gsk GSK983M-H Connection Manual

GSK983M-H/M-V Milling CNC System Connection Manual

CONTENTS

Precautions for Connection ............................................................. 1

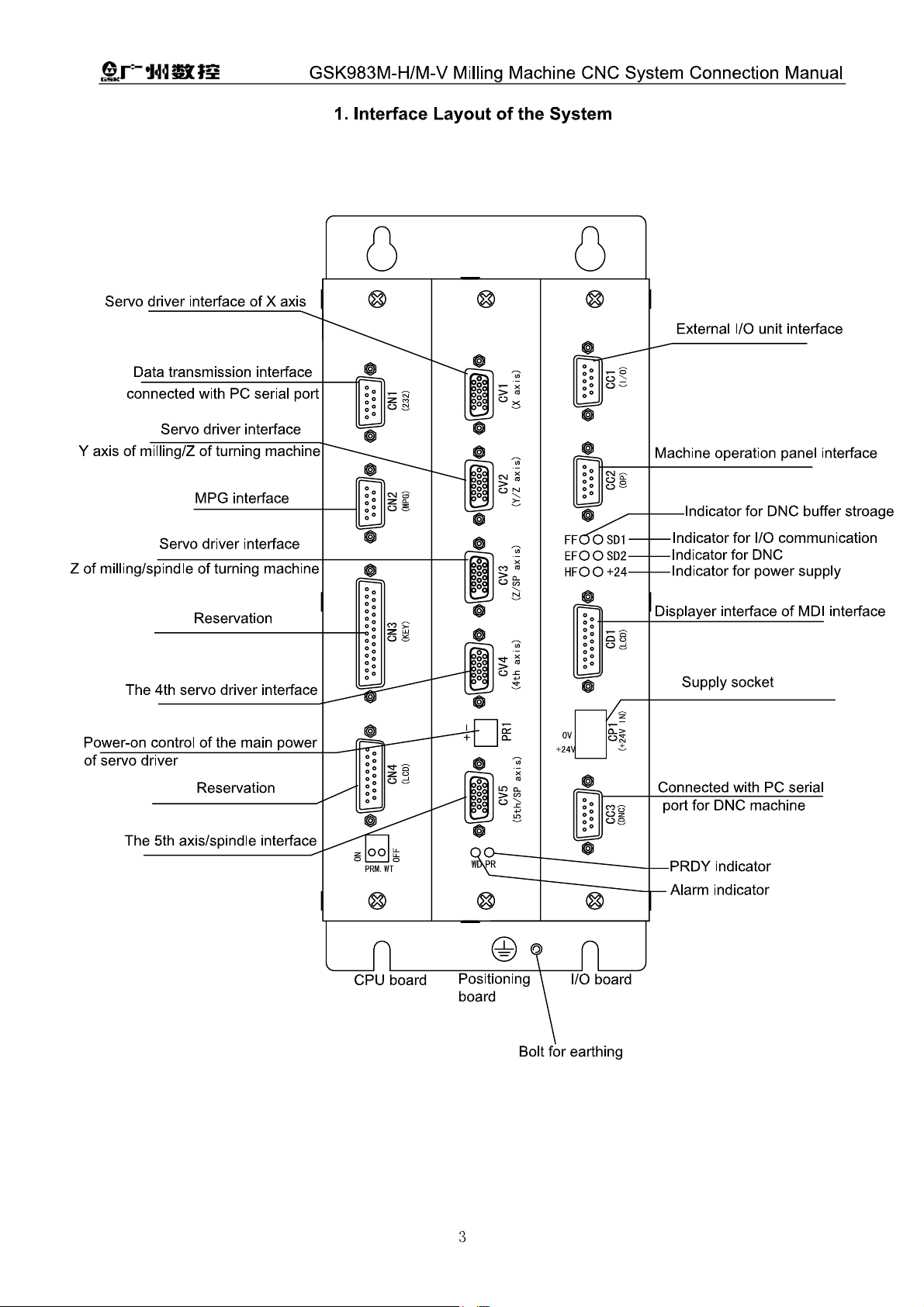

1 Interface Layout of the System ....................................................... 3

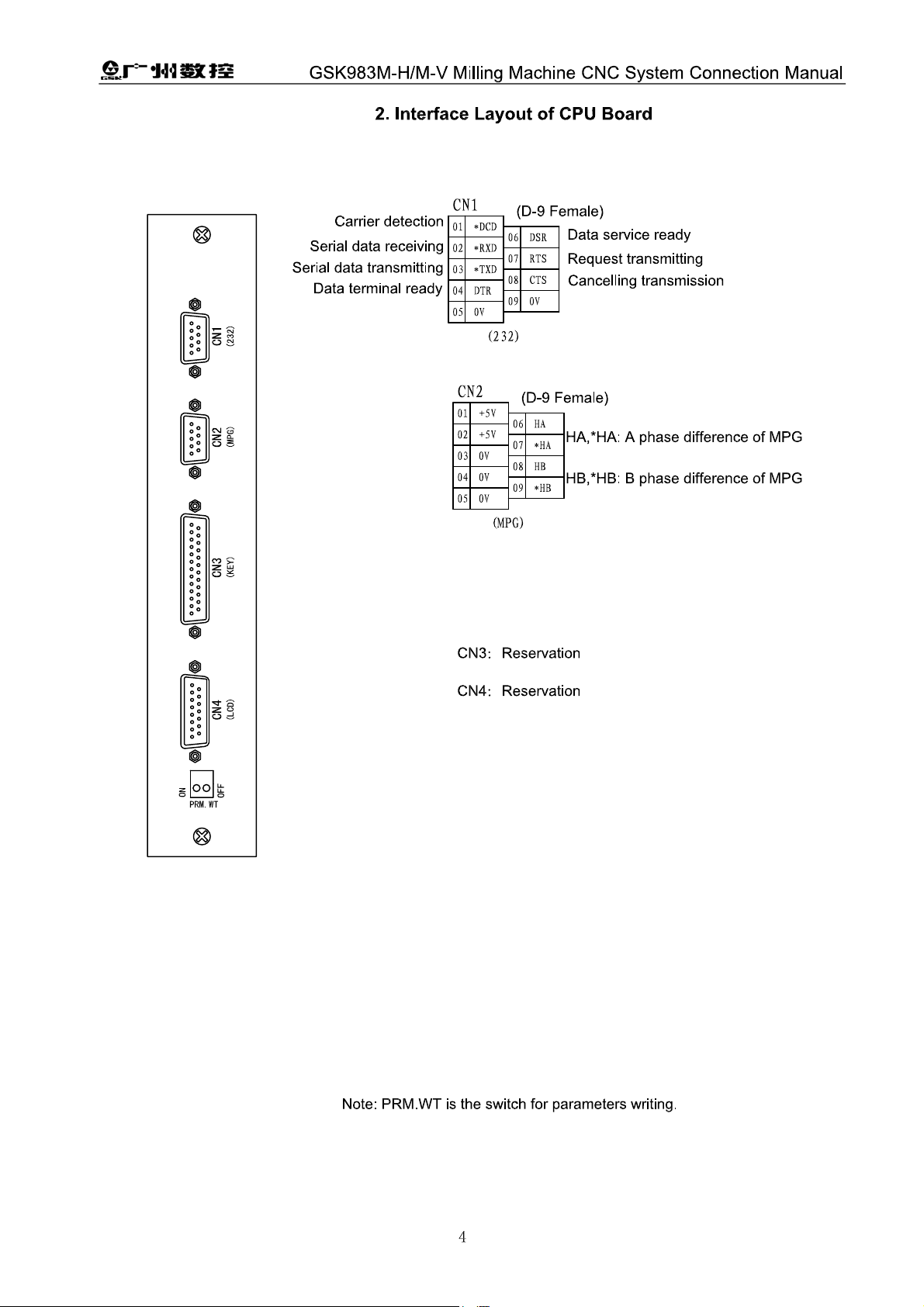

