Groen TDB-40 User Manual

OPERATOR MANUAL

IMPORTANT INFORMATION, KEEP FOR OPERATOR

This manual provides information for:

MODELS TDB/TDBC

Domestic/Government

STEAM JACKETED KETTLE

·Self Contained

·Table Top Mounted

·Electrically Heated

·Tilting

THIS MANUAL MUST BE RETAINED FOR FUTURE REFERENCE. READ, UNDERSTAND AND FOLLOW THE INSTRUCTIONS AND WARNINGS CONTAINED IN THIS MANUAL.

FOR YOUR SAFETY

Do not store or use gasoline or other flammable vapors and liquids in the vicinity of this or any other appliance.

WARNING

Improper installation, adjustment, alteration, service or maintenance can cause property damage, injury or death. Read the installation, operating and maintenance instructions thoroughly before installing or servicing this equipment.

NOTIFY CARRIER OF DAMAGE AT ONCE

It is the responsibility of the consignee to inspect the container upon receipt of same and to determine the possibility of any damage, including concealed damage. Unified Brands suggests that if you are suspicious of damage to make a notation on the delivery receipt. It will be the responsibility of the consignee to file a claim with the carrier. We recommend that you do so at once.

Manufacture Service/Questions 888-994-7636.

Information contained in this document is known to be current and accurate at the time of printing/creation. Unified Brands recommends referencing our product line websites, unifiedbrands.net, for the most updated product information and specifications.

1055 Mendell Davis Drive Jackson, MS 39272 888-994-7636, fax 888-864-7636 unifiedbrands.net

PART NUMBER 148733, REV. F (08/13)

IMPORTANT - READ FIRST - IMPORTANT

CAUTION: BE SURE ALL OPERATORS READ, UNDERSTAND AND FOLLOW THE OPERATING INSTRUCTIONS, CAUTIONS, AND SAFETY INSTRUCTIONS CONTAINED IN THIS MANUAL.

WARNING: THIS UNIT IS INTENDED FOR USE IN THE COMMERCIAL HEATING, COOKING AND HOLDING OF WATER AND FOOD PRODUCTS, PER THE INSTRUCTIONS CONTAINED IN THIS MANUAL. ANY OTHER USE COULD RESULT IN SERIOUS PERSONAL INJURY OR DAMAGE TO THE EQUIPMENT AND WILL VOID WARRANTY.

WARNING: KETTLE MUST BE INSTALLED BY PERSONNEL QUALIFIED TO WORK WITH ELECTRICITY. IMPROPER INSTALLATION CAN RESULT IN INJURY TO PERSONNEL AND/OR DAMAGE TO EQUIPMENT.

DANGER: ELECTRICALLY GROUND THE UNIT AT THE TERMINAL PROVIDED. FAILURE TO GROUND UNIT COULD RESULT IN ELECTROCUTION AND DEATH.

WARNING: AVOID ALL DIRECT CONTACT WITH HOT EQUIPMENT SURFACES. DIRECT SKIN CONTACT COULD RESULT IN SEVERE BURNS.

WARNING: AVOID ALL DIRECT CONTACT WITH HOT FOOD OR WATER IN THE KETTLE. DIRECT CONTACT COULD RESULT IN SEVERE BURNS.

CAUTION: DO NOT OVER FILL THE KETTLE WHEN COOKING, HOLDING OR CLEANING. KEEP LIQUIDS A MINIMUM OF 2-3” (5-8 cM) BELOW THE KETTLE BODY RIM TO ALLOW CLEARANCE FOR STIRRING, BOILING AND SAFE PRODUCT TRANSFER.

WARNING: TAKE SPECIAL CARE TO AVOID CONTACT WITH HOT KETTLE BODY OR HOT PRODUCT WHEN ADDING INGREDIENTS, STIRRING OR TRANSFERRING PRODUCT TO ANOTHER CONTAINER.

