Page 1

multiFiltrate

Service Manual

Technical Manual

Edition: 6/03.07

Part no. M28 003 1

Page 2

Page 3

Table of Contents

1 Important Information

1.1 Organization of the Technical Manual ..................................................................................... 1-1

1.2 How to Use the Technical Manual............................................................................................ 1-2

1.3 Precautions for Working on the System ................................................................................. 1-3

1.4 Addresses .................................................................................................................................. 1-4

2 Functional Description

2.1 Extracorporeal Circuit............................................................................................................... 2-1

2.1.1 Pumps ......................................................................................................................................... 2-1

2.1.2 Heaters ........................................................................................................................................ 2-2

2.1.3 Pressure Transducer ................................................................................................................... 2-2

2.1.4 Air Detector and Venous Clamp .................................................................................................. 2-2

2.1.5 Optical Detector (Non-Opaque/Opaque Fluid Detector).............................................................. 2-3

2.1.6 Blood Leak Detector .................................................................................................................... 2-3

2.1.7 Heparin Pump.............................................................................................................................. 2-3

2.2 Weighing Units .......................................................................................................................... 2-3

2.3 Ci-Ca Module (Option)............................................................................................................... 2-4

2.4 Functional Test (T1 Test) and Error Messages....................................................................... 2-4

2.4.1 Battery Test, Part 1...................................................................................................................... 2-5

2.4.2 Scales Test .................................................................................................................................. 2-5

2.4.3 Pump Test ................................................................................................................................... 2-6

2.4.4 Pressure Transducer ................................................................................................................... 2-8

2.4.5 Optical Detector........................................................................................................................... 2-9

2.4.6 Air Detector................................................................................................................................ 2-10

2.4.7 Blood Leak Detector .................................................................................................................. 2-11

2.4.8 Heater ........................................................................................................................................ 2-12

2.4.9 Battery Test, Part 2.................................................................................................................... 2-15

2.4.10 Audible Alarm ............................................................................................................................ 2-16

2.4.11 Heparin Pump ............................................................................................................................ 2-17

2.4.12 multiDataLink............................................................................................................................. 2-18

2.4.13 Ci-Ca Module (Option)............................................................................................................... 2-18

2.5 Error Messages........................................................................................................................ 2-20

2.5.1 Alarm Messages........................................................................................................................ 2-20

2.5.2 Warning Messages.................................................................................................................... 2-22

2.5.3 Fatal Errors ................................................................................................................................ 2-30

2.5.4 Error Codes of Scales Lo-Level Routines ............................................................................... 2-33

2.5.5 Error Codes of Pressures Lo-Level Routines.......................................................................... 2-35

2.5.6 Error Codes of Heparin Pump Lo-Level Routines................................................................... 2-36

2.5.7 Error Codes of Pumps Lo-Level Routines............................................................................... 2-37

2.6 Overview of Display Identification Numbers ........................................................................ 2-37

Fresenius Medical Care multiFiltrate TM 6/03.07 0-1

Page 4

3 Installation

3.1 Preface........................................................................................................................................ 3-1

3.2 Important Information on Initial Start-Up ................................................................................ 3-2

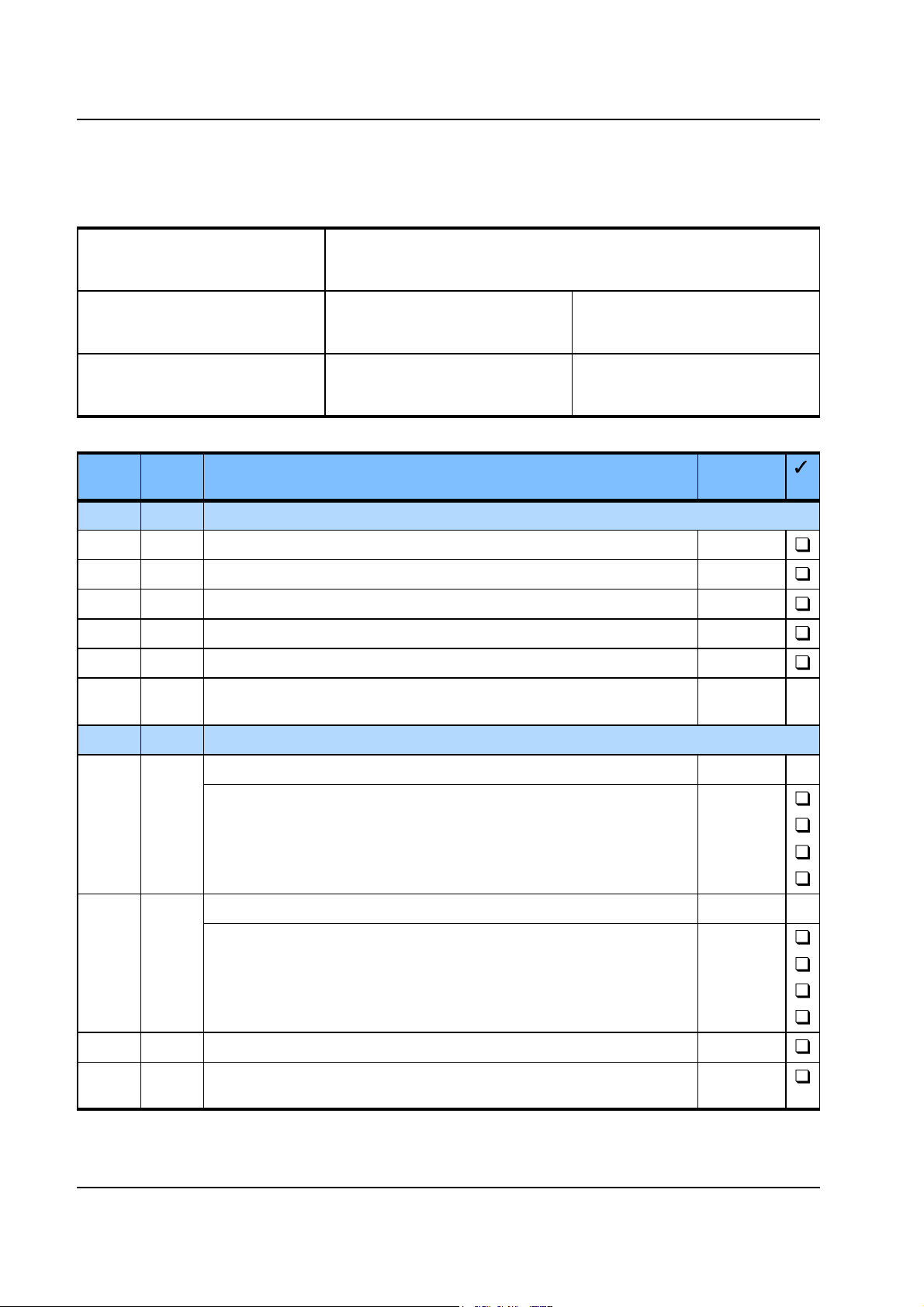

3.3 Initial Start-Up Report multiFiltrate.......................................................................................... 3-3

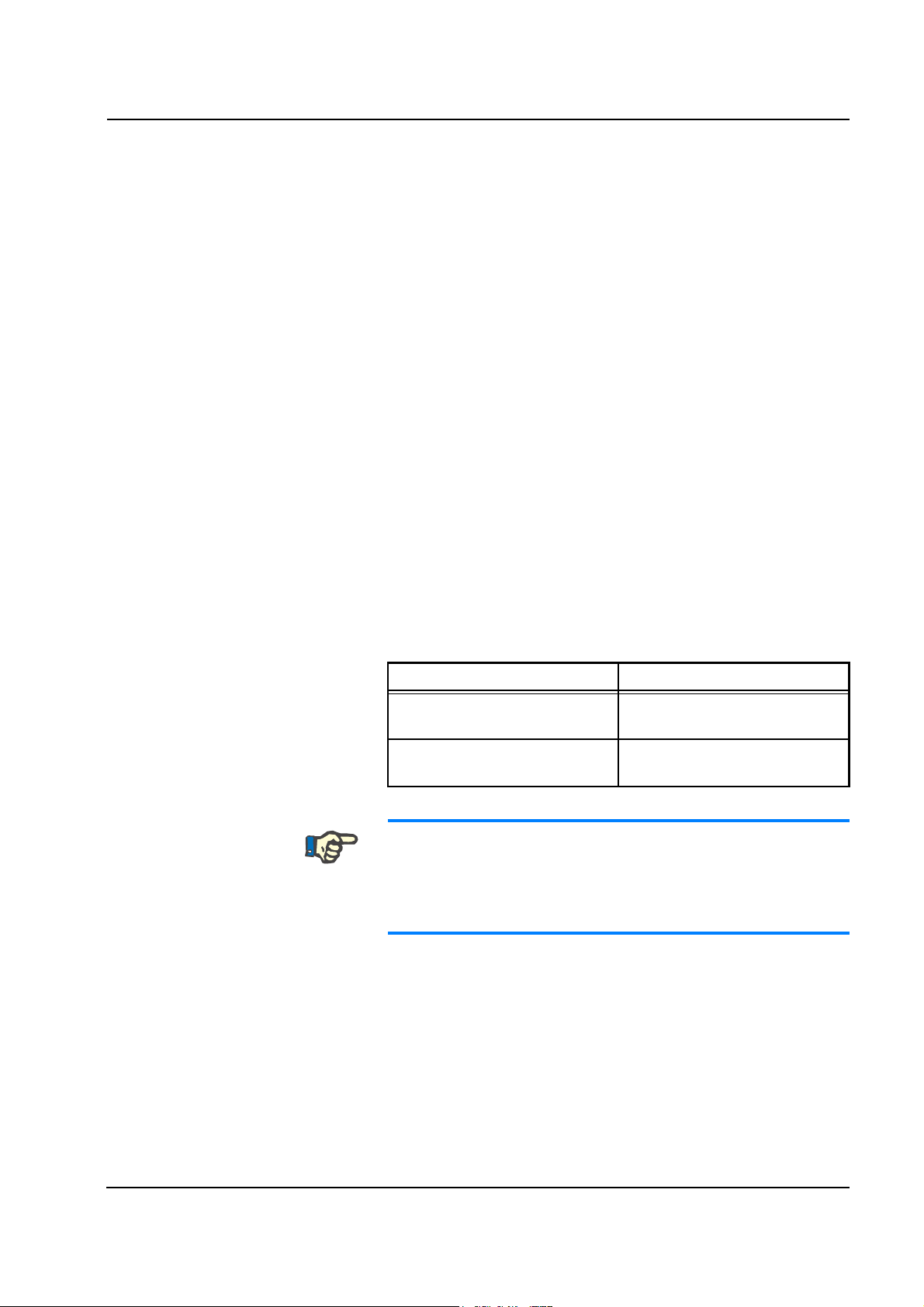

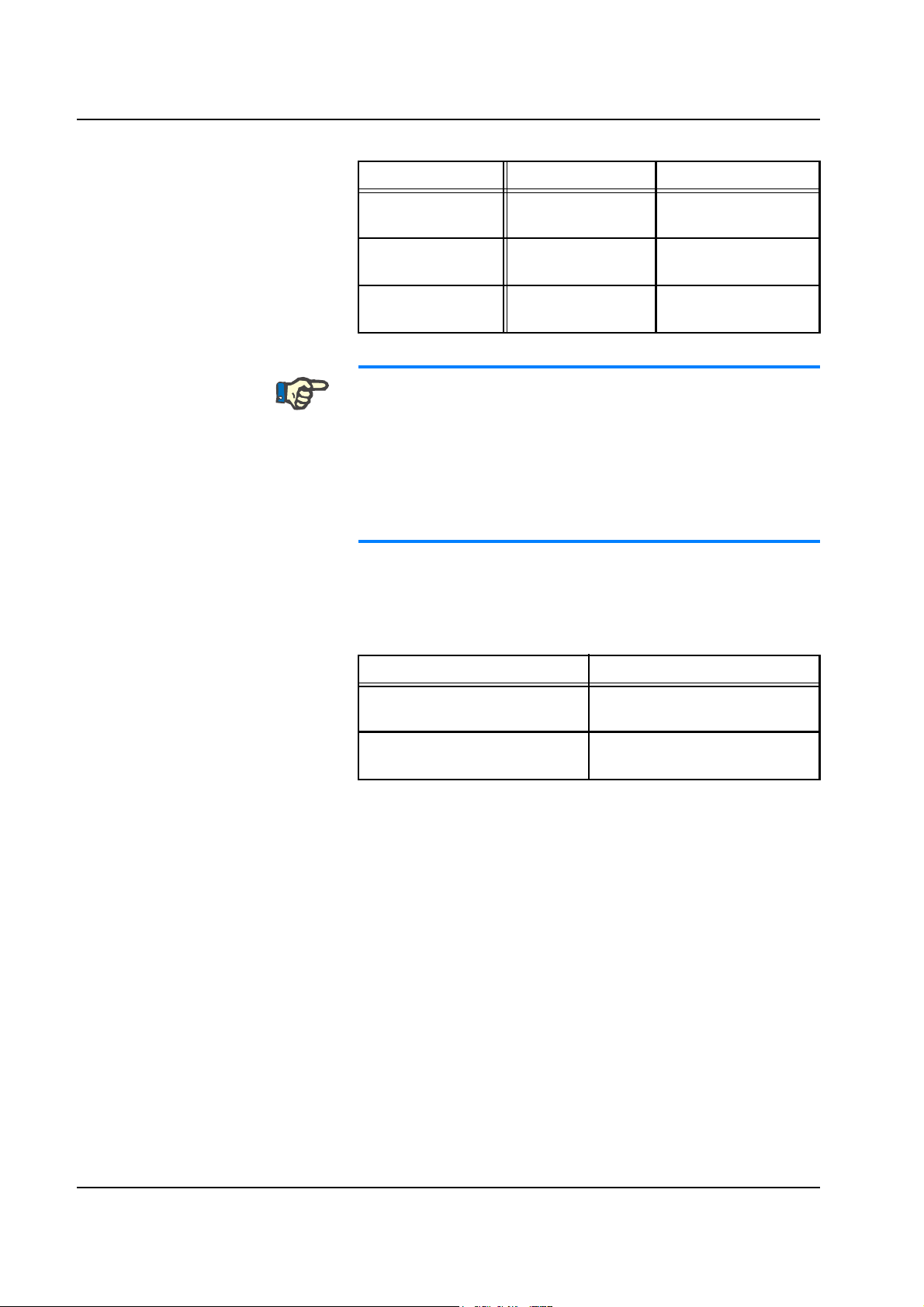

3.4 Explanations on the Initial Start-Up Report ............................................................................ 3-8

3.5 Installing the Ci-Ca Module (Option)...................................................................................... 3-16

4 TSC / TMC / Maintenance

4.1 Important Information Regarding the Procedure ................................................................... 4-1

4.2 TSC / MA Report multiFiltrate................................................................................................... 4-2

4.3 multiFiltrate TSC Report ........................................................................................................... 4-8

4.4 Explanations on the TSC / MA Report ................................................................................... 4-12

5 Adjustment Instructions and Tests

5.1 Service Tools ............................................................................................................................. 5-1

5.2 Service Program ........................................................................................................................ 5-2

5.2.1 Start ............................................................................................................................................. 5-2

5.2.2 Selecting the Language ............................................................................................................... 5-3

5.2.3 System Messages ....................................................................................................................... 5-3

5.2.4 Deactivating and Activating the Heparin Pump ........................................................................... 5-3

5.2.5 Filtrate Bag Monitoring Limit ........................................................................................................ 5-4

5.2.6 Dialysate Tubing Arrangement .................................................................................................... 5-4

5.2.7 Option MultiDataLink (mDL) ........................................................................................................ 5-5

5.2.8 Taring and Calibrating the Scales................................................................................................ 5-7

5.2.9 Calibrating the Pressures ............................................................................................................ 5-8

5.2.10 Calibrating the Blood Leak Detector .......................................................................................... 5-10

5.2.11 Verifying the System Values...................................................................................................... 5-11

5.2.12 Events Memory.......................................................................................................................... 5-13

5.2.13 Program Treatment Modes........................................................................................................ 5-15

5.2.14 Programming the Ci-Ca Data (Option) ...................................................................................... 5-16

5.3 Extracorporeal Components .................................................................................................. 5-17

5.3.1 Tightness of the Venous Occlusion Clamp................................................................................ 5-17

5.3.2 Checking the Pressure Transducers ......................................................................................... 5-17

5.3.3 Venous Pressure Transducer (P.C.B. LP 450-3)....................................................................... 5-18

5.3.4 Air Detector (P.C.B. LP 450-3) .................................................................................................. 5-20

5.3.5 Optical Detector Sensing Opaque / Non-Opaque Fluid (P.C.B. LP 450-3) ............................... 5-21

5.3.6 Arterial / Filtrate / PHF Pressure Transducers (P.C.B. LP 343-1) ............................................. 5-21

5.3.7 Blood Leak Detector .................................................................................................................. 5-22

5.3.8 Setting the Heparin Pump.......................................................................................................... 5-23

5.4 Programming the Processors ................................................................................................ 5-25

5.4.1 Display Processor (DP) ............................................................................................................. 5-26

5.4.2 Operating and Safety Processors (OP and SP) ........................................................................ 5-26

5.4.3 Interchangeability of Safety and Operating Processor .............................................................. 5-30

5.5 Ci-Ca Module (Option) ............................................................................................................. 5-31

0-2 Fresenius Medical Care multiFiltrate TM 6/03.07

Page 5

5.5.1 Preparing the Functional Test ................................................................................................... 5-31

5.5.2 Functional Test of the Drip Counter........................................................................................... 5-32

5.5.3 Functional Test of the Hall Sensor ............................................................................................ 5-32

5.5.4 Functional Test of the Insertion Switch...................................................................................... 5-32

5.5.5 Functional Test of the Line Occlusion ....................................................................................... 5-33

6 PC Service Software MFT

6.1 Organization of the Quick Guide.............................................................................................. 6-1

6.2 General Information .................................................................................................................. 6-1

6.3 Preparation................................................................................................................................. 6-1

6.3.1 System Requirements ................................................................................................................. 6-1

6.3.2 Software Installation .................................................................................................................... 6-2

6.3.3 Hardware Installation................................................................................................................... 6-3

6.3.4 ServiceCard Description .............................................................................................................. 6-3

6.3.5 Starting the Software ................................................................................................................... 6-3

7 Block Diagrams and Component Layouts

7.1 Block Diagram ........................................................................................................................... 7-2

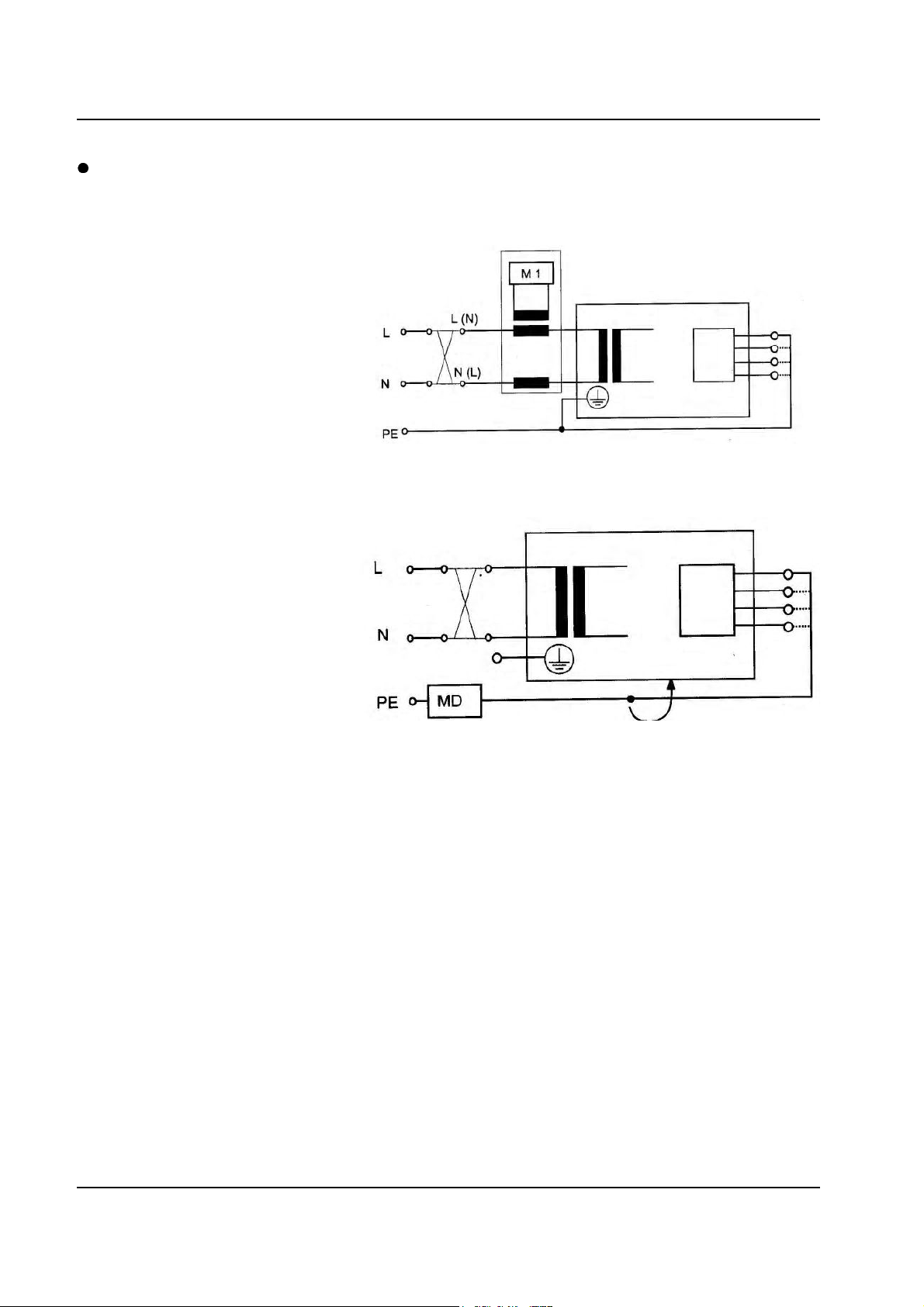

7.2 AC Wiring ................................................................................................................................... 7-3

7.3 P.C.B. LP 122 Heater Control ................................................................................................... 7-4

7.3.1 Block Diagram ............................................................................................................................. 7-4

7.3.2 Description................................................................................................................................... 7-4

7.3.3 Component Layout ...................................................................................................................... 7-5

7.4 P.C.B. LP 123 Pump Control..................................................................................................... 7-6

7.4.1 Description................................................................................................................................... 7-6

7.4.2 Component Layout ...................................................................................................................... 7-7

7.5 P.C.B. LP 124 Motherboard ...................................................................................................... 7-8

7.5.1 Description................................................................................................................................... 7-8

7.5.2 Component Layout ...................................................................................................................... 7-9

7.6 P.C.B. LP 125 Blood Leak Detector ....................................................................................... 7-10

7.6.1 Component Layout .................................................................................................................... 7-10

7.7 P.C.B. LP 127 Scales Board.................................................................................................... 7-11

7.7.1 Description................................................................................................................................. 7-11

7.7.2 Component Layout .................................................................................................................... 7-11

7.8 P.C.B. LP 128, Power Supply Unit.......................................................................................... 7-12

7.8.1 Block Diagram ........................................................................................................................... 7-12

7.8.2 Description................................................................................................................................. 7-12

7.8.3 Component Layout .................................................................................................................... 7-13

7.9 P.C.B. LP 129 User Interface .................................................................................................. 7-14

7.9.1 Component Layout .................................................................................................................... 7-14

7.10 P.C.B. LP 244 Operating and Safety Processors.................................................................. 7-15

7.10.1 Block Diagram ........................................................................................................................... 7-15

7.10.2 Jumper Description.................................................................................................................... 7-15

7.10.3 Component Layout .................................................................................................................... 7-17

Fresenius Medical Care multiFiltrate TM 6/03.07 0-3

Page 6

7.11 P.C.B LP 343-4 Pressure Transducer .................................................................................... 7-18

7.11.1 Component Layout .................................................................................................................... 7-18

7.12 P.C.B. LP 450-3 multiFiltrate Air Detector Control ............................................................... 7-19

7.12.1 Component Layout .................................................................................................................... 7-19

7.13 P.C.B. LP 950, Control Board (Heparin Pump)...................................................................... 7-20

7.13.1 Component Layout .................................................................................................................... 7-20

7.14 Ci-Ca Module............................................................................................................................ 7-21

7.14.1 Block Diagram ........................................................................................................................... 7-21

7.14.2 Component Layout (P.C.B. LP MS 0407) .................................................................................. 7-22

0-4 Fresenius Medical Care multiFiltrate TM 6/03.07

Page 7

1 Important Information

1.1 Organization of the Technical Manual

Page identification Page number 1-3 is to be interpreted as: Chapter 1, page 3.

