Groen DEE-4 Service Manual

IMPORTANT INFORMATION KEEP FOR OPERATOR IMPORTANT INFORMATION

OPERATOR MANUAL OM-DEE/4

Part Number 121013, Rev. B DOMESTIC

MODEL: DEE/4

Steam Jacketed Kettle

Self-Contained

Electrically heated

Floor mounted

Tilting

THIS MANUAL MUST BE RETAINED FOR FUTURE REFERENCE.

READ, UNDERSTAND AND FOLLOW THE INSTRUCTIONS AND

WARNINGS CONTAINED IN THIS MANUAL.

FOR YOUR SAFETY

DO NOT STORE OR USE GASOLINE OR OTHER FLAMMABLE

VAPORS AND LIQUIDS IN THE VICINITY OF THIS OR ANY OTHER

APPLIANCE.

Information contained in this document is

known to be current and accurate at the time

of printing/creation. Unified Brands recom-

mends referencing our product line websites,

unifiedbrands.net, for the most updated

product information and specifications.

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

OM-DEE/4

2

IMPORTANT — READ FIRST — IMPORTANT

CAUTION: BE SURE ALL OPERATORS READ, UNDERSTAND AND FOLLOW THE OPERATING

INSTRUCTIONS, CAUTIONS, AND SAFETY INSTRUCTIONS CONTAINED IN THIS

MANUAL.

WARNING: THIS UNIT IS INTENDED FOR USE IN THE COMMERCIAL HEATING, COOKING AND

HOLDING OF WATER AND FOOD PRODUCTS, PER THE INSTRUCTIONS

CONTAINED IN THIS MANUAL. ANY OTHER USE COULD RESULT IN SERIOUS

PERSONAL INJURY OR DAMAGE TO THE EQUIPMENT AND WILL VOID

WARRANTY.

WARNING: KETTLE MUST BE INSTALLED BY PERSONNEL QUALIFIED TO WORK WITH

ELECTRICITY. IMPROPER INSTALLATION CAN RESULT IN INJURY TO

PERSONNEL AND/OR DAMAGE TO EQUIPMENT.

DANGER: ELECTRICALLY GROUND THE UNIT AT THE TERMINAL PROVIDED. FAILURE TO

GROUND UNIT COULD RESULT IN ELECTROCUTION AND DEATH.

WARNING: AVOID ALL DIRECT CONTACT WITH HOT EQUIPMENT SURFACES. DIRECT SKIN

CONTACT COULD RESULT IN SEVERE BURNS.

WARNING: AVOID ALL DIRECT CONTACT WITH HOT FOOD OR WATER IN THE KETTLE.

DIRECT CONTACT COULD RESULT IN SEVERE BURNS.

CAUTION: DO NOT OVER FILL THE KETTLE WHEN COOKING, HOLDING OR CLEANING.

KEEP LIQUIDS A MINIMUM OF 2-3” (5-8 cm) BELOW THE KETTLE BODY RIM TO

ALLOW CLEARANCE FOR STIRRING, BOILING AND SAFE PRODUCT TRANSFER.

WARNING: TAKE SPECIAL CARE TO AVOID CONTACT WITH HOT KETTLE BODY OR HOT

PRODUCT WHEN ADDING INGREDIENTS, STIRRING OR TRANSFERRING

PRODUCT TO ANOTHER CONTAINER.

WARNING: WHEN TILTING KETTLE FOR PRODUCT TRANSFER:

1) USE CONTAINER DEEP ENOUGH TO CONTAIN AND MINIMIZE PRODUCT

SPLASHING.

2) PLACE CONTAINER ON STABLE, FLAT SURFACE, AS CLOSE TO KETTLE AS

POSSIBLE.

3) DO NOT OVER FILL CONTAINER. AVOID DIRECT SKIN CONTACT WITH HOT

CONTAINER AND ITS CONTENTS.

CAUTION: KEEP FLOORS IN FRONT OF KETTLE WORK AREA CLEAN AND DRY. IF SPILLS

OCCUR, CLEAN IMMEDIATELY, TO AVOID SLIPS OR FALLS.

WARNING: FAILURE TO CHECK SAFETY VALVE OPERATION PERIODICALLY COULD RESULT

IN PERSONAL INJURY AND/OR DAMAGE TO EQUIPMENT.

