Cooling on and off (M08, M09) ................................................................149

5.1.4 A axis release and clamping(M10, M11)...................................................149

5.1.5 Tool release and clamping(M16, M17) .....................................................150

5.1.6 Spindle orientation(M19) .............................................................................150

5.1.7 Tool search instruction(M21, M22) ...........................................................150

5.1.8 Magazine rotation instruction(M23, M24)..................................................150

5.1.9 Rigid tapping(M29) ......................................................................................150

5.1.10 Lubricating on and off(M32, M33)...........................................................150

5.1.11 Helical chip remover on and off(M35, M36) ............................................150

5.1.12 Mirror image instructions(M40, M41, M42, M43) ...............................150

5.1.13 Spindle blowing on and off(M44, M45) ...................................................150

5.1.14 Auto tool change start and end(M50, M51).............................................150

5.1.15 Tool judging after tool change(M53)..........................................................151

5.2 M codes used by program...........................................................................................151

5.2.1 Program end and return (

5.2.2 Program dwell(M00) ....................................................................................151

5.2.3 Program optional stop(M01)........................................................................151

5.2.4 Subprogram calling (M98) ..........................................................................151

5.2.5 Program end and return(M99).....................................................................152

M30, M02) .......................................................151

6 S codes for Spindle Function.........................................................................................153

IX

Contents

6.1 Spindle analog control ................................................................................................153

6.2 Spindle switch volume control..................................................................................... 153

6.3 Constant surface speed control (G96/G97) ................................................................153

7 Feed Functions: F code.................................................................................................. 156

7.1 Traverse......................................................................................................................156

7.2 Cutting feedrate .......................................................................................................... 156

7.2.1 Feed per minute(G94).................................................................................157

7.2.2 Feed per revolution(G95)............................................................................ 157

7.3 Tangential speed control............................................................................................. 158

7.4 Feedrate override keys ............................................................................................... 158

7.5 Auto acceleration/deceleration ................................................................................... 158

7.6 Acceleration/deceleration for corner of a block ...........................................................159

8 Tool Function................................................................................................................. 161

8.1 Tool function ...............................................................................................................161

Ⅲ OPERATION....................................................................................................................162

1 Operator Panel............................................................................................................... 163

1.1 Panel layout................................................................................................................ 163

1.2 Explanation of the panel function................................................................................ 163

1.2.1 LCD area ......................................................................................................... 163

1.2.2 Edit area .......................................................................................................... 163

1.2.3 Screen operation keys .....................................................................................164

1.2.4 Control area..................................................................................................... 165

2 System Power On/Off and Safety Operations............................................................. 169

2.1 System power on ........................................................................................................169

2.2 System power off ........................................................................................................169

2.3 Safety operations........................................................................................................ 170

2.3.1 Reset operation ...............................................................................................170

2.3.2 Emergency stop............................................................................................... 170

2.3.3 Feed hold......................................................................................................... 171

2.4 Cycle start and feed hold ............................................................................................ 171

2.5 Overtravel protection ..................................................................................................171

2.5.1 Hardware overtravel protection........................................................................ 171

2.5.2 Software overtravel protection ......................................................................... 172

2.5.3 Release of the overtravel alarm....................................................................... 172

2.6 Stroke detection..........................................................................................................172

3 Interface Display and Data Modification and setting................................................ 176

3.1 Position display........................................................................................................... 176

3.1.1 Four types of position display ..........................................................................176

X

GSK990MA CNC System Programming and Operation Manual

3.1.2 Display of run time, part count, programming speed and override, actual speed

etc. ..................................................................................................................178

3.1.3 Relative coordinate clearing and mediating .....................................................179

3.2 Program display ..........................................................................................................179

3.3 System display............................................................................................................181

3.3.1 Display. Modification and setting for parameter ...............................................182

3.3.1.2 Modification and setting of the parameter values..........................................182

3.3.2 Display, modification and setting for macro variables ......................................183

3.3.3 Display, modification and setting for offset.......................................................184

3.3.4 Display, modification and setting for screw pitch offset....................................186

3.4 PMC display................................................................................................................186

3.5 Setting display.............................................................................................................188

3.5.1 Setting page.....................................................................................................188

3.5.2 Parameter and program on-off page -..............................................................189

3.5.3 Coordinate setting interface .............................................................................190

3.5.4 Data processing interface ................................................................................192

3.5.5 Password authority interface............................................................................193

3.6 Graphic display ...........................................................................................................194

3.7 Diagnosis display ........................................................................................................195

3.7.1 Diagnosis data display .....................................................................................196

3.7.2 Signal viewing ..................................................................................................197

3.8 Alarm display ..............................................................................................................198

3.9 Help display (this function is invalid temporarity ) .......................................................199

4 Manual Operation..........................................................................................................200

4.1 Coordinate axis movement .........................................................................................200

4.1.1 Manual feed .....................................................................................................200

4.1.2 Manual rapid traverse ......................................................................................200

4.1.3 JOG feedrate and manual rapid traverse speed selection ...............................200

4.1.4 Manual intervention..........................................................................................201

4.1.5 Workpiece alignment .......................................................................................202

4.2 Spindle control ............................................................................................................204

4.2.1 Spindle CCW ...................................................................................................204

4.2.2 Spindle CW......................................................................................................204

4.2.3 Spindle stop .....................................................................................................204

4.2.4 Spindle auto gear shift .....................................................................................204

4.3 Other manual operations.............................................................................................205

4.3.1 Cooling control .................................................................................................205

4.3.2 Lubricating control............................................................................................205

4.3.3 Work light control .............................................................................................205

5 Step Operation................................................................................................................206

5.1 Step feed.....................................................................................................................206

XI

Contents

5.1.1 Selection of moving amount ............................................................................ 206

5.1.2 Selection of moving axis and direction ............................................................206

5.1.3 Step feed explanation...................................................................................... 206

5.2 Step interruption..........................................................................................................207

5.3 Auxiliary control in Step mode ....................................................................................207

6 MPG Operation............................................................................................................. 208

6.1 MPG feed ...................................................................................................................208

6.1.1 Moving amount selection .................................................................................208

6.1.2 Selection of moving axis and direction ............................................................208

6.1.3 Explanation of MPG feed................................................................................. 209

6.2 Control in MPG interruption ........................................................................................ 209

6.2.1 MPG interruption operation.............................................................................. 209

6.2.2 Relation of MPG interruption with other functions............................................ 210

6.3 Auxiliary control in MPG mode.................................................................................... 211

6.4 MPG drive function ..................................................................................................... 211

7 Auto Operation.............................................................................................................. 212

7.1 Selection of the auto run programs ............................................................................. 212

7.2 Auto run start .............................................................................................................. 212

7.3 Auto run stop ..............................................................................................................213

7.4 Auto running from an arbitrary block........................................................................... 214

7.5 Dry run........................................................................................................................ 215

7.6 Single block running ...................................................................................................215

7.7 Running with machine lock ......................................................................................... 216

7.8 Running with M.S.T. lock ............................................................................................216

7.9 Feedrate and rapid override in Auto run ..................................................................... 216

7.10 Spindle override in Auto run...................................................................................... 217

7.11 Background edit in Auto run...................................................................................... 218

8 MDI Operation .............................................................................................................. 219

8.1 MDI instructions input ................................................................................................. 219

8.2 Run and stop of MDI instructions................................................................................ 220

8.3 Words modification and clearing of MDI instructions .................................................. 220

8.4 Modes changing .........................................................................................................221

9 Machine Zero Operation............................................................................................... 222

9.1 Conception of machine zero ....................................................................................... 222

9.2 Steps for machine zero ...............................................................................................223

9.3 Machine zero steps by program.................................................................................. 224

10 Edit Operation............................................................................................................. 225

10.1 Program edit .............................................................................................................225

XII

GSK990MA CNC System Programming and Operation Manual

10.1.1 Program creation ...........................................................................................225

10.1.2 Deletion of a single program ..........................................................................231

10.1.3 Deletion of all programs .................................................................................232

10.1.4 Copy of a program .........................................................................................232

10.1.5 Copy and paste of blocks...............................................................................233

10.1.6 Cut and paste of block ...................................................................................233

10.1.7 Replacement of the blocks.............................................................................234

10.1.8 Rename of a program ....................................................................................234

10.1.9 Program restart ..............................................................................................234

10.2 Program management ..............................................................................................235

