Page 1

This user manual describes all particulars concerning the operation of

the system in detail as much as possible. However, it is impractical to

give special descriptions of all unnecessary and/or unavailable

operations of the system due to the manual content limit, product

specific operations and other causes. Therefore, the operations not

specified herein may be considered impractical or unavailable.

This user manual is the property of GSK CNC Equipment Co., Ltd. All

rights are reserved. It is against the law for any organization or

individual to publish or reprint this manual without the express written

permission of GSK and the latter reserves the right to ascertain their

legal liability.

Page 2

GSK983T Turning CNC system User Manual

Foreword

Dear user,

We are really grateful for your patronage and purchase of this GSK983T Turning

CNC system made by GSK CNC Equipment Co., Ltd.

This user manual includes Volume Ⅰand Volume Ⅱ, Volume Ⅰ

mainly decribes the system programming and specifications, Volume Ⅱ

mainly decribes operations, codes, parameters etc. as well as

appendix.(This book is Volume Ⅱ.)

This system can only be operated by authorized and qualified personnel as

improper operations may cause accidents. Please carefully read this user

manual before usage!

All specifications and designs herein are subject to change without further notice.

This manual should be reserved by final user.

Chinese version of all technical documents in Chinese and English languages is

regarded as final.

We are full of heartfelt gratitude to you for supporting us in the use of GSK’s

products.

Technical Spot Service

You can ask for spot service if you have the problems that can’t be solved by

telephone. We will send the authorized engineers to your place to resolve the

technological problems for you.

II

Page 3

Volume Ⅱ Contents

CONTENTS

CHAPTER 4 OPERATION ........................................................................................................................... 1

4.1 Power On/Off......................................................................................................................................1

4.1.1 Power on .................................................................................................................................1

4.1.2 Power off .................................................................................................................................1

4.2 Key switch...........................................................................................................................................1

4.3 Control Operations on Panel.............................................................................................................2

4.3.1 Operation panel......................................................................................................................3

4.3.2 Emergency stop .....................................................................................................................3

4.3.3 Mode selection .......................................................................................................................3

4.3.4 Operations related with manual operation .........................................................................4

4.3.4.1 Continuous Manual feed................................................................................................ 4

4.3.4.2 MPG .............................................................................................................................. 5

4.3.4.3 MANUAL ABSOLUTE ON/OFF................................................................................. 6

4.3.5 Manually returning to reference point ...............................................................................11

4.3.6 Operations on automatic running ......................................................................................11

4.3.6.1 Start of automatic running............................................................................................11

4.3.6.2 Dwell of automatic running......................................................................................... 12

4.3.6.3 Single block................................................................................................................. 13

4.3.6.4 Restart after feed hold or stop...................................................................................... 14

4.3.6.5 Manual operations in auto running.............................................................................. 14

4.3.6.6 MDI operations in auto running .................................................................................. 15

4.3.6.7 Skipping over optional blocks ..................................................................................... 15

4.3.6.8 Feedrate override......................................................................................................... 16

4.3.6.9 Dry run ........................................................................................................................ 16

4.3.6.10 Machine Lock............................................................................................................ 16

4.3.6.11 Auxiliary Lock........................................................................................................... 17

4.3.6.12 Rapid Override .......................................................................................................... 17

4.3.7 MPG Interruption..................................................................................................................18

4.3.7.1 Summary ..................................................................................................................... 18

4.3.7.2 MPG (manual pulse generator) interruption................................................................ 18

4.3.7.3 Movement of manual insertion.................................................................................... 18

4.3.8 Manual spindle function ......................................................................................................19

4.3.9 Interlocking switch of spindle feed axis ............................................................................20

4.3.10 Manual miscellaneous function .......................................................................................21

4.4 Operations and Display on MDI/LCD Panel....................................................................................22

4.4.1 Status display .......................................................................................................................26

4.4.2 Keys input display ................................................................................................................26

4.4.3 Display of program number and sequence numbers .....................................................27

4.4.4 Alarm display (functional key ALARM ) .........................................................................27

4.4.5 Operation information..........................................................................................................28

4.4.6 Current position display and reset (functional key POSITION ) ................................28

4.4.7 Display of command value (functional key COMMAND ) ...........................................30

4.4.8 Setting (functional key SETTING ) .................................................................................31

4.4.8.1 Display and setting of input, output, etc...................................................................... 31

4.4.8.2 Display and setting of user macro program variables ................................................. 33

4.4.9 MDI operation (functional key COMMAND ).................................................................34

4.4.10 MDI start and running .......................................................................................................35

4.4.11 Reset ...................................................................................................................................36

4.4.12 Setting and display of the tool offset, tool nose radius compenstation (functional key

offset )..............................................................................................................................................36

4.4.12.1 Absolute input ........................................................................................................... 36

4.4.12.2 Incremental input....................................................................................................... 38

4.4.12.3 Setting of tool figure and wear offset ........................................................................ 38

4.4.12.4 Offset of the workpiece coordinate system................................................................ 39

4.4.12.5 Direct measured value input of workpiece coordinate system offsetting .................. 41

4.4.12.6 Direct input of the tool offset .................................................................................... 42

III

Page 4

GSK983T Turning CNC System User Manual

4.4.12.7 Offset input by counter (optional)..............................................................................43

4.4.13 Program display (functional key PROGRAM )........................................................... 44

4.4.14 Program number search (functional key PROGRAM )............................................. 45

4.4.15 Program input .................................................................................................................... 46

4.4.16 Deletion of a program (functional key PROGRAM )................................................. 47

4.4.17 Deletion of all programs (functional key PROGRAM ) ............................................. 47

4.4.18 Sequence number search (functional key PROGRAM ).......................................... 47

4.4.19 Restart of a program......................................................................................................... 49

4.4.20 Comparison and Stop function for sequence number ................................................. 51

4.4.21 Display of parameters (functional key PARAMETER ) ............................................ 52

4.4.22 Program edit (functional key PROGRAM )................................................................. 52

4.4.22.1 Word scanning ...........................................................................................................52

4.4.22.2 Word search ...............................................................................................................53

4.4.22.3 Address search ........................................................................................................... 53

4.4.22.4 Methods for returning to the beginning of a program................................................ 53

4.4.22.5 Word insertion (active when the program lock is ON) ..............................................54

4.4.22.6 Word alteration (active when the program lock is ON) ............................................. 54

4.4.22.7 Insertion or alteration of words, blocks and strings...................................................54

4.4.22.8 Word deletion (active when the program lock is OFF)..............................................55

4.4.22.9 The deletion till EOB(active when the program lock is ON).....................................55

4.4.22.10 Deletion of blocks (active when the program lock is ON).......................................55

4.4.22.11 Memory sorting........................................................................................................ 55

4.4.22.12 Display of all stored program numbers....................................................................56

4.4.22.13 Edit of user macro program .....................................................................................56

4.4.23 Display of running time..................................................................................................... 57

4.4.24 Menu switch function ........................................................................................................ 58

4.4.25 Graphic function ............................................................................................................... 59

4.4.25.1 Function introduction................................................................................................. 59

4.4.25.2 Operations..................................................................................................................61

4.5 Display on Position Displayer (Optional) ...................................................................................... 64

Appendix 1 Codes for Programming .....................................................................................................65

Appendix 2 G Codes List ..........................................................................................................................66

Appendix 3 Range of Command Values ...............................................................................................68

Appendix 4 Calculation Chart..................................................................................................................70

Appendix 5 Parameters .............................................................................................................................74

Appendix 6 Alarm List .............................................................................................................................120

Appendix 7 State List of Power On Reset&Clearing........................................................................126

Appendix 8 Storage Type Pitch Error Compensation Function ...................................................127

Appendix 9 Operation List......................................................................................................................132

Appendix 10 Program Lock

....................................................................................................................135

Appendix 11 Interruption Function of User Macro Program .........................................................137

IV

Page 5

Volume Ⅱ Chapter 4 Operation

CHAPTER 4 OPERATION

4.1 Power On/Off

4.1.1 Power on

(1) Make sure all parts of the machine are properly wired and secured.

(2) Switch on the machine power by its manual.

(3) Pressing the “POWER ON” button and hold for 1 or 2 seconds, make sure there is display on

the screen after several seconds as switching on the machine power.

4.1.2 Power off

(1) It should be confirmed that the “CYCLE START” LED on the machine operator panel has

been gone out.

(2) All movable parts of the machine has been stopped.

(3) Press down and hold the POWER OFF button for 1 or 2 seconds.

(4) Cut off the power of the machine by following its manual.

Note 1: Never use the keys on the MDI keypad as powering on/off the machine.

Note 2: Power on after power off for 5 seconds。

4.2 Key switch

A key is available in this machine CNC operator panel.

Fig.4-1 Key switch

Some operation functions cannot be performed unless the key switch is actuated.

Operations that can or cannot be performed without actuating the key switch can be set by

parameter 10.6(SETE), which will be described in this chapter.

1

Page 6

GSK983T Turning CNC System User Manual

4.3 Control Operations on Panel

Fig.4-2 Operation panel

2

Page 7

Volume Ⅱ Chapter 4 Operation

4.3.1 Operation panel

The functions of the operation panel and the layout of switches on it vary depending on different

machine types, see machine user manual and the PLC manual of corresponding version for the

details.

The typical operation panel is shown in this manual(see the figure in previous page.)

4.3.2 Emergency stop

In an emergency situation, by pressing the EMERGENCY STOP button, the movements of all

the machine axes are stopped immediately. At the same time, the button keep self-locked in the stop

position.

Fig.4-3 Emergency stop

The release of the button varies with different machine manufacturers. Generally, it is released

by rotating the button clockwise.

Note 1: The enable of the motor is cut off when this button is pressed.

Note 2: The control unit is reset.

Note 3: Make sure all faults are eliminated before releasing this button.

Note 4: Perform the reference point return by manual operations or G28 code after this button is released.

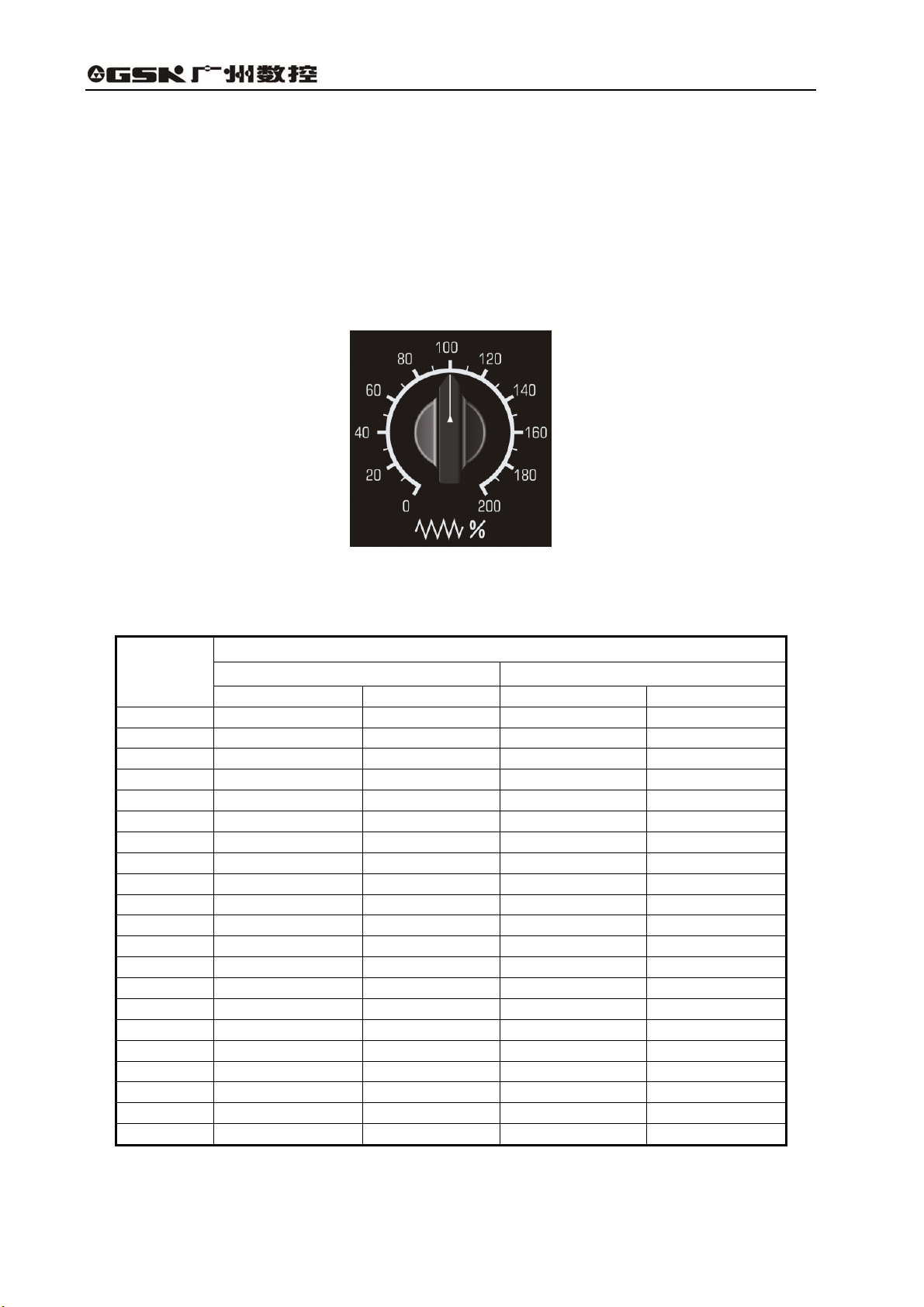

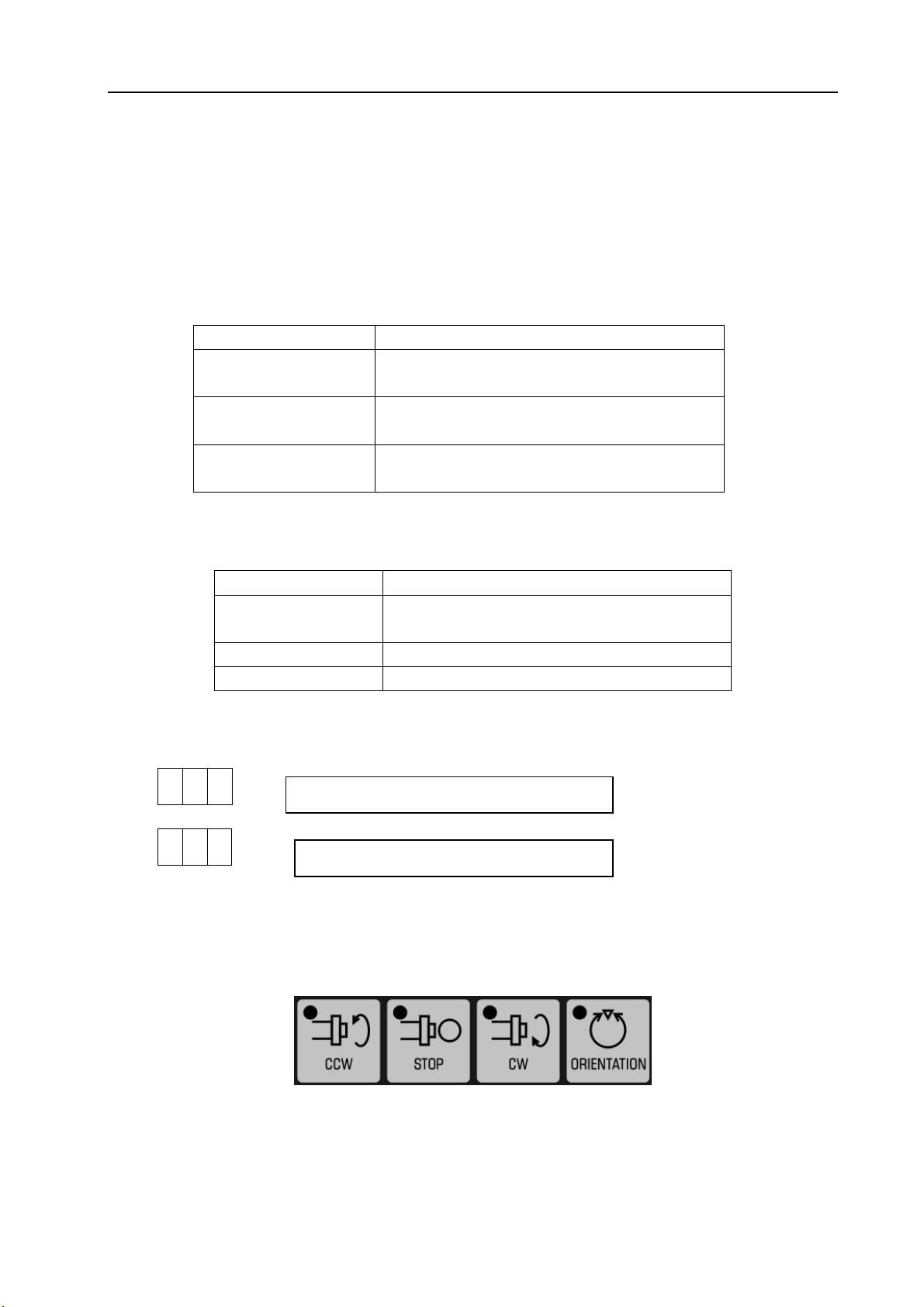

4.3.3 Mode selection

Operation modes available:

Fig.4-4 Mode selection

Table 4-1 Mode and Function

Mode Function

AUTO

EDIT

MDI MDI may be performed through MDI/LCD panel of the machine.

