Groen FPC-1-4 Operators Manual

IMPORTANT INFORMATION ? KEEP FOR OPERATOR ? IMPOR TANT I NFORMAT ION

Mo del FPC /1-4

Mo del M W/FPC-4

OPERATOR MANUAL OM-FPC

DO M E S T IC

Par t Nu mb er 1 21 024 R e v B

MODELS: FPC, MW/FPC,

FPC/1, MW/FPC/1

Brais ing Pan s

Stainl ess Steel

Manual Tiltin g

Electr ical ly Heate d

THIS MANUAL MUST BE R ETAINED FOR FUTU RE REFERENCE. READ,

UNDERSTAND AN D FOLL OW THE INSTRUCTIONS AND WARNINGS

CONTAINED IN THIS MANUAL.

WARNING

DO NOT STORE OR USE GASOLINE OR OTHER FLA MMABL E VAPORS AND

LIQUIDS IN THE VICINITY OF THIS OR ANY OTHER APPLI ANCE.

.

Information contained in this document is known to be current

and accurate at the time of printing/creation. Unified Brands

recommends referencing our product line websites,

unifiedbrands.net, for the most updated product information and

specifications.

OM-FPC

2

IMPORTANT — READ FIRST — IMPORTANT

CAUTION: BE SURE OPERATORS READ, UNDERSTAND AND FOLLOW THE OPERATING

INSTRUCTIONS, CAUTIONS, AND SAFETY INSTRUCTIONS IN THIS MANUAL.

WARNING: THIS UNIT IS INTENDED FOR USE IN THE COMMERCIAL HEATING, COOKING AND

HOLDING OF WATER AND FOOD PRODUCTS, PER THE INSTRUCTIONS

CONTAINED IN THIS MANUAL. ANY OTHER USE COULD RESULT IN SERIOUS

PERSONAL INJURY OR DAMAGE TO EQUIPMENT AND WILL VOID WARRANTY.

WARNING: ELECTRICALLY GROUND THE PAN AT THE TERMINAL PROVIDED.

WARNING: THE BRAISING PAN MUST BE INSTALLED BY PERSONNEL WHO ARE QUALIFIED

TO WORK WITH ELECTRIC ITY. IMP ROP ER INSTALLATION COULD RES ULT IN

PERSONAL INJURY OR EQUIPMENT DAMAGE.

CAUTION: STAND AWAY FROM HOT WATER OR FOOD PRODUCTS WHILE TILTING THE PAN

WARNING: WHEN TILTING BRAISING PAN FOR PRODUCT TRANSFER:

1) USE CONTAINER DEEP ENOUGH TO CONTAIN AND MINIMIZE SPLASHING.

2) PLACE CONTAINER ON STABLE, FLAT SURFACE, AS CLOSE TO PAN AS

POSSIBLE.

3) STAND TO SIDE OF PAN WHILE POURING — NOT DIRECTLY IN POUR

PATH OF HOT CONTENTS.

4) RETURN PAN BODY TO LEVEL POSITION AFTER CONTAINER IS FILLED

OR TRANSFER IS COMPLETE.

5) DO NOT OVER FILL CONTAINER. AVOID DIRECT SKIN CONTACT WITH

HOT CONTAINER AND ITS CONTENTS.

WARNING: DO NOT HEAT AN EMPTY PAN FOR MORE THAN FIVE MINUTES AT A SETTING

HIGHER THAN 300

o

F.

WARNING: AVOID ANY EXPOSURE TO T HE STEAM ESCA PING FROM THE CO VER VENT.

DIRECT CONTACT COULD RESULT IN SEVERE BURNS

WARNING: AVOID ALL DIRECT CON TACT W ITH HOT EQU IPM ENT SURFACES. DIRECT SKIN

CONTACT COULD RESULT IN SEVERE BURNS.

WARNING: AVOID ALL DIRECT CONTACT WITH HOT FOOD OR WATER IN THE BRAISING

PAN. DIRECT CONTACT COULD RESULT IN SEVERE BURNS.

