GSK980TDa Turning CNC

Concise User Manual

This user manual describes all proceedings concerning the operations of

this CNC system. However, it is impractical to give particular descriptions for

all unnecessary or unallowable system operations due to the manual content,

product specific applications and other causes. Therefore, the proceedings

not indicated herein should be considered impractical or unallowable.

This user manual is the property of GSK CNC Equipment Co., Ltd. All

rights are reserved. It is against the law for any organization or individual to

publish or reprint this manual without the express written permission of GSK

and the latter reserves the right to ascertain their legal liability.

2

PREFACE

Your excellency,

It’s our pleasure for your patronage and purchase of this GSK980TDa CNC system

made by GSK CNC Equipment Co., Ltd.

This book is the concise user manual of GSK980TDa Turning CNC System.

Warning

! Accident may occur by improper connection and operation! Please carefully

read this manual before usage!

Special tips:

The system power fixed on the cabinet is special for the CNC system made

by our company.

And this power is unallowed to be used for other purposes. Otherwise it

may cause severe danger.

This manual is reserved by final user.

All specifications and designs herein are subject to change without further notice.

We are full of heartfelt gratitude to you for supporting us in the use of GSK’s products.

Contents

Contents

Chapter 1 Programming Fundamentals..................................................................................... 1

1.1 Technology Flow of CNC Machining........................................................................................................1

1.2 Axis and Coordinate System......................................................................................................................1

1.3 Structure of an NC Program......................................................................................................................2

1.4 Absolute Programming and Incremental Programming ........................................................................3

1.5 Diameter programming and Radius programming.................................................................................4

Chapter 2 Programming................................................................................................................. 6

2.1 S Command.................................................................................................................................................6

2.2 M Command ...............................................................................................................................................6

2.3 T Command.................................................................................................................................................7

2.4 F Command.................................................................................................................................................7

2.5 G Command ................................................................................................................................................7

2.5.1 Rapid Traverse (Positioning) G00 ....................................................................................................................7

2.5.2 Linear Interpolation G01 ....................................................................................................................................8

2.5.3 Circular Interpolation G02/G03.........................................................................................................................8

2.5.4 Dwell G04.............................................................................................................................................................9

2.5.5 Workpiece Coordinate System G50.................................................................................................................9

2.5.6 Axial Cutting Cycle G90 ...................................................................................................................................10

2.5.7 Radial Cutting Cycle G94 ................................................................................................................................11

2.5.8 Axial Roughing Cycle G71...............................................................................................................................12

2.5.9 Radial Roughing Cycle G72............................................................................................................................14

2.5.10 Closed Cutting Cycle G73 .............................................................................................................................16

2.5.11 Finishing Cycle G70 .......................................................................................................................................17

2.5.12 Axial Grooving Multiple Cycle G74 ..............................................................................................................18

2.5.13 Radial Grooving Multiple Cycle G75............................................................................................................19

2.5.14 Thread Cutting with Constant Lead G32.....................................................................................................21

2.5.15 Thread Cutting with Variable Lead G34 .................................................................................................22

2.5.16 Z Tapping Cycle G33......................................................................................................................................23

2.5.17 Thread Cutting Cycle G92.............................................................................................................................24

2.5.18 Multiple Thread Cutting Cycle G76 ..............................................................................................................25

2.6 Compound Program Example.................................................................................................................27

Chapter 3 Operation ......................................................................................................................28

3.1 Operation Mode and Display Interface..................................................................................................28

3.1.1 GSK980TDa Panel Introduction .....................................................................................................................28

3.1.2 Machine Panel Keys.........................................................................................................................................29

3.1.3 Display Menu .....................................................................................................................................................30

3.1.4 Summary of Interface and Operation.............................................................................................................31

3.1.4.1 Position Interface...........................................................................................................................................31

3.1.4.2 Program Interface..........................................................................................................................................33

3.1.4.3 TOOL OFFSET&WEAR, MACRO Interface...............................................................................................35

3.1.4.4 Alarm Interface .............................................................................................................................................35

3.1.4.5 Setting Interface ............................................................................................................................................37

3.1.4.6 BIT PARAMET ER, DATA PARAMETER, SCREW-PITCH COMP Interface............................................40

3.1.4.7 CNC DIAGNOSIS, PLC STATE, PL C VALUE, machine soft panel, VERSION MESSAGE Interface.....42

3.2 Program Edit.............................................................................................................................................44

3.2.1 Program Creation..............................................................................................................................................44

3.2.2 Input of the Program.........................................................................................................................................45

3.2.3 Deletion and Insertion of the Character.........................................................................................................45

3.2.4 Selection of the Program .................................................................................................................................46

3.2.5 Execution of the Program ................................................................................................................................46

I

GSK980TDa Turning CNC System

3.3 Manual Operation.................................................................................................................................... 47

3.3.1 Manual Feed and Rapid Traverse..................................................................................................................47

3.3.2 Handwheel feed................................................................................................................................................ 47

3.3.3 Manual Tool Change ........................................................................................................................................48

3.3.4 Spindle Control..................................................................................................................................................48

3.3.5 Coolant Control .................................................................................................................................................48

3.3.6 Emergency Operation ......................................................................................................................................48

3.4 MDI Operation......................................................................................................................................... 49

3.4.1 Code words input..............................................................................................................................................49

3.4.2 Code Words Execution.................................................................................................................................... 50

3.5 Tool Setting............................................................................................................................................... 50

3.5.1 Tool Setting Operation (Trial Tool Setting) .................................................................................................... 50

3.5.2 Tool Setting Operation (Tool Setting by machine zero return, machine zero switch needed)...............51

3.5.3 The Alteration of the Offset Value ..................................................................................................................53

3.5.4 Clearing of the Offset Values ..........................................................................................................................54

3.6 Part Machining Example ........................................................................................................................54

Chapter 4 Appendix........................................................................................................................58

Operation List................................................................................................................................................... 58

II

Chapter 1 Programming Fundamentals

Chapter 1 Programming Fundamentals

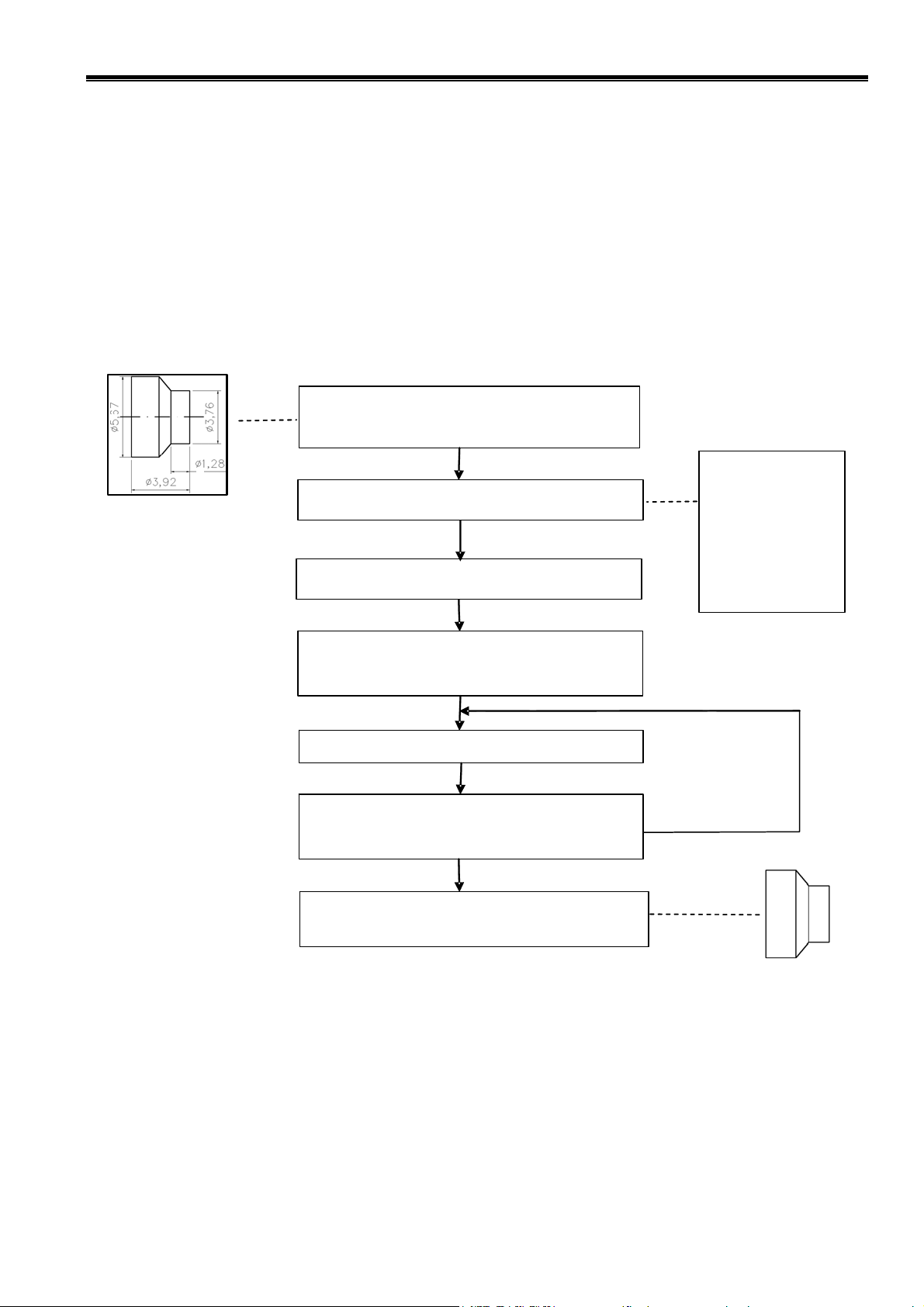

1.1 Technology Flow of CNC Machining

Programming is a course of workpiece contours, machining technologies, technology parameters and

tool parameters being edit into part programs according to special CNC programming commands. CNC

machining is a course of CNC controlling a machine tool to complete machining of workpiece according to

requirements of part programs. Technology flow of CNC machining is as following Fig. 1-1.

