Page 1

Powerful 2 HP motor with thermal overload

protection.

Front and rear fold-down extension tables

(12 L x 15 1/4 W) with end rollers for

smooth easy stock feeding.

Top mounted return rollers for smooth

stock handling for consecutive

planning/multiple passes.

Convenient power cord storage brackets

and inset lifting handles.

Dual position depth of cut adjustment

handle mounts left or right – one full

rotation equals 1/16”.

Dual feed speeds for smooth planning

with either soft or hard wood.

Adjustable pre-set depth gauge for

accurate repeat cuts.

Easy to read graduated scale in both

inches and metric indicates workpiece

thickness.

Safety On/Off switch with key. Unit cannot

be started when key is removed from

switch.

Snipe eliminating head lock.

Depth of cut indicator.

Includes magnetic knife setting guide.

TABLE AREA WITH EXTENSIONS (L X W)

36 5/8” X 15 1⁄4” (930 x 387 mm)

MAXIMUM PLANING

WIDTH

13” (330 mm)

MAXIMUM

THICKNESS OF STOCK

6” (152 mm)

MINIMUM

THICKNESS OF STOCK

1⁄8” (3 mm)

MINIMUM LENGTH OF ST

OCK

5” (127 mm)

MAXIMUM DEPTH OF CUT (FULL

WIDTH)

1⁄16” (1.5 mm)

KNIVES

2 - DOUBLE EDGED

CUTTERHEAD SPEED

9500 RPM

FEED SPEEDS (2)

18 & 26 FPM

CUTS PER INCH

88 / 61

MO

TOR

2 HP, 120 V, 1 Ph, 15 A

REVISION 1 - JUNE 7/07

© COPYRIGHT GENERAL INTERNATIONAL 06/2007

Page 2

THANK YOU

for choosing this General® International model 30-010 M1

13” single surface planer.This planer has been carefully tested and inspected before shipment

and if properly used and maintained, will provide you with years of reliable service. To ensure

optimum performance and trouble-free operation, and to get the most from your investment,

please take the time to read this manual before assembling, installing and operating the unit.

The manual’s purpose is to familiarize you with the safe operation, basic function, and features

of this planer as well as the set-up, maintenance and identification of its parts and components. This manual is not intended as a substitute for formal woodworking instruction, nor to

offer the user instruction in the craft of woodworking. If you are not sure about the safety of

performing a certain operation or procedure, do not proceed until you can confirm, from

knowledgeable and qualified sources, that it is safe to do so.

Once you’ve read through these instructions, keep this manual handy for future reference.

All component parts of General® International machinery are carefully tested and inspected during all stages of

production, and each machine is thoroughly inspected upon completion of assembly. Because of our commitment to quality and customer satisfaction, General® International agrees to repair or replace, within a period of 24

months from date of purchase, any genuine part or parts which, upon examination, prove to be defective in workmanship or material. In order to obtain this warranty, all defective parts must be returned freight pre-paid to

General® International Mfg. Co., Ltd. Repairs attempted without our written authorization will void this warranty.

GENERAL ® INTERNATIONAL WARRANTY

Disclaimer:

The information and specifications in this manual pertain to

the unit as it was supplied from the factory at the time of printing.

Because we are committed to making constant improvements, General

International reserves the right to make changes to components, parts

or features of this unit as deemed necessary, without prior notice and

without obligation to install any such changes on previously delivered

units. Reasonable care is taken at the factory to ensure that the specifications and information in this manual corresponds with that of the unit

with which it was supplied. However, special orders and “after factory”

modifications may render some or all information in this manual

inapplicable to your machine. Further, as several generations of this

model of planer and several versions of this manual may be in circulation, if you own an earlier or later version of this unit, this manual may not

depict your machine exactly. If you have any doubts or questions

contact your retailer or our support line with the model and serial number of your unit for clarification.

GENERAL® INTERNATIONAL

8360 Champ-d’Eau, Montreal (Quebec) Canada H1P 1Y3

Telephone (514) 326-1161 • Fax (514) 326-5555 • www.general.ca

Page 3

1. Read, understand and follow all safety warnings and

instructions in the supplied Operator’s Manual.

2. Do not operate the planer when tired, distracted, or

under the effects of drugs, alcohol or any medication

that impairs reflexes or alertness.

3. The working area should be well lit, clean and free of

debris.

4. Keep children and shop visitors at a safe distance

when the planer is in operation; do not permit them to

operate the planer.

5. Childproof and tamper proof your shop and all machinery with locks, master electrical switches and

switch keys, to prevent unauthorized or unsupervised

use.

6. Stay alert! Give your work your undivided attention.

Even a momentary distraction can lead to serious

injury.

7. Wear approved safety glasses, dust mask and hearing

protection, and do not wear loose clothing, gloves,

bracelets, necklaces or jewelry while operating the

planer. Wear protective hair covering to contain long

hair and wear non-slip footwear.

8. Fine particulate dust is a carcinogen that can be hazardous to health. Work in a well-ventilated area and

whenever possible use a dust collector.

9. Keep hands well away from the cutterhead and all

moving parts. Do not clear chips and sawdust away

with hands, use a brush.

10. Be sure that wrenches, tools, drinks and other clutter

are removed from the machine and/or the table surfaces before operation.

11. Kickback is when the workpiece is ejected at high

speeds by the force of the cutterhead.To minimize the

risk of injury from kickback, use proper feeding technique and stand to one side, out of the path of a potential kickback.

12. Be sure the blades are securely installed in the cutterhead and in proper cutting direction before operation.

13. Make sure the cutterhead has gained full operating

speed before feeding stock into the planer.

14. Always use clean, properly sharpened knives in the

cutterhead. Dirty or dull knives are unsafe and can

lead to accidents.

15. Inspect stock and remove all foreign objects before

planing. Make sure that any stock you plane is clean

and free of dirt, nails, staples, tiny rocks or any other

foreign objects that may damage the blades. Only

process natural solid wood boards. Never plane MDF,

particle board, plywood, laminates or other synthetic

materials.

16. Do not push or force stock into the cutterhead. The

planer will perform better and safer when working at

the rate for which it was designed.

17. The maximum depth of cut for one pass is 1/8” for a

board of 5 -1/2" or less In width and 1/16" for a board

wider than 5 -1/2". Never attempt to remove more material than the maximum in any single pass.

18. Select appropriate feed speed for the stock being planed: high speed for softwood and slow for hardwoods.

19. Place stock firmly against the table and use suitable

in-feed and out-feed support if stock is too long.

20. Keep guards in place and in working order. If a guard

must be removed for maintenance or cleaning make

sure it is properly attached before using the machine

again.

21. Never leave the machine unattended while running

or with the power “ON”.

22. Always turn off and disconnect from power source

before servicing or changing accessories, blades, or

before performing any maintenance or adjustments.

23. Make sure the switch is in the "off" position before plugging in the power cord.

24. Make sure planer is properly grounded. If equipped

with a 3-prong plug it should be used with a three-pole

receptacle. Never remove the third prong.

25. Use only parts and accessories that are designed for

use with this planer. The use of parts or accessories

NOT recommended by General International may result in equipment malfunction and an increased risk

of injury.

26. Do not use this planer fro anything other than its intended use. If used for other, General International

disclaims any real or implied warranty and holds itself

harmless for any injury which may result from that use.

Rules for Safe Operation

To help ensure safe operation, please take a moment to learn the machine’s applications and limitations, as well as potential hazards. General® International disclaims any real or implied warranty and

holds itself harmless for any injury that may result from improper use of its equipment.

