Page 1

Page 2

In this manual, we have tried as much as possible to describe all

the various matters about the system. However, we can not describe

all the matters which must not be done or which can not be done

because there are so many possibilities. Therefore, matters which are

not especially described in this manual should be regarded as

“impossible” or “forbidden”.

The copyright of the user manual is owned by GSK CNC

Equipment Co., Ltd (Hereinafter referred to as GSK).It is against the

law for any organization or individual to reproduce this manual in any

form without the permission of GSK and GSK reserves the right to

investigate its law duty.

Page 3

PREFACE

Dear user:

It’s our great pleasure that you select GSK928GA/GE surface/cylindrical

grinding machine CNC system (hereinafter referred to as system).

This manual is divided as three parts: the operation, the programming and

PLC programming chapters, which introduces CNC basic operation,

programming and the installation, connection and setting of the system,

and also lists some examples, which can be taken as the reference for the

programmer.

This manual applies to the software (V3.1 or the above version) of

GSK928GA/GE surface/

cylindrical grinding machine CNC system. Before

programming, please read the manual carefully.

This manual covers the content of using the system and the precautions.

Page 4

SAFETY PRECAUTIONS

The incorrect operation may cause the accident, so before using the

system, please read the manual carefully!

Before using the system, please pay attention to the following matters.

● Connect the emergency button of the system. Because the emergence

stop input is the normally closed contact, if the button isn’t connected or

it’s the normally open contact, the system will alarm and not work after

the system is turned on. Note: It’s not the system malfunction.

● Set the reference position based on the tool actual installed position.

The accidence may happen if the reference position return function is

used without setting the reference position.

Note: The system power supply installed on/in the cabinet is

dedicated for GSK CNC system.

It’s forbidden that the user uses the power supply as the other

purpose, otherwise, it may cause the great hazard.

Page 5

RESPONSIBILITY

Responsibility of the manufacturer

——The manufacturer should be in charge of the design and the structure of CNC

system and the its accessories.

——The manufacturer should be responsible for the safety of CNC system and its

accessories.

——The manufacturer should be in charge of the information and suggestion

providing for the user.

Responsibility of the end user

——The user should be very familiar with the safety operation through learning CNC

system or participating in the training session.

——The user should be responsible for the safety after adding, changing or modifying

the original CNC system or its accessories.

——The user should be in charge of the danger resulted from the operation, adjusting,

maintenance, installation and storage which are not complied with the manual

stipulation.

All specifications and designs are subject to change without notice.

The manual is kept by the end user.

Thank you for your friendly support during using GSK product.

Page 6

GSK928GA/GE Grinding Machine CNC System Operator’s Manual

CONTENTS

CONTENTS...................................................................................................I

SECTION Ⅰ OPERATION .........................................................................1

CHAPTER 1 SYSTEM OVERVIEW ...........................................................2

1.1 Introduction of the system.................................................................................2

1.1.1 Introduction of GSK928GA/GE system .......................................................................... 2

1.1.2 Main function and performance ....................................................................................... 2

1.1.3 The differences between GSK928GA and GSK928GE...............................................3

1.2 Introduction of system operation panels ...........................................................4

1.2.1 Introduction of the address keypad panel ...................................................................... 5

1.2.2 Introduction of the panel with function keys................................................................... 7

1.2.3 Introduction of the machine operation panel .................................................................8

CHAPTER 2 SYSTEM BASIC OPERATION .............................................9

2.1 System power on/off .........................................................................................9

2.1.1 Power on ............................................................................................................................. 9

2.1.2 Debugging mode.............................................................................................................. 10

2.1.3 Power off ............................................................................................................................11

2.1.4 Initializing CNC system....................................................................................................11

2.2 Machine zero return (HOME).......................................................................... 11

2.3 Emergency stop..............................................................................................12

2.4 Alarm ..............................................................................................................13

2.4.1 Limit switch alarm ............................................................................................................ 13

2.4.2 Software limit alarm......................................................................................................... 13

2.4.4 Drive unit alarm...................................................................................................................... 13

2.4.5 Other alarms...........................................................................................................................13

2.5 LCD brightness adjustment.............................................................................14

CHAPTER 3 EDIT MODE ........................................................................15

3.1 Edit mode........................................................................................................15

3.2 Part program directory search ........................................................................17

3.3 Part program management.............................................................................17

3.3.1 Creating a new part program ......................................................................................... 17

3.3.2 Selecting a part program ................................................................................................ 18

3.3.3 Copying a part program .................................................................................................. 19

3.3.4 Renaming a part program............................................................................................... 19

3.3.5 Deleting a part program .................................................................................................. 19

I

Page 7

GSK928GA/GE Grinding Machine CNC System Operator’s Manual

3.4 Inputting and editing a part program ...............................................................21

3.4.1 Automatic generating the serial number ......................................................................21

3.4.2 Inputting the program content........................................................................................ 21

3.4.3 Inserting a program line .................................................................................................. 22

3.4.4 Deleting a character or a block...................................................................................... 23

3.4.5 Inputting a field in a block............................................................................................... 24

3.4.6 Rewriting the content of a block .................................................................................... 25

3.4.7 Skipping a block...............................................................................................................26

3.5 External inputting a part program....................................................................27

3.6 External outputting a part program .................................................................27

3.7 Deleting all part programs............................................................................... 28

CHAPTER 4 JOG MODE.........................................................................29

4.1 Overview of Jog mode ....................................................................................29

4.1.1 Manual operation ............................................................................................................. 29

4.1.2 Manual step operation ....................................................................................................30

4.1.3 MPG operation ................................................................................................................. 31

4.2 Selecting the manual feedrate ........................................................................31

4.2.1 Selecting manual feedrate overrides ............................................................................ 32

4.2.2 Selecting manual rapid feedrate overrides .................................................................. 32

4.2.3 Manual setting feedrate F...............................................................................................33

4.3 Setting a workpiece coordinate system ..........................................................33

4.4 Manual input movement control......................................................................35

4.5 Manual measuring instrument control.............................................................35

4.6 Manual grinding wheel spindle control............................................................35

4.7 Manual machine-head control.........................................................................36

4.8 Manual hydraulic pressure control ..................................................................36

4.9 Manual cooling control....................................................................................36

4.10 Manual spindle control....................................................................................36

4.11 Manual inputting and executing M function..................................................... 36

4.12 Manual inputting and switching into G state....................................................37

4.13 System angular axis function in Jog mode .....................................................38

CHAPTER 5 AUTO MODE ......................................................................40

5.1 Function key in Auto mode..............................................................................40

5.2 Automatic running a machining program ........................................................41

5.2.1 Starting from the first line of a machining program ..................................................... 41

5.2.2 Starting from the specified line of a machining program............................................42

5.2.3 A machining program running in single block or continuous running ...................... 42

5.3 Dry run (machine lock)....................................................................................43

II

Page 8

GSK928GA/GE Grinding Machine CNC System Operator’s Manual

5.4 Checking the macro variable in Auto mode ....................................................44

5.5 Manual operating the machine miscellaneous function ..................................44

5.6 Adjusting speed overrides...............................................................................45

CHAPTER 6 SETTING SYSTEM PARAMETERS ...................................46

6.1 Introduction of parameters..............................................................................47

6.1.1 User passwords ............................................................................................................... 47

6.1.2 Movement parameters .................................................................................................... 48

6.1.3 Drive parameters .............................................................................................................50

6.1.4 Servo parameters ............................................................................................................ 52

6.1.5 Other parameters............................................................................................................. 54

6.1.6 X axis pitch error compensation .................................................................................... 65

6.1.7 Z axis pitch error compensation .................................................................................... 65

6.1.8 Macro variable in floating-point type ............................................................................. 65

6.1.9 Macro variables in integral type.....................................................................................65

6.2 Inputting parameters.......................................................................................69

6.3 Initializing parameters.....................................................................................69

6.4 Rewriting bit parameters.................................................................................70

6.5 Method of inputting parameters ......................................................................70

6.6 Backup and restoring parameters...................................................................71

CHAPTER 7 GRINDING WHEEL DRESSING.........................................72

7.1 Overview of grinding wheel dressing ..............................................................72

7.2 Dressing point return ......................................................................................73

7.3 Manual dressing .............................................................................................73

7.4 Automatic dressing .........................................................................................74

CHAPTER 8 SYSTEM DIAGNOSIS AND SOFTWARE PLC ..................75

8.1 System diagnosis............................................................................................75

8.1.1 Introduction of diagnosis PLC input signals................................................................. 75

8.1.2 Introduction of diagnosis PLC output signals .............................................................. 80

8.1.3 Other signals of system and alarm record inquiry ...................................................... 83

8.2 System software PLC .....................................................................................85

8.2.1 Initializing PLC.................................................................................................................. 86

8.2.2 PLC programming............................................................................................................ 87

8.3 Detecting the system keyboard.......................................................................87

CHAPTER 9 ADDITIONAL AXIS CONTROL FUNCTION.......................89

9.1 Spindle control ................................................................................................89

9.1.1 Spindle switch control......................................................................................................89

9.1.2 Analog voltage control of servo spindle........................................................................ 89

9.1.3 Spindle trial running speed.............................................................................................90

III

Page 9

GSK928GA/GE Grinding Machine CNC System Operator’s Manual

9.2 Position axis control........................................................................................90

9.2.1 Manual operating additional position axes................................................................... 91

9.2.2 Programming method of additional position axes....................................................... 91

9.3 Rotation axis control .......................................................................................92

9.4 Setting relative parameters of the second spindle ..........................................92

CHAPTER 10 DEFINITION AND CONNECTION DIAGRAM OF SYSTEM

INTERFACE SIGNALS ..............................................................................95

10.1 Installation layout of the system......................................................................95

10.1.1 Installation layout of the system back cover ................................................................ 95

10.1.2 Introduction of back cover interfaces............................................................................ 95

10.1.3 Overall connection diagram ...........................................................................................96

10.2 Definition of system interfaces ........................................................................97

10.2.1 Definition of motor drive interfaces ............................................................................... 97

10.2.2 Definition of MPG interface ............................................................................................ 99

10.2.3 External output interface definition.............................................................................. 100

10.2.4 External input Interface definition................................................................................ 101

10.2.5 Definition of communication interface......................................................................... 102

10.3 System connection diagram..........................................................................103

10.3.1 Motor drive unit connection diagram........................................................................... 103

10.4 Connection diagram of external signal input/output ......................................109

10.4.1 Input interfaces of external signals .............................................................................109

10.4.2 Output interface of the external signals...................................................................... 109

10.4.3 Connecting a photoelectric isolator..............................................................................110

10.5 Installation dimension ................................................................................... 111

SECTION Ⅱ PROGRAMMING..............................................................112

CHAPTER 1 PROGRAMMING FUNDAMENTALS ............................... 113

1.1 Coordinate systems of the cylindrical grinding machine ............................... 113

1.2 Machine zero ................................................................................................ 114

1.3 Programming coordinate system .................................................................. 114

1.3.1 Absolute coordinate........................................................................................................115

1.3.2 Relative coordinate.........................................................................................................115

1.4 Radius and diameter programming............................................................... 116

1.5 Program reference position........................................................................... 117

1.5.1 Reference position..........................................................................................................117

1.5.2 Setting method ................................................................................................................117

CHAPTER 2 PROGRAM STRUCTURE ................................................118

2.1 Composing a program .................................................................................. 118

2.2 Program numbers ......................................................................................... 118

IV

Page 10

GSK928GA/GE Grinding Machine CNC System Operator’s Manual

2.3 Blocks ........................................................................................................... 119

2.3.1 Serial numbers ................................................................................................................119

2.3.2 Fields ............................................................................................................................... 120

2.3.3 Characters ......................................................................................................................120

2.4 Program end code ........................................................................................122

2.5 Subprograms ................................................................................................122

2.5.1 Program calling process ............................................................................................... 122

2.5.2 Subprogram nested calling........................................................................................... 123

CHAPTER 3 COMMAND CODE FORMAT AND FUNCTION ...............124

3.1 Mode and one-shot commands ....................................................................124

3.2 G function — preparing function ...................................................................124

3.2.1 G90 and G91 — absolute and incremental coordinate programming ................... 126

3.2.2 G00 — rapid position ....................................................................................................126

3.2.3 G01 — linear interpolation............................................................................................ 127

