Page 1

SETUP & OPERATION MANUAL

RIVING KNIFE CONVERSION /

RETROFIT KIT

For General MFG model 350 right-tilt saw.

Kit contains all parts and components to retrofit /convert a non-riving knife model 350, 3HP*

saw to the new type 350R saw with riving style

(raises and lowers with the blade) splitter /

blade guard assembly with anti-kickback

pawls and a European style “true” riving knife

- both included with kit.

*Note for 5 HP motors, modifications to the

motor shaft will be required - contact our

technical service or your local distributor for

details.

350RNK KIT INCLUDES:

New cast-iron saw chute assembly.

New arbor bracket assembly (with arbor)

with built-in riving knife mounting

block/receptacle.

New riving style splitter/blade guard

assembly.

Riving knife

New table insert

Retro-fit instructional DVD

New & improved saw manual for new

350R saw.

ITEM

#350RNK

REVISION 1 - March 29/09

ight General®MFG / General® Inter

yr

© Cop

national 03/2009

Page 2

GENERAL® MFG (CO) LTD.

835, Cherrier Street, Drummondville (Quebec) Canada J2B 5A8

Telephone (514) 326-1161 • Fax (514) 326-5555 • www.general.ca

THANK YOU for choosing this General

®

MFG model 350RNK Riving knife conversion / Retrofit kit. This Retrofit kit has been carefully tested and inspected before shipment

and if properly installed, will provide you with years of reliable service. To ensure optimum performance and trouble-free operation, and to get the most from your investment, please take

the time to read this manual before assembling, installing and operating the unit.

The manual’

s purpose is to familiarize you with the safe operation, basic function, and features

of this retrofit kit as well as the set-up, maintenance and identification of its parts and compo-

ormal w

. This man

nents

fer the user instruction in the craft of woodworking. If you are not sure about the safety of

of

orming a certain operation or procedure, do not proceed until you can confirm, from

perf

ual is not intended as a substitute f

or f

oodworking instruction, nor to

knowledgeable and qualified sources, that it is safe to do so.

Once you’ve read through these instructions, keep this manual handy for future reference.

Disclaimer: The information and specifications in this

manual pertain to the unit as it was supplied from the

actory at the time of printing. Because we are commit-

f

ted to making constant improvements, General

ves the right to make changes to

ble car

eser

e is tak

en a

t the f

y to ensure that

actor

tional r

na

Inter

components, parts or features of this unit as deemed

necessary,without prior notice and without obligation to

install any such changes on previously delivered units.

Reasona

the specifications and information in this manual corres-

ponds with that of the unit with which it was supplied.

However, special orders and “after factory” modifications may r

®

inapplicable to your machine. Further, as several gene-

tions of this model and se

ra

may be in circulation, if you own an earlier or later version of this unit, this manual may not depict your tool

exactly. If you have any doubts or questions contact

our r

y

of your unit for clarification.

ender some or all information in this manual

ersions of this manual

eral v

v

etailer or our suppor

t line with the model n

umber

Page 3

RULES FOR SAFE OPERATION

To help ensure safe operation, please take a moment to learn the machine’s applications and limitations, as well as poten-

ial hazards. General® MFG disclaims any real or implied warranty and holds itself harmless for any injury that may result

t

from improper use of its equipment.

o not operate the saw when tired, distracted, or

1.D

under the effects of drugs, alcohol or any medication that impairs reflexes or alertness.

he working area should be well lit, clean and free

2.T

of debris.

3. Keep children and visitors at a safe distance when

the saw is in operation; do not permit them to

operate the saw.

4. Childproof and tamper proof your shop and all

machiner

and switch keys, to prevent unauthorized or unsupervised use.

5. Stay alert! Give your work your undivided atten

tion. Even a momentary distraction can lead to serious injury.

6. Fine particulate dust is a carcinogen that can be

hazardous to health. Work in a well-ventilated area

and whenever possible use a dust collector and

wear eye, ear and respiratory protection devices.

7. Do not wear loose clothing, gloves, bracelets, necklaces or other jewelry while the saw is in operation.

Wear protective hair covering to contain long hair

and wear non-slip footwear.

8. Be sure that adjusting wrenches, tools, drinks and

other clutter are removed from the machine and/or

the feed table surface before operating.

9. Keep hands well away from the blade and all moving parts. Use a brush, not hands, to clear away

chips and dus

10. Be sure that the blade is securely installed and in

proper cutting direction before operation.

11. Be sure the blade has gained full operating speed

before beginning to cut.

w

12. Al

Dirty or dull blades are unsafe and can lead to

accidents.

13. If using a power feeder,stop the feeder before stopping the ta

y with locks, master electrical switches

t.

ly sharpened blade.

ays use a clean,

ble saw.

proper

se suitable support when cutting stock that does

15.U

not have a flat surface. Always hold stock firmly

against the fence when ripping, or against the miter

gauge when cross-cutting.

16. To minimize risk of injury in the event of workpiece

kickback, never stand directly in-line with the blade

or in the potential kickback path of the work piece.

17. Avoid working from awkward or off balance positions. Do not overreach while cutting; keep both

feet on floor. Never lean over or reach over the

blade and never pull the work piece over the blade

from behind. Use out feed support or have an assistant help when ripping long material.

18. Keep blade guards in place and in working order.

If a guard must be removed for maintenance or

cleaning, be sure it is properly reattached before

using the tool again.

19. Never leave the machine running with the power

on when not in operation.

20. Use of parts and accessories NOT recommended

by

GENERAL MFG

function or risk of injury.

