Page 1

GSK980T

Turning Machine CNC System

User Manual

Page 2

GSK980T CNC SYSTEM USER MANUAL

Ⅰ

INTRODUCTION······························································································································1

1.1 Introduction································································································································· 1

1.2 Type Signification························································································································ 1

1.3 Type Table ··································································································································· 1

II. Programming ······································································································································2

2.1 General······································································································································ 2

2.1.1 Axes Definition ·················································································································· 2

2.1.2 Reference Point (Machine Zero Point) ··············································································· 2

2.1.3 Coordinate value and direction and dimension··································································· 2

2.1.4 Unit and Range of coordinate····························································································· 3

2.1.5 Initial and Modal Status of the Command ·········································································· 3

2.1.6 The Start of a Program········································································································3

2.1.7 The End of a Program········································································································· 3

2.1.8 Program Configuration······································································································· 3

2.1.9 Program Configuration······································································································· 3

2.2 controlled Axis·························································································································· 5

2.2.1 Number of Controlled Axis ································································································ 5

2.2.2 Unit Setting ························································································································ 5

2.2.3 Maximum Strokes ·············································································································· 5

2.3 Preparatory Function (G Function)···························································································· 6

2.3.1 Positioning(G00) ················································································································ 7

2.3.2 Linear Interpolation (G01)·································································································· 7

2.3.3 Circular Interpolation (G02,G03) ······················································································· 8

2.3.4 Thread Cutting (G32) ······································································································· 11

2.3.5 Return to Reference Point Automatically (G28) ······························································· 14

2.3.6 Dwell(G04) ······················································································································ 14

2.3.7 Work Coordinate System Setting(G0) ··············································································14

2.3.8 Feed per Minute (G98) ····································································································· 15

2.3.9 Feed per Revolution(G99) ································································································ 15

2.3.10 Constant Surface Speed Control(G96, G97)··································································· 17

2.3.11 Canned Cycle(G90, G92 G94)························································································ 20

2.3.12 Multiple Repetitive Cycle (G70~G75) ··········································································· 25

2.3.13 Notes on Multiple Repetitive Cutting Cycle (G70~G75)················································ 34

2.4 Spindle Function(S Function)·································································································· 34

2.4.1 Spindle Speed Command·································································································· 34

2.5 Tool Function·························································································································· 35

2.5.1 Procedures of tool Change································································································ 35

2.5.2 Tool selection (Change) Related Parameters ···································································· 36

2.6 Auxiliary Function(M function) ······························································································ 36

2.6.1 Description of M F unction ······························································································ 37

2.6.2 M function Related Data··································································································· 37

2.7 Program Configuration············································································································ 39

2.7.1 Program···························································································································· 39

2.7.2 Program Number ·············································································································· 41

GUANGZHOU CNC EQUIPMENT CO., LTD.

Page 3

GSK980T CNC SYSTEM USER MANUAL

2.7.3 Sequence Number and Block···························································································· 42

2.7.4 Word and Address ············································································································ 42

2.7.5 Basic Addresses and Ranges of Command Values···························································· 43

2.7.6 End of Program ················································································································ 43

2.8 Coordinate Values and Dimensions························································································· 43

2.8.1 Absolute Commands and Incremental Commands ··························································· 43

2.8.2 Decimal Point Programming ···························································································· 45

2.8.3 Diameter Designation and Radius Designation ································································45

2.9 Tool Offset ······························································································································ 46

2.9.1 Geometry Tool Offset ······································································································· 46

2.9.2 T Code for Tool offset ······································································································ 46

2.9.3 Tool Offset Value Input by Moving the Tool To a Fixed Point ········································· 47

2.9.4 Direct Input of Tool Offset by Trial Cutting ·····································································47

2.10 Automatic Acceleration and Deceleration ············································································· 49

2.10.1 Speed Control In the Corner Between Blocks ···································································50

2.11 The Macro Program to User ·································································································· 50

2.11.1 The Macro Command ········································································································ 51

2.11.2 The Macro Program Body ······························································································ 51

2.11.3 Operation and Transfer Dictate(G65) ··········································································· 52

2.11.4 The Note about the Macro Program Body ······································································ 54

2.11.5 Example for User··············································································································· 55

III. Operation·········································································································································56

3.1 Operation Panel······················································································································· 56

3.1.1 LCD/MDI Panel ··············································································································· 56

3.1.2 Screen Change Keys········································································································· 57

3.1.3 Explanation of Key Board ································································································ 57

3.1.4 Machine Operation Panel ································································································· 58

3.2 Manual Operation···················································································································· 59

3.2.1 Manual Reference Point Return························································································ 59

3.2.2 Manual start Point Return································································································· 59

3.2.3 Manual Continuous Feed·································································································· 60

3.2.4 Step Feed ·························································································································· 61

3.2.5 Manual Handle Feed (Optional function) ········································································· 62

3.2.6 Manual auxiliary operation······························································································· 62

3.3 Automatic Operation ··············································································································· 64

3.3.1 Automatic Operation mode ······························································································ 64

3.3.2 Starting Automatic Operation ··························································································· 65

3.3.3 Executing Automatic Operation ······················································································· 65

3.3.4 Stopping and Terminating Memory Operation ·································································65

3.4 TEST OPERATION················································································································ 67

3.4.1 All Axis Machine Lock ···································································································· 67

3.4.2 Auxiliary Function Lock ·································································································· 67

3.4.3 Feedrate Override ············································································································· 67

3.4.4 Rapid Traverse Override··································································································· 68

3.4.5 Dry Running····················································································································· 68

3.4.6 Restart After Feed Hold···································································································· 68

GUANGZHOU CNC EQUIPMENT CO., LTD.

Page 4

GSK980T CNC SYSTEM USER MANUAL

3.4.7 Single Block ····················································································································· 68

3.5 Safety Operation······················································································································ 69

3.5.1 Emergency Operation ······································································································· 69

3.5.2 Overtravel························································································································· 70

3.6 Alarm ······································································································································ 70

3.7 Program Storage & Edit ······································································································· 70

3.7.1 Preparation for Part Program Storage & Edit Operation ················································ 70

3.7.2 Registering Program to Memory ······················································································ 70

3.7.3 Program Number Searching ····························································································· 71

3.7.4 Deleting Program ············································································································· 71

3.7.5 Deleting All Program········································································································ 71

3.7.6 Output a program ············································································································· 72

3.7.7 Output All Programs········································································································· 72

3.7.8 Sequence Number Search································································································· 72

3.7.9 Inserting, Amending and Deleting of word······································································· 73

3.7.10 Number of Registered Programs····················································································· 76

3.7.11 Capacity of System Memory ·························································································· 76

3.8 Display and Setting Data········································································································· 76

3.8.1 Offset Amount ·················································································································· 76

3.8.2 The setting of setting parameter························································································ 77

3.8.3 The Setting and Display of Custom Macro Variable························································· 79

3.8.4 Parameter ························································································································· 80

3.8.5 Diagnoses ························································································································· 82

3.9 Display ···································································································································· 82

3.9.1 Status display···················································································································· 82

3.9.2 Display of key in data······································································································· 83

3.9.3 Program Number, Sequence Number Display ·································································· 83

3.9.4 The Display of Program Memory Used.··········································································· 84

3.9.5 Display of Command Value ([PRG] key) ········································································· 84

3.9.6 Current position display ([POS] key) ··············································································· 85

3.9.7 Display of Run Time and Parts Count ·············································································· 86

3.9.8 Alarm Display([ALM] key)······························································································ 86

3.9.9 Adjusting Brightness of LCD ··························································································· 87

IV CONNECTION·································································································································88

4.1 SYSTEM CONNECTION DIAGRAM··················································································· 88

4.1.1 Layout diagram of interfaces···························································································· 88

4.1.2 Descriptions of Interfaces································································································· 88

4.1.3 Connection Diagram········································································································· 89

4.2 Detail of connection ················································································································ 89

4.2.1 From CNC to Axis Driver ································································································ 89

4.2.2 Description of Signal········································································································ 90

4.3 Connection between CNC and Axis Driver············································································· 92

4.4 Spindle Encoder ······················································································································ 93

4.5 RS232-C Serial Interface(Optional) ························································································ 93

GUANGZHOU CNC EQUIPMENT CO., LTD.

Page 5

GSK980T CNC SYSTEM USER MANUAL

4-6 Spindle Analogue Control Interface(Optional) ······································································· 94

4-7 Handwheel ······························································································································ 94

4.8 Connection of power supply···································································································· 95

4.9 In put/output Interface············································································································· 96

4.9.1 Connecting Diagram········································································································· 96

4.9.2 Input Signals····················································································································· 96

4.9.3 Signal Description ············································································································ 97

4.9.4 Output Signal ················································································································· 100

4.9.5 Diagnose Address Table of Input and Output Signal ······················································ 101

V Adjustment of Machine ····················································································································102

5.1 Preparation before Power On ································································································ 102

5.2 Adjustment of Machine ········································································································· 102

5.2.1 Emergency Stop Button·································································································· 102

5.2.2 Adjustment of Drive Axis······························································································· 102

5.2.3 Toolpost Adjustment······································································································· 104

5.2.4 Spindle Adjustment ········································································································ 104

5.2.5 Single step/ Handle Feed ································································································ 104

5.2.6 Others Adjustment·········································································································· 104

5.3 Standard Parameter Setting and the Storage of Parameter, Diagnosis and Program ·············· 105

Appendix Ⅰ Parameter ·····················································································································106

Appendix II Diagnosis·························································································································114

Appendix III Alarm Code List·············································································································119

Appendix IV Binary to Decimal Conversion Table·············································································122

Appendix V Installation dimension·········································································································I

GUANGZHOU CNC EQUIPMENT CO., LTD.

Page 6

GSK980T CNC SYSTEM USER MANUAL

Ⅰ INTRODUCTION

1.1 Introduction

GSK980T is a well-pervading machine numerical-controlled system produced by my factory. As

a upgrading production of the economical CNC,GSK980T has following characteristic:

△ Adopting 16-bit CPU,CPLD and hardware interpolation to realize high-speed and um

level control

△ Adopting 4-layer PCB and having high integration, reasonable technology and high

reliability

△ Having Chinese display with LCD and friendly interface, convenient operation

△ Being able to adjusting accelerating or decelerating speed, matching step- motor or servo

motor

△ Being able to adjust the ratio of electronic gear and having convenient application

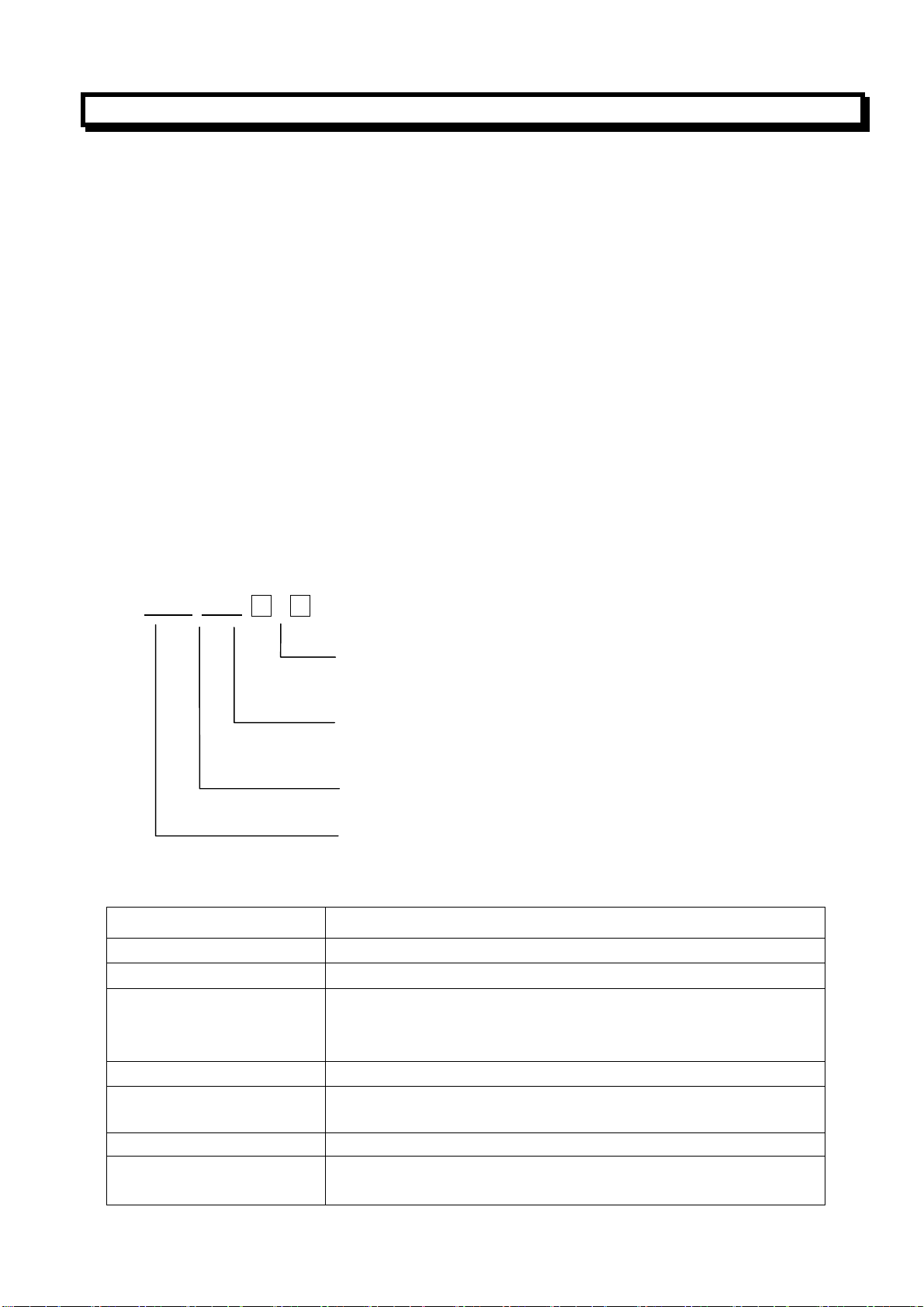

1.2 Type Signification

GSK 980T — 。

Assembly form: none:small panel(420×260mm)

L: big panel(420×320mm)

B: boxed assembly

Sort symbol :none: surface operation panel

A: alloy-solid operation panel

1.3 Type Table

Order type specification

GSK980T

GSK980T-L

GSK980T-B

GSK980TA

GSK980TA-L

GSK980TA-B

GSK980T-DF3A □□□

□

420×260mm surface operation panel

420×320mm surface operation panel

GSK980T-L boxed assembly,line goes out from the hole

of box bottom(line going out from the top of box must be

specified)

420×260mm alloy-solid operation panel

GSK980TA being assembled with the additional panel of

AP01,the size is 420×320mm

GSK980TA-L boxed assembly

Being assembled with DF3A with line going out from the

bottom of box(from the bottom of box)

GUANGZHOU CNC EQUIPMENT CO., LTD.

Machine CNC of 980T series

Production symbol of GSK

1

Page 7

GSK980T CNC SYSTEM USER MANUAL

GSK980T-DF3A □□□

□-B

GSK980T-DY3 □□□□

-B

GSK980T-DY3□□□□

Note :“□□□□”is 4-bit digit. the first 2-bit means the specification of driver in X axis, the

second 2-bit means the specification of driver in Z axis.

assembled in that axis.