WARNING: IF THE PAN CONTAINS ITEMS IN SAUCE OR MELTED FAT, THEY COULD SLIDE

FORWARD SUDDENLY DURING TILTING AND CAUSE HOT LIQUID TO SPLASH

OUT.

WARNING: USE OF ANY REPLACEMENT PARTS OTHER THAN THOSE SUPPLIED BY GROEN

OR ITS AUTHORIZED DISTRIBUTORS VOIDSALL WARRANTIES AND MAY CAUSE

BODILY INJURY OR EQUIPMENT DAMAGE. SERVICE PERFORMED BY OTHER

THAN FACTORY AUTHORIZED PERSONNEL WILL VOID ALL WARRANTIES.

WARNING: TURN OFF ELECTRIC POWER BEFORE WORKING ON INTERNAL COMPONENTS.

WARNING: BEFORE ANY CLEANING OPERATION, TURN THE THERMOSTAT TO “OFF” TO

CUT OFF POWER TO THE HEATING ELEMENTS. BEFORE CLEANING ANY PART

OTHER THAN THE INSIDE OF THE PAN, DISCONNECT THE ELECTRICAL SUPPLY

AT THE CIRCUIT BREAKER OR FUSE BOX.

WARNING: BE CAREFUL TO AVOID CONTACT WITH CLEANING PRODUCTS IN ACCORDANCE

WITH SUPPLIER AND MANUFACTURER RECOMMENDATIONS. MANY CLEANERS

ARE HARMFUL TO THE SKIN, EYES, MUCOUS MEMBRANES AND CLOTH ING.

READ THE WARNINGS AND FOLLOW DIRECTIONS ON THE CLEANER LABEL.

CAUTION: NEVER LEAVE A CHLORINE SANITIZER IN CONTACT WITH STAINLESS STEEL

FOR LONGER THAN 30 MINUTES. LONGER CONTACT CAN CAUSE CORROSION.

WARNING: DO NOT USE ANY FUSE WITH A HIGHER AMP RATING THAN THE RATING

SPECIFIED FOR THAT CIRCUIT.

OM-FPC

3

Table of Contents

IMPORTANT OPERATOR WARNINGS .................................................. 2

EQUIPMENT DESCRIPTION .......................................................... 4

INSTALLATION ..................................................................... 5

INITIAL START-UP .................................................................. 7

OPERATION ....................................................................... 7

SEQUENCE OF OPERATION .......................................................... 8

CLEANING ........................................................................ 9

MAINTENANCE ................................................................... 10

TROUBLESHOOTING .............................................................. 11

PARTS LISTS ..................................................................... 12

ELECTRICAL PARTS CHART ........................................................ 15

REFERENCES ................................................ .................... 15

DIAGRAMS & SCHEMATICS ....................................................... 16-18

MAINTENANCE LOG ............................................................... 19

WARRANTY ...................................................................... 20

OM-FPC

4

Optional 2" draw-off

valve

Equipment Description

The Gro en F PC is a stainless steel, electrically

heated Braising Pan which is equ ipped with

integrated heating elements, a hand operated

tilting mechanism, electrical controls and a

hinged cover. The Braising Pan serves as a

braising unit, griddle, fry pan, oven, kettle, bain-

marie, or food warmer and server. It can also

be adapted for use as a non-pressure steam er.

The pan body is cons tructed of heavy-duty

stainless steel, welded into a solid piece. It has

a polished interior and exterior finish. A pouring

lip is welded to the top of the front wall. The

cooking surface is a stainless steel clad plate

fitted with clamped-on electrical heating

elements. The elem ents are po sitioned to

ensure uniform heat transfer over the entire

surface.

Models FPC and FPC/1 are mounted on an

open-leg frame which is fabricated from tubular

stainless steel. Models MW/FPC and

MW/FPC/1 are designed to be wall-mounted

with side support arms and a back-splash. They

do not have legs.

