This user manual describes all items concerning the operation of

this CNC system in detail. However, it is impossible to give particular

descriptions for all unnecessary or unallowable operations due to length

limitation and products application conditions;Therefore, the items not

presented herein should be considered impractical or unallowable.

Copyright is reserved to GSK CNC Equipment Co., Ltd. It is illegal

for any organization or individual to publish or reprint this manual. GSK CNC

Equipment Co., Ltd. reserves the right to ascertain their legal liability.

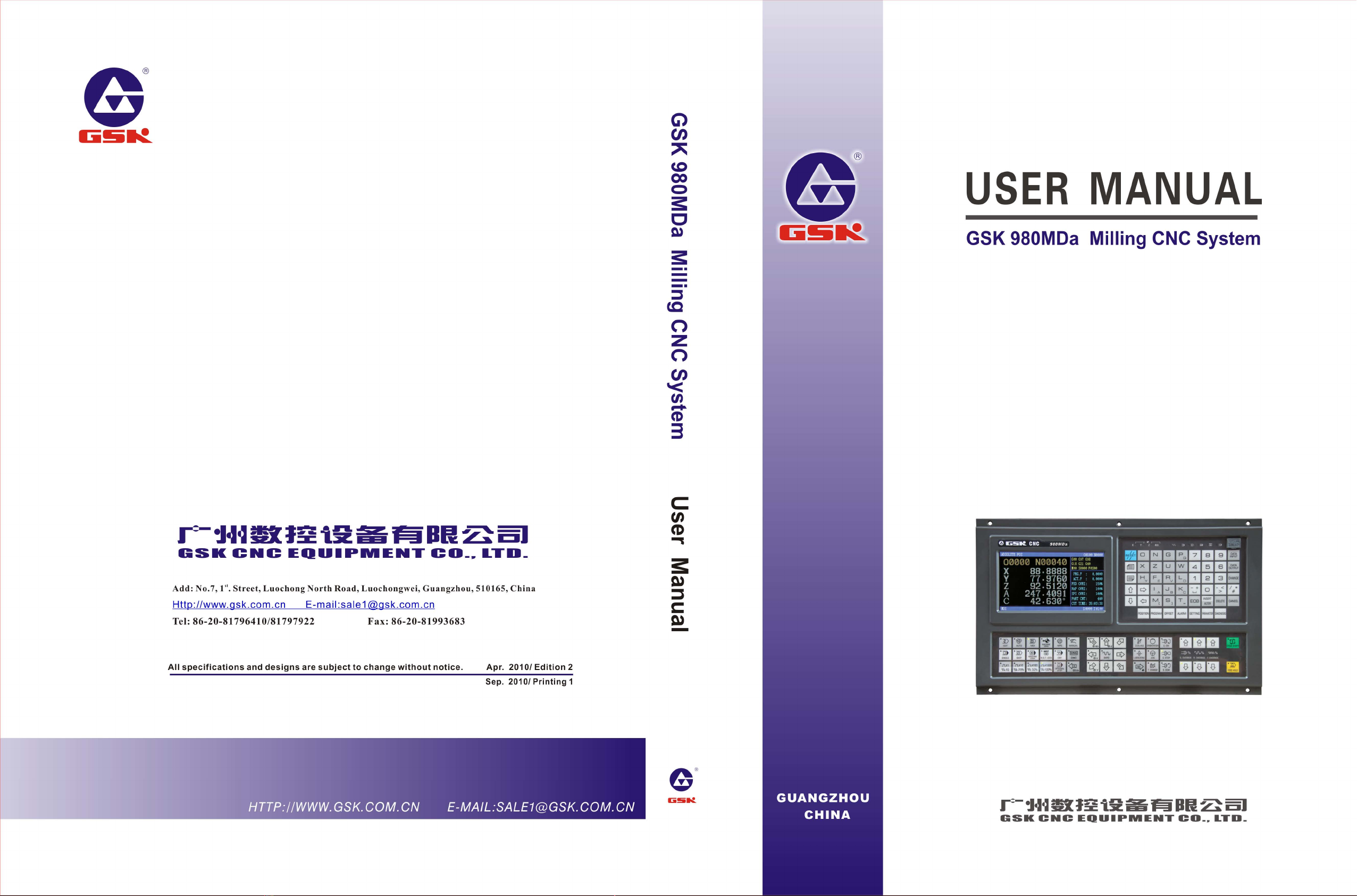

GSK980MDa Milling CNC System User Manual

Preface

Your Excellency,

We are honored by your purchase of products from GSK CNC Equipment Co.,

Ltd.

This manual introduces programming, operation and connection of GSK980MDa

CNC Milling Machine in detail. To ensure safe and efficient work, please read this

manual carefully before installation and operation.

Warning and Precaution

Accident may occur by improper connection and operation!This system can

only be operated by authorized and qualified personnel.

Please read this manual carefully before operation!

Special caution:

The power supply fixed on/in the cabinet is exclusively used for the CNC system

made by GSK.

It can't be applied to other purposes, or else it may cause serious danger.

This manual is subject to change without further notice.

This manual is reserved by end user.

II

CAUTIONS

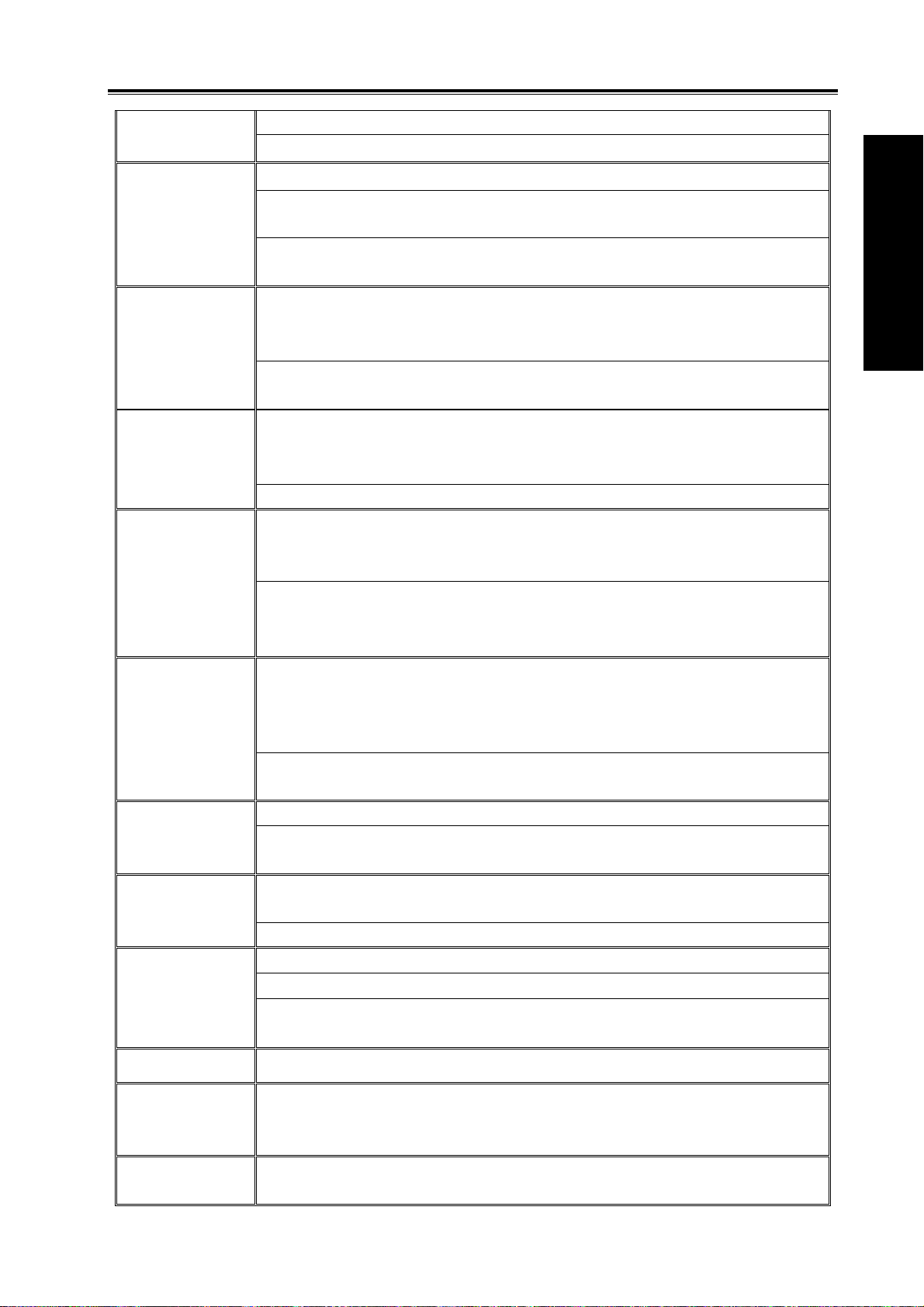

■ Transportation and Storage

z Packing box over 6 layers in pile is not allowed.

z Never climb the packing box, neither stand on it, nor place heavy objects on it.

z Do not move or drag the products by the cables connected to it.

z Forbid collision or scratch to the panel and display screen.

z Avoid dampness, insolation and drenching.

■ Open-package Inspection

z Confirm that the products are the required ones.

z Check that the products are not damaged in delivery.

Cautions

z Confirm that the parts in packing box are in accordance with the packing list.

z Contact us in time if any inconsistence, shortage or damage is found.

■ Wiring

z Only qualified personnel can connect the system or check the connection.

z The system must be earthed, and the earth resistance must be less than 0.1Ω.

The earth wire cannot be replaced by a neutral wire (zero wire).

z The connection must be correct and firm to avoid any fault or unexpected

consequence.

z Connect with surge diode in the specified direction to avoid damage to the

system.

z Switch off power supply before plugging out or opening electric cabinet.

■ Troubleshooting

z Cut off the power supply before troubleshooting or component replacement.

z Check for fault when short circuit or overload occurs. Restart can only be done

after troubleshooting.

z Frequent switching on/off of the power is forbidden, and the interval time should

be at least 1 minute.

III

GSK980MDa Milling CNC System User Manual

ANNOUNCEMENT!

z This manual describes various possibilities as much as possible. However,

operations allowable or unallowable cannot be explained one by one due to

so many possibilities that may involve with, so the contents that are not

specially stated in this manual shall be considered as unallowable.

WARNING!

z Please read this manual and a manual from machine tool builder carefully

before installation, programming and operation, and strictly observe the

requirements. Otherwise, products and machine may be damaged,

workpiece be scrapped or the user be injured.

NOTE!

z Functions, technical indexes (such as precision and speed) described in

this user manual are only for this system. Actual function deployment and

technical performance of a machine tool with this CNC system are

determined by machine tool builder’s design, so functions and technical

indexes are subject to the user manual from machine tool builder.

z Though this system is employed with integrated operator panel, the

functions of the keys on the panel are defined by PLC program (ladder

diagram). It should be noted that the keys functions described herein are for

the standard PLC program (ladder diagram).

z Refer to the user manual from machine tool builder for function and

meaning of keys on control panel.

