gsk GSK983M Connection Manual

GSK983M Milling CNC System

Connection Manual

GSK983M Milling Machine CNC System Connection Manual

The operating manual describes all matters concerning the operation of the system in detail as

much as possible. However, it is impractical to give particular descriptions of all unnecessary

and/or unavailable works on the system due to the length limit of the manual, specific

operations of the product and other causes. Therefore, the matters not specified herein may be

considered impractical or unavailable.

This operating manual is the property of GSK CNC Equipment Co., Ltd. All rights reserved. It is

against the law for any organization or single to publish or reprint this manual without the

express written permission of GSK and the latter reserves the right to ascertain their legal

liability.

Ⅰ

GSK983M Milling Machine CNC System Connection Manual

Company Profile

GSK CNC EQUIPMENT CO., LTD(GSK) , CNC Industry Base of South China, is responsible for the

National High Technology Research and Development Program of China (863 Program): Moderate

CNC Industrialization Key Technology. For ten years, we are exclusively engaged in research,

Development, manufacture, sale, training and popularization of Machine Tool CNC system, Servo

Motor and driver, and other mechanical products. Today, GSK has already expressed into a

large-scale new high-tech enterprise that deals with research, teaching, working and trading. Our

products support more than 60 domestic manufacturers of machine tools with after-sales service

network through the country. With a yield in the lead in China from 2000 to 2005 in succession, GSK

series products are in great demand in the domestic demand and have a ready sale in Southeast

Asia at high performance-to-price ratio.

Field technical support services

Field support services are available when you encounter a problem insolvable through telephone.

GSK CNC Equipment Company Limited will designate a technical support engineer to the field to

solve technical problems for you.

Chinese version of all technical documents in Chinese and English languages is regarded as

final.

Ⅱ

GSK983M Milling Machine CNC System Connection Manual

Foreword

Dear user,

We are really grateful for your patronage and purchase of GSK983M milling CNC system,

which is made by GSK CNC Equipment Co., Ltd.

This manual consists of two volumes. Volume I mainly describes the specifications and

programming of the system while Volume II operations, all codes, parameters, I/O interfaces

and other appendices.

! This system can only be operated by authorized and qualified personnel as improper

operations may cause accidents. Please carefully read this operating manual before

usage.

All specifications and designs herein are subject to change without further notice.

We are full of heartfelt gratitude to you for supporting us in the use of GSK’s products.

Ⅲ

GSK983M Milling Machine CNC System Connection Manual

Content

Precautions for Connection .................................................................................................................1

