Page 1

GSK983M Milling CNC System

User Manual

(Volume I: Specifications and Programming)

Page 2

This user manual describes all items concerning the operation of the

system in detail as much as possible. However, it is impractical to give

particular descriptions of all unnecessary and/or unavailable works of the

system due to the length limit of the manual, specific operations of the

product and other causes. Therefore, the operations not specified herein

may be considered impractical or unavailable.

This user manual is the property of GSK CNC Equipment Co., Ltd. All

rights are reserved. It is against the law for any organization or individual

to publish or reprint this manual without the express written permission

of GSK and the latter reserves the right to ascertain their legal liability.

I

Page 3

Company Profile

GSK, GSK CNC Equipment Co,. Ltd, is the largest CNC system production and

marketing enterprise in China at present. It is the Numerical Control industrial

base of South China, and the undertaking enterprise of the national 863 main

project Industrialization Support Technology for Medium Numerical Control

System. It is also one of the 20 basic equipment manufacture enterprises in

Guangdong province. It has been taking up the research and development,

design and the manufacture of machine CNC system (CNC device, drive unit and

servo motor) in recent 10 years. Now it has developed into a large high-tech

enterprise integrated with technology, education, industry and trade by enhancing

the popularization and trade of CNC machine tools. There are more than 1400

staffs in this company that involves 4 doctors, more than 50 graduate students

and 500 engineers; more than 50 among these staffs are qualified with senior

engineer post titles. The high performance-cost ratio products of GSK are

popularized in China and Southeast Asia. And the market occupation of GSK’s

product dominates the first and the turnout and sale ranks the top for successive

7 years in domestic market for the same product from the year 2000 to 2006,

which makes GSK the largest CNC manufacture base throughout China.

Field technical support services

Field support services are available when you encounter a problem insolvable

through telephone. GSK CNC Equipment Co. Ltd will designate a technical

support engineer to your place to solve technical problems for you.

Chinese version of all technical documents in Chinese and English

languages is regarded as final.

II

Page 4

Foreword

Dear user,

We are really grateful for your patronage and purchase of GSK983M milling CNC

system made by GSK CNC Equipment Co., Ltd.

This manual consists of two volumes. Volume I mainly describes the

specifications and programming of the system while Volume II operations, all

codes, parameters, I/O interfaces and other appendices.

This system can only be operated by authorized and qualified personnel as

!

improper operations may cause accidents. Please carefully read this user

manual before usage.

All specifications and designs herein are subject to change without further

notice.

We are full of heartfelt gratitude to you for supporting us in the use of GSK’ s

products.

III

Page 5

CONTENTS

1. GENERAL....................................................................................................................................1

1.1 Overview............................................................................................................................................1

1.2 Introduction to the Manual.............................................................................................................1

2. SPECIFICATIONS........................................................................................................................2

3. PROGRAMMING........................................................................................................................13

3.1 What Is Programming?.................................................................................................................13

3.2 Program Make-up ..........................................................................................................................13

3.2.1 Block........................................................................................................................................................14

3.2.2 Program word........................................................................................................................................14

3.2.3 Input format............................................................................................................................................16

3.2.4 Decimal programming .........................................................................................................................18

3.2.5 Maximum instruction value.................................................................................................................19

3.2.6 Program number...................................................................................................................................20

3.2.7 Sequence number ................................................................................................................................21

3.2.8 To skip over an optional block............................................................................................................21

3.3 Dimension Word............................................................................................................................23

3.3.1 Controllable axis ...................................................................................................................................23

3.3.2 Set unit....................................................................................................................................................25

3.3.2.1 Minimum set unit and minimum travel unit..............................................................................25

3.3.2.2 Input unit×10 ..................................................................................................................................26

3.3.3 Maximum travel.....................................................................................................................................26

3.3.4 Program origin and coordinate system............................................................................................26

3.3.5 Coordinate system and origin of processing ..................................................................................27

3.3.6 Workpiece coordinate system............................................................................................................27

3.3.7 Reference (position) point ..................................................................................................................28

3.3.8 Absolute value instruction and incremental value instruction .....................................................29

3.4 Feed Function (F function) ..........................................................................................................30

3.4.1 Rapid traverse (positioning) function ...............................................................................................30

3.4.2 Cutting feedrate ....................................................................................................................................30

3.4.3 To reduce feedrate to 1/10..................................................................................................................31

3.4.4 Synchronous feed (feed per rotation) ..............................................................................................31

3.4.5 F1 digit feed ...........................................................................................................................................32

3.4.6 Automatic acceleration and deceleration ........................................................................................33

3.4.7 Automatic angle adjustment...............................................................................................................34

3.4.7.1 Automatic adjustment of inner angle........................................................................................34

3.4.7.2 Switch of inner arc cutting feedrate ..........................................................................................37

3.5 Preparation Function (G function)..............................................................................................38

3.5.1 Selection of planes (G17, G18, G19)...............................................................................................40

3.5.2 Positioning (G00)..................................................................................................................................41

IV

Page 6

3.5.3 Unidirectional positioning (G60) ........................................................................................................42

3.5.4 Linear interpolation (G01)...................................................................................................................42

3.5.5 Arc interpolation (G02, G03) ..............................................................................................................44

3.5.5.1 Arc interpolation without any additional axis ...........................................................................44

3.5.5.2 Arc interpolation with an additional axis...................................................................................48

3.5.6 Sine-curve interpolation ......................................................................................................................48

3.5.7 Thread cutting (G33)............................................................................................................................49

3.5.8 Automatic return to reference point (reference positions G27~G30) ......................................51

3.5.8.1 Check of return to reference point (G27).................................................................................51

3.5.8.2 Automatic return to reference point (G28)...............................................................................52

3.5.8.3 Automatic return from reference point (G29)..........................................................................53

3.5.8.4 Return to the 2nd, 3rd or 4th reference point (G30) .............................................................55

3.5.9 Dwell (G04) ............................................................................................................................................55

3.5.10 Accurate stop detection (G09).........................................................................................................56

3.5.11 Accurate stop detecting mode (G61) and cutting mode (G64) ................................................56

3.5.12 Coordinate system setting (G92)....................................................................................................56

3.5.13 Workpiece coordinate system (G54~G59) .................................................................................57

3.5.14 To change workpiece coordinate system by program instruction ...........................................59

3.5.15 Automatic setting of a coordinate system .....................................................................................59

3.5.16 To switch between Inch and metric systems (G20, G21)..........................................................59

3.5.17 Storage travel limit (G22, G23) .......................................................................................................60

3.5.18 Skip function (G31) ............................................................................................................................63

3.6 Compensation................................................................................................................................65

3.6.1 Tool length compensation (G43, G44, G49)...................................................................................65

3.6.2 Tool offset (G45~G48) .......................................................................................................................67

3.6.3 Tool radius compensation (G40~G42) ...........................................................................................74

3.6.3.1 Tool radius compensation function............................................................................................74

3.6.3.2 Offset (D codes) ............................................................................................................................74

3.6.3.3 Offset vector...................................................................................................................................75

3.6.3.4 Plane selection and vector..........................................................................................................75

3.6.3.5 G40, G41 and G42 .......................................................................................................................75

3.6.3.6 Details about tool radius compensation C...............................................................................77

3.6.4 D and H functions ...............................................................................................................................109

3.6.5 External tool offset..............................................................................................................................110

3.6.6 To input offset through program (G10)...........................................................................................110

3.6.7 Zooming function (G50, G51) ..........................................................................................................110

3.7 Cycle Machining Function .........................................................................................................113

3.7.1 External moving function ..................................................................................................................113

3.7.2 Fixed cycles (G73, G74, G76 and G80~G89)............................................................................114

3.7.2.1 Repeating a fixed cycle .............................................................................................................126

3.7.3 Specifying an origin and Point R in a fixed cycle (G98, G99)...................................................132

3.8 Spindle Function (S function), Tool Function (T function), Miscellaneous

Function (M function) and Secondary Miscellaneous Function (B function)

.........................133

3.8.1 Spindle function (S function) ............................................................................................................134

3.8.1.1 S 2 digits .......................................................................................................................................134

V

Page 7

3.8.1.2 S 4 digits .......................................................................................................................................134

3.8.2 Constant surface speed control ......................................................................................................134

3.8.2.1 Instructed methods .....................................................................................................................135

3.8.2.2 Spindle speed ..............................................................................................................................135

3.8.2.3 Restraint of maximum rotational speed of spindle ..............................................................135

3.8.2.4 Rapid traverse (positioning) (G00)..........................................................................................136

3.8.3 Tool function (T function)...................................................................................................................137

3.8.4 Miscellaneous function (M function)...............................................................................................137

3.8.5 Secondary miscellaneous function (B function) ..........................................................................138

3.9 Subprogram......................................................................................................................................138

3.9.1 Creation of a subprogram.................................................................................................................139

3.9.2 Execution of a subprogram ..............................................................................................................139

3.9.3 Special methods of application........................................................................................................140

3.10 User Macro .....................................................................................................................................142

3.10.1 General...............................................................................................................................................142

3.10.2 Variables.............................................................................................................................................144

3.10.2.1 Indication of a variable ............................................................................................................144

3.10.2.2 Introduction of variables..........................................................................................................144

3.10.2.3 Undefined variables .................................................................................................................145

3.10.2.4 Display and setting of variable...............................................................................................146

3.10.3 Types of variables ............................................................................................................................146

3.10.3.1 Local variables # 1~# 33 .......................................................................................................147

3.10.3.2 Common variables #100~ #149 , #500~ #509 .............................................................147

3.10.3.3 System variables (for user Macro B)....................................................................................147

3.10.4 Operation instructions .....................................................................................................................160

3.10.4.1 Definition and substitution of variable ..................................................................................160

3.10.4.2 Additive operation.....................................................................................................................160

3.10.4.3 Multiply operation (Macro B option) .....................................................................................160

3.10.4.4 Function (Macro B option) ......................................................................................................160

3.10.4.5 Hybrid operation........................................................................................................................161

3.10.4.6 Changing operational order using [ ].................................................................................162

3.10.4.7 Accuracy .....................................................................................................................................162

3.10.4.8 Cautions regarding deterioration of precision ....................................................................162

3.10.5 Control instruction ............................................................................................................................163

3.10.5.1 Branch (GOTO).........................................................................................................................163

3.10.5.2 Repeat (how to select Macro B)............................................................................................165

3.10.6 Creation and storage of user macro body ..................................................................................169

3.10.6.1 Creation of user macro body..................................................................................................169

3.10.6.2 Storage of user macro body...................................................................................................170

3.10.6.3 Macro statement and NC statement ....................................................................................170

3.10.7 Macro call instruction.......................................................................................................................173

3.10.7.1 Simple calling ............................................................................................................................173

3.10.7.2 Modal calling..............................................................................................................................180

3.10.7.3 Multiple calling...........................................................................................................................181

3.10.7.4 Multiple modal calling ..............................................................................................................181

3.10.7.5 Calling a macro with G codes................................................................................................182

VI

Page 8

3.10.7.6 Calling a subprogram with an M code .................................................................................183

3.10.7.7 Calling macros with M codes .................................................................................................184

3.10.7.8 Calling a subprogram with a T code.....................................................................................185

3.10.7.9 The position of the decimal point of an independent variable........................................185

3.10.7.10 The difference between M98 (calling a subprogram) and G65 (calling a

macro body) ...............................................................................................................................................186

3.10.7.11 The nesting and local variables of user macro ................................................................186

3.10.8 The relationship with other functions ...........................................................................................187

3.10.9 Special codes and words used in user programs.....................................................................189

3.10.10 Restrictions......................................................................................................................................190

3.10.11 Descriptions for P/S alarm ...........................................................................................................191

3.10.12 Examples of user macros ............................................................................................................191

3.10.12.1 Groove machining ..................................................................................................................191

3.10.13 External output instructions .........................................................................................................193

3.10.13.1 OPEN instruction: POPEN...................................................................................................194

3.10.13.2 Data output instruction BPRNT DPRNT ...........................................................................194

3.10.13.3 Close instruction PCLOS......................................................................................................195

3.10.13.4 Necessary settings for using the function.........................................................................195

3.10.13.5 Cautions ...................................................................................................................................195

3.10.14 Macro interruption function (Macro B).......................................................................................196

3.11 Tool Life Management...............................................................................................................196

3.11.1 Setting of tool groups.......................................................................................................................196

3.11.2 Setting in machining processes ....................................................................................................198

3.11.3 Performance of tool life administration ........................................................................................200

3.11.3.1 Tool life calculation....................................................................................................................200

3.11.3.2 Tool change signal and tool change reset signal...............................................................200

3.11.3.3 New tool selection signal.........................................................................................................201

3.11.3.4 Tool skip signal ..........................................................................................................................201

3.11.4 The display and input of tool data.................................................................................................201

3.11.4.1 The display and modification of tool group number ..........................................................201

3.11.4.2 The display of tool life data during the execution of machine program ........................201

3.11.4.3 Presetting tool life counter ......................................................................................................202

3.11.5 Other cautions ...................................................................................................................................203

3.12 The Indexing Function of Indexing Worktable.....................................................................203

3.12.1 Instructing methods .........................................................................................................................203

3.12.1.1 Input unit.....................................................................................................................................203

3.12.1.2 Absolute / incremental instruction .........................................................................................203

3.12.1.3 Concurrently controlled axes .................................................................................................204

3.12.2 Minimum travel unit: 0.001 degree/pulse....................................................................................204

3.12.3 Feedrate .............................................................................................................................................204

3.12.4 The clamping and release of indexing worktable......................................................................204

3.12.5 Jog/step/handwheel.........................................................................................................................205

3.12.6 Other cautions...................................................................................................................................205

VII

Page 9

GSK983M Milling CNC System Operation Manual (Volume I: Specifications and Programming)

1. GENERAL

1.1 Overview

As a high-accuracy and high-performance closed-loop CNC system with firmware, GSK983M

milling CNC system (hereinafter called “System”) was newly developed and launched by GSK

CNC Equipment Co., Ltd. to satisfy the demands of NC market and intended for CNC milling

machine and processing center. By employing a high-speed microprocessor, a general large scale

integrated circuit (LSI), a semiconductor memory and up-to-date storage elements, the reliability

as well as performance-to-price ratio of its control circuit are greatly improved, thereby facilitating

the reliability, functions/ performance to price ratio to a large extent.

