Page 1

This manual is used for both GSK928TD system and

GSK928TD-L system. However, the contents are described based on

GSK928TD system.

This manual describes the various matters concerning the

operations of this CNC system as much as possible. However, it is

impossible to give detailed descriptions to all the unnecessary or

unallowable operations due to space limitation and product specific

applications. Therefore, the matters not specially described herein

should be considered as “impossible” or “unallowable”.

This user manual is the property of GSK CNC Equipment Co.,

Ltd. All rights are reserved. It is illegal for any organization or

individual to publish or reprint this manual. GSK CNC Equipment Co.,

Ltd. reserves the right to ascertain their legal liability.

Page 2

GSK928TD Turning CNC System User Manual

Preface

Dear users,

It is our pleasure for your patronage and purchase of this GSK928TD

turning machine CNC system (hereafter referred to as “system”) produced

by GSK CNC Equipment Co., Ltd.

This manual covers the use of the system and related precautions.

Warnings

Improper operations may cause unexpected accidents.

Before using the system, please read this manual thoroughly.

Note the following precautions before using the manual:

● Connect the Emergency Stop button of the system. As the emergency

stop input of the system adopts a normally closed contact, the system

will issue an alarm (not a system fault) after Power On if the emergency

button is poorly connected or connected as a normal-open contact.

● Set the program reference point according to the actual installation

position of the tool. If the Program Reference Point Return function is

used before the reference point is set, unexpected accidents may occur.

Special notes: The power supply fixed on/in the cabinet is

exclusively used for the CNC systems developed

by GSK.

It cannot be applied for other purposes. Otherwise

it may result in serious danger.

II

Page 3

Safety and Precautions

Declaration!

z We try to describe all the various matters as much as possible in this

manual. However, it is impossible to give detailed descriptions to all

the unnecessary or unallowable operations because there are too

many possibilities. Therefore, the matters not specially described

herein should be considered as “impossible” or “unallowable”.

z Before installing, connecting, programming and operating the product,

please read this manual and the manual provided by the machine tool

builder carefully, and operate the product according to these manuals.

Otherwise, the operation may cause damage to the product and

machine tool, or even cause personal injury.

z The functions and specifications (e.g., precision and speed) described

in this manual are only for this product itself. For those CNC machine

tools with this product installed, the actual function configuration and

specifications depend on the designs of the machine tool builders.

Warning!

Caution!

Moreover, the function configuration and specifications of the CNC

machine tool are subject to the manual provided by the machine tool

builder.

z Please refer to the user manual issued by the machine tool builder for

All specifications and designs in this manual are subject to change without notice.

the function and meaning of each key on the panel.

III

Page 4

GSK928TD Turning CNC System User Manual

Safety precautions

Please read the safety precautions carefully before connecting and using the

system.

The user must observe the safety operation specifications to ensure personal

and equipment safety.

The user must observe the related safety specifications described in the user

manual issued by GSK. Never attempt to operate the system before you are fully

familiar with its contents.

The user must observe the safety operation specifications about the machine

tool described in the user manual issued by the machine tool builder.

The user must be fully familiar with the contents of this manual and

the one issued by the machine tool builder before operating the

machine tool or controlling the machine tool by editing programs.

Ⅰ Meanings of signs

Warning Failure to observe the specified operation methods or

procedures may cause death.

Caution Improper operation may cause personal injury or equipment

damage.

Note Improper use may cause damage to the equipment and

product.

It reminds the user of important contents.

IV

Page 5

Safety and Precautions

Ⅱ Precautions

1) Inspection and acceptance

Caution ● It is not allowed to use damaged or defective products.

2) Transport and storage

Note ● Guard the products against moisture during transit and storage;

do not climb up or stand on the packages of the products, or

place heavy objects on the packages; do not pile up the

packages more than 5 layers; avoid impact and scratch to the

front panel and LCD screen.

3)Installation

Caution ● Protect the system from sunlight and raindrops because the

Note

4)Connection

shell of the system is not waterproof.

z Prevent dust, corrosive air, liquid, conductors and inflammable

substances from entering the system.

z Keep the system away from inflammable and explosive

substances. Avoid places where there is powerful

electromagnetic interference.

z Install the system firmly in case of vibration.

Warning ● Only qualified persons can connect the system or check the

connection. No damage should be caused to the connecting

wires. Do not press or open the cover of the system with power

on.

V

Page 6

GSK928TD Turning CNC System User Manual

Caution ● The voltage and the polarity of connecting plugs must

accord with the manual.

● Wet hands are dangerous to grasp the plug or the switch.

Note ● The connection must be proper and firm.

● The system must be earthed.

5)Debugging

Warning ● Make sure that the parameters of the system are correct

before running.

● No parameter should be beyond the setting limit in the

6)Operation

manual.

Warning ● Only qualified operators can operate the system.

● Ensure the switch is OFF before connecting the power supply.

Warning ● The operator can not leave the system to work alone.

● Make sure the connection is correct before Power On.

● The emergency stop button should be able to cut off all power

supplies when the system breaks down. Do not switch on/off

the system frequently.

Warning ● Prevent the system from environmental interference.

7)Troubleshooting

Caution ● Unqualified persons cannot repair the system.

Warning ● After an alarm occurs, do not restart the system until the

breakdown is fixed.

VI

Page 7

Safety and Precautions

Ⅲ Safety and precautions for programming

1) Coordinate system

Incorrect coordinate system may cause the machine not to work as expected

even if the instruction is correct, which may injure the operator, and damage the

machine as well as its tool and workpiece.

2) G00 rapid traverse

G00 rapid traverse performs nonlinear motion between its starting point and

end point. Make sure that the path for the tool is safe before G00 rapid traverse

starts, otherwise the tool, the machine and the workpiece may be damaged, and

even the operator injured.

3) Use of this manual

This manual introduces in details all functions of the system, including optional

functions and max. controllable ranges, which are subject to change with the

machine. Therefore, some functions described in this manual may not be

applicable to a specific machine tool. If there is any doubt, please read the

instruction for the machine.

4) Functions of the CNC and machine tool

The functions of CNC machines not only depend on CNC systems, but also

power voltage cabinets, servo systems, CNC and the operator panels. It is hard to

explain all the integrated functions, programming and operation. Do not use

integrated instructions not included in the manual until they have been tested

successfully.