Editorial information The current edition of this Technical Manual is

6/03.07 = 5th edition, September 2006

In case of updates, the chapters concerned will be replaced.

Refer to the table below to verify that the Technical Manual is up-todate.

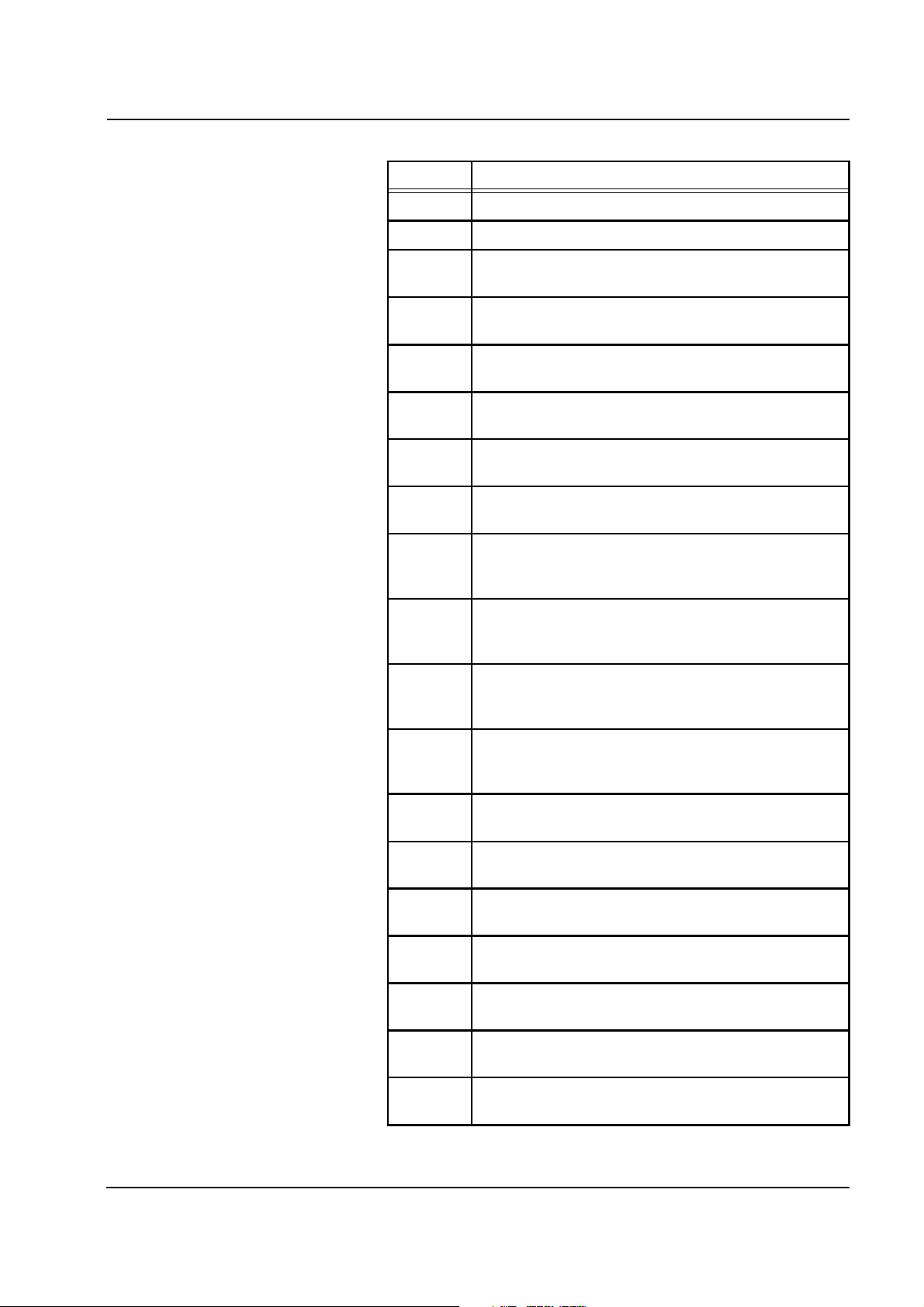

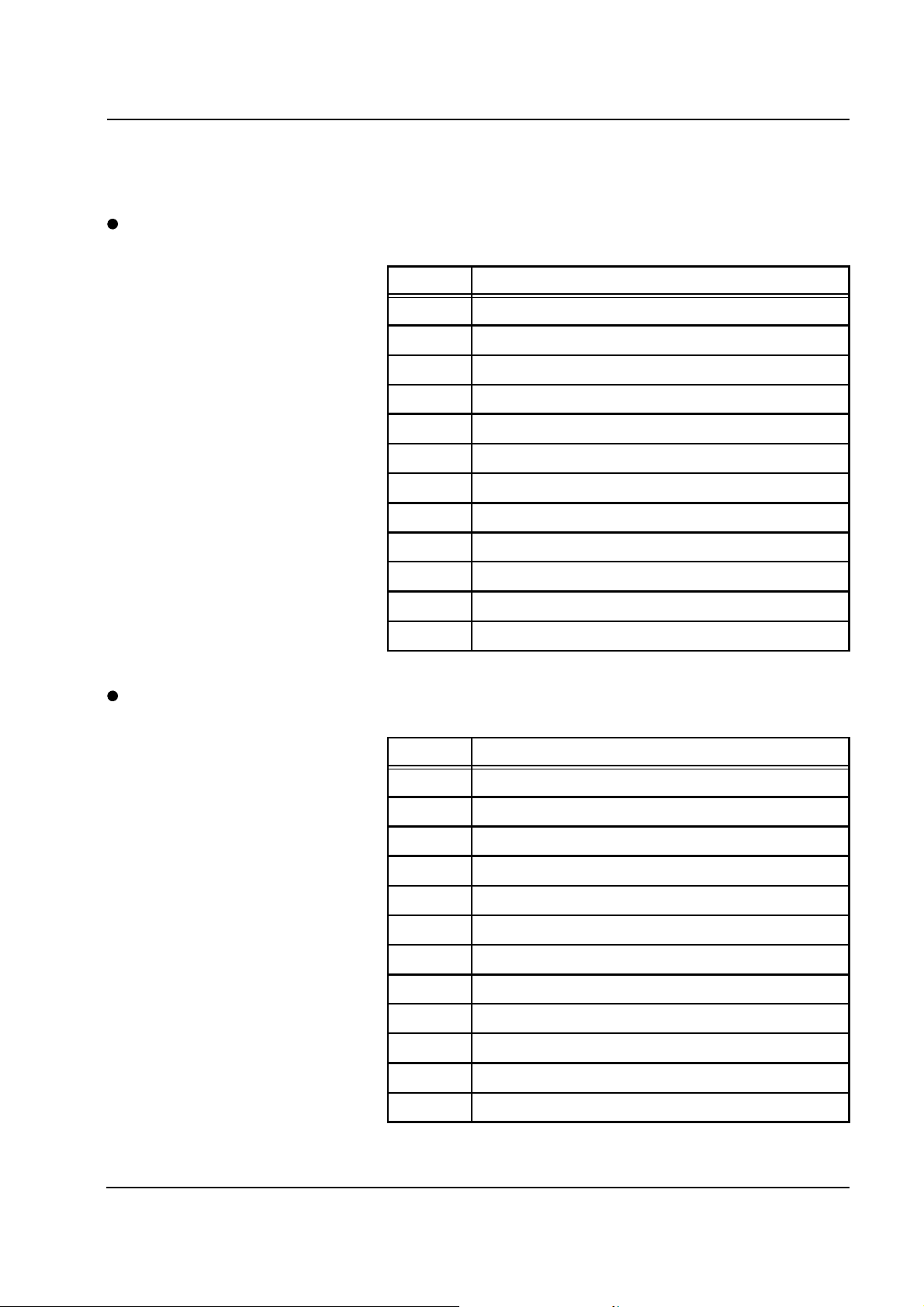

Chapter Current version

1 6/03.07

2 6/03.07

3 6/03.07

4 6/03.07

5 6/03.07

6 6/03.07

7 6/03.07

Chapter 1: Important Information

Changes Manual changes will be released as new editions and supplements. In

general - subject to change without notice.

Fresenius Medical Care multiFiltrate TM 6/03.07 1-1

Page 8

Chapter 1: Important Information

1.2 How to Use the Technical Manual

Purpose This Technical Manual is intended for service technicians and is to be

used for first studies (to acquire a basic knowledge) and for reference

purposes (for TSC, maintenance and repair). The Technical Manual,

however, does not replace the training courses offered by the

manufacturer.

Requirements Knowledge of the current Operating Instructions for the respective

system.

Background experience in mechanics, electrical and medical

engineering.

Specifications For the specifications of the respective system, refer to the current

Operating Instructions.

Circuit diagrams and

component layouts

Explanation of the Note

and Caution symbols used

The identification on the PCB permits the operator/technician to verify if

the circuit diagram/component layout matches the PCB actually

installed in the system.

Note

Informs the operator that in case of a failure to follow the steps as

described, a specific function will be executed incorrectly or will not be

executed at all, or will not produce the desired effect.

Caution

Advises the operator against certain procedures or actions that could

cause damage to the equipment or may have adverse effects on

operators and patients.

1-2 Fresenius Medical Care multiFiltrate TM 6/03.07

Page 9

1.3 Precautions for Working on the System

Authorized persons Assembly, extensions, adjustments, modifications or repairs may only

be carried out by the manufacturer or persons authorized by him.

Chapter 1: Important Information

Test equipment and

accessories

Precautions When working on the open system, the following precautions must be

ESD precautions When repairing and when replacing spare parts, observe the applicable

The activities described in the Technical Manual require the availability

of the necessary technical test equipment and accessories.

respected:

Protect the components against ingress of fluids.

Do not touch live parts.

All plugs, connections and components may only be disconnected or

connected if de-energized.

ESD precautions (e.g. EN 100 015-1).

Fresenius Medical Care multiFiltrate TM 6/03.07 1-3

Page 10

Chapter 1: Important Information

1.4 Addresses

Manufacturer Fresenius Medical Care AG & Co. KGaA

Please address any inquiries to:

D-61346 Bad Homburg

Germany

+49 (0)6172/609-0

www.fmc-ag.com

Service

Central Europe

International

service

Local service

Fresenius Medical Care

Deutschland GmbH

Geschäftsbereich Zentraleuropa

Kundendienst / Servicecenter

Steinmühlstrasse 24b

61352 Bad Homburg

Germany

Phone: +49 6172 609-7100

Fax: +49 6172 609-7102

E-mail: ServicecenterD@fmc-ag.com

Fresenius Medical Care

Deutschland GmbH

Service Support International

Hafenstrasse 9

D-97424 Schweinfurt

Germany

Phone: +49 9721 678-333 (hotline)

Fax: +49 9721 678-130

1-4 Fresenius Medical Care multiFiltrate TM 6/03.07

Page 11

2 Functional Description

2.1 Extracorporeal Circuit

The elements for maintaining and monitoring the extracorporeal circuit

of the multiFiltrate are as follows:

Pumps

Heaters

Pressure transducer

Air detector

Venous clamp

Non-opaque/opaque fluid detector

Blood leak detector

Heparin pump

Chapter 2: Functional Description

2.1.1 Pumps

Altogether, the multiFiltrate is provided with four pumps:

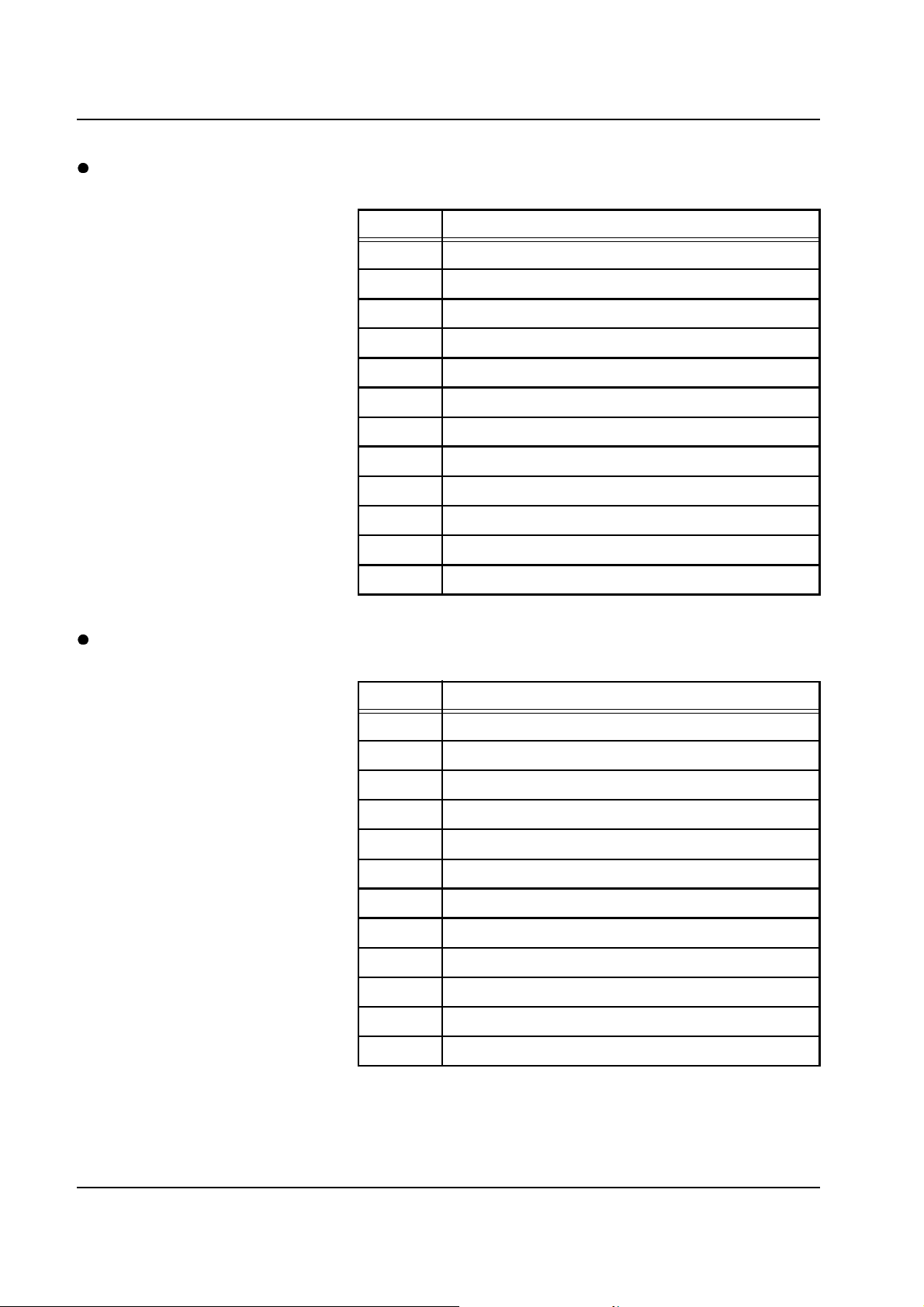

Pump Delivery rate

Blood pump 10 500 ml/min

Filtrate pump 10 180 ml/min

Substituate pump 10 170 ml/min

Dialysate pump 10 170 ml/min

The pumps are driven by direct-current geared motors. To control the

speed, these motors are each provided with a clock pulse generator,

which is directly connected to the motor shaft. The pump processors for

controlling the individual pumps (P.C.B. LP 123) are fitted on the motor

housing.

All pumps are supplied with 24 V. The nominal voltage of the blood

pump motor is 20 V. The nominal voltage of the other pumps, however,

is 24 V.

A Hall sensor in the pump housing and a permanent magnet in each

pump door monitor the state of the pump door.

The line inserting position of the pump rotors for inserting and removing

the pump segments is detected by a combination of a reed switch (in

the pump housing) and a permanent magnet (in the rotor).

The functional test covers a check of all pumps.

Fresenius Medical Care multiFiltrate TM 6/03.07 2-1

Page 12

Chapter 2: Functional Description

2.1.2 Heaters

2.1.3 Pressure Transducer

To allow heating of replacement fluids, two heaters, which are activated

and monitored independently of each other, are installed in the

multiFiltrate.

The heater foil is applied to the outside of the heater rod and supplied

with approx. 28 V. The temperatures are controlled and monitored by

altogether four NTC sensors (two for the operating processor and two

for the safety processor). This is implemented on P.C.B. LP 122.

Both heaters are tested during the functional test.

Four pressures are measured at the multiFiltrate:

Arterial pressure,

Measuring transducer (P.C.B. LP 343-1) between the patients

arterial access and the blood pump

Measuring range: 280 300 mmHg

Pre-hemofilter pressure

Measuring transducer (P.C.B. LP 343-1) between the blood pump

and the filter inlet

Measuring range: 0 750 mmHg

Venous pressure,

Measuring transducer (P.C.B. LP 450-3) between the filter outlet

and the patients venous access,

Measuring range: 80 500 mmHg.

Filtrate pressure or dialysate pressure

Measuring transducer (P.C.B. LP 343-1) between the filter

connector and the filtrate pump

Measuring range: 300 300mmHg.

All pressure transducers are subjected to the functional tests.

2.1.4 Air Detector and Venous Clamp

The air detector (P.C.B. LP 450-3) serves for the detection of air in the

extracorporeal blood circuit and operates on the ultrasound principle .

Both the transmitter and the receiver are integrated in the drip chamber

holder. Once the level in the venous drip chamber has fallen below a

certain threshold, the venous clamp is closed. This function is executed

independently of the operating or safety processor. The additional

board AD 28 increases the transmitter voltage during Preparation to

ensure that the level of saline solution is reliably detected.

The air detector is subjected to the functional test.

2-2 Fresenius Medical Care multiFiltrate TM 6/03.07

Page 13

2.1.5 Optical Detector (Non-Opaque/Opaque Fluid Detector)

The optical detector (P.C.B. LP 450-3) detects, according to the infrared

principle, whether saline solution or blood is present in the tubing

system.

The optical detector is subjected to the functional test.

2.1.6 Blood Leak Detector

The blood leak detector (P.C.B. LP 125) is provided for the detection of

a potential blood loss through the membrane. It is operated applying a

two-color measuring section. In the course of this, red and green light is

alternately transmitted to a reference receiver or, through the filtrate

line, to a measuring receiver.

Both the transmitter and the receiver are integrated in the line holder.

The blood leak detector is subjected to the functional test.

2.1.7 Heparin Pump

Chapter 2: Functional Description

2.2 Weighing Units

The heparin pump is used for continuous heparinization of the blood.

A syringe plunger is moved by means of a carriage bar. The carriage

bar is connected to a threaded spindle via a slide. A microprocessorcontrolled stepper motor causes the spindle to rotate. Depending on the

activation, the piston will move up or down.

One Hall sensor each signals when the piston has reached its upper

and lower end of travel. The safety system of the pump comprises a

speed monitoring device (slotted disc with optical sensor) and a motor

current monitoring function. The syringe types are set via a coding

switch (HEX switch).

The weighing units are used for managing the fluid balance during

treatment.

The weighing cells are operated according to the strain gauge principle.

Signal conditioning, including analog-to-digital conversion, is achieved

per weighing cell on the P.C.B. LP 127. The actual weights are

produced by the operating processor.

Scale 1 and scale 2 each have a useful load of approx. 12 kg.

The scales are subjected to the functional test. To test the scales, a test

weight (ball) of defined value must be taken off each scale. Proper

functioning of the scales can be concluded from the correct difference

between the weights before and after lifting.

Fresenius Medical Care multiFiltrate TM 6/03.07 2-3

Page 14

Chapter 2: Functional Description

2.3 Ci-Ca Module (Option)

The Ci-Ca module is intended for regional citrate anticoagulation in the

CVVHD treatment therapy.

Turning power on The Ci-Ca module requires a supply voltage of 24VDC. This voltage is

provided by the multiFiltrate system's power supply unit via the

connector in the lower IV pole support of the IV pole located on the right

of the system.

After the multiFiltrate system was turned on by pressing the power

switch on its rear, the supply voltage of the module is connected. The

operating processor of the Ci-Ca module switches into the standby

mode.

If the multiFiltrate systems is then turned on via the I/O key on the front

of the system, the operating processor of the Ci-Ca module will perform

an internal processor test. This test is performed simultaneously to the

processor test of the multiFiltrate system.

The Ci-Ca module communicates with the multiFiltrate basic system via

a serial interface.

Processor test If a test is not passed successfully, the module will not establish

communications with the multiFiltrate system. It is not possible to

perform a treatment with citrate anticoagulation. The multiFiltrate

system recognizes this problem and displays a message which

proposes to use an alternative anticoagulation equipment (e.g. heparin

pump) and which has to be confirmed by the operator.

T1 test The Ci-Ca module performs its own T1 test, independent of the T1 test

of the multiFiltrate system. This test will be started automatically and

simultaneously to the multiFiltrate T1 test after the prompt whether the

starting conditions are met was confirmed with [OK].

This test cannot be skipped or deselected.

System errors If it is still possible, system errors in the Ci-Ca module are shown on the

multiFiltrate display with the indication that citrate anticoagulation is not

available.

2.4 Functional Test (T1 Test) and Error Messages

After it has been turned on the rear and the [I/O] key has been pressed,

the system automatically starts the processor test. After completion of

the processor test, the display test will be performed. In this test, the

numerical characters are represented for 2 seconds in all of the three

fonts used. After this test, the functional test (T1 test) is started

automatically. Depending on the configuration in the SETUP (SETUP

automatic), the test is running in the background or (SETUP detailed)

the test steps are represented separately on the display.

2-4 Fresenius Medical Care multiFiltrate TM 6/03.07

Page 15

Chapter 2: Functional Description

2.4.1 Battery Test, Part 1

At the beginning of the T1 test, the system assumes the terminal voltage

and loads the battery with a defined resistance over the entire test.

