Groen HY-3E Service Manual

?

? IMPORTANT INFORMATION

IMPORTANT INFORMATION ???? KEEP FOR OPERATOR

? ?

IMPORTANT INFORMATION IMPORTANT INFORMATION

KEEP FOR OPERATOR ???? IMPORTANT INFORMATION

KEEP FOR OPERATOR KEEP FOR OPERATOR

OPERATOR MANUAL OM-HY-5E/HY-3E

Part Number 142412 DOMESTIC

MODELS: HY-3E,(2)HY-3E,

HY-5E, (2)HY-5E

HyPerSteam™

Atmospheric Convection

Steamer

Self-Contained

Electric Heated

Capacity: 5 Steamer Pans [per cavity] (HY-5E)

3 Steamer Pans [per cavity] (HY-3E)

(12" x 20" x 2½”)

(Re-Designed)

IMPORTANT INFORMATION ????

IMPORTANT INFORMATION IMPORTANT INFORMATION

THIS MANUAL MUST BE RETAINED FOR FUTURE REFERENCE. READ,

UNDERSTAND AND FOLLOW THE INSTRUCTIONS AND WARNINGS

CONTAINED IN THIS MANUAL.

FOR YOUR SAFETY

DO NOT STORE OR USE GASOLINE OR OTHER FLAMMABLE VAPORS AND

LIQUIDS IN THE VICINITY OF THIS OR ANY OTHER APPLIANCE

Information contained in this document is

known to be current and accurate at the time

of printing/creation. Unified Brands recommends referencing our product line websites,

unifiedbrands.net, for the most updated

product information and specifications.

.

IMP O RTANT — READ FIRST — IMPORTANT

WARNING: THE UNIT MUST BE INSTALLED BY PE RS ONNEL QUALIFIE D TO WORK WITH

ELECTRICITY AND PLUMBING. IMPROPER INSTALLATION CAN CAUSE INJURY TO

PERSONNEL AND/OR DAMAGE TO THE EQUIPMENT. THE UNIT MUST BE INSTALLED IN

ACCORDANCE WITH APPLICABLE CODE S .

CAUTION: SHIPPING S TRAPS ARE UNDER TENSION AND CAN SNAP BACK WHEN CUT.

CAUTION: DO NOT INSTALL THE UNIT IN ANY WAY WHICH WILL BLOCK THE S IDE VENTS, OR

WITHIN 12 INCHES O F A HEAT SOURCE SUCH AS A BRAISING PAN, DEEP FRYER, CHAR

BROILER OR KETTLE.

CAUTION: LEVEL THE UNIT FRONT T O BACK, OR PITCH IT SLIGHTLY TO THE REAR, TO AVOID

DRAINAGE PROBLEMS.

WARNING: FOLLOW THE WIRING DIAGRAM EXACTLY WHEN CONNECTING A UNIT TO AVOID

DAMAGE OR INJURY.

CAUTION: DO NOT US E P LASTIC PIPE. DRAIN MUST BE RATED FOR BOILING WATER.

WARNING: DO NOT CONNECT T HE DRAIN DI RE CTLY T O A BUILDING DRAIN.

WARNING: BLOCKING THE DRAIN IS HAZARDOUS.

Important: Improper drain connection will void warranty.

Important: Do not allow any wat er t raps in the line. A trap can cause p ressure to build up inside the

cavity during steaming , which will make the door gasket l eak.

WARNING: WHEN YOU OPEN THE DOOR, STAY AWAY FROM STEAM COMING OUT OF THE UNIT .

STEAM CAN CAUSE BURNS.

WARNING: BEFORE CLEANING THE OUTSIDE OF THE STEAMER, DISCONNECT THE ELECTRIC

POWER SUPPLY. KEEP WATER AND CLEANING SOLUTIONS OUT OF CONTROLS AND

ELECTRICAL COMPONENTS. NEVER HOSE OR STEAM CLEAN ANY PART OF THE UNIT .

WARNING: ALLOW COOKING CHAMBER TO COOL BEFORE CLEANING.

WARNING: CAREFULLY READ THE WARNINGS AND FO LLOW THE DI RE CTIONS ON THE LABEL OF

EACH CLEANING AGENT.

RECOMMENDED BY DE LIMING AGENT MANUFACTURER.

WARNING: DO NOT M IX DE-LIMING AGENTS (ACID) AND DE-GREASERS (ALKALI) .

