Page 1

GSK928TEⅡ Turning CNC System User Manual

The user manual describes all items concerning the operation of

the system in detail as much as possible. However, it is

impractical to give particular descriptions of all unnecessary

and/or unavailable works of the system due to the length limit of

the manual, specific operations of the product and other causes.

Therefore, the operations not specified herein may be

considered impractical or unavailable.

This user manual is the property of GSK CNC Equipment Co., Ltd.

All rights reserved. It is against the law for any organization or

individual to publish or reprint this manual without the express written

permission of GSK and the latter reserves the right to ascertain their

legal liability.

1

Page 2

Dear user,

GSK928TEⅡ Turning CNC System User Manual

We are really grateful for your patronage and purchase of GSK928

TEⅡ

Turning CNC

system made by GSK CNC Equipment Co., Ltd.

Caution

This system can only be operated by authorized and qualified personnel as

improper operations may cause accidents. Please carefully read this user

manual before use!

Before Use:

z Connect the emergency stop button of the system firmly and correctly, otherwise an

emergency stop alarm will occur when switch on the system, so that the system cannot

work properly.

z Set the reference point of the program of the system according to the actual mounting

position of the tool of the machine that the system controls.

Note: The power supply of the sy stem inst alled in the cabinet is exclusiv e to GSK’

CNC systems.

Must not take the power supply as other uses, otherwise, there maybe

cause great accidence!

Chinese version of all technical documents in Chinese and English

languages is regarded as final.

All specifications and designs are subject to change wi thout notice.

All rights reserved.

We are full of heartfelt gratitude to you for supporting us in the use of GSK’s

products.

2

Page 3

GSK928TEⅡ Turning CNC System User Manual

Contents

Suggestions for Safety ....................................................................................................................... 1

Operation..............................................................................................................................................7

Chapter One Overview ................................................................................................................. 7

Chapter Two Technical Specifications........................................................................................ 8

Chapter Three Operator Panel..................................................................................................... 9

Chapter Four System Operation ............................................................................................... 14

4.1 System ON/OFF.................................................................................................................. 14

4.2 CNC System Operating Mode............................................................................................. 15

4.3 EDIT Mode........................................................................................................................... 15

4.4 Manual Mode....................................................................................................................... 28

4.5 AUTO Mode......................................................................................................................... 47

4.6 Parameter Setting................................................................................................................ 58

4.7 Tool Offset Setting Mode ..................................................................................................... 69

4.8 Diagnosis ............................................................................................................................. 70

4.9 Alarm of Emergency Stop and Overtravel........................................................................... 74

4.10 Drive Unit Switch Control .................................................................................................. 75

Programming ..................................................................................................................................... 76

Chapter 1 Programming Fundamentals ................................................................................... 76

1.1 Coordinate Axis and its Direction ........................................................................................ 76

1.2 Machine Zero....................................................................................................................... 76

1.3 Programming Coordinate .................................................................................................... 76

1.4 Workpiece Coordinate System............................................................................................ 78

1.5 Reference Point................................................................................................................... 78

Chapter 2 Program Structure..................................................................................................... 79

2.1 Character ............................................................................................................................. 79

2.2 Word .................................................................................................................................... 79

2.3 Block Number ...................................................................................................................... 80

2.4 Block .................................................................................................................................... 80

2.5 Program Structure ............................................................................................................... 80

Chapter 3 Commands and their Functions.............................................................................. 81

3.1 G commands — Preparatory Function .......................................................................... 81

3.2 M function — Miscellaneous Function.............................................................................113

3.3 S function — Spindle Function ........................................................................................118

3.4 T Function — Tool Function ..........................................................................................119

3.5 F function — Feedrate Function .................................................................................. 120

Chapter Four Programming Rules .......................................................................................... 121

I

Page 4

Contents

4.1 Some Commands in One Block ........................................................................................ 121

4.2 Modal and Initial State of Commands ............................................................................... 121

4.3 Other Rules ....................................................................................................................... 122

4.4 Programming Example ...................................................................................................... 122

4.5 Alarm List........................................................................................................................... 129

Appendix 1 GSKRS232 Communication Use......................................................................... 132

Appendix 2 C5.1 FLASH Chip Copy and Check.................................................................. 141

Connection....................................................................................................................................... 143

Chapter One Interface .............................................................................................................. 143

1.1 Interface Layout................................................................................................................. 143

1.2 Total Frame........................................................................................................................ 144

1.3 Total Connection Layout .................................................................................................... 145

Chapter Two Interface Function .............................................................................................. 146

2.1 Specifications..................................................................................................................... 146

2.2 Interface Graph.................................................................................................................. 147

Chapter Three CNC Device Connection................................................................................. 148

3.1 X1 Communication Interface ............................................................................................. 148

3.3 X3 Spindle Encoder Interface............................................................................................ 150

3.4 X4 Tool Post Device Interface ........................................................................................... 152

3.5 X5 Feed Drive Unit Interface............................................................................................. 154

3.5.3.3 Pulse signal.......................................................................................................................155

3.6 X Switching Value Input Interface ..................................................................................... 163

3.7 X7 Switching Value Output................................................................................................ 165

3.8 X7 Spindle Converter Interface ......................................................................................... 167

Appendix 1 GSK928TEⅡ Tool post Controller Circuit Diagram ......................................... 170

Appendix 2 Interface Circuit Diagram..................................................................................... 171

Appendix 3 Machine Zero Return Mode ................................................................................. 174

Appendix 5 GSK928TEⅡ Integrated Wiring Table................................................................ 177

Appendix 6 Appeara nce Installation Dimension of GSK928TEⅡ Tur ning CNC System.. 181

II

Page 5

GSK928TEⅡ Turning CNC System User Manual

Suggestions for Safety

The user must carefully read the suggestions for the system before installing and operating the

system.

The user must follow the suggestions of the system to ensure that the person is not hurt and the

equipments are not damaged.

The user must follow the related suggestions for safety described in the manual, and must not

operate it until the manual is read completely.

Follow safety instructions for the machine that the system will control. Do not run the machine

until you have completely read both the instructions and this manual.

User must follow the suggestions of safety described in the user manual from the machine

manufacture

User can operate the machine or compile the program to control the machine after completely

reading the User Manual and the one from the machine manufacturer.

The power supply of the system installed in the cabinet is exclusive to GSK’ CNC systems. Must

not take the power supply as other uses, otherwise, there maybe cause great accidence!

1

Page 6

Safety Warning

Ⅰ.Graphic symbol

Caution Operation against the instructions may cause the operator serious injuries.

Alarm Wrong operation may injure the operator and damage the system.

Warning Improper operation may result in damage to the machine, as well its products.

Important information

Shield

Earthing (PE)

Encoder

Coil of contact or relay

Exchange

Connecting terminal

2

Page 7

GSK928TEⅡ Turning CNC System User Manual

Ⅱ. Notes

1)Check before acceptance

Warning ● The damaged or defect product must not be used.

2)Delivery and storage

Warning ●Moistureproof measures are needed while the system is delivered and stored.

Never climb the packing box, neither stand on it, nor place heavy items on it. Do

not put over five packing boxes in piles. Take particular care of the front panel

and the display of the system.

3)Installation

Warning ●Protect the system from sunlight and raindrops. The shell of the system is not

waterproof.

Warning ●Prevent dust, corrosive air, liquid, conductors and inflammable substances from

entering the system.

●Keep the system away from inflammable and explosive substances. Avoid

places where there is powerful electromagnetic interference.

●Install the system firmly without vibration.

4)Wiring

Caution ●Only qualified persons can connect the system or check the connection. The

connecting wires cannot be damaged. Do not press or open the cover of the

system with power on.

Caution ●The voltage and the polarity of connecting plugs must accord with the manual.

●Wet hands are dangerous to grasp the plug or the switch.

Warning ●The connection must be proper and firm.

●The system must be earthed.

5)Debugging

Warning ●Make sure that the parameters of the system is correct before the system runs.

●No parameter is beyond the setting limit in the manual.

3

Page 8

Safety Warning

6)Operation

Caution ●Only qualified operators can operate the system.

●Ensure the switch is OFF before connecting the power supply.

Warning ●The operator can not leave the system to work alone.

●Do not switch on the system until making sure the connection is correct.

●The emergency stop button is able to disconnect all power supplies when the

system breaks down. Do not switch on/off the system frequently

Warning ●Prevent the system from the environmental interference.

7)Troubleshooting

Caution ●Unqualified persons cannot repair the system.

Warning ●After alarms, do not restart the system until the breakdown is fixed.

4

Page 9

GSK928TEⅡ Turning CNC System User Manual

Ⅲ. Safety Suggestions for Programming

1)Setting a coordinate system

Incorrect coordinate system may cause the machine not to work as expected even if the

program is correct, which may injure the operator, and damage the machine as well as its

tool and workpiece.

2) Rapid traverse (positioning)

When G00 rapid traverse performs the positioning( nonlinear motion to position between

its starting point and end point), make sure that the path for the tool is safe before

programming. The positioning is to perform the rapid traverse, and when the tool and the

workpiece are interfered, the tool, the machine and the workpiece may be damaged, and

even the operator injured.

3) Applicability of user manual

The manual introduces in detail all functions of the system, including optional functions

and max. controllable ranges, which are subject to change with the machine. If there is

any doubt, please read the instruction for the machine。

4) Functions of CNC system and machine

CNC machines depend on CNC systems, but also power voltage cabinets, servo systems,

CNC and the operator panels. It is hard to explain all the integrated functions,

programming and operation. Do not use integrated instructions not included in the manual

until they have been tested successfully.

5

Page 10

Safety Warning

Ⅳ. Notes and Safety Suggestions for Operating Machine

1)Test the machine without workpieces or tools. Make sure that the machine runs well before

it starts to work.

2)Check the input data of the system carefully before operating the machine. Incorrect input

data may cause the machine to work improperly, so as to damage the workpiece and the

tool, as well injure the operator.

3)Make sure that the input feedrate of the system is suitable for the expected operation.

Feedrate has a maximum for each machine, and the amount of the feed rate is subject to

change with operation. Choose the maximum according to the instructions of the machine.

Improper feedrate leads the machine to work wrongly, so as to damage the workpiece and

the tool, as well injure the operator.

4 ) When tool compensation is needed, check the direction and the amount of the

compensation. Improper compensation causes the machine to work wrongly, so as to

damage the workpiece and the tool, as well injure the operator.

5)If the machine is to run in Manual mode, check the current position of the tool and the

workpiece, and correctly specify the moving axis, moving direction and the feedrate.

MPG(Handwheel) control with great override, such as 100, may damage the machine and

its tool, even injure the operator.

6)If the tool is return to the reference point, make sure that the machine has been equipped

with the device to detect the reference point, otherwise, the tool can not reach the

reference point, which may damage the machine and its tool, and even injure the operator.

6

Page 11

GSK928TEⅡ Turning CNC System User Manual

Operation

Chapter One Overview

With 480×240 lattice TFT color graphic LCD, GSK 928TEⅡ CNC system takes as key control the

high-speed CPU and the complex programmable logic device of super-large-scale integrated

circuits. ISO CNC code is used to write part programs. The system is characterized by μ-level

precision control, a full screen editing, Chinese operation interface, real time demonstration of the

machining process, and high cost-performance ratio. By means of programming, the system can be

used to control stepper motors, so as to machine outer cylinders, end faces, grooves, tapers,

circular arcs, and threads.

7

Page 12

Operation Chapter Two System Operator Panel

Chapter Two Technical Specifications

2.1 Controlled axes 2 (X, Z axis)

2.2

Link axes 2 (X, Z axis)

2.3

Min. setting unit 0.001 mm

2.4

Min. motion unit X: 0.0005mm; Z: 0.001mm

2.5

Max. dimension for programs ±8000.000 mm

Max. traverse rate 15000 mm/min

2.6

Feedrate 5-6000 mm/min (G98/G99)

2.7

Capacity of part program 62KB

2.8

2.9

Max. number of part programs 100

2.1

Graphic LCD 480×240 lattice TFT color LCD

Communication interface Standard RS-232

2.11

2.12

Tool selection 4(up to 8)

Compensation Tool compensation, clearance compensation

2.13

2.14

MPG(MPG) ×0.001 ×0.01 ×0.1

S1, S2, S3, S4 direct output; S0~S15 output

Spindle

2.15

2.16

G codes

2.17

Thread functions

with BCD code; three automatic gear shifting with

0~10V analog output; 1024p/r, 1200p/r spindle

encoder available

24 codes,including the fixed /compound cycles, Z

threading

Metric/inch single and multiple straight, taper

thread, high-speed retraction with setting the

retraction distance

8

Page 13

928TE-II

GSK928TEⅡ Turning CNC System User Manual

Chapter Three Operator Panel

EDIT

JOG

AUTO

PARAM ETER

OFFSET

DI AG NOS IS

Introduction of GSK 928TEⅡ Turning CNC System operator panel as follows:

3.1 LCD display: CNC man-machine dialogue interface. Resolution 480×240 lattice TFT color

LCD display.