An easily operated worm and gear mechanism

tilts the pan body and provides precise control

for pouring or dumping its contents.

This handwheel controlled mechanism is located

in a stainless steel console to right of the pan

body. To facilitate cleaning, the pan body can

be tilted past the vertical position.

Heating elements and other electrical

components are enclosed for safety. The

thermostat and heating indicator light are

contained in a com pact control console wh ich is

mounted to the left of the pa n body.

The thermostat provides automatic control of

cooking temperature. Turning the thermostat

dial starts and stops heating and sets the pan

temperature. Only one electrica l con nec tion is

required to install the unit.

A vented, heavy gauge, one-piece, stainless

steel cover with a rear condensate drip shield on

the underside is standard o n the Braising Pan.

A fully enclosed spring-type actuator counter-

balances the cover to maintain either the

opened or closed pos ition. The cove r opens to

the back. It is hinged to the frame, so it moves

independently from the p an body.

The following sizes and options are available:

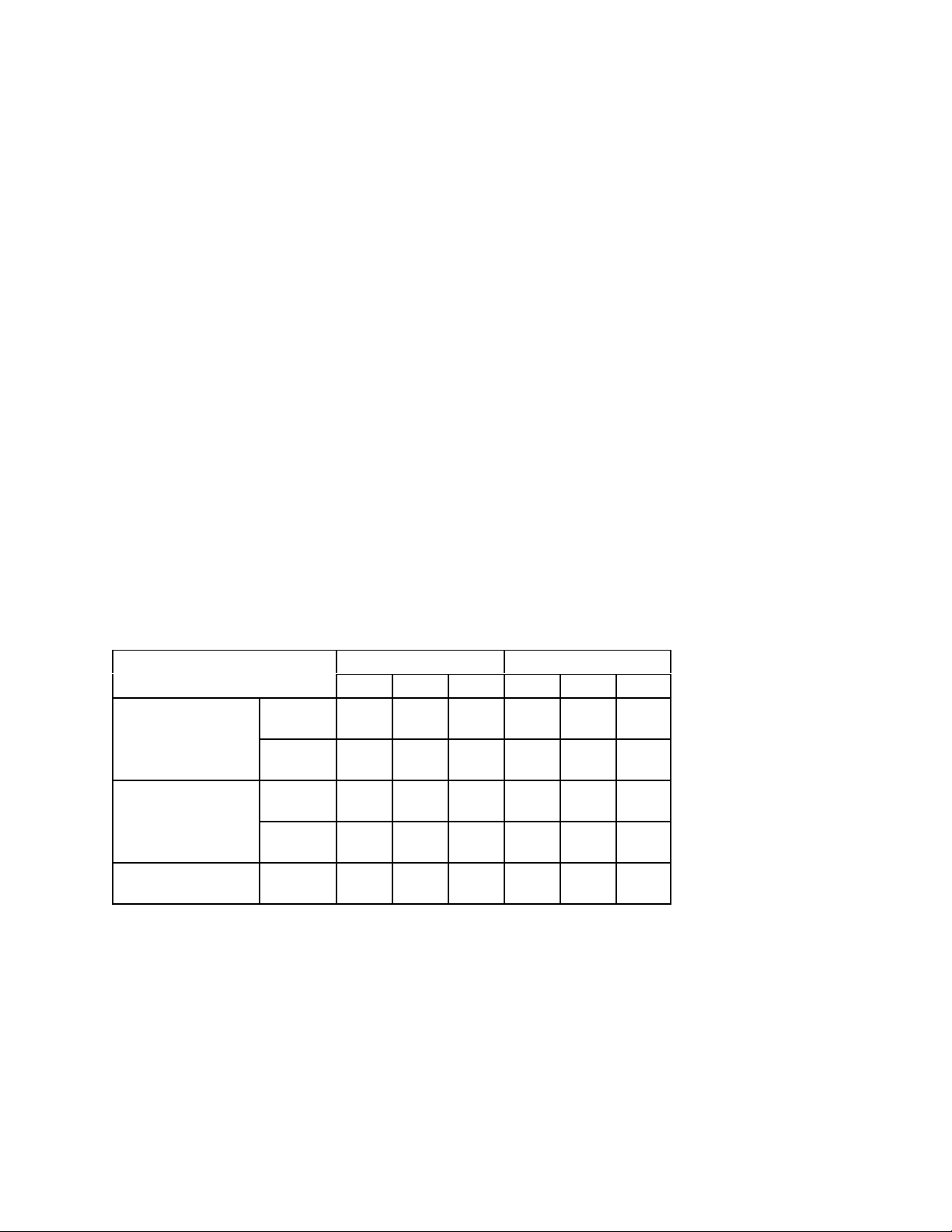

MODELS

FPC/1 MW/FPC/1

Size 2 Size 3 Size 4 Size 2 Size 3 Size 4

Unit Dimensions

in inches (mm)

Left to

Right

42

(1067)

49

(1245)

59

(1500)

39½

(1000)

46½

(1181)

56½

(1435)

Front to

Back

36½

(927)

36½

(927)

36½

(927)

41¾

(1060)

41¾

(1060)

41¾

(1060)

Pan Body

Dimensions in

inches (mm)

Left to

Right

24d

(619)

30¾

(781)

41d

(1051)

24d

(619)

30¾

(781)

41d

(1051)

Front to

Back

25

(635)

25

(635)

25

(635)

25

(635)

25

(635)

25

(635)

Capacity in

Gallons (liters)

9" Pan

Depth

23

(584)

30

(762)

40

(1016)

23

(584)

30

(762)

40

(1016)

The following optional equipment may

be added to any floor model listed above:

1. Fill faucet - swing spout 4. Draw-Off Valve

2. Casters 5. Steamer insert

3. Fold down work tray(s) 6. Steamer pan carrier

OM-FPC

5

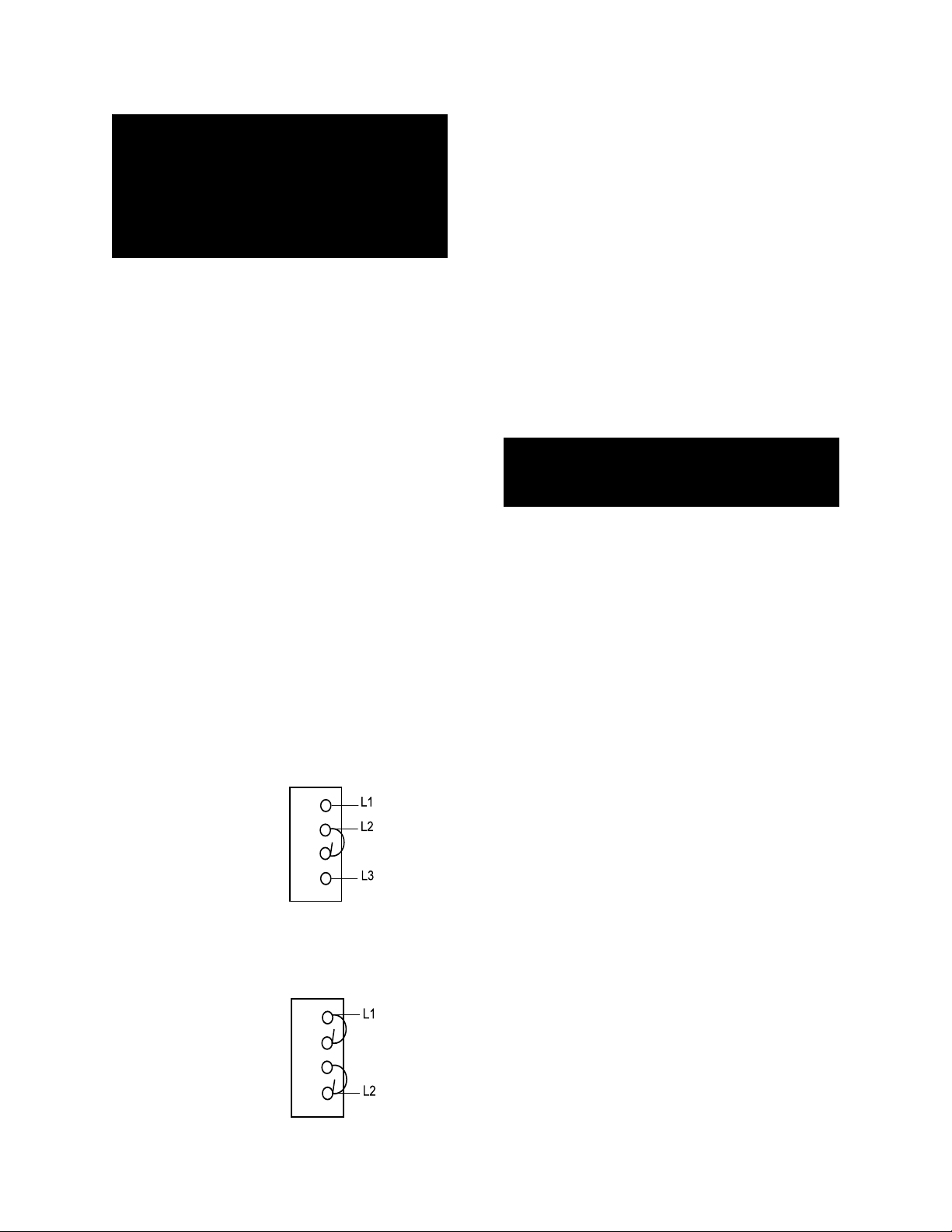

Three Phase

Single Phase

Installation

WARNING

THE BRAISING PAN MUST BE INSTALLED

BY PERSONNEL WHO ARE QUALIFIED TO

WORK WITH ELECTRICITY. IMPROPER

INSTALLATION COULD RESULT IN

PERSONAL INJURY OR EQUIPMENT

DAMAGE.

Internal wiring for the Braising Pan is supplied

complete. W hen you rece ive the unit, it is

ready for connect ion. A wiring d iagra m is

located inside the control box on the left side of

the pan, as well as in this manual (pp. 14 -21).

Your pan was perform ance-tested at the factory

to confirm that all controls and hea ting elements

were functioning correctly.

Installation is as follows:

A. For All Models:

6. Provide the proper electrical supply as

specified on the electrical information

plate. Comply with local codes and the

National Electrical Code ANSI/NFPA 7-

latest edition.

7. Use only #6 gauge copper wire, rated at

least 200ºC (392ºF)

8. Units are wired at the factory for three

phase operation and should be

connected as follows:

TERMINAL

BLOCK

9. For s ingle

phase

operation, change the wiring

with jumpers, as follows:

TERMINAL

BLOCK

B. For Model FPC or FPC/1:

1. Set the unit in place and level it by

turning the adjustable feet. Crank the

pan body to a completely horizontal

position. Check levelness by placing a

spirit level on the bottom of the pan.

The unit must be level to avoid uneven

cooking across the pan.

2. Make a waterproof connection with the

incoming power line at the electrical

service entrance in the bottom of the

control cons ole. A BX c onn ection is

NOT recommended. ELECTRICALLY

GROUND THE UNIT at the proper

terminal.

WARNING

ELECTRICALLY GROUND THE PAN AT THE

TERMINAL PROVIDED.

C. For Model MW/FPC or MW/FPC/1:

1. Install the provided “chair carrier” frame

in the wall to which the pan (and/or

other equipment) will be attached.

Follow accompanying instructions

regarding anchoring and location.

2. Stu b in the electrical service so that it

will be aligned with the con trol c ons ole

on the left side of the pan when it is

mounted.

3. Mount the pan on the protruding studs

of the chair carrier. Make sure the

OM-FPC

6

bottom of the pan body is level

before you proceed to the next step.

