Page 1

GSK980TD Turning CNC

PLC User Manual

GSK CNC Equipment

Page 2

Page 3

g

g

pp

Book 1 PROGRAMMING

PLC specification, PLC address, ladder

rammin

Book 2 FUNCTION

PLC function control logic and relative signals

Book 3 CNC CONFIGRUTION SOFTWARE

GSKCC software and usage

Book 2 FunctionBook 1 Pro

Book 3 CNC Configuration software

APPENDIX

Appendix 1:input signal(X)……………………………………………appendix-1

Appendix 2:output signal(Y)………………………………………….appendix-2

Appendix 3:G, F signal……………………….…………………………. appendix-3

Appendix 4:GSK980TD standard function configuration……………. appendix-8

A

endix

Page 4

Page 5

g

g

Book 1 Pro

BOOK 1

rammin

PROGRAMMING

Page 6

Page 7

Contents

g

g

Chapter 1 SEQUENTIAL PROGRAM ........................................................................................Ⅰ-1

1.1 PLC SPECIFICATION....................................................................................................Ⅰ-1

1.2 STRUCTURE of SEQUENTIAL PROGRAM ...............................................................Ⅰ-1

1.2.1 Subprogram............................................................................................................Ⅰ-1

1.2.2 Subprogram Embedding ........................................................................................Ⅰ-2

1.2.3 Conditional Branch................................................................................................ Ⅰ-3

1.3 EXECUTING SEQUENTIAL PROGRAM....................................................................Ⅰ-3

1.3.1 Execution Process of Sequential Program............................................................. Ⅰ-3

1.3.2 Cycle Execution of Sequential Program................................................................Ⅰ-4

1.3.3 Priority Order of Executing Sequential Program...................................................Ⅰ-4

1.4 PROCESSING INPUT/OUTPUT SIGNAL....................................................................Ⅰ-5

1.4.1 Processing Input Signal..........................................................................................Ⅰ-5

1.4.2 Processing Input Signal..........................................................................................Ⅰ-6

1.4.3 Synchronous Procession of Short Pulse Signal ..................................................... Ⅰ-7

1.4.4 Interlock Signal......................................................................................................Ⅰ-7

1.5 EDITING SEQUENTIAL PROGRAM...........................................................................Ⅰ-7

1.5.1 Distributing Interface (Step 1)...............................................................................Ⅰ-8

1.5.2 Editing Ladder (Step 2).......................................................................................... Ⅰ-8

1.5.3 Debugging Ladder (Step 3).................................................................................... Ⅰ-8

1.5.4 Program Editing Limit........................................................................................... Ⅰ-8

Chapter 2 ADDRESS.................................................................................................................... Ⅱ-1

2.1 MACHINE→PLC ADDRESS(X)..............................................................................Ⅱ-1

2.1.1 X Address in I/O Interface.....................................................................................Ⅱ-2

2.1.2 X Address on Operator Panel.................................................................................Ⅱ-2

2.2 PLC→MACHINE ADDRESS(Y)..............................................................................Ⅱ-3

2.2.1 Y Address in I/O Interface .....................................................................................Ⅱ-3

2.2.2 Y Addresses on Operator Panel..............................................................................Ⅱ-4

2.3 PLC→NC ADDRESS(G)...........................................................................................Ⅱ-4

2.4 NC→PLC ADDRESS(F) ...........................................................................................Ⅱ-4

2.5 INTERNAL RELAY ADDRESS.....................................................................................Ⅱ-4

2.6 INFORMATION DISPLAYING REQUEST ADDRESS(A)..................................... Ⅱ-5

2.7 HOLD RELAY ADDRESS(K)...................................................................................Ⅱ-5

2.8 COUNTER ADDRESS(C).........................................................................................Ⅱ-6

2.9 COUNTER PRESET VALUE ADDRESS(DC).........................................................Ⅱ-6

2.10 TIMER ADDRESS(T)..............................................................................................Ⅱ-6

2.11 TIMER PRESET VALUE ADDRESS(DT).............................................................. Ⅱ-7

2.12 DATA LIST ADDRESS(D) ...................................................................................... Ⅱ-7

2.13 LABEL ADDRESS(L) .............................................................................................Ⅱ-8

2.14 SUBPROGRAM NUMBER(P)................................................................................ Ⅱ-8

Chapter 3 PLC BASIC INSTRUCTIONS....................................................................................Ⅲ-1

3.1 LD,LDI,OUT INSTRUCTION.................................................................................. Ⅲ-1

3.2 AND, ANI INSTRUCTION.............................................................................................Ⅲ-2

3.3 OR, ORI INSTRUCTION ...............................................................................................Ⅲ-2

3.4 ORB INSTRUCTION...................................................................................................... Ⅲ-3

3.5 ANB INSTRUCTION......................................................................................................Ⅲ-3

Chapter 4 PLC FUNCTION INSTRUCTIONS ...........................................................................

Ⅳ-1

Book 1 Pro

rammin

I

Page 8

g

g

4.1 END1(END of GRADE ONE PROGRAM).............................................................. Ⅳ-1

4.2 END2(END of GRADE TWO PROGRAM) ............................................................. Ⅳ-1

Book 1 Pro

rammin

4.3 SET.................................................................................................................................. Ⅳ-2

4.4 RST(RESET)................................................................................................................... Ⅳ-2

4.5 CMP(BINARY COMPARATIVE SET).....................................................................Ⅳ-3

4.6 TMRB(TIMER).......................................................................................................... Ⅳ-4

4.7 CTRC(BINARY COUNTER) .................................................................................... Ⅳ-5

4.8 MOVN(BINARY DATA COPY) ............................................................................... Ⅳ-6

4.9 DECB(BINARY ENCODING).................................................................................. Ⅳ-7

4.10 CODB(BINARY CODE CONVERSION)............................................................... Ⅳ-7

4.11 JMPB(PROGRAM JUMPING) ............................................................................... Ⅳ-9

4.12 LBL(PROGRAM JUMPING LABEL).................................................................... Ⅳ-9

4.13 CALL(SUBPROGRAM CALLING)..................................................................... Ⅳ-10

4.14 SP(START of SUBPROGRAM), SPE(END of SUBPROGRAM) .................. Ⅳ-10

4.15 ROTB(BINARY ROTATION CONTROL) ...........................................................

4.16 PARI(PARITY CHECK) ........................................................................................ Ⅳ-13

4.17 ADDB(BINARY DATA ADDING)........................................................................ Ⅳ-14

4.18 SUBB(BINARY DATA SUBTRACTING)............................................................Ⅳ-15

4.19 DIFU(DRIFT UP SET) .......................................................................................... Ⅳ-16

4.20 DIFD(DRIFT DOWN SET)................................................................................... Ⅳ-16

4.21 MOVE(AND)......................................................................................................... Ⅳ-17

4.22 AL T(ALTERNATIVE OUTPUT) .......................................................................... Ⅳ-18

GSK980TD Turning Machine CNC System

Ⅳ-11

II

Page 9

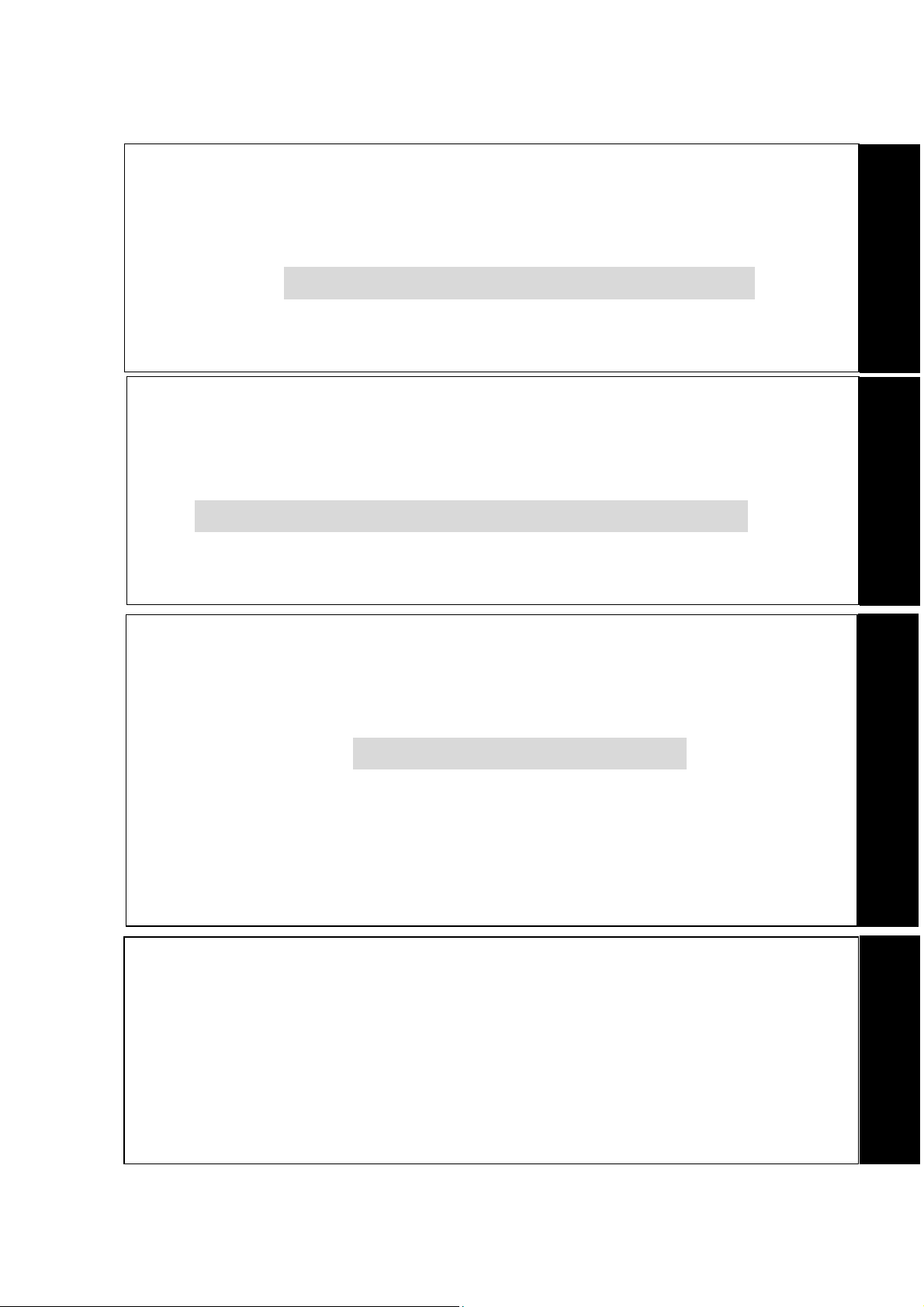

Chapter 1 Sequential Program

g

g

Chapter 1 SEQUENTIAL PROGRAM

1.1 PLC SPECIFICATION

For different CNC PLC, there are different program capacity, processing speed, function instructions and

nonvolatile memory addresses. Specifications of GSK980TD PLC are as follows:

Specification

Programming language

Programming software

Programming grades

Executive cycle of grade one program

Average processing time of basic instruction

Max. step of program

Programming instruction

Internal relay address(R) R0000~R0999

Information displaying request address(A) A0000~A0024

Timer address (T) T0000~T0099

Counter address(C) C0000~C0099

Programming address

Data tablet address(D) D0000~D0999

Hold relay address(K) K0000~K0039

Counter preset value address(DC) DC0000~DC0099

Timer preset value address(DT) DT0000~DT0099

Subprogram address(P) P0000~P9999

Label address (L) L0000~L9999

Machine→PLC address(X) X0000~X0029

PLC→machine address(Y) Y0000~Y0019

CNC→PLC address (F) F0000~F0255

PLC→CNC address(G) G0000~G0255

980TD-PLC

Chinese ladder

GSKCC.exe

2

8ms

<2μs

5000 steps

Basic instruction +function instruction

Book 1 Pro

rammin

1.2 STRUCTURE of SEQUENTIAL PROGRAM

Sequential program is defined to logically control the machine and relative devices according to sequence of

ladder. The sequence of ladder is compiled in a traditional PLC but GSK980TD CNC PLC is integrated by

traditional one and advanced structured programming, employed with subprogram, embedded subprogram and

conditional branch,and with apparent advantages compared to the traditional.

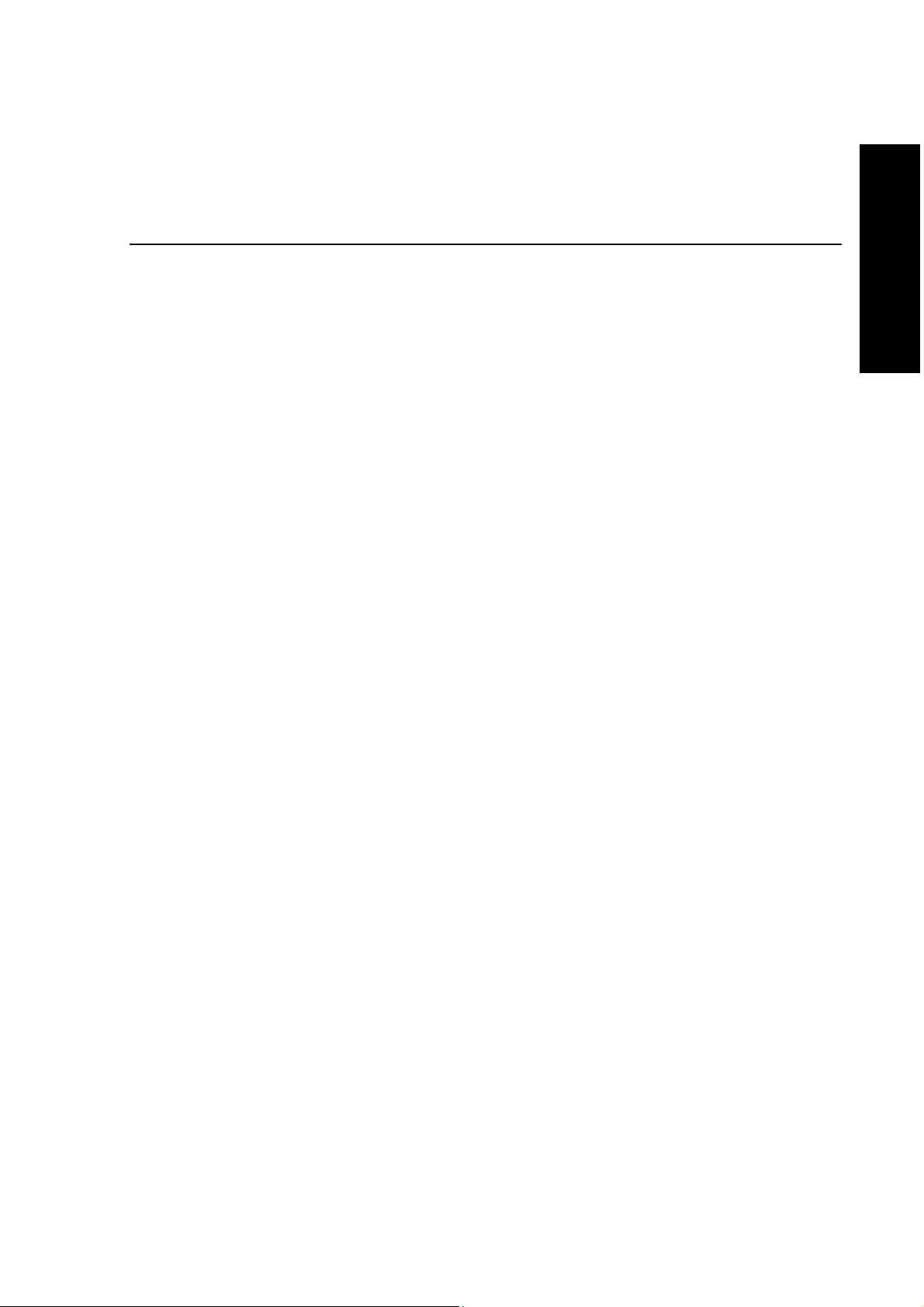

1.2.1 Subprogram

In GSK980TD CNC PLC program, a special subprogram can be called according to requirements of

programming. For example, subprogram P0001 can be called when contactor X0000.0 is closed as follows:

