Page 1

In this user manual we have tried to describe the matters

concerning the operation of this CNC system to the greatest extent.

However, it is impossible to give particular descriptions for all

unnecessary or unallowable operations due to length limitation and

products application conditions;Therefore, the items not presented

herein should be regarded as “impossible” or “unallowable”.

Copyright is reserved to GSK CNC Equipment Co., Ltd. It

is illegal for any organization or individual to publish or reprint this

manual. GSK CNC Equipment Co., Ltd. reserves the right to ascertain

their legal liability.

Page 2

GSK988T Turning CNC System User Manual

Preface

Your Excellency,

We are honored by your purchase of this GSK 988T Turning CNC

System made by GSK CNC Equipment Co., Ltd.

This book is User Manual “Programming and Operation”.

To ensure safe and effective running, please read this manual carefully

before installation and operation.

Warning

Accident may occur by improper connection and operation!This

system can only be operated by authorized and qualified personnel.

Special caution:

The power supply fixed on/in the cabinet is exclusively used for the

CNC system made by GSK.

It can't be applied to other purposes, or else it may cause serious

danger!

II

Page 3

Cautions

■ Delivery and storage

● Packing box over 6 layers in pile is unallowed.

● Never climb the packing box, stand on it or place heavy objects on it.

● Do not move or drag the products by the cables connected to it.

● Forbid collision or scratch to the panel and display screen.

● Avoid dampness, insolation and drenching.

■

Open-package inspection

● Confirm that the products are the required ones.

● Check whether the products are damaged in transit.

● Confirm that the parts in packing box are in accordance with the packing list.

● Contact us in time if any inconsistence, shortage or damage is found.

Contents

■ Connection

● Only qualified personnel can connect the system or check the connection.

● The system must be earthed, and the earth resistance must be less than 0.1Ω.

The earth wire cannot be replaced by zero wire.

● The connection must be correct and firm to avoid any fault or unexpected

consequence.

● Connect with surge diode in the specified direction to avoid damage to the

system.

● Switch off power supply before plugging out or opening electric cabinet.

■ Troubleshooting

● Switch off power supply before troubleshooting or changing components.

● Check the fault when short circuit or overload occurs. Restart can only be done

after troubleshooting.

● Frequent switching on/off of the power is forbidden, and the interval time should

be at least 1 min.

III

Page 4

GSK988T Turning CNC System User Manual

ANNOUNCEMENT!

z This manual describes various possibilities as much as possible. However,

operations allowable or unallowable cannot be explained one by one due to

so many possibilities that may involve with, so the contents that are not

specially stated in this manual shall be regarded as unallowable.

WARNING!

z Please read this manual and a manual from machine tool builder carefully

before installation, programming and operation, and strictly observe the

requirements. Otherwise, products and machine may be damaged,

workpiece be scrapped or the user be injured.

CAUTION!

z Functions, technical indexes (such as precision and speed) described in

this user manual are only for this system. Actual function configuration and

technical performance of a machine tool with this CNC system are

determined by machine tool builder’s design, so functions and technical

indexes are subject to the user manual from machine tool builder.

z Though this system adopts standard operation panel, the functions of the

keys on the panel are defined by PLC program (ladder diagram). It should be

noted that the keys functions described herein are for the standard PLC

program (ladder diagram).

z For functions and effects of keys on control panel, please refer to the user

manual from machine tool builder.

IV

Page 5

Contents

Safety Responsibility

Manufacturer’s Responsibility

——Be responsible for the danger which should be eliminated and/or controlled on

design and configuration of the provided CNC systems and accessories.

——Be responsible for the safety of the provided CNC systems and accessories.

——Be responsible for the provided information and advice for the users.

User’s Responsibility

——Be trained with the safety operation of CNC system and familiar with the safety

operation procedures.

——Be responsible for the dangers caused by adding, changing or altering to the

original CNC systems and the accessories.

——Be responsible for the failure to observe the provisions for operation, adjustment,

maintenance, installation and storage in the manual.

This manual is subject to change without further notice.

This manual is reserved by end user.

We are full of heartfelt gratitude to you for supporting us in the use of GSK’s products.

V

Page 6

GSK988T Turning CNC System User Manual

VI

Page 7

Contents

Contents

Ⅰ PROGRAMMING ..........................................................................................................................1

Chapter I Programming Fundamentals ............................................................................................3

1.1 GSK988T Introduction ........................................................................................................3

1.2 CNC system of machine tools and CNC machine tools......................................................5

1.3 Programming Fundamentals...............................................................................................7

1.3.1 Coordinates definition ...............................................................................................7

1.3.2 Increment system .....................................................................................................9

1.3.3 Max. travel ..............................................................................................................10

1.3.4 Reference position..................................................................................................10

1.3.5 Machine coordinate system ....................................................................................10

1.3.6 Workpice coordinate system................................................................................... 11

1.3.7 Local coordinate system ......................................................................................... 11

1.3.8 Interpolation function ..............................................................................................11

1.4 Coordinate Value and Dimension......................................................................................12

1.4.1 Absolute programming and incremental programming ...........................................12

1.4.2 Diameter programming and radius programming ...................................................13

1.4.3 Decimal programming.............................................................................................14

1.4.4 Conversion between the metric and the inch ..........................................................14

1.4.5 Linear axis and rotary axis ......................................................................................15

1.5 Structure of an NC Program..............................................................................................15

1.5.1 Program name ........................................................................................................16

1.5.2 Block format............................................................................................................16

1.5.3 Word .......................................................................................................................17

1.5.4 Block number..........................................................................................................26

1.5.5 Main program and subprogram...............................................................................26

1.6 Program Run ....................................................................................................................27

1.6.1 Sequence of program run .......................................................................................27

1.6.2 Execution sequence of word...................................................................................28

Chapter II G Commands ................................................................................................................29

2.1 Summary ..........................................................................................................................29

2.1.1 G command classification .......................................................................................29

2.1.2 Omitting word input.................................................................................................31

2.1.3 Related definitions ..................................................................................................33

2.2 Rapid Traverse (Positioning) G00.....................................................................................33

2.3 Linear Interpolation G01 ...................................................................................................34

2.4 Arc Interpolation G02, G03 ...............................................................................................35

2.5 Dwell G04 .........................................................................................................................38

2.6 Cylindrical Interpolation 7.1...............................................................................................39

2.7 Polar Coordinate Interpolation G12.1, G13.1 ....................................................................43

2.8 Metric/Inch Switch G20, G21 ............................................................................................45

2.9 Stored Travel Check G22, G23 .........................................................................................45

2.10 Skip Interpolation G31 ....................................................................................................46

2.11 Automatic Tool Offset G36, G37 ...................................................................................48

2.12 Reference Position Function...........................................................................................50

VII

Page 8

GSK988T Turning CNC System User Manual

2.12.1 Reference position return G28.............................................................................. 50

nd

2.12.2 2

2.13 Related Function of Coordinate System .........................................................................52

2.13.1 Selecting machine coordinate system position G53 .............................................53

2.13.2 Workpiece coordinate system setting G50 ...........................................................54

2.13.3 Workpiece coordinate system selection command G54~G59............................. 55

2.13.4 Local coordinate system setting G52....................................................................57

2.13.5 Level selection command G17~G19 ................................................................... 59

2.13.6 Exact stop mode G61/cutting mode G64.............................................................. 59

2.14 Fixed Cycle Command ...................................................................................................60

2.14.1 Axial cutting cycle G90 .........................................................................................60

2.14.2 Radial cutting cycle G94 .......................................................................................63

2.15 Multiple Cycle Commands .............................................................................................. 66

2.15.1 Axial Roughing Cycle G71.................................................................................... 66

2.15.2 Radial Roughing Cycle G72 ............................................................................... 72

2.15.3 Closed Cutting Cycle G73 ....................................................................................77

2.15.4 Finishing Cycle G70 .............................................................................................82

2.15.5 Axial Grooving Multiple Cycle G74 .......................................................................83

2.15.6 Radial Grooving Multiple Cycle G75 .....................................................................86

2.15.7 Notes for multi cycle machining ............................................................................ 89

2.16 Threading Cutting ........................................................................................................... 90

2.16.1 Thread Cutting with Constant Lead G32............................................................... 90

2.16.2 Thread cutting with variable lead G34 ..................................................................93

2.16.3 Thread cutting cycle G92......................................................................................95

2.16.4 Multiple thread cutting cycle G76..........................................................................97

2.17 Constant Surface Speed Control G96, Constant Rotational Speed Control G97..... 103

2.18 Feedrate per Minute G98, Feedrate per Rev G99 ................................................... 105

2.19 Drilling/Boring Fixed Cycle Command ..........................................................................106

2.19.1 End drilling cycle G83 /side drilling cycle G87 ....................................................107

2.19.2 End Boring CycleG85 / Side Boring Cycle G89 .................................................. 111

2.19.3 Cancelling Drilling/Boring G80............................................................................ 112

2.19.4 Notes for Drilling/Boring Cycle ............................................................................ 112

2.20 Tapping Cycle Command.............................................................................................. 112

2.20.1 Tapping Mode ..................................................................................................... 113

2.20.2 End Rigid Tapping Cycle (G84) / Side Rigid Tapping Cycle (G88)...................... 114

2.20.3 End Common Tapping Cycle (G84) /Side Common Tapping Cycle (G88) .......... 120

2.21 Automatic Chamfering Function.................................................................................... 123

2.22 Macro Command ..........................................................................................................126

2.22.1 Variable...............................................................................................................126

2.22.2 System variable ..................................................................................................127

2.22.3 Operation and jump command ...........................................................................131

2.22.4 Macro program statement and NC statement ..................................................... 136

2.22.5 Macro program call ............................................................................................. 136

, 3rd, 4th reference position return G30 .............................................................51

Chapter Ⅲ MSTF Commands..................................................................................................... 139

3.1 M (Miscellaneous Function) ............................................................................................139

3.1.1 End of program M02 .............................................................................................139

VIII

Page 9

Contents

3.1.2 End of program run M30 .......................................................................................139

3.1.3 Program stop M00 ................................................................................................139

3.1.4 Optional stop M01.................................................................................................140

3.1.5 Subprogram call M98 .........................................................................................140

3.1.6 Subprogram Call M198.........................................................................................141

3.1.7 Return from Subprogram M99............................................................................141

3.1.8 The Following M commands for standard ladder(some functions modified by K

parameters)......................................................................................................................142

3.1.9 M Commands defined by standard PLC ladder ....................................................143

3.2 Spindle Function .............................................................................................................143

3.2.1 Spindle speed analog voltage control ...................................................................143

3.2.2 Spindle override....................................................................................................144

3.3 Tool Function ..................................................................................................................144

3.3.1 Tool offset .............................................................................................................144

3.3.2 Tool Life Management ..........................................................................................147

Chapter IV Tool Nose Radius Compensation...............................................................................151

4.1 Application ......................................................................................................................151

4.1.1 Overview...............................................................................................................151

4.1.2 Imaginary tool nose direction ................................................................................152

4.1.3 Compensation value setting..................................................................................155

4.1.4 G40/G41/G42 command function .........................................................................156

4.1.5 Compensation direction ........................................................................................157

4.1.6 Cautions ...............................................................................................................159