MANUAL For Jog feed

MPG For MPG feed

MACHINE ZERO For X, Z axes zero returns

(1) For execution of the programs in the memory

(2) For the program sequence number search in the memory

For the following program editing:

(1) Saving programs in memory;

(2) Altering, inserting and deleting programs;

(3) Outputting the programs in memory.

3

Page 8

GSK983T Turning CNC System User Manual

4.3.4 Operations related with manual operation

The following manual operations are available by the switches, keys, handwheel etc. on the

panel.

4.3.4.1 Continuous Manual feed

Continuous Manual feed can move the machine.

(1) Select the “Manual” mode;

(2) Select the feederate ( feederate switch is vaiable only when the rapid traverse switch is OFF).

Fig.4-5 Jog federate selection (mm /min )

Table 4-2 Jog federate

Switch

position

0 0 0 0 0

1 1.0 0.04 0.02 0.508

2 1.4 0.055 0.028 0.711

3 2.0 0.079 0.04 1.02

4 2.7 0.106 0.054 1.37

5 3.7 0.146 0.074 1.88

6 5.2 0.205 0.104 2.64

7 7.2 0.283 0.144 3.66

8 10 0.394 0.2 5.08

9 14 0.551 0.28 7.11

10 20 0.787 0.40 10.2

11 27 1.06 0.54 13.7

12 37 1.46 0.74 18.8

13 52 2.05 1.04 26.4

14 72 2.83 1.44 36.6

15 100 3.94 2.00 50.8

16 140 5.51 2.80 71.1

17 200 7.87 4.00 102

18 270 10.6 5.40 137

19 370 14.6 7.40 188

20 520 20.5 10.40 264

Note 1: The numerical values listed in above table vary with different machine builders.

Note 2; The error of the feedrates listed in the above table is approximately ±3%.

Lead screw for feed in metric system Lead screw for feed in inch system

mm /min Inch /min Inch /min mm /min

Jog feedrate

4

Page 9

Volume Ⅱ Chapter 4 Operation

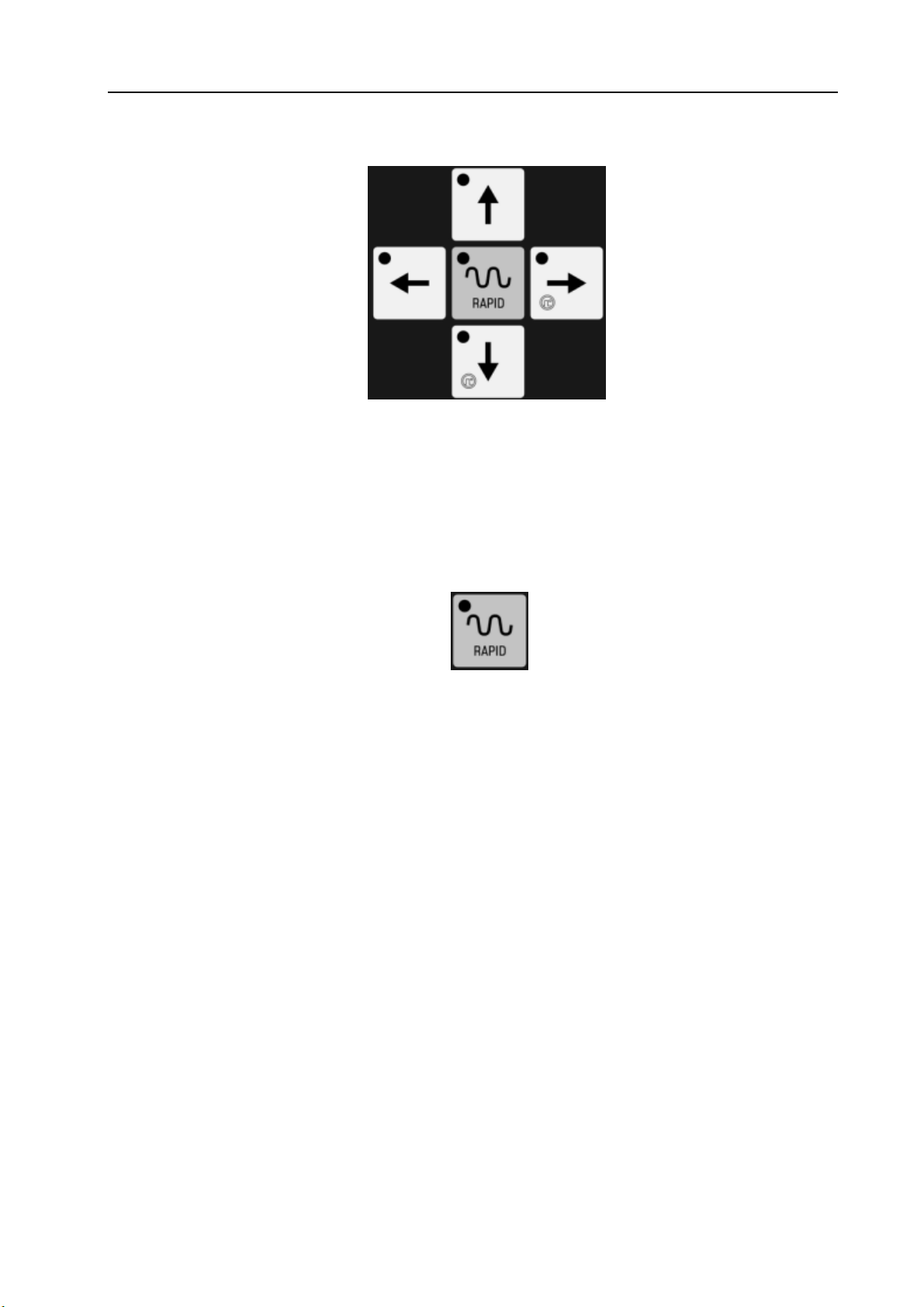

(3) Select the moving axis

Press the direction key corresponding to this axis, the tool moves in the selected direction.

Fig.4-6 Select the moving axis

Note1: Two axes can be controlled simultaneously by Manual operation.

Note2: After power on, if the tool don’t move by the selected axis even the Mode selection is preset to

“MANUAL” position with an axis selected. Now it is necessary to reselect an axis.

(4) Rapid traverse

An axis rapidly traverses in the selected direction when this key is pressed.

Fig.4-7 Rapid traverse

Note 1: The time constant and acceleration/deceleration mode for JOG rapid traverse are the same as

that of by G00 code ( it is set by machine tool manufacturer ).

Note 2: The federate of JOG rapid traverse can be set as 0.25 times ,0.5 times or 1 time of the speed

specified by G00. F0 is set by system parameter NO.113 ( it is set by machine tool

manufacturer ).

Note 3: When the machine has a storage type travel limit selecting function (parameter No.9.0 ISOT ), for

an axis with the function of reference point return, if the [RAPID] key is pressed after power on

or emergency stop, the feedrate will not change into rapid rate but maintain at a Jog feedrate

provided that the reference point return is not performed.

This is because storage type travel limit does not take effect before the manual reference point return,

thereby preventing the machine from quickly reaching the end of travel.

4.3.4.2 MPG

Accurate adjustment for the rate of the machine feed and move can be done with a manual pulse

generator(MPG).

(1) Select the MPG mode;

(2) Select a move amount

5

Page 10

GSK983T Turning CNC System User Manual

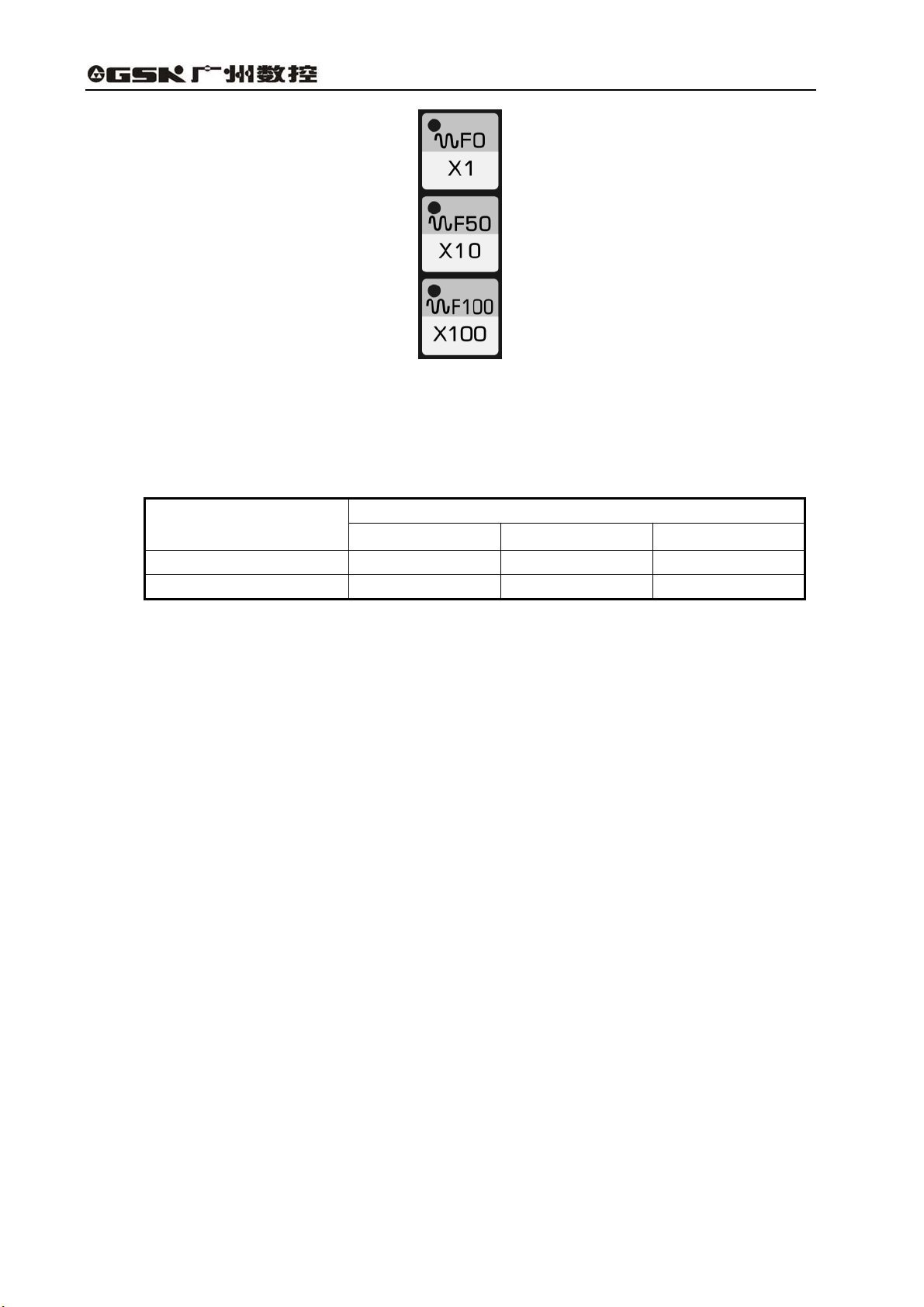

Fig.4-8

Amount of move: X 1 means move is multiplied by 1; while ×10 is by 10; while ×100 is by

100.

Table 4-3 Each step move amount

Input system

The move amount each step

×1 ×10 ×100

Metric system 0.001 mm 0.01 mm 0.1 mm

Inch system 0.0001 inch 0.001 inch 0.01 inch

(3) Select a move axis: press X or Z axis move key (either + or - direction)

(4) Turn the handwheel of the manual pulse generator.

Clockwise……………….+ direction

Counter clockwise………- direction

(The rotating direction depends on the settings of the machine builders)

Note 1; If the MPG rotates at a speed over 5 turns per second, the amount of the rotation of the MPG will

differ from the move distance of the machine. Hence do not rotate the MPG too quickly.

Note 2: Incremental feed function is not required if MPG is fixed on the machine.

Note 3: When ×100 override is selected and the MPG is turned at quick speed to make the tools or work table

move at “rapid traverse” rate, the machine will be subject to impact if it is stopped abruptly. The

selection automatic acceleration/deceleration function is also active for JOG feed, thereby it may

reduce mechanical shock.

Note 4: See section 4.3.7 for the MPG insertion function.

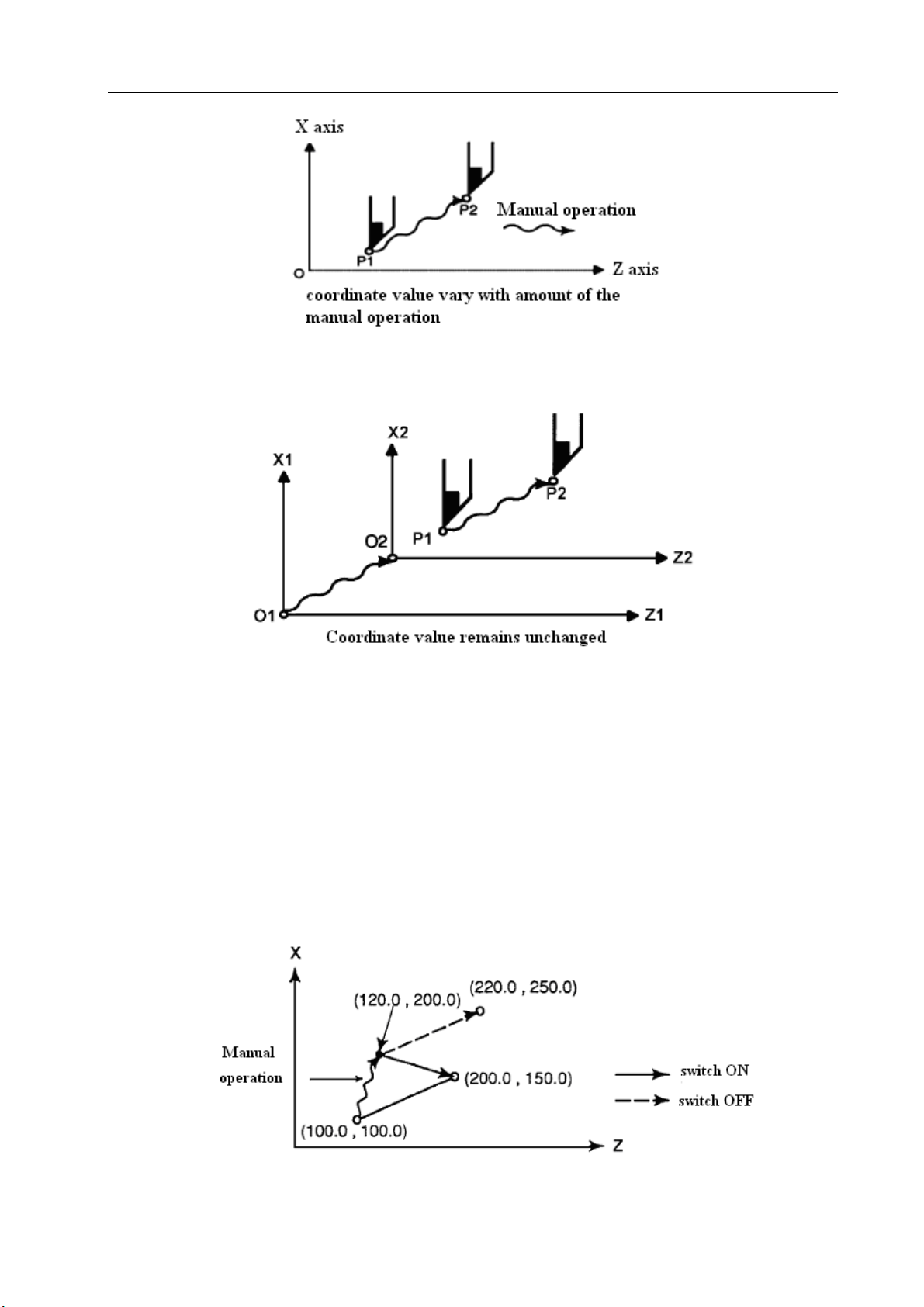

4.3.4.3 MANUAL ABSOLUTE ON/OFF

MANUAL ABSOLUTE ON/OFF is used to define whether the move amount because of JOG

operation is added to the automatic axis coordinate. When it is ON, the move amount is added to the

coordinate system, or else, not.