21. Never stand on machinery. Serious injury could

result if the tool is tipped over or if the blade is unintentionally contacted.

22. Always disconnect tool from power before servicing

or changing accessories such as blades, or before

orming an

perf

ments, or if the machine will be left unattended.

e that switch is in "OFF" position bef

23. Mak

24. Make sure the tool is properly grounded. If equip-

25. Do not use this saw for other than its intended use. If

e sur

plugging in the power cord.

ped with a 3-prong plug it should be used with a

ee-pole receptacle. Never remove the third

thr

prong.

used for other purposes,

any real implied warranty and holds itself harmless

or any injury, which may result from that use.

f

may result in equipment mal-

y maintenance,

cleaning or adjust-

GENERAL MFG

ore

disclaims

14. Do not push or force stock into the blade. The saw

will perform better and more safely when working

at the rate for which it was designed.

3

Page 4

RIVING KNIFE CONVERSION / RETROFIT KIT

350RNK

BASIC FUNCTIONS

The parts and components supplied in this 350RNK riving knife retro-fit / conversion kit have been designed to fit on

General MFG 3HP* right tilt model 350** saw only.

a

*For 5 HP motors, modifications to the motor shaft will be required - contact our technical service or your local distributor for details

before attempting this conversion.

** If you have a model 650 left-tilt saw, you will require retro-fit kit model #650RNK. This kit cannot be fitted to a model 650 left-tilt

saw!

HIS KIT HAS NOT BEEN DESIGNED NOR TESTED TO FIT ON ANY SAW MODEL OTHER THAN AS SPECIFIED IN THIS MANUAL. ANY

T

TTEMPTS TO FIT OR USE THESE PARTS AND COMPONENTS ON ANY SAW OTHER THAN THE MODEL INTENDED, MAY LEAD TO

A

SERIOUS PERSONAL INJURY, DAMAGE TO YOUR SAW AND/OR TO THE PARTS AND COMPONENTS OF THIS KIT.

A word about riving knives:

Upon completion of your saw conversion using this kit, your saw will be equipped with the latest feature available

for North American table saws: A quick connect/ quick release riving knife style of splitter.

A riving knife is considered a newer design for North American saws which traditionally have been equipped with

various fixed height splitter assemblies which perform a similar function. The riving knife has proven effective and

has been in use on saws in Europe for many years and is becoming a required table saw safety accessory for new

saws throughout most of North America.

The riving knife sits behind the blade to help prevent a workpiece, as it is pushed through the cut, from closing back

and “pinching” the blade or from drifting away from the rip fence and catching the rear portion of the saw blade.

Such situations can lead to what is commonly referred to as a kickback, where by the shear force of the saws motor

and with the forward rotation of the blade, the workpiece is lifted and violently ejected towards the front of the saw.

A kickback can cause serious injury to the user or to anyone within its path.

A traditional splitter does not raise or lower with the blade – it stays at a fixed height at all times, meaning that when

the blade is lowered, the distance between the splitter and the back of the blade increases. The generally accepted theory is that more space between the splitter and the back of the blade does slightly increase the possibility

that the w

saw.

The riving knife however is designed into the blade height adjustment mechanism and not only will it tilt with the

blade but also raise or lower as the blade is raised or lowered, thus keeping it at the exact same distance, usually

some

considered to be a more effective means of helping to prevent kickback caused by the workpiece pinching or

tching on the back of blade.

ca

Like a traditional splitter/blade guard assembly, a riving knife can also be part of an assembly that includes a

blade guar

splitter/guard assembly, because unlike a traditional splitter/blade guard assembly it does still raise and lower with

the blade.

orkpiece could pinch or catch on the back end of the blade and then be thrown towards the front of the

where between 1/4” – 3/8” from the back of the blade at all times. Because of this, a riving knife is generally

d and anti-kickback pawls. This type of an assembly is commonly referred to as a “riving style”

It is important to note however, that though generally considered more effective at preventing kickback from workpiece pinching or ca

to the user against accidental contact with the blade. In such cases a stand alone or independently mounted

blade guar

d/co

tching on the blade, because there is no blade guard, a true riving knife offers no protection

ver is required.

4

Page 5

ARNING! TO REDUCE THE RISK OF SERIOUS INJURY FROM CONTACT WITH THE BLADE, THE RIVING KNIFE MUST ALWAYS BE

W

SED WITH A BLADE GUARD IN PLACE TO COVER THE BLADE. IF YOU DO NOT OWN AN INDEPENDENTLY ATTACHED BLADE

U

GUARD, THEN USE THE SUPPLIED RIVING STYLE SPLITTER/BLADE GUARD ASSEMBLY FOR ALL OPERATIONS THAT LEAVE THE

BLADE EXPOSED.

Before Starting:

To obtain a good understanding of what will be required, start by watching the DVD video which shows the major

steps and includes some helpful tips and tricks.

After watching the DVD video, read this entire manual and make sure you have all the tools and equipment

required to complete this conversion before starting.

The conversion of an older saw to the new style riving knife design involves heavy lifting, as well as partial disassembly and then re-assembly of some of the major internal components of your saw. Upon completion of re-assembly,

e-alignment of the saws table in relation to the blade is also required. If you are not equipped for or comfortable

r

with this type of mechanical work or if you have any doubt that the required lifting, disassembly, re-assembly or realignment steps are beyond your abilities or skill level:

Stop immediately and proceed no further. Return this kit

and all components in its original packaging to the place of purchase for refund, or contact your local

General/General International distributor to inquire if any on-staff technicians are available and to obtain a quote

to have this kit installed by a trained technician.