Analyse workpiece drawings and confirm

machining technologies

Edit part programs and record into CNC

Test part programs and execute trial run

Execute tool setting and set tool offsets and

coordinates

Run part programs and machine workpieces

Check part dimension and modify part

programs and compensations

The machining ends and the workpiece is

formed

O0001

G01 Z- 1.28 F50

…

M30

%

;

G00 X3.76 Z0

;

;

;

Fig. 1-1

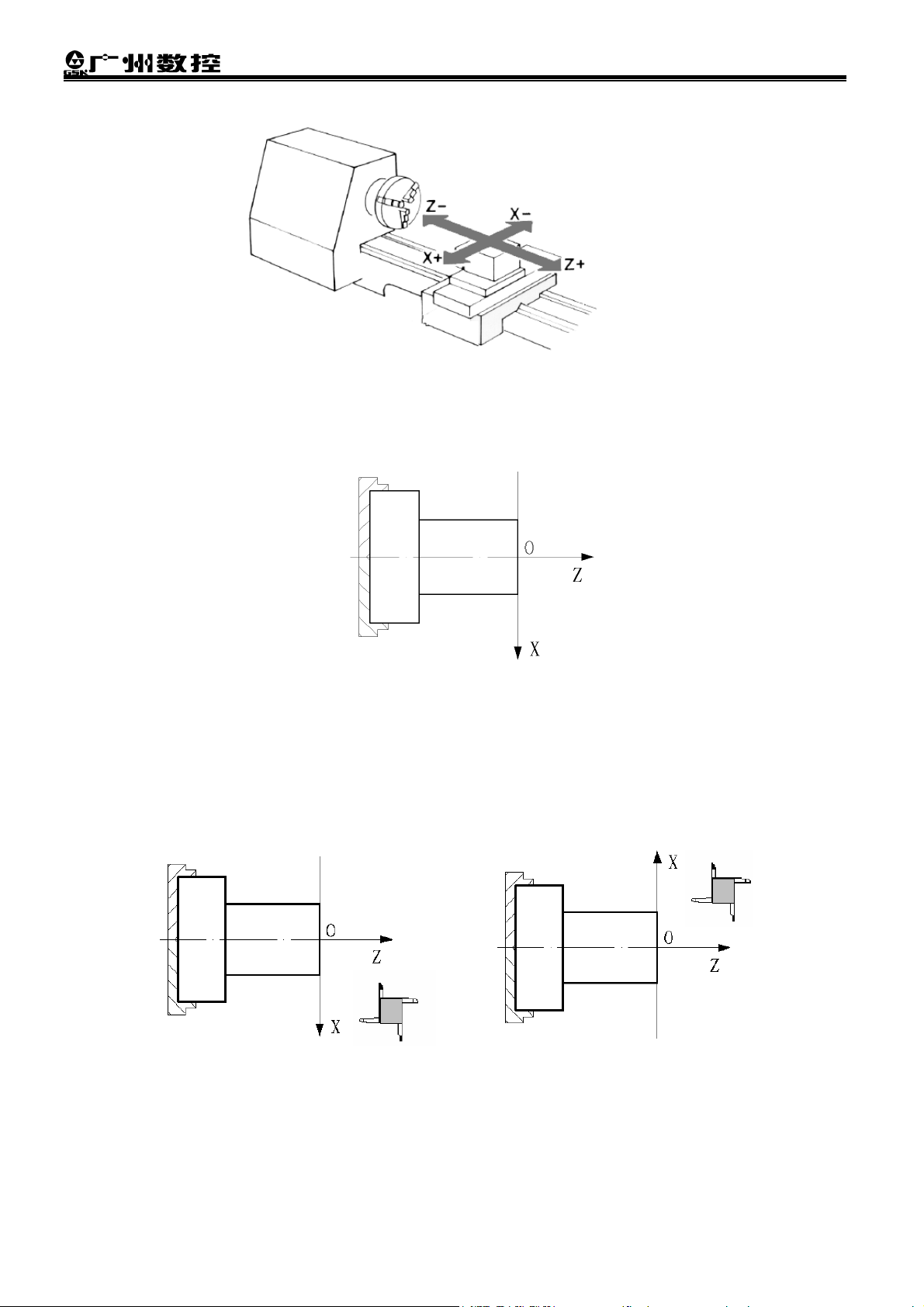

1.2 Axis and Coordinate System

GSK980TDa uses a rectangular coordinate system composed of X, Z axis. X axis is perpendicular with

axes of spindle and Z axis is parallel with axes of spindle; negative directions of them approach to the

workpiece and positive ones are away from it. GSK980TDa uses a rectangular coordinate system composed

of X and Z axis, and the coordinate system plane is the motion plane of tool post. Fig. 1-2 is the front tool

post coordinate sketch map of a vertical turning machine.

1

GSK980TDa Turning CNC System

After the coordinate system plane is established, we need to establish the coordinate system.

GSK980TDa uses G50 to establish the workpiece, and the established workpiece is valid till it is replaced by

a new one. Generally, Z axis of the workpiece coordinate system coincides with the spindle axis.

Fig. 1-2

Fig. 1-3

There are a front tool post and a rear tool post of NC turning machine according to their relative position

between the tool post and the spindle, Fig. 1-4 is a coordinate system of the front tool post and Fig. 1-5 is a

rear toolpost one. It shows exactly the opposite of X axis, but the same of Z axis from figures. In the manual,

it will introduce programming application with the front tool post coordinate system in the following figures

and examples.

Fig.1-4 Front tool post coordinate system Fig. 1-5

Rear tool post coordinate system

1.3 Structure of an NC Program

A program consists of a sequence of blocks, beginning with “OXXXX”(program name)and ending with

“%”; a block begins with block number (omitted) and ends with “;” or “*”. See the general structure of program

as Fig.1-6:

2

Program name

Chapter 1 Programming Fundamentals

Word

Block

Character for end of block

Character of end of program

Program

Fig. 1-6 Structure of program

Program name To identify it, each program has only one program name (there is no the same

program name), beginning with command address O and the following 4-bit digits.

Word A word is the basic command unit to command CNC system to complete the control function,

composed of an English letter (called command address) and the following number (operation

command with/without sign). The command address describes the meaning of its following

operation command. The common words include G, M, F, S, T and so on.

Block number A block number consists of an address N and its following 4-bit digits: N0000~N9999.

The block number must be at the beginning of block, otherwise the block is invalid. In

programming, the block number is generally omitted.

Character for end of block “;” marking the block is completed.

Example: block N0001 G01 X100 Z100 G98 F200;

Meanings as follows:

Block number is N0001, G 01 is the linear interpolation, X100 Z100 is the position of absolute

coordinate of end point. G98 is the feed per minute, F200 is the cutting speed 200mm/min. The

block indicates the tool cuts linearly with the cutting speed 200mm/min from the current point to the

one which absolute position is X100, Z100.

Character for end of program “%” is an ending character of program. “%” is a mark of

communication ended when the program is transmitted. The

system will automatically insert “%” at the end of program.