3.2 Digit key: input all kind: Input all kinds of data(0-9).

3.3 Address keys:Input English letters in word addresses of part programs.

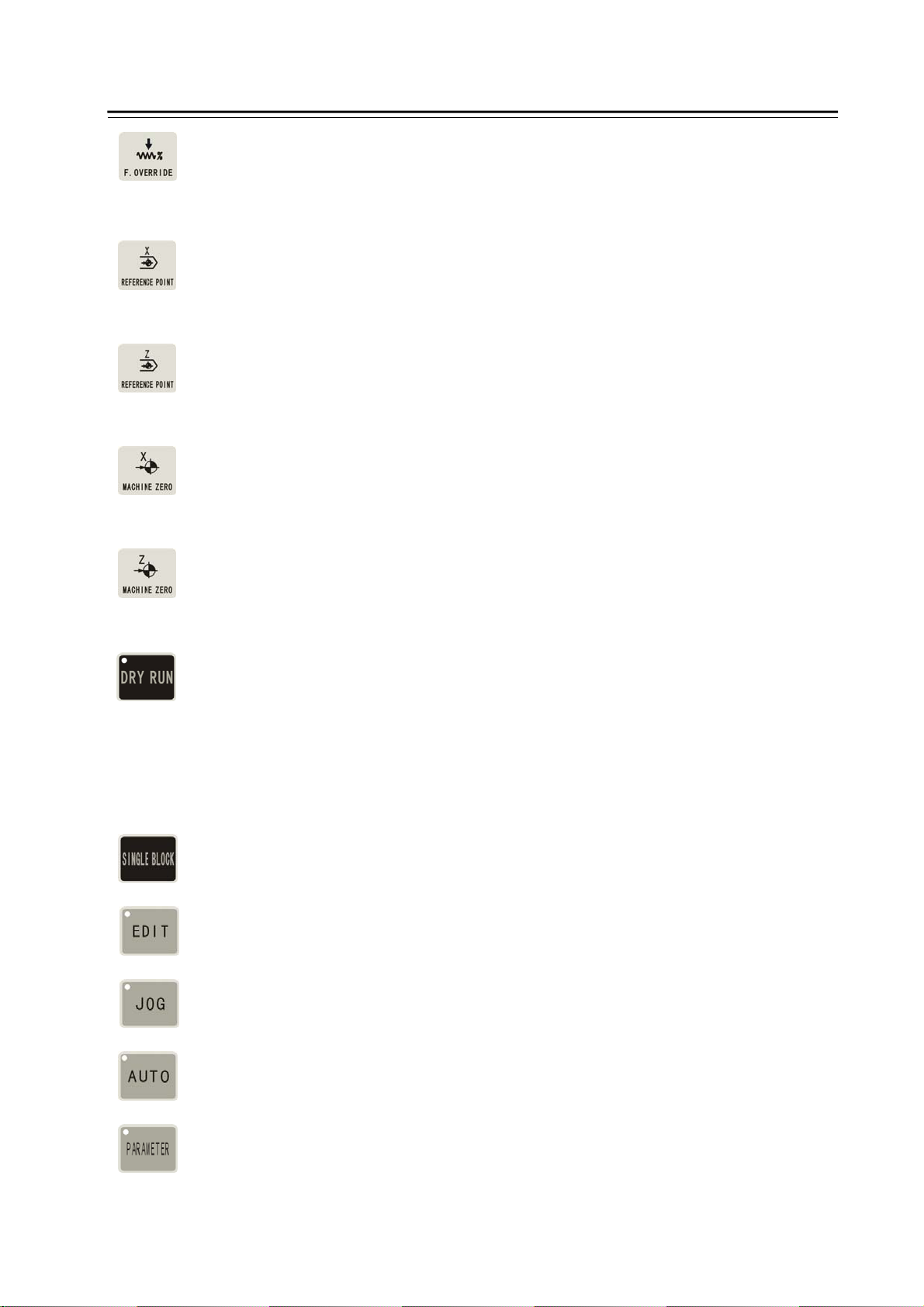

3.4 Function key s :All function keys are based on Numerical Contr ol of Machine-Symbol.

INCREASI NG RAPID OVER RIDE TRA VERSE OVERRIDE: Increase rapid traverse

override in JOG mode and G00 rapid traverse override in AUTO mode.

REDUCING RAPID TRAVERSE OVERRIDE: Reduce rapid traverse override in JOG

mode and G00 rapid traverse override in AUTO mode.

INCREA SING FEEDRATE OVERRIDE: Increase feedrate override in JOG mode

and G01 feedrate override in AUTO mode.

9

Page 14

Operation Chapter Two System Operator Panel

REDUCING FEEDATE OVERRIDE: Reduce feedrate override in JOG mode and G01

feedrate override in AUTO mode.

X PROGRAM REFERENCE POINT(PROGRAM ZERO) RETURN : It is valid in

JOG/AUTO mode.

Z PROGRAM REFERENCE POINT (PROGRAM ZERO) RETURN : It is valid in

JOG/AUTO mode.

X MACHINE ZE RO RETU RN : It is valid in JOG/AUTO mode.(whether machine zero is

valid is defined by Bit7 of P12 ).

Z MACHINE ZERO RETURN: It is valid in JOG/AUTO mode.(whether machine zero is

valid is defined by Bit7 of P12 ).

DRY RUN: In AUTO mode, DRY RUN tests a program without G, S, M, and T functions

output. In EDIT mode, moves the cursor directly to the first character behind the block

number. The machine coordinate data become white from yellow besides LED ON after it

is pressed.

SINGLE BLOCK : A single block runs in AUTO mode.

EDIT mode

JOG mode

AUTO mode

PARAMET E R mode

10

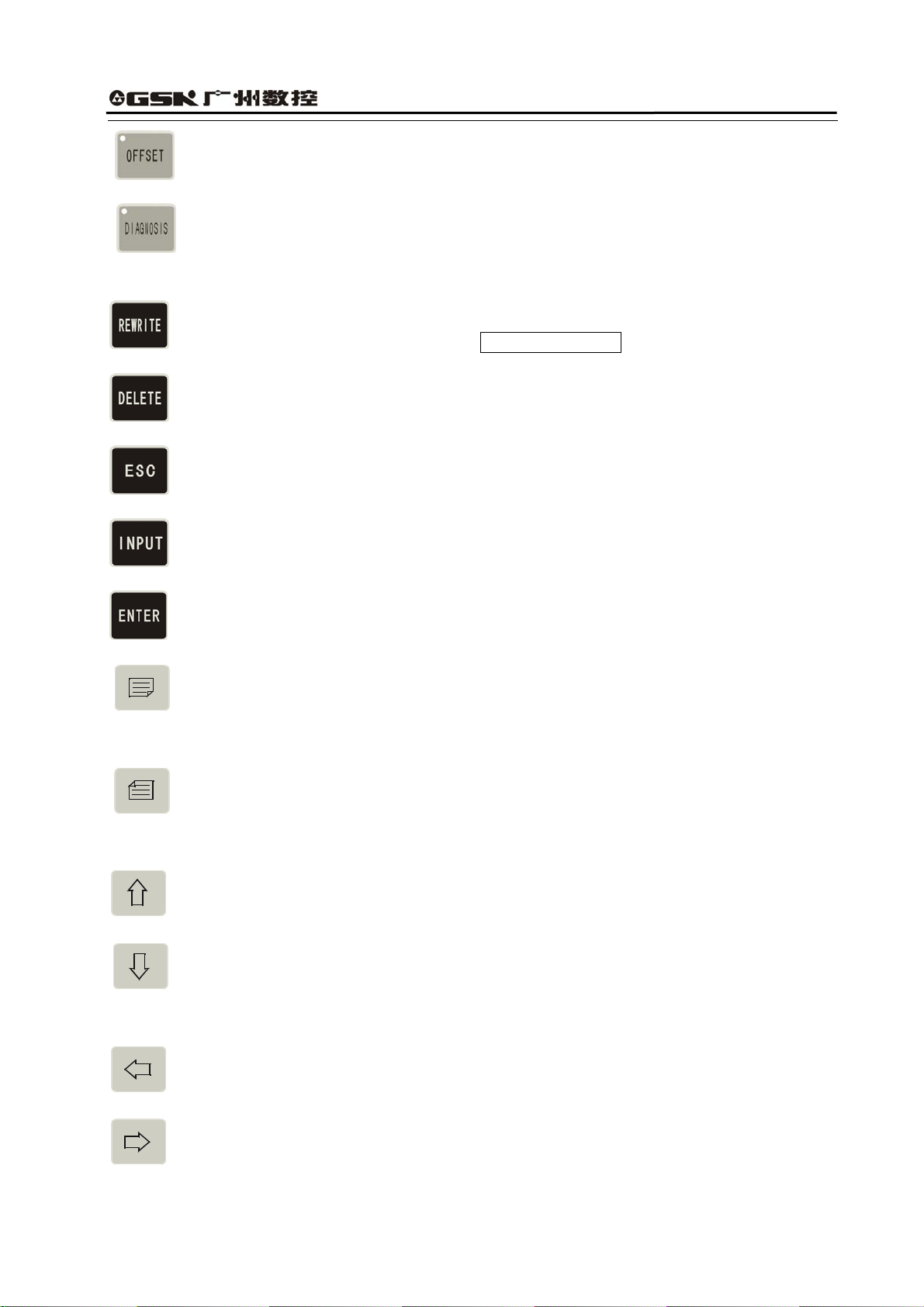

Page 15

OFFSET mode

DIAGNOSIS mode

3.5 Edit/state key

Switch the input method in EDIT mode—- INSERT/REWRITE .

Delete a number, a letter, a block or a whole program.

Cancel the current input all kind of data or escape from the current operation state.

GSK928TEⅡ Turning CNC System User Manual

Input all kind of data or select the required or run program or create a new part program.

Press ENTER to confirmation.

PAGE UP: page up to search programs or parameters in EDIT/PARAMETER/OFFSET

operation mode.

PAGE DOWN: page down to search programs or parameters in EDIT/ PARAMETER/

OFFSET mode.

Cursor moving up:the cursor moves up one line in EDIT/PARAMETER/OFFSET mode.

Cursor moving down: the cursor moves down one line in EDIT/PARAMETER/OFFSET

mode.

Cursor moving left: the cursor moves one character position left in EDIT mode.

Cursor moving right: the cursor moves one character position right in EDIT mode.

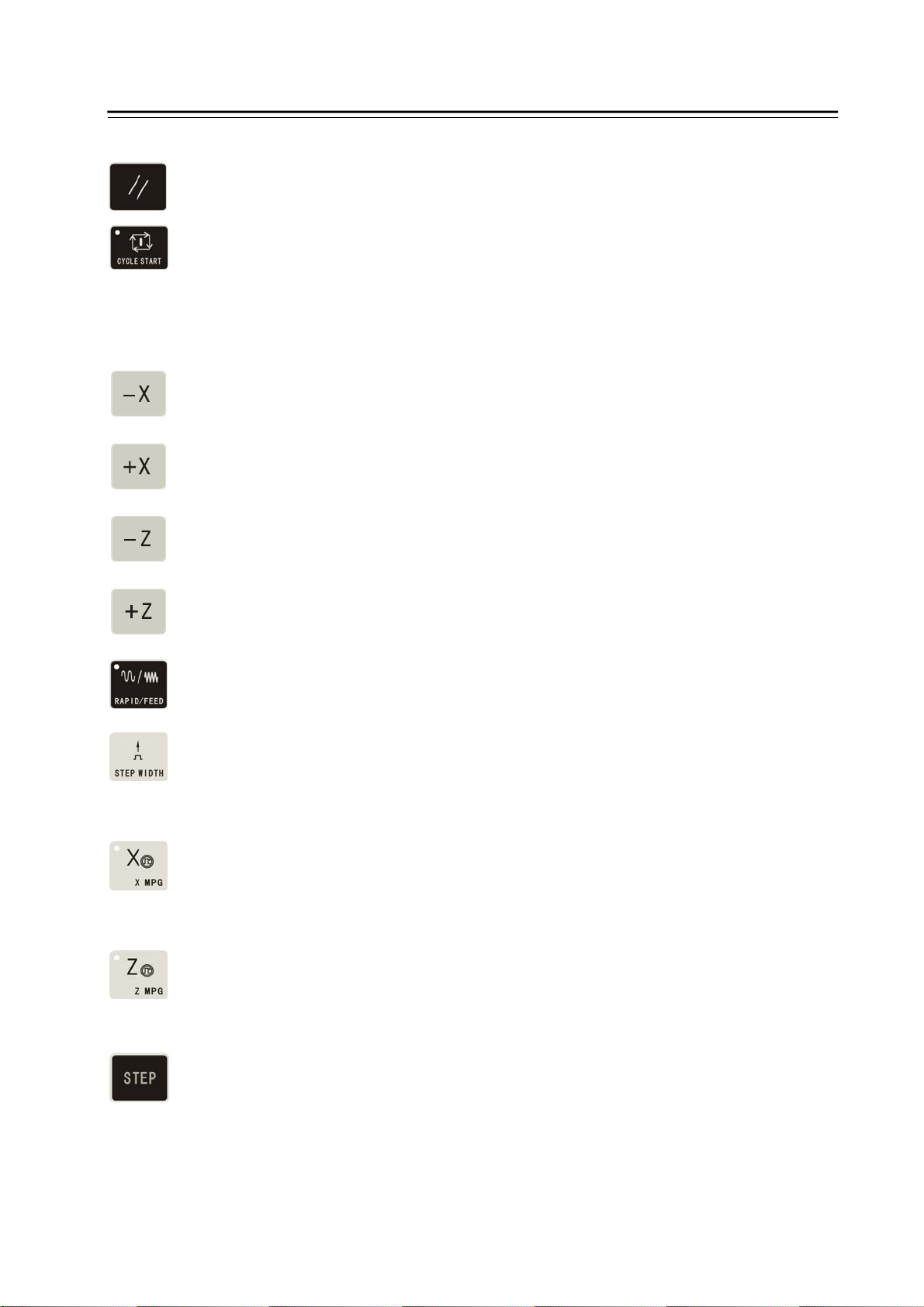

3.6 Cycle start and feed hold button

11

Page 16

Operation Chapter Two System Operator Panel

Start and pause programs in AUTO mode.

CYCLE START: Start to run programs in AUTO mode.

FEED HOLD: Motor reduces to pause in JOG or AUTO mode.

3.7 Manual axis control key

The selected axis and its direction in JOG mode:

X axis moves negatively in JOG mode.

X axis moves positively in JOG mode.

Z axis moves negatively in JOG mode.

Z axis moves positively in JOG mode.

RAPID TRAVERSE/FEED Switching rapid traverse and feed.

MANUAL STEP Selecting each step width or MPG feed in STEP/ MPG(Handwheel)

mode.

X MPG(Handwheel) X motion is controlled by the MPG(Handwheel) (when the control

is valid, other control keys related to the axis moving are invalid) .

Z MPG Z motion is controlled by the MPG(Handwheel) (when the control is valid, other

control keys related to the axis moving are invalid).

STEP/JOG mode Switch STEP/JOG mode.

