Page 1

This user manual describes all items concerning the operation of

this CNC system in detail. However, it is impossible to give particular

descriptions for all unnecessary or unallowable operations due to length

limitation and products application conditions;Therefore, the items not

presented herein should be considered impractical or unallowable.

Copyright is reserved to GSK CNC Equipment Co., Ltd. It is illegal

for any organization or individual to publish or reprint this manual. GSK CNC

Equipment Co., Ltd. reserves the right to ascertain their legal liability.

Page 2

DAT Series AC Servo Drive Unit User Manual

Preface

Your Excellency,

We are honored by your purchase of products from GSK CNC Equipment Co., Ltd.

This manual introduces property, installation, connection, debugging, operation and

maintenance of DAT Series AC Servo Driver in detail. To ensure safe and efficient work,

please read this manual carefully before installation and operation.

New products of DAT Series AC Servo Drive Unit include DAT2030, DAT2050,

DAT2075, DAT2100 and bus-type ones such as DAT2030C, DAT2050C, DAT2075C

and DAT2100C.

This manual applies to the software version: V1.05 of DAT2000 series and

V1.05 of DAT2000C series.

Please read the manual carefully before installation and using the product to

ensure it works safely, normally and efficiently.

To avoid operator and other personal injury and machine damage, please pay

special attention to the following warning label while you read the manual.

Danger

If the motor operates incorrectly, it will cause damage or death.

If the motor operates incorrectly, it will cause medium or slight

injury, even property loss.

Caution

If this label is not noticed, unexpected result and situation will

Note

Remind important requirements and instructions to user during the

operation.

occur.

II

It indicates prohibition (mustn’t do)

It indicates forced execution (must do)

Page 3

Cautions

Danger

III

Page 4

DAT Series AC Servo Drive Unit User Manual

Note

The drive unit may startup when the power is

recovered, the user don’t operate the shaft

device of the servo motor.

If the user does not obey the

instruction, it will cause

personal injury.

Don’t put the cable on sharp edge. Don’t

make the cable bear heavy load or tension.

If the user does not obey the

instruction, it will cause

electric shock, trouble or

damage.

Caution

Don’t prevent heat diffusion or put object

on radiator fan or radiator.

If the user does not obey the

instruction, it will cause

damage or a fire.

When removing the cover on the terminal

board, the user don’t operate drive device

during power is on.

If the user does not obey the

instruction, it will cause

electric shock.

IV

Page 5

Cautions

Caution

V

Page 6

DAT Series AC Servo Drive Unit User Manual

Safety responsibility

Manufacturer Responsibility

——Be responsible for the danger which should be eliminated and/or controlled on

design and configuration of the provided servo unit and accessories.

——Be responsible for the safety of the provided servo unit and accessories.

——Be responsible for the provided information and advice for the users.

User Responsibility

——Be trained with the safety operation of servo unit and familiar with the safety

operation procedures.

——Be responsible for the dangers caused by adding, changing or altering to the

original servo unit and the accessories.

——Be responsible for the failure to observe the provisions for operation, adjustment,

maintenance, installation and storage in the manual.

This manual is kept by final user.

We are full of heartfelt gratitude to you for supporting us in the use of GSK’s

products.

VI

Page 7

Contents

contents

CHAPTER 1 PRODUCT INTRODUCTION .........................................................................................1

1.1 Basic Knowledge .................................................................................................................1

1.2 Confirmation of the Arrived Goods.......................................................................................6

1.2.1 Instruction of Servo Motor Model ...............................................................................6

1.2.2 Instruction of Servo Motor Models Unit......................................................................7

1.2.3 Appearance of servo unit ...........................................................................................8

1.3 Technical Specifications ..................................................................................................10

1.3.1 Servo motor technical specifications........................................................................10

1.3.2 Technical Specification of Servo Unit ......................................................................13

1.4 Order instruction ..............................................................................................................15

1.4.1 Order model example ..............................................................................................15

1.4.2 Standard Products Accessories...............................................................................17

CHAPTER 2 INSTALLATION ........................................................................................................19

2.1 Servo Motor .......................................................................................................................19

2.1.1 Mounting Dimension of the Servo Motor..................................................................19

2.1.2 Servo Motor Installation ...........................................................................................21

2.2 Servo Unit ..........................................................................................................................22

2.2.1 Installation Dimension..............................................................................................23

2.2.2 Mounting Interval .....................................................................................................24

Chapter 3 CONNECTION.................................................................................................................25

3.1 Connection of Peripherals..................................................................................................26

3.2 Terminal Connection of Main Circuit ...................................................................................30

3.2.1 Terminal Connection of Servo Unit ..........................................................................30

3.2.2 Instructions for Servo Motor Interface......................................................................32

3.3 Connection of Control Signal .............................................................................................33

3.3.1 Definition of Pin CN1 of DAT Series Products .........................................................33

3.3.2 Input of Speed Command ........................................................................................35

3.3.3 Input of Position Command......................................................................................36

3.3.4 Switching Value Input ..............................................................................................39

3.3.5 Output of Switch Value ............................................................................................41

3.4 Connection of Feedback Signal .........................................................................................44

3.4.1 Introductions for CN2 of DAT2000...........................................................................44

3.4.2 Introductions for CN2 OF DAT2000C ......................................................................45

3.4.3 Connection to Encoder Signal of the Motor .............................................................46

3.5 GSKLink Communication Function ....................................................................................48

3.6 Examples for Different Working Mode ...............................................................................50

3.6.1 Speed Mode Wiring of DAT2000 Series Products ...................................................50

3.6.2 Position Mode Connection of DAT2000 Series Products.........................................51

3.6.3 Speed Mode Connection of DAT2000C Series Products ........................................52

3.6.4 Position Mode Connection of DAT2000C Series Products ......................................53

CHAPTER 4 DISPLAY AND OPERATION.......................................................................................54

VII

Page 8

DAT Series AC Servo Drive Unit User Manual

4.1 Operation Panel.................................................................................................................54

4.2 Display Menu.....................................................................................................................54

4.3 State Monitoring.................................................................................................................55

4.4 Parameter Setting.............................................................................................................. 59

4.5 Parameter Management ....................................................................................................60

CHAPTER 5 DEBUGGING AND OPERATION .............................................................................62

5.1 Manual and Jog operation .................................................................................................63

5.1.1 Manual Operation ....................................................................................................64

5.1.2 Jog Operation ..........................................................................................................65

5.2 Speed mode operation ......................................................................................................66

5.2.1 External analog voltage command ..........................................................................66

5.2.2 Internal digital command..........................................................................................69

5.3 Position Mode Operation ...................................................................................................71

Chapter 6 FUNCTION DEBUGGING............................................................................................. 73

6.1 Fundamental performance parameter debugging illustration.............................................73

6.2 Application of brake releasing signal .................................................................................75

6.3 The switchover of motor rotating direction .........................................................................79

6.4 Output of position feedback signal..................................................................................... 80

6.5 Function Debugging of Position Mode ...............................................................................82

6.5.1 Position Command E-gear Ratio .............................................................................82

6.5.2 Position arrival signal (COIN).............................................................................83

6.5.3 Pulse deviation zero clearing(CLE)..................................................................... 84

6.5.4 Pulse command inhibition (INH).........................................................................84

6.6 Function debugging under speed mode ............................................................................84

6.6.1 Adjustment of analog command ..............................................................................84

6.6.2 Speed arrival signal

(COIN) .................................................................................85

6.6.3 Zero speed clamping(ZSL) ................................................................................. 86

CHAPTER 7 PARAMETERS .........................................................................................................87

7.1 Parameter List......................................................................................................................87

7.2 Parameter Description..........................................................................................................89

CHAPTER 8 ABNORMALITIES AND REMEDIES ........................................................................98

8.1 Abnormalities Caused by Misuse .........................................................................................98

8.2 Alarms and Remedies ........................................................................................................100

8.3 Inspection and Maintenance ..............................................................................................105

APPENDIX A MODEL CODE PARAMETERS AND FEED SERVO MOTOR TABLE................. 106

APPENDIX B PERIPHERAL EQUIPMENTS ............................................................................... 108

B. 1 External Braking Resistor (Optional).................................................................................108

B. 2 Circuit Breaker and Contactor (Necessary) ......................................................................109

B.3 Three-Phase AC Filter (Recommended)............................................................................ 110

B.4 Isolation Transformer (Necessary).....................................................................................110

APPENDIX C VERSION UPGRADE INSTRUCTION .....................................................................114

VIII

Page 9

Chapter 1 Product Introduction

CHAPTER 1 PRODUCT INTRODUCTION

1.1 Basic Knowledge

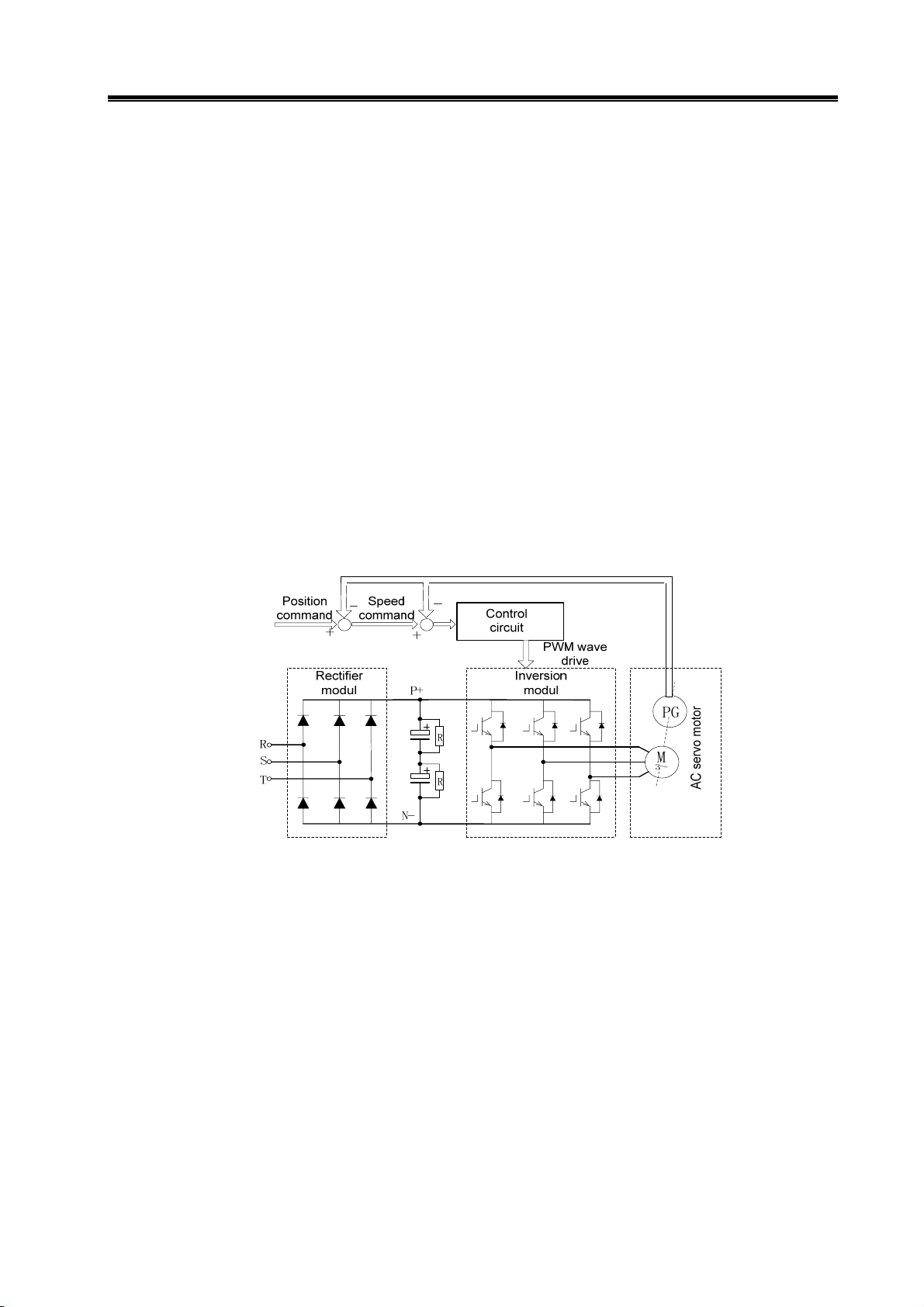

¾ Basic principle of AC servo drive device

The AC servo drive unit consists of AC servo unit and AC servo motor (three-phase

permanent magnet synchronous servo motor, hereafter referred to as the servo motor).

Approximate sine wave current with 120° phase difference (namely: DC—AC) are generated in

three-phase stator winding of the servo motor through controlling on/off of the power switch tube

after three-phase alternating current is rectified to direct current by the servo unit (namely:

AC—DC). Rotary magnetic field is formed by the sine wave current and the rotor of the servo

motor is made of rare earth permanent materials that with fine anti-degaussing property,

therefore, the interaction between the field of motor rotor and rotary field generates

electromagnetic torque to rotate the rotor. The higher the current frequency flowing through the

motor winding is, the faster speed will be. The bigger the current amplitude flowing through the

motor winding is, the bigger the output torque (Torque=force × arm length of the force) will be.