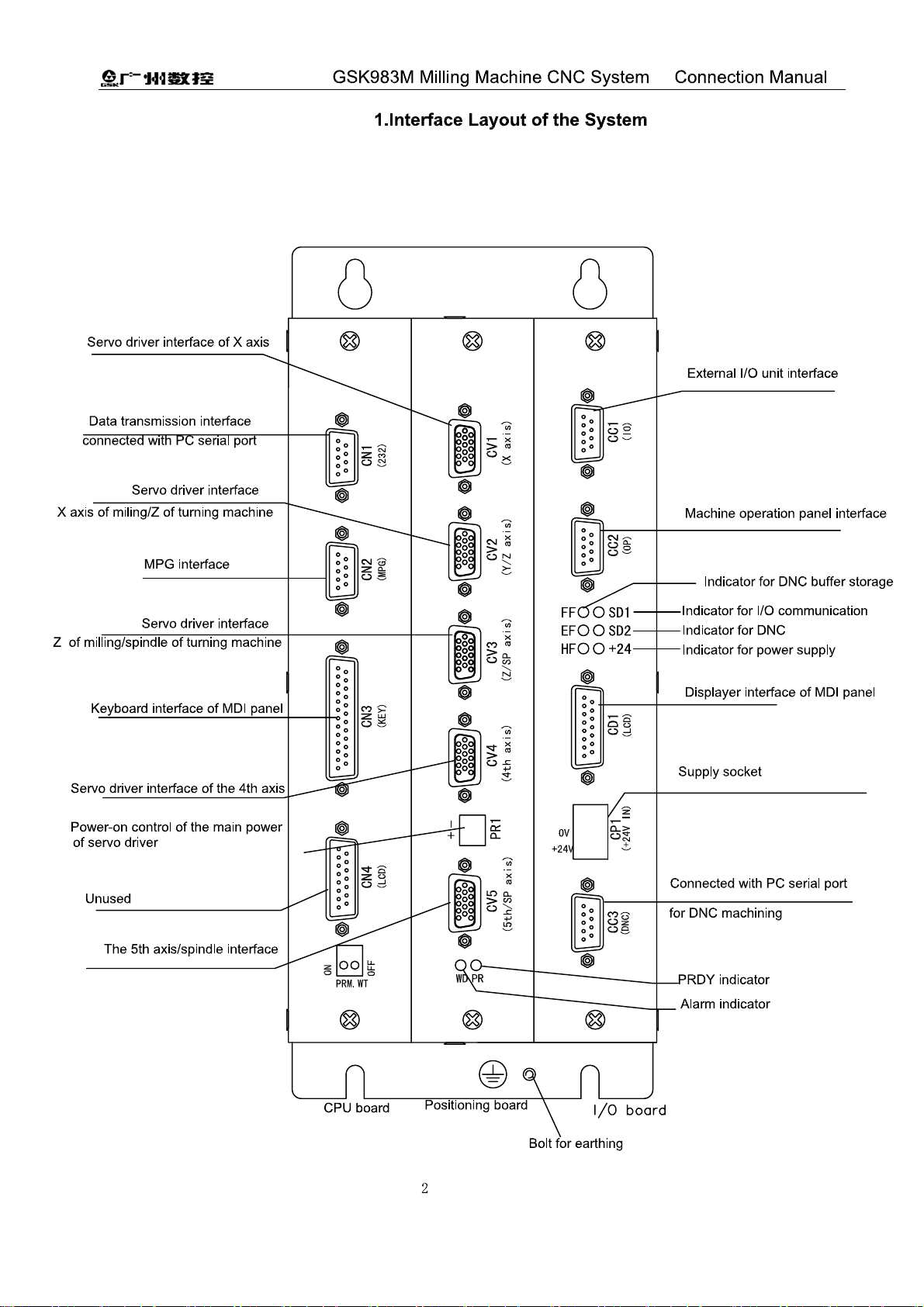

1. Interface Layout of the System........................................................................................................2

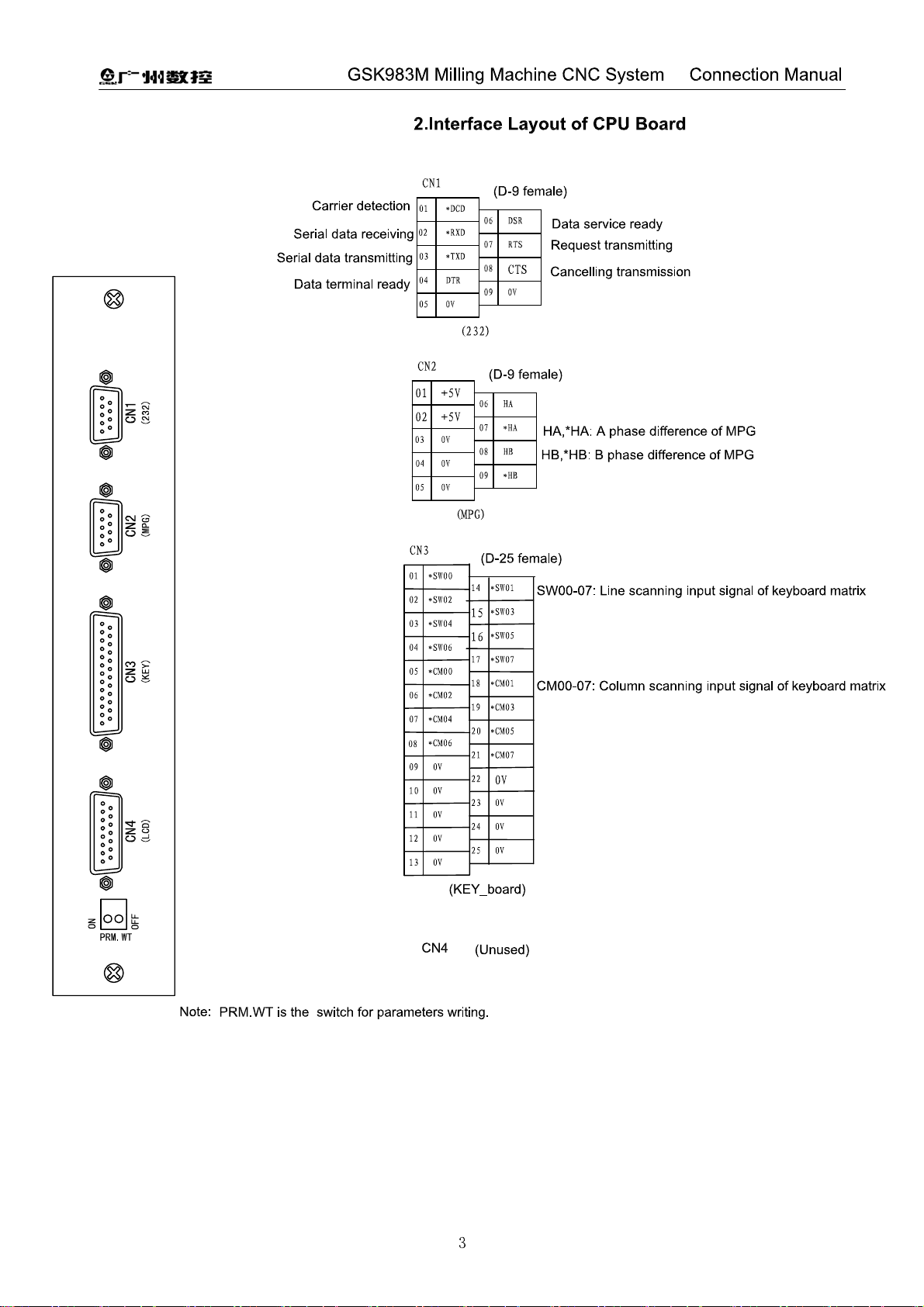

2. Interface Layout of CPU Board .......................................................................................................3

