Page 1

In this user manual we have tried to describe the matters

concerning the operation of this CNC system to the greatest extent.

However, it is impossible to give particular descriptions for all

unnecessary or unallowable operations due to length limitation and

products application conditions; Therefore, the items not presented

herein should be regarded as ―impossible‖ or ―unallowable‖.

Copyright is reserved to GSK CNC Equipment Co., Ltd. It

is illegal for any organization or individual to publish or reprint this

manual. GSK CNC Equipment Co., Ltd. reserves the right to ascertain

their legal liability.

I

Page 2

GSK96 Multi-function Position Control System User Manual

II

Preface

Dear Users,

We are honored by your purchase of the products made by GSK CNC

Equipment Co., Ltd.

The manual describes the programming, operation, installation and

connection of this GSK96 multi-function position control system in detail.

To ensure safe and effective running, please read this manual carefully

before installation and operation.

Notes before operation:

Connect the emergency stop button of the system firmly and correctly. As the

system uses the normal-closed contact, an emergency stop alarm will occur

upon power on if the buttion is poorly connected or connected as the

normal-open contact, and the system cannot work properly (it does not belong to

system fault).

Set the program reference point of the system according to the actual mounting

position of the tool. Using program reference point function before setting the

point may casue unexpected accidents.

Warning

Accident may occur by improper connection and operation!This

system can only be operated by authorized and qualified personnel.

Special caution:

The power supply fixed on/in the cabinet is exclusively used for the

CNC system made by GSK.

It can't be applied to other purposes, or else it may cause serious

danger!

Page 3

ANNOUNCEMENT!

This manual describes various possibilities as much as possible. However,

operations allowable or unallowable cannot be explained one by one due to

so many possibilities that may involve with, so the contents not specially

stated in this manual shall be regarded as unallowable.

WARNING!

Please read this manual and a manual from machine tool builder carefully

before installation, programming and operation, and strictly observe the

requirements. Otherwise, products and machine may be damaged,

workpiece be scrapped or the user be injured.

CAUTION!

Functions, technical indexes (such as precision and speed) described in

this user manual are only for this system. Actual function configuration and

technical performance of a machine tool with this CNC system are

determined by machine tool builder’s design, so functions and technical

indexes are subject to the user manual from machine tool builder.

Though this system adopts standard operation panel, the functions of the

keys on the panel are defined by PLC program (ladder diagram). It should be

noted that the keys functions described herein are for the standard PLC

program (ladder diagram).

For functions and effects of keys on control panel, please refer to the user

manual from machine tool builder.

This manual is subject to change without further notice.

III

Page 4

GSK96 Multi-function Position Control System User Manual

IV

Suggestions for Safety

The user must carefully read the suggestions for the system before installing and operating the

system.

The user must follow the suggestions of the system to ensure that the person is not hurt and the

equipments are not damaged.

The user must follow the related suggestions for safety described in the user manual, and must not

operate it until the manual is read completely.

The user must follow the suggestions of safety described in the user manual from the machine

manufacture.

The user can operate the machine or compile the program to control the machine after completely

reading the manual and the one from the machine manufacturer.

I. Graphic symbol

Caution Operation against the instructions may cause the operator serious

injuries.

Alarm Wrong operation may injure the operator and damage the system.

Warning Improper operation may result in damage to the machine, as well its

products.

Important information

Page 5

V

II. Notes

1) Check before acceptance

Warning ● The damaged or defect product must not be used.

2) Delivery and storage

Warning ●Moistureproof measures are needed while the system is delivered and stored.

Never climb the packing box, stand on it, or place heavy items on it. Do not put

over five packing boxes in piles. Take particular care of the front panel and the

display of the system.

3) Installation

Warning ●Protect the system from sunlight and raindrops. The shell of the system is not

Contents

waterproof.

Warning ●Prevent dust, corrosive air, liquid, conductors and inflammable substances

from entering the system.

●Keep the system away from inflammable and explosive substances. Avoid

places where there is powerful electromagnetic interference.

●Install the system firmly without vibration.

4) Wiring

Caution ●Only qualified persons can connect the system or check the connection. The

connecting wires cannot be damaged. Do not press or open the cover of the

system with power on.

Caution ●The voltage and the polarity of connecting plugs must accord with the user

manual.

●Wet hands are dangerous to grasp the plug or the switch.

Warning ●The connection must be proper and firm.

●The system must be earthed.

Page 6

GSK96 Multi-function Position Control System User Manual

VI

5) Debugging

Warning ●Make sure that the parameters of the system is correct before the system runs.

●No parameter is beyond the setting limit in the manual.

6) Operation

Caution ●Only qualified operators can operate the system.

●Ensure the switch is OFF before connecting the power supply.

Warning ●The operator cannot leave the system to work alone.

●Do not switch on the system until making sure the connection is correct.

●The emergency stop button is able to disconnect all power supplies when the

system breaks down. Do not switch on/off the system frequently

Warning ●Prevent the system from the environmental interference.

7) Troubleshooting

Caution ●Unqualified persons cannot repair the system.

Warning ●After alarms, do not restart the system until the breakdown is fixed.

Page 7

VII

III. Safety suggestions for programming

1) Setting a coordinate system

Incorrect coordinate system may cause the machine not to work as expected even if the

program is correct, which may injure the operator, and damage the machine as well as its

tool and workpiece.

2) Rapid traverse (positioning)

When G00 rapid traverse performs the positioning (nonlinear motion to position between

its starting point and end point), make sure that the path for the tool is safe before

programming. The positioning is to perform the rapid traverse, and when the tool and the

workpiece are interfered, the tool, the machine and the workpiece may be damaged, and

even the operator injured.

Contents

3) Applicability of user manual

The manual introduces in detail all functions of the system, including optional functions

and max. controllable ranges, which are subject to change with the machine. Therefore,

some functions discribled in this manual will not work out for other specified manchines.If

there is any doubt, please read the instruction for the machine.

4) Functions of CNC system and machine

CNC machines depend on CNC systems, but also power voltage cabinets, servo systems,

CNC and the operator panels. It is hard to explain all the integrated functions,

programming and operation. Do not use integrated instructions not included in the manual

until they have been tested successfully.

Page 8

GSK96 Multi-function Position Control System User Manual

VIII

IV. Notes and Safety Suggestions for Operating Machine

1) Before parts processing

Test the machine without workpiece or tools. Make sure that the machine runs well before it

starts to work.

2) Before operating the machine

Check the input data of the system carefully before operating the machine. Incorrect input

data may cause the machine to work improperly, and damage the workpiece and the tool,

as well as injure the operator.

3) Adaptations between appointed federate and machine operations

Make sure that the input feedrate of the system is suitable for the expected operation.

Feedrate has a maximum for each machine, and the amount of the feed rate is subject to

change with operation. Choose the maximum according to the instructions of the machine.

Improper feedrate leads the machine to work wrongly, and damage the workpiece and the

tool, as well as injure the operator.

4) Compensation function

When offset is needed, check the direction and the amount of the compensation.

Improper compensation causes the machine to work wrongly, and damage the workpiece

and the tool, as well as injure the operator.

5) Manual operation

If the machine is to run in JOG working mode, check the current position of the tool and the

workpiece, and correctly specify the moving axis, moving direction and the feedrate. MPG

(Hand wheel) control with great override, such as 100%, rotate MPG (used to call electric

hand wheel), then the tools and workbench will move fast, which may lead the stop of the

MPG. However, the tools and workbench will not stop immediately. The high override of

MPG movement may damage the machine and its tool, even injure the operator.

6) MPG returns to the reference point

If the tool is return to the reference point, make sure that the machine has been equipped

with the device to detect the reference point; otherwise, the tool cannot reach the reference

Page 9

Contents

IX

point, which may damage the machine and its tool, and even injure the operator.

Safety Responsibility

Manufacturer’s Responsibility

——Be responsible for the danger which should be eliminated and/or controlled on

design and configuration of the provided CNC systems and accessories.

——Be responsible for the safety of the provided CNC systems and accessories.

——Be responsible for the provided information and advice for the users.

User’s Responsibility

——Be trained with the safety operation of CNC system and familiar with the safety

operation procedures.

——Be responsible for the dangers caused by adding, changing or altering on original

CNC systems and the accessories.

——Be responsible for the failure to observe the provisions for operation, adjustment,

maintenance, installation and storage in the manual.

This manual is reserved by end user.

We are full of heartfelt gratitude for your support by using GSK’s

products.

Page 10

GSK96 Multi-function Position Control System User Manual

X

Operation

Introduces operation methods, technical specifications and

parameter settings of GSK96 multi-function position control

system.

Programming

Introduces command codes and program format of GSK96

multi-function position control system.

Appendix

Introduces supplementary information to installation and

connection of GSK96 multi-function position control system.

Connection

Introduces installation and connection methods of GSK96

multi-function position control system.