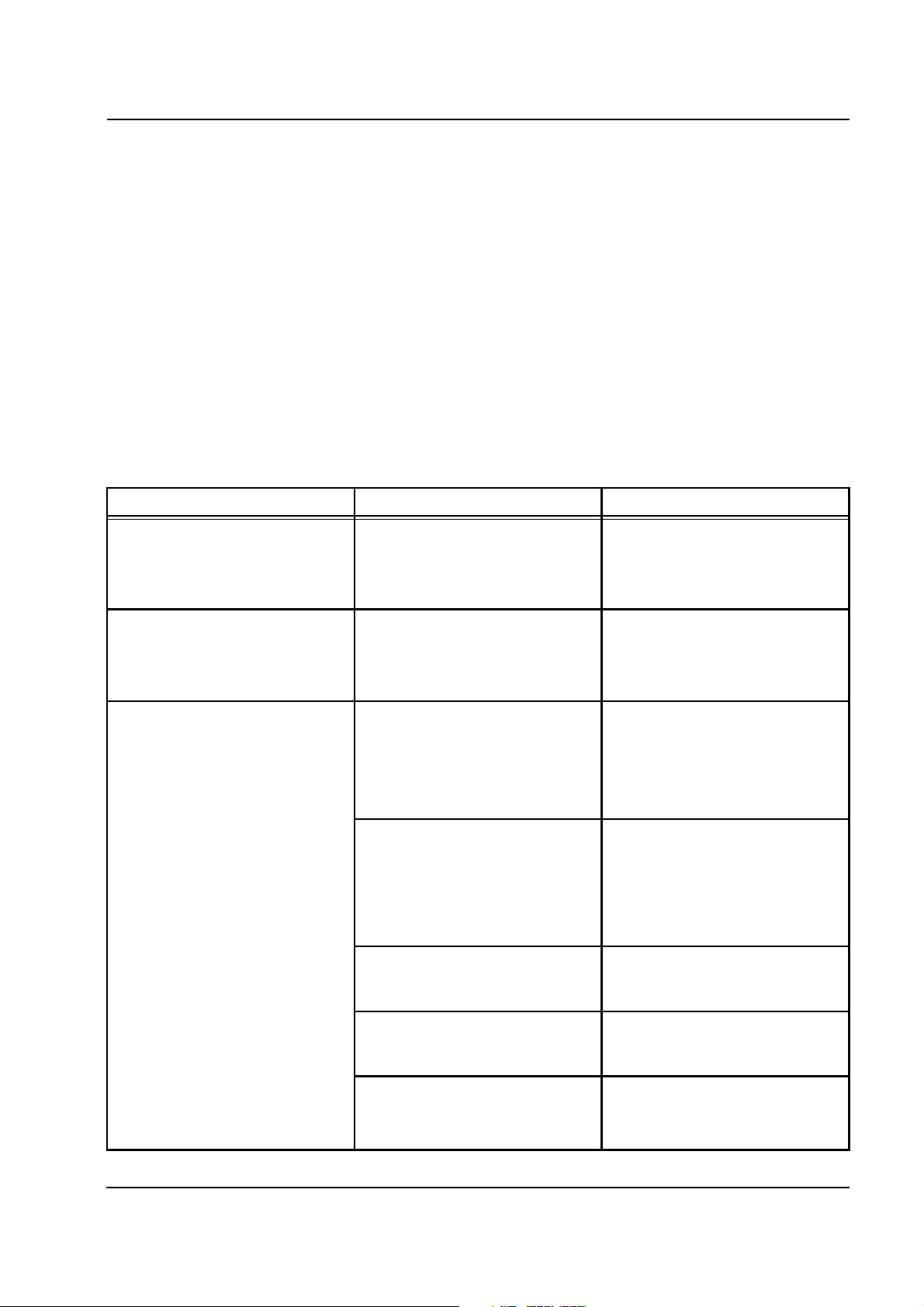

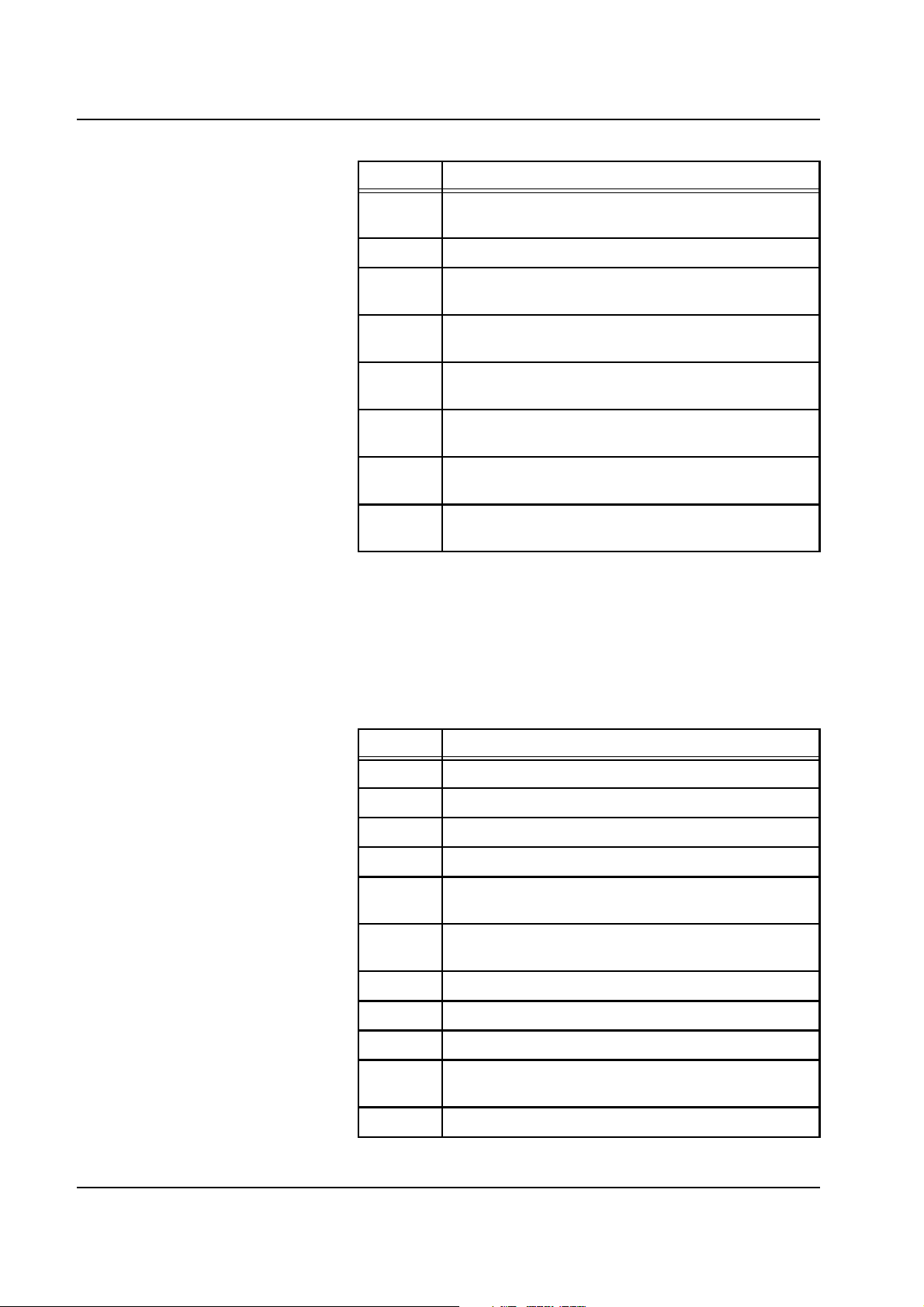

2.4.2 Scales Test

In the first step, the temperature compensation and calibration factors

are tested. In the second step, the scales are tared. The linearity test

follows in step three. The 4 test weights are lifted, and the weight (44.3

g) is tested for a tolerance of ±0.5 g. The offset drift is tested in step four.

The test weights are lowered again; the system expects a weight of 0.0

g with a tolerance of ±0.5 g. The time out for each step (2 to 4) is 10 sec.

In the event of an error, messages are emitted. Here, the error

messages section only relates to scales I. The messages are identical

for scales II to IV.