Ⅰ-1

Page 10

GSK980TD Turning Machine CNC System

g

g

Book 1 Pro

Call subprogram P0001

rammin

Subprogram P0001

1.2.2 Subprogram Embedding

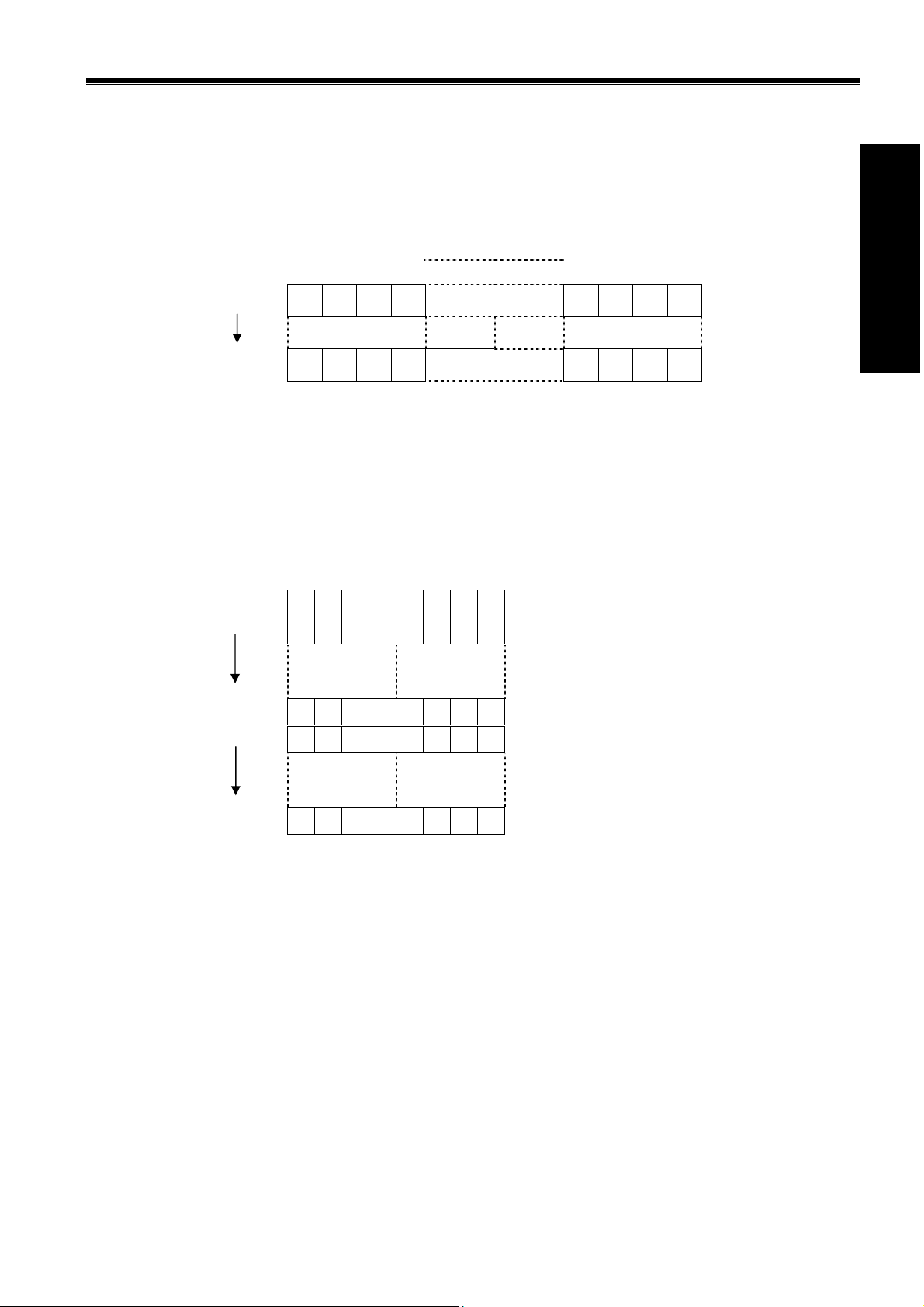

GSK980TD CNC PLC can realize 20 grades subprogram embedding as the following figure. Subprogram

P0001 can be called when contractor X0000.0 is closed in main program; subprogram P0002 can be called

when contractor X0002.0 is closed in the subprogram P0001.

Subprogram P0001

Subprogram P0001

Call subprogram P0002

Ⅰ-2

Page 11

Chapter 1 Sequential Program

g

g

Subprogram P0002

Book 1 Pro

1.2.3 Conditional Branch

The system can judge whether the setting conditions to execute a corresponding subprogram are satisfactory

when a main program is executed circularly, otherwise the system executes subprograms in order as the

above-mentioned figure.

1.3 EXECUTING SEQUENTIAL PROGRAM

The edited sequential programs(ladder program)are downloaded to 980TD by serial, CNC reads the ladder and

converts into some format identified by it after it is switched on again, and then CPU decodes and operation

processes them to store into RAM, and last reads every instruction in memory to execute it by arithmetical

operation.

1.3.1 Execution Process of Sequential Program

rammin

PLC sequence control is executed by software and there is different from general relay circuit, and so its method

is understandingly considered in editing PLC sequential programs.

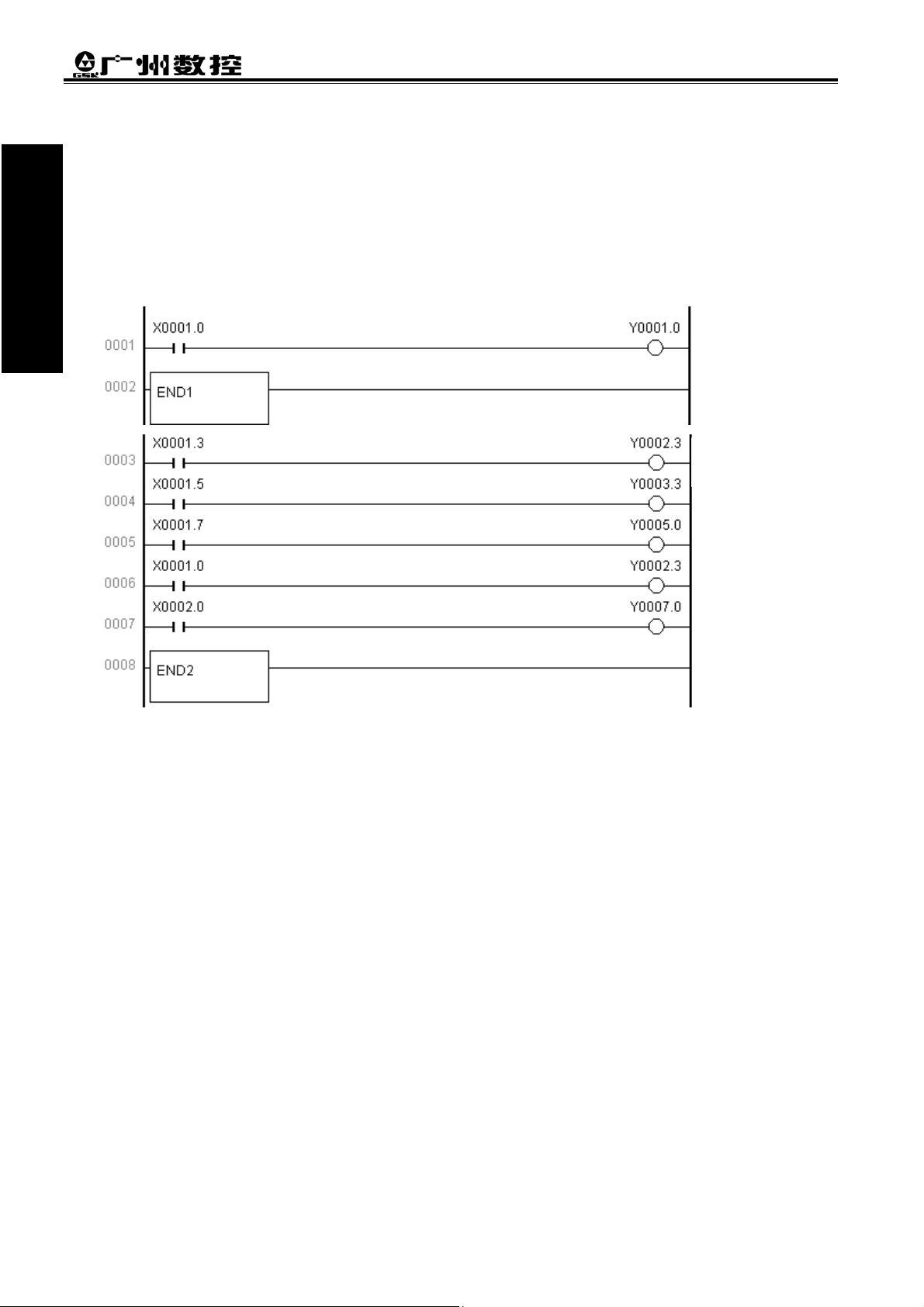

Every relay can output simultaneously for general relay control circuit as the following figure. Y0002.3 and

Y0002.5 output simultaneously when contactor X0000.0, X0002.0 and X0002.2 are closed; in PLC sequence

control, every relay outputs in order. For example, Y0002.3 outputs and then Y0002.5 does when X0000.0,

X0002.0 and X0002.2 are closed, namely, outputs are executed in order as ladder.

Ⅰ-3

Page 12

1.3.2 Cycle Execution of Sequential Program 1.3.2 Cycle Execution of Sequential Program

g

g

p

p

GSK980TD Turning Machine CNC System

Book 1 Pro

rammin

Cycle execution of sequential program is defined that PLC executes ladder from its home to end, and again

Cycle execution of sequential program is defined that PLC executes ladder from its home to end, and again

from its home to end after the run is completed.

from its home to end after the run is completed.

Processing cycle is defined to runtime of ladder from home to end. The shorter the processing cycle is, the

Processing cycle is defined to runtime of ladder from home to end. The shorter the processing cycle is, the

stronger the response of signal is.

stronger the response of signal is.

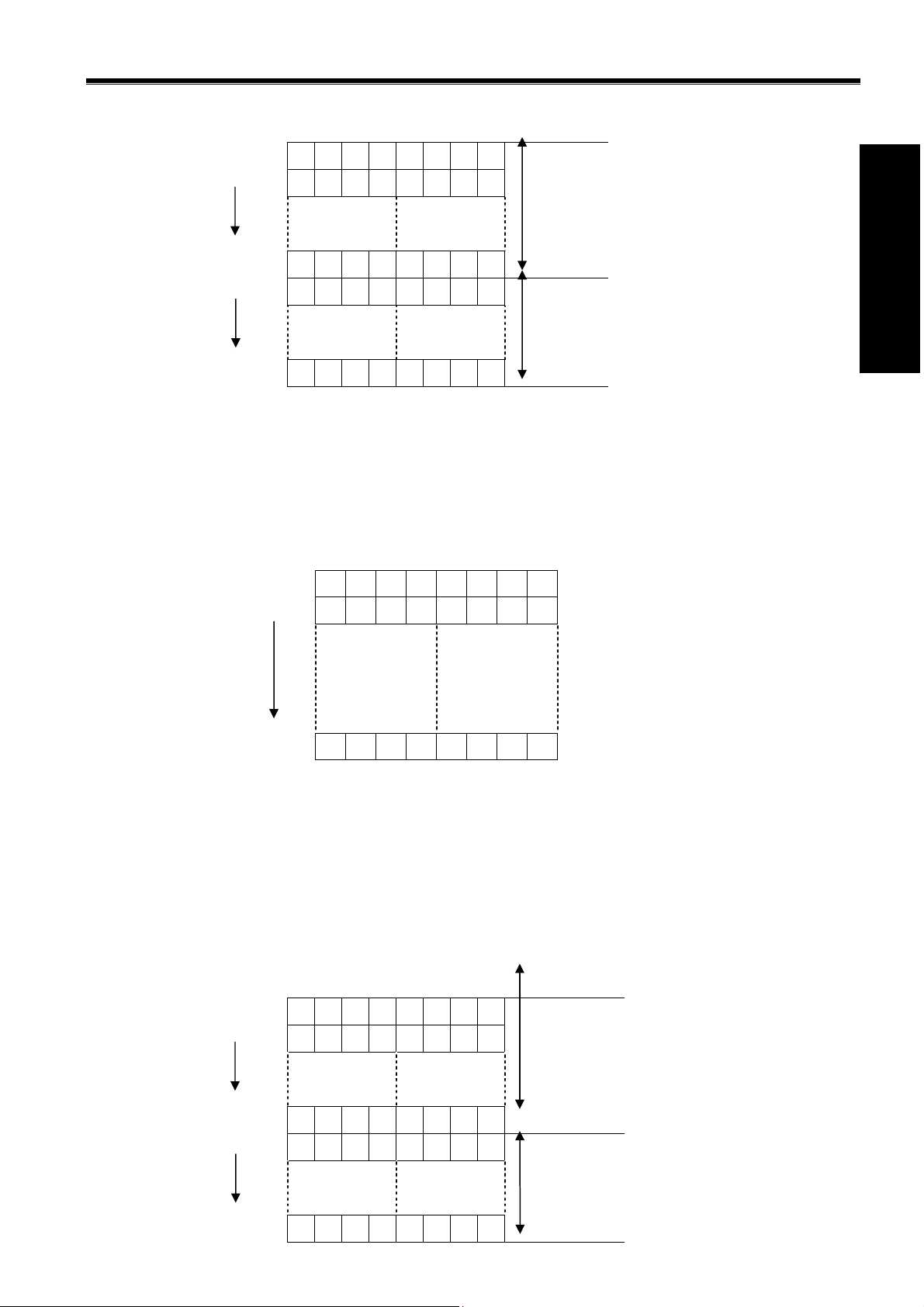

1.3

.3 Priority Order of Executing Sequential Program 1.3.3 Priority Order of Executing Sequential Program

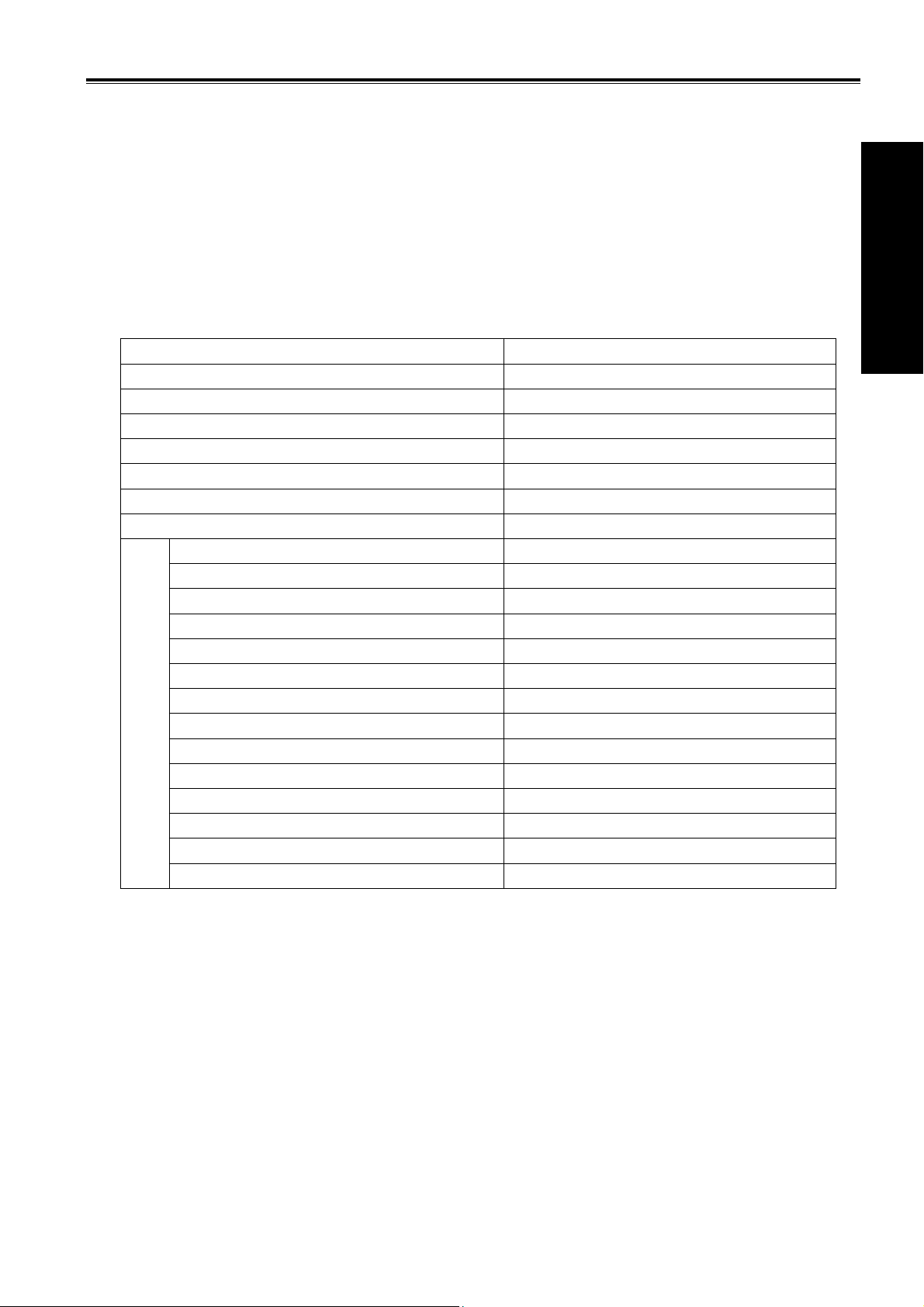

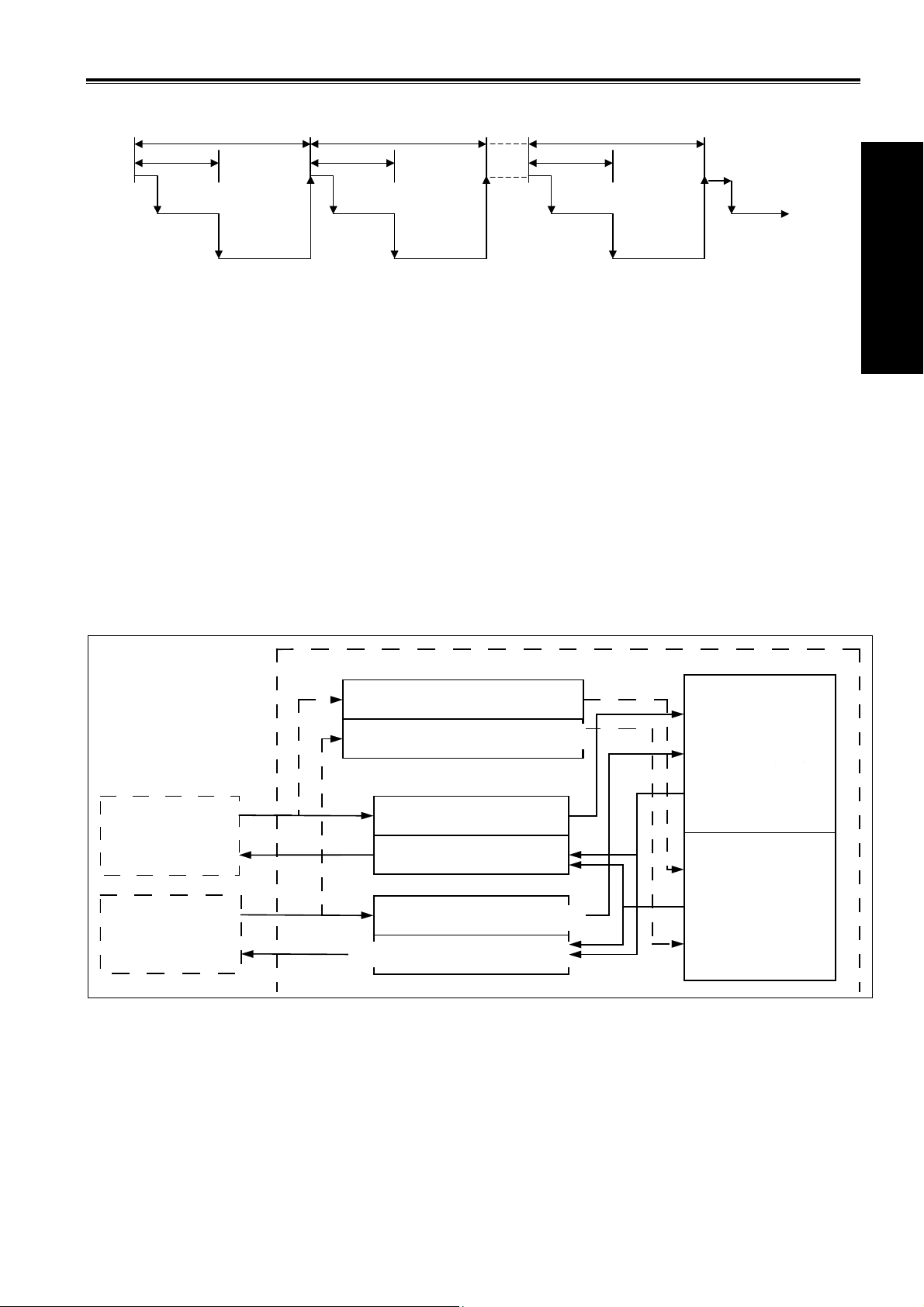

GSK980TD PLC programs are divided into grade one and grade two programs which processing cycles are

