Page 1

Foreword

This user manual describes all items concerning the operation of the system

in detail as much as possible. However, it is impractical to give particular descriptions of

all unnecessary and/or unavailable operations of the system due to the manual content

limit, product specific operations and other causes. Therefore, the operations not

specified herein shall be considered impossible or unallowable.

This user manual is the property of GSK CNC Equipment Co., Ltd. All rights

are reserved. It is against the law for any organization or individual to publish or reprint

this manual without the express written permission of GSK and the latter reserves the

right to ascertain their legal liability.

Page 2

GSK980TA1/TA2, GSK980TB1/TB2, GSK98T CNC System User Manual

The User Manual is applied to the following CNC systems:

GSK 980TA1

GSK 980TA2

GSK 980TB1

GSK 980TB2

GSK 98T

GSK980TA1/TA2, GSK980TB1/TB2 and GSK98T are made by GSK

Equipment Co., Ltd.. GSK980TA1/TA2, GSK980TB1/TB2 are upgraded from

GSK980TA. GSK980TA2 and GSK980TB2 have USB communication

interfaces; GSK98T addes USB communication and three-state switch based

on GSK980TB1.

II

Page 3

Foreword

FOREWORD

Dear user,

We are really grateful for your patronage and purchase of CNC systems made

by GSK CNC Equipment Co., Ltd.

The user manual describes the programming, operation, installation and

connection. Please read it carefully before operation in order to get the safe and

effective working.

Warning

This system can only be operated by authorized and qualified personnel as

improper operations may cause accidents.

Please carefully read this user manual before use!

Note: The power supply installed on (in) the cabinet is exclusive to GSK’S CNC

systems.

The power supply form is forbidden to be used for other purposes.

Otherwise, there may be extreme danger!

III

Page 4

GSK980TA1/TA2, GSK980TB1/TB2, GSK98T CNC System User Manual

Safety Precaution

Warning, caution and note

This manual includes safety precaution for protecting the user and preventing

damage to the machine. Precautions are clssified into Warning and Caution

according totheir bearing on safety. Read the Warning, Caution and Note thoroughly

before attempting to use the machine.

Warning

There is a danger of the user being injured or the equipment being damaged if

the approved procedure is not observed.

Caution

There is a danger of the equipment being damaged if the approved procedure is

not observed.

Note

It is used to indicate supplementary information other than Warning and Caution.

All specifications and designs herein are subject to change without further notice.

This manual is reserved by end user.

IV

Page 5

Foreword

■ Delivery and storage

z Packing box over 6 layers in pile is unallowed.

z Never climb the packing box, neither stand on it, nor place heavy objects on it.

z Do not move or drag the product by the cables connected with it.

z Forbid collision or scratch to the panel and displayer.

z Packing box should be protected from damping, insolation and raining.

■ Open packing box to check

z Ensure things in packing box are the required ones.

z Ensure the product is not damaged in delivery.

z Ensure the parts in packing box are in accordance to the order.

z Contact us in time if the product type is inconsistent with the order, there is short

of accessories, or product damage in delivery.

■ Connection

z Only qualified persons can connect the system or check the connection.

z The system must be earthed, its resistance must be less than 4 Ω and the

ground wire cannot be replaced by zero wire.

z Connection must be correct and firm to avoid the product to be damaged or other

unexpected result.

z Connect with surge diode in the specified direction to avoid the damage to the

system.

z Switch off power supply before pulling out plug or opening electric cabinet.

■ Troubleshooting

z Switch off power supply before troubleshooting or changing components.

z Troubleshoot and then startup the system when there is short circuit or overload.

z Do not switch on or off it frequently and an interval is 1 minute at least after the

system is powered on again.

V

Page 6

GSK980TA1/TA2, GSK980TB1/TB2, GSK98T CNC System User Manual

Safety Responsibility

Manufacturer’s safety responsibility

——The manufacturer should be responsible for the cleared or the controlled safety in

the design and the structure of the CNC system and the accessories.

——The manufacturer should be responsible for the CNC system and the

accessories.

——The manufacturer should be responsible for the message and the suggestion for

the user.

User’s safety responsibility

——The user should study and train the system safety operation, master the safety

operation content.

——The user should be responsible for the danger caused by increasing, changing or

modifying the CNC system, the accessories by itself.

——The user should be responsible for the danger because of the mistaken operation,

regulation, maintenance, installation and storage.

This user manual shall be kept by final user.

All specification and designs are subject to change without further notice.

VI

Page 7

Contents

Contents

■ Delivery and storage ........................................................................................................................... V

■ Open packing box to check................................................................................................................. V

■ Connection .......................................................................................................................................... V

■ Troubleshooting .................................................................................................................................. V

PART ONE SUMMARY ................................................................................................ 1

Chapter One Summary ............................................................................................................................ 3

1.1 Summary .......................................................................................................................................... 3

1.2 Product Brief .................................................................................................................................... 3

1.3 Model and Meaning.......................................................................................................................... 4

1.4 Order ................................................................................................................................................ 4

PART TWO PROGRAMMING ......................................................................................... 5

Chapter One Programming Fundamentals ........................................................................................... 7

1.1 Coordinate axis definition ................................................................................................................. 7

1.2 Machine coordinate system, Machine Zero ..................................................................................... 8

1.3 Workpiece Coordinate System and Reference Point(Program Zero) .............................................. 8

1.4 Controlled axes ................................................................................................................................ 9

1.5 Input Increment ................................................................................................................................ 9

1.6 Maximum Stroke .............................................................................................................................. 9

1.7 Absolute Programming and Incremental Programming ................................................................... 9

1.8 Diameter and Radius Programming ............................................................................................... 10

1.9 Modal, Simple and Initial State ........................................................................................................ 11

Chapter Two Structure of an Part Program ......................................................................................... 13

2.1 General Structure of a Program ..................................................................................................... 13

2.1.1 Program Name ........................................................................................................................ 13

2.1.2 Sequence Number and Block ................................................................................................. 14

2.1.3 Word ........................................................................................................................................ 14

2.2 Relationship between Command Numerical Value and Decimal Point ....................................... 16

2.3 Subprogram ................................................................................................................................... 17

2.3.1 Main Program and Subprogram .............................................................................................. 17

2.3.2 Subprogram Call(M98) ....................................................................................................... 17

2.3.3 Return from subprogram(M99) ........................................................................................... 17

Chapter Three Preparatory Function G Command ............................................................................. 20

3.1 Category of Preparatory Function G Command ............................................................................ 20

3.2 Simple G Command ....................................................................................................................... 22

3.2.1 Rapid Positioning(G00) ...................................................................................................... 22

3.2.2 Linear Interpolation(G01) ................................................................................................... 23

3.2.3 Circular Interpolation(G02/G03) ......................................................................................... 25

3.2.4 Chamfering/Cornering Arc ....................................................................................................... 27

3.2.5 Dwell G04 ................................................................................................................................ 28

3.2.6 Programs Specifying Parameter Function (G10) ............................................................... 29

3.2.7 Machine Zero Return(G28) ................................................................................................ 29

3.2.8 Workpiece Coordinate System Setting(G50) ..................................................................... 30

3.2.9 Workpiece Coordinate System Offset(G51) ....................................................................... 32

3.2.10 Feed per minute (G98) .......................................................................................................... 33

3.2.11 Feed per Rev (G99) ............................................................................................................... 33

3.2.12 Constant Surface Control (G96, G97) ................................................................................... 33

3.2.13 Skip Function (G31) ......................................................................................................... 35

3.2.14 Thread Cutting with Invariable Pitch(G32) ....................................................................... 36

3.2.15 Thread Cutting with Variable Pitch(G34) .......................................................................... 39

3.2.16 Tapping Cycle(G33) .......................................................................................................... 40

3.3 Single Fixed Cycle Command ........................................................................................................ 41

VII

Page 8

GSK980TA1/TA2, GSK980TB1/TB2, GSK98T CNC System User Manual

3.3.1 Outer(Inner)Cutting Cycle(G90)..................................................................................... 41

3.3.2 End Cutting Cycle(G94) ...................................................................................................... 44

3.3.3 Thread Cutting Cycle(G92) ................................................................................................. 46

3.3.4 Notes in Single Fixed Cycle Commands ................................................................................. 48

3.4 Compound Fixed Cycle Commands .............................................................................................. 49

3.4.1 Outer(Inner)Roughing Cycle(G71) ................................................................................ 49

3.4.2 End Roughing Cycle(G72) .................................................................................................. 53

3.4.3 Closed Cutting Cycle(G73) ................................................................................................. 56

3.4.4 Finishing Cycle(G70) .......................................................................................................... 59

3.4.5 End Deep Hole Machining Cycle(G74) .............................................................................. 60

3.4.6 Outer Grooving Cycle(G75) ................................................................................................ 61

3.4.7 Compound Thread Cutting Cycle(G76) .............................................................................. 63

3.4.8 Notes of Compound Fixed Cycle Codes ................................................................................. 66

Chapter Four Miscellaneous Function M Codes .............................................................................. 67

4.1 Miscellaneous Function (M function) ........................................................................................ 67

4.2 Special M Codes(M21.M22.M23.M24 ) .................................................................................... 68

4.3 M Code Calling Subprograms ........................................................................................................ 69

4.4 S Codes Calling Subprograms ....................................................................................................... 69

4.5 T Codes Calling Subprograms ....................................................................................................... 70

4.6 Parameters of Miscellaneous Function .......................................................................................... 70

4.7 Alarm Related to Miscellaneous Function ...................................................................................... 70

Chapter Five Spindle Function S Code ................................................................................................ 72

5.1 Spindle Switching Value Control .................................................................................................... 72

5.2 Spindle Analog Value Control ......................................................................................................... 72

Chapter Six Tool Function T Code ....................................................................................................... 73

6.1 Tool change Process ...................................................................................................................... 73

6.2 Relevant Parameters of Tool Change ............................................................................................ 74

6.3 Tool Offset ...................................................................................................................................... 75

6.3.1 Basic Tool Offset ...................................................................................................................... 75

6.3.2 T Code for tool offset ............................................................................................................... 75

6.3.3 Offset ....................................................................................................................................... 76

6.3.4 Programming Example ............................................................................................................ 77

6.3.5 Single T code ........................................................................................................................... 78

Chapter Seven User Macro Program ................................................................................................... 79

7.1 User Macro Code ........................................................................................................................... 79

7.2 User Macro Program Body ............................................................................................................. 79

7.3 Operation Command and Transfer Command(G65) ................................................................. 82

7.4 Notes for User Macro Program Body ............................................................................................. 86

7.5 User Macro Program Example ....................................................................................................... 86

Chapter Eight Tool Compensation C Function ................................................................................. 88

8.1 Basic Concept of Tool Compensation C Function .......................................................................... 88

8.1.1 Imaginary Tool Nose ................................................................................................................ 88

8.1.2 Imaginary Tool Nose Direction ................................................................................................ 90

8.1.3 Compensation Value Setting ................................................................................................... 94

8.1.4 Relative Position between Tool and Workpiece ...................................................................... 94

8.1.5 Inside and outside ................................................................................................................... 96

8.1.6 Command Format of G41, G42, G40 ...................................................................................... 97

8.2 Concrete Tool Compensation ......................................................................................................... 97

8.2.1 Concrete Path Decomposition of Tool Nose Radius Compensation ....................................... 97

8.2.2 Compensation direction change when tool compensation proceeding ................................. 103

8.2.3 Temporary Tool Compensation Cancel ................................................................................. 105

8.2.4 Non-Movement Command when Tool Compensation ........................................................... 107

8.2.5 Tool Compensation Interference Check ................................................................................ 108

8.2.6 Tool Nose Radius Compensation in G90/G94 .......................................................................110

8.2.7 Tool Nose Radius Compensation in G70 ............................................................................... 111