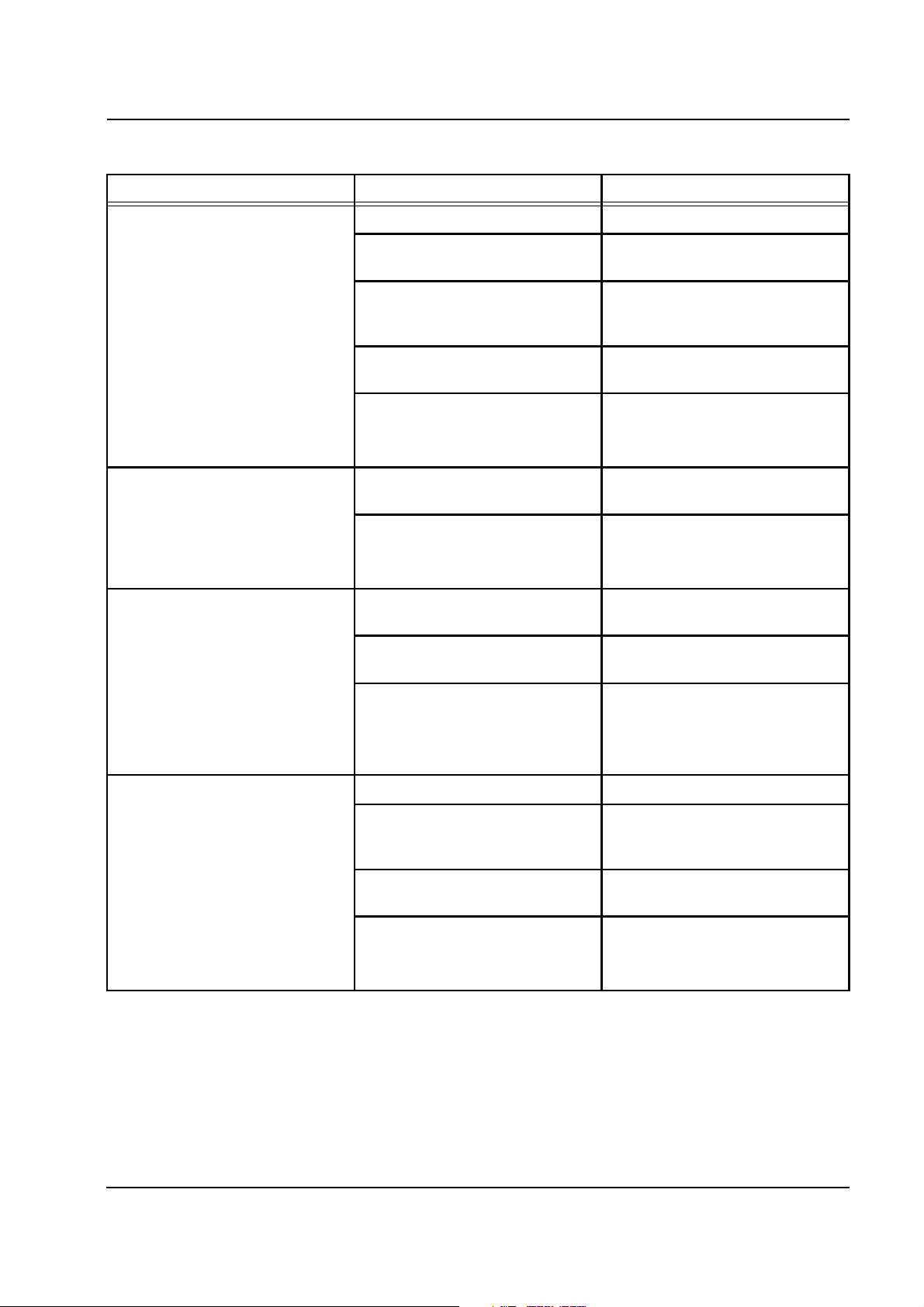

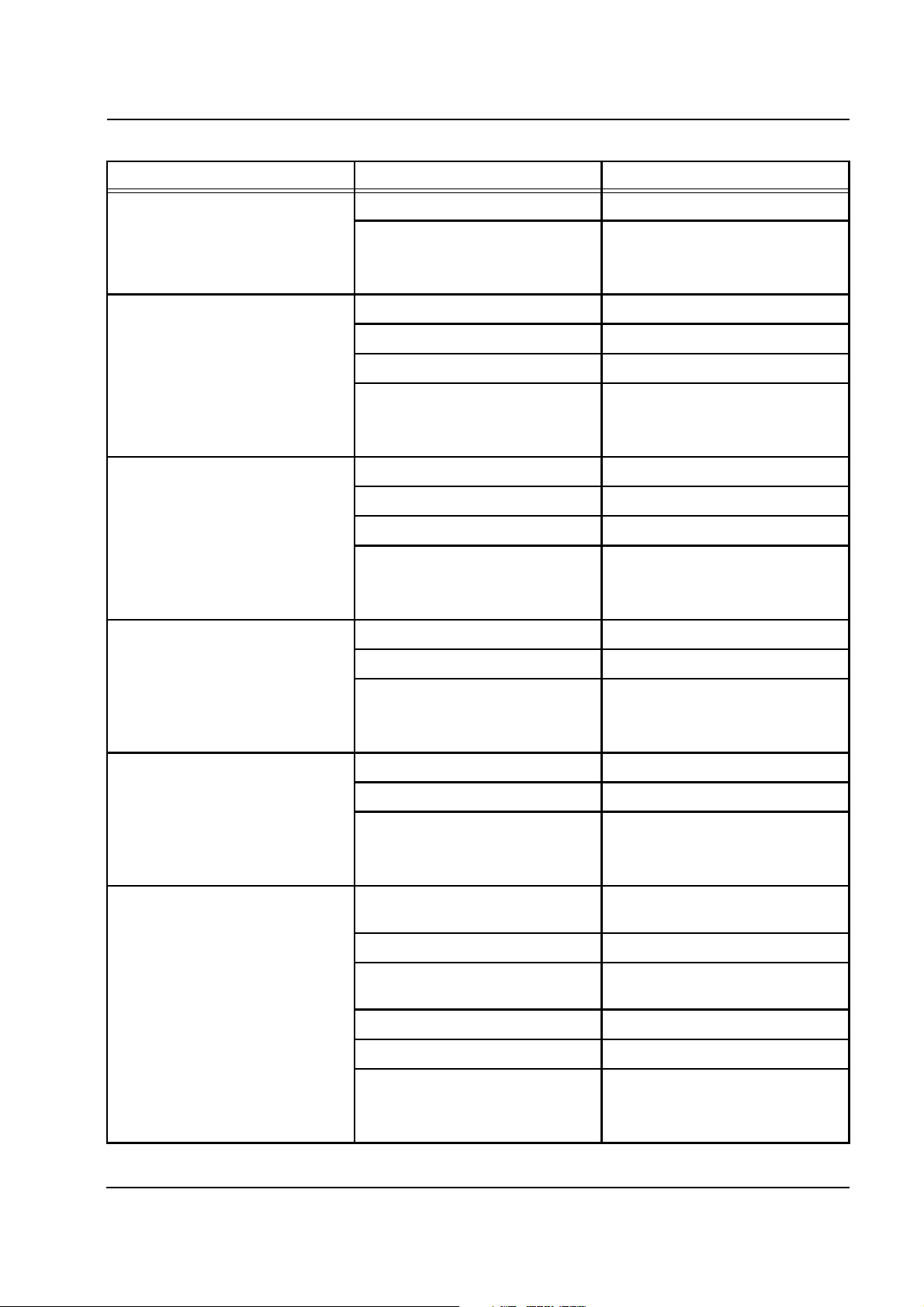

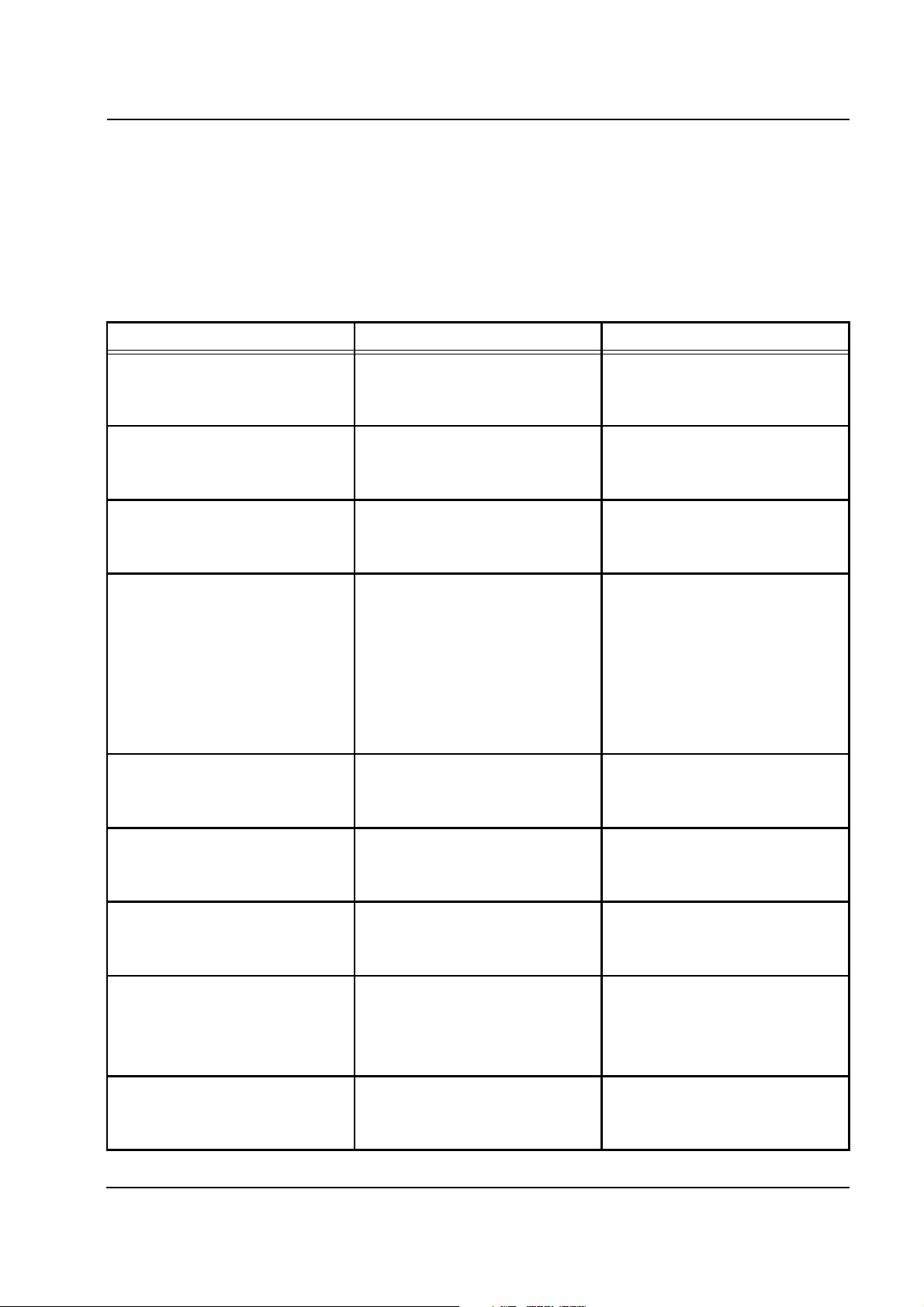

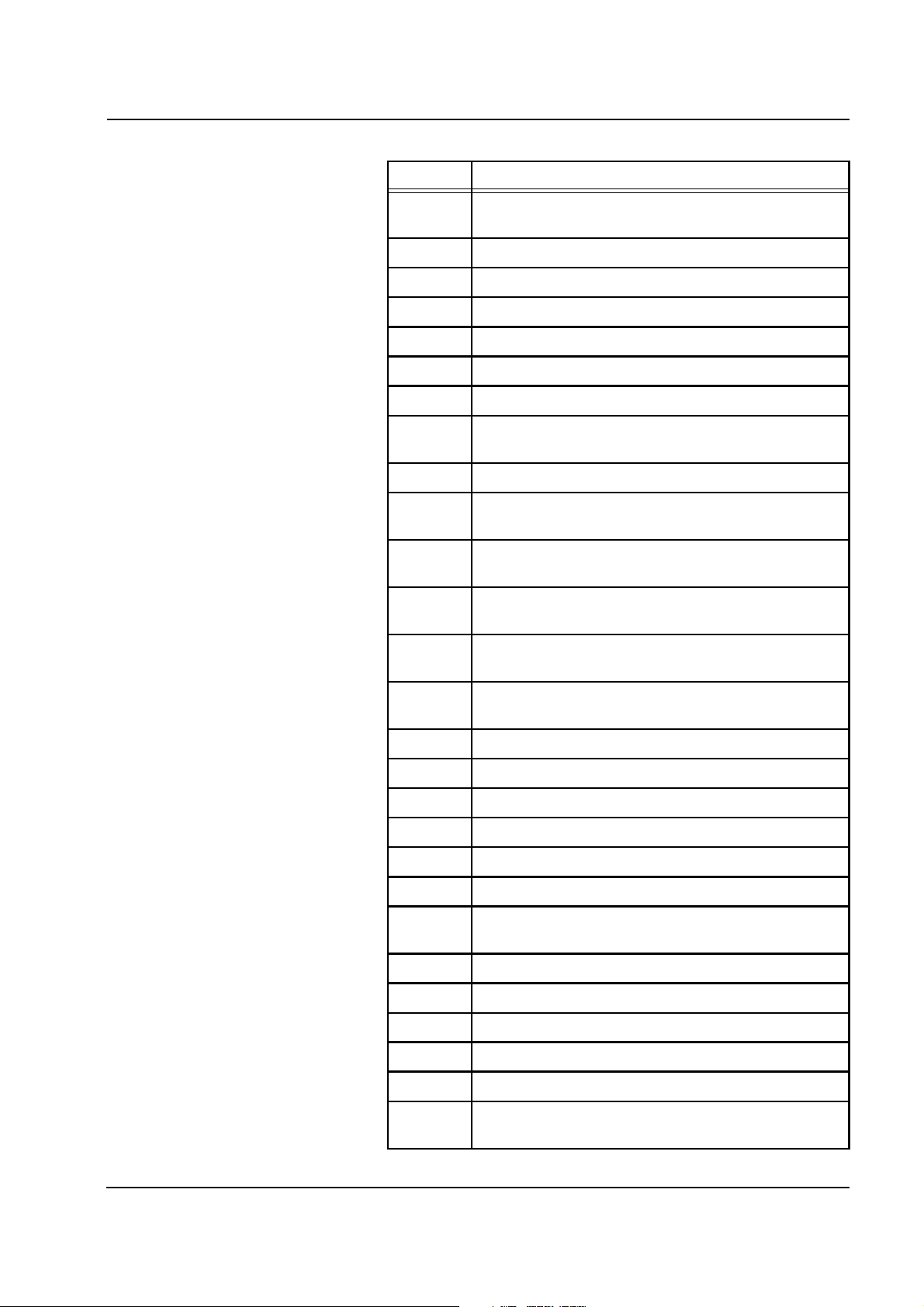

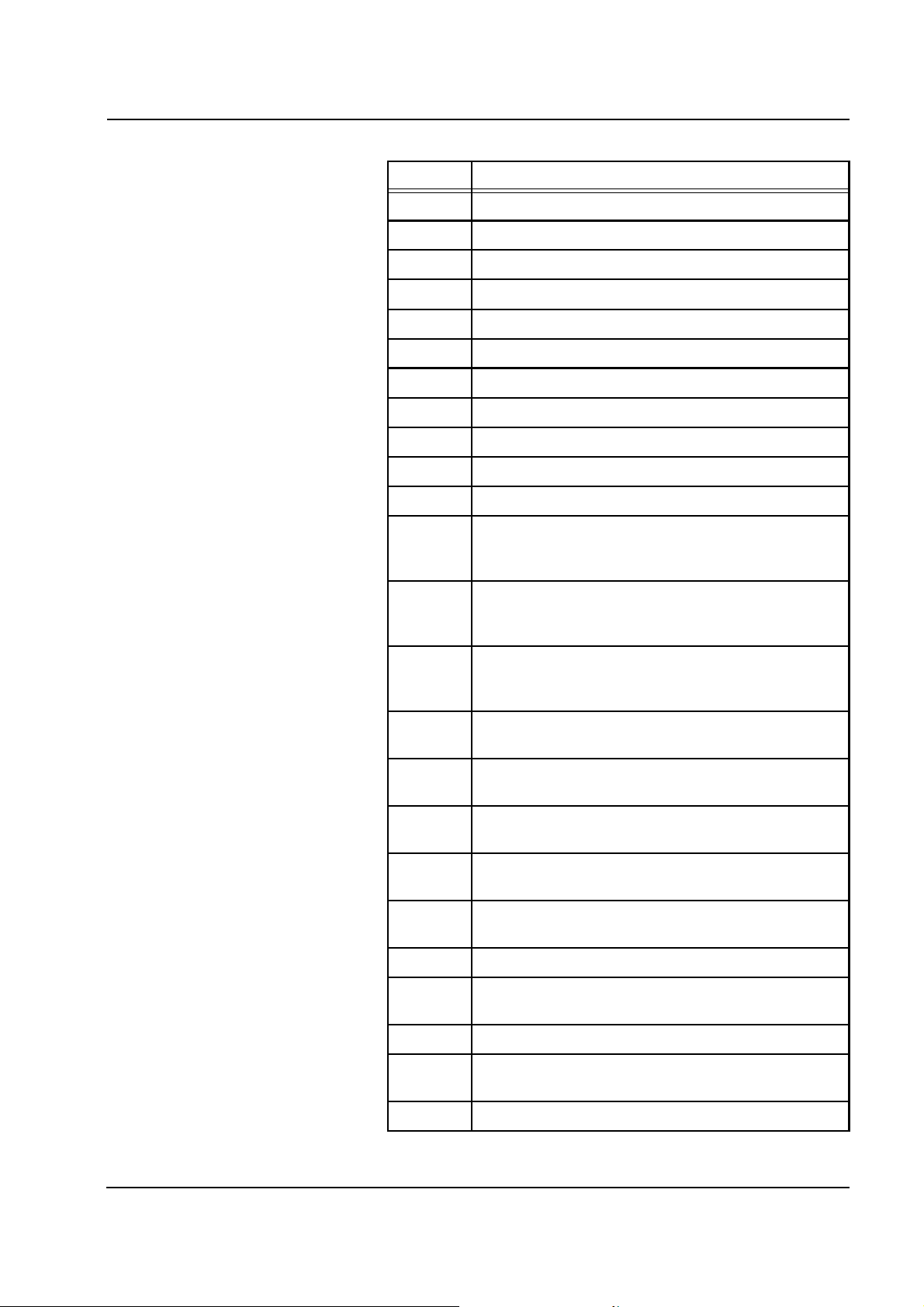

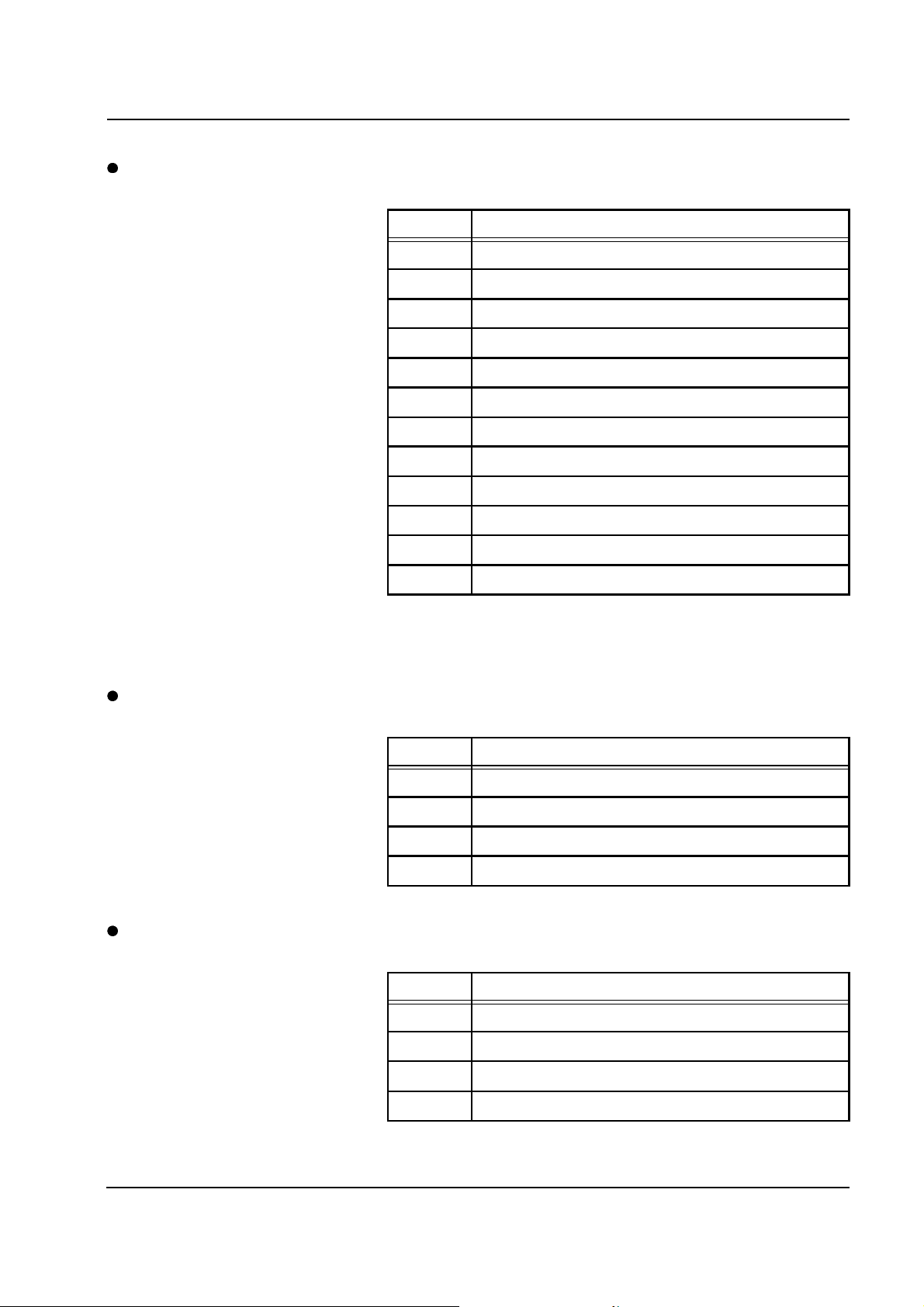

Error message Causes Action required

Scale I

Cal. factor missing, error.

Acknowledge with

[START/RESET] key.

Scale I

Temp. coeff. factors missing, error.

Acknowledge with

[START/RESET] key.

Scale I

Movement detected on Scale I.

Acknowledge with

[START/RESET] key.

Lithium battery on P.C.B. LP 244OP discharged.

Defect of the EPROM on P.C.B.

LP 127 of the scales specified.

The system is not in a stable

position. The scales are subjected

to a draft. Bags with tubing system

are placed on the scales; this is

especially applicable to filtrate

scales.

The +12 V and/or 12 V voltage(s)

is (are) missing.

Scales mechanics not smooth. Check for smoothness and adjust,

Replace the battery and execute

the calibration step in the Service

program.

Replace the P.C.B. and the

weighing bar and execute the

calibration step in the Service

program.

Set up the system in a stable

position. Remove the system from

the draft, or close the window.

Relieve the scales.

Check the fuses on the PSU board

LP 128 and replace the P.C.B.

LP 128, if necessary.

Caution: All pressures must be

checked and calibrated, if

necessary.

if necessary. Weight check in the

Service program.

Connector not fitted or defective

ribbon cable.

P.C.B. LP 244-OP defective. Replace P.C.B. LP 244-OP.

Fresenius Medical Care multiFiltrate TM 6/03.07 2-5

Fit the connector to the

motherboard and/or to the P.C.B.

LP 127. Replace the ribbon cable.

Caution: All scales and pressures

must be calibrated.