Page 4

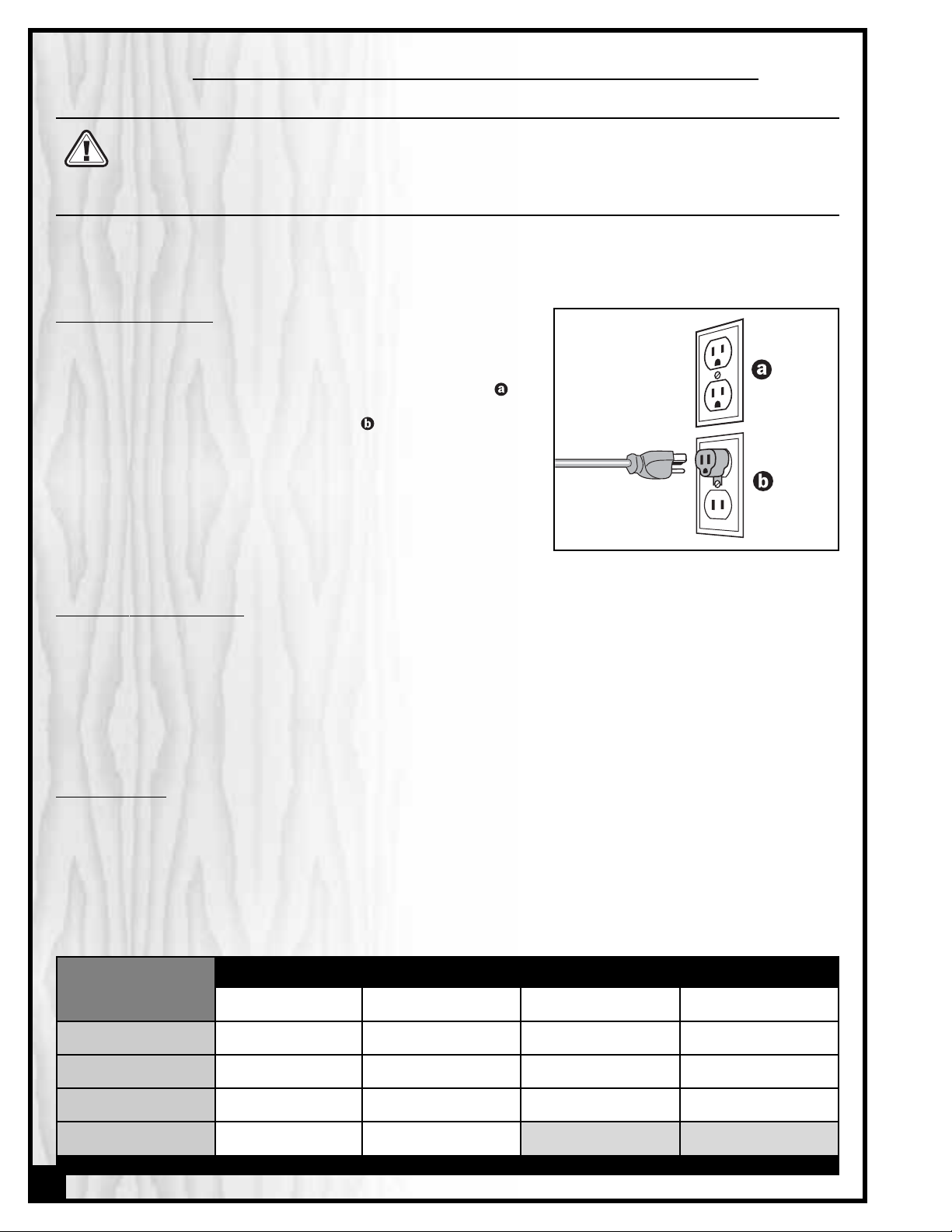

ELECTRICAL REQUIREMENTS

Before connecting the machine to the power source, verify that the voltage of your power supply corresponds

with the voltage specified on the motor I.D. nameplate. A power source with greater voltage than needed can

result in serious injury to the user as well as damage to the machine. If in doubt, contact a qualified electrician

before connecting to the power source.

This tool is for indoor use only. Do not expose to rain or use in wet or damp locations.

GROUNDING INSTRUCTIONS

In the event of an electrical malfunction or short circuit, grounding

reduces the risk of electric shock. The motor of this machine is wired for

110V single phase operation and is equipped with a 3-conductor cord

and a 3-prong grounded plug to fit a grounded type receptacle, . Do

not remove the 3rd prong (grounding pin) to make it fit into an old 2hole wall socket. If an adaptor plug is used, , it must be attached to

the metal screw of the receptacle.

Note: The use of an adaptor plug is illegal in some areas. Check your

local codes.

DO NOT MODIFY THE PLUG PROVIDED.

If it will not fit your receptacle, have the proper receptacle installed by a qualified electrician.

CHECK with a qualified electrician or service person if you do not completely understand these grounding instruc-

tions, or if you are not sure the tool is properly grounded.

EXTENSION CORDS

USE ONLY 3-WIRE EXTENSION CORDS THAT HAVE 3-PRONG GROUNDING PLUGS AND 3-POLE RECEPTACLES THAT ACCEPT

THE TOOLS’ PLUG. REPAIR OR REPLACE A DAMAGED OR WORN POWER CORD OR PLUG IMMEDIATELY.

If you find it necessary to use an extension cord with your machine make sure the cord rating is suitable for the

amperage listed on the motor I.D. plate. An undersized cord will cause a drop in line voltage resulting in loss of

power and overheating. The accompanying chart shows the correct size extension cord to be used based on cord

length and motor I.D. plate amp rating. If in doubt, use the next heavier gauge. The smaller the number the heavier

the gauge.

AMPERES

(AMPS)

