gsk GSK983Ma-H Connection Manual

GSK983Ma-H/V Milling CNC System Connection Manual

In this user manual we have tried to describe the matters

concerning the operation of this CNC system to the greatest extent.

However, it is impossible to give particular descriptions for all

unnecessary or unallowable operations due to length limitation and

products application conditions;Therefore, the items not presented

herein should be regarded as “impossible” or “unallowable”.

Copyright is reserved to GSK CNC Equipment Co., Ltd. It

is illegal for any organization or individual to publish or reprint this

manual. GSK CNC Equipment Co., Ltd. reserves the right to ascertain

their legal liability.

I

GSK983Ma-H/V Milling CNC System Connection Manual

Preface

Your Excellency,

We are honored by your purchase of this GSK 983Ma Milling CNC System made by

GSK CNC Equipment Co., Ltd.

Warning

Accident may occur by improper connection and operation!This system can

only be operated by authorized and qualified personnel.

Please read this manual and a manual from machine tool builder carefully before

installation, programming and operation, and strictly observe the requirements.

Otherwise, products and machine may be damaged, workpiece be scrapped or the user

be injured.

Safety Responsibility

Manufacturer’s Responsibility

——Be responsible for the danger which should be eliminated and/or controlled on

design and configuration of the provided CNC systems and accessories.

——Be responsible for the safety of the provided CNC systems and accessories.

——Be responsible for the provided information and advice for the users.

User’s Responsibility

——Be trained with the safety operation of CNC system and familiar with the safety

operation procedures.

——Be responsible for the dangers caused by adding, changing or altering to the

original CNC systems and the accessories.

——Be responsible for the failure to observe the provisions for operation, adjustment,

maintenance, installation and storage in the manual.

This manual is reserved by end user.

We are full of heartfelt gratitude to you for supporting us in the use of GSK’s

products.

II

GSK983Ma-H/V Milling CNC System Connection Manual

Contents

Precautions .................................................................................................................................. 1