With a widely applicable advanced servo, GSK983M milling CNC system uses a high-duty pulse

encoder as its detecting element, thereby composing a closed-loop CNC system.

This operating manual describes all available functions of the system. However, a real unit may not

necessarily be provided with all the optional functions. Should the specifications of the control panel

and operating mode of the machine change, the instruction manual supplied with the machine by the

manufacturer shall be referred to.

1.2 Introduction to the Manual

The functions of a NC machine system are not only dependent on its NC, but also on its mechanical

part. That is to say, its heavy current circuit, servo system, NC and mechanical operation panel

jointly determines its performance. The manual only gives a general account from the angle of NC as

it is difficult to describe all the functions of an NC machine and programming and operating

procedures in detail. As for a specific NC machine, please refer to the instruction manual supplied

with the machine by the manufacturer. The contents of the machine instruction manual are more

important than those herein.

The performance of a NC machine system is jointly determined by its NC system, mechanical

structure, heavy current control and servo system including its mechanical operation panel. The

operating manual only describes GSK983M CNC system. To know the performance, programming

and operating instructions of the entire NC machine system further, please refer to the machine

instruction manual supplied by the manufacturer.

The operating manual describes all matters in detail as much as possible. However, the listing of all

matters is unnecessary and impossible as this will complicate the contents of the manual. Therefore,

the functions that are not described in this manual may be considered impractical.

The functions that are not described in this manual may be deemed unavailable so far.

Some items are specifically explained in Note sections. Therefore, if any explanation is not available

in the current Note section, it is advisable to skip over it, thoroughly read the manual and then return

to the part.

1

Page 10

GSK983M Milling CNC System Operation Manual (Volume I: Specifications and Programming)

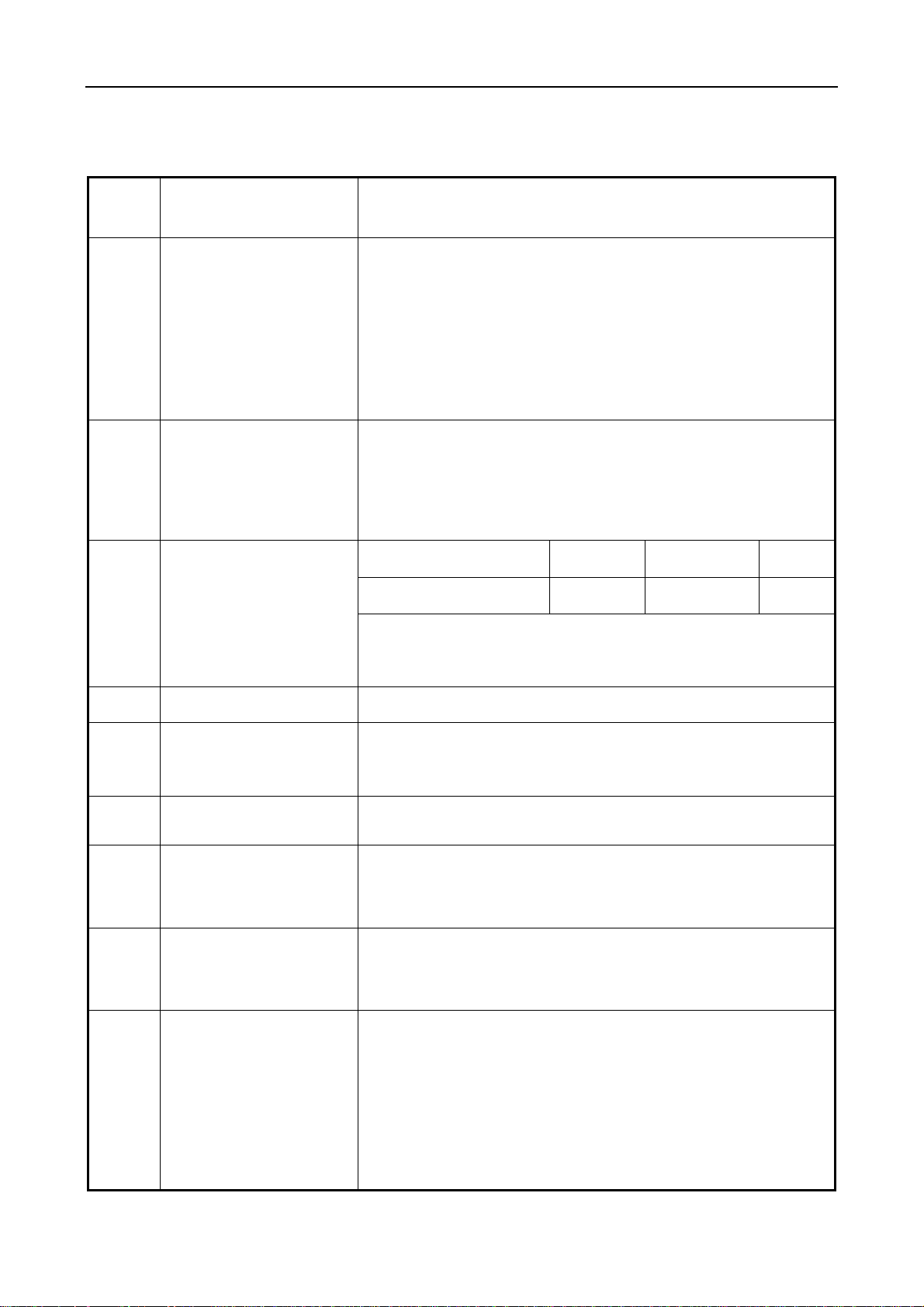

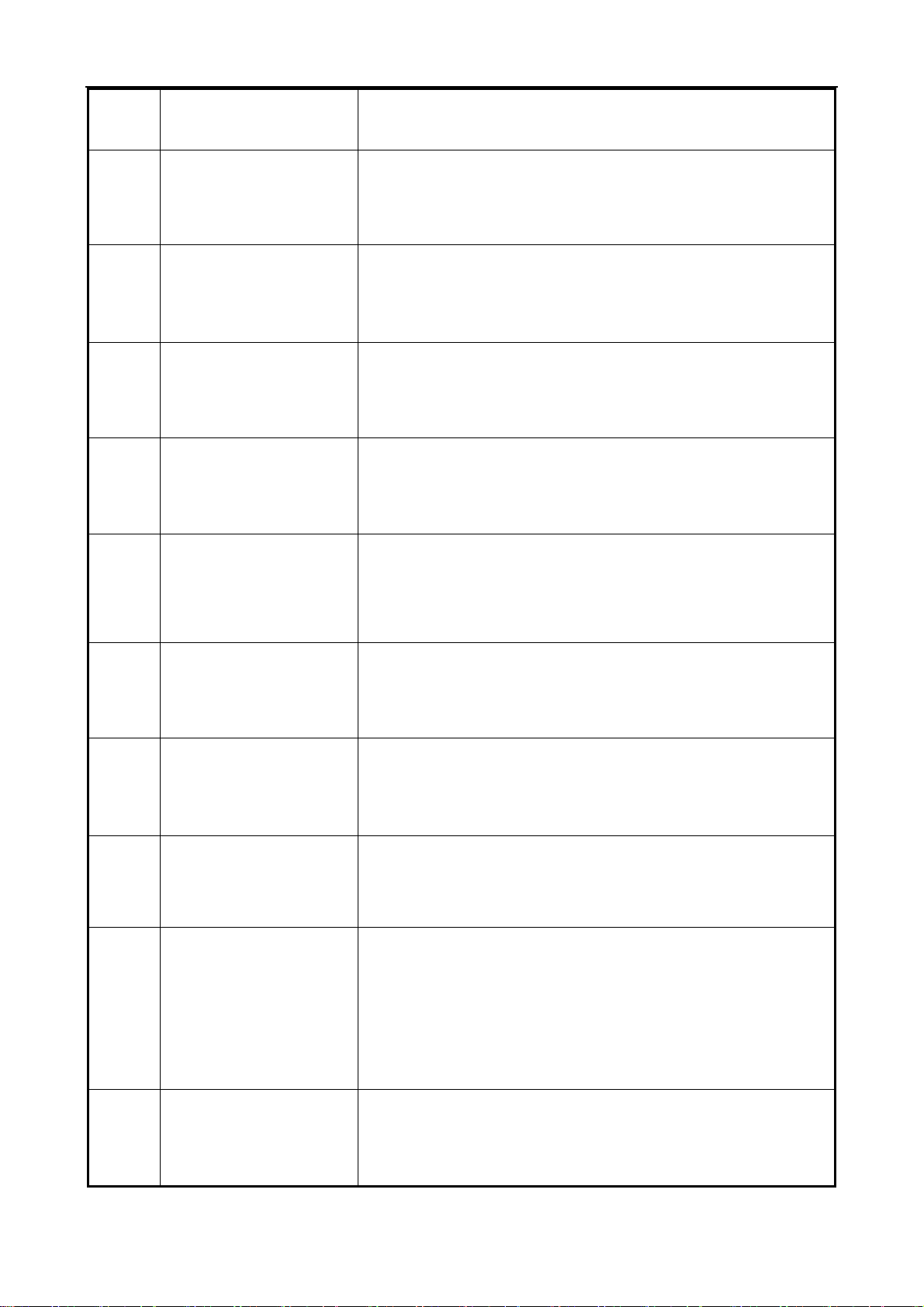

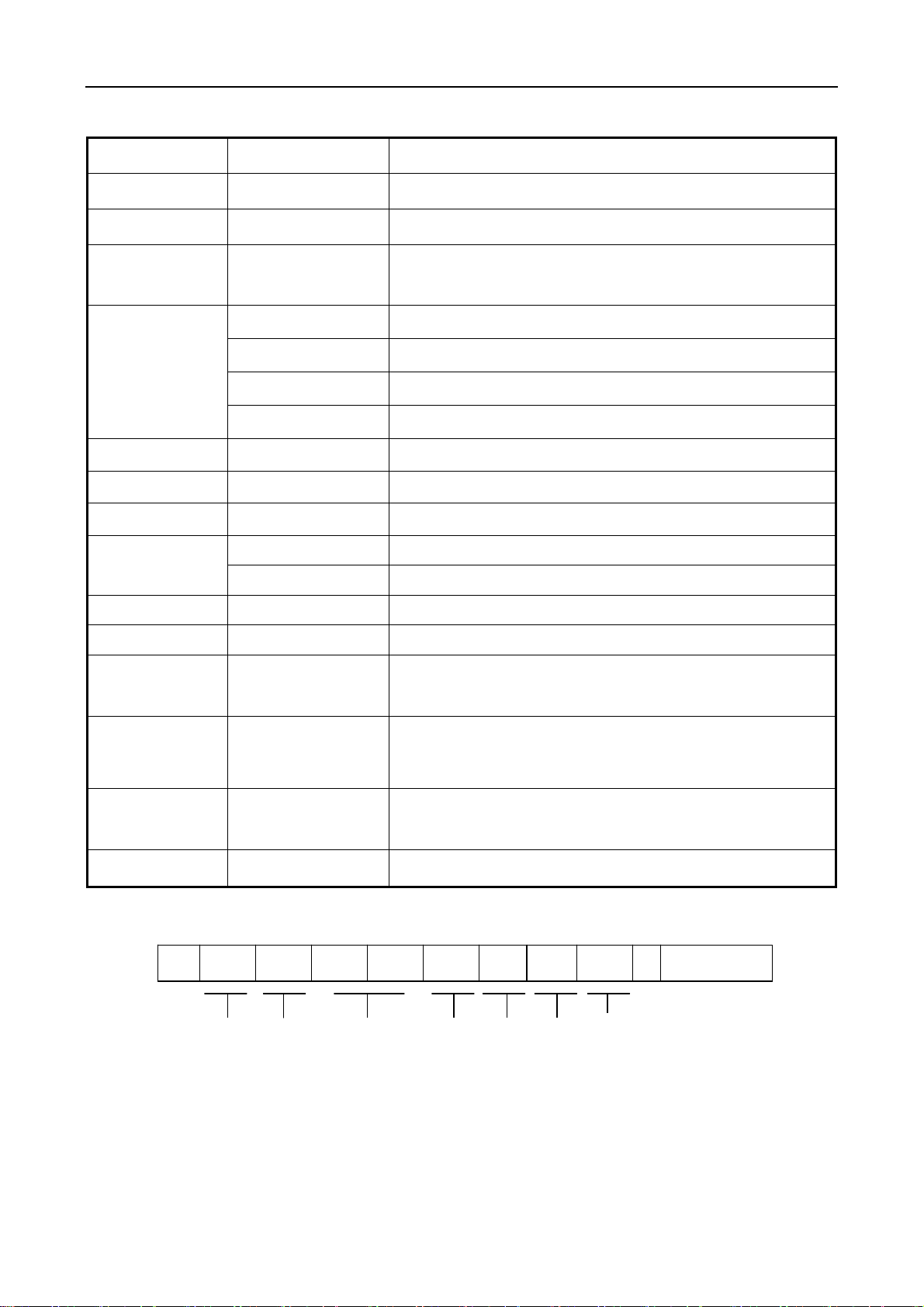

2. SPECIFICATIONS

Serial

No.

Designation Descriptions

1 Controllable axes

2

3

Number of concurrently

controllable axes

Incremental system

Standard: 3 axes, namely axes X, Y and Z

(4 or 5 axes are also available upon customer’s request. The

th

address of the 4

That the 4

th

The address of the 5

or C. It is possible to specify whether the 5

axis can be selected from A, B, C, U, V or W.

axis is linear or rotary may be set by parameters.

th

axis can be designated as U, V, W, A, B

th

axis is linear or

rotary by parameters.)

Standard: 3, axis 3, link,

(The following configurations are also available upon customer’s

request: 4, axis 3, link; 4, axis 4, link; 5, axis 3, link; and 5, axis 4

and link.)

Min. set increment 0.001mm 0.0001 inch 0.001°

Min entered increment 0.001mm 0.0001 inch 0.001°

The minimal increment entered in accordance with parameter

setting metric system may be 0.01mm.

4 Bit detecting device Pulse encoder

±99999.999 mm

5 Max. instruction value

±9999.9999 inch

±99999.999°

6 Input format

7

Decimal point

programming

Changeable block, character and address formats are

employed.