WARNING: WHEN TESTING, AVOID ANY EXPOSURE TO THE STEAM BLOWING OUT OF THE

SAFETY VALVE. DIRECT CONTACT COULD RESULT IN SEVERE BURNS.

WARNING: TO AVOID INJURY, READ AND FOLLOW ALL PRECAUTIONS STATED ON THE

LABEL OF THE WATER TREATMENT COMPOUND.

WARNING: BEFORE REPLACING ANY PARTS, DISCONNECT THE UNIT FROM THE ELECTRIC

POWER SUPPLY.

WARNING: KEEP WATER AND SOLUTIONS OUT OF CONTROLS AND ELECTRICAL

EQUIPMENT. NEVER SPRAY OR HOSE THE SUPPORT HOUSING OR ELECTRICAL

CONNECTIONS.

CAUTION: MOST CLEANERS ARE HARMFUL TO THE SKIN, EYES, MUCOUS MEMBRANES

AND CLOTHING. PRECAUTIONS SHOULD BE TAKEN. WEAR RUBBER GLOVES,

GOGGLES OR FACE SHIELD AND PROTECTIVE CLOTHING. CAREFULLY READ

THE WARNINGS AND FOLLOW THE DIRECTIONS ON THE LABEL OF THE

CLEANER TO BE USED.

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

OM-DEE/4

3

IMPORTANT — READ FIRST — IMPORTANT

CAUTION: USE OF ANY REPLACEMENT PARTS OTHER THAN THOSE SUPPLIED BY GROEN

OR THEIR AUTHORIZED DISTRIBUTORS CAN CAUSE OPERATOR INJURY AND

DAMAGE TO THE EQUIPMENT, AND WILL VOID ALL WARRANTIES.

IMPORTANT: SERVICE PERFORMED BY OTHER THAN FACTORY AUTHORIZED PERSONNEL

WILL VOID WARRANTIES.

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

OM-DEE/4

4

Table of Contents

IMPORTANT OPERATOR WARNINGS ................................... 2

REFERENCES ....................................................... 4

EQUIPMENT DESCRIPTION ............................................ 5

INSPECTION & UNPACKING ........................................... 6

INSTALLATION ...................................................... 7

INITIAL START-UP ................................................... 8

OPERATION ........................................................ 9

SEQUENCE OF OPERATION .......................................... 11

MAINTENANCE .................................................... 12

CLEANING ......................................................... 14

TROUBLESHOOTING ................................................ 15

PARTS LISTS ....................................................... 17

DIAGRAMS & SCHEMATICS ........................................... 18

MAINTENANCE LOG ................................................. 22

WARRANTY ........................................................ 23

NOTES ............................................................ 45

References

NATIONAL FIRE PROTECTION ASSOCIATION

60 Battery March Park

Quincy, Massachusetts 02269

NFPA/70 - The National Electrical Code

NATIONAL SANITATION FOUNDATION

3475 Plymouth Rd.

Ann Arbor, Michigan 48106

NSF/ANSI-4

UNDERWRITERS LABORATORIES, INC.

