Page 1

GSK990MA CNC System Connection and PLC Manual

This manual describes the various matters concerning the

operations of this CNC system as much as possible. However, it is

impossible to give detailed descriptions to all the unnecessary or

unallowable operations due to space limitation and product specific

applications. Therefore, the matters not specially described herein

should be considered as “impossible” or “unallowable”.

This user manual is the property of GSK CNC Equipment Co.,

Ltd. All rights are reserved. It is illegal for any organization or

individual to publish or reprint this manual. GSK CNC Equipment Co.,

Ltd. reserves the right to ascertain their legal liability.

I

Page 2

Preface and Precaution

Preface

Dear users,

It is our pleasure for your patronage and purchase of this machining center

CNC system of GSK990MA produced by GSK CNC Equipment Co., Ltd.

This book is “Programming and Operation Manual”, which introduces

the programming and operation of the machining center CNC system of

GSK990MA in detail.

To ensure the product works in a safe and efficient state, please read this manual

carefully before installation and operation.

Warnings

Improper operations may cause unexpected accidents. Only

those qualified staff are allowed to operate this system.

Special notes: The power supply fixed on/in the cabinet is exclusively

used for the CNC system made by GSK.

It cannot be applied for other purposes, or else it may

cause serious danger.

II

Page 3

GSK990MA CNC System Connection and PLC Manual

Declaration!

z We try to describe all the various matters as much as possible in this

manual. However, it is impossible to give detailed descriptions to all

the unnecessary or unallowable operations because there are too

many possibilities. Therefore, the matters not specially described

herein should be considered as “impossible” or “unallowable”.

z Before installing, connecting, programming and operating the product,

please read this manual and the manual provided by the machine tool

builder carefully, and operate the product according to these manuals.

Otherwise, the operation may cause damage to the product and

machine tool, or even cause personal injury.

Warning!

Caution!

z The functions and specifications (e.g., precision and speed) described

in this manual are only for this product itself. For those CNC machine

tools installing this product, the actual function configuration and

specifications depend on the designs of the machine tool builders.

Moreover, the function configuration and specifications of the CNC

machine tool are subject to the manual provided by the machine tool

All specifications and designs in this manual are subject to change without notice.

III

Page 4

Preface and Precaution

Safety notes

■ Transportation and storage

z Do not pile up the packing boxes over 6 layers.

z Never climb the packing box, neither stand on it, nor place heavy objects on it.

z Do not move or drag the product by the cables connected to it.

z Avoid impact or scratch to the panel and screen.

z Packing box should be protected from dampness, insolation and drench.

■ Open-package inspection

z Confirm the product is the one you purchased after opening the package.

z Check whether the product is damaged during transportation.

z Confirm all the elements are complete without damage by referring to the list.

z If there is incorrect product type, incomplete accessories or damage, please

contact us in time.

■ Connection

z Only qualified personnel can connect and inspect the system.

z The system must be earthed. The earth resistance should not be greater than

0.1Ω, and a neutral wire (zero wire) cannot be used as an earth wire.

z The connection must be correct and secured. Otherwise, the product may be

damaged or unexpected results may occur.

z Connect the surge absorbing diode to the product in the specified direction;

otherwise the product may be damaged.

z Turn off the power before inserting or unplugging a plug, or opening the electric

cabinet.

■ Troubleshooting

z Turn off the power supply before troubleshooting or replacing components.

z Overhaul the system when there is a short circuit or overload, and do not restart

it until the trouble is removed.

z Do not turn ON/OFF the product frequently, and the ON/OFF interval should be

1 minute at least.

IV

Page 5

GSK990MA CNC System Connection and PLC Manual

Volume Ⅰ Programming Description

Introduce the technical specification, product type series and parameter

configuration, command code and program format of 990MA machining center CNC

system.

Volume Ⅱ Function Description

Introduce the main function of the GSK990MA series machining center CNC

system.

Volume Ⅲ Operation Description

Introduce the relative operations of PLC software of the GSK990MA machining

center CNC system.

Volume Ⅳ Installation and Connection

Introduce the installation, connection and setting methods of the GSK990MA

machining center CNC system.

Appendix

Introduce the use explanations of the GSK990MA machining center CNC

system and the appendix.

V

Page 6

Preface and Precaution

Safety responsibility

Manufacturer Responsibility

——Be responsible for the danger which should be eliminated on the design

and configuration of the provided CNC systems

——Be responsible for the safety of the provided CNC and its accessories

——Be responsible for the provided information and advice

User Responsibility

——Be trained with the safety operation of CNC system operation

procedures and familiar with the safety operation.

——Be responsible for the dangers caused by adding, changing or

modifying the original CNC systems and accessories.

——Be responsible for the danger caused by failing to observe the

operation, maintenance, installation and storage in the manual.

This user manual shall be kept by the end user.

Thank you for your kind support when you are using the

products of Guangzhou CNC Equipment Co., Ltd.

VI

Page 7

GSK990MA CNC System Connection and PLC Manual

Contents

Ⅰ PROGRAMMING .................................................................................................1

1 Sequence Program Creating Process........................................................................................3

1.1 GSK990MA PLC specification ...............................................................................................3

1.2 What is a sequence program.................................................................................................3

1.3 Assignment of interface specifications(step 1)..................................................................3

1.4 Establishment of ladder diagram(step 2)...........................................................................4

1.5 Sequence program debugging(step 3)..............................................................................4

2 Sequence Program......................................................................................................................5

2.1 Execution process of sequence program ...............................................................................5

2.2 Cycle execution .....................................................................................................................6

2.3 Priority of execution(1st level, and 2nd level).........................................................................6

2.4 Sequence program structure .................................................................................................7

2.5 Processing I/O ( input / output ) signals .................................................................................9

2.5.1 Input signal processing ............................................................................................10

2.5.2 Output signal processing .........................................................................................10

2.5.3 Difference state of signals between 1st level and 2nd level .....................................10

2.6 Interlocking ............................................................................................................................ 11

3 Address......................................................................................................................................12

3.1 Addresses from Machine tool to PLC(X) ...........................................................................12

3.1.1 Assignment of IO module X address........................................................................13

3.1.2 Assignment of MDI panel X address........................................................................13

3.2 Address (Y) from PLC to machine tool ..................................................................................14

3.2.1 Assignment of IO module Y address........................................................................14

3.2.2 Assignment of IO module Y address........................................................................14

3.3 Address (G) from PLC to CNC.............................................................................................15

3.4 Address (F) from CNC to PLC .............................................................................................16

3.5 Internal relay address(R).................................................................................................16

3.6 Address of keep relay(K).................................................................................................17

3.7 Addresses(A) for message selection displayed on CRT......................................................17

3.8 Address of meter(C)........................................................................................................18

3.9 Meter preset address(DC) ...................................................................................................18

3.10 Timer addresses(T).........................................................................................................18

3.11 Addresses of timer preset value(DT)...............................................................................18

3.12 Address of data table(D) .................................................................................................19

3.13 Label address(L) .............................................................................................................19

3.14 Subprogram numbers(P) ................................................................................................19

4 PLC Basic Instruction..............................................................................................................20

4.1 RD, RD.NOT, WRT, WRT.NOT ............................................................................................21

4.2 AND, AND.NOT instructions ................................................................................................21

VII

Page 8

Contents

4.3 OR, OR.NOT instructions .................................................................................................... 22

4.4 OR. STK instruction............................................................................................................. 22

4.5 AND.STK instruction............................................................................................................ 23

5 PLC Functional instructions...................................................................................................25

5.1 END1(1

5.2 END2(2

5.3 CALL(call subprogram)................................................................................................... 27

5.4 CALLU(unconditional subprogram call) ..........................................................................27

5.5 SP(Subprogram).............................................................................................................28

5.6 SPE(subprogram end) .................................................................................................... 28

5.7 SET(set) ......................................................................................................................... 29

5.8 RST(reset) ...................................................................................................................... 30

5.9 JMPB(label jump) ........................................................................................................... 30

5.10 LBL(Label) ...................................................................................................................... 31

5.11 TMR(timer)......................................................................................................................32

5.12 TMRB(fixed timer) .......................................................................................................... 33

5.13 TMRC(timer)................................................................................................................... 34

5.14 CTR(binary counter) ....................................................................................................... 35

5.15 DEC(binary decode) ....................................................................................................... 37

5.16 COD(binary code conversion) ........................................................................................ 38

5.17 COM (common line control) ................................................................................................ 40

5.18 COME (common line control end) ....................................................................................... 40

5.19 ROT(Binary rotation control)

5.20 SFT(shift register)...........................................................................................................44

5.21 DIFU(rising edge check)................................................................................................. 45

5.22 DIFD(falling edge check) ................................................................................................ 46

5.23 COMP(binary comparison) ............................................................................................. 47

5.24 COIN(coincidence check)............................................................................................... 48

5.25 MOVN(transfer of data) .................................................................................................. 49

5.26 MOVB(transfer of one byte)............................................................................................ 50

5.27 MOVW(transfer of two bytes............................................................................................. 50

5.28 XMOV(Binary index data transfer).................................................................................. 51

5.29 DSCH (binary data search)............................................................................................ 53

5.30 ADD(addition) ................................................................................................................. 54

5.31 SUB(binary subtraction) ................................................................................................. 55

5.32 ANDF(functional and) ..................................................................................................... 56

5.33 ORF(functional or) .......................................................................................................... 58

5.34 NOT(logical not) ............................................................................................................. 59

5.35 EOR(exclusive or) .......................................................................................................... 60

st

level sequence program end)..........................................................................26

nd

level sequence program end) ......................................................................... 26

........................................................................................... 41

6 Ladder Writing Limit.............................................................................................................. 62

Ⅱ FUNCTION ...........................................................................................................65

1 Controlled Axis......................................................................................................................... 67

VIII

Page 9

GSK990MA CNC System Connection and PLC Manual

1.1 Output of movement state of an axis .....................................................................................67

1.2 Servo ready signal .................................................................................................................68

2 Preparation for Operation.......................................................................................................69

2.1 Emergency stop...................................................................................................................69

2.2 CNC overtravel signal ..........................................................................................................69

2.3 Alarm signal .........................................................................................................................71

2.4 Running mode selection ......................................................................................................71

2.5 Status output signal..............................................................................................................72

3 Manual Operation....................................................................................................................73

3.1 JOG feed/incremental feed ..................................................................................................73

3.2 MPG/Step feed ....................................................................................................................75

4 Reference Point Return............................................................................................................76

4.1 Manual reference point return ..............................................................................................76

4.2 Reference point return check signal ....................................................................................77

4.3 Area check signal ................................................................................................................79

5 Automatic Operation................................................................................................................80

5.1 Cycle start/feed hold ............................................................................................................80

5.2 Reset ...................................................................................................................................82

5.3 Testing a program ................................................................................................................83

5.3.1 Machine tool lock .....................................................................................................83

5.3.2 Dry run .....................................................................................................................84

5.3.3 Single block..............................................................................................................85

5.4 Optional block skip...............................................................................................................86

5.5 Program restart....................................................................................................................86

6 Feedrate Control.......................................................................................................................88

6.1 Rapid traverse rate ..............................................................................................................88

6.2 Feedrate override ................................................................................................................89

6.3 Override cancel....................................................................................................................89

7 Auxiliary Function....................................................................................................................90

7.1 Miscellaneous function (M code) ....................................................................................90

7.2 Miscellaneous function (S code) ..........................................................................................91

7.3 Miscellaneous function (T code).....................................................................................92

7.4 Auxiliary function lock ..........................................................................................................96

8 Spindle Speed Function............................................................................................................97

8.1 Spindle speed control mode.................................................................................................97

8.1.1 Gear spindle.............................................................................................................97

8.1.2 Analog spindle .........................................................................................................97

8.2 Rigid tapping......................................................................................................................100

9 Programming Instruciton......................................................................................................101

IX

Page 10

Contents

9.1 Customer macro program..................................................................................................101