VIII

Page 9

Contents

8.3 Notes of Tool Compensation C ..................................................................................................... 111

8.4 Tool Compensation C Example ..................................................................................................... 112

PART THREE OPERATION ..................................................................................... 117

Chapter One Operation Panel .............................................................................................................. 119

1.1 Panel division ................................................................................................................................ 119

1.2 Instructions for Panel Functions ................................................................................................... 120

1.2.1 LCD (liquid crystal) display area ........................................................................................... 120

1.2.2 Edit Keypad Area ................................................................................................................... 120

1.2.3 Introduction for Screen Operation Keys ................................................................................ 122

1.2.4 Machine Control Area ............................................................................................................ 123

Chapter Two System Power ON/OFF and Safety Operation ............................................................ 126

2.1 System Power-on ......................................................................................................................... 126

2.2 System Power-off ......................................................................................................................... 126

2.3 Safety Operation .......................................................................................................................... 127

2.3.1 Reset ..................................................................................................................................... 127

2.3.2 Emergency Stop .................................................................................................................... 127

2.3.3 Feed Hold .............................................................................................................................. 127

2.3.4 Power-off ............................................................................................................................... 127

2.4 Cycle Start and Feed Hold ........................................................................................................... 128

2.5 Overtravel Protection ................................................................................................................... 128

2.5.1 Hardware Overtravel Protection ............................................................................................ 128

2.5.2 Software Overtravel Protection ............................................................................................. 128

Chapter Three Interface Display and Data Modification and Setting ............................................. 129

3.1 Position Display ............................................................................................................................ 129

3.1.1 Four Ways for Interface Display ............................................................................................ 129

3.1.2 Display of Machining Time, Parts Number, Programming Speed, Override and Actual Speed

.......................................................................................................................................................... 131

3.1.3 Clearing Methods of Parts Number and Cutting Time .......................................................... 131

3.2 Program Display ........................................................................................................................... 132

3.3 Display, Modification and Setting of the Tool Offset ..................................................................... 133

3.3.1 Tool Offset Display ................................................................................................................ 133

3.3.2 Tool Offset Modification and Setting ...................................................................................... 134

3.4 Alarm Display ............................................................................................................................... 135

3.5 Setting Display ............................................................................................................................. 136

3.5.1 Instruction for 【Setting】Interface Operation ..................................................................... 136

3.5.2 Operating Instructions for 【Graph】Interface ..................................................................... 137

3.6 Display, Modification and Setting of the Parameter ..................................................................... 139

3.6.1 Parameter Display ................................................................................................................. 139

3.6.2 Modification and Setting for Parameter and Screw Pitch Compensation Value ................... 140

3.7 Diagonosis Display....................................................................................................................... 142

3.7.1 Diagnosis Data Display ......................................................................................................... 143

Chapter Four Manual Opoeration ....................................................................................................... 145

4.1 Coordinate Axis Movement ............................................................................................................. 145

4.1.1 Manual Feed ......................................................................................................................... 145

4.1.2 Manual Rapid Traverse ......................................................................................................... 145

4.1.3 Manual Feed and Manual Rapid Traverse Rate Selection ................................................... 145

4.2 Spindle Control ............................................................................................................................. 146

4.2.1 Spindle CW (Negative rotation) ............................................................................................. 146

4.2.2 Spindle CCW (Positive rotation) ............................................................................................ 147

4.2.3 Spindle Stop .......................................................................................................................... 147

4.3 Other Manual Operations ............................................................................................................. 147

4.3.1 Cooling Control ...................................................................................................................... 147

4.3.2 Lubricating Control ................................................................................................................ 147

4.3.3 Manual Tool Change ............................................................................................................. 147

4.4 Tool Setting .................................................................................................................................. 147

IX

Page 10

GSK980TA1/TA2, GSK980TB1/TB2, GSK98T CNC System User Manual

4.4.1 Fixed-point Tool Setting ......................................................................................................... 147

4.4.2 Tool Setting by Test Cutting ................................................................................................... 148

4.4.3 Tool Setting by Machine Zero Return .................................................................................... 150

4.5 Offset Alteration ............................................................................................................................ 152

Chapter Five MPG/Sing Step Operation ............................................................................................ 154

5.1 Step Feed ..................................................................................................................................... 154

5.2 MPG (Manual pulse generator) Feed........................................................................................... 154

5.2.1 Moving Axis and Direction Selection ..................................................................................... 155

5.2.2 Instructions for MPG Feed .................................................................................................... 156

5.3 The Miscellaneous Control in MPG/Step Operation .................................................................... 156

Chapter Six MDI Operation ................................................................................................................. 157

6.1 MDI Blocks Input .......................................................................................................................... 157

6.2 MDI Block Operation and Stop ..................................................................................................... 157

6.3 MDI Block Words Alteration and Clearing .................................................................................... 158

6.4 Conversion of Operation Modes .................................................................................................. 158

Chapter Seven Edit Operation ............................................................................................................ 159

7.1 Program Edit ................................................................................................................................ 159

7.1.1 Program Creation .................................................................................................................. 159

7.1.2 Deletion of a program ............................................................................................................ 163

7.1.3 Deletion of All Programs ........................................................................................................ 163

7.1.4 Duplication of the Program .................................................................................................... 163

7.1.5 Rename of the Program ........................................................................................................ 163

7.2 Program Management ................................................................................................................. 164

7.2.1 Search of Program List .......................................................................................................... 164

7.2.2 Quantity of the Saved Programs ........................................................................................... 164

7.2.3 Memory Capacity ................................................................................................................... 164

7.2.4 Program Lock ........................................................................................................................ 165

7.3 Other Operations Available in Edit Mode ..................................................................................... 165

Chapter Eight AUTO Operation .......................................................................................................... 166

8.1 Selection of the Program To Be Run ............................................................................................ 166

8.2 Start of the Auto Run .................................................................................................................... 166

8.3 Auto Run Stop .............................................................................................................................. 167

8.4 Auto Run From an Arbitrary Block ................................................................................................ 167

8.5 Dry Run ........................................................................................................................................ 168

8.6 Single Block Execution ................................................................................................................. 169

8.7 Machine Lock ............................................................................................................................... 170

8.8 M. S. T Lock ................................................................................................................................. 171

8.9 Block Skip ..................................................................................................................................... 171

8.10 Ajustment of the Feedrate, Rapid Rate in Auto Mode................................................................ 171

8.11 Spindle Speed Adjustment in Auto Mode ................................................................................... 172

8.12 Cooling Control........................................................................................................................... 172

Chapter Nine Zero Return Operation ................................................................................................. 173

9.1 Concept of the Machine Zero Return ........................................................................................... 173

9.2 The Operation Procedures of Machine Zero Return .................................................................... 174

9.3 Concept of Program Zero Point ................................................................................................... 175

9.4 The Operation Procedures of Program Zero Return .................................................................... 175

Chapter Ten System Communication ................................................................................................ 176

10.1 Serial Port Communication ........................................................................................................ 176

10.1.1 Program Start ...................................................................................................................... 176

10.1.2 Function Instruction ............................................................................................................. 177

10.1.3 Software Usage ................................................................................................................... 177

10.1.4 Communication between CNC and CNC ............................................................................ 180

10.2 USB Communication .................................................................................................................. 181

10.2.1 Overview and Cautions ....................................................................................................... 181

10.2.2 Enter U-disk ......................................................................................................................... 181

X

Page 11

Contents

10.2.3 Procedures .......................................................................................................................... 182

10.2.4 U-disk Removal ................................................................................................................... 184

PART FOUR CONNECTION .................................................................................... 185

Chapter One System Configuration and Installation ....................................................................... 187

1.1 System Configuration ................................................................................................................... 187

1.2 System Installation ....................................................................................................................... 187

1.3 Mounting Dimension of the CNC System .................................................................................... 188

1.4 Additional Panel ........................................................................................................................... 190

Chapter Two Equipment Connection ............................................................................................... 192

2.1 System Interfaces ........................................................................................................................ 192

2.1.1 Interface Layout ..................................................................................................................... 192

2.1.2 Explanations for Interfaces .................................................................................................... 193

2.1.3 Connection Diagram.............................................................................................................. 194

2.2 Connection of the System to the Drive Unit ................................................................................. 194

2.2.1 Connection to the Drive Unit ................................................................................................. 194

2.2.2 Signal Explanation................................................................................................................. 195

2.2.3 Connection Between the System and the Drive Unit ............................................................ 198

2.3 Connection to the Spindle Encoder.............................................................................................. 199

2.4 RS232-C Standard Serial Port (Optional) .................................................................................... 200

2.5 Analog Spindle Interface (Optional) ............................................................................................. 200

2.5 MPG Interface .............................................................................................................................. 201

2.6 Connection of the Power Interface............................................................................................... 201

Chapter Three I/O Interface of Machine Tool .................................................................................... 203

3.1 List of the Machine Tool I/O Interface .......................................................................................... 203

3.1.2 Expansion I/O Interface of GSK980TA1(2)/980TB1(2) ......................................................... 205

3.1.3 Standard I/O Output Interface of GSK98T ............................................................................ 207

3.2 Input Signal .................................................................................................................................. 208

3.3 Signal Expalnation ....................................................................................................................... 209

3.4 Output Signal ............................................................................................................................... 215

3.5 Spindle Automatic Gearing Control .............................................................................................. 218

3.6 Chuck Control (Chuck Detection Function) ................................................................................. 219

3.7 Tailstock Control (Tailstock hierarchical advance/retreat control) ................................................ 221

3.8 Handhold Unit .............................................................................................................................. 222

3.9 External Program Lock ................................................................................................................ 223

3.10 External Feed Pause and Spindle Pause .................................................................................. 223

3.11 I/O Signal Disgnosis List ............................................................................................................ 224

3.12 Function Description .................................................................................................................. 224

Chapter Four Machine Tool Debugging ............................................................................................. 226

4.1 Debugging Preparation ................................................................................................................ 226

4.2 System Power On ........................................................................................................................ 226

4.3 Emergency Stop and Limit ........................................................................................................... 226

4.4 Drive Axis Debugging ................................................................................................................... 227

4.5 Gear Ratio Adjustment ................................................................................................................. 227

4.6 Rapid Traverse Rate and Linear ACC&DEC Adjustment............................................................. 227

4.7 Upper Speed of the Cutting Feed ................................................................................................ 228

4.8 Adjustment for Thread Machining ................................................................................................ 228

4.9 Machine (mechanical) Zero Adjustment....................................................................................... 228

4.10 Offset between Lead Screws ..................................................................................................... 229

4.11 Electronic Toolpost Debugging ................................................................................................... 229

4.12 Spindle Adjustment .................................................................................................................... 229

4.13 Step/MPG Adjustment ................................................................................................................ 229

4.14 Three-state Switch Adjustment .................................................................................................. 230

4.15 Internal Emergency Stop Adjustment ......................................................................................... 230

4.16 Other Adjustment ....................................................................................................................... 230

Chapter Five Memorizing Screw-pitch Error Compensation .......................................................... 232

XI

Page 12

GSK980TA1/TA2, GSK980TB1/TB2, GSK98T CNC System User Manual

APPENDIX ................................................................................................................. 237

Appendix I Paremeter List ................................................................................................................... 239

1. Explanations for parameter ............................................................................................................ 239

2. Bit parameter .................................................................................................................................. 239

3. Data Parameter .............................................................................................................................. 246

Appendix II Alarm List ......................................................................................................................... 269

Appendix III Diagnosis List ................................................................................................................. 278

1. DI/DO Diagnosis Message ............................................................................................................... 278

1.1 Input Signal from Machine Side (I/O board) ............................................................................. 278

1.2 Signal Input to Machine Side (I/O board) ................................................................................. 279

2. CNC Interface Signal ........................................................................................................................ 279

3. Operation Panel Key ......................................................................................................................... 280

4. CNC Input/Output Signal .................................................................................................................. 281

5. Signals from CNC ............................................................................................................................. 282

6. CNC Internal State Message ............................................................................................................ 282

Appendix Specification ListⅣ ........................................................................................................... 284

Appendix V Wiring for CNC Matching Taiwan LIO SHING Tool Post .............................................. 286

Appendix VI Factory Parameters ........................................................................................................ 288

XII

Page 13

Part One Summary

Part One Summary

PART ONE SUMMARY

1

Page 14

GSK980TA1/TA2, GSK980TB1/TB2, GSK98T CNC System User Manual

Part One Summary

2

Page 15

Chapter One Summary

Chapter One Summary

1.1 Summary

Part One Summary Introduce the system, composition of chapters, he system model, relavant use

explanations, and precautions before reading the user manual.

