Page 1

This user manual describes all proceedings concerning the

operations of this system in detail as much as possible. However, it is

impractical to give particular descriptions for all unnecessary or

unallowable system operations due to the manual text limit, product

specific applications and other causes. Therefore, the proceedings not

indicated herein should be considered impractical or unallowable.

This user manual is the property of GSK CNC Equipment Co., Ltd.

All rights are reserved. It is against the law for any organization or

individual to publish or reprint this manual without the express written

permission of GSK and the latter reserves the right to ascertain their

legal liability.

I

Page 2

GSK6000 All-Electric Injection Molding Machine Digit Control System

Preface

Your Excellency,

It’s our pleasure for your patronage and purchase of this

GSK6000 series, the All-Electric Injection Molding Machine made

by GSK CNC Equipment Co., Ltd.

The GSK6000 All-electric Injection Molding Machine Digit Control

System researched and manufactured by GSK Company adopts

multi-core frameworks platform with high-side 32-bit industrial-grade

ARM, DSP and FPGA. It is combined the advance control technique and

carried out the high-speed and accuracy control, so the control system

owns the strong function and capacity ensuring that the integral machine

can be stably and reliably operated.

The accident hazard may occur due to the

misoperation. Carefully read this manual and

the related description before using this system.

II

Page 3

GSK6000 All-Electric Injection Molding Machine Digit Control System User Manual

Safety Warning and Precaution

The main controllable objection of the GSK6000 All-Electric

Injection Molding Machine Digit Control System: high-speed motor,

high-temperature heating equipment and other assistance movement

mechanism. It may hurt the user by the moving equipment and scald the

operator by the heater and high-temperature plastic, as well the electric

shock hazard and other unexpected behavior if the incorrect operations

are performed.

To guard against the above-mentioned hazards, the operator,

administrator and maintainer should entirely comprehend the User

Manual and its related descriptions, and strictly observe the

corresponding specifications of this system and equipment safe

operations.

We are afraid of that our company will not undertake any obligation

if the incorrect operation and maintenance are performed without

observing the User Manual, as well freely modify or change the control

system causing the accident and damage without any authorization or

permission.

It is better to put this manual aside the machine, so that the

operator can refer it when some troubles are generated.

Page 4

GSK6000 All-Electric Injection Molding Machine Digit Control System

The manual offers the relative contents and some precautions of ※

the GSK6000 series injection molding machine.

※ This version manual is suitable for the injection machine, which

is assembled with GSK6000 All-Electric Injection Molding

Machine Digit Control System.

Chinese version of all technical documents in Chinese and

English languages is regarded as final.

It is necessary to note the following items before using the

system:

● Ensure the ESP button is enabled. Because the ESP input of

this system uses the normally closed contactor; the system

ESP alarm may occur and can not normally operate if it does

not connect the ESP button or connect it as normally open

contractor.

● Ensure the effective of the safe protection components

related with the system (For example: the limit switch of the

mechanism).

IV

Page 5

GSK6000 All-Electric Injection Molding Machine Digit Control System User Manual

Special Tips: User can not use the system power as other purpose!

Security Responsibility

Security responsibility of the manufacturer

——Manufacturer should take responsibility for the design and structure

danger of the digital control systems and the accessories which have

been eliminated and/or controlled.

——Manufacturer should take responsibility for the security of the digital

control systems and accessories.

——Manufacturer should take responsibility for the offered information and

suggestions for the user.

Security responsibility of the users

——User should know and understand about the contents of security

operations by learning and training the security operations of the

digital control system.

——User should take responsibility for the security and danger because of

increasing, changing or modifying the original digital control system or

accessory by themselves.

——User should take responsibility for the danger without following the

corresponding operations, regulation, maintenances, installations and

storages digital control system described in the manual.

This manual is reserved by final user.

Sincere thanks for your supporting of GSK’s products.

Page 6

GSK6000 All-Electric Injection Molding Machine Digit Control System

CONTENT

CHAPTER ONE PURPOSE....................................................................................1

1.1 Reading Object ................................................................................................ 1

1.2 How to Use this Manual .................................................................................. 1

1.3 Related document ........................................................................................... 1

1.4 Appointment .................................................................................................... 1

CHAPTER TWO BRIEF .......................................................................................... 4

2.1 The Main Character of the GSK6000 Digital Control System ...................... 4

2.2 GSK6000 Control System Configuration....................................................... 5

2.3 The Briefs both the Man-Machine Interface Constitution and the Button

Function of the Miscellaneous Operator Panel .................................................. 6

CHAPTER THREE SAFETY APPLICATION........................................................12

3.1 Safety Using................................................................................................... 12

3.1.1 The Definition of the User............................................................................................ 12

3.2 The Precautions of the Safety Use .............................................................. 13

3.2.1 The Precaution of the System Installation ................................................................... 13

3.2.2 The Precaution of Guard Against the Electric Shock Hazard ...................................... 13

3.3 The Main Proceeding of the Circuit ............................................................. 15

3.3.1 The Controllable Circuit ............................................................................................... 15

3.3.2 The Precaution of the Circuit Board............................................................................. 16

3.4 The Requirement Proceedings of the Installation Auxiliary Functions.... 17

3.4.1 The Grounding of the Auxiliary Equipments ................................................................ 17

3.4.2 The Grounding for the Noise Wave ............................................................................. 17

3.4.3 Precautions for the Static Noise Wave ........................................................................ 17

3.4.4 The Shield of the Electromagnetic Field Equipment.................................................... 18

3.4.5 The Use of the Internal DC Power............................................................................... 18

3.4.6 The Usage of the Thermocouple ................................................................................. 18

CHAPTER FOUR OPERATION............................................................................ 19

4.1 The Brief of the Operation ............................................................................ 19

4.1.1 System Working Mode ................................................................................................ 19

4.1.2 The Confirmation Before Injection ............................................................................... 23

4.1.3 Plan Injection Function ................................................................................................ 27

4.1.4 Injection Condition Setting........................................................................................... 29

4.1.5 Confirm Before the Batch Production .......................................................................... 36

4.2 The Button Operation of the Auxiliary Panel .............................................. 40

VI

Page 7

GSK6000 All-Electric Injection Molding Machine Digit Control System User Manual

4.2.1 Preparation/Confirmation Before Operation ................................................................ 40

4.2.2 The Processing of each Operational mode ................................................................. 45

4.2.3 The Button Operation of the Automatic Purge/Discharging ......................................... 67

4.2.4 The Confirmation/Stop Operation in the End of the Injection Molding Machine........... 68

4.3 Parameter/Function Setting.......................................................................... 79

4.3.1 Mold Opening/Clamping .............................................................................................. 79

4.3.2 Temperature................................................................................................................ 91

4.3.3 Injection and Metering ................................................................................................. 96

4.4 Production Management.......................................................................... 104

4.4.1 Process Monitoring ............................................................................................... 104

4.4.2 Production Management....................................................................................... 106

4.4.3 Quality Management............................................................................................. 110

4.4.4 Historical Records................................................................................................. 121

4.5 Input/Output State Monitoring................................................................. 125

4.5.1 I/O Diagnosis ........................................................................................................ 125

4.5.2 Motor Diagnosis.................................................................................................... 126

4.6 Causes and solutions of defective product in injection molding ........ 128

4.7 Calculation Method for Mold Clamping Force ....................................... 143

Page 8

Page 9

GSK6000 All-Electric Injection Molding Machine Digit Control System User Manual

CHAPTER ONE PURPOSE

That the GSK6000 All-electric Injection Molding Machine Digit Control

System User Manual is compiled for who is use this manual.

This manual is detailed in the button operation, main parameter setting

and each function usage, so that the user can entirely comprehend this digital

control system, set the related parameter, correctly use and operate the

qualified product produced by this system.

1.1 Reading Object

This manual is suitable for the operator; maintainer and related administrator who are use this

system.

1.2 How to Use this Manual

This manual is detailed the usage and related setting of the digital control system, it is better

to fully read this User Manual. Combine the man-robot interface of the control system, gradually

understand and grasp the operation methods and techniques of this digital control system based

upon the basis working schedule of the injection molding machine. Integrate the theory with

practice and manual practice, so that you can rapidly grasp each function and usage of the

GSK6000 All-electric Injection Molding Machine Digital Control system.

1.3 Related document

Refer to this User Manual for the Injection Machine Digital Control System

Refer to the operation and maintenance of the mechanical explanations for the injection

molding machine mechanism.

1.4 Appointment

(1) “GSK” is the Guangzhou CNC Equipment Co., Ltd.”

(2) If there is no special explanation, the “SYSTEM” in this manual means

“GSK6000 All-electric injection molding machine digital control system” of the

Guangzhou CNC Equipment Company.

(3) As for the appointment of the clamping and die assembly: the clamping is an

important operation in the final period of the die assembly, and therefore if there

is no special explanation, the clamping and the die assembly will be treated as a

same motion.