9.2 Canned cycle..................................................................................................................... 103

10 Display/Setting...................................................................................................................... 106

10.1 Clock Function................................................................................................................. 106

10.2 Displaying operation history ............................................................................................ 106

10.3 Help function ...................................................................................................................106

11 Measurement........................................................................................................................ 107

11.1 Skip function ...................................................................................................................... 107

12 Panel locked setting.............................................................................................................. 108

Appendix.................................................................................................................................... 109

Ⅲ PLC EDITTING.....................................................................................................113

1 Summary................................................................................................................................. 115

2 Software introduction............................................................................................................ 116

2.1 Start software..................................................................................................................... 116

2.2 Function introduction ......................................................................................................... 116

3 Software operarion ................................................................................................................ 118

3.1 Tool bar.............................................................................................................................. 118

3.1.1 Main tool bar.......................................................................................................... 118

3.1.2 Edit tool bar ........................................................................................................... 11 8

3.2 Selecting a graph............................................................................................................... 120

3.3 Editing a graph .................................................................................................................. 121

3.3.1 Cutting ................................................................................................................... 121

3.3.2 Copying .................................................................................................................121

3.3.3 Paste .....................................................................................................................122

3.3.4 Deleting ................................................................................................................. 122

3.3.5 Inserting one row ................................................................................................... 122

3.3.6 Deleting one row.................................................................................................... 122

3.3.7 Converting .............................................................................................................122

3.4 Ladder annotation.............................................................................................................. 123

3.4.1 Row annotation......................................................................................................123

3.4.2 Element annotation................................................................................................ 123

3.5 Exporting ...........................................................................................................................125

Ⅳ CONNECTION .....................................................................................................127

1 System Structure and Installation........................................................................................ 129

1.1 System composition ..........................................................................................................129

1.2 System installation & connection ....................................................................................... 129

1.3 CNC system installation dimension ................................................................................... 130

2 Device Connection.................................................................................................................. 134

X

Page 11

GSK990MA CNC System Connection and PLC Manual

2.1 CNC external connection ...................................................................................................134

2.2 Connection between system and driver.............................................................................134

2.2.1 System interface ....................................................................................................135

2.2.2 Interface signal list .................................................................................................135

2.2.3 Signal specification ................................................................................................136

2.2.4 Cable connection ...................................................................................................138

2.3 RS232 standard serial interface.........................................................................................139

2.4 MPG ( handwheel ), hand unit connection.........................................................................140

2.4.1 Interface signal list .................................................................................................140

2.4.2 Interface signal explanation ...................................................................................141

2.5 Spindle unit connection......................................................................................................143

2.5.1 Interface signal list .................................................................................................143

2.5.2 Interface signal explanation ...................................................................................144

2.5.3 DAP01 interface connection...................................................................................144

2.5.4 Connection Circuit of DAP03 Interfaces...............................................................146

2.6 Power supply interface.......................................................................................................147

3 Machine Control I/O Interface..............................................................................................148

3.1 Interface signal list .............................................................................................................148

3.2 Input interface ....................................................................................................................148

3.2.1 Input interface principle ..........................................................................................148

3.2.2 Input signal interface definition...............................................................................149

3.3 Output signal......................................................................................................................151

3.3.1 Output interface principle .......................................................................................151

3.3.2 Output signal interface definition............................................................................152

4 Debugging Machine................................................................................................................154

4.1 Debugging preparation ......................................................................................................154

4.2 System power on ...............................................................................................................155

4.3 Emergency stop and limit...................................................................................................155

4.4 Gear ratio adjustment ........................................................................................................157

4.5 Backlash compensation .....................................................................................................159

4.6 Parameter of servo ............................................................................................................160

4.7 Machine pitch compensation .............................................................................................162

4.8 Machine zero return ...........................................................................................................165

4.9 Input/output signal control of spindle CW/CCW .................................................................169

4.10 Spindle automatic gear change control..............................................................................170

4.11 External cycle start and feed hold......................................................................................172

4.12 External editing lock and external operator panel lock.......................................................173

4.13 Cooling, lubricant and chip removal control .......................................................................173

4.14 Parameter of feedrate........................................................................................................174

4.15 Parameter of tapping .........................................................................................................176

Appendix 1: .............................................................................................................................179

Guide of ladder for GSK990MA matching with turret tool magazine ............................................179

一. Notices of GSK990MA matching with turret tool magazine.................................179

XI

Page 12

Contents

二. Allocation and definition of GSK990MA PLC/IO address and internal auxiliary

relay and register...................................................................................................179

三. Usage and maintenance of GSK 990MA CNC System matching with turret tool

magazine................................................................................................................. 203

四. Macro program statement of GSK990MA CNC System matching with turret

tool magazine.........................................................................................................210

APPENDIX 2 ...............................................................................................................211

一. F signal and meaning for M00-M99 of M code.................................................... 211

二. “%” that occupies a line exclusively means the end of M code information

storage. ................................................................................................................. 211

三. The codes and meaning of X signal X0.0-X6.7................................................... 211

四. The codes and meaning of Y signal Y0.0---Y5.7 ................................................. 212

五. The codes and meaning of K signal Y6.0---Y63.7............................................... 212

六. The codes and meaning of A signal A0.0-A31.7................................................. 212

七. end//end sign......................................................................................................... 212

XII

Page 13

GSK990MA CNC System Connection and PLC Manual

Ⅰ Programming

1

Page 14

Programming Chapter One Sequence Program Creating Process

2

Page 15

GSK990MA CNC System Connection and PLC Manual

1 Sequence Program Creating Process

1.1 GSK990MA PLC specification

Specifications of GSK990MA PLC are as follows:

Specification GSK990MA PLC

Programming method language Ladder

Number of ladder level 2

1st level execution period 8ms

Mean processing time of basic instruction 10μs

Program capacity 4700 step

Instruction Basic instruction +function

instruction

Internal relay (R)

PLC alarm detection (A)

Keep memory

* Timer (T)

* Meter (C)

* Data table (D)

* Keep relay (K)

* Meter preset value data register (DC)

* Timer preset value data register (DT)

Subprogram (P)

Label (L)

I/O module(X)

(Y)

0~511 byte

0~31 byte

0~127 byte

0~127 byte

0~255 byte

0~63 byte

0~127 byte

0~127 byte

0~99

0~99

0~63 byte

0~47 byte

1.2 What is a sequence program

A sequence program is a program for sequence control of machine tools and other systems.

The program is converted into a format to enable CPU execute encoding and arithmetic

processing, and stored into RAM. CPU reads out every instruction stored in the memory at a

high-speed and executes the program by arithmetic operation

The sequence program is written firstly from ladder.

1.3 Assignment of interface specifications(step 1)

interface may be assigned after control object is determined and the relevant input/output signal

points are counted.

For interface assignment, see input /output interface signal table in Book 4 Connection of

this manual

3

Page 16

Programming Chapter One Sequence Program Creating Process

1.4 Establishment of ladder diagram(step 2)

by GSK990MA ladder online edit function, use the ladder to express the machine control actions.

As for the timer, counter, etc, which cannot be expressed with the relay symbol, express them with

the designated functional instructions symbol.

The edited ladder should be stored and it should be converted into the corresponding PLC

instruction namely so-called instruction table before running.

1.5 Sequence program debugging(step 3)

The sequence program can be debugged in two ways:

1) Debug by simulator

Instead of the machine, connect a simulator (consisting of lamps and switches). Switch

ON/OFF stands for the input signal state of machine, lamp ON/OFF for the output signal

state.

2) Actual operation debugging

Debug sequence program through operating the machine. Do measures against the

unexpected affairs before debugging.

4

Page 17

GSK990MA CNC System Connection and PLC Manual

2 Sequence Program

Since PLC sequence control handled by ladder online edit function and operates on principle

difference from a general relay circuit, the sequence control method must be fully understood in

order to design PLC sequence program.

2.1 Execution process of sequence program

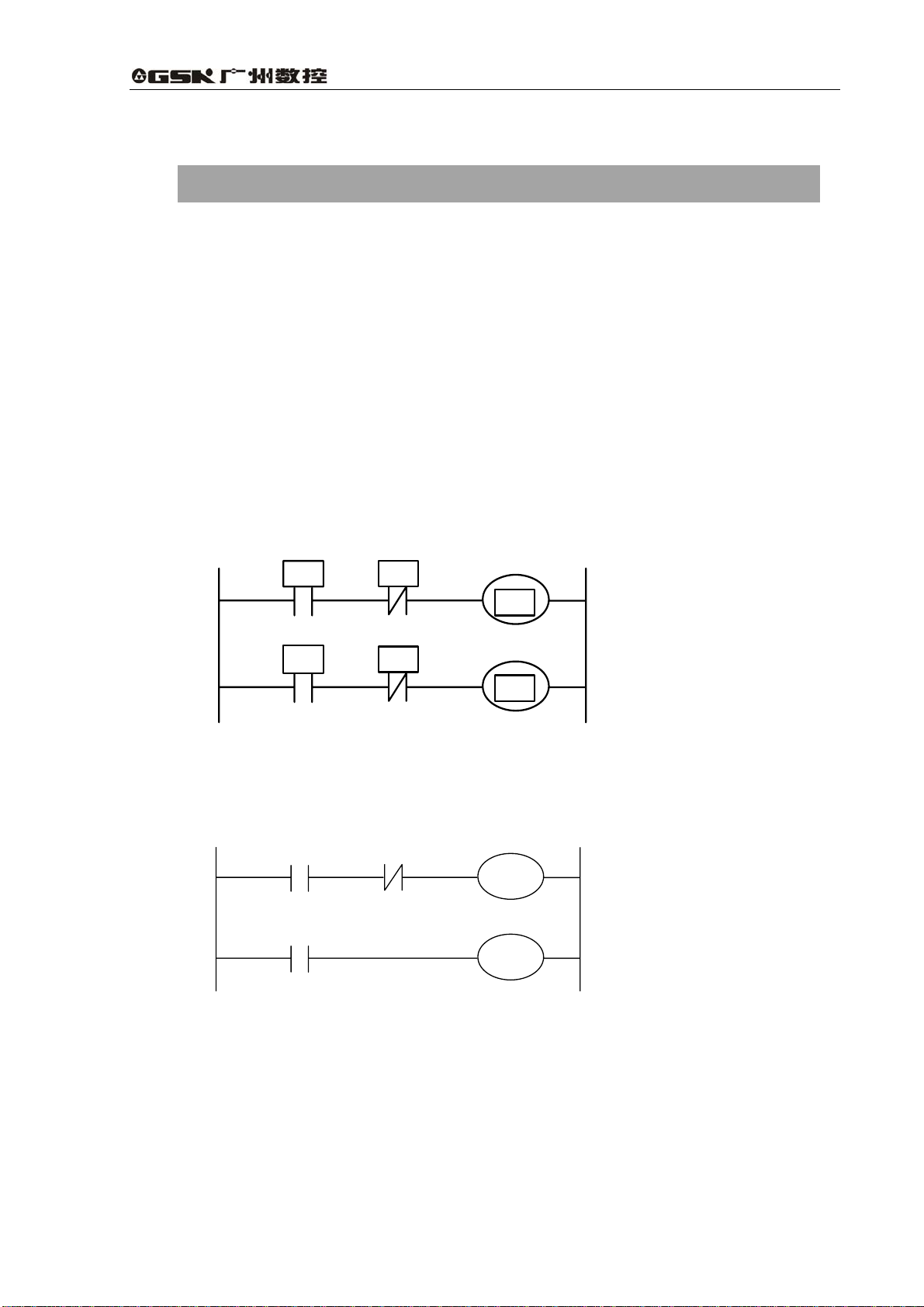

In general relay control circuit, each relay operates at approximately the same time, in the figure

below for example, when relay A operates, the relay D and E operate at approximately the same

time(when contacts B and C are off)., In PLC sequence control, each relay of circuit operates

sequentially. When relay A operates, relay D operates, then relay E operates (see the below figure).

