Page 1

SETUP & OPERATION MANUAL

FEATURES

Powerful 2 HP 15 A motor with thermal overload

protection.

Front and rear fold-down extension tables for

smooth easy stock feeding.

Top mounted rollers for multiple passes.

Built-in inset lifting handles.

Large depth of cut adjustment handle – one full

rotation equals 1/16”.

Easy to read thickness indicator with graduated

scale in inches and metric.

Safety on/off switch with key. Unit cannot be

started when key is removed from switch.

Depth of cut indicator.

Pre-set depth stop for repeat cuts at 1/8”, 1/4”,

1/2” and 3/4”.

Included dust hood has both 2 1/2” and 4” dust

hose outlets.

Helical head with 26 reversible two-sided carbide inserts.

Cutter head supported on 4 threaded posts to

ensure head stability and minimize workpiece

snipe.

13” PLANER WITH HELICAL HEAD

SPECIFICATIONS

• Table area with extensions (L x W)

28 5⁄8” x 13” (720 x 330 mm)

• Maximum planing width

13” (330 mm)

• Maximum thickness of stock

6” (152 mm)

• Minimum thickness of stock

1/8” (3 mm)

• Minimum length of stock

5” (127 mm)

• Maximum depth of cut (full width)

1/16” (1.5 mm)

• speed

9,700 RPM

• Feed speed

26 FPM

• Motor

2 HP, 120 V, 1 Ph, 15 A

• Weight

64 LBS (29 Kg)

Version #2/Revision #1 - (S/N 32349814) May 29, 2014

© Copyright General International

MODEL

#30-005HC MI

Page 2

GENERAL® INTERNATIONAL

8360 Champ-d’Eau, Montreal (Quebec) Canada H1P 1Y3

Telephone (514) 326-1161 • Fax (514) 326-5555 • www.general.ca

THANK YOU for choosing this General

®

International model 30-005HC M1

13” Planer with Helical . This planer has been carefully tested and inspected before shipment

and if properly used and maintained, will provide you with years of reliable service. For your

safety, as well as to ensure optimum performance and trouble-free operation, and to get the

most from your investment, please take the time to read this manual before assembling, installing and operating the unit.

The manual’s purpose is to familiarize you with the safe operation, basic function, and features

of this planer as well as the set-up, maintenance and identification of its parts and components. This manual is not intended as a substitute for formal woodworking instruction, nor to

offer the user instruction in the craft of woodworking. If you are not sure about the safety of

performing a certain operation or procedure, do not proceed until you can confirm, from

knowledgeable and qualified sources, that it is safe to do so.

Once you’ve read through these instructions, keep this manual handy for future reference.

Disclaimer: The information and specifications in this

manual pertain to the unit as it was supplied from the

factory at the time of printing. Because we are committed to making constant improvements, General

International reserves the right to make changes to

components, parts or features of this unit as deemed

necessary, without prior notice and without obligation

to install any such changes on previously delivered

units. Reasonable care is taken at the factory to ensure

that the specifications and information in this manual corres-ponds with that of the unit with which it was

®

supplied. However, special orders and “after factory”

modifications may render some or all information in

this manual inapplicable to your machine. Further, as

several gene-rations of this model of planer and several versions of this manual may be in circulation, if you

own an earlier or later version of this unit, this manual

may not depict your machine exactly. If you have any

doubts or questions contact your retailer or our support

line with the model and serial number of your unit for

clarification.

Page 3

GENERAL®INTERNATIONAL WARRANTY

All component parts of General® International and Excalibur by General International® products are

carefully inspected during all stages of production and each unit is thoroughly inspected upon completion of assembly.

Limited Lifetime Warranty

Because of our commitment to quality and customer satisfaction, General® International agrees to

repair or replace any part or component which upon examination, proves to be defective in either

workmanship or material to the original purchaser for the life of the tool. However, the Limited Lifetime

Warranty does not cover any product used for professional or commercial production purposes nor for

industrial or educational applications. Such cases are covered by our Standard 2-year Limited Warranty

only. The Limited Lifetime Warranty is also subject to the “Conditions and Exceptions” as listed below.

Standard 2-Year Limited Warranty

All products not covered by our lifetime warranty including products used in commercial, industrial and

educational applications are warranted for a period of 2 years (24 months) from the date of purchase.

General® International agree to repair or replace any part or component which upon examination,

proves to be defective in either workmanship or material to the original purchaser during this 2-year

warranty period, subject to the “conditions and exceptions” as listed below.

To file a Claim

To file a claim under our Standard 2-year Limited Warranty or under our Limited Lifetime Warranty, all defective parts, components or machinery must be returned freight or postage prepaid to

General® International, or to a nearby distributor, repair center or other location designated by

General® International. For further details call our service department at 1-888-949-1161 or your local

distributor for assistance when filing your claim.

Along with the return of the product being claimed for warranty, a copy of the original proof of purchase

and a “letter of claim” must be included (a warranty claim form can also be used and can be obtained,

upon request, from General® International or an authorized distributor) clearly stating the model and

serial number of the unit (if applicable) and including an explanation of the complaint or presumed

defect in material or workmanship.

CONDITIONS AND EXCEPTIONS:

This coverage is extended to the original purchaser only. Prior warranty registration is not required but

documented proof of purchase i.e. a copy of original sales invoice or receipt showing the date and location of the purchase as well as the purchase price paid, must be provided at the time of claim.

Warranty does not include failures, breakage or defects deemed after inspection by

General® International to have been directly or indirectly caused by or resulting from; improper use, or

lack of or improper maintenance, misuse or abuse, negligence, accidents, damage in handling or transport, or normal wear and tear of any generally considered consumable parts or components.

Repairs made without the written consent of General® International will void all warranty.

Page 4

TABLE OF CONTENTS

Rules for safe operation.................................... 5

Electrical requirements .............................. 6

Grounding instructions ........................................................ 6

Circuit capacity ................................................................... 6

Extension cords .................................................................... 6

Identification of main parts and components .. 7

Unpacking .................................................. 8

Assembly Instruction ........................... 8

Attach the depth of cut adjustment handle .................... 9

Attach the dust chute .......................................................... 9

Operating Instructions ...................... 11

Basic principles of planing ............................................... 11

Selecting boards suitable for planing ............................ 11

Rated limits of this planer ................................................. 12

Checklist before starting ................................................... 12

Planing step-by-step .......................................................... 13

Maintenance & Adjustments ............ 14

Periodic maintenance ...................................................... 14

Inspecting/Replacing cutter head knives ..................... 15

Replacing the v-belt .......................................................... 17

Drive chain/gear lubrication ........................................... 17

Recommended optional accessories ...........18

Basic Adjustments and Controls ....... 9

Connecting to a power source ......................................... 9

On/Off power switch ......................................................... 10

Surge protection/Circuit breaker .................................... 10

Raising/Lowering the ....................................................... 11

Pre-set tickness stop gauge .............................................. 11

Depth of cut indicator ....................................................... 11

Parts list & diagrams ................................ 19-23

Page 5

RULES FOR SAFE OPERATION

To help ensure safe operation, please take a moment to learn the machine’s applications and limitations, as well as potential hazards. General® International disclaims any real or implied warranty and holds itself harmless for any injury that

may result from improper use of its equipment.