(1) MANUAL ABSOLUTE switch ON : Coordinates vary with the manual operation.

6

Page 11

Volume Ⅱ Chapter 4 Operation

Fig.4-9

(2) MANUAL ABSOLUTE switch OFF: Coordinates do not vary with the manual operation.

Fig.4-10

The following example shows the relationshiop between MANUAL ABSOLUTE ON/OFF and

coordinate:

G01 X100.0 Z100.0 F100; (1)

X200.0Z150 ; (2)

X300.0Z200.0 ; (3)

(A) Manual operation after block end

The manual operation (move by +20.0 in X direction and +100.0 in Z direction) will be

performed while the block (1) ends, and then block (2) will be executed.

Fig.4-11

7

Page 12

GSK983T Turning CNC System User Manual

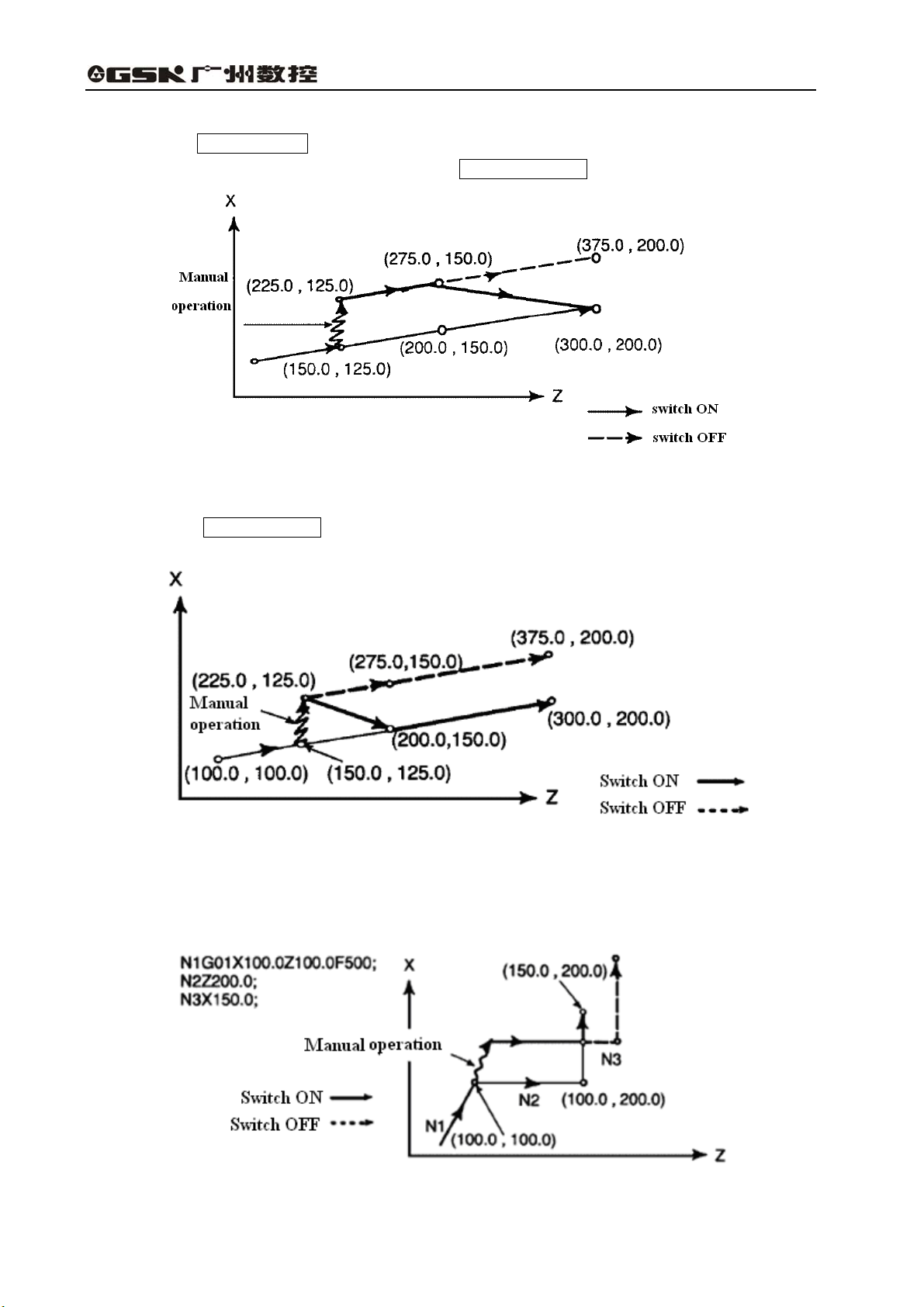

(B) Manual operation after FEED HOLD

Press the FEED HOLD key in the execution of the block (2). After manual operation (X+75.0),

re-execute the the coordinate value while pressing CYCLE START key .

Fig.4-12

(C) When Manual operation after FEED HOLD is followed by Reset

Press the FEED HOLD key in the execution of the block (2). Reset the machine and

re-execute the block (2) after manual operation (X+75.0).

Fig.4-13

(D) When a single axis is specified in the move command of the next block

When a single axis is specified in the following command, only the axis specified returns.

Fig.4-14

8

Page 13

Volume Ⅱ Chapter 4 Operation

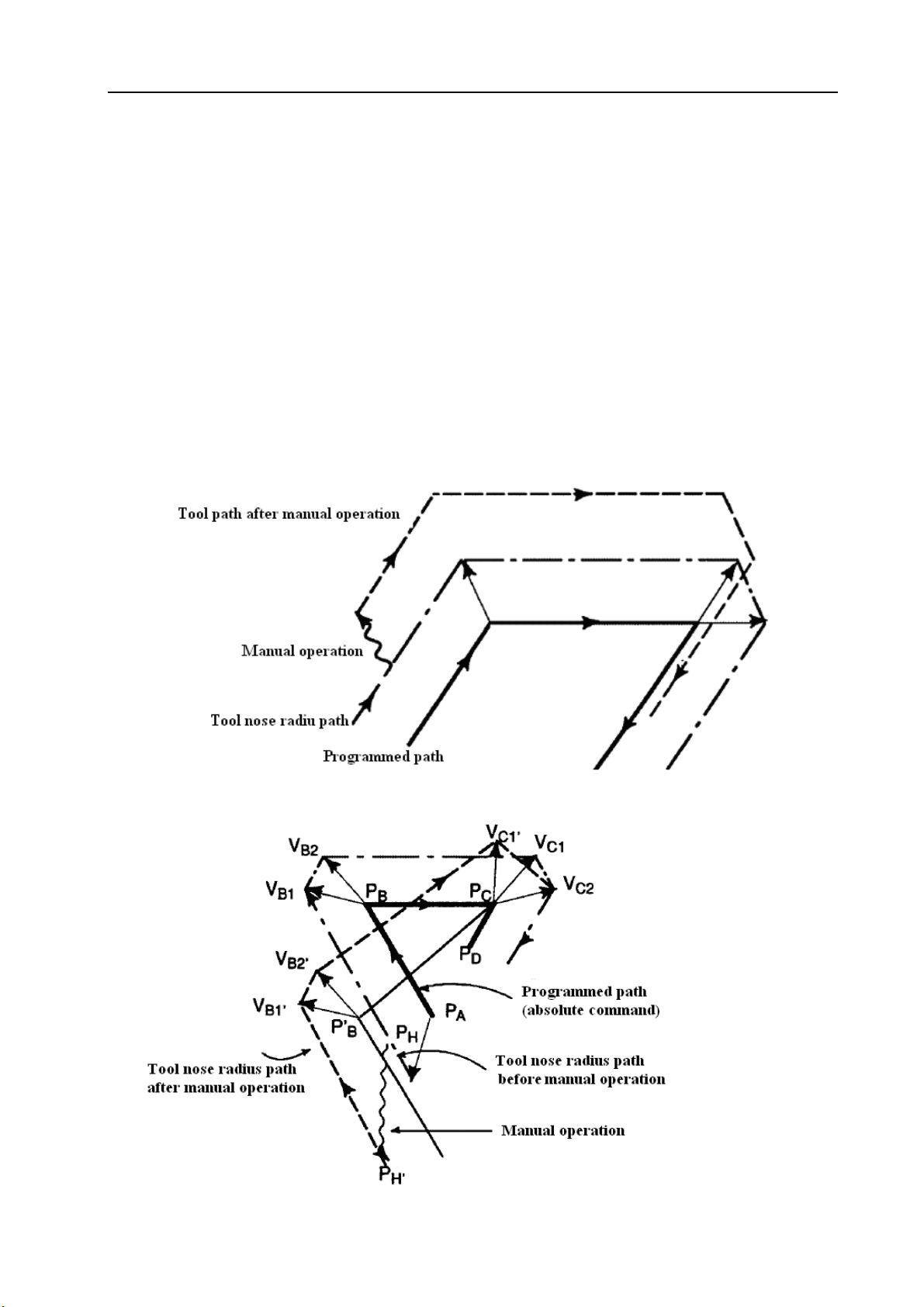

(E) Manual operation during tool nose radius compensation

When the next block is an incremental command, then the action is identical with that is

commanded while the MANUAL ABSOLUTE switch is set to ON or OFF.

(F) Manual operation during tool nose radius compensation

If MANUAL ABSOLUTE switch is switched OFF:

If manual operation is executed when MANUAL ABSOLUTE switch is switched off during tool

radius compensation, the tool will move along the tool path wihich parallel to that without manual

operation in the restarting auto mode. The parallel space equals to the move amount in manual

operation.

If MANUAL ABSOLUTE switch is switched ON:

If MANUAL ABSOLUTE switch is set for ON for manual operation in the tool nose radius

compensation mode, the automatic running path of the tool by absolute command after restart is as

follows. The vectors set in the rest of the block and the origin of the next block will be offset parallelly.

Tool path is determined by the vector between the next block and the block that follows as well as

the move amount generated by manual operation. This is also applicable for the case by manual

operation during corner.

Fig.4-15

Performing manual operation when no corner

Fig.4-16

9

Page 14

GSK983T Turning CNC System User Manual

In the above programmed path (PA→PB→PC→PD), the tool is moved from the point PH between

P

and PB to point PH′ by manual operation provided the FEED HOLD key is pressed. due to the

A

offset as a result of manual operation and the vectors VB1 and VB2 of point PB also offset to V

V

The vectors between the next block tha (tool path from PB to PC) and the one that follows (from PC

B2’.

) do not need compensation. The new vectors VC1′ and VC2′ will be generated according to the

to P

D

B1’

and

relationship between the two blocks (in this example VC1′ =VC2′). Since vector VB2′ is not

re-calculated, however, the section of path between PB’ and PC as a result of tool offset is not

accurately performed. But for the block after point P

, tool nose compensation can be precisely

C

performed.

Performing manual operation during the executin of corner

Fig.4-17

The above figure is an example for the manual operation during execution of corner. the vector

V

, V

A2′

and V

B1′

in above figure respectively parallel to the vectors VA2, VB1 and VB2 by a jog move

B2′

amount. And the new vectors is generated according to VC1 and VC2′. The blocks after point P

be precisely executed by the tool nose radius compensation

Manual operation after single block end

will

C

10

Fig.4-18

Page 15

Volume Ⅱ Chapter 4 Operation

Perform the manual operation after the execution of a single block,

If manual operation is performed after the execution of a single block, the vectors VB1 and VB2

offste the move amount by JOG operation. And the method for the following tool path is identical with

that mentioned above. MDI operation may be inserted just like the JOG operation. The tool path after

MDI operation coincides with that after the insertion of a manual operation.

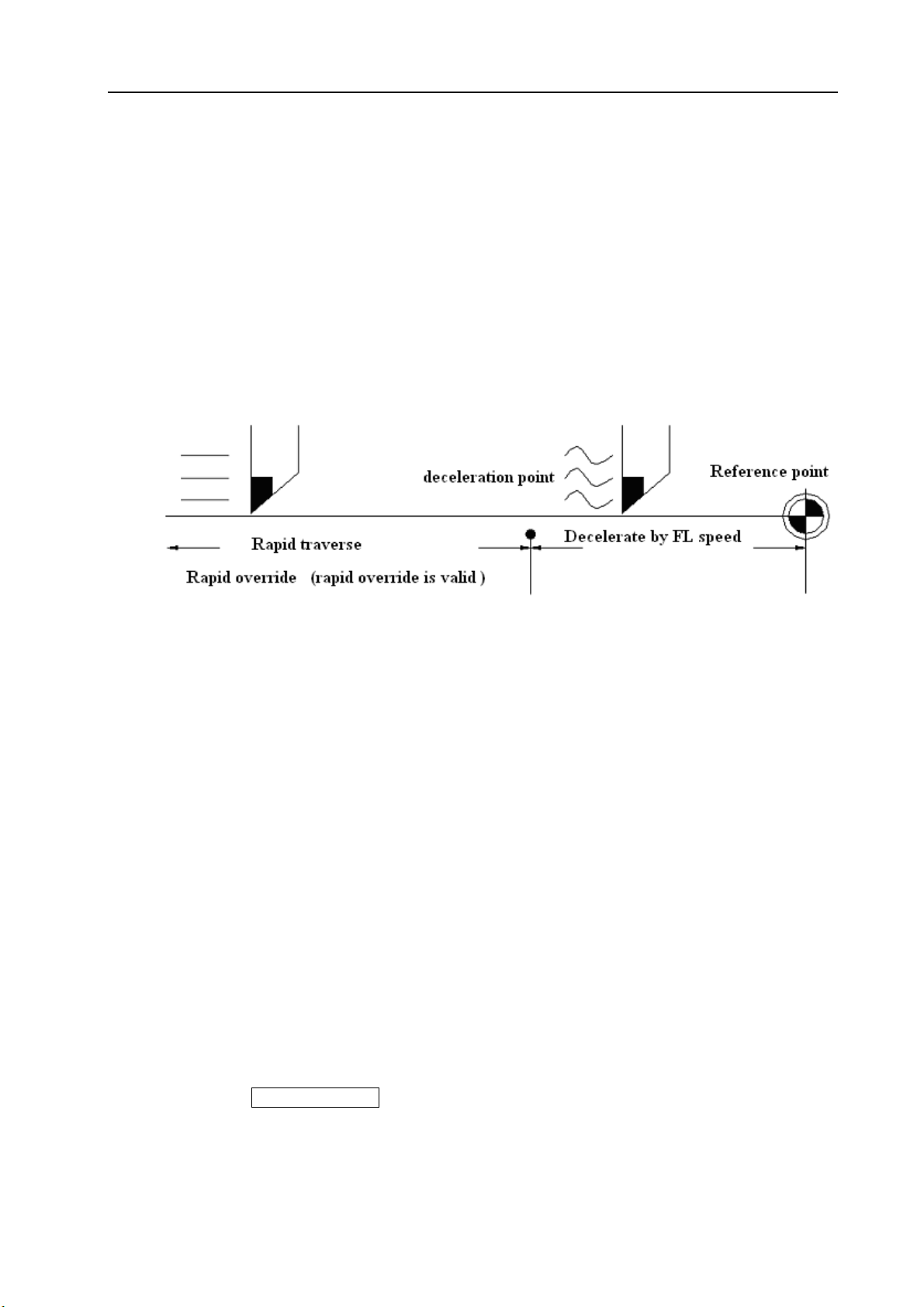

4.3.5 Manually returning to reference point

The tool may be returned to the reference point by manual operation:

(1) Select “MACHINE ZERO” mode;

(2) Press ”ZERO” axial direction key, the machine enter zero self-insurance state and the state will

not be cancelled until arrive at the reference point, of course, the state also can be cancelled by

pressing EMERGENCY or RESET key in the midway.