WARNING: DO NOT PUT HANDS OR TOOLS INTO THE COOKING CHAMBER UNTIL THE FAN HAS

STOPPED TURNING.

WARNING: DO NOT OPERATE T HE UNIT UNLESS THE REMOVABLE RIGHT SIDE PANEL HAS BEEN

RETURNED TO IT S P ROPER LOCATION.

NOTI CE : DO NOT US E A CLEANING OR DE-LIMING AGENT THAT CONTAINS ANY SULFAMIC ACID

OR ANY CHLORIDE, INCLUDING HYDROCHLORIC ACID. IF THE CHLORIDE CONTENT OF

ANY PRODUCT IS UNCLEAR, CONSULT THE MANUFACTURER.

NOTI CE : DO NOT US E ANY DE-GREASER THAT CONTAINS POTASSI UM HY DROXIDE OR SODI UM

HYDROXIDE O R THAT IS ALKALINE.

WARNING: USE OF ANY REPLACEMENT PARTS OTHER THAN THOSE SUPPLIED BY GROEN OR

THEIR AUTHORIZED DISTRIBUTOR VOIDS ALL WARRANTIES AND CAN RESULT IN

BODILY INJURY TO THE OPERATOR AND DAMAGE THE EQUIPMENT. SERVICE BY

OTHER THAN FACTORY-AUTHORIZED PERSONNEL WILL VOID ALL WARRANTIES.

USE SAFETY GLASSES AND RUBBER GLOVES AS

WARNING: HIGH VOL TAGE EXISTS INSIDE CONTROL COMP ARTMENTS. DISCONNECT F ROM

BRANCH CIRCUIT BEF ORE SERVICING. FAILURE TO DO SO CAN RESULT I N S E RIOUS

INJURY OR DEATH.

2

Table of Contents

OPERATOR WARNINGS................................................................. 2

REFERENCES ......................................................................... 3

EQUIPMENT DESCRIPTION .............................................................. 4

INSPECTION AND UNPACKING ........................................................... 4

WATER CONDITIONING ................................................................. 5

INSTALLATION AND START-UP ........................................................... 6

OPERATION........................................................................... 9

CLEANING ........................................................................... 11

MAINTENANCE ....................................................................... 13

TROUBLESHOOTING .................................................................. 13

PARTS LIST ........................................................................14-19

ELECTRICAL SCHEMATICS ...........................................................20-21

SERVICE LOG ........................................................................ 22

WARRANTY PROTECTION .............................................................. 23

References

UNDERW RITERS LABORAT ORIES, INC.

333 Pfi ngsten Road

Northbrook, Illinois 60062

NATIONAL FIRE PROTECTION ASSOCIATION

60 Batterymarch Park

Quincy, Massachusetts 02269

NFPA/70 The National Elec trical Code

NATIONAL S A NITATION F OUNDATION

3475 Plym outh Road

Ann Arbor, Michigan 48106

3

Equipment Description

Your Groen HY-5E or HY-3E HyPerSteam

Convection Steam er is designed to give years of

servi ce. It has a stainless steel c avity ( c ook ing

chamber) whic h is served by an independent

atmospheri c steam generator which i s el ec tricall y heated. A powerf ul blower circul ates the steam in

the cavity to increase heating effici enc y .

The cavity holds up to five (HY-5E) or thr ee ( HY - 3E )

steam table pans (12" x 20" x 2½ " deep) . An 18

gauge stainless steel case encl oses the cavity , the

steam generator and the control compartment that

houses electrical components. Door hinges are

rever sible (the door m ay be set to open from the left

or right) . Operating Contr ols are on the front panel.

HY-3E and HY-5E steamers are equipped with f ully

electronic controls and a butt on- ac tiv ated, preprogrammed CLEAN cycle. These units are readily

identified by their unique control panels. The OnOff switch is operated by t ouc h pad c ontrols, and

the disti nc tive symbol for st eam is integrat ed into

the panel. T he new models also have fewer panel

louvers on the right side.

The HY- 3E st eamer holds three

standard 12" x 20" x 2½ ” st eamer

pans.