IV

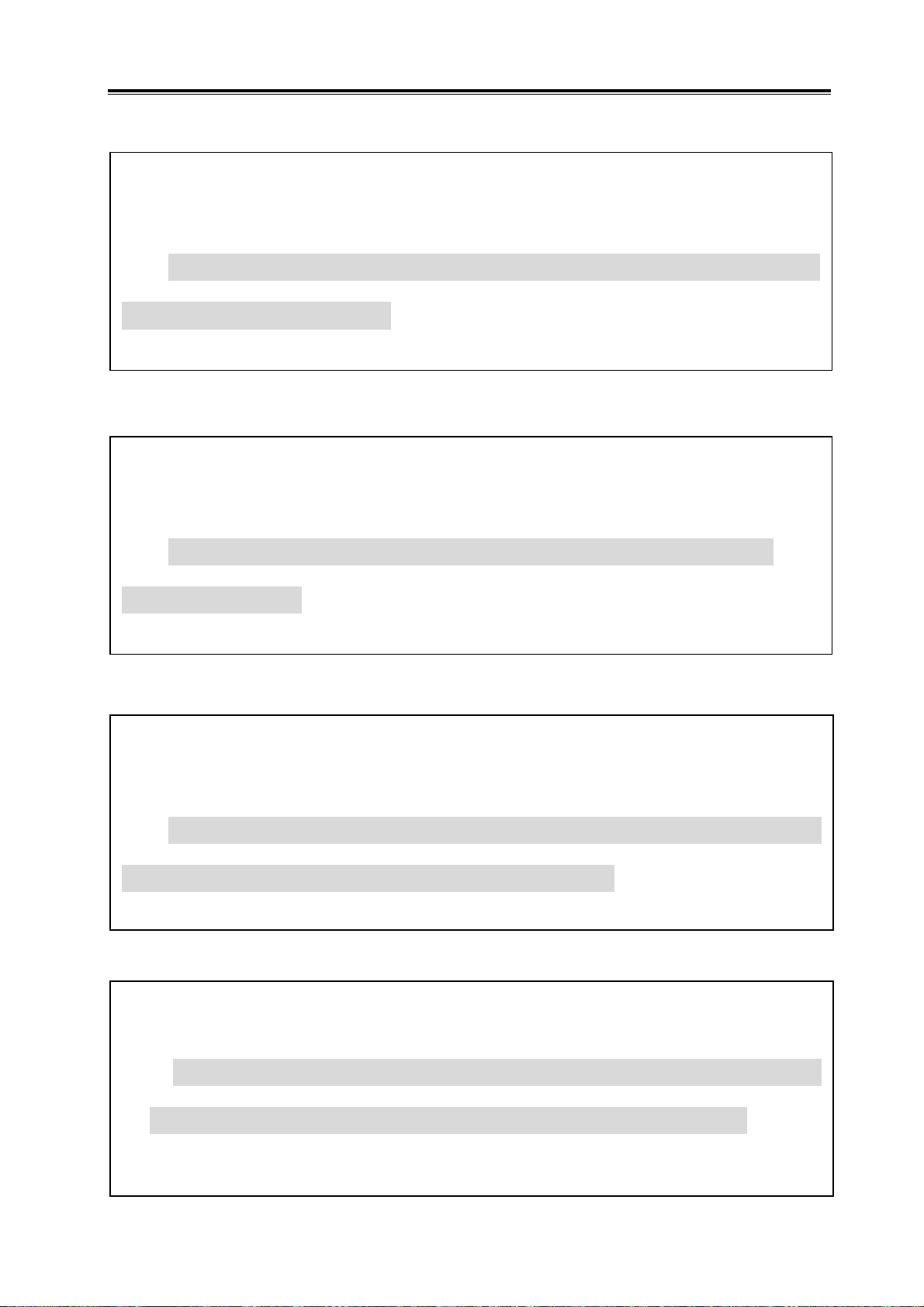

General

Volume Ⅰ PROGRAMMING

Introduces product specification, types, command codes

and format of programs.

VolumeⅡ OPERATION

Describes the operation methods of GSK980MDa CNC

Milling Machine.

VolumeⅢ INSTALLATION

Describes the methods for installation, connection and

setting of GSK980MDa CNC Milling Machine.

APPENDIX

Describes appearance dimensions, rigid tapping and

alarm messages of GSK980MDa CNC Milling Machine.

V

GSK980MDa Milling CNC System User Manual

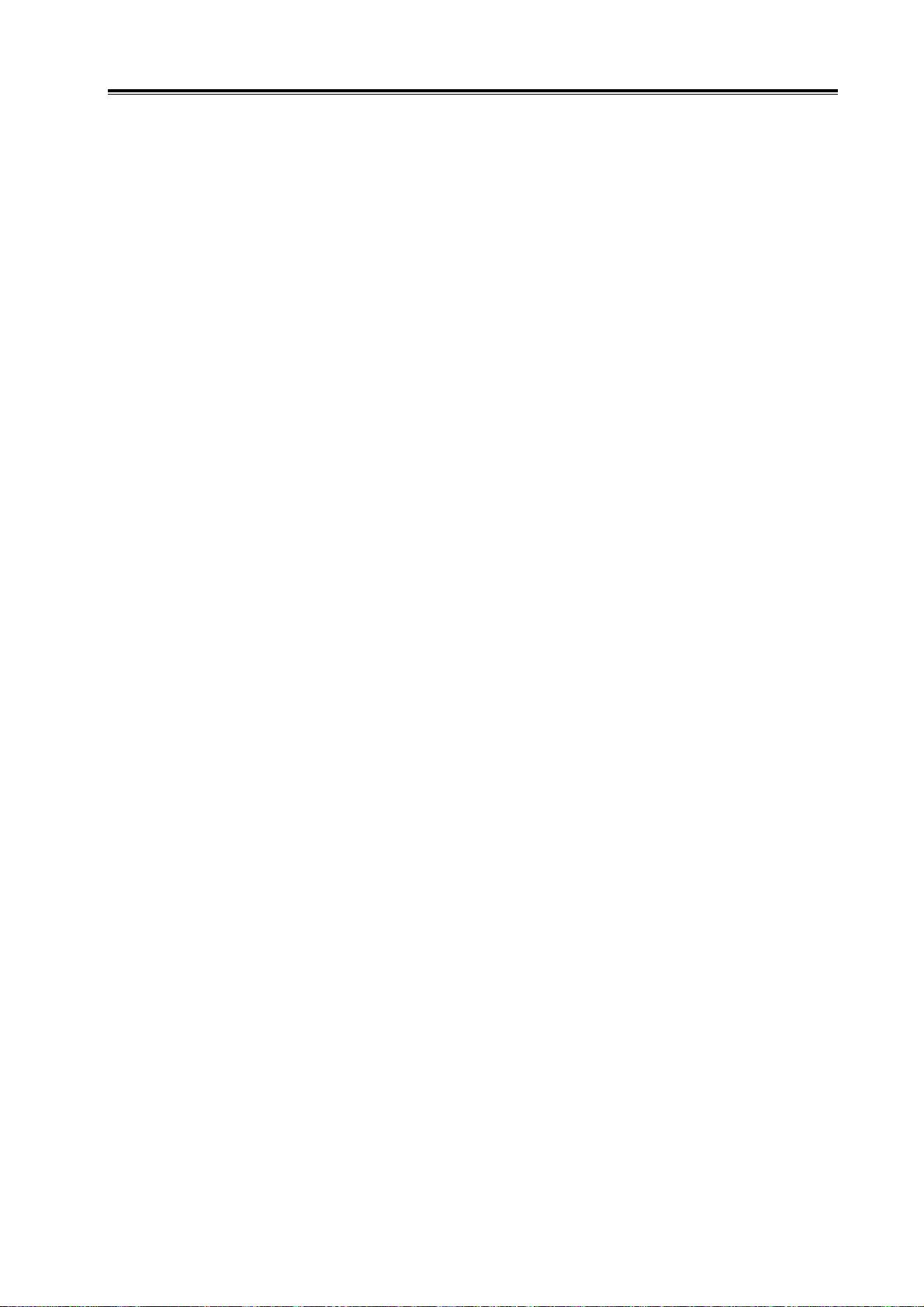

Safety Responsibility

Manufacturer Responsibility

——Be responsible for the danger which should be eliminated and/or controlled on

design and configuration of the provided CNC systems and accessories.

——Be responsible for the safety of the provided CNC systems and accessories.

——Be responsible for the provided information and advice for the users.

User Responsibility

——Be trained with the safety operation of CNC system and familiar with the safety

operation procedures.

——Be responsible for the dangers caused by adding, changing or altering to the

original CNC systems and the accessories.

—— Be responsible for the failure to observe the provisions for operation, adjustment,

maintenance, installation and storage in the manual.

This manual is reserved by end user.

We are full of heartfelt gratitude to you for supporting us in the use of GSK’s

products.

VI

Contents

CONTENTS

VOLUME I PROGRAMMING

CHAPTER 1 PROGRAMMING FUNDMENTALS .............................................................................3

1.1 Introduction.............................................................................................................................3

1.2 Program Execution.................................................................................................................7

1.2.1 Program Execution Sequence......................................................................................7

1.2.2 Word Execution Sequence within Block .......................................................................8

1.3 Basic Axes Increment System ................................................................................................9

1.3.1 Speed of Increment Systems .......................................................................................9

1.3.2 Unit of Increment Systems ...........................................................................................9

1.3.3 Data Ranges of Increment System.............................................................................10

1.3.4 Data Ranges and Unit of Increment System ..............................................................10

1.3.5 The Units and Ranges of Program Address Values....................................................13

1.4 Additional Axes Increment System .......................................................................................13

1.4.1 Additional Axes in Current Increment System.............................................................14

1.4.2 Additonal Axes in IS-A Increment System ..................................................................14

CHAPTER 2 MSTF CODES ...........................................................................................................15

2.1 M Codes (Miscellaneous Function) ......................................................................................15

2.1.1 End of Program (M02)................................................................................................15

2.1.2 Rigid Tapping Designation M29 ..................................................................................16

2.1.3 End of Run (M30) .......................................................................................................16

2.1.4 Subprogram Call (M98) ..............................................................................................16

2.1.5 Return from Subprogram (M99) .................................................................................16

2.1.6 Macro Program Call (M9000~M9999) ........................................................................18

2.1.7 M Command Defined by Standard PLC Ladder Diagram...........................................18

2.1.8 Program Stop M00 .....................................................................................................18

2.1.9 Spindle CCW, CW, Stop Control(M03, M04 and M05)................................................18

2.1.10 Cooling Control (M08, M09) .....................................................................................19

2.1.11 Lubricating Control (M32,M33) .................................................................................19

2.2 Spindle Function...................................................................................................................19

2.2.1 Spindle Speed Switch Value Control ..........................................................................19

2.2.2 Spindle Speed Analog Voltage Control.......................................................................20

2.2.3 Spindle Override.........................................................................................................21

2.3 Tool Function ........................................................................................................................21

2.4 Feeding Function..................................................................................................................21

2.4.1 Cutting Feed (G94/G95, F command) ........................................................................21

2.4.2 Manual Feed ..............................................................................................................23

2.4.3 MPG/ Step Feed.........................................................................................................24

2.4.4 Automatic Acceleration or Deceleration......................................................................24

CHAPTER3 G COMMAND................................................................................................................27

3.1 G Command Brief.................................................................................................................27

3.1.1 Modal, Non-modal and Initial State.............................................................................29

3.1.2 Examples ...................................................................................................................29

VII

GSK980MDa Milling CNC System User Manual

3.1.3 Related Definition.......................................................................................................30

3.1.4 Address Definition ......................................................................................................30

3.2 Rapid Positioning G00 .......................................................................................................33

3.3 Linear Interpolation G01.......................................................................................................34

3.4 Arc and Helical Interpolation G02, G03 ................................................................................35

3.5 Dwell G04.............................................................................................................................40

3.6 Cylindrical Interpolation G07.1 .............................................................................................41

3.7 Polar Coordinate Command (G15, G16) .............................................................................. 45

3.8 Plane Selection Command G17, G18 and G19 ................................................................. 48

3.9 Conversion of Inch and Metric G20 and G21.....................................................................48

3.10 Reference Point Return G28 ..............................................................................................49

3.11 Return from Reference Point G29 ......................................................................................50

3.12 The 2nd, 3rd and 4th Reference Point Return G30 ............................................................51

3.13 Skip Function G31..............................................................................................................53

3.14 Tool Nose Radius Compensation C (G40, G41 and G42) ..................................................55

3.15 Tool Length Compensation (G43, G44, G49)................................................................... 57

3.16 Scaling G50, G51 ...............................................................................................................60

3.17 Programmable Mirror Image G50.1, G51.1 ........................................................................63

3.18 Setting Local Coordinate System G52 ...............................................................................65

3.19 Select Machine Coordinate System G53............................................................................68

3.20 Workpiece Coordinate System G54~G59........................................................................69

3.21 Coordinate System Rotation G68, G69 ..............................................................................71

3.22 Compound Cycle Command ..............................................................................................76

