Page 1

TECHNICAL

MANUAL

MODULE DPS VISIO

TECHNICAL MANUAL

Serial N°18212421 to ...

Page 2

Page 3

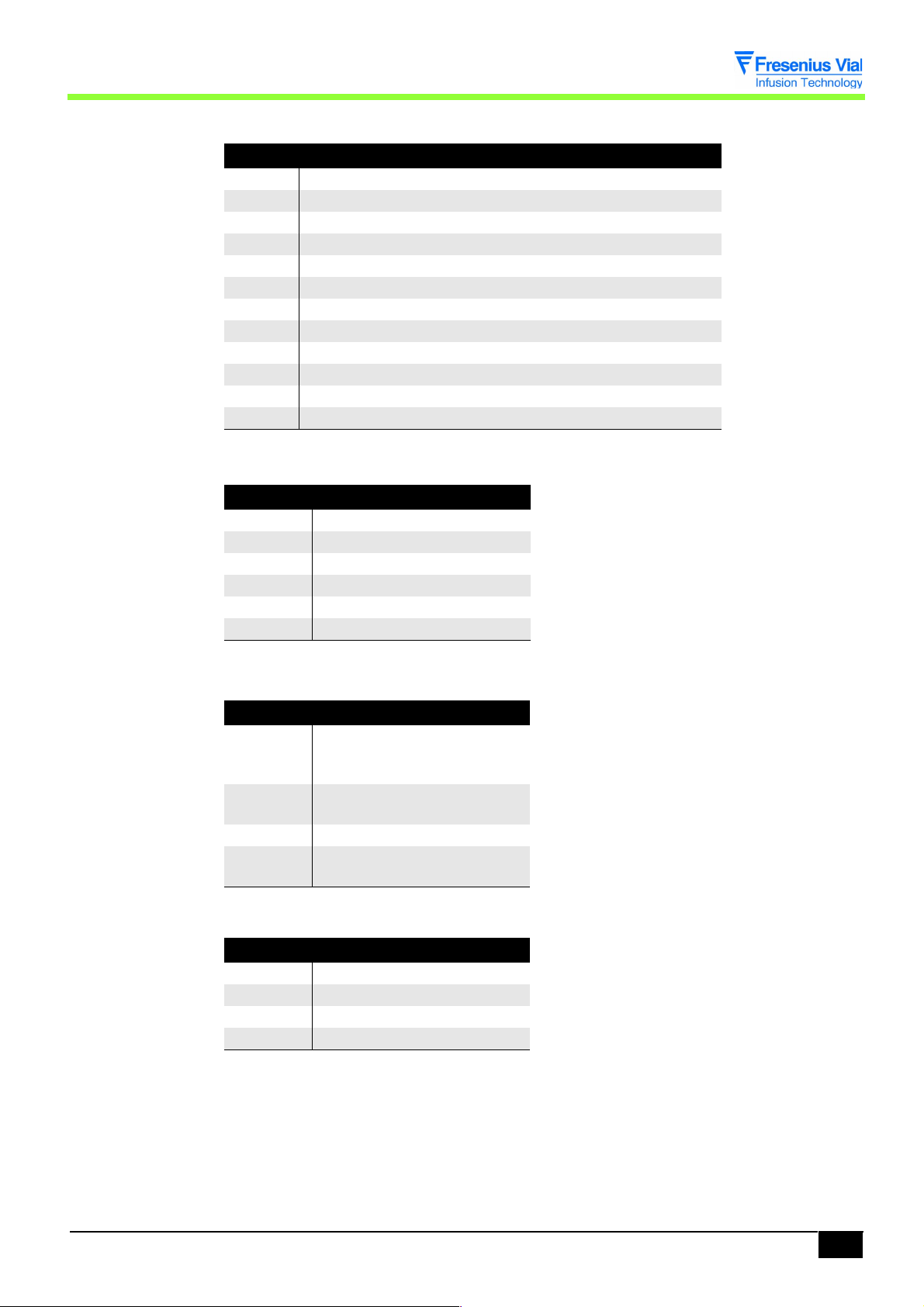

1 Presentation...................................................................................................... 7

1.1 General features.....................................................................................7

1.2 Overview diagram .................................................................................. 8

1.3 Precautions to be taken before use......................................................9

1.4 Internal safety features..........................................................................9

1.5 Technical characteristics ...................................................................... 9

1.5.1 Electrical specifications .............................................................................................. 9

1.5.2 Electronic specifications............................................................................................. 9

1.5.3 Mechanical specifications .......................................................................................... 9

1.5.4 Compliance, standards ............................................................................................ 10

2 Description and operation............................................................................. 11

2.1 Physical description ............................................................................ 11

2.1.1 Display board and front panel .................................................................................. 12

2.1.2 CPU-POWER SUPPLY board ................................................................................. 14

2.1.3 Mechanical gear box unit ......................................................................................... 17

2.1.4 Mechanical plunger unit ........................................................................................... 17

2.2 Functional description......................................................................... 18

2.2.1 Syringe control and maintenance sub-assembly ..................................................... 18

2.2.2 Motorisation sub-assembly ...................................................................................... 18

2.2.3 External connection sub-assembly .......................................................................... 18

2.2.4 Locking sub-assembly.............................................................................................. 18

3 Description of the menus .............................................................................. 19

3.1 Pressure parameters configuration menu ......................................... 19

3.1.1 Menu access ............................................................................................................ 20

3.1.2 PrES1, configuration of the variable pressure limits............................................ 21

3.1.3 PrES2, pressure limit configuration ..................................................................... 22

3.1.4 PrES3, Pressure decrease threshold configuration............................................. 23

3.2 Menu configuration of current operation parameters ...................... 25

3.2.1 Menu access ............................................................................................................ 26

3.2.2 PAr1, Flow rate memorisation.............................................................................. 27

3.2.3 PAr2, syringe type selection mode....................................................................... 27

3.2.4 PAr3, Maximum flow rate selection via the keyboard .......................................... 28

3.2.5 PAr4, syringes list selection ................................................................................. 29

3.2.6 PAr5, mandatory priming confirmation................................................................. 30

3.2.7 PAr6, quick infusion start-up mode ...................................................................... 30

3.2.8 PAr7, KVO / flow rate selection mode.................................................................. 31

3.2.9 PArA, empty syringe mode................................................................................... 31

3.2.10 PArb, maintenance periodicity ............................................................................. 32

3.2.11 PArC, Drug name indication ................................................................................. 32

3.2.12 PArd, flanges detection mode.............................................................................. 33

3.2.13 PArE, programmable bolus flow rate memorisation ............................................. 34

3.2.14 PArF, manual bolus flow rate memorisation......................................................... 35

3.2.15 PArG, drug name selection................................................................................... 36

Module_DPS_Visio_enTDM.fm 3

Page 4

3.2.16 PArH, back-light operation .................................................................................... 36

3.2.17 PArL, screen alternation....................................................................................... 37

3.2.18 PArP, ward name ................................................................................................. 37

3.3 Service test menu ................................................................................ 39

4 Preventive maintenance.................................................................................41

4.1 Recommendations............................................................................... 41

4.2 Maintenance schedule......................................................................... 41

4.2.1 Use beyond the framework of the departmental order............................................. 41

4.2.2 Use within the framework of the departmental order ............................................... 41

4.3 Checks .................................................................................................. 43

4.3.1 Test access .............................................................................................................. 43

4.3.2 Visual check ............................................................................................................. 43

4.3.3 Running time and service inspection date ............................................................... 44

4.3.4 Indicator lights check................................................................................................ 44

4.3.5 Keyboard check ....................................................................................................... 45

4.3.6 Battery voltage check............................................................................................... 46

4.3.7 Checking the last 10 alarms..................................................................................... 47

4.3.8 Total running time check .......................................................................................... 48

4.3.9 Checking the force sensor ....................................................................................... 48

4.3.10 Software and language version check ..................................................................... 49

4.3.11 ADC check ............................................................................................................... 50

4.3.12 Displacement sensor check ..................................................................................... 51

4.3.13 Checking the calibration values ............................................................................... 51

4.3.14 Checking the syringe clamp ..................................................................................... 52