VII

Page 8

GSK928TD Turning CNC System User Manual

Ⅳ Precautions and warnings for operation

1) Before machining a part

First check whether the machine tool works normally. Make sure that the

machine tool works normally by means of trial run before machining, with no

workpiece and tool mounted on the machine tool.

2) Before operating the machine tool

Check the input data of the system carefully before operating the machine.

Incorrect input data may cause the machine to work improperly, and thus damage

the workpiece and the tool, as well injure the operator.

3) Make sure the system input feedrate is suitable for the expected operation.

In general, there is a maximum feedrate for each machine tool. The proper

feedrate varies with different operations. Please refer to the user manual to

determine the maximum feedrate. If the user doest not operate the machine tool at

a proper speed, the machine tool may work incorrectly, thus causing damage to

the workpiece or the machine tool itself, or even cause personal injury.

4) Compensation function

When tool compensation is needed, check the direction and the amount of the

compensation. Improper compensation causes the machine to work wrongly, so

as to damage the workpiece and the tool, as well injure the operator.

5) Manual operation

If the machine is to run in Manual Mode, check the current position of the tool

and the workpiece, and correctly specify the moving axis, moving direction and the

feedrate. During MPG feed, rotating the MPG (previously called electronic

handwheel) with a large override, such as 100%, causes the tool and worktable to

move rapidly. In such a case, the tool and worktable will not stop immediately even

when the MPG is not rotated. Therefore, MPG movement with a large override may

cause damage to the tool or machine, or even injury to the operator.

6) Manual reference point return

VIII

Page 9

Safety and Precautions

If manual reference point return is required, make sure that the machine has

been equipped with the detecting element for the reference point. If the manual

reference point return is performed without installing the detecting element, the tool

keeps moving until it hits the stroke limit, which may cause damage to the machine,

workpiece and tool, or even injury to the operator.

IX

Page 10

GSK928TD Turning CNC System User Manual

Safety responsibility

Manufacturer Responsibility

——Be responsible for the danger which should be eliminated on the design

and configuration of the provided CNC systems

——Be responsible for the safety of the provided CNC and its accessories

——Be responsible for the provided information and advice

User Responsibility

——Be trained with the safety operation of CNC system operation

procedures and familiar with the safety operation.

——Be responsible for the dangers caused by adding, changing or

modifying the original CNC systems and accessories.

——Be responsible for the danger caused by failing to observe the

operation, maintenance, installation and storage in the manual.

This user manual shall be kept by the end user.

Thank you for your support when you are using the products

of Guangzhou CNC Equipment Co., Ltd.

X

Page 11

Contents

introduces the operation methods, technical specifications and

parameter setting for GSK928TD turning machine CNC system.

Ⅰ OPERATION

Ⅱ PROGRAMMING

introduces the instruction codes and program formats of the CNC

system.

ConnectionⅢ

introduces the installation and connection of the CNC system.

Ⅳ Appendix

introduces the supplementary explanations for the installation and

connection of the CNC system.

XI

Page 12

GSK928TD Turning CNC System User Manual

XII

Page 13

Contents

CONTENTS

OPERATION ·································································································································3

CHAPTER ONE OVERVIEW···············································································································3

CHAPTER TWO TECHNICAL SPECIFICATION ············································································5

2.1 928TD Technical Specifications ··········································································································· 5

CHAPTER THREE OPERATION PANEL·························································································7

3.1 LCD························································································································································· 7

3.2 LED Status Indicator ····························································································································· 7

3.3 Keyboard ················································································································································ 7

3.3.1 Character Key································································································································· 7

3.3.2 Operation Mode Select Key·········································································································· 8

3.3.3 Function Key··································································································································· 8

3.3.4 Cycle Start Key and Cycle Pause Key (Feed Hold key) ···························································· 9

3.3.5 Manual Axis Control Key ··············································································································· 9

3.3.6 Manual Auxiliary Function Key ··································································································· 10

3.3.7 Edit Key········································································································································· 11

3.3.8 Reset Key ····································································································································· 12

CHAPTER FOUR SYSTEM OPERATION ······················································································13

4.1 System Power-on, Power-off, Initial State, Modal State, and Safety Protection ·························· 13

4.1.1 Power On ······································································································································ 13

4.1.2 Power Off ······································································································································ 14

4.1.3 Initial State and Modal State of System and Program······························································ 14

4.1.3.1 Initial State and Modal State of System·············································································· 14

4.1.3.2 Initial State and Modal State of Program············································································ 15

4.1.4 Safety Protection·························································································································· 15

4.1.4.1 Hard Limit Protection············································································································ 15

4.1.4.2 Soft Limit Protection ············································································································· 16

4.1.4.3 Emergency Stop Alarm (Stopping System Emergently) ··················································· 17

4.1.4.4 Drive Unit Alarm ···················································································································· 19

4.1.4.5 Other Alarms ························································································································· 19

4.1.4.6 Power Off······························································································································· 20

4.1.4.7 Reset Operation···················································································································· 20

4.2 Operation Mode Selection for CNC System····················································································· 21

4.3 Edit Operation Mode ··························································································································· 21

4.3.1 Part Program Directory Search ·································································································· 22

4.3.2 Selecting, Creating, Deleting, Renaming and Copying a Part Program ································ 23

4.3.2.1 Selecting and Creating a Part Program ············································································· 23

4.3.2.2 Deleting a Part Program ······································································································ 24

4.3.2.3 Deleting All Part Programs··································································································· 24

4.3.2.4 Renaming a Part Program··································································································· 24

4.3.2.5 Copying a Part Program ········································································································· 25

4.3.3 Part Program Communication ···································································································· 25

4.3.3.1 Sending Part Program (CNC→PC, CNC→USB, CNC→CNC) ······································· 25

4.3.3.2 Receiving Part Programs (PC→CNC, USB→CNC, CNC→CNC) ·································· 26

4.3.3.3 Standard Format of TXT Part Program on PC··································································· 27

4.3.4 Inputting and Editing the Contents of Part Program································································· 28

4.3.4.1 Inputting Program Contents································································································· 31

4.3.4.2 Inserting a Block ··················································································································· 32

4.3.4.3 Deleting a Block···················································································································· 32

4.3.4.4 Inserting a Character in a Block·························································································· 33

4.3.4.5 Deleting a Character in a Block··························································································· 33

