Getinge Arjohuntleigh Nimbus 3 Professional, Arjohuntleigh Nimbus 3 Instructions For Use Manual

Page 1

Product Photo

NIMBUS®3

NIMBUS

Instructions For Use

®

3 PROFESSIONAL

Page 2

Page 3

Contents

General Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . iii

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

About this Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

About Nimbus 3 and Nimbus 3 Professional . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Nimbus 3 Pump . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Nimbus 3 Mattress . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Nimbus 3 Professional Mattress . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Clinical Applications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Indications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Contraindications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Cautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Care of the patient when sitting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Preparing the Nimbus 3 and Nimbus 3 Professional Systems for Use . . . . . . . . . . . 7

Installing the Nimbus 3 or Nimbus 3 Professional Mattress . . . . . . . . . . . . . . . . . . . 7

Installing the Pump . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Connecting the Tubeset . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Disconnecting the Tubeset . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

System Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Controls, Alarms and Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Pump Controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Pump Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Mattress Controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Additional Controls on the Nimbus 3 Professional Mattress . . . . . . . . . . . . . . . . . . 14

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Installing the System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Inflating the Mattress . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Testing the Power Fail Alarm . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Deflating the Mattress . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

System Optimisation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Selecting the Operating Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Silencing Audible Alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Comfort Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Transport Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

CPR Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Patient Positioning Guidance for the Nimbus 3 Professional Mattress . . . . . . . . . . 21

Decontamination . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Routine Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Nimbus 3 and Nimbus 3 Professional Systems . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Nimbus 3 Pump . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Nimbus 3 and Nimbus 3 Professional Mattresses . . . . . . . . . . . . . . . . . . . . . . . . . 25

(i)

Page 4

Serial Number Labels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Technical Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Pump . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Mattress . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Cover Specification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Cleaning Symbols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

(ii)

Page 5

GENERAL SAFETY

Before you connect the system pump to a mains socket, read carefully all the installation

instructions contained within this manual.

The system has been designed to comply with regulatory safety standards including:

• EN60601-1:1990/A13:1996 and IEC 60601-1:1988/A2:1995

• UL60601-1, UL2601-1 and CAN/CSA C22.2 No. 601.1-M90

Safety Warnings

• It is the responsibility of the care giver to ensure that the user can use this product

safely.

• Whilst the patient is unattended, safety sides should be used based on clinical

assessment and in line with local policy.

• Alignment of the bed frame, safety sides and the mattress should leave no gap

wide enough to entrap a patient's head or body, or to allow egress to occur in a

hazardous manner where entanglement with the mains power cable and tubeset or

air hoses may result. Care should be exercised to prevent occurrence of gaps by

compression or movement of the mattress. Death or serious injury may occur.

• Make sure that the mains power cable and tubeset or air hoses are positioned to

avoid causing a trip or other hazard, and are clear of moving bed mechanisms or

other possible entrapment areas. Where cable management flaps are provided

along the sides of the mattress, these should be used to cover the mains power

cable.

• Electrical equipment may be hazardous if misused. There are no user-serviceable

parts inside the pump. The pump's case must only be removed by authorised

technical personnel. No modification of this equipment is allowed.

• The mains power socket/plug must be accessible at all times. To disconnect the

pump completely from the electricity supply, remove the plug from the mains

power socket.

• The CPR control and/or the CPR indicator tag must be visible and accessible at all

times.

• Disconnect the pump from the mains power socket before cleaning and inspecting.

• Keep the pump away from sources of liquids and do not immerse in water.

• Do not use the pump in the presence of uncontained flammable liquids or gasses.

• The cover of this product is vapour permeable but not air permeable and may

present a suffocation risk.

• Only the pump and mattress combination as indicated by ArjoHuntleigh should be

used. The correct function of the product cannot be guaranteed if incorrect pump

and mattress combinations are used.

• To avoid the risk of electric shock, this equipment must only be connected to a

supply mains with protective earth.

• Due to the inherently lower flame retardancy of the high performance eVENT

®1

fabric, it is NOT suitable for use in the homecare environment.

Precautions

For your own safety and the safety of the equipment, always take the following

precautions:

1. eVENT® is a registered trademark of BHA Technologies Inc.

(iii)

Page 6

• Placing extra layers between the patient and the mattress potentially reduces the benefit s

provided by the mattress and sh ould be avoid ed or kept to a minimum. As p art of sens ible

pressure area care, it is advisable to avoid wearing clothing which may cause areas of

localised high pressure due to creases, seams, etc. Placing objects in pockets should be

avoided for the same reason.

• Do not expose the system, especially the mattress, to naked flames, such as cigarettes,

etc.

• In the event of a fire, a leak in the seat or mattress could propagate the fire.

• Do not store the system in direct sunlight.

• Do not use phenol-based solutions to clean the system.

• Make sure the system is clean and dry prior to use or storage.

• Never use sharp objects or electrically heated under blankets on or under the system.

• Store the pump and mattress in the protective bags supplied.

Electromagnetic Compatibility (EMC)

This product complies with the requiremen ts of applicable EMC Standa rds. Medical ele ctrical

equipment needs special precautions regarding EMC and needs to be installed in accordance

with the following instructions:

• The use of accessories not specified by the manufacturer may result in increased

emissions by, or decreased immunity of, the equipment, affecting its performance.

• Portable and mobile radio frequency (RF) communications equipment (e.g. mobile/cell

phones) can affect medical electrical equipment.

• If this equipment needs to be used adjacent to other electrical equipment, normal

operation must be checked before use.

• For detailed EMC information contact ArjoHuntleigh service personnel.

Environmental Protection

Incorrect disposal of this equipment and its component parts, particularly batt eries or other

electrical components, may produce substances that are hazardous to the environment. To

minimise these hazards, contact ArjoHuntleigh for information on correct disposal.

Service Information

ArjoHuntleigh recommend that th is system sh ou ld b e se rviced e ver y 12 ca le nd ar m on th s or,

where applicable, when the service indicator is illuminated.

Design Policy and Copyright

® and ™ are trademarks belonging to the ArjoHu ntleigh g roup of co mpanies. As our pol icy is

one of continuous improvement, we reserve the right to modify designs without prior notice.

© ArjoHuntleigh 2009.

(iv)

Page 7

1. Introduction

About this Manual This manual is your introduction to the Nimbus

Nimbus 3 Professional systems. Use it to initially set up

the system, and keep it as a reference for day-to-day

routines and as a guide to maintenance.

About Nimbus 3 and Nimbus 3 Professional

Nimbus 3 and Nimbus 3 Professional are Dynamic

Flotation Systems for the prevention, treatment and

management of pressure ulcers.

Nimbus 3 and Nimbus 3 Professional systems comprise

a pump and mattress replacement which can be used on

standard hospital and normal domestic beds. Beds can

be adjusted or profiled with the mattress in position.

Nimbus 3 Professional mattress has the following

The

additional features to enable the patient to be proned,

and to assist with pressure area and patient care

management:

• A Head Section Deflate Control to allow the three

head cells to be fully deflated.

®

3 and

• Individual Vent Valves to allow 16 of the 20 cells to

be independently deflated.

Nimbus 3 and Nimbus 3 Professional mattresses

The

incorporate an advanced

AutoMatt® sensor pad which

makes sure that the patient is automatically supported at

optimum pressures regardless of size, height, position or

weight distribution.

If cardiac arrest occurs, the

Professional mattresses can be deflated in less than 10

Nimbus 3 and Nimbus 3

seconds to allow cardiac resuscitation procedures to be

performed.

Caution

Federal law restricts this device to sale by or on the order of a

physician.