4.3.15 Checking the syringe group number ........................................................................ 52

4.3.16 Checking the last 10 events before fail .................................................................... 53

4.3.17 Checking the drugs change information................................................................... 53

4.3.18 Checking the disengagement system ...................................................................... 53

4.3.19 Checking the anti-siphon arm .................................................................................. 54

4.3.20 Back pressure test ................................................................................................... 54

4.3.21 Checking the end of infusion pre-alarm ................................................................... 55

4.3.22 Checking linearity.................................................................................................... 56

4.3.23 Locking/unlocking check .......................................................................................... 56

4.3.24 Checking mains/battery functioning ......................................................................... 57

4.3.25 Battery autonomy test .............................................................................................. 57

4.3.26 Continuity test .......................................................................................................... 57

4.3.27 Quality control certificate......................................................................................... 59

4.4 Flow rate control.................................................................................. 61

4.4.1 Measurement with a computer................................................................................. 61

4.4.2 Measurement with scale .......................................................................................... 63

4.4.3 Measurement using a test tubet............................................................................... 65

4.5 Cleaning and disinfection ................................................................... 67

4.6 Storage.................................................................................................. 68

5 Diagnostic........................................................................................................69

44 Module_DPS_Visio_enTDM.fm

Page 5

5.1 Troubleshooting guide ....................................................................... 69

5.2 Error messages ....................................................................................71

6 Operation sheets ............................................................................................ 73

Fiche n°1 : Display board........................................................................... 75

N°2, Procedure: Syringe clamp ................................................................. 77

N°3, Procedure: Motor + Opto + Disk........................................................ 81

N°4, Procedure: Pressure sensor.............................................................. 85

N°5, Procedure: Plunger advance control

potentiometer .............................................................................................. 91

N°6, Procedure: Pusher flask and /or disengagement lever + anti-siphon

arm ............................................................................................................... 95

N°7, Procedure: Power supply / CPU board ............................................. 97

N°8, Procedure: Locking, Magnet, Proximity Detector unit ..................101

N°9, Procedure: Battery-door and battery.............................................. 105

N°10, Procedure: Centering ring kit ........................................................ 107

N°11, Procedure: Flex circuit and tube kit.............................................. 111

N°12, Procedure: Front and rear cases................................................... 117

N°13, Procedure: Syringe detection system ..........................................119

7 Calibrations................................................................................................... 123

7.1 Calibration procedure........................................................................ 123

7.1.1 Calibration access.................................................................................................. 123

7.1.2 EtAL.4 Calibration of the 3 battery voltage levels............................................. 125

7.1.3 EtAL.6 Calibration of the position sensor. ........................................................ 125

7.1.4 EtAL.9 Calibration of the force sensor.............................................................. 126

7.1.5 EtAL.D Calibration of the syringe clamp ........................................................... 127

8 Spare parts catalogue.................................................................................. 129

8.1 Front case ...........................................................................................129

8.2 Rear case ............................................................................................ 131

8.3 Plunger / Mechanical frame unit....................................................... 133

8.4 Locking unit........................................................................................ 137

Module_DPS_Visio_enTDM.fm 5

Page 6

66 Module_DPS_Visio_enTDM.fm

Page 7

1 Presentation

1.1 General features

The ORCHESTRA infusion station is a system composed of a base and 1 up to 8 modules.

As from the 4th module, the station has to be equipped with the Multiflix 6 or Multiflix 8

accessory to ensure that the unit is perfectly rigid.

Depending on the infusions prescribed, users can modulate the number of channels needed

for each patient in intensive care.

The Module DPS is a syringe pump with its own control keyboard and separate displays. It

has a built-in battery that gives it an autonomy of 7 hours

8 Modules DPS can be installed on the base of the ORCHESTRA infusion station. Their

battery is automatically recharged when the base is connected to the mains.

The ORCHESTRA infusion station can be integrated into and communicates with all

computer systems through the base, which groups the links together.

There is a choice of easily accessible configurations for an optimal use of functions according

to the requirements of each department.

at a flow rate of 5 ml/h.

The Modules DPS installed in position 7 and 8 are accepted, but not recognised by the

Base A. It only displays data concerning Modules DPS 1 to 6. Only the Base Intensive

can take all 8 devices into account and exchange information with all of them.

mod01_001a_en.fm 7

Presentation

Page 8

1.2 Overview diagram

BATTERY

SOUND

MODULE

MOTOR

ROTATION

Card

Displays

7,2V

TON

INTERF

Mains LED

Power

Supply

ON/OFF

CD ROT

MOT

8 cde ANODES

4 cde ANODES

3 KEYBOARD COLUMNS

FAIL

3 KEYBOARD LINES

8 cde KATHODES

BUS SPI

POT DIAMETER

LOCK LED

ONOFF

SROT

VbatC

Vbat NC

Lmains LED

SUPERV

WATCH

DOG

Power supply

OFF

REG

ANOD

REG

ANOD

CLAV

REG

KATH

KEYBOARD LINE 14

5V

RESET

ALIM EXT MP

RDCRT

TON

DOG

UV

EEPROM

Or

FLASH

RELEASE

WINGLET

PRESS EXT

EXT. POWER

SUPPLY

TON MP

LOCK

SROT

SPIST

EOC

CD EXT

STATUS

REG

STATUS

EXT PRESS

RAM

REG

INP1

INP2

CD BUZZ MP

RDCRT

latch

EEPROMREG

REG

CDE

SPI BUS

Filtrer

PAGE

I2C

DOG

POWER

SUPPLY OFF

CS LCD

CS ADC

CD PIST

CD EXT

CD ANA

ADC

AMPLI

BUZZER VbatCCD BUZZ MP

80C32

LOCK

LOCK LED

LOCK BUZZ

VREF

AMPLI

TX

RX

TXEN

AD MP

RELEASE ON/OFF

ADDRESS

OVERLOAD

LOCK

5V

SPIST

CD PIST

INTERF

MODULE

VbatC

ILS

OUT

NETWORK

IN

Vbat BASE C

ON

7,2V

KEYBOARD1

EXT PRESS EXT

DISPLACEMENT

POTENTIOMETER

GAUGE BRIDGE

DISENGAGEMENT

PISTON

Presentation

8 mod01_001a_en.fm

Page 9

1.3 Precautions to be taken before use

The symbol on the condensed Operating Instructions of the device recommends that

users read the operating instructions completly, in accordance with standard EN 60 601-1.

Fresenius Vial may in no way be held liable for any problem, whether medical or other, that

may result from the improper use of the device.

Read the operating instructions for more details.

!

1.4 Internal safety features

The device incorporates a system that constantly monitors its functions. Any internal failure or

any anomaly in the procedure for use is immediately detected. Nevertheless, you must notify

the qualified personnel of your hospital or our Service Department of an abnormal functioning

of the device that has no known cause.

For a first fault, an alarm is activated for any difference in flow rate that is 5% higher than the

normal rate.

A second check activates an alarm when there is a difference of 1 ml in relation to the infused

volume or when a difference in flow rate of more than 20% is identified. The alarm is triggered

by the most rapidly detected difference.

The Module DPS has an internal battery that ensures that it continues to work normally when

the mains supply is cut off. The faulty mains section is also protected by a safety fuse.

The Orchestra Module DPS is equipped with a time clock that can record up to 760 dated

events. These events can be read using the "IS Control" software application.

1.5 Technical characteristics

1.5.1 Electrical specifications

External power supply (via the base or the mainy Mod): 7.2 V dc.

Power: 10 W.

Battery: 6 V – 1.1 Ah/1.2 Ah or 1.3Ah.

1.5.2 Electronic specifications

The Module DPS syringe pump comprises 2 electronic cards:

The power supply and CPU card.

The keyboard display card.

1.5.3 Mechanical specifications

Dimensions H x L x D: 105 x 315 x 130 mm.

Weight: approximately 2.3 kg.

mod01_001a_en.fm 9

Presentation

Page 10

1.5.4 Compliance, standards

Compliant with European directive 93/42/EEC on medical equipment. CE0459.

Compliant with European Directive 89/336 EEC: Electromagnetic compatibility.

Compliant with EN 60601.1 and PrEN60601-2-24 standards.

Protection against leakage current: CF type.

Protection against electric shocks: Class II.

Protection grade: IP34.