Thus each relay operates in sequence which can be written as a ladder diagram. (programmed

sequence).

A

B

D

A

Fig. 2.1(a) circuit example

Fig.(b) and (c) illustrate operations varying from the relay circuit to PLC program.

A

A

Fig. 2.1(b)

C

E

C

B

C

5

Page 18

Programming Chapter Two Sequence Program

Fig. 2.1(c)

(1) Relay circuit

In Fig. (A) and (B), the operations are the same. Turning on A turns on B and C. Turning on C

turns off B.

(2) PLC program

In Fig. (B), as in the relay circuit, turning on A turns on B and C, and after one cycle of the PLC

sequence, turns off B. But in Fig.(C), turning on A turns on C, but does not turn on B.

2.2 Cycle execution

The PLC executes the ladder diagram from the beginning to the end . When the ladder diagram

ends, the program starts over from the beginning. This is called cycle execution.

The execution time from the beginning to the end of the ladder diagram is called the cycle

processing time. The shorter the process time is, the better the signal response becomes.

2.3 Priority of execution(1st level, and 2nd level)

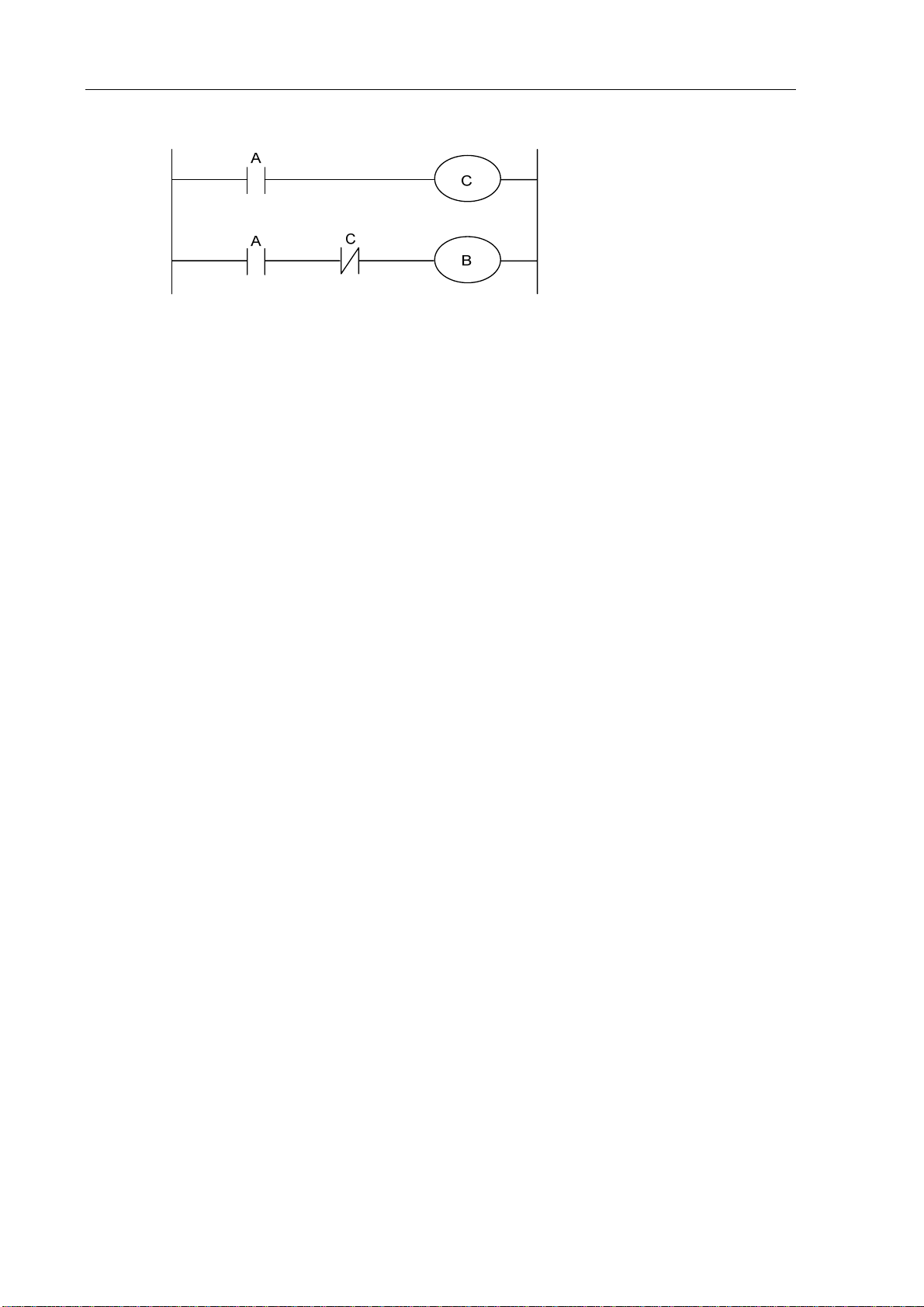

GSK990MA PLC consists of two parts: 1st level sequence part, 2nd level sequence part. They have

different execution period.

st

The 1

high-speed response.

The 2

sequence part. The 2nd level sequence part is divided into n parts, and every part is executed every

8ms.

level sequence part operates every 8*n ms, which can deal with the short pulse signal with

nd

level sequence part operates every 8*n ms. Here n is a dividing number for the 2nd level

6

Page 19

GSK990MA CNC System Connection and PLC Manual

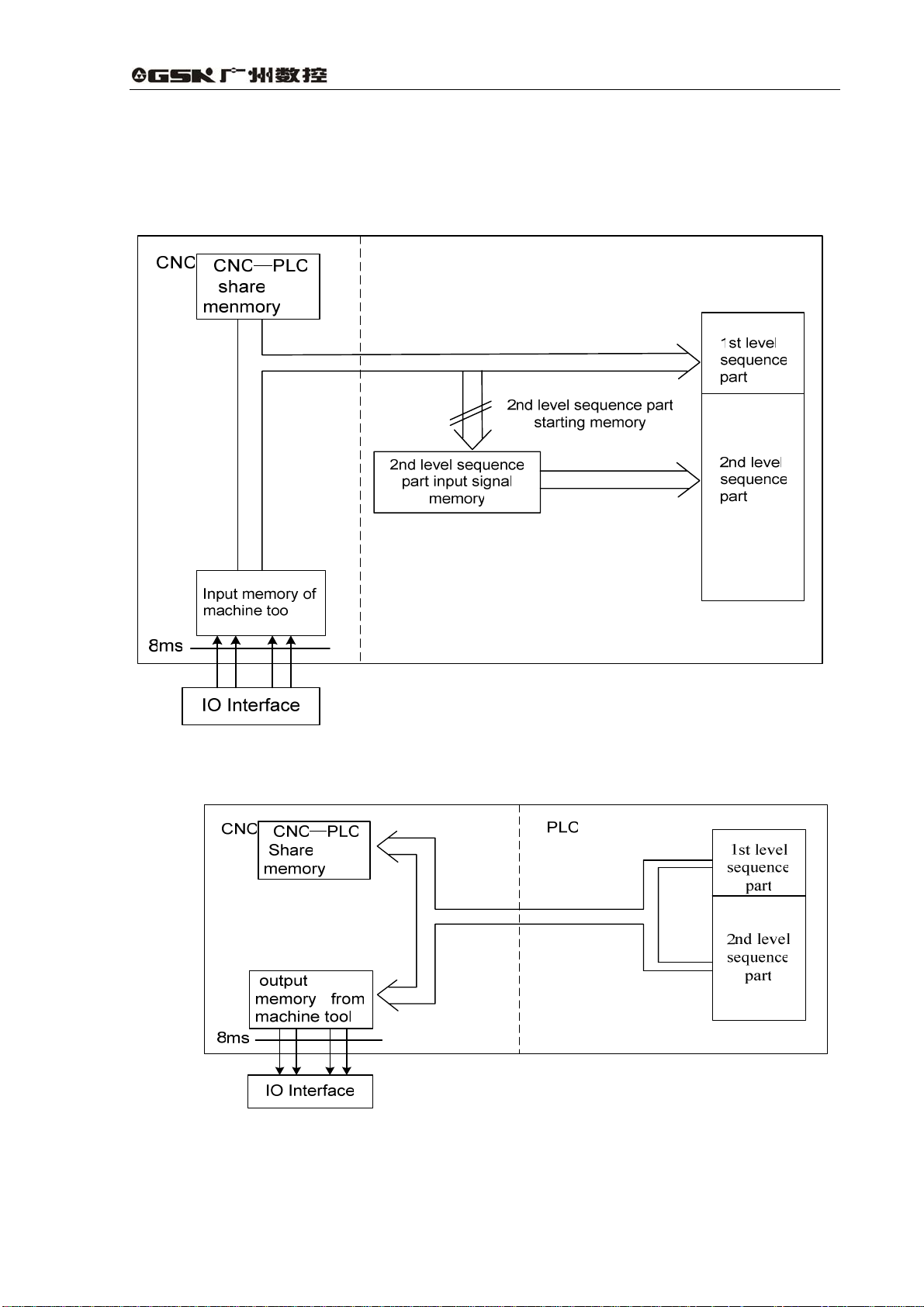

Fig. 2-3-1

990MA PLC is solely executed in PLC-AVR single chip, and the first 1ms of each 8ms is the

communication time of CNC reading or writing PLC data. The fifth 1ms is the time that the PLC

receives the system control signal (F、X)and uploads the control result data(G、Y parameter)

to the external I/O interface(X、Y), except for the time responding the interruption to exchange the

data, the PLC executes the ladder operation at the rest time.

Fig. 2-3-2

nd

After the last 2

level sequence part (division n) is executed, the sequence program is executed

again from the beginning. Thus, when the dividing number is n, the cycle of execution is 8*n ms.

st

The 1

of the 1

level sequence operates every 8ms, and the 2nd level sequence every 8*n ms. If the steps

st

level sequence is increased, the steps of the 2nd level sequence operating within 8ms

becomes less, thereby increasing the dividing number and making the processing time longer.

Therefore, it is desirable to program so as to reduce the 1st level sequence to a minimum.

