Page 1

TECHNICAL MANUAL

Injectomat 2000 MC

Page 2

Page 3

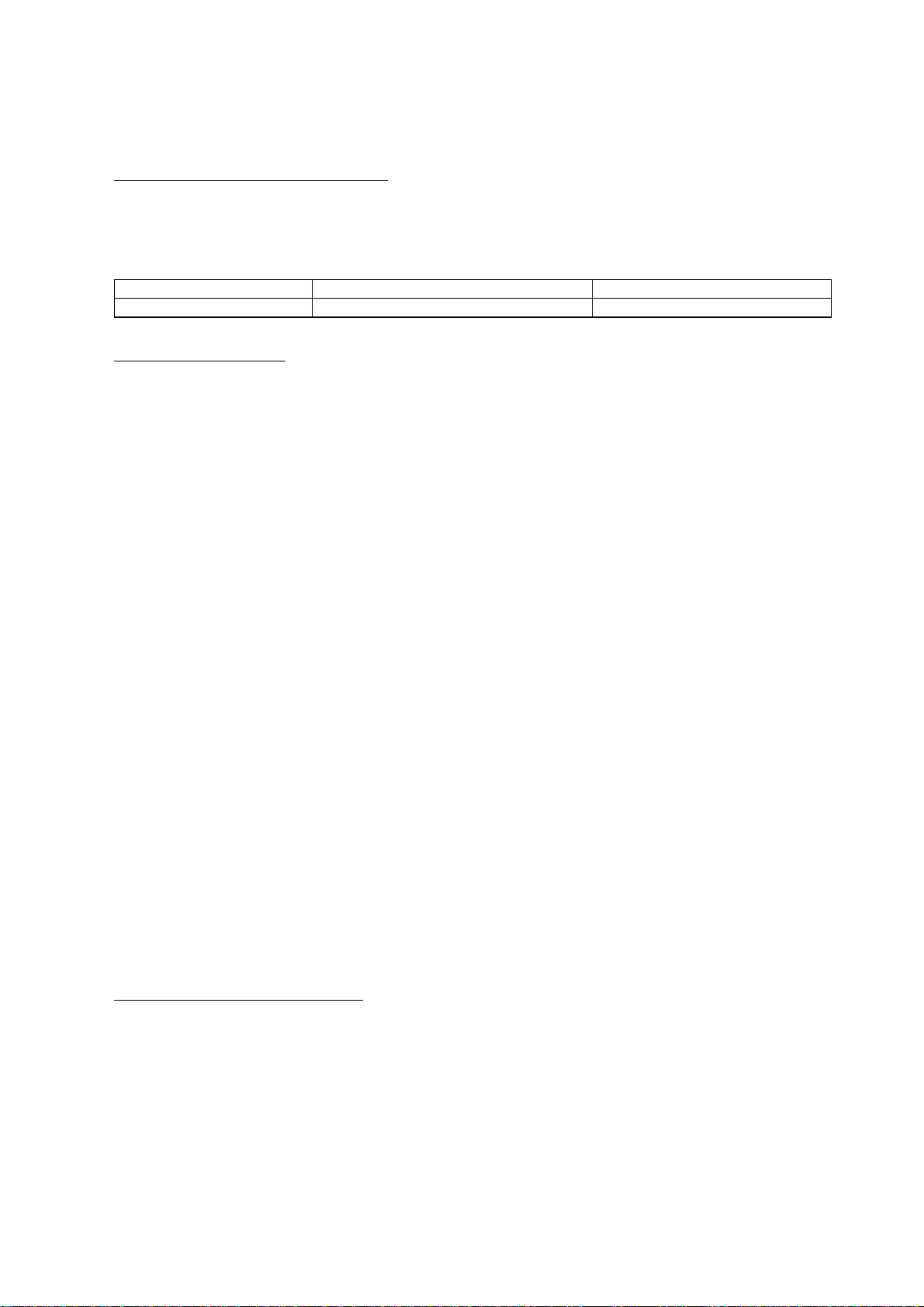

TABLE OF CHANGES

The information given in this document only concern devices of Injectomat 2000 MC / Pilot Delta

Technical reference N° ...............................................NT 1023

Revision date: ............................................................02/07/02

Applicable from serial N°.............................................18091461

Date Revision no. Pages concerned Changes

01/08/00 A0 all creation

• Reference Injectomat 2000 MC / Pilot

02/07/02 B0 55 & 61

Delta RS232 HE13 power supply board,

• Equivalence table

Page 4

Page 5

TABLE OF CONTENT

1 OVERVIEW.......................................................................................... 5

1.1. Block diagram .............................................................................................................. 5

1.2. Precautions before use................................................................................................6

1.3. Overall product specifications...................................................................................... 6

1.3.1. Biological specifications ............................................................................................ 6

1.3.2. Mechanical specifications.......................................................................................... 6

1.3.3. Dimensions................................................................................................................ 6

1.3.4. Electrical specifications.............................................................................................6

1.3.5. Electronic specifications............................................................................................ 6

1.3.6. Injectomat 2000 MC / Pilot Delta Operator's guide................................................... 6

2 ELECTRONIC BOARD........................................................................7

2.1. MOTOR POWER SUPPLY AND CONTROL BOARD................................................. 7

2.1.1. Functional description ............................................................................................... 7

2.1.2. Description of connectors........................................................................................ 14

2.1.3. Electrical layout....................................................................................................... 16

2.1.4. Installation layout..................................................................................................... 16

2.2. CPU BOARD.............................................................................................................. 16

2.2.1. Functional description ............................................................................................. 16

2.2.2. Description of connectors........................................................................................ 19

2.2.3. Electrical layout....................................................................................................... 21

2.2.4. Installation layout..................................................................................................... 21

2.3. DISPLAY BOARD ...................................................................................................... 21

2.3.1. Overview................................................................................................................. 21

2.3.2. Functional description ............................................................................................. 21

2.3.3. Description of connectors........................................................................................ 23

2.3.4. Power consumption................................................................................................. 24

2.3.5. Electrical layout....................................................................................................... 24

2.3.6. Implantation layout..................................................................................................24

3 Configurations..................................................................................24

3.1. Configuration of the pressure functionalities.............................................................. 24

3.2. Configurations of the various parameters.................................................................. 24

3.3. CHECKING THE PILOT............................................................................................. 29

3.3.1. The After Sale Service test ..................................................................................... 29

3.3.2. Running time tESt.1............................................................................................ 30

3.3.3. Lights test tESt.2................................................................................................30

3.3.4. Key board test tESt.3 .......................................................................................... 30

3.3.5. Battery voltage display tESt.4 ............................................................................. 31

3.3.6. Last 10 alarms codes tESt.5 .............................................................................. 31

3.3.7. Total running time tESt.6.................................................................................... 32

3.3.8. TTL Serial link test: tESt.7................................................................................... 32

3.3.9. Serial link test: tESt.8.......................................................................................... 32

3.3.10. Strength on the plunger display: tESt.9............................................................ 33

3.3.11. Software version tESt.A.....................................................................................33

3.3.12. Analog input display tESt.B ............................................................................... 33

3.3.13. Driving block position display tESt.C ................................................................. 34

3.3.14. Calibration values display tESt.E.......................................................................34

3.3.15. Syringe type display tESt.F ............................................................................... 34

3.3.16. Displays of the last 10 events before the last blocking error tESt.J.................. 34

3.3.17. Drug library tESt.L............................................................................................. 34

4 REPLACING SUB-ASSEMBLIES.....................................................34

NT 1023 Rev.B0 page : 1

Page 6

4.1. Mounting the flexible circuit........................................................................................ 35

4.2. Wiring the components on the flexible circuit............................................................. 35

4.2.1. Mounting the potentiometer.....................................................................................36

4.2.2. Wiring the potentiometer.........................................................................................37

4.2.3. Plug holder connector ............................................................................................. 37

4.2.4. Lubricating the mechanical parts............................................................................. 37

5 MAINTENANCE.................................................................................39

5.1. Recommendations .....................................................................................................39

5.2. Cleaning and disinfection...........................................................................................39

5.3. Storage.......................................................................................................................39

5.4. Routine inspections.................................................................................................... 39

5.4.1. Checking before use ...............................................................................................40

5.4.2. Checking protocol (Technical manual).................................................................... 40

5.5. Technical check procedure PILOT anaesthesia 2 .....................................................42

5.6. Checking disengagement system ..............................................................................43

5.7. Checking force sensor ............................................................................................... 44

5.8. Checking back-pressure ............................................................................................44

5.9. Checking registered syringe list /syringe list label...................................................... 45

5.10. Checking Mains/Battery operation ........................................................................... 45

5.11. Checking linearity..................................................................................................... 45

5.11.1. Equipment used .................................................................................................... 45

5.11.2. Operating mode..................................................................................................... 45

5.12. Checking end of infusion..........................................................................................46

5.12.1. End of infusion pre-alarm......................................................................................46

5.12.2. End of infusion alarm............................................................................................. 46

5.13. Checking the Led's and keyboard............................................................................ 47

5.14. Battery autonomy test...............................................................................................47

5.15. Continuity test........................................................................................................... 47

5.16. Trouble Shooting...................................................................................................... 48

5.17. Error message Er(-)0, Er01, Er(-)2, Er03, CFPc...................................................... 49

5.18. Flow rate control protocol: flow rate measurement with computer...........................49

5.18.1. Equipment used: ................................................................................................... 50

5.18.2. installation..............................................................................................................50

5.18.3. Operating mode..................................................................................................... 51

5.18.4. Installation drawing................................................................................................ 51

5.19. Flow rate control: flow rate control measurement with scales.................................. 51

5.19.1. Equipment used: ................................................................................................... 51

5.19.2. Installation .............................................................................................................52

5.19.3. Operating mode..................................................................................................... 52

5.20. Flow rate control: flow rate measurement using a test tube..................................... 53

5.20.1. Equipment used .................................................................................................... 53

5.20.2. Installation .............................................................................................................53

5.20.3. Operating mode..................................................................................................... 53