1. Do not operate this planer when tired, distracted, or

under the effects of drugs, alcohol or any medication

that impairs reflexes or alertness.

2. The working area should be well lit, clean and free of

debris.

3. Keep children and visitors at a safe distance when the

planer is in operation; do not permit them to operate

the planer.

4. Childproof and tamper proof your shop and all ma chinery with locks, master electrical switches and

switch keys, to prevent unauthorized or unsupervised

use.

5. Stay alert! Give your work your undivided attention.

Even a momentary distraction can lead to serious

injury.

6. Fine particulate dust is a carcinogen that can be

hazardous to health. Work in a well-ventilated area

and whenever possible use a dust collector. Wear

face, eye, ear, respiratory and body protection

devices.

7. Do not wear loose clothing, gloves, bracelets, neck laces or other jewelry while the planer is in operation.

Wear protective hair covering to contain long hair

and wear non-slip footwear.

8. Be sure that adjusting wrenches, tools, drinks and

other clutter are removed from the machine and/or

the table surface before operating.

13. Do not push or force stock into the . The

planer will perform better and safer when working at

the rate for which it was designed.

14. Kickback is when the workpiece is ejected at high

speeds by the force of the . To minimize the

risk of injury from kickback, use proper feeding tech nique and stand to one side, out of the path of a po tential kickback.

15. Select appropriate feed speed for the stock being

planed: high speed for softwood and slow for hard woods.

16. Place stock firmly against the table and use suitable

in-feed and out-feed support if stock is too long.

17. Keep guards in place and in working order. If a guard

must be removed for maintenance or cleaning make

sure it is properly attached before using the machine

again.

18. Use of parts and accessories NOT recommended by

GENERAL®INTERNATIONAL may result in equipment

malfunction or risk of injury.

19. Never stand or lean on machinery. Serious injury could

result if the tool is tipped over or if the cutting tool is unin tentionally contacted.

20. Always disconnect the tool from the power source

before servicing or changing accessories such as

knives, or before performing any maintenance or

cleaning, or if the machine will be left unattended.

9. Keep hands well away from knives and all moving

parts. Use a push stick to feed stock, and a brush, not

hands, to clear away chips and dust.

10. Be sure that the knives are securely installed in the

.

11. Always use clean, properly sharpened knives. Dirty or

dull knives are unsafe and can lead to accidents.

12. Inspect stock and remove all foreign objects before

planing. Make sure that any stock you plane is clean

and free of any dirt, nails, staples, tiny rocks or any other

foreign objects that may damage the planer knives.

Only process natural solid wood boards. Never plane

MDF, particle board, plywood, laminates or other syn thetic materials.

21. Make sure that the switch is in the “OFF” position before

plugging in the power cord.

22. Make sure the tool is properly grounded. If equipped

with a 3-prong plug it should be used with a three-pole

receptacle. Never remove the third prong.

23. Do not use this planer for other than its intended use.

If used for other purposes, GENERAL®INTERNATIONAL

disclaims any real implied warranty and holds itself

harmless for any injury, which may result from that

use.

5

Page 6

ELECTRICAL REQUIREMENTS

BEFORE CONNECTING THE MACHINE TO THE POWER SOURCE, VERIFY THAT THE VOLTAGE OF YOUR POWER SUPPLY CORRESPONDS WITH THE VOLTAGE SPECIFIED ON THE MOTOR I.D. NAMEPLATE. A POWER SOURCE WITH GREATER VOLTAGE THAN NEEDED CAN RESULT IN SERIOUS INJURY TO THE USER AS WELL AS DAMAGE TO THE MACHINE. IF IN DOUBT, CONTACT A QUALIFIED

ELECTRICIAN BEFORE CONNECTING TO THE POWER SOURCE.

THIS TOOL IS FOR INDOOR USE ONLY. DO NOT EXPOSE TO RAIN OR USE IN WET OR DAMP LOCATIONS.

GROUNDING INSTRUCTIONS

In the event of an electrical malfunction or short circuit,

grounding reduces the risk of electric shock. The motor

of this machine is wired for 120V single phase operation

and is equipped with a 3-conductor cord and a

3-prong grounding plug

receptacle

ing pin) to make it fit into an old 2-hole wall socket or

extension cord. If an adaptor plug is used

attached to the metal screw of the receptacle.

Note: The use of an adaptor plug is illegal in some

areas. Check your local codes. If you have any doubts

or if the supplied plug does not correspond to your

electrical outlet, consult a qualified eletrician before

proceeding.

. Do not remove the 3rd prong (ground-

to fit a grounded type

, it must be

EXTENSION CORDS

If you find it necessary to use an extension cord with

your machine, use only 3-wire extension cords that have

3-prong grounding plug and a matching 3-pole receptacle that accepts the tool’s plug. Repair or replace a

damaged extension cord or plug immediately.

Make sure the cord rating is suitable for the amperage

listed on the motor I.D. plate. An undersized cord will

cause a drop in line voltage resulting in loss of power

and overheating. The accompanying chart shows the

correct size extension cord to be used based on cord

length and motor I.D. plate amp rating. If in doubt, use

the next heavier gauge. The smaller the number, the

heavier the gauge.

AMPERES

(AMPS)

< 5

6 TO 10 18 16 14 12

10 TO 12 16 16 14 14

12 TO 16 14 12

* NR = Not Recommended

EXTENSION CORD LENGTH

25 FEET 50 FEET 100 FEET 150 FEET

18 16 16 14

* NR * NR

`

CIRCUIT CAPACITY

Make sure that the wires in your circuit are capable of

handling the amperage draw from your machine, as

well as any other machines that could be operating on

the same circuit. If you are unsure, consult a qualified

electrician. If the circuit breaker trips or the fuse blows

regularly, your machine may be operating on a circuit

that is close to its amperage draw capacity. However,

if an unusual amperage draw does not exist and a

power failure still occurs, contact a qualified technician

or our service department.