Special note regarding images in this manual: The model 350 right tilt saw is basically a mirror image version of the

650 left tilt saw that is depicted in this manual and on the included DVD. Though the images in this manual, and on

the included DVD, show installation on a left tilt saw, for installation on your right tilt model 350, all steps and procedures are the same.

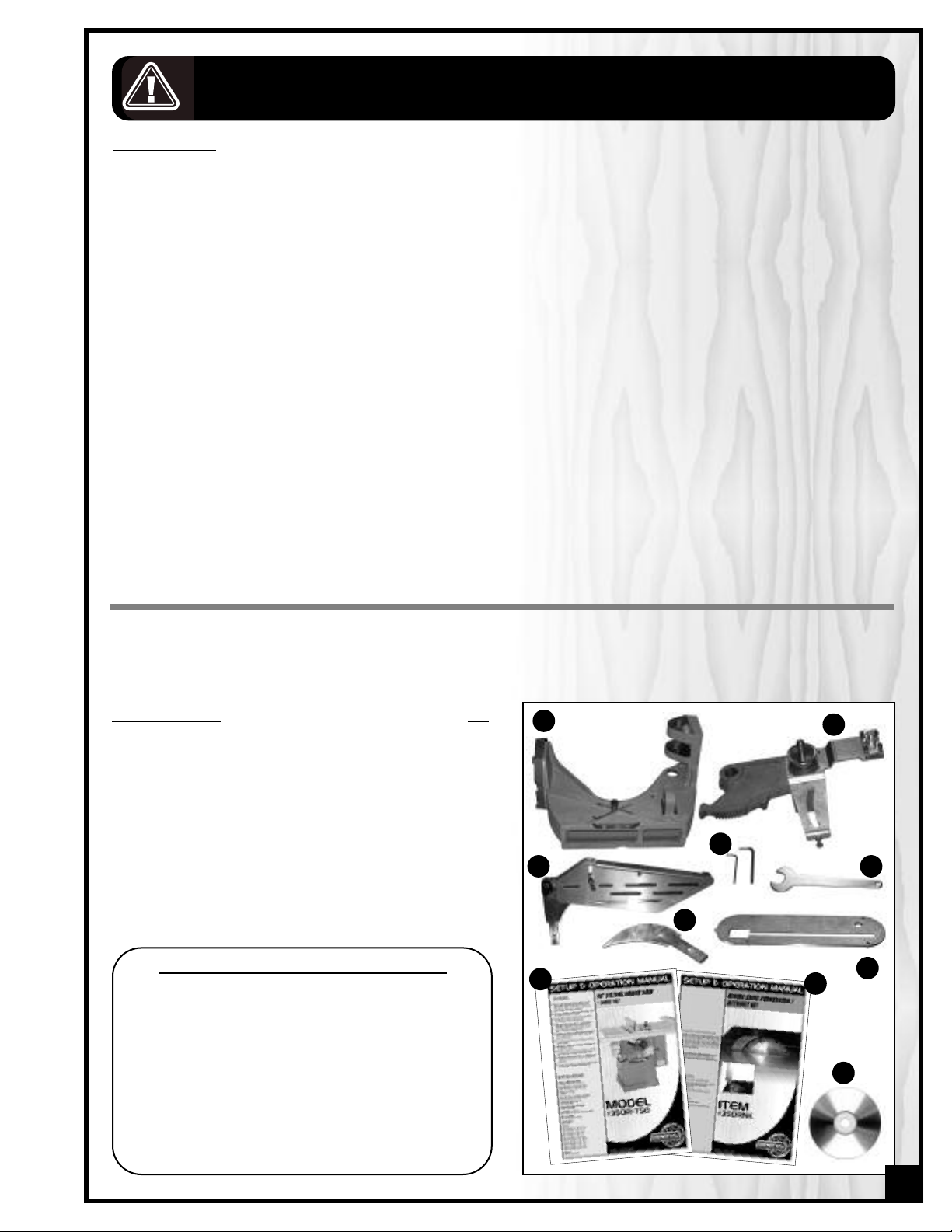

UNPACKING

Carefully unpack and remove the components from the box and check for damaged or missing items as per the

list of contents below.

NOTE: Please report any damaged or missing items to your General® International distributor immediately.

LIST OF CONTENTS QTY

A - CHUTE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

B - ARBOR BRACKET . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

C - SPLITTER /BLADE GUARD ASSEMBLY . . . . . . . . . . . . . .1

D - 3/32" ALLEN KEY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

5/32"

ALLEN KEY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

E - ARBOR WRENCH . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

F - EUROPEAN STYLE RIVING KNIFE . . . . . . . . . . . . . . . . .1

G - T

ABLE INSERT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

H - OPERATION MANUAL FOR 350R SAW . . . . . . . . . . . . .1

I - OPERA

TION MANUAL FOR 350RNK

. . . . . . . . . . . . . . .