Presentation

10 mod01_001a_en.fm

Page 11

2 Description and operation

2.1 Physical description

Front case

Syringe clamp

Flanges positioning groove

Anti-siphon arm

Plunger disengagement

control

Rear case

The Module DPS is composed of a front case and a rear case.

The front case holds the syringe clamp and contains:

The rear case contains:

Front control panel

V A display board linked to the front control panel.

V A power supply board and CPU fitted with a flash EPROM,

V A mechanical base unit,

V A plunger unit,

V An RS 232 connection (via the Base).

mod02_005a_en.fm 11

Description and operation

Page 12

2.1.1 Display board and front panel

The display board is positioned under the control front panel and contains all the necessary

elements for man-machine interaction:

keyboard interface.

control lamps and overview diagrams.

7-segment display units.

LCD screen.

J4

Solder side display board

This board is linked to the various equipment parts by means of connectors.

J5 connector to CPU-power supply

Pin Description

1 GND mass

2 PDIAM syringe clamp potentiometer

medium point

3 VREF syringe clamp potentiometer

reference voltage

4 GND mass

5 LED VERROU

6 CSLCD selection driver LCD bus SPI LCD

7 LEDFAIL N.U

8 CLK clock bus SPI LCD

9 LEDEXT led external power supply control

10 SO data out bus SPI LCD

11 +5V power supply

12 AIL/OFF

13 V BAT NC power supply

14 KATH 8 cathode matrix display column 8

15 AIL/ON flange detection switch

16 KATH 7 cathode matrix display column 7

17 ANOD 8 anode matrix display line 8

18 KATH 6 cathode matrix display column 6

19 ANOD 7 anode matrix display line 7

20 KATH 5 cathode matrix display column 5

21 ANOD 6 anode matrix display line 6

22 KATH 4 cathode matrix display column 4

23 ANOD 5 anode matrix display line 5

24 KATH 3 cathode matrix display column 3

25 ANOD 4 anode matrix display line 4

26 KATH 2 cathode matrix display column 2

27 ANOD 3 anode matrix display line 3

28 KATH 1 cathode matrix display column 1

Description and operation

J5

J2

J3

12 mod02_005a_en.fm

Page 13

J5 connector to CPU-power supply

Pin Description

29 COL 1 keyboard interface column 1

30 ANOD 2 anode matrix display line 2

31 COL 2 keyboard interface column 2

32 ANOD 1 anode matrix display line 1

33 COL 3 keyboard interface column 3

34 ANOD 12 anode matrix display line 12

35 LIG 1 keyboard interface line 1

36 ANOD 11 anode matrix display line 11

37 LIG 2 keyboard interface line 2

38 ANOD 10 anode matrix display line 10

39 LIG 3 keyboard interface line 3

40 ANOD 9 anode matrix display line 9

J4 connector to keyboard

Pin Description

1 Line 3

2 Line 2

3 Line 1

4 Column 3

5 Column 2

6 Column 1

J2 connector to syringe clamp potentiometer

Pin Description

2 VREF syringe clamp

potentiometer reference

voltage

3 PDIAM syringe clamp

potentiometer medium point

4 GND

1 AIL/ON Flanges detection

switch

J3 connector to keybord

Pin Description

1 Line 4

2 Column 1

3 TON/OFF

4 GND

mod02_005a_en.fm 13

Description and operation

Page 14

2.1.2 CPU-POWER SUPPLY board

The CPU board contains an 80C32 micro-processor which is fitted and connected to the

display board by means of J7 connector.

TP5

TP1234

P1

J3

J4

Fus

Fus

J6

J7

J9

CPU board

J3 connector to plunger flexible ribbon cable

Pin Description

1 VREF/ power supply (+) gauge bridge R

2 S(-) / output (-) gauge bridge J

3 S(+) / output (+) gauge bridge V

4 GND power supply (-) gauge bridge N-E

5 cathode diode opto anti-siphon K

6 anode diode opto anti-siphon /5V A

7 collector transistor opto anti-siphon C

8 micro-switch disengagement OFF

9 micro-switch disengagement ON F

10 GND C1

J5

TP8

TP9

J10

J4 connector to internal battery

Pin Description

1 Vbat + battery

2 0V - battery

3 0V

4 Presence battery connector

J5 connector to test external power supply

Pin Description

1 + power supply 7,2 V

2 - power supply GND

Description and operation

14 mod02_005a_en.fm

Page 15

J6 connector to potentiometric sensor

Pin Description

1 VREF

2 medium point

3 GND

J7 connector to display board

Pin Description

1 GND mass

2 PDIAM syringue clamp potentiometer medium

point

3 VREF suringe clamp potentiometer reference

voltage

4 GND mass

5 LED VERROU

6 CSLCD selection driver LCD bus SPI LCD

7 LEDFAIL N.U

8 CLK clock bus SPI LCD

9 LEDEXT led external power supply control

10 SO data out bus SPI LCD

11 +5V power supply

12 AIL/OFF

13 V BAT NC power supply

14 KATH 8 cathode matrix display column 8

15 AIL/ON flange detection switch

16 KATH 7 cathode matrix display column 7

17 ANOD 8 anode matrix display line 8

18 KATH 6 cathode matrix display column 6

19 ANOD 7 anode matrix display line 7

20 KATH 5 cathode matrix display column 5

21 ANOD 6 anode matrix display line 6

22 KATH 4 cathode matrix display column 4

23 ANOD 5 anode matrix display line 5

24 KATH 3 cayhode matrix display column 3

25 ANOD 4 anode matrix display line 4

26 KATH 2 cathode matrix display column 2

27 ANOD 3 anode matrix display line 3

28 KATH 1 cathode matrix display column 1

29 COL 1 keyboard interface column 1

30 ANOD 2 anode matrix display line 2

31 COL 2 keyboard interface column 2

32 ANOD 1 anode matrix dispaly line 1

33 COL 3 keyboard interface column 3

34 ANOD 12 anode matrix display line 12

35 LIG 1 keuboard interface line 1

36 ANOD 11 anode matrix display line 11

37 LIG 2 keyboard interface line 2

38 ANOD 10 anode matrix display line 10

Description and operation

mod02_005a_en.fm 15

Page 16

Pin Description

39 LIG 3 keyboard interface line 3

40 ANOD 9 anode matrix display line 9

J9 connector to motor

Pin Description

1 NC

2 NC

3 phase A

4 phase A

5 phase B

6 phase B

7 anode diode opto rotation 5V

8 cathode diode opto rotation

9 collector transistor rotation

10 emitter transistor opto rotation (GND)

J10 connector to network

Pin Description

1 power supply base 7,2 V

2 power supply base 7,2 V

3 DR* reception-transmission line

4 DR reception-transmission line

5 V base +5 V base

6 GND

7 *MODON start base

8 VERIN locking input

9 SURCH overload

10 GND

11 GND

12 ADIN addressing input

13 ADOUT addressing output

14 GND

Description and operation

16 mod02_005a_en.fm

Page 17

2.1.3 Mechanical gear box unit

The mechanical gear box unit consists of a motor-reducer block which drives a threaded

screw-and-nut unit. At the shaft end, the motor receives a set of controls linked to an optoelectronic sensor.

The mechanical base unit also contains a potentiometer fitted with a rack pinion system.

2.1.4 Mechanical plunger unit

The mechanical plunger unit is fitted onto the mechanical gear box. The gear box guides the

translational motion and displacement of the plunger by means of the threaded screw-and-nut

system.

The plunger is fitted with a disengagement control which allows it to separate from the

threaded screw-and-nut system.

mod02_005a_en.fm 17

Description and operation

Page 18

2.2 Functional description

From a functional point of view, the Module DPS is made up of four sub-assemblies:

a syringe position control and maintenance sub-assembly.

a motorisation sub-assembly.

an external connection sub-assembly.

a locking sub-assembly.

2.2.1 Syringe control and maintenance sub-assembly

The syringe is positionned on the front case and held in position by the syringe clamp. The

correct positioning of the flanges is ensured by the syringe clamp groove.

Detection of the syringe size (60 cc, 20 cc, 10 cc or 5 cc) is carried out by a potentiometer on

the syringe clamp.

The correct positioning of the piston against the plunger is controlled by the anti-siphon arm

linked to an opto-electronic sensor and a micro switch.