WARNING: DO NOT STAND ON OR APPLY UNNECESSARY WEIGHT OR PRESSURE ON THE KETTLE FRONT OR POURING LIP. THIS COULD RESULT IN OVERLOAD AND FAILURE OF THE TILT MECHANISM, AND POSSIBLE SERIOUS INJURY AND BURNS TO THE OPERATOR AND OTHERS.

WARNING: WHEN TILTING KETTLE FOR PRODUCT TRANSFER:

1)WEAR PROTECTIVE OVEN MITT AND PROTECTIVE APRON.

2)USE CONTAINER DEEP ENOUGH TO CONTAIN AND MINIMIZE PRODUCT SPLASHING.

3)PLACE CONTAINER ON STABLE, FLAT SURFACE, AS CLOSE TO KETTLE AS POSSIBLE.

4)STAND TO LEFT OR RIGHT SIDE OF KETTLE (DEPENDING ON TILTING HANDLE PLACEMENT) WHILE POURING . DO NOT STAND DIRECTLY IN POUR PATH OF HOT CONTENTS.

5)POUR SLOWLY, MAINTAIN CONTROL OF KETTLE BODY HANDLE AT ALL TIMES, AND RETURN KETTLE BODY TO UPRIGHT POSITION AFTER CONTAINER IS FILLED OR TRANSFER IS COMPLETE.

6)DO NOT OVER FILL CONTAINER. AVOID DIRECT SKIN CONTACT WITH HOT CONTAINER AND ITS CONTENTS.

CAUTION: KEEP FLOORS IN FRONT OF KETTLE WORK AREA CLEAN AND DRY. IF SPILLS OCCUR, CLEAN IMMEDIATELY, TO AVOID SLIPS OR FALLS.

WARNING: FAILURE TO CHECK PRESSURE RELIEF VALVE OPERATION PERIODICALLY COULD RESULT IN PERSONAL INJURY AND/OR DAMAGE TO EQUIPMENT.

2 OM-TDB/TDBC

IMPORTANT - READ FIRST - IMPORTANT

WARNING: WHEN TESTING, AVOID ANY EXPOSURE TO THE STEAM BLOWING OUT OF THE PRESSURE RELIEF VALVE. DIRECT CONTACT COULD RESULT IN SEVERE BURNS.

WARNING: TO AVOID INJURY, READ AND FOLLOW ALL PRECAUTIONS STATED ON THE LABEL OF THE WATER TREATMENT COMPOUND.

WARNING: BEFORE REPLACING ANY PARTS, DISCONNECT THE UNIT FROM THE ELECTRIC POWER SUPPLY.

WARNING: KEEP WATER AND SOLUTIONS OUT OF CONTROLS AND ELECTRICAL EQUIPMENT. NEVER USE A HIGH PRESSURE HOSE TO CLEAN KETTLE SURFACES.

CAUTION: MOST CLEANERS ARE HARMFUL TO THE SKIN, EYES, MUCOUS MEMBRANES AND CLOTHING. PRECAUTIONS SHOULD BE TAKEN. WEAR RUBBER GLOVES, GOGGLES OR FACE SHIELD AND PROTECTIVE CLOTHING. CAREFULLY READ THE WARNINGS AND FOLLOW THE DIRECTIONS ON THE LABEL OF THE CLEANER TO BE USED.

CAUTION: USE OF ANY REPLACEMENT PARTS OTHER THAN THOSE SUPPLIED BY BLODGETT OR THEIR AUTHORIZED DISTRIBUTORS CAN CAUSE OPERATOR INJURY AND DAMAGE TO THE EQUIPMENT, AND WILL VOID ALL WARRANTIES.

IMPORTANT: SERVICE PERFORMED BY OTHER THAN FACTORY AUTHORIZED PERSONNEL WILL VOID WARRANTIES.

WARNING: DO NOT HEAT AN EMPTY KETTLE. EXCESSIVE STEAM PRESSURE COULD DEVELOP.