10.2.1 Program directory search...............................................................................235

10.2.2 Number of the program stored.......................................................................236

10.2.3 Memory capacity............................................................................................236

10.2.4 Viewing of the program list.............................................................................236

10.2.5 Program lock..................................................................................................237

11 Communication............................................................................................................238

11.1 Serial communication ................................................................................................238

11.1.1 Program start .................................................................................................238

11.1.2 Function introduction......................................................................................239

11.1.3 Serial port data transmission..........................................................................240

11.1.4 Serial port DNC on-line machining.................................................................245

11.2 USB communication..................................................................................................247

11.2.1 General and precautions................................................................................247

11.2.2 USB part program operation steps.................................................................247

11.2.3 DNC processing operation steps ...................................................................248

11.2.4 U flash disk system exit .................................................................................249

APPENDIX 1 ..............................................................................................................................250

GSK990MA PARAMETER LIST ................................................................................................250

1 Bit parameter .................................................................................................................251

2 Number parameter .........................................................................................................271

APPENDIX 2 ..............................................................................................................................298

XIII

GSK990MA CNC System Programming and Operation Manual

Ⅰ OVERVIEW

1

Overview Chapter One Overview

1 Overview

This manual is comprised by following parts:

I Overview

It describes the chapter structure, system model available, relative instructions and the

note.

Ⅱ Programming

It describes G functions and the programming format, characteristics and restrictions by

NC language.

OperationⅢ

It describes the manual and auto operation, program input/output and editing methods.

Appendix

It describes parameter list, alarm list and programming data table.

The manual is used for GSK990MA CNC system.

2

GSK990MA CNC System Programming and Operation Manual

Ⅱ PROGRAMMING

3

Programming Chapter One General

1 General

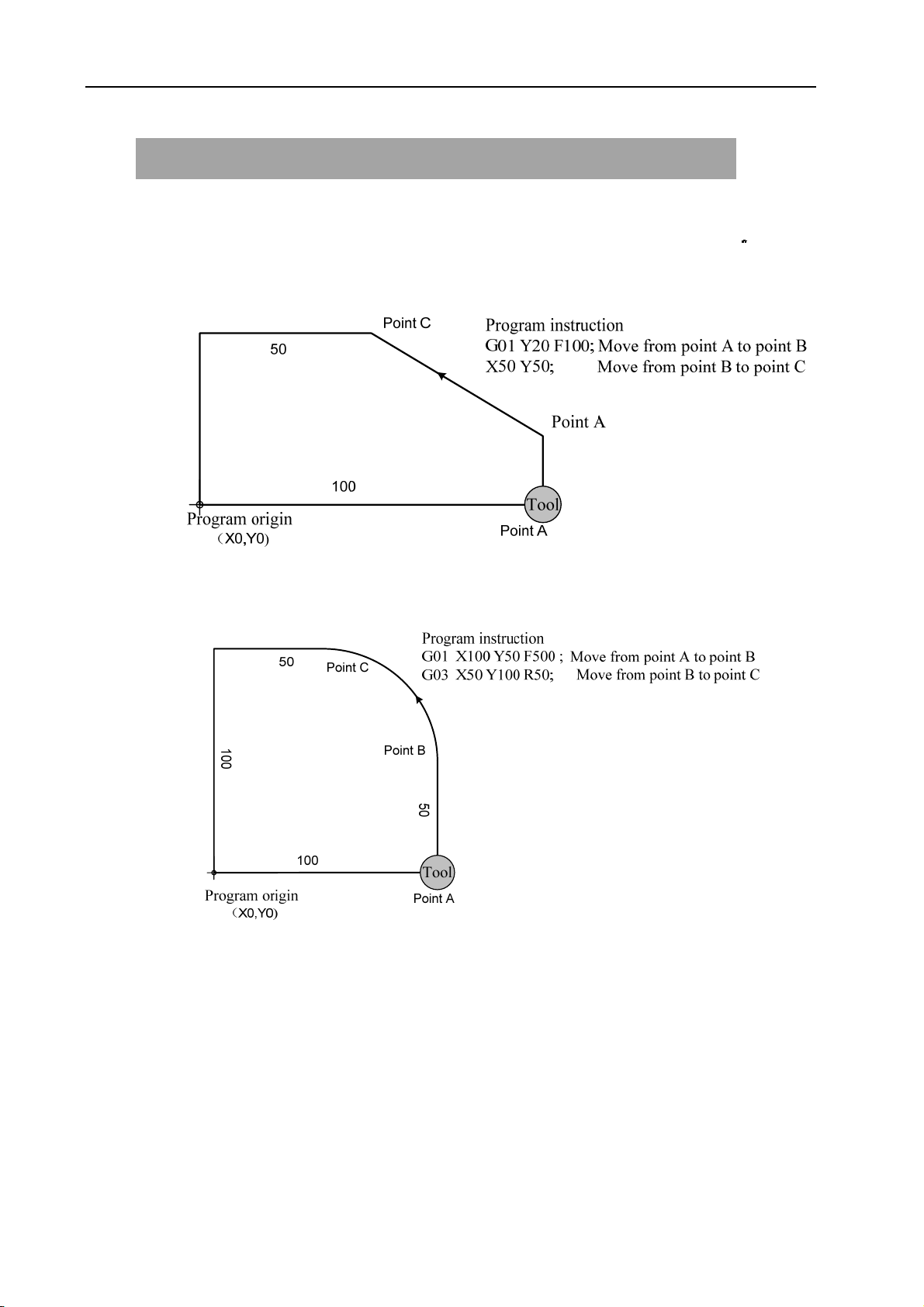

1.1 Tool movement along workpiece contour —interpolation

1) Tool movement along a straight line

50

20

Fig. 1-1-1

2) Tool movement along an arc

Fig. 1-1-2

The tool linear and arc motion function is called interpolation.

The programming instructions such as G01, G02 are called preparatory function, which is used

for interpolation for CNC device.

4

GSK990MA CNC System Programming and Operation Manual

(a) Movement along straight Line

G01 Y_ _;

X_ _Y_ _;

(b) Movement along arc

G03_ Y_ R_;

Interpolation

(a) Movement along

straight Line

(b) Movement along

arc

X axis (Motor)

Y axis (Motor)

Tool movement

Fig. 1-1-3

Note For some machines, it is the worktable moving other than tool moving in practice. It

is assumed that the tool moves relative to the workpiece in this manual. Refer to the

machine actual movement direction in practice to protect against personnel hurt and

machine damage.