(4) The Metric system unit is used only in this manual, wherein, the unit and

dimension used in this manual are shown below:

1

Page 10

GSK6000 All-Electric Injection Molding Machine Digit Control System

1) mm: Millimeter

2) cm: Centimeter

3) m: Meter

3

4) cm

:Cubic centimeter

5) g: Gram

6) kg: Kilogram

7) t: Ton (clamping close unit)

8) N: Newton

9) kN: Kilonewton (The unit of the clamping force)

10) kw: Kilowatt (The unit of the power)

11) Pa: Pascal (The unit of the pressure)

12) MPa: Megapascal (The unit of the pressure)

2

13) kg.f/cm

o

14)

C: Celsius degree

:Kilogram/square centimeter (Pressure unit)

15) ℉: Fahrenheit

16) Sec (S): Second

17) h: Hour

18) min: Minute

19) r/min: Rev./min. (The unit of the rotation speed)

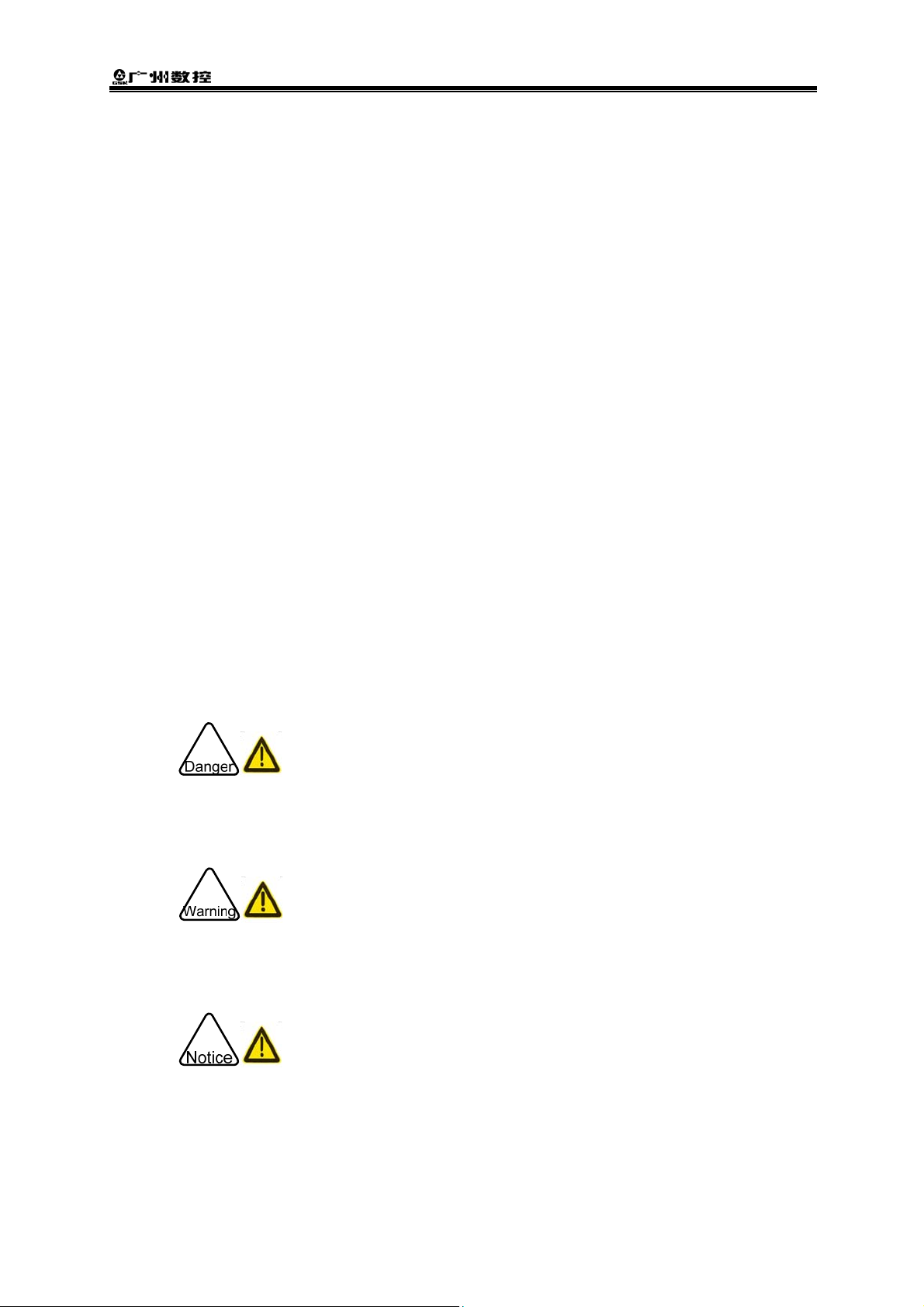

(5) The relative figure symbol in this manual

[Danger] It is reminded the user to hold the uppermost warning. You

must strictly abide by the operation specifications and

methods in the User Manual, otherwise, the death hazard

may occur.

[Warning] It is reminded the user to hold the uppermost warning. You

must strictly abide by the operation specification and

methods in the User Manual; otherwise, it may result in

severe injury or death.

[Notice] It is reminded the user to hold the uppermost warning. You

must strictly abide by the operation specification and

methods in the User Manual; otherwise, it may cause injury

or danger.

2

Page 11

GSK6000 All-Electric Injection Molding Machine Digit Control System User Manual

Instruction

[Instruction] It means that the user should hold the uppermost

warning. You must strictly abide by the operation

specification and methods in the User Manual; otherwise,

the device may be damaged or destroyed.

[Reminder] It means that the readers should read its content carefully.

3

Page 12

GSK6000 All-Electric Injection Molding Machine Digit Control System

CHAPTER TWO BRIEF

2.1 The Main Character of the GSK6000 Digital Control System

GSK6000 All-electric Injection Molding Machine Digital Control System is newly

developed and manufactured by the Guangzhou CNC Equipment Company based

on 10-year successful experiences in machining CNC system, AC servo motor and

servo drive products. It is high capacity digital control equipment used for high-speed

and high-precision all-electric injection molding machine. Guangzhou CNC

Equipment Company owns the whole intellectual property rights.

This series product is combined the user’s habit, and inherited the

advantage with high capacity of our digital control system. It uses the advance

production technology control method in the injection industry.

Its characters are shown below:

(1) The 32-bit high capacity industry level ARM, DSP multiprocessor and the FPGA

design are used; fast calculation speed and high control precision;

(2) It uses the 15 inch hi-lite and high resolution industry LCD;

(3) It uses the touch screen input; it is very convenient to operate;

(4) The common-use buttons are freely set, one-step operation, convenient and

utility

(5) Multi-level parameter password and data lock is very convenient to the user to

administrate the equipment and the product data;

(6) History operation and malfunction real-time record for analyzing the troubles;

(7) It owns the multiple-circuit USB interfaces, which can be connected with the

keyboard, mouse and U-disk.

(8) The GSK-Link high speed industry Ethernet bus is adopted to connect the

external mould;

(9) PLC control built-in, it is very convenient to extend the periphery auxiliary

equipment for the users;

(10) The weekly temperature timing heat equipment; it is very convenient to product

and improve the efficiency;

(11) Temperature control with the study type intelligent PID, faster and more

accuracy in temperature control;

4

Page 13

GSK6000 All-Electric Injection Molding Machine Digit Control System User Manual

(12) The strong self-diagnosis function is very convenient to maintain the

equipments;

(13) The input/output adopts the photoelectricity insulation, the antijamming

capacity is strong with the short-circuit protecting function of the output;

(14) The automatic molding-adjustment function and purge/discharging function

are performed; the operation is convenient and faster;

(15) The mould protecting function can be protected the mould effectively;

(16) It owns the multi-step injection and multi-level protection, which can be

improved the product quality;

(17) It owns the molding video monitoring and the connection interface of the

robot;

(18) Multiple types core-pulling twist programs, which uses for different controls

for it (Option);

(19) The Ethernet interface can be carried out the long-distance manufacture

monitor, long-distance malfunction diagnosis and long-distance program

promotion (Option);

(20) The multi-machine networking operation, the long-distance administration

product and the data table statistic and print can be achieved by the Ethernet

(Option);

(21) The common-use interface of the import motor injection molding machine can

be customized, which is used the change of the old equipment system

(Option);