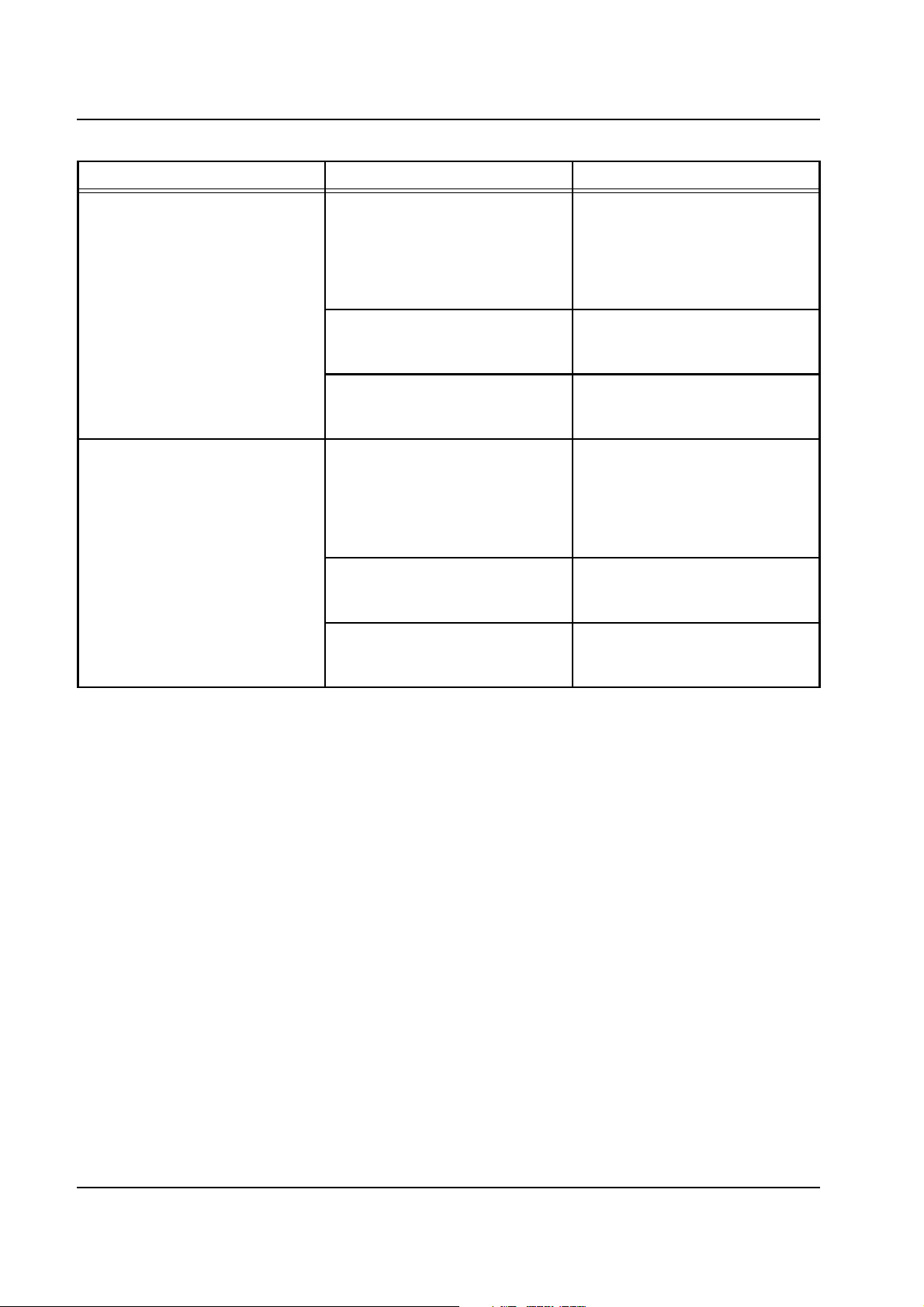

Page 16

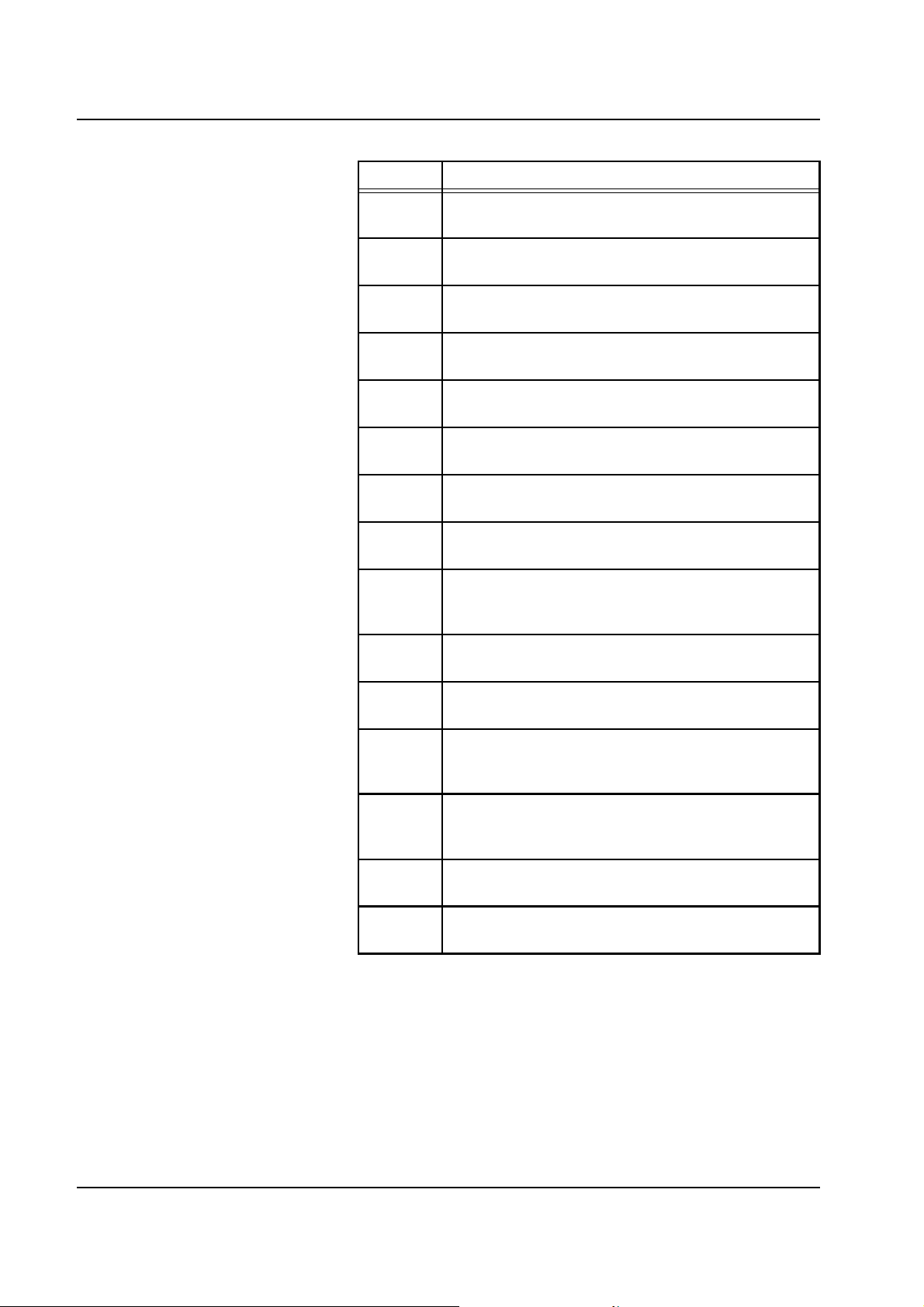

Chapter 2: Functional Description

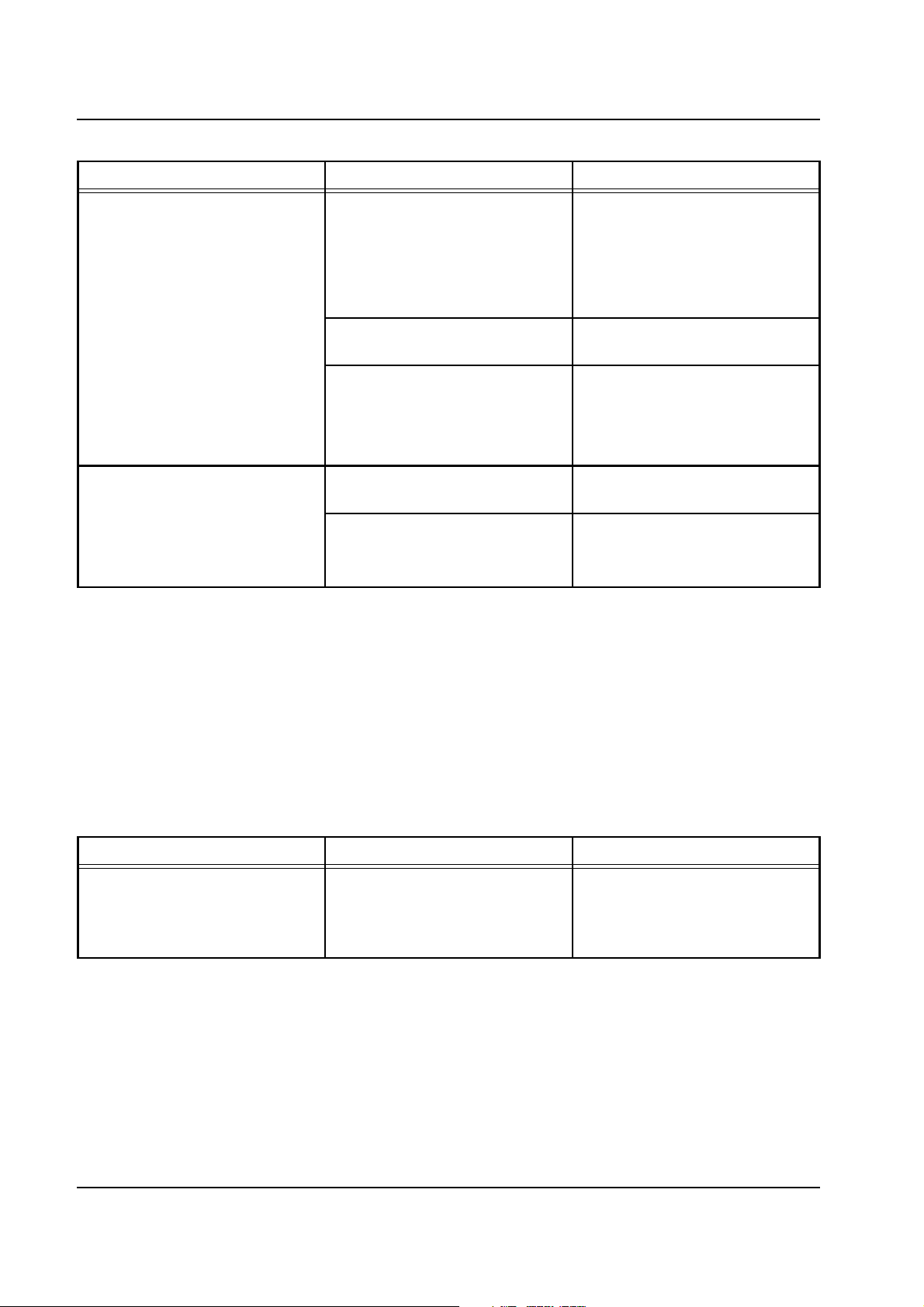

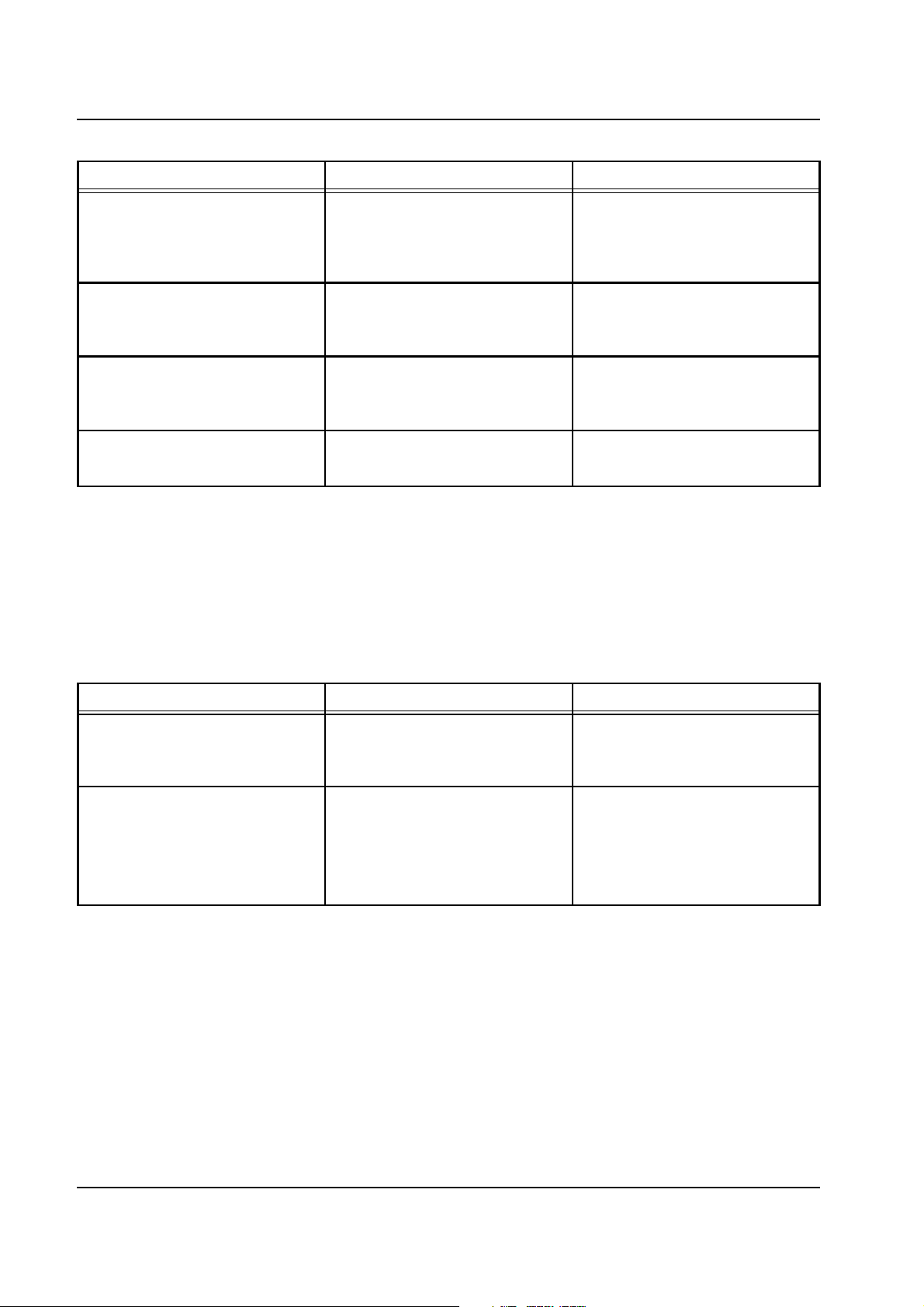

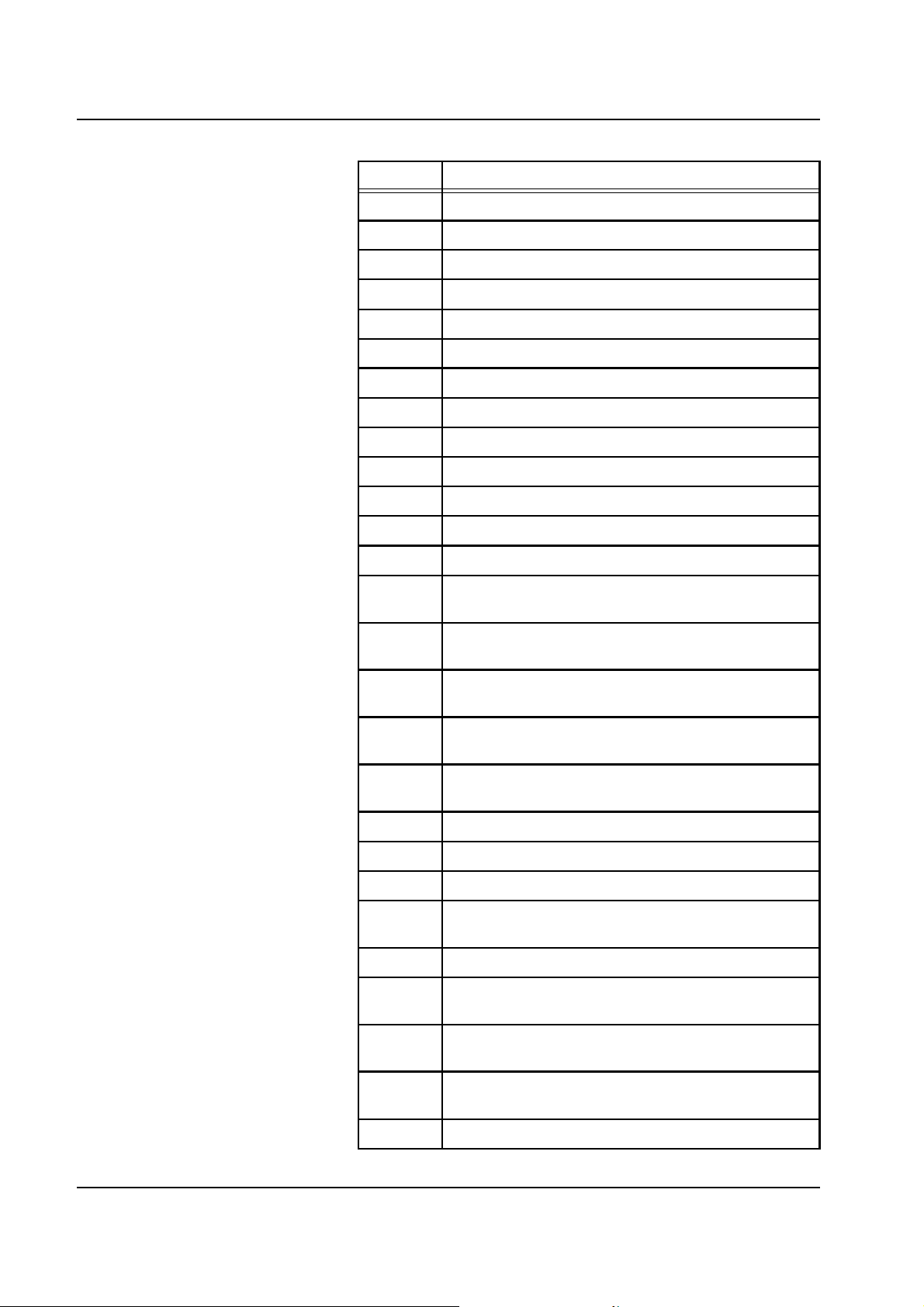

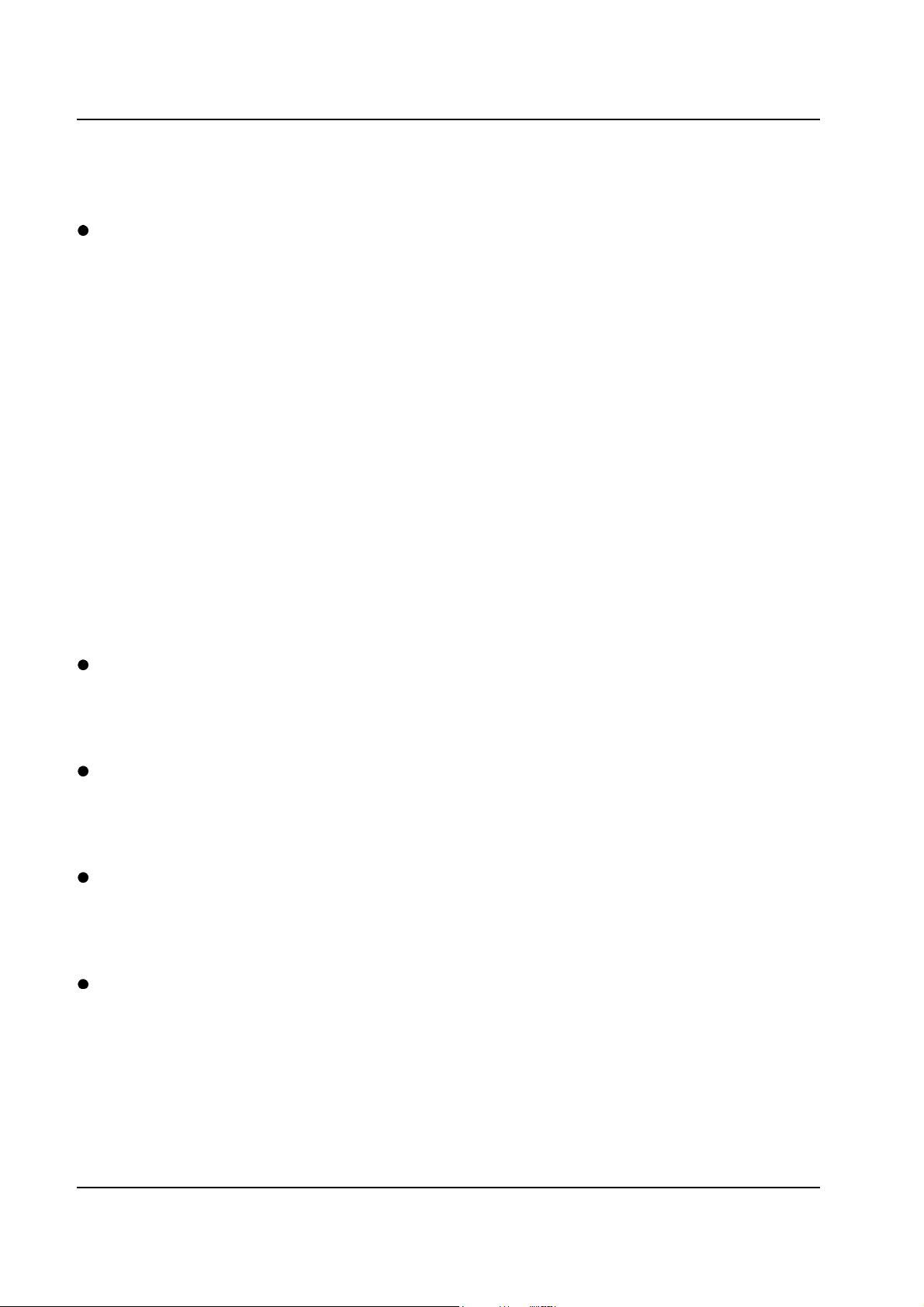

Error message Causes Action required

Scale I

Test weight outside tolerance.

Acknowledge with

[START/RESET] key.

Scale I

Zero offset outside tolerance.

Acknowledge with

[START/RESET] key.

The system is not in a stable

position. The scales are subjected

to a draft. Bags with tubing system

are placed on the scales; this is

especially applicable to filtrate

scales.

Lifting magnet for ball not

connected or defective.

Ball mechanics not smooth. Check for smoothness and adjust,

The system is not in a stable

position. The scales are subjected

to a draft. Bags with tubing system

are placed on the scales; this is

especially applicable to filtrate

scales.

Scales mechanics not smooth. Check for smoothness and adjust,

Test weight fails to drop back. Ball

mechanics not smooth.

Set up the system in a stable

position. Remove the system from

the draft, or close the window.

Relieve the scales.

Fit the connector to the

motherboard. If defective, the lifting

magnet must be replaced.

if necessary. Weight check in the

Service program.

Set up the system in a stable

position. Remove the system from

the draft, or close the window.

Relieve the scales.

if necessary. Weight check in the

Service program.

Check for smoothness and adjust,

if necessary. Weight check in the

Service program (ESC Service).

2.4.3 Pump Test

In the first step, the stop-by-OP function is tested, i.e. the pumps must

stop running. In this step, the safety processor releases the pumps, and

the operating processor does not activate the pumps. In the second

step, all of the four pumps are activated with a rate of 100 ml/min. The

safety processor checks whether the pumps are running at the correct

rate and whether the reed contact (line inserting position) is actuated. In

the third step, the operating processor activates the pumps and the

safety processor disables the pump activation, i.e. the pumps may not

be running. In the event of an error, messages are emitted. Here, the

error messages section only relates to the blood pump. The messages

are identical for the other pumps, i.e. the filtrate, substituate and

dialysate pumps.

2-6 Fresenius Medical Care multiFiltrate TM 6/03.07

Page 17

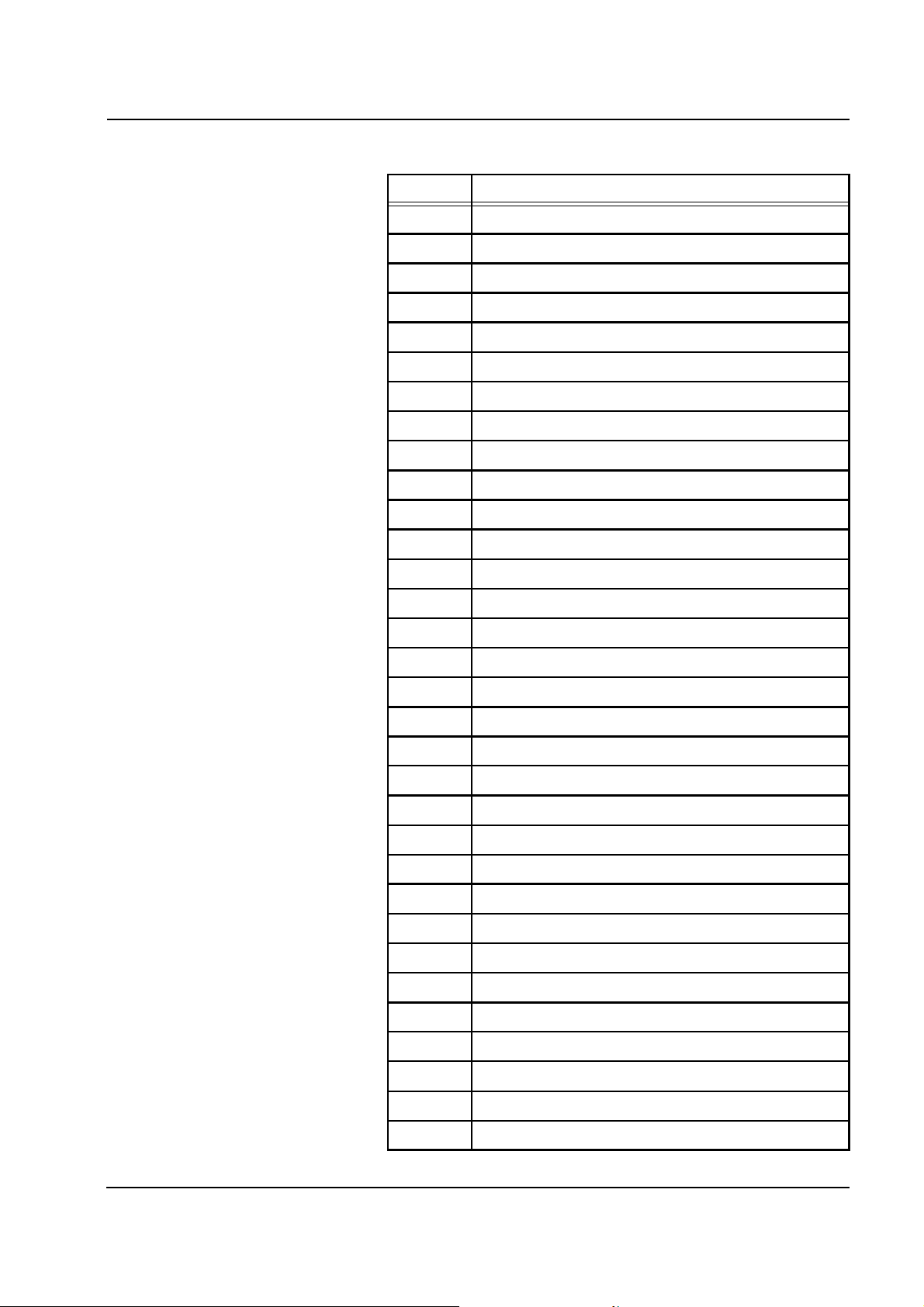

Chapter 2: Functional Description

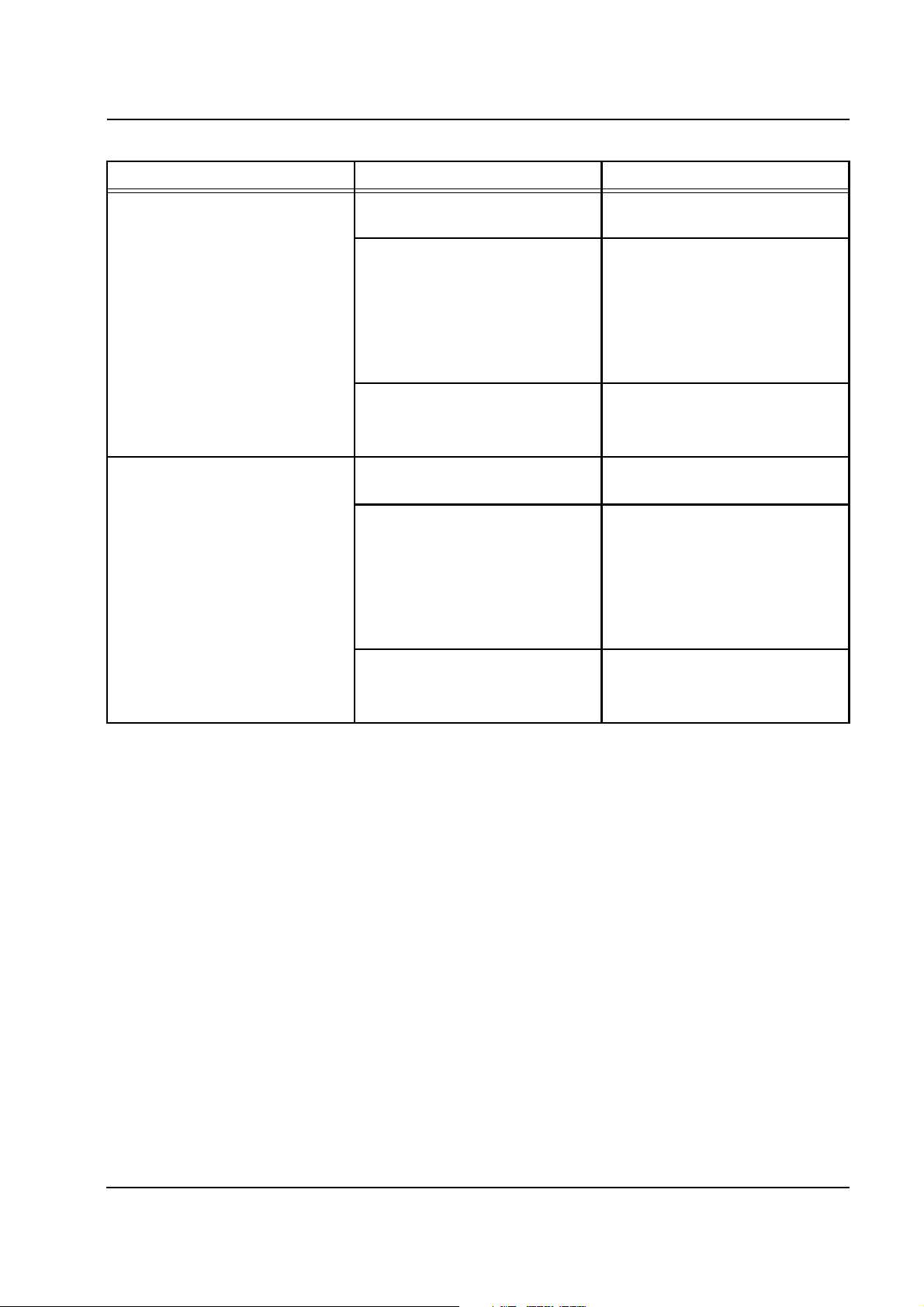

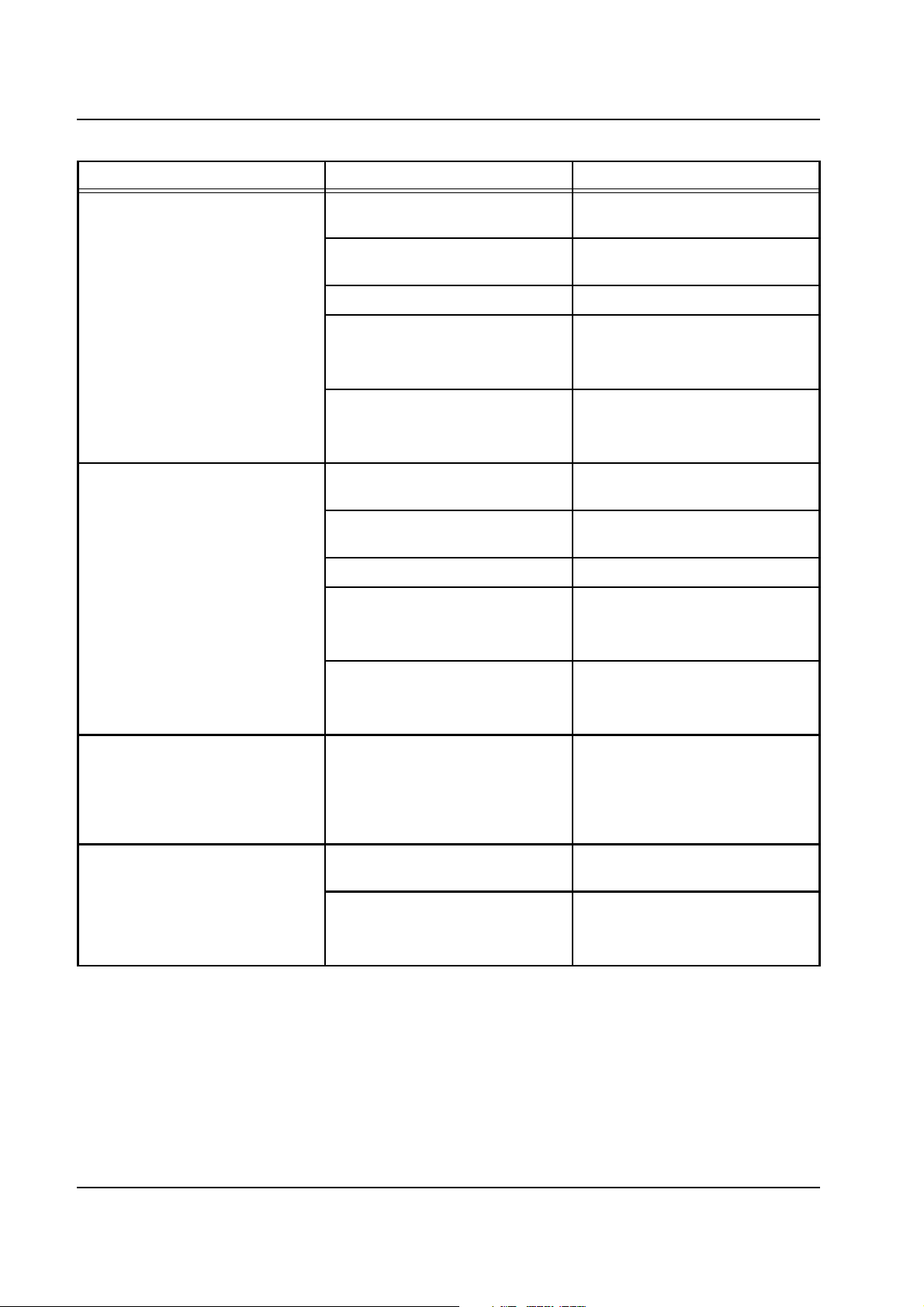

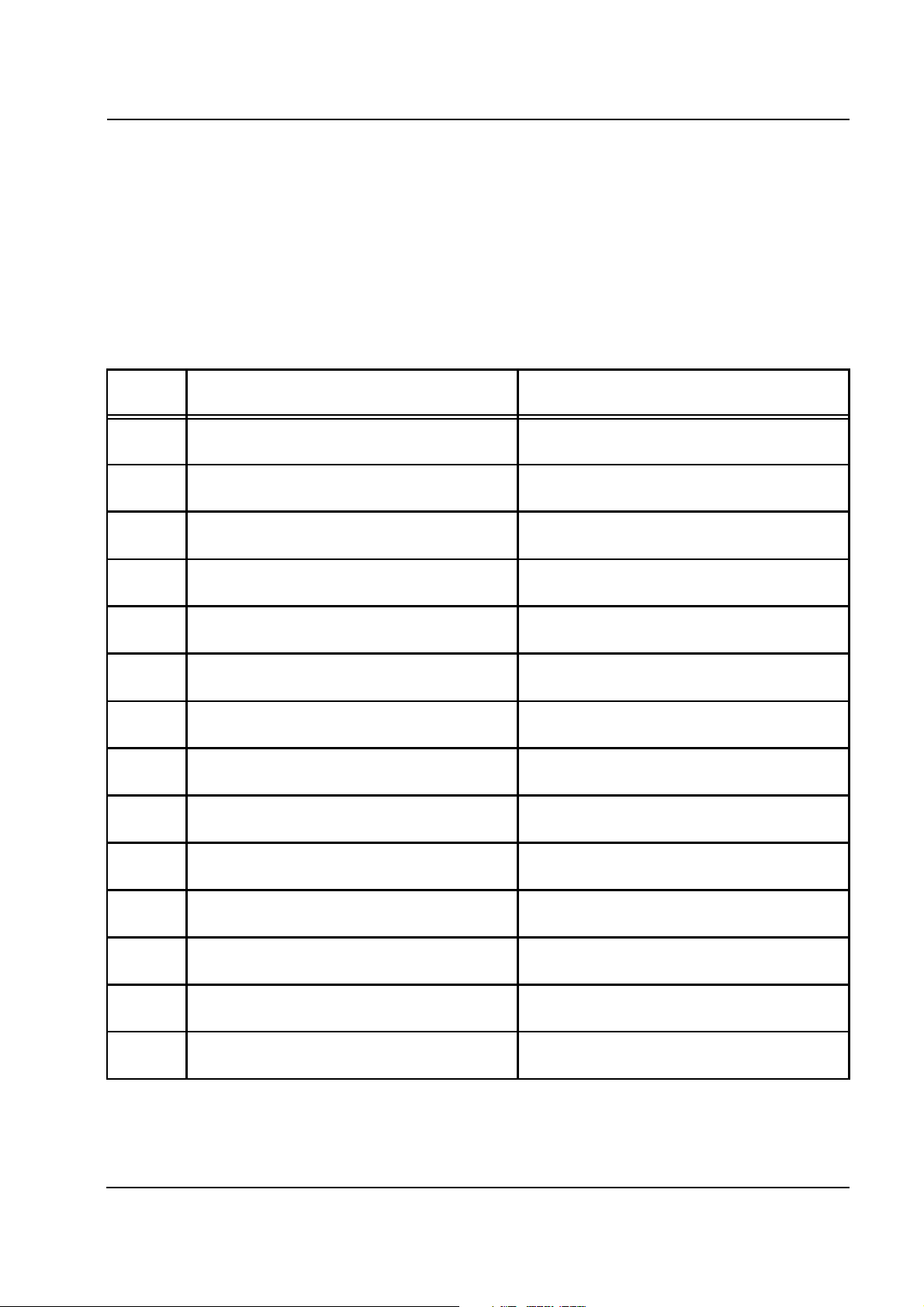

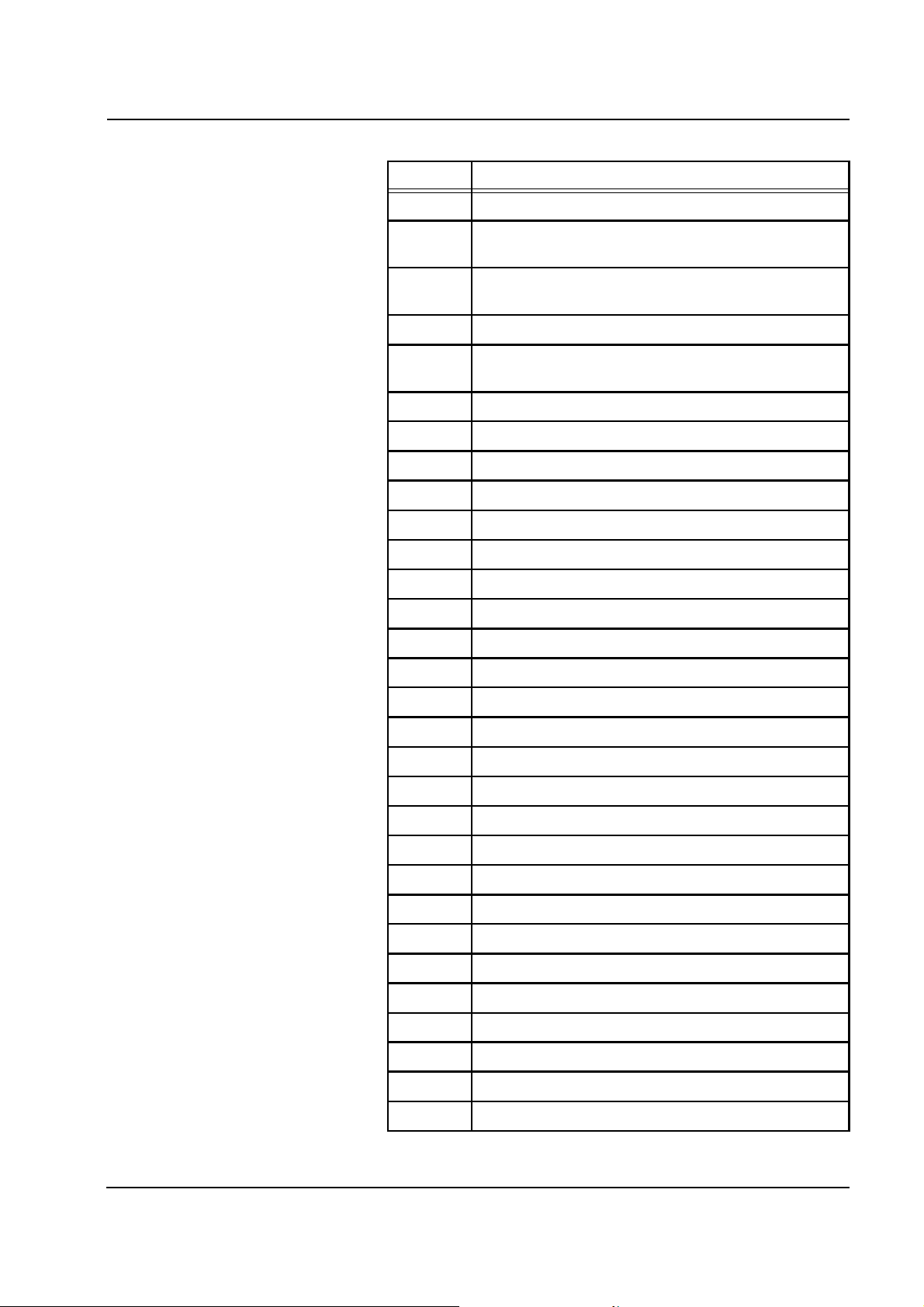

Error message Causes Action required

Blood pump

Blood pump door open.