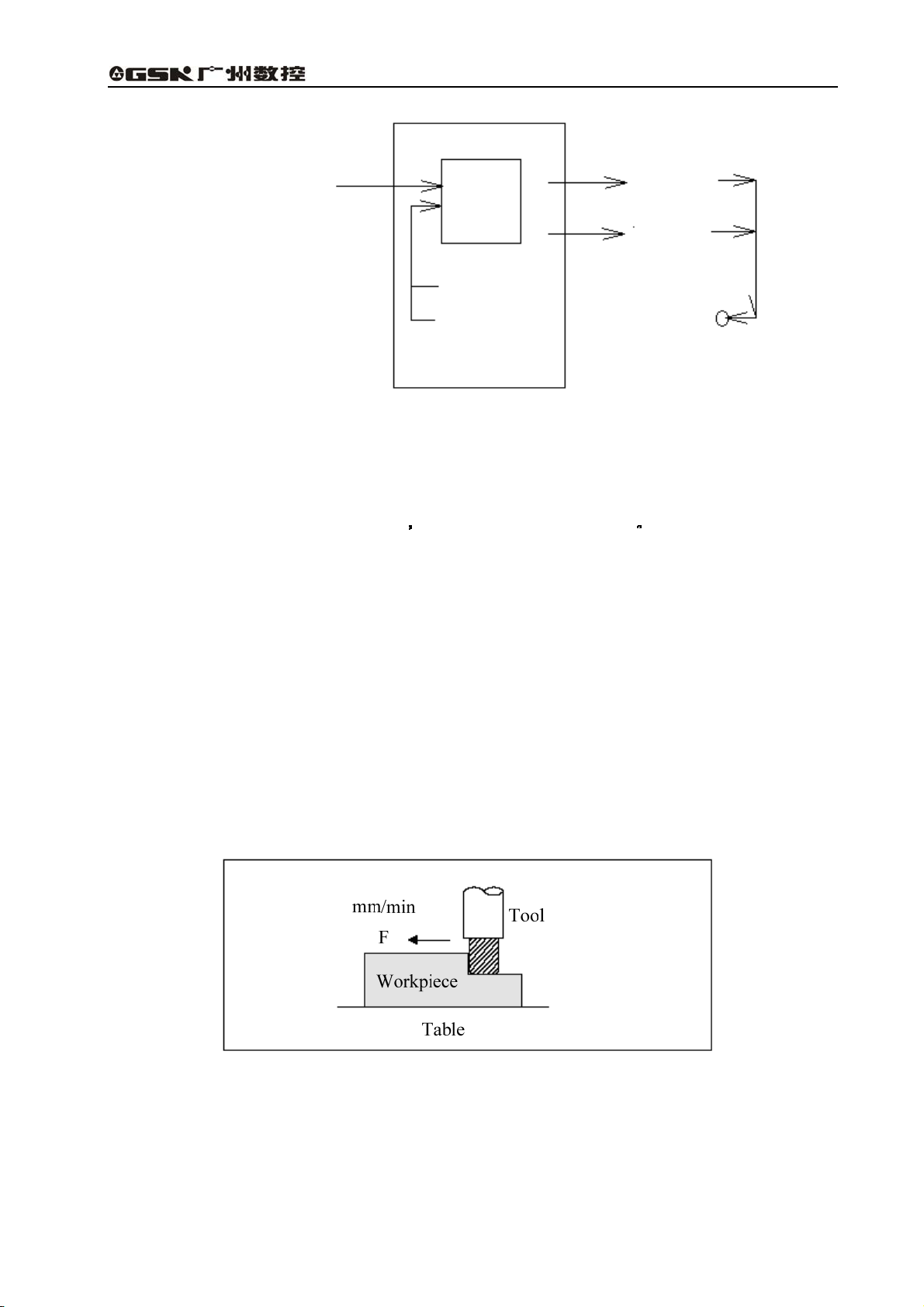

1.2 Feed——Feed function

The feedrate specification is called feed function.

1. Rapid traverse

The rapid traverse is used to specify the rapid speed when G00 is used for positioning.

The rapid traverse speed of each axis is set by parameters, so it is unnecessary to specify it

in the program.

2. Cutting feedrate

Moving a tool at a specified speed to cut a workpiece is called feed. The feedrate is specified

with numerical values. E.g., the program code is F150 when the tool is moved at the speed of

150m/min.

Fig. 1-2-1

5

Programming Chapter One General

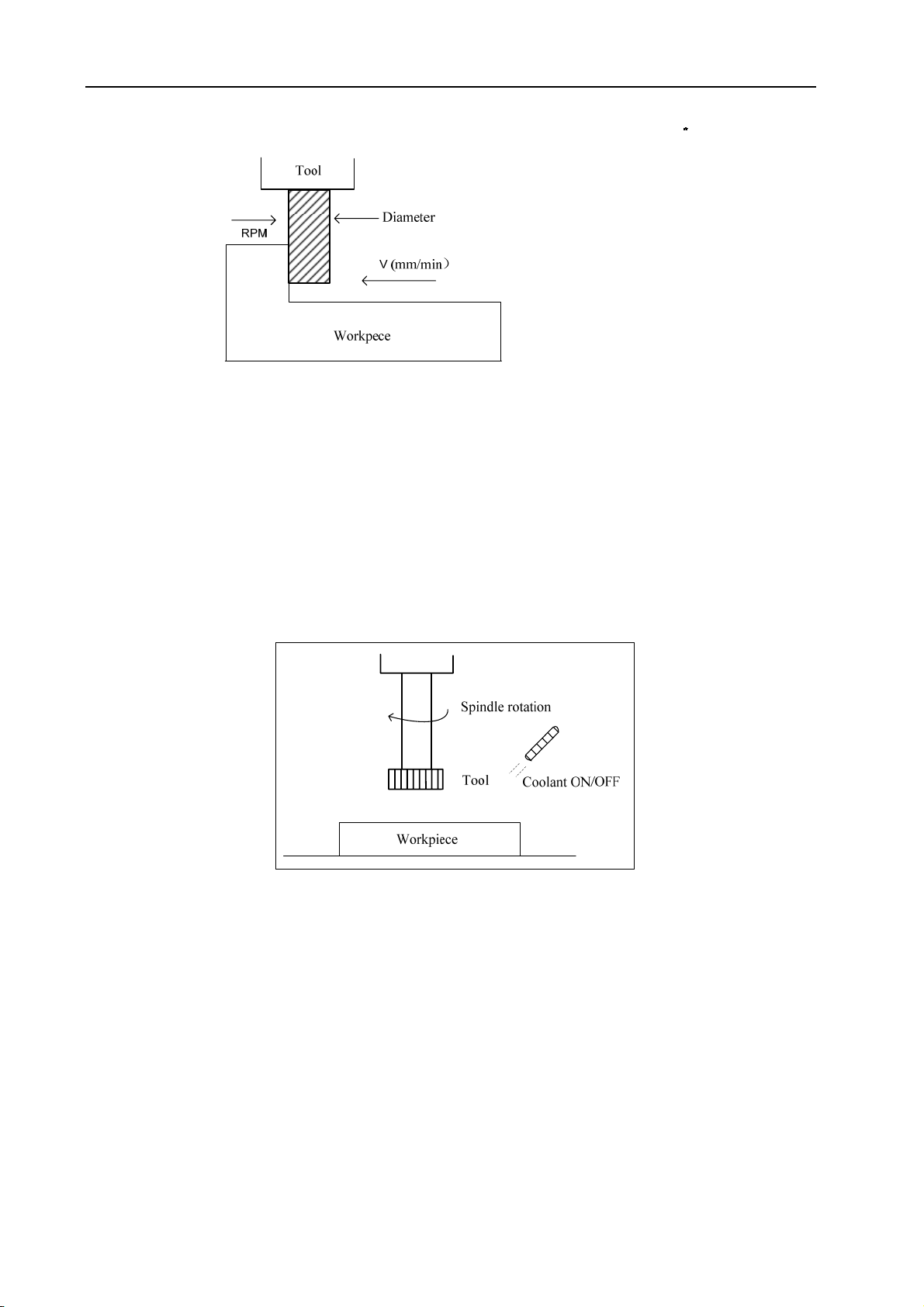

1.3 Cutting feedrate, spindle speed function

The speed of tool relative to workpiece in cutting is called cutting feedrate. It can be instructed

by spindle speed RPM(r/min) by CNC.

Example: If the tool diameter is 10mm, cutting linear speed is 8 m/min, the spindle speed is

about 255RPM according to N=1000V/πD, so the instruction is: S255

Instructions related to spindle speed are called spindle speed function.

Fig.1-3-1

1.4 Operation instruction——miscellaneous function

When the workpiece is to be machined, to make the spindle run and supply coolant, the

machine spindle motor and cooling pump switches must be controlled by actual requirement.

Fig. 1-4-1

The programs or machine on-off actions controlled by system NC instructions are called

miscellaneous functions, which are instructed by M code.

Example: If M03 is instructed, the spindle rotates clockwise by the speed specified.

(Clockwise direction means the direction viewed from the spindle –Z negative direction.)

