Page 1

Page 2

This user manual describes all items concerning the operation of

this CNC system in detail. However, it is impossible to give particular

descriptions for all unnecessary or unallowable operations due to length

limitation and products application conditions;Therefore, the items not

presented herein should be considered impractical or unallowable.

Copyright is reserved to GSK CNC Equipment Co., Ltd. It is illegal

for any organization or individual to publish or reprint this manual. GSK CNC

Equipment Co., Ltd. reserves the right to ascertain their legal liability.

Page 3

GSK25i Milling CNC System User Manual

Preface

Your Excellency,

We are honored by your purchase of this GSK 25i Milling CNC System

made by GSK CNC Equipment Co., Ltd.

This book is “PARAMETER” section of the User Manual Volume Ⅲ.

Special caution:

The power supply fixed on/in the cabinet is exclusively used for the

CNC system made by GSK.

It can't be applied to other purposes, or else it may cause serious

danger.

II

Page 4

Volume Ⅲ Parameter

Warning and Precaution

Accident may occur by improper connection and operation!This system can

only be operated by authorized and qualified personnel.

Please read this manual carefully before operation!

Please read this manual and a manual from machine tool builder carefully before

installation, programming and operation, and strictly observe the requirements.

This manual includes the precautions for protecting user and machine tool. The

precautions are classified into Warning and Caution according to their bearing on safety,

and supplementary information is described as Note. Read these Warnings, Cautions

and Notes carefully before operation.

Warning

User may be injured or equipment be damaged if operation instructions and

procedures are not observed.

Caution

Equipment may be damaged if operation instructions or procedures are not

observed.

Note

It is used to indicate the supplementary information other than Warning and Caution.

III

Page 5

GSK25i Milling CNC System User Manual

Announcement

● This manual describes various possibilities as much as possible.

However, operations allowable or unallowable cannot be explained

one by one due to so many possibilities that may involve with, so the

contents that are not specially stated in this manual shall be

considered as unallowable.

Caution

● Functions, technical indexes (such as precision and speed) described

in this user manual are only for this system. Actual function

deployment and technical performance of a machine tool with this

CNC system are determined by machine tool builder’s design, so

functions and technical indexes are subject to the user manual from

machine tool builder.

● Refer to the user manual from machine tool builder for function and

meaning of keys on control panel.

IV

Page 6

Volume Ⅲ Parameter

Precautions

■ Delivery and storage

● Packing box over 6 layers in pile is unallowed.

● Never climb the packing box, neither stand on it, nor place heavy objects on it.

● Do not move or drag the products by the cables connected to it.

● Forbid collision or scratch to the panel and display screen.

● Avoid dampness, insolation and drenching.

■ Open-package inspection

● Confirm that the products are the required ones.

● Check that the products are not damaged in delivery.

● Confirm that the parts in packing box are in accordance with the packing list.

● Contact us in time if any inconsistence, shortage or damage is found.

■ Connection

● Only qualified personnel can connect the system or check the connection.

● The system must be earthed, and the earth resistance must be less than 0.1Ω.

The earth wire cannot be replaced by zero wire.

● The connection must be correct and firm to avoid any fault or unexpected

consequence.

● Connect with surge diode in the specified direction to avoid damage to the

system.

● Switch off power supply before plugging out or opening electric cabinet.

■ Troubleshooting

● Only competent personnel are supposed to inspect the system or machine.

● Switch off power supply before troubleshooting or changing components.

● Check for fault when short circuit or overload occurs. Restart can only be done

after troubleshooting.

● Frequent switching on/off of the power is forbidden, and the interval time should

be at least 1 min.

V

Page 7

GSK25i Milling CNC System User Manual

Safety Responsibility

Manufacturer’s Responsibility

——Be responsible for the danger which should be eliminated and/or controlled on

design and configuration of the provided CNC systems and accessories.

——Be responsible for the safety of the provided CNC systems and accessories.

——Be responsible for the provided information and advice for the users.

User’s Responsibility

——Be trained with the safety operation of CNC system and familiar with the safety

operation procedures.

——Be responsible for the dangers caused by adding, changing or altering to the

original CNC systems and the accessories.

——Be responsible for the failure to observe the provisions for operation, adjustment,

maintenance, installation and storage in the manual.

All specifications and designs herein are subject to change without

further notice.

This manual is reserved by end user.

We are full of heartfelt gratitude to you for supporting us in the use of

GSK’s products.

VI

Page 8

Volume Ⅲ Parameter

Contents

1 PARAMETER DISPLAY..........................................................................................................................1

2 PARAMETER SETTING IN THE MODE OF MDI .........................................................................................2

3 SETTING OR MAINTAINING THE SYSTEM PARAMETERS BY PC INSTRUCTION CONTROL UNIT SOFTWARE..4

3.1 Editing of System Parameters................................................................................................4

3.2 Editing of Tool and Offset Parameter......................................................................................5

3.3 Editing of the Pitch Error Compensation Data........................................................................ 6

3.4 Editing of PLC Parameter.......................................................................................................7

4

PARAMETER EXPLANATION .................................................................................................................8

4.1 Parameter Setting (1~99)......................................................................................................8

4.2 Communication Parameter (100~999)..................................................................................9

4.3 Coordinate Parameter (1000~1199)....................................................................................11

4.4 Feedrate Parameter (1200~1399).......................................................................................21

4.5 Interpolation and Acceleration/Deceleration Control Parameter (1400~1599)....................24

4.6 Editing Parameter Display (1600~1799).............................................................................31

4.7 Programming Parameter (1800~1999) ...............................................................................35

4.8 Fixed Cycle Parameter (2000~2099)..................................................................................39

4.9 Rigid Tapping Parameter (2100~2299)...............................................................................40

4.10 Parameter of Manual, Auto and MPG Operation (2300~2499).........................................42

4.11 Parameter (2500~2599) Input/Output ............................................................................... 43

4.12 Tool Administration Parameter (2600~2799).....................................................................45

4.13 Pitch Compensation Parameter (2800~2999)...................................................................48

4.14 Servo Parameter (4000~4999) .........................................................................................49

4.15 Spindle Control Parameter (5000~5999)...........................................................................61

4.16 Custom Macro Program Parameter (6000~6999).............................................................65

4.17 System Diagnosis Configuration Parameter (9000~9999)................................................68

VII

Page 9

GSK25i Milling CNC System User Manual

VIII

Page 10

1 Parameter Display

The operations are shown below:

Volume Ⅲ Parameter

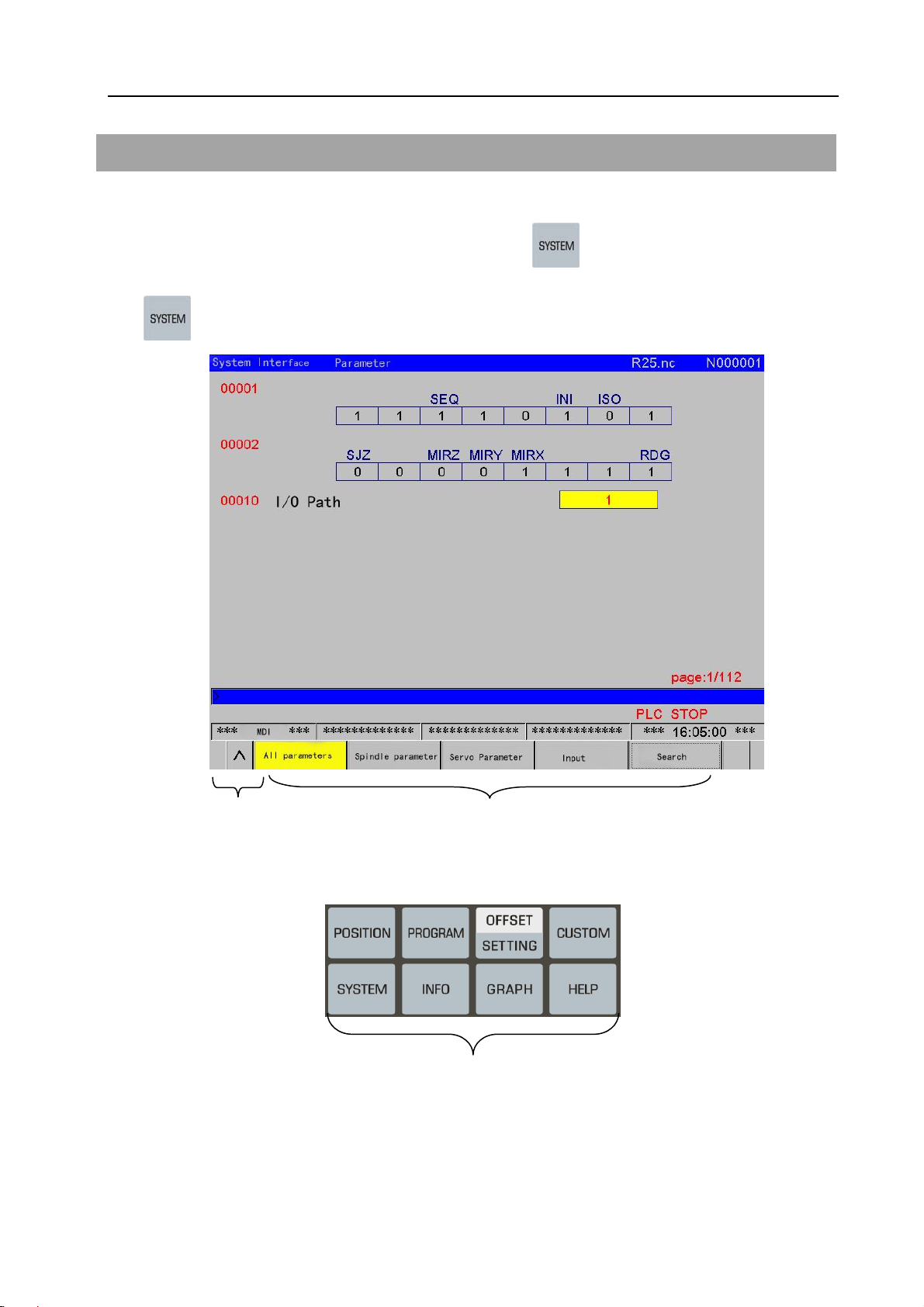

(1) Enter the parameter screen after the function key

times, or press the [Parameter] and [Operation] soft keys subsequently after pressing the function

key

once.

on MDI panel is controlled for many

(2) The parameter screen consists of multiple pages. Use two steps to display the page that

contains the parameter you want to display.

(a) The required relative parameters are selected using the soft key, and then the page to be

Return to the manual

Soft Keyboard

Fig.1-1

Fig.1-2 Function keys

1

Page 11

GSK25i Milling CNC System User Manual

found by the page keys or cursor move keys.

(b) The parameter numbers to be displayed are input from keyboard, and press the [search]

softkey to search, then the specified parameter page is displayed, and the cursor is positioned to the

specified parameter (the data part is turned into the selected color).