EXTENSION CORD LENGTH

25 FEET 50 FEET 100 FEET 150 FEET

< 5

18 16 16 14

6 TO 10 18 16 14 12

10 TO 12 16 16 14 14

12 TO 16 14 12

* NR * NR

* NR = Not Recommended

4

Page 5

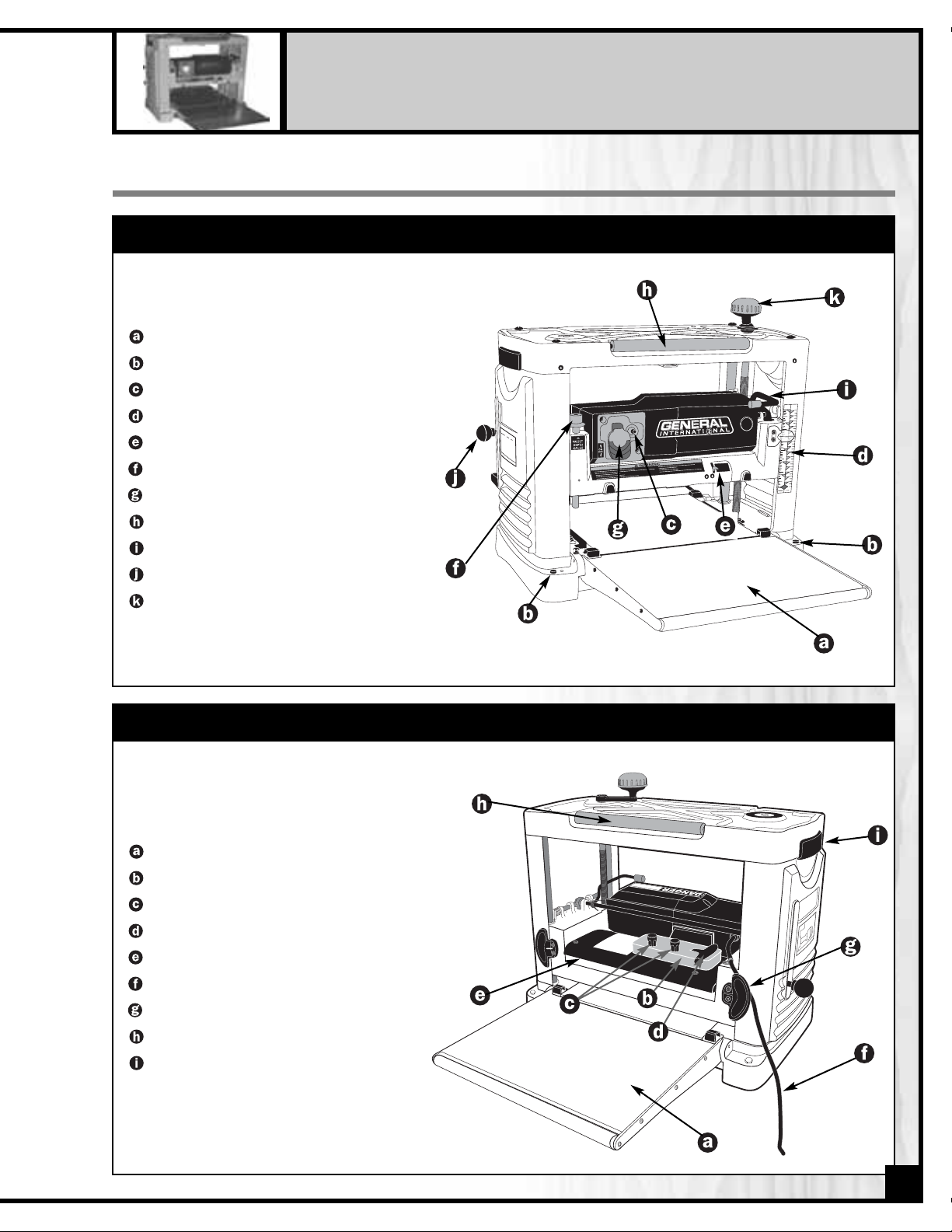

13” SINGLE SURFACE PLANER

30-010

IDENTIFICATION OF MAIN PARTS AND COMPONENTS

IN-FEED TABLE

MOUNTING HOLES

CIRCUIT BREAKER

STOCK THICKNESS SCALE

DEPTH OF CUT INDICATOR

PRESET DEPTH GAUGE

ON/OFF SWITCH

RETURN ROLLER

CUTTERHEAD LOCKING HANDLE

SPEED SELECTION HANDLE

HEIGHT ADJUSTMENT HANDLE

FRONT VIEW

OUT-FEED TABLE

TOOL TRAY

KNIFE SETTING MAGNETS

T-HANDLE WRENCH

CHIP DEFLECTOR

POWER CORD

POWER CORD STORAGE HOOKS

RETURN ROLLER

LIFTING HANDLE

REAR VIEW

5

Page 6

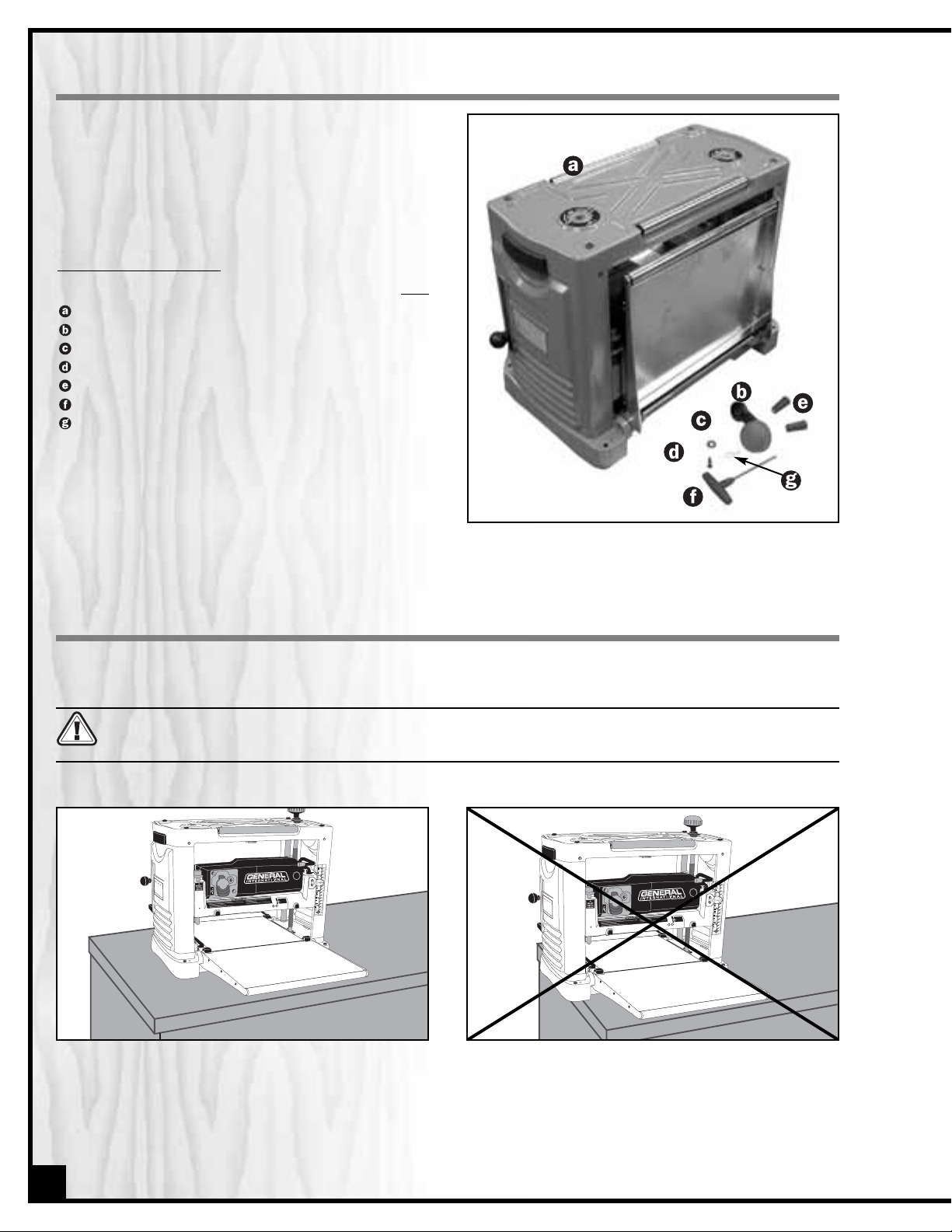

Carefully unpack and remove the planer and its components from the box and check for damaged or missing

items as per the list of contents below.

NOTE: Please report any damaged or missing items to your

General International distributor immediately.