1

Page 8

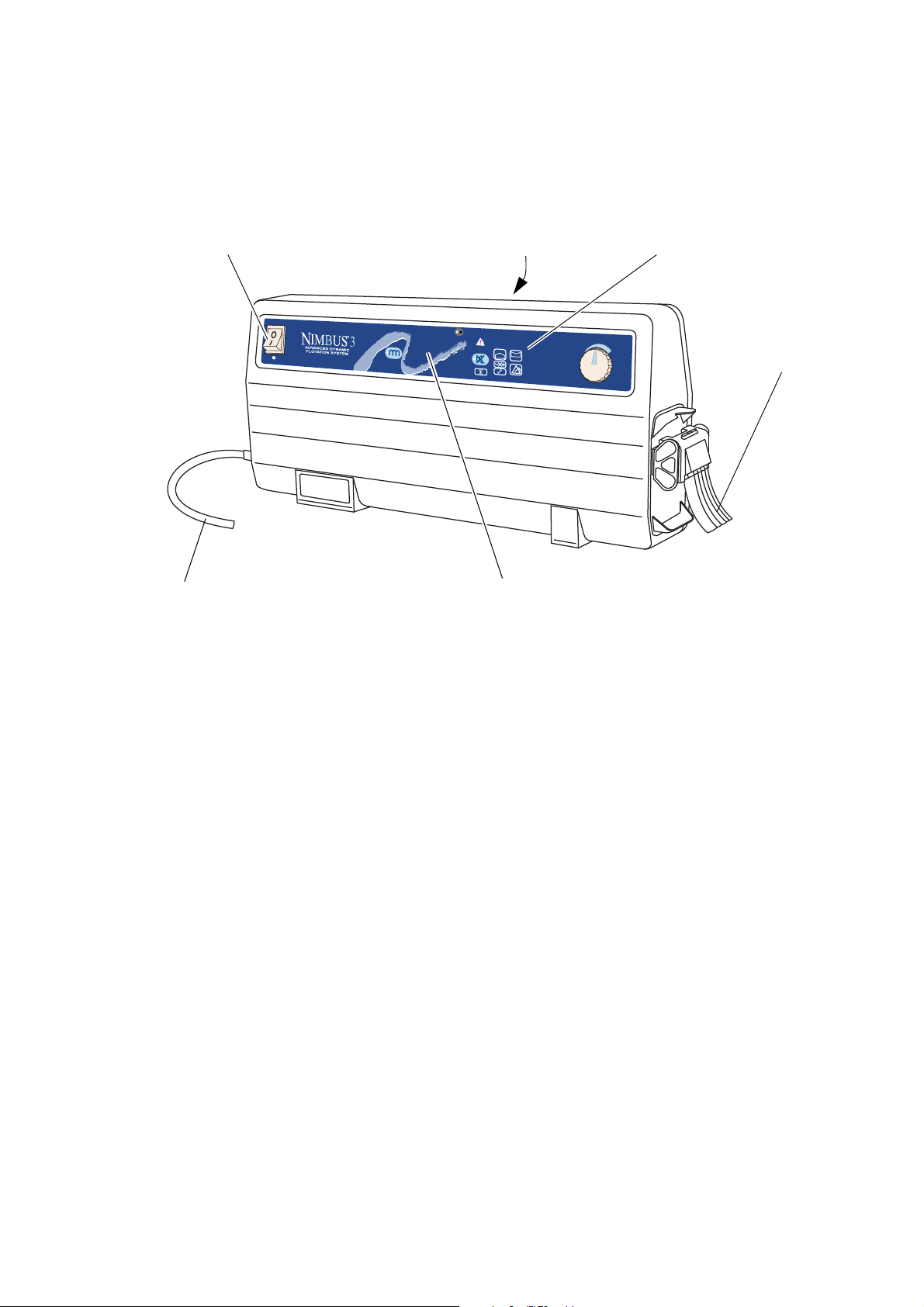

Nimbus 3 Pump The same pump is used on the

Hi

mmHg

Lo

mmHg

-

+

mmHg

Front Panel

Mains Power Switch Alarm Indicators

Tubeset

Mains Power Cord

Carry Handle

Professional systems.

The pump comprises a moulded case with non-slip feet

on the base and rear, and an integral carry handle.

Nimbus 3 and Nimbus 3

The pump has two modes of operation:

•

Dynamic mode that cycles the support surface

beneath the patient every 10 minutes providing

periods of pressure relief for the whole body.

Static mode where the support surface remains

•

constant (all cells equally inflated).

The controls and indicators are located on the front

panel, and a sophisticated alarm system differentiates

between normal operation and genuine system faults. If

an alarm situation is detected a flashing indicator will

illuminate, together with an indication of the cause of

alarm, and an audible warning will sound.

The pump can be fixed to the foot end of a hospital bed

by the separate bed bracket. The bed bracket fits in the

pump handle and then clips onto most common bed

frames. The pump can also be stood on the floor, either

upright or on its rear cover.