3.22.1 Brief for Canned Cycle .............................................................................................76

3.22.2 Description for canned cycle ....................................................................................80

3.22.3 Continous Drilling ...................................................................................................101

3.22.4 Cautions for Canned Cycle ....................................................................................104

3.22.5 Examples for Modal Data Specified in Canned Cycle ............................................106

3.22.6 Examples for Canned Cycle and Tool Length Compensation ................................ 107

3.23 Absolute and Incremental Commands G90 and G91 .......................................................109

3.24 Workpiece Coordinate System Setting G92 ..................................................................... 109

3.25 Feed per min. G94, Feed per rev. G95............................................................................. 110

3.26 G98, G99.......................................................................................................................... 110

3.27 Chamfering Function ........................................................................................................111

3.27.1 Linear Chamfering.................................................................................................. 111

3.27.2 Circular Chamfering ............................................................................................... 113

3.27.3 Exceptional Cases ................................................................................................. 114

3.28 Rigid Tapping.................................................................................................................... 115

3.28.1 Rigid Tapping ......................................................................................................... 116

3.28.2 Peck Rigid Tapping................................................................................................. 117

3.28.3 Address Explanation .............................................................................................. 118

3.28.4 Technic Specification .............................................................................................. 119

3.28.5 Specify a Rigid Tapping Mode ................................................................................ 120

3.28.6 The Cancellation of Rigid Tapping Mode ................................................................ 121

3.28.7 F and G Signals .....................................................................................................121

3.28.8 Alarm Message ......................................................................................................122

3.28.9 Program Example ..................................................................................................122

VIII

Contents

CHAPTER 4 CONTROL FUNCTION of ADDITIONAL AXIS............................................................123

4.1 General...............................................................................................................................123

4.2 Axis Name ..........................................................................................................................123

4.3 Axis Display ........................................................................................................................123

4.4 Axis Startup ........................................................................................................................124

4.5 The Additional Axis is Linear Axis .......................................................................................124

4.6 The Additional Axis is Rotation Axis ....................................................................................125

4.7 The Zero Return D of Rotation Axis....................................................................................127

4.8 The Function of Cs Axis......................................................................................................128

CHAPTER 5 MACRO PROGRAM...................................................................................................133

5.1 Macro Call ..........................................................................................................................133

5.2 Variables.............................................................................................................................137

5.2.1 Null Variables ...........................................................................................................141

5.2.2 Local Variables .........................................................................................................142

5.2.3 Common Variable .....................................................................................................143

5.2.4 System Variables......................................................................................................143

5.3 Arithmetic and Logic Operation ..........................................................................................146

5.3.1 Tranditional Format ..................................................................................................147

5.3.2 Macro Statement ......................................................................................................151

5.3.3 Priority of Operations................................................................................................153

5.3.4 Bracket Nesting........................................................................................................153

5.4 Branch and Repetition ........................................................................................................153

5.4.1 Unconditional Branch (GO TO statement)................................................................154

5.4.2 Conditional Branch (IF statement)............................................................................154

5.4.3 Conditional Expression.............................................................................................154

5.4.4 Repetition(WHILE Statement)..............................................................................155

5.5 Macro Statement and NC statement...................................................................................156

5.5.1 Macro Programming and Registering.......................................................................156

5.5.2 Limitation..................................................................................................................156

CHAPTER 6 CUTTER COMPENSATION.....................................................................................158

6.1 Application for Cutter Radius Compensation......................................................................158

6.1.1 Brief..........................................................................................................................158

6.1.2 Compensation value setting .....................................................................................158

6.1.3 Command format......................................................................................................159

6.1.4 Compensation direction............................................................................................160

6.1.5 Caution.....................................................................................................................160

6.1.6 Example for application ............................................................................................161

6.2 Offset Path Explanation for Cutter Radius Compensation..................................................162

6.2.1 Conception for inner side or outer side.....................................................................162

6.2.2 Tool movement in start-up ........................................................................................162

6.2.3 Tool movement in offset mode..................................................................................164

6.2.4 Tool operation in offset cancellation mode................................................................169

6.2.5 Interference check....................................................................................................170

6.2.6 Command of compensation vector cancel temporarily.............................................172

6.2.7 Exceptional case ......................................................................................................173

IX

GSK980MDa Milling CNC System User Manual

Volume Ⅱ OPERATION

CHAPTER1 OPERATION MODE AND DISPLAY .........................................................................179

1.1 Panel Division.....................................................................................................................179

1.1.1 State Indication.........................................................................................................180

1.1.2 Edit Keypad..............................................................................................................180

1.1.3 Menu Display ...........................................................................................................181

1.1.4 Machine Panel .........................................................................................................182

1.2 Summary of Operation Mode .............................................................................................184

1.3 Display Interface.................................................................................................................185

1.3.1 Position Interface .....................................................................................................187

1.3.2 Program Interface ....................................................................................................190

1.3.3 Tool Offset, Macro Variable and Tool Life Management Interface ............................192

1.3.4 Alarm Interface .........................................................................................................195

1.3.5 Setting interface .......................................................................................................197

1.3.6 BIT PARAMETER, DATA PARAMETER, PITCH COMP Interface............................201

1.3.7 CNC DIAGNOSIS, PLC STATE, PLC VALUE, Machine Soft Panel, VERSION

MESSAGE Interface .........................................................................................................203

1.4 List of General Operations .................................................................................................205

CHAPTER 2 POWER ON OR OFF AND PROTECTION.............................................................. 211

2.1 System Power On ..............................................................................................................211

2.2 System Power Off ..............................................................................................................211

2.3 Overtravel Protection..........................................................................................................212

2.3.1 Hardware Overtravel Protection ............................................................................... 212

2.3.2 Software Overtravel Protection ................................................................................212

2.4 Emergency Operation ........................................................................................................212

2.4.1 Reset........................................................................................................................212

2.4.2 Emergency Stop.......................................................................................................213

2.4.3 Feed Hold.................................................................................................................213

2.4.4 Power Off .................................................................................................................213

CHAPTER 3 MANUAL OPERATION...............................................................................................214

3.1 Coordinate Axis Moving......................................................................................................214

3.1.1 Manual Feed ............................................................................................................214

3.1.2 Manual rapid traverse ..............................................................................................214

3.2 Feedrate Override Adjustment ...........................................................................................215

3.2.1 Manual Feedrate Override Adjustment..................................................................... 215

3.2.2 Manual Rapid Override Adjustment..........................................................................215

3.2.3 Spindle Override Adjustment....................................................................................216

3.3 Relative Coordinate Clearing .............................................................................................216

CHAPTER 4 MPG/STEP OPERATION ........................................................................................ 217

4.1 Step Feed...........................................................................................................................217

4.1.1 Increment Selection .................................................................................................217

4.1.2 Moving Direction Selection....................................................................................... 218

X

Contents

4.2 MPG (Handwheel) Feed.....................................................................................................218

4.2.1 Increment Selection..................................................................................................218

4.2.2 Moving Axis and Direction Selection ........................................................................219

4.2.3 Explanation Items.....................................................................................................219

CHAPTER 5 MDI OPERATION .......................................................................................................220

5.1 Code Words Input...............................................................................................................220

5.2 Code Words Execution.......................................................................................................221

5.3 Parameter Setting...............................................................................................................221

5.4 Data Modification................................................................................................................222

5.5 OUT Key Start ....................................................................................................................223

CHAPTER 6 PROGRAM EDIT AND MANAGEMENT .................................................................224

6.1

Program Creation

6.1.1 Creation of the Block Number ..................................................................................224

6.1.2 Input the Program Content .......................................................................................224

6.1.3 Search of the character ............................................................................................226

6.1.4 Insertion of the Character.........................................................................................228

6.1.5 Deletion of the Character .........................................................................................229

6.1.6 Modification of the Character....................................................................................229

6.1.7 Deletion of a Single Block ........................................................................................229

6.1.8 Deletion of the Blocks...............................................................................................229

6.1.9 Segment Deletion.....................................................................................................231

6.2 Program Annotation............................................................................................................232

6.2.1 Annotation for Program Name ..................................................................................232

6.2.2 Block Annotation.......................................................................................................233

6.2.3 Alter Program Annotation..........................................................................................234

6.3 Deletion of the Program......................................................................................................234

6.3.1 Deletion a Single Program .......................................................................................234

6.3.2 Deletion of All Programs ...........................................................................................234

6.4 Selection of the Program...................................................................................................234

6.4.1 Search Method .........................................................................................................235

6.4.2 Scanning method .....................................................................................................235

6.4.3 Cursor Method..........................................................................................................235

6.4.4 Select File by Using File List ....................................................................................236

6.5 Execution of the Program..................................................................................................236

6.6 Rename of the Program ....................................................................................................236

6.7 Copy of the Program ..........................................................................................................236

6.8 Program Positioning ...........................................................................................................237

6.9 Program Preview................................................................................................................237

...............................................................................................................224

CHAPTER 7 AUTO OPERATION................................................................................................239

7.1 Auto Run ...........................................................................................................................239

7.1.1 Selection of the Program To Be Run ........................................................................239

7.1.2 Program Start...........................................................................................................240

7.1.3 Stop of the Auto Run ................................................................................................240

7.1.4 Auto Run From an Arbitrary Block ............................................................................241

7.1.5 Adjustment of the feedrate override, rapid override..................................................242

XI

GSK980MDa Milling CNC System User Manual

7.1.6 Spindle override adjustment.....................................................................................243

7.2 DNC Running .....................................................................................................................243

7.3 Running State.....................................................................................................................243

7.3.1 Single Block Execution............................................................................................. 243

7.3.2 Dry Run....................................................................................................................244

7.3.3 Machine lock ............................................................................................................244

7.3.4 MST Lock.................................................................................................................244

7.3.5 Block Skip ................................................................................................................245

7.3.6 Optional Stop............................................................................................................245

7.4 Memorizing at Power-down................................................................................................245

7.4.1 Program Interruption in Non-DNC Auto Operation ...................................................245

7.4.2 Interruption at Power-down on DNC Auto Operation................................................246

CHAPTER 8 MACHINE ZERO RETURN OPERATION..................................................................247

8.1 Machine Zero .....................................................................................................................247

8.2 Machine Zero Return Steps ..............................................................................................247

CHAPTER 9 DATA SETTING, BACKUP and RESTORE ..............................................................248

9.1 Data Setting ......................................................................................................................248

9.1.1 Switch Setting ..........................................................................................................248

9.1.2 Graphic setting .........................................................................................................249

9.1.3 Parameter Setting ....................................................................................................250

9.2 The Password Setting and Alteration .................................................................................255

9.2.1 Entry of the Operation Level.....................................................................................256

9.2.2 Alteration of the Password........................................................................................257

9.2.3 Lower Level Set .......................................................................................................259

9.3 Operations under Different Operation Authorities...............................................................260

9.3.1 Operation of Communication....................................................................................260

9.3.2 CNC Operation.........................................................................................................261

9.3.3 Operation of File List ................................................................................................ 262

9.3.4 Advanced Operation of U-disk..................................................................................262

9.4 Data Restore and Backup ..................................................................................................26

3

CHAPTER 10 ADVANCE OPERATION........................................................................................265

10.1 Operation Path .................................................................................................................265

10.2 Operation instructions ......................................................................................................266

10.3 Attentions .........................................................................................................................267

CHAPTER 11 FLASH OPERATION..............................................................................................268

11.1. File List ............................................................................................................................268

11.2. Introduction of General File Operation Function ..............................................................269

11.2.1 Open and Close File Folder.................................................................................... 269

11.2.2 Copy the File by One Key(current list in C disk←→current list in U disk)...............270

11.2.3 CNC File Search ....................................................................................................271

11.2.4 Open CNC File .......................................................................................................271

XII

Contents

VOLUME Ⅲ INSTALLATION

CHAPTER 1 INSTALLATION LAYOUT........................................................................................275

1.1 GSK980MDa Connection ...................................................................................................275

1.1.1 GSK980MDa Back Cover Interface Layout ..............................................................275

1.1.2 Interface Explanation................................................................................................275