J - DVD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

TOOLS REQUIRED TO COMPLETE THIS CONVERSION:

• Socket kit

y set

e

Allen k

•

• 2 large flat head screw

drivers

Rubber mallet

•

Hammer

•

• 3/16” punch or metal

marking awl

• Brass knock-out bar or

long hardwood dowel

General pur

•

machine gr

• Machinists square

Dial indica

•

alignment)

Another per

•

with lifting

pose

ease

or ta

tor/ (f

son for help

ble

1

A

D

C

F

H

B

E

G

I

J

5

Page 6

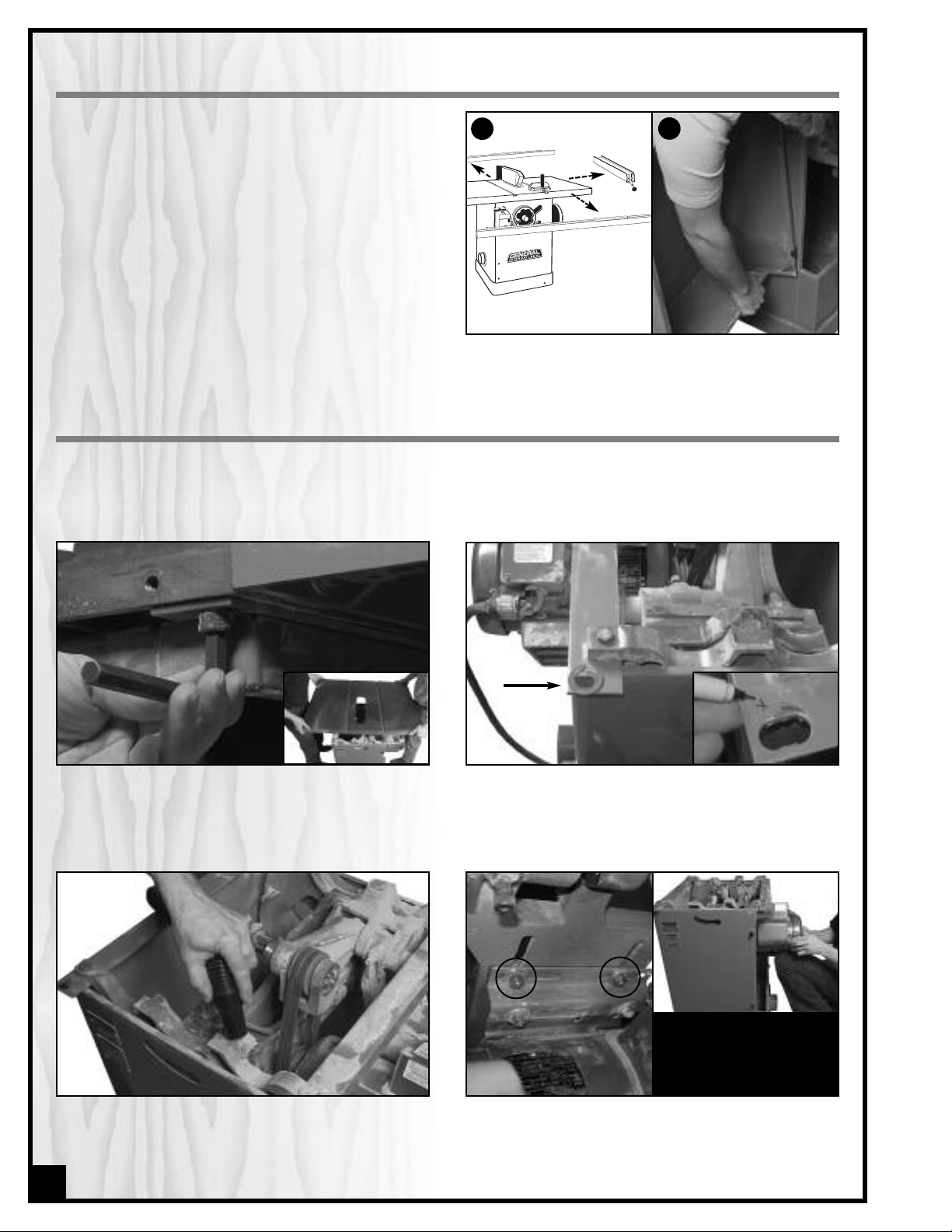

PREPARATION BEFORE STARTING

45

3

5

4

0

0

5

1

0

1. Turn off and disconnect the saw from the power source.

A

B

2. Set the blade to 90° and then remove the blade.

3. Remove and set aside the fence and rails, A.

4. Remove the switch.

5. Remove motor cover door, B.

DISASSEMBLY

Note: The parts reference numbers in brackets in the instructions written in this manual refer to the reference number of the

item as shown in the parts diagram in the original saw manual (a copy of this diagram is included on page #18 of this

manual) during disassembly, and to the new 350R saw manual (supplied with this kit) for re-assembly.

ten the 4 cap screws under the table and with

as

1. Unf

the help of an assistant carefully remove and set the

table aside.

2. Vacuum out any sawdust inside the saw cabinet.

6

Note: If the table has been factory shimmed, take note of

shim placement and be sure to re-install shims to the same

location(s) during re-assembly later.

2 above & 2 below motor

Hint – to avoid dropping or

ing the motor, brace the

damag

motor against y

shown, while loosening and

emoving it from the base plate.

r

our knee as

3. Unfasten the 4 bolts holding the motor mounting

bracket to the motor base plate (#59) and carefully

remove and set aside the motor and the drive belts.