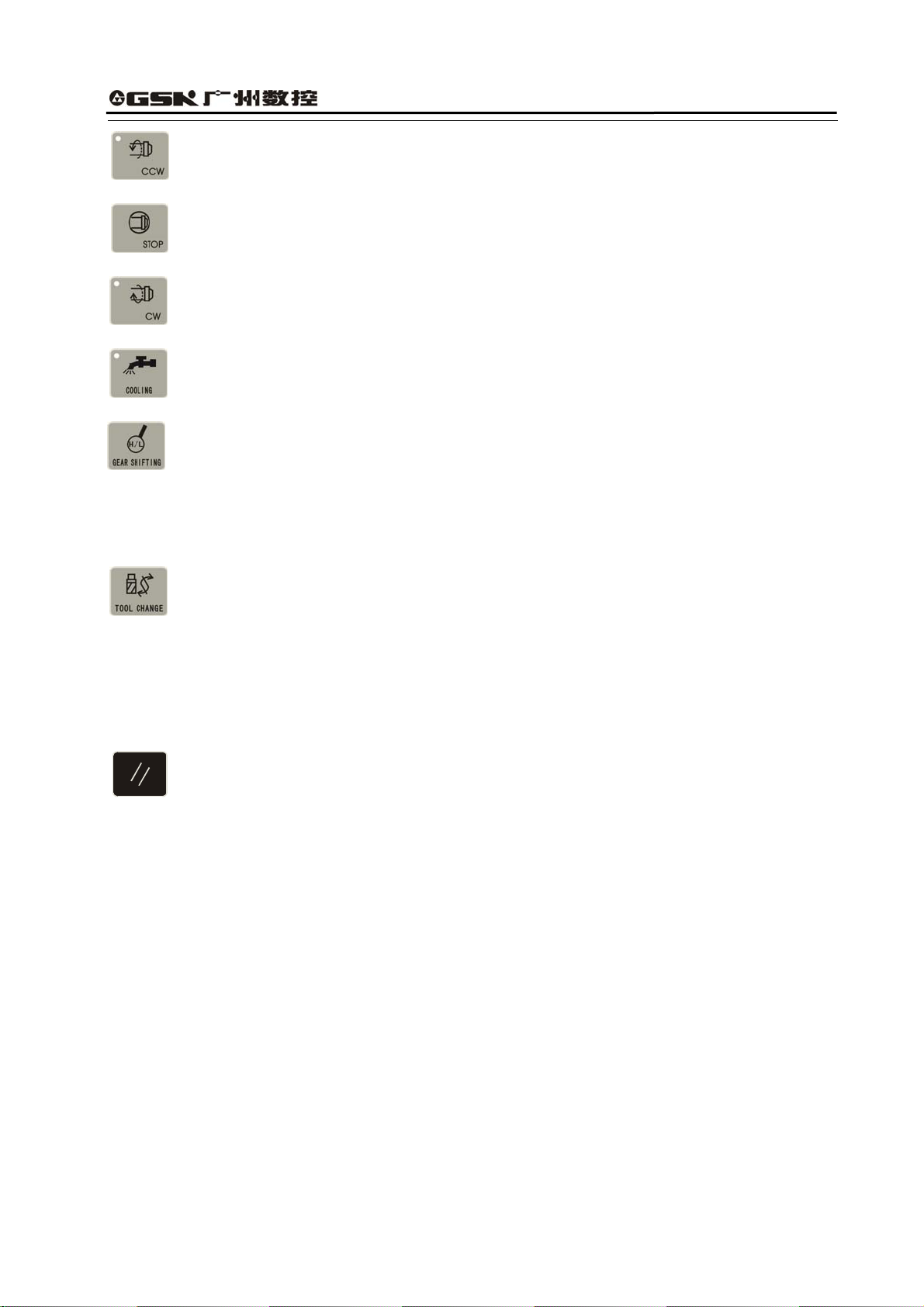

3.8 Manual tool change and auxiliary function keys

Select directly the next tool number and control the machine to complete auxiliary functions as

follows:

12

Page 17

GSK928TEⅡ Turning CNC System User Manual

Spindle rotation (CCW) Spindle rotates counterclockwise.

Spindle stop Spindle stops.

Spindle rotation (CW) Spindle rotates clockwise.

Cooling control Cooling ON/OFF

Spindle gear shifting Select the speed of each gear when the machine is equipped

with multi-gear (up to 16 gears) spindle motor and control

loops.

Tool change Select the next tool number neighboring to the current one.

Note

:

The above-mentioned pressing keys are valid in JOG, AUTO and DIAGNOSIS mode when X,

Z does not move, but only cooling control is valid

.

3.9 Reset key

System reset When the system resets, all axes stop motion, all auxiliary function

outputs are invalid, and the machine stops and returns to the initialization.

3.10 State indicator

It indicates the current state of CNC system. There are 15 function keys with LED indicator.

When LED ON, its function of corresponding key is valid, otherwise it is invalid.

13

Page 18

GSK928TEⅡ Turning CNC System User Manual

Chapter Four System Operation

This chapter introduces operations of GSK928TEⅡ Turning CNC system. Please read carefully

before operation.

4.1 System ON/OFF

GSK928TE Turning CNC System is not equipped with the system power switch. User installs it Ⅱ

according to the different machine to avoid bad effects to CNC system owing to the impaction of

power supply.

CNC system is turned on as follows:

1. The master power switch of machine is turned on.

2. Connect with the power switch of the CNC system. Press

GSK mark and caption, at the time, the system displays the software and hardware version

number, delivery date by pressing other keys persistently except for the reset key.

CNC system is turned off as follows:

1. The power switch of the CNC is turned off.

2. the power switch of the machine is turned off.

Note : The system should be initialized when it is turned on firstly.

The initialization operations are as follows:

Press the reset key and “9” key, and then release firstly the reset key and then “9” to enter the

debugging window.

1. CNC PAR P01—P26 DY3

2. CNC PAR P01—P26 DA98

3. CLEAR PRO %00—%99

4. DEBUG

5. COPY FLASH 29C010

0. ESC PLEASE INPUT

Pressing 1: initialize the system parameters for stepper motor

Pressing 2: initialize the system parameters for servo motor

Pressing 3: delete all part programs

Pressing 4: enter the system development system

Pressing 5: FLASH copy and check

Pressing 9: escape from the system EDIT menu

and the system displays

Note 1: Measure the machine backlash of X, Z,and input their values to the machine parameters

P07 and P08. For input methods, see Section Operation, Parameter mode.

Note 2: Set P11 according to the electric circuit design and the motor’s direction of the machine.

Note 3: Adjust parameters P05, P06, P17~P22 according to the load of machine, which make it

14

Page 19

GSK928TEⅡ Turning CNC System User Manual

run efficiently and stably.

Fig. 1 System initialization display

4.2 CNC System Operating Mode

GSK928TEII CNC System uses operating mode keys to select directly the operating mode,

which is helpful to directly change operating modes, easy, convenient and direct operations.

After GSK928TE CNC System is switched on, the dynamic display window iⅡ s as Fig. 1. The

window is displayed circularly until any key is pressed except for

the operating mode which is that of last power off.

, the system will enter

4.3 EDIT Mode

In EDIT mode, the user manually inputs or modifies the content of part program by operation

panel. In EDIT mode, create, select and delete part programs by keyboard, and insert, modify

and delete the content of selected part program. Besides, transmit part programs of the system

to the external PC or the edited part programs of external PC to CNC system by the serial

connection between RS232 communication interfaces and general-purpose PC.

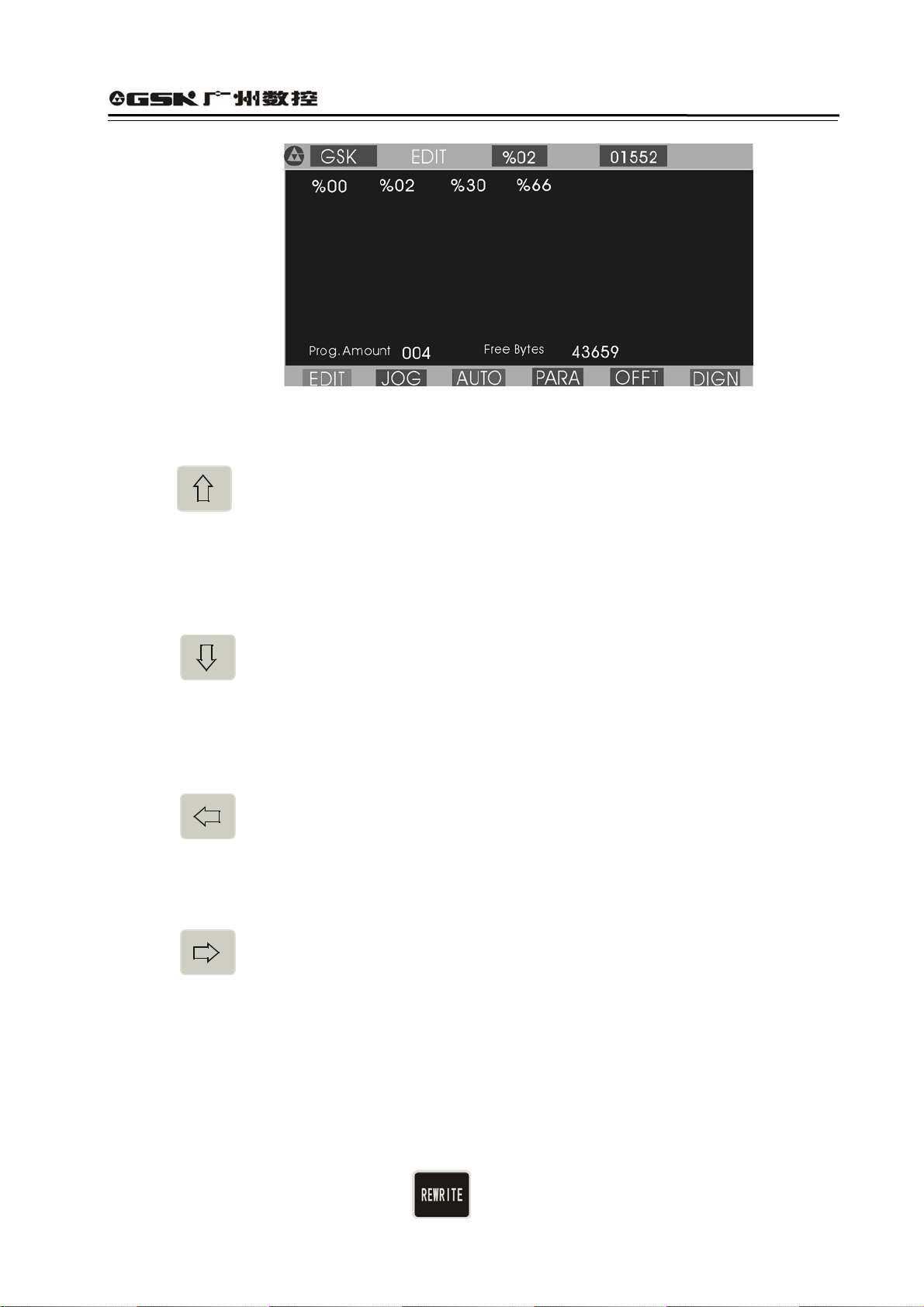

After pressing

to enter EDIT mode, the system displays program names of all part

programs stored in the current program, the byte amount contained in current program and the

available memory bytes of system. See Fig. 2:

15

Page 20

Edit keys in EDIT mode

GSK928TEⅡ Turning CNC System User Manual

Fig. 2 EDIT operating mode

(1)

cursor UP key

The cursor moves to the first character behind the block number of the upper block when the

key is pressed once.

The key being pressed down, the cursor sequentially moves up till the first block of block or

the key is released.

(2)

cursor DOWN key

The cursor moves to the first character behind the block number of the next down block

when the key is pressed once.

The key being pressed down, the cursor sequentially moves down till the last block number

of block or the key is released.

(3)

cursor LEFT key

The cursor moves left one character when the key is pressed once.

The key being pressed down, the cursor sequentially moves left till the first character of

block or the key is released.

(4)

cursor RIGHT key

The cursor moves right one character when the key is pressed.

The key being pressed down, the cursor sequentially moves right till the last character of block

or the key is released.

:

Note

Cursor — prompt identifier to indicate the current editable character position. There are

two states of CNC system.

A. The cursor is displayed to a horizontal line under a character in Insert mode.

B. The cursor is displayed to the pointed character in inverse and highlight. The two

cursors can be switched by

16

.

Page 21

GSK928TEⅡ Turning CNC System User Manual

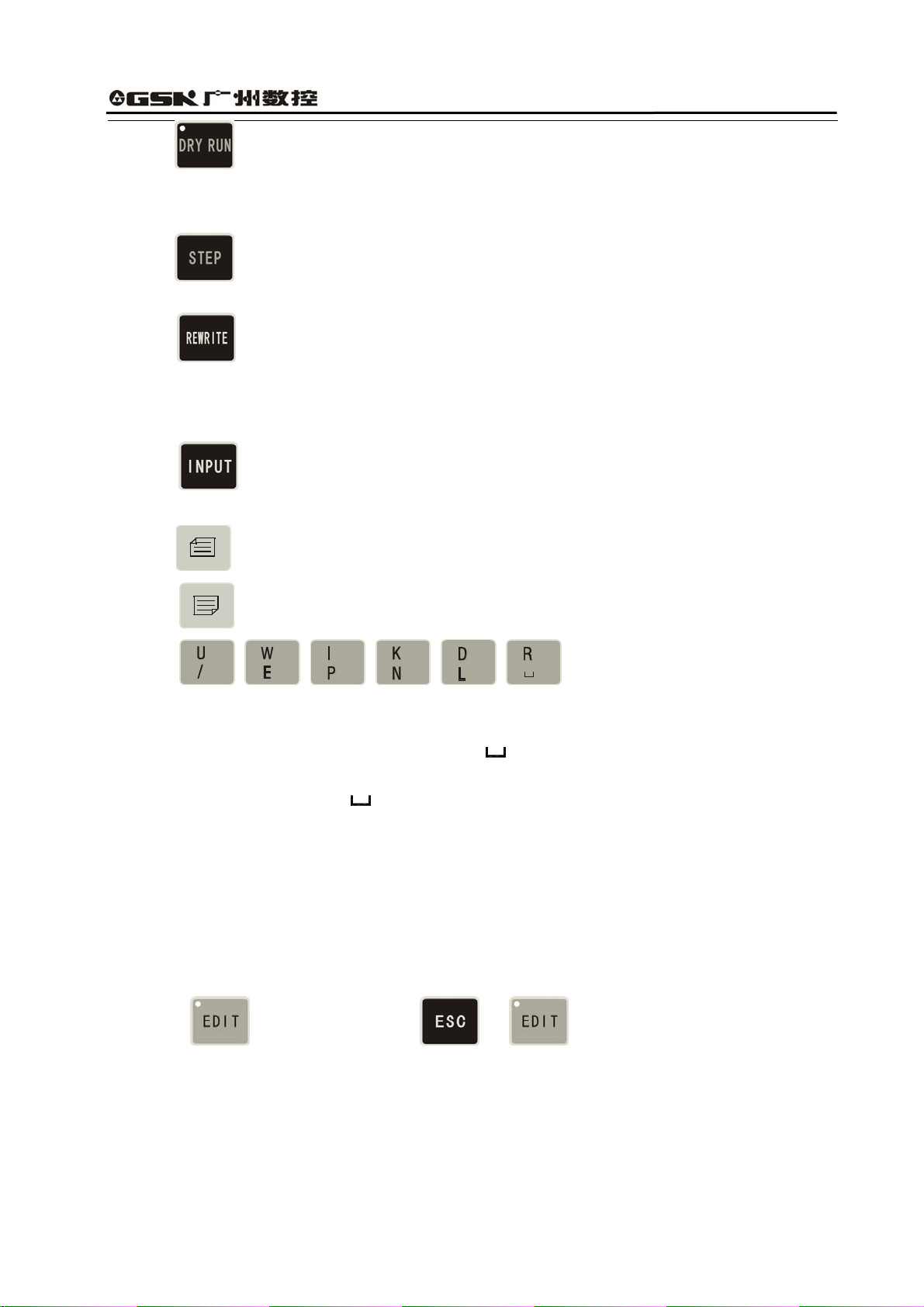

(5) DRY Run key

The cursor moves to the head of block or the head of first word of this block by pressing

continuously.