1.2 GSK980MDa Installation ....................................................................................................276

1.2.1 GSK980MDa External Dimensions ..........................................................................276

1.2.2 Installation Conditions of the Cabinet .......................................................................276

1.2.3 Protection Methods Against Interference..................................................................276

CHAPTER 2 DEFINITION&CONNECTION OF INTERFACE SIGNALS....................................279

2.1 Connection to Drive Unit.....................................................................................................279

2.1.1 Drive Interface Definition ..........................................................................................279

2.1.2 Command Pulse and Direction Signals ....................................................................279

2.1.3 Drive Unit Alarm Signal ............................................................................................279

2.1.4 Axis Enable Signal ENn............................................................................................280

2.1.5 Pulse Disable Signal SETn.......................................................................................280

2.1.6 Zero Signal nPC .......................................................................................................280

2.1.7 Connection to Drive Unit ..........................................................................................282

2.2 Connection of 4th Axis........................................................................................................282

2.2.1 4th Axis Interface Definition ......................................................................................282

2.2.2 Connection of 4th Axis Interface as Linear Axis........................................................283

2.2.3 Connection of 4th Axis Interface as Rotary Axis .......................................................284

2.3 Connection of Spindle Port.................................................................................................284

2.3.1 Definition of Signal ...................................................................................................284

2.3.2 Spindle Zero Signal ..................................................................................................285

2.3.3 Linear Axis................................................................................................................285

2.3.4 Connection of Spindle interface and Servo Spindle..................................................285

2.3.5 SVC Signal Explanation ...........................................................................................285

2.3.6 Explanations for ALM5(X5.3)....................................................................................286

2.4 Connection to Spindle Encoder ..........................................................................................286

2.4.1 Spindle Encoder Interface Definition ........................................................................286

2.4.2 Signal Explanation....................................................................................................286

2.4.3 Connection of Spindle Encoder Interface .................................................................286

2.5 Connection to Handwheel ..................................................................................................287

2.5.1 Handwheel Interface Definition.................................................................................287

2.5.2 Signal Explanation....................................................................................................288

2.6 Connection of GSK980MDa to PC .....................................................................................288

2.6.1 Communication Interface Definition..........................................................................288

2.6.2 Communication Interface Connection ......................................................................289

2.7 Connection of Power Interface ...........................................................................................289

2.8 I/O Interface Definition: ....................................................................................................290

2.8.1 Input Signal ..............................................................................................................292

2.8.2 Output Signal............................................................................................................293

2.9 Function of Standard Ladder Diagram................................................................................294

XIII

GSK980MDa Milling CNC System User Manual

2.9.1 Spindle Rotation Control........................................................................................294

2.9.2 Spindle Jog............................................................................................................295

2.9.3 Spindle Switching Volume Control.........................................................................296

2.9.4 Cycle Start and Feed Hold.....................................................................................297

2.9.5 Coolant Control......................................................................................................297

2.9.6 Lubrication Control ................................................................................................298

2.9.7 Block Skip..............................................................................................................299

2.9.8 Machine Lock ........................................................................................................299

2.9.9 Auxiliary Lock ........................................................................................................300

2.9.10 Single Block ...........................................................................................................300

2.9.11 Dry Run..................................................................................................................300

2.9.12 Optional Stop..........................................................................................................301

2.9.13 Stroke Limit and Emergency Stop..........................................................................301

2.9.14 Tri-colour Indicator .................................................................................................302

2.9.15 Reset and Cursor Return .......................................................................................302

2.9.16 Rigid Tapping ......................................................................................................... 302

2.9.17 Spindle Exact Stop.................................................................................................303

2.9.18 External MPG Control ............................................................................................304

2.9.19 Cs Axis Switching...................................................................................................304

2.10 Machine Zero ...................................................................................................................304

CHAPTER 3 PARAMETER.............................................................................................................314

3.1 Parameter Description (by Sequence) ...............................................................................314

3.1.1 Bit Parameter...........................................................................................................314

3.1.2 Data Parameter........................................................................................................324

3.2 Parameter Description (by Function Sequence).................................................................331

3.2.1 Axis Control Logic ....................................................................................................331

3.2.2 Acceleration & Deceleration Control.........................................................................333

3.2.3 Machine Protection ..................................................................................................335

3.2.4 Thread Function.......................................................................................................335

3.2.5 Spindle Control.........................................................................................................336

3.2.6 Tool Function............................................................................................................337

3.2.7 Edit and Display.......................................................................................................337

3.2.8 Precision Compensation ..........................................................................................338

3.2.9 Communication Setting............................................................................................339

3.2.10 Machine Zero Return .............................................................................................339

3.2.11 Rotary Axis Function...............................................................................................343

CHAPTER 4 MACHINE DEBUGGING METHODS AND STEPS................................................346

4.1 Emergency Stop and Stroke Limit......................................................................................346

4.2 Drive unit Unit Setting.........................................................................................................346

4.3 Gear Ratio Adjustment.......................................................................................................346

4.3.1 Servo Feed Axis.......................................................................................................346

4.3.2 Servo Spindle...........................................................................................................348

4.4 Acceleration&deceleration Characteristic Adjustment ........................................................349

4.5 Machine Zero Adjustment...................................................................................................350

4.6 Spindle Adjustment.............................................................................................................352

XIV

Contents

4.6.1 Spindle Encoder.......................................................................................................352

4.6.2 Spindle Brake...........................................................................................................352

4.6.3 Switch Volume Control of Spindle Speed.................................................................352

4.6.4 Analog Voltage Control for Spindle Speed................................................................352

4.7 Backlash Offset..................................................................................................................353

4.8 Step/MPG Adjustment........................................................................................................354

4.9 Other Adjustment................................................................................................................355

CHAPTER 5 DIAGNOSIS MESSAGE.........................................................................................356

5.1 CNC Diagnosis...................................................................................................................356

5.1.1 Signal Diagnosis from Machine to CNC...................................................................356

5.1.2 Axes Moving State and Data Diagnosis Signal of CNC............................................ 356

5.1.3 MDI Panel Keys Diagnosis.......................................................................................357

5.1.4 CNC Internal State...................................................................................................358

5.2 PLC State ...........................................................................................................................359

5.2.1 X Address (Fixed Addresses)...................................................................................359

5.2.2 Y Address (Fixed Addresses)...................................................................................361

5.3 PLC Data............................................................................................................................361

CHAPTER 6 MEMORIZING SCREW-PITCH ERROR COMPENSATION FUNCTION...................362

6.1 Function Explanation..........................................................................................................362

6.2 Specifications.....................................................................................................................362

6.3 Parameter Setting...............................................................................................................362

6.3.1 Screw-Pitch Compensation......................................................................................362

6.3.2 Screw-Pitch Error Origin...........................................................................................362

6.3.3 Offset Interval...........................................................................................................363

6.3.4 Compensation Value ................................................................................................363

6.4 Cautions for Offset Setting .................................................................................................363

6.5 Examples of Offset Parameters Setting..............................................................................364

XV

GSK980MDa Milling CNC System User Manual

APPENDIX

Appendix 1 Outline Dimension of GSK980MDa ...............................................................................371

Appendix 2 Dimensions of Additional Panel AP01............................................................................371

Appendix 3 Dimensions for Additional Panel AP02 ..........................................................................371

Appendix 4 Diagram of I/O Deconcentrator......................................................................................372

4.1 MCT01B .............................................................................................................................372

4.2 MCT01B-1..........................................................................................................................374

4.3 MCT05 ...............................................................................................................................375

Appendix 5 Explanations of Rigid tapping ........................................................................................375

5.1 Definition of Spindle Signal Line......................................................................................... 375

5.2 Wiring Diagram of the Spindle............................................................................................ 378

5.3 Setting of Spindle Electronic Gear Ratio ............................................................................379

5.4 Related Parameter Setting ................................................................................................. 380

Appendix 6 Communication Software GSKComm Instruction ..........................................................381

6.1 GSKComm Introduction .....................................................................................................381

6.2 Project Creation, Import and Removal ...............................................................................382

6.2.1 Project Creation ....................................................................................................... 382

6.2.2 Project Import........................................................................................................... 384

6.2.3 Project Removal....................................................................................................... 385

6.3 File Creation, Import, Removal and Edit.............................................................................385

6.3.1 File Creation............................................................................................................. 385

6.3.2 File Edit .................................................................................................................... 386

6.3.3 Add Files .................................................................................................................. 388

6.3.4 File Removal ............................................................................................................ 389

6.4 File Download (PC→CNC).................................................................................................389

6.5 View Tool Compensation and Pitch Error Compensation ...................................................392

6.6 DNC Transmission .............................................................................................................393

6.7 CNC Part Programs Management......................................................................................394

6.8 Preparations before Communication .................................................................................. 395

6.9 Communication between CNC and CNC ...........................................................................396

Appendix 7 Alarm Message..............................................................................................................398

Appendix 8 Notes for the Ladder Diagram of the GSK980MDa Software ( Post Version

V3.03 ,including V3.03) ....................................................................................................................406

Appendix 9 Standard Ladder Diagram .............................................................................................407

XVI

Contents

VOLUME I PROGRAMMING

1

GSK980MDa Milling CNC System User Manual

2

Chapter 1 Programming Fundmentals

CHAPTER 1 PROGRAMMING FUNDMENTALS

1.1 Introduction

GSK980MDa Milling Machine is a new generation of CNC system developed by GSK Company.

As the upgraded version of GSK980MD, it supports milling, boring and drilling cycle. It employs 32 bits

high-capability CPU and very large scale programmable device FPGA, applies real-time multi-task

control technology and hardware interpolation technology, and is able to perform μm level precision

motion control and PLC logic control. GSK980MDa is the optimum choice for upgrading CNC milling

machine.

Volume I Programming

Characteristics:

9 Five axes control (X, Y, Z ,4th and 5th); 3 axes linkage; optional interpolation precision

(1μm/0.1μm); maximum speed 60m/min; optional axis types (linear axis or revolving axis)

for the 4th and 5th axes; CS axis control available for the 4th and 5th axes.

9 Electronic gear ratio: (1~32767):(1~32767)

9 Screw-pitch error compensation, backlash compensation, tool length compensation, tool

abrasion compensation and tool nose radius compensation.

9 Embedded with PLC can be downloaded to CNC from PC.

9 DNC function supports for real-time program transmission for machining.

9 Compatible with G commands in GSK980MC, GSK928MA and GSK980MD. 26 kinds of

canned cycles, such as drilling/boring, circular/rectangular groove rough-milling, full

circle/rectangular finish-milling, linear/rectangular/arc continuous drilling.

9 Spindle encoder tapping and rigid tapping can be detected during tapping cycle, so that

high precision machining can be performed.

9 Metric/inch programming; automatic chamfering function and tool life management function.

9 Chinese, English, Russian and Spanish display selected by the parameters.

3

9 Full screen program editing; 40MB program capacity for storing up to 40000 of part

Volume I Programming

programs.

9 USB data communication; CNC system upgrading, machining programs reading through U

disk and bidirectional transfer between CNC and U disk.

9 Alarm log; multi-level passwords for equipment maintenance and management.

9 Bidirectional transfer between CNC and CNC, CNC and PC; upgrade of CNC software and

PLC programs;

9 The installation dimensions and the electric ports are compatible with GSK980MD,

GSK980MC.