2

Page 9

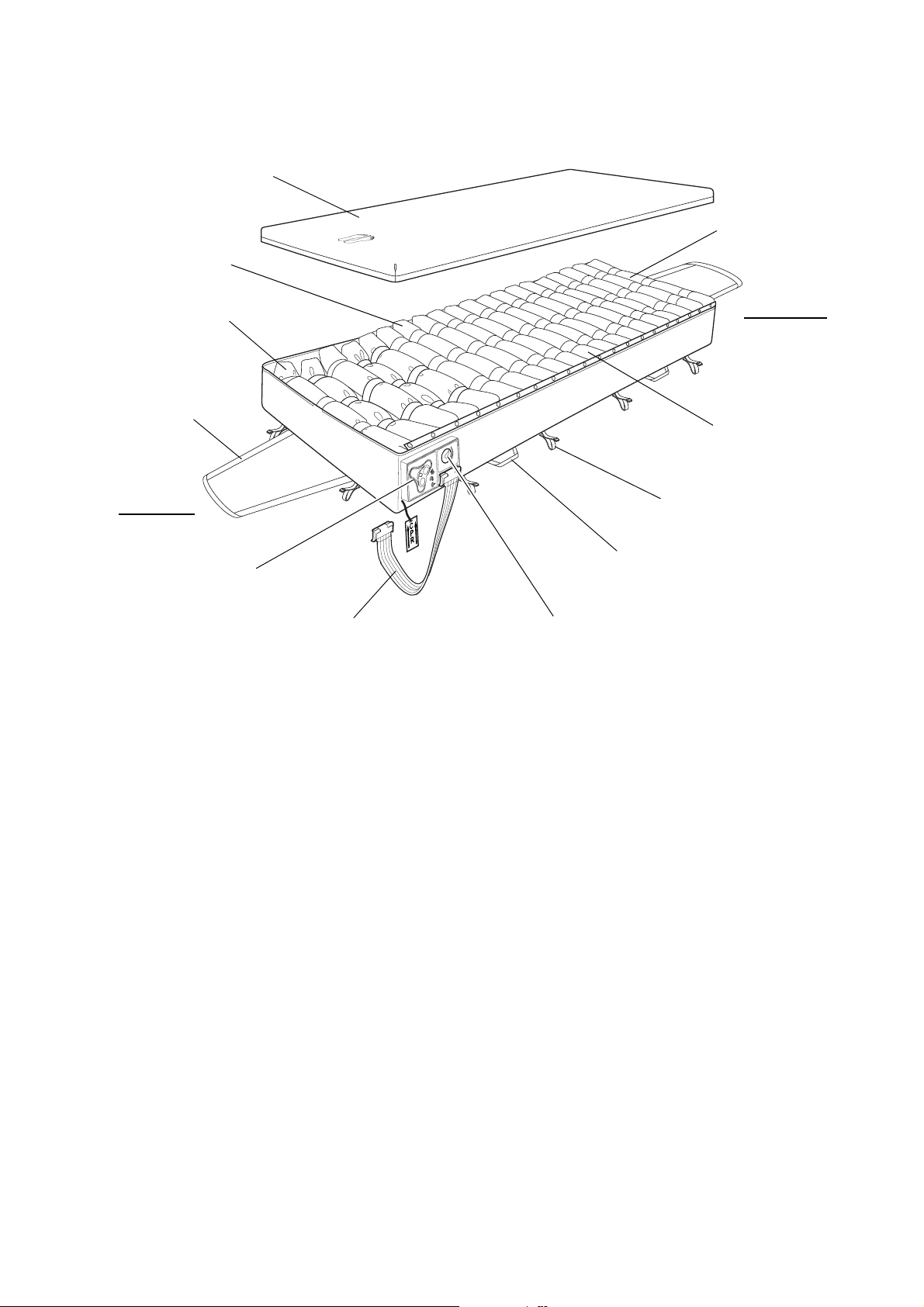

Nimbus 3 Mattress The

CPRCPR

1

3

N

O

R

M

A

L

NORMAL

T

R

A

N

S

P

O

R

T

TRANSPORT

2

FAS

T

D

E

F

L

A

T

E

FASTDEFLATE

Detachable Cover

CPR Control

Transport Control

Carry Handle

Securing Strap

Pump Tubeset

5 “Heelguard” Cells

3 Head Cells

8 Torso Cells

4 Thigh Cells

Head End

Foot End

Drag Handle

components:

Nimbus 3 mattress comprises the following

Detachable Cover The standard protective cover comprises a 2-way stretch

cover zipped to a durable anti-slip base. The zips are

protected by flaps to prevent ingress of contaminants,

and allow easy removal of the cover for cleaning.

Alternative covers with advanced properties, such as

®

Advantex

and eVENT®, are also available (Refer to

“Cover Specification” on page 30).

Cells The Nimbus 3 mattress comprises 20 polyurethane (PU)

cells providing support to the user in either Alternating

or Static modes. The cells are grouped in four sections,

each of which has a specific function:

• The three Head cells remain at a constant pressure

for pillow stability and patient comfort.

• The eight Torso cells combine alternating and static

pressure characteristics to support patients fully in

both lying and sitting positions without the risk of

‘bottoming’.

• The four Thigh cells cycle dynamically to maximise

pressure relief.

• The five

Heelguard

maximise the pressure relief under the heels.

®

cells are specially powered to

3

Page 10

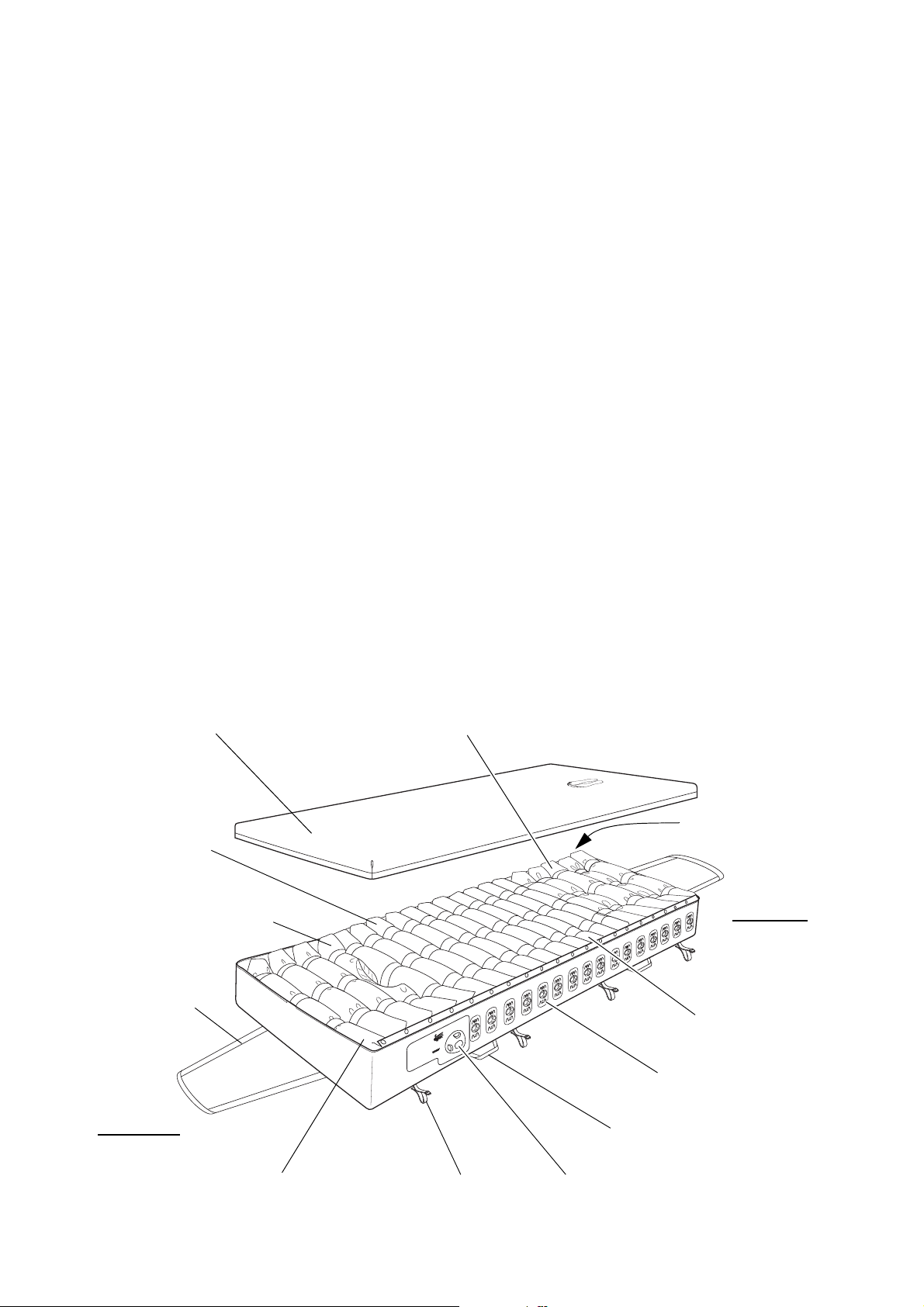

AutoMatt The advanced AutoMatt sensor pad is under the cells,

Detachable Cover

CPR/Transport

Shoulder Support Cell

Carry Handle

Securing Strap

5 “Heelguard” Cells

3 Head Section Cells

7 Torso Cells

4 Thigh Cells

Head End

Foot End

16 Vent Valves

Head Section Deflate Control

Control

Drag Handle

(with Central Cutout)

(“Power-Down” Cells)

and makes sure that the patient is automatically

supported at optimum pressures regardless of size,

height, position or weight distribution.

CPR Control The CPR (Cardio-Pulmonary Resuscitation) Control is

at the foot end of the mattress, and allows the air to be

evacuated in under 10 seconds.

Transport Control The Transport Control is next to the CPR Control. When

operated, it seals the mattress so that air is not exhausted

when the tubeset is disconnected and also creates an

even pressure in all the cells.

Tubeset The tubeset incorporates a flexible, compact anti-kink

tube that is resistant to crushing and any subsequent

obstruction of air flow. Each end has a quick-lock

system for easily connecting and disconnecting the air

supply at the pump and mattress.

