Page 1

This user manual describes all proceedings concerning the

operations of this CNC system in detail as much as possible. However, it is

impractical to give particular descriptions for all unnecessary or unallowable

system operations due to the manual text limit, product specific applications

and other causes. Therefore, the proceedings not indicated herein should

be considered impractical or unallowable.

This user manual is the property of GSK CNC Equipment Co., Ltd. All

rights are reserved. It is against the law for any organization or individual

to publish or reprint this manual without the express written permission of

GSK and the latter reserves the right to ascertain their legal liability.

Page 2

GSK983Ma Milling Machine Center CNC System User Manual

Preface

Your Excellency,

It’s our pleasure for your patronage and purchase of this

GSK983Ma Milling machining center CNC system made by GSK CNC

Equipment Co., Ltd.

GSK983Ma User Manual divides into three parts, that is,

“Programming”, “Operation” and “Appendix”.

Special prompt: 24V switch power box matched with the system is the

special power offered by our company.

User can not use the power to other purpose. Otherwise, the

enormous danger may occur!

II

Page 3

Safty Caution

Safty Caution

! Accident may occur by improper connection and operation!This system

can only be operated by authorized and qualified personnel. Please

carefully read this manual before using!

Refer to user manual issued by the manufacturer carefully

before installing, programming and operating this product, and

the relative operation should be performed based upon the user

manual strictly.

III

Page 4

GSK983Ma Milling Machine Center CNC System User Manual

Statement

● In this manual we have tried as much as possible to describe all the

various matters. However, we cannot describe all the matters which

must not be done, or which cannot be done, because there are so

many possibilities. Therefore, matters which are not especially

described as possible in this manual should be regarded as

“impossible”

Notice

● The product function and qualification (such as the accuracy, speed)

described in this manual is only for this product, which is installed the

CNC machine of this product. The actual function configuration and

technical capacity are determined by the setting of the manufacturer.

● The system is matched with the standard operation panel, but its

function of each key is defined by the PLC program (ladder diagram). It

is very important to note that the function of the key in this manual is

described for the standard PLC program!

● Refer to the manual issued by the manufacturer for the function of

each key on the operation panel and the meaning.

IV

Page 5

Cautions

Cautions

■ Transportation and storage

● Do not pile the carton more than six layers.

● Do not climb, stand or place the heavy on the carton.

● Do not drag or move the production using the cable connected with the

production.

● Do not bump the carton or scratch the panel and the display screen.

● The product packing should be avoid the damp, sun and rain.

■ Checking

● Confirm whether it is your purchased product after opening the packing.

● Confirm whether the product is being damaged during transporting.

● Confirm whether the spare parts are completed or being damaged.

● If the unconfirmed type, the lack of accessories or the damage of transportation

may occur, touch our company freely.

■ Wiring

● The wiring or checking should be performed with the professional.

● Refer to the Connection Manual for the wiring.

● The product should be grounded, and the grounding resistance should be less

than 0.1Ω. The neutral line (zero line) can not be replaced by the grounding.

● The wiring should be correct and firm, so that the product malfunction or

undesired result may occur.

● The surge absorber diode connected with this product should be connected in

the specified direction, or the product may be damaged.

● The power should be cut off when Inserting or pulling out the plug or opening the

machine of the product

■ Detection

● The man who is the professional can be detected the machine.

● The power should be cut off before detecting or repairing or changing the

elements.

● Checking the malfunction when the short-circuit or the overloading occurs, it can

be started after the malfunction is eliminated.

● Never attempt to turn on/off the product frequently, if you want to start it again

after the power is turned off, it is necessary to wait for 1min at least.

V

Page 6

GSK983Ma Milling Machine Center CNC System User Manual

Security Responsibility

Security responsibility for manufacturer

——Manufacturer should be take responsibility for the danger of the motor and the

accessories which have been eliminated and/ or controlled in design and in

structure.

——Manufacturer should be take responsibility for the security of the motor and

accessories.

——Manufacturer should be take responsibility for use information and suggestion

offered to the user.

Security responsibility for the user

——User should be know and understand about the content for security operation by

learning and training the security operation of the motor.

——User should be take responsibility for the security and danger about the increase,

change or original motor modification or accessory by themselves.

——User should be take responsibility for operating, adjusting, maintaining, installing

and storing the products without following the descriptions of this manual,

All specifications and design are subject to change without further

notice.

This manual is reserved by final user.

Sincere thanks for your friendly patronage for the products

made by GSK CNC Equipment Co., Ltd.

Chinese version of all technical documents in Chinese and

English languages is regarded as final.

VI

Page 7

List

List

Programming

Programming .......................................................................................................................................1

Chapter One General........................................................................................................................1

1.1

GENERAL............................................................................................................................................ 1

CAUTIONS FOR READING THIS MANUAL ............................................................................................... 1

1.2

Chapter Two Specification.................................................................................................................3

Chapter Three Programming ..........................................................................................................13

3.1

WHAT IS PROGRAMMING..................................................................................................................... 13

PROGRAM STRUCTURE........................................................................................................................ 13

3.2

3.2.1 Block .....................................................................................................................................14

3.2.2 Program Word ..................................................................................................................... 14

3.2.3 Input format.......................................................................................................................... 16

3.2.4 Decimal point programming ..............................................................................................17

3.2.5 The maximum command value......................................................................................... 18

3.2.6 Program number................................................................................................................. 19

3.2.7 Sequence number .............................................................................................................. 20

3.2.8 Skip to optional block ......................................................................................................... 20

DIMENSION WORD .............................................................................................................................. 21

3.3

3.3.1 Controlled axis..................................................................................................................... 21

3.3.2 Setting unit ...........................................................................................................................22

3.3.3 The maximum stroke.......................................................................................................... 24

3.3.4 Program origin and coordinate system............................................................................ 24

3.3.5 The coordinate system and the machining start point................................................... 24

3.3.6 Workpiece coordinate system........................................................................................... 25

3.3.7 Reference (position) point ................................................................................................. 25

3.3.8 Absolute and incremental commands.............................................................................. 26

FEED FUNCTION (F FUNCTION) ........................................................................................................... 27

3.4

3.4.1 Rapid traverse rate............................................................................................................. 27

3.4.2 Cutting Feedrate ................................................................................................................. 27

3.4.3 Feedrate decelerates to 1/10.......................................................................................... 28

3.4.4 Synchronous feed (feed/rev.)............................................................................................ 28

3.4.5 F1-digit Feed ....................................................................................................................... 29

3.4.6 Automatic acceleration/deceleration................................................................................ 30

3.4.7 Automatic Corner Modification.......................................................................................... 31

PREPARATION FUNCTION (G FUNCTION) ............................................................................................. 34

3.5

3.5.1 Plain Selection (G17, G18, G19)...................................................................................... 37

3.5.2 Positioning (G00)................................................................................................................ 37

3.5.3 Single Direction Positioning (G60) ................................................................................... 38

3.5.4 Linear interpolation (G01)................................................................................................ 39

3.5.5 Circular Interpolation (G02, G03)..................................................................................... 41

3.5.6 Sine curve interpolation ..................................................................................................... 44

3.5.7 Thread Cutting (G33) ...................................................................................................... 45

~

3.5.8 Automatic reference position return (Reference position G27

3.5.9 Dwell (G04) ..........................................................................................................................51

3.5.10 Exact stop check (G09) ...................................................................................................51

3.5.11 Exact stop check (G60) and cutting mode (G64)......................................................... 51

3.5.12 Coordinate system setting (G92) ................................................................................... 51

~

3.5.13 Workpiece coordinate system (G54

G59).................................................................. 53

3.5.14 Workpiece coordinate system changes by the program command.......................... 55

3.5.15 Automatic coordinate system setting............................................................................. 55

3.5.16 Inch/Metric conversion (G20, G21)................................................................................ 56

3.5.17 Stored stroke limit (G22, G23)........................................................................................ 56

3.5.18 Skip Function (G31) ......................................................................................................... 59

COMPENSATION FUNCTION ................................................................................................................. 60

3.6

G30)........................ 47

VII

Page 8

GSK983Ma Milling Machine Center CNC System User Manual

3.6.1 Tool length compensation (G43, G44, G49) ...................................................................60

~

3.6.2 Tool position offset (G45

3.6.3 Cutter compensation (G40

G48)........................................................................................63

~

G42)....................................................................................70

3.6.4 Functions D and H ............................................................................................................101

3.6.5 External tool offset ............................................................................................................102

3.6.6 Enter offset value from the program (G10)..................................................................102

3.6.7 Scaling (G50, G51) ...........................................................................................................102

3.6.8 Coordinate system rotation (G68, G69).........................................................................105

THE FUNCTION OF CYCLE MACHINING .............................................................................................. 113

3.7

3.7.1 The function of the external operation........................................................................... 113

~

3.7.2 Canned cycle (G73, G74, G76, G80

G89)................................................................. 113

3.7.3 The initial point and point R in the canned cycle (G98, G99).....................................134

3.7.4 Rigid tapping cycle (G180, G184)...................................................................................135

SPINDLE FUNCTION (S FUNCTION), TOOL FUNCTION (T FUNCTION), MISCELLANEOUS FUNCTION (M

3.8

FUNCTION), THE 2

ND

MISCELLANEOUS FUNCTION (B FUNCTION) ............................................................138

3.8.1 Spindle function (S function)............................................................................................139

3.8.2 Constant surface speed control ......................................................................................139

3.8.3 Tool function (T function)..................................................................................................141

3.8.4 Miscellaneous function (M function)...............................................................................141

3.8.5 The 2nd Miscellaneous Function (B function)...............................................................142

SUB-PROGRAM..................................................................................................................................142

3.9

3.9.1 The Manufacture of the Sub-pr ogram............................................................................142

3.9.2 The Performance of the Sub-program...........................................................................143

3.9.3 Special usage ....................................................................................................................143

USER MACRO PROGRAM.................................................................................................................145

3.10

3.10.1 General Brief....................................................................................................................145

3.10.2 Variable.............................................................................................................................145

3.10.3 Type of the Variable........................................................................................................147

3.10.4 Operation command .......................................................................................................157

3.10.5 Control command............................................................................................................160

3.10.6 The Compilation of the User Macro Program Body and Memory............................164

3.10.7 Macro Call command......................................................................................................167

3.10.8 The Relationships with Other Functions......................................................................177

3.10.9 Special Codes and Words Used in User Programs................................................... 178

3.10.10 Restrictions....................................................................................................................179

3.10.11 The Description of the P/S Alarm ...............................................................................179

3.10.12 Examples of User Macro .............................................................................................180

3.10.13 External Output Command..........................................................................................181

3.10.14 Macro interruption function (Macro B)....................................................................... 183

TOOL LIFE MANAGEMENT ..............................................................................................................184

3.11

3.11.1 Setting of the Tool Groups .............................................................................................184

3.11.2 Specification in the Machining process........................................................................186

3.11.3 Performance of the Tool Life Management.................................................................187

3.11.4 The Display and Input of the Tool Data........................................................................187

3.11.5 Other Cautions.................................................................................................................188

THE INDEXING FUNCTION OF THE INDEX WORKTABLE ..................................................................189

3.12

3.12.1 Instruction method ..........................................................................................................189

3.12.2 The Minimum Movement Unit: 0.001 degree/pulse...................................................189

3.12.3 Feedrate ...........................................................................................................................189

3.12.4 The Clamping and Release of the Indexing Worktable.............................................190

3.12.5 JOG/Step/MPG................................................................................................................191

3.12.6 Other Cautions ................................................................................................................191

Chapter Four Operation................................................................................................................ 193

POWER ON/OFF...............................................................................................................................193

4.1

4.1.1 Power ON ...........................................................................................................................193

4.1.2 Power OFF .........................................................................................................................193

PROGRAM LOCK................................................................................................................................193

4.2

RELATED OPERATIONS TO MACHINE PANEL ....................................................................................194

4.3

VIII

Page 9

List

4.3.1 Machine Panel................................................................................................................... 194

4.3.2 Emergency Stop (red)...................................................................................................... 196

4.3.3 Mode Selection ................................................................................................................. 196

4.3.4 Operations Related to Manual Operatio n...................................................................... 198

4.3.5 Manual Reference Point Return (reference position).................................................. 205

4.3.6 Related Operations in Automatic Running.................................................................... 205

4.3.7 MPG (manual pulse generator) Interruption ................................................................. 221

4.3.8 Manual Spindle Function .................................................................................................222

4.3.9 Manual Auxiliary Function ............................................................................................... 223

DISPLAY AND OPERATION OF THE NC UNIT WITH LCD CHARACTER DISPLAYER........................... 224

4.4

4.4.1 State Display ..................................................................................................................... 228

4.4.2 Key Input ............................................................................................................................ 230

4.4.3 Display of Program Number and Sequence Numbers................................................ 231

4.4.4 Alarm Display (functional key ALARM )..................................................................... 232

4.4.5 Operation Information (the content of external alarm message)............................... 232

4.4.6 Current Position Display and Reset (functional key POSITION )........................... 233

4.4.7 Display of Command Value (functional key COMMAND ) ...................................... 234

4.4.8 Setting (functional key SETTING ).............................................................................. 235

4.4.9 MDI Operation (functional key COMMAND )............................................................. 239

4.4.10 MDI Start and Running .................................................................................................. 240

4.4.11 Reset ................................................................................................................................240