An anti-occlusion system, made up of a force sensor integrated with the plunger, detects the

force exerted on the piston and sets off an alarm when this force is too great.

2.2.2 Motorisation sub-assembly

The motorisation sub-assembly moves the piston in the syringe.

It is put in motion by a motor-reducer unit linked to a threaded screw-and-nut system.

A motor rotation disk fitted to the shaft end of the motor and linked to an opto-electronic

sensor, controls the rotation.

A potentiometer controls the plunger movement by means of a rack pinion system.

A micro-switch controls the disengagement device.

2.2.3 External connection sub-assembly

The Module DPS has two connectors on the locking unit:

a subD 15 pts female connector.

a subD 15 pts male connector.

2.2.4 Locking sub-assembly

The Module is positioned on the upper case of the base or on another module and maintained

by the lock. The positioning of the module is ensured by the female locking unit subD 15 of

the base or module positioned underneath. The module detection is validated by the ILS

"read switch".

Description and operation

18 mod02_005a_en.fm

Page 19

3 Description of the menus

3.1 Pressure parameters configuration menu

The configuration menu allows the Module DPS to be adapted to the specific needs of each

department. It provides access to the menus which allow the pressure parameters to be

customised.

Fresenius Vial recommends the presence of one of its qualified personnel, or a

representative from your Technical Service, to help implement the configuration procedures

you wish to select.

You may exit the configuration mode at any time by pressing the OFF key.

This menu allows users to:

PrES1 : memorise the variable pressure limits.

PrES2 : modify the upper pressure limit.

PrES3 : modify the pressure drop detection threshold.

mod03.1_003a_en.fm 19

Description of the menus

Page 20

3.1.1 Menu access

OP

Useful keys

Key Function

ON switches on the device

OFF switches off the device

SILENCE ALARM accesses the configuration mode

OPT

OPTION, linked to the "SILENCE ALARM" key, accesses the pressure

configuration mode

The selection keys scroll through the figures and letters on the tenths,

units, tens segments, etc.

CONFIRM, validates a choice

STOP

STOP cancels the current configuration

Pressure configuration mode

Press "START".

Press "SILENCE ALARM" and "OPTION"simultaneously

When PrES appears, release "SILENCE ALARM" and

"OPTION" then validate by pressing "CONFIRM" within

3 seconds.

PrEs1 appears by default

Switching from PrEs1 to PrEs3 is carried out using

the selection keys

OPT

Description of the menus

20 mod03.1_003a_en.fm

Page 21

3.1.2 PrES1, configuration of the variable pressure limits

OP

This configuration allows the user to select the variable pressure limit and its memorisation

mode when the machine is cut off.

PrEs1, press "CONFIRM".

the pressure limit display on LCD.

Pres 1

mmHg

900

V Using the selection keys, select the limit value:

--- : it will be equal to the last value selected

or display the default value.

This value is adjustable from 100 to 1100 mmHg.

V Press "CONFIRM" to store the limit in EEprom.

By pressing "STOP" the modification is cancelled.

You may exit the configuration mode at any time by pressing "OFF".

STOP

Description of the menus

mod03.1_003a_en.fm 21

Page 22

3.1.3 PrES2, pressure limit configuration

OP

This configuration adjusts and memorises the maximum limit values for each type of syringe.

Only maximum limit values with a valid syringe are proposed for configuration.

PrEs2, press "CONFIRM"

the value of for a 50 cc syringe is displayed on the LCD

as "1100 mmHg".

Pres 2

50cc

1100

mmHg

V Modify this value using the selection keys and press "OK".

V The value for the 20 cc syringes is displayed.

V The value for the 10 cc syringes is displayed.

V The value for the 5 cc syringes is displayed.

V Press "OK" to switch from a syringe type to the other.

V At each reading, it is possible to modify the values using

the selection keys.

Syringe type Value of limits Increments

50 cc 100 to 1100 mmHg 50 mmHg

20 cc 100 to 1500 mmHg 50 mm Hg

5 cc / 10 cc 100 to 1600 mmHg 50 mmHg

V Press "CONFIRM" to store the limit in EEprom.

By pressing "STOP" the modification is cancelled.

You may exit the configuration mode at any time by pressing "OFF".

OK

OK

STOP

Description of the menus

22 mod03.1_003a_en.fm

Page 23

3.1.4 PrES3, Pressure decrease threshold configuration

OP

This configuration sets the threshold used for supervising the pressure decrease. During

infusion, an alarm is triggered when pressure in the syringe exceeds this threshold.

The threshold should be between 50 and 1100 mmHg.

PrES3, press "CONFIRM"

V The threshold value is displayed on the LCD screen.

Modify its value using the selection keys.

V By validating again, the value is memorised and another

configuration can be selected.

An adjustment of the threshold to 0mm Hg indicates that the drop detection

pressure surveillance has been desactivated.

Pres 3

1100

mmHg

By pressing "STOP" the modification is cancelled.

You may exit the configuration mode at any time by pressing "OFF".

STOP

Description of the menus

mod03.1_003a_en.fm 23

Page 24

Description of the menus

24 mod03.1_003a_en.fm

Page 25

Configuration, calibration et contrôle

3.2 Menu configuration of current operation parameters

The configuration menu allows the user to adapt the Module DPS to the specific needs of

each department. It provides access to the menus customising current operating mode

parameters.

Fresenius Vial recommends the presence of one of its qualified personnel, or a member of

your Technical Service, to help implement the selected configuration procedures.

You may exit the configuration mode at any time by pressing the OFF key.

This menu allows the user to:

PAr1: Flow rate memorisation.

PAr2: Syringe type selection mode.

PAr3: Maximum flow rate selection via the keyboard.

PAr4: Syringes list selection.

PAr5: Mandatory priming confirmation.

PAr6: Quick infusion start-up mode.

PAr7: KVO / flow rate selection mode.

PArA: Empty syringe mode.

PArb: Maintenance periodicity.

PArC: Drug name indication.

PArd: Flange detection mode.

PArE: Programmable bolus flow rate memorisation.

PArF: Manual bolus flow rate memorisation.

PArG: Drug name selection.

PArH: Back-light operation.

PArL: Screen alternation.

PArP: Ward name.

mod03.2_003a_en.fm 25

Description of the menus

Page 26

3.2.1 Menu access

OP

Useful keys

Key Function

ON starts up the device.

OFF switches the device off

SILENCE ALARM, accesses the configuration mode of the current

operation parameters.

The selection keys scroll through the figures and letters on the tenths,

units, tens segments etc.

CONFIRM validates a choice.

STSTOP

STOP cancels the current configuration

Switch to configuration mode

Press "SILENCE ALARM" and "INCREMENT"

simultaneously

.

Maintain this position while pressing "ON"

When PAr appears on the display unit, release the

"SILENCE ALARM" and "TENS" keys, then validate within

three seconds by pressing "CONFIRM".

PAr1 appears by default.

The switch from PAr1 to PArP is done using

the selection keys.

Description of the menus

26 mod03.2_003a_en.fm

Page 27

3.2.2 PAr1, Flow rate memorisation

OP

OP

This mode allows the user to choose whether or not to memorise the infusion flow rate when

the Module is shut down.

PAr1, press "CONFIRM"

V If , the flow rate is memorised when the Module is shut

down. This value will be displayed by default when the

device is next switched on.

V If the flow rate is not memorised, the value by default

00.0each time the device is switched on.

is

Select the memorisation type using the selection

keys.

V By validating once again, the mode is memorised and it is

possible to select another configuration.

The modification may be cancelled by pressing the "STOP" key.

STSTOP

It is possible to exit the configuration mode at any time by

pressing the "OFF" key.

3.2.3 PAr2, syringe type selection mode

This configuration allows the user to choose the syringe type selection.

PAr2, press "CONFIRM"

V If Automatic, automatic validation of the only syringe that

may be selected.

V If Manual, when the Module is switched on, the user must

select the type of syringe installed.

Choose the selection type using the selection keys.

V The type is memorised by confirming once again, and

another configuration may be selected.

When the Automatic mode is chosen and if there is a choice of more than one syringe, the

Module automatically moves onto the configuration of the list of syringes that may be

selected

PAr4 when the machine is next switched on.