Nimbus 3 Professional Mattress

Nimbus 3 Professional mattress is of similar

The

construction to the

Nimbus 3 mattress, with the addition

of a Head Section Deflate Control, individual Vent

Valves on 16 of the 20 cells and a Shoulder Support

Cell.

4

Page 11

Head Section Deflate

Control

Cells The Nimbus 3 Professional mattress has the same

This is a two-position rotary-action control at the head

end of the mattress:

• Dynamic (Normal) Mode. The three cells in the Head

Section are inflated at a constant pressure and the

remaining 17 cells alternate.

T riCell Head Section Deflate. The three cells in the

•

Head Section are fully deflated to assist with patient

care management, and the Shoulder Support Cell (the

fourth cell, next to the Head Section) is inflated to a

constant pressure to support the patient’s shoulders.

The remaining 16 cells alternate.

number of cells as the

Nimbus 3 mattress (20 cells). The

function of the first four cells at the head end of the

mattress is different on the

Nimbus 3 Professional:

• The three cells in the Head Section are either fully

inflated or fully deflated, depending on the position

of the Head Deflate Control, to assist with patient

care management. The cells are specially powered to

enable them to be fully deflated.

• The single Shoulder Support Cell (the fourth cell,

next to the Head Section) has a shallow cutout in the

mid-section of the cell. This is to allow access to the

neck area for clinical procedures and to ensure the

smooth, uniform extension of the neck during

deflation. Its operation is controlled by the Head

Section Deflate Control: the cell is either fully

inflated to support the patient’s shoulders or

alternates (together with the remaining 16 cells).

• The remaining 16 cells (seven T orso cells, four Thigh

cells and five

function as on the

Vent Valves The seven Torso cells, four Thigh cells and five

Heelguard cells have individual Vent Valves to allow

Heelguard cells) have the same basic

Nimbus 3 mattress.

each cell to be independently deflated, to assist with

pressure area and patient care management.

5

Page 12

2. Clinical Applications

Indications The Nimbus 3 and Nimbus 3 Professional systems are

indicated for the prevention and management of all

categories1 of pressure ulcer when combined with an

individualised monitoring, repositioning and wound care

programme.

The

designed for patients weighing up to 250 kg (550 lb).

The

designed for patients weighing up to

Nimbus 3 and Nimbus 3 Professional mattress is

Nimbus 3 and Nimbus 3 Professional cushion is

250 kg (550 lb).

Contraindications Do not use

for patients with unstable spinal fractures.

Cautions If patients have other unstable fractures, or conditions

which may be complicated by a soft or moving surface,

advice should be sought from an appropriate clinician

before use.

While the

have been designed to manage patients up to the weight

limits indicated above, those approaching this upper limit

are likely to have additional care and mobility needs and

may be better suited to a specialist bariatric system.

Active therapy (alternating) cushions may be unsuitable

for patients with poor sitting posture or pelvic deformity;

advice from a seating specialist should be sought.

Care of the patient

when sitting

Seated patients are at increased risk of pressure ulcers

particularly if they are immobile or have wounds over the

seating area. For optimal outcome, provide a pressure

redistributing seat cushion in a chair which promotes a

good sitting posture and has a level base seat to support the

cushion, in addition to an individualised repositioning

programme.

Nimbus 3 and Nimbus 3 Professional systems

Nimbus 3 and Nimbus 3 Professional systems

The above are guidelines only and should not replace clinical judgement.

The

Nimbus 3 and Nimbus 3 Professional systems represent one aspect of a

pressure ulcer management strategy; if existing wounds do not improve or the

patients condition changes the overall therapy regimen should be reviewed by

the prescribing clinician.

Mattress and cushion combinations may have different upper weight limits.

Cushions should be used in combination with pressure-redistributing

mattresses to provide 24-hour therapy.

1. NPUAP/EPUAP International Pressure Ulcer Guideline, 2009.

6

Page 13

3. Installation

The Nimbus 3 and Nimbus 3 Professional systems are very simple to install

using the following guidelines.

Refer to Section 4, Page 11 “Controls, Alarms and Indicators” for a

comprehensive description of the controls and indicators on the pump and

mattress.

Preparing the Nimbus 3 and Nimbus 3 Professional Systems for Use

1. Remove the system from the packaging. You

should have the following items:

Nimbus 3 pump, with integral mains power cord.

•

•

Nimbus 3 mattress replacement or the

Nimbus 3 Professional mattress replacement.

• Bed bracket.

•Tubeset.

Installing the Nimbus 3 or Nimbus 3 Professional Mattress

1. Remove the conventional mattress from the bed

frame and check that there are no protruding bed

springs or sharp objects on the bed frame surface.

Heavily ridged bed baseboards may require special considerations for

correct system operation - consult your ArjoHuntleigh representative.

2. Unroll the mattress onto the bed base and make

sure that the CPR is at the foot end, and the CPR

label is hanging freely.

3. Attach the mattress to the bed frame using the hook

and loop securing straps.

If the bed can be profiled to any position (i.e. raised or lowered), attach the

mattress to the movable parts of the bed only.

7

Page 14

4. For

C

P

R

1

3

N

O

R

M

A

L

T

R

A

N

S

P

O

R

T

2

FA

S

T

D

E

F

L

A

T

E

Head End

Foot End

Soft Foam Sheet

Hard Foam Sheet

AutoMatt

Sensor Pad

Cover

Cells

Hard Foam Sheet

AutoMatt Sensor Pad

CPR

1

3

NORMAL

TRANSPORT

2

FAST DEFLATE

Transport ControlCPR Control

NORMAL

TRANSPORT

Nimbus 3 mattresses only, check the AutoMatt

sensor pad, as follows:

• Unzip the cover on one side of the mattress only.

• Pull the side of the mattress away from the cells.

•The

AutoMatt sensor pad is situated under the cells

between the soft and hard foam sheets.

• Make sure that the

AutoMatt sensor pad is lying

flat and is not “kinked”.

• Zip the cover back onto the mattress, taking care

not to trap any cell material in the zip.

For Nimbus 3 Professional mattresses, the AutoMatt is encapsulated and

does not need to be checked.

5. Leave the ends of the mattress cover free when

profiling the bed.

6. Make sure the CPR control is closed and locked in

position and the Transport control is set to

NORMAL.

8

Page 15

Additional Checks on

Closed

Open

Dynamic (Normal) Mode

TriCell Head Section Deflate

the Nimbus 3

Professional Mattress

1. Make sure that all 16 Vent Valves are closed.

2. Make sure that the Head Section Deflate Control is

set to

Dynamic (Normal) Mode.

Installing the Pump 1. If the pump is to be hung from the end of the bed,

make sure that the bed bracket is securely attached

to the pump, and then attach the pump and bed

bracket to the bed frame.

2. Alternatively the pump can be placed underneath

the bed, either upright or lying on its back.

3. Insert the connector on the end of the mains power

cord into a suitable mains power outlet.

9

Page 16

Connecting the

1

2

1

2

Tubeset

To connect the tubeset to the mattress and pump:

1. Locate the bottom of the tubeset connector onto the

bottom of the pump/mattress connector.

2. Pull the top of the tubeset connector up and over the

top of the pump/mattress connector, until the

tubeset connector “clicks” into position.

3. Make sure both connections are secure.

Disconnecting the

Tubeset

To disconnect the tubeset from the mattress and pump:

1. Move the tubeset connector down by pulling the

tubeset extrusion downwards, and then pull the

bottom of the tubeset connector away from the

bottom of the pump/mattress connector.