OM-TDB/TDBC 3

Table of Contents

Important Operator Warnings |

....................................................page 2-3 |

References.................................................................................... |

page 4 |

Equipment Description.................................................................. |

page 5 |

Inspection and Unpacking ............................................................ |

page 6 |

Installation .................................................................................. |

page 7-8 |

Initial Start-Up............................................................................... |

page 9 |

Operation................................................................................ |

page10-11 |

Sequence of Operation ............................................................... |

page 12 |

Cleaning................................................................................... |

page13-14 |

Maintenance............................................................................ |

page15-16 |

Troubleshooting............................................................................ |

page17 |

Wiring Diagram ............................................................................ |

page 22 |

Service Log ................................................................................. |

page 23 |

References

KLENZADE SALES CENTER ECOLAB. Inc. 370 Wabasha

St. Paul, Minnesota 55102 800/352-5326 or 612/293-2233

NATIONAL FIRE PROTECTION ASSOCIATION

60 Battery March Park

Quincy, Massachusetts 02269

NFPA/70 - The National Electrical Code

NSF INTERNATIONAL

789 N. Dixboro Road

P.O. Box 130140

Ann Arbor, Michigan 48113-0140

UNDERWRITERS LABORATORIES, INC.

333 Pfingsten Road

Northbrook, Illinois 60062

ZEP MANUFACTURING CO.

1310-T Seaboard Industrial Blvd.

Atlanta, Georgia 30318

4 OM-TDB/TDBC

Equipment Description

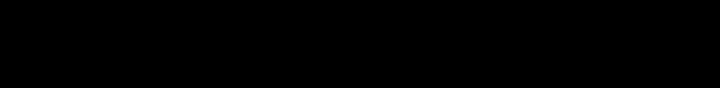

Model TDB

Model TDBC

The TDB and TDBC are table top, tilting, steam jacketed kettles with a thermostatically controlled, self-contained, electrically-heated steam supply and appropriate controls, mounted on a sturdy base. Models are available in 20, 24, 40 and 48 quart (5, 6, 10, 12 gallon) capacity.

The body of the kettle is constructed of stainless steel, welded into one solid piece. The kettle is furnished with a reinforced rim and a butterfly shaped pouring lip. It has a steam jacket rated for a design pressure of 50 PSI (3.45 Bar/345 kPa). Kettle finish is 180 emery grit on the inside and bright semi-deluxe on the outside. A tilt handle on the TDB kettle and a hand wheel crank on the TDBC kettle allows the operator to

manually tilt the kettle body in a controlled manner. Pouring height accepts pans up to four inches high on a table top.

A built-in steam generator, sized for the kettle capacity and heated by electricity, delivers steam into the jacket. “Airless” operation of the steam jacket permits uniform, efficient heating at temperatures as low as 150°F (66°C) and as high as 295°F (146°C). In addition to the adjustable thermostat for operating control, the unit has

a tilt cut-off switch, low water cut-off, pressure relief valve, and high-limit pressure switch as safety features. A heating indicator light, pressure gauge, and sight glass are provided for monitoring kettle operation.

A single electrical connection is required for installation. The unit may be ordered for use with 208/240 or 480 volt power. All 208/240 volt kettles are wired for 208 volt, three-phase operation. For 240 volt, three-phase OR single-phase conversion, see the wiring diagrams and installation instructions in this manual.

KETTLE CHARACTERISTICS

Description |

TDB/TDBC-20 |

|

TDB/TDBC-24 |

TDB/TDBC-40 |

TDB/TDBC-48 |

|

|

|

|

|

|

Kettle Capacity |

20 qt (5 gal) / |

|

24 qt (6 gal) / |

40 qt (10 gal) / |

48 qt (12 gal) / |

|

18.9 liter |

|

22.7 liter |

37.8 liter |

45.4 liter |

Jacket Capacity |

7 quart / 6.6 liter |

9 quart / 8.5 liter |

|||

Inside Diameter |

14 in / 36 cm |

16-1/2 in / 42 cm |

|||

Depth |

11 in / 28 cm |

|

12.5 in / 32 cm |

14-1/4 in / 36 cm |

16-1/2 in / 42 cm |

kW at 208 Volts |

|

6.3 |

10.8 |

||

kW at 240 Volts |

|

8.4 |

14.4 |

||

kW at 480 Volts |

|

6.3 |

12.0 |

||

Base Width |

24 in / 61 cm |

28 in / 71 cm |

|||

Base Depth |

16 in / 41 cm |

16 in / 41 cm |

|||

Optional equipment available with TDB & TDBC kettles:

