Page 1

Operation GSK928TC Turning CNC System

OPERATION

I. Introduction

GSK928TC Turning CNC system, realized high-speed ìm-precision control with highspeed CPU and CPLD

as its control part, has 320×240 lattice graphic LCD with friendly Chinese/English menu, fullscreen edition,

realtime tool-trail graphic display. It runs the user program with international standard CNC language-ISO code. It

is widely suitable for response stepmotor driver, complex stepmotor driver and servomotor driver. By the

programming, it makes the machine to cut cylinder, end, slot, taper, arc, thread and so on.

II. Specification

2.1 Controllable axes 2 axes (X Z axis)

2.2 Linkage axes 2 axes (X Z axis)

2.3 Min. enactment unit 0.001 mm

2.4 Min. move unit X axis 0.0005 mm Z axis 0.001 mm

2.5 Max program travel 8000.000 mm

2.6 Max move speed 15000 mm/min

2.7 Cuting speed 5-6000 mm/min

2.8 User Data Storage 24KB

2.9 Max program numbers 100

2.10 Graphic LCD 320 240 lattice

2.11 Communication interface standard RS-232

2.12 Controllable tool positions 4 extendable to 8

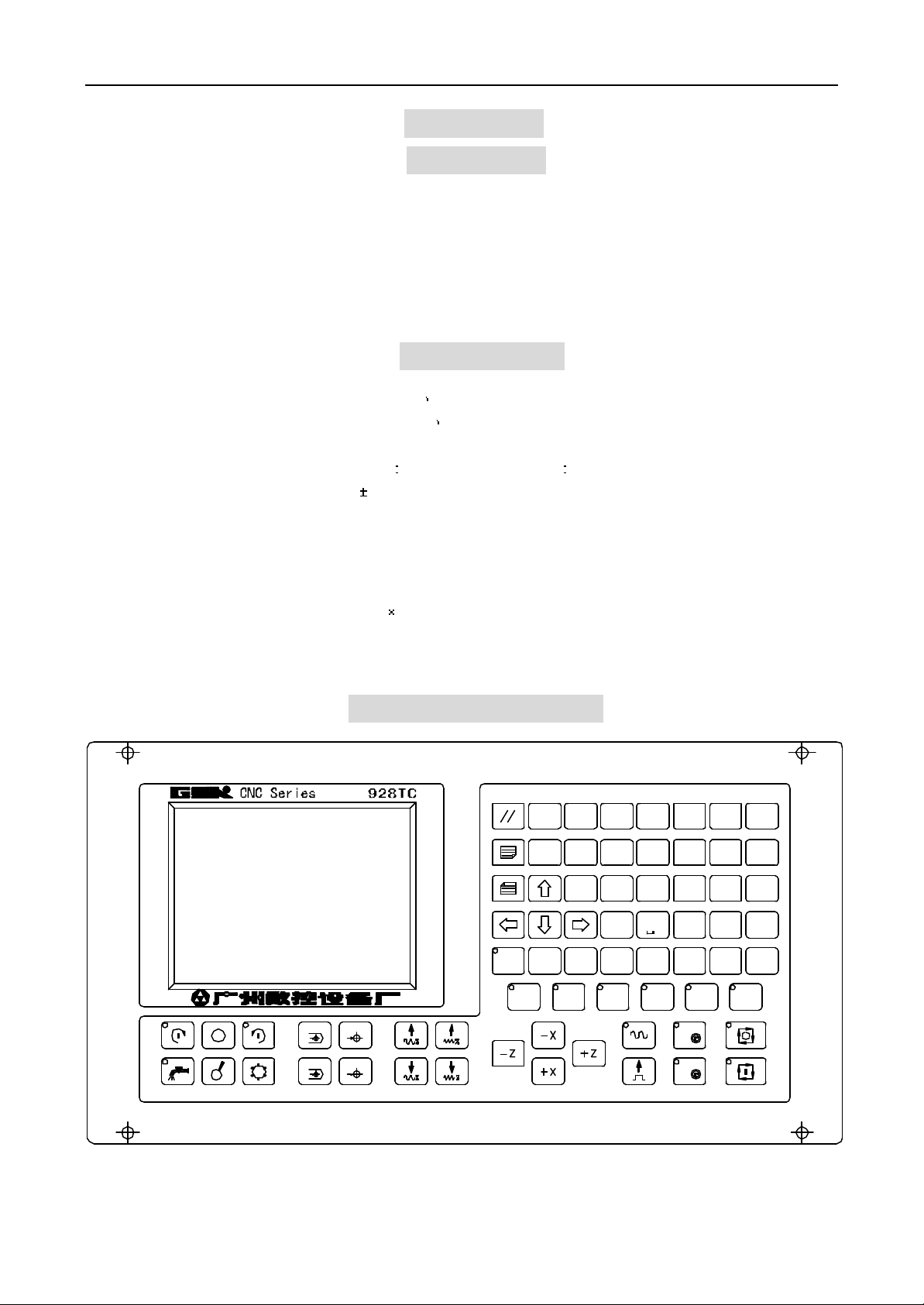

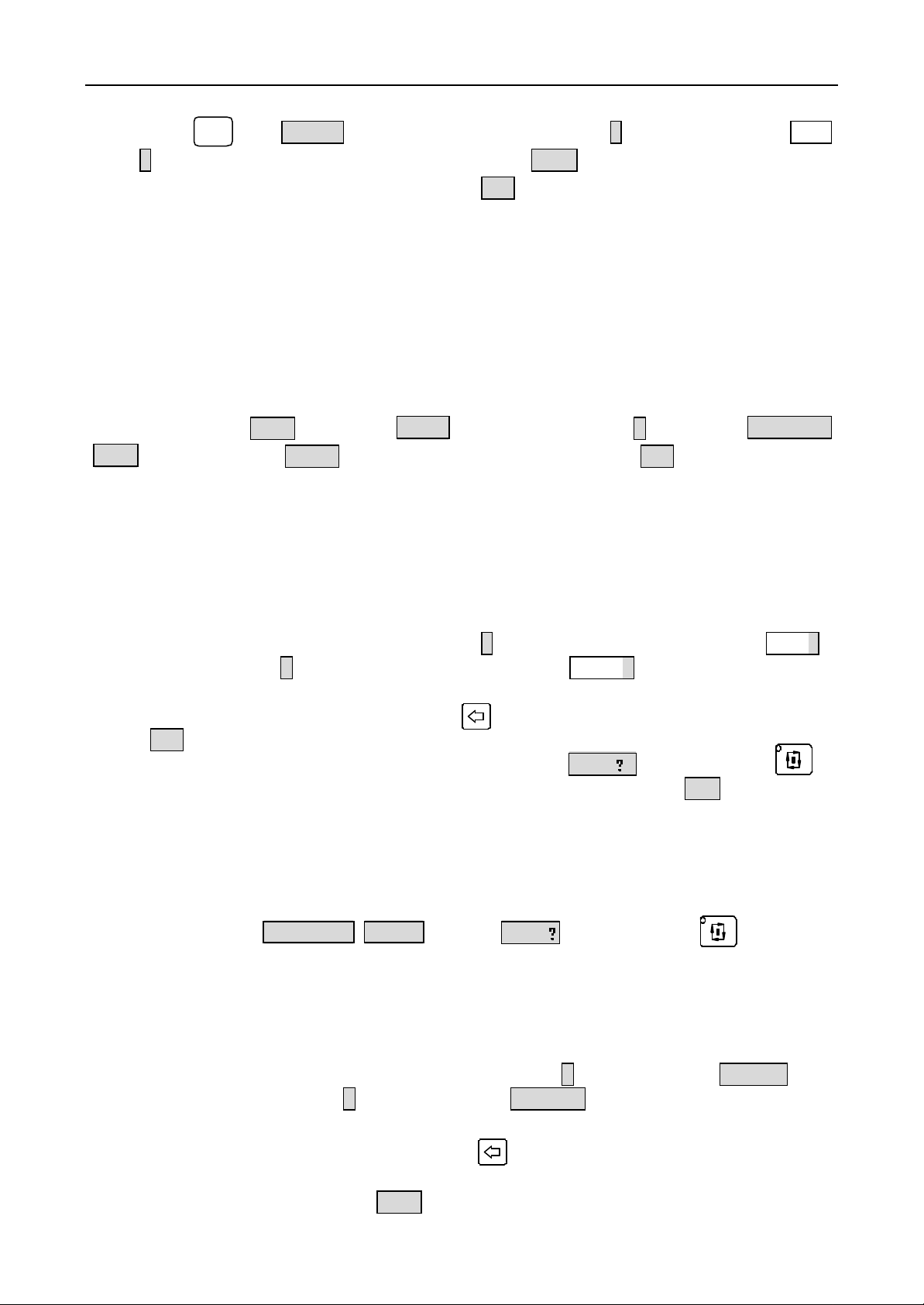

III. OPERATION PANEL

MG

X Z 7 8 9

RIE

DLN

改写

REW

自动

AUTO

WU

K

/P

删除

参数

PAR

1

.

退出

ESC

X

Z

刀补

OFT

2 3

0 -

输入

INPUTDEL

诊断

DGN

654

回车

ENTER

TS

F

空运行

单段

SINGLE

手动

JOG

单步

STEP

DRY

编辑

EDIT

X

X

Z

H/L

Z

GSK CNC Equipment Company 1

Page 2

Operation GSK928TC Turning CNC System

Instructions of the GSK928TC turning CNC system panel:

3.1 LCD display: 320x240 lattice distinguishability, the communication interface between the machine and

human.

3.2 Digit button: input all kinds of data (0~9).

3.3 Address button: input letters, addresses, segments and programs.

3.4 Funtion button: this system was designed with the visualized symbol function button according to the

standard ‘the visualized symbols of CNC machine tool’ as follows:

Fast multiple increase button: Increase the multiple of the max move speed on JOG mode. Increase

the speed multiple of dictate G00 on AUTO mode.

Fast multiple decrease button: Decrease the multiple of the max move speed on JOG mode.

Decrease the speed multiple of dictate G00 on AUTO mode.

Feed multiple increase button : Increase the feed speed multiple on JOG mode. Increase the speed

multiple of dictate G01 on AUTO mode.

Feed multiple decrease button : Decrease the feed speed multiple on JOG mode. Decrease the speed

multiple of dictate G01 on AUTO mode.

X

X axis returnning to program reference point Button: It is valid only on the JOG/AUTO mode

Z

Z axis returnning to program reference point Button: It is valid only on the JOG/AUTO mode

X

X axis returnning to machine reference point Button: It is valid only on the JOG mode

(Whether the machine reference point is valid can be defined by the MZRO bit of the parameter P12)

Z

Z axis returnning to machine reference point Button: It is valid only on the JOG mode

(Whether the machine reference point is valid can be defined by the MZRO bit of the parameter P12)

空运行

Dry run button: When the dry run is selected on AUTO mode, neither the coordinates of the

Dry

machine move nor the S , M, T functions run if the program starts. On EDIT mode, it moves the cursor

to the the first character following this line number

单段

Single button: to select the single segment run/continuum run on the AUTO mode

Single

编辑

Edit button: to select the edit operation mode

EDIT

手动

JOG button: to select manual operation mode

JOG

AUTO button: to select auto operation mode

自动

PAR button: to select parameter operation mode

参数

刀补

OFT button: to select tool offset operation mode

DGN button: to select diagnosis operation mode

诊断

2 GSK CNC Equipment Company

Page 3

Operation GSK928TC Turning CNC System

3.5 Edit button /State-selection button

改写

Rew

Switch between the inset and rewrite ways on the edit mode.

删除

Del

Delete the figure, letter, segment, or whole the program.

退出

Esc

Cancel the local inputing data or escape from local state.

输入

Input

Input all kinds of data, select the needed edition, run the program or establish the new user

program.

回车

Enter

Confirm the input.

Page up to searches the program or parameter on the edit/parameter/tool offset mode, or

increase the brightness to the display on the other modes.

Page down to searches the program or parameter on the edit/parameter/tool offset mode, or

decrease the brightness to the display on the other modes.

Move the cursor up on the edit/parameter/tool offset mode

Move the cursor down on the edit/parameter/tool offset mode

Move the cursor ahead on the edit/parameter/tool offset mode

Move the cursor backwards on the edit/parameter/tool offset mode

3.6 Loop start button and Feed-hold button

Start the program to run on the AUTO mode, pause on the operation

Loop start button Start the program to run automatically on the AUTO mode.

Feed-hold button The motors slow down to pause on the AUTO or JOG mode

3.7 Manual axis-control button

Move the selected axis along the moving direction on the JOG mode

Move the x axis along negative direction on JOG mode.

Move the x axis along positive direction on JOG mode.

Move the z axis along negative direction on JOG mode.

Move the z axis along positive direction on JOG mode.

GSK CNC Equipment Company 3

Page 4

Operation GSK928TC Turning CNC System

Fast move/Feed button Switch between fast move speed and feed speed in JOG.

JOG step select button Select the step of the monostep feed or handwheel feed in Single

feed/handwheel feed mode.

X axis Handwheel select button Select handwheel to control X axis when this system

X

assembled the handwheel.

Z axis Handwheel select button Select handwheel to control Z axis when this system

Z

assembled the handwheel.

单步

Single/JOG mode Switch between the manual monostep and jog mode.

3.8 Manual Toolchange and Assistant Functions Buttons

Select the next tool position directly and manage the machine to run all assistant function. The buttons are

defined as follows:

Spindle stop button The spindle stops running when push this button.

Coolant button Switch the coolant on/off

Tool change button Select the next tool postion when push this button once.

Remark: All above buttons are efficient in JOG/AUTO mode when X,Z axes stop. But onlythecoolant

Step

Spindle positive rotation button The spindle rotates counter-clockwise (watch from the motor

shaft) by pushing this button.

Spindle negative rotation button The spindle rotates clockwise (watch from the motor shaft) by

pushing this button.

Spindle shift button Select the spindle speed when the main spindle motor has more then one

step speed (not more then 16 steps) and the machine has the control loop.

button is efficient in running.

3.9 Reset Button

System reset button All axes will stop when this system resets, and all output of assistant

functions are inefficacy, the machine stops running and return to the initial status of

electrification.