6

Page 7

13” PLANER WITH HELICAL

30-005HC M1

IDENTIFICATION OF MAIN PARTS AND COMPONENTS

REAR VIEW

D

E

G

F

C

B

A

J

H

IN-FEED TABLE

STOCK THICKNESS SCALE

HEIGHT ADJUSTMENT HANDLE

RETURN ROLLERS

CIRCUIT BREAKER

ON/OFF SWITCH W/SAFETY KEY

I

DEPTH OF CUT INDICATOR

OUT-FEED TABLE

TOOL STORAGE

DUST CHUTE

7

Page 8

UNPACKING

Carefully unpack and remove the planer and its components from the box and check for damaged or missing

items as per the list of contents below.

NOTE: Please report any damaged or missing items to

your General International distributor immediately.

LIST OF CONTENTS QTY

PLANER ........................................................................... 1

A-

ADJUSTMENT HANDLE ...................................................1

B-

DUST CHUTE ...................................................................1

C-

SAFETY KEY ....................................................................1

D-

CAP SCREW ................................................................... 1

E-

BUTTON HEAD SCREW ...................................................4

F-

T-HANDLE WRENCH .......................................................1

G-

4 MM ALLEN KEY ........................................................... 1

H-

A

B

D

E

F

C

G

H

ASSEMBLY INSTRUCTIONS

For your convenience this planer is shipped from the factory partially assembled and requires only minimal assembly and set up before being put into service.

BEFORE STARTING THE INSTALLATION AND ASSEMBLY, MAKE SURE THAT THE POWER SWITCH IS IN THE “OFF” POSITION

AND THAT THE POWER CORD IS UNPLUGGED. DO NOT PLUG IN OR TURN ON THE PLANER UNTIL YOU HAVE COMPLE-TED THE INSTALLATION AND ASSEMBLY STEPS DESCRIBED IN THIS SECTION OF THE MANUAL.

The unit should be installed on a flat, level, sturdy

and stable surface, able to support the weight of the

machine and the workpiece with ease.

8

Never install or operate the planer over the edge of a

table, workbench or other mounting surface.

Page 9

HEX HEAD BOLT (1)

FLAT WASHERS (2)

LOCK WASHER (1)

HEX NUT (1)

If a permanent shop placement or installation is practical, consider using the mounting holes and drilling

matching through holes in your workbench or mounting surface to bolt the planer in place (hardware not

included) on your workbench.

ATTACH THE DEPTH OF CUT ADJUSTMENT HANDLE

Attach the adjustment handle on top of the machine

as shown, using the supplied allen key and cap screw.

If you prefer an optional steel stand (item #30-006)

is available from your local General International

dealer.

ATTACH THE DUST CHUTE

Install the dust chute on the rear of the machine as

shown, using the 4 supplied button head screws.

BASIC ADJUSTMENTS AND CONTROLS

CONNECTING TO A POWER SOURCE

TO REDUCE THE RISK OF SHOCK OR FIRE DO NOT OPERATE THE UNIT WITH A DAMAGED POWER CORD OR PLUG.

REPLACE DAMAGED CORD OR PLUG IMMEDIATELY.

TO AVOID UNEXPECTED OR UNINTENTIONAL START-UP, MAKE SURE THAT THE POWER SWITCH IS IN THE OFF POSITION

BEFORE CONNECTING TO A POWER SOURCE.

C

SWITCH OFF

B

A

Once the assembly steps have been completed and the unit is safely secured or installed on a work surface such

as a bench, stand or worktable, uncoil the power cord. With the switch locked-out (i.e. without the supplied safety

key A installed, as shown in B, or in the off position C), plug the power cord into an appropriate outlet. Refer back

to the section entitled Electrical Requirements and make sure all requirements and grounding instructions are followed. When planing operations have been completed unplug the unit from the power source.