2 Interface Layout of CPU Board ........................................................ 4

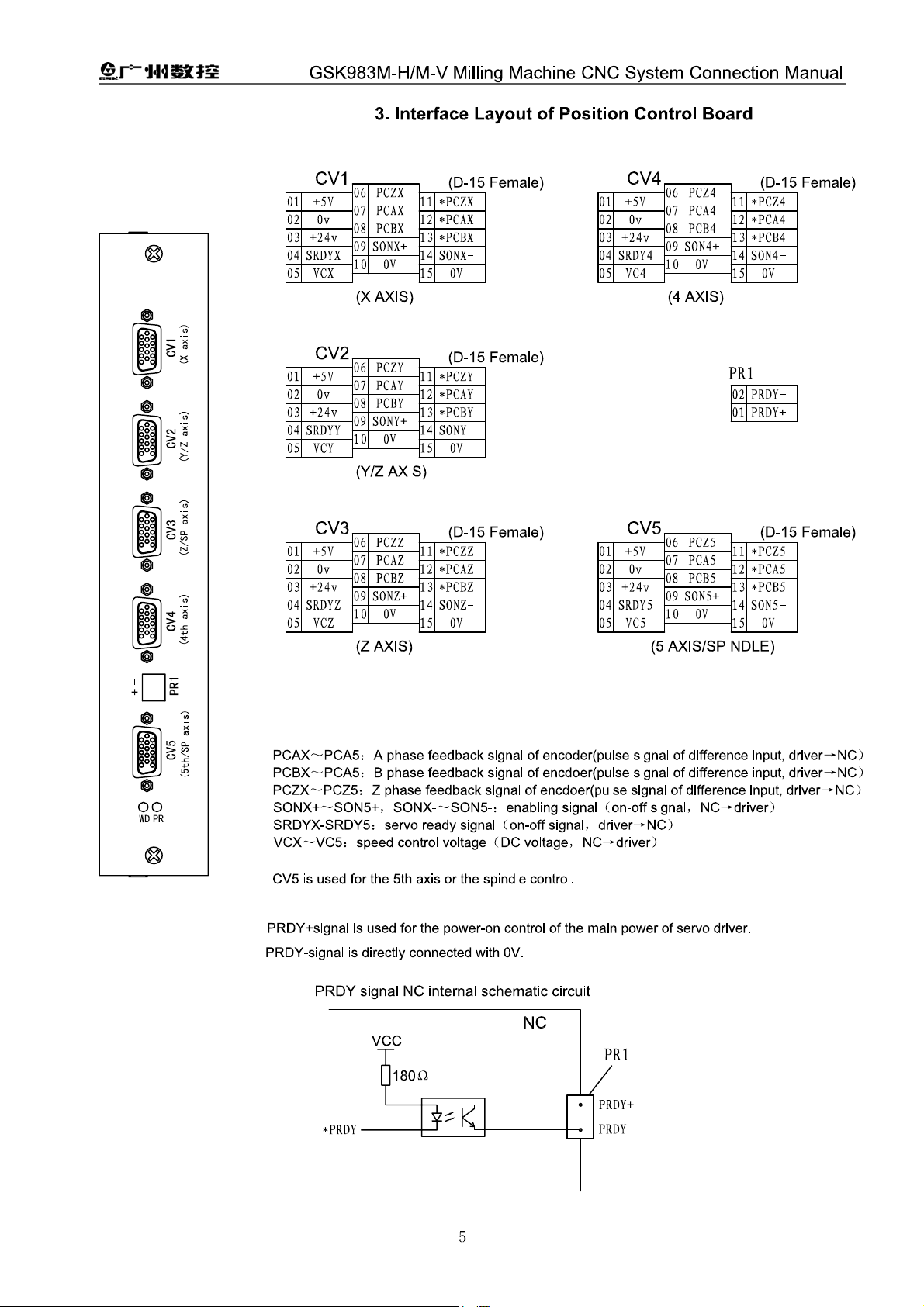

3 Interface Layout of Position Control Board ........................................... 5

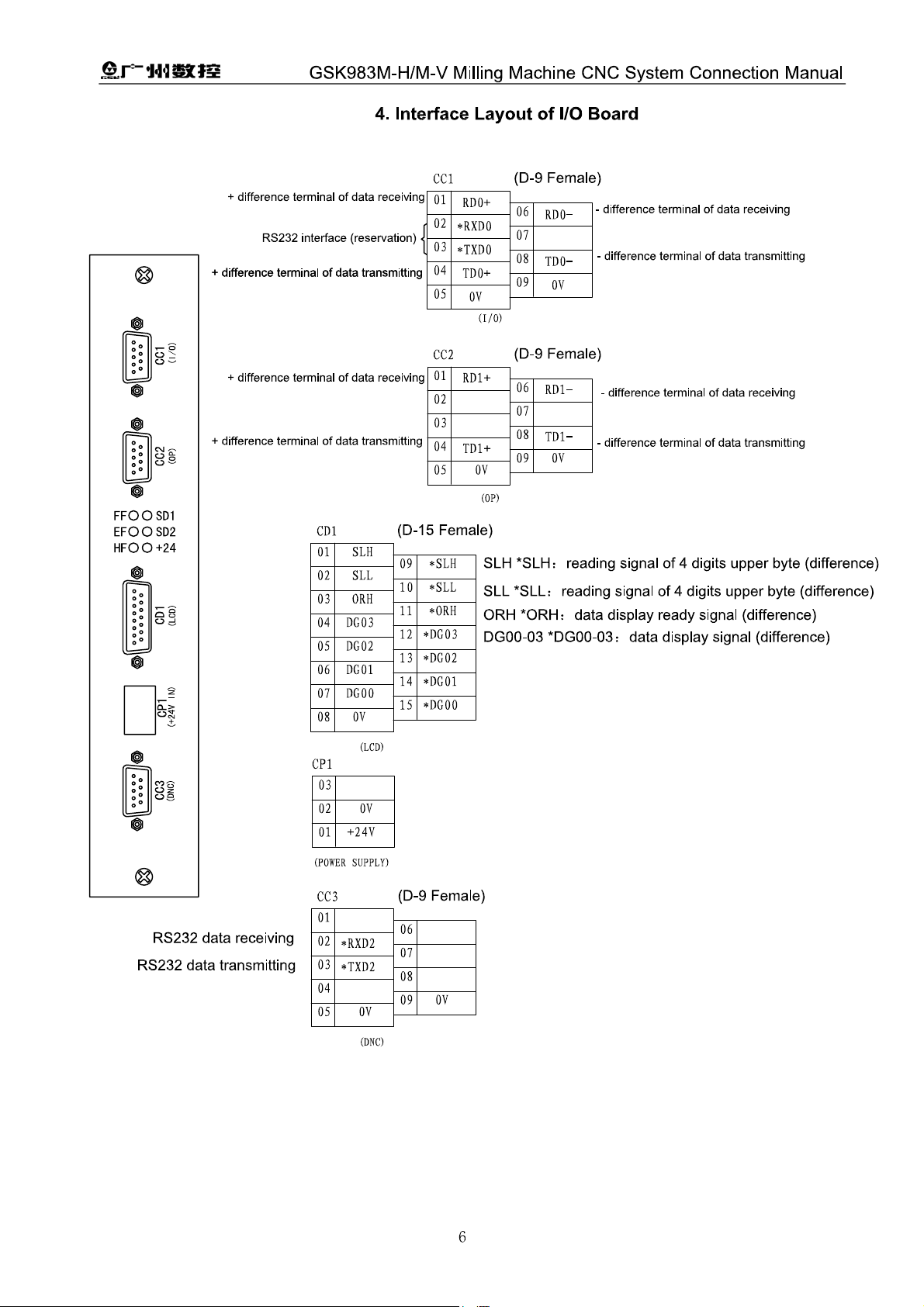

4 Interface Layout of I/O Board ........................................................ 6

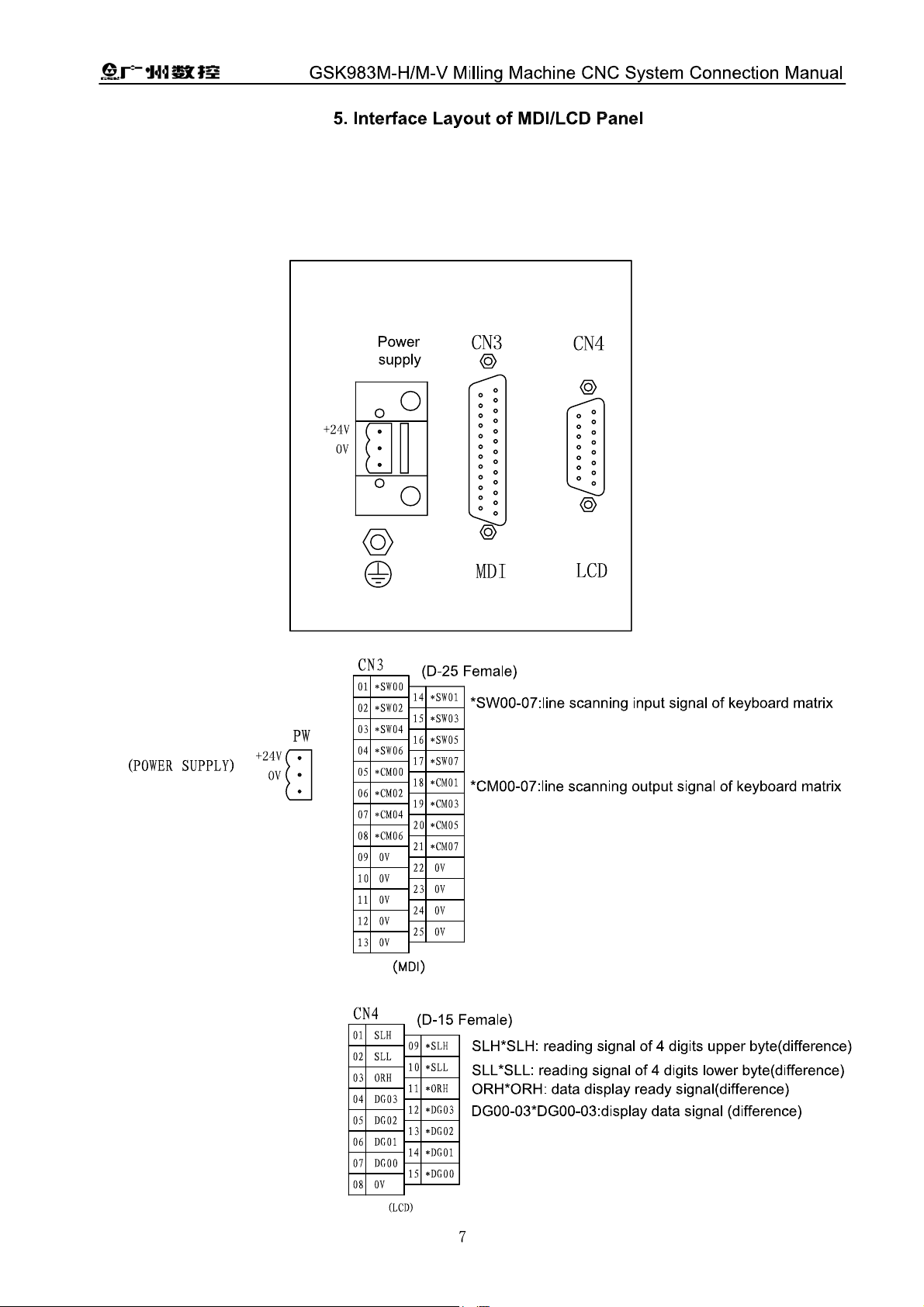