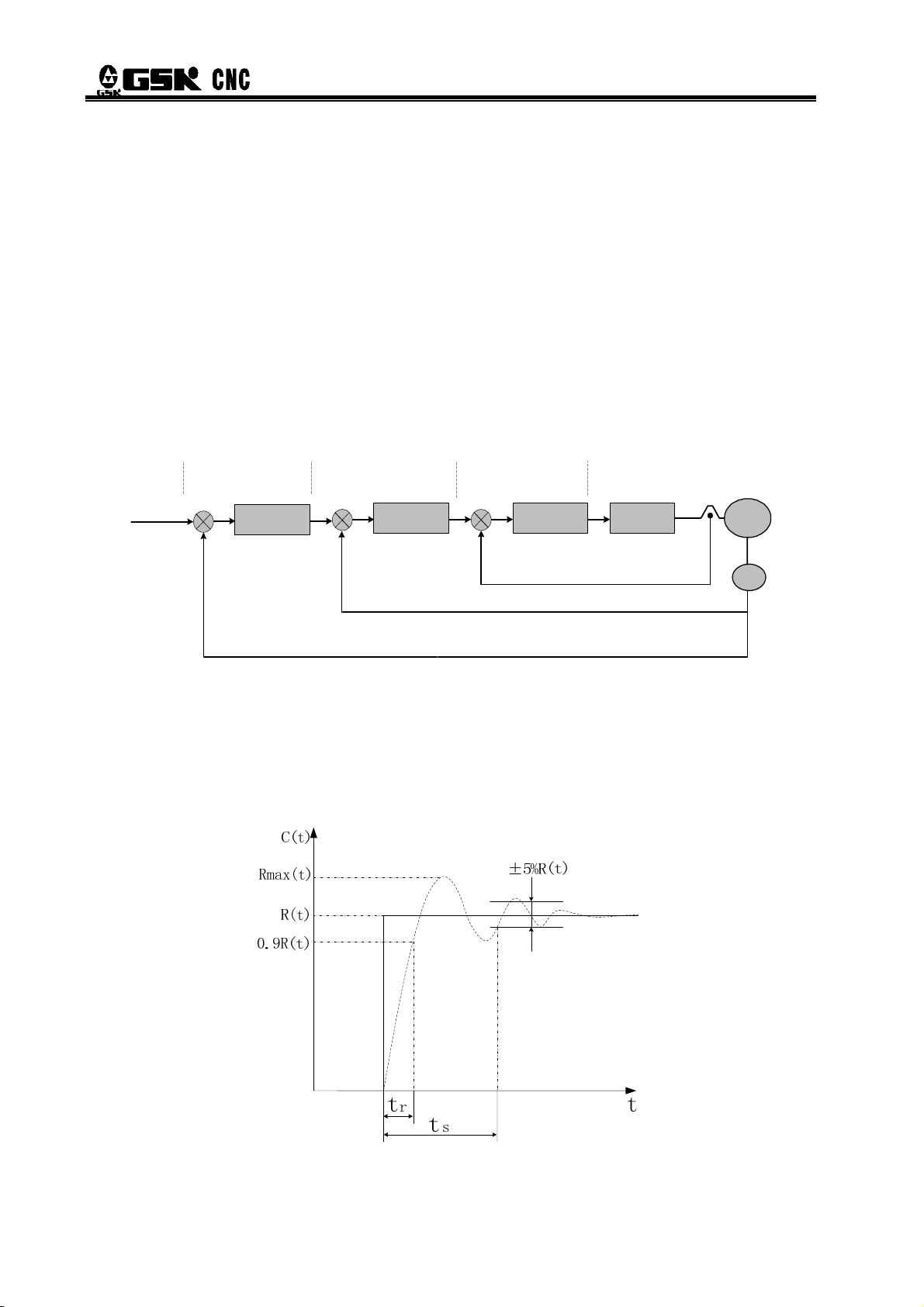

The diagram of main return current, see Fig. 1-1, PG in the figure represents encoder.

Fig.1-1 Main return current diagram of the AC servo drive unit

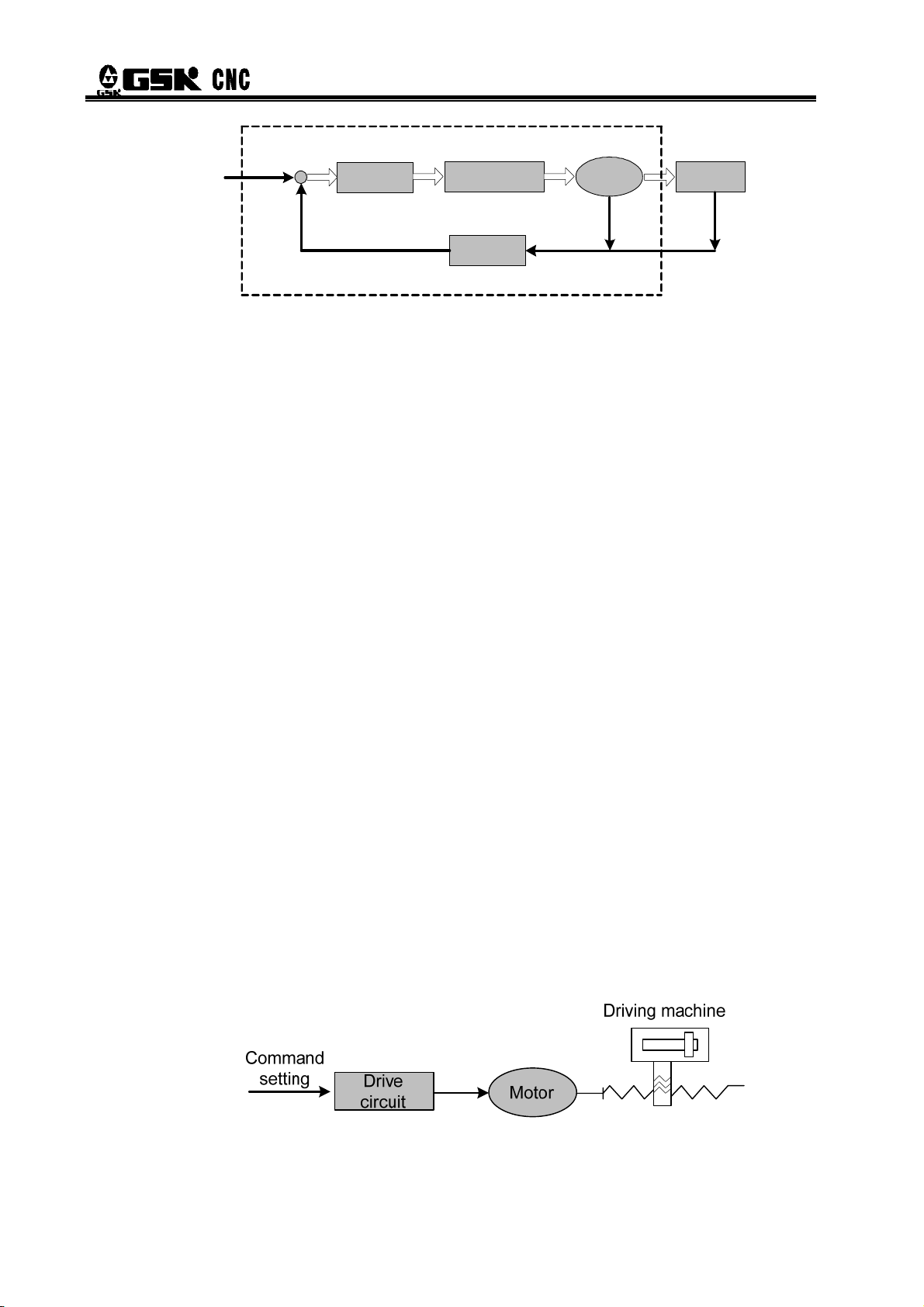

¾ Basic configuration of AC servo drive device

The servo unit receives the speed (or position) command from a control unit(PC)like

computerized numerical control system (CNC) to control the frequency and magnitude of the

motor winding current, and make the speed (or rotor angle) of motor rotor approach to the speed

(or position) command value. The deviation between the actual value of motor rotor speed (or

rotor angle) and the command value is obtained through the feedback signal from the encoder.

In addition, the servo unit constantly adjusts frequency and magnitude of the motor winding

current to make the deviation between the actual value of motor speed (or rotor anger) and the

command value within a required range. The basic configuration of the servo system is shown in

Fig 1-2.

1

Page 10

DAT Series AC Servo Drive Unit User Manual

setting

CNC

equipment

+

-

Spindle servo drive equipment

Control

unit

Power drive unit

Feedback

check

Motor

Fig.1-2 Basic configuration of AC servo drive device

¾ General concept of control

¾ Control: The process of making the property (eg. Speed) of the object (eg. Servo motor) get

or close to the predicted value is called control. The forementioned object is called controlled

object. Controlled quantity (Variable): The property of the controlled object. Control unit

(controller): The device to achieve control. Setting: The predicted value (command value) of the

controlled quantity that is received by the control unit. Feedback: The controlled quantity is taken

as input of the controller to affect itself. Feedback device: The device to detect the controlled

quantity. According to the vary direction of controlled quantity and setting to the controller output,

the feedback is divided into positive feedback (the same direction) and negative feedback

(opposite direction). Control system consists of the controller used to achieve the controlled

quantity control, the controlled object and the feedback device. The drive device is divided into

closed-loop control and open-loop control according to the presence and absence of feedback

device, and the position of feedback unit .The closed loop introduced in this manual are all

closed loop of negative feedback.

In the AC servo drive unit introduced by this manual, servo unit is a controller, the servo

motor is controlled object, the motor speed (or rotor angle) is a controlled quantity, the encoder of

the servo motor is a feedback device. The actual speed is detected by the encoder and it is used

to speed control to achieve speed feedback. Therefore, the AC servo drive unit belongs to closed

loop control system.

z Open loop control: There is no feedback device in the control system, and the actual value

of the controlled quantity does not affect the controller output. Example: Drive unit of step motor.

After output current phase sequence of servo unit of step motor is changed, the rotation of rotor

of the step motor should vary with it. Because the step motor are not usually installed speed or

position feedback device, the rotation of motor rotor may not vary accurately with the changing of

the current phase sequence, which causes so-called “step out”.

Open loop control is shown in Fig. 1-3.

Driving

machine

Fig. 1-3 Open loop control

2

Page 11

Chapter 1 Product Introduction

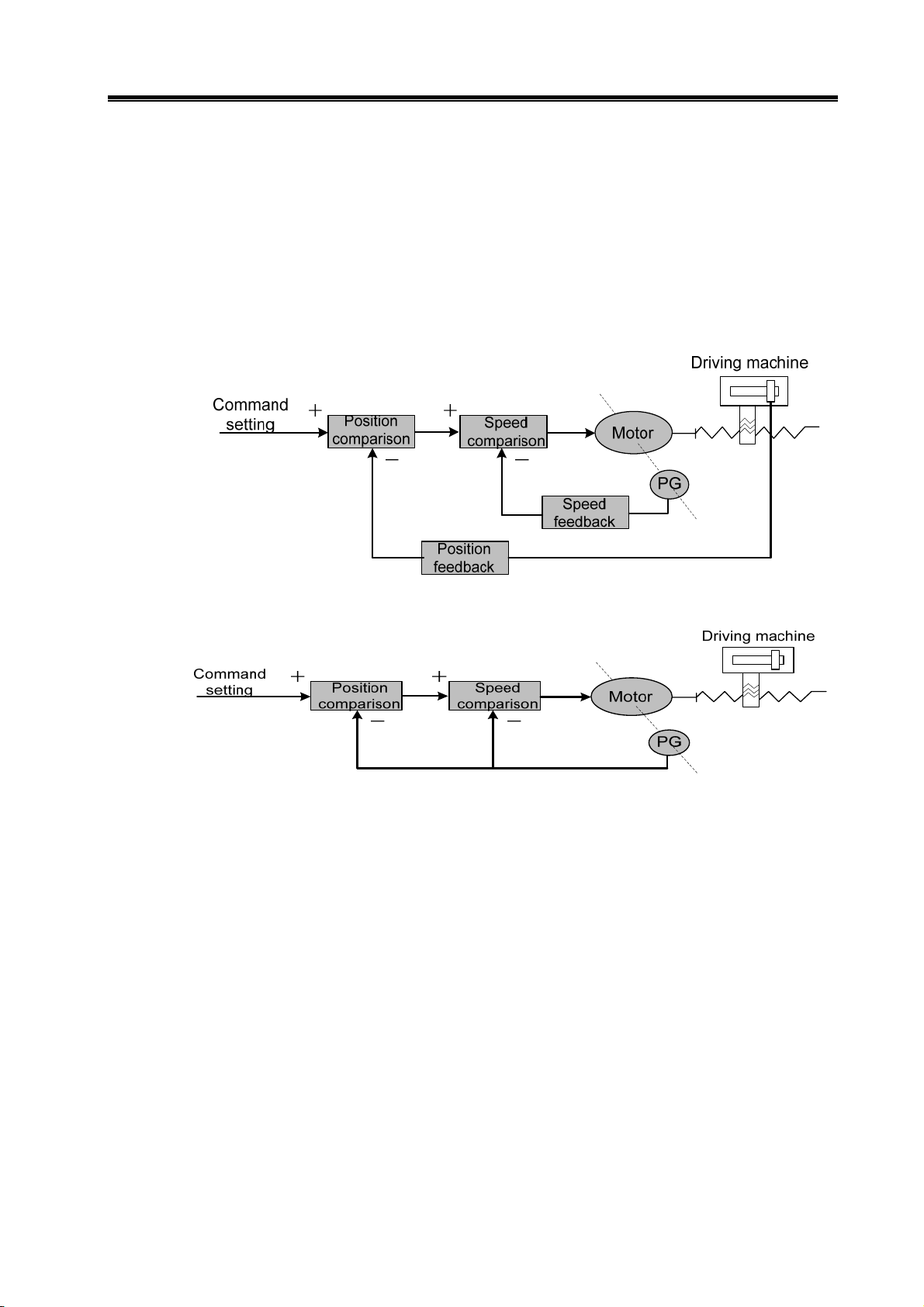

z Closed loop control: The controlled quantity of the control system is detected by feedback

device and is output to the controller. This process affects the output of the controller and then

changes the controlled quantity. According to the detection point of the feedback device, the

closed loop control id divided into entirely closed loop control and semi closed loop control.

Entirely closed loop control (Fig. 1-4): The controlled quantity is detected directly by the feedback

device and it is used for feedback. Mechanical position is used as controlled quantity, grating

ruler fixed on the machine as position feedback device, and the encoder of the servo motor is

taken as a speed feedback device, realizing the entirely closed loop control of machine position.

If the grating ruler is not fixed, the encoder of the servo motor is used as speed feedback device

(Fig. 1-5), therefore, this is a semi-closed loop control of a mechanical position.

Fig. 1-4 Full-closed loop control

Fig. 1-5 semi-closed loop control

z PID Control: also called PID adjustment, is a common algorithm the controller adopted to

mathematically deal with input data (setting, feedback). P stands for proportional, which means

the input of the controller is to be linearly proportional to the output, the larger the adjustment

coefficient is, the more sensitive the system will react and smaller the error is (can not completely

eliminated), however, over larger adjustment coefficient will result in system oscillation and

instability. I stands for integral, means time integral of system input affects the output (input

gradually affects output), the larger the integration time constant is, the more stable the system

will be, which can eliminate steady-state error but slows system response at the same time. D

stands for differential, which means input differential (slope of input change) affects output,

differential control may predict deviation and produce advanced correction action to decrease

tracking error and improve dynamic performance; while over large differential coefficient will also

result in system oscillation and instability. Along with the adjustment of PID control coefficient at

specific control system, the proportional, integral and differential adjustment are mutually

affected to make a balance between system reaction speed, control accuracy and stability. As

differential adjustment is prone to produce impact and oscillation, the servo system introduced in

this manual adopts PI adjustment, that is, proportional and differential adjustment.