By pressing "STOP" the modification is cancelled.

STSTOP

You may exit the configuration mode at any time by

pressing the "OFF" key.

Description of the menus

mod03.2_003a_en.fm 27

Page 28

3.2.4 PAr3, Maximum flow rate selection via the keyboard

OP

This mode allows the user to choose the maximum flow rate that may be selected using the

keyboard for each type of syringe.

Syringe type Min. flow rate (ml/h) Max. flow rate (ml/h)

50/60 cc 0,1 1200.0

20/25 cc 0,1 600.0

10 cc 0,1 350.0

5 cc 0,1 250.0

PAr3, press "CONFIRM".

V Select the syringe type using the "OK" key.

5ml.

10ml.

20ml.

50ml.

Select the maximum flow rate using the selection

keys.

V By validating again, the type is memorised and a different

configuration can be chosen.

By pressing "STOP" you may cancel the modification.

You may exit the configuration mode at any time by

pressing the "OFF" key.

OK

STSTOP

Description of the menus

28 mod03.2_003a_en.fm

Page 29

3.2.5 PAr4, syringes list selection

OP

This configuration enables users to choose, for each type of active syringe, whether or not it

may be selected .

PAr4, press "CONFIRM"

the configuration mode is displayed on LCD as :

If this type of syringe may be selected in the

Module list configuration.

If this type of syringe may not be selected in the

Module list configuration.

V Make your choice, whether it may or may not be selected,

using the keys.

V Press "OK" to select the following syringe type:

V This configuration is activated automatically when the

machine is switched on and the type of syringe that can

be selected is > 1; and the selection is made with a selfvalidation.

V Press "CONFIRM" to record the modifications.

By pressing the "STOP" key, the modification is cancelled.

You may exit the configuration mode at any time by

pressing the "OFF" key.

OK

STSTOP

Description of the menus

mod03.2_003a_en.fm 29

Page 30

3.2.6 PAr5, mandatory priming confirmation

OP

OP

This mode allows the user to choose whether or not priming is compulsory once the syringe

has been selected.

PAr5 is displayed.

V Press "CONFIRM"

If press "BOLUS" during start-up is compulsory in

order to switch to flow rate selection.

If the flow rate may be directly selected after

validation of the syringe.

V Make your choice using the selection keys.

V The type is memorised by confirming once again and

another configuration may be selected.

The modification may be cancelled by pressing the "STOP" key.

STSTOP

You may exit the configuration mode at any time by

pressing the "OFF" key.

3.2.7 PAr6, quick infusion start-up mode

This mode allows the user to choose whether or not to activate the quick start-up system.

PAr6, press "CONFIRM".

V If , quick start-up is activated. When there is a low flow

rate, the plunger moves more quickly at the start of

infusion until it comes into contact with the syringe piston.

This fast movement is controlled by the force sensor and

is limited in distance.

V If , there is no quick start-up mode and the infusion

always starts with the flow rate selected.

V Make your choice using the selection keys.

V The type is memorised by confirming once again and

another configuration may be selected.

The modification may be cancelled by pressing the "STOP" key.

STSTOP

You may exit the configuration mode at any time by

pressing the "OFF" key.

Description of the menus

30 mod03.2_003a_en.fm

Page 31

3.2.8 PAr7, KVO / flow rate selection mode

OP

OP

This mode allows the user to choose whether or not to activate and adjust the KVO flow rate.

PAr7, press "CONFIRM".

V If , KVO flow is activated. The infusion continues at

KVO flow rate value programmed (or at the same flow rate

if this is under limit memorised) when the volume infused

reaches the volume limit.

V If , there is no KVO flow and infusion stops with a

volume limit alarm when the infused volume reaches the

volume limit.

V Make your choice using the selection keys.

V Switch to the flow rate selection by pressing "OK".

V Select the flow rate between 0,1 and 5 ml/h in steps of

OK

0,1 ml/h by pressing the selection keys.

V This mode is memorised by confirming once again and

another configuration may be selected.

The modification may be cancelled by pressing the "STOP" key.

STSTOP

You may exit the configuration mode at any time by

pressing the "OFF" key.

3.2.9 PArA, empty syringe mode

This mode allows the user to select an operation for the instrument using the empty syringe

mode.

PArA, press "CONFIRM".

V If the empty syringe mode is activated.

To use empty syringe mode during perfusion, press

"CONFIRM" when end of infusion prealarm is

triggered

V If the activation of the empty syringe mode is de-

activated.

By pressing "CONFIRM" at the presence of an end of

infusion alarm, a beep will be emitted.

.

V Make your choice using the selection keys.

V By validating once again, this mode is memorised and

another configuration may be chosen. .

Press "STOP" to cancel the modification.

STSTOP

You may exit the configuration mode at any time by

pressing the "OFF" key.

Description of the menus

mod03.2_003a_en.fm 31

Page 32

3.2.10 PArb, maintenance periodicity

OP

OP

This configuration enables the maintenance periodicity to be selected:

- from 1 until 999 hours,

- or using the date.

PArb, press "CONFIRM".

V The actual value is displayed on the LCD screen.

V Modify the number of maintenance hours using the keys.

Par B 3000 H

00/00/0000

V Press "OK" key to select and modify the maintenance date.

V By validating once again, the type is memorised and

OK

another configuration may be selected.

If the date is incorrect in the year selection validation (e.g. 31/02002), a flashing Err

appears.

By pressing "STOP" the modification is cancelled.

STSTOP

You may exit the configuration mode at any time by

pressing the "OFF" key.

3.2.11 PArC, Drug name indication

This configuration enables the user to choose whether or not to display the drug name in

alternance with the syringe brand or the pressure (see

PArC, press "CONFIRM".

V If the alternance mode is selected, the drug name and

the syringe brand are displayed in alternance.

V If the alternance mode is not selected, the drug name

is not displayed in alternance with the pressure monitor.

PArL).

ALFENTANIL

0,01µg/ml

V Make your choice using the keys.

V By validating once again the mode is memorised and

another configuration may be chosen.

The modification is cancelled by pressing the "STOP" key.

STSTOP

You may exit the configuration mode at any time by

pressing the "OFF" key.

Description of the menus

32 mod03.2_003a_en.fm

Page 33

3.2.12 PArd, flanges detection mode

OP

This configuration enables users to choose whether or not to activate the syringe flanges

detection.

PArd, press "CONFIRM".

V If detection activated, inappropriate positioning of the

syringe flanges is identified by syringe clamp alarm.

V If no detection, the inappropriate positioning of the

flanges is not detected.

V Make your choice using the keys.

V By validating once again, the mode is memorised and it is

possible to select another configuration .

The modification may be cancelled by pressing the "STOP" key.

It is possible to exit the configuration mode at any time by

pressing the "OFF" key.

STSTOP

Description of the menus

mod03.2_003a_en.fm 33

Page 34

3.2.13 PArE, programmable bolus flow rate memorisation

OP

This configuration allows the user to select the bolus flow rate memorisation mode.

PArE, press "CONFIRM".

V If bolus is memorised. When the Module starts up

the proposed bolus flow corresponds to the last one

selected.

V If bolus is not memorised. When the Module starts

up the proposed bolus flow is the default value.

V Make your selection using the keys.

If the "not memorised" mode is selected, the bolus default value must be defined

V If you select the last flow rate configured for 50/60 cc

syringes is displayed..

Enter the bolus value to be defined by default for a

50 cc syringe using the keys.

V Press "OK" to memorise it.

V The default flow rate configured for 20 cc syringe is

displayed.

Enter the bolus value to be defined by default for a

20 cc syringe using the keys.

V Press "OK" to memorise it.

V Continue in this procedure until all the syringe types are

validated and

The modification is cancelled by pressing "STOP".

PArE is displayed.

You may exit the configuration mode at any time by

pressing the "OFF" key.

OK

OK

STSTOP

Description of the menus

34 mod03.2_003a_en.fm

Page 35

3.2.14 PArF, manual bolus flow rate memorisation

OP

This configuration allows the user to select the Manual bolus flow memorisation mode.

PArF, press "CONFIRM".

V If bolus is memorised. When the Module starts up the

proposed bolus flow corresponds to the last one selected.

V If bolus is not memorised. When the Module starts up

the proposed bolus flow is the default value.