Being assembled with DF3A with line going out from back

(from aerial socket in the back of box)

Being assembled with DY3 with line going out from back(from

aerial socket in the back of box)

Being assembled with DY3 with line going out from the bottom

of box(from the bottom of box)

“00” means no driver being

II. Programming

2.1 General

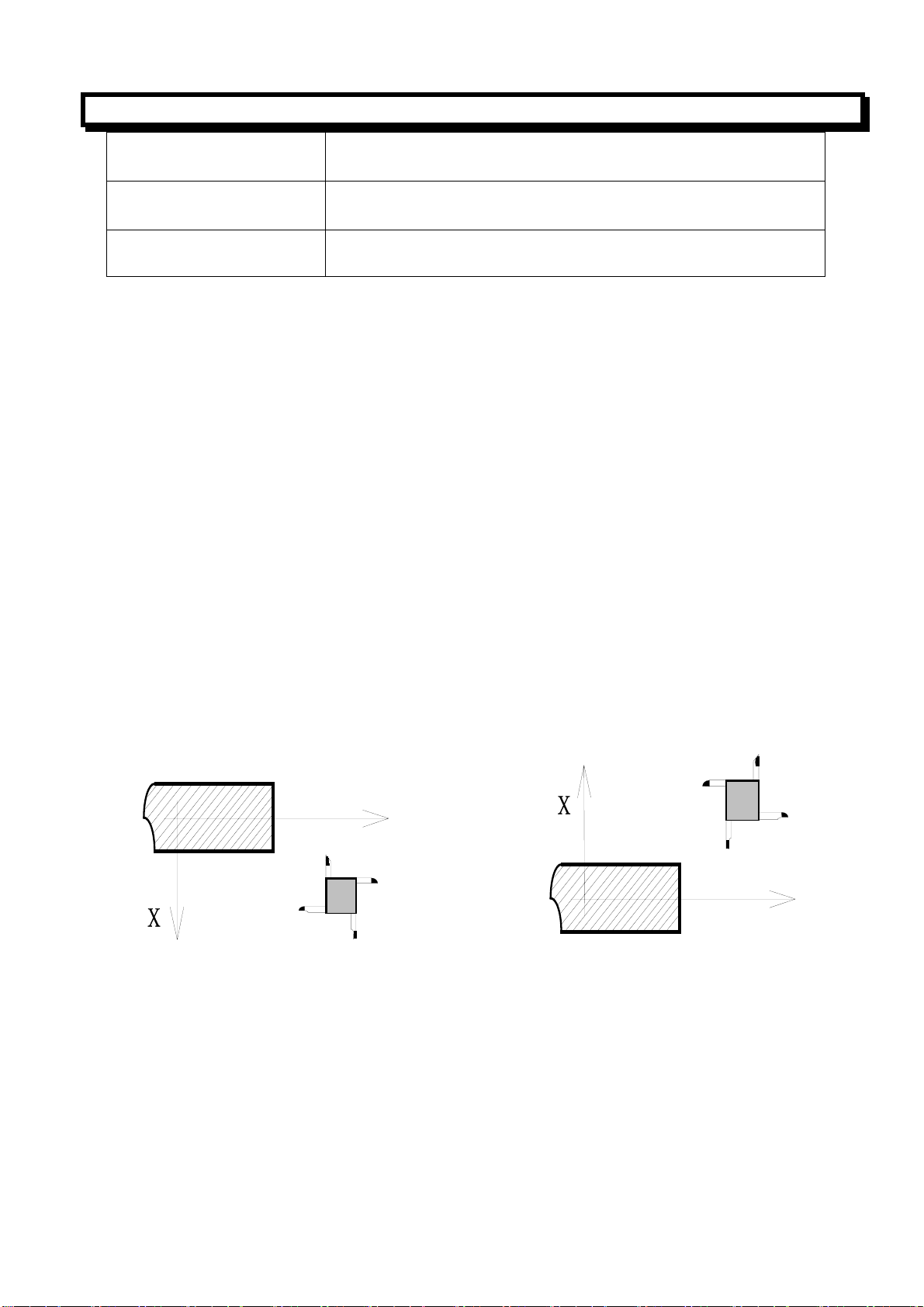

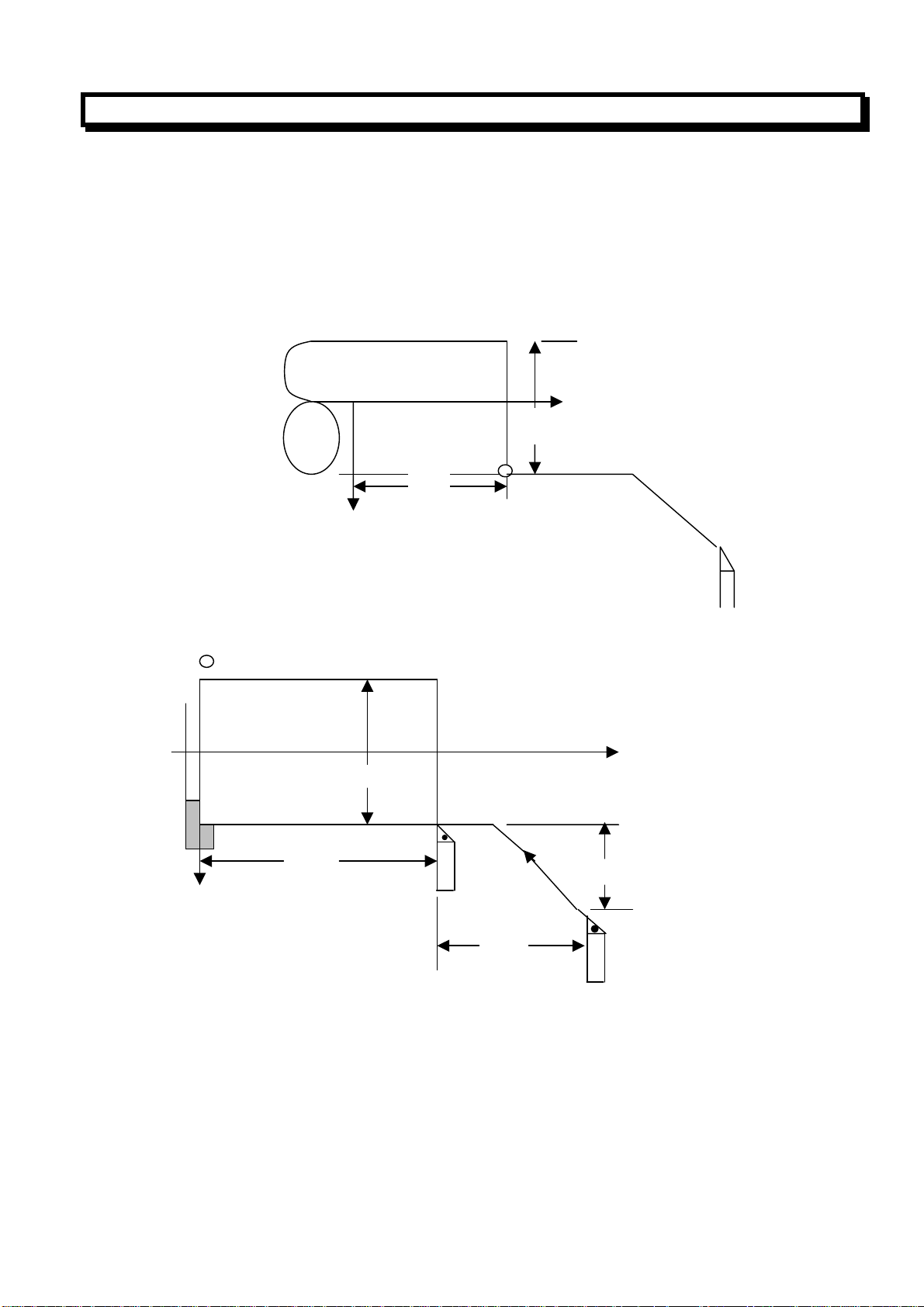

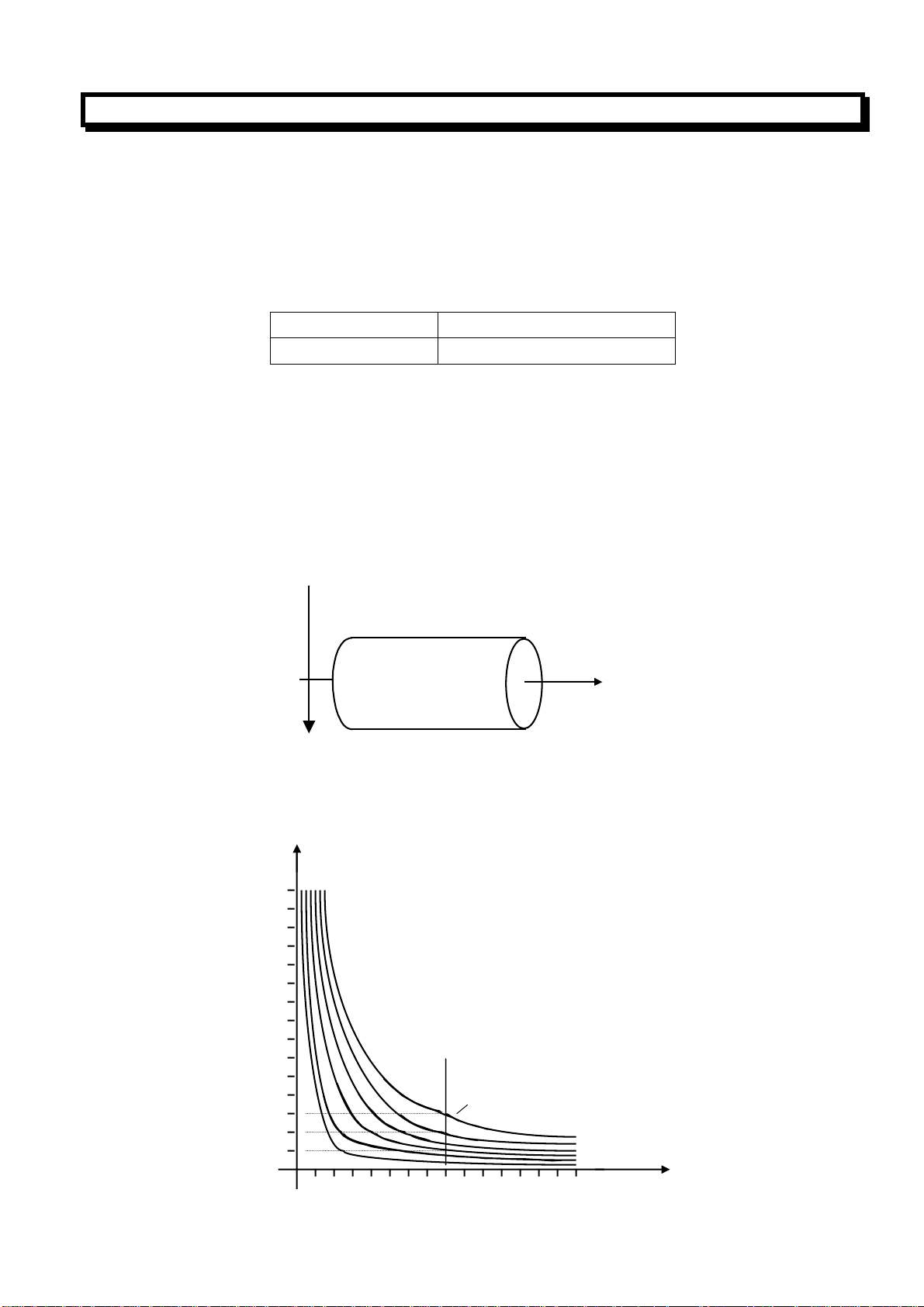

2.1.1 Axes Definition

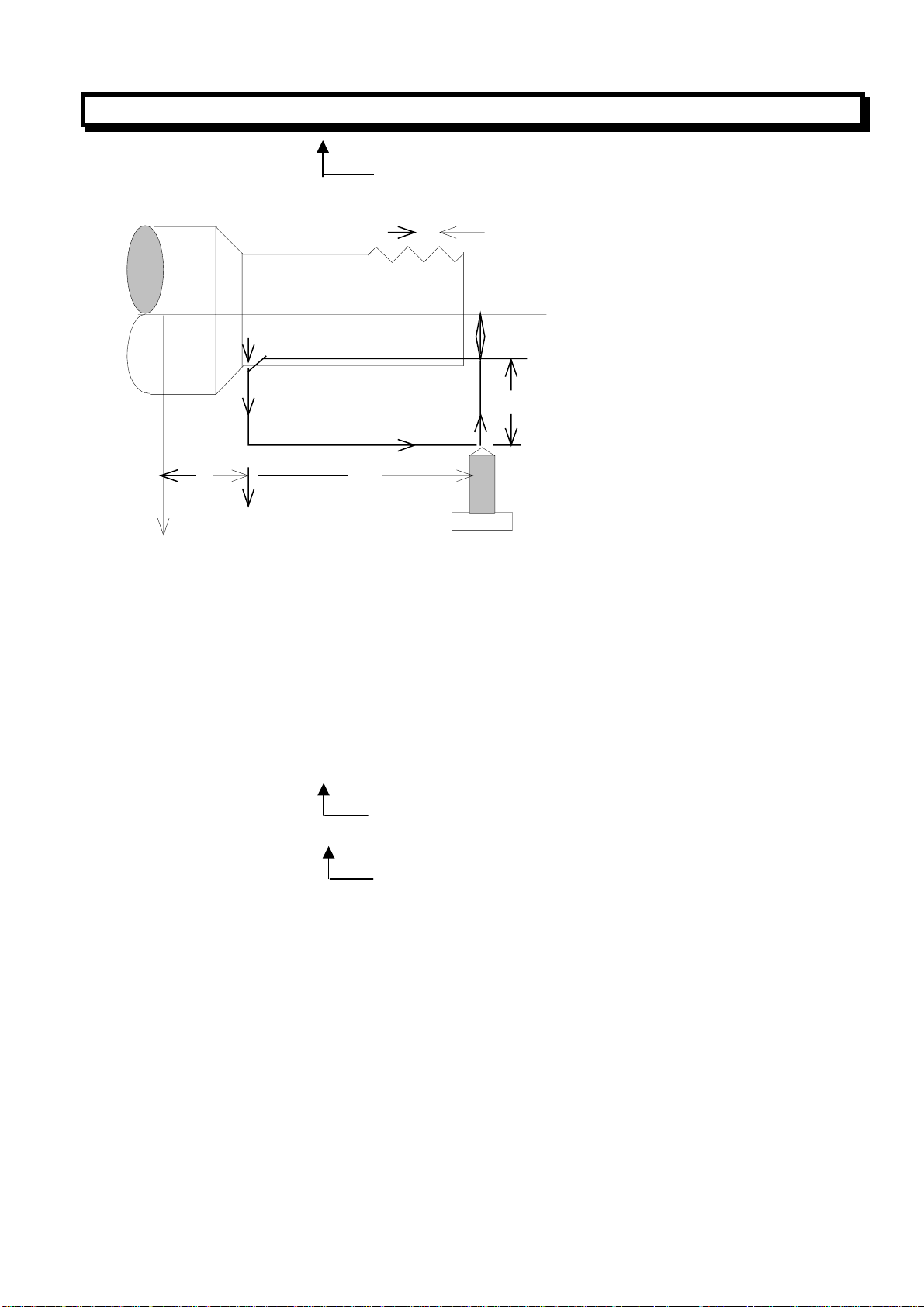

In this CNC system, the main two axis of motion of the lathe machine is referred to as X and Z axis in

a right hand coordinate system. Since the spindle of the lathe is horizontal, the Z axis is horizontal as

well, the cross axis is denoted by X.A positive motion in both X and Z direction moves the tool away

from the workpiece.