GSK980TD PLC programs are divided into grade one and grade two programs which processing cycles are

different. The first one is executed per 8ms to do with short pulse signal with quick reaction, and the second one

different. The first one is executed per 8ms to do with short pulse signal with quick reaction, and the second one

is executed per 8n(ms),in which n is fraction times. PLC divides the grade two program into n blocks according

is executed per 8n(ms),in which n is fraction times. PLC divides the grade two program into n blocks according

to runtime, and executes one block per each 8(ms).

to runtime, and executes one block per each 8(ms).

End of grade one

rogram

Fraction 1:

0004~0006

Fraction 1:

0007~0011

End of grade one

rogram

Fraction of the grade two program is to execute the first and execution process is as the following figure when

the fraction number is n; T11, T12, T1n are runtime to execute the first. T21, T22, T2n separately corresponds

to runtime of No. n block in executing the second when No. n cycle is execute. Tc1, Tc2, Tcn separately

corresponds to hold time by CNC when No. n cycle is executed.

The program returns to its beginning to continue execution when the last fraction block of the second is

executed completely. The first is executed every 8ms, No. n block of the second is done every 8n, and runtime

Ⅰ-4

Page 13

Chapter 1 Sequential Program

g

g

of one cycle is 8n(ms). The more the fraction number of the second is, the longer the runtime of one cycle is. of one cycle is 8n(ms). The more the fraction number of the second is, the longer the runtime of one cycle is.

1ms

Block 1

T21

8ms

1ms

Block 2

T22

8ms

T1nT12 T11

1ms

Block n

T2n

8ms

Block 1

Tcn Tc2Tc1

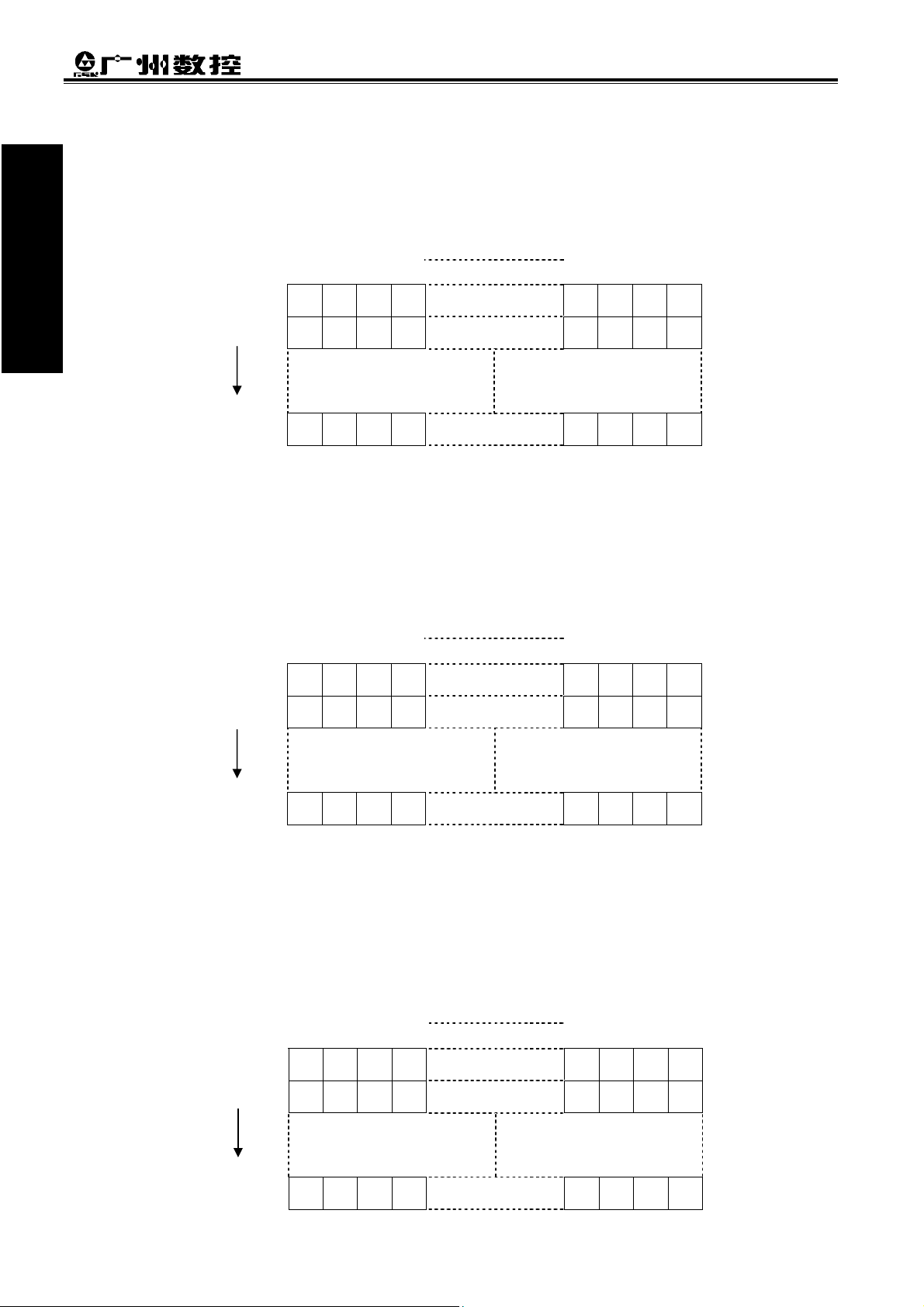

1.4 PROCESSING INPUT/OUTPUT SIGNAL 1.4 PROCESSING INPUT/OUTPUT SIGNAL

Processing of input/output signal is as the following figure. X signal of machine I/O interface and F signal of

Processing of input/output signal is as the following figure. X signal of machine I/O interface and F signal of

NC are separately input to input memories at machine side and NC side, and directly used by the first grade

NC are separately input to input memories at machine side and NC side, and directly used by the first grade

program; they separately input to synchronous input memories are used by the second. Output signals of the

program; they separately input to synchronous input memories are used by the second. Output signals of the

first and the second are separately output to output memories at NC side and machine side,and then separately

first and the second are separately output to output memories at NC side and machine side,and then separately

output to NC and I/O interface of machine

output to NC and I/O interface of machine

Signal states of the above-mentioned memories are displayed by diag no st i c inte rfa ce, an d th e diagn o s tic nu mber

Signal states of the above-mentioned memories are displayed by diag no st i c inte rfa ce, an d th e diagn o s tic nu mber

corresponds to address number of program.

corresponds to address number of program.

Book 1 Pro

rammin

PLC

NC

侧同步输入存储器

Syn. input memory at CN side

Syn. input memory at machine side

机床侧同步输入存储器

Grade one program

第一级程序

F

NC

侧输入存储器

Input memory at CN side

N C

Machine

机

床

G

X

Y

NC

侧输出存储器

Output memory at CN side

机床侧输入存储器

Input memory at machine side

Output memory at machine side

机床侧输出存储器

Grade two program

第二级程序

1.4.1 Processing Input Signal 1.4.1 Processing Input Signal

A:Input signal of grade one program: A:Input signal of grade one program:

Input memory at NC side is scanned every 8ms and stores F signal from NC, and the system directly use its state

Input memory at NC side is scanned every 8ms and stores F signal from NC, and the system directly use its state

when the first is executed.

when the first is executed.

B:Input signal of grade two program: B:Input signal of grade two program:

Input signal of the second is the one stored by the first. The first directly use F and X signal and so the input Input signal of the second is the one stored by the first. The first directly use F and X signal and so the input

Ⅰ-5

Page 14

signal of the second lags the first one and its max. lag time is runtime of one grade two program. signal of the second lags the first one and its max. lag time is runtime of one grade two program.

g

g

p

p

C:Difference of input signal states of the first and the second: C:Difference of input signal states of the first and the second:

Book 1 Pro

For the same input signal, its states are different in the first and the second when PLC reads input signals,

For the same input signal, its states are different in the first and the second when PLC reads input signals,

because the first reads input memories at NC side and machine side but the second reads the synchronous input

because the first reads input memories at NC side and machine side but the second reads the synchronous input

memory at NC side and ones at machine side. The input signal of the second lags behind that of the first and its

memory at NC side and ones at machine side. The input signal of the second lags behind that of the first and its

lag time is 8nms which should be noted.

lag time is 8nms which should be noted.

rammin

Example: Example:

GSK980TD Turning Machine CNC System

End of grade one

rogram

Fraction1:

0003~0005

Fraction1:

0006~0007

End of grade two

rogram

When the lag time is the first 8ms, X0001.0=1 and the system executes the first Y0001.0=1. When the system

starts to execute the second, X0001.0=1 inputs to the synchronous input memory and starts to execute the first

block of the fractional second.

When the lag time is the second 8ms, X0001.0=0 and the system executes the first one Y0001.0=1. And then the

system executes the second block of the fractional second but X0001.0 =1 which state is still the previous

synchronous input memory and Y0002.3=1 after execution.

1.4.2 Processing Input Signal

A:Signal to NC

PLC transmits output signal to the output memory at NC side every 8ms, and then directly outputs to NC.

B:Signal to machine

PLC transmits output signal to the output memory at machine side, and then directly outputs to memory every

2ms.

Ⅰ-6

Page 15

Chapter 1 Sequential Program

g

g

p

1.4.3 Synchronous Procession of Short Pulse Signal 1.4.3 Synchronous Procession of Short Pulse Signal

The first is used for processing the short pulse signal. When it is less than 8ms, namely when the system

The first is used for processing the short pulse signal. When it is less than 8ms, namely when the system

executes the first, the input signal state may be changed, which may execute programs by mistake.

executes the first, the input signal state may be changed, which may execute programs by mistake.

End of grade one

rogram

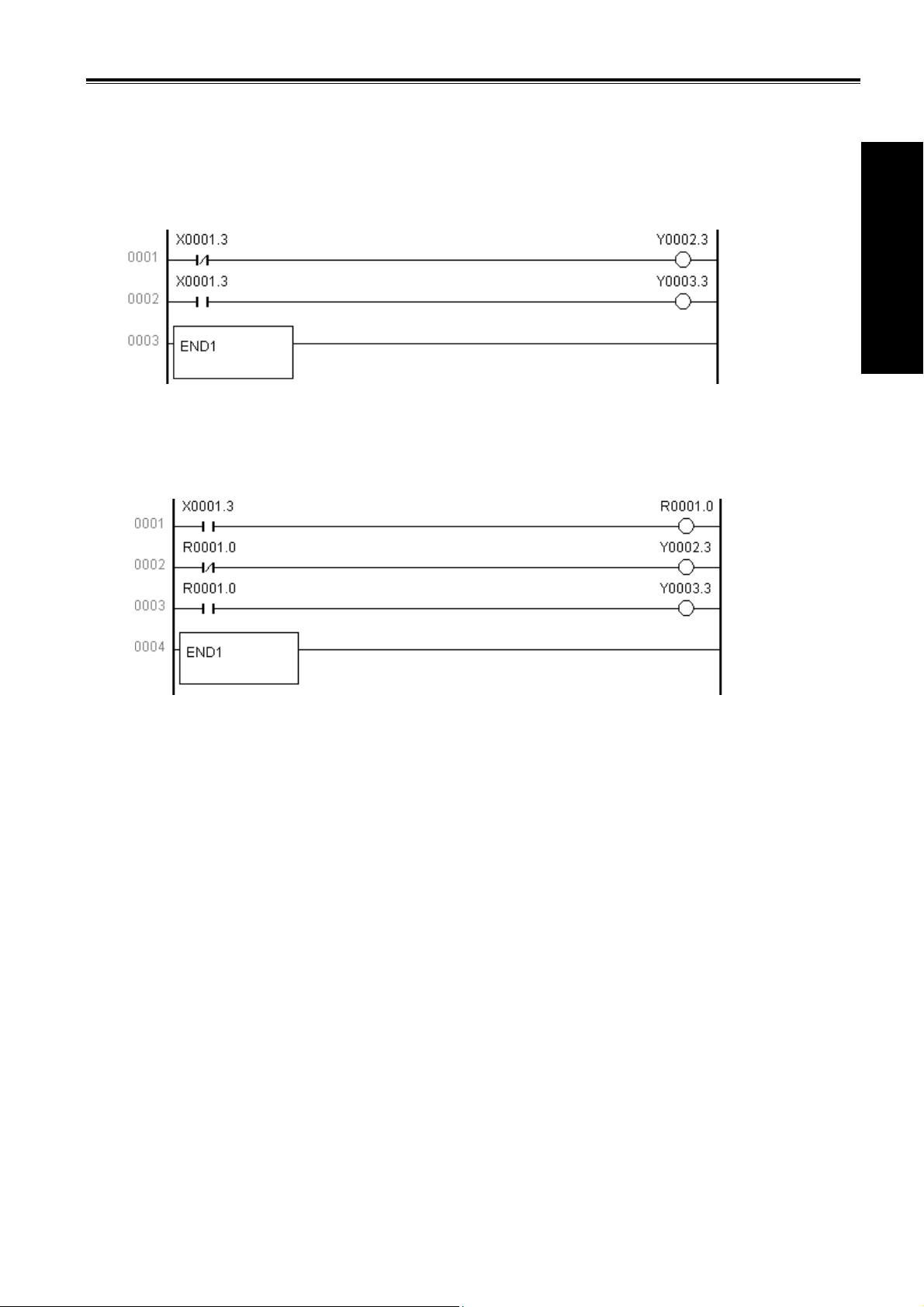

As above, X0001.3=0 is changed to X0001.3=1 after Y0002.3=1 is executed, and if the system executes the

next line of ladder and Y0003.3=1, at the moment Y0002.3=1 and Y0003.3=1. To avoid the above, process

synchronously the short pulse signal as follows:

Book 1 Pro

rammin

End of the first

grade program

After the program is executed synchronously and when X0001.3=1,Y0003.3=1,Y0002.3=0, X0001.3=0,

Y0002.3=1,and Y0003.3=0,but Y0003.3=1 or Y0002.3=1.

1.4.4 Interlock Signal

For safety, the signals must be employed with soft interlock in sequence control, and with hard interlock to relay

control circuit of power electric box at machine side at the same time. Because the hardware is failure, the

interlock is invalid in executing sequential program even if it is employed logically with soft interlock, which

can ensure the operator is not injured and the machine is prevented from damage.

1.5 EDITING SEQUENTIAL PROGRAM

Edit the sequential program from ladder which is composed of relay contacts, symbols and function instructions.

Logic relationship in ladder consists of sequential program which is edited by two methods: one is employed

with input to use program instructions and the other is with relay symbols by their corresponding contactor,

symbol and function instruction. Edit the sequential program employed with the ladder format instead of

mnemonic code language when the system is employed with the relay symbol.

In actual editing sequential program, use programming instruction or ladder to edit it according to PLC. In the

User Manual, the system is employed with ladder as follows:

Ⅰ-7

Page 16

1.5.1 Distributing Interface (Step 1)

g

g

GSK980TD Turning Machine CNC System

Book 1 Pr

The interfaces can be distributed after control target is defined and the corresponding input/output signal points

are counted. Refer to input/output interface signal list

o

1.5.2 Editing Ladder (Step 2)

rammin

Edit the software GSKCC.EXE by 980TD ladder to represent the required control operations of machine.

Counter, timer which are not done by relay symbol is represented by the specified function instructions. The

edited ladder is downloaded to CNC by serial.