V Make your selection using the keys.

If the "not memorised" mode is selected, the bolus default value must be defined

V If you select the last flow rate configured for 50/60 cc

syringes is displayed.

Enter the bolus value to be defined by default for a

50 cc syringe using the keys.

V Press "OK" to memorise it.

V The default flow rate configured for 20 cc syringes is

OK

displayed.

Enter the bolus value to be defined by default for a

20 cc syringe using the keys.

V Press "OK" to memorise it.

OK

Continue in this procedure until all the syringe types

are validated and

The modification is cancelled by pressing "STOP".

PArE is displayed.

STSTOP

You may exit the configuration mode at any time by

pressing the "OFF" key.

.

Description of the menus

mod03.2_003a_en.fm 35

Page 36

3.2.15 PArG, drug name selection

OP

OP

This configuration enables the user to select the list of drugs that may be used by the Module.

PArG, press "CONFIRM".

V The first drug name appears on the LCD screen.

V If , the name of the drug is selected.

V If , the name of the drug is not selected.

V Make you selection using the selection keys.

V Press "OK" to memorise it and go to the next medication.

V To validate the modification(s), the entire list of drugs must

be scrolled through. When the last drug is validated,

OK

PArGmenu is displayed.

The modification may be cancelled by pressing "STOP" .

You may exit the configuration mode at any time by

pressing the "OFF" key.

3.2.16 PArH, back-light operation

This configuration determines the operation of the back-light while the Module is running on

battery.

PArH, press "CONFIRM".

V The back-light status is displayed on the LCD screen.

back-light switched OFF

back-light ON low

back-light is permanent

V Make your choice using the keys.

STSTOP

V Press "CONFIRM".

The modification may be cancelled by pressing "STOP" .

STSTOP

You may exit the configuration mode at any time by

pressing the "OFF" key.

Description of the menus

36 mod03.2_003a_en.fm

Page 37

3.2.17 PArL, screen alternation

OP

OP

This configuration enables the user to determine the screen alternation during infusion.

PArL, press "CONFIRM".

V The status of screen alternation is displayed.

no alternation

syringe priority

pressure priority

V Make your choice using the keys.

V Press "CONFIRM".

The modification may be cancelled by pressing "STOP" .

STSTOP

You may exit the configuration mode at any time by

pressing the "OFF" key.

.

3.2.18 PArP, ward name

This configuration enables the name of the department using the Module to be adjusted.

PArP, press "CONFIRM".

V The curser is positioned under the letter to be selected.

V Select a letter using the selection keys.

V To validate the letter and move to the next one, press

"OK".

Move to the next letter using the "OK" , "RAPID DECREMENT" or.

"RAPID INCREMENT" keys.

OK

OK

V Press "CONFIRM", to validate the whole name of the

department.

The modification may be cancelled by pressing "STOP" .

STSTOP

You may exit the configuration mode at any time by

pressing the "OFF" key.

Description of the menus

mod03.2_003a_en.fm 37

Page 38

Description of the menus

38 mod03.2_003a_en.fm

Page 39

Configuration, calibration et contrôle

3.3 Service test menu

The service test menu is reserved for authorised personnel only. It allows the carrying out of

a series of Module checks to validate its efficient operation (see “Checks” chapter). These

must be carried out after each maintenance procedure.

The service tests can also be carried out more quickly and simply from a PC

installed with maintenance software (consult our After Sales Service).

The service test menu allows for a series of 17 tests or checks:

tSt1: Display of running time and last maintenance date.

tSt2: Indicator lights test.

tSt3: Keyboard test.

tSt4: Battery voltage test.

tSt5: Display of the last 10 alarm codes.

tSt6: Display of the total running time.

tSt9: Piston force test.

tStA: Display of software version and language.

tStb : Analogue input test.

tStC: Display of the plunger position.

tStE: Display of the calibration values.

tStf: Syringe type display.

tStG: Syringe group display.

tStJ: Display of history before fault.

tStL: Display of drugs librairy information.

An events log of more than 760 entries can be consulted by an intermediary of the

"ISCTRL" Maintenance software version 4 and above. (Please consult our Service

department for more details).

mod03.4_003a_en.fm 39

Description of the menus

Page 40

Description of the menus

40 mod03.4_003a_en.fm

Page 41

4 Preventive maintenance

4.1 Recommendations

The Module DPS syringe pump can only be inspected, serviced or repaired by Fresenius

Vial or by an authorised and appointed service. The qualified technicians in your

establishment and our After Sales Service should be notified of any abnormal operation of the

device.

If a repair is necessary, send the instrument in its original packaging if possible with a precise

description of the observed fault, to the official dealer for Fresenius Vial.

For further information concerning troubleshooting or the usage procedure, please contact

our Service Department or our Sales Department.

Fresenius Vial is not liable for loss or damage to the equipment during transport to our After

Sales Service.

4.2 Maintenance schedule

4.2.1 Use beyond the framework of the departmental order

Frequency Name

3 years Replace the battery (see "Battery-holder and battery" operation sheet).

4.2.2 Use within the framework of the departmental order

When the equipment is used within the framework of the departmental order of October 3

1995, inspections are performed on a less frequent basis. This is due to the fact that the

equipment is inspected before each use.

Frequency Name

st

1

inspection in

rd

year

the 3

Then every 2

years

3 years Replace the battery (see "Battery-holder and battery" operation sheet).

Perform the first servicing inspection and replace the battery.

Perform a servicing inspection.

mod04.1&2_001a_en.fm 41

Preventive maintenance

Page 42

Preventive maintenance

42 mod04.1&2_001a_en.fm

Page 43

OP

Maintenance préventive

4.3 Checks

In order to ensure apparatus follow-up in terms of an effective preventive maintenance

programme, a regular servicing inspection is recommended every 24 months (see "Regular

Servicing Sheet").

To ensure the checking procedure is carried out efficiently, the battery should be

recharged beforehand for 16 hours.

4.3.1 Test access

Keyboard description.

Key Function

ON starts up the device

OFF switches the device off

SILENCE ALARM accesses the test mode

STSTOP

STOP cancels the test in progress

CONFIRM validates a choice

OK

" OK" validation a choice

The selection keys scroll through the figures and letters on the tenths,

units, tens segments etc

Activating the Service test

Press "SILENCE ALARM" and "DECREMENT"

simultaneously.

Maintain this position while pressing "ON".

When tSt. is displayed on screen, release selection of

the "SILENCE ALARM" and "DECREMENT", then validate

within three seconds by pressing the "CONFIRM" key.

By default, the equipment starts with tSt.1

Using the selection keys, scroll through the various tests on

the display unit.

4.3.2 Visual check

Check the general appearance of the case and labels and for traces of shock.

Preventive maintenance

mod04.3_004a_en.fm 43

Page 44

4.3.3 Running time and service inspection date

OP

OP

This test displays

the Module

running time since

its last service

inspection. It also

displays and

modifies the "last"

service inspection

date.

When the service

inspection date is

modified, the

running time is

reset to zero.

tSt.1, press the "CONFIRM" key.

V If xxx.H: number of hours, the running time is

displayed in hours if it is lower than 72 h.

V If xxx.J: number of days, the running time is

displayed in day if it is lower than 120 days.

V If xxx.M : number of months, the running time is

displayed in month if it is higher than 120 days .

(average duration of one month considered as 30 days).

Press "OK" to display the date of the last service inspection..

Each time this information is read, the month, day and year of the

service inspection date may be modified by using the selection

keys. This date will be stored in the EEPROM and

the running time will be reset to zero.

V By validating once again, a another test may be selected

V When the number of hours or the date programmed on

PArb is over, CtrL message appears after

switching ON the pumps indicating the unit should be

checked.

OK

This test checks

the efficiency of

the indicator

lamps, the display

units and the front

panel LCD screen.

The test may be stopped at any time by pressing the "STOP" key,

and a different test may be selected.

4.3.4 Indicator lights check

tSt.2, press "CONFIRM".

V All LEDS, 7-segment display units and LCD are ON.

V By validating once again,

the LEDS and display units are scrolled through one

by one, from left to right. (Display of the LEDS, 7segment display unit by segment and then by sets of

8, LCD display unit).

The test is OK if all indicator lamps are lit up.