Part Two Programming Describe composition of part programs, fundamentals of programming,

each code’s function, command format, characteristics and restricts in NC

programming, and so on.

Part Three Operation Narrate each window and setting of the system, each operation of machine,

program input/output, edit, and the system’s communication, and so on.

Part Four Connection Mention the system’s structure, installation dimension, connection among

devices, I/O interface definition, machine debugging, the system’s

specification, optional memory pitch error compensation function.

Appendix List parameter tables (including parameter default value and parameter setting range),

alarm tables and diagnosis table.

The user manual is applied to GSK980TA1/TA2, GSK980TB1/TB2, GSK98T CNC systems.

Part One Summary

1.2 Product Brief

GSK980TA1/TA2, GSK980TB1/TB2 and GSK98T are made by GSK Equipment Co., Ltd..

GSK980TA1/TA2, GSK980TB1/TB2 are upgraded from GSK980TA. GSK980TA2 and

GSK980TB2 have USB communication interfaces; GSK98T addes USB communication and

three-state switch based on GSK980TB1.

As upgraded productes, the systems have the following features:

● 32-bit CUP, CPLD hardward interpolation technology to realize high-speed μm level control;

● 4-layer circuit board with high integrated level, proper system technology structure and high

reliability;

● Chinese/English LCD,friendly interface and easy operation;

● Adjustable acceleration/deceleration to be matched with stepper drive unit or servo drive unit

● Changeable electronic gear ratio;

● Prepositioning USB interfaces and RS232 interfaces to be convenient to the user managing

programs.

Note: GSK980TA1, TB1 have no USB interfaces, GSK98T has no RS232 interfaces.

3

Page 16

GSK980TA1/TA2, GSK980TB1/TB2, GSK98T CNC System User Manual

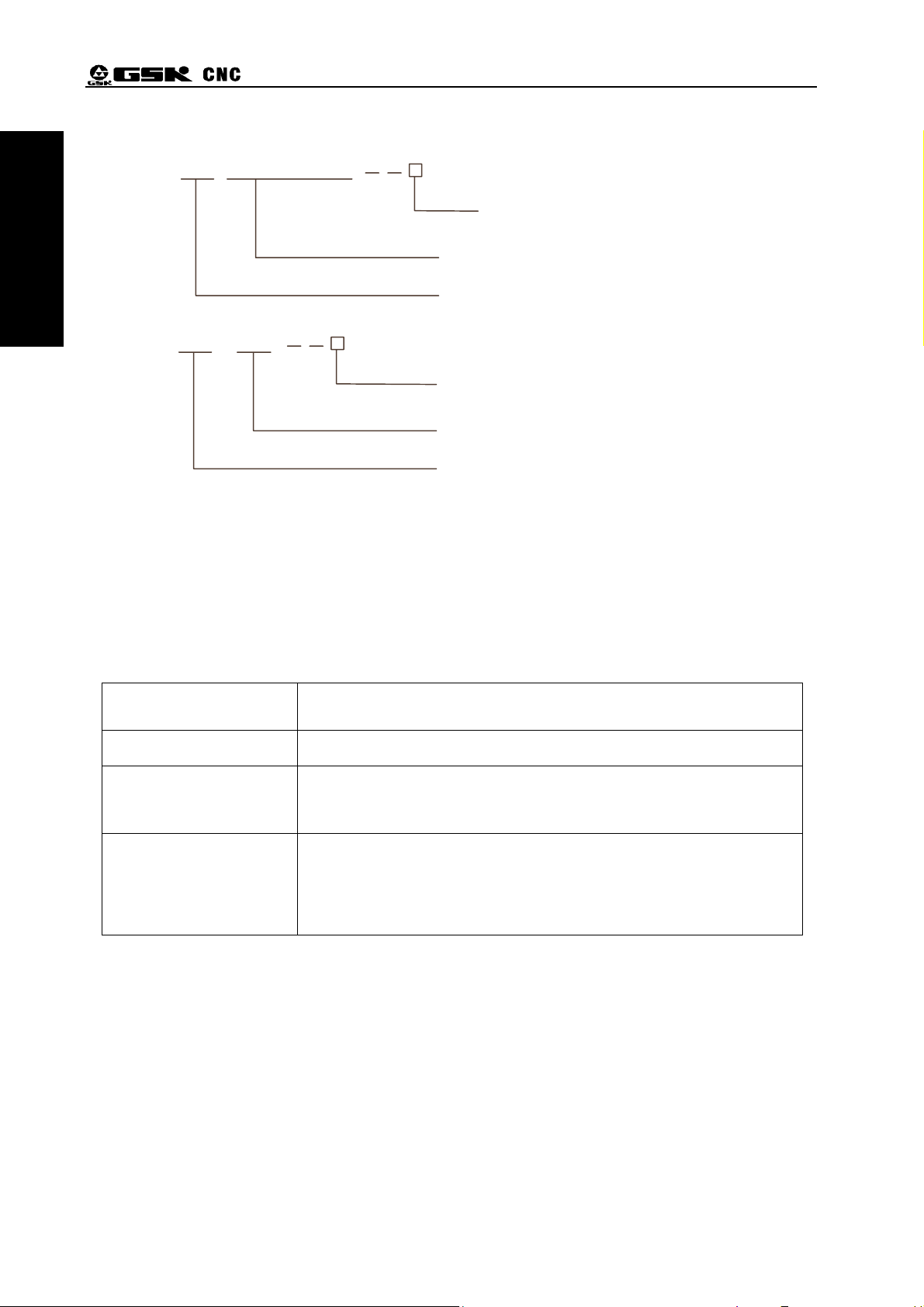

1.3 Model and Meaning

Part One Summary

GSK 980TA1(2)/TB1(2)

Assembly method:none:standard panel

(420mm×260mm)

B:box assembly

GSK980TA1(2)/TB1(2) series turning CNC system

Product logo for GSK CNC Equipment Co., Ltd.

GSK 98T

Assembly method:none:standard panel

(320mm×200mm)

B:box assembly

GSK98T series turning CNC system

Product logo for GSK CNC Equipment Co., Ltd.

Fig. 1-3

1.4 Order

Standard configuration of GSK98T is two-axis link.

GSK980TA1/TA2.GSK980TB1/TB2 can select Y as the additional axis and the user must remark

it. Refer to the supplementary about Y axis explanation.

Table 1-4

Model Explanation

GSK98T 320mm×200mm aluminium operation panel

GSK980TA1/TA2

GSK980TB1/TB2

GSK980TA1/TA2

GSK980TB1/TB2-B

420mm×260mm aluminium operation panel

GSK980TA1/TA2.GSK980TB1/TB2

Be matched with AP01 to operation box

(445mm×345mm×182mm)