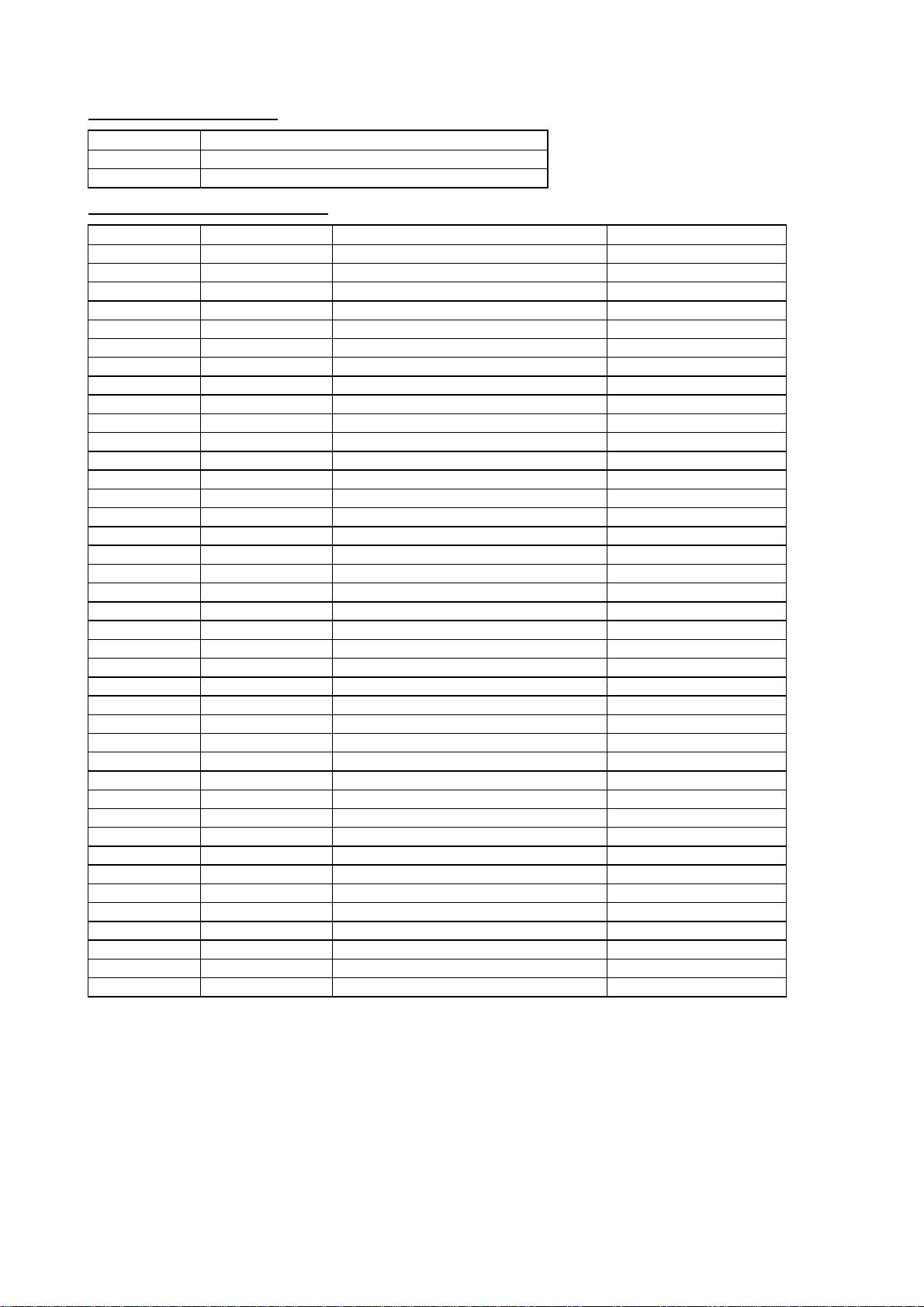

6 ANNEX 1: ILLUSTRATED PARTS LIST........................................... 54

6.1. Subassembly traceability table................................................................................... 54

6.1.1. Introduction.............................................................................................................. 54

6.1.2. Replacement parts table ......................................................................................... 54

6.2. Exploded views and related parts lists .......................................................................55

6.2.1. Mechanical part list.................................................................................................. 55

6.2.2. Electronical parts list ............................................................................................... 60

6.2.3. Operator’s guide of Injectomat 2000 MC / Pilot Delta(NU)...................................... 61

Page : 2 NT 1023 Rev.B0

Page 7

6.2.4. Labels......................................................................................................................61

7 ANNEX 2: ELECTRONIC LAYOUT................................................... 62

7.1. Rear door wiring.................................................... Fehler! Textmarke nicht definiert.

7.2. Power supply and control board.................................................................................62

7.2.1. Electronic layout...................................................................................................... 62

7.2.2. Installation layout..................................................................................................... 62

7.3. CPU board.................................................................................................................. 62

7.3.1. Electronic layout...................................................................................................... 62

7.3.2. Installation layout..................................................................................................... 62

7.4. Display board ............................................................................................................. 62

7.4.1. Electronic layout...................................................................................................... 62

7.4.2. Installation layout..................................................................................................... 62

8 ADDENDA AND INFORMATION BULLETINS.................................... 1

9 USEFUL ADDRESSES........................................................................4

NT 1023 Rev.B0 page : 3

Page 8

Page : 4 NT 1023 Rev.B0

Page 9

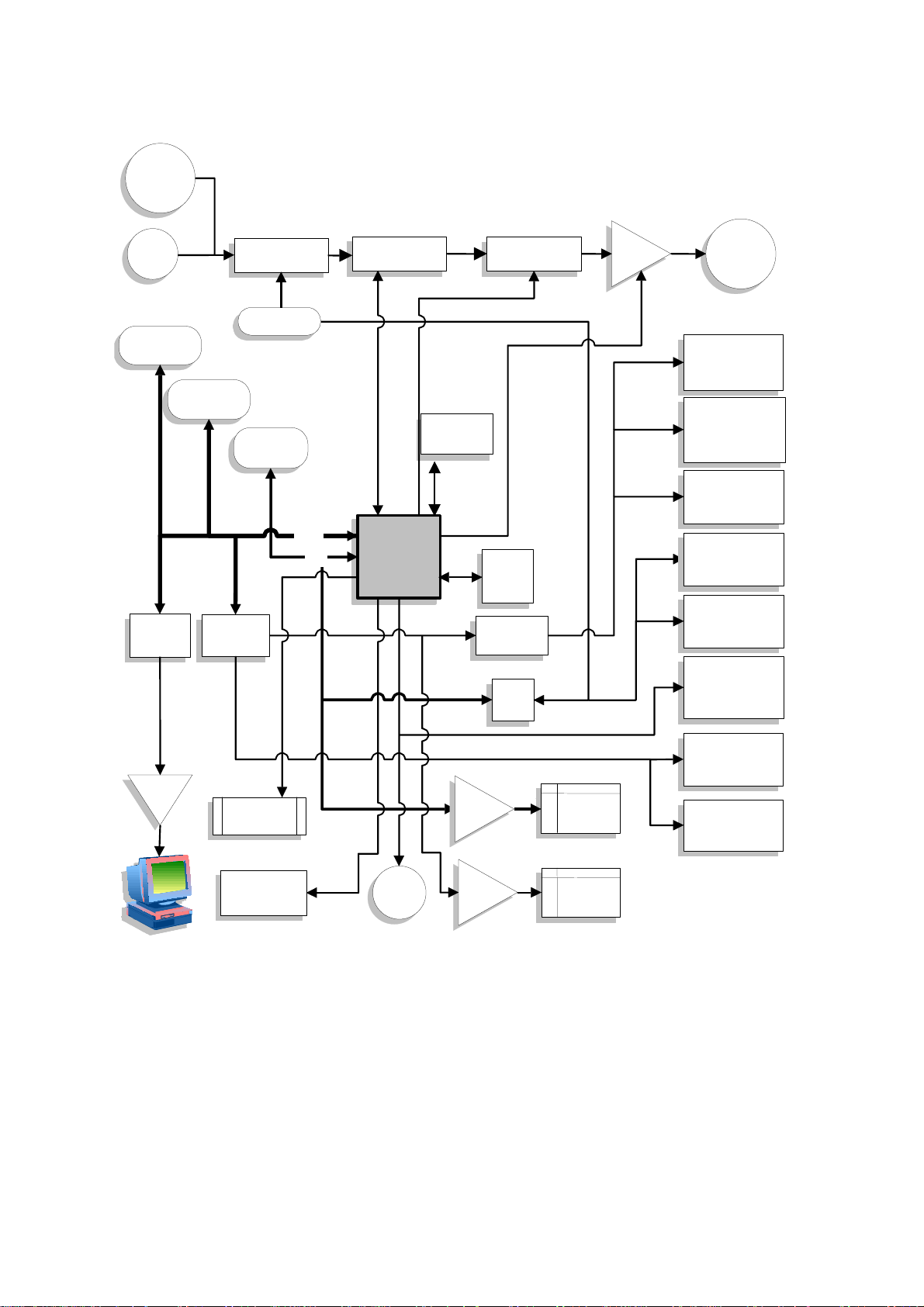

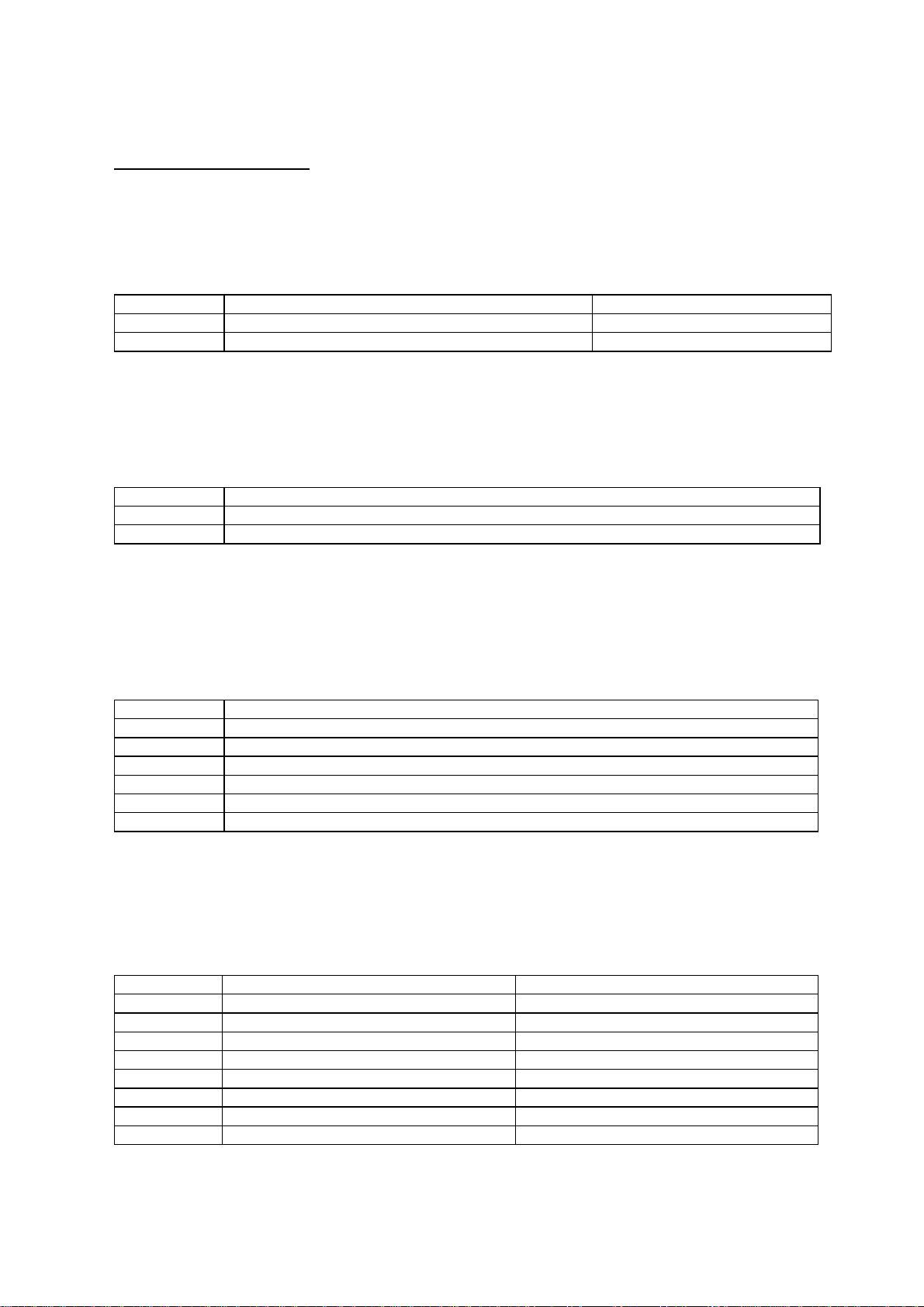

1 OVERVIEW

keeper

1.1. Block diagram

Ext

12/15V

15W

230V

EPROM

512K x 8

UART

RAM

8K x 8

interface

Power supply

Battery

EEPROM

16K

Bus

BUS

SPI

ON / OFF

CPU

Time

DC-DC

Converter

Watch

dog

opto

Interface

ADC

Motor

driver

Step

by step

motor

Motor

rotation

sensor

Syringe

barrel

sensor

Antisiphon

sensor

Occlusion

strength

sensor

Displacement

sensor

Nurse

call

(option)

RS232

Keyboard

Master

Buzzer

LCD

driver

LED

driver

LCD

Display

LED

Display

Disengagement

Switch

Flange

Switch

NT 1023 Rev.B0 page : 5

Page 10

1.2. Precautions before use

Please consult the user guide

1.3. Overall product specifications

1.3.1. Biological specifications

Infusion liquid only comes into contact with the syringe and associated disposable.