LIST OF CONTENTS

QTY

PLANER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

ADJUSTMENT HANDLE . . . . . . . . . . . . . . . . . . . . . . . . .1

FLAT WASHER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

PAN HEAD BOLT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

KNIFE SETTING MAGNETS . . . . . . . . . . . . . . . . . . . . . .2

T-HANDLE WRENCH . . . . . . . . . . . . . . . . . . . . . . . . . . .1

POINTER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

6

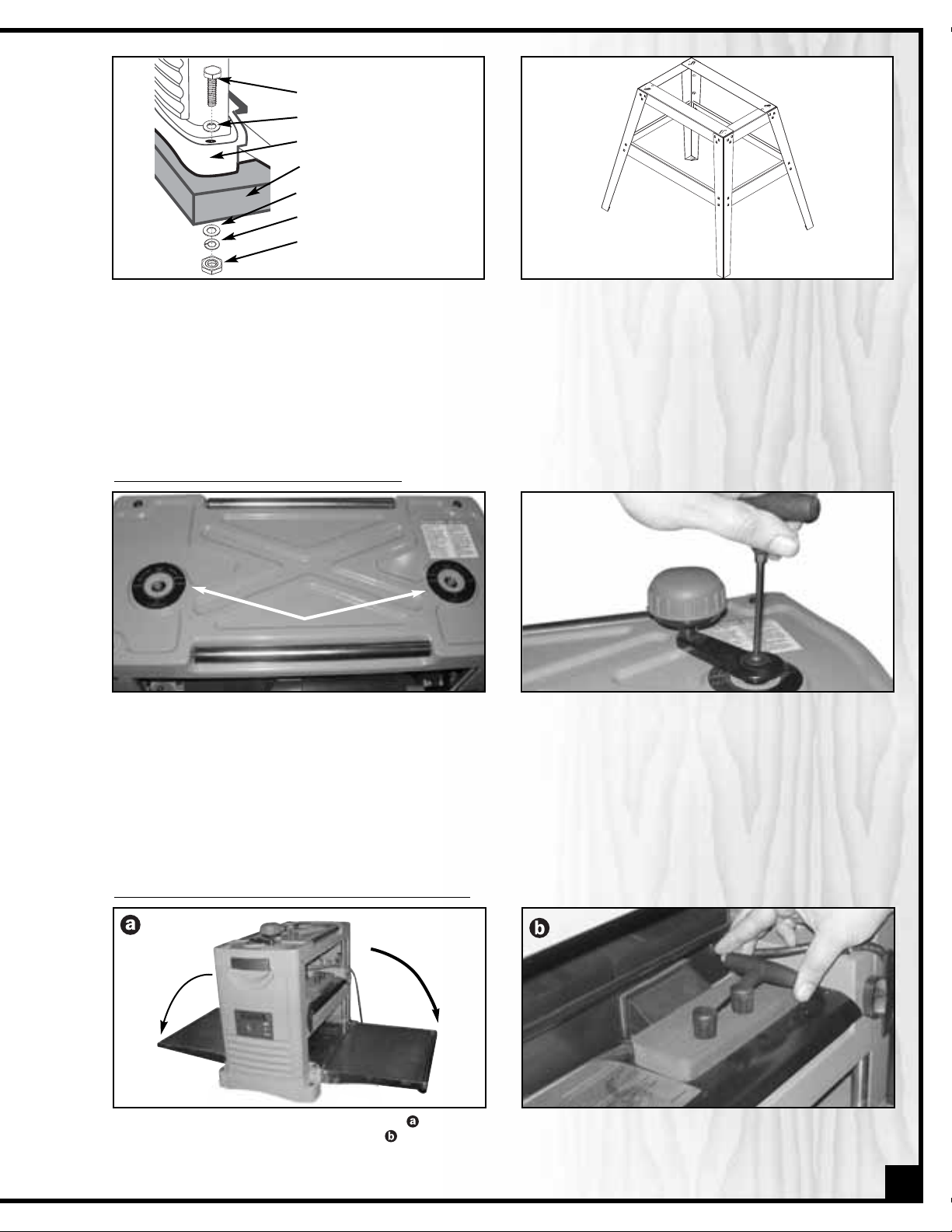

The unit should be installed on a flat, level, sturdy and

stable surface, able to support the weight of the

machine and the workpiece with ease.

ASSEMBLY INSTRUCTIONS

BEFORE STARTING THE INSTALLATION AND ASSEMBLY, MAKE SURE THAT THE POWER SWITCH IS IN THE “OFF” POSITION

AND THAT THE POWER CORD IS UNPLUGGED. DO NOT PLUG IN OR TURN ON THE PLANER UNTIL YOU HAVE COMPLETED THE INSTALLATION AND ASSEMBLY STEPS DESCRIBED IN THIS SECTION OF THE MANUAL.

For your convenience this planer is shipped from the factory partially assembled and requires only minimal assembly and set up before being put into service.

Never install or operate the planer over the edge of a

table, workbench or other mounting surface.

UNPACKING & SET UP

Page 7

To accommodate the users personal preference or

work habits the adjustment handle can be installed on

either side of the top of the planer.

ATTACH THE DEPTH OF CUT ADJUSTMENT HANDLE

With the T-Handle wrench,use the supplied washer and

pan head screw to attach the depth of cut adjustment

handle as shown.

Fold down the in-feed and out-feed tables, , and stow the knife setting magnets and T-handle wrench in the holder at the rear of the machine as shown, .

STOW THE KNIFE SETTING MAGNETS AND T-HANDLE WRENCH

7

HEX. HEAD BOLT

FLAT WASHER

PLANER

WORKBENCH OR STAND

FLAT WASHER

LOCK WASHER

HEX. NUT

If a permanent shop placement or installation is practical, consider using the mounting holes and drilling

matching through holes in your workbench or mounting surface to bolt the planer in place (hardware not

included) on your workbench.

If you prefer an optional steel stand (item #30-015)

is available from your local General International

dealer.

Page 8

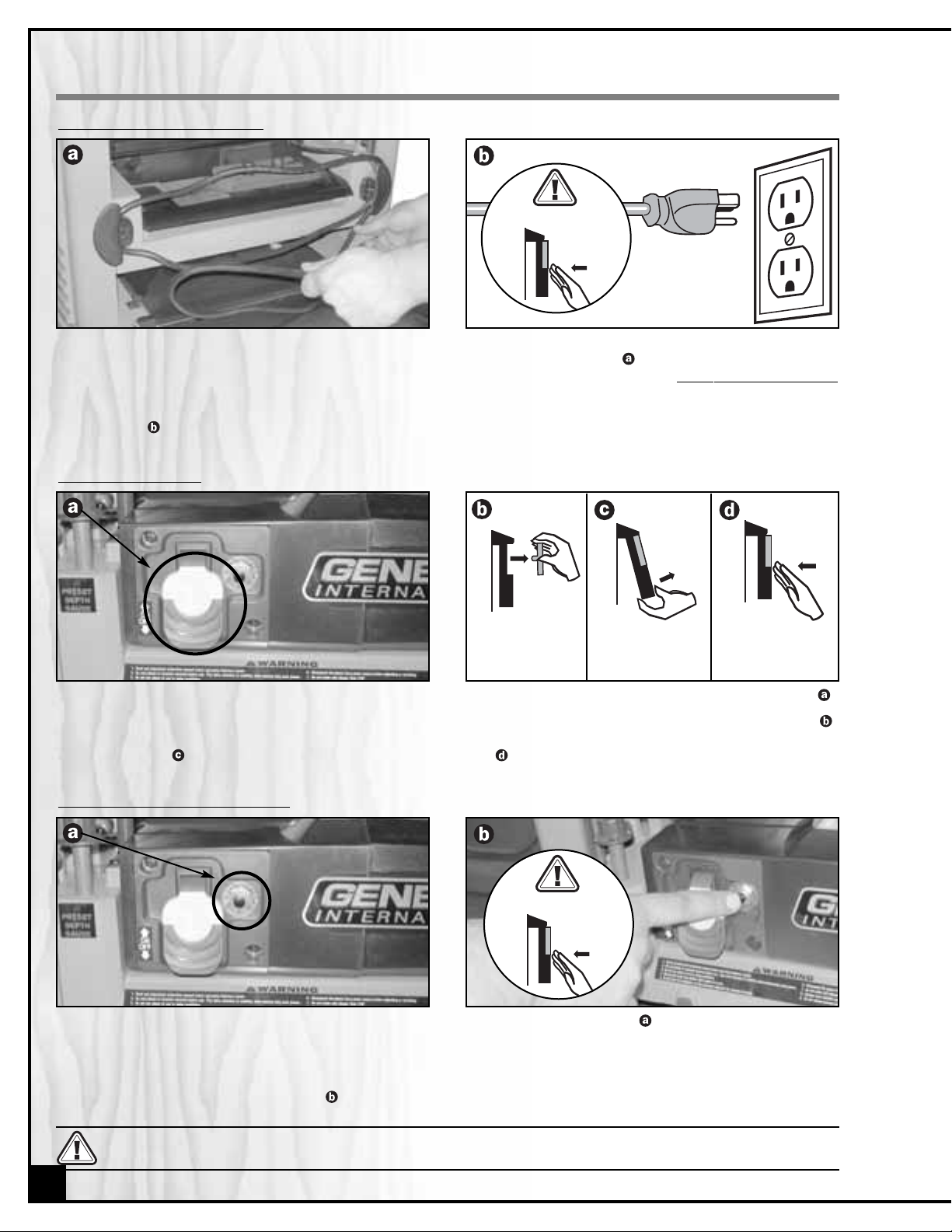

The unit is equipped with a circuit breaker located to the right of the power switch,,to protect the motor from

power surges or spikes in line voltage. In the event of a power surge,the circuit breaker will be automatically tripped

thereby cutting off the power to the motor.

To reset the circuit breaker after it has been tripped; set the power switch to the “off”position and depress the reset

button on the circuit breaker as shown,,then restart the machine.

SURGE PROTECTION/CIRCUIT BREAKER

The planer is equipped with a rocker style ON/OFF switch located on the front left hand side of the cutter head, .