4.4.12 Offset of the Tool Position............................................................................................. 241

4.4.13 Setting and Display of Workpiece Origin Point Offset............................................... 242

4.4.14 The method of Measuring Tool Length ....................................................................... 243

4.4.15 Program Display (Functional key PROGRAM).......................................................... 243

4.4.16 Program Number Retrieving (functional key PROGRAM)....................................... 245

4.4.17 Input a Single Program File ............................................................................................. 245

4.4.18 Input Program File with Multiple Programs.................................................................... 246

4.4.19 Input Programs by Keys................................................................................................ 246

4.4.20 Deletion of a Program.................................................................................................... 248

4.4.21 Deletion of All Programs................................................................................................ 248

4.4.22 Output a Program........................................................................................................... 248

4.4.23 Output All Programs.......................................................................................................... 248

4.4.24 Sequence Number Search............................................................................................ 248

4.4.25 Restart the Program....................................................................................................... 249

4.4.26 Comparison and Stop Function for Block ................................................................... 252

4.4.27 Input Offset Value (any functional key).......................................................................... 252

4.4.28 Output Offset Value(functional key: OFFSET) .............................................................. 252

:

4.4.29 Display Parameter (functional key

PARAMETER )................................................ 253

4.4.30 Program Edit (functional key:PARAMETER )......................................................... 253

4.4.31 Display of Running Time ............................................................................................... 262

4.4.32 Menu Switch Function.................................................................................................... 262

4.4.33 Operation for LCD Soft Functional Key....................................................................... 264

4.4.34 Input/Output of NC Parameter...................................................................................... 273

GRAPHIC FUNCTION............................................................................................................................ 274

4.5

4.5.1 Display Type of The Graphic........................................................................................... 274

4.5.2 Graphic Parameter Setting.............................................................................................. 274

4.5.3 The Meaning of Graphic Parameter............................................................................... 275

4.5.4 Drafting............................................................................................................................... 280

APPENDIX ......................................................................................................................................282

Appendix 1 System Version Display................................................................................................282

Appendix 2 G Codes List.................................................................................................................283

Appendix 3 Range of Command Values..........................................................................................285

Appendix 4 Nomographs .................................................................................................................286

Appendix 5 Parameters ...................................................................................................................289

Appendix 6 Alarm List......................................................................................................................329

Appendix 7 Status when Turning Power on, Reset and Cleared .....................................................338

Appendix 8 Stored Pitch Error Compensation Function................................................................340

IX

Page 10

GSK983Ma Milling Machine Center CNC System User Manual

Appendix 9 Operation List ...............................................................................................................347

Appendix10 Program Lock ..............................................................................................................351

Appendix 11 USB Interface Parameter Transfer Operation .............................................................353

Appendix 12 System Clock Setting and PLC Programming ............................................................354

Appendix 13 The supplement of the GSK983Ma Milling Machining Center CNC System User

Manual.............................................................................................................................................359

X

Page 11

Chapter One General

Programming

Chapter One General

1.1 General

GSK983Ma Milling machining center CNC system (The following are abbreviated to

“System”), which is a medium and high grade manufactured goods with high speed, high accuracy,

high stability, and high cost performance. It has been developed base on the stable and reliable and

the market requirement and the updated technical development by the GSK CNC Equipment

Company.

This horizontal type/vertical type installation of this system adopts the 8.4

Part 1 Programming

inch/10.4 inch HR, hi-lite LCD screen separately. The system uses the full paster

automatic product technology and built-in PLC. The operating interpolation is

distributed processing by the multiply high-speed microprocessors, which owns the

treatment capacity for 500 blocks per second. The special hardware circuit is externally

connected the raster rule, which can be controlled of the position full-close. It has the

boundary CNC alarm detecting function, which is used for the serial high-speed, high

accuracy, Hi-Rel.

1.2 Cautions for Reading this Manual

The capacity of the CNC machine are determined by the CNC system, machine

structure, strong current control and the servo system (the mechanical operation pane

included), this manual is only described for the GSK983Ma CNC system.

This manual is introduced the function (Selection function included) of the system

with detailed, but the actual device is not included all the selection function. The function

of the CNC system is not only determined by the NC, but also the mechanical part, the

strong circuit of the machine side, servo system and the machine operator panel. It is

very hard to describe the whole functions of the system, programming and operation

thoroughly; it is only expressed from the angle of the system.

The specification of the operation panel, the capacity of the CNC machine, the

machine programming and operation method of the character CNC machine are

performed by referring the manual issued by the manufacturer.

1

Page 12

Note: The notes are described for some items. However, when the notes without any expresses are

described in this manual, just skip the notes until you return to read it again after finishing this

manual, it is very easy to understand for this manual.