2 Parameter Setting in the Mode of MDI

The operation steps of parameters setting are shown below:

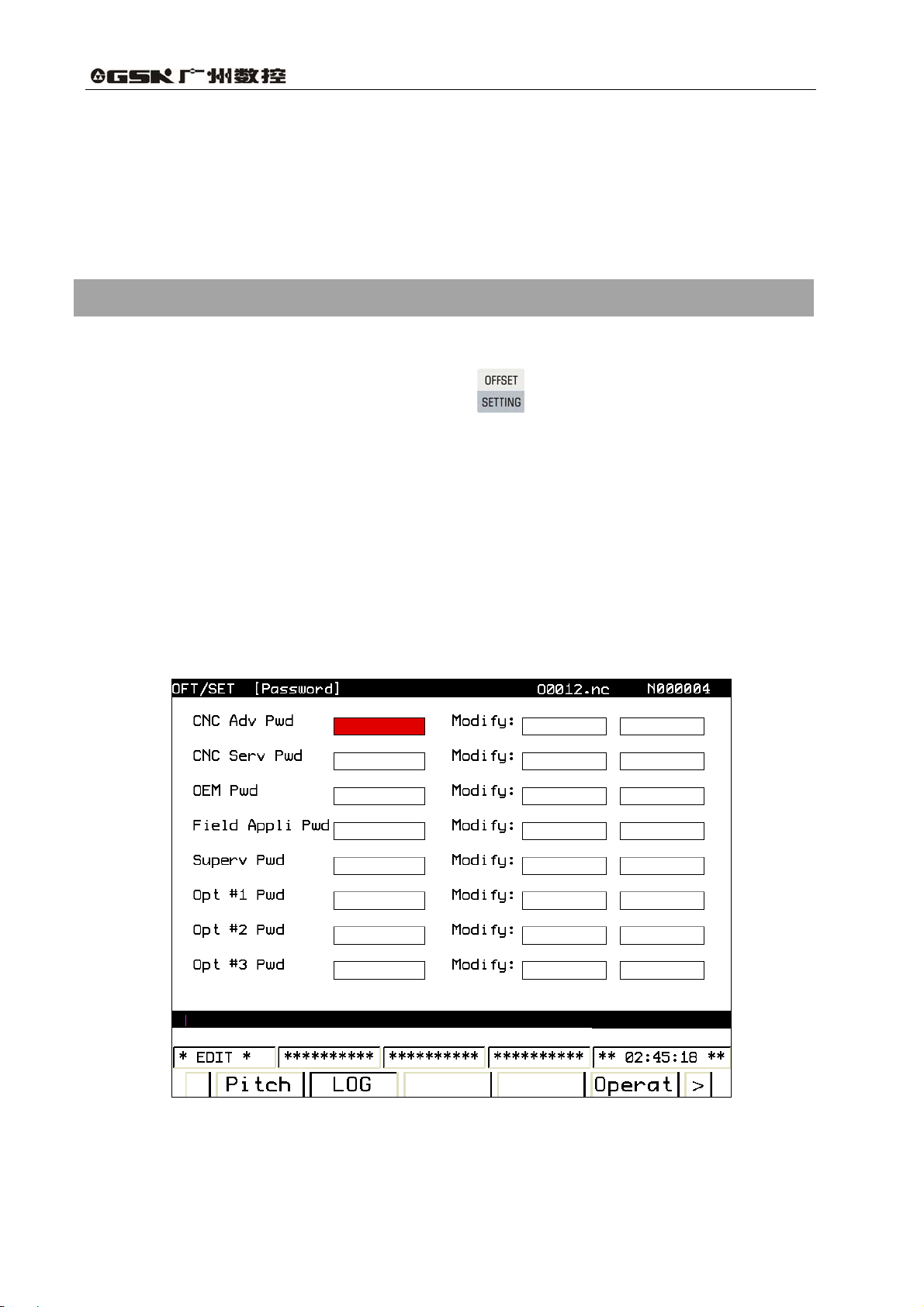

(1) Enter the offset setting page by pressing the

password.

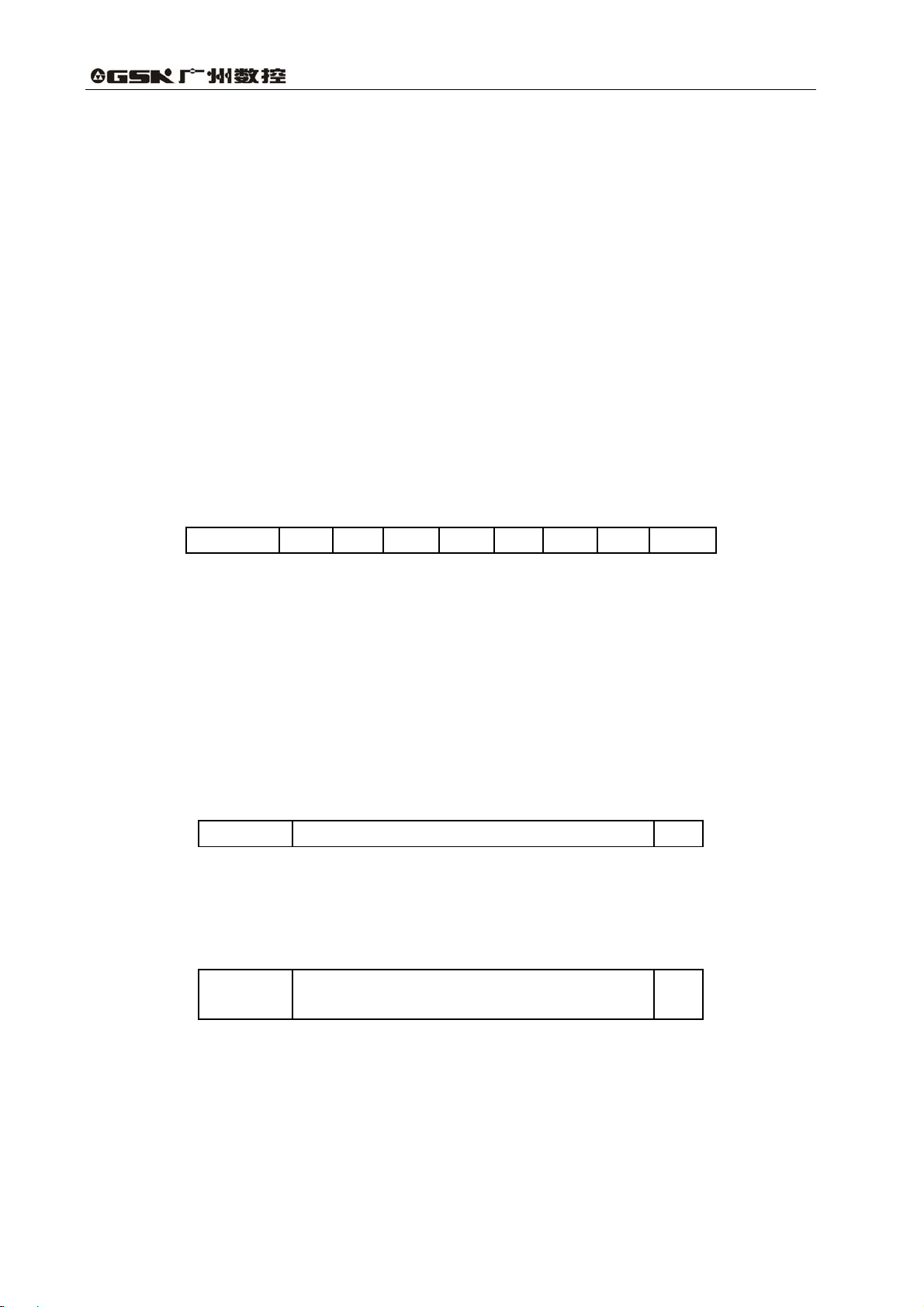

To prevent the machining program and CNC parameters from being maliciously modified, the

GSK 25i offers an authority setting function and the password can be divided into 9 levels, from the

higher to the lower level, such as the 0 level (the system high level), the 1st level (the system service),

the 2nd level (the machine manufacturer), the 3rd level (the installation and debugging), the 4th level

(the terminal administration), as well as the 5th level (the operator 1 level), the 6th level (the operator

2 level), the 7th level (the operator 3 level) and the lowest default level (see the figure 2-1). The 0

level is enjoys the highest protection; contrarily, the lowest levels are from 5 to 7, and the highest level

can be administrated the lowest levels, which is the low authority function. The parameter password

level is 3 except for the special explaination.

, and firstly to input the correspondence

Fig. 2-1

2

Page 12

Volume Ⅲ Parameter

Level 0: the highest authority, reserved by the developer.

Level 1: It is used for the system manufacturer service, which can modified various data.

Level 2: The PLC program, PLC note and the pitch error compensation are modified. The PLC

and the pitch error compensation files are input or output. The user customized interface authority is

modified/ input or output.

Level 3: The parameter and PLC source data can be modified; the PLC operation is

started/stopped; the alarm/operation messages are eliminated; and the files are input or output, and

the system, interpolation and positional control maintenance softwares can be upgraded.

Level 4: The program, tool offset, setting, workpiece coordinate system offset and macro

program value are modified; these files are input or output and it also has the authority to modify the

passward.

th

The 5

, 6th and 7th levels: it is an operation authorized to corresponding person with

bit-parameter by the end user administrator.

The lowest level default by the system: it is an authority operation donated with bit-parameter by

end user administrator; no password inputs.

The bit-parameter definitions are authorized by the end user administrator, refer to the following table:

Bit Significance Note

0 Modify/input or output the authority of G code program. Authority

1 Modify the authority of geometrical tool offset/input or output tool

Authority

offset.

2 Modify the authority of wear tool offset/input or output tool offset. Authority

3 Modify the authority of setting Authority

4 Modify/input or output the authority of a workpiece coordinate

Authority

system offset.

5 Modify/input or output the authority of a macro program value Authority

6 Reserved

7 Reserved

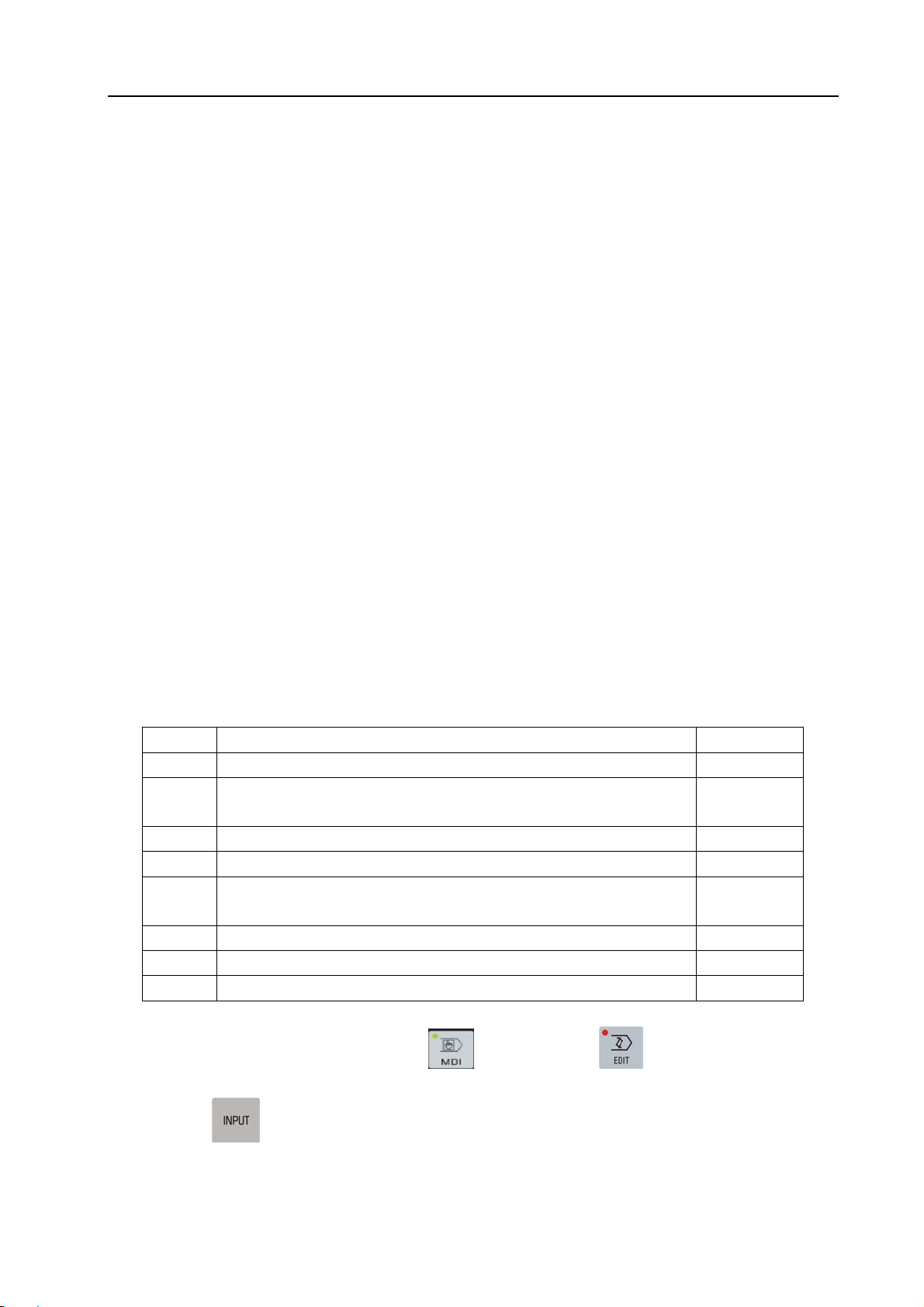

(2) In the [MDI/Edit] mode, the MDI mode and Edit mode can be selected, and the

cursor can be moved based on the password authority to the required items.