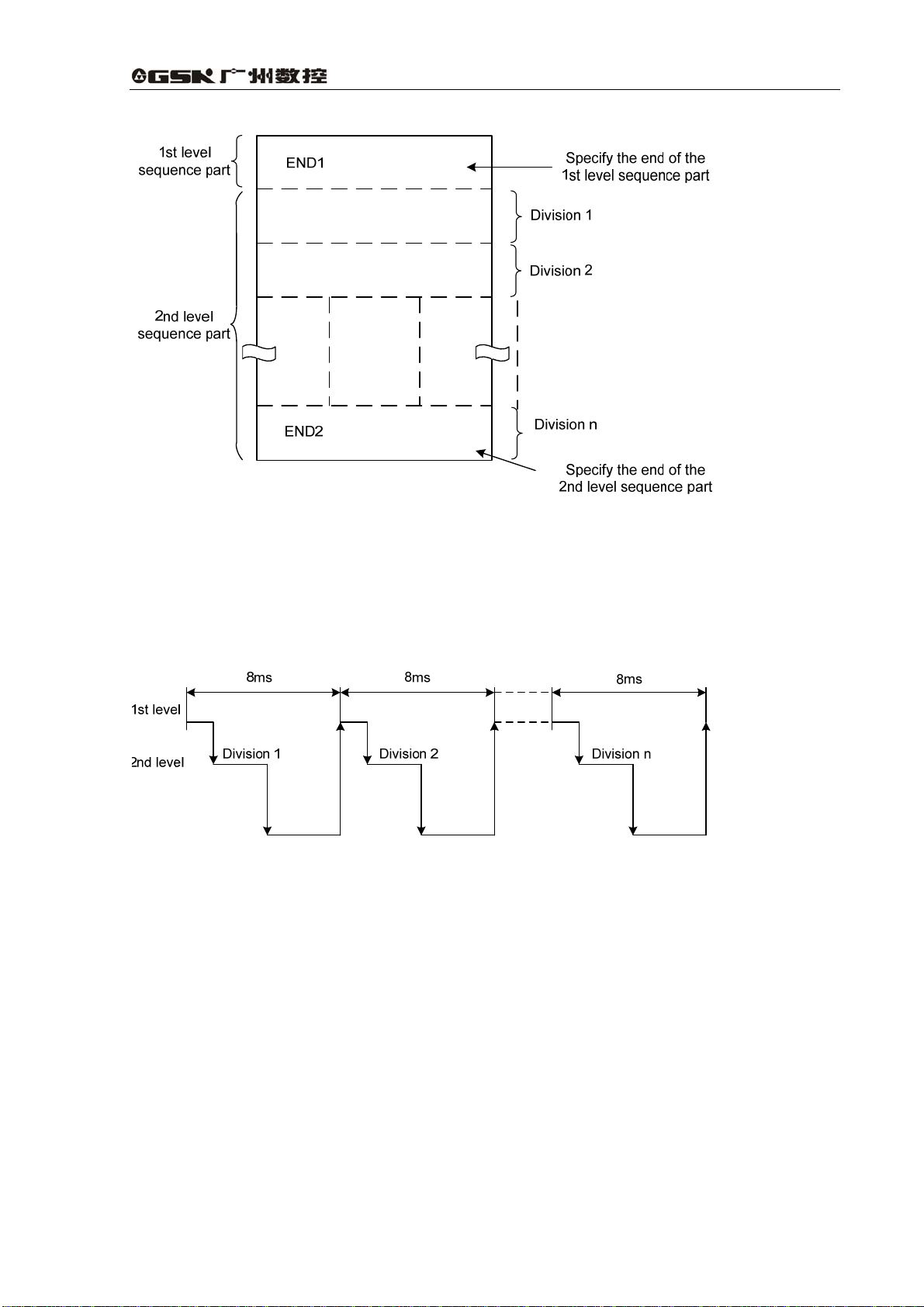

2.4 Sequence program structure

With the conventional PLC, a ladder program is created sequentially. By employing a ladder

language that allows structured programming, the following benefits are as following :

7

Page 20

Programming Chapter Two Sequence Program

1. A program can be understood and developed easily

2. A program error can be found easily.

3.When an operation error occurs, the cause can be found easily.

Three major structured programming capabilities are supported:

1) Subprogram

A subprogram can consist of a ladder sequence as the processing unit.

Fig. 2-4-1

2) Nesting

The Ladder subprograms can call the other ladder subprogram to execute the job.

Fig. 2-4-2

3) Conditional branch

The main program loops and checks whether conditions are satisfied. If a condition is satisfied, the

corresponding subprogram is executed. If the condition is not satisfied, the subprogram is skipped.

Fig. 2-4-3

8

Page 21

GSK990MA CNC System Connection and PLC Manual

2.5 Processing I/O ( input / output ) signals

Input signal processing:

Output signal processi ng:

Fig. 2-5-1

Fig. 2-5-2

9

Page 22

Programming Chapter Two Sequence Program

2.5.1 Input signal processing

(1)NC input memory

The input signals from NC are loaded in memory of NC and are transferred to the PLC at intervals

of 8ms. Since the 1

(2)Input signal memory to machine tool

The input signal memory stores signals transferred from the machine tool at intervals of 8ms

period. Since the 1st level sequence part directly refer to these signal and process operations.

nd

(3)2

level input signal memory

The 2nd level input signal memory is also called 2nd level synchronous input signal memory. The

stored signals are processed by the 2

synchronizes with that of 2nd level sequence part.

Input memory Signals from NC and machine tool are transferred to the 2

memory only at the beginning of execution of the 2nd level sequence part. Therefore, the state of

nd

the 2

level synchronous input signal memory does not change from the beginning to end of the

execution of the 2nd level sequence part.

st

level sequence part directly refer to these signal and process operations.

nd

level sequence part. State of the signals set this memory

nd

level input signal

2.5.2 Output signal processing

(1)NC output memory

The output signals are transferred form the PLC to the NC output memory at intervals of 8ms.

(2)Output signals memory to machine tool

Signals stored in the machine tool output memory are transferred to the machine tool at intervals of

8ms.

Note:

The state of the NC input memory, NC output memory, input signals from machine, input/output

memory signals to machine can be checked by using the PC self-diagnosis function. The

self-diagnosis number specified is the address number used by the sequence program.

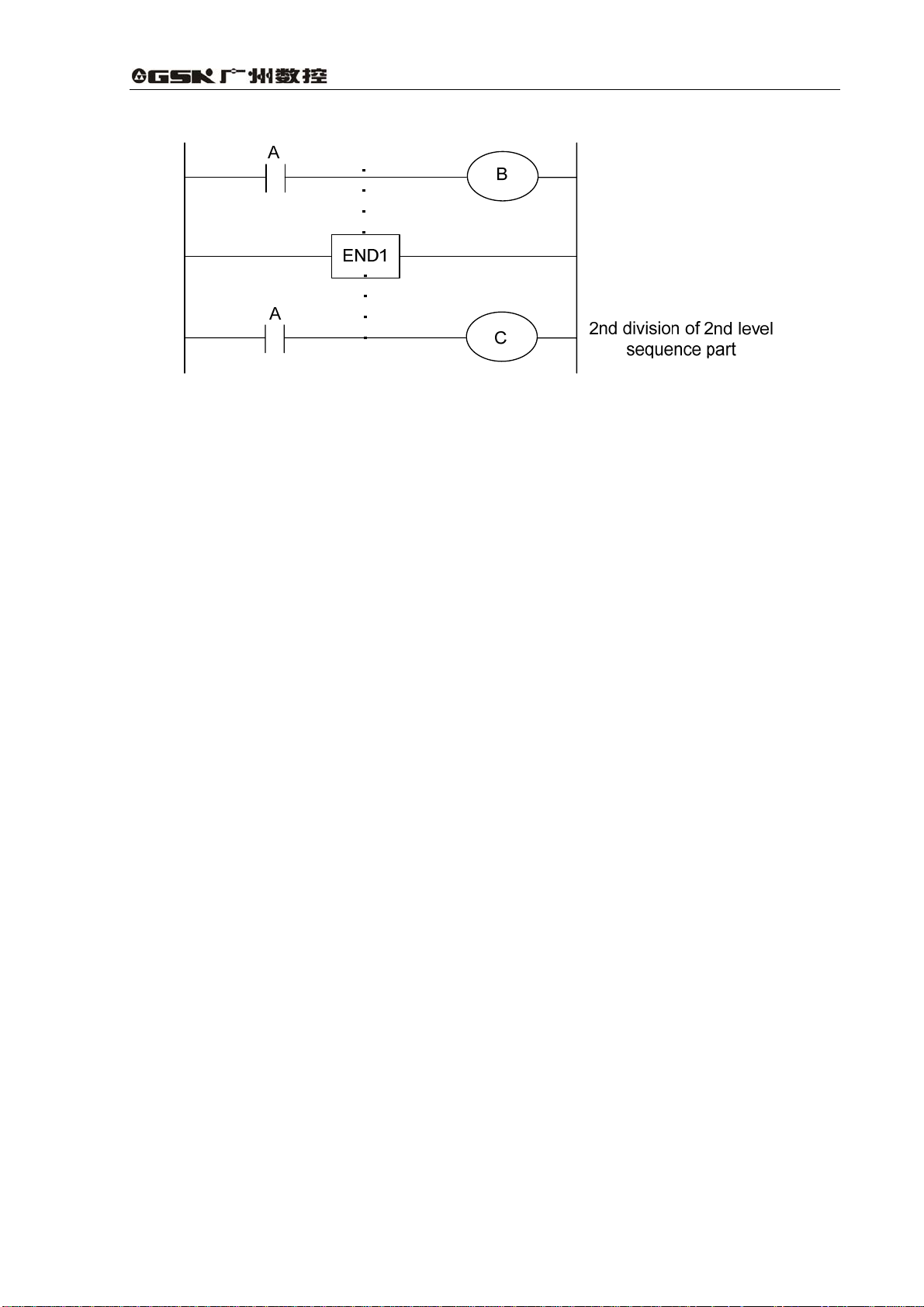

2.5.3 Difference state of signals between 1st level and 2nd level

The state of the same input signal may be different in the 1

Because they use different input memory. That is, at 1

signal memory and at 2nd level, processing is performed using the 2nd level synchronous input

nd

signal memory. Therefore, it is possible for a 2

level sequence execution at the worst, compared

with a 1st level input signal.

This must be kept in mind when writing the sequence program.

st

level and 2nd level sequences.

st

level, processing is performed using input

10

Page 23

GSK990MA CNC System Connection and PLC Manual

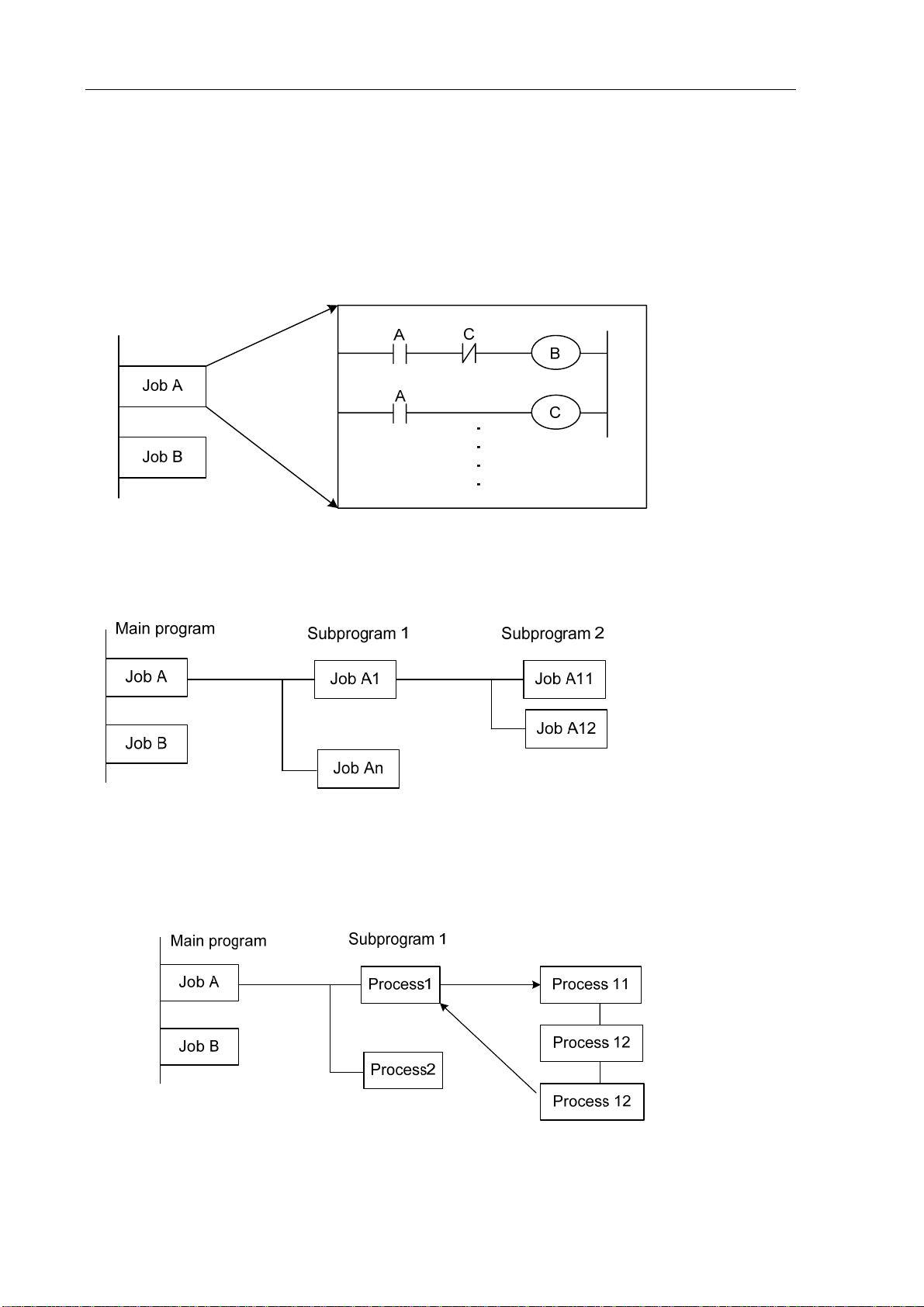

Fig. 2-5-3-1

When the processing is 1st 8ms, A=1, and B=1 after 1st sequence part is executed. At the same

time, 2nd sequence part is started to execute, A=1 is stored to the 2nd sequence part and the 1st

division of 2nd sequence part is executed.