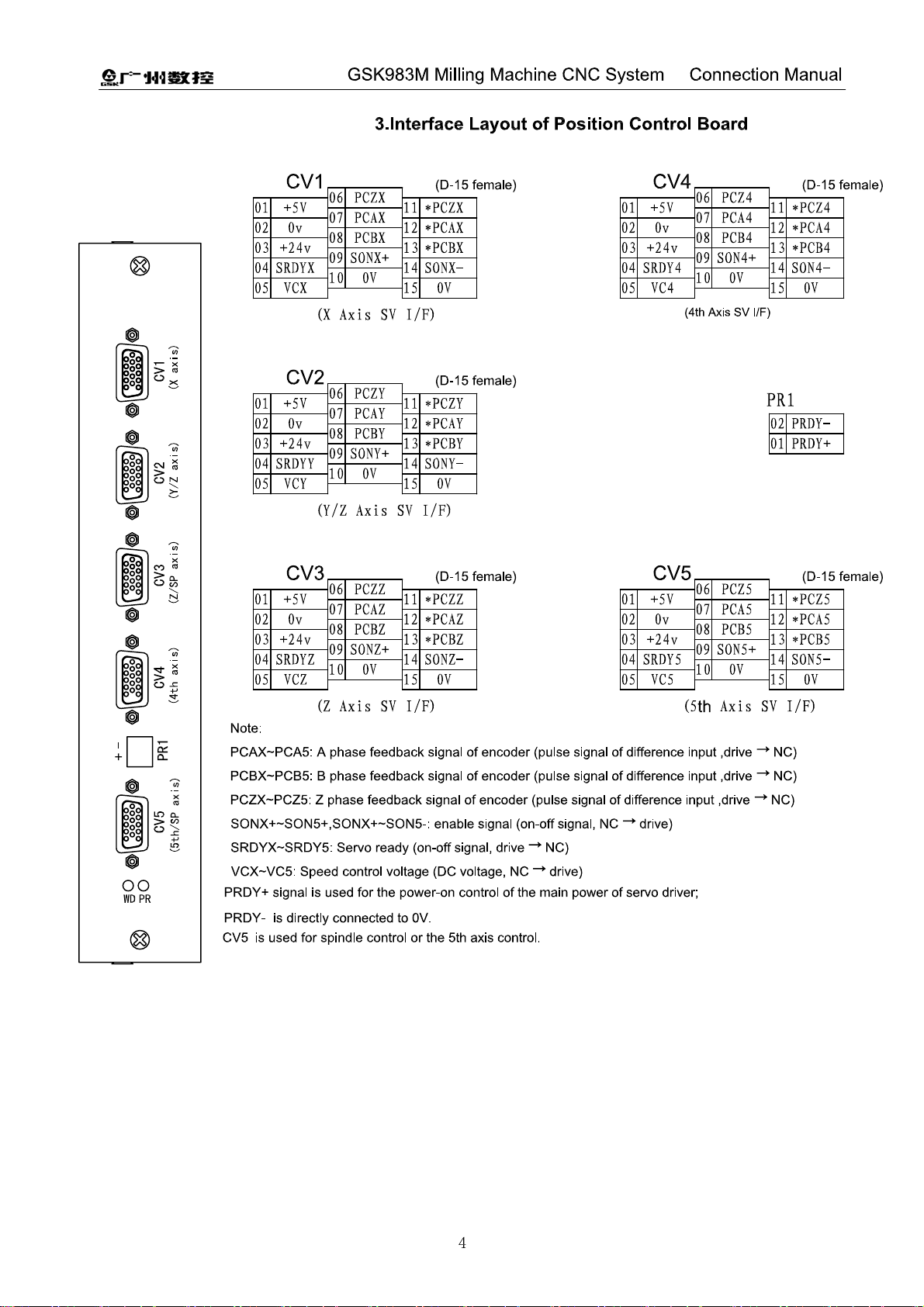

3. Interface Layout of Position Control Board......................................................................................4