3

Page 12

DAT Series AC Servo Drive Unit User Manual

¾ Concepts of servo control

There are three basic control models in servo system: location control, speed control and

torque control. The system chart is shown in Fig. 1-6.

z Position control: set the direction and angle of motor rotation through digital pulse or data

communication, the motor rotor controlled by servo unit will rotate to the corresponding angle in

accordance with the preset direction. The rotary angle (position) and speed are both controllable.

z Speed control: set the direction and angle of motor rotation through analog voltage or data

communication, the motor rotor controlled by servo unit will rotate in accordance with the set

direction and speed.

z Torque control: set the value and direction of the motor output torque through analog

voltage or data communication, the servo unit controls the motor rotor’s rotation direction and the

value of output torque.

The servo device introduced in this manual does not receive signals set by torque at present

and the torque control operational mode is not available for the time being.

+

Command

position

Position

controller

Position

adjustment

-

Position

feedback signal

Speed

controller

+ Speed

adjustment

-

Speed feedback

signal

+

Current

controller

Current

adjustment

-

Current feedback

signal

Power

amplification

Motor

PG

Fig. 1-6 Three-loop control diagram

¾ Servo performance index

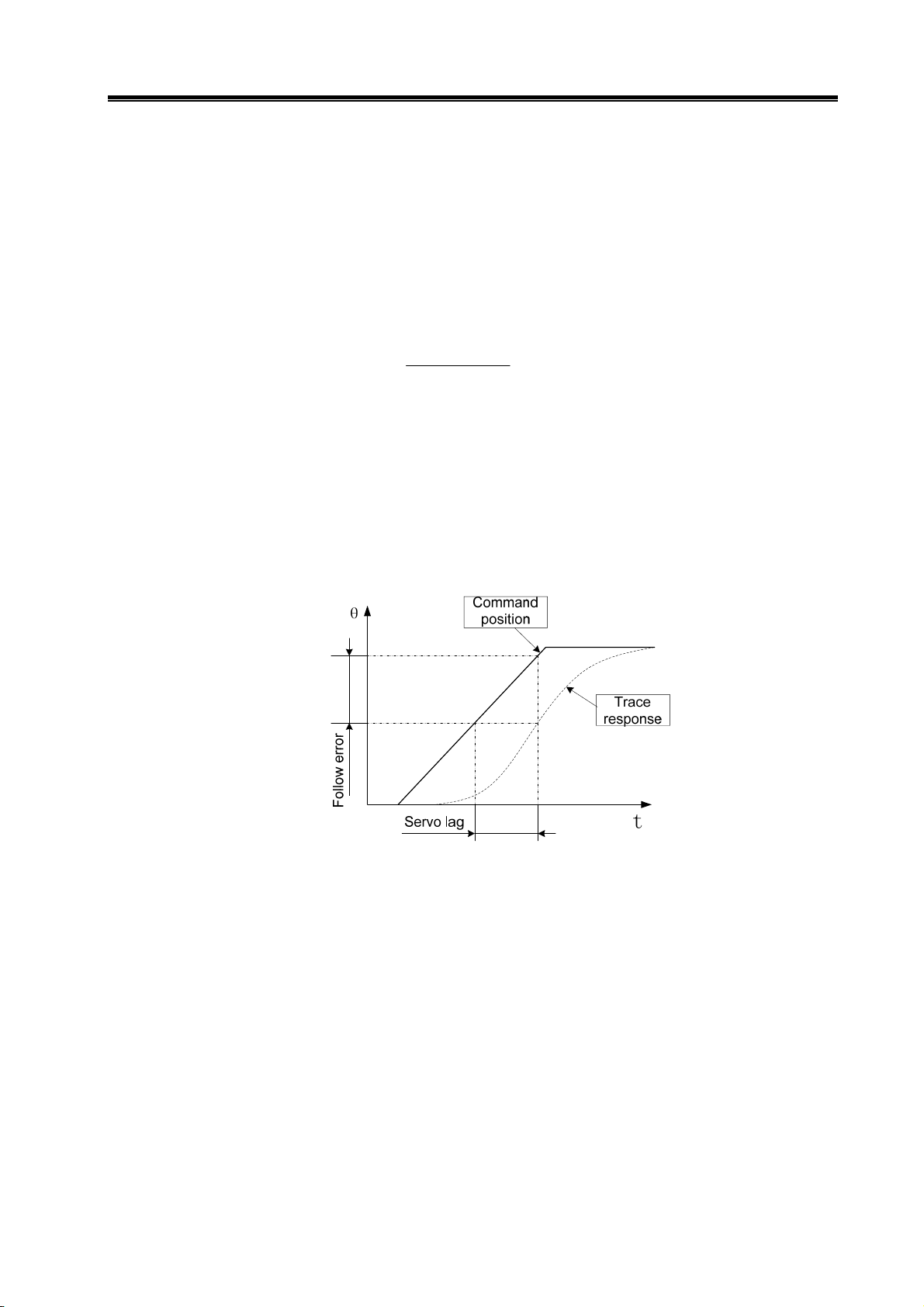

Servo dynamic reaction characteristics: refers to the reaction speed, dynamic control error

and stable control error of the servo system with set signal or load change. Fig. 1-7 indicates

reaction characteristics of the servo system set with step signals (solid line represents the setting

signal and dashed line represents the output signal of the servo system).

Fig. 1-7 Servo dynamic reaction curve

4

Page 13

Chapter 1 Product Introduction

Rise time tr: the length of time of the speed quantity rise for the first time from zero to 90% of a stable

value R (t), which shows the rapidity of dynamic reaction.

Adjustment time t

error interval which is used to measure the whole adjustment tempo of the device. The allowed

interval refers to plus or minus 5% of the stable value proximal to the step reaction curve stable

value R (t).

Overshoot σ:The ratio between the maximum D-value that the rotation output quantity overpasses

the stable value(Rmax(t)- R (t))and the stable value R (t), which reflects the relative stability of

the servo device and expressed as percentages, i.e.:

Steady-state error: the difference between the expected output steady-state value and the practical

output value after the system rotation speed turned into stable.

Servo static performance: Stability is the most important issue of the servo control system. Servo

static performance index, mainly the position accuracy, refers to deviation degree between the

practical state and expected state when the system transient process comes to cease. Not only

errors from the position measurement device and from the system will affect servo steady-state

accuracy, but the internal structure and parameters of the system can also matter. Fig.1-8 shows

the position servo static curve.

: The minimum time needed to make the reaction curve reach but not exceed

s

)()(

−

σ

(%)

max

=

tRtR

)(

tR

%100

×

Fig. 1-8 Position servo static curves

Tracking error: The difference between the movable position of the workbench requested by the

command signals (commanding position) and the practical movable position, i.e., tracking error

equals to the value of commanding position minus the value of practical position.

Servo rigidity: servo system’s capability to resist the position deviation resulted from load

interference.

5

Page 14

DAT Series AC Servo Drive Unit User Manual

1.2 Confirmation of the Arrived Goods

Please promptly inspect the received goods in accordance with the following items, any question,

please feel free to contact suppliers or our company.

Inspected Items Notes

Check and confirm if the servo units

and servo motors are the ordered.

Accessories complete or not

Damaged or not in transport

Screw loose or not

Please check by the nameplates on the servo units

and servo motors

Please check accessories according to packing list,

any unmatched ones, refer to order instruction 1.4.

Check the general appearance of goods to ensure

products intact and with no damage.

Please check if there is any screw loose with

screwdrivers.

1. Damaged AC servo unit or the ones without integrated parts can not be installed.

2. AC servo unit should be matched with servo motor with proper property.

1.2.1 Instruction of Servo Motor Model

Rated speed

Rated voltage and rated current

Servo motor model

交流伺服电动机

N

U :220V

N

: 2500r/min

S/N:

Product No.

Class of Insulation

N

I :10A

081016100D0000107H

max

IP65INS.CLASS: B

Grade of protection

Encoder lines

Rated torque

NS

: 3000 r/min

M: 17 bit

Max speed

Fig. 1-9 Instruction of servo motor models:

6

Page 15

Chapter 1 Product Introduction

130 SJT

Machine model

AC synchonic servo motor

M:Photoelectric encoder

Non:Non-electricity-breaking brake

Z:With-electricity-breaking brake

Zero-speed torque

150: 15N·m

Rated

rotation

speed

#1:Working power of electricity-breaking brake: DC(0.9~1.1)×24V, interface: triax socket, 1,2

pin are power terminals (have no polarity), 3 pin is the earth terminal. When the 1 and 2 pin plug

in power, the electricity-breaking brake doesn’t work, while when the power is disconnected, it

will brake and the operating time is less or equal to 0.1s.

#2:A three-digital number “150” is used to show its value: 150×10

A:1000 r / min

B:1500

C:2000

D:2500

E:3000

2

r/min

r/min

r/min

r/min

-

M

Z

150 D(A□Y□X

□

)

Non:Aviation sockettype

X:Cable direct type

Shaft or installation config.#3

Non:Standard shaft

Y□:Special ballpoint shaft

Z□:Special cone shaft

S□:Stepping motor installation config.

Encoder type

A or None:

A2:Increment type 5000 p/r

A3:Increment split-type 5000 p/r

A4:Absolute type 17bit

A41:Danaher multi-circle 17bit absolute type

A4S1:Danaher single-17bit absolute type

Increment type 2500 p/r

-1

=15, unit: N.m.

#3:‘□’ is a numeric codes, please refer to the installation outline drawing of the motor for the

special shaft represented by a certain number.

1.2.2 Instruction of Servo Motor Models Unit

Nameplate examples:

Motor model corresponded to factory parameter of the drive unit

Drive unit order model

Digital AC servo drive unit

DAT2075C

Version: Model :

V1.05

Adapted motor:130SJT-M150D(A4

Power:3-phase 220V

SN:E03DN00088

Date:2009/3

Tel.020-81986247 Fax.81993683

)

Software version

of Drive unit

Production date

of drive unit

Production No. of drive unit

Power of drive unit

7

Page 16

DAT Series AC Servo Drive Unit User Manual

DAT 2 050

130

-

C

SJT M-

IPM module nominal current

Input power grade:2:AC220V

Product model code

150 D

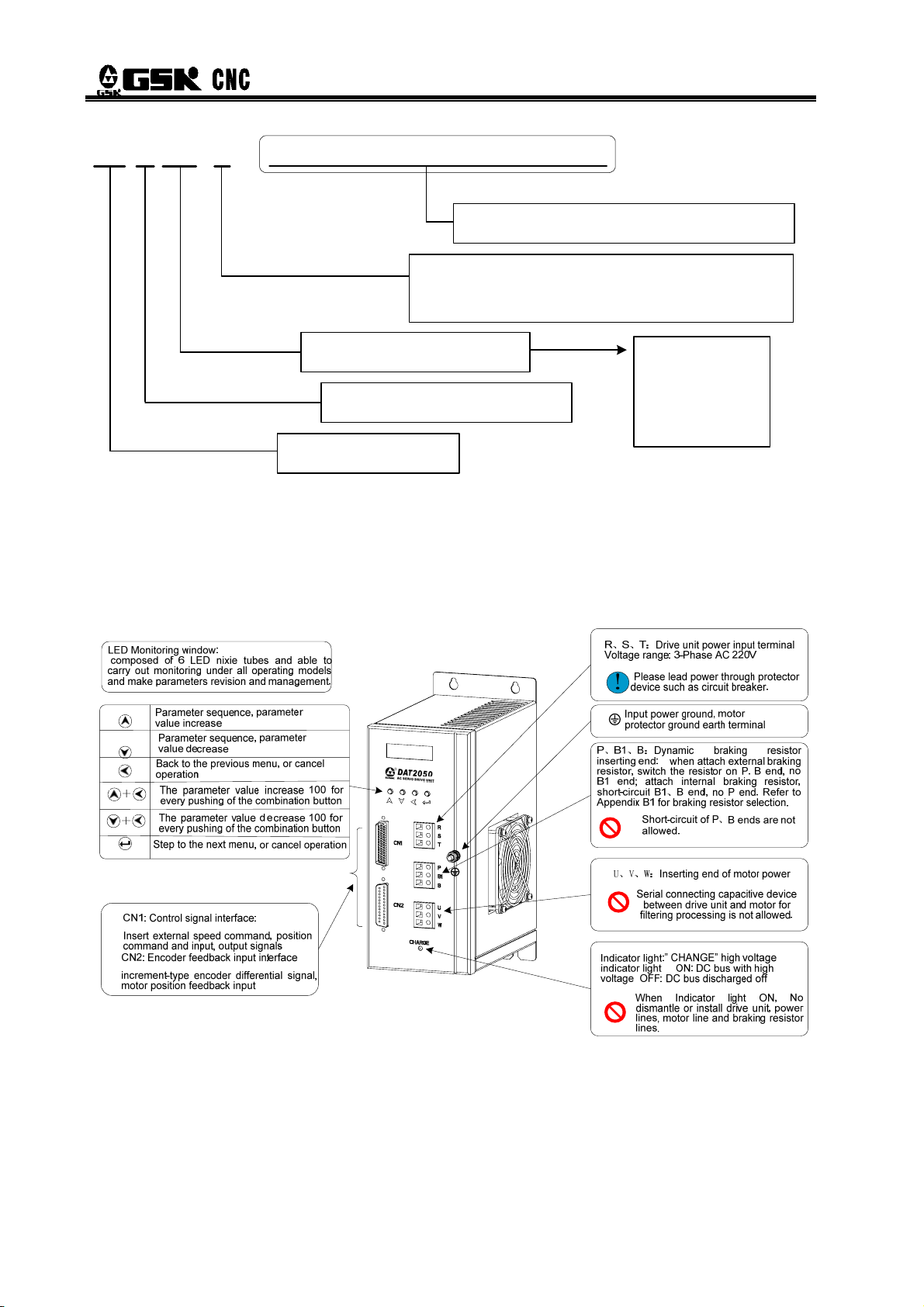

1.2.3 Appearance of servo unit

z Appearance of DAT2030 and DAT2050

A □ Y □X □)

(

Matching AC servo motor model (omit if no matching)

Communications Mode:

C: GSKLink serial communications

None: No serial communications function

030:30A;

050:50A;

075:75A;

100:100A。

8

Page 17

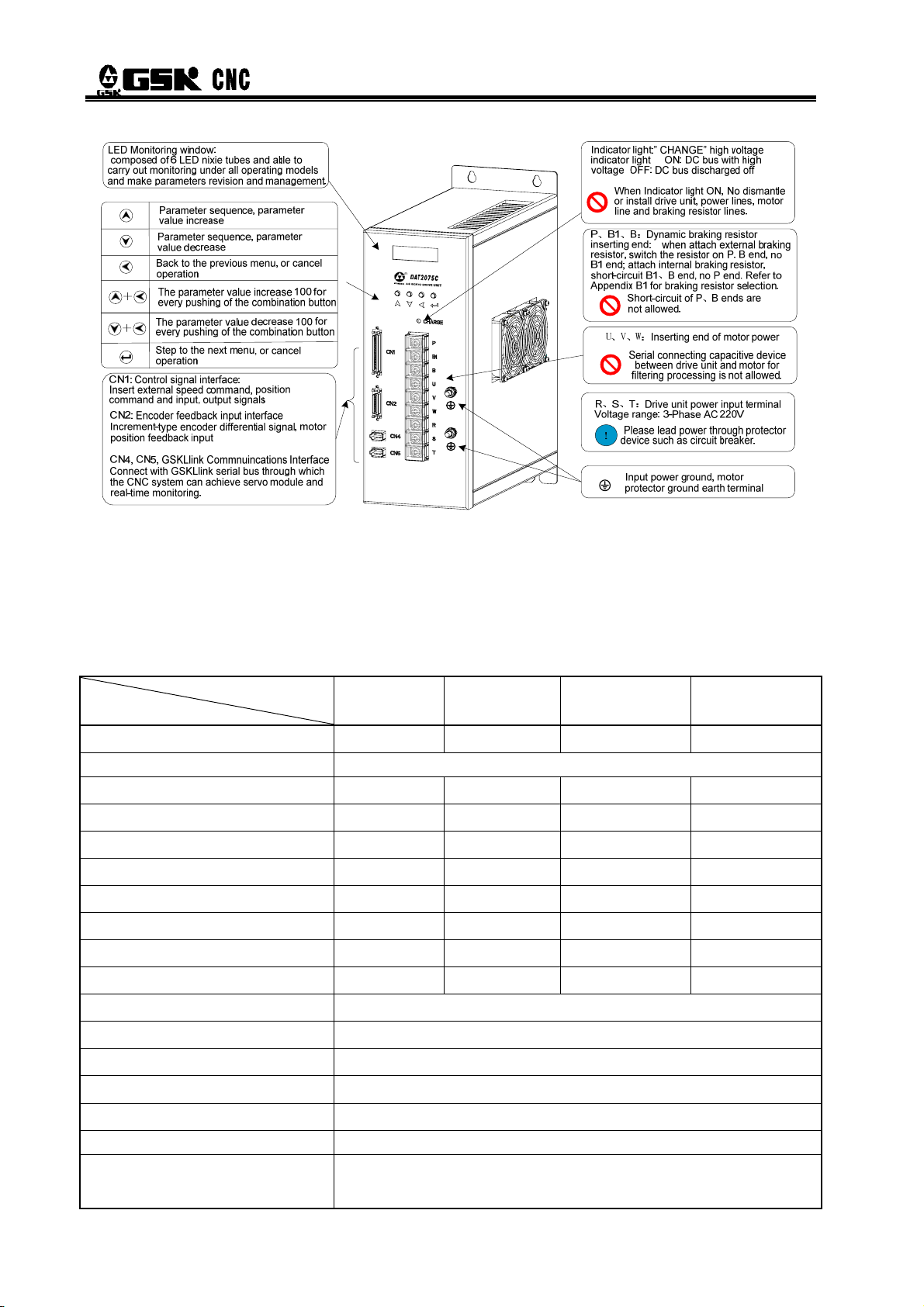

z Appearance of DAT2030C and DAT2050C

LED Monitoring window:

composed of 6 LED nixie tubes and able to

carry out monitoring under all operating models

and make parameters revision and management.

Parameter sequence, parameter

value increase

Parameter sequence, parameter

value decrease

Back to the previous menu, or cancel

operation

The parameter value increase 100 for

every pushing of the combination button+

The parameter value decrease 100 for

+

every pushing of the combination button

Step to the next menu, or cancel operation

CN1: Control signal interface:

Insert external speed command, position command

and input, output signals

CN2: Encoder feedback input interface

Increment-type encoder differential signal, motor

position feedback input

CN4, CN5, GSKLlink Commnuincations Interface

Connect with GSKLlink serial bus through which

the CNC system can achieve servo module and

real-time monitoring.

z Appearance of DAT2075 and DAT2100

Chapter 1 Product Introduction

R、S、T:Drive unit power input terminal

Voltage range: 3-Phase AC 220V

Please lead power through protector

!

device such as circuit breaker.

Input power ground, motor protector

ground earth terminal

P、B1、B:Dynamic braking resistor inserting

end: when attach external braking resistor,

switch the resistor on P. B end, no B1 end;

attach internal braking resistor, short-circuit

B1、B end, no P end. Refer to Appendix B1 for

braking resistor selection.

Indicator light:” CHANGE” high voltage

indicator light ON: DC bus with high voltage

OFF: DC bus discharged off

Short-circuit of P、B ends are

not allowed.

U、V、W:Inserting end of motor power

Serial connecting capacitive device

between drive unit and motor for

filtering processing is not allowed.

When Indicator light ON, No dismantle

or install drive unit, power lines, motor

line and braking resistor lines.

9

Page 18

DAT Series AC Servo Drive Unit User Manual

z Appearance of DAT2075C,DAT2100C

1.3 Technical Specifications

1.3.1 Servo motor technical specifications

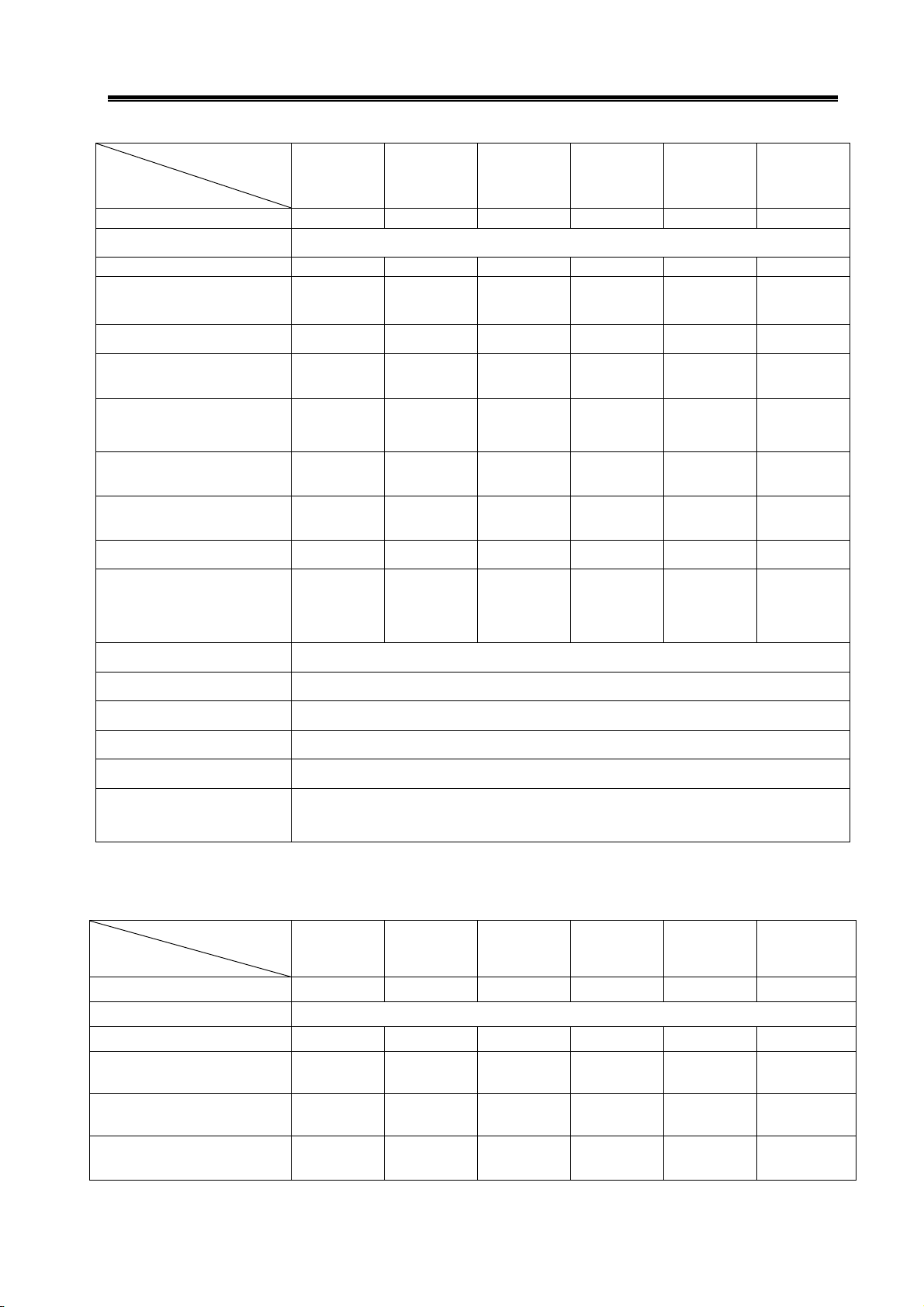

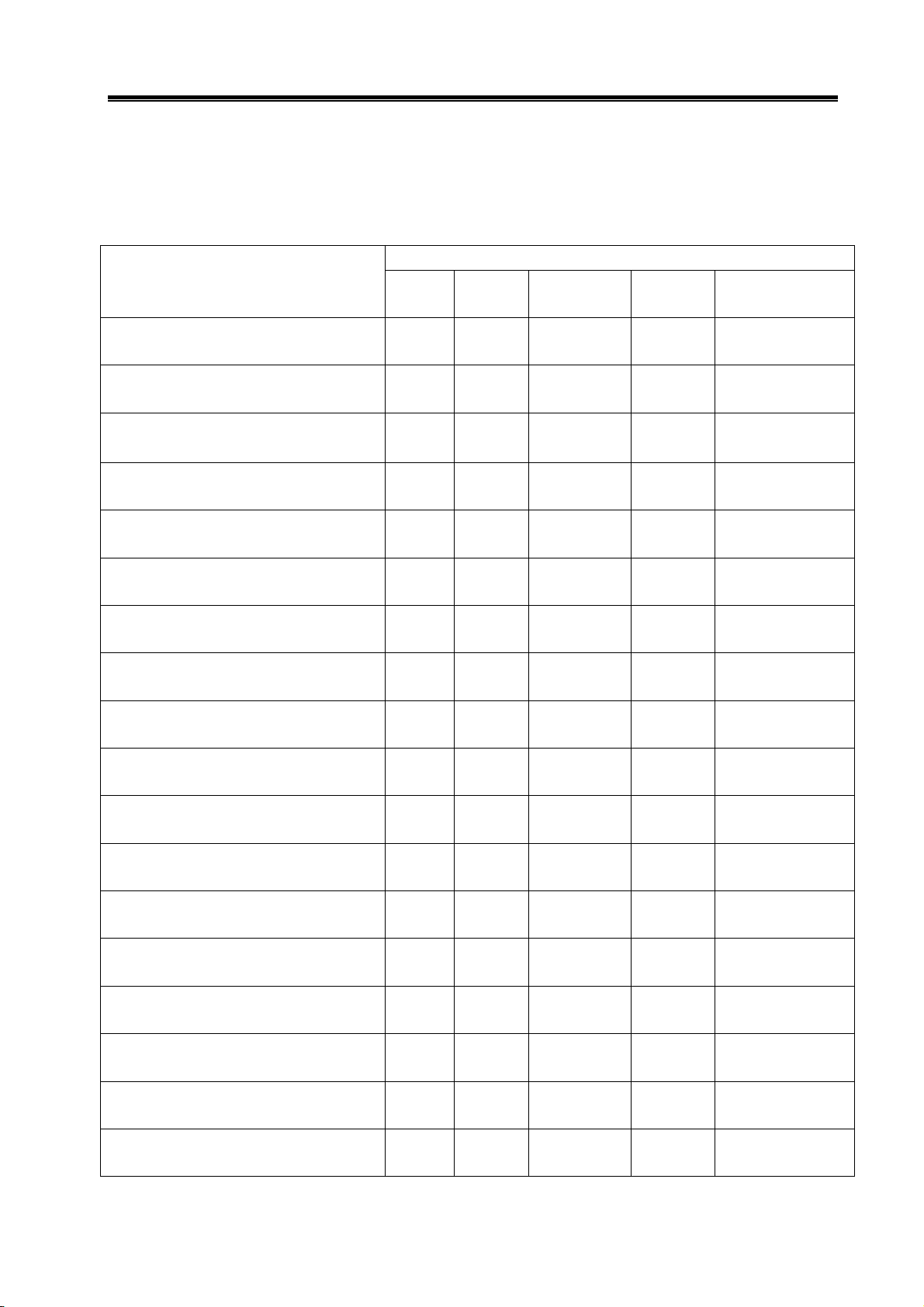

Table 1-1 Principle Technical Parameters of 80SJT Series Motor

Model

Project

Rated Voltage(kW)

Pole-pairs 4

Rated Current(A)

Zero-speed Torque(N·m)

Rated Torque(N·m)

Maximum Torque (N·m)

Rate Rotary speed(r/min)

Maximum Rotary speed(r/min)

Moment of Inertia(kg·m2)

Weight(kg)

80SJT-M024C

(A□)

0.5 0.75 0.66 1.0

3 4.8 5 6.2

2.4 2.4 3.2 3.2

2.4 2.4 3.2 3.2

7.2 7.2 9.6 9.6

2000 3000 2000 3000

2500 4000 2500 4000

0.83×10

2.8 2.9 3.4 3.5

80SJT-M024E

(A□)

-4

0.83×10-4 1.23×10-4 1.23×10-4

80SJT-M032C

(A□)

80SJT-M032E

(A□)

Insulation Grade

Oscillation Grade

Protection Grade

Installation Type

character of service

electricity-breaking brake Not available

Adaptive Encoder

10

IP65(GB 4208—2008/IEC 60529:2001,GB/T 4942.1—2006)