When the processing is 2nd 8ms, A=0, and B=0 after 1st sequence part is executed. And then

2nd division of 2nd sequence part is executed, at this time, A is still 1. So C=1.

So, B and C are different.

2.6 Interlocking

Interlocking is important on sequence control safety.

Interlocking is necessary in the sequence control program. However, hard interlocking for the relay

circuit should be applied in the machine strong power cabinet. This is because even interlocking is

logically used in the sequence program (software), the interlock will not work when trouble occurs

in the hardware used to execute the sequence program. Therefore, provide an interlock inside the

machine tool magnetic cabinet to ensure the safety and to protect the machine from damage.

11

Page 24

Programming Chapter Three Address

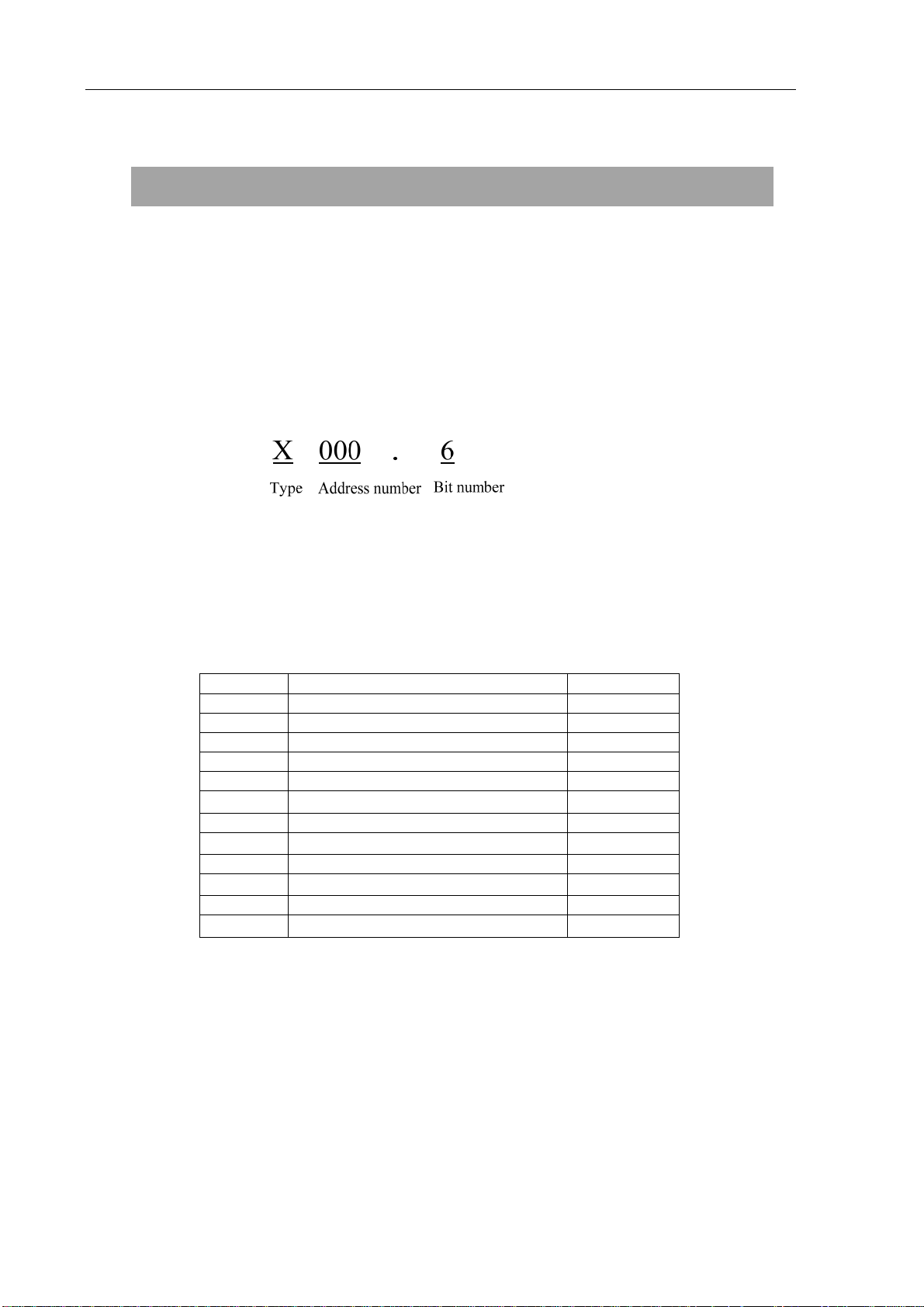

3 Address

An address shows a signal location. Addresses include input/output signals with respect to the

machine, the input/output signals with respect to the CNC, the internal relays, the meters, the keep

relays, and data table. Each address consists of an address number and a bit number. Its serial

number regulations are as follows:

Address regulations:

The address comprises the address type, address number and the bit number in the format as

shown below:

Type: including X, Y, R, F, G K, A, D ,C, , T

Address number: decimal serial number stands for one byte.

Bit number: octal serial number, 0~7 stands for 0~7 bit of byte of front address number

990MA PLC address type is as follows:

Table 3-1

Address Signal description Length

X Machine tool → PLC(64 byte) INT8U

Y PLC→ Machine tool (48 byte) INT8U

F CNC→PLC(64 byte) INT8U

G PLC→CNC(64 byte) INT8U

R Auxiliary relay(512 byte) INT8U

D

DC Counter preset data register INT16U

C

A PLC message request signal INT8U

T

DT Timer preset data register INT16U

K

Data register (0~255)

Meter (0~127)

Timer (0~127)

Keep relay(64 byte)

INT16U

INT16U

INT16U

INT8U

INT8U data type is 8-bit character without signs, INT16U data type is 16-bit integer without signs.

3.1 Addresses from Machine tool to PLC(X)

X addresses of GSK990MA PLC are divided into two:

1. X addresses are assigned to IO input interface of XS43, XS44 and XS45.

2. X addresses are assigned to the input press keys on MDI panel.

12

Page 25

GSK990MA CNC System Connection and PLC Manual

3.1.1 Assignment of IO module X address

The addresses are from X0 to X5. Its type is INT8U, 48 types. They are assigned to three IO input

interface of XS 43, XS44 and XS45.

The signal specification of X addresses can be customized by customer according to the actual

operation. X addresses are used for machine (tool) connection and the ladder editing. For the

initial definition of input address, see Book 4 Connection of this manual.

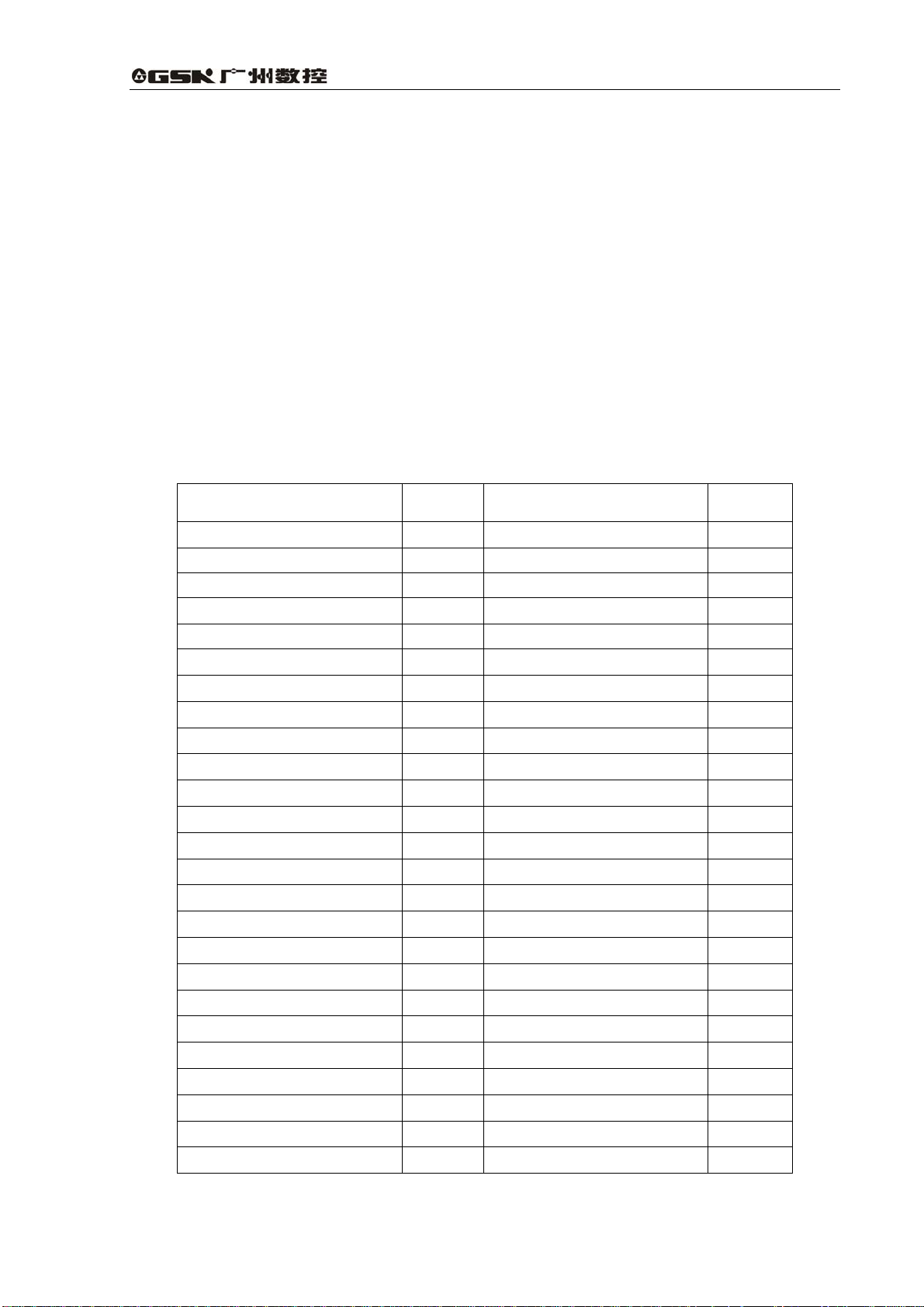

3.1.2 Assignment of MDI panel X address

The addresses are from X20 to X30, 11 bytes. They correspond to the press keys on MDI panel,

and their signal definitions cannot be changed by user.