4.3.4.6 Altering Contents of a Block ································································································ 33

4.3.4.7 Inserting a Macro String ······································································································· 34

4.3.4.8 Storage Capacity for Programs ··························································································· 34

4.3.4.9 Operating No. 253 Program ································································································ 34

4.3.4.10 Operating No. 254 program······························································································· 35

XIII

Page 14

GSK928TD Turning CNC System User Manual

4.3.5 Function of hp5 Key···················································································································35

4.3.5.1 Help for Part Program Command························································································35

4.3.5.2 Help for Obtaining Relative Parameters of Arc ··································································36

4.3.5.3 Rearrangement of Program Line Numbers········································································37

4.3.5.4 Replacement of Strings ········································································································37

4.3.5.5 Cursor Position ······················································································································37

4.3.5.6 Cursor Movement by MPG···································································································37

4.3.6 Compiling a Part Program ···········································································································38

4.3.6.1 hp3 Compiling Command·····································································································38

4.3.6.2 Result Analysis of Program Compilation ············································································38

4.3.6.3 Prompts of Program Compound Check··············································································39

4.4 JOG Operation Mode ··························································································································40

4.4.1 Coordinate Axis Movement··········································································································42

4.4.1.1 JOG movement ·····················································································································42

4.4.1.2 Step Movement······················································································································42

4.4.1.3 MPG Control Movement·······································································································43

4.4.1.4 Selecting Rapid Traverse Rate ····························································································44

4.4.1.5 Selecting Speed for Low-speed Feed ·················································································45

4.4.1.6 Inputting a Word to Move, Setting Feedrate ······································································45

4.4.1.7 Drive Unit Enabling Control··································································································47

4.4.1.8 Alarm Prompts for Coordinate Axis Movement··································································47

4.4.2 Establishing a Coordinate System······························································································48

4.4.2.1 Establishing Machine Coordinate System—Machine Zero Return (Machine Reference

Point Return) ·········································································································································48

4.4.2.2 Establishing Machine Coordinate System— without Machine Zero (No Machine

Reference Point) ···································································································································50

4.4.2.3 Setting Workpiece Coordinate System···············································································50

4.4.2.4 Setting Program Reference Point························································································52

4.4.2.5 Program Reference Point Return ························································································52

4.4.2.6 Recovering Workpiece Coordinate System and Program Reference Point ···················53

4.4.3 Spindle Control Function··············································································································53

4.4.3.1 Spindle Start/Stop Control ····································································································53

4.4.3.2 Spindle S Command – Gear Shift Control ··········································································55

4.4.3.3 Spindle S Command— Rotating Speed Control ································································56

4.4.4 Coolant Control·····························································································································59

4.4.5 Manual Tool Change Control ·······································································································59

4.4.6 Manual Tool Change ····················································································································61

4.4.7 Hydraulic Chuck Control Function ······························································································65

4.4.8 Hydraulic Tailstock Control Function ··························································································67

4.4.9 Other Option Functions················································································································69

4.4.9.1 Triple-color Indicator Control································································································69

4.4.9.2 Lubricant Control ···················································································································70

4.4.9.3 Machine Electricity Delay Power-on Control······································································70

4.4.9.4 Safety Door Detection Function ··························································································70

4.4.9.5 Low-pressure Detection Function························································································71

4.4.10 Viewing Operation Information in Manual Mode·····································································71

4.4.11 Appendix Table····························································································································71

4.4.11.1 List of M function Commands Controlled by MDI Input···················································71

4.5 Auto Operation Mode ··························································································································73

4.5.1 System Working States in Auto Operation Mode······································································74

4.5.2 Explanations for Function Key Operation in Auto Operation Mode ········································74

4.5.2.1 Switching between Single and Continuous Operation······················································74

4.5.2.2 Switching bewteen Dry Run and Machining Run ······························································75

4.5.2.3 Switching between Coordinate Display and Graph Display ·············································76

4.5.2.4 Starting Execution from First Block of Program ·································································76

4.5.2.5 Starting Execution from a Specified Block··········································································76

4.5.3 Display during Program Execution ·····························································································77

4.5.3.1 Definition of Graph Display Data ·························································································77

4.5.3.2 Inputting Graph Display Data·······························································································78

4.5.3.3 Part Count and Timing··········································································································79

4.5.4 Manual Operation for Machine Auxiliary Functions ··································································80

4.5.5 Speed Override Adjustment in Auto Operation Mode ·······························································80

4.5.5.1 Speed Override Adjustment ·································································································80

XIV

Page 15

Contents

4.5.5.2 MPG Speed Control·············································································································· 81

4.5.6 Interruption Operation during Program Execution···································································· 82

4.5.6.1 Interruption with Keys during Program Execution····························································· 82

4.5.6.2 External feed/Spindle hold Knob ························································································· 83

4.5.6.3 External Start and Pause Signals ······················································································· 84

4.5.6.4 Feeding Device Alarm Function ·························································································· 84

4.5.7 Modifying Tool Offset during Program Execution ····································································· 84

4.5.7.1 Methods of Modifying Tool Offsets during Program Execution ········································ 84

4.5.7.2 Modifying Validity of Tool Offsets during Program Execution··········································· 85

4.5.8 Viewing Running Information in AUTO Operation Mode ························································· 85

4.5.9 Return to Program Reference Point in AUTO Operation Mode ·············································· 87

4.5.10 System Reset Key and Emergency Stop Signal Processing in Auto Mode ························ 87

4.5.11 Adjusting Brightness of LCD screen in AUTO, MANUAL Operation Mode·························· 87

4.5.12 Displaying Executing States of M Commands in Auto, Manual Operation Mode··············· 88

4.5.13 Additional Operation in Auto Operation Mode ········································································ 88

4.6 Parameter Operation Mode················································································································ 89

4.6.1 Parameter Overview···················································································································· 90

4.6.1.1 Parameter Authority·············································································································· 90

4.6.1.2 Entering an Operation Level································································································ 90

4.6.1.3 Parameter Management ······································································································ 90

4.6.2 Modifying Parameters·················································································································· 92

4.6.2.1 Searching Parameters ········································································································· 92

4.6.2.2 Modifying Parameters ·········································································································· 92

4.6.3 Parameter hp6 Function·············································································································· 93