4.1.7 Application ............................................................................................................1

4.2 Tool Nose Radius Compensation Offset Path.................................................................161

4.2.1 Inner and outer side ..............................................................................................161

4.2.2 Tool traversing when starting tool .........................................................................161

4.2.3 Tool traversing in Offset mode ..............................................................................163

4.2.4 Tool traversing in Offset canceling mode ..............................................................168

4.2.5 Tool interference check......................................................................................... 169

4.2.6 Commands for canceling compensation vector temporarily .................................171

4.2.7 Particulars.............................................................................................................174

60

Ⅱ OPERATION ...........................................................................................................................181

Chapter Ⅰ Overview.....................................................................................................................183

1.1 Operation Overview ........................................................................................................183

1.2 System Setting................................................................................................................184

1.3 Display ............................................................................................................................185

1.4 System............................................................................................................................187

1.4.1 System panel........................................................................................................187

1.4.2 System key definitions ..........................................................................................188

1.5 Machine Operation Panel ...............................................................................................190

1.5.1 Division of machine operation panel ..................................................................... 190

1.5.2 State indicator and press key definition on the panel............................................191

Chapter Ⅱ Power on, Power off and Safety Protection ................................................................196

IX

Page 10

GSK988T Turning CNC System User Manual

2.1 Power on ........................................................................................................................196

2.2 Power off.........................................................................................................................197

2.3 Overtravel Protection ......................................................................................................197

2.4 Overtravel Protection in Memory Travel Limit .................................................................197

2.5 Emergence Operation..................................................................................................... 199

2.5.1 Reset ....................................................................................................................199

2.5.2 Emergency stop.................................................................................................... 199

2.5.3 Feed hold..............................................................................................................199

2.5.4 Cutting off power supply ....................................................................................... 199

Chapter Ⅲ Windows ................................................................................................................... 200

3.1 Position Display Window ................................................................................................205

3.1.1 Absolute coordinate window ................................................................................. 206

3.1.2 Relative coordinate display................................................................................... 207

3.1.3 Machine coordinate display ..................................................................................208

3.1.4 Comprehensive coordinate...................................................................................208

3.1.5 Setting the relative coordinate ..............................................................................209

3.1.6 Switching between the mode and the comprehensive message ..........................210

3.1.7 Clearing workpiece count ..................................................................................... 211

3.1.8 Clearing run time .................................................................................................. 211

3.2 Program Window ............................................................................................................ 212

3.2.1 Local directory and U disk directory......................................................................212

3.2.2 MDI program......................................................................................................... 213

3.2.3 Item/times ............................................................................................................. 214

3.3 System Window .............................................................................................................. 214

3.3.1 System parameter setting and rewriting window ..................................................215

3.3.2 Screw pitch compensation setting and rewriting window...................................... 218

3.3.3 System message and operation authority levels ..................................................219

3.3.4 System file management ......................................................................................222

3.3.5 Ladder diagram ....................................................................................................223

3.4 Setting Window............................................................................................................... 229

3.4.1 Tool offset setting.................................................................................................. 229

3.4.2 CNC setting window .............................................................................................233

3.4.3 Macro variable window .........................................................................................238

3.5 Message Window ...........................................................................................................239

3.5.1 Alarm message check window .............................................................................240

3.5.2 Alarm record check window.................................................................................. 241

3.5.3 Diagnosis window................................................................................................. 242

3.5.4 Oscillograph window............................................................................................. 245

3.5.5 GSK-CAN window ................................................................................................248

3.6 Graph Window ................................................................................................................ 249

3.6.1 Setting graph parameter .......................................................................................249

3.6.2 Processing graph path.......................................................................................... 250

3.6.3 Simulation graph................................................................................................... 251

3.7 Help Windows................................................................................................................. 252

Chapter Ⅳ Editing and Managing a Program .............................................................................254

X

Page 11

Contents

4.1 Searching, Creating, Executing and Opening a Program ...............................................254

4.1.1 Searching a program ............................................................................................254

4.1.2 Creating a program ...............................................................................................254

4.1.3 Executing a program.............................................................................................255

4.1.4 Opening a program...............................................................................................256

4.2 Renaming, Outputting, Deleting and Arraying Programs, Saving a Program as.............257

4.2.1 Renaming a program ............................................................................................257

4.2.2 Saving a program as.............................................................................................258

4.2.3 Deleting a program ...............................................................................................259

4.2.4 Outputting a program............................................................................................259

4.2.5 Arraying programs ................................................................................................260

4.3 Editing and Rewriting a Program ....................................................................................260

4.3.1 Editing a program .................................................................................................260

4.3.2 Rewriting a program .............................................................................................261

4.3.3 Shortcut key..........................................................................................................262

4.4 Block Comment...............................................................................................................263

4.5 Generating a Block Number............................................................................................263

4.6 Background Editing a Program .......................................................................................263

Chapter Ⅴ Manual Operation .....................................................................................................264

5.1 Manual Reference Position Return .................................................................................264

5.2 Manual Feed...................................................................................................................265

5.3 Increment Feeding ..........................................................................................................266

5.4 MPG Feeding...............................................................................................................

...267

Chapter Ⅵ Auto Operation............................................................................................................270

6.1 Auto Running ..................................................................................................................270

6.1.1 Selecting the running program..............................................................................270

6.1.2 Program running ...................................................................................................271

6.1.3 Running from any block ........................................................................................272

6.1.4 Skip.......................................................................................................................272

6.1.5 G31 skip ...............................................................................................................273

6.1.6 Stop auto running..................................................................................................273

6.2 MDI Running ...................................................................................................................274

6.2.1 Editing and running the program in MDI mode .....................................................274

6.2.2 Running from any block ........................................................................................275

6.2.3 Stop MDI running .................................................................................................. 275

6.3 DNC Running..................................................................................................................275

6.4 Auto Running Control......................................................................................................278

6.4.1 Machine and miscellaneous function lock.............................................................278

6.4.2 Dry run..................................................................................................................279

6.4.3 Single block running .............................................................................................280

6.4.4 Feedrate override .................................................................................................280

6.4.5 Rapid traverse override ........................................................................................281

Chapter Ⅶ Tool Offset and Setting Tools ....................................................................................282

7.1 Setting the Tool Offset and the Wearing Values..............................................................282

XI

Page 12

GSK988T Turning CNC System User Manual

7.1.1 Direct input method ..............................................................................................282

7.1.2 Measuring mode................................................................................................... 283

7.1.3 +input mode.......................................................................................................... 284

7.1.4 C input method .....................................................................................................285

7.1.5 Clearing the offset value or the wearing value ......................................................286

7.2 Fixed-Point Tool Setting ..................................................................................................287

7.3 Trial Cut Toolsetting ........................................................................................................287

7.4 Position Record ..............................................................................................................290

7.5 Automatic Tool Compensation ........................................................................................290

Chapter Ⅷ Setting and Display Graphs ...................................................................................... 292

8.1 Setting the Graph Parameter .......................................................................................... 292

8.2 Path Graph Display and Operation ................................................................................. 293

8.3 Simulation graph display and operation ..........................................................................294

Chapter Ⅸ U disk Use ................................................................................................................ 296

9.1 Sending a Program......................................................................................................... 296

9.2 Backup Value..................................................................................................................297

9.2.1 System file backup ...............................................................................................297

9.2.2 Servo parameter backup ......................................................................................298

Chapter Ⅹ Processing Examples ................................................................................................. 301

10.1 Outer End Face Machining ...........................................................................................301

10.2 Compound Machining................................................................................................... 304

Chapter Ⅺ Parameters ............................................................................................................... 310

11.1 Parameters Related to System Setting ......................................................................... 311

11.2 Parameters Related to Interfaces of Input and Output .................................................. 311

11.3 Parameters Related to Axis Control/Setting Unit........................................................... 311

11.4 Parameters Related to Coordinate System................................................................... 315

11.5 Parameters Related to the Stroke Detection................................................................. 317

11.6 Parameters Related to Feedrate ................................................................................... 320

11.7 Parameters Related to Control of Acceleration and Deceleration ................................. 324

11.8 Parameters Related to Servo and Backlash Compensation .........................................326

11.9 Parameters Related to Input/Output .............................................................................330

11.10 Parameters Related to Display and Editing................................................................. 332

11.11 Parameters Related to Programming .......................................................................... 334

11.12 Parameters Related to Screw Pitch Error Compensation ...........................................336

11.13 Parameters Related to the Spindle Control................................................................. 339

11.14 Parameters Related to the Tool Compensation........................................................... 344

11.15 Parameters Related to the Canned Cycle................................................................. 347

11.15.1 Parameter of the Drilling Canned Cycle ............................................................347

11.15.2 Parameters Related to the Thread Cutting Cycle.............................................. 348

11.15.3 Parameters Related to the Combined Canned Cycle .......................................348

11.16 Parameters Related to the Rigid Tapping.................................................................... 349

11.17 Parameters Related to the Polar Coordinate Interpolation.......................................... 351

11.18 Parameters Related to the User Macro Program ........................................................ 352

XII

Page 13

Contents

11.19 Parameters Related to Skip Function..........................................................................353

11.20 Parameters Related to Graphic Display ......................................................................355

11.21 Parameters Related to Run Hour and Parts Count Display.........................................355

11.22 Parameters Related to MPG Feed ..............................................................................356

11.23 Parameters Related to PLC Axis Control ....................................................................357

11.24 Parameters Related to Basic Function........................................................................360

11.25 Parameters Related to GSK-CAN Communication Function ......................................361

Appendix 1 Alarm List ..................................................................................................................363

1.1 Program Alarms (P/S Alarms) .........................................................................................363

1.2 Parameter Alarms ...........................................................................................................372

1.3 Pulse Encoder Alarms.....................................................................................................373

1.4 Servo Alarms ..................................................................................................................373

1.5 Overtravel Alarms ...........................................................................................................373

1.6 Spindle Alarms................................................................................................................374

1.7 System Alarms................................................................................................................374

1.8 Communication prompt on the operation panel ..............................................................375

1.9 GSK-CAN Communication Prompts ...............................................................................375

1.10 Servo Inner Alarms .......................................................................................................377

Appendix 2 Standard Ladder Function Allocation.........................................................................381

2.1 X, Y Addresses Definition................................................................................................381

2.2 Standard Operation Panel...............................................................................................384

2.2.1 Address X .............................................................................................................384

2.2.2 Address Y .............................................................................................................386

2.3 Standard PLC Parameter Instruction ..............................................................................389

2.3.1 Parameter K..........................................................................................................389

2.3.2 Parameter DT .......................................................................................................390

2.3.3 Parameter DC.......................................................................................................391

2.3.4 Parameter D .........................................................................................................391

2.4 PLC(Address A) Alarms (the Followings are Referred to V2.03b)...................................392

Appendix 3 Installation .................................................................................................................394

3.1 GSK988T Appearance Dimension ..................................................................................394

3.2 Machine Operation Panel MPU02A of GSK988T............................................................395

3.3 Machine Operation Panel MPU02B Appearance dimension of GSK988T ......................396

3.4 GSK988T-H Appearance Dimension...............................................................................397

3.5 Appearance Dimension of GSK988T-H Operation panel................................................397

Appendix 4 Operation List............................................................................................................399