2. Lift the top of the tubeset connector off the top of

the pump/mattress connector.

System Operation The system is now ready for use. Refer to

Section 4, Page 11 “Controls, Alarms and Indicators”

and Section 5, Page 16 “Operation” for day-to-day

operating instructions.

WARNING

Make sure the mains power cord and tubeset are positioned to

avoid causing a hazard.

Caution

Make sure the mains power cord and tubeset are clear of moving

bed mechanisms or other possible entrapment areas.

10

Page 17

4. Controls, Alarms and Indicators

-

+

mmHg

Hi

mmHg

Lo

mmHg

N

R

Power Switch Mute Control

Static Control

ComfortWait

High Pressure

Indicator

Low Pressure

Indicator

Power Fail

Indicator

Service

Indicator ControlIndicator

& Alarm Reset & Indicator

& Indicator

Pump Fault

Indicator

Alarm

Indicator

On/Reset Alarm

Indicator

mmHg

+

Pump Controls The pump front panel has the following controls:

POWER Switch (and

RESET ALARM)

STATIC Mode Selects the operating mode, either Static or Dynamic.

Alarm MUTE An audible alarm mute is provided to cancel warning

Switches the mains power to the pump on and off.

The green indicator is illuminated when the mains

power is connected and the pump switched on.

The switch is also used to reset the pump after an alarm

condition has been detected.

Static mode is confirmed when the yellow indicator on

the button is illuminated.

When Dynamic mode (default) is selected the yellow

indicator will be extinguished.

sounds during an alarm condition.

COMFORT CONTROL This is a rotary action control to set the relative firmness/

softness of the mattress for patient comfort.

11

Page 18

Pump Indicators The pump front panel has the following indicators:

Hi

mmHg

Lo

mmHg

ON / RESET ALARM The green ON / RESET ALARM indicator below the

POWER switch is illuminated when the mains power is

connected and the pump switched on.

STATIC Mode The indicator on the STATIC button is illuminated when

Static mode has been selected for operation.

Alarm MUTE The indicator on the MUTE button is illuminated when

an audible alarm has been silenced.

The indicator will NOT be illuminated when a Power Fail alarm is muted.

WAIT The WAIT indicator is illuminated when the mattress is

being inflated.

The indicator will remain illuminated until the mattress

has been fully inflated. This may take up to 15 minutes.

HIGH PRESSURE The HIGH PRESSURE indicator is illuminated whenever

the pump detects high pressure within the mattress.

If this condition occurs, the air supply from the pump is

switched off until normal pressure is detected. After 2

seconds of normal pressure being detected the indicator

is switched off and the air supply restarted.

LOW PRESSURE The LOW PRESSURE indicator is illuminated whenever

the pump detects low pressure within the mattress.

This may indicate that there is insufficient pressure to

support a patient or that the Transport control is turned

to the

TRANSPORT position whilst the pump is on and

connected to the mattress.

The LOW PRESSURE indicator will be switched off

once normal pressure is reached.

Alarm The pump unit incorporates a sophisticated alarm

detection system that differentiates between patient

movement and genuine alarm conditions.

Whenever an alarm condition is detected the red

Alarm

triangle starts flashing together with an indicator of the

cause of the alarm. Additionally, an audible warning

will sound, which can be cancelled by pressing the

Alarm MUTE button (Refer to “Alarm MUTE” on

page 11).

The triangular Alarm symbol is displayed with one or

more of the following indicators:

12

Page 19

• LOW PRESSURE (Refer to “LOW PRESSURE” on

page 12).

• HIGH PRESSURE (Refer to “HIGH PRESSURE” on

page 12).

•PUMP FAULT (Refer to “PUMP FAULT” on

page 13).

•

POWER (Refer to “POWER Fail” on page 13).

For all alarm conditions except Power Fail, once the alarm condition has

been detected and displayed, it can only be cancelled by switching the pump

unit off and then back on.

Refer to Section 8, Page 27 “Troubleshooting” for

possible causes of the above alarm conditions.

PUMP FAULT The PUMP FAULT indicator is illuminated when an

internal pump malfunction is detected.

The fault can only be rectified by carrying out a service

on the pump.

POWER Fail The POWER indicator will flash when a mains power

failure has been detected.

The alarm will continue until the mains power is

resumed or the pump is switched off using the

POWER

switch on the pump control panel.

Service Indicator The symbol will be illuminated after a set number of

running hours to indicate that the pump is ready for a

service.

This service period is set to 12 months.

The pump will continue to operate normally even when the symbol is

illuminated.

13

Page 20

Mattress Controls All

CPR

1

3

NORMAL

TRANSPORT

2

FAST DEFLATE

Transport ControlCPR Control

NORMAL

TRANSPORT

Nimbus 3 and Nimbus 3 Professional mattresses

have the following two controls, situated at the foot end

of the mattress:

Transport Control This sets the mattress into TRANSPORT mode where the

support surface is equally pressurised and the pump and

tubeset can be removed. In this mode the mattress will

support the patient for up to 12 hours.

CPR Control The CPR (Cardio-Pulmonary Resuscitation) Control

provides a means of rapidly deflating the mattress to

allow normal resuscitation procedures to be carried out.

The CPR control is used to deflate the mattress for packing and storage.

Additional Controls on the Nimbus 3 Professional Mattress

The following two controls are on the opposite side of

the mattress to the CPR/Transport Control:

Head Section Deflate

Control

This is a two-position rotary-action control at the head

end of the mattress:

Dynamic (Normal) Mode. The three cells in the Head

•

Section are inflated at a constant pressure and the

remaining 17 cells alternate.

TriCell Head Section Deflate. The three cells in the

•

Head Section are fully deflated to assist with patient

care management, and the Shoulder Support Cell

(next to the Head Section) is inflated to a constant

14

Page 21

pressure to support the patient’s shoulders. The

Dynamic (Normal) Mode

TriCell Head Section Deflate

Closed

Open

remaining 16 cells alternate.

16 Vent Valves The seven Torso cells, four Thigh cells and five

Heelguard cells have individual Vent Valves to allow

each cell to be independently deflated, to assist with

pressure area and patient care management.

15

Page 22

5. Operation

These instructions cover day-to-day operation of the system. Other operations, such

as maintenance and repair, should only be carried out by suitably qualified

personnel.

Refer to Section 4, Page 11 “Controls, Alarms and Indicators” for a

comprehensive description of the controls and indicators on the pump and

mattress.

Installing the System Before using the

system make sure:

1. The system has been installed correctly in

accordance with Section 3, Page 7 “Installation”.

2. The CPR unit on the mattress is closed and locked

in position.

3. The Transport control on the mattress is set to

NORMAL.

4. If a Nimbus 3 Professional system is being

installed, make sure that on the mattress:

• All 16 Vent Valves are closed.

• The Head Section Deflate Control is set to

Dynamic (Normal) Mode.

Inflating the Mattress 1. Switch the pump POWER switch to ON.

ON / RESET ALARM indicator below the

The

POWER switch should illuminate.

2. The pump will now run a self test for

approximately 3 seconds when all the indicators on

the front panel will be illuminated.

Nimbus 3 or Nimbus 3 Professional

3. If the pump detects low pressure (e.g. a deflated

mattress) it will enter an inflation sequence with the

LOW PRESSURE and WAIT indicators illuminated.

4. Once normal operating pressure has been reached

both the

extinguish.

LOW PRESSURE and WAIT lights will

It may take up to 15 minutes to inflate the mattress.

The three Head Section cells and the five Heelguard cells will inflate more

slowly than the rest of the mattress.