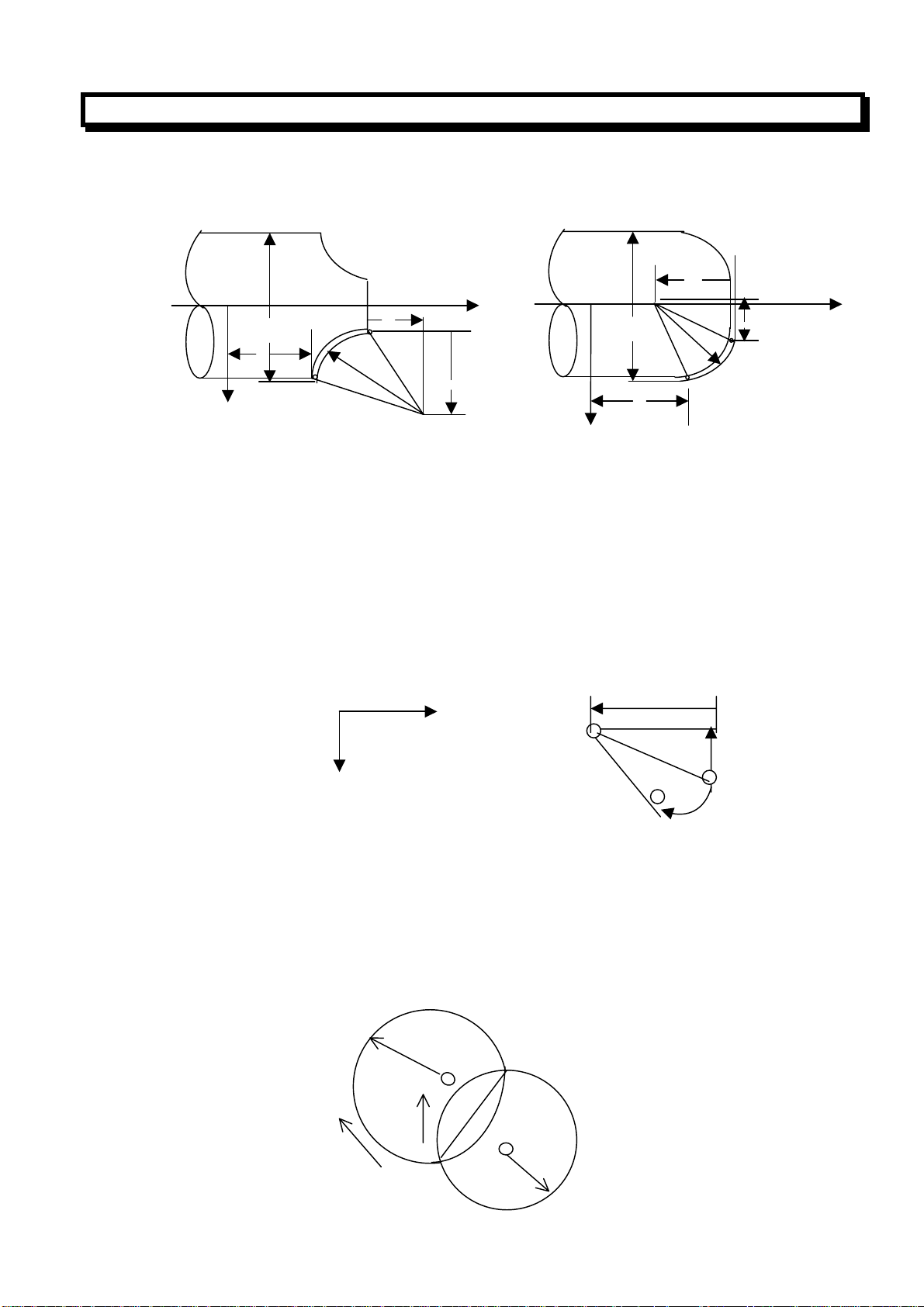

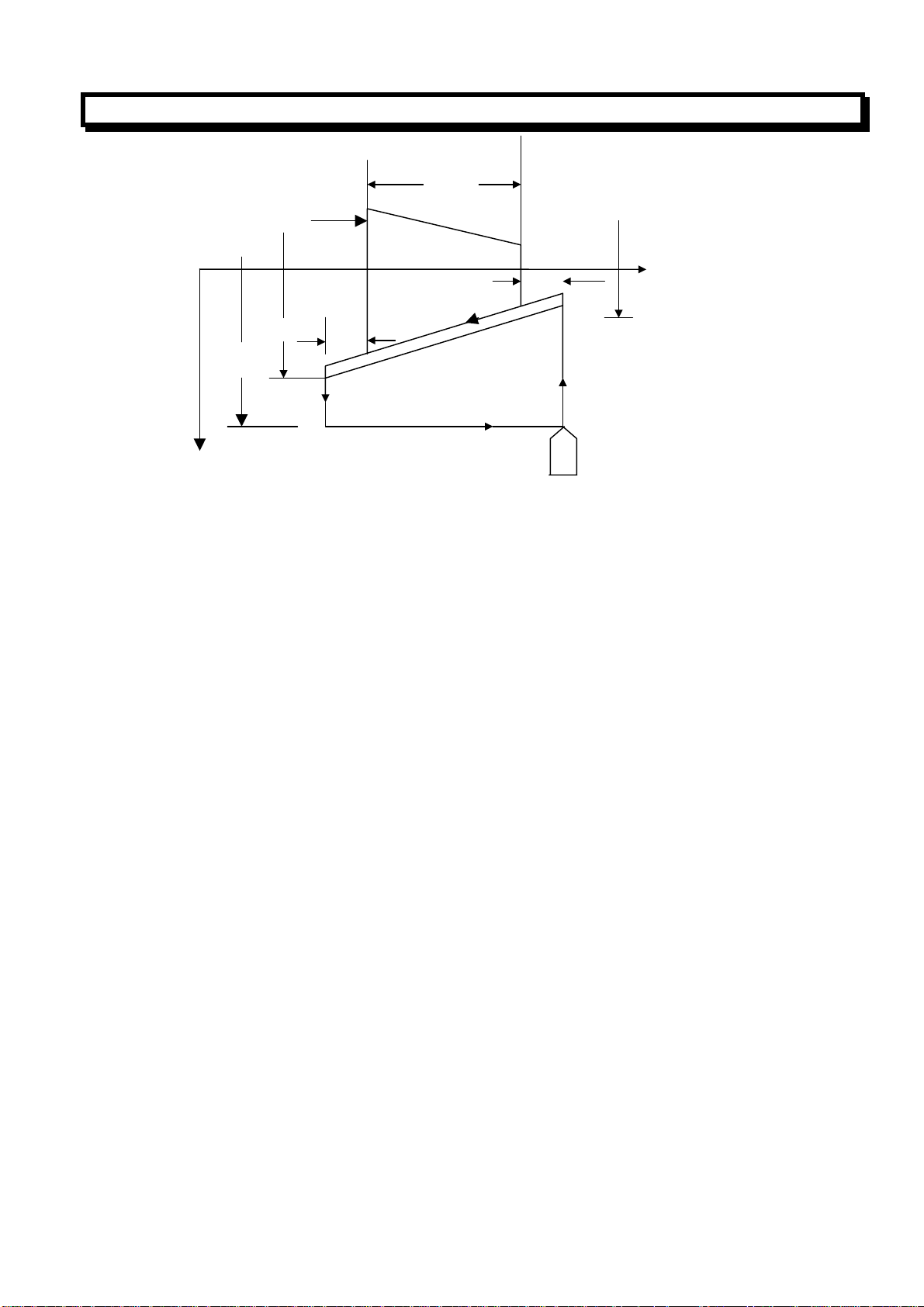

The figure below shows the coordinate system of front toolpost lathe system and rear toolpost lathe

system. In the front toolpost system, a positive command moves the Z axis from left to right and the X

axis from back to front. In this CNC system we use front toolpost system for introducing the

programming.

Front toolpost system Rear toolpost system

Z

X

X

2.1.2 Reference Point (Machine Zero Point)

Reference point is a fixed position on a machine tool which the tool can easily be moved. Usually, the

reference point is set at the max. travel position of each axis at positive direction. Don’t use the

reference point return function (such as G28).if the reference point is not available on the

corresponding machine tool.

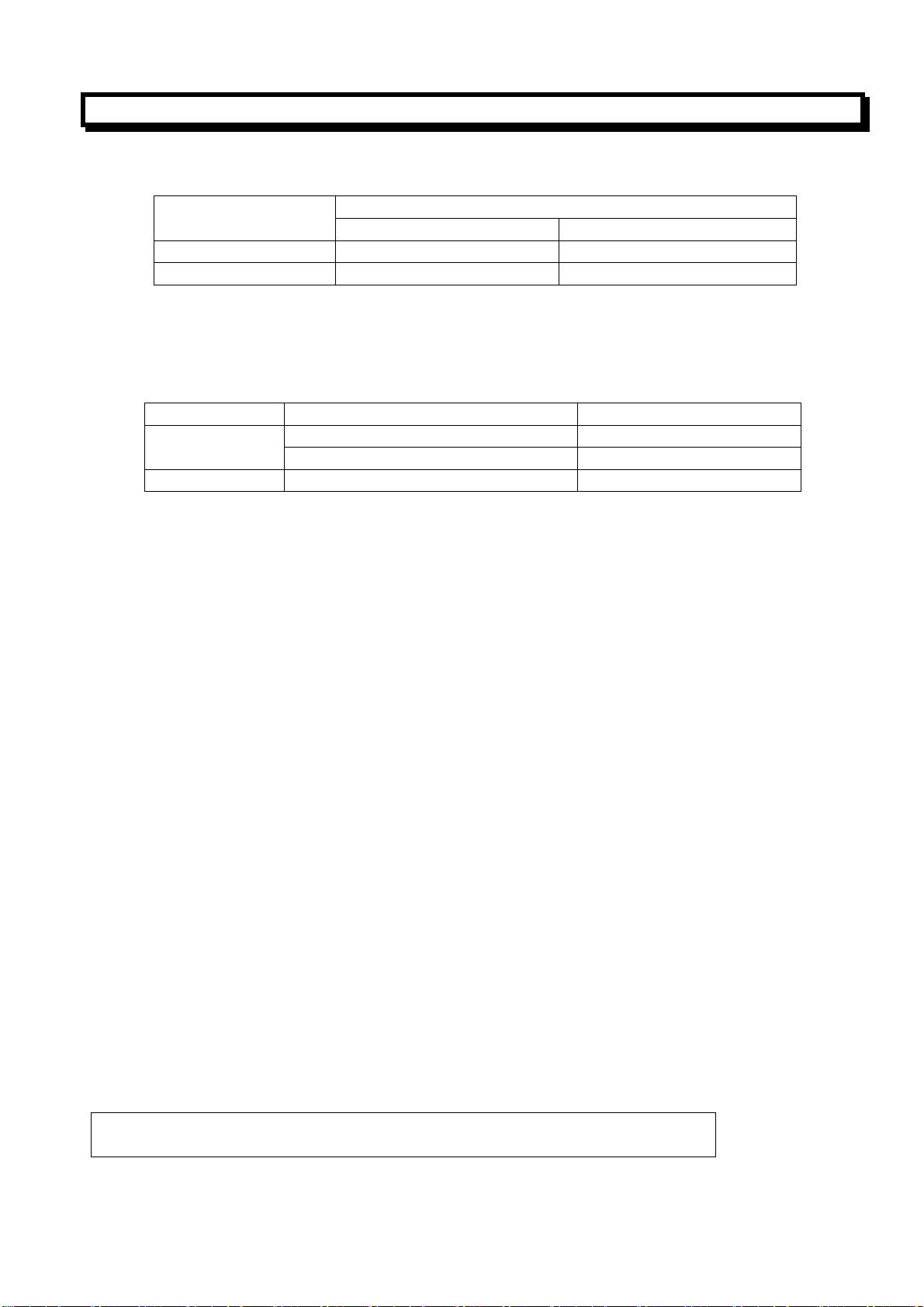

2.1.3 Coordinate value and direction and dimension

In this system, there are two ways to command the travels of the tool, the absolute command and

incremental command, the using of the absolute command and the incremental command depending

GUANGZHOU CNC EQUIPMENT CO., LTD.

2

Z

Page 8

GSK980T CNC SYSTEM USER MANUAL

on the address used. Absolute and incremental commands can be used together in one block. The

format of the address is as follows:

X axis X U

Z axis Z W

Address

Absolute command Incremental command

2.1.4 Unit and Range of coordinate

The least input of this system is 0.001mm and the maximum input is ±9999.99.

Axis Least input unit Least motion increment

0.001mm(Diameter program) 0.0005mm X axis

0.001mm(Radius program) 0.001mm

Z axis 0.001mm 0.001mm

2.1.5 Initial and Modal Status of the Command

Initial status is the status of the control before it is programmed. Modal status means after the

command is specified; it is effective until another command in the same group is specified .

2.1.6 The Start of a Program

At the beginning of program executing, the tool tips of the first programmed tool(standard tool)should

be the start point of the programmed workpiece coordinate system. Usually, the first programmed tool

is used as a standard tool which its offset compensation value is (0,0).

2.1.7 The End of a Program

Command code M30 is specified in the last block of a program to end the executing of a program.

Before ending the executing of grogram by M30, the tool must be programmed to return to the start

point of the workpiece coordinate system, and the corresponding tool offset compensation must be

cancelled.

2.1.8 Program Configuration

The definition of the work coordinate system is depending on the start point of the tool in the

corresponding work program by specifying a value after G50 is a floating coordinate, if G50 is not

commanded the current absolute coordinate value is treated as the start point of the program.

After a workpiece coordinate system is set, a point on the tool, such as the tool tip, is at specified

coordinate.

2.1.9 Program Configuration

(1) Bock

The configuration of one block of program in this system is designated as follows:

N O O O O G O O X O O .O Z O O . O M O O S O O T O O O

CR

N: Sequence Number

GUANGZHOU CNC EQUIPMENT CO., LTD.

3

Page 9

GSK980T CNC SYSTEM USER MANUAL

p

p

G: Preparatory Function

X,Z: Dimension word

M: Miscellaneous function

S: spindle function

T: Tool function

CR: End of block

Each block of a program contains a sequence number for discriminating the executed sequence of

each block the beginning of the block , and an end of bock code CR for indicating the end of the

block..

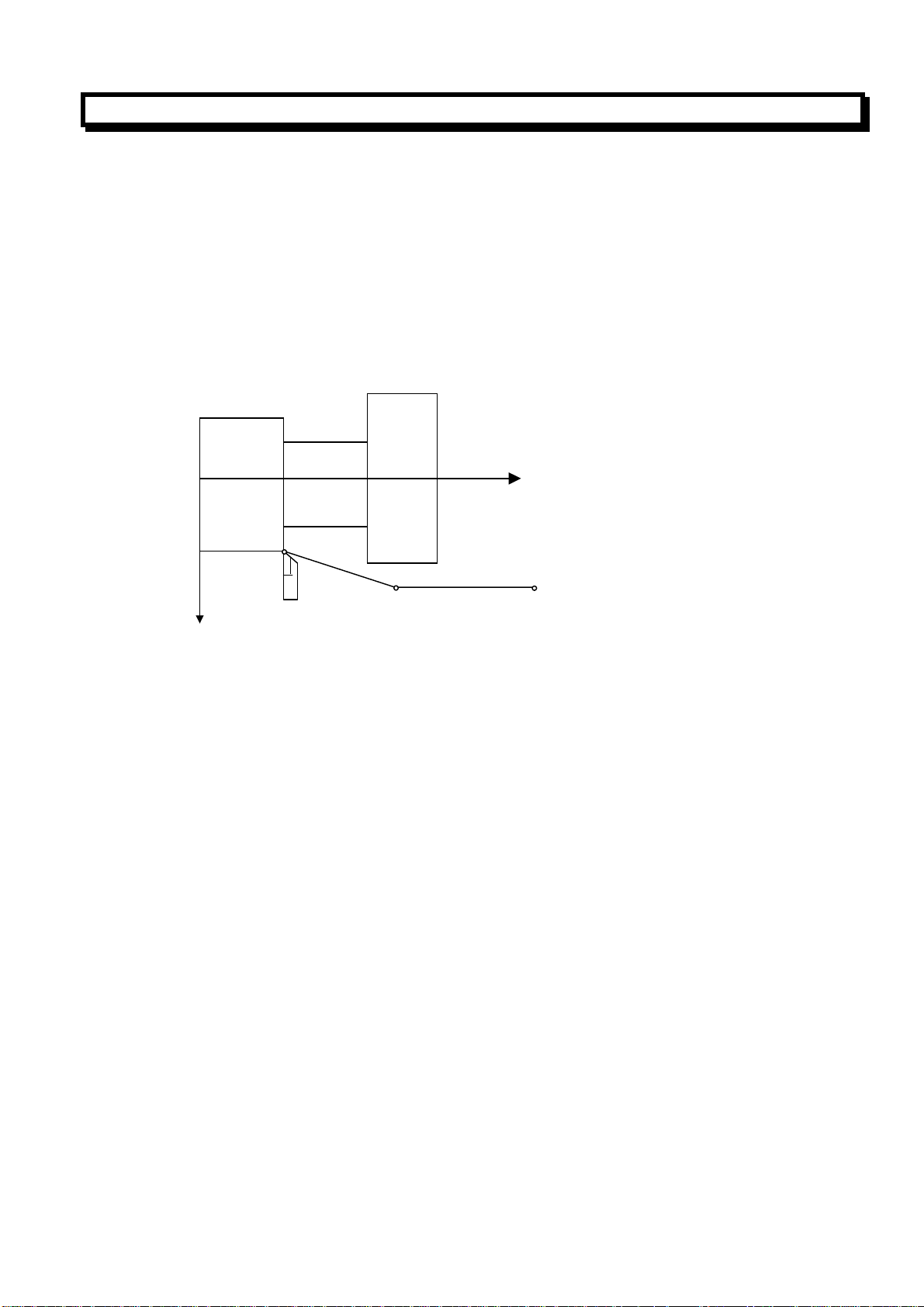

(2)Program

Normally, a program number is specified at the beginning of the program, and a program end code

M30 is specified at the end of the program.

CR:

00000:

M30CR

Program number

Block

Block

Block

End of program

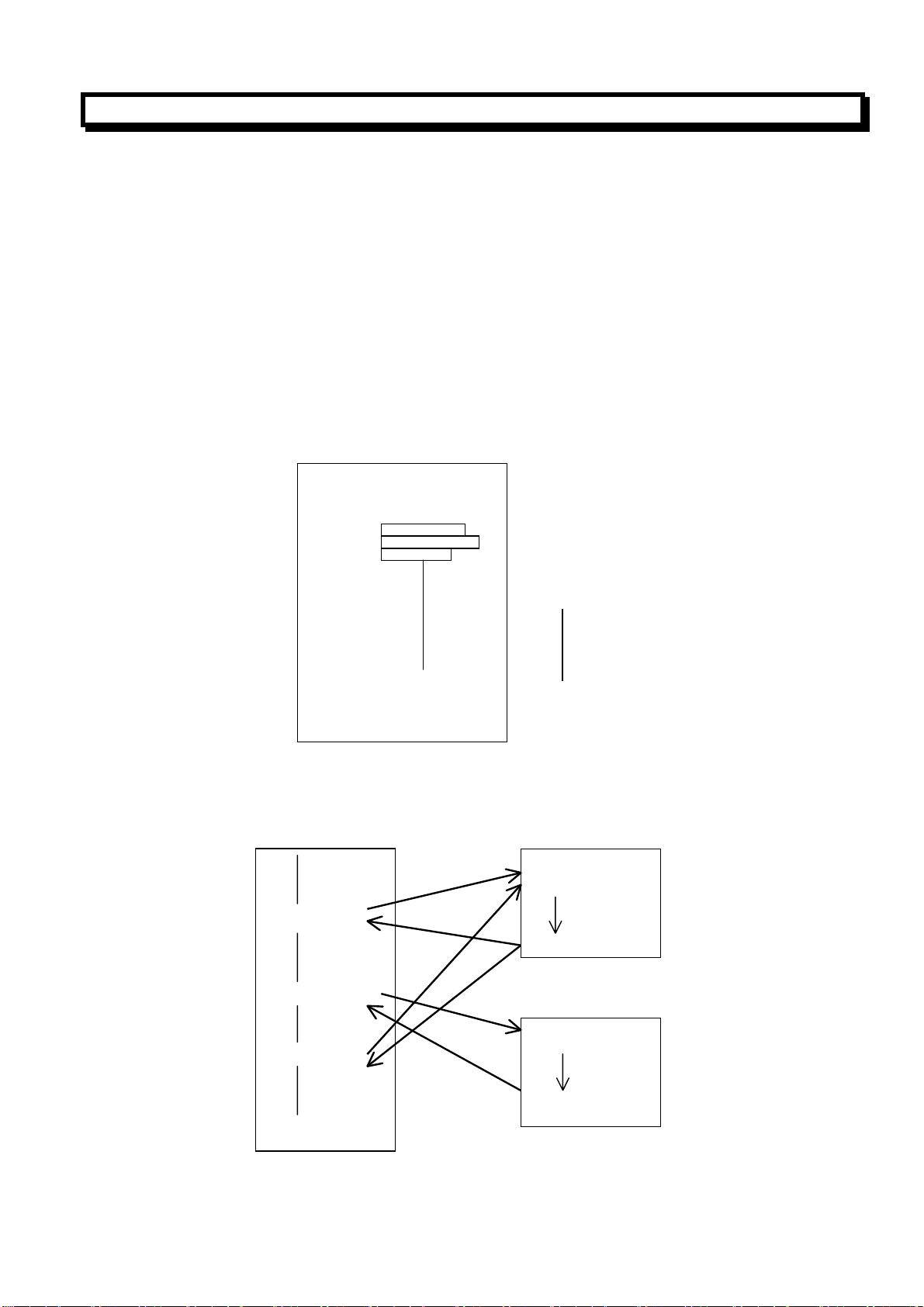

(3) Main Program and Subprogram

M98p1001

M98P1002

M98p1001

Subprogram #1

01001;

M99

Subprogram #2

01002;

M99

Program for

attern #1

Program for

attern #2

GUANGZHOU CNC EQUIPMENT CO., LTD.