1.Kit, cover and holder

2.One-piece, lift-off cover

3.Holder for lift-off cover

4.Basket insert

5.Lip strainer

6.Stand that supports the unit and holds a pan in position for filling

7.Water fill swing faucet

8.316 stainless steel interior (must be ordered with original equipment order)

OM-TDB/TDBC 5

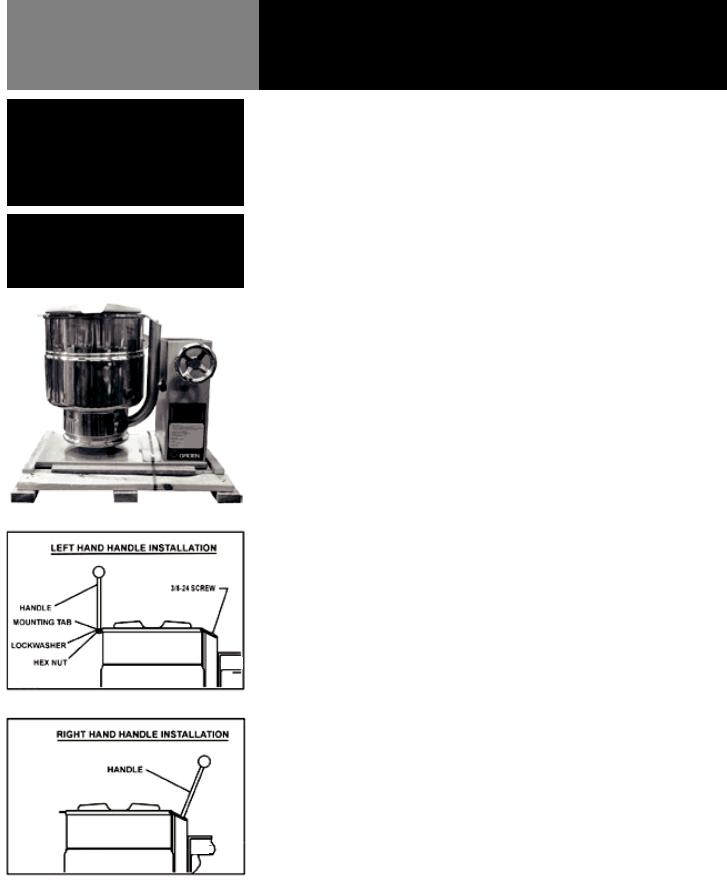

Inspection & Unpacking

CAUTION

SHIPPING STRAPS ARE UNDER TENSION AND CAN SNAP BACK WHEN CUT. TAKE CARE TO AVOID PERSONAL INJURY OR DAMAGE TO THE UNIT BY STAPLES LEFT IN THE WALLS OF THE CARTON.

CAUTION

THIS UNIT WEIGHS 140 TO 165 LBS (64 TO 75.3 KG). INSTALLER SHOULD OBTAIN HELP AS NEEDED TO LIFT THIS WEIGHT SAFELY.

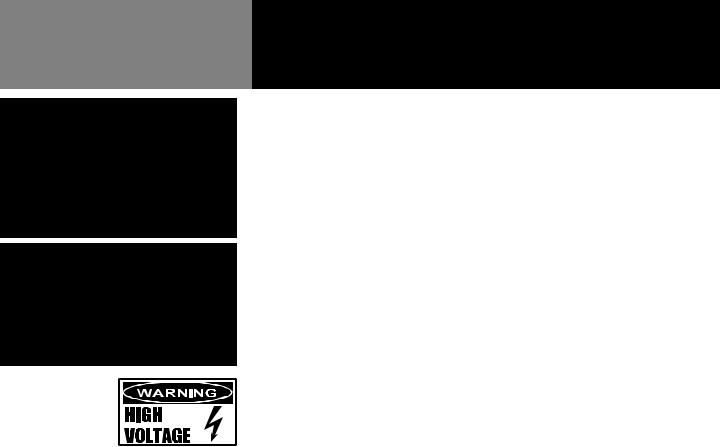

NOTE: After handle installation on the right hand side, retain the hardware supplied with the unit for left hand installation.