(3) Press the

key, the corresponding level password can be input. If the password is correct,

a “correct password” may be displayed in the system; otherwise a “wrong password input” may occur.

(4) After the corresponding parameters are modified, the password is cancelled after logging out.

3

Page 13

GSK25i Milling CNC System User Manual

3 Setting or Maintaining the System Parameters by PC Instruction

Control Unit Software

3.1 Editing of System Parameters

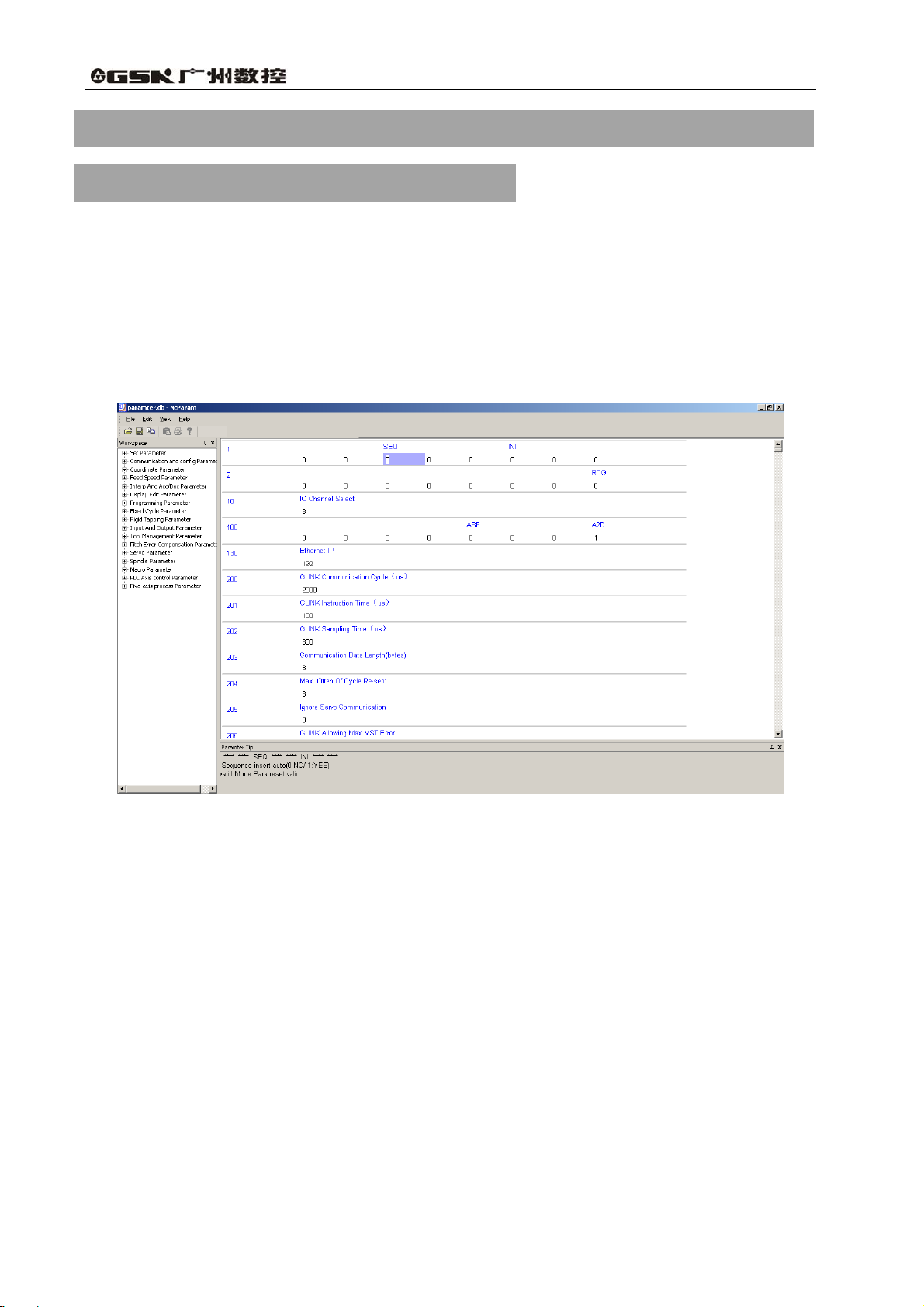

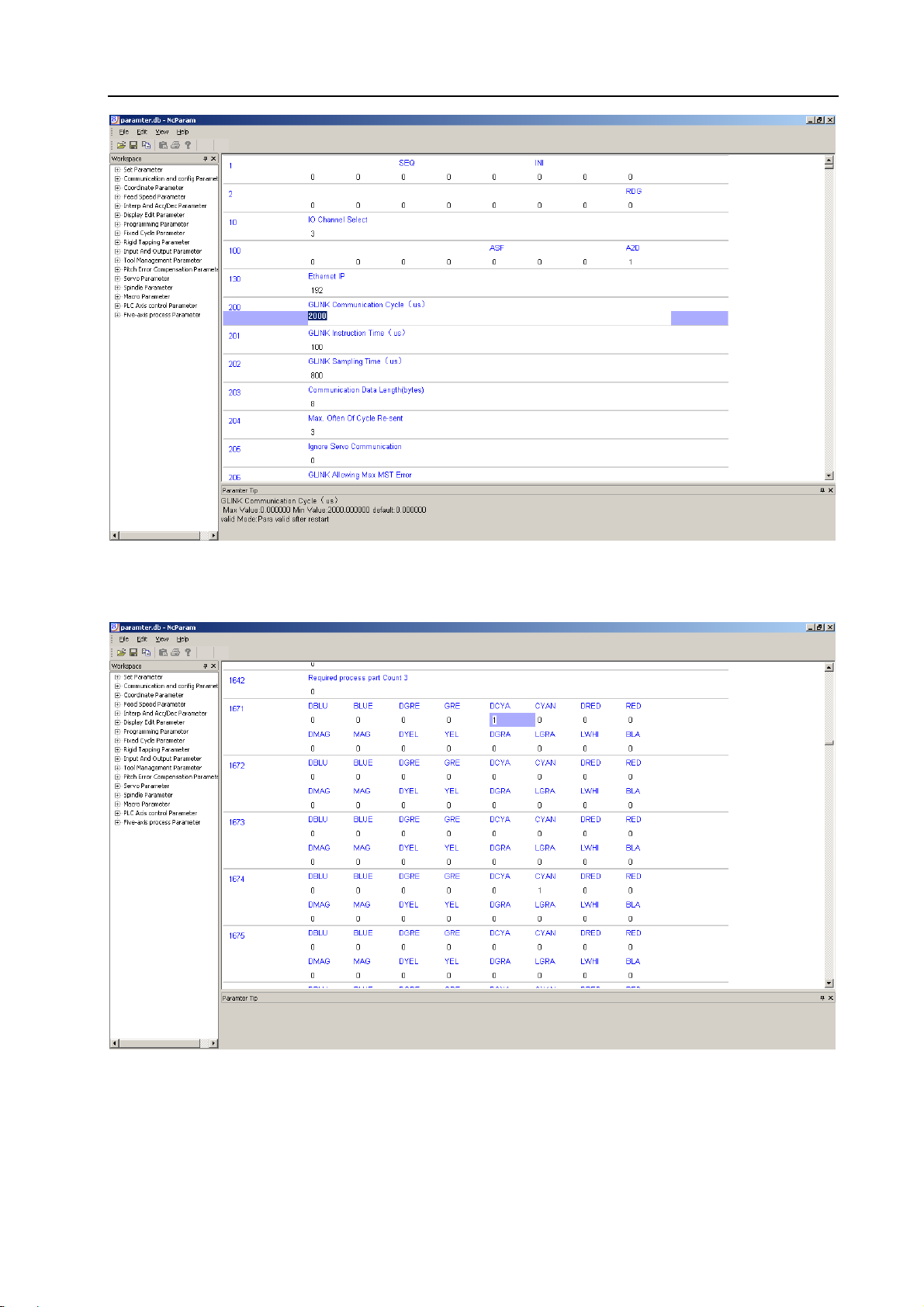

This software can be edited the system parameter on CNC in the program, and the

corresponding backup parameter files can be uploaded and downloaded through the internet. (Refer

to the Fig. 3-1, Fig. 3-2 and Fig. 3-3)

Fig.3-1 Editing the system parametersⅠ (Editing of the bit parameters)

4

Page 14

Volume Ⅲ Parameter

Fig.3-2 Editing the system parameters II (Editing of data parameters)

Fig.3-3 Editing the system parameters III (Editing of color parameters)

3.2 Editing of Tool and Offset Parameter

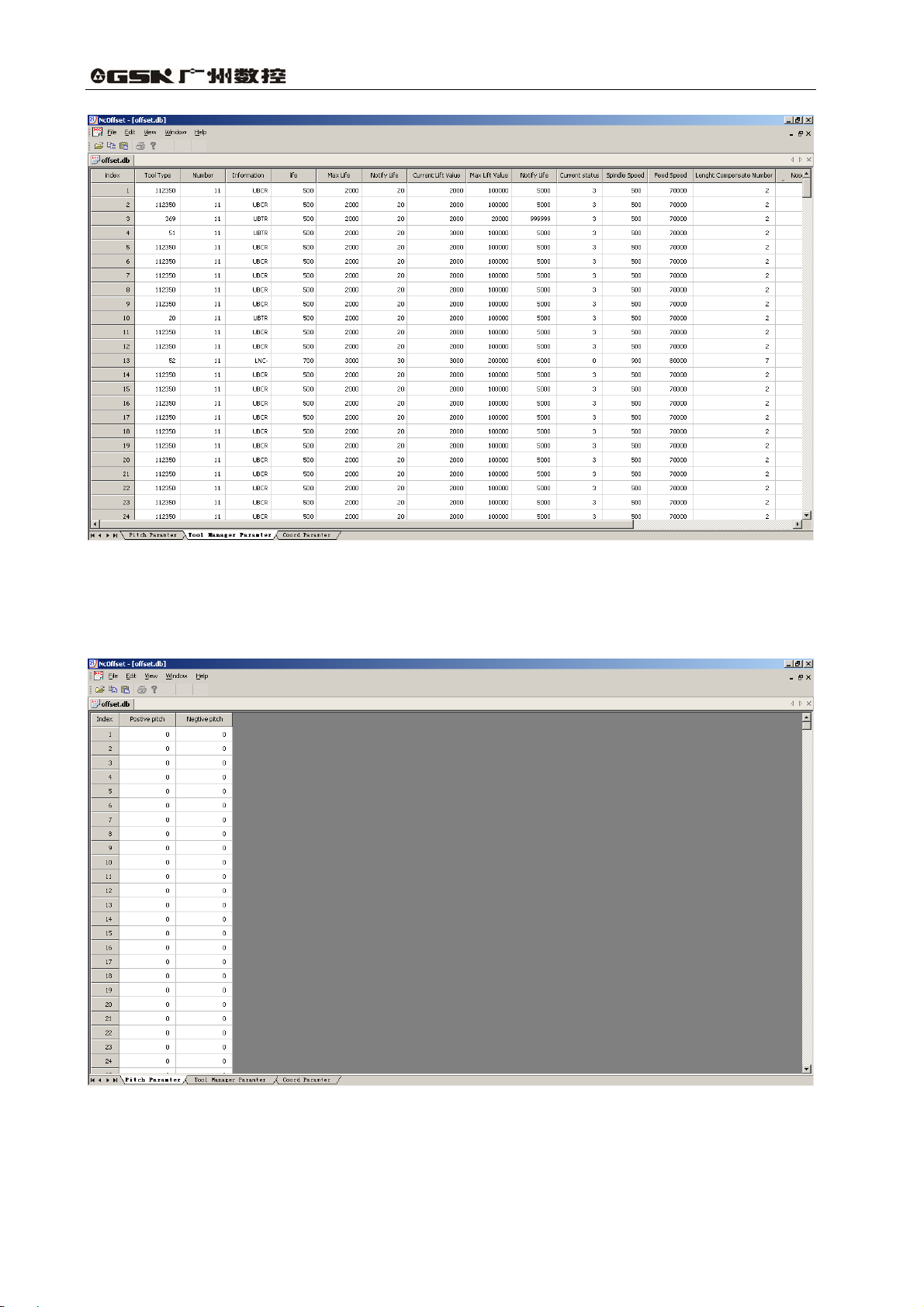

Editing of the tool and offset parameter is as the Fig. 3-4.