4

Page 10

GSK980T CNC SYSTEM USER MANUAL

When machining of the same pattern appears at many sections of a workpiece program, a program for

this pattern is created first, this is called the subprogram, on the other hand, the original program is

called the main program. When a subprogram execution command is executed during the executing of

the main program, commands of the subprogram are executed. When the executing of the subprogram

is finished, the sequence returns to the main program.

2.2 controlled Axis

2.2.1 Number of Controlled Axis

Number of Controlled Axis 2 Axis (X, Z)

Number of Simultaneously control axis 2 Axis (X, Z)

2.2.2 Unit Setting

Input /Output The least input unit The least Command unit

X:0.001mm (Diameter designation)

Metric input /output

When radius Program is designated, the movement on X axis is program in Radius.

Refer to the Operation manual issued by the machine builder for detail.

X:0.001mm (Radius designation )

Z:0.001 mm

Z:0.001 mm

X:0.0005mm

Z:0.001mm

X:0.001mm

Z:0.001mm

2.2.3 Maximum Strokes

Maximum Stroke = The least setting unit × 9999999

GUANGZHOU CNC EQUIPMENT CO., LTD.

5

Page 11

GSK980T CNC SYSTEM USER MANUAL

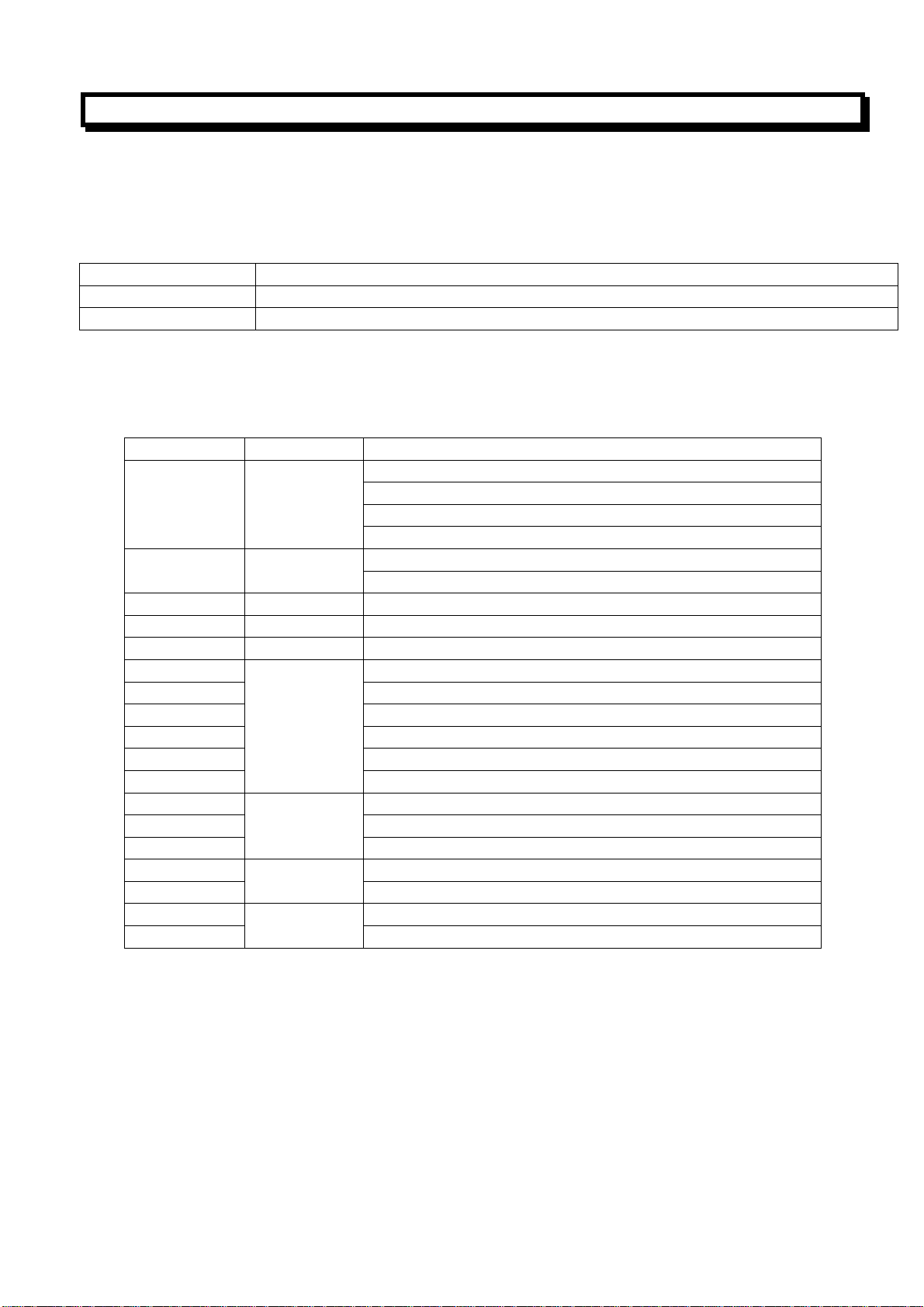

2.3 Preparatory Function (G Function)

A two-digit number following address G determines the meaning of the command for the concerned

block. G codes are divided into the following two types:

Type Meaning

One-shot G code The G code is effective only in the block in which it is specified

Modal G code The G code is effective until another G code in the same group is specified

(Example) G01 and G00 are modal G code in the same group

G01X_;

Z_; G01 is effective

G00Z_ ; G00 is effective

G Code List

G Code Group Function

G00

*G01

G02

G03

G28

G32 01 Thread cutting

G50 00 Coordination system setting

G65 00 Macro command

G70 Finishing cutting cycle

G71 Outer diameter coarse cutting cycle

G72 End face peck drilling cycle

G73 Pattern repeating

G74 End face peck drilling cycle

G75

G90 Outer diameter/internal diameter slot cutting cycle

G92 Thread cutting cycle

G94

G96 Constant surface speed control enable

G97

*G98 Feed per minute

G99

Note1: G codes marked with*are initial G codes when turning on power.

Note2: The G codes of 2:00 are one-shot G codes.

Note3: when a G code which is not listed in this G codes list or a G code

without a corresponding option function is specified, alarm (No.010) is

displayed.

Note4: G codes of different groups can be specified in the same block

of the program. If G codes of the same groups are specified in the same

block, the last specified one is effective.

Note5: The maximum spindle speed can be specified by G50 under the constant

line speed control.

Note6: G codes are displayed by each group number.

01

00

00

00

01

02

03

Positioning (Rapid traverse)

Linear interpolation (Cutting feed)

Circular interpolation CW

Circular interpolation CCW

Dwell, exactly stop G04

Return to reference point (Machine zero point)

Outer diameter/internal diameter slot cutting cycle

End face cutting cycle

Constant surface speed control disable

Feed per revolution

GUANGZHOU CNC EQUIPMENT CO., LTD.

6

Page 12

GSK980T CNC SYSTEM USER MANUAL

N

Note7: The clock wise or counterclockwise of G02,G03 commands are defined

by the direction of the coordination system.

2.3.1 Positioning(G00)

The G00 command moves the tool to the specified position at a rapid traverse rate.

Format:G00X((U)__Z(W)__;

The tool is positioned with the rapid traverse rate for each axis separately.

(Example)

Note: the Rapid traverse speed of the G00 command is set by the machine builder

(ParameterNo.022~023),

The rapid traverse feed rate for each axis of G00 command depends on the machine builder’s setting

(Parameter No.022~023),it is controlled by Rapid traverse feed rate override switch on the operation

panel. (F0,25%,50%,100%),rapid traverse can not be specified by F code.

56.0

X

φ40.0

X

on linear interpolation positioning

X (Diameter programming)

36.0

Z

Z

G00 U-60.0 W-36.0;

G00 X40.0 Z56.0;or

(Diameter programming)

30.0

2.3.2 Linear Interpolation (G01)

G01X (U) __Z (W) __F__;

GUANGZHOU CNC EQUIPMENT CO., LTD.

7

Page 13

GSK980T CNC SYSTEM USER MANUAL

This command specified a linear interpolation movement. Absolute or incremental dimension depends

on the address X, Z/U, W .The feedrate is specified by address F, and is effective until a new value is

specified .The feedrate need not be specified every time.

(Example)

φ40.0

20.0

Start Point

End point

46.0

φ20.0

G00 U20.0 W-26.0;

G01 X40.0 Z20.0;or

Diameter Programming

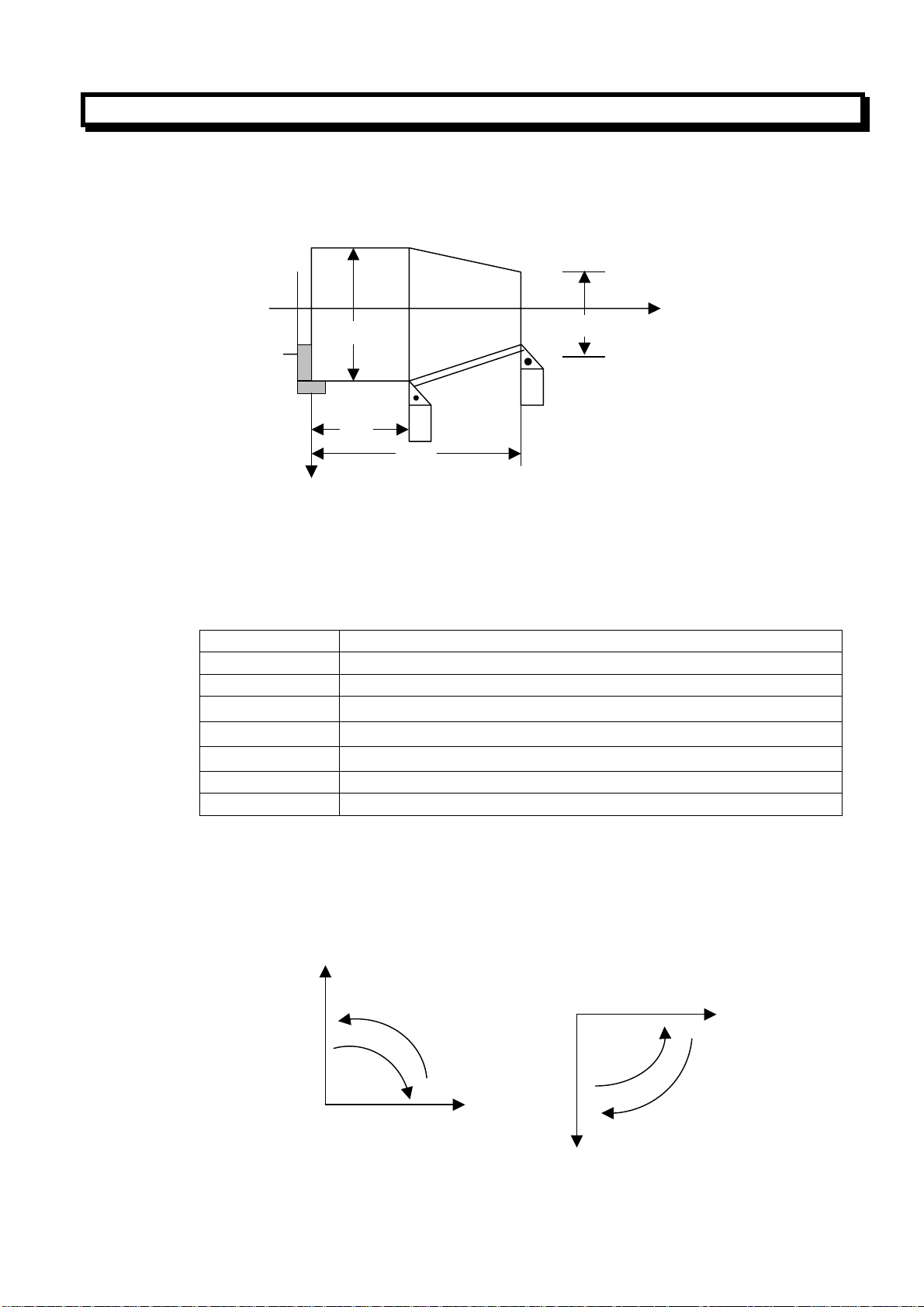

2.3.3 Circular Interpolation (G02,G03)

The command below can move the tool along a circular arc on the specified plane.

G02 X__Z__ R_F

G03 X__Z__ I_K_F

Command Description

G02 Clockwise direction(CW)

G03 Counterclockwise direction(CCW)

X、Z

U、Z

I、K

R Radius of arc (radius value)

F Feedrate along the arc

“Clockwise” and “Counterclockwise” on the Z-X plane of the Cartesian coordinate system are

defined when the Z-X plane is views from the positive to negative direction of the Y-axis, as

illustrated in the figure below:

The end point of the arc in the work coordinate system

Distance from the start point to the end point

Distance from the start point to the center of an arc

X

G03

G02

G02

Z

X

Cartesian coordinate system

GUANGZHOU CNC EQUIPMENT CO., LTD.

8

G03

Z

Page 14

GSK980T CNC SYSTEM USER MANUAL

X

Z

X

(Diameter programming)

(absolute value)

G02 X..Z..R..F..;

Or

G02 X..Z..I..K..F..;

K

R

Center of arc

Z

I

Center

of arc

K

X

R

Z

X

(Diameter Programming)

(absolute value)

G03 X..Z..R..F..;

or

G03 X..Z..I..k..F..;

Z

I

The end point of the arc is specified by address X, Z or U, W. Address U and W specify the distance

from the start point to the end point. The arc center is specified by address I and K for the X and Z

axis. However, the value following K or I is a vector component in which the arc is seem from the

start point, and is specified as an incremental value. As show below:

Z

Center

K

X

Start point

End point (X, Z)

I, K must be signed according to the direction. The arc center also can be specified by address R. As

show below:

G02 X_Z_R_F_;

G03 X_Z_R_F_;

In this case, two types of arcs are considered (One arc is less than 180°, the other is more than 180°),

as show in below figure. An arc exceeding 180° can not be commanded.

R=50

End point

1

2

R=50

Start point

GUANGZHOU CNC EQUIPMENT CO., LTD.

9

Page 15

GSK980T CNC SYSTEM USER MANUAL

(Example)

Absolute and increment programming:

G02 X50.0 Z30.0 125.0 F30;or

G02 U20.0 W-20.0 125.0 F30;or

G02 X50.0 Z30.0 R25.0 F30;or

G02 U20.0 W-20.0 R25. F30;

The federate in circular interpolation is specified by address F, and the federate is controlled to be the

feed rate along the arc (the tangential feedrate of the arc).

Note1:10, K0 can be omitted.

Note2: When X and Z are omitted simultaneously, the end point is the same as the start point,

and the center is specified with I and K, a 360° arc is specified

G02 I_;(Full circle)

When R is used ,an arc of 0° is specified:

G02 R_; (The tool does not move)

Note3: The error between the specified feedrate and the actual tool feedrate is ±2%. The

feedrate is measured along the arc after the tool nose compensation is applied.

Note4: If I, K and R addresses are specified simultaneously, the arc is specified by address R

and the I and K address are ignored.

Note5: When I and K are used, the difference in the radius values at the start point and the end

point of the arc dose not cause an alarm…

φ50.0

x

30.0

50.0

10.0

15.0

Z

R25.0

GUANGZHOU CNC EQUIPMENT CO., LTD.