IMB5(Flange installation)(GB/T 997—2008 / IEC 60034-7:2001)

S1(Continuous duty)(GB 755—2008)

Increment-type 2500 p/r,5000 p/r etc,absolute encoder17bit

F(GB 755—2008)

R(GB 10068—2008)

single-circuit or multi-coil。

Page 19

Chapter 1 Product Introduction

Table 1-2 Principle Parameters of 110SJT Series, 130SJT Series Motor

Model

Project

Rated Voltage(kW)

Pole-Pairs 4

Rated Current (A)

Zero-speed Torque

(N·m)

Rated Torque (N·m)

Maximum Torque (N·m)

Rated Rotary speed

(r/min)

Maximum Rotary speed

(r/min)

Moment of Inertia

(kg·m

2

)

Weight(kg)

Weight of motor with

electricity-breaking

brake(kg)

110SJT-M

040D(A□)

110SJT-M

040E(A□)

110SJT-M

060D(A□)

110SJT-M

060E(A□)

130SJT-M

040D(A□)

130SJT-M

050D(A□)

1.0 1.2 1.5 1.8 1.0 1.3

4.5 5 7 8 4 5

4 4 6 6 4

4 4 6 6 4

12 10 12 12 10

5

5

12.5

2500 3000 2500 3000 2500 2500

3000 3300 3000 3300 3000 3000

0.68×10

-3

0.68×10

-3

0.95×10

-3

0.95×10

-3

1.1×10-3 1.1×10-3

6.1 6.1 7.9 7.9 6.5 6.5

7.7 7.7 9.5 9.5 8.1 8.1

Insulation Grade

Oscillation Grade

Protection Grade

Installation Type

Character of Service

Adaptive Encoder

Table 1-2 Principle Parameters of 110SJT Series, 130SJT Series Motor(continue)

Model

Project

Rated Voltage(kW)

Pole-Pairs 4

Rated Current (A)

Zero-speed Torque

(N·m)

Rated Torque (N·m)

B(GB 755-2008)

R(GB 10068-2008)

IP65(GB/T4942.1-2006)

IMB5(Flange Installation)(GB/T 997-2008 / IEC 60034-7:2001)

S1(Continuous Duty)(GB 755-2008)

Increment-type 2500 p/r,5000 p/r etc,absolute encoder17bit single-circuit

or multi-coil。

130SJT-M

060D(A□)

1.5 1.88 1.5 2.5 2.3

130SJT-M

075D(A□)

130SJT-M

100B(A□)

130SJT-M

100D(A□)

130SJT-M

150B(A□)

130SJT-M

150D(A□)

3.9

6 7.5 6 10 8.5 14.5

6 7.5 10 10 15 15

6 7.5 10 10 15 15

Maximum Torque (N·m)

18 20 25 25 30 30

11

Page 20

DAT Series AC Servo Drive Unit User Manual

Rated Rotary speed

(r/min)

Maximum Rotary speed

(r/min)

Moment of Inertia(kg·m2)

Weight(kg)

Weight of motor with

electricity-breaking brake

(kg)

Insulation Grade

Oscillation Grade

Protection Grade

Installation Type

Character of Service

Adaptive Encoder

2500 2500 1500 2500 1500 2500

3000 3000 2000 3000 2000 3000

1.33×10

-3

1.85×10

-3

2.42×10

-3

2.42×10

-3

3.1×10-3 3.6×10-3

7.2 8.1 9.6 9.7 11.9 12.7

10.1 11 12.5 12.6 14.8 15.6

B(GB 755-2008)

R(GB 10068-2008)

IP65(GB/T4942.1-2006)

IMB5(Flange Installation)(GB/T 997-2008 / IEC 60034-7:2001)

S1(Continuous Duty)(GB 755-2008)

Increment-type 2500 p/r,5000 p/r etc,absolute encoder17bit single-circuit or

multi-coil

Model

Project

Rated Voltage(kW)

Pole-Pairs 3

Rated Current (A)

Zero-speed Torque (N·m)

Rated Torque (N·m)

Maximum Torque (N·m)

Rated Rotary speed(r/min)

Maximum Rotary speed

(r/min)

Moment of Inertia(kg·m2)

Weight(kg)

Weight of motor with

electricity-breaking brake

(kg)

Insulation Grade

Oscillation Grade

Protection Grade

Installation Type

Character of Service

Adaptive Encoder

Table 1-3 Principle Parameters of 175SJT Series Motor

175SJT-M

180B(A□)

175SJT-M

180D(A□)

175SJT-M

220B(A□)

175SJT-M

220D(A□)

175SJT-M

300B(A□)

175SJT-M

300D(A□)

2.8 3.8 3.5 4.5 3.8 6

15 16.5 17.5 19 19 27.5

18 18 22 22 30 30

18 14.5 22 17.6 24 24

36 29 44 35.2 48 48

1500 2500 1500 2500 1500 2500

2000 3000 2000 3000 2000 3000

6.5×10

-3

6.5×10

-3

9.0×10-3 9.0×10-3 11.2×10-3 11.2×10

22.8 22.9 28.9 29.2 34.3 34.4

28.4 28.5 34.5 36.8 42 42.1

F(GB 755-2008)

R(GB 10068-2008)

IP65(GB/T4942.1-2006)

IMB5(Flange Installation)(GB/T 997-2008 / IEC 60034-7:2001)

S1(Continuous Duty)(GB 755-2008)

Increment-type 2500 p/r,5000 p/r etc,absolute encoder17bit

single-circuit or multi-coil。

-3

12

Page 21

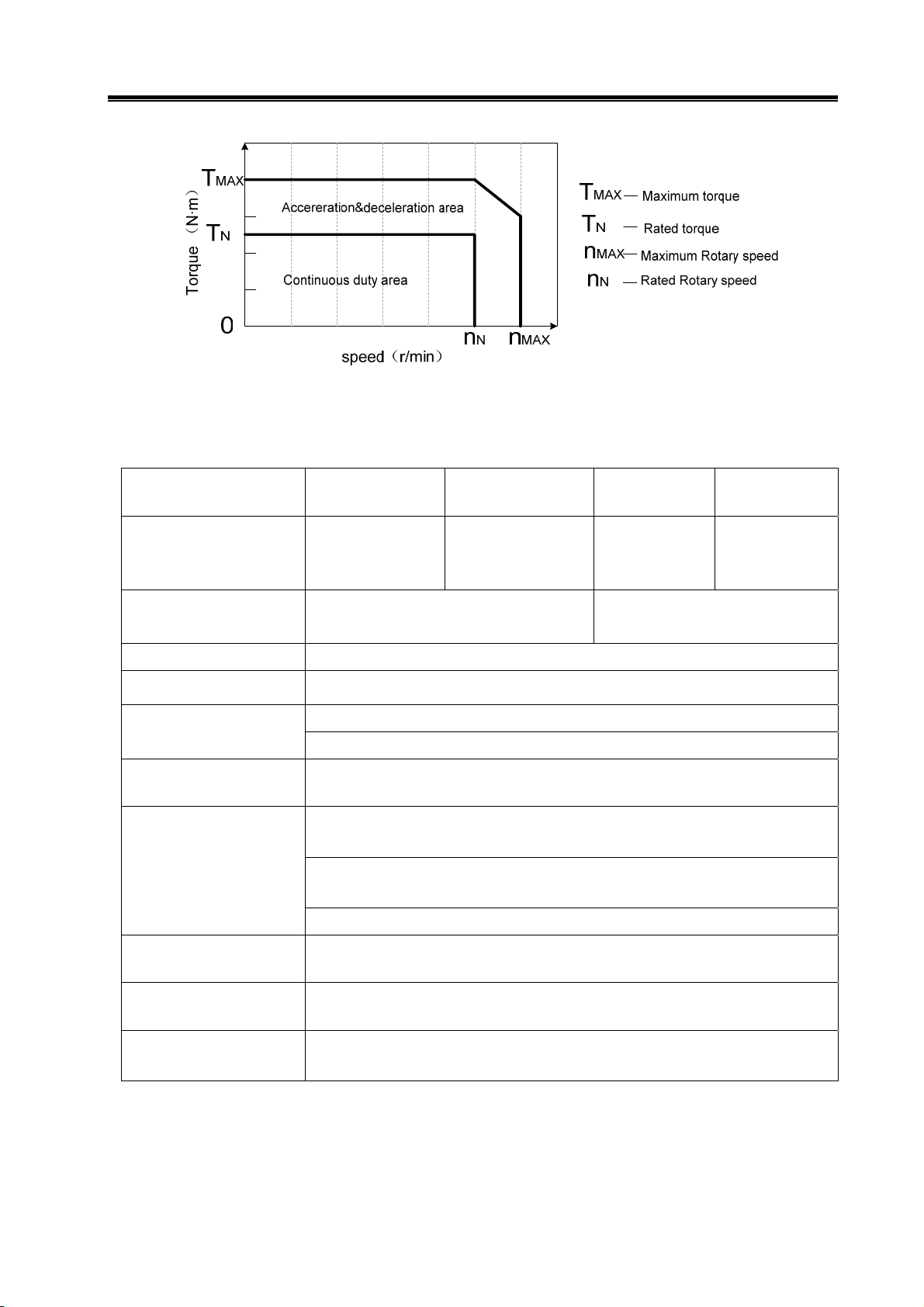

Mechanical Properties of Servo Motor

1.3.2 Technical Specification of Servo Unit

Servo unit model

Rated current of

adaptive servo current

(A)

DAT2030

DAT2030C

<6

DAT2050

DAT2050C

6~10.5 11~21 22~28

Chapter 1 Product Introduction

DAT2075

DAT2075C

DAT2100

DAT2100C

Dimension(mm)

(width*height*depth)

Main power

speed regulation ratio

Speed fluctuation ratio

Speed frequency

response

Position accuracy

Work mode

Internal speed pattern

External speed pattern

Position pattern

263×115×197 300×105×240

3-phase AC(0.85~1.1)×220 V, 50Hz/60Hz

5000:1

DAT2000 adaptive to 5000p/r increment encoder, <0.03%;

DAT2000C adaptive to 17bit absolute encoder,<0.01%;

≥300Hz

DAT2000 adaptive to 2500p/rspeed regulation ratio, Position error:

±0.036°

DAT2000 adaptive to 5000p/rspeed regulation ratio, Position error:

±0.018°

DAT2000C adaptive to 17bit absolute encoder,Position error:±0.005°

As manual operation, jog, internal speed, external speed, position, zero

setting etc.

Servo motor operates at the 4-stage speed set in accordance with

parameters and selected by input signals.

Servo motor operated at the speed corresponding to VCMD input

(-10V~+10V or 0V~+10V) analog voltage).

13

Page 22

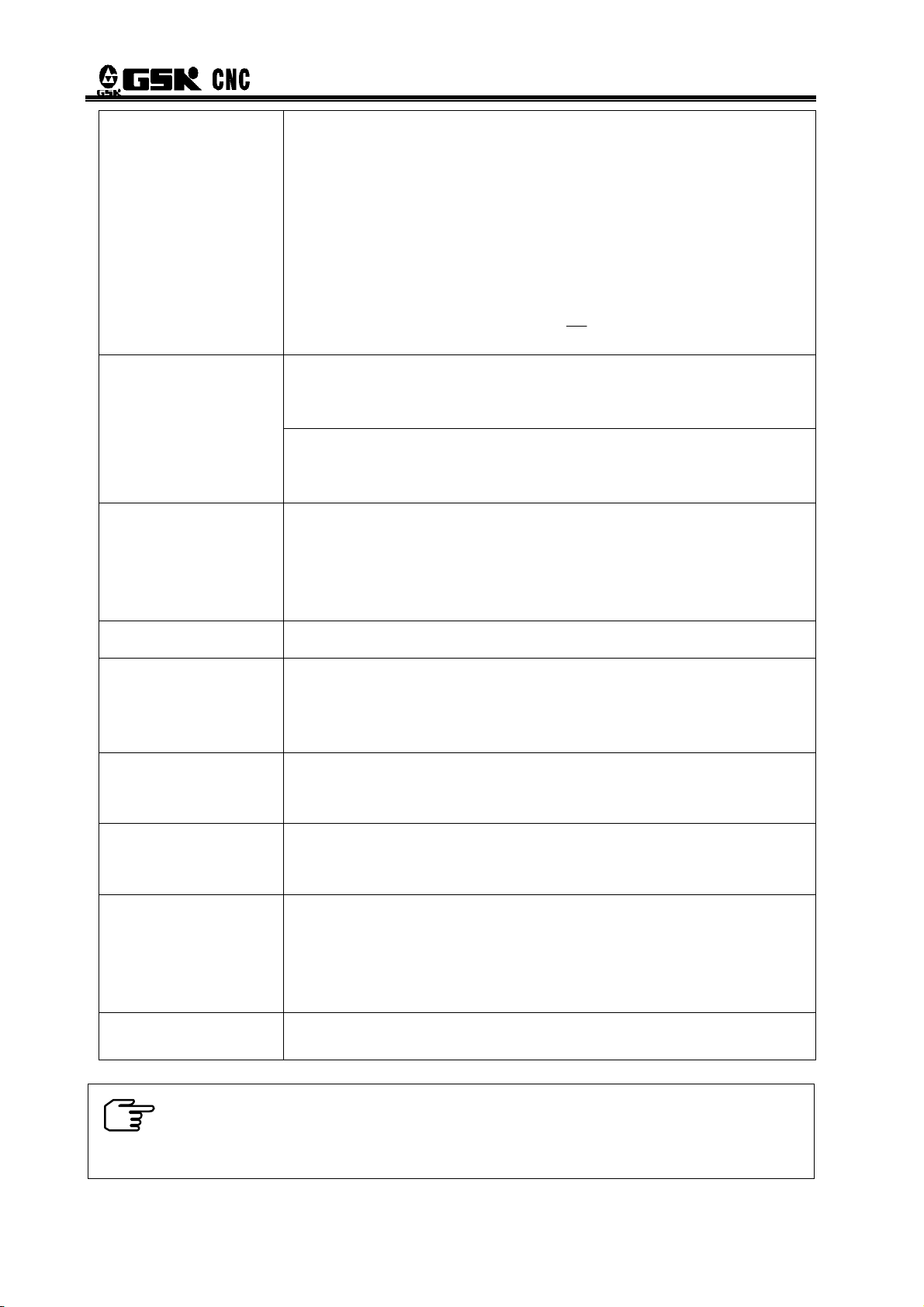

Position feedback input

position feedback

output

DAT Series AC Servo Drive Unit User Manual

Rotary angle of servo motor is controlled according to the pulse quantity

of position command and the rotary speed determined by the pulse

frequency of position command.