XIII

Page 14

GSK988T Turning CNC System User Manual

XIV

Page 15

Chapter 1 Programming Fundamentals

Ⅰ Programming

Ⅰ PROGRAMMING

1

Page 16

GSK988T Turning CNC System User Manual

Ⅰ Programming

2

Page 17

Chapter Ⅰ Programming Fundamentals

Chapter I Programming Fundamentals

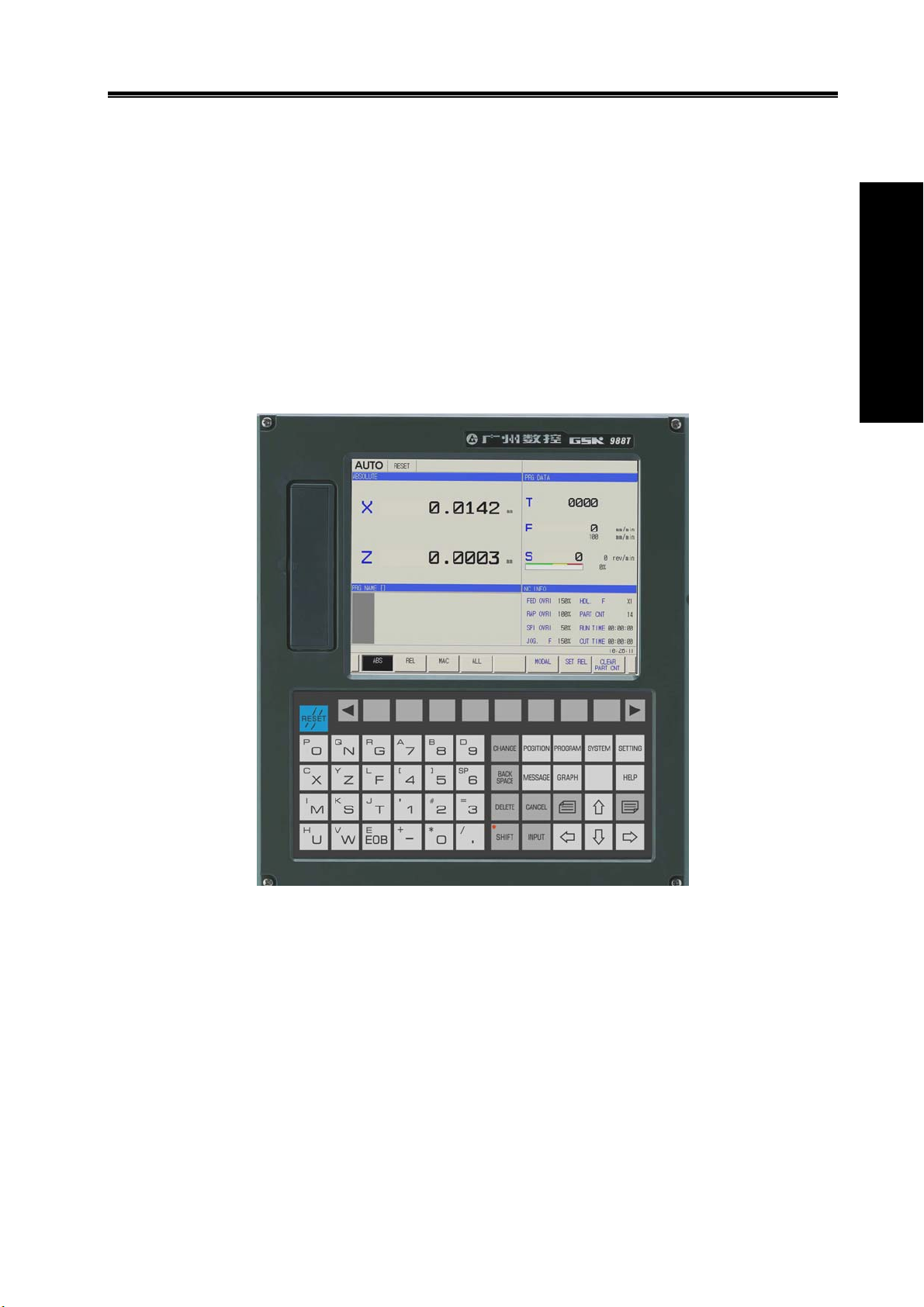

1.1 GSK988T Introduction

GSK988T is exclusive to the slant bed CNC turning machine and turning center with the

horizontal and the vertical structures. It uses 400MHz high-performance process to control 5 feed

axes(including Cs axis) and 2 spindles, communicates with the servo unit through GSK-CAN serial

bus, and its matched servo motor uses the high-resolution absolute encoder to realize 0.1μm

position precision, which can meet the requirements of high-precision turning and milling compound

machining. It has the network interface to support the remote monitor and file transmission and to

meet the network teaching and workshop management. GSK988T is the best choice for the slant bed

CNC turning and turning center.

Programming Ⅰ

Fig. 1-1 GSK988T appearance

Technical characteristics

5 feed axes(including Cs axis), 3-axis link, 2 analog spindles to realize the turning, milling compound

machining

Command unit 1μm and 0.1μm, max. speed 60m/min(max. speed 24m/min in 0.1μm)

Optional to GSK-CAN servo unit to read/write the servo parameter and monitor servo unit

Extended I/O unit and GSK-CAN axis through serial bus

Nested many PLC programs, on-line editing, real-time monitoring PLC ladder

Part programs edited on the background

Network interface, remote monitoring and file transmission

USB interface, U disc file operation, system allocation and software upgrading

8.4 inch truecolor LCD, two-dimensional motion path and solid graph display

3

Page 18

GSK988T Turning CNC System User Manual

Technical specifications

Controllable axes

Max. controllable axes:5(including Cs axis)

Max. link axes:3

PLC controllable axes:5

Ⅰ Programming

Feed axis function

Least command unit:0.001mm, 0.0001mm

Least command range:±99999999× least command unit

Rapid traverse speed:max. 60m/min in 0.001mm command unit, max. 24m/min in 0.0001mm

command unit

Rapid override:F0, 25%, 50%, 100% real-timing tuning

Cutting feedrate:

0.01 mm/min~60000 mm/min or 0.01 inch/min~4000 inch/min(G98: feed per minute)

0.01 mm/rev~500 mm/r or 0.01 inch/rev~9.99 inch/rev(G99: feed per revolution)

Feedrate override:0~150% 16-level real-time tuning

Interpolation mode: linear, arc, thread, polar interpolation, and rigid tapping

Thread function

Thread type: constant pitch straight thread/taper thread/end thread, variable pitch straight

thread/taper thread/end thread

Thread head:1~99 heads

Thread pitch: 0.01mm~500mm(metric thread)or 0.01inch~9.99inch(inch thread)

Thread run-out:thread lenght, angle, speed can be set

Acceleration/deceleration function

Cutting feed: linear, exponential

Rapid traverse: linear

Thread cutting: linear, exponential

Initial speed, terminal speed and time of acceleration/deceleration are set by the parameter

Spindle function

2-channel 0V~10V analog voltage output,2-channel spindle encode feedback, double-spindle

control

Spindle speed: spindle speed specified by S or PLC signal, its range: 0rpm~20000rpm

Spindle override:50%~120% 8-level real-time tuning

Spindle constant surface control

Rigid tapping

Tool function

Tool length compensation(tool offset):99 groups

Tool wear compensation:99 groups of tool wear compensation data

Tool nose radius compensation(C type)

Toolsetting mode: fixed-point toolsetting, trial-cutting toolsetting, reference position return toolsetting

Offset execution mode: modifying coordinate mode, tool traverse mode

Precision compensation

Backlash compensation: compensation range (-9999~9999)× check unit

Memory pitch error compensation:1024 compensation points,compensation point number of each is

set by the parameter, each point compensation range (-700~700) × check unit

PLC function

13 basic commands, 30 functional commands

4

Page 19

Chapter Ⅰ Programming Fundamentals

PLC ladder on-line edit, real-time monitoring

st

2-level PLC program, up to 5000 steps, the 1

Many PLC programs(up to 16 programs),the current running PLC program can be selected

level program refresh period

I/O unit

Basic I/O:40 input /32 output

Operation panel I/O:96 input/96 output

Human-computer interface

Display in Chinese, English and others

Two-dimensional tool path and solid graph display

Servo state monitoring

Servo parameter on-line allocation

Real-time clock

On-line help

Operation management

Operation mode: Auto, Manual, Edit, MDI, DNC, MPG, Reference position return

Multi-level operation Authorization Management

Alarm log

Timed stop

Program edit

Program capacity:36M, 10000 programs(including subprogram and macro program)

Edit mode: full-screen edit, part program edit on the background

Edit function:searching, modifying and deleting program/block/word, copying/deleting block

Program format: ISO code, word without blank space, relative coordinates, absolute coordinate

compound programming

Macro command: statement macro command program

Program call: macro program call with parameters, 12-level subprogram nesting

Grammar check: executing the rapid grammar check for the program(do not run the program) after it

has been edit

Communication function

RS232 interface: part program and parameter transmission, DNC machining, upgrading PLC

program and system software U disc

USB:U disc file operation, U disc file directly machining, upgrading PLC program and system

software U disc

LAN: remote monitoring, network DNC machining, file transmission, remotely upgrading PLC

program, system software

Safety function

Emergency stop

Hardware travel limit

Many storage travel checks

Data backup and recover

Programming Ⅰ

1.2 CNC system of machine tools and CNC machine tools

CNC machine tool is an electro-mechanical integrated product, composed of Numerical Control

Systems of Machine Tools, machines, electric control components, hydraulic components, pneumatic

components, lubricating, cooling and other subsystems (components), and CNC systems of machine

tools are control cores of CNC machine tools. CNC systems of machine tools are made up of

computerized numerical control(CNC), servo (stepper) motor drive devices, servo (or stepper) motor

5

Page 20

GSK988T Turning CNC System User Manual

etc.

Operational principles of CNC machine tools: according to requirements of machining technology,

edit user programs and input them to CNC, then CNC outputs motion control commands to the servo

(stepper) motor drive devices, and last the servo (or stepper) motor completes the cutting feed of

machine tool by mechanical driving device; logic control commands in user programs to control

Ⅰ Programming

spindle start/stop, tool selections, cooling ON/OFF, lubricant ON/OFF are output to electric control

systems of machine tools from CNC, and then the electric control systems control output components

including buttons, switches, indicators, relays, contactors and so on. Presently, the electric control

systems are employed with Programmable Logic Controller (PLC) with characteristics of compact,

convenience and high reliance. Thereof, the motion control systems and logic control systems are the

main of CNC machine tools.

The system has simultaneously motion control and logic control function to control two axes of CNC

machine tool to move, and has PLC function. Edit PLC programs (ladder diagram) according to

requirements of input and output control of machine tool and then download them to GSK988T

Turning Machine CNC system, which realizes the required electric control requirements of machine

tool, is convenient to electric design of machine tool and reduces cost of CNC machine tool.

Softwares used for controlling GSK988T Turning Machine CNC system are divided into system

software (NC for short) and PLC software (PLC for short). NC system is used for controlling display,

communication, edit, decoding, interpolation and acceleration/deceleration, and PLC system for

controlling explanations, executions, inputs and outputs of ladder diagrams.