(6)

STEP/JOG mode

The cursor moves to the behind of the last character of this block.

(7)

REWRITE key

Switch INSERT/REWRITE mode once when the key is pressed once, and the cursor will

change correspondingly. The cursor in Insert mode is a flashing horizontal line, but that in

Rewrite is a character in flashing highlight.

(8)

When the key is pressed once, the program number with 2-digit is input to create a

new program, select or delete the existing program and all programs.

(9) PAGE UP Search the program number and display the content of previous page.

(10) PAGE DOWN Search the program number and display the content of next page.

(11)

Double functions key. Each key has

two definitions. Pressing it once is the first definition value,namely, U W I K D R. The same

key is pressed again, the system will automatically rewrite the previous input value into the

second definition value, namely / E P N L

. If the same key is pressed continuously, the

input value will be switched between the first definition value and the second one. ‘/’ is the

skip block character,‘

’is the space character.

4.3.1 Searching Directory of Part Program

In EDIT mode, the system displays the program name list of all part programs, all part program

amount and the leftover bytes in the part program memory area of CNC system. In EDIT mode,

the system displays the program name list of all part programs, all part program amount and the

leftover bytes in the part program memory area of CNC system.

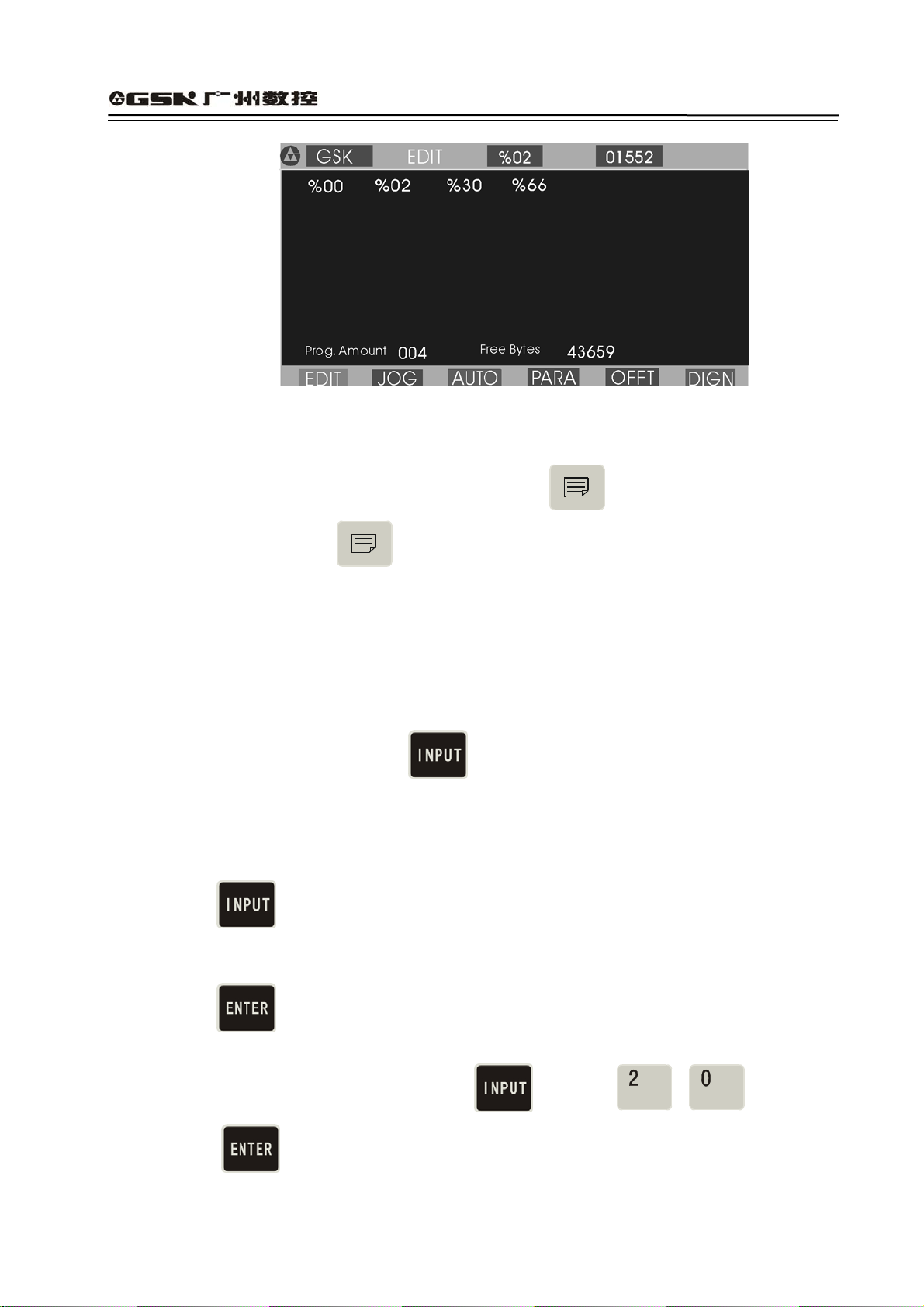

Press in EDIT mode or press or when editing programs as Fig. 3:

17

Page 22

GSK928TEⅡ Turning CNC System User Manual

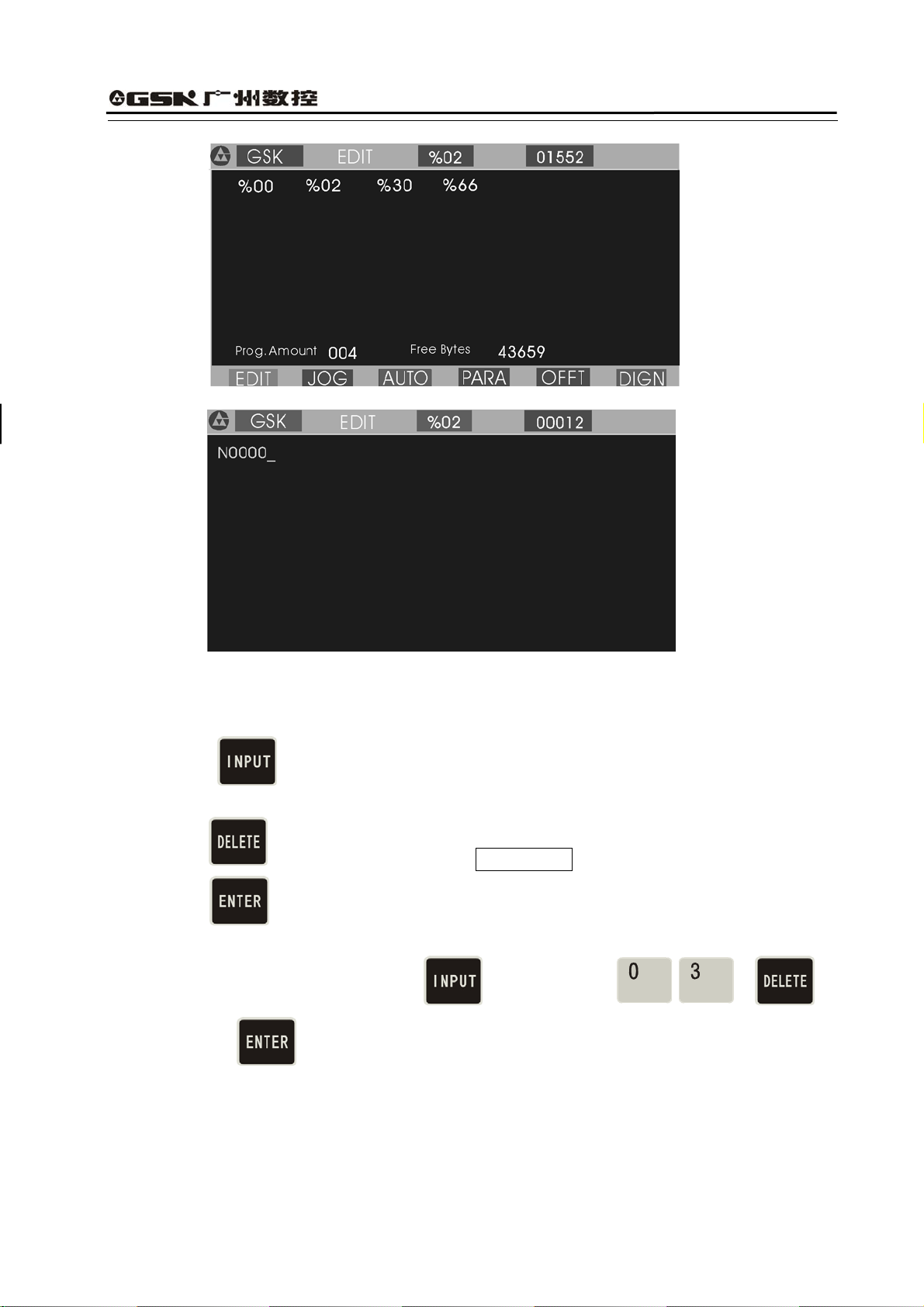

Fig. 3 Searching a part program catalog / creating, selecting and deleting part programs

Most %00~%99 program names are displayed in each screen. When part programs in memory

area are over 100, they are displayed by paging. Press

list of next page and press

to display again the program number list of first page till the

to display the program number

last page.

4.3.2 Creating, Selecting, Deleting, Renaming and Copying a Part Program

The above-mentioned operations can be executed in the state of catalog search of part program or

in the course of editing program content.

The system displays as Fig. 4 when

program.

4.3.2.1 Creating a New Part Program

(1) Press

in the state of catalog search of part program.

(2) Input a new program number which does not exist in the program catalog list with 2-digit by

keyboard. See Fig. 4.

is pressed in the state of catalogue search of part

(3) Press

.

(4) After part programs are created, the system will automatically enter EDIT mode.

Example: Creating %20 program: Press to input and press

. So the program has been created to enter EDIT mode of %20 program. See

Fig. 5:

18

Page 23

GSK928TEⅡ Turning CNC System User Manual

Fig. 4 Inputting a program number

Fig. 5 Creating a new part program

4.3.2.2 Deleting a Part Program

(1) Press

in the state of catalog search of part program.

(2) Input the required deleted program number by keyboard.

(3) Press

and the system will display Confirm ?.

(4) Press to delete the part program which program number has been input; press any

keys to cancel the deletion.

Example: Deleting %03 program: press and then orderly , ,

and

, so the program is deleted as Fig. 6:

19

Page 24

GSK928TEⅡ Turning CNC System User Manual

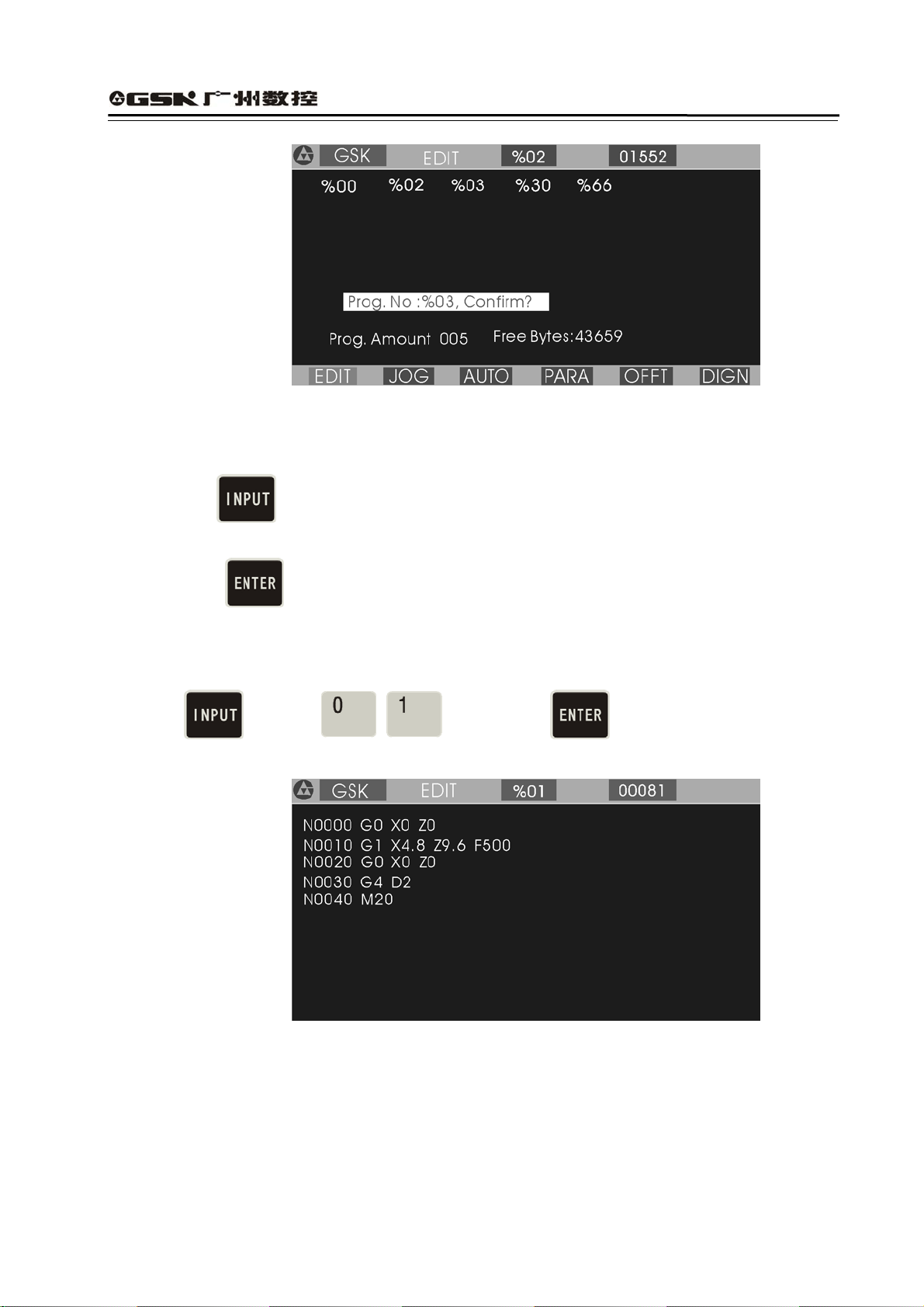

4.3.2.3 Selecting a Part Program

Fig. 6 Deleting a part program

(1) Press

in the state of catalog search of part program.