10

Page 16

GSK980T CNC SYSTEM USER MANUAL

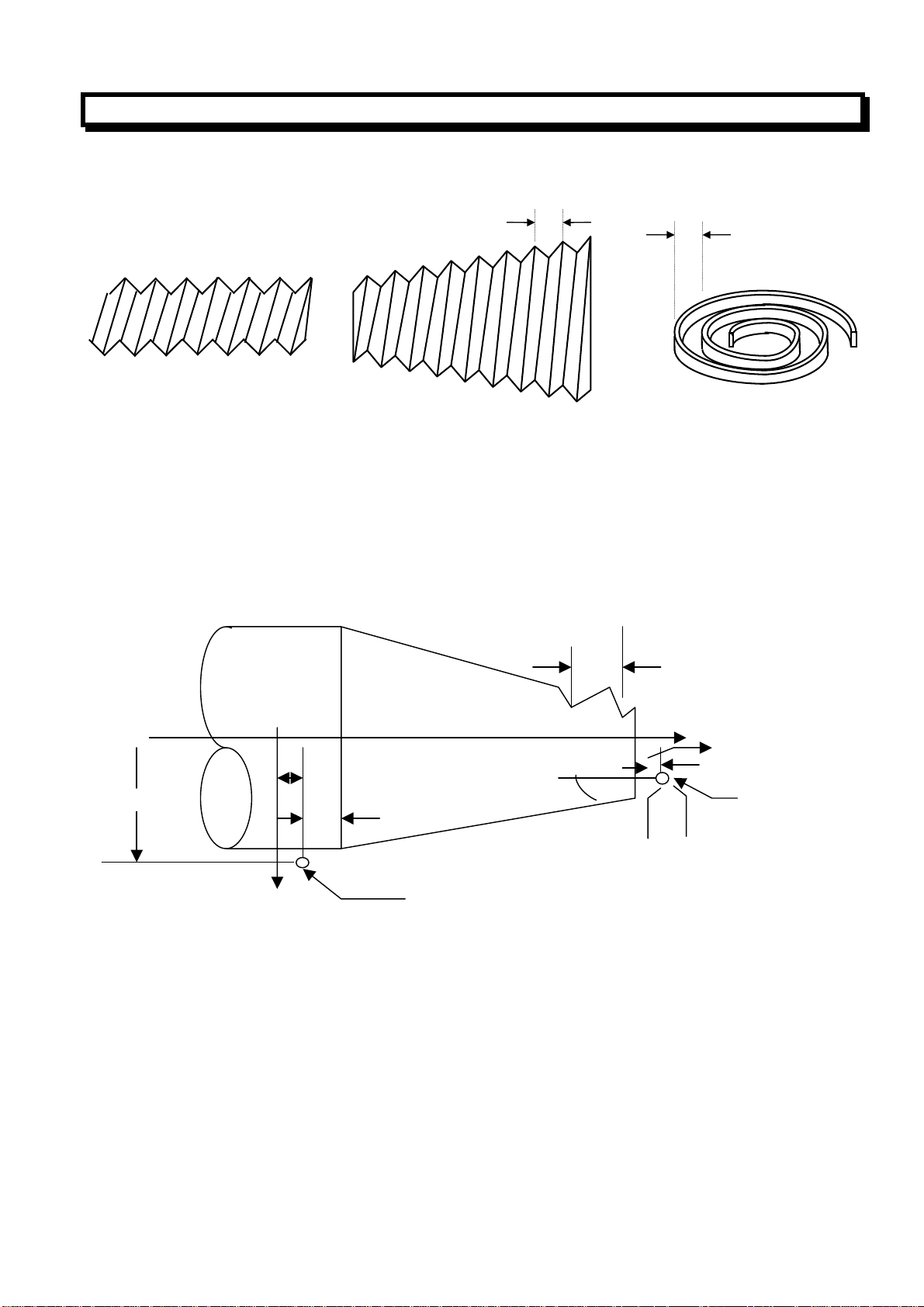

2.3.4 Thread Cutting (G32)

Equal lead straight thread, tapered screws and scroll threads can be cut by using Command G32.

Metric thread can be cut by using the below command (the lead of the thread is specified by F

address):

G32 X (U) _Z(W) _F_;(Metric thread)

F address specify the lead in long axis ranged from 0.001 to 500.000mm

Inch thread can be cut by using the below command(the teeth number is specified by I address):

G32 X (U) _Z(W) _I_;(Inch thread)

I address specified the teeth number per inch in long axis ranged from 0.060 to 254000.000 teeth/inch.

(Example)

G32 X__Z__F__;

X

Z

δ

X axis End point

In general, the thread cutting need to repeat along the same path in rough cutting through finish cuts

for a thread. Since the thread cutting starts when a I-revolution signal is output from the spindle

position encoder, thread cutting is started at a fixed point and the tool path on the workpiece is

unchanged for repeated threading cutting. The spindle speed must remain constant from rough cutting

through finish cutting. if not, thread lead error will occur.

L

L

L

Z axis

δ

Start point

GUANGZHOU CNC EQUIPMENT CO., LTD.

11

Page 17

GSK980T CNC SYSTEM USER MANUAL

LZ

Z

X

LX

α

Tapered thread

If

α≤45°

If

α>45°

the lead is LZ

the lead is LX

The lead always is specified in radius.

The lead can not be cut correctly due to reason of deceleration and acceleration in the beginning and

ending of the threading cutting, To cut a correct lead, the programmed length of the thread must be

longer than the actual length of the thread.

Example: thread cutting

70mm

Z

δ2

δ

1

X

Lead of thread: 4mm

δ1=3mm

δ2=1.5 mm

Depth of cutting in X-axis direction: 1MM(cut twice)

(Metric input, diameter programming)

G00 U-62.0;

G32 W_74.5 F4.0;

G00 U62.0;

W74.5

U-64.0;(Cut 1MM more in second cut )

G32 W-74.5 F4.0;

G00 U64.0

W74.5;

GUANGZHOU CNC EQUIPMENT CO., LTD.

12

30mm

Page 18

GSK980T CNC SYSTEM USER MANUAL

30mm

40mm

φ14.0

φ43.0

φ50.0

δ1

δ2

Z

X

Lead of thread :In Z axis direction:3.5mm

δ1=2mm

δ2=1mm

Depth of cutting in X axis direction:1MM(cut twice)

Using the above mentioned data to program:

(Metric Input, diameter programming)

G00 X12.0 Z72.0;

G32 X41.0 Z29.0 F3.5;

G00 X50.0 Z72.0;

X10.0; (1MM more in second cut)

G32 X39.0 Z29.0

G00 X50.0 Z72.0:

Note1: When the previous block also was a thread cutting block, the cutting will start immediately

without detecting the 1-revolution signal.

G32 Z__F__;

Z__; (1-revolution signal is not detected before the executing of this block)

G32__; (this block also is thread cutting block)

Z__F__;(1-revolution signal is also not detected)

GUANGZHOU CNC EQUIPMENT CO., LTD.

13

Page 19

GSK980T CNC SYSTEM USER MANUAL

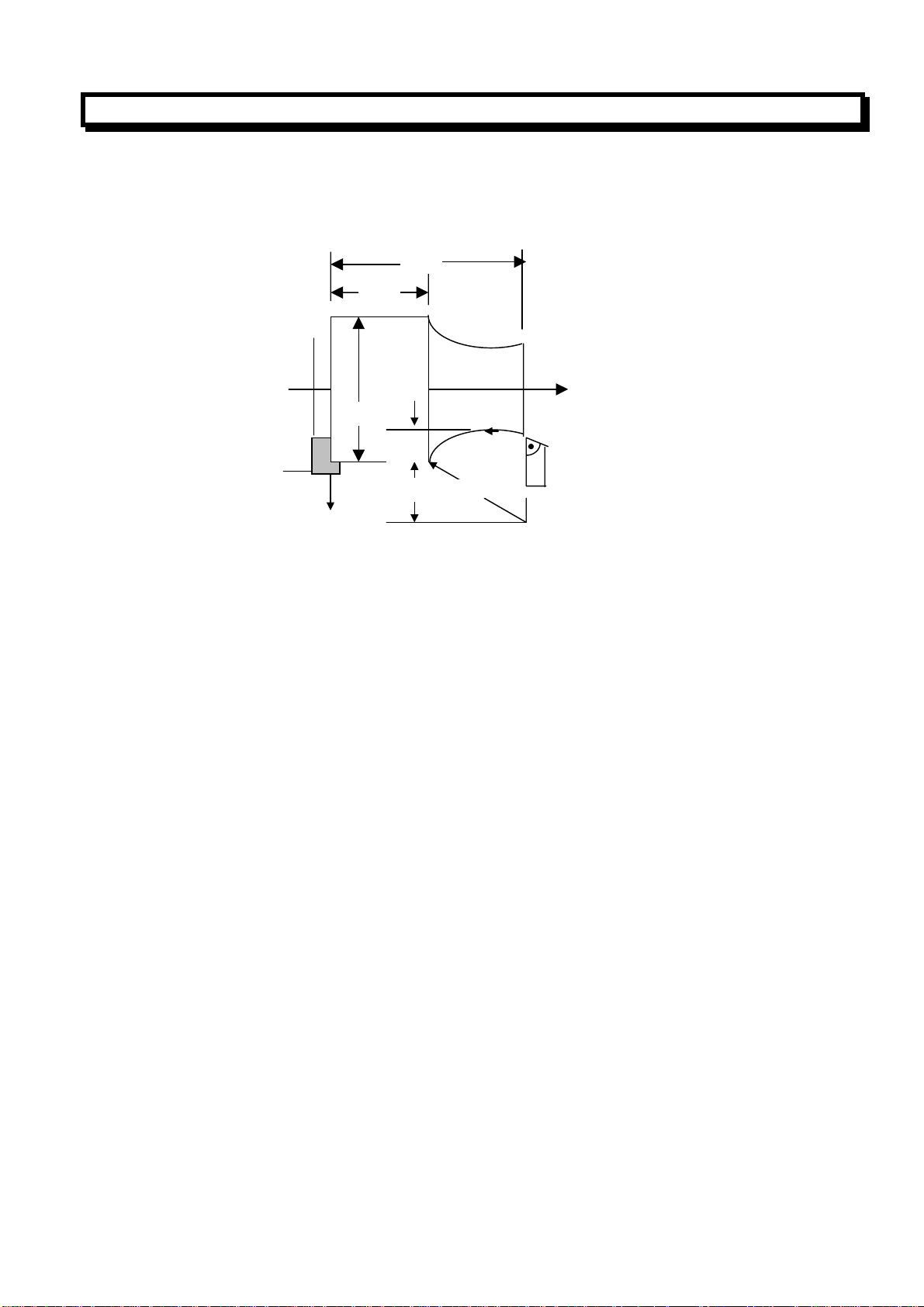

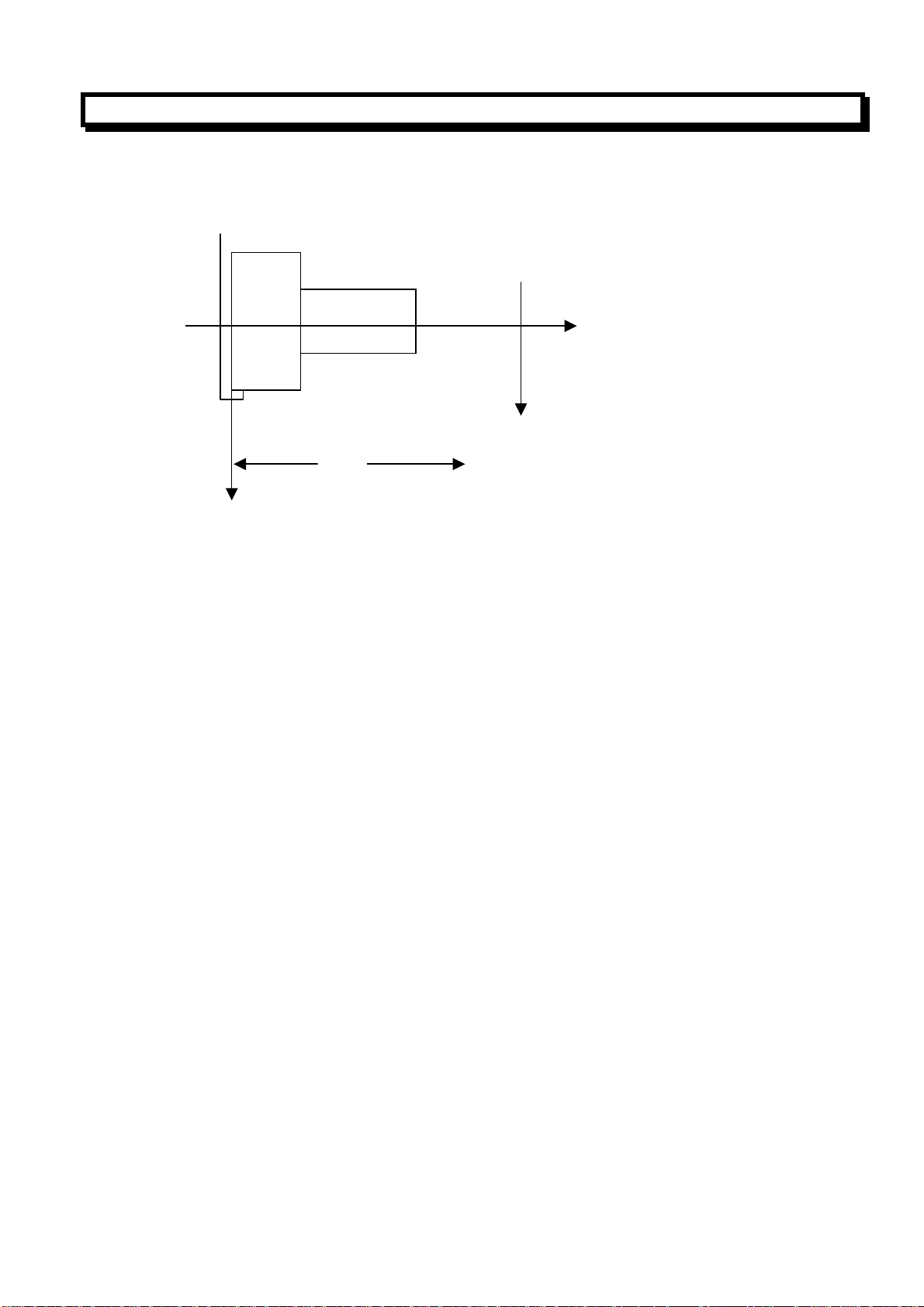

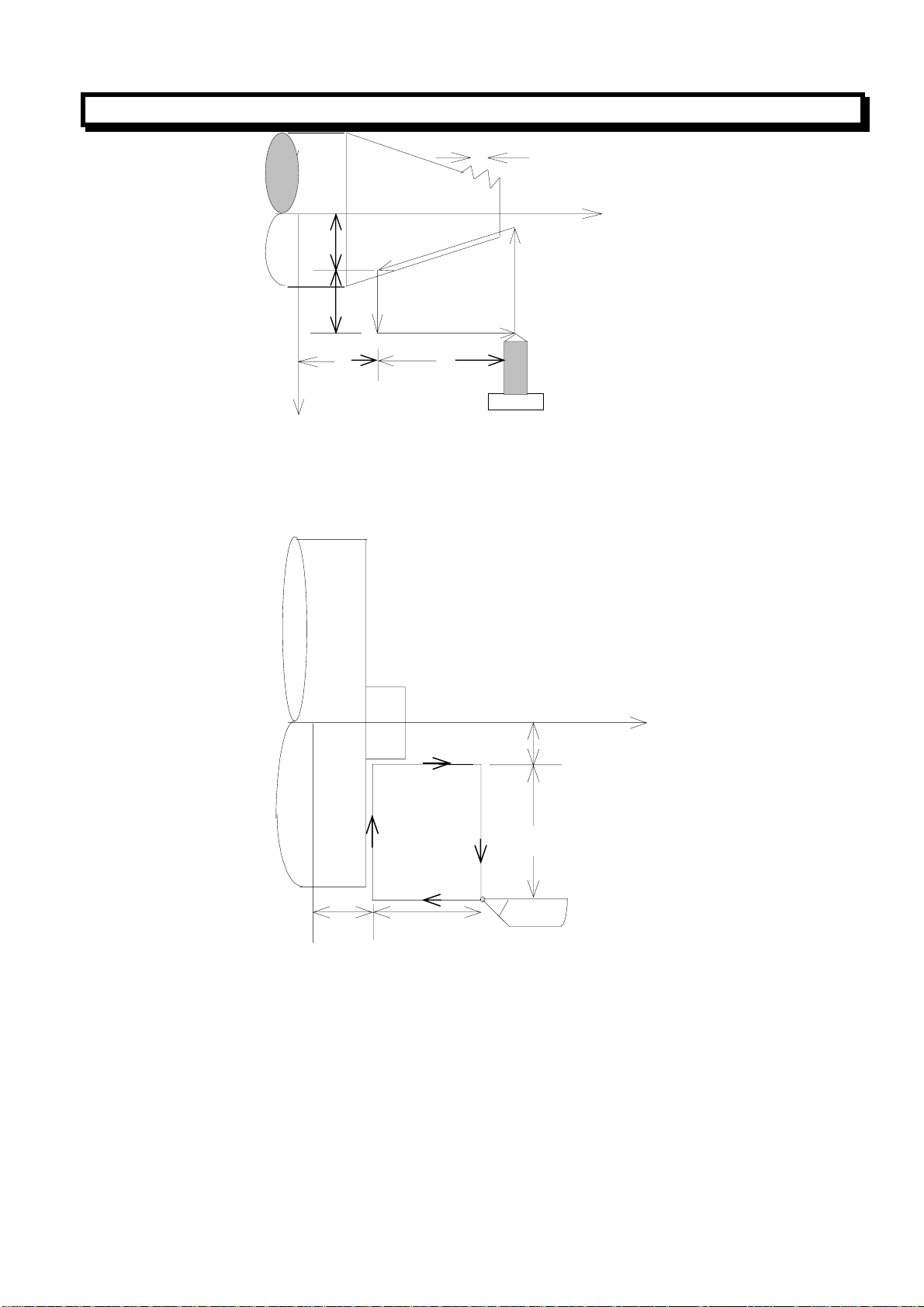

2.3.5 Return to Reference Point Automatically (G28)

G28 X (U)__Z(W)__;

This command can make the tools return to reference point automatically via an intermediate position,

the intermediate position is specified by addresses X(U)__Z(W).