Position command mode: pulse plus direction, CCW pulse/CW pulse,

A/B two phase orthogonal pulse

Maximum pulse frequency: 1MHz

Command pulse frequency multiplication ratio and frequency

demultiplication: 1~32767

1

Position command electric gear ratio

~50

50

With DAT2000 standard adaptive increment type encoder as the

position feedback input, A/B/Z/U/V/W differential signal , encoder

resolution ratio: 2500 pixels or 5000 pixels.

With DAT2000C standard adaptive absolute encoder as the position

feedback input, i.e. 17bit absolute encoder, 12bit circles of power-down

memory。

Carry out frequency division processing to the pulse data from

electromotor encoder (PG or pulse generator) in drive unit and output

them to upper computer through CN1 in accordance with the preset

pulse number so as to realize function such as the positional

closed-loop control of upper computer.

Communications bus

10 input points as servo enabling, alarming elimination, CCW

Input signal

Output signal

Protection function

Operation and display

braking mode

CCW indicates the main drive shaft of motor installation plane rotates counterclockwise

when you see it from the shaft extension direction (CCW-Counter Clockwise).

CW indicates the main drive shaft of motor installation plane rotates clockwise when you

see it from the shaft extension direction (CW- Clockwise).

prohibition, CW prohibition, Zero-speed clamping, internal speed

option1,internal speed option 2,CCW torque limitation, CW torque

limitation, general input etc.

7 output points as S-RDY, servo alarming, position arrival/speed arrival,

band-type brake release, zero-speed output, Z pulse(encoder zero

point), general output, etc.

With protection functions as overvoltage, undervoltage, overcurrent,

overload, overspeed, position deviation, drive abnormality, encoder

abnormality, etc.

4 buttons, manual operation, jog as well as parameter revision, setting,

writing-in and back-up are available.

6 LEDs which display information as rotary speed, current position,

pulse accumulation, position deviation, motor torque, motor current,

absolute rotor position, input & output signal states.

Dynamic braking, built-in braking resistor (DAT2100 or DAT2100C

excluded) and can attach external braking resistor.

GSKLink Bus(V1.0)

14

Page 23

Chapter 1 Product Introduction

1.4 Order instruction

1.4.1 Order model example

Order model examples of adaptive SJT series servo motor are listed on the following chart:

Principle motor parameters

Order model

DAT2030-05-80SJT-M024C 0.5kW 3 A 2.4 N·m 2000r/min

DAT2030-08-80SJT-M024E 0.75kW 4.8 A 2.4 N·m 3000r/min

DAT2030-07-80SJT-M032C 0.66kW 5 A 3.2 N·m 2000r/min

DAT2050-10-80SJT-M032E 1.0kW 6.2 A 3.2 N·m 3000r/min

DAT2030-10-110SJT-M040D(A2)

DAT2030-10-110SJT-MZ040D(A2)

DAT2050-15-110SJT-M060D(A2)

DAT2050-15-110SJT-MZ060D(A2)

DAT2030-10-130SJT-M040D(A2)

DAT2030-10-130SJT-MZ040D(A2)

DAT2030-13-130SJT-M050D(A2)

DAT2030-13-130SJT-MZ050D(A2)

DAT2050-15-130SJT-M060D(A2)

DAT2050-19B-130SJT-M075D(A2)

DAT2050-15-130SJT-M100B(A2)

DAT2050-25B-130SJT-M100D(A2)

DAT2050-23B-130SJT-M150B(A2)

DAT2075-39E-130SJT-M150D(A2)

DAT2075-28E-175SJT-M180B(A2)

DAT2075-38E-175SJT-M180D(A2)

DAT2075-35-175SJT-M220B(A2)

DAT2075-45-175SJT-M220D(A2)

Rated

Voltage

1.0kW 4.5A 4N·m 2500r/min

1.5kW 7A 6N·m 2500r/min

1.0kW 4A 4N·m 2500r/min

1.3kW 5A 5N·m 2500r/min

1.5kW 6 A 6 N·m 2500r/min

1.9kW 7.5 A 7.5 N·m 2500r/min

1.5kW 6 A 10 N·m 2500r/min

2.5kW 10 A 10 N·m 2500r/min

2.3kW 8.5 A 15 N·m 1500r/min

3.9kW 14.5 A 15 N·m 2500r/min

2.8kW 15 A 18 N·m 1500r/min

3.8kW 16.5 A 18 N·m 2500r/min

3.5kW 17.5 A 22 N·m 1500r/min

4.5kW 19 A 22 N·m 2500r/min

Rated

Current

Zero-speed

Torque

Rated

speed

Encoder

2500p/r

Incremental type

2500p/r

Incremental type

2500p/r

Incremental type

2500p/r

Incremental type

5000p/r

Incremental type

5000p/r

Incremental type

5000p/r

Incremental type

5000p/r

Incremental type

5000p/r

Incremental type

5000p/r

Incremental type

5000p/r

Incremental type

5000p/r

Incremental type

5000p/r

Incremental type

5000p/r

Incremental type

5000p/r

Incremental type

5000p/r

Incremental type

5000p/r

Incremental type

5000p/r

Incremental type

15

Page 24

DAT Series AC Servo Drive Unit User Manual

Principle motor parameters

Order model

DAT2075-38-175SJT-M300B(A2)

DAT2100-60-175SJT-M300D(A2)

DAT2030C-10-110SJT-M040D(A4I)

DAT2030C-10-110SJT-MZ040D(A4I)

DAT2050C-15-110SJT-M060D(A4I)

DAT2050C-15-110SJT-MZ060D(A4I)

DAT2030C-10-130SJT-M040D(A4I)

DAT2030C-10-130SJT-MZ040D(A4I)

DAT2030C-13-130SJT-M050D(A4I)

DAT2030C-13-130SJT-MZ050D(A4I)

Rated

Voltage

Rated

Current

3.8kW 19 A 30 N·m 1500r/min

6.0kW 27.5 A 30 N·m 2500r/min

1.0kW 4.5A 4N·m 2500r/min

1.5kW 7A 6N·m 2500r/min

1.0kW 4A 4N·m 2500r/min

1.3kW 5A 5N·m 2500r/min

DAT2050C-15-130SJT-M060D(A4I) 1.5kW 6 A 6 N·m 2500r/min

DAT2050C-19B-130SJT-M075D(A4I) 1.9kW 7.5 A 7.5 N·m 2500r/min

DAT2050C-15-130SJT-M100B(A4I) 1.5kW 6 A 10 N·m 2500r/min

DAT2050C-25B-130SJT-M100D(A4I) 2.5kW 10 A 10 N·m 2500r/min

DAT2050C-23B-130SJT-M150B(A4I) 2.3kW 8.5 A 15 N·m 1500r/min

DAT2075C-39E-130SJT-M150D(A4I) 3.9kW 14.5 A 15 N·m 2500r/min

DAT2075C-28E-175SJT-M180B(A4I) 2.8kW 15 A 18 N·m 1500r/min

DAT2075C-38E-175SJT-M180D(A4I) 3.8kW 16.5 A 18 N·m 2500r/min

DAT2075C-35-175SJT-M220B(A4I) 3.5kW 17.5 A 22 N·m 1500r/min

DAT2075C-45-175SJT-M220D(A4I) 4.5kW 19 A 22 N·m 2500r/min

DAT2075C-38-175SJT-M300B(A4I) 3.8kW 19 A 30 N·m 1500r/min

DAT2100C-60-175SJT-M300D(A4I) 6.0kW 27.5 A 30 N·m 2500r/min

Zero-speed

Torque

Rated

speed

Encoder

5000p/r

Incremental type

5000p/r

Incremental type

17bit multi-coil

absolute type

17bit multi-coil

absolute type

17bit Multi-coil

absolute type

17bit Multi-coil

absolute type

17bit Multi-coil

absolute type

17bit Multi-coil

absolute type

17bit Multi-coil

absolute type

17bit Multi-coil

absolute type

17bit Multi-coil

absolute type

17bit Multi-coil

absolute type

17bit Multi-coil

absolute type

17bitMulti-coil

absolute type

17bit Multi-coil

absolute type

17bit Multi-coil

absolute type

17bit Multi-coil

absolute type

17bit Multi-coil

absolute type

16

Page 25

Chapter 1 Product Introduction

1.4.2 Standard Products Accessories

Following list shows the standard products accessories which are allocated on the basis that

no special requirement asked by users. If users need other accessories not included in the list,

please contact salesperson or consult our technicians for further information.

DAT2000 series servo unit standard accessories list(allocated per each servo unit)

Order

Type

servo unit

and servo

motor kit

Servo unit

and CNC

Kit(without

servo

motor)

Servo unit,

servo

motor and

CNC Kit

Note: Please mark on the order if you need other length of wire except for the standard 3M.

Accessories Name Quantity Description Note

44DB cellular type plug and

1set CN1 connection plug

plastic box

motor encoder wire 1strip standard length 3M

motor wire 1strip standard length 3M

“Instruction Manual of DAT

Series AC Servo Drive Unit”

RXLG-1500W-10ΩJ braking

resistor

25DB pin-type plug and plastic

1 PCS Accompanying

technical document

1 PCS Only DAT2100 adaptive

to this accessory

1 set CN2 connection plug

welded cable wire

box

“Instruction Manual of DAT

Series AC Servo Drive Unit

RXLG-1500W-10ΩJ braking

resistor

1PC Accompanying

technical document

1PC Only DAT2100 adaptive

to this accessory

motor encoder wire 1strip standard length 3M

motor wire 1 strip standard length 3M

“Instruction Manual of DAT

Series AC Servo Drive Unit

RXLG-1500W-10ΩJ braking

resistor

1PC Accompanying

technical document

1PC Only DAT2100C

adaptive to this

CN1-CNC signals

accessory

are available

CN1-CNC

signals.

connection wires

are available

along with CNC

products

connection wires

are available

along with CNC

products

17

Page 26

DAT Series AC Servo Drive Unit User Manual

DAT2000C Series Servo Unit Standard Accessories List(allocated per each servo unit)

Order

Type

Servo unit

and CNC

Kit(without

servo

motor)

servo unit,

servo

motor and

CNC Kit

DAT Series Selective Accessories

Accessory Name Quantity Description Note

26P high density plug and

plastic box

“Instruction Manual of DAT

Series AC Servo Drive Unit

RXLG-1500W-10ΩJ braking

resistor

1set CN2 connection plug

1 pc Accompanied

technical document

1 pc Only DAT2100C

adaptive to this

CN1-CNC,

GSKLinK signals

connection wire and

terminal socket are

available along with

CNC products

accessory

motor encoder wire 1strip standard length 3M

motor wire 1 strip standard length 3M

“Instruction Manual of DAT

Series AC Servo Drive Unit

RXLG-1500W-10ΩJ braking

resistor

1 pc Accompanied

technical document

1 pc Only DAT2100C

adaptive to this

CN1-CNC,

GSKLinK signals

connection wire and

terminal socket are

available along with

CNC products

accessory

Accessory Name Description Note

Braking resistor

RXLG-300W-30ΩJ

Braking resistor

RXLG-500W-22ΩJ

Power:300W,resistivity: 30Ω; DAT2030

or DAT2030C external selective

Power 500W,resistivity: 22Ω;DAT2050

or DAT2050C external selective

Refer to

Appendix B1

“Outlay Braking

Resistor” for

detailed the

Braking resistor

RXLG-1000W-15ΩJ

4*1.5mm2 BVVB

4*2.5mm2 BVVB

Power 1000W,resistivity:15Ω; DAT2075

or DAT2075C external selective

4-core wire, wire diameter:1.5mm2; DAT2030

or DAT2030C for motor wire

4-core wire, wire diameter:2.5mm

2

; DAT2050

installation

dimension.

or DAT2050C for motor wire

2

;

4*4.0mm2 BVVB

4-core wire, wire diameter:4.0mm

DAT2075,DAT2075C,DAT2100,DAT2100C for

motor wire

10-core twinning

shielding wire

matching motor encoder wire

18

Page 27

Chapter 2 Installation

CHAPTER 2 INSTALLATION

2.1 Servo Motor

2.1.1 Mounting Dimension of the Servo Motor

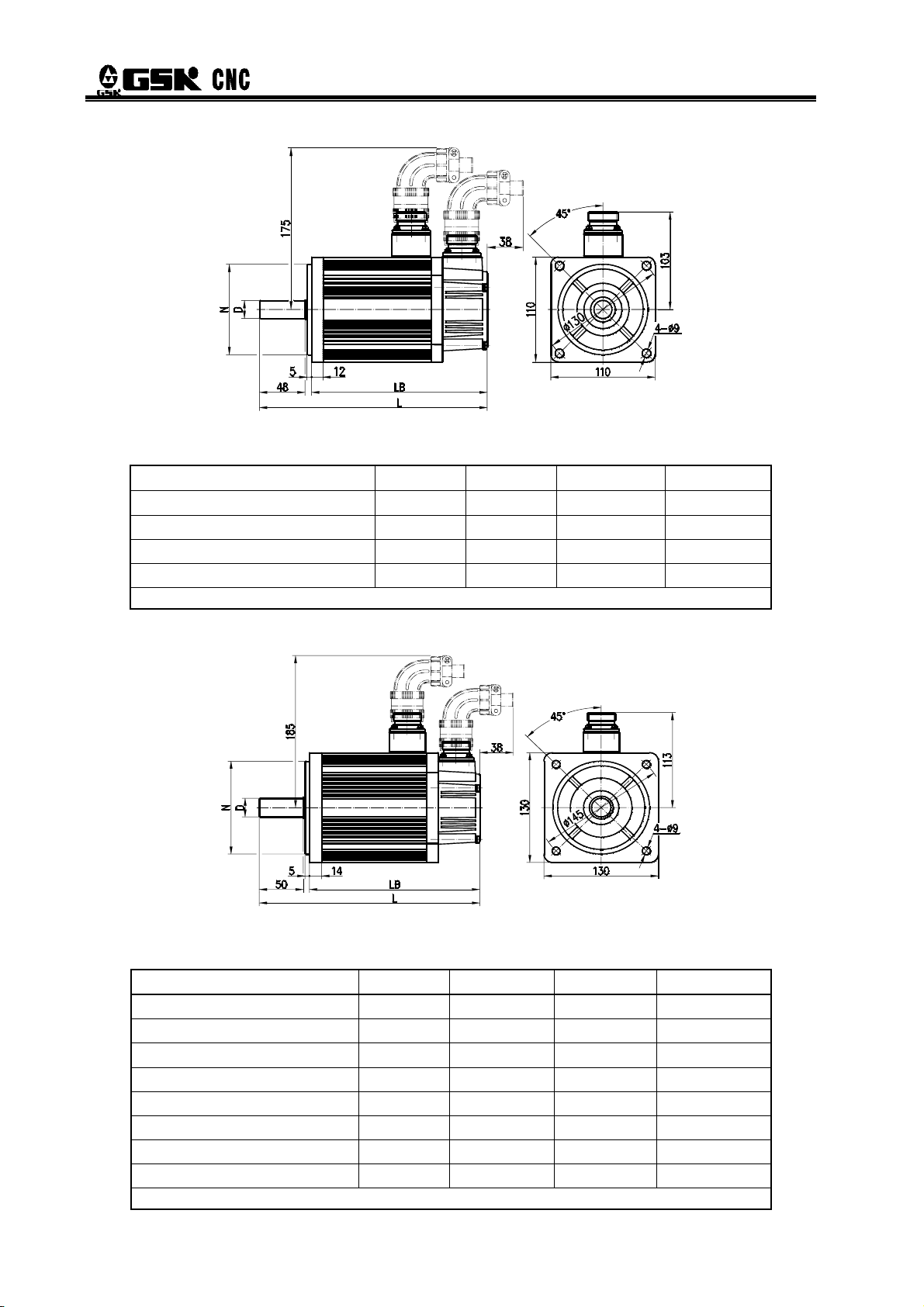

¾ For external dimensions and installation of 80SJT series motor, see figure 2-1, table 2-1.