Standard PLC programs are loaded (except for the special order) when GSK980TDa Turning

Machine CNC System is delivered, concerned PLC control functions in following functions and

operations are described according to control logics of standard PLC programs, marking with

“Standard PLC functions” in GSK980TDa Turning CNC System User Manual. Refer to Operation

Manual of machine manufacturer about functions and operations of PLC control because the

machine manufacturer may modify or edit PLC programs again.

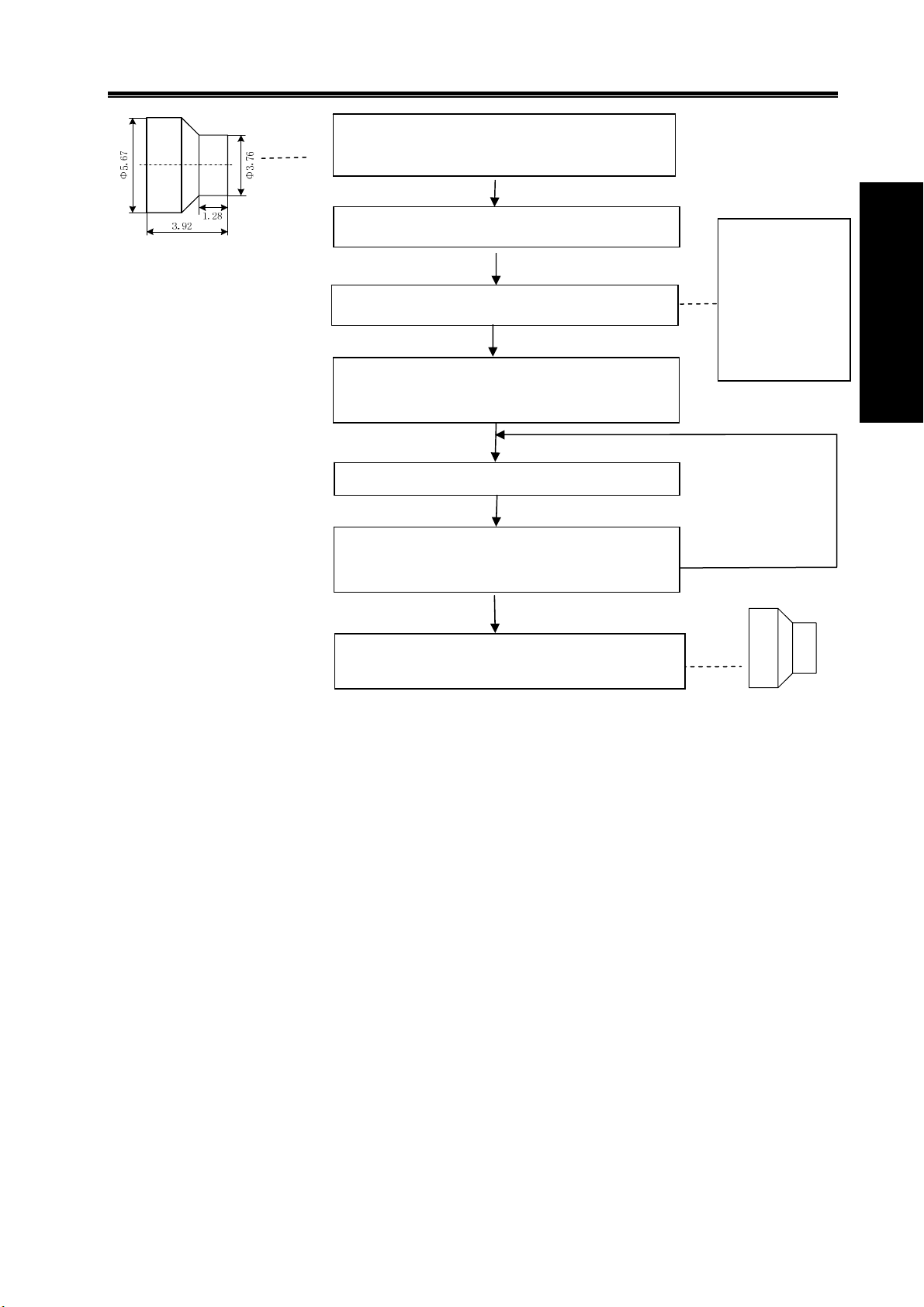

Programming is a course of workpiece contours, machining technologies, technology parameters and

tool parameters being edit into part programs according to special CNC programming G codes. CNC

machining is a course of CNC controlling a machine tool to complete machining of workpiece

according requirements of part programs. Technical flow of CNC machining is shown in Fig. 1-2.

6

Page 21

Chapter Ⅰ Programming Fundamentals

Analyse workpiece drawings and confirm

machining processing

Edit part programs and record into CNC

Test part programs and execute trial run

O0001;

G00 X3.76 Z0;

G01 Z-1.28 F50;

…

M30;

%

Programming Ⅰ

Execute toolsetting and set tool offsets and

coordinates

Run part programs and machine workpiece

Check part dimension and modify part

programs and compensations

The machining ends and the workpiece is

formed

Fig. 1-2

1.3 Programming Fundamentals

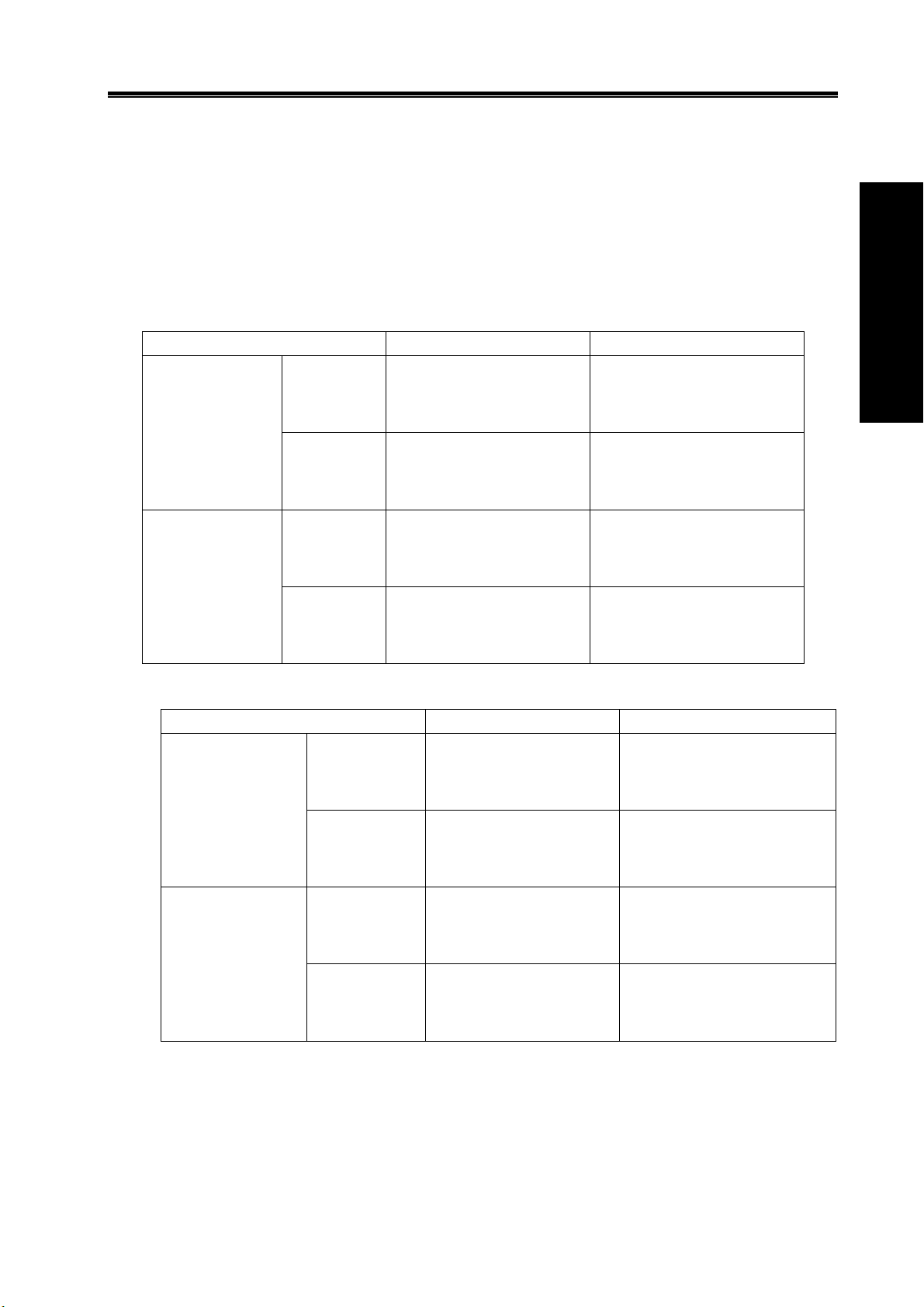

1.3.1 Coordinates definition

The following figure is the sketch of CNC turning:

7

Page 22

GSK988T Turning CNC System User Manual

Ⅰ Programming

Fig. 1-3

GSK988T uses a rectangular coordinate system composed of X, Z axis. X axis is perpendicular

with axes of spindle and Z axis is parallel with axes of spindle; negative directions of them approach

to the workpiece and positive ones are away from it.

Parameter NO.1020 can set and modify program names for each axis and their responding

relationship is as follows:

Table 1-3(a)

Axis name Setting value Axis name Setting value

X 88 Z 90

Y 89 A 65

B 66 C 67

There is a front tool post and a rear tool post of NC turning machine according to their relative

position between the tool post and the spindle, Fig. 1-5 is a coordinate system of the front tool post

and Fig. 1-6 is a rear toolpost one. It shows exactly the opposite of X axes, but the same of Z axes

from figures. In the manual, it will introduce programming application with the front tool post

coordinate system in the following figures and examples.

Fig.1-4 Front tool post coordinate system Fig.1-5 Rear tool post coordinate system

8

X

Z

Z

X

Page 23

Chapter Ⅰ Programming Fundamentals

1.3.2 Increment system

Increment system includes least input increment (input) and least command increment (output).

Least input increment is the least unit of programming movement distance. Least command

increment is the least unit of tool movement on the machine tool. Their unit: mm, inch or degree.

Increment systems are separately IS-B and IS-C. Bit 1 of NO. 1004 decides to select IS-B or IS-C. Bit

1 (ISC) setting of No.1001 is applied to all axes. For example: increment system of all axes is set to

IS-C when the parameter selects IS-C.