333 Pfingsten Road

Northbrook, Illinois 60062

UL / ANSI-197

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

OM-DEE/4

5

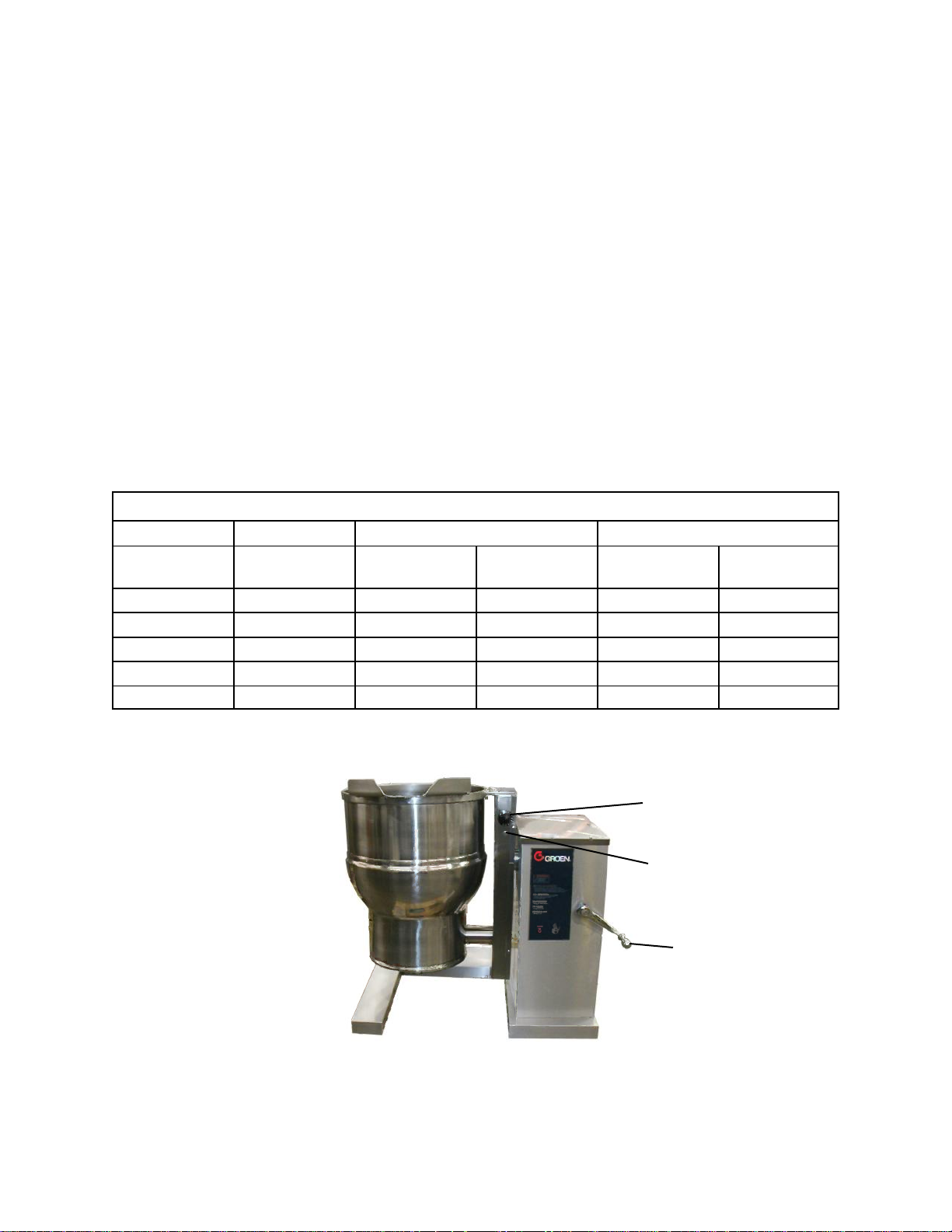

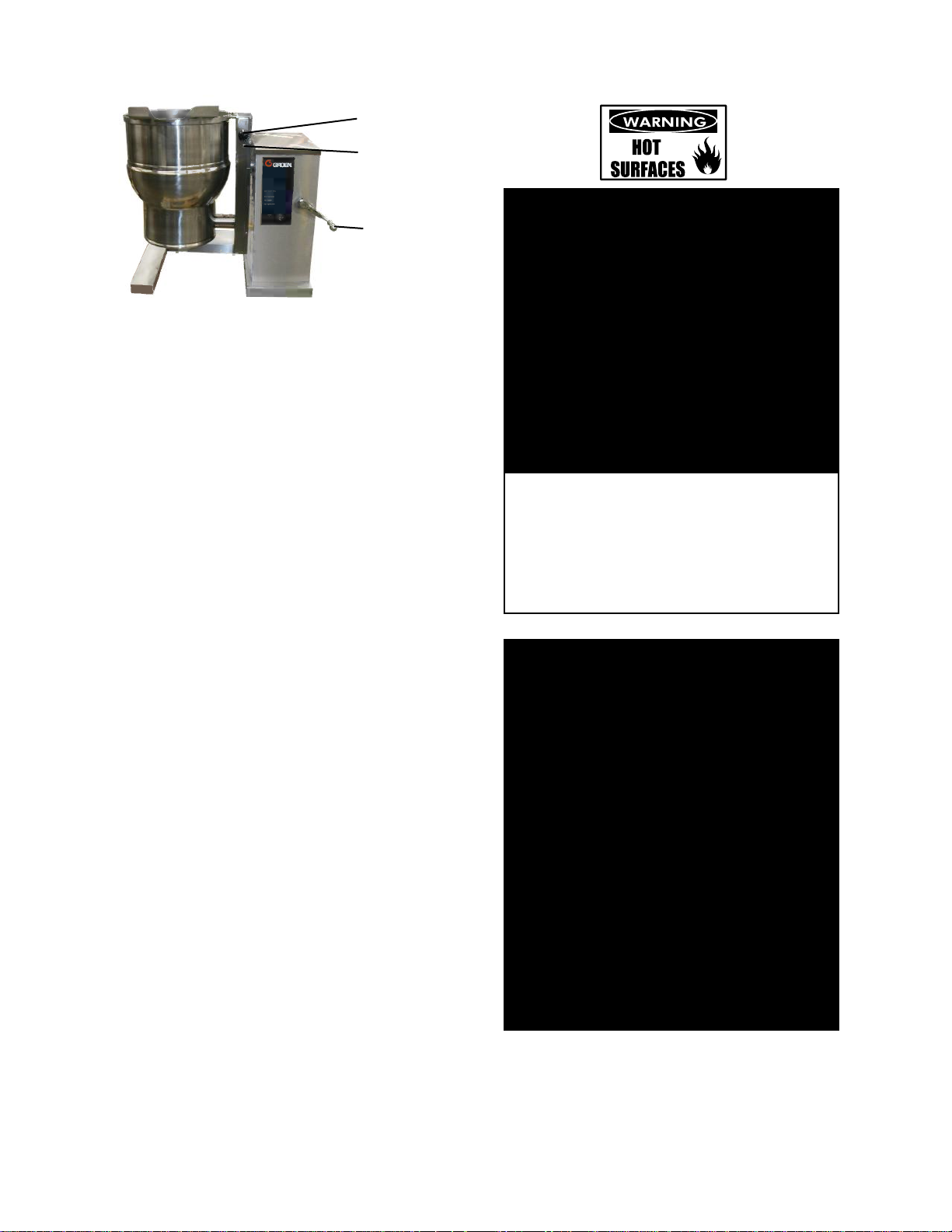

FRONT VIEW

Equipment Description

The Groen DEE/4 is a floor-mounted, tilting,

steam jacketed kettle with a thermostatically

controlled, self-contained, electrically-heated

steam supply and appropriate controls, mounted

on a sturdy base. The Model DEE/4 is available

in 20, 40 or 60 gallon capacities.

The body of the DEE/4 Kettle is constructed of

stainless steel, welded into one solid piece. The

kettle is furnished with a reinforced rim and a

butterfly shaped pouring lip. It has a steam

jacket rated for working pressures up to 50 PSI.

Kettle finish is 180 emery grit on the inside and

bright semi-deluxe on the outside.

The kettle can be tilted with a hand crank to pour

out its contents. Stainless steel panels enclose

the controls and the base. Four stainless steel,

tubular legs support the unit. Bullet feet on each

of the legs can be adjusted to level the kettle.

A built-in steam generator, sized for the kettle

capacity and heated by electricity, delivers steam

into the jacket. “Airless” operation of the steam

jacket permits uniform, efficient heating at

temperatures as low as 150°F and as high as

298°F. In addition to the adjustable thermostat

for operating control, the unit has a tilt cut-off

switch, low water cut-off, safety valve, and high-

limit pressure switch as safety features. A

heating indicator light, pressure gauge, and sight

glass are provided for monitoring kettle

operation.

A single electrical connection is required for

installation. The unit may be ordered for use with

208/240, 400 or 480 volt power. All kettles are

wired for three-phase operation. Single-phase

units are also available.

KETTLE CHARACTERISTICS

DEE/4-20 DEE/4-40 DEE/4-60

Before

January 1989.

After

January 1989

Before

January 1989.