Corresponding relationship for addresses and press keys are as follows:

Table 3-1-2-1

Input key on operator panel PLC

address

Edit mode

Auto mode

MDI mode

Machine zero return mode

Single step mode

Manual mode

MPG mode

DNC mode

Skip

Single block

Dry run

Miscellaneous(M, S, T) lock

Machine lock

Optional stop

Program restart

Spindle CCW

Spindle stop

Spindle CW

Spindle negative override

Spindle override cancel

Spindle positive override

Spindle jog

Lubrication

Cooling

Chip removal

X20.0

X20.1

X20.2

X20.3

X20.4

X20.5

X20.6

X20.7

X21.0

X21.1

X21.2

X21.3

X21.4

X21.5

X21.6

X22.0

X22.1

X22.2

X22.3

X22.4

X22.5

X22.6

X23.0

X23.1

X23.2

Input key on operator panel PLC

address

Feedrate positive override

Feedrate override cancel

Feedrate negative override

Rapid

Rapid F0 / 0.001

Rapid 25% / 0.01

Rapid 50% / 0.1

Rapid 100% / 1

Manual feed axis +X

Manual feed axis +Y

Manual feed axis +Z

Manual feed axis +4TH

USER1

Manual feed axis -X

Manual feed axis -Y

Manual feed axis -Z

Manual feed axis -4TH

USER2

USER3

Spindle orientation

Tool magazine zero return

Tool clamp/ release

Tool magazine CW

Tool magazine CCW

tool infeed

X24.0

X24.1

X24.2

X24.7

X26.0

X26.1

X26.2

X26.3

X27.0

X27.1

X27.2

X27.3

X27.4

X28.0

X28.1

X28.2

X28.3

X28.4

X28.7

X29.0

X29.1

X29.2

X29.3

X29.4

X29.5

13

Page 26

Programming Chapter Three Address

Cycle start

Feed hold

X23.6

X23.7

tool retraction

Tool change manipulator

Overtravel release

X29.6

X29.7

X30.0

3.2 Address (Y) from PLC to machine tool

Y addresses of GSK990MA PLC are divided into two:

1. Y addresses are assigned to IO input interface of XS40, XS41 and XS42.

2. Y addresses are assigned to the indicators on MDI panel.

3.2.1 Assignment of IO module Y address

The addresses are from Y0 to Y5. Its type is INT8U, 48 types. They are assigned to three IO output

interfaces of XS40, XS41 and XS42.

The signal specification of Y addresses can be customized by customer according to the actual

operation. Y addresses are used for machine tool connection and the ladder editing. For the initial

definition of input address, see Appendix one Allocation and definition of PLC IO address, auxiliary

relay and register for GSK990MA CNC system

3.2.2 Assignment of IO module Y address

The addresses are from Y12 to Y19, 8 bytes. They correspond to the indicators on MDI panel, and

their signal definitions cannot be changed by user.

Corresponding relationship for addresses and indicators are as follows:

Table 3-2-2-1

Output key on operator panel PLC

address

Edit key indicator Y12.0 0.01/25% indicator Y15.4

Auto key indicator Y12.1 0.1/50% indicator Y15.5

MDI key indicator Y12.2 1/100% indicator Y15.6

Machine zero return indicator Y12.3 Spindle orientation indicator Y15.7

Single step key indicator Y12.4 Tool magazine zero return

Manual key indicator Y12.5 Tool magazine CCW indicator Y16.1

MPG key indicator Y12.6 Tool magazine CW indicator Y16.2

DNC key indicator Y12.7 Tool magazine infeed indicator Y16.3

Spindle CCW indicator Y13.0 Tool magazine retraction

Spindle CW indicator Y13.1 Tool magazine clamp indicator Y16.5

Spindle override cancel

indicator

Y13.2 Tool change manipulator

Output key on operator panel PLC

address

Y16.0

indicator

Y16.4

indicator

Y16.6

indicator

14

Page 27

GSK990MA CNC System Connection and PLC Manual

X machine zero return

indicator

Y machine zero return

indicator

Z machine zero return

indicator

4TH machine zero indicator Y13.6 +Z indicator Y17.2

Optional stop indicator Y13.7 +4TH indicator Y17.3

Skip indicator Y14.0 USER1 indicator Y17.4

Single block indicator Y14.1 -X indicator Y18.0

Dry run indicator Y14.2 -Y indicator Y18.1

Miscellaneous(M, S, T) lock

indicator

Y13.3

Y13.4 +X indicator Y17.0

Y13.5 +Y indicator Y17.1

Y14.3 -A indicator Y18.2

USER3(tool change position)

indicator

3.3 Address (G) from PLC to CNC

Addresses are from G0 to G63. Type: INT8U, 64 bytes.

Key signals on the operator panel

Table 3-3-1

Y16.7

Key signal on operator

panel

Edit mode

Auto mode G20.1 Rapid F0

MDI mode G20.2 Rapid 25%

Machine zero return mode

Single step mode

Manual mode

MPG mode G20.6 Incremental step 0.01 G261

DNC mode G20.7 Incremental step 0.1

Skip

Single block

Dry run

Miscellaneous (M,S, T) lock

Machine tool lock

Selection stop G21.5 Manual feed axis +Y

Program restart G21.6 Manual feed axis +Z

Spindle CW

Spindle stop

Spindle CCW G22.2 Manual feed axis -Y

Spindle negative override G22.3 Manual feed axis -Z

Spindle override cancel

PLC

address

G20.0

G20.3

G20.4

G20.5

G21.0

G21.1

G21.2

G21.3

G21.4

G22.0

G22.1

G22.4

Key signal on operator panel PLC

address

Rapid switch G24.7

G25.0

G25.1

Rapid 50%

Rapid 100%

Incremental step 0.001 G26.0

Incremental step 1

MPG step 0.001

MPG step 0.01

MPG step 0.1

Manual feed axis +X

Manual feed axis +4TH

Manual feed axis -X G28.0

Manual feed axis -4TH

G25.2

G25.3

G26.2

G26.3

G26.4

G26.5

G26.6

G27.0

G27.1

G27.2

G27.3

G28.1

G28.2

G28.3

15

Page 28

Programming Chapter Three Address

Spindle positive override

Spindle jog

The bit signals of G63 bytes are internally used by the system, G63.0, G63.1 and G63.2 are

separately the system internal response signals for M, S, T code completion.

G22.5

G22.6

Spindle orientation

Tool magazine zero return

G29.0

G29.1

3.4 Address (F) from CNC to PLC

Addresses are from F0 to F63. Type: INT8U, 64 bytes.

For signals, see Volume Function.

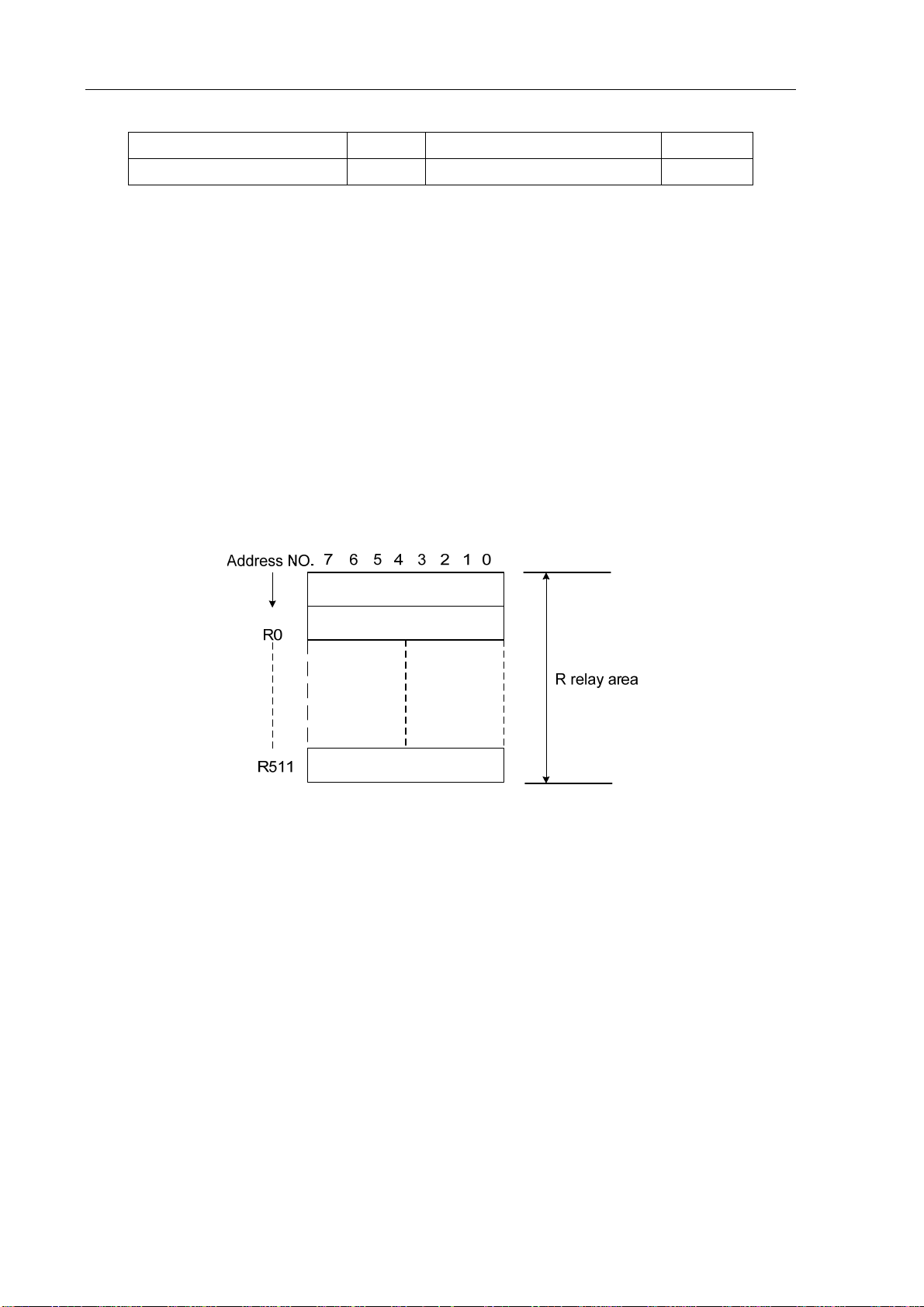

3.5 Internal relay address(R)

The address area is cleared to zero when the power is turned on. R510 and R511 are used by the

system.

Type: INT8U, 512 bytes.

Fig. 3-5-1

System program management area:

R510

Address signal of R510.0 is set to 1 when PLC is started or restarted, which is used for the

signal set by user in initialization. It is set to 0 after the ladder finishing the first pass.

R511(timer for system)

The following four signals are used as system timer:

16

Page 29

GSK990MA CNC System Connection and PLC Manual

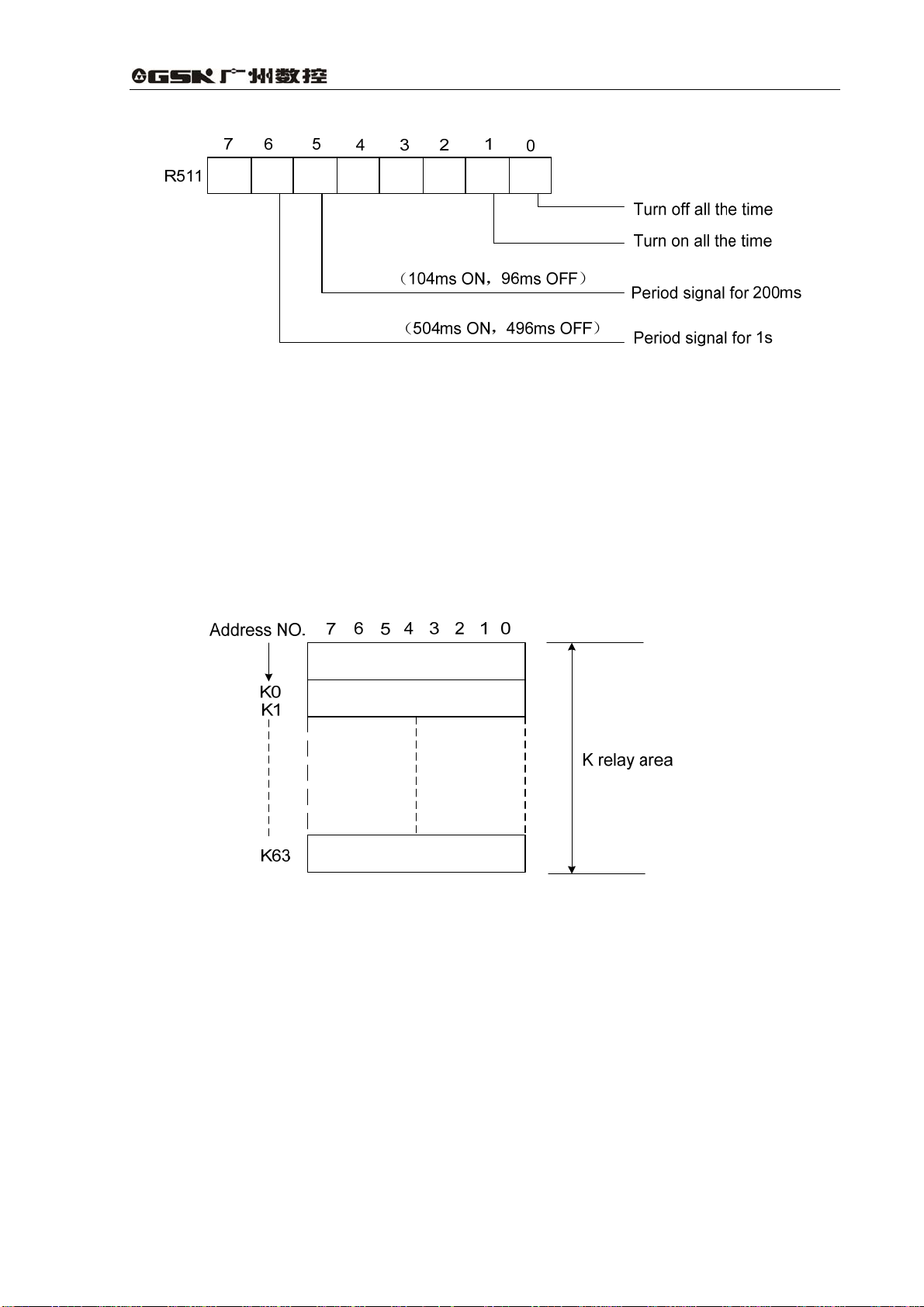

Fig. 3-5-2

3.6 Address of keep relay(K)

The area is used as keep relays and PLC parameters. Since this area is nonvolatile, the content of

the memory do not disappear even when the power is turned off. K000~~K005 are used by the

system, which are used for storing the PLC system parameter. It is convenient for the user to

control the PLC by CNC.

Type: INT8U, with 64 bytes.

Fig. 3-6-1

Note: When PLC address K K005.2=1, PLC enters the debug mode, cancel all the external alarm

signals and machine interlock signals, the tool change instruction can’t be executed. The

parameter can be modified under fully understanding it to avoid the machine damage or

the person accidence.

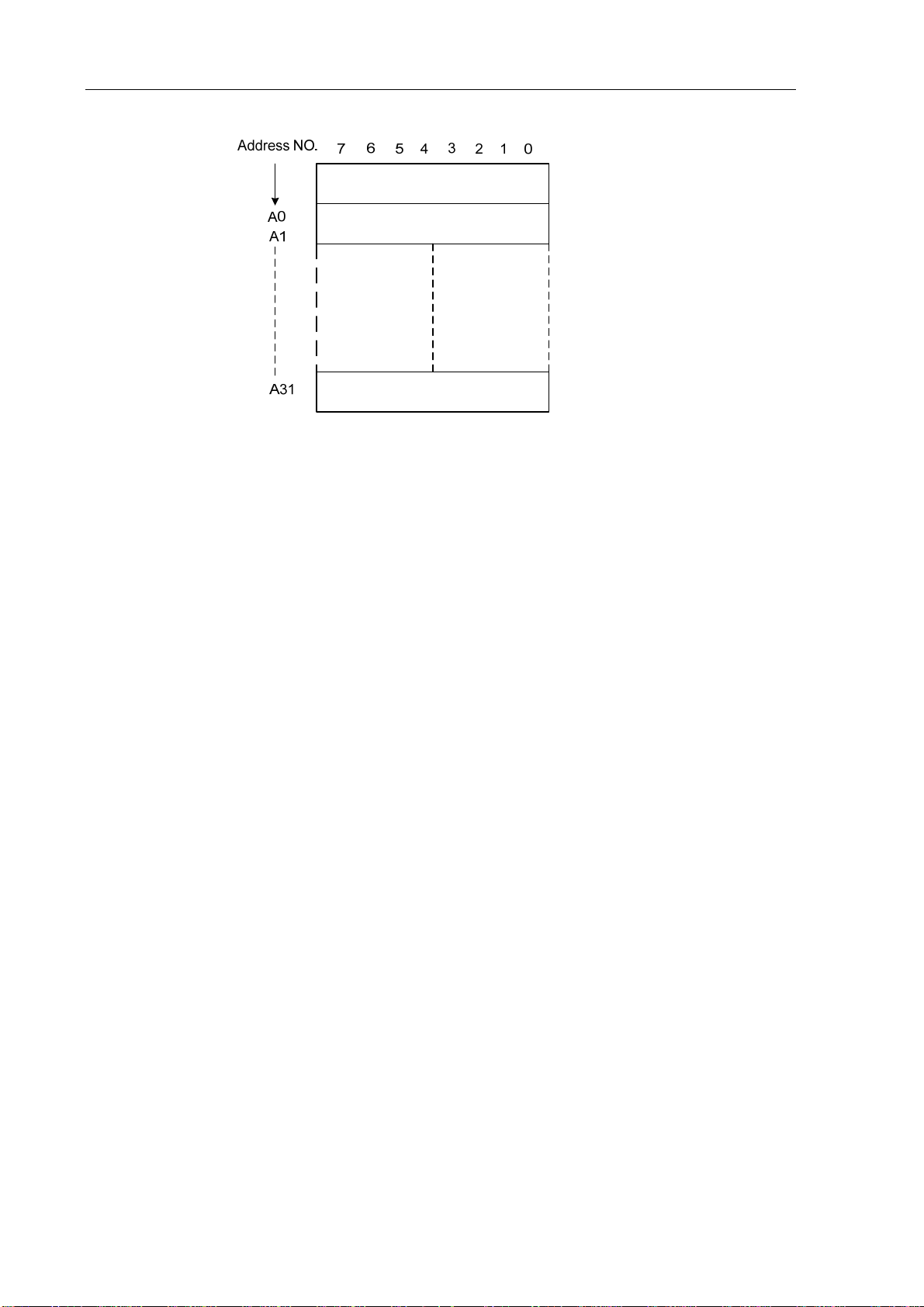

3.7 Addresses(A) for message selection displayed on CRT

The address area is cleared to zero when the power is turned on.

Type: INT8U, with 32 bytes.

17

Page 30

Programming Chapter Three Address

Fig. 3-7-1

3.8 Address of meter(C)

The area is used as storing current counting value in meter. The address area is cleared to zero

when the power is turned on.

Type: 128 addresses.

3.9 Meter preset address(DC)

The address area is used to store the meter preset value. Since this area is nonvolatile, the

content of the memory do not disappear even when the power is turned off.

Type: 128 addresses.

3.10 Timer addresses(T)

The area is used as storing current counting value in timer. The initial data is the preset value

when the system is turned off. When preset value is 0, the current data is preset value.

Type: 128 addresses.

3.11 Addresses of timer preset value(DT)

The address area is used as storing preset value. Since this area is nonvolatile, the content of the

memory do not disappear even when the power is turned off.

Type: 128 addresses.

18

Page 31

GSK990MA CNC System Connection and PLC Manual

3.12 Address of data table(D)

The content of the memory do not disappear even when the power is turned off.

Type: 256 addresses.D240~247 are used by the system and cannot be defined by the user.

3.13 Label address(L)

Label addresses are used to specify jump destination labels and LBL labels in JMPB instructions.

Range: 0~99

3.14 Subprogram numbers(P)

Subprogram numbers are used to specify jump destination subprogram labels and SP instruction

subprogram labels in CALL instruction.

Range: 0~99

19

Page 32

Programming Chapter Four PLC Basic Instruction

4 PLC Basic Instruction

Designing a sequence program begins with creating a ladder diagram. The ladder diagram is

written using relay contact symbols and functional instruction code. Logic written in the ladder

diagram is entered as a sequence program in the Programmer. There are two sequence program

entry methods. One is the entry method with the mnemonic language (PLC instructions such as

RD, AND, OR but currently the system does not support it). The other is the relay symbols of the

ladder diagram. When the relay symbol method is used, the ladder diagram format can be used

and programming can be performed without understanding the PLC instruction format.

Actually, however, the sequence program entered by the relay symbol method is also internally

converted into the instruction corresponding to the PLC instruction.

The basic instructions are often used when the sequence program is designed, and they execute

one-bit operation.

GSK990MA basic instructions are as follows:

Table 4-1

Instruction Function

RD Shifts left the content by one bit in register and sets the state of a

specified signal in ST0.

RD.NOT Shifts left the content by one bit in register and sets the logic state

of a specified signal in ST0.

WRT Outputs the results of logic operation to a specified address.

WRT.NOT Inverts the results of logical operations and output it to a specified

address.

AND Induces a logical product.

AND.NOT Inverts the state of a specified signal and induces a logical

product.

OR Induces a logical sum.

OR.NOT Inverts the state of a specified signal and induces a logical sum.

OR.STK Sets the logical sum of ST0 and ST1, and shifts the stack register

right by one bit.

AND.STK Sets the logical product of ST0 and ST1, and shifts the stack

register right by one bit.

20

Page 33

GSK990MA CNC System Connection and PLC Manual

4.1 RD, RD.NOT, WRT, WRT.NOT

Instructions and functions

Table 4-1-1

Instruction Function

RD

RD.NOT

WRT

WRT.NOT

Instruction explanation:

z WRT, WRT. NOT are the output relays, internal relay instructions. They cannot be used for

input relay.

z The parallel WRT instruction can be continuously used many times, but double-coil output

is disabled.

Programming:

Shifts left the content by one bit in register and sets the state of a

specified signal in ST0.

Shifts left the content by one bit in register and sets the logic state of

a specified signal in ST0.

Outputs the results of logic operation to a specified address.

Inverts the results of logical operations and output it to a specified

address.

Fig. 4-1

4.2 AND, AND.NOT instructions

Instructions and functions

Table 4-2-1

Instruction Function

AND Induces a logical product.

AND.NOT

21

Inverts the state of a specified signal

and induces a logical product.

Page 34

Programming Chapter Four PLC Basic Instruction

Instruction explanation:

z AND, AND NOT can connect with one contact in serial. The serial contact numbers are not

limited and they can be used many times.

Programming

Fig. 4-2-1

4.3 OR, OR.NOT instructions

Instructions and functions

Table 4-3-1

Instruction Function

OR Induces a logical sum.

OR.NOT Inverts the state of a specified signal

and induces a logical sum.

Instruction specification:

z OR, OR_NOT can connect with one contact in parallel.

z OR, OR.NOT begins from their step, which can connect with the RD,RD.NOT instructions

step mentioned before in parallel.

Programming:

Fig. 4-3-1

4.4 OR. STK instruction

Instruction and function:

22

Page 35

GSK990MA CNC System Connection and PLC Manual

Table 4-4-1

Instruction Function

OR. STK Sets the logical sum of ST0 and ST1, and shifts the

stack register right by one bit.

Instruction specification:

z OR.STK a sole instruction without other address.

Programming

Fig. 4-4-1

As the above figure, there are three branch circuit ①,②, from left bus to the node N1, among ③

which ①, is circuit block② in series; when there is the serial circuit block in the parallel from the

bus to node or between nodes, the following branch end uses RD instruction except for the first

branch. The branch is not serial circuit block to use OR instruction. ③

OR.STK and AND.STK are instructions without operation components, indicating the OR, AND

relationship between circuit blocks.

4.5 AND.STK instruction

Instruction and function

Table 4-4-1

Instruction Function

AND.STK Sets the logical product of ST0 and ST1, and shifts the

stack register right by one bit.