Part 1 Programming

GSK983Ma Milling Machine Center CNC System User Manual

2

Page 13

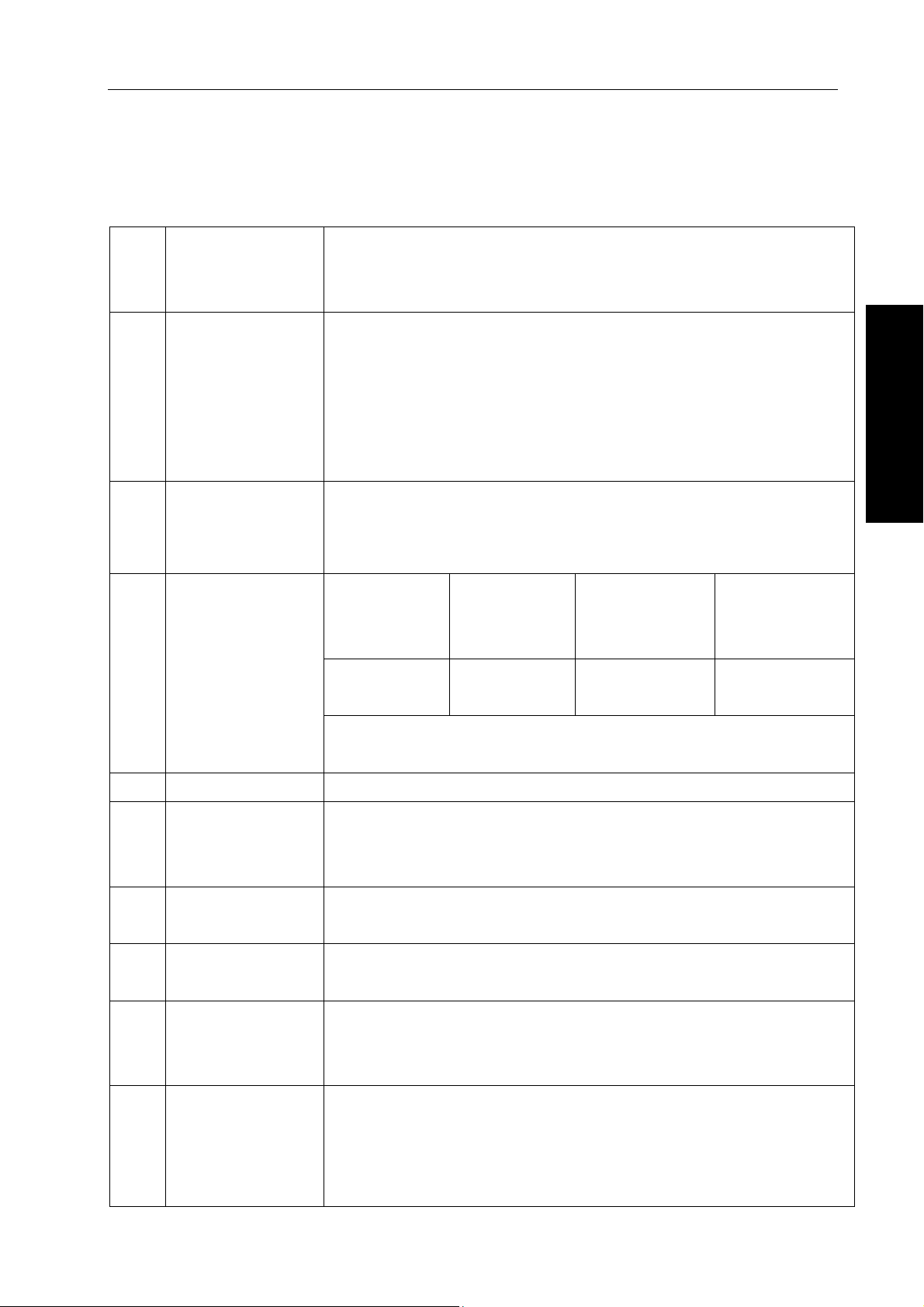

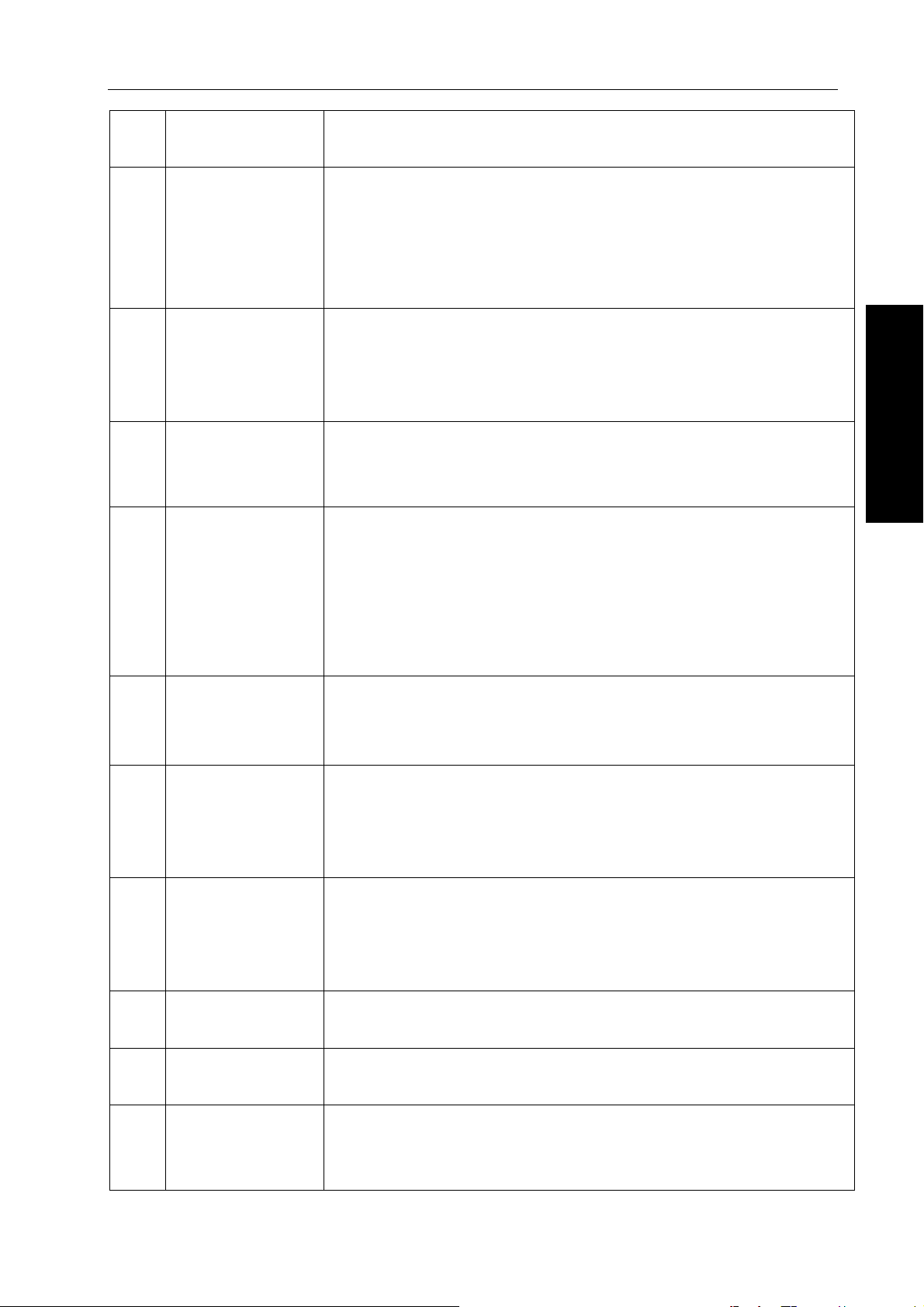

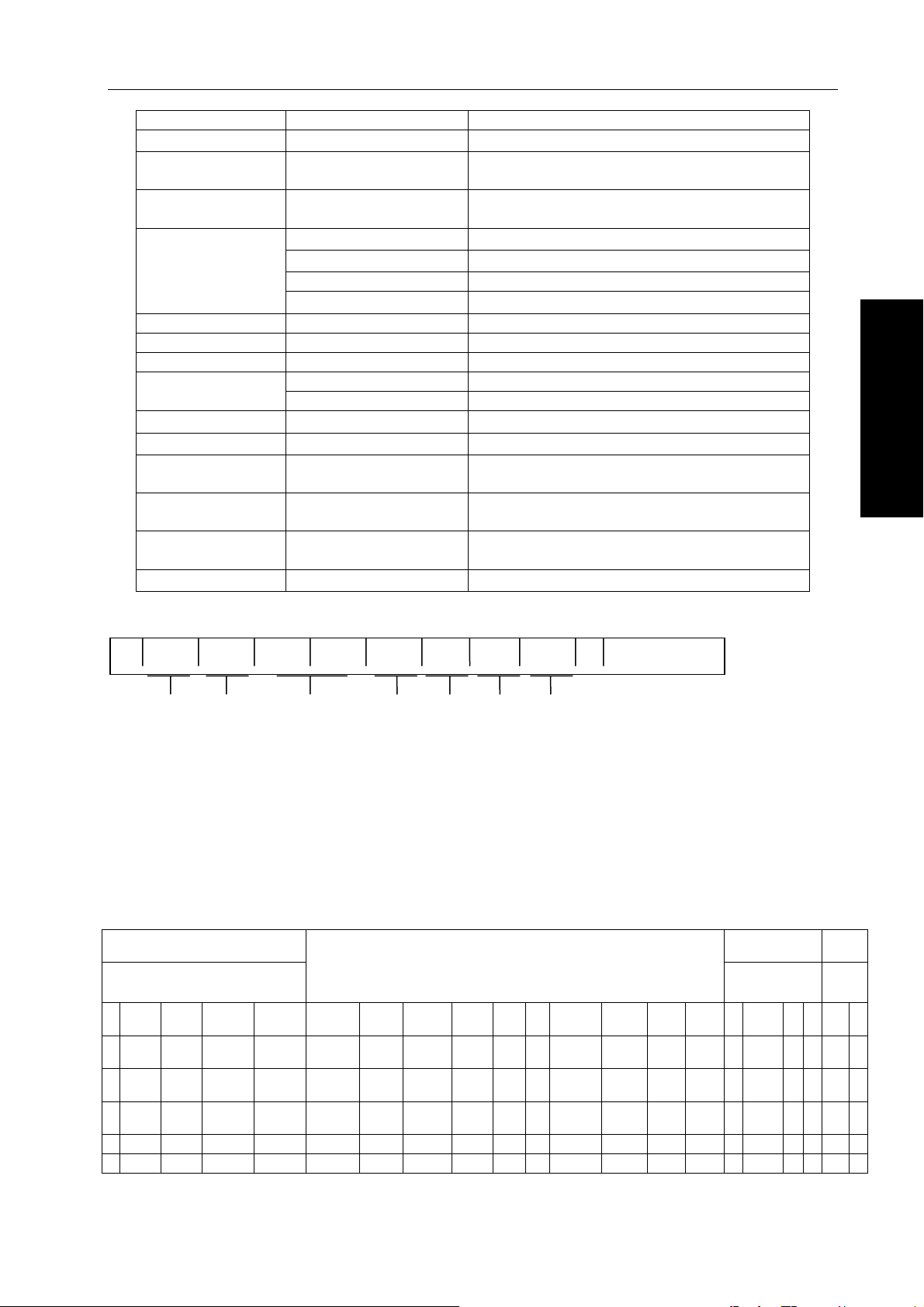

No.

Chapter two Specification

Chapter Two Specification

of

Name Specification

item

1 Controlled axes

No. of

2

simultaneously

controlled axes

3 Increment system

Standard: 3 axes (X, Y and Z)

(It can be set to the 4

address of 4

th

is selected from A, B, C, U, V and W, the 4th axis is

th

axis or the 5th axis based on the order. The

straight line axis or rotation one which is set by parameter; and the

address of the 5

th

axis is selected from U, V, W, A, B and C, the 5th axis

is straight line axis or the rotation one which is set by parameter, too).

The standard is 3 axes and 3-linkage simultaneously.

(It can be set to the 4 axes and 3-linkage, 4 axes and 4-linkage, 5 axes

and 3-linkage and 5 axes and 4-linkage base on the order).

Note: The functions, such as the rigid tapping and the feed per revolution, can

not be used by the 5 axes.

The least

setting

0.001mm 0.0001inch 0.001°

increment

The least input

0.001mm 0.0001inch 0.001°

increment

Part 1 Programming

The least input increment by metric based on the parameter setting is

0.01mm.

4 Digit check device Pulse encoder

±99999.999mm

The Max.

5

±9999.9999inch

command value

±99999.999°

Use the formats, such as, changeable block, changeable character and

6 Input format

the changeable address.

Decimal point

The digit can be inputted with the decimal point, the addresses with

7

programming

decimal point: X, Y, Z, A, B, C, U, V, W, I, J, K, Q, R and F.

The axis direction speed is up to 60.000m/min or 2400inch/min. The

8 Rapid traverse

rapid traverse speed can be modified into F0, 25%, 50% and 100%

using the rapid traverse override (selection).

The feedrate can be set within the following range: 1mm/min ~

30,000mm/min, the upper limited speed of cutting feed 0.01inch/min~

9 Cutting feedrate

1200.00 inch/min can be set by the parameter. The feedrate override

10% is regarded as a gear which can be selected a feedrate within the

3

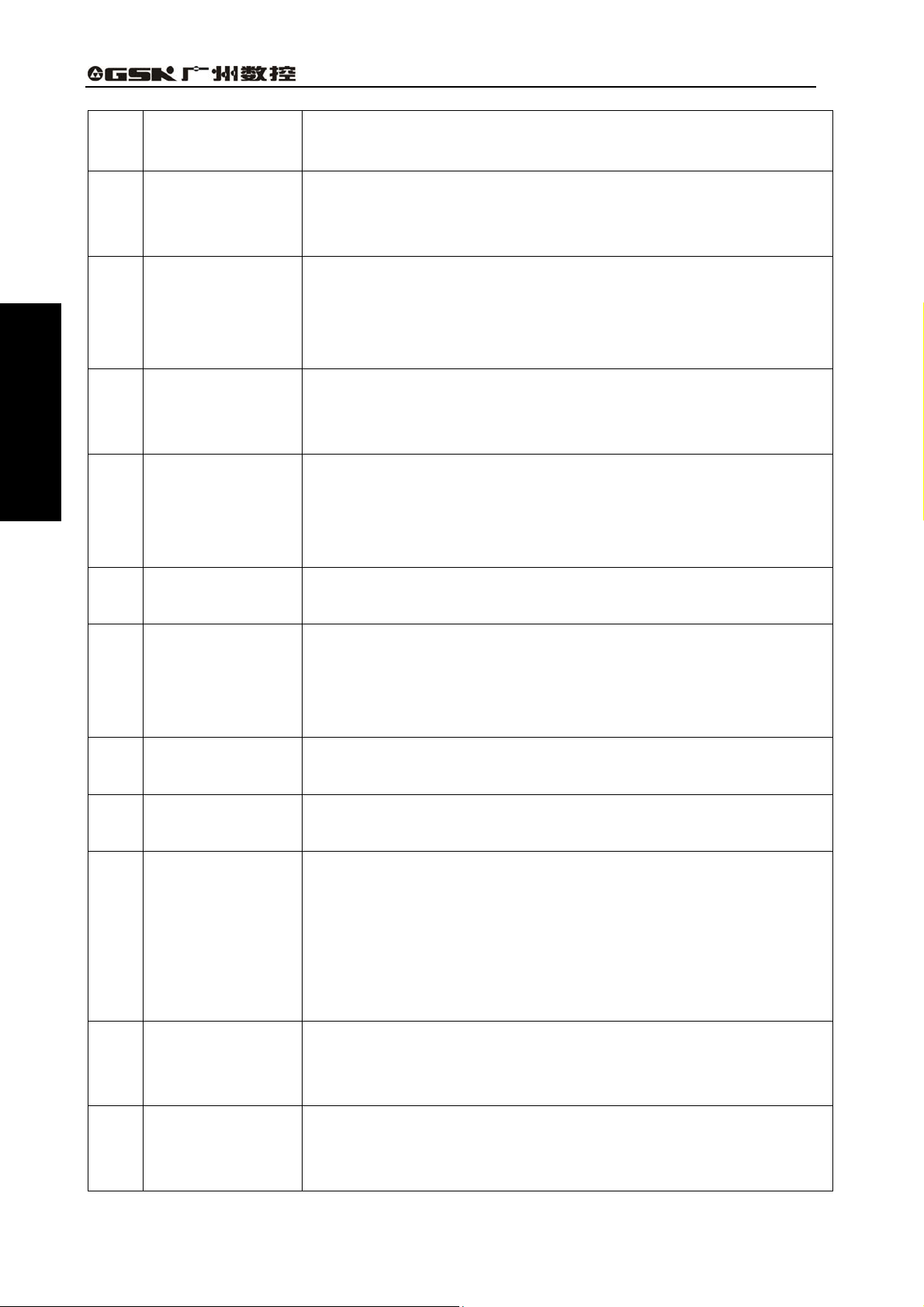

Page 14

GSK983Ma Milling Machine Center CNC System User Manual

range of 0~200%, the unit of feedrate set by parameter can be

modified into 0.01 mm/min, 0.001 mm/min or 0.001inch/min.

Automatic

10

acceleration/decele

ration

Absolute/increment

Part 1 Programming

11

value command

Coordinate system

12

setting (G92)

13 Positioning (G00)

Linear interpolation

14

(G01)

The linear acceleration or deceleration mode can be used at the rapid

traverse rate regardless of the manual or Auto to shorten the positioning

time.

Either the absolute programming or increment programming can be

selected by the G code.

G90: Absolute value programming

G91: Incremental value programming

The command value followed with the G92 can be used to set a

coordinate system, the tool position coordinate value is the command

value of this coordinate system.

Each axis can separately and rapidly move to the end then stops by

specifying G00, and whether the machine can be performed the

in-position (whether the machine is reached the specified position)

check by the parameter setting.

Use the G01 code, the linear interpolation can be performed based on

the feedrate specified by F code.

15 Buffer register

16 Dwell (G04)

Exact stop check

17

(G09)

Checking mode of

18

exact stop/cutting

mode (G61, G64)

Miscellaneous

19

function (M2 digit)

The next block can be read to the buffer register in advance before the

former block is performed. In this case, avoid the intermittence of NC

command because the time for reading. When the data is inputted to

the buffer register, the BUF is displayed at the lower right of LCD.

The next block movement can be delayed using the G04 code.

The delay time can be specified by the address P or X.

Specify a block of G09, it decelerates to 0 when the block ends, and

then performs the following block after positioning.

If the G61 is specified, the movement command followed with the G61

decelerates to 0 at the end of each block, and then performs the

following block after positioning.

If the G64 is specified, the movement command followed with the G64

other than the position does not decelerate but perform the following

block immediately, generally, it is for cutting mode.

The command after the address M followed 2-digit can be controlled for

the ON/OFF signal of the machine side. Only one M code can be

specified in a block.

20 Dry run

4

In the dry run mode, the feedrate becomes JOG.

The rapid traverse holds invariable in G00 command, the rapid traverse

override (selection) is still valid. Whether the rapid feedrate is run based

Page 15

Chapter two Specification

upon the dry run which is determined by the parameter setting.

Each axis can be separately forbidden the feed of the commanded axis,

21 Interlocking

if any commanded axis is added an interlocking during movement, all of

the axes of machine may decelerate and then stops. The machine

accelerates then starts as long as the interlocking releases.

22 Single block One block command can be performed once.

The block with / (slash) code (A / (slash) code followed by a block) can

23 Optional block skip

be omitted the start by switching on the optional block skip switch

installed on the machine side.

The movement direction or the mirror image of X, Y and 4

External mirror

program command and the MDI command can either set using MDI &

24

image

LCD panel or using the switches (selected function) at the machine

side.

Whether the movement amount of the tool is moved by manual

operation is added to the absolute coordinate value can be selected by

Manual absolute

25

turning the manual absolute switch on or off on the machine side.

ON/OFF

When the switch is turned off: added

When the switch is turned off: do not add

th

axis

Part 1 Programming

26

Miscellaneous

function lock

27 Machine lock

Z-axis command

28

cancel

29 Feed hold

Override

30

cancellation

31 ESP

External resetting,

32

resetting signal

The BCD code signal and strobe signal of M, S, T and B function are

forbidden to send to the machine side.

The machine does not move, but the position display is still enabled as

the machine is moving, the machine locking is enabled even if the block

is performing.

This function is only valid to the Z axis lock; use this function to check

NC program by drawing.

The feed of all axes can be temporarily stopped, the resetting can be

performed by pressing the cycle start button, before the feed resetting,

the manual operation can be performed in the mode of manual.

The cutting feedrate can be fixed on the 100% based on the signal

(selection function) from machine side.

All feed commands are being stopped (immediately interrupted) by

pressing the ESP button, the machine is stopped simultaneously.

NC can be reset from NC external. All of the feed commands are

stopped with this signal by resetting, and the machine decelerates to

stop. Additional, during the resetting button of MDI & LCD, ESP and

external resetting added; input a resetting signal to the machine side.

When the machine motion components arrived to the end of the stroke,

33 Overtravel

the arrival signal is received, the axis is decelerated then stopped, and

the overtravel alarm may issue simultaneously.