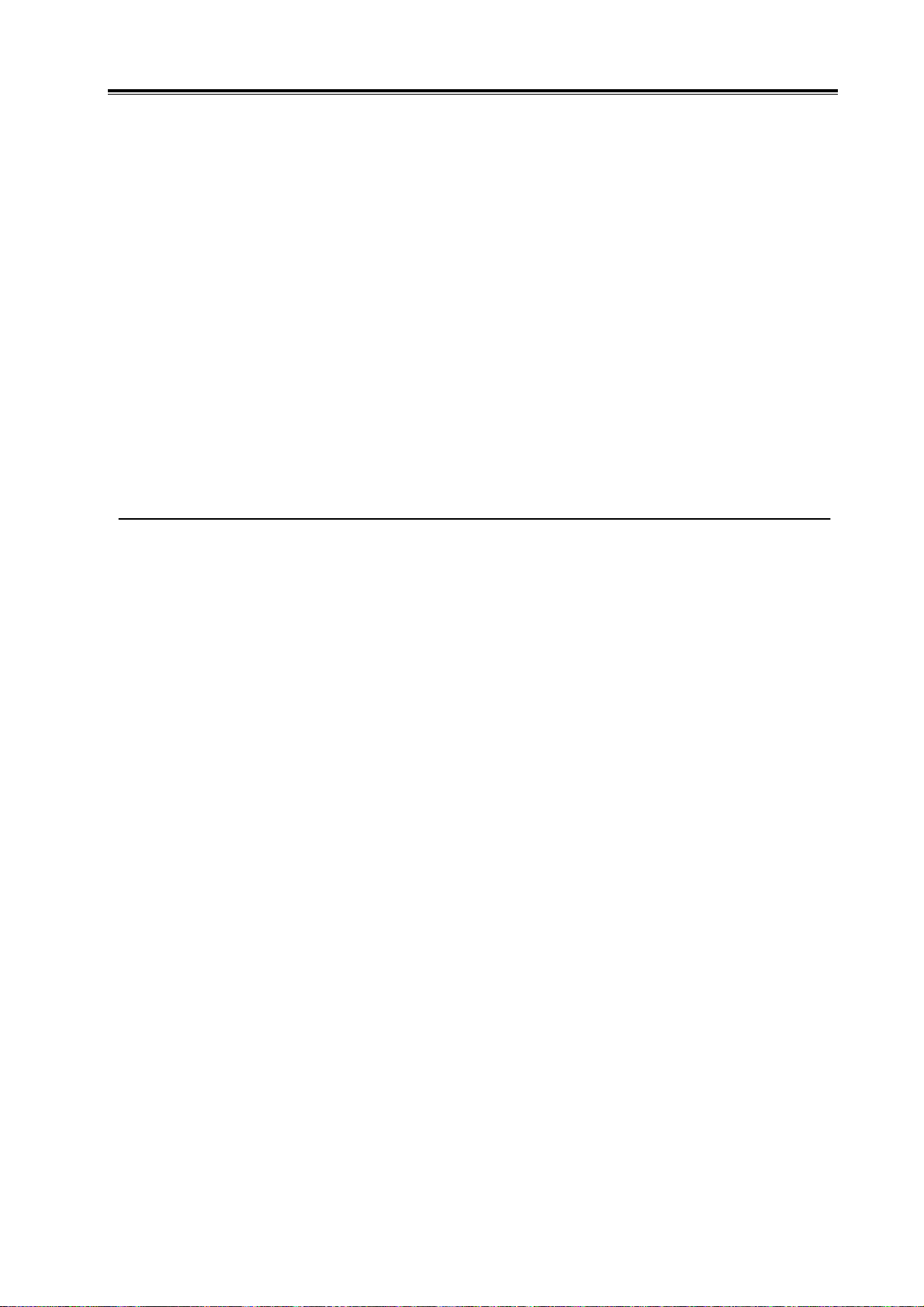

Specifications

Motion control

GSK980MDa Milling CNC System User Manual

Controlled axes: five axes (X,Y,Z,4th and

optional axis types (linear axis or revolving axis) and CS contouring control

available;

Interpolation functions: linear interpolation (for X, Y, Z, 4th and 5th axes);

helical interpolation (for X, Y and Z axes); circular interpolation (for arbitrary 2

axes).

Position command range: -99999999~99999999; least command increment:

1μm/0.1μm; (selected via parameters)

Electronic gear ratio: command multiplier 1~32767, command frequency

divisor 1~32767

Rapid traverse speed: maximum 60000mm/min

Rapid traverse override: F0, 25%, 50%, 100% four levels real-time tuning

Cutting feedrate: maximum 15000mm/min (feed per min.) or 500mm/r. (feed

per rotation)

Feedrate override: 0~150% sixteen-level real-time tuning

5th); (for the 4th and 5th axes)

G Code

Macro

command

Operation

mode

Tapping

Manual feedrate: 0~1260mm/min sixteen-level real-time tuning

MPG feed: 0.001, 0.010, 0.100,1.000mm four gears.

Acceleration/deceleration type: S-type for rapid traverse; exponential-type for

cutting feed.

Automatic chamfering

65 kinds of G codes:G00, G01, G02, G03, G04, G10, G11, G17, G18, G19,

G20, G21, G28, G29, G30, G31, G40, G41, G42, G43, G44, G49, G54, G55,

G56, G57, G58, G59, G65, G66, G67, G73, G74, G80, G81, G82, G83, G84,

G85, G86, G88, G89, G90, G91, G92, G94, G95, G98, G99, G110, G111,

G112, G113, G114, G115, G134, G135, G136, G137, G138, G139, G140,

G141, G142, G143

31 kinds of arithmetic, logical operations and skip can be achieved by macro

command G65

Macro statement command. eg: IF, WHILE, GOTO

Seven operation modes: EDIT, AUTO, MDI, DNC, MACHINE ZERO,

MPG/STEP and MANUAL.

Tapping function: lead 0.001~500mm or 0.06~25400 pitch/inch

Encoder tapping: settable line number of encoder(0 or100p/r~5000p/r); no

detect for spindle encoder (when the line number is set to 0)

4

Precision

compensation

M command

T command

Spindle speed

control

PLC function

Display

interface

Program edit

USB

Chapter 1 Programming Fundmentals

Rigid tapping: by rotary axis

Drive ratio between encoder and spindle:(1~255):(1~255)

Backlash compensation: 0~2.000mm

Pitch error compensation: 255 compensation points per axis; compensation

amount of each point: ±0.255mm.

Tool compensation: 32 groups tool length compensation, tool wear

compensation, cutter compensation C

Special M commands (redefinition unallowed): M02,M29, M30, M98,

M99,M9000~M9999.

Other M □□ commands are defined or disposed by PLC program.

M commands defined by standard PLC program: M00, M03, M04, M05 M08,

M09, M10, M11, M32, M33

tool number T01~T32 (32 numbers at most); manual tool change or auto-tool

change selected by the parameters; auto tool change sequence set by PLC

program.

Tool life management; 32 groups, 8 kinds/groups of tool life management data

Speed switching value control: S □□ command is defined or disposed by PLC

program; the standard PLC programs S1, S2, S3 and S4 directly output; The

output of S1,S2, S3, and S4 are closed by S0.

Speed analog voltage control: the spindle speed per minute commanded by S

codes; output 0~10V voltage to spindle converter; spindle stepless speed

changing supports 4 spindle mechanical gears

9 kinds of basic commands; 23 kinds of function commands; 2-level PLC

program involving up to 5000 steps (2μs processing time for each step). 8ms

refresh cycle for the first level program; Ladder diagram edit software and

communication software downloadable

Integrated machine panel: 44 points input (key), 44 points output (LED)

Basic I/O: 41 points input/ 36 points output

Displayer: 480×234 lattice, 7’’ wide-screen multi-color LCD,

Display modes: Chinese, English, Russian, Spanish display selected by

parameters; machining path displayable

Capacity: 40MB for up to 40000 part programs; custom macro program call; 4

nesting-levels of subprogram

Edit modes: full-screen editing; absolute/incremental programming

CNC system upgrade

Part programs reading in USB

Bidirectional files transfer between CNC and USB (including programs,

parameters, PLC backup and recovery)

Volume I Programming

Clock display Clock, date and week display.

Serial

Communication

Matching drive

unit

Bidirectional transfer between CNC and PC, CNC and CNC (involving

programs, parameters, tool compensation data); download and upgrade of

system software and PLC program serial ports

AC servo or step drive device by using the pulse+direction signal input. (DA98

or DY3 series)