3.2.4 G02 and G03 — circular interpolation ........................................................................ 129

3.2.5 G04 — fixed time dwell................................................................................................. 131

3.2.6 G27 — grinding wheel returning to X axis dressing position ..................................131

3.2.7 G28 and G29 — X and Z axes returning to the reference position........................132

3.2.8 G37 — C axis returning to the reference position..................................................... 132

3.2.9 G30 — feeding compensation ..................................................................................... 133

3.2.10 G31 — interpolation skip .............................................................................................. 134

3.2.11 G39 — macro variable assignment............................................................................. 135

3.2.12 G71 — grinding comprehensive cycle........................................................................135

3.2.13 G94 — Feedrate per minute ........................................................................................ 137

3.2.14 G95 — Feedrate per revolution ................................................................................... 137

3.3 M function — miscellaneous function ...........................................................138

3.3.1 M00 — Pause................................................................................................................. 140

3.3.2 M02 — Program end..................................................................................................... 140

3.3.3 M30 — Program end, spindle stop and cooling off................................................... 140

3.3.4 M03 and M05 — Grinding wheel spindle control ...................................................... 140

3.3.5 M08 and M09 — Cooling control.................................................................................141

3.3.6 M10 and M11 — Tailstock control ...............................................................................141

3.3.7 M12 and M13 — Machine-head control ..................................................................... 141

3.3.8 M14 and M15 — Hydraulic control.............................................................................. 141

3.3.9 M18 and M19 — On/off valve control ......................................................................... 142

3.3.10 M33 and M35 — Spindle (the second spindle) control ............................................ 142

3.3.11 M70 and M75 — Measuring instrument head (radial) control................................. 142

3.3.12 M78 and M79 — Measuring instrument head (axial) control .................................. 142

3.3.13 M40 and M41 — Activating MPG................................................................................ 143

V

Page 11

GSK928GA/GE Grinding Machine CNC System Operator’s Manual

3.3.14 M50 and M51 — Angular linkage control................................................................... 143

3.3.15 M97 — Unconditional branch....................................................................................... 143

3.3.16 M98 — Subprogram call function................................................................................ 143

3.3.17 M99 — Subprogram return........................................................................................... 144

3.3.18 User output control ........................................................................................................ 144

3.3.19 User input control........................................................................................................... 145

3.4 F Function — feedrate function.....................................................................146

3.5 Function of macro variables..........................................................................146

3.6 Macro command function..............................................................................148

3.6.1 Arithmetic operation command.................................................................................... 148

3.6.2 Operator skip macro command ................................................................................... 148

CHAPTER 4 PROGRAMMING RULES.................................................150

4.1 Many commands sharing with same block ...................................................150

4.1.1 Single block command..................................................................................................150

4.1.2 Command grouping ....................................................................................................... 150

4.2 Command executing sequence in a block ....................................................151

4.3 Optional block skip........................................................................................151

4.4 Usage of mode commands...........................................................................152

CHAPTER 5 COMPREHENSIVE PROGRAMMING EXAMPLES.........153

SECTION Ⅲ PLC PROGRAMMING......................................................159

CHAPTER 1 OVERVIEW.......................................................................160

1.1 Specification of software PLC .......................................................................160

1.2 Editing and debugging PLC program............................................................161

1.2.1 Distributing interface...................................................................................................... 161

1.2.2 Editing the command sequence .................................................................................. 161

1.2.3 Debugging a sequence program ................................................................................. 161

CHAPTER 2 PLC COMMAND SYSTEM ...............................................162

2.1 Basic commands ..........................................................................................162

2.1.1 Overview ......................................................................................................................... 162

2.1.2 Basic command collection............................................................................................163

2.2 Function commands .....................................................................................171

CHAPTER 3 FILE MANAGEMENT OF PLC USER PROGRAM ..........175

3.1 User authority code management.................................................................175

3.2 Editing and rewriting PLC program ...............................................................175

3.3 Deleting PLC program .................................................................................. 176

3.4 Serial transmission of PLC program .............................................................177

3.4.1 Outputting a program .................................................................................................... 177

VI

Page 12

GSK928GA/GE Grinding Machine CNC System Operator’s Manual

3.4.2 Inputting a program .......................................................................................................178

CHAPTER 4 INTRODUCTION OF EDITING PLC .................................179

4.1 Input method of commands and addresses..................................................179

4.2 Inputting, rewriting, inserting and deleting a program line............................. 181

4.2.1 Inputting and rewriting a command and an address ................................................183

4.2.2 Inserting a block............................................................................................................. 186

4.2.3 Deleting a command and an address......................................................................... 187

4.3 PLC editing rules ..........................................................................................187

4.4 Process method of PLC signals....................................................................189

4.5 PLC programming application examples ......................................................191

CHAPTER 5 INTERFACE DISTRIBUTION AND INTRODUCTION OF

ADDRESSES ..........................................................................................195

5.1 G address, PLC→NC address (G)................................................................197

5.2 F address, NC →PLC address (F) ............................................................... 198

5.3 X address and machine→PLC address (X) ..................................................199

5.4 Y address, PLC→address of machine (Y) ....................................................200

5.5 Addresses of internal relay R, timer T and counter C ...................................201

CHAPTER 6 SEQUENCE PROGRAMS ................................................202

6.1 Sequence program executing process .........................................................202

6.2 Input and output signal process ....................................................................203

6.3 Self-lock and interlock circuit ........................................................................ 204

APPENDIX Ⅰ PITCH ERROR COMPENSATION.................................205

APPENDIX Ⅱ LIST OF PROGRAM EDITING MISTAKES ...................210

APPENDIX Ⅲ PLC COMMAND LIST.................................................... 211

APPENDIX Ⅳ STANDARD PLC EXAMPLES (V2.0) ............................212

APPENDIX Ⅴ INTRODUCTION OF MEASURING INSTRUMENT.......216

APPENDIX Ⅵ COMMUNICATION SOFTWARE ...................................219

VII

Page 13

GSK928GA/GE Grinding Machine CNC System Operator’s Manual

SECTION Ⅰ OPERATION

Introduce the operation, installation, connection and parameter setting of

GSK928GA/GE system.

1

Page 14

GSK928GA/GE Grinding Machine CNC System Operator’s Manual

CHAPTER 1 SYSTEM OVERVIEW

1.1 Introduction of the system

1.1.1 Introduction of GSK928GA/GE system

GSK928GA/GE surface/cylindrical grinding machine CNC system is developed by the GSK CNC

EQUIPMENT CO., LTD. It is a product of new type with embedded DSP+MCU control, LCD and

complete keypads panel.

GSK928GA/GE uses blue LCD, international standard CNC language—ISO code part program and

includes standard G and M code. It is embedded with the software PLC, and matches with the various

servo drive units. The precision control and prompt reaches the level. Display in μm precision and

control, with full screen program, simple operation, openness, compact structure, convenient

maintenance, high precision, reliability and expansibility, which can be used as the multi-functional

CNC system of grinding machine.

1.1.2 Main function and performance

Main function of controller and technical index:

(1) Number of axes in the controller: Two three axes, including the servo spindle;

(2) S curve line can automatic increase and reduce speed, full closed AC servo control, and

realizing the machine closed-loop control;

(3) Electronic MPG functions; (able to support external extended MPG.)

(4) Minimum prompt and setting unit:0.001mm;

(5) Standard stroke range: ±8000 mm;

(6) Rapid traverse rate: 0~8000mm/min;

(7) Built-in PLC software: input 32 points; output 24 points (isolated by photo electricity);

(8) Standard ISO code block, relative / absolute programming;

(9) Macro variable programming (100 floating points macro variables,40 integer macro points);

(10) Number of the storable part programs:100;

(11) IO interface and M code programming design only for grinding machine;

(12) Automatic grinding wheel correcting and compensation function of grinding dimension which is

specified by the machine manufacturer;

(13) Special application for the slow feeding and design of stable speed during grinding;

(14) Protection of position overrun; overtravel protection of software/hardware overtravel; drive

alarm detection;

(15) Convenient and friendly parameter input method of grinding;

(16) Built-in RS-232C interface with PC for communication;

(17) Angular axis function only for grinding machine and the adjustable angle of angular axis from 0

to 45°;

2

Page 15

GSK928GA/GE Grinding Machine CNC System Operator’s Manual

(18) External measuring tool control function;

(19) Protection of rapid retraction in grinding machine;

(20) System parameter, automatic backup of PLC user program and read function;

(21) Servo spindle control, analog spindle, rotation axis graduation and orientation function.

1.1.3 The differences between GSK928GA and GSK928GE

GSK928GA and GSK928GE are the products of GSK with its own intellectual property. GSK928GA is

CNC system of the surface grinding machine; GSK928GE is CNC system of the cylindrical grinding

machine.

About them, except the definitions of the coordinate systems and I/O definitions are different, other

operations, programming and PLC control mode are exactly same. And the manual takes GSK928GE

as the example to introduce the operation of grinding machine CNC system.

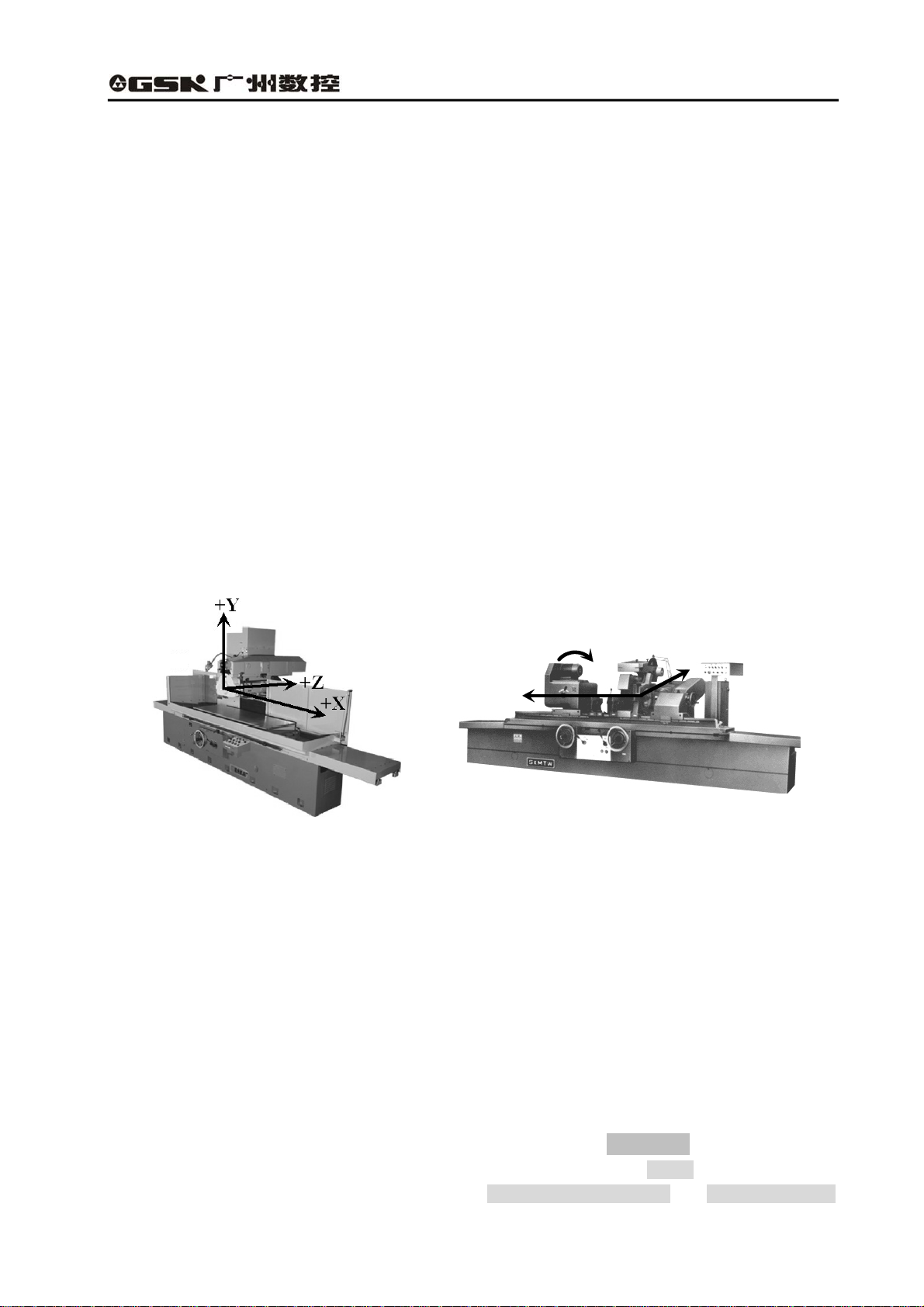

1.1.3.1 The differences between the coordinate systems

Based on the Cartesian coordinate system, the coordinate system of GSK928GA CNC system is Y/Z

one, X is normally the hydraulic control axis without displaying the position; while the coordinate

system of GSK928GE CNC system is X/Z one. The coordinate system is shown as the following

figures:

+C

+X

+Z

Fig. 1-1 The machine coordinate system Fig.1-2 The machine coordinate system

of the surface grinding machine of the cylindrical grinding machine

Moreover, the outer grinding machine belongs to the rotational machine. The cross section of its work

piece is normally round, and the dimensions marked on the machining drawing are diameter and the

radius. For the user to edit the machining program based on the machining drawing of the part,

GSK928GE cylindrical grinding machine CNC system provides the radius and diameter programming.