9

Page 10

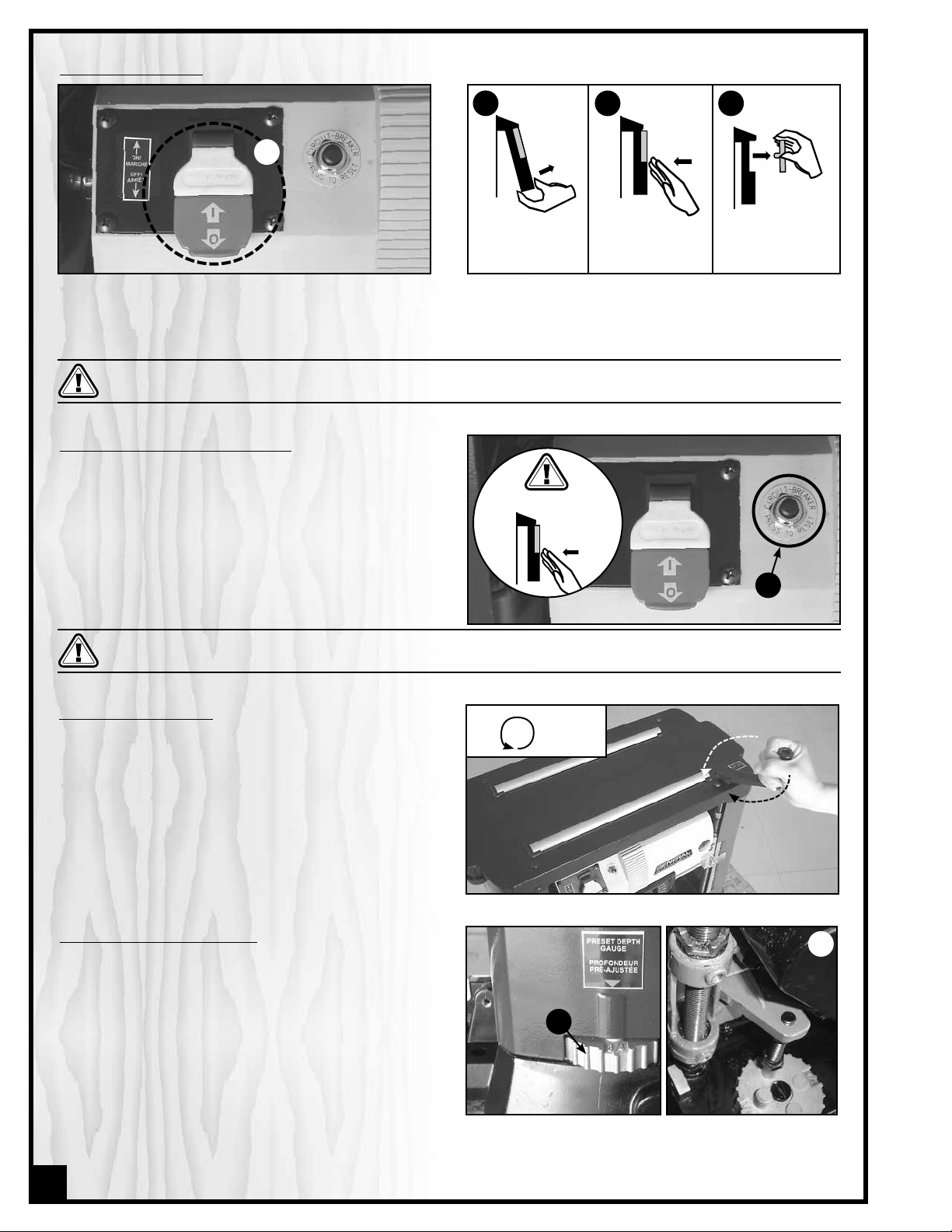

ON/OFF POWER SWITCH

B

C

D

A

POWER ON

This planer is equipped with a rocker style ON/OFF switch located on the front left hand side of the . To start the

planer, insert the lock-out key as shown in A and pull up on the lower portion of the switch as shown, B. To stop the

planer, push down on the switch, C. To prevent unwanted or unauthorized start-up or usage, remove the lock-out

key D and store it in a safe place, out of the reach of children, whenever the planer is not in use.

TO PREVENT UNWANTED OR UNAUTHORIZED START-UP OR USAGE, REMOVE THE LOCK-OUT KEY AND STORE IT IN A SAFE

PLACE, OUT OF THE REACH OF CHILDREN, WHENEVER THE PLANER IS NOT IN USE.

POWER OFF

a

SAFETY KEY

(PREVENTS START-UP

WHEN REMOVED)

SURGE PROTECTION/CIRCUIT BREAKER

The unit is equipped with a circuit breaker located to the

right of the power switch, A, to protect the motor from

power surges or spikes in line voltage. In the event of a

power surge, the circuit breaker will be automatically

tripped thereby cutting off the power to the motor.

SWITCH OFF

To reset the circuit breaker after it has been tripped;

set the power switch to the “off” position and depress

the reset button on the circuit breaker, then restart the

machine.

TO AVOID UNEXPECTED OR UNINTENTIONAL START-UP BE CERTAIN THAT THE POWER SWITCH HAS BEEN SET TO THE

OFF POSITION BEFORE RE-SETTING THE CIRCUIT BREAKER.

A

RAISING / LOWERING THE

To adjust the depth of cut, the cutter head assembly can

be raised or lowered as needed by rotating the depth of

cut adjustment handle.

NOTE: Each full clockwise rotation of the handle will lower the

cutter head by 1/16”. Each full counterclockwise rotation will

raise the cutter head by 1/16”.

1 x = 1/16”

PRE-SET THICKNESS STOP GAUGE

The adjustable pre-set depth gauge located on the right

side of the planer, A, allows the user to select one of four

commonly used workpiece final thickness settings.

With the cutter head set slightly above the height of the

workpiece press down and rotate the spring loaded

adjustment knob to select the desired final thickness setting from either 1/8”, 1/4”, 1/2” & 3/4”. This will set the stop

pin to prevent the cutter head from going any lower than

the selected thickness, B.

NOTE: Once you have planed the workpiece down to the selected thickness, do not attempt to lower the cutter head

further. Forcing the depth of cut handle when the cutter head has bottomed out on the pre-set stop pin will damage the

raising mechanism.

A

DOWN

UP

B

10

Page 11

DEPTH OF CUT INDICATOR

The depth of cut indicator, A, will indicate how much

material the cutter head is set to remove from the workpiece for a given pass.

The pointer will read zero until the workpiece engages

the front of the cutter head. Place the workpiece under

the front of the cutter head and turn the height adjustment handle clockwise until the cutter head makes contact with the workpiece & until the depth of cut indicator

shows the reading that matches the desired cut.

Failure to follow these recommendations will lead to

premature blade wear and may cause premature

motor failure.

It is recommended that for both hard and soft wood:

For stock up to 6” in width, never remove more that 1/8”

per pass, A

For stock of 6”-13” in width, never remove more than

1/16” per pass, B

Removing less material per pass and taking multiple

passes is always preferred to more aggressive planing.

Advantages include longer blade life, better finish quality (resulting in less time sanding later) and less likelihood

of removing too much material causing the workpiece to be too thin for its intended use.

.

.

A

1/8”

or less

B

A

1/16”

or less

OPERATING INSTRUCTIONS

BASIC PRINCIPLES OF PLANING

This thickness planer is designed to remove material from

the top face of a board in order to bring the board (or

a series of boards) down to a specific desired thickness.

To obtain even, uniform thickness across the length of a

board, the stock being planed must have one face that

has already been machined perfectly flat (usually on

a jointer) and the stock should be fed with this flat face

against the table, A

If it is not possible to machine one face perfectly flat before planing, take shallow passes all on the same face of

the board until this face has been machined level. Then the board should be flipped over and the leveled face

should be fed face down against the table to allow you to dimension the board to final thickness.

.

SELECTING BOARDS SUITABLE FOR PLANING

This planer is not intended (and should not be used) to

plane any material other than solid wood.

The workpiece should always be fed through the planer in

the general direction of the grain in the wood, B

Before being fed through the planer all lumber should be

inspected for debris and foreign objects such as staples

or nails. Foreign objects stuck to, or embedded in your

workpiece can be ejected from the machine at high

speed and cause serious injury or damage cutter knives. Make sure to remove all such foreign objects from the

wood before running it through the planer.

Select lumber carefully and avoid workpieces with loose or protruding knots. Workpieces that are twisted, severely

deformed or warped should also be avoided. Warped, twisted, damaged or fragile stock runs an increased risk

of jamming in or damaging the machine or cutters. There is also a much greater risk of injury to the operator or

bystanders from kickback, where the workpiece is forcefully or violently ejected from the machine due to a jam,

whenever working with such damaged or warped wood.

.

A

FLAT SIDE DOWN

B

GRAIN DIRECTION

GRAIN DIRECTION

11

Page 12

RATED LIMITS OF THIS PLANER

THE MAXIMUM PLANING

WIDTH OF THIS UNIT IS 13”.