Page 7

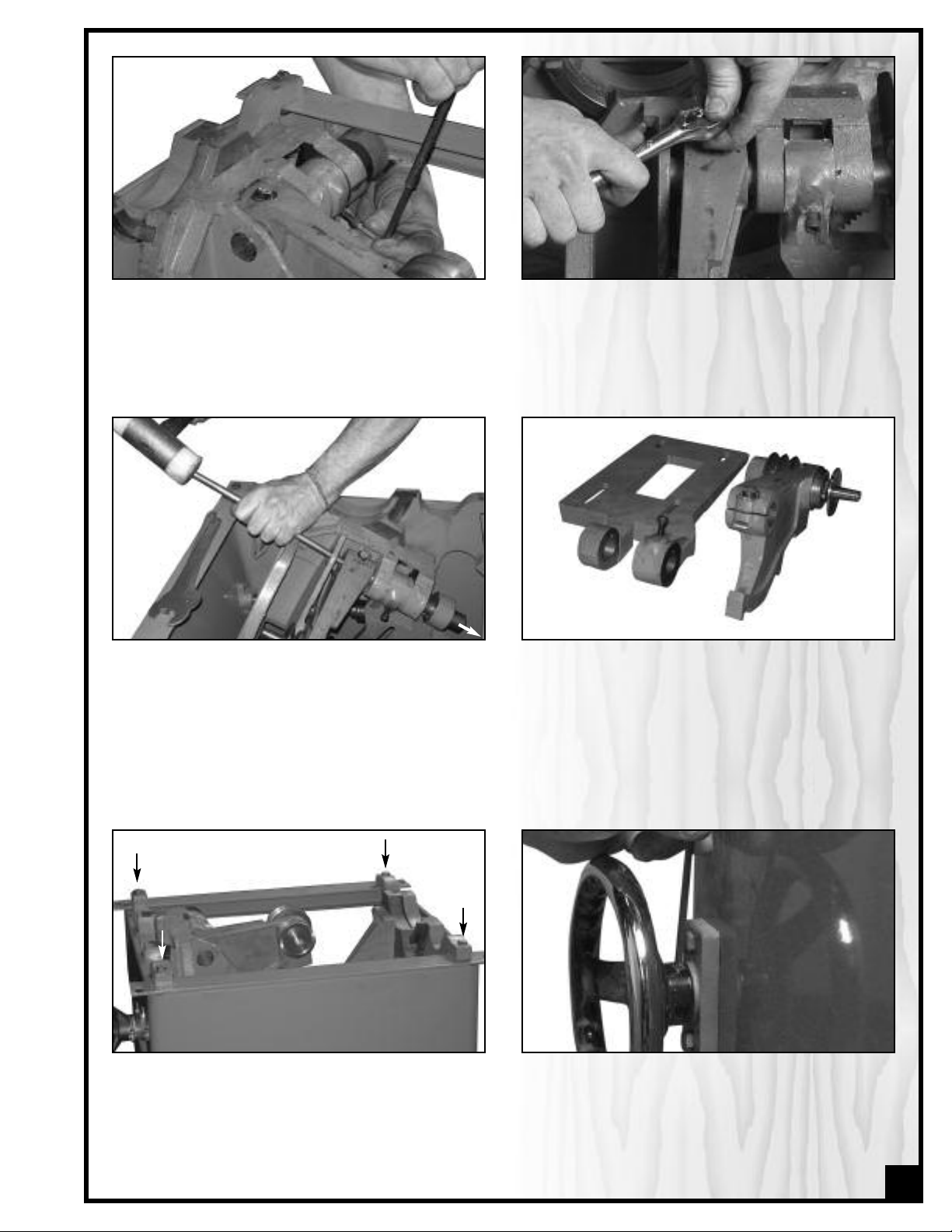

4. Loosen, but do not remove, the cap screw (#36) on

the motor base (#59).

5. Loosen but do not remove the bolt (#2) on the top of

the arbor bracket (#37).

6. Tilt the arbor mechanism to 45° and using a brass

bar or hardwood dowel and mallet, remove and set

aside the pin (#34) through the arbor bracket, chute

and motor base plate.

9. Unfasten and remove the 4 bolts that secure the

trunnions to the cabinet, along with their corresponding washers and nuts.

7. Carefully remove and set aside the motor base

plate (#59) and the arbor bracket (#37).

8. Tilt the arbor mechanism back to 90°.

10. Loosen the set screw (#19) that holds the blade

tilt hand wheel (#58) onto its shaft (#13).

7

Page 8

11. Unscrew and remove the lock knob (#20) and then

remove the hand wheel.

12. Remove and set aside the key in the keyway on the

shaft.

13. Remove the 2 bolts (#7) that hold the blade tilt

flange (#5) to the cabinet, and remove the flange.

#58

#20

15. Remove the front hand wheel (#58) by removing

the lock knob #20) and loosening the set screw

(#19).

#19

14. Temporarily re-install the lock-knob (#20) threading

it slowly back onto the shaft (#13). This will push out

the 2 guide pins (#14) in the shaft. Remove and set

the pins aside.

Note: when re-installing the guide pins later, make sure to

insert them in the shaft with the pointed ends facing

inwards.

16. Remove and set aside the key in the keyway on the

shaft.

8

Page 9

17. Unscrew and remove the angle pointer (#23 & 24)

from the front of the saw.

19. With the rear trunnion removed carefully remove

and set aside the chute (#30), hanging from the

front trunnion (#1).

Carefully pry one end of the rear trunnion (#53)

18.

down into the cabinet and then slide the rear trunnion up and away from the saw through the top

opening. If needed, use large flat head screwdrivers for leverage when prying.

TRANSFERRING PARTS

Before disposing of the old chute you must transfer some of the components from the old chute onto the new one.

ollowing steps explain how to remove and then re-install the blade height adjustment worm gear (#32) and

The f

shaft (#31), as well as the front tilt trunnion (#26).