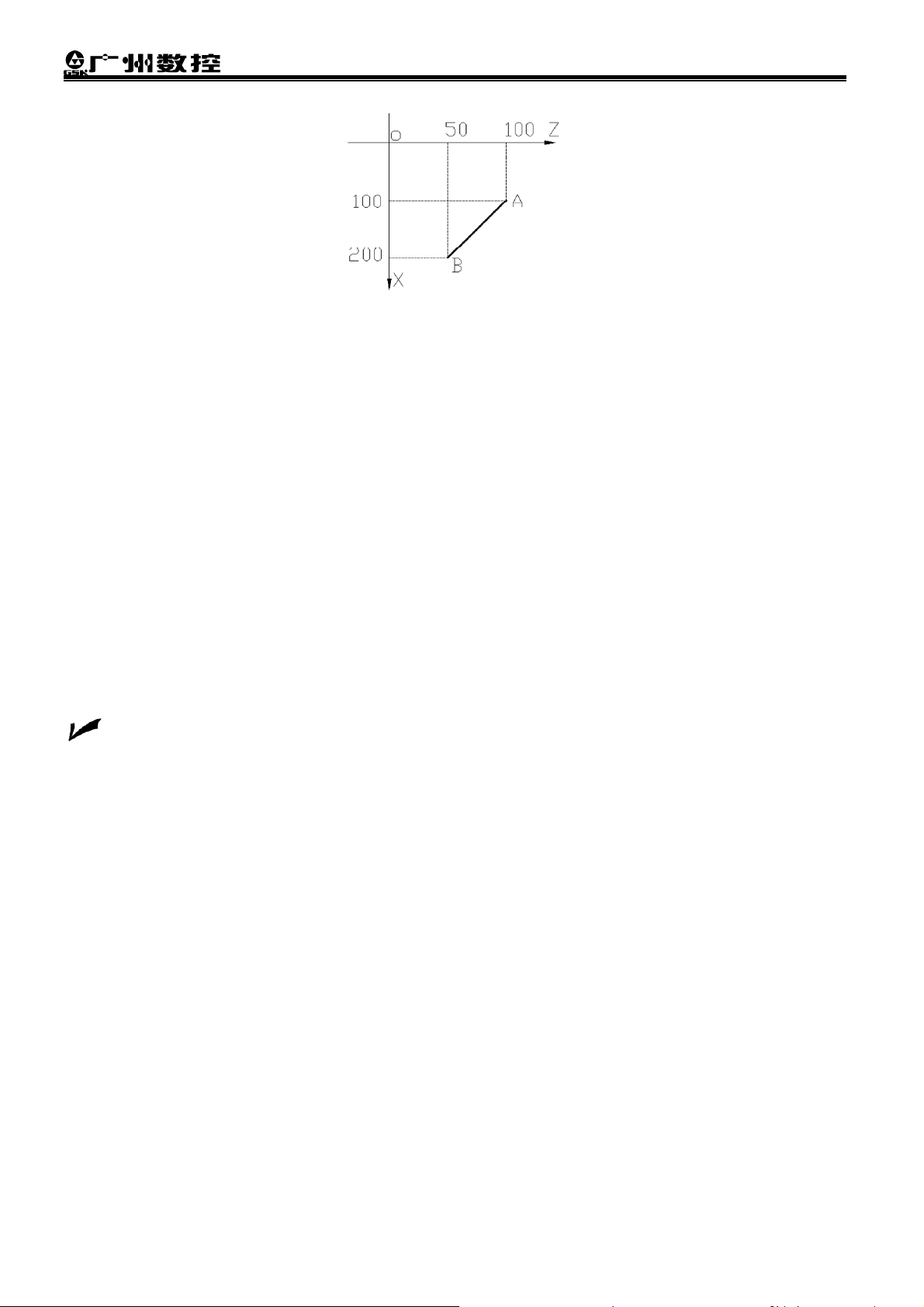

1.4 Absolute Programming and Incremental Programming

Describing the position of target point uses the absolute value and incremental value methods in CNC

programming.

3

GSK980TDa Turning CNC System

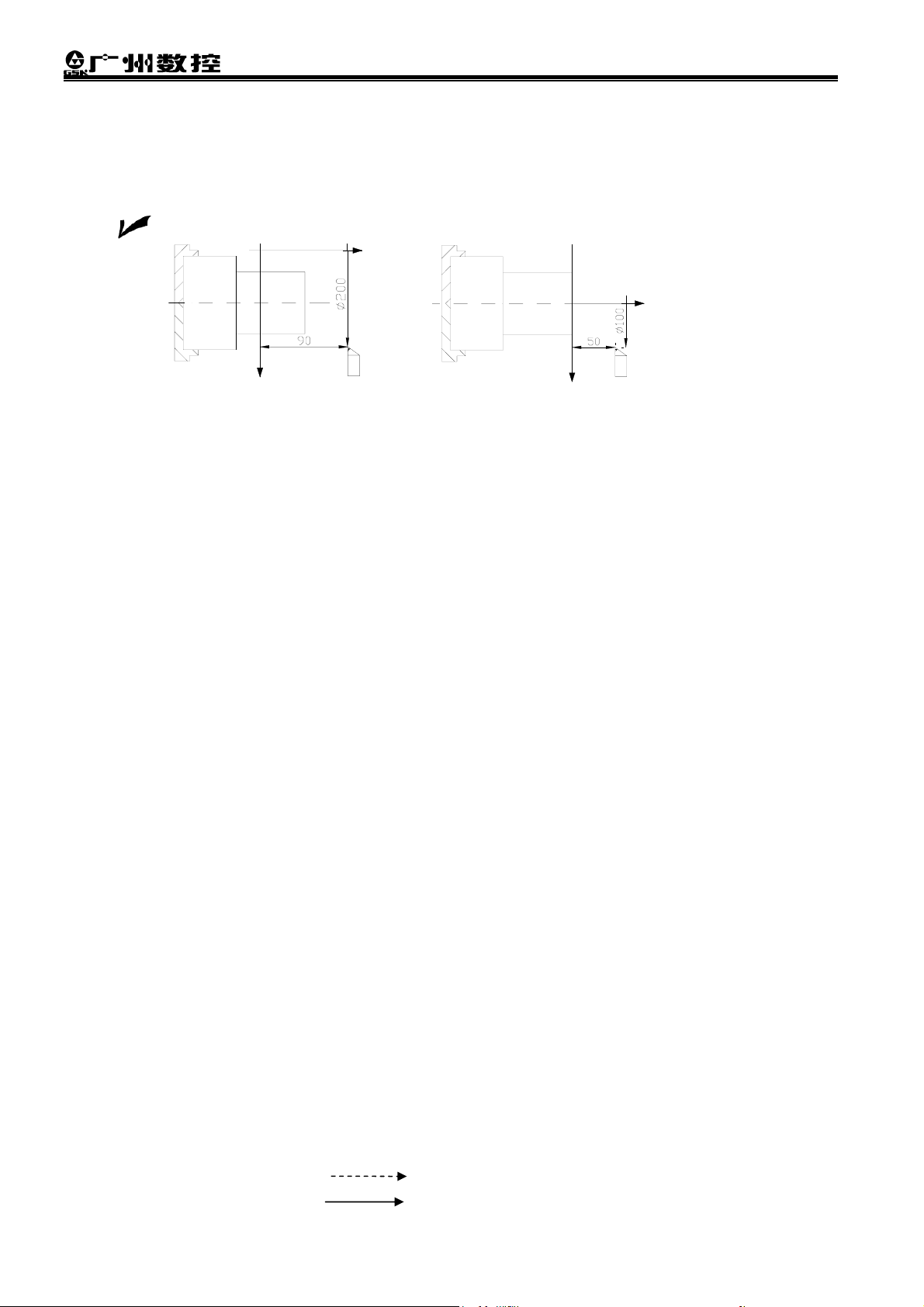

Fig. 1-7

Absolute value method uses the absolute position of target position in the workpiece coordinate system

to describe the target point; as Fig. 1-7, A absolute coordinates: X100, Z100; B absolute coordinates: Z200,

Z50.

Programming with absolute value to program (X, Z) is defined to be the absolute programming;

Incremental value method uses the offset of target point compared to the coordinates of starting point to

describe the target point; In the figure, A coordinates compared to those of B point are U100, W-50. U100 is

the X positive offset 100 of B compared to A point; W-50 is Z negative offset 50 of B compared to A point.

Programming with incremental movement (U, W) is defined to be the incremental programming;

In GSK980TDa, X, Z axis separately uses the absolute programming and incremental program, which is

called the compound programming.

Example: A→B linear interpolation. As Fig.1-7, use three methods to execute the linear

interpolation from the starting point of A to B point. G01 is the linear interpolation.

Absolute programming: G01 X200 Z50;

Incremental programming: G01 U100 W-50;

Compound programming: G01 X200 W-50;or G01 U100 Z50

1.5 Diameter programming and Radius programming

Programming methods of X coordinates are divided into: diameter programming and radius

programming.

Diameter programming: When X input command value is by diameter and X coordinates are shown

in diameter at the moment;

Radius programming: When X input command value is by diameter and X coordinates are shown in

radius at the moment

Whether the diameter programming or the radius programming is determined by the system parameter,

generally, we use the diameter programming.

4

Chapter 1 Programming Fundamentals

Note: The diameter programming is used except for the special description in the following

explanation.