5

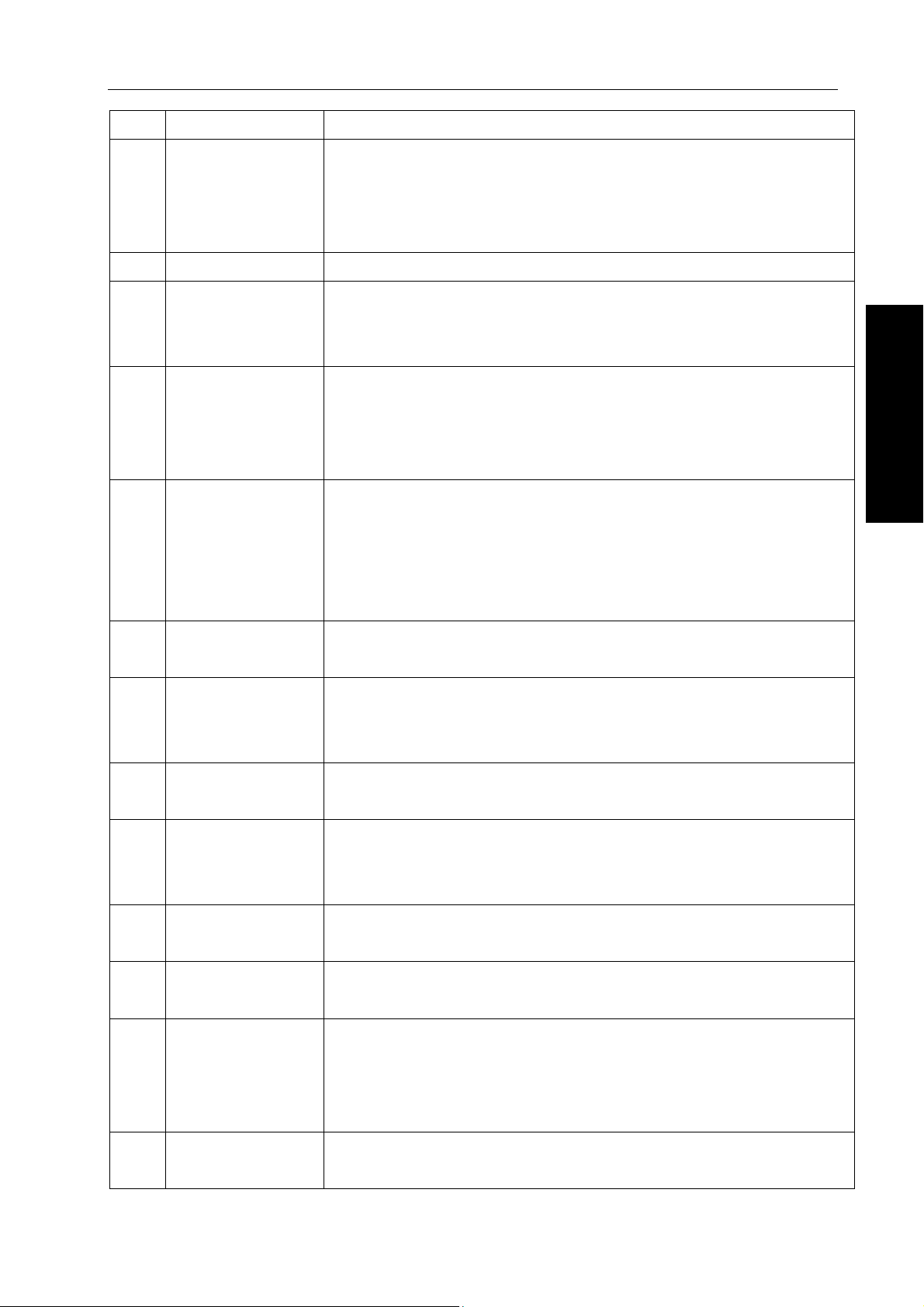

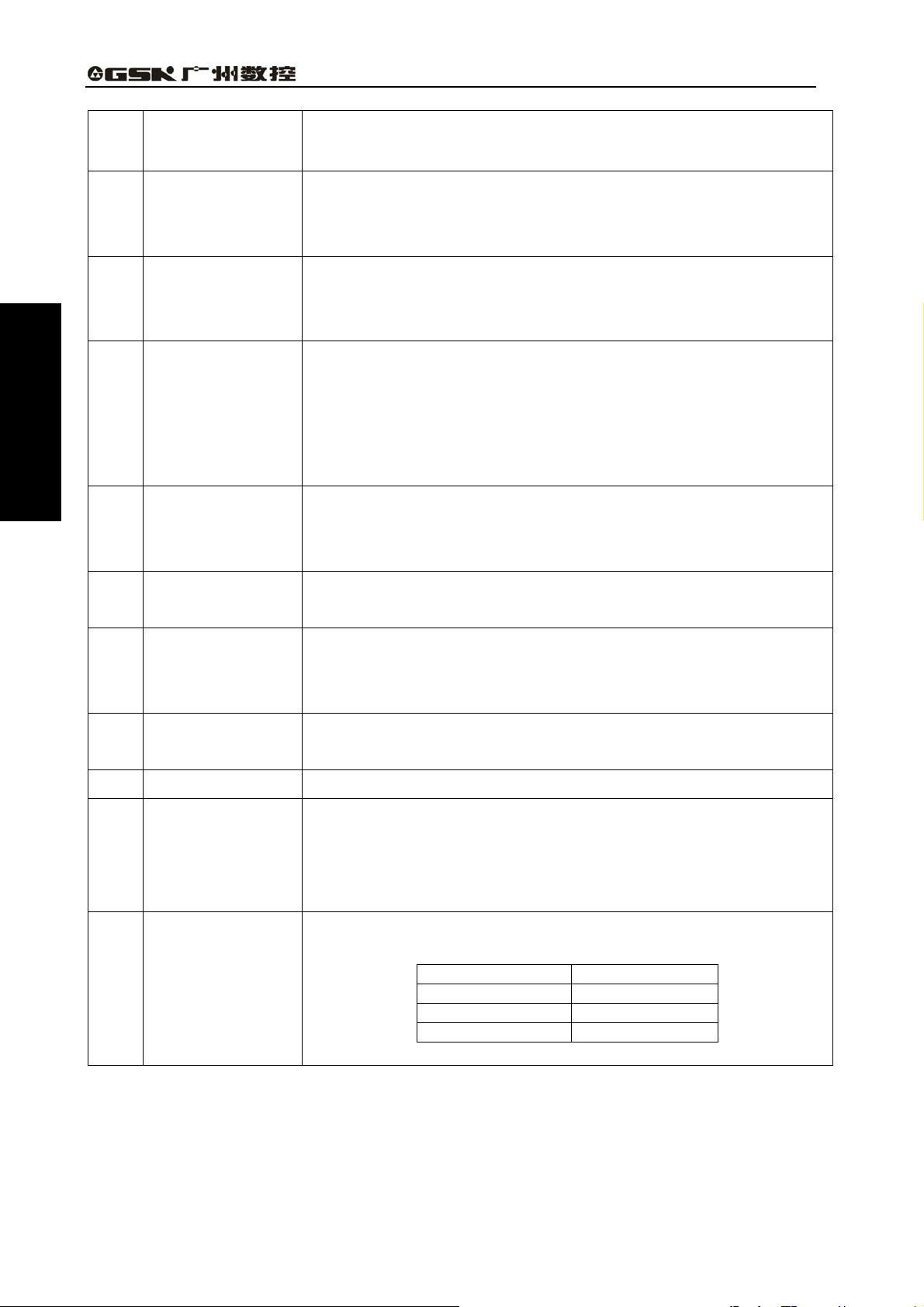

Page 16

GSK983Ma Milling Machine Center CNC System User Manual

When the power is turned on and when NC is at the controllable state,

34 Ready NC signal

35 Ready servo signal

Part 1 Programming

36 NC alarm signal The signal from NC issues at the alarm state.

37 Distributed signal

Cycle operation

38

signal

Cycle operation

39

start indicator

signal

Feed hold indicator

40

signal

send this signal to the machine side; when the power is turned off or the

controllable unit is overheat, stop to send any signal to the machine

side.

Send a signal to the machine side after a servo system is ready. The

axis must be braked in this signal which does not send out is locked.

The NO READY is displayed on LCD when this signal is not executed.

When the movement command ends, NC outputs this signal. If the M,

S, T or B function and movement command in a block, this signal is

issued after movement command is performed, and the M, S, T or B

function can be performed.

NC sends out this signal in the cycle operation.

NC sends out this signal in cycle start.

NC issues this signal when the feed hold is on the dwell state.

41

Manual

consecution feed

42 Incremental feed

Sequence number

43

index

Program number

44

index

Interval

45

compensation

(1) JOG feed The JOG feedrate can be shifted in 24-step using the

rotation switch. The ratio of the 24-step is geometric series. (Standard

panel matches 20-step)

(2) Manual rapid traverse The rapid traverse can be performed by

manual, the rapid override can be used the rapid traverse of the

parameter setting.

The manual consecution is valid in 2-axis simultaneously.

The increment position control and high-efficiency manual position

(selection function) can be performed

The increment can be performed in 2-axis simultaneously. (the feed of

increment)

The sequence number within program for currently selected can be

indexed using MDI & LCD panel.

The program number of 4 digits followed with O can be indexed using

MDI & LCD panel.

It is a compensation function for the machine movement vector. The

compensation value is set by parameter within the range 0~255, which

is regarded as a unit of the least movement for each axis.

46 Locking of program

6

This function is forbidden a display, setting or edit of the program

number (9000~9899) by the locking.

Page 17

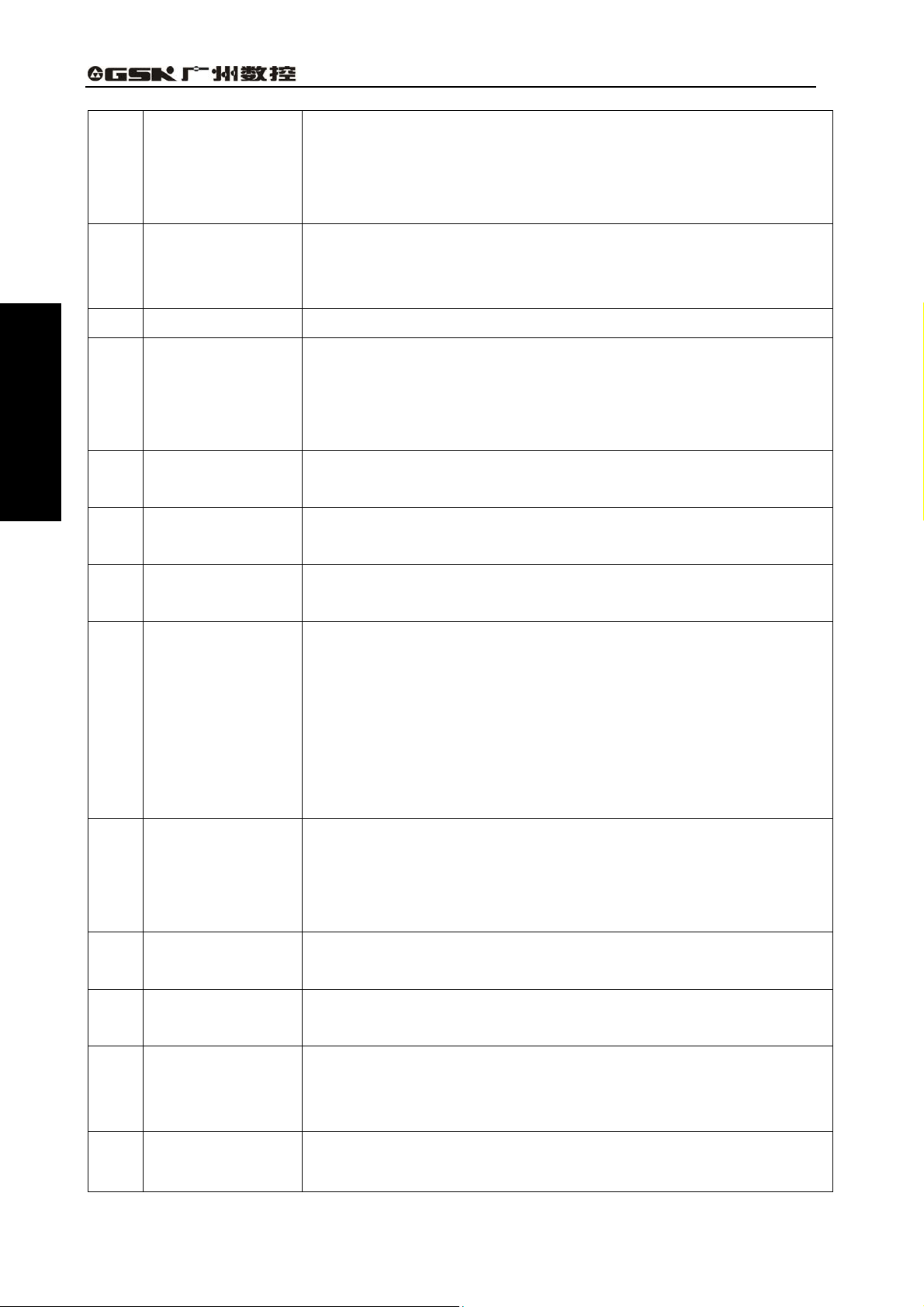

Chapter two Specification

(1) Ambient temperature

Work temperature: 0℃~45℃

Storage and transportation temperature: -20℃~55℃

(2) Relative humidity

≤90% (condensing), ≤95% (40 )℃

47 Ambient condition

Self-diagnosis

48

function

(3) Vibration

Work vibration<0.5G,

Storage and transportation vibration<1G

(4) Ambient temperature

When the NC device is used at the high concentration

circumstances, such as in the dust, cutting oil or the organic solvent, is

important to touch the manufacturer.