3.10 State indicator

Indicate the current running state of this CNC system. There have 15 function buttons with LED

indicators. The corresponding function of this button is availability when the LED indicator lights.

4 GSK CNC Equipment Company

Page 5

Operation GSK928TC Turning CNC System

IV. SYSTEM OPERATION

In this chapter, details the all functions modules of this GSK928TC turning CNC system and their operations

and notices. Please read this chapter carefully before start the machine with this system.

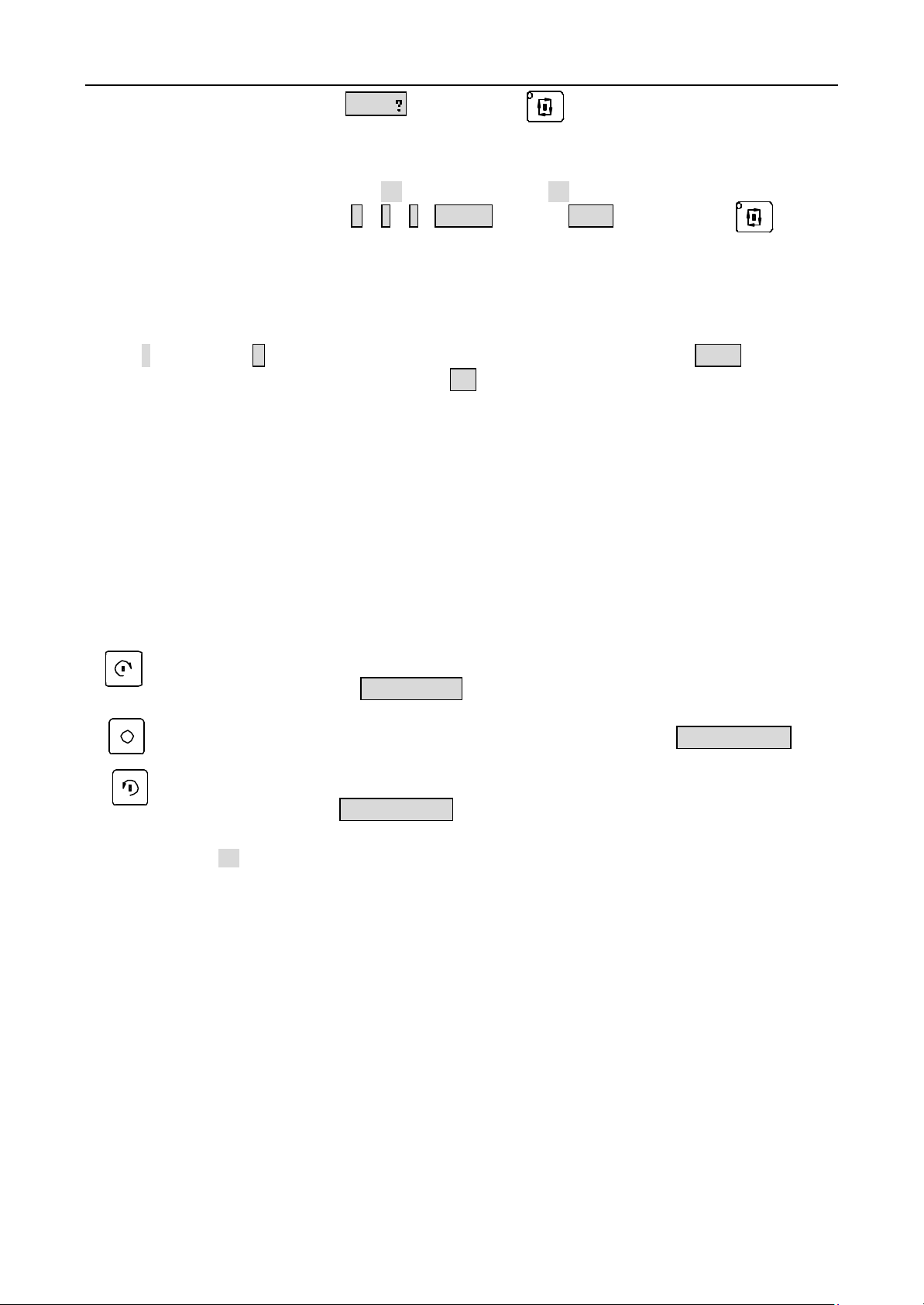

4.1 System turn on/off

There has not the power switch on this system. To avoid the power concussion, install the power switch for

this system according to the actual state of the machine.

Turn on as follows:

1 Power on the machine’s electrical source first.

2 Put through the system’s switch if there has, and then the system appears as picture1. Keep pushing any

button with the exception of the buttons , , when it is displaying the picture1, the

system will display the version number of this system. After release the button, the system enters the

normal run state.

Turn off as follows:

1 Cut off the system’s switch if there has.

2 Power off the machine’s electrical source.

CAUTION: When the system powers on first, it is needed usually to operate as follows:

1. Initialize the system’s parameter section such as:

Push the button and at the same time . First release the button , after 3 seconds, release the

button , the system was initialized. At then, all the parameters of tool offset are 0, all the parameters of the

machine reset as initial value. Please consult the offset and parameter instruction in this manual.

2. Measure the reverse transmission clearance of X, Z axes, and enter system parameters P07 and P08. Please consult

the parameters instruction in this manual.

3. Define the DIRZ and DIRX in parameter P11 according to the electric design and motor direction of the machine.

4. Adjust the parameters P05, P06, P17~P22 to let the machine run reposefully and availably according to the

machine’s load.

删除

Del

删除

Del

广 州 数 控

Picture1. System initial display

4.2 System run mode selection

Select or change the run mode of GSK928TC by push button directly. It is maneuverable, convenient and

directviewing.

If no one of button is pushed, this system displays the picture1 circularly when it powers on. If any button

except button was pushed, this system will return to the mode of last power off. If power on with pushing

button or push button and button at the same time, release first, a moment later,

releases the button , this system will enter the MANUAL mode.

退出

Esc

退出

Esc

GSK CNC Equipment Company 5

退出

Esc

Page 6

Operation GSK928TC Turning CNC System

4.3 EDIT Mode

On EDIT mode, input or edit the cutting programs and their contents by pushing buttons on the keyboard. All

the cutting programs can be built, selected or deleted by the keyboard. And the contents of the selected cutting

program can be edited such as inset, amend, deleted and so on. And the RS232 communication port of this system

can be connected to the serial port of the current pc, so the cutting program can be exchanged between this system

and the current pc.

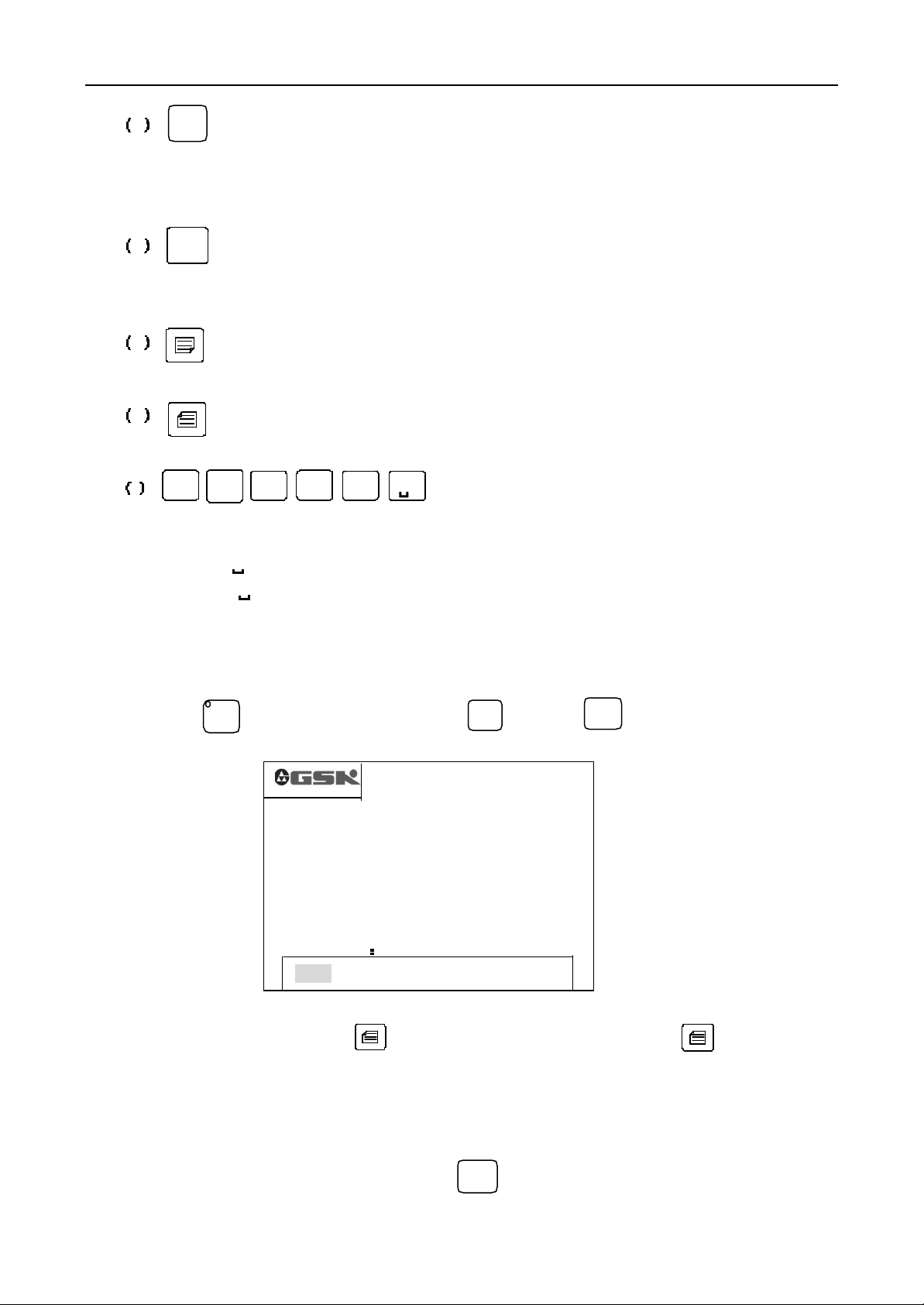

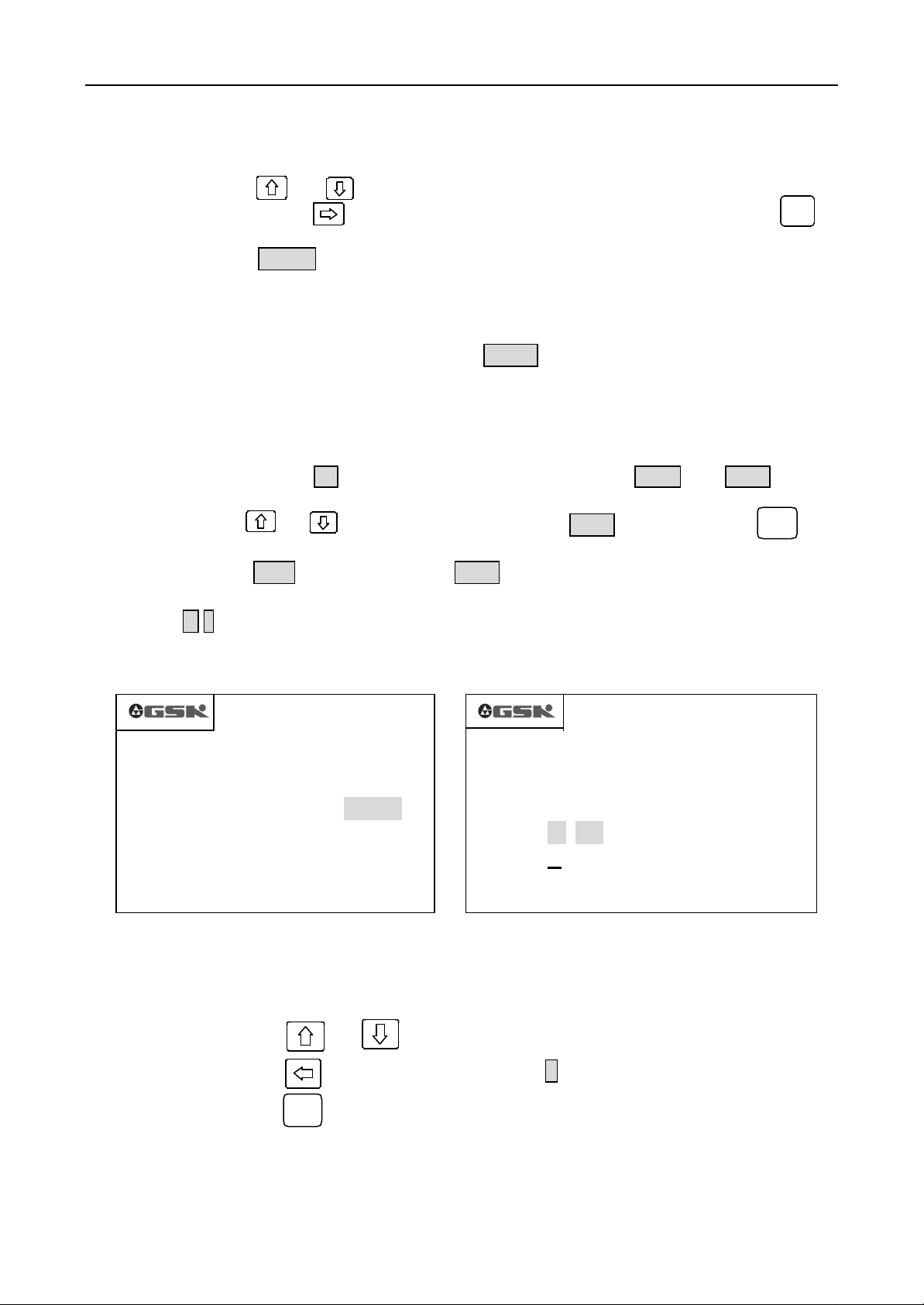

Push the button to enter EDIT mode, this system appears the names of all stored program, bytes of the

编辑

EDIT

current programs and the spare capability of this system as follows:

%00 %02 %03 %04 %10

PROG. NO. 05 FREE BYTE 15750

EEDDIIT

EDIT %02 0223

T MANU AUTO PARA OFFT DIAG

Picture2 edit mode

On the EDIT mode, the definitions and usage s of the buttons

1 Upmove cursor button

The cursor moves to the position of the first charater after front program row number when push this

button once.