After

January 1989

Kettle Capacity 20 gal (75 l) 40 gal (150l) 40 gal (150l) 60 gal (226l) 60 gal (226l)

Kettle Diameter 20 in (51 cm) 26 in (66 cm) 26 in (66 cm) 30 in (76 cm) 30 in (76 cm)

Rim Height 39 in (99 cm) 40 in (102 cm) 40 in (102 cm) 43 in (110 cm) 44 in (112 cm)

Total Width 38 in (97 cm) 44 in (112 cm) 42 in (107 cm) 50 in (127 cm) 47 in (119 cm)

Front to Back 28 in (71 cm) 31 in (79 cm) 32 in (81 cm) 33 in (84 cm) 35 in (90 cm)

Thermostat Dial

Indicator Light

Tilting Crank

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

OM-DEE/4

6

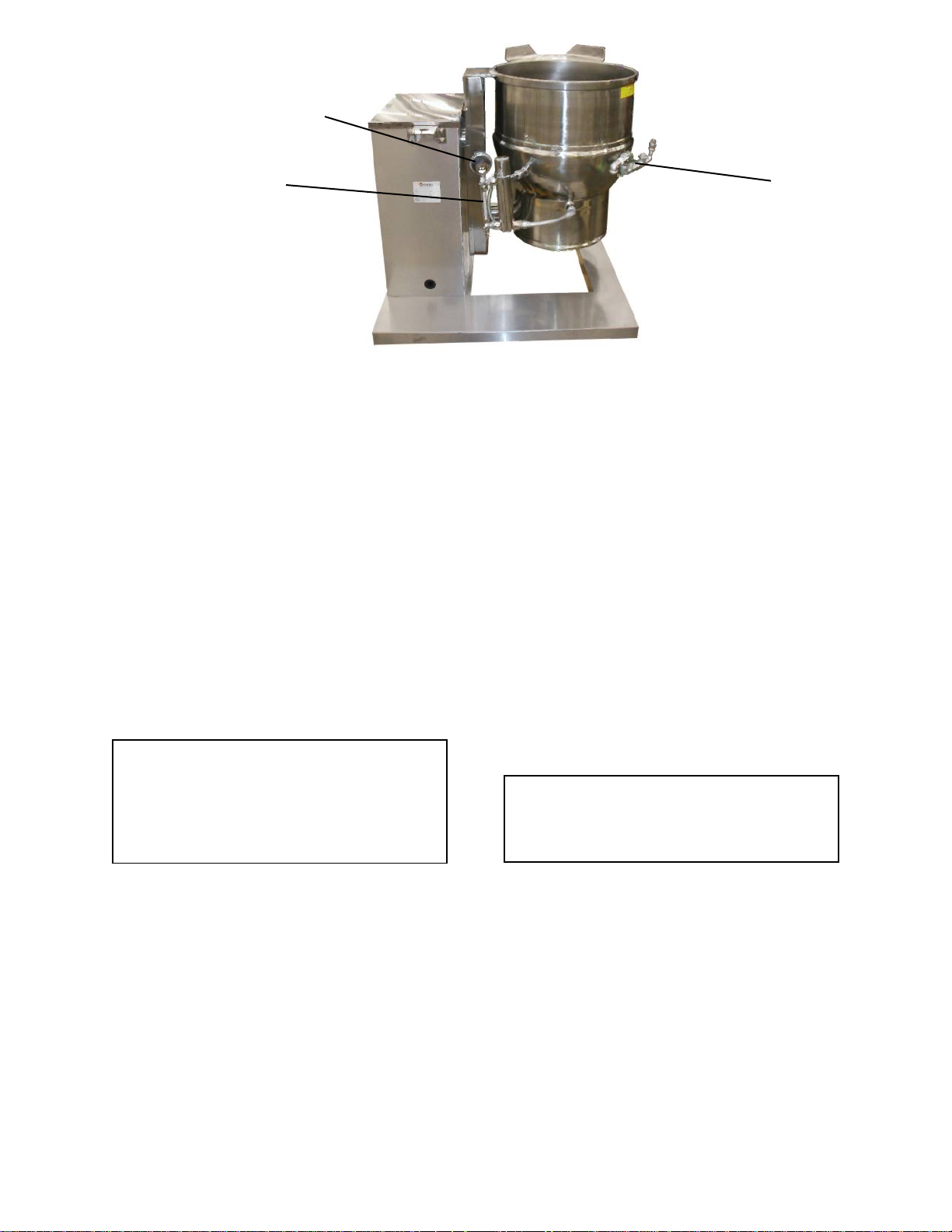

REAR VIEW

Optional equipment available with DEE/4 kettles:

1. 2” or 3" diameter tangent draw-off (product

valve)

2. Lift-off or counterbalanced cover

3. Water fill faucets

4. TRI-BC basket cooking system

5. Powered agitators (TA/3 or INA/2)

6. Kettle brush kit

7. Gallon etch marks

Inspection & Unpacking

The unit will arrive in a heavy shipping carton

and will be bolted or banded to a skid.