Page 11

Contents

XI

CONTENTS

Suggestions for Safety ·················································································· IV

OPERATION ·································································································· 1

Chapter 1 Overview ··························································································· 1

Chapter 2 Technical Specifications ········································································ 2

2.1 GSK96 Technical specifications ···················································································· 2

Chapter 3 Operation Panel ··················································································· 3

3.1 LCD Display ············································································································· 3

3.2 LED Status Indicator ·································································································· 3

3.3 Keyboard ················································································································ 3

3.3.1 Character keys ································································································ 3

3.3.2 Working mode selection key ············································································· 3

3.3.3 Function keys ································································································· 4

3.3.4 Cycle start and cycle pause (feed hold) key ························································· 5

3.3.5 Manual axis control key ···················································································· 5

3.3.6 Manual auxiliary function key ············································································ 5

3.3.7 Edit keys ········································································································ 6

3.3.8 Reset Key ······································································································· 7

Chapter 4 System Operation ················································································· 8

4.1 System ON/OFF, Initial State, Modal, and Safe Protection ·················································· 8

4.1.1 Power on ·········································································································· 8

4.1.2 Power off ·········································································································· 8

4.1.3 System, program initial and modal ······································································· 9

4.1.3.1 the initial state and modal of the system ······························································ 9

4.1.3.2 Initial mode and modal of program ····································································· 9

4.1.4 Safe protection ································································································ 10

4.1.4.1 Hardware limit protection ·············································································· 10

4.1.4.2 Software limit safe protection ········································································· 11

4.1.4.3 Emergency stop alarm (emergently stopping the system) ···································· 12

4.1.4.4 Drive unit alarm ·························································································· 14

4.1.4.5 Other alarms ······························································································ 14

4.1.4.6 Switching off power supply ············································································ 14

4.1.4.7 Reset operation ·························································································· 14

4.2 CNC Working Mode Selection ····················································································· 15

4.3 EDIT Working Mode·································································································· 16

4.3.1 Part program catalog search ············································································· 17

4.3.2 Selecting, creating, deleting, renaming and copying a part program ····················· 17

4.3.2.1 Selecting and creating a part program ····························································· 17

4.3.2.2 Delete a part program ·················································································· 18

4.3.2.3 Deleting all part programs ············································································· 19

4.3.2.4 Renaming a part program ············································································· 19

4.3.2.5 Copying a part program ················································································ 19

4.3.3 Part program communication ·········································································· 20

4.3.3.1 Sending part programs (CNC→USB) ······························································ 20

4.3.3.2 Receiving part programs(USB→CNC) ····························································· 20

4.3.3.3 TXT part program standard format in U disc ····················································· 21

4.3.4 Part program content input and edit ································································· 22

4.3.4.1 Inputting program content ············································································· 24

4.3.4.2 Inserting program line ·················································································· 24

4.3.4.3 Deleting a block ·························································································· 25

4.3.4.4 Inserting a character in a block ······································································ 25

4.3.4.5 Deleting a character in a block ······································································· 25

4.3.4.6 Modifying a block content ············································································· 25

4.3.4.7 Program stored space ·················································································· 26

4.3.4.8 No. 253 program operation ··········································································· 26

4.3.4.9 No. 254 program operation ··········································································· 26

4.3.5 hp1 function ·································································································· 27

Page 12

GSK96 Multi-function Position Control System User Manual

XII

4.3.5.1 Part program command help ········································································ 27

4.3.5.2 Inserting macro string ················································································· 27

4.3.5.3 Line number sort ························································································ 28

4.3.5.4 Replacing character string············································································ 28

4.3.5.5 Cursor position ·························································································· 28

4.3.5.6 MPG controlling cursor moving ····································································· 28

4.3.6 Part program compiling ·················································································· 29

4.3.6.1 hp2 compiling command ·············································································· 29

4.3.6.2 Program compiling result analysis ·································································· 29

4.3.6.3 Program compound check prompt ································································· 30

4.4 JOG Working Mode ······························································································· 30

4.4.1 Coordinate axis movement ·············································································· 32

4.4.1.1 JOG movement ························································································· 32

4.4.1.2 Step movement ························································································· 33

4.4.1.3 MPG control ······························································································ 33

4.4.1.4 Rapid traverse speed selection ····································································· 34

4.4.1.5 Low speed feed speed selection ···································································· 35

4.4.1.6 Inputting field moving, setting feedrate ···························································· 36

4.4.1.7 Drive unit enabling control ············································································ 38

4.4.1.8 Coordinate axis motion alarm prompt ····························································· 38

4.4.2 Creating coordinate system ············································································ 38

4.4.2.1 Creating machine coordinate system_machine zero return(machine reference point

return) ················································································································· 38

4.4.2.2 Creating machine coordinate system_without machine zero(no machine reference point)

·························································································································· 40

4.4.2.3 Setting workpiece coordinate system ······························································ 40

4.4.2.4 Setting program reference point ···································································· 42

4.4.2.5 Program reference point return ····································································· 42

4.4.2.6 Recovering the workpiece coordinate system and program reference point ············ 42

4.4.3 Spindle control function ················································································· 43

4.4.3.1 Spindle starting/stopping control ···································································· 43

4.4.3.2 Spindle S command _gear shifting control ······················································· 44

4.4.3.3 Spindle S_ speed control ············································································· 45

4.4.3.4 Servo spindle working state setting ································································ 47

4.4.4 Cooling control ······························································································ 48

4.4.5 Manual tool change control ············································································· 49

4.4.6 Manual tool setting operation ·········································································· 50

4.4.7 Hydraulic chuck control function ····································································· 53

4.4.8 Hydraulic tailstock control function ·································································· 55

4.4.9 Other option functions ···················································································· 57

4.4.9.1 Three-color indicator control ········································································· 57

4.4.9.2 Lubricating control ······················································································ 57

4.4.9.3 Machine electricity delay power-on control ······················································· 58

4.4.9.4 External MPG operation ·············································································· 58

4.4.9.5 Safety door check function ··········································································· 59

4.4.9.6 Pressure low alarm check function ································································· 59

4.4.10 Searching run message in JOG working mode ················································· 59

4.4.11 Appendix: ···································································································· 59

4.4.11.1 MDI input controlling M command table MDI ··················································· 59

4.4.12 Spindle turn function ···················································································· 60

4.5 AUTO Working Mode ····························································································· 61

4.5.1 System working mode in AUTO working mode··················································· 62

4.5.2 Function key operation in AUTO working mode ················································· 62

4.5.2.1 SINGLE execution and CONTINUOUS execution switch ···································· 62

4.5.2.2 Dry run and machining run switch ·································································· 63

4.5.2.3 Running a part program from the first block ························································ 63

4.5.2.4 Running a part program from a specified block ················································· 64

4.5.3 Displaying in a part program running ······························································· 64

4.5.3.3 Machining workpiece count and timing ···························································· 65

4.5.4 Manual operation of miscellaneous function ····················································· 65

4.5.5 Speed override tune in AUTO working mode ······················································ 65

4.5.5.1 Speed override tune ··················································································· 65

4.5.5.2 MPG speed control ····················································································· 66

Page 13

Contents

XIII

4.5.6 Interference operation in program execution process ········································· 67

4.5.6.1 Press key interference in program execution ····················································· 67

4.5.6.2 External feed/ spindle hold knob ···································································· 68

4.5.6.3 External start and pause signal ······································································ 69

4.5.6.4 Feed device alarm function ··········································································· 69

4.5.7 Modifying offset in program run ······································································ 69

4.5.7.1 Modifying offset method in program run ··························································· 69

4.5.7.2 Modifying tool compensation validity in program running ····································· 70

4.5.8 Searching run message in AUTO working mode ················································ 70

4.5.9 Program reference point return in AUTO working mode ······································ 72

4.5.10 System reset and emergence stop signal processing in AUTO working mode ······ 72

4.5.11 Regulating LCD brightness in AUTO, JOG working mode ·································· 72

4.5.12 Display of M command execution state in AUTO, MANUAL mode ······················· 73

4.5.13 Operations in AUTO mode ············································································· 73

4.6 Parameter Working Mode ························································································ 73

4.6.1 Parameter overview ······················································································· 74

4.6.1.1 Parameter privilege ····················································································· 74

4.6.1.2 Entering operation level ················································································ 75

4.6.1.3 Parameter management ··············································································· 75

4.6.2 Parameter modification ·················································································· 76

4.6.2.1 Parameter search ······················································································· 76

4.6.2.2 Parameter modification ················································································ 77

4.6.3 Parameter function key prompt hp1 ································································· 77

4.6.3.1 Parameter communication and standard format ················································· 78

4.6.3.2 Parameter draw and solidifying ······································································ 79

4.6.3.3 System software upgrade and memory update ·················································· 80

4.6.3.4 Functional command privilege ······································································· 80

4.6.4 Parameter explanation ··················································································· 81

4.6.4.1 Reference point, software limit bit parameter __ P000~P020 ······························· 81

4.6.4.2 Parameters related to zero return function __ P021~P026, P109~P111, P406~

P407 ···················································································································· 82