4

Page 17

Chapter One Programming Fundamentals

Part Two Programming

PART TWO PROGRAMMING

5

Page 18

Part Two Pro

g

g

rammin

GSK980TA1/TA2, GSK980TB1/TB2, GSK98T CNC System User Manual

6

Page 19

Chapter One Programming Fundamentals

Chapter One Programming Fundamentals

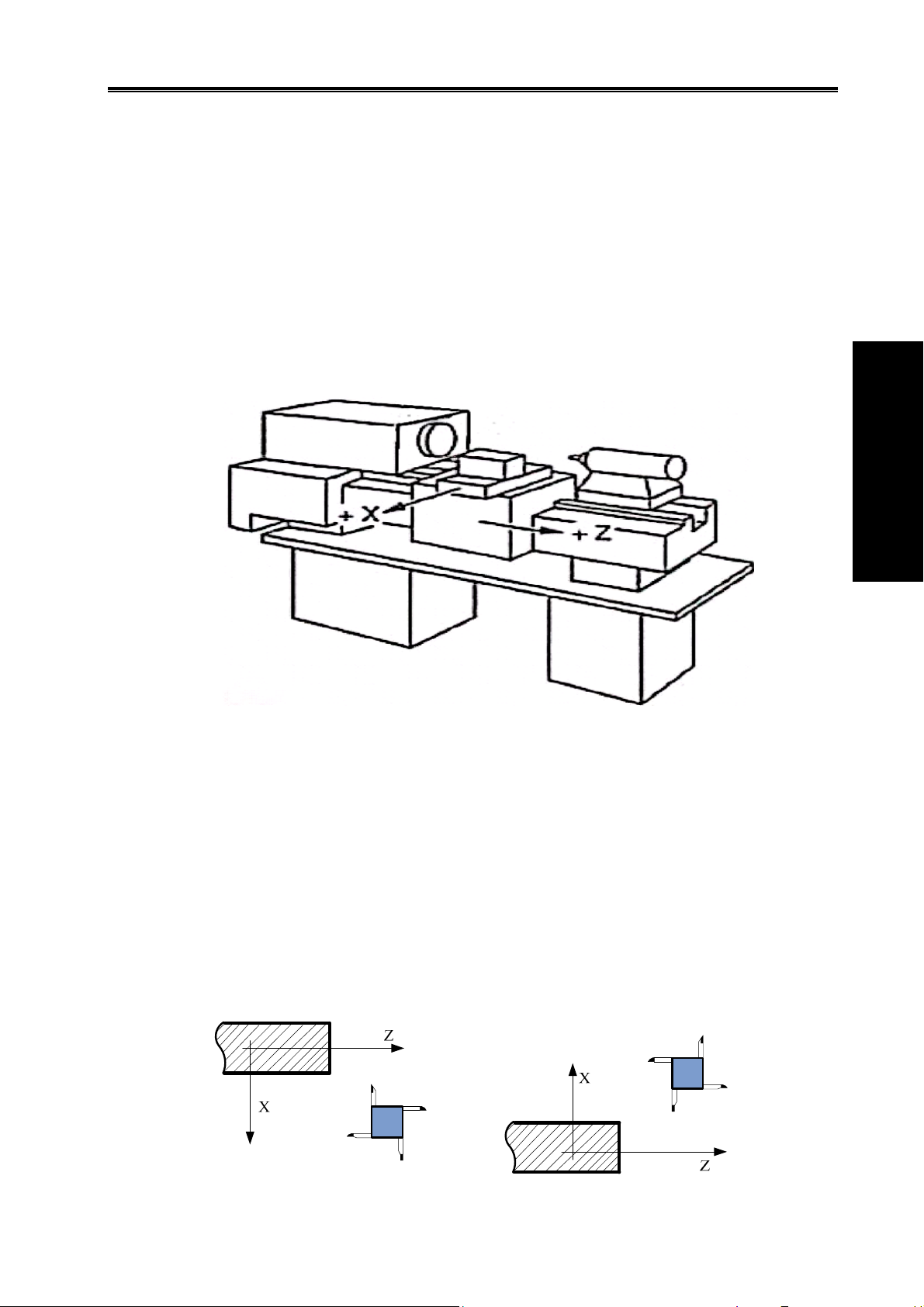

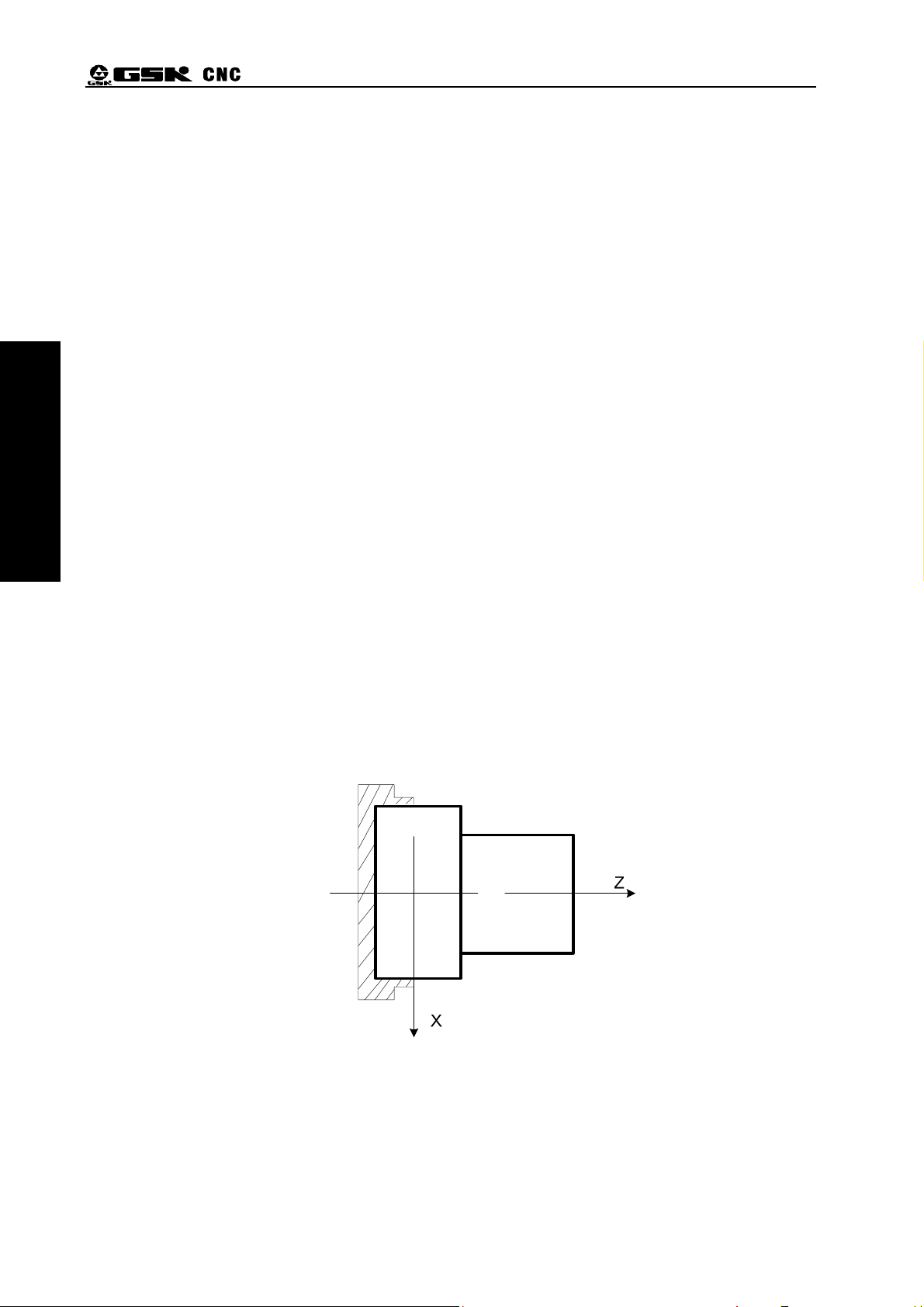

1.1 Coordinate axis definition

It is important to stipulate the coordinate axis name and movement direction of CNC machine.

Designers, operators and maintenance personnel of CNC machine should correctly understand it,

otherwise, it causes the mistaken programming and data communication, operation accidence,

abnormal maintenance, and so on.

Fig.1-1-1 is a axis sketch map of CNC turning machine.

Part Two Programming

Fig.1-1-1

The system uses a rectangular coordinate system composed of X, Z axis to execute the positioning

and the interpolation movement. X axis is in the direction of front and back in the plane, and Z axis is

of left and right. The negative direction of them approach to the workpiece and positive one is away

from it, which are shown in Fig.1-1-1.

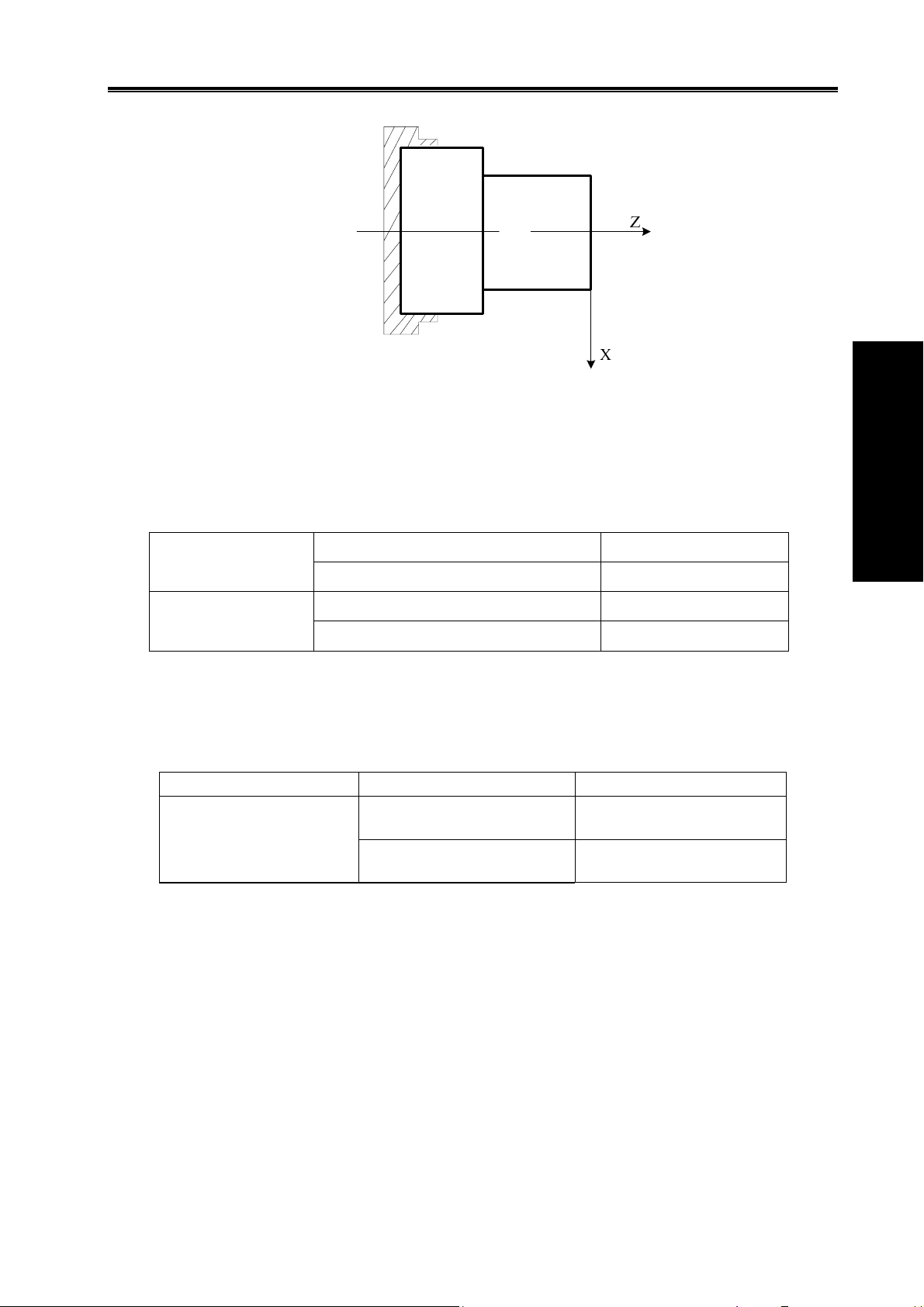

The system supports a front tool post, a rear tool post function, and describes that the tool post

before the workpiece is called as a front tool post and it behind the workpiece is called as a rear tool

post. Fig. 1-1-2 is a coordinate system of the front tool post and Fig. 1—1-3 is a rear toolpost one. It

shows exactly the opposite of X axes, but the same of Z axes from figures. In the manual, it will

introduce programming application with the front tool post coordinate system in the following figures

and examples.

Fig.1-1-2 Front tool post coordinate system Fig.1-1-3 Rear tool post coordinate system

7

Page 20

GSK980TA1/TA2, GSK980TB1/TB2, GSK98T CNC System User Manual

g

g

1.2 Machine coordinate system, Machine Zero

Machine tool coordinate system is a fixed one, its origin is taken as the machine zero installed on

the max. travel in positive X, Z axis. The machine zero is defined after the machine is designed,

manufactured and adjusted, and it is a fixed point. The machine zero is not defined when the CNC is

turned on, and generally, the automatic or manual machine zero return is executed to create the

machine coordinate system. CNC has created the machine coordinate system after the machine zero

return is completed.

Part Two Pro

rammin

Note: Do not execute the machine zero function(such as G28) without the machine zero switch installed on

the machine tool.

1.3 Workpiece Coordinate System and Reference Point(Program Zero)

A workpiece coordinate system (also called floating coordinate system) is used when programmers

in programming, programmer selects a known point on the workpiece as reference point (also called

program zero) to establish a new coordinate system, which is called a workpiece coordinate system.

Once the workpiece coordinate system has been established, it is valid until it is replaced by a new

one. When the system is turned off or power down, the program zero position is not saved. Using

G50 for the system creates a workpiece coordinate system. When there is no G50 in programs, the

current absolute coordinate value is taken the reference point to create a workpiece coordinate

system. The reference point selection of the workpiece coordinate system should meet the simple

programming, few dimension conversions and machining error. Generally, the reference point should

be on the reference marked by the dimension or positioning reference. For turning machine

programming, the reference point should be on the intersection point between the workpiece’s axis

and the end face of the chuck (Fig.1-3-1) or the workpiece’s end face (Fig.1-3-2).

Fig.1-3-1 reference point on end face of chuck

8

Page 21

1.4 Controlled axes

GSK98T

GSK980TA1/TA2,

GSK980TB1/TB2

Chapter One Programming Fundamentals

Fig. 1-3-2 reference point on workpiece’s end face

Table 1-4-1

Controlled axes

Simultaneously controlled axes

Controlled axes

Simultaneously controlled axes

2 axes(X,Z)

2 axes(X,Z)

3 axes X,Z,Y)

3 axes(X,Z,Y)

Part Two Programming

1.5 Input Increment

Table 1-5-1

Input/output Least input increment Least command increment

X:0.001 mm(Diameter

Metric input /metric output

Diameter/radius designation is set by NO:1#2 and the parameter is valid only to X.

The input increment is referred to the machine manufacture’s User Manual.

Z:0.001 mm

X:0.001 mm (Radius

Z:0.001 mm

)

)

X:0.0005 mm

Z:0.001 mm

X:0.001 mm

Z:0.001 mm

1.6 Maximum Stroke

Maximum stroke = least input increment×9999999

1.7 Absolute Programming and Incremental Programming

The movement of the command axis is divided into: absolute command and incremental

command. The absolute command is to use the end point of axis movement to execute programming,

which is called absolute programming. The incremental command is to use the axis movement to

directly execute programming, which is called incremental programming. For the system, the

absolute programming uses X,Z and the incremental programming uses U, W.