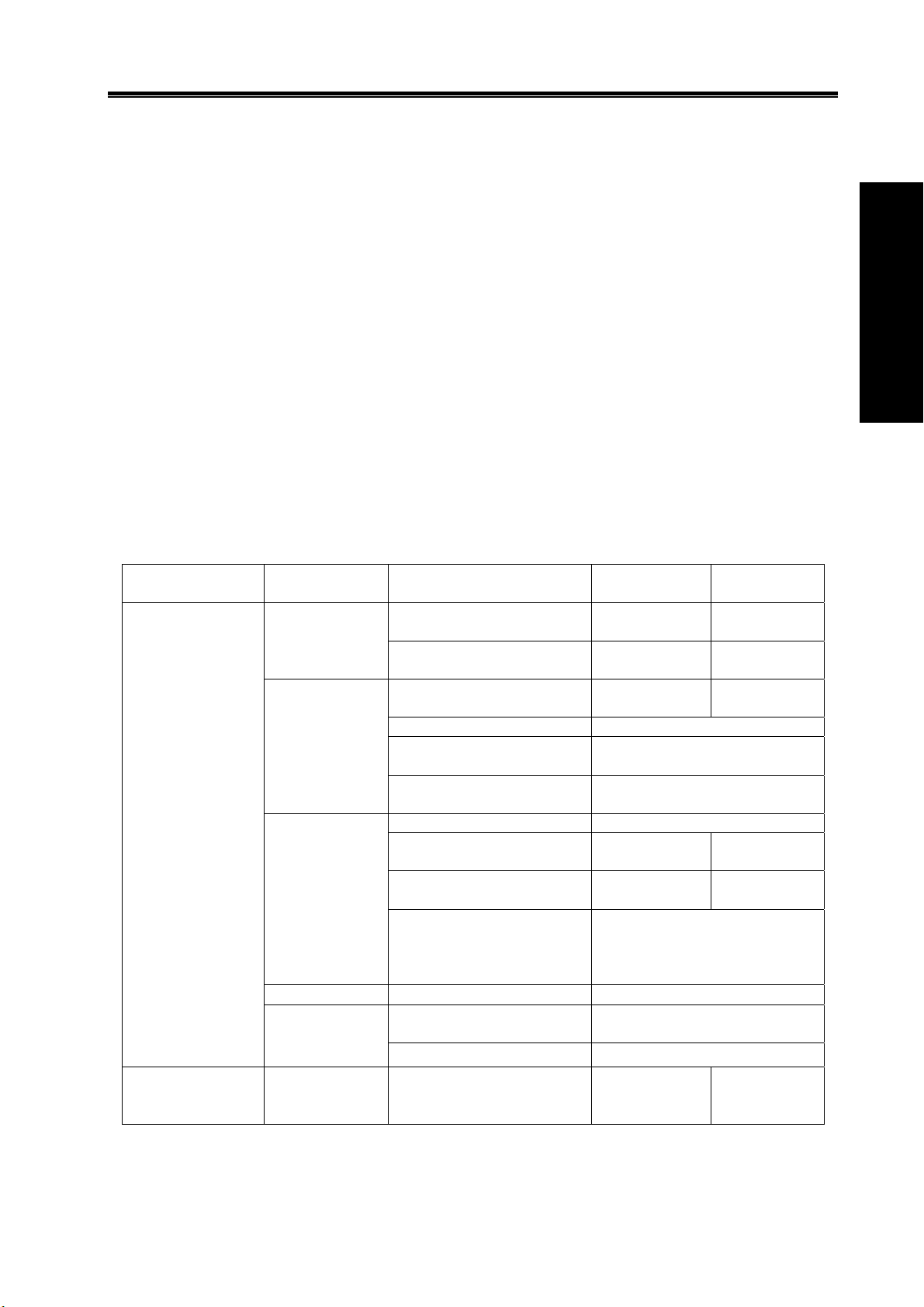

Table 1-3(b) increment system IS-B

Least input increment Least command increment

Metric machine

Inch machine

Least input increment Least command increment

Metric machine

Inch machine

Whether the least input increment is mm or inch is determined by the machine based on the

parameter INM(1001#0). The least input increment can be switched between the inch and the mm

input, which is controlled by G codes( G20 or G21) or the set parameter.

mm input

Inch input

mm input

Inch input

mm input

Inch input

mm input

Inch input

0.001mm(diameter)

0.001mm(radius)

0.001deg

0.0001inch(diameter)

0.0001inch(radius)

0.001deg

0.001mm(diameter)

0.001mm(radius)

0.001deg

0.0001inch(diameter)

0.0001inch(radius)

0.001deg

Table 1-3(c) increment system IS-C

0.0001mm(diameter)

0.0001mm(radius)

0.0001deg

0.00001inch(diameter)

0.00001inch(radius)

0.0001deg

0.0001mm(diameter)

0.0001mm(radius)

0.0001deg

0.00001inch(diameter)

0.00001inch(radius)

0.0001deg

0.0005mm

0.001mm

0.001deg

0.0005inch

0.001inch

0.001deg

0.00005mm

0.0001mm

0.001deg

0.00005inch

0.0001inch

0.001deg

0.00005mm

0.0001mm

0.0001deg

0.00005inch

0.0001inch

0.0001deg

0.000005mm

0.00001mm

0.0001deg

0.000005inch

0.00001inch

0.0001deg

Programming Ⅰ

9

Page 24

GSK988T Turning CNC System User Manual

1.3.3 Max. travel

Max. travel=least command increment X(±)99999999

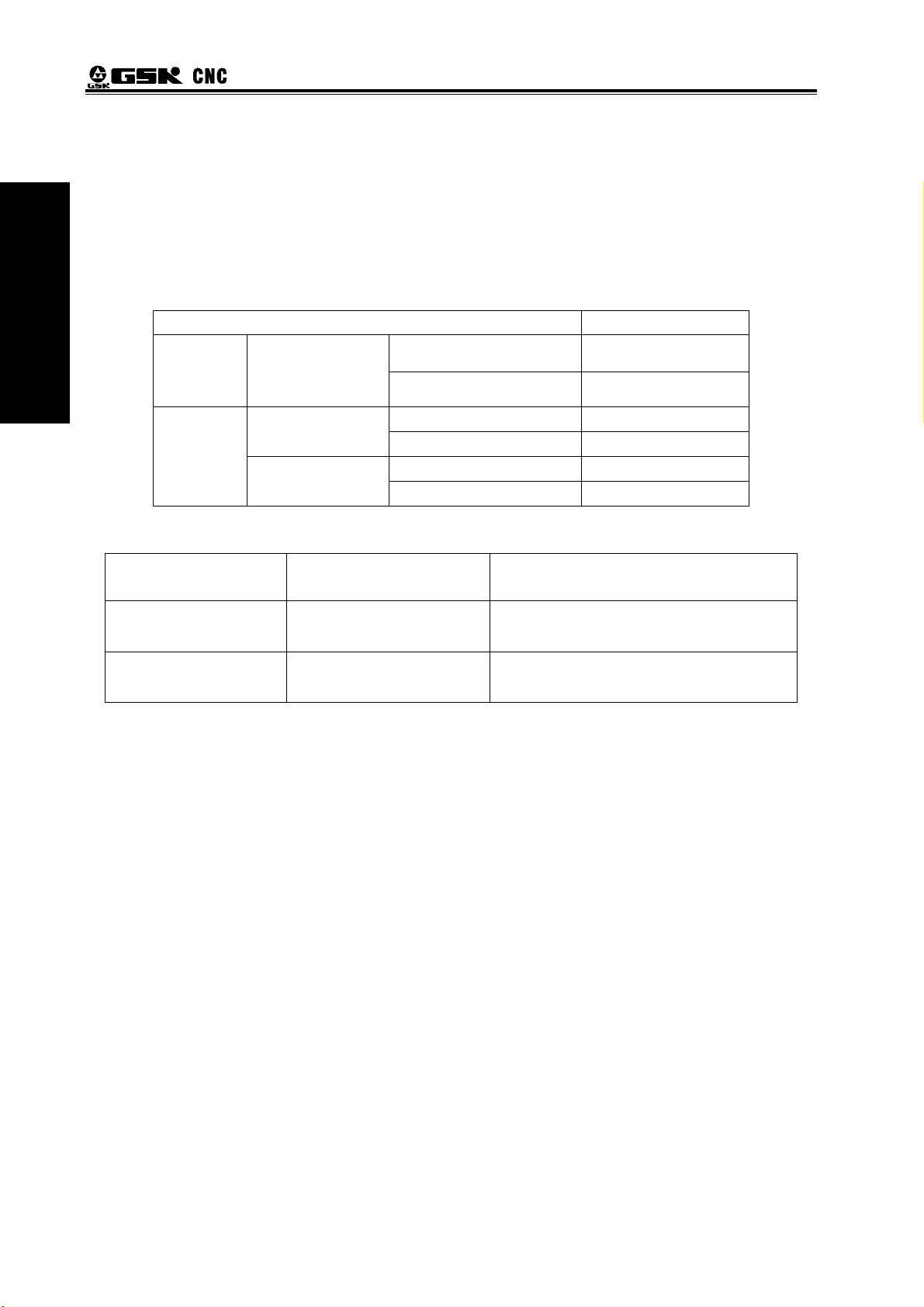

Table 1-3 (d) max. travel IS-C

Ⅰ Programming

IS-B

IS-C

Note 1: The unit is diameter value in diameter programming, is radius value in radius programming in the

above table.

Note 2: The input command cannot exceed max. travel command.

Note 3: The actual travel decides the machine tool.