(2) Input the required selected program number by keyboard.

(3) Press

.

(4) The part program is selected completely and the system displays its content to enter EDIT

mode.

Example: Selecting %01 part program.

Press

See Fig. 7:

to input and then press , so the selection is completed.

:

Note 1

After the first power on, the system enters EDIT mode or there is no content in the

Fig. 7 Selecting a part program

memory area of part program, it will automatically create and select %00 program. The

system will consider %00 as the current program after it be initialized.

Note 2: After the system has selected one program, the required one is changed only by

selecting it. Even if the system powers off, the selected program number cannot be

changed once it is selected.

20

Page 25

GSK928TEⅡ Turning CNC System User Manual

4.3.2.4 Outputting a Part Program

Output part programs from CNC system internal memory to the external computer.

1. Connect the communication cable between CNC system and the computer when power off.

1. After CNC powers on, select EDIT mode.

2. Select the required part program according to Section Operation, 4.3.2.3 Select a part

program (do not select it if the current program is to be sent).

3. Press

, and the system prompts Ready To Send !.

4. Keep the computer in the state of waiting for the receiving(See appendix: GSKR 232

communication program specification).

5. After the computer is ready, if

is pressed, the system will prompt Sending … , and

so the system sends the selected program to the computer.

6. After the sending has completed, the system prompts Finished ! , and any keys are

pressed to return to EDIT mode.

7. Press

to pause the sending.

4.3.2.5 Inputting a Part Program

Input the stored part program from the external PC to CNC system.

(1) Connect the communication cable between CNC system and the computer when power off.

(2)After CNC system powers on, select EDIT mode.

(3)Press

and the system prompts Ready To receive!.

(4) Keep the computer in the state of output. (See Appendix GSKTR communication

program specification ).

(5) After the system is ready, if

is pressed, the system will prompt Receiving … ,

and so the system sends the selected program to the CNC system.

(6) After the receiving is completed ,the system prompts Finished ! and returns to EDIT

mode if any keys are pressed. The system displays the input program name in the catalog

list of part program.

(7) Press

to interrupt the receiving.

Note 1: In the course of inputting part program, CNC system considers the character string “%

XX” contained in the first block of the sent program from the computer as the program

21

Page 26

GSK928TEⅡ Turning CNC System User Manual

name to save. If the sent program name is the same as one in CNC system, the system

cannot display the program name content of the sent program name, and will display it if

the old one is deleted.

Note 2: Send/receive part programs between 2 GSK928TE

Ⅱ

CNC systems according to the

above–mentioned methods. 2 CNC systems separately operate according to part

program input/output ways.

Note 3: It must have the block number of part program when the part program is sent from PC to

CNC system, otherwise there is a mistake.

4.3.2.6 Deleting All Part Programs

Delete all programs once in the program memory area of CNC system.

Press

Input ⑵

Press⑶

in the state of catalog search of part program.

, by keyboard.

,and the system prompts Confirm ?

Press⑷ to delete all part programs. Press other keys, and the system does not execute

the deletion and returns to EDIT mode.

Note: Press and then , release and then to delete all part program.

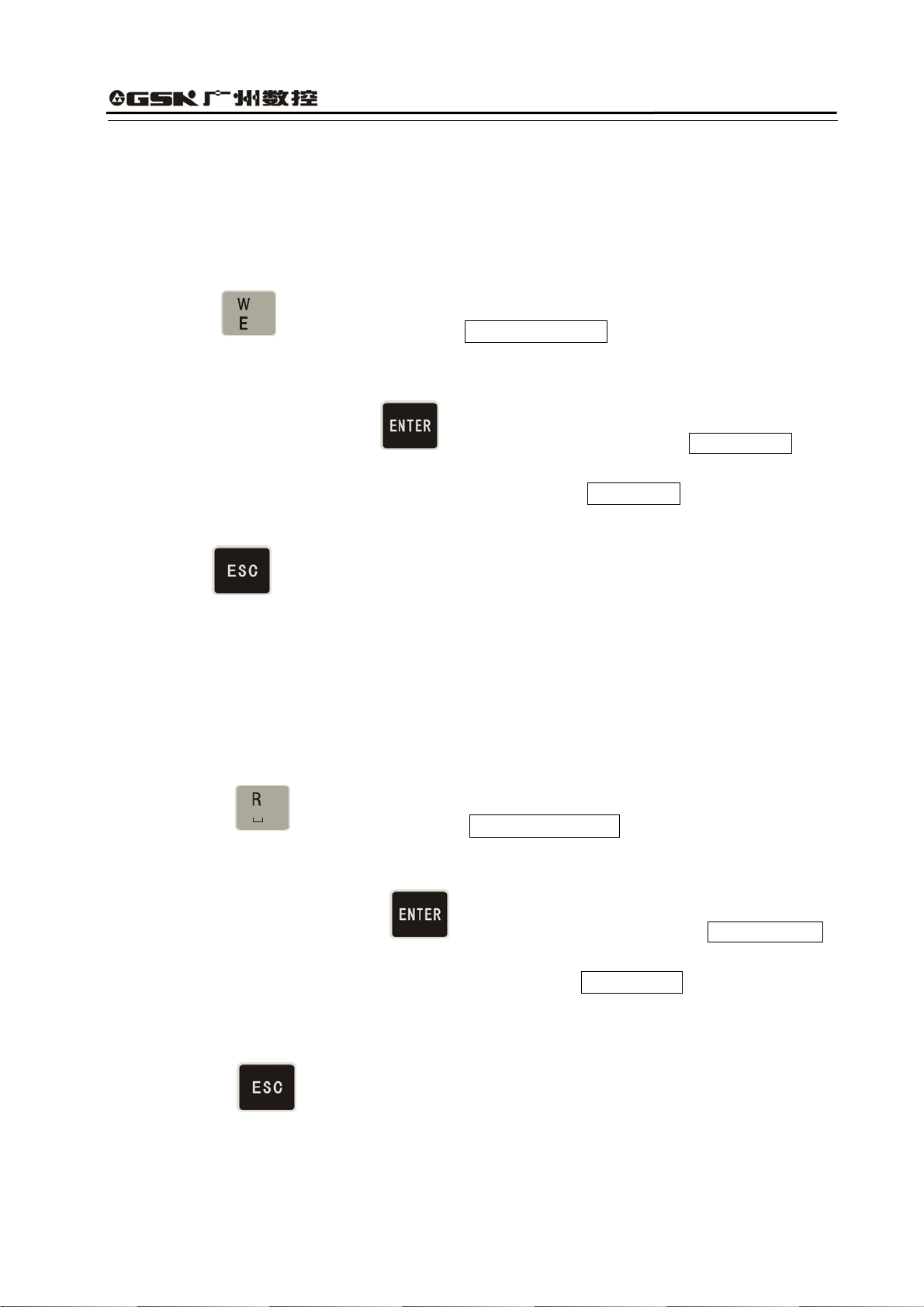

4.3.2.7 Renaming a Part Program

Rewrite the current program name to another one.

Press ⑴

, and the system displays % .

Input the program name which does not exist in the program name list, and press ⑵

to rewrite the current program name to the input program name.

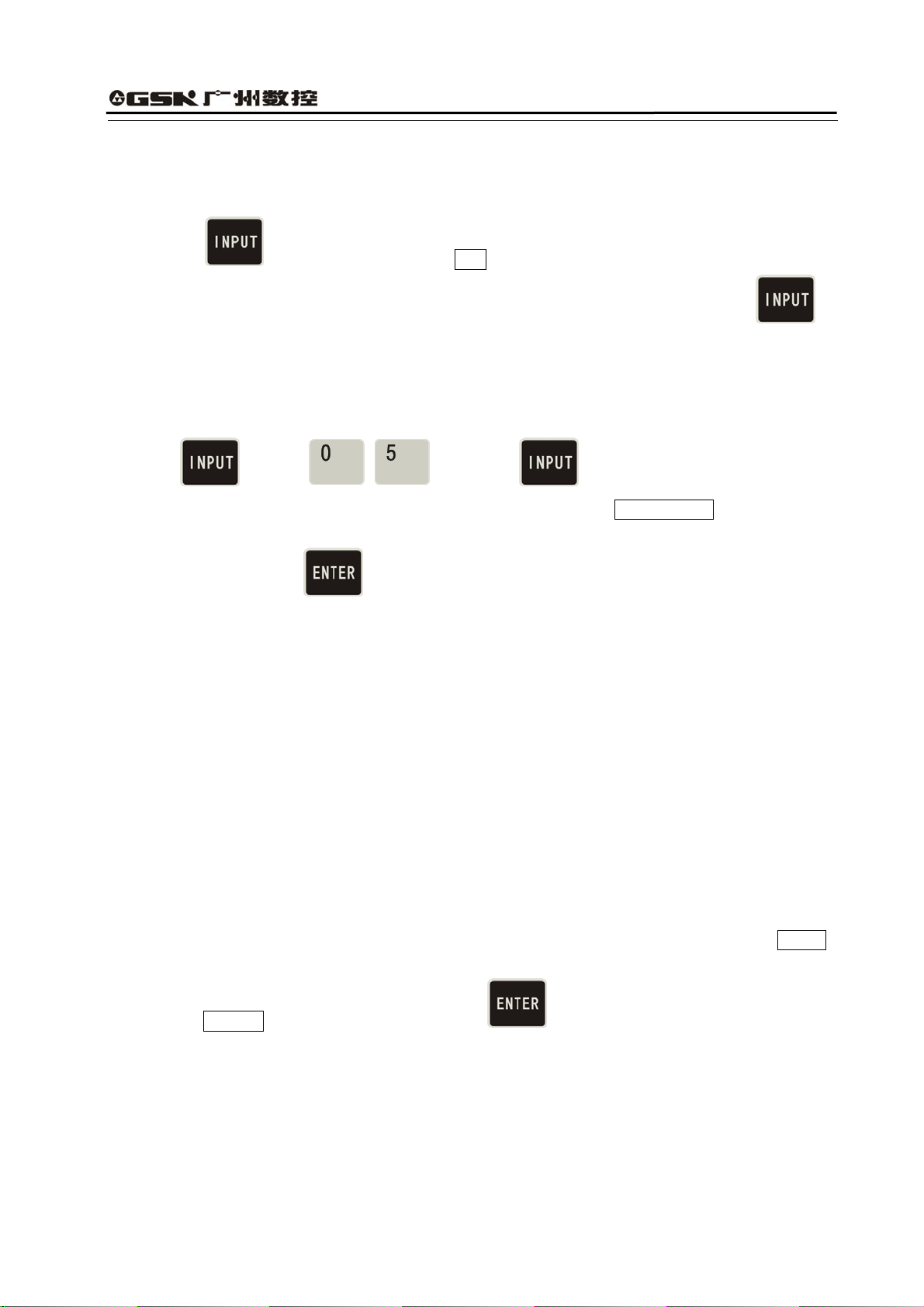

Example: Rename the current program name %00 to % 05.

Press

to input , and press , so the renaming is

completed.

22

Page 27

GSK928TEⅡ Turning CNC System User Manual

4.3.2.8 Copying a Part Program

Copy the content of current program to another new one and consider it as the current one.

Press⑴

, and the system displays % .

In⑵ put a program name which does not exist in the program name list, and press to

copy all contents of current program to the program whose number is input.

The new program name becomes the current one.

Example: Copy program of current program name % 00 to that of %05.

Press

to input , and press , so the copy is completed.

Note: If the input program name exists, the system will prompt File Existed . At the moment,

press any keys to input again the program name which does not exist in the program area,

and then press

, So the copy is completed.

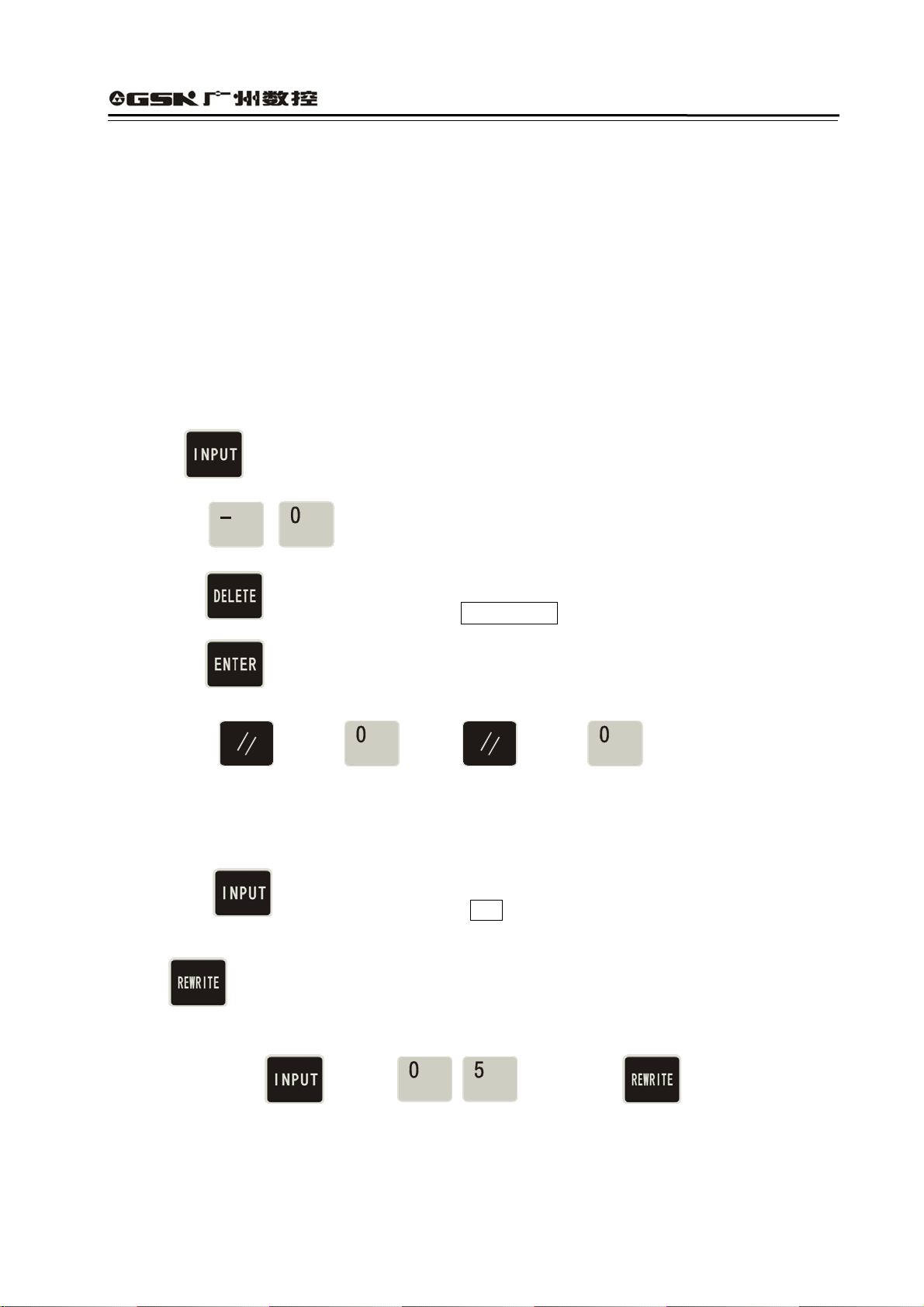

4.3.3 Inputting/Editing Content of Part Program

CNC machining is defined that the system automatically completes the machining of workpiece

according to the part program sequence input by user. Each program is composed of many

blocks and each block consists of a block number, codes and data. Start the machine and gain

the standard workpiece after inputting the part program content according to the technology flow.