However, the part drawing of the surface grinding machine doesn’t have the problem of the diameter

dimension, therefore, GSK928GA only provides the radius programming.

1.1.3.2 Differences between I/O interface definitions

About GSK928GA and GSK928GE, I/O interface definition corresponds to PLC address. The tool

clamp of the surface grinding machine is the electromagnetic chuck, while that of the outer grinding

machine is the head and tail stocks. Therefore, in PLC definitions, Head stock is displayed on the

status bar of GSK928GE cylindrical grinding machine CNC system, while Chuck is displayed on the

status bar of GSK928GA surface grinding machine; Head stock motor control and Head stock motor

3

Page 16

GSK928GA/GE Grinding Machine CNC System Operator’s Manual

alarm are defined in PLC of GSK928GE, while Electromagnetic chuck magnet control and

Electromagnetic chuck alarm are defined in GSK928GA, which are shown as the following figures:

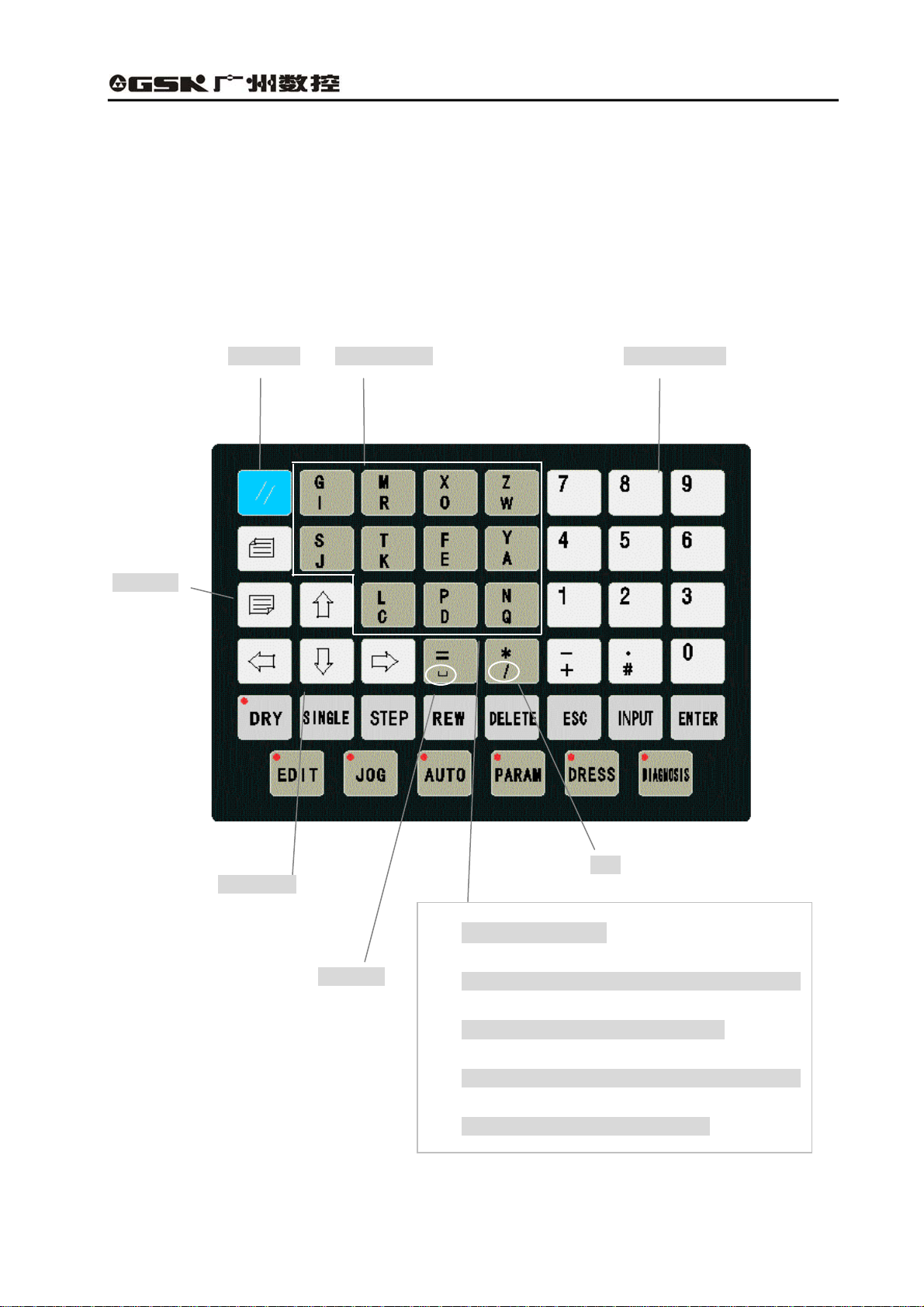

1.2 Introduction of system operation panels

Prompt screen

Address keypad

Function keypad

Fig. 1-3 Introduction of system operation panel

(1) LCD monitor: The top left part of the system is blue LCD, the resolution is 320 X 240 lattices,

which is for prompt of Chinese menu status of system, operational information and fault alarm.

Operation panel of machine

4

Page 17

GSK928GA/GE Grinding Machine CNC System Operator’s Manual

(2) Operation panel: The key is set, according to customer’s requirement, and control the machine

to finish the various accessorial function and basic operation;

(3) Address keys: English letter input of part program field address;

(4) Functional keys: Various graphic symbol function key is set according to CNN machine graphic

symbols;

1.2.1 Introduction of the address keypad panel

Reset key

Address keys

Numerical keys

Page keys

Cursor keys

Space key

Skip

Double address key:

z Prompt the address code which is above the address

key when press this key at the first time;

Fig. 1-4 Address keypad panel

z Prompt the address code which is below the

address key when press the key again.

5

Page 18

GSK928GA/GE Grinding Machine CNC System Operator’s Manual

(1) Reset key

System reset key

All the movement of shaft stops when the system resets. All axis output function doesn’t

work, and the machine stops running and prompts electrified status.

(2) Page keys:

Page up:

Turn a page up to search the program or parameter in the Edit/Para (parameter) mode.

Change the type of displayed coordinate system in Auto/Jog mode.

Page down:

Turn a page down to search the program or parameter in the Edit/Para (parameter) mode.

Display/hide the follow error in Auto/Jog mode.

(3)Cursor control keys

The cursor moves upward:

Move the cursor to one upper row in the Edit/Para mode. The brightness of LCD is

enhanced in Jog mode.

The cursor moves downward:

Move the cursor to the next row in Edit/Para mode. The brightness of LCD fades in Jog

mode.

The cursor moves left:

Move the cursor to left in a character space in Edit mode. Delete the last input figures during

the status of data input.

The cursor moves right:

The cursor moves to right in a character space in Edit mode.

(4)Address key

Input the English letter of the part program field address.

6

Page 19

GSK928GA/GE Grinding Machine CNC System Operator’s Manual

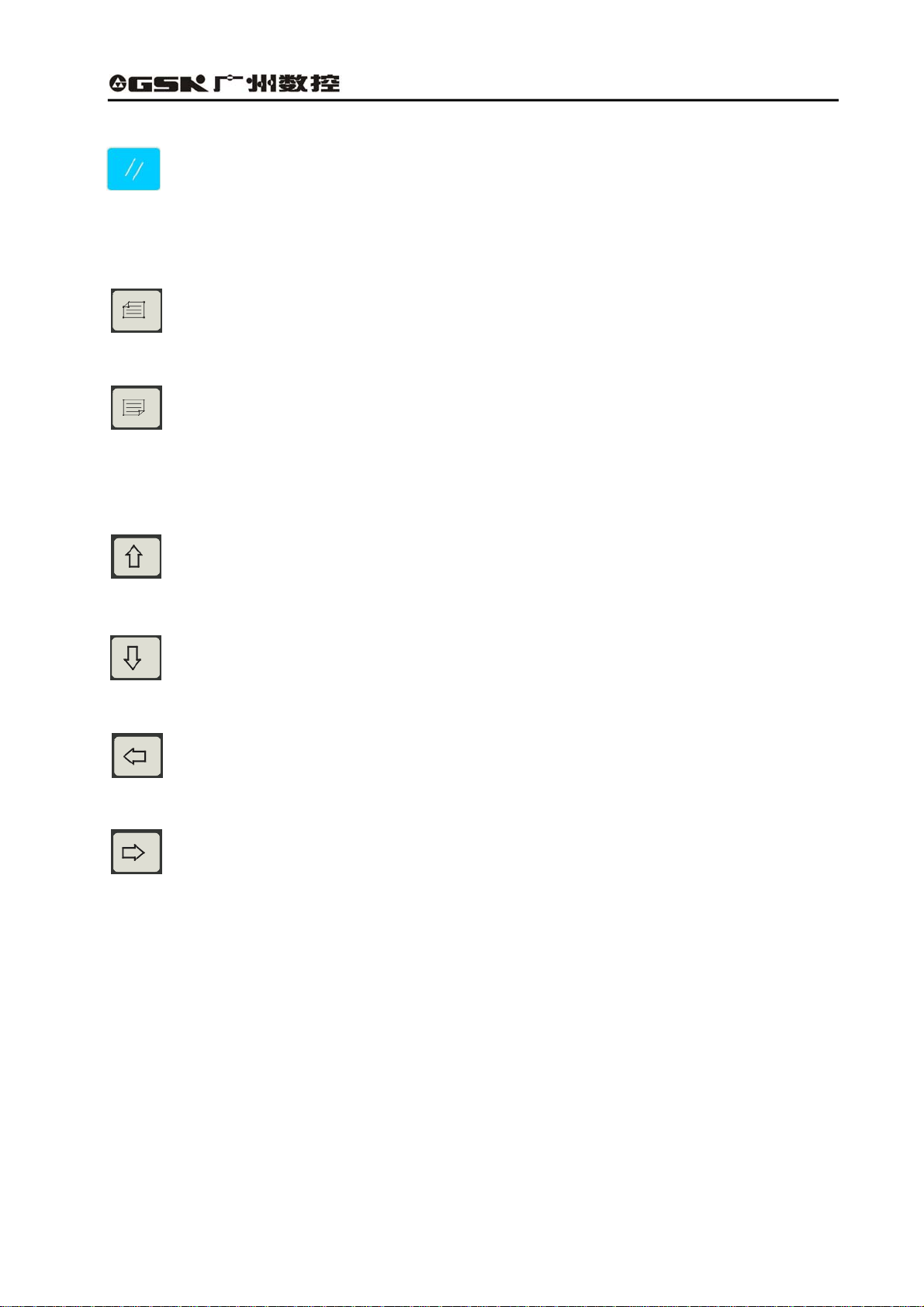

1.2.2 Introduction of the panel with function keys

Select the dry run in Auto mode. The cursor can be directly moved to the initial

character of this line during editing the machining program.

In Auto mode, select single/continuous mode.

In Manual mode, switch between step and jog.

Switch the input mode (insert/rewrite) during editing the

machining program; In Auto mode, return to the initial line of

the machining program.

Delete the digit, letter or block.

Cancel the currently input various data or exit

from the mode.

Select the display or

setting para. mode.

Select Auto mode.

Select Jog mode.

Select Edit mode.

Fig. 1-5 Panel of function keys

Input the various data or select

the program to be edit or run and

create a new user program.