2.2 GSK6000 Control System Configuration

System main machine: one set

I/O board: a block

Display board: one set

Operator panel: one set

Switch: one piece

5

Page 14

GSK6000 All-Electric Injection Molding Machine Digit Control System

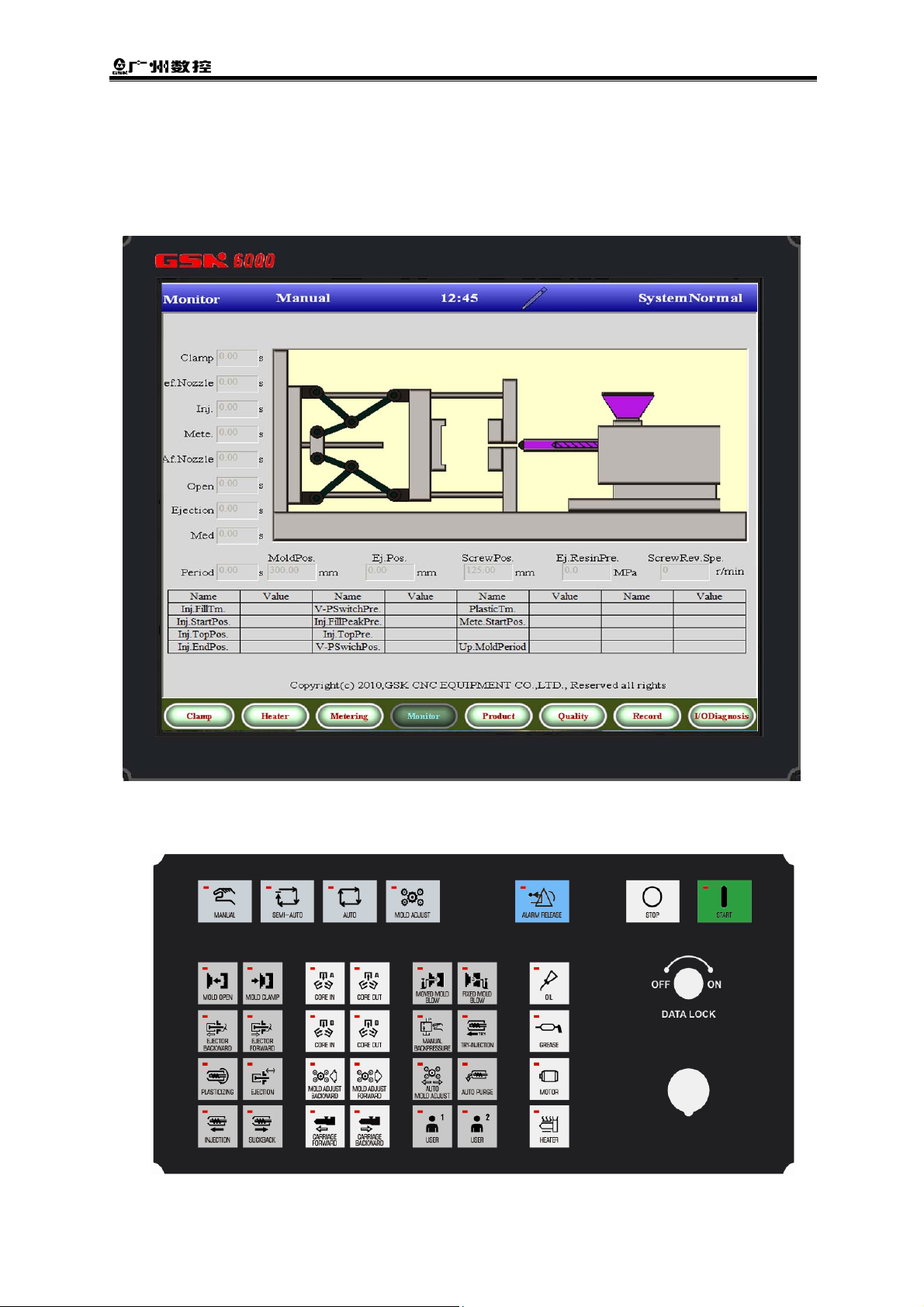

2.3 The Briefs both the Man-Machine Interface Constitution and the

Button Function of the Miscellaneous Operator Panel

(1) Full-touch LCD screen

(2) Miscellaneous operation panel

6

Page 15

GSK6000 All-Electric Injection Molding Machine Digit Control System User Manual

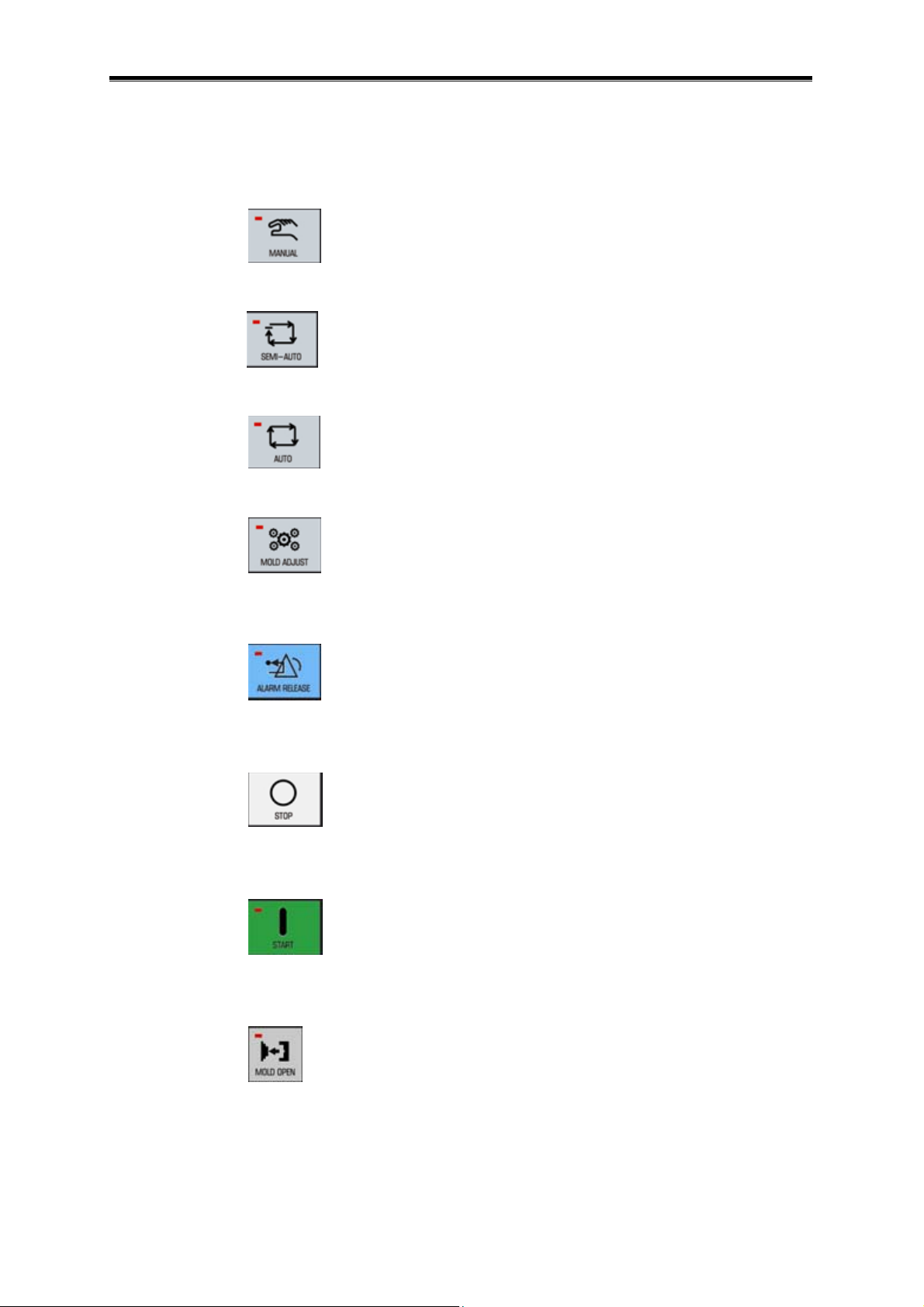

(3) The button function (Refer to the relative contents in the following chapter

Operation for the operation methods) of the miscellaneous operator panel is

described blow:

[MANUAL] button, the indicator is normally on after controlling this

button; the [MANUA] working mode is then performed.

[SEMI-AUTO] button, the indicator is normally on after controlling

this button; the [SEMI-AUTO] working mode is then performed.

[AUTO] button, the indicator is normally on after controlling this

button; the [AUTO] working mode is then performed.

[MOLD ADJUST] button, the indicator is normally on after

controlling this button; the [MOLD ADJUST] working mode is then

performed.

[ALARM RELEASE] button, after cleaning the alarm resource

when the system displays the alarm prompt, the alarm prompt

displayed on the screen can be removed by this button.

[STOP] button, the system may stop the current working

procedure during the operation of the [AUTO], [SEMI-AUTO] or

[AUTO MOLD ADJUST].

[START] button, the indicator is normally on after controlling this

button during the subschema, namely, [AUTO], [SEMI-AUTO] or

[AUTO MOLD ADJUST].

[MOLD OPEN] button, the indicator is turned on after controlling this

button in the [MANUAL] or [MOLD ADJUST] working mode; the

mold-opening is then performed, the indicator is OFF and the

operation is stopped after releasing this button.

7

Page 16

GSK6000 All-Electric Injection Molding Machine Digit Control System

[MOLD CLAMP] button, the indicator is turned on after controlling this

button in the [MANUAL] or [MOLD ADJUST] working mode; the

mold-clamping is then performed, the indicator is OFF and the

operation is stopped after releasing this button.

[EJECTOR FORWARD] button, the indicator is turned on after

controlling this button in the [MANUAL] working mode, the ejector pin

advance is then performed; the indicator is turned off and the

operation is stopped after releasing this button. It is better to eject

based upon the ejection speed 1.

[EJECTOR FORWARD] button, the indicator is turned on after

controlling this button in the [MANUAL] working mode, the ejector

pin retreat is then performed; the indicator is turned off and the

operation is stopped after releasing this button. It is better to retract

based upon the retreat speed 1.

[EJECTION] button, the indicator is turned on after controlling this

button in the [MANUAL] working mode, the multi-ejection series

operation is then performed with thimble; the indicator is turned off

and the operation is stopped after releasing this button.

[INJECTION] button, the indicator is turned on after controlling this

button in the [MANUAL] working mode, the injection is then

performed; this indicator is turned off and the injection is stopped

after releasing this button.

[SUCKBACK] button, the indicator is turned on after controlling this

button in the [MANUAL] working mode, the suck back is then

performed; this indicator is turned off and the suck back is stopped

after releasing this button.

[PLASTICIZING] button, the indicator is turned on after controlling

this button in the [MANUAL] working mode, the plasticizing is then

performed; this indicator is turned off and the plasticizing is stopped

after releasing this button.

8

Page 17

GSK6000 All-Electric Injection Molding Machine Digit Control System User Manual

[CORE IN A] button, it can not be used now.

[CORE OUT A] button, it can not be used now.

[CORE IN B] button, it can not be used now.