The unit will arrive in a heavy shipping carton and will be bolted or banded to a skid. Immediately upon receipt, inspect the carton carefully for exterior damage.

Carefully cut any polyester straps around the carton and detach the sides of the box from the skid. Pull the carton up off the unit. Thoroughly inspect the unit for concealed damage. Report any shipping damage or incorrect shipments to the delivery agent.

Write down the model number, serial number, and installation date, and retain this information for future reference. Space for these entries is provided at the top of the Service Log at the back of this manual. Keep this manual on file and available for operators to use.

When installation is to begin, carefully cut any straps which hold the unit on the skid. Lift the unit straight up off the skid. Examine packing materials to be sure loose parts are not discarded with the materials.

For TDB units, attach the tilt handle (normally shipped inside the kettle) by carefully threading it into the socket on the trunnion support. Be careful to avoid cross-threading the fine threads on the trunnion.

6 OM-TDB/TDBC

WARNING

INSTALLATION OF THE KETTLE MUST BE DONE BY A CERTIFIED ELECTRICIAN OR AUTHORIZED REPRESENTATIVE QUALIFIED TO WORK WITH ELECTRICITY. IMPROPER INSTALLATION CAN RESULT IN INJURY TO PERSONNEL AN/OR DAMAGE

TO EQUIPMENT.

CAUTION

BEFORE ANY ELECTRICAL CONVERSION, VERIFY THAT THE BRANCH CIRCUIT WIRING IS ADEQUATE TO HANDLE ANY INCREASE AMPERAGE REQUIREMENTS. REFER TO THE ELECTRICAL SPECIFICATIONS LISTED BELOW.

Installation

The TDB/TDBC Kettle is provided with complete internal wiring and is ready for immediate connection. Wiring diagrams are provided in this manual and on the inside of the control housing service panel. Any mechanical or electrical changes must be approved by the Engineering Department.

The completed unit has been operated at the factory to test all controls and heater elements.

1.Set the kettle in place and level it. The base should be securely fastened to a table or work surface. Four 3/8”-16 N.C. threaded couplings are provided in the base of unit. Installation under a ventilation hood is recommended.

2.Once the unit is anchored to a mounting surface, apply a small bead of silicone caulk around the perimeter of the kettle base and seal the joint.

3.Provide electrical power as specified on the electrical information plate attached to the equipment. Observe local codes and/or The National Electrical Code in accordance with ANSI/NFPA 70 - (current edition).

4.Standard equipment is shipped ready for 208V, 3-phase or 480V, 3-phase operation. Refer to the wiring diagram located on the inside cover of the control box and the instructions below for conversion to single-phase operation. A jumper wire and “conversion” label are included with the unit. They can be found in a plastic bag attached to the trunnion assembly inside the control box.

a.For conversion from 208V, 3-phase to 208V or 240V 1-phase or 480V, 3-phase to 480V, 1-phase:

i.Verify that the branch circuit wiring is adequate for any increased amperage requirements (see table on page 8).

ii.For 240V 1-phase only, enlarge electrical inlet opening for 1” conduit fitting. Use a 1” sealtite conduit fitting.

iii.Refer to wiring diagram for field conversion.