Instruction specification

z When the branch loop (parallel loop block) is connected to the previous loop in series, use

AND.STK instruction. The starting point of branch uses RD, RD.NOT instruction, after the

parallel loop block ends, AND,STK instruction is connected to previous loop in series.

z AND.STK a sole instruction without other address.

23

Page 36

Programming Chapter Four PLC Basic Instruction

Programming

RD X002.1

OR.NOT F100.3

OR.NOT X011.0

RD R100.0

AND.NOT R100.3

RD G003.3

AND R009.7

OR.STK ← ⑴

AND.STK ← ⑵

WRT Y003.7

As the above figure and instruction list, ⑴ RD reports the circuit block in series is connected

parallel AND.STK ⑵ reports the block and are connected in series. ①②

Block ①

Block ②

Fig. 4-5-1

24

Page 37

GSK990MA CNC System Connection and PLC Manual

5 PLC Functional instructions

If basic instructions such as controlling operations of machine tool are difficult to program,

functional instructions are available to facilitate programming.

Table 5-1(990MA PLC functional instruction code)

No. Instruction Processing

1 END1

2 END2

3 CALL

4 CALLU

5 SP

6 SPE

7 SET

8 RST

9 JMPB

10 LBL

11 TM R

12 TMRB

13 TMRC

14 CTR

15 DEC

End of a first-level ladder program

End of a second-level ladder program

Calling subprogram

Subprogram

End of subprogram

Set

Reset

Label jump

Label

Timer

Fixed Timer

Timer

Binary meter

Binary decoding

16 COD

17 COM

18 COME

19 ROT

20 SFT

21 DIFU

22 DIFD

23 COMP

24 COIN

25 MOVN

25

Binary code conversion

Common line control

End of common line control

Binary rotation control

Register shift

Rising edge check

Failing edge check

Binary comparison

Coincidence check

Data transfer

Page 38

Programming Chapter Five PLC Functional Instructions

26 MOVB

27 MOVW

28 XMOV

29 DSCH

30 ADD

31 SUB

32 ANDF

33 ORF

34 NOT

35 EOR

Transfer of an arbitrary number of bytes

Transfer of two arbitrary number of bytes

Binary Indexed data transfer

Binary data search

Binary addition

Binary subtraction

Functional AND

Functional OR

Logical Negation

Exclusive OR

5.1 END1(1st level sequence program end)

Function:

It must be specified once in a sequence program, either at the end of the 1st level sequence, or at

the beginning of the 2

at most.

Format:

nd

level sequence when there is no 1st level sequence. It can write 500 steps

Fig. 5-1-1

5.2 END2(2nd level sequence program end)

Function

It is specified at the end of 2nd level sequence.

Format:

Fig. 5-2-1

26

Page 39

GSK990MA CNC System Connection and PLC Manual

5.3 CALL(call subprogram)

Function

Call a specified subprogram.

CALL has the following features and restrictions:

The subprogram may be nested up to 18 levels by other subprograms, but if a dead cycle is

made by the closed loop calling, an alarm will be issued by system. Therefore to execute the

data volume under the control, the allowable subprogram calling times are 100, and the

subprogram calling in the 1st level is disabled. Alarm will be issued for the instructions or network

between SP and END2, SPE and SP which can't be executed by system.

Format:

Fig. 5-3-1

Control condition:

ACT=0,execute the next instruction behind CALL.

ACT=1,call subprogram which number is specified.

Parameter:

Subprogram number.: specifies the number of a subprogram to be called.

Range: 0~99.

5.4 CALLU(unconditional subprogram call)

Function:

Call a specified subprogram without condition.

CALL has the following features and restrictions:

The subprogram may be nested up to 18 levels by other subprograms, but if a dead cycle is

made by the closed loop calling, an alarm will be issued by system. Therefore to execute the data

volume under the control, the allowable subprogram calling times are 100, and the subprogram

calling in the 1st level is disabled. Alarm will be issued for the instructions or network between SP

27

Page 40

Programming Chapter Five PLC Functional Instructions

and END2, SPE and SP which can't be executed by system

Format:

Fig. 5-4-1

Parameter:

Subprogram number:specifies the number of a subprogram to be called. Range:0~99.

5.5 SP(Subprogram)

Function:

The SP functional instruction is used to create a subprogram. A subprogram number is specified

as a subprogram name. SP is used with the SPE functional instruction to specify the subprogram

range.

Note:

1. A subprogram must be written after END2.

2. Another subprogram cannot be nested into a subprogram.

Format:

Fig. 5-5-1

Parameter:

Subprogram number: specifies the subprogram number of a subprogram to be called.

Range: 0~99.

5.6 SPE(subprogram end)

Function:

* it is used to specify the range of subprogram when SPE is used with the S P.

* the control will return to the main program which called the subprogram when the

instruction is executed.

* the subprogram must be written after END2.

28

Page 41

Format:

GSK990MA CNC System Connection and PLC Manual

Example:

5.7 SET(set)

Fig. 5-6-1

Fig. 5-6-1

Function:

Set to 1 for the specified address.

Format:

ACT

SET

Control condition:

ACT=0,add.b keep invariably.

ACT=1,add.b set to1.

Parameter:

Add.b:set element address bit can be the output coil, Add= Y,G,R,K,A.

Add.b

Fig. 5-7-1

address

29

Page 42

Programming Chapter Five PLC Functional Instructions

5.8 RST(reset)

Function:

Set to 0 for the specified address.

Format:

Fig.5-8-1

Control condition:

ACT=0,add.b keep invariably.

ACT=1,add.b set to1.

Parameter:

Add.b:reset element address bit can be the output coil, Add= Y,G,R,K,A.

5.9 JMPB(label jump)

Function:

The JUMP functional instruction transfer control to a Ladder immediately after the lable set in a

Ladder program.

JMPB has the following features and restrictions:

* More than one jump instruction can be coded for the same label.

* Jump between 1

* Jump between subprograms is forbidden.

* Jump back is permitted, but the user should handle the endless loop may be

caused by it .

* Jump between main program and subprogram is forbidden.

Format:

st

level program and 2nd level is forbidden.

Control conditions:

30

Fig. 5-9-1

Page 43

GSK990MA CNC System Connection and PLC Manual

ACT=0: The next instruction after the JMPB instruction is executed.

ACT=1: Control is transferred to the Ladder immediately after the specified label.

Parameter:

Lx: specifies the label of the jump destination. A value from 0 to 99 can be specified.

5.10 LBL(Label)

Function:

The LBL functional instruction specifies a label in a ladder program. It specifies the jump

destination for JMPB functional instruction.

Note: one Lx label is only specified one time with LBL. Otherwise, the system alarms.

Format:

Fig. 5-10-1

Parameter:

Lx: specifies the label of the jump destination. Label number range: 0~99

Example:

JMPB 33

LBL 33

JMPB 33

Fig. 5-10-2

31

Page 44

Programming Chapter Five PLC Functional Instructions

5.11 TMR(timer)

Function:

This is an on-delay timer.

Format:

Fig. 5-11-1

Control condition:

ACT=0: turns off the timer relay.

ACT=1: initiates the timer.

Detailed functions:

Parameter:

TIMER :timer serial number is named with xxx which are numbers (0~127).

Output:

W : output coil. W=1 when the output reaches the preset value. W=0 when the output

does not reach the preset value.

Note:

Timer is executed each 8ms, take ms as its setting unit, and 8ms is taken as the execution

base. Those time less than 8ms are taken as 8ms. i.e. it is set for 54ms, 54=6*8+6, 2ms is

needed to be added, so the actual execution time is 56ms.

Fig. 5-11-2

The time of the timer is set under the 【TMR】of 【PLCPAR】in PRG interface.

The system will automatically detect the range of the sequence number of the timer, alarm

will be issued for those duplicate or beyond range sequence numbers.

32

Page 45

GSK990MA CNC System Connection and PLC Manual

5.12 TMRB(fixed timer)

Function:

This is an on-delay timer.

Format:

Fig. 5-12-1

Control condition:

ACT=0: turns off the timer.

ACT=1: initiates the timer.

Detailed functions:

Fig. 5-12-2

Parameter:

TIMER :fixed timer serial number is named with xxx which are numbers (0~127).

Table 5-12-1(timer precision)

Timer precision Setting number Setting time range Error range

8msec 0 From 8msec to

524.280sec

48msec 1 From 48msec to

31.456 min

1sec 2 From 1sec to

546 min

10sec 3 From 10sec to

182 h

1min 4 From 1min to

From 0 to scan period

for1st level program

From 0 to scan period

for1st level program

From 0 to scan period

for1st level program

From 0 to scan period

for1st level program

From 0 to 1sec

1092 h

1msec 5 From 1msec to

65.4sec

From 0 to scan period

for1st level program

33

Page 46

Programming Chapter Five PLC Functional Instructions

Preset time:

Fixed timer timing setting, range (0~65535).

Output:

W : output coil. W=1 when the output reaches the preset value. W=0 when the output does not

reach the preset value.

Note:

The system will automatically detect the range of the sequence number of the timer, alarm

will be issued for those duplicate or beyond range sequence numbers.

The preset time of the timer will be fixed in ROM with the ladder, therefore, the time can be

changed only by altering the ladder.

5.13 TMRC(timer)

Function:

This is an on-delay timer.

Format:

Control condition:

ACT=0: turns off the timer.

ACT=1: initiates the timer.

Detailed functions:

Fig. 5-13-1

Fig. 5-13-2

34

Page 47

GSK990MA CNC System Connection and PLC Manual

Parameter:

TIMER :timer serial number is named with xxx which are numbers (0~127).

Table 5-12-1(timer precision)

Timer precision Setting number Setting time range Error range

8msec 0

48msec 1

1sec 2

10sec

3 From 10sec to 182 h

From 8msec to

524.280sec

From 48msec to

31.456 min

From 1sec to

546 min

From 0 to scan period

for1st level program

From 0 to scan period

for1st level program

From 0 to scan period

for1st level program

From 0 to scan period

for1st level program

1min

1msec

Output:

4 From 1min to 1092 h From 0 to 1sec

5 From 1msec to

65.4sec

From 0 to scan period

for1st level program

W : output coil. W=1 when the output reaches the preset value. W=0 when the output does not

reach the preset value.

Note:

The time can be set via 【TMR】in 【PLCPAR】of PLC windowns.

TMRC timer and TMR timer use a same address, therefore, their sequence number

cannot be the same.

The system will automatically detect the range of the sequence number of the timer,

alarm will be issued for those duplicate or beyond range sequence numbers.

5.14 CTR(binary counter)

Function:

The data in the counter are binary and their functions are as follows:

1) Preset counter

Preset the count. It outputs a signal when the preset count is reached.

2) Ring counter

If the counter reaches the preset value, input the count signal to restore the initial value and

recount.

3) Up/down counter

35

Page 48

Programming Chapter Five PLC Functional Instructions

The count can be either up or down.

4) Selection of initial value

Its initial value is 0 or 1.

Format:

Control condition:

Specifies the initial value(CN0):

CN0=0: begins the value of the counter with 0.

CN0=1 begins the value of the counter with 1.

Specify up or down counter (UPDOWN):

UPDOWN=1: Up counter

UPDOWN=0: Down counter

Reset (RST):

RST=0: release reset.

RST=1: enable reset. When W=0, the integrated value is reset to the initial value.

Count signal(ACT):

Fig. 5-14-1

RST is set to 1 only when reset is required.

Parameter:

METER:specifies the counter serial number with xxx which are numbers (0~127).

36

ACT=1:count is made by catching the rise of ACT.

ACT=0:counter does not operate. W does not change.

Page 49

GSK990MA CNC System Connection and PLC Manual

Output:

W:coil output. W=1 when the counter reaches the preset value.

Note: The system will automatically detect the range of the sequence number of the counter, alarm

will be issued for those duplicate or beyond range sequence numbers.