5 Interface Layout of MDI/LCD Panel .................................................... 7

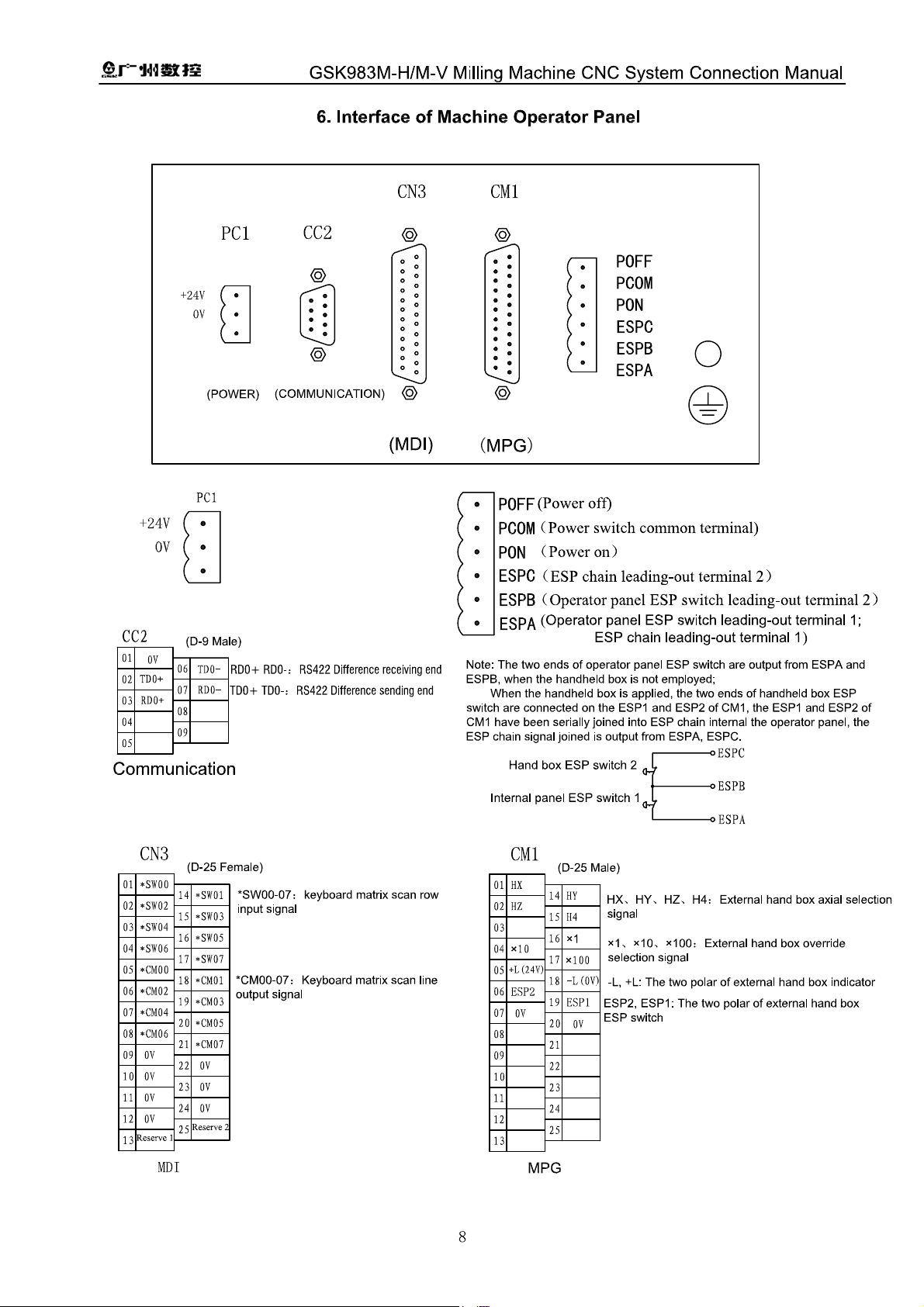

6 Interface of Machine Operator Panel .................................................. 8

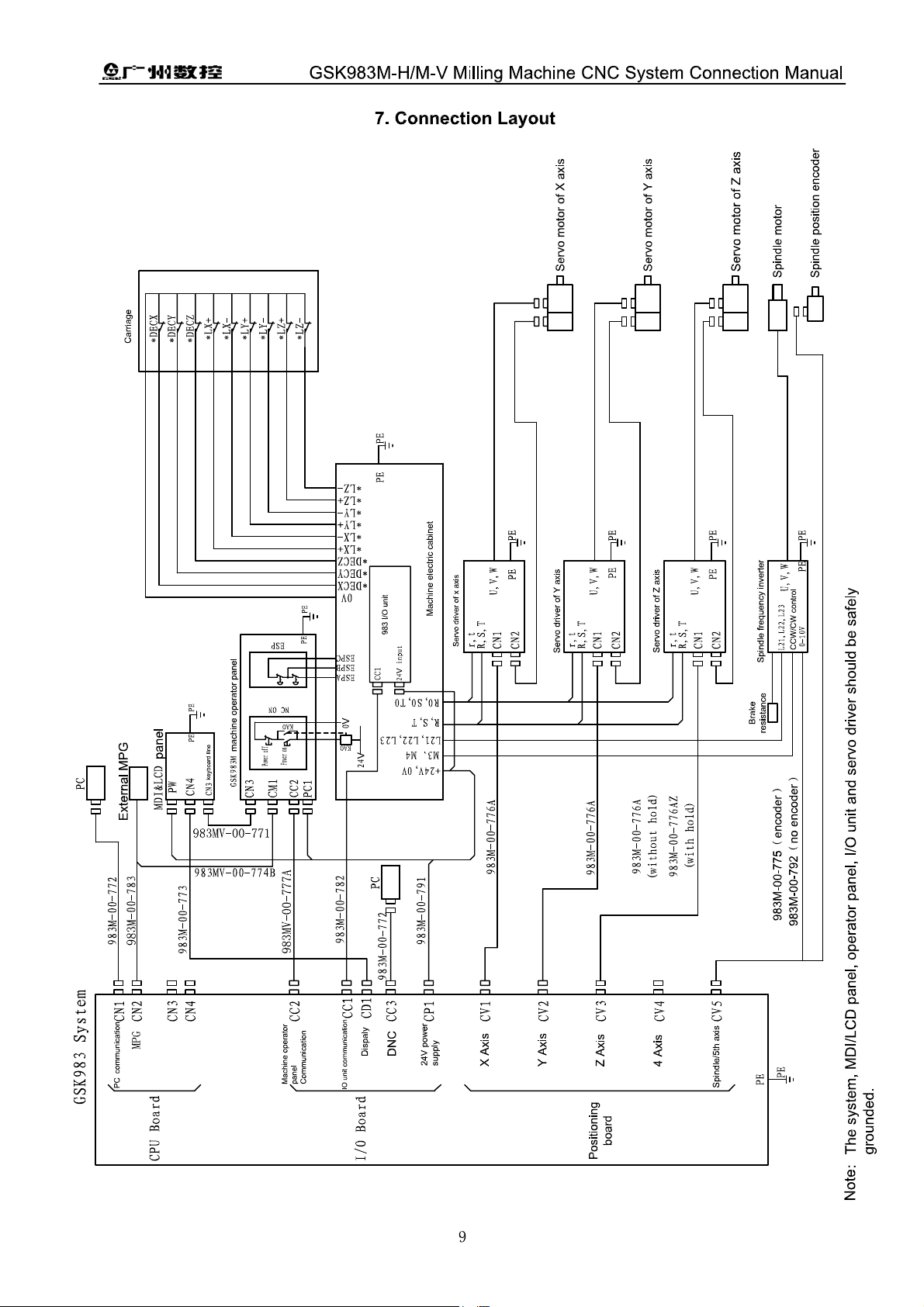

7 Connection Layout .................................................................... 9