(1)Positioning from the present position to the intermediate position of the designated axis at rapid

traverse rate(point A→point B).

(2)Return to reference point from the intermediate position at rapid traverse rate(point B→point R).

(3)If the machine lock is turn off, when the tool has returned to the reference point, the reference point

return completion led goes on.

Note1: If returning to the reference point manually has never been done after power on ,the motion of

returning to the reference point automatically from the intermediate point in G28 is same as that in

manual way. The direction of intermediate point is specified by parameter No.006(ZMX,ZMZ).

Note2:If the start point of machining program is same as the reference point ,doing G28 can return to

the start point of machining program.

Note3:If the start point of machining program is not same as the reference point ,returning to the start

point of machining program can be realized by rapid positioning command or operation of returning

to the start point, not by G28.

G28 X40 Z50

Present

Point A

X

Z

Reference point R

Intermediate point

B (40, 50)

2.3.6 Dwell(G04)

By specifying a dwell, the execution of the next block is delayed by the specified time.

Format:

G04 P__; or G04 X__; or G04 U__;

The unit of the delay time is second. Command value of the dwell time is from 0.001 to

99999.999second. If addresses P, X is omitted, this command can specified an exact stop.

2.3.7 Work Coordinate System Setting(G0)

A work coordinate system can be set using the following the blow command:

G50 X(x) Z(z);

Use this command to set a coordinate system ,this coordinate system is referred as a workpiece

coordinate system, so a point on the tool, such as the tool tip ,is specified as coordinate value(x, z).

Once a workpiece coordinate system has been set, the absolute position of following blocks is

specified according to this coordinate system

When diameter programming, X address is specified by diameter value. When radius programming, X

address is specified by radius value.

GUANGZHOU CNC EQUIPMENT CO., LTD.

14

Page 20

GSK980T CNC SYSTEM USER MANUAL

(Example) Coordinate system setting with diameter designation

G50 X100.0 Z150.0;

100.00mm

Z

150.00mm

Start point = reference point

X

As illustrated in above figure, the reference point on the turret is superposition with the start point,

and the coordinate system is set by G50 at the start of the program. Thus, when an absolute command

is carried out, The start point will move to the position commanded. In order to move the tool tip to

the position commanded, the difference between the reference and the tool tip is compensated by the

too offset.

Note: If the coordinate system setting is carried out by G50, a coordinate system in which the position prior to

the effecting of the offset becomes the designated position, is set.

2.3.8 Feed per Minute (G98)

G98 specify the feed per minute, a number follows F specify the amount of feed of the cutting tool per

minute.

G98 is a modal code. Once a G98 is specified, it is available until a G99 (feed per revolution )is

specified.

2.3.9 Feed per Revolution(G99)

G99 specified the feed per spindle revolution. A number follows F specified the amount of feed the

cutting tool per spindle revolution.

G99 is also a modal code, once a G99 is specified; it is available until a G98 is specified.

GUANGZHOU CNC EQUIPMENT CO., LTD.

15

Page 21

GSK980T CNC SYSTEM USER MANUAL

Table 2.3.9 Feed Per Minute and Feed Per Revolution

Feed per minute Feed per revolution

Address F F

Command

code

Command

ranges

Limitation value

Override

The limitation takes place at a certain specified speed for both feed per

minute and feed per revolution. This clamping value is set by the machine

tool builder. (Override is applied to implement clamping of speed)

An override from 0~150%(10%per step)can be applied to both feed per

minute mode and feed per revolution mode

G98 G99

1~8000mm/min

(F1~F8000)

0.01~500.00mm/rev

(F1~F50000)

Note: when using feed per revolution mode, if it necessary to affix a position encoder to the spindle.

GUANGZHOU CNC EQUIPMENT CO., LTD.

16

Page 22

GSK980T CNC SYSTEM USER MANUAL

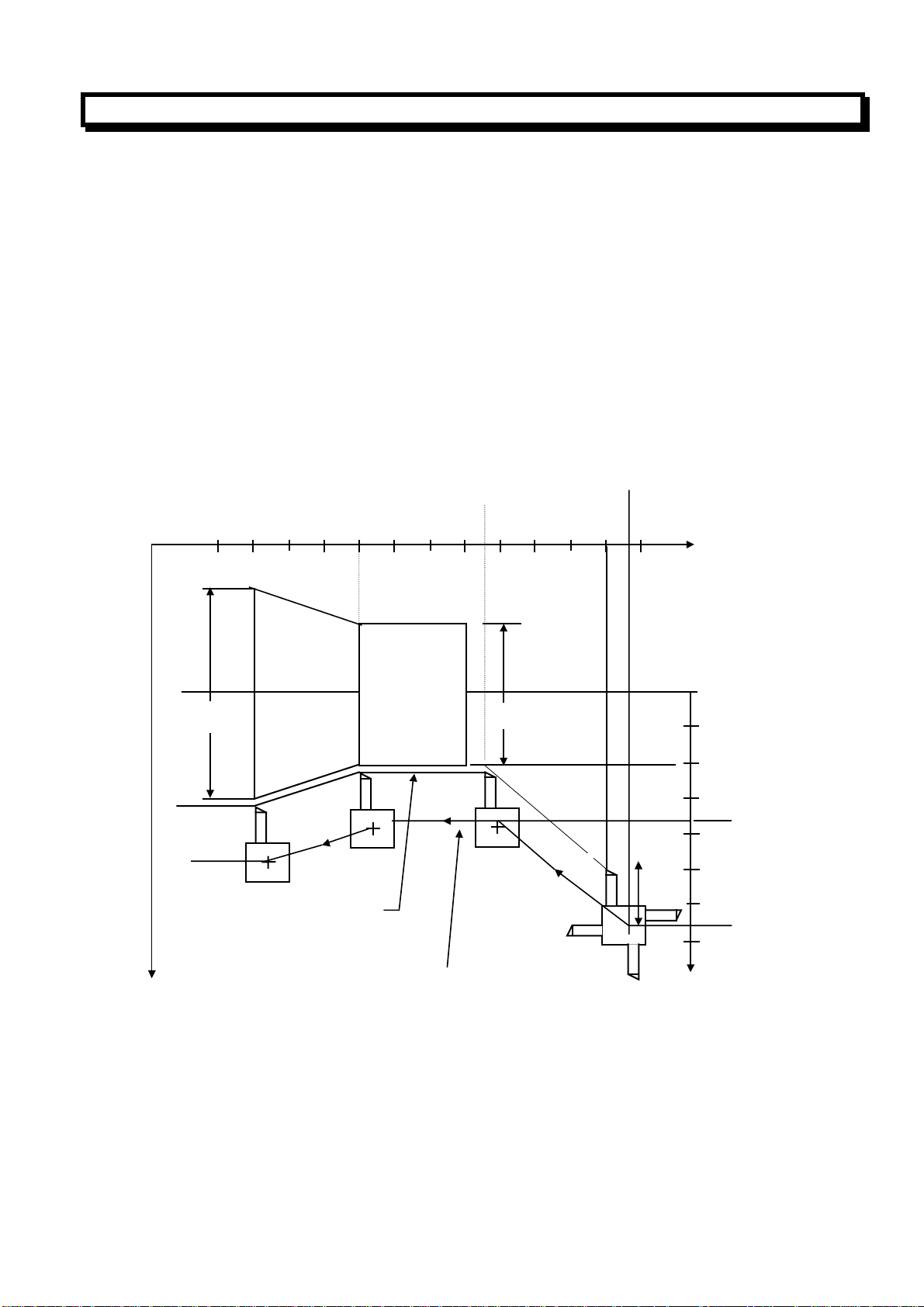

2.3.10 Constant Surface Speed Control(G96, G97)

When the surface speed is set by a value after address S, and the spindle speed is calculated according

to the relative position between the tool and the workpiece to keep the surface speed always the

specified value, so-called constant surface speed control. Voltage is fed to the spindle control section

so that the spindle rotates to produce the correct surface speed.

The units of the surface speed is as follows:

Input unit Surface speed unit

Metric system m/min

The units of the surface speed depend on the setting of the machine tool builder.

The Constant surface speed control is specified by the follow command:

G96 S__;

The surface speed is set after address S.

The constant speed control can be canceled by the following command:

G97 S__;

The spindle speed is set after address S.

It is necessary to apply the constant speed control on Z axis.

Z

X

Spindle speed (rpm)

(n)

3000

2800

2600

2400

2200

2000

1800

1600

1400

1200

1000

800

600

400

200

0

5

20

40 60 80

0

GUANGZHOU CNC EQUIPMENT CO., LTD.

As show in the figure, the spindle

speed (rpm) coincides with the surface4

speed (m/min) at approx.

160mm(radius).

S

为

6

0

4

0

0

3

0

0

2

0

1

0

0

0

0

100

120140 160

m

0

min

180

200220 240260280300

17

单位(mm)

Page 23

GSK980T CNC SYSTEM USER MANUAL

(1)Spindle Speed Override

An override for the specified surface speed or the spindle speed can be specified in

50,60,70,80,90,100,110,120%

(2)Maximum Spindle Speed Limitation

The value follows G50 S specify the maximum spindle speed for constant surface speed control in

rpm:

G50 S__;

When the spindle speed in constant surface speed control reaches the value specified in the above

command, the spindle speed is clamped at this maximum value.

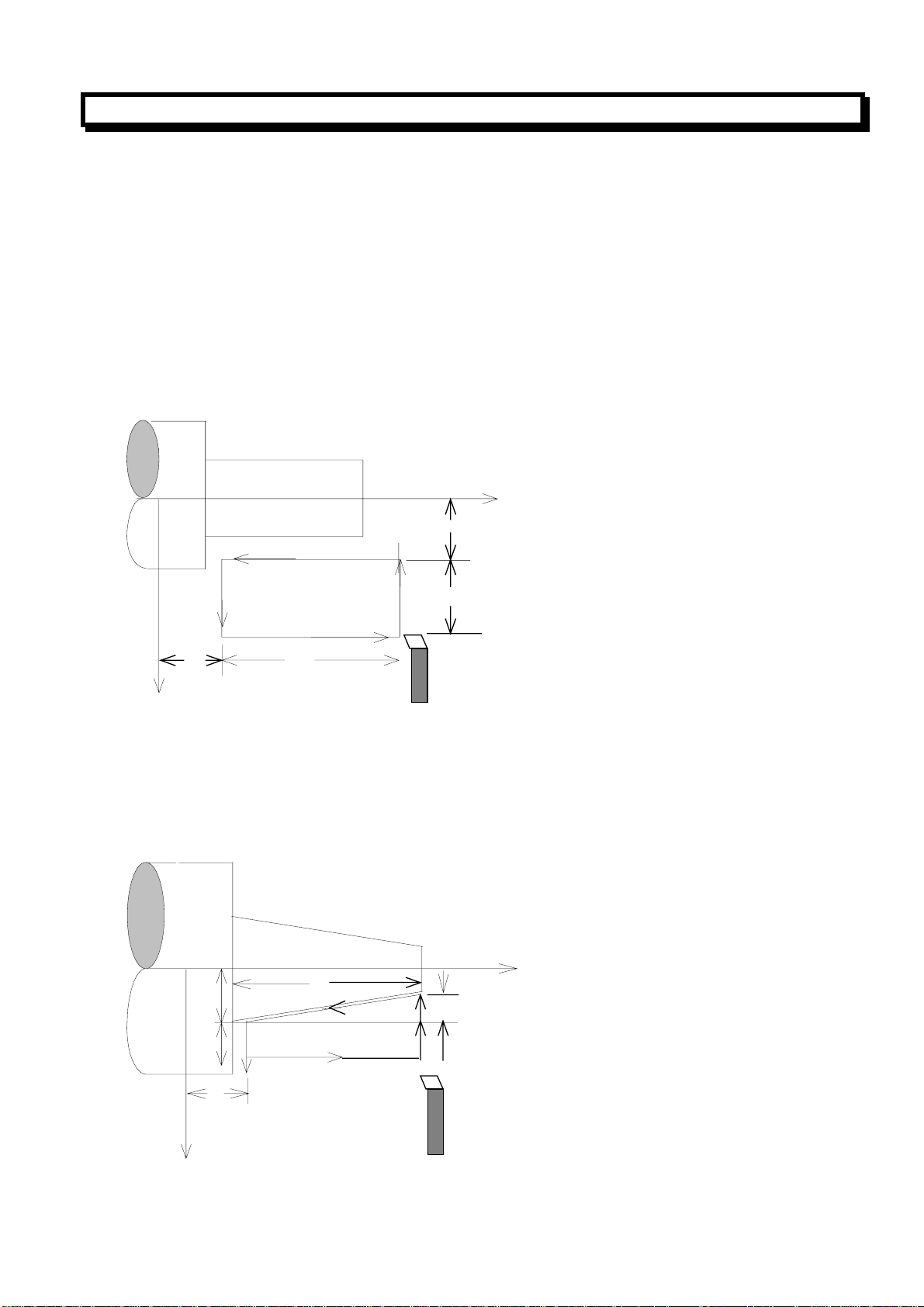

(3)Constant Surface Speed Control for Rapid Traverse(G00)

For a Block in which G00is specified, the constant surface speed control is made by calculating the

surface speed based on the position at the end point of the rapid traverse block instead of calculating

the surface speed to a transient change of the tool position, Because at rapid traverse condition,

cutting is not executed.

(Example:)

1050

300 400 500 600 700 800 900 1000 1100 1200 1300 1400 1500

600

X

Φ

N1

Programmed path

Path after compensation

N15

N14

Φ

400

3

N11

2

1

Z

100

200

300

375

400

500

4

Radius value

1

600

700

675

(Diameter programming)

N8 G00 X1000.Z1400.;

N9 T0303;

N11 X400.Z1050.;

N12 G50 S3000; (Designation of Maximum spindle speed)

N13 G96 S200; (Surface speed 200m/,in)

N14 G01 Z700. F1000;

N15 X600. Z400.;

GUANGZHOU CNC EQUIPMENT CO., LTD.

18

Page 24

GSK980T CNC SYSTEM USER MANUAL

N16 Z....;

The CNC use the programmed coordinate value on the X axis to calculate the surface speed. When

offset compensation is valid, this is not the value calculated according to the X axis coordinate after

offset. At the end point N15 in example above is not the turret center, but the tool nose, that is to say

at 600dia, the surface speed is 200m/min. If X axis coordinate value is negative, the CNC uses the

absolute value.

GUANGZHOU CNC EQUIPMENT CO., LTD.

19

Page 25

GSK980T CNC SYSTEM USER MANUAL

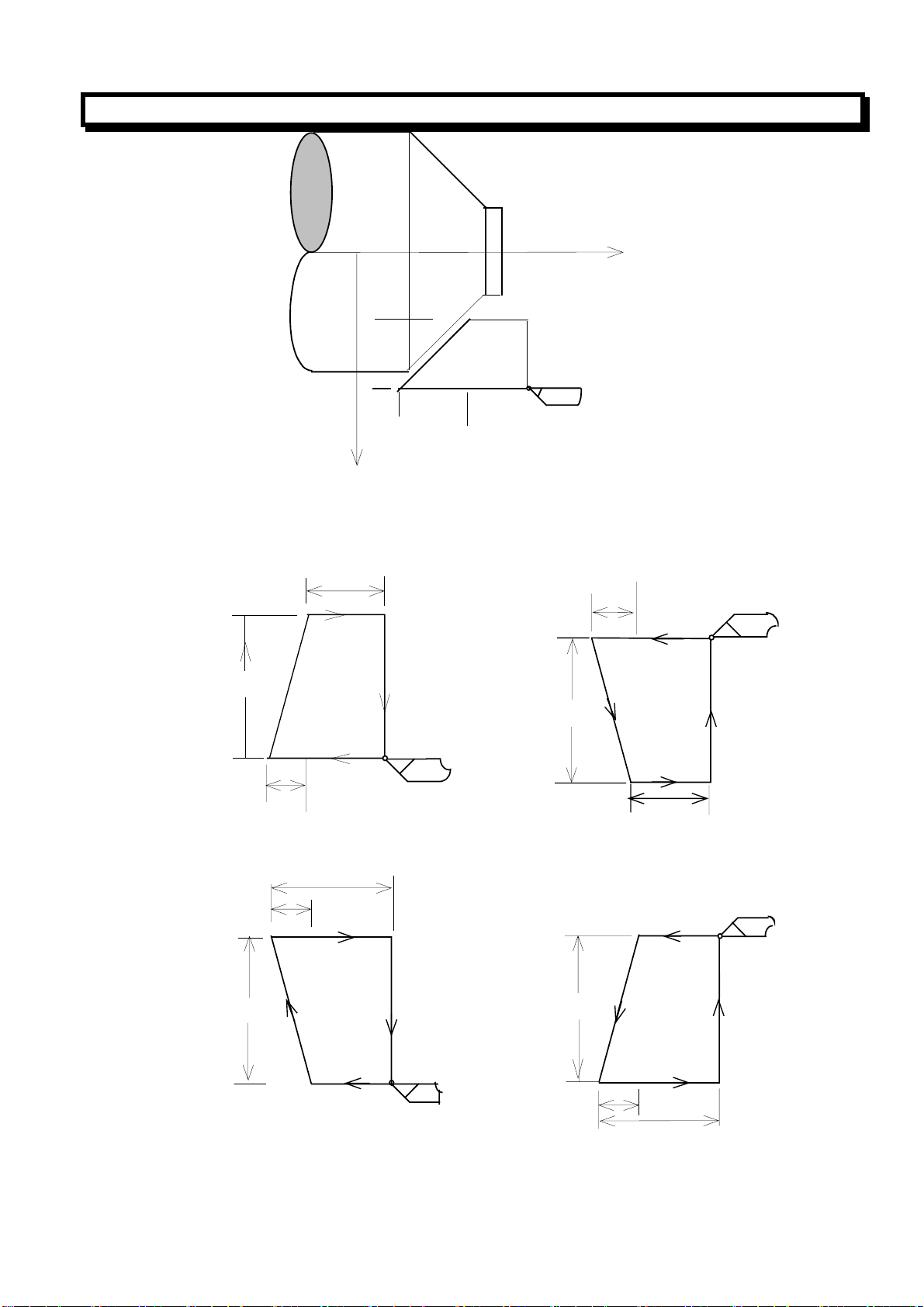

2.3.11 Canned Cycle(G90, G92 G94)

For repetitive machining peculiar to turning, such as the metal removal in rough cutting, the cutting of

the same path is made repetitively, by using these cycles. The said cutting specified in a range of three

to several dozen blocks can be specified in one block. In addition, only the values to be changed need

to be specified for repetition, the program using this cycle is very simple and useful.