Confirm

Select the diagnosis

mode or program PLC.

Select Dress mode

7

Page 20

GSK928GA/GE Grinding Machine CNC System Operator’s Manual

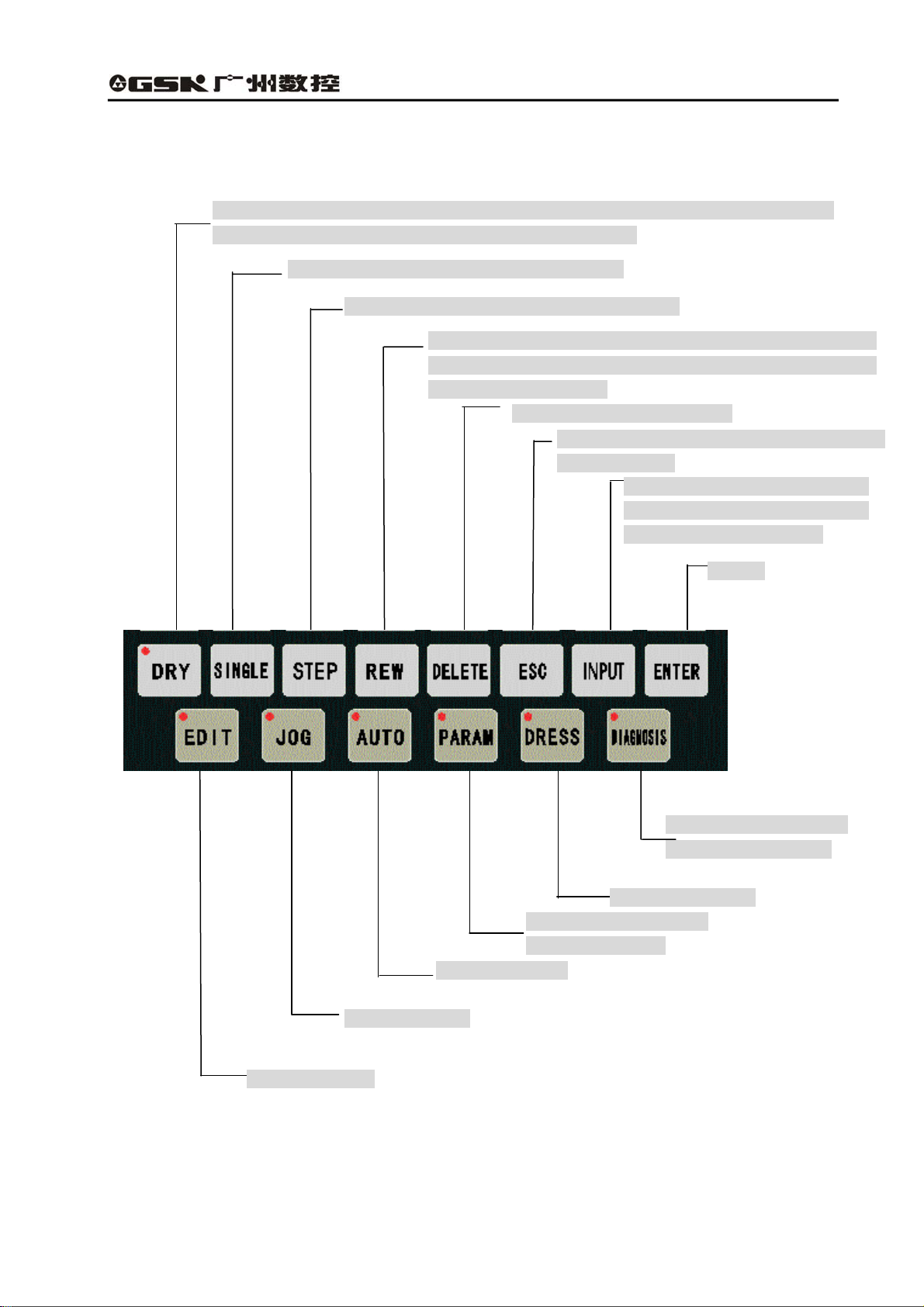

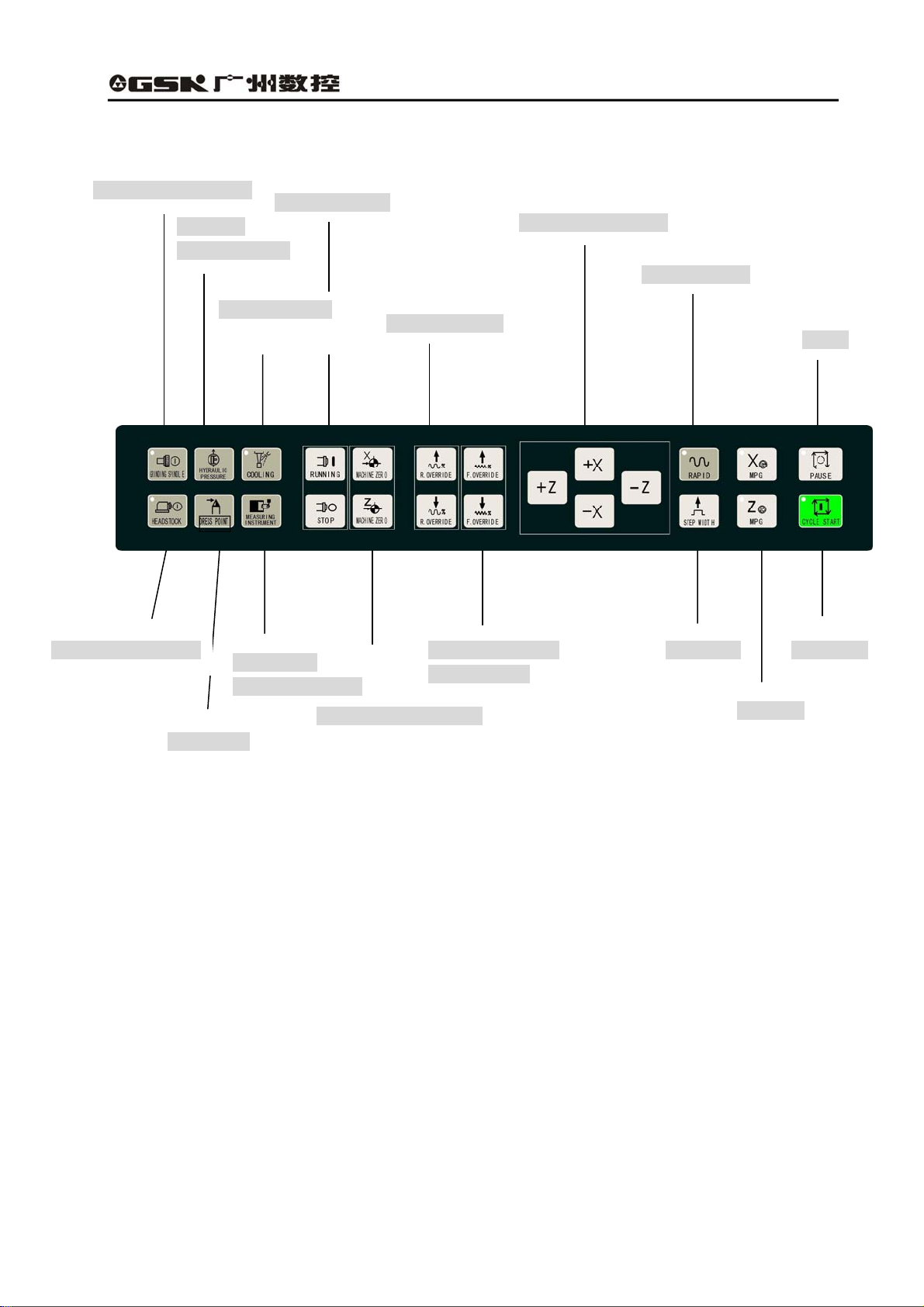

1.2.3 Introduction of the machine operation panel

Hydraulic

pressure switch

Cooling switch

Dress point

Spindle control

Measuring

instrument control

Mechanical zero return

Rapid override

Feedrate override

increase/reduce

Manual direction key

Rapid feed key

Pause

X/Z MPG

Grinding wheel switch

Machine-head motor Step width Cycle start

Fig. 1-6 Machine operation panel

8

Page 21

GSK928GA/GE Grinding Machine CNC System Operator’s Manual

CHAPTER 2 SYSTEM BASIC OPERATION

2.1 System power on/off

After connecting the external power supply, switch on the main power supply of machine. During the

situation, the machine is not started. Press the start button in the accessorial machine operation

panel of GSK928GE grinding machine CNC system and turn on the power supply of CNC system and

external drive. After system detects each configuration work is OK, then, the machine is allowed to

operate.

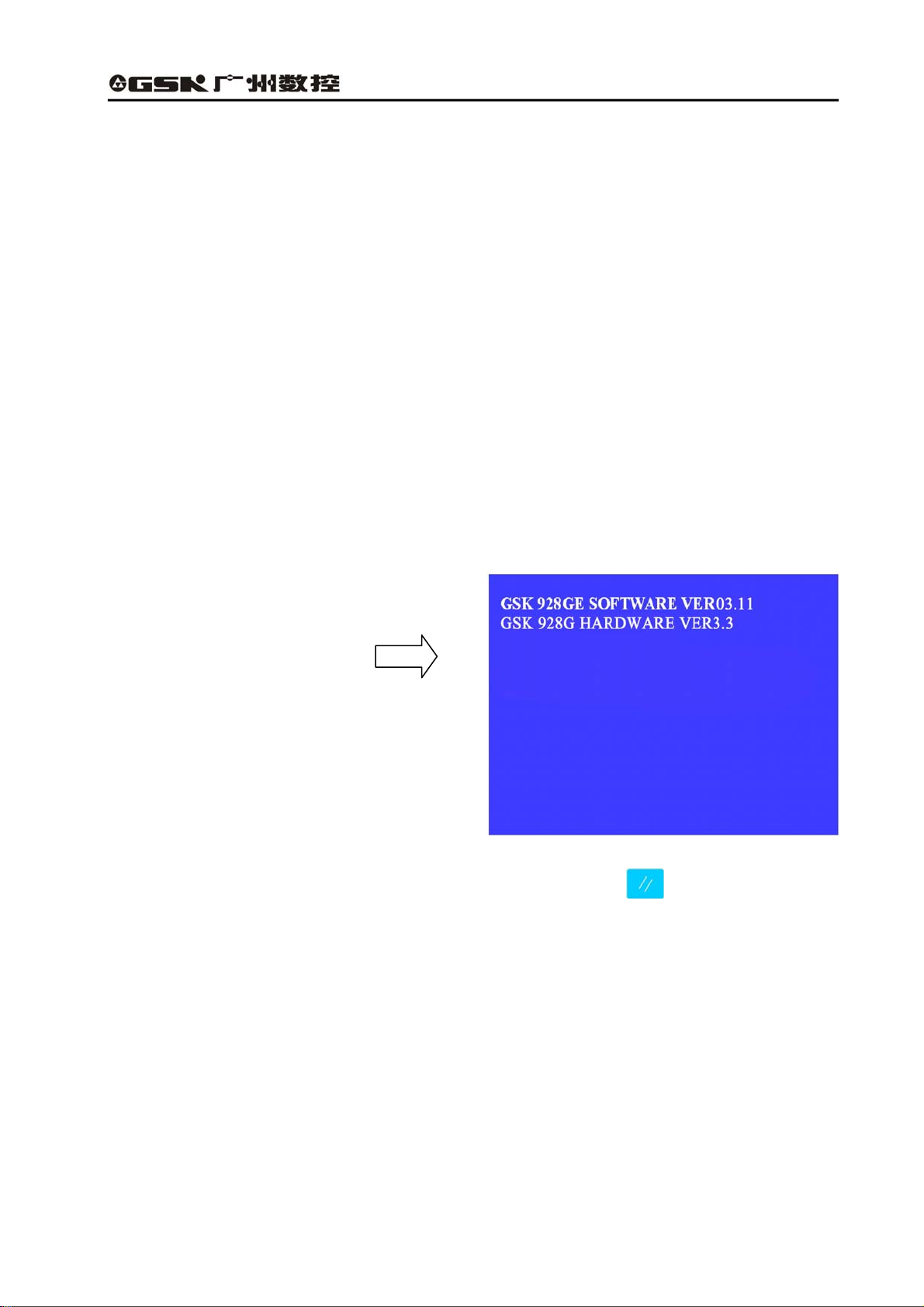

2.1.1 Power on

The steps of turning on CNC system:

1. Switch on the main switch of power supply, and turn on the system.

(1) System starting initialization

After switching on the system and initializing at the first time, the screen is displayed the version

numbers of software and hardware, which is shown in the right figure:

After initializing the system, the system checks PLC program. If PLC program is not correct, the

system shows the start-up screen and press any keys except reset key , the system comes into

debugging mode, then, the movement function does not work. If PLC program is OK, the system

starts initializing DSP.