4.6.4.3 Traverse speed, acceleration time parameter __P100~P108, P112~P119··········· 84

4.6.4.4 Parameters related to transmission and compensation__ P200~P209, P411 ·········· 85

4.6.4.5 Parameters related to spindle, cooling __ P300~P317, P326, P329, P341, P410 ····· 87

4.6.4.6 Parameters related to tool post __ P318~P319 ·············································· 90

4.6.4.7 Parameters related to chuck and tailstock __ P327~P328, P409 ·························· 91

4.6.4.8 Run and efficiency bit parameter __ P400~P401 ·············································· 92

4.6.4.9 Relationship between path and run, efficiency parameter····································· 94

4.6.4.10 Safety and debugging bit parameter __ P402~P404, P419 ······························· 94

4.6.4.11 Motor drive bit parameter __ P405 ································································ 99

4.6.4.12 Parameters related to other interfaces __ P412, P330~P332 ··························· 99

4.6.4.13 Auxiliary parameter __ P413~P418, P333 , P335, P027~P029 ······················· 100

4.6.4.14 Interface parameter __P500~P556 ···························································· 103

4.6.4.15 Variable initial value __P600~P639 ···························································· 104

4.6.5 Appendix: parameter list ················································································ 104

4.6.5.1 Reference parameter list ············································································ 104

4.6.5.2 Motion parameter list ················································································· 104

4.6.5.3 Transmission parameter list ········································································ 105

4.6.5.4 Auxiliary parameter list ··············································································· 105

4.6.5.5 Bit parameter ··························································································· 106

4.6.5.6 Variable initial value list ·············································································· 107

4.6.5.7 Interface parameter list ·············································································· 107

4.6.5.8 Parameter list related to command forbidden ················································ 108

4.6.5.9 Parameter list related to output interface release ············································· 108

4.6.5.10 Parameter list related to input interface release ············································· 109

4.7 OFFSET Working Mode ························································································ 110

4.7.1 Tool offset value search ················································································· 111

4.7.2 Input tool offset data by keyboard key ····························································· 111

4.7.3 Tool offset hp1 function ················································································· 112

4.7.3.1 Communication of tool offset data ································································· 112

4.7.3.2 Clearing offset values of each group in offset data ··········································· 112

Page 14

GSK96 Multi-function Position Control System User Manual

XIV

4.7.3.3 Clearing Offset data ··················································································· 112

4.8 Diagnosis Working Mode ······················································································· 113

4.8.1 Interface signal search ·················································································· 113

4.8.2 Interface signal name display explanations ······················································ 113

4.8.3 Input interface diagnosis explanation ······························································ 114

4.8.4 Output interface diagnosis explanation ···························································· 114

4.8.5 Output interface operation function ································································· 114

4.8.6 Spindle encoder and spindle speed check························································ 115

4.8.7 Diagnosis hp2 function ·················································································· 115

4.8.7.1 Alarm record display ·················································································· 116

4.8.7.2 Alarm record search ·················································································· 117

4.8.7.3 Alarm record hp2 function ··········································································· 117

4.8.8 Machine miscellaneous function control ·························································· 117

Chapter 5 USB System Communication ···························································· 119

5.1 USB Communication ····························································································· 119

5.1.1 USB Operation ····························································································· 119

5.1.2 USB file catalog requirements ········································································ 119

PROGRAMMING ························································································ 121

Chapter 1 Programming Fundamental······························································· 121

1.1 Coordinate Axis and its Direction ············································································· 121

1.2 Machine Coordinate System, Machine Zero ······························································· 121

1.3 Program Reference Point ······················································································· 121

1.4 Machine 2nd, 3rd Program Reference Point ······························································· 122

1.5 Workpiece Coordinate System ················································································ 122

1.6 Positioning and Interpolation Function······································································· 122

1.7 Programming Coordinate ······················································································· 122

1.7.1 Absolute Coordinate Values ·········································································· 123

1.7.2 Relative (Incremental) Coordinate Values ························································ 123

1.7.3 Compound Coordinate Values ······································································· 123

Chapter 2 Program Structure ··········································································· 124

2.1 Character ··········································································································· 124

2.2 Block ················································································································· 124

2.3 Block Number ······································································································ 125

2.4 Block ················································································································· 125

2.5 Block Skip Symbol and Comment ············································································ 126

2.6 Program Structure ································································································ 126

Chapter 3 MSTF Commands and Functions ······················································· 128

3.1 M — Miscellaneous Function (Command List) ···························································· 128

3.1.1 M00 — Pause ······························································································ 129

3.1.2 M02 — End of Program ················································································· 129

3.1.3 M20 — End of Program Cycle Machine ··························································· 129

3.1.4 M30 — End of Program Spindle OFF Cooling OFF ········································ 130

3.1.5 M03, M04, M05 —Spindle Control ··································································· 130

3.1.6 M08, M09 — Cooling control ·········································································· 130

3.1.7 M10,M11, M12 — clamping/releasing workpiece, cancelling chuck output signal 131

3.1.8 M32, M33 — Lubricating ON/OFF···································································· 131

3.1.9 M41, M42, M44, M43 — Spindle Automatic Gear Shifting Control ························ 131

3.1.10 M78, M79, M80 —Tailstock going forward and retreating backward, cancelling

tailstock output signal ···························································································· 131

3.1.11 M96 —Cycle execution call ·········································································· 132

3.1.12 M97 — Program transfer ············································································· 132

3.1.13 M98, M99 — Subprogram call and subprogram return ····································· 133

3.1.14 M21, M22, M23, M24 —User Output Control ··················································· 133

3.1.15 M91, M92, M93, M94 — User input ································································· 134

3.1.16 M47, M48 — Set spindle working state ·························································· 135

3.1.17 M60~M74 — Customized commands ····························································· 135

3.2 M81, M82, M83—User input/output condition control ··················································· 135

3.2.1 M82—output control and detection ································································· 136

3.2.2 M81—Control according to input signal state ·················································· 136

Page 15

Contents

XV

3.2.3 M83—Control according to output signal state ················································· 136

3.3 S function — Spindle Function ················································································ 137

3.3.1 Gear shifting controlling spindle motor ··························································· 137

3.3.2 Spindle controlling variable-frequency motor ··················································· 137

3.4 T function — Tool Function ····················································································· 138

3.5 F function — Feedrate Function ·········································································· 139

Chapter 4 G Commands and Functions ····························································· 141

4.1 G00 —Rapid Positioning ······················································································· 141

4.2 G01 — Linear Interpolation ···················································································· 142

4.3 G06—Enter G06 motion mode with single axis;G07—Stop G06 motion;G08—Enbale/Disable

G06 mode ················································································································· 144

4.4 Thread Cutting Command ······················································································ 147

4.4.1 G33 —thread cutting ····················································································· 147

4.4.2 G34 — variable pitch thread cutting ································································ 150

4.5 G32 —Tapping Cycle ···························································································· 151

4.6 G50 — Setting a Workpiece Coordinate System ························································· 153

4.7 G51 — Recovering Workpiece Coordinate System Setting ············································ 154

4.8 G26 — X, Z, Y Reference Point Return ····································································· 154

4.9 G28 — Return to Machine Zero(Machine Reference Point) ··········································· 155

4.10 G30 — 2nd, 3rd Program Reference Point Return ······················································· 156

4.11 G04 — Dwell ····································································································· 156

4.12 G96 —Constant Surface Speed Control, G97 —Constant Surface Speed Cancel ············· 157

4.13 G22, G80 —Program Part Cycle ············································································ 159

4.14 G98 —Feed per Minute, G99 —Feed per Revolution ················································· 161

4.15 G31 — Skip ······································································································ 162

4.16 G52 — rotary axis Y axis coordinate clearing ···························································· 163

4.17 G66—Store the current coordinates, G67—Return to the stored coordinates ··················· 164

4.18 G81 — drilling;G83 — deep hole drilling ································································ 165

4.19 Appendix: G function and Its Explanation Table (table 4-2) ·········································· 166

4.20 Appendix:G and its Relative Parameter Explanation ················································ 167

Chapter 5 General Programming Rules and Examples··········································· 169

5.1 General Programming Rules ·················································································· 169

5.2 Programming Rules for Commands in One Block ························································ 169

5.3 Command Execution Sequence ·············································································· 170

Chapter 6 Alarm Message ··············································································· 173

6.1 Emergency Alarm ································································································· 173

6.2 Alarm Table in PARAMETER, OFFSET Working Mode(i.e. E001~E009) ·························· 173

6.3 General Chart of Alarm in Edit Working Mode(i.e. E100~ E199) ····································· 175

6.4 Emergency Alarm Program Alarm Table (i.e.E200~ E299, E600~ E699) ··························· 177

6.4.1 Alarm in program command (i.e. E200~299) ····················································· 177

6.4.2 Alarm in program compound check (i.e. E600~699) ··········································· 179

6.5 Alarm Table in JOG OR AUTO Working Mode (i.e.E300~ E499) ····································· 181

6.5.1 Alarm in Executing Relative Operations (i.e E300~E399) ···································· 181

6.5.2 Relative alarm in executing statement (i.e.E400~ E499) ······································ 184

Chapter 7 Statement Programming ··································································· 186

7.1 Variable ············································································································· 186

7.1.1 Variable expression method ··········································································· 186

7.1.2 Classification of variable ··············································································· 186

7.1.2.1 Command variable ···················································································· 186

7.1.2.2 Pointer variable ························································································ 188

7.1.2.3 Interface variable ······················································································ 190

7.1.2.4 Keyboard scan register r5001 ······································································ 191

7.1.2.5 Display window register r5002 ····································································· 192

7.1.2.6 Display value register r5003 ········································································ 195

7.1.2.7 Graph update register r5004 ······································································· 195

7.1.2.8 Program control register r5008 ···································································· 195

7.1.2.9 System special variable set 1 ······································································ 197

7.1.2.10 System special variable set 2 ····································································· 197

7.2 Statement ··········································································································· 198