Fig.4-19

Note: The speed of FL is set by parameter No.114 ( set by machine manufacturer)

(3) The machine stops at the reference point indicating the end of the return and the LED lights

for X ZERO/Z ZERO on the panel light up.

Note 1: The following procedures may set the LED light for the reference point return over to OFF:

(1)Move away from the reference point.

(2)Enter emergency stop state.

(3)Servo alarm.

Note 2: For the distance to the reference point return, please refer to machine user manual issued by

machine tool manufacturer.

4.3.6 Operations on automatic running

The machine may operate automatically by commands. The steps are as following:

4.3.6.1 Start of automatic running

Procedures for starting the program stored in memory:

(Ⅰ) Select the program number, see Section 4.4.14 “ program number search”;

(Ⅱ) Select the AUTO mode;

(Ⅲ) Press the CYCLE START key.

11

Page 16

GSK983T Turning CNC System User Manual

Fig.4-20 Cycle Start

Automatic running starts once the CYCLE START key is pressed. And the LED light for

CYCLE START lights up.

Note: The CYCLE START key is inactive or cancelled in the following conditions:

(a) When the FEED HOLD key is pressed;

Fig.4-21 Feed Hold

(b) When the EMERGENCY STOP button is pressed;

(c) When the RESET signal is enabled (contact the machine builder for details);

(d) When the “Mode selection” button is set to a wrong position (except AUTO, DNC and MDI

modes);

(e) When it is searching a sequence number;

(f) When an alarm is given;

(g) When automatic running is being performed (not in feed hold or stop state);

(h) When the NC system is not ready.

4.3.6.2 Dwell of automatic running

Press FEED HOLD key:

The CYCLE START LED light is gone out and the FEED HOLD LED light lights up when the

FEED HOLD key is pressed. Now:

(I) If the tool is moving, the feed slows down and stops;

(II) If the machine is in G04 dwell state, the dwell state will not continue ;

(III) The machine stops after the of M, S, T codes are executed.

Note: In case of the thread cutting commanded by G32, G34, G76 or G92 (special G code B: G33, G34,

G76 or G78; special G code C: G33, G78 or G21), even the FEED HOLD key is pressed, the

feeding will not stop until the cutting is finished.However, if the FEED HOLD key is pressed as

the thread cutting cycle is being executed, the tool retractes by slant and returns to the start point

of cycle.

12

Page 17

Volume Ⅱ Chapter 4 Operation

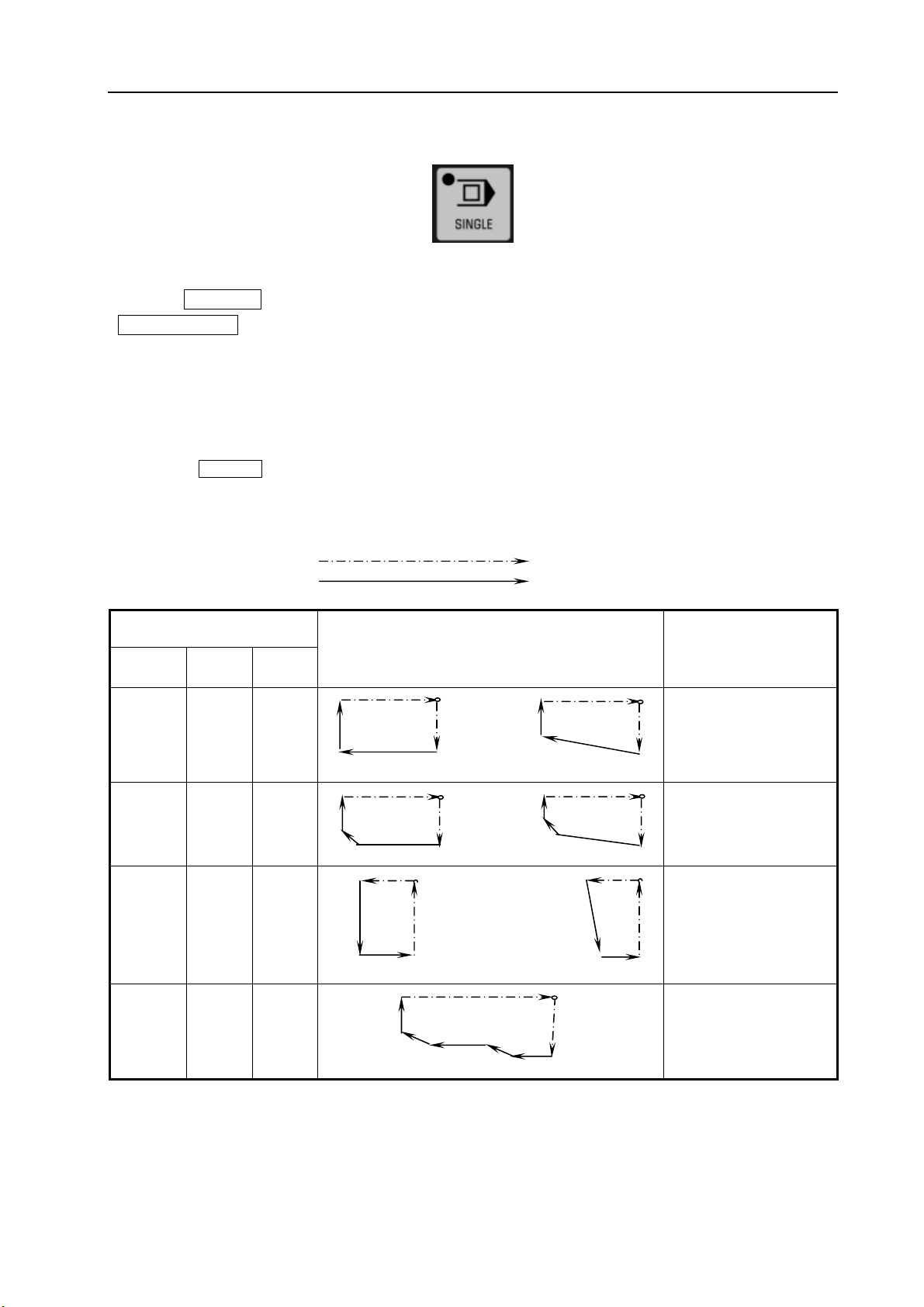

4.3.6.3 Single block

Fig.4-22 Single block

If the SINGLE key is pressed, the control only executes a block and stops each time when the

CYCLE START key is pressed .

(1) reference point return and single block commands

If the reference point return commands G28~G30 are executed, the single block is enabled at

the intermediate

(2) single block during canned cycle

The stop points of the single block In the canned cycle are as follows:

If the SINGLE key is pressed, the actual running paths for the canned cycle G90, G92,G94 or G70~G76

(special G code B: G77, G78, G79 and G70~G76; special G code C: G20, G24, G21 and G72~G78) are as

following:

Rapid traverse

Feeding

point.

Table 4-4 Tool path

G code

Standard

G90 G77 G20

G92 G78 G21

G94 G79 G24

G70 G70 G72

Special B Special

C

Tool path Explanation

4 4

3 1 3

1

2 2

Assuming tool path from

segment 1 to 4 is a cycle,

and it stops when the

segment 4 is finished

4 4

3 1 3

As above

2 2

1 1

2 4 2

As above

4

3 3

7

1

5

6

4

3

2

Assuming tool path from

segment 1 to 7 is a cycle,

and it stops when each

7-segment is finished

13

Page 18

GSK983T Turning CNC System User Manual

G71

G72

G71

G72

G73

G74

Note The path in this figure is all the same for

G71 or G72 code.

G73 G73 G75

G74

G75

G74

G75

G76

G77

Note The path in this figure is all the same for

G74 or G75 code.

3

7

11

15

4

2

8

6

12

10

16

19

14

19

1

5

9

13

17

Assuming tool path from

segment from 1 to 4, 5 to

6, 9 to 12, 13 to 16, 17 to

20 is a cycle, and it stops

when each cycle is

finished.

6

5

4

3

1

2

Assuming tool path from

segment 1 to 6 is a cycle,

and it stops when each

6-segment is finished.

9

8

5

7

6

4

10

1

3

2

Assuming tool path from

segment 1 to 10 is a

cycle, and it stops when

the segment 10 is

finished.

G76 G76 G78

4

3

1

2

Assuming tool path from

segment 1 to 4 is a cycle,

and it stops when each

4-segment is finished.

(3) Subprogram calling and single block running

For the blocks of M98P__, M99, G65, G66 or G67, the stop of the single block is inactive. However, it is

active if the addresses other than O, N, L and P codes are commanded together with M98 or M99 code.

4.3.6.4 Restart after feed hold or stop

(1) Select the AUTO or MDI mode in the feed hold;

(2) Press the CYCLE START key. The FEED HOLD indicator light is gone out and CYCEL

START indicator light lights up.

4.3.6.5 Manual operations in auto running

In auto run, make the operation to pause by pressing the FEED HOLD key or the SINGLE

key on the operation panel.

(1) Record the coordinates of the stop position displayed by the position display unit.

(2) Perform manual operation (see Section 4.3.4).

(3) Return the tool to the recorded coordinates (the start point of manual operation).

(4) Set the working and mode to be that before manual operation so as to restart auto

running.

(5) Press the CYCLE START key.

14

Page 19

Volume Ⅱ Chapter 4 Operation

4.3.6.6 MDI operations in auto running

(1) Press the SINGLE key, the single block is active, execute a block and stop;

(2) Select “ MDI ” mode;

(3) Perform MDI operation;

(4) Select the primary working and mode and press the CYCLE START key on the

operation to restart auto running

Note 1: The MDI command is influenced by modal data reserved in auto running.

Note 2: The modal data commanded by MDI will be active in auto running.

Note 3: Tool nose radius compensation R is unallowed in MDI operation.

Note 4: The auto running will be paused if FEED HOLD button is pressed in the execution of a block, and it

cann’t be restarted by MDI command.

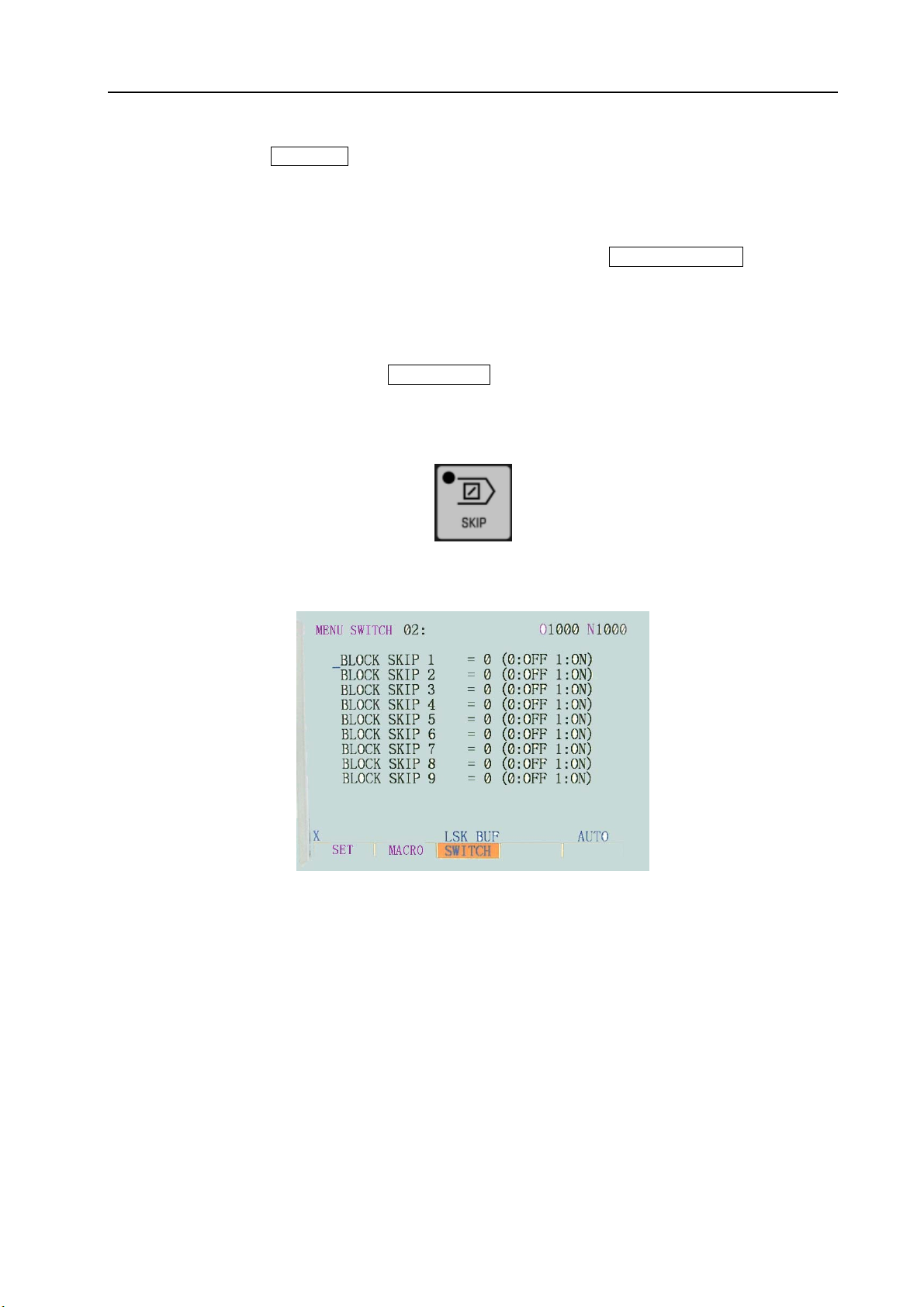

4.3.6.7 Skipping over optional blocks

Fig.4-23 Skip block

This function is used to make the control to skip over the block headed with “/”.

Fig.4-24

When the “/” is defined to be followed by a numeral, and the BLOCK SKIP SWITCH on the

operator panel of machine is set to “ON”, in the memorizer working, the information is ignored which

is contained in the block /n corresponding to the specified BLOCK SKIP number n.

When the BLOCK SKIP SWITCH on the operator panel of machine is set to “OFF”, the

information of the block specified by /n is active. That means the operater can determine whether to

skip over the block containing /n.

The 1 in the character /1 can be ignored. However, if two or more BLOCK SKIP SWITCH are

used for one block,it can not be ignored.

Example:

( incorrect ) ( correct )

//3G100×10.0; /1/3G00×10.0;

The function is ignored when the program is inputed into the memory, and the block containing

/n is stored into it regardless of the setting of BLOCK SKIP SWITCH.

15

Page 20

GSK983T Turning CNC System User Manual

The block stored in the memory can be outputed regardless of the setting of BLOCK SKIP

SWITCH. The BLOCK SKIP is active even in the operation of sequence search.

The number of BLOCK SKIP SWITCH on the operator panenl is different for different machines,

for the details, please see the machine user manual. The BLOCK SKIP on the operator panle is

generally set to be BLOCK SKIP 1.