5

Page 15

GSK25i Milling CNC System User Manual

Fig. 3-4 Editing of tool and offset parameter

3.3 Editing of the Pitch Error Compensation Data

Editing the pitch error compensation data is as Fig. 3-5.

Fig. 3-5 Editing of the pitch error compensation data

6

Page 16

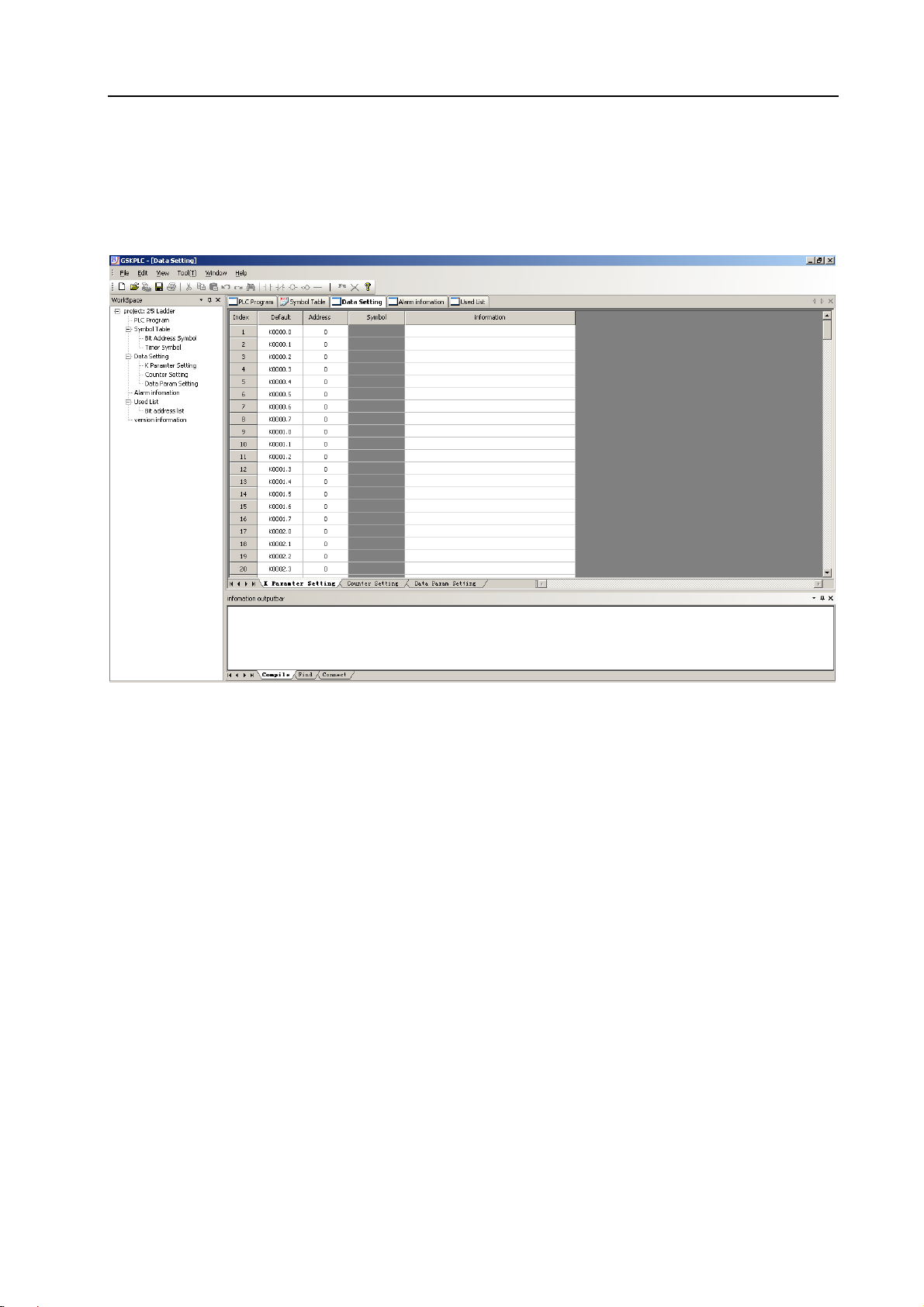

3.4 Editing of PLC Parameter

Editing the PLC parameter is as Fig. 3-6.

Volume Ⅲ Parameter

Fig. 3-6 Editing of PLC parameter

7

Page 17

GSK25i Milling CNC System User Manual

4 Parameter Explanation

[Parameter type]

The system parameters can be divided into several types based upon the following parameters

(refer to the fig. 4-1).

Table 4-1 data type and data effective range

Data type Effective data range

Bit

Bit axis

Integrated

Integral axis

Real number

Real number axis

The displayed number of axis type is determined on the total setting axis amount.

-99999999~99999999

-99999999~99999999

-99999999~99999999

-99999999~99999999

[Parameter explanation format]

The system parameter can be defined based on the following format.

Parameter number Parameter significance explanation

It is important to notice that the cautions may occur in the notice column to remind the user

Note

1. Notice 1

2. Notice 2

3. Notice 3

4,……

0 or 1

0 or 1

4.1 Parameter Setting (1~99)

7# 6# 5# 4# 3# 2# 1# 0#

0001

[Data type] Bit

[Data range] 0 or 1

INI: Unit of input

0:In mm

1:In inches

SEQ: Automatic insertion of sequence numbers

0:Not performed

1:Performed

8

SEQ INI

Page 18

Note:

The incremental of sequence number is set in parameter No.1621.

[Standard setting] 0 0 0 0 0 0 0 0

7# 6# 5# 4# 3# 2# 1# 0#

Volume Ⅲ Parameter

0002

RDG

[Data type] Bit

[Data range] 0 or 1

RDG: Remote diagnosis is

0:Not performed

1:Performed

Standard setting] 0 0 0 0 0 0 0 0

[

0010

I/O CHANNEL selection 3

[Data type] Integrated type

[Data range] 0-4

[

Standard setting]

Setting value Significance

0 RS232C serial port

1 Reserved

2 Reserved

3 USB interface

4 Ethernet interface

4.2 Communication Parameter (100~999)

7# 6# 5# 4# 3# 2# 1# 0#

0100

[Data type] Bit type

[Data range] 0 or 1

A2D: DSP loading method

0:DSP directly start mode

1:Loading DSP using cnc program

ASF:The current file of previous one is whether to save automatically while the file is loaded.

0:Yes

1:No

[

Standard set] 0 0 0 0 0 0 0 1

ASF A2D

9

Page 19

GSK25i Milling CNC System User Manual

0130

Ethernet IP address 192

[Data type] Integrated type

[Data range] 0-255

Note

For example: The value of IP:192.168.2.10 is 10 (192.168.2 is a fixed

value)

200

GSK-LINK communication period 200000

[Data type] Integrated type

[Data unit] 10ns

[Data range] 10000~1000000(100us-10ms)

201

GSK-LINK command time 10000

[Data type] Integrated type

[Data unit] 10ns

[Data range] 100~1000000

202

GSK-LINK sampling time 80000

[Data type] Integrated type

[Data unit] 10ns

[Data range] 100~1000000

203

The length of period communication data 8

[Data type] Integrated type

[Data unit] Byte

[Data range] 6~16(Required in multiples of 2)

204

The maximum period repeated times 3

[Data type] Integrated type

[Data unit]

[Data range] 0~16

205

Servo communication ignorance 0

[Data type] Integrated

[Dtat unit]

[Data range] 0~1

10

Page 20

Note:

The system may ignore the servo net communication when it is set to

1, which is mainly used for debugging; when this parameter is set, the

power must be turned off before operation is continued.

4.3 Coordinate Parameter (1000~1199)

7# 6# 5# 4# 3# 2# 1# 0#

Volume Ⅲ Parameter

1000

ISC INM

[Data type] Bit

[Data range] 0 or 1

INM: Least command increment on the linear axis

0:In mm (Metric system)

1:In inches (Inch system)

ISC:The least move unit

0:0.001mm, 0.001deg

1:0.0001mm, 0.0001deg

Note:

When this parameter is set, the power must be turned off before

operation is continued.

Standard setting] 0 0 0 0 0 0 1 0

[

7# 6# 5# 4# 3# 2# 1# 0#

1001

SFD DLZ

[Data type] Bit

[Data range] 0 or 1

DLZ: Function setting the reference position without dog

0:Disabled

1:Enabled

SFD: The function for shifting the reference position is

0:Not used

1:Used

[Standard setting] 0 0 0 0 0 0 0 0

11

Page 21

GSK25i Milling CNC System User Manual

7# 6# 5# 4# 3# 2# 1# 0#

1002

EDN EDP HJZ

[Data type] Bit

[Data range] 0 or 1

HJZ: When a reference position is already set:

0: Manual reference position return is performed with deceleration dogs.

1: Manual reference position return is performed using rapid traverse without

deceleration dogs.

EDP: External deceleration signal in the positive direction for each axis

0: Valid only for the rapid traverse

1: Valid for rapid traverse and cutting feed

EDN: External deceleration signal in the negative direction for each axis

0: Valid only for rapid traverse

1: Valid for rapid traverse and cutting feed

[

Standard setting] 0 0 0 0 1 0 0 0

7# 6# 5# 4# 3# 2# 1# 0#

1004

ZMI

[Data type] Bit axis

[Data range] 0 or 1

RRLn: Relative coordinates are

0: Not rounded by the amount of the shift per one rotation

1: Rounded by the amount of the shift per one rotation

ZMIx: Reference position return direction is set for each axis

0: In positive

1: In negative

Note:

When this parameter is set, the power must be turned off before

operation is continued.

Standard setting] 0 0 0 0 0 0 0 0

[

1020

Program axis name for each axis

[Data type] Integrated axis

[Data range] 0~127

X RRLn

12

Note

The display name is ASCII code, and the allowable input values are

X-88, Y-89, Z-90, A-65, B-66 and C-67.

Page 22

Volume Ⅲ Parameter

1021

The attribute of each axis in the basic

coordinate system

[Data type] Integrated

[Data range] 0~7

Setting value Significance

0 Neither the basic three axes nor a parallel axis

1 X axis of the basic three axes

2 Y axis of the basic three axes

3 Z axis of the basic three axes

4 Axis parallel to the X axis

5 Axis parallel to the Y axis

6 Axis parallel to the Z axis

1022

Servo logic address for each axis

[Data type] Integrated

[Data range] 0~25

Note

The setting of servo logic address is related to the connection of servo

network, the 1

is 0, according to this, servo logic address is its corresponding set

value; Usually, set a same value both the control axis number and the

controlled axis number.