1.3.2. Mechanical specifications

Device operation is based on a "lead screew/nut" principle. The mechanism pushes the piston of a syringe, of a given diameter, in a linear manner.

1.3.3. Dimensions

q H x L x D 120 x 330 x 155 mm.

q CarrWeight 2.2 kg approximately.

1.3.4. Electrical specifications

q Power supply 230V - 50-60 Hz.(Check on the pump the identification label).

q Maximum consumption 23 VA.

q Fuse F2 100 mAT 250V IEC 127

q Battery 6V - 1.2Ah./1.3 Ah

q External power supply 12 - 15 DC - 15W

1.3.5. Electronic specifications

The Injectomat 2000 MC / Pilot Delta syringe pump is fitted with 3 circuit boards whose features vary in

line with product specifications and options.

q Motor power supply and control board.

q CPU board.

q Keyboard display board.

1.3.6. Injectomat 2000 MC / Pilot Delta Operator's guide

Operator's Guide can be obtained from our After Sales Service (see chapter 10.Useful addresses).

Page : 6 NT 1023 Rev.B0

Page 11

2 ELECTRONIC BOARD

2.1. MOTOR POWER SUPPLY AND CONTROL BOARD

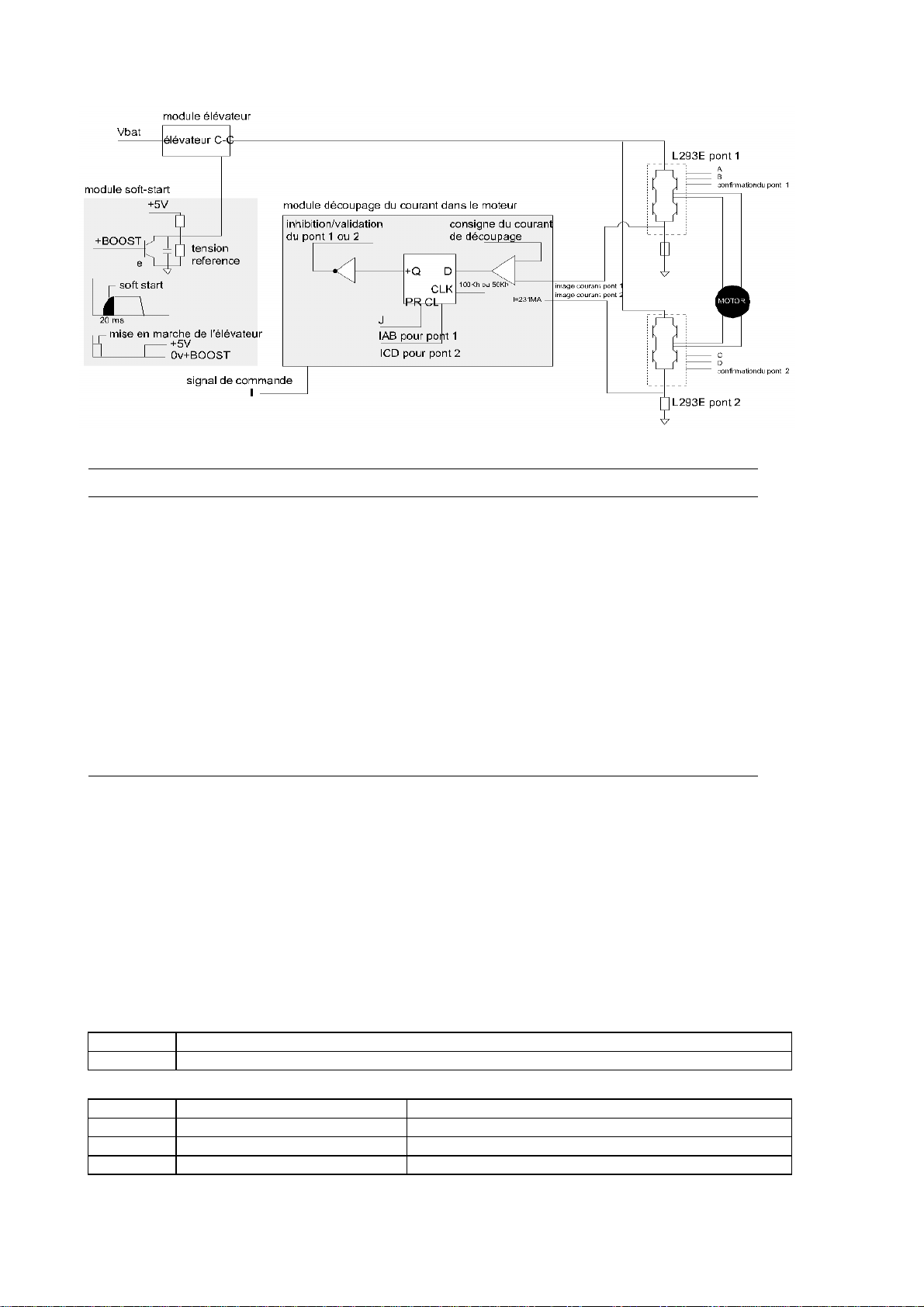

2.1.1. Functional description

In order to simplify wiring the motor power supply control board concentrates 6 functional modules, which

may be described separately:

q power supply module,

q motor control module,

q analog output module,

q disengage and anti-siphon opto switch module,

q microswitch input module,

q optional nurse call and RS232 interface module.

2.1.1.1. Power supply module

The power supply module consists of a cut-out power unit. It supplies all electronic components and

charges a 1,1 -1,2 or 1,3 Ah backup battery from a mains voltage input or a 12/15 volt DC power source. It

generates the + 5V and Vbat voltage required by the electronic components. Finally it comprises an

ON/OFF switch controlling the various power supplies.

2.1.1.1.1. Mains power supply

The mains power supply generates a DC voltage ranging from 10 and 16 volts for a maximum current of

1,2 A.

J1 mains input connector: 1 phase

2 neutral

Transformer: TR1(see Electrical chart), 15VA output voltage: 9 Vac

Fuse protection: F2 Principal characteristics chap1.1

Primary filtering 4.7 nf 4000 V HR capacitor, type DS1510 VDE

Secondary filtering C10 Chemical Capacitor

Output voltage measured on TP3 for mains voltage: 230V measured (±± 10%)

Min Max Unit

power off: 14 16 V dc

7 ohm charged on J4: 10 16 V dc

primary current charged: 80 mA ac

Maximum voltage 16 volts limited by the diode D 41

Minimum voltage 10 volts limited by the mains voltage - 10% and U1(MAX 652)

voltage higher than 10 volts.

NT 1023 Rev.B0 page : 7

Page 12

2.1.1.1.2. External 12-15V AC/DC power supply

The DC power supply input is designed to provide the syringe pump with a constant, external power

source, such as a 12V battery.

Maximum input voltage ± 15 volts protection against polarity inversion by the PR2 WO4 diode bridge.

Minimum input voltage ± 11 volts 1.2 A limited by input voltage MAX 625 and loss, diode bridge on the PR2.

Limitation ± 16 volts maximum for through D 41.

2.1.1.1.3. Cut-out charger/controller

The controller is powered either from the mains or from an external DC power source. It generates a

maximum voltage of 6.9V VBC, as required to charge the 1.1/1.2 Ah gelified lead battery, connected to

J4, and power the electronic components.

J4 Connector: 1 battery +

2 battery -

VBC power comes directly from the battery if neither the mains nor the external power source are connected. Otherwise power, from an external source, supplies the electronic components and charges the

battery via diode D8 and the delayed protection fuse, F1, 1.6A.

Maximum fuse resistance 0.5 Ohms

Controller operation is indicated by two signals responsible for reporting operation using an external

power source either mains power or the external DC power unit.

LDSECT 10 mA drives a diode which checks that the SECT diode is on, using a TTL signal, with + 5V

pull up collector open, mains presence active at 0.

Cut-out controller: U1(MAX625) output voltage 7.05V 1.3 A min

Output voltage measured on J4.1

for 230 V mains:

Min. Max. Unit

Power OFF 3 mA charge on J4. : 6.7V 7V V DC

8 ohm charge on J4: 6.5V 7V V DC

On J4 the voltage must never exceed 7V, the maximum voltage of the charged battery.

The 6.5 minimum voltage is higher than the battery pre-alarm threshold.

2.1.1.1.4. ON/OFF control

The VBAT and + 5V control system is implemented using the following circuits: U2 4011, U4 4528 and an

G6AK 234P flip-flop relay.

This system is powered, at all times, by the VBC voltage.

2.1.1.1.4.1 System:

3 inputs:

TON ON key dry contact/GND

TOFF OFF key dry contact/GND

CDALIM active TTL signal with voltage cut-out

2 ouputs:

VBAT Battery power/mains power.

OFF TTL signal collector, + 5V PULL-UP open, OFF key pressed down, active at 0

Page : 8 NT 1023 Rev.B0

Page 13

2.1.1.1.4.2 Operation:

Press TON briefly to turn power on.

Press TOFF continuously (5s<t<7s) to turn power off during a technical Failure.

Press OFF 3 seconds to power OFF via CDALIM micro signal.

The device can set ON or OFF via an external. Master module using the CD ON or CD OFF signal.

2.1.1.1.5. VBAT and + 5V power supply

VBAT voltage corresponds to mains voltage taken directly from the power unit/charger. Voltage is not

controlled. It powers the display system and the motor, both of which are heavy duty energy consumers.

This voltage is available on TP1 and J2

Min Max

VBAT 6,5V 7V

The + 5V ± 5% is generated, using VBAT voltage, by the NS 2931 V3 controller low drop-out 0.6V for a

100 mA output current.

It is thus possible to make the best possible use of the battery. This voltage is available on TP2.

The 5V rise time must be greater than 100 ms to allow for the RESET function on the CPU board.

2.1.1.2. Motor control module

The control module of step by step motor is equipped with a gear reduction of 89.286. which makes the

double threaded screw 2 mm turn.

- One motor step is equivalent to 0.8233 µm of linear displacement of the driving bloc.

- One motor turn is equivalent to 22.4 µm of linear displacement of the driving bloc.

2.1.1.2.1. Motor control

Injectomat 2000 MC / Pilot Delta motor control is implemented by a stepper motor driver, dual pole control module for a motor - UBB 5N model - (11.5 Ohm coil) built using an ST L293E IC7 motor control circuit.

It features two functional modules:

The motor control electronic parts, built around the L293E U13 circuit, optimises consumption and opti-

mal motor torque according to the pump flow rate.

2.1.1.2.1.1 Input signals

These signals are generated by the CPU board microprocessor and available on J02.

They drive the U15 ULN2803 circuit.

2.1.1.2.1.2 Output signals

These signals are connected to the motor coils via J5 connector.