[CORE OUT B] button, it can not be used now.

[MOLD ADJUST FORWARD] button, the indicator is turned on after

controlling this button in the [MOLD ADJUST] working mode, the

mould-adjustment forward is then performed; the indicator is turned

off and the operation is stopped after releasing this button.

[MOLD ADJUST BACKWARD] button, the indicator is turned on after

controlling this button in the [MOLD ADJUST] working mode, the

mould-adjustment backward is then performed; the indicator is

turned off and the operation is stopped after releasing this button.

[CARRIAGE FORWARD] button, the indicator is turned on after

pressing this button in the [MANUAL] working mode, the carriage

forward is then performed, the indicator is turned off and the

operation is stopped after releasing this button.

[CARRIAGE BACKWARD] button, the indicator is turned on after

controlling this button in the [MANUAL] working mode, the carriage

backward is then performed; the indicator is turned off and the

operation is stopped after releasing this button.

[MOVED MOLD BLOW] button, in the [MANUAL] working mode, the

indicator is turned on after pressing this button in the safety close

process, the moveable plate blowing is then performed; the indicator

is turned off and the operation is stopped after releasing this button.

9

Page 18

GSK6000 All-Electric Injection Molding Machine Digit Control System

[FIXED MOLD BLOW] button, in the [MANUAL] working mode, the

indicator is turned on after pressing this button in the safety close

process, the stationary plate blowing is then performed; the indicator

is turned off and the operation is stopped after releasing this button.

[MANUAL BACKPRESSURE] button, it can not be used now.

[TRY-INJECTION] button, it can not be used now.

[AUTO MOLD ADJUST] button, the indicator is normally on after

pressing this button in the [MOLD ADJUST] working mode; the

indicator is normally on after controlling the [START] button again,

the automatic mould-adjustment is then performed. The [AUTO

MOLD ADJUST] is performed the automatic mould-adjustment

function based upon the parameter setting based upon the “

HighPre.”

(the desired clamping force, for example: 80T×50%=40T) in the

[Clamp] screen and the one inside the “InstallMold”. Other working

modes can be switched when the indicator of the “START” button is

OFF after the mould-adjustment operation is performed. If you want

to stop this operation in the halfway, press the “STOP” button.

[AUTO PURGE], in the [MANUAL] working mode, the indicator is

normally on after controlling this button when the carriage backward

is reached to the limitation. The automatic purge/discharging function

is performed based upon the setting parameter inside the “Purge” in

the [Mete.Detail] screen. The indicator is automatically turned off and

the operation is stopped after this process is executed. The indicator

is turned off and the current purge/discharging is stopped if this

button is pressed again when the automatic purge/discharging is

being performed.

[USER 1] button, it is reserved for the user, which is used for the

customized button 1 of the function extension.

[USER 2] button, it is reserved for the user, which is used for the

customized button 2 of the function extension.

10

Page 19

GSK6000 All-Electric Injection Molding Machine Digit Control System User Manual

[OIL] button, it can not be used now.

[GREASE] button, firstly, shift to the [Product] screen, switch the

“Open” button following the “GreaseAutoFre.” into the “Close”, then

press the [GREASE] button again; the indicator is normally on and

the automatic filling grease is then performed; the indicator is turned

off and the operation is stopped after the filling is completed.

[MOTOR] button, the indicator is normally on after pressing this

button. All of the motors’ power inside the equipment is turned on;

the indicator is turned off when this button is controlled again, and all

motors’ power is cut off.

[HEATER] button, the indicator is normally on after pressing this

button, the electric heating part then starts its heating function. The

indicator is turned off and the heating is stopped after controlling this

button again.

[Data lock], it can not be used now.

[ESP] button, it is only used for stopping the equipment in the

emergency case. The power both the motor and electric heating of

the system is cut off after pressing this button. After the emergency

stop occurs, the [ESP] button can be controlled after the danger has

been eliminated, and the indicator direction rotates releasing the

emergency stop. (Do not use the common stop).

11

Page 20

GSK6000 All-Electric Injection Molding Machine Digit Control System

CHAPTER THREE SAFETY APPLICATION

In order to enhance the stability of the integral machine, and avoid the hazard accident, it is

important to read this User Manual and comprehend its content before installing and using this

system. Abide by the installation described in the User Manual and the using safety

specifications.

3.1 Safety Using

3.1.1 The Definition of the User

The technician of the system

In this manual, the person who is performing the system maintenance is defined as [System

maintenance technician]. That he who is trained with this system maintenance and acquainted

with this installation system and operation, as well should gain the operation authorities from our

company.

[System maintenance technician] should abide by the following precautions:

(1) It is better to inform the related operator that the operation can not be

performed when the maintenance and detection are operated until mark a

signboard “Do not operate it, system is being maintaining”;

(2) Confirm the ESP of the system and other safety switches can be correctly

operated before performing;

(3) Do not pull out and insert each control cable related with system during

operating;

(4) It is better to protect the multimeter probe (test pen) when metering with

power, prevent against the short-circuit happens during metering;

(5) Ensure the related motor and the mechanism position is within the safety

range when the movement parts are operated.

(6) The operation exceeded the system safety range should be firstly consulted

the maintainer during the operation.

(7) Detect and confirm whether the related cable is connected reliably and

correctly after the system maintenance is finished, as well the overall

disassembly components have been installed correctly.

(8) When the maintenance detection is performed and returns to the normal

operation state, confirm whether the equipment and miscellaneous device

holds in the original state, and if it is in the usable state, notice the whole

relative operators.

Equipment Operator

In this user manual, the high level maintenance professional during operating is defined as

[Equipment operator].

[Equipment operator], is the equipment operators of the GSK, or trained and gained the

12

Page 21

GSK6000 All-Electric Injection Molding Machine Digit Control System User Manual

qualification from the GSK, can perform the following operations.

(1) The system installation uses the technical instruction;

(2) The elimination of the system malfunction.

The repair of the equipment (the exchange of the unit and the replacement of the setting and

the adjusted electrical elements), the [Equipment operator] should comply with the

above-mentioned “Precautions during working maintenance”, as the maintenance professional. It

is very necessary to notice the accidents because the carelessness caused by the skillful for the

equipment operators.

3.2 The Precautions of the Safety Use

This system is fully considered for the security when designing. It is necessary to read and

sufficiently comprehend this User Manual before installing and using, and ensure that the system

can be reliably operated after installing.

3.2.1 The Precaution of the System Installation

Danger

z The ESP is the upmost level safety precaution when the

abnormity occurs. It is important to confirm this signal is

connected and used normally before using the system.

Otherwise, an unexpected result may occur.

z

3.2.2 The Precaution of Guard Against the Electric Shock Hazard

z The power connection of the injection molding machine and

accessory equipments should be installed the breaker, which

should be operated with grounding.

z The insulation resistance (Check whether the electric heater is

normal) should be measured once a year at least.

z The equipment can not be operated when the electrical control

cabinet is opening, because the cabinet should be disassembled

when the maintenance or detection is performed. So, it is

necessary to cut the main breaker and then operate until the

electrolytic capacitor is discharged (discharge 10s).

z The equipment innovation and modification can not be

performed without the permission from the manufacturer.

13

Page 22

GSK6000 All-Electric Injection Molding Machine Digit Control System

The precaution of guard against the electric shock hazard

The facility of the leakage breaker

The product delivered to your esteem company is not installed the

safety equipment such as the leakage breaker.

The national standard of the breaker:

GB 10963-1989| Domestic and similar purpose breaker

GB 14048.2-1994| Low-pressure switch equipment and controllable

equipment, Low-pressure breaker

GB 16916.1-1997| The remaining current motion breaker (RCCB)

without OCP (over-current protection) for domestic and similar

purpose - The Part 1: General regulation

GB 16916.21-1997| The remaining current motion breaker (RCCB)

without OCP (over-current protection) for domestic and similar

purpose – Part 2.1: General regulation is regardless of the RCCB

applicability of the motion function and circuit voltage

GB 16916.22-1997| The remaining current motion breaker (RCCB)

without OCP (over-current protection) for domestic and similar

purpose – Part 2.2: General regulation is related with the RCCB

applicability of the motion function and circuit voltage

GB 16917.1-1997| The remaining current motion breaker (RCBO)

with OCP (over-current protection) for domestic and similar purpose

– Part 1: General regulation

GB 16917.21-1997| The remaining current motion breaker (RCBO)

with OCP (over-current protection) for domestic and similar purpose

– Part 2.1: General regulation is regardless of the RCBO applicability

of the motion function and circuit voltage

GB 16917.22-1997| The remaining current motion breaker (RCBO)

with OCP (over-current protection) for domestic and similar purpose

– Part 2.2: General regulation is related with the RCBO applicability

of the motion function and circuit voltage

GB 1984-1989| AC high pressure breaker

GB 4876-1985| The charge current on-off experiment of the circuit of

the AC high pressure breaker

GB 7675-1987| The on-off capacity group experiment of the AC high

pressure breaker

Supply the AC electric power equipment to the injection molding

machine and others around it, it is recommended that this equipment

should be installed based on the safety countermeasure when the

abovementioned equipments are not set.

The slight high-frequency noise may occur when the inverter is

operating, because the different kind of the leakage breaker, the

current may leak due to the high frequency, and then the malfunction

occurs.

14

Page 23

GSK6000 All-Electric Injection Molding Machine Digit Control System User Manual

System grounding

The power circuit filter is installed inside the control system, and

therefore, the slight leakage current will go through the shell of the

system; the electric shock hazard may occur if the unreliable

grounding is performed. So, never attempt to install and use system

without grounding.