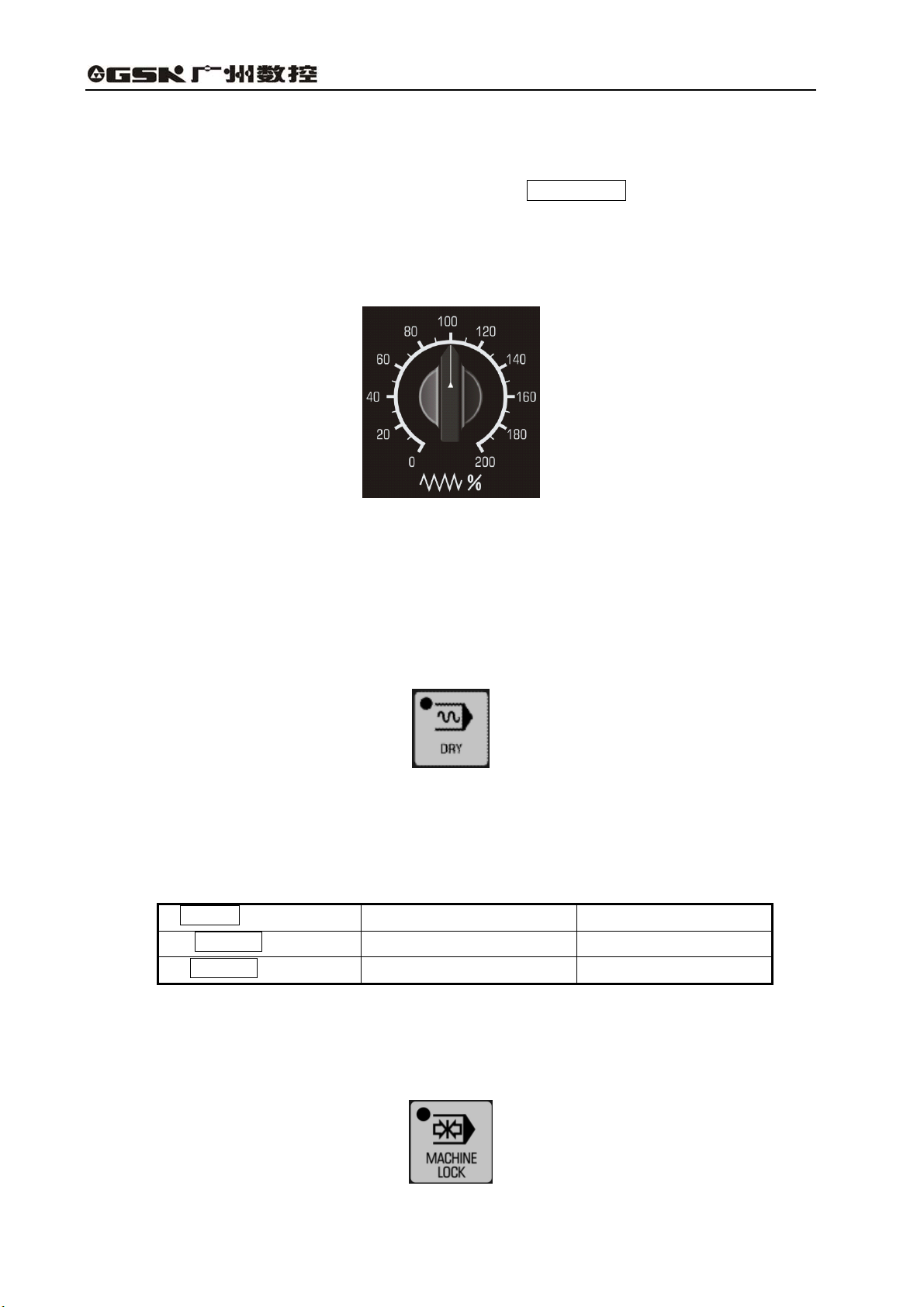

4.3.6.8 Feedrate override

The programmed feedrate may be multiplied by override.

Fig.4-25 Feedrate override

The programmed feederate multiplied by the override 0~200% of corresponding scale and the

increment is 10%.

Note 1: This switch is used together with the JOG feedrate for some machine builders.

Note 2: This switch is inactive in thead cutting and its override is usually 100%.

4.3.6.9 Dry run

Fig.4-26 dry run

If the dry run is active in the cycle running in the memory or commanded by MDI, then F function

is disenabled, and the control may move at the following speed:

Table 4-5

RAPID key ON/OFF

RAPID key ON

RAPID key OFF

Note 1: Wether the dry run is enabled in the rapid feed is set by parameter No.6.0 (RDRN).

Note 2: Wether the dry run in threading is disabled or enabled is set by parameter No.8.0 (TDRN).

Rapid traverse Cutting feed

Rapid traverse Maximum Jog feedrate

Jog feedrate (see Note ) Jog feedrate

4.3.6.10 Machine Lock

16

Fig.4-27 Machine lock

Page 21

Volume Ⅱ Chapter 4 Operation

When the MACHINE LOCK switch on the frame is set to be “ON” or that on operator panel is

active, the move command pluse will be repressed. Therefor, the position display of feed cycle start

or manual operation will be refreshed by the command inputed, however, the carriage doesn’t move

in the program execution, and the machine coordinates don’t change either. This function is used to

check program.

Note 1: When G27, G28 or G30 command is set, the machine will not return to the reference point. Hence the

indicator light for reference return is not lit up.

Note 2; M, S, T functions are performed.

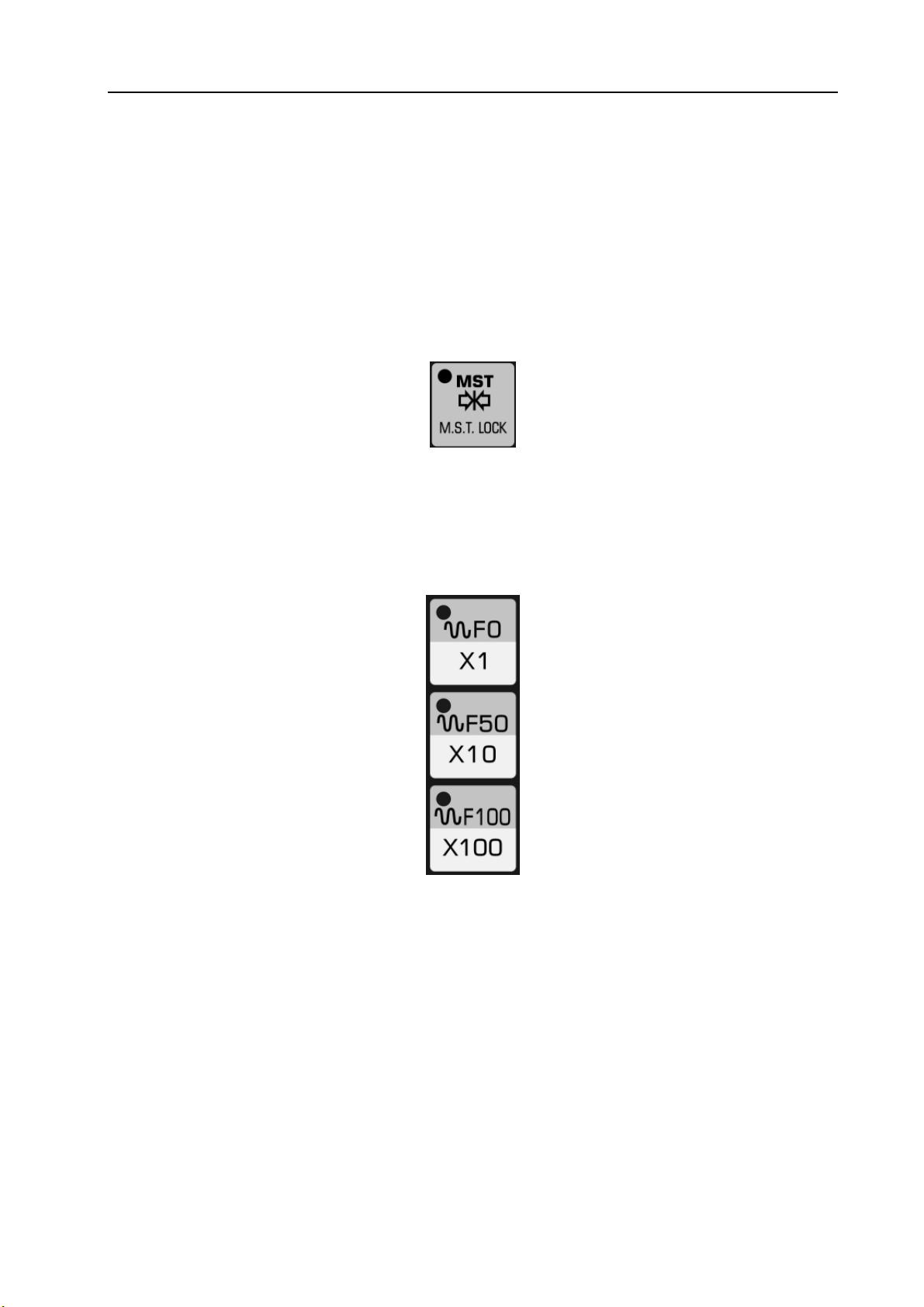

4.3.6.11 Auxiliary Lock

Fig.4-27 Auxiliary Lock

When the AUXILIARY LOCK is ON, the machine carriage moves normally, but the M,S,T function

is not performed, this function is used to check program.

4.3.6.12 Rapid Override

Fig.4-28 Rapid Override

The rapid overrides F0, 50%, 100% are available on the operation panel of the machine. If the

rapid rate is 10m/min, and the override is 50%, then the rate becomes to be 5m/min. F0 is a fixed

speed (feedrate) specified by the machine builder.

This override applies to the following conditions:

(1) Determine the rapid rate of G00;

(2) Determine the rapid rate in canned cycles;

(3) Determine the rapid rate in G27, G28, G29 and G30 modes;

(4) Determine Jog rapid rate;

(5) Determine the rapid rate in manual reference point return.

17

Page 22

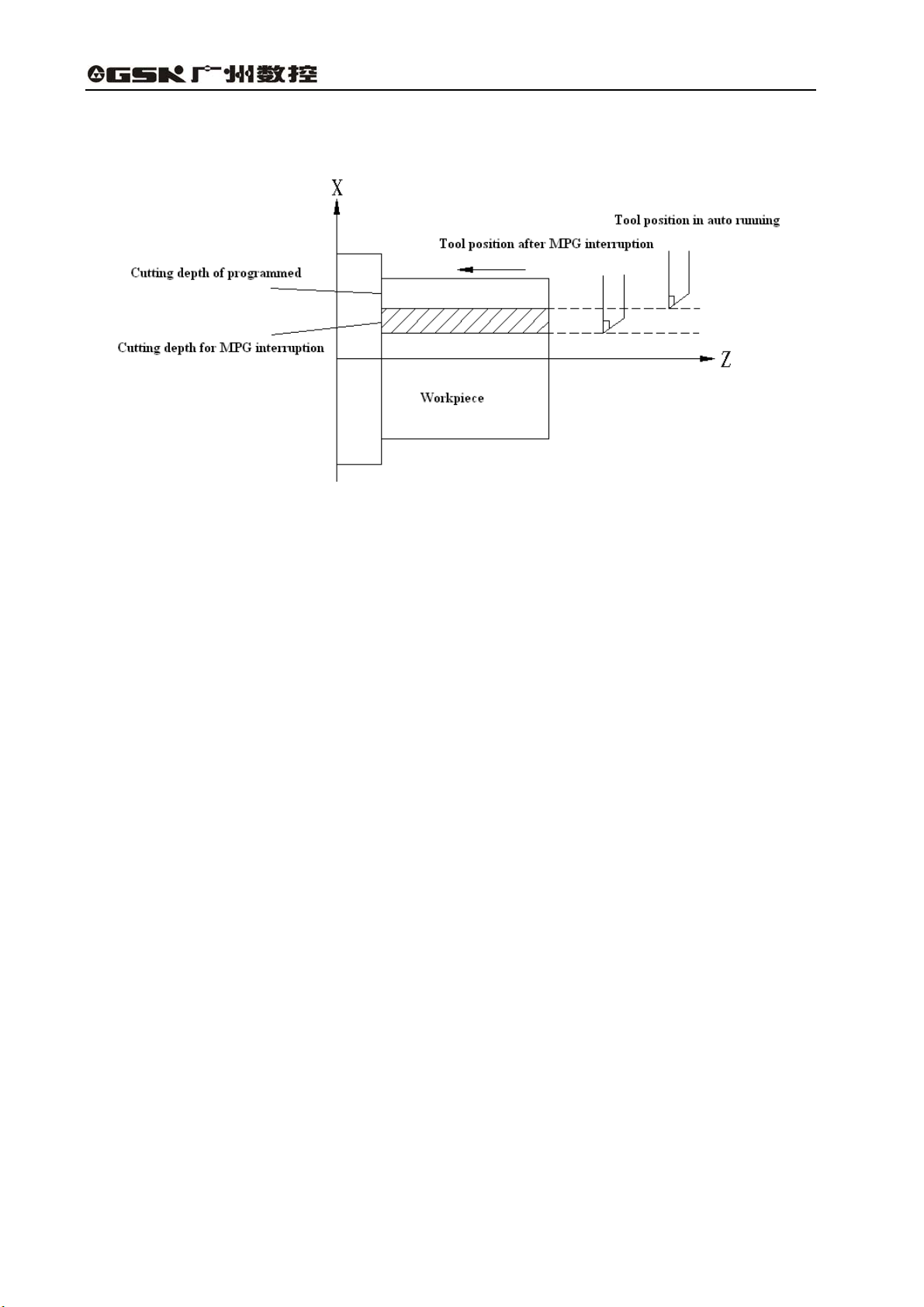

4.3.7 MPG Interruption

GSK983T Turning CNC System User Manual

Fig. 4-29

4.3.7.1 Summary

For the specific axis (set by parameter No.314.0 和 No.314.1) in auto running, it may be moved

manually by handwheel (MPG) to overlap the path in the auto running.

4.3.7.2 MPG (manual pulse generator) interruption

Manual interruption can be performed by turning the manual pulse generator in the following

conditions.

(1) Auto mode or MDI mode.

(2) Operating state: Manual insertion is possible during auto running and linear interpolation, arc

interpolation.

However, the following conditions are excluded:

(Ⅰ)When an alarm is being given;

(Ⅱ)When machine lock is active;

(Ⅲ)When positioning is valid;

(Ⅳ)When interlocking is valid;

(Ⅴ)No move command.

(3) Manual axis selection signal

Manual axis selection signals (HX , HZ) are powered up (contacts making) for the axis to perform

manual insertion.

4.3.7.3 Movement of manual insertion

(1)Amount of move

The amount of move by manual insertion is identical with that of the MPG feed. The amount of

move depends on the scale of the manual pulse generator and manual feed overrides (X1, X10 and

X100) and is added to that of automatic running.

18

Page 23

Volume Ⅱ Chapter 4 Operation

(2)Move speed:

The axial speed for manual insertion is the result of the addition of the move speed of auto

running to that by manual insertion. Therefore, axial speed will be limited to rapid traverse rate

(parameter #92(RPDFX)and #93(RPDFX)) in the event that axial speed exceeds rapid traverse rate.

Because the distance whose speed exceeds the rapid traverse rate is lost, the scale value displayed

on the MPG is invalid.

(3)The relations of manual insertion to various signals are as the following table:

Table 4-6

Signal Move

Machine locked

Displayed locked

Mirror image of X axis

(4)The relations of manual insertion to various signals are as following table:

It is affected, that is, the tool does not move if the

machine is set to ON

It is affected, that is, the relative coordinate does

not change if the display is locked

It is not affected, that is, machine moves positively

if hand disk is rotated in positive direction

Table 4-7

Display Move

Absolute coordinates

Not affected: Manual-inserted pulse is not added

to absolute coordinates

Relative coordinates Affected: Manual-inserted pulse is added

Machine coordinates Affected: Manual-inserted pulse is added

(5)Display of move amount

Move amount by manual insertion may be displayed by(DGNOS)key.

8 0 5

Manual-inserted move amount of Axis X

8 0

6

Manual-inserted move amount of Axis Z

Unit: 0.001mm (metric system)

0.0001inch(inch system)

Note: The move amounts may be cleared by clearing operation.