To prevent unwanted or unauthorized start-up or usage, remove the lock-out key and store it in a safe place,

,

whenever the planer is not in use. To start the planer, insert the lock-out key and pull up on the lower portion of the

switch as shown, . To stop the planer, push down on the switch,

.

ON/OFF POWER SWITCH

SAFETY KEY

(PREVENTS START-UP

WHEN REMOVED)

POWER ON POWER OFF

TO AVOID UNEXPECTED OR UNINTENTIONAL START-UP BE CERTAIN THAT THE POWER SWITCH HAS BEEN SET TO THE OFF

POSITION BEFORE RE-SETTING THE CIRCUIT BREAKER.

8

BASIC ADJUSTMENTS AND CONTROLS

CONNECTING TO A POWER SOURCE

Once the assembly steps have been completed and the unit is safely secured or installed on a work surface such

as a bench, stand or worktable, uncoil the power cord from the storage brackets, . With the switch in the off position, plug the power cord into an appropriate outlet. Refer back to the section entitled Electr

ical Requirements

and make sure all requirements and grounding instructions are followed. When planing operations have been

completed unplug the unit from the power source and wrap the power cord back onto the storage brackets for

safe storage, .

SWITCH OFF

SWITCH OFF

Page 9

To adjust the depth of cut, the cutterhead assembly can be raised or lowered as needed by rotating the depth of

cut adjustment handle,

.

Before adjusting the height of the cutterhead, make sure the cutterhead locking lever is unlocked (raised position),

. Attempting to adjust the height of the cutterhead with the locking lever engaged will cause premature wear of

the locking mechanism.

NOTE: Each full clockwise rotation of the handle will lower the cutterhead by 1/16”. Each full counterclockwise rotation will raise the cutterhead by 1/16”

,.

RAISING/L

OWERING THE CUTTERHEAD

UNLOCK

LOCK

DOWN

UP

9

1 x = 1/16”

The adjustable pre-set depth gauge located on the top left of the cutterhead assembly,,allows the user to select

one of six commonly used workpiece final thickness settings.

With the cutterhead set slightly above the height of the workpiece press down and rotate the spring loaded adjustment knob to select the desired final thickness setting from either 1/8”, 3/8”, 1/2”, 3/4”, 1”& 1 1/4”, . This will set the

stop pin to prevent the cutterhead from going any lower than the selected thickness, .

NOTE: Once you have planed the workpiece down to the selected thickness, do not attempt to lower the cutterhead

further. Forcing the depth of cut handle when the cutterhead has bottomed out on the preset stop pin will damage

the raising mechanism.

1/8”

1 1/4”

1“

3/8”

1/2”

PRE-SE

T THICKNESS STOP GAUGE

DEPTH OF CUT INDICATOR

The depth of cut indicator on the lower right hand side of

the cutterhead,,will indicate how much material the

cutterhead is set to remove from the workpiece for a

given pass.

The pointer will read zero until the workpiece engages the

front of the cutterhead. Place the workpiece under the

front of the cutterhead and turn the height adjustment

handle clockwise until the cutterhead makes contact

with the workpiece & until the depth of cut indicator

shows the reading that matches the desired cut,

.

Page 10

CHANGING FEED SPEEDS

The unit is equipped with a two feed speed transmission.

The feed speed adjustment knob is located on the left

hand side of the machine,

.

With the knob pushed all the way in the feed speed is set

for 18 feet per minute (FPM). With the knob pulled out to

the first stop the transmission will be in the neutral position

- stock will not feed. With the knob pulled out to its maximum the feed rate is set for 26 FPM,

.

Experiment with feed speeds based on the workpiece

material and its width as well as the depth of cut, to find

which setting work best for your needs. As a general

guideline however, for best results more aggressive cuts

or wider materials should be planed at slower speeds

and lighter cuts or narrow materials can be planed at

higher speeds.

TO AVOID DAMAGE TO THE GEARBOX, SPEED CHANGES SHOULD ONLY BE MADE WHILE THE MACHINE IS

RUNNING.

10

Failure to follow these recommendations will lead to premature blade wear and may cause premature motor

failure.

It is recommended that for both hard and soft wood:

For stock up to 5 1/2” in width never remove more that

1/8” per pass,

.

For stock of 5 1/2”-13” in width never remove more than

1/16” per pass,

.

Removing less material per pass and taking multiple

passes is always preferred to more aggressive planing.

Advantages include longer blade life, better finish quality (resulting in less time sanding later) and less likelihood of

removing too much material causing the workpiece to be too thin for its intended use.

OPERATING INSTRUCTIONS

BASIC PRINCIPLES OF PLANING

This thickness planer is designed to remove material from

the top face of a board in order to bring the board (or a

series of boards) down to a specific desired thickness.

To obtain even, uniform thickness across the length of a

board, the stock being planed must have one face that

has already been machined perfectly flat (usually on a

jointer) and the stock should be fed with this flat face

against the table,

.

If it is not possible to machine one face perfectly flat before planing, take shallow passes all on the same face of

the board until this face has been machined level. Then the board should be flipped over and the leveled face

should be fed face down against the table to allow you to dimension the board to final thickness.

1/8”

1/16”

1/32”

1/64”

0

1/8”

or less

1/16”

or less

1/8”

1/16”

1/32”

1/64”

0

1/8”

1/16”

1/32”

1/64”

0

1/8”

1/16”

1/32”

1/64”

0

5 1/2”

(or less)

5 1/2”- 13”

FLAT SIDE DOWN

Page 11

This planer is not intended (and should not be used) to

plane any material other than solid wood.

The workpiece should always be fed through the planer

in the general direction of the grain in the wood,

.

Before being fed through the planer all lumber should be

inspected for debris and foreign objects such as staples

or nails. Foreign objects stuck to, or embedded in your

workpiece can be ejected from the machine at high

speed and cause serious injury or damage cutter knives.

Make sure to remove all such foreign objects from the

wood before running it through the planer.

Select lumber carefully and avoid workpieces with loose or protruding knots. Workpieces that are twisted, severely

deformed or warped should also be avoided. Warped, twisted, damaged or fragile stock runs an increased risk of

jamming in or damaging the machine or cutters. There is also a much greater risk of injury to the operator or

bystanders from kickback, where the workpiece is forcefully or violently ejected from the machine due to a jam,

whenever working with such damaged or warped wood.

THE MAXIMUM PLANING

WIDTH OF THIS UNIT IS 13”.

THE MAXIMUM WORKPIECE

THICKNESS OF THIS UNIT IS 6”

THE MINIMUM THICKNESS TO WHICH A WORKPIECE

CAN BE SAFELY PLANED WITH THIS

UNIT IS 1/8” .

THE MINIMUM WORKPIECE LENGTH THAT CAN BE

SAFELY PLANED WITH THIS UNIT IS 5”.

RESPECT THE RATED LIMITS OF THIS MACHINE IGNORING THESE LIMITS AND FEEDING NON COMPATIBLE STOCK INTO

THIS PLANER CAN LEAD TO SERIOUS INJURY TO THE USER OR SHOP BYSTANDERS, AND CAUSE DAMAGE TO THE WORKPIECE AND/OR THE MACHINE. IF THE STOCK YOU WISH TO PLANE DOES NOT MEET OR COMPLY WITH THE LIMITATIONS

LISTED ABOVE, FIND ANOTHER SAFER WAY TO PERFORM THE REQUIRED TASK.

11

CHECKLIST BEFORE STARTING

Make sure the workpiece has been inspected and is suitable for planing as explained in the previous section

“Basic Principles of Planing”.

If multiple boards are to be planed, collect all workpieces together and set them nearby on a table or bench

within easy reach. To limit the potential for injury in the

event of a kickback,avoid having to step or reach in front

of the machine to pick up the next workpiece, .

Make sure to have on safety glasses as well as hearing

and respiratory protection at all times when using the

planer.