Increment system Max. travel

Metric machine system ±99999.999mm

±99999.999deg

Inch machine system ±9999.9999inch

±9999.9999deg

Metric machine system ±9999.9999mm

±9999.9999deg

Inch machine system ±999.99999inch

±9999.9999deg

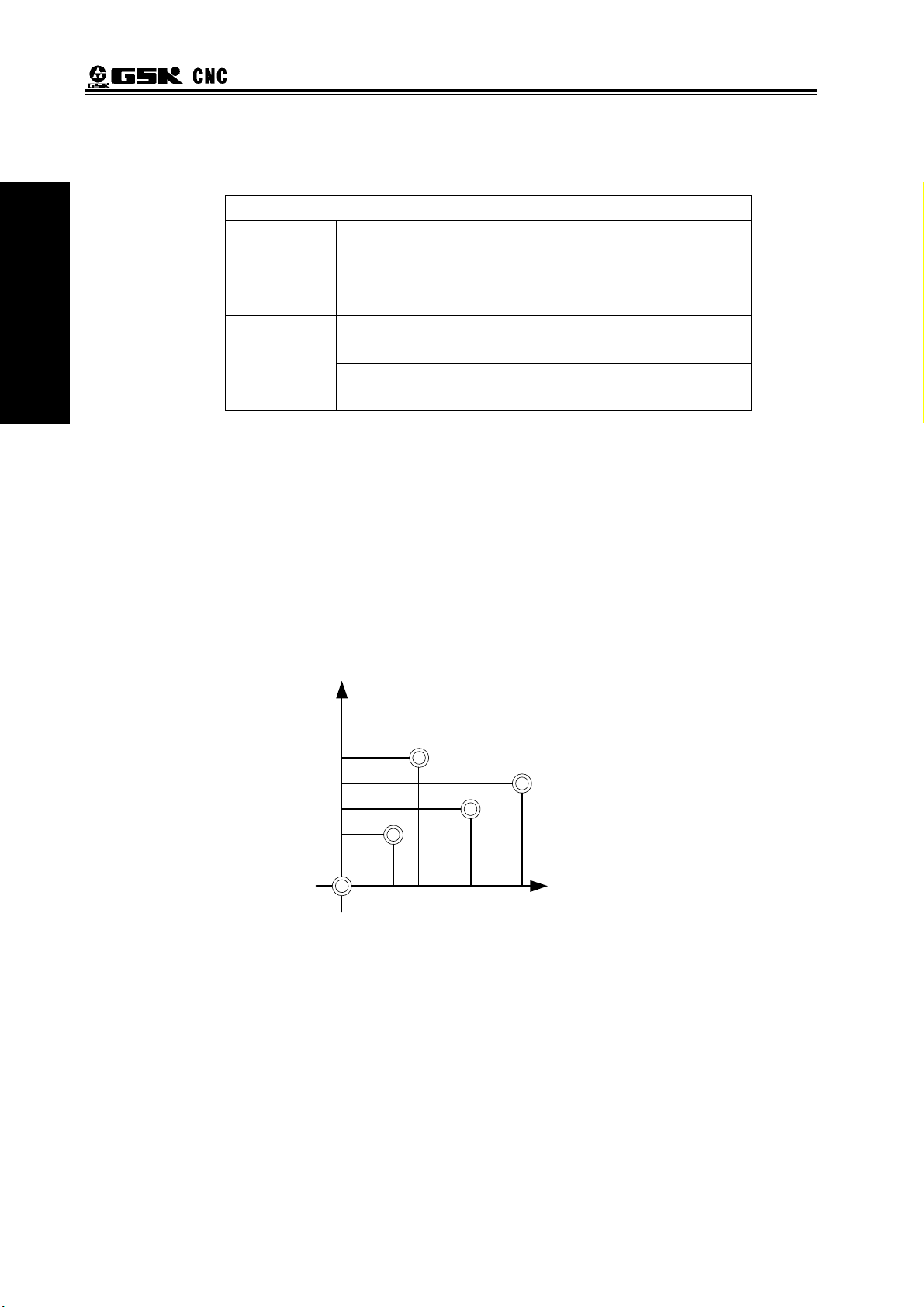

1.3.4 Reference position

Reference position is a fixed point on the machine tool. The tool can move to the position by

executing the reference position return function. Generally, the reference position is used to tool

change and setting coordinate system. GSK988T Turning CNC System can set 4 reference positions

by parameters as follows:

Y

nd

reference point

2

rd

3

reference point

reference point

Machine zero

th

reference point

4

X

Fig. 1-6 reference position

1.3.5 Machine coordinate system

Machine tool coordinate system is a benchmark one used for CNC counting coordinates and a

fixed one on the machine tool. Machine tool zero is a fixed point which position is specified by zero

switch or zero return switch on the machine tool. Usually, the zero return switch is installed on max.

stroke in axis positive direction. After the system is turned on, the reference position return is

executed to set machine coordinate system. The machine coordinate system is not keeping until the

system is turned off.

Note: For the machine with the incremental encoder, must execute the reference position return every time to

set the machine coordinate system after power-off; for the machine with the multi-coil absolute encoder,

need not execute the reference position return every time after power-off.

10

Page 25

Chapter Ⅰ Programming Fundamentals

1.3.6 Workpice coordinate system

The workpiece coordinate system is a rectangular coordinate system based on the part drawing,

also called floating coordinate system. The workpiece coordinate system is set by the system in

advance, can be changed by moving its coordinate origin point. The established workpiece is valid till

it is replaced by a new one. The system has preset 6 workpice coordinate systems (G54-G59).

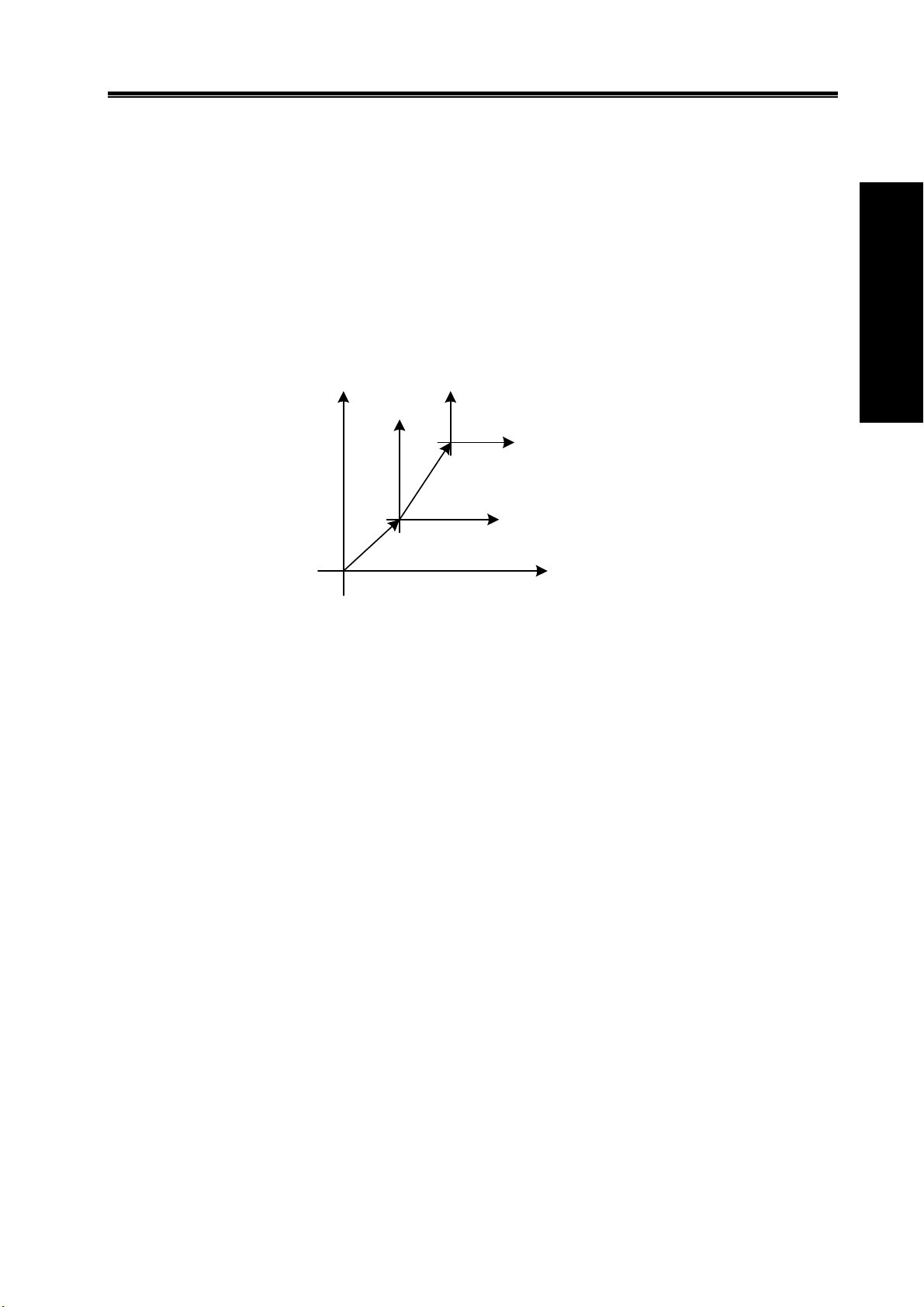

1.3.7 Local coordinate system

When the system compiling programs in the workpiece coordinate system, sub-coordinate

system of workpiece coordinate system can be set for easily programming, called local coordinate

system as follows:

Local coordinate system

Workpiece coordinate system

Programming Ⅰ

Machine coordinate system

Fig. 1-7 local coordinate system

1.3.8 Interpolation function

Interpolation is defined as a planar or three dimensional contour formed by path of 2 or multiple

axes moving at the same time, also called Contour control. The controlled moving axis is called link

axis when the interpolation is executed. The moving distance, direction and speed of it are controlled

synchronously in the course of running to form the required Composite motion path. Positioning

control is defined that motion end point of one axis or multiple axes instead of the motion path in the

course of running is controlled.

GSK988T has linear, arc and thread interpolation function.

Linear interpolation: Composite motion path of X, Z axis is a straight line from starting point to

end point.

Circular interpolation: Composite motion path of X, Z axis is arc radius defined by R or the circle

center (I, K) from starting point to end point.

Thread interpolation: Moving distance of X or Z axis or X and Z axis is defined by rotation angle

of spindle to form spiral cutting path on the workpiece surface to realize the

thread cutting. For thread interpolation, the feed axis rotates along with the

spindle, the long axis moves one pitch when the spindle rotates one rev,

and the short axis and the long axis directly interpolate.

Note 1:Xp, Yp, Zp are separately X or its parallel axis, Y or its parallel axis, Z or its parallel axis. The followings

are the same as those.

Note 2: IP expresses the combination of X_Y_Z_(used in programming).