Phase A A Motor phase control J2.5

Phase B B Motor phase control J2.6

Phase C C Motor phase control J2.7

Phase D D Motor phase control J2.8

I Motor current reduction control J2.9

B00ST Booster activation and regulation current J2.10

NT 1023 Rev.B0 page : 9

Page 14

2.1.1.2.1.3 Booster module

BOOST = 0 The motor is powered via VBAT voltage.

BOOST = 1 Booster function activated, the motor is powered at 12 Volts.

L2 reactor, D18 diode, C15 capacitor and T8 transistor assembly allows a voltage of 12 V +/- 2 volts to

be obtained from VBAT.

This voltage is available on TP5.

The uncoupling frequency, 100 kHz, is generated by U9 oscillator, the booster is activated when the

boost line is at 1.

2.1.1.2.1.4 Soft-start module

The soft-start module, which is designed around the T9 transistor and C21 capacitor allows the pick up

current of the uncoupling elevator to be limited when BOOST goes to 1.

2.1.1.2.1.5 Current regulation module

BOOST = 1 and I = 1 regulation motor current module is activated.

The regulated current in the motor is 240 mA +/- 10% per motor phase.

The signals amplitude and current image are available in TP6 and TP7.

The current image of each coil is compared to a fixed level, which is implemented from the Divider bridge

using R31, R41/R37 and R42.

The control is achieved through the U11 toggle, via a divider bridge by inhibition or confirmation of the

L293E control H bridge driving the CE1 and CE2 inputs.

The calibrating frequency of 25 kHz is supplied by the U10 toggle.

2.1.1.2.1.6 Reduction current module

When the Boost signal sets at 0, the I line is used as current reducer.

I = 1 The H divider bridge is controlled by the A, B,C and D lines.

I = 0 The H divider bridge is inhibited, the coils are not forwarded.

According to its rotation frequency (step/second), the motor is driven in one of the 3 control modes.

Mode Frequency motor (step/second) Control description

Phase 1 from 0 to 32.3 Current reduction one ON supply

Phase 2 from 32.3 to 90 No current reduction and regulation, one ON supply

Phase 3 from 90 to 850 Current reduction, booster ON two supply

Page : 10 NT 1023 Rev.B0

Page 15

2.1.1.3. Analog output module

The analog output module is built around a 10 bit, 5 channel analog/digital converter (MC 145053 U17)

with an SPI bus.

The following SPI CLK, SI, SO, CSADC bus signals are available on connector J2:

In addition the component generates an end of conversion signal (EOC).

The CDANA signal, which is active when set to 1, controls the transistor T14 IRFD 9120 which digitally

drives VREF. This voltage supplies the sensors and serves as a reference value for the ADC convertor.

All the test points are concentrated on connector J9.

Measurement of VREF on J9.7

VREF Pulsated signal of 5Volt ± 0.25V.

Convertor input:

ANO VBAT battery voltage measurement.

AN1 not in use

AN2 internal occlusion gauge bridge

AN3 NU

AN4 Absolute potentiometric position sensor

2.1.1.3.1. Battery voltage measurement

VBAT voltage is measured using a peak detection circuit comprising D19, R59, R60 and C23 in order to

overcome the lower voltage created by the motor's pulsing demand for current.

The voltage is available on J9.3.

For VBAT = 6.5V, V(J9.3)= 4V ± 10% motor running at 150 ml/h

2.1.1.3.2. Gauge bridge interfaces

The only Injectomat 2000 MC / Pilot Delta includes a force sensor fixed on the pusher.

2.1.1.3.2.1 Force sensor characteristics

Sensor technical Complete bridge with 4 gauges

Impedance 350 Ohms ± 15% or 1 KOhms ± 15%

Measurement range 0 to 150 N

Surcharge 250 N

Zero

< ± 10mV

Sensibility 8.5 to 12 mV at 150 N

zero derivation

2.1.1.3.2.2 Operation

85 µV /year

The force sensor generates a differential voltage proportional to the force sensor applied on the driving

bloc. This force is amplified by a gain of 200 +/- 20% via an amplifier built around U18 TLC 251. The potentiometer P1 allows the offset to be compensated and for any other offset to be reset from the beginning. The sensor measurement chain transfer function can be defined by calibrating the sensor with two

known forces.

AN3 J9.4 Pulsated amplitude signal sets at 0.6 V +/- 0.05 V for no force applied on the driving bloc

2.1.1.3.2.3 Force sensor connector

J8.1 VREF Gauge bridge power supply (+)

J8.2 S(-) Out put Gauge bridge (-)

J8.3 S(+) Out put Gauge bridge (+)

J8.4 GND Gauge bridge power supply (-)

NT 1023 Rev.B0 page : 11

Page 16

2.1.1.3.3. Driving bloc position sensor

The absolute position of the driving bloc is obtained by a potentiometric sensor driven by a movement of

the driving bloc.

The transfer function of the sensor can be characterised by calibration in two known positions.

The sensor is powered by a pulsated voltage. The output is filtered by R62 and C22 linked directly to the

input AN4 (J2)

Potentiometer connector:

J3.1 VREF

J3.2 Center point J9.2

J3.3 GND

2.1.1.4. Opto switch module

The opto switch module comprise 2 optical switches:

q A motor rotation detection switch

q A syringe position head detector switch

2.1.1.4.1. Motor rotation opto

The opto switch is mounted on a disk which is pierced with a hole and assembled on the motor.

It is used to check motor rotation, the opto diode is controlled in pulse mode to save energy.

The optical switch is connected on J5.

Control T11 transistor Current limitation (R51) at 8mA

Output T10 transistor TTL level

J2.14 Control signal CDOPT1 activate at 1

J2.11 Output signal SOPT1 activate at 1

J5.7 Diode anode

J5.8 Diode cathode

J5.10 Transistor transmitter

J5.9 Transistor collector

TdON max 100 µsec

TdOFF max 200 µsec

An anti-rebound device made of U20 flip-flop, reshapes the SOPT1 signal.

The CDOPT1 and SOPT1 are emitted by the CPU board, and available on J2 connector

2.1.1.4.2. Anti-siphon opto switch

The opto switch is mounted on the plunger holder, it is used to check the presence or not of the syringe

head.

It is connected on J8 connector.

Control T12 Transistor Current limitation (R52) 8mA

Output T13 Transistor TTL level

Control signal CDOPT2 activate at 1 J2.15

Output signal SOPT2 activate at 1 J2.12

Anode diode J8.6

Cathode diode J8.5

Transistor transmitter common ground J8.10

Transistor collector J8.7

SOPT2 0V Anti - siphon present

SOPT2 5V Anti - siphon missing

Page : 12 NT 1023 Rev.B0

Page 17

J8 is the ribbon cable linking the occlusion, disengagement and position sensors located on the syringe

pump driver.

The CDOPT2 and SOPT2 signals are emitted by the CPU board and available on J2 connector.

The opto diode is powered by pulsated voltage in order to save energy.

2.1.1.5. Micro switch module

2.1.1.5.1. Disengagement micro - switch

The microswitch is mounted on the driving bloc ribbon cable. The centre point of the microswitch is connected to the ground.

The signals are available on J2 connector.

J8.8 DEB/ON NU

J8.9 DEB/OFF OV engaged / 5V disengaged

J8.10 GRD

2.1.1.5.2. Nurse call option

This is implemented by a monostable inverter relay RL2, whose two contacts and common point are

available on J6 connector, the relay is driven by the BUZ signal which also drives the buzzer on the display board.

J6.6 common point

J6.7 contact normally open cut out power 24V/ 1A

J6.8 contact normally shut

2.1.1.5.3. RS 232 option

The RS232 option interface RXD1 and TXD1 signals, in compliance with the V24 standard, signals come

from the UART 2691 serial link external controller on the CPU board. It is implemented using a U19 LT

1180 CS circuit, associated with +/- 12V voltage generator, C31, C32, C33, C34 capacitors. This circuit

is operational only if the pins 2 and 5 of J6 are short-circuited.

J6.1 output transmits data TX1

J6.2 +5V (DSR)

J6.3 input receives data RX1

J6.4 GND

J6.5 confirmation (DTR)

J6.17 CTS

J6.18 RTS

2.1.1.5.4. Configuration link and Master plug

The syringe pump Injectomat 2000 MC / Pilot Delta may be fitted to master module connected to the SUB

15 points plug located on the pump rear panel.

The module master communication link is done by the RX2 and TX2 signals.

J6.13 +VBAT Master power

J6.14 RX2 Receive data

J6.15 TX2 Transmit data

J6.16 GND Master ground

J6.9 CD-ON Syringe pump ON via master

J6.10 CD-OFF Syringe pump OFF via master

J6.12 I-SECT Master led main signal

J6.11 I-OPTOM Motor rotation opto master control signal

J6.19 BUZ Pilot buzzer command signal

NT 1023 Rev.B0 page : 13

Page 18

2.1.2. Description of connectors

2.1.2.1. J1 mains connector

Pin description

1 Neutral

2 Phase

2.1.2.2. J2 board / CPU connection

Pin Description

1 + 5V controlled power supply

2 GND power supply

3 + VBAT power supply

4 GND power supply

5 phase A motor control

6 phase B motor control

7 phase C motor control

8 phase D motor control

9 I signal motor control

10 BOOST signal booster command

11 sopt1 opto rotation module out put

12 sopt2 opto anti-siphon module out put

13 not in use

14 cdopt1 opto rotation control module

15 cdopt2 opto anti-siphon module control

16 OFF signal off key pressed ON/OFF

17 SECT mains power on signal power supply

18 CDALIM power cut signal

19 LDSECT mains LED control

20 CTS clear to send

21 DEB/OFF disengage signal active, set to 0

22 RTS request to send

23 OCC/OFF occlusion signal active, set to 0

24 BUZ nurse call relay control

25 EOC end of conversion ADC

26 CSADC selection bus SPI ADC

27 CLK clock bus SPI ADC

28 SI data IN bus SPI ADC

29 SO data out bus SPI ADC

30 CDANA analog sensor power control

31 RX2 receive data TTL line 2

32 TX2 transmit data TTL line 2

33 TXD1 transmit data TTL line 1

34 RXD1 receive data TTL line 1

35 TOFF OFF key

36 TON ON key

37 + VBAT power supply

38 GND power supply

39 + 5V power supply

40 GND power supply

Page : 14 NT 1023 Rev.B0

Page 19

2.1.2.3. J3 potentiometric sensor connector

Pin Description

1 VREF

2 centre point

3 GND

2.1.2.4. J4 internal battery connector

Pin Description

1

2

2.1.2.5. J5 motor connector

Pin Description

1 + VBAT

2 + VBAT

3 PHASE D

4 PHASE C

5 PHASE B

6 PHASE A

7 opto rotation anode diode/ + 5V

8 opto rotation cathode diode

9 opto rotation collector transistor

10 opto rotation transmitter transistor / GND

battery +

battery -

2.1.2.6. J6 rear panel connector

The connector on the rear panel concentrates signals from the external gauge bridge, the optional RS232

series link, the nurse call relay output and the configuration series link.

Pin Description

1 TX1 transmit data line 1

2 + 5V power supply

3 RX1 receive data line 1

4 GND power supply

5 DTR interface confirm

6 APP-INF COM nurse call relay common point

7 APP-INF NO nurse call relay normally open

8 APP-INF NF nurse call relay normally closed

9 CD ON external ON

10 CD OFF external OFF

11 I-OPTON motor control out put

12 I-SECT main led

13 + V BAT external power plug

14 RX 2 receive data line 2

15 T X 2 receive data line 2

16 GND power supply

17 CTS clear to send

18 RTS Request to send

19 BUZ buzzer external control

2.1.2.7. J7 external DC power supply connector

Pin Description

1 External power +/2 External power -/ +

2.1.2.8. J8 pump ribbon cable connector

The pump ribbon cable connector concentrates all the signals from the sensors located in the plunger:

disengage microswitch, gauge bridge and anti-siphon opto switch.