EDIT mode of CNC system uses the full-screen and part programs are employed with the file

management mode.

4.3.3.1 Automatically Creating a Block Number

Each part program contains many blocks and each block begins with the block number“ N**** ”;

After a new program is created, the system will automatically generate the first block

number“ N0000 ”; After one block is input and

is pressed, the system will generate the

next block number. In the course of input, the increment of block number is defined by P23.

When a block is inserted, the system will automatically consider the 1/4 integer value of P23 as

the increment to generate the block number. When M98, M97, M91, M92, M93, M94 and others

codes related with the block number are executed, there are no repetitive block numbers in the

program, otherwise the system will alarm. If the above codes are not executed, the block number

can be repeated.

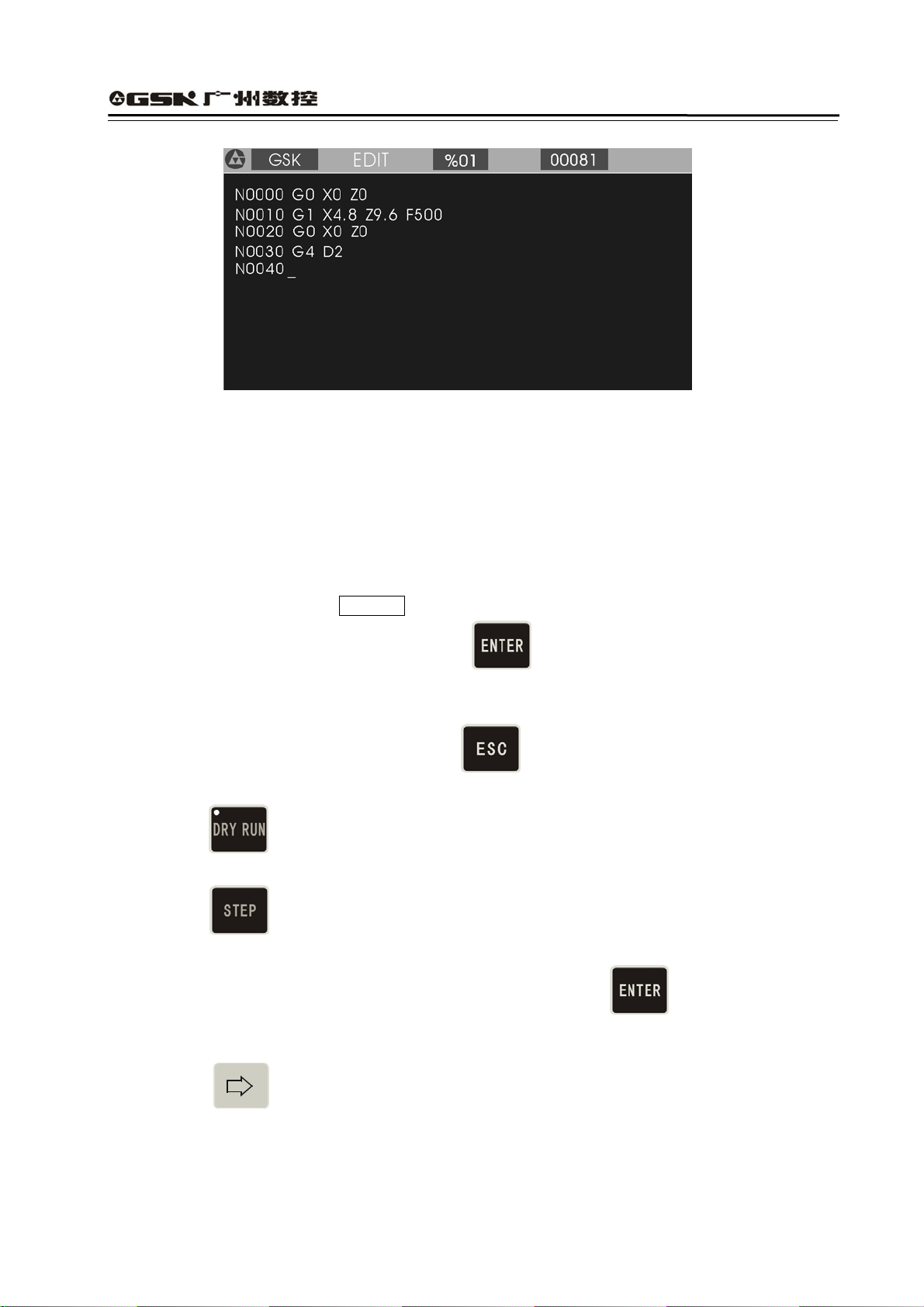

See Fig. 8 for a program generation and inserting a block number in a block (P23 value is 10).

23

Page 28

GSK928TEⅡ Turning CNC System User Manual

Fig. 8 automatically creating block number and inputting program content

4.3.3.2 Inputting Content of Program

EDIT mode of the CNC system is employed with the full screen. Inputting content of program is

executed in EDIT mode.

(1) Create a new program according to the creating method of new part program.

(2) After the block number N0000 is displayed, input the content of one block by keyboard.

(3) Input completely one block and then press .

(4) The system will generate the sequence number of next block and the content of program

should be input continuously.

(5) Input completely the last block and press

to end the input of content of program.

(6) The cursor rapidly moves in the block.

Press

once, and the cursor will point to the head of word; press it again,and the

cursor points to the head of block, and the above steps are executed circularly.

Press

once, the cursor points to the end of block.

(7) Insert a block in the first block.

Move the cursor to the head of the first block and then press .

Note: There are 255 characters at most in one block. When the characters exceed the screen,

pressing

displays one character left.

4.3.3.3 Inserting a Block

Insert one or more blocks between two blocks.

24

Page 29

GSK928TEⅡ Turning CNC System User Manual

(1) Press to move the cursor to the first one of two blocks.

(2) Press

to move the cursor to the behind of last character, or press to move

directly the cursor to the behind of last character.

(3) Press , and the system will generate a new block number between two blocks (the

increment of sequence number is 1/4 integral value of P23, and if there is not enough, the

block number of the next block is rewritten.) and blank one block.

(4) Input the content of required block.

(5) After the content is input,

is pressed to insert blocks. When only one block is inserted,

the operation is not executed.

(6) The inserting is completed.

(7) If the block is inserted before the first block,

is pressed to move the cursor to the

under “N” of the first block, and the system will generate a new block number before the first

block after is pressed.

Note

:

After one block is inserted behind the last block and is pressed, the system will

automatically generate the next block number.

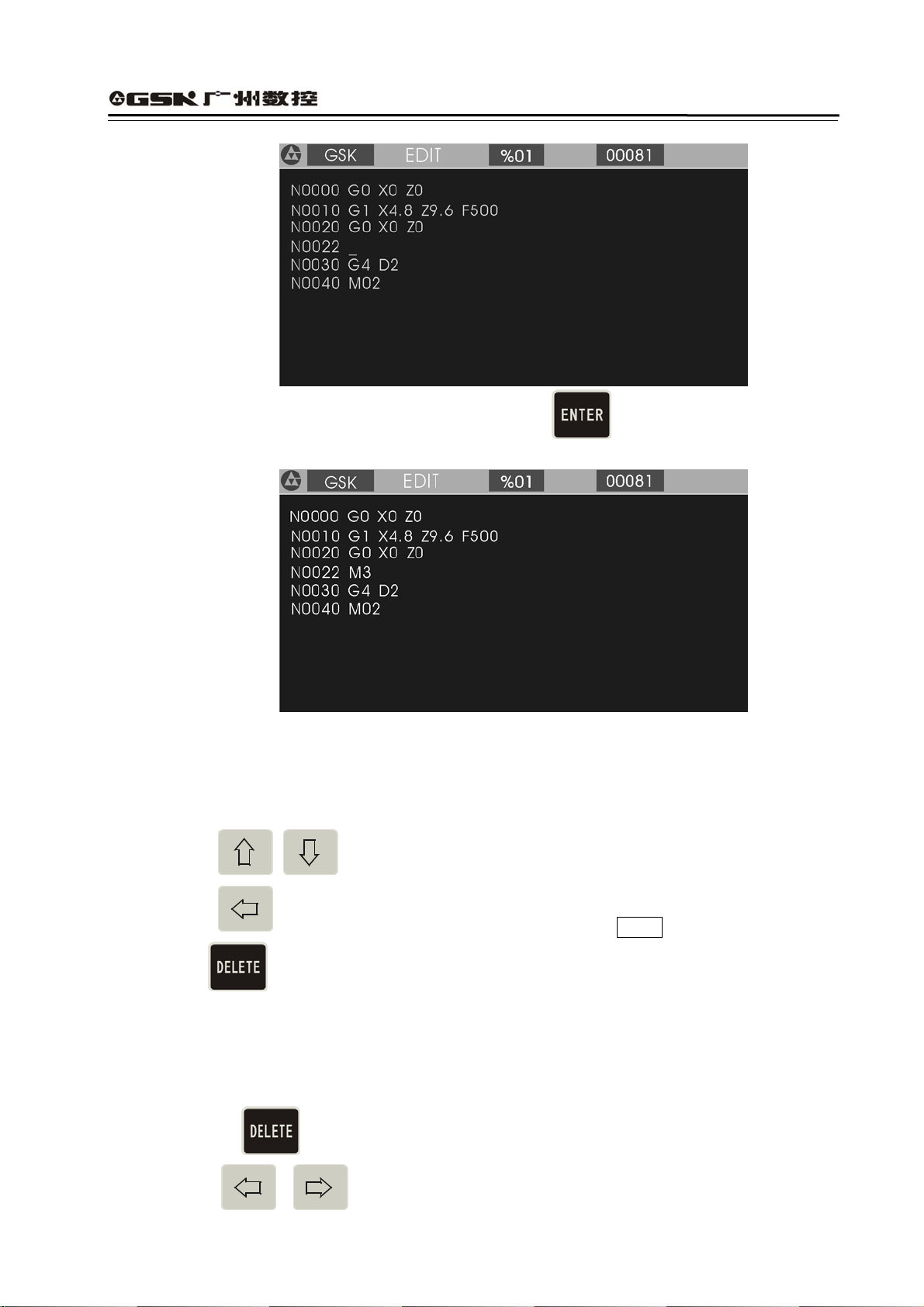

Example:Insert a new block M3 between N0020 and N0030 in Fig. 8 as follows:

(1) Press to move the cursor to N0020 , and press to move the

cursor to the behind of Z0.0.

(2) Press

, and the system will automatically generate one block number and blank a

block to display N0022 as Fig. 9. The cursor points to the first input character of the new

block.

(3) Input

.

(4) The inserting is completed as Fig. 10.

25

Page 30

GSK928TEⅡ Turning CNC System User Manual

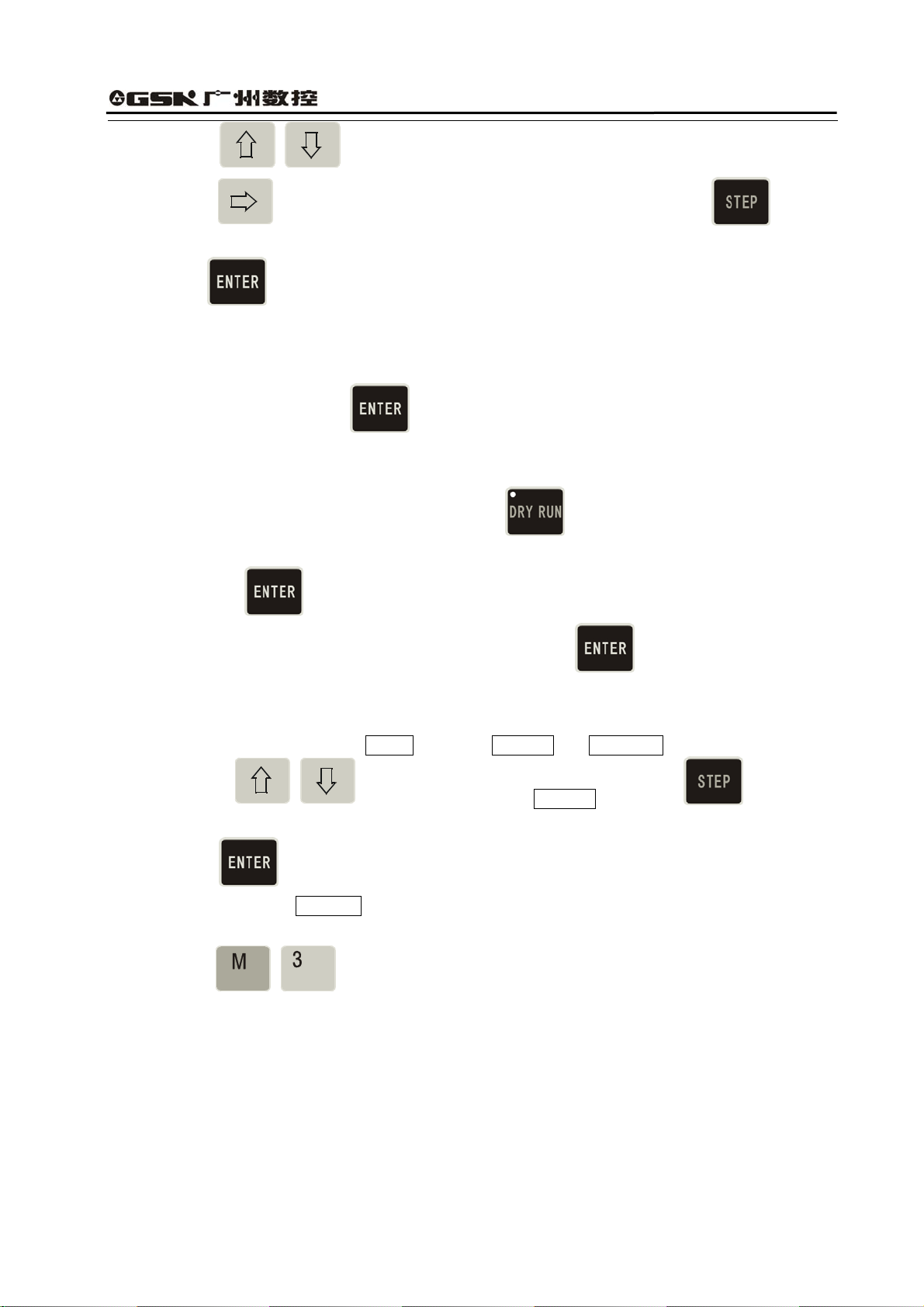

Fig 9. Generating a new block number after

Fig. 10 Input and end the insertion

4.3.3.4 Deleting a Block

Delete all content in one block (including block number).