Immediately upon receipt, inspect the carton

carefully for exterior damage.

CAUTION

SHIPPING STRAPS ARE UNDER TENSION

AND CAN SNAP BACK WHEN CUT. TAKE

CARE TO AVOID PERSONAL INJURY OR

DAMAGE TO THE UNIT BY STAPLES LEFT

IN THE WALLS OF THE CARTON.

Carefully cut any polyester straps around the

carton and detach the sides of the box from the

skid. Pull the carton up off the unit.

Thoroughly inspect the unit for concealed

damage. Report any shipping damage or

incorrect shipments to the delivery agent.

Write down the model number, serial number,

and installation date, and retain this information

for future reference. Space for these entries is

provided at the top of the Service Log at the

back of this manual. Keep this manual on file

and available for operators to use.

CAUTION

THIS UNIT IS VERY HEAVY. INSTALLER

SHOULD OBTAIN HELP AS NEEDED TO

LIFT THIS WEIGHT SAFELY.

When installation is to begin, carefully cut any

straps which hold the unit on the skid. Lift the

unit straight up off the skid. Examine packing

materials to be sure loose parts are not

discarded with the materials.

Pressure/Vacuum

Gauge

Water Gauge

Glass

Safety

Valve

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

OM-DEE/4

7

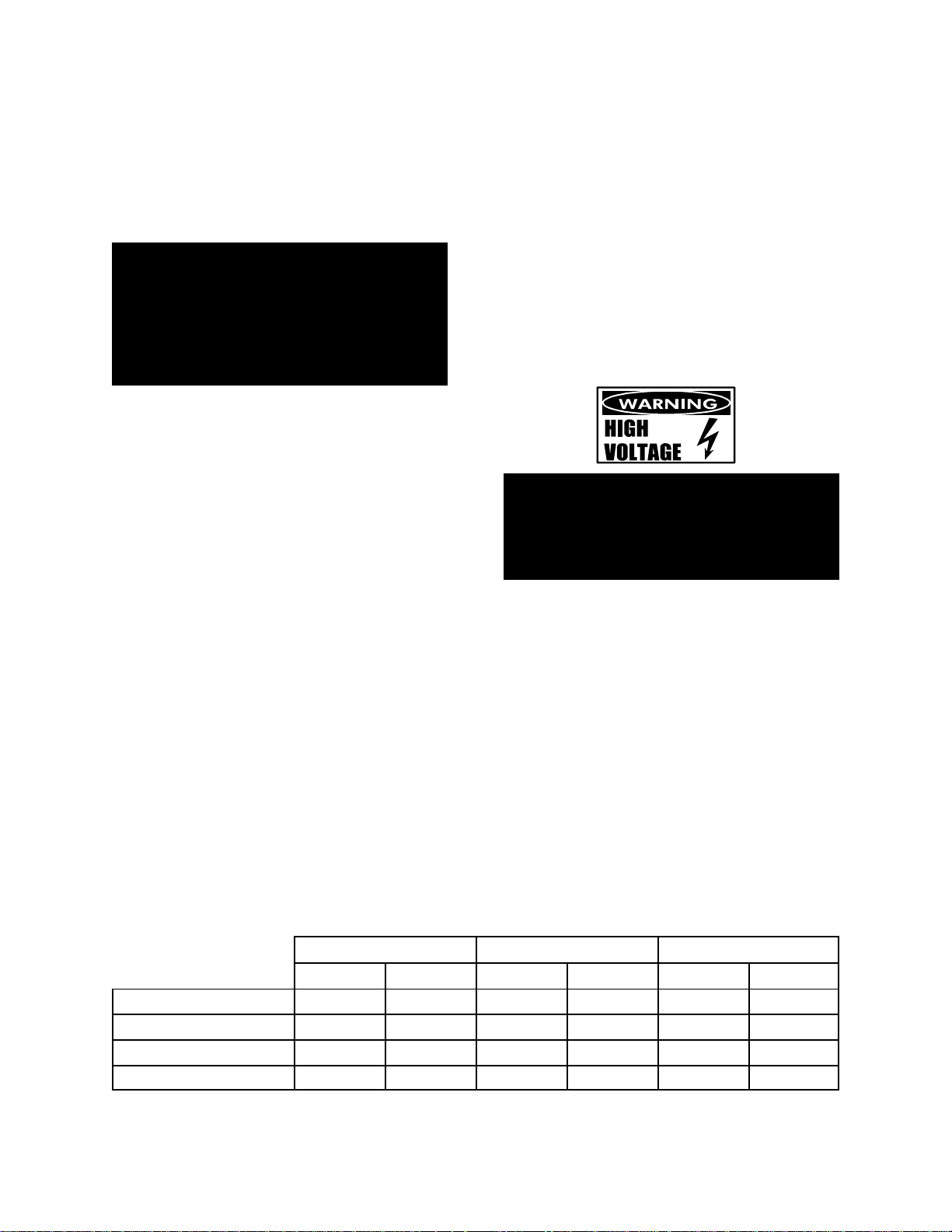

Installation

The Groen Kettle is provided with complete

internal wiring and is ready for immediate

connection. Wiring diagrams are provided in this

manual and on the inside of the control housing

service panel. Any mechanical or electrical

changes must be approved by Groen’s Food

Service Engineering Department.

WARNING

INSTALLATION OF THE KETTLE MUST BE

DONE BY PERSONNEL QUALIFIED TO

WORK WITH ELECTRICITY. IMPROPER

INSTALLATION CAN RESULT IN INJURY

TO PERSONNEL AND/OR DAMAGE TO

EQUIPMENT.

The completed unit has been operated at the

factory to test all controls and heater elements.

1. Set the kettle in place and level it by turning

the bullet feet to adjust leg length. Allow

clearance around the unit for cleaning,

maintenance and service.

2. Confirm that the jacket water level is above

the mid point of sight glass (new models) or

between the marks on the gauge glass (old

models). If the level is low, follow the