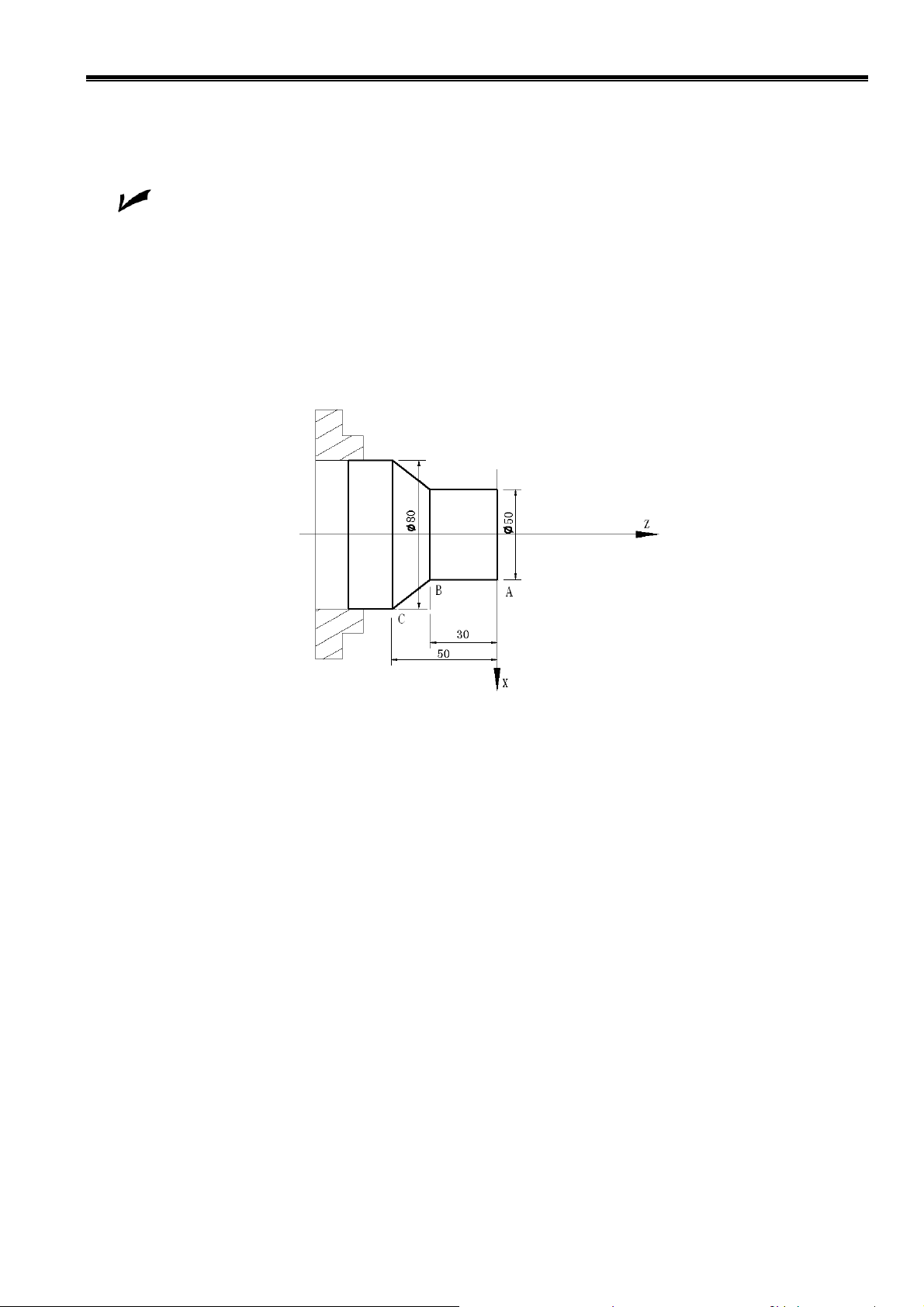

Example: As Fig.1-8, X axis of workpiece coordinate system is right end face of workpiece,

Diameter programming: A coordinates X50 Z0;

B coordinates X50 Z-30

C coordinates X80 Z-50

Radius programming: A coordinates X25 Z0;

B coordinates X25 Z-30;

C coordinates X40 Z-50;

Fig. 1-8

5

GSK980TDa Turning CNC System

Chapter 2 Programming

Automatic machining process of CNC machine is defined to the automatic run course of part programs

which have been edit in advance. Programming is that we use commands (words) which are exclusive to

CNC system to describe the drawings and technology to compile the machining programs of parts.

The chapter mainly introduces the common commands of programs.

2.1 S Command

S command is used for controlling spindle speed and GSK980TD has two modes to control it, Spindle

speed switching value control: spindle speed gear control and spindle speed frequency conversion control.

One of them used by GSK980TDa is determined by the system parameter (after delivery, the spindle

control mode is determined by the machine manufacturer), and can be judged by the display windows.

Spindle speed gear control mode Spindle speed frequency conversion mode

MDI

Note: Press

program window.

Spindle speed gear control mode: S□□□□(01~04)specifies the spindle gear and controls the spindle

speed.

spindle. Unit: rev/min.

Example: S01 specifies the first gear of spindle speed, and the actual speed is determined by

the machine.

Spindle speed frequency conversion control mode: S□□□□(0~9999)specifies the actual speed of

Example: S300 specifies the spindle speed to be 300 rev//min; S1260 specifies the spindle

speed to be 1260 rev/min.

into MDI operation mode, press (press or ) into the

2.2 M Command

M command consists of command address M and its following 1~2 digits, used for controlling the

operations ON/OFF of the machine and run sequence of machining program, and the common M

commands are as follows:

6

Chapter 2 Programming

Common M commands

Command Function Remark

M03 Spindle CCW

M04 Spindle CW

M05 Spindle stop

M03 and M04 control the spindle direction, and the actual speed is

specified by S command, so, M03/M04 and S command should be

matched in machining. “M03, S500” is the CCW spindle 500

rev/min.

M08 Cooling ON

M09 Cooling OFF

M30 End of program

2.3 T Command

Machining one workpiece needs several different tools which coordinates are different coordinates of

cutting position because their installation and tool length are different. So, the system must automatically

execute the tool change to eliminate the influence caused by the above difference, otherwise, which causes

the difficult programming and large calculation. T command of GSK980TDa can execute the automatic tool

change and tool compensation.

Command format:

T □□ 〇〇

Tool offset number (00-32)

Target tool number (01-32)

Command function: The automatic tool post rotates to the target tool number and the tool offset of tool

offset number commanded is executed. After tool offset is executed, the system

can execute T□□00 to cancel the tool offset, and there is only one T command in

one block.

Example: T0202 indicates that the system executes the No. 2 tool change and the No. 2 tool offset.

2.4 F Command

Use F command to specify the cutting feedrate in the block.

In G98, the format: F ;(F0001~F8000, feed distance per minute of slide, unit: mm/min)

In G99, the format: F;(F0.001~F500,

The actual cutting feed of the tool is controlled by F value and feedrate override, and the system

provides 16 steps feedrate override (0~150%, increment of 10%), which is controlled by the feedrate

FEEDRATE

OVERRIDE

FEEDRATE

override key

OVERRIDE

or

on the machine panel.

2.5 G Command

G command consists of command address G and its following 1~2 bits command value, used for

defining the motion mode of tool relative to the workpiece, defining the coordinates and so on.

2.5.1 Rapid Traverse (Positioning) G00

Command format: G00 X(U) Z(W) ;

7

GSK980TDa Turning CNC System

Command function: rapid traverse

Command specifications: X(U),Z(W)are coordinate values of end points, X, Z are absolute values,

U, W are incremental values.

All or one of X (U), Z (W) can be omitted. When one of them is omitted, the

coordinate values of starting point and end point of the axis; when they are

omitted, the starting point and end point are in the same position.

Note: For the following G commands in the User Manual, X (U), Z (W) specifications are the same

except for the special notes.