The drawings in the examples below are for diameter programming. In radius programming,

change U/2 or X/2 to U or X respectively.

(1)Outer Diameter/Internal Diameter Cutting Cycle(G90)

(a)Cylinder cutting cycle

G90 X (U)__Z(W)__F__;

Z axis

X/2

2(F)

Xaxis

Z

3(F)

4(R)

W

1(R)

U/2

F:Cutting feed

R:Rapid traverse

Tool

In incremental programming, the signs of the numbers following address U and W depend on the

direction of paths1 and 2, in the cycle of above figure, the signs of U and W are negative. In single

block mode, Operation of 1,2,3,4 are performed by pressing the cycle start key.

(b)Taper cutting cycle

G90 X (U)__Z(W)__R__F__;

Z axis

X/2

2(F)

W

R

U/2

X axis

Z

3(F)

1(R)

4(R)

F:Cutting feed

R:Rapid traverse

Tool

GUANGZHOU CNC EQUIPMENT CO., LTD.

20

Page 26

GSK980T CNC SYSTEM USER MANUAL

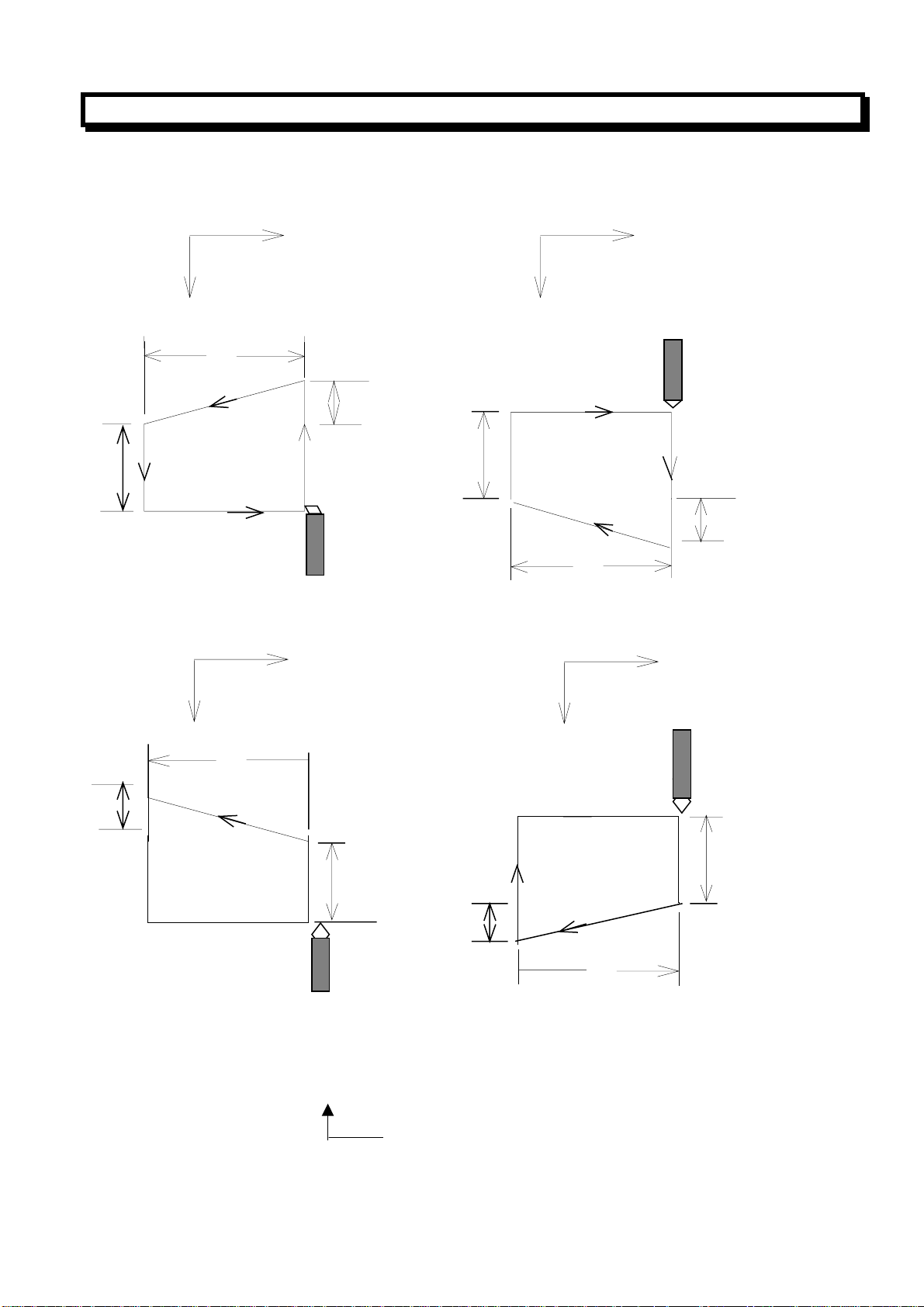

In incremental programming, the relation between the signs of the numbers following the address U、

W、R, and the tool paths are as follows:

1) U <, W<0, R<0 2) U >0, W<0, R>0

Z

Z

U/2

3(F)

X

W

R

2(F)

U/2

1(R)

4(R)

X

4(R)

3(F)

2(F)

W

U<0, W<0, R>0 4) U>0, W<0, R<0

But ︱R︱≤︱U/2︱ But ︱R︱≤︱U/2︱

X

W

Z

X

1(R)

R

Z

R

2(F)

3(F)

1(R)

4(R)

U/2

(2) Thread Cutting Cycle (G92)

(a) Straight thread cutting

G92X (U)__Z(W)__F__; (Metric thread)

G92X (U)__Z(W)__I__; (Inch thread)

GUANGZHOU CNC EQUIPMENT CO., LTD.

R

Pitch specified (L)

21

3(F)

2(F)

4(R)

W

1(R)

U/2

Page 27

GSK980T CNC SYSTEM USER MANUAL

Note: Address I for inch thread is not a modal command.

Pitch specified (Number of teeth/inch)

L

Z axis

F:Cutting feel

R:Rapid traverse

X axis

Z

Width of chanferring

2(F)

3(R)

4(R)

W

1(R)

X/2

U/2

Tool

In incremental programming, the signs of values of U and W commands depend on the direction of

paths 1 and 2. It is to say, if the direction of path 1 is negative along X axis, the value of U is negative.

The command of the lead of thread and the limitation of spindle is same with command G32. In single

block mode, single block is effective for operation1,2,3,4.

The length of the chamfering is set by parameter No.019THDCH. The width of the chamfering is set

by parameter No.THDCH*1/10*L (lead of thread)

Note 1:As mentioned in Note of G32.And, When the FEED HOLD key is pressed during the

execution of the thread cutting block, the feed would not stop until path 3 is finished.

(b)Taper Thread Cutting Cycle:

G92 X (U)__Z (W)__R__F__;

lead specified (L)

G92 X (U)__ Z (W)__R__I__;

lead specified (number of teeth/inch)

Note: Address I for inch thread is not a modal command.

GUANGZHOU CNC EQUIPMENT CO., LTD.

22

Page 28

GSK980T CNC SYSTEM USER MANUAL

X/2

U/2

X axis

3(R)

Z

(3) End Face Cutting Cycle(G94)

(a)End Face Cutting Cycle

G94 X (U)__ Z(W)__F__;

2(F)

4(R)

W

L

Z axis

1(R)

F:Cutting feed

R:Rapid traverse

Tool

o

X axis

3(F)

2(F)

4(R)

1(R)

W

X/2

U/2

F:Cutting feed

R:Rapid traverse

Tool

Zaxis

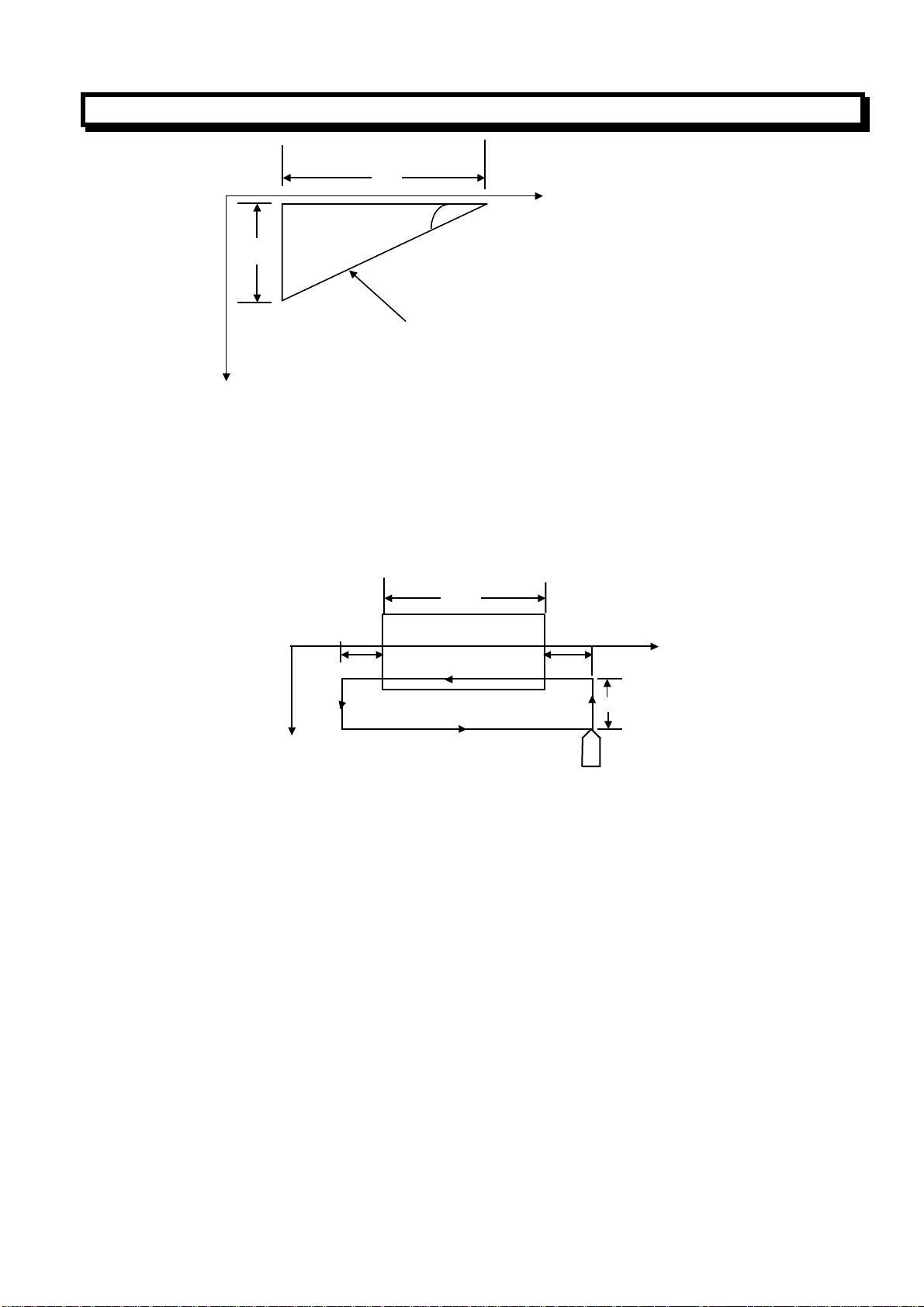

In incremental programming, the signs of the value following address U and W depend on the

direction of paths 1 and 2. That is, if the path 1 is negative along Z axis, the sign of the value of W is

negative.

In single running mode, press Cycle start Key to perform the operation 1,2,3 and 4.

(b)Taper Face Cutting Cycle

G94 X (U)__Z (W)__R__F__;

GUANGZHOU CNC EQUIPMENT CO., LTD.

23

Page 29

GSK980T CNC SYSTEM USER MANUAL

Z axis

X/2

3(F)

U/2

2(F)

1(R)

4(R)

R

Z

X axis

W

F:Cutting feed

R:Rapid traverse

In incremental programming, the relationship between the signs of the values of U, W and R and the

tool paths is as follows:

1) U<0, W<0, R<0 2)U>0, W<0, R<0

U/2

R

2(F)

W

3(F)

4(R)

U/2

1(R)

3)U<0, W<0, R>0(︱R︱≤︱W︱) 4)U>0, W<0, R>0(︱R︱≤︱W︱)

R

2(F)

1(R)

3(F)

W

4(R)

W

R

1(R)

4(R)

2(F)

3(F)

W

U/2

2(F)

3(F)

1(R)

4(R)

U/2

R

Note 1: The data value of X (U), Z (W) and R of during canned cycle are modal as same as

G90,G92 and G94, if X (U), Z (W) or R is not newly commanded, the previously commanded

GUANGZHOU CNC EQUIPMENT CO., LTD.

24

Page 30

GSK980T CNC SYSTEM USER MANUAL

e

data is still effective.

In the example below, a canned cycle can be repeated only by specifying the new movement

commands for X axis, but the Z axis movement need not be re-commanded.

However, these data are cleared if a one-shot G code expect G04 or a G code, which is not in the same

group with G90, G92 and G94, is command.

(Example):

O

66

Z axis

1

6

1

2

8

4

X axis

The following program can perform the cycle in the above figure:

N030 G90 U-8.0 W-66.0 F4000;

N031 U-16.0;

N032 U-24.0;

N033 U-32.0;

2.3.12 Multiple Repetitive Cycle (G70~G75)

This optional canned cycle function is used to make the programming easy. For example, the data for

the finish workpiece shape can be used as the data for rough cutting automatically.

(1)Multiple Repetitive Cycle for Outer Diameter (G71)

As in the figure below, a finished shape of A to A’ to B is given by a program, the specified area is

removed by depth of cut △D, and the finish cutting allowance of △ U/2, and △W is left.

Program commanded

path

△W

Aˊ

△U/2

Cutting feed

Rapid travers

E

B

A

45

△D

C

GUANGZHOU CNC EQUIPMENT CO., LTD.

25

Page 31

GSK980T CNC SYSTEM USER MANUAL

p

Format:

G71 U(ΔD) R(E) F(F) S(S) T(T);

G71 P(NS) Q(NF) U(ΔU)W(ΔW) ;

N(NS) ......

........

· F

· S

· T

The move commands of finished shape from A to A’ to B are

specified in the blocks from N (NS) to N (NF).

Sequence number must be s

ecified for each

N(NF) ......

△D: Cutting depth without sign. The cutting direction depends on the direction of AA’ (Radius

designation). This designation is modal and remains unchanged until the other value is

designated. This value also can be specified by the parameter No. 051, and the value of this

parameter can also be changed by the program command.

E: Escaping amount. It is a modal designation that remains unchanged until other value is designated.

This value also can be specified by parameter No. 052, and the value of parameter can also be

changed by program command.

NS: The sequence number of the first block of the program for finished shape.

NF: The sequence number of the last block of the program for finished shape.

△U: Distance and direction of finish cutting allowance in X direction (Diameter/Radius designation)

△W: Distance and direction of finish cutting allowance in Z direction.

F, S, T: Any F, S and T function specified in blocks N (NS) to N (NF) in the G71 cycle is ignored,

only the F, S, and T function in the G71 Command Block is effective.

F,S,T: During the cycle of G71,the function of F/S/T is noneffective

The following four cutting patterns of G 71 are considered. All these cutting cycle are made paralleled

to Z axis and the signs of △ U and △ W are as follows:

B

U(+)..W(+)

A

A

U(+)..W(-)

B

Z

A'

X

B

U(-)..W(+)

A'

A

A'

A'

U(-)..W(-)

A

Linear or

circular

interpolation

B

The tool path between A and A’ is specified in the block with sequence number NS including G00 or

G01, and in this block, a move command in the Z axis is not allowed. The tool path between A’ and B

must be steadily increasing or decreasing pattern in both X and Z axis.

Note1: subprogram can not be called in the blocks with sequence number from NS to NF.

Note2: Between sequence NS and NF, more than five blocks are not permitted.