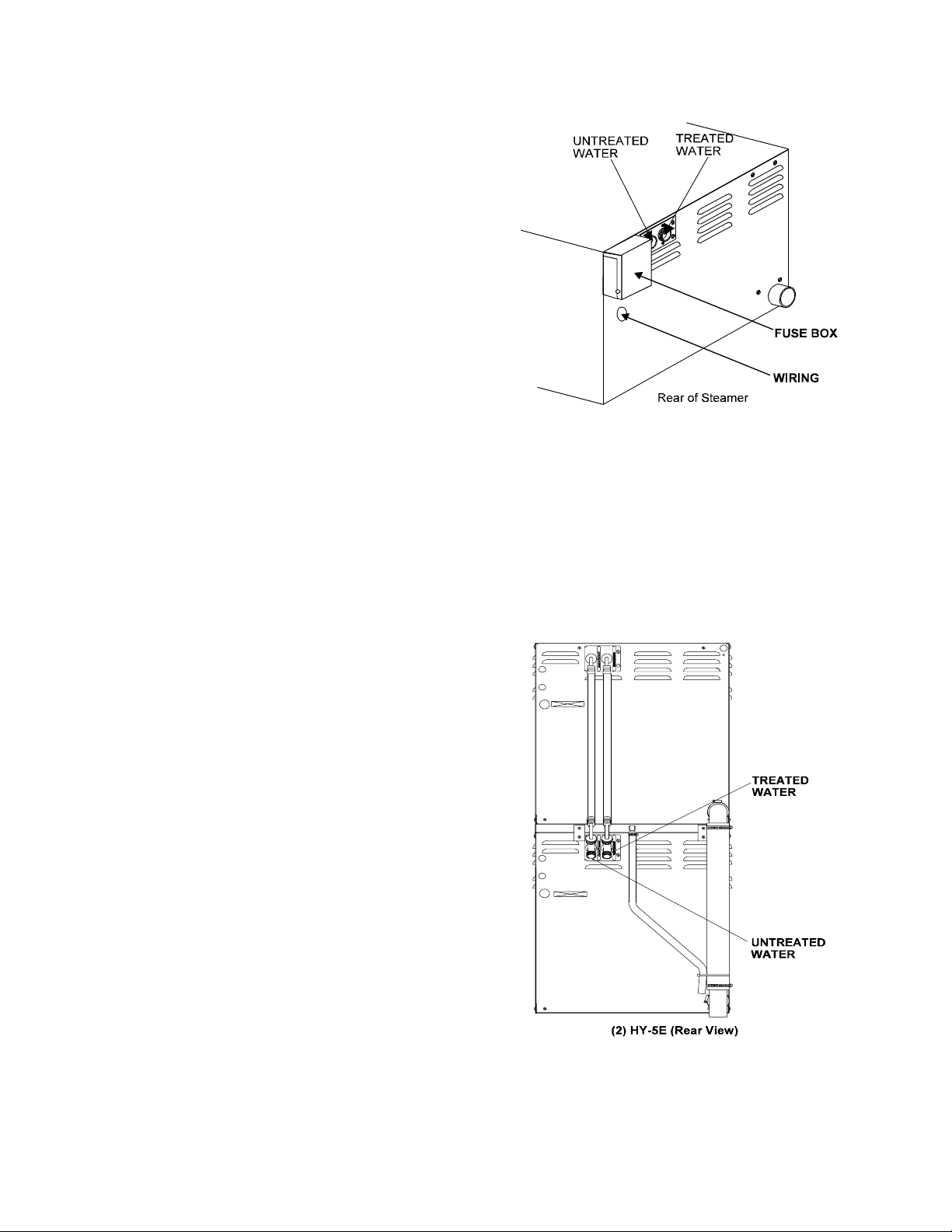

From t he rear HY-3E and HY-5E units are

distinguished by the addition of a fuse box, whi c h

lets operators change fuses without removing

panels.

The drain system on all models includes a spray

condenser, which helps keep steam from escaping

from the chamber and cools drain water.

Inspection and Unpacking

The Steamer will be delivered completely

assembled in a heavy shipping car ton strapped to a

skid. On receipt, inspect carton carefully for exterior

damage.

CAUTION

SHIPPING STRAPS ARE UNDER TENSION AND

CAN SNAP BACK WHEN CUT.

Caref ul ly cut the straps and detach the si des of the

car t o n f r om the ski d. P ull t he cart on up of f t he un i t .

Be careful to avoid personal injury or equipment

damage from staples which might be left in the carton

walls.

The HY-5E holds up to five pans.

CAUTION

THE HY-5E WEIGHS 230 POUNDS (104 KG).

THE THE HY-3E WEIGHS 180 POUNDS (82 KG).