THE MAXIMUM WORKPIECE

THICKNESS OF THIS UNIT IS 6”

Max. 13”

THE MINIMUM THICKNESS TO WHICH A WORKPIECE

CAN BE SAFELY PLANED WITH THIS

UNIT IS 1/8” .

THE MINIMUM WORKPIECE LENGTH THAT CAN BE

SAFELY PLANED WITH THIS UNIT IS 5”.

RESPECT THE RATED LIMITS OF THIS MACHINE IGNORING THESE LIMITS AND FEEDING NON COMPATIBLE STOCK INTO

THIS PLANER CAN LEAD TO SERIOUS INJURY TO THE USER OR SHOP BYSTANDERS, AND CAUSE DAMAGE TO THE WORKPIECE AND/OR THE MACHINE. IF THE STOCK YOU WISH TO PLANE DOES NOT MEET OR COMPLY WITH THE LIMITATIONS

LISTED ABOVE, FIND ANOTHER SAFER WAY TO PERFORM THE REQUIRED TASK.

Min. 1/8”

Max. 6”

CONNECTING TO A DUST COLLECTOR

A dust port A with a 4” opening is provided to accommodate connection to a dust collector (not included).

Be sure to use appropriate sized hose and fittings (not

included) and check that all connections are sealed

tightly to help minimize airborne dust.

If you do not already own a dust collection system

consider contacting your General® International distributor for information on our complete line of dust

collection systems and accessories or visit our Web Site

at www.general.ca

Min. 5”

A

CHECKLIST BEFORE STARTING

VERIFY ALL CHECK POINTS BEFORE STARTING. FAILURE TO COMPLY CAN RESULT IN SERIOUS INJURIES.

• Make sure the board has been inspected and is suitable for planing as explained in section “Selecting

boards suitable for planing”.

• Make sure you and any assistants are wearing safe appropriate workshop attire. Roll up long sleeves, secu re long hair and remove any jewelry: watches, rings, bracelets or anything that could become caught in the

moving parts, potentially causing serious injury.

• Make sure to have on safety glasses as well as hearing and respiratory protection at all times when using the

planer.

• To reduce the risk of damage to the planer or the workpiece, as well as a potential for personal injury, after ini tial set-up as well as before each use, make sure that everything is securely installed and that all fasteners

and moving parts on this machine are locked in placebefore starting the machine.

• If multiple boards are to be planed, collect all workpieces together and set them nearby on a table or bench

within easy reach A. To limit the potential for injury in the event of a kickback, avoid having to step or reach in

front of the machine to pick up the next workpiece B.

A

AVOID HAVING TO STEP OR REACH IN

FRONT OF THE MACHINE.

12

B

Page 13

PLANING STEP-BY-STEP

1. With the planer turned off, position the workpiece

on the infeed table with the flat face down and the

face to be planed facing up.

3. Slide the workpiece up to the cutter head and

using the depth of cut adjustment handle, raise or

lower the cutter head as needed to obtain the

desired depth of cut.

2. If a specific pre-set thickness is required, set the

depth stop to the desired final workpiece thickness.

A

4. Set the board aside, then insert the safety key in the

switch A and turn on the planer B.

B

5. Stand to one side of the machine and set the

board back on the infeed table with the face to be

planed facing up.

TO LIMIT THE POTENTIAL FOR INJURY IN THE EVENT OF

A KICKBACK, AVOID STANDING DIRECTLY IN LINE WITH

THE FRONT OR BACK OF THE PLANER WHENEVER A

BOARD IS ENGAGED IN THE CUTTER HEAD.

7. Slowly slide the workpiece forward until the infeed

roller “grips” the board.

6. Align the board laterally so that it will be fed

through the planer in the general direction of the

grain, and allow the workpiece enough clearance

to feed properly without rubbing or catching on

either side of the machine.

8. Release the board allowing the feed roller to

automatically feed the board through the planer.

|

13

Page 14

9. Step to the rear of the machine and recover the

planed board on the outfeed table once it has

cleared the outfeed roller and has stopped

advancing.

NEVER PUSH, PULL OR OTHERWISE TRY TO MOVE OR

RE-POSITION THE WORKPIECE ONCE IT IS IN THE CONTROL OF THE AUTOMATIC FEED ROLLERS.

10. The return rollers on the top of the planer can be

used to pass the workpiece back to the front of

the machine for repeat passes.

11. Repeat these steps as needed for all

need to be planed to the same thickness.

MAINTENANCE AND ADJUSTMENTS

PERIODIC MAINTENANCE

boards that

MAKE SURE THE PLANER HAS BEEN TURNED OFF AND UNPLUGGED FROM THE POWER SOURCE BEFORE PERFORMING

ANY MAINTENANCE OR ADJUSTMENT.

• Inspect/test the ON/OFF switch before each use. Do not operate the planer with a damaged switch; replace a

damaged switch immediately.

• Keep the machine as well as the in-feed out-feed tables clean and free of saw dust, woodchips, pitch or glue.

Vacuum or brush off any loose debris and wipe down the machine and the tables occasionally with a damp

rag.

• An occasional light coating of paste wax can help protect the tables’ surface and reduce workpiece friction.

Ask your local distributor for suggestions on aftermarket surface cleaners, protectant and dry lubricants based

on what is readily available in your area.

• Avoid using silicon based products that may affect wood finishing products such as oil, solvent or water-based

stains, varnishes and lacquers.

• Periodically inspect the power cord and plug for damage. To minimize the risk of electric shock or fire, never

operate the planer with a damaged power cord or plug. Replace a damaged power cord or plug at the first

visible signs of damage.

• The motor and cutter head bearings are sealed and permanently lubricated – no further lubrication is required.

• The drive gears, chain and elevation screws should be cleaned of woodchips, dust, debris and old grease after

every 10-15 hours of use. After cleaning, re-apply a generous coating of any common automotive bearing

grease.

• Regularly inspect planed workpieces for signs of knife damage or wear and replace damaged or worn knives

immediately.

14

Page 15

INSPECTING/REPLACING CUTTER HEAD KNIVES

MAKE SURE THE PLANER HAS BEEN TURNED OFF AND UNPLUGGED FROM THE POWER SOURCE BEFORE PERFORMING

ANY MAINTENANCE.