Acknowledge with

[START/RESET] key.

Blood pump

Not stopped by operating

processor.

Acknowledge with

[START/RESET] key.

Blood pump

Wrong speed, rate.

Acknowledge with

[START/RESET] key.

Blood pump door open. Close the blood pump door.

Magnet in blood pump door

missing.

Hall sensor in pump housing not

connected or defective.

Control electronics (P.C.B. LP 123)

of the specified pump defective.

P.C.B. LP 244-SR defective. Replace P.C.B. LP 244-SR.

Control electronics (P.C.B. LP 123)

of the specified pump defective.

P.C.B. LP 244-SR defective. Replace P.C.B. LP 244-SR.

Clock pulse generator of motor on

P.C.B. LP 123 not connected.

Control electronics (P.C.B. LP 123)

of the specified pump defective.

Replace the blood pump door.

Plug the connector onto the

appropriate P.C.B. LP 123 or

replace the pump housing.

Replace P.C.B. LP 123.

Caution: The BLD must be

calibrated.

Replace P.C.B. LP 123.

Caution: The BLD must be

calibrated.

Connect the clock pulse generator

socket.

Replace P.C.B. LP 123.

Blood pump

Reed contact line threading

position

Acknowledge with

[START/RESET] key.

Defect of the clock pulse generator

on the geared motor.

Magnet in rotor missing, defective. Replace the rotor.

Reed switch in pump housing not

connected or defective.

Control electronics (P.C.B. LP 123)

of the specified pump defective.

P.C.B. LP 244-SR defective. Replace P.C.B. LP 244-SR.

Replace the geared motor.

Caution: Blood pump

20 V/3300 rpm; all other pumps

24 V/3300 rpm.

Plug the connector onto the

appropriate P.C.B. LP 123 or

replace the pump housing.

Replace P.C.B. LP 123.

Caution: The BLD must be

calibrated.

Fresenius Medical Care multiFiltrate TM 6/03.07 2-7

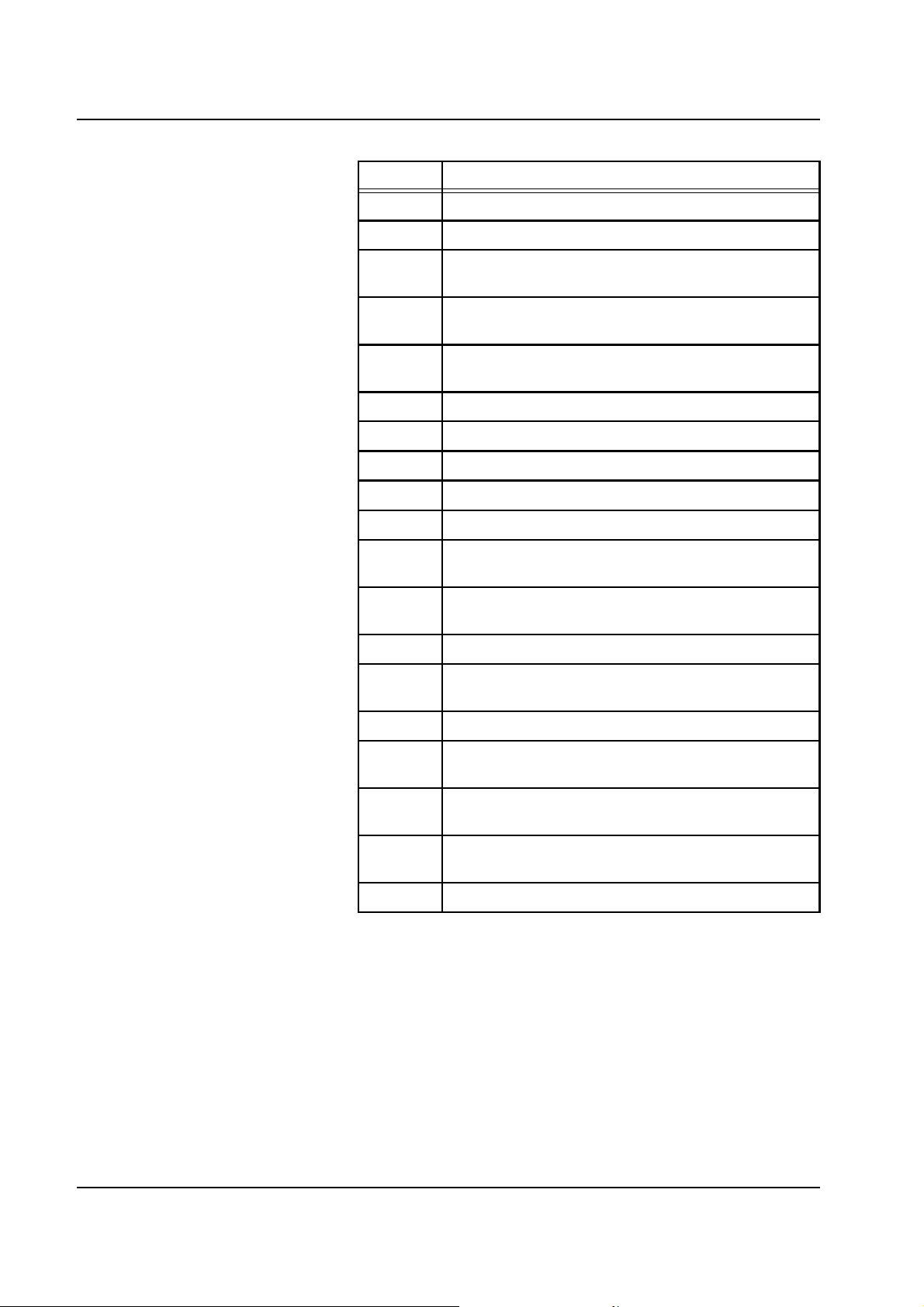

Page 18

Chapter 2: Functional Description

Error message Causes Action required

Blood pump

Stop.

Acknowledge with

[START/RESET] key.

Blood pump

Not stopped by safety processor.

Acknowledge with

[START/RESET] key.

2.4.4 Pressure Transducer

+24-V supply voltage missing. Check the fuse on the PSU board

LP 128. If necessary, replace

P.C.B. LP 128.

Caution: All pressures must be

checked and calibrated, if

necessary.

Control electronics (P.C.B. LP 123)

of the specified pump defective.

P.C.B. LP 244-OP defective.

(The pumps are activated serially,

i.e. the operating processor is

defective only if all pumps fail to be

activated.)

Control electronics (P.C.B. LP 123)

of the specified pump defective.

P.C.B. LP 244-SR defective. Replace P.C.B. LP 244-SR.

Replace P.C.B. LP 123.

Replace P.C.B. LP 244-OP.

Caution: All scales and pressures

must be calibrated.

Replace P.C.B. LP 123.

Caution: The BLD must be

calibrated.

In the first step, the zero point, amplification and detuning factors are

tested. In the second step, the zero points of the pressure transducers

are checked with a tolerance of ±20 mmHg. In the third step, Part and

Pven are detuned to 300 mmHg. The values are checked with a

tolerance of ±20 mmHg. In the fourth step, PPHF and PFil are detuned

to 300 mmHg. The values are checked with a tolerance of ±20 mmHg.

In the event of an error, messages are emitted. The following table only

shows the error messages for "arterial pressure". The messages are

identical for the venous, pre-hemofilter and filtrate pressures.

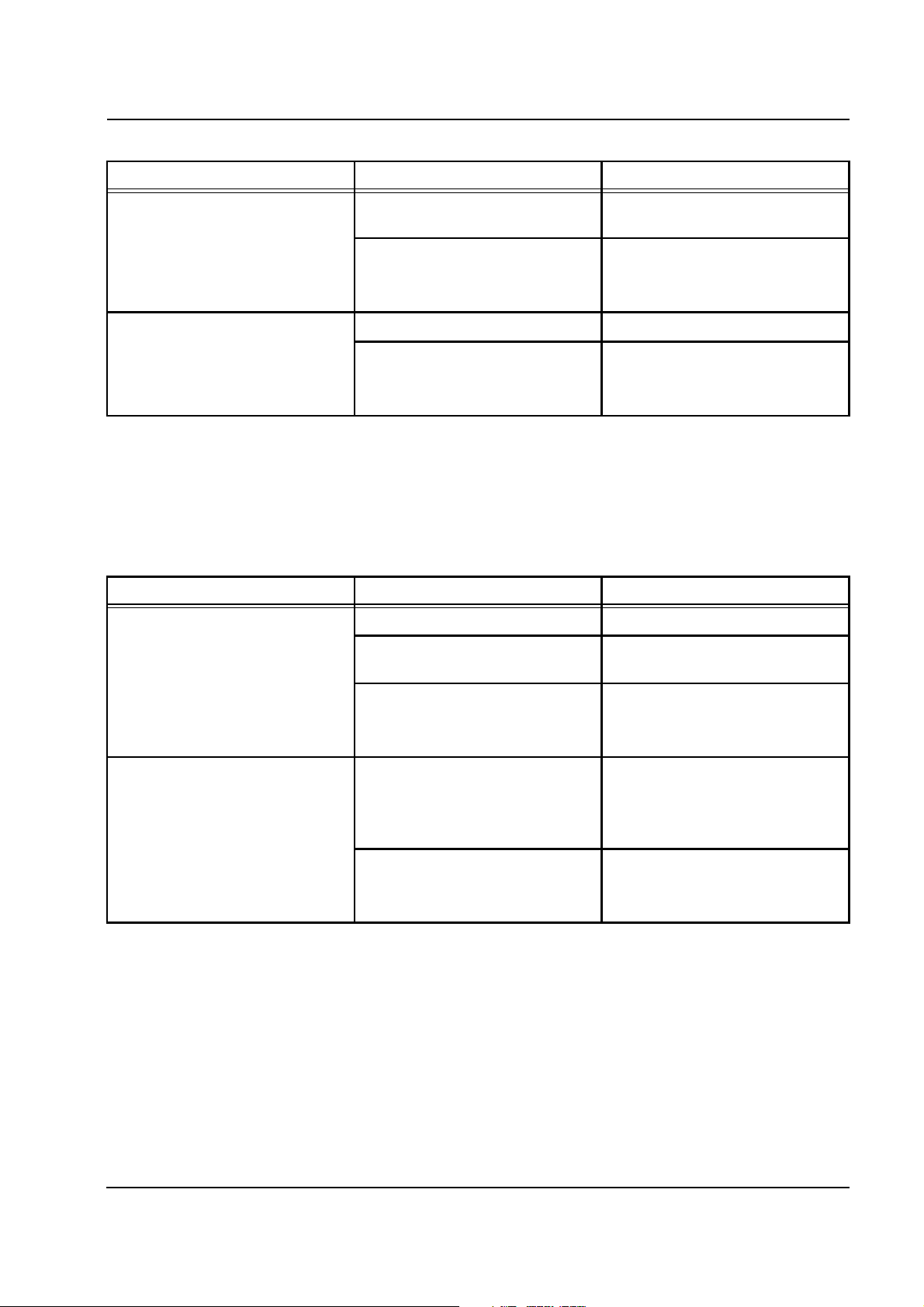

Error message Causes Action required

Arterial pressure

Factors / Offset lost.

Acknowledge with

[START/RESET] key.

Lithium battery on P.C.B. LP 244OP discharged.

Replace the battery and execute

the calibration step in the Service

program.

2-8 Fresenius Medical Care multiFiltrate TM 6/03.07

Page 19

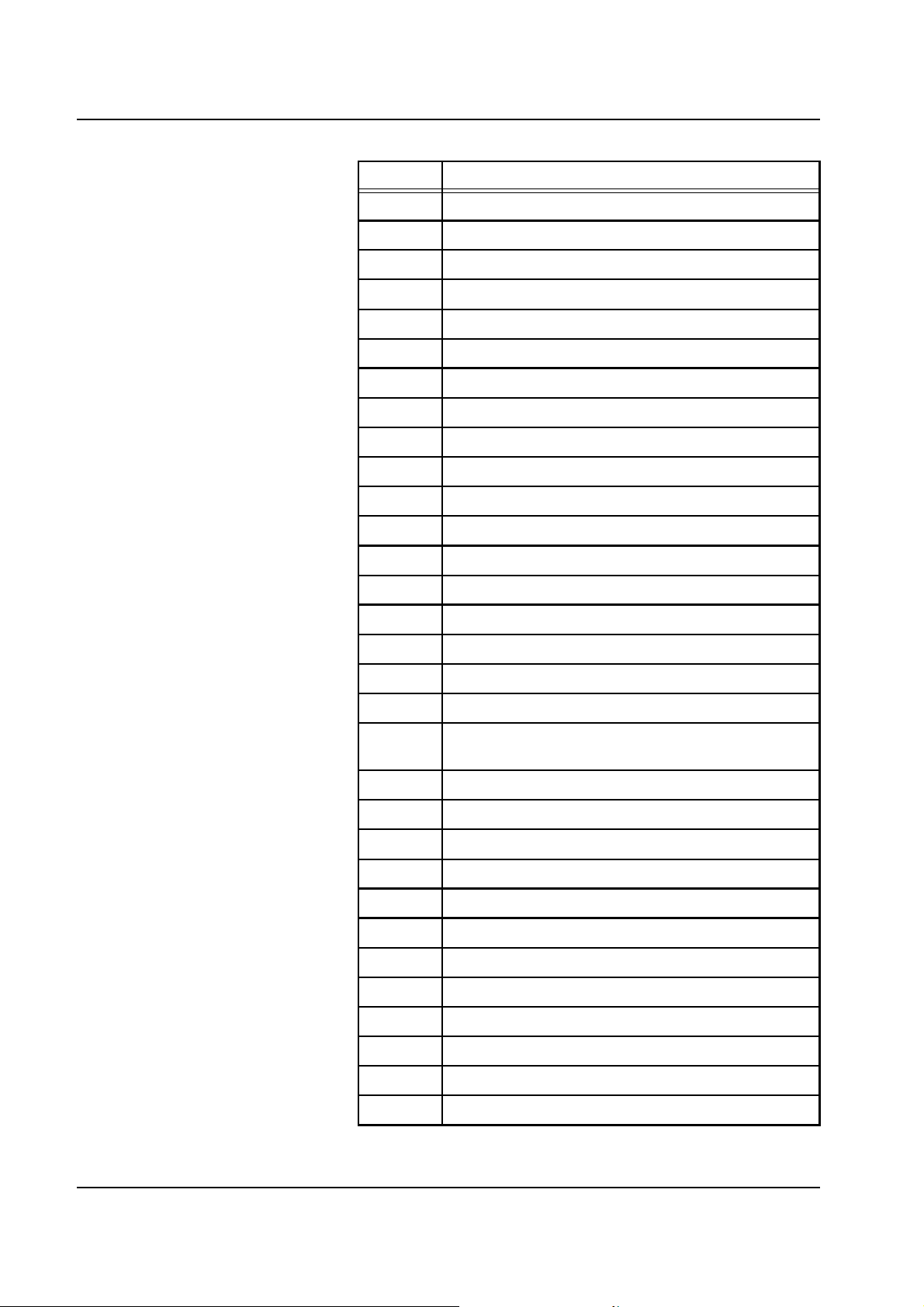

Chapter 2: Functional Description

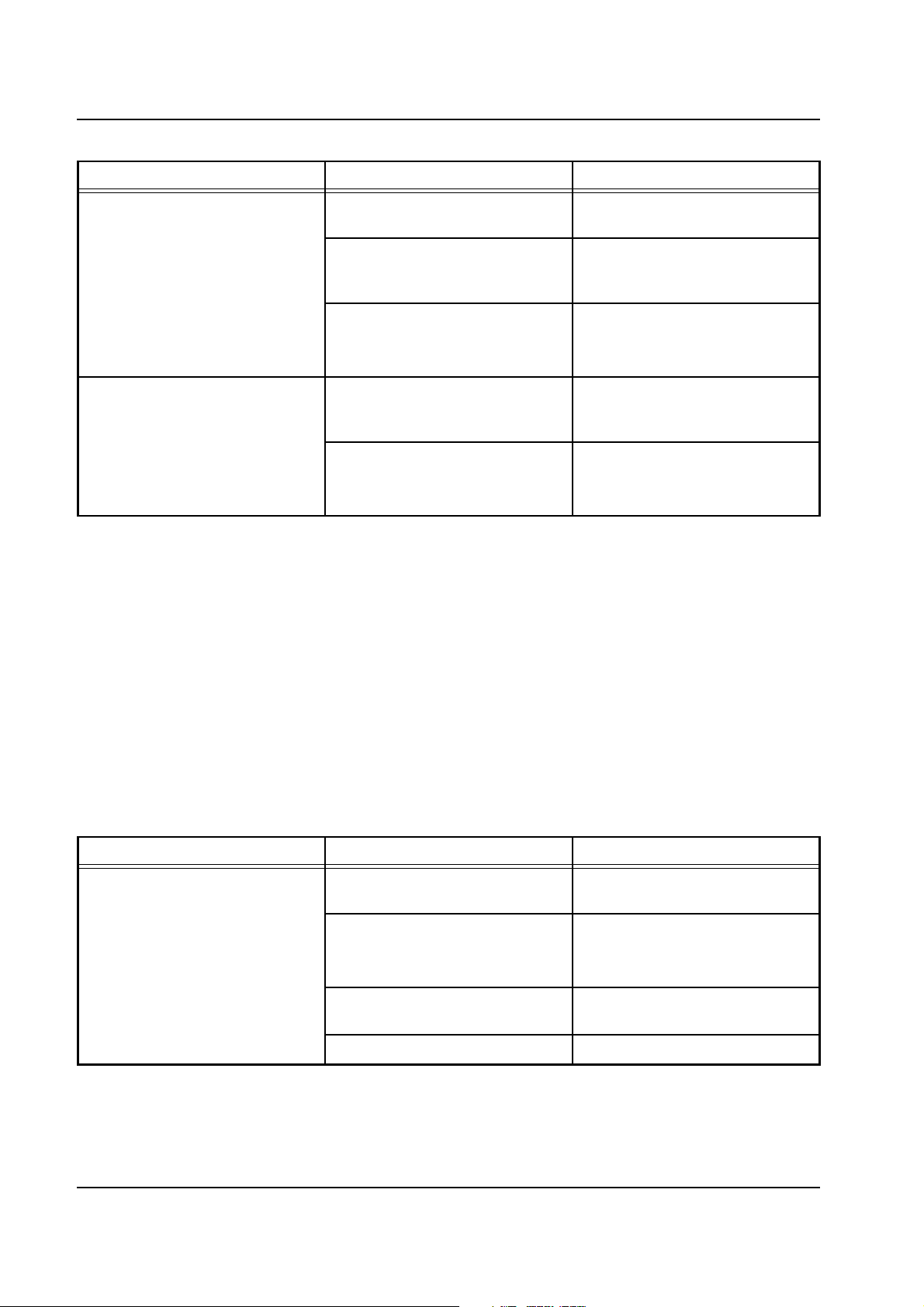

Error message Causes Action required

Arterial pressure

Zero outside tolerance.

Acknowledge with

[START/RESET] key.

Arterial pressure

Detuning outside tolerance

Acknowledge with

[START/RESET] key.

Zero point drifted off. Check the setting and calibrate the

pressure in the Service program.

P.C.B. LP 343-1 (for venous

pressure: P.C.B. LP 450-3)

defective.

P.C.B. LP 244-OP defective. Replace P.C.B. LP 244-OP.

Amplification drifted off. Check the setting and calibrate the

P.C.B. LP 343-1 (for venous

pressure: P.C.B. LP 450-3)

defective.

Replace P.C.B. LP 343-1 (LP 450-

3) and calibrate the pressure in the

Service program.

Caution: When replacing the

P.C.B. LP 450-3, check / adjust the

air detector, optical detector and

venous pressure transducer.

Caution: All scales and pressures

must be calibrated.

pressure in the Service program.

Replace P.C.B. LP 343-1 (LP 450-

3) and calibrate the pressure in the

Service program.

Caution: When replacing the

P.C.B. LP 450-3, check / adjust the

air detector, optical detector and

venous pressure transducer.

2.4.5 Optical Detector

P.C.B. LP 244-OP defective. Replace P.C.B. LP 244-OP.

Caution: All scales and pressures

must be calibrated.

In the first step, the non-opaque state is checked. In the second step,

the optical detector is detuned and the opaque state is checked. In the

event of an error, messages are emitted.

Fresenius Medical Care multiFiltrate TM 6/03.07 2-9

Page 20

Chapter 2: Functional Description

Error message Causes Action required

Opt. detector

Senses opaque fluid.