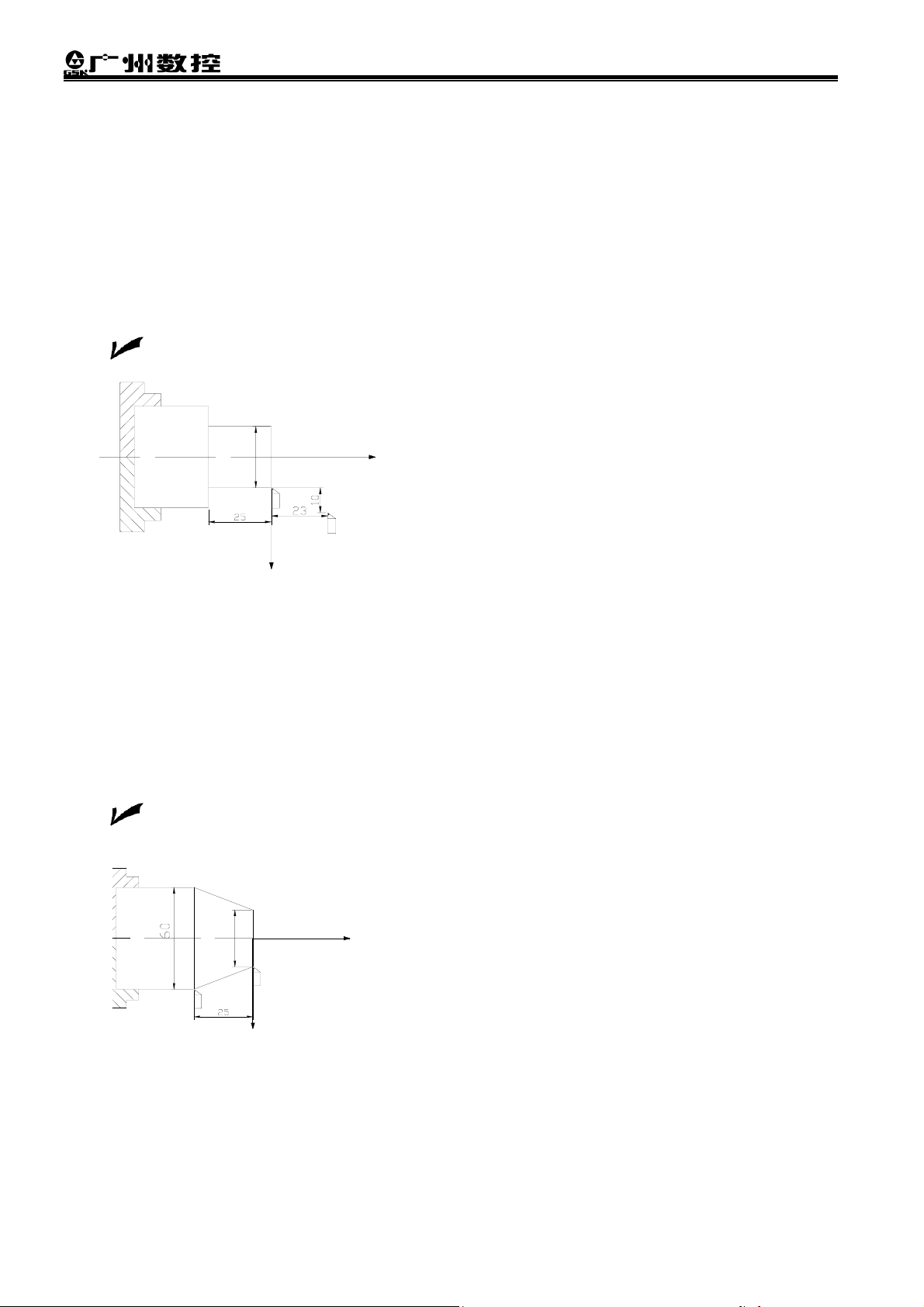

Example: The program is realized by the tool rapidly traversing from A (60, 23) to B (40, 0) as

follows:

Program:

G00 X40 Z0 (absolute programming)

G00 U-20 W-23 (incremental programming)

Φ40

End point B

终点 B

Z

G00 X40 W-23 (compound programming)

G00 U-20 Z0 (compound programming)

起点 A

Starting point A

X

Fig. 2-1

2.5.2 Linear Interpolation G01

Command format:G01 X(U)_ Z(W)_ F_;

Command function: linear cutting.

Command specification: F is the feedrate when the linear interpolation is being executed. After F

command value is executed, it has been reserved unless the new one is

executed.

Example: The program is realized by the tool executing the linear cutting with 500mm/min from

A (40, 0) to B (60, -25) as follows:

Program:

G01 X60 Z-25 F500; (Absolute programming)

G01 U20 W-25 F500; (Incremental programming)

Φ

Φ40

Starting point A

Z

G01 X60 W-25 F500; (Compound programming)

G01 U20 Z-25 F500; (Compound programming)

End

point B

X

Fig. 2-2

图 2-2

2.5.3 Circular Interpolation G02/G03

Command format:G02 X(U)_ Z(W)_ R_;

G03 X(U)_ Z(W)_ R_;

Command function: G02, CW circular cutting

G03, CCW circular cutting

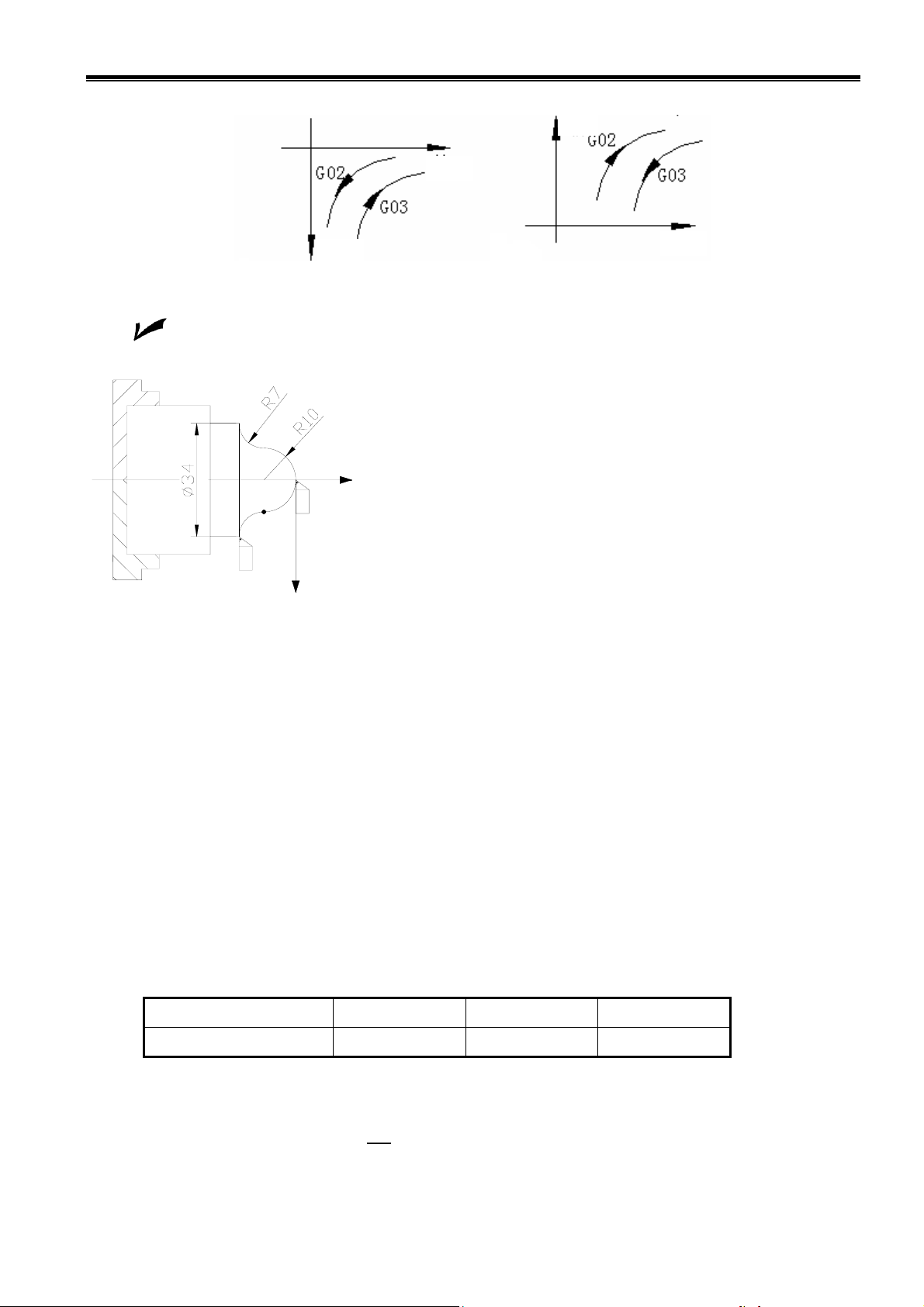

In the front tool post coordinate system and rear tool post coordinate system, G02/G03 direction is as

8

Chapter 2 Programming

Fig. 2-3.

X axis

Command specification: R is the circular radius;

Example: The program is realized by the tool executing the circular interpolation with

30mm/min from A (0, 0) to C (34,-17) as follows:

B(20,-10)is the tangential point of two circulars;

R10, R7 is separately the radius of the two circular.

A

B

Program:

G03 X20 Z-10 R10 F300 (A→B)

Z

G02 X34 Z-17 R7 (B→C) (Absolute program)

C

G03 U20 W-10 R10 F300 (A→B)

G02 U14 W-7 R7 (B→C) (Incremental programming)

X

Fig. 2-4

X axis

Z axis

Z axis

Fig. 2-3

Or

2.5.4 Dwell G04

Command format: G04 P__ ;or

G04 X__ ;or

G04 U__ ;or

G04;

Command function: each axis stops the motion, the modal of G commands and the reserved data,

state are not changed, and execute the next block after dwelling the defined

time.

Command specifications: G04 is non-modal.

Command address P U X

Unit 0.001 second Second Second

2.5.5 Workpiece Coordinate System G50

The dwell time is defined by the word P__, X__ or U__.

Range of P, X, U: 0.001~99999.999 seconds.

Time of P__, X__ or U__ is as follows:

Table 3-3

Command format: G50 X_ Z

Command function: To define the absolute coordinates of current position and create the workpiece

coordinates system (called floating coordinates system) by setting the absolute

coordinates of current position in the system.

;

9

GSK980TDa Turning CNC System

Command specifications:

G50 is non-modal;

X: X new absolute coordinates of current position;

Z: Z new absolute coordinates of current position;

Example:

Z

Z

A(200,90)

X

Previous workpiece cooridnate system

X

New workpiece corridnate system set by G50

A(100,50)

Fig. 2-5

As Fig. 2-5, before the coordinate system is set by G50, the absolute coordinates of A point are (200,

90). After “G50 X100 Z50;” is executed, the absolute coordinates of A become (100,50), and the origin of

coordinate system is also changed to the right figure in Fig.2-5.