Testing the Power

Fail Alarm

The Power Fail Alarm is powered by a rechargeable

battery. The duration of the alarm will depend on the

level of charge in the battery.

16

Page 23

The battery may have become discharged or reached the

end of its life. It is therefore recommended that the alarm

is tested before the pump is used, as follows.

1. Connect the pump to the mains power supply,

switch

2. Remove the mains power at the wall socket without

switching the pump off.

3. The power fail alarm should operate within 10

seconds, as follows:

ON and allow it to run for 10-15 seconds.

• The red

•The

• An audible warning will sound.

4. The alarm will continue until the mains power is

resumed or the pump is switched off using the

POWER switch on the pump control panel.

5. If the alarm does not operate, run the pump for

approximately four hours to recharge the battery.

6. Retest the alarm after the battery has been

recharged. Allow the alarm to operate for

approximately two minutes to ensure that it has

been adequately recharged.

7. If the alarm does not operate for two minutes, call

the service engineer.

Alarm triangle will flash.

POWER indicator will flash.

If the Power Fail Alarm does not operate after this test and a service

engineer has been called, the pump can continue to be used with regular

checks of the Power-On status.

All other alarms will continue to function as normal.

Deflating the

Mattress

To deflate and store the mattress, do the following:

1. Switch off the pump, and disconnect the pump from

the mains power supply.

2. Remove the tubeset from the pump and mattress

(Refer to “Disconnecting the Tubeset” on page 10).

3. Activate the CPR control.

4. Make sure the Transport control is set to

5. Roll up the mattress, starting at the foot end.

Make sure the mattress is dry before rolling it up.

17

NORMAL.

Page 24

System Optimisation The

Nimbus 3 and Nimbus 3 Professional systems

automatically compensate for patient weight

distribution and position, to optimise the pressure

relieving performance.

To make sure that the pressure relieving properties are not impaired, the

mattress cover must not be pulled tight and covering sheets should fit loosely

using the attached clips.

The system provides two modes of operation:

•

Dynamic mode provides the optimum pressure

relieving performance and should be used in most

cases. In

the patient is cycled every 10 minutes.

Static mode provides a stable, non-moving support

•

surface for instances where a dynamic support

surface is contra-indicated. In

support surface remains constant (all cells are

equally inflated).

Dynamic mode the support surface beneath

Static mode the

Nimbus 3 Professional

Mattress only

On the Nimbus 3 Professional system, the following

therapeutic positioning controls along the side of the

mattress offer further operating modes in combination

with the

Dynamic pressure relief option, to assist with

pressure area and patient care management:

1. Head Section Deflate Control. This controls the

three cells in the Head Section:

Dynamic (Normal) Mode, where the three Head

•

cells are inflated at a constant pressure and the

remaining 17 cells alternate.

T riCell Head Section Deflate, where the three Head

•

cells are fully deflated, and the Shoulder Support

Cell is inflated to a constant pressure to support

the patient’s shoulders. The remaining 16 cells

alternate.

2. 16 Vent Valves.

The seven Torso cells, four Thigh cells and five

Heelguard cells have individual Vent Valves to

allow each cell to be independently deflated.

Selecting the

Operating Mode

• The pump defaults to the

when switched on.

• Both

selected by the

• When

STATIC button illuminates.

Static and Dynamic modes of operation are

STATIC button on the front panel.

Static mode is selected the indicator on the

18

Dynamic operating mode

Page 25

To change the operating mode:

1. T o select

STATIC button once. An audible tone will sound

Static mode from Dynamic mode press the

and the indicator on the button will illuminate to

show that the system is in

2. T o select

STATIC button once. An audible tone will sound

Dynamic mode from Static mode press the

Static mode.

and the indicator on the button will extinguish.

Silencing Audible

Alarms

Audible alarms can be silenced using the

To silence an alarm push the

indicator on the

MUTE button will remain illuminated).

MUTE button once (the

MUTE button.

In its normal operating mode an audible alarm can only be silenced after an

alarm has occurred. An internal setting can be used to change the mode of

operation so that this button can pre-silence an alarm. Call your service

engineer if this option is required.

Comfort Control The mattress cell pressure can be manually adjusted for

patient comfort using the rotary

To change the comfort setting:

COMFORT CONTROL.

• Turn COMFORT CONTROL clockwise for a firmer

setting and counterclockwise for a softer setting.

• The mattress minimum pressure is maintained at the

chosen level.

The system automatically compensates for patient size, height, position and

weight distribution to provide optimum support regardless of the

CONTROL setting.

Transport Control This seals the mattress and allows the removal of the

pump for patient transport. The patient will remain

supported by the mattress for up to 12 hours in

mode. To set the

Transport mode:

1. At the foot end of the mattress turn the Transport

control knob clockwise to TRANSPORT.

2. Turn the pump off and disconnect the tubeset.

COMFORT

Transport

If the Transport control is set to TRANSPORT with the tubeset connected and

the pump switched on, then the pump will indicate a

alarm.

Low Pressure fault

To resume normal operation:

1. Re-connect the pump and tubeset to the mattress.

2. Turn the Transport control knob counterclockwise

NORMAL.

to

19

Page 26

CPR Control

CPR

1

3

NORMAL

TRANSPORT

2

FAST DEFLATE

CPR

1

3

NORMAL

TRANSPORT

2

FAST DEFLATE

1

3

NORMAL

TRANSPORT

2

FAST DEFLATE

CPR

IMPORTANT

IN THE EVENT OF CARDIAC ARREST.

In the event of a patient suffering cardiac arrest and CPR

needing to be administered:

To Activate the CPR 1. Lift the red CPR handle at the foot end of the

mattress.

2. Turn the handle counterclockwise.

3. Pull the handle away from panel.

4. The grey triangular seal will rotate and the air will

exhaust from the mattress. The torso area of the

patient will bottom out in less than 10 seconds.

To Reset the CPR 1. Turn the grey triangular seal clockwise and push

onto the connectors.

2. Turn the red handle clockwise.

3. Fold the handle flat to lock in position.

20

Page 27

Patient Positioning Guidance for the Nimbus 3 Professional Mattress

Cell 4Head Section Cells

(1 - 3) Fully Inflated

Nimbus 3 Professional mattress allows the patient to be placed in either the

The

Supine or Prone positions.

WARNING

A full patient assessment, as to the suitability for Prone Nursing, is

essential before commencing the procedure.

Safety sides should be used where appropriate (Refer to “General

Safety” on page iii).

It is important that the p atient’ s head, neck and shoulders are in the

correct anatomical position.

Care should be taken at all times to check that all tubes/lines are

positioned correctly.

In the Prone position, regular checks should be made to make sure

the patient is free from a build up of pressure on the anatomically

sensitive areas such as:

• Head and facial areas including eyes

• Top of the shoulders

•Sternum

• Breasts and genitals

• Knees and toes

It is important for the optimal use of the system that patients are positioned

correctly on the mattress.

1. In both the Supine and Prone positions, patients

should be positioned on the mattress so that the tops

of their shoulders lie between the third and fourth

cells.

2. Supine Position.

21

Page 28

3. Prone Position.

Cell 4

Head Section Cells

(1 - 3) Fully Deflated

4. It is recommended that a minimum of four staff will

be required to turn the patient from the Supine to

the Prone position.

• The anaesthetist or most senior member of the

team should be positioned at the head end of the

bed and will co-ordinate the turning procedure.

This person will also be responsible for the safety

of the patient’s head, neck and ventilation tubing.

• The other members of the team will help safeguard

all lines, and assist with the turning procedure as

directed.

Before commencing the turn, it is recommended that all non-essential lines

and monitoring equipment are disconnected.