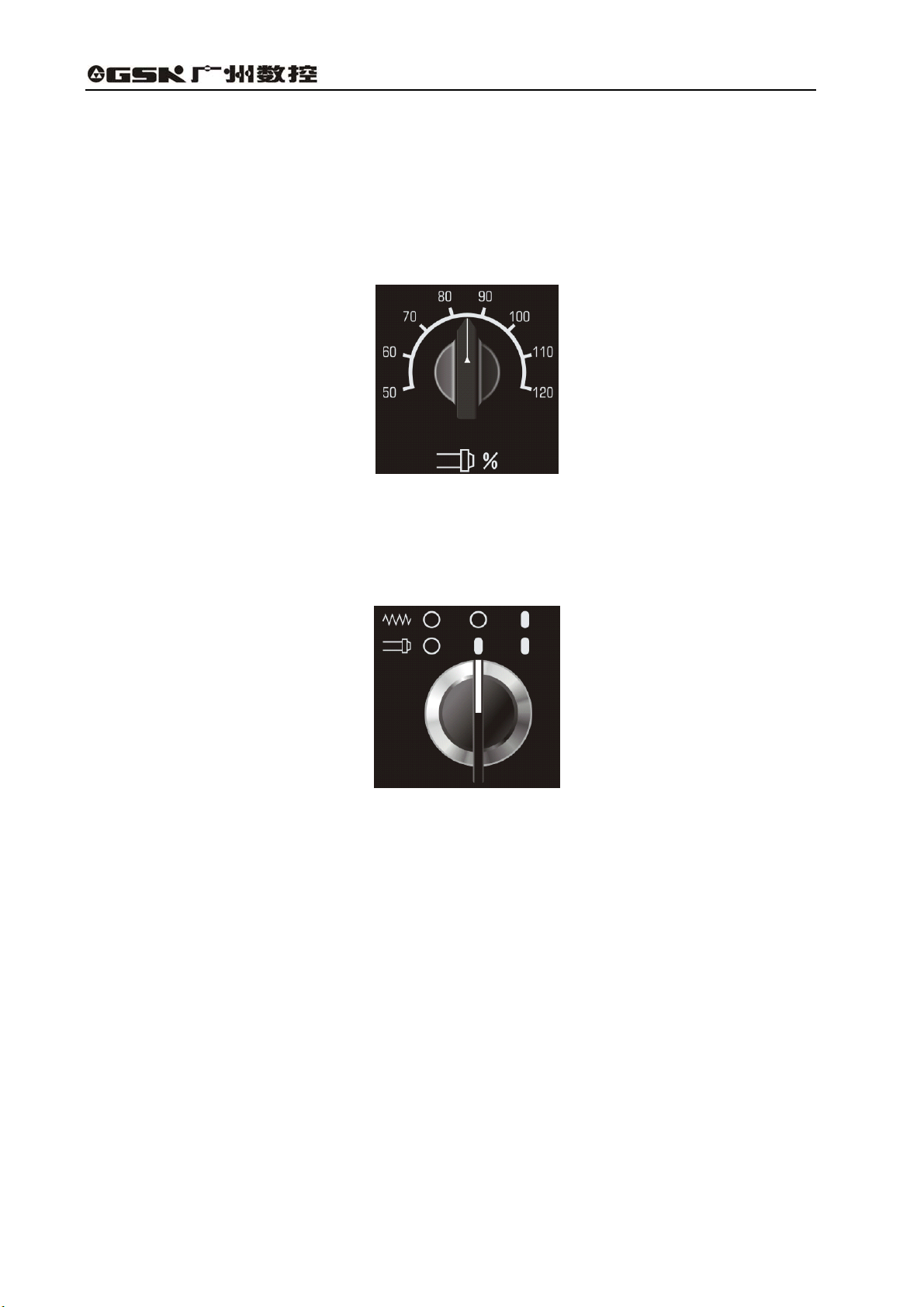

4.3.8 Manual spindle function

Fig. 4-29

Press SPINDLE CCW key in manual mode, spindle rotates CCW.

Press SPINDLE STOP key in manual mode, spindle decelerates to stop.

Press SPINDLE CW key in manual mode, spindle rotates CW.

19

Page 24

GSK983T Turning CNC System User Manual

Note:Actual rotational direction of spindle is different for various machines, please refer to machine tool builder’ s

manual.

Spindle orientation:Because the machine is matched with servo spindle driver, the system will send

orientation start signal to servo driver by pressing Spindle Exact Stop key in Manual mode or Auto, MDI

command M19. After spindle orientation is performed in the driver, completion signal is sent to CNC, and the

spindle orientation is finished. This function is used mainly for tool shifting and hole boring.

Spindle speed override:

Fig. 4-30

Spindle speed override can be adjusted from 50% to 120% by this switch.

4.3.9 Interlocking switch of spindle feed axis

Fig. 4-31

Position with 0 is OFF, and 1 is ON. In any states:

When feed axis and spindle are ON, feed axis and spindle interlocking are invalid.

When feed is off and spindle is ON, feed axis interlocking is valid and spindle interlocking is invalid. No.

2001 prompt appears in screen external information.

When feed axis and spindle are OFF, feed axis and spindle interlocking are valid. No. 2002 prompt

appears in screen external information.

20

Page 25

Volume Ⅱ Chapter 4 Operation

4.3.10 Manual miscellaneous function

Fig. 4-32

The functions and execution logic of these keys are defined by PLC programming. Please refer to

corresponding version of PLC manual. They control ON and OFF of each machine part separately. Usually,

press ON first and then press OFF. The functions of USER1~USER10 keys are not defined, which can be

defined according to user requirements.

Fig. 4-33

Tool shift key can be used for adjustment of manual tool change. Please refer to corresponding version of

PLC manual for details.

LED displays current tool No..

21

Page 26

GSK983T Turning CNC System User Manual

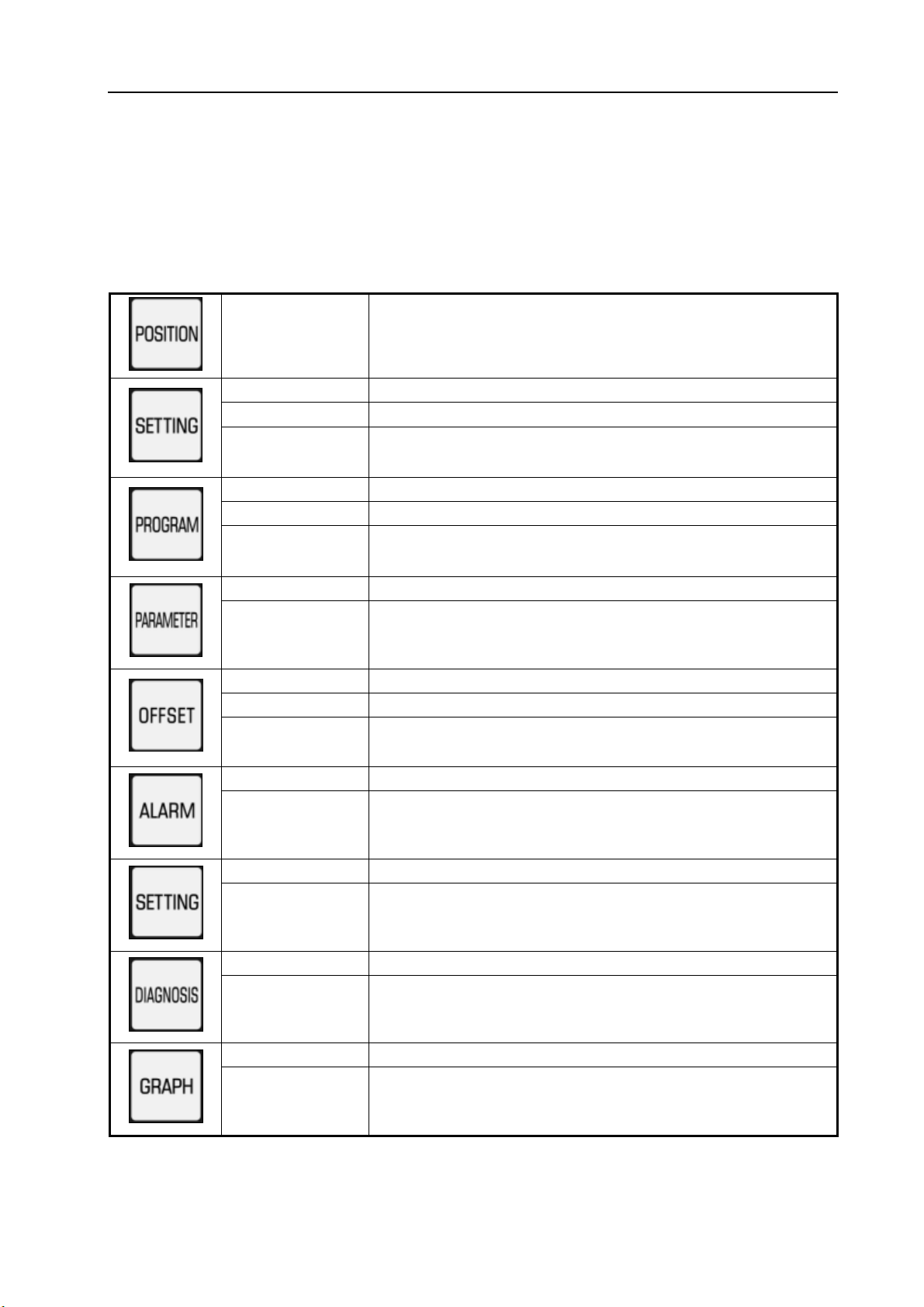

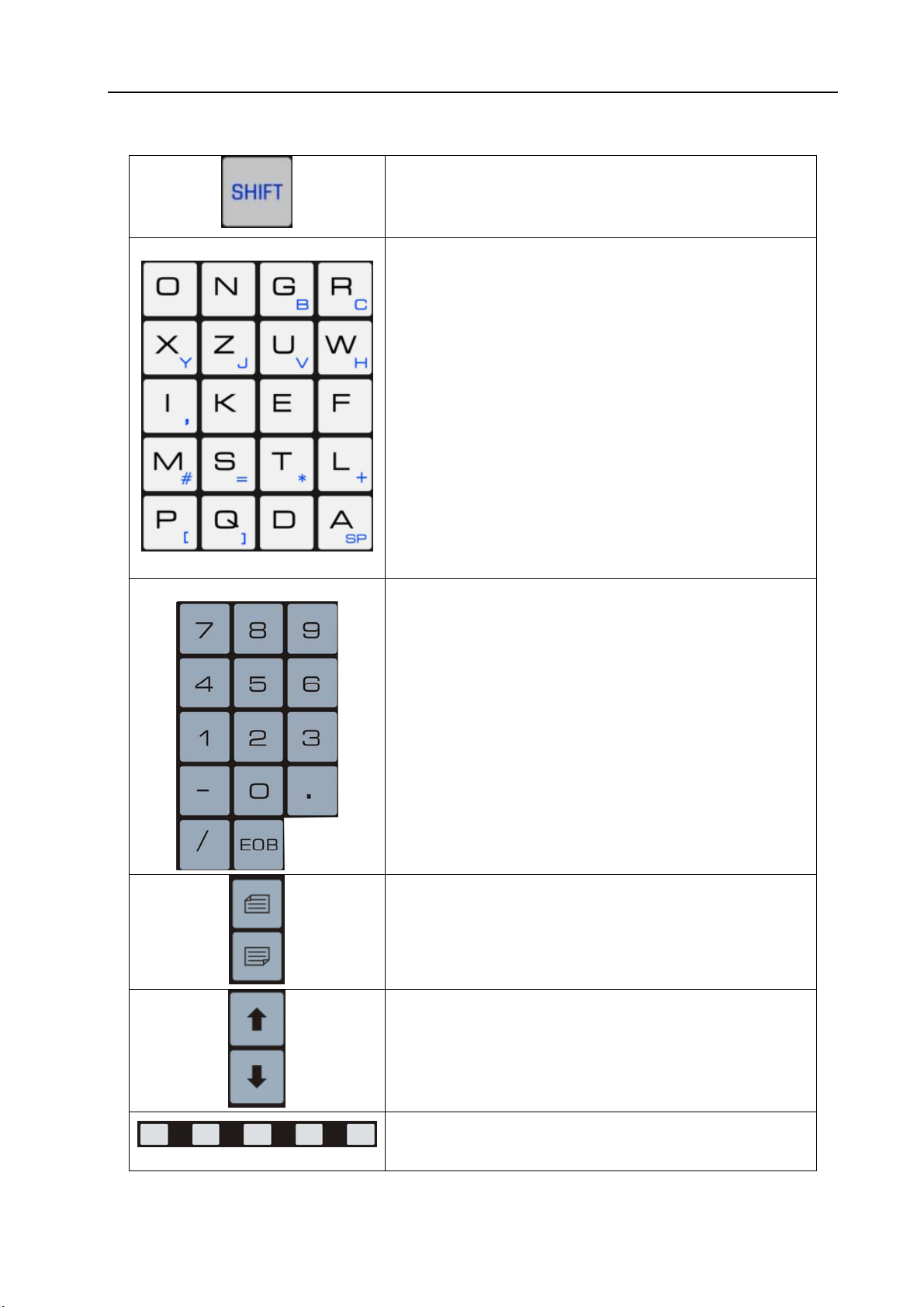

4.4 Operations and Display on MDI/LCD Panel

The MDI/LCD panel is usually placed at the upper front the device, and it is composed by the

LCD and keys as following figure shows:

22

Fig. 4-34

Page 27

Volume Ⅱ Chapter 4 Operation

Functional keys:

The large items displayed by the function keys are just like the chapters of a book. When a function

key is pressed for the second time or third time, the chapter 2 or 3 of the corresponding function is

displayed (if the function key for the chapter is provided).

Each chapter by functional keys includes several pages and each page may be selected with the

PAGE keys. The chapters and meanings for the functional keys are listed below.

Table 4-8

Pressing once Display of actual position and reset

Pressing once Display and setting of the set data

Pressing twice Display and setting of user macro program variables

Pressing for the

third time

Pressing once Display for program check

Pressing twice Display of the list of program numbers

Pressing for the

third time

Pressing once Display and setting of parameters

Display and setting of menu switch

Display the program

Pressing twice Display and setting of PC( PLC) parameters

Pressing once Display and setting of tool wear offset

Pressing twice Display and setting of workpiece coordinate system

Pressing for the

third time

Display and setting of tool contour offset

Pressing once Display of the information of an alarm

Pressing twice Display of an external alarm

Pressing once Display of command value and the commands input by MDI

Pressing twice Display of the information regarding program restart

Pressing once Display of NC diagnosis information

Pressing twice Display of the information regarding tool life management

Pressing once Display of the machining program tracking

Pressing twice

Setting of graph menu

23

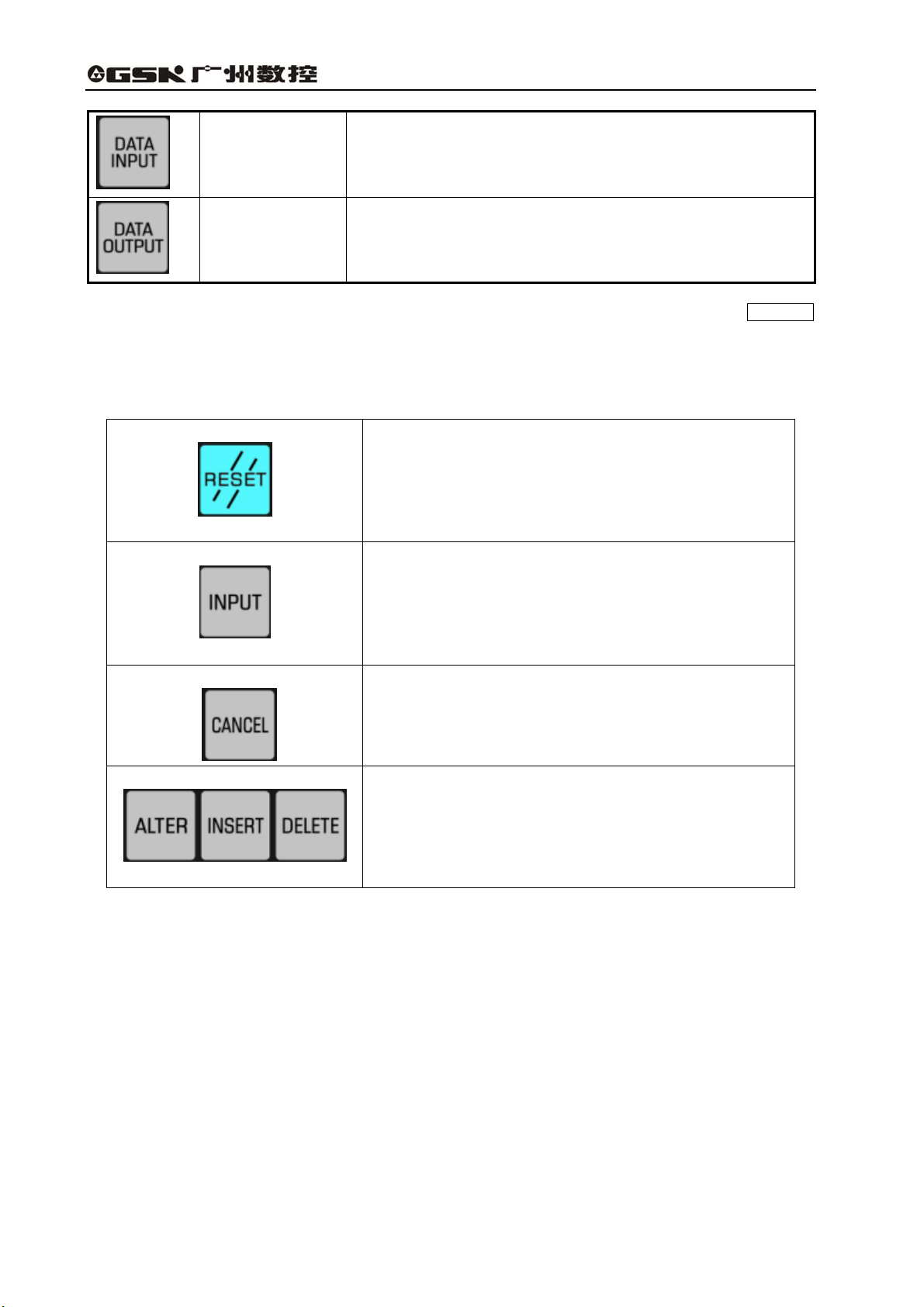

Page 28

GSK983T Turning CNC System User Manual

In Chapter 1

Waiting for external data transfer, highest level interruption,

inactive for other function keys.