Industrial (aviation)

Socket mount

Cable type

Type D(mm) N(mm) LB(mm) L(mm)

80SJT—M024C (A□) φ19

80SJT—M024E(A□) φ19

80SJT—M032C(A□) φ19

80SJT—M032E(A□) φ19

Fig. 2-1

Table 2-1

0

-0.013

0

-0.013

0

-0.013

0

-0.013

φ70

φ70

φ70

φ70

0

171 206

-0.03

0

171 206

-0.03

0

189 224

-0.03

0

189 224

-0.03

19

Page 28

DAT Series AC Servo Drive Unit User Manual

¾ For external dimensions of 110SJT series motor, see figure 2-2, table 2-2.

Fig. 2-2

Table 2-2

Type D(mm) N(mm) LB(mm) L(mm)

110SJT—M040D(A□) φ19

110SJT—M040E(A□) φ19

110SJT—M060D(A□) φ19

110SJT—M060E(A□) φ19

0

-0.013

0

-0.013

0

-0.013

0

-0.013

Note: LB, L values in the brackets are the length of corresponding motor that with safe brake.

φ95

φ95

φ95

φ95

0

-0.035

0

-0.035

0

-0.035

0

-0.035

186 (237) 241 (292)

186 (237) 241 (292)

212 (263) 267 (318)

212 (263) 267 (318)

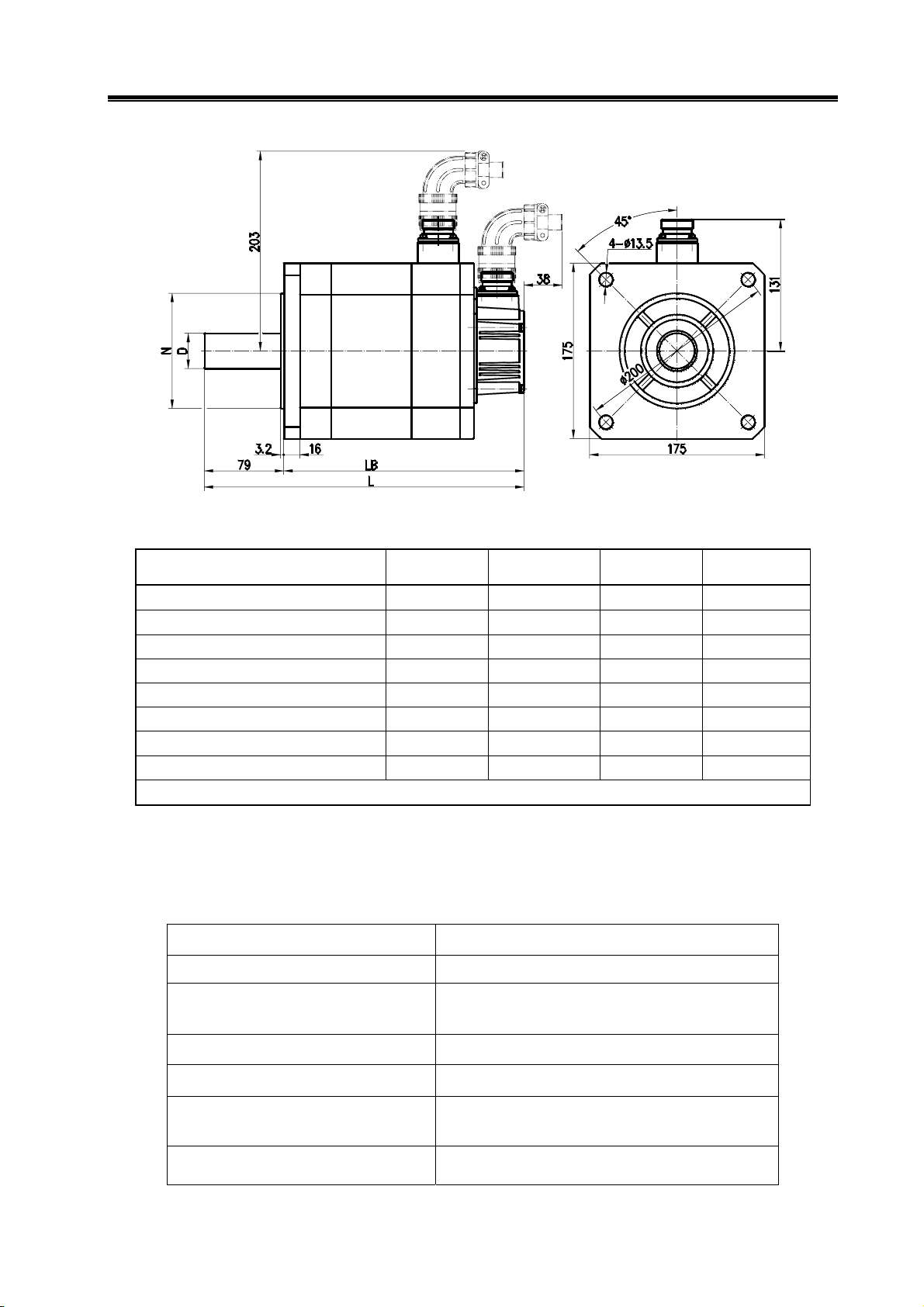

¾ For external dimensions of 130SJT series motor, see figure 2-3, table 2-3.

Fig. 2-3

Table 2-3

Type D(mm) N(mm) LB(mm) L(mm)

0

130SJT—M040D(A□) φ22

130SJT—M050D(A□) φ22

130SJT—M060D(A□) φ22

130SJT—M075D(A□) φ22

130SJT—M100B(A□) φ22

130SJT—M100D(A□) φ22

130SJT—M150B(A□) φ22

130SJT—M150D(A□) φ22

-0.013

0

-0.013

0

-0.013

0

-0.013

0

-0.013

0

-0.013

0

-0.013

0

-0.013

Note: LB, L values in the brackets are the length of corresponding motor that with safe brake.

φ110

φ110

φ110

φ110

φ110

φ110

φ110

φ110

0

-0.035

0

-0.035

0

-0.035

0

-0.035

0

-0.035

0

-0.035

0

-0.035

0

-0.035

168 (227) 225 (284)

168 (227) 225 (284)

176 (235) 233 (292)

188 (247) 245 (304)

208 (267) 265 (324)

208 (267) 265 (324)

238 (297) 295 (354)

248 (307) 305 (364)

20

Page 29

Chapter 2 Installation

¾ For external dimensions of 175SJT series motor, see figure 2-4, table 2-4.

Fig. 2-4

Table 2-4

Type D(mm) N(mm) LB(mm) L(mm)

175SJT—M150D(A□) φ35

175SJT—M180B(A□) φ35

175SJT—M180D(A□) φ35

175SJT—M220B(A□) φ35

175SJT—M220D(A□) φ35

175SJT—M300B(A□) φ35

175SJT—M300D(A□) φ35

175SJT—M380B(A□) φ35

Note: LB, L values in the brackets are the length of corresponding motor that with safe brake.

+0.01

φ114.3

0

+0.01

φ114.3

0

+0.01

φ114.3

0

+0.01

φ114.3

0

+0.01

φ114.3

0

+0.01

φ114.3

0

+0.01

φ114.3

0

+0.01

φ114.3

0

0

-0.025

0

-0.025

0

-0.025

0

-0.025

0

-0.025

0

-0.025

0

-0.025

0

-0.025

224 (291) 303 (370)

244 (311) 323 (390)

244 (311) 323 (390)

279 (346) 358 (425)

279 (346) 358 (425)

309 (382) 388 (461)

309 (382) 388 (461)

359 (432) 438 (561)

2.1.2 Servo Motor Installation

Servo motor installation, storage and transportation environment

Item Parameter and requirement

Operation temperature

Storage and transportation

temperature

0℃~40℃

-40℃~70℃

Operation humidity

Storage and transportation humidity

Atmosphere environment

There is no corrosive or flammable gas, oil

30%~95%(no dewing)

≤95%(40℃)

mist or dust etc. in the control cabinet

Altitude Altitude of below 1000m

21

Page 30

DAT Series AC Servo Drive Unit User Manual

Attentions

the motor or the motor axis to avoid damage

to internal encoder. Spiral insert and pull

out tools should be used for dismounting.

radial load. Spring coupling is recommended

to connect the load.

to avoid motor loosening.

against water and oil. The cable will bring water and

oil to the motor if it immerses in water and oil.

Therefore, this situation should be prevented from happening.

1. When install the belt pulley, do not strike

2. The servo motor can not bear axial and

3. Stop washer should be used to fix the motor

4. The motor mounting position should be protected

2.2 Servo Unit

The installation environment of the servo motor has direct effect on its functions and service life.

Please install it correctly under the instructions below.

Storage and transportation temperature

Storage and transportation humidity

Operation temperature

Operation humidity

Atmosphere environment

Atmosphere pressure

Item Parameter and requirement

0℃~40℃

-40℃~70℃

30%~95%(no dewing)

≤95%(40℃)

There is no corrosive or flammable gas, oil

mist or dust etc. in the control cabinet

Altitude Altitude of below 1000m

Vibration ≤0.6G(5.9m/s2)

86kPa~106kPa

22

Page 31

2.2.1 Installation Dimension

Chapter 2 Installation

Fig. 2-5 DAT2030,DAT2030C,DAT2050,DAT2050C installation dimension (unit:mm)

Fig. 2-6 DAT2075,DAT2075C,DAT2100,DAT2100C installation dimension (unit:mm)

23

Page 32

DAT Series AC Servo Drive Unit User Manual

2.2.2 Mounting Interval

DAT series servo unit adopts base-plate installation mode, install direction is perpendicular

to the mounting surface. Put the front side of the servo unit forward, and top side upward to

dissipate heat. Please leave space around it.

Fig. 2-7 DAT servo unit mounting interval

Fig. 2-8 shows intervals between servo units, more space should leave in actual installation to

ensure well heat elimination.

24

Fig. 2-8 Mounting intervals between DAT servo units

To prevent environment temperature continuously from being increased, ensure

convection current flows to radiator of the servo unit in the electric cabinet.

Page 33

Please read the following notes carefully and follow it to get safe and smooth operations.

Attentions

Chapter 3 Connection

Chapter 3 CONNECTION

Wiring can only be done by professional technical persons according to

corresponding instructions.

Do wiring and maintenance operation at least 5 minutes after the servo unit is

power off. Ensure the voltage that each main circuit terminal to ground is safe

voltage, or you will be electrocuted.

Please confirm that servo unit and servo motor are earthed correctly.

When you wiring, do not damage the cable by a sharp object, do not pull the

cable lustily, otherwise, it will cause electric shock or poor contact.

Do not cross the main return circuit and signal wire through the same pipe, and

do not tie them together. When wiring, the user separates or crosses the main

return circuit and signal wire, and leaves an interval of 30cm to prevent

interference (from high current wire to signal wire) that makes the servo unit

unable to work properly.

Do not switch on or off the servo unit frequently, because high capacitance in it

will generate high charging current when power on. Power on or off frequently

will decrease the performance of internal components of the servo unit.

Recommended power on or off interval is above 3 minutes.

Power capacity, surge absorber, radio noise filter and other devices should not

be installed at output side of the servo unit or between servo motors.

Keep the main return circuit wire and signal line away from heat abstractor and

motor to avoid insulation property decreasing by heat.

After connection of the main return circuit wire, the terminal protective cap is

covered to avoid electric shock.

25

Page 34

DAT Series AC Servo Drive Unit User Manual

3.1 Connection of Peripherals

Servo unit must be equipped with some peripherals. Proper peripheral ensures the servo

unit works stably. Otherwise, service life will be shortened and even the servo unit will be

damaged.

26

Fig. 3-2 Connection of peripheral DAT2030, DAT2050

Page 35

Chapter 3 Connection

For circuit breaker, isolation transformer, AC wave filter, AC contactor selection, please refer to

appendix B.

Fig. 3-3 Connection of peripheral DAT2030C, DAT2050C

For circuit breaker, isolation transformer, AC wave filter, AC contactor selection, please refer to

appendix B.

27

Page 36

DAT Series AC Servo Drive Unit User Manual

L3L2L1

3-phase AC 380V power

RESET

CNC system

位置

转换

信息

退格

取消删除

上档

输入

程序 系统

图形

Braking resistor (optional)

Not connect to external braking resistor,

B, B1 are connected;

Connect to external braking resistor,

设置

帮助

B, B1 are not connected

AC380V

AC220V

PE

U

V

W

R

S

T

Protective earth wire

Control circuit

Fig. 3-4 Connection of peripheral DAT2075, DAT2100

For circuit breaker, isolation transformer, AC wave filter, AC contactor selection, please refer to

appendix B.