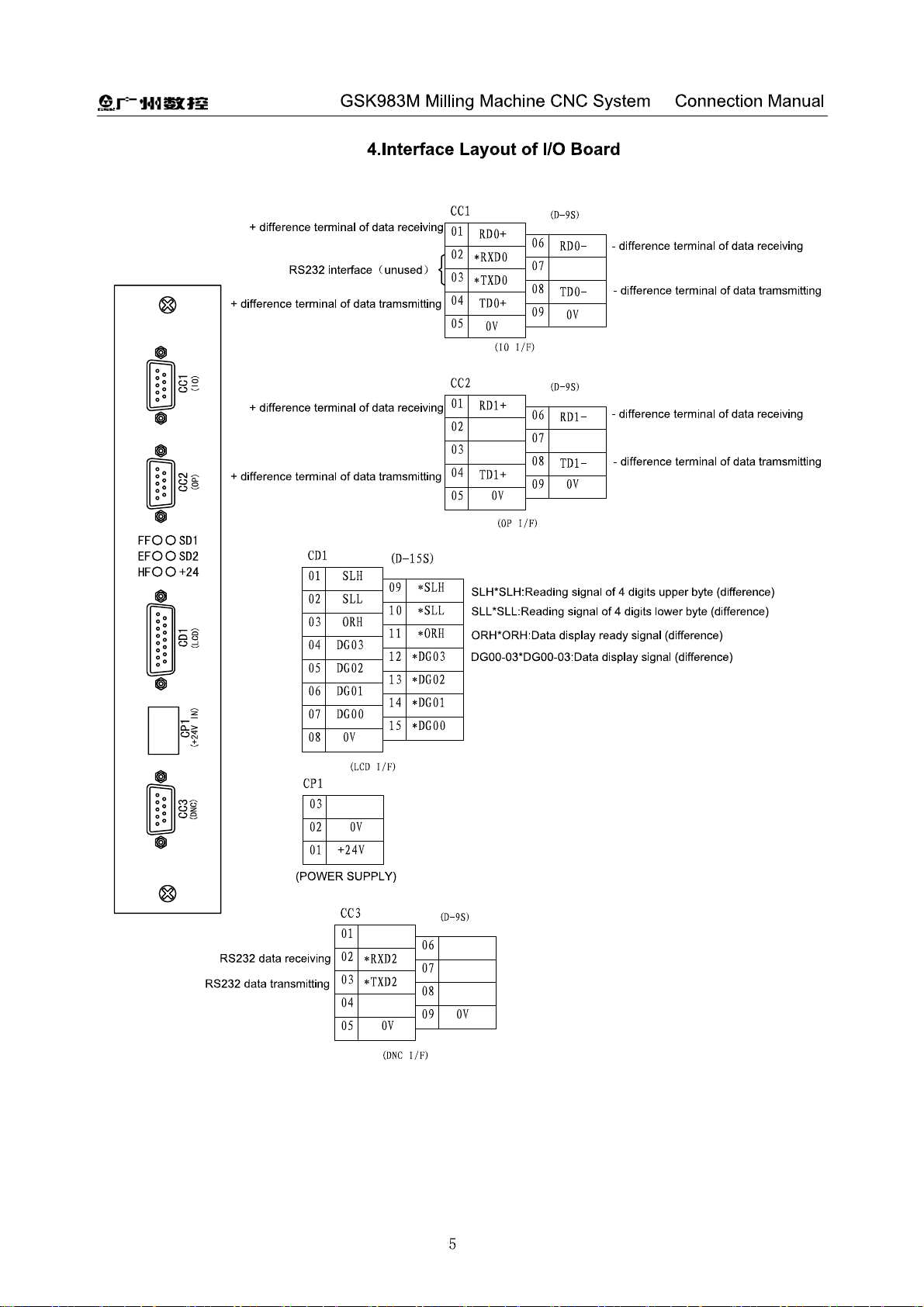

4. Interface Layout of I/O Board ..........................................................................................................5