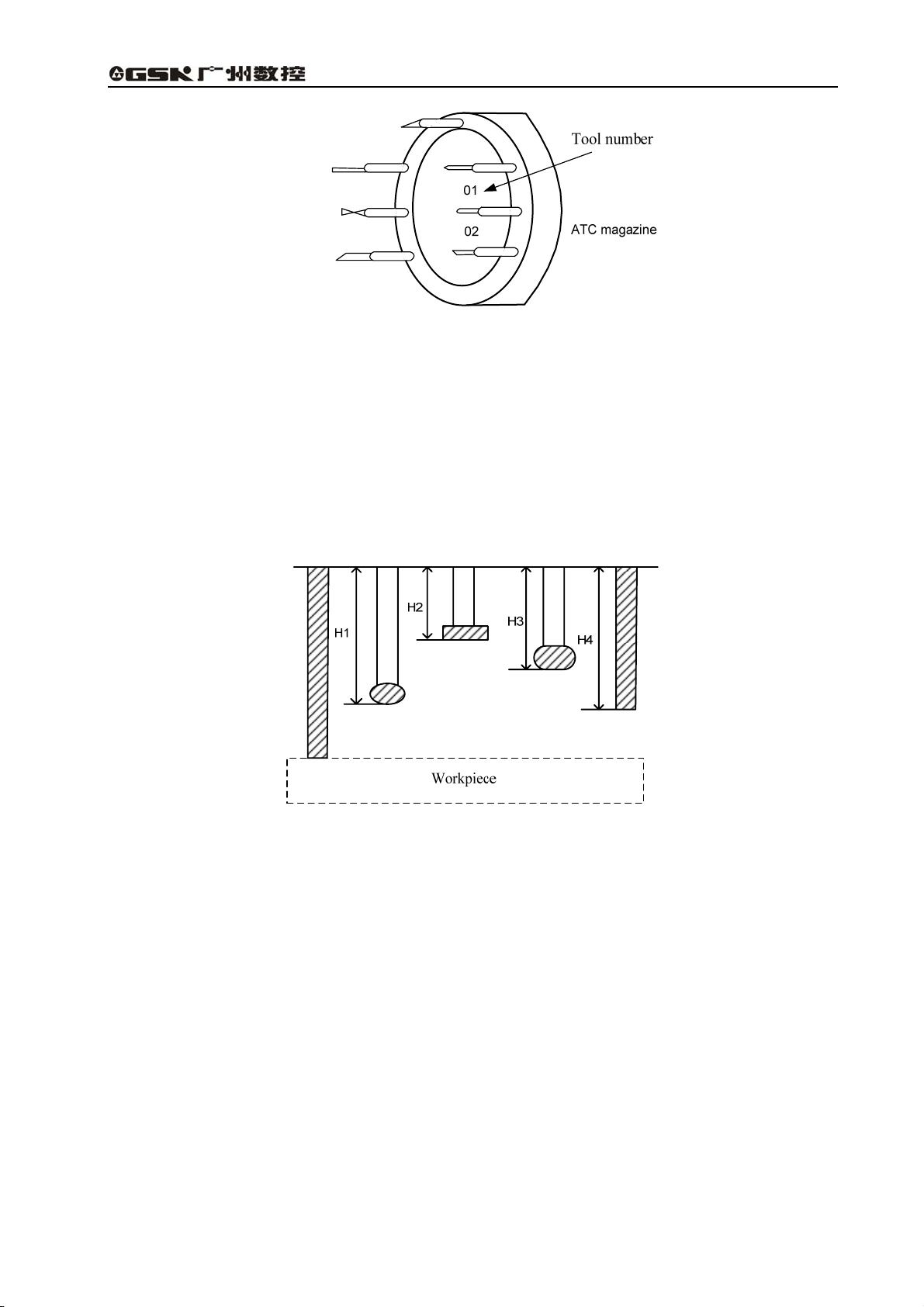

1.5 Tool selection for various machining——Tool function

It is necessary to select a proper tool when drilling, tapping, boring, milling, etc. is performed.

When a number is assigned for each tool and the number is specified in the program, the

corresponding tool is selected.

6

GSK990MA CNC System Programming and Operation Manual

Fig. 1-5-1

Example: When the tool is stored at location 01 in the ATC magazine, the tool can be selected by

specifying T01. This is called the tool function.

1.6 Tool figure and tool motion by program

1.6.1 Tool length compensation

Usually several tools are used for machining one workpiece. If instructions such as G0 Z0 are

executed in a same coordinate system, because tools have different tool lengths, the distances from

tool end to workpiece are different. It is very troublesome to change the program frequently.

Fig. 1-6-1-1

Therefore, the length of each tool used should be measured in advance. By setting the

difference between the length of the standard tool and the length of each tool in the CNC (usually the

1st tool), machining can be performed without altering the program even when the tool is changed.

After the tool positioning in Z axis (e.g. G0Z0), the distances of the tool end to the workpiece are

identical. This function is called tool length compensation.

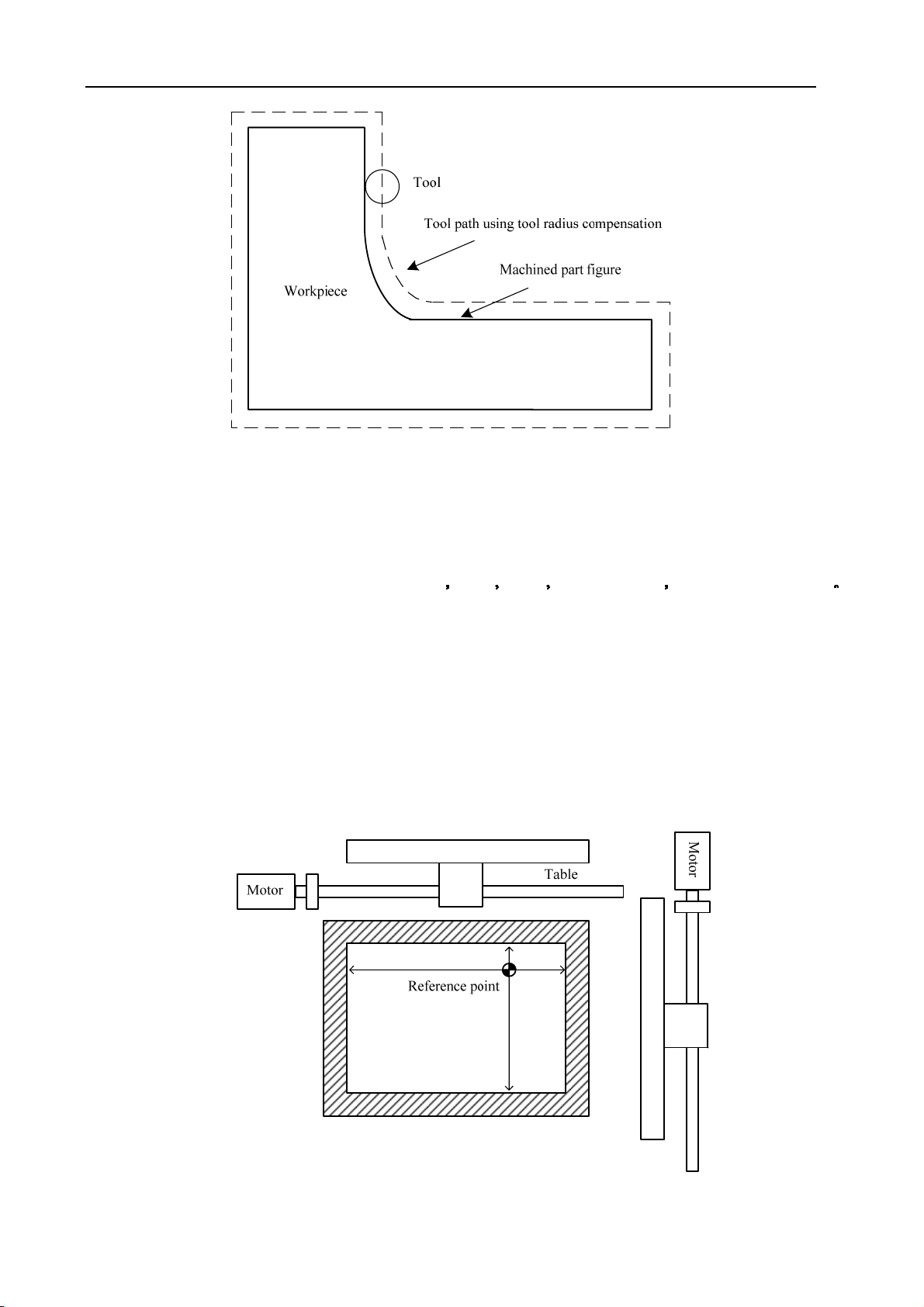

1.6.2 Tool radius compensation

Because a tool has a radius, if the tool goes by the path given by program, the workpiece will be

cut off a part for a radius wide. To simplify the programming, the program can be ran by CNC around

the workpiece with the tool radius deviated, while the transient path of the intersections of the lines or

the arcs can be processed automatically by system.