The grounding equipment of the machine

Connect the grounding terminal of the mechanical power and the

factory power, so that the earthing can be performed mechanically.

As for the wiring’s resistance, it is below 100Ω when the power

voltage is below 300V; and it is below 10Ω when the voltage is below

300V.

Inspection of the insulation resistance

The inspection should be performed once yearly, for example,

among the cables, cables other than the grounding, and the

insulation resistance between the grounds. The voltage among the

wires is below 300V, and the insulation resistance is more than

0.2MΩ; if the voltage is more than 300V, and its insulation resistance

is above 0.4MΩ. It is necessary to check the insulation resistance at

least once yearly, such as the motor, electric heater and other

insulation states of the machines. When the insulation resistance is

examinated, do not offer the high voltage of the insulation resistance

megameter in the CMOS circuit, servo motor controllable connector

and the adjacent switches. The connection cable is cut off with the

servo motor’s terminal or the connector. Determinate the insulation

resistance of the servo motor without the connection state, so that

the internal circuit may be damaged.

3.3 The Main Proceeding of the Circuit

3.3.1 The Controllable Circuit

The large amount of digit and analog integral component are used inside the injection

molding machine controller, which are produced with the advanced electronic technique and

possessed of the high reliability and durability and guaranteed the high performance and

accuracy of the control system.

15

Page 24

GSK6000 All-Electric Injection Molding Machine Digit Control System

3.3.2 The Precaution of the Circuit Board

The neutral part of this injection molding machine has several circuit boards inside the

cabinet. The parts installed into these boards are used the most advanced electronic technique

integrated circuit. In these integrated circuits, some IC contains of more than 10000 circuits, so

the circuits are very compact, and greatly improves the reliability and extends its life span.

High pressure (such as the AC220V, AC380V) may occur during the system use equipment,

if the pressure is applied to the control circuit board; it may be damaged the system, so it is

important to pay attention to it when operating.

As for the circuit board, abide by the following items

(1) When the circuit is pull out, inserted, assembled or disassembled, the

controllable power should be cut off, and then it can be performed after

waiting for 10 seconds (the discharge time of the capacitor charging)

(2) Link the fixed card of the cable connector. The malfunction may occur due to

he poor connection.

(3) When the welding or cutting (gas welding or electric welding) is performed

nearby the control cabinet, close the door of the control cabinet.

Environment setting

In order to protect the control equipment, it is necessary to avoid the following

environments for the use conditions of the injection molding machine.

(1) The ambient temperature around the injection molding machine is more than

the range of 0~40 .℃

(2) The place where the ambient humidity is more than 85%RH and the one the

condensing is generated because the change of the rapid temperature.

(3) The place where is with the sunshine directly.

(4) The place of the strong electric field and high magnetic field.

z The variation of the power voltage holds at the range of the ±10%.

(It can not be exceeded at one moment.)

z The variation of the power frequency holds at the range of the

±1Hz.

z The injection molding machine can be stopped after the time of

the simultaneous power-off is cut off one week.

z When it is used in the place where multiple simultaneous

power-off, the

continuous power equipment should be installed

based upon requires.

16

Page 25

GSK6000 All-Electric Injection Molding Machine Digit Control System User Manual

3.4 The Requirement Proceedings of the Installation Auxiliary

Functions

Because the electric flash is easily affected, so pay attention to the following items when

installing the auxiliary equipments.

3.4.1 The Grounding of the Auxiliary Equipments

The cables of the equipments, such as the unloading machine, hopper dryer and mold

temperature adjustor etc are concentrated on the main grounding terminator of the injection

molding machine. Thus, the injection molding machine and all the peripheral machines are

treated as the equal potential, it is added the safety and reduced the noise wave.

The reserved socket of the injection molding machine is a system based upon the

above-mentioned grounding cables, which is connected with the grounding terminal of the

injection molding machine, so if you use this socket, the grounding of the peripheral machines

will be easier.

3.4.2 The Grounding for the Noise Wave

It is recommended that separate the power of the injection molding machine and the other

machines (discharge processing machining, arc welding machine, commutator motor, and the

total number changeable equipment of the silicon controlled etc.) generated the noise wave, the

grounding system of the injection molding machine can not be shared a same place with the

abovementioned machines which may generate the noise wave. The grounding of the injection

molding machine should be performed separately, which can be stably operated without any

noise wave.

3.4.3 Precautions for the Static Noise Wave

The transportation equipments (specially, deliver the plastic inside its plastic tube by the air)

such as the plastic and molding product may generate an intense static noise wave. So, the

grounding joint of the equipment is practically performed.

The material transportation tube should be used the shortest limit length, and depart from

the controller and the screw position detection encoder as much as possible when the channel is

set. The molding product taken from the molds which do not pile nearby the operation panel,

because the strong static may cause the malfunction of the equipment, so it is necessary to

avoid it.

17

Page 26

GSK6000 All-Electric Injection Molding Machine Digit Control System

3.4.4 The Shield of the Electromagnetic Field Equipment

When the injection molding machine grounding connection is performed nearby the

equipment of the strong electromagnetic field, namely, the arc welding machine, discharging

processing machine, and the high frequency heater, the equipment with the noise wave should

be covered by the grounding metal shielding board.

3.4.5 The Use of the Internal DC Power

The AC power such as the DC24V, DC12V and DC5V inside the injection molding machine is

specially used for its internal system, not for the power of the external equipment. Do not use this

power on other purpose other than it is indicated in the User Manual. If you use it freely, it may

cause the low voltage or the noise wave may issue, and the malfunction or other stoppage of this

injection molding machine may generate.

3.4.6 The Usage of the Thermocouple

The thermocouple used in the injection molding machine and a microscale voltage value

may output based upon the temperature at the top of the temperature measure. This value is

formed a digital signal by the signal amplification and A/D conversion, so the voltage that gives

to the thermocouple circuit can not excessive, otherwise, the thermocouple amplification may be

damaged, and therefore, pay attention to the following proceedings when using.

(1) Pay attention to the leakage of the electric heater, which should be changed it

as for the one with poor insulation. Specially, the mold may be leaked using

the mini electric heater, so check the insulation resistance periodically.

(2) When the thermocouple top connected with the circuit should be disassembled

from the mold and heater hopper, do not put the static on the metal part of the

thermocouple. In this case, it is recommended that the top of the thermocouple

is temporarily connected with the metal parts such as the frame of the injection

molding machine.

18

Page 27

GSK6000 All-Electric Injection Molding Machine Digit Control System User Manual

CHAPTER FOUR OPERATION

4.1 The Brief of the Operation

Mainly, this chapter is introduced the corresponding functions of the operation system in

each stage of the injection molding machine.

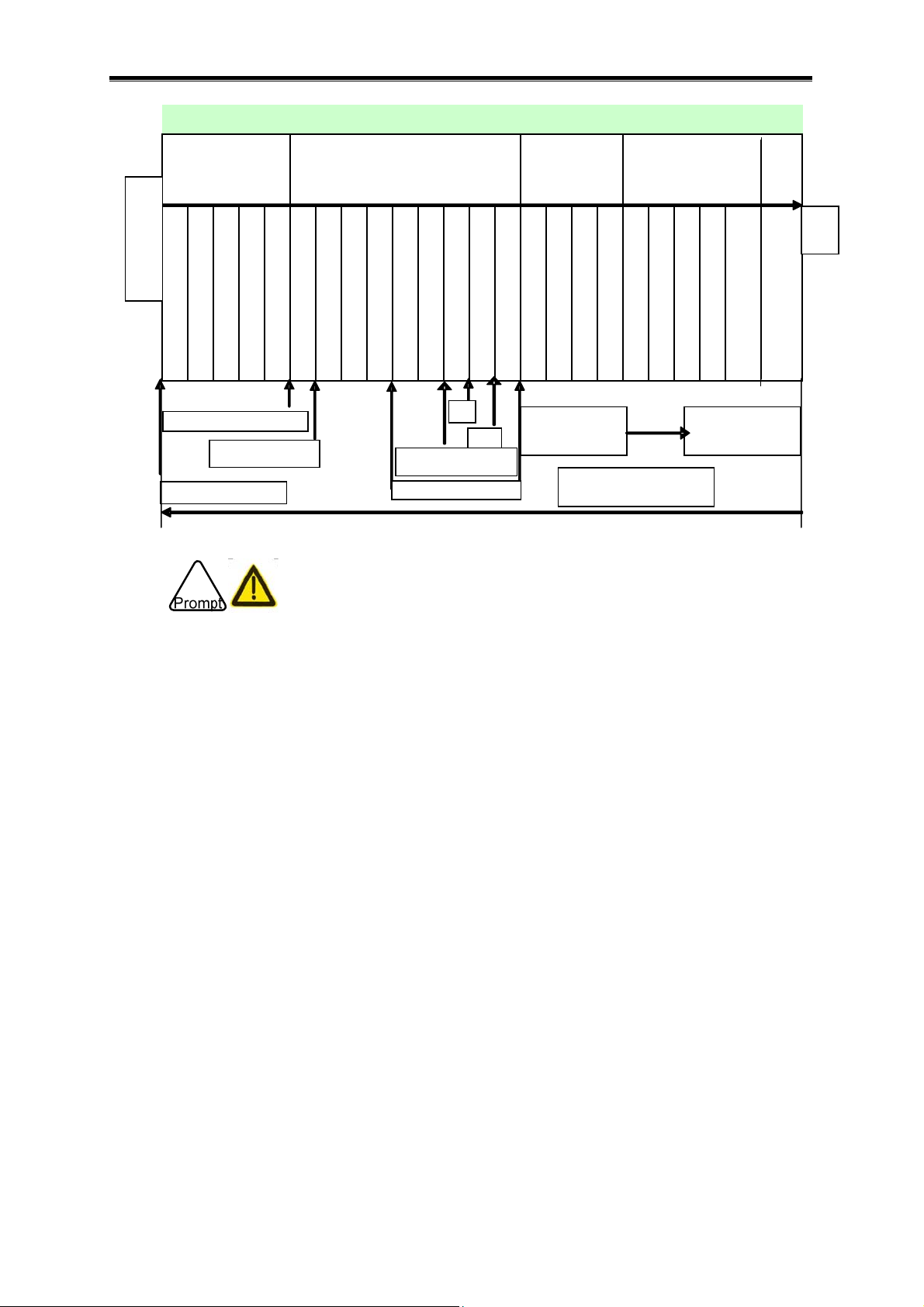

4.1.1 System Working Mode

The system has four kinds of working modes: [MANUAL] mode; [SEMI-AUTO] mode;

[AUTO] mode and [MOLD ADJUST] mode. The working modes (For example, the figure ①) can

be shifted by the buttons on the miscellaneous panel, which can not be operated simultaneously.