It is possible to enter numerical values including a decimal point.

The addresses that may include a decimal point are X, Y, Z, A,

B, C, U, V, W, I, J, K, Q, R and F.

Axial speed can be up to 24,000m/min or 960 inch/min. In

8 Rapid traverse

addition, rapid traverse speed may be changed to FO,25,50 or

100% using rapid traverse override (optional).

Feedrate can be set within the following ranges: 1 mm/min~

15,000mm/min and 0.01inch/min ~ 600.00 inch/min. It is

possible to set the upper speed limit of cutting feed by

parameters. A feedrate may be selected from 0 to 200% by

setting the override of feedrate to 10% as a step. The unit of

9

Miscellaneous function

(Bit M2)

feedrate may be changed to 0.01 mm/min, 0.001 mm/min or

0.001 inch/min according to parameter setting.

2

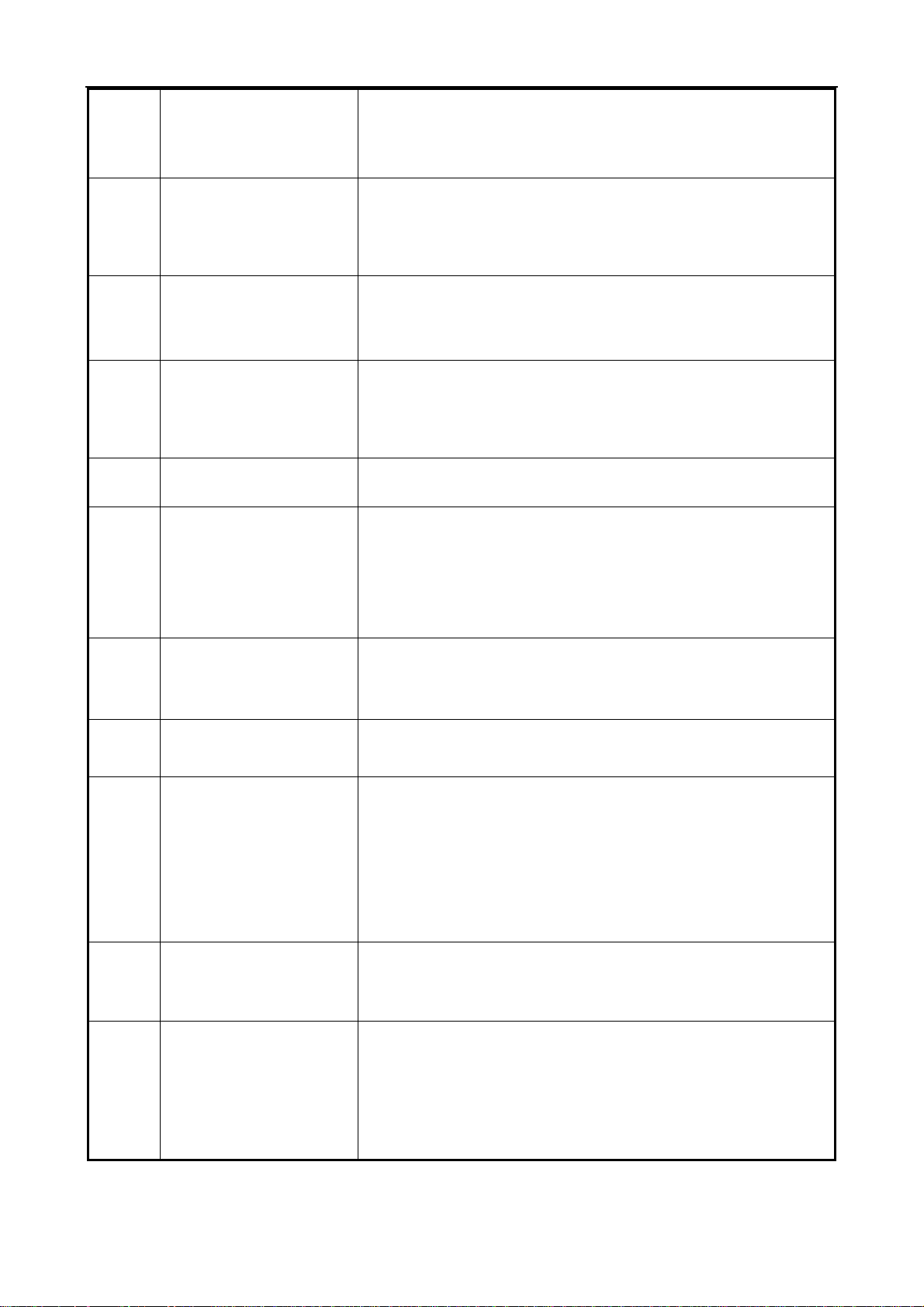

Page 11

GSK983M Milling CNC System Operation Manual (Volume I: Specifications and Programming)

Both manual rapid traverse and automatic rapid traverse are

performed in linear acceleration/deceleration mode so as to

reduce positioning time.

10

Automatic

acceleration/deceleration

G codes may be used to select absolute or Incremental

11

Absolute/incremental

value instruction

programming.

G90: Absolute programming

G91: Incremental programming

When the instruction value for subsequent axes of G92 is used

to establish a coordinate system, the actual position of cutting

tool will become the instruction value for the coordinate system.

12

Coordinate system

setting (G92)

All axes individually move to the end point rapidly and

13 Positioning (G00)

decelerate until stop through instruction G00, and the machine

performs positioning (whether the machine reaches the

instructed position) detection by parameters setting.

14

Linear interpolation

(G01)

Linear interpolation may be conducted at the feedrate specified

by F codes using instruction G01.

When executing a block, the unit reads the next one in buffer

register in advance. In this way the intermittence of the NC

15 Buffer register

instruction operation caused by the time required for reading

may be avoided. While inputting data in buffer register, BUF will

appear on the lower right of LCD screen.

The operation of the next block can be delayed before execution

16 Dwell (G04)

using instruction G04. The delay time must be specified with

address P or X.

17

Accurate stop detection

(G09)

The block of instruction G09 decelerates and performs

positioning detection by the end of the block.

If G61 is instructed, the travel instructions following G61

decelerate from doubtful points of all blocks and continue to

execute the next block when it is positioned.

If G64 is instructed, the travel instructions following G64 rather

than positioning instruction do not decelerate but execute the

18

Accurate stop detecting

mode/cutting mode

(G61, G64)

following blocks. As a rule, they are applicable for cutting mode.

The instructions of M2 with 2 digits following may be used to

control the ON/OFF signal on machine side. Only one M code

can be instructed in one block.

19

Miscellaneous function

(Bit M2)

In dry running mode, feedrate becomes Jog (JOG) feedrate.

The rapid traverse speed keeps constant and rapid traverse

20 Dry run

override (option) is still valid in rapid traverse instruction (G00).

However, the dry running of instruction is available when it is set

to rapid traverse (positioning) according to parameters.

3

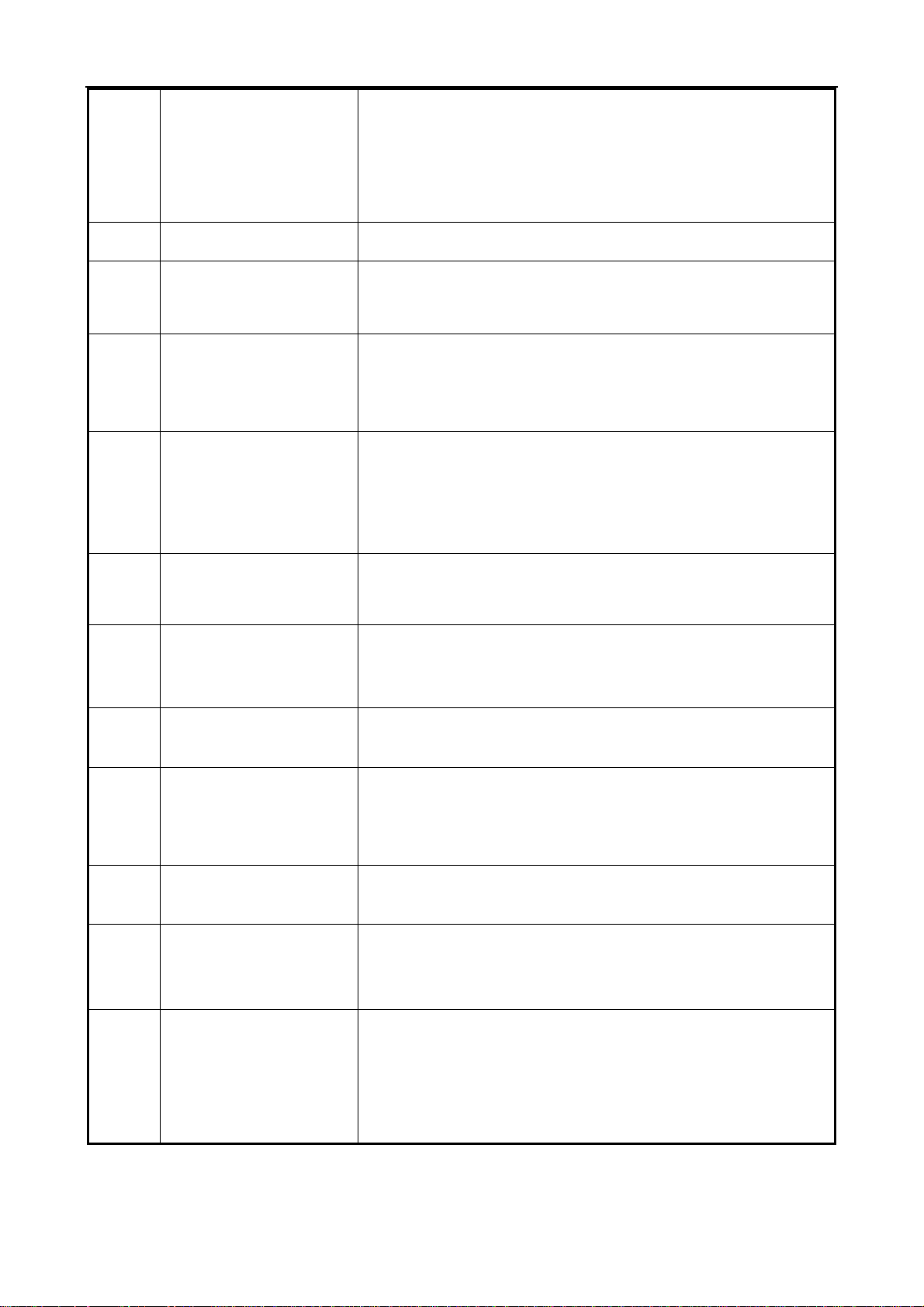

Page 12

GSK983M Milling CNC System Operation Manual (Volume I: Specifications and Programming)

It is possible for all axes to individually disable the feed of an

instructed axis. If any instructed axis in interlocked during

21 Interlock

traveling, all axes of the machine will decelerate until stop. Once

the interlock signal is cancelled, the machine will accelerate and

restart.

22 Single block A block instruction can be executed each time.

The block preceded by a “/” (slash) code may be ignored by

turning on the OPTIONAL BLOCK SKTP switch on the machine

side.

23

To skip over an optional

block

The switch may be used to reverse the program instructions of

24 External mirroring

axes X and the 4

to set mirroring with the MDI/LCD panel or the switch on the

machine side.

It is possible to determine whether to add the traveling amount

through the manual traveling tool to absolute coordinates by

switching the manual absolute value switch on the machine

side.

25

Manual Absolute Value

ON/OFF

Manual Absolute Value switch ON: To add; OFF: Not to add.

26 To lock auxiliary function

BCD code signal and strobe signal of M, S, T and B are sent to

the machine side.

The machine keeps still. However, position display is still valid

27 To lock the machine

as the machine is moving and machine locking is also valid even

in the execution of a block.

th

axis as well as the travel of MDI. It is possible

28

To cancel the instruction

for axis Z

The function is only equivalent to Z-axis locking. It is to be used

when NC program is checked by drawing a picture with a pen.

The function is used to temporarily stop the feed of all axes that

29 To feedrate feed

can be restarted by pressing Cycle Start button. Before the

restart of feed, it is possible to insert manual operation in

manual mode.

30 To cancel override

The function is used to fix the cutting feedrate at 100%

depending on the signals from the machine side.

By pressing the Emergent stop button all feed instructions stops

31 Emergent stop

(interrupt immediately) and the machine stops running at the

same time.

The function is used to reset NC from the outside of NC. The

signal stops all feed instruction and the machine decelerates

until stop by reset. Additionally, the Reset button on MDI/LCD

outputs reset signals to the machine side during emergent stop

32

External reset, reset

signal

and external reset.