Note: Before the coordinate system is set by G50, the system must be without (with) tool offset

value, and the tool offset value must have been executed. T display on the panel can display

whether the current tool offset value exists, i.e., when the T offset number is displayed without the

highlight at the bottom right on the panel (such as the display is T0100), the tool offset value has

been executed, and the new coordinate system can be set by G50; when it is displayed with the

highlight, (the display is T0100), the tool offset value has not been executed, at the time, the

coordinate system is set correctly till the tool offset value has been executed, otherwise, the new

set coordinate value is less one tool offset value than the input value. Executing the tool offset

value is as follows:

(1) Executing tool change function. After the target tool is changed, the slide traverses to the middle of

two guides;

(2) The system is switched to “PROGRAM” window in MDI mode, G01 G98 U0 W0 F50 is input and the

CYCLE START is pressed; when the slide is traversing, the RESET stops. At the same time, the offset

number in T command is no more displayed reversely; the tool offset value has been executed.

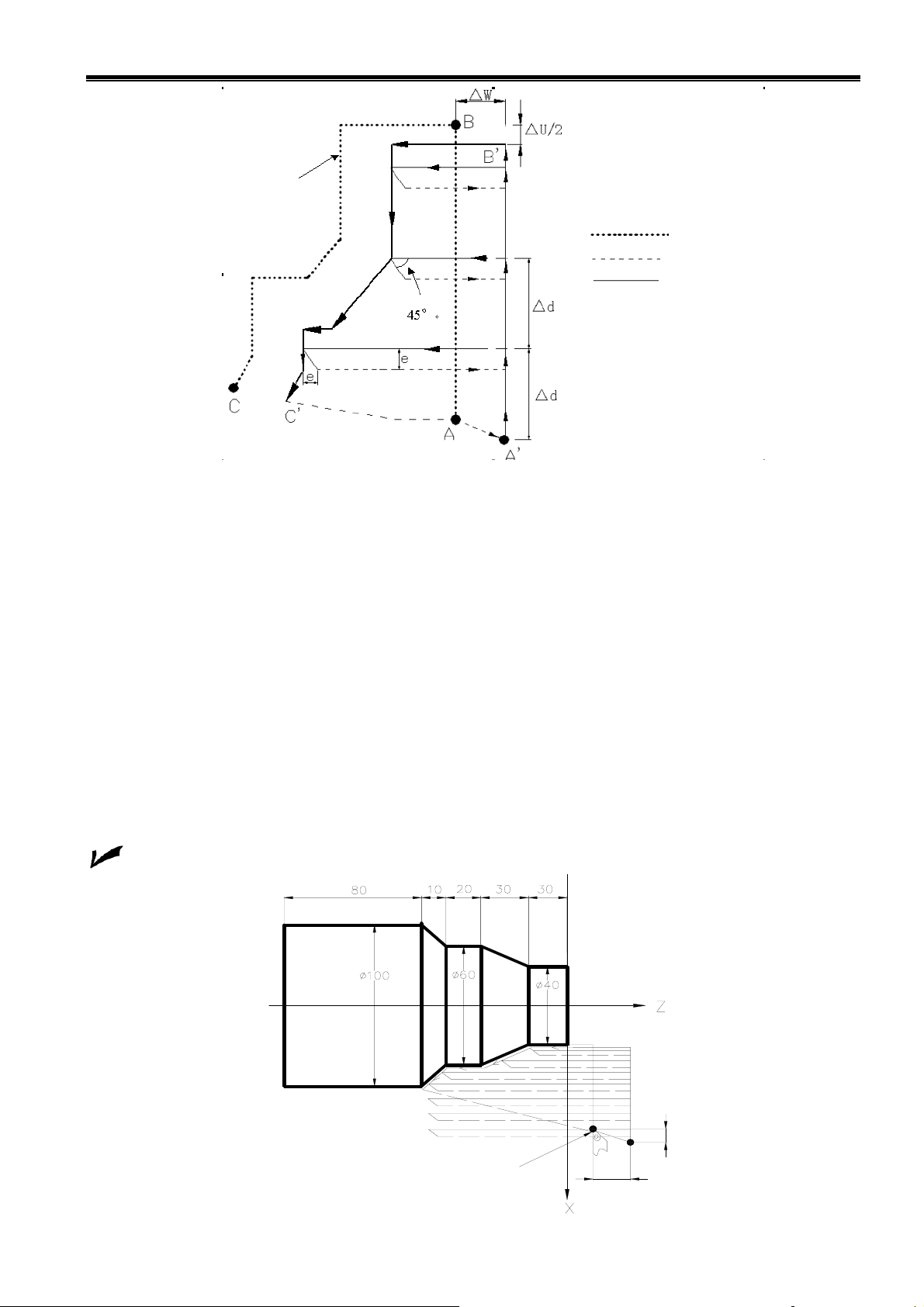

2.5.6 Axial Cutting Cycle G90

Command format: G90 X(U)__ Z(W)__ F__; (column cutting)

G90 X(U)__ Z(W)__ R__ F__;(taper cutting)

Command path: A→B→C→D→A

A→B, D→A are the rapid traverse speed, B→C, C→D is the cutting feed.

Rapid traverse

Cutting feed

10

Chapter 2 Programming

Z axis

X

C

D

Z

X axis

C

D

Z

W

B

U/2

A

X axis

Fig. 2-5 Fig. 2-6

Command specifications: X (U): X coordinate of column/taper end point(C), unit: mm;

Z (W): Z coordinate of column/taper end point(C), unit: mm;

R: difference value (radius value) of X absolute coordinates between the (B)

and end point (C) with sign symbols, when R and U have the different sign

symbols, │R│≤│U/2│; R=0 or the input is defaulted, the column cutting is

executed as Fig. 2-5, otherwise, the taper cutting is done as Fig. 2-6; unit:

mm.

Example:Fig.2-7,rod Φ125×110

Program:O0002;

M3 S300 G0 X130 Z3;

G90 X120 Z-110 F200;(A→D,cut Φ120)

Z axis

X110 Z-30;

X100;

(A→B,6 times

cutting cy

Φ60,increment of

10mm)

( B → C ,

times taper

cutting)

Φ120

Fig. 2-7

Φ60

X90;

X80;

X70;

X60;

X axis

G0 X120 Z-30;

G90 X120 Z-44 R-7.5 F150;

Z-56 R-15;

Z-68 R-22.5;

Z-80 R-30;

M30;

2.5.7 Radial Cutting Cycle G94

W

Z axis

B

A

cle

4

X

R

U/2

Command format:G94 X(U)__ Z(W)__ F__; (end face cutting)

G94 X(U)__ Z(W)__ R__ F__;(taper end face cutting)

Command path:A→B→C→D→A

A→B, D→A are the rapid traverse speed,B→C, C→D are the cutting feed.

Rapid traverse

Cutting feed

11

Z axis

R

X

GSK980TDa Turning CNC System

X

Z axis

X

D

U/2

A

axis

B

Z

C

D

A

W

X axis

C

B

Z

W

Fig. 2-8 Fig. 2-9

Command specifications: X (U): X coordinate of end point, unit: mm;

Z (W): Z coordinate of end point, unit: mm;

R: different value of Z absolute coordinates from end point to starting point.

When the sign symbols of R is not the same that of U, R, │R│≤│W│, the

radial linear cutting is as Fig.2-8, the radial taper cutting is as Fig. 2-9, unit:

mm.

Example: Fig. 2-10, rod Φ125×112

Program:O0003;

G00 X130 Z5 M3 S1;

Z axis

Φ60

Φ120

G94 X0 Z0 F200;

X120 Z-110 F300;

G00 X120 Z0;

G94 X108 Z-30 R-10;

(cut outer Φ12)

X96 R-20;

X84 R-30;

Fig. 2-10

X axis

X72 R-40;

X60 R-50;

M30;

(C→B→A, cut Φ60)

U/2

2.5.8 Axial Roughing Cycle G71

Command format: G71 U

G71 P

(Δd) R(e)

F S T

(ns) Q(nf) U(Δu) W(Δw); ⑵

;

⑴

N(ns) .....;

....;

....F;

....S;

....