(2)Stock Removal in Facing (G72)

GUANGZHOU CNC EQUIPMENT CO., LTD.

26

Page 32

GSK980T CNC SYSTEM USER MANUAL

As show in the figure below, this cycle is the same as G71 except that the cutting is made by an

operation parallel to X axis.

△W

B

△U/2

Program command

path

45

E

Tool path

A

A'

C

Cutting feed

△D

Rapid traverse

G72 W (△D) R(E) F(F) S(S) T(T);

G72 P(NS)Q(NF)U(△U)W(△W);

The means of △D, E, NS, △U, △W, F, S, T are the same as those in G71.

Using G72, the following four cutting patterns are considered. All of these cutting cycles are made

paralleled to X axis.

The signs of △ U and △ W are as follows:

RR

U(+)..W(-)..

U (+)..W (+)..

Both linear and circular

interpolation is possible

A’

A’

A

A

A

A

A’

A’

The tool path between A and A’ is specified in the block with sequence number “NS” in which G00 or

G01 can be included, but in and in this block, a move command in the X axis can not be specified.

The tool path between A’ and B must be steadily increasing or decreasing pattern in both X and Z

axis.

Note1:The subprogram is not called in the block with the sequence number from NS to NF.

Note2: Between sequence NS and NF, more than five blocks are not permitted.

U (-)..W (+)..

R

U (-)..W (-)..

R

Z

X

GUANGZHOU CNC EQUIPMENT CO., LTD.

27

Page 33

GSK980T CNC SYSTEM USER MANUAL

N

(3)Pattern Repetitive Cutting Cycle (G73)

Using cutting cycle permits cutting a fixed pattern repeatedly, with a pattern being displaced bit by

bit. By this cutting cycle, it is possible to efficiently cut work whose rough shape has already been

made by forging or casting method, etc.

B

A'

△W

A

△U/2

C

△U/2

△u/2 △i+

△W

△K+△W

D

The pattern commanded in the program should be as follows:

A to A’ to B.

G73 U(△I)W(△K)R(D) F(F) S(S) T(T);

G73 P(NS)Q(NF)U(△U)W(△W);

N (NS)………

· · · · · · · · · · · · · ·

·

The finish move command between A and B is

specified in the block from sequence number NS to

F

N (NF) · · · ·

△I: Distance and direction of relief in the X axis direction (Radius designation). This

designation is modal and is not changed until the other value is designated. This value also can

be specified by parameter No.053, and the parameter is changes by the program command.

△K: Distance and direction of relief in the Z axis direction (Radius designation). This

designation is modal and is not changed until the other value is designated. This value also can

be specified by parameter No.054, and the parameter is changes by the program command.

D: The number of division, which is the same as the repetitive count for rough cutting. This

designation is modal and is not changed until the other value is designated. This value also can

be set by parameter No.055, and the parameter is changed by the program command.

NS: The sequence number of the last block of the program of finish shape.

NF: The sequence number of the last block of the program of finish shape.

△U: The finish cutting allowance in X direction (Diameter/Radius designation).

△W: The finish cutting allowance in Z direction.

F, S, and T: Any F, S, and T function specified in the blocks between sequence number from NS to NF

are non effective, but the F, S and T function is effective in the G73 block.

Note1: △I, △K, or△U, △W is specified by address U and W respectively, the difference of

them is determined by the address of P and Q.

GUANGZHOU CNC EQUIPMENT CO., LTD.

28

Page 34

GSK980T CNC SYSTEM USER MANUAL

Note 2:The cutting cycle is performed by G73 command with P and Q specification. The four

cutting patterns are considered. Take care of the sign of △U, △W, △I, △K. When the

cutting cycle is terminated, the tool returns to point A.

Note3: Between sequence NS and NF, more than five blocks are not permitted.

(4) Finish Cutting Cycle (G70)

After rough cutting by G71, G72 and G73, the finish cutting can be performed by the following

command:

G70 P (NS)Q(NF);

NS: The sequence number of the first block of the program of finish shape.

NF: The sequence number of the last block of the program of finish shape.

Note 1: F, S and T specified in the block G71, G72 and G73 are noneffective for the G70

block .but F, S and T specified in the blocks between sequence number from Ns to NF for finish

cutting are effective.

Note 2: When the cutting specified by G70 is terminated, the tool returns to the start point and

the next block is read.

Note3: The subprogram can not be called in the blocks with sequence number from NS to NF

between G70 and G73.

Note4:Between sequence NS and NF, more than five blocks are not permitted.

Example:

●Multiple repetitive cycle for outer diameter(G71):

80

10

20 30

d

e

c

100 60

30

b

a

40

2 10

X axis

0.2

End point`

Z axis

Diameter designation, metric input)

(

Start point

N010 G50 X200.0 Z220.0 ;(Workpiece coordinate system setting)

N020 M3 S300;(Spindle CW rotation, spindle speed: 300 rpm)

N030 M8;(Coolant on)

N040 T0101;(Rough cutting tool)

N050 G00 X160.0 Z180.0 ;(Positioning, come close to the workpiece)

N060 G71 U4.0 R1.0 F300 S200;(Cutting depth 8mm[diameter designation] for each cut,1mm

relief)

GUANGZHOU CNC EQUIPMENT CO., LTD.

29

Page 35

GSK980T CNC SYSTEM USER MANUAL

N070 G71 P080 Q120 U0.2 W2.0;

N080 G00 X40.0 ;

( rough cutting a---d ,Finishing allowance in X

direction 0.2mm, Z direction 2mm)

N090 G01 Z140.0 F100 S800 ;(The federate and spindle speed in finish cutting of G70)

N100 X60.0 W-30.0 ;

N110 W-20.0 ;

N120 X100.0 W-10.0 ;

N130 G00 X200.0 Z220.0 (Rapid traverse to a safe point)

N140 T0202;(Tool No.2 and No.2 Offset)

N150 G00 Z175.0(Positioning at rapid traverse speed)

N160 G70 P80 Q120;(finish cutting a---d)

N170 G00 X200.0 Z220.0 M05 S0; (Return to start point, stop the spindle)

N180 M09;(Coolant off)

N190 T0100;(Standard tool, cancel tool offset)

N200 M30;(End of program)

●Multiple repetitive cycle(G70 G72)

70

190

20

a

15

20

2

b

c

d

Z

4

0

8

0

160

8

8

110

X

7

Start poinp

O0002;

N010 G50 X220.0 Z190.0 ; (Workpiece coordinate system setting)

N015 T0202; (Exchange the tool No.2 and do No.2 tool-compensation)

N017 M03 S200; (Spindle CW rotation and the speed is 200rpm)

GUANGZHOU CNC EQUIPMENT CO., LTD.

30

Page 36

GSK980T CNC SYSTEM USER MANUAL

N020 G00 X176.0 Z132.0 ; (Rapid positioning and closing to workpiece)

N030 G72 W7.0 R1.0 F200; (Forward distance 7mm and backward distance 1mm)

N040 G72 P050 Q090 U4.0 W2.0 ; (Rough cutting a—d, Finishing allowance X4mm, Z2mm)

N050 G00 Z70.0 S500 ; (Rapid positioning)

N060 G01 X160.0 F120 ;

N070 X80.0 W20.0 ; (Cutting a—b)

N080 Z105.0 ; (Cutting b—c)

N090 X40.0Z125.0 ; (Cutting c—d)

N100 G0 X220.0 Z190.0; (Rapid traverse to stare point)

N105 T0303;

N107 G00 X176 Z132 ;

N110 G70 P050 Q090 ; (Finishing cutting a--d)

N120 G0 X220.0 Z190.0; (rapid traverse to start point)

N130 M5 S0; (Spindle stopping)

N140 T0200;

N150 M30; (End of program)

●Multiple repetitive cycle(G73)

40

180 160

X

10

40

R20

120

10

80

20

2

40

14

2

220

Z

14

110

130

16

起点

(Diameter designation, metric input)

N010 G50 X260.0 Z220.0 ;

N011 G99 G00 X220.0 Z160.0 M03;

GUANGZHOU CNC EQUIPMENT CO., LTD.

31

16

Page 37

GSK980T CNC SYSTEM USER MANUAL

R

R

N012 G73 U14.0 W14.0 R0.003 F0.3 S280;(R0.003 means cycling 3 times)

N013 G73 P014 Q018 U4.0 W2.0 ;

N014 G00 X80.0 W-40.0 ;

N015 G01 W-20.0 F0.15 S0600 ;

N016 X120.0 W-10.0 ;

N017 W-20.0 S0400 ;

N018 G02 X160.0 W-20.0 R20.0 ;

N019 G0 X250.0 Z200.0 ;

N020 G70 P014 G018;

N021 G0 X260.0 Z220.0;

N022 M30;

(5) End Face Peck Drilling(G74)

The cutting path showed in the figure below is performed by the following command. Chip breaking

is possible in this cycle as shown below: If X(U) and P are omitted, operation only in the Z axis

direction, to be used for drilling.

Z

△K’

W

e

X

B

F F F F F

C

R R

△i’

U/2

△i

△d

△k△k△k

△k

A

0<△i’≤△i

0<△k’≤△k

G74 R(e) F(f);

G74X(U)Z(W)P(△i)Q(△k)R(△d);

e: Return amount along Z axis after a cutting of depth △K. This value also can be set by parameter

No.056 and the parameter is changed by the program command.

X: X component of point B.

U: The incremental amount from A to B.

Z: The Z component of point C.

W: The increment amount from A to C.

△i; Movement amount in X direction(without sign, diameter).

△k: Movement amount in Z direction (without sign)

GUANGZHOU CNC EQUIPMENT CO., LTD.

32

Page 38

GSK980T CNC SYSTEM USER MANUAL

△d: Relief amount of the tool at the bottom of the cutting(diameter).Usually, the sign of △d is

plus(+). If address X(U) and △I are omitted, It need a sign to specified the relief direction.

F: Cutting federate.

Note 1: Both e and △d are specified by address R, the meaning of address R is determined by

the present of address X(U), that is, if (X(U) is specified, R represents △d.

Note 2: The cycle operation is performed by the G74 command with X(U) specification.

Note 3: Between sequence NS and NF, more than five blocks are not permitted.

(6)Outer Diameter and Inner Diameter Grooving Cycle(G75)

The following command can execute operation as show in the figure below. It is equivalent to G74

except Thai X is replaced by Z. Chip breaking is possible in this cycle, and grooving, cutting off in X

axis is possible.(In this case Z, W and Q are omitted).

G75 R(e) F(f);

G75X(U)Z(W)P(△I)Q(△k)R(△d);

Z

W

△d

X

F

F

F

F

F

R

R

R

R

U/2

e

B

F

C

△i

E: Return amount along X axis after a cutting of depth △I. This value also can be set by parameter

No.056 and the parameter is changed by the program command.

X: X component of point C.

U: The incremental amount from A to C.

Z: The Z component of point B.

W: The incremental amount from A to B.

△i: Movement amount in X direction(without sign, diameter)

△k: Movement amount in Z direction (without sign)

△d: Relief amount of the tool at the bottom of the cutting (diameter). Usually, the sign of △d is plus

(+). If address X(U) and △ I are omitted, It need a sign to specified the relief direction.

GUANGZHOU CNC EQUIPMENT CO., LTD.

33

Page 39

GSK980T CNC SYSTEM USER MANUAL

F: Cutting federate.

Both G74 and G75 are used for grooving, cutting off and drilling. They can control the tool relief

automatically.

Note: Between sequence NS and NF, more than five blocks are not permitted.

2.3.13 Notes on Multiple Repetitive Cutting Cycle (G70~G75)

(1). In the where the multiple repetitive cutting cycle is command, the address P, Q.

X, Z, U, W, and R must be specified correctly for each block.

(2). In the block which is specified by the address P in G71, G72 and G73 commands, G00 or G01 of

01 group must be commanded, if it is not commanded, alarm No.065 is generated.

(3)G70,G71 and G72 can not be commanded in MDI mode. If on of them is commanded, alarm

No.67 is generated. G74 and G75 can be command in MDI mode.

(4) In the blocks in which G70,G71,G72 or G73 are commanded and in the blocks between the

sequence number specified by address P and Q, M98/M99 can not be commanded.

(5) in the blocks between the sequence number specified by address P and Q of G70, G71 G72,

G73,the following commands can not be specified:

★ One shot G code except for G04 (Dwell)

★ 01 group G code except G00, G01 G02 and G03

★ 06 group G code.

★ M98/M99

(6) While multiple repetitive cutting cycle(G70~G75) is being executed, it is permitted to stop the

cycle operation to perform manual operation. But when the cycle operation is restart the tool should

be returned to the position where the cycle operation is stop. It the cycle operation is added to the

absolute value. And operation following is not correct, the tool path is shifted by the movement

amount in manual operation.

(7) When G70,G71,G72,and G73 is being executed, the sequence number specified by address P and

Q should not be specified twice or more in the same program.

(8) In G70,G71,G72and G73 cutting cycle, the last block of the finishing shape blocks group specified

by address P and Q can not be chamfering or corner rounding, if is ,alarm No.69 is generated.

2.4 Spindle Function(S Function)

2.4.1 Spindle Speed Command

By specified a numerical value following address S, to transmitted code signal to the machine tool for

spindle speed control. Only one S code can be specified in one block.

Refer to the appropriate operator manual issued by the machine tool builder for detail such as the

number of digits of S code of how to use S code, etc…

When a movement command and a S command is specified in the same block, they are executed at

the sam4e time.

(1) S 2-digit

By specifying address S followed by 2-digit numerical value to control the speed of the spindle

(Parameter No.001BIT-0).

This system support 4 levels mechanical spindle speed gear change.(When the spindle analogue

control in not available). Refer to the operation manual issued by the machine tool builder for the

detail of the number of the levels of the spindle speed change and the relation between the S code and

the spindle speed.

GUANGZHOU CNC EQUIPMENT CO., LTD.

34

Page 40

GSK980T CNC SYSTEM USER MANUAL

t

t

S1~S4

The execution time of S code is set by diagnosis No.081.

Setting value:0~255(128msec.~32.640msec.)

Setting time=Setting value ×128 m sec.

(2)S4-digit(Optional function)

The spindle speed can be specified directly by address S followed by a 4-digit value (unit:

rpm)(Parameter No.001BIT4=1), The unit for specifying the spindle speed may vary depending s the

machine tool builder.

2.5 Tool Function

By specifying a 2-digit numerical value following address T to select tools on the machine. One tool

code can be commanded in one block. When a movement command and a T code are specified in the

same block, they are executed simultaneously.

Refer to the manual issued by the machine tool builder for detail of the using of T code.

The value after the T code indicates the desired tool, the last two digits is used as the offset number

which indicating the compensation amount for tool offset.

T○○ ○○

Tool offset number

Tool selection

The number of the tools of the system can be set by the parameter No.084; the maximum value is 8.

2.5.1 Procedures of tool Change

Ta<#077,076*selec ti on num ber

positive rot at ion output ( TL+ 0 0 5。6)

rever se output signal(TL- 005。7)

lpost in-postiton( T4~T1 00.3~00.0)

lock up input signal(TCP 00.7)

Tb<#085

In above figure,#076,#077are time constant set by diagnosis correspondingly.

If Ta≥(#077,076) × current commanded tool number, system alarms: tool change overtime

If Tb≥#083, system alarms: Toolpost motor reverse rotation overtime.

When T code being executed, TL+ signal is output to rotate the toolpost ,and TL+ signal is cancelled

when tool in-position signal is received(input),TL- is output after a delay of time T1 to rotate the

toolpost in opposite direction while the control detected the signal*TCP. When signal *TCP is

detected, system delays a time set by diagnosis No.D085, and then cancels the output of signal TL-,

Tool changing is same with the tool number stored in Diagnosis No.075, Tool change is not performed,

GUANGZHOU CNC EQUIPMENT CO., LTD.

35

T1=#082

T2=#083

Page 41

GSK980T CNC SYSTEM USER MANUAL

control go on to the executing of the next program directly.

If the TCP can not be detected in the time set by diagnoses No.083, system alarms and turns off the

signal TL-.

2.5.2 Tool selection (Change) Related Parameters

1. System parameter

Toolpost in-position signal(*T6~*T1), set by parameter No.P011 Bit 1 TSGN.

TSGN 0: Toolpost in-position signal logic “1”is valid(constant opened).

1: Toolpost in-position signal logic “0”is valid(constant closed)

Toolpost lock up signal(*TCP),set by parameter No.P011 Bit0 TCPS.

TCPS 0: Toolpost lock up signal logic“0”is valid(constant closed).

1: Toolpost lock up signal logic“1”is valid(constant opened)

Note: If the TCP signal is not provided with the toolpost controller, Set the Bit 0 TCPS of parameter No.011

to“0”,The control dose not detect the TCP signal during tool changing. By setting toolpost lock up time

constant D085 to control the toolpost reverse time directly.

2.Diagnosis

T1: Time delay from toolpost positive rotation signal is turned off to the toolpost reverse signal is

turned off.

Ttool selection number: Tool selection number.

Diagnosis No.084, Setting Value 0~8

T2: Time delay after the toolpost lock up signal is detected.]

Diagnosis No.085, Setting value 0~255 (0~4080 msec) Unit: 16 msec.

T—Tool number: The maximum time for tool changing(on time):

Diagnosis No.076(lower byte),No.77(upper byte).Setting value 0~65535

(0~1048s) Unit: 16 msec.

Tt: The maximum time of the tool change between the first tool to the last tool.