7

Programming Chapter One General

Fig.1-6-2-1

If diameters of tools are stored in the CNC tool compensation list, the tool can be moved by tool

radius apart from the machining part figure by calling different radius compensation according to

program. This function is called tool radius compensation.

1.7 Tool movement range——stroke

The overtravel limit switches are fixed at the positive and negative maximum stroke of the

machine X, Y, Z axis respectively. If the overtravel occurs, the moving axis slows down and stops

after it touches the limit switch, and the overtravel alarm is issued. This function is usually called

hardware limit.

The parameter setting can specify the safe tool running range, if the tool exceeds the range, the

system stops all the axes moving with overtravel alarm given. This function is called stroke

verification, namely, the software limit.

Fig. 1-7-1

8

GSK990MA CNC System Programming and Operation Manual

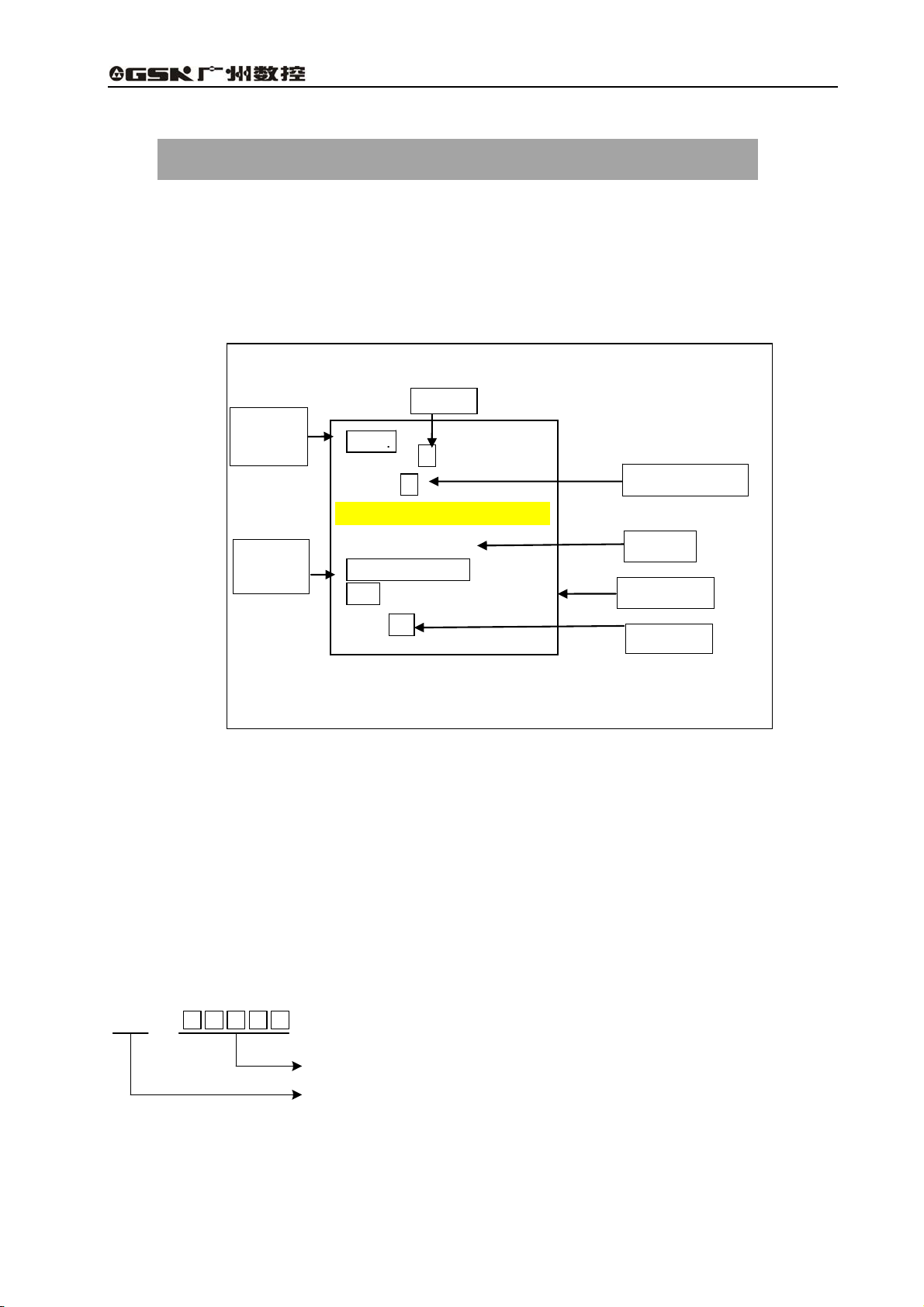

2 Part Program Composition

2.1 Program composition

A program is composed by many blocks which are formed by words. The blocks are separated

by the end code (LF for ISO,CR for EIA). In this manual the end code is represented by “;”character.

O00002 N00180

PROGRAM

NAME

PROGRAM

O00002;

N60 X100 Y0;

N120 X0;

N180 G01 X50 Y50 F2000 ;

WORD

EOB CODE

SEQUENCE

NO.

N240 G01 X100 ;

N300 G01 Y100;

N360 G02 X200 R50;

N420 M30;

ADD: Ln:2

S0000 T0100

BLOCK

PROGRAM

END

EDIT

Fig. 2-1-1 Program structure

The set instructions to control the CNC machine tool to machine the parts are called program.

After the program edited is entered into the CNC system, the system controls the tool to move along

straight line, arc or make the spindle run or stop by these instructions. And the instructions should be

edited by the machine actual movement sequence. The program structure is shown in Fig.2-1-1.

2.1.1 Program name

In this system the system memory may store many programs. In order to differentiate these

programs, address O with five figures behind it is headed in the beginning of the program. And it is

shown in Fig. 2-1-1-1.

O

Program number (0~99999, leading 0 negligible

Address O

Fig.2-1-1-1 Program name composition

in inputing )

9

Programming Chapter Two Part Program Compostion

2.1.2 Sequence number and block

A program consisted of many instructions, and an instruction unit is called block (see Fig. 2-1-1).

The blocks are separated by program end code (see Fig. 2-1-1). In this manual the block end code is

represented by character“;”.

Address N with 4 figures sequence number behind it can be used at the beginning of the block

(see Fig. 2-1-1), and the leading zero can be omitted. The sequence of the sequence number

(insertion set by bit parameter No. 0 # 5) can be arbitrary, and the intervals between them can be

inequal (set by Parameter P210). Sequence number can be either in all blocks, or in some important

blocks. But by common machining sequence, the number should be arranged by ascending. That the

sequence number is placed in important part of the program is for convenience. (e.g. in tool changing,

or worktable indexed to a new plane).