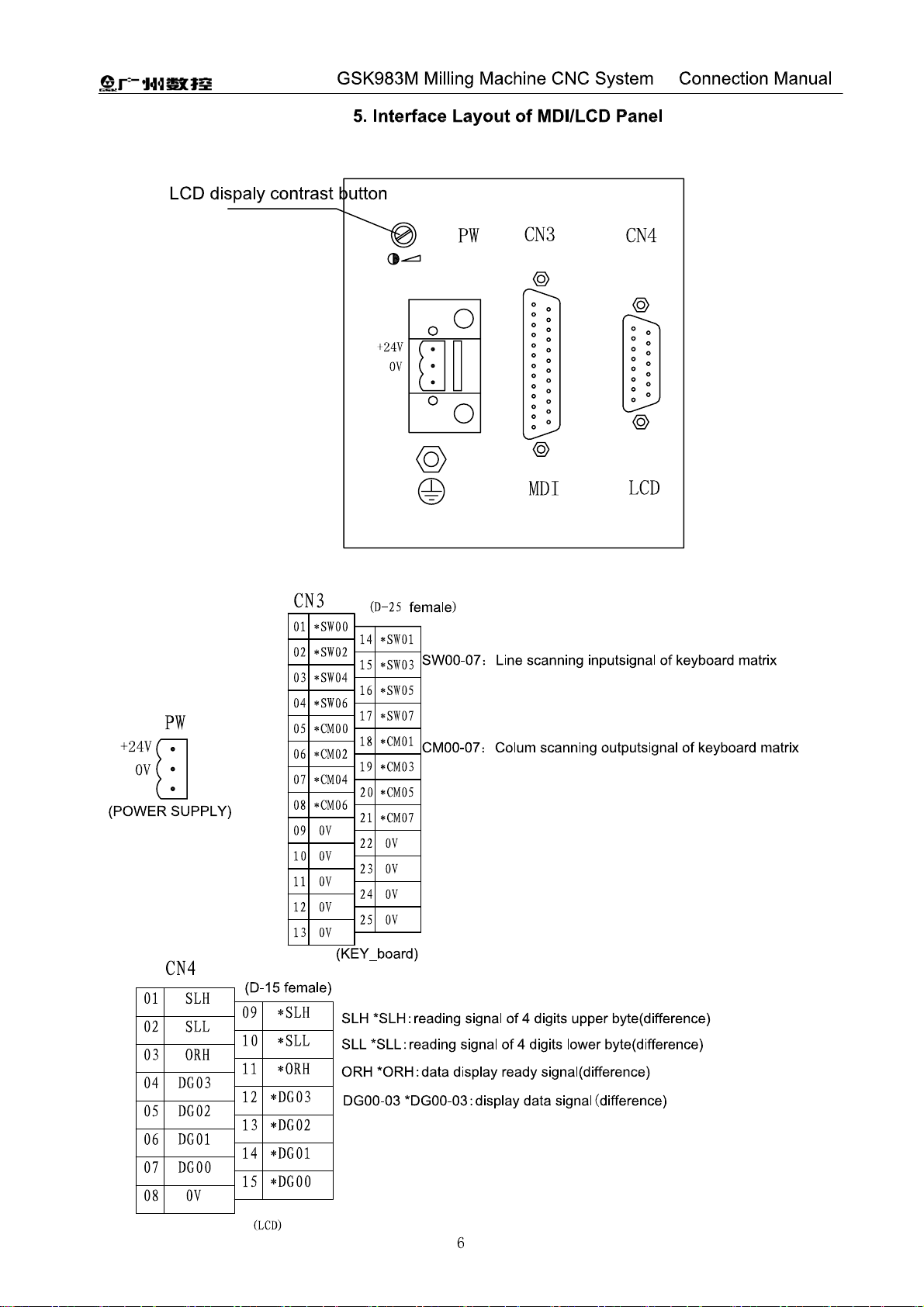

5. Interface Layout of MDI/LCD Panel.................................................................................................6