7.2.1 Assignment statement ·················································································· 198

Page 16

GSK96 Multi-function Position Control System User Manual

XVI

7.2.2 Conditional statement ··················································································· 199

7.2.3 Statement program example ·········································································· 200

7.3 Process Monitoring and Execution ··········································································· 201

7.3.1 Process monitor description (r7000) ································································ 201

7.3.2 The start and close of process monitor ····························································· 203

7.3.3 Monitor program example ·············································································· 204

7.3.4 Pulse monitoring (r7100) ··············································································· 206

7.3.5 Pulse monitoring program example ································································· 207

7.3.6 Variable transfer register (r7900) ····································································· 208

7.4 Attached List ······································································································· 209

7.4.1 ASCII list ··································································································· 209

7.4.2 Often used color and code value corresponding list ············································· 209

Chapter 8 Customization Command Program ······················································ 210

8.1 Customization Command ······················································································· 210

8.1.1 Customization command program format ······················································· 210

8.2 Customization Command Store (P254) ····································································· 211

8.2.1 Format and debugging of customization command storeroom ··························· 211

8.2.2 Explanation of customized command storage·················································· 212

8.2.3 Customized command machining example ····················································· 212

8.3. Foot switch in M61 command ················································································· 215

CONNECTION ···························································································· 217

Chapter 1 Interface ························································································· 217

1.1 Rear Cover Interface Position Layout ······································································· 217

1.2 Total Frame ········································································································· 218

Chapter 2 Interface Graph ··············································································· 219

Chapter 3 CNC Device Connection ····································································· 221

3.1 Front Cover Communication Interface ······································································· 221

3.1.1 USB interface ······························································································ 221

3.2 X1, X2 Interface ··································································································· 221

3.2.1 X1, X2 interface signal definition ···································································· 221

3.2.2 Connection method of input signal ································································· 225

3.2.3 Connection method of output signal ······························································· 227

3.2.4 Input/output signal technical specification ······················································ 228

3.3 Machine Zero Return Function and Connection ·························································· 228

3.4 Tool Exchange Control Function and Connection ························································ 230

3.4.1 Tool exchange control signal definition ·························································· 230

3.4.2 Signal connection ························································································ 231

3.4.3 Function description ···················································································· 231

3.4.3.1 Tool change mode 0 ·················································································· 231

3.4.3.2 Tool change mode 9 ·················································································· 231

3.5 X3 Motor Interface ································································································ 233

3.5.1 Signal definition··························································································· 233

3.5.2 Technical specifications ··············································································· 233

3.5.3 Equivalent circuit ························································································· 233

3.5.3.1 Drive unit alarm signal XALM, ZALM, YALM ················································· 233

3.5.3.2 Enable signal Xen, Zen ·············································································· 234

3.5.3.3 Pulse signal and direction signal ··································································· 234

3.5.4 Connection between CNC system and drive unit of compound stepper motor ····· 234

3.5.5 Connecting between CNC and drive unit of reaction stepper motor ···················· 236

3.5.6 Connection layout between CNC and AC servo drive unit ·································· 239

3.5.7 Connection layout between CNC and Panasonic drive unit ································ 241

3.5.8 Connection layout between CNC system and Japanese Yaskawa drive unit ········· 241

3.6 X4 Spindle Interface and Y interface ········································································· 243

3.6.1 Signal definitions ························································································· 243

3.6.2 Converter technical specification ··································································· 243

3.6.3 Encoder technical specifications ··································································· 243

3.6.4 Connection layout of converter analog voltage ················································ 244

3.6.5 Encoder interface method ············································································· 244

3.6.6 Encoder interface connection layout ······························································ 244

3.6.7 Connection between CNC system Y and AC servo drive unit ····························· 244

Page 17

Contents

XVII

3.6.8 Connection between CNC system Y and DAP03 spindle drive unit ······················ 246

3.7 X5 MPG Interface ································································································ 246

3.7.1 Signal definition ··························································································· 247

3.7.2 Interface Circuit Principle ·············································································· 247

3.7.3 Connection layout ························································································ 247

Chapter 4 Use and Maintenance ······································································· 248

4.1 Environmental Condition ························································································ 248

4.2 Earthing ············································································································· 248

4.3 Power Supply Requirements ·················································································· 248

4.4 Guard ················································································································ 248

4.5 Use after Long-Time Unuse ···················································································· 248

APPENDIX ································································································ 249

Appendix 1 CNC system electrical component symbol explanations ····················· 249

Appendix 2 CNC system tool post controller circuit method layout ······················· 250

Appendix 3 Interface circuit method layout ························································ 251

Appendix 4 External control connection layout ·················································· 254

Appendix 5 CNC system appearance installation dimension ································ 255

Page 18

GSK96 Multi-function Position Control System User Manual

XVIII

Page 19

Operation Chapter One Overview

1

OPERATION

Chapter 1 Overview

GSK96 is a newly-developed multi-function position control system with the precision control

function of μm level for Z/X/Y axis. The single-axis, double-axis or three-axis control can be set by

parameters. This system can realize motion functions such as positioning and feeding, two-axis linkage,

taping and threading, rotation indexing and servo spindle control, and has plenty of input/output signal

control functions, which can realize complicated control of multi-signal detection and output.

GSK96 control system is applicable to the control like indexing drilling, grinding, taping and feeding,

cutting and welding rather than the control of the turning machine.

This product is easy to operate and has a visible lattice true color LCD interface with resolution of

800X480. It is characterized by its powerful functions, stable performance, full-screen program editing,

Chinese operation interface, outstanding safety, machining precision and machining efficiency as well as

the high cost performance. In addition, it employs the international standard CNC language ISO code to

write programs.

Technical Specifications:

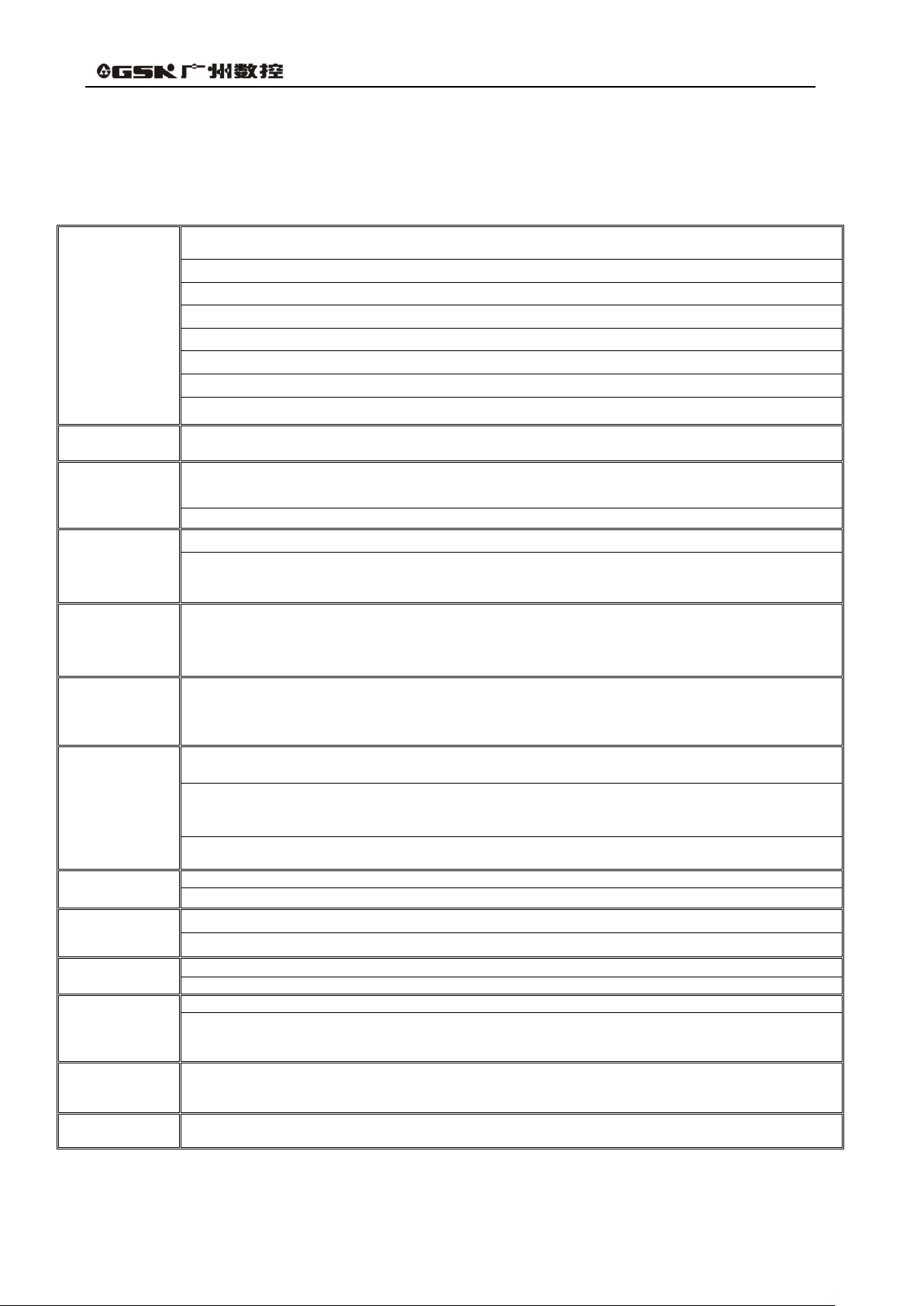

X, Z Y single-axis motion, which can realize the linkage of any two axes; interpolation

precision: 0.001mm, max. rapid traverse speed: 30m/min

Any of X, Z, Y axis can be set as the rotation axis control

Control servo spindle

Flexible and convenient programming, with statement programming function

USB interface communication to get the convenient and fast operation

Least command unit 0.001mm, command electronic gear ratio (1~99999) /(1~99999)