4

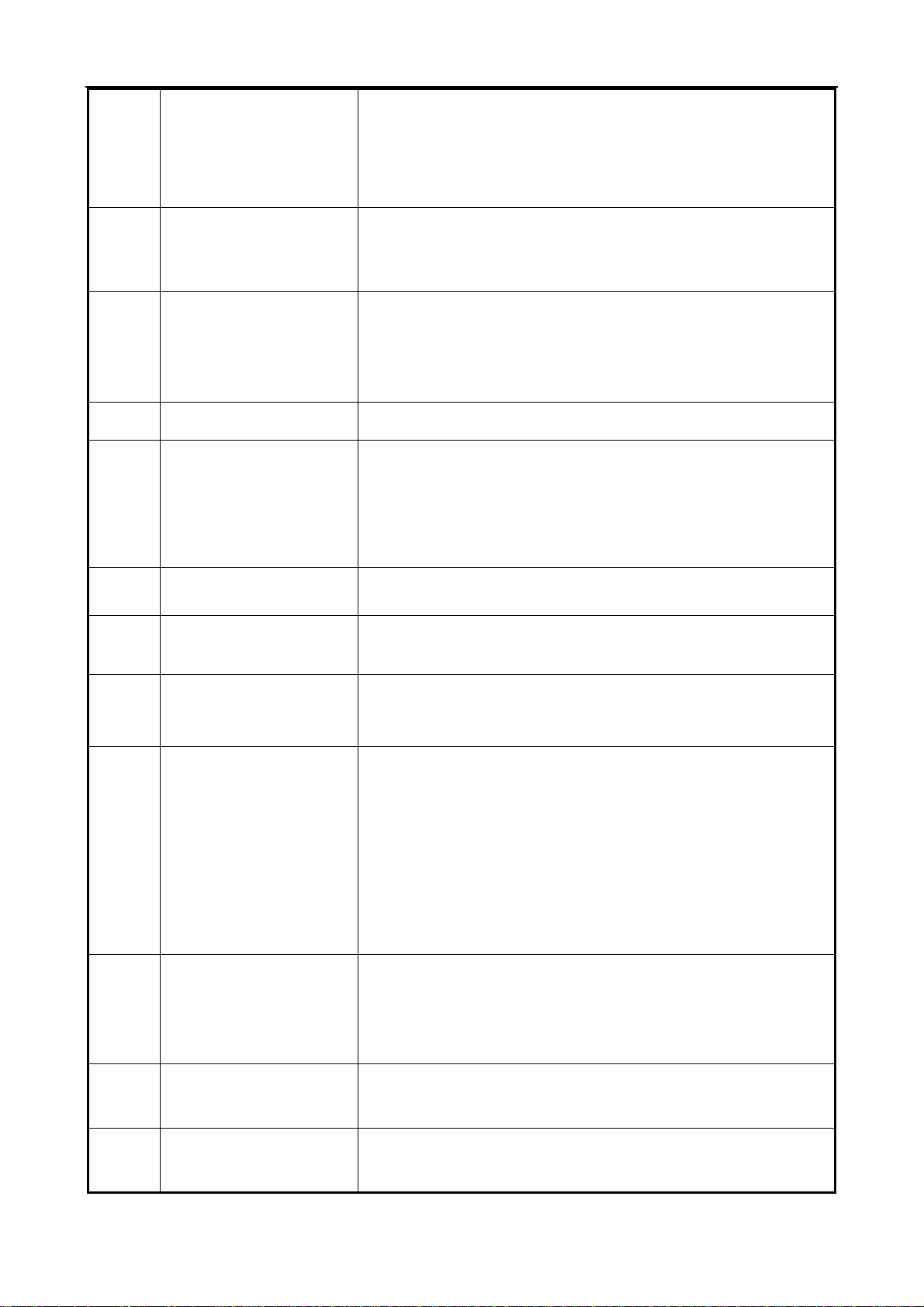

Page 13

GSK983M Milling CNC System Operation Manual (Volume I: Specifications and Programming)

The moving parts of the machine receives arriving signal when

33 Overtravel

they come to the end of travel. Then the movement of axis

decelerates until stop and overtravel warning is displayed at the

same time.

When the power supply is switched on, NC gives the signal in

34 NC Ready signal

controllable state. It stops sending signals to the machine side

once the power supply is cut off or the control unit overheats.

When the servo system is ready, the signal is sent to the

35 Servo Ready signal

machine side. For the axis to be braked, it is locked when the

signal has not been given off. LCD displays NO READY in the

absence of the signal.

36 NC warning signal The signal is sent out when NC is in warning state.

NC outputs the signal when the motion order ends up. If the

functions of M, S, T or B and motion instruction are active in a

block, the signal is given after the completion of the execution of

traveling instruction and the functions of M, S, T or B can be

37

Distribution Completed

signal

executed.

38 Cycle Operation signal NC gives the signal in cycle operation.

39

40

Cycle Operation Start

Indicator signal

Feed Hold Indicator

signal

NC sends out the signal at the start of cycle operation.

NC outputs the signal when it is in holding state through feed

hold.

(1) JOG feed: For JOG feedrate, the rotary switch may be used

for 24-step switching. The ratio of 24-step is geometric

progression.

41 Manual continuous feed

(2) Manual rapid traverse: Rapid traverse may also be achieved

by manual means. Rapid traverse override may be used for

the rapid traverse speed set by parameters. Rapid traverse

override is an optional function.

Manual continuous feed is available for 2 axes at one time.

Since the following increments may exert positioning control,

42 Incremental feed

manual positioning can be performed efficiently. Incremental

feed is available for 2 axes at one time (incremental feed

amount).

43

44

Sequence number

searching

Program number

searching

It is possible to search the sequence numbers in the currently

selected program with the MDI/LCD panel.

It is possible to search the program numbers of 4 digits following

O with the MDI/LCD panel.

5

Page 14

GSK983M Milling CNC System Operation Manual (Volume I: Specifications and Programming)

It is this function that compensates the lost amount of movement

45 Clearance compensation

of the machine. The amount of compensation is set in the

minimum amount of movement within 0 ~ 255 by parameters.

The function disables the display, setting and editing of the

46 Program key locking

program with a program number of 9000~9899 by means of

key locking.

(1) Ambient temperature

0℃~45 for operation and ℃ -20℃~55 for storage and ℃

shipment.

(2) Relative humidity

≤90%(without condensation), ≤95%(40 )℃

47

Environmental

conditions

(3) Vibration

Less than 0.5G for operation and 1G for storage and

shipment

(4) Ambient air

To install an NC in an environment with high density of dust,

machining fluid and organic solvent, contact the

manufacturer.

(1) Servo system

48 Self-diagnostics

(2) NC

(3) Status display

a. To give an alarm when the error of the error register

goes beyond the setting in halted state.

b. To give an alarm when the value of the error register

goes beyond the maximum setting.

c. To give an alarm in case of malfunction of positioning

detection system.

d. To give an alarm when the drift voltage is excessive.

e. To give an alarm in case of malfunction of speed control

unit.

a. To give an alarm in case of malfunction of the memory.

b. To give an alarm in case of malfunction of ROM and

RAM.

c. To give an alarm in case of malfunction of the

microprocessor.

a. To display the status of NC on LCD.

b. To display the status of I/O on LCD.

49

S function/T function

(BCD2 bit)

Once the instructions of 2 digits following S and T are instructed,

the code signal of BCD2 bit may be sent out while codes S and

T ad other codes are individually output. They are reserved until

the following S and T are instructed.

6

Page 15

GSK983M Milling CNC System Operation Manual (Volume I: Specifications and Programming)

The binary 12-bit or analog voltage corresponding to the speed

of principal axis is output to the machine side. The analog

voltage is up to ±10V, 2mA and the speed (r/min) of principal

axis is directly specified by S4 Bit. The speed of principal axis

may be regulated in the following range depending on the

contact signal on the machine side: 50, 60, 70, 80, 90, 100, 110

50

S4 Bit (binary 12-bit

output)

A/S4 Bit (analog output)

A

and 120%.

When the speed (r/min) of principal axis is directly specified, the

voltage for the current speed of principal axis is output by the

presently selected gear numbers 1 to 4.The switching of gear is

performed in a heavy-current circuit, resulting that the signal of

GRA or GRB is input in NC side. As the judging message for

switching gears on the heavy-current side, NC outputs the

51

S4 Bit (binary 12-bit

output)

A/S4 Bit (analog output)

B

higher 2 bits or lower 2 bits of S4 bit in BCD codes.

A position coder is installed on the principal axis. It is possible to

perform thread cutting using the pulse synchronous speed of the

position coder.

52

Thread cutting

/synchronous feeding

To achieve the feed that is in step with the rotation of the

principal axis, a device that may generate pulse voltage of which

53 Position coder

frequency is proportional to the number of revolutions of the

principal axis and generates 1024 pulses in each rotation shall

be directly connected.

Generally surface speed is instructed with B codes. In this way

54

Constant surface speed

control

the principal axis accordingly changes when the position of the

tool changes so that its surface cutting speed is always equal to

the linear speed set by S codes.

Address B is followed by three digits. Once it is instructed, a

BCD three-bit code signal will be sent out to position the index

table.

55

Second auxiliary function

(B3 bit)

Addresses S and T are followed by a 2-digit instruction. Once

they are instructed, the code signal of BCD2 bit will likely to be

56 T-function (BCD4 bit)

sent out and other codes of the addresses S and T are

individually sent out and held until the next S and T are

instructed.

ISO codes (ISO840) and EIA codes (EIA RS-244-A) can be

57 Code standards

used for program code. The identification of ISO codes and EIA

codes may be performed automatically.

7

Page 16

GSK983M Milling CNC System Operation Manual (Volume I: Specifications and Programming)

The automatic or manual rapid traverse speed can be set in 4

58 Rapid traverse override

levels, i.e. FO, 25, 50 and 100% and FO is likely to be set to a

specific speed by parameters.

Return to reference point A consists the following procedures:

59

Return to reference point

A

(1) Manual return to the reference point;

(2) Examination of the return to the reference point (G27);

(3) Automatic return to the reference point (G28).

60

61

62

63

Return to reference point

B

Return to the 3

rd

and 4th

reference points

Storage travel limits 1

and 2

Memory type pitch error

compensation

Besides the functions of returning to reference point A, the

return to reference point B also includes the return to the 2

nd

reference point (G30).

It is possible to set the 3

their distances from the 1

rd

and 4th reference points by setting

st

reference point and return to these

reference points.

For storage travel limit 1, the area beyond those set by

parameters are exclusion areas. For storage travel limit 2, the

inside or outside of the area specified by parameters or

programs are exclusion areas. The validity or invalidity of

storage travel limit 2 is set by G codes.

G22: Valid G23: Invalid

The function is designed to compensate the pitch error caused

by the mechanical wear of the feed screw so as to maximize

processing accuracy and mechanical life. Compensation data is

saved in memory, thereby omitting the compensation

mechanism such as the stop and the relevant setting

operations.

64

65

The selection of a

workpiece coordinate

system

Tool offset (G45~G48)

It is possible to preset one of the 6 workpiece coordinate

systems using six G codes, i.e. G54~G59 and subsequent

programming can be made in the selected coordinate system.

Tools can be offset using instructions G45~G48. Tool offset

refers to the side-play mount corresponding to a move

instruction’s elongation or reduction of an instruction of D or H

codes in axial direction. D or H codes may instruct 1~32 and

the maximum offset shall be ±999.999mm or ±99.999 inches.

G45: To increase the set value;

G46: To reduce the set value;

G47: To increase the set value by twice;

G48: To reduce the set value by twice.

8

Page 17

GSK983M Milling CNC System Operation Manual (Volume I: Specifications and Programming)

To manually return to a reference point, parameters must be

66

Automatic setting of a

coordinate system

preset to establish a coordinate system, namely automatic

execution is similar to the condition that the instruction G92 is

used at the reference point.

Tool length offset (tool length compensation) is possible in the

67

Tool length offset (G43,

G44, G49)

direction of the axis Z using instructions G43 and G44. The

offset number must be selected within 01~32 using H codes.

The offset shall fall within ±999.999mm or ±99.999 inches.

Tool radius compensation is possible using instructions G40~

G42. The offset number must be specified within 01~32 using

D codes. The offset shall fall within ±999.999mm or ±99.999

inches. Cutter compensation B is unavailable for a tool of a

medial angle less than 90°.

68

Tool radius

compensation B, C

(G40~G42)

Cutter compensation 0 can be used for the tool of a medial

angle less than 90°.

Manually position the standard tool to the fixed point of the

machine tool. Then manually position the machine tool to be

measured to the same mechanical point. The length

compensation of the tool will be input as offset once z INPUT

69

Tool length

measurement

is pressed.

70

71

72

73

Tool life management

function

Additional offset memory A The numbers of tool offset and tool radius compensation may be

Additional offset memory B The numbers of tool offset and tool radius compensation may be

Additional offset memory

C

74 F1- bit feed

Divide the tools in the cutting tool room into several groups and

specify service life for each group of cutting tools. Accumulate

the tool processing time or processing number that serves as

the evaluation standard for tool life whenever a tool in the

groups is used. The next cutting tool in the predetermined

sequence is automatically selected in the same group when the

tool reaches its service life.

increased to 64.

increased to 99.

The number of cutter compensation is increased to 200.

Once the number of F followed by one digit of 1~9 is instructed,

the feedrate corresponding to the number will be set. The

instruction FO is a rapid traverse speed. The feedrate of the

currently selected number can be increased or reduced by

turning the manual pulse generator when the machine side

gives a speed-changing signal.

9

Page 18

GSK983M Milling CNC System Operation Manual (Volume I: Specifications and Programming)

75

76

77

78

79

External moving function

(G80, G81)

Fixed cycle A (G80, G81,

G82, G84, G85, G86 and

G89)

Fixed cycle B (G73,

G74, G76,

G80~G89)

Switch between Inch and

metric systems (G20,

G21)

Arc interpolation (G02,

G03)

Instruction G81 is used to output external movement signals

after the positioning of X and Y axes and G80 to cancel it.

It is possible to perform 6 fixed cycles including drilling cycle,

tapping cycle and boring cycle.

It is possible to perform 12 fixed cycles including gun drilling

cycle, finish boring cycle, tapping cycle and reverse-tapping

cycle.

Input in Inch or metric system can be selected by switching G

codes.

G20: Input in Inch system G21: Input in metric system

Using G02 (or G03) may achieve any arc interpolation within

0~360° with the feedrate of F code instruction.

G02: Clockwise (CW) G03: Counterclockwise (CCW)

When an axis in the arc plane does not move (the axis is

80 Sine-curve interpolation

considered as an imaginary axis) in the spiral-curve

interpolation instruction, the other 2 axes may be used for

sine-curve interpolation.

81

The arc interpolation

using arc radius R for

programming

In arc interpolation, directly specifying radius with radius value R

rather than I, J and K simplifies programming. An arc over or

below 180° can be instructed.

The mechanical vibration at the end of travel can be minimized

82 External deceleration

and the range of effective travel maximized through the function.

External deceleration is not applicable for an additional axis.

The function is used to input any program number among 1~31

for NC from the outside such as machine side and to select

these programs from the memory of NC.

83

External workpiece

number search A

The function is used to transmit the following data from the

outside such as machine side:

84 External data input

(1) External workpiece number search C;

(2) External cutter compensation C;

(3) External warning message;

(4) External operation information.

85

Automatic acceleration/

deceleration of cutting

feed

Cutting feed and manual continuous feed can be set by

parameters to make power type acceleration/ deceleration in

8ms~4000ms time constant.