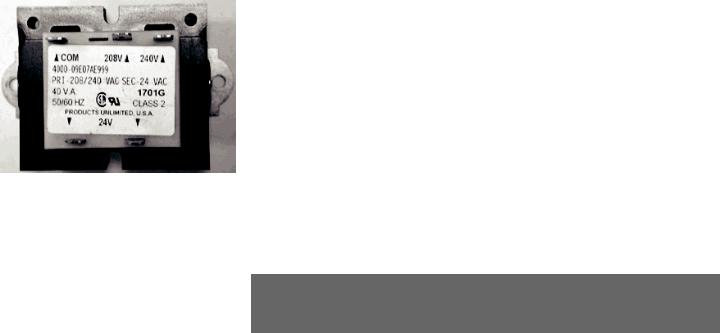

iv.For 240V 1-phase only, pull lead from 208V tab on control transformer and insert on 240V tab (See photo on page 8).

v.Complete “conversion label” (supplied in bag) and adhere it to the control box near the UL dataplate.

b.For conversion from 208V, 3-phase to 240V, 3-phase:

i.Verify that the branch circuit wiring is adequate for any increased amperage requirements (see table on page 8).

ii.Pull lead from 208V tab on control transformer and insert on 240V tab. (See photo on page 8)

iii.Complete “conversion label” (supplied in bag and adhere it to the control box near the UL dataplate).

OM-TDB/TDBC 7

|

|

|

|

|

|

Installation |

|

|

|

||

|

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|

DANGER |

|

|

c. |

For conversion from 480V, 3-phase to 460V, 3-phase: |

|

||||||

ELECTRICALLY GROUND THE UNIT AT |

|

|

|

|

|

|

|

|

|

|

|

THE TERMINAL PROVIDED. FAILURE TO |

|

|

|

i. |

Verify that the branch circuit wiring is adequate for any |

||||||

GROUND UNIT COULD RESULT IN |

|

|

|

|

increase amperage requirements (see table on page 8). |

||||||

ELECTROCUTION AND DEATH. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

ii. |

Complete “conversion label” (supplied in bag and adhere it |

||||||

|

|

|

|

||||||||

|

|

|

|

|

to the control box near the UL dataplate). |

|

|||||

|

|

5. |

Bring incoming electrical service through the conduit fitting (for 240V |

||||||||

|

|

|

1-phase, a new one inch conduit fitting is required) at the rear of the support |

||||||||

|

|

|

housing, making a watertight connection with the incoming lines. A BX style |

||||||||

|

|

|

connection is not recommended. |

|

|

|

|

||||

|

|

6. |

Confirm that the jacket water level is at or just above mid point of sight glass |

||||||||

|

|

|

(new models). If the level is low, follow the instructions under “Jacket Filling |

||||||||

|

|

|

and Water Treatment” in the “Maintenance” section of the manual. |

|

|||||||

Pull lead from 208V tab and insert on 240V tab. |

7. |

Ensure that the open end of the elbow on the outlet of the pressure relief |

|||||||||

|

valve is directed downward. |

|

|

|

|

||||||

|

|

|

|

|

|

|

|||||

|

|

TDB/TDBC SUPPLY WIRE REQUIREMENTS |

|

|

|

|

|||||

|

|

THWN (75°) / THHN (90°) COPPER ONLY |

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

TDB/TDBC-20, -24 |

|

TDB/TDBC-40, -48 |

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

VOLTAGE |

AMPS |

|

SUPPLY |

|

VOLTAGE |

AMPS |

|

SUPPLY |

|

|

|

|

WIRE |

|

|

WIRE |

||||

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

208V1PH |

31 |

|

8 |

|

208V1PH |

52 |

|

6 |

|

|

|

3PH |

18 |

|

12 |

|

3PH |

30 |

|

8 |

|

|

|

240V1PH |

35 |

|

8 |

|

240V1PH |

60 |

|

4 |

|

|

|

3PH |

20 |

|

12 |

|

3PH |

35 |

|

8 |

|

|

|

460V3PH |

7.3 |

|

14 |

|

460V3PH |

14 |

|

12 |

|

|

|

480V1PH |

14 |

|

14 |

|

480V1PH |

25 |

|

10 |

|

|

|

3PH |

8 |

|

14 |

|

3PH |

15 |

|

12 |

8 OM-TDB/TDBC

Loading...

Loading...