Automatic gear shifting of all kinds of spindle

Backlash compensation, tool length compensation function

Tapping function

Course monitoring function

Cutting metric/inch straight thread, variable pitch thread

Full-screen part programs editing, capable of storing 255 machining programs; No. 253

program up to 4MB

Big screen color LCD, color configuration is selected by the parameter

MSTE state real-time display in machining

Multi-level operation password for convenient device management

Parameter backup function

Parameter, offset data communication function

Bilateral communication between CNC and USB, CNC is upgraded by USB

Page 20

GSK96 Multi-function Position Control System User Manual

2

Motion control

Controlled axes: X, Y, Z; The three axes are respectively set as the linear axis or rotation axis control;

simultaneous controlled axes(interpolation axes): 2-axis linear interpolation

Interpolation: X/Z, Z/Y or X/Y two-axis linear interpolation,X/Z single-axis linear interpolation

Position command range:-9999.999 mm~9999.999mm; least command unit: 0.001mm

Electronic gear: Command multiplier coefficient 1~99999,command division coefficient 1~99999

Rapid traverse speed:up to 30000mm/min; rapid override:F25%, 50%, 75%, 100% real-time regulation

Cutting feedrate: up to 15000mm/min; feedrate override:0~150% 16 grades real-time regulation

MANUAL feedrate:: 0mm/min~1260mm/min 16-grade real-time regulation or it is defined in real time

MPG feed:0.001mm, 0.01mm, 0.1mm

G command

G commands:G00, G01, G06, G07, G08, G04, (G22/G80) , G26, G28, G30, G31, G32, G33, G34, G50,

G51, G52, G81, G83, G96, G97, G98, G99

Thread

machining

Capable of machining single/multiple straight thread, variable pitch thread; pitch: 0.001mm~500mm or

0.06tooth/inch~25400 teeth/inch; with tapping function

Spindle encoder: lines can be set within 100p/r~5000p/r; Drive ratio between encoder and spindle is 1:1

Precision

compensation

Backlash compensation: 0 mm~10.000mm

Tool offset: 16 tool numbers, 64 groups of tool length compensation;

Tool setting method: trial cutting;

Tool offset can be modified during program execution, and can be modified by statement command

M command

M00, M02, M20, M30, M03, M04, M05, M08, M09, M10, M11, M12, M32, M33, M41, M42, M43, M44,

M47, M48, M87,M88,M78, M79, M80, M81, M82, M83, M96, M97, M98, M99, M91, M92, M93, M94,

M21, M22, M23, M24; M commands defined by operator: M60~M74, which can realize the special

function control

T command

Up to 16 tools,setting tool post type parameters to select the control process of too change (the system

has no the integrated function to control the electric tool post on the machine)

Tool change action is not executed if the tool post type is set to 0, and the system calls M60 command to

execute tool change when set to 9.

Spindle speed

control

Speed switching value control: S 4-gear directly controlling output range is S01~S04; or 16-gear BCD

output range is S00~S15

Speed analog voltage control: S specifies the spindle speed per minute or the cutting surface speed

(constant surface speed) , outputs 0~10V voltage to spindle converter, supports 4-gear spindle speed

M41~M44 with stepless shifting gear

Support for the speed/position control mode switch for DAP03 servo spindle, which realizes Z or X axis linkage

function

I/O

function

I/O function diagnosis display

I/O interface:23 input/18 output interfaces

Statement

programming

Assignment statement: complete assignment, many arithmetic and logic operations

Conditional statement: complete conditional judgment and skip

Display window

Display: 800x480 lattice, color LCD,with LED or CCFL backlight

Display method: Chinese or English window set by a parameter

Program edit

Program capacity: max. 255 programs with 4400KB

Edit method: edit in full screen, relative/absolute coordinate compound programming, support for

subprogram call and subprogram multi-level embedding

Communication

USB interface; bidirectional transmission of programs, parameters and offset between CNC and USB;

Support for USB to download and upgrade

Optional drive

unit

DA98 Series Digital AC Servo or DY3 Series Stepper Drive unit with pulse + direction signal input

Chapter 2 Technical Specifications

2.1 GSK96 Technical specifications

Page 21

Operation Chapter Three System Operation Panel

3

Chapter 3 Operation Panel

GSK96 multi-function position control system (abbreviated to system hereafter ) employs the

aluminum alloy operation panel.

3.1 LCD Display

LCD display: CNC man-machine dialogue interface. Lattice color LCD display with resolution of

800x480.

3.2 LED Status Indicator

LED indicator indicates the current working state of the system. There are 14 function keys with LED

indicators. The function executed by the corresponding key is valid when LED is ON, and it is invalid

when LED is OFF.

3.3 Keyboard

Based on GB/T 3168-1993 Numerical Control of Machine-Symbol, the system sets the following

symbol function keys that complete the corresponding functions when they are pressed as follows:

3.3.1 Character keys

Character keys include numbers, letter, and some other symbols.

In EDIT working mode, each letter key can switch into 2 or 3 letter keys; in other working mode, each

letter key only expresses one letter key. (For example, I and P are on one key, the operator directly

press the key when ―I‖ or ―P‖ is required, and the system automatically indentifies other letters.)

Numeric keys: input data(0~9) ;

Letter keys: input letters;

Symbolic keys: input +(plus) , -(minus) , *(multiply) , /(devide) , +(positive) ,

-(negative) , .(decimal point) ,

Logic keys: >(larger than) , =(equal to) , <(smaller than) , and, or , (), etc.

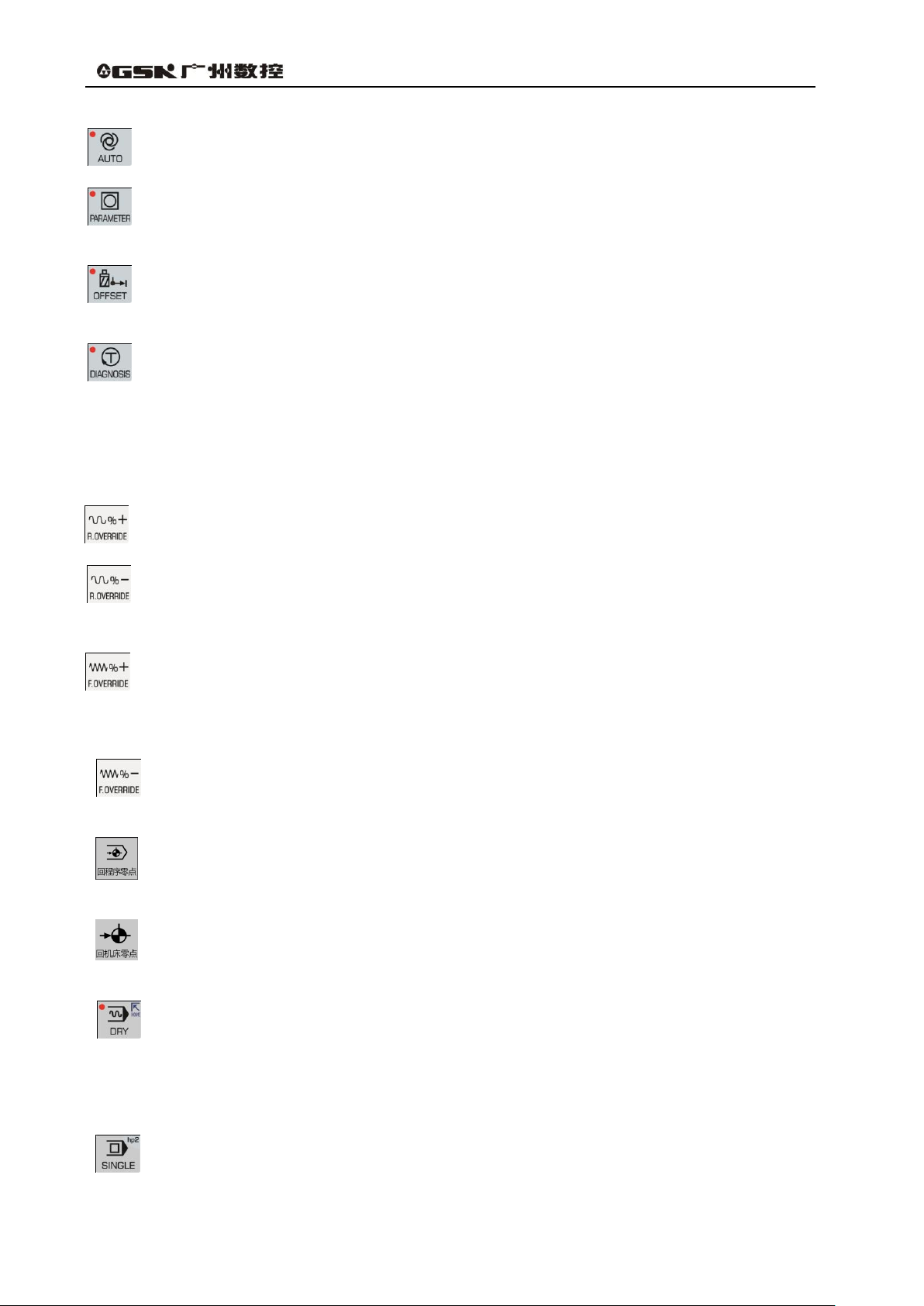

3.3.2 Working mode selection key

Marking with the symbols and characters, the working mode selection keys are pressed to

complete the corresponding function, and their definitions are as follows:

: select EDIT working mode

: select JOG working mode

Page 22

GSK96 Multi-function Position Control System User Manual

4

: select AUTO working mode

: select PARAMETER working mode

: select OFFSET working mode

: select DIAGNOSIS working mode

3.3.3 Function keys

Press function keys with the visualization symbol and letter to complete the corresponding functions

and each symbol definition is as follows:

INCREASING RAPID OVERRIDE Increase rapid traverse override in JOG working mode

and G00 rapid traverse override in AUTO working mode.