1.5.3 Debugging Ladder (Step 3)

After the ladder is downloaded to 980TD, the ladder is debugged as follows:

A: emulator

Use one emulator instead of machine to debug it. Machine signal state is represented with switch ON/OFF,

and output signal state is done with indicat or ON/OFF. Observe if every indicator on the emulator is correct

when executing CNC.

B: CNC diagnosis

Observe if the diagnostic state of every signal is consistent with the function requirement when executing

CNC. Check the ladder by checking each function in order.

C: actual run

There may be an unexpected result in the actual debugging machine and so do preventive measures before

debugging.

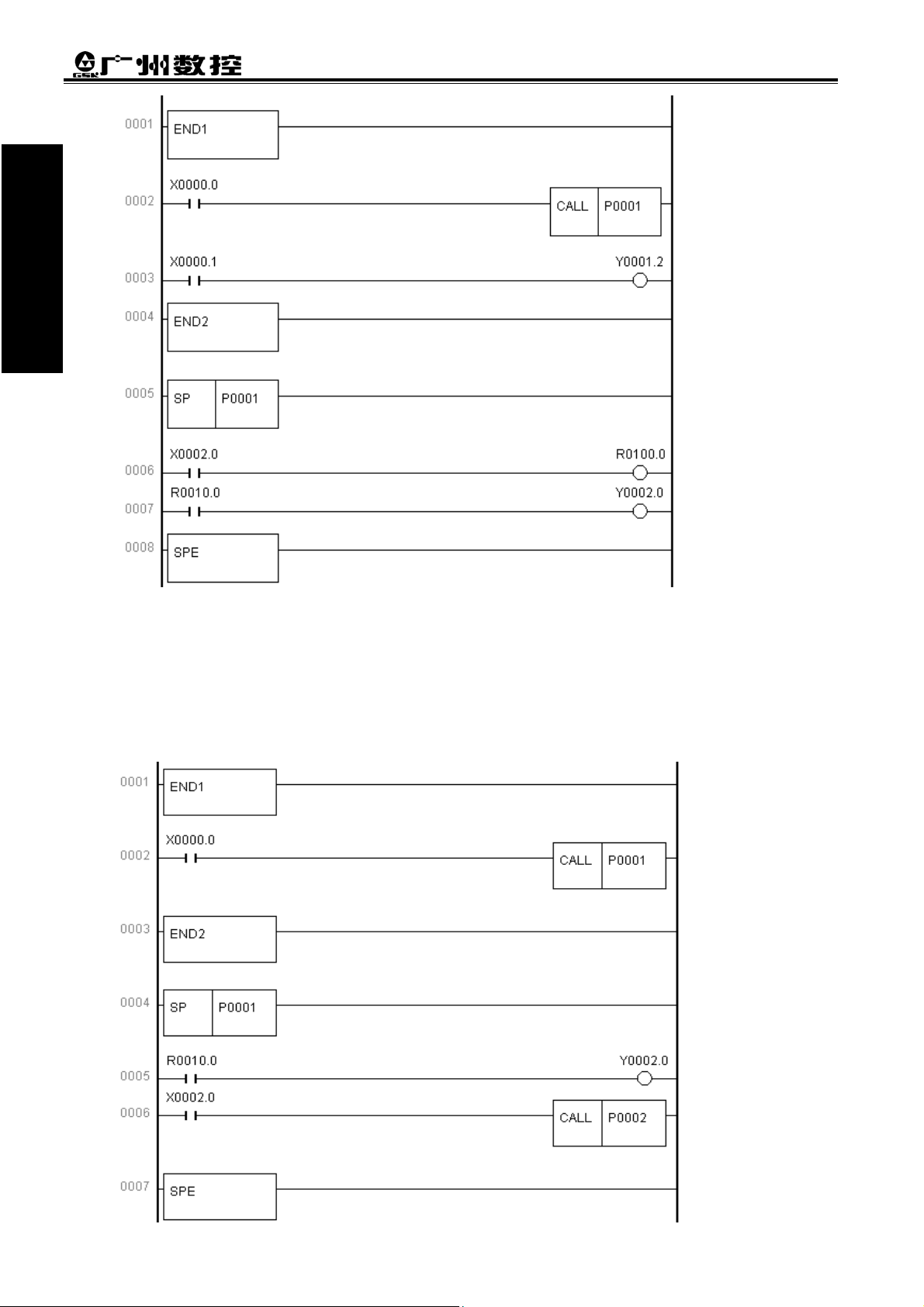

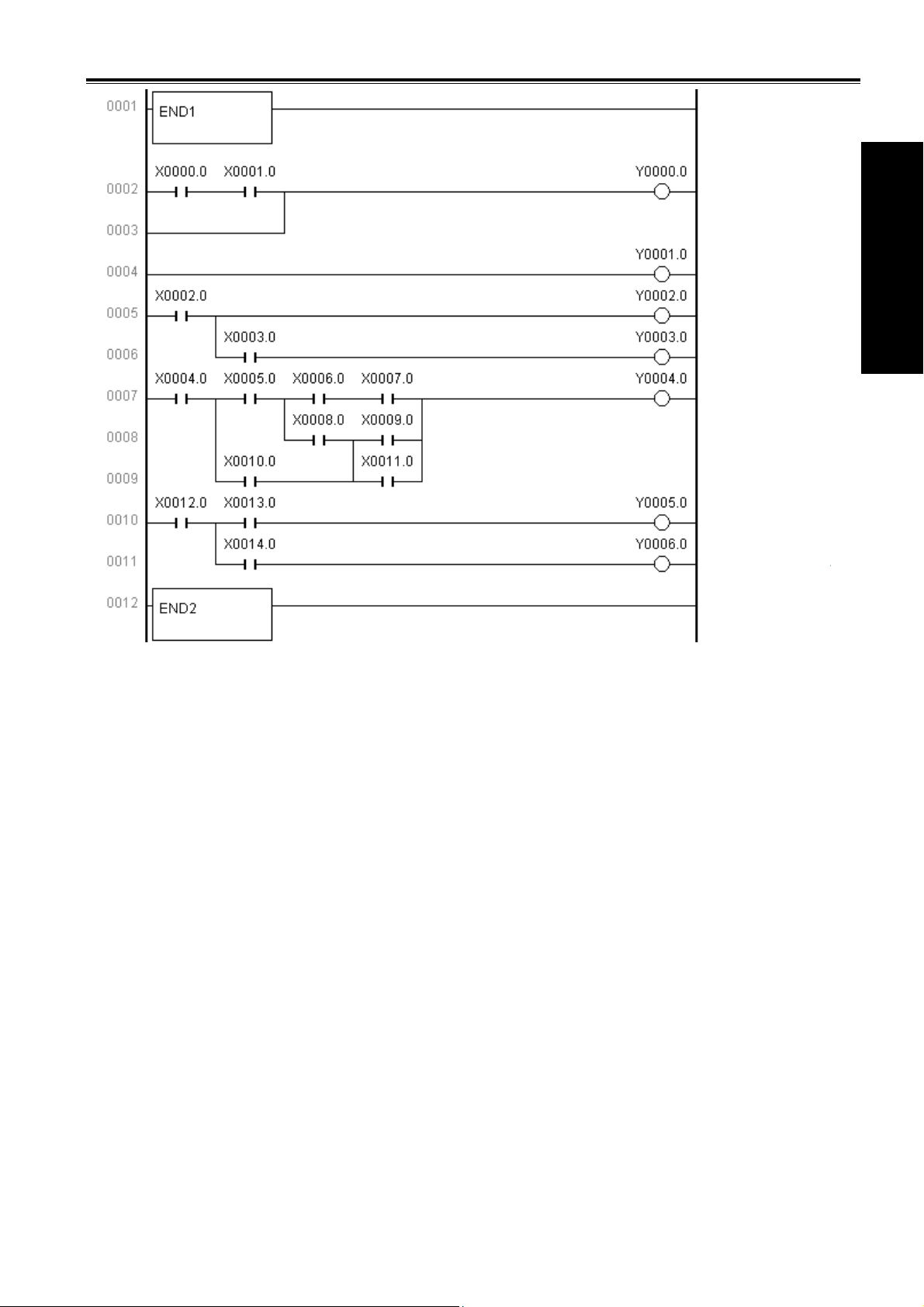

1.5.4 Program Editing Limit

In program, END1 and END2 are needed, which are taken separately as ending character of the first and the

second, and END1 must be before END2. The system only supports parallel output instead of multi grades

output and there are syntactic errors as follows:

Ⅰ-8

Page 17

Chapter 1 Sequential Program

p

g

g

End of grade one

rogram

Syntactic error:

0002~0003

Book 1 Pro

Syntactic error:

0004

Syntactic error:

0005~0006

Syntactic error:

0007~0009

Syntactic error:

0010~0011

rammin

Ⅰ-9

Page 18

Page 19

Chapter 2 Address

g

g

Chapter 2 ADDRESS

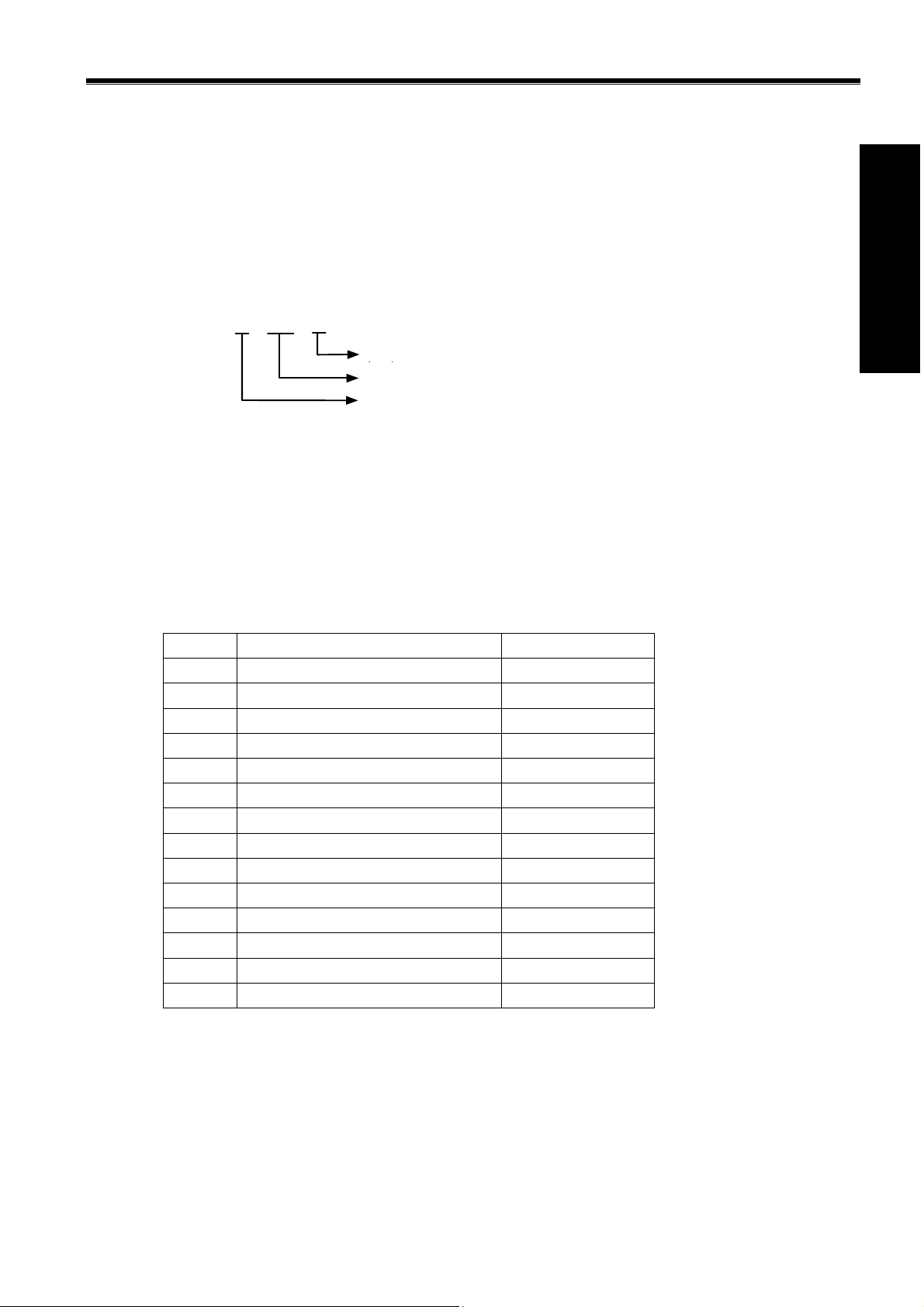

Addresses are used for distinguishing signals. Different addresses separately correspond to input/output signal

at machine side and CNC side, internal relay, counter, timer, holding relay and data list. An address number is

consisted of address type, address number and bit number as follows:

X 0001.6

Bit number

位号

地址号

Address number

地址类型

Address type

Address type: X, Y, R, F, G, K, A, T, DT, DC, C, D, L, P

Address number: decimal number to express one byte

Bit number: octal number, 0~7 separately expressing byte 0~7 bit of front address number

980TD PLC addresses are divided into fixed addresses and definable addresses. Signal definitions of the fixed

addresses cannot be changed and are defined by CNC; the definable addresses can be defined again by user

according to the actual requirements. Address types are as follows:

Address Explanation Range

X Machine→PLC X0000~X0029

Y PLC→machine Y0000~Y0019

F NC→PLC F0000~F0255

G PLC→NC G0000~G0255

R Intermediate relay R0000~R0999

D Data register D0000~D0999

C Counter C0000~C0099

T Timer T0000~T0099

DC Counter preset value register DC0000~DC0099

DT Timer preset value register DT0000~DT0099

A Information displaying request signal A0000~A0024

K Hold relay K0000~K0039

L Jump label L0000~L9999

P Subprogram label P0000~P9999

Note: address R900~R999, K30~39 are used for reserved area of CNC program instead of output relay.

Book 1 Pro

rammin

2.1 MACHINE→PLC ADDRESS(X)

980TD PLC X addresses are divided into two types,the first one is X0000.0~X0003.7,which are mainly

distributed to CNC XS40 and XS41 I/O interfaces, including fixed addresses and definable addresses,and the

second one is X0020.0~X0026.7,which are fixed addresses and mainly be distributed to input keys on operator

panel. Other addresses are reserved ones. The value range is 0 or 1.