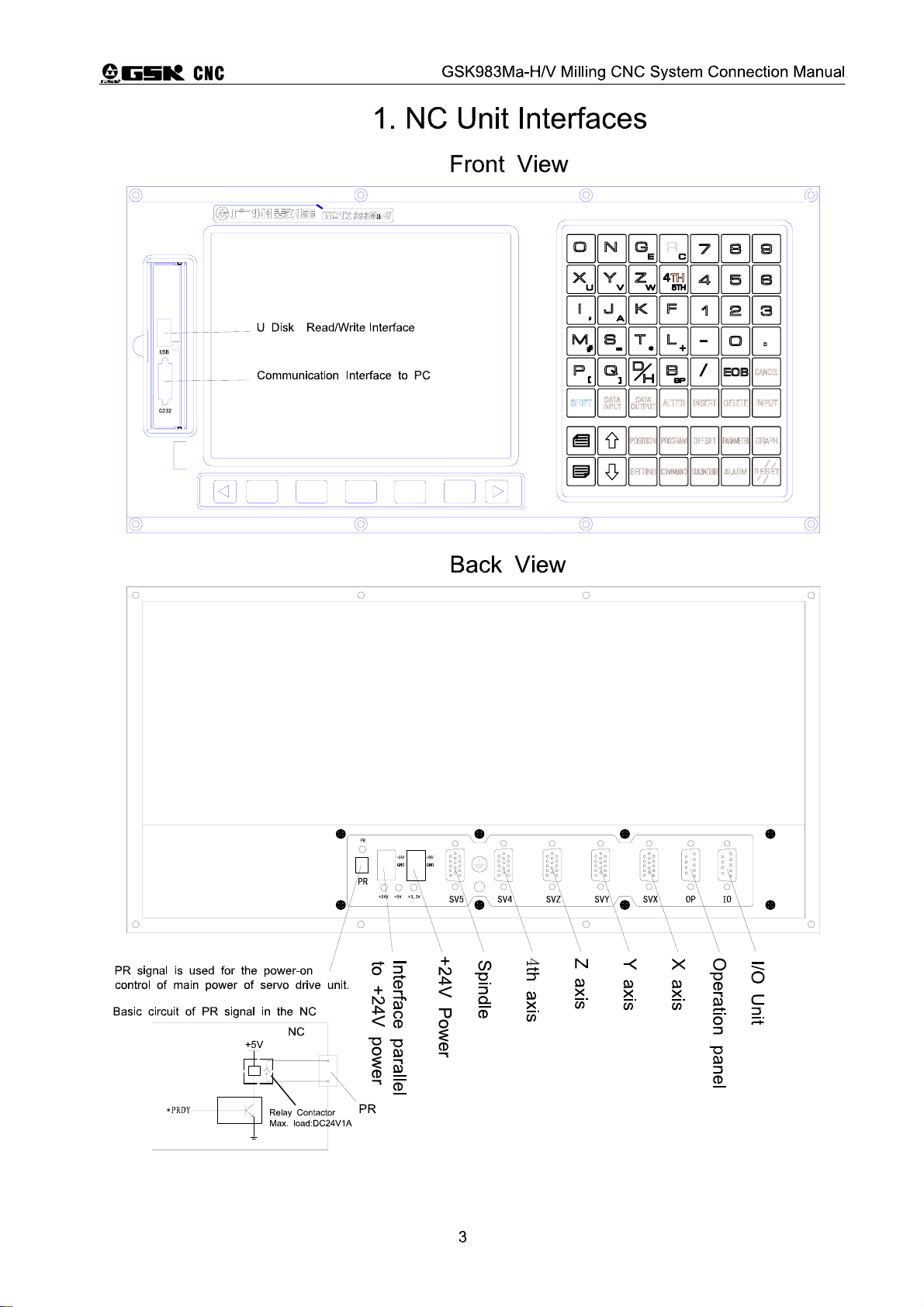

1. NC Unit Interfaces.................................................................................................................... 3