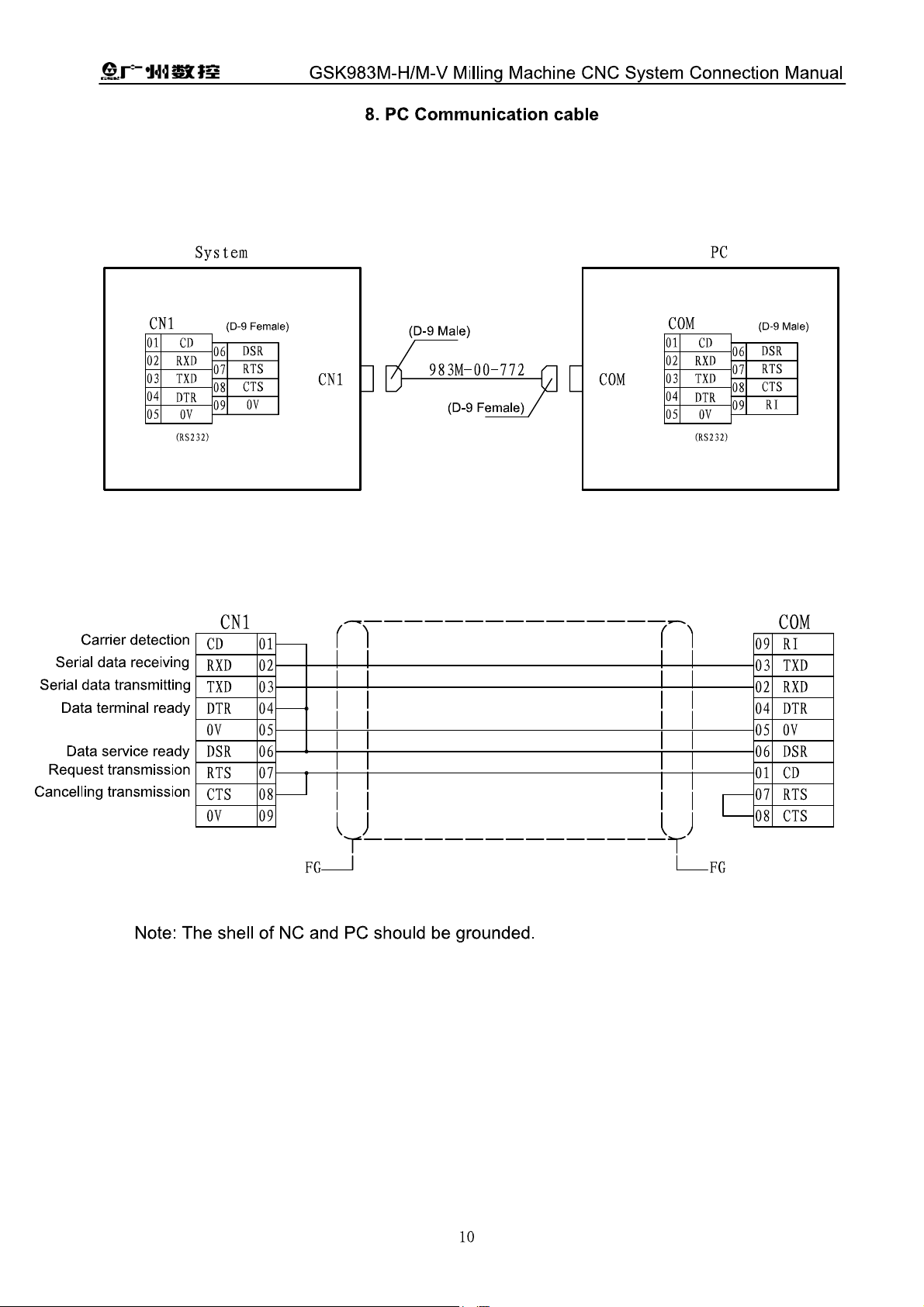

8 PC Communication cable .............................................................. 10

9 Connection Scheme for External MPG .................................................. 11

10 Signal Cables for Keyboard ......................................................... 12

11 Display Signal Cables .............................................................. 13

12 Communication Cables of Operator Panel ............................................. 14

13 Signal Cables for Connecting DA98D Drive Unit ...................................... 15

14 Z Axis Connecting Holding Cable of DA98D Drive unit ................................ 16

15 Connecting with Spindle Transformer ................................................ 17

16 Spindle Servo Signal Cable Connecting .............................................. 18

17 Installation of spindle orientation in position input signal from mechanical side .. 19

18 Installation of Z axis 2nd reference point in position input signal from mechanical side

...................................................................................... 20