9

Page 22

GSK980TA1/TA2, GSK980TB1/TB2, GSK98T CNC System User Manual

g

g

Table 1-7-1

Absolute command Incremental command Remark

X U X movement command

Z W Z movement command

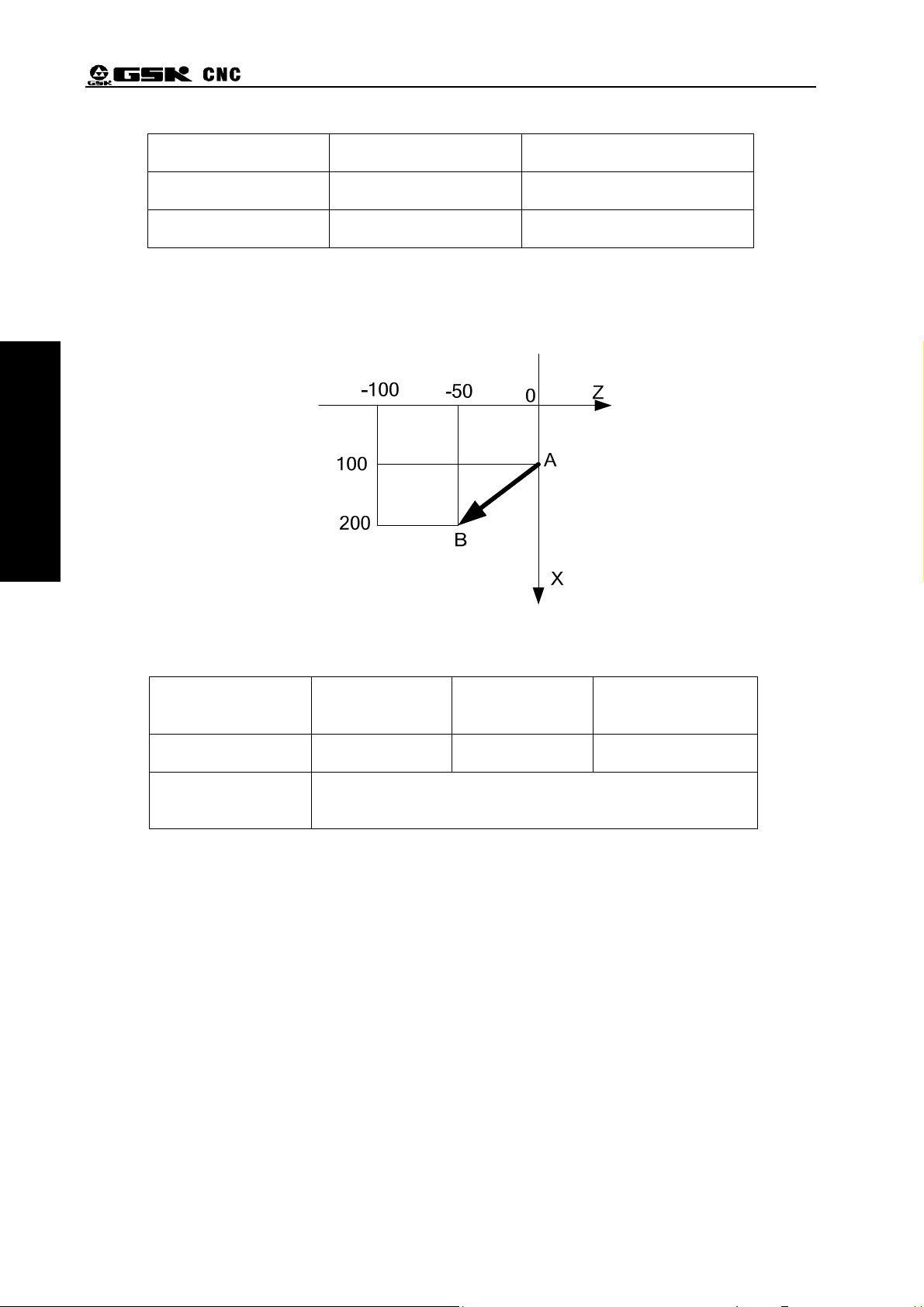

Example: Using an absolute coordinates, incremental coordinates and compound coordinates

compile A→B program described in Fig.1-7-1.

Part Two Pro

rammin

Fig. 1-7-1

Table 1-7-2

Programming mode

Absolute

programming

Incremental

programming

Compound

programming

Programming G1 X200 Z-50 G1 U100 W-50 G1 X200 W-50

Remark

Suppose that current coordinate point of the tool is on A, the

linear interpolation is executed.

Note: When there are command address X/ U or Z/ W at the same time, #132 alarm occurs: X, U or Z,W

exist simultaneously.

Example: G50 X10 Z20;

G01 X20 W30 U20 Z30;

1.8 Diameter and Radius Programming

The appearance of the machined workpiece is a rotating body, among which X dimension can be

specified by: the diameter and the radius, which is set by the bit of NO:1#2.

When NO:1#2 is set to 1, the radius is specified to execute programming.

When NO:1#2 is set to 0, the diameter is specified to execute programming.

10

Page 23

Chapter One Programming Fundamentals

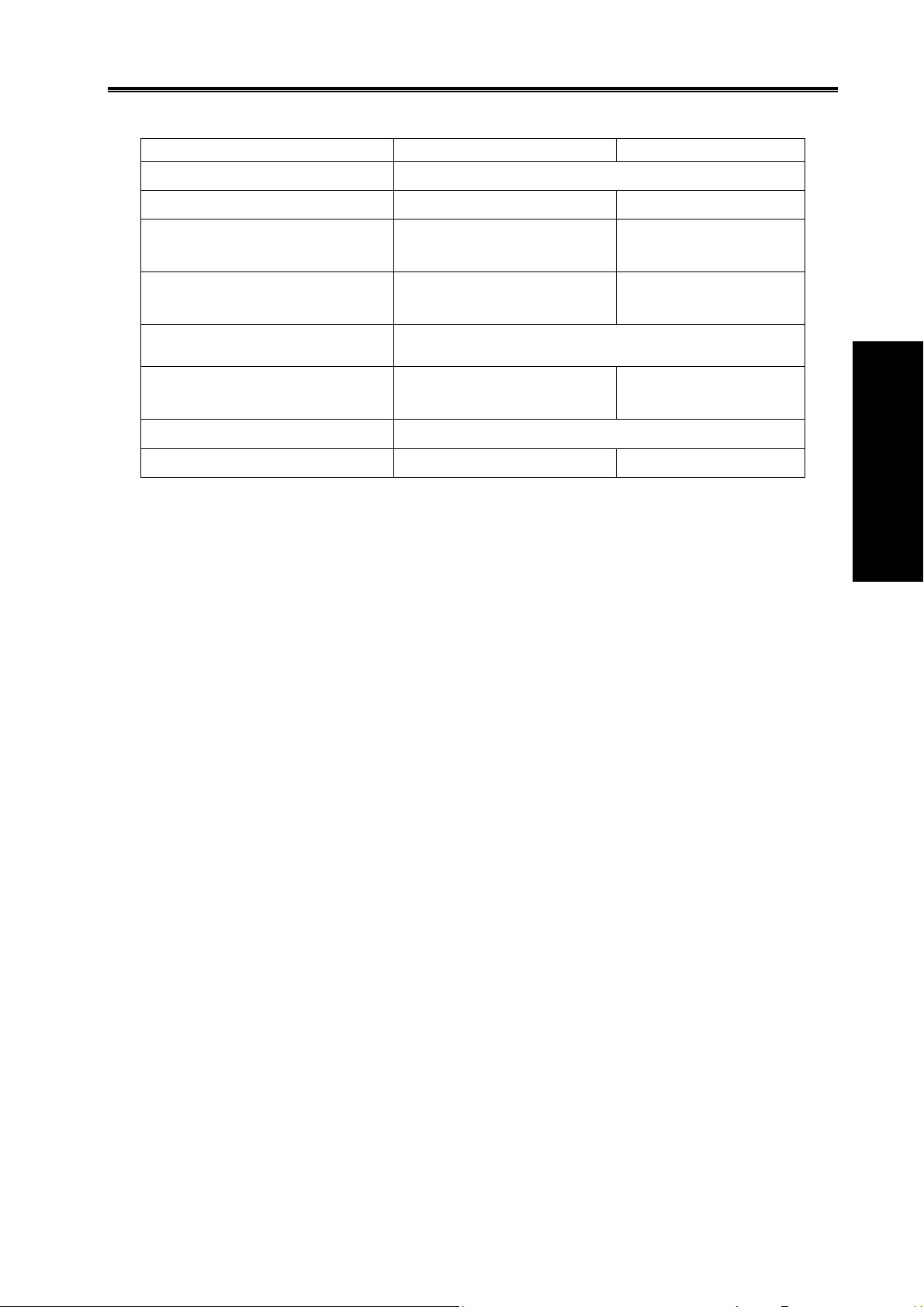

Table 1-8-1 diameter, radius designation

Item Diameter designation Radius designation

Z command

X command

Not related to diameter, radius designation

Diameter designation Radius designation

Incremental command of

Diameter designation Radius designation

address U

Coordinate system setting

Diameter designation Radius designation

(G50)

X value of too offset

NO:2#5 specifies the diameter designation or radius

designation

Radius command of circular

Radius designation Radius designation

interpolation(R,I,K)

X feedrate

X position display

Radius change (mm/min, mm/r)

Display diameter value Display radius value

Note 1: The diameter designation is used except for special explanation in the User Manual.

Note 2: The tool offset using diameter/radius is defined that the outside diameter of workpiece

uses diameter or radius when the tool offset is changed.

Example: when the diameter is specified, and the compensation value changes 10mm,

the diameter value of the workpiece’s outside diameter changes 10mm; when the radius

is specified, and the compensation value changes 10mm, the diameter value of the

workpiece’s outside diameter changes 20mm.

Part Two Programming

1.9 Modal, Simple and Initial State

The modal is defined that after the function and state of the corresponding word are executed,

they are valid till they are done again, namely, and the same functions and states are used in the

following blocks are, the word need not be input again.

Example:

G0 X100 Z100;(rapid position to X100 Z100)

X120 Z30;(rapid position to X120 Z30,G0 is modal and can be omitted)

G1 X50 Z50 F300;(linear interpolation to X50 Z50,feedrate 300mm/min G0→G1,)

X100;(linear interpolation to X100 Z50,feedrate 300 mm/min, G1Z, 50, F300 are modal and

can be omitted)

G0 X0 Z0;(rapid position to X0 Z0)

The simple is defined that after the function and state of the corresponding word are executed,

they are valid one time, namely, and the same functions and states are used in the following blocks

are, the word needs be input again.

The initial state is defined to the default function and state after the system is turned, namely, the

system executes the initial function and state when the system is turned but does not define the

corresponding function and state. The initial state of the system includes G00, G40, G97, G98, M05,

M09, M33.

Example:

11

Page 24

Part Two Pro

g

g

rammin

GSK980TA1/TA2, GSK980TB1/TB2, GSK98T CNC System User Manual

O0001;

G0 X100 Z100; (rapid position to X100 Z100,G0 is the system’s initial state)

G1 X0 Z0 F100; (linear interpolation X0 Z0,feed per minute,feedrate 100 mm/min,

G98 is the initial state after power on)

12

Page 25

Chapter Two Structure of an Part Program

Chapter Two Structure of an Part Program

A program is defined to a series collection of commands to control the CNC machine to complete

workpiece machining. After the complied programs are input to the CNC system, the CNC system

controls the tool movement along the linear and arc, the spindle starting/stopping, the cooling and the

lubricating ON/OFF according to the commands. The commands in the program are compiled

according to the actual movement sequence of the machine.

2.1 General Structure of a Program

A program consists of a sequence of block which is composed by words. Each block is

separated by the block end command (ISO is LF, EIA is CR). “;” is used in the User Manual to mean

the end of block.