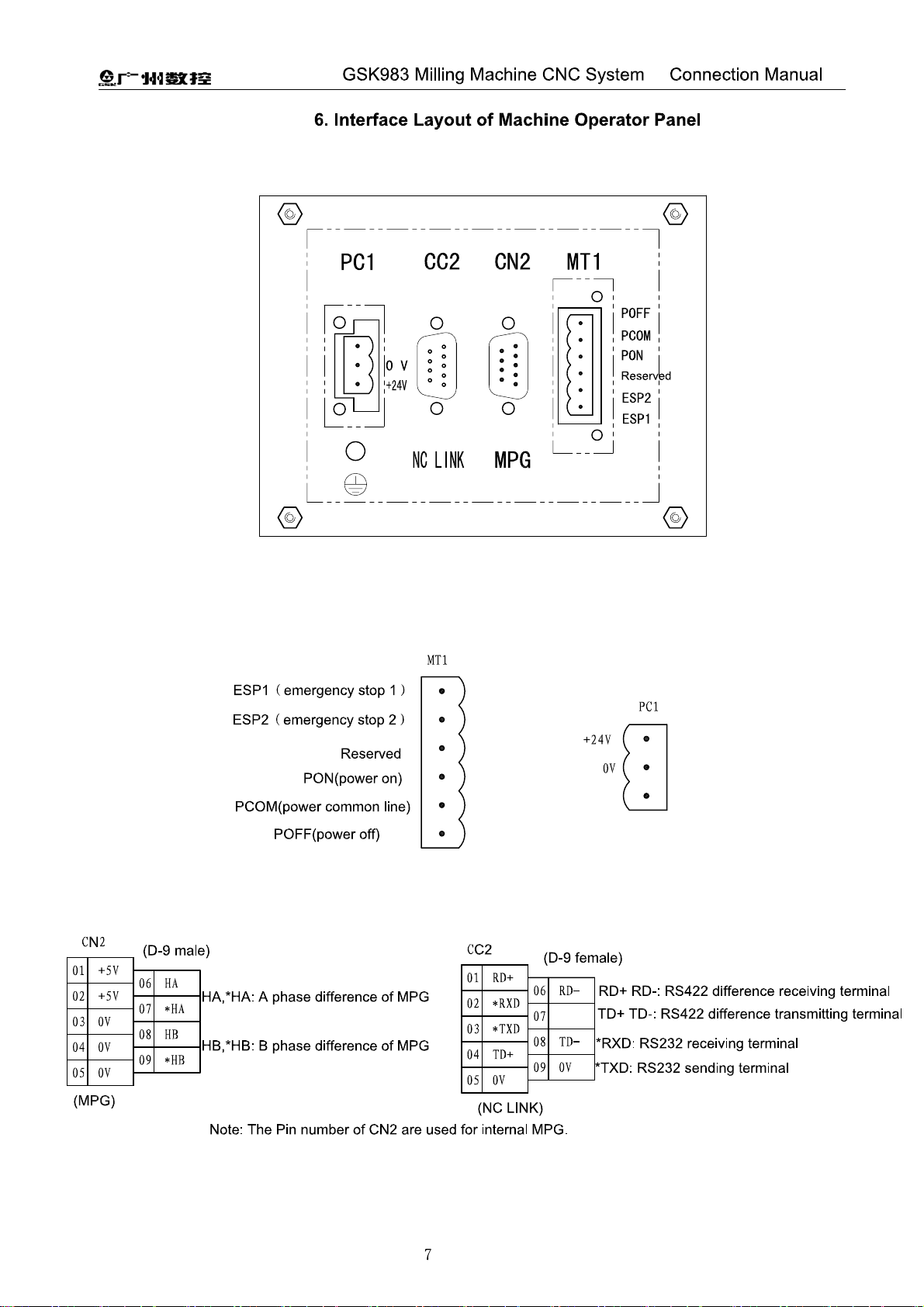

6. Interface Layout of Machine Operator panel ...................................................................................7

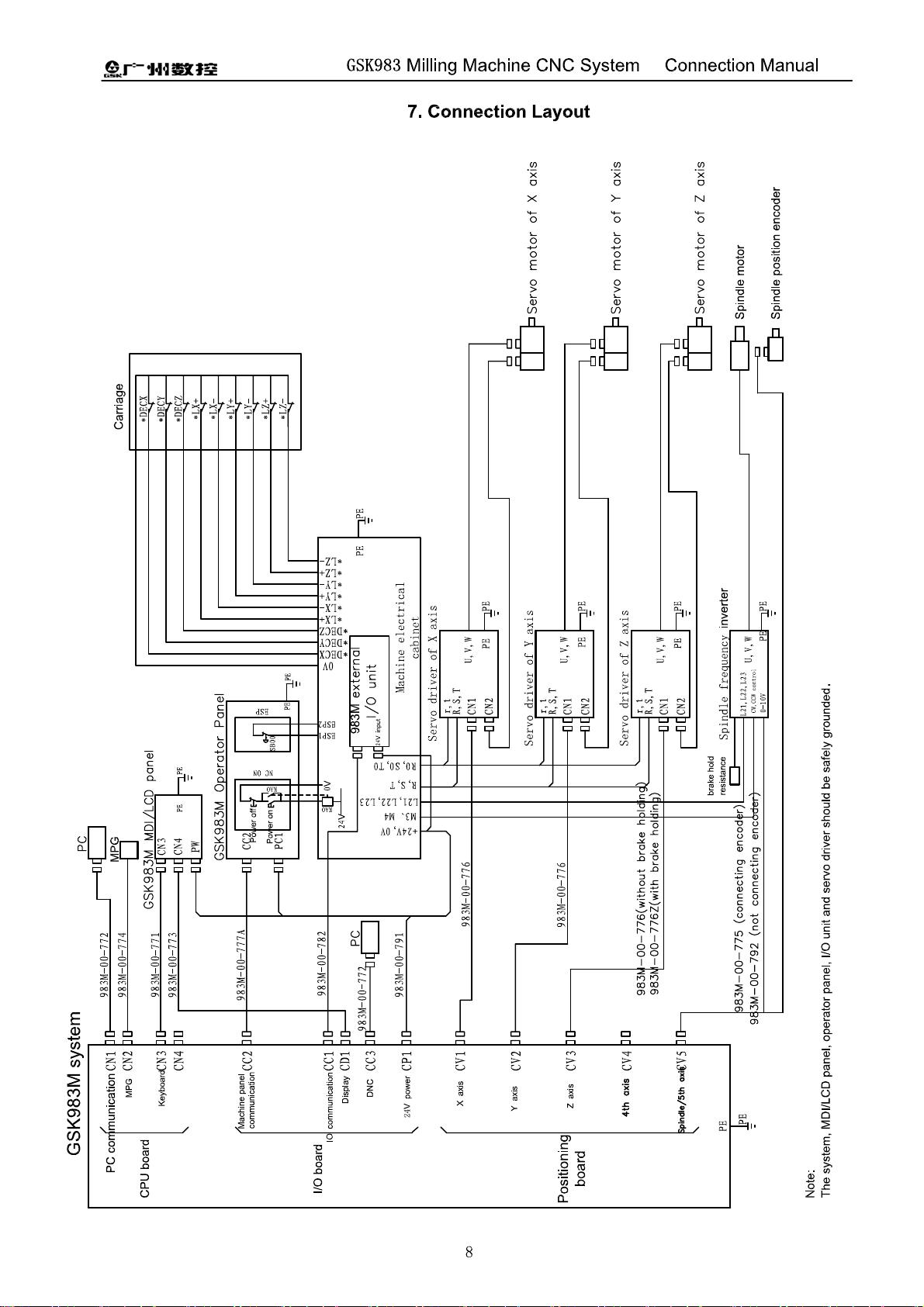

7. Connection Layout ..........................................................................................................................8