Keep pushing this button, the cursor continues to move above until the cursor arrives at the first program

row or the button is released.

2 Downmove cursor button

The cursor moves to the position of the first charater after next program row number when push this button

once.

Keep pushing this button, the cursor continues to move down until the cursor arrives at the last program

row or the button is released.

3 Leftmove cursor button

The cursor moves to the position of the front charater when push this button once.

Keep pushing this button, the cursor continues to move left until the cursor arrives at the first charater or the

button is released.

4 Rightmove cursor button

The cursor moves to the position of the next charater when push this button once.

Keep pushing this button, the cursor continues to move right until the cursor arrives at the last charater or the

button is released.

CAUTIONS: Cursor – Pompt of Local editing position. There have two forms:

A On inset mode, the cursor is a line segment under the charater.

B On rewrite mode, the cursor appers such that the charater is displayed with highlight and color inverse.

The cursor forms can be switched by button .

6 GSK CNC Equipment Company

改写

Rew

Page 7

Operation GSK928TC Turning CNC System

编辑

once, and the cursor forms will switch accordingly. On inset mode, the cursor is a flashing line segment. On rewrite

mode, the cursor appers such that the charater is displayed with a flashing highlight square charater.

pushing Input button, and inputing the serial number with two digits.

改写

5 In set/rewrite Button

Rew

Push the Inset/rewrite button once, then the input modes will switch between inset and rewrite mode

输入

6 Input button

Input

To establish a new program, select a existent program or delete a existent program or all programs by

7 Pageup button

Push this button to display the front page when search serial numbers list or program contents,

8 Pagedown button

Push this button to display the next page when search serial numbers list or program contents,

U

9 Double-functions button

W I

/

E

K

P

D R

N L

Each button can be defined two functions. Push these buttons once, the system performs the first

function: U, W, I, K, D, and R. Push these button twice in series, the system performs the second functions: /,

E, P, N, L, and . If push these button continuously, the system switches between the two functions. ‘/’ is

newline prompt, ‘ ’ is blank.

4.3.1 Search the cutting program list

On EDIT mode, list all the nemes of the cutting programs in the system’s storage, the cutting program

numbers and the spare capability.

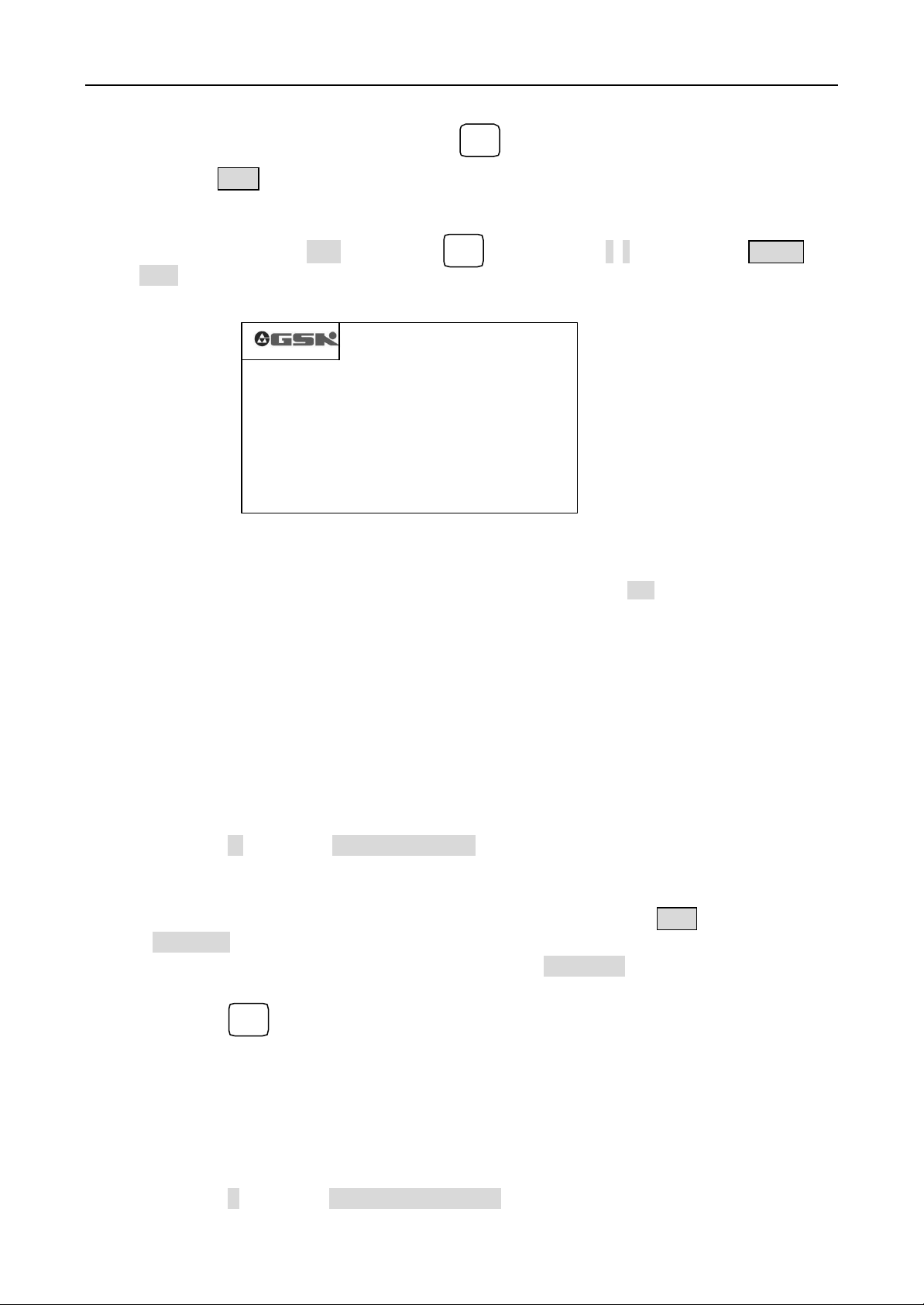

Push button on EDIT mode, or push button or button in editing, the system displays

as PICTURE3.

EDIT

退出

Esc

%00 %02 %03 %04 %10

PROG. NO. 05 FREE BYTE 15750

PICTURE3 Program search, establish, select, delete and etc.

EEDDIIT

EDIT %02 0223

T MANU AUTO PARA OFFT DIAG

输入

Input

40 pcs program names can be displayed once. If the displayed program names are more then 40 pcs, the

display will be paging. Push the button , it displays the next page. Push the button , it displays the

front page.

4.3.2 Cutting program’s establish, selection, deletion, rename, and copy

The establish, selection, deletion, rename, and copy of cutting program can be processed on the program list

display state or program content display state

On the program list display state, push the button , the system displays ‘INPUT PROG. NO. %’ to

prompt the program’s number.

GSK CNC Equipment Company 7

输入

Input

Page 8

Operation GSK928TC Turning CNC System

05 FREE BYTE 15750

4.3.2.1 Establish a new cutting program

1. On the program list display state, push the button .

2. Input the 2 bits program number that isn’t existent in the system as PICTURE 4.

输入

Input

3. Push button Enter

4. The new program is established, the system enters the program content edit state automatically.

Ex. Establish the program%20, push the button then input digit buttons 2 0 , and put the

输入

Input

button Enter. New program %20 is established, and the system turns to edit the new program %20 automatically

as PICTURE 5.

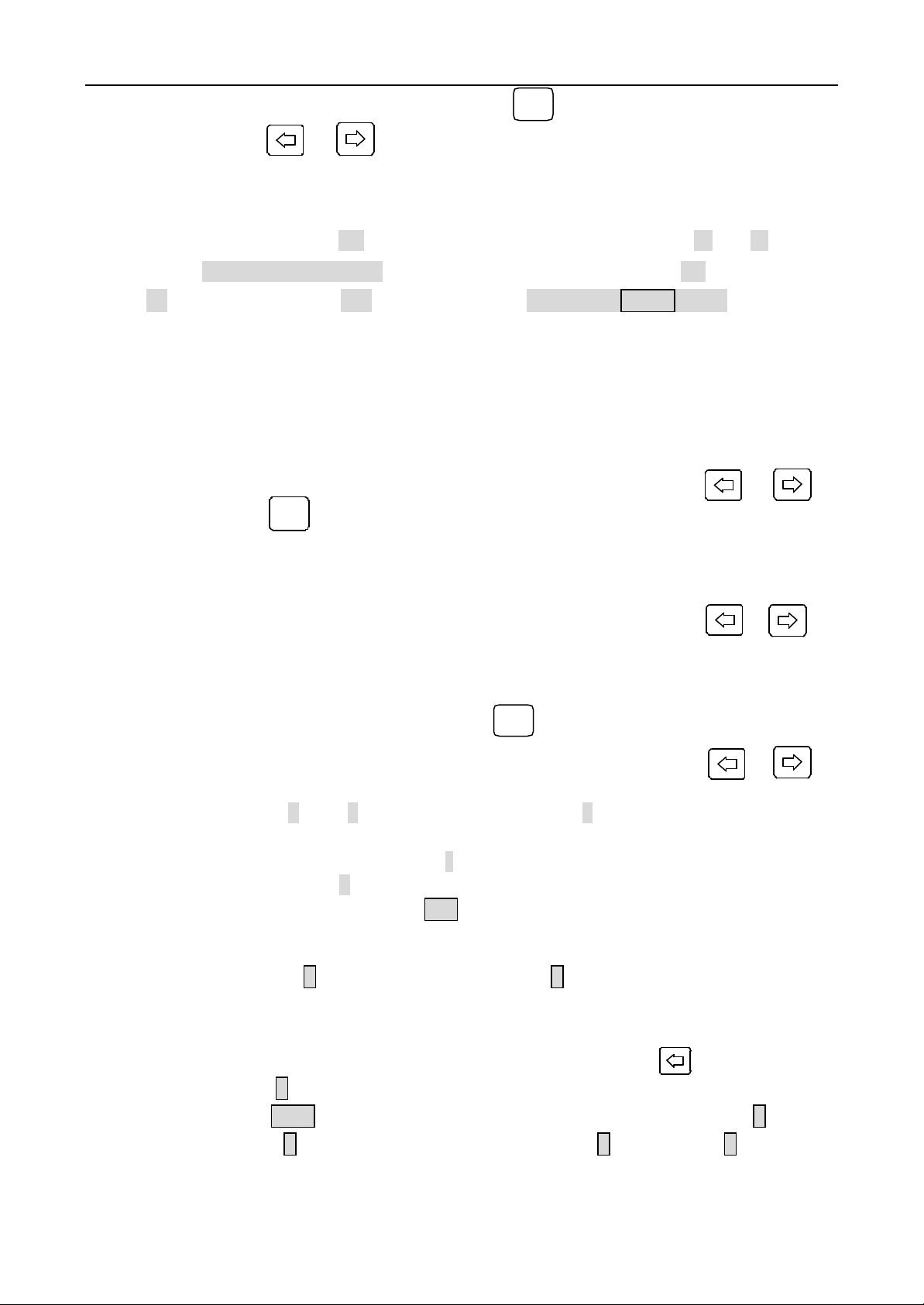

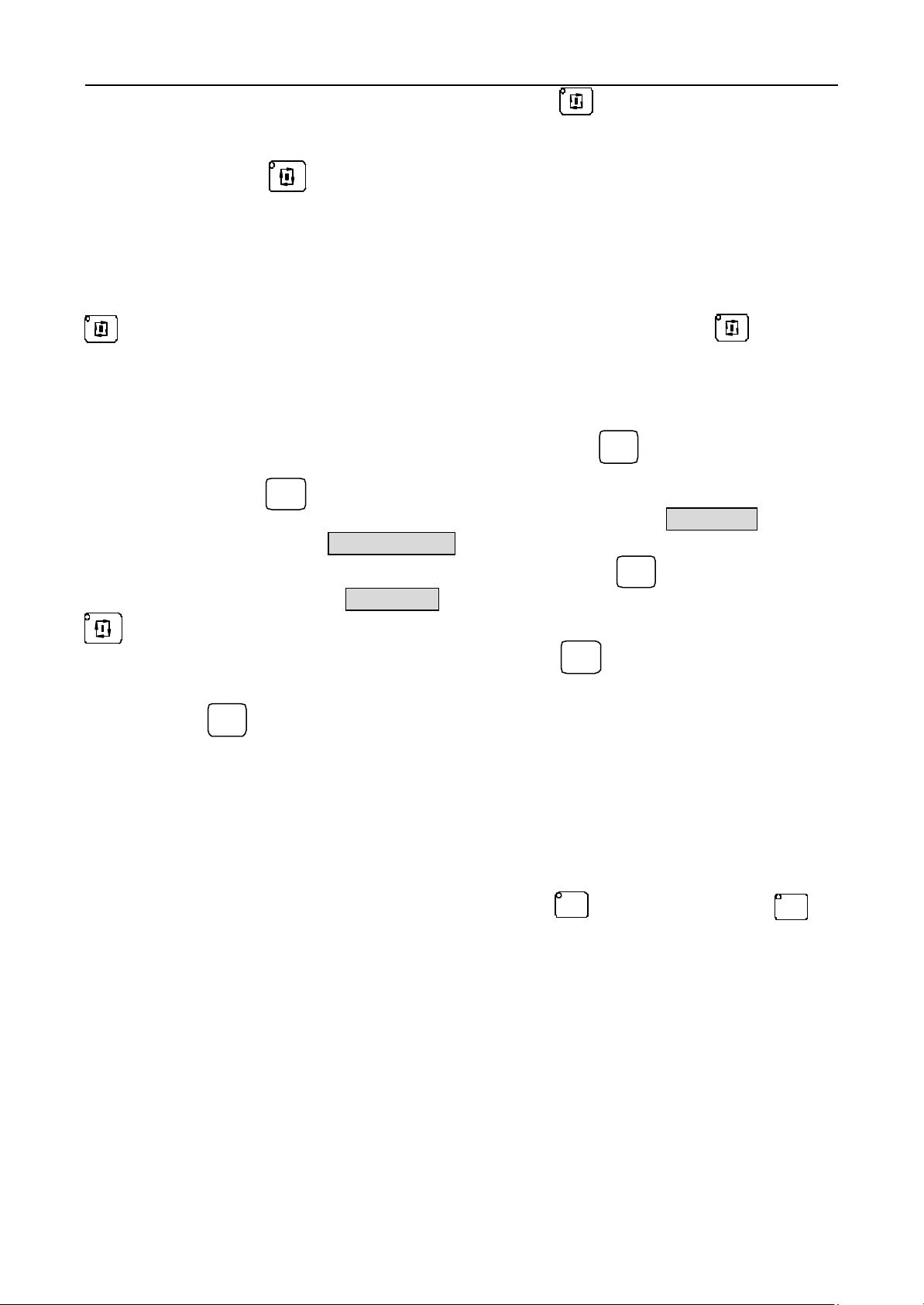

%00 %02 %03 %04 %10

INPUT PROG. NO. %20 Enter

PROG. NO. 05 FREE BYTE 15750

EEDDIIT

EDIT %02 0223

N0000 _

T MANU AUTO PARA OFFT DIAG

EDIT %20 0007

PICTURE 4 INPUT THE PROGRAM NUMBER PICTURE 5 ESTABLISH A NEW PROGRAM

4.3.2.2 Delete the cutting program

1. On the program list display state, push the button .

2. Input the program number that needs to be deleted.

3. Push button , then the system displays DEL?

删除

Del

4. Push button Enter to delete the program, or not, push any button except for Enter to escape.

Ex. Delete the program %03 , Push button Enter, input the digits 0 , 3 , then push button and

button Enter, the program %03 is deleted from the storage of this system as PICTURE 6.