⑶

·

N(nf).....;

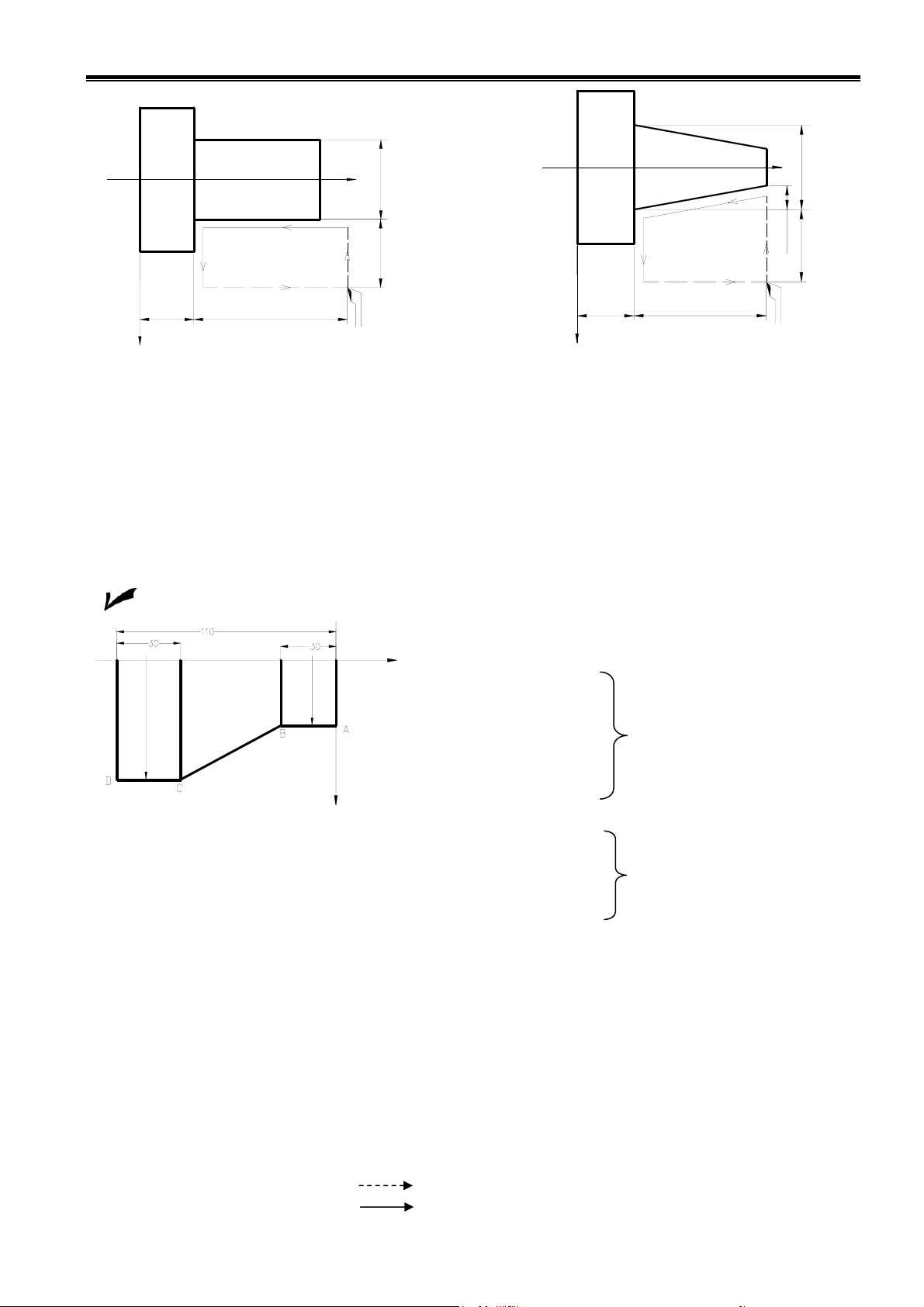

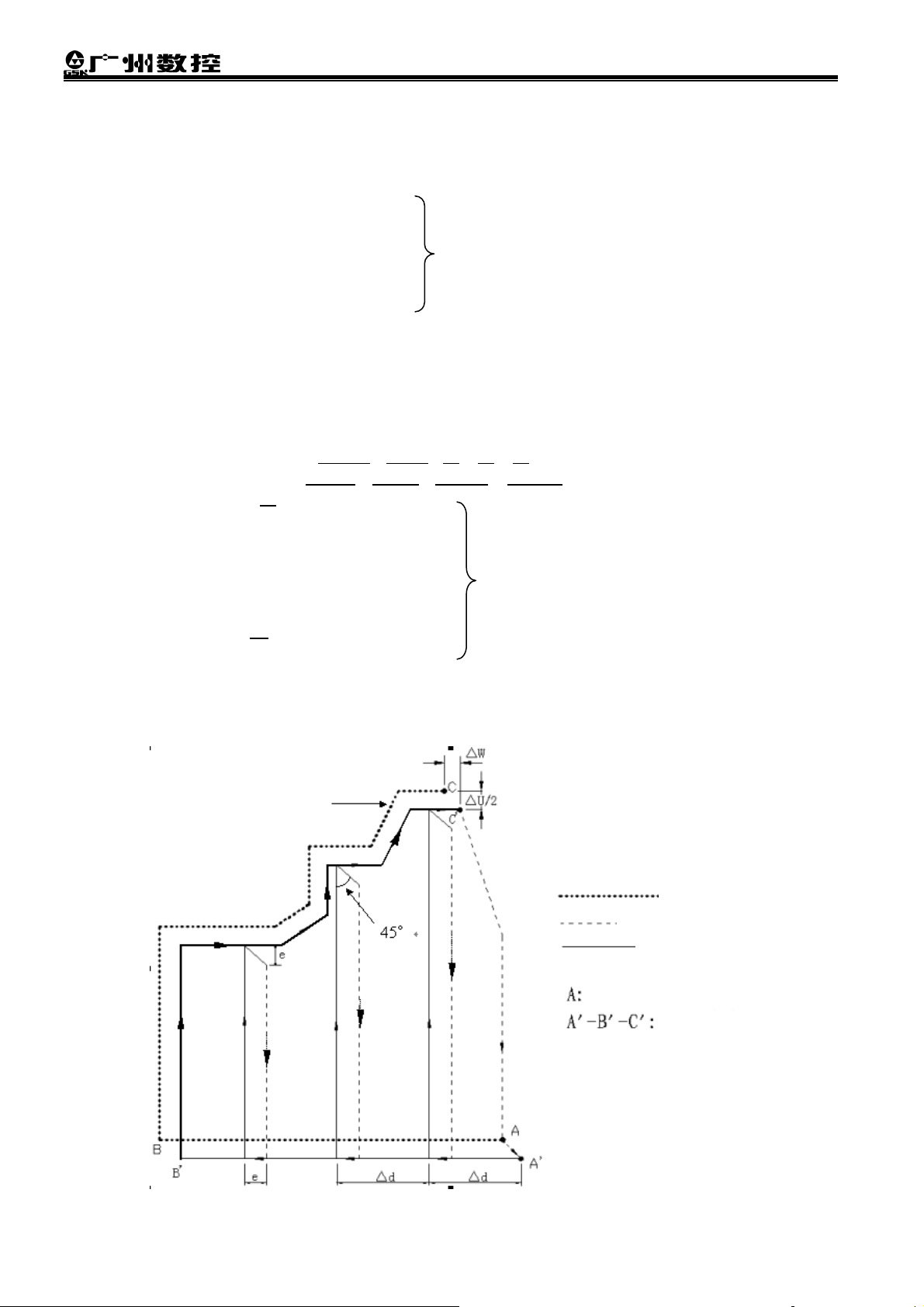

Command path: A→A’→……B’→C’→A→B→C→A

A’→……B’ is the roughing cycle (tool infeed →cutting→tool retraction→tool

infeed……).

12

Chapter 2 Programming

Specified path by program

Finishing path

Rapid traverse

Cutting feed

Starting point (end point)

Roughing path

Fig. 2-11

Command specifications:

Δd:it is each travel(unit:mm,radius value)of X tool infeed in roughing, its value: 0.001~99.999(unit

:

mm,radius value)without sign symbols.

e: it is travel(unit:mm,radius value)of X tool retraction in roughing its value: 0.001~99.999(unit

mm,radius value)without sign symbols.

ns: Block number of the first block of finishing path.

nf: Block number of the last block of finishing path.

Δu: X finishing allowance is -9999.999~9999.999 (unit: mm, in diameter) with sign symbol, i.e. the

different value of X absolute coordinates between A’ and A.

Δw: Z finishing allowance is -9999.999~9999.999 with sign symbol (unit: mm in diameter). i.e. the

different value of Z absolute coordinates between A’ and A.

F: Feedrate; S: Spindle speed; T: Tool number, tool offset number.

Example: Fig. 2-12

:

b

d

c

a

e

0.5

Starting

point

(200,10)

2

13

Program:O0004;

G00 X200 Z10 M3 S800; (Spindle clockwise with 800 rev/min)

G71 U2 R1 F200; (Cutting depth each time 4mm,tool retraction 2mm,[diameter])

G71 P80 Q120 U1 W2; (Roughing a---e,X machining allowance 0.5mm , Z 2mm)

N80 G00 X40 S1200; (Position)

G01 Z-30 F100 ; (a→b)

X60 W-30; (b→c) a→b→c→d→e blocks for finishing path

W-20; (c→d)

N120 X100 W-10; (d→e)

G70 P80 Q120; (a---e blocks for finishing path)

M30; (End of program)