REDUCING RAPID OVERRIDE: Reduce rapid traverse override in JOG working mode and

G00 rapid traverse override in AUTO working mode.

INCREASING FEEDRATE OVERRIDE: Increase feedrate override in JOG working mode and

G01 feedrate override in AUTO working mode.

REDUCING FEEDATE OVERRIDE: Reduce feedrate override in JOG working mode and

G01 feedrate override in AUTO working mode.

X, Z, Y PROGRAM REFERENCE POINT RETURN: It is valid in JOG /AUTO working mode.

(Program reference point is also called program zero point in the user manual.)

X, Z, Y MACHINE REFERENCE POINT RETURN: It is valid in JOG working mode. (Machine

reference point is also called machine zero point in the user manual.)

Dry run key When Dry Run is selected in AUTO operation mode to execute commands,

whether M, S, T commands are valid is determined by bit parameter P401_d7. After the Dry

Run state is exited, the coordinate of each axis of the system automatically resumes to the

one before Dry Run.

Single/Continuous key selects Single/Continuous mode in AUTO operation mode.

Page 23

Operation Chapter Three System Operation Panel

5

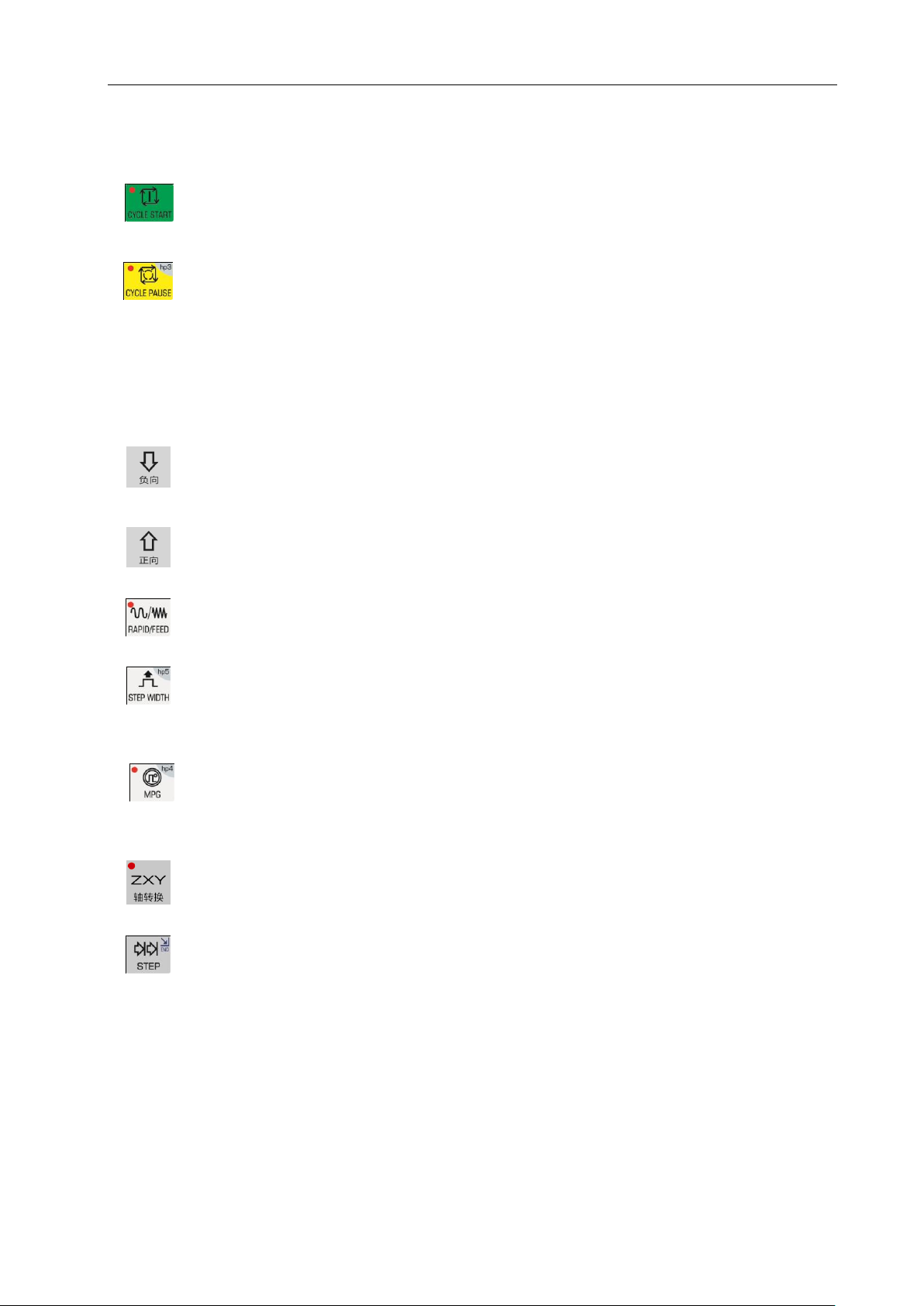

3.3.4 Cycle start and cycle pause (feed hold) key

Start and pause programs in AUTO working mode and each key symbol definition are as follows:

CYCLE START: Start to run programs in AUTO working mode; move coordinate axis in

JOG working mode.

CYCLE PAUSE (FEED HOLD): pause the running in JOG or AUTO working mode; hp

function in other working modes.

3.3.5 Manual axis control key

Manual key symbol definitions in JOG working mode are as follows:

X/Y/Z axis moves negatively in JOG working mode.

X/Y/Z axis moves positively in JOG working mode.

RAPID TRAVERSE/FEED Switching rapid traverse and feed in JOG working mode.

JOG STEP Select each step width or MPG feed in STEP/ MPG(Handwheel) working

mode; hp function in other working modes.

MPG (Handwheel) MPG control selection and axis selection in JOG working mode; hp

function in other working modes.

X/Z/Y and MPG axis selection in JOG working mode.

STEP/JOG mode Switch STEP/JOG mode in JOG working mode.