NT 1023 Rev.B0 page : 15

Page 20

Pin Description

1 + VREF + internal gauge bridge

2 E1 internal gauge bridge/occlusion input on

3 E2 internal gauge bridge/occlusion input off

4 GND internal gauge bridge

5 C DOPT2 anti-siphon cathode diode

6 + 5V opto anti-siphon anode diode / + 5V

7 S OPT 2 opto anti-siphon collector transistor

8 DEB / ON disengage microswitch on

9 DEB / OFF disengage microswitch off

10 GND

♦ Important: Disassemble the ribbon cable holder on the supply board before extracting the me-

chanical assembly from the lower housing.

2.1.2.9. J9 Test Points

Pin Description

1 GND

2 out put position sensor

3 out put low battery control

4 out put force sensor amplifier

5 N.U.

6 out put optical switch motor control

7 force and position sensor voltage Ref.

8 out put optical switch syringe led detection

2.1.3. Electrical layout

(Refer to Annex 2)

2.1.4. Installation layout

(Refer to Annex 2)

2.2. CPU BOARD

Overview

The CPU board is fitted to Injectomat 2000 MC / Pilot Delta version, around a 80C32 microproces-

sor used in open mode. It concentrates all the peripheral devices directly connected to the 80C32

bus. It is connected to the power supply board by a 40 contacts ribbon cable and to the display

board by fixed connectors. It forms a single unit, with the display board, which is fixed to the front

panel.

The CPU board uses CMOS technology in order to minimise power consumption.

Current used: 5 Volts 80 mA maximum.

2.2.1. Functional description

The CPU board comprises six functional units:

q Ram rom decoding processor

q Reset WATCH DOG

q Parallel port extensions

display/keyboard interface,

motor interface,

sensor interface.

Page : 16 NT 1023 Rev.B0

Page 21

q SPI BUS

q Asynchronous serial link

q Optical sensor

2.2.1.1. RAM ROM decoding processor

Decoding is carried out by an IC3 80C32 circuit, running at 12 MHz, clocked by Q1. It is used in open

mode, with the EA*/VP line connected to GND.

Address/data de-multiplexing is carried out by a 74HC573 U3.

On this BUS are implemented:

32 Ko static RAM U6

27C040 512 Ko U4

2.2.1.2. Reset watch-dog

The RESET WATCH-DOG module comprises two TL7705 U10 and U11 circuits.

Operation: the U10 circuit generates RESET signals, active at 1, for the processor and the UART; RST*

active at 0 generates RESET signals for the other peripheral devices.

The signals are activate in two cases:

q when the system is powered up,

q as soon as the WATCH-DOG circuit is triggered. It remains active until the power is turned off.

2.2.1.2.1. Reset at power-up

The TL 7705 circuit guarantees the minimum duration of the reset lines, in the active state, once the + 5V

voltage has exceeded the circuit operating threshold (4.75V). It returns to the active state, if the + 5V voltage drops below the threshold or if the RESTIN* (U11.2) is at 0. The line is driven by the WATCH-DOG

module.

The duration of the reset, in the active state, at power-up is set by the C10 capacitor 220nF 100 ms.

2.2.1.2.2. Watch-dog

The WATCHDOG circuit comprises the following elements: U10, U11, C12, D2, D1, R4, C11.

When powered up the capacitor C12 is charged by the U10 circuit, via diode D1.

The charge is maintained at a threshold of over 1.5 V during operation.

The software writes, every 1 ms. This writing generates a 5V/1µs impulse on the U7.10 output, which re-

charges the capacitor C12 via a high pass peak detector circuit made up C8, D3, D2. The C12 capacitor

discharges in resistor R4.

When the software stops, the capacitor C12 completely discharges. The U11 RESTIN* line falls to 0 and

the RESET signals are activated, stopping all syringe-pump control operations in the inactive state. Fault

signals, the blinking FAIL diode and the continuous BUZZER are stuck in an active state.

WATCH-DOG trigger time is less than 400 ms.

2.2.1.3. Keyboard/display interfacing

2.2.1.3.1. Display registers

The display system is made of LED’s and of a 2 lines of 20 characters LCD graphic screen. The U7 circuit allows to address the matrix of the LED’s, the U8 circuit allows the writing and reading in the display

controller.

The LED’s matrix are DIG0 to DIG7 and SEG0 to SEG7.

The FAIL LED shows the device is failed, the command is inverted to be active by default at RESET. It is

active at 1 on the display board. The FAIL diode is out of the matrix to be able to light on when the micropossor does not work.

NT 1023 Rev.B0 page : 17

Page 22

2.2.1.3.2. Buzzer

The BUZZER command is inverted and controls the transistor, T3, which is mounted as a common transmitter. Working in parallel, the transistor collector drives the BUZZER on the display board and the nurse

call relay on the motor control power supply board. After starting the pump, the BUZZER is activated for

added safety.

BUZZ signal: J5 pin 6 and J3 pin 24 50 mA 6.75 Volts maximum.

2.2.1.3.3. Keyboard register

The keyboard is based on a 6 x 3 matrix, with 2 separate keys - TON and TOFF - with 1 common point

(GND). They turn power ON and OFF respectively and are connected to the display board. TON and

TOFF signals only transits via the CPU board.

The columns of the keyboard are driven by the same signals as the columns in the display matrix, thus

facilitating simultaneous keyboard and display monitoring. Register U15 reads the status of the three keyboard lines, LIG1, LIG2 and LIG3 in order to check whether a key has been activated.

2.2.1.3.4. Motor control register

The U12 motor control register generates 4 motor phase signals, A,B,C and D, the I current control signal, the motor rotation opto control CDOPT1 signal and the BOOST BOOSTER control signal.

2.2.1.3.5. Sensor status register

The U16 sensor status register reads the microswitch digital sensors and the syringe pump opto switch.

2.2.1.4. SPI bus EEPROM

The SPI bus is synchronous series communication bus using various peripheral circuits. The SPI bus is

driven by the 80C32 ports.

The Injectomat 2000 MC / Pilot Delta syringe pump has 2 peripheral devices on the SPI bus:

q The EEPROM 16 Ko 24C128 U12 located on the CPU board.

q The MC 145053 analog/digital converter located on the motor board.

This bus has 2 communication lines: 80C32 (see electrical diagrams)

Micoprocessor Ports

CLK clock generated by the microprocessor P 1.1

SI peripheral to processor data (input) P 1.2

2.2.1.5. Asynchronous serial links

The Injectomat 2000 MC / Pilot Delta syringe pump is fitted with two asynchronous serial links.

RS232 option line 1

TTL configuration serial link line 2

2.2.1.5.1. RS232 serial link

The RS232 serial link is implemented using the U8 SCC2691 circuit, which controls asynchronous communication, and RS232 interface circuit which is located on the motor power supply board.

The circuit is clocked by quartz Q2 at 3.6864 MHz. It includes a programmable baud rate generator. It

generates interrupts on the ITRS232 line connected to the processor at INTO.

The SCC2691 is on the microprocessor bus. It drives the RXD1 receive data signals on J3 (pin 34) and

TXD1 transmit data signals on J3 (pin 35).

The RS232 option is reserved for dialogue with the host computer responsible for monitoring or controlling the system.

Page : 18 NT 1023 Rev.B0

Page 23

2.2.1.5.2. TTL serial link

The TTL serial link is driven by the serial link controller inside the microprocessor. It uses one of the internal timers to generate its baud rate, from the basis of the processor 12 MHz clock. The serial link

drives the TXD2 transmit data and RXD2 receive data lines. The input and output lines are buffered by

the U9 74HC14 buffer trigger inverter circuit.

The lines are available on J3.

TX2 J3 pin 33

RX2 J3 pin 34

This serial communication line is reserved for Injectomat 2000 MC / Pilot Delta software configuration

and, when appropriate, for connecting an external MASTER module.

2.2.1.6. Opto switch sensors

Injectomat 2000 MC / Pilot Delta syringe pump opto switch sensors are for piston pressure and syringe

body presence and motor rotation.

The syringe body opto switch interface is located on the CPU board. It is implemented using transistors

T1, T2 and T3. Resistor R9 limits current in the diode to 8 mA.

2.2.1.6.1. Opto switch body syringe measurement.

q Note: The CI opto and the obturator are specific to the Injectomat 2000 MC / Pilot Delta equipped

with "flange detector" and are not compatible with previous versions.

q 2 opto devices allow to detect 2 syringe sizes: 60 cc and 20 cc.

J2.1 opto diode +5V anode

J2.2 opto cathode common point and transistor transmitter

J2.3 opto 1 transistor collector

J2.4 opto 2 transistor collector

Control signal: CODPT3 activate at 1 driven by microprocessor line T0.

Output signal: SOPT4 activate at 1 register U16 D1 address $ C000

Output signal: SOPT3 activate at 1 register U16 D0 address $ C000

.

SOPT3 SOPT4

Syringe clamp detection alarm, high position 1 0

60 cc detection 1 1

20 cc detection 0 1

Syringe clamp detection alarm, low position 0 0

The motor rotation and piston presence opto switch interfaces are located on the POWER SUPPLY

BOARD.

2.2.1.6.2. Motor rotation opto switch

Control signal: CDOPT1 activate at 1

Output signal: SOPT1 activate at 1

2.2.1.6.3. Piston presence opto switch (anti-siphon)

Control signal: CDOPT2 activate at 1

Output signal: SOPT2 activate at 1

2.2.2. Description of connectors

2.2.2.1. J1 not used

This connector is not used for the moment but it will be used for a future evolution of the software.

NT 1023 Rev.B0 page : 19

Page 24

2.2.2.2. J2 Opto switch - syringe body connector

Pin Description

1 ground

2 flange switch

3 opto +5 V diode anode

4 cathode diode transmitter transistor opto 1 and opto 2 common points

5 collector transistor opto 1

6 collector transistor opto 2

2.2.2.3. J3 Power supply/CPU ribbon cable

A 40 channel ribbon cable is soldered directly to J3, linking the power supply and the CPU.