(2)DSP initialization

After the system initializes at the first step, and PLC program is normal, it initializes DSP, if it is normal,

and the screen is displayed “INITIALIZING DSP……OK!”

The start-up screen prompts when finish starting the system.

9

Page 22

GSK928GA/GE Grinding Machine CNC System Operator’s Manual

If DSP initialization fails, the screen shows:

Press , the system tries to initialize DSP

again. Press other key, the system comes into

debugging mode and shows the start-up screen.

2. After system finishes initializing, the screen

Shows the trademark of GSK, and press any key

except reset key , the system comes into

working mode.

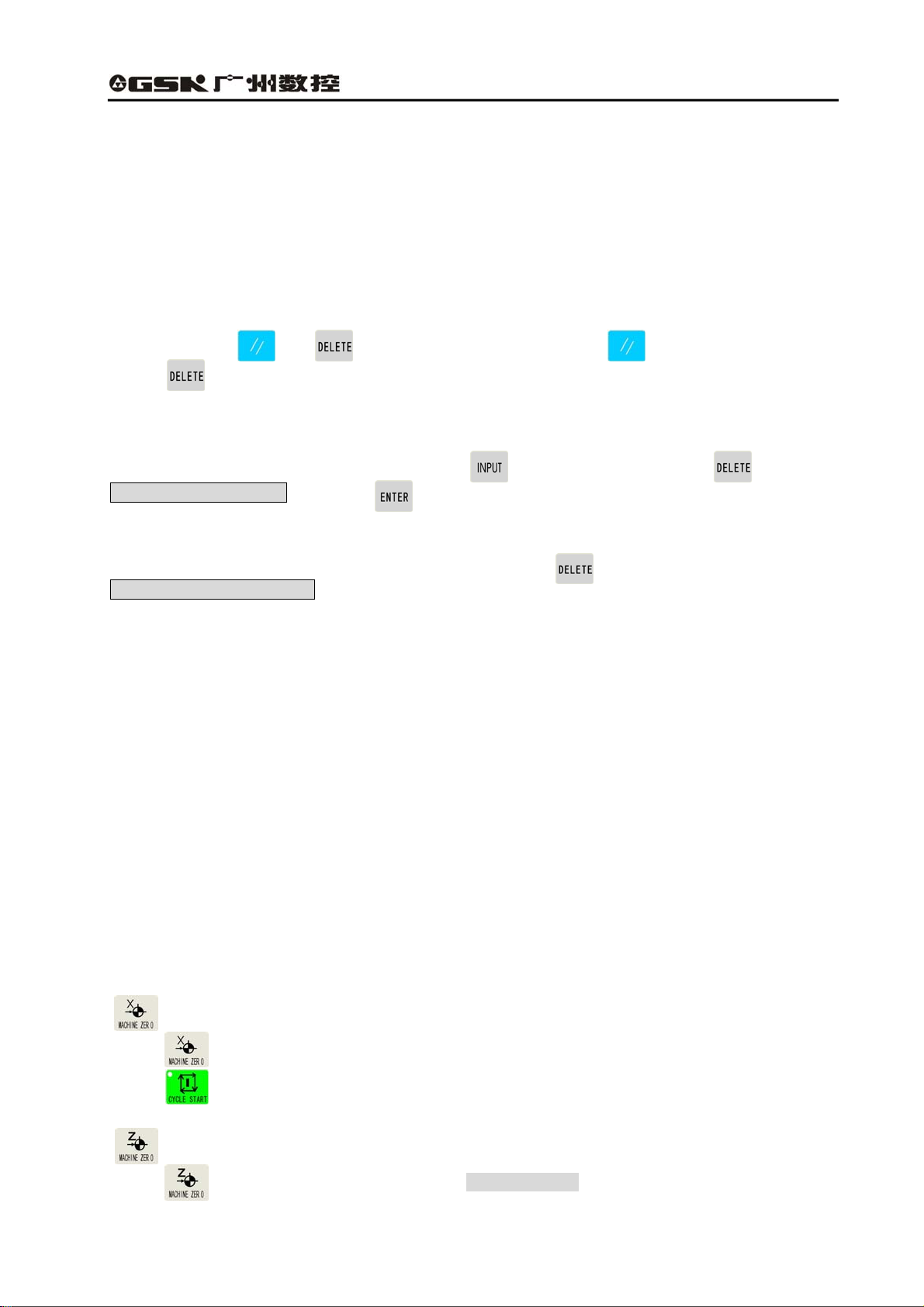

2.1.2 Debugging mode

If any mistake in PLC program or failure of DSP initialization at the start stage, the system enters

debugging mode. When emergency stop alarms, press for 5 seconds, the system enters

debugging mode. The movement function of the system does not work in the debugging mode, and

the system can not execute the relevant operation regarding to movement. The user can debug the

system, find the fault, and modify the parameter, the machining and PLC programs. In Jog/ Auto

mode, the system reminds the users that the system enters debugging by displaying the “debugging”

in the status bar under the working mode.

As above figure shows, in the debugging mode,

the user can modify PLC program in the

diagnose mode. After detection of PLC program,

press and restart the system, it enters

working mode.

10

Page 23

GSK928GA/GE Grinding Machine CNC System Operator’s Manual

2.1.3 Power off

(1) Press the switch of CNC power supply, cut off power supply, and the system turns off.

(2) Cut off the machine main switch of power supply.

2.1.4 Initializing CNC system

If power on the system at the first time, the initialization is operated according to the following steps:

Press and hold and at the same time, first release , after 3 seconds, then

release , the system completes the parameter initialization. Then, the parameter of the machine

is set as internal initialization of CNC system; refer to introduction of parameter about the details.

Initialization of system space:

●If the password is right, enter Edit mode, press and input “-01”, then press , it reminds

Sure to delete program? And press to specify.

Initialization of system PLC:

●If the password is right, enter diagnosis state, then press for two seconds and it reminds

PLC initialization completes!

2.2 Machine zero return (HOME)

Every machine sets one point as its zero point. After power on or reset each time, the worktable can

return to the zero point of machine, and return to the machining start point, then, the cumulative errors

are eliminated. The worktable returns to the machine’s zero point before machining, then, specify the

start point of machining and record the coordinate system of the machining start point which was

recorded last time. After power off each time, the machine returns to the zero point and then comes to

the machining start point which was recorded last time; finally, the program starts. Therefore, it can

avoid the situation that the system coordinate system is not consistent with the actual position which

may be moved by the operators after power off, and the accident may occur if the program starts

without specifying the machining start point after power on the machine.

The function is that “whether it must return zero after CNC system power on, again or resetting, and

then execute machining through selecting the parameter. Regarding to the details, refer to Bit 4 and 5

in the parameter 3.

Return to zero point of machine X axis

Press in Jog mode, the system prompts “X back to zero?”

Press , X axis rapidly returns to the machine zero point at rapid feedrate which is set in the

parameter.

Return to zero point of machine Z axis

Press in Jog mode, the system prompts “Z back to zero?”

11

Page 24

GSK928GA/GE Grinding Machine CNC System Operator’s Manual

Press , Z axis returns to the machine zero point at rapid speed which is set in the parameter.

Regarding to the method and process of the return to machine zero point, refer to 6.1.5.1.

1. The movement direction of machine returning to zero point is set by parameter Home

Polar X and Home Polar Z of parameter P041. The grinding wheel base should be kept at

the reverse direction of the switch during machine returns to the zero point.

2. Without the reference position switch on the machine, do not use the function of machine

returning to zero function, otherwise, accident may occur because the grinding wheel base is

moving at the high speed all the time without switch for reducing the speed.

3. Pay attention to it that during the machine return to zero, firstly the machine tries to return

the X axis where the grinding wheel motor is installed and the switch should be fit in the other

side which is far away from the Z axis work table.

!

REMARK

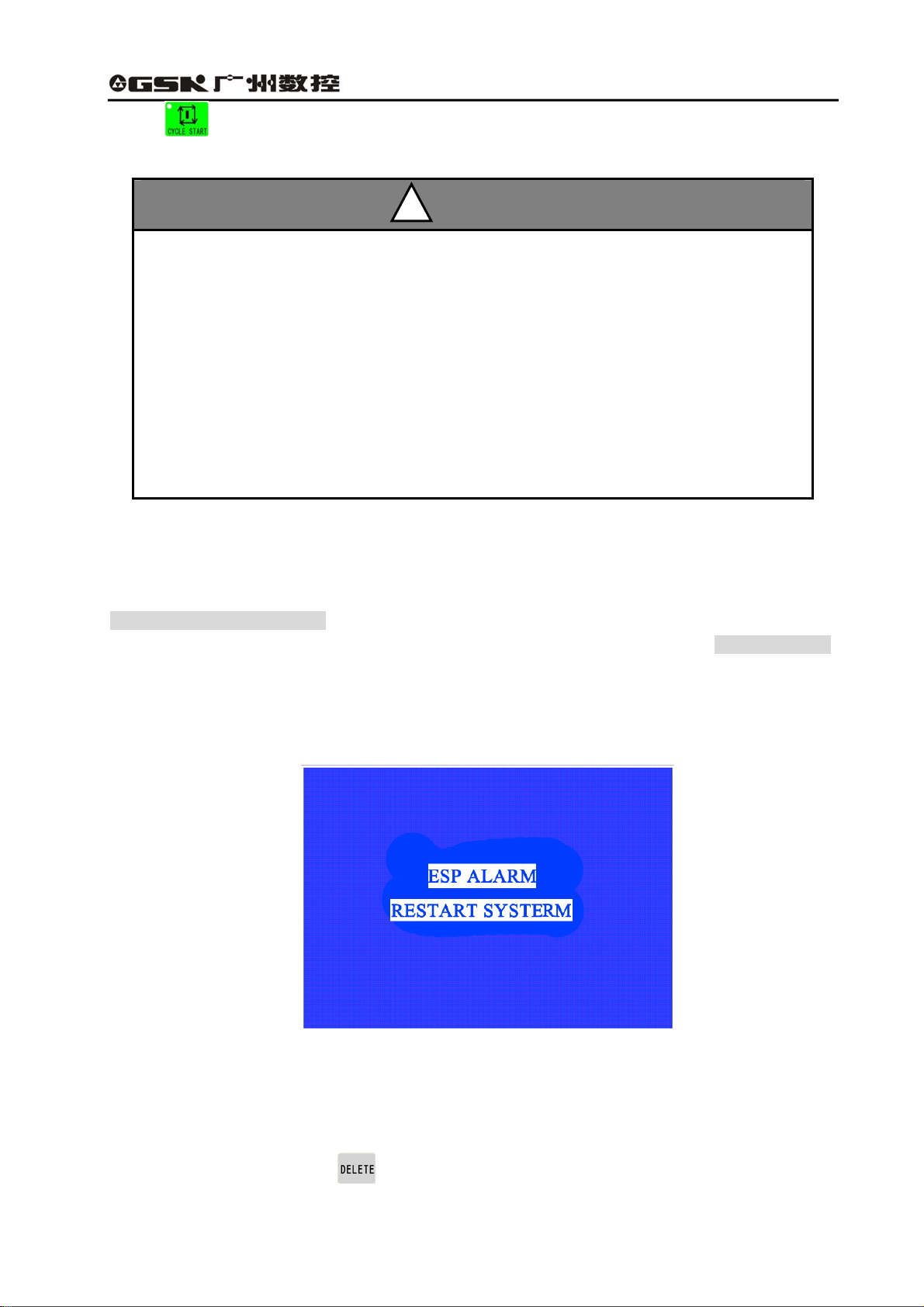

2.3 Emergency stop

There is an external emergency input port in the system input interface. The user should connect the

normally closed contract point, which is on the emergency stop of the red mushroom on the machine

panel, with the emergency input port. In the emergency situation, please press the emergency stop,

the system enters emergent status; all the feeds stop, and the spindle of grinding wheel, switching

value control and so on are edited by user through PLC. For safety, spindle and relevant equipment

are closed. About the editing mode, refer to some chapters of PLC program section. The screen

flickers and prompts as the figure 2.1 shows:

Fig. 2-1 Emergency stop alarm

Rotate the emergency switch according to the direction of an arrow, the emergency stop button

automatic springs up, then, press the reset key and restart the system, the system can come back to

the normal working status. If the system has no external emergency stop button, when the

emergency stop alarms, press for a while, the system can enter the debugging mode. Then,

modify PLC program, take the inverse value of the emergency stop signal and restart the system.