4.6.3.1 Parameter Communication and Standard Format ···························································· 93

4.6.3.2 Parameter Extraction and Solidification ············································································· 96

4.6.3.3 System Software Upgrade and Internal Memory Update················································· 97

4.6.3.4 Function Command Authority ······························································································ 98

4.6.4 Description of Parameters··········································································································· 98

4.6.4.1 Parameters of Reference Point, Soft Limit __ P000~P020 ············································ 98

4.6.4.2 Parameters of Zero Return Function__ P021~P026, P109~P111, P406~P407······· 99

4.6.4.3 Parameters of Movement Speed and Acceleration Time __P100~P108, P112~P119

······························································································································································ 101

4.6.4.4 Parameters of Drive and Compensation P200~P209, P411, P1000~P1905············ 103

4.6.4.5 Parameters of Spindle and Coolant __ P300~P317, P326, P329, P341, P410········· 106

4.6.4.6 Parameters of Tool Post __ P318~P325, P408····························································· 109

4.6.4.7 Parameters of Chuck and Tailstock __ P327~P328, P409··········································· 112

4.6.4.8 Bit Parameters of Running and Efficiency__ P400~P401············································ 113

4.6.4.9 Relationship between Path and Parameters of Running and Efficiency ······················ 115

4.6.4.10 Bit Parameters of Safety and Debugging__ P402~P404, P419································ 116

4.6.4.11 Bit Parameter of Motor Driver__ P405 ··········································································· 121

4.6.4.12 Parameters of Other Interfaces__ P412, P330~P332 ············································· 121

4.6.4.13 Other Parameters__ P413~P416, P333 ······································································ 123

4.6.4.14 Parameters of Interface __P500~P556········································································ 126

4.6.4.15 Initial Values of Variables __P600~P639······································································ 127

4.6.4.16 Parameters of G76 __P336~P339················································································ 127

4.6.5 Appendix Parameter List ········································································································ 128

4.6.5.1 Reference Parameter List·································································································· 128

4.6.5.2 Motion Parameter List ········································································································ 129

4.6.5.3 Drive Parameter List··········································································································· 130

4.6.5.4 Auxiliary Parameter List ····································································································· 130

4.6.5.5 Bit Parameter List ··············································································································· 131

4.6.5.6 Interface Parameter List····································································································· 132

4.6.5.7 Variable Initial Value List···································································································· 133

4.6.5.8 Pitch Error Compensation Parameter List ······································································· 134

4.6.5.9 List of Parameters Relative to Command Disabling ······················································· 134

4.6.5.10 List of Parameters Relative to Output Interface Releasing·········································· 135

4.6.5.11 List of Parameters Related to Input Interface Releasing·············································· 135

4.7 Tool Offset Operation Mode ············································································································· 137

4.7.1 Searching Tool Offset Value······································································································ 138

4.7.2 Inputting Tool Offset Data from Keyboard ··············································································· 138

XV

Page 16

GSK928TD Turning CNC System User Manual

4.7.3 Clearing Offset Values of Each Group ·····················································································139

4.7.4 Tool Compensation hp6 Function ····························································································· 139

4.7.4.1 Communication and Standard Format of Tool Offset Data ·············································140

4.7.4.2 Tool Compensation Data Clearing·····················································································141

4.8 Diagnosis Operation Mode ···············································································································142

4.8.1 Searching Interface Signal ········································································································142

4.8.2 Explanations for Display of Interface Signals Names·····························································143

4.8.3 Explanation of Input Interface Diagnosis ·················································································143

4.8.4 Explanation of Output Interface Diagnosis ··············································································143

4.8.5 Output Interface Operation Function························································································144

4.8.6 Spindle Encoder and Spindle Speed Detection·······································································144

4.8.7 Diagnosis hp6 Function ·············································································································144

4.8.7.1 Display of Alarm Record ·····································································································145

4.8.7.2 Searching Alarm Record·····································································································146

4.8.7.3 Alarm Record hp6 Function ·······························································································147

4.8.8 Machine Auxiliary Function Control ··························································································148

CHAPTER FIVE RS232 AND USB SYSTEM COMMUNICATION ·········································149

5.1 RS232 Communication ·····················································································································149

5.1.1 Communication between CNC and PC····················································································149

5.1.2 Communication between CNC and CNC·················································································150

5.2 USB Communication ·························································································································150

5.2.1 USB Operation···························································································································· 151

5.2.2 USB File Directory Requirements·····························································································151

PROGRAMMING····················································································································· 155

CHAPTER ONE PROGRAMMING FUNDAMENTAL································································ 155

1.1 Coordinate Axis and Its Direction ·····································································································155

1.2 Machine Coordinate System, Machine Zero··················································································· 156

1.3 Program Reference Point ·················································································································156

1.4 Machine 2nd, 3rd Program Reference Point ··················································································156

1.5 Workpiece Coordinate System·········································································································156

1.6 Programming Coordinate··················································································································157

1.6.1 Absolute Coordinate Values······································································································157

1.6.2 Relative Coordinate Values ·······································································································157

1.6.3 Compound Coordinate Values ··································································································158

1.7 Diameter Programming and Radius Programming········································································158

1.8 Interpolation Function························································································································158

CHAPTER 2 PROGRAM CONFIGURATION ·············································································· 160

2.1 Character ············································································································································160

2.2 Word····················································································································································160

2.3 Block Number····································································································································· 161

2.4 Block····················································································································································161

2.5 Block Skip Symbol and Comment····································································································162

2.6 Program Structure······························································································································163

CHAPTER 3 MSTF COMMANDS AND FUNCTIONS ······························································· 164

3.1 M — Auxiliary Function (Command List) ························································································· 164

3.1.1 M00 — Pause ·····························································································································165

3.1.2 M02 — End of Program ············································································································· 165

3.1.3 M20 — Program End Cycle Machining····················································································165

3.1.4 M30 — End of Program, Spindle OFF, Cooling OFF······························································166

3.1.5 M03, M04, M05 —Spindle Control····························································································166

3.1.6 M08, M09 —Coolant Control·····································································································166

3.1.7 M10,M11, M12 — Clamping/Releasing Chuck, Cancelling Chuck Output Signal············ 167

3.1.8 M32, M33 — Lubricating ON/OFF····························································································167