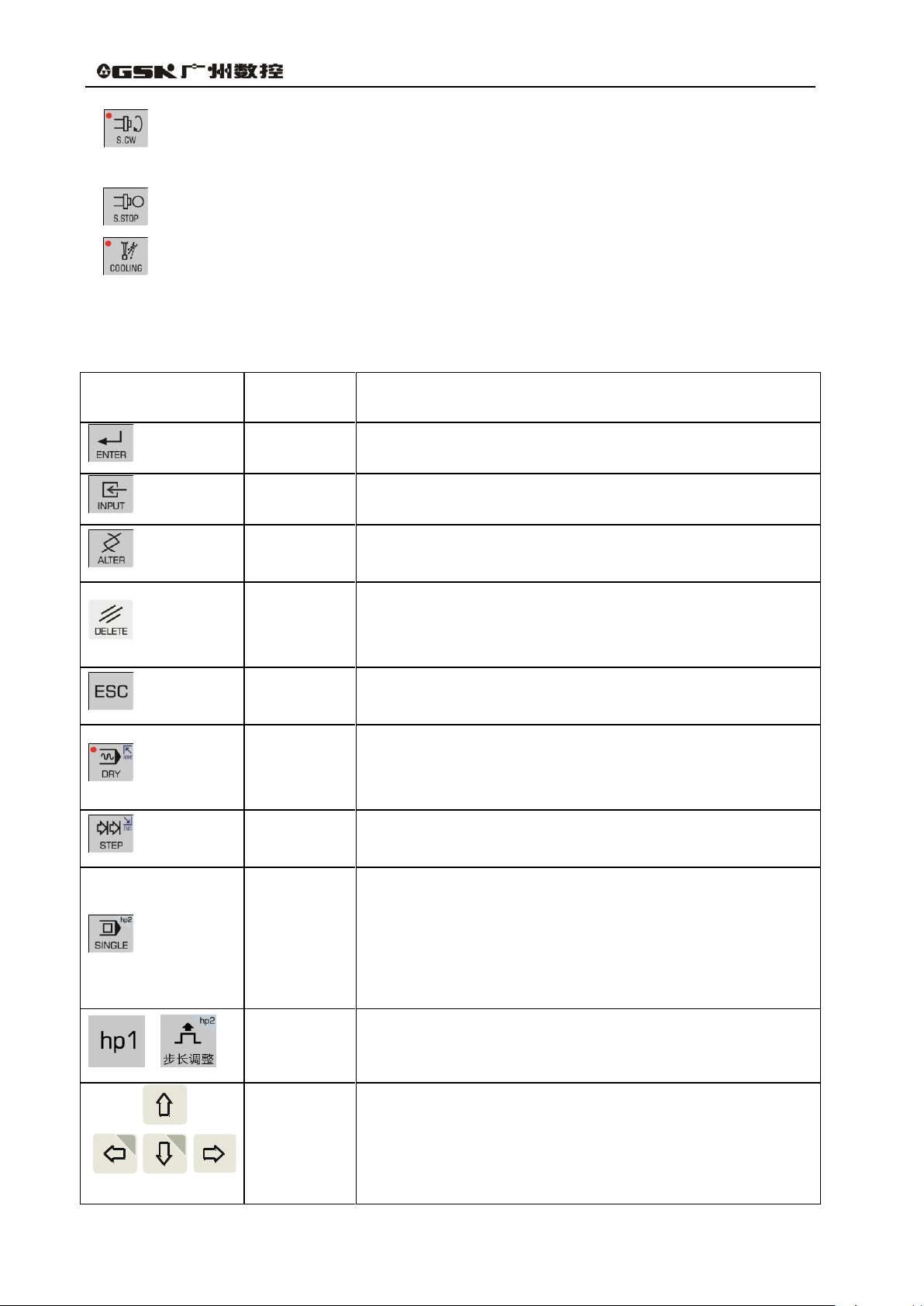

3.3.6 Manual auxiliary function key

The following press keys are used to control and complete all miscellaneous function of the machine

and each key symbol definition is as follows:

Page 24

GSK96 Multi-function Position Control System User Manual

6

Press key

Name

Function explanation

ENTER key

Press it after the corresponding operation is performed.

INPUT key

Input the required content.

ALTER key

Switch character insert/alter state in EDIT working mode;

Special definition in other working modes.

DELETE key

Delete character, letter, block or whole program in EDIT

working mode;

Special definition in other working modes.

ESCAPE

key

Cancel the current input data or exit from the working state;

exit from the current operation or setting.

HOME key

―DRY RUN‖ in AUTO working mode;

Cursor moving to the beginning of the current line in EDIT

working mode.

END key

―STEP‖ in JOG working mode;

Cursor moving the end of the line in EDIT working mode.

SINGLE

BLOCK key

―SINGLE/CONTINUOUS‖ executing programs in AUTO

working mode;

―SINGLE/CONTINUOUS‖ analog executing programs in

AUTO working mode;

hp function in other working modes.

Help key

Two help keys: h1~h2

When step adjustment is invalid, h2 is valid.

Cursor

movement

key

Control cursor movement in EDIT/PARAMETER/OFFSET

working mode;

Hp function or other special definitions in other working

modes.

hp1

hp0

Spindle rotation (CW) Spindle rotates clockwise. (View from tailstock to chuck along

the spindle)

Spindle stop Spindle stops.

Cooling control Switch cooling ON/OFF.

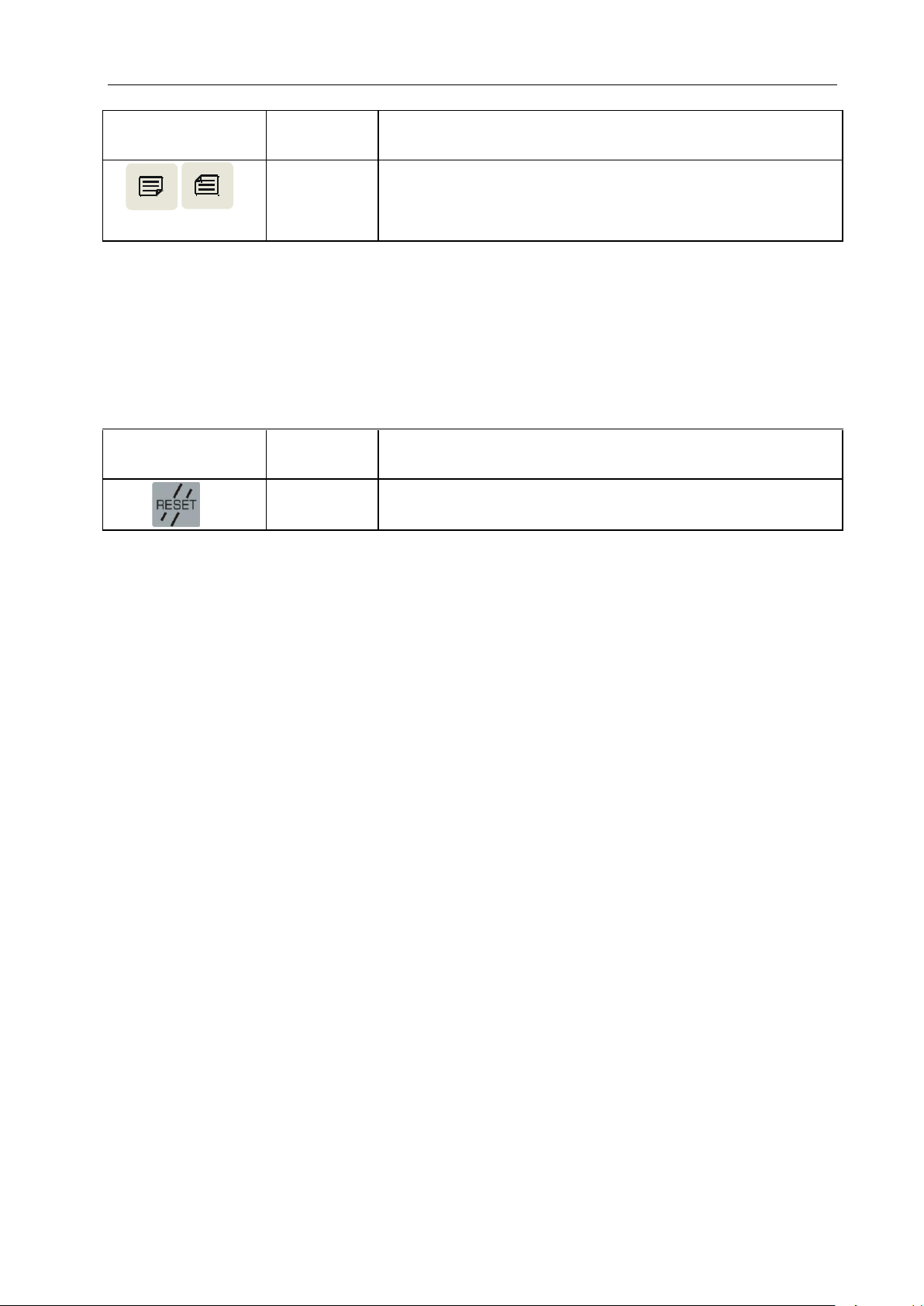

3.3.7 Edit keys

Page 25

Operation Chapter Three System Operation Panel

7

Press key

Name

Function explanation

PAGE

UP/DOWN

Display page up/down in EDIT/PARAMETER/OFFSET;

Special definition in JOG /AUTO working mode.

Press key

Name

Function explanation

RESET key

Reset

3.3.8 Reset Key

.

Page 26

GSK96 Multi-function Position Control System User Manual

8

Chapter 4 System Operation

This chapter introduces operations and notes of the system. Please read carefully before operation.

4.1 System ON/OFF, Initial State, Modal, and Safe Protection

4.1.1 Power on

There is no power switch on the operation panel of the system. The operator installs it according to

the different machine to avoid bad effects to CNC system owing to the impaction of power supply.

Check before the system is turned on:

1) Ensure the machine state is normal;

2) Ensure the voltage meets the requirements;

3) Ensure the wiring is correct and firm.

The system is turned on as follows:

1) The master power switch of machine is turned on.

Switch on the power switch of the CNC system, and the system displays as Fig. 4-1. Press

any keys, and the system enters into EDIT working mode.

Fig. 4-1 System initialization display window

2) The system orderly completes the following work after power-on:

The system controls the program loading.

The system automatically checks itself and executes the initialization.

The system loads and checks parameters.

I/O interface initialization.

The system loads and checks the operator programs.

【Note】

1) Must not press any keys on the system panel when the system is turned on. Press

RESET key when the system enters the press key test window at the moment.

4.1.2 Power off

The system is turned off as follows:

1) The power switch of the CNC is turned off.

2) The power switch of the machine is turned off.