To prevent sanitation problems, seal

the junction between the pan and

wall with an appropriate NSF-

approved material such as Silastic.

4. Make waterproof connection with the

incoming electrical line. A BX

connection is NOT recom mended.

ELECTRICA LLY GROUND THE UNIT

at the pro per t erm inal.

CAUTION

ELECTRICALLY GROUND THE PAN AT THE

TERMINAL PROVIDED.

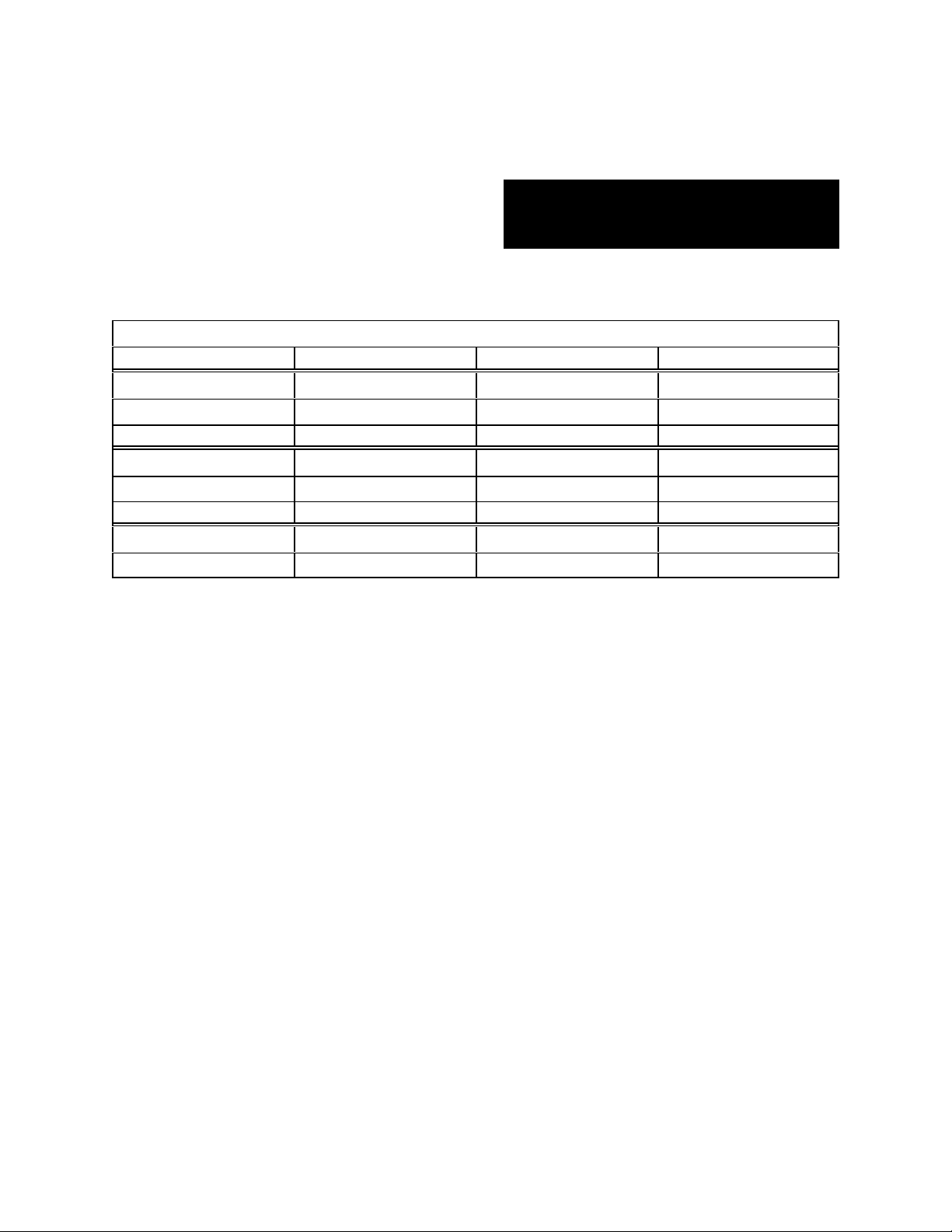

ELECTRICAL REQUIREMENTS

Model FPC or FPC/1-2 FPC or FPC/1-3 FPC or FPC/1-4

208 Volt 8.5 KW 11.5 KW 14.5 KW

Single Phase 42 Amp 55 Amp 69 Amp

Three Phase 24 Amp 32 Amp 40 Amp

240 Volt 9 KW 12 KW 15 KW

Single Phase 38 Amp 50 Amp 63 Amp

Three Phase 22 Amp 29 Amp 36 Amp

480 Volt 9 KW 12 KW 15 KW

Three Phase 11 Amp 15 Amp 18 Amp

OM-FPC

7

Initial Start-Up

Now that the Braising Pan has been installed,

you should test it to ensure that it is operating

correctly.

1. Remove all literature and packing

materials from the interior and exterior

of the unit.

2. Turn on the electrical power to the unit.

3. Put enough water into the pan to cover

its bottom to a depth of ¼” to ½” (6 to 13

mm). With the pan body in the

horizontal position, note how the water

covers the pan bottom. This is a good

method to use for confirming that the

unit is properly leveled.

4. Set the thermostat to 235

o

F. The

heating indicator light should com e on to

show that the pan is heating. Heating

should continue until the water boils.

5. To shut the unit down, turn the

thermostat dial to “OFF.”

CAUTION

STAND AWAY FROM THE HOT WATER

WHILE TILTING THE PAN TO EMPTY IT.

6. Position a con tainer for the pour-off.

Turn the handwheel clockwise to pour

the water out. This will confirm that the

pan bod y tilts fr om horizo ntal to vertical.

Operation

Operator Controls on the Braising Pan include

the thermostat dial on the console to the left of

the pan body and the tilting handwheel, to the