#9

1. Set the chute on its side on a ta

and rotate the worm gear (#32) until the spring pin

(#9) that holds the collar (#10) onto the shaft is

ds.

acing upw

f

ar

ble or w

or

kbench,

ith a metal punch,

2. W

both the collar and the shaft that line up with the

spring pin. This will facilitate re-aligning the collar

and shaft to r

during re-assembly later.

e-ins

mak

tall the spr

ing pin in its hole

ence mar

efer

e a r

k on

9

Page 10

3. Using a punch and a hammer, gently tap on one

end of the spring pin and remove it from the

collar/shaft.

4. Slip the collar off of the shaft and set it aside along

with any spacers (fibre washers) on the shaft.

Note: when re-installing these parts on the new chute, your

retro-fit kit also includes extra spacers that can be used (if

needed) to help eliminate any play on the shaft between

the collar and the worm gear.

5. Unscrew and remove the 4 bolts (#22) that hold the

front tilt trunnion to the chute.

8. Apply a generous dab of any common machine

et on the

ease to the opening in the shaft brac

gr

k

new chute as well as the worm gear and shaft.

6. Gently tap or pry as needed to remove the front tilt

trunnion from the chute. The worm and shaft will

follow.

7. Set aside the old chute and bring the new chute

onto your work table to begin transferring the parts

that were just removed.

Note: The alignment pins protruding from the tilt trunnion will

help facilitate lining up the bolt

holes in the chute.

9. Using a rubber mallet carefully fit the front tilt trun-

m gear

nion onto the ne

w chute,

sliding the w

or

shaft into the hole in the bracket on the chute.

10

Page 11

10. Secure the tilt trunnion to the chute using the 4 bolts.

11. Slip the collar and spacer onto the end of the

worm gear shaft and line up the alignment marks

(made with the punch during disassembly) on the

shaft and collar.

12. Tap the spring pin all the way into the hole in the

collar to secure the collar to the shaft. Tug on the

shaft to verify for play between the collar and

the bracket.

If needed, remove the spring pin and collar again and

add extra spacers to eliminate any play.

RE-ASSEMBLING AND ALIGNING THE SAW

unnion (s

wn the trac

ipe do

1. W

installed on the saw) and the rear trunnion removed earlier) to clean off old grease and dust

and then a

grease to both.

ks in both the fr

pply a gener

ont tr

ous amount of fr

till

esh

e and set aside the thr

2. Remo

v

lower part of the new chute and set it aside.

eaded knob on the

11

Page 12

3. Install the new chute back in the saw, hanging it in

the cabinet from the front trunnion.

4. Slip the rear trunnion back into place through the

top opening, mating it with the back end of the

new chute and sitting it on the cabinet.

5. Loosely install the 4 trunnion bolts with their washers

and nuts into the holes through the trunnions and

the corners of the cabinet.

7. To keep the cabinet more or less square, gradually begin tightening the tr

checking that the diagonal measurements match

from corner to corner to the center of the bolt

heads. Gently tap on the cabinet corners with a

rubber mallet as needed, while tightening the bolts

ing the cabinet into square.

to br

Note: extremely high precision is not required; diagonal

corner to corner measurements that are within 1 /16” of

each other are more than adequate.

unnion bolts while

6. Slip a large flat head screwdriver between the front

and rear trunnions and the cabinet to remove any

play between them.

8. Remove the screwdrivers from the cabinet once

unnions have been secur

the tr

9. Re-install the alignment pins in the shaft on the

table tilt hand wheel with the points facing inward.

ed to the ca

binet.

12

Page 13

10. Re-install the blade tilt flange on the cabinet and

secure it loosely with the 2 bolts.

11. Before completely tightening the flange to the

cabinet, install the lock knob (temporarily) to push

on the guide pins and help align the flange and

then tighten the 2 bolts to tighten the flange to the

cabinet.

12. Remove the lock knob and re-install the key in the

keyway on the shaft.

pointer will be properly aligned later).

13. Install the blade tilt hand wheel on the shaft, reinstall the lock knob and tighten the set screw to

secure the hand wheel on the shaft.

15. Re-install the key in the keyway on the shaft 14. Re-install the pointer and the front hand wheel (the

13

Page 14

the set screw and then install the lock knob.

17. Turn the tilt hand wheel to set the chute to 45°.16. Secure the hand wheel to the shaft by tightening

18. Fit the pin into the first part of the motor base plate

(lining up the keys with the keyway in the bracket,

and keyway in the pin with the cap screw on the

motor base plate.

Flush her

20. Fit the new arbor bracket in place making sure to

position the slotted ar

assembly (#57) pointing more or less downwards.

Tap on the pin until the end of the pin is through the

holes in the arbor bracket and sits flush with the

opening in the hole in the chute.

m of mounting brack

e

et

19. Fit the base plate onto the chute and gently tap

the pin through the holes in the bracket of both the

base plate and the chute, only enough to hold the

base plate onto the chute.

21. Tighten the cap screw to secure the motor base

te to the pin.

pla

14

Page 15

22. Turn the tilt hand wheel and set the carriage

assembly to 90°.

23. Align the threaded hole in the bottom of the chute

with the curved slot in the arm of the mounting

bracket and re-install the threaded knob removed

and set aside earlier (step #12).

24. Verify the gaps between the head of the knob and

the arm, and also the arm and the chute are more

of less equal. If needed lightly pry the arbor bracket left or right on the pin to center the arm

een the knob and the chute.

betw

Loosen

set screw

to remove

Tighten

set screw

26. Before re-installing the motor on the base plate,

remove and reverse the motor pulley on the shaft.

This will facilitate pulley alignment with this new

.

ter

tion la

igura

conf

25. Tighten the hex head bolt on the arbor bracket to

secure everything in place on the pin.