5

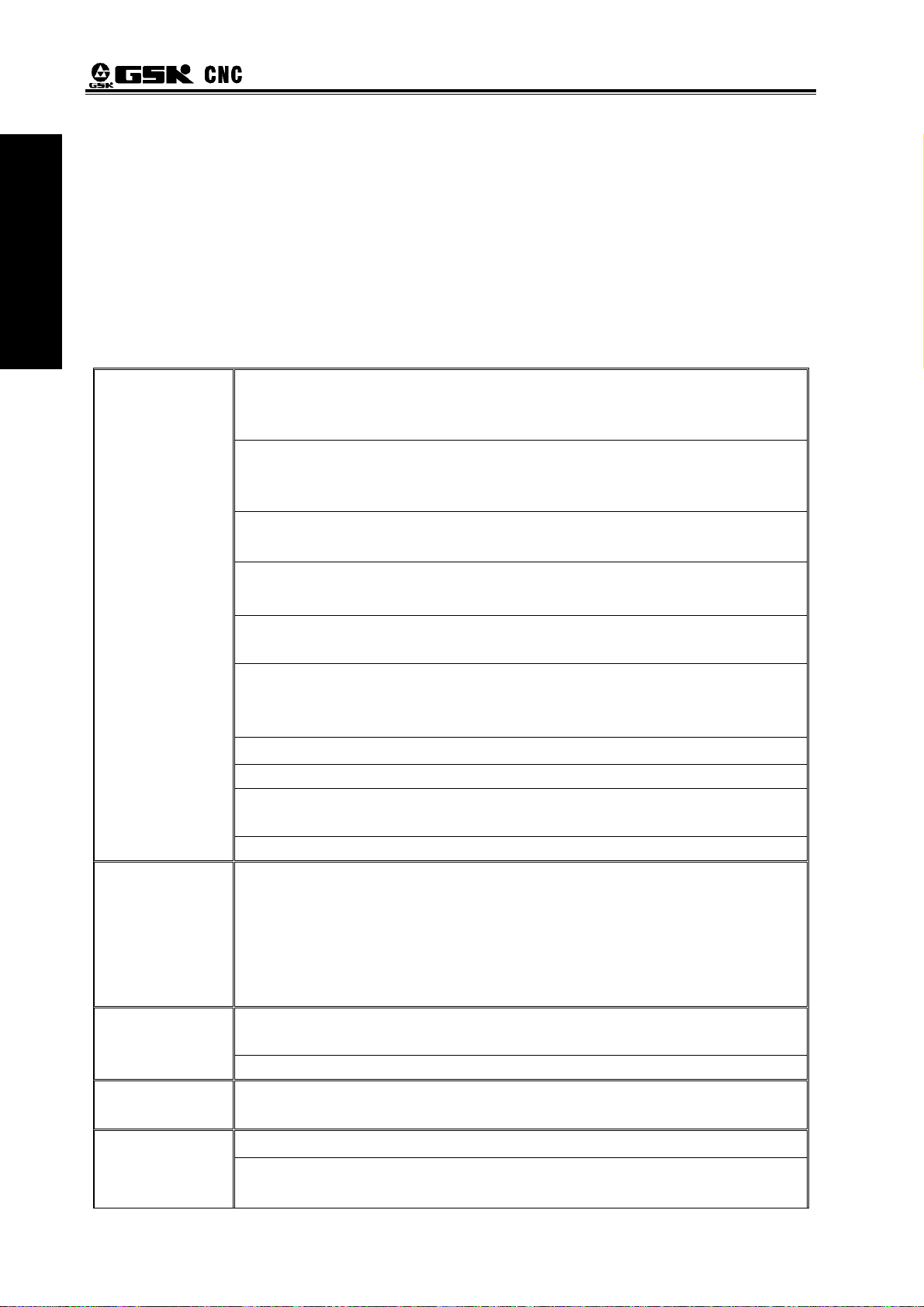

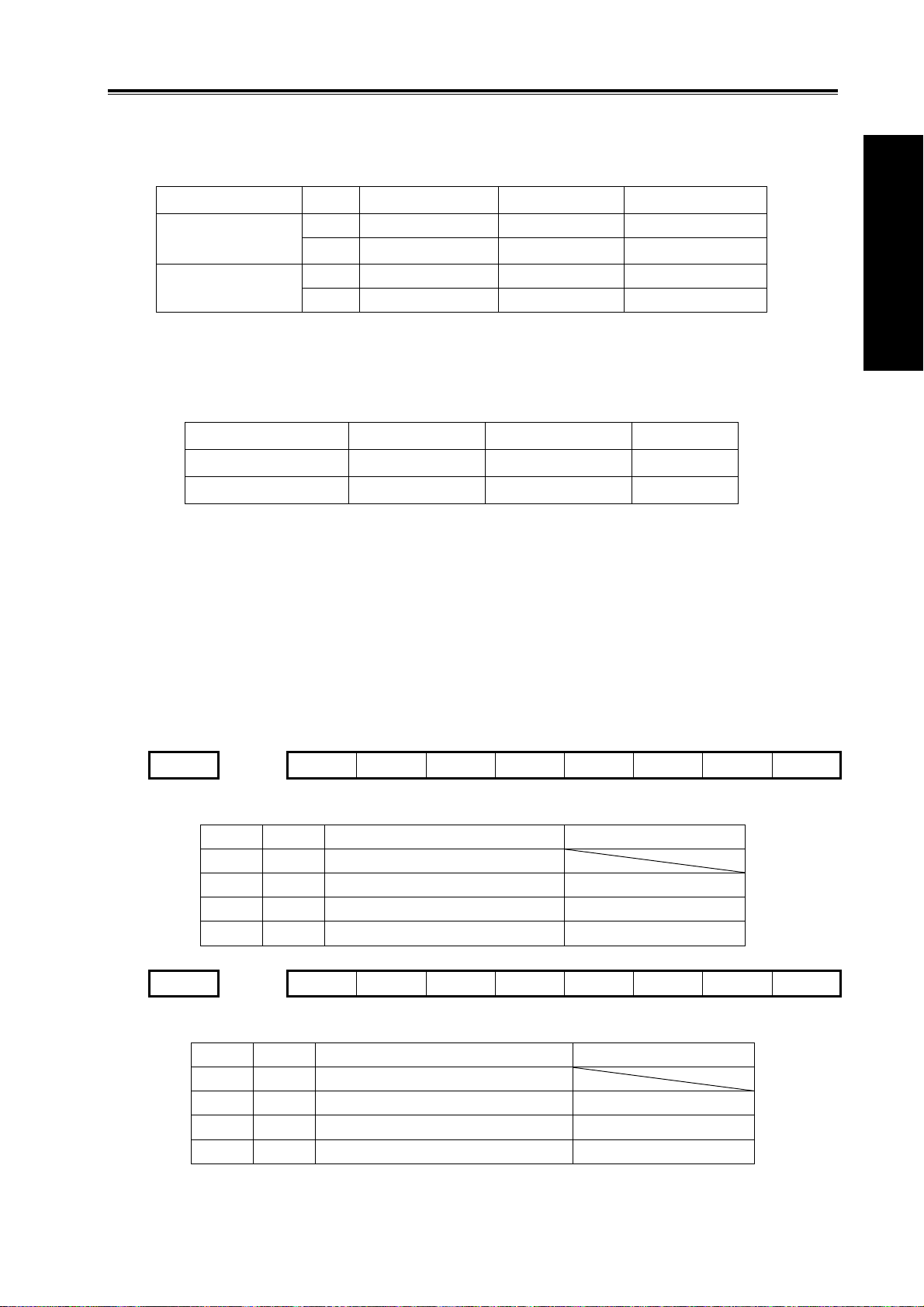

G Code Table

Volume I Programming

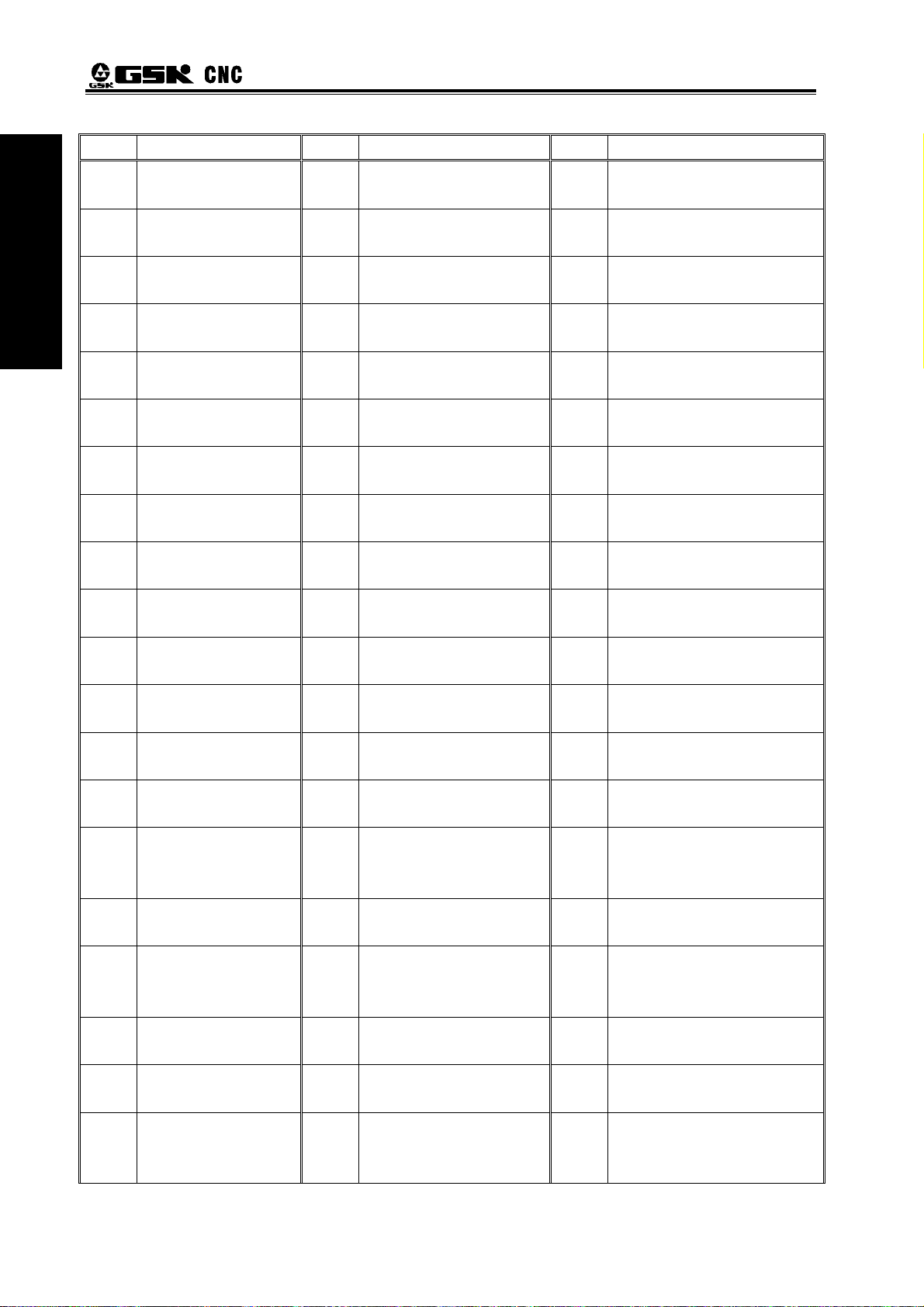

Code Function Code Function Code Function

G00

*G01 Linear interpolation G55

G02

G03

G04 Dwell, exact stop G58

G10

G11

*G17 XY plane selection G66

G18 ZX plane selection *G67

G19 YZ plane selection G73 High-speed peck drilling G114

G20 Inch input G74 Counter tapping cycle G115

G21 Metric input *G80 Canned cycle cancel G134

G28

G29

G30

G31 Skip function G84 Tapping cycle G138

*G40

G41

G42

G43

Positioning (rapid

traverse)

Circular/helical

interpolation (CW)

Circular/helical

interpolation (CCW)

Tool life

management

Tool life

management end

Reference position

return

Return from

reference position

2nd, 3rd, 4th,

reference position

return

Cutter

Compensation

cancel

Cutter

compensation left

Cutter

compensation right

Tool length

compensation +

direction

GSK980MDa Milling CNC System User Manual

*G54

G56

G57

G59

G65

G81

G82

G83 Peck drilling cycle G137

G85 Boring cycle G139

G86 Drilling cycle G140

G88 Boring cycle G141

G89 Boring cycle G142

Workpiece coordinate

system 1

Workpiece coordinate

system 2

Workpiece coordinate

system 3

Workpiece coordinate

system 4

Workpiece coordinate

system 5

Workpiece coordinate

system 6

Macro program/ macro

code

Macro program modal

call

Macro program modal

call cancel

Drilling cycle (spot

drilling cycle)

Drilling cycle (stepped

hole boring cycle)

G92 Coordinate system setting

*G94 Feed per min.

G95 Feed per rotation

*G98

G99

G110

G111

G112 Inner circle finishing (CCW)

G113 Inner circle finishing (CW)

G135

G136

Return to initial plane in

canned cycle

Return to R point in canned

cycle

Inner circle groove

roughing (CCW)

Inner circle groove

roughing (CW)

Circular outer finish milling

(CW)

Outer circle finishing

(CCW)

Rectangular groove

roughing (CCW)

Rectangular groove

roughing (CW)

Rectangular groove inner

finishing (CCW)

Rectangular groove inner

finishing (CW)

Rectangular outer finishing

(CCW)

Rectangular outer finishing

(CW)

Rectangular continuous

drilling (CW)

Rectangular continuous

drilling (CCW)

Arc continuous drilling

(CW)

6

Chapter 1 Programming Fundmentals

Tool length

G44

*G49

Note: mark “ * ” means initial state.

PLC Codes List

Code Function Code Function Code Function

LD Normal open contact

LDI Normal closed

OUT Output coil CMP Comparison setting SUBB Binary subtraction

AND Normal open contact

ANI Normal closed

OR

ORI Normal closed

ORB Serial block in

ANB Parallel block in

END1

END2

compensation –

direction

Tool length

compensation

cancel

read

contact read

in series

contact in series

Normal open contact

in parallel

contact in parallel

parallel

series

First level program

end

Second level

program end

*G90

G91

Absolute

programming

Incremental

programming

SET Setting SPE Subprogram end

RST Resetting ADDB Binary addition

CTRC Counter ALT Alternative output

TMRB Timer DIFU Differential up

CODB

ROTB

MOVN Data copy PARI Parity check

DECB Binary decode LBL Program skip numbering

JMPB Jump CALL Subprogram call

SP

Binary code

transformation

Binary rotational

control

Subprogram

numbering

G143

DIFD Differential down

MOVE Logical AND

Arc continuous drilling

(CCW)

Volume I Programming

1.2 Program Execution

1.2.1 Program Execution Sequence

The current program can only be run in automatic mode. GSK980MDa cannot run more than 1

program at the same time, so only one program can be performed at a time. The cursor is ahead of the

first block when a program is opened, and can be moved in EDIT mode. In automatic mode, when the

machine is in stop state, the cycle start signal ( key on the panel or external cycle start signal)

enables the program to be run from the block where the cursor is located. Usually, blocks are executed

in sequence programmed in advanced. Program stops running till M02 or M30 is executed. The cursor

moves along with program execution. The program execution sequence or state will be changed in

following conditions:

7

GSK980MDa Milling CNC System User Manual

Volume I Programming

z Program running stops when key or the Emergency Stop button is pressed;

Program running stops when the CNC alarm or PLC alarm occurs;

z When the system is switched in EDIT or MDI mode, program stops running after the current

block is executed. After switching to automatic mode again, when

is pressed or external cycle start signal is ON, the program runs from the block where the

cursor is located.

z If the operation mode is switched to MANUAL/MPG/STEP/MACHINE ZERO RETURN

mode when the program is running, the execution dwells; after switching to automatic mode

again, when

program runs from where it stops.

z The execution dwells when

program starts running from where it stops when

external cycle start signal is ON;

z The program dwells at the end of each block when the single block switch is on; after

pressing key or switching on external cycle signal, program continuously runs from

the next block;

z Blocks with mark “/” is skipped when the skip switch is ON.

z The object block is executed when command G65 or macro program skip (GOTO) is

specified.

z When M98 or M9000~M9999 command is performed, the corresponding subprogram or

macro program is called; M99 is executed at the end of the subprogram or macro program,

after returning to the main program, the subsequent block (the one after the block in which

the subprogram is called) is executed. (return to a specified block, if it is commanded by

M99);

z When M99 command is specified in the middle of a main program which is not called by

other programs, the current program is repeatly executed after returning to the head of the

program.

key on the panel

key on the panel is pressed or external cycle start signal is ON, the

key is pressed or external pause signal is cut off;

key on the panel is pressed or

1.2.2 Word Execution Sequence within Block

When multiple words (such as G, X, Y, Z, F, R, M, S, T,) are in one block, most of M, S, and T

words are interpreted by NC and sent to PLC for processing. Other words are processed by NC

directly. M98, M99, M9000~M9999 and S word (which specify the spindle speed in r/min, m/min) are

directly processed by NC as well.