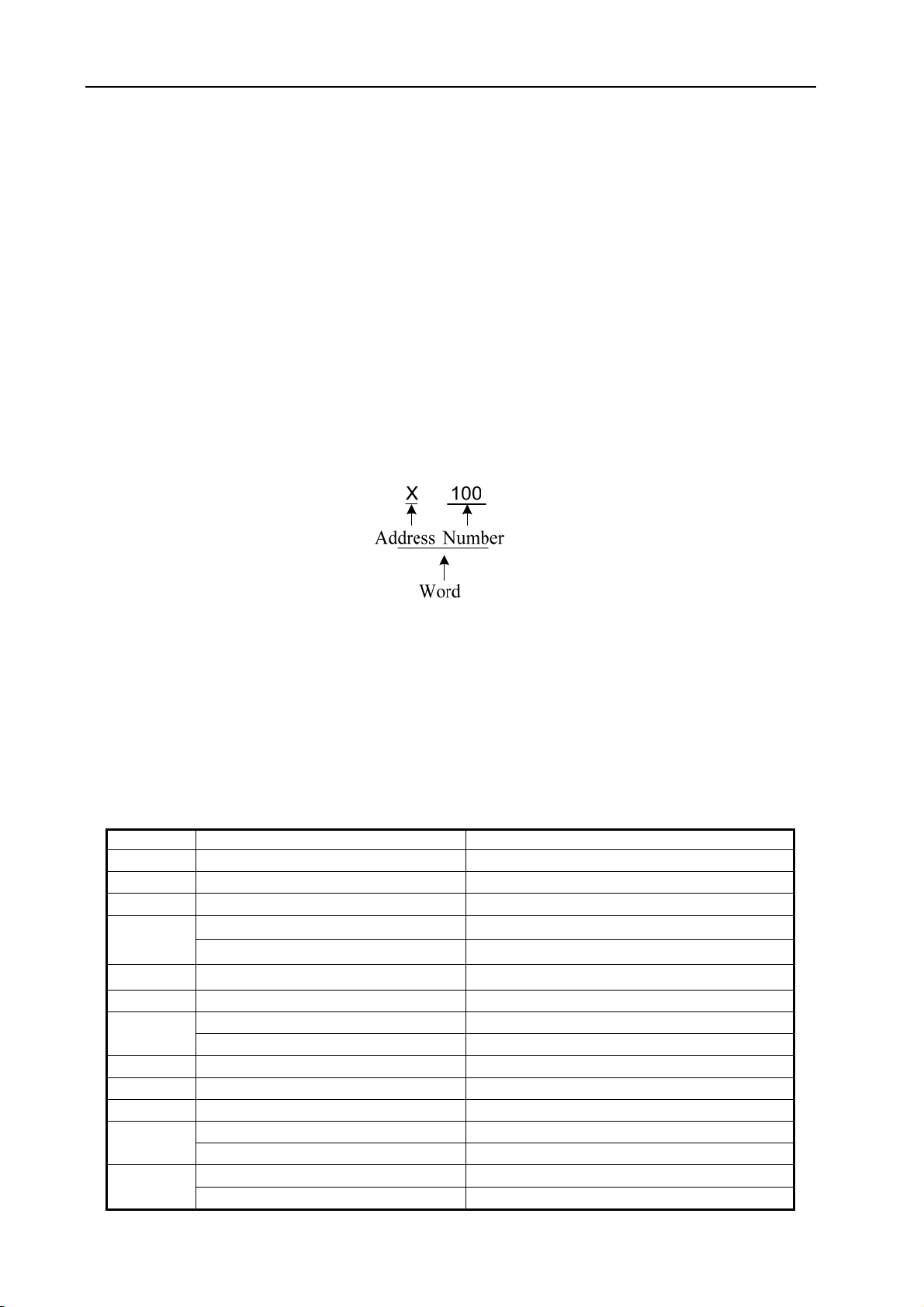

2.1.3 Instruction word

Word (Fig. 2-1-3-1) is a factor to block composition. It is formed by an address and figures

behind it (sometimes +, - added before figures)

Fig.2-1-3-1 Word composition

The address is a character from English alphabetic table which defines the meaning of the figure

behind it. In this system, the usable addresses and their meaning as well as value range are shown

as Table2-1-3-1:

Sometimes an address has a different meaning for different preparatory function.

If 2 or more identical addresses appear in an instruction, the alarm for it will be set by parameter

N0. 32#6.

Table 2-1-3-1

Address Range Meaning

O

N

G

X

Y

Z

R

I

J

K

F

S

-99999.999~99999.999(mm)

0.001~9999.999(s)

-99999.999~99999.999(mm)

-99999.999~99999.999(mm)

-99999.999~99999.999(mm)

-99999.999~99999.999(mm)

-99999.999~99999.999(mm)

-99999.999~99999.999(mm)

-99999.999~99999.999(mm)

0~99999

0~99999

00~99

0~99999(mm/min)

0.001~500(mm/r)

0~99999(r/min)

00~04

Program name

Sequence number

Preparatory function

X coordinate address

Dwell time

Y coordinate address

Z coordinate address

Arc radius/angle displacement

R level in canned cycle

vector of arc center to start point in X axis

vector of arc center to start point in Y axis

vector of arc center to start point in Z axis

Feed in a minute

Feed in a revolution

Spindle speed

Multi-gear spindle output

10

GSK990MA CNC System Programming and Operation Manual

Address Range Meaning

T

M

P

Q

H

D

0~9999

00~99

1~99999.9999(ms)

1~99999

-99999.9999~99999.9999(mm)

01~99

00~256

00~256

Tool function

Miscellaneous function output, program

executing process, subprogram calling

Dwell time

Subprogram number calling

Cutting depth or hole bottom offset in

canned cycle

Operator for G65

Length offset number

Radius offset number

Special attention should be paid that the limits in table 2-1-3-1 are all for CNC device, but not for

machine tool. Therefore, programming should be done on a basis of good understanding of the

programming limitation of machine builder manual besides this manual.

Note: each word should not exceed 79 characters.

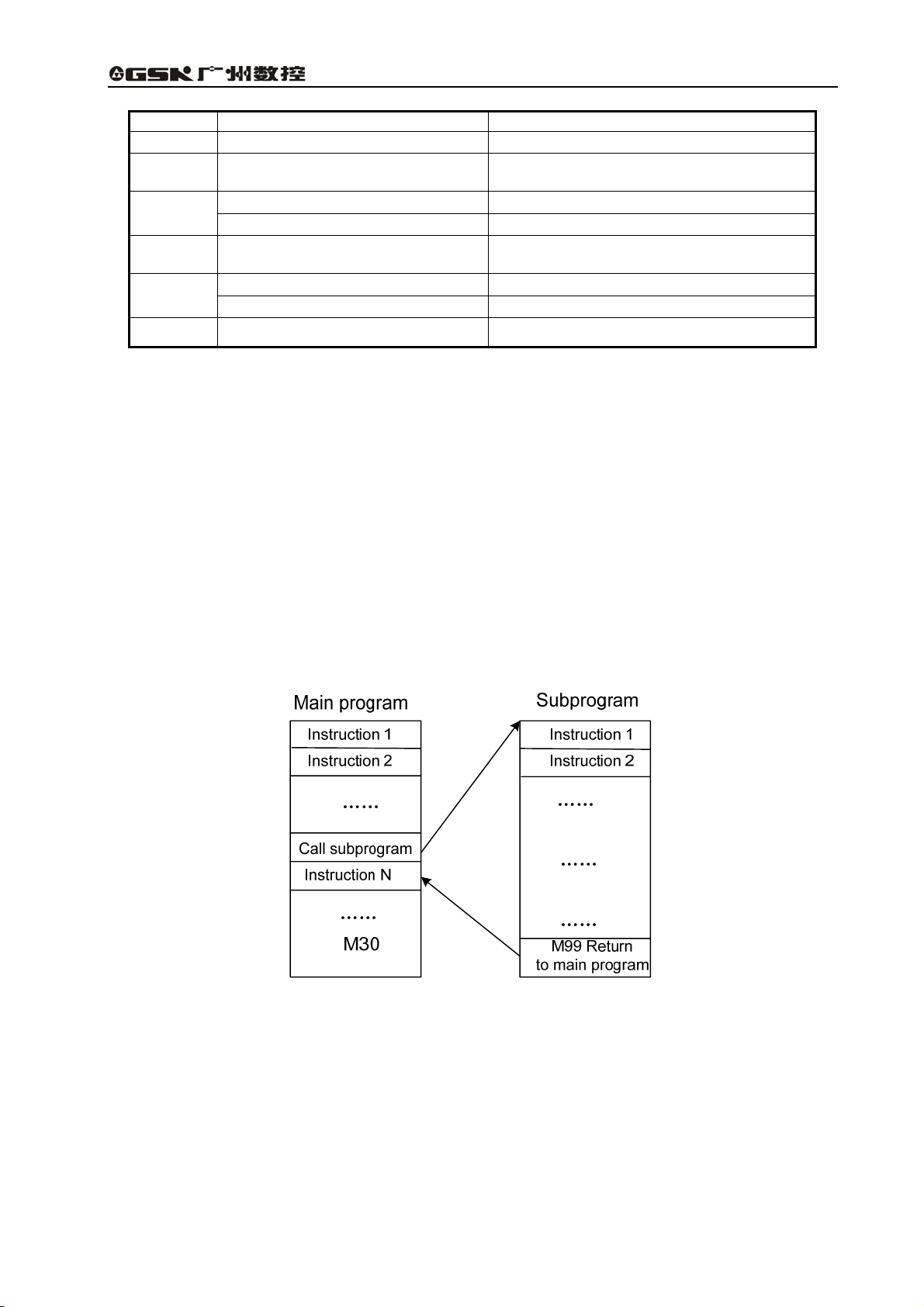

2.2 General structure of a program

The program is classified for main program and subprogram. Generally, the CNC system is

acutated by the main program. If the main program contains the subprogram call, the CNC system

acts by the subprogram. If the subprogram contains the instruction of returning to main program, the

CNC system returns to the main program to go on execution. The program execution sequence is

shown as Fig.2-2-1.