Transfer the system data to external, highest level interruption,

In Chapter 1

inactive for other function keys.

Note The screen display may be cleared by concurrently pressing a functional key and the CANCEL

key. And the corresponding screen display may be displayed when a functional key is pressed

then.

Table 4-9 Introduction for other keys on MDI keypad

Reset key

For CNC reset and alarm eliminating, etc.

Input key

When address key or numerical key is pressed, input data is

displayed on screen but it still in buffer. Press input key, and

these data are saved in register.

Cancel key

Edit key

Delete characters in buffer from the end by pressing cancel

key.

Alteration, insertion and deletion can be done by pressing these

three keys in keying in data.

24

Page 29

Volume Ⅱ Chapter 4 Operation

Table 4-9 Introduction for other keys on MDI keypad(continue)

Some address keys include two kinds of characters, which are

selected by pressing shift key. Input characters in the lower

Address key

right corner when sign “^”is displayed on the screen.

Input letters by pressing address key.

Numerical key

Digits and punctuation can be input by pressing numerical key.

Key in “;” by EOB key.

Page Up/Down:turn display screen forward or backward for

one page.

Cursor moving up or down.

Soft keys:its function is defined by the contents in the lower

part of the display screen.

25

Page 30

GSK983T Turning CNC System User Manual

4.4.1 Status display

The status indication of the system is displayed on the lower right part of the screen:

Fig. 4-35

The display for status is as follows:

NOT READY: It indicates that the control or servo system fails to operate.

LSK : It indicates the label skip mode created after power on or control reset other than MDI

mode.

BUF : It indicates that a block is read in but not executed. The blocks not executed are

eliminated after reset in modes other than MDI.

ALM : It indicates that an alarm is given. The alarm will be displayed (this symbol blinks) when

the ALARM key is pressed.

EDIT : It indicates that the editing function is being executed or is to be done..

As for the different position of the mode selection, besides the EDIT, there are modes such as

AUTO, MDI, HNDL, JOG, MACHINE ZERO (not displayed).

SRCH : It indicates the program number search is being executed (blinking).

RESTR: It indicates the period from the program restart to the last axis return is completed

(blinking).

4.4.2 Keys input display

The contents input by address keys or numerical keys are displayed at the lower left of the

screen.

Fig. 4-36

26

Page 31

Volume Ⅱ Chapter 4 Operation

Data cannot be keyed in when the POSITION or ALARM key among the function keys is

pressed to display a screen.

Only a word consisting of one address and a figure can be keyed in when program edit is not

being performed. Pressing CANCEL key once, this word may be cleared.

One or more words are not limited in program editing, a line of up to 32 characters can be

entered for a block.

The last entered character may be cleared by pressing the CANCEL key. If the CANCEL

key is pressed continuously, the typed characters will be cleared in succession.

Note: In Edit mode, program edit is enabled when the PROGRAM key is pressed.

4.4.3 Display of program number and sequence numbers

Program number and sequence numbers are displayed at the top of the screen as shown in the

following figure.

Fig. 4-37

4.4.4 Alarm display (functional key ALARM )

When “ALM” is indicated at right bottom of the screen in case of alarm, warning messages may

be shown through the following procedures:

Press the ALARM key, when the information about operation is displayed, press the

ALARM key again to display alarm message.

Refer to Appendix 7 for the meaning of the alarm number.

Fig. 4-38

Note: As a rule, alarm message automatically appears on the screen in the event of alarm.

27

Page 32

GSK983T Turning CNC System User Manual

4.4.5 Operation information

Table 4-10 Operation information

Mode Operation Contents

Excluded in case of the following

Other than EDIT

AUTO

EDIT

AUTO Program number search Display the program number searched

condition:

Sequence number search

Press ∧ key in PROG mode

Press ∧ key continuously in PROG

mode

Press ∧ key continuously in PROG

mode

In reset mode by pressing RESET

key

Once the machine sends out operation information, the information will be automatically

displayed on the screen.

Display last sequence number executed

Display random sequence number in

searching

Return to program home and display the

program number(return unallowed as

program being executed )

Review the program positively from the

memory current position and display the N

value that appears firstly

Review the program negatively from the

memory current position and display the N

value that appears firstly

Return to the current program home and

display the program number

Fig. 4-38

If operation information is needed after some other page is displayed, press the ALARM key.

External message is shown if the ALARM key is pressed again in this alarm page.

4.4.6 Current position display and reset (functional key POSITION )

(1) Press the POSITION key;

(2) Press the PAGE key. Data is displayed in one of the following three modes:

(Ⅰ) Position display in a relative coordinate system

28

Page 33

Volume Ⅱ Chapter 4 Operation

Fig. 4-39

Ralative position is displayed, once resetting, the position is cleared to zero.

Reset: By pressing the U or W key, the resetting may be done in this page. Address

code pressed will continuously blink. The relative position of the blinking address will be 0 if the

SHIFT key is pressed then.

(Ⅱ) Position display in a workpiece coordinate system

Fig. 4-40

It displays the current position of the automatic coordinate system set by G50, or by coordinate

system by reset.

Reset (program lock ON for active, OFF for inactive)

Reset: By pressing the X or Z key, the resetting may be done in this page. Address

code pressed will continuously blink. The absolute position of the blinking address will be 0 if the

SHIFT key is pressed then.

Note: Reset operation can only be performed during the stop of the auto running.

(Ⅲ) Display of the ALL position

The actual position may be displayed in the coordinate systems as following at the same time:

(a) Relative coordinate system

(b) Absolute coordinate system

(c) Machine coordinate system

(d) Distance to go

29

Page 34

GSK983T Turning CNC System User Manual

Fig. 4-41

DISTANCE TO GO indicates the remaining move amount of a block.

The positions in the coordinate systems cannot be reset in the ALL position interface.

4.4.7 Display of command value (functional key COMMAND )

(1) Press the COMMAND key.

(2) Press the PAGE key. The page is displayed in the following 3 modes:

(Ⅰ) It displays the command value being executed and the formerly commanded modal values.

Max. speed of constant surface speed

Speed by G96, G97

Actual speed

Fig. 4-42

Note: As shown in the above figure, the figure following character % stands for the feedrate that has been

multiply by overrided.

(Ⅱ) It displays the command value input by MDI or the command value to be executed.

30

Page 35

Volume Ⅱ Chapter 4 Operation

Fig. 4-43

(Ⅲ) It displays the command value of the next block to be executed during the tool nose radius

compensation R.

Fig. 4-44

4.4.8 Setting (functional key SETTING )

4.4.8.1 Display and setting of input, output, etc.

(1) Press the SETTING key;

(2) Press the PAGE key. Setting and display may be performed in the following two modes.

(I) Setting and display of input and output:

Fig. 4-45

31

Page 36

GSK983T Turning CNC System User Manual

Setting (execution unallowed when the program lock is disabled; or execution allowed when it is

disabled, whose state can be switched by parameter SETE)

(a) Set the mode selection to MDI mode.

(b) Press the cursor key ∧ , ∨ to move the cursor to the item to be altered. (The cursor

cannot be moved with the address key N .)

(c) Enter 1 or 0 by pressing the P 0 or 1 INPUT key as shown in the following table.

Table 4-11

Display

Item

TV CHECK Not do TV check Do TV check

PUNCH CKDE Output EIA code Output ISO code

INPUT UNIT mm input Inch input

INPUT DEVICE1 Standard set for 0

INPUT DEVICE2 Standard set for 1

Note 1: Unselected function cannot be set. For example, INCH=1 cannot be used for a metric-system

machine when metric/inch conversion function is not available. ISO=1 cannot be set when ISO

code input selection function is not available.

Note 2: INPUT UNIT is automatically rewritten when G20 (in inch system) and G21 (in metric system) code

is executed.

0

1

(II) Other settings and display

32

Fig. 4-46(a)

Fig. 4-46(b)

Page 37

Volume Ⅱ Chapter 4 Operation

Table 4-12 The displayed numbers and their meanings

Data No. Meaning

057 * Running time (Unit: hr) (TMHOR)

058 * Running time (Unit: min) (TMMIN)

059 * Running time (Unit: s) (TMSEC)

064 * Thread chamfering width (THDCH)

065 * Retraction amount of G74, G75 (GROVE)

066 * Finish allowance of G76 (THDFN)

067 * The retraction amount of G71, G72 (MRCDT)

068 * The minimum allowance of G76 (THCLM)

141 * Running time (TIME)

151 * X value of Acme 1 of storage travel limit 2

152 * Z value of Acme 1 of storage travel limit 2

153 * X value of Acme 2 of storage travel limit 2

154 * Z value of Acme 2 of storage travel limit 2

155 * X value of Acme 1 of storage travel limit 3

156 * Z value of Acme 1 of storage travel limit 3

157 * X value of Acme 2 of storage travel limit 3

158 * Z value of Acme 2 of storage travel limit 3

180 * Sequence number for corresponding stop

319 * Settings (PRG8,MSBL)

340 * Reserved

341 * Reserved

Note 1: The data numbers other than those listed in the above table are not displayed.

Note 2: The parameters are also set by the same data numbers.

Note 3: Please refer to the manual for details about the parameters that have the same data numbers.

Setting (execution unallowed when the program lock is disabled; or execution allowed when it is

disabled, whose state can be switched by parameter SETE)

(a) Set the mode selection to MDI mode.

(b) Press the cursor key ∧ , ∨ to move the cursor to the item to be altered. The cursor

cannot be moved with the address key N .

(c) Press address key P , numerical keys and INPUT key in succession to proceed.

4.4.8.2 Display and setting of user macro program variables

It is possible to display common variable values and the local variable values of the currently

called user macro program body on LCD.

33

Page 38

GSK983T Turning CNC System User Manual

Fig. 4-47

When a variable value is <null>, the display will be blank.(see chapter 3 10.2.3 <undefined

variable>)

When an absolute value is over 99999999, it displays OVER FLOW.

When an absolute value is not zero, but less than 0.0000001, it displays UNDR FLOW.

It displays:

(1) Select the set chapter 2 (Steps: press SETTING to display the setting page, and press it

again.)

(2) Since the display covers 6 pages, you need to press the PAGE key to display the required

page.

Page 1——Local variables #1~#20

Page 2——Local variables #21~#33

Page 3——Common variables #100~#119

Page 4——Common variables #120~#139

Page 5——Common variables #140~#149

Page 6——Common variables #500~#509

(3) Search variable number

Method 1 Press the cursor key and move the cursor ∧ , ∨ in succession. The

next page will be switched to once the cursor goes beyond the current page.

Method 2 Press N , variable number and INPUT key for inputting.

(4) Set variable number

(a) Select MDI mode;

(b) Key in P , variable number and INPUT when the variable is displayed and the

cursor is moved to the variable number to be changed.

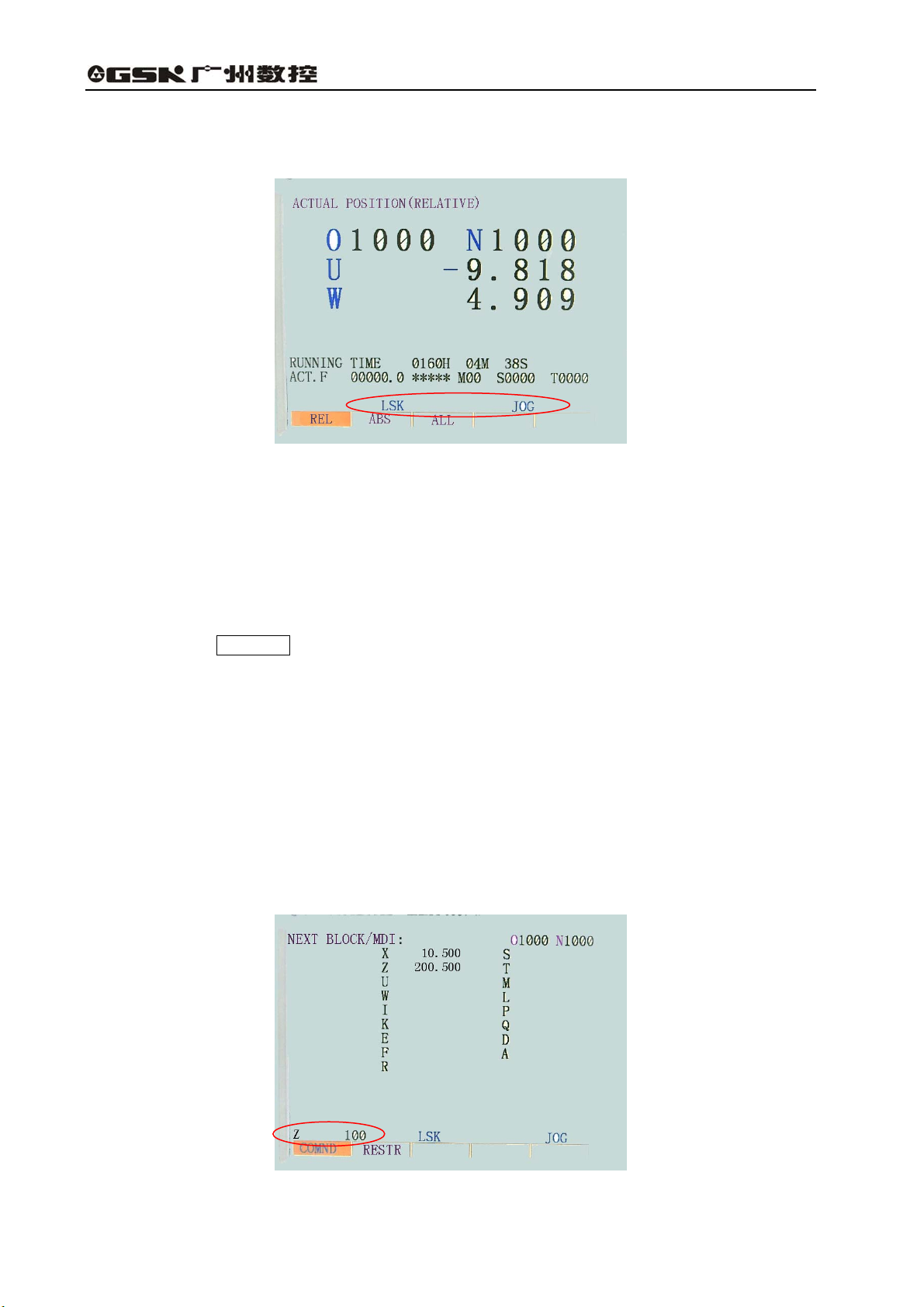

4.4.9 MDI operation (functional key COMMAND )

A block command to be executed may be input through MDI panel.