11

Page 26

GSK988T Turning CNC System User Manual

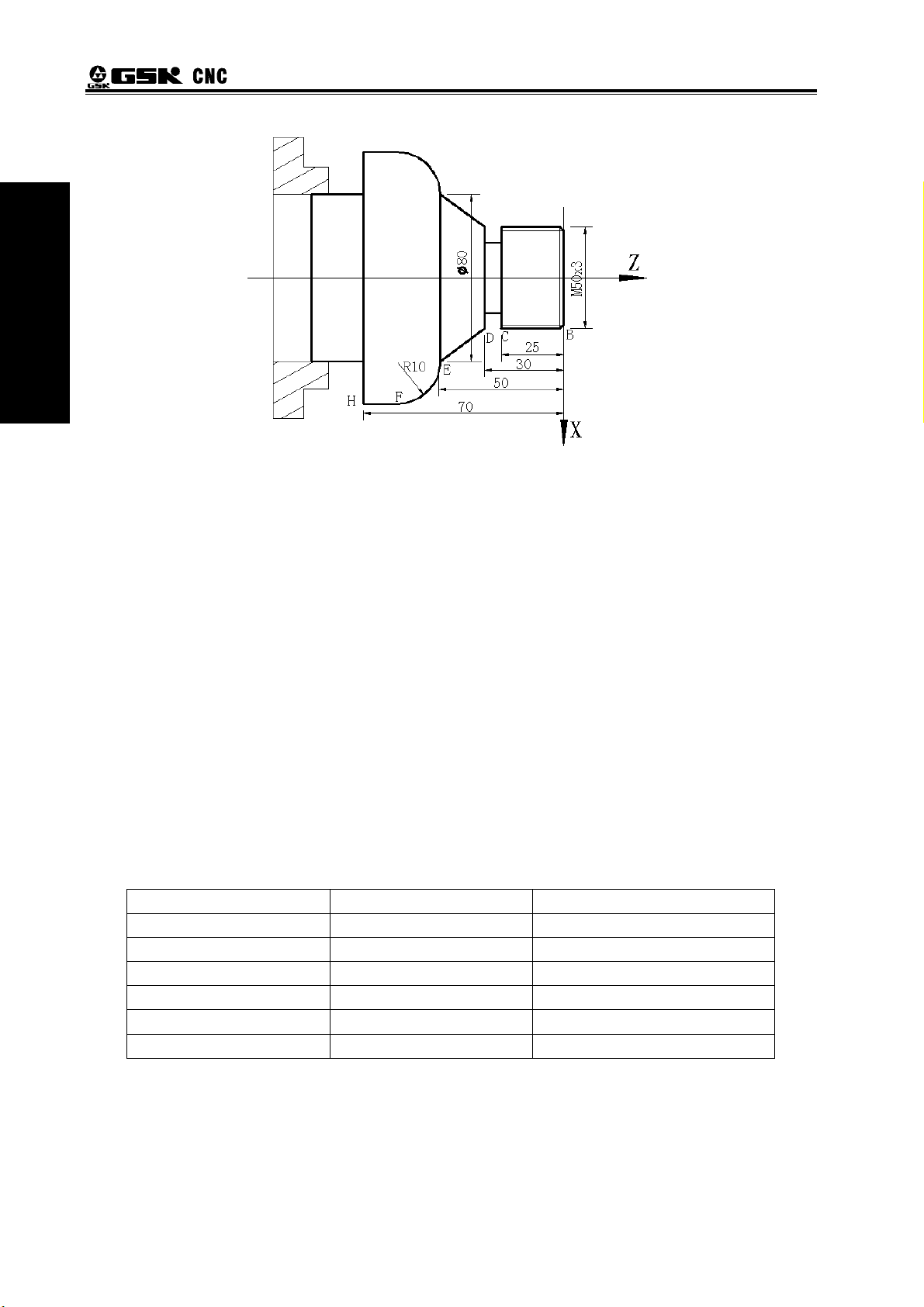

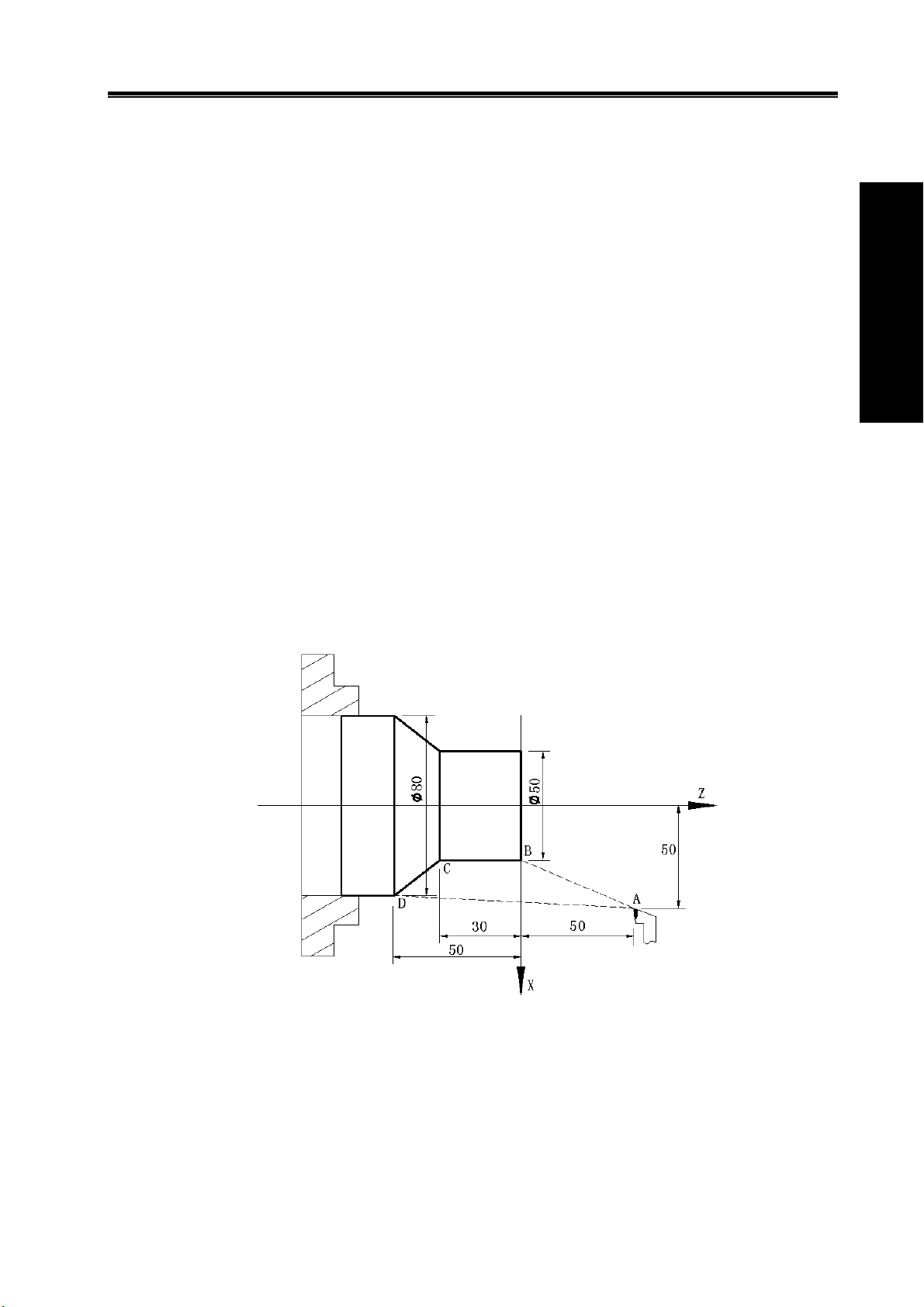

Example:

Ⅰ Programming

Fig.1-8

…

G32 W-27 F3; (B→C;thread interpolation)

G1 X50 Z-30 F100;

G1 X80 Z-50; (D→E;linear interpolation)

G3 X100 W-10 R10; (E→F;arc interpolation)

…

M30;

1.4 Coordinate Value and Dimension

1.4.1 Absolute programming and incremental programming

The system has two methods to command the too traverse: absolute value and incremental

value command. In the absolute programming, use the coordinate value programming of the end

point; in the incremental programming, use the traverse distance programming. In the system, using

the absolute programming or incremental programming is depended on the word of the command as

follows:

Table 1- 4(a)

Absolute value command Incremental value command

X movement command X U

Y movement command Y V

Z movement command Z W

C movement command C H

A movement command A None

B movement command B None

The system can select the incremental programming or the absolute programming mode, or the

incremental/absolute compound programming; the absolute command and the incremental command

can be in the same block as follow:

X100.0 W100.0;

When the absolute command and the incremental command of one axis are in the same block,

the following command value is valid.

12

Page 27

Chapter Ⅰ Programming Fundamentals

The axis word can exist repetitively in the same block and the later value is valid, but when

No.3403 Bit 6 (AD2) is set 1, the alarm occurs. U, W in other G command has bee specified to others.

For example: in G73, the above conditions

1.4.2 Diameter programming and radius programming

Because the workpiece section is the circle in CNC turning controlled program, X dimension can

use two kind of method; diameter programming command and radius programming command.

1. The user can select the radius programming or diameter programming, which is set by state

parameter (No. 1006 Bit 3(DIAX)).

2. Parameters related to diameter/radius programming:

State parameter No.1006 BIT3 (DIAx):

0—radius programming;

1—diameter programming;

State parameter No.5004 Bit1(ORC):

0—offset value is expressed with diameter;

1—offset value is expressed with radius;

Pay more attention to the conditions in the following table when X uses diameter programming:

Table 1- 4 (b) related addresses and data to the diameter or radius programming

Word Explanation Diameter

programming

X

X coordinate, polar

coordinate

G50 sets X coordinate Diameter

Diameter

value

value

X increment Diameter

value

G71 infeed amount Radius value

U

X finishing allowance in

Parameter definition

G71, G72, G73

Related

addresses to

diameter/radius

programming

R

tool retraction

amount in G73

Clearance in G71, G72 Radius value

Clearance after cutting in

G75

Clearance to end point in

G74

Taper in G90, G92, G94,

Radius value

Diameter

value

Diameter

value

Radius value

G76, radius in G02, G03,

thread finishing amount in

G76

I X amount of circle center Radius value

F

G32,G34,G92,Pitch long

axis is X in G76

Radius value

X feedrate display Radius/rev, radius /min

Others X or U value of

position

Display Diameter

value

window

Radius

programming

Radius value

Radius value

Radius value

Radius value

Radius value

Radius value

Programming Ⅰ

Note: Besides the above-mentioned addresses and data related to the diameter programming or the radius

programming, other related to word and data related to X numerical value are expressed with radius

value.

13

Page 28

GSK988T Turning CNC System User Manual

1.4.3 Decimal programming

Value can be input by decimal programming. Distance, time and speed can be input by decimal

programming. The following addresses can use decimal point: X, Y, Z, A, B, C, U, V, W, H, I, J, K, R

and F, and other addresses cannot use decimal programming.

Ⅰ Programming

There are two types of decimal point usage which is decided by No. 3401 Bit0(DPI).

When NO.3401 Bit 0(DPI) is set to 1, value without decimal point is with mm, inch.

When NO.3401 Bit0(DPI) is set to 0, input value is specified by least input increment.

Parameter setting Least command unit

Rotary axis is

Rotary axis

ROTx=1

Linear axis

Example: when the metric input, the least input increment unit are set to 0.001:

Program command The corresponding actual

X1000 without decimal

command value

X1000.0 with decimal

command value

The decimal which is less than the least input increment unit is discarded in course of program

being executed.

Example: X2.34567. When the least unit of input increment is 0.001mm, X2.34567 becomes

X2.345, when the least unit is 0.0001inch, it becomes X2.3456.

The system alarms when the specified is more than 8-digit value.

not related to

parameter INI

Metric

INI=1

Inch

value when DPI is 1

1000mm

Unit:mm

1000mm

unit:mm

ISC=0(ISC system)

ISC=1

(ISB system)

ISC=0(ISC system)

ISC=1(ISB system)

ISC=0(ISC system)

ISC=1(ISB system)

The corresponding actual value when

DPI is 0

1 mm

Unit: least input increment( set to 0.001)

1000mm

Unit:mm

0.001deg ROTx=0

0.0001deg

0.001mm INI=0

0.0001mm

0.0001inch

0.00001inch

1.4.4 Conversion between the metric and the inch

Metric input or inch input is set by NO.0000 Bit2(INI). G commands corresponding to metric/inch

system is as follows:

G20: inch input ;

G21: mm input.

Input data unit becomes the inch or metric input unit when NO.0000 Bit2 (INI) setting is changed.

But, the angle unit is not changed.

Input data unit becomes the inch or metric input unit when NO.0000 Bit2 (INI) setting is changed.

But, the angle unit is not changed.

——F feedrate;

——position command;

——zero offset of workpiece;

——tool compensation value;

14

Page 29

Chapter Ⅰ Programming Fundamentals

——graduation unit of MPG;

——movement distance in incremental feed.

NO.1001 Bit0 (INM) can set MM or INCH input of least command increment in linear axis.

0:mm input( metric machine)

1:inch input(inch machine)

1.4.5 Linear axis and rotary axis

NO.1006 Bit0(ROTx) can set each axis to linear axis or rotary axis. NO. 1006 Bit 1 (ROSx) can

be used to select the rotary type for each axis.

Absolute coordinate value is displayed circularly with the movement per rev set by NO.1260

when the cycle function is executed, which can prevent the rotary axis from overflowing. The cycle

function is valid when NO.1008 Bit 0(ROAx) is set to 1.