Make sure you and any assistants are wearing safe appropriate workshop attire. Roll up long sleeves, secure long

hair and remove any jewelry: watches, rings, bracelets or anything that could become caught in the feed rollers or

other moving parts, potentially causing serious injury.

If working with longer workpieces, make sure to have adequate outfeed support safely set-up and ready before

planing.

AVOID HAVING TO STEP OR REACH IN

FRONT OF THE MACHINE.

GRAIN DIRECTION

GRAIN DIRECTION

Max. 13”

Min. 1/8”

Max. 6”

Min. 5”

Page 12

1/8”

1 1/4”

1“

3/8”

1/2”

With the planer turned off position the workpiece on

the infeed table with the flat face down and the face

to be planed facing up.

RAISING/L

OWERING THE CUTTERHEAD

If a specific pre-set thickness is required, set the depth

stop to the desired final workpiece thickness.

Slide the workpiece up to the cutterhead and using

the depth of cut adjustment handle, raise or lower the

cutterhead as needed to obtain the desired depth of

cut.

Set the board aside, pull down on the cutterhead locking lever, , and turn on the planer, .

If necessary change the feed speed to select the desired feed rate: 18 or 26 FPM.

Stand to one side of the machine and set the board

back on the infeed table with the face to be planed

facing up.

TO LIMIT THE POTENTIAL FOR INJURY IN THE EVENT OF A

KICKBACK, AVOID STANDING DIRECTLY IN LINE WITH

THE FRONT OR BACK OF THE PLANER WHENEVER A

BOARD IS ENGAGED IN THE CUTTERHEAD.

12

LOCK

Align the board laterally so that it will be fed through

the planer in the general direction of the grain, and

allow the workpiece enough clearance to feed properly without rubbing or catching on either side of the

machine.

18FPM

26FPM

0

Page 13

13

The return rollers on the top of the planer can be used

to pass the workpiece back to the front of the machine

for repeat passes.

Repeat these steps as needed for all boards that need

to be planed to the same thickness.

Step to the rear of the machine and recover the planed board on the outfeed table once it has cleared

the outfeed roller and has stopped advancing.

REPEA

T/MULTIPLE PASSES

In most cases several passes through the planer will be required to bring the workpiece(s) down to final thickness

dimension. In fact, it is generally preferable to remove less material per pass and achieve final thickness dimension

by taking multiple passes. This can extend blade life, place less strain on the motor and provide better workpiece

finish quality that will require less time spent sanding later.

Once all the boards have been passed through the planer once, set them aside and turn off the machine.

Inspect and measure the workpiece(s) thickness (not necessary if using the pre-set stop) and if more material

needs to be removed to reach the desired stock thickness, repeat the steps listed in the previous section “Planing”.

Take as many passes as needed to achieve final workpiece thickness, stopping the machine after each pass to

reset the cutterhead height.

NEVER PUSH, PULL OR OTHERWISE TRY TO MOVE OR REPOSITION THE WORKPIECE ONCE IT IS IN THE CONTROL

OF THE AUTOMATIC FEED ROLLERS.

Slowly slide the workpiece forward until the infeed roller “grips” the board. Release the board allowing the

feed roller to automatically feed the board through

the planer.

Page 14

14

MAINTENANCE AND ADJUSTMENTS

PERIODIC MAINTENANCE

• Inspect/test the ON/OFF switch before each use. Do not operate the planer with a damaged switch; replace a

damaged switch immediately.

• Keep the machine as well as the in-feed out-feed tables clean and free of saw dust, woodchips, pitch or glue.

Vacuum or brush off any loose debris and wipe down the machine and the tables occasionally with a damp

rag.

• An occasional light coating of paste wax can help protect the tables’ surface and reduce workpiece friction.

Ask your local distributor for suggestions on aftermarket surface cleaners, protectant and dry lubricants based

on what is readily available in your area.

• Avoid using silicon based products that may affect wood finishing products such as oil, solvent or water-based

stains, varnishes and lacquers.

• Periodically inspect the power cord and plug for damage. To minimize the risk of electric shock or fire, never

operate the planer with a damaged power cord or plug. Replace a damaged power cord or plug at the first

visible signs of damage.

• The motor and cutterhead bearings are sealed and permanently lubricated – no further lubrication is required.

• The drive gears, chain and elevation screws should be cleaned of woodchips, dust, debris and old grease after

every 10-15 hours of use. After cleaning, re-apply a generous coating of any common automotive bearing

grease.

• Regularly inspect planed workpieces for signs of knife damage or wear and replace damaged or worn knives

immediately.

MAKE SURE THE PLANER HAS BEEN TURNED OFF AND UNPLUGGED FROM THE POWER SOURCE BEFORE PERFORMING

ANY MAINTENANCE.

There are 2 reversible cutterhead knives (blades) installed in the planer at the factory, . With usage and normal

wear over time, it will eventually become necessary to reverse and/or replace the knives.

When needed, replacement knives (sold in sets of 2), , can be ordered through your local General International

distributor under part #30-013.

Tip/Hint: To avoid potentially costly downtime, consider having a spare set of replacement knives on hand and

ready for use when needed.

Observing planed workpieces as they come out of the machine and looking for signs of knife damage or wear is

the best method to help you to determine when knives are due to be changed.

MAKE SURE THE PLANER HAS BEEN TURNED OFF AND UNPLUGGED FROM THE POWER SOURCE BEFORE PERFORMING

ANY MAINTENANCE.

INSPECTING/REPL

ACING CUTTERHEAD KNIVES

DOUBLE EDGE

Page 15

1. A raised ridgeline in the workpiece that runs a straight line from beginning to end of the board , . This is ge-

nerally an indication that one or both of the knives has been nicked or damaged by a foreign object such as

a nail, staple or other hard object hidden or embedded in the workpiece.

2. A slight washboard or chatter effect, , which can be an indication of uneven knife wear causing one knife to

cut slightly deeper than the other.

3. Rough, irregular, torn or fuzzy grain on a freshly planed surface may be a sign of worn or dull blades

causing the wood to tear out. Sharp blades cut crisply and leave a relatively smooth finish.

Note: Fuzzy grain can also be a sign of high moisture content in the workpiece. If knives have recently been changed or if you suspect that moisture content and not dull knives is the cause, set the workpiece aside and test by

planing other boards with known or acceptable moisture content. If the planed results using a different workpiece

are smooth, then moisture content in your wood is the problem - no adjustments can be made to the machine for

this. Set the “wet” stock aside and simply work with drier wood.

15

Signs to look for include:

To maintain even knife wear always reverse or replace both knives each time knife reversal or replacement is

required.

T

o replace the knives:

1. Turn off and unplug the machine from the power source.

2. Using the t-handle allen wrench, remove the screws holding the chip deflector to the rear of the planer

and remove the chip deflector from the machine, .

3. Rotate the cutterhead towards you by hand until the spring-loaded stop latch engages and prevents the

cutterhead from turning. This will expose the knife retaining plate screws, .

4. Unscrew and set aside the 6 screws, .

5. Using the supplied magnets, , remove the knife retaining plate as shown, , and set it aside.

EFFECT EXAGGERATED

FOR CLARITY

Page 16

16

NEVER RUN A FINGER OR OTHER BODY PART ALONG THE CUTTING EDGE OF THE KNIFE TO TEST FOR SHARPNESS

OR TO DETERMINE IF THE EDGE IS WORN OR HAS ALREADY BEEN USED. FAILURE TO HEED THIS WARNING CAN

LEAD TO SERIOUS INJURY.

CUTTERHEAD KNIVES HAVE SHARP EDGES AND CAN CAUSE DEEP CUTS TO FINGERS OR OTHER BODY PARTS. EXERCISE

EXTREME CAUTION WHEN HANDLING THE KNIVES. TO LIMIT THE POTENTIAL FOR INJURY, USE THE SUPPLIED MAGNETS

TO REMOVE, INSTALL OR OTHERWISE HANDLE CUTTERHEAD KNIVES.

Tip/Hint: To disengage the magnets from the knives after removal or installation, simply tilt the magnets slightly until

their “grip” on the metal surface is broken

,.