19 Z Axis Hold and Control connecting method with power on ............................ 21

20 External I/O Unit (X1) ............................................................. 22

21 Communication Cables for I/O Unit .................................................. 23

22 I/O Unit (X1) Input/Output Signal Connection Scheme ................................ 24

23 Definition of I/O Unit (X1) Input/Output Interface ................................. 25

Appendix: Installation dimension ...................................................... 28

GSK983M-V Connection Manual Version Upgrade Registration Form ......................... 34

I

GSK983M-H/M-V Milling CNC System Connection Manual

Precautions for Connection

1、Requirement of the machine cabinet:

The cabinet installation of the system and driver should apply the full-close

dust-proof design. The temperature difference between the inside and outside of the

cabinet should be below 10℃. Heat exchange system is needed if the above condition is

not met. The ambient temperature around the system should be below 45℃. And the liquids

such as lubricant, coolant should be prevented from entering the inside of the system

components.

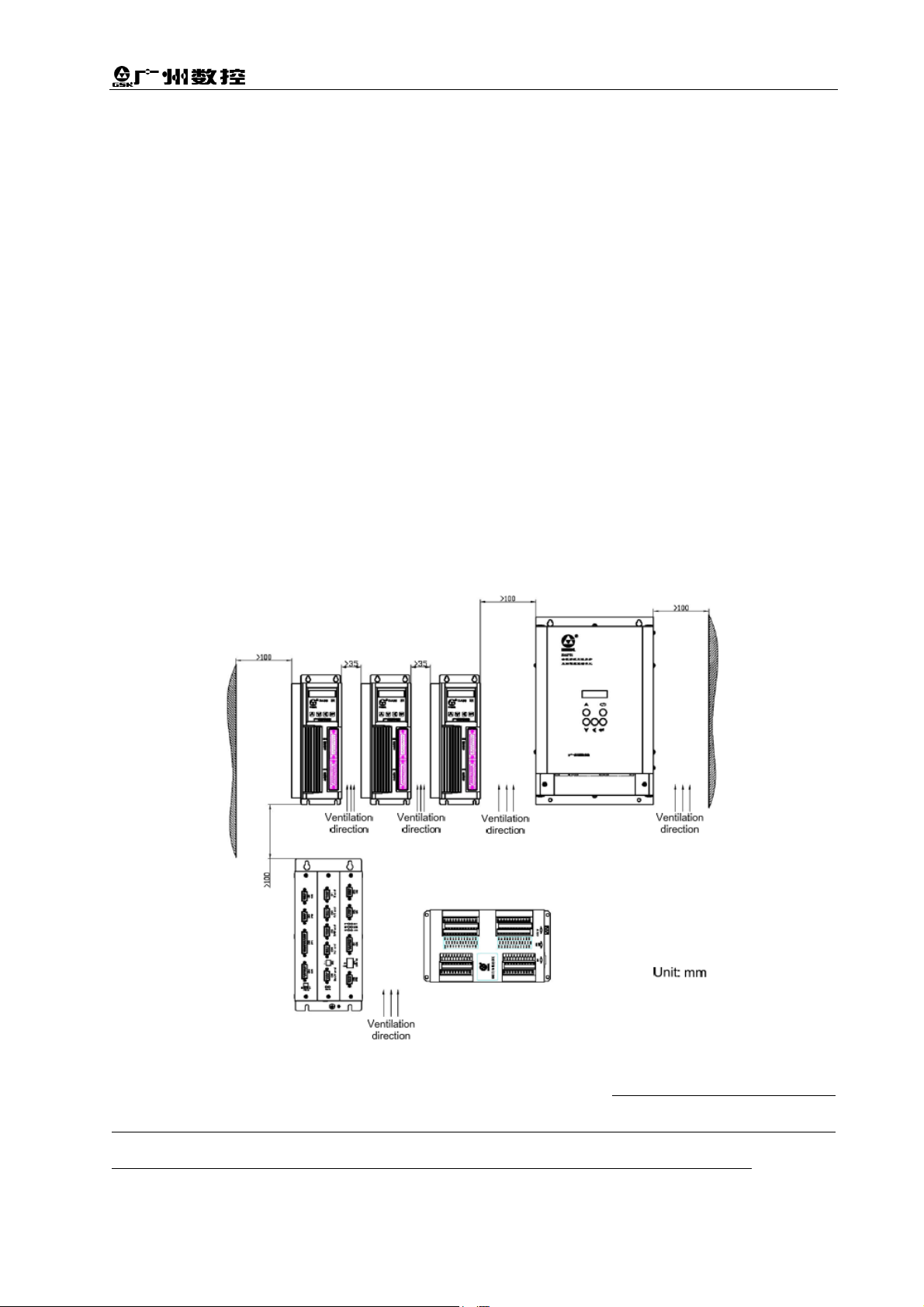

2、System fixation position:

Since the main cabinet is the control core of the CNC machine, it should be fixed

in priority at a location that has a little temperature rising, little electromagnetic

disturbance. Due to that the large power spindle driver and feed axis driver produce a

huge heating during their running, so the main cabinet and the I/O unit should be fixed

below them with over 100mm clearance as much as possible. Please refer to the appendix

of this manual for their installation drawing dimensions of the system.

3、Power should be supplied to system by isolation transformer.

is from power supply box only for CNC control, connecting this DC24V with another device(for

example brake、valve etc. ) is strictly prohibit, otherwise it is very danger!