Pin Description

1 + 5V controlled power supply

2 GND "

3 + VBAT "

4 GND "

5 A phase motor control

6 B phase "

7 C phase "

8 D phase "

9 I signal "

10 BOOST signal "

11 SOPT1 opto rotation module output

12 SOPT2 opto anti-siphon module output

13 APINF nurse call independent from buzzer signal

14 CDOPT1 opto rotation module control

15 CDOPT2 opto anti-siphon module control

16 OFF ON/OFF key depressed signal

17 SECT mains power supply on signal

18 CDALIM power cut signal

19 LDSECT mains LED control

20 CTS Clear to send line 2

21 DEB/OFF disengage active at 0 signal

22 RTS Request to send line 2

23 OCC/OFF occlusion active at 0 signal

24 BUZ nurse call relay control

25 EOC end of conversion ADC

26 CSADC selection SPI ADC bus

27 CLK clock SPI ADC bus

28 SI data INSPI ADC bus

29 SO data out SPI ADC bus

30 CDANA analogue sensor power supply control

31 RX2 receive TTL data line 2

32 TX2 transmit TTL data line 2

33 TXD1 transmit TTL data line 1

34 RXD1 receive TTL data line 1

35 TON ON key

36 TOFF OFF key

37 + VBAT power supply

38 GND

39 + 5V

40 GND

2.2.2.4. J4 Display board interconnection

Pin Description

1 SEG1 display matrix line 1

2 SEG2 display matrix line 2

3 SEG3 display matrix line 3

4 SEG4 display matrix line 4

Page : 20 NT 1023 Rev.B0

Page 25

5 SEG5 display matrix line 5

6 SEG6 display matrix line 6

7 SEG7 display matrix line 7

8 SEG8 display matrix line 8

9 COL1 display matrix column 1

10 COL2 display matrix column 2

11 COL3 display matrix column 3

12 diode FAIL control

13 RDCRT current reduction control

14 LIG1 keyboard interface line 1

15 LIG2 keyboard interface line 2

16 LIG3 keyboard interface line 3

17 LDSECT mains LED lighting control

18 + 5V power supply

19 VBAT power supply

20 GND power supply

2.2.2.5. J5: Display/CPU connection

Pin Description

1 TON ON key

2 TOFF OFF key

3 SI SPI bus

4 CLK SPI bus

5 CSLCD bus

7 VBAT power supply

8 GND power supply

2.2.3. Electrical layout

(Refer to Annex 2)

2.2.4. Installation layout

(Refer to Annex 2)

2.3. DISPLAY BOARD

2.3.1. Overview

The display board is mounted directly beneath the front plate of the syringe pump. It brings together all

the facilities for operator/device dialogue: Keyboard, buzzer and display.

It is connected to the CPU by rigid connectors, forming a sandwich, with the former, held in place by

struts.

The soft keyboard is connected to the display board.

2.3.2. Functional description

The display board comprises four modules:

q The electroluminescent display,

q The keyboard interface,

q The liquid crystal display,

q The buzzer.

2.3.2.1. Electroluminescent display

The electroluminescent display is made of eighteen LED's and five 7 segment display units, with the dec-

imal point, except two of them which are marked (*) in the table below.

NT 1023 Rev.B0 page : 21

Page 26

The diodes and display units are driven in a multiplexed, 8 segments x 8 digit matrix. The LED's and display units are mounted with a common cathode.

The 8 segments are driven by signals SEG0 to SEG7 and the 8 digit by signals DIG0 to DIG7.

The 2 LED’s, "MAIN PRESENCE" and "FAIL" are controlled independently of the matrix.

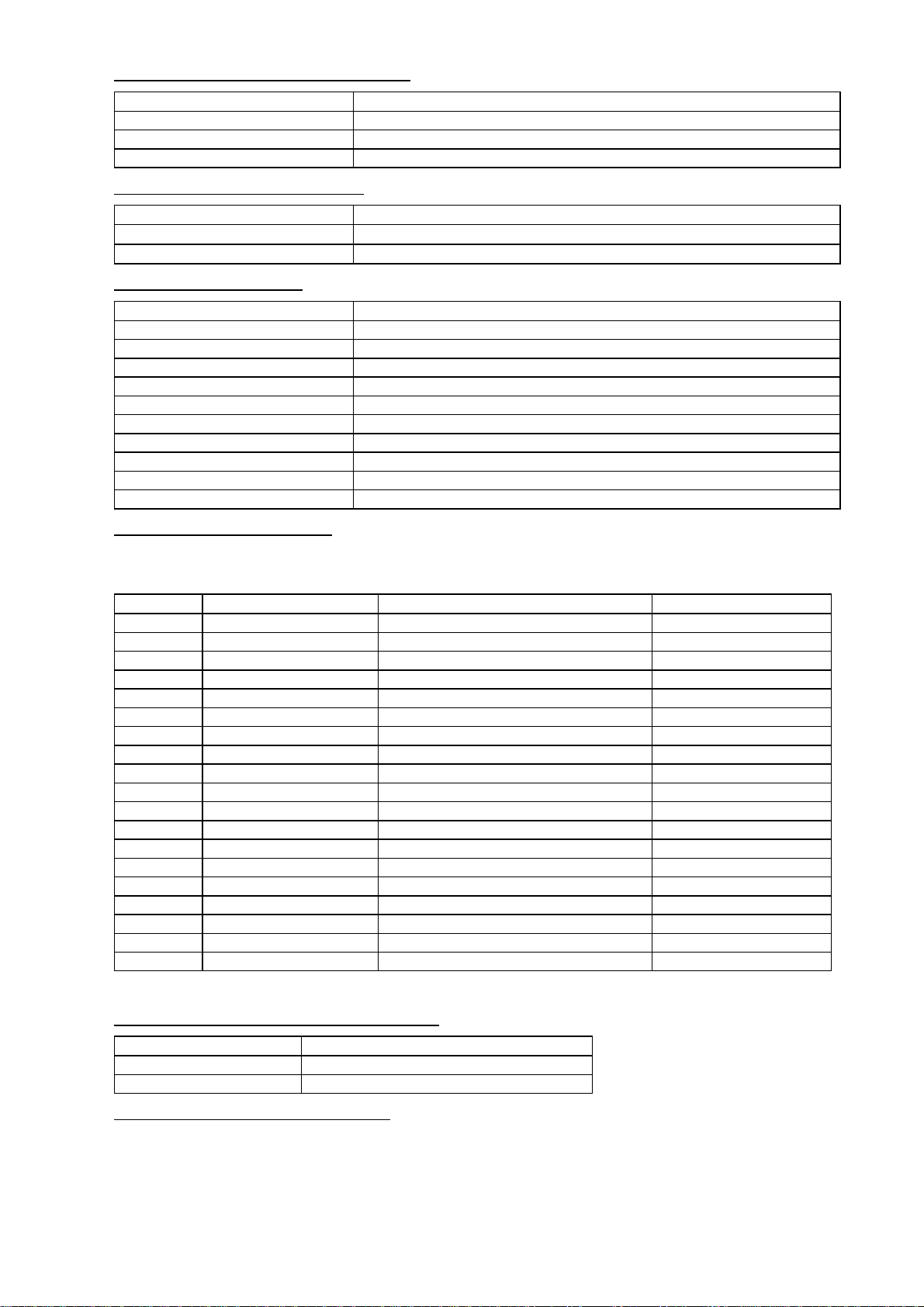

2.3.2.1.1. LED’s table

The following table lists the various diodes used in different models.

Ref Name Type Seg Dig

LD1 Mains On yellow * *

LD2 Body Alarm red 1 0

LD3 Piston Alarm red 2 0

LD4 ml green 5 1

LD5 Battery green 7 1

LD6 Fail red * *

LD7 Alarm red 4 to7 0

LD8 Worm screw 3 green 2 1

LD9 Prealarm orange 1 to 4 2

LD10 Occlusion Alarm red 0 0

LD11 Worm screw 2 green 3 1

LD12 Infusion End Alarm orange 0 2

LD13 Worm screw 1 green 4 1

LD14 NU

LD15 Connection to PC green 0 1

LD16 disengagement alarm red 3 0

LD17 ml/h green 5 1

LD18 Battery Alarm red 5 2

LD19 Validation Demand green 1 1

2.3.2.1.2. Seven segment display units

Ref Name Type Seg Dig

U3 hundreds green 0 to 7 6

U4 tens green 0 to 7 5

U5 units green 0 to 7 4

U6 tenths orange 0 to 7 3

U2 thousands green 0 to 7 7

2.3.2.2. Keyboard interface

The keyboard is an 18 key matrix keyboard. The keys are arranged in 3 rows of 6, with two separate keys

with a common point (GND), TON and TOFF, and power on and off switches, connected to J2.

Ref Digit Ligne

SILENT 2 2

STOP 1 2

VALIDATION 0 2

PURGE 3 2

BOLUS 2 0

DECAL 4 0

SELINC 3 0

SELDEC 2 1

ENTER 3 1

HISTO 4 1

Description of the connector

J2. 1 DIG 5

J2. 2 DIG 4

Page : 22 NT 1023 Rev.B0

Page 27

J2. 3 DIG 3

J2. 4 DIG 2

J2. 5 DIG 1

J2. 6 DIG 0

J2. 7 LINE 0

J2. 8 LINE 1

J2. 9 LINE 2

J2. 10 TON

J2. 11 TOFF

J2. 12 GND

2.3.2.3. LCD display unit

The LCD display unit is "chip on glass" type, the controller is fixed on the glass. It has 2 lines of 20 char-

acters.

The BUS gestion is multiplexed with the command of SEG0 and SEG7.

It has a double powered retrolighting.

The power supply of the LED pair, one by one, allows an optimum light for a minimum consumption.

2.3.2.4. The buzzer

The buzzer is an auto-exit buzzer supplied by VBAT.

It is driven by the BUZZ signal, available on connector J3, pin 6, which is generated by the CPU board. It

is mounted in parallel with the optional nurse call circuit, located on the motor power supply board.

2.3.2.5. Time keeper

Real time device DS1307

2.3.3. Description of connectors

2.3.3.1. J2 Display board / CPU board connection

Pin Description

1 SEG0 display matrix and command LCD display line 1

2 SEG1 display matrix and command LCD display line 2

3 SEG2 display matrix and command LCD display line 3

4 SEG3 display matrix and command LCD display line 4

5 SEG4 display matrix and command LCD display line 5

6 SEG5 display matrix and command LCD display line 6

7 SEG6 display matrix and command LCD display line 7

8 SEG7 display matrix and command LCD display line 8

9 COL1 display matrix and keyboard column 1

10 COL2 display matrix and keyboard column 2

11 COL3 display matrix and keyboard column 3

12 FAIL diode FAIL control Fail

13 RDCRT display control writing command

14 LIG1 keyboard interface line 1

15 LIG2 keyboard interface line 2

16 LIG3 keyboard interface line 3

17 LDSECT LED mains lighting control LED sector

18 + 5V power supply

19 VBAT power supply

20 GND power supply

2.3.3.2. J3 CPU board connection

Pin Description

1 TON ON key

2 TOFF OFF key

3 SI bus SPI

NT 1023 Rev.B0 page : 23

Page 28

4 CLK bus SPI

OPT

OK

OK

OK

OK

OK

OK

OK

OK

OK

5 CSLCD bus SPI

6 BUZZ BUZZER control

7 VBAT power supply

8 GND power supply

2.3.4. Power consumption

Main supply (without battery) Battery supply (without main supply)

measurement made on the battery

0 ml/h 1200 ml/h 0 ml/h 1200 ml/h

31 mA / 230v ~ 47 mA / 230v ~

< 125 mA / 6,0 VDC 700 mA / 6,0 VDC

2.3.5. Electrical layout

(Refer to Annex 2)

2.3.6. Implantation layout

(Refer to Annex 2)

3 Configurations

Fresenius Vial recommends the presence of its qualified personnel or of a trained member of the Technical Department of your establishment to help you implement the configuration procedures you wish to choose.

Note: press STOP to cancel modification at any time - Press to leave configuration mode at any time.

3.1. Configuration of the pressure functionalities

Moving to the pressure configuration mode: press +

Press Configuration mode Valid. Choice

Pres 1 : variable threshold mode.

Pres 2 :pressure limit by syringe capacity.

: Pres appears on display.

Pres 1

900 mmHg

50/60 ml syringes

Pres 2

50 cc 800 mmHg

20 ml syringes

Pres 2

20 cc 600 mmHg

Note: at any time, it is possible to press START key to store programmed

values and resume Pres 2.

Press ( ) to select

preset pressure limit at a value sets

between 100 and 900 mmHg at power on

or use the last programmed value (___)

from 100 to 900 mmHg

from 100 to 900 mmHg

Valid.

Pres 3 : pressure drop warning level.