Check before the system is turned off:

Page 27

Operation Chapter Four System Operation

9

System state

Initial mode

Modal

Machine coordinate system

of the system

Keep last power-on state

Keep till being changed

Tool nose coordinate system

of the system

Keep last power-on state

Keep till being changed

Cutting feedrate:F

In Auto mode:30mm/min

Keep till being changed

In JOG mode: Keep last power-on state

Frequency conversion spindle

speed:S

S200

Keep till being changed

Spindle gear

Shifting gear spindle gear:S0

Keep till being changed

Conversion spindle gear:M41

MANUAL slow feed/rapid feed state

Slow feed

Keep till being changed

Feedrate override

Keep last power-on state

Keep till being changed

Rapid override

Keep last power-on state

Keep till being changed

Spindle state

M05 spindle stop

Keep till being changed

Cooling state

M09 cooling OFF

Keep till being changed

Chuck state

M11 chuck release

Keep till being changed

Lubricating state

M33 lubricating OFF

Keep till being changed

T number state

Keep last power-on state

Keep till being changed

Tailstock state

M79 tailstock run-out state

Keep till being changed

Set spindle speed/position mode

M48

Keep till being changed

1) X, Z, Y are in the stop state;

2) Miscellaneous function(spindle, cooling) OFF;

3) Turn off the power supply.

【Note】

1) The system should be checked itself and initialized when it is turned on at first (it is

completed by the machine manufacturer, and the operator cannot execute the operation,

otherwise, the parameter set by the machine manufacture will lose).

2) Operations related to turn off the machine power supply are referred to the operator manual

machine manufacturer.

4.1.3 System, program initial and modal

4.1.3.1 the initial state and modal of the system

The initial mode of the system is defined to be a special initial state of all functions set by itself when

the system is turned on; all auxiliary functions do not execute the actual output.

The modal of the system is defined to be their kept states after the system executes all functions.

Initial mode and modal of the system:

4.1.3.2 Initial mode and modal of program

The initial mode is the automatic initialization setting state before the system executes the machining

program; i.e. the initial default state of the default programming word and speed word.

Program initialization state of the system:

G command:G00, G97, G98;

Cutting speed:30mm/min;

Miscellaneous function: current state;

System coordinates: current coordinates are those of the last automatic executing

program or manual operation

G modal is always valid till it is changed by other modal commands in the same group after the

word is set. After the modal meaning is set, the G command may not be input again when the

Page 28

GSK96 Multi-function Position Control System User Manual

10

same function is used in the later block.

There are three groups of G command with modal characteristics, and there is only one

command in the modal state:

Group 1:G00, G01; (initial mode:G00 ) ;

Group 2:G96, G97; (initial mode:G97 ) ;

Group 3:G98, G99; (initial mode:G98 F30 ) ;

The command without modal characteristics has effect in the block and must be defined to use every

time.

【Note】

In AUTO working mode, the system automatically recovers to the program initial mode when it

executes the first command of workpiece program or executes the first block command after M20, or

selects the middle block as the first command.

4.1.4 Safe protection

The CNC system sets a perfect protection measure to prevent the operator from danger and the

machine from being damaged.

4.1.4.1 Hardware limit protection

The system can check the travel limit switch installed on the machined. When the machine slide

moves to press the travel limit switch, the system stops feeding instead of closing other

miscellaneous functions, and the program stops running and the system displays the hardware limit

alarm information of corresponding axis.

After the travel limit switch alarms, the system can select JOG working mode, the key for axis

movement which is reversed to the limited direction is pressed, i.e. the system exits the travel limit

and the travel limit switch alarm automatically disappears on the screen.

【Explanation】

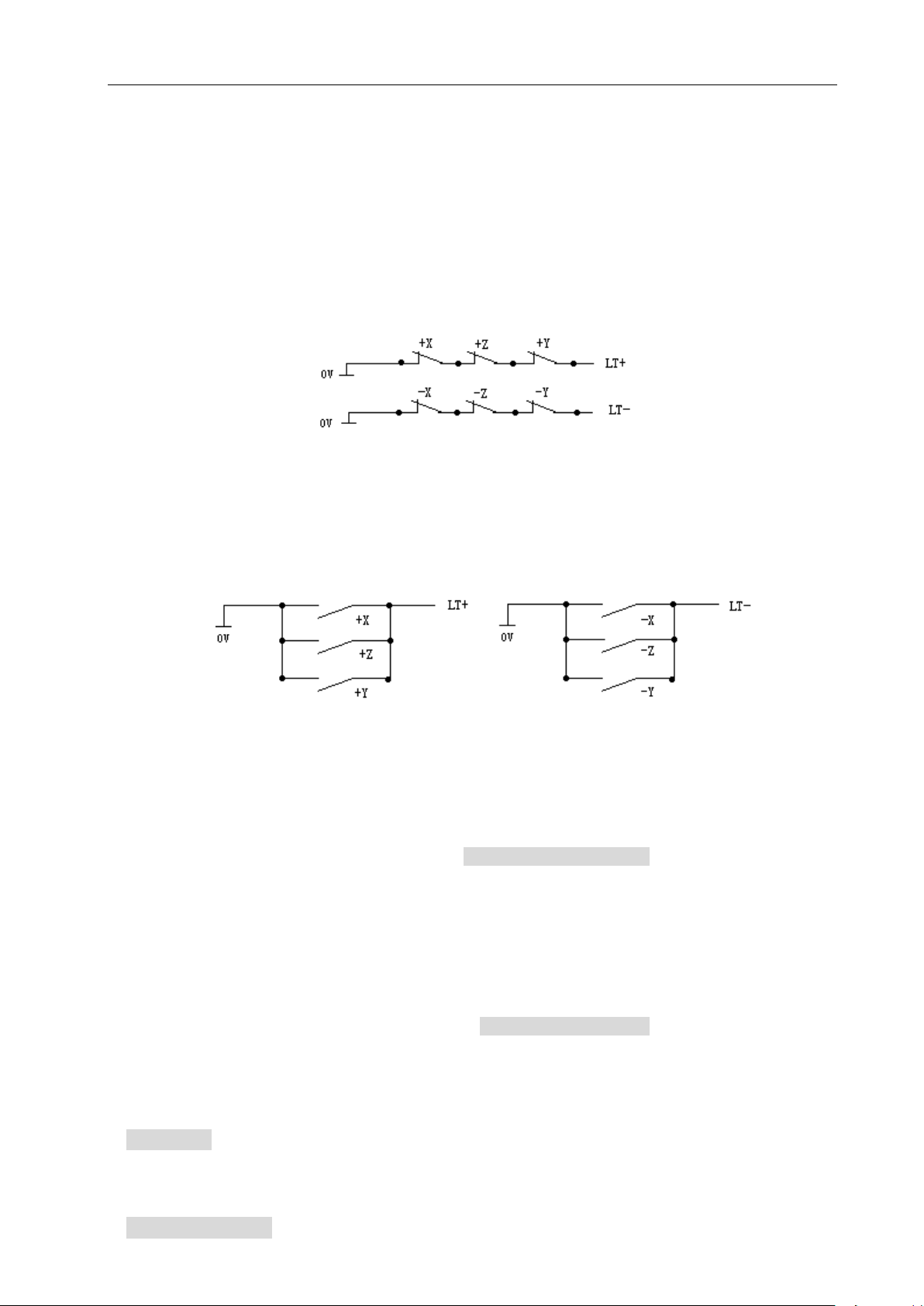

1) X, Y, Z positive limit check shares one pin LT+, and their negative limit check shares one pin

LT-; when the positive limit alarms, all axes cannot move positively but move negatively; and

vice versa.

2) When the travel limit switch runs across the limit block, the limit signal appears; the valid

length of limit block signal is more than 30mm or more to avoid rush out the valid area of the

signal.

3) When the parameter is set to ―limit emergency stop‖ mode (bit parameter P402_d7=1), and

the system runs across the limit block, there may be great deviation between the coordinates

displayed by the system and the actual position. Adjust the machine coordinates.

【Relative parameters】

Bit parameters: P402_d7, P404_d6, P404_d1.

Bit parameter P402_d7 sets the hardware limit alarm mode;

Bit parameter P402_d6 sets whether the hardware limit alarm checks;

Page 29

Operation Chapter Four System Operation

11

Bit parameter P402_d1 sets the hardware limit alarm level of each axis;

When P404_d1=1 is high level alarm, the positive limit switch +X, +Y, +Z of each axis are normally

closed contact, are connected to X/Z/Y positive limit input interface +LT (they are open and the

system alarms) in serial; the negative limit switch -X, -Y, -Z of each axis are normally closed contact,

are connected to X/Z/Y negative limit input interface -LT (it is off and the system alarms) in serial; it is

suggested that the operator should select in prior the hardware limit to the normally closed contact of

each axis as follows:

When P404_d1=0 is low level alarm, the positive limit switch +X, +Y, +Z of each axis are normally

open contact, are connected to X/Z/Y positive limit input interface LT+ (they are closed and the

system alarms) in serial; the negative limit switch -X, -Y, -Z of each axis are normally open contact,

are connected to X/Z/Y negative limit input interface LT- (it is off and the system alarms) in serial; the

connection is as follows:

4.1.4.2 Software limit safe protection

1) Mechanical software limit safe protection

The mechanical software limit safe protection is to limit machine coordinate motion range to

avoid slide to exceed the motion range. The mechanical software limit alarms when the machine

position (machine coordinates) exceeds the range.

Releasing overtravel alarm methods: reversely movement in JOG working mode (negatively

moves for positive overtravel; positively moves for negative overtravel).

2) Tool nose software limit safe protection

The tool nose software limit safe protection is to limit tool nose coordinate motion range to avoid