%00 %02 %03 %04 %10

INPUT PROG. NO. %03 DEL?

PROG. NO.

EEDDIIT

EDIT %02 0223

T MANU AUTO PARA OFFT DIAG

PICTURE 6 DELETE THE CUTTING PROGRAM

输入

Input

删除

Del

8 GSK CNC Equipment Company

Page 9

Operation GSK928TC Turning CNC System

4.3.2.3 Select a cutting program

1. On the program list display state, push the button .

2. Input the program number that needs to be selected.

输入

Input

3. Push button Enter

4. Select the cutting program and the system displays the program contents, and it can be edited.

Ex. Select cutting program %01. Push button , input the digits 0, 1 then push button ENTER, the

输入

Input

program %01 is selected as PICTURE 7.

N0000 G0 X0 Z0

N0010 G1 X4.80 Z9.6 F500

N0020 G0 X0.0 Z00

N0030 G4 D2

N0040 M20

EDIT %01 0082

PICTURE 7 SELECT A CUTTING PROGRAM

Cautions:

1. This NC system automatically establishes and selects a new cutting program %00 if there has not any cutting

program or program content when the system powers on first.

2. After a cutting program is selected, it will stands in current state until the other program is selected, even if the

system powers off.

4.3.2.4 Output of the cutting program

Output the cutting program stored in the system’s storage to the external pc.

1. Connect the communication cable between the system and external pc when the system powers off.

2. The system powers on and enters the EDIT mode.

3. Select the cutting program that need to be output (It doesn’t need to be selected if the program to be sent

out is current).

4. Push button W, it prompts ‘PREPARE TO SEND ’.

5. Start the GSK928TC communication program in the external pc to the receiving state. (Please refer to the

appendix of the <Operation Instruction of the GSK928TC Communication Program>).

6. Afer the external pc is convinced that it is in the receiving state, push button Enter, the system prompts

‘SENDING…’, and it send the cutting program to the external pc.

7. As soon as the system sends out the program, it prompts ‘SENT OUT’, and then push any button to

return to the EDIT mode.

8. Push button to interrupt the program sending.

退出

Esc

4.3.2.5 Input of the cutting program

Input the cutting program from the external pc to this system.

1. Connect the communication cable between the system and external pc when the system powers off.

2. The system powers on and enters the EDIT mode.

3. Select the cutting program that need to be output (It doesn’t need to be selected if the program to be sent

out is current).

4. Push button R, it prompts ‘PREPARE TO RECEIVE’.

GSK CNC Equipment Company 9

Page 10

Operation GSK928TC Turning CNC System

5. Start the GSK928TC communication program in the external pc to the receiving state. (Please refer to the

appendix of the <Operation Instruction of the GSK928TC Communication Program>).

6. Afer the external pc is convinced that it is prepared, push button Enter, the system prompts

‘RECEIVE…’, and it send the cutting program to the external pc.

7. As soon as the system sends out the program, it prompts ‘RECEIVED’, and then push any button to

return to the EDIT mode.

8. Push button to interrupt the program receiving.

退出

Esc

Cautions:

1. When the cutting program is sent from the external pc to this system, this system makes the program name with

the character string ‘%xx” in the first row. If the name of the received program is same as the stored program,

the name and contents of the received program can’t be displayed. So the stored program with same name must

be deleted first before check the new program.

2.

All the cutting programs can be exchanged as above method between GSK928TC systems. Just operate two

GSK928TC systems with input/output mode.

4.3.2.6 Delete all cutting programs

Delete all cutting program in the CNC system once.

1. Push button on the EDIT mode.

2. Input

3. Push button , then the system display DEL? .

4. Push button , the all programs in storage will be deleted, or not, push any other button to return to

the EDIT mode without any change.

输入

O

删除

Del

回车

by keyboard.

4.3.2.7 Rename the cutting program

Rename the local cutting program.

1. Push button , display % .

输入

Input

2. Input a new program number inexistent in this system, and push button , and then the inputted

改写

program name is instead of the local program number.

Example: Change the file name %00 to %05

Push button and input 0 5 ,then push button to finish the rename.

输入

Input

改写

4.3.2.8 Copy the cutting program

Copy the contents of the local program to another program and the new program will be regarded as the local

program.

1. Pree button , display %,

2. Input the program number inexistent in this system, push button , copy the contents of local

program to the program with the inputted program number, and the new program is regarded as the local

program.

输入

Input

输入

Input

10 GSK CNC Equipment Company

Page 11

Operation GSK928TC Turning CNC System

Example: Copy the contents of the local program %00 to the local program %05

Push button , intput 0 5 ,and then push button to finish copy.

输入

Input

输入

Input

Caution: If the inputted program number existed in the system, the system display EXISTED.Push any button

to escape, then input the other program number inexistent in this system, push button .

回车

Enter

4.3.3 Input and edit the contents of the cutting program

This CNC system automatically runs according to the sequence of the cutting programs inputted by

user. The program consists of some program segments. The segment consists of serial number, dictate, data

and so on. Only correctly input the contents of the cutting program in the light of the cutting technics, the

system can run normally.

The edit model of this system is full screen. The programs are managed as documents.

4.3.3.1 Create the serial number automatically

Every program consists of some program segment. And each segement begans at N**** . After a

new program is built, the system will create the first serial numbe as N0000 . And when push button

Enter after inputted a segment, the system will create the next serial number automatically. The increment of

the serial number in program input is set by the parameter P23. The parameter P23 can create the serial

number with the integer of the 1/4 increment.

Create the serial number of segment as PICTURE 8 (Parameter P16 is 10):

N0000 G0 X0 Z0 <

N0010 G1 X4.8 Z9.0 F500<

N0020 G0 X0.0 Z0.0 <

N0030 G4 D2 <

NOTE: The Enter and Esc in above picture aren’t displayed on the screen

PICTURE 8 SERIAL NUMBER CREATION AND PROGRAM CONTENT INPUT

N0040 M20 <

EDIT %01 0082

Enter>

Esc>

Enter>

Enter>

Enter>

4.3.3.2 The program contents input

Edits of this system is on the full screen mode. The program contents were inputted on the EDIT mode.

1. Setup a new program as Chapter 4.3.2.1;

2. Input the contents of the first program row after the Serial Number

N0000

is displayed;

3. Push the button Enter to end the input of this row after this row was inputted;

4. The next Serial Number is created automatically after push button Enter , then the new row can be

inputted;

5. Push the button

NOTE: Only ahead 40 characters can be displayed in every segment if there has more then 40 characters in the segment.

When push the button once, the displayed characters indent one bit to left. There can’t be more then 255 characters in

one row, or not the inputted contents can be accepted. The 13 segments can be displayed in one screen. The segment will move

up automatically after the segments are more then 13 rows.

Esc

to end the input after the all contents of the program were inputted.

GSK CNC Equipment Company 11

Page 12

Operation GSK928TC Turning CNC System

4.3.3.3 Insert the program segment insert

Insert one segment or more between two program segments.

1. Push the button or to move the cursor to the frontal one in the two segments;

2. Keep pushing the button as far as the cursor arrives at the last character, or push the button to

move the cursor to the last character;

3. Push the button

increment is set by the integer part of 1/4 the parameter No. P16. If the numbers are no enough, the next

segment number can be rewrited artificially;

4. Input the contents of the inputted segment;

5. The segment was inserted, except push the button

NOTE 1: Insert the segment after the last segment, push the button directly, the new serial number will be created

automatically.

NOTE 2: A new segment can’t be inserted in front of the first segment directly. If it is necessarily, only rewrite the first

segment with new segment contents, and then insert the contents of the foregoing first segment thereafter.

For example:

1. Push the button or to move the cursor to the segment

the characters

2. Push the button Enter , a new serial number N0022 was created such as PICTURE 9, and the cursor

points to the first character of the new segment;

3. Input M 3 ;

3. the new segment was inserted as PICTURE 10.

N0000 G0 X0 Z0

N0010 G1 X4.80 Z9.6 F500

N0020 G0 X0.0 Z0.0

N0022 __

N0030 G4 D2

N0040 M20

PICTURE 9 PICTURE 10

The segment M3 needs to be inserted between the segments N0020 and N0030 such as

the Picture 8, operate as follows:

EDIT %01 0089

Enter , a new Serial Number is created between these two segments ( The number

Enter

to input the next inputted segments,

N0020

, then push the button after

Z0.0;

EDIT %01 0091

N0000 G0 X0 Z0

N0010 G1 X4.80 Z9.6 F500

< E nter>

N0020 G0 X0.0 Z0.0

N0022 M 3

N0030 G4 D2

N0040 M20

单步

STEP

单步

Step

4.3.3.4 Delete the program segment

Delet the all contents including serial number of one segment.

1. Push the button or to move the cursor to the segment to be deleted;

2. Push the button to move the cursor at the N of the serial number

3. Push the button ;

4. Whole the segment was deleted.

4.3.3.5 Insert the field in the segment

1. Check if it is on INSERT mode. When it is on INSERT mode, the cursor is displayed as an

12 GSK CNC Equipment Company

删除

Del

Page 13

Operation GSK928TC Turning CNC System

underline. Or not, change the mode by pushing button

2. Push the button or to move the cursor to the character after insert position;

3. Input the contents to be inserted

4. The inputted contents were inserted in front of the character with cursor.

改写

Rew

For example: The character

segment

X

NOTE: Each field (a letter and t he following figures) must be blocked off by the space in the segment.

When input the program, the space can be created automatically. But when insert characters, the field

can’t be identified automatically, so the space must be inputted manually to ensure the integrality

og the program.

N0020 G0 X0.0 Z0.0

and input character

4.3.3.6 Delete the field in the segment

1

needs to be inserted between characters X and O in the

, Move the cursor under the character

1

, Now the segment

N0020 G0 X10.0 Z0.0.

0

after character

Delete the needless fields in the segment

1. Move the cursor to the character to be deleted by pushing the button or

2. Push the button to delete the character at the cursor.

4.3.3.7 Amend the segment’s contents

删除

Amend the segment’s contents with two methods (Insert/ Rrewrite).

In Insert Mode, amend the contents by delete and insert.

1. Move the cursor to the character to be amended by pushing the button or

2. Input the new contents

3. Then delete the needless contents

In Rewrite Mode, amend the character with cursor.

1. Select rewrite mode by pushing the button . (The character with the cursor is

改写

Rew

displayed as highlight square;

2. Move the cursor to the character to be amended by pushing the button or ;

3. The cursor move to the next character after input a new character.

For example: Replace X with U in the segment

N0020 G0 X 0.0 Z0.0

1. Select the Rewrite Mode

2. Move the cursor to the character X

3. Input the character U

Then the segment

N0020 G0 U 0 .0 Z0.0

is displayed.

4.3.3.8 Overleap the segment

If insert the character / in front of the Serial Number N , this segment will be overleapped

to run the next segment when this system runs this program.

1. Select the Insert Mode

2. Move the cursor to the segment to be overleapped, and push the button to move the cursor

to the charater N

3. push the button

N /

twice continuously, the first is insert the character U in front

of the character N ,the second is change the character U to character /

GSK CNC Equipment Company 13

Page 14

Operation GSK928TC Turning CNC System

X 0090. 000

Z 0125. 000

手动

4.4 JOG Mode (Manu Mode?)

In JOG Mode, the movement of the machine ’s slider, the stop and start of the spindle and the

coolant, tool change, return to reference point and mechanic point in X, Z axis and other functions

can be finished by keyboard.When the CHCD bit of the parameter P11 is 1, the actual speed of the

spindle can be displayed. When the CHCD bit of the parameter P11 is 0, the setting speed is

displayed.

Push button to enter the JOG Mode (Manu Mode?). There have

in this mode. Initial mode is JOG mode, push button to switch between JOG and Step Mode.If

the Electric handwheel is assemblied in this system. The handwheel control can be adopted. The

display in JOG mode is PICTURE 11 as follows:

JOG

FEEDRATE 100% SPINDLE STOP

FASTRATE 100% SPDL REV 0000

COOLANT OFF TOOL 1 OFFSET 0

EDIT MANU AUTO PARA OFFT DIAG

PICTURE 11 Manual Jog Feed

单步

Step

MANUAL JOG

MANUAL JOG

and

MANUAL STEP

4.4.1 Jog in JOG Mode

Keep pushing the manual axis move button, the slider of the machine will be continuous to

move along the axis direction that was selected until the button is released. It moves with

the speed preestablished. The Manual axis move buttons are as follows:

Move the x axis along negative direction.