10

Page 19

GSK983M Milling CNC System Operation Manual (Volume I: Specifications and Programming)

9 switches for skipping over selected blocks can be set on

machine side by adding a digit (1~9) after the switching

instruction”/” of a block. When a switch n for skipping over

selected blocks is enabled, the blocks with “/n” will be skipped

86

Additional skipping over

selected blocks

over.

th

When G31 is followed by X, Y, Z, the 4

or 5th axis instruction as

same as G01, it is possible to make line interpolation. If skip

87 Skip function (G31)

signal is input from the outside during the execution of the

instruction, the remaining part of the instruction stops executing

and the blocks that follow will be executed.

88 Program restart

89 Unidirectional positioning

90

Addition of the number of

storable programs

91 Zoom

92

93

Insertion of a manual

tray

Automatic angle

adjustment

When the sequence number to be restarted is specified, the

program will restarts from here.

Positioning can only be performed in one direction in order to

eliminate clearance and achieve accurate positioning.

96 programs can be added to the standard programs to reach

191 programs in total.

The tool path instructed in a program can be zoomed in a range

of 0.001~99.999x.

The tool movement overlapping an automatic running instruction

can be done only with the pulses of the manual pulse generator

without processing interruption.

When cutting the inner side of an angle in tool radius

compensation mode, adjustment can be automatically added in

the set area for processing at low speed.

The function is used to set the angle of the positive direction of

axis X on the dial gauge of the operation panel of the machine

and to make Jog feed in the set direction. In the XY plane, this

function is only valid for the increment of 5° spacing within 0°~

94

Manual feed at any

angle

360° range.

Once the block with the same sequence number as the preset

95

Sequence number

comparison stop

one appears in the execution of a program, a single block will be

in stop status when the execution of the program ends. The

function is used to check a program.

96 Indication of running time

The NC automatic running time can be indicated on LCD in

seconds, minutes and hours.

The ON/OFF can be controlled by using the settings on

97 Menu switch

MDI/LCD rather than the switches on the operation panel on the

machine

11

Page 20

GSK983M Milling CNC System Operation Manual (Volume I: Specifications and Programming)

98

User macros

A and B

These are the intrinsic functions available for manufacturer and

user and types A and B are provided due to functional limits.

99 Graphic display The tracks of cutting tools are traced out on LCD.

The manual pulse generator on the operation panel can be used

to perform Jog feed of the machine. The manual pulse

100 Manual pulse generator

generator sends out 100 pulses each turn. The travel of each

pulse can be switched between 1x, 10x and 100x depending on

the signals on the machine side.

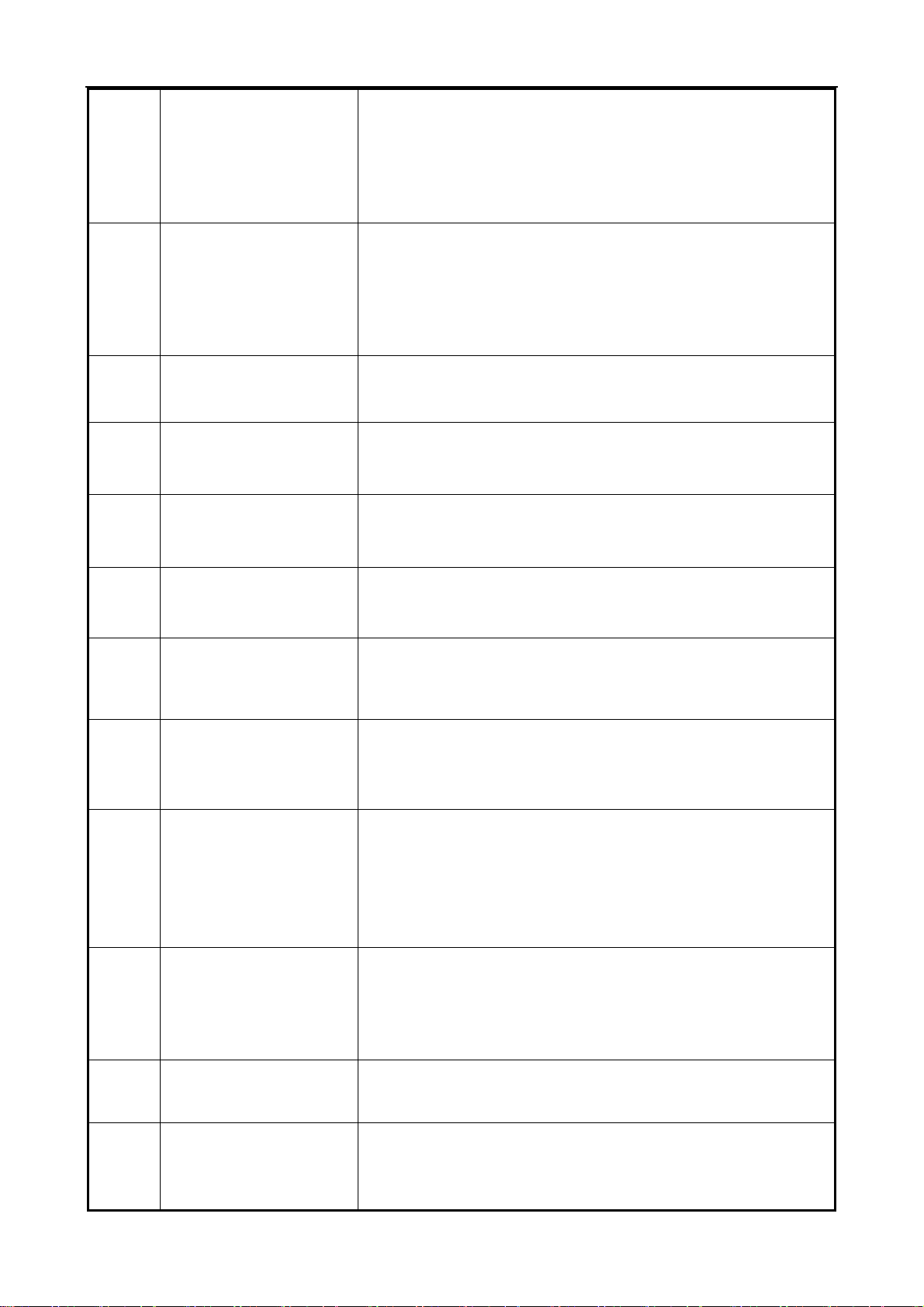

PLC MODELS A and B are available.

101 PLC

Quantity of input

points

Quantity of output

points

Program step

PLC MODEL-A PLC MODEL-B

192 points 192 points

128 points 128 points

Up to 2,000

steps

Up to 5,000 steps

12

Page 21

GSK983M Milling CNC System Operation Manual (Volume I: Specifications and Programming)

3. PROGRAMMING

3.1 What Is Programming?

NC processing machine operates by developed programs. To process a part on the NC machine,

the route and other processing conditions of cutting feed shall be included in the program. The

program is called “part program”.

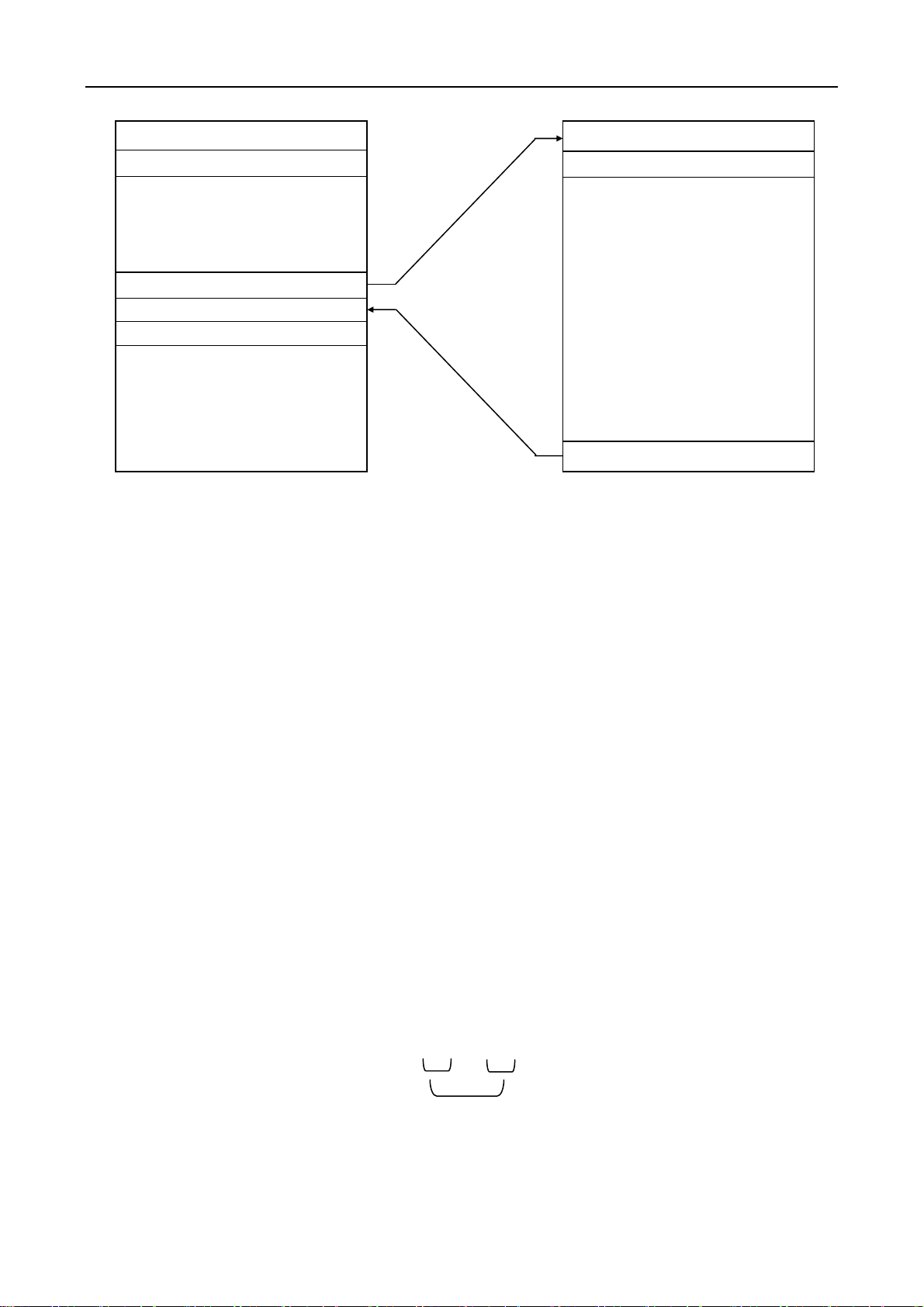

The following diagram indicates the processes from preparation of detail drawing to NC’s

execution of the processing program.

Detail drawing Processing plan Part programming NC’s execution of processing program

(1) Determine the NC processing range and select an NC machine to be used.

(2) Determine the assembling method of the workblank on the machine and select a

Part program is an NC instruction for controlling feed route and the auxiliary movement of a

machine written according to the rules for NC. The instructions are usually written in a program list.

necessary clamping device and a tool.

(3) Determine the cutting sequence (process type, home point of the cutting tool, the cut

depths of rough cutting and finish cutting and route of cutting feed).

(4) Select a cutting tool and a tool clamping device and determine the mounting position on

the machine.

(5) Set cutting conditions (spindle rotating speed, feed speed and whether to use cooling

fluid, etc).

This chapter will describe how to develop a part program.

3.2 Program Make-up

A program consists of main program and subprogram. As a rule, NC moves by the instructions of a

main program. When the main program gives an instruction to switch to a subprogram, NC moves

by the subprogram.

When there is an instruction to return to a main program in a subprogram, NC will return to the

main program and continue to move by the instructions of the main program.

NC memory can store 95 main programs and subprograms in total. When one of the main

programs is selected, NC machine can move by its instructions.

13

Page 22

GSK983M Milling CNC System Operation Manual (Volume I: Specifications and Programming)

Main program Subprogram

[Instruction to switch to a subprogram]

Instruction 1

Instruction 2

┊

┊

┊

┊

Instruction n

Instruction n+1

┊

┊

┊

┊

┊

Instruction 1

Instruction 2

┊

┊

┊

┊

┊

┊

┊

┊

┊

┊

┊

[Instruction to return to a main program]

Note: The number of programs that can be stored will be increased to 191 if the function

“Addition of the number of storable programs” (Optional) is selected.

Refer to Chapter 4: Operations for the storage method of program.

3.2.1 Block

A program is composed of a number of instructions. Each instruction unit in a program is called a

block. Blocks are distinguished from each other by end code. As described below, end-of-block

code is indicated with a “;”.

For example:

XXXX;

XXXX;

XXXX;

Note 1: The maximum number of characters a block is not limited in.

Note 2: End-of-block code: CR for EIA codes and LF for ISO codes.

3.2.2 Program word

The elements composing a block are program words. The program word below consists of an

address and a subsequent figure. A “+” and a “ –“ can also be added before the figure.

X - 1000

Address Figure

Program word

An address is indicated with a letter among A~Z. An address determines the meaning of its

subsequent figure. The addresses that can be used in an NC and their meanings are as follows.