1023

st

slave station connected from the system P1 terminal

7# 6# 5# 4# 3# 2# 1# 0#

[Data type] Bit axis

[Data range] 0 or 1

AXUn: Enabling for each axis is

0: Not used

1: Used

ISRn: It is either rotation axis or pallel axis for each axis

0: Pallel axis

1: Rotation axis

[Standard setting] 0 0 0 0 0 0 0 1

7# 6# 5# 4# 3# 2# 1# 0#

ISRn AXUn

1030

[Data type] Bit

[Data range] 0 or 1

RMOD: G code rotation command movement method

0: The approximate principle moves to the nearest position

ITI IDX ABS REL RMOD

13

Page 23

GSK25i Milling CNC System User Manual

1: Value magnitude moves

REL: Relative coordinate display of rotation axis

0: Out of the 360°

1: Within 360°

ABS: Absolute coordinate display of rotation axis

0: Out of the 360°

1: Within 360°

IDX: Index table indexing sequence.

0: Type A

1: Type B

ITI: The index function of the index table is:

0: Disabled

1: Enabled

[

Standard setting] 0 0 0 0 0 0 0 0

7# 6# 5# 4# 3# 2# 1# 0#

1031

[Data type] Bit

[Data range] 0 or 1

RLC: Local coordinate system is

0: Not cancelled by reset

1: Cancelled by reset

G52: In local coordinate system setting, a cutter compensation vector is

0: Not considered

1: Considered

[Standard setting] 0 0 0 0 1 0 0 0

1040

External workpiece origin offset value 0

[Data type] Real number axis

[Data unit] mm

[Data range] -9999.9999~9999.9999

1041

The origin offset amount of workpiece

coordinate system 1(G54)

G52 RLC

0

[Data type] Real number axis

[Data unit] mm

[Data range] -9999.9999~9999.9999

14

Page 24

Volume Ⅲ Parameter

1042

The origin offset amount of workpiece

[Data type] Real number axis

[Data unit] mm

[Data range] -9999.9999~9999.9999

1043

The origin offset amount of workpiece

[Data type] Real number axis

[Data unit] mm

[Data range] -9999.9999~9999.9999

1044

The origin offset amount of workpiece

[Data type] Real number axis

[Data unit] mm

[Data range] -9999.9999~9999.9999

1045

The origin offset amount of workpiece coordinate

0

coordinate system 2(G55)

0

coordinate system 3(G56)

0

coordinate system 4(G57)

0

system 5(G58)

[Data type] Real number axis

[Data unit] mm

[Data range] -9999.9999~9999.9999

1046

The origin offset amount of workpiece coordinate

[Data type] Real number axis

[Data unit] mm

[Data range] -9999.9999~9999.9999

1050

Coordinate value of the 1

each axis in the mechanical coordinate system

[Data type] Real number axis

[Data unit] mm

[Data range] -9999.9999~9999.9999

Note:

When this parameter is set, the power must be turned off before

operation is continued.

system 6(G59)

st

reference position on

0

0

15

Page 25

GSK25i Milling CNC System User Manual

1051

Coordinate value of the 2

each axis in the mechanical coordinate system

[Data type] Real number axis

[Data unit] mm

[Data range] -9999.9999~9999.9999

Note:

When this parameter is set, the power must be turned off before

operation is continued.

1052

Coordinate value of the 3rd reference position on

each axis in the mechanical coordinate system

[Data type] Real number axis

[Data unit] mm

[Data range] -9999.9999~9999.9999

nd

reference position on

0

0

Note

When this parameter is set, the power must be turned off before

operation is continued.

1053

Coordinate value of the 4th reference position

on each axis in the mechanical coordinate

[Data type] Real number axis

[Data unit] mm

[Data range] -9999.9999~9999.9999

Note

When this parameter has been set, the power must be turned off

before operation is continued.

1060

Amount of a shift per one rotationof a feed

0

system

0

axis

[Data type] Real number axis

[Data unit] mm or degree

[Data range] 0~999.9999

Note

When this parameter is set, the power must be turned off before

operation is continued.

16

Page 26

1068

Amount of rotation angle per one rotation

[Data type] Real number axis

[Data unit] Degree

[Data range] 0~9999.9999

Note

1. This parameter is used during cylinderical interpolation.

2. When this parameter is set, the power must be turned off before

operation is continued.

7# 6# 5# 4# 3# 2# 1# 0#

Volume Ⅲ Parameter

360

of a revolution axis

1070

LZR

[Data type] Bit

[Data range] 0 or 1

OUT: The area inside or outside of the stored stroke check 2 is set as an inhibition area.

0: Inside

1: Outside

OT2: Whether stored stroke check 2 is checked for each axis is set.

0: Stored stroke check 2 is not checked.

1: Stored stroke check 2 is checked.

OT3: Whether stored stroke check 3 is checked for each axis is set.

0: Stored stroke check 3 is not checked.

1: Stored stroke check 3 is checked.

XWG: Overtravel alarm switch

0: Alarm ON

1: Alarm OFF

LZR: Checking of stored stroke check 1 during the time from power-on to the manual

reference position return.

0: Not checked

1: Checked

[

Standard setting] 0 0 0 0 0 0 0 0

1080

Coordinate value of stored stroke check 1 in the

positive direction on each axis.

XWG

OT3 OT2

OUT

999999.9999

[Data type] Real number axis

[Data unit] mm

[Data range] 0~999999.9999

17

Page 27

GSK25i Milling CNC System User Manual

1081

Coordinate value of stroed stroke check 1 in the

negative direction on each axis.

[Data type] Real number axis

[Data unit] mm

[Data range] -999999.9999~0

1082

Coordinate value of stored stroke check 2 in the

positive direction on each axis.

[Data type] Real number axis

[Data unit] mm

[Data range] 0~999999.9999

1083

Coordinate value of stored stroke check 2 in the

negative direction on each axis.

-999999.9999

999999.9999

-999999.9999

[Data type] Real number axis

[Data unit] mm

[Data range] -999999.9999~0

1084

Coordinate value of stored stroke check 3 in the

positive direction on each axis.

[Data type] Real number axis

[Data unit] mm

[Data range] 0~999999.9999

1085

Coordinate value of stored stroke check 3 in the

negative direction on each axis.

[Data type] Real number axis

[Data unit] mm

[Data range] -999999.9999~0

1100 Machine struction type 12

999999.9999

-999999.9999

[Data type] Integrated

[Data range] 0~21

1101 Controlled axis number of the 1

[Data type] Integrated

[Data range] 0~5

18

st

rotation axis 4

Page 28

1102 The axis direction of the 1

[Data type] Integrated

[Data range] 0~5

1103 The rotation direction of the 1

[Data type] Integrated

[Data range] 0: negative/ 1: positive

st

1104 The 1

angular aixs

rotation axis is an inclination angle for

[Data type] Real number

[Data unit] deg

[Data range] -999999.9999 ~ 999999.9999

1105 The controlled axis number of the 2

axis

Volume Ⅲ Parameter

st

rotation axis 2

st

rotation axis 1

nd

rotation

0

5

[Data type] Integrated

[Data range] 0~5

1106 The axis diretion of the 2

[Data type] Integrated

[Data range] 0~5

1107 The rotation direction of the 2

[Data type] Integrated

[Data range] 0: negative/ 1: positive

nd

1108 The 2

the angular axis

rotation axis is an inclination angle of

[Data type] Real number

[Data unit] deg

[Data range] -999999.9999 ~ 999999.9999

1109 The axis direction of tool axis 3

nd

rotation axis 3

nd

rotation axis 1

0

[Data type] Integrated

[Data range] 0~3

19

Page 29

GSK25i Milling CNC System User Manual

1110

The position of index table 0

[Data type] Real number axis

[Data unit] mm

[Data range] -9999.9999~9999.9999

Note

Coordinate parameters of three axes X, Y and Z are included

1111

Offset vector between the 1st and 2nd working

table rotation axes

[Data type] Real number axis

[Data unit] mm

[Data range] -9999.9999~9999.9999

Note

Coordinate parameters of three axes X, Y and Z are included

1112

Offset vector between the tool axis and tool

rotation axis

0

0

[Data type] Real number axis

[Data unit] mm

[Data range] -9999.9999~9999.9999

Note

Coordinate parameters of three axes X, Y and Z are included

1113

Offset vector between the 2nd and 1st tool rotation

axes

[Data type] Real number axis

[Data unit] mm

[Data range] -9999.9999~9999.9999

Note

Coordinate parameters of three axes X, Y and Z are included

1114

Tool post offset 0

[Data type] Real number axis

[Data unit] mm

[Data range] -9999.9999~9999.9999

0

20

Page 30

4.4 Feedrate Parameter (1200~1399)

7# 6# 5# 4# 3# 2# 1# 0#

Volume Ⅲ Parameter

1200

[Data type] Bit

[Data range] 0 or 1

RPD: Manual rapid traverse during the period from the power-on time to the completion of the

reference position return.

0: Disabled

1: Enabled

RF0: When the rapid feedrate override is F0,

0: The machine tool does not stop moving.

1: The machine tool stops moving.

RDR: When the rapid traverse is performed,

0: Dry run is disabled.

1: Dry run is enabled.

[

Standard setting] 0 0 0 0 0 0 0 0

1210

Dry run speed (common to all axes) 10000

[Data type] Real number

[Data unit] mm/min

[Data range] 0~1000000

RDR RF0 RPD

Note

The dry run speed is set when the manual feedrate is set to 100%.

1211

[Data type] Real number

[Data unit] mm/min

[Data range] 0~1000000

Note

The feedrate is set when the automatic feedrate is set to 100%.

1224

[Data type] Real number

[Data unit] mm/min

[Data range] 0~1000000

The cutting feedrate occurs by default in the

automatic mode

The maximum cutting composite feedrate

(common to all axes)

1000

4000

21

Page 31

GSK25i Milling CNC System User Manual

1225

Maximum cutting feedrate for each axis in the

automation mode

[Data type] Real number axis

[Data unit] mm/min or degree/min

[Data range] 0~1000000

1226

Rapid traverse rate for each axis in the

automation mode

[Data type] Real number axis

[Data unit] mm/min or degree/min

[Data range] 0~1000000

Note

1. The rapid traverse rate is set when the rapid traverse rate is set to

100%.

1227

The top allowable speed of move axis is shown

when it is started or stopped suddenly during

the linkage.

4000

10000

1000

[Data type] Real number axis

[Data unit] mm/min or degree/min

[Data range] 0~1000000

1228

The top allowable speed of move axis is shown

when it is performed in negative suddenly

during the linkage.

[Data type] Real number axis

[Data unit] mm/min or degree/min

[Data range] 0~1000000

1229

The top allowable acceleration speed

of move axis is shown when it is

performed in negative suddenly during

the linkage.

[Data type] Real number axis

[Data unit] m/s

2

[Data range] 0~90000000

1000

0.3

[The rotation

axis is 75]

22

Page 32

1231

F0 speed of rapid traverse feedrate override

(common to all axes)

[Data type] Real number

[Data unit] mm/min or degree/min

[Data range] 0~100000

1232

Feedrate in manual continuous feed (JOG feed)

for each axis

[Data type] Real number axis

[Data unit] mm/min or degree/min

[Data range] 0~100000

Note

JOG feedrate is set when manual feedrate is 100%.

1233

Manual rapid traverse rate for each axis

[Data type] Real number axis

[Data unit] mm/min or degree/min

[Data range] 0~100000

Volume Ⅲ Parameter

100

1000

3000

Note

1. Rapid traverse rate is set when the rapid traverse rate is 100%,

and the value set by No.1226 [the top speed at rapid traverse rate]

is employed when this parameter is set to 0.