A

There are 26 reversible two-sided cardide inserts (knives) A installed in the helical B at the factory. With usage

and normal wear over time, it will eventually become necessary to reverse and/or replace the inserts. To maintain

even insert wear always reverse all 26 inserts each time knife replacement is required. If one of the inserts has been

nicked or damaged on one of it’s edges, it can be simply reversed instead of replaced.

When needed, replacement carbide inserts B can be ordered through your local General International distributor

under item #30-006.

Observing planed workpieces as they come out of the machine and looking for signs of knife damage or wear is

the best method to help you to determine when knives are due to be changed.

B

Signs to look for include:

A

B

EFFECT EXAGGERATED

FOR CLARITY

1. A raised ridgeline in the workpiece that runs a straight line from beginning to end of the board, A. This is ge nerally an indication that one of the knives has been nicked or damaged by a foreign object such as a nail,

staple or other hard object hidden or embedded in the workpiece.

2. A slight washboard or chatter effect, B, which can be an indication of uneven knife wear causing one knife to

cut slightly deeper than the other.

3. Rough, irregular, torn or fuzzy grain on a freshly planed surface may be a sign of worn or dull blades

causing the wood to tear out. Sharp blades cut crisply and leave a relatively smooth finish.

Note: Fuzzy grain can also be a sign of high moisture content in the workpiece. If knives have recently been changed or if you suspect that moisture content and not dull knives is the cause, set the workpiece aside and test by

planing other boards with known or acceptable moisture content. If the planed results using a different workpiece

are smooth, then moisture content in your wood is the problem - no adjustments can be made to the machine for

this. Set the “wet” stock aside and simply work with drier wood.

15

Page 16

A

1. Turn off and unplug the machine from the power

source.

2. Set the pre-set depth gauge to 3/4” so that the stop

pin prevents the from going any lower.

B

4. Using the supplied allen key, loosen and remove

the 2 button head screw B, then remove the chip

deflector.

NEVER RUN A FINGER OR OTHER BODY PART ALONG THE CUTTING EDGE OF THE KNIFE TO TEST FOR SHARPNESS OR

TO DETERMINE IF THE EDGE IS WORN OR HAS ALREADY BEEN USED. FAILURE TO HEED THIS WARNING CAN LEAD TO

SERIOUS INJURY.

3. Using the supplied allen key, loosen and remove

the 4 button head screws A, and remove the dust

chute.

5. Insert the supplied allen key into the hole on the

side of the planer as shown to keep the

from turning while changing knives

.

6. Using the supplied t-handle wrench, loosen the

screws as shown, then remove the screws and

inserts.

7. Thoroughly clean the housing and cavity before

reversing/replacing an insert.

9. Place the insert in the housing and firmly secure it

in place with a screw.

Note: To avoid stripped screws and cracked inserts, do

not overtighten the screws

Note: When tightening the screws, make sure the head of

the screw is aligned flush with the hole of the insert and

does not protrude.

10. Re-install the chip deflector.

11. Re-install the dust chute.

D

C

E

Important! To prevent knife height discrepencies, the

inserts and screws must be clean and free of debris. <?>

8. Thoroughly clean the inserts C and screws D using

a lacquer thinner and small brush then apply a

light coating of machine oil on the screws, taking

care to remove any excess.

Tip: When reversing the inserts in the , refer to the etched

mark E on the inserts to keep track of the rotations.

16

Page 17

REPLACING THE V-BELT

The is driven by a flat ribbed belt that is located on the right-hand side of the planer facing the infeed side.

MAKE SURE THE PLANER HAS BEEN TURNED OFF AND UNPLUGGED FROM THE POWER SOURCE BEFORE PERFORMING

ANY MAINTENANCE.

1. Using a 4 mm Allen wrench, remove the 5 button

head cap screws holding the right hand side cover

on. Lift the cover upwards slightly while pulling the

bottom outwards until it is off of the machine.

3. Roll the belt off of the pulleys by spinning the larg er pulley and pulling the belt off of the smaller pul

ley one rib at a time until it is free from the pulleys.

4. Install the replacement belt in the reverse order of

removal.

5. Re-install the belt guard.

6. Re-install the right hand side cover.

DRIVE CHAIN/GEAR LUBRICATION

Periodically the drive chain & gears G and elevation

screws H will need to be cleaned and greased to

help maintain smooth feeding and contribute to longer

machine life and trouble free operation.

To clean and grease the drive chain & gears and elevation screws:

2. Using a phillips screwdriver, remove the 2 phillips

head screws holding the belt guard in place.

H

H

1. Turn off and unplug the machine from the power

source.

2. Unfasten the 5 screws holding the frame cover in

place and remove frame cover.

3. Unfasten the 2 screws holding the drive chain/gear

cover in place and remove the drive chain/gear

cover, I.

4. Remove old grease and dust deposits by wiping with

a dry rag.

5. Apply generous dabs of any common automotive bearing grease to the gears & chain, G and four elevation

screws H.

6. Re-install the chain/gear cover and frame cover.

G

I

17

Page 18

RECOMMENDED OPTIONAL ACCESSORIES

We offer a large variety of products for increased convenience, productivity, accuracy and safety when using

your planer. Here’s a small sampling of optional accessories available from your local General International

dealer.

For more information about our products, please visit our website at www.general.ca

DUST COLLECTORS

We offer a wide selection

of top quality dust collectors to suit all your shop

needs. Dust collectors contribute to a cleaner more

healthful workshop environment.

ELECTRONIC EARMUFFS

- #99-200

Highly efficient noise

reduction to help protect your hearing when

operating power tools.

ROLLER STANDS

#50-150, #50-170 &

#50-167S

We offer a selection

of roller stands for

added in-feed or outfeed support when

working with longer

stock.

REPLACEMENT INSERTS

#30-006

Reversible two-sided

carbide inserts (sold in

sets of ten).

REPLACEMENT INSERTS

#30-007

Reversible two-sided

high speed steel inserts

(sold in sets of ten).

HEAVY DUTY OPEN BASED

STEEL STAND

#30-006

Easy to assemble, wide

based stable design with

mounting slots for permanent planer installation.

Foot print measures 33”

(833) x 24 1/2”. Floor to

top of stand height: 28”

(711mm).

SET OF TEN M5

SCREWS #30-008

For items: 30-006 &

30-007.