3.1.9 M41, M42, M44, M43 — Spindle Automatic Gear Shift Control ············································167

3.1.10 M78, M79, M80 —Tailstock Advancing and Retracting, Tailstock Output Signal Cancelling

··································································································································································168

3.1.11 M96 —Calling Cycle Execution·······························································································168

3.1.12 M97 — Program Transfer ········································································································169

3.1.13 M98, M99 — Subprogram Call and Subprogram Return·····················································169

XVI

Page 17

Contents

3.1.14 M21, M22, M23, M24 —User Output Control ······································································· 171

3.1.15 M91, M92, M93, M94 — User Input Control ········································································· 171

3.1.16 M60~M74 — Custom Command ··························································································· 172

3.2 M81, M82, M83—User Input/Output Condition Control ································································ 172

3.2.1 M82— Output Control and Detection······················································································· 173

3.2.2 M81—Control According to Input Signal State········································································ 173

3.2.3 M83—Control According to Output Signal State····································································· 174

3.3 S function — Spindle Function········································································································· 174

3.3.1 Spindle Motor Controlled by Gear Shift ··················································································· 174

3.3.2 Variable-frequency Motor Controlled by Speed······································································ 175

3.4 T Function — Tool Function ············································································································· 176

3.4.1 Tool Offset Execution Mode-Moving Slide Carriage······························································· 176

3.4.2 Tool Offset Execution Mode- Modifying Coordinates····························································· 177

3.5 F Function — Feedrate Function ······························································································· 177

CHAPTER FOUR G COMMANDS AND FUNCTIONS ······························································180

4.1 G00 — Rapid Positioning G00········································································································· 180

4.2 G01 — Linear Interpolation·············································································································· 182

4.3 G02, G03, G05 —Circular Interpolation·························································································· 183

4.4 Thread Cutting Command················································································································ 188

4.4.1 G33 — Thread Cutting ·············································································································· 188

4.5 G32 —Tapping Cycle ························································································································ 196

4.6 G50 — Setting Workpiece Coordinate System·············································································· 197

4.7 G51 — Recovering Workpiece Coordinate System Setting························································· 198

4.8 G26 — X, Z Reference Point Return······························································································· 199

4.9 G28 — Return to Machine Zero (Machine Reference Point) ······················································· 200

4.10 G30 — 2nd, 3rd Program Reference Point Return ········································································ 201

4.11 G04 — Timing Delay······················································································································· 201

4.12 G96 —Constant Surface Speed Control, G97 —Constant Surface Speed Cancel ················· 202

4.13 Single Canned Cycle ······················································································································ 205

4.13.1 G90 —Outer Cylinder Face Turning Cycle (Axial Cutting Cycle) ······································· 205

4.13.2 G92 —Thread Cutting Cycle ·································································································· 208

4.13.3 G94 — Inner/outer End (Taper) Face Turning Cycle ··························································· 216

4.13.4 G74 —End Face Deep Hole Machining Cycle ····································································· 219

4.13.5 G75 —Grooving Cycle ············································································································ 221

4.14 Compound Cycle····························································································································· 223

4.14.1 G71 —Axial Plane Rough and Finish Command Group ····················································· 223

4.14.2 G72 —End Face Roughing/Finishing Command Group ····················································· 228

4.14.3 G73 — Closed-loop Cutting Cycle Command Group ·························································· 232

4.14.4 G76 —Multiple Repetitive Threading Cycle ·········································································· 236

4.15 G22, G80 —Program Local Cycle································································································· 241

4.16 G98 — Feed per Minute, G99 — Feed per Revolution ······························································ 243

4.17 G31 — Skip Function······················································································································ 244

4.18 G66 -Memorizing Current Coordinates, G67-Return to Memorized Coordinates···················· 246

4.19 Appendix: G function and Its Explanation Table (Table 4-3)······················································· 246

4.20 Appendix:G and Its Relative Parameter Explanation (Table 4-4)············································ 248

CHAPTER FIVE GENERAL PROGRAMMING RULES AND EXAMPLES ···························249

5.1 General Programming Rules············································································································ 249

5.2 Programming Rules for Commands in One Block········································································· 250

5.3 Command Execution Sequence ······································································································ 251

5.4 Programming Example ····················································································································· 253

5.4.1 Outer Machining Example········································································································· 253

5.4.2 Thread Machining Example ······································································································ 254

5.4.3 Compound Machining Example ······························································································· 257

CHAPTER SIX ALARM MESSAGE·······························································································261

6.1 Emergency Stop Alarm ····················································································································· 261

6.2 Alarm Table in PARAMETER, OFFSET Operation Mode (i.e. E001~E009)······························· 261

6.3 Table of Alarm in Edit Operation Mode(i.e. E100~ E199) ····························································· 263

6.4 Table of Alarms Relative to Program (i.e.E200~ E299, E600~ E699) ········································· 265

6.4.1 Alarm in Program Command (i.e. E200~299)········································································· 265

6.4.2 Alarm in Program Comprehensive Check Alarm (E600~E699)············································ 268

6.5 Table of Alarm in JOG or AUTO Operation Mode (i.e. E300~ E499)··········································· 270

XVII

Page 18

GSK928TD Turning CNC System User Manual

6.5.1 Alarm in Executing Relative Operations (i.e. E300~E399) ···················································· 270

6.5.2 Relative Alarm in Executing Statement (E400~ E499) ···························································274

CHAPTER SEVEN STATEMENT PROGRAMMING (not for GSK928TD)··························· 276

7.1 Variable ···············································································································································276

7.1.1 Variable Expression Method······································································································ 276

7.1.2 Classification of Variable············································································································276

7.1.2.1 Command Variable··············································································································277

7.1.2.2 Pointer Variable ···················································································································279

7.1.2.3 Interface Variable ················································································································280

7.1.2.4 Keyboard Scan Register r5001··························································································281

7.1.2.5 Display Window Register r5002 ························································································282

7.1.2.6 Display Value Register r5003·····························································································285

7.1.2.7 Graph Refresh Register r5004···························································································285

7.1.2.8 Program Control Register r5008························································································286

7.1.2.9 System Special Variable Group 1······················································································287

7.1.2.10 System Special Variable Group 2···················································································· 288

7.2 Statement············································································································································289

7.2.1 Assignment Statement ···········································································································289

7.2.2 Conditional Statement ············································································································290

7.2.3 Statement Program Example ································································································290