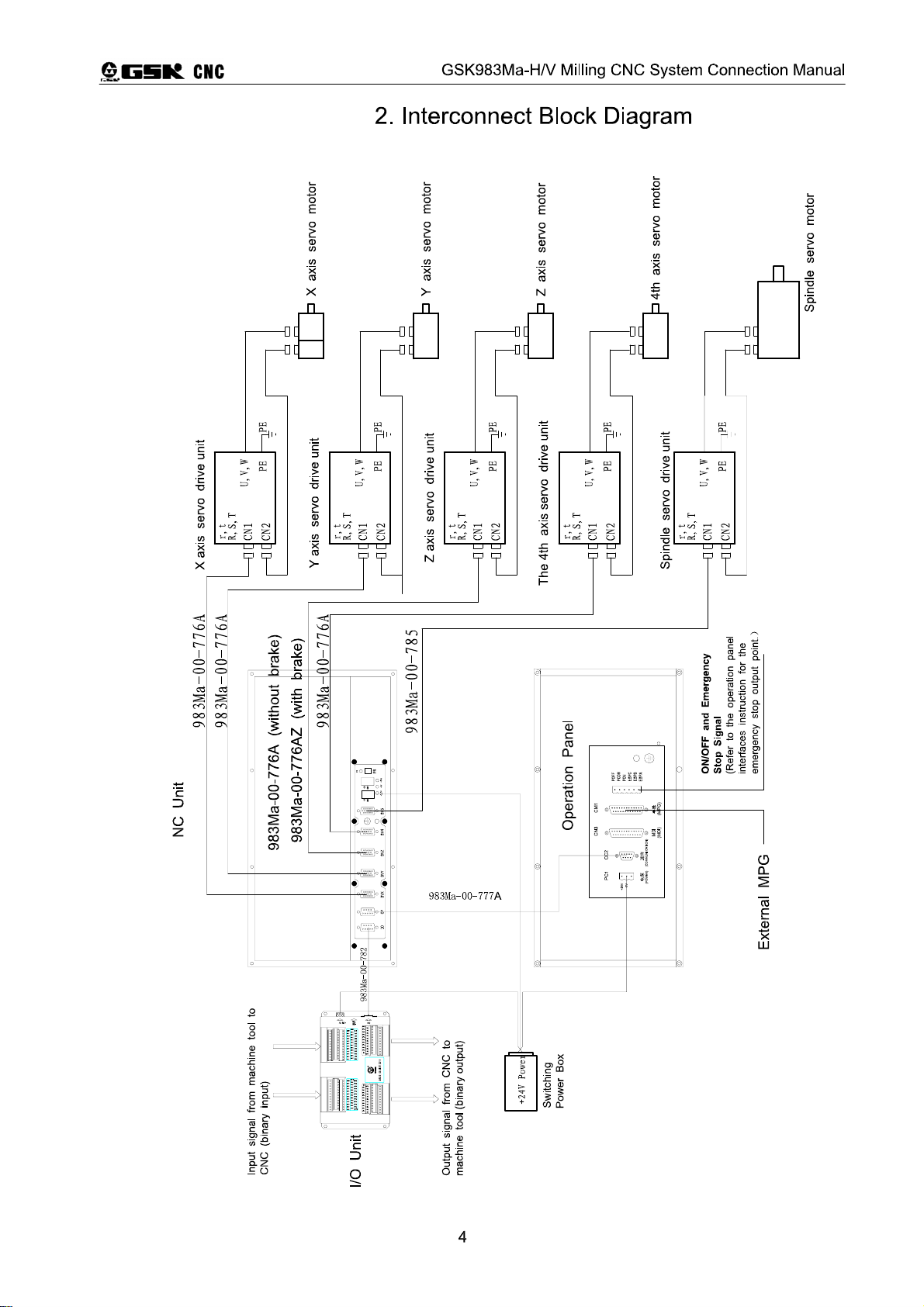

2. Interconnect Block Diagram ..................................................................................................... 4