YOU SHOULD GET HELP AS NEEDED TO LIFT

THIS WEIGHT SAFELY.

Wr ite down the model number, serial number and

installation date. Keep this information for reference.

Space for these entries is provided at the top of the

Serv ice Log in the back of this manual.

When starting instal lation, chec k pac k ing materi als

to make sure loose parts such as the condensate

drip tray ar e not discarded with thi s material.

4

Water Conditioning

It is essential to supply the steam generator with water

that will not form scale. Even though the steam

generator is engi neer ed to minimize scale formation,

scale dev elopment depends on the hardness of y our

water and the number of hours per day you operate

the equipm ent.

Most water supplies are full of minerals which form

scale. It is this scale which could lead to an early

component failure.

Your water utility can tell you about the minerals in

your water. The water going to the steam generator

should have more than 10 to 30 part s per million

(ppm) t otal dissolved solids (TDS) and should have a

pH (acidity rating) of 7.0 or higher. Please follow

these simpl e pr ec autions:

1. The best way to prevent scal e is to use a Groen

PureSteem™ Wat er Treatment S y stem which has

been specifically designed for Groen steamers

and combination ov ens. Do not rely on

unproven water treatment systems sold for

scale prevention and rem oval. They are not

specifically designed to work with Groen

steamers and combination ovens.

Models built sin ce 1998 have a fuse box

mounted on the rear.

On both the HY-3E and HY -5E, the dual water

connections are side by si de on the rear of the unit.

When seen from from the back of the unit, the

treated (softened) water intake is on the right.

2. A well-maint ained water treatm ent system and a

regular cartridge replacement schedule is

essential.

3. Using a Groen PureSteem™ Water Treatment

System will provide longer steam generator/boiler

life, higher steam capacity, and reduce

maint enanc e requirements.

4. If you notic e a sl owdown in steam production or

an increase in deliming, have the steamer

checked for scale build-up. This could be an

indicat ion that the water tr eatment cart r idges need

replacing. Heavy scal e r educ es the unit’s ability to

boil water, and c an even cause component failur e.

MINIMIZE SCALE PROBLEMS BY USING AND

MAINTAINING A SOFTENER AND BY CLEANING

(DELIMING) THE STEAMER REGULARLY.

The optional second water connection can

reduce treated water requirements.

5

Installation and Start-Up

WARNING

THE UNIT MUST BE INSTALLED BY PERSONNEL WHO ARE QUALIFIED TO WORK WITH ELECTRICITY

AND PLUMBING. IMPROPE R INSTALLATION CAN CAUSE INJURY T O PERSONNEL AND/OR DAMAGE

TO THE EQUIPME NT. THE UNIT MUST BE INSTALLE D IN ACCORDANCE WITH APPLICABLE CODES

CAUTION

DO NOT INSTALL THE UNIT WITH THE RIGHT OR LEFT SIDE VENTS BLOCKED OR WITHIN 12 INCHES

OF A HEAT SOURCE (SUCH AS A BRAISING PAN, DEEP FAT FRYER, CHARBROILER OR KETTLE).

TO AVOID DRAINAGE PROBLEMS, LEVEL THE UNIT FRONT TO BACK.

1. Electrical Supply Connection

.

A. Panel Removal

Open the wiri ng and c ontrol panel by removing

screws from the r ight side panel. S lide the

panel for ward, and set it aside.

B. Supply Vol tage

The unit must be operated at the rated

nameplat e volt age.

C. Phase Select ion

Refer to st eamer schemati c s (P ages 20-21) for

wiring information.

CAUTION

EACH UNIT MUST HAVE A SEPARATE

GROUND WIRE FOR SAFE OPERATIO N.

D. Terminal Bloc k

The terminal block for incoming power is

located at the back of the c ontrol compar tment.

The ground terminal is l oc ated in the wiring

compart ment near the terminal block.