27. Install the drive belts on the arbor pulleys and slip

the motor pulleys onto the lower portion of the belts

to essentially hang the motor from the belts.

15

Page 16

28. Line the motor bracket holes up with the holes in

the motor base plate and loosely fasten the motor

to the base plate using all 4 bolts.

29. Use a piece of scrap wood for leverage and pry

down on the inside portion of the motor to help

hold the motor shaft as close to horizontal as possible and to tension the belts. Have an assistant

hold a straight edge to the pulleys to check and

adjust pulley alignment while tightening the bolts

to secure the motor to the base plate.

30. With the help of an assistant put the table back on

the saw and secure it loosely with the cap screws –

make sure to re-install any factory installed table

shims to their correct locations.

32. Slowly tilt the blade to 45° and then back to 90°

while looking for obstructions or unwanted contact

een the blade and the ta

betw

between the newly installed carriage under the

table and the underside or opening in the table.

t the ta

Adjus

ble positioning slightly if needed.

ble insert and also

31. Install a blade on the saw and raise it to maximum

height and install the new table insert in the table

opening. Depending on your table casting it may

be necessary to file down a portion of the inserts

alignment pin.

Note: Depending on your table casting it may be necessary to partially grind down one or several of the protrusions in the table opening to obtain full clearance.

16

Page 17

33. Set the blade to 90° and using an accurate dial

indicator in either of the miter slots. Check and set

the miter slot parallel to the blade to within 5 thousandths of an inch, by gently tapping on the

appropriate edge of the table with a rubber mallet. Gradually tighten all 4 cap screws while regularly double checking alignment until the table is

secured in place.

35. Adjust the saws 90° and 45° bevel stops and the angle indicator pointer as per the instructions supplied on

page 22 of the new manual supplied in your kit for the 350R saw.

36. Install and adjust the riving knife as per the instructions supplied on page #11-13 of the new manual supplied

in your kit for the 350R saw.

37. With the blade at maximum height and the riving knife installed, manually rotate the blade at least one full turn

at both 90° and again at 45°. Check for obstructions and to confirm that you have full blade and saw carriage

clearance. If needed, return to previous steps and re-adjust or grind down any obstructions before turning on

the saw.

34. Raise the blade to its maximum and measure it’s

height above the table. Maximum blade height

(for a 10” diameter blade) is 3 1/8”. If needed,

adjust the blade height limiter bolt on the bottom

of the slotted arm, to obtain a 3 1/8” blade height.

O AVOID DAMAGING THE BLADE OR ANY OF THE

T

INTERNAL COMPONENTS OF THE SAW, DO NOT

ADJUST TO GO BEYOND A 3 1/8” BLADE HEIGHT.

38. Re-install the fence rails, switch and motor cover door . Before plugging in and using the saw, follow the instruc-

tions in your new 350R saw manual (supplied with this kit) to:

A) Align the r

B) Check and adjust the 90° and 45° bevel stops.

C) Re-align the angle pointer.

D) Install, align, and use your new riving knife.

Congratulations! Y

Thank y

ou for choosing General MFG – w

ip fence parallel to the blade.

ersion should now be completed.

our saw con

v

e wish you safe and ha

ppy woodworking!

17

Page 18

55

40

38

3

9

19

43

2

3

3

7

1

9

54

50

35

34

63

57

3

6

5

9

64

65

53

2

3

4

22

51

6

7

21

52

9

1

0

11

8

30

56

60

3

9

42

6

1

62

48

49

11

32

9

8

29

2

8

21

27

6

26

22

31

15

14

25

24

23

2

3

4

1

10

9

11

19

8

58

17

20

18

11

12

9

8

13

15

14

5

7

58

19

20

17

18

350 SAW MECHANISM

(Without riving knife kit)

18

Page 19

40

38

39

52

42

18

18

51

6

53

35

48

3

4

36

33

54

55

57

59

58

37

3

2

50

2

3

4

21

49

20

56

47

46

45

44

41

39

4

3

30

9

8

10

7

32

31

14

13

10

8

7

20

27

26

2

5

29

28

21

24

23

22

2

1

3

4

9

8

10

7

15

19

16

17

5

6

10

11

8

7

12

13

14

18

15

19

16

17

18

350R SAW MECHANISM

(With riving knife kit)

19

Page 20

350R SAW MECHANISM

P

ARTS LIST

350R

EF. N0. PART N0. DESCRIPTION SPECIFICATION QTY

R

1 354-1 FRONT TRUNNION 1

2 P-6 HEX. HEAD BOLT 3/8-16 UNC X 1 1/2 5

3 P-15 LOCK WASHER 3/8" 5

4 P-17 NUT 3/8-16 UNC 4

5 354-11 FLANGE 1

6 P-99 HEX. HEAD BOLT 5/16" -18 UNC X 1" 8

7

8 P-126 SPRING PIN 3/16" X 1 1/4" 4

9 354-6 COLLAR 2

10 P-77 FIBER WASHER 3/4 X 1 1/4 X 1/32 4

(With riving knife kit)