8. Connection Cables for Communication with PC(RS232) ................................................................9

9. Connection Cables for MPG (Handwheel) ....................................................................................10

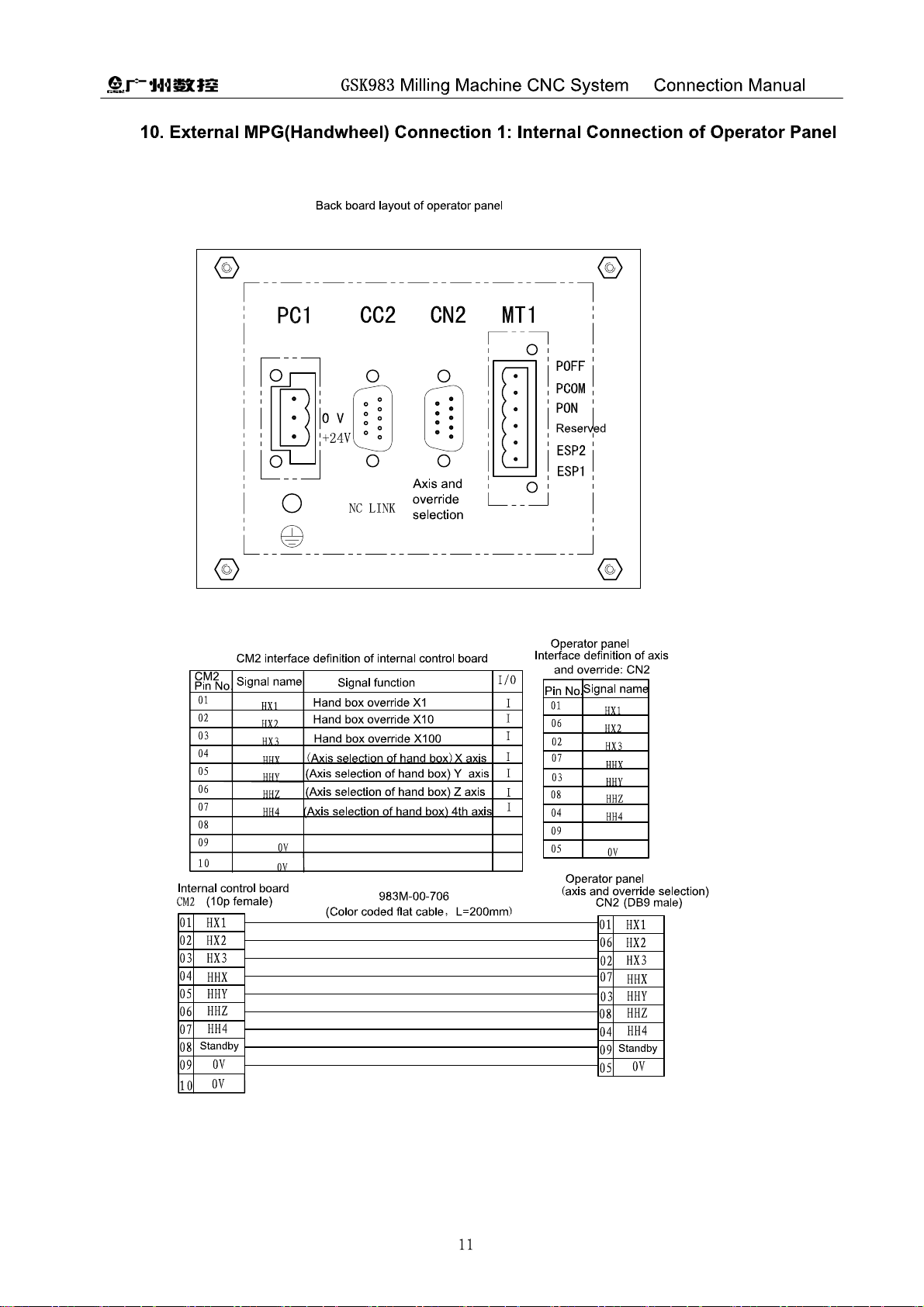

10. External MPG(Handwheel) Connection 1: Internal Connection of Operator panel...................... 11

11. External MPG(Handwheel) Connection 2: external MPG connection ..........................................12

12 . Connection Cables for Keyboard ...............................................................................................13

13. Connection Cables for Display ....................................................................................................14

14. Communication Cable between Operator panel and System......................................................15

15. Cables for Connecting DA98B Drive ...........................................................................................16

16. Z Axis Connecting Holding Cable of DA98B Drive ......................................................................17

17. Cables for Spindle Frequency Changer ......................................................................................18

18. Cables for Connecting DAP01 Servo Spindle .............................................................................19

19. Connection Diagram of Machine Emergency Stop and Holding Brake .......................................20

20. External I/O Unit..........................................................................................................................21

21. Communication Connection Cables for External I/O Unit and System........................................22

22. Definition for I/O input/output point..............................................................................................23

Appendix 1: MV2.02A-16 PLC use....................................................................................................25

Appendix 2: Installation Dimension Diagram ..................................................................................42

ⅰ

GSK983M Milling Machine CNC System Connection Manual

Precautions for Connection

1. Power should be supplied by isolating transformer.

2. Shells of the system parts and the machine must be securely grounded.

3. The system should be installed far away from place where the interference may occur (such as

converter, AC contactor, static generator, high voltage generator and subsection devices of

power line); and the space dimension around the system should also be complied with the

installation dimension described in the manual.