12

Page 25

GSK928GA/GE Grinding Machine CNC System Operator’s Manual

2.4 Alarm

2.4.1 Limit switch alarm

The system can check limit switches if the machine has installed. When the socket is moved and the

limit switch is pressed, the feeding stops but other miscellaneous function is still on, the program

stops running, and the grinding wheel spindle and switching value control and so on are set by the

user through PLC editing. When it alarms, the limit switch alarm information of corresponding axes is

displayed at the top right corner.

After the limit switch alarms, Jog mode can be selected. Press “cancel limit”, meanwhile, press the

manual feeding key or enter MPG operation, which is opposite to the limit direction, then, exit the limit

and the limit switch alarm automatically exits from the screen.

2.4.2 Software limit alarm

The system sets the limit range, and if the machine exceeds the setting value, the system reminds

axis software limit alarm, at the same time, press “limit release” and the corresponding direction keys,

it moves again. If it still exceeds the limit setting value, the machine can not respond in the exceeded

range.

2.4.3 Emergency retraction alarm

Using axis emergency retraction function can solve the problem of emergency retraction, and cancel

the alarm by releasing the limit key.

2.4.4 Drive unit alarm

When the alarm output signal of drive connects with CNC system and drive alarms, the system cuts

off all feeding operation automatically, and the screen also prompt X axis drive alarm or Z axis drive

alarm. The system stops running and closes the entire output signal which is specified by PLC.

Please check the drive and relevant connection,shoot trouble and switch on again.

2.4.5 Other alarms

It prompts in the screen in Chinese if CNC system alarms, and then it can be dealt with based on the

message. When many alarms occur at the same time, the system prompts in interval of 3 seconds,

and also calls the alarm information through pressing page down key in the diagnosis mode, and it

can save the latest 8 pieces of information.

13

Page 26

GSK928GA/GE Grinding Machine CNC System Operator’s Manual

2.5 LCD brightness adjustment

The brightness of GSK928GE CNC system LCD can be adjusted by keys to reach the best visual

effect. The method is as below:

(1) Switch CNC system to Jog mode.

(2) Press , the brightness of LCD screen becomes brighter or darker, and the result is

locked automatically. After the system power on again or reset, the brightness of LCD screen is kept

the same state before power off.

(3) If the temperature of environment changes obviously, the specialty affects the brightness of LCD,

which is not the fault of CNC system. And the same brightness adjustment may cause different effect;

therefore, it requires readjustment to reach the best effect.

14

Page 27

GSK928GA/GE Grinding Machine CNC System Operator’s Manual

CHAPTER 3 EDIT MODE

3.1 Edit mode

The Edit mode is to manually input or rewrite the part program through system operation panel. In the

Edit mode, the part program can be created, chosen or deleted through keypad; also, the selected

part program content can be inserted, edited or deleted. Moreover, via the RS232 communication

interface can connect with the serial interface of universal PC, then, transmit the part program of

system to the external computer, vise versa.

When the user edits the program, the system checks the right of user. The user possesses the right to

edit the program. The user can input correspondent password in the Para mode to change the right of

the user. Otherwise, the screen prompts User has no right!

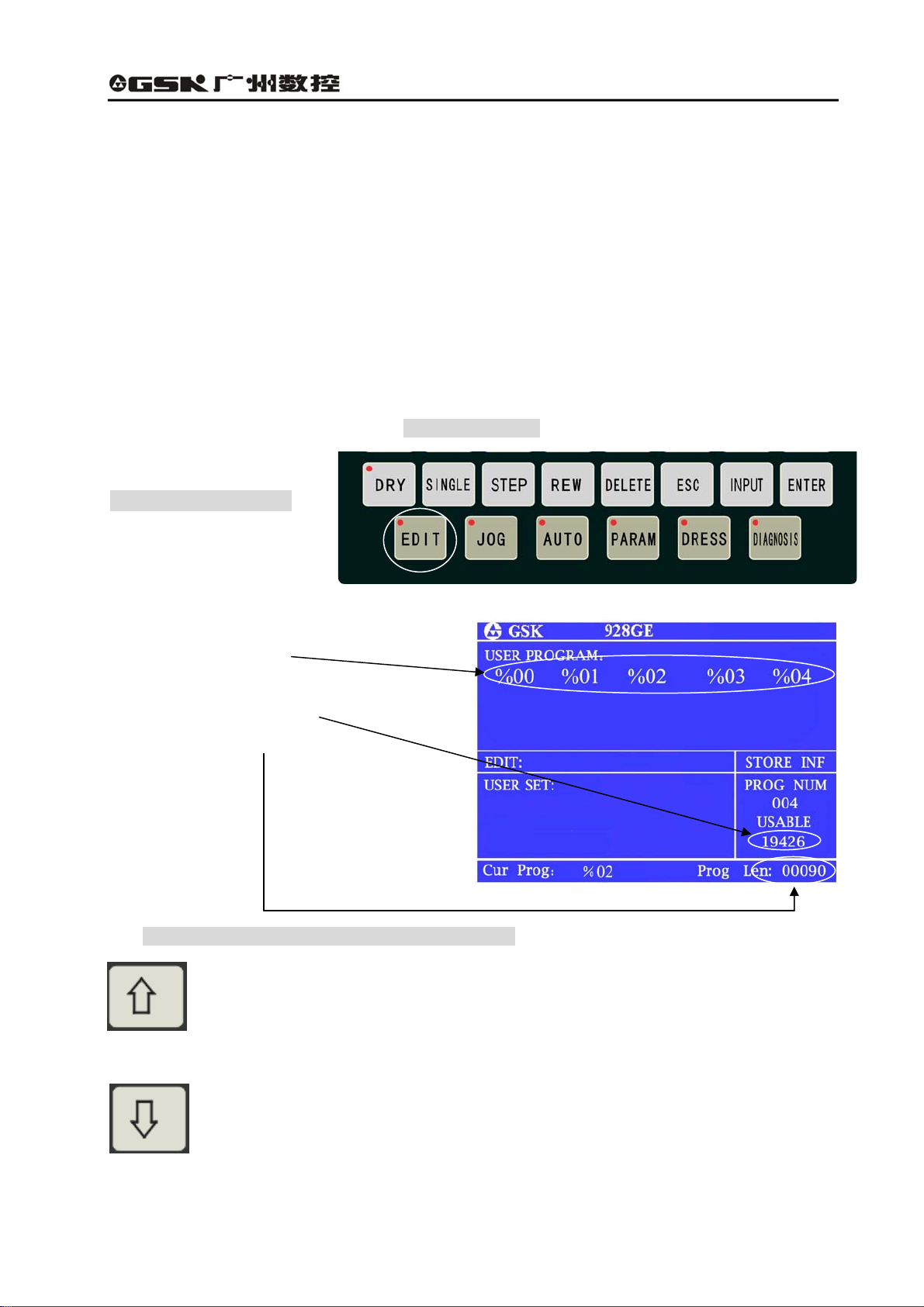

● Press Edit mode key

z Edit mode interface

a. All the present registered part program

names;

b. Usable memory bytes;

c. They bytes for the present program.

The meaning and usage of EDIT key in Edit mode:

Cursor moving upward key:

Press the key each time, the cursor moves to the first character behind last block number.

Press the key without releasing, the key continuously moves up till the first program line;

otherwise, the key is released.

Cursor moving downward key

Press the key each time, the cursor moves to the first character of next program row.

Press the key without releasing, the key continuously moves up till the last program line; otherwise,

the key is released.

15

Page 28

GSK928GA/GE Grinding Machine CNC System Operator’s Manual

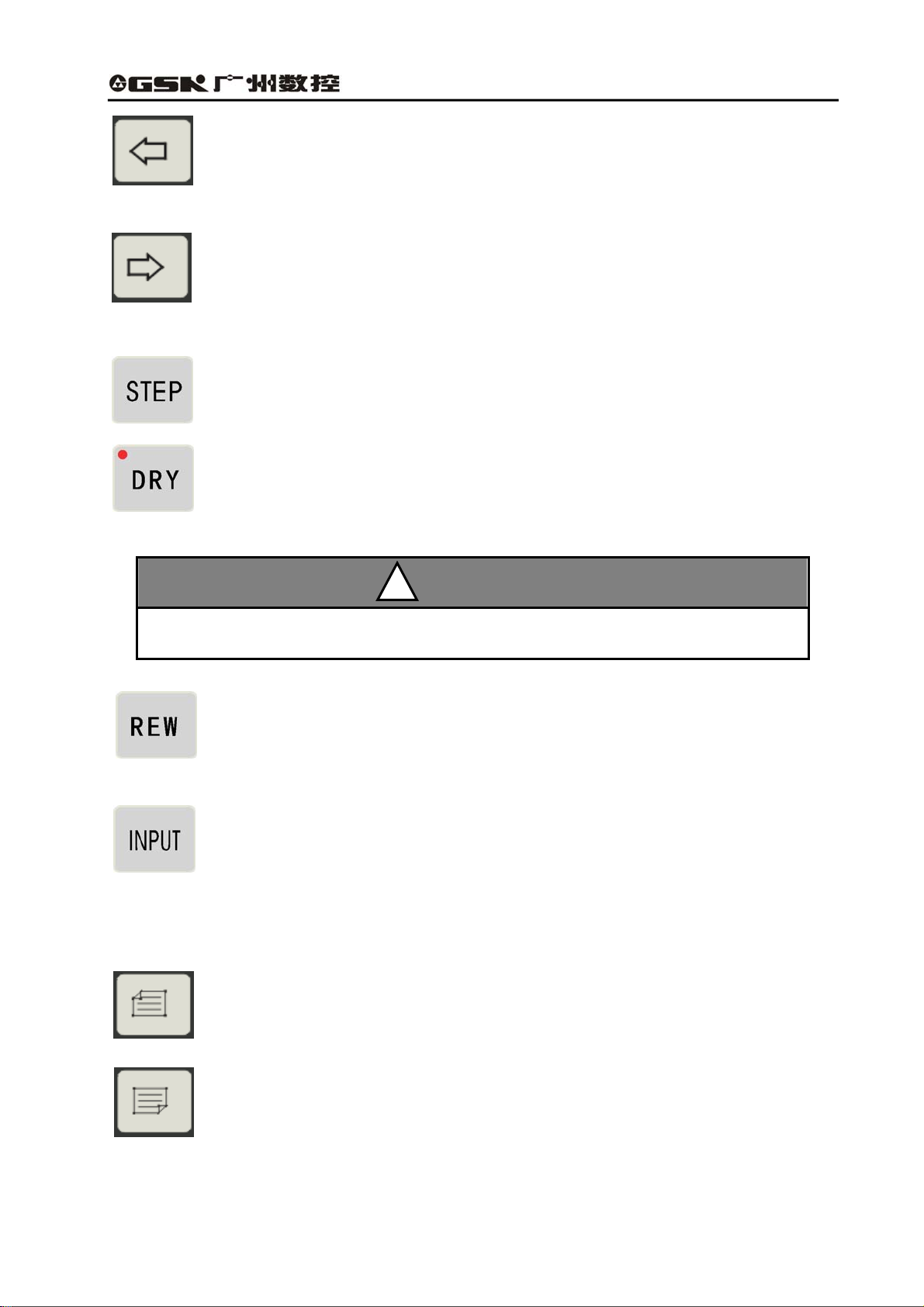

Cursor moving to left key

Press the key each time, the cursor is moved by one character to left side. Press the

key without releasing, the cursor continuously moves towards the left side until the first

character of the same program line, otherwise, the key is released.

Cursor moving to right key

Press the key each time, the cursor is moved by one byte to right side. Press the key

without releasing, the cursor continuously moves toward the right side until the first

character of the same program line, or the key is released.