Acknowledge with

[START/RESET] key.

Opt. detector

Fails to sense opaque fluid after

attenuation.

Acknowledge with

[START/RESET] key.

Blood present in the system or

objects inserted in the OD.

OD adjusted improperly. Check the setting of the OD.

P.C.B. LP 450-3 defective. Replace the P.C.B. LP 450-3.

Measuring head of OD defective. Replace and adjust the OD

P.C.B. LP 244-SR defective. Replace P.C.B. LP 244-SR.

OD adjusted improperly. Check the setting of the OD.

P.C.B. LP 450-3 defective. Replace the P.C.B. LP 450-3.

P.C.B. LP 244-OP defective. Replace P.C.B. LP 244-OP.

Remove the blood line or the

objects from the OD.

Caution: When replacing the

P.C.B. LP 450-3, check / adjust the

air detector, optical detector and

venous pressure transducer.

measuring head.

Caution: The BLD must be

calibrated.

Caution: When replacing the

P.C.B. LP 450-3, check / adjust the

air detector, optical detector and

venous pressure transducer.

2.4.6 Air Detector

Caution: All scales and pressures

must be calibrated.

AD 28 defective. Replace AD 28-1.

In the first step, it is checked whether fluid is present in the drip

chamber. if YES, the clamp is activated (opened). In the second step,

the air detector is detuned and the alarm state checked. In the event of

an error, messages are emitted.

2-10 Fresenius Medical Care multiFiltrate TM 6/03.07

Page 21

Chapter 2: Functional Description

Error message Causes Action required

Air detector

LDA1 not in alarm mode.

Acknowledge with

[START/RESET] key.

Air detector

Clamp does not close.

Acknowledge with

[START/RESET] key.

LD adjusted improperly. Check the setting of the LD.

P.C.B. LP 450-3 defective. Replace the P.C.B. LP 450-3.

Caution: When replacing the

P.C.B. LP 450-3, check / adjust the

air detector, optical detector and

venous pressure transducer.

Ultrasonic detector defective. Replace and adjust the ultrasonic

detector.

P.C.B. LP 244-SR defective. Replace P.C.B. LP 244-SR.

Caution: The BLD must be

calibrated.

LD adjusted improperly (LDA2). Check the setting of the LD.

P.C.B. LP 450-3 defective. Replace the P.C.B. LP 450-3.

Caution: When replacing the

P.C.B. LP 450-3, check / adjust the

air detector, optical detector and

venous pressure transducer.

P.C.B. LP 244-SR defective. Replace P.C.B. LP 244-SR.

Caution: The BLD must be

calibrated.

2.4.7 Blood Leak Detector

In the first step, the blood leak detector is checked for being in an

acceptable state. In the second step, the blood leak detector is detuned

and the alarm state checked. In the event of an error, messages are

emitted.

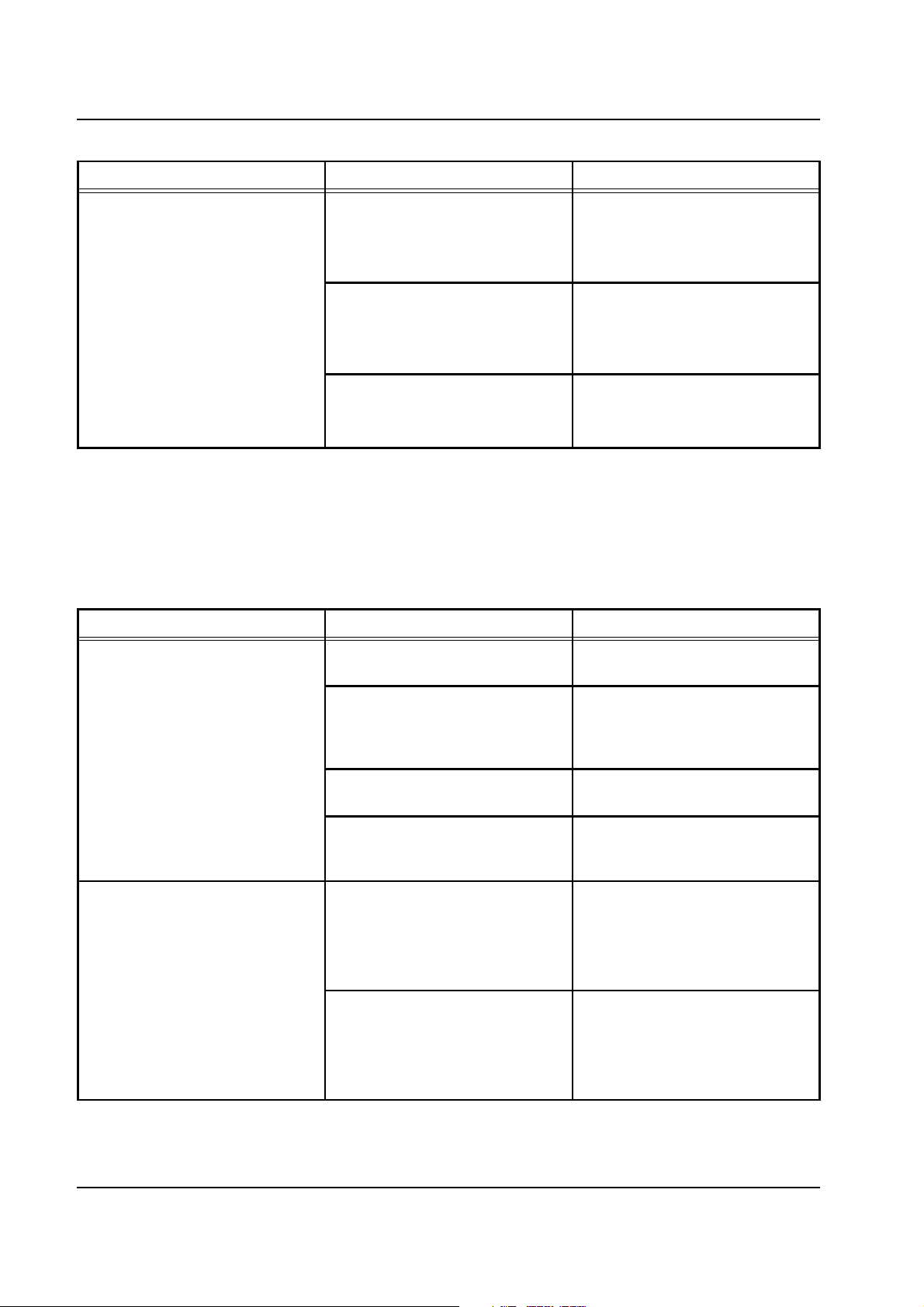

Error message Causes Action required

Blood leak detector

Calibration values incorrect

or missing.

Acknowledge with

[START/RESET] key.

Lithium battery on P.C.B. LP 244SP discharged.

Replace the battery and execute

the calibration step in the Service

program.

Fresenius Medical Care multiFiltrate TM 6/03.07 2-11

Page 22

Chapter 2: Functional Description

Error message Causes Action required

Blood leak detector

Outside acceptable range.

Remove filtrate line.

Acknowledge with

[START/RESET] key.

Blood leak detector

Alarm-free after signal attenuation.

Acknowledge with

[START/RESET] key.

2.4.8 Heater

Empty filtrate line or objects

inserted in the BLD sensor head.

P.C.B. LP 125 and/or BLD sensor

head defective.

P.C.B. LP 244-SR defective. Replace P.C.B. LP 244-SR.

P.C.B. LP 125 and/or BLD sensor

head defective.

P.C.B. LP 244-OP defective. Replace P.C.B. LP 244-OP.

In the first step, the safety relay is checked for being in the open state.

In addition, the sensors are checked for interruption and short-circuit. In

the second step, the safety relay is activated and checked for being in

the closed state. In the third step, the bag and foil sensors of OP and

SP are checked for being synchronized. Tolerances are ±1 °C. In the

fourth step, the foil sensor is detuned to >120 °C and, thus, the safety

shutoff mechanism (fire protection) is checked. In the fifth step, the bag

and foil sensors are detuned to >41 °C to check whether the heater is

switched off in case of an overtemperature of the solutions. In the sixth

step, it is checked whether the heater can be activated. In the event of

an error, messages are emitted. Here, the error messages section only

relates to the lower heater. The messages are identical for the upper

heater.

Remove the filtrate line or the

objects.

Replace P.C.B. LP 125 and the

BLD sensor head, and calibrate the

BLD.

Caution: The BLD must be

calibrated.

Replace P.C.B. LP 125 and the

BLD sensor head, and calibrate the

BLD.

Caution: All scales and pressures

must be calibrated.

Error message Causes Action required

Lower heater

Switch-off path SP defective

(Sub. relay not open)

Voltage missing.

Fuse defective.

Acknowledge with

[START/RESET] key.

2-12 Fresenius Medical Care multiFiltrate TM 6/03.07

Safety relay on P.C.B. LP 122

defective.

Activation on P.C.B. LP 244-SR

defective.

Supply voltage for heater not

connected.

Fuse on P.C.B. LP 122 defective. Replace the fuse.

Replace P.C.B. LP 122.

Replace P.C.B. LP 244-SR.

Caution: The BLD must be

calibrated.

Fit the socket on P.C.B. LP 122.

Page 23

Chapter 2: Functional Description

Error message Causes Action required

Lower heater

Control FET short-circuit

Acknowledge with

[START/RESET] key.

Lower heater

Bag sensor broken.

Acknowledge with

[START/RESET] key.

Lower heater

Foil sensor broken.

Acknowledge with

[START/RESET] key.

Lower heater

Control FET defective. Replace P.C.B. LP 122.

Activation on P.C.B. LP 244-OP

defective.

Socket of sensors not fitted. Fit the socket on P.C.B. LP 122.

Sensor interrupted. Replace the heater.

P.C.B. LP 122 defective Replace P.C.B. LP 122.

Converter on P.C.B. LP 244-SR

defective.

Socket of sensors not fitted. Fit the socket on P.C.B. LP 122.

Sensor interrupted. Replace the heater.

P.C.B. LP 122 defective Replace P.C.B. LP 122.

Converter on P.C.B. LP 244-SR

defective.

Bag sensor short-circuit. Replace the heater.

Replace P.C.B. LP 244-OP.

Caution: All scales and pressures

must be calibrated.

Replace P.C.B. LP 244-SR.

Caution: The BLD must be

calibrated.

Replace P.C.B. LP 244-SR.

Caution: The BLD must be

calibrated.

Bag sensor short-circuit.

Acknowledge with

[START/RESET] key.

Lower heater

Foil sensor short-circuit.

Acknowledge with

[START/RESET] key.

Lower heater

Sub. relay not closed,

foil defective.

Acknowledge with

[START/RESET] key.

P.C.B. LP 122 defective Replace P.C.B. LP 122.

Converter on P.C.B. LP 244-SR

defective.

Bag sensor short-circuit. Replace the heater.

P.C.B. LP 122 defective Replace P.C.B. LP 122.

Converter on P.C.B. LP 244-SR

defective.

Supply voltage for heater not

connected.

Fuse on P.C.B. LP 122 defective. Replace the fuse.

Heater foil not connected. Connect the heater foil to P.C.B.

Heater foil interrupted. Replace the heater.

Safety relay defective. Replace P.C.B. LP 122.

Activation on P.C.B. LP 244-SR

defective.

Replace P.C.B. LP 244-SR.

Caution: The BLD must be

calibrated.

Replace P.C.B. LP 244-SR.

Caution: The BLD must be

calibrated.

Fit the socket on P.C.B. LP 122.

LP 122.

Replace P.C.B. LP 244-SR.

Caution: The BLD must be

calibrated.

Fresenius Medical Care multiFiltrate TM 6/03.07 2-13

Page 24

Chapter 2: Functional Description

Error message Causes Action required

Lower heater

Bag sensors,

OP-SP not synchronous

Acknowledge with

[START/RESET] key.

Lower heater

Foil sensors,

OP-SP not synchronous

Acknowledge with

[START/RESET] key.

Heater still warm after last

treatment or Service program.

Sensor board (P.C.B. LP 1220)

defective.

P.C.B. LP 122 defective Replace P.C.B. LP 122.

Converter on P.C.B. LP 244-SR

defective.

Converter on P.C.B. LP 244-OP

defective.

Heater still warm after last

treatment or Service program.

Sensor board (P.C.B. LP 1220)

defective.

P.C.B. LP 122 defective Replace P.C.B. LP 122.

Converter on P.C.B. LP 244-SR

defective.

Allow the heater to cool down.

Replace the heater.

Replace P.C.B. LP 244-SR.

Caution: The BLD must be

calibrated.

Replace P.C.B. LP 244-OP.

Caution: All scales and pressures

must be calibrated.

Allow the heater to cool down.

Replace the heater.

Replace P.C.B. LP 244-SR.

Caution: The BLD must be

calibrated.

Lower heater

Foil sensor detuning,

no overtemperature cutoff.

Acknowledge with

[START/RESET] key.

Lower heater

Bag sensor detuning,

no overtemperature.

Acknowledge with

[START/RESET] key.

Converter on P.C.B. LP 244-OP

defective.

DIL relay on P.C.B. LP 122

defective.

DIL relay on P.C.B. LP 122

defective.

Activation on P.C.B. LP 244-OP

defective.

Replace P.C.B. LP 244-OP.

Caution: All scales and pressures

must be calibrated.

Replace P.C.B. LP 122.

Replace P.C.B. LP 122.

Replace P.C.B. LP 244-OP.

Caution: All scales and pressures

must be calibrated.

2-14 Fresenius Medical Care multiFiltrate TM 6/03.07

Page 25

Chapter 2: Functional Description

Error message Causes Action required

Lower heater

Foil sensor detuning,

no overtemperature.

Acknowledge with

[START/RESET] key.

Lower heater

FET control defective

Acknowledge with

[START/RESET] key.

DIL relay on P.C.B. LP 122

defective.

Activation on P.C.B. LP 244-OP

defective.

FET on P.C.B. LP 122 defective. Replace P.C.B. LP 122.

Activation on P.C.B. LP 44-OP

defective.

Replace P.C.B. LP 122.

Replace P.C.B. LP 244-OP.

Caution: All scales and pressures

must be calibrated.

Replace P.C.B. LP 244-OP.

Caution: All scales and pressures

must be calibrated.

2.4.9 Battery Test, Part 2

The first step was carried out at the beginning of the functional test, with

acceptance of the starting value and loading of the battery. In the

second step, the voltage is checked after loading and is compared with

the starting value. In the event of an error, messages are emitted.

Error message Causes Action required

Battery test

Battery not connected, defective.

Acknowledge with

[START/RESET] key.

Battery not connected. Connect the rechargeable battery.

Battery terminal voltage without

load <<18 V.

Converter on P.C.B. LP 244-OP

defective.

Replace the battery.

Replace P.C.B. LP 244-OP.

Caution: All scales and pressures

must be calibrated.

Battery test

Load test failed.

Acknowledge with

[START/RESET] key.

Fresenius Medical Care multiFiltrate TM 6/03.07 2-15

Resistor or load relay on the PSU,

P.C.B. LP 128, defective.

Converter or activation on P.C.B.

LP 244-OP defective.

Replace P.C.B. LP 128.

Caution: All pressures must be

checked and calibrated, if

necessary.

Replace P.C.B. LP 244-OP.

Caution: All scales and pressures

must be calibrated.

Page 26

Chapter 2: Functional Description

Error message Causes Action required

Battery test

Insufficient capacity.

Acknowledge with

[START/RESET] key.

System not used for a prolonged

period or frequent power failure

(preparation).

Battery defective.

Charging circuit on the PSU board,

P.C.B. LP 128, defective.

Converter on P.C.B. LP 244-OP

defective.

Load the battery from the mains for

a minimum of 10 hours.

Replace the battery.

Replace P.C.B. LP 128.

Caution: All pressures must be

checked and calibrated, if

necessary.

Replace P.C.B. LP 244-OP.

Caution: All scales and pressures

must be calibrated.

2.4.10 Audible Alarm

In the first step, it is checked whether the audible alarm is silenced. In

the second step, the audible alarm is generated and checked for proper

functioning by means of a microphone. In the event of an error,

messages are emitted.

Error message Causes Action required

Audible alarm

Not silenced.

Acknowledge with

[START/RESET] key.

Constant ambient noise. Repeat the test after the noise has

stopped.

Loud humming noise on the

loudspeaker.

Check the route of the loudspeaker

cable. Replace the loudspeakermicrophone unit or the

motherboard P.C.B. LP 124.

The microphone line is disturbed. Check the route of the microphone

cable.

Microphone or amplifier defective. Replace the loudspeaker-

microphone unit or the

motherboard P.C.B. LP 124.

Audible alarm

Not active.

Acknowledge with

[START/RESET] key.

2-16 Fresenius Medical Care multiFiltrate TM 6/03.07

Alarm tone not audible. Loudspeaker cable connected to

P.C.B. LP 124?

Replace the loudspeakermicrophone unit or the

motherboard P.C.B. LP 124.

Error message despite audible

alarm.

Microphone cable connected to

P.C.B. LP 124?

Replace the loudspeakermicrophone unit or the

motherboard P.C.B. LP 124.

Page 27

Chapter 2: Functional Description

2.4.11 Heparin Pump

After turning power on to the multiFiltrate, a self-test of the heparin

pump will be performed. Immediately before the multiFiltrate self-test,

the operating processor will query the heparin pump status. In the event

of an error, messages are emitted. If the heparin pump is not installed,

not connected to the power supply or deactivated via Service option, no

error message will be displayed.

Error message Causes Action required

Heparin pump

Heparin pump not ready.

No communication.

Heparin pump

Heparin pump optionally

deactivated in Service mode

Heparin pump

Heparin pump detects internal error

Heparin pump

Wrong / unauthorized syringe type

detected

Heparin pump

Unknown hardware error

Heparin pump does not respond. Acknowledge with

[START/RESET] key.

Heparin pump deactivated.

Heparin pump manually

deactivated in the Service mode

Internal heparin pump error without

definite cause.

Wrong syringe type set. Acknowledge with

Heparin pump detects an unknown

hardware error.

Acknowledge with

[START/RESET] key.

Heparin pump deactivated.

Acknowledge with

[START/RESET] key.

Heparin pump deactivated.

[START/RESET] key.

Heparin pump deactivated.

Select a valid syringe type.

0 = 50 ml P syringe

1 = 30 ml heparin syringe

2 = 50 ml Injectomat syringe

Acknowledge with

[START/RESET] key.

Heparin pump deactivated.

Heparin pump

Heparin pump hardware error

Gate array error

Heparin pump

Spike on reset line

Heparin pump

Wrong HEX switch position

Heparin pump

Powerdown

Fresenius Medical Care multiFiltrate TM 6/03.07 2-17

Heparin pump detects an error in

the gate array.

A reset occurred during operation. Acknowledge with

Wrong HEX switch position set. Acknowledge with

Powerdown without 24 V-cutoff. Acknowledge with

Acknowledge with

[START/RESET] key.

Heparin pump deactivated.

[START/RESET] key.

Heparin pump deactivated.

[START/RESET] key.

Heparin pump deactivated.

Set a valid HEX switch position.

[START/RESET] key.

Heparin pump deactivated.

Page 28

Chapter 2: Functional Description

Error message Causes Action required

Heparin pump

Operating processor internal

communication error with heparin

pump

Heparin pump

Watchdog error

Heparin pump

NOVRAM error

Heparin pump

CAMUS transmission error

2.4.12 multiDataLink

Erroneous data transmission.

Wrong or missing characters.

Check sum error.

The watchdog is not able to

interrupt the 24 V control voltage

for the stepper motor.

The CRC protection of the data

saved in the E2PROM is not

correct.

Not used in the multiFiltrate. Not used in the multiFiltrate.

Immediately before the multiFiltrate self-test, the operating processor

will query the multiDataLink version identifications. A response given by

the mDL is an indicator for its operability. In the event of an error,

messages are emitted. If the multiDataLink is not installed, not

connected to the power supply or deactivated via Service option, no

error message will be displayed.

Acknowledge with

[START/RESET] key.

Heparin pump deactivated.

Acknowledge with

[START/RESET] key.

Heparin pump deactivated.

Acknowledge with

[START/RESET] key.

Heparin pump deactivated.

Error message Causes Action required

multiDataLink

multiDataLink not standby

No communication

multiDataLink

multiDataLink optionally

deactivated in Service mode

multiDataLink does not respond. Acknowledge with

[START/RESET] key.

multiDataLink deactivated.

multiDataLink manually

deactivated in the Service program.

Acknowledge with

[START/RESET] key.

multiDataLink deactivated.

Activate multiDataLink in the

Service program.

2.4.13 Ci-Ca Module (Option)

The test for the Ci-Ca module can not be enabled if the processor test

of the module and the multiFiltrate was not passed successfully. If these

processor tests are performed successfully, the T1 test will be started

automatically as soon as the operator has confirmed that the starting

conditions are met.

The following functions of the Ci-Ca module are tested:

2-18 Fresenius Medical Care multiFiltrate TM 6/03.07

Page 29

Chapter 2: Functional Description

Stop of the citrate and the calcium pump by the module's operating

processor

Stop of the citrate and the calcium pump by the system's watchdog.

Function of the citrate pump and the insertion switch

Function of the calcium pump and the insertion switch

If a test could not be passed successfully, a warning indicating an error

number appears on the multiFiltrate display. The test can be repeated

any number of times, however, it cannot be skipped.

The T1 test of the multiFiltrate system is performed simultaneously to

the T1 test of the Ci-Ca module.

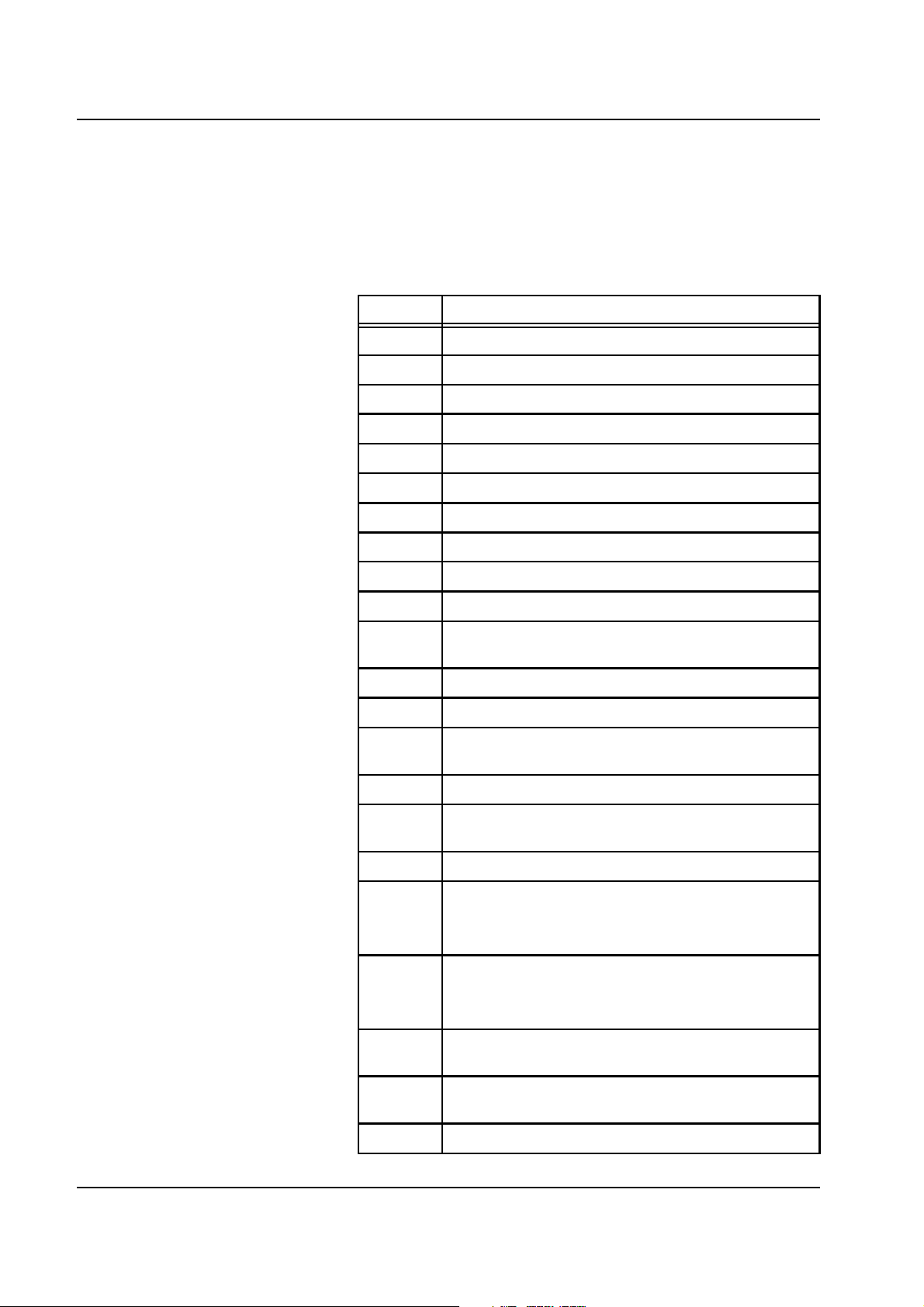

Error

number

281 Lacking Ci Hall impulse after test was started

282 Ci Hall impulse too early during pump stop test

283 Ci Hall impulse too late during pump stop test

285 Ci Hall impulse too early during pump stop test

286 Ci Hall impulse too late during pump stop test

288 Ci Hall impulse too early during insertion switch

289 Ci Hall impulse too late during insertion switch

291 Lacking Ca Hall impulse after test was started

292 Ca Hall impulse too early during pump stop test

Description Possible cause

(>5 s).