(1) Press

to move the cursor to the required block.

is pressed

(2) Press

to move the cursor to the under of the address N of required block.

(3) Press .

(4) Delete all content of the selected blocks.

4.3.3.5 Inserting a Word in a Block

(1) Ensure the current input operation is in Insert mode, i.e. the cursor displays to the under of

block. If

(2) Press

26

is not pressed, switch Input to Insert mode.

or to move the cursor to the address character behind the required

Page 31

GSK928TEⅡ Turning CNC System User Manual

inserting position.

(3) Input the inserting content.

(4) Insert the content before the address character pointed by the cursor.

Example:Insert 1 between X and 0 of N0020 G0 X0.0 Z0.0. Move the cursor to

the under of O behind of X ,and input 1 . N0020 G0 X10.0 Z0.0 is displayed.

:

Note

The system requires there is a space between each word (a letter adding the following

digits) in block. The system can automatically judge and generate a space in the course

of inputting when the program is edit, but cannot automatically judge in the course of

inserting, and so the user will input the space to ensure the complete program.

4.3.3.6 Deleting a Word in a Block

Delete the invalid content.

(1) Press to move the cursor to the required address character.

(2) Press

to delete the address character.

4.3.3.7 Modifying a Word in a Block

Adopt two methods to modify an address character of block according to the input mode

(INSERT/REWRITE).

INSERT mode: use the insert and the delete methods together.

(1) Press

,move the cursor to the required address character.

(2) Input the new word.

(3) Delete the invalid word according to the operation of deleting the content of block.

REWRITE mode: modify the character where the cursor points.

(1) Press

to switch to REWRITE mode (the cursor pointing to the address character in

highlight square).

(2) Press

to the required address character.

(3) Input the new address character, and the cursor points to the next one.

Example:Rewrite X of N0020 G0 X0.0 Z0.0 to U .

(1) Switch to Rewrite mode.

(2) Move the cursor to the under of X .

(3) Input U .

27

Page 32

GSK928TEⅡ Turning CNC System User Manual

The end is :N0020 G0 U 0.0 Z0.0.

4.3.3.8 Skipping a Block

Add / before the block number N of block, and the system will skip the block to execute

the next one when executing the program.

(1) Switch to INSERT mode.

(2) Move the cursor to the required block and press

the block number N of block.

(3) Sequentially press two times: the first time, insert before N ; the second

time, insert / before N .

to move the cursor to the under of

4.4 Manual Mode

In “Manual” mode, the motion of slider, the starting/stopping of spindle, cooling ON/OFF, manual tool

change, the program reference point return and the machine zero return in X, Z direction, and other

functions can be completed by operating the keyboard. When P11 Bit3 is set to 1, the actual spindle

speed can be displayed real time; when P11 Bit3 is set to 0, the programming spindle speed is

displayed. When the machine is equipped with the hydraulic chuck and the tailstock, the system can

control the operation of the hydraulic chuck and the tailstock by a pedal switch or external keys. They

keep interlock between the hydraulic chuck, the tailstock and the spindle.

Press

to enter Manual mode. There are JOG Jog mode and JOG Step mode. The initial

mode is JOG. Press to switch between JOG mode and Step mode. If the system is equipped

with the MPG, the system can adopt MPG control mode. JOG mode. is as follows:

Fig.11 JOG mode

4.4.1 Manual JOG

In JOG mode, press down a manual feed direction key, and the slider will continuously

28

Page 33

GSK928TEⅡ Turning CNC System User Manual

traverse along the selected axis and direction. The slider will stop once the key is released.

The traverse speed will be executed according to the selected rapid traverse speed or feedrate.

Meanings of manual feed direction keys in JOG mode are as follows:

X negative key

X positive key

Z negative key

Z positive key

Note 1: Press the feed key in JOG mode, and the slider will traverse when the external spindle

and the feed hold knob are permitted to feed; press the manual feed key, and the

slider does not traverse in the state of feed hold.

Note 2: Even though the feed key is released, because the system automatically

accelerates/decelerates, the slide will continuously traverse not to stop when the

motor runs rapidly. The actual moving distance is determined by max. speed of the

motor, the acceleration/deceleration time and the feedrate override. The more the

acceleration /deceleration time is and the rapider the speed is, the longer the moving

distance of motor decelerating is, otherwise the moving distance is shorter.

4.4.2 Manual(JOG) Step

In STEP mode, the moving distance of slider each time is preset. The slider will traverse one

setting step in the selected coordinate axis and its direction when the manual feed direction key

is pressed once. When the key is pressed down, the slider feeds as one step until the last step

after it is released. The step width value is displayed with black.

Manual Step feed mode as Fig. 12:

Fig. 12 Manual step feed mode

29

Page 34

GSK928TEⅡ Turning CNC System User Manual

Its step width is divided into 6 grades: 0.001 0.01 0.1 1.0 10.0 50.0

Press

to select each step width. The step width degrades one grade if it is pressed once. It

returns to the first grade after the last one is selected.

Note 1: In STEP mode, press

to stop slider traversing. When the key is pressed down,

the slider stops and the unfinished step will not be reserved, and then the feed key is

pressed to execute the next step feed. X step width is the moving distance in diameter.

Note 2: When the manual feed key is pressed, the external spindle and the feed hold knob are

permitted to feed, the slider traverses. When the manual step feed key is pressed, the

slider does not traverse in the state of feed hold.

Note 3: When the slider is traversing and the feed hold knob rotates to the feed hold position,

the slider will decelerate to stop and the unfinished step width will not be reserved.

4.4.3 Manual MPG (Handwheel) Control

In MPG mode, the micro motion of slider is controlled by rotating the manual pulse generator

(MPG). Press

or to enter MPG mode and select the coordinate axis controlled by

the MPG at the same time. See Fig. 13 (taking X axis as example).

Fig. 13 MPG control

z Rotate the MPG after selecting the required coordinate axis to move. The selected axis will

move along with the MPG rotating.

The MPG rotates (CW), the axis moves positively.

The MPG rotates (CCW), the axis moves negatively.

z There are three gears for each motion amount of MPG: 0.001, 0.01, 0.1mm. Press

to switch among them. The system will automatically select 0.1 mm when the previous step

size exceeds 0.1 from STEP mode to MPG mode.

z The system does not display the current speed of the spindle in MPG mode.

30

Page 35

GSK928TEⅡ Turning CNC System User Manual

Note 1: The MPG speed of should be lower than 5 rev/s, otherwise the motor still moves even if

the MPG has stopped, which causes the moving distance does not correspond with the

scale.

Note 2: In MPG mode, all the functions related to the axis moving including JOG, zero return,

incremental/absolute movement are invalid, but S, M, T and other auxiliary functions

are valid.

Note 3: Even if the MPG is shaken, the slider does not traverse when the external spindle and

the feed hold knob forbid the slider to traverse. The spindle speed cannot be changed

real time.

Note 4: When the bigger override (X 100) is selected, the motor will rapidly traverse if the MPG

is rotated rapidly. At the moment, because the system automatically accelerates/

decelerate, the motor will traverse not to stop although the MPG stops. The actual

moving distance is determined by max. speed of motor, the acceleration/ deceleration

time, the feedrate override and the MPG speed. The rapider the speed is, the longer the

acceleration/deceleration time is and the rapider the MPG speed is, the longer the

moving distance of motor decelerating is, otherwise the shorter the moving distance of

motor is.

4.4.4 Manual Feedrate

Select the feedrate override in JOG feed mode.

The feedrate override increases one gear by pressing it once. Max. value :150%.

The feedrate override degrades one gear by pressing it once. Min. value : 0%.

Note 1: In JOG or MPG feed mode, select the feedrate override and then traverse the axis by

pressing manual feed direction key or rotating the MPG.

Note 2: In Step feed mode, select the feedrate override or increase/decrease the feedrate

override in the course of moving to change the feedrate.

Feedrate override (16 gears) as follows:

Feed override

0 0

10 7.5

20 22

30 38

40 60

50 82

60 110

70 180

80 240

90 300

100 420

110 525

31

Feedrate(mm/ min )

Page 36

GSK928TEⅡ Turning CNC System User Manual

120 675

130 850

140 1000

150 1260

4.4.5 Manual Rapid Traverse Speed/Feedrate

Select the rapid traverse speed/feedrate in JOG feed mode. The rapid traverse speed can be

selected by rapid traverse override divided into four gears 25%, 50%, 75%, 100%.

The actual feedrate is defined by the rapid traverse speed and the rapid traverse override:

X actual rapid traverse speed = P06 ×rapid traverse override

Z actual rapid traverse speed = P05 ×rapid traverse override

Selecting the manual rapid feed and the rapid traverse override is as follows:

Press

and rapid traverse override is displayed in a highlight square. Press

manual feed mode. See Fig. 14 for manual rapid traverse mode:

Switch feed/ rapid traverse.

Increase one gear of rapid traverse speed by pressing it once (Max. 100%).

Reduce one gear of rapid traverse speed by pressing it once (Min. 25%).

to switch to manual rapid traverse with the indicator ON. The feedrate override

again to switch to

Fig. 14 Manual rapid traverse

Note 1: In JOG feed mode, select the rapid traverse override and then press the coordinate axis

feed key.

Note 2: In Step feed mode, select the rapid traverse override or increase/reduce the rapid traverse

override in the course of traversing to change the rapid traverse speed.

32

Page 37

GSK928TEⅡ Turning CNC System User Manual

4.4.6 Creating a Workpiece Coordinate

GSK928TE CNC system Ⅱ uses a floating workpiece coordinate which is the benchmark of

toolsetting and related dimension. After the system is installed, the workpiece coordinate must be

created firstly. When the actual position is inconsistent with that of the workpiece coordinate, the

coordinate is created again as follows:

(1) Install the trial workpiece reliably on the machine, and select a tool (usually select the first

one used in machining).

Select the proper spindle speed, and then start the spindle. Traverse the tool in “Manual”

mode, and cut a small sidestep of the workpiece.

X does not move but Z does to the safe position, and stop the spindle.

Measure the diameter of the cut sidestep. Press

to display Setting , and then

press to display Setting X, at last, input the metrical diameter and press ,

so the system creates automatically X workpiece coordinate, if is pressed , the

system cancels the creation of X workpiece coordinate.

(2) Start the spindle again and traverse the tool to cut a face on the workpiece in “Manual”

mode.

(3) Do not move Z but X to the safe position, and stop the spindle.

Select a datum mark (it is a fixed point on the machine, such as the face of chuck, the datum

plane of fixture, which can ensure the created new workpiece coordinate system coincides

with the previous broken one). Measure Z distance from the cut end face to the datum mark.

Press

to display Setting and press to display Setting Z , at last, input

the metrical diameter and press , the system creates automatically Z workpiece

coordinate, if

coordinate.

is pressed , the system cancels the creation of Z workpiece

Clear out the previous system offset after the workpiece coordinate system has been

created as the above-mentioned operation. If the workpiece coordinate system is not

created, there is warp between the current X, Z coordinate values displayed and the actual

tool position. Initialize the system before creating the workpiece coordinate system.

4.4.7 Setting Program Reference Point

The program reference point can be any position on the machine. Once the program reference

point is created, the slider anywhere else will return to this point by executing the program

33

Page 38

GSK928TEⅡ Turning CNC System User Manual

reference point return (G26, G27, G29) or pressing the reference point return keys, at the

moment, cancel the tool compensation and the system offset. There are two methods to modify

the tool offset values(absolute input and incremental input) as follows:

The first method:

Move the cursor to the required tool offset number, press

to display Setting, and then

press to display Program Reference Point ?, at the moment, the point is the program

reference point by pressing . Cancel the setting of reference point by pressing .

There is no responding by pressing other keys.

The second method:

move the cursor to the required tool offset number, directly input the tool offset value and press

to complete the tool offset modification.

After the program reference point set, the previous reference point coordinate values do not be

changed in the new one if the workpiece coordinate is created again, and at the moment, the

program reference point needs to be set again. The initial value of program reference point is

X=150, Z=150.

4.4.8 Incremental Movement of Coordinate Axis

In “Manual” mode, traverse one axis according to the distance and direction input by user instead

of the step size defined by the system. Operations are as follows:

(1) Select the required axis to traverse. Press

displays Move U; press

to traverse Z, the system displays Move W.

to traverse X axis, and the system

(2) Input the required actual moving distance by keyboard. Input X, Z values with negative sign.

X value is in diameter. Press

to delete the wrong input. Press to cancel

the input and return to “Manual” mode.

(3) After inputting the data, press

, and the system displays “Run ?”; press

to traverse the selected axis according to the input distance and the direction.

Press

to cancel the movement and return to “Manual” mode.

(4) The incremental speed is the current selected manual speed.

34

Page 39

GSK928TEⅡ Turning CNC System User Manual

Example:X moves negatively 15.8 mm from the current position as follows:

Press U – 1 5 . 8

, and the system displays Run ?; press , and

X moves negatively 15.8 mm.