An address may have different meanings depending on different instructions of preparation

14

Page 23

GSK983M Milling CNC System Operation Manual (Volume I: Specifications and Programming)

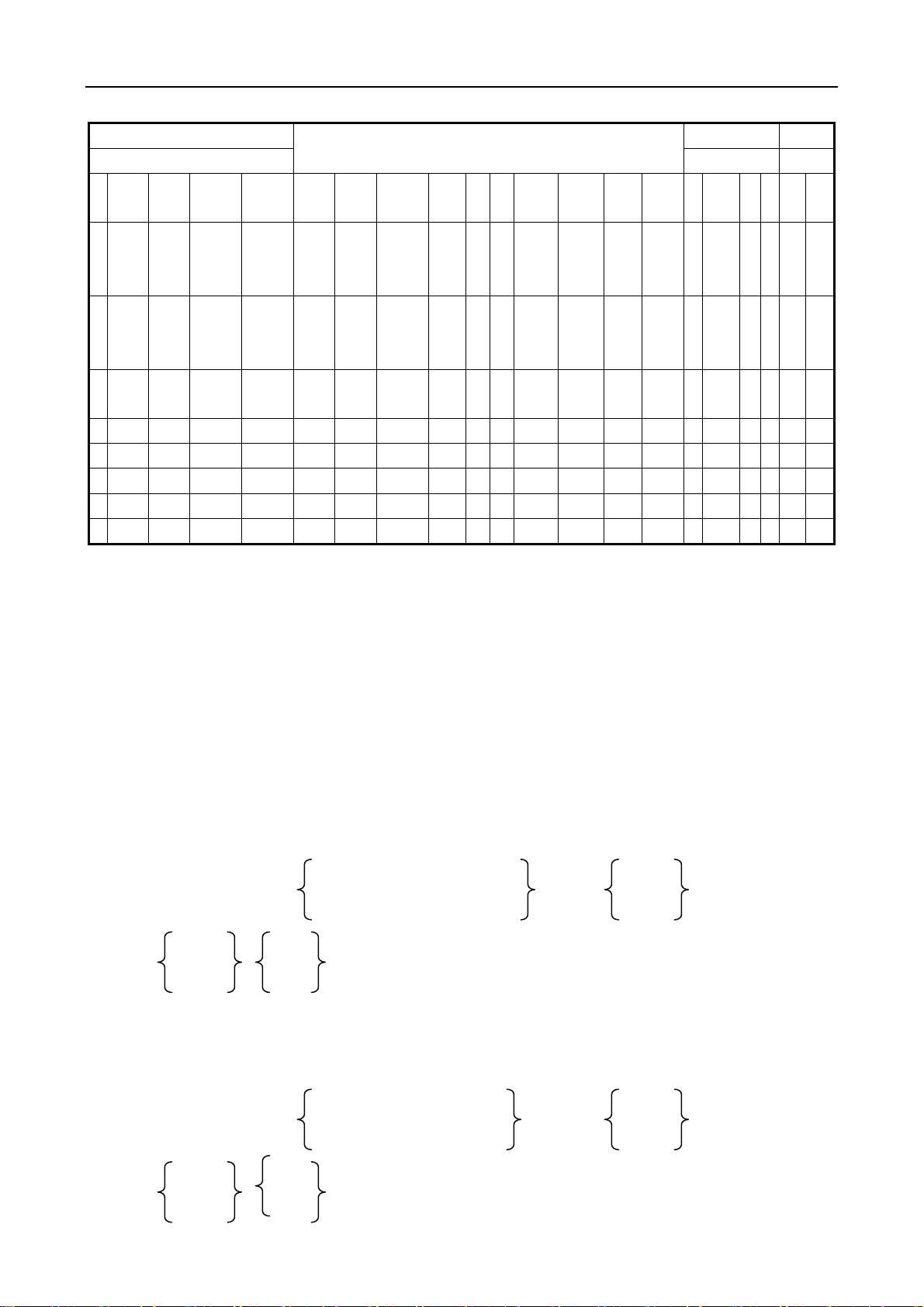

Sequenc No.

eed

u

c

o

Sp

d

e

u

c

o

oo

u

c

o

function in a program.

Name Address Meaning

Program No. : (ISO) /O (EIA) Program number

Sequence No. N Sequence number

Preparatory

function

G Instructed move mode (linear, arc, etc)

X, Y, Z Move instruction of coordinate axis

A, B, C, U, V, W Move instruction of additional axis

Coordinate word

R Arc radius

I, J, K Coordinates of arc center

Feed function F Designation of feedrate

Spindle function S Designation of spindle rotational speed

Tool function T Designation of tool number and tool offset number

Auxiliary

function

M Designation of ON/OFF control on machine side

B Worktable indexing, etc.

Offset No. H, D Designation of offset number

Dwell P, X Designation of dwell time

Designation of

program No.

P Designation of subprogram number

Designation of

sequence No.

Number of

repetition

P

L Numbers of repetition of subprogram and fixed cycles

Designation of sequence number: Program is repeatedly

executed at this sequence number.

Parameter P, Q, R Parameters of fixed cycle

For example, these program words may compose the following block.

; N— G— X— Y— F— S— T— M— ;

Preparatory function

Coordinate No.

F

in

f

n

ti

n

l

f

n

ti

T

l f

n

ti

n

n

15

Miscellaneous

Page 24

GSK983M Milling CNC System Operation Manual (Volume I: Specifications and Programming)

In the following program list, a line indicates a block and a case in the block indicates a program word.

Name S57.10.10 Page/

Program No. 0 (: ) 2002

/ N G X Y Z A/B/C C/V/W R/I J K F S T M B H/D L P Q

N20 G92 X

100.0 Y 200.0 Z 300

N21 G00 X

196.0 Y 315.0 Z 500

N22 G01 F10.0

(Note ) CR(EIA),LF(ISO)

.0

S400 T15 M03

.0

;

;

;

;

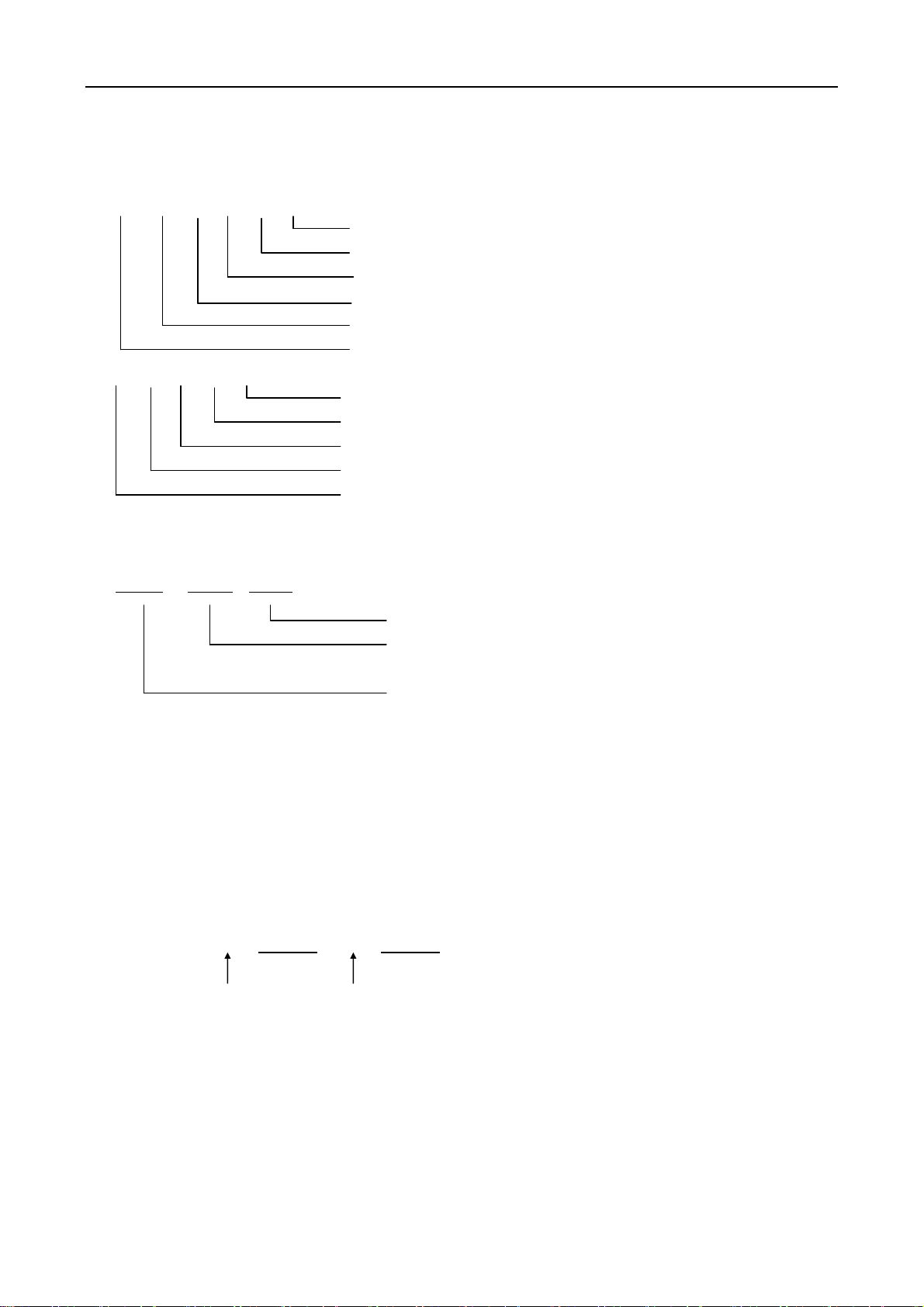

3.2.3 Input format

All program words composing a block shall be instructed in the formats as specified below. The

input format of this system is a variable block format. Therefore, the number of the program

words in a block and the number of characters in a program word are variable, which makes

programming easier.

(1) Input in metric system

NO4·G02·XL+053·YL053·ZL+053·

RD053 D02

αL+053·βL+053· ·F050· ·

ID053·JD053·KD+053 H02

S02 T02

· ·B03·M02;

S04 T04

(2) Input in Inch system

NO4·G02·XL+044·YL+044·ZL+044·

RD044 D02

αL+053·βL+053· ·F032· ·

ID044·JD044·KD044 H02

S02 T02

· ·B03·M02;

16

Page 25

GSK983M Milling CNC System Operation Manual (Volume I: Specifications and Programming)

S04 T04

Note 1: α and β are for any one of A, B, C, U, V and W.

Note 2: The address and digits in the above formats have the following meanings.

X L + 0 5 3

The three digits behind decimal point

The five digits before decimal point

Leading zero may be omitted.

With a symbol

Absolute value or incremental value

Address

J D 0 5 3

The three digits behind decimal point

The five digits before decimal point

Leading zero may be omitted.

Incremental value with a symbol

Address

For example: When a cutting tool moves to 50.123mm along X axis, its move instruction is as follows:

G00

X50 123

The three digits behind decimal point

The five digits before decimal point: 00050

The leading zero and T are omitted.

G00 must not be omitted even the leading zero may be

omitted. (G00 specifies rapid traverse (positioning)).

Note 3: When an address word in a block is instructed twice or more times, the last instruction will be

valid and not give any alarm in principle.

For example: G01 M03 S200 M08;

Now M08 is valid and M03 invalid. For G codes, the lastly specified one in each group of G

codes in a block is valid. However, G90/G91 is only valid at the specified location in a block

(see Section 3.3.8.).

Example G90 X10.0

G91 Y20.0 ;

Absolute Incremental

If R and I, J or K are concurrently instructed in an arc interpolation instruction, R is always valid

and this is not related to instruction sequence.

Note 4:F050 in Inch-system input format may also be changed into F051 through parameter switching.

Refer to Section 3.4.3 “To multiply feedrate by 1/10”.

Note 5: Since P and Q have a number of meanings, they are omitted in the above format.

Note 6: Refer to Section 3.2.4 ”Decimal entries”.

17

Page 26

GSK983M Milling CNC System Operation Manual (Volume I: Specifications and Programming)

Note 7: Multiply the value input in metric system of X, Y, Z, A, B, C, U, V, W, I, J, K, Q and R by 10 by

means of parameter setting.

RD052

XL+052·YL+052·ZL+052·αL+052·βL+052· ID052·JD052·KD052

(α and β are A, B, C, U, V and W) (Input in metric system) Refer to Section 3.3.2.2 “To multiply

an input unit by 10”.

Note 8: Refer to Section 3.3.2.2 “To multiply an input unit by 10”.

3.2.4 Decimal programming

It is possible for this unit to input the numerical values with a decimal point. Decimal point is

used in the values in the unit of distance, time or speed. However, some addresses may not

use decimal for entry. The location of a decimal point indicates the position of mm, inch,

degree or second.

X15.0 X15mm or x15 inches

F10.0 10mm/min for 10 inch/min

G04×1 Feedrate for 1 second

B90.0 B90deg

The addresses that can be entered with decimal point are as follows:

X, Y, Z, A, B, C, I, J, K, R, Q and F.

Note 1: During the dwell of an instruction, X can be input with the decimal point but P cannot (because

P is also specified with a sequence number).

Note 2: When G codes are used to change the location of the decimal point, it is necessary to

predetermine G codes even in a block. G20; (specify in Inch system ) X1.0G04;X1.0 is

considered as a travel distance (in inch) because it does not indicate time. The result is held

for 10 seconds in relation to X10000G04.

When G04 is entered, its indication changes from 1.0 to 10.0.

G04X1.0 is treated as G04X1000 and the result is held for 1 second.

Note 3: Take note that the condition with or without a decimal point is quite different. Its programming

mode differs from an electronic computer.

G21; (specified in metric system)

X1……X1 mm

X1……X0.001 mm

G20; (specified in Inch system )

X1……X1 inch

18

Page 27

GSK983M Milling CNC System Operation Manual (Volume I: Specifications and Programming)

X1……X0.0001 inch

Note 4: The numerical values with/without a decimal point can be mixed.

X1000 Y23.7;

X10 Y22359;

Note 5: If a specified value is less than the minimum setting, the value will be rounded down. The

instruction of X1.23456 is considered as X1.234 when it is entered in metric system and

1.2345 in Inch system . It has cumulative error for an incremental value instruction and has no

cumulative error but rounding error for an absolute value instruction. The instructed digits must

not exceed the allowable maximum digit.

X1.23456789……There is an error because it has more than 8 digits.

X1.2345678…… There is no error when it is up to 8 digits inclusive.

Note 6: When a figure with a decimal point is entered, the figure will be converted into the integer of the

minimum input increment.

(Example)X12.34 12340(entered in metric system)

In addition, it is necessary to perform digit number verification for the converted integer.

(Example)X1234567.8 X1234567800(entered in metric system). It gives an alarm

because the number of digits exceeds 8.

3.2.5 Maximum instruction value

The maximum instruction values of all addresses are as listed in the table below. Take note

that what the table lists are the ranges of the maximum specified values for the NC unit rather

than the mechanical moving ranges of the NC machine tool. For instance, the moving range of

X axis is about 100m (entered in metric system) for an NC unit while the travel distance of axis

X is likely to be limited to 2m for a machine tool and so is its feedrate. The cutting feedrate of

an NC unit is up to 15m/min while that of an NC machine tool is likely to be limited to 6m/min.

In actual programming, both this manual and the instruction manual supplied by machine

builder shall be referred to. Programming shall be performed on the basis of full knowledge

about the programming ranges of a specific machine tool.