The test may be stopped at any time by pressing the "STOP" key,

and a different test may be selected.

STSTOP

STSTOP

Preventive maintenance

44 mod04.3_004a_en.fm

Page 45

4.3.5 Keyboard check

This test checks

that all keyboard

keys function

correctly.

tSt.3, press the "CONFIRM" key.

V Keep each key pressed down, one by one,

Check the name of the key displayed on the display

unit.

The name of each key is displayed as follows.

Display Selected key

SIAL Silence Alarm

STOP Stop

START Start

BOLU Bolus

OK OK

OPT Option

INC Increment

INCR Rapid increment

DEC Decrement

DECR Rapid decrement

OFF On/Off

If two or more keys are held down simultaneously, the display unit will show Err and a

sound alert "beep!beep!beep!" will indicate an error.

If "OFF" is held down for more than one second the Module switches off.

The test may be interrupted at any time by pressing the "CONFIRM" key

for over three seconds, and a different test may be selected.

If the display is faulty, replace the display board (see "Display boards" operation sheet).

mod04.3_004a_en.fm 45

Preventive maintenance

Page 46

4.3.6 Battery voltage check

OP

This test displays

the battery voltage

in Volts and in

tenths of a Volt.

tSt.4, press "CONFIRM".

The LCD screen can now be read.

V The voltage is displayed in Volts. "B" indicates the

battery voltage value.

V The voltage is displayed in Volts. "C" indicates the

battery voltage when the device is connected to the

base or Mainy mode.

Tes t 4

B 6.0 V

Tes t 4

C 6.0 V

If the voltage is below the threshold calibrated for the pre-alarm, the leds "Battery alarm

and Pre-alarm" flash.

If the voltage is below the threshold calibrated for the alarm, the leds "Battery alarm and

Alarm flash.

V By validating once again, another test may be selected.

The test may be interrupted at any time by pressing the "STOP" key

and a different test may be selected.

STSTOP

Preventive maintenance

46 mod04.3_004a_en.fm

Page 47

4.3.7 Checking the last 10 alarms

This test allows for

code display of the

last 10 alarms

triggered on the

Module.

tSt.5, press "CONFIRM".

Details may be read on the LCD screen.

V The most recent alarm code is displayed.

"A" for an alarm.

"E" for an error.

V Press the keys to display the following codes from 0 to 9.

V By validating once again, a different test may be selected.

Test 5 0

Meaning of the codes :

Erreur Description Erreur Description

A10 Battery alarm E10 Error internal RAM

A11 Syringe support

E20 Error external RAM

alarm

A12 End of infusion

E30 Error check-sum EPROM

alarm

A13 Limit volume alarm E40 Error EPROM

A14 Disengagement

E50 ADC access auto-test error.

alarm

A15 Piston head alarm E60 Error concerning checking of syringe parameter coherence

(incoherence of the syringe diameter in relation to the motor step for

0,1 ml calculated at the time of syringe validation).

A16 Occlusion alarm E70 Error concerning incorrect motor frequency (motor step period

calculated in related in relation to the syringe diameter and the flow

rate selected either too low or too high).

A25 Flange Alarm E80 Error keyboard

E90 Erreur détection ailette

E01 Rotation check error.

E32 Segment advance check error

E52 Advance check error during take-up.

E72 Advance check error over the whole lenght

E82 Error mechanical

E03 Communication error

E14 Error motor frequency

E24 Error direction or rotation fault

E34 Error motor period

E44 CPU/UART frequency check error

E84 Error fuse

E55 Error time clock

E16 Error time clock

E56 Error software

A 11

mod04.3_004a_en.fm 47

Preventive maintenance

Page 48

Errors 10, 20, 30 and 40 cannot be stored in the EEPROM.

OP

OP

OP

If the Module switches off normally, the OFF message is displayed.

If the Module switches off due to a malfunction, the Off message is displayed with a

flashing

Fin front: FOFF.

The test may be interrupted at any time by pressing the "STOP" key

and a different test may be selected.

STSTOP

4.3.8 Total running time check

This test displays

the total running

time of the

Module. It is not

possible to modify

this time manually.

This test displays

the force exerted

on the piston in

grams.

tSt.6, press "CONFIRM".

V If xxx.H: number of hours of use, 72 hours max.

V If xxx.J: number of days of use, 120 days max.

V If xxx.M: number of months, > 120 days.

(average duration of one month considered as 30 days)

By pressing the " OPTION" key, the number of times

the machine has been switched on is displayed..

V By validating again, a different test may be selected.

The test may be interrupted at any time by pressing the "STOP" key.

A different test may then be selected.

4.3.9 Checking the force sensor

tSt9, press "CONFIRM".

V 000.g: displayed in grams. The result must lie

between 0 and 100 g.

V Press and release the bonding pad.

The result displayed must always lie between

0 and 100 g.

V By validating once again, a different test may be selected.

STSTOP

V If the value is out of limits, recalibrate the force sensor

(see "

EtA.9 Force sensor calibration.").

The test may be interrupted at any time by pressing the "STOP" key,

and a different test may be selected.

STSTOP

Preventive maintenance

48 mod04.3_004a_en.fm

Page 49

4.3.10 Software and language version check

OP

This test displays

the software

version number

and revision .

tSt.A, press "CONFIRM".

V The software version number and revision as well as the

check sum and creation date of the software are

displayed.

Test A V01.32

(A15A) 06/07/1998

V By pressing "OK" again, the language chosen is displayed

on a second screen.

V Scroll through the language screens (if several languages

Test A French

(A15A) 06/07/1998

are programmed) using the "SELECTION" keys.

The letter "V" appears and flashes if there is an additional version message.

OK

The test may be interrupted at any time by pressing the "STOP" key,

and a different test may be selected.

STSTOP

Preventive maintenance

mod04.3_004a_en.fm 49

Page 50

4.3.11 ADC check

OP

This test displays

the converter

conversion results,

in hexa-decimals,

of the five

analogue inputs

and three test

inputs.

tSt.b, press "CONFIRM".

V The result displayed is the first of five analogue inputs

(from 0 to 4).

V The second type of result displayed corresponds to the

converter test according to the channel number, (L, M, H)

Test B 0

Use the "INCREMENTATION or DECREMENTATION"

keys to move from one input to another.

The analogue inputs are distributed in the following way:

Channel

number

Component concerned

0 battery voltage

1 n.u.

2 force sensor

3 n.u.

4 potentiometer displacement

L zero converter test, between 000 and 004 if correct

M mid-scale converter test, between 01FB and 204 if correct

H full-scale converter test, between 03FB and 3FF if correct

305

V By validating once again, a different test may be selected.

If the value is out of limits, recalibrate the force sensor (see "EtA.9 Force sensor

calibration").

The test may be interrupted at any time by pressing the "STOP" key,

and a different test may be selected.

STSTOP

Preventive maintenance

50 mod04.3_004a_en.fm

Page 51

4.3.12 Displacement sensor check

OP

This test displays

the plunger

position in mm and

ths

of a mm.

10

This test displays

the calibration

values stored in

the EEPROM.

tSt.C, using jig ref.8104 high and low, press "CONFIRM".

V Position the jig ref. 8104 in high position.

in high position the display unit shows

115.0 + 0,5 mm.

V Position the jig ref. 8104 in low position.

in low position the display unit shows

20.0 + 0,5 mm.

V By validating once again, a different test may be selected.

If the value is out of limits, recalibrate the displacement sensor (see "EtA.6Calibration).

The test may be interrupted at any time by pressing the "STOP" key,

and a different test may be selected.

4.3.13 Checking the calibration values

tSt.E, press "CONFIRM".

V bAT.1 is displayed on the LCD screen with its

calibration value.

Test E BAT1

(2) 33C

STSTOP

V Press the "SELECTION" keys to move on to another

value.