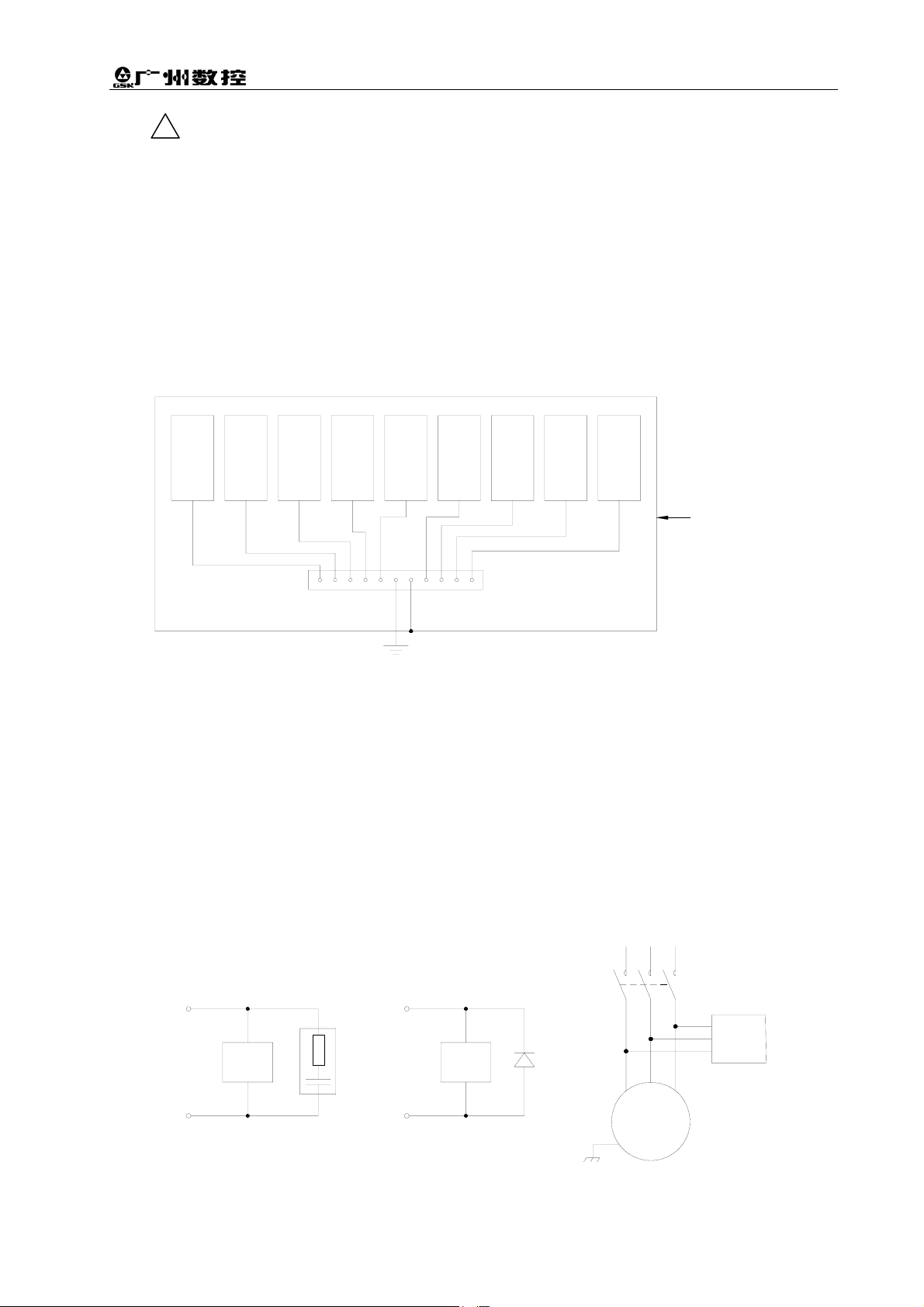

4、Ground:

1

It is DC24V power supply that

GSK983M-H/M-V Milling CNC System Connection Manual

! The machine cabinet must install protective grounding, the demand of grounding must

measure up GB5226.1-2002.It is well grounding that is necessarily for system in working order,

it cannot be in series system of each unit of grounding, it must install ground plate of

cabinet(can use a thick copperplate that thickness is 3mm or more),The ground resistance

in protective grounding must be 4Ω or less. The cable used for protective grounding must

be of a sufficient cross section for each unit to connect ground plate, Generally the cable

is short-thick, and the color of cable is yellow-green.

P

o

w

e

r

s

u

p

p

l

y

System

Display panel

O

p

e

r

a

t

o

r

P

a

n

e

l

I/O

Unit

X

axis

drive

unit

Y

axis

drive

unit

Z

axis

drive

unit

Spindle

drive

unit

Electric cabinet

Grounding block

PE

5、Wiring:

The signal cables and control cables of weak current should be distributed far away

from the place where heavy current and heavy electromagnetic disturbance exist. They

should be distributed straightly against interference signal that may occur by twisted

cables.

6、Interference inhibition:

Connect shunt RC loop circuit to the AC coil (Fig.1). And the RC loop circuit should

be fixed as near as possible to the inductive load; connect reversely shunt freewheeling

diode to the DC coil (Fig.2); connect shunt surge absorber to the AC motor coil (Fig.3).

KM

+24V

Surge

absorber

AC220V

0V

Fig. 1)

(

(Fig. 2)

2

M

3

~

(Fig. 3)

Loading...

Loading...