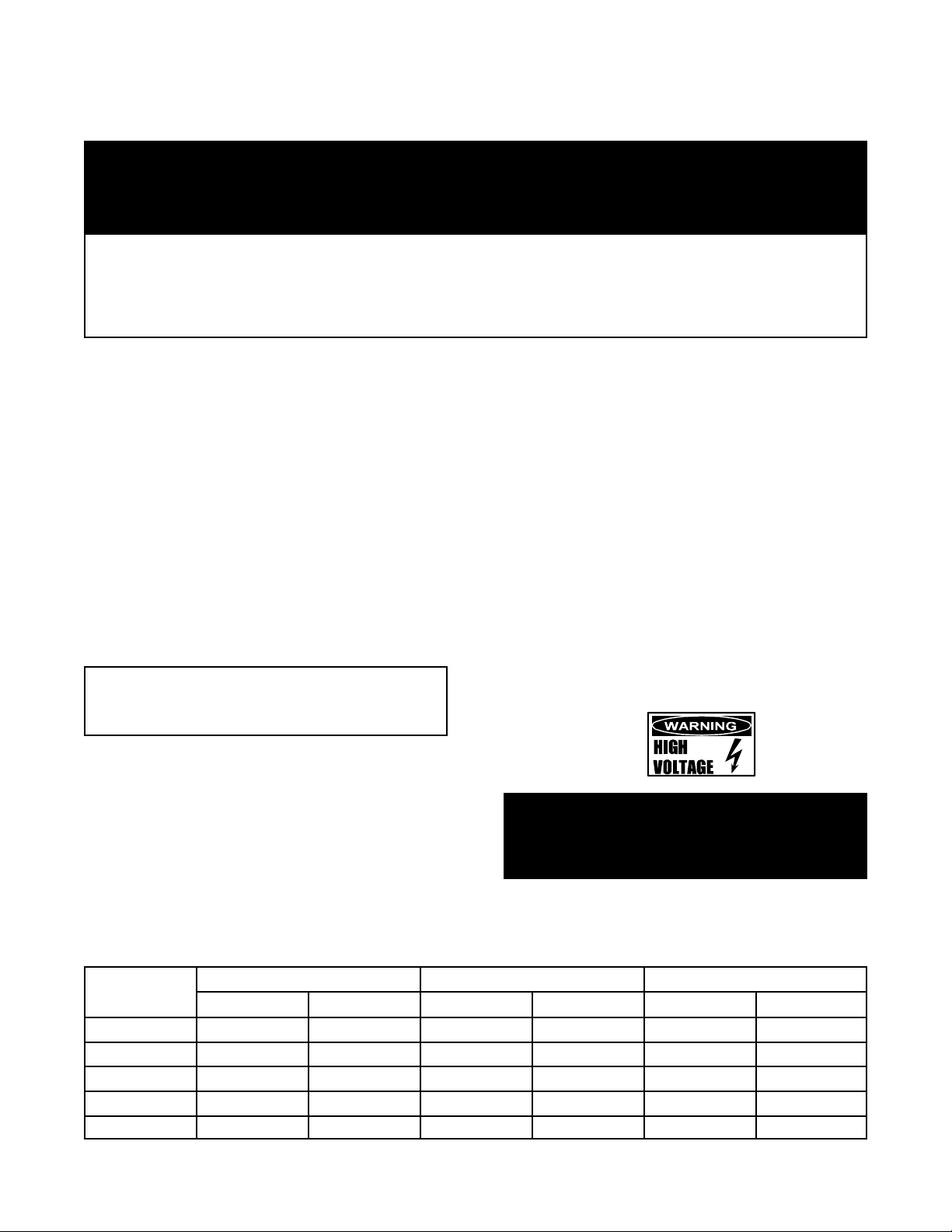

E. Supply Wire

To determine the type of wire you need for the

power supply, find the operating voltage and

number of phases on the unit data plat e. Refer

to the tabl e below or to the label on the unit’s

back for correct wire size and t emperature

rating. The equipment gr ounding wire must

comply wi th the National E lectrical Code (NEC)

requirements. The schematic on the inside of

the unit’s right side cov er gives dir ec tions for

proper connection of the terminal bl ock jumpers.

The specified wire must be used, or the unit will

not meet Under writers Laboratories and NEC

requirements. The knockout hole is sized for a

¾ inch condui t fit ting on the HY-3E and for a

one inch conduit fit ting on the HY-5E.

WARNING

TO AVO ID DAMAGE OR PERSO NAL INJURY,

FOLLOW THE ELECTRICAL SCHEMATIC

EXACTLY WHEN CO NNE CTING THE UNIT..