28

Page 37

Chapter 3 Connection

RESET

CNC system

位置

转换

信息

退格

取消删除

上档

输入

程序 系统

图形

3-phase AC 380V power

L3L2L1

Braking resistor (optional)

Not connect to external braking resistor,

B, B1 are connected;

设置

帮助

Connect to external braking resistor,

B, B1 are not connected

AC380V

AC220V

PE

U

V

W

R

S

T

(necessary)

Circuit breaker

(necessary

Transformer

(Optional)

Wave filter

Protective earth wire

See section 3.5 for connection of GSKLink

Control circuit

Fig. 3-5 Connection of peripheral DAT2075C, DAT2100C

For circuit breaker, isolation transformer, AC wave filter, AC contactor selection, please refer to

appendix B.

(necessary)

AC contactor

29

Page 38

DAT Series AC Servo Drive Unit User Manual

3.2 Terminal Connection of Main Circuit

3.2.1 Terminal Connection of Servo Unit

drive unit

DAT series AC servo

Encoder feedback signal

Fig. 3-6 Main circuit connection of DAT series products

The following circuit diagram is recommended for connection of KM1 control circuit in Fig. 3-5:

30

Page 39

Chapter 3 Connection

Section selection of main circuit wiring:

R S T

PE

U V W P B1 B

Current of

the adapted

motor

Input terminal of

AC current

≤6A 1.5 mm2 ≥1.5 mm

6A~10.5A

11A~21A

22A~28A

2.5 mm

4 mm

4 mm

2

≥2.5 mm

2

≥ 4 mm

2

≥ 4 mm

Protective

ground

end

2

2

2

2

Power output end

1.5 mm2 1.5mm2

2.5 mm2 2.5 mm2

4 mm2 4 mm2

4 mm2 4 mm2

For DAT2030 or DAT2030C, DAT2050 or DAT2050C terminal, its

insulation covering is stripped off and the exposed copper wire is

twisted according to the following figure. Press wiring (press terminal

with special tools) with H2.5/18D type tubular terminal (Weidmuller

Company). Insert terminal as the figure, and tighten up terminal screw.

10m m ~ 12m m

For DAT2075 or DAT2075C, DAT2100 or DAT2100C terminal and DAT

series PE terminal connections, insulation covering is stripped off and exposed

copper wire is twisted according to the following figure. Press wiring (press

terminal with special tools) with HRV 2―5S type round pre-insulation terminal.

(Huxi Electric Apparatus co., Ltd), and tighten it up to the ground screw at the

front of the shell.

6m m ~ 8m m

Connection

terminal of

external, internal

brake resistor

31

Page 40

DAT Series AC Servo Drive Unit User Manual

3.2.2 Instructions for Servo Motor Interface

¾ Corresponding relationship between pins of motor power socket and output terminal of the

servo unit

Pin No. of the motor power socket 1 2 3 4

Terminal tab the servo unit PE U V W

¾ Pins connection of safe brake socket

z Pin1, Pin 2 is connected to DC24V, and their positive and negative poles are not distinguished,

pin 3 is earthed.

z For controlling of controlled contact KA, refer to section 6.2 :application of release signal of

band-type brake.

For motor with different power is adapted to the safe brake with different power. When selecting

24V switch power supply, please refer to the following technical parameters of arrester brakes

adapted to different motors.

Seat No. of

the motor

110 4 24V DC 20 0.037

130 8 24V DC 25 0.042

175 32 24V DC 40 0.135

¾ For connection of pins of encoder signal socket, please refer to section 3.4.3.

Rated

torque

Supply

voltage

Coil power of the brake at

20 (unit℃ : W)

Release time

(s)

32

Page 41

Chapter 3 Connection

3.3 Connection of Control Signal

3.3.1 Definition of Pin CN1 of DAT Series Products

¾ The control signal interface CN1 of DAT2000 series products is Pin 44 male, the connector

for making control wire is Pin 44 female (the type is G3150-44FBNS1X1, provided by

WIESON Company). See the following figure for the definition of the pins.

Figure 3-13 Pin CN1 of DAT2000

In the above figure, pins with the same name are connected and shorted in the inner

circuit board.

33

Page 42

DAT Series AC Servo Drive Unit User Manual

¾ Control signal interface CN1 of DAT2000C series products is high-density socket with 50

cores (type: MDR50-10250-55H3JL, provided by 3M company), which pin layout is as

follows:

Fig. 3-14 Pin CN1

Pin

No.

1

2

3

Name Meaning

PBO-

Position

feedback

output

PBO+

signal A

pase

PAO-

Position

Reference

item

6.4

Pin

No.

26

Name Meaning

PZO-

Position

Reference

feedback

output

27

PZO+

signal Z

pase

28 GND digital ground

item

feedback

4

PAO+

output

signal B

6.4

29 NC

pase

5

6

PULS-

PULS+

Position

command pulse

input

3.3.3

30

31

SIGN-

SIGN+

Input direction

of position

command

3.3.3

Speed

7 SC2/INH

selection

2/pulse

5.2.2

6.5.4

32 RIL

CW torque

limit

3.3.4

prohibited

Speed

8 SC1/CLE

selection 1/

pulse clearing

9 NC 34 ZSL

10 RSTP

11 FSTP

CW drive

prohibited

CCW drive

prohibited

5.2.2

6.5.3

33 FIL

CCW torque

limit

Zero-speed

clamped

3.3.4

6.6.3

3.3.4 35 GIN reserve

3.3.4 36 NC

12 ALRS Alarm clearing 3.3.4 37 NC

6.4

13 SON Enabling 3.3.4 38

14 NC 39

Speed arrival

15

COIN+

+/ position

6.6.2

6.5.2

arrival+

34

COM-

COM+

41

COM+

Input power

of control

signal (15~

24VDC)

Page 43

Chapter 3 Connection

Speed arrival

16

17

18 NC 43

19 NC 44 NC

20

21

22

23

24

25

SRDY-

SRDY+

ZSP-

ZSP+

ALM-

ALM+

VCMD+

VCMD-

Servo be

ready to

output

Motor

zero-speed

output

Alarm output 3.3.5

Simulated

command

input

3.3.5

3.3.5

3.3.2

40

42

45 NC

46

47

48 0VA

49 NC

50 NC

COIN-

HOLD-

HOLD+

CZ-

CZ+

+/ position

arrival+

Release

signal of safe

brake output

Zero-point

signal of

encode

output

3.3.2 Input of Speed Command

6.6.2

6.5.2

6.2

3.3.5

VCMD+/ VCMD- are input terminals of speed command input, which receives max. 10V DC

voltage signal, and its terminal input resistance is 20KΩ.

Note: The signal cable uses a shielded line, and the differential signal must use a twisted-pair line.

35

Page 44

DAT Series AC Servo Drive Unit User Manual

3.3.3 Input of Position Command

Position commands PULS+/PULS-,SIGN+/SIGN- can use differential drive method or use

single-end drive method. See example as follows:

z Differential drive method

z Single-end drive method

36

Fig. 3-18 Wiring of NPN type single-end drive

4.7K

4.7K

Fig. 3-19 Wiring of PNP type single-end drive

Page 45

Chapter 3 Connection

~

1. Differential drive method is recommended to use in order to avoid high interference;

In differential drive mode, AM26LS31, MC3487 or similar RS422 drive chip are

recommended.

2. Single-end drive method will decrease action frequency. Under the condition that the

pulse input to circuit, drive current is 10 mA~15mA, external max. power voltage is

limited to 25V, resistance R value is defined. Experiential data: VCC=24V,R=1.3kΩ

2kΩ;VCC=12V,R=510Ω~820Ω;VCC=5V,R=0Ω

There are three kinds of position command input modes, which are set by parameter PA14, can

be received. See the table bellow, and arrow represents the counting edge.

37

Page 46

DAT Series AC Servo Drive Unit User Manual

a. Input interface sequence diagram of pulse + symbol (max. pulse frequency 1MHz)

PULS

SIGN

90%

10%

90%

10%

th

trh trl

ts

tck

tl

ts

CW

trh

CCW

trl

CW

b. Input interface sequence diagram of CCW pulse/CW pulse (max. pulse frequency 1MHz)

c. Input interface sequence diagram of 2-phase command pulse (max. pulse frequency 1MHz)

Parameter

Differential

drive input

(μs)

Single-end

drive input

(μs)

38

Sequence parameters of pulse input are listed bellow.

tck th t

trh trl ts t

l

qcktqh

>1 >0.3 >0.3 <0.2 <0.2 >2 >1 >0.3 >0.3 <0.2 <0.2 >0.2

>5 >2.5 >2.5 <0.3 <0.3 >2.5 >10 >5 >5 <0.3 <0.3 >2.5

tql t

qrh

t

qrl

tqs

Page 47

Chapter 3 Connection

3.3.4 Switching Value Input

Two examples of wiring are provided bellow, Inx represents input point: (SON, ALRS, FSTP,

RSTP, SC1/CLE, SC2/INH, ZSL, FIL, RIL, GIN).

Example of external

switch value

Example of external

photocoupler

DC15V~24V power (above 1A) should be provided for servo unit. It is suggested the same

power with output circuit should be used.

Input coupler is on when Inx connects to 0V, and the signal is ON, input is active. Monitor window

can be used for judgment, when the input point is ON, corresponding LED lights up. When

the input point is OFF, corresponding LED is not work. This monitor window is used for debugging

and examining the control signal of the servo unit.

Detailed instructions for input signals:

¾ COM+, COM- are input ports of external specified power (15V~24V).

39

Page 48

DAT Series AC Servo Drive Unit User Manual

¾ Servo enable is operated when SON is ON. Check the monitor window and

is displayed.

Related

parameters

PA54

Meaning Unit

When there is no external SON signal

input, motor enable is enforced in the

servo unit.

PA54=0:When external input signal

SON is ON, the motor is enabled.

PA54=1:Motor enable is enforced in the

servo unit, and the external SON signal

is not needed.

0

Default

value

Applicable

modes

P,S

The motor is turned on when the servo unit works normally. If the servo unit has troubles,

the alarm code occurs. Please refer to chapter 8 troubles and troubleshooting.

¾ When ALRS is ON, alarms that smaller than No. 9 alarm are cleared by ALRS signal

after trouble clearing. Alarms that bigger than No. 9 alarm can only be cleared after trouble

clearing and power on again. When SON is ON, the function of alarm clearing is invalid.

¾ FSTP, RSTP: Drive prohibition signal is usually matched with stroke switch to avoid

over travel.

Input signal Operation

FSTP RSTP CCW CW

ON ON O O

ON OFF O Prohibited

OFF ON Prohibited O

OFF OFF Prohibited Prohibited

Note: O represents normal. When drive prohibition function is not used, PA20 is set to 1 to shield drive

prohibition function.

40

Page 49

¾ FIL: CCW torque limit. When FIL is ON, the maximum torque of the motor is limited by

the setting of PA36.

¾ RIL: CW torque limit. When RIL is ON, the maximum torque of the motor is limited by the

setting of PA37.

3.3.5 Output of Switch Value

1. In DAT2000 series product, except signal HOLD, CZ, other output signals are

single-end transistor output. Emitter of the coupler has been connected to COM-.

2. Switching value output of DAT2000C series product is double-end transistor output:

Chapter 3 Connection

OUTx represents output points (ALM, SRDY, ZSP, COIN, HOLD, CZ)

z Wiring diagram of single-end transistor output

Example 1: Servo unit matches with system GSK980TDb

External controller

Example 2: Servo unit matches with system 983M

Output of external

relay

41

Page 50

DAT Series AC Servo Drive Unit User Manual

z Wiring diagram of double-end transistor output

External controller

External relay output

When OUTx is connected to COM- or OUTx+ is connected to OUTx, input point is ON.

Monitor window

can be used for judgment, when input point is ON, corresponding

LED lights up. When input point is OFF, corresponding LED does not light.

¾ ALM of the servo unit is output when abnormity is detected. Output state is relevant to PA47.

PA47=0

PA47=1

ALM signal output coupler is OFF when alarm occurs

ALM signal output coupler is ON when alarm occurs

42

Page 51

Chapter 3 Connection

ALM

ALM

Power

(PA47=1)

(PA47=0)

OFF ON

OFF

OFF

No alarm

0.5s

<

No alarm alarm

alarm

¾ SRDY represents servo unit is ready. SRDY signal output photo coupler is connected when

the motor power-on is excited.

¾ ZSP represents zero-speed output, i.e. when the speed of the motor is zero, photo coupler

of ZSP signal output is ON.

¾ CZ represents zero point signal of encode: For incremental encoder, sequence is in

accordance with Z signal (one-rotation signal) feedback from motor encoder, as shown

below:

For absolute type encoder, AB-phase pulse number per circle is set by servo parameter, zero

point signal CZ is output at the same time.

¾ HOLD:Release signal of safe brake of the motor with a band-type brake. Refer to 6.2 for

output logic of this signal.

1. When output signal is open collector type, its maximum load current is 100mA, maximum

voltage of external DC current is 25V. If it exceeds the specific requirement or output end directly

connect to the power, servo unit will be damaged.

2. If the load is inductive load, freewheeling diode should be paralleled with two ends of the

load. If the freewheeling diode is connected reversely, the servo unit will be damaged.

43

Page 52

DAT Series AC Servo Drive Unit User Manual

3.4 Connection of Feedback Signal

3.4.1 Introductions for CN2 of DAT2000

The encoder interface CN2 of the motor of the DAT2000 servo unit is Pin 25 female. The

connector for making control wire is Pin 25 male (the type is G3150-44FBNS1X1, provided by

WIESON Company). See the following figure for the definition of the pins.

Fig. 3-42 CN2 DB 25 female socket

Pin

No.

1 0V 14 FG

2 0V 15 FG

3 0V 16 0V

4 0V

5 5V 18 5V

Name Meaning Pin No. Name Meaning

Frame ground

Encoder power(-)

17 5V

Encoder power(-)

Encoder power(+)

6 5V

7

8

9

10

11

12

W-

V-

U-

Z-

B-

A-

Encoder power(+)

Feedback of

incremental type

encoder W-

Feedback of

incremental type

encoder V-

Feedback of

incremental type

encoder U-

Feedback of

incremental type

encoder Z-

Feedback of

incremental type

encoder B-

Feedback of

incremental type

encoder A-

19

20

21

22

23

24

25 NC

W+

V+

U+

Z+

B+

A+