Pres 3

100 mmHg

from 50 to 1100 mmHg (disable this

warning 0 mmHg)

3.2. Configurations of the various parameters

Moving to configuration of the various parameters mode, press simultaneously + : Par appears on display.

Press Configuration mode Valid. Display

Par 1 : preset parameters at power on.

Par1

(parameters: flow rate, rate mode unit, drug

name, drug concentration, patient weight)

Press ( ) to select

use last parameters

preset parameters:

flow rate: 00.0 ml/h

Page : 24 NT 1023 Rev.B0

Valid.

Page 29

rate mode proposed :ml/h

OK

OK

OK

OK

OK

OK

OK

OK

OK

OK

OK

OK

OK

OK

OK

OK

OK

OK

OK

OK

OK

OK

OK

OK

OK

OK

OK

OK

OK

patient weight,

V/T values : preset at last

values before selection

Par 2 : syringe selection type.

Par 3: maximum flow rate selectable via the

keyboard.

Par2

SEL4

50 ml syringe

Par3

50 cc 800 ml/h

20 ml syringe

Par3

20 cc 550 ml/h

Par 4 : selectable syringes/syringe list restric-

tion.

Par 5 : prime compulsory.

Par 6 : rapid infusion start up.

BD Plastipak

50 cc

Par 5

Par 6

Press Configuration mode Valid. Display

Par 7 : KVO rate.

KVO = 1.0 ml/h

KVO = 2.0 ml/h

SEL3 only one syringe per capacity with

automatic confirm

SEL4 multisyringe mode

from 0.1 to 1200 ml/h

from 0.1 to 600 ml/h

selectable syringe on display

not selectable on display

Selection for any syringe

priming compulsory

no priming compulsory

running rapid infusion start up

no rapid infusion start up

Press ( ) to select

From 0.1 to 5 ml/h

Valid.

Par 9 : RS 232 baud rate.

Par A : empty syringe mode (finish on occlu-

sion).

Par B : frequency of maintenance and date of

next maintenance

Par C : drug library (see page 9)

Par D : syringe flanges detection.

Par E : pre-programmed bolus dose rate and

volume preset value at power on

Par 9

4800, 9600, 19200 Bauds

19200

Par A

activated

disabled

Par B 200 h

12/05/2000

from 1 hour to 9 999 hours of continuous

use (preset at 3 000 hours)

Note : select 0000h to desable

Par B 200 h

12/05/2000

Select date and shift to next item by

pressing OK key.

Note : select 00/00/0000 to desable date

of next maintenance mode

Note: at any time, it is possible to press START key to store programmed

parameters and resume Par B.

ADRENALIN

Drug library configuration

200ng/ml

Par D

activated

disabled

Par E

use the last rate and volume settings

used a preset fixed value for rate

volume = 0.1 ml

Preset

fixed

value

50 ml syringe

Par E

50cc 800.0 ml/h

20 ml syringe

From 50.0 to 1200.0 ml/h

From 50.0 to 600.0 ml/h

Par E

20cc 600.0 ml/h

Par F : bolus rate value at power on

Par F

use the last set rate setting

Page : 28 NT 1023 Rev.B0

Page 30

used a preset fixed value

OK

OK

OK

OK

OK

OK

OK

Preset

fixed

value

Par G : rate mode selection

Par J : mains disconnection warning inhibition.

Par P : name of the service

Important: measurements of the friction forces on the plunger stoppers do not show stable characteristic. For this reason, we recommend not

to use Star mode (Par6).

50 ml syringe

Par F

50cc 800.0 ml/h

20 ml syringe

Par F

20cc 600.0 ml/h

Ml/h

Par J

Par P

ICU 15210 ____

From 50.0 to 1200.0 ml/h

From 50.0 to 600.0 ml/h

Activate or disable rate mode with .

Shift to the next item by pressing OK OK

key

activated

inhibited

inhibited

mains disconnection warning active

Select the service name

3.3. CHECKING THE PILOT

N.B.: the tests outlined below do not include the occlusion tests, the flow rate tests, the electrical safety tests,

etc.

3.3.1. The After Sale Service test

The ASS test is activated by pressing simultaneously on the keys:

and

until following display:

TESt.1

The validation LED flashes.If

The device display, for example:

START

is not pressed, within 3 seconds, the device returns to normal running.

Test1Test1

0h0h

The keys , and

START

allows to scroll in the following list:

"TEst.1TEst.1" = displays running time with zero reset if necessary and service date modification

"TEst.2TEst.2" = tests all indicator lights (LED's, 7-segment display unit AND LCD screen)

"TEst.3TEst.3" = tests keyboard.

"TEst.4TEst.4" = displays battery voltage

NT 1023 Rev.B0 page : 29

Page 31

"TEst.5TEst.5" = displays code of last 10 alarms.

STOP

STOP

"TEst.6TEst.6" = displays total running time.

"TEst.7TEst.7" = TTL serial link test.

"TEst.8TEst.8" = RS232 serial link test.

"TEst.9TEst.9" = displays force on plunger.

"TEst.ATEst.A" = software version, check sum, loading date and language.

"TEst.BTEst.B" = displays ADC analog inputs.

"TEst.CTEst.C" = displays driving block position.

"TEst.ETEst.E" = displays calibration values.

"TEst.FTEst.F" = displays calibration syringe type.

"TEstTEst.JJ" = displays of the last 10 events before the last blocking error.

"TEst.LTEst.L" = drugs library.

3.3.2. Running time tESt.1tESt.1

This test allows to display, first, the running time in hours, days and months.

Press on

START

gives the maintenance date. This date may actualised with the key board.

3.3.3. Lights test tESt.2tESt.2

This test allows to check the lighting of LED’s of the front panel, of the 7 segments display and of the LCD screen.

First, all the items light at the same time and then light one after another.

This test can be stopped at any time by pressing

3.3.4. Key board test tESt.3tESt.3

This test allows to test the correct functioning of every key. The message “Test 3” is permanently displayed.

When pressing on a key, its name displayed on the screen

OFF Switch off

SIAL Alarm silent / Information keys

STOP Stop infusion

START

START Validation (note: pressing longer than 2 seconds on this key, drives back

to tests choice)

BOLUS

BOLU Bolus manual control

DECAL Moving the traveller

INC Increase

DEC Decrease

OK

OK Enter, validation

OPT

OPT Options menu

Page : 30 NT 1023 Rev.B0

Page 32

1 2 3

6 : DEC +

1 : INC +++

2 : INC ++

4 5 6

3 : INC +

4 : DEC +++

5 : DEC ++

Nota: ON, can’t be tested

If several keys are pressed simultaneously, the device displays “Err” and gives an alternative "BIP".

The key works normally: the message “OFF”is displayed as soon as pressed, the device is switched off if

pressed more than one second.

3.3.5. Battery voltage display tESt.4tESt.4

This test displays the battery voltage over 5 digits. The voltage is calculated in accordance with corresponding analog input value and calibrating values. The values used are those for escape from an alarm or pre-alarm (6.3 V) or

starting an alarm (5.7 V).

The display is in volts and tenths of volts. The display is continuously updated according to the voltage changes.

The battery and mains LED's are also updated. The battery LED begins to flash if the voltage displayed is below the

calibrated pre-alarm threshold and stops flashing if the voltage is above the pre-alarm output threshold.

Press the CONFIRM key to select another test.

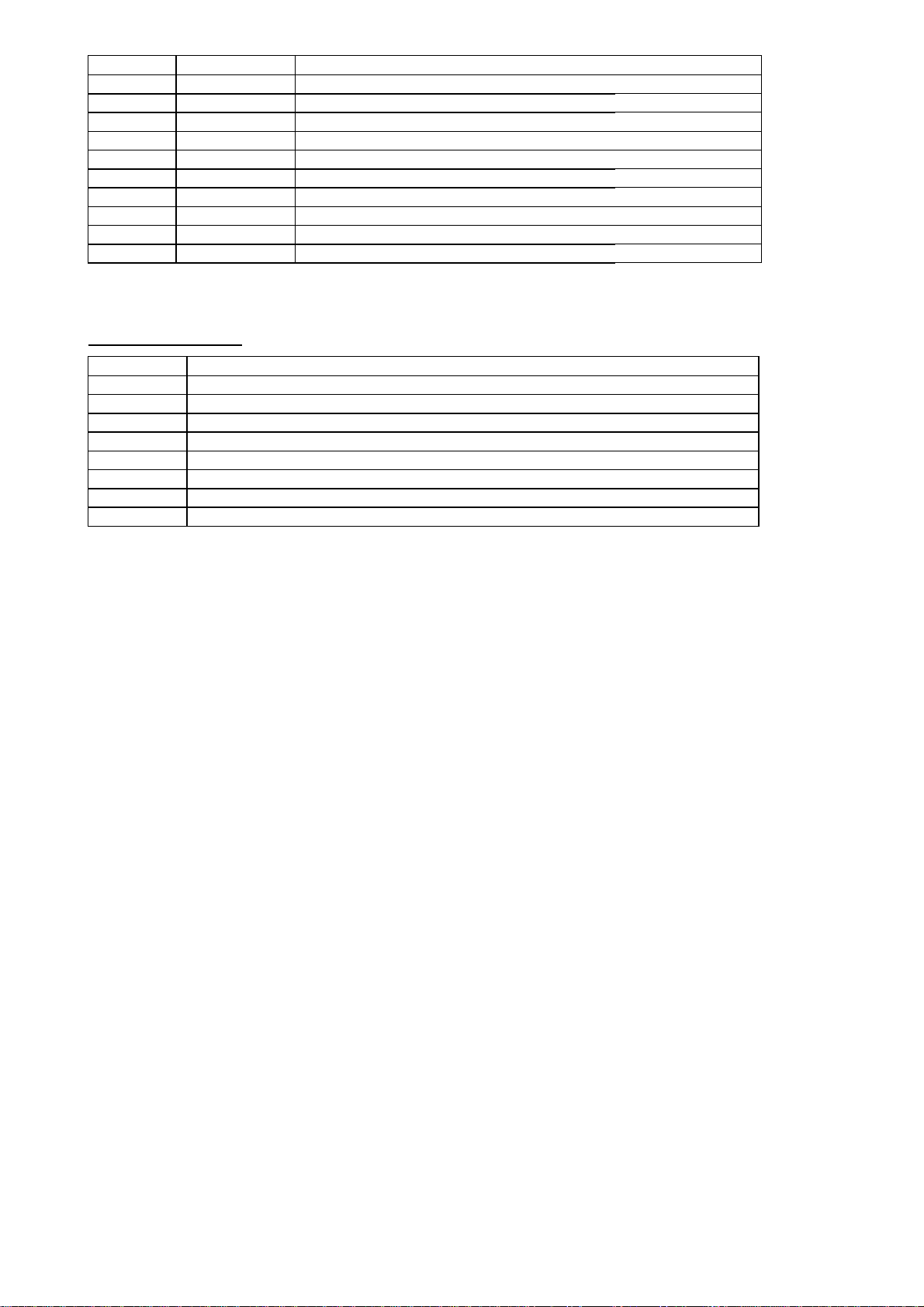

3.3.6. Last 10 alarms codes tESt.5tESt.5

This test displays the codes of the last 10 events on the display units. Three types of events are memorised :

q ALARM

q ERROR

q SWITCH OFF: two cases

Normal SWITCH OFF by pressing the OFF key.

Abnormal SWITCH OFF due to misfonctioning.