7.3 Process Monitoring and Execution ··································································································292

7.3.1 Process Monitor Description (r7000)····················································································292

7.3.2 Process Monitor ON/OFF······································································································293

7.3.3 Monitor Program Example·····································································································295

7.3.4 Pulse Monitoring (r7100) ·······································································································297

7.3.5 Pulse Monitoring Programming Example ············································································298

7.3.6 Variable Transfer Register (r7900) ·······················································································299

7.4 Attached List·······································································································································300

7.4.1 ASCII List·································································································································300

7.4.2 Corresponding List between Common Colors and Code Values······································300

CHAPTER EIGHT CUSTOMIZED COMMAND PROGRAMMING ········································· 301

8.1 Customized Command······················································································································301

8.1.1 Programming Format of Customized Command ····································································301

8.2 Customized Command Library (P254)····························································································301

8.2.1 Programming Format and Debugging of Customized Command Library ···························· 302

8.2.2 Use of Customized Command Library ·····················································································302

8.3. Foot Switch of M61 command·········································································································303

CONNECTION··························································································································307

CHAPTER ONE INTERFACE OVERVIEW·················································································· 307

1.1 Rear Cover Interface Layout ············································································································307

1.2 Overall Frame·····································································································································308

CHAPTER TWO INTERFACE TABLE·························································································· 309

CHAPTER THREE CNC DEVICE CONNECTION ······································································311

3.1 Communication Interface ··················································································································311

3.1.1 USB Interface······························································································································ 311

3.2 X1, X2 Interface ································································································································· 311

3.2.1 X1, X2 Interface Signal Definition····························································································· 311

3.2.2 Connection Method of Input Signal ··························································································314

3.2.3 Connection Method of Output Signal ·······················································································316

3.2.4 Input/Output Signal Specification······························································································318

3.3 Machine Zero Return Function and Connection·············································································318

3.4 Tool Change Control Function and Connection··············································································321

3.4.1 Definition of Tool Change Control Signal ·················································································321

3.4.2 Signal Connection ······················································································································321

3.4.3 Function Description ··················································································································321

3.4.3.1 Tool Change Mode 0···········································································································322

3.4.3.2 Tool Change Mode 1···········································································································322

3.4.3.3 Tool Change Mode 2···········································································································323

3.4.3.4 Tool Change Mode 3···········································································································323

XVIII

Page 19

Contents

3.4.3.5 Tool Change Mode 4 ·········································································································· 325

3.4.4 Tool Signal Check and Parameter Setting ·············································································· 326

3.4.4.1 Default mode (P408_d7=0) ······························································································· 326

3.4.4.2 Table Checking Mode········································································································· 327

3.5 X3 Motor Interface····························································································································· 328

3.5.1 Signal Definition ························································································································· 328

3.5.2 Technical Specifications ············································································································ 329

3.5.3 Equivalent Circuit ······················································································································· 329

3.5.3.1 Drive Unit Alarm Signal Xalm, Zalm ················································································· 329

3.5.3.2 Enable Signal Xen, Zen ····································································································· 330

3.5.3.3 Pulse Signal and Direction Signal····················································································· 330

3.5.4 Connection between CNC System and Drive Unit of Compound Stepper Motor ··············· 330

3.5.5 Connection between CNC and Drive Unit of Reaction Stepper Motor································· 333

3.5.6 Connection between CNC and AC Servo Drive Unit ····························································· 335

3.5.7 Connection Diagram between CNC and Panasonic Drive Unit············································ 337

3.5.8 Connection Diagram between CNC and Yaskawa Drive Unit··············································· 338

3.6 X4 Spindle Interface·························································································································· 339

3.6.1 Signal Definitions ······················································································································· 339

3.6.2 Converter Technical Specification ···························································································· 339

3.6.3 Encoder Technical Specifications····························································································· 340

3.6.4 Connection Diagram of Converter Analog Voltage Interface················································· 340

3.6.5 Encoder Interface Principle······································································································· 340

3.6.6 Encode Interface Connection Diagram···················································································· 340

3.7 X5 MPG Interface······························································································································ 341

3.7.1 Signal Definition ························································································································· 341

3.7.2 MPG Interface Principle ············································································································ 341

3.7.3 MPG Interface Connection Diagram ···················································································· 341

CHAPTER FOUR USE AND MAINTENANCE INFORMATION ···············································342

4.1 Ambient Condition····························································································································· 342

4.2 Earthing ·············································································································································· 342

4.3 Power Supply Requirements············································································································ 342

4.4 Protection ··········································································································································· 342

4.5 Use after Long-time Unuse ·············································································································· 342

Appendix 1 CNC System Electrical Symbol Explanations ··················································345

Appendix 2 CNC System Tool Post Controller Circuit Method Layout····························346

Appendix 3 Interface Schematic Circuit····················································································347

Appendix 4 External Control Connection Diagram································································350

Appendix 5 GSK928TD CNC System Appearance Installation Dimension ·····················351

Appendix 6 GSK928TD-L CNC System Appearance Installation Dimension ·················352

Supplementary Explanation·············································································································353

1. Modified Functions and Commands······················································································353

1.1 Newly-added Interface Parameter P538, P539, P540—Z/X/Y Move Limit································· 353

1.2 Newly-added Interface Parameter P351 — Alarm of Lubrication Check before Machining ····· 353

1.3 G76 Command Modification············································································································· 353

1.4 Diagnosis Operation Mode··············································································································· 354

1.5 AUTO Operation Mode····················································································································· 354

2. Newly-added M Command: M50—M59, M84········································································354

2.1 Customized Commands Expanded to M50-M74 from M60-M74.················································ 354

2.2 Newly-added Function of Calling M50-M72 before Machining····················································· 354

2.3 M84 — Input Signal Check within a Specified Time······································································ 355

3. Newly-added G Commands and Functions ·········································································355

3.1 G38 — Rigid Taping, Threading ······································································································ 355

3.2 G21, G20— Metric, Inch Input ········································································································· 357

3.3 Detailed Explanation of Metric/Inch Switch ···················································································· 358

3.3.1 Metric/Inch Switch Parameter······························································································· 358

XIX

Page 20

GSK928TD Turning CNC System User Manual

XX

Page 21

Chapter One Overview

Ⅰ

OPERATION

Ⅰ OPERATION

1

Page 22

Ⅰ

OPERATION

GSK928TD Turning CNC System User Manual

2

Page 23

Chapter One Overview

Ⅰ

OPERATION

CHAPTER ONE OVERVIEW

The GSK928TD system employs a 32-bit high performance CPU and a complex

programmable logic device of very-large-scale programmable array integrated circuits

as its control center, thus realizing the movement control with a μm-level precision.