Move the x axis along positive direction.

Move the z axis along negative direction.

Move the z axis along positive direction.

4.4.2 Step feed in JOG mode

In Single Steep Feed, push the manual axis move button once, the slider of the machine moves

one preestablished step along the select direction. Keep pushing the manual axis move button,

the slider will be continuous to move with step until the last step is achieved when the button

is released. Ref. PICUTRE 12.

14 GSK CNC Equipment Company

Page 15

Operation GSK928TC Turning CNC System

X 0090. 000

Z 0125. 000

X 0000. 000

Z 0000. 000

FEEDRATE 100% SPINDLE STOP

FASTRATE 100% SPDL REV 0000

EDIT MANU AUTO PARA OFFT DIAG

MANUALSTEP 0.001

COOLANT OFF TOOL 1 OFFSET 0

PICTURE 12 Single Steep Feed

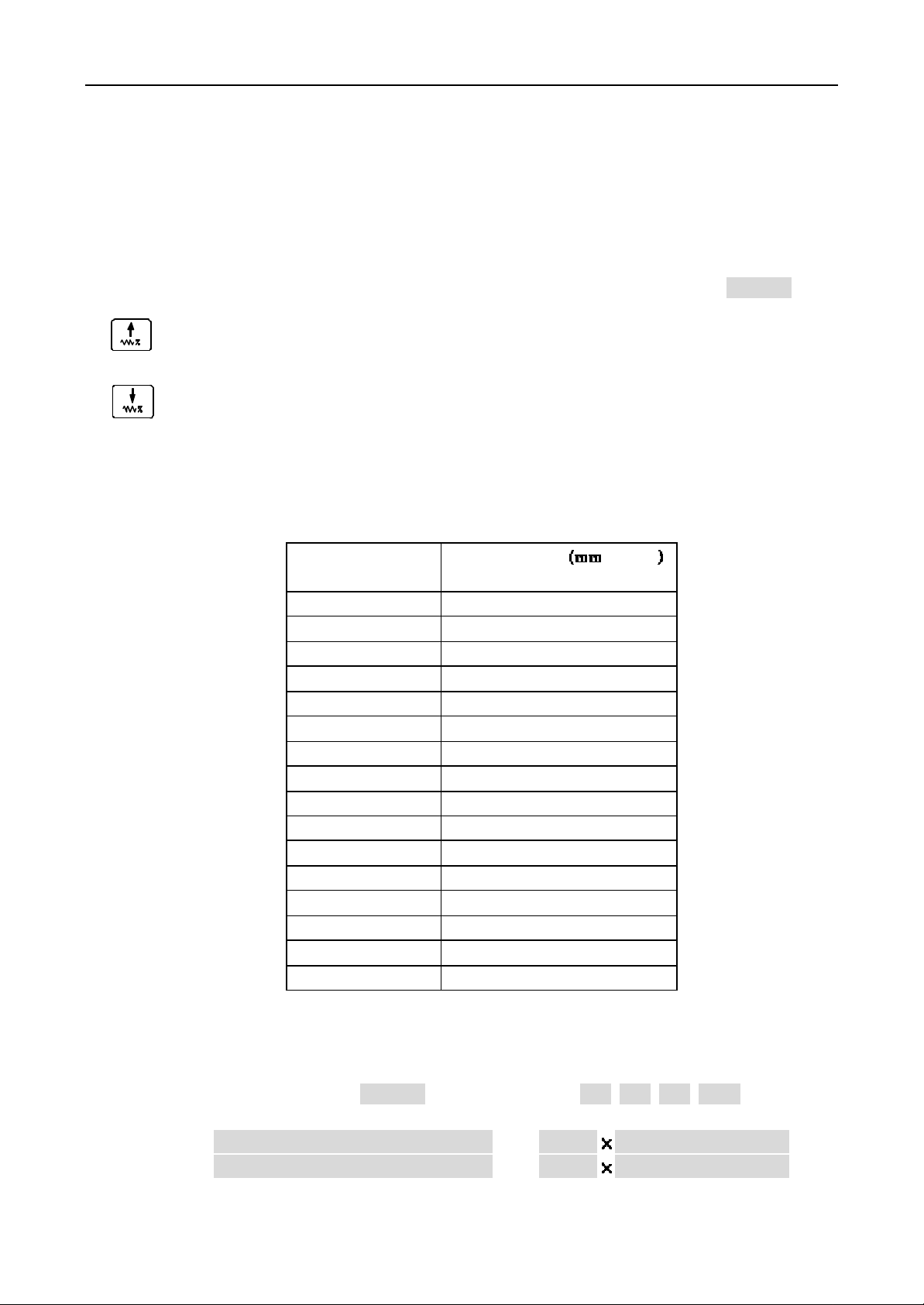

In Single Step Feed, the step can be defined as 7 grades

Push the button to switch from one kind of step to another orderly.

Note 1: In single step feed, push the button to stop the move of the slider, the unfinished steps

don’t be held . To move continuously, it is necessary to push the manual axis-control button again. The step

in X axis is move value in diameter.

Note 2: The the slider can move after push the manual axis move button only when the external switch of

the spindle and feed-hold is in appropriate state. In feed-hold state, the slider does not move by pushing

the manual axis move button.

Note 3: When the slider is moving in Single step feed, the feed - hold button is changed to the feed-hold

state, the slider will reduce the sp eed to stop, and the unfinished steps don

4.4.3 Handwheel Control Mode

In the handwheel control mode, the move of the slider can be controlled by turning the handwheel.

Push the button or to enter the Handwheel Control Mode and to select the move axis.

For example ( X axis):

EDIT MANU AUTO PARA OFFT DIAG

HANDWHEEL X 0.001

FEEDRATE 100% SPINDLE STOP

FASTRATE 100% SPDL REV 0000

COOLANT OFF TOOL 1 OFFSET 0

0.001 0. 01 0.1 1.0 10.0 50.0

’

t be held.

1. Select the axis to be moved by handwheel, turn the handwheel to move the axis

Turn the handwheel clockwise, the axis moves forward

Turn the handwheel withershins, the axis moves forward

2. The move unit of the handwheel has three grades 0.001,0.01,0.1mm. Push the button

To switch from one grade to the next one. When change between the handwheel control and the

Single Step feed, the move grade keeps the enactment.

GSK CNC Equipment Company 15

PICTURE 13 Handwheel Control

Page 16

Operation GSK928TC Turning CNC System

Note 1: The rev of the handwheel should not be more then 5 rev/second, otherwise the move of slider will not

accord with the scale of the handwheel.

Note 2: In handwheel control, all the functions relatved with axis such as JOG, Reset, relative/absolute

movement are invalid, but the S, M, T ans other assistant functions are available.

Note 3: The handwheel will not work if the external spindle stop button or feedhold button keeps valid.

4.4.4 Manual Feedspeed Selection

In Manual Feed, select the multiple of the feed speed. (It is displayed as FEEDRATE)

The feed multiple increases one grade when push this button once. The max multiplies

is 150%.

The feed multiple reduces one grade when push this button once. The min. multiple is

0%.

Note 1: In Manual JOG or handwheel feed, the feed multiple must be seted exactly before operation.

Note 2: In Manual Step, the feed multiple can be seted in operating.

The manual feedspeed multiple is 16 grades from 0% to 150% as follows:

F eed multiple

(FEEDRATE)

0 0

10 4.3

20 12.6

30 20

40 32

50 50

60 79

70 123

80 200

90 312

100 420

110 530

120 600

130 850

140 1000

150 1262

Feedspeed /

min

4.4.5 Manual quick move speed selection

In manual feed, the slider can be moved quickly. The quick move speed can be seted by quick

move multiple (It is displayed as FESTRATE) with four grades

25%,50%,75%,100%

.

The actual move speed is defined by quick feed move and quick multiple.

X axis actual move speed = P06 quick multiple

Z axis actual move speed = P05 quick multiple

16 GSK CNC Equipment Company

Page 17

Operation GSK928TC Turning CNC System

X 0090. 000

Z 0125. 000

The slection of the Manual quick move and quick multiple are as follows:

Switch between manual feed and manual quick move.

Push this button to increase the multiple one grade.

Push this button to reduce the multiple one grade.

In Manual Feed, push button to switch to quick manual move, and the quick indicator lights,

the quick multiple and feed multiple indicate as highlight square. Push this button again to return

to the manual feed.

The PICTURE 14 is in manual feed.

Note 1: In Manual Jog, the quick multiple must be defined before operation.

Note 2: In Manual Step, the quick multiple can be defined in operation.

FEEDRATE 100% SPINDLE STOP

FASTRATE 100% SPDL REV 0000

COOLANT OFF TOOL 1 OFFSET 0

EDIT MANU AUTO PARA OFFT DIAG

P icture 14 MANUAL FEED

MANUAL JOG

4.4.6 Define the workpiece coordinate

This

GSK928TC

benchmark of the tool regulation and correlative dimension. As soon as the system is assemblied,

the workpiece coordinate must be defined first. And when the loss of synchronism or the other

unapt coordinate position, it is necessary to define the coordinate again.

Define the workpiece coordinate as follows:

1 Install the trial workpiece reliably on the machine, and select any one of the tools (usually

the earlier using tool is selected)

2 Select the seemly spindle speed, then start spindle, move the tool in manual feed, cut

a little shoulder on the workpiece.

3 Under the tool hasn’t move on the X axis direction, the tool moves to the safe position

along the Z axis direction. Stop the spindle.

4 Measure the diameter of the shoulder, push the button ,the

push the button X , the system displays

the button

button

5 Start the spindle again, move the tool in manual feed, cut an end on the workpiece.

6 Under the tool hasn’t move on the Z axis direction, the tool moves to the safe position

along the X axis direction. Stop the spindle.

system adopts the floating point scale. The workpiece coordinate is the

Enter

, the X axis coordinate is defined automatically. Otherwise, Push the

ESC

to cancel the X axis coordinate.

SETUP X

输入

Input

, input the metrical diameter and push

SETUP

is displayed,then

7 Select a datum mark (a fixure on the machine, such as chuck end,frock datum plane),measure

GSK CNC Equipment Company 17

Page 18

Operation GSK928TC Turning CNC System

the distance from the datum mark to the machined end on the Z axis direction. push the

button , the

Z

, input the metrical diameter and push the button

输入

Input

SETUP

is displayed,then push the button Z , the system displays

Enter

, the Z axis coordinate is defined

SETUP

automatically. Otherwise, Push the button

After establish the workpiece coordinate, all the system offsets are cleanned out. If the

workpiece coordinate isn’t defined, there have warp between displayed scale and the actual

dimensions in the X, Z axis. Before define the workpiece coordinate, please initialize the system.

4.4.7 Define the program reference point

The program reference point can be the any position on the machine. Once the program reference

point is defined, the machine will return to this point by running G26, G27, G29 dictates or pushing

the return buttons and quash the tool compensation and system offset, except for defining the

coordinate again.

Push the button

ZERO .Push the button

After define the workpiece coordinate again, the primary scales are kept in the new coordinate.

So the program reference point needs to be defined again. The initial value of the reference

point in this system is X=150, Z=150

INPUT

to display SETUP.Then push the button 0 to display PROGRAM

Enter

again to confirm or push the button

4.4.8 The relative coordinate move of the axis

In Manual Jog mode, the slider can move with the input stage and direction or with the system

setting step.

1. select the axis to move, push the button U to move the X axis, then display

push the button U to move the Z axis, then display

2. Input the move stage by keyboard (negative value for axis negative direction), the value

of X axis is Diameter. Push the button to delete the wrong input. Push the button

ESC

to cancel the input and return to the Manual Jog mode.

3. Push the button Enter after finish the input to display RUN ,push the button to

move the input stage along the setting direction. Push the button

move and return to Manual jog mode.

4. The move speed is the current seting speed.

For example: If the slider of the machine moves 15.8 mmm in the negative direction of the

X axis.

Push U – 1 5 . 8 Enter to display RUN , push the button to move

15.8mm in the negative direction og the X axis.

ESC

to cancel the Z axis coordinate.

ESC

to cancel.

MOVE W

.

ESC

MOVE U

to cancel the

,

4.4.9 The absolute coordinate move of the axis

In Manual Jog mode, any axis can move from the current position to the appointed position

directly.

1. Select the axis to move, push the button X to move the X axis, and display

the button Z to move the Z axis, and display

2. Input the axis coordinate (diameter in X axis) of the destination by keyboard, the wrong

input can be deleted bu pushing the button . Push the button ESC to cancel the input

and return to Manual Jog mode.

3. After input, push the button

18 GSK CNC Equipment Company

Enter

MOVE X

MOVE Z

to let the system cacaulate the move distance and

.

, push

Page 19

Operation GSK928TC Turning CNC System

direction, then display RUN . Push the button to move to the appointed position. Push

ESC to stop and return to the Manual Jog mode.

4. It moves with the current defined speed.

For example: the Z axis scale is 50, need to move to 85.

Push the buttons Z 8 5 Enter to display RUN? , push the button to move

the Z axis to the postion of Z85.

Note: In Manual Jog mode, only one axis can move with the prearanged speed at one time.

4.4.10 Manual Input and M functions

In Manual Jog mode, The M functions can be run by inputing the M functions’ code. Push the

button M to display M, input one or two bit figure, and push the button

corresponding M function, or push the button ESC to cancel.

Push the buttons M,0,3 and Enter to start the spindle to run forwards.

The following M functions can be run:

M03 M04 M05 M08 M09 M10 M11 M32 M33 M21 M22 M23 M24

If the left digit is zero, it can be omitted.

4.4.11 Manual Spindle Control

In Manual Jog mode, the positive/reverse turn and stop of the spindle spindle can be controlled

by the keyboard.(pls reference to the operation manual of the machine, If the external Emergency

button or Feed/spindle hold button is set on the prohibited state, the machine doesn’t run even

if the run buttons are pushed) .

Spindle positive rotation button The spindle rotates counter -clockwise (watch from the motor shaft)

by pushing this button. Display SPINDLE CW

Spindle stop button The spindle stops running when push this button. Display SPINDLE STOP

Spindle negative rotation button The spindle rotates clockwise (watch from the motor shaft) by

pushing this button. Display SPINDLE CCW

Note: With the MSP bit of the paramtere P12, define if there has the signal output of the spindle control

when the spindle stops. If the MSP is 1, there has the signal output of the spindle control when the spindle

stops. I f the MSP is 0, there hasn’t the signal output of the spindle control when the spindle stops.