When an alarm goes off, an “AA” is displayed followed by a number identifying the alarm:

Alarm Description

10 battery

11 syringe clamp

12 end of infusion

13 volume limit

14 disengagement

15 plunger head

16 occlusion

25 Flange

26 Main line disconnection

NT 1023 Rev.B0 page : 31

Page 33

In case of error, an “E” is displayed followed by error number:

Error Description

01 rotation control

03 communication

32 / 52 / 72 / 82 segment advance check

44 CPU / UART frequency control

50 ADC access self-test

52 advance check during take-up

14 / 60 checking coherence of syringe parameters (incoherence of the syringe diameter in relation

to the number of motor steps for 0.1 ml calculated when the syringe is confirmed)

70 incorrect motor frequency (motor step period too big or too small, calculated from the sy-

ringe diameter and the selected flow rate)

72 advance check over the whole length

80 important electromagnetic interference’s or bad key board.

16 / 55 Time keeper

18 Max infused (1,7l) reached

28 Language file error

24 / 34 / 44 / 56 Software error

66 LCD error

The error codes: 10 (internal Ram self-test(+)

20 (external Ram self-test(+)

30 (EEPROM check-sum self-test) and

40 (EEPROM access)

These errors cannot be stored in the EEPROM; the running of the device is too pertubated to allow it to write in the

EEPROM.

When normally stop, the “OFF” message is displayed.

For abnormal stop “OFF” + flashing "F" (Fail) are displayed on the LCD screen.

The events are numbered from 0 to 9. 0 is the last event, 9 is the eldest one.

The keys and allows to scroll the events one way or the other

Example:

Test 5 8Test 5 8

E 01E 01

Means: event N° 8 was a type 01 error (rotation control)

3.3.7. Total running time tESt.6tESt.6

Use this test to display the total running time of the Pilot. Unlike “Test 1" which resets the time at zero when the

service date is modified, it is not possible to modify this time manually.

Example:

Test 6Test 6

28 H28 H

3.3.8. TTL Serial link test: tESt.7tESt.7

This test allows to verify the TTL serial link TTL (80C32), by placing a plug on which the Rx and Tx lines are " shortcircuited "(pin 2 and 3).

If link is correct: LTOKLTOK is displayed

If link is not correct or if plug is not connected: LTER LTER is displayed

3.3.9. Serial link test: tESt.8tESt.8

Page : 32 NT 1023 Rev.B0

Page 34

This test allows to verify the RS 232 serial link (2691), by placing a plug on which the Rx and Tx, RTS and CTS,

DSR and +5 V lines are "short-circuited" (pin 2 and 3), (7 and 8),(4 and 6)

LROKLROK = RS 232 correct link.

LRERLRER = break between Tx and Rx

NORCNORC = - break between RTS and CTS,

- break between DSR and + 5 V

- no plug

3.3.10. Strength on the plunger display: tESt.9tESt.9

This test displays the strength applied on the plunger. The strength is calculated according to the value of the corresponding analogue input and the calibrating values. The display is in grams. The value is continually updated according to changes in the strength value.

3.3.11. Software version tESt.AtESt.A

This test allows to display the software number version, the check sum and the loading date.

OK

Press on

allow to display the language.

Example:

rst

1

screen

Test A V01.1a

OCFO 01/12/2000

nd

2

screen

Test A Français

V01.0 09/09/1998

Press on for other language screen

3.3.12. Analog input display tESt.BtESt.B

This test allows to read the hexadecimal value of the 5 analogic inputs and of the 3 converter test inputs. The channel number is displayed above this value.

Example

Test B M

200

The keys and allows to pass from one channel to an other.

The analogue inputs are divided as follows:

0 battery voltage

1 N.U.

2 force sensor

3 NU

4 potentiometer displacement

NT 1023 Rev.B0 page : 33

Page 35

L converter zero test, between 0000 and 0004 if correct

M converter mid-scale test, between 01FB and 204 if correct

H converter full-scale test, between 03B and 3FF if correct

3.3.13. Driving block position display tESt.CtESt.C

This test displays the position of the driving block. The position is calculated in relation to the value of the corresponding analogue input and calibrating values. The display is in mm and tens of mm. The value is continually updated as the driving block moves. The value displayed is ± 0,1 mm.

3.3.14. Calibration values display tESt.EtESt.E

This test allows to show the calibration values stored in the EEPROM.

Every value is displayed on 3 digits.

The first line gives the shorted name of the value.

Example:

Test E LOWTest E LOW

082082

The keys and allows to pass from one channel to an other.

bat1 alarm and pre-alarm battery voltage: 6.3 V

bat2 pre-alarm battery voltage: 5.9 V

bat3 alarm battery voltage: 5.7 V

HIGH displacement potentiometer with large 115.0 mm spacer

LOW displacement potentiometer with small 20.0 mm spacer

0G force meter with 0 kg

5Kg force meter with 5 kg

3.3.15. Syringe type display tESt.FtESt.F

This test displays the type of syringe fitted to the Pilot. The type is defined with the indications given by the optos of

the syringe clamp.

The type of syringe is displayed with its capacity: 20cc (20/25cc), 50cc (50/60cc). The capacity may not be displayed if the parameters in EEPROM indicate that certain types of syringes are not included. When the syringe

clamp is in the higher and the lower position 4 dashes are displayed.

The display is constantly updated in relation to changes in the syringe clamp system.

3.3.16. Displays of the last 10 events before the last blocking error tESt.JtESt.J

This test allows to display the 10 last events before the last blocking error.

3.3.17. Drug library tESt.LtESt.L

This test allows to read the name, the author and the date of the protocol library registered in the device.

4 REPLACING SUB-ASSEMBLIES

q Important: Disassemble the flexible circuit holder on the supply board before extracting the mechanical as-

sembly from the lower box.

q Important: Device operation must be completely checked after all intervention inside the device.

Page : 34 NT 1023 Rev.B0

Page 36

4.1. Mounting the flexible circuit

diam.12 tube

q Important: Handle the flat cable with great care when mounting this sub-assembly: damage to the flat cable

will result in complete disassembly of the mechanical block.

Fitting the flat cable

1. Take the flat cable and, using the "flat cable insertion" tool, wind the flat cable on the opposite side to the 10point connector in the tool slot, keeping the flat cable tightened, wind it onto the equipment.

hood

2. Take the black hood of the flat cable insertion equipment and position it on the wound flat cable part.

3. Insert the driving block cover and the input bearing on the diam. 12 tube, in the proper direction for mounting

the various components.

Important: The input bearing flange must be placed on the side external to the driving block cover.

q Visually check that the "input bearing + driving block cover" are properly mounted on the tube.

4. Insert the "flat cable insertion" tool in the diam. 12 tube on the input bearing side.

q The perpendicular flat cable parts are placed in the slits found at the ends of the tube.

5. Remove the black hood and the flat cable insertion equipment.

6. Correctly position the flat cable in the two slits visible at each end of the tube.

Important: The flat cable must not be twisted inside the tube.

7. Place the flexible circuit guards at both ends of the tube, passing the flat cable between the two holding lugs

8. Place the diam. 12 tube on the driving block making match the indexing finger of the driving block with the hole

of the tube (opposite side of the 10 point connector)

flat cable

9. Match up the flexible circuit hole with the driving block holder centring tube.

10. Secure the clamping collar onto the driving block using two 2.5 x10 screws and two washers.

4.2. Wiring the components on the flexible circuit

q Important: it is essential that the component mounting direction be respected.

1. Position the strut (1.5mm) between the 4 pin photo switch and weld the syringe head detection photo switch

flattening it against the flat cable.

Important: use a silicone between the optical switch and the flat ribbon cable. The silicon should not be over the

soldering area.

NT 1023 Rev.B0 page : 35

Page 37

Important: verify there is no resistor continuity between the optical switch axis stop and the flat ribbon cable.

Photo switch

2. Weld the disengaging switch flattening it against the flat cable.(at roughly 1.5 mm).

3. Cut the part of the flat cable corresponding to the back pressure microswitch of version A2 (see cutting zone in

the diagram below).

Disengaging switch

Diam 12 tube

Syringe head detection

Photo switch

anode long lug

Weld the disengaging microswitch without flattening it against the flat cable (at roughly 1.5 mm).

4. Weld the force sensor wires

Important: when disassembling a force sensor, take care not to damage the welding pellets.

green wire

lower marking

5. Pass the flat cable in the force sensor oblong.

Important: When disassembling the flexible circuit from the driving block holder, take care not to detach or damage the holder protection square. The purpose of this square is to hold the flexible circuit correctly in place and

avoid short-circuits with the holder.

6. Mount the force sensor on the driving block holder using a TF HC M4x10 screw with weak lactate.

Important: avoid all contact between the force sensor and its holder.

7. Mount the contact plate on the force sensor using a TF M4x10 screw with weak loctite.

Important: Before calibrating the force sensor, adjust the threshold voltage (0.6V + 0.05V) using an oscilloscope

between pin 1 (earth) of J09 and pin 4 of J09 (square pulse).

Important: The device must be in the calibration mode (EtA9), obtained by simultaneously pressing the SILENCE

ALARM key, the bolus key and the "ON" key.

8. Check that the amplitude of the square pulse increases when a manual force is exerted on the force sensor.

When the force is removed from the sensor, the signal must return to the initial position.

Otherwise, check that the sensor is correctly mounted (sensor/holder friction).

4.2.1. Mounting the potentiometer

1. Disassemble the reducer flask end shield.

Page : 36 NT 1023 Rev.B0

Page 38

2. Mount the potentiometer on the flask (take the nut on a thread).

3. Position the flask in equipment T 300 869 and lock it in place using the knurled screw.

4. Position the potentiometer in the equipment and bring it up against the end shield.

5. Tighten the potentiometer.

6. Extract the flask from equipment T 300 869.

7. Mount the pinion on the potentiometer (match up the indexing half flat).

q The pinion large diameter must be flattened against the potentiometer.

8. With the potentiometer facing you, turn the pinion in an anticlockwise direction until it blocks, then turn it 1/4 of

a turn in the opposite direction.

9. Mount the moving mechanical assembly on the reducer frame.

10. Insert the flask on the guides and rack.

q Check the position of the input bearing which must be on the driving block side.

q Important: Take care not to damage the flexible circuit when mounting (folding).

11. Secure the end shield using the three M3x3 TC screws.

12. Secure the input bearing using the two M3x3 TC screws.

4.2.2. Wiring the potentiometer

1. Weld the 3 wires perpendicular to the lugs by placing them in the holes.

Important: Do not fold the potentiometer lugs

2. Mount the pinion and the potentiometer matching the indexing half flat with the

3

21

brown

red

black

small diameter of the pinion towards the potentiometer.

1

2

3

3. Mount the pinion hocking diameter 4 Truarc ring using a pair of flat mose fliers bearing down on the potentiometer shaft half flat.

4. With the pinion facing you, turn the potentiometer anticlockwise until it blocks, then turn it 1/4 of a turn in the

opposite direction.

5. Disengage the moving assembly and slide it until it blocks against the reduction gear flange.

6. See EtA6EtA6 calibrating test for the calibration of the potentiometer (section 3.2.2.).

4.2.3. Plug holder connector

If the total pins on the plug holder connector does not correspond to the total pins on the power supply board connector, the connecting method should be done as follows:

plug holder

straight

Power supply board

4.2.4. Lubricating the mechanical parts

NT 1023 Rev.B0 page : 37

Page 39

NOTE: Use silicon grease exclusively.

Parts to be lubricated:

The two mechanical block guide rods

The screw rod

The top of the rack at guide level

The full length of the rack teeth

The disengaging spring housing in the 1/2 nut

The inside of the mechanical block.

Page : 38 NT 1023 Rev.B0

Page 40

5 MAINTENANCE

5.1. Recommendations