The product, equipped with a true color LCD with resolution of 480×234, uses the

international standard NC language, also known as ISO codes, to write part programs.

It is characterized by the full-screen program editing, Chinese/English operation

interface, real-time track and display of the part graph and simple operation as well as

the high cost performance. It can be matched with stepper motors or AC servo drive

units, and by means of programming, it is capable of machining outer cylinders, end

faces, grooves, tapers, circular arcs, threads, etc.

Technical specifications

9 Link axes: 2 (X, Z axes), short linear smooth interpolation at a high speed realizable;

Interpolation precision: 0.001mm, max. rapid traverse: 15m/min

9 Flexible and convenient programming

9 USB interface communication, fast and easy to operate

9 Least command increment: 0.001mm, electronic gear ratio:(1~99999)/(1~99999)

OPERATION

9 Realizing controls like automatic tool post, spindle automatic gear shift.

9 Backlash compensation, tool length compensation

9 Exponential acceleration/deceleration control, applicable to high-speed and high-precision

machining

9 Tapping function

9 Available to cut inch/metric thread, end face thread, continuous thread; with thread high-speed

run-out

9 Full-screen part program editing, capable of storing 255 programs; a capacity of 4 MB for No.

253 program

9 True color LCD with a large screen, color profiles selected by parameters

9 Real-time tracking and display of MSTF status during processing

9 Multi-level passwords, convenient for equipment management

9 Parameter backup function

9 Communication of parameters and tool compensation data

9 Support for two-way communication between CNC and CNC, and between CNC and PC; CNC

software upgraded through a serial port

9 Support for two-way communication between CNC and USB; CNC software upgraded through

USB

3

Page 24

GSK928TD Turning CNC System User Manual

Ⅰ

9 Installation dimension, electrical characteristics and part of interfaces compatible with

GSK928TC turning machine NC system

Note

1. Neither the parameters nor the functions of Y axis described in this manual are valid.

2. The interface RS232 of the system has not been led out; to lead it out from the inside of the

OPERATION

system, special tools and professional technician are required.

4

Page 25

Chapter Two Technical Specification

Ⅰ

CHAPTER TWO TECHNICAL SPECIFICATION

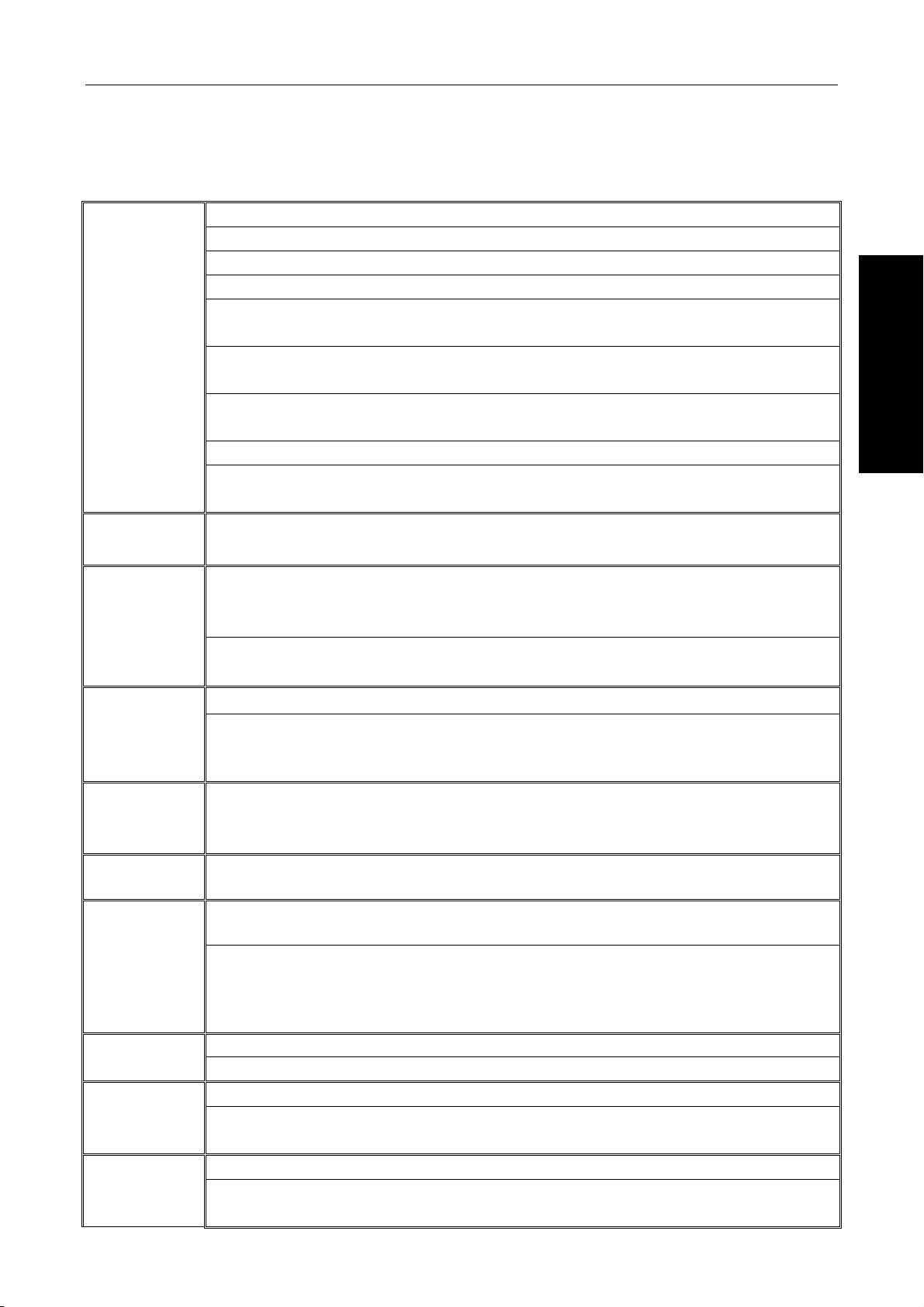

2.1 928TD Technical Specifications

Simultaneously controlled axes (interpolation axes): 2 (X, Y axes)