Display Name

bat.1

bat.2

bat.3

HIG.H

Low

0.G

5KG

5cc

5 - 10cc

10 - 20cc

20 - 30cc

30 - 50cc

Battery voltage 6.3 V

Pre-alarm battery voltage 5.9 V

Alarm battery voltage 5.7 V

Displacement potentiometer with 115.0 mm spacer

Displacement potentiometer with 20.0 mm spacer

Force sensor with 0 kg

Force sensor with 5 kg

Syringe potentiometer diameter, low limit 5 cc

Syringe potentiometer diameter, limit between 5cc and 10cc

Syringe potentiometer diameter, limit between 10cc and 20/25cc

Syringe potentiometer diameter, limit between 20/25cc and 30/35cc

Syringe potentiometer diameter, limit between 30/35cc and 50/60cc

50cc

mod04.3_004a_en.fm 51

Syringe potentiometer diameter, high limit 50/60cc

Preventive maintenance

Page 52

4.3.14 Checking the syringe clamp

OP

OP

This test displays

the type of syringe

fitted to the

Module.

tSt.F, press "CONFIRM"

using for verification each diameter a syringe.

V Place the syringe clamp in the high position.

The display unit shows ---.-

V Fit the 50 cc syringe. The display unit shows 50c.c

V Fit the 20 cc syringe. The display unit shows 20c.c

V Fit the 10 cc syringe. The display unit shows10c.c

V Fit the 5 cc syringe. The display unit shows 5 c.c

V Fit the syringe clamp in the low position.

The display unit shows ---.-

If the capacity of the syringe type does not comply with the corresponding syringe, new

calibration is need

EEPROM are displayed in the form of

V By validating once again, another test may be selected.

EtalD.Capacities which are non-existent or non-configured in the

---.-.

The test may be interrupted at any time by pressing the "STOP" key,

and a different test may be selected.

STSTOP

This test displays

the list of syringes

for which the

machine has been

configured.

4.3.15 Checking the syringe group number

tSt.G, press "CONFIRM".

V The syringe group number configured in EEPROM is

displayed, e.g.

V By validating once again, another test can be selected.

The test may be interrupted at any time by pressing the "STOP" key,

and a different test may be selected.

G03.

STSTOP

Preventive maintenance

52 mod04.3_004a_en.fm

Page 53

4.3.16 Checking the last 10 events before fail

OP

This test displays

the list of syringes

programmed in the

Module.

This test displays

the name of the

person in charge,

the name and date

of the file allowing

the drugs to be

updated.

tSt.J, press "CONFIRM".

V The last locking error code is displayed on the LCD

screen.

"A" for an alarm (see table tSt.5)

"E" for an error (see table tSt.5)

V Press the "INCREMENTATION" keys to display the

following codes from 0 to 9.

V By validating once again, a different test can be selected.

The test may be interrupted at any time by pressing the "STOP" key,

and a different test can be selected.

4.3.17 Checking the drugs change information

tSt.L, press "CONFIRM".

This screen displays the drug list name.

Downloaded by the user or the manufacturer.

V By validating once again, a different test can be selected.

4.3.18 Checking the disengagement system

Test J 0

E 80

STSTOP

To carry out this operation, exit the test mode and press "OFF".

Press "ON".

V Push the disengagement lever.

Check for presence of the mechanical disengagement

alarm (red Led at the end of the syringe diagram).

V Fit the machine with the 50 cc syringe, ensuring the

flanges and plunger are in position.

V Release the disengagement lever.

Ensure there is no mechanical lever alarm.

Preventive maintenance

mod04.3_004a_en.fm 53

Page 54

4.3.19 Checking the anti-siphon arm

This check must be carried out for each syringe provided with the machine.

To carry out this operation, exit the test mode and press

"OFF",

Check functioning.

V Free play, without axial movement or disassembly.

Check for alarm presence:

V anti-siphon arm in the upper position.

V anti-siphon arm in the lower position.

V Check there is no alarm in presence of each syringe provided by the machine.

Do not press the anti-siphon arm. Disengage and press the button to ensure its descent.

If the result is not satisfactory, go to sheet n°6.

4.3.20 Back pressure test

To carry out this operation, exit the test mode and press "OFF".

The instrument initialises the sensor once the plunger is disengaged.

The back pressure test must be performed with zero back pressure.

Press "ON".

V Fit the Fresenius Vial pressure dynanometer.

V Select a "Perfusor" 50 ml syringe, pressing

"CONFIRM".

V By pressing the "OPT" key, select a limit:

V Select the limit pressure : 600 mmHg + 70 mmHg.

V Press "OK".

V Select a flow rate of 120 ml/h and start the infusion by

pressing "CONFIRM".

Check absence of sound and visual alarms back

pressure on the LCD.

Check the infusion Leds are flashing.

Ensure the alarm is triggered for a value of 600 mmHg

+ 70 mmHg.

OPT

OK

Preventive maintenance

54 mod04.3_004a_en.fm

Page 55

V Repeat this test, selecting a higher limit by pressing the

"OPT" key.

V Select the limit pressure :1100 mmHg + 150 mmHg.

OK

Where the value of the measured pressure, depending on the selection made, is situated

outside of the reference values, (see

EtA.9"Calibrating the force sensor").

4.3.21 Checking the end of infusion pre-alarm

To carry out this operation, exit the test mode and press "OFF",

Press "ON".

V Fit the syringe to the device, ensuring that the flanges and

plunger are in position.

V Ensure the syringe is detected correctly, e.g. 50c.c.

V Select a "Perfusor" or other brand of syringe

available on the device syringe filled to 20 ml.

V Select a flow rate of 120 ml/hr.

For normal flow rates, the pre-alarm is activated five

minutes before end of infusion.

Flow rate example: > 60 ml/hr, the pre-alarm is

activated when the remaining volume equals 10% of

the total syringe capacity.

Ensure the end of infusion pre-alarm is present.

V Press the "SILENCE ALARM" key.

The sound alarm is silenced and the visual signal is

maintained.

V Measure the "hard height" distance at "end of infusion".

38 < x < 39 for Perfusor.

For other syringe brand (please contact our Service department)

For accurate checking of the "hard height", do not move

Top view

the plunger while measuring.

If the "hard height" reading is out of limits, recalibrate the position sensor (see "EtA.6

Position sensor calibration").

mod04.3_004a_en.fm 55

Preventive maintenance

Page 56

4.3.22 Checking linearity

OP

To carry out this operation, exit the test mode and press "OFF",

Equipment required: Stop-clock, electronic calliper,

Perfusor 50 ml. syringe.

Press "ON".

V Fit the device with the "Perfusor" 50 ml syringe

maximum volume ensuring the flanges and plunger are in

starting position.

V Measure the displacement X1 in mm.

V Ensure the syringe is detected correctly, e.g. 50c.c.

V Select a flow rate of 50 ml/hr.

V Press "CONFIRM" to start infusion and simultaneously

View from above

start the stop-clock

V At 50 minutes, stop the infusion by pressing "STOP" and

measure the displacement X2.

V Ensure X = X1 - X2 lies between

68,2 mm < X < 69,58 mm.

For accurate checking of the linearity, do not move the plunger while measuring.

4.3.23 Locking/unlocking check

Install a Module on the base.

The installed Module must be locked to the base.

Switch on the module by pressing the ON key.

V The base is in operation.

STSTOP

V The module number is displayed on the module and on

the base.

Check the correspondence: module number

displayed/ location of the module on the base (the first

module installed takes the number 1, the second

takes the number 2, etc.).

V The module unlocking indicator switches off.

Slowly unlock the module from the base.

V The module "C" unlocking indicator flashes.

Preventive maintenance

56 mod04.3_004a_en.fm

Page 57

4.3.24 Checking mains/battery functioning

To carry out this operation, exit the test mode and press "OFF",

Connect the device to a mains exterior power supply (Base

A) or Mainy Mod adapter.

V Check the operation of the mains presence Led (indicator

in the shape of a plug).

Disconnect the apparatus from the base A or the Mainy Mod

check the battery LED’s light up.

4.3.25 Battery autonomy test

Recharge the battery for 16 hours (100 % of its capacity.)

Battery autonomy is a minimum of 2 hours with a 50/60 cc syringe with a flow rate of

120 ml/h.

Carry out an autonomy test for more than one hour.

V Fit the device with a Perfusor 50 ml/hr syringe with a

flow rate of 120 ml/hr, then confirm.

V The "battery discharge" pre-alarm warns the user of an

remaining autonomy of 30 minutes before the stop of the

device.

4.3.26 Continuity test

Use a multimeter.

To carry out this operation, exit the test mode and press "OFF",

The Module must be locked to the base.