The cursor moves to the end of the program line.

The cursor moves toward to the first letter after program number.

Cursor—the symbol that shows the character which can be edited at present.

Insert/rewrite key

The key is for changing the edit input mode. Press key for each time, the input method

is switched between insert and rewrite, and the cursor prompt changes correspondingly.

The cursor of inserting is a flickering short line and the cursor of rewriting is a flickering square shape.

Input key

Press input key each time, and it inputs the program number in two digits, the new

program can be created, selected, or the exist program and all programs can be

deleted.

Page up

It prompts the content of last page when searching the list of program number.

!

REMARK

Page down

It prompts the program content of next page when searching the list of program

number.

16

Page 29

GSK928GA/GE Grinding Machine CNC System Operator’s Manual

Double function definition key:

Each key has two definitions, press the key for the first time, then it is the first definition value, that is

G M X Z S T F Y L P N = * — ﹒. Press the same key for the second time,

system changes into the second definition value, that is I R O W J K E A C D Q #

/ + . If the same key is pressed continuously, the input value is changed from the first

definition value to the second one or the second to the first. Among them, the “/” is skip block key,

“ ”is space key. But under special working mode, if the key has one definition, then the key is

switch to single function key automatically.

3.2 Part program directory search

Through part program directory searches, the users can search all stored part program number, and

the remaining bytes of the part program storage and all part program name list in the Edit mode.

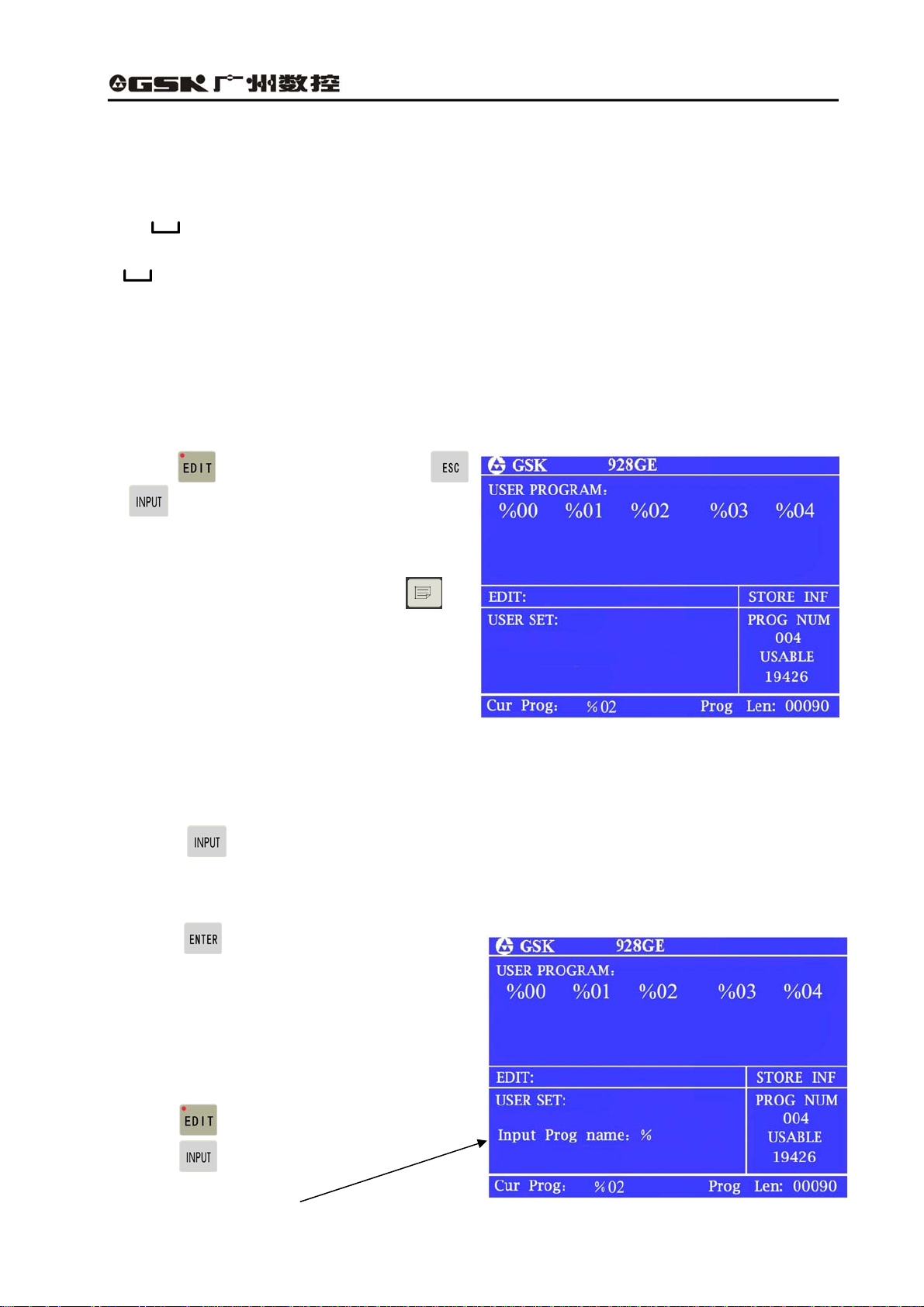

(1)Press in the editing mode or press

or during program edit.

(2)Each screen can prompt 20 program names.

When the part programs of storage exceed 20,

it can prompt by pagination. Then, press ,

and turn to the next page, it prompts the list of

program numbers in the next page.

3.3 Part program management

3.3.1 Creating a new part program

(1) Press under the status of part program directory search;

(2) Input program numbers of two digits from keypad, which does not exist in the directory list, as new

program number;

(3) Press ;

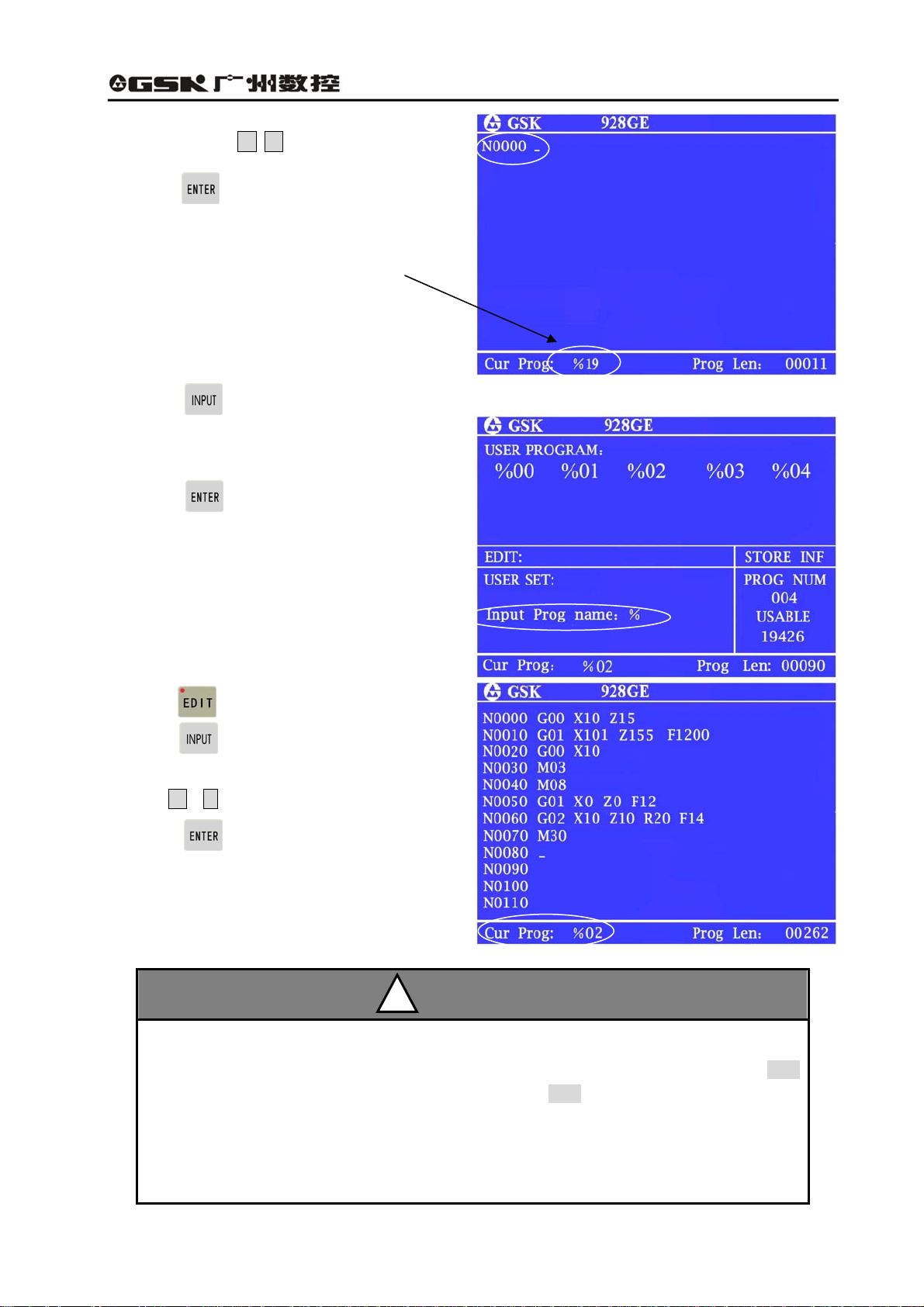

(4) After creating the new part program, the system

enters program edit state automatically.

For example:

Create No.%19, which is new program number.

a. Press and enter Edit mode;

b. Press , the screen is displayed

Input prog number: % ;

17

Page 30

GSK928GA/GE Grinding Machine CNC System Operator’s Manual

c. Press digit key 1 9

d. Press , No. %19 program number is

created. Block number is generated automatically

Current program number is displayed: %19

3.3.2 Selecting a part program

(1) Press under the status of part program directory search;

(2) From keypad, input the selected program

number;

(3) Press ;

(4) After selecting the part program, and prompt

the content, then, it enters Edit mode.

For example: select No. %02 program

a. Press and enter the Edit mode;

b. Press and screen prompts Input prog

%

number:

c. Input 0 2 ;

d. Press , program number % 02 is

selected.

;

!

REMARK

1. CNC system is powered on for the first time, it enters the Edit mode or system part

program storage area without any content, then, the system creates and selects %00

automatically. After system initialization, it also chooses %00 as present program.

2. After system selects one program, the program can only be changed through part

program selection. Once the program is selected, it always keeps same. Even power is off,

the program number can not be changed.

18

Page 31

GSK928GA/GE Grinding Machine CNC System Operator’s Manual

3.3.3 Copying a part program

Copy the present content of file to other one, and select the new files as present one.

(1) Press , the screen is displayed Input prog number: %

(2) Input the file name which does not exist in the file list, press , and all the content of current

file is copied into the file with the new name and the new file become current one.

For example, copy the current %02 into the file of %05 program.

Press , and input 0 5 , and press , the copy is completed.

If the input file name exists, the system prompts Name repeat! Press any key exit, and input

the file name again, which does not exist in the file list, and press .

!

REMARK

3.3.4 Renaming a part program

Rename the current file name.

(1) Press , the screen prompts Input prog number: %.

(2) Input the file name which doesn’t exist in the file list, press , and rename the current file

name.

For example: Rename the current % 02 file as %05.

Press , input 0 5 , press , renaming is completed.

3.3.5 Deleting a part program

(1) Press under the state of the part program directory searches;

(2) From keypad input the program name which is required to delete;

(3) Press , the screen prompts Sure?

(4) Press to delete the part program

which has the program number and press

to cancel the deleting operation.

For example: delete No. %05 program.

Press , input 0 5 , and press

and to delete %05 program from

part program storage.

19

Page 32

GSK928GA/GE Grinding Machine CNC System Operator’s Manual

The methods of copy, renaming and deleting are displayed on the screen:

① Press and enter Edit mode.

② Press and the screen prompts Input prog number: %.

③ Press 0 5 ;

RENAME

DELETE

(1)After copy, the screen is displayed:

No. %05 program is same as No. %02 one.

COPY

(5) After renaming, the screen prompts %05

program during the Edit mode.

No. %05 program replaces %02 one.

(3)During deleting, the screen is displayed:

Press , No. %05 program is deleted.