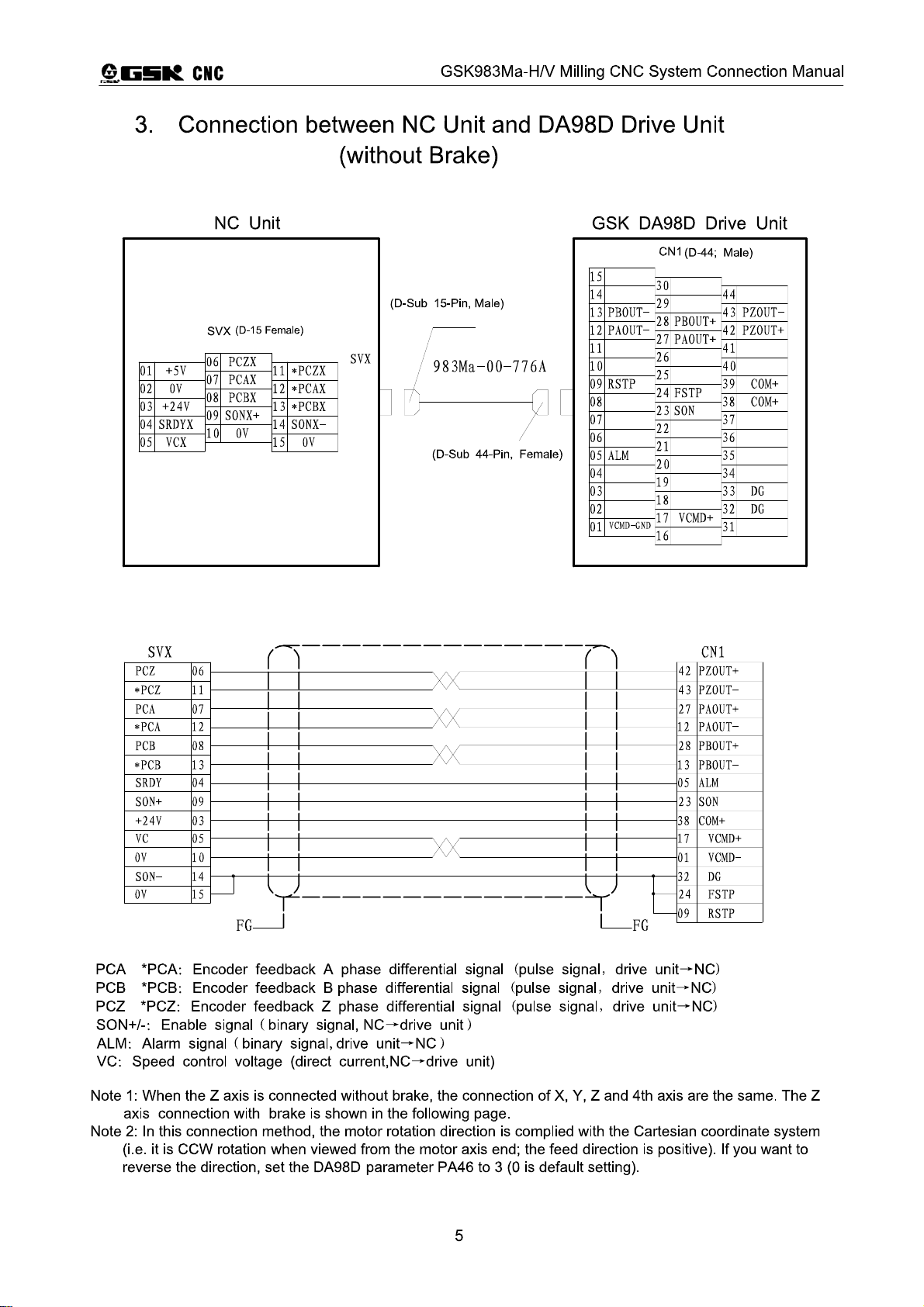

3. Connection between NC Unit and DA98D Drive Unit (without Brake) ................................... 5

4. Connection between NC Unit and DA98D Drive Unit (Z Axis with Brake) ............................. 6

5. Connection between NC Unit and Spindle Servo Drive Unit .................................................... 7

6. Connection between NC Unit and Spindle Inverter.................................................................. 8

7. Connection between NC Unit and I/O Unit............................................................................... 9

8. Machine Tool Panel Interfaces............................................................................................... 10

9. Connection between NC Unit and Operation Panel ............................................................... 11

10. Connection between External MPG and Operation Panel ................................................... 12

11. Connection between NC Unit and PC .................................................................................. 13

12. Connection Method for Z Axis Brake and System Power-on Control................................... 14

13. General of External I/O Unit (X1) Interfaces......................................................................... 15

14. Connectivity Diagrams for I/O Unit (X1) Input/Output Signals.............................................. 16

15. I/O Points Definition (X1)...................................................................................................... 17

16. Instructions for Installing Mechanical Position Detection Switch for Spindle Orientation...... 20

17. Instruction for installing mechanical position detection switch at Z axis 2nd reference point 21

Appendix. Installation Dimension Drawings ............................................................................... 22

GSK983Ma-H/V Milling CNC System Connection Manual Version Upgrading Records ............ 27

III

GSK983Ma-H/V Milling CNC System Connection Manual

IV

GSK983Ma-H/V Milling CNC System Connection Manual

Precautions

1. The system-matched power box is exclusive for GSK983Ma. Do NOT supply this power to

other devices (such as brake and magnetic valve); otherwise, serious danger may occur!

2. Requirements for electrical cabinet

The electrical cabinet adopts full-enclosed structure and dustproof design. The temperature

difference between outside and inside of the cabinet should be less than 10℃; or, a heat-exchange

system should be installed. The ambient temperature should not exceed 45℃. Prevent the entry of

dust, coolant and organic solution.