Enter

to run the

4.4.12 Manual spindle rev control

For machine with the motor of the multilevel speed, in Manual Jog mode, Push the button or

input the rev code directly to define the spindle speed.

l When the MDSP of the parameter P12 is zero ( the spindle rev control is the multilevel

rev), Select the multilevel rev control by the SCOD bit of the parameter P11.When the

MDSP is 1, the SCOD bit is of no effect.

SCOD=0,output the signal with the bit directly, each bit corresponds to a speed. There have

4 bits from S0 to S4 , the output signal is ineffective.

SCOD=1,output the signal with the code, the code must be translated into the spindle speed

with the outer circuitry. The scope is from S00 to S15 as follows:

GSK CNC Equipment Company 19

Page 20

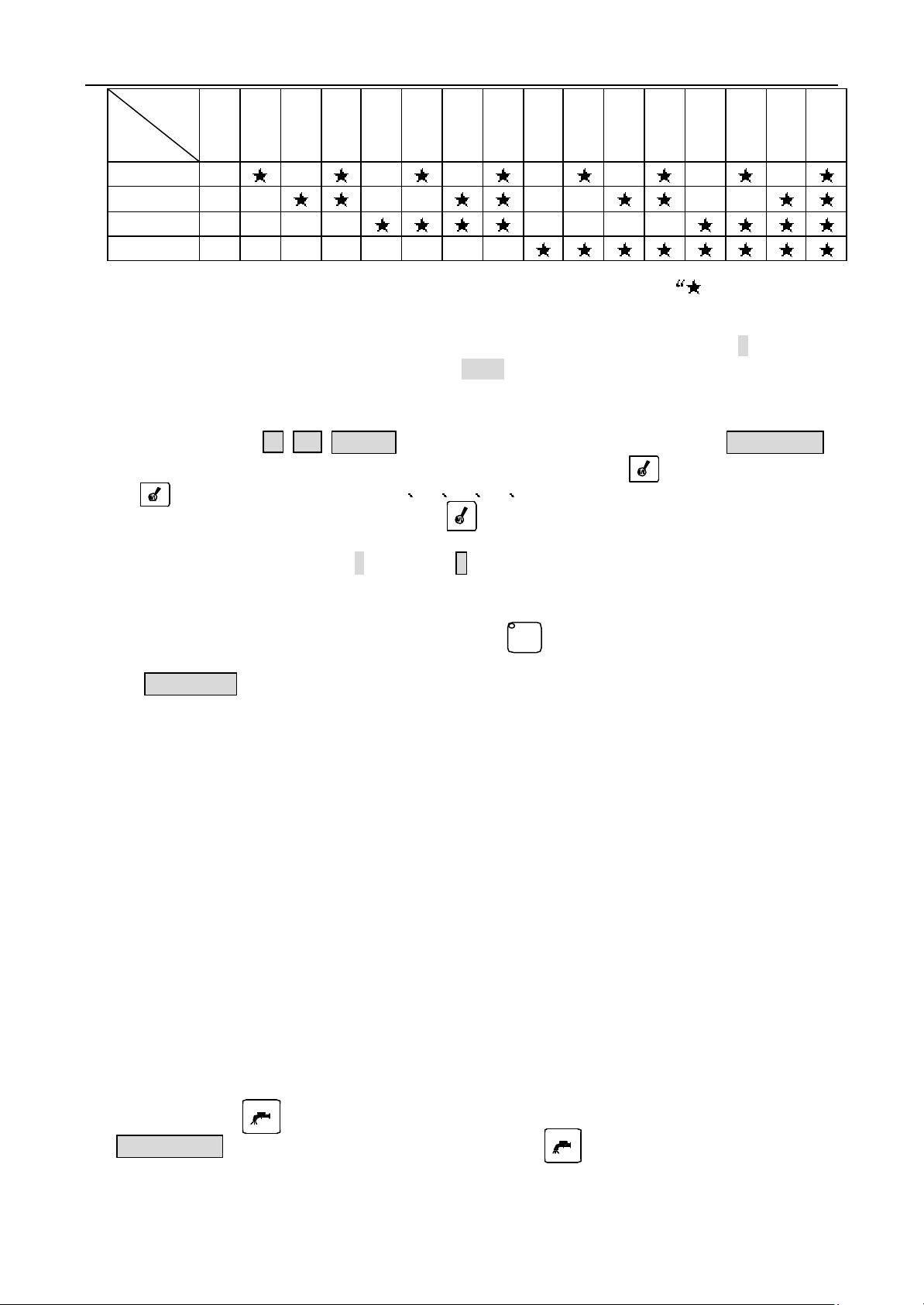

Operation GSK928TC Turning CNC System

code

output

bit

S1

S2

S3

S4

The output signal is valid to correspond to the bit with the symbol ”.

l Input the S code with keyboard to control the spindle rev. Push the button S, input the

required rev code, and push the button

with the defined code.

For example: Select the No.8 step spindle rev.

Orderly input S 8

In addition, switch the spindle rev by pushing the button too. By pushing this

button , the spindle rev changes in S1 S2 S3 S4 (P11,SCOD=0) or S0~S15(P11,SCOD=1). The

spindle rev switch from S2 to S1 by pushing the button trice when the spindle rev only has two steps.

l If the frequency conversion motor drives, input the the rev to control the spindle rev

directly. Push the button S to display S, then input the rev, and push the button Enter

to output the 0 ̄10V simulate voltage to the frequency invertor.

l Check the encoder lines. In Manual Jog mode, the pulse numbers per rotate can be checked

directly. Start the spindle, push the button , and then display the pulse number

per rotate. If the encoder isn’t assemblied exactly or the spindle isn’t started,

编码器信号错

l To increase the torque at the low frequency, some machine adopts teo steps gearshift.

This sytem offers a input signal SHL and the parameter P09, P10. The input signal SHL

is used to check the gearshift step. The parameter P09 is used to define the biggest rev

in the low gearshift step. The parameter P10 is used to define the biggest rev in the

high gearshift step. After input the rev directly, the rev will be translated into the

simulate voltage to control the frequency invertor.

l If the CHCD bit of the parameter P11 is 0, display the seting spindle rev. If the CHCD

bit of the parameter P11 is 1, display the actual spindle rev.

Note 1: The spindle rev control mode can be set by the MDSP bit of the parameter P12. MDSP=0, multilevel

Note 2: If the MDSP bit of the parameter P12 is 1, the SCOD bit of the parameter is invalid, the spindle

S00 S01 S02 S03 S04 S05 S06 S07 S08 S09 S10 S11 S12 S13 S14 S15

Enter

, then the rev control signal is exported

E nter

to output the S8 rev signal and display 编程转速 S08.

空运行

Dry

is displayed,push any button to return to the Manual Jog mode.

control; MDSP=1, 0 ̄10V simulate voltage control.

control is only frequency conversion control, and the outputs S1,S2,S3,S4 ,S0 ̄S15 and the s pindle

shift button are ineffective.

4.4.13 Manual coolant control

In manual Jog mode, start/stop the coolant

Push the button to start/stop the coolant. When the coolant is working, display

COOLANT ON

, at the same tome, the LED on the button is lightened.

20 GSK CNC Equipment Company

Page 21

Operation GSK928TC Turning CNC System

4.4.14 Manual Tool-exchange Control

Usually, this system can control the 4 position electric toolpost. By coding the tool number

T1 T4, it can control the 8 postion toolpost.

Three kinds of toolexchange methods:

Method 1. If set the MODT of the parameter P12 as 0, Push the button once, the toolpost

switches to the next postion, and display the next tool number.

Method 2. If set the MODT of the parameter P12 as 1, Push the buttons ,

switches to the next postion, and display the next tool number. After push the

button , push any other button except the button

Method 3. Input T * 0 directly by keyboard (* is the tool number to be employed), and push

the button

Note 1: In method 1 and 2, the tools can be exchanged, but it can

3, input the compensation number following the tool number *, the tool compensation can be executed.

For example:

Input T22, switch the No.2 tool and apply the No.2 tool compensation

Input T31, switch the No.3 tool and apply the No.1 tool compensation

Input T40, switch the No.4 tool and cancel the tool compe nsation

Input T00, escape the toolexchange and cancel the tool compensation

Note 2: If the electric toolpost is failure, display 刀位号报警 .

Note 3: This system adopts the absolute tool exchange, so every tool number is immovable on the toolpost.

When install the tool, the actual tool position must be accordant with the displayed tool number.

Note 4: When the TCON of the parameter P11 is 1, the lineup tool is choosed, there is not the signal output

when the tool exchanges.

Note 5: In method 3, the tool compensation can be realized by moving the slider of the machine or amendingthe

coordinate. It is defined with the PTSR of the paramete r P11.

PTSR=0 Move the slider to realize the tool compensation.

PTSR=1 Amend the coordinate to realize the tool compensation.

Enter

to switch to the

Enter

,the toolpost

Enter

, the tool will not exchange.

*

tool.

’

t realize the tool compensation. In Method

4.4.15 Manual Tool Regulate

Usually, many different tools are adopted in cutting one workpiece. The tools’ point can not

coincide due to install warp and different abrasion. To avoid the tool compensation at programming,

this system set the tool regulation that the tool offset can be created by this system automatically.

When user edits the user program according to the workpiece drawing and the cutting art, the tool

offset isn’t considered. In user program, transfer the corresponding tool compensation with

toolexchange dictate.

Here are the two methods in this system:

Trial cutting tool regulation:

(The workpiece coordinate must be defined first. The regulattion method is same as to define

the workpiece coordinate)

1. Install the trial workpiece reliably on the machine, and select any one of the tools

(usually the earlier using tool is selected)

2. Select the seemly spindle speed, then start spindle, move the tool in manual feed, cut

a little shoulder on the workpiece.

GSK CNC Equipment Company 21

Page 22

Operation GSK928TC Turning CNC System

3. Under the tool hasn’t any move on the X axis direction, the tool moves to the safe position

along the Z axis direction. Stop the spindle.

4. Measure the diameter of the shoulder, push the button I , the

input the metrical diameter then push the button

is the tool number), and push the button

Enter

Enter

, the system displays

, the tool offset in X axis is figured out

automatically, the system deposits the offset in the corresponding offset parameter

storage.

In the OFFSET mode, it can be amended or viewed. When display

of 1 ̄8,and push the button

Enter

,then the tool offset in X axis is figured out

automatically, the system deposits the offset in the corresponding offset parameter

storage. Otherwise push the button ESC to cancel the figuring and depositing the offset

in the X axis.

5. Start the spindle again, move the tool in manual feed, cut an end on the workpiece.

6. Under the t ool hasn’t any move on the Z axis direction, the tool moves to the safe position

along the X axis direction. Stop the spindle.

Select a datum mark (a fixure on the machine, such as chuck end, frock datum plane), measure

the distance from the datum mark to the machined end in the Z axis. Push the button K,

OFFSET X

T * X

is displayed,

T * X

(*

,input the a figure

the

OFFSET Z

display

is displayed,then input the metrical diameter and push the button

T * Z ( *

is the tool number), and push the button

Enter

, the tool offset in Z

Enter

,

axis is figured out automatically, the system deposits the offset in the corresponding

offset parameter storage.

In the OFFSET mode, it can be amended or viewed. When display

of 1 8,and push the button

Enter

,then the tool offset in Z axis is figured out

T * Z

,input the a figure

automatically, the system deposits the offset in the corresponding offset parameter

storage. Otherwise push the button

ESC

to cancel the figuring and depositing the offset

in the Z axis.

7. Change the next tool, Repeat the above approaches to seting this tool.

8. If the workpiece coordinate hasn’t any change, All tools can be regulated such this.

Pointing tool regulation

1. Install the trial workpiece reliably on the machine, and select any one of the tools

(usually the earlier using tool is selected) as a reference tool.

2. Select the seemly spindle speed and start the spindle.

3. Select the seemly manual feed speed. In Manual Jog mode, move the tool to close to the selected point

on the workpiece. After confirm the tool point coincides with the selected point on the workpiece, stop

moving the tool.

4. Push the button Enter, the tool number and tool offset are displayed with highlight, push the

button twice continuously. The display of the tool number and tool offset is in normal again,

now the tool coordinate is deposited, and this tool coordinate goes into the benchmark to regulate the

other tools. (Except the reference tool, the other tool can’t be operated with this approach).

5. Push the button Enter, and the button to confirm, (if regulate the tool again for the damage of the

primary tool, please push the button ), the display of the tool number and the tool offset is in

输入

改写

normal, the tool number and the tool offset are figured out and deposited the current tool parameter

storage. In the OFFSET mode, the tool offset can be amended or viewed.

22 GSK CNC Equipment Company

Page 23

Operation GSK928TC Turning CNC System

6. In Manual Jog mode, Move out the toolpost to the position where the tool can be exchanged safely.

Exchange the regulating tool to the working position.

7. Repeat the above approach 2, 3, 5 up to finished the all tool regulations.

Note 1: With tool regulator, the regulate point should be set at the cross point of the tool regulator

when the spindle stops.

Note 2: In the OFFSET mode, the created tool offset can be amended and viewed. C onsult the description

on the OFFSET mode.

Note 3: If the tool is damaged or replaced, select any other tool as the reference tool. Fisrt, regulate

the reference tool to the selected pointg on the workpiece and confirm the oofset as reference

tool such as above approach 4, but refuse above approach 5. Escape to the safe positon to exchange

the new tool, and then repeat above approaches 2, 3, 5 to regulate the non-reference tools. (The

offset of the primary tool isnot always zero)

Note 4: If there are the lineup tools in use, the metrical offset is negative in trial cutting tool regulation

when the regulating tool is on the other side of the workpiece. Rewrite the sign of the offset

by pushing the button +/ - in the pointing tool regulation.

4.4.16 Manually return to the program reference point.

After defined the program reference point (program origin), push this button to return to

this point at any moment.

X

X axis returnning to program reference point Button : It is valid only on the JOG/AUTO mode.