(1) Servo system

a. When the error of error register is more than the setting value of

stop state, the alarm issues.

b. When the value of error register is more than the maximum

setting value, the alarm issues.

c. When the position check system is abnormal, the alarm issues.

d. When the drifting voltage is excessive large, the alarm issues.

e. When the speed control unit is abnormal, the alarm issues.

(2) NC

Part 1 Programming

49

50

S function/T

function (BCD

2-digit)

S4-digit (Binary

system 12-digit

output) A/S4 digit

(analog output) A

a. When the memory is abnormal, the alarm occurs.

b. When ROM or RAM is abnormal, the alarm occurs.

c. When the MPU is abnormal, the alarm occurs.

(3) State display

a. Display the NC state on LCD.

b. Display I/O state on LCD.

2-digit command is followed with address S and T, the code signal of

BCD2-digit can be sent out once the command is performed, the S or T

code is separately sent out with other codes till to the following S or T is

specified.

The binary system 12-digit corresponding with the spindle speed or the

analog voltage outputs to the machine side, the maximum analog

voltage is ±10V, 2mA. The spindle speed (r/min) is directly specified by

S4, the spindle speed can be modified within the 50%, 60%, 70%, 80%,

90%, 100%, 110% or 120% based on the contact signal of the machine

side.

51 S4-digit (Binary When the spindle speed (r/min) is directly specified by S4-digit, output

7

Page 18

GSK983Ma Milling Machine Center CNC System User Manual

system 12-digit

output) A/S4 digit

(analog output) B

Thread cutting/

52

synchronic feed

Part 1 Programming

53 Position encoder

54

55

Constant surface

Speed control

nd

The 2

function (B3-digit)

the current spindle speed voltage based upon the selected gear

number 1~4. The shift of gear is performed during strong circuit, and its

consequent GRA or GRB signal outputs to the side of NC. The higher

2-digit of S4 or lower 2-digit number of NC program command is

outputted in terms of the BCD code.

The position encoder is installed on the spindle; the thread cutting can

be performed by using the pulse speed of position encoder.

To achieve the above-mentioned feed as the spindle rotation, a

frequency can be introduced to connect it on the spindle directly and the

pulse voltage device which becomes a proportion to the number of

spindle rotation, 1024 pulses for each revolution.

Usually, the surface speed is specified with S code, in this case, when

the tool position is changed, the spindle speed is correspondingly

changed, and the surface speed is always equalled to the linear speed

specified with S code.

Three-digit command followed with address B is performed once, the

auxiliary

BCD three-digit code signal is sent out immediately for specifying the

index table positioning.

56

T function

(BCD4-digit)

57 Code standard

58 Rapid override

Reference position

59

return A

Reference position

60

return B

rd

and the 4th

61

The 3

reference position

Four-digit command followed with address T is performed once, the

BCD three-digit code signal is sent out immediately, the T code is sent

out with other codes separately until they are reserved to the following T

code is specified.

ISO code (ISO840) and EIA code (EIARS-244-A) can be used by the

program code, which they can automatically and distinguishingly

performed.

The rapid traverse rate of Auto or Manual can be set based upon the

four gears, namely, F0, 25, 50 and 100%. F0 can be set a certain speed

by a parameter.

Reference position return A contains of the following items:

(1) Manual reference position return

(2) Reference position return check (G27)

(3) Automatically reference position return (G28)

The reference position return B is not only contained of the function of

reference position return B but also the 2

nd

reference position return

(G30).

Set the distance of the 1st reference position by the parameter, the 3rd

and the 4

th

reference position can be set, and these reference positions

return

8

can be returned.

Page 19

Chapter two Specification

As for the stored stroke limit 1, the area other than the one of parameter

62

63

64

Stored stroke limit

1

Stored stroke limit

2

Stored pitch error

compensation

The selection of

workpiece

coordinate system

setting is the forbidden area. As for the stored stroke limit 2, the internal

or the external area specified with parameter or program is forbidden

area. The enabled or disabled of stored stroke limit 2 is determined by

the G code.

G22: Enabled G23: Disabled

This function is used for the pitch error compensation caused by the

mechanical wearing of screw feed to improve the mechanical precise

and prolong the mechanical life. The compensation data is stored in the

memory which is regarded as a parameter; in this case, the relative

operations such as dog and the compensation structure are omitted.

One of the six workpiece coordinate systems can be set in advanced by

using six G codes, namely, G54~G59; and the following program should

be performed within the selected coordinate system.

The tool position offset can be performed using the G45~G48

commands. Tool position offset is the corresponding move command

extends or cuts an offset using the D or H code along axis. 1~184

Part 1 Programming

65

66

67

Tool position offset

commands can be specified by the D or H code, the maximum value of

offset is ±999.999 mm or ±99.999 inch.

(G45~G48)

G45: Extend the setting number.

G46: Short the setting number.

G47: Extend 2 times of setting number.

G48: Short 2 times of setting number.

When the manual reference position return is performed, the coordinate

The setting of

system can be set for setting the parameter in advance, namely, the

automatical

automatical performance is same as the G92 specified with reference

coordinate system

position.

The tool position offset (tool length compensation) can be performed in

the Z axis direction using G43 and G44 codes.

Tool length

The selection of offset number can be specified with 01~184 using H

compensation

code.

(G43, G44, G49)

The maximum value of offset is indicated as ±999.999 mm or

±99.999inch.

compensation (Tool

68

compensation) B,

C (G40~G42)

Cutter

radius

Cutter compensation can be performed using the G40~G42 codes. The

selection of offset number is specified within 1~184 using D code, the

maximum value of offset is ±999.999 mm or ±99.999inch.

The tool of the inner angle is less than 90° which can not use a tool

compensation B.

The tool of the inner angle is less than 90° which can use a tool

9

Page 20

GSK983Ma Milling Machine Center CNC System User Manual

compensation C.

After the standard tool is positioned at the fixed point, and then the tool

69

Tool length

measure

Tool life

Part 1 Programming

70

71

72

73

administration

function

Additional offset

memory A

Additional offset

memory B

Additional offset

memory C

to be measured is fixed at the same mechanical fixed position manually.

The length offset value of this tool is input regarded as an offset as long

as the Z INPUT is pressed.

The tool is divided into several groups within the tool magazine. Specify

a life to the tool of each group, when the tool of each group is used, the

accumulation is regarded as a criterion of the tool life for the tool

machining time or machining frequency. After the tool has been reached

the tool life, namely, the next tool is automatically selected within the

same group in advance

Tool position offset, the number of the cutter compensation can be

extended up to 64.

Tool position offset, the number of the cutter compensation can be

extended up to 64

The number of the tool compensation can be extended up to 184.

Once when the number of one-digit of 1~9 followed F is specified, the

74 F1-digit feed

External motion

75

function

Canned cycle A

(G80,G81,G82,G8

76

4,G85,G86,G89)

Canned cycle B

77

(G73, G74, G76,

G80~G89)

Inch/Metric

78

conversion (G20,

G21)

feedrate of corresponding number is then set. Specify the F0 is a rapid

traverse rate, the speed change signal issued from the side of machine,

the feedrate of the selected number can be increased or decrease by

the MPG.

After the X or Y axis is positioned, the external motion signal is output

by using the G81 command code, and G80 cancels this function

therefore.

Six canned cycles can be performed, for example, the drilling cycle,

tapping cycle and boring cycle etc.

Twelve canned cycles can be performed, namely, the peck drilling

cycle, finishing boring cycle, tapping cycle and counter-tapping cycle.

The inch or metric input can be switched by the G code.

G20: Inch input G21: Metric input

Specify G02 (or G03), the feedrate specified with F code is achieved an

optional arc interpolation within the rage of 0°~360°.

G02: Clockwise (CW) G03: Counterclockwise (CCW)

79

Circular arc

Interpolation

(G02,G03)

80 Sine curve In the helical interpolation command, when one axis within an arc plane

10

Page 21

Chapter two Specification

interpolation does not move (this axis is treated as an imagination axis), the other 2

axes can be performed a sine curve interpolation.

The circular

compensation is

81

performed using

radius R

programming

External

82

deceleration

External workpiece

83

number index A

84 External data input

In the arc interpolation, the radius value R instead of I, J and K is

directly specified a radius to simplify a program. The arc more than or

less than 180° can be performed.

The mechanical vibration during stopping at the end of stroke which can

be reduced to the least by this function, and the valid stroke can be

increased to the maximum, the additional axis does not an external

deceleration function. (Selected function)

Input any of the program number from 1~31 to NC from the machine

side and these programs (Selected function) are selected from NC

memory.

Transfer the data to NC from an external specified operation such as

the machine side, the input data are shown below:

(1) External workpiece number index C

(2) External tool compensation C

(3) External alarm information

Part 1 Programming

Automatical

85

acceleration of

cutting feed

Additional skip

86

block selection

87 Skip function (G31)

Restarting of

88

program

Single direction

89

position

(4) External operation information

The cutting feed and manual consecution feed can be set by the

parameter, the constant is accelerated or decelerated with exponential

at the time of 8ms~4000ms.

The 1~9 digits followed with the switch command / of the block, 9 skip

optional program switch can be set at the side of machine, when one

optional program skip switch n is turned on, the block with / n is

skipped.

When the X, Y, Z, the 4

th

or the 5th axis commands are followed with

G31, they are performed a linear interpolation as G01. When this

command is performed, if it skips to this signal from the external input,

the rest of part of this command is stopped to perform the next block.

Specify a sequence number to be restarted, and the restart is

performed from here.

The positioning can be performed from unique direction to eliminate an

interval for realizing a precise position.

90

Storable program

Superaddition of

number

96 programs can be added at the standard program, totally 191

programs.

11

Page 22

GSK983Ma Milling Machine Center CNC System User Manual

91 Scaling

The tool path specified in program can be scaled up or down with the

range of 0.001~99.999.

The pulse only uses a MPG which can be performed a tool movement

92 MPG insertion

Automatic corner

93

Part 1 Programming

modification

Manual optional

94

angle feed

Sequence number

95

comparative stop

Operation time

96

display

97

Menu switch

overlapped with the automatical operation command in the case of the

machining is consecutively performed.

In the state of cutter compensation, when the inner corner is cut, the

modification can be automatically added to perform a low-speed

machining within the set area.

Set an angle corresponding with the positive direction along X axis on

the calibrated scale of machine operator panel, the JOG feed is

performed on the setting direction by using the start button. In the XY

plane, this function is only valid of 5° interval increment with the range

of 0°~360°. (Selected function)

The block is same as the preset sequence number during the program

performance, after this program has been performed which becomes a

stop state of single block, and this function is used to check a program.

The NC automatic operation time in second, minute or hour can be

displayed on the LCD.

The switches on machine operation panel are replaced by the setting

operation by the MDI & LCD which can be controlled the ON/OFF of

some functions.

User macro

There are two function limits, one is A, the other is B. It belongs to the

98

program A, B

manufacturer and the inherent function of the user.

99 Graphic display Tool path can be described on LCD

The MPG installed on the machine panel can be performed a

micro-feed for the machine, MPG issues 100 pulses for each revolution,

100 MPG

the movement amount for each pulse can be shifted 1, 10 and 100 folds

based upon the signal of machine side.

PLC MODEL—B can be used.

101 PLC

PLC MODEL-B

Numbers of input 192 points

Numbers of output 128 points

Steps of program Up to 5000 steps

12

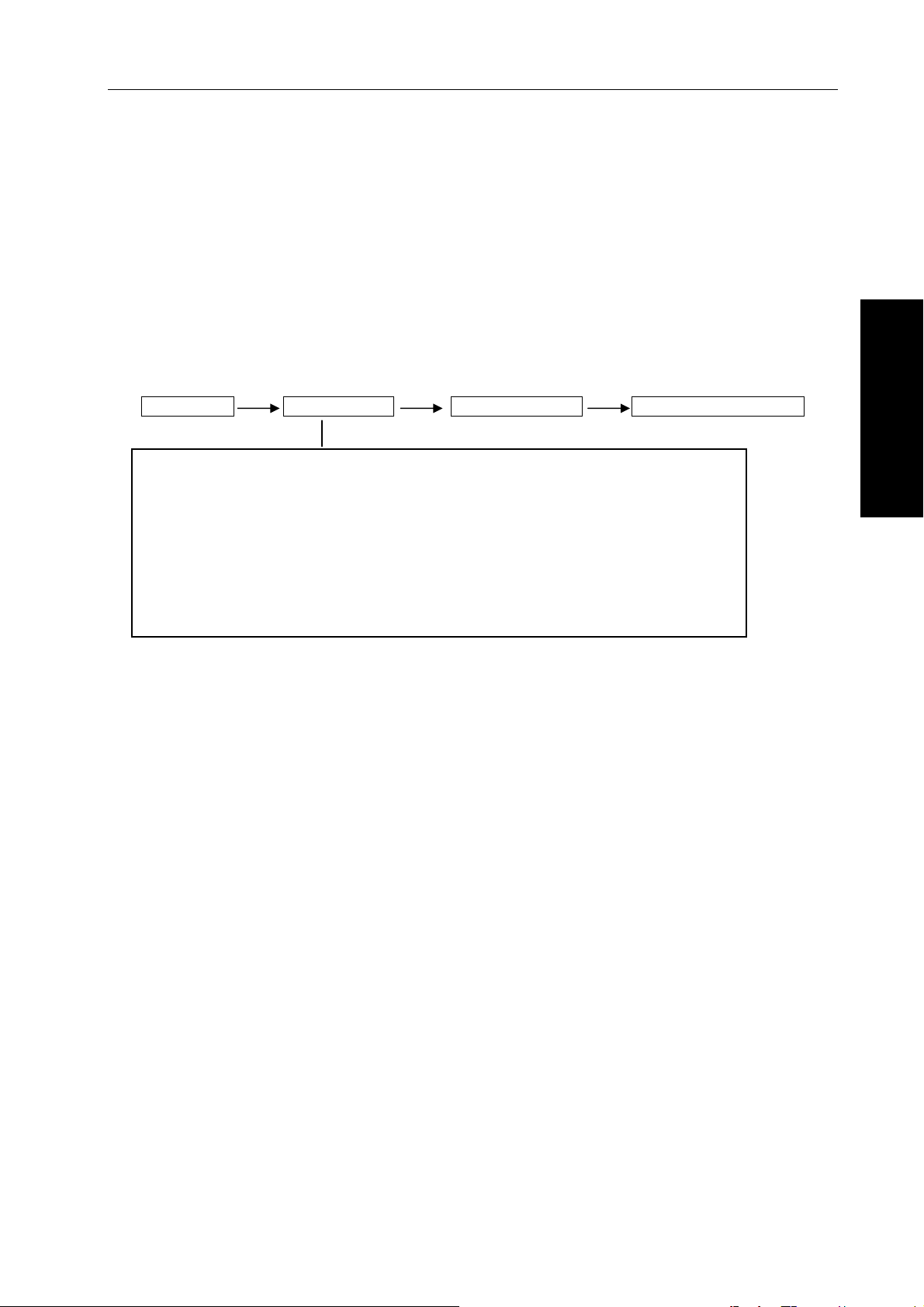

Page 23

Chapter Three Programming

Chapter Three Programming

3.1 What is Programming

The CNC machine moves in terms of the compiled program. When the parts are machined in NC,

the tool path and other machining conditions should be edited into this program, and this program is

regarded as part program.