Interpolation function: linear, circular, and thread interpolation of X and Z axes

Position command range: -9999.999 mm~9999.999mm; least command increment: 0.001mm

Electronic gear: Command multiplier coefficient 1~99999, command division coefficient 1~99999

Rapid traverse rate: Max. 15000mm/min; rapid override: F25%, 50%, 75%, 100% four-level real time

adjustment

Motion control

Cutting feedrate: Max. 4000mm/min; feedrate override: 16-level real time adjustment from 0~150%

(increment 10%)

Manual feedrate: 0mm/min~1260mm/min 16-level real time adjustment, or user-defined speed in

real time

MPG feed: Three gears, 0.001mm, 0.01mm, 0.1mm

Acceleration/deceleration: Either exponential or linear acceleration/deceleration can be selected for

cutting feed.

OPERATION

G codes

Thread

machining

Precision

compensation

M codes

T codes

Spindle speed

control

I/O function

Display

interface

Program edit

G codes: G00, G01, G02, G03, G04, G05, (G22/G80), G26, G28, G30, G31, G32, G33, G50, G51,

G66, G67, G71, G72, G73, G74, G75, G76, G90, G92, G94, G96, G97, G98, G99

Capable of machining single /multiple metric/inch straight thread, taper thread and end face thread;

Thread run-out length, angle and speed characteristics settable, with high-speed run-out processing;

thread pitch: 0.001mm~500mm or 0.06 teeth/inch ~ 25400 teeth/inch; taping function available

Spindle encoder: Setting range of encoder lines: 100 p/r~5000p/r; drive ratio between encoder and

spindle: 1:1

Backlash compensation: 0 mm~10.000mm

Tool compensation: 16 tool numbers, 64 groups of tool length compensations

Tool setting mode: Trial tool setting, fixed point tool setting; Tool compensation execution mode: tool

compensation executed by modifying coordinates, tool compensation executed by moving tool post

M00, M02, M20, M30, M03, M04, M05, M08, M09, M10, M11, M12, M32, M33, M41, M42, M43, M44,

M78, M79, M80, M81, M82, M83, M96, M97, M98, M99, M91, M92, M93, M94, M21, M22, M23,

M24;user defined M codes:M60~M74;

Up to 16 tool numbers (T01□□~T16□□), control process of tool change is selected by setting tool

post type parameters; tool post type is set to 0 when using a line-up tool.

Speed switch value control mode: The output range of S command 4-gear direct control is S01~

S04; or the output range of the 16-gear BCD code is S00~S15.

Speed analog voltage control mode: S commands specify the spindle speed per minute or cutting

linear speed (constant surface speed control); the CNC outputs 0V~10V voltage to the spindle

frequency converter; spindle stepless speed variation; support for 4 spindle mechanical gears M41~

M44

I/O function diagnosis display

I/O interface: 23 points input/18 points output

Display: 480×234 lattice true color LCD, with LED or CCFL backlight

Display mode: Chinese or English display interface set by parameters; real-time display of machining

path

Program number: up to 255 programs, program storage capacity: 4400KB

Edit mode: Full-screen editing, support for incremental/absolute coordinate mixed programming,

program calling, and subprogram multi-level nesting

5

Page 26

GSK928TD Turning CNC System User Manual

Ⅰ

OPERATION

Communication

Adaptive driver

With USB interface; bidirectional transmission of programs, parameters and tool compensations

between CNC and USB; support for system software upgrade by USB download

GSK DA98 series digital AC servo or DY3 series step drive device, with pulse + direction signal input

6

Page 27

Chapter Three Operation Panel

Ⅰ

CHAPTER THREE OPERATION PANEL

This turning machine CNC system (abbreviated to system or CNC) employs an operation

panel made from aluminum alloy.

3.1 LCD

LCD: Human-machine interface, with resolution of 480×234, lattice true color LCD

3.2 LED Status Indicator

LED indicators are used to indicate the current working states of the system. There are 15 function

keys with a LED indicator. When the indicator lights up, the corresponding function of the key is enabled;

when it goes out, the function is disabled.

3.3 Keyboard

According to the standard of GSK, the function keys with the visible signs below are designed for

OPERATION

the system. The corresponding function of a function key is enabled when it is pressed. The meaning of

each key is as follows:

3.3.1 Character Key

Character keys consist of numbers, letters and some signs.

In the Edit mode, each letter key can switches between two or three keycodes; in other modes, each

letter key only indicates one keycode. (E.g. Though I and P are on the same key, the system will

automatically identify the keycode (I or P) to be used after pressing this key.)

Numeric key: Inputs data (0 ~9)

Letter key: Inputs letters

Sign key: Inputs signs such as + (plus sign), - (minus sign), * (multiplication sign), / (division sign) , +

(positive sign), - (negative sign), . (decimal point), > (is greater than), = (is equal to), <

(is less than), and, or, as well as ( ).

7

Page 28

GSK928TD Turning CNC System User Manual

Ⅰ

3.3.2 Operation Mode Select Key

The keys are identified by a sign and letters. The user can finish the corresponding function by

pressing an operation mode select key. The meaning of each key is as follows:

selects Edit operation mode

OPERATION

selects Manual operation mode

selects AUTO operation mode

selects Parameter operation mode

selects Tool Offset operation mode

selects Diagnosis operation mode

3.3.3 Function Key

The keys are indicated by a sign and letters. With a function key pressed, its function is enabled. The

meaning of each key is as follows:

Rapid override increase increases the rapid traverse override in MANUAL operation

mode, and increases the speed override of G00 command in AUTO operation mode.

Rapid override decrease decreases the rapid traverse override in MANUAL operation

mode, and decreases the speed override of G00 command in AUTO operation mode.

Feedrate override increase increases the feedrate override in MANUAL operation mode,

and increases the speed override of G01 command in AUTO operation mode.

Feedrate override decrease decreases the feedrate override in MANUL operation mode,

and decreases the speed override of G01 command in AUTO operation mode.

X axis reference point return is only valid in MANUAL/AUTO operation mode. (In this

manual, the program reference point is also called the program zero point)

8

Page 29