Ⅱ-1

Page 20

g

g

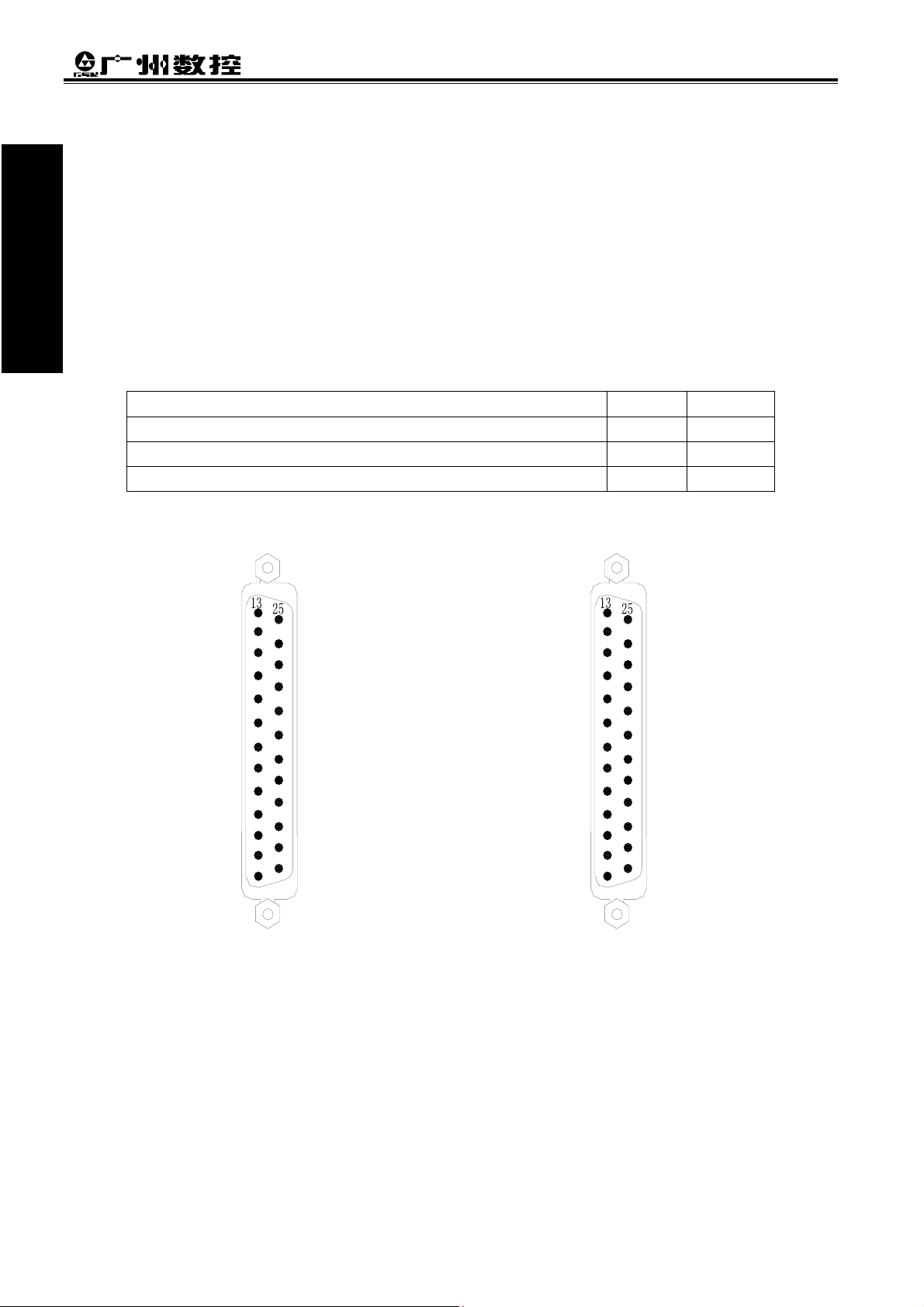

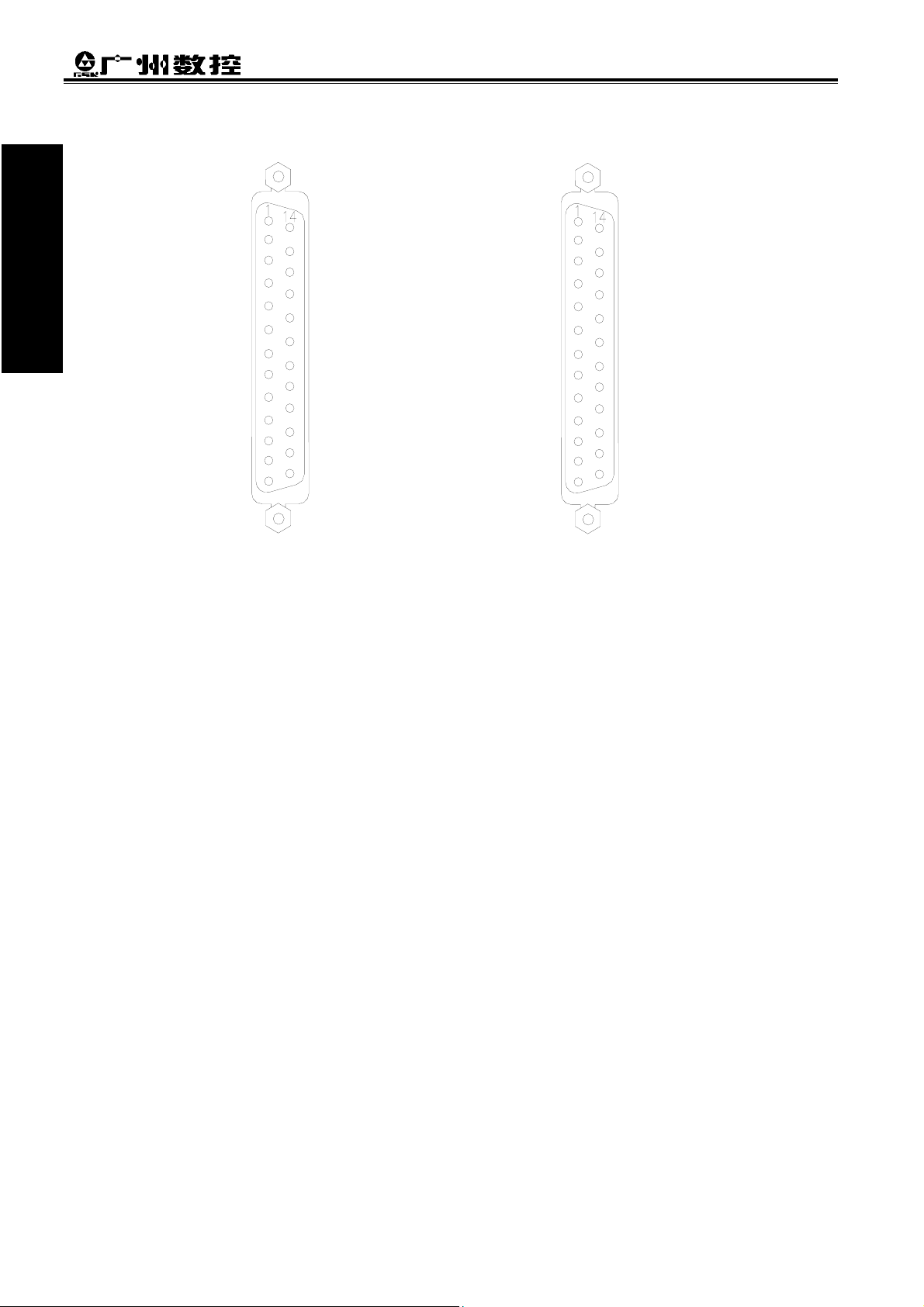

2.1.1 X Address in I/O Interface

GSK980TD Turning Machine CNC System

Book 1 Pro

rammin

13:Y0001.7

12:Y0001.6

11:+24V

10:X0000.5(ESP)

9: X0001.3(ZDEC)

8:X0001.1

7:X0001.4

6:X0001.6

5:X0001.7

4:X0000.0

3:X0000.1

2:X0000.2

1:X0000.3(XDEC)

z Address range: X0000.0~X0003.7 are separately distributed to CNC XS40 and XS41 I/O interface.

z Fixed address: X0000.3, X0000.5, X0001.3 separately corresponds to XDEC, ESP, ZDEC signal

Example: ESP signal is can be connected to X0000.5, CNC directly distinguishes signals on it and judge if there

Namely: CNC alarms to emergently stop when X0000.5 is 0;

CNC alarms to emergently stop when G8.4 is 0 by PLC control.

Emergent stop signal ESP X0000.5

Deceleration signal of machine reference point return in X direction XDEC X0000.3

Deceleration signal of machine reference point return in Z direction ZDEC X0001.3

z Definable address: their functions can be defined by user according to requirement and used for connecting

with external electric circuit and ladder. Distribution graph of X address in I/O interface is as follows:

which can be directly distinguished by CNC in CNC run.

is ESP signal; CNC alarms to emergently stop when G8.4 signal is valid by PLC control.

Input signal of fixed addresses

Signal Symbol Address

25:COM

24:COM

23:+24V

22:X0000.4

21:X0001.2

20:X0001.0

19:X0001.5

18:COM

17:COM

16:COM

15:COM

14:COM

13:X0002.1

12:X0002.2

11:+24V

10:X0002.3

9:X0002.5

8:X0003.1

7:X0003.3

6:X0003.6

5:X0003.5

4:X0003.7

3:X0003.0

2:X0002.7

1:X0002.0

25:COM

24:COM

23:+24V

22:X0002.4

21:X0002.6

20:X0003.2

19:X0003.4

18:COM

17:COM

16:COM

15:COM

14:COM

XS41(female) XS40(female)

2.1.2 X Address on Operator Panel

Address range: X0020.0~X0026.0 are fixed addresses which correspond to press keys on operator panel and

which signal definitions cannot be changed by user.

Ⅱ-2

Page 21

Chapter 2 Address

g

g

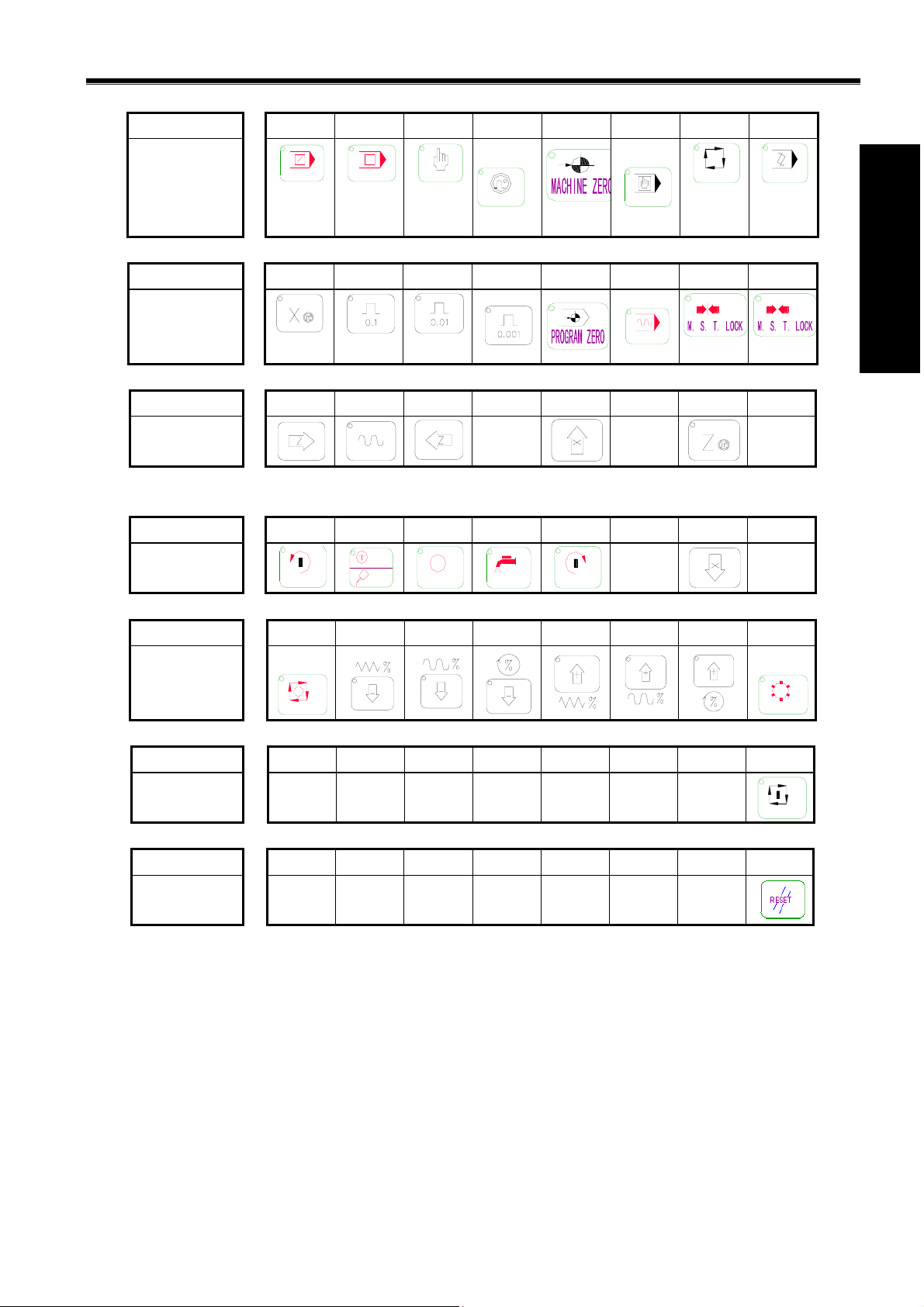

Relationship between addresses and press keys is as follows:

X0020 7 6 5 4 3 2 1 0

SKIP

Key

SINGLE

JOG

MPG

AUTO

MDI

Book 1 Pro

EDIT

X0021 7 6 5 4 3 2 1 0

MST MST

Key

DRY

X0022 7 6 5 4 3 2 1 0

Key

X0023 7 6 5 4 3 2 1 0

Key

CCW

JOG

LUR.

STOP

COOLANT

CW

X0024 7 6 5 4 3 2 1 0

Key

PAUSE

X0025 7 6 5 4 3 2 1 0

Key

rammin

TOOL

RUN

X0026 7 6 5 4 3 2 1 0

Key

2.2 PLC→MACHINE ADDRESS(Y)

980TD-PLC Y address are divided into tw o: Y0 00 0.0~Y0003.7 are mainly distributed to CNC XS42 and XS39

I/O interfaces, including fixed address and definable address; Y0004.0~X0009.7 which are mainly distributed

to indicators on the operator panel. Other addresses are reserved ones. Their values are 0 or 1.

2.2.1 Y Address in I/O Interface

Address range: Y0000.0~Y0003.7 are separately distributed to CNC XS42 and XS39 I/O interfaces and their

signal definitions can be defined by user according to requirements to connect to external

Ⅱ-3

Page 22

g

g

Distribution graph of 980TD output interfaces address is as follows:

Book 1 Pro

rammin

electric circuit and ladder.

1:Y0003.0

2:Y0002.7

3:Y0002.6

4:Y0002.2

5:Y0002.0

6:Y0002.1

7:Y0003.2

8:Y0003.3

9:Y0003.4

10:Y0003.5

11:Y0003.6

12:Y0003.7

13:+24V

14:Y0003.1

15:Y0002.5

16:Y0002.4

17:Y0002.3

18:COM

19:COM

20:COM

21:COM

22:COM

23:COM

24:COM

25:+24V

XS42(male)

GSK980TD Turning Machine CNC System

1:Y0000.0

2:Y0000.2

3:Y0000.4

4:Y0000.6

5:Y0001.0

6:Y0001.1

7:Y0001.2

8:Y0001.3

9:Y0001.4

10:Y0001.5

11:X0000.6

12:X0000.7

13:+24V

XS39(male)

14:Y0000.1

15:Y0000.3

16:Y0000.5

17:Y0000.7

18:COM

19:COM

20:COM

21:COM

22:COM

23:COM

24:COM

25:+24V

2.2.2 Y Addresses on Operator Panel

Address range: Y0004.0~Y0009.0 are fixed addresses which correspond to indicators on the operator panel,

and which signal definitions cannot be changed by user. Relationship corresponding to each state indicator is

referred to Appendix2: Output signal(Y).

2.3 PLC→NC ADDRESS(G)

Address range: G0000.0~G0255.7, value range: 0 or 1. Refer to Appendix3: G, F signals about definitions of

address signals.

2.4 NC→PLC ADDRESS(F)

Address range: F0000.0~F0255.7, value range: 0 or 1. Refer to Appendix3: G, F signal about definitions of

address signals.

2.5 INTERNAL RELAY ADDRESS

Address range: R0000.0~R0999.7, value range: 0 or 1. They are zero after CNC is switched on.

Ⅱ-4

Page 23

Chapter 2 Address

g

g

Address

number

R0000

R0001

R0899

R0900

R0999

7 6 5 4 3 2 1 0

Definable

addresses

NC

2.6 INFORMATION DISPLAYING REQUEST ADDRESS(A)

Address range: A0000.0~A00024.7 and they are zero after CNC is switched on.

Address

number

A0000

A0001

A0024

7 6 543210

Book 1 Pro

rammin

2.7 HOLD RELAY ADDRESS(K)

The address area is used for hold relay and setting PLC parameters and data are saved after the system is

switched off. Address range: K0000.0~K0039.7, value range: 0 or 1.

Address

number

K0000

K0001

K0029

K0030

K0039

7 6 5 4 3 2 1 0

Definable

addresses

NC

Ⅱ-5

Page 24

GSK980TD Turning Machine CNC System

g

g

2.8 COUNTER ADDRESS(C)

Book 1 Pro

The address area is used for storing current counting value of counter and data are saved after the system is

switched off. Address range: C0000~C0099, value range: 0~21,4748,3647.

rammin

Address

number

C0000

C0001

C0099

31 30 29 28

2.9 COUNTER PRESET VALUE ADDRESS(DC)

3 2 1 0

The address area is used for storing preset value of counter and data are saved after the system is switched off.

Address range: DC0000~DC0099, value range: 0~21,4748,3647.

Address

number

DC0000

DC0001

DC0099

31 30 29 28

3 2 1 0

2.10 TIMER ADDRESS(T)

The address area is used for storing current value of timer and T0000~T0079 are zero after the system is

switched on.T0080~T0099 are saved after it is switched off. Value range: 0~21,4748,3647.

Address

number

T0000

T0001

T0099

31 30 29 28

3 2 1 0

Ⅱ-6

Page 25

Chapter 2 Address

g

g

2.1 1 TIMER PRESET VALUE ADDRESS(DT)

The address area is used for storing preset value of timer and data are saved after the system is switched off.

Address range: DT0000~DT0099 and value range: 0~21,4748,3647.

Address

number

DT0000

DT0099

31 30 29 28

3 2 1 0

2.12 DATA LIST ADDRESS(D)

D0000~D0299 are zero when CNC is switched on. D0300~D0999 are saved after it is switched off. Value

range: 0~255.

Address

number

D0000

D0001

D0299

D0300

D0999

7 6 5 4 3 2 1 0

Book 1 Pro

rammin

2.13 LABEL ADDRESS(L)

It is used for specifying jump target label in JMPB and LBL label.

Range: L0~L9999

2.14 SUBPROGRAM NUMBER(P)

It is used for specifying the target subprogram number to call in CALL and subprogram number in SP.