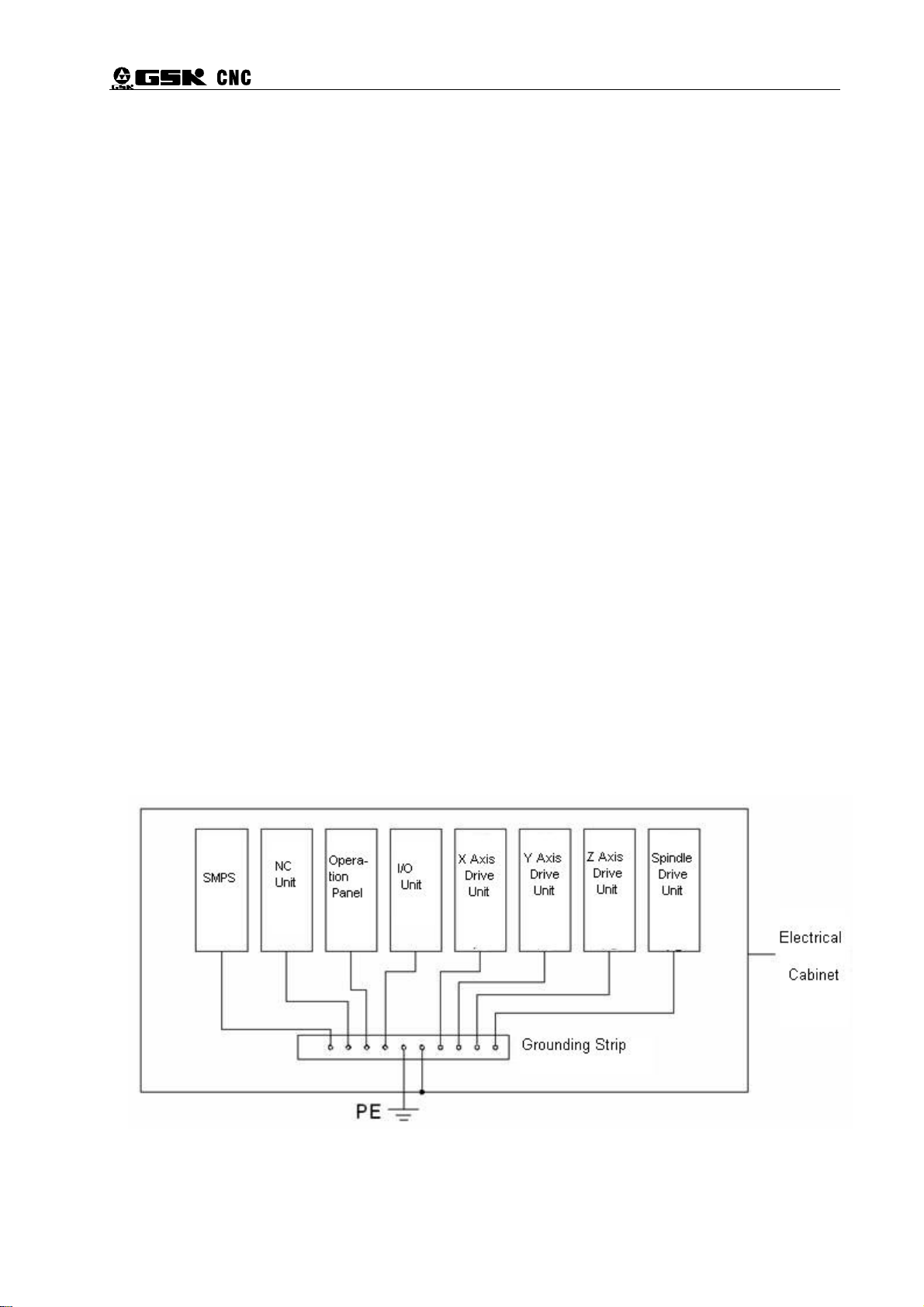

3. Grounding

The cabinet should be protectively grounded, and the continuity should meet the requirement of

GB5226.1-2002. Well grounding is the essential condition for a stable operation. The grounding wires

of different parts cannot be connected with each other in series; rather, the protective grounding

terminals should be connected to grounding strip with yellow-green wires independently. The

grounding strip mentioned here is installed in the cabinet and the thickness is not less than 3mm ; its

grounding resistance should be less than 0.1Ω.

4. The system power should be supplied through isolation transformer.

1

GSK983Ma-H/V Milling CNC System Connection Manual

5. Wiring

The joints between wires and the system or drive unit should be tight and firm. The low-current

type wires such as signal wires and control wires should be laid far away from heavy current and

electromagnetic interference, and be arranged in an uncurled manner as far as possible, because

winding annularly could easily cause the acquisition of interference signal.