/

18

Page 19

6

5

4

3

2

1

0

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

0

27

44

43

52

36

40

20

32

31

48

35

39

50

49

47

46

30

29

28

26

21

19

45

34

33

2

1

8

9

10

14

13

12

11

25

24

23

22

34

42

8

15

16

8

8

17

37

38

41

51

54

53

55

17-1

FRAME ASSEMBLY

19

Page 20

N

MAIN ASSEMBLY

20

Page 21

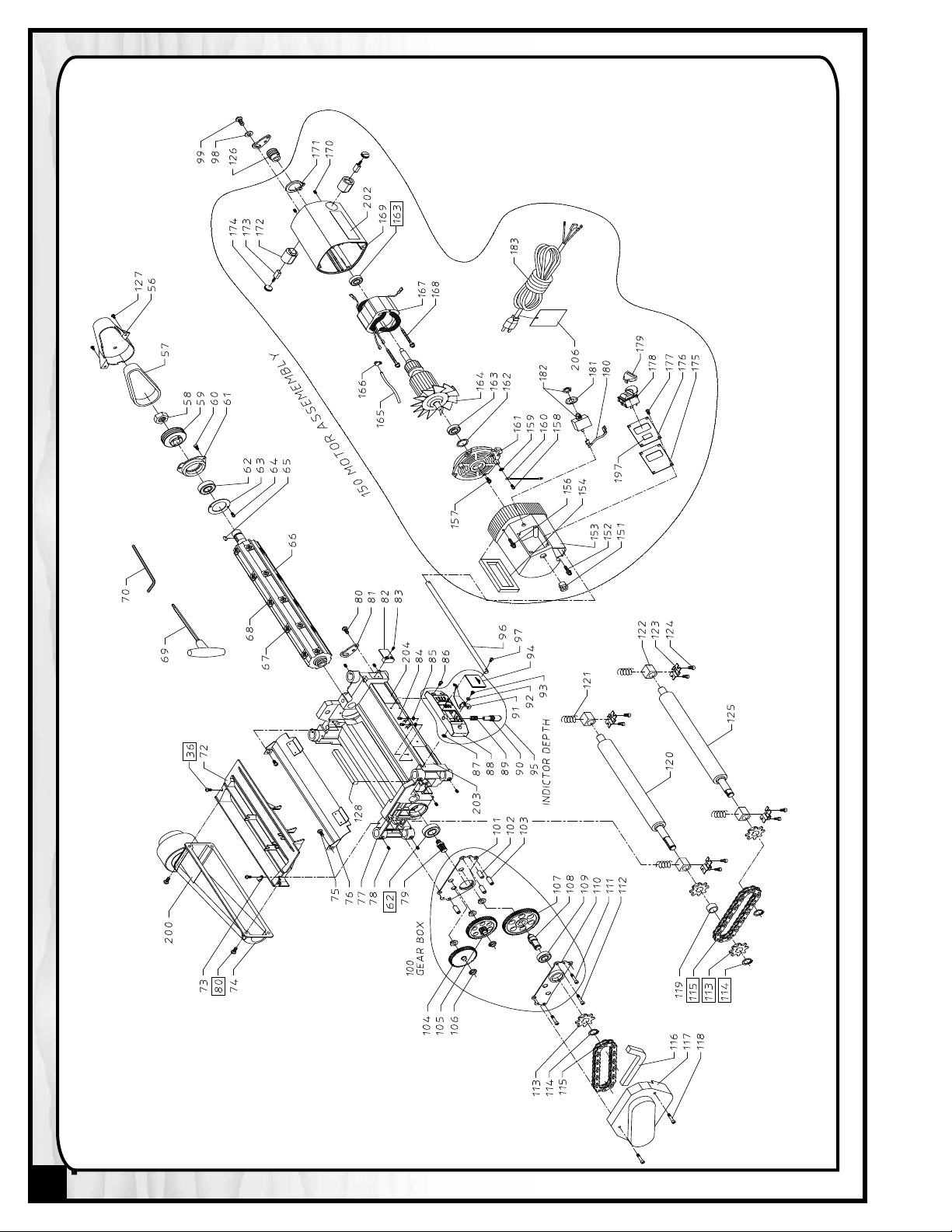

PARTS LIST

30-005HC M1

PART N0. REF. N0. DESCRIPTION SPECIFICATION QTY

1 30005-01 HANDLE ASSEMBLY 1

2 30005-02 CAP SCREW M5xP0.8x20L 1

8 30005-08 BUTTON HEAD SCREW M6xP1.0x8L 15

9 30005-09 TOP COVER 1

10 30005-10 SHAFT BUSHING 3

11 30005-11 UPPER BEARING SEAT 1

12 30005-12 RETURN ROLLER 2

13 30005-13 ROLLER SEAT 4

14 30005-14 LIFTING HANDLE 2

15 30005-15 SPACER 1

16 30005-16 SET SCREW M5xP0.8x5L 1

17 30005-17 UPPER ELEVATION NUT 4

17-1 30005-17-1 FLANGE NUT M6xP1.0 4

19 30005-19 SIDE PANEL (RIGHT) 1

20 30005-20 THICKNESS SCALE 1

21 30005-21 HEIGHT ADJUSTMENT LEAD SCREW 1

22 30005-22 CAP SCREW M6xP1.0 1

23 30005-23 PRE-SET STOP DIAL 1

24 30005-24 STEEL BALL Ø10 1

25 30005-25 SPRING Ø7.62xØ15.75x0.7t 1

26 30005-26 MAIN TABLE 1

27 30005-27 LEAD SCREW 3

28 30005-28 PHILLIPS HEAD SCREW M4xP0.7x10L 4

29 30005-29 RIGHT GUIDE PLATE 1

30 30005-30 BASE 1

31 30005-31 HEX. HEAD BOLT M6xP1.0x20L 4

32 30005-32 HEX. NUT M6xP1.0 4

33 30005-33 FLAT WASHER Ø12.2xØ25.8x2t 4

34 30005-34 SPINDLE BEARING 6000ZZ 5

35 30005-35 BEARING SEAT 4

36 30005-36 BUTTON HEAD SCREW M5xP0.8x12L 10

37 30005-37 FLAT WASHER Ø10.3xØ18x1t 4

38 30005-38 SPINDLE SPROCKET 4

39 30005-39 FLAT WASHER Ø4.2xØ15x2t 4

40 30005-40 CAP SCREW M4xP0.7x12L 4

41 30005-41 LEFT GUIDE PLATE 1

42 30005-42 IDLE WHEEL 2

43 30005-43 ECCENTRIC BUSHING 2

44 30005-44 CAP SCREW M5xP0.8x25L 2

45 30005-45 SIDE PANEL - LEFT 1

46 30005-46 PHILLIPS HEAD SCREW M4xP0.7x6L 12

47 30005-47 TABLE SUPPORT BRACKET 4

48 30005-48 LOCK WASHER TP305 4

49 30005-49 TABLE BUSHING 4

50 30005-50 PHILLIPS HEAD SCREW M6xP1.0x16L 4

51 30005-51 TABLE EXTENSION 2

52 30005-52 ELEVATION CHAIN #410, 100 1

53 30005-53 HEX HEAD BOLT M8xP1.25x45L 1

54 30005-54 HEX NUT M8xP1.25 1

55 30005-55 FLAT WASHER 4

56 30005-56 BELT GUARD 1

57 30005-57 BELT 140 J6 1

58 30005-58 L.H. HEX NUT M16xP2.0L.H. 1

59 30005-59 DRIVE PULLEY 1

60 30005-60 BUTTON HEAD SCREW M5xP0.8x12L 11

21

Page 22

22

PARTS LIST

30-005HC M1

PART N0. REF. N0. DESCRIPTION SPECIFICATION QTY

61 30005-61 BEARING SEAT 1

62 30005-62 BEARING 6203ZZ 2

63 30005-63 BEARING RETAINER 1

64 30005-64 PHILLIPS HEAD SCREW M3xP0.5X8L 2

65 30005-65 KEY 5x5x12mm 1

66N 30005-66N HELICAL CUTTER HEAD 1

67 30005-67 CARBIDE INSERTS (see #30-006 - set of 10 inserts) 14 x14 x 2 mm 26

68 30005-68 TORX SCREW (see #30-008) M5 x P0.8 26

69 30005-69 TORX WRENCH 1

70 30005-70 ALLEN WRENCH 4x120mmL 1

72 30005-72 CHIP BREAKER 1

73 30005-73 POWER CORD CLAMP GCL 5/16 S 1

74 30005-74 DUST CHUTE 1