Different working modes can be chosen based upon your circumstance, and the four modes will

be introduced below.

The button classification figure of the auxiliary operator panel

① The button area of the working mode selection;

② The same operation button area both the [MANUAL] and [MOLD ADJUST]modes;

③ The [START], [STOP] button of the operation of the system [SEMI-AUTO] or [AUTO]

or [MOLD ADJUST];

④ Specially for [MANUAL] mode operation button area;

⑤ Specially for [MOLD ADJUST] mode operation button area;

⑥ The button area of the user selection (fail to offer);

19

Page 28

GSK6000 All-Electric Injection Molding Machine Digit Control System

z When the system is turned on, the manual mode is started by default.

z The operation of each mode, refer to the switch conditions among the modes and

the system response after shifting in the Section 4.2.2 in this manual.

4.1.1.1 [MANUAL] Mode Explanation

[MANUAL] Mode is mainly used for the system debugging at the first time and the

operation for a certain movement after the produce dwells. It is necessary to enter the

Manual mode when the ②④ areas buttons on the auxiliary operator panel should be

performed by manual. Refer to the Section 4.2.2.2 (Manual Operation Mode) for the

button explanations. The system will be controlled this operation by which the parameter

is set by this operation when the button of a certain movement is pressed, till it is

automatically stopped after the completion of the operation.

z The operation will be stopped too when releasing the button before the controllable

operation does not completed.

z The system may be performed different treatments to the same operation with the

[MOLD ADJUST] mode. Refer to the “[MOLD ADJUST] mode explanation” for details.

4.1.1.2 [SEMI-AUTO] Mode Explanation

The system is automatically controlled the injection molding machine based upon the

injection molding flow to complete a molding period from the clamping to the ejector, and

then the machine is stopped. Refer to the Section 4.2.2.3 [SEMI-AUTO] Mode Operation

in this User Manual for details. The purpose of the [SEMI-AUTO] mode is that the

trial-production can be performed based upon the [SEMI-AUTO] mode before entering

the [AUTO] batch-production mode. Judge whether the parameter is adjusted checking

the productive quality, so that the batch-production can be performed.

The flow of the injection molding machine is shown below:

20

Page 29

GSK6000 All-Electric Injection Molding Machine Digit Control System User Manual

g

g

j

y

Injection

g

Carriage retreat

A

g

Mold-clamping

utomatic start

Intermediate speed

High speed

Low voltage and speed

High speed

Safety door close

Mold-clamping completion

Nozzle contract

Mold-opening stop

Hi

Carriage

h volta

e

Period time

Injection metering

In

ection dela

Metering delay

Screw retreat

Packin

Depressure before

meterin

Cooling time

Screw retreat

Metering

SM

SD

Mold-opening

High speed 2

High speed 1

Low speed

Slow speed

Blowing start

time

Restart pressing the

automatic start

Ejection

Ejector advance

Ejector delay

Ejection dwell

Ejector retreat

Blowing

operation time

ejector plate retreat

Confirmation of mold

ate time

Intermedi

End

z If you want to start the [SEMI-AUTO] or [AUTO] operation, the following contents

should be applied:

(1) Mold-opening in-position, ejector backward in-position, screw backward in-position

(metering plasticizing in-position);

(2) Motor’s power ON, electric heat power is ON and its temperature reaches the setting

value;

(3) Motor is on the static state

(4) Safety door closes;

The system alarm may occur pressing the [START] key if the above-mentioned

contents are not applied.

z The in-position check of the three signals belonging (1) can be viewed by the “I/O

diagnosis” page (Refer to the Section 4.5.1 I/O diagnosis for details); if it does not,

adjust it to the in-position mode by the [MANUAL].

4.1.1.3 [AUTO]] Mode Explanation

The injection molding machine can be mass-produced after the system enters the

[AUTO] mode, which is same as the [SEMI-AUTO] mode; the system does not stop

instead of beginning a new period after a molding period is completed, till the production

plan is finished. Refer to the Section 4.2.2.4

4.1.1.4 [MOLD ADJUST] Mode Explanation

[AUTO] mode operation for the details.

21

Page 30

GSK6000 All-Electric Injection Molding Machine Digit Control System

It is necessary to enter this mode if the mould-adjustment is needed to be performed.

The buttons on the miscellaneous panel can be operated, namely, the , in the ②⑤

following figure, refer to the Section 4.2.2.5 [MOLD ADJUST] mode operation for details.

Mould-adjustment (molding thickness adjustment) is adjusted the mold-clamping

mechanism position based upon the thickness of the mold; so that its elbow can be

entirely extended reaching the top clamping force. It can be performed with the Manual

or Automatic mode, usually, select the automatic mold thickness to adjust it. The [AUTO

MOLD ADJUST] operation should be performed when the following cases are

generated:

(1) After the mold is installed;

(2) Change the setting value of the mold thickness or “ClampPre.”;

(3) After the mould-adjustment is performed by manual;

(4) The mold heating can be performed after its stable temperature lasts for a period

time.

z The operation is performed in the [MOLD ADJUST] mode; the system controls the

motor’s operation based upon the parameter setting of the “InstallMold” on the page

of the “Clamp”, which is shown as the following figure . It ① is different with the

operation of the [MANUAL] mode.

22

Page 31

GSK6000 All-Electric Injection Molding Machine Digit Control System User Manual

4.1.2 The Confirmation Before Injection

The following items should be detected before operating this machine.

4.1.2.1 Start or Stop the Motor

(1) Start the motor

The indicator on the button is ON after the button on the miscellaneous panel is

controlled.

(2) Stop the motor

The indicator on the button is OFF after the

button is controlled.

23

Page 32

GSK6000 All-Electric Injection Molding Machine Digit Control System

4.1.2.2 Mold Clamping and Mold Opening

(1) The operation of the mold clamping

Close the safety door → Enter the manual mode → Press ①② ③

the mold-clamping operation

z Do not perform the interrupted mold-clamping operation when the high speed

clamping is performed. It is better to set the clamping speed at the low one if the

interrupted operation will be performed.

(2) Mold-opening operation

Close the safety door → Enter the manual mode → Press the ①② ②

the open-molding operation

4.1.2.3 Ejector Operation

① Close the safety door → ② Confirm the clamping plate at the mold-opening position

→ Start ④

→ Start ④

→ Set the “Ej.Open” after entering the “Ejection” page → Press the ③④

or → Start the ejector operation.⑤

The speed and position parameter of the ejector are determined by the “Ejection” page.

z The ejector would not be operated if the mold does not reach to the mold-opening

stop position;

z It is necessary to stop the safety door;

z When the ejector is adjusted, the ejector stroke is regulated as short as possible at

the beginning for guard against the damage of the mold; and then improve the

stroke step by step till to the desired ejector one.

z When the ejector is operated, it is better not take out the product from the mold’s top

or bottom by your hand to prevent accident.

or

24

Page 33

GSK6000 All-Electric Injection Molding Machine Digit Control System User Manual

4.1.2.4 The Operation of the Ejection Equipment

Press the key, the ejection equipment forwards to the mold; press key,

the ejection equipments backwards. If the move is reverse, replace any of two phases’

power of the carriage motor. Stop the move when touching the limit switch. Note: firstly

use the “MOLD ADJUST” mode, after the power is turned on at the first time; confirm that

the directions between the mould-adjustment forward and mold-clamping are normal,

and then ensure the carriage forward direction.

4.1.2.5 Mold Installation

(1) Ensure the used installation specification of the machine; refer to the “MachinePara.”

in the

[Clamp] page;

(2) Mold installation; refer to the Section 4.3.1.1.1 Mold Installation for details;

(3) Adjust the position of the ejector pin and its quantity to fit the mold;

(4) Adjust the automatic mold thickness;

4.1.2.6 Screw Operation

The movement modes of the screw are vary from the operations, for example, injection,

suck back, plasticizing, purge/discharging and screw operation, and refer to the following

items:

(1) [INJECTION]

The screw directly forwards with a constant speed when the injection is operated.

In the [MANUAL] mode, press

set by Pv1 of the “Inj.Pre.” and the speed set by “V1” of the “FillSpe.”, and then it is

stopped after reaching to the position value set by the “V-PSwitch”.