11 354-5 RIGHT GEAR 1

12 354-10 TILT SHAFT 1

13 354-13 GUIDE PIN 4

14 354-23 KEY 1

15 354-9SA HANDWHEEL ASSEMBLY 2

16 P-332 HANDLE 354-14 2

17 354-15 HANDLE PIN 2

18 P-7 ALLEN SET SCREW 5/16-18 UNC X 5/16" 4

19 354-12SA LOCK KNOB ASSEMBLED 2

20 P-111 SPRING PIN 1/4 X 3/4 4

21 P-35 HEX. HEAD BOLT 3/8"-16 UNC X 1" 6

22 P-116 TAPPING-SCREW 8-32 UNC X 3/8 1

23 354-17 POINTER 1

24 354-8 MAIN BEARING 1

25 354-2 FRONT TILT TRUNNION 1

26 P-135 LOCK WASHER 5/16" 4

27 P-305 HEX. HEAD BOLT 5/16"-18 UNC X 1 1/2" 2

28 P-51 LOCK NUT 5/16-18 UNC 2

29 P-100 HEX. HEAD BOLT 5/16"-18 UNC X 3/4" 2

30 354 CHUTE 1

31 354-7 ELEVATING SHAFT 1

32 554-23 LEFT WORM 1

33 354-19A MOTOR BASE 1

34 354-20 PIN 1

35 354-21 KEY 1

36 P-304 HEXAGONAL SOCKET HEAD CAP SCREW 5/16-18 UNC X 1" 1

37 353 ARBOR BRACKET 1

38 P-108 SNAP RING N-1308-168 2

39

40 P-106

41 P-4 WOODRUFF KEY #9-3/16" X 3/4" 1

42 353-3 ARBOR PULLEY 1

43

44 353-1ASS ARBOR WITH FLANGE AND NUT 1

45

46 353-2 CURVED WASHER 1

47 353-6 LEFT-HAND THREAD 5/8-10 ACME 29 DEGREES 1

48 354-22 KEY 1

49 354-3

50 354-4 REAR TRUNNION 1

51 353-8 MOTOR PULLEY (STANDARD) 7/8" 1

52 P-1217

53 354-24 MOTOR SPACER 2

54

55 P-182 NUT 5/16-18 UNC 4

56 353-7 ARBOR WRENCH 1

57 357 MOUNTING BRACKET ASSEMBLY (350R) 1

58

59 P-308 OUTER HOLD-DOWN RING SERIE R3100-200 1

P-70 COPPER BEARING SS-2428-12 4

P-279 BEARING 6203-2RS 2

HEXAGONAL LOCK NUT

353-5B LARGE SP

P-1029 C

P-1084

P1717

ARBIDE COMBINATION BLADE 9.840" - 50 TEETH 1

TIL

REAR

BELT A-24 26" LONG 2

T WASHER 5/16" 4

FLA

SHOULDER BOL

ACER 1

TRUNNION 1

T

T

3/8-06 UNCX1/2 X 1/2

5/8-18 UNC

1

1

20

Page 21

3

2

1

29

19

28

20

21

22

24

25

26

2

7

23

30

31

1

0

18

1

7

16

7

12

6

1

1

4

8

5

1

4

15

13

9

SPLITTER / BLADE GUARD ASSEMBLY – RIVING KNIFE

PARTS LIST

REF. N0. PART N0. DESCRIPTION SPECIFICATION QTY

1 357 MOUNTING BRACKET ASSEMBLY (350) 1

2 357-21 RIVING KNIFE 1

3 350-7R SPLITTER/BLADE GUARD ASSEMBLY 1

4 357-24 SPLITTER 1

5 P-221 ROUND HOOK 5100-31 4

6 357-29 WASHER 4

7 357-25 GUARD ARM 2

8 357-28 MIDDLE WASHER 1

9 357-1S GUARD ASSEMBLY 1

10 357-26 ANTI-KICKBACK PAWL 2

11 P-208

SPRING PIN

3/16 "X 3/4" 1

12 P-445 SPUR SPRING 1

13 357-30 GUARD PIN 1

14

P-166

NYLON

WASHER .062 X 5/16 I.D. X 3/4 O.D. 2

15 357-31 GUARD PIVOT 1

16 357-32 ANTI-KICKBACK PAWL PIN 1

T WASHER #8, .062 X 3/16 I.D. X 1/2 O.D. 1

17

18 P-116 ROUND HEAD MACHINE SCREW, SQUARE GRIP #2,#8-32 UNF X 3/8 1

P-203

FLA

19 357-20 ROCKER ARM (350) 1

ADJUSTMENT SP

COMPRESSION SPRING 1

357-22

20

21 P-152 SET SCREW 10-32 X .375 14

22 P-312 CAP SCREW 10-24 X 3/4 1

23 P-140

ACER 1

24 357-23 HOLD-DOWN BLOCK 1

25 P-496 LOCK WASHER 3/16 4

SOCKET HEAD CAP SCREW 10-32 X 3/4 4

SHOULDER BOLT 3/8-06 UNC X 1/2 X 1/2 1

P-395

P-717

26

27 P-449 KNOB 1

28 P-308 OUTER HOLD-DOWN RING SERIE R3100-20 1

29

30 P-160 STOP NUT 1/4-20 UNC 1

31 P-355 HEX HEAD BOLT 1/4-20 UNC X 1 1

SPLITTER / BLADE GUARD ASSEMBLY – RIVING KNIFE

21

Page 22

RIVING KNIFE CONVERSION/RETROFIT KIT

835, Cherrier Street, Drummondville (Quebec) Canada J2B 5A8

Tel.: (514) 326-1161

F

ax: (514) 326-5565 -

P

arts & Service /

orderdesk@general.ca

www

F

ax: (514) 326-5555 -

.general.ca

Or

der Desk

IMPORTANT

When ordering replacement parts, always give the model number, serial number of the machine and

part number. Also a brief description of each item and quantity desired.

Loading...

Loading...