4.4.9 Absolute Movement of Coordinate Axis

In “Manual” mode, traverse directly one axis from the current position to the input coordinate

position. Operations are as follows:

1. Select the required axis. Press

to move X axis, and the system displays Move X ; press

to move Z axis, the system displays Move Z.

2. Input the required actual coordinate value to reach the position (X value is in diameter) by

keyboard, and press

to delete the wrong input. Press to cancel the input and

return to “Manual” mode.

3. After inputting the data, press , the system automatically counts the required moving

distance and direction. With Run ?on the screen, press to move to the input coordinate

position. Press to stop and return to “Manual” mode.

4. The absolute speed is the current defined manual speed.

Example: Modify it into 85 if Z coordinate value is 50.

Press Z 8 5 and , the system displays Run ?, and the coordinate is

modified into 85 by pressing .

Note: In “Manual” mode, only one axis can be executed the incremental or absolute movement

at the current selected manual speed

.

4.4.10 MDI Function

In “Manual” mode, M functions can be executed by inputting M codes. Press

to display M,

and then input one or two-digit and press to execute the corresponding M function, or

press

to cancel the execution of M function.

Press ‘M’, ‘0’, ‘3’ to start the spindle rotating (CCW). Input and execute the following M codes:

35

Page 40

GSK928TEⅡ Turning CNC System User Manual

M03 M04 M05 M08 M09 M10 M11 M32 M33 M21 M22 M23 M24. Omit it if

the first digit of M code is zero. The function is the same that in AUTO mode. For the explanations

of M codes, see Programming.

When MDI is error, the system prompts “DATA INVALID” and disappears by pressing

MDI mode, when the data is input or the coordinate is set,

instead of is

pressed, the system prompts “DATA INVALID” to escape. For example: input orderly T22 and

press , the system prompts “DATA INVALID” and escapes.

4.4.11 Manual Spindle Control

In “Manual” mode, the rotation (CCW/CW) and stop of spindle can be controlled by the keyboard

(if the feed/spindle hold knob is set in the position where the spindle is forbidden to rotate, the

spindle cannot be started even if the spindle rotation (CCW/CW) key is pressed. See User

Manual from the machine manufacture for gears of feed hold knob and mark symbols, and

Connection in the manual if the spindle needs to be connected separately).

Spindle rotation (CCW)

Displaying:SPINDLE CCW and LED ON

. In

Spindle stop

Displaying:SPINDLE STOP and LED OFF

Spindle rotation (CW)

Displaying:SPINDLE CW and LED ON

Note: Whether its brake signal is output is defined by MSP bit of P12 when the spindle stops. If

P12 MSP is 1, there is the brake signal when the spindle stops. If MSP is 0, there is

nothing. The time sequence relationships of the spindle brake, starting and stopping

signal are as follows:

1) In pulse control mode,M3, M4, M5, MSP output time sequence:

M3 or M4

M5

MSP

T1

T1

T2

T3

36

Page 41

GSK928TEⅡ Turning CNC System User Manual

2) In level control mode,M3, M4, M5, MSP output time sequence

M3 or M4

M5

T1

T2

MSP

T3

T1:In pulse control mode,M3, M4, M5 signal duration is set by P15;

T2:Setting value: 0.2s;

T3:The output duration of spindle braking signal MSP is set by P16.

4.4.12 Manual Spindle Speed Control

For the machine with the multi-gear motor, press

to control the speed in JOG mode.

(1) Mechanical gear shifting control

When the P12 bit 0=0 (spindle speed controlled by the mechanical gear shifting), the output

mode of gear signal with multi-gear control is selected by P11 Bit4. When P12 bit 0=1, P11

Bit4 is invalid.

P11 Bit4=0: the gear signal is directly output for each bit. Each gear signal corresponds to an

output point from S0 to S4. S0 means that all output is invalid.

P11 Bit4=1: the gear signal is output according to the code. At the moment, the specific

spindle speed is gained from S00 to S15 by the external power circuit decode as

follows:

Code

Output point

S00 S01 S02 S03 S04 S05 S06 S07 S08 S09 S10 S11 S12 S13 S14 S15

or directly input the spindle speed code

S1 ★ ★ ★ ★ ★ ★ ★ ★

S2 ★ ★ ★ ★ ★ ★ ★ ★

S3 ★ ★ ★ ★ ★ ★ ★ ★

S4 ★ ★ ★ ★ ★ ★ ★ ★

“ ” means the output of corresponding output point is invalid.★

Spindle speed control operation:

Input S codes by keyboard to control the spindle speed. Pressing“ S” inputs the required speed

code; press

, and the system outputs the control signal according to the selected S code

mode.

Example: Select the eighth gear spindle speed.

37

Page 42

GSK928TEⅡ Turning CNC System User Manual

Input orderly S 8

, and S8 signal is output with the displaying Prg. Speed S08.

Besides, press to change the spindle speed. If it is pressed once, the spindle speed is

output circularly S1, S2, S3, S4,(P11 bit 4=0) or S0~S15 ((P11 bit 4=1). The spindle speed

switches from S2 to S1 by pressing

three times when the spindle speed only has

two-gear.

(2) Frequency conversion control:

Select the converter to control the spindle speed when P12 Bit =1. Directly input the speed to

control the spindle when the machine is equipped with the converter to control the spindle.

Press

key to display S and input the required speed, then press , the system

converts the speed to 0-0V analog voltage by the output interface to output to the converter.

z To settle problems of the converter with low speed and torque, the system can execute

automatically the three-gear output signal, matching with the converter to ensure the

machine gain the low speed and power torque under the high frequency.

The system

provides three codes: M41, M42, M43 and three parameters: P09, P10, P24.

P09: Reach max. speed when the reduction gear of spindle is positioned on the low gear.

P10: Reach max. speed when the reduction gear of spindle is positioned on the high gear.

P24: Reach max. speed when the reduction gear of spindle is positioned on the medium gear.

M41: Output the low gear signal and use max. speed set by P09.

M42: Output the medium gear signal and use max. speed set by P24.

M43: Output the high gear signal and use max. speed set by P10.

Use M41, M42, M43 to select the required gear of spindle and then input directly the required

speed, and the system will automatically convert the output voltage to control the speed of

converter according to the current position of reduction gear. After power on, the system will

fault M43, i.e. the spindle is positioned on the high gear.

z Display the spindle speed: when P11 Bit 3=0, the programmed spindle speed is displayed

on the screen. When P11 Bit 3=1, the actual spindle speed is displayed.

z Detecting the encoder lines of spindle: the system directly detects the pulse amount per rev

of spindle encoder in “Manual” mode as follows:

Start the spindle and press

, and the system displays the pulse amount per rev of

spindle encoder. The system will prompt Encoder Error if the spindle is not started or the

encoder does not be installed. Press any keys to end the detection and return to “Manual”

mode.

38

Page 43

GSK928TEⅡ Turning CNC System User Manual

Note 1: The spindle speed is controlled by P12 Bit0. When Bit0=0: it is the multi-gear control; when

Bit0=1: it is 0-10V analog voltage control.

Note 2: When P12 Bit0=1, P11 Bit4 is invalid, i.e. the spindle is always controlled by the converter. At

the moment, the output point S1, S2, S3, S4 is controlled by M41, M42, M43, and the

corresponding output point cannot be controlled by the spindle gear shifting key.

4.4.13 Manual Cooling Control

In “ Manual “ mode, press the key to control the cooling ON/OFF.

Cooling ON/OFF

Press

to switch the cooling ON/OFF. Start the cooling, and the system displays the

cooling is ON and LED is ON; stop the cooling, and the system displays the cooling OFF

and LED OFF.

4.4.14 Manual Tool Change Control

This system can control the tool post with 4 tool selections. It also can be extended to 8 tool

selections when T5~T8 tool selection signals are input in code mode. Three kinds of tool

change methods are as follows:

● Set P12 Bit1 to 0 and press

once, and the tool post rotates to the next controllable tool

number and the system displays the corresponding one.

● Set P12 Bit1 to 1, press once and , and the tool post rotates to the next

controllable tool number and the system displays the corresponding controllable tool number. If

is pressed, the tool post cannot execute the tool change when other keys are pressed.

● Input T * O directly by keyboard (* standing for rotating to the required controllable tool number)

and then press , and the tool post rotates to * which is pointing to the controllable tool,

and 0 stands for canceling the tool offset.

Note 1: For the first two methods, do not execute the tool compensation but the tool change, but

for the third, execute the corresponding tool compensation after inputting the tool

compensation number behind * .

39

Page 44

GSK928TEⅡ Turning CNC System User Manual

Example: Input T22: switching to No. 2 tool and executing its compensation.

Input T31: switching to No. 3 tool and executing its compensation.

Input T40: switching to No. 4 tool and executing its compensation.

Input T00: canceling the tool change and the tool compensation.

Note 2: If the rotation tool post is failure, the system displays Tool NO. Lost , which indicates that

the system has not found the corresponding tool number in the specified time.

Note 3: The system is employed with the absolute tool change. When adopting the rotation tool

post, the tool number is fixed on the tool post. It ensures the tool number on the tool post

is the same as the one displayed on the screen.

Note 4: When P11 Bit5 is 1, select the line-up tool post. There is no signal output when executing

the tool change.

Note 5: When using the third method, execute the tool compensation by traversing the slider or

modifying the system coordinate which is defined by P11 Bit6.

Bit6=0: do not modify the coordinate but traverse the slider to execute the tool

compensation.

Bit6=1: do not traverse the slider but modify the coordinate to execute the tool

compensation.

4.4.15 Manual Toolsetting Operations

Usually, several tools are used in the course of machining a workpiece. Owing to the installation

and tool offset, the cutting position to which each tool rotates cannot coincide with that of the tool

nose. To avoid the tool offset in programming, this system set the automatic toolsettig method

according to the tool offset. User does not consider the tool offset but edits the part program

according to the workpiece drawing and the cutting technology, and calls the corresponding tool

compensation in the tool change command during the course of machining (For the usage, see

Program, tool compensation function).

Here are the two methods in this system:

GSK928TE CNC system has set the trial cutting and the fixed point toolsetting, and user can Ⅱ

select anyone. The specifications are as follows:

Trial cutting toolsetting mode:

(Create the workpiece coordinate system before adopting the trial cutting toolsetting mode. The

operations are the same those of ones after setting the workpiece coordinate system or

executing the program reference point return〔program home return〕)

1. Prepare for the toolsetting.

2. Input T00 to cancel the previous tool offset and then execute the toolsetting when the tool

offset number is not zero,otherwise the system will count all values between the previous tool

offset value and the new one (the operations must be executed when the tool is worn and

needed to execute the toolsetting again). If necessary, execute the toolsetting with the tool

40

Page 45

GSK928TEⅡ Turning CNC System User Manual

offset.

3. Select any one tool after the workpiece is fixed on the machine (usually, the tool is the first one

used in machining).

4. Start the spindle with the proper speed. Traverse the tool to cut a little sidestep on the

workpiece in “Manual” mode.

5. X does not move but Z does to the safe position, and stop the spindle.

6. Measure the diameter of sidestep cut. Press

to display Offset X and input the

metrical diameter, and then press to display T * X (* standing for the current

controllable tool number) and press to count X tool offset value and store the value to

X tool offset parameter area to which * corresponds. The offset value can be searched and

modified in OFFSET mode. When T * X is displayed on the screen, input the digit 1~8 and

press to count the tool offset value and store it to X tool offset parameter area to

which the input digit corresponds. Press not

but to cancel the count and the

storage of tool offset.

7. Start the spindle again and traverse the tool to cut a face in “Manual” mode.

8. Z does not move but X does to the safe position, and stop the spindle. Select a point as a

datum mark (usually, the datum mark is a fixed point such as the chuck face, the fixture

datum plane, which is contributed to find easily the previous datum mark when executing the

toolsetting again), and measure X distance from the cut face to the selected datum mark.

Press

to display Offset Z and input the metrical data, and then press to

display T * Z(* standing for the current tool position No.), and last press to count Z

tool offset value and store it to Z tool offset parameter area to which * corresponds. The offset

value can be searched and modified in OFFSET mode. When T *Z is displayed on the

screen, input the number 1~8 and press to count the tool offset value and store it to

Z s tool offset parameter area to which the input number corresponds. Press not

but

to cancel the count and the storage.

9. Change another tool and repeat the above-mentioned operations 1-6 to execute other

toolsetting.

10. If the workpiece coordinate system has not been changed, all toolsettings are executed like

the above-mentioned. The toolsetting is easy and convenient when the tool is worn or

41

Page 46

GSK928TEⅡ Turning CNC System User Manual

needed to tune. Firstly, cancel the tool compensation (T00) or execute program reference

point return (program home) when the tool compensation cannot be input or the counting

data is wrong.

Fixed point toolsetting mode:

1. Select anyone tool (usually it is the first one used in machining) as a reference tool after

installing the trial cutting workpiece on the machine.

2. Start the spindle with the proper speed.

3. Select the proper manual feedrate, traverse the tool to the specified toolsetting point on the

workpiece in the manual feed mode, and stop the movement when the tool coincides with

the toolsetting point.

4. Press

highlight, then press continuously

, and the system display the current tool number and tool offset number in

two times, and the system displays normally the

current tool number and tool offset number, and automatically records the current coordinate

and considers it as the toolsetting reference of other tools (the operation cannot executed if

it is not the reference tool). It is necessary to execute the following operation for the

reference tool.

5. Press

and then (if the tool wears, press to execute the toolsetting

by taking the executed toolsetting tool as a reference), and the system displays normally the

current tool number and tool offset number, counts the offset value of the current

corresponding tool number and stores it to the corresponding parameter area. The offset

value can be searched and modified in OFFSET mode.

6. Traverse the tool to the tool change position from the toolsetting position in “Manual” mode

and rotate the next required one to the cutting position by manual tool change.

7. Repeat the above-mentioned operations 2, 3, 5 until all toolsettings have been completed.

Note 1: When adopting the optic toolsetting instrument, do not start the spindle but fix the

toolsetting point on the cross point of the toolsetting instrument, other operations are

the same as the above-mentioned.

Note 2: The tool offset automatically created by the system can be displayed and modified in

OFFSET mode. See OPERATION, OFFSET mode.

Note 3: If the tool is worn to change or a new one is installed, select another one which has been

executed the toolsetting as the reference tool. Firstly, fix the tool to the selected point on

the workpiece according to the toolsetting of reference tool (as the above-mentioned

operation No. 4 instead of No. 5), then, return to the safe position, last, change the new

tool and repeat the above No. 2, 3, 5 step to execute the toolsetting (the previous offset

value is not always zero).