5. With the patient in the Supine or Prone positions,

the mattress controls can be configured as follows:

• Set the Head Section Deflate Control to

Head Section Deflate (where the 3 Head cells are

fully deflated, and the Shoulder Support Cell is

fully inflated to support the patient’s shoulders)

which can assist with intubation and insertion of

central monitoring lines.

• Open individual Vent Valves (on the seven Torso

cells, four Thigh cells and five

Heelguard cells) to

allow single cell deflation to assist with pressure

area care and patient management, including

everyday interventions such as CXR imaging.

TriCell

Vent Valve Restrictions. For periods longer than 10 minutes, have

no more than 4 cells deflated at any one time (excluding the three

cells in the Head Section).

WARNING

22

Page 29

6. Decontamination

The following processes are recommended, but should be adapted to comply with

the local or national guidelines (Decontamination of Medical Devices) which may

apply within the Healthcare Facility or the country of use. If you are uncertain, you

should seek advice from your local Infection Control Specialist.

Nimbus 3 and Nimbus 3 Professional system should be routinely

The

decontaminated between patients and at regular intervals while in use; as is good

practice for all reusable medical devices.

WARNING

Remove the electrical supply to the pump by disconnecting the

mains power cord from the mains power supply before cleaning.

Protective clothing should always be worn when carrying out

decontamination procedures.

Caution

Do not use Phenol-based solutions or abrasive compounds or pads

during the decontamination process as these will damage the

surface coating. Do not boil or autoclave the cover.

Avoid immersing electrical parts in water during the cleaning

process. Do not spray cleaning solutions directly onto the pump.

To clean Clean all exposed surfaces and remove any organic

debris by wiping with a cloth moistened with a simple

(neutral) detergent and water. Dry thoroughly.

Chemical Disinfection To protect the integrity of the cover we recommend a

chlorine-releasing agent, such as sodium hypochlorite,

at a strength of 1,000ppm available chlorine (this may

vary from 250ppm to 10,000ppm depending on local

policy and contamination status).

Wipe all cleaned surfaces with the solution, rinse and

dry thoroughly.

Alcohol based disinfectants (maximum strength 70%)

may be used as an alternative.

Ensure the product is dry before storage.

If an alternative disinfectant is selected from the wide

variety available we recommend that suitability for use

is confirmed with the chemical supplier prior to use.

23

Page 30

DO NOT WRING/MANGLE, AUTOCLAVE OR USE

PHENOLIC BASED SOLUTIONS.

Thermal Disinfection For information for the mattress top cover, including

laundering guidelines, refer to “Cover Specification” on

page 30.

24

Page 31

7. Routine Maintenance

Nimbus 3 and Nimbus 3 Professional Systems

Maintenance The equipment has been designed to be virtually

maintenance-free between service periods.

Servicing ArjoHuntleigh will make available on request service

manuals, component parts lists and other information

necessary for ArjoHuntleigh trained personnel to repair

the system.

Service Period It is recommended that the pump is serviced every 12

months by a ArjoHuntleigh authorised service agent.

The service symbol will be illuminated on the pump

front panel to indicate that the pump is ready for a

service (Refer to “Service Indicator” on page 13).

Nimbus 3 Pump

General Care,

Maintenance and

Inspection

Check all electrical connections and the mains power

cord for signs of excessive wear.

Test the Power Fail Alarm before use (Refer to “Testing

the Power Fail Alarm” on page 16).

In the event of the pump being subjected to abnormal

treatment, e.g. immersed in water or dropped, the unit

must be returned to an authorised service centre.

Biofilter The internal biofilter can be run continuously for two

years before it requires autoclaving or replacement.

The biofilter can only be replaced by a service engineer.

Nimbus 3 and Nimbus 3 Professional Mattresses

General Care Remove the cover from the mattress.

Inspect the cover for signs of wear or any tears, and

check that all cover fasteners are secure.

Check the security of all internal connections, including:

• Between the cells and the manifold.

• To the CPR/Transport Controls.

• T o the Head Section Deflate Control on the

Professional.

Nimbus 3

Make sure all cell fasteners are correctly connected to

the mattress base sheet and are not loose or damaged.

25

Page 32

Serial Number Labels

Pump The serial number label for the pump is on the back of

Mattress The serial number label for the mattress is on the top of

the pump case.

the CPR/Transport Control, on the outside of the

mattress at the foot end.

26

Page 33

8. Troubleshooting

The following table provides a troubleshooting guide for the Nimbus 3 and

Nimbus 3 Professional systems in the event of malfunction.

Refer to Section 4, Page 11 “Controls, Alarms and Indicators” for a

comprehensive description of the alarms and indicators on the pump.

Indicator Possible Cause Remedy

LOW PRESSURE and WAIT. 1. The pump is inflating the

mattress.

2. CPR control not fully closed.

LOW PRESSURE. 1. The tubeset is not connected

properly.

2. CPR control not fully closed.

3. The Transport control on the

mattress is set to

TRANSPORT.

4. There is a leak in the system

HIGH PRESSURE. 1. The tubeset is blocked.

2. The AutoMatt sensor pad is

blocked.

Flashing POWER and

symbol.

1. Power Fail Alarm.

The pump has detected that

mains power has been

removed.

(a)

1. Both indicators will extinguish

when the operating pressure

is reached.

2. Close CPR control.

1. Check the tubeset

connectors and make sure

they are securely connected

to the pump and mattress.

2. Close CPR control.

3. Turn the Transport control to

NORMAL.

4. Call the service engineer.

1. Check that the tubeset is not

kinked.

2. Check that the AutoMatt

sensor pad is flat and not

kinked.

1. Re-apply mains power or

switch off the pump using the

POWER switch on the

control panel.

If power failure is prolonged,

switch to TRANSPORT

mode and disconnect the

tubeset. The mattress will

remain inflated for 12 hours.

Flashing PUMP FAULT and

symbol.

symbol.

Mattress cells will not inflate

(Nimbus 3 Professional only).

a. If the pump has not been used for a long period, the internal battery which provides the

Power Fail Alarm indication may be discharged. Run the pu mp for a few hours t o recharge

the internal battery, and the Power Fail Alarm indication will be provided as normal.

To check that the Power Fail Alarm is operating correctly, refer to “Testing the Power Fail

Alarm” on page 16.

b. The service period is set to 12 months.

1. Internal pump malfunction. 1. Call the service engineer.

(b)

1. The pump needs a service.

1. Vent Valves are open. 1. Close Vent Valves.

1. Call the service engineer.

27

Page 34

9. Technical Description

i

PUMP

Model: Nimbus 3 / Nimbus 3 Professional

Part Numbers: 151033

Supply Voltage: 120 VAC

Supply Frequency: 60 Hz

Power Input: 35 VA

Size: 20 x 8.7 x 4”

(508 x 220 x 100 mm)

Weight: 12.5 lb

(5.7 kg)

Case Material: ABS Plastic

Pump Fuse Rating: 2 x F500 mAH 250 V

Degree of protection against

Mains Connected - Class I

electric shock:

Type BF

Degree of protection against

liquid ingress: IPX0

Mode of operation: Continuous

SYMBOLS

Power

O

Disconnects from

(Off)

the mains supply

Power

I

Connects to the

(On)

mains supply

With respect to electric

shock, fire and

mechanical hazards

only in accordance

with UL60601-1 and

CAN/CSA C22.2 No.