4. The environment around the system should conform to the requirements described in the

manual.

5. The signal cables and control cables of weak current should be distributed far away from the

place where there are strong current and strong electromagnetic interference; they should be

distributed straightly against interfering signal, otherwise, it easily receives the interfering

signal.

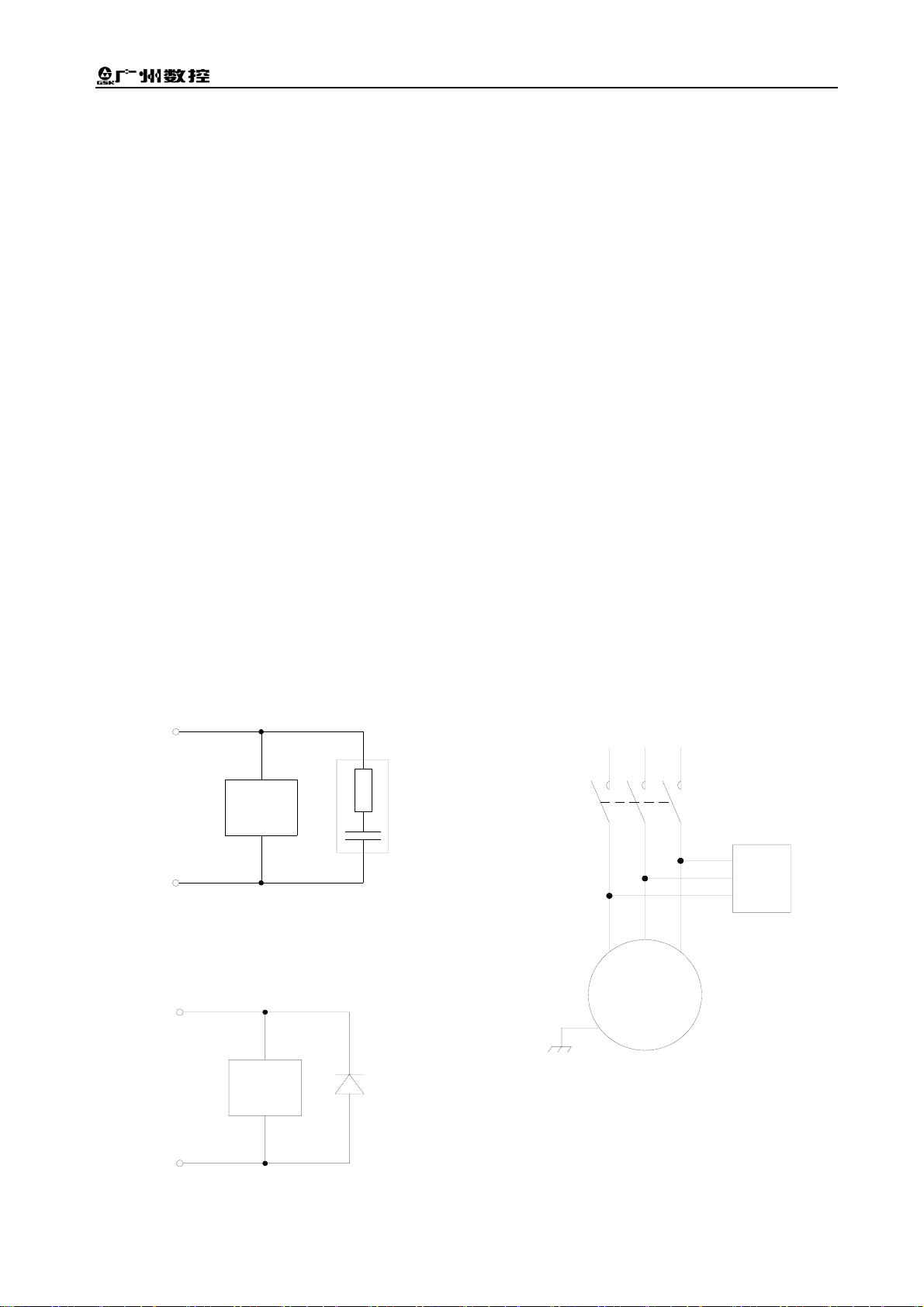

6. Interference suppression: Connect parallel RC loop to the two connector lugs of AC coil(Fig.1)

and the RC loop should be fixed as near as possible to the inductive load; connect reversely

parallel freewheeling diode at the two connector lugs of DC coil(Fig.2); connect parallel surge

absorber at the connector lugs of AC motor winding(Fig.3).

AC220V

(

Fig. 1)

KM

Surge

absorber

M

+24V

0

3~

(Fig. 3)

V

(Fig. 2)

1

Loading...

Loading...