When G words share the same block with M00, M01, M02 and M30, M words are executed after

G words, and NC sends corresponding signals to PLC for processing.

When the G words share the same block with the M98, M99, M9000~M9999, these M words are

performed by NC after G words (the M signal not sent to PLC).

When G words and M, S, T words share the same block, PLC program (ladder diagram)

determines the execution consequence (executed at the same time or G words before M, S, T words).

Refer to the manual from tool builder for relevant words execution sequence.

8

Chapter 1 Programming Fundmentals

1.3 Basic Axes Increment System

The increment system consists of the least input increment (for input) and least command

increment (for output). The least input increment is the minimum unit for programming moving

distance. The least command increment is the minimum unit for moving the tool on the machine. Both

increments are represented in mm,inches.or deg.

The basic axes herein means X, Y, Z axes. The basic increment system includes IS-B and IS-C

types which can be selected by bit ISC of parameter NO.038.

038 ISC

ISC =1:The increment system is IS-C(0.1μ);

=0:The increment system is IS-B(1μ)

In different increment system, different pulse output type enables different output speed.

(Selected by bit ABPx of parameter NO.039)

039 ABP5 ABP4 ABPZ ABPY ABPX

ABPx =1:The impulse mode of axis is AB phases;

=0:The impulse mode of axis is impulse and direction.

Volume I Programming

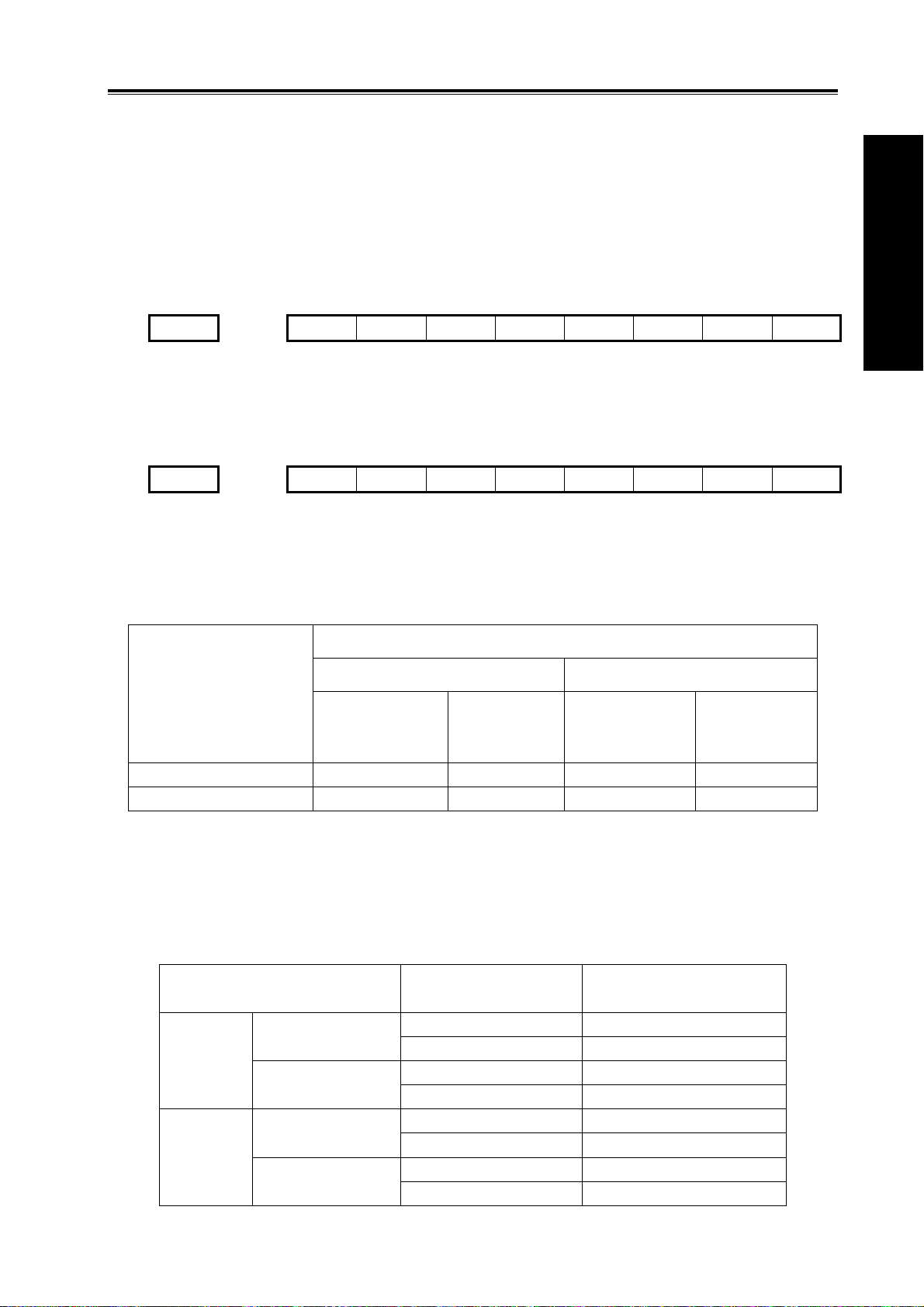

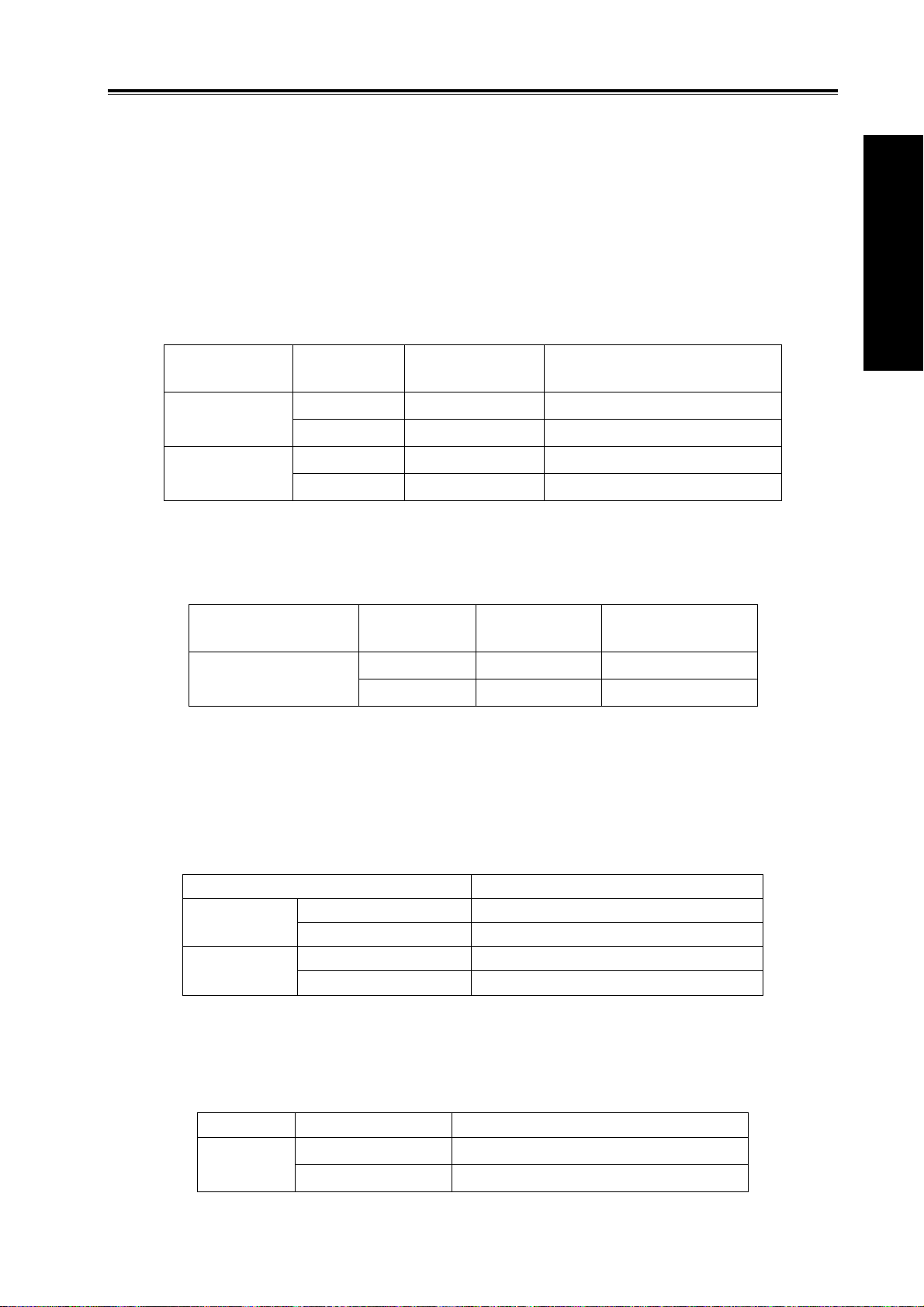

1.3.1 Speed of Increment Systems

Output mode

Metric machine

system

(mm/min)

Pulse + direction 60,000 6,000 6,000 600

AB quadrature phase 240,000 24,000 24,000 2,400

1μ(IS-B) 0.1μ(IS-C)

Inch machine

system

(inch/min)

Speed

Metric machine

system

(mm/min)

Inch machine

system

(inch/min)

1.3.2 Unit of Increment Systems

In different increment system, the least input/output increment varies with metric/inch system.

The specific data is shown as follows:

Metric

machine

system

Inch

machine

system

1μ(IS-B)

Metric input (G21)

Inch input (G20)

Metric input (G21)

Inch input (G20)

Least input

increment (for input)

0.001 (mm) 0.001 (mm)

0.001 (deg) 0.001 (deg)

0.0001 (inch) 0.001 (mm)

0.001 (deg) 0.001 (deg)

0.001 (mm) 0.0001 (inch)

0.001 (deg) 0.001 (deg)

0.0001 (inch) 0.0001 (inch)

0.001 (deg) 0.001 (deg)

Least command

increment (for output)

9

Volume I Programming

Metric machine

system

Inch machine

system

Least input increment (for input) is metric or inch can be set by G20 or G21.

Least command increment (for output) is metric or inch is determined by machine tool and set by

bit SCW of parameter NO.004.