instructions under “Jacket Filling and Water

Treatment,” Page 13.

3. The open end of the

elbow on the outlet of

the safety valve must

face downward. If it

does not, turn it to

the correct position.

4. Provide electrical

power specified on

the equipment electrical information plate.

Observe local codes and/or The National

Electrical Code in accordance with

ANSI/NFPA 70 - (current edition).

5. The equipment is shipped ready for three

phase operation. Refer to the wiring diagram

for single phase operation.

6. Bringing the electrical service through the

entrance at the rear of the support housing

with one inch conduit, making a watertight

connection with the incoming lines. Observe

local codes and/or the National Electrical

Code in compliance with ANSI/NFPA 70

(latest edition). When there is a choice

between applicable codes, Groen

recommends following the more stringent

code. (A BX connection is not

recommended.)

DANGER

ELECTRICALLY GROUND THE UNIT AT

THE TERMINAL PROVIDED. FAILURE TO

GROUND UNIT COULD RESULT IN

ELECTROCUTION AND DEATH.

7. Electrically ground the unit at the terminal

provided.

8. Check the following to confirm that your

DEE/4 kettle is properly installed:

• Room for cleaning and servicing

• The kettle is level

• The correct amount of water is in the

kettle jacket

• Safety valve is pointed down

• Unit is connected with a waterproof

supply of the proper voltage, phase and

amperage rating

ELECTRICAL SPECIFICATIONS*

DEE/4-20 DEE/4-40 DEE/4-60

KW AMP KW AMP KE AMP

208 Volts 11 30 21 59 21 59

240 Volts 12 31 24 61 24 61

480 Volts 12 15 24 29 24 29

400 Volts 12 17 24 35 24 35

*All three phase. Single phase is also available.

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

OM-DEE/4

8

Each day, confirm the jacket water level by checking

the water gauge.

Initial Start-Up

IMPORTANT:

BE SURE ALL OPERATORS READ, UNDERSTAND AND FOLLOW THE OPERATING

INSTRUCTIONS, CAUTIONS AND SAFETY INSTRUCTIONS CONTAINED IN THIS MANUAL.

Now that the kettle has been installed, you

should test it to ensure that the unit is operating

correctly.

1. Remove all literature and packing materials

from inside and outside of the unit.