When the [SEMI-AUTO] and [AUTO] operations are performed, the screw will be

operated injecting the related parameter based on the “Metering”. Refer to the Section

4.3.3.1 Injection Metering for details.

(2) [SUCKBACK] (the screw retreats)

key, the screw moves based upon the pressure

In the [MANUAL] mode, press the

position according to the speed value set from the “deceleration speed”.

[SEMI-AUTO] and [AUTO] are automatically performed the suck back. Refer to the

Section 4.3.3.1 Injection Metering for details.

(3) ([PLASTICIZING] metering)

key, the screw retreats to the “SD” setting

25

Page 34

GSK6000 All-Electric Injection Molding Machine Digit Control System

When the metering is performed, the plasticizing retreats along with the rotation of the

screw.

In the [MANUAL] mode, press the

key, the screw will be rotated with the “VS”

setting speed, it retreats to the “SM” setting position after overcoming the “PB”

backpressure setting. Note: The plastic may flow out when the backpressure is higher, to

prevent the plastic from flowing, it is better to operate it by the suck back and

plasticizaing each other.

When the [SEMI-AUTO] and [AUTO] are operated, the screw is metered to the “VSLL”

setting position at the “VS” rotation speed, then meter to the “SM” position at the “VSL”

rotation speed, and then retreat to the “SD” position at the “Dec.Spe.” after completing

the plasticizing (the screw stops rotation).

Refer to the Section 4.3.3.1 Injection Metering for the related parameters.

(4) [AUTO PURGE]

The material-cleaning is composed of three operations: Injection, Front screw back and

metering.

The “ForwardScrewBack” is that the screw retreats to a certain distance to reduce the

pressure after the injection packing is performed.

As for the purge/discharging operation, refer to the Section 4.3.3.2.3 purge/discharging

for details.

z In order to guard against the screw, firstly, check the protection precautions of the

screw before operating it. Refer to the Section 4.3.3.2.3 Purge/discharging

4.1.2.7 Temperature Control

(1) Heater (Heating cylinder) temperature

Set the appropriate heating temperature to warm up based upon the selected material.

(2) Mold temperature

The temperature should be set if the mold heating should be performed; the insulating

board should be installed when the molding temperature is higher.

Refer to the Section 4.3.2.2 Heating for the temperature setting.

(3) The molding temperature of the plastic and the mold temperature table is shown

below (This is for your reference only, it is better to consult the material manufacturer for

the upmost reasonable molding temperature).

26

Page 35

GSK6000 All-Electric Injection Molding Machine Digit Control System User Manual

Plastic name English Molding

temperature ℃

Polystyrene/Stryron PS 180~260 30~50

HIPS (High Impact

Polystyrene)

Polypropylene –

Butadiene - Styrol

Low Density

Polyethylene

High Density

Polyethylene

Polypropylene PP 180~270 30~60

Soft Polrvinyl

Chloride

Hard Polrvinyl

Chloride

Polymethyl

Methacrylate

Polyformaldehyde POM 190~210 40~80

Makrolon PC 280~320 80~100

HI-PS 170~260 30~50

ABS 190~260 40~70

LDPE 160~260 30

HDPE 260~300 30~50

PVC 150~180 20~50

PVC 180~200 30~60

PMMA 210~240 50~70

Mold temperature

℃

Polyamide 6 PA 6 240~260 80~110

Polyamide66 PA 66 260~290 80~110

Polyamide 610 PA 610 60~90

Polyethylene

Terephthalate

Polyethylene

Terephthalate

Polyphenylene

Sulfide

PET 280 60~120

PBT 250~270 80~110

PPS 300~330 90~130

4.1.3 Plan Injection Function

The system is offered the automatic start heating function after the power is turned on.

4.1.3.1 Automatically start the electrical heating

Enter the “AutoStart” page clicking the button from the “Heater” page.

27

Page 36

GSK6000 All-Electric Injection Molding Machine Digit Control System

4.1.3.2 Automatically Start the Electrical Heating Setting Method

Step one: Calibrate the display data and time on the screen and its working data and

time is normal.

Step two: Set the “Close” of the automatic start heater, and then shift it as “Start”.

Step three: Set the week and time, for example, Monday, touch “Mon”, if the color is thin,

which means that it is selected.

Step four: Select the heating method. For example: the current heating method is

“Holding temperature”, the shift selection can be performed after touching it.

Step five: Start the automatic start.

Step six: Confirm the “HEATER” indicator is normally ON on the miscellaneous panel,

and then complete the automatic start setting. Note: If the “HEATER” indicator is OFF,

the automatic heating function can not be started. In order to the safety, it is better to

install an automatic open on the water-supply equipment.

28

Page 37

GSK6000 All-Electric Injection Molding Machine Digit Control System User Manual

4.1.4 Injection Condition Setting

4.1.4.1 Read Parameter

z The system offers the injection parameter function for saving the current setting. The

saved parameter can be read that you can use the saved one as the current

parameter. Refer to the Section 4.4.4.2 for details.

The parameter range saved by the system is mold clamping/opening parameter, injection

metering parameter, ejector parameter, temperature parameter, but the administration

parameter does not include. It can be set again by the production status.

It is better to save the current parameter before extracting the existing parameter.

If the extracted parameter is the one which is the acceptable product for the previous

production; the qualified product can not be consecutively performed after using it again; it is

better to trial product at the first time.

4.1.4.2 Mold Opening/Clamping Parameter

4.1.4.2.1 Mold Opening/Clamping Page

29

Page 38

GSK6000 All-Electric Injection Molding Machine Digit Control System

: Mold① -clamping parameter area.

: Mold② -opening parameter area.

: Mold③ -adjustment parameter area.

: Check the machine specification.④

: Foreign matter detection.⑤

: Display the current mould⑤ -adjustment position and mold position.

: Page shift key.⑦

The mold opening/clamping can be manually operated after finishing the

above-mentioned and .①② ⑤

The mould③ -parameter is the movement parameter of the mold clamping/opening when

the [MOLD ADJUST] or [AUTO MOLD ADJUST] is performed.

The mechanical parameter specification of the machine can be checked after entering

.④

Refer to the Section 4.3.1.1 Mold Opening/Clamping Page for details.

30

Page 39

GSK6000 All-Electric Injection Molding Machine Digit Control System User Manual

4.1.4.2.2 The Detailed Page of the Mold Opening/Clamping

: The parameter section of the molding protection.①

: Blowing pa② rameter section.

: Core③ -pulling parameter area.

: Page shift key.④

Refer to the Section 4.3.1 Mold Opening/Clamping for details.

31

Page 40

GSK6000 All-Electric Injection Molding Machine Digit Control System

4.1.4.3 Injection Metering Parameter

4.1.4.3.1 Injection Metering Page

: Injection metering time parameter area.①

②: Injection filling speed and the screw position parameter area.

: Metering parameter area.③

: V④ -P shift parameter area.

: Injection pressure parameter area.⑤

: Packing parameter area.⑥

: Open the “DataDescription” window.⑦

: Page shift key.⑧

The ejection (injection) operation can be performed in the manual mode after the values

of the ”④ Pos.”, “V1” and “Pv1” are set; the suck back and the plasticizing ②⑤

(metering) operation can be performed after item is performed.③

An integral injection metering operation can be formed after all parameters on the page

are set.

Refer to the Section 4.3.3.1 Injection Metering for details.

32

Page 41

GSK6000 All-Electric Injection Molding Machine Digit Control System User Manual

4.1.4.3.2 Metering Detail Page

: Injection the Max. acceleration/deceleration and the compression/depression time ①

parameter area.

: Nozzle retreat and the metering function set. [ParalMete.Operate] operation does not ②

use now.

: Injection metering miscellaneous parameter area.③

: Purge/discharging parameter area.④

: Pressure detection treatment. Do not use temporarily⑤

: Page shift⑥ key.

The parameters in the areas are mainly controlled to the injection metering ①②③

operation when it is performed in the semi-automatic or full-automatic.

is the purge/discharging detail parameter setting.④

Refer to the Section 4.3.3.2 Injection Metering for details.

33

Page 42

GSK6000 All-Electric Injection Molding Machine Digit Control System

4.1.4.4 Ejector Parameter

: Set the start/close times of the ejector.①

: Ejector mode and the movement parameter area.②

: Ejector time setting area.③

: The ejection function during mold④ -opening, it does not use now.

: Display the pos⑤ ition of the ejector.

: Page shift key.⑥

Note: the “Ej.Open” in the must be opened, so that the ejector can be performed.①

is the ejector movement method when it is automatically performed.②

When the different ejector modes in the are selected, the dif② ferent parameters may be

generated on the screen. It is better to set it according to the mold ejection requirement

when automatic operation is performed. The first ejector speed and pressure value

should be set in the different modes, when the manual operation is performed.

Refer to the Section 4.3.1.3 Ejector for details.

34

Page 43

GSK6000 All-Electric Injection Molding Machine Digit Control System User Manual

4.1.4.5 Temperature Parameter

4.1.4.5.1 Heater Temperature

: The display area of the heating control status.①

: Set the cold② -start prevention time of the screw. Warming-up and the resin detaining

monitoring time does not use temporarily.

: The parameter setting area of the heater temperature ③

: Force the holdin④ g temperature function. The holding is performed in the abnormity

case. Do not use temporarily.

: Page shift key.⑤

Set the “Object” based upon the plastic type.③

Purpose 2 is that the screw may be damaged during operating when the plastic does not

reach the setting temperature.

