GE phoenix microme|x DXR-HD Operating Manual

GE

Measurement & Control

Brilliant |

|

|

high |

|

|

dynamic |

imaging |

|

|

|

|

|

with |

|

|

live |

|

|

CAD |

|

|

data |

overlay |

|

|

phoenix microme|x / nanome|x

High resolution 180 kV micro- / nanofocus X-ray inspection systems with 3D CT option

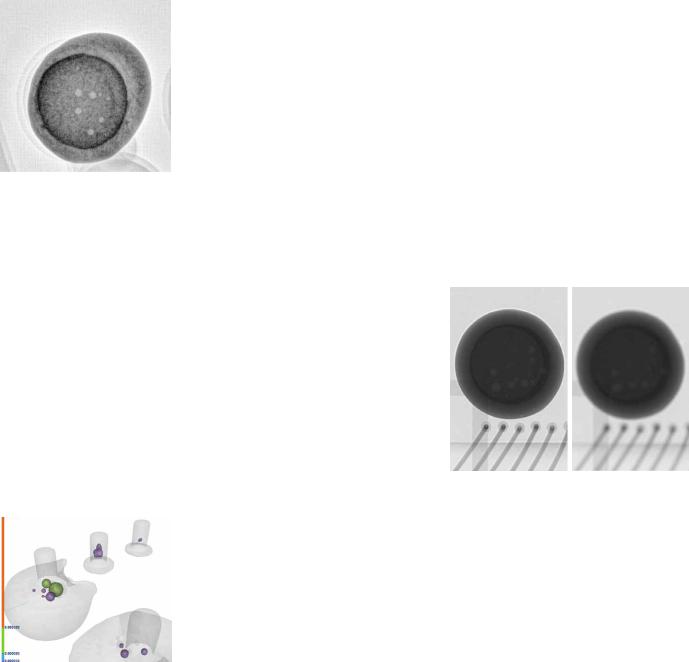

Open BGA ball with live |

3D Computed Tomogra- |

Automated PTH solder |

CAD data overlay and |

phy of an USB flash drive |

joint inspection with live |

Flash! FiltersTM image |

|

CAD data overlay and |

optimization |

|

Flash! FiltersTM image |

|

|

optimization |

Unique features

•Temperature stabilized digital DXR detector with active cooling for high dynamic live imaging

•180 kV / 20 W high-power micro- /nanofocus tube with up to 0.5 µm or 0.2 µm detail detectability

•x|act package for CAD based µAXI programming and automatic inspection

•diamond|window for up to 2 times faster data acquisition at the same high image quality level

•Optionally 3D computed tomography scans within 10 seconds

phoenix microme|x / nanome|x

The high performance X-ray inspection solution

The phoenix microme|x and nanome|x series combines high-resolution 2D X-ray technology and 3D CT in one system. Innovative and unique features and an extreme high positioning accuracy make both systems the effective and reliable solution for a wide spectrum of 2D and 3D offline inspection tasks: R&D, failure analysis, process and quality control.

The phoenix|x-ray x|act technology offers easy to program CAD based µAXI ensuring automated inspection in the micrometer range. Another unique benefit is GE´s highly dynamic DXR flat panel detector with active cooling. Offering up to 30 frames per second, it provides outstanding brilliant live imaging and fast data acquisition for 3D CT.

Flash! filtered voids in an open µBGA ball: 1,970x geometric zoom for extreme high magnification

Brilliant DXR-HD live imaging

With GE´s proprietary high dynamic DXR detector with enhanced scintillator technology phoenix|x-ray introduces a new industry standard for efficient

live inspection:

•Full frame rate of 30 frames per second at 1000x1000 pixels offers low noise coupled with brilliant image quality ensuring fast and detailed live inspection

•Active temperature stabilization for precise and reliable inspection results

•Extremely fast data acquisition in 3D CT mode

•Detail detectability down to 0.5 µm / 0.2 µm for high performance failure analysis

High output with high-resolution: diamond|window

Compared to conventional beryllium targets, the diamond|window allows higher power at a smaller focal spot. This ensures high-

resolution even at a high output.

•Up to 2 times faster CT data acquisition at the same high image quality level

•High output with high-resolution

•Non-toxic target

•Improved focal spot position stability within long term measurements

•Increased target lifetime due to less degradation with higher power density

diamond|window beryllium window

(same X-ray tube parameter: 130 kV, 11.4 W)

nanoCT® of TSVs in an electronic package. The voids in the copper filling

are clearly visible.

High-resolution 3D computed tomography

For advanced inspection and 3D analysis of smaller samples, phoenix|x- ray’s proprietary 3D-CT technology is optionally available.

•180 kV high power X-ray technology, fast image acquisition with DXR detector and diamond window combined with phoenix|x-rays fast reconstruction software deliver high quality inspection results

•Maximum voxel resolution down to 2 microns; the nanoCT® capability of the nanome|x allows even a higher image sharpness

Loading...

Loading...