2. If the unit is equipped with a draw-off valve

(product outlet), clean out any material which

might clog or damage the draw-off.

3. Confirm that the tilting mechanism is

operating properly by tilting the kettle

through its full range. Then return the kettle

to the upright position.

4. Turn on the electrical service to the unit.

5. Pour 1-2 quarts of water into the kettle.

6. Following “To Start Kettle” instructions in the

“Operation” section of this manual, begin

heating the water at the highest thermostat

setting. The heating indicator light should

come on immediately, and heating should

continue until the water boils.

WARNING

AVOID ALL DIRECT CONTACT WITH HOT

SURFACES. DIRECT SKIN CONTACT

COULD RESULT IN SEVERE BURNS.

AVOID ALL DIRECT CONTACT WITH HOT

FOOD OR WATER IN THE KETTLE.

DIRECT CONTACT COULD RESULT IN

SEVERE BURNS.

5. To shut down the unit, turn the thermostat

dial to “OFF”.

If the unit functions as described above, it is

ready for use. If the unit does not function as

described, contact your local Groen Certified

Service Agency.

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

OM-DEE/4

9

Operation

The operator controls kettle heating with the

thermostat dial. The dial turns heating element

power on or off and sets the kettle operating

temperature.

A. To Start Kettle

1. EVERY DAY make sure that the jacket

water level is between the marks on the

gauge glass. If the level is too low, see

“Jacket Filling and Water Treatment” on

page 13.

2. Check the pressure gauge. If the gauge

does not show 20 to 30 inches of

vacuum (that is, a reading of 20 to 30

below 0), see “Jacket Vacuum” on page

13.

3. Turn on the electrical power to the unit.

4. Turn the thermostat dial to the desired

setting. The heating indicator light

indicates that the kettle is heating.

Cycling of the light on and off shows that

the kettle is being held at the set

temperature. Once in each cycle the

contactors in the support housing will

make a clicking sound. This is

normal.

B. To Transfer Product or Empty Kettle:

1. The kettle is tilted by means of the crank

on the front of the control housing. The

kettle remains in the position to which

tilted until cranked again.

2. Product may also be transfered by

means of the optional draw-off valve if

the kettle is so equipped.

WARNING

AVOID ALL DIRECT CONTACT WITH HOT

SURFACES. DIRECT SKIN CONTACT

COULD RESULT IN SEVERE BURNS.

AVOID ALL DIRECT CONTACT WITH HOT

FOOD OR WATER IN THE KETTLE. DIRECT

CONTACT COULD RESULT IN SEVERE

BURNS.

TAKE SPECIAL CARE TO AVOID CONTACT

WITH HOT KETTLE BODY OR HOT

PRODUCT, WHEN ADDING INGREDIENTS,

STIRRING OR TRANSFERRING PRODUCT

TO ANOTHER CONTAINER.

CAUTION

DO NOT OVERFILL THE KETTLE WHEN

COOKING, HOLDING OR CLEANING. KEEP

LIQUIDS AT LEAST 2-3” (5-8 cm) BELOW

THE KETTLE BODY RIM TO ALLOW

CLEARANCE FOR STIRRING, BOILING

PRODUCT AND SAFE TRANSFER.

WARNING

WHEN TILTING KETTLE FOR PRODUCT

TRANSFER:

1) WEAR PROTECTIVE OVEN MITT AND

PROTECTIVE APRON.

2) USE DEEP CONTAINER TO CONTAIN

AND MINIMIZE PRODUCT SPLASHING.

3) PLACE CONTAINER ON STABLE, FLAT

SURFACE, AS CLOSE TO KETTLE AS

POSSIBLE.

4) STAND TO LEFT OR RIGHT OF KETTLE

WHILE POURING — NOT DIRECTLY IN

POUR PATH OF HOT CONTENTS.

5) POUR SLOWLY, MAINTAINING

CONTROL OF KETTLE AT ALL TIMES,

AND RETURN KETTLE BODY TO

UPRIGHT POSITION AFTER CONTAINER

IS FILLED OR TRANSFER IS COMPLETE.

6) DO NOT OVERFILL CONTAINER. AVOID

DIRECT SKIN CONTACT WITH HOT

CONTAINER AND ITS CONTENTS.

Thermostat Dial

Indicator Light

Tilting Crank

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

Loading...

Loading...