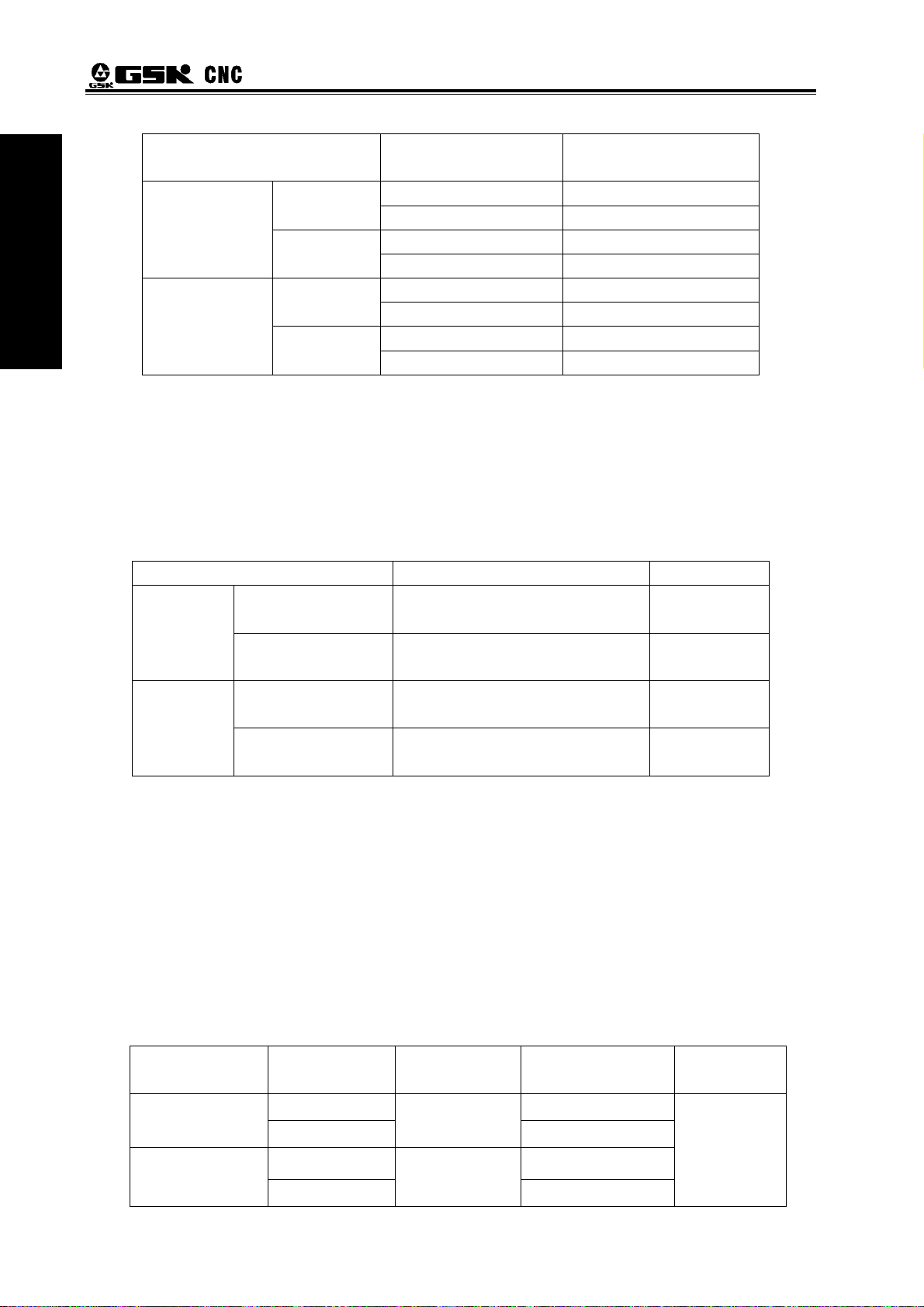

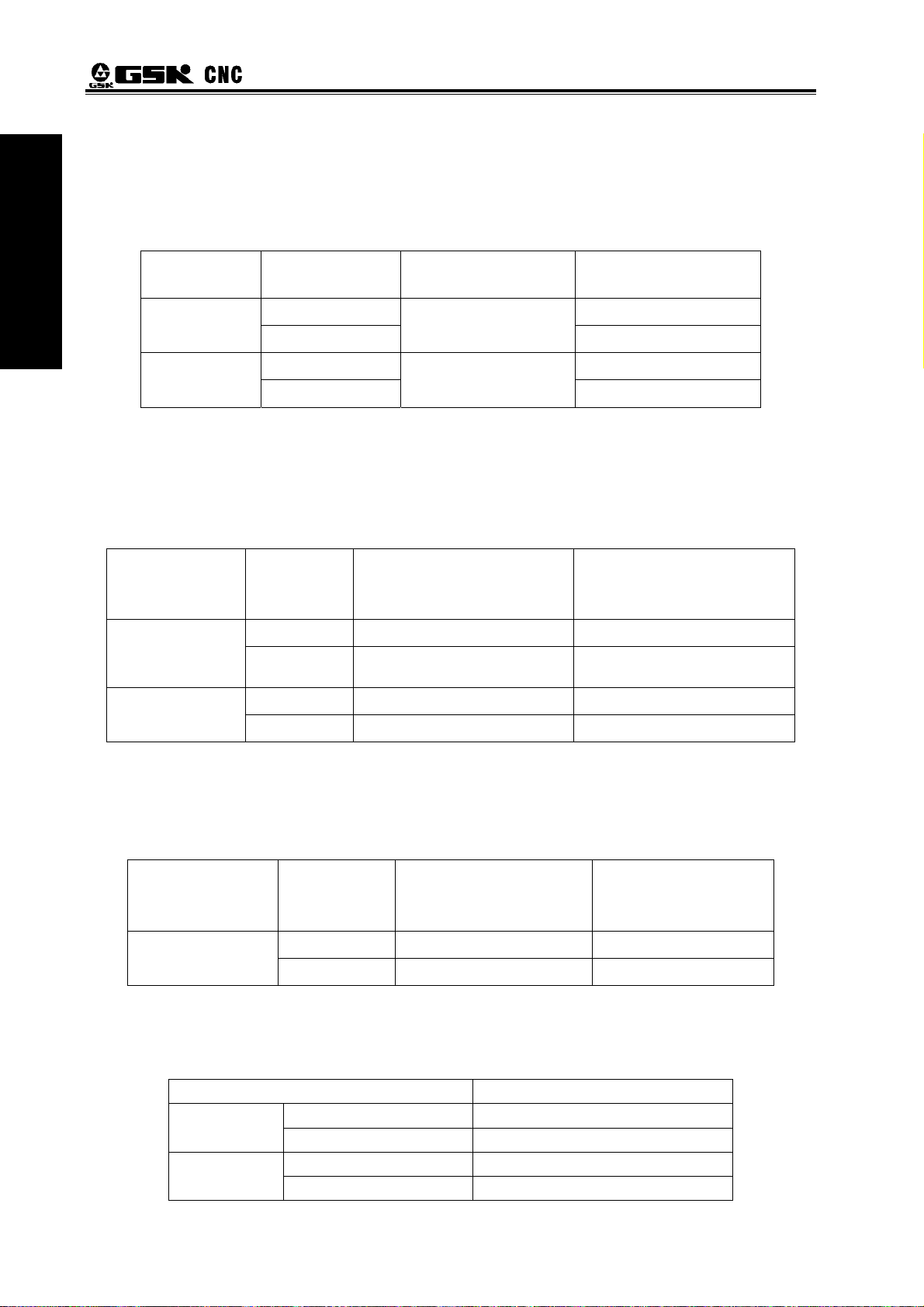

1.3.3 Data Ranges of Increment System

Limited by pulse output frequency, the data ranges may vary due to different increment system.

Increment system Command data input ranges Data format

1 u(IS-B)

0.1μ(IS-C)

Note:5.3 in the table above indicates 5 integers and 3 decimals. Other data are alike.

0.1μ(IS-C)

(G21)

Inch input

(G20)

(G21)

Inch input

(G20)

Metric input (G21)

Inch input (G20)

Metric input (G21)

Inch input (G20)

GSK980MDa Milling CNC System User Manual

Least input

increment (for input)

0.0001 (mm) 0.0001 (mm) Metric input

0.0001 (deg) 0.0001 (deg)

0.00001 (inch) 0.0001 (mm)

0.0001 (deg) 0.0001 (deg)

0.0001 (mm) 0.00001 (inch) Metric input

0.0001 (deg) 0.0001 (deg)

0.00001 (inch) 0.00001 (inch)

0.0001 (deg) 0.0001 (deg)

-99999.999 ~ 99999.999 (mm)

-99999.999 ~ 99999.999 (deg)

-9999.9999 ~ 9999.9999 (inch)

-9999.999 ~ 9999.999 (deg)

-9999.9999 ~ 9999.9999 (mm)

-9999.9999 ~ 9999.9999 (deg)

-999.99999 ~ 999.99999 (inch)

-999.9999 ~ 999.9999 (deg)

Least command

increment (for output)

5.3

5.3

4.4

4.3

4.4

4.4

3.5

3.4

1.3.4 Data Ranges and Unit of Increment System

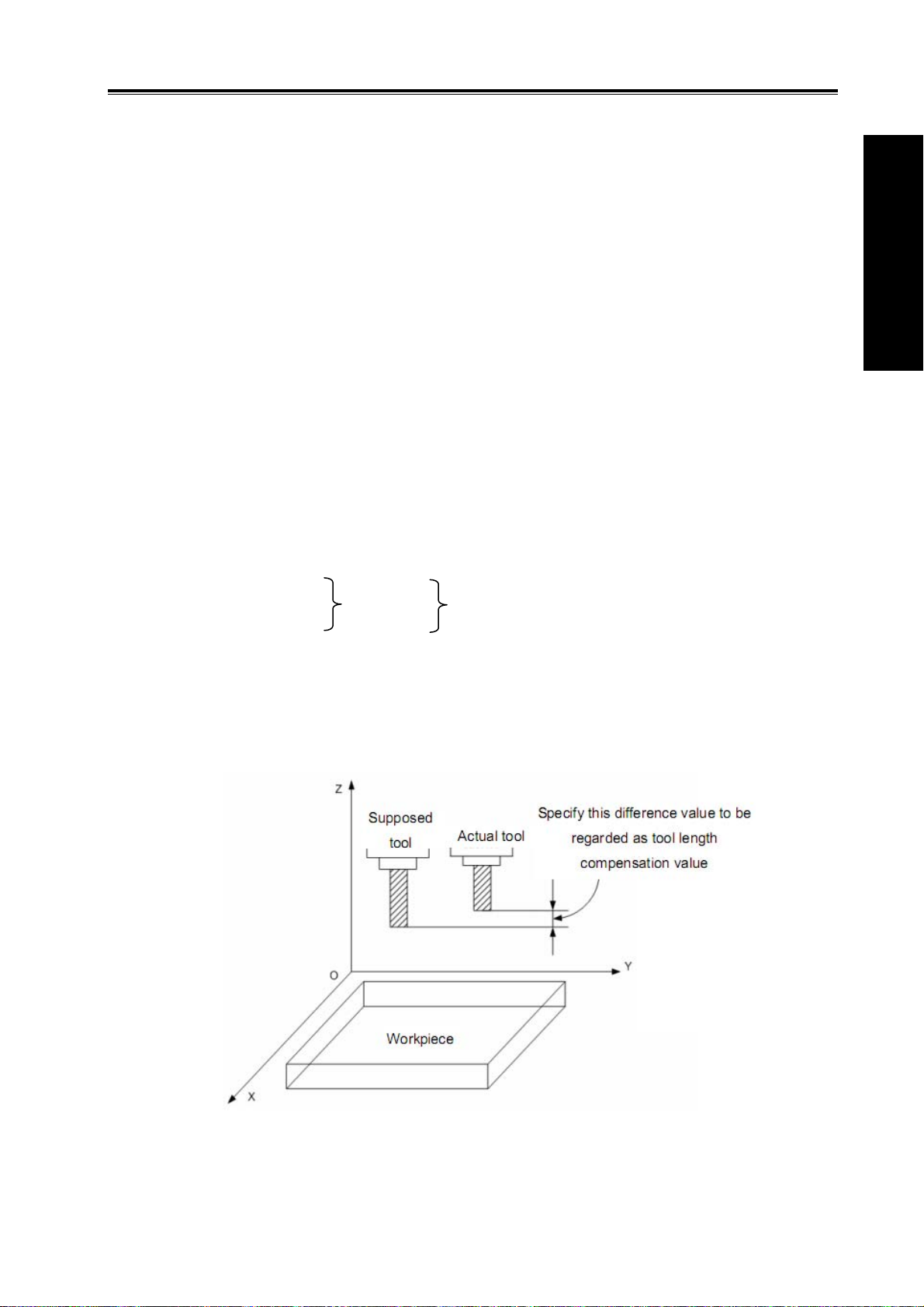

z Speed parameter