601.1. MEDICAL

EQUIPENT

Do not dispose of in

domestic refuse

Refer to

accompanying

documents

Type BF

SN:

Alternating Current Dangerous voltage

Refer to the User

Manual

Serial number

Ref:

Fuse

Model Number

ENVIRONMENTAL INFORMATION

Condition Temperature Range Relative Humidity Atmospheric Pressure

Operating +50°F to +104°F

30% to 75% 700hPa to 1060 hPa

(+10°C to +40°C)

Storage and Transport -40°F to +158°F

(-40°C to +70°C)

10% to 95%

(non-condensing)

500 hPa to 1060 hPa

28

Page 35

ACCESSORIES

Part: Tube Set

Part Number: 151200 151201

Length: 39.4” (1000 mm) 98.4” (2500 mm)

Materials: Tube: 5-way moulded PVC

Connectors: Moulded Nylon

MATTRESS

Nimbus 3 Standard Width Narrow Width

Standard Cover 152010DAR 237010

Advantex® Cover

Length 82.0“ (2085 mm)

Height: 8.5” (215 mm)

Width: 35” (890 mm) 31.5” (800 mm)

Weight: 25.3 lb (11.5 kg) 22.7 lb (10.3 kg)

Cell Material: Polyurethane

Base Material: PU Coated Nylon

Top Cover Material: PU Coated Fabric or Advantex PU Coated Fabric

Nimbus 3

Professional

Standard Cover 412001DAR 412201DAR

Advantex® Cover

®

eVENT

Length 82.0“ (2085 mm)

Height: 8.5” (215 mm)

Fabric Cover

152010ADV (not applicable)

Standard Width Narrow Width

412001ADV 412201ADV

412001EVE 412201EVE

Width: 35” (890 mm) 31.5” (800 mm)

Weight: 34.1 lb (15.5 kg) 31.5 lb (14.3 kg)

Cell Material: Polyurethane

Base Material: PU Coated Nylon

Top Cover Material: PU Coated Fabric or Advantex or eVENT Fabric

29

Page 36

COVER SPECIFICATION

Feature

Standard Cover

(Dartex)

®

Advantex

®

eVENT® Fabric

Removable Cover Yes Yes Yes

Moisture Vapour

Permeable

Yes Yes 12 times higher

Air Permeable No No Yes

Low Friction Yes 18% lower 20% lower

Water Resistant /

Repellent

Infection

Control

Fire Retardant BS 7175: 0,1 & 5 BS 7175: 0,1 & 5

Yes Yes Yes

Material coating is

Bacteriostatic,

fungistatic,

antimicrobial

Material coating is

Bacteriostatic,

fungistatic,

antimicrobial

INERT MATERIAL

does not support bacterial

growth

BS EN ISO 12952-1 ONLY

(a)

2-Way Stretch Yes Some No

Washing Conditions MAX 95°C (203°F)

for 15 mins

(b)

Drying Conditions Tumble Dry up to 130°C

(266°F) or Air Dry

MAX 95°C (203°F)

for 15 mins

(b)

Tumble Dry ONLY

at 80-85°C

71°C for 3 minutes or

65°C for 10 minutes

Tumble Dry up to 130°C

(266°F) or Air Dry

(176°F-185°F)

(a)

Life Span

Application Area

50 Wash Cycles

(minimum)

Acute and Homecare Acute and Homecare

50 Wash Cycles

(minimum)

15 Wash Cycles

Acute ONLY

a. Due to the inherently lower flame retardancy of the high performance eVENT® fabric, it is NOT

suitable for use in the homecare environment.

b. Check your local po licy to determine the time/temperature ratio required to achieve thermal

disinfection.

c. The life span of the eVENT cover is significantly lower due to the inherent nature of the eVENT

material.

(c)

(a)

30

Page 37

CLEANING SYMBOLS

95

130

Wash at 160°F (71°C) for a minimum

of 3 minutes

Wash at 95°C (203°F) for a minimum

of 15 minutes

Wash at 149°F (65°C) for a minimum

of 10 minutes

Do not iron Do Not Use Phenol-based cleaning Solutions

Use solution diluted to 1000 ppm of

Available Chlorine

Tumble dry at 176-185°F

Tumble dry at 130°C

Wipe surface with damp cloth

(80-85°C)

31

Page 38

32

Page 39

AUSTRALIA

ArjoHuntleigh Pty Ltd

PO Box 330

Hamilton Hill

AU-6963 WESTERN

AUSTRALIA

T: +61 8 9 337 4111

F: +61 8 9 337 9077

ITALY

ArjoHuntleigh S.p.A.

Via Tor Vergata, 432

IT-ROMA 00133

T: +39 06-87426214

F: +39 06-87426222

SWITZERLAND

ArjoHuntleigh AG

Florenzstrasse 1D

CH-BASEL 4023

T: +41 (0) 61 337 97 77

F: +41 (0) 61 311 97 42

AUSTRIA

ArjoHuntleigh GmbH

Dörrstrasse 85

AT-6020 INNSBRUCK

T: +43 512 20 4160-0

F: +43 512 20 4160 75

BELGIUM

ArjoHuntleigh NV/SA

Evenbroekveld 16

B-9420 ERPE MERE

T: +32 (0) 53 60 73 80

F: +32 (0) 53 60 73 81

DENMARK

ArjoHuntleigh A/S

Vassingerødvej 52

DK-3540 LYNGE

T: +45 4 913 8486

F: +45 4 913 8487

FINLAND

ArjoHuntleigh OY

Vanha Porvoontie 229

FI-01380 VANTAA

T: +35 8 9 4730 4320

F: +35 8 9 4730 4999

NETHERLANDS

ArjoHuntleigh BV

Biezenwei 21

NL-4004 MB TIEL

Postbus 6116

NL-4000 HC TIEL

T: +31 (0) 344 64 08 00

F: +31 (0) 344 64 08 85

NEW ZEALAND

ArjoHuntleigh Ltd

Unit 6/38 Eaglehurst Road

Ellerslie

NZ-AUCKLAND

T: +64 9 525 2488

F: +64 9 525 2433

POLAND

ArjoHuntleigh Polska Sp. z.o.o.

ul. Ks. Wawrzyniaka 2

PL-62052 KOMORNIKI

T: +48 61 662 1550

F: +48 61 662 1590

SOUTH AFRICA

Huntleigh Africa Pty Ltd

120 Willem Cruywagen Avenue

Klerksoord

ZA-PRETORIA

T: +27 12 542 4680

F: +27 12 542 4982

UNITED KINGDOM

Huntleigh Healthcare Ltd

310-312 Dallow Road

Luton, Bedfordshire

LU1 1TD

T: +44 (0)1582 413104

F: +44 (0)1582 459100

USA

ArjoHuntleigh

2349 W Lake Street - Suite 250

Addison, IL 60101

T: +1 630 307 2756

Toll Free US: (800) 323 1245

F: +1 630 307 6195

FRANCE

HNE

451 Chemin de Champivost

BP20

FR-69579 LIMONEST CEDEX

T: +33 (0)4 78 66 62 66

F: +33 (0)4 78 66 62 67

GERMANY

ArjoHuntleigh GmbH

Peter-Sander-Strasse 10

DE-55252 MAINZ-KASTEL

T: +49 6134 1860

F: +49 6134 186 160

SPAIN

ArjoHuntleigh Ibérica S.L.

Carratera de Rubi, 88,

a

planta-A1

1

Sant Cugat del Valles

ES-BARCELONA 08173

T: +34 93 583 1120

F: +34 93 583 1122

SWEDEN

ArjoHuntleigh AB

Box 61

S-241 21 ESLÖV

T: +46 413 645 00

F: +46 413 645 83

Page 40

151996US_03: October 2009

Loading...

Loading...