Push this button to return from the current positon to the program reference point in x axis with the current quick

move speed.

Z

Z axis returnning to program reference point Button: It is valid only on the JOG/AUTO mode.

Push this button to return from the current positon to the program reference point in z axis with the current quick

move speed.

Note: After return to the program reference point in X axis and Z axis, all tool offset and system offset are cancelled,

and display T * 0 ( the * is the current tool number).

4.4.17 Manually return to the machine reference point (mechanic origin)

Fix a machine reference point on the machine. After return to the machine reference point,

go back to the start position (the start position must be set first) to delete cumulation error

or to avoid the accident.

Note: to cancel the function to return to the machine reference point, set the MZRO bit

of the parameter P12 on 0.

X axis returnning to machine reference point Button: It is valid only on the JOG mode. By

X

pushing this button, move the tool to the machine reference point in X axis with the current quick move speed.

Z

Z axis returnning to machine reference point Button: It is valid only on the JOG mode. By

pushing this button, move the tool to the machine reference point in X axis with the current quick move speed.

If the MZRM bit of the parameter P12 is 0, the reset process is as follows:

1 The slider moves along the positive direction of the appointed axis. After the block on the

GSK CNC Equipment Company 23

Page 24

Operation GSK928TC Turning CNC System

X 0090. 000

Z 0125. 000

自动

slider pushes down the reset deceleration switch, the slider begin to decelerate to the lowest

speed (it is defined by the parameters P17 or P18), and keep moving with this speed until

the block disengages from the reset deceleration switch.

2 When this system receive the encode signal (or the zero signal of the proximity switch),

the slider arrive at the coordinate origin, the slider stops to finish the reset.

If the MZRM bit of the parameter P12 is 1, the reset process is as follows:

1 The slider moves along the positive direction of the appointed axis. After the block on the

slider pushes down the reset deceleration switch, the slider begin to decelerate to the lowest

speed (it is defined by the parameters P17 or P18), and keep moving with this speed to reset

the coordinate.

2 When the block disengages from the reset deceleration switch, the reset finishes.

Note 1: Returnning to the machine reference point is positive, so confirm that the toolpost i s in the negative

direction of the machine reference point before returning to the machine reference point.

Note 2: To avoid the accident, the MZRO bit of the parameter P12 must be defined in 0, if there has n ot

the reset deceleration switch on the machine .

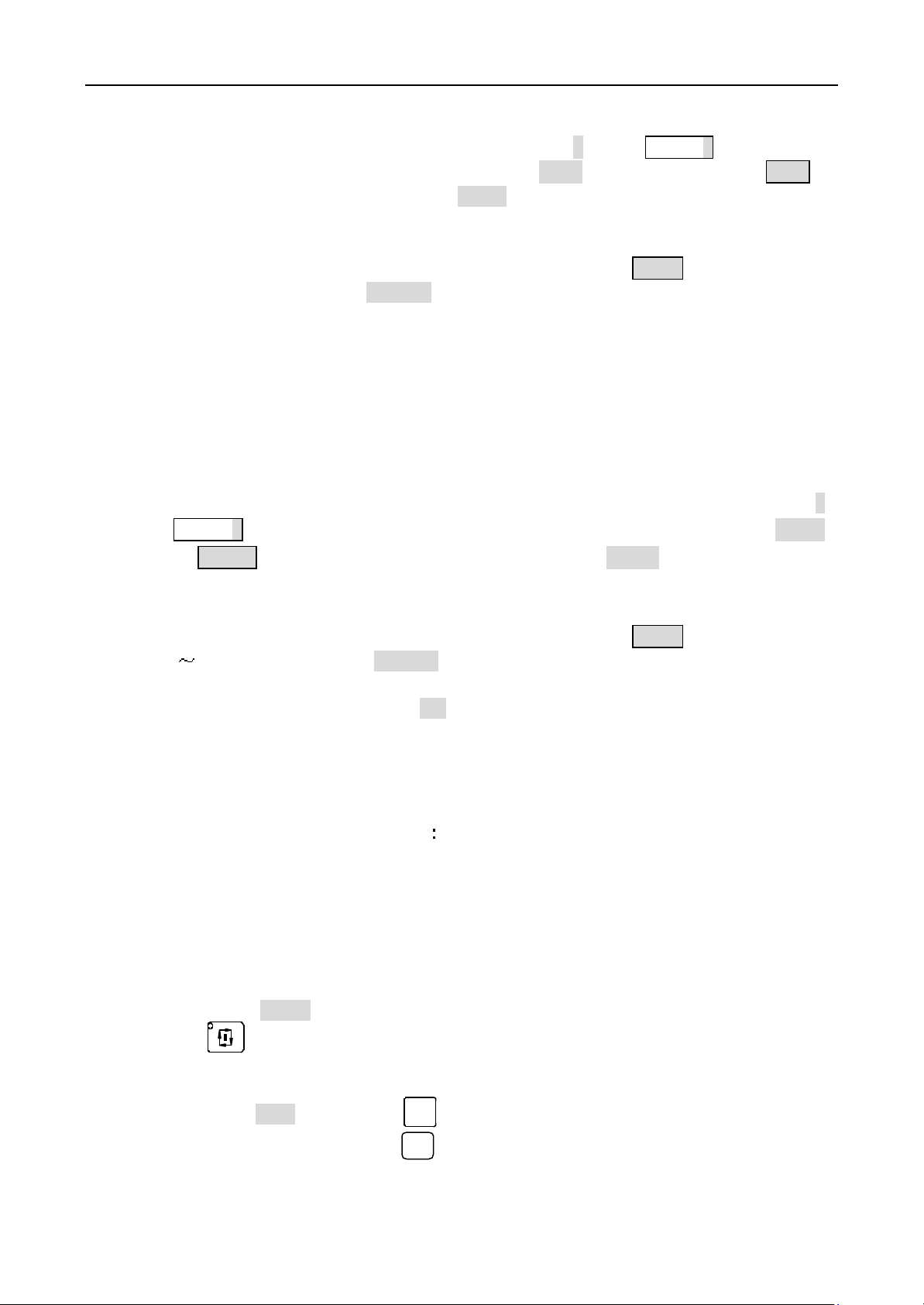

4.5 AUTO mode

In AUTO mode, this system runs according to the user program step by step.

Push the button to enter AUTO mode. There have try run, machining run, single segment

run and continuous machining run in AUTO mode.

AUTO

AUTOCONTINUE %00

*N0000 G50 X100 Z100

N0010 M3 S2

FEEDRATE 100% SPINDLE STOP

FASTRATE 100% SPDL REV 0000

COOLANT OFF TOOL 1 OFFSET 0

EDIT MANU AUTO PARA OFFT DIAG

PICTURE 15 AUTO mode

4.5.1 Fuction buttons in AUTO mode

单段

Single

Change the run mode between AUTO SINGLE and AUTO CONTINUE by pushing the button , the

corresponding run mode is displayed as

mode. When the program is running in Auto Continue mode, it can pause after the current segment

24 GSK CNC Equipment Company

Switch between AUTO SINGLE mode and AUTO CONTINUE mode.

AUTO SINGLE

in singlo mode or

AUTO CONTINUE

单段

Single

in continue

Page 25

Operation GSK928TC Turning CNC System

Input

by pushing this button. Run the next segments by pushing the RUN button .

空运行

Dry

Change the run mode between dry running mode and machining mode by pushing this button .

In dry running mode, the LED on the button is light, the sliders of the machine are actionless

and the other assistant functions are invalid. In machining mode, the LED on the button is

lightless.

Push this button to select the segment to be run, then push then button to

start from this segment.

In AUTO SINGLE mode, push this button to run one segment. In loop dictate, an action

will be carried out by pushing this button.

In AUTO continue mode, push this button to run the all program once from cover to cover.

When the program is running, push this button to speed-down and stop, then it displays

Switch between dry running mode and machining mode

空运行

Dry

输入

Select the segment number

Input

输入

Input

Run button

Feed hold button

空运行

Dry

PAUSE!

with highlight. Push the run button to next program, otherwise, push the button

ESC

to

escape from the current program running.

4.5.2 Run the program automatically

Enter the Auto mode after all are ready, run the selected program orderly to machine the

workpiece automatically.

4.5.2.1 Run from the first row of the program

After enter the AUTO mode, the two segment to be run are displayed, and the sign * is displayed

in front of the current segment. Push the Run button to start running automatically.The

running segment is displayed on top, the second row is the segment to be run.

4.5.2.2 Run from the appointed row in the program

In some special conditions, it is necessary to run from the appointed segment in the program.

This system allows to start the current program from any segment in this program and to park the

toolpost on the corresponding position.

1. Select the appointed row in the program to be run.

a) Push the button to display the first row in the current program.

输入

b) Push the buttons to page up/down the displayed segments. Push ESC to return

to the former displayed segment.

2. When the appointed segment is displayed on top, push the button

prompts

RUN?

to wait for the next operation.

Enter

, then the system

GSK CNC Equipment Company 25

Page 26

Operation GSK928TC Turning CNC System

3. When the system prompts RUN? , push the Run button to move to the corresponding

coordinates automatically as same as G00 mode. Otherwise, push the button ESC to return

to the former displayed segment.

4. Push the button again to run from the appointed segment automatically.

Note 1: The appoint segment can’t be in any fixed loop or compound loop, otherwise the result must be out of

expectation.

4.5.2.3 Single segment run and continue run

Validate the new program with Single mode. Run one segment by pushing the Run button

once.After confirm the action of the machine is exact, push the Run button to run the

next segment, repeat above operation up to the end of the program. Otherwise, if there has any

segment unsuitable for the expectant action, stop running to return to the program reference point.

Correct the program thouroughly, then can run the program in Auto continue mode.

Switch between SINGLE mode and CONTINUE mode by pushing the button .

单段

Single

1. Push the button when there has not the program that it is running, switch between

SINGLE mode and CONTINUE mode, and display the corresponding mode. Display

segment running mode, display

2. When there has a program that it is running, push this button to pause after finish

the current segment, and display

单段

Single

AUTOCONTINUE

SINGLE STOP

in continue running mode.

with highlight as PICTURE 16. Push the Run button

单段

Single

AUTO SINGLE

in single

to continue running the next segments in AUTOCONTINUE mode. Only after finish the current

program, can switch to the SINGLE mode by pushing the button . Single Stop can be repeated

单段

Single

in running one program continuously.

3. The button is invalid in running the program with SINGLE mode.

单段

Single

Note: The initial state is AUTOCONTINUE mode.

4.5.2.4 Dry run and machining

Validate the new program with dry run mode before machining with the program. This system

can display the coordinates in dry run mode, so can check if the coordinates agree with the actual

demand, if the relations between segments are exactly to avoild the accident of error data input.

Switch Dry run mode and machining mode bu pushing the button . The led on the button is

空运行

Dry

空运行

Dry

lighting in Dry run mode.

N ote 1 . In Dry run mode, the coordinates don

Note 2. The initial state is Machining mode when enter AUTO mode.

’

t move, the assistant functions are invalid.

26 GSK CNC Equipment Company

Page 27

Operation GSK928TC Turning CNC System

X 0090. 000

Z 0125. 000

X 0090. 000

Z 0125. 000

PICTURE 17 DISPLAY IN PROGRAM RUNNING

AUTOCONTINUE %00 SINGLE STOP

*N0000 G50 X100 Z100

N0010 M3 S2

FEEDRATE 100% SPINDLE STOP

FASTRATE 100% SPDL REV 0000

COOLANT OFF TOOL 1 OFFSET 0

EDIT MANU AUTO PARA OFFT DIAG

PICTURE 16 SINGLE STOP

4.5.3 Display in program running

In program running, this system can display the running states, coordinates, workpiece planar

skeleton map, and trail of tool point and so on. It is very convenient to monitor and control

the system and the machine.

Display contents:

1. The dynamical coordinates, the dynamical planer outline or the trail of tool point

2. The contents of the current running segment

3. The states of spindle, coolant, rev, tool and other assistant functions

4. Feed and quickmove speed multiple

4.5.3.1 Coordinates display in program running

The initial display mode is the coordinates display when enter the AUTO mode as PICTURE17.

Push the button

change from the coordinates display into trace display, only can display the trail of the tool

point after switch, the trail of the tool point can’t be displayed before switch.