The process from part drawing to the machining program is being performed by NC, as follows:

Part drawing Machining plan Part programming NC performs machining

(1) Confirm the NC machining range and the selected NC machine.

(2) Confirm the installation of the workpiece material on the machine and select

miscellaneous motion, based on the NC rule. Usually, these commands are written into block.

the required jig and tool.

(3) Cutting sequence (The cutting depth and tool path of machining process type,

tool start, rough cutting and finish cutting).

(4) Select the cutting tool and tool jig, and decide their installation position on the

machine.

(5) Cutting condition (Spindle rotation speed, feedrate or the coolant ect.).

The part program, reads the controllable tool path and the NC command from machine

The part program will describe in this chapter.

Part 1 Programming

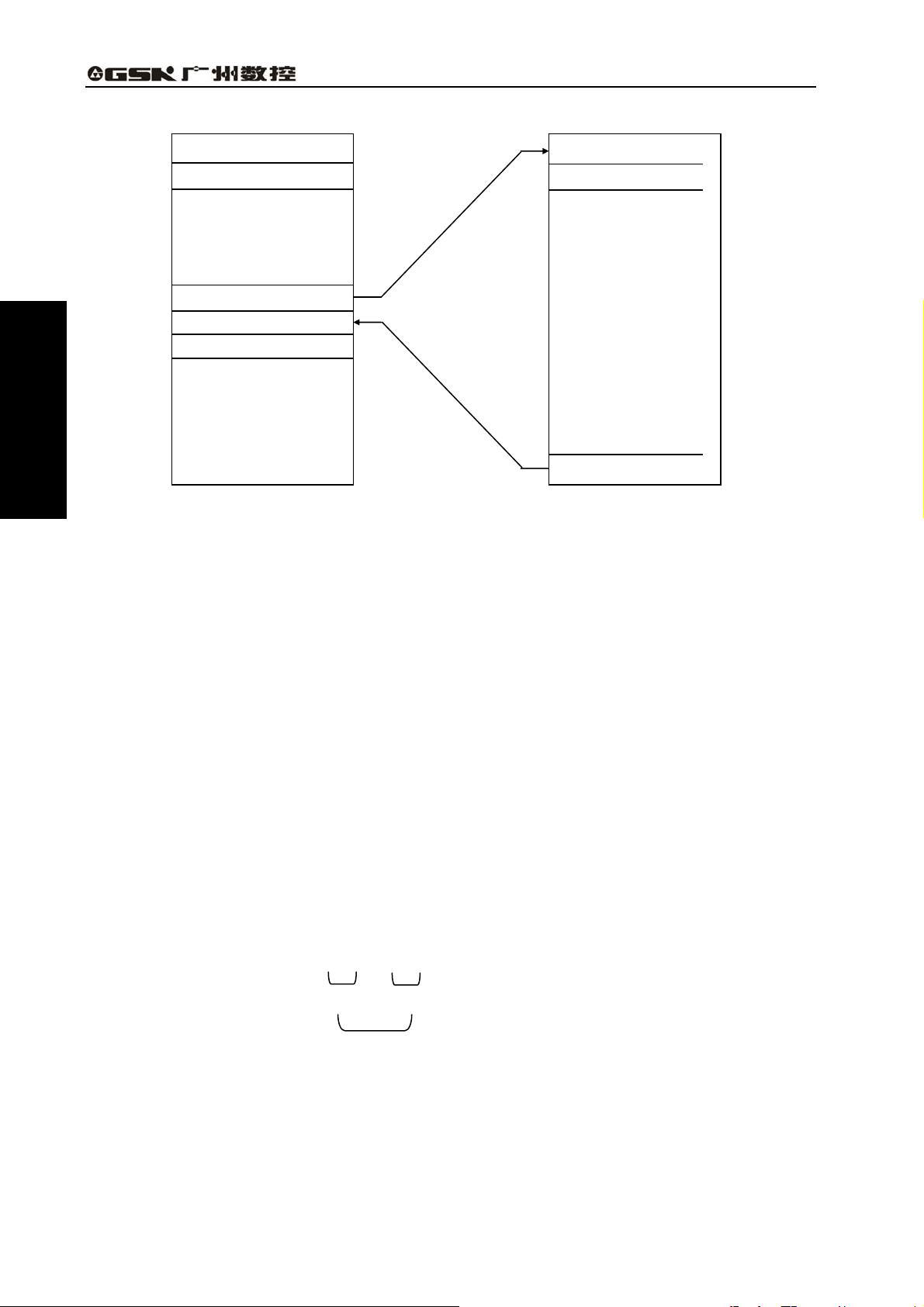

3.2 Program Structure

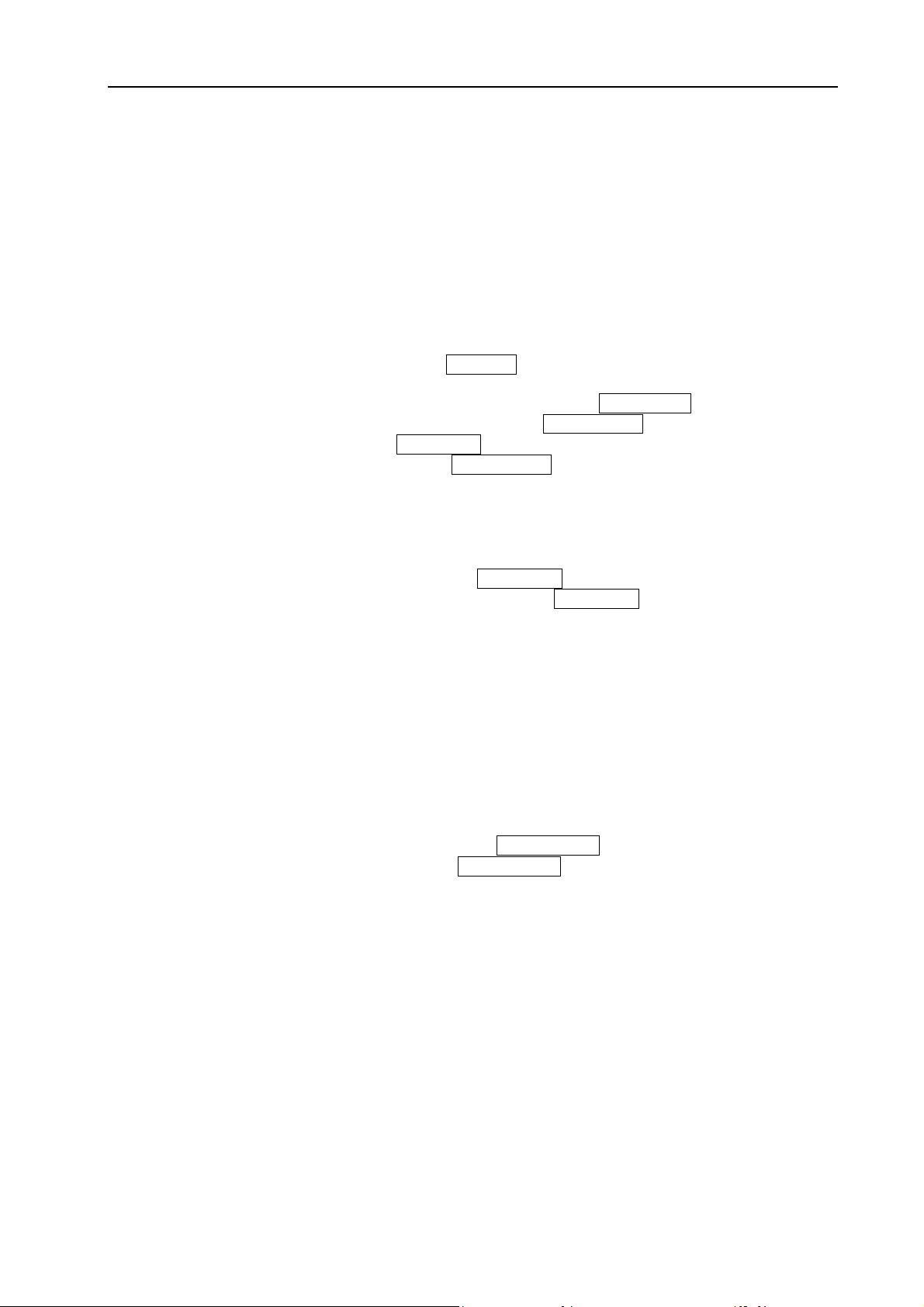

The program is divided into main program and subprogram. Usually, the NC moved based on the

command of main program, when the command of subprogram calling on the main program, the NC

is then moved based upon the command of subprogram.

When the main program return command is performed in the subprogram command, NC returns

to the main program then moves in terms of the command of main program.

In NC memory, 95 main programs and subprograms can be stored separately, and one of the

main programs is selected. NC machine can be moved based on its command.

13

Page 24

GSK983Ma Milling Machine Center CNC System User Manual

Main program Subprogram

Part 1 Programming

Command 1

Command 2

┊

┊

┊

┊

[Rotor program

command]

Command n

Command n+1

┊

┊

┊

┊

┊

[Return to the main

program command]

Note: The number function (selection) of the additional storage program is selected. The program

numbers to be stored is added to 191.

Refer to the [4 Operation] for the storage and selection methods of a program.

Command 1

Command 2

┊

┊

┊

┊

┊

┊

┊

┊

┊

┊

┊

3.2.1 Block

The program is composed of several command, a command unit in a program is called the block.

Distinguish the blocks using end code. EOB code is indicated with “;”.

For example:

XXXX;

XXXX;

XXXX;

Note 1: The maximum character in one block is free.

Note 2: EOB code: EIA code uses CR, ISO code uses LF.

3.2.2 Program Word

The element composed with block is program word. The program word consists of the address

and its following digit. The + or – can be performed before the digit.

X - 1000

Address Digit

Program word

The address is indicated using one of the A~Z which describes the meaning of its following

umbers, the address and meaning in this NC can be used as follows. Same address may have

different meanings based on the different preparation function command in program.

14

Page 25

Chapter Three Programming

Name Address Meaning

Program number

Sequence

number

Preparation

function

Coordinate word

Feed function F Feedrate specification

Spindle function S Specify a spindle rotation speed

Tool function T Specify the tool number or tool offset number

function

Offset number

Dwell

Specify a program

number

Specify a

sequence number

Times of repetition L

Parameter

For example, the following block can be formed using these program words.

; N— G— X— Y— F— S— T— M— ;

Sequence number

Preparation function

In the following blocks, one row means one block, one grid of a block means a program word.