Fig. 2-2-1

The structure of the subprogram is same as that of the main program.

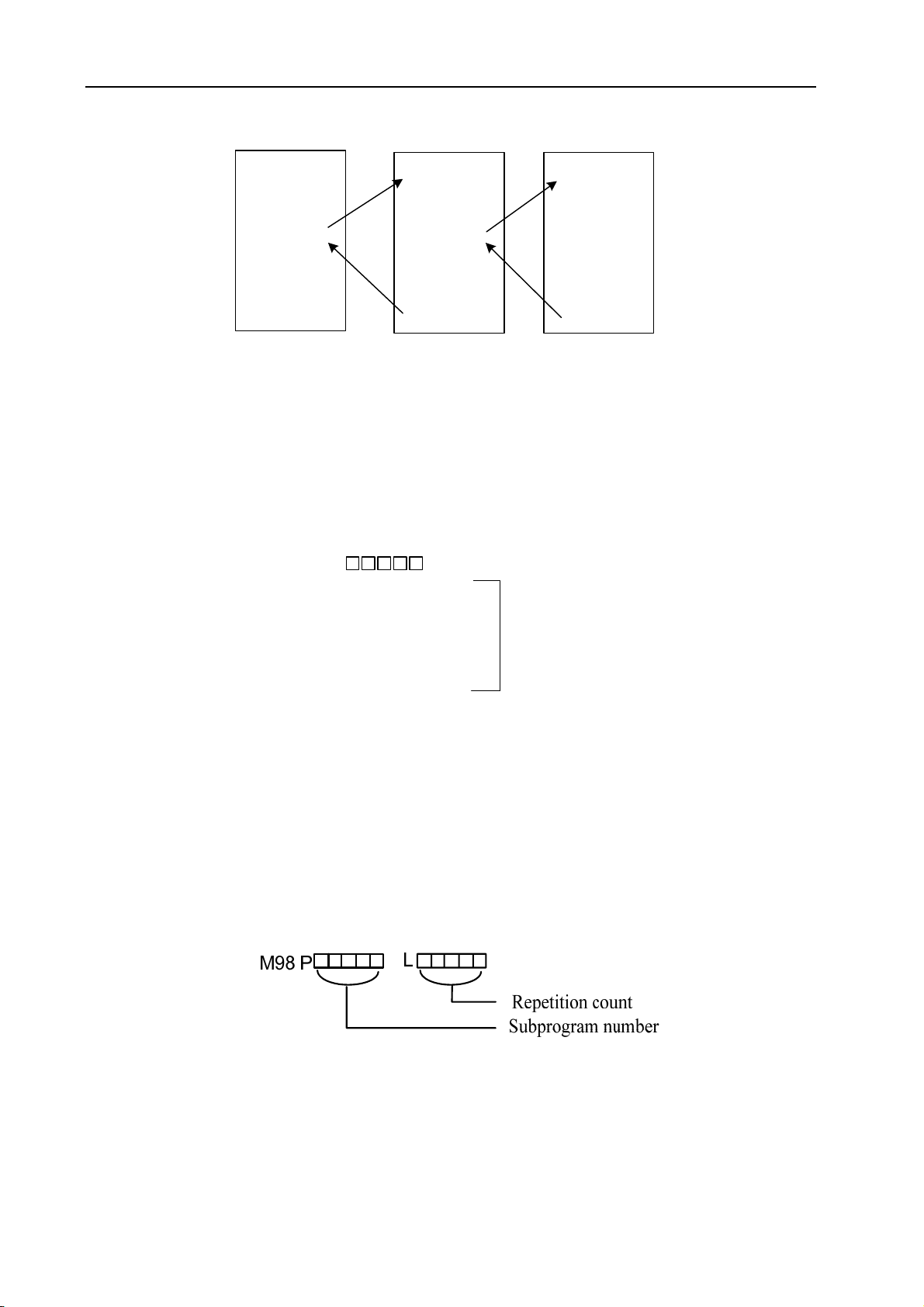

If there are fixed sequence blocks occurring repeatedly in a program, it can be taken as a

subprogram which can be stored in the memory in advance with no need to be edited repeatedly. So

it can simplify the program. The subprogram can be called in Auto mode, usually by M98 in the main

program. And the subprogram called can also call other subprograms. The subprogram called from

the main program is called the 1

st

level subprogram. 4 levels subprogram at most can be called in a

program (Fig.2-2-2). The last block in the subprogram must be the returning instruction M99. After

M99 execution, the control returns to next block following the block that calls the subprogram in the

main program to go on execution. If the main program end is M99, the program execution can be

repeated.

11

Programming Chapter Two Part Program Compostion

Main program

O00001;

…

…

…

M98 P10000;

…

…

…

…

M30;

Subprogram

O10000;

…

…

…

M98 P20000;

…

…

…

…

M99;

Subprogram

O20000;

…

…

…

M98 P30000;

…

…

…

…

M99;

One-level nesting Two-level nesting

Fig. 2-2-2 Two-level subprogram nesting

A single subprogram call instruction can be continuously and repeatedly used to call a subprogram

up to 9999 times.

2.2.1 Subprogram edit

Write out a subprogram by following format:

Subprogram number

O

;

……

……

Subprogram

……

M99;

Fig. 2-2-1-1

Write out the subprogram number behind the address O at the subprogram beginning, and the

M99 instruction at the subprogram end (M99 format as above).