1234

FL rate of the reference position return for each

axis

[Data type] Real number axis

[Data unit] mm/min or degree/min

[Data range] 0~15000

1235

Reference position return speed for each axis

[Data type] Real number axis

[Data unit] mm/min or degree/min

[Data range] 0~100000

300

4000 [the rotation

axis is 2000]

23

Page 33

GSK25i Milling CNC System User Manual

1236

The 2

return for each axis

nd

FL speed of reference position

[Data type] Real number axis

[Data unit] mm/min or degree/min

[Data range] 0~100000

1239

[Data type] Real number

[Data unit] mm/min or degree/min

[Data range] 0~100000

1240

The maximum operation speed of single-step

[Data type] Real number

[Data unit] mm/min or degree/min

[Data range] 0~100000

1241

[Data type] Real number

[Data unit] mm/min or degree/min

[Data range] 0~100000

The top speed of manual feed

The maximum feed speed of MPG

7 [The rotation

axis is 2]

5000

10000

15000

4.5 Interpolation and Acceleration/Deceleration Control Parameter

(1400~1599)

7# 6# 5# 4# 3# 2# 1# 0#

1400

[Data type] Bit

[Data range] 0 or 1

PPCK: In-position check

0: Not performed

1: Performed

P ACD: The acceleration/deceleration mode before the interpolation

0: Linear type

1: Type S

[

Standard setting] 0 0 0 0 0 0 0 0

PACD PPCK

24

Page 34

Volume Ⅲ Parameter

7# 6# 5# 4# 3# 2# 1# 0#

1401

ALS WFM DEF EFL

[Data type] Bit

[Data range] 0 or 1

EFL: The flag of the transition of small line segment fold

0: No employed

1: Employed

DEF: The speed is whether to control the speed variable when the controlled axis is stopped

suddenly

0: Not considered

1: Considered

WFM: MPG interpolation mode

0: It is treated by the impounding reservoir mode

1: It is treated by the real-time mode

ALS: Automatic corner feed function

0: Invalid

1: Valid

[

Standard setting] 0 0 0 0 0 0 0 0

7# 6# 5# 4# 3# 2# 1# 0#

1403

RCOK RBK HXS

[Data type] Bit

[Data range] 0 or 1

HXS: The rotation diretion between MPG and each axis

0: Different

1: Same

RBK: The backlash compensation is performed between the cutting and rapid traverse.

0: Not separately

1: Separately

RCOK: Backlash compensation

0: Not performed

1: Performed

[

Standard setting] 0 0 0 0 0 0 1 0

1404

Curve frequency of Nurbs interpolation

[Data type] Integrated

[Data unit] times

[Data range] 1~4

3

25

Page 35

1405

[Data type] Integrated

[Data unit] Point/mm

[Data range] 5~1000

1406

[Data type] Integrated

[Data unit] Section

[Data range] 0~2000

1407

[Data type] Integrated

[Data unit] Section

[Data range] 10~500

1409

[Data type] Integrated

[Data unit] Section

[Data range] 0~2000

GSK25i Milling CNC System User Manual

Standard indensity setting of Nurbs curve

interpolation

Pre-read sections in its look-ahead treatment

The maximum program sections of Nurbs curve

interpolation

Prospective treatment program section amount

10

1000

200

10

Note

The prospective program section amount is set when adopting the

prospect, and the 0 does not indicate prospect.

100

1410

Acceleration/deceleration type S and time

constant T1 are specified before the rapid

traverse feed is performed

[Data type] Integrated axis

[Data unit] ms

[Data range] 1~4000

The parameter value of its corresponding number is indicated by the P+ parameter number , such

as, P A1233 means the No. 1233 pa rameter. The acceleration/deceleration calculation mode of type S

is shown below, where, the t

acceleration time, and A

indicates an uniform acceleration time, t2 means a jerk and decelerating

1

is the maximum acceleration.

m

26

Page 36

Volume Ⅲ Parameter

t

a

V

2

t

1

=0.

Q

V

3

2A

R

2/2t

A)*tt(t

V

++

2

m

+

V

m

t

2

m

A

m

=

=

m211

)t(2t

21

A

m

O

As the above figure mentioned, the ladder area is:

The maximum acceleration calculation is concluded:

And, the calculation of jerk time is:

The linear acceleration/deceleration can be regarded as a special example when the type S

acceleration/deceleration is on the state of t

Before the Goo rapid traverse, the maximum acceleration calculation format of

acceleration/deceleration type S is:

P2

×

A

m00

=

1226

+×

14111410

P

V

1

2/2t

J =

m

2

, And the maximum acceleration calculation format of jerk type

)PP(2

S before the Goo rapid traverse is

Note

1. When the acceleration or jerk calculation is used this format during

the actual application; it is very necessary to note that the unit

conversion must be performed in terms of the unit of parameters.

1411

[Data type] Integral axis

[Data unit] ms

[Data range] 0~4000

S-type acceleration/deceleration time constant

T

at the rapid traverse feed

2

Note

1. When the acceleration or jerk calculation is used this format during

the actual application; it is very necessary to note that the unit

conversion must be performed in terms of the unit of parameters.

J =

m00

2A

P

m00

1411

.

100

27

Page 37

GSK25i Milling CNC System User Manual

1440

[Data type] Real number axis

[Data unit] m/ s

related to the parallel axis.

[Data range] 0~25000

2

, the rotation axis is: degree/s2, a general rotation axis value is up to 250 folds

Note

It is only valid to the linear acceleration/deceleration control.

1442

[Data type] Real number

[Data unit] m/ s

[Data range] 0~25000

[Data type] Real number axis

[Data unit] m/s

to the parallel axis.

[Data range] 0~25000

2

1444

Mechanical zero return acceleration speed by

default

2

, the rotation axis is: degree/s2, a general rotation axis value is up to 250 folds related

1445

[Data type] Real number

[Data unit] m/ s

[Data range] 0~25000

2

1446

[Data type] Real number

[Data unit] m/s

[Data range] 0~25000

[Data type] Real number

[Data unit] m/s

[Data range] 0~25000

2

2

1447

The maximum acceleration speed

0.4 [The

rotation axis is

100]

The maximum acceleration speed of the circular

arc interpolation feed

0.139[The

rotation axis

is 80]

The acceleration speed is performed during

deceleration when dwelling or RESETTING in

the process of operation

MPG acceleration speed

Manual acceleration speed

0.5

0.5

0.5

0.5

28

Page 38

Volume Ⅲ Parameter

1471

[Data type] Real number

[Data unit] mm

[Data range] 0~1

1472

[Data type] Real number

[Data unit] mm

[Data range] 0~1

1473

[Data type] Real number

[Data unit] mm

[Data range] 0~1

1480

[Data type] Integral axis

[Data unit] ms

[Data range] 0~4000

The maximum acceleration calculation format of acceleration/deceleration type S before the Goo

rapid traverse is:

The acceleration/deceleration S-type time

constant T1 before cutting feed

Cutting feed in-position accuracy

Circular arc interpolation control accuracy

The maximum contour error of the system

0.001

0.001

0.001

16

2

P

×

A

acceleration/deceleration type S before the Goo rapid traverse is

=

01

m

Note

1. When the acceleration or jerk calculation is used this format during the

actual application; it is very necessary to note that the unit conversion

must be performed in terms of the unit of parameters.

1481

[Data type] Integral axis

[Data unit] ms

[Data range] 0~4000

1225

, and the maximum jerk calculation format of

)2(

PP

+×

14811480

Accleration/deceleration S type time constant

T2 before cutting feed

J =

01

m

2

16

P

A

1481

m

01

.

29

Page 39

Note

1. When the acceleration or jerk calculation is used this format during the

actual application; it is very necessary to note that the unit conversion

must be performed in terms of the unit of parameters.

1493

[Data type] Real number

[Data unit] mm

[Data rang] 0~50.0000mm

1494

[Datat type] Real number

[Data unit] deg

[Data range] 0~30

1495

[Datat type] Real number

[Data unit] deg

[Data range] 120~180

The least conversion corner of fold line transition

1500

[Datat type] Real number

[Data unit] deg

[Data range] 0~60

1501

[Datat type] Real number

[Data unit] mm/min

[Data range] 60~1000

The lowest federate of automatic corner deceleration

1502

[Datat type] Real number

[Data unit] %

[Data range] 0.00~100.00

GSK25i Milling CNC System User Manual

Judging the least distance of Nurbs interpolation

deceleration point

Judge the least corner of Nurbs interpolation

deceleration point

Two blocks’ boundary corner of the automatic

corner deceleration

The least circular arc cutting feed deceleration

rate inside the automatic corner override

1.000

10

150

0

120

50

30

Page 40

1503

[Datat type] Real number

The start distance of the internal corner override

[Data unit] 0.1mm

[Data range] 0~4000

1504

[Datat type] Real number

The end distance of the internal corner override

[Data unit] 0.1mm

[Data range] 0~3999

1505

[Datat type] Real number

[Data unit

[Data range] 0~9999.9999

] mm/min

The lowest speed of circular interpolation

Volume Ⅲ Parameter

1

1

200

4. 6 Editing Parameter Display (1600~1799)

7# 6# 5# 4# 3# 2# 1# 0#

1601

[Data type] Bit

[Data range] 0 or 1

ENG, CHI: Language selection

Standard setting] 0 0 0 1 0 0 0 0

[

1603

[Data type] Bit

[Data range] 0 or 1

DRL: The relative position display is whether to consider the tool length compensation

0: Considered

1: Not considered

DRC: The relative position display is whether to consider the tool radius compensation

0: Considered

1: Not considered

ENG CHI

ENG CHI Language display

0 * Simplified Chinese

1 0 English

7# 6# 5# 4# 3# 2# 1# 0#

DAC DAL DRC DRL

31

Page 41

GSK25i Milling CNC System User Manual

DAL: The absolute position display is whether to consider the tool length compensation

0: Considered

1: Not considered

DAC: The absolute position display is whether to consider the tool radius compensation

0: Considered

1: Not considered

[

Standard setting] 0 0 0 0 0 0 0 0

7# 6# 5# 4# 3# 2# 1# 0#

1605

NPA PLCD

[Data type] Bit

[Data range] 0 or 1

PLCD: PLC ladder diagram display

0: Not displayed

1: Displayed

NPA: Whether to shift to an alarm screen when the alarm occurs.

0: No

1: Yes

[

Standard setting] 0 0 0 0 0 0 0 1

7# 6# 5# 4# 3# 2# 1# 0#

1610

NE9 NE8

[Data type] Bit

[Data range] 0 or 1

NE8: Whether to forbid the subprogram edit of the program numbers from 8000 to 8999

0: Not forbidden

1: Forbidden

NE9: Whether to forbid the subprogram edit of the program numbers from 9000 to 9999

0: Not forbidden

1: Forbidden

[Standard setting] 0 0 0 1 0 0 0 1

1621

Automatically insert the incremental value in

10

sequence number

[Data type] Integrated

[Data range] 0~9999

1640

[Data type] Integrated

[Data range] 0~99999999

32

The required machining parts are added 1

0

Page 42

1641

[Data type] Integrated

[Data range] 0~99999999

1642

[Data type] Integrated

[Data range] 0~99999999

1671

[Data type] Bit

1672

[Data type] Bit

1673

[Data type] Bit

1674

[Data type] Bit

1675

[Data type] Bit

1676

[Data type] Bit

1677

[Data type] Bit

1678

[Data type] Bit

Volume Ⅲ Parameter

The required machining parts are added 2

The required machining parts are added 3

Main surface ground colour

Fixed output color

Dynamic output color

Selected basis color

Selected font color

The ground color of controllable parts

The selected color of controllable parts

The ground color of input column

0

0

33

Page 43

[Data type] Bit

[Data type] Bit

[Data type] Bit

[Data type] Bit

[Data type] Bit

[Data type] Bit

[Data type] Bit

[Data type] Bit

1679

1680

1681

1682

1683

1684

1685

1686

GSK25i Milling CNC System User Manual

The font color of input column

The ground color of title column

The font color of title column

The ground color of state column

The font color of state column

Alarm color

Setting-out color

Shared color

7# 6# 5# 4# 3# 2# 1# 0#

1687

[Data type] Bit

[Data range] 0 or 1

Note

DEF1-DEF3, the default color configuration program, the above-mentioned

configuration color can be regarded as valid as long as all default bits are

set to 0.