Range: P0000~P9999

Ⅱ-7

Page 26

Page 27

Chapter 3 PLC Basic Instructions

g

g

Chapter 3 PLC BASIC INSTRUCTIONS

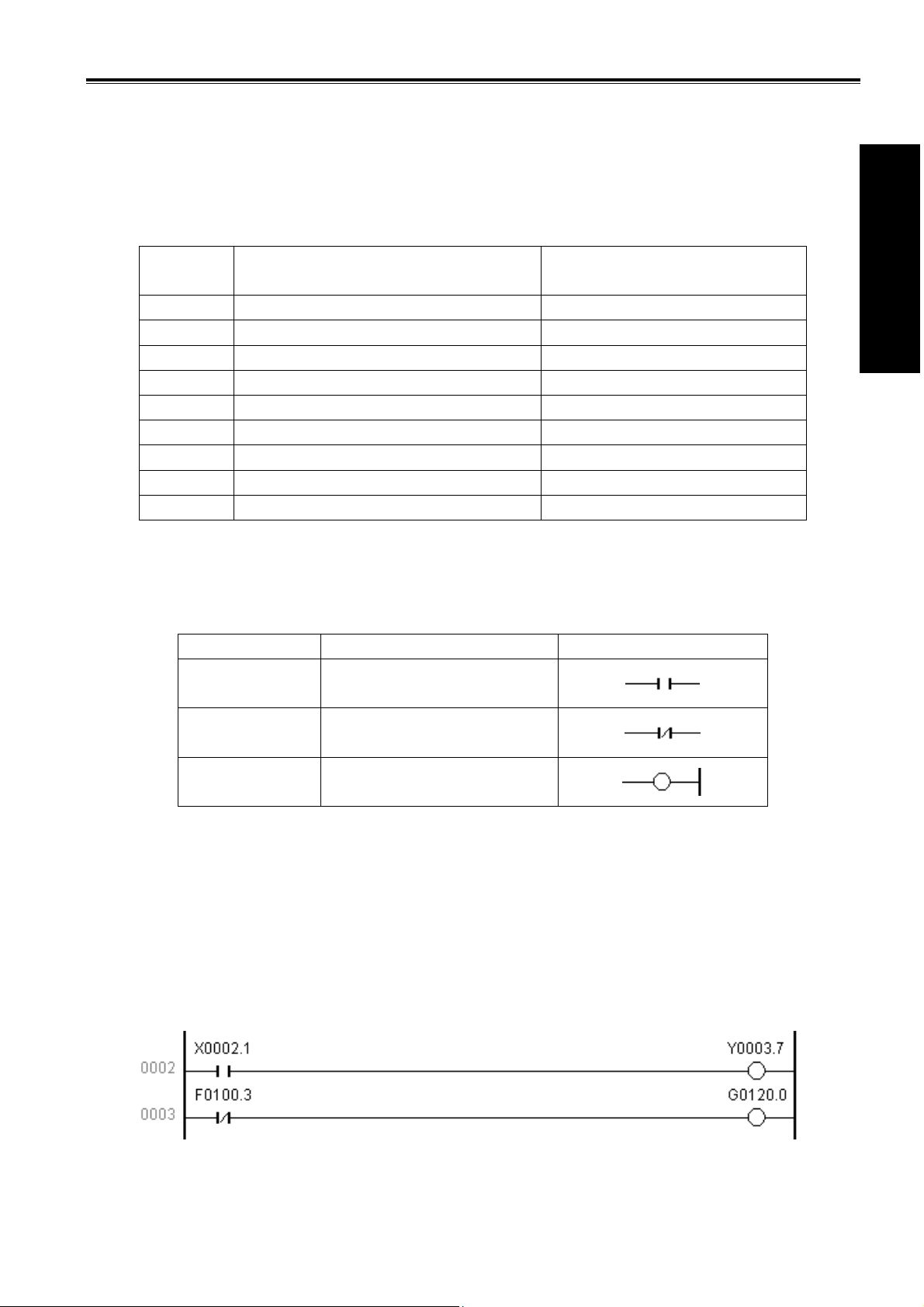

Basic instructions are used for editing sequential programs and executing 1-bit operation. There are basic instructions

for GSK980TD PLC as follows:

Instruction

name

LD Read normally-open contact X, Y, F, G, R, K, A

LDI Read normally-closed contact X, Y, F, G, R, K, A

OUT Output coil Y, G, R, K, A

AND Normally-open contact in series X, Y, F, G, R, K, A

ANI Normally-closed contact in series X, Y, F, G, R, K, A

OR Parallel normally-open contact X, Y, F, G, R, K, A

ORI Parallel normally-closed contact X, Y, F, G, R, K, A

ORB Parallel series circuit block

ANB Parallel circuit block in series

3.1 LD,LDI,OUT INSTRUCTION

Function Component

Book 1 Pro

rammin

● Mnemonic code and function

Mnemonic code Function Ladder symbol

LD Read normally-open contact

LDI Read normally-closed contact

OUT Output coil

● Instruction explanation

A: LD, LDI are used for connecting contact to bus bar. Each one can combine with instruction ANB and can be

used at starting point of branch.

B: OUT is used for driving output relay, internal relay coil instead of input relay.

C: Parallel instruction OUT can be continuously used.

● Programming example

Program explanation:

When X0002.1 is 1, the system outputs Y0003.7

When F0100.3 is 0, the system outputs G0120.0

Ⅲ-1

Page 28

3.2 AND, ANI INSTRUCTION

g

g

Bo

● Mnemonic code and function

ok 1 Pro

Mnemonic code Function Ladder symbol

GSK980TD Turning Machine CNC System

ram i

m

n

● Instruction explanation

AND, ANI can connect one contact in serial. There can be many contacts in serial and the instructions can be

used many times.

● Programming example

Program explanation:

Use X0002.1,

Use F0100.3 and X0002.1 in series

Use X0008.6, and F0100.3 and X0002.1 in series

If X0002.1=1, X0008.6=1 and F0100.3 is 0, the system outputs Y0003.7.

AND Normally-open contact in series

ANI Normally-closed contact in series

3.3 OR, ORI INSTRUCTION

● Mnemonic code and function

Mnemonic code Function Ladder symbol

OR Parallel normally-open contact

ORI Parallel normally-closed contact

● Instruction explanation

A: OR, ORI can be connected to one contact in parallel. When more than two contacts are connected in series

and the serial loop is connected with other loop in parallel, the system should use ORB.

B: The system executes OR, ORI from its current step with LD, LDI in parallel.

● Programming example

Ⅲ-2

Page 29

Chapter 3 PLC Basic Instructions

g

g

N

Program explanation: Program explanation:

Use X0002.1 Use X0002.1

Use F0100.3 and X0002.1 in series Use F0100.3 and X0002.1 in series

If X0002.1=1, and F0100.3 is 0, the system outputs Y0003.7. If X0002.1=1, and F0100.3 is 0, the system outputs Y0003.7.

Book 1 Pro

3.4 ORB INSTRUCTION 3.4 ORB INSTRUCTION

●Mnemonic code and function ●Mnemonic code and function

Mnemonic code Mnemonic code Function Function Ladder symbol Ladder symbol

ORB Parallel series circuit block

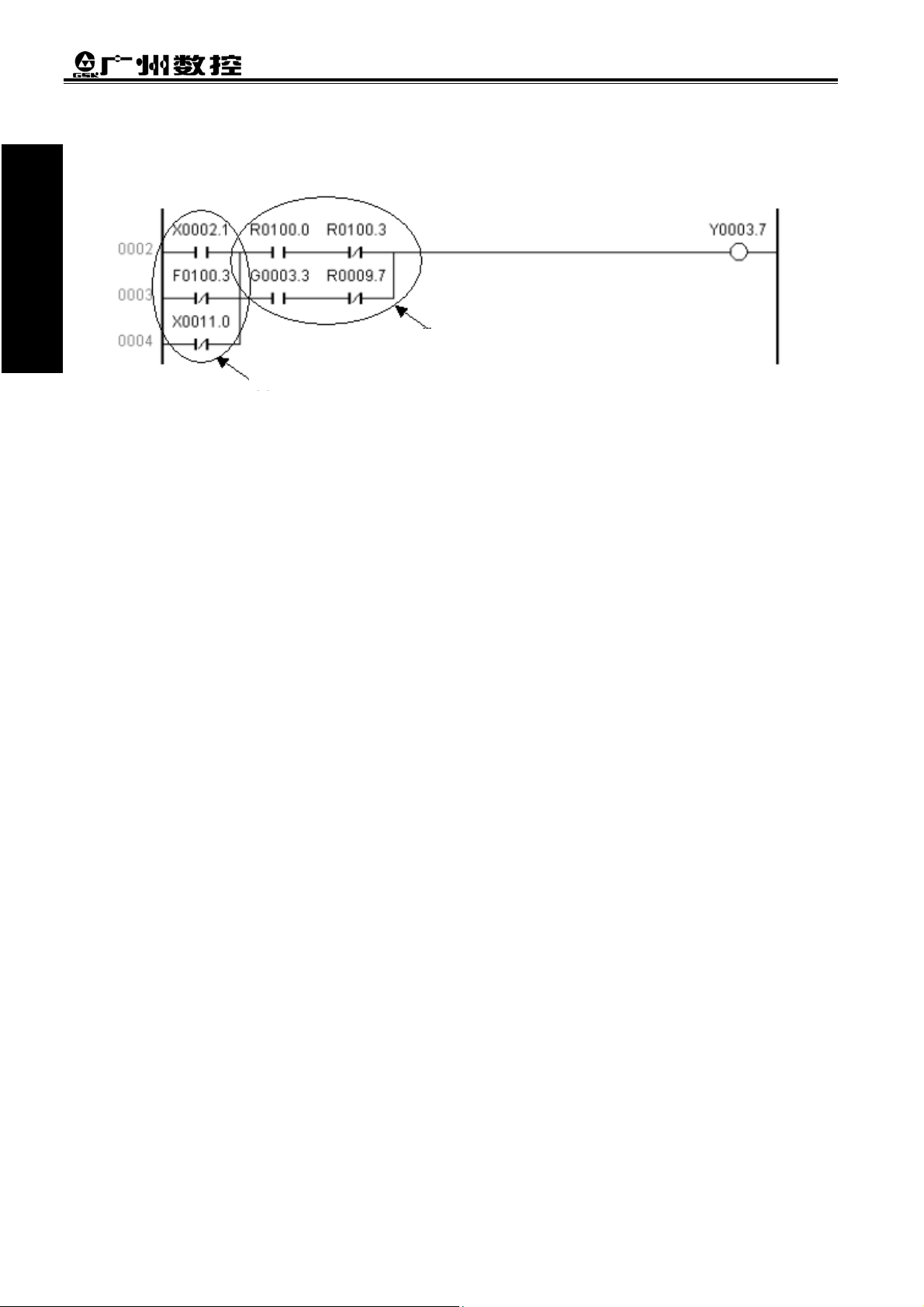

● Instruction explanation

A: Serial loop block is defined to its loop combined by more than contacts in series. When the serial loop is

connected in parallel, starting point of branch uses LD and its end point uses ORB.

B: ORB is sole instruction without address.

● Programming example

ode

rammin

Program explanation:

As above figure, there are three branches(0002,0003,0004) from left bus line to node, and 0002 and 0003 are

serial circuit blocks. There is parallel serial circuit block between bus line and node or among nodes, the

following ending of branch use ORB except for the first one. Use OR instruction if the branch 0004 is not serial

circuit block.

ORB and ANB are instructions without operation function, representing or, and relationship among circuit

blocks.

3.5 ANB INSTRUCTION

●Mnemonic code and function

Mnemonic code Function Ladder symbol

ANB Parallel circuit block in series

● Instruction explanation

A: Use ANB when the branch loop is serially connected with the previous loop. Use LD, LDI at the starting

Ⅲ-3

Page 30

point of branch, and use ANB to serially connect with the previous loop. point of branch, and use ANB to serially connect with the previous loop.

g

g

B: ANB is sole instruction without address. B: ANB is sole instruction without address.

Book 1 Pro

● Programming example ● Programming example

rammin

GSK980TD Turning Machine CNC System

Block 1

Program explanation:

As above ladder, ORB represents the parallel serial circuit block in block 2 and ANB represents block 1 and 2 in

series.

Block 2

Ⅲ-4

Page 31

Chapter 4 PLC Function Instructions

g

g

Chapter 4 PLC FUNCTION INSTRUCTIONS

Some functions are completed by function instructions instead of basic ones. The function instructions in the

system are as follows:

Instruction

name

END1 End of grade one program ROTB Binary rotation control

END2 End of grade two program DECB Binary decoding

SET Set CODB Binary code conversion

RST Reset JMPB Program jumping

CMP Comparative set LBL Program jumping label

CTRC Counter CALL Subprogram calling

TMRB Timer SP Start of subprogram

MOVN Binary Data copy SPE End of subprogram

PARI Parity check DIFU Ascending edge set

ADDB Binary data adding DIFD Descending edge set

SUBB Binary data subtracting MOVE And

ALT Alternative output

Function Instruction

name

Function

Book 1 Pro

rammin

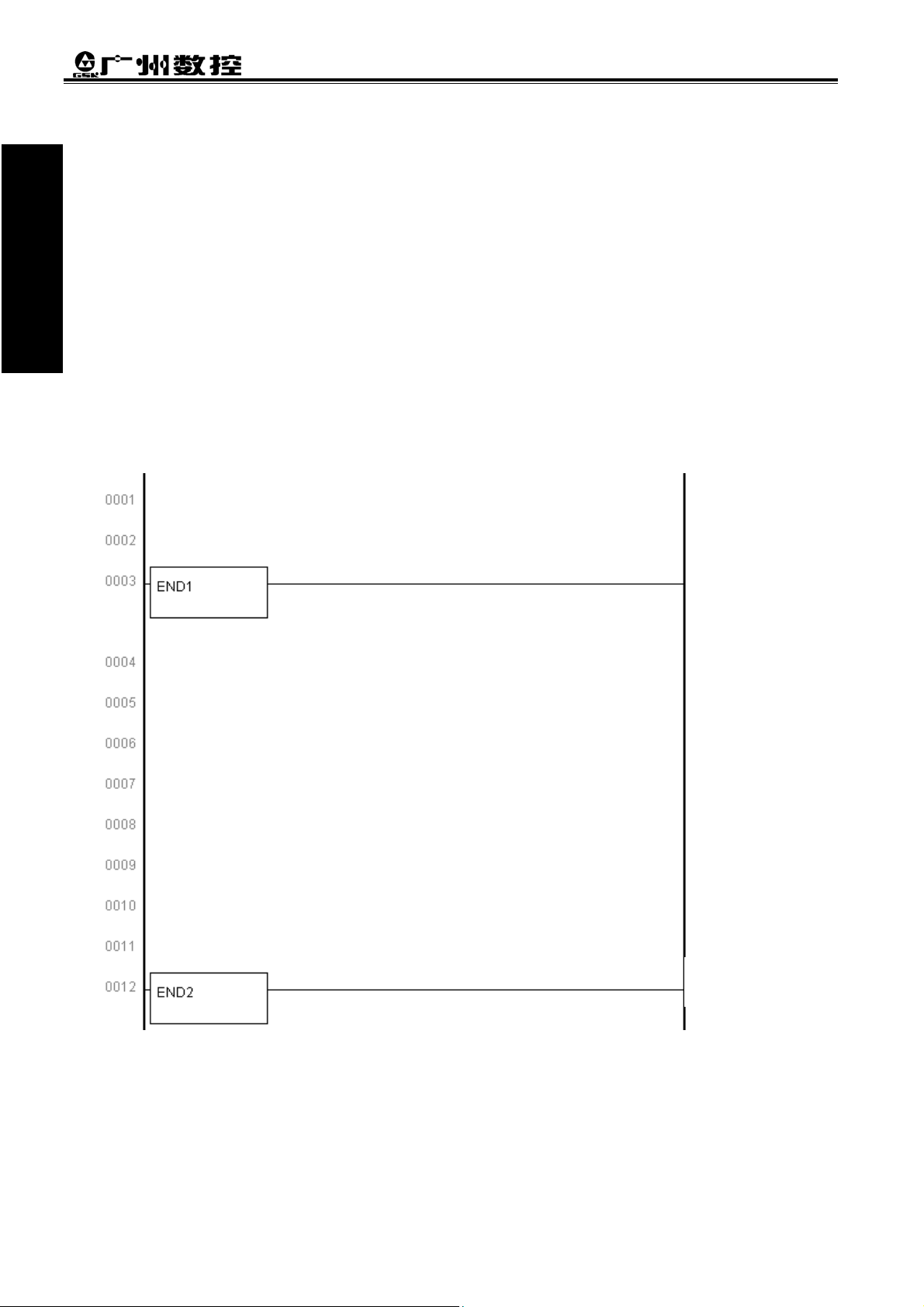

4.1 END1(END of GRADE ONE PROGRAM)

● Instruction function

There must be END1 in the sequential program one time, located at the end of grade one program. It should be

located at the home of the second when there is no grade one program.

● Ladder format

4.2 END2(END of GRADE TWO PROGRAM)

● Instruction function

There must be END2 at the end of grade two program which representing end of grade two program.

● Ladder format

Ⅳ-1

Page 32

4.3 SET

g

g

Bo

● Instruction function

ok Pro

1

Specified address is set to 1.

● Ladder format

ramm

GSK980TD Turning Machine CNC System

in

● Control condition

ACT =0:add.b is reserved.

=1:add.b is set to 1.

● Relative parameter

add.b:set address bit,which can be a contact or output coil, and add is Y, G, R, K or A.

● Program example:

Explanation: When X0002.1 is 1, R0002.0 is set to 1; when X0002.1 is 0, R0002.0 is reserved.

4.4 RST(RESET)

● Instruction function

Specified address is set to 0.

● Ladder format

● Control condition

ACT =0:add.b is reserved.

=1:add.b is set to 0.

● Relative parameter

add.b:reset address bit ,which can a contact or output coil ,and add is Y, G, R, K or A.

● Program example:

Explanation: When X0002.1 is 0, R0002.0 is reserved; when X0002.1 is 1, R0002.0 is set to 0.

Ⅳ-2

Page 33

Chapter 4 PLC Function Instructions

g

g

4.5 CMP(BINARY COMPARATIVE SET)

● Instruction function

Compare two binary data and output its result.

● Ladder format

● Control condition

ACT =0:add.b is reserved.

=1: compare S1, S2 and output the result as follows:

add.(b+2) add.(b+1) add.(b+0)

S1>S2 0 0 1

S1=S2 0 1 0

S1<S2 1 0 0

● Relative parameter

Length: specify data length, when it is set to 1, 2, 4, the corresponding data length is 1byte, 2bytes,4 bytes.

S1, S2: compare source data 1 with data 2, and the comparative result can be constant or address number(it is not

address bit. For example: add.b is illegal.). Address number is R, X, Y, F, G, K, A, D, T, C, DC and DT.

add.b:it is the comparative result and can be R, Y, G, K and A.