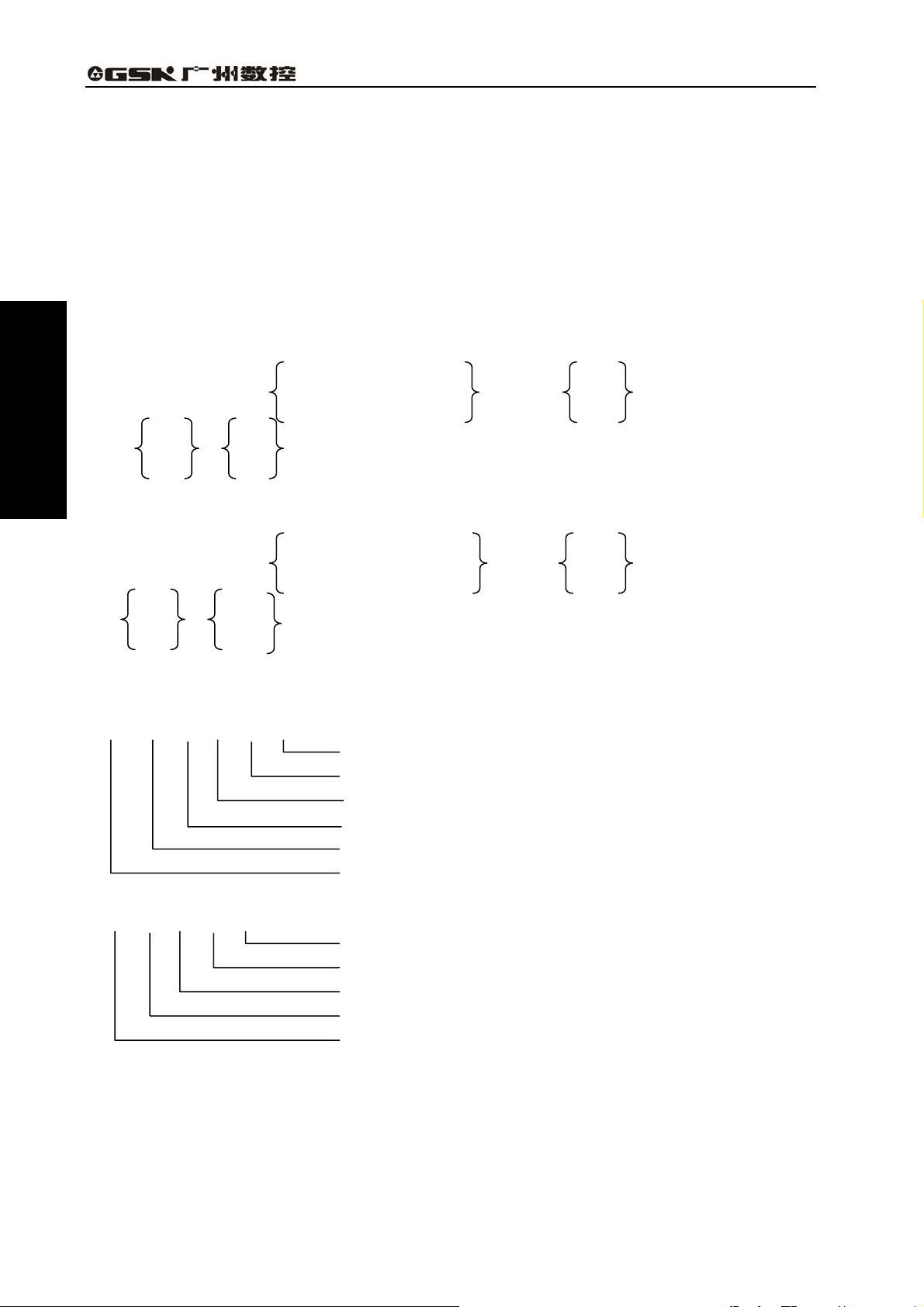

Name S57.10.10

Program number 0(:)

2002

/ N G X Y Z A/B/C C/V/W R/I J K F S T M B H/D LPQ

:(ISO)/O(EIA)

N Sequence number

G

X、Y、Z

A、B、C、U、V、W

R Arc radius

I、J、K

M Specify the ON/OFF of the machine tool sideMiscellaneous

B Such as the table index

H、D

P、X

P Specify a subprogram number

P

P、Q、R

Coordinate number

Feed function

Spindle function

Program number

Command motion mode (linear, circular arc

etc.)

Movement command of coordinate axis

Movement command of additional axis

Coordinate of circular arc center

Specify an offset number

Specify a dwell time

Specify a sequence number; the program is

repeatedly performed in this number.

The repetition count of program, the

repetition of canned cycle.

Parameter of canned cycle

Tool function

Micellaneous function

Pag

e /

Part 1 Programming

;

N20 G92 X

100.0 Y 200.0 Z 300.0

N21 G00 X

196.0 Y 315.0 Z 500.0

N22 G01 F10.0

S400 T15 M03

;

;

;

Note: CR(EIA),LF(ISO)

15

Page 26

GSK983Ma Milling Machine Center CNC System User Manual

3.2.3 Input format

Each program word is composed of a block which must be specified in terms of the following

description. This input format of this system is a changeable block format, therefore, both the number

of program word of a block and the character number of one program word which can be changed, in

this case, it is very convenient for programming.

Part 1 Programming

(1) Input in metric

NO4·G02·XL+053·YL053·ZL+053·

RD053 D02

αL+053·βL+053· ·F050· ·

ID053·JD053·KD+053 H02

S02 T02

· ·B03·M02;

S04 T04

(2) Input in inch

NO4·G02·XL+044·YL+044·ZL+044·

RD044 D02

αL+053·βL+053· ·F032· ·

ID044·JD044·KD044 H02

S02 T02

· · B03·M02;

S04 T04

Note 1: α or β is one of the additional axes A, B, C, U, V and W.

Note: The addresses and meanings which are described above format are shown below:

X L + 0 5 3

Three digits following with the decimal point

Five digits before the decimal point

Leading zero can be omitted

With symbol

Absolute or incremental

Address

J D 0 5 3

Five digits before the decimal point

Leading zero can be omitted

Incremental with symbol

Address

Three digits following with the decimal point

For example: when the tool move to the 50.123mm along X-axis at the rapid traverse rate, and its movement

command is as follows:

16

Page 27

Chapter Three Programming

G00 X50 . 123

Three digits following with the decimal point

Five digits before the decimal point is 00050.

Leading zero is omitted

G00 can not be omitted (G00 specifies a rapid feed) even if the

leading zero is omitted.

Note 3: When an address is specified twice at one block, in principle, the last command is enabled, and

the alarm does not perform.

For example: G01 M03 S200 M08;

In this case, M08 is enabled, and the M03 is invalid. G code of each group in a block is valid which is

specified at last. G90/G91 is in a block, which is separately valid in its specified place. (See the Section 3.3.8)

For example: G90 X10.0

Absolute Incremental

R is always valid when the R and I, J or K are specified simultaneously in circular arc interpolation

command, which is regardless of the command sequence.

Note 4: F050 can be changed into F051 in metric input format. Refer to the [Section 3.4.3 for the feedrate x

1/10].

Note 5: P or Q is omitted in the above-mentioned format due to it owns several meanings.

Note 6: When inputting in decimal point, refer to the [Section 3.2.4 for the decimal point input].

Note 7: The number input in metric, namely, X, Y, Z, A, B, C, U, V, W, I, J, K, Q, and R are set by parameter

which multiplies 10 times.

RD052

XL+052·YL+052·ZL+052·αL+052·βL+052·

ID052·JD052·KD052

(α or β is A, B, C, U, V or W) (input in metric), refer to the [Section 3.3.2.2, the input unit multiplies 10]

Note 8: Refer to the [Section 3.3.2.2, the input unit multiplies 10].

G91 Y20.0 ;

Part 1 Programming

3.2.4 Decimal point programming

Numerical values can be entered with a decimal point for this device. A decimal point is used for

the number of which is regarded as a unit of the distance, time or speed. However, some addresses

can not input in decimal point, the position of decimal points are indicated the one of the mm, inch,

degree or second.

X15.0 X15mm or x15inch

F10.0 10mm/min or 10inch/min

G04X1. Dwell 1s

B90.0 B90deg

Decimal points can be inputted the following address:

X、Y、Z、A、B、C、U、V、W、I、J、K、R、Q、F

X, Y, Z, A, B, C, U, V, W, I, J, K, R, Q, F

Note 1: When the dwell is specified, X, but P, can be input in the decimal point. (Because the P can be

specified in the sequence number)

Note 2: Change the position of decimal point using the G code, the G code should be specified in

advance even in the same block. G20: (Specify in metric)

X1.0G04;……The X1.0 does not indicate a time instead of a movement distance (inch), as for the

X10000G04, its dwell time of the consequence is 10 seconds.

When G04 is inputted, the display becomes 10.0 from 1.0.

G04X1.0: …… is regarded as G04X1000, the dwell time of its consequence is 1 second.

Note 3: Note that it is a large difference with or without decimal point; the program is different from the

electronic-computer.

G21: (Specify a metric)

X1.……X1

X1……X0.001

G20: (Specify an inch)

X1.……X1inch

17

mm

mm

Page 28

GSK983Ma Milling Machine Center CNC System User Manual

X1……X0.0001inch

Note 4: The numbers can be used with or without the decimal point

X1000 Y23.7;

X10 Y22359;

Note 5: If the value specified is less than the value of the least input increment, and this value is then

omitted. When the X1.23456 is specified, it is treated as X1.234 in metric, and it is regarded as

1.2345 in inch. The accumulation error occurs when the incremental value is specified, the

accumulation error does not issue but its error omitted when the absolute value is specified.

The specified digits can not exceed the maximum allowance digits.

X1.23456789……has an error due to it exceeds 8 digits.

X1.2345678……does not an error because it is within the 8 digits.

Note 6: When a number with a decimal point is input which is converted into an integer of the least

Part 1 Programming

number is more than 8 digits.

input increment.

(For example) X12.34 12340 (Input in Metric)

The converted integer should be checked, still.

(For example) X1234567.8 X1234567800 (Input in Metric). The alarm may occur due to this

3.2.5 The maximum command value

Note that the maximum commanded value range of NC device is expressed in the following table

instead of the mechanical movement range of NC machine. For example, the movement of X axis for

the NC device is about 100m (Input in Metric). As for a certain machine, the stroke distance of X axis

may limit within 2m, as the feedrate. The cutting feedrate of NC device can be set to 30m/min, but the

NC machine side may limit within 6m/min. In the actual programming, refer to this manual and the

manual issued from the manufacturer at the same time. Program can be performed after

comprehending the special machine program fully. The maximum command value of each address is

shown below:

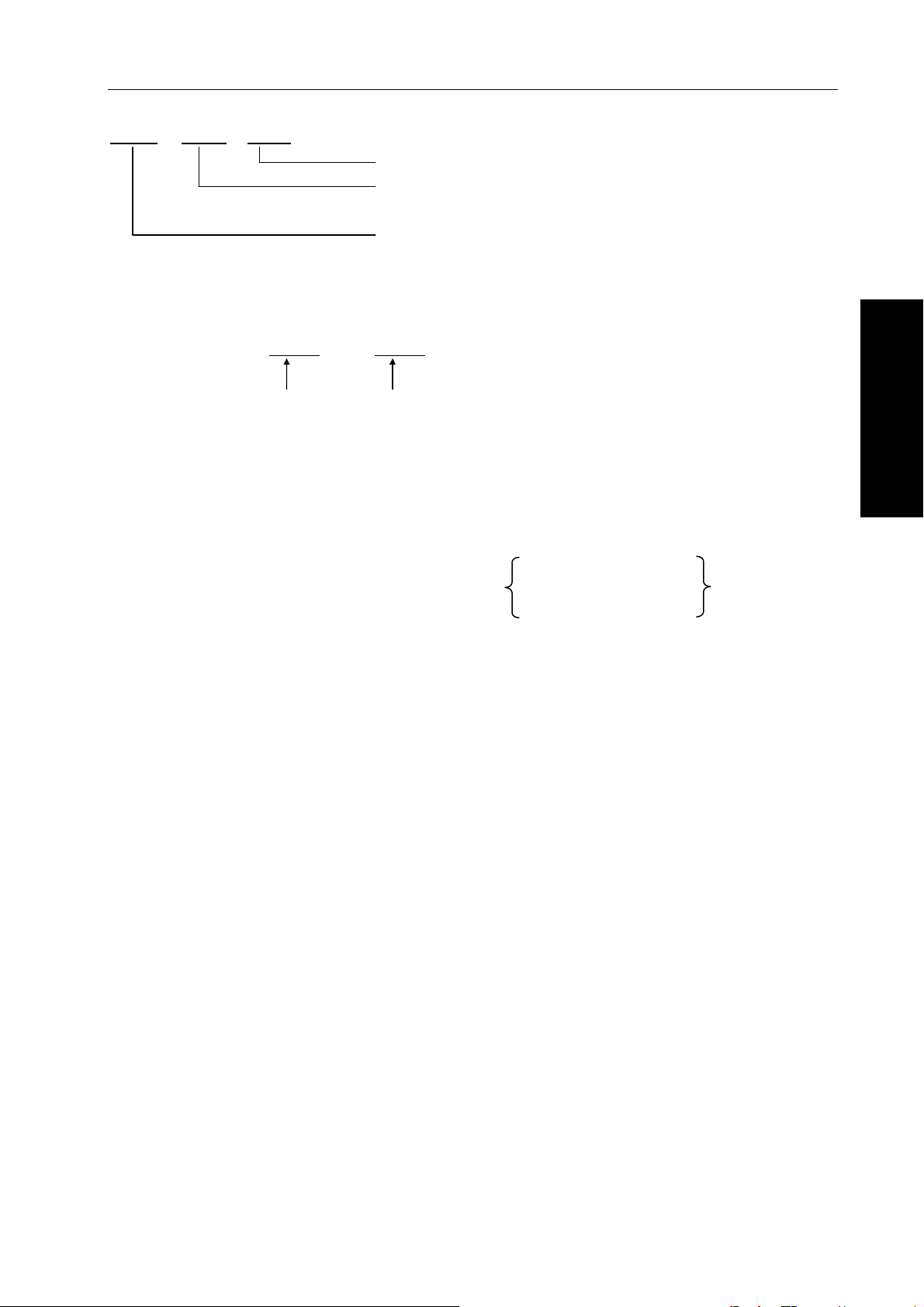

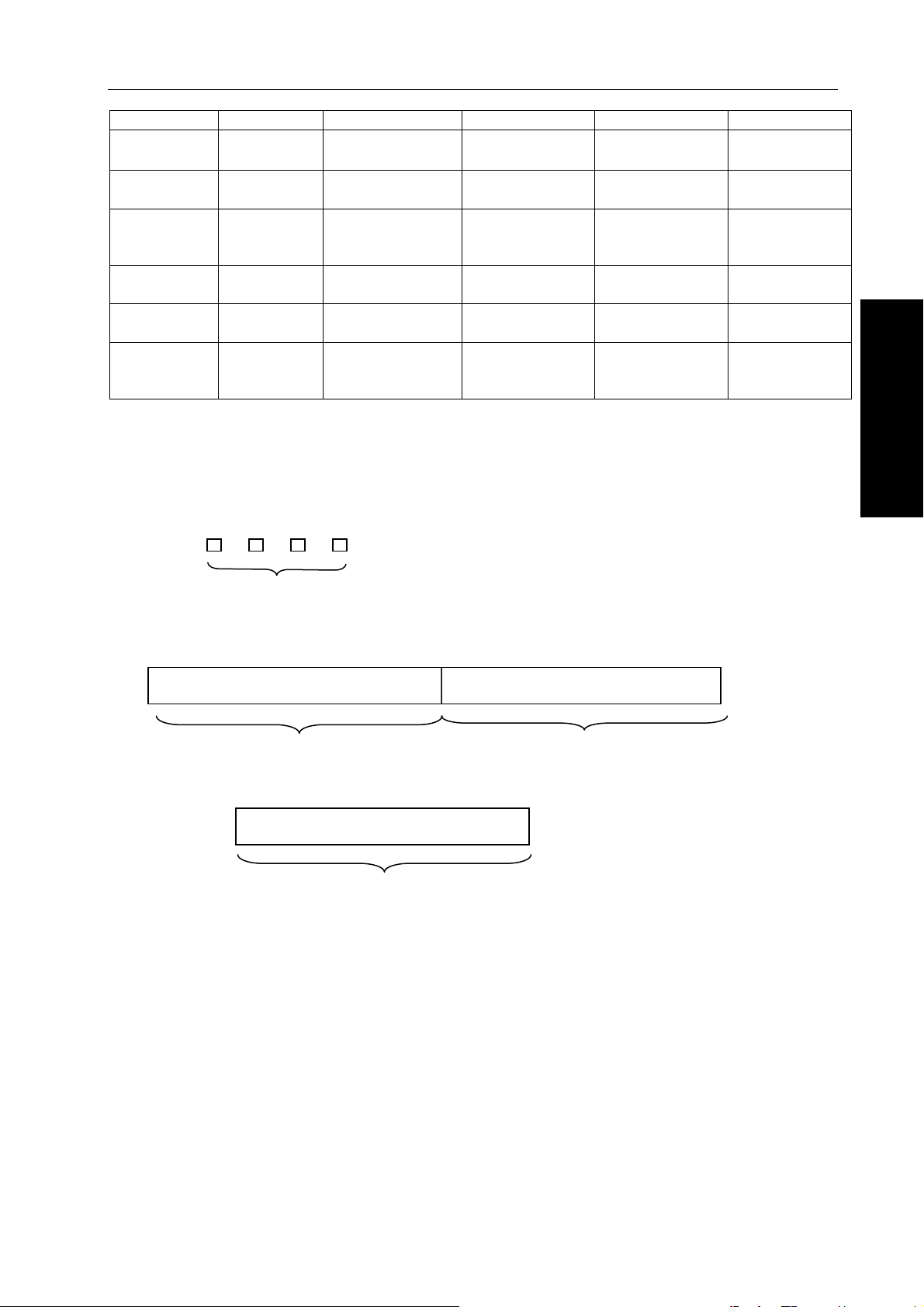

Table 3.5 The basis address and the range of command value (the additional selection

included)

Input in inch

±3937.0078in

0.01inch/min

1200.00inch/

0.01inch/min

1200.00inch/

Name Address

Program

number

Sequence

number

Preparation

function

:(ISO)

O(EIA)

N

G

X、Y、Z、I、

Coordinate

word

J、K、Q、R、

A、B、C、U、

V、W

Feed per

minute

F

Feed per

minute

(feedrate

1/10)

F

(Parameter

setting)

Spindle

function

S

Tool function T

Miscellaneo M

18

Input in mm

Output in mm

1~9999

1~9999

0~99

±99999.999mm

±99999.999°

1 mm/min~

30000mm/min

0.1 mm/min~

30000.0mm/min

Input in inch

Output in mm

Input in mm

Output in inch

As the left As the left

″ ″ ″

″ ″ ″

±3937.0078inc

h

±99999.999°

0.01 inch/min~

1200.00inch/mi

n

0.01 inch/min~

1200.00inch/mi

n

±99999.999mm

±99999.999°

1 mm/min~

30000mm/min

0.1 mm/min~

30000.0mm/min

0~30000 0~30000 0~30000 0~30000

0~9999

0~99

″ ″ ″

″ ″ ″

Output in

inch

As the left

ch

±9999.999°

~

min

~

min

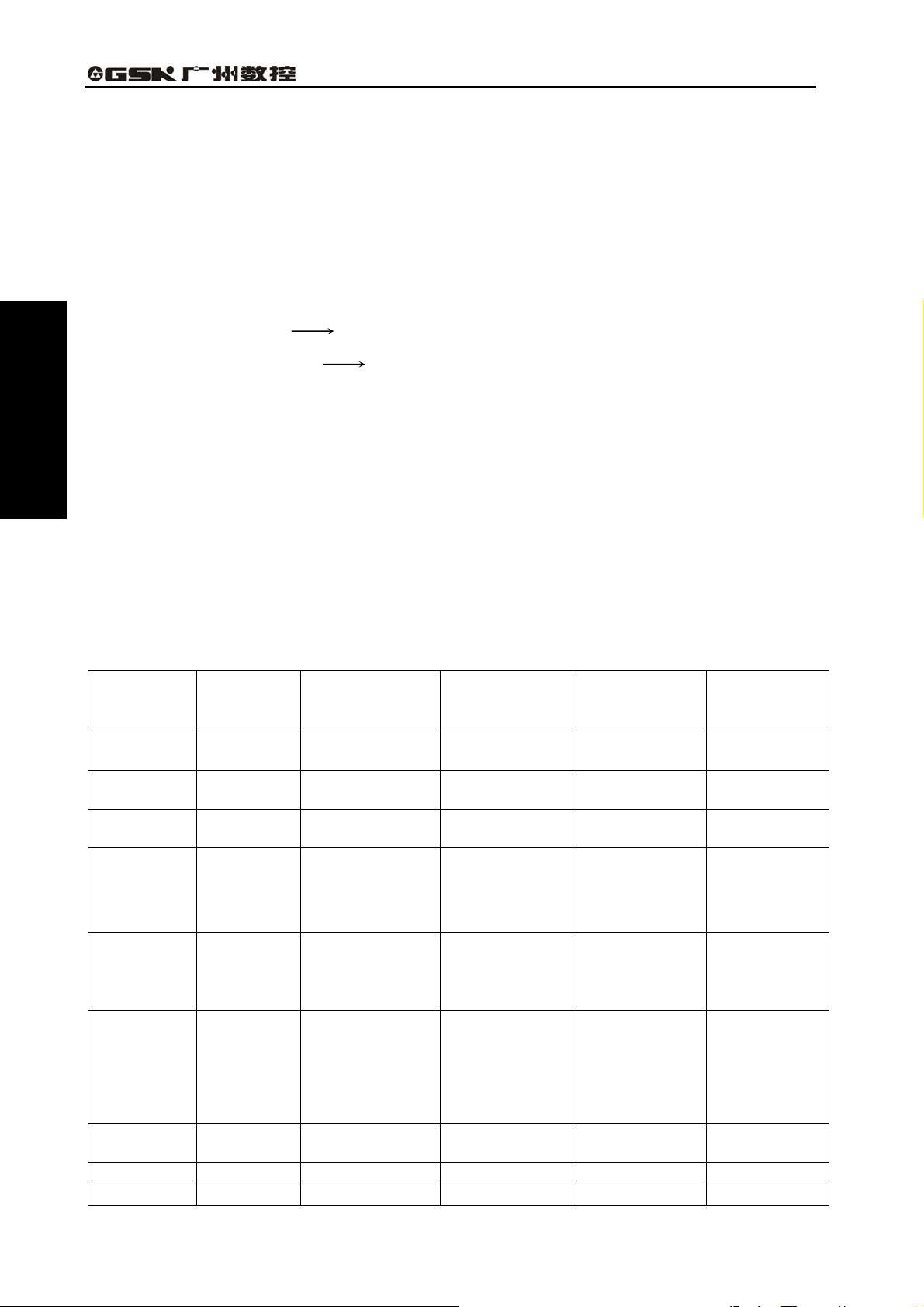

Page 29

Chapter Three Programming

us function

Dwell X

Dwell P

0 s~

99999.999s

0ms~99999999

ms

″ ″ ″

″ ″ ″

Sequence

number

P

1~9999

″ ″ ″

setting

Times of

repeated

Offset

number

L

D、H 0~184

1~9999

″ ″ ″

″ ″ ″

The 2nd

M.S.T

B

0~999

″ ″ ″

function

3.2.6 Program number

This controllable device can be stored several programs into the NC memory, the program

number is added to each program to distinguish these programs.

Program number

O The solution range is from 1 to 9999, the leading zero can be

omitted. (Program O0000 is used for transforming during the

program replication.)

4 digits

Program starts at the beginning of the program number which ends till met the M02, M30 or M99.

The program of O1111 The program of O2222

01111………………………M02; 02222………………………M30;

M02 and M30: the end of main program. M99: the end of subprogram.

05555………………………M99;

The subprogram of O5555

Note 1: The “:” before the program number is replaced by “O” in ISO code.

Note 2: The block of the code with optional block skip, such as /M02; /M30 or /M99 which can not treat

as an end of program.

Note 3: When the program number does not at the beginning of the program, the first sequence number

of this program (N…) can be replaced by the program number, but the NO program number is

unallowable.

Note 4: If neither the program number nor the sequence number is performed at the beginning of the

program, the program number should be specified by the MDI & LCD panel when the program is

stored to the memory.

Note: When several programs are performed, the EOB code without a flag is skipped after the 2

program and before its followed program, but the end of the previous program is finished by the

ER (EIA) RO % (ISO), the program at its beginning should be used the EOB code.

Note 6: The run can be performed without a sequence number. However, the subprogram must always

have a program number.

Note 7: In some cases, the program numbers from 9000 to 9899 are used for the manufacturer, but the

user can not employ it.

nd

Part 1 Programming

19

Page 30

GSK983Ma Milling Machine Center CNC System User Manual

Note 8: When the selection is performed by the manipulator, the program numbers 9900~9999 are used

as a manipulator data.

Note 9: M02, M30 or M99 does not performed at the end of a program, which is followed with ER (EIA) %

(ISO) or next program number 0, the end of program is set by BIT3 (NEOP) of parameter 306.

Note 10: When the maloperation is performed to cause the program is more than 4 digits, the program

may not call for the subprogram. In this case, the characters more than 4 digits are deleted.

Deletion method: editing-> program lock open-> move the cursor to the program O-> insert the

“EOB”-> move the cursor to the program O again-> press “deletion” key after the “EOB” is

pressed.

3.2.7 Sequence number

Part 1 Programming

At the beginning of the block, the numbers 1~9999 within 4-digit followed with address N can be

specified the sequence number, and the sequence of its sequence number is optional. Either the

sequence number can be performed for all the blocks, or the sequence number is added at the

required place during program.

The sequence number should be continuously specified in the key place, for example, when a

new tool is used when it is used, or the working table index transfers to the new machining surface.

Note: For compatibility with other program formats of NC device, the sequence number N0 does not used

3.2.8 Skip to optional block

The slash /n (n=1~9) followed with numbers are specified at the beginning of the block, and

when the skip optional block switch n is ON, during the DNC operation or automatic operation, the

block with /n corresponding to the switch number n is then ignored.

The block with /n is enabled after the skip optional block n is OFF. Namely, operator can

alternatively select the skip block which with /n. The 1 in the /1 can be omitted, however, it can not be

omitted when there are 2 or above skip optional block switches at the same block.

When the optional block switch is ON, the ignored area is shown below:

;/2N123G01X4……………………;N7856

Ignored area

For example:N100X100;

N101/2z100;

N102/2/3X200;

N103/3z200;

In the above-mentioned example, when the No.2 switch is ON, the blocks N101 and N102 are

skipped; and when the No.3 switch is ON, the blocks N102 and N103 are skipped.

Note 1: The slash (/) must be placed at the beginning of the block, if it is placed at other places, the

information in which from / to the EOB code is then omitted, and the information in the front of the / is

still effective.

Note 2: The TH and TV are still checked to the skipped part while the skip optional block switch is opened,

which is same as the switch OFF.

Note 3: The block to be skipped is identified when the memory transfers the information to the buffer. When