Subprogram end

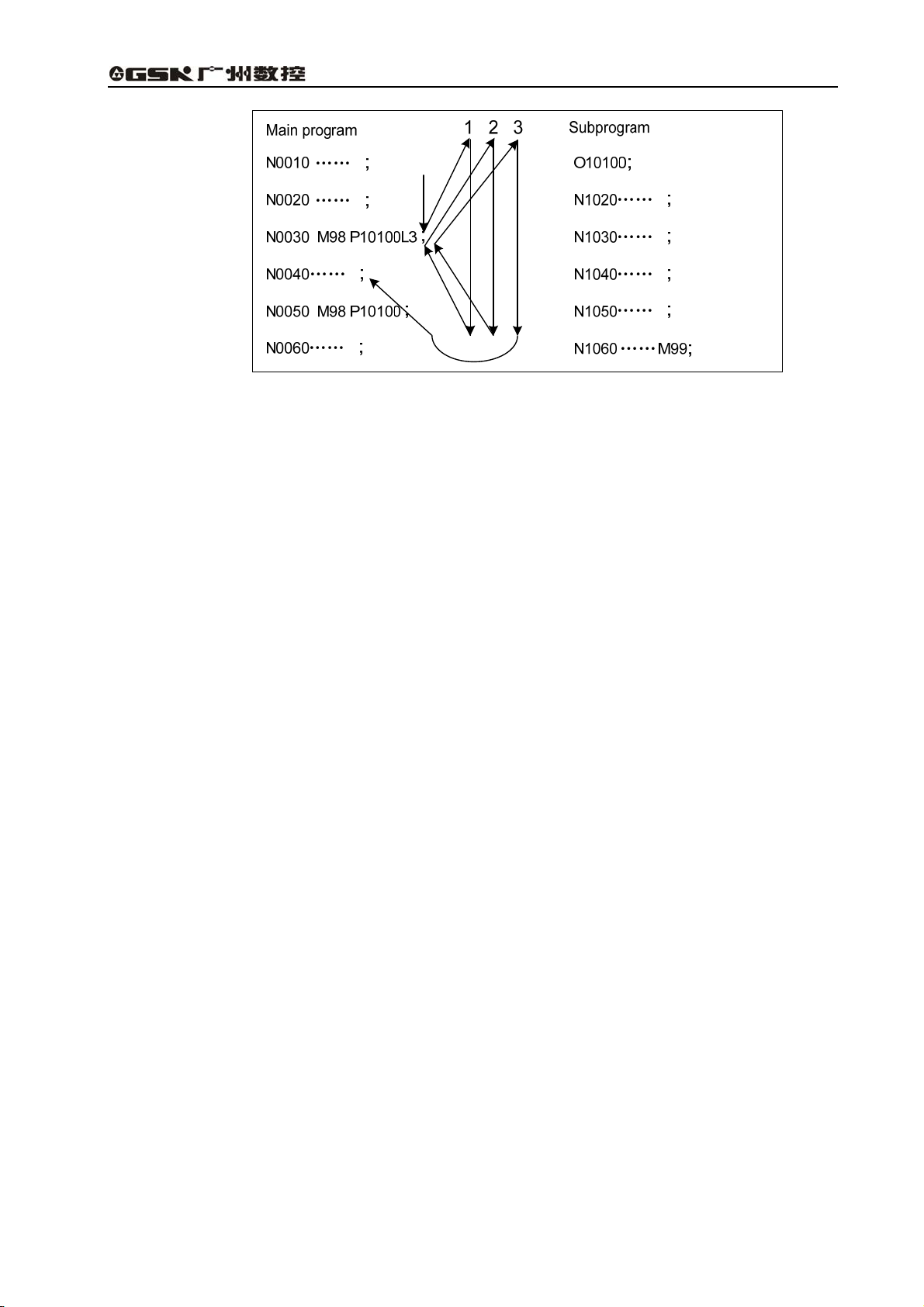

2.2.2 Subprogram call

The subprogram is called out for execution by the main program or the subprogram. The

instruction format is as following:

Fig. 2-2-2-1

● If the repeat time is omitted, the default is 1.

Example M98 P1002L5 ;(It means No.1002 subprogram is continuously called for 5

times.)

● Execution sequence of subprogram call from main program

12

GSK990MA CNC System Programming and Operation Manual

Fig. 2-2-2-2

Subprogram call from subprogram are identical with that from main program.

Note 1、Alarm (PS 078) occurs if subprogram number specified by address P is not found.

2、No. 90000~99999 subprograms are the system reserved programs, if they are called,

they can be executed, and can be displayed.

2.2.3 Program end

The program begins with program name, ends with M02, M30 or M99 (see Fig. 2-2-2-2). For the

end code M02,,M30 or M99 detected in program execution: if M02, M30 specifies the end, the program

finishes and reset; and M30 can be set by bit parameter N0.33#4 for returning to the program beginning,

and M02 can be set by bit parameter N0.33#2 for returning to the program beginning. if M99 specifies

the end, the control returns to the program beginning to restart the program; if M99 、M02 and M30 is at

the end of the subprogram, the control returns to the program that calls the subprogram and go on

executing the following block.

13

Programming Chapter Three Programming Fundamentals

3 Programming Fundamentals

3.1 Controlled axis

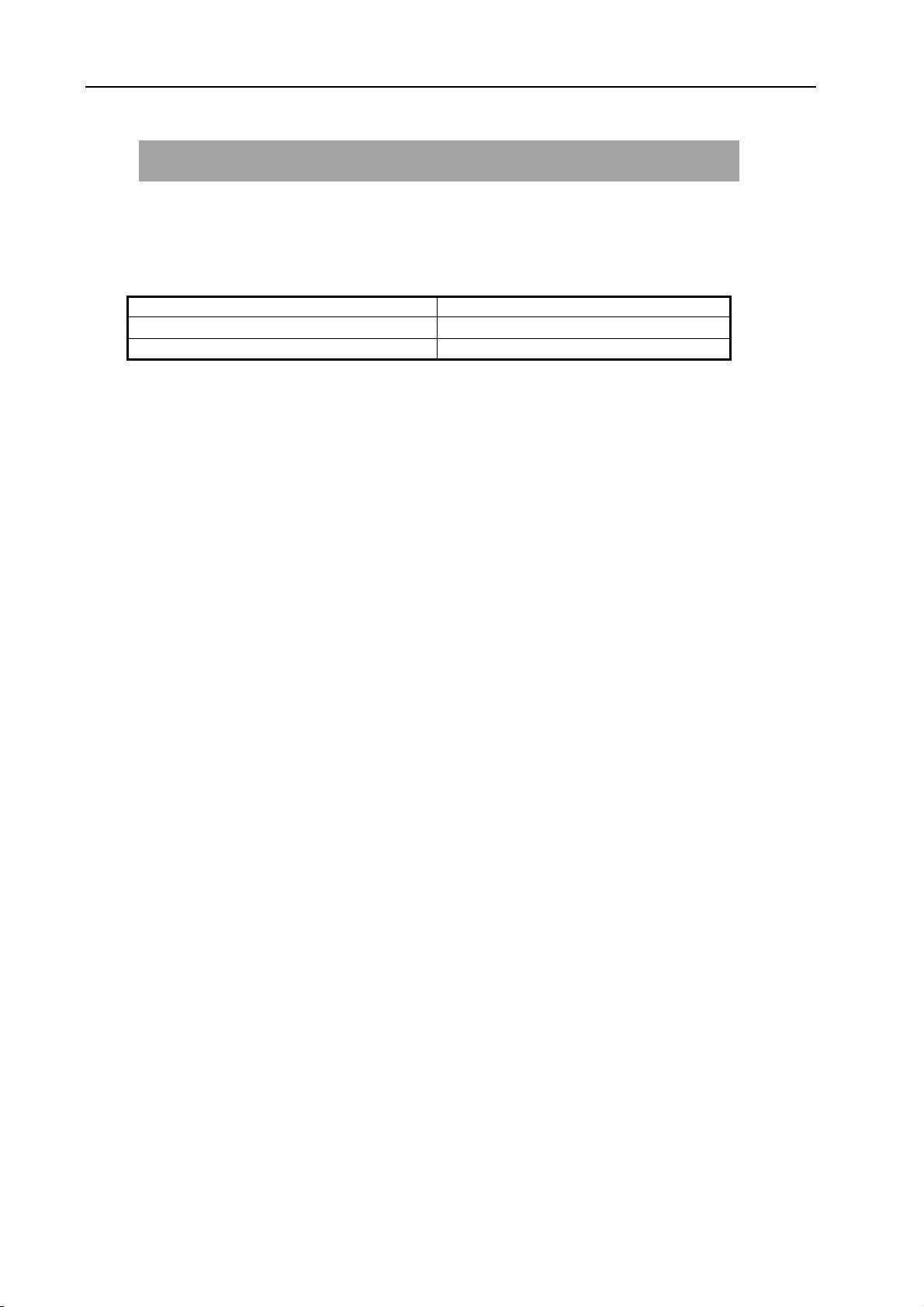

Table 3-1-1

Item GSK990MA

Basic controlled axes

Extended controlled axes (total) 4 axes

3.2 Axis name

The 3 primary axis names are always X, Y, or Z. And the controlled axes are set by data

parameter P005. The additional axis names are set by data parameter P006 accordingly, such as A,

B, C.

3 axes(X, Y, Z)

3.3 Coordinate system

3.3.1 Machine coordinate system

A special point on machine used as machine benchmark is called machine zero, which is set by

the machine builder. The coordinate system set by machine zero taken as origin is called machine

coordinate system. It is set up by manual machine zero return after power on. Once set, it remains

unchanged till the power off, system reset or emergency stop.

This system uses right-hand Cartesian coordinate system. The motion along spindle is Z axis

motion. Viewed from spindle, the motion of headstock approaching the workpiece is negative Z axis

motion, and departing for positive. The other directions are determined by right-hand Cartesian

coordinate system.

3.3.2 Reference point

There is a special point on CNC machine tool for tool change and coordinate system setup,

which is called reference point. It is a fixed point in machine coordinate system set by machine builder.

By reference point return, the tool can easily move to this position. Generally this point in CNC milling

system coincides with the machine zero, while the reference point of Machine Center is usually the

tool change point.

14

Loading...

Loading...