● Relative operation information register:

R900 overflow

● Program example:

Negative Zero

Book 1 Pro

rammin

Explanation: When X0002.1 is 0, the system does not compare the data and R0300.0 is reserved;

When X0002.1 is 1, the system compares the data as follows:

R0300.2 R0300.1 R0300.0

R0100>R0200 0 0 1

R0100=R0200 0 1 0

R0100<R0200 1 0 0

Ⅳ-3

Page 34

4.6 TMRB(TIMER) 4.6 TMRB(TIMER)

g

g

Book 1 Pro

●

Instruction function ● Instruction function

Delay connecting the timer. Delay connecting the timer.

●

Ladder format ● Ladder format

rammin

● Control condition

ACT =0:reset TIMER and add.b.

=1:TIMER times from 0, and add.b=1 when TIMER reaches the preset time.

Logic relation is as follows:

● Relative parameter

TIMER: timer number, range: T0000~T0099.

TIME: timing constant or data register with DT in front. DT range is from 0 21,4748,3647(ms) .

add.b:it is timer output address and can be R, Y, G, K and A.

TIMER is executed every 8ms and timing with 8ms as unit.

● Program example:

ACT

add.b

GSK980TD Turning Machine CNC System

TIME

Explanation: When X0002.1 is 0, T0002 and R0300.0 are 0;

When X0002.1 is 1, T0002 starts to count, and R0300.0 is set to 1 after it reaches the time set by

DT0004.

Ⅳ-4

Page 35

Chapter 4 PLC Function Instructions

g

g

m

4.7 CTRC(BINARY COUNTER) 4.7 CTRC(BINARY COUNTER)

● Instruction function ● Instruction function

Data in the counter is binary and the functions of CTRC is as follows: Data in the counter is binary and the functions of CTRC is as follows:

A: reset counter: it resets count value and the system outputs the corresponding signal when the count value

A: reset counter: it resets count value and the system outputs the corresponding signal when the count value

reaches the resetting count value.

reaches the resetting count value.

B: ring counter:input the count value signal when the counter reaches the reset value, and count again the

B: ring counter:input the count value signal when the counter reaches the reset value, and count again the

counter reset to initial value.

counter reset to initial value.

C: adding/subtracting counter: bit bidirectional counter used for addition and subtraction. C: adding/subtracting counter: bit bidirectional counter used for addition and subtraction.

D: initial value selection: it can be 0 or 1. D: initial value selection: it can be 0 or 1.

● Ladder format ● Ladder format

Book 1 Pro

rammin

● Control condition

ACT is at ascending edge:

Adding: COUNTER counts from its setting initial value, adds the count one time when it reaches the

ascending edge, and O_add.b =1 when it reaches the reset count value. O_add.b =0 when

COUNTER is less than NCOUNT; COUNTER resumes and starts to count and O_add.b =0 when

it reaches the ascending edge again.

Subtracting: COUNTER subtracts from its setting initial value, subtracts the count one time when it

reaches the ascending edge, and O_add.b =1 when it reaches the reset count value. O_add.b

=0 when COUNTER is more than NCOUNT; COUNTER resumes and starts to count and

O_add.b =0 when it reaches the ascending edge again.

ACT=0:

COUNTER and O_add.b are reserved.

● Relative parameter

Data format:

R_add.b :when it is 1 whatever ACT is , COUNTER=CN0,O_add.b =0. R_add can be X, Y, G, F, R, K, A.

COUNTER: specify the counter number( Cxxx, xxxx is digit(0~99),

0 0 CN0 U/D

Specify adding/subtracting count

0:adding count and counting from 0

1:subtracting count and counting fro

reset value

Specify the counter initial value

0:count from 0

1:count from 1

Ⅳ-5

Page 36

NCOUNT: it is counter preset value(constant) and also can be data register beginning with DC. If it is constant,

g

g

Book Pro

1

O_add.b: when it reaches to the count value, the output is 1 and O_add can be R, Y, G, K and A.

● Program example:

rammin

Explanation: When R0100.0 is 1, C0001=0 and R0500.0=0;

When R0100.0 is 0, X0002.1 reaches the drift up one time, C0001 adds the count one time, and

When X0002.1 reaches the drift up again, C0001 is reset to 0 and start to count, and R0500.0 is

GSK980TD Turning Machine CNC System

its value is 0~21,4748,3647.

R0500.0 is 1 if the count reaches 10.

reset to 0.

4.8 MOVN(BINARY DATA COPY)

● Instruction function

Transmit data at source address or specified binary data to destination address.

● Ladder format

● Control condition

ACT =0:ADD-D is reserved.

=1:copy the value in ADD-S or constant CON to ADD-D

● Relative parameter

Length : it is the copy data(1, 2, 4 byte).

ADD-S/CON: it is initial byte of source data address or constant, and its address number is R, X, Y, F, G, K, A,

D, T, C, DC and DT.

ADD-D: it is initial byte of target address, and its address number is R, Y, G, K, A, D, T, C, DC, DT.

● Program example:

Explanation:R0100 value is transmitted to G0043 when X0003.3 is 1.

Ⅳ-6

Page 37

Chapter 4 PLC Function Instructions

g

g

4.9 DECB(BINARY ENCODING)

● Instruction function

DECB can decode the binary code data. When there is the same one between one of 8 successive data and the

code data, the corresponding output data is 1; when there is no the same one, the output data is 0. DECB is used

for encoding data of M or T function.

● Ladder format

● Control condition

ACT =0:reset the 8 data bits of ADD2. ADD2.

=1:compare the content value of decoding address(ADD1) with 8 successive data beginning with DATA.

When the value of ADD1 is equal to one of 8 data and the output address (ADD2)

bit which sequence number is that of equal data in these 8 data is set to 1.

● Relative parameter

Length:specify the length(1, 2, 4) of ADD1.

ADD1: it is initial address of encoding and the address number is R, X, Y, F, G, K, A, D, T, C, DC and DT.

.

DATA: reference value of comparative constant.

ADD2: output comparative result. Its address number is R, Y, G, K and A.

● Program example:

‘

s corresponding

Book 1 Pro

rammin

X0003.3=1:

When F0010=8,R0010.0=1;

When F0010=9,R0010.1=1;

…………………………

When F0010=15,R0010.7=1

4.10 CODB(BINARY CODE CONVERSION)

● Instruction function

The instruction is used for binary code conversion.

● Ladder format

Ⅳ-7

Page 38

Book 1 Pro

g

g

● Control condition

ACT =0:ADD2 is reserved.

rammin

● Relative parameter

● Program example:

=1:value of conversing input data addre ss(ADD 1) is taken as list number of conversion list, from which

Converting input data

Address ADD1

Length1: binary data length and output address length of conversion data in conversion list, 1-1, 2-2, 4-4 byte.

Length2:conversion length, 1-2, 2-4, 3-8, 4-16, 5-32, 6-64, 7-128, 8-256.

ADD1:input address of conversion data. Its address has data with only one byte. Its address is R, X, Y, G, F,A,

K, and D.

ADD2:output address of conversion data and its address is R, Y, G, K and D.

GSK980TD Turning Machine CNC System

the conversion data corresponding to the list number is transmitted to output address(ADD2) of

conversion data.

Conversion data list

Converting input data

Number Value

……..

……….

Address ADD2

D2

Example

X0003.3=1:

X0003.3=1, R0100=0:R0200=1

X0003.3=1, R0100=1:R0200=2

X0003.3=1, R0100=2:R0200=3

X0003.3=1, R0100=3:R0200=4

Conversion data list

Number

Value

4 003

Ⅳ-8

Page 39

Chapter 4 PLC Function Instructions

g

g

4.11 JMPB(PROGRAM JUMPING)

● Instruction function

Immediately jump the program to the position set by label with characteristics as follows: jump instructions can

use the same label; forbid jumping END1 and END2; forbid jumping subprogram; jump forward or backward.

● Ladder format

Book 1 Pro

rammin

● Control condition

ACT =0:do not jump and execute the next instruction following JMPB.

=1:execute the next instruction following the label after jumping to the specified label.

● Relative parameter

Lx :specify the jumping target label, label number must be specified with beginning L address t and it can

specify one of L1 to L999.

● Program example:

Explanation: When X0003.3 is 1, the program jumps 0003 and orderly executes from 0004; when X0003.3 is 0, the

system orderly executes the program from 0003.

4.12 LBL(PROGRAM JUMPING LABEL)

● Instruction function

Specify one label in ladder, namely jumping target position specified by JMPB. One Lx is only specified one

time by LBL.

● Ladder format

Ⅳ-9

Page 40

● Relative parameter

g

g

Book 1 P

Lx :specify jumping target label. The label number is specified with beginning L address t and it can specify

one of L1 to L999.

ro

4.13 CALL(SUBPROGRAM CALLING)

ra minm

● Instruction function

Call the specified subprogram with characteristics as follows: call instructions can use the same subprogram;

call instruction can be embedded; cannot call a subprogram in grade one program; a subprogram is edited

following END2.

● Ladder format

● Control condition

ACT =0:execute the next instruction following CALL.

=1:call subprogram which number is specified.

● Relative parameter

Px :specify the called subprogram label, its label number is specified with beginning P address and it can

specify one of from P1 to P999.

GSK980TD Turning Machine CNC System

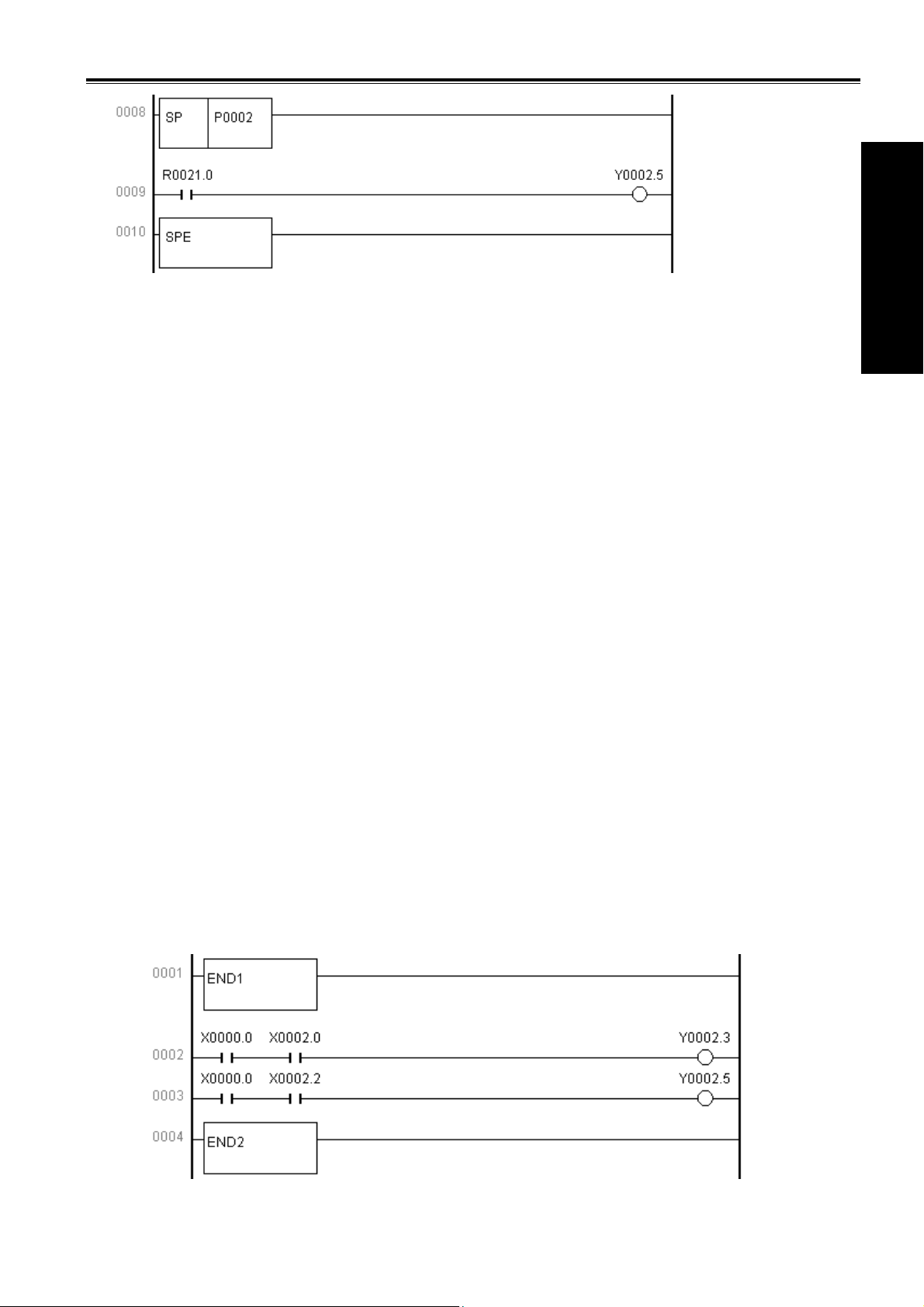

4.14 SP(START of SUBPROGRAM), SPE(END of SUBPROGRAM)

● Instruction function

SP is to create a subprogram which number is used for subprogram name ,and SPE is taken as end symbol of

program ,when SPE is executed, the main program will be returned to. SP and SPE are together used for

specifying the subprogram range ,and the subprogram must be edited following END2.

● Ladder format

● Relative parameter

Px :specify the call subprogram label, its label number is specified with beginning P address and it can specify

one of P1 to P999.

Ⅳ-10

Page 41

● Program example:

g

g

Chapter 4 PLC Function Instructions

Book 1 Pro

rammin

Explanation: When X0003.3 is 1, the program calls P0000 subprogram and jumps to execute 0006, and the

system orderly executes the program from 0003 after executing 0009.

When X0003.3 is 0, the system does not call P0000 subprogram and orderly executes

subprograms from 0003.

4.15 ROTB(BINARY ROTATION CONTROL)

● Instruction function

The instruction is used for rotation control, such as toolpost, rotary worktable. Its functions are as follows: to

select rotation direction of short path ,to count steps from current position to target position ;or to count steps

from the previous one of current position to the previous one of target position ,to count the position number of

the previous one of target position.

● Ladder format

Ⅳ-11

Page 42

GSK980TD Turning Machine CNC System

g

g

p

N

● Control condition ● Control condition

ACT =0:do not execute instructions, and E_add and O_add.b are reserved. ACT =0:do not execute instructions, and E_add and O_add.b are reserved.

Book 1 Pro

● Relative parameter ● Relative parameter

Format: Format:

rammin

CNT :centigrade position number of swivel table. CNT :centigrade position number of swivel table.

length :specify the length of W_add ,D_add and E_add(1, 2, 4 byte). length :specify the length of W_add ,D_add and E_add(1, 2, 4 byte).

W_add :it is current position address used for storing current position number. Its address W_add :it is current position address used for storing current position number. Its address

D_add :it is target position address used for storing target position number. Its address number is R, X, Y, F, G,

D_add :it is target position address used for storing target position number. Its address number is R, X, Y, F, G,

E_add :it is used for counting the result output address. Its address number is R, Y, G, K, A, D, DC and DT. E_add :it is used for counting the result output address. Its address number is R, Y, G, K, A, D, DC and DT.

O_add.b :it is used for outputting the rotary direction to ensure adding position number of swivel table is

O_add.b :it is used for outputting the rotary direction to ensure adding position number of swivel table is

● Program example: ● Program example:

Example: The current position corresponds to No. 1 tool selection when the toolpost is rotating. Example: The current position corresponds to No. 1 tool selection when the toolpost is rotating.

=1:execute instruction and output its result to E_add and O_add.b. =1:execute instruction and output its result to E_add and O_add.b.

Count position number or steps

0:Count position number

1:Count ste

number is R, X, Y, F, G , K, A, D, DC and DT. number is R, X, Y, F, G , K, A, D, DC and DT.

K, A, D, DC and DT.

K, A, D, DC and DT.

positive(FOR); if it is subtracting, its direction is negative(rev). When O_add.b=0, the rotary

positive(FOR); if it is subtracting, its direction is negative(rev). When O_add.b=0, the rotary

direction is positive; O_add.b=1, it is negative. Its address number is R, Y, G, K and A.

direction is positive; O_add.b=1, it is negative. Its address number is R, Y, G, K and A.

Current position

1

2

Position D

Position C

3

egative

4

5

6

7

Count position Count position

0:Count target position 0:Count target position

1:Count the position before target 1:Count the position before target

Short circuit selection

0:No selection. Positive rotation,i.e. O_add.b=0

1:Selection. Its direction is defined by specifics

Specify the initial number of swivel table

0:Position number of swivel table is from 0

1:Position number of swivel table is from 1

12

Positive

9

8

Position B

11

10

s

Position A

Ⅳ-12

Page 43

Chapter 4 PLC Function Instructions

g

g

Count the previous position number before target position when the toolpost rotates in short circuit. When the

current position number R0007=1 and centigrade position number of swivel table CNT=12, X0003.3=1:

When F0026=10 and the target position is A, R0027=11,R0037.0=1

When F0026=8 and the target position is B,R0027=9 ,R0037.0=1

When F0026=5 and the target position is C,R0027=4 ,R0037.0=0

When F0026=3 and the target position is D,R0027=2 ,R0037.0=0

4.16 PARI(PARITY CHECK)

Book 1 Pro

rammin

● Instruction function

Check parity of input data ,which is 1 byte(8 bits)

● Ladder format

● Control condition

ACT=1: Execute the parity check for input data. If the input data is inconsistent with the one specified by O_E,

Addr_Err.b is 1; otherwise, Addr_Err.b is 0

ACT=0: Do not execute instructions and Addr_Err.b is reserved.

● Relative parameter

O_E =0:number of “1” in put data is even

=1:number of “1” in put data is old number

Addr_Rst.b:when it is 1, Addr_Err.b is reset to 0 and its address is X, Y, G, R, F, A, K and K. 为 1 时,

Addr_Err.b .

Addr_In :it is the input data address and its address is X, Y, G, R, F, A, K and D.