(<7 s).

(>9 s).

(<7 s).

(>9 s).

test (<7 s).

test (>9 s).

(>5 s).

(<7 s).

The rotor of the citrate pump is loose, jammed or

blocked.

Insertion switch pressed --> citrate line already

inserted.

The rotor of the citrate pump is loose, jammed or

blocked.

Insertion switch pressed --> citrate line already

inserted during the test.

The rotor of the citrate pump is loose, jammed or

blocked.

Insertion switch pressed --> citrate line already

inserted during the test.

The rotor of the citrate pump is loose, jammed or

blocked.

The rotor of the Ca pump is loose, jammed or

blocked.

Insertion switch pressed --> calcium line already

inserted.

293 Ca Hall impulse too late during pump stop test

(>9 s).

295 Ca Hall impulse too early during pump stop test

(<7 s).

296 Ca Hall impulse too late during pump stop test

(>9 s).

298 Ca Hall impulse too early during insertion switch

test (<7 s).

299 Ca Hall impulse too late during insertion switch

test (>9 s).

Fresenius Medical Care multiFiltrate TM 6/03.07 2-19

The rotor of the Ca pump is loose, jammed or

blocked.

Insertion switch pressed --> calcium line already

inserted during the test.

The rotor of the Ca pump is loose, jammed or

blocked.

Insertion switch pressed --> calcium line already

inserted during the test.

The rotor of the Ca pump is loose, jammed or

blocked.

Page 30

Chapter 2: Functional Description

2.5 Error Messages

2.5.1 Alarm Messages

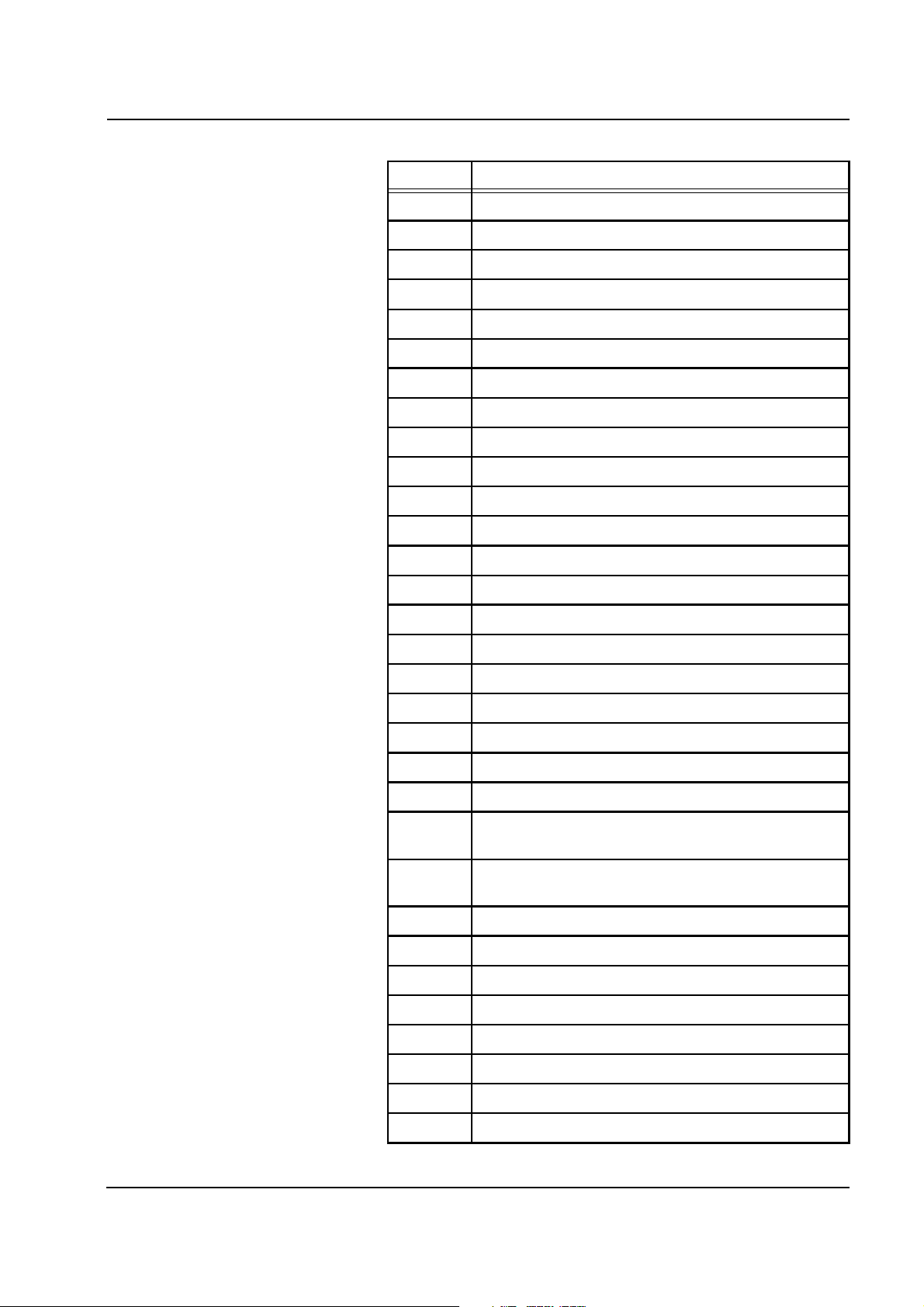

These messages cause all pumps to stop

Code Description

E10 Blood pump: Blood pump door open

E11 Blood pump: Stop

E12 Blood pump: Wrong speed, rate

E13 Arterial pressure, arterial pressure too low

E14 Arterial pressure, arterial pressure too high

E15 Venous pressure, venous pressure too low

E16 Venous pressure, venous pressure too high

E17 TMP, TMP too low

E18 TMP, TMP too high

E19 System stopped, Stop key has been pressed

E20 Pre-filter pressure/ Pre-filter pressure too low (for

hemoperfusion)

E21 Pre-filter pressure, pre-filter pressure too low

E22 Pre-filter pressure, pre-filter pressure too high

E23 Non-opaque/opaque fluid detector, venous detector

senses non-opaque or opaque fluid

E24 Air detector, air and/or microbubbles

E25 Blood leak detector, blood leak, hemolysis, membrane

rupture

E26 Blood leak detector, 2 min override active

E27 Power failure, emergency operation available for max.

15 min.

Converted by OP from SP code 130.

E28 End of emergency operation, the unit will turn itself off

automatically after 5 minutes.

Converted by OP from SP code 189.

E29 Pre-filter pressure/ Pre-filter pressure too high (for

hemoperfusion)

E30 Blood lines: Blood line jammed / Hydrophobic filter

P_pHF wet

E31 Blood lines: Rotor broken

2-20 Fresenius Medical Care multiFiltrate TM 6/03.07

Page 31

Code Description

Chapter 2: Functional Description

E32 Blood lines: Hydrophobic filter P

E33 Blood lines: Hydrophobic filter P

art

ven

wet

wet

E34 Air detector: Transmitting voltage on the air detector too

high

E35 Ci-Ca module: Citrate pump turning too slowly (volume

monitoring)

E36 Ci-Ca module: Citrate pump turning too fast (volume

monitoring)

E37 Ci-Ca module: Calcium pump turning too slowly

(volume monitoring)

E38 Ci-Ca module: Calcium pump turning too fast (volume

monitoring)

E39 Ci-Ca module: Dialysis is started although the primed

Ci/Ca lines are not free from air

E40 Ci-Ca module: Drop counter citrate insufficient

number of drops; check citrate bag, drip chamber and

tubing system!

E41 Ci-Ca module: Number of drops counted by citrate drop

counter too high; check citrate drip chamber and tubing

system!

E42 Ci-Ca module: Drop counter calcium insufficient

number of drops; check calcium bag, drip chamber and

tubing system!

E43 Ci-Ca module: Number of drops counted by calcium

drop counter too high; check calcium drip chamber and

tubing system!

E44 Ci-Ca module: Citrate pump turning too slowly; (motor

steps)

E45 Ci-Ca module: Citrate pump turning too fast; (motor

steps)

E46 Ci-Ca module: Calcium pump turning too slowly (motor

steps)

E47 Ci-Ca module: Calcium pump turning too fast (motor

steps)

E48 Ci-Ca module: Citrate insertion switch without

contact,Ci pump segment inserted properly?

E49 Ci-Ca module: Calcium insertion switch without

contact,Ca pump segment inserted properly?

E50 Ci-Ca module: The citrate bag change takes more than

2 min; finish bag change!

Fresenius Medical Care multiFiltrate TM 6/03.07 2-21

Page 32

Chapter 2: Functional Description

Code Description

E51 Ci-Ca module: The Ca bag change takes more than

2 min; finish bag change!

E52-54 Not used

E55 Ci-Ca module: MPS treatment is permitted for a

maximum of 4 hours!; initiate reinfusion!

E56 Ci-Ca module: HP treatment is permitted for a

maximum of 4 hours!; initiate reinfusion!

E57 Ci-Ca module: Balance switched off; Ca supply

interrupted!

E58 Ci-Ca module: System error of Ci-Ca module:

Anitcoagulation with citrate completed!

E59 Ci-Ca module: Drop counter citrate insufficient

number of drops; Ci bag change required?

E60 Ci-Ca module: Drop counter calcium insufficient

number of drops; Ca bag change required?

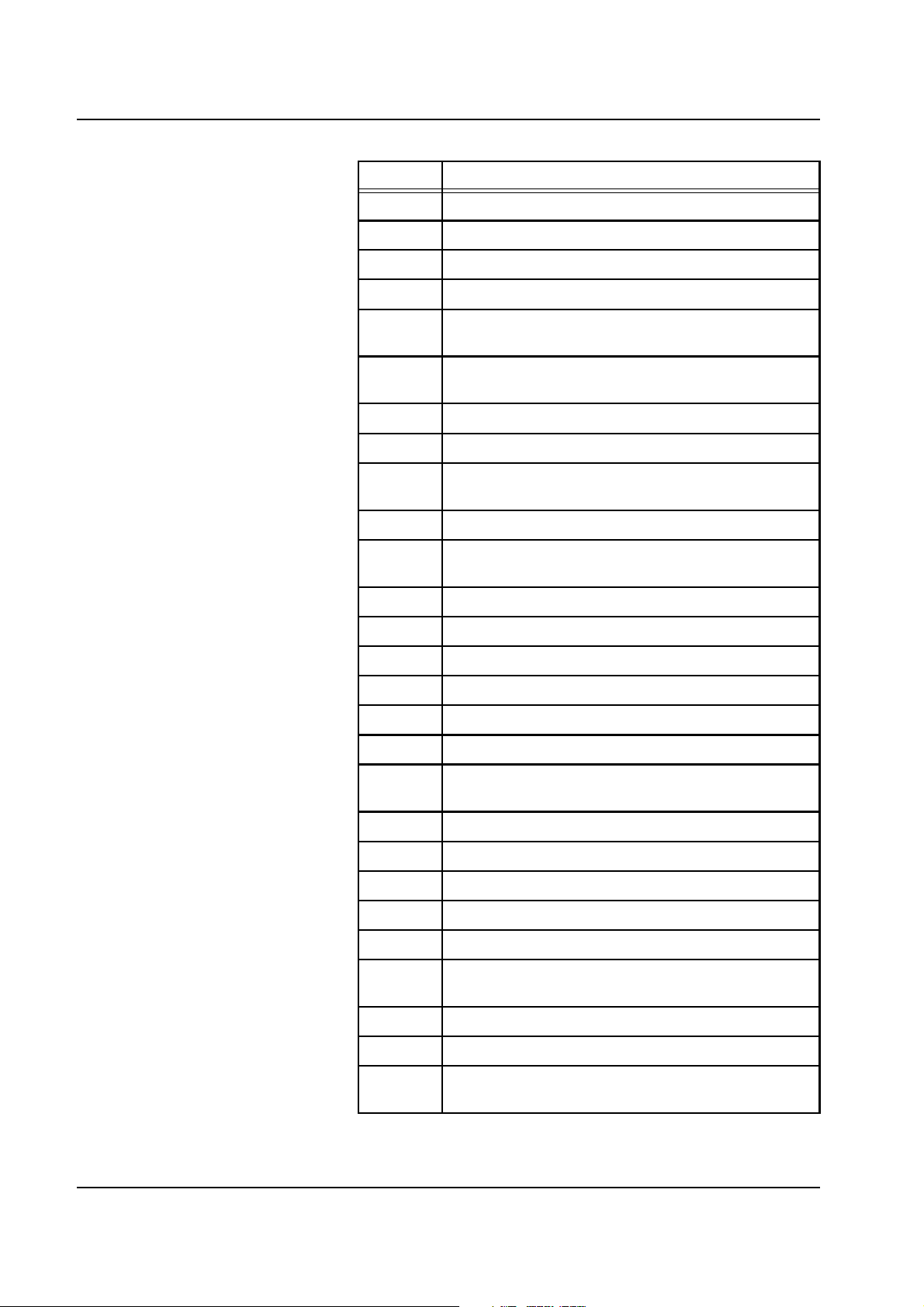

2.5.2 Warning Messages

These messages cause the balancing to stop. The blood circuit will be

maintained.

For error messages no. 132 through 144 the scales must be

recalibrated.

Code Description

W62 Blood pump: Blood pump door open

W63 Filtrate pump: Cover open

W64 Sub pump: Cover open

W65 Dialysate pump: Cover open

W66 Prime mode: No weight loss on sub-scale-post

(HVCVVH)

W67 Prime mode: No weight loss on sub-scale-pre

(HVCVVH)

W68 Bag change: Overload on sub-scale-post (HVCVVH)

W69 Bag change: Sub-scale post underload (HVCVVH)

W70 Opt. detector: is opaque

W71 Opt. detector: Fails to sense opaque fluid after

attenuation

W72 Scale 1: Temp. coeff. factors missing, incorrect

2-22 Fresenius Medical Care multiFiltrate TM 6/03.07

Page 33

Chapter 2: Functional Description

Code Description

W73 Scale 2: Temp. coeff. factors missing, incorrect

W74 Scale 3: Temp. coeff. factors missing, incorrect

W75 Scale 4: Temp. coeff. factors missing, incorrect

W76 Scale 1: Calibration factor missing, incorrect

W77 Scale 2: Calibration factor missing, incorrect

W78 Scale 3: Calibration factor missing, incorrect

W79 Scale 4: Calibration factor missing, incorrect

W80 Scale 1: Movement detected on Scale 1

W81 Scale 2: Movement detected on Scale 2

W82 Scale 3: Movement detected on Scale 3

W83 Scale 4: Movement detected on Scale 4

W84 Scale 1: Test weight outside tolerance

W85 Scale 2: Test weight outside tolerance

W86 Scale 3: Test weight outside tolerance

W87 Scale 4: Test weight outside tolerance

W88 Scale 1: Test weight fails to drop back

W89 Scale 2: Test weight fails to drop back

W90 Scale 3: Test weight fails to drop back

W91 Scale 4: Test weight fails to drop back

W92 Air detector: LDA1 not in alarm mode

W93 Air detector: Clamp fails to close

W94 Lower heater: Switch-off path SP defective (Sub-relay

not open)

W95 Upper heater: Switch-off path SP defective (dial. relay

not open)

W96 Lower heater: Control FET short-circuit

W97 Upper heater: Control FET short-circuit

W98 Lower heater: Bag sensor broken

W99 Lower heater: Foil sensor broken

W100 Upper heater: Bag sensor broken

W101 Upper heater: Foil sensor broken

W102 Lower heater: Bag sensor short-circuit

W103 Lower heater: Foil sensor short-circuit

Fresenius Medical Care multiFiltrate TM 6/03.07 2-23

Page 34

Chapter 2: Functional Description

Code Description

W104 Upper heater: Bag sensor short-circuit

W105 Upper heater: Foil sensor short-circuit

W106 Lower heater: Sub. relay not closed, foil defective

W107 Upper heater: Dial. relay not closed, foil defective

W108 Lower heater: Foil sensor detuning, no over-

temperature cutoff

W109 Upper heater: Foil sensor detuning, no over-

temperature cutoff

W110 Lower heater: Bag sensors, OP-SP not synchronous

W111 Upper heater: Bag sensors, OP-SP not synchronous

W112 Lower heater: Bag sensor detuning, no

overtemperature

W113 Lower heater: Foil sensor detuning, no overtemperature

W114 Upper heater: Bag sensor detuning, no

overtemperature

W115 Upper heater: Foil sensor detuning, no overtemperature

W116 Lower heater: FET control defective

W117 Upper heater: FET control defective

W118 Battery test: Battery not connected, defective

W119 Battery test: Load test failed

W120 Battery test: Insufficient capacity

W121 Blood leak detector: Outside acceptable range, remove

filtrate line

W122 Blood leak detector: Alarm-free after attenuation

W123 Prime mode: No weight loss on SUB scale

W124 Prime mode: No weight loss on DIA scale

W125 Prime mode: No weight loss on SUB scale (CVVHDF)

W126 Prime mode: No weight loss on DIA scale (CVVHDF)

W127 Blood leak detector: Calibration values missing,

incorrect

W128 Audible alarm: Not silenced

W129 Audible alarm: not active

W130 Power failure: Emergency operation available for max.

15 minutes (OP generates code 27)

2-24 Fresenius Medical Care multiFiltrate TM 6/03.07

Page 35

Chapter 2: Functional Description

Code Description

W131 Incorrect allocation of scales, repeat Preparation (very

unusual)

W132 Load on scale, incorrect load on scale I (initial weight)

W133 Load on scale, incorrect load on scale II (initial weight)

W134 Load on scale, incorrect load on scale III (initial weight)

W135 Load on scale, incorrect load on scale IV (initial weight)

W136 Balancing, Scale I, leakage from tubing system, objects

W137 Balancing, Scale II, leakage from tubing system, objects

W138 Balancing, upper scales, leakage from tubing system,

objects

W139 Balancing, filtrate bag full, replace or empty filtrate bag

W140 Balancing, filtrate scales moved, leakage from tubing

system

W141 Scale 1, overload or underload, check load, scale

jammed?

W142 Scale 2, overload or underload, check load, scale

jammed?

W143 Scale 3, overload or underload, check load, scale

jammed?

W144 Scale 4, overload or underload, check load, scale

jammed?

W145 Bag change: Overload on SUB scale (CVVHDF)

W146 Bag change: Overload on SUB scale 1 (CVVH, HF)

W147 Bag change: Overload on SUB scale 2 (CVVH, HF)

W148 Bag change: SUB on wrong scale (CVVHDF)

W149 Bag change: Insufficient substituate (CVVH, HF)

W150 Bag change: Insufficient substituate (CVVHDF)

W151 Bag change: Insufficient saline solution on scale 1

(MPS)

W152 Bag change: Overload on plasma scale 1 (MPS)

W153 Bag change: Overload on plasma scale 2 (MPS)

W154 Bag change: Overload on dialysate scale (CVVHDF)

W155 Bag change: Overload on dialysate scale 1 (CVVHD)

W156 Bag change: Overload on dialysate scale 2 (CVVHD)

W157 Dialysate on wrong scale (tubing arrangement test after

bag change HDF)

Fresenius Medical Care multiFiltrate TM 6/03.07 2-25

Page 36

Chapter 2: Functional Description

Code Description

W158 Bag change: Insufficient dialysate (CVVHD)

W159 Bag change: Insufficient dialysate (CVVHDF)

W160 Bag change: Overload on filtrate scale

W161 TMP/MPS TMP >100mmHg

W162 Lower heater: MPS temperature > 37°C

W163 Upper heater: MPS temperature > 37°C

W164 Lower heater: Temperature too high

W165 Upper heater: Temperature too high

W166 Bag change: Overload SUB pre (HVCVVH)

W167 Bag change: Insufficient SUB pre (HVCVVH)

W168 Balancing: Ultrafiltration or substitution rate too high

W169 Lower heater: Foil sensors, OP-SP not synchronous

W170 Upper heater: Foil sensors, OP-SP not synchronous

W171 Balancing: Aborted because maximum allowable

deviation of 500g was exceeded

W172 Lower heater: MPS foil temperature too high, risk of

hemolysis

W173 Upper heater: MPS foil temperature too high, risk of

hemolysis

W174 Balancing: Balancing stopped, balancing was switched

off

W175 Battery capacity: Charging voltage too high, battery

deactivated, no power failure

W176 Filtrate scale: Test weight outside tolerance (T0 test)

W177 Filtrate scale: Test weight fails to drop back (T0 test)

W178 Balancing: UF goal reached, ultrafiltration was set to 0

W179 Balancing: Substituate bag empty, replace substituate

bag

W180 Balancing: Dialysate bag empty, replace dialysate bag

W181 Balancing: Movement detected on filtrate scales,

leakage from tubing system

W182 Filtrate scale: Overload or underload, check load, scale

jammed?

W183 Balancing: Plasma bag empty, open outlet line(s) on

plasma bags

W184 Balancing: Plasma pump delivers from wrong scale (I)

2-26 Fresenius Medical Care multiFiltrate TM 6/03.07

Page 37

Chapter 2: Functional Description

Code Description

W185 Balancing: Plasma pump delivers from wrong scale (II)

W186 Balancing: Sub-postdilution bag empty, replace

substituate bag

W187 Balancing: Sub-predilution bag empty, replace

substituate bag

W188 End of treatment: Plasma infused (MPS only)

W189 End of emergency operation: The unit will turn itself off

automatically after 5 minutes

W190 Power failure end

W191 Bag change: Insufficient plasma on scale 2

W192 Prime mode: Overload on dialysate scale (CVVHDF)

W193 Prime mode: Overload on SUB scale (CVVHDF)

W194 Prime mode: Insufficient substituate (CVVHDF)

W195 Prime mode: Insufficient dialysate (CVVHDF)

W196 Prime mode: Overload on sub-scale-pre (HVCVVH)