6. Using the supplied magnets remove the knife from the cutterhead, . If the reverse edge of the knife

has not already been used, simply rotate the knife 180° and re-install it. If both edges of the knife have been

used, discard the old knife and replace with a new one.

Tip/Hint: For the next future blade change and to eliminate guesswork and avoid having to remember if a knife

edge has already been used, using a marker, simply make a line or an “X” next to the edge that has already been

used

,.

Once you have marked an edge as having already been used, you will know that it cannot be used again.

Tip/Hint: To disengage the magnets from the knives after removal or installation, simply tilt the magnets slightly until

their “grip” on the metal surface is broken

,.

7. Note the knife alignment pins in the cutterhead, . These alignment pins take the guesswork out of aligning

both knives to the same height in the cutterhead. Using the magnets, install the knife, making sure the pins

are properly seated inside the alignment slots in the knife. The knife will be automatically set to the correct

height with no further adjustment required.

8. Using the supplied magnets, re-install the knife retaining plate and all 6 six screws that hold it in place.

Tip/Hint: Tighten the screws just slightly beyond hand tight. Over tightening the screws will make them very difficult

to remove for the next blade change.

9. Release the spring-loaded stop latch and rotate the cutterhead to expose the second knife retaining plate.

10. To reverse or replace the second knife, repeat steps 4-8.

11. After the second knife has been replaced and the knife retaining plate re-installed, re-install the chip

deflector.

Page 17

REPL

ACING THE V-BELT

With use over time, the v-belt can wear and may eventually need to be replaced.

To replace a worn v-belt:

1. Turn off and unplug the machine from the power source.

2. To access the belt, unfasten the screws holding the right side panel in place and remove the side panel, .

3. Slip the belt off the pulleys by carefully pulling on the belt by hand while pulling outwards (away from the

pulley) to gradually rotate the belt off of the pulley, .

4. Install a new belt using the same technique taking care to ensure the the belt is properly seated in the grooves

of both pulleys.

5. Re-install the side panel and tighten down the screws.

17

DRIVE CHAIN/GEAR LUBRICA

TION

Periodically the drive chain and gears will need to be cleaned and greased to help maintain smooth feeding and

contribute to longer machine life and trouble free operation.

To clean and grease the drive chain and gears:

1. Turn off and unplug the machine from the power source.

2. To access the chain and gears, unfasten the screws holding the left side panel in place and remove the side

panel, .

3. Remove old grease and dust deposits by wiping with a dry rag.

4. Apply generous dabs of any common automotive bearing grease to the gears and chain, .

5. Re-install the side panel and tighten down the screws.

Page 18

Replacement Knife Set

(2 kniv

es per set)

#30-013

13” steel replacement

knives. Double edged

(reversible design) for

longer service life.

Alignment slots for autoaligning; takes the guesswork out of setting knife

height for quick easy knife

changes.

Heavy Duty Open Based

Steel Stand

#30-015

Easy to assemble, wide

based stable design with

mounting slots for permanent planer installation.

Foot print measures 33”

(833) x 24 1/2”. Floor to top

of stand height: 28”

(711mm).

Dust Hood

#30-020

Connects to the chip

deflector at the rear of the

planer includes 4” dia

outlet to connect standard

dust hose for efficient

dust/chip collection (dust

hose and dust collection

systems sold separately).

Roller Stands

#50-150, 50-170 & 50-167S

For added in-feed or

out-feed support when

planing longer stock. Ask

your General International

distributor about our wide

selection of heavy duty

roller stands.

Dust Collector

s

We offer a wide selection

of top quality dust collectors to suit all your shop

needs. Dust collectors

contribute to a cleaner

more healthful workshop

environment.

RECOMMENDED OPTIONAL ACCESSORIES

FOR YOUR PLANER

We offer a large variety of products to

help you increase convenience, productivity, accuracy and safety when using

your planer. Here’s a small sampling of

optional accessories available from your

local General International dealer.