ELECTRICAL SUPPLY CONNECTIONS

FIELD WIRING TABLE - USE COPPER WIRE ONLY - INSULATION RATING THHN (90ºC)

VOLTAGE

(60 Hz Only)

480 3 PHASE 8.1 15.5 14 AWG 12 AW G 10 Amps 18.6 Amps

240 1 PHASE 8.1 15.5 8 AW G 4 AW G 33 A mps 64.6 Amps

240 3 PHASE 8.1 15.5 10 AWG 8 AWG 20 Amps 37.3 Am ps

208 1 PHASE 8.1 15.5 8 AW G 4 AW G 39 A mps 74.5 Amps

208 3 PHASE 8.1 15.5 10 AWG 6 AWG 23 Amps 43.0 Am ps

HY-3E HY-5E HY-3E HY-5E HY-3E HY-5E

KW FIELD WIRING RATED CURRENT DE M AND

6

Branch Circ uit Protection

Each Steamer, including individual units of

stacked models, should have its own branch

circuit protection and ground wire. Current

and power demands for each unit are as shown

on Page six.

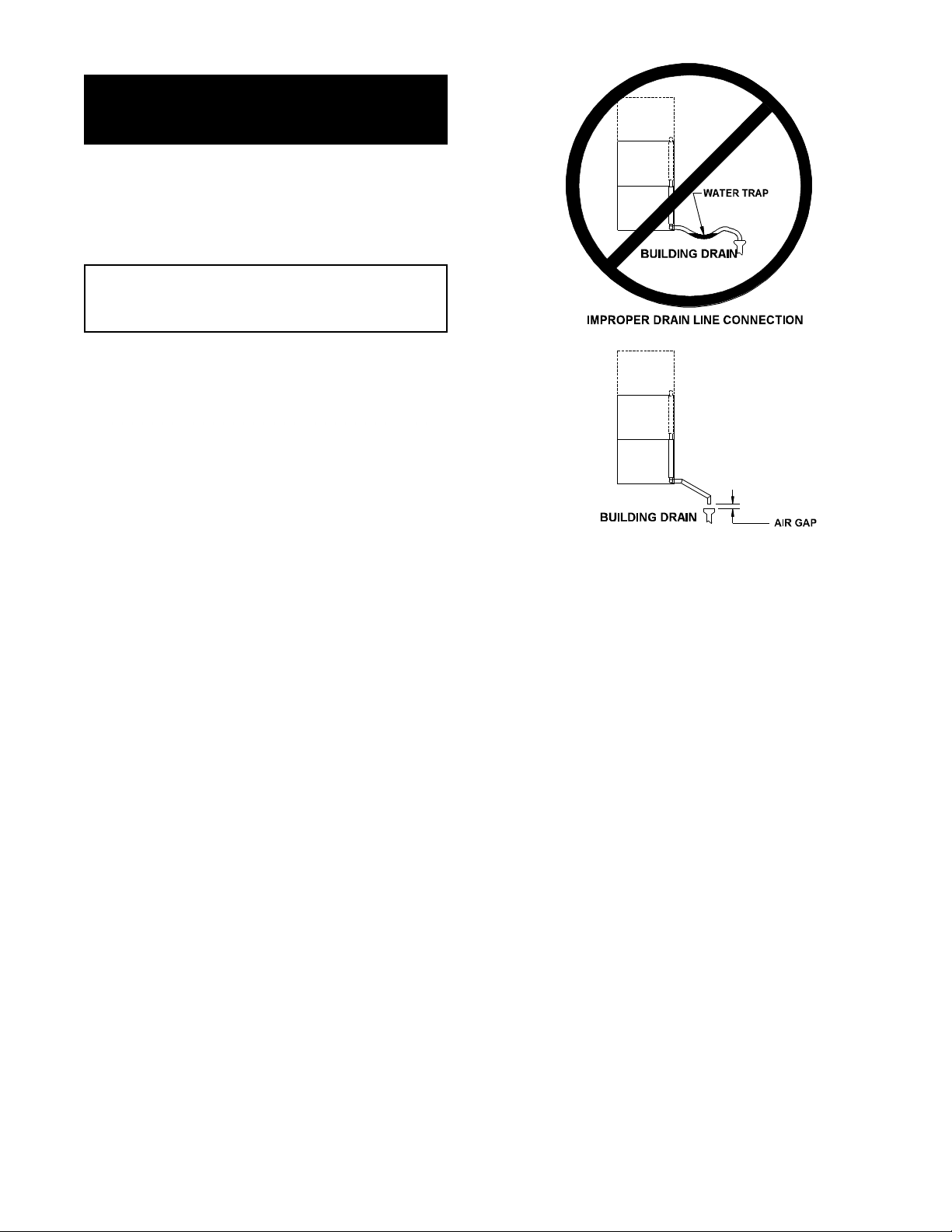

IMPORTANT: Do not allow water traps in the

line. A trap can cause pressure bu ild-up i n the

cavity, which may cause the door gasket to leak.