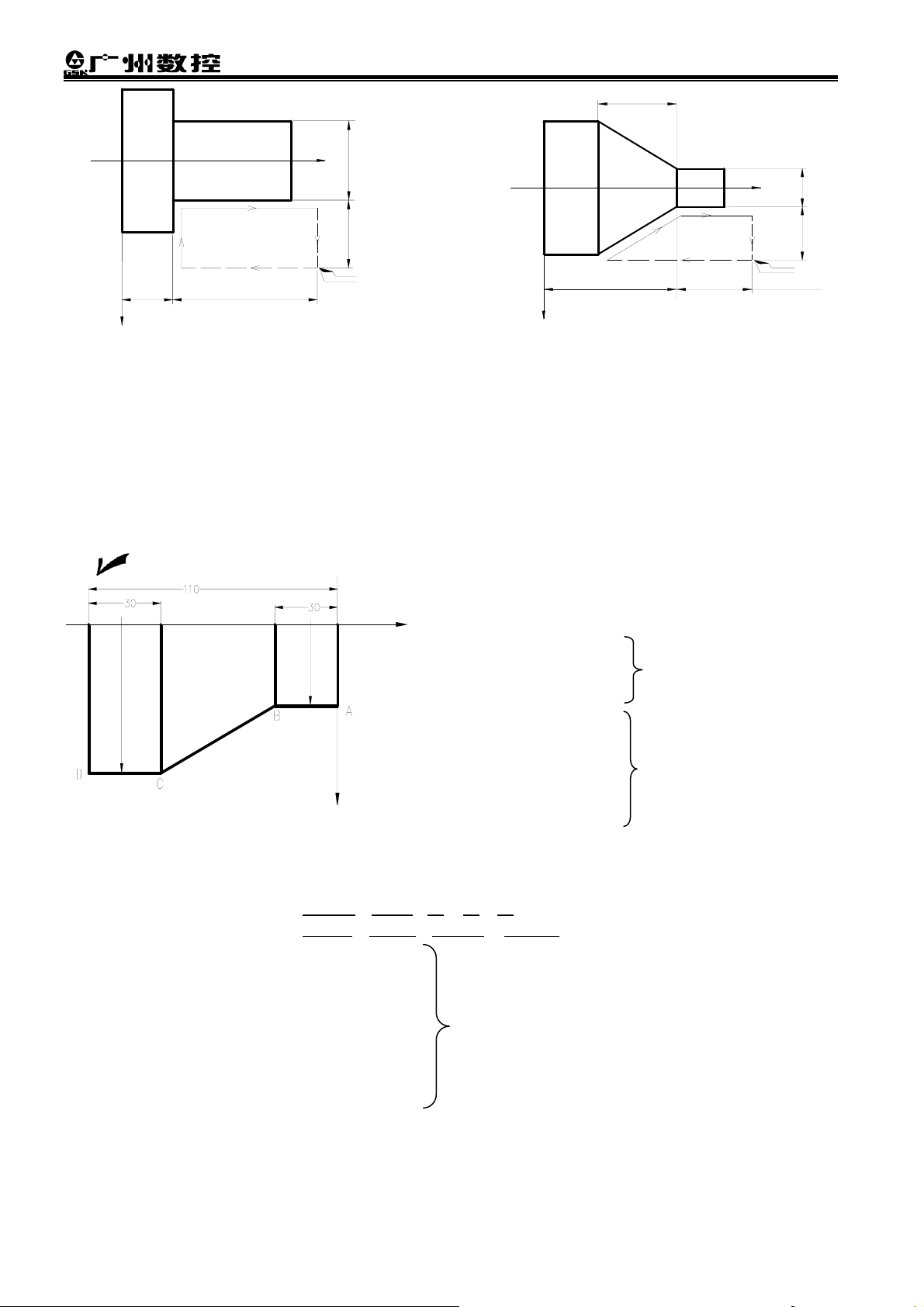

2.5.9 Radial Roughing Cycle G72

GSK980TDa Turning CNC System

Command format: G72 W

G72 P

N

......;

....F;

....S;

....;

(Δd) R(e)

(ns) Q(nf) U(Δu) W(Δw); ⑵

(ns) .....;

⑶

·

N (nf

).....;

Command path: A→A’→……B’→C’→A→B→C→A

A’→……B’ is the roughing cycle (tool infeed→cutting→tool retraction→tool

infeed……)

Specified path by program

F S T

;

⑴

Finishing path

Rapid traverse

Cutting feed

14

Starting point (end point)

Roughing path

Fig. 2-13

Chapter 2 Programming

)

Command specifications:

Δd: it is each travel(unit:mm,)of Z tool infeed in roughing, its value: 0.001~99.999(unit:mm,without

sign symbols).

e: it is each travel(unit:mm)of Z tool infeed in roughing, its value: 0.001~99.999(unit:mm, without

sign symbols).

ns: Block number of the first block of finishing path.

Nf: Block number of the last block of finishing path.

Δu: X finishing allowance in roughing, its value: -9999.999~9999.999 (unit: mm, with sign symbol, in

diameter), i.e. the different value of X absolute coordinates between A’ and A.

Δu: Z finishing allowance in roughing, its value: -9999.999~9999.999 (unit: mm, with sign symbol, in

diameter), i.e. the different value of X absolute coordinates between A’ and A.

F: Cutting feedrate; S: Spindle speed; T : Tool number, tool offset number.

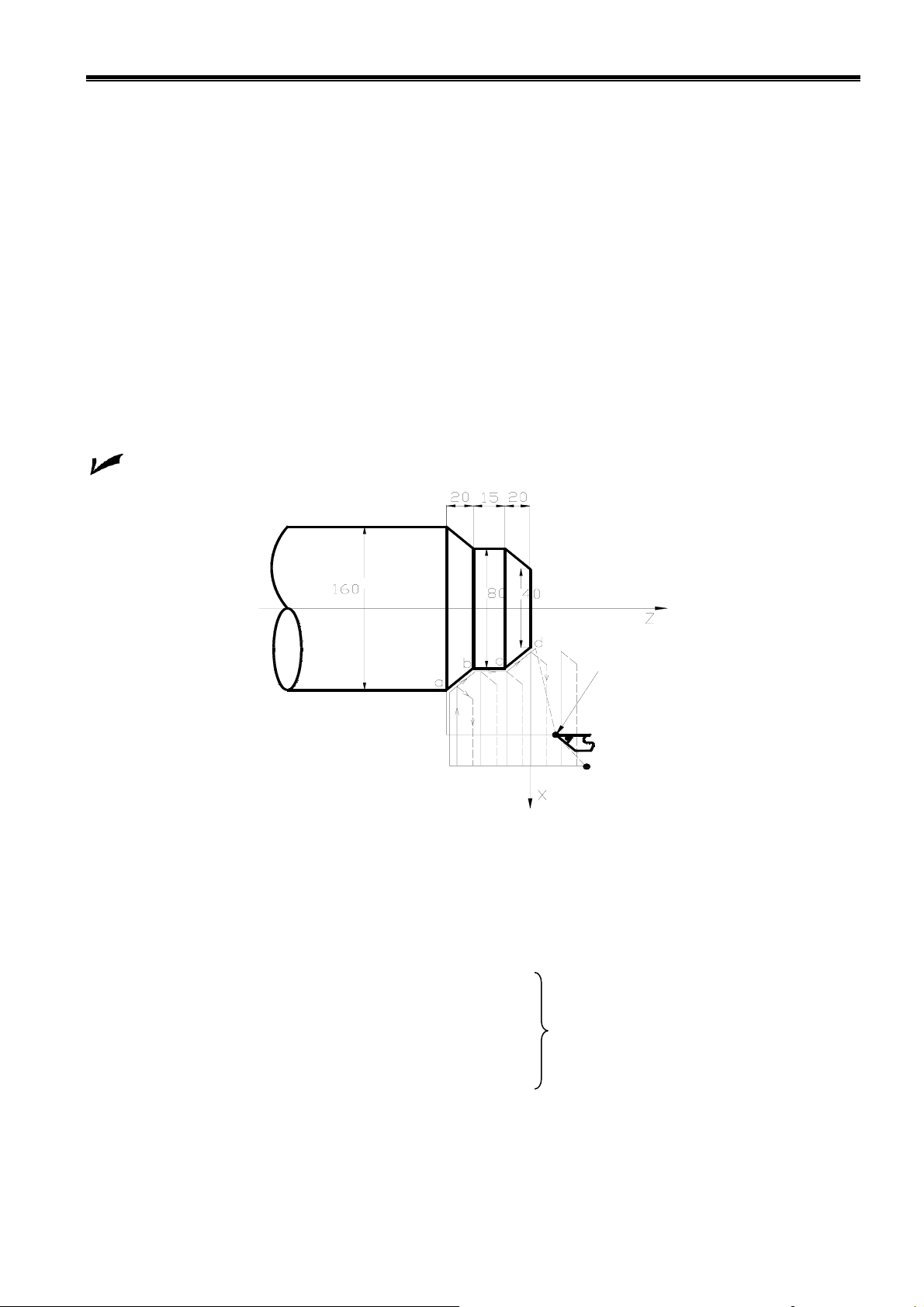

Example: Fig. 2-14

φ

Fig.2-14

φ

φ

Starting

point

(176,10

Program:O0005;

G00 X176 Z10 M03 S500 (Change No.2 tool and execute its compensation, spindle rotation

with 500 rev/min)

G72 W2.0 R0.5 F300; (Tool infeed 2mm, tool retraction 2mm)

G72 P10 Q20 U0.2 W0.1; (Roughing a--d,X roughing allowance 0.2mm and Z 0.1mm)

N10 G00 Z-55 S800 ; (Rapid traverse)

G01 X160 F120; (Infeed to a point)

X80 W20; (Machining a—b) Blocks for finishing path

W15; (Machining b—c)

N20 X40 W20 ; (Machining c—d)

G70 P050 Q090 M30; (Finishing a—d)

15

Loading...

Loading...