Addr_Err.b :it is the output address of check result and its address is Y, G, R, A and K.

● Program example:

Ⅳ-13

Page 44

Book 1 Pro

g

g

Explanation: When X0003.3 is 1, the system executes PARI instruction, O_E=0000 to execute the even check.

When R0010.0 is 1, R0030.0 is reset to 0 and the system does not execute the check. When

rammin

R0010.0 is 0, it does. When there is an even number for “1”in R0020, R0030.0 is 0. When there is

an odd number for “1”in R0020, R0030.0 is 1.

4.17 ADDB(BINARY DATA ADDING)

● Instruction function

Add binary data

● Ladder format

GSK980TD Turning Machine CNC System

● Control condition

ACT=1: the system executes Addr_Out=AGD1+AGD2. If the operation is mistake, Addr_Err.b is 1; otherwise,

it is 0.

ACT=0: the system does not execute instruction, Addr_Out and Addr_Err.b are reserved.

● Relative parameter

Length :1-1,2-2,4-4 byte.

AGD1 :it is a summand and can be constant or address. Its address number is R, X, Y, F, G, A, K, D, T, C, DC

and DT.

AGD2 :it is addend and can be constant or address. Its address number is R, X, Y, F, G, A, K, D, T, C, DC and

DT.

Addr_Rst.b:when it is 1, Addr_Err.b is reset to 0 and Addr_Out is reserved. Its address number is R, X, Y, F, G,

A and K.

Addr_Out :it is the output data address of run result. Its address is Y, G, R, A, K, DC, DT, D, C, and T.

Addr_Err.b:it is the output address of mistake operation result and its address is Y, G, R, A and K.

● Relative operation information register

R900 overflow negative zero

● Program example:

Ⅳ-14

Page 45

Chapter 4 PLC Function Instructions

g

g

Explanation: When X0003.3=1, the system executes ADDB instruction. When R0040=R0010+R0020 and if the

operation is mistake, R0050.0 is 1, otherwise it is 0. When R0030.0 is 1, R0040 is reserved and R0050.0 is reset to 0.

4.18 SUBB(BINARY DATA SUBTRACTING)

● Instruction function

Subtract the binary data.

● Ladder format

Book 1 Pro

rammin

● Control condition

ACT=1: the system executes Addr_Out= MIND-SUBD. If the operation is mistake, Addr_Err.b is 1; otherwise,

it is 0.

ACT=0: the system does not execute instruction, and Addr_Out and Addr_Err.b are reserved.

● Relative parameter

Length :1-1,2-2,4-4 byte.

MIND :it is minend and can be constant or address. Its address number is R, X, Y, F, G, A, K, D, T, C, DC and

DT.

SUBD :it is subtrahend and can be constant or address. Its address number is R, X, Y, F, G, A, K, D, T, C, DC

and DT.

Addr_Rst.b:when it is 1, Addr_Err.b is reset. Its address number is R, X, Y, F, G, A and K.

Addr_Out:it is the output data address of run result. Its address is Y, G, R, A, K, DC, DT, D, C, and T.

Addr_Err.b:it is the output address of mistake operation result and its address is Y, G, R, A and K.

● Relative operation information register

R900 Overflow negative Zero

Note: the reset has no related to R900.

● Program example:

Ⅳ-15

Page 46

GSK980TD Turning Machine CNC System

g

g

Book 1 Pro

rammin

Explanation: When X0003.3=1, the system executes SUBB instruction. When R0040=R0010-R0020 , and if the

operation is mistake, R0050.0 is 0, otherwise it is 1. When R0030.0 is 1, R0040 is reserved and

R0050.0 is reset to 0.

4.19 DIFU(ASCENDING EDGE SET)

● Instruction function Set the output signal to 1 when the ascending edge of input signal is valid.

● Ladder format

● Control condition

Input signal ACT: the output signal is set to 1 at the ascending edge of ACT(0->1).

Output signal Add.b: when it is executed, one scanning period of Add.b in ladder is 1.

● Relative parameter

add.b :it is the operation result output address and its address is Y, G, R, A and K.

● Program example

Explanation: R0040.0 output is 1 when X0003.3 reaches the ascending edge.

4.20 DIFD(DESCENDING EDGE SET)

● Instruction function

Set the output signal to 1 when drift down of input signal is valid.

● Ladder format

● Control condition

Input signal ACT: the output signal is set to 1 at the descending edge of ACT(1->0).

Ⅳ-16

Page 47

Chapter 4 PLC Function Instructions

g

g

Output signal Add.b: when it is executed, one scanning period of Add.b in ladder is 1.

● Relative parameter

Add.b :it is the operation result output address and its address is Y, G, R, A and K.

● Program example:

Book 1 Pro

rammin

Explanation: R0040.0 output is 1 when X0003.3 reaches the descending edge.

4.21 MOVE(AND)

● Instruction function

Logic multiply and input data execute logic and operation, and then the system output the result to the specified

address.

● Ladder format

● Control condition

ACT=1: Logic multiply (HIGH4、LOW4)and input data(Addr_In)execute logical operation, and output the

result to the specified address (Addr_Out), which can remove the needless number of bit from 8-bit

signal of the specified address.

ACT=0: Addr_Out is reserved.

● Relative parameter

HIGH4 :high 4-bit logic multiply

LOW4 :low 4-bit logic multiply

Addr_In :input data address. Its address number is R, A, K, X, Y, F, G, and D.

Addr_Out:output data address. Its address number is R, A, K, X, Y, F, G, and D.

● Program example:

Explanation: When X0003.3 is 1, logically execute R0010 and 01001110 to save its result to R0020.

Ⅳ-17

Page 48

4.22 AL T(ALTERNATIVE OUTPUT)

g

g

Bo

● Instruction function

ok 1 oPr

It is alternative output instruction. The output signal outputs reversely when the ascending edge of input signal

changes(0->1).

● Ladder format

rammin

GSK980TD Turning Machine CNC System

● Control condition

The output signal Add.b outputs reversely when the input signal ACT changes 0->1 every time.

● Relative parameter

Add.b:it is the output signal and its address is Y, G, R, A and K.

● Program example:

Explanation: R0033.0 oversets one time when X0003.3 reaches the ascending edge every time.

Ⅳ-18

Page 49

BOOK 2

FUNCTION

Book2 Function

Page 50

Page 51

Chapter 1 Axes Control Signal

Chapter 1 AXES CONTROL SIGNAL

GSK980TD defines 4 axes: Axis 1, 2, 3 and 4. The detailed functions of each axis vary from one software version to

another. Now only Axis 1 and 2 are controllable, i.e. Axis X and Z.

1.1 AXIS MOVING STATUS

NC can transmit current axis moving status to PLC, and then PLC works according to the status of axis moving.

1.1.1 Feed Axis and Direction Selection Signal

+J1~+J4(G100.0~G100.3)

-J1~-J4(G102.0~G102.3)

● Signal type: PLC→NC

● Signal functions: For detailed functions, please refer to section 3.1.1.

1.1.2 Axis Moving Signal

MV1~MV4(F102.0~F102.3)

● Signal type: NC→PLC

● Signal functions: MV1, MV2, MV3, MV4 are moving signals for Axis 1, 2, 3, 4 respectively. When an axis is

moving, NC sets corresponding axis moving signal to 1. When an axis stops moving, the axis moving

signal is 0.

● Signal addresses:

F102 MV4 MV3 MV2 MV1

1.1.3 Axis Moving Direction Signal

Book 2 Function

MVD1~MVD4(F106.0~F106.3)

● Signal type: NC→PLC

● Signal functions: MVD1, MVD2, MVD3, MVD4 are axis moving direction signals for Axis 1, 2, 3, 4 respectively.

When an axis is moving backwards, NC sets the axis moving direction signal to 1; when an axis is

moving forward, the axis moving direction signal is 0; If an axis stops moving, the direction signal

will be 1 or 0 depending on the moving status before the axis stopping.

● Signal addresses:

F106 MVD4 MVD3 MVD2 MVD1

1.2 SERVO READY SIGNAL

SA(F000.6)

● Signal type:NC→PLC

Ⅰ-1

Page 52

GSK980TD Turning Machine CNC

● Signal functions: When CNC gives out a warning, NC sets SA signal to 0 to stop axis moving. When the warning is

cancelled, NC sets SA to 1 to move axis again.

● Signal address:

F0 SA

Boo

k 2

Fun

c o

ti

n

Ⅰ-2

Page 53

Chapter 2 Preparation for Operation

Chapter 2 PREPARATION for OPERATION

2.1 EMERGENT STOP

Emergency stop signal ESP(X0.5):

● Signal type: machine tool → NC

● Signal function: If external emergency stop signal X0.5 is not shielded and is detected to be 0, CNC will give out

an emergency stop warning (no matter whether PLC program is configured in CNC or not). At this

time CNC resets, and the machine tool stops running.

● Signal address:

X0 ESP

Emergency stop signal ESP(G8.4):

● Signal type: PLC→NC

● Signal function: If the voltage of G8.4 is 0, once NC detects this signal, an emergency stop warning will be given

out.

● Signal address:

Book 2 Function

G8 ESP

2.2 CNC READY SIGNAL

MA(F001.7):

● Signal type: NC→PLC

● Signal function: CNC Ready Signal indicates that CNC is ready for working.

● Output conditions: When CNC is powered on without warning, F1.7 will be set to 1 in several seconds. otherwise,

CNC ready signal will be 0.

● Signal address:

F001 MA

2.3 CNC OVERTRAVEL SIGNAL

+L1~+L4(G114.0~G114.3)

-L1~-L4(G116.0~G116.3)

● Signal type: PLC→NC

● Signal functions: If a tool moves beyond the distance which the machine limit switch sets, the limit switch starts

working, the tool slows down and then stops, and overtravel alarm is given out. This signal indicates

that control axis already reaches the limit distance. Every direction of each control axis has this signal.

“+” and “-” displays the direction, and the number means corresponding axis name.

Ⅱ-1

Page 54

GSK980TD Turning Machine CNC

● Output conditions: If CNC overtravel signal is 0, the control unit will response as follows: ● Output conditions: If CNC overtravel signal is 0, the control unit will response as follows:

*During automatic operation, if any one of the axis overtravel signal is 0, all axes will slow down and

*During automatic operation, if any one of the axis overtravel signal is 0, all axes will slow down and

stop, also alarm will be given out.

stop, also alarm will be given out.

*During manual operation, only the axis with a moving signal of 0 is going to slow down and stop.

*During manual operation, only the axis with a moving signal of 0 is going to slow down and stop.

Book 2 Function

*Once an axis overtravel signal turns to 0, the moving direction will be saved in the memory. Even

*Once an axis overtravel signal turns to 0, the moving direction will be saved in the memory. Even

though the signal changes to 1 again before the warning is cancelled, the axis cannot move on in the

k 2 Func n

● Signal addresses: ● Signal addresses:

tio

G114 G114 +L4 +L4 +L3 +L3 +L2 +L2 +L1 +L1

though the signal changes to 1 again before the warning is cancelled, the axis cannot move on in the

foregoing direction.

foregoing direction.

+ L 1

1 Axis 1 overtravel

2 Axis 2 overtravel

3 Axis 3 overtravel

4 Axis 4 overtravel

+ “forward” overtravel

- “backward” overtravel

The axis can move backwards after it stops.

The axis can move backwards after it stops.

G116 -L4 -L3 -L2 -L1

2.4 ALARM SIGNAL

AL(F001.0):

● Signal type: NC→PLC

● Signal functions: When an alarm is given out, the cause message of the alarm will be displayed, and NC will set

F1.0 signal to 1. There are two types of alarm: PLC alarm and CNC alarm. When the alarm is

cancelled and CNC resets, F1.0 will turns to 0.

● Signal address:

F001 AL

2.5 START LOCK SIGNAL

STLK(G007.1)

● Signal type: PLC→NC

● Signal functions: When PLC sets G7.1 to 1, and transmits to NC, NC control axis slows down and stops. During

automatic operation, if G7.1 is 1, and the commands before axis moving command block contain M, S,

T commands, M, S, T commands can execute constantly until all the axis moving command blocks are

finished and axis slows down and stops. Unless G7.1 signal is 0, program can restart.

● Signal address:

Ⅱ-2

G007 STLK

Page 55

Chapter 2 Preparation for Operation

2.6 MODE SELECTION

Mode selection signals include MD1, MD2, MD4, DNC1 and ZRN. Eight types of work mode can be selected: Edit

mode, Auto mode, MDI mode, Jog mode, Handwheel mode/Increment mode, Machine Reference Point Return mode and

Program Reference Point Return mode. CNC outputs work mode detection signals and informs PLC which working mode

CNC is using.

2.6.1 Mode Selection Signal

MD1、MD2、MD4(G043.0~G043.2) DNC1(G043.5) ZRN(G043.7):

● Signal type: PLC→NC

● Signal function: Work mode codes are as follows.

No. Code signal

Work mode

1 Edit mode 0 0 0 1 1

2 Auto mode 0 0 0 0 1

3 MDI mode 0 0 0 0 0

4 Handwheel mode/Increment mode

(HANDLE/INC)

5 Jog mode (JOG) 0 0 1 0 1

9 Machine Reference Point Return mode

(REF)

10 Program Reference Point Return mode

(PROG_ZERO)

PLC sets a value/digit to a Code signal, and then transfers to NC. NC will determine the working method of CNC

according to the code signal value.

● Signal addresses:

ZRN DNC1 MD4 MD2 MD1

0 0 1 0 0

1 0 1 0 1

0 0 0 1 0

Book 2 Function

G43 ZRN DNCI MD4 MD2 MD1

2.6.2 Work Mode Detection Signal

MINC(F3.0)、MH(F3.1)、MJ(F3.2)、MMDI(F3.3)、MMEM(F3.5)、MEDT(F3.6)、MREF(F4.5)、MPST(F4.6)

● Signal type: NC→PLC

● Signal functions: when CNC is working under a certain mode, if related “F” signal is set to 1, and transmitted to

PLC, PLC can be informed about the current working method.

Increment mode detection signal MINC

Handwheel mode detection signal MH

Jog mode detection signal MJ

MDI mode detection signal MMDI

Auto mode detection signal MMEM

Edit mode detection signal MEDT

Machine Reference Point Return mode detection signal MREF

Program Reference Point Return mode detection signal MPRO

Ⅱ-3

Page 56

● Signal addresses: ● Signal addresses:

n

F3 F3 MEDT MEDT MMEMMMEM MMDIMMDI MJ MJ MH MH MINCMINC

F4 MPRO MREF

2.6.3 Sequence of Work Mode Signals 2 Function

Work mode keys

Book 2 Functionk 2 Fun on

Work mode detection signal

cti

工作方式键输入(X20.0、

X20.1、X20.2、X20.3、

X20.4、X20.5、X21.3)

Work mode selection

signal G43

工作方

式检测信号(F3.0、

F3.1、F3.2、F3.3、F3.5、

F3.6、F4.5、F4.6)

方式指示灯(Y5.3、

Work mode indicator

工作

Y5.2、Y5.5、Y5.6、

Y5.7、Y5.4、Y6.2)

工作方式选

择信号G43

1

0

1

0

1

0

1

0

GSK980TD Turning Machine CNC

2.6.4 Work Mode Control Flowchart

Resume hold mode after power on

Input X20.0 by edit mode key

Input X20.1 by auto mode key

Input X20.2 by MDI mode key

Input X20.3 by machine reference point return key

Input X20.4 by handwheel/incremental mode key

Ⅱ-4

Input X20.5 by JOG mode key

Input X21.3 by program reference point retur

Select G43:11 in Edit mode

Page 57

Chapter 2 Preparation for Operation

Select G43:0 in MDI mode

Select G43:1 in Auto mode

Select G43:10000101 in

machine reference point return mode

Book 2 Function

Select G43:100 in Handwheel/

incremental mode

Select G43:101 in Manual

mode

Select G43:10 in program reference

point return mode

Save G43:100 in current mode

Y5.3: light in Handwheel/

incremental mode

Ⅱ-5

Page 58

GSK980TD Turning Machine CNC

Book 2 Function

2.7 STATUS OUTPUT

2.7.1 Rapid Feed Signal

RPDO(F002.1):

● Signal type: NC→PLC

● Signal function: CNC feeds signals rapidly

● Notes: When an axis feeds rapidly, NC sets F2.1 to be 1. If the feeding stops, F2.1 remains at the same status, and

then selects the “un-rapid” feeding, moves the axis or resets CNC, then F2.1 will change to 0.

● Signal address:

Y5.2: light in Manual mode

Y5.5: light in MDI mode

Y5.6: light in Auto mode

Y5.7: light in Edit mode

Y5.4:light in Machine reference

point return mode

Y6.2:ligh in program reference point

return mode

F2 PRDO

2.7.2 Cutting Feed Signal

CUT(F002.6):

● Signal type: NC→PLC

● Signal function: when CNC is performing cutting feed (linear interpolation, circular interpolation, helical

interpolation, thread cutting, skip cutting or fixed cycle cutting), NC sets F2.6 to 1, and then transmits

to PLC. When it changes to rapid feed, F2.6 turns to be 0.

● Signal address:

F2 CUT

2.7.3 Tap Cutting Signal

TAP(F1.5):

● Signal type: NC→PLC

● Signal functions: when CNC is performing tap cutting, NC sets F1.5 to 1.When CNC is not performing tap cutting,

and under the state of emergency stop or reset, NC sets F1.5 to 0.

● Signal address:

Ⅱ-6

F1 TAP

Page 59

Chapter 2 Preparation for Operation

2.7.4 Thread Cutting Signal

THRD(F2.3):

● Signal type: NC→PLC

● Signal functions: when CNC is executing thread cutting, NC sets F2.3 to 1. While on the contrary F2.3 is 0.

● Signal address:

F2 THRD