75 30005-75 BUTTON HEAD SCREW M6xP1.0x10L 2

76 30005-76 CHIP DEFLECTOR 1

77 30005-77 UPPER FRAME 1

78 30005-78 SET SCREW M5xP0.8x6L 8

79 30005-79 PINION 1

80 30005-80 BUTTON HEAD SCREW M6xP1.0x12L 6

81 30005-81 MOTOR MOUNTING PLATE 1

82 30005-82 POINTER 1

83 30005-83 PHILLIPS HEAD SCREW M3xP0.5x16L 2

84 30005-84 PHILLIPS HEAD SCREW M5xP0.8x8L 2

85 30005-85 EXT TOOTH WASHER Ø5 2

86 30005-86 PHILLIPS HEAD SCREW M4xP0.7x12L 3

95 30005-95 DEPTH OF CUT INDICATOR 1

96 30005-96 MOTOR PIVOT ROD 1

97 30005-97 BUTTON HEAD SCREW M5xP0.8x16L 2

98 30005-98 FLAT WASHER Ø8.4xØ18x2t 1

99 30005-99 BUTTON HEAD SCREW M8xP1.25x20L 1

100 30005-100 GEAR BOX ASSY 1

112 30005-112 CAP SCREW M5xP0.8x35L 2

113 30005-113 SPROCKET 8T 4

114 30005-114 CIRCLIP STW15 3

115 30005-115 GEARBOX DRIVE CHAIN #410, 27 2

116 30005-116 SPONGE 1

117 30005-117 GEARBOX GUARD 1

118 30005-118 CAP SCREW M5xP0.8x40L 2

119 30005-119 SPROCKET SPACER 1

120 30005-120 OUTFEED ROLLER 1

121 30005-121 SPRING 4

122 30005-122 BEARING BLOCK 4

123 30005-123 BEARING BLOCK RETAINER 4

125 30005-125 INFEED ROLLER 1

127 30005-127 PHILLIPS HEAD SCREW W/WASHER M4xP0.7x8L 2

150 30005-150 MOTOR ASSY 1

151 30005-151 STRAIN RELIEF BUSHING HALO(6P3-4) 1

152 30005-152 PHILLIPS HEAD SCREW M5xP0.8x40L 1

153 30005-153 FAN HOUSING 1

154 30005-154 SPONGE GASKET 1

155 30005-155 WARNING LABEL (UL) 1

156 30005-156 PHILLIPS HEAD SCREW M5xP0.8x50L 1

157 30005-157 PHILLIPS HEAD SCREW M4.8xP1.2x16L 4

158 30005-158 PHILLIPS HEAD SCREW M5xP0.8x8L 1

159 30005-159 SPROCKET WASHER M5 1

160 30005-160 GROUND WIRE 300mm +/- 3mm± 1

Page 23

PARTS LIST

30-005HC M1

PART N0. REF. N0. DESCRIPTION SPECIFICATION QTY

161 30005-161 MOTOR FAN COVER 1

162 30005-162 WAVE WASHER 1

163 30005-163 BEARING 6201 LLB 2

164 30005-164 ARMATURE 1

165 30005-165 SLEEVE 1

166 30005-166 POWER CORD CLAMP GCL5/16S 1

167 30005-167 STATOR 120V/60Hz 1

168 30005-168 PHILLIPS HEAD SCREW M4.8x75L 2

169 30005-169 MOTOR HOUSING 1

170 30005-170 SET SCREW M5xP0.8x8mmL 2

171 30005-171 RETENTION RING RTW32 1

172 30005-172 BRUSH HOLDER TP305 2

173 30005-173 MOTOR BRUSH 2

174 30005-174 BRUSH CAP TP305 2

175 30005-175 INSULATOR 1

176 30005-176 SWITCH COVER 1

177 30005-177 PHILLIPS HEAD SCREW 3/16»x3/8»L 4

178 30005-178 SWITCH HT-18 ¨ı 1

179 30005-179 SWITCH KEY 1

180 30005-180 CIRCUIT BREAKER CONNECTING WIRE 1

181 30005-181 NAME PLATE 1

182 30005-182 CIRCUIT BREAKER RESET 20A,A-0701 1

183 30005-183 POWER CORD (UL/CSA) 14AWG,120V,2.4mL 1

NOTES

23

Page 24

MODEL 30-005HC M1

8360 Champ-d’Eau, Montreal (Quebec) Canada H1P 1Y3

Tel.: (514) 326-1161

Fax: (514) 326-5565 - Parts & Service / Fax: (514) 326-5555 - Order Desk

orderdesk@general.ca

www.general.ca

IMPORTANT

When ordering replacement parts, always give the model number, serial number of the machine and

part number. Also a brief description of each item and quantity desired.í

Loading...

Loading...