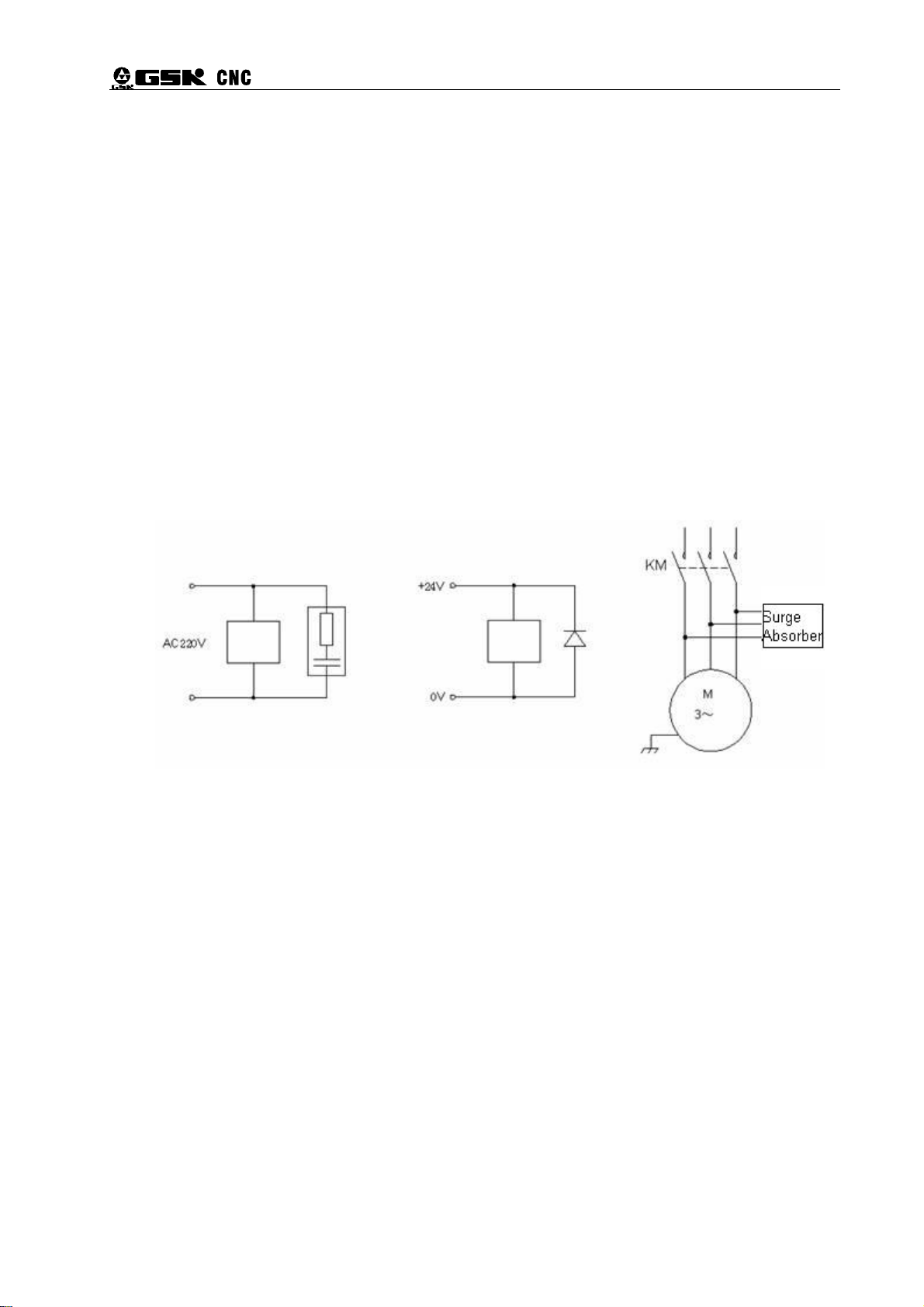

6. Interference suppression

Connect the RC circuits at the two ends of AC coil in parallel. The RC circuits should be closed to

inductive load as far as possible. Connect FWD at the ends of DC coil reversely in parallel. Connect

the surge absorber at the winding head of AC motor.

2

Loading...

Loading...