(1) Example: For X 10.5 Y200.5

(a) Select the MDI mode;

(b) Press the COMMAND key;

(c) Press the PAGE key. “NEXT BLOCK (MDI)” appears on the upper left of the screen.

34

Page 39

Volume Ⅱ Chapter 4 Operation

Fig. 4-48

(d) Press the X , 1 , 0 , • , 5 and the INPUT key in succession.

If the numeral entered before pressing the INPUT key is incorrect, press the

CANCEL key and enter the correct numeral again.

If an error is found after pressing the INPUT key, it is necessary to enter the numeral

again.

(e) Press the Z , 2 , 0 , 0 , • and 5 and the INPUT keys in succession.

If the typed numeral is found incorrect, proceed in the same way as inputting X.

Fig. 4-49

(f) Press the CYCLE START key on the control panel of the machine.

(2) Delete Z200.500 from X10.500 Z200.500 before pressing the CYCLE START key.

(a) Press the Z , CANCEL and INPUT key in succession.

(b) Press the CYCLE START key on the control panel.

(3) Delete modal data

Since modal G code and F, E and T data cannot be deleted, it is necessary to input correct data

for alteration.

4.4.10 MDI start and running

By pressing CYCLE START key, the commands by MDI is executed.

35

Page 40

GSK983T Turning CNC System User Manual

4.4.11 Reset

RESET key is usually used to cancel the alarm state.

By pressing this key, the NC turns into the following state:

Table 4-13

Before resetting After resetting

Move commands being executed

M,S,T codes being outputted

When a block is

read into the buffer

MDI mode The content in buffer is not eliminated.

Modes other

than above

The NC turns into reset state under any modes, but skip state in a mode other than MDI if

RESET key is pressed.

Slow down to stop and the remaining move is

cancelled.

Output sequence is terminated.

Refer to machine manual for actions at

machine side.

The content in buffer and BUF display are

both eliminated.

4.4.12 Setting and display of the tool offset, tool nose radius compenstation

(functional key offset )

4.4.12.1 Absolute input

(1) Press OFFSET key;

(2) Due to multiple pages to be displayed, PAGE keys are needed to select the page required;

st

1

page Offset 1~7

nd

page Offset 8~9 or 8~14(optional)

2

rd

3

page Offset 15~21(by selection)

th

page Offset 22~28(by selection)

4

th

page Offset 29~32 or (by selection)

5

36

st

Fig. 4-50 1

page of the offset values

Page 41

Volume Ⅱ Chapter 4 Operation

(3) Move the cursor to the No. of the offset to be altered

Method 1 Press ∧ , ∨ key, move the cursor sequently, and it changes to next

page if the cursor is over a page;

Method 2 Key in N , offset No., INPUT keys.

(4) Select a mode other than Edit

(5) Key in : X or Z or R or T offset value, INPUT

X Z : offset values of X, Z axes (absolute)

R : offset value of tool nose radius (absolute)

T : Assumed tool nose No.

If keying in Z 1 5 . 4 INPUT at an offset No. 4, it is shown as following

figure:

Fig. 4-51

Note1: The maximum offset value is restained by parameter No.338.

Note2: it can be keyed in when the figures at the right and bottom edge without blinking, and key in NO can

clear the blinking state.

37

Page 42

GSK983T Turning CNC System User Manual

4.4.12.2 Incremental input

By selection, it may choose the incremental offset input, so it can be done by U W keys.

X

Z

U

W

R

T

X

,

U

,

R

T

The input of R value by absolute or increment is defined by parameter #7.6 (IOF).

The incremental offset input is the increasement or decreasement of the offset.

(1) Incremental offset input

Now the tool nose R offset is 5.678, key in R 1 . 5 INPUT keys by

sequence, the offset turns to 7.178.

(2) When the absolute is needed in the incremental offset input:

Now the offset is 5.678, press R CANCEL INPUT keys by sequence, the offset turns to

0. Then press R 1 . 5 INPUT keys by sequence, the offset turns to 1.5.

Note1: When an offset is altered in Auto mode, the new one takes effect from next block or next T code

commanded is defined by parameter (TLCC) .

Note2: it can be keyed in when the figures at the right and bottom edge without blinking, and key in NO can

clear the blinking state.

Offset number Input

Z

:Offset in X or Z axis(abslute)

W

:Offset in X or Z axis(incremental)

:Tool nose R Offset (absolute or incremental)

:Assumed tool nose number

4.4.12.3 Setting of tool figure and wear offset

(1) Display of the tool wear offset

st

chapter of the OFFSET page it displays: (by pressing OFFSET key several

Fig. 4-52

times)

38

Under the 1

Page 43

Volume Ⅱ Chapter 4 Operation

(2) Display of the tool figure offset

Under the 3rd chapter of the OFFSET page it displays: (by pressing OFFSET key several

times)

Fig. 4-53

Setting:

(Ⅰ)It shows the page for tool figure offset or wear offset.

(Ⅱ)The setting is the same as that in section 5.12.1 and 5.12.2.

4.4.12.4 Offset of the workpiece coordinate system

It is the coordinate offset while there are deviation between the workpiece coordinate system

concerned in programming and the coordinate system commanded by G50 and automatic coordinate

system.

The offset value is set to the offset No.00, its setting steps are as the same as that of the tool

position offset.

Fig.4-54 Offset from 0′ to 0 set by offset No.00

XZ – 0 Coordinate system in programming

XZ – 0′ Current coordinate system

(Modifiable coordinate system by offsetting)

39

Page 44

GSK983T Turning CNC System User Manual

Fig. 4-55

As the above figure shows, the desired start point is X=120.0(diameter), Z=70.0 (offset value 0),

but the actual start point is X=121.0(diameter),Z=69.0), key in the offset value:

X=1.0 Z=-1.0

The desired coordinate system may be obtained.

Fig. 4-56

Also in above figure, if the start point locates at the tool nose tip, and it needs to be set at a point

of X=120.0(diameter),Z=70.0, while it actually locates at X=121.0 (diameter), Z=69.0, key in the

offset value of the workpiece coordinate system:

X=1.0 Z=-1.0

The desired coordinate system may be obtained.

The actual offset may be simply set by the direct offset input method for workpiece coordinate

system in section 5.12.5.

40

Page 45

Volume Ⅱ Chapter 4 Operation

Note 1: The offset of the workpiece coordinate system takes effect immediately after the offset value is set.

Note 2: After the offset value is set , then set coordinate system by G50, the offset doesn’t take effect.

e.g. Whatever the offset is, the current tool start point X=100.0 Z=80.0 is set for the new

coordinate system if the point G50 X=100.0 Z=80.0 is set.

Note 3: When performing the manual reference return after the offset value is set, once the automatic

coordinate system is set, the offset takes effect immediately, and the set coordinate system will be

offset right away.

Note 4: The offset in X axis by diameter or by radius is specified by the diameter or radius value in part

program.

4.4.12.5 Direct measured value input of workpiece coordinate system offsetting

If there are deviation between the coordinate system used in programming and the coordinate

system actually commanded by G50 and automatic coordinate system, offset the coordinate system

by direct measured values as follows:

Surface B

Origin of

programming

Surface A

Fig. 4-57

(a) Cut surface A with a reference tool in Manual mode.

(b) Press the POS RECORD key on the machine operation panel to make the tool detach the

part, and stop the spindle.

(c) Measure the distance β from programming origin to surface A in above figure.

(d) Press OFFSET. Press it again if the page of workpiece coordinate system offset has not been

selected.

(e) Key in N 1 0 0 INPUT , and the “N” keyed in will blink.

Fig. 4-58

41

Page 46

GSK983T Turning CNC System User Manual

(f) Key in Z , measured value β , INPUT , the offset value will be entered to Z of the

workpiece coordinate system offset.

(g) Cut surface B in Manual mode.

(h) Press the POS RECORD key on the machine operation panel to make the tool detach the

surface B, and stop the spindle.

(i) Measure the diameter α of the surface B.

(j) Key in X , measured value α, INPUT , the offset value will be entered to X of

theworkpiece coordinate system offset.

By the above operation, the offset from O′→ O will be automatically set to offset No.00, and the

set actual coordinate system will be consistent with the programming one.

Then the coordinate system X=0,Z=0 will be set if the reference tool offset is 0, i.e. the tool nose

is taken as the origin of the workpiece coordinate system of programming.

Note 1: When the offsets of X, Z in above figure is set for reference tool, under the active offset state(TXXXX

commanded) α,β settings are actually finished when finishing cutting surface A, B. When the start point

locates at the workpiece origin, the coordinate system X=0, Z=0 will be set.

Reference point

Fig. 4-59

Note 2:The value in X axis is usually measured by diameter.

4.4.12.6 Direct input of the tool offset

The offset by the deviation of the start point(reference tool nose or toolpost center) to the actual

tool nose point may be set by the following method:

While workpiece coordinate system is set:

Surface B

42

Surface A

Fig. 4-60

Page 47

Volume Ⅱ Chapter 4 Operation

(a) Select an actual tool to cut surface A in Manual mode.

(b) Press the POS RECORD key on the machine operation panel to make the tool

detach surface A, and stop the spindle.

(c) Measure the distance β from workpiece coordinate system origin to surface A.

(d) Press OFFSET key many times to switch to the page of the tool contour offset .

(e) Key in N , offset No.+No.100, INPUT to enter the direct input state.

So the desired page contains the offset No. is got with cursor pointing to this No., and the “N”

keyed in blinks.

Fig. 4-61

(f) Key in Z , measured value β, INPUT , so the Z offset is entered into this offset No.

(g) Cut surface B in Manual mode.

(h) Press the POS RECORD key on the machine operation panel to make the tool detach the

part, and stop the spindle.

(i) Measure the diameter α of the cylindrical surface B.

(j) Key in X , measured value α, INPUT , so the X offset calculated is entered into this offset

number.

Note1: The X value is usually measured by diameter.

Note2:when N or the figurs on left and bottom edge of the screen is binking, the operation of the clearing for

tool offset or input for increment is disabled, only after the N0 is inputed and canceling the N or the

blingking of the the figures, can the operation be enabled by X0 or Z0.

4.4.12.7 Offset input by counter (optional)

In the offset setting, press the INPUT key, the offset value will be set by relative coordinate U

(address X or U) or W (address Z or W) when address (X,Z,U or W)is keyed in without numerals.

Usage:

(a) Press the OFFSET key many times to select the OFFSET page of tool contour.

(b) Press ∧ , ∨ to select the page that contains the offset No. to be set. Or key in N ,

offset No. , INPUT .

(c) Move the reference tool to the start point by Manual mode.

(d) Reset the relative coordinates U, W in the page to 0 ( U SHIFT , W SHIFT )

43

Page 48

GSK983T Turning CNC System User Manual

Fig. 4-62

(e) Move the tool to be offset to the start point, the offset value will be shown at the Relative

position.

(f ) In tool contour offset page, by pressing U INPUT , W INPUT keys, the value at the

Relative position will be set for the tool offset.

4.4.13 Program display (functional key PROGRAM )

(1) In Edit mode:

Press the PROGRAM key, the current machining program is displayed.

Fig. 4-63

See Program number search in Section 4.4.14 for displaying a selected program.

Pressing the cursor ∧ , ∨ key to display the content of the program in sequence. By

pressing ∨ key, the page is displayed in forward direction. By ∧ key, in backward direction.

Note: If it is switched to Edit mode from other mode and the PROGRAM key is pressed, the content of

the program is displayed from the block being executed or executed. However, the beginning of the

program will be displayed when it is returned to program beginning (see 4.4.24.4).

(2) Automatic operation

Press the PROGRAM key, it displays the current block being executed.

44

Page 49

Volume Ⅱ Chapter 4 Operation

Fig. 4-64

Significance of the cursor (for auto running )

(a) When the cursor blinks, it indicates the block to be executed next time.

(b) When the cursor does not blink, it indicates the currently executing or executed block.

Note 1: Strictly speaking, when the buffer register is empty the cursor blinks neither in automatic

running nor in feed hold, which indicates the next block to be executed is going to be read into

the buffer register.

Note 2: When ∧ , ∨ key of the PAGE is pressed in Edit mode to move the cursor to Auto mode

and run, the block locating at the cursor in Edit mode is read into the buffer register.

4.4.14 Program number search (functional key PROGRAM )

When a lot of programs are stored in memory, each one can be searched out.

O1001 O3054 O1972

Searching a program number

(1) Method 1

(a) Select a mode (Edit or Auto).

(b) Press the PROGRAM key to switch to PROGRAM or PROGRAM CHECK page.

(c) Key in O , the program No. to be searched, ↓

The home page of the program is displayed after searching.

(2) Method 2

(a) Select the Auto mode.

(b) Press the PROGRAM key to switch to PROGRAM or PROGRAM CHECK page.

(c) Press O , V , Cancel, ↓ key in sequence. The next stored program is displayed.

(3) Method 3

(a) Select the Edit mode

(b) Press the PROGRAM key to switch to PROGRAM or PROGRAM CHECK page.

(c) Press O , ↓ key in sequence. The next stored program is displayed.

Note 1: It returns to the 1st program number as the display for all stored is over.

Note 2: The content in the buffer register is deleted when program number search starts.

45

Page 50

GSK983T Turning CNC System User Manual

4.4.15 Program input

A machining program can be directly stored into memory by the MDI keypads.

(a) Select the Edit mode (it is enabled when the program protection lock is open, it is disabled

when locked).

(b) Press the PROGRAM key to display the current program.

(c) Enter the program number to be stored by keying in O , program number , INSERT keys.

Fig. 4-65

(d) Key in a block according to the program

e.g. When keying in G50 X500.0 Z200.0 M12;

G 5 0 × 5 0 0 . 0

Z 2 0 0 . 0 M 1 2 EOB

Fig. 4-66

(e) If a keyed in character is incorrect, press the CANCEL key to delete the lastly keyed in

character. By pressing the CANCEL key continuously it deletes the keyed in characters

one by one from the last keyed in one. If the number of the characters of a block exceeds 32,

the block cannot be entered. Now it the block is needed to be divided for several segments.

(f) If the keyed in program is correct, press the INSERT key.

46

Page 51

Volume Ⅱ Chapter 4 Operation

Fig. 4-67

(g) Enter the following program by this means.

(h) For correcting a keyed in block, proceed as indicated in the section 5.30.

(i) For restart, move the cursor to the lastly keyed in character for continuous inputting. The

procedure is the same as the insertion operation.

(j) When all blocks are keyed in it finishes and at the end of the procedures, press the RESET

key if you want to return to the program beginning.

4.4.16 Deletion of a program (functional key PROGRAM )

Deleting a program stored in memory (Program lock ON for active; OFF for inactive):

(a) Select the Edit mode.

(b) Press the PROGRAM key.

(c) Press O , program number, and DELETE keys, the program with this number is deleted.

4.4.17 Deletion of all programs (functional key PROGRAM )

Deleting all programs stored in memory (Program lock ON for active; OFF for inactive):

(a) Select the Edit mode.

(b) Press the PROGRAM key to PROGRAM page.

(c) Press O , - , 9 , 9 , 9 , 9 and DELETE keys.

4.4.18 Sequence number search (functional key PROGRAM )

Sequence number search is usually used to search a sequence number in a program and start

or restart the program from the block whose sequence number is searched. Its skipping over blocks

exert no influence on the NC system. Namely when skipping over blocks, the coordinates of the

blocks skipped over, M, S, T or G codes do not change the coordinates and modal values of the NC.

When a user macro program is supplied, sequence number will not be displayed in searching.

Therefore, necessary M, S, T, G codes and coordinate system should be set for the blocks to be

started or restarted according to sequence number search. This block searched is usually a breaking

point in a process. If it needs to restart from the block searched in program, the present state of the

machine and NC system must be checked by specifying M, S, T, G codes and coordinate system etc.

with MDI.

47

Page 52