20

Page 33

GSK928GA/GE Grinding Machine CNC System Operator’s Manual

3.4 Inputting and editing a part program

CNC system machining is that the system automatically completes machining parts according to the

part program sequence input by the users.

Each program consists of some blocks; each block is composed by components of sequence number,

commands and data, etc. By inputting the part program content based on the processing sequence,

the machine can be started to machine the qualified parts.

3.4.1 Automatic generating the serial number

Each part program includes many blocks; each block is begun with a block number of .

When a new program is created, the system automatically generates the first number N0000.

Press , after inputting a block, then, the system automatically generates the next block number.

During input, the number increment depends on the content of P061 parameter. While inserting

blocks, the system automatically generates the block number based on integral part of 1/4 parameter

P061 content.

When use the jump instruction, the program line which is specified by P should be the only one;

otherwise, the same program line number may cause the jumping mistake.

The sequence of number generation and insertion of program line is as below: (the value of P956 is

10)

Automatic generation of

number (P061)

Insert program

line (1/4 of P061)

N****

3.4.2 Inputting the program content

The editing mode of CNC system adopts the full

screen. The input of program content is in the

editing mode.

(1)Create a new program as creating a new

part program;

21

Page 34

GSK928GA/GE Grinding Machine CNC System Operator’s Manual

(2)The monitor prompts the number N0000;Insert one line of program content through keypad.

(3)After input one line of program, press , complete inputting of the line. The system generates

the next block number, and then continues to input the program content.

(4)Repeat operation of the(3)step until the last line of program. Press and complete the input

of program content. If any mistake in editing, the system alarms. Then Press again; it exits the

edit interface.

Prompt the program ends without

end command of M02.

Each block only prompts 38 characters. It just prompts the leading 38 characters of the block

if exceeding 38 characters. Press , it prompts a character of the block to the right side.

But each line can not include more than 255 charactes, otherwise, the system does not

accept the content any more. The monitor can prompt 12 lines of program, it automatically

moves upward if more than 12 lines.

!

REMARK

3.4.3 Inserting a program line

Insert one or multiple program lines between two program lines.

(1) Press and move cursor to the first block between two blocks.

(2) Press until the cursor moves behind the last character, or press and move the cursor

directly to the last character.

(3) Press , the system automatically generates number of a new block between two blocks and

leaves one blank line. The number increment is 1/4 integral value of P061 parameter, if it is not

enough, then the next line number can be rewritten.

(4) Input the block content to be inserted;

(5) After inputting all the content; press if multiple program lines should be input. If there is one

program line, the operation is not required.

(6) Inserting the block is over.

22

Page 35

GSK928GA/GE Grinding Machine CNC System Operator’s Manual

1. Insert the block behind the last one and press and it automatically generates the next

block number.

2. Before the first program line, it is not allowed to insert block. If it requires inserting block before

the first line, rewrite the content of the first line into that of the line to be inserted, and insert the

original first line into this program line.

For example: Insert the new block M3 between blocks N0020 and N0030 .

(1) Press and move the cursor to

N0020 .

Press and move the cursor behind X50.

!

REMARK

(2) Press , the system automatically generates new program line number and leaves one blank

line to prompt N0022 . The cursor points to the first character, which can be input, of the new

program line.

Input M 3 。

(3) Press and finish inserting operation.

3.4.4 Deleting a character or a block

Delete the character of one program line or the whole content of program line including the serial

number.

(1) Press and move the cursor to the block which requires deleting;

(2) Press and move the cursor to the character which should be deleted; if delete the block of

the whole line, move the cursor to the beginning of block to be deleted.

(3) Press and delete the character which is pointed by cursor. If the cursor is at the line

beginning of block, then the block of the whole line is deleted.

23

Page 36

GSK928GA/GE Grinding Machine CNC System Operator’s Manual

3.4.5 Inputting a field in a block

(1) Specify whether the current input is inserting; if it is not, press and switch the input to

inserting;

INSERT

(2) Press or and move the cursor

to the position that is after the character and should insert the content;

(3) Input the content which should be inserted, and insert the content before the character which is

pointed to by cursor.

For example: In N0020 G0 X50,

insert 1 between X and 5.

REWRITE

Because CNC system requires each filed of program line must be partitioned by space,

which is one letter followed with digits. During input, the editing program can automaticly

judge and generate the space. However, during the inserting Operation, sometimes, the

system can not judge automatically sometimes. Therefore, the operator should input by

himself the space to gurantee the intergrity of the program.

REMARK

!

24

Page 37

GSK928GA/GE Grinding Machine CNC System Operator’s Manual

3.4.6 Rewriting the content of a block

Change the content of a block into a new one. There are two methods as options based on the input:

insert or rewrite.

In insert mode, use inserting and deleting to complete it.

(1) Press , move the cursor to the character which should be rewritten;

(2) Insert new contents;

(3) Delete the surplus content through the same operation which is used for deleting the block

content.

In rewrite mode, directly rewrite the content which is pointed to by the cursor.

(1) Press and switch the input mode to rewrite mode, and the character which is pointed to by

cursor is bright square shape.

(2) Press and move the cursor to the character which should be rewritten.

(3) Input new content, the cursor points to the next character.

For example,

Change N0050 X10 to X120

In insert mode:

(1) Move the cursor to X10, below 0.

(2) Input 2

(3) Move the cursor to X120, which is below 1 ;

(4) Press , then, X120 is changed to X20.

25

Page 38

GSK928GA/GE Grinding Machine CNC System Operator’s Manual

In rewriting method:

(1) Press and change the input mode to rewrite mode, and the character pointed to by cursor is

displayed in bright square shape.

(2) Put the cursor above 1 of X10.

The character selected prompt as

bright square shape.

(3) Insert 2, it is changed to X20.

3.4.7 Skipping a block

Insert a sign of / before number N of a block.

During executing a program, the system skips

this block and executes the next one.

(1) Switch the input mode into the insert one.

(2) Move the cursor to the block which should be

skipped, and press to the block, which is

below N ;

(3) Continuously press , and insert the

character / before N;

(4) When complete programming, if it encounters the mistakes of program during exit, press for

the next operation!

26

Page 39

GSK928GA/GE Grinding Machine CNC System Operator’s Manual

3.5 External inputting a part program

Input the part program which is stored in the external computer into CNC system.

(1) After power off, connect the communication

cable between CNC system and computer;

(2) CNC system is switched on and

select the Edit mode;

(3) Press and it prompts Receive ready!

(4) Specify the system is ready, press ,

it prompts Receiving……, and the program of

the external computer is input into CNC system;

(5) Set the communication software of computer to the output mode;

(6).After receiving, it prompts Receiving is over! Press and come back Edit mode. In the list of

part program, it prompts the input program name by ascending sequence.

(7) During receiving, press to terminate the receiving process.

During part program input, if CNC system has the same program number, the system

reminds Same program name, then change or delete the program name, the

communication works again.

!

REMARK

3.6 External outputting a part program

Send the part program stored in CNC system to the external computer.

(1) During power off,connect CNC system with

computer through communication cable.

(2) CNC system is switched on and selected Edit

mode;

(3) Select the part program which should be sent

by the operation of selecting the part program;

(No option if send the current programs)

(4) Press , it prompts Sending ready!

(5) Set computer as the status of receiving.

27

Page 40

GSK928GA/GE Grinding Machine CNC System Operator’s Manual

(6) Specify the external computer ready, press , and it prompts sending……, the selected

program is sent to the external computer.

(7) After sending, it prompts Sending is over! Press and return Edit mode.

(8) During sending, press and terminate the sending.

3.7 Deleting all part programs

Delete all programs in the storage of CNC system.

(1) Press in the status of part program directory researches.

(2) Input - and 0 from the keypad;

(3) Press , the system prompts Confirm delete?

(4) Press and delete all part programs,

If is pressed, the deleting operation is not executed and come back to Edit mode.

28

Page 41

GSK928GA/GE Grinding Machine CNC System Operator’s Manual

CHAPTER 4 JOG MODE

4.1 Overview of Jog mode

Press , the machine comes into Jog mode.

During Jog mode, press , the two methods of Jog and Step can be switched.

Press MPG key or , it comes into MPG mode; meanwhile, the coordinate axes which are

controlled by MPG are selected. Through keypad, it can operate the movement of worktable and

movable socket of grinding wheel, start and stop spindle of grinding wheel and cooling fluid,

adjustment of feed override and the function of X axis machine returning to home position.

The system initialization mode is Jog mode, as

the following figure shows::

4.1.1 Manual operation

(1) Select Jog mode;

(2) Press , select Jog mode. The maximum movement distance of each continuous pressing

same key is 1000.000mm.

(3) Press one direction key, the work table or the movable socket of grinding wheel moves in the

direction of selected coordinate axes. Press the key without releasing, the worktable or the socket is

moved continuously. Release the key, the socket or the worktable decelerates and stops.

29

Page 42

GSK928GA/GE Grinding Machine CNC System Operator’s Manual

Z axis positive direction

Z 轴正方向

4.1.2 Manual step operation

(1) Press and select Step mode.

(2) Press and select the step.

X axis positive direction

X 轴正方向

X axis negative direction

X 轴负方向

Z axis negative direction

Z 轴负方向

(3) The steps are divided into 6 levels: 0.001, 0.01, 0.1.1.0, 10.0 and 50.0, press the key for one time,

the step increases by one level, and it switches in circulation.

(4) Press , the worktable and movable socket of grinding wheel is moved in the selected

direction of coordinate axis by the chosen distance of step. Press one direction key without releasing;

it is moved one level of step.

!

REMARK

Press and stop moving in Step mode.Press the key, the worktable and the socket of

grinding wheel decelerates and stops, the remaining step is not kept, and press feeding key

to execute the next feeding process of single step.

30

Page 43

GSK928GA/GE Grinding Machine CNC System Operator’s Manual

4.1.3 MPG operation

In MPG mode, the movement of worktable and movable socket of grinding wheel can be controlled by

turning the manual pulse generator (MPG).

(1) Select MPG axis or , it enters MPG mode.

(2) Press and select the moving distance.

● There are three options of circulation switches: 0.001、0.01、0.1mm

● When the working mode is switched from Step mode into MPG, the move distance value of each

scale is automatically selected as 0.010mm.

(3) Running MPG.

● CW running, the coordinate axis moves

in the positive direction;

● CCW running, the coordinate axis moves

in the negative direction.

During MPG mode, other function key on axis move are not working, such as jog, return to

home positon, relative and absolute movement, but other M accessorial functions are still

valid.

!

REMARK

4.2 Selecting the manual feedrate

In the manual feeding mode, there are two selections that include the override of manual feedrate

and manual rapid override.

Selecting

rapid overrides

Selecting

feedrate overrides

Selection between speed

override and rapid override

31

Page 44

GSK928GA/GE Grinding Machine CNC System Operator’s Manual

4.2.1 Selecting manual feedrate overrides

Select the feedrate override in Jog mode.

Feed rate override increases 1%.

Feed rate override reduces 1%.

In Manual feeding mode, press and rapid indicator is OFF, the screen prompts as below:

For example:

The feedrate F is 6000, and selective speed

override 80%, then the actual feedrate is

6000*80%=4800.

Feedrate override

4.2.2 Selecting manual rapid feedrate overrides

The rapid mode is selective in manual feeding mode. During rapid feeding, the speed is selected by

override.

In manual rapid feeding, the actual feedrate depends on rapid traverse speed and override:

X axis actual rapid speed = P005 X rapid override

Z axis actual rapid speed = P006 X rapid override

In Manual Feeding mode, press and select the manual rapid feeding mode, then the indicator is

ON, the feedrate and rapid override are displayed as bright square shape, and the screen is shown

as below:

32

Page 45

GSK928GA/GE Grinding Machine CNC System Operator’s Manual

4.2.3 Manual setting feedrate F

In Jog mode, it can set the feedrate in Jog and Auto modes by inputting the feedrate F. The method is

as below:

a) Select Jog mode;

b) Press , then, F shows brightly, in the rapid parameter range of X and Z axes, any digit

between 0000.000 and 8000.000 can be input.

c) Press , the feedrate value is the input digit value on the screen; Press , then the

feedrate doesn’t change.

For example, manually input F3000

(1) Select Jog mode and input F3000, then, the

feedrate F in the information prompt bar is

“6000”.

(2) Press , the feedrate F