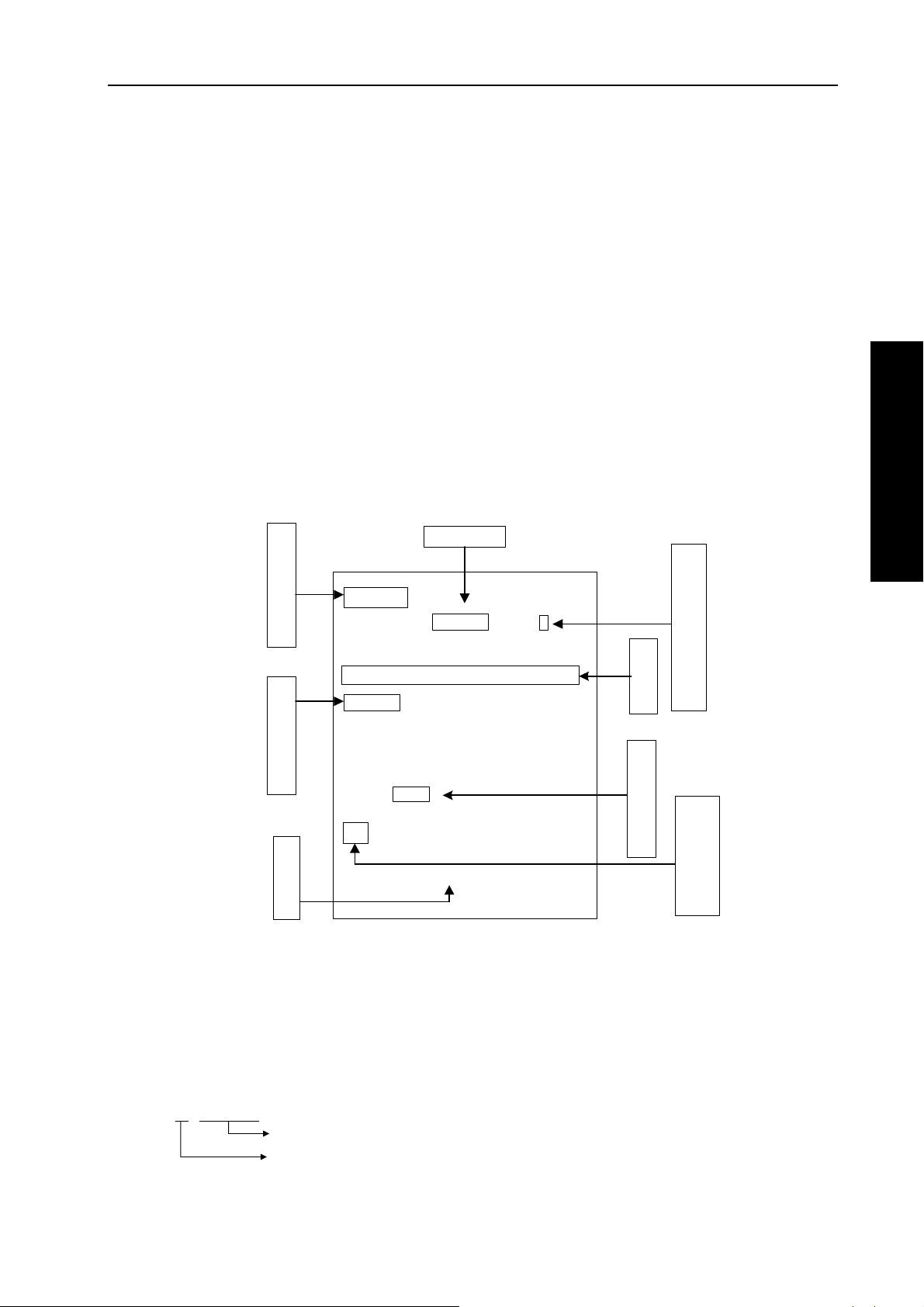

General structure of a program is shown in Fig. 2-1-1.

Program name Serial number

O0001

N0010 G50 X1000 Z100 ;

N0020 G0 X40 Z5 ;

N0030 G01 X10 Z-30 F200 ;

N0040 G01 U50 W20 F100 ;

… … ;

… … ;

… … ;

N0200 M30 ;

;

Word

End of program

Character of block end

Block

program end

Character of

Part Two Programming

Program

Fig. 2-1-1

2.1.1 Program Name

There are most 500 programs stored in GSK980TDa. To identify it, each program has only one

program name (there is no the same program name) beginning with command address O and the

following 4 digits.

○ □□□□

Program number (0000~9999, the leading zero can be omitted)

Address O

13

%

Page 26

Part Two Pro

g

g

rammin

GSK980TA1/TA2, GSK980TB1/TB2, GSK98T CNC System User Manual

End of a program

A program starts with its program name and ends with “%”.

2.1.2 Sequence Number and Block

A program consists of many commands and one command unit is called a block (Fig.2-1-1). A

block end command is used to separate blocks (Fig. 2-1-1), and “;” is the block end command in the

User Manual.

The beginning of a block can use a sequence number composed by the address N and its

following 4 digits.

N □□□□

sequence number (0001~9999, the leading zero can be omitted)

Address N

The sequence of a sequence number is arbitrary (NO:2 # 7 sets whether another sequence

number is inserted) and its interval is not equal (the interval size is set by P50, the interval of GSK98T

system is set by P119). All blocks can be with sequence numbers and some key blocks can be with

them. Generally, sequence number is from the small to the big according to machining sequence.

2.1.3 Word

A word is an element of a block. A word is composed by an address and its following

digit(some is with + or - before the digit), which is shown in Fig. 2-1-3:

X

1000

Address Digit

Word

Fig. 2-1-3-1

An address is one of English letters. The address describes the meaning of its following

numerical. In the system, the useful addresses and meanings are shown in Fig. 2-1-3-1. Some

address has different meanings according to different commands.

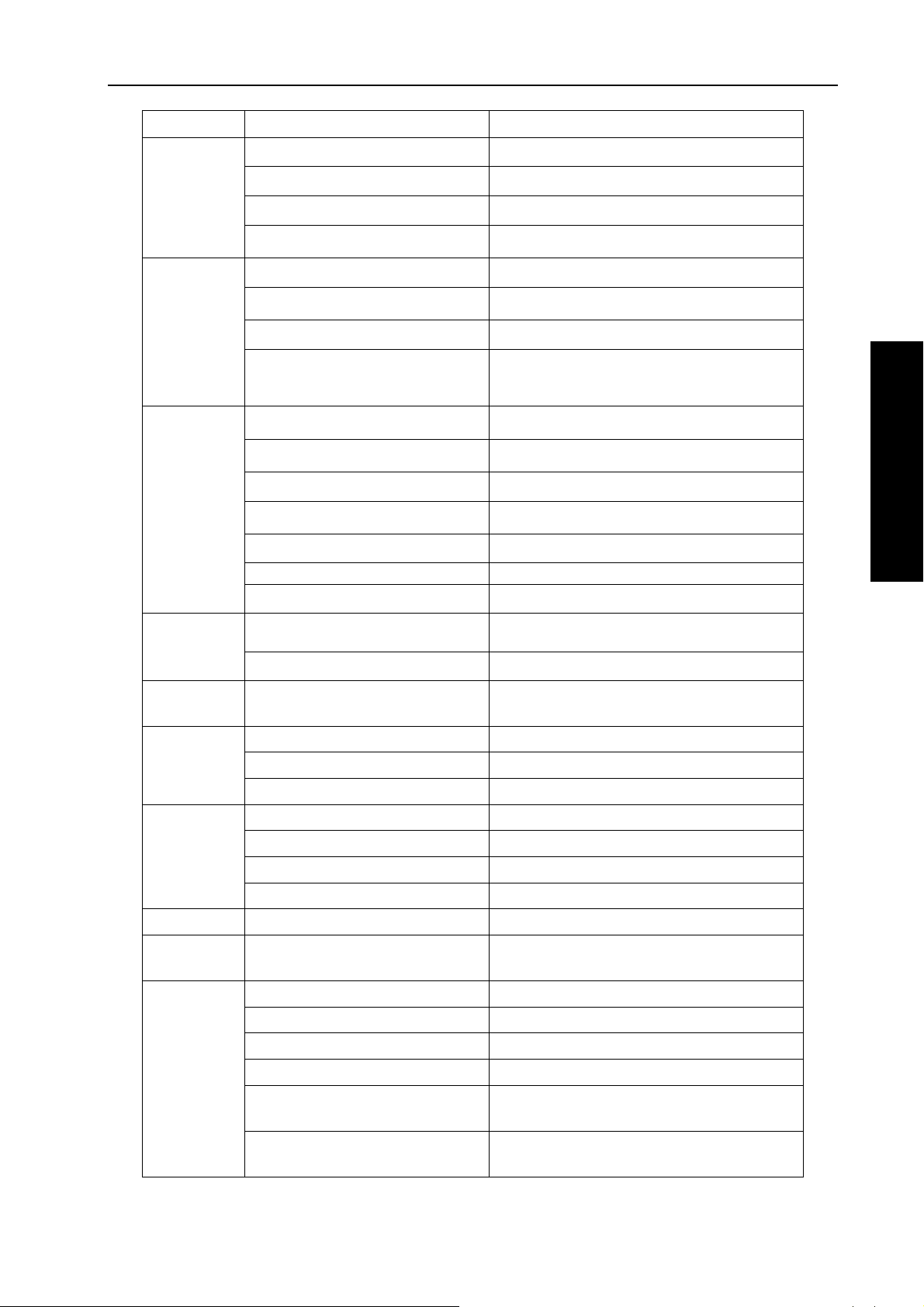

Address Value range Function

Table 2-1-3-1 address list

Z

Address Digit

-500

Word

O

N

G

X

14

Z

-9999.999~9999.999(mm)

-9999.999~9999.999(mm)

0~9999

1~9999

00~99

0~9999.999(s)

Program name

Block number

Preparatory function

X coordinate

Pause time

Z coordinate

Page 27

Chapter Two Structure of an Part Program

Address Value range Function

U

W

R

-9999.999~9999.999(mm)

-9999.999~9999.999(mm)

0.001~9999.999 (mm)

-9999.999~9999.999(mm)

-9999.999~9999.999(mm)

0.001~9999.999(mm)

-9999.999~9999.999(mm)

-9999.999~9999.999

(mm)

0~9999.999(mm)

0.001~9999.999(mm)

1~9999999(times)

0~9999.999(mm)

0~9999.999(mm)

0~9999.999(mm)

-9999.999~9999.999(mm)

X increment

X finishing allowance in G71,G72, G73

Cutting depth in G71

Travel of X tool retraction in G73

Z increment

Cutting depth in G72

Z finishing allowance in G71,G72, G73

Z tool retraction in G73

Arc radius

Tool retraction in G71, G72

Roughing cycle times in G 73

Tool retraction in G74, G75

Tool retraction distance G74, G75

Finishing allowance in G76

Taper in G90, G92, G94, G96

Part Two Programming

K

F

S

T

M

P

-9999.999~9999.999(mm)

I

0.06~25400(tooth/inch)

-9999.999~9999.999(mm)

X vector between arc center and starting

point

Metric thread tooth

Z vector between arc center and starting

point

1~8000(mm/min)

0.001~500(mm/r)

0.001~500(mm)

0~9999(r/min)

0~9999(m/min)

00~04

10~99

0100~0800

00~99

Specifying spindle constant surface speed

Miscellaneous function output, program

Feedrate per minute

Feedrate per rev

Metric thread lead

Specifying spindle speed

Multi-gear spindle output

Subprogram call

Tool function, subprogram call

executed flow, subprogram call

1~9999999(0.001s)

0~9999

0~999

0.001~9999.999(mm)

See Chapter 3.4, G76

Call subprogram number

Call times of subprogram

X circular moving distance in G74, G75

Thread cutting parameter in G76

Pause time

Explanation

1~9999

Initial block number of finishing in the

compound cycle command

15

Page 28

Part Two Pro

g

g

rammin

GSK980TA1/TA2, GSK980TB1/TB2, GSK98T CNC System User Manual

Address Value range Function

1~9999

Q

H

L

The limited values described in Table 2-1-3-1 are for the CNC device, but the limited values for

the machine are not described here. Please refer to the user manual, another user manual from the

machine manufacturer when programming.