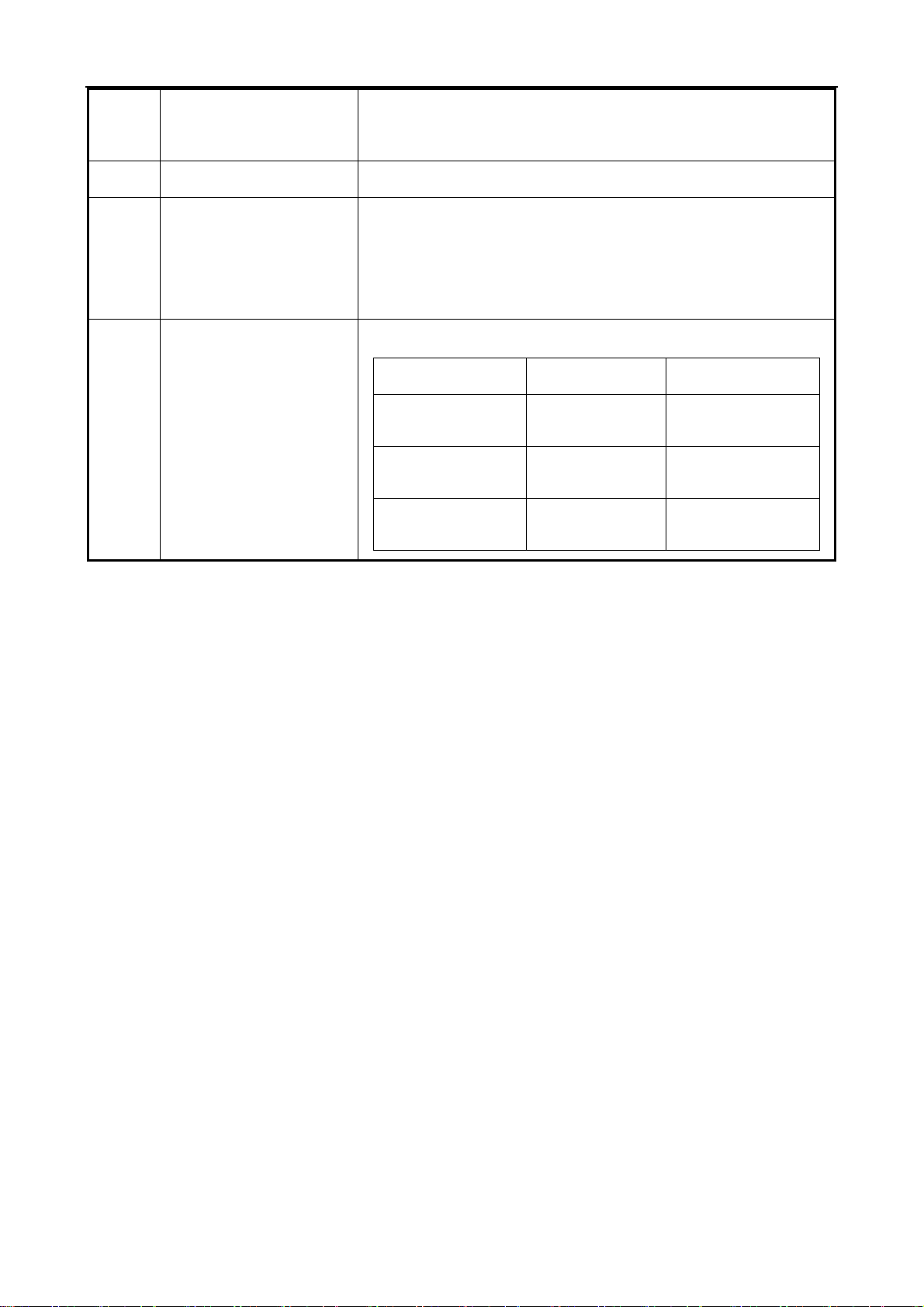

Table 2.5: Basic addresses and ranges of instruction values (including additional options)

Name Address

Program No.

Sequence No. N

: (ISO)

O (EIA)

Input in mm

Output in mm

1~9999

1~9999

Input in inch

Output in mm

See the left See the left See the left

″ ″ ″

19

Input in mm

Output in inch

Input in inch

Output in

inch

Page 28

GSK983M Milling CNC System Operation Manual (Volume I: Specifications and Programming)

Preparatory

function

Coordinate word

Feed per minute F

Feed per minute

(feedrate l/10)

(parameter

setting)

Spindle function S

Tool function T

Miscellaneous

function

Dwell X, P

Sequence No.