4. Factory Stacked Units

2. Water Connection(s)

Install a c hec k valve to prevent back f low in the

incoming cold water line, as required by loc al

plumbing codes. Water pressure in the li ne

should be between 30 and 60 PSIG and must

deliver a flow rate of 1.5 to 3.0 gallons per

minut e. If pressure is above 60 PSIG, a

pressure regulator will be needed.

A ¾ inch female NH connec tor (garden hose

type) is used to attach the water supply to the

inlet valve. Minimum insi de diameter of the

water feed line is ½ inch. Use a washer in the

hose connection. Do not allow the connection to

leak, no matter how slowly. The dual water

standard connecti on, treated (soft ened) water

goes to the right ( seen from the rear of the unit ) ,

and untreated water to the left. Connections for

both are made as shown on Page Five.

3. Drain Connection

Level the steamer front to back, or pitch it

slightly to the rear (maximum ¼ inch) by

adjusting t he bullet f eet on the stand or cabinet

base.

A 2 inch [HY-5E] or 1½ inch [HY-3E] ID hose

may be att ached to the drain pi pe ( suppl ied).

WARNING:

DO NOT CONNECT T HE DRAIN DI RECT L Y T O

A BUILDING DRAIN. BLOCKING THE DRAIN IS

HAZARDOUS.

This section is applicable only if you are installing

factor y-stacked units. If you plan to stac k steamers

yourself , whether purchasing a new one for stacking

or a kit to stack two units you already own, you will

require O M-HY-3E(S), RET ROFIT SUPPLEMENT

(Part Number 121014). These instructions are also

valid for stac k ing HY-5E steamers.

Install ing stacked steamers is similar to installi ng a

single unit. The steamers are stack ed and

assembled at the factory and del ivered with the

water connections and drain hoses required for a

single point connection.

A. Water Connection

At the water inlet valve a ¾ inch female NH

connector (garden hose ty pe) is used for the

water supply. The dual water connection has

two connections to be made. Treated water

(softened) is connected to the ri ght val ve fitting

(looking from t he r ear of the unit) and untreated

water to the left fitting.

B. Electr ical Supply Connec tion

Separate, i ndividual electrical connections

will be required for each steamer in the

stack. Each St eamer must have its own

branch circuit protection.

C. Drain Connection

Steamers must be lev eled front t o back, or

pitched to the rear (maximum ¼ inch) by

adjusting t he bullet f eet on the cabinet or stand

base.

There must be a free air gap between the end of

the hose and the buil ding drain. The free air

gap should be as close as possible to the uni t

drain. T her e must also be no other elbows or

other restri c tions between the unit drain and the

free ai r gap.

CAUTION

DO NOT USE PLASTIC PIPE. DRA IN MUST BE

RATED FOR BO ILING WATER.

Install the drain line with a constant downward pitch.

For HY-3E a 1½ inch and for HY-5E a 2 inch ID

hose may be attac hed to the unit drai n. It must

be rated for boiling water.

7

WARNING

DO NOT CONNECT THE UNIT DRAIN DIRECTLY

TO THE BUILDING DRAIN.

Ensure that there is a free air gap bet ween the end

of the unit drain and the building drain. This gap

should be as close as possible to the uni t drain. Do

not allow el bows or restri c tions between the unit and

the free air gap.

CAUTION

DO NOT USE PLASTIC PIPE. DRA IN MUST BE

RATED FOR BO ILING WATER.

Install the line with a constant downward pit c h.

Rear view of (2) HY-5E — Note: Some drain parts

(elbow, clamps) for single mod els are packed inside

the steamer cavity

assembled. Installati on is the same fo r st acked HY-

5E and HY-3E units.

Rear view of (2) HY-5E — Note: Some drain parts

(elbow, clamps) for single mod els are packed inside

the steamer cavity

assembled. Installati on is the same fo r st acked HY5E and HY-3E units.

. Stacked un its are factory-

. Stacked un its are factory-

Proper Drain Line Connection — Drain Line

must have a constant downward pitch of at

least ¼” per f oot. (3)HY-3E shown. Connection

is 1½” for HY-3E, 2" for HY-5E.

8

Loading...

Loading...