Refer to the Section 4.3.2.2.2 Heater Page for details.

35

Page 44

GSK6000 All-Electric Injection Molding Machine Digit Control System

4.1.5 Confirm Before the Batch Production

4.1.5.1 Purge/discharging

The purge/discharging operation should be performed in the following cases:

1. If the used plastic is a kind of decomposition resin of which the resin should be

cleaned to guard against remain.

2. The color or the type of the raw material is changed.

3. After the batch production is performed, the heater should be performed the heating

as short as possible before the next molding operation occurs.

Refer to the Section 4.3.3.2.3 Purge/discharging for details.

4.1.5.2 Production Quantity Setting and the Treatment After Producing

①: Set the batch production quantity.

②: Production status.

③: The production state treatment by the system.

④: Detailed information of the Inferior product status.

36

Page 45

GSK6000 All-Electric Injection Molding Machine Digit Control System User Manual

⑤: Record the historical machining times and it can not be changed. Set the automatic

grease-supply

⑥: Clear the production record.

The system alarm may occur after a box of quality products are manufactured when the

“AlarmAf.Package” is started. The production will be continued after the “Delay” is

finished.

Refer to the Section 4.4.2 Production Management for details.

4.1.5.3 Quality Management

①: Display the reference time in the automatic batch production.

②: Quality product judge switch, reference value obtaining setting.

③: M3, do not use temporarily.

④: Quality/inferior production judgment condition.

⑤: The treatment of the inferior production

⑥: Page shift key.

If you want to get the reference value and the related parameter setting, refer to the

Section 4.4.3 Quality Management for details.

37

Page 46

GSK6000 All-Electric Injection Molding Machine Digit Control System

4.1.5.4 Tendency Chart

: Select the displayed items:①

: Display the chart data.②

: Operate the chart data.③

: Page shift ④ key.

Select the 4 data which is to be monitored and its wave displays with the chart. Refer to

the Section 4.4.3.2 Tendency Chart for details.

38

Page 47

GSK6000 All-Electric Injection Molding Machine Digit Control System User Manual

4.1.5.5 Statistics

: Display the previous 8 modules during the system batch production.①

: Operate the s② tatistics table

: Page shift key.③

Note: This page is only displayed the data of the previous 8 modules. The system is only

record the data of the previous 8 modules when the external memory does not

insert. If the external is performed, record all data of the module to it.

39

Page 48

GSK6000 All-Electric Injection Molding Machine Digit Control System

4.2 The Button Operation of the Auxiliary Panel

4.2.1 Preparation/Confirmation Before Operation

4.2.1.1 The Reset Operation of the ESP Button

(1) The alarm prompt occurs on the upper right corner after

pressing the

(2) The reset operation is performed based upon the arrow’s direction of the

alarm prompt is cancelled at the upper right corner after resetting.

z The

which is only use in the emergency case instead of stopping the machine as usually.

button is used for immediately stopping the injection molding machine,

.

4.2.1.2 The Operation of the Main Power ON

Step one: The power for switching on the main power.

Step two: Switch on the controllable system power.

Step three: The default interface appears after the power is turned on.

, the

z GSK6000 digit control system has a page display function after the machine is ON.

The following operations are shown below:

40

Page 49

GSK6000 All-Electric Injection Molding Machine Digit Control System User Manual

Step one: Press the , then shift to the “I/ODiagnosis” interface on

the “Monitor” interface.

Step two: Enter the “StyleSet” interface after pressing

.

41

Page 50

GSK6000 All-Electric Injection Molding Machine Digit Control System

Step three: Control the green frame button at the left of the

setting page after the machine is ON.

z For example: If user hopes the page is “Heater” one after the machine

is ON, the following operations should be performed after entering the

“StyleSet” interface.

Step one: Click the green frame button at the left of the .

, and then select the

Step two: Select the user specified page (for example: the “Heater”

interface).

42

Page 51

GSK6000 All-Electric Injection Molding Machine Digit Control System User Manual

Firstly enter the user specified page after the control system is restarted.

z Press the

(“Monitor” page).

4.2.1.3 Motor’s Power ON

The button indicator is normally ON after pressing button, the motor is then

started.

z The motor’s button is used for switching on the strong current of the servo

driver. The protection circuit should be set because the driver strong

current may be generated the tremendous current impact during switching

on, and therefore, do not frequently ON/OFF to the driver, otherwise, the

normally alarm of the driver may occur. It is recommended that the motor

only can be opened after the power is turned off for 6 seconds.

button to restore the system’s default page

2.1.1.1 The Power ON of the Electric Heater

Step: Shift to the “Heater” interface after pressing button, and the set

the appropriate range to the processing of the raw-material plastic heating.

43

Page 52

GSK6000 All-Electric Injection Molding Machine Digit Control System

Step two: Confirm the heater state, object temperature, upper limit temperature, lower

limit temperature, holding temperature and forced holding temperature.

Step three: Press the button.

Step four: Set the temperature base upon the using plastic character; set the

“ColdStartPreventTm.”.

44

Page 53

GSK6000 All-Electric Injection Molding Machine Digit Control System User Manual

z The “ColdStartPreventTm.” is the screw protection time against damaging

the screw of which the material inside the charging barrel does not

completely melt after preventing the temperature of the charging barrel

reaches.

z Refer to the Section 4.3.2.2.2 Heater Page for details.

4.2.2 The Processing of each Operational mode

4.2.2.1 The Mutual Operation of each Mode

The buttons on the auxiliary panel can be operated regardless of the [MANUAL],

[SEMI-AUTO], [AUTO] and [MOLD ADJUST]:

(1)

button: The indicator is ON after pressing one button, and then the

motor’s power is turned on. The power is turned off after press it again.

z In order to the safety operation, it is better to cut the power of the

motor in the [MANUAL] mode.

45

Page 54

GSK6000 All-Electric Injection Molding Machine Digit Control System

(2) button: The indicator is ON after pressing the button, and then the

electric heater’s power is turned on. Cut off the electric heater’s power after pressing

it again.

z In order to safety operation, it is better to cut off the electric heater’s

power in the [MANUAL] mode.

(3)

button: The corresponding indicator is ON after pressing the button, the

lubrication is then started.

z The grease-supply and automatic grease-supply can be carried out in

GSK6000 control system:

1) Automatic grease-supply. The

grease-supply mode. The automatic grease-supply should be

performed based upon the following steps:

button is disabled in this

Step one: Shift to the “I/ODiagnosis” interface pressing the

in the “Monitor” interface.

46

button

Page 55

GSK6000 All-Electric Injection Molding Machine Digit Control System User Manual

Step two: The password input interface occurs after pressing the

button.

47

Page 56

GSK6000 All-Electric Injection Molding Machine Digit Control System

Step three: Enter the “SystemSet” interface inputting the password.

Step four: Set the data of the “GreaseAutoFre.” frame.

Step three: Press the

“GreaseAutoFre.” input frame, the button displays

button at the right after pressing the

, then the

grease-supply switch is turned on. The automatic grease-supply then performs once

after the control system is machined the module of the “GreaseAutoFre.”

48

Page 57

GSK6000 All-Electric Injection Molding Machine Digit Control System User Manual

2) Manual grease-supply:

Step one: Confirming the button at the right of the “GreaseAutoFre.”

input frame displays

state, the automatic-supply

function is then closed.

Step two: Press the

immediately started.

(4) In the case of emergency, press the button, the power both the electric

heater and the motor is cut off, every operating motor is immediately stopped.

, the grease-supply operation is then

(5) button: the alarm prompt displays at the upper right corner on the

controllable system interface. User can clear the alarm or the alarm prompt based

upon the alarm resource which is displayed with the system after pressing this

button, and then the other operations can be performed.

4.2.2.2 Manual Operation Mode

4.2.2.2.1 Button Operation Explanations both the Operation Mode Shift ([MANUAL] mode)

and the Auxiliary Operation Panel.

Press the

[MANUAL] one, and then the following buttons can be operated.

[MANUAL] button, after the operation mode is set to the

49

Page 58

GSK6000 All-Electric Injection Molding Machine Digit Control System

(1) The button operation of the injection molding equipment

: [CARRIAGE FORWARD] key: the corresponding indicator is ON after

pressing this button, the injection molding equipment forwards, and vice versa.

: [CARRIAGE BACKWARD] key: the corresponding indicator is ON after

pressing this button, the injection molding equipment backwards, and vice versa.

(2) Ejector-pin button operation

[EJECTOR FORWARD] button: the corresponding indicator is ON after

pressing this button, the ejector-pin is then performed, and vice versa. Note: Do not

stop for long time after the ejector-pin is performed, so that the alarm of the ejector

driver protection occurs, it may cause restart the whole machine.

[EJECTOR BACKWARD] button: the corresponding indicator is ON after

pressing this button, the ejector-pin is then retreated, and vice versa.

50

Page 59

GSK6000 All-Electric Injection Molding Machine Digit Control System User Manual

[EJECTION]: The corresponding indicator is ON after pressing this button,

the multi-ejection of the ejector-pin is retreated. The ejection times can be set based

upon the value in the “Ej.Times” input frame on the “Enection” interface. The

corresponding indicator is OFF after releasing this button; the ejector operation is

then stopped.

z The advanced condition of the ejector button operation:

i. The ejector switch should be opened, refer to the following steps:

Step one: Enter the “Clamp” interface after pressing the

button.

51

Page 60

GSK6000 All-Electric Injection Molding Machine Digit Control System