T

N0010 M3 S2

to switch between the coordinates display and the trail display. When

AUTOCONTINUE %00

*N0000 G50 X100 Z100

FEEDRATE 100% SPINDLE STOP

FASTRATE 100% SPDL REV 0000

COOLANT OFF TOOL 1 OFFSET 0

EDIT MANU AUTO PARA OFFT DIAG

4.5.3.2 Figure display in program running

When there has not the program that is running in AUTO mode, push the button

GSK CNC Equipment Company 27

T

to display the

Page 28

Operation GSK928TC Turning CNC System

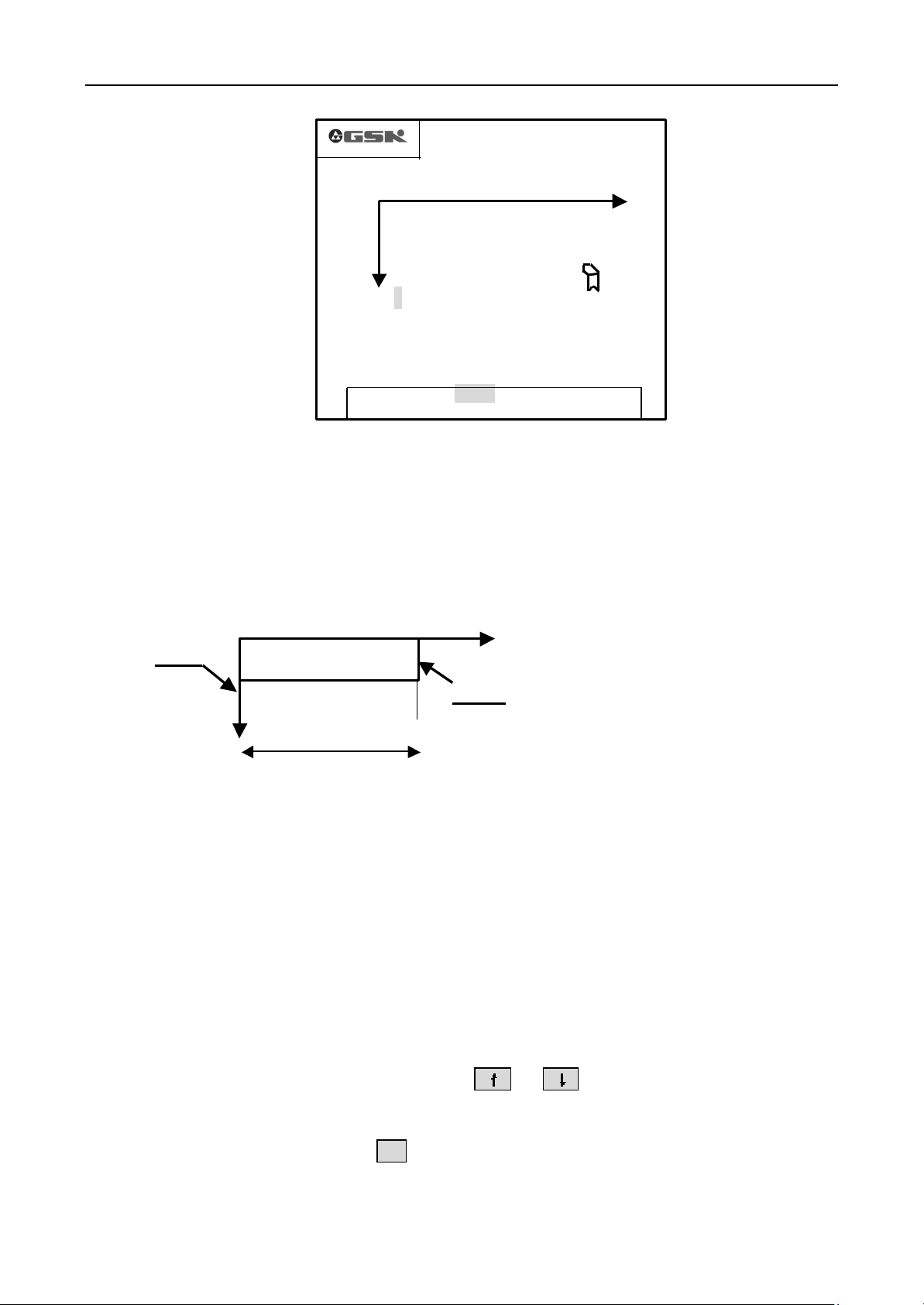

PARA OFFT DIAG

workblank outline with actual planar dimensions and the simulated tool shape as PICTURE 18.

Switch between the actual planar outline display and the trail display of the tool point

by pushing the button

PICTURE 18 ACTUAL PLANAR OUTLINE DISPLAY IN AUTO MODE

N0000 G50 X100 Z100

EDIT MANU AUTO PARA OFFT DIAG

Z

when there has not program that is running in AUTO mode as PICTURE19.

N0000 G50 X100 Z100

PICTURE 19 THE TRAIL DISPLAY OF THE TOOL POINT

AUTO CONTINUE %00

Z

X

FEEDRATE 100% SPINDLE STOP

FASTRATE 100% SPDL REV 0000

COOLANT OFF TOOL 1 OFFSET 0

AUTO CONTINUE %00

Z

X

FEEDRATE 100% SPINDLE STOP

FASTRATE 100% SPDL REV 0000

COOLANT OFF TOOL 1 OFFSET 0

EDIT MANU AUTO

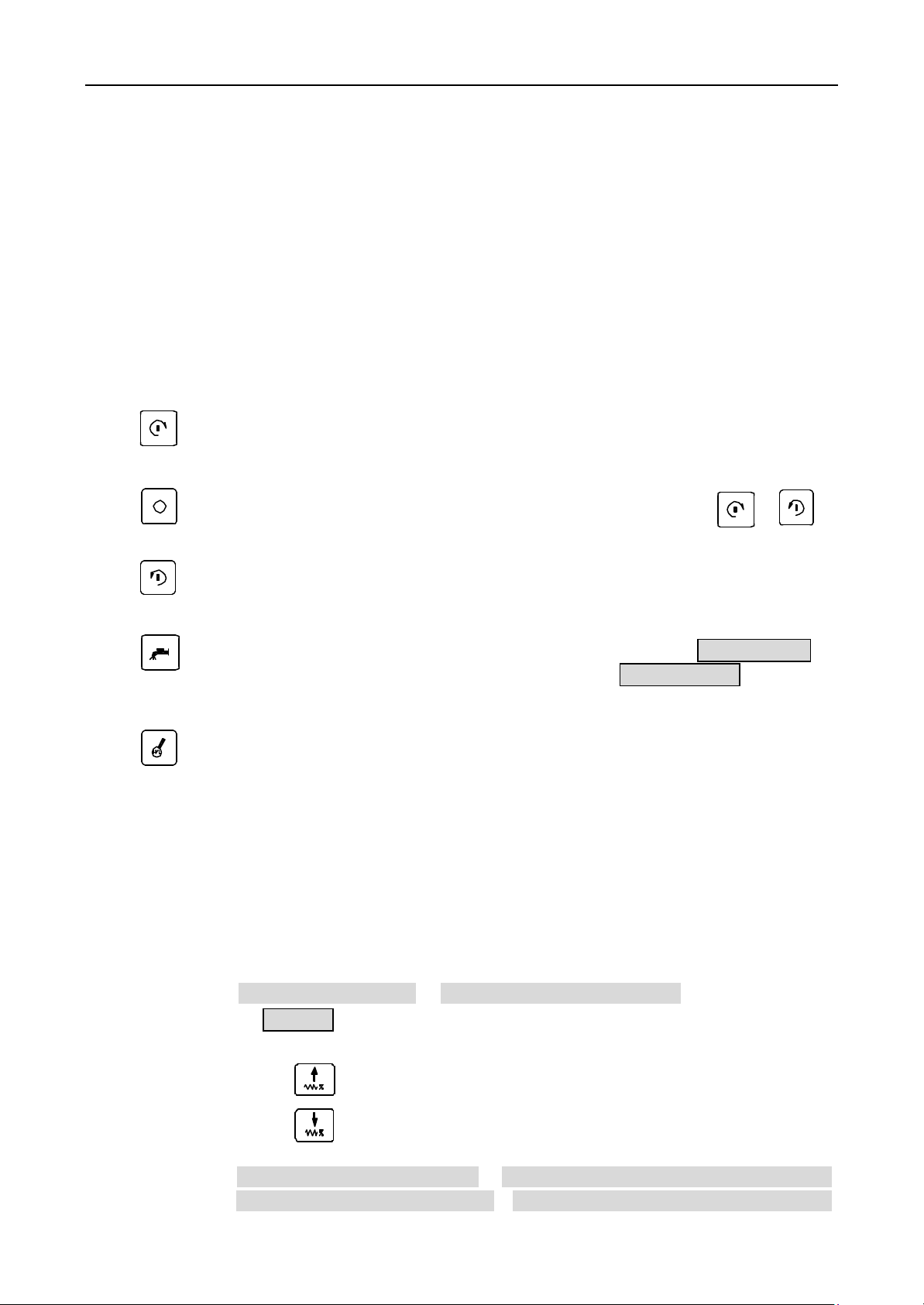

4.5.3.3 Define the data of the figure display

The screen area of this system is limited, so the figure display can be defined in this system with workblank

length and diameter, tool initial offset and display scale. Push the button Enter to set the workblank length and

diameter, tool initial offset and display scale in the actual planar outline display or the trail display of

the tool point as PICTURE 20.

28 GSK CNC Equipment Company

Page 29

Operation GSK928TC Turning CNC System

Z

PICTURE 20 DEFINE THE DATA OF THE FIGURE

Length: Total length of the workblank, unit : mm

Diameter: Max. Diameter of the workblank, unit : mm

Offset: The distance in Z axis from the program reference point to the machining start on the workblank (the

program reference point in X axis is the center of the workblank), unit: mm

N0000 G50 X100 Z100

长度

FEEDRATE 100% SPINDLE STOP

FASTRATE 100% SPDL REV 0000

COOLANT OFF TOOL 1 OFFSET 0

EDIT MANU AUTO PARA OFFT DIAG

AUTO CONTINUE %00

Z

X

100

直径

80

偏移

0

比例

2:1

e.g. Workblank length: 100mm

Endface1

Endface 2

If the program reference point is at the endface 1, the offset is 0.

If the program reference point is at the endface 2, the offset is 100.

Display scale: It ensures the display size but it doesn’t change the actual machining dimensions. If the

dimension of the workblank isnot suitable for the screen size, the display scale can be adjusted to display the

workblank properly.

X

4.5.3.4 Input the data of figure display

When there has no program that is running or that pauses in AUTO mode, push the button Enter

to display the current data as PICTURE 18, and the cursor points to the first figure of the

length.Input the data, push the button Enter to confirm and input the next group of data. Recycle

in the 4 group of data by pushing the button Enter.

Adjust the display scale by pushing the button

scale.The display scale has 7 steps as 4:1 3:1 2:1 1:1 1:2 1:3 1:4. It can be adjusted to

realize the best display effect.

After adjustment, push the button

the figure dimensions are amended according to the new display scale and the other new data

automatically.

ESC

to return to the Auto mode. If it is the figure display,

or

when the cursor is at the display

GSK CNC Equipment Company 29

Page 30

Operation GSK928TC Turning CNC System

When the display data overrun the screen. The system prompts XZ overlimit, the display data

must be modified again.

Note 1: The start position of the tool must be out of the workblank outline, otherwise, the machining processs

can’t be displayed exactly.

Note 2: Switch from coordinates display to figure display in machining, only the part of next machining

trail can be displayed, but the part of former machining trail can’t be displayed. Especially switch

to the actual planar outlind display, the workpiece outline can

new loop.

’

t be displayed normally before a

4.5.4 Operation of the assistant functions

In Auto mode, all the machine assistant functions such as spindle, coolant, speed and other controls can be

operated by pushing corresponding buttons manually without the program in running. The coolant can be

controlled in running.

Spindle positive rotation button The spindle rotates counter-clockwise (watch from the motor

shaft) and the Led on this button is lighted by pushing this button.

Spindle stop button The spindle stops running and the Led on the button or is

extinguished when push this button.

Spindle negative rotation button The spindle rotates clockwise (watch from the motor shaft)

and the Led on this button is lighted by pushing this button.

Coolant button Switch the coolant on/off. When start the coolant, display COOLANT ON on

the secreen and the Led on this button is lighted. When stop the coolant, display COOLANT OFF on the screen

and the Led on this button is extinguished.

Spindle shift button Select the spindle speed when the main spindle motor has more then one

step speed (not more then 16 steps) and the machine has the control loop.

Note 1: The toolchange fuction can

’

t be operated in Auto mode.

4.5.5 Adjustment of the speed mutiple

In Auto mode, the speeds can be adjusted by the speed multiple, but the program or the

parameter hasn’t to be amended.

Feed speed multiple

It is displayed as

Actual feed speed

FEEDRATE

: adjust the feed speed defined by F dictate.

=

F * feed speed multiple

.It has 16 steps from 0% ̄150% (distance 10%). All the feed speed

dictates are restricted by the f eed speed multiple. When the multiple is 0, the running stops.

By pushing the button , increase the feed speed multiple up to 150%

By pushing the button , reduce the feed speed multiple up to 0%.

Fast move speed multiple

X axie actual fast move speed

Z axie actual fast move speed

: adjust the fast move speed defined in

=

Parameter P05 * fast move speed multiple

=

Parameter P06 * fast move speed multiple

G00

and other dictates.

30 GSK CNC Equipment Company

Page 31

Operation GSK928TC Turning CNC System

It is displayed as fastrate. It has 4 steps 25%, 50%, 75%, 100%. All the fast move dictates

and the actions are restricted by the fast move speed multiple.

By pushing the button , increase the fast move speed multiple up to 100%

By pushing the button , reduce the fast move speed multiple up to 25%.

Note 1: whether there has the program in running, the feed speed multiple and the fase move speed multiple

can be adjusted by push the corresponding buttons. And the speed will be changed in running with the

corresponding multiple.

4.5.6 Some operations in running

Feed hold

Push the button , the tool speeds down and stop, display

PAUSE!

on the screen.

For run the next segments, push the button . For escape from feedhold, stop running the

next segments, and switch to AUTO SINGLE mode, push the button .

退出

Esc

Single stop

Push the button , the running pauses after finish the current segment running, and

display

SINGLE STOP

from SINGLE stop to AUTO mode, and stop the running, push the button .

单段

Single

on the screen. For run the next segments, push the button .For escape

退出

Esc

Note 1: The single stop is valid in AUTOCONTINUE mode. It is invalid in AUTO SINGLE mode. In running

the fixed loop dictates, it is valid after finish once of this loop.

Coolant start/stop

Push the button , start or stop the coolant. When it switches on, the Led on

the button is lighted. When it switches off, the Led on the Button is extinguished.

Speed multiple adjustment

Both feed speed multiple and fast move speed multiple can be amended in running, and it is invalid

immediately as soon as it is amended. The multiple adjustment is as chapter 4.5.5 Adjustment of the

speed multiple .

If the feed speed multiple is 0 before running, the system prompts FEEDRATE 0%. When adjust the

feed speed multiple to 0% in running, the running stops without prompt. If adjust the feed speed multiple

isnot 0, the running carrys on.

4.5.7 Return to the program reference point in AUTO mode

For simplify the operation, the program can be started anywhere the tool stays after the workpiece coordinates

and the program reference point are defined. But the first dictate must be G00, and the X and Z axes cooedinates

must be defined with absolute coordinates. All resets by the reset button, and G26/G27/G29 dictates are returning

to the program reference point. After G26/G27/G29, the two axes absolute coordintes must be positioned with

G00 at the same time to ensure that the current workpiece keeps on being machined exactly. After reset by the

reset button, the system returns to the first segment of the program automatically. If push the run button ,

then the system runs from the first segment.

GSK CNC Equipment Company 31

Page 32

Operation GSK928TC Turning CNC System

on the

different machine. Please refer to the operation manual of the

4.5.8 Feedhold knob in running automatically

There has an interface to the external feed/spindl hold knob, It can control the spindle rotation and slider