0.001~9999.999(mm)

1~9999.999(mm)

01~99

01~99

End block number of finishing in the

compound cycle

Z circular moving distance in G74, G75

First cutting depth in G76

Operand in G65

Thread heads in G92

2.2 Relationship between Command Numerical Value and Decimal Point

In the system, some command cannot be with a decimal point, and No:11#0 sets whether the

decimal point is used when programming, and the relationship between the command numerical

value and the decimal point is shown in Fig.2-2-1:

Address

X

Z

U

W

R

I

K

P

S

Table 2-2-1

Having a

decimal point

Yes

Yes Command:G1 Z20

Yes Command:G1 U20

Yes Command:G1 W20

Yes

Yes

Yes

No

No

NO:11#0=1 NO:11#0=0 Remark

Command:G1 X20

Positioning point:20

Command:G4 X20

Delay:20s

Positioning point:20

Incremental value:

20mm

Incremental value:

20mm

Command:G4 P2

Delay:0.002s

Command:G1 X20

Positioning point:0.02

Command:G4 X20

Delay:0.02s

Command:G1 Z20

Positioning point:0.02

Command:G1 U20

Incremental value:

0.02mm

Command:G1 W20

Incremental value:

0.02mm

It is the

same as the

address X

It is not

related to

the decimal

point

16

Page 29

Chapter Two Structure of an Part Program

2.3 Subprogram

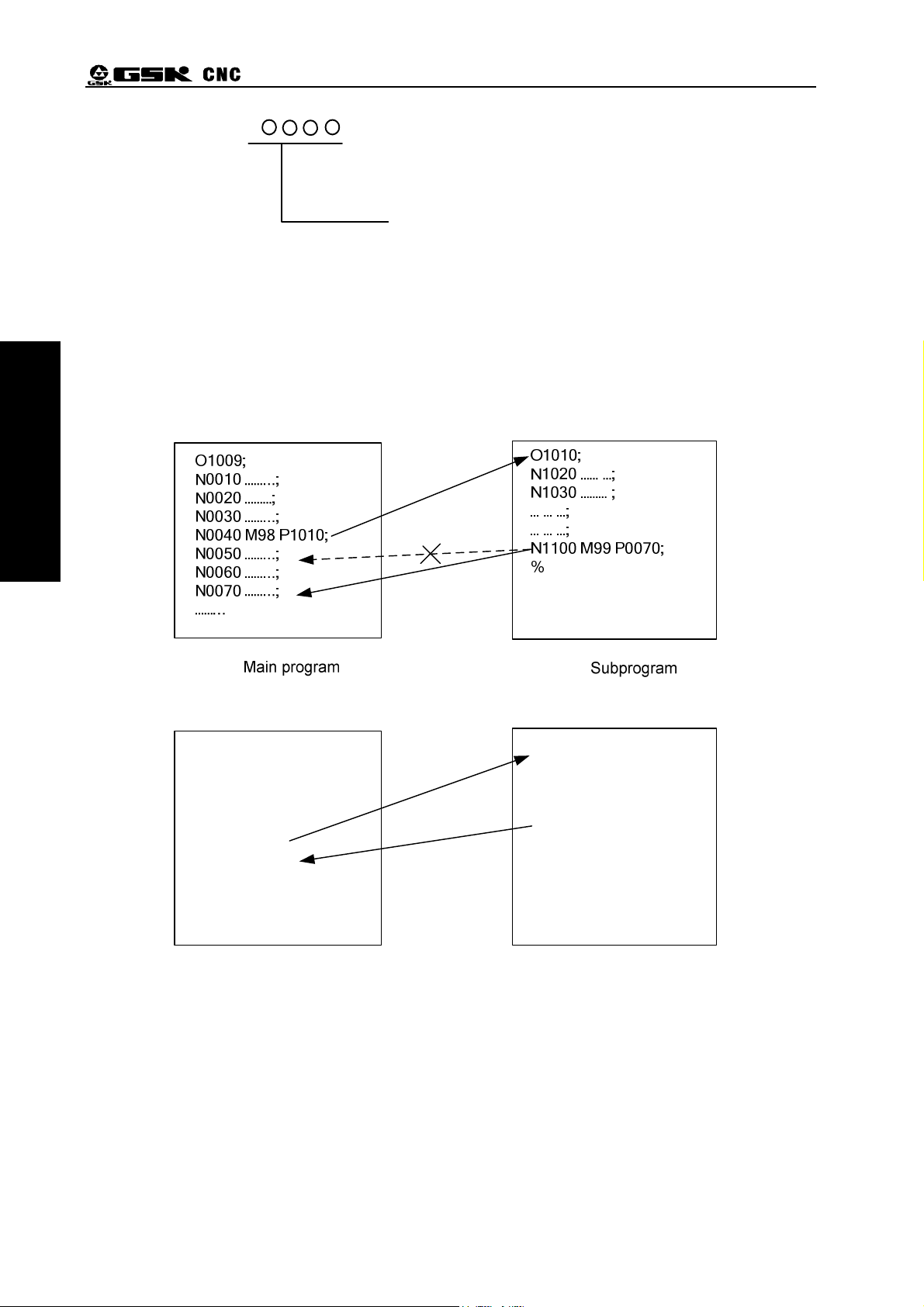

2.3.1 Main Program and Subprogram

To simply the programming, when the same or similar machining path and control procedure is

used many times, its program commands are edited to a sole program to call. The main program is

defined to call others and the subprogram(end with M99) is to be called. They both take up the

program capacity and storage space of system. The subprogram has own name, and can be called at

will by the main program and also can run separately. The system returns to the main program to

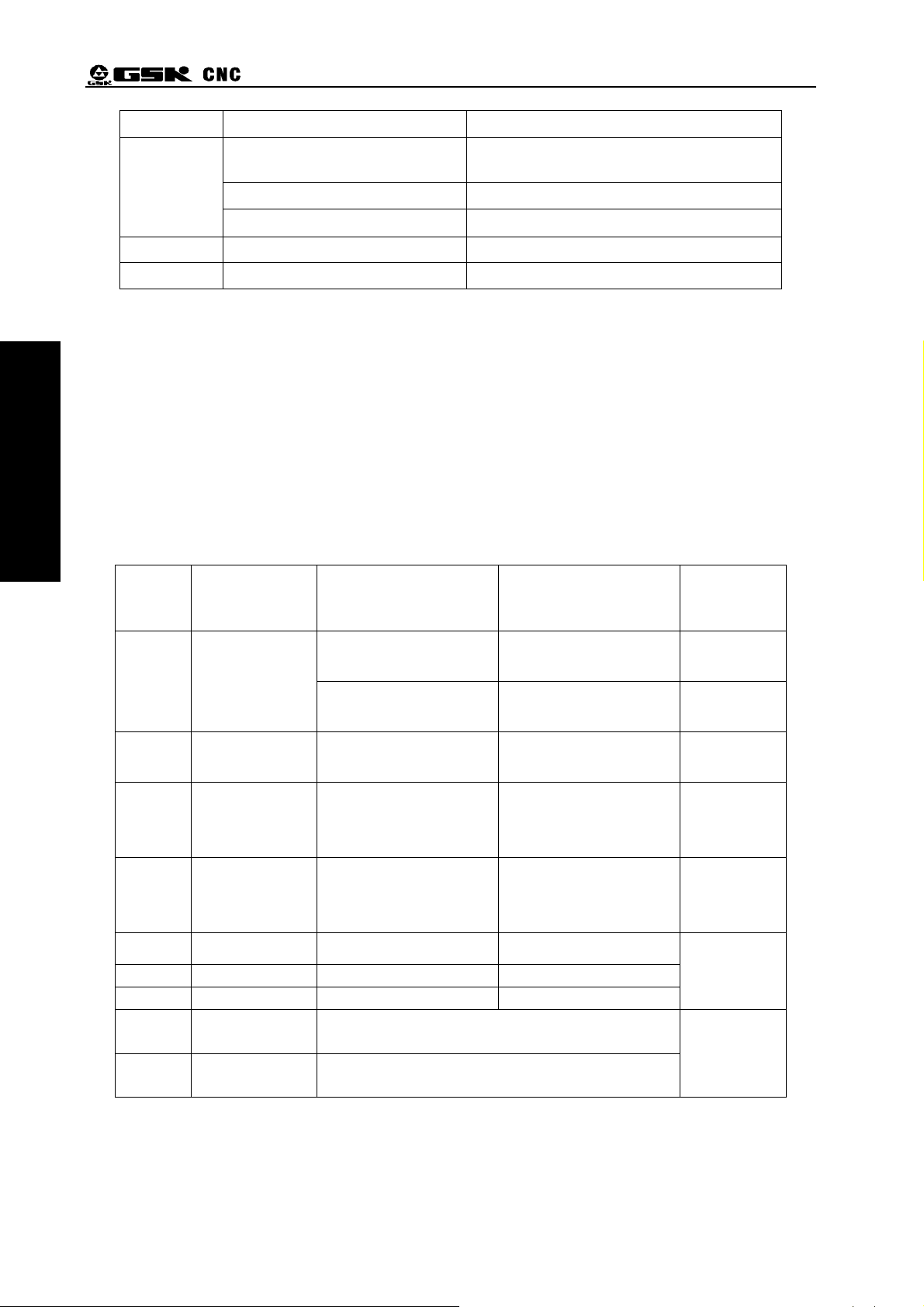

continue when the subprogram ends, which is shown below:

Part Two Programming

Ο0001;

G50 X100 Z100;

M3 S1 T0101;

G0 X0 Z0;

G1 U200 Z200 F200;

M98 P21006;

Call

Return

Ο1006;

G1 X50 Z50;

U100 W200;

G03 U30 W-15 R15 F250;

M99;

%

G0 X100 Z100;

M5 S0 T0100;

M30;

%

Main program

Fig. 2-3-1-1

2.3.2 Subprogram Call(M98)

Command format:

M98

P

Called subprogram number(0000~9999). The leading zero

of subprogram number can be omitted when the calling times is

not input; the subprogram number must be with 4 digits when

the calling times is input;

Subprogram

Call times: 1-9999. The calling times cannot be input when it is 1.

Command function: After other commands of current block are executed in M98, CNC calls

subprograms specified by P instead of the next block, and subprograms are

executed 9999 times at most.

Note: The system cannot call a subprogram in MDI mode.

2.3.3 Return from subprogram(M99)

Command format

17

Page 30

GSK980TA1/TA2, GSK980TB1/TB2, GSK98T CNC System User Manual

g

g

Part Two Pro

rammin

M99

Command function: After other commands of the current block (in the subprogram) are executed,

Example: Execution path of calling subprogram (with P in M99) is shown in Fig. 2-3-3-1.

Execution path of calling subprogram (without P in M99) is shown in Fig. 2-3-3-2.

P

Return to the block number (0001~9999)of the main program, the

leading zero can be omitted.

the system returns to the main program and continues to execute next block

specified by P, and calls a block following M98 of current subprogram when P

is not input. The current program is executed repeatedly when M99 is defined

to end of the main program.