setting

G

X, Y, Z, I,

J, K, Q, R,

A, B, C,

U, V, W

F

M

P

0~99

±99999.999mm

±99999.999°

1~15000

mm/min

0.1~15000.0

mm/min

0~30000

0~9999

0~99

0s~99999.99s

1~9999

″ ″ ″

±3937.0078inch

±99999.999°

0.01~600.00

inch/min

See the above

See the left See the left See the left

″ ″ ″

″ ″ ″

″ ″ ″

″ ″ ″

±99999.999mm

±99999.999°

1~15000

mm/min

0.1~15000.0

mm/min

±937.0078inch

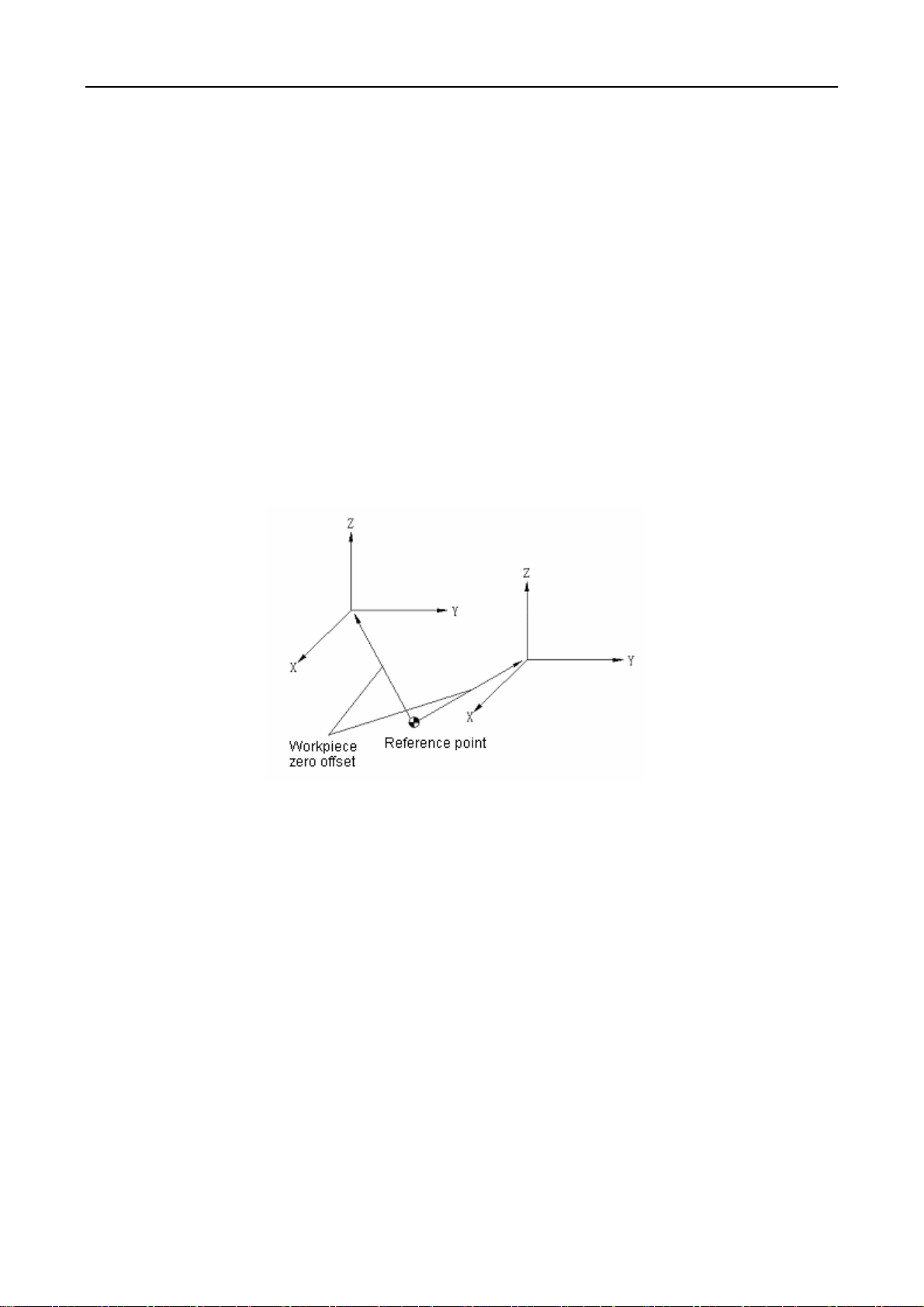

±9999.999°

0.01~600.00

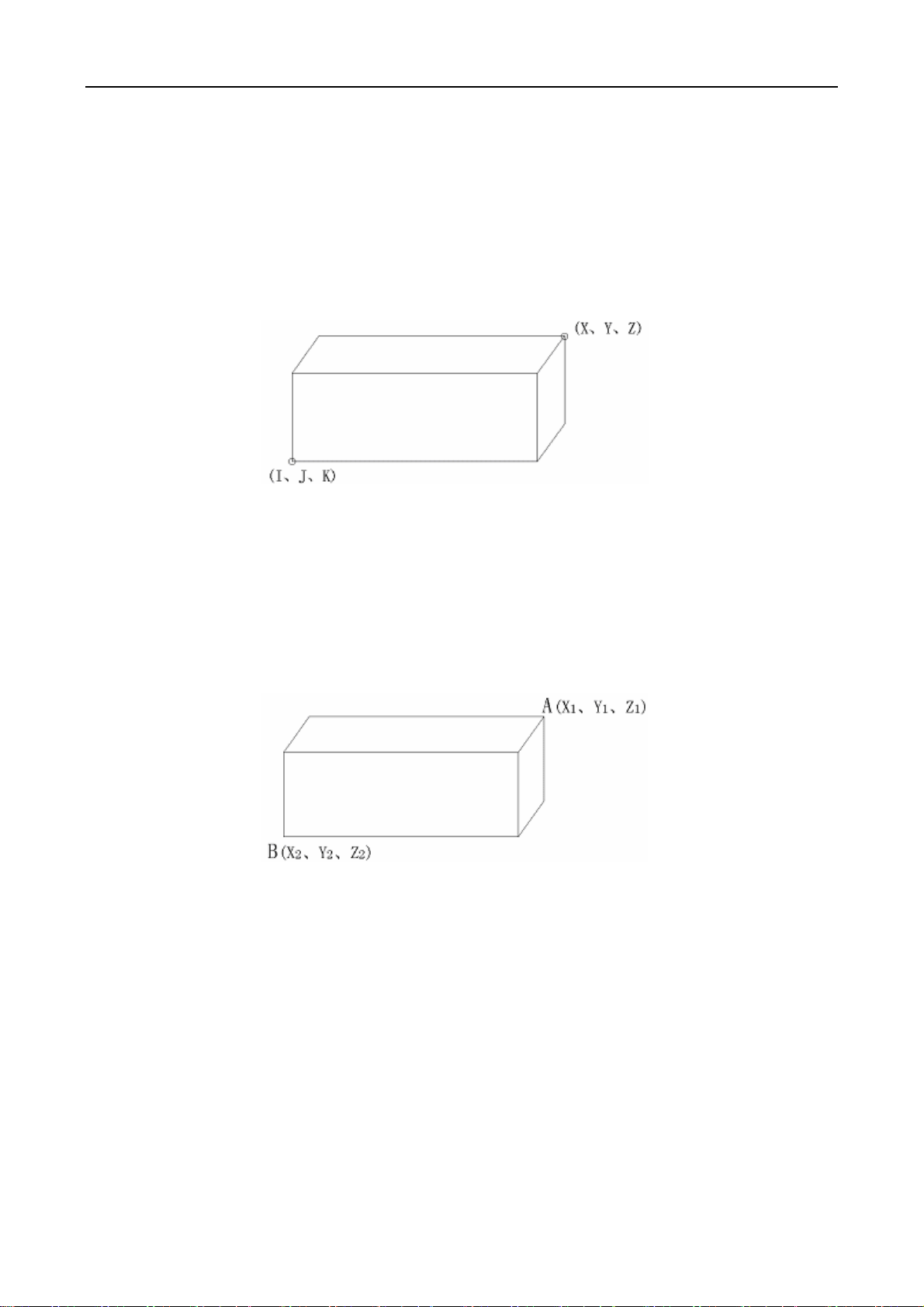

inch/min

See the above

Repeated times L

Offset No. S, H

2nd auxiliary

function

B

1~9999

0~200

0~999

″ ″ ″

″ ″ ″

″ ″ ″

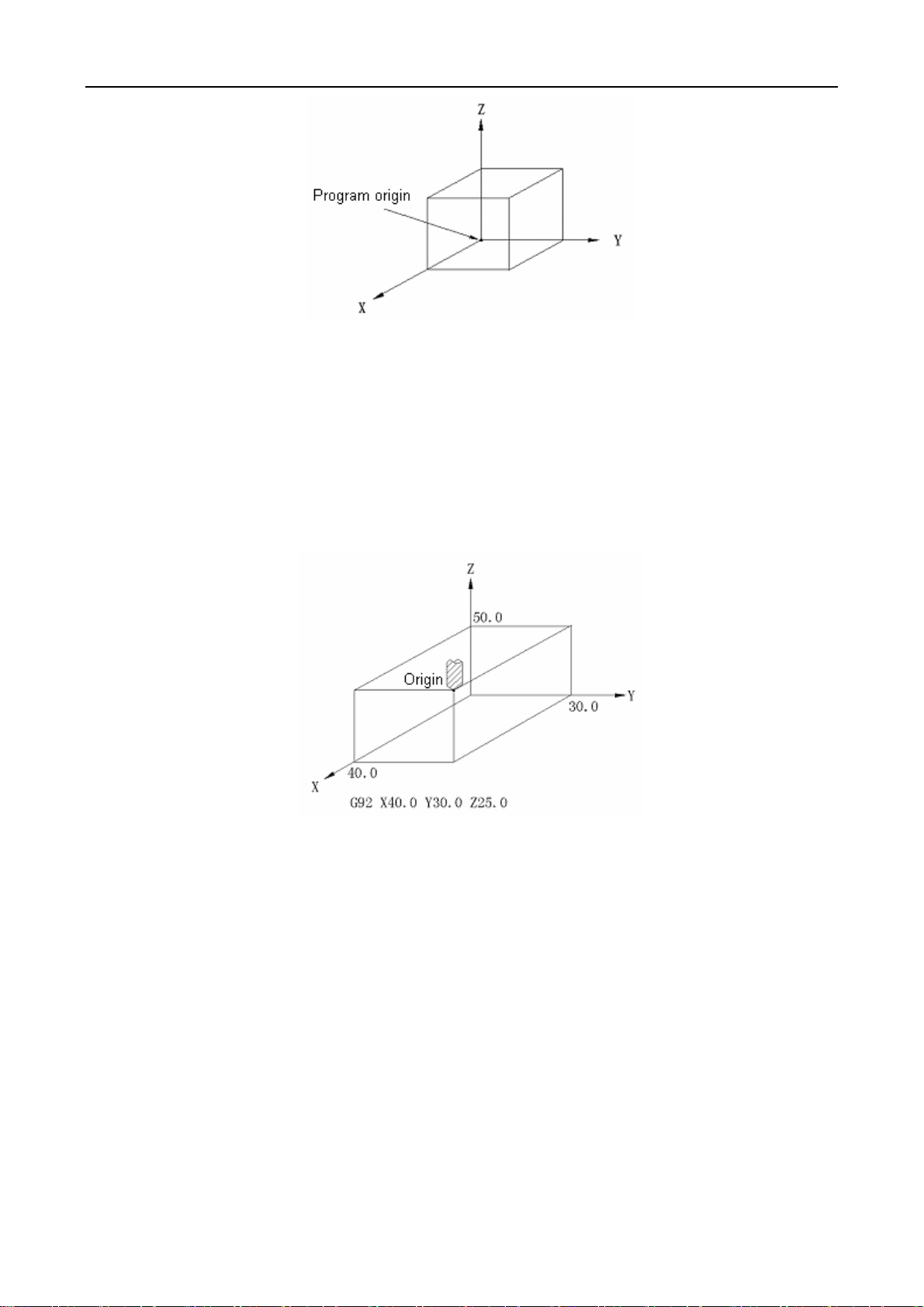

3.2.6 Program number

The control unit can store a number of programs in the memory of the NC. Program numbers

are added to all programs in order to distinguish them.

Program number

(From 1 to 9999.0 and preceding 0 may be omitted)

4 digits

The program starts from the program number and ends at M02, M30 or M99.

#1111 pr ogr am #2222 program

01111……………………M02; 02222………………………M30;

M02 and M30 indicate the end of a main program. M99 indicates the end of a subprogram.

20

Page 29

GSK983M Milling CNC System Operation Manual (Volume I: Specifications and Programming)

05555………………………M99;

#5555 subprogram

Note 1: For ISO codes, replace O with a “:”.

Note 2: The block with an optional block skip code such as /M02, /M30 and /M99 shall not be deemed

as the end of a program.

Note 3: When a program is not provided with a preceding program number, the first sequence number

(N…) other than NO of the program may be used to replace the program number.

Note 4: If a program is not provided with a preceding program number or sequence number, MDI/LCD

panel shall be used to specify a program number when storing the program into the memory.

Note 5: For several programs, the second program and the succeeding ones are not necessarily

provided with an EOB code skipped wit a mark. However, an EOB code shall be used before

the program when the foregoing program ends by ER (EIA) or %(ISO).

Note 6: It is possible to operate without a program number. Subprogram shall be provided with a

program number.

Note 7: In some cases, the program number from 9000 ~ 9899 can only used by machine

manufacturer rather than user.

Note 8: When it has a robot option, program numbers 9900~9999 are used as robot data.

Note 9: When there is no M02, M30 or M99 but ER (EIA)%(ISO) at the end of the program, or the next

program number is 0, the end of the program shall be set by parameter No.306 BIT3 (NEOP).

3.2.7 Sequence number

A sequence number may be specified with N followed by four or less digits (1~9999) at the

start of a block. The order of sequence numbers is random and discontinuous. It is likely that

all blocks are provided with sequence numbers or sequence numbers are only added at the

necessary locations of a program.

It is recommended to specify sequence number in succession at key locations, e.g. when

replacing new tools or change the worktable indexing to a new machined surface.

Note 1: The use of the sequence number NO. is not allowed for the purpose of compatibility with the

program formats of other NC units.

Note 2: Since 0 cannot be used as a program number, the sequence number treated as a program

number shall not be 0.

3.2.8 To skip over an optional block

When a slash followed by a digit /n(n=1~9) is specified at the beginning of a block and the

21

Page 30

GSK983M Milling CNC System Operation Manual (Volume I: Specifications and Programming)

OPTIONAL BLOCK SKTP switch n is enabled on the operation panel , the block with a /n

corresponding to switch number n will be ignored.

When the OPTIONAL BLOCK SKTP switch n is disabled, the block with a /n is valid, namely

operator may choose to skip over the block with a /n. The 1 in /1 can be ignored. However, the

1 in /1 must not be ignored when two or more OPTIONAL BLOCK SKTP switches are used.

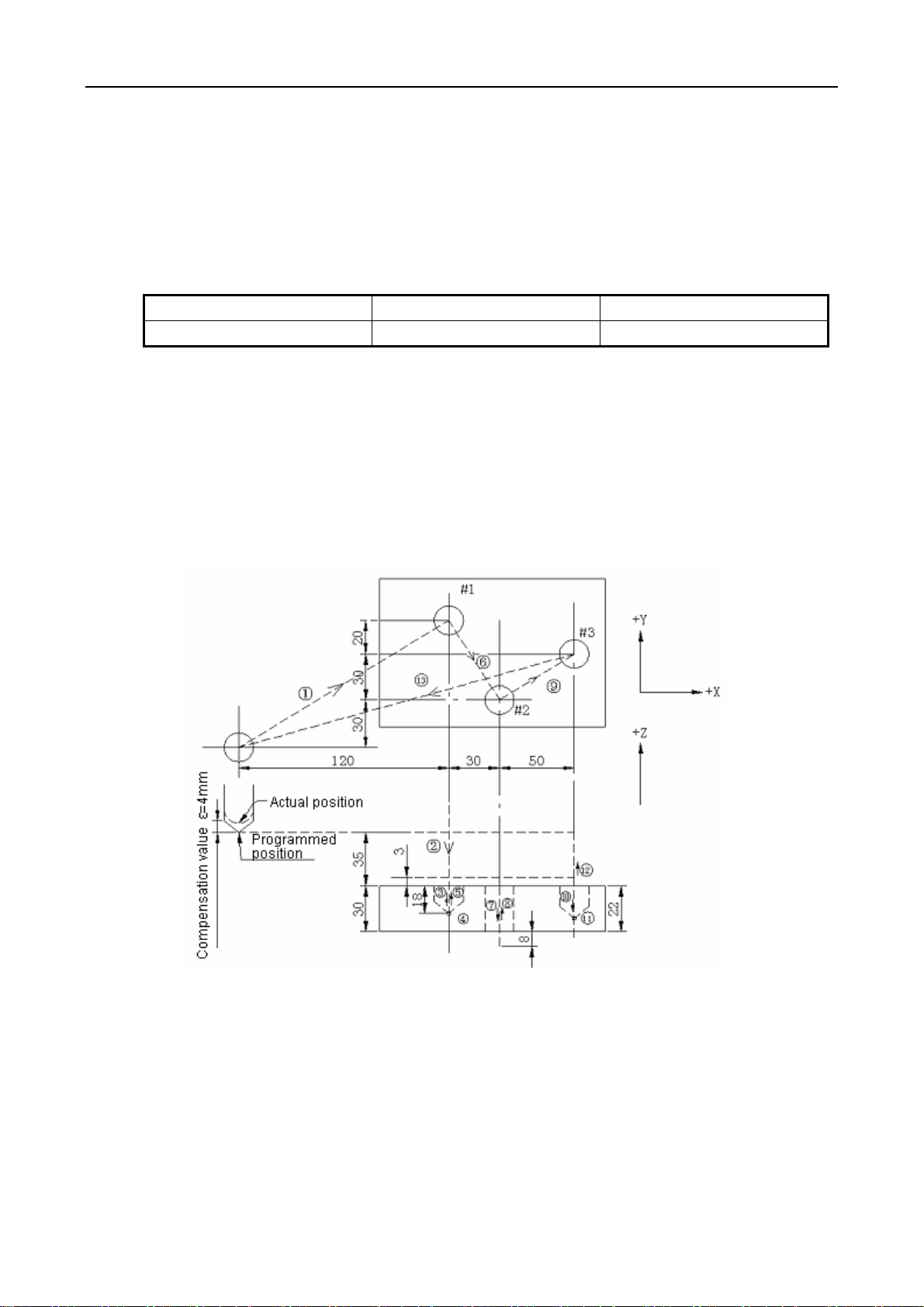

When an OPTIONAL BLOCK SKTP switch is enabled, the ignored area is as follows:

;/2N123G01X4……………………;N7856

Ignored area

Example: N100X100;

N101/2z100;

N102/2/3X200;

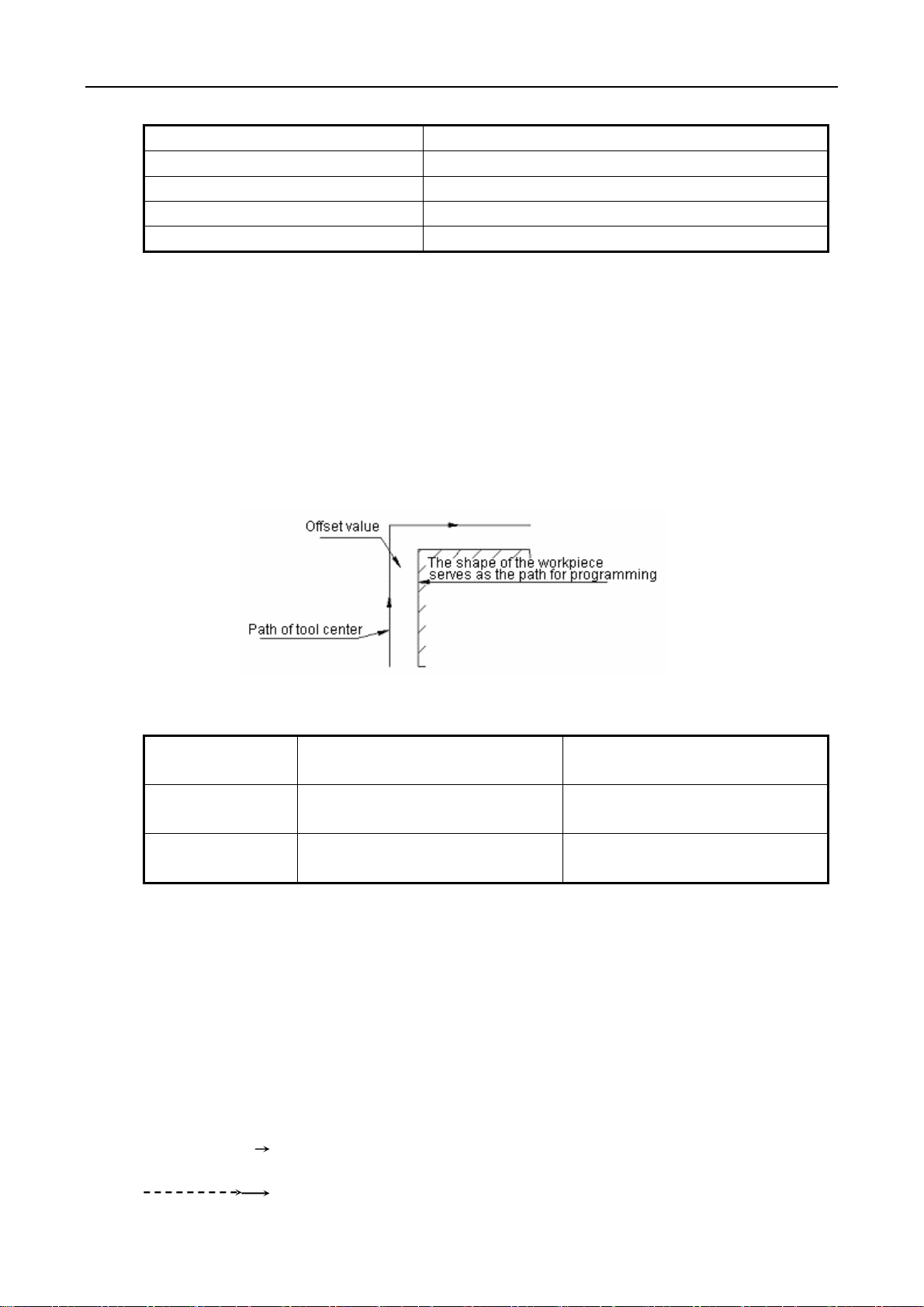

N103/3z200;

In the above example, blocks N101 and N102 will be skipped over when No. 2 switch is

enabled and N102 and N103 skipped over when No. 3 switch enabled.

Note 1:Slash (/) shall be specified at the beginning of a block. If it is specified at other places of a block,

the information from the slash (/) to EOB code will be ignored but the information before the

slash (/) will remain valid.

Note 2: When the OPTIONAL BLOCK SKTP switch is enabled, TH and TV checkouts shall be

performed for the skipped part as the switch is disabled.

Note 3: The block to be skipped over is identified when the memory sends information to the buffer

register. When the block preceded by a slash is written in the buffer register, it will not be

ignored even if the OPTIONAL BLOCK SKTP switch is enabled.

Note 4: The function remains available during sequence number searching.

Note 5: The function is invalid when saving a program in the memory. That is, the block preceded by a

slash (/) will be written in the memory regardless the state of OPTIONIAL BLOCK SKIP.

Note 6: The programs may be completely output from the memory regardless the state of OPTIONIAL

BLOCK SKIP.