For a complete list of products, please visit

our website at www.general.ca

18

Page 19

31

137

138

15

44

105

115

121

119

120

138

118

117

107

106

113

114

43

42

103

103

102

104

60

110

101

76

108

4

78

2

1

124

99

101

100

135

25

29

77

125

7

135

3

4

6

64

122

97

47

96

90

85

89

144

17

48

49

47

126

46

15

139

43

40

39

123

45

16

51

47

49

50

19

18

20

22

23

21

13

14

16

57

60

55

54

52

56

63

111

141

53

61

142

76

30

98

24

47

28

28

47

21

47

30

65

29

140

27

26

68

70

69

36

38

71

35

71

33

82

5

32

83

37

38

34

21

72

12

6

7

87

91

92

93

94

95

109

88

86

47

80

75

74

79

41

73

127

136

56

54

57

58

58

59

59

62

16

81

84

66

47

143

8

9

10

11

19

PLANER

Page 20

20

PARTS LIST

30-010

PART N0. REF. N0. DESCRIPTION SPECIFICATION QTY

30010-01 170387-000 UPPER COVER 1

30010-02 340008-615 BUSHING 1

30010-03 000802-101 ROUND HEAD SCREW M8 X 1.25P X 16 4

30010-04 001102-503 SELF TAPPING SCREW M4 X 1.59P X 10 12

30010-05 130121-000 BUSHING 1

30010-06 250087-615 BUSHING 4

30010-07 190021-906 RETURN ROLLER 2

30010-08 280049-905 POINTER 1

30010-09 006001-035 FLAT WASHER 6.7 X 19 X 1.0 1

30010-10 000801-104 ROUND HEAD SCREW M6 X 1.0P X 20 1

30010-11 920124-000 HANDLE ASSEMBLY 1

30010-12 250098-615 LIFTING HANDLE 2

30010-13* PH05-01 MOTOR ASSEMBLY

30010-14 021102-000 CORD CLAMP ACC-2.5 1

30010-15 001901-101 SET SCREW M5 X 0.8P X 5 3

30010-16 001601-101 PHILLIPS HEAD SCREW W/WASHER M4 X 0.7P X 8/4 X 10 X 0.8t 7

30010-17 920125-000 DUST CHUTE 1

30010-18 170390-904 CHIP DEFLECTOR 1

30010-19 000801-102 ROUND HEAD SCREW M6 X 1.0P X 12 2

30010-20 220031-000 CUTTERHEAD 1

30010-21 360338-000 KNIFE POSITIONING PIN 8

30010-22 210122-000 KNIFE 2

30010-23 170280-904 KNIFE RETAINING PLATE 2

30010-24 250650-000 SIDE PANEL - RIGHT 1

30010-25 250676-000 SIDE PANEL - LEFT 1

30010-26 002402-101 PHILLIPS HEAD SCREW W/WASHER M5 X 0.8P X 12/5 X 10.5 X 1.0t 1

30010-27 280082-000 SPRING 1

30010-28 000102-313 CAP HEAD SCREW M5 X 0.8P X 75 4

30010-29 010006-000 "S" RING STW-15 3

30010-30 380257-901 CHAIN SPROCKET 3

30010-31 250372-615 KNOB 1

30010-32 012002-008 KEY 4 X 4 X 40 1

30010-33 360571-000 SHAFT 1

30010-34 170773-902 GEAR BOX COVER 1

30010-35 160037-000 BUSHING 1

30010-36 320236-000 GEAR 1

30010-37 320238-000 DOUBLE GEAR 1

30010-38 160019-000 BRONZE BUSHING 3

30010-39 000103-103 CAP SCREW M6 X 1.0P X 12 1

30010-40 250143-616 PRE-SET STOP DIAL 1

30010-41 030403-000 BEARING 6202-2NK 1

30010-42 000102-102 CAP SCREW M5 X 0.8P X 8 4

30010-43 170292-901 RETENTION PLATE 4

30010-44 000103-102 CAP SCREW M6 X 1.0P X 10 4

30010-45 250144-615 CORD STORAGE BRACKET 2

30010-46 280038-901 SPRING 1

30010-47 000303-103 PHILLIPS HEAD SCREW M5 X 0.8P X 10 20

30010-48 170316-905 RATCHET PLATE 1

30010-49 001602-101 PHILLIPS HEAD SCREW W/WASHER M5 X 0.8P X 10/5 X 12 X 0.8t 2

30010-50 170396-901 BELT COVER 1

30010-51 090057-000 UPPER FRAME 1

30010-52 920126-000 LOCK LEVER ASSY 1

30010-53 010105-000 "D" RING RTW-40 1

30010-54 360340-902 ROD 4

30010-55 012003-002 KEY 5 X 5 X 10 1

30010-56 280046-901 SPRING 4

PLANER

Page 21

21

PARTS LIST

30-010

PART N0. REF. N0. DESCRIPTION SPECIFICATION QTY

30010-57 130030-000 PAD 4

30010-58 008004-100 HEX NUT M5 X 0.8P 4

30010-59 000001-104 HEX BOLT M5 X 0.8P X 16 4

30010-60 010205-000 "E" CIRCLIP ETW-8 4

30010-61 010103-000 "D" CIRCLIP RTW-35 1

30010-62 011001-104 SPRING PIN 3 X 12 1

30010-63 130032-000 CAM 1

30010-64 008006-100 NUT M8 X 1.25P-13 1

30010-65 290029-902 SHOULDER BOLT 1

30010-66 920261-000 IDLER ASSEMBLY 1

30010-68 160034-000 BUSHING 2

30010-69 320239-000 GEAR 1

30010-70 320235-000 GEAR SHAFT 1

30010-71 012002-002 KEY 4 X 4 X 7 2

30010-72 090104-000 GEAR BOX 1

30010-73 320229-000 GEAR 1

30010-74 360345-902 DEPTH ROD 1

30010-75 011001-103 SPRING PIN 3 X 10 1

30010-76 008005-100 HEX NUT M6 X 1.0P 5

30010-77 000002-102 HEX BOLT M6 X 1.0P X 15 1

30010-78 016205-000 CHAIN #410 X 32P 1

30010-79 110016-000 BRACKET 1

30010-80 280048-000 SPRING 1

30010-81 920129-000 POINTER ASSEMBLY 1

30010-82 360048-901 SHAFT 1

30010-83 130099-000 CLUTCH 1

30010-84 200019-615 SPACER 1

30010-85 280036-901 SPRING 2

30010-86 250141-620 POINTER 1

30010-87 006303-100 LOCK WASHER 6.1 X 12.3 1

30010-88 000103-108 CAP SCREW M6 X 1.0P X 25 1

30010-89 280035-901 BRACKET SPRING 2

30010-90 130067-000 ROLLER BRACKET 4

30010-91 030404-000 BEARING 6203-2NK 1

30010-92 160020-000 SPACER 1

30010-93 014302-000 V-BELT 135J-6 1

30010-94 110009-000 CUTTERHEAD PULLEY 1

30010-95 008016-200 HEX NUT M16 X 1.5P 1

30010-96 170298-901 BRACKET PLATE 4

30010-97 340030-000 RUBBER ROLLER 2

30010-98 280037-000 BRACKET SPRING 2

30010-99 360307-000 COLUMN 4

30010-100 360343-902 LEFT SCREW 1

30010-101 012002-003 KEY 4 X 4 X 8 4

30010-102 270005-000 RETENTION PLATE 2

30010-103 320183-629 BEVEL GEAR 4

30010-104 010001-000 "C" CIRCLIP STW-10 2

30010-105 170392-000 MAIN TABLE 1

30010-106 000304-102 PHILLIPS HEAD SCREW M6 X 1.0P X 10 4

30010-107 170393-901 GUIDE PLATE 2

30010-108 270014-901 SPRING PLATE 4

30010-109 230238-905 SELF TAPPING SCREW/LOCK WASHER 1

30010-110 360344-902 DRIVE SHAFT 1

30010-111 090061-000 BASE 1

30010-113 000002-111 HEX HEAD BOLT M6 X 1.0P X 20 4

PLANER

Page 22

PARTS LIST

30-010

PART N0. REF. N0. DESCRIPTION SPECIFICATION QTY

30010-114 011004-103 SPRING PIN 6 X 25 4

30010-115 000302-102 PHILLIPS HEAD SCREW M4 X 0.7P X 8 12

30010-117 170394-906 TABLE EXTENSION 2

30010-118 006001-026 FLAT WASHER 6.4 X 20 X 3.0t 4

30010-119 000103-101 HEX HEAD SCREW M6 X 1.0P X 8 4

30010-120 250084-615 BUSHING 4

30010-121 190022-906 TABLE EXTENSION ROLLER 2

30010-122 360342-902 RIGHT SCREW 1

30010-123 200014-615 TOOL TRAY 1

30010-124 230119-000 "T" HANDLE ALLEN WRENCH 1

30010-125 920130-000 KNIFE SETTING MAGNET 2

30010-126 006502-100 SPROCKET WASHER 5.3 X 10(BW-5) 1

30010-127 002603-101 CAP SCREW M5 X 0.8P X 10 1

30010-135 360305-901 SPRING PIN 4

30010-136 320237-000 GEAR 1

30010-137 001501-101 CAP SCREW W/LOCK WASHER

M8 X 1.25P X 20/8.2 X 15.4/8.5 X 19 X 2t

4

30010-138 170391-906 BRACKET 4

30010-139 000303-102 PHILLIPS HEAD SCREW M5 X 0.8P X 8 4

30010-140 160038-000 BUSHING 1

30010-141 006305-100 LOCK WASHER 8.2 X 15.4 1

30010-142 001102-502 SELF TAPPING SCREW M4 X 1.59P X 8 4

30010-143 170672-902 TRANSMISSION SHAFT GUIDE PLATE 1

30010-144 230215-901 SCREW 12

PLANER

22

NOTES

Page 23

23

22

15

17

18

16

1

7

10

9

8

12

11

14

13

3

5

4

6

2

19

20

21

PARTS LIST

30-010

PART N0. REF. N0. DESCRIPTION SPECIFICATION QTY

30010-01A 920137-000 TEMPERATURE CONTROL SWITCH 18AMP 1

30010-02A 000303-103 PHILLIPS HEAD SCREW M5 X 0.8P X 10 2

30010-03A 250151-615 MOTOR HOUSING (LEFT) 1

30010-04A 020005-000 STRAIN RELIEF SB8R-3 1

30010-05A 230113-905 SELF TAPPING SCREW 4

30010-06A 090064-000 MOTOR COVER 1

30010-07A 030401-000 BEARING 6200-2NK 1

30010-08A 800011-000 ROTOR ASSEMBLY 110-120V 1

30010-09A 230103-905 SELF TAPPING SCREW 2

30010-10A 030402-000 BEARING 6201-2NK 1

30010-11A 250152-615 BRACKET 1

30010-12A 410007-000 STATOR ASSEMBLY 120V 1

30010-13A 920235-000 MOTOR HOUSING (RIGHT) 1

30010-14A 430003-000 BRUSH BRACKET 2

30010-15A 430012-000 MOTOR BRUSH 120V 2

30010-16A 430006-000 BRUSH COVER 2

30010-17A 230106-000 SELF TAPPING SCREW 2

30010-18A 380047-901 MOTOR PULLEY 1

30010-19A 250153-616 SWITCH MOUNTING PLATE 1

30010-20A 001201-501 SELF TAPPING SCREW M4 X 1.59P X 12 2

30010-21A 937152-000 SWITCH ASSEMBLY 1

30010-22A 453013-006 POWER CORD 14AWG X 3C X 2.8m 1

MOTOR

MOTOR

Page 24

IMPORTANT: When ordering replacement parts, always give the model number, serial number of

the machine and part number. Also a brief description of each item and quantity

desired.

8360, Champ-d’Eau, Montreal (Quebec)

Canada H1P 1Y3

Tel.: (514) 326-1161

Fax : (514) 326-5565

Parts & Service

Fax : (514) 326-5555 Order Desk

orderdesk@general.ca

www.general.ca

30-010

Loading...

Loading...