34

DEF3 DEF2 DEF1

Page 44

4. 7 Programming Parameter (1800~1999)

7# 6# 5# 4# 3# 2# 1# 0#

Volume Ⅲ Parameter

1800

DPI

[Data type] Bit

[Data range] 0 or 1

DPI: The decimal point is ignored when programming

0: It is treated as the least set unit

1: It is regarded as mm, sec

Starndard setting] 0 0 0 0 0 0 0 1

[

7# 6# 5# 4# 3# 2# 1# 0#

1801

G23 CLR G91 G19 G18 G01

[Data type] Bit

[Data range] 0 or 1

G01: The modul issues when the power is turned on or off

0: G00 mode

1:G01 mode

G18, G19: When the power is turned on or off, the panel selection is:

G19 G18 Panel selection

0 0 G17

0 1 G18

1 0 G19

G91: When the power is turned on or off, its set is:

0: G90 mode

1: G91 mode

CLR: When the reset is performed

0: The system is reset

1: The system is eliminated

G23: When the power is turned on

0: G22 mode

1: G23 mode

[

Standard setting] 1 0 0 0 0 0 0 0

7# 6# 5# 4# 3# 2# 1# 0#

1802

AD2

[Data type] Bit

[Data range] 0 or 1

AD2: More than two same addresses are specified in a same command.

0: Command is valid

1: System alarm

Standard set] 0 0 0 0 0 0 0 0

[

35

Page 45

GSK25i Milling CNC System User Manual

7# 6# 5# 4# 3# 2# 1# 0#

1803

M3B POL

[Data type] Bit

[Data range] 0 or 1

POL: Decimal point command address program

0: Used

1: Not used

M3B: M code number can be specified in program

0: One

1: Up to 3

[Standard setting] 0 1 0 0 0 0 0 0

1810

Allowable error of circular arc radius

[Data type] Real number

[Data unit] mm

[Data range] 0~9999.9999

Note

The circular arc radius error is not to be checked when the

set value is 0.

7# 6# 5# 4# 3# 2# 1# 0#

0.01

1850

SCR XSC SCL RIN

[Data type] Bit

[Data range] 0 or 1

RIN: The rotation angle of its coordinate rotation

0: Absolute coordinate command

1: G90/G9 command

SCL: Scaling for each axis

0: Disabled

1:Enabled

XSC: Scaling override for each axis

0: Disabled

1:Enabled

SCR: The scaling override unit

0: 0.001 times

1: 0.0001 times

[

Standard setting] 0 0 0 0 0 0 0 0

36

Page 46

1860

The rotation angle is used when the angle in

coordinate rotation does not occur.

[Data type] Real number

[Data unit] deg

[Data range] -360.000~ 360.000

1861

The scaling override is used when the scaling

command override does not occur.

[Data type] Real number

[Data range] 0~ 99.999

1862

[Data type] Real number axis

[Data range] 0~ 99.999

7# 6# 5# 4# 3# 2# 1# 0#

Scaling for each axis

Volume Ⅲ Parameter

0

1

1

1870

PDI MDL

[Data type] Bit

[Data range] 0 or 1

MDL: Single direction positioning G code (G60)

0: The modul code does not set

1: Modul code

PDI: Single direction positioning in-position check

0: Not performed

1: Performed

[Standard set] 0 0 0 0 0 0 0 0

1880

The direction and overtravel amount of single

direction positioning for each axis

[Data type] Real number axis

[Data unit] mm

[Data range] -999.9999~ 999.9999

1931

The least angle of index table

[Data type] Real number

[Data unit] deg

[Data range] 0~360.000

0

0

37

Page 47

GSK25i Milling CNC System User Manual

7# 6# 5# 4# 3# 2# 1# 0#

1940

SKF

[Data type] Bit

[Data range] 0 or 1

SKF: Whether the G31 skip command is valid to the dry run, override and authomatic

acceleration/deceleration:

0: Valid

1: Invalid

Standard set] 0 0 0 0 0 0 0 0

[

7# 6# 5# 4# 3# 2# 1# 0#

1950

MOU

[Data type] Bit

[Data range] 0 or 1

MOU: Whether to input the M, S, T and B codes when the program is restarted:

0: Not output

1: Output

Standard set] 0 0 0 0 0 0 0 0

[

1960

The move sequence for each axis moves to the

program restart position

[Data type] Integral axis

[Data range] 0~ Controllable axis number

7# 6# 5# 4# 3# 2# 1# 0#

1971

ESC ESR

[Data type] Bit

[Data range] 0 or 1

ESR: External program number index

0: Ineffective

1: Effective

ESC: The reset is input from ESTB input to index.

0: Index performed

1: Not performed

[Standard set] 0 0 0 0 0 0 0 0

38

Page 48

4.8 Fixed Cycle Parameter (2000~2099)

7# 6# 5# 4# 3# 2# 1# 0#

Volume Ⅲ Parameter

2000

M5B RD2 RD1 FXY

[Data type] Bit

[Data range] 0 or 1

FXY: The drilling axis in the drilling canned cycle is:

0: Always the Z-axis

1: The axis selected by the program

RD2, RD1 Set the retraction axis direction of G76 or G87

RD2 RD1 G17 G18 G19

0 0 +X +Z +Y

0 1 -X -Z -Y

1 0 +Y +X +Z

1 1 -Y -X -Z

M5B: G76 G87 spindle orientation

0: Outputs M05 before an orientated spindle stops

1: Not ouput M05 before an oriented spindle stops

[

Standard setting] 0 0 0 0 0 0 0 0

2010

Return d of high speed peck drilling G73 0.5

[Data type] Real number

[Data unit] mm

[Data range] 0~99.9999

2011

Clearance d of canned cycle G83 0.5

[Data type] Real number

[Data unit] mm

[Data range] 0~99.9999

2034

Clearance of small diameter peck drilling cycle 0.5

[Data type] Real number

[Data unit] mm

[Data range] 0~99.9999

39

Page 49

GSK25i Milling CNC System User Manual

4.9 Rigid Tapping Parameter (2100~2299)

2112

[Data type] Real number

[Data unit] mm

[Data range] 0~99.9999

2140

[Data type] Integrated

[Data unit] r/min

[Data range] 0~9999

2141

[Data type] Integrated

[Data unit] r/min

[Data range] 0~9999

2142

[Data type] Integrated

[Data unit] r/min

[Data range] 0~9999

2170

[Data type] Integrated

[Data unit] 0.01/s

[Data range] 0~9999

Return or clearance in peck tapping cycle 0.5

The maximum speed of spindle (the 1

gear) in rigid tapping

The maximum speed of spindle (the 2

gear) in rigid tapping

The maximum speed of spindle (the 3

gear) in rigid tapping

The position control circuit gain is performed

(the 1st step gear) between spindle and tapping

axis when the rigid tapping is performed.

st

step

nd

step

rd

step

1000

1000

1000

1000

Note

When this parameter is set, the power must be turned off before

operation is continued.

2171

[Data type] Integrated

[Data unit] 0.01/s

40

The position control circuit gain is performed

nd

(the 2

step gear) between spindle and tapping

axis when the rigid tapping is performed.

1000

Page 50

[Data range] 0~9999

Note

When this parameter is set, the power must be turned off

before operation is continued.

2172

[Data type] Integrated

[Data unit] 0.01/s

[Data range] 0~9999

Note

When this parameter is set, the power must be turned off before

operation is continued.

2180

[Data type] Integrated

[Data range] 0~32767

2181

[Data type] Integrated

[Data range] 0~32767

2182

[Data type] Integrated

[Data range] 0~32767

2210

[Data type] Integrated

[Data unit] Check unit

[Data range] 1~127

2211

[Data type] Integrated

Volume Ⅲ Parameter

The position control circuit gain is performed

(the 3rd step gear) between spindle and tapping

axis when the rigid tapping is performed.

Spindle circuit gain coefficient in rigid tapping

Spindle circuit gain coefficient in rigid tapping

Spindle circuit gain coefficient in rigid tapping

Spindle backlash compensating value of rigid

tapping (the 1

Spindle backlash compensating value of rigid

tapping (the 2nd step gear)

st

(the 1

(the 2nd step gear)

(the 3rd step gear)

step gear)

st

step gear)

1000

1000

1000

1000

10

10

41

Page 51

GSK25i Milling CNC System User Manual

[Data unit] Check unit

[Data range] 1~127

2212

Spindle backlash compensating value of rigid

[Data type] Integrated

[Data unit] Check unit

[Data range] 1~127

2221

[Data type] Real number

[Data unit] mm

[Data range] 0~9999.9999

10

tapping (the 3rd step gear)

Return value of rigid tapping 0.5

4.10 Parameter of Manual, Auto and MPG Operation (2300~2499)

7# 6# 5# 4# 3# 2# 1# 0#

2300

[Data type] Bit

[Data range] 0 or 1

JHD: MPG feed in JOG mode or incremental feed in MPG feed mode

0: Invalid

1: Valid

IHD: The travel increment of MPG is:

0: Output unit

1: Input unit

HCL: Whether the softkey is cleared the display of MPG interruption

0: Disabled

1: Enabled

HPF: When a MPG feedrate exceeding the rapit traverse rate is issued, the rate is clamped at

the rapid traverse rate and exceeded part of pulse

0: Ignored

HNGD JAG HPF HCL IHD JHD

1: Not ignored, but stored in the CNC

JAG: Manual absolute switch of system

0: OFF

1: ON

HNGD: Axis movement direction for rotation direction of MPG

0: Same in direction

1: Reverse in direction

[

Standard setting] 0 0 0 0 0 0 0 0

42

Page 52

2310

[Data type] 2-word

[Data unit] mm

[Data range] 0~10.000

2320

[Data type] Byte

[Data range] 1~3

2321

[Data type] Byte

[Data range] 1~127

2322

[Data type] Word

[Data range] 1~999

MP2(G19#5) MP1(G19#4) MPG movement

Volume Ⅲ Parameter

Least command increment setting for JOG feed

Number of MPG

MPG feedrate override m

MPG feedrate override n

0 0

0 1

1 0

1 1 Least input increment ×n

Least input increment ×1

Least input increment ×10

Least input increment ×m

0.001

2323

Allowable number of pulses that can be

accumulated during MPG feed

[Data type] 2-Word

[Data range] 0~99999999

4.11 Parameter (2500~2599) Input/Output

7# 6# 5# 4# 3# 2# 1# 0#

2501

[Data type] Bit

[Data range] 0 or 1

SWI: Position switch symbol

0: Invalid

1: Valid

DEC: Deceleration signal for reference position return

LTM DEC SWI

43

Page 53

GSK25i Milling CNC System User Manual

0: Deceleration is applied when the signal is 0.

1: Deceleration is applied when the signal is 1.

LTM: Hard limit treatment method

0: Hard limit deceleration treatment

1: Stops immediately

[

Standard setting] 0 0 0 0 0 0 0 0

2510

The delay time of strobe signal MF, SF, TF and

BF

[Data type] Integrated

[Data unit] ms

[Data range] 16~32767

2511

The acceptable width of the M, S, T and B

[Data type] Integrated

[Data unit] ms

[Data range] 16~32767

2512

Distributed address to the skip signal 0

[Data type] Integrated

[Data range] 0~127

64

64

completion signal

Note

1. It is invalid when the parameter is less than 10.

2513

[Data type] Integrated

[Data range] 0~127

Note

1. It is invalid when the parameter is less than 10.

2518

[Data type] Integrated

[Data unit] ms

[Data range] 0~1000

Distributed address to the measure arrival

signal

Output time of reset signal 100

0

44

Page 54

Volume Ⅲ Parameter

2540-2555

[Data type] Integrated

[Data range] 0~6

Note

1. Position switch function is valid when the bit SWI is set to 1.

2. Position switch function is invalid when the bit SWI is set to 0.

2556-2571

The maximum range of position switch positive 0

[Data type] Integrated

[Data range] 0~99999999

2572-2587

The maximum range of position switch negative 0

[Data type] Integrated

[Data range] -99999999~ 0

Position switch corresponds servo axis 0

4.12 Tool Administration Parameter (2600~2799)

7# 6# 5# 4# 3# 2# 1# 0#

2600

[Data type] Bit

[Data range] 0 or 1

TLB: Tool length compensation selection

0: Tool compensation A (Always Z axis irrespective of plane specification)

1: Tool compensation B (Axis perpendicular to plane specification)

Standard setting] 0 0 0 0 0 0 1 0

[

2601

[Data type] Bit

[Data range] 0 or 1

CCN: G28 command moves to the intermediate point in radius compensation

0: The radius compensation is cancelled in movement to an intermediated position

1: The radius compensation is not cancelled in movement to an intermediate position,

but is cancelled in movement to the reference position.