right. The dial turns electric power for the pan

on or off, and sets the pan’s operating

temperature. The ha ndwheel controls the worm

and gear mechanism that tilts the pan body and

holds it in the desired position.

A. Start-up Procedure

1. Set the thermostat dial to the desired

temperature between 100 and 400

o

F.

The Heat Indicator Light shows that the

pan is heating. When the light cycles on

and off, it in dica tes that the pan is

holding at the set temperature. During

these cycles you may hear the

contactors in the control box make a

clicking soun d. Th is is n orm al.

2. For best results when braising or frying,

preheat the pan before putting in any

food. For an even temperature across

the pan, preheat at a setting of 300

o

F

or less for 15 minutes, or through

several on/off cycles of the thermostat.

WARNING

DO NOT HEAT AN EMPTY PAN FOR MORE

THAN FIVE MINUTES AT SETTINGS ABOVE

300

o

F. DAMAGE TO THE PAN COULD

RESULT.

B. Cooking

1. To simmer or slowly heat an item, set

the dial at about 210

o

F or lower. Put

the cover down to keep moisture loss at

a minimum, or leave it up to help dryor

reduce the product. Set the thermostat

higher to cook or drive m oisture off

faster. The thermostat may be adjusted

to any setting in its range to cook

exactly as you wish.

2. Leave the cover vent open to allow

excess steam to escape. For longer

simmering, you may wish to close the

vent to retain moisture.

WARNING

AVOID ANY EXPOSURE TO THE STEAM

ESCAPING FROM THE COVER VENT.

DIRECT CONTACT COULD RES ULT IN

SEVERE BURNS

3. To check cooking progress when the

cover has been closed, grasp the p last ic

handle o f ve nt co ve r and lift it sligh tly

while moving it quickly to either side.

Standin g at o ne s ide o f the pan to avoid

the steam that will be released, grasp

the nea rest corner of the cover handle

and raise the cover. The cover will stay

Loading...

Loading...