Fig. 2-3-3-1

Ο0001;

G50 X100 Z100;

M3 S1 T0101;

G0 X0 Z0;

G1 U200 Z200 F200;

M98 P21006;

G0 X100 Z100;

M5 S0 T0100;

M30;

%

Main program Subprogram

The system can call fourfold-embedded subprograms, namely can call other subprograms in

another subprogram (Fig.2-3-3-3 is an example of double-embedded).

Call

Return

Fig. 2-3-3-2

Ο1006;

G1 X50 Z50;

U100 W200;

G03 U30 W-15 R15 F250;

M99;

%

18

Page 31

Chapter Two Structure of an Part Program

Fig. 2-3-3-3 double-embedded subprogram

Part Two Programming

19

Page 32

Part Two Pro

g

g

GSK980TA1/TA2, GSK980TB1/TB2, GSK98T CNC System User Manual

Chapter Three Preparatory Function G Command

3.1 Category of Preparatory Function G Command

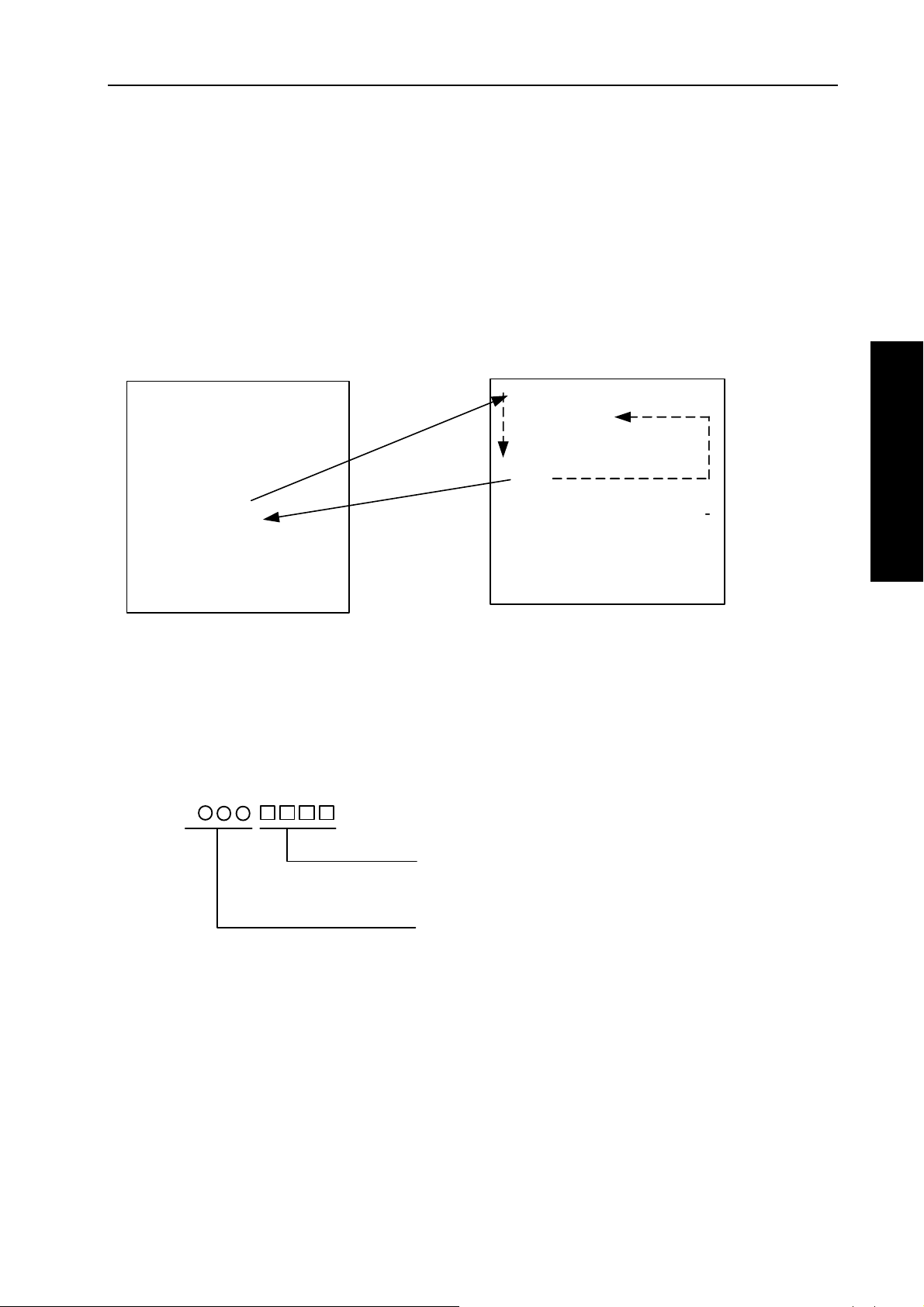

Preparatory function---A G command consists of command address G and its following 2 digits

numerical value, and is used for defining the motion path of the tool relative to the workpiece, setting

the coordinates and so on. G commands are shown in Fig. 3-1-1.

G

Command value(00~99,the leading zero can be omitted)

rammin

Address G

G words are divided into 6 groups (00, 01, 02, 03, 06, 07). That commands in the group 01 are

simple and others are modal.

After G commands are executed, their defined functions and states are valid until they are

changed by others in the same group, the previous functions and states are cancelled.

The initial G command is the initial mode after the system is turned on, the commands in the

initial mode include G00, G97, G98, G40, G21.

The defined functions and state are valid one time after the simple G command is executed, and

it must be input again when it is executed every time

After the system is switched on, the valid modal G commands which are not executed their

functions or states are called initial mode G command. Take it as the initial mode G command to be

executed when it is not be input after the system is switched on. The initial commands of GSK980TDa

include G00, G40, G97, G98.

Several G codes (Group 00 and 01 must not be in the same block) which belong to different

groups can be commanded in the same block. No.129 alarm occurs when more than two G codes

which belong to the same group are commanded in the same block. When G codes with common

word which belong to different group are in the same block, their functions are valid simultaneously

and are unconcerned with their sequence. The system alarms when other G codes except for ones

described in Table 3-1-1 or G codes which have no selection functions.

Table 3-1-1 G command list

ommand Group Format Explanation

Positioning, rapid

*G00

01

G01 G01 X(U)__Z(W) __ __F Linear interpolation

G02 G02 X(U)_Z(W)_R_(I_K_) F_ Circular interpolation CW

20

G00 X(U)__Z(W) __

traverse, speed rate of

each aixs set by

parameters

Page 33

Chapter Three Preparatory Function G Code

G03

G04 00

G10 00

G20

*G21 G21 Metric selection

06

G03 X(U)_Z(W)_R_(I_K_) F_ Circular interpolation

CCW,

G04 P_;or G04 X_;

G10 P__(parameter number)Q__

(numerical value)

A program specifying a

parameter function

Dwell

G20 Inch selection

G28 X(U)__Z(W) __ Return to reference point,

G28 00

and X, Z specifies the

middle point

G31 00

G32

G33

G34

01

01

01

*G40

G41

07

G42

G31 X(U)__ Z(W)__ F__

Skip function

G32 X(U)__Z(W) __F(I) Invariable pitch thread

cutting

G33 Z(W) __F(I);G33 X(U) __F(I)

Tapping cycle

G34 X(U)__Z(W) __F(I) K__ Variable pitch thread

cutting

G40 Tool radius compensation

cancel

G41 Tool radius compensation

(left)

G42 Tool radius compensation

(right)

Part Two Programming

G50 00 G50 X(U)__Z(W)__ Coordinate system setting

G51

00

G65 00

G70

G71

G51 X(U)__ Z(W)__

G65 Hm P#I Q#J R#K

G70 P(ns) Q(nf) Finishing cycle

G71 U(ΔD) R(E)

Local coordinate system

function

Macro code(see the

following)

Outer roughing cycle

G71 P(NS) Q(NF) U(ΔU)W(ΔW) F(F)

S(S) T(T)

G72

G72 W (ΔD) R (E)

End roughing cycle

G72 P(NS) Q(NF) U(ΔU) W(ΔW) F(F)

S(S) T(T)

G73

00

G73 U (ΔI) W (ΔK) R (D)

G73 P(NS) Q(NF) U(ΔU) W(ΔW) F(F)

Closed cutting cycle

S(S) T(T)

G74

G75

G74 R(e)

G74 X(U) Z(W) P(Δi) Q(Δk) R(Δd) F(f)

G75 R(e)

End deep hole machining

cycle

Outer/inner grooving cycle

G75 X(U) Z(W) P(Δi) Q(Δk) R(Δd) F(f)

G76

G90

G92 G92 X(U)__ Z(W)__ R__ F(I) __J __K__ Thread turning cycle

01

G76 P(m) (r) (a) Q( dmin) R(d)

G76 X(U) Z(W) R(i) P(k) Q( d) F(L)

△

△

G90 X(U)__ Z(W)__ R__ F__ Outer, inner turning cycle

Compound thread cutting

cycle

G94 G94 X(U)__ Z(W)__ R__ F__ End turning cycle

G96 02 G96 S Constant surface control

21

Page 34

Part Two Pro

g

g

GSK980TA1/TA2, GSK980TB1/TB2, GSK98T CNC System User Manual

*G97 G97 S Constant surface control

cancel

*G98

G99 G99 Feed per rev

Note 1: When the system is turned on, it is in the state of G command with *.

Note 2: G commands in Group 00 are simple.

Note 3: 98T system has G41/G42/G40, G65.

03

G98 Feed per minute

3.2 Simple G Command

3.2.1 Rapid Positioning(G00)

rammin

Command format

Function:

X, Z rapidly traverses at the respective traverse speed to the position specified by X(U),

:G00 X(U)_ Z(W)_ ;

Z(W).

Explanation:X(U):absolute (incremental) coordinate of X positioning end point;

Z(W):absolute (incremental) coordinate of Z positioning end point;

1. X, Z rapidly traverses at the respective traverse speed and their combined path is really

not linear, so maybe they cannot reach the end points simultaneously, please pay

attention to it when programming ( Fig. 3-2-1-1).

2. X, Z rapidly traverses at the speed separately set by P21, P22, for 98T system, they are

separately set by P17, P18 or are adjusted by pressing

operation panel, or are performed by selecting manual rapid override which has five

grades including Fo, 25%, 50%, 75%, 100%. (Fo speed is set by P32, but for 98T

system, it is set by P69)

3. The tool does not traverse when there is a positioning parameter after G00, the system

only changes the current tool traverse mode into G00.

on the

Fig. 3-2-1-1

Example:the tool rapidly traverses from A to B, which is shown in Fig. 3-2-1-2:

22

Page 35

Programming:

Chapter Three Preparatory Function G Code

Part Two Programming

Fig. 3-2-1-2

G0 X20 Z0;(absolute programming, diameter programming)

G0 U-22 W-18;(incremental programming, diameter programming)

G0 U-22 Z0;(compound programming, diameter programming)

3.2.2 Linear Interpolation(G01)

Command format

:G01 X(U)_ Z(W)_ F_;

Function:the tool traverses to the specified position at the feedrate (mm/min)specified by F. The

interpolation path is shown in Fig. 3-2-2-1.

Explanation:X(U):absolute (incremental) coordinate of X interpolation’s end point;

Z(W):absolute (incremental) coordinate of Z interpolation’s end point;

F:is combined federate of X, Z, is modal. It value is related to G98 OR G99, which is

shown in 3-2-2-1:

Table 3-2-2-1

G98(mm/min) G99(mm/r)

Value range 1~8000 0.001~500

Command path:

23

Page 36

GSK980TA1/TA2, GSK980TB1/TB2, GSK98T CNC System User Manual

g

g

L

L

Part Two Pro

rammin

Z

X

L

End point

0

Current point

U/2

Z(W)

X

1. Feedrate specified by F is valid until a new F value is specified. Feedrate specified by F is