LVK: Tool length offset value

0: Not cleared, but held by reset

1: Cleared by reset

ODI: A cutter compensation amount is set using:

0: A diameter

TLB

7# 6# 5# 4# 3# 2# 1# 0#

ODI LVK CCN

45

Page 55

GSK25i Milling CNC System User Manual

1: A radius

Standard setting] 0 0 0 0 0 1 0 0

[

7# 6# 5# 4# 3# 2# 1# 0#

2602

G39 TPH CNI OIM

[Data type] Bit

[Data range] 0 or 1

OIM: When the unit is switched between the inch and metric systems, automatic tool offset

value conversion is:

0: Not performed

1: Performed

CNI: Interference check for radius compensation is:

0: Performed

1: Not performed

TPH: Tool format of cutter compensation

0: Type A

1: Type B

G39: The corner rounding function in radius compensation mode is:

0: Disabled

1: Enabled

[

Standard setting] 0 0 0 0 0 0 0 0

2610

The vector limit value is ignored when cutter

compensation moves along with the corner

external.

[Data type] Real number

[Data unit] mm

[Data range] 0~99.9999

2611

The maximum amount of tool wear

compensation value

[Data type] Real number

[Data unit] mm

[Data range] 0~99.9999

2651

Automatic tool length compensation measure

[Data type] Real number

[Data unit] mm/min

[Data range] 0~15000

10

60

1000

speed

46

Page 56

Volume Ⅲ Parameter

2652

[Data type] Real number

[Data range] 0~9999.9999

2653

[Data type] Real number

[Data range] 0~9999.9999

7# 6# 5# 4# 3# 2# 1# 0#

2700

EIS LTM GS2 GS1

[Data type] Bit

[Data range] 0 or 1

GS2 and GS1 are composed of tool number combination

GS2 GS1 Group Tool number

0 0

0 1

1 0

1 1

The r value of automatic tool length

compensation measure

The e value of automatic tool length

compensation

1~16 1~16

1~32 1~8

1~64 1~4

1~128 1~2

0

0

L TM: Tool life

0: Specified by the number of times

1: Specified by time

EIS: When the life of a tool is measured in time-based units:

0: The life is counted every four seconds.

1: The life is counted every second.

[

Standard setting] 0 0 0 0 0 0 0 0

2710

The omissive number of tool life administration

[Data type] Integrated

[Data range] 0~ 9999

2711

M code for restarting tool life count

[Data type] Integrated

[Data range] 0~255

2712

The rest of tool life (frequence of use)

[Data type] Integrated

[Data range] 0~ 9999

47

Page 57

GSK25i Milling CNC System User Manual

2713

The rest of tool life (time of use)

[Data type] Integrated

[Data unit] min

[Data range] 0~ 9999

4.13 Pitch Compensation Parameter (2800~2999)

7# 6# 5# 4# 3# 2# 1# 0#

2800

[Data type] Bit

[Data range] 0 or 1

SCRW: Pitch compensation

0: Not performed

1: Performed

WDIR: Pitch compensation selection

0: Unidirection

1: Bidirection

[Standard set] 0 0 0 0 0 0 0 1

WDIR SCRW

Note

When this parameter is set, the power must be turned off before

operation is continued.

2810

[Data type] Integral axis

[Data range] 0~1023

Note

1. When this parameter is set, the power must be turned off before

operation is continued.

2811

[Data type] Integral axis

[Data range] 0~1023

Reference position pitch error compensation

number for each axis

The farthest pitch error compensation point

number for each axis in negative direction

48

Note

1. When this parameter is set, the power must be turned off before

operation is continued.

Page 58

Volume Ⅲ Parameter

2812

The farthest pitch error compensation point

[Data type] Integral axis

[Data range] 0~1023

Note

1. When this parameter is set, the power must be turned off before

operation is continued.

2. This parameter setting value is more than the No.2810 (reference

position pitch error compensation number).

2813

Pitch error compensation override for each axis

[Data type] Real number axis

[Data unit] %

[Data range] 1~100

Note

1. When this parameter is set, the power must be turned off before

operation is continued.

2814

The interval of pitch error compensation point

[Data type] Real number axis

[Data unit] mm

[Data range] 0~9999.9999

number for each axis in positive direction

for each axis

Note

1. Pitch error compensation point is distributed in equidistant, the least

value of interval = the maximum feedrate/7500 * compensation override

2. When this parameter is set, the power must be turned off before

operation is continued.

4.14 Servo Parameter (4000~4999)

7# 6# 5# 4# 3# 2# 1# 0#

4000

[Data type] Bit

[Data range] 0 or 1

IGNn: The servo axis is:

0: Not ignored

1: Ignored

ALMG: The corresponding switch for system alarms to servo

ALMG IGN5 IGN4 IGNZ IGNY IGNX

49

Page 59

GSK25i Milling CNC System User Manual

0: Not alarmed

1: Alarmed

Standard setting] 0 0 0 0 0 0 0 0

[

7# 6# 5# 4# 3# 2# 1# 0#

4001

RAST APZ

[Data type] Bit axis

[Data range] 0 or 1

APZ: Absolute encoder position and machine position

0: Not corresponding

1: Corresponding

RST: Whether to use the optical grating

0: No

1: Yes

[Standard setting] 0 0 0 0 1 0 0 0

4100

Move axis pulse equivalent

[Data type] Real number axis

[Data unit] Pulse/mm

[Data range]1~99999999

Note

1. This parameter is valid when the pulse drive servo is used.

4111

The maximum allowable position offset when

[Data type] Real number axis

[Data unit] um

[Data range] 0~32767

4120

Grid or reference point offset value for each axis

[Data type] Real number axis

[Data range] 0~99999999

4121

Backlash compensating value for each axis

[Data type] Real number axis

[Data unit] mm

[Data range] -9999.9999~9999.9999

30

each axis is stopped

1

50

Page 60

Volume Ⅲ Parameter

4122

Backlash compensating value in rapid traverse

[Data type] Real number axis

[Data unit] mm

[Data range] -9999.9999~9999.9999

4123

Step distance of backlash compensation

[Data type] Real number axis

[Data unit] mm

[Data range] 0~9999.9999

4200

[Data type] Integral number axis

[Data range] 0~9999

4201

[Data type] Integral number axis

[Data range] 0~100

4202

[Data type] Integral number axis

4203

[Data type] Integral number axis

4204

[Data type] Integral number axis

[Data range] 0~7

4205

[Data type] Integral number axis

[Data range] 5~1280

4206

Speed integration time constant (ms)

[Data type] Integral number axis

[Data unit] ms

[Data range] 0~32767

rate for each axis

Password 315

Motor type code 65

Version number

Initial display state

Control mode selection

Speed proportional gain

0

0

135

80

1

1

51

Page 61

GSK25i Milling CNC System User Manual

4207

[Data type] Integral number axis

[Data range] 1~2000

4208

[Data type] Integral number axis

[Data range] 40~2000

4209

[Data type] Integral number axis

[Data range] 0~2000

4210

[Data type] Integral number axis

[Data range] 0~1280

4211

Position feedforward low-pass cut-off frequency

Torque command filter (%)

Speed check low-pass filter (%)

Position proportional gain

Position feedforward gain (%)

(Hz)

50

245

110

0

300

[Data type] Integral number axis

[Data unit] Hz

[Data range] 2000

4212

[Data type] Integral number axis

[Data range] 0~32767

4213

[Data type] Integral number axis

[Data range] 0~32767

4214

[Data type] Integral number axis

[Data range] 0~2

Electron gear rate numerator

Electron gear rate denominator

Position pulse input mode

0

8192

5000

52

Page 62

4215

[Data type] Integral number axis

[Data range] 0~1

4216

The completion range of positioning

[Data type] Integral number axis

[Data range] 0~32767

4217

[Data type] Integral number axis

[Data range] 0~10000000

4218

Position excess-error check is enabled

[Data type] Integral number axis

[Data range] 0~1

4219

[Data type] Integral number axis

[Data range] 0~127

4220

[Data type] Integral number axis

[Data range]

0~1

4221

[Data type] Integral number axis

[Data range] -6000~6000

4223

[Data type] Integral number axis

[Data range]

0~6000

4224

[Data type] Integral number axis

[Data range]

-6000~6000

Position pulse direction

Position excess-error check range

Differential proportional coefficient

Invalid drive forbiddance

JOG speed

The maximum speed limit

Internal speed 1

0

0

100

2500

0

Volume Ⅲ Parameter

20

30000

0

0

53

Page 63

GSK25i Milling CNC System User Manual

4225

[Data type] Integral number axis

[Data range] -6000~6000

4226

[Data type] Integral number axis

[Data range] -6000~6000

4227

[Data type] Integral number axis

[Data range] -6000~6000

4228

[Data type] Integral number axis

[Data range] -6000~6000

4229

The 2

[Data type] Integral number axis

[Data range] 0~32767

4230

Linear speed conversion numerator

[Data type] Integral number axis

[Data range]

0~32767

4231

Linear speed conversion denominator

[Data type] Integral number axis

[Data range] 0~32767

4232

Linear speed decimal point position

[Data type] Integral number axis

[Data range]

0~4

4233

The speed in the mode of motor check 100

[Data type] Integral number axis

[Data range]

0~6000

Internal speed 2

Internal speed 3

Internal speed 4

Arrvial speed

nd

integration time constant of speed 220

100

300

-100

500

10

1

3

54

Page 64

4239

[Data type] Integral number axis

[Data unit] ms

[Data range] 0~10000

4241

[Data type] Integral number axis

[Data unit]

[Data range] 0~32767

4246

Analog command and pulse output are reverse 0

[Data type] Integral number axis

[Data range] 0~3

4256

The output time is performed in advance when

the feedback pulse is more than 10000

Acceleration time ms

Servo output pulse number

0

Volume Ⅲ Parameter

0

20

[Data type] Integral number axis

[Data unit] ms

[Data range] 0~32767

4257

Speed command feedforward gain

[Data type] Integral number axis

[Data range] 0~32767

4258

Acceleration command feedforward gain

[Data type] Integral number axis

[Data range] 0~32767

4259

[Data type] Integral number axis

[Data range] 1~4

4260

[Data type] Integral number axis

[Data range] 0~12800

Inertia stop decay coefficient

Current proportional gain

200

200

2

1050

55

Page 65

GSK25i Milling CNC System User Manual

4261

[Data type] Integral number axis

[Data unit] ms

[Data range] 0~32767

4262

Current integration separation point

[Data type] Integral number axis

[Data range] 0~32767

4264

[Data type] Integral number axis

[Data unit] Hz

[Data range] 0~32767

4265

[Data type] Integral number axis

[Data range] 0~32767

4267

[Data type] Integral number axis

[Data range] 0~32767

4268

[Data type] Integral number axis

[Data range] 0~32767

4269

The position proportional gain change rate of

Current integration time constant 130

20

Current low-pass cut-off frequency

Speed integration separation point

Position excess-error corner 0

Position excess-error corner 1

position excess-error corner 0

280

200

20

350

100

[Data type] Integral number axis

[Data range] 0~32767

4270

The position proportional gain change rate of

[Data type] Integral number axis

[Data range] 0~32767

56

position excess-error corner 1

100

Page 66

4271

[Data type] Integral number axis

[Data range] 0~32767

4272

[Data type] Integral number axis

[Data range] 0~32767

4273

[Data type] Integral number axis

[Data range] 0~32767

4274

The maximum allowable current of current

Motor rotor inertia

Motor rated torque

Motor rated speed

sampling circuit

Volume Ⅲ Parameter

133

60

2500

2500

[Data type] Integral number axis

[Data range] 0~32767

4275

[Data type] Integral number axis

[Data range] 0~32767

4276

[Data type] Integral number axis

[Data range] 0~32767

4279