For absolute value command, the coordinate values is the corresponding angle cycle value of

per rev set by NO. 1260 after the machine moves. When NO.1008 Bit 1(RABx) is set to 0, the

machine rotates according to the shortest distance(to the target point). For incremental command, the

machine moves according to the angle defined by the command.

Programming Ⅰ

1.5 Structure of an NC Program

User needs to compile part programs (called program) according to command formats of CNC

system. CNC system executes programs to control the machine tool movement, the spindle

starting/stopping, the cooling and the lubricant ON/OFF to complete the machine of workpiece.

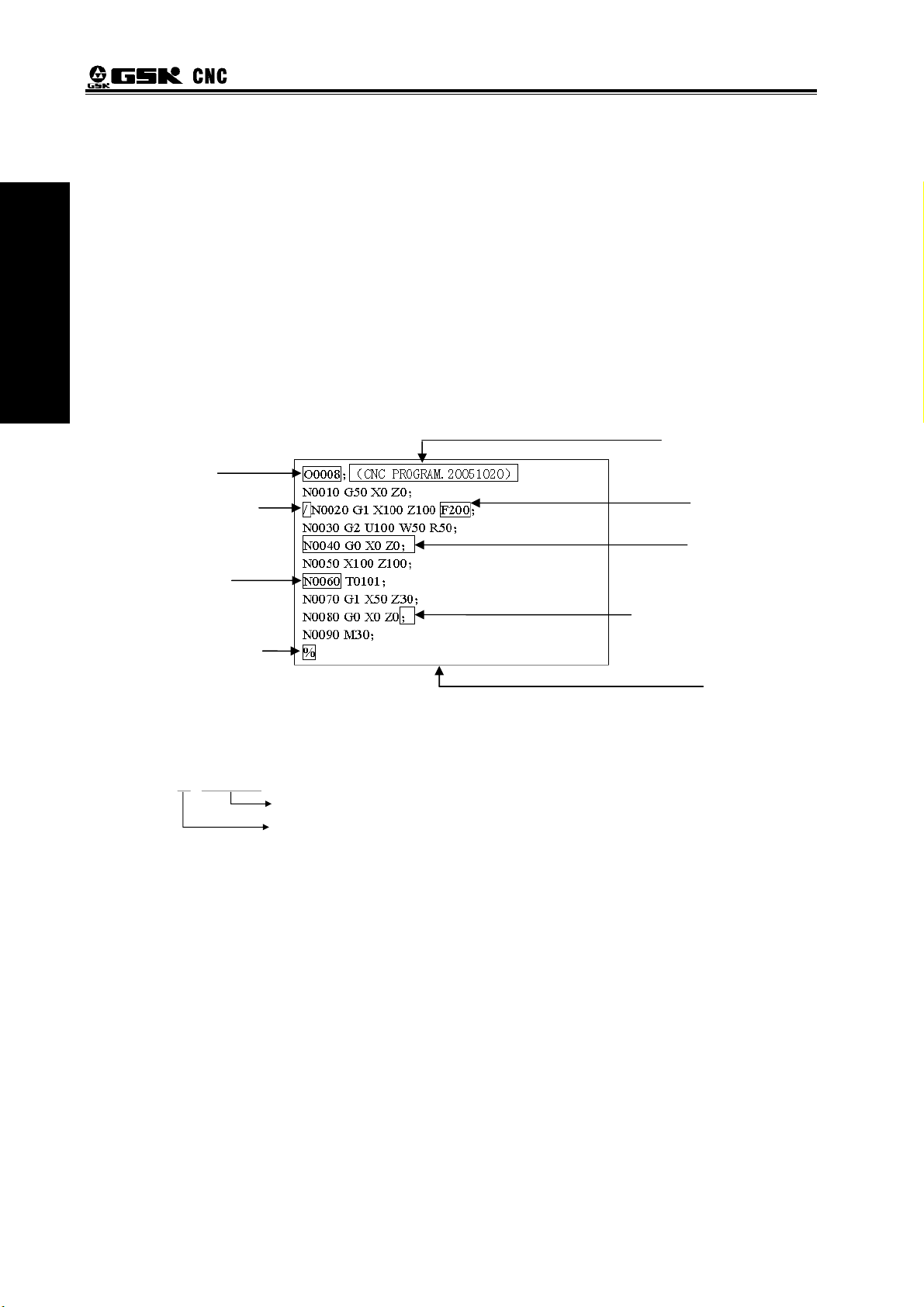

Program example:

Fig. 1-9

O0001 ; (Program name)

N0005 G0 X100 Z50; (Rapidly positioning to A point)

N0010 M12; (Clamping workpiece)

N0015 T0101; (Changing No.1 tool and executing its offset)

N0020 M3 S600; (Starting the spindle with 600 r/min)

N0025 M8 (Cooling ON)

N0030 G1 X50 Z0 F600; (Approaching B point with 600mm/min)

15

Page 30

GSK988T Turning CNC System User Manual

N0040 W-30 F200; (Cutting from B point to C point)

N0050 X80 W-20 F150; (Cutting from C point to D point)

N0060 G0 X100 Z50; (Rapidly retracting to A point)

N0070 T0100; (Canceling the tool offset)

Ⅰ Programming

The tool leaves the path of A→B→C→D→A after the above-mentioned programs are executed.

ending with “%”; a block begins with block number (omitted) and ends with “;” or “*”. See the general

structure of program as Fig. 1-10:

Program name

N0080 M5 S0; (Stopping the spindle)

N0090 M9; (Cooling OFF)

N0100 M13; (Releasing workpiece)

N0110 M30; (End of program, spindle stopping and Cooling OFF)

A program consists of a sequence of blocks, beginning with “OXXXX”(program name)and

Program annotation

Block skip character

Block number

Character for end of block

Character for end of block

Fig. 1-10 Structure of a program

Word

Block

Program

1.5.1 Program name

Format: ○ △△△△

Program number (0000~9999, the leading zero can be omitted)

Address O

is number of a program name, its range is 4△△△△ -digit integer 0000~9999, the system

alarms when the negative program name is input. The system ignores NC commands when program

are edited and other NC commands are edited in the first line.

1.5.2 Block format

1. Format: / N countless words; △△△△

/: skip character. A block can have or not it, generally, it is placed in the initial

position of a program; user can press “SKIP” on the operation panel to

execute the operation when the skip function is valid, otherwise, the

“SKIP” key on the operation panel is valid, i.e. the skip character in the

block is invalid;

N△△△△△:block number. A block can have or not it; number following N is △△△△△

5-digit positive integer 00001~99999, and the system alarms when the

input number is decimal.

16

Page 31

Chapter Ⅰ Programming Fundamentals

Countless words: one block can input countless words, and one block can have one or

more words or have no words.

,:

“EOB” is a end character when one block is completed, “;” is displayed in

LCD, there must be have one end character for one block;

2. Format requirements

(1)

In one block, there can be no blank space between block number and word, and can

be countless blank space(the total characters of one block is within 255);

(2)In one block, there can be not or be countless space between skip character and block

number or words;

(3)

In one block, there can be not or be countless space between end character of block

and its front word or blocks;

Each block can be up to 255 characters, including skip character, block number,

command, space, end character of block “;”;

(4)

The system automatically ignores the content with small bracket “(”,“)”.

Explanations of program annotation:

Note: The annotation of program home as the total annotation of a program is displayed in the program

catalog window, the created program automatically creates the small brackets “(”、“)”, if they are

deleted, the system has no them and they can be replaced by “;”.

3.Parameters related block number:

(1)

whether the system automatically creates block number or not:

User can set whether the system automatically creates block number or not in

editing program by setting Bit 5(SEQ) of NO.0000;

(2)

Note: Sprit(/) explanations:

1. When the sprit (/) is used to skip character, it is generally placed the beginning of block, otherwise , and the

messages from the sprit to EOB code are ignored. For example: U10.G00/04; when the skip function is

started, the system executes U10. G00;(G00 U10.), when it stops, the system executes U10. G0004;(G04

U10.);

2. For cycle command buffer, when a block reads from memory to buffer memory, whether the skip function is

valid or not has been executed. After a block reads into buffer memory, i.e. the system changes skip switch

state, but does not influence the block which has read into the buffer memory;

3. Sprit (/) (closed in bracket[]) and sprit(/) right to value statement “=” in <Expression> are taken as division

operation character instead of skip character.

Use can set the interval value in automatically creating block number by setting

NO.3216.

Programming Ⅰ

1.5.3 Word

1. Format: address + number. There must not be space between address and number.

Presently, the system permissively input addresses: G, M, S, T, F, X, Y, Z, U, V, W, P, Q, I, J, K, R,

L, A, B, C, H , N, O, and will add other;

Command number range following address is referred to the following table.

Table 1-5-1 word table

Address

O

N

G

Function mm input inch input Related G

Program name

Line label

Preparatory function See G code See G code

0~9999 0~9999

1~99999 1~99999

codes

17

Page 32

GSK988T Turning CNC System User Manual

M

S

Miscellaneous function

Spindle speed

Ⅰ Programming

T

F

X

Y

Z

A

B

C

U

Tool offset

Feedrate per minute

Feedrate per rev

Pitch

X absolute coordinate

value((linear axis),

delay time

(*1)

Y absolute coordinate

value(linear axis)

(*1)

Z absolute coordinate

value (linear axis)

(*1)

A absolute coordinate

value(linear axis)

(*1)

B absolute coordinate

value(linear axis)

(*1)

C absolute coordinate

value (rotary axis)

(*1)

X relative coordinate

value, finishing

allowance in G71, G72,

G73, X tool retraction

distance and specified

delay time(*1) in G73,

(*1)

0~9999 0~9999

(G96)

0~20000 m/min

(G97)

0~20000 r/min

0000~9999 0000~9999

(ISB system)

1~60000 mm/min

(ISC system)

1~24000 mm/min

(ISB system)

0.01~500mm/r

(ISC system)

0.01~500mm/r

0.01~500 mm 0.01~9.99inch

(ISB system)

-99999.999~99999.999mm

(ISC system)

-9999.9999~9999.9999mm

(ISB system)

-99999.999~99999.999 mm

(ISC system)

-9999.9999~9999.9999 mm

(ISB system)

-99999.999~99999.999 mm

(ISC system)

-9999.9999~9999.9999 mm

(ISB system)

-99999.999~99999.999 mm

(ISC system)

-9999.9999~9999.9999 mm

(ISB system)

-99999.999~99999.999 mm

(ISC system)

-9999.9999~9999.9999 mm

(ISB system)

-99999.999~99999.999 deg

(ISC system)

-9999.9999~9999.9999 deg

(ISB system)

-99999.999~99999.999 mm

(ISC system)

-9999.9999~9999.9999 mm

(G96)

0~2000 feet/min

(G97)

0~20000 r/min

(ISB system)

0.01~2400 inch/min

(ISC system)

0.01~960 inch/min

(ISB system)

0.01~9.99inch/r

(ISC system)

0.01~9.99 inch/r

(ISB system)

-9999.9999~9999.9999inch

-999.99999~999.99999inch

(ISB system)

-9999.9999~9999.9999 inch

(ISC system)

-999.99999~999.99999 inch

(ISB system)

-9999.9999~9999.9999 inch

(ISC system)

-999.99999~999.99999